Demulsification method of emulsion formed by extracting rice oil with aqueous enzymatic method

A technology of emulsion and rice oil, which is applied in the direction of fat oil/fat production and fat production, can solve the problems of limited free oil, reduce the oil yield of oil, limit the development of oil extraction by aqueous enzymatic method, etc., and achieve the purpose of improving the demulsification rate, The effect of low energy consumption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

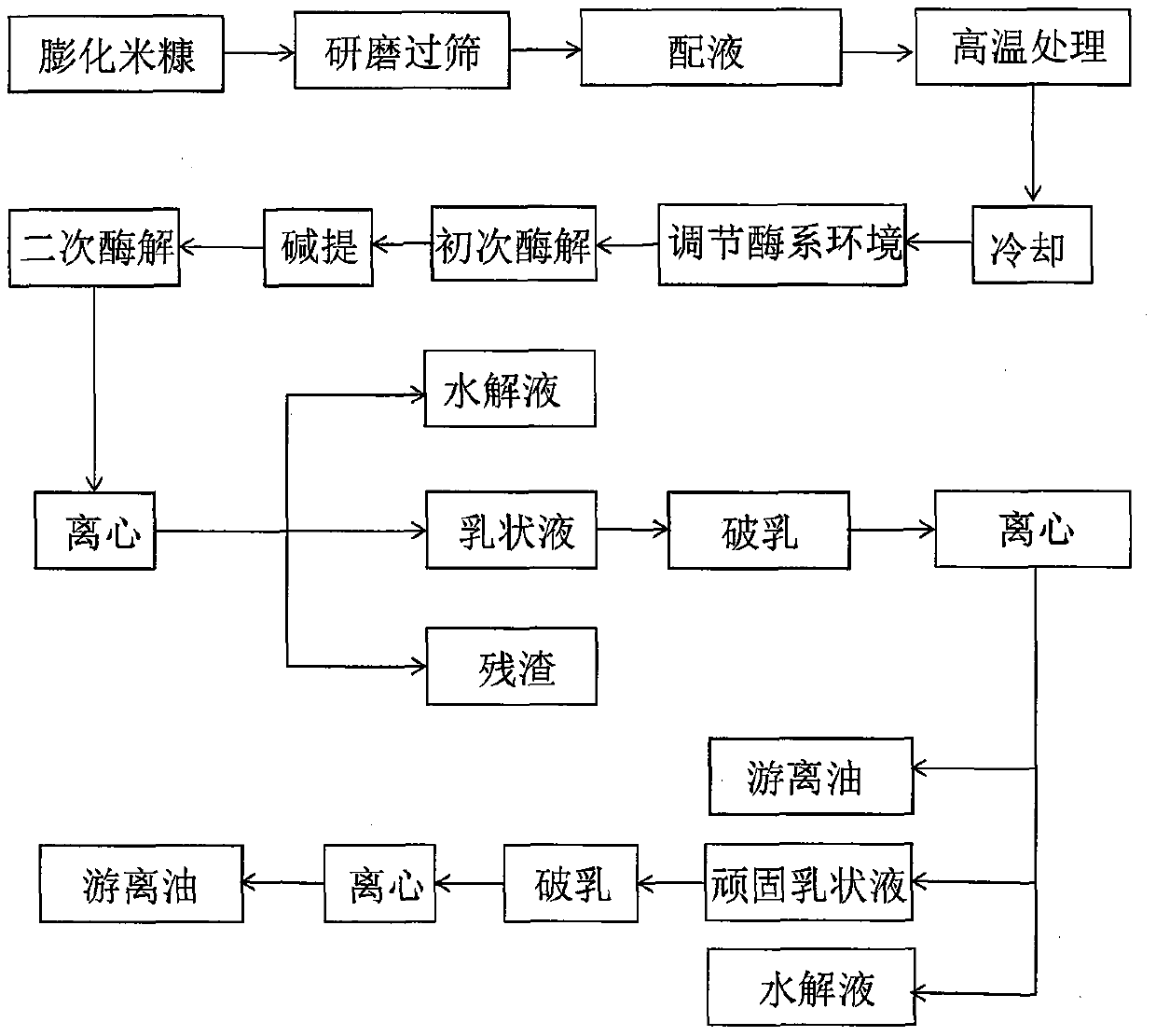

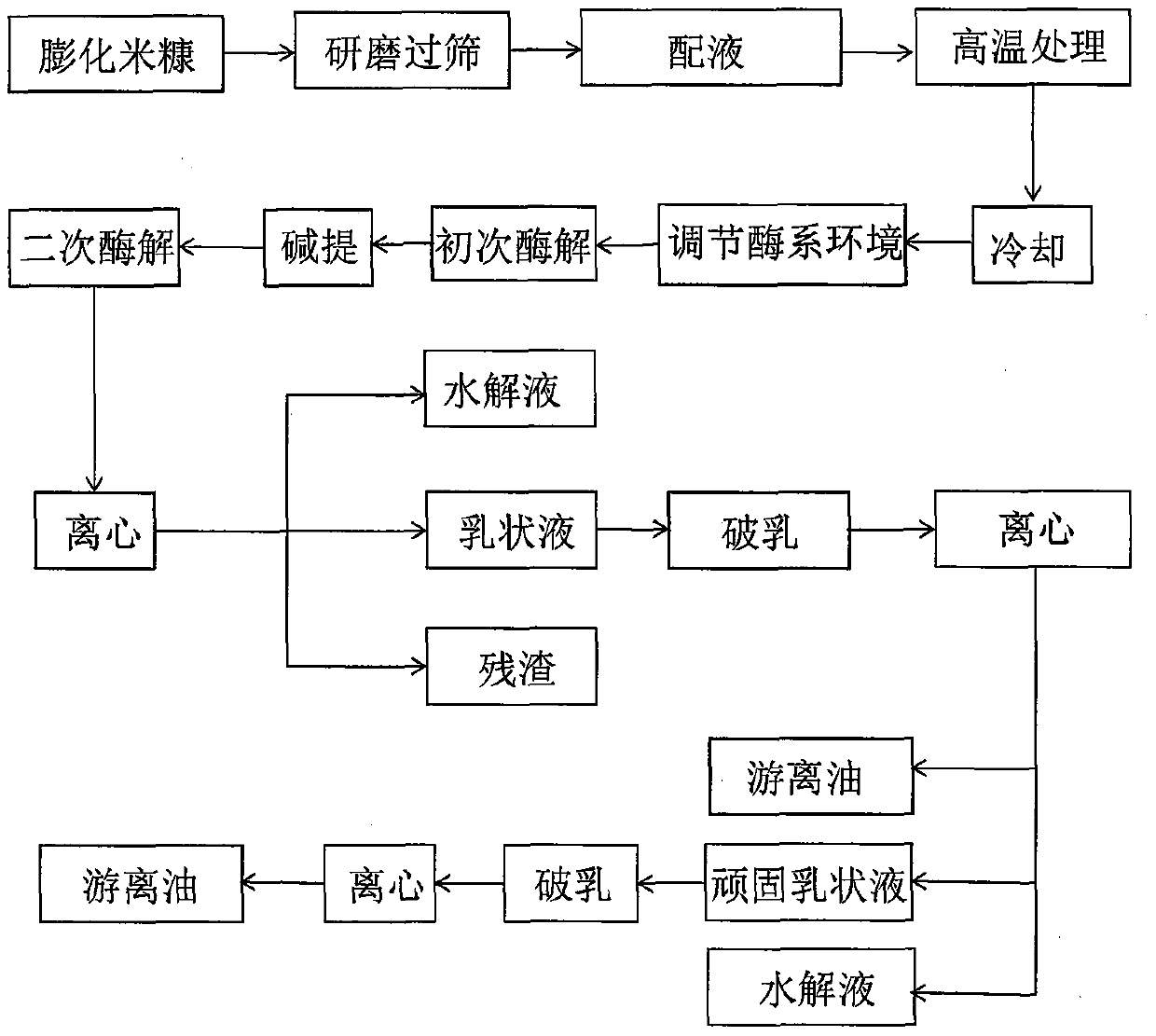

Method used

Image

Examples

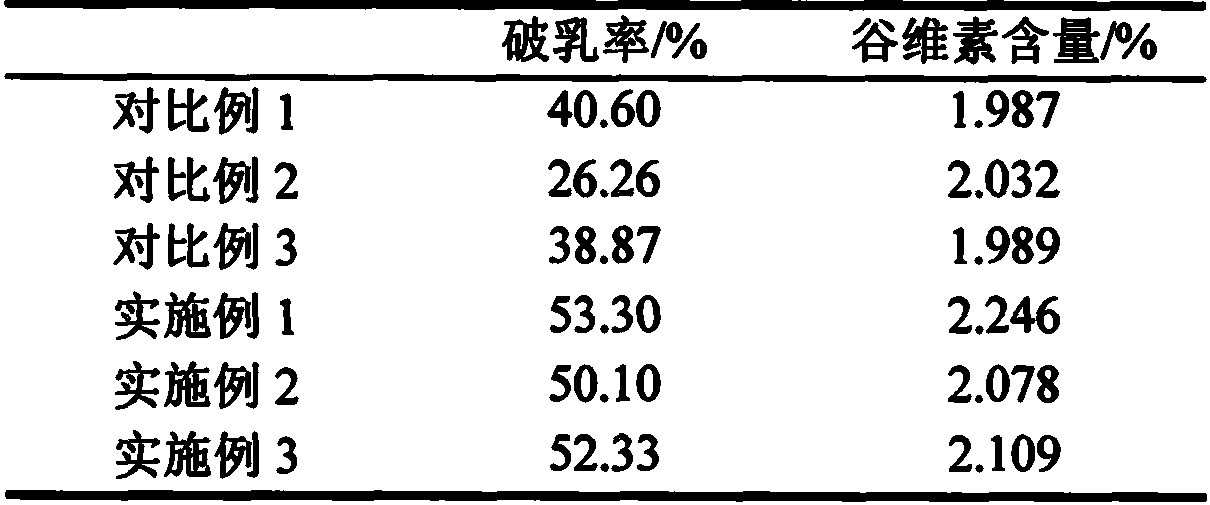

Embodiment 1

[0033] (1) Rice bran sample processing: crush the puffed rice bran and pass through a 40-mesh sieve to obtain rice bran powder;

[0034] (2) Enzymatic treatment: add deionized water to the rice bran powder obtained in step (1), adjust the ratio of material to liquid at 1:6 (weight of rice bran: weight of deionized water) to form a mixed solution, and raise the temperature of the mixed solution to 90°C Inactivate the enzyme for 15 min, then cool to room temperature. Use 2 mol / L HCL solution to adjust the pH of the rice bran mixture to 5.0, add 3% rice bran