Patents

Literature

35results about How to "Increase magnetic saturation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic ferromanganese oxide-loaded mesoporous cellulose biochar composite, and preparation method and application thereof

ActiveCN108704611AAchieve reuseNo pollution in the processOther chemical processesWater contaminantsDispersion stabilityCellulose

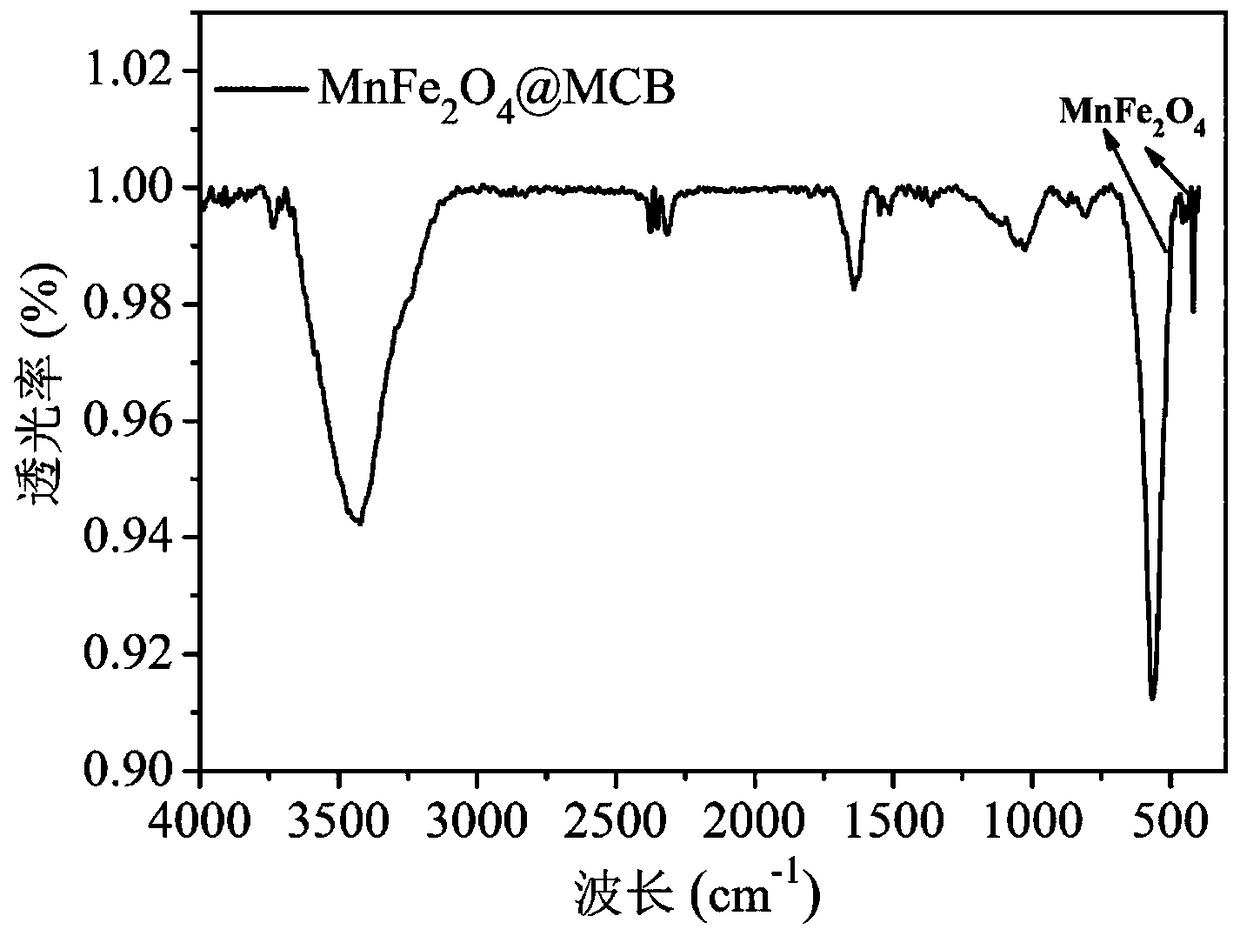

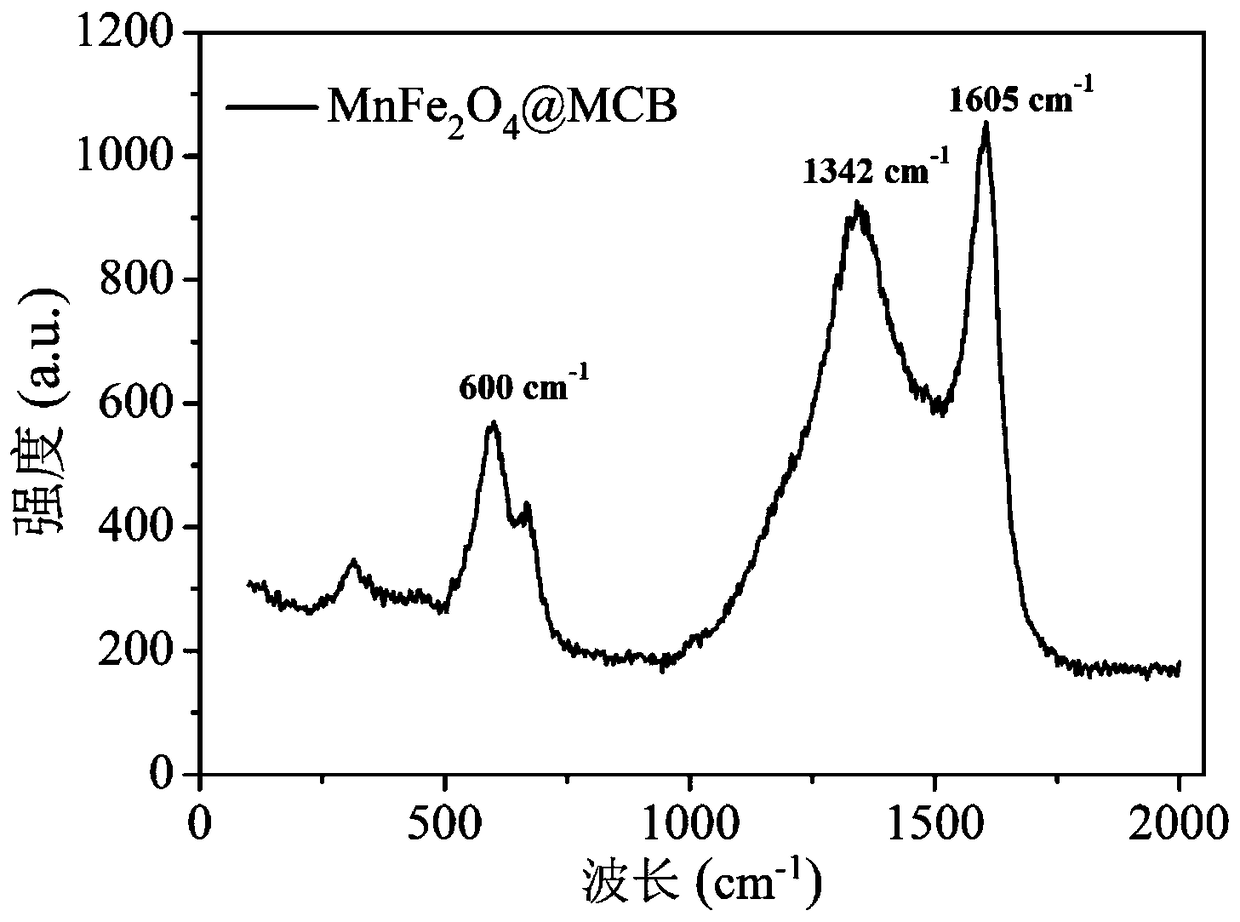

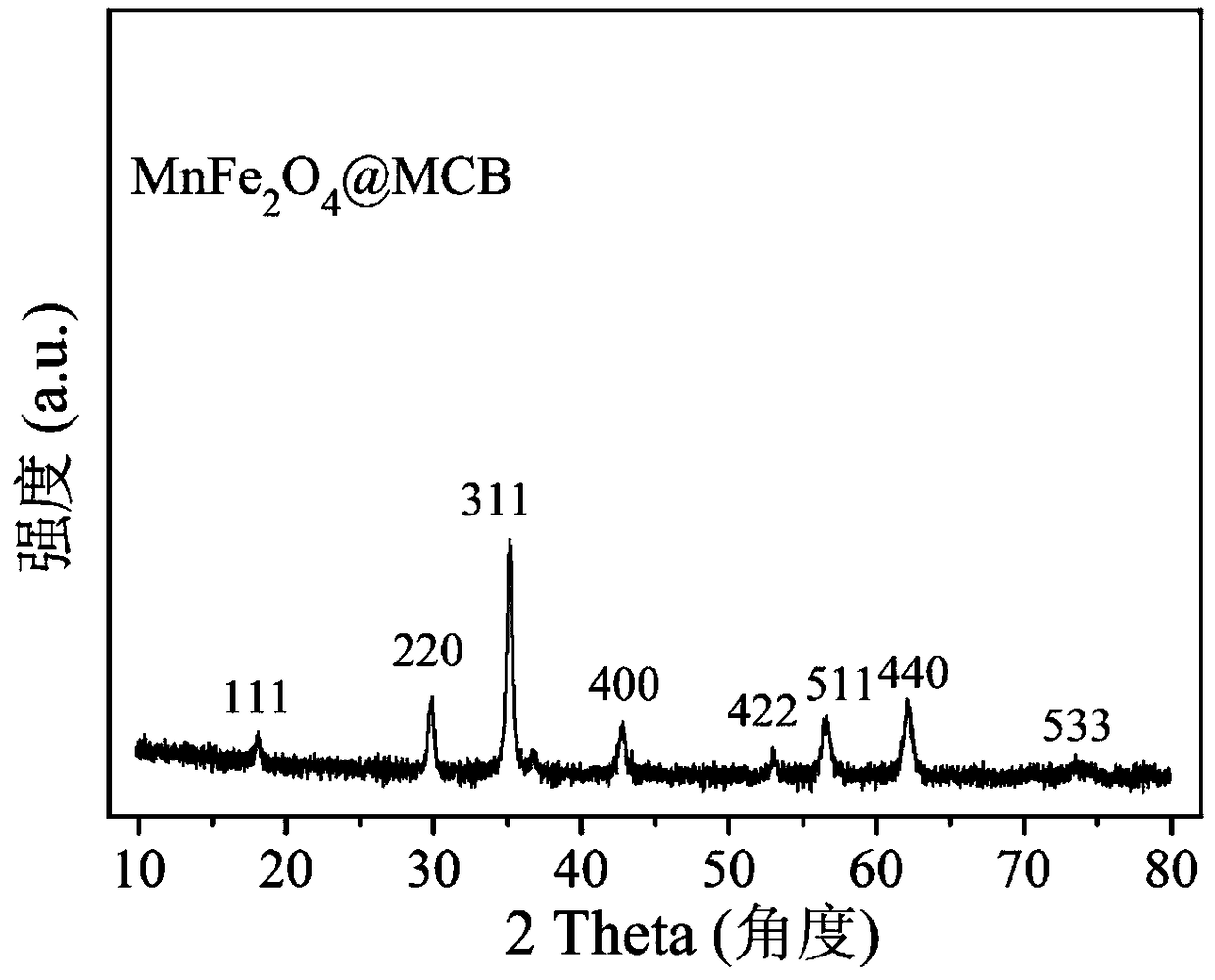

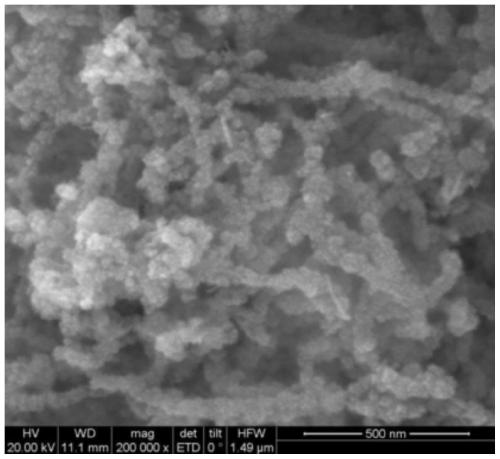

The invention belongs to the technical field of biomass resource recycling and new environmental functional materials, discloses a magnetic ferromanganese oxide-loaded mesoporous cellulose biochar composite, a preparation method thereof and application of the mesoporous cellulose biochar composite in environmental governance and remediation, and is particularly applicable to the field of adsorption of anionic pollutants. The preparation method comprises preparing mesoporous cellulose biochar, compositing MnFe2O4 in one step according to a solvothermal method, and loading the MnFe2O4 onto the mesoporous cellulose biochar to obtain the magnetic ferromanganese oxide-loaded mesoporous cellulose biochar composite. The mesoporous cellulose biochar composite prepared according to the method has the characteristics of strong magnetism, capability of being charged positively under acidic conditions, high dispersion stability, high adsorptive property and the like, can be widely applied to the field of environmental governance and remediation, is particularly applicable to pollution remediation of the anionic pollutants, such as adsorption of heavy metal and organophosphorus pesticides, andhas the glyphosate adsorption capacity as high as 167.2mg / g.

Owner:SOUTH CHINA UNIV OF TECH

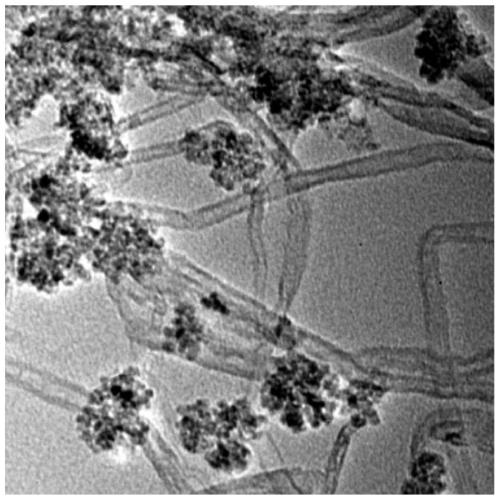

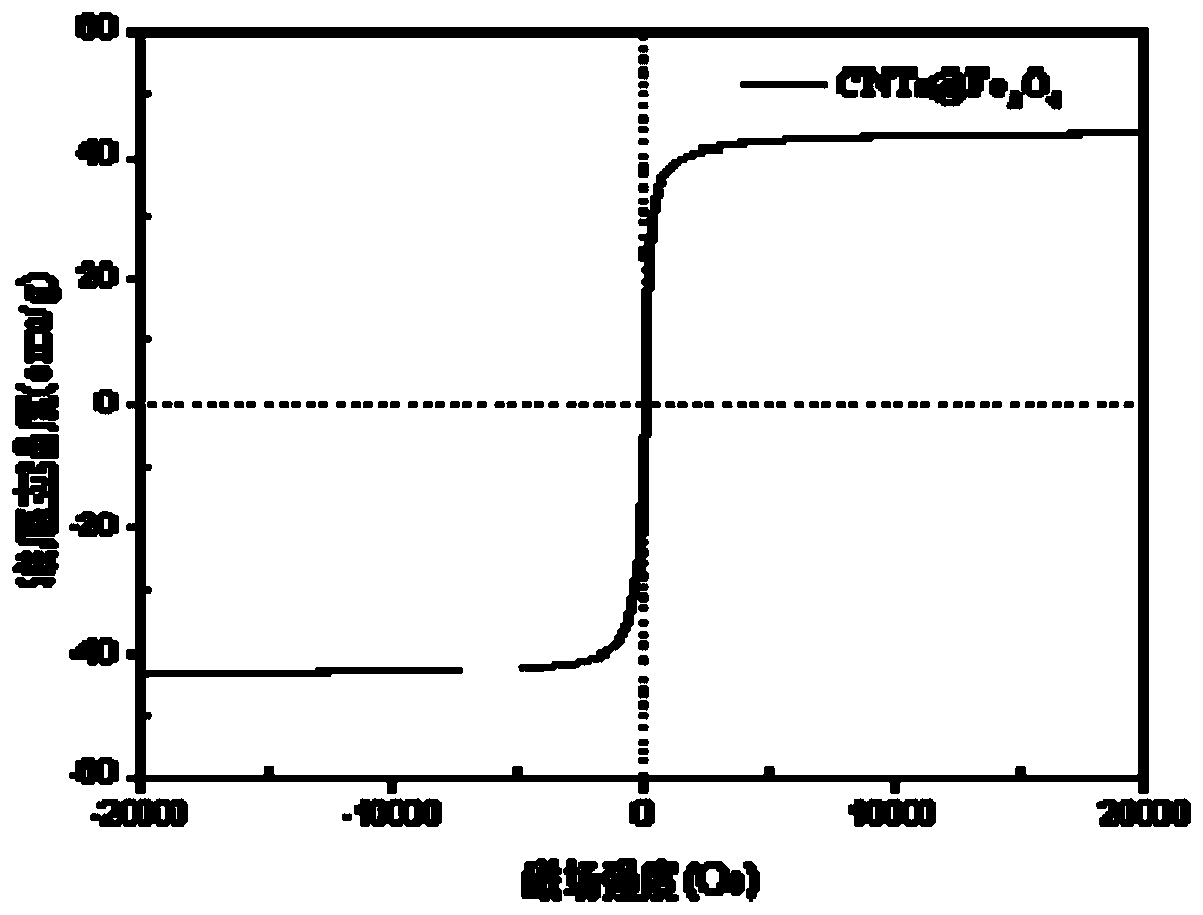

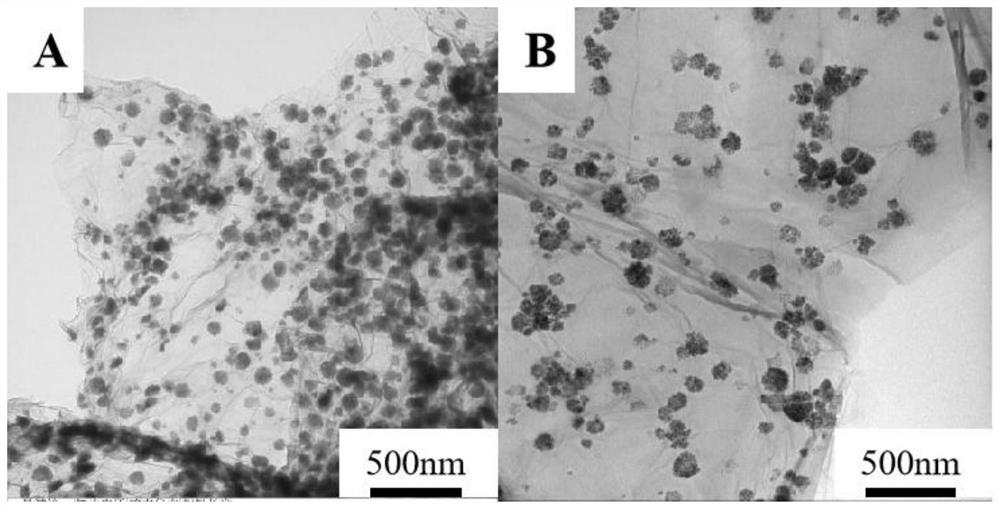

Preparation method for magnetic carbon nanotube demulsifier and application of magnetic carbon nanotube demulsifier

ActiveCN110182894AEasy to prepareEasy to implementWaste water treatment from quariesFatty/oily/floating substances removal devicesDemulsifierMagnetic carbon

The invention discloses a preparation method for a magnetic carbon nanotube demulsifier. The preparation method comprises the following steps: (1) subjecting carbon nanotubes and mixed acid to a refluxing reaction, so as to obtain oxidation modified carbon nanotubes; (2) preparing a Fe3O4 precursor solution; and (3) uniformly mixing the oxidation modified carbon nanotubes with the Fe3O4 precursorsolution, and carrying out a reaction at a temperature of 180 DEG C to 220 DEG C, thereby preparing the magnetic carbon nanotube demulsifier. According to the preparation method provided by the invention, firstly, the carbon nanotubes are subjected to oxidation modification through the mixed acid to introduce a large number of carboxyl groups and hydroxyl groups to defects and edges of the carbonnanotubes, and then, Fe3O4 nanoparticles are prepared in situ by utilizing a hydrothermal method to modify the oxidation modified carbon nanotubes; the preparation method is simple and is easy to implement; and the prepared magnetic carbon nanotube demulsifier can be used for rapidly achieving oil-water separation of oily wastewater and is relatively good in demulsification effect. A technical scheme of the invention further provides an application of the magnetic carbon nanotube demulsifier in the oily wastewater.

