Patents

Literature

46results about How to "High demulsification rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

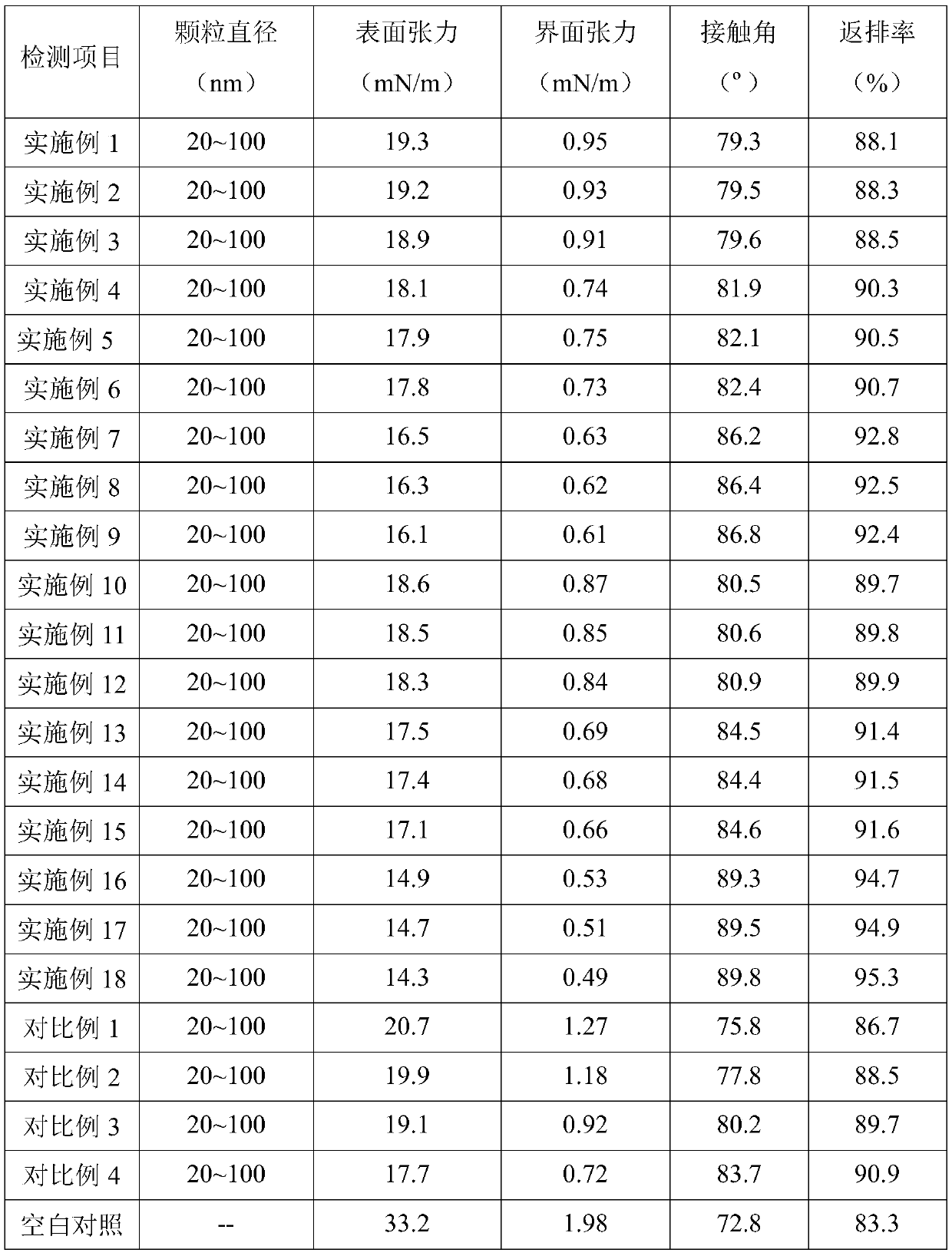

Demulsification method by soybean grease microbe extraction through aqueous enzymatic method

ActiveCN102796613AImprove thermal stabilitySimple process equipmentFatty-oils/fats refiningFatty-oils/fats productionLiquid mediumProcess equipment

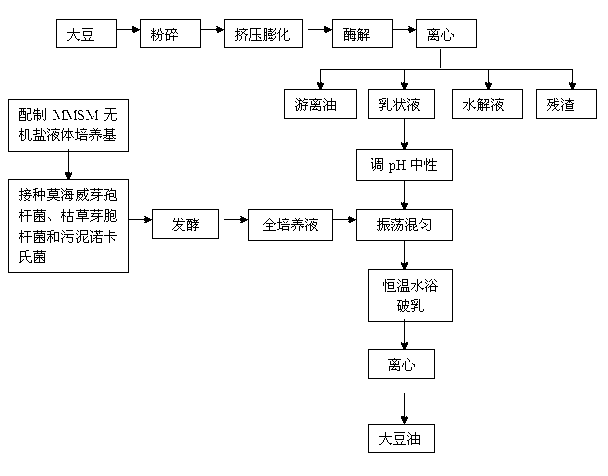

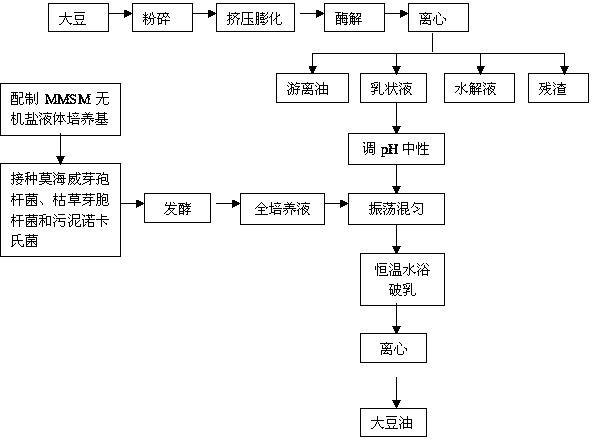

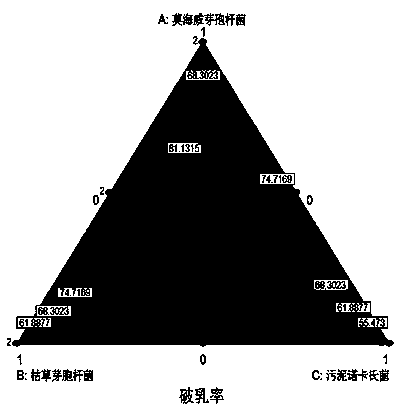

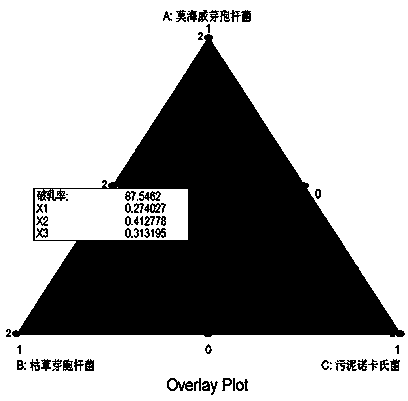

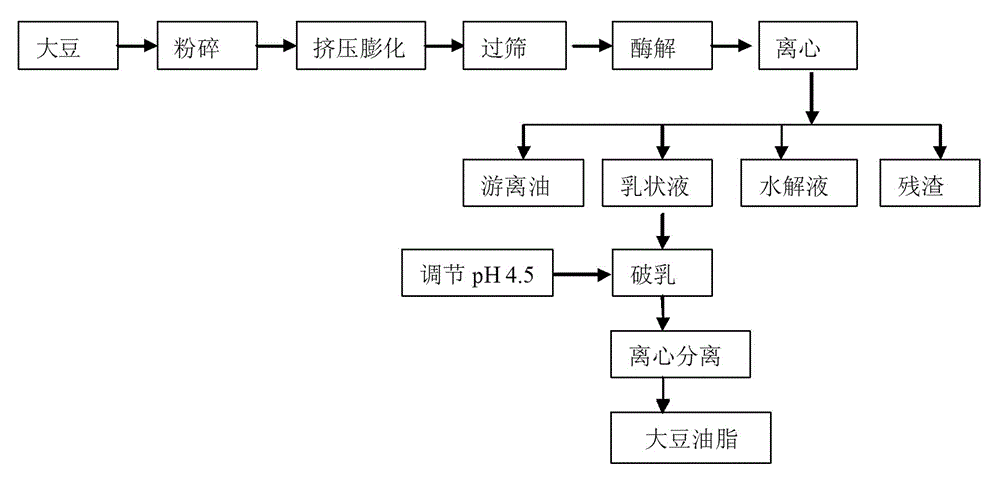

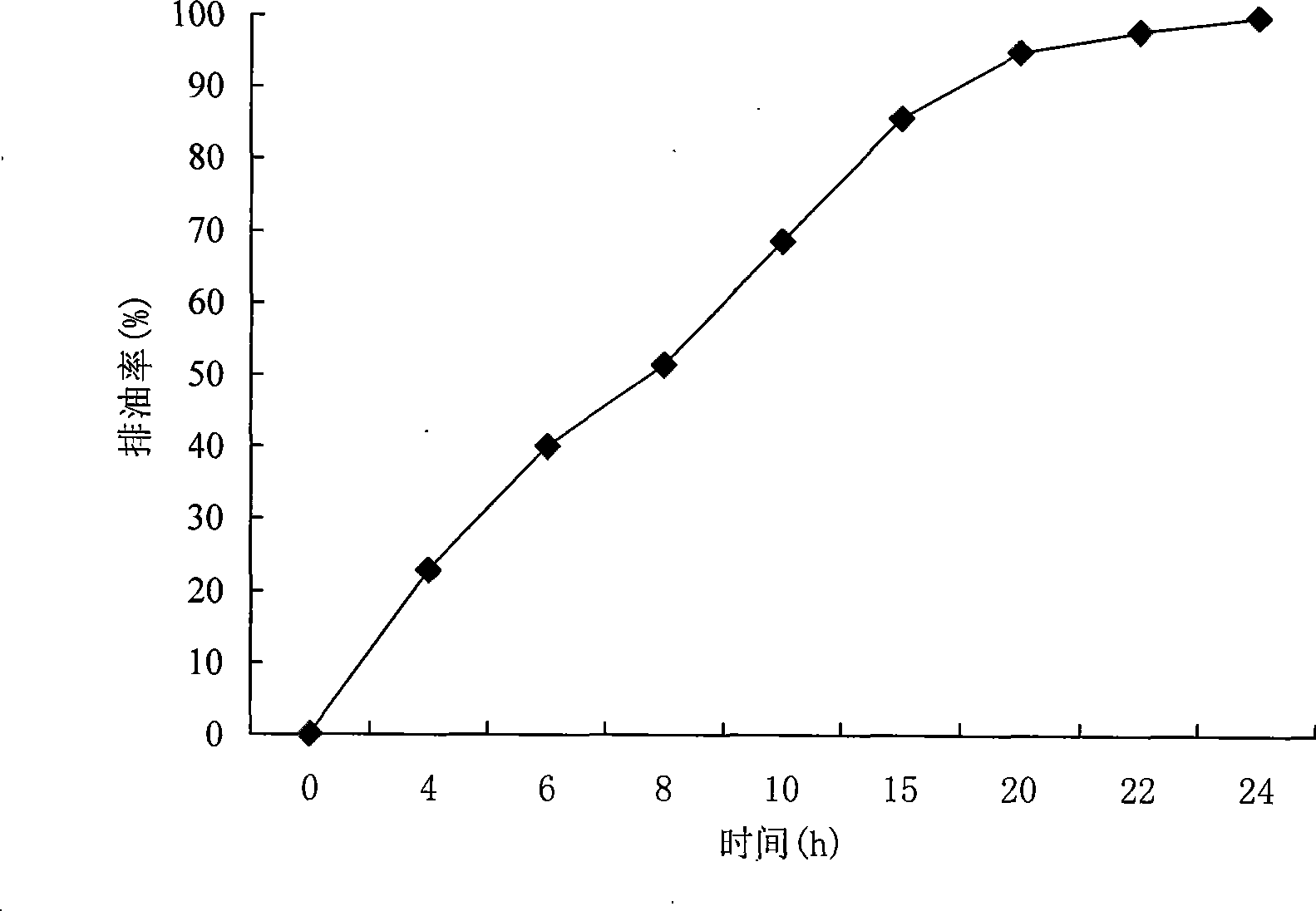

The invention relates to a demulsification method by soybean grease microbe extraction through an aqueous enzymatic method, which belongs to the plant grease extraction technology. The method comprises the following steps: 1) crushing soybean to obtain a puffed material by using an extruding puffed pretreatment, mixing the puffed material and water to obtain a mixed liquor, adding alkaline protease in the mixed liquor for enzymatic hydrolysis, centrifuging after enzymatic hydrolysis to obtain free oil, an emulsion, a hydrolysate and residues; 2) fermenting the mixed demulsifying bacteria with different complex formulation proportion through a MMSM inorganic salt liquid medium to obtain a mixed demulsifying bacteria whole liquid culture medium; 3) adjusting the pH value to the emulsion obtained in the step 1) to neutrality, fully and uniformly mixing with the mixed demulsifying bacteria whole liquid culture medium, and standing and performing constant temperature demulsification, centrifuging after demulsification to obtain soybean oil. The method of the invention has the advantages of simple technology device, low cost, easy degradation of waste liquid, low toxicity and no pollution generation, and the mixed demulsifying bacteria whole liquid culture medium has good thermostability and repeated usage.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

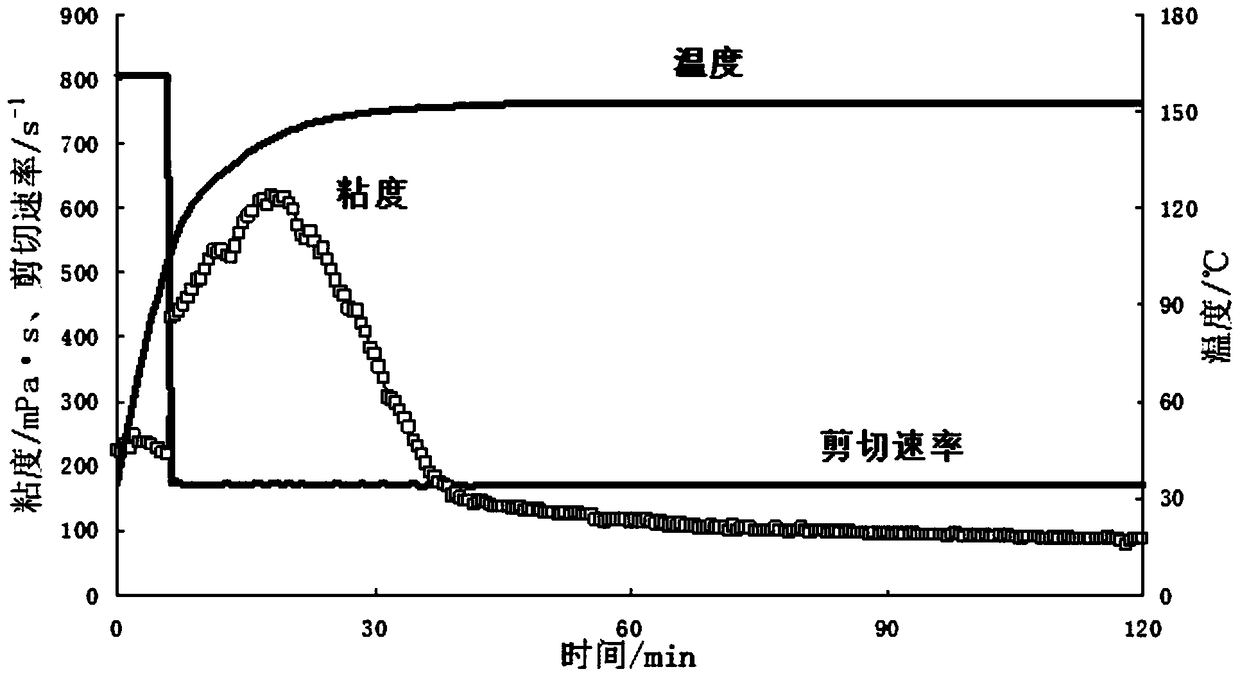

Inverse-phase micro-emulsion polymer fracturing fluid system with online construction function

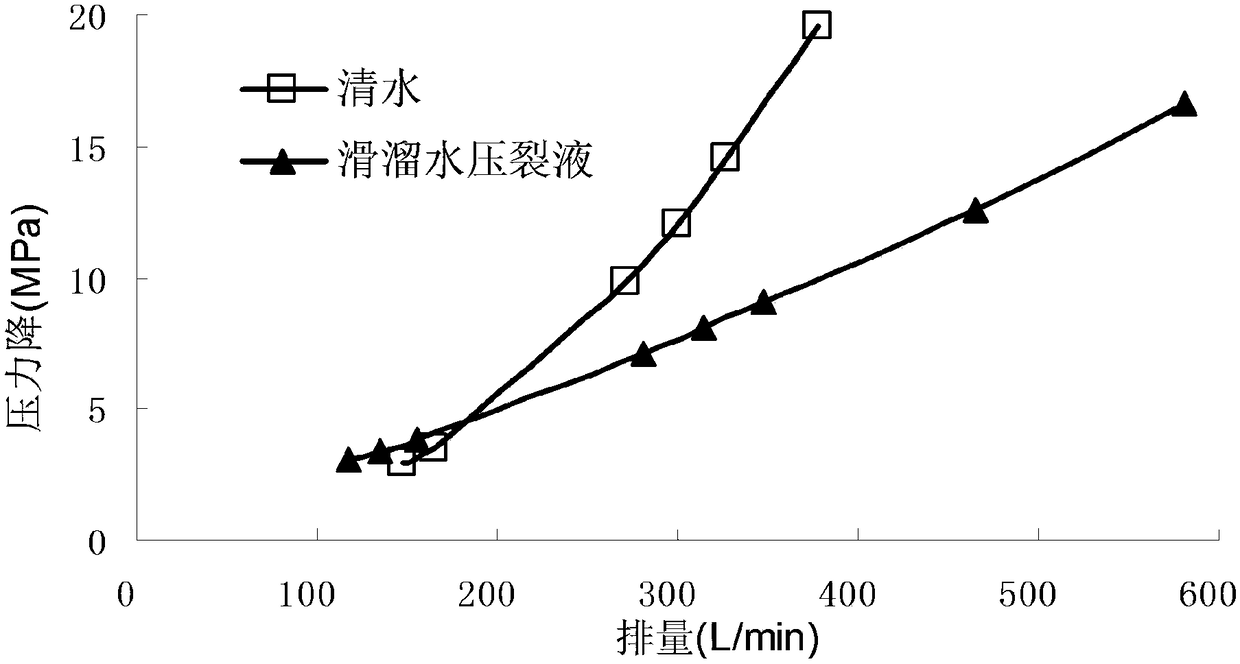

ActiveCN108559479AGood resistance reduction effectEasy to reuseDrilling compositionMethacrylatePolymer science

The invention discloses an inverse-phase micro-emulsion polymer fracturing fluid system with an online construction function. The inverse-phase micro-emulsion polymer fracturing fluid system comprisesinstant dissolving emulsion thickening agents, functional auxiliaries, a clay stabilizer and fluid preparation water. The instant dissolving emulsion thickening agents are inverse-phase micro-emulsion polymers, and inverse-phase micro-emulsion polymerization is carried out on raw materials including acrylamide, acrylic acid, strong-hydrophilicity monomers, a functional monomer A, a functional monomer B, pH (potential of hydrogen) regulators, solubilizers, composite emulsifiers, oil solvents, initiators and deionized water to obtain the instant dissolving emulsion thickening agents; the functional monomer A is methyl methacrylate or ethyl methacrylate or a mixture of the methyl methacrylate and the ethyl methacrylate; the functional monomer B is vinylphosphonic acid or vinyl sulfonic acid;the functional auxiliaries are non-ionic surfactants; the clay stabilizer is potassium chloride, and the fluid preparation water is clear water or high-mineralization water or treated stratum flow-back fluid. The inverse-phase micro-emulsion polymer fracturing fluid system has the advantages that the inverse-phase micro-emulsion polymer fracturing fluid system is high in dispersing and swelling speed and can be prepared in a batch manner or can be continuously mixed, 'online construction' requirements even can be completely met by the inverse-phase micro-emulsion polymer fracturing fluid system, processes for constructing the inverse-phase micro-emulsion polymer fracturing fluid system are simple, and the fracturing cost can be reduced.