weight β-glucanase and plant extract enzyme, the ratio of the two is 1:2, and enzymatically hydrolyze for 2 hours at 50°C to obtain Primary rice bran hydrolyzate. Adjust the pH of the primary rice bran hydrolyzate to 9.0 with 2mol / L NaOH solution, and carry out alkaline extraction at 60°C for 10 minutes. Then use 2mol / L NaOH solution to continue to adjust the pH to 9.0, add Acalase 2.4L alkaline protease with 3% rice bran w...

Embodiment 2

[0037] (1) Rice bran sample processing: crush the puffed rice bran and pass through a 40-mesh sieve to obtain rice bran powder;

[0038] (2) Enzymatic treatment: add deionized water to the rice bran powder obtained in step (1), adjust the ratio of material to liquid at 1:8 (weight of rice bran: weight of deionized water) to form a mixed solution, and heat the mixed solution to 90°C Inactivate the enzyme for 15 min, then cool to room temperature. Use 2 mol / L HCL solution to adjust the pH of the rice bran mixture to 5.0, add 4% rice bran weight β-glucanase and plant extract enzyme, the ratio of the two is 1:3, and enzymatically hydrolyze for 3 hours at 50°C to obtain Primary rice bran hydrolyzate. The pH of the primary rice bran hydrolyzate was adjusted to 9.0 with 2mol / L NaOH solution, and the alkaline extraction was carried out at 60°C for 30min. Then use 2mol / L NaOH solution to continue to adjust the pH to 9.0, add Acalase 2.4L alkaline protease with 5% rice bran weight, an...

Embodiment 3

[0041] (1) Rice bran sample processing: crush the puffed rice bran and pass through a 40-mesh sieve to obtain rice bran powder;

[0042] (2) Enzymatic treatment: add deionized water to the rice bran powder obtained in step (1), adjust the ratio of material to liquid at 1:5 (weight of rice bran: weight of deionized water) to form a mixed solution, and heat the mixed solution to 90°C Inactivate the enzyme for 15 min, then cool to room temperature. Use 2mol / L HCL solution to adjust the pH of the rice bran mixture to 5.0, add 2% rice bran weight β-glucanase and plant extract enzyme, the ratio of the two is 1:1, and enzymatically hydrolyze for 1 hour at 50°C to obtain Primary rice bran hydrolyzate. The pH of the primary rice bran hydrolyzate was adjusted to 9.0 with 2mol / L NaOH solution, and the alkaline extraction was carried out at 60°C for 60min. Then use 2mol / L NaOH solution to continue to adjust the pH to 9.0, add Acalase2.4L alkaline protease with 2% rice bran weight, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com