Preparation method for magnetic carbon nanotube demulsifier and application of magnetic carbon nanotube demulsifier

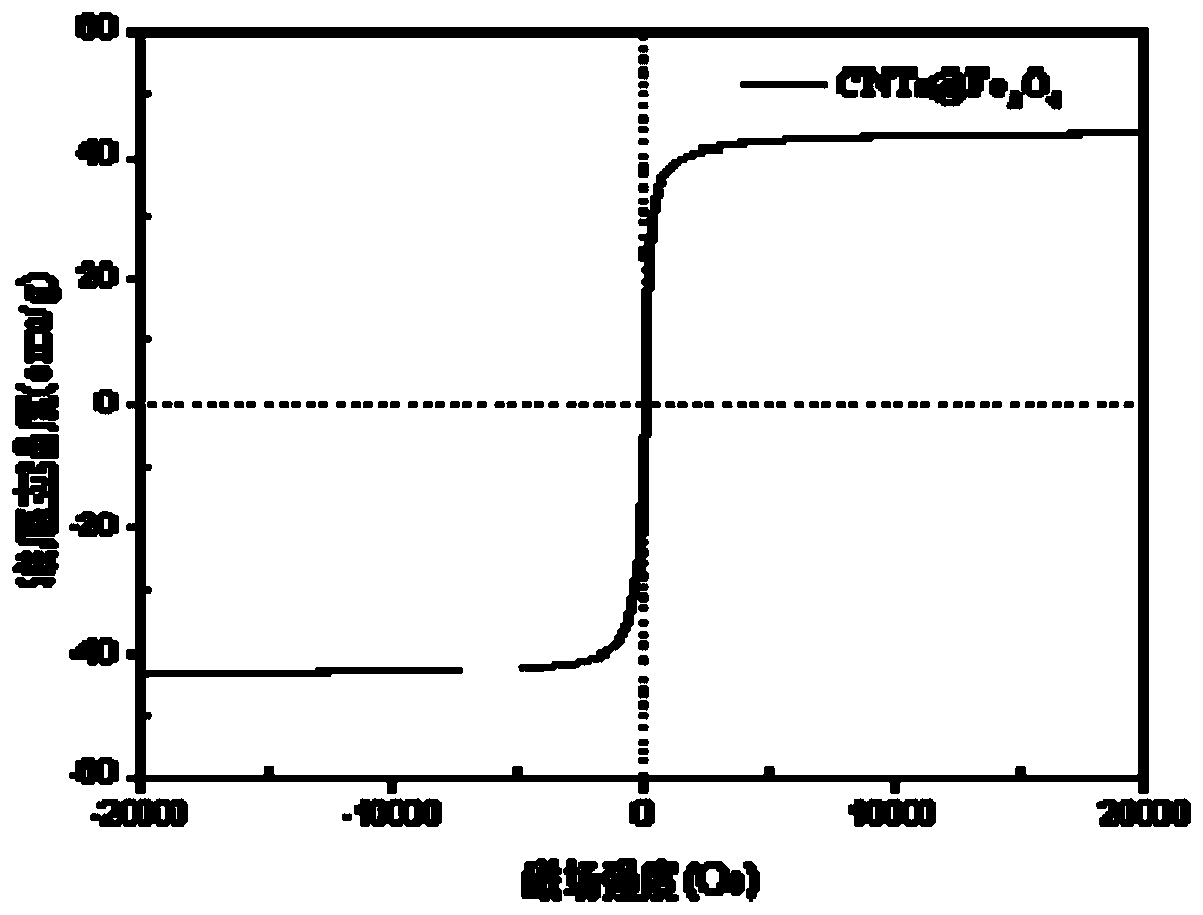

A magnetic carbon nanotube and carbon nanotube technology, applied in separation methods, magnetic field/electric field water/sewage treatment, grease/oily substance/suspton removal devices, etc., can solve the problem of limiting the application of nanotubes, not easy to separate and recycle and other problems, to achieve good demulsification effect, easy to implement, super paramagnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Embodiments of the present invention provide a method for preparing a magnetic carbon nanotube demulsifier, comprising the steps of:

[0022] (1) The carbon nanotubes are refluxed with the mixed acid to obtain oxidatively modified carbon nanotubes;

[0023] (2) Preparation of Fe 3 o 4 Precursor solution;

[0024] (3) The oxidatively modified carbon nanotubes and Fe 3 o 4 The precursor solution is uniformly mixed and reacted at 180-220° C. to prepare the magnetic carbon nanotube demulsifier.