Owner:新疆澄润环保科技有限公司

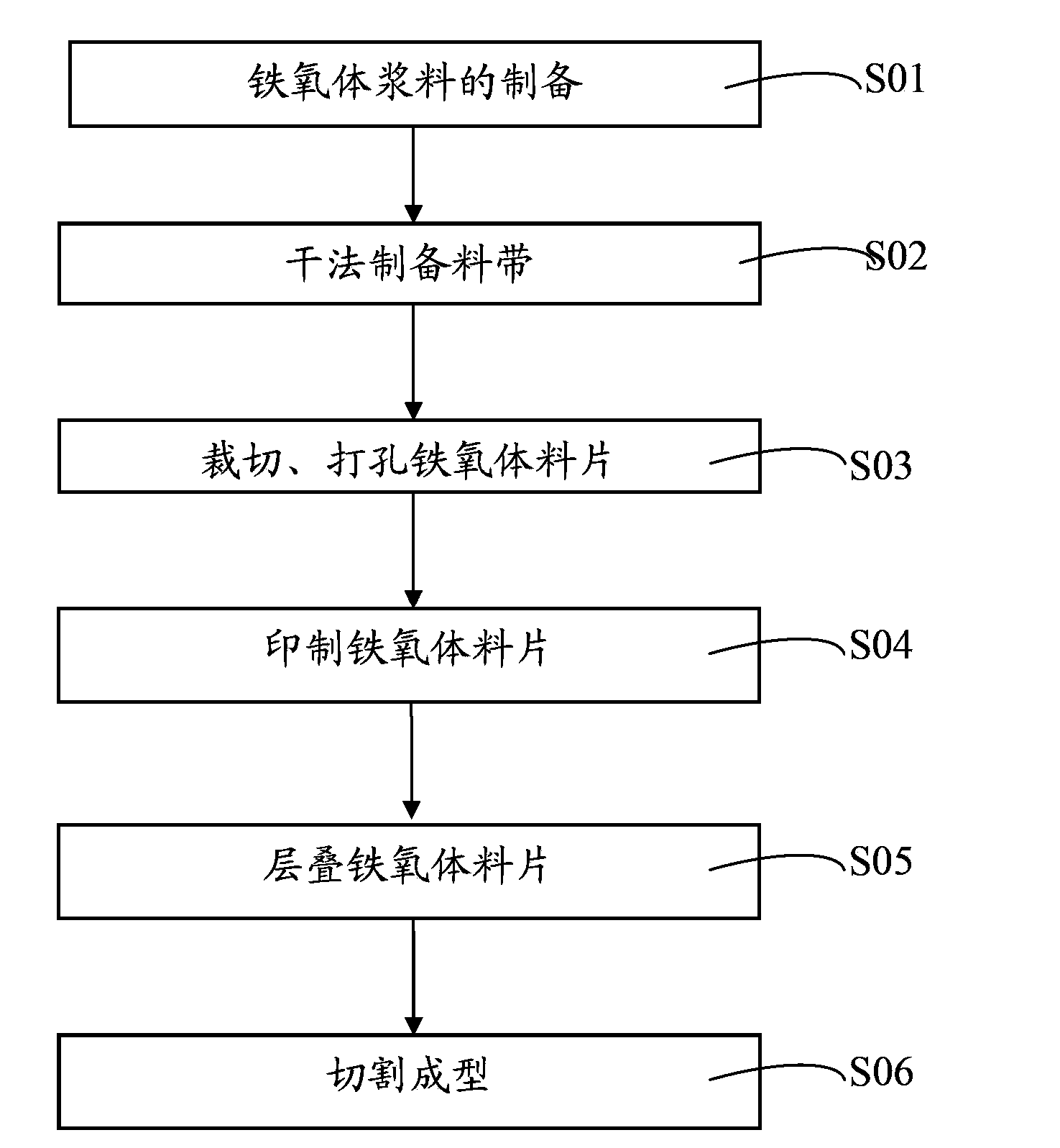

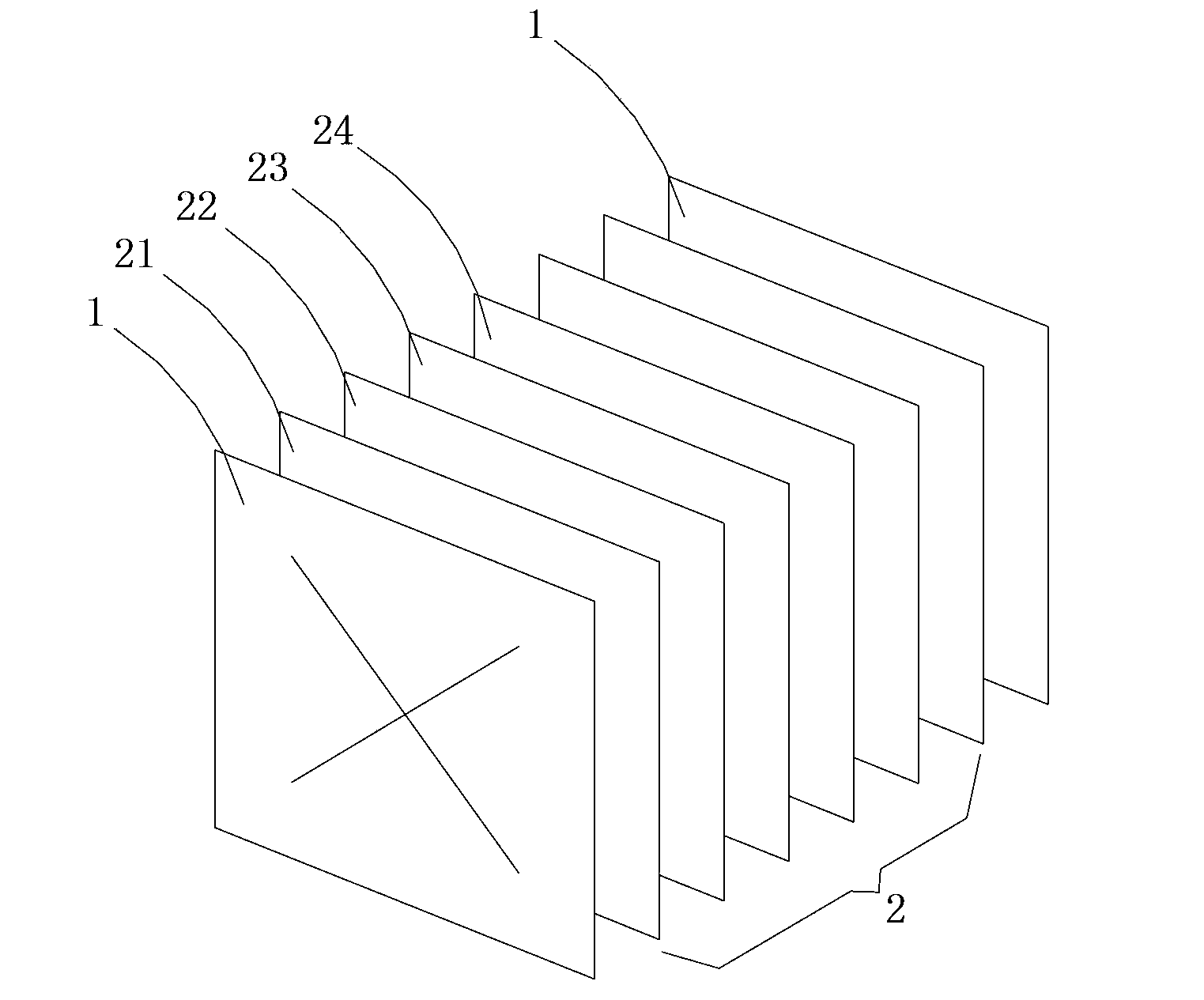

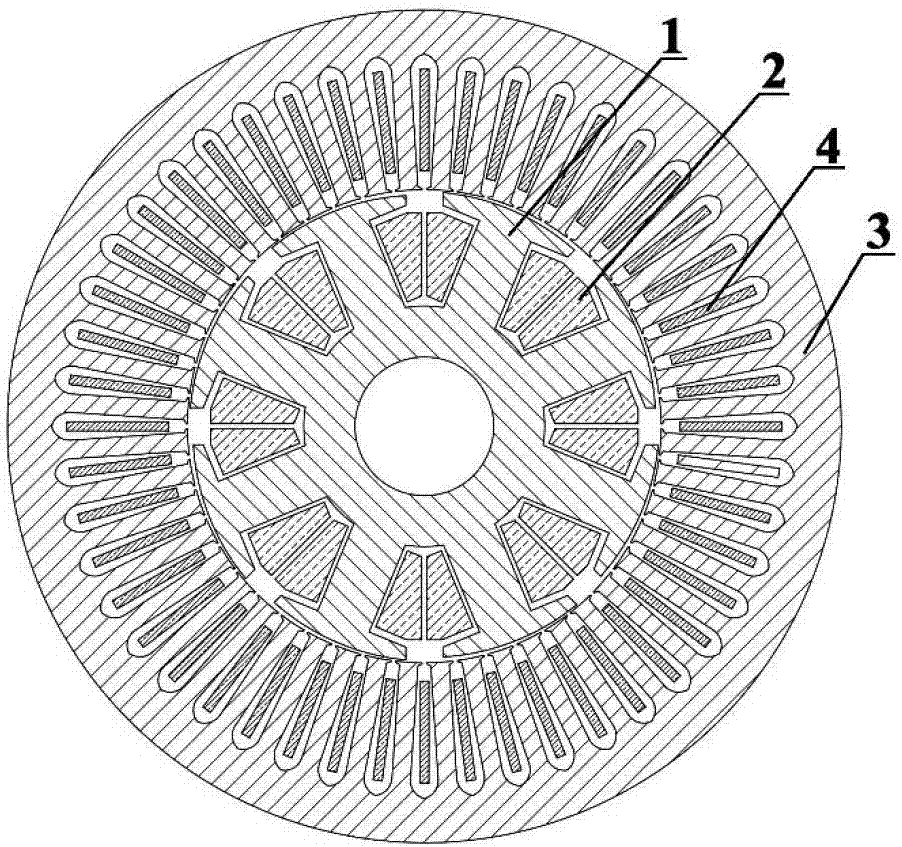

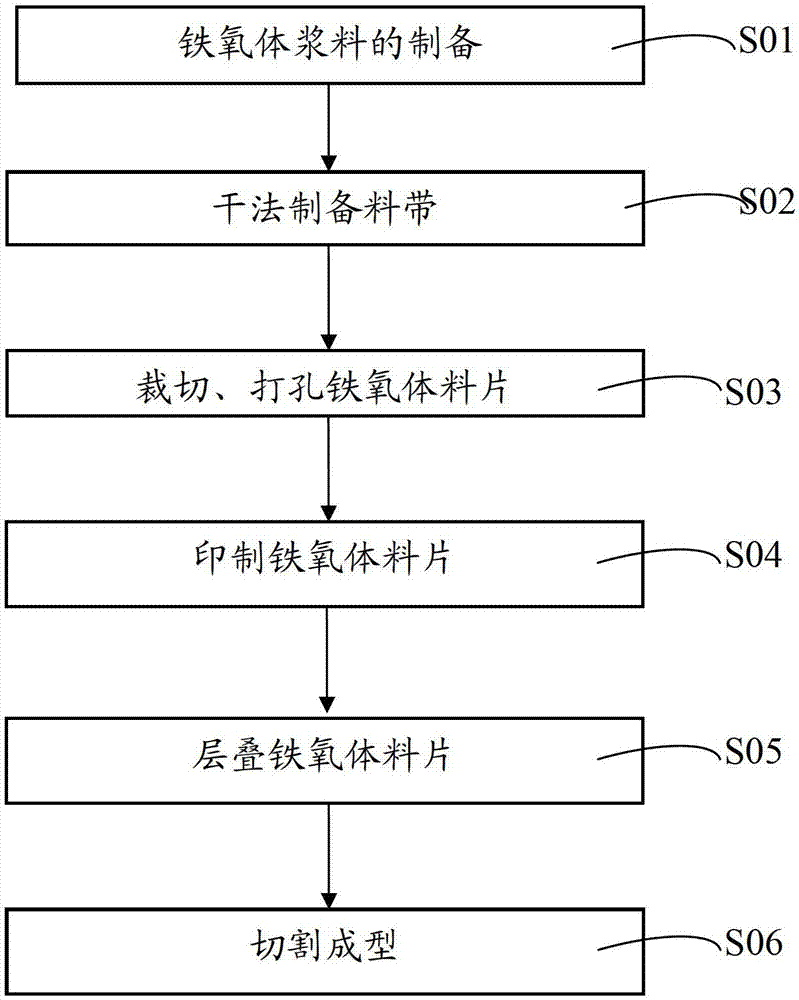

Ferrite material, small large-current laminated-chip wideband magnetic beads, and preparation method thereof

ActiveCN103387388AIncrease magnetic saturationReduce DC resistanceInorganic material magnetismFixed signal inductancesPunchingMagnetic bead

The invention discloses a ferrite material, small large-current laminated-chip wideband magnetic beads, and a preparation method thereof. The ferrite main materials comprise: 49-55mol% of Fe2O3, 25-35mol% of ZnO, 4-8mol% of CuO, 8-15mol% of NiO, 0.1-0.6mol% of Co3O4, 1-3mol% of Bi2O3, and 0.5-1.5mol% of Nb2O5. The magnetic bead preparation method comprises the steps of ferrite slurry preparation, material band dry preparation, cutting, ferrite material sheet punching, ferrite material sheet printing, ferrite material sheet lamination, cutting and forming, and the like. With the ferrite material, magnetic saturation degree is improved, and direct current resistance is reduced, such that larger current can be withstood. According to the magnetic bead preparation method, production period is shortened, and production efficiency is improved. The volume of the magnetic beads is small. The magnetic beads have good electromagnetic interference inhibition capacity from 100MHz to higher than 1GHz.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