Owner:SOUTHWEST PETROLEUM UNIV +1

Demulsification method by soybean grease microbe extraction through aqueous enzymatic method

ActiveCN102796613BImprove thermal stabilitySimple process equipmentFatty-oils/fats refiningFatty-oils/fats productionLiquid mediumProcess equipment

The invention relates to a demulsification method by soybean grease microbe extraction through an aqueous enzymatic method, which belongs to the plant grease extraction technology. The method comprises the following steps: 1) crushing soybean to obtain a puffed material by using an extruding puffed pretreatment, mixing the puffed material and water to obtain a mixed liquor, adding alkaline protease in the mixed liquor for enzymatic hydrolysis, centrifuging after enzymatic hydrolysis to obtain free oil, an emulsion, a hydrolysate and residues; 2) fermenting the mixed demulsifying bacteria with different complex formulation proportion through a MMSM inorganic salt liquid medium to obtain a mixed demulsifying bacteria whole liquid culture medium; 3) adjusting the pH value to the emulsion obtained in the step 1) to neutrality, fully and uniformly mixing with the mixed demulsifying bacteria whole liquid culture medium, and standing and performing constant temperature demulsification, centrifuging after demulsification to obtain soybean oil. The method of the invention has the advantages of simple technology device, low cost, easy degradation of waste liquid, low toxicity and no pollution generation, and the mixed demulsifying bacteria whole liquid culture medium has good thermostability and repeated usage.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

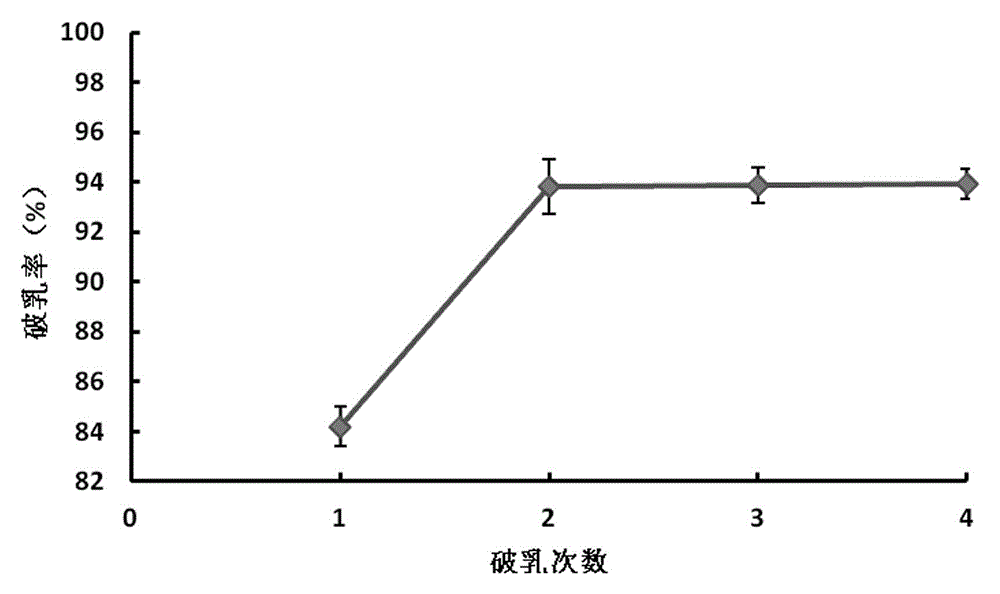

Biological enzyme demulsification method for extracting soybean oil and fat by aqueous enzymatic method

ActiveCN102766533AHigh recovery rateImprove qualityFatty-oils/fats refiningFatty-oils/fats productionAlkaline proteaseAlcohol

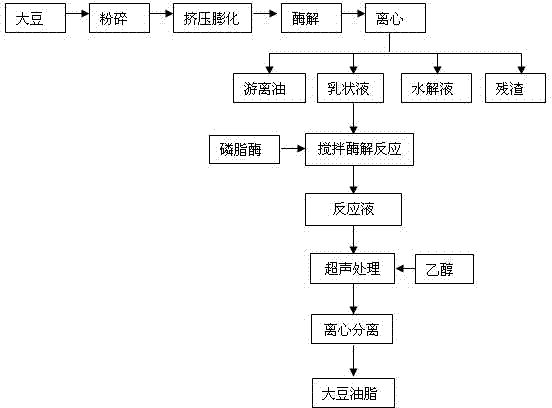

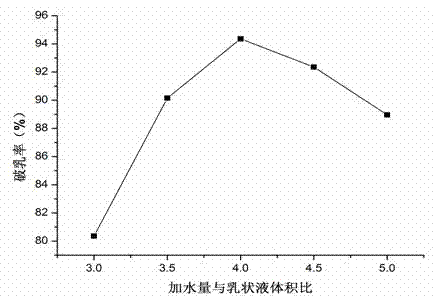

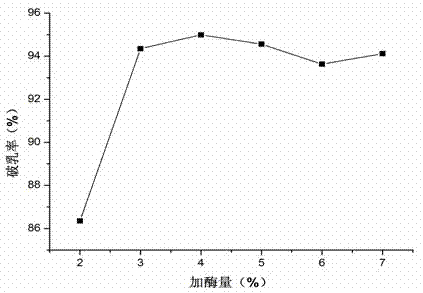

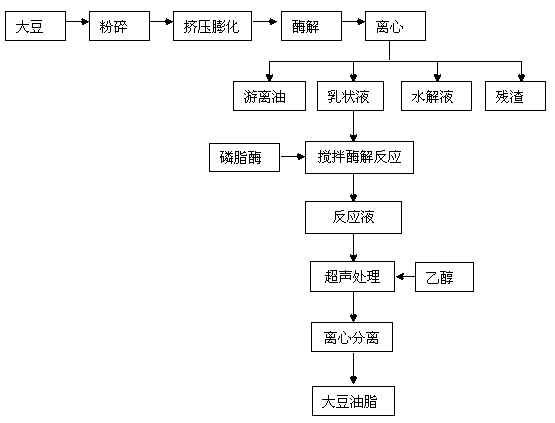

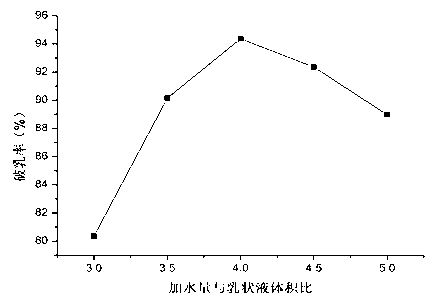

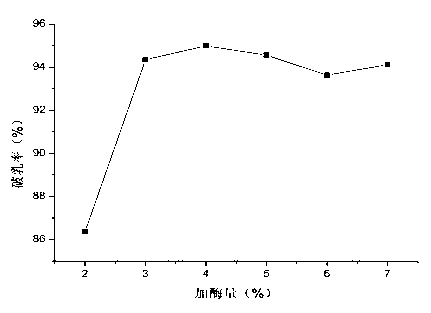

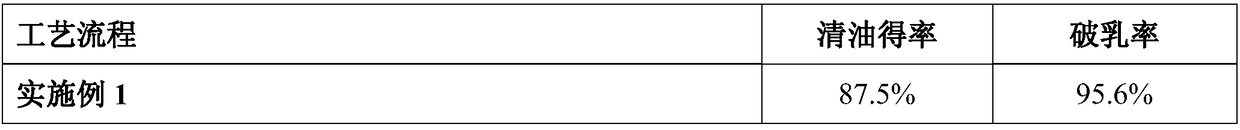

The invention discloses a biological enzyme demulsification method for extracting soybean oil and fat by an aqueous enzymatic method and belongs to vegetable oil and fat extraction technologies. The method includes the following steps of (1) smashing puffed soybeans, mixing the smashed soybeans with water to obtain a mixed liquor, adding alkaline protease in the mixed liquor to perform an enzymolysis reaction, and after the enzymolysis, performing a centrifugal separation to obtain free oil, an emulsion, a hydrolysate and residues; (2) adding water and phospholipase in the emulsion obtained from the step (1) to stir to perform the enzymolysis reaction to obtain a reaction solution; and (3) adding alcohol in the reaction solution obtained from the step (2) to perform an ultrasonic processing, and then performing the centrifugal separation to obtain the soybean oil and fat. The biological enzyme demulsification method for extracting the soybean oil and fat by the aqueous enzymatic method has the advantages that the required processing equipment is simple, the demulsification time is short, the method is environment-friendly, and the demulsification rate is high.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Demulsification method for aqueous enzymatic extraction of soybean oil and fat

InactiveCN102911782ASimplified demulsification processHigh demulsification rateFatty-oils/fats productionOil and greaseVegetable oil

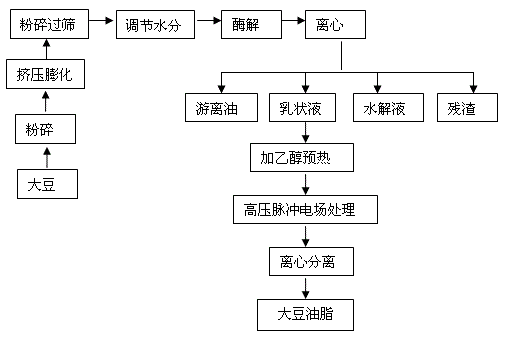

The invention relates to a demulsification method for aqueous enzymatic extraction of soybean oil and fat, which belongs to the vegetable oil and fat extraction technology and comprises the steps as follows: crushing soybeans and performing extrusion preprocessing after moisture adjustment to obtain an extruded material; crushing the extruded material and mixing the extruded material with water after sieving to obtain a mixed liquor; adding alkaline protease into the mixed liquor to perform enzymolysis, and performing centrifugal separation after enzymolysis to obtain free oil, emulsion, hydrolysate and residue; adding ethanol into the emulsion, heating up to 60 DEG C after stirring, keeping for 30 min, and performing demulsification processing through a high intensity pulsed electric field; and performing centrifugal separation after the demulsification processing, so as to obtain the soybean oil and fat. The demulsification method has the advantages of simple required technology equipment, convenience for operation, high demulsification rate, and short time and high safety for demulsification.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method for extracting soybean oil compound breakdown emulsion by virtue of aqueous enzymatic method

ActiveCN104893817AHigh demulsification rateHigh purityFatty-oils/fats productionOil and greaseVegetable oil

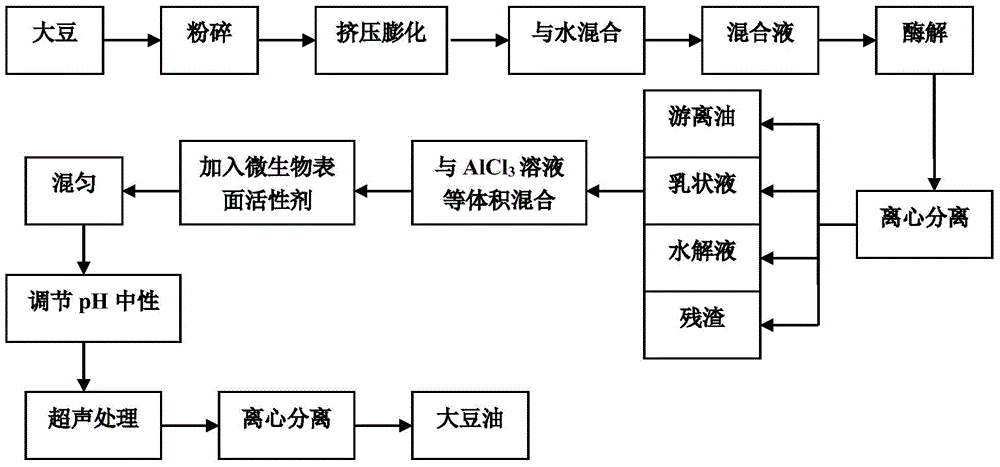

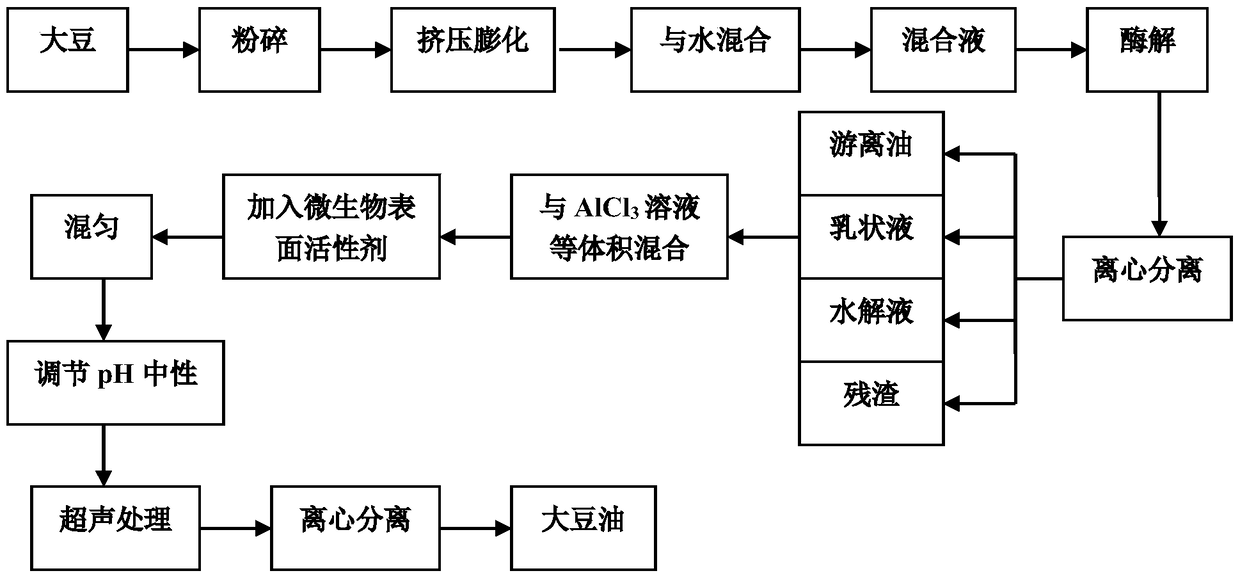

The invention provides a method for extracting soybean oil compound breakdown emulsion by virtue of an aqueous enzymatic method, and belongs to extracting and processing technologies of vegetable oil and fat. The method comprises the following steps: (1) crushing soybeans, then performing extrusion puffing to obtain a puffed material, mixing the puffed material with water to obtain a mixed solution, adding alkali protease into the mixed solution to perform enzymolysis, and then performing centrifugal separation to obtain free oil, emulsion, hydrolysate and residues; (2) mixing the emulsion with a AlCl3 solution at equal volumes, then adding a microbial surfactant, mixing uniformly, and then adjusting the pH value to be neutral; and (3) performing ultrasonic treatment on the treated emulsion, and then performing centrifugal separation to obtain soybean oil. By adopting the method, the inorganic salt AlCl3, the microbial surfactant and an ultrasonic technology are organically combined together to form an integral compound demulsification system which is low in cost and pollution-free, and is short in demulsification time and high in demulsification rate, and the obtained soybean oil is high in purity and good in quality and has a wide application prospect in processing of the vegetable oil and fat.

