Method for processing emulsified oil in soybean oil waste water

A technology of soybean oil and emulsified oil, which is applied in the field of microbial technology and environmental engineering, can solve the problems of difficult biodegradation, large dosage, environmental pollution, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] (1) Preparation of Acinetobacter calcium acetate bacterial suspension:

[0020] Inoculate a single colony of Acinetobacter calcoaceticus (Acinetobacter calcoaceticus) preserved on the slant with the strain number CGMCCNO: 1.2906 into 100mL sterile seed medium, wherein each group of Acinetobacter calcoaceticus seed medium The dosages are: yeast extract powder 3g / L; peptone 8g / L; NaCl 6g / L; pH=7.5; cultured on a shaker at 30°C at 180rpm for 1 day to obtain a cultured Acinetobacter calcoacetate suspension. The obtained bacterial suspension was stored in a 4°C refrigerator for later use;

[0021] (2) Preparation of microbial flocculant by Acinetobacter johnsonii:

[0022] A single colony of Acinetobacter johnsonii (Acinetobacter johnsonii) preserved on the slant with the strain number CGMCCNO: 1.8030 was inserted into 100mL sterile fermentation medium, and in the fermentation medium of Acinetobacter johnsonii The dosage of each component is respectively: glucose 15.0g / L; ...

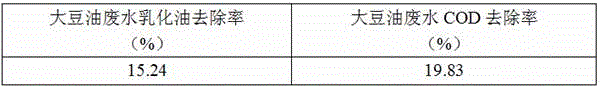

Embodiment 1

[0030] Example 1 (Flocculation and removal of emulsified oil in soybean oil wastewater by simply using the microbial flocculant produced by Acinetobacter johnsonii):

[0031] (1) Preparation of microbial flocculant by Acinetobacter johnsonii

[0032] A single colony of Acinetobacter johnsonii (Acinetobacter johnsonii) preserved on the slant with the strain number CGMCCNO: 1.8030 was inserted into 100mL sterile fermentation medium, and in the fermentation medium of Acinetobacter johnsonii The dosage of each component is respectively: glucose 15.0g / L; K 2 HPO 4 3g / L; KH 2 PO 4 3g / L; urea 0.3g / L; yeast extract 0.3g / L; MgSO 4 ·7H 2 O0.1g / L; NaCl0.1g / L; pH=7.5; cultivated on a shaker at 30°C at 150rpm for 5 days to obtain a cultured Acinetobacter johnsonii microbial flocculant; after cooling to room temperature, store the microbial flocculant Store in a 4°C refrigerator for later use;

[0033] (2) Acinetobacter johnsoni with the strain number CGMCCNO: 1.8030 treats the emuls...

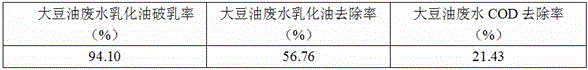

Embodiment 2

[0038] Example 2 (Use Acinetobacter calcium acetate to demulsify the emulsified oil in soybean oil wastewater, and then use the inorganic flocculant polyaluminum sulfate to remove the emulsified oil after demulsification)

[0039] (1) Preparation of Acinetobacter calcoacetate bacterial suspension

[0040] Inoculate a single colony of Acinetobacter calcoaceticus (Acinetobacter calcoaceticus) preserved on the slant with the strain number CGMCCNO: 1.2906 into 100 mL of sterile seed medium, and in the seed medium of Acinetobacter calcoaceticus The dosage of each component is: yeast extract powder 3g / L; peptone 8g / L; NaCl 6g / L; pH=7.5; culture on a shaker at 30°C at 180rpm for 1 day to obtain a cultured Acinetobacter calcoacetate suspension , Store the obtained bacterial suspension in a 4°C refrigerator for future use;

[0041] (2) Acinetobacter calcoaceticus with the strain number CGMCCNO: 1.2906 demulsifies the emulsified oil in soybean oil wastewater

[0042] Take 15mL of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com