[0025] As a preferred embodiment, the preparation of oxidatively modified carbon nanotubes in step (1) specifically adopts the following method: disperse the carbon nanotubes in mixed acid, and ultrasonicate for 0.5 to 1.5 hours to form a black suspension. The liquid is subjected to reflux reaction, and the obtained product is diluted and suction-filtered, and the filtrate is washed to 6.5-7.5, and then vacuum-dried at 55-65° C. to obtain oxidatively modified carbon nanotubes....

Embodiment 1

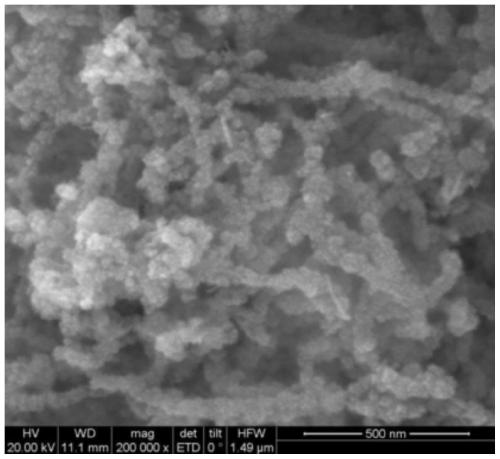

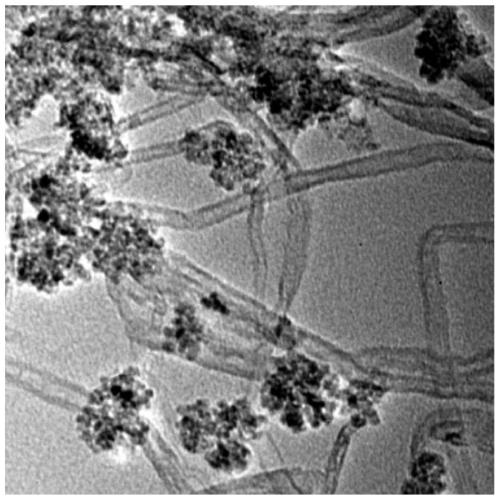

[0044] Embodiment 1 of the present invention provides a nano-demulsifier for magnetic carbon nanotube composite material, which is prepared by the following steps:

[0045] (1) Oxidative modification of carbon nanotubes: get 0.5g carbon nanotubes and disperse them in a mixed solution of 150mL nitric acid (65wt%) and 50mL concentrated sulfuric acid (98wt%), ultrasonically disperse for 30 minutes to form a black suspension, Heat the black suspension and reflux at 80°C for 10 hours. After cooling to room temperature, dilute the suspension to 2L with distilled water, cool to room temperature and filter it with a 0.45 μm microporous polytetrafluoroethylene filter membrane. Repeatedly washing with water until the pH value of the filtered solution is 7, and then vacuum-drying at 60°C to obtain oxidatively modified carbon nanotubes;

[0046] (2) Fe 3 o 4 Preparation of precursor solution: Take 0.25g Fe(acac) 3 Ultrasonic dispersion in 20g ethylene glycol for 0.5 hours to obtain ora...

Embodiment 2

[0054] Embodiment 2 of the present invention provides a nano-demulsifier for magnetic carbon nanotube composite material, which is prepared by the following steps:

[0055] (1) Oxidative modification of carbon nanotubes: get 1.0g carbon nanotubes and disperse them in a mixed solution of 150mL nitric acid (65wt%) and 50mL concentrated sulfuric acid (96wt%), ultrasonically disperse for 30 minutes to form a black suspension, Heat the black suspension and reflux at 80°C for 12 hours. After cooling to room temperature, dilute the suspension to 2L with distilled water, cool to room temperature and filter with a 0.45 μm microporous polytetrafluoroethylene filter membrane. Repeatedly washing with water until the pH value of the filtered solution is 7, and then vacuum-drying at 60°C to obtain oxidatively modified carbon nanotubes;

[0056] (2) Fe 3 o 4 Preparation of precursor solution: take 0.3g Fe(acac) 3 Ultrasonic dispersion in 28g ethylene glycol for 0.5 hours to obtain orange-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com