Owner:山东国宏生物科技有限公司

Demulsification method for extracting soybean oil by aqueous enzymatic method

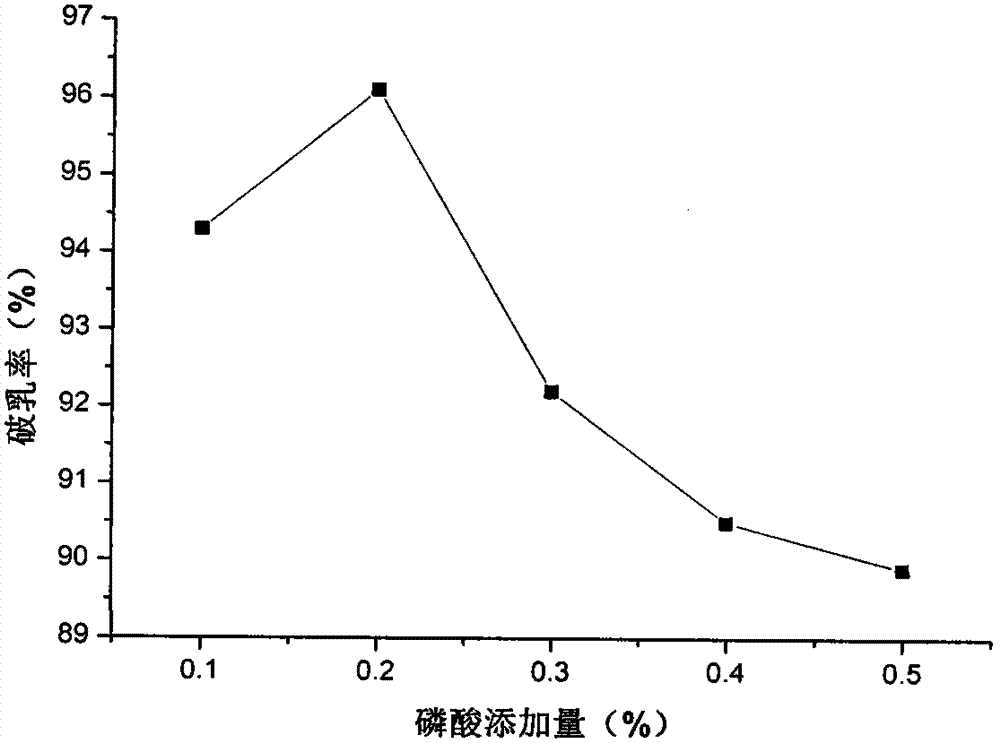

ActiveCN102732371ASimple process equipmentShort demulsification timeFatty-oils/fats productionVegetable oilProcess equipment

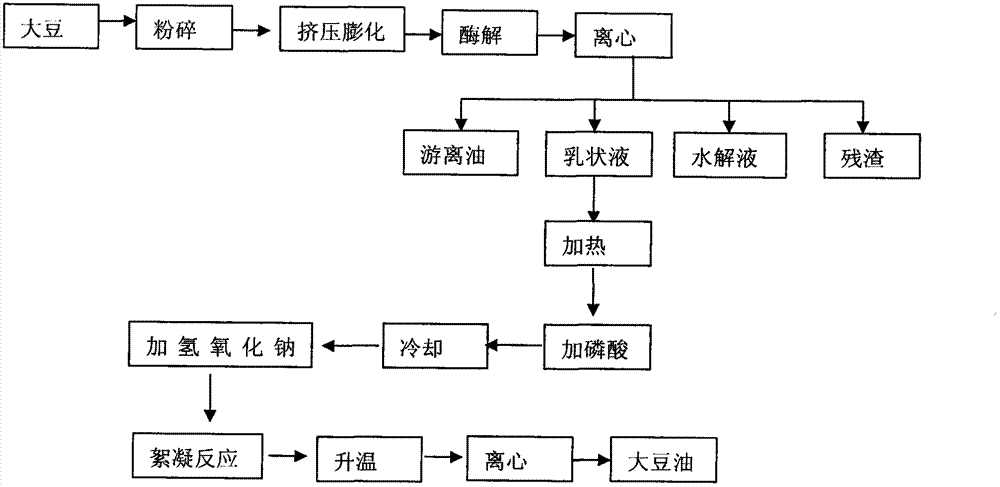

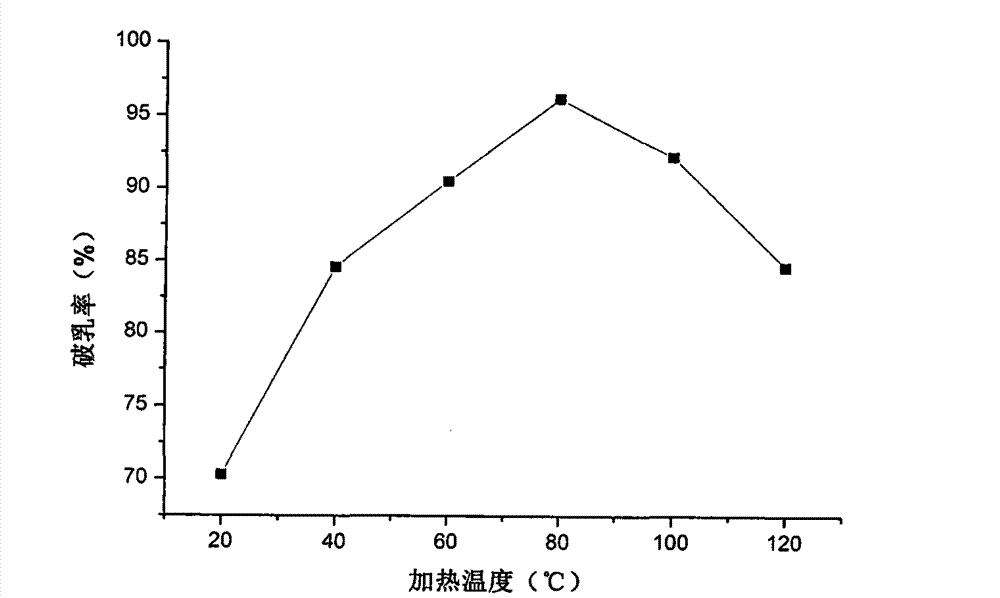

The invention relates to a demulsification method for extracting soybean oil by an aqueous enzymatic method, belonging to a vegetable oil and fat extraction technology. The method comprises the following steps of: (1) pulverizing soybeans, extruding, puffing and pretreating to obtain a puffed material; mixing the puffed material with water to obtain a mixed solution; adding alkali protease to themixed solution for enzymolysis, and then centrifuging and separating to obtain free oil, an emulsion, hydrolysate and residues; (2) heating the emulsion obtained in the step (1), and adding phosphoric acid to the heated emulsion for conditioning; cooling the reaction system, and then adding a sodium hydroxide solution to carry out a flocculation reaction; and continuously heating the system afterthe reaction, and centrifuging and separating to obtain soybean oil. The method has the advantages of simple required process equipment, short demulsification time and high demulsification rate.

Owner:山东万得福生物科技有限公司

Supercritical carbon dioxide extraction technology of suaeda salsa seed oil

InactiveCN108004015AImprove oil yieldFacilitated releaseFatty-oils/fats refiningFatty-oils/fats productionCulture fluidLinoleic acid

The invention relates to the technical field of plant oil extraction, in particular to a supercritical carbon dioxide extraction technology of suaeda salsa seed oil. The supercritical carbon dioxide extraction technology comprises the following steps: performing raw material pretreatment, performing primary enzymolysis treatment, performing supercritical extraction, performing secondary enzymolysis treatment, preparing a whole culture fluid of composite demulsifying bacteria and performing demulsification treatment. By the preparation method, through enzymolysis, supercritical extraction, enzymolysis treatment, and then demulsification treatment with the composite demulsifying bacteria, the oil extraction rate of suaeda salsa seeds is greatly increased and the linoleic acid content of thesuaeda salsa seed oil is also increased.

Owner:WEIFANG YOURONG IND

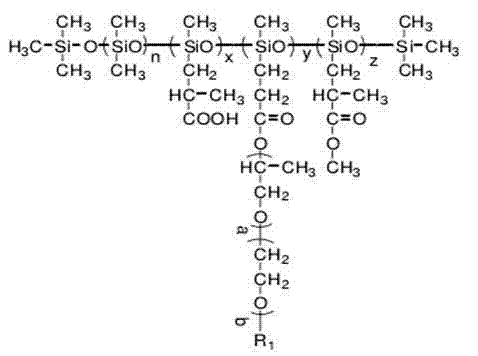

Oil-soluble condensate oil emulsion breaker and preparation method thereof

ActiveCN104498080ALow recovery rateFast demulsificationDewatering/demulsification with chemical meansHydrocarbon oils treatmentBetaineOil emulsion

The invention discloses an oil-soluble condensate oil emulsion breaker and a preparation method thereof. The oil-soluble condensate oil emulsion breaker is a compound formed by adding a cross-linking type block polyether emulsion breaker, a comb-type polysiloxane emulsion breaker and a glycine betaine type fluorocarbon surfactant to a solvent, and the compound comprises the following components in percentage by weight: 10%-25% of the cross-linking type block polyether emulsion breaker, 5%-15% of the comb-type polysiloxane emulsion breaker, 0.05%-0.2% of the glycine betaine type fluorocarbon surfactant and the balance of the solvent. The oil-soluble condensate oil emulsion breaker disclosed by the invention is suitable for the recovery of condensate oil contained in a produced fluid of a natural gas well foaming drainage gas recovery process, can achieve an ideal emulsion breaking effect of an condensate oil emulsion formed from different foaming drainage agents, has the characteristics of high emulsion breaking speed and high emulsion breaking efficiency at normal temperature, and can ensure the high-efficiency recovery of the condensate oil of a gas field.

Owner:成都华阳兴华化工有限公司

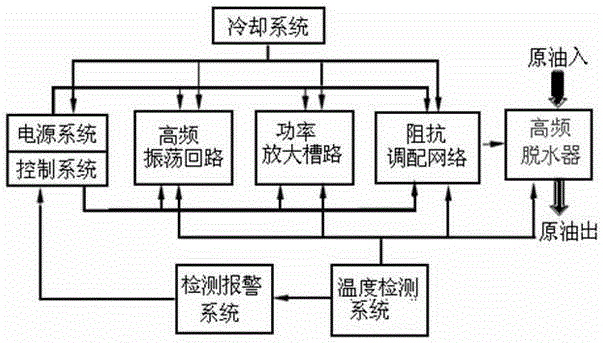

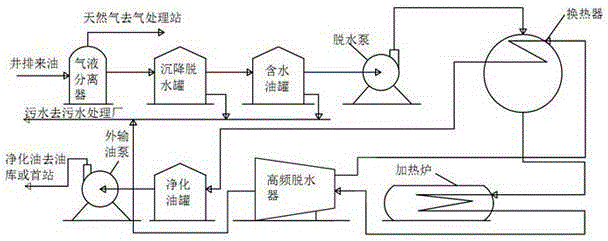

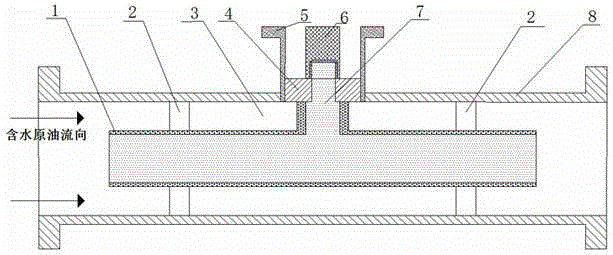

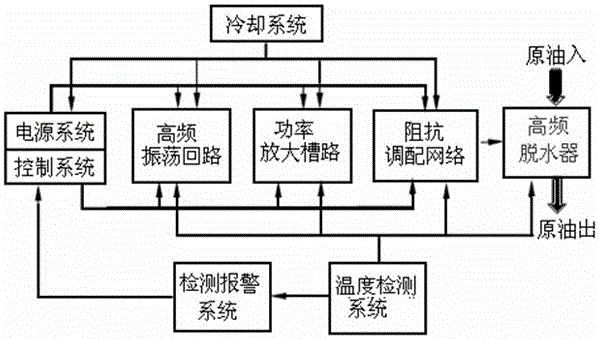

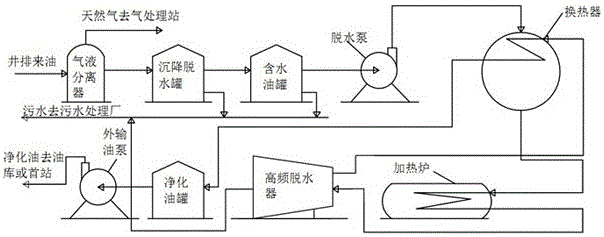

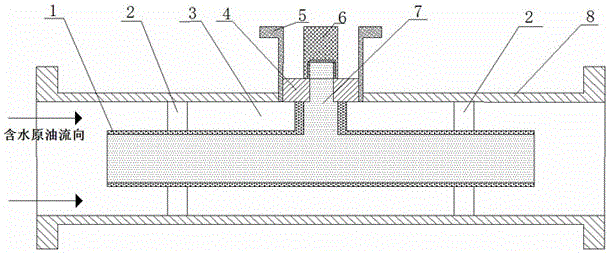

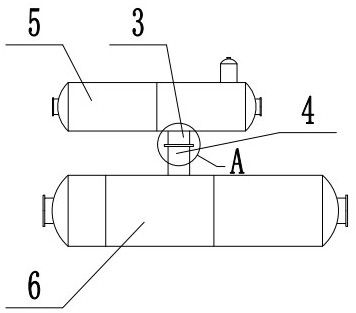

High-frequency crude oil dehydrator

ActiveCN105199777ALow viscosityEasy to separateHydrocarbon oil dewatering/demulsificationThermodynamicsControl system

The invention discloses a high-frequency crude oil dehydrator. A high-frequency dehydrator is connected with an impedance allocating network; a high-frequency radiator is connected with a temperature detection system; the temperature detection system is respectively connected with the impedance allocating network, a power amplification tank circuit, a high-frequency oscillation circuit and a detection and alarm system; the detection and alarm system is connected with a control system of a power supply system; the control system of the power supply system, the high-frequency oscillation circuit, the power amplification tank circuit and the impedance allocating network are all connected with a cooling system; a radial high-frequency electric field is generated by the high-frequency dehydrator at the high frequency; the orientation polarization is generated under the action of the electric field; two ends of water droplets induce and generate opposite charges to form an induction electric field; dipole coalescence is generated between the similar water droplets; the water droplets are condensed to form large water droplets; the large water droplets are demulsified and settled; the high-frequency electric field accelerates polar molecules to rotate at high speed and cause charge neutralization; when liquid globules lose the action of double electric layers, the liquid globules collide and gather, so that the oil and the water are separated. The high-frequency crude oil dehydrator has the characteristics of low operation cost, dehydration simplicity, high dehydration efficiency, stability and safety in dehydration, and green and environment-friendly performance.