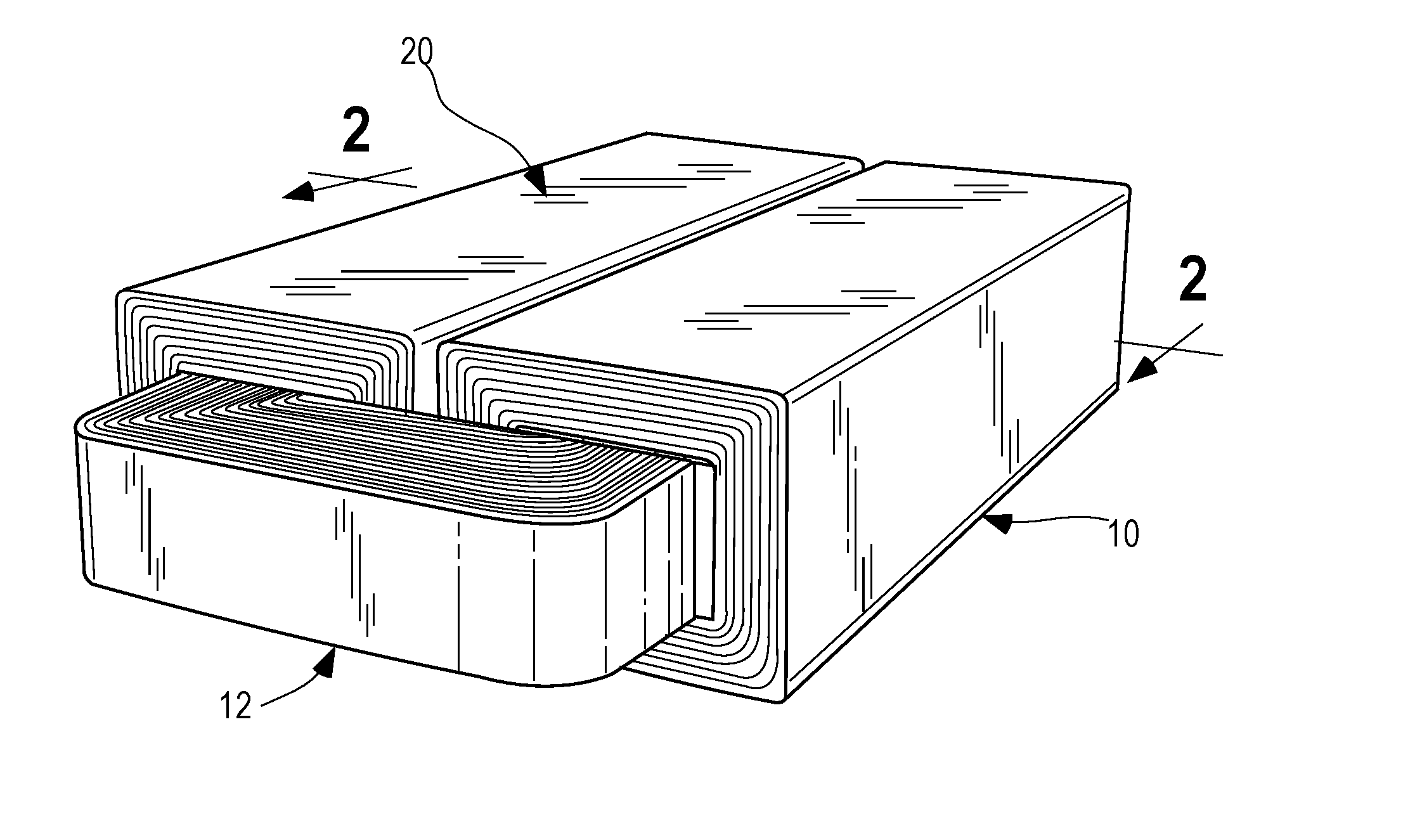

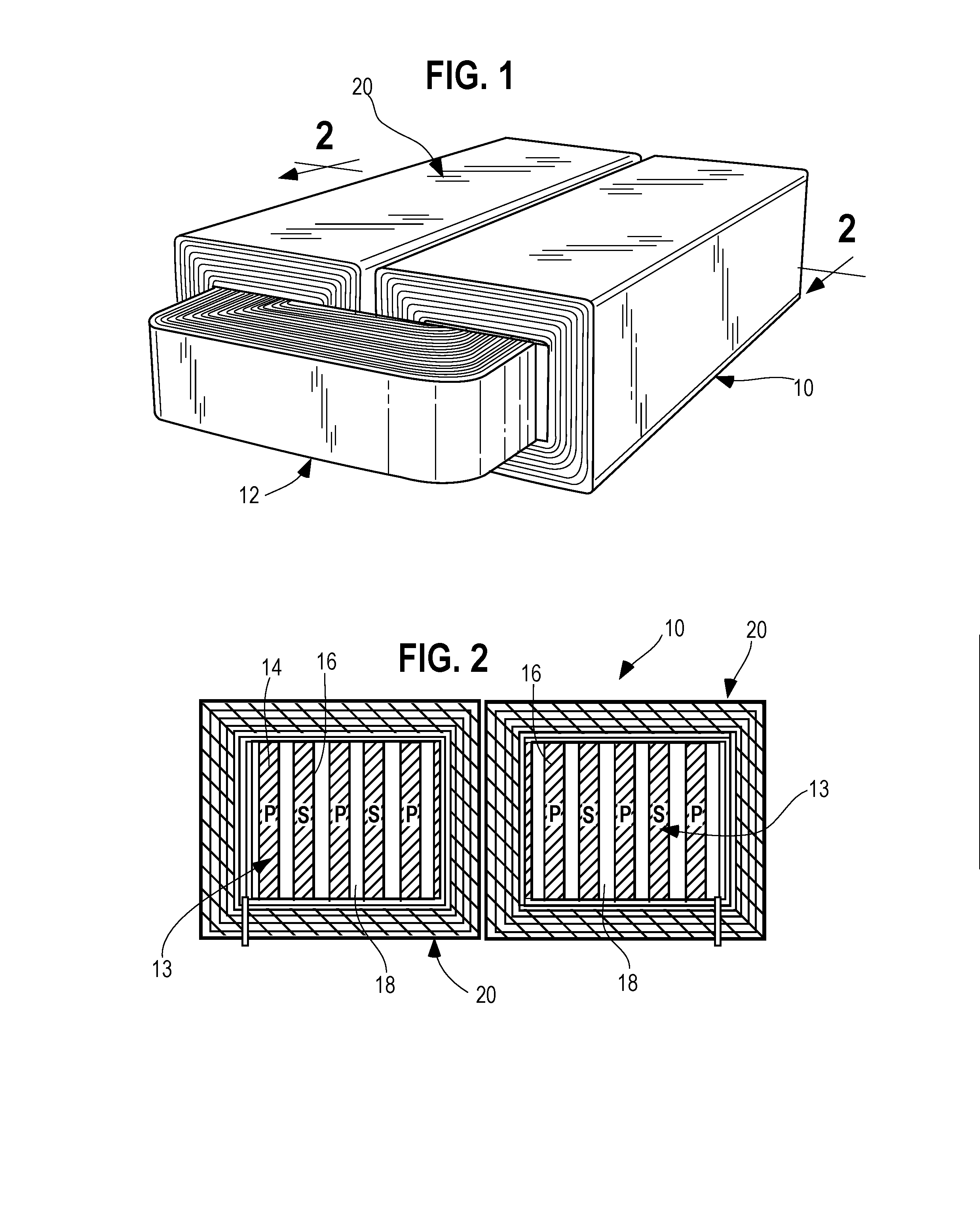

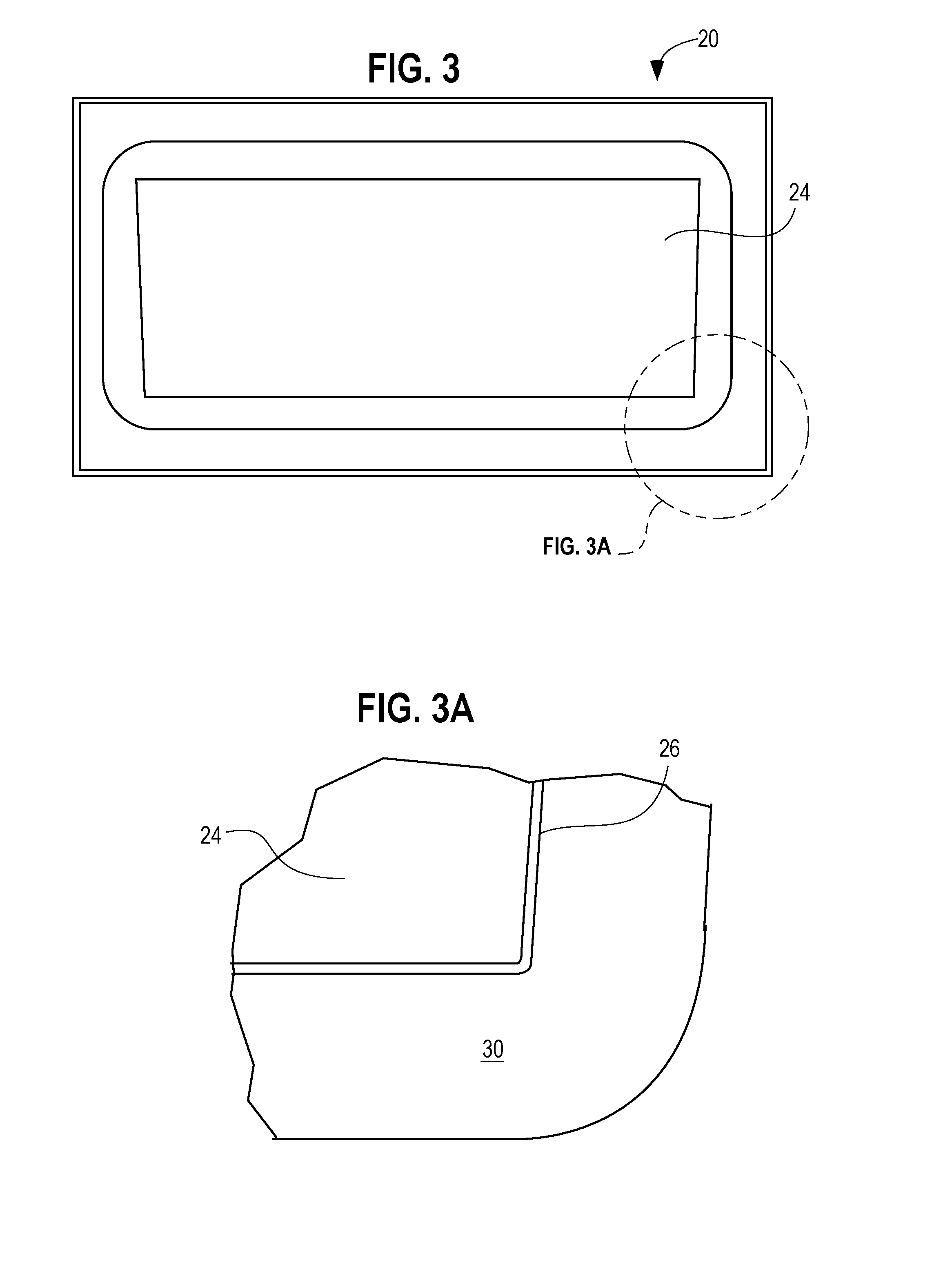

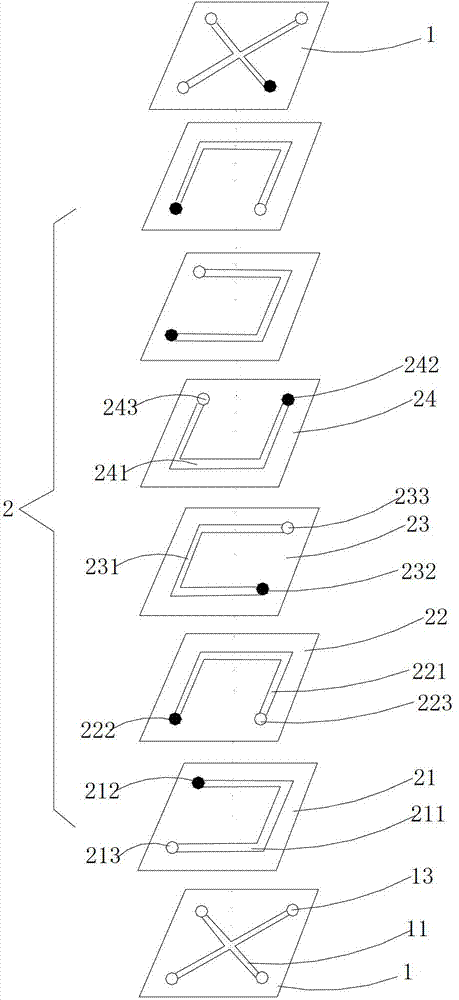

Electromagnetic device having layered magnetic material components and methods for making same

ActiveUS20170053728A1Improve performanceReduce energy lossLiquid applicationTransformers/inductances coils/windings/connectionsProduction ratePerformance results

A micro fabricated electromagnetic device and method for fabricating its component structures, the device having a layered magnetic core of a potentially unlimited number of alternating insulating and magnetic layers depending upon application, physical property and performance characteristic requirements for the device. Methods for fabricating the high performing device permit cost effective, high production rates of the device and its component structures without any degradation in device performance resulting from component layering.

Owner:TELEDYNE SCI & IMAGING

Soft magnetic high-entropy alloy material of island magnetic crystal structure and preparation method thereof

ActiveCN110373596AIncrease magnetic saturationHigh strengthTransportation and packagingMetal-working apparatusHigh entropy alloysMicro nano

The invention discloses a soft magnetic high-entropy alloy material of an island magnetic crystal structure. The soft magnetic high-entropy alloy material is of a core-shell structure. By taking a micro-nano high-entropy alloy with soft magnetic performance as a core and a nonmagnetic metal oxide which is prepared by a hydrothermal method and coats a magnetic crystal surface layer of the micro-nano high-entropy alloy as a shell, high-entropy alloy magnetic crystals of the core-shell structure are densified by spark plasma sintering to form the soft magnetic of the island magnetic crystal structure. The nano magnetic crystals of the soft magnetic material obtained by the preparation method generate a magnetic coupling effect, so that the saturated magnetic intensity and the coercive force of the high-entropy alloy are improved favorably.

