A kind of demulsifier, treatment method and application of rice straw

A technology of rice straw and demulsifier, which is applied to the treatment of raw materials of rice straw and the field of demulsifier, can solve the problems of poor demulsification effect and complicated preparation process, and achieve the effect of efficient demulsification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment proposes a demulsifier, which is obtained by the following processing method: crush the rice straw raw material into powder and sieve it with a 200-mesh sieve, mix 1.5 g of the sieved rice straw powder with an acetic acid solution with a concentration of 0.25 mol / L Mix 100mL in a 250mL Erlenmeyer flask, carry out a stirring reaction at room temperature at a stirring speed of 1000 rpm for 24 hours, filter the reacted rice straw raw material and wash it with distilled water until neutral, then dry it at 70°C for 24 hours. .

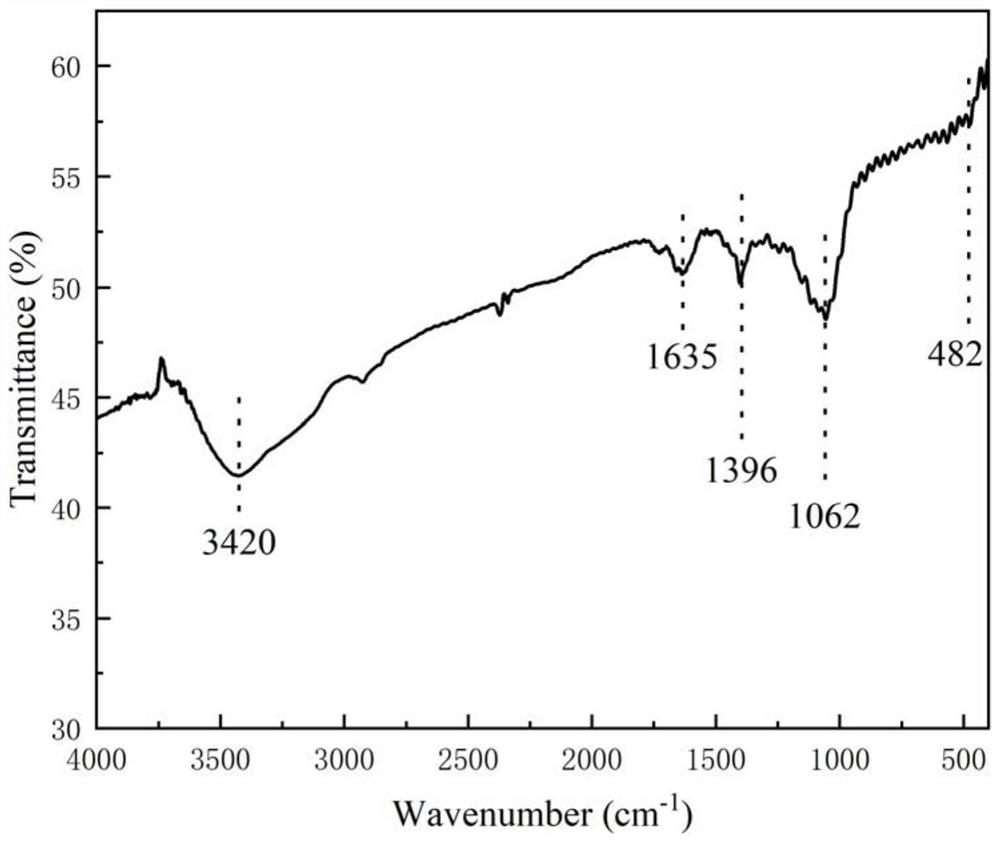

[0027] From figure 1 It can be seen that at 482cm -1 SiO 2 Si-O-Si and Si-O-C characteristic peaks at 3420cm -1 、1635cm -1 、1062cm -1 The characteristic peaks of hydroxyl groups appeared at , indicating that Si-O-Si, Si-O-C and hydroxyl groups existed in the treated rice straw at the same time.