Owner:XI'AN PETROLEUM UNIVERSITY

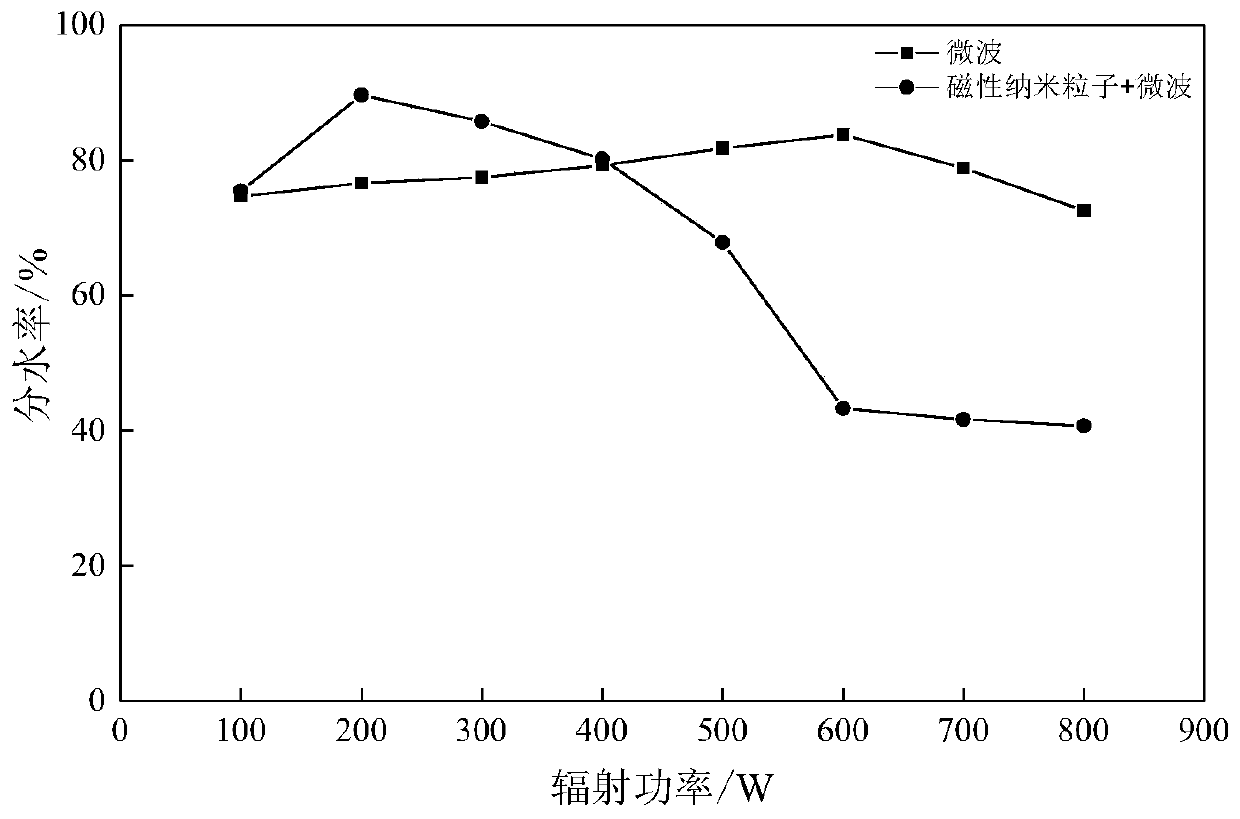

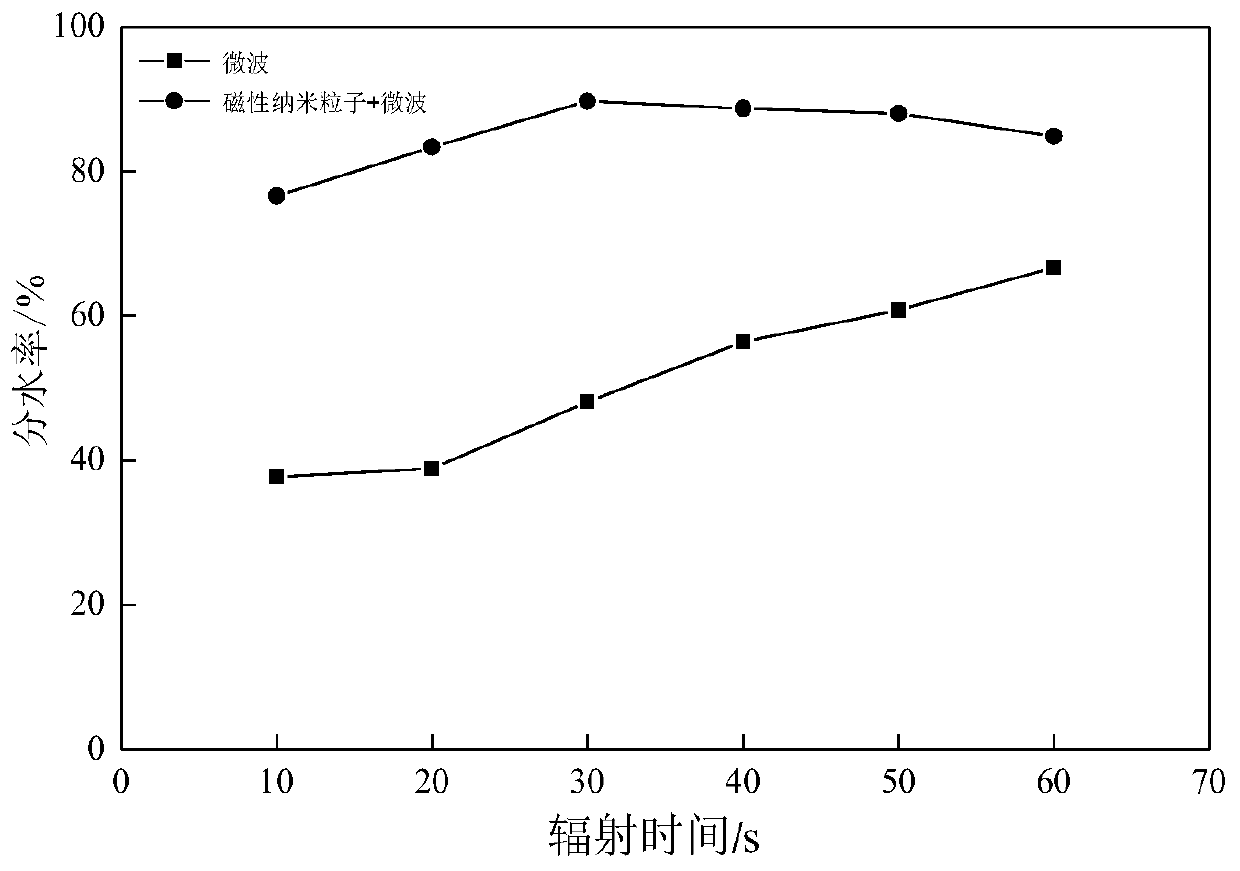

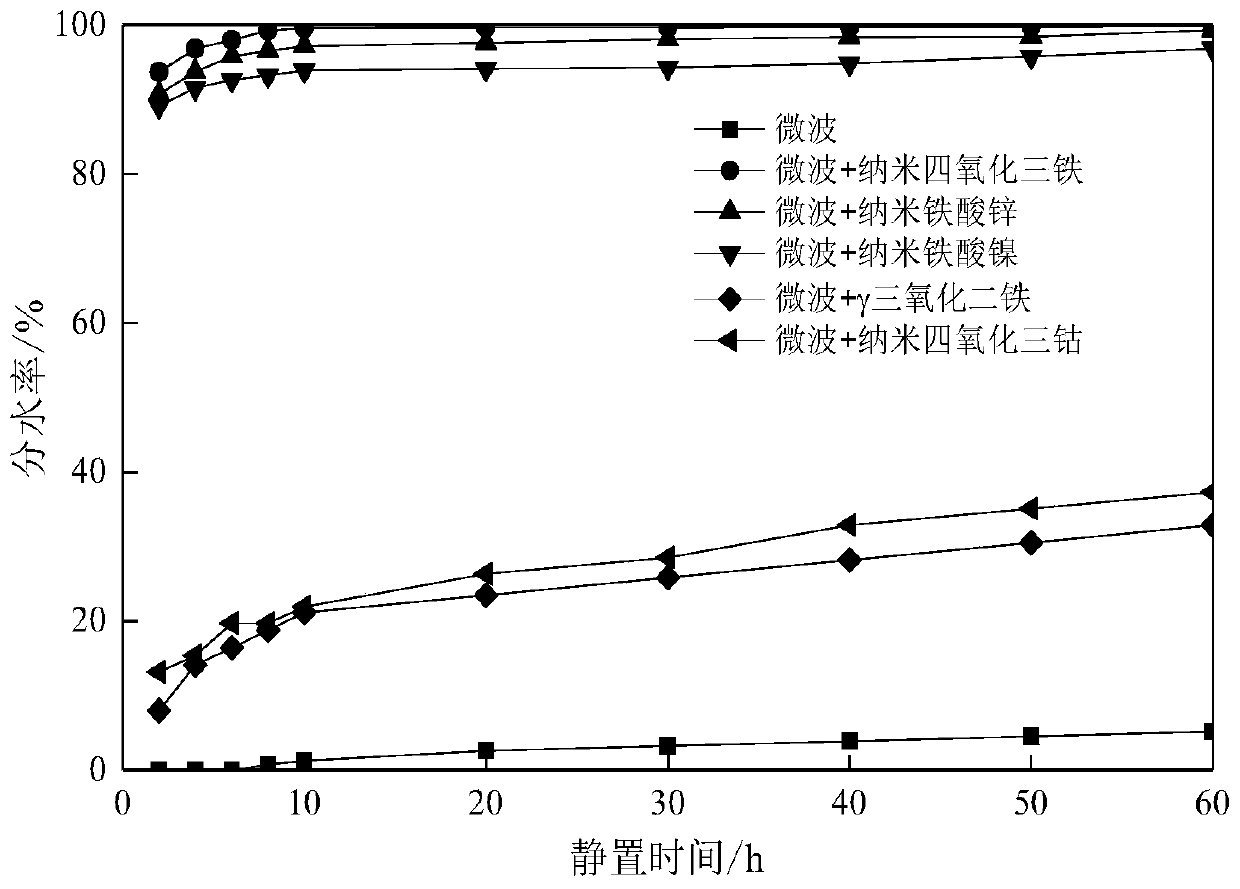

Method for treating thickened oil oil-in-water type emulsion by magnetic nanoparticles and microwave

ActiveCN111253968AHigh demulsification rateImprove demulsification efficiencyDewatering/demulsification with electric/magnetic meansEnvironmental geologyOil phase

The invention discloses a method for treating thickened oil oil-in-water type emulsion through magnetic nano particles and microwaves, which belongs to the technical field of oil-water separation engineering. By means of the coupling synergistic effect of the magnetic nanoparticles and the microwave high-frequency electromagnetic field, the demulsification rate and demulsification efficiency are greatly improved, and the water diversion rate of a high-stability thick oil O / W type emulsion can exceed 99% in a short time. The problems that a traditional chemical demulsifier is large in dosage and limited in application range, so that a catalyst is poisoned, flocculate generated after demulsification stays in a water phase or an oil phase all the time, and secondary pollution is caused to theenvironment are solved. Besides, the magnetic nanoparticles can be repeatedly recycled for multiple times, the demulsification cost is reduced to a great extent, the demulsified magnetic nanoparticles can be adsorbed and recycled again under the action of an external magnetic field, environmental pollution is avoided, and the magnetic nanoparticles have good application prospects.

Owner:XI'AN PETROLEUM UNIVERSITY

Aqueous enzymatic method for soybean fat extraction through isoelectric point demulsification

InactiveCN104987947AGuaranteed stabilitySimple process equipmentFatty-oils/fats productionOil and greaseEmulsion

The invention relates to an aqueous enzymatic method for soybean fat extraction through isoelectric point demulsification. The method comprises the following steps: crushing soybeans, extruding, crushing, screening, and adding water for mixing; adding basic protease (Protex 6L), and performing enzymolysis; centrifuging a mixed solution after enzymolysis, performing demulsification, and collecting demulsified oil and free oil together. As the emulsion contains lots of discretely distributed oil bodies serving as the main storage parts of fat, the oil bodies are positioned in the same protein net, and protein plays a role of maintaining the oil body stability, the protein structure can be destroyed to release the fat through isoelectric point demulsification. The method is simple in process and equipment, short in demulsification time and high in demulsification rate.

