Oil-soluble condensate oil emulsion breaker and preparation method thereof

A technology of demulsifier and condensate oil, which is applied in the fields of chemical dehydration/demulsification, petroleum industry, treatment of hydrocarbon oil, etc., which can solve the problem of low recovery rate of condensate oil, unsatisfactory demulsification effect, and small output of condensate oil. and other problems, to achieve the effects of high demulsification efficiency, high demulsification rate and fast demulsification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

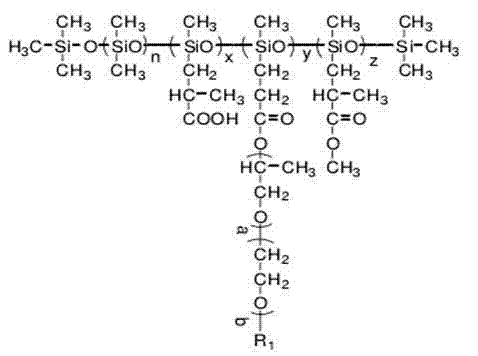

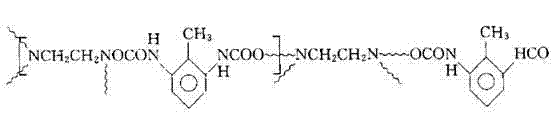

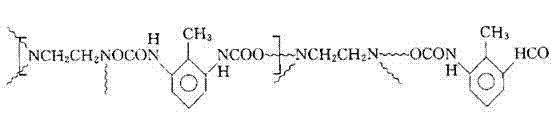

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of above-mentioned oil-soluble condensate demulsifier is as follows:

[0045] Add the cross-linked block polyether demulsifier, comb-type polysiloxane demulsifier, and betaine-type fluorocarbon surfactant into the reaction kettle, and add the solvent at the same time, then raise the temperature to 40°C while stirring, and cool down after fully mixing Let it cool down to room temperature to obtain an oil-soluble condensate oil demulsifier.

[0046] Use of the oil-soluble condensate oil demulsifier of the present invention: when using the oil-soluble condensate oil demulsifier of the present invention, the amount of addition depends on the amount of foam drainage agent, and the amount of addition is generally 0.2-0.6% of the liquid production. Its application effect is mainly determined by measuring the recovery rate of condensate oil.

Embodiment 1

[0048] When the foam drainage agent content≤0.3%, the condensate oil demulsifier of the present invention consists of the following components by weight percentage:

[0049] Scheme 1: 10% cross-linked block polyether demulsifier, 8% comb-type polysiloxane demulsifier, 0.05% betaine-type fluorocarbon surfactant, and 81.95% solvent.

[0050] Scheme 2: 11% cross-linked block polyether demulsifier, 7.5% comb polysiloxane demulsifier, 0.1% betaine fluorocarbon surfactant, and 81.4% solvent.

[0051] Scheme 3: 15% cross-linked block polyether demulsifier, 5% comb polysiloxane demulsifier, 0.08% betaine fluorocarbon surfactant, and 79.92% solvent.

[0052] Scheme 4: 13% crosslinked block polyether demulsifier, 6% comb polysiloxane demulsifier, 0.065% betaine fluorocarbon surfactant, and 80.935% solvent.

[0053] Scheme 5: 14% cross-linked block polyether demulsifier, 7% comb polysiloxane demulsifier, 0.09% betaine fluorocarbon surfactant, and 78.91% solvent.

[0054] Scheme 6: 12% ...

Embodiment 2

[0060] When the foam drainage agent content is 0.3-0.5%, the oil-soluble condensate oil demulsifier consists of the following components by weight percentage:

[0061] Option 1: 15% crosslinked block polyether demulsifier, 8% comb polysiloxane demulsifier, 0.1% betaine fluorocarbon surfactant, and 76.9% solvent.

[0062] Scheme 2: 15.5% crosslinked block polyether demulsifier, 9% comb polysiloxane demulsifier, 0.12% betaine fluorocarbon surfactant, and 75.38% solvent.

[0063] Scheme 3: 19.5% cross-linked block polyether demulsifier, 11% comb polysiloxane demulsifier, 0.14% betaine fluorocarbon surfactant, and 69.36% solvent.

[0064] Scheme 4: 18% cross-linked block polyether demulsifier, 10% comb polysiloxane demulsifier, 0.135% betaine fluorocarbon surfactant, and 71.865% solvent.

[0065] Scheme 5: 16% cross-linked block polyether demulsifier, 8.5% comb polysiloxane demulsifier, 0.15% betaine fluorocarbon surfactant, and 75.35% solvent.

[0066] Scheme 6: 19% cross-linke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com