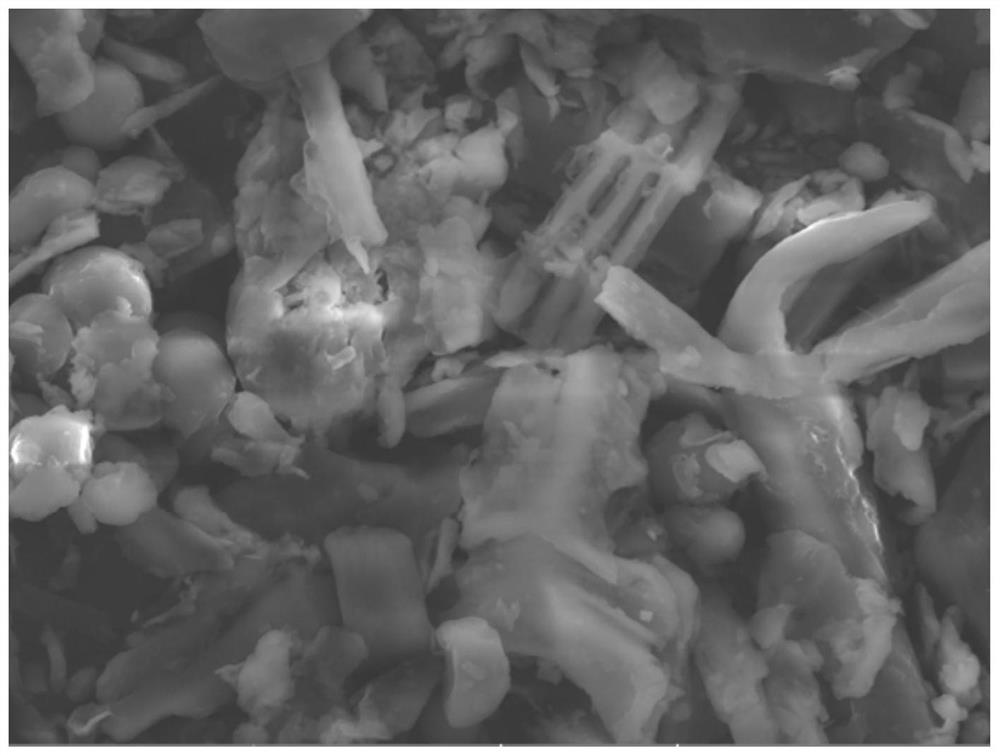

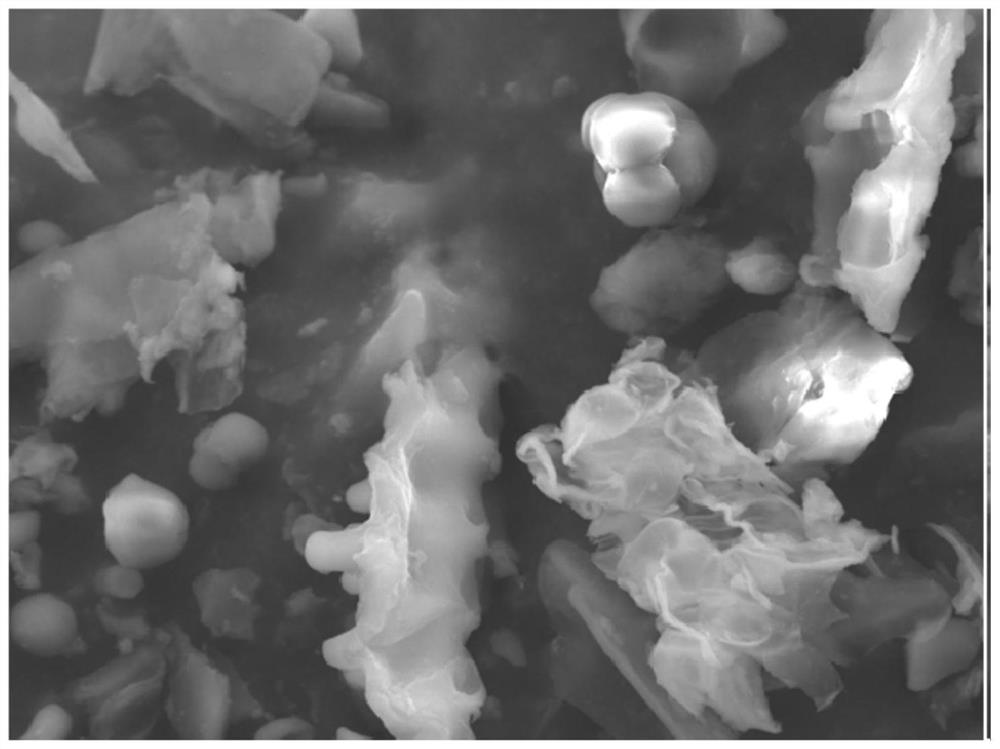

[0028] From figure 2 It can be seen that the surface of the untreated straw is relatively smooth, from image 3 It can be seen that...

Embodiment 2

[0030] This embodiment proposes a demulsifier, which is obtained by the following processing method: including pulverizing the raw material of rice straw into powder and sieving with a 200-mesh sieve, and mixing 1.5 g of the sieved rice straw powder with 0.25 mol / L of acetic acid Mix 100mL of the solution in a 250mL Erlenmeyer flask, carry out a stirring reaction at room temperature at a stirring speed of 1000 rpm for 12 hours, filter the reacted straw raw material and wash it with distilled water until it is neutral, and then dry it at 70°C for 24 hours. Can.

Embodiment 3

[0032] This embodiment proposes a demulsifier, which is obtained by the following processing method: comprising pulverizing the raw material of rice straw into powder and sieving with a 100-mesh sieve, and mixing 1.5 g of the sieved rice straw powder with acetic acid having a concentration of 0.25 mol / L Mix 100mL of the solution in a 250mL Erlenmeyer flask, carry out a stirring reaction at room temperature at a stirring speed of 1000 rpm for 12 hours, filter the reacted straw raw material and wash it with distilled water until it is neutral, and then dry it at 70°C for 24 hours. Can.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com