Owner:SHENYANG INST OF TECH

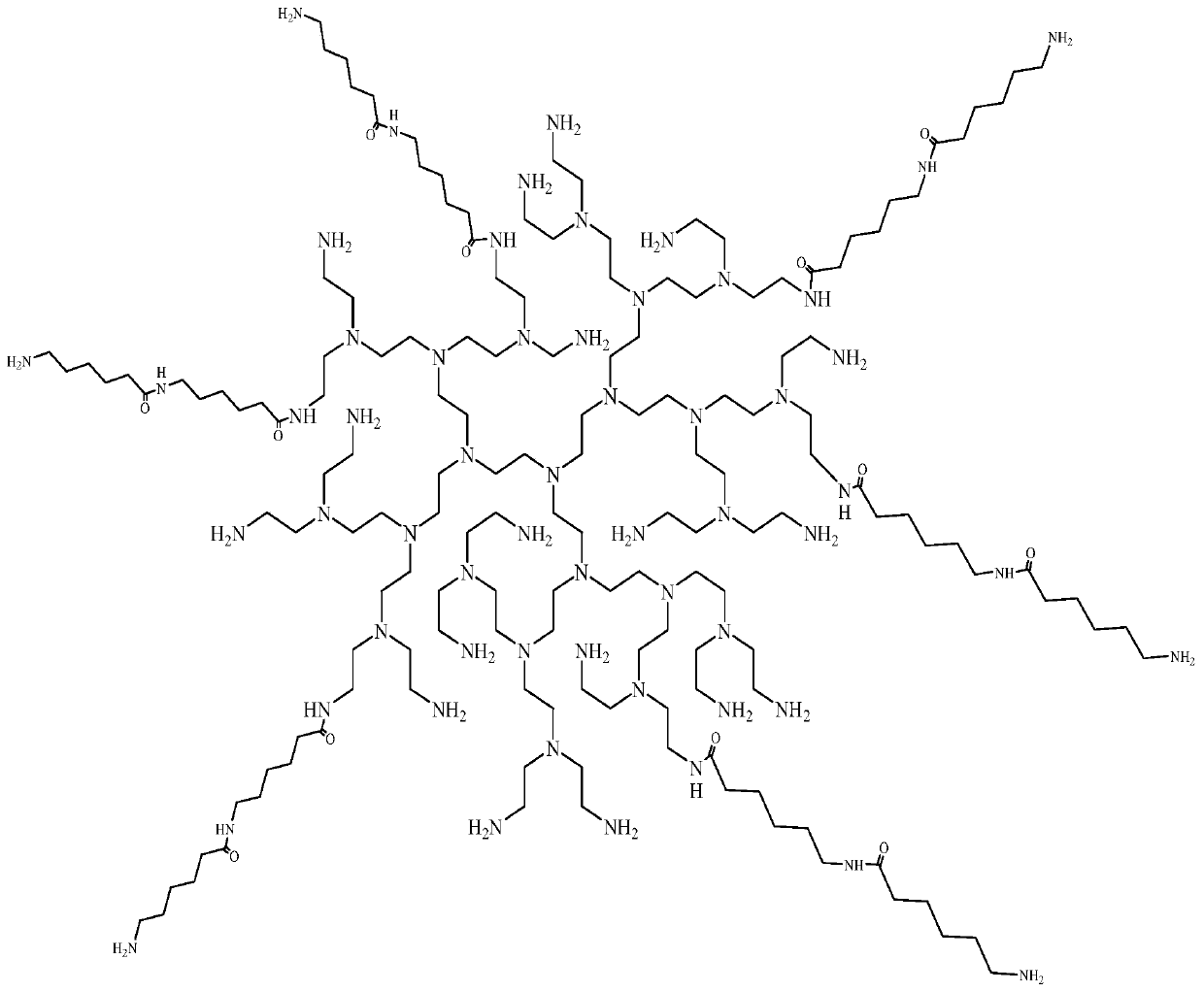

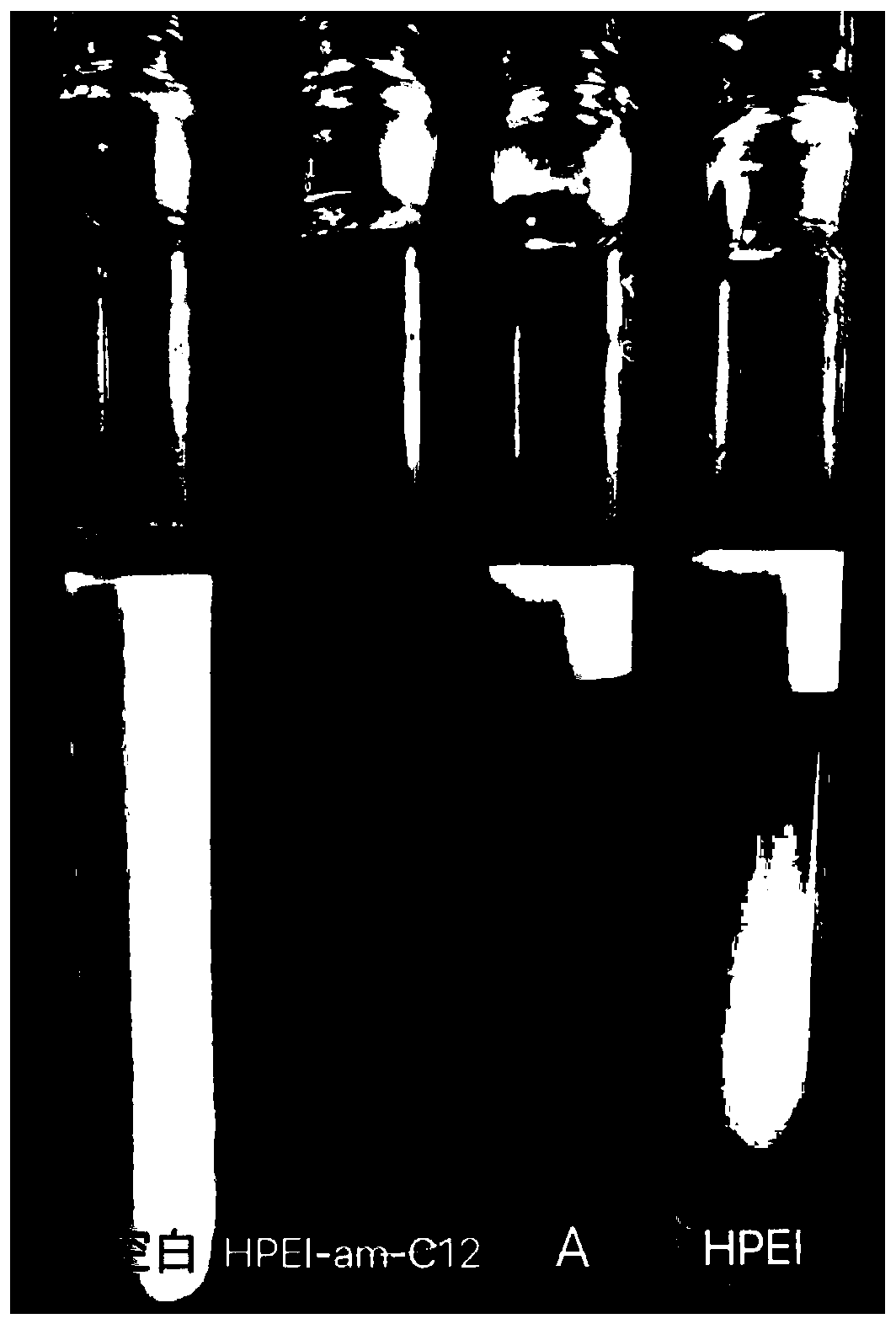

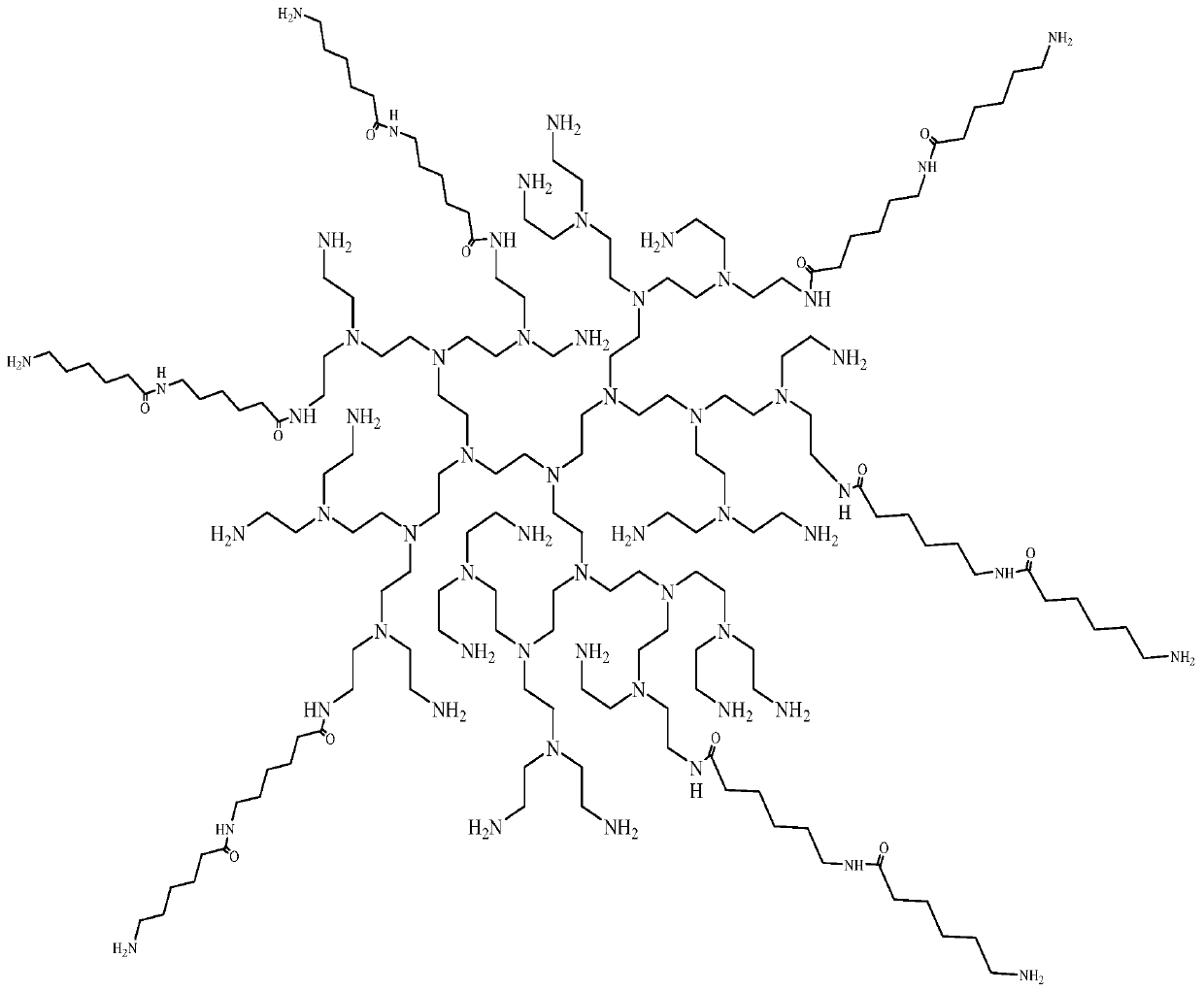

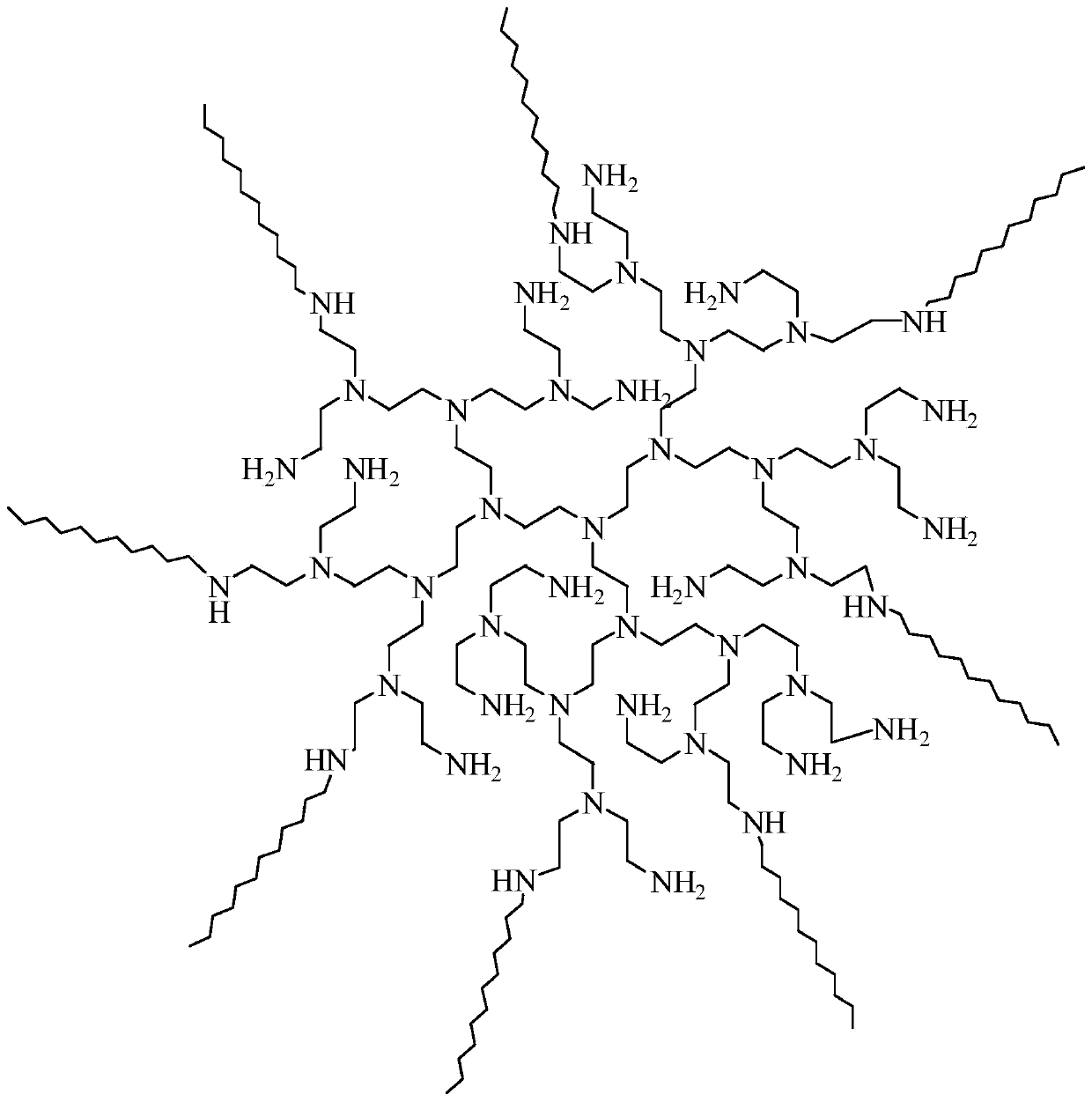

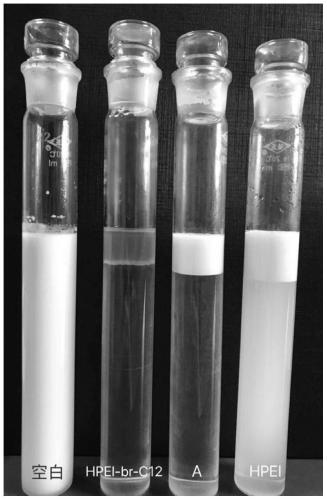

Method for demulsifying oil-in-water emulsion

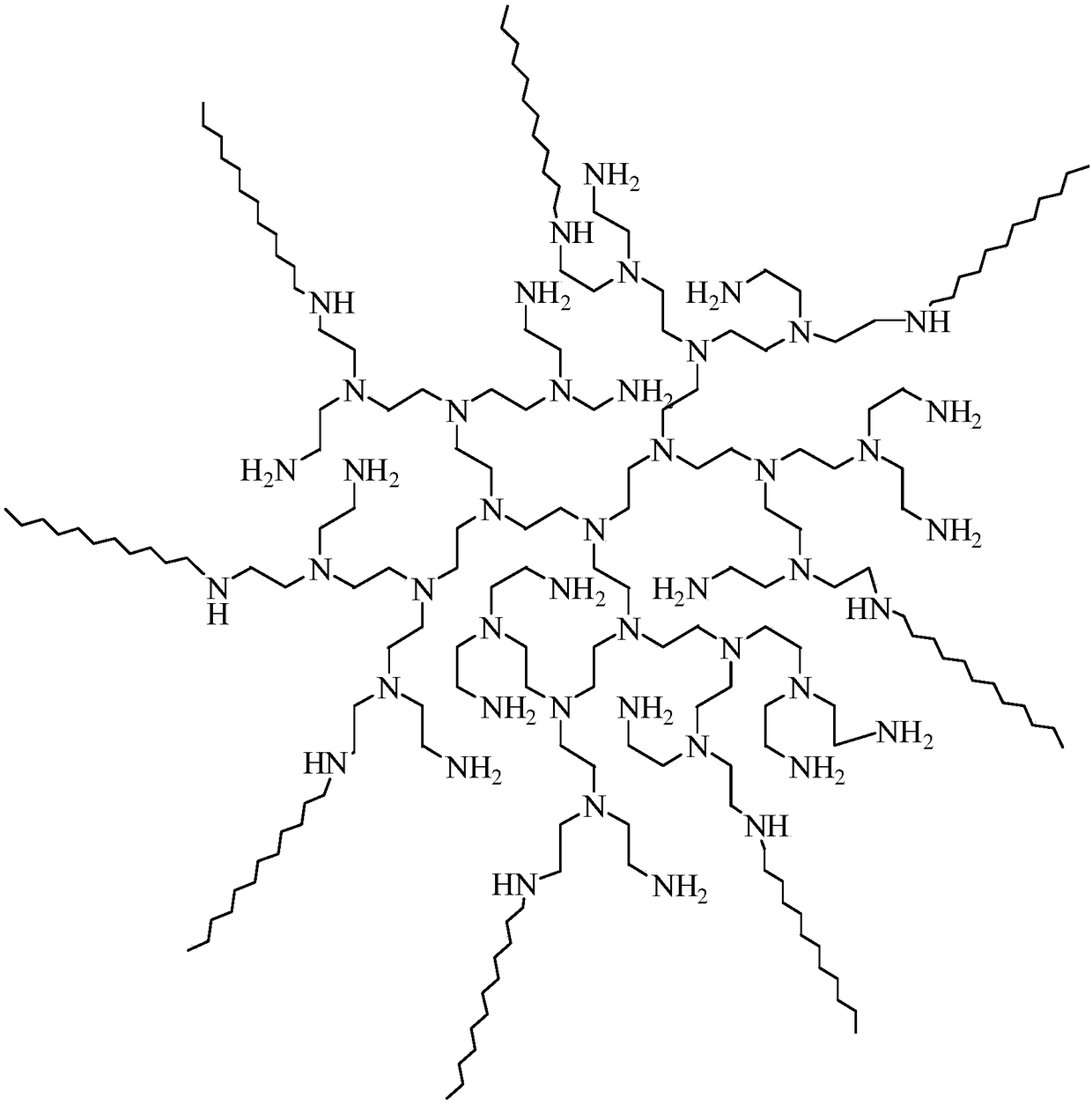

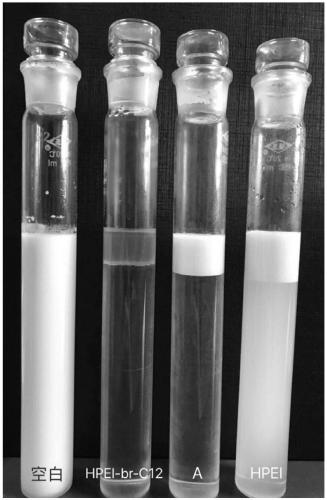

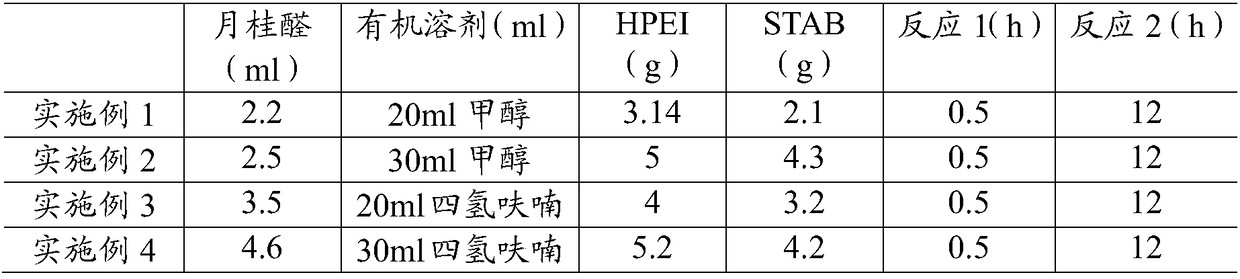

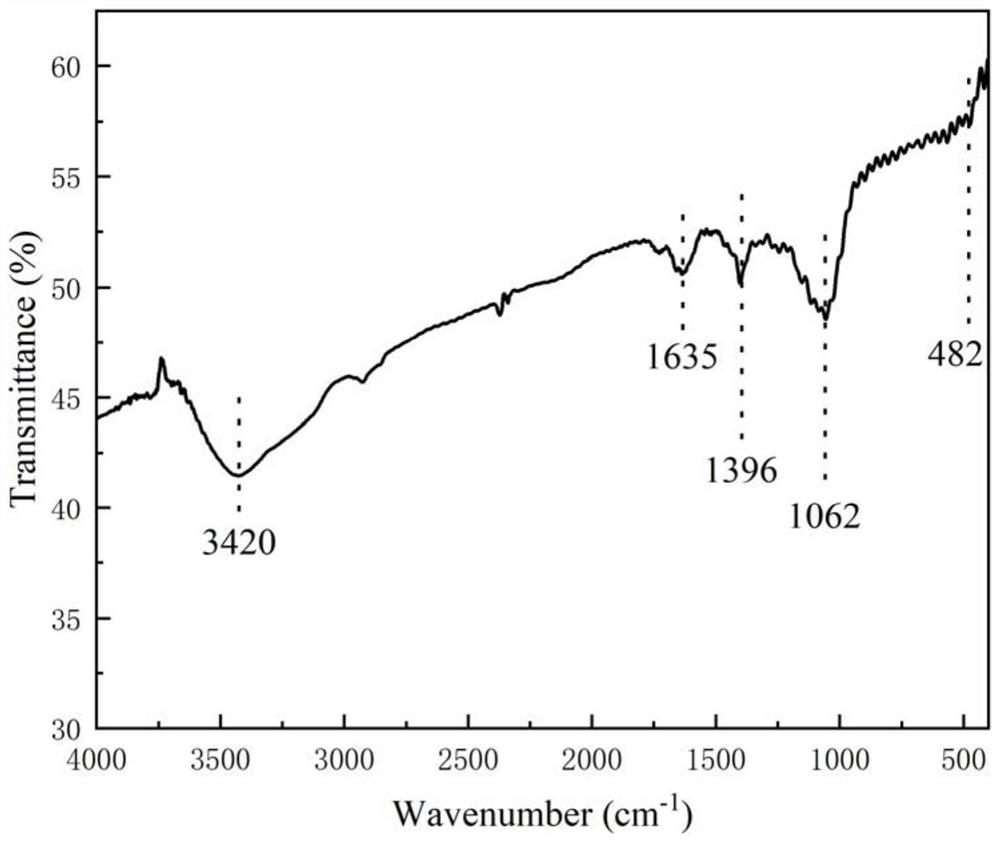

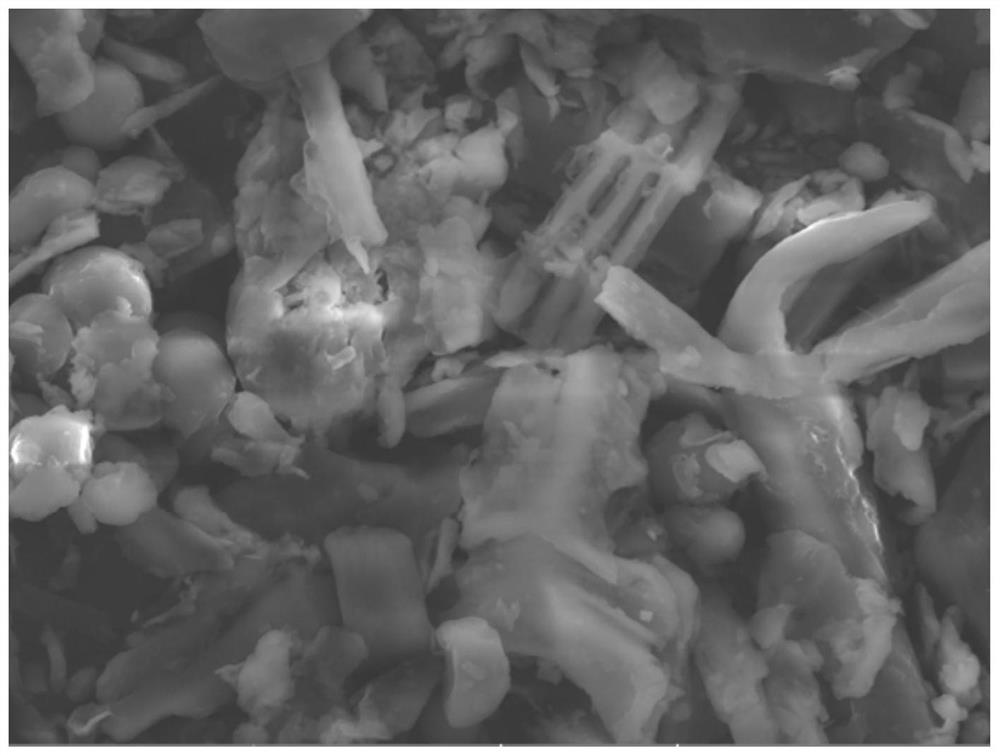

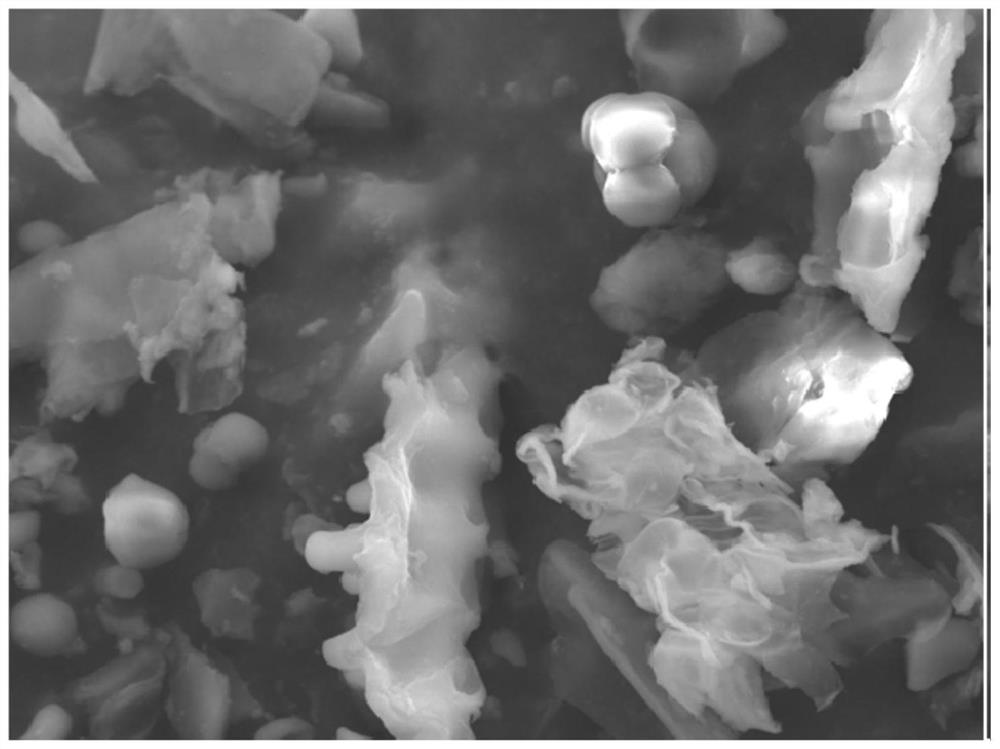

ActiveCN109370635AStrong adsorption capacityHigh demulsification rateDewatering/demulsification with chemical meansAldehydeOil content

