Microemulsion and nano-fracturing stimulation agent and preparation method thereof

A production stimulation agent and nano-technology, applied in the field of microemulsion nano-fracture stimulation agent and its preparation, can solve the problem of inability to clean and inhibit the organic blockage of pore throats, the improvement of fracturing fluid flowback rate is not obvious, and the reduction of fracturing fluid Surface activity and other problems, to achieve the effect of eliminating liquid lock damage, improving circulation effect, and reducing capillary force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

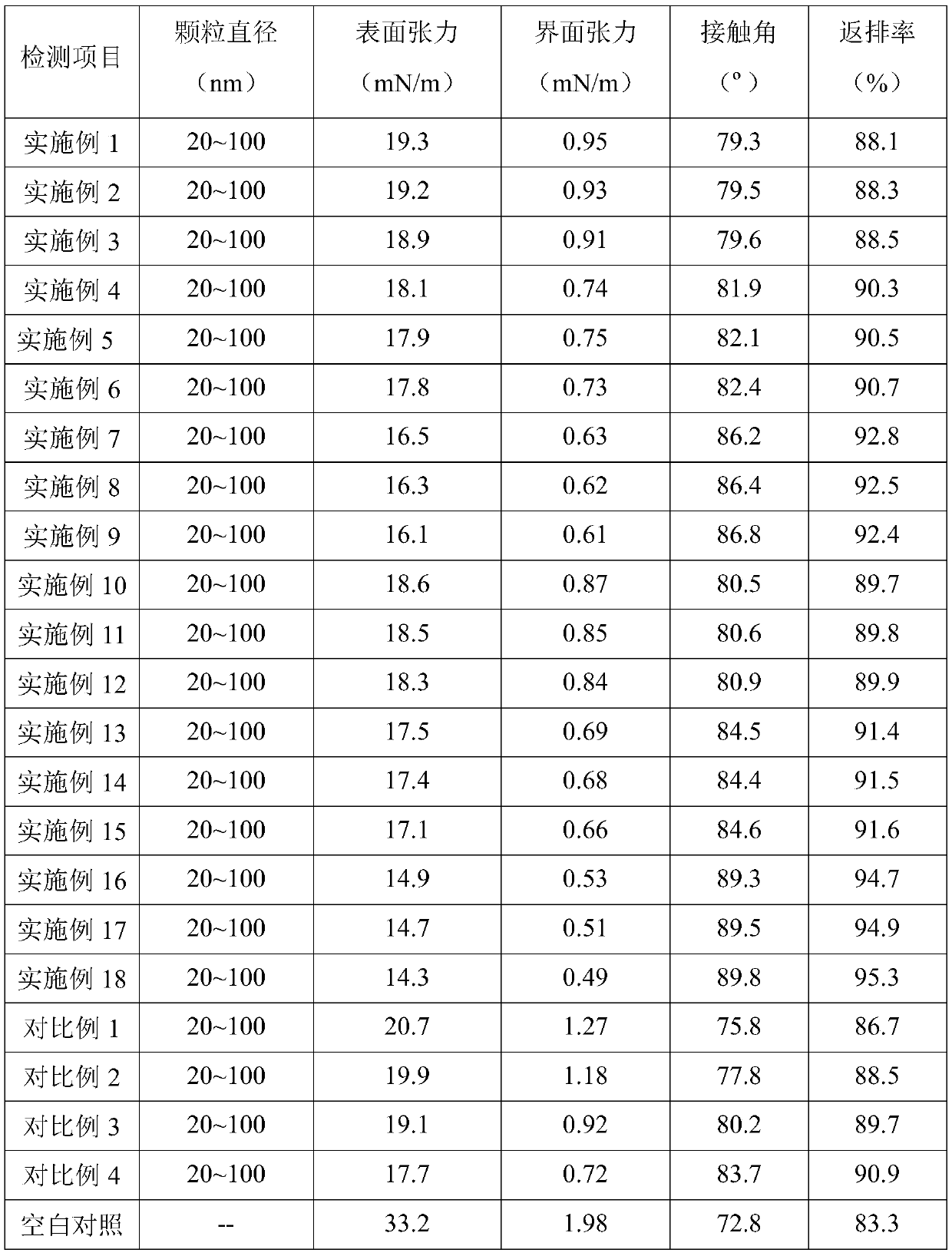

Examples

Embodiment 1

[0045] A microemulsion nano-fracture stimulation agent, which includes the following components in parts by weight:

[0046] 20 parts by weight of surfactant, 20 parts by weight of limonene, 1 part by weight of fatty acid, 1 part by weight of fatty amine, 1 part by weight of the first coated microsphere and 10 parts by weight of water;

[0047] Wherein, said surfactant comprises alkylamidopropyl betaine, fluorine-containing carbon chain Gemini surfactant and alkylamine polyoxyethylene ether, and the weight ratio of the three is 1:3:2;

[0048] The first coated microspheres are nanospheres coated with chitosan hydroxyapatite powder, and the preparation method is as follows: divide acetic acid into two parts at a weight ratio of 2:1, mix hydroxyapatite powder with one part acetic acid to obtain the first mixed solution, mix another part of acetic acid, chitosan and paraffin, heat to 50°C and keep stirring for 20 minutes to obtain the first embedding solution, add the first embed...

Embodiment 2

[0054] A microemulsion nano-fracture stimulation agent, which includes the following components in parts by weight:

[0055] The surfactant of 40 parts by weight, the limonene of 40 parts by weight, the fatty acid of 7 parts by weight, the fatty amine of 7 parts by weight, the first coating microsphere of 3 parts by weight and the water of 30 parts by weight;

[0056] Wherein, said surfactant comprises alkylamidopropyl betaine, fluorine-containing carbon chain Gemini surfactant and alkylamine polyoxyethylene ether, and the weight ratio of the three is 1:3:2;

[0057] The first coated microspheres are nanospheres coated with chitosan hydroxyapatite powder, and the preparation method is as follows: divide acetic acid into two parts at a weight ratio of 2:1, mix hydroxyapatite powder with one part Mix the acetic acid to get the first mixed solution, mix another part of acetic acid, chitosan and paraffin, heat to 60°C and keep stirring for 30min to get the first embedding solution...

Embodiment 3

[0063] A microemulsion nano-fracture stimulation agent, which includes the following components in parts by weight:

[0064] The surfactant of 30 parts by weight, the limonene of 30 parts by weight, the fatty acid of 4 parts by weight, the fatty amine of 4 parts by weight, the first coated microsphere of 2 parts by weight and the water of 20 parts by weight;

[0065] Wherein, said surfactant comprises alkylamidopropyl betaine, fluorine-containing carbon chain Gemini surfactant and alkylamine polyoxyethylene ether, and the weight ratio of the three is 1:3:2;

[0066] The first coated microspheres are nanospheres coated with chitosan hydroxyapatite powder, and the preparation method is as follows: divide acetic acid into two parts at a weight ratio of 2:1, mix hydroxyapatite powder with one part Mix the acetic acid to get the first mixed solution, mix another part of acetic acid, chitosan and paraffin, heat to 55°C and keep stirring for 25min to get the first embedding solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com