Owner:NANJING INST OF TECH

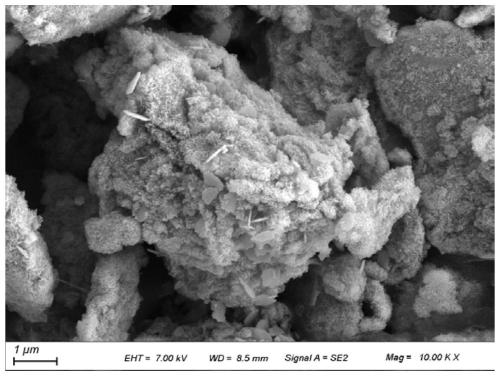

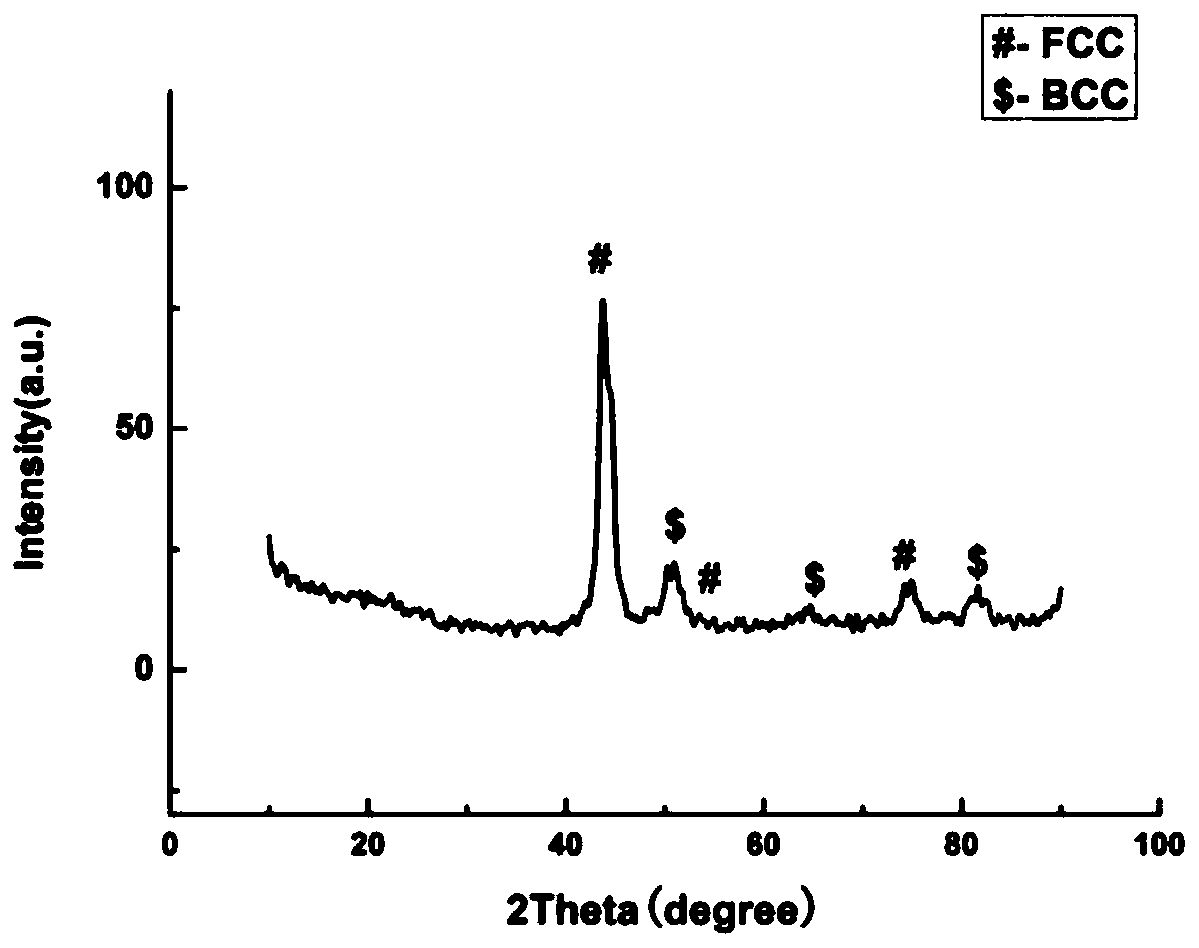

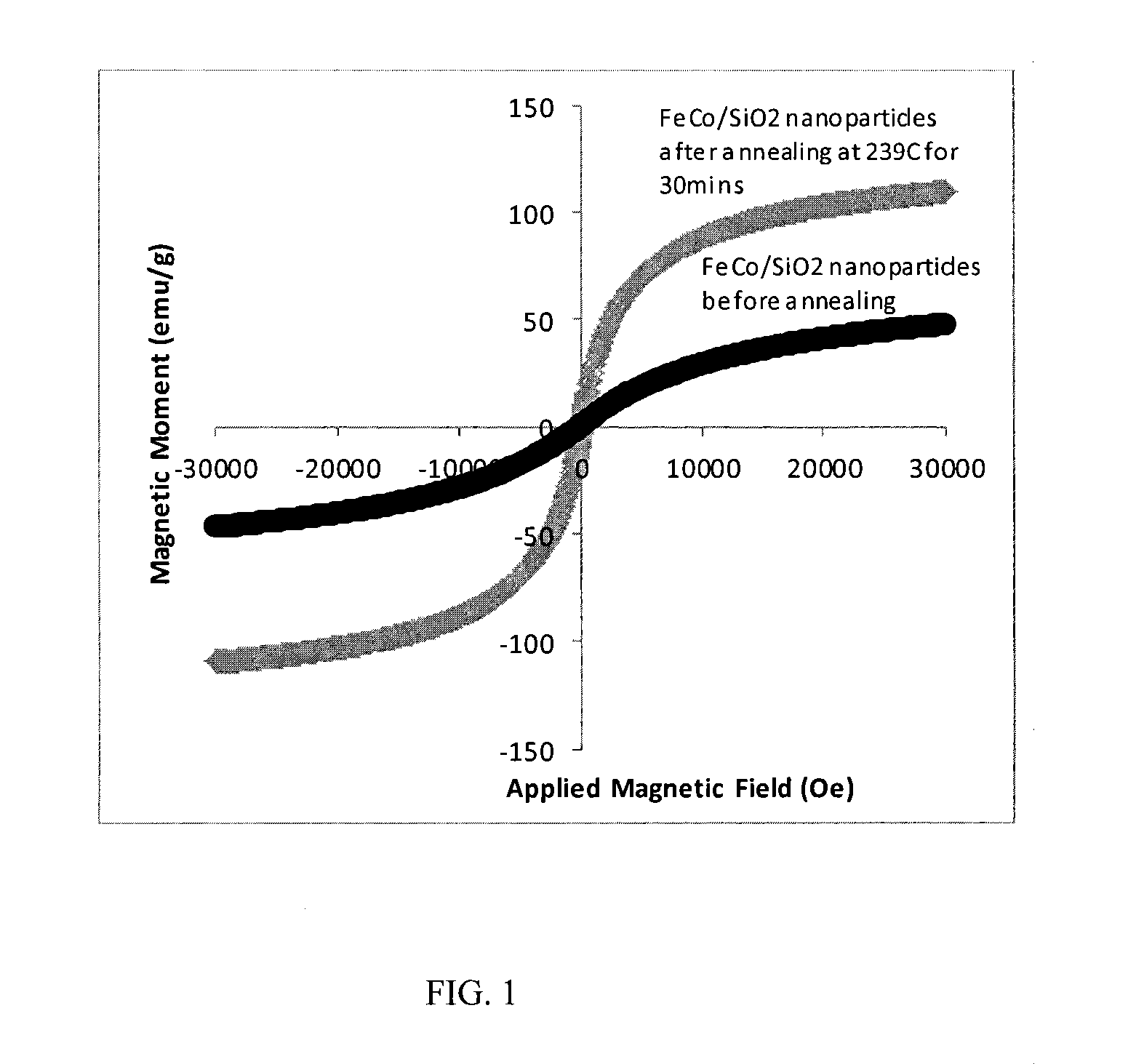

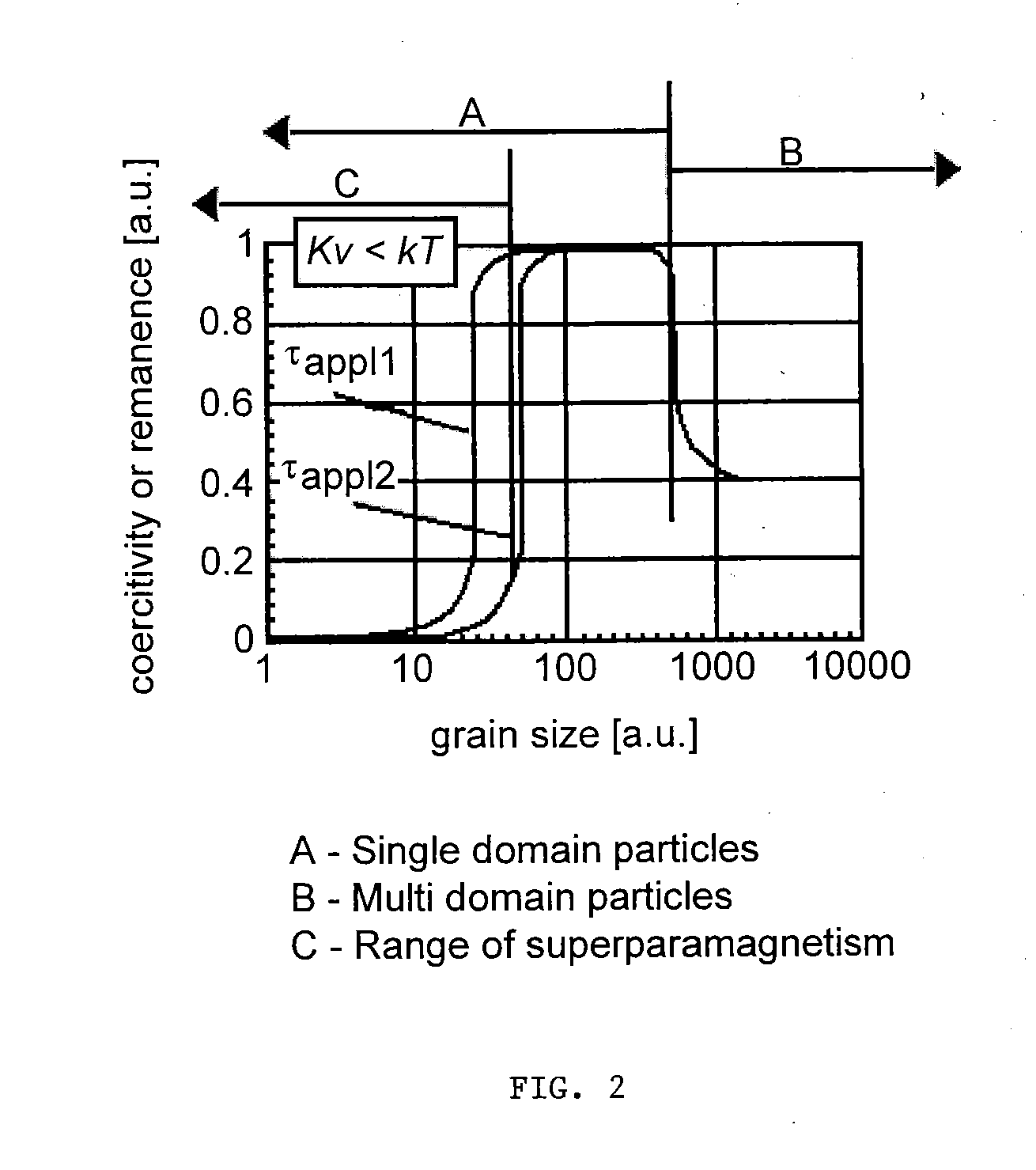

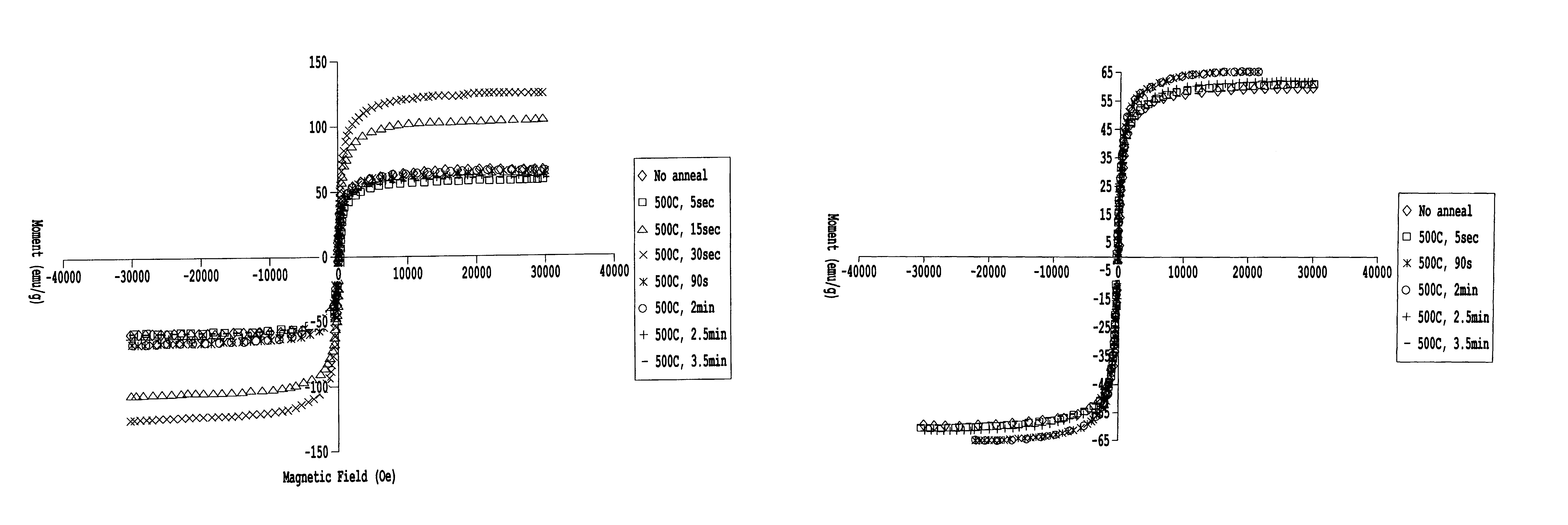

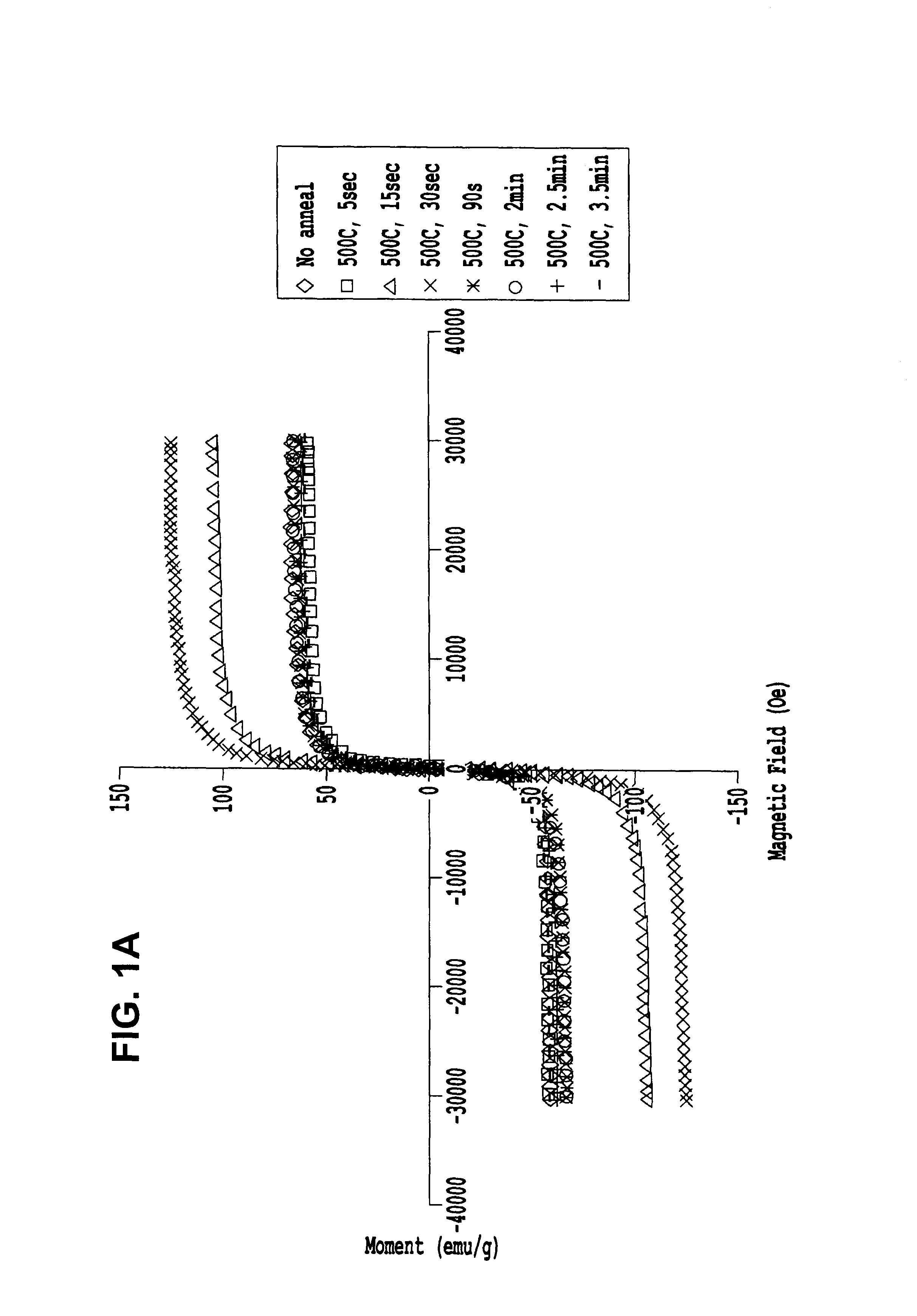

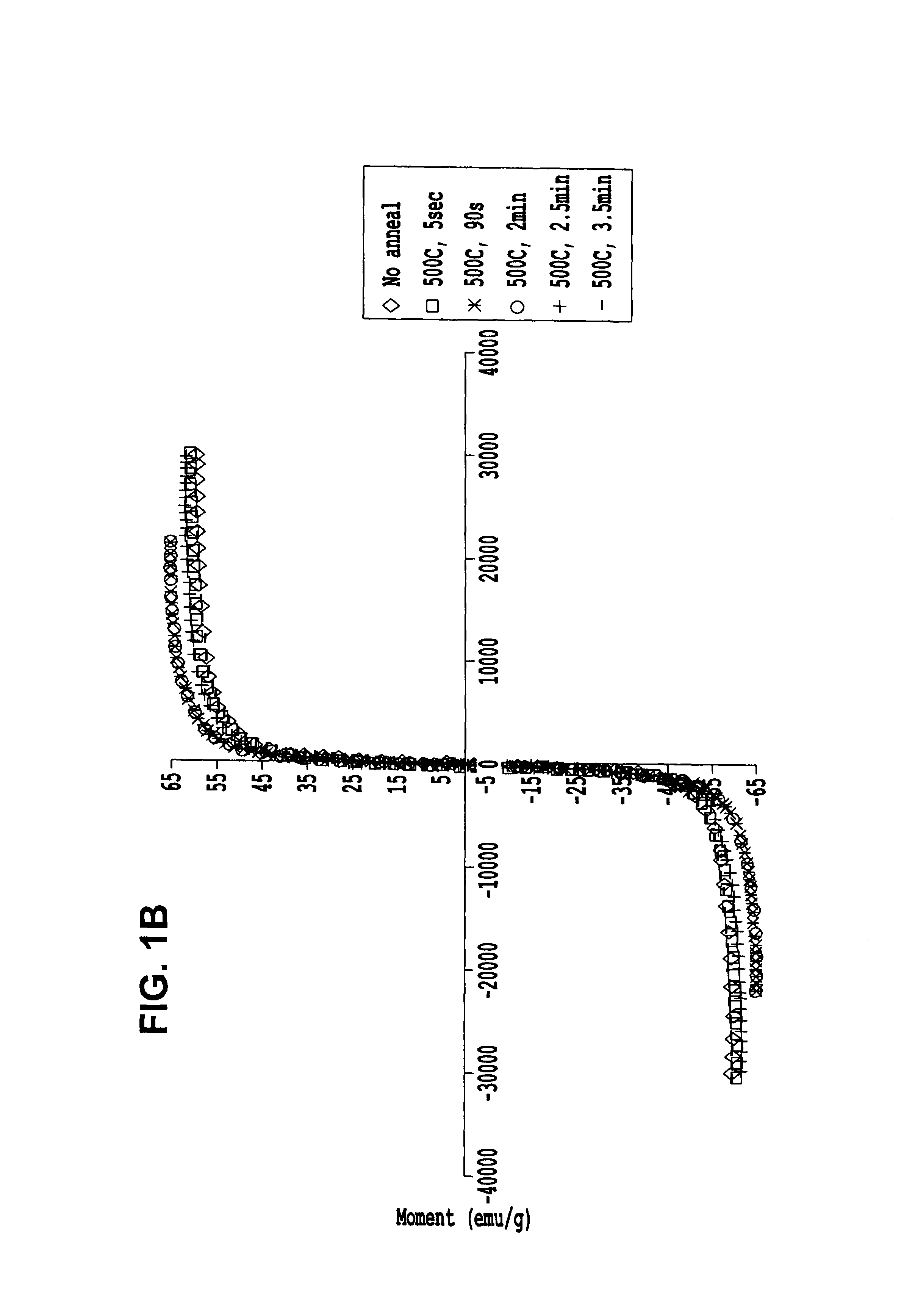

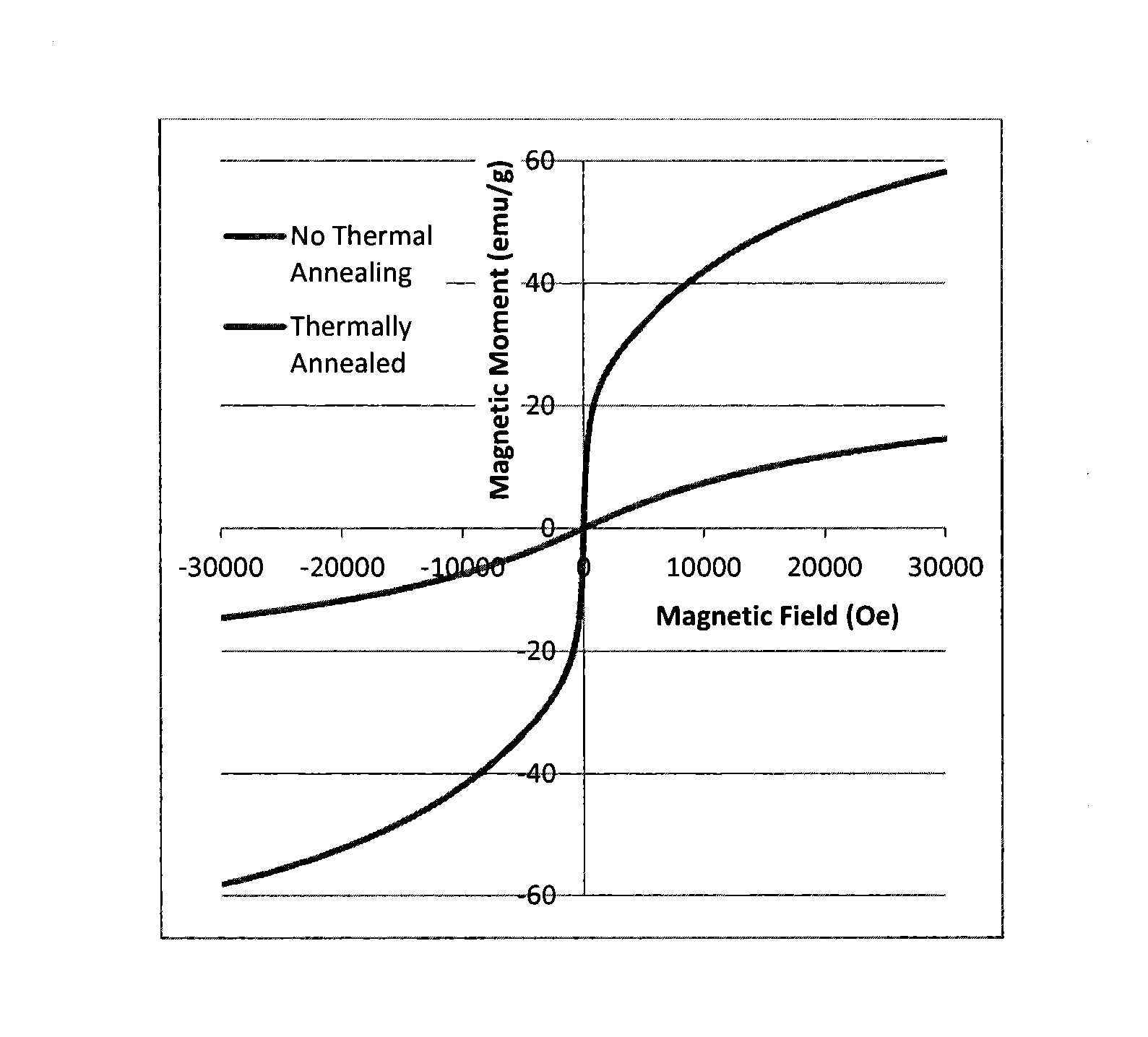

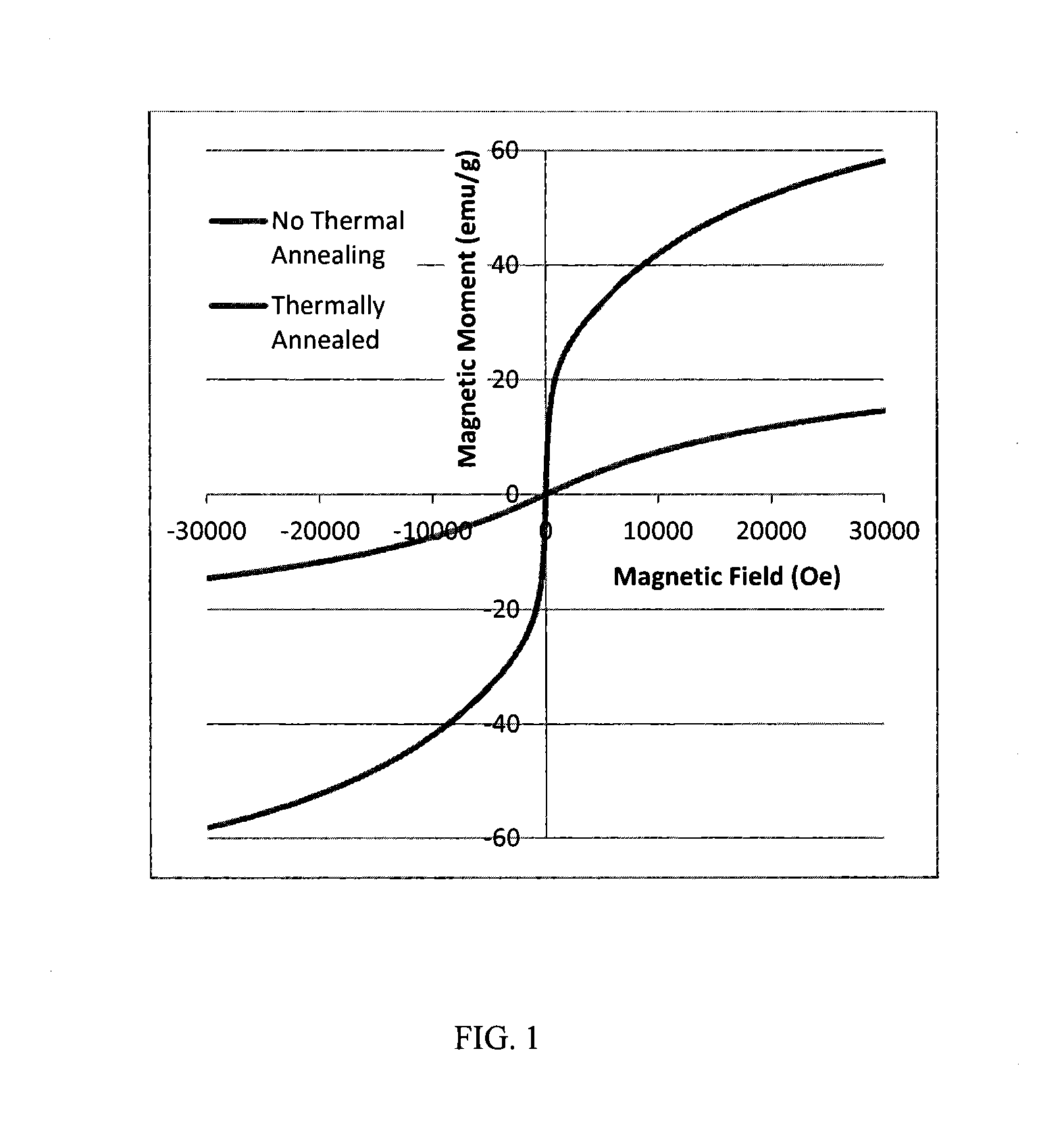

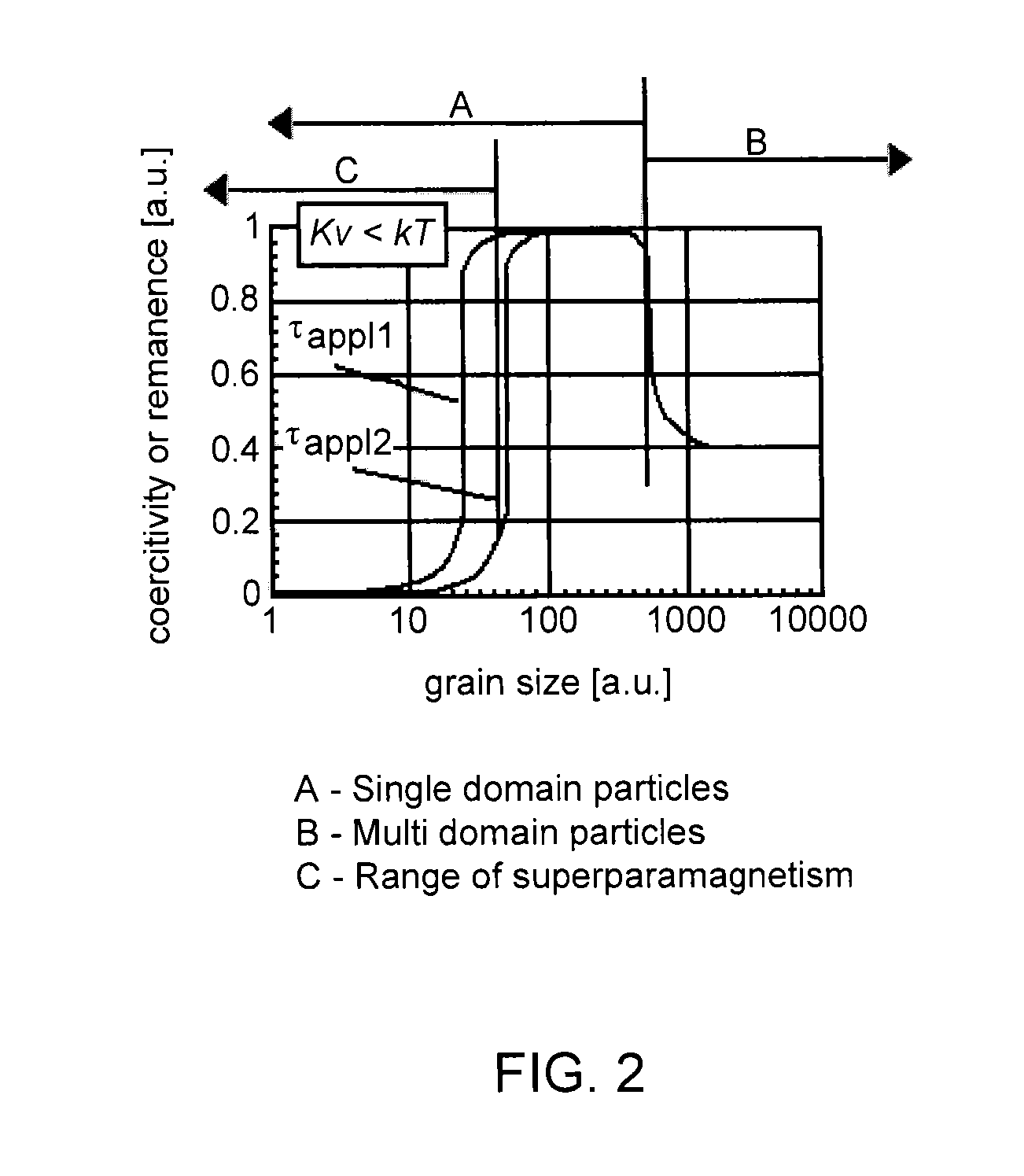

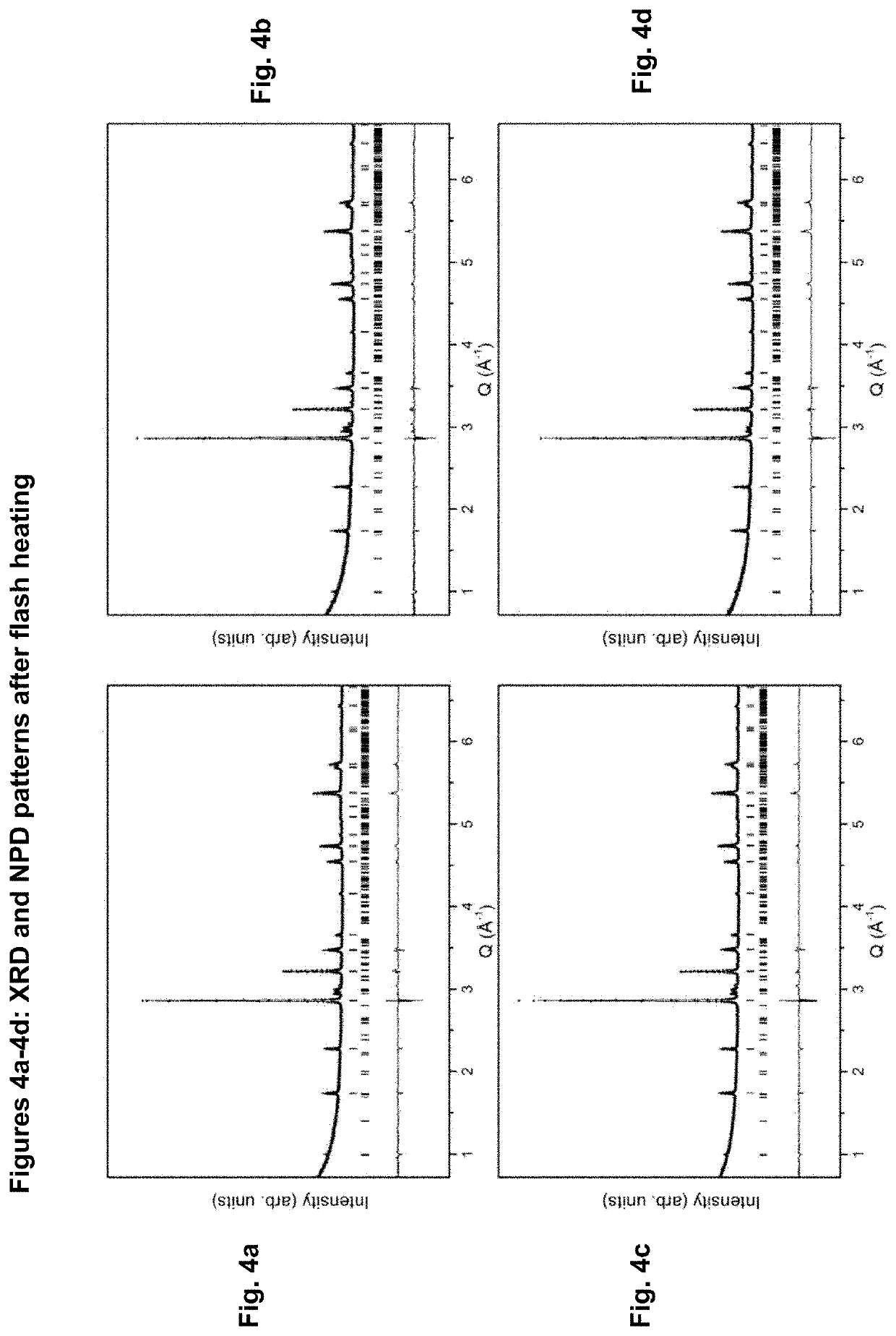

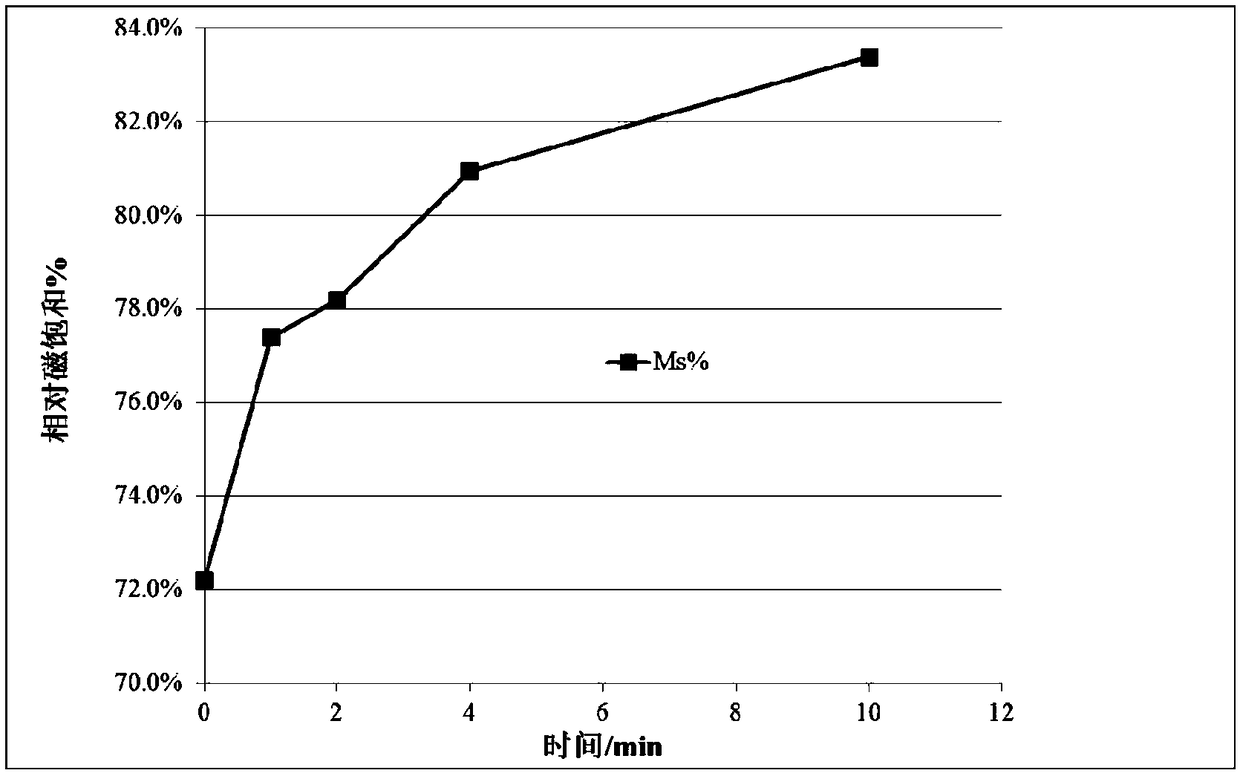

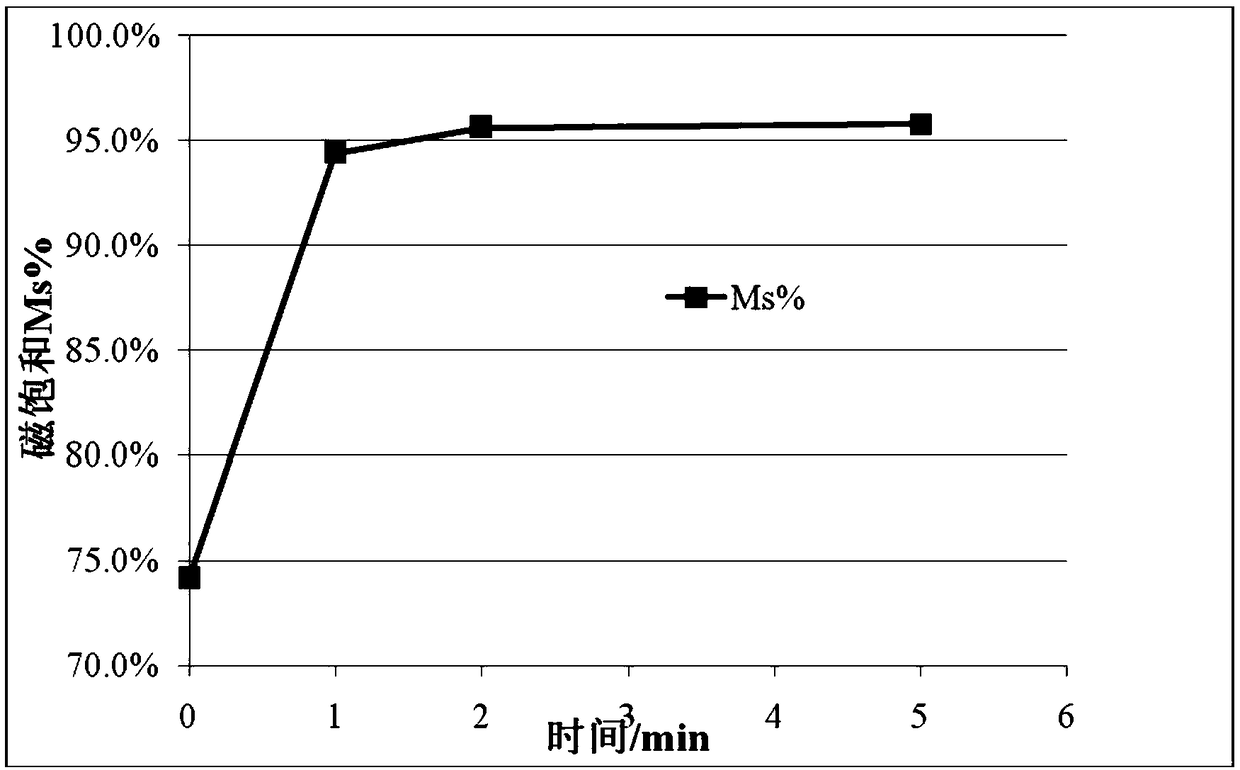

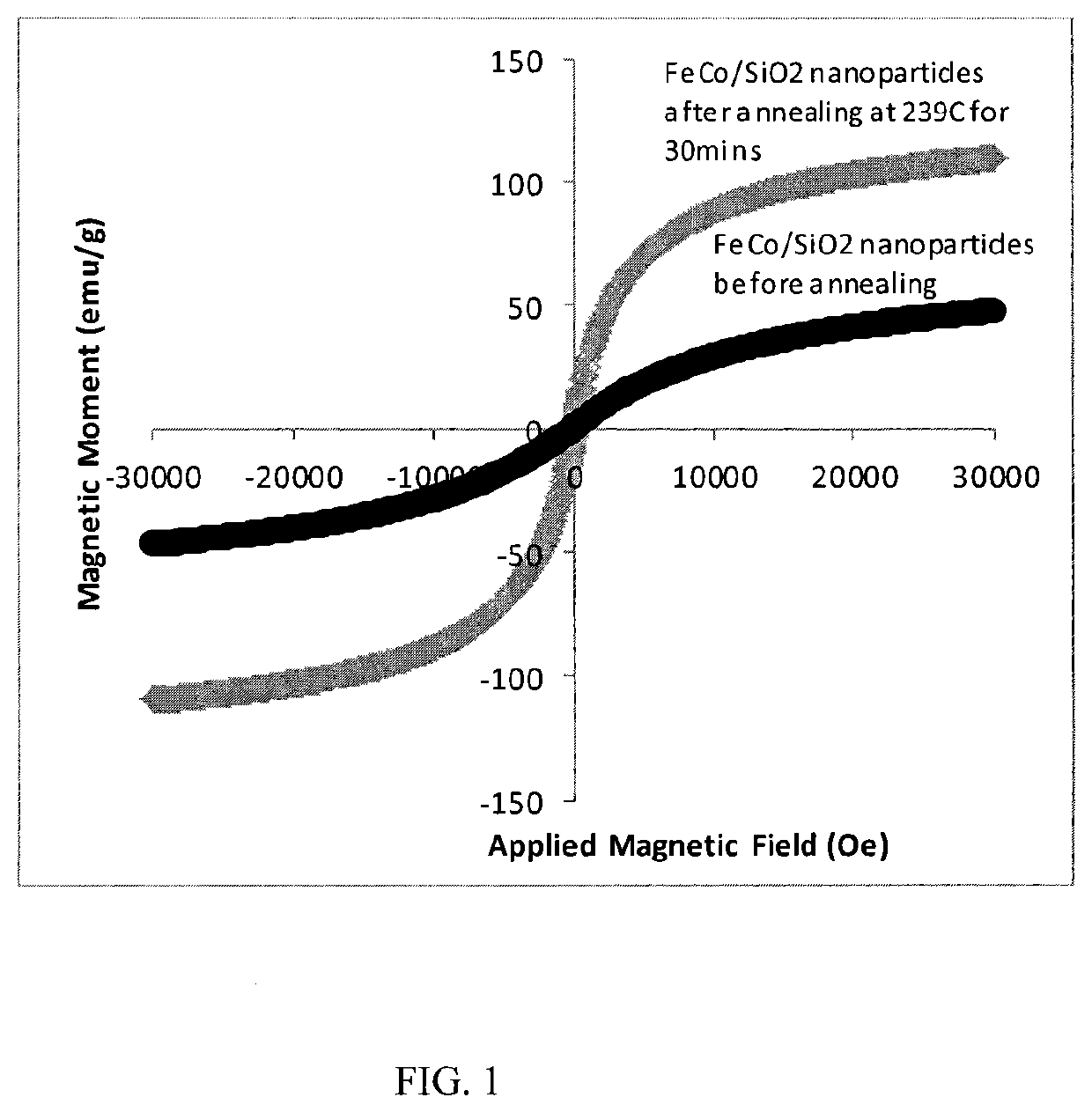

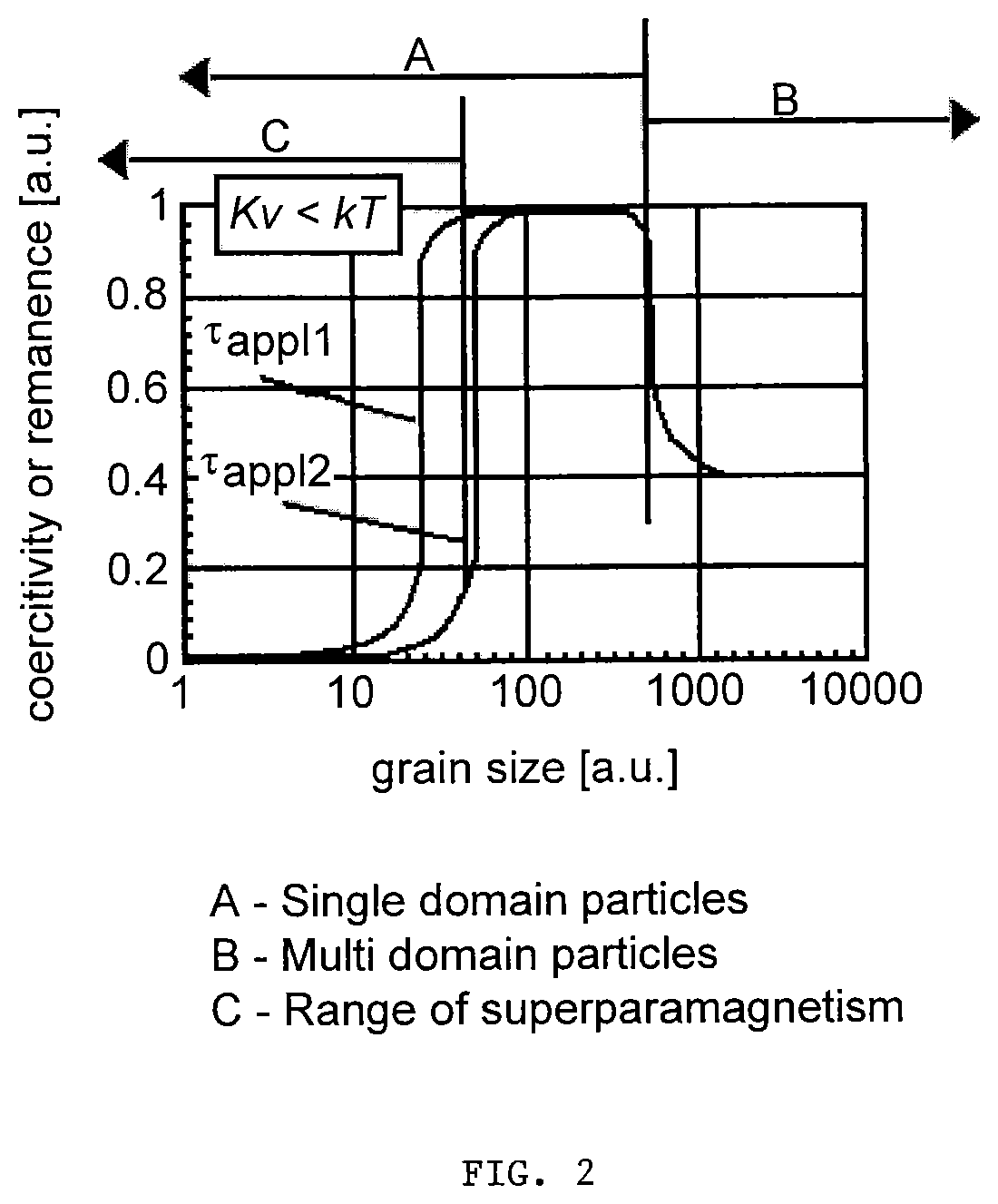

Superparamagnetic iron cobalt alloy and silica nanoparticles of high magnetic saturation and a magnetic core containing the nanoparticles

ActiveUS20150014573A1Increase green strengthHigh temperature toleranceTransportation and packagingMetal-working apparatusNanometreCore shell nanoparticles

Thermally annealed superparamagnetic core shell nanoparticles of an iron-cobalt alloy core and a silicon dioxide shell having high magnetic saturation are provided. A magnetic core of high magnetic moment obtained by compression sintering the thermally annealed superparamagnetic core shell nanoparticles is also provided. The magnetic core has little core loss due to hysteresis or eddy current flow.

Owner:TOYOTA JIDOSHA KK

Preparation method of iron-based soft magnetic material

InactiveCN104087840AExcellent soft magnetic propertiesGood soft magneticMagnetic materialsIngotSaturation intensity

The invention relates to a preparation method of an iron-based soft magnetic material. The soft magnetic material is prepared by using an alloy with the chemical formula of (Fe[1-x-y]Co[x]Cu[y])[1-a-b-c](Si[1-z]Cr[z])[a]Yb[b]B[c], wherein x is 0.15-0.18, y is 0.12-0.16, z is 0.21-0.25, a is 0.12-0.15, b is 0.02-0.03, and c is 0.03-0.04. The method comprises the steps of burdening, melting ingot production, electroslag remelting, alloy strip preparation and heat treatment. The soft magnetic material prepared in the invention adopts Co and Cu to substitute parts of Ni in order to improve the soft magnetic performance of the material, the doping of Yb improves the magnetic saturation intensity of the material, the doping of Si, B and Cr improves the resistivity and the corrosion resistance of the material, and the adoption of an electroslag remelting technology enhances the stability of the material. The material has a good soft magnetic performance and low energy loss when the material is used in humid environment and other severe environments for a long term.

Owner:深圳市贝塔电子股份有限公司

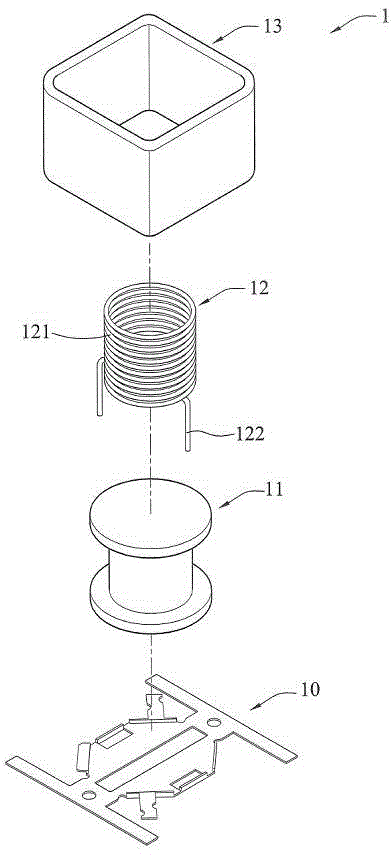

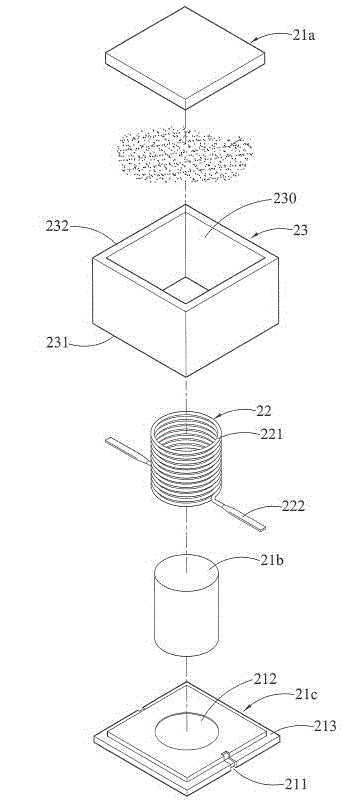

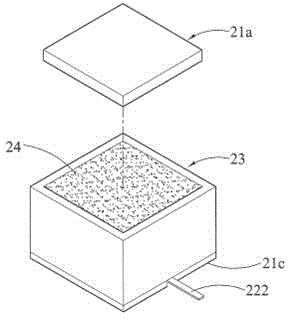

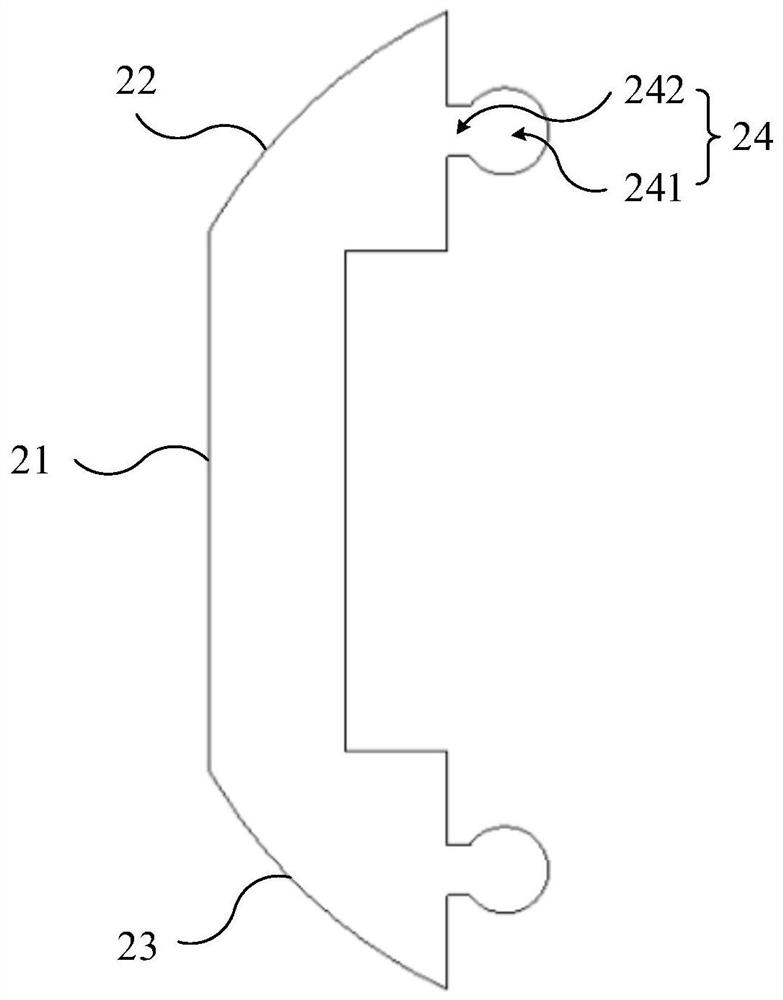

Inductor and manufacturing method thereof