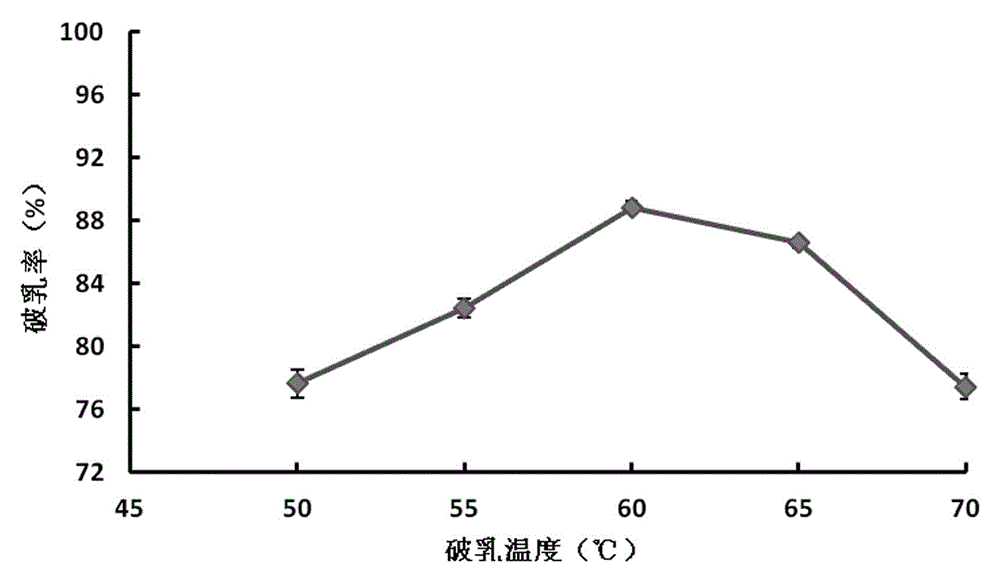

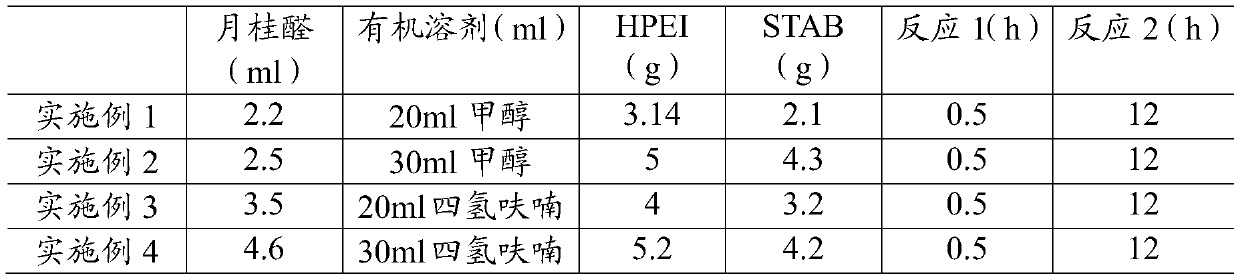

The invention relates to a method for demulsifying oil-in-water emulsion. The method comprises the following steps: 1) carrying out an aldimine condensation reaction on lauric aldehyde and hyperbranched polyethyleneimine, and performing reductive amination to obtain amphipathic hyperbranched polyethyleneimine modifier, wherein a feed ratio of the lauric aldehyde to hyperbranched polyethyleneimineis (1-6ml):(2-6g); the core of the amphipathic hyperbranched polyethyleneimine modifier is hyperbranched polyethyleneimine with strong hydrophilic property, and the shell is composed of oleophilic dodecyl and hydrophilic amino; and 2) dispersing the amphipathic hyperbranched polyethyleneimine modifier into the oil-in-water emulsion for demulsifying. According to the method, the oil content of an aqueous phase of the oil-in-water emulsion is less than 5% in a short time, the moisture content of an oil phase can be reduced to 0.1% or less, the residual emulsion layer is extremely thin even disappears, and a clear oil-water interface is formed.

Owner:ZHEJIANG UNIV

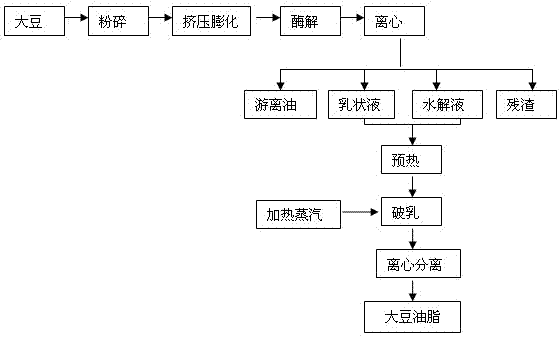

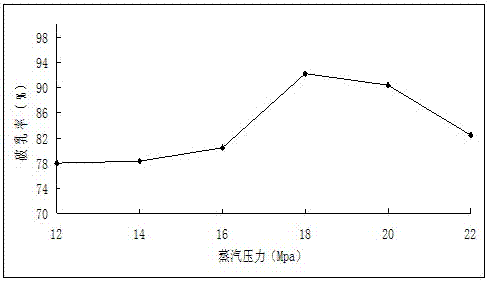

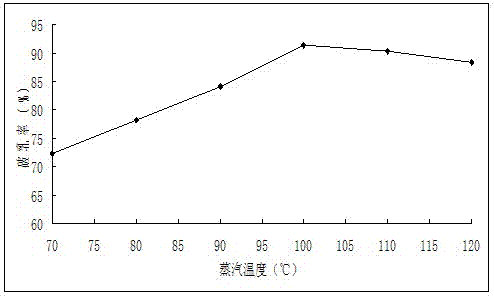

High-pressure steam emulsion breaking method for aqueous enzymatic extraction of soybean oil

ActiveCN102827686ASimplified demulsification processHigh demulsification rateFatty-oils/fats refiningFatty-oils/fats productionOil and greaseAlkaline protease

The invention discloses a high-pressure steam emulsion breaking method for the aqueous enzymatic extraction of soybean oil, and belongs to a vegetable oil and fat extraction technology. The method comprises the following steps of: (1) performing extruding-expansion pre-treatment on crushed soybeans to obtain expanded materials, mixing the expanded materials and water to obtain a mixed solution, adding alkaline proteases into the mixed solution for enzymolysis, and performing centrifugal separation to obtain free oil, emulsion, hydrolysate and residues after the enzymolysis; (2) preheating theemulsion and the hydrolysate, which are obtained in the step (1), and introducing high-pressure heating steam into the preheated emulsion and the preheated hydrolysate for emulsion breaking; and (3) performing centrifugal separation to obtain the soybean oil after the emulsion breaking. Process equipment required by the method is simple, and the method is convenient to operate, high in emulsion breaking rate and short in emulsion breaking time.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

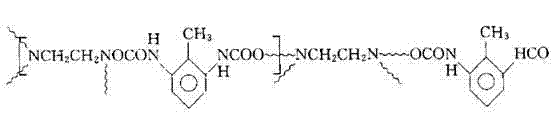

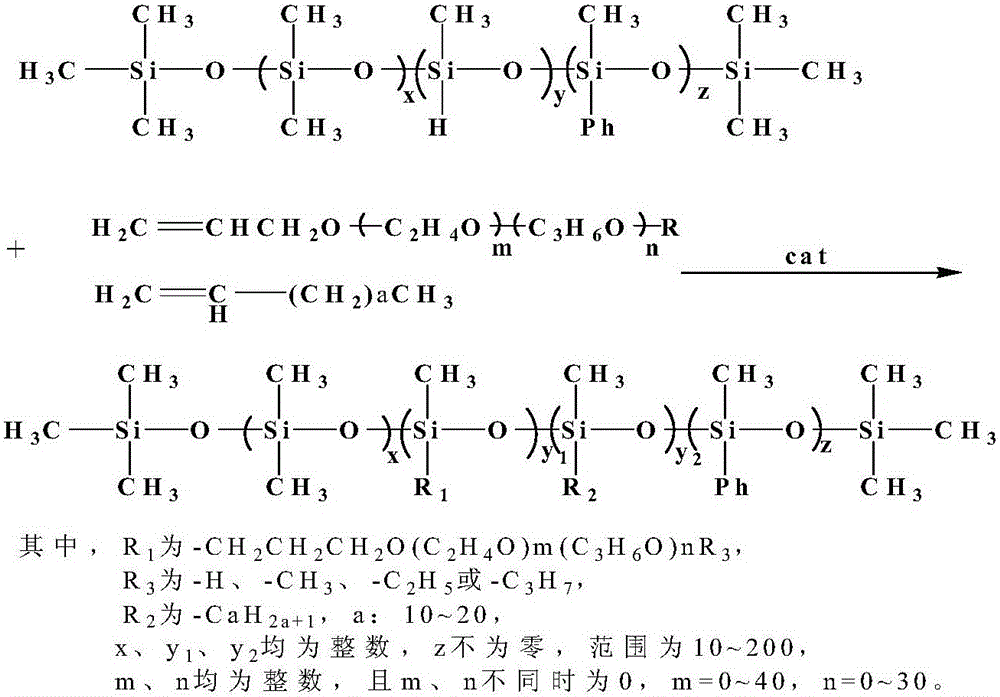

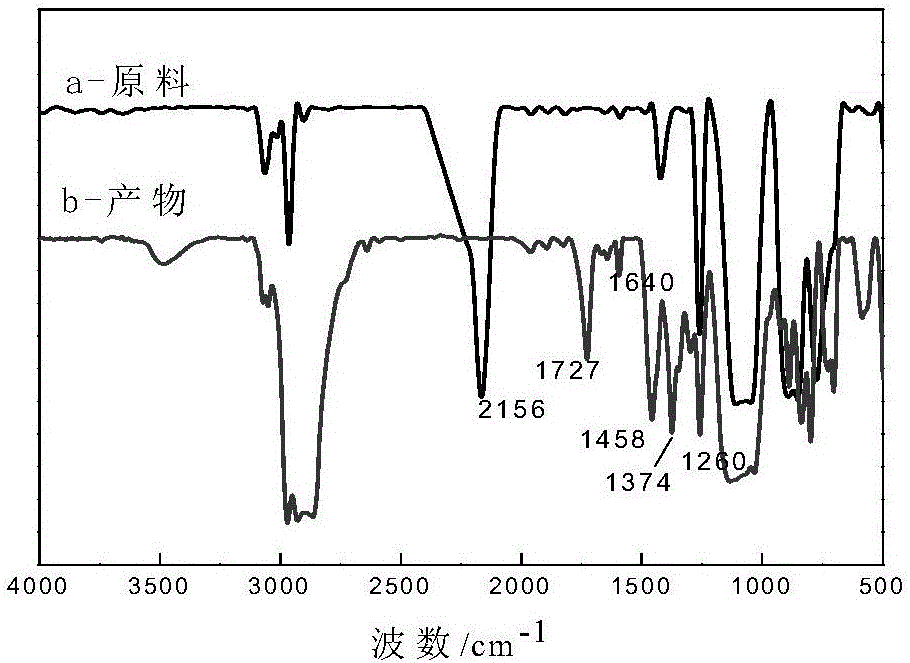

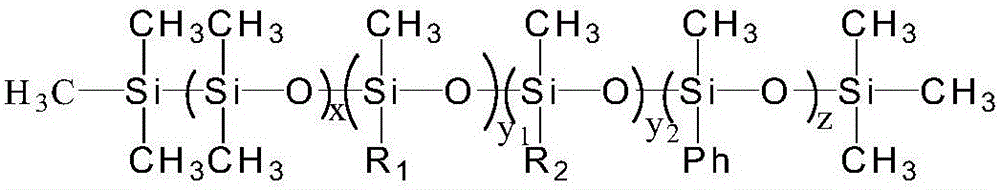

Oil-soluble demulsifier and preparation method thereof

InactiveCN105778107AGood solubility and diffusionAchieve separationDewatering/demulsification with chemical meansDemulsifierHydrogen

The invention discloses an oil-soluble demulsifier and a preparation method thereof. The preparation method comprises the following steps: adding phenyl hydrogen-containing silicone oil and an organic solvent into a reaction kettle; heating to 70 to 75 DEG C with stirring; adding a suitable amount of catalyst at the temperature; then heating to 80 to 130 DEG C; dropwise adding a mixture of long-chain carbon olefins and polyether; after the mixture is dropwise added, reacting for 5 to 10 hours at the temperature; distilling under a reduced pressure to remove low-boiling-point substances and unreacted raw materials to obtain the novel oil-soluble demulsifier, wherein the molar ratio of the phenyl hydrogen-containing silicone oil to the mixture of polyether and long-chain alkyl is 1:(1-1.3); the molar ratio of polyether to long-chain carbon olefins is 1:(1-4). The novel oil-soluble demulsifier provided by the invention can prolong action time in demulsification application, and moreover, has the advantages of high-efficiency demulsifying effect, wide application range, small using amount and low toxicity.

Owner:SHAANXI UNIV OF SCI & TECH

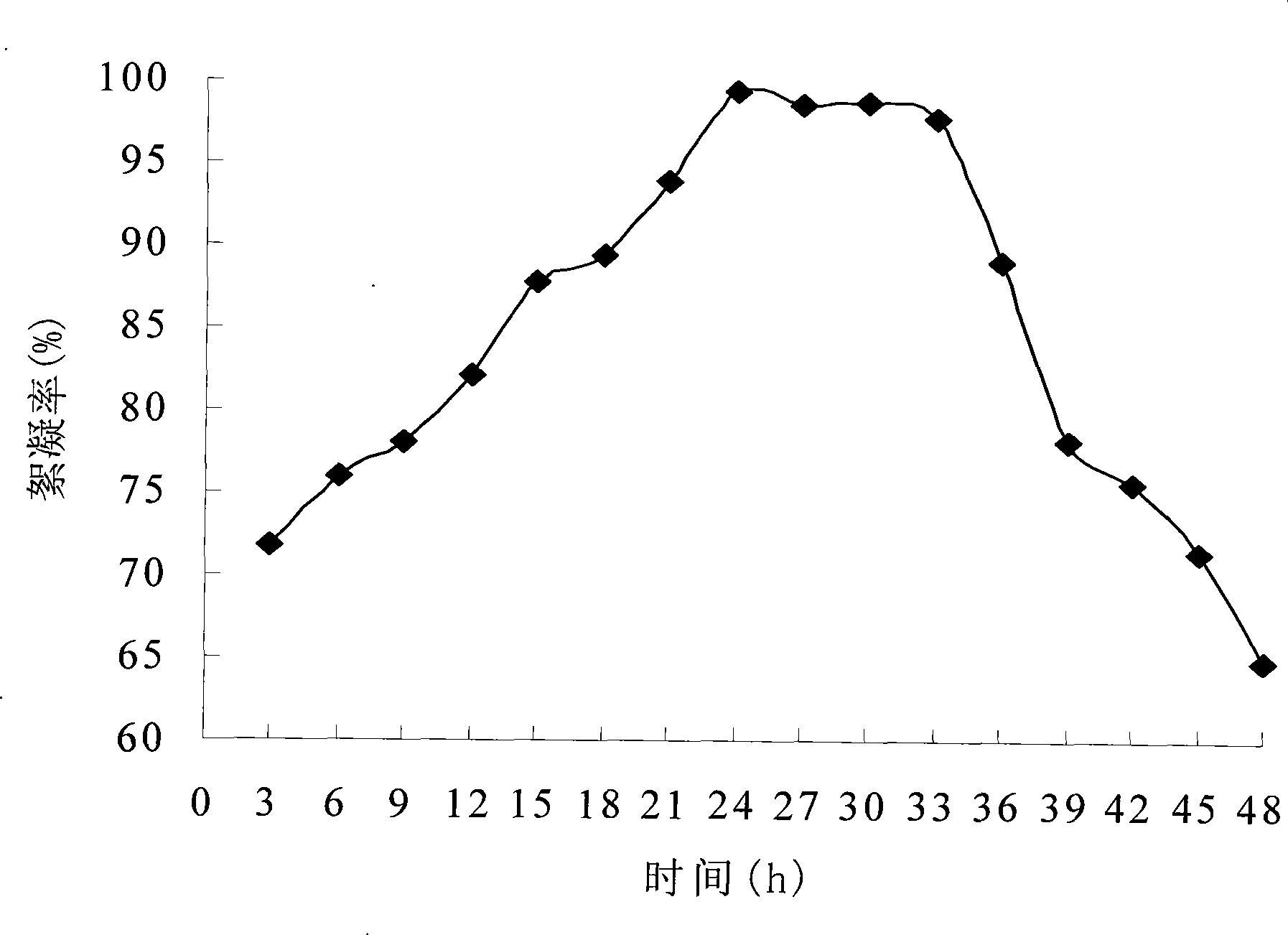

Method for separating and screening flocculation and demulsification double-function bacterial strain and culture medium used thereby

InactiveCN101434925AHigh demulsification rateHigh flocculation rateBacteriaMicroorganism based processesSewageBacterial colony

The invention discloses a method for separating and filtering flocculating-demulsificating dual-functional strains and a culture medium that is used, relates to a strain separating and filtering method and a culture medium that is used, and solves the problems that existing oily sewage or oily sludge processing methods need two-stage processing of industrial strains that is divided into flocculating and demulsificating, has long process time, high energy consumption, high cost and more equipments, and two industrial strains cannot process oily sewage or oily sludge in high efficiency simultaneously in the same environment. The separating method comprises the following steps: 1. diluents with a plurality of proportions and different concentrations are prepared; 2. bacteria colonies are cultivated in a test tube; 3. individual bacterial colonies are selected and cultivated at constant temperature; and 4. separation and purification are implemented until the appearance of pure strains, and then the separation can be implemented. The separated and filtered flocculating-demulsificating dual-functional strains can simultaneously generate demulsificating and flocculating active ingredients, and are characterized by high demulsificating and flocculating rate. The culture medium that is used for filtering has strong directivity. The method for separating and filtering flocculating-demulsificating dual-functional strains has the advantages of short process time, saved energy, less cost and simple equipments.

Owner:HARBIN INST OF TECH

Biological enzyme demulsification method for extracting soybean oil and fat by aqueous enzymatic method

ActiveCN102766533BHigh recovery rateImprove qualityFatty-oils/fats refiningFatty-oils/fats productionAlkaline proteaseAlcohol

The invention discloses a biological enzyme demulsification method for extracting soybean oil and fat by an aqueous enzymatic method and belongs to vegetable oil and fat extraction technologies. The method includes the following steps of (1) smashing puffed soybeans, mixing the smashed soybeans with water to obtain a mixed liquor, adding alkaline protease in the mixed liquor to perform an enzymolysis reaction, and after the enzymolysis, performing a centrifugal separation to obtain free oil, an emulsion, a hydrolysate and residues; (2) adding water and phospholipase in the emulsion obtained from the step (1) to stir to perform the enzymolysis reaction to obtain a reaction solution; and (3) adding alcohol in the reaction solution obtained from the step (2) to perform an ultrasonic processing, and then performing the centrifugal separation to obtain the soybean oil and fat. The biological enzyme demulsification method for extracting the soybean oil and fat by the aqueous enzymatic method has the advantages that the required processing equipment is simple, the demulsification time is short, the method is environment-friendly, and the demulsification rate is high.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

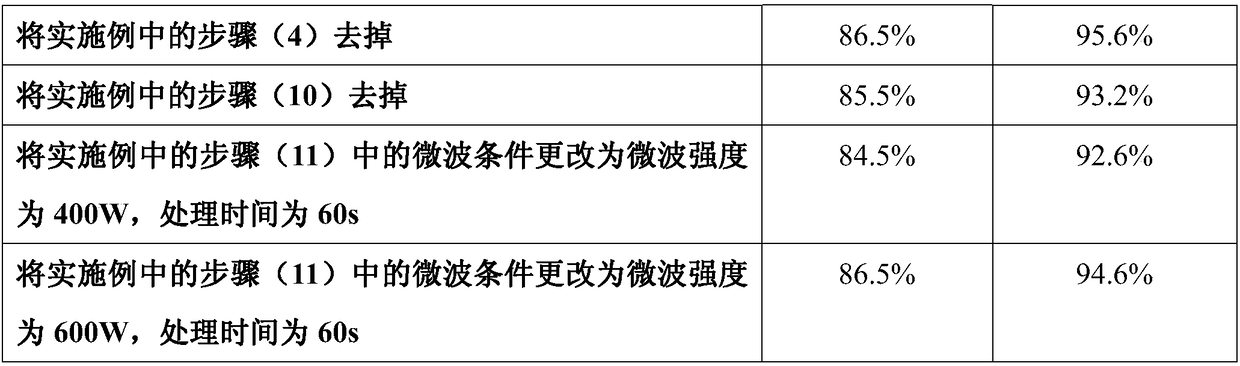

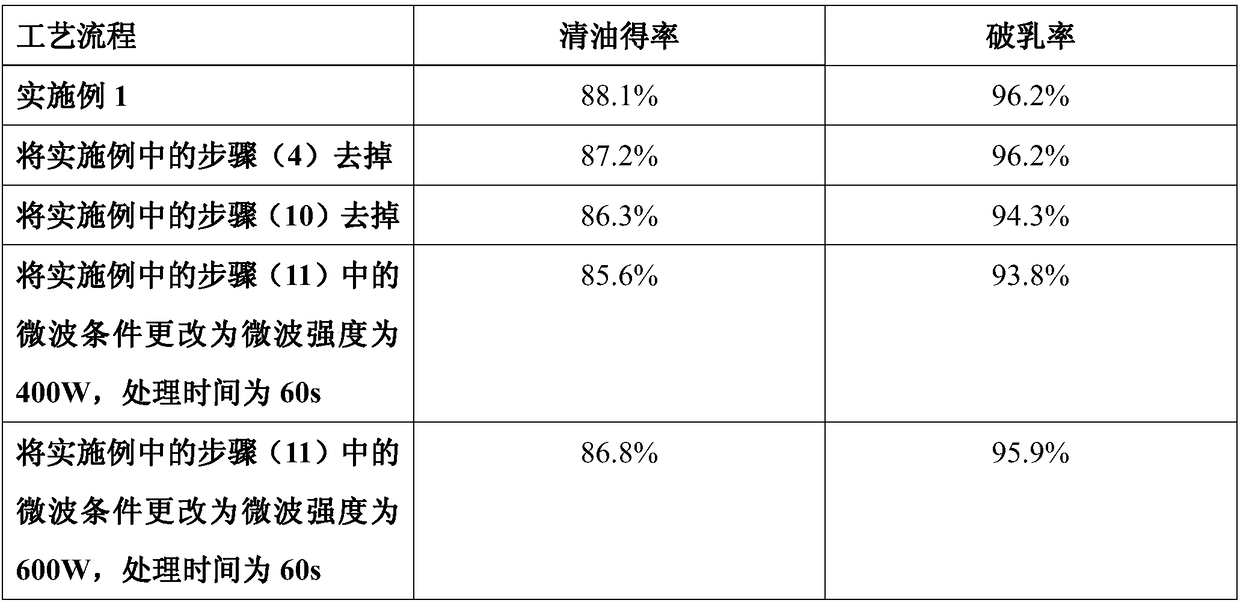

Process for preparing rapeseed oil by microwave method

InactiveCN108690704AImprove the oil yieldVaporization fastFatty-oils/fats refiningFatty-oils/fats productionMicrowave methodRapeseed

The invention discloses a process for preparing rapeseed oil by a microwave method. The process comprises the following steps of (1) seed selection; (2) crushing; (3) soaking; (4) ultrasound treatment; (5) enzyme addition; (6) alkaline extraction; (7) hydrolysis; (8) high-temperature enzyme deactivation; (9) centrifugal separation, and upper layer grease suction; (10) water adding uniform mixing on lower layer emulsion, and secondary ultrasound treatment; (11) mixed liquid regulation to the acid state; (12) segmented vacuum microwave treatment; (13) centrifugation and rapeseed clear oil obtaining. In the process of preparing the rapeseed oil, the twice grease extraction is performed; the clear oil yield is effectively improved; the ultrasound is used for assisting the water enzyme method to process the rapeseeds; the duplex effects of the ultrasound and the enzyme are utilized; the plant cell structure is damaged; the moisture in the rapeseeds is fast vaporized; the dissolute-out of the grease micro particles in the rapeseeds and the formation of porous structures inside plant tissues can be promoted; the oil yield is improved; the ultrasound assisted segmented microwave method isused for performing demulsification process on emulsion generated in the rapeseed oil process by the ultrasound assisted segmented microwave method; the demulsification rate is improved; the high clear oil yield is further improved.

Owner:镇江虎瑞生物科技有限公司

Comprehensive preparation method for seed oil, crude proteins and crude fibers of Suaeda salsa

InactiveCN108192719AImprove oil yieldHigh yieldPeptide preparation methodsFermentationFiberEnzymatic hydrolysis

The invention especially relates to a comprehensive preparation method for the seed oil, crude proteins and crude fibers of Suaeda salsa, belonging to the technical field of vegetable fat extraction.The comprehensive preparation method comprises the following steps: ultrasonic enzymatic hydrolysis pretreatment of raw materials; supercritical extraction; secondary enzymatic hydrolysis treatment; preparation of a total nutrient solution for composite demulsifying bacteria; demulsification; and preparation of the crude proteins; and preparation of the crude fibers. The preparation method of theinvention can prepare the seed oil, the crude proteins and the crude fibers of Suaeda salsa at the same time, and greatly improves the oil yield of the seeds of Suaeda salsa and the yield of the crudeproteins and the crude fibers.

Owner:WEIFANG YOURONG IND

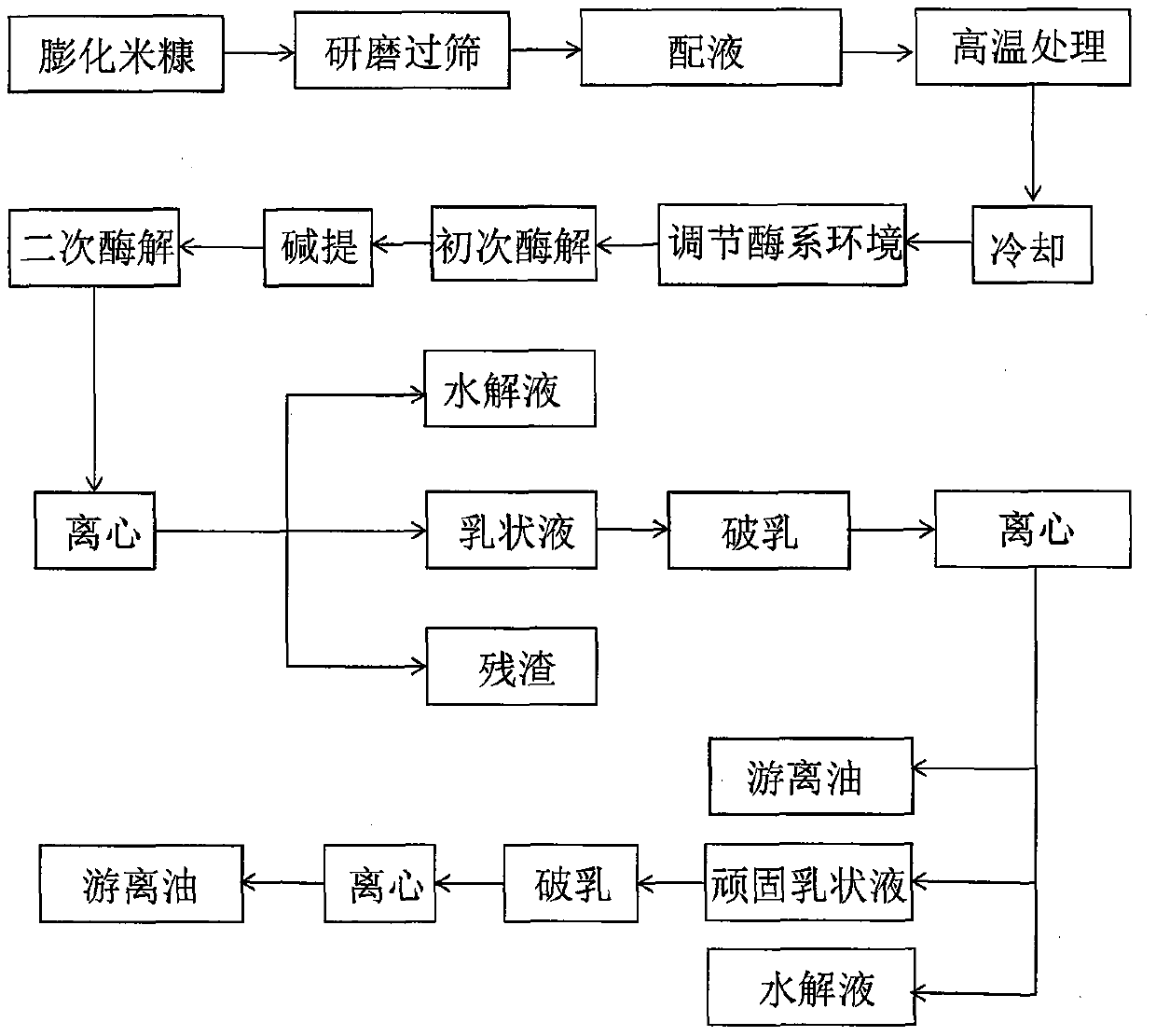

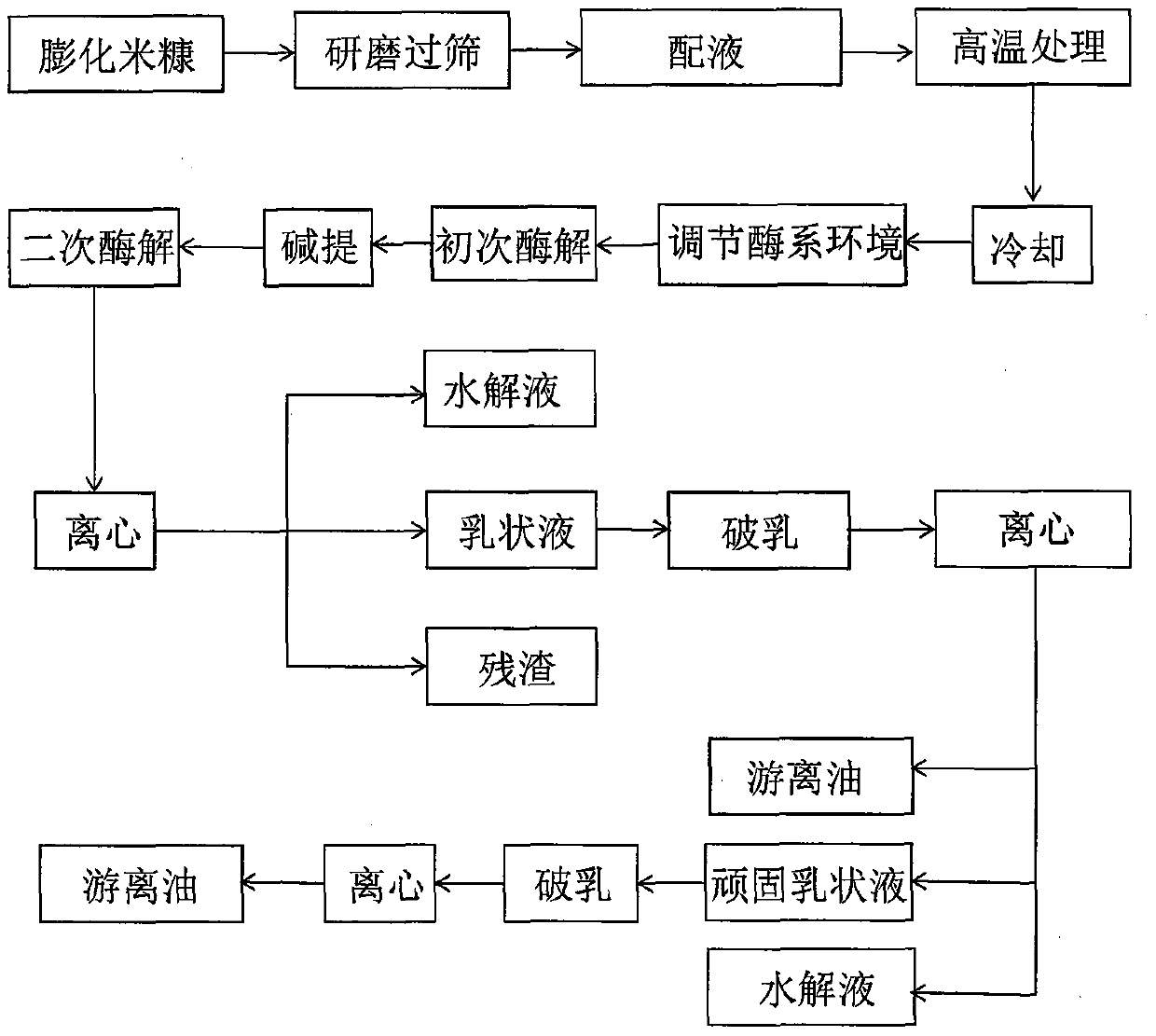

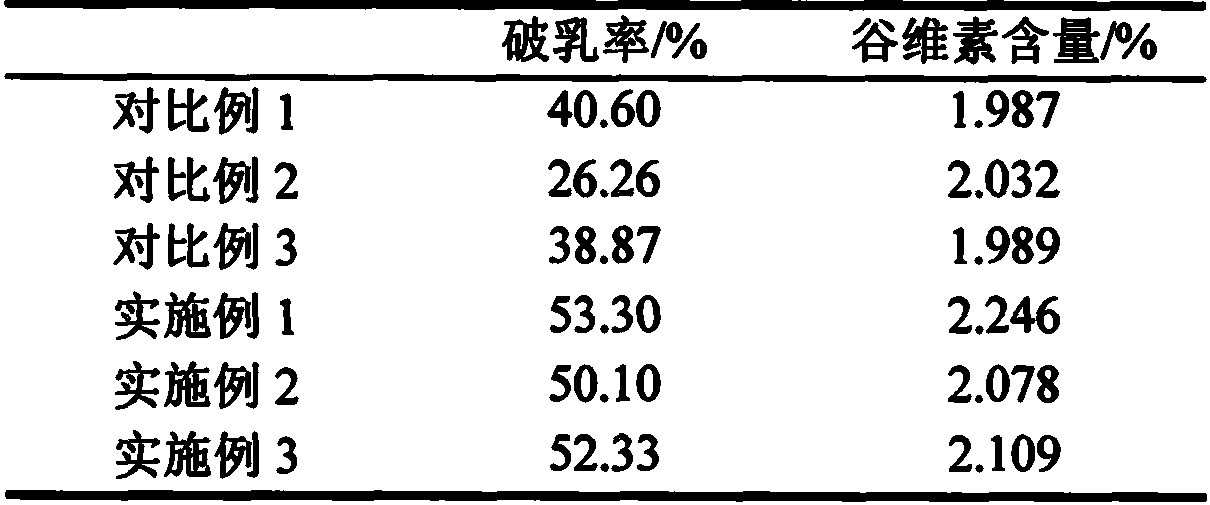

Demulsification method of emulsion formed by extracting rice oil with aqueous enzymatic method

The invention discloses a demulsification method of an emulsion formed by extracting rice oil with an aqueous enzymatic method. After centrifugation of rice bran enzymolysate obtained after biologicalenzyme treatment, an emulsion layer, a hydrolysate layer and a residue layer can be obtained. The emulsion layer is taken, the pH is adjusted, and after centrifugation, free oil and a stubborn emulsion are obtained; a certain amount of calcium chloride solution is added into the stubborn emulsion, and after centrifugation, upper-layer oil is obtained; a mixture of the free oil obtained by twice demulsification is total crude rice bran oil. A pH adjusting method is carried out by changing the pH environment of an emulsion system to achieve the purposes of changing the structure and the chargeability of an interfacial film and further achieve effective demulsification. After initial demulsification and centrifugation, a part of stubborn emulsion still exists, and through addition of the calcium chloride solution destruction of a double-electric layer structure of protein, aggregation between oil droplets takes place to cause demulsification. When the demulsification method provided by the invention is used for performing demulsification treatment to the emulsion produced by extracting the rice oil with the aqueous enzymatic method, the demulsification rate can be effectively increased, and meanwhile, the content of oryzanol in the obtained crude rice bran oil is also significantly increased; the demulsification method has the advantages of low energy consumption, no pollution, environment friendliness, health, simple operation and the like.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

A kind of amphiphilic hyperbranched polymer and its preparation and application

ActiveCN109517169BImprove adsorption capacityGuaranteed water solubilityLiquid carbonaceous fuelsFuel additivesDemulsifierPolymer science

The invention relates to an amphiphilic hyperbranched polymer as well as preparation and application thereof. The core of the amphiphilic hyperbranched polymer is hyperbranched polyethyleneimine withstrong hydrophilic property, wherein partial end amino of the hyperbranched polyethyleneimine is grafted with carboxyl on NH2(CH2)5CONH(CH2)5COOH by virtue of amido bonds. When the amphiphilic hyperbranched polymer serves as a demulsifier, the oil-in-water emulsion reaches the aqueous oil content of lower than 5% in a short time under the condition that the addition amount of the demulsifier is small. Meanwhile, the oil phase moisture content can be as low as 1% or less, the residual emulsion layer is extremely thin even disappears, and a clear oil-water interface is formed.