InactiveCN104425100AIncrease magnetic saturationImprove featuresTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresInductorInductance

The invention discloses an inductor and a manufacturing method thereof. The manufacturing method includes that one end of a magnetic core column is abutted against a first magnetic end cap, a coil with two connecting parts is sleeved with the magnetic core column, the two connecting parts are arranged in two opening holes, and then the first magnetic end cap covers the first end of a shell with an accommodation space, so that the magnetic core column and the coil can be accommodated in the accommodation space; magnetic powder is filled into the accommodation space to form a magnetic powder layer so as to cover the coil and the magnetic core column, and then a second magnetic end cap covers the second end of the shell and is abutted against the other end of the magnetic core column, so that the magnetic powder layer and the coil sleeved with the magnetic core column are sealed in the accommodation space, and the two connecting part are bent towards one side of the first magnetic end cap away from the shell. The magnetic core column and the first and second magnetic end caps can be manufactured by different materials, magnetic saturation characteristics of the inductor can be added, and manufacturing cost is reduced.

Owner:重庆美桀电子科技有限公司

Method for improving carbon potential of low-carbon hard alloy

ActiveCN106637052AIncrease magnetic saturationSolve the problem of difficult carburizationSolid state diffusion coatingCarbon potentialRoom temperature

A method for improving carbon potential of a low-carbon hard alloy is characterized in that gas carbonizing treatment is carried out on the low-carbon hard alloy, wherein gas carbonizing treatment comprises the following steps that firstly, the low-carbon hard alloy is arranged in a sintering furnace, the room temperature is raised to 1,340 DEG C to 1,400 DEG C, then, the temperature is kept for 30-180 min, during the temperature keeping time, mixed gas of H2 and CH4 is introduced into the sintering furnace in a pulse manner, low pressure is adopted after high pressure is adopted, the high pressure ranges from 200 mbar to 800 mbar, and the lower pressure ranges from 10 mbar to 50 mbar; moreover, the pulse period ranges from 5 min to 10 min, the time ratio of the high-pressure stage to the low-pressure stage ranges from 2: 1 to 4: 1; secondly, the low-carbon hard alloy is cooled to 1,270 DEG C to 1,330 DEG C, then, the temperature is kept for 30 min to 180 min, and during the temperature keeping time, inert gas with the pressure ranging from 1,000 mbar to 2,000 mbar is introduced into the sintering furnace; and thirdly, the low-carbon hard alloy is cooled to the room temperature, and the product is taken out of the furnace.