Owner:ZHEJIANG UNIV

A high frequency crude oil dehydrator

ActiveCN105199777BLow viscosityEasy to separateHydrocarbon oil dewatering/demulsificationElectricityControl system

The invention discloses a high-frequency crude oil dehydrator. A high-frequency dehydrator is connected with an impedance allocating network; a high-frequency radiator is connected with a temperature detection system; the temperature detection system is respectively connected with the impedance allocating network, a power amplification tank circuit, a high-frequency oscillation circuit and a detection and alarm system; the detection and alarm system is connected with a control system of a power supply system; the control system of the power supply system, the high-frequency oscillation circuit, the power amplification tank circuit and the impedance allocating network are all connected with a cooling system; a radial high-frequency electric field is generated by the high-frequency dehydrator at the high frequency; the orientation polarization is generated under the action of the electric field; two ends of water droplets induce and generate opposite charges to form an induction electric field; dipole coalescence is generated between the similar water droplets; the water droplets are condensed to form large water droplets; the large water droplets are demulsified and settled; the high-frequency electric field accelerates polar molecules to rotate at high speed and cause charge neutralization; when liquid globules lose the action of double electric layers, the liquid globules collide and gather, so that the oil and the water are separated. The high-frequency crude oil dehydrator has the characteristics of low operation cost, dehydration simplicity, high dehydration efficiency, stability and safety in dehydration, and green and environment-friendly performance.

Owner:XI'AN PETROLEUM UNIVERSITY

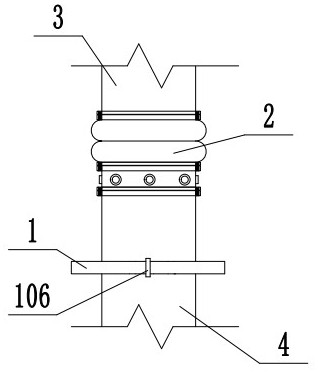

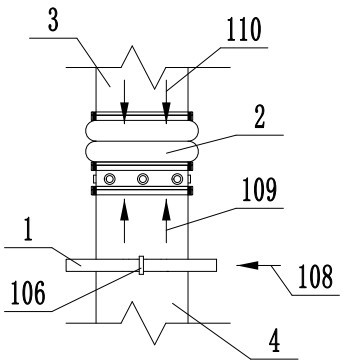

Using method of device for fully mixing demulsifier and well flow substances within ultra-short distance

InactiveCN112370982AHigh demulsification rateReduce usageFlow mixersTransportation and packagingDemulsifierPhysical chemistry

The invention relates to the technical field of oilfield development and production, in particular to a using method of a device for fully mixing a demulsifier and well flow substances in an ultra-short distance. The method comprises the following steps: injecting the demulsifier into a water-containing and natural gas-containing mixture to form a water-containing and demulsifier-containing liquidand natural gas-containing mixture, i.e., dissolved gas liquid; the demulsifier, the natural gas and the water are in the form of a gas-liquid-containing film in the dissolved gas liquid, namely, thedemulsifier and the natural gas are contained in the liquid film; the dissolved gas liquid is injected through an injection device; in the filling process, the liquid film of the dissolved gas liquidis broken; the demulsifier is uniformly released along with the natural gas wrapped in the liquid film through an air floatation process; and the demulsifier and the well flow substances with reducedgravity generate convection in the corrugated pipe compensator, are uniformly mixed and fulfill the aim of demulsifying. According to the invention, the mixing time and distance of the demulsifier and the well flow substances are shortened, the mixing efficiency is improved, and low investment, low operation cost, high cost performance and good economic benefit can be realized.

Owner:SENUO TECH CO LTD +1

A method for demulsifying oil-in-water emulsions

ActiveCN109370635BImprove adsorption capacityComprehensive adsorptionDewatering/demulsification with chemical meansOil phaseOil water

Owner:ZHEJIANG UNIV

A kind of demulsifier, treatment method and application of rice straw

ActiveCN113500672BHigh interface activityAchieve the purpose of separationDewatering/demulsification with chemical meansWood treatment detailsDemulsifierPulp and paper industry

The invention discloses a treatment method and application of a demulsifier and rice straw raw materials, belonging to the technical field of oil field chemicals. The processing method of the rice straw comprises reacting the raw material of the rice straw with an acid solution according to the material ratio (1.5-3) g:(100-150) mL, and then filtering and drying. The present invention also proposes a demulsifier, including the rice straw obtained by the above treatment method. In addition, the present invention also proposes an application of the above-mentioned demulsifier in the treatment of W / O crude oil emulsion. The demulsifier proposed by the invention can realize high-efficiency demulsification in a short time, and the demulsification rate is as high as more than 89%.

Owner:湖北鑫城普瑞化学科技有限公司

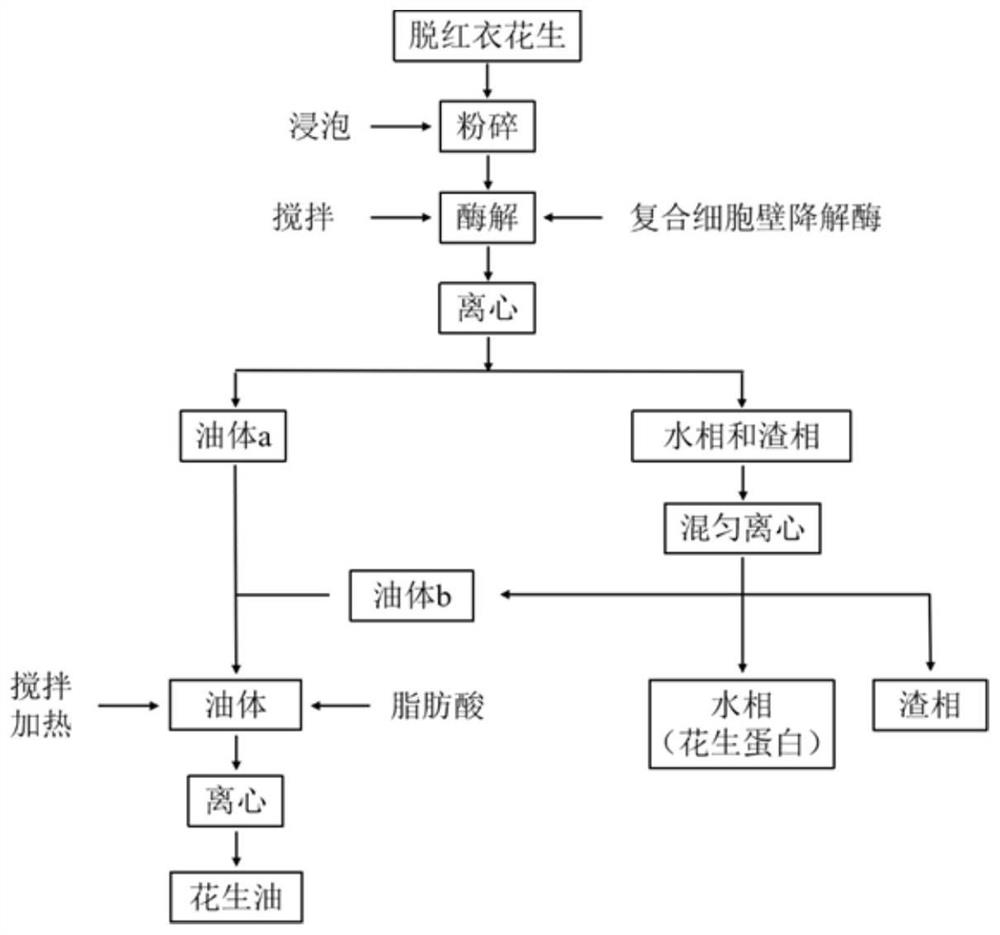

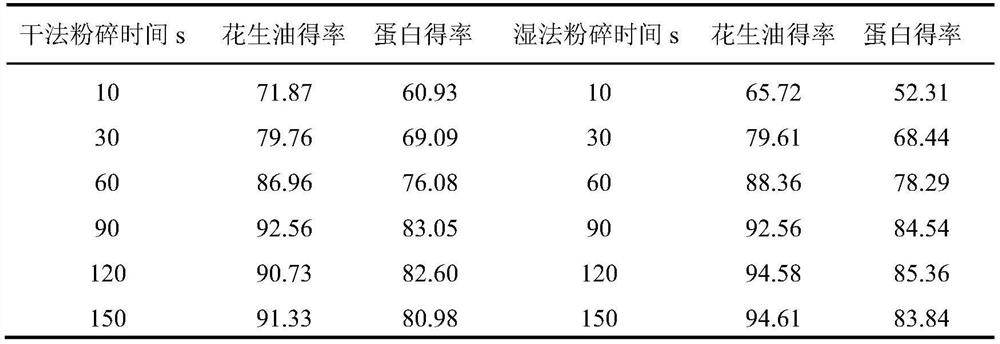

Method for preparing peanut oil by aqueous enzymatic method based on fatty acid demulsification

PendingCN113372988AReduced stabilityChange the interfacial tensionFatty-oils/fats refiningFatty-oils/fats productionFatty acidOil body

The invention discloses a method for preparing peanut oil by an aqueous enzymatic method based on fatty acid demulsification, which comprises the following steps: extracting the peanut oil with the assistance of a compound cell wall degrading enzyme, conducting centrifuging to obtain an oil body, aqueous phase protein and a residue phase, and demulsifying the oil body with fatty acid to extract the peanut oil. According to the method disclosed by the invention, the pretreatment steps of the peanuts are optimized, the types and concentrations of fatty acids are screened, meanwhile, the demulsification conditions (the material-liquid ratio, the stirring speed, the temperature and the time) are subjected to single-factor optimization, and the method is determined after optimization, so that the yield of the peanut oil and the protein can be improved, and the demulsification rate can be remarkably improved. The method for preparing the peanut oil by the aqueous enzymatic method based on fatty acid demulsification has the advantages of high demulsification rate, high yield, low cost, simplicity in operation, greenness, safety and the like, and is beneficial to large-scale industrial production.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Comprehensive suaeda salsa seed oil and protein extraction technology

InactiveCN108004009AImprove oil yieldHigh yieldFatty-oils/fats refiningFood ingredientsCulture fluidFermentation

The invention relates to the technical field of plant oil extraction, in particular to comprehensive suaeda salsa seed oil and protein extraction technology. The comprehensive suaeda salsa seed oil and protein extraction technology comprises the following steps: performing raw material pretreatment, performing fermentation treatment, performing primary enzymolysis treatment, preparing a whole culture fluid of composite demulsifying bacteria, performing demulsification treatment, performing secondary enzymolysis and performing washing and drying treatment. By the preparation method, through enzymolysis, fermentation, enzymolysis treatment, and then demulsification treatment with the composite demulsifying bacteria, the oil extraction rate of suaeda salsa seeds is greatly increased and the yield of protein is also increased.

Owner:WEIFANG YOURONG IND

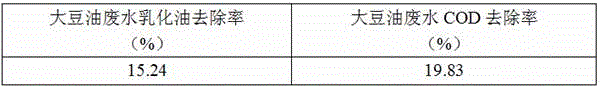

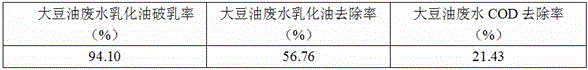

Method for processing emulsified oil in soybean oil waste water

InactiveCN105776573ANo secondary pollutionReduce energy consumptionBacteriaMicroorganism based processesFlocculationEmulsion

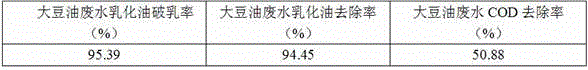

The invention aims to provide a method for processing emulsified oil in soybean oil waste water, and belongs to the technical field of microbial technology and environmental engineering. According to the method provided by the invention, acinetobacter calcoaceticus is used for performing emulsion-breaking treatment on the emulsified oil in the soybean oil waste water; then acinetobacter johnsonii is used for producing a microbial flocculant for performing flocculation treatment on the emulsion-broken emulsified oil to remove the emulsified oil in the soybean oil waste water. The method comprises the following steps: (1) preparing a bacterial suspension of acinetobacter calcoaceticus; (2) preparing the microbial flocculant with acinetobacter johnsonii; (3) performing emulsion-breaking treatment on the emulsified oil in the soybean oil waste water; (4) processing the emulsion-broken emulsified oil. The method provided by the invention has a high emulsified oil emulsion-breaking rate kept at 95.39%-96.70%; the microbial flocculant produced by the acinetobacter johnsonii is used for flocculation removal of the emulsion-broken emulsified oil, so as to achieve a higher removal rate of the emulsified oil in the soybean oil waste water, kept at 92.01%-94.45%, and also achieve a higher removal rate of COD in the soybean oil waste water, kept at 47.32%-50.88%.

Owner:NORTHEAST DIANLI UNIVERSITY

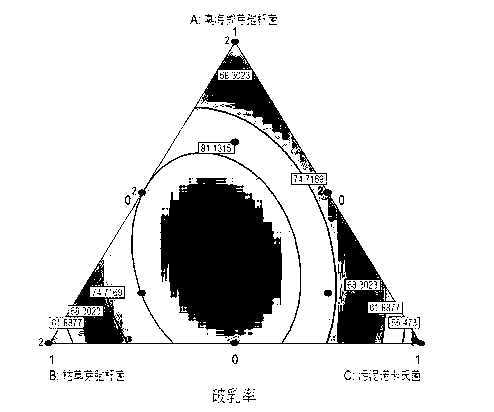

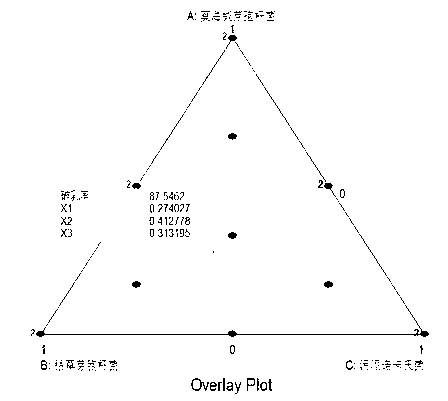

A method for compound demulsification of soybean oil extracted by aqueous enzymatic method

ActiveCN104893817BHigh demulsification rateHigh purityFatty-oils/fats productionOil and greaseVegetable oil

The invention provides a method for extracting soybean oil compound breakdown emulsion by virtue of an aqueous enzymatic method, and belongs to extracting and processing technologies of vegetable oil and fat. The method comprises the following steps: (1) crushing soybeans, then performing extrusion puffing to obtain a puffed material, mixing the puffed material with water to obtain a mixed solution, adding alkali protease into the mixed solution to perform enzymolysis, and then performing centrifugal separation to obtain free oil, emulsion, hydrolysate and residues; (2) mixing the emulsion with a AlCl3 solution at equal volumes, then adding a microbial surfactant, mixing uniformly, and then adjusting the pH value to be neutral; and (3) performing ultrasonic treatment on the treated emulsion, and then performing centrifugal separation to obtain soybean oil. By adopting the method, the inorganic salt AlCl3, the microbial surfactant and an ultrasonic technology are organically combined together to form an integral compound demulsification system which is low in cost and pollution-free, and is short in demulsification time and high in demulsification rate, and the obtained soybean oil is high in purity and good in quality and has a wide application prospect in processing of the vegetable oil and fat.

Owner:山东国宏生物科技有限公司

Microemulsion and nano-fracturing stimulation agent and preparation method thereof

ActiveCN109135715BReduce interfacial tensionReduce surface tensionDrilling compositionBulk chemical productionMicrosphereFatty amine

The invention discloses a microemulsion nano fracturing yield increase agent and a preparation method thereof. The microemulsion nano fracturing yield increase agent is prepared from the following components in parts by weight: 20 to 40 parts of a surfactant, 20 to 40 parts of limonene, 1 to 7 parts of fatty acid, 1 to 7 parts of fatty amine, 1 to 3 parts of first coated microspheres and 10 to 30parts of water. The microemulsion nano fracturing yield increase agent is a nano-level tiny particle and can go deep into a small hole and reach all regions affected by fracturing liquid; when required to be subjected to gel breaking, the fracturing liquid is in contact with a gel breaking agent to exert the effect, so that the interfacial tension and the surface tension of the fracturing liquid gel breaking liquid are greatly reduced; the absorption amount of the fracturing liquid on a fracture shale solid interface is reduced, and the treatment area of the deep part of a fracture is relatively large; the capillary force of the fracturing liquid gel breaking liquid can be lowered; the wettability of the surface of a solid is improved; the liquid locking damage is relieved. Therefore, thefracturing liquid flowback rate is increased, and the yield of fluid ores is finally increased.

Owner:BEIJING DADE GUANGYUAN PETROLEUM TECH SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com