Owner:潜江新锐硬质合金工具有限公司

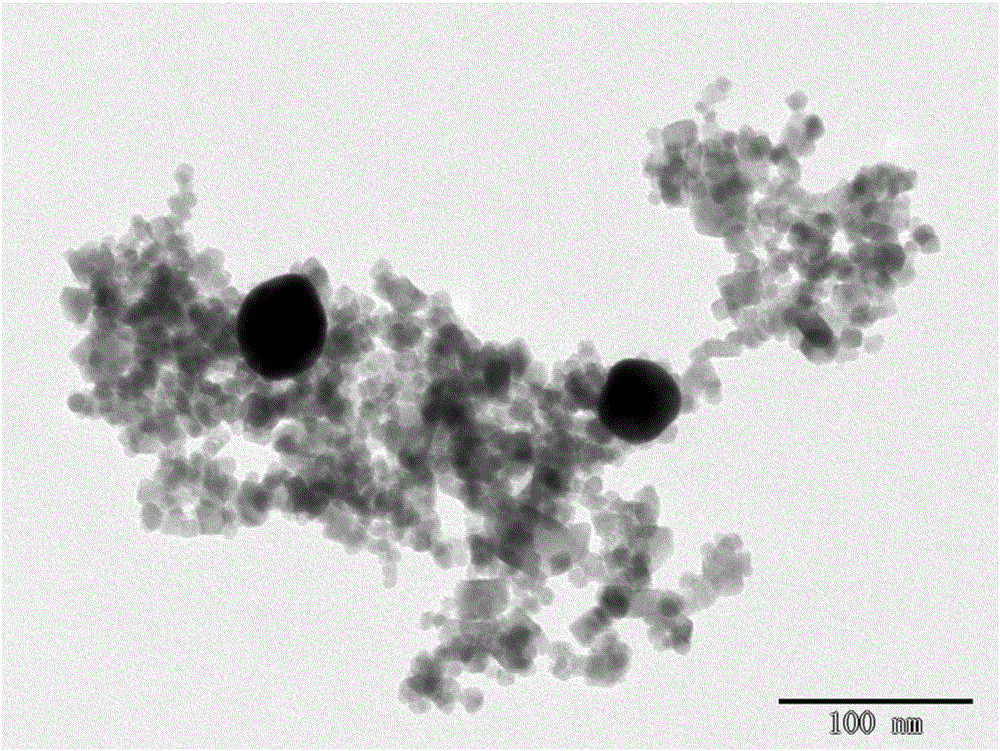

Superparamagnetic iron oxide and silica nanoparticles of high magnetic saturation and a magnetic core containing the nanoparticles

InactiveUS9093205B2High green strengthImprove mechanical propertiesInorganic material magnetismInductances/transformers/magnets manufactureSilica nanoparticlesHysteresis

Thermally annealed superparamagnetic core shell nanoparticles of an iron oxide core and a silicon dioxide shell having high magnetic saturation are provided. A magnetic core of high magnetic moment obtained by compression sintering the thermally annealed superparamagnetic core shell nanoparticles is also provided. The magnetic core has little core loss due to hysteresis or eddy current flow.

Owner:TOYOTA JIDOSHA KK

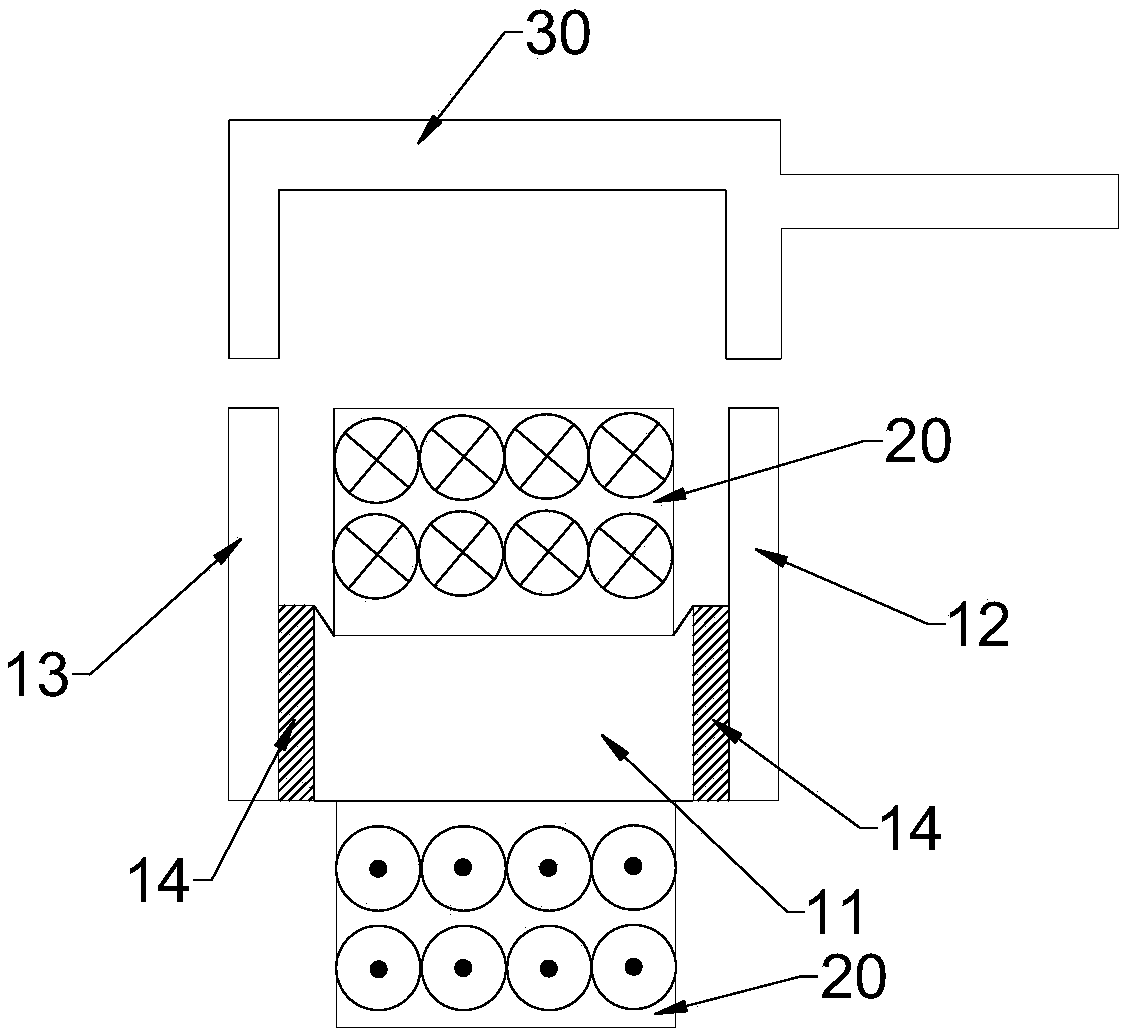

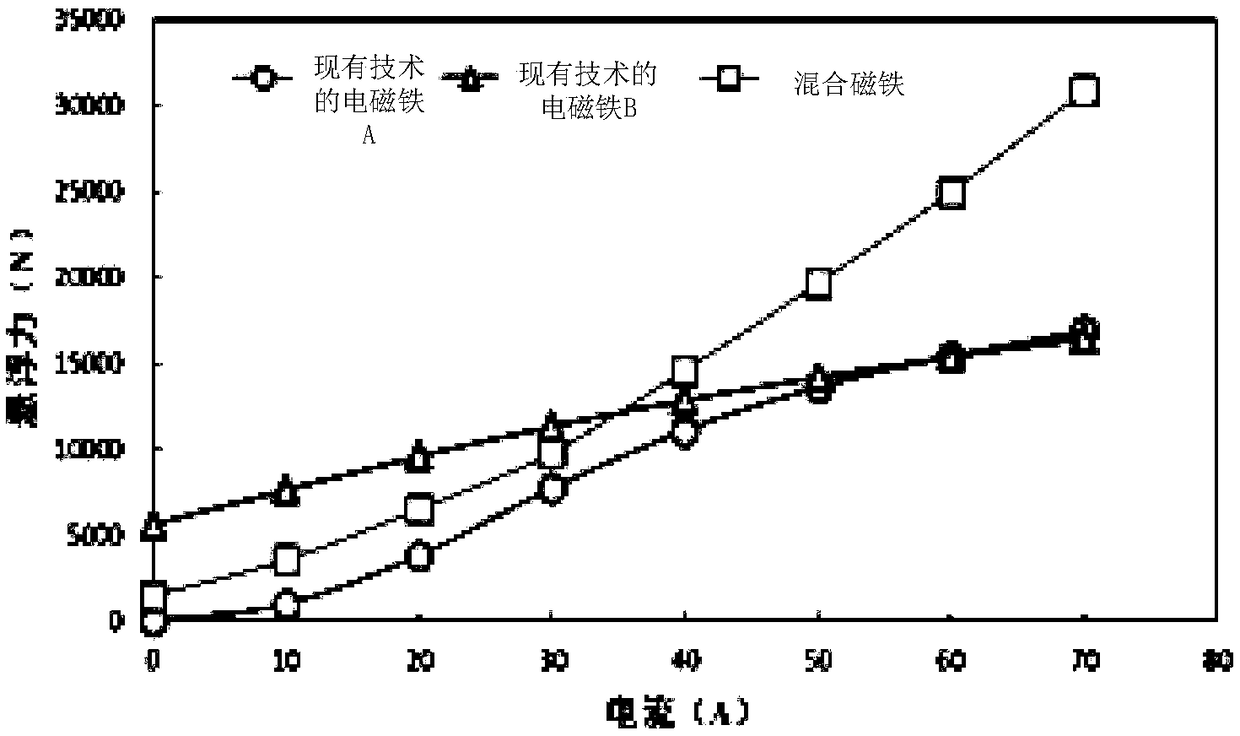

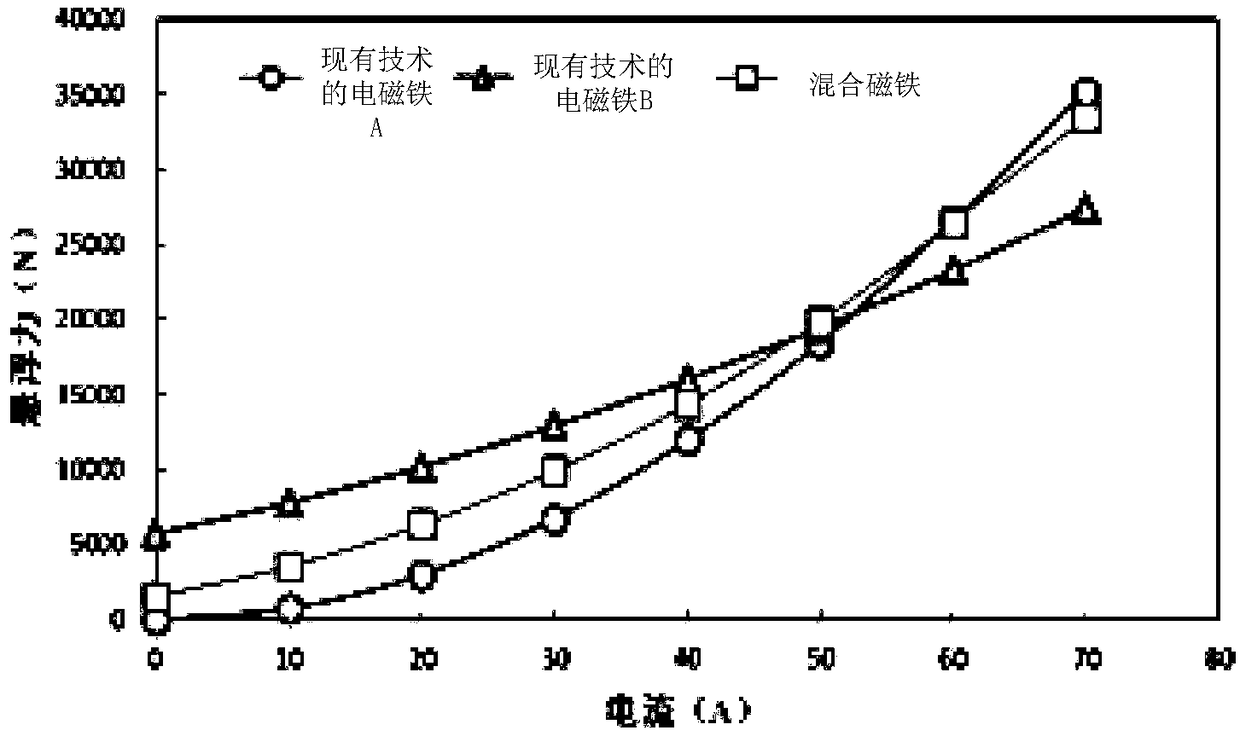

Suspension electromagnet based on medium and low speed maglev train

InactiveCN109326407AImprove performanceIncrease electromagnetic forceElectromagnets without armaturesElectric propulsionLow speedEngineering

The embodiment of the invention discloses a suspension electromagnet based on a medium and low speed maglev train, which comprises a hybrid magnet corresponding to an F-shaped orbit and an excitationcoil corresponding to the hybrid magnet, the hybrid magnet comprises an electromagnet and two permanent magnets, the electromagnet comprises a bottom iron, an inner plate and an outer plate, the innerplate and the outer plate are located on inside and outside of the bottom iron respectively, and the two permanent magnets are arranged correspondingly between the inner plate and the bottom iron andthe outer plate and the bottom iron respectively, and the two sides of the bottom iron are higher than that of the middle height. By adopting the hybrid magnet, the effective area and the length of the permanent magnet are no longer limited by the installation and size of the electromagnet, the deivce has the advantages of that the hybrid magnet not only improves an electromagnetic force, but also is favorable for steering stability, meanwhile, effectively improves a magnetic saturation and a suspension performance, and achieves a performance optimization of medium and low speed maglev trainsystem.

Owner:深圳市深信创联智能科技有限责任公司

Superparamagnetic iron cobalt ternary alloy and silica nanoparticles of high magnetic saturation and a magnetic core containing the nanoparticles

ActiveUS20140375403A1Increase green strengthHigh temperature toleranceInorganic material magnetismCeramic shaping apparatusMagnetic coreSuperparamagnetism

Thermally annealed superparamagnetic core shell nanoparticles of an iron-cobalt ternary alloy core and a silicon dioxide shell having high magnetic saturation are provided. A magnetic core of high magnetic moment obtained by compression sintering the thermally annealed superparamagnetic core shell nanoparticles is also provided. The magnetic core has little core loss due to hysteresis or eddy current flow.

Owner:TOYOTA JIDOSHA KK

06Cr19Ni10N austenite stainless steel tube and production process

The invention discloses a 06Cr19Ni10N austenite stainless steel tube, which comprises the following components in percentage by weight: 0.04-0.06% of C, 0.010-0.015% of S, 0.020-0.024% of P, 0.35-0.38% of Si, 1.85-1.90% of Mn, 8.2-8.5% of Ni, 19.5-19.8% of Cr, 0.63-0.65% of Ti, 0.02-0.04% of Cu, 0.05-0.08% of B, 0.02-0.04% of Co, 3.2-3.5% of Mo, 2.85-2.90% of V, 4.6-4.8% of composite rare earth, and the balance of Fe. The 06Cr19Ni10N austenite stainless steel tube disclosed by the invention is good in anti-oxidation property, high in tensile strength and yield strength, smooth in surface, good in abrasive resistance and attractive in appearance.

Owner:WUXI XINCHANG STEEL PIPE

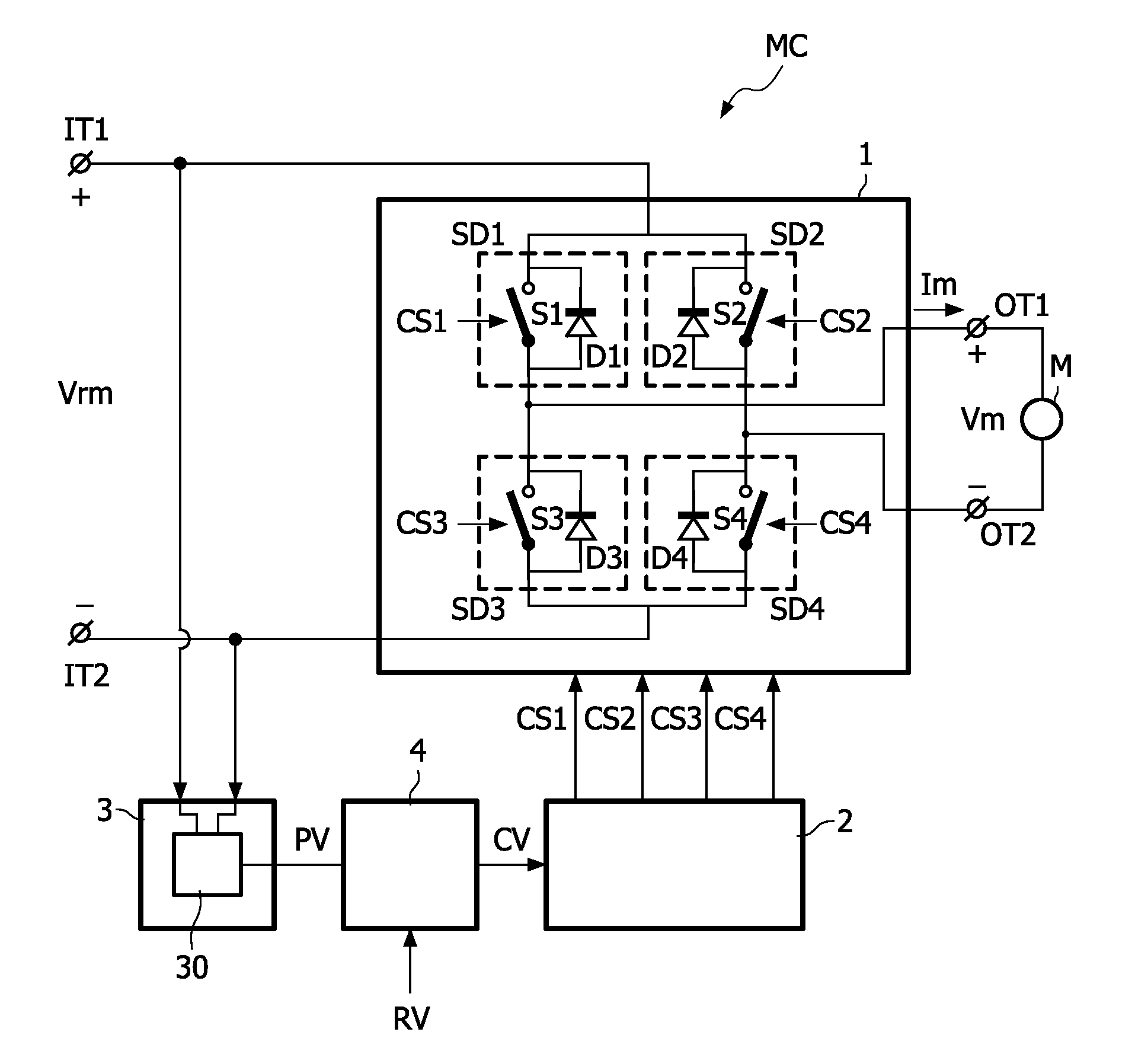

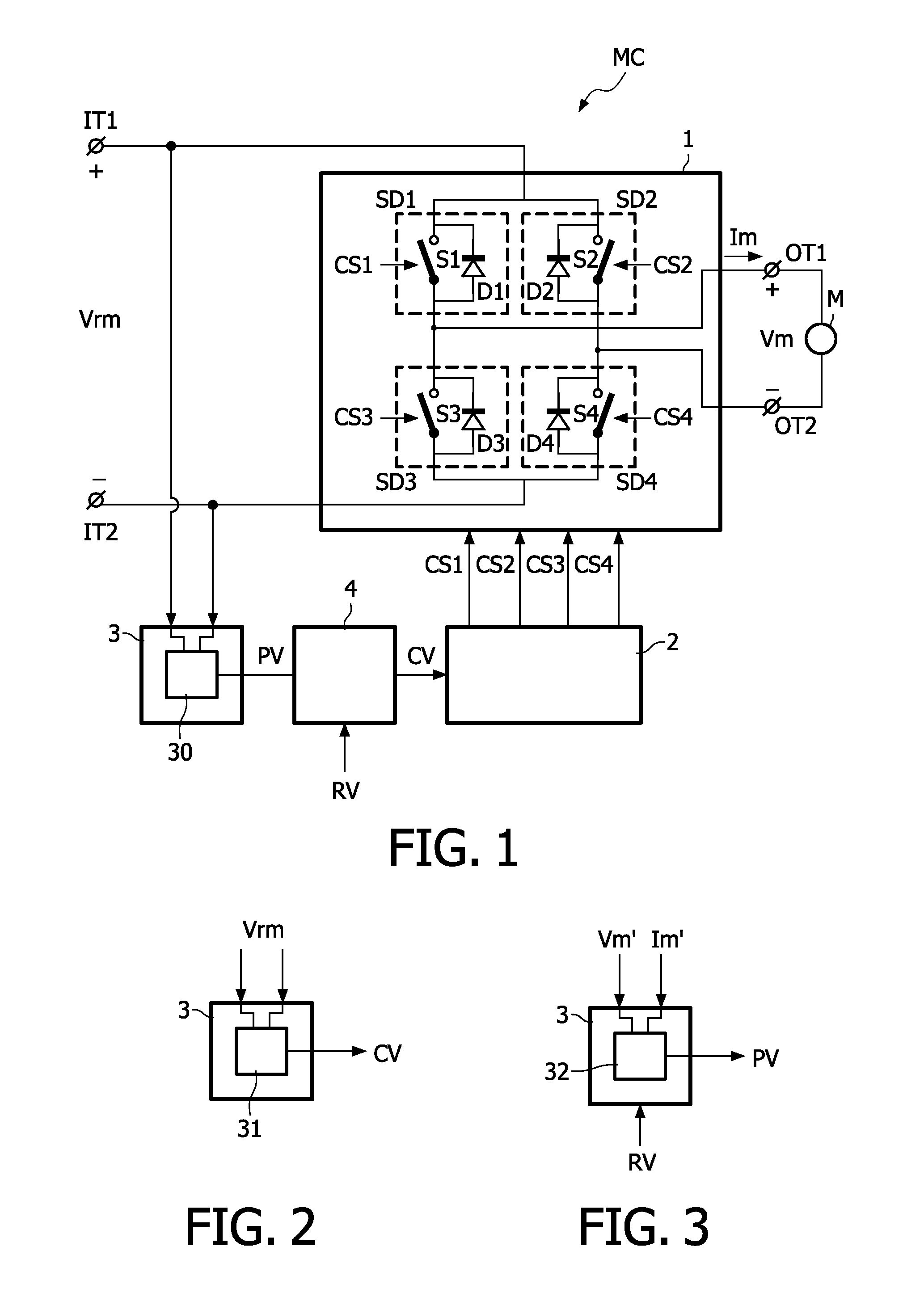

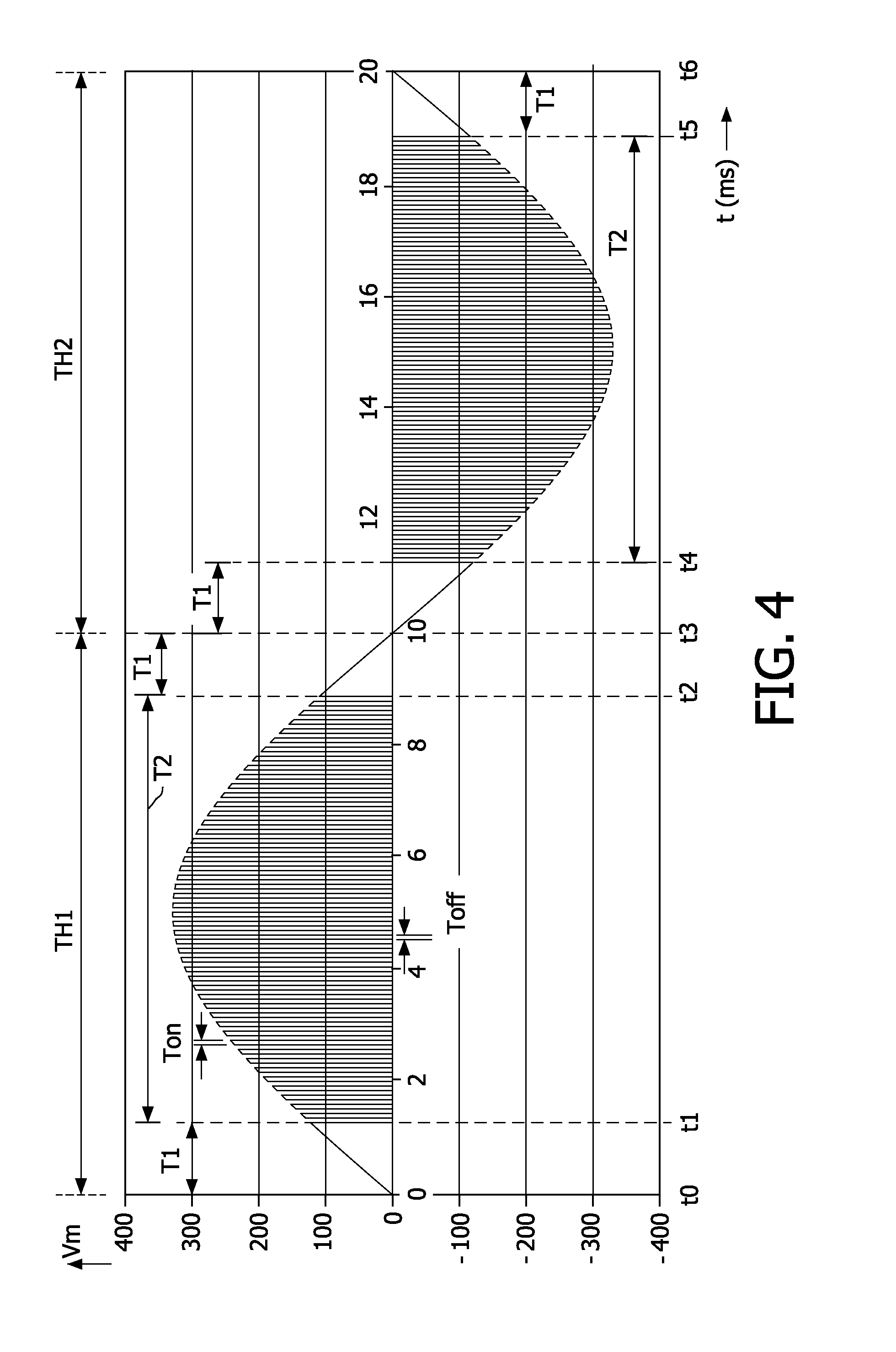

Controlling a power of an electrical motor

ActiveUS20100109598A1Long life-timeLong lastingElectronic commutation motor controlMotor/generator/converter stoppersMotor driveControl theory

A motor control circuit (MC) comprising input terminals (IT1, IT2) to receive a rectified input voltage (Vrm), and output terminals (OT1, OT2) to supply a motor drive signal (Vm). A switching circuit (1) is alternately in an on-state (Ton) and an off-state (Toff) for intermittently coupling the input terminals (IT1, IT2) to the output terminals (OT1, OT2). A controller (2) controls the switching circuit (1) to be (i) in the on-state (Ton) during a first period in time (T1) when an amount of magnetic saturation of the motor is smaller than a predetermined value, and (ii) alternately in the on-state (Ton) and the off-state (Toff) to obtain a pulse width control of the motor drive signal (Vm) during a second period in time (T2) when the amount of magnetic saturation of the motor is larger than the predetermined value.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Preparation method for magnetic water-based ink with nano-gold magnetic powder

The invention relates to magnetic water-based ink with nano-gold magnetic powder. The magnetic water-based ink comprises the following components in percent by weight: 2-4% of nano-gold magnetic powder and 96-98% of water-based ink. A method for the magnetic water-based ink with the nano-gold magnetic powder comprises the following steps of (S1) preparing Fe3O4 nanoparticles; (S2) preparing Fe3O4 / Au nanoparticles; (S3) continuously reacting for 5-6 hours at the temperature of 80 DEG C, and after separation, washing with water for spare use; (S4) adding water-based colour paste, a solvent, a surface active agent and a corresponding additive into Fe3O4 / Au powder till generating corresponding water-based ink. The magnetic water-based ink and the preparation method have the advantages that (1) the magnetic saturation degree is large, the size is uniform, the dispersity is good, the stability is strong, the timeliness is long, the coloring power is high and the color saturation degree is high; (2) the obvious defects of nano-size Fe3O4 as a permanent magnetic material, such as easy aggregation and loss of magnetism due to certain complex samples, can be overcome; and (3) a layer of Au housing is wrapped outside Fe3O4, so that effective protection for Fe3O4 can be realized.

Owner:HUBEI UNIV

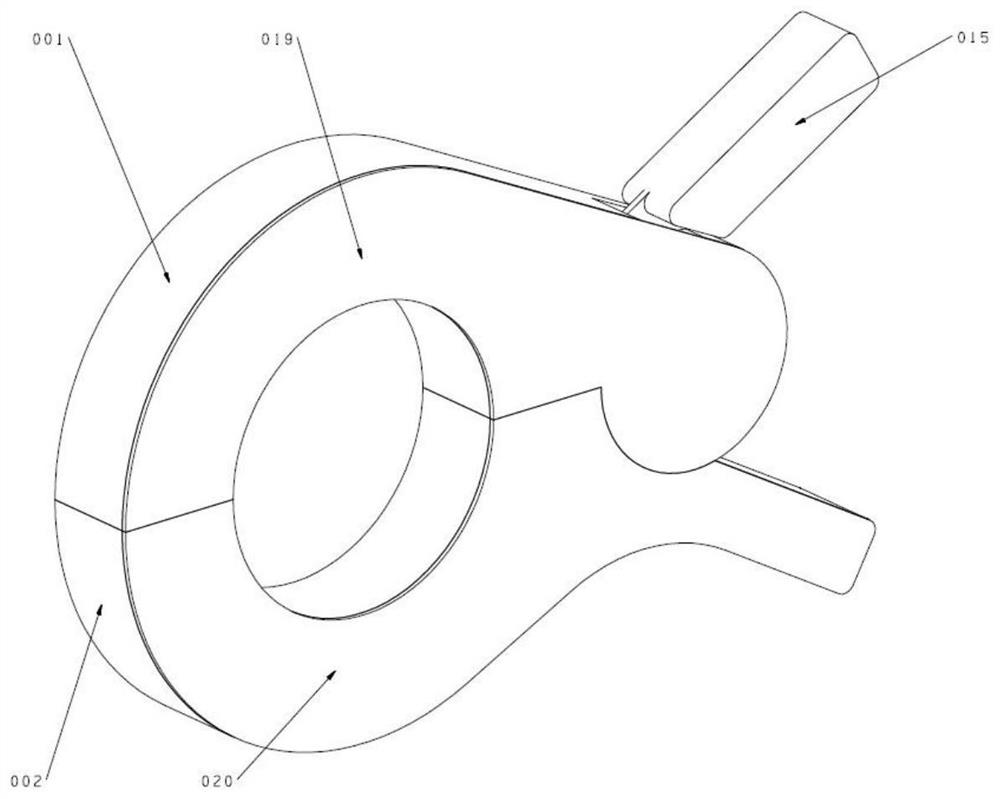

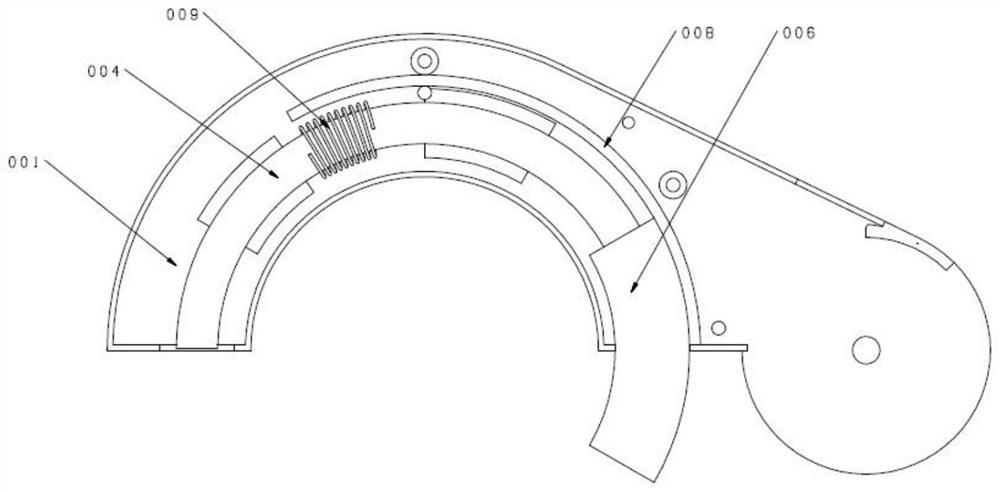

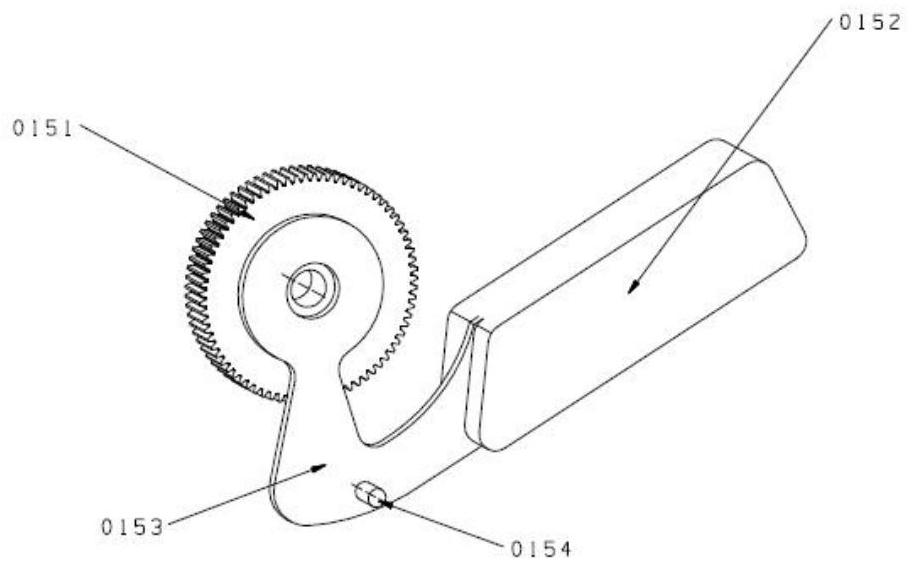

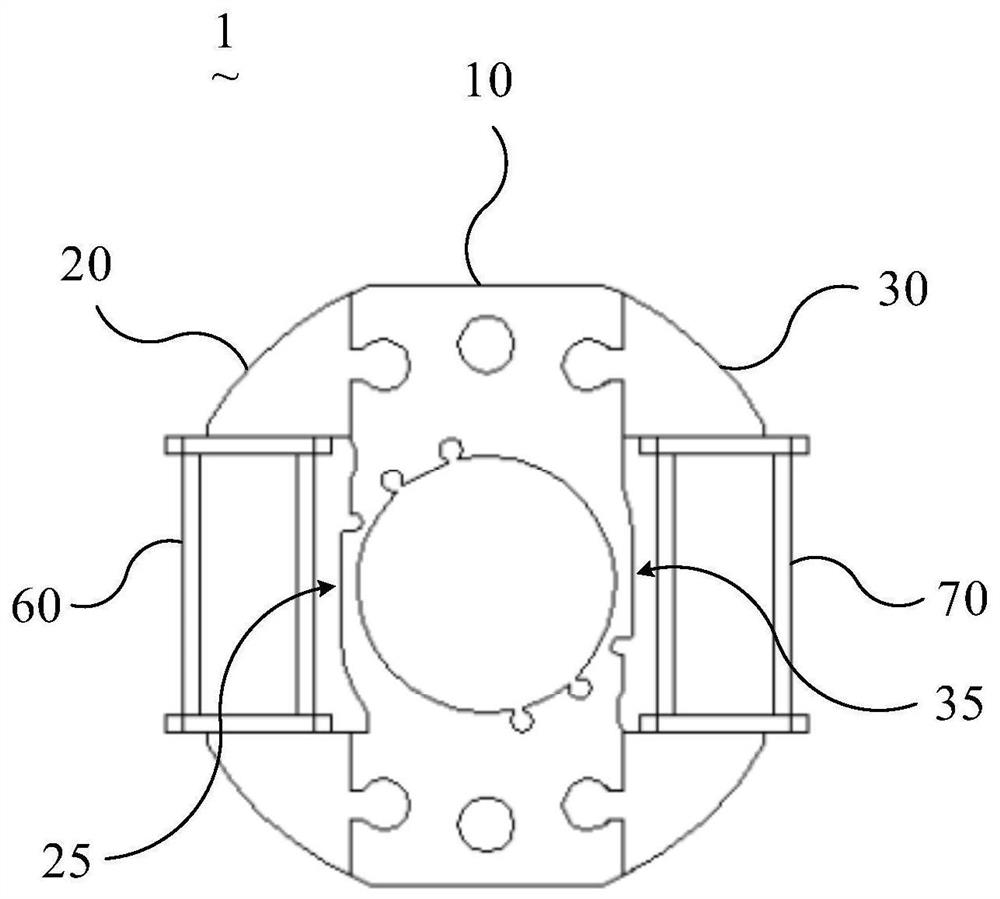

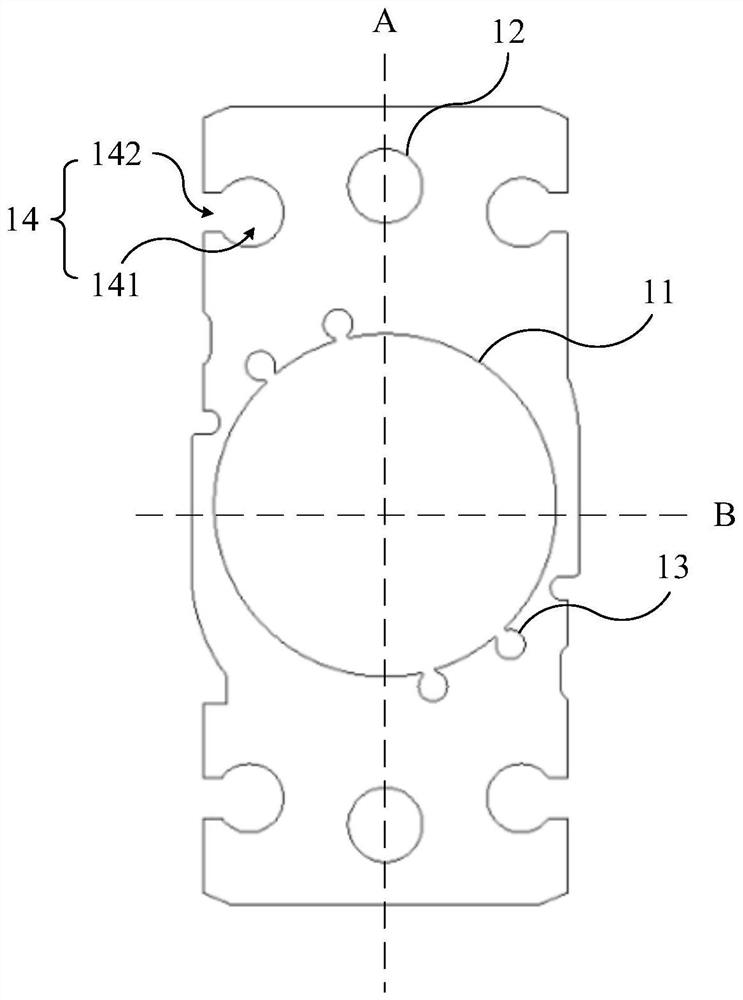

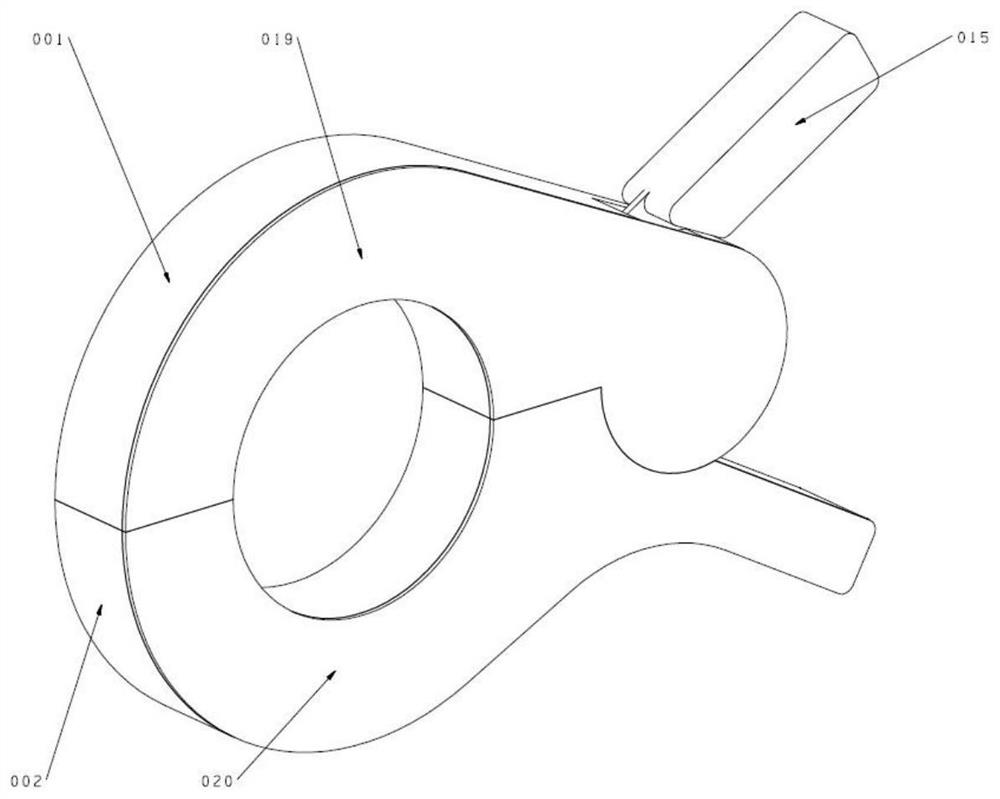

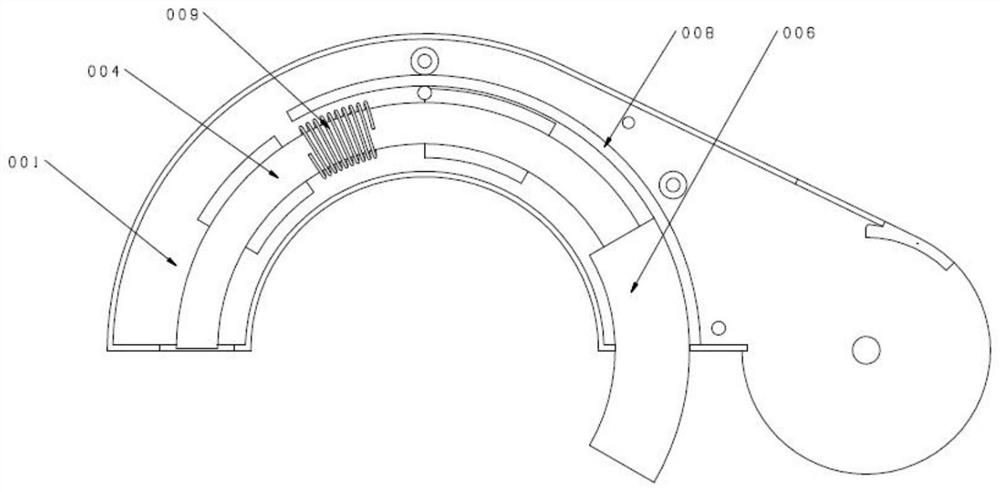

A coupled signal transmitter

ActiveCN113376410BPrevent closing impactIncrease magnetic saturationElectrical testingMeasurement instrument housingGear wheelTransmitter

The invention provides a coupling signal transmitting device, comprising a handleless upper clamp device, a handle lower clamp device and a driving gear device with a handle, the handleless upper clamp device and the handle lower clamp device are semicircular Structure, the driving gear device with handle is fixed on the tail of the handleless upper pincer device, the tail of the handleless upper pincer device and the handle lower pincer device are combined through positioning pins and positioning tables of the two shells. The handleless upper pincer device includes a handleless pincer shell, an upper half magnetic core, an excitation coil 1, an upper magnetic conducting sleeve, and an upper stroke guide rail; the described lower pincer device with a handle includes a handle pincer shell 1. Lower half magnetic core, excitation coil 2. Lower magnetic sleeve, lower stroke guide rail; can effectively solve the problem that the accuracy and effectiveness of the test are affected by the impact deformation of the magnetic core and the leakage of the magnetic induction line.

Owner:深圳潜宇科技有限公司

Special magnetic pressure-sensitive adhesive for prism film

ActiveCN111040676AMagnetic long-lastingIncrease the saturation magnetic strengthNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceAdhesive

The invention discloses a special magnetic pressure-sensitive adhesive for a prism film and belongs to the technical field of reflective film adhesives. The magnetic pressure-sensitive adhesive comprises a component A and a component B, wherein the component A mainly comprises the following raw material components (by weight): 80-100 parts of a water-based acrylate emulsion, 2-8 parts of a silanecoupling agent KH-570 and 8-12 parts of modified magnetic particles; and the component B mainly comprises the following raw material components (by weight): 20-30 parts of a curing agent, 15-25 partsof water and 2-3 parts of an emulsifier. According to the special pressure-sensitive adhesive prepared by the invention, the pressure-sensitive adhesive has certain saturated magnetic strength after being used and cured, so that a prism film still has usability after the pressure-sensitive adhesive fails, and the repeated utilization rate is increased.

Owner:CHANGZHOU HUA R SHENG REFLECTIVE MATERIAL

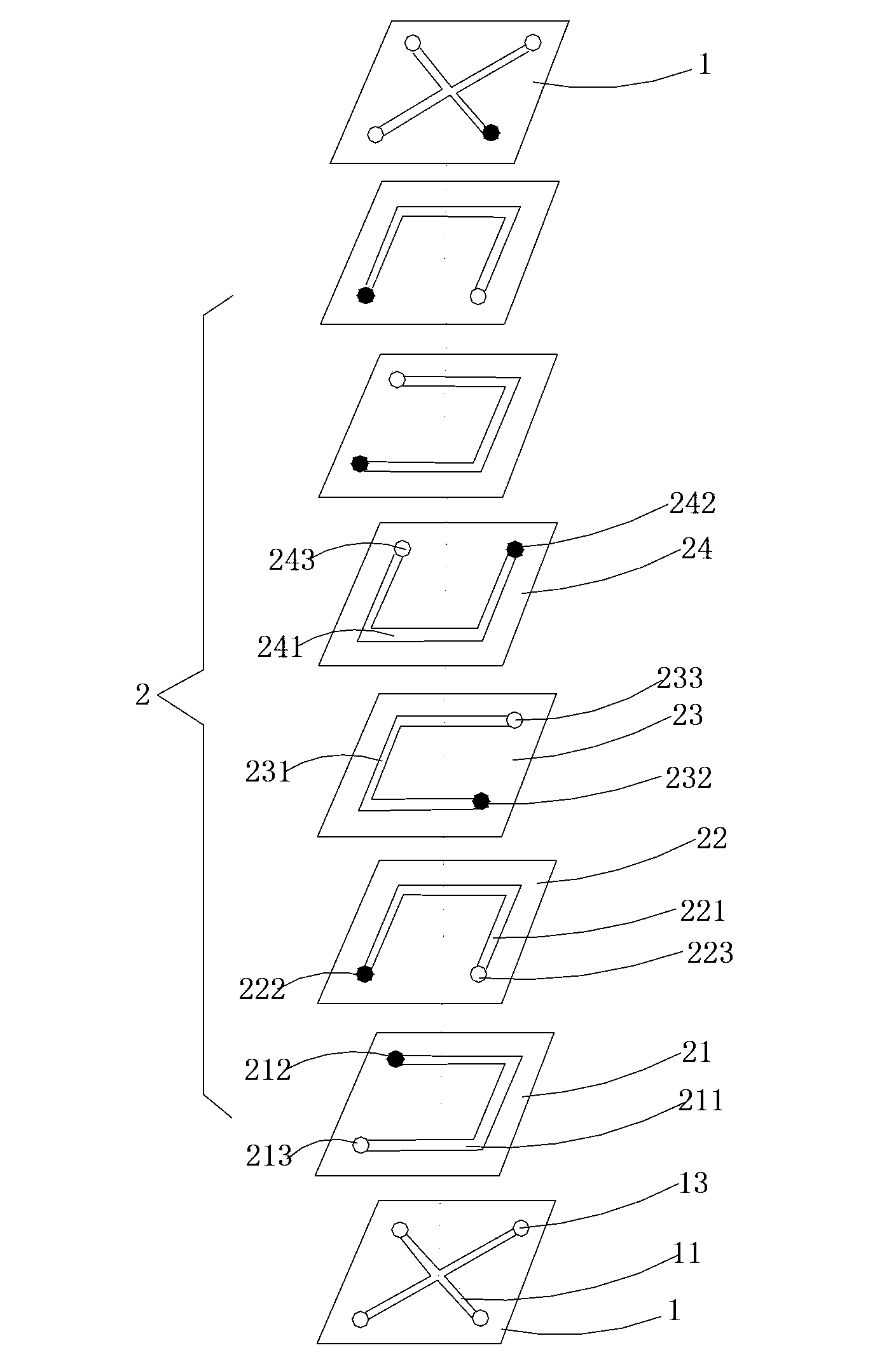

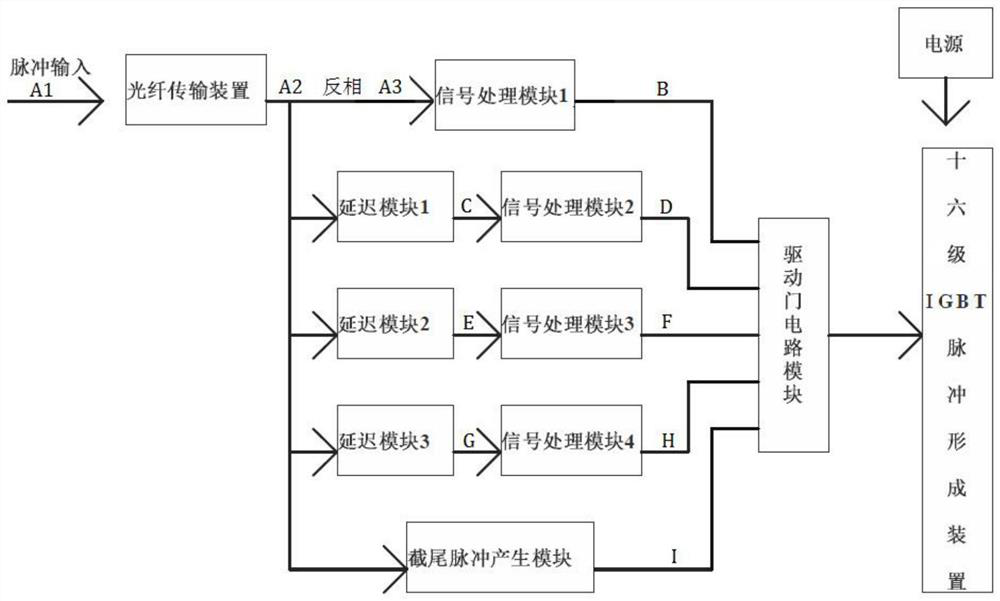

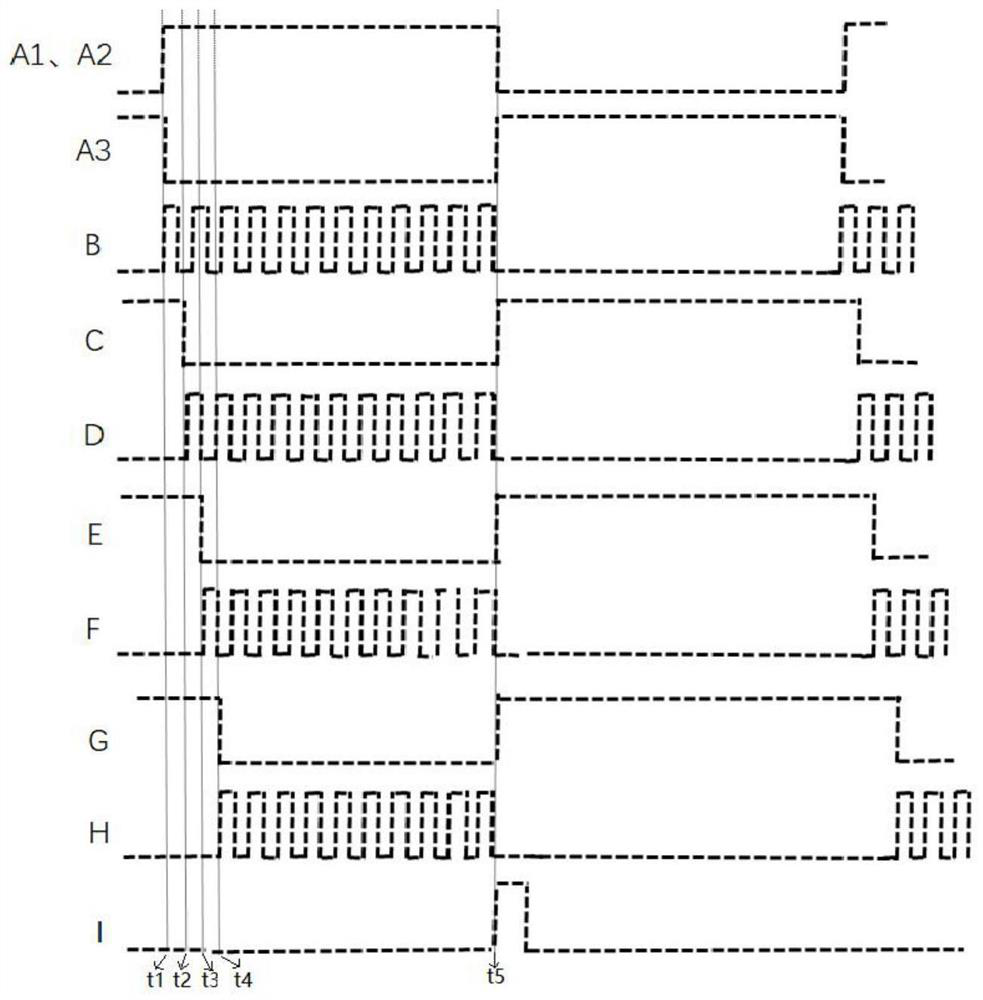

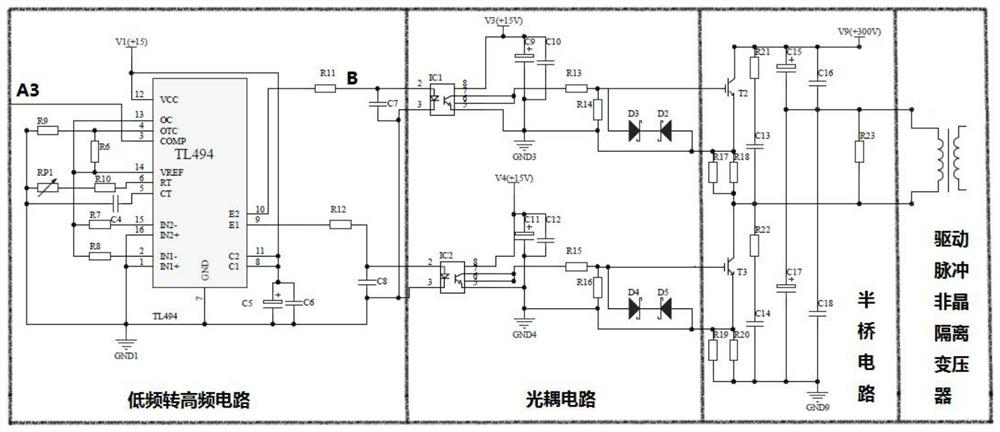

An Asynchronous Triggered High Voltage Pulse Modulator Based on igbt

ActiveCN109687855BLarge voltage reductionFast shutdownPulse modulationPulse manipulationVoltage pulseHemt circuits

The invention discloses an IGBT-based asynchronous trigger high-voltage pulse modulator, which belongs to the field of high-voltage pulse modulation circuits. The modulator includes a pulse generating device, an optical fiber transmission device, a delay module, a signal processing module, a truncated pulse generating module, a driving gate circuit module, a sixteen-level IGBT pulse forming device, and a power supply. The present invention adopts a pulse forming device with an additive superposition structure and a gate truncated pulse discharge circuit, which is triggered by an asynchronous signal, which can not only greatly reduce the overshoot of the output pulse, but also make the rising edge and falling edge of the pulse steeper. Thus, a high-voltage pulse signal output with a narrower pulse width can be realized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

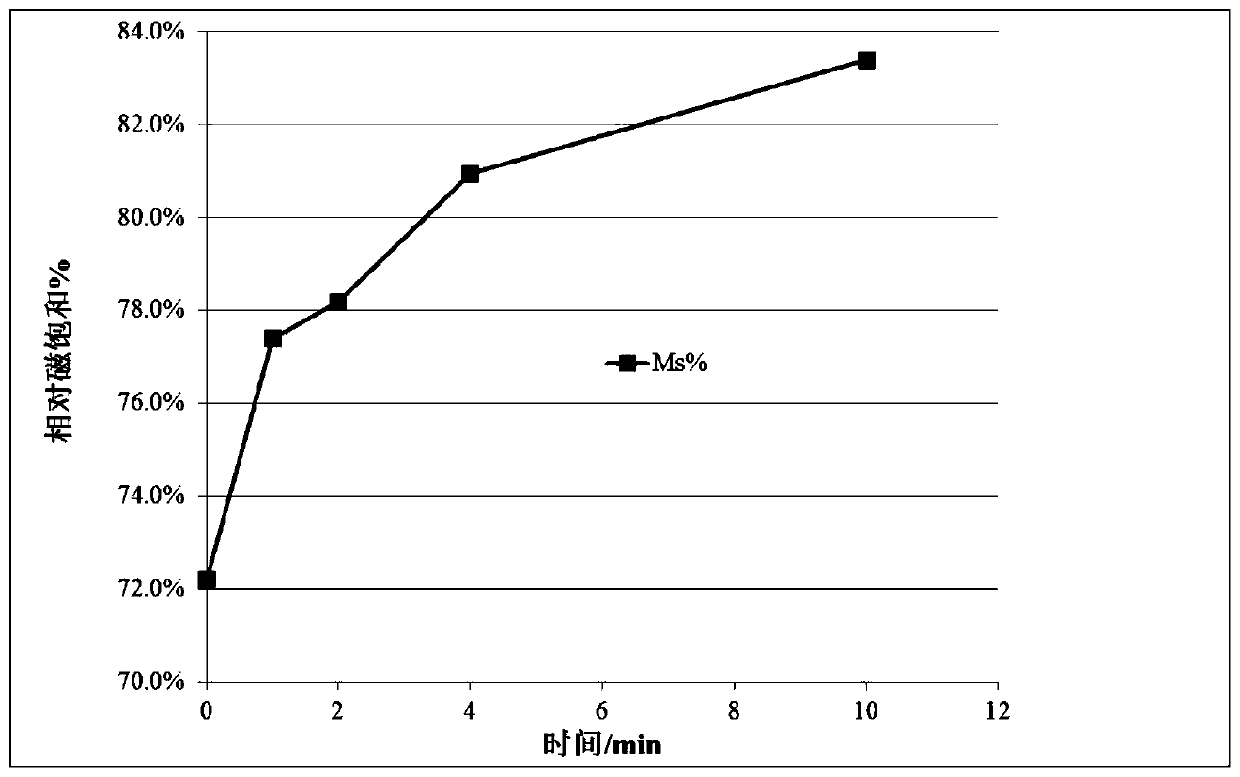

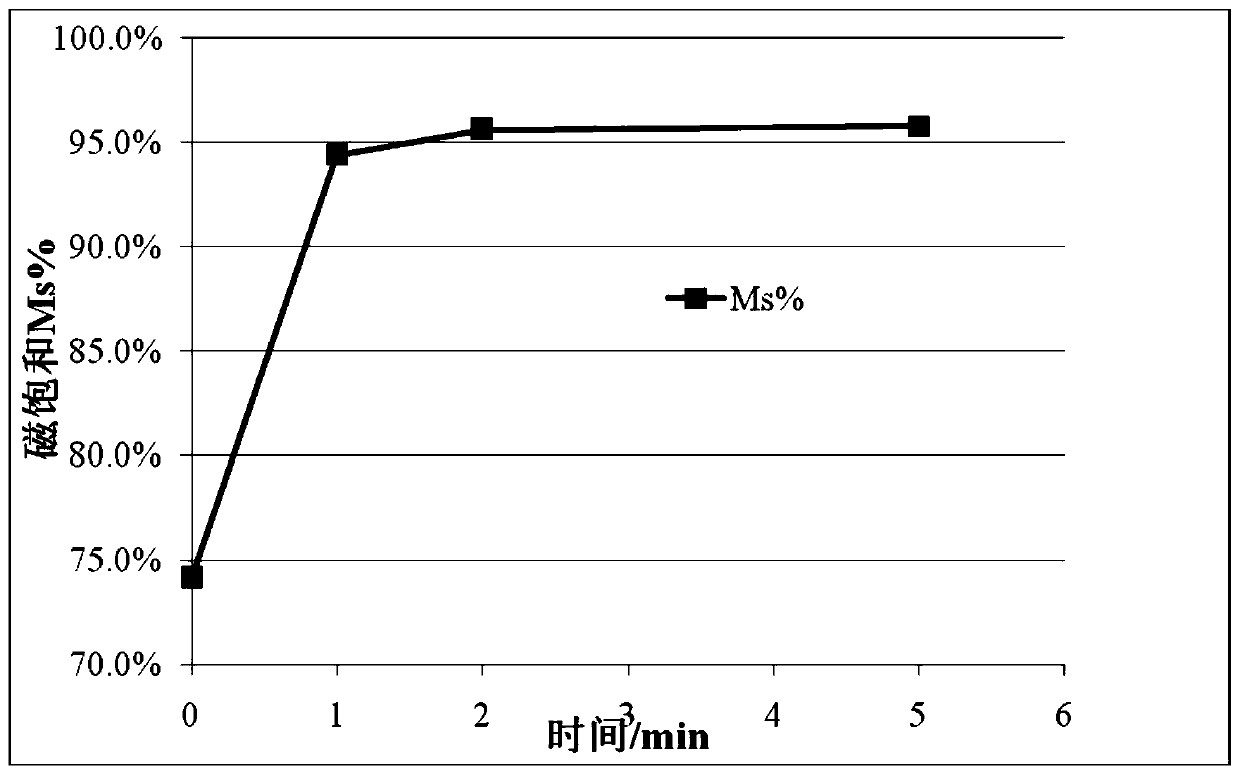

A method capable of improving the magnetic saturation of cemented carbide calcined billets

The invention discloses a method capable of improving magnetic saturation of hard alloy pre-sintered blanks. The method comprises the following steps that a proper amount of solid paraffin is taken, and is put into a preset utensil; the utensil where the solid paraffin is put into is placed on a heating device for heating, and is heated until the solid paraffin is melted to be in a liquid state; the hard alloy pre-sintered blanks are put into the utensil in a batch mode, and are completely soaked in the paraffin in the liquid state; the temperature in the soaking process is controlled, and thehard alloy pre-sintered blanks are soaked for a certain time according to the carbon content requirements of the pre-sintered blanks; and when the soaking time is up, the hard alloy pre-sintered blanks are taken out, and then are sintered according to a conventional sintering method in the prior art, so that hard alloy products with improved magnetic saturation and uniform magnetic saturation areobtained. According to the method, through the improvement of the process, the magnetic saturation of the hard alloy pre-sintered blanks can be effectively improved, and the magnetic saturation is uniform and controllable.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

Motor stator and motor

PendingCN114696484AIncrease magnetic saturationImprove magnetic permeabilityWindings insulation shape/form/constructionMagnetic circuit stationary partsElectric machineControl theory

The invention discloses a motor stator and a motor, the motor stator comprises a first side stator block and a second side stator block, the first side stator block and the second side stator block are arranged on two opposite sides of a middle stator block along the vertical direction of the central axis of a shaft hole, and the first side stator block and the second side stator block are clamped and fixed with the middle stator block; the first winding is wound on the first side stator block, and the second winding is wound on the second side stator block. The first side stator block and the middle stator block as well as the second side stator block and the middle stator block are clamped and fixed, and the first winding and the second winding are respectively arranged on the first side stator block and the second side stator block, so that the positions of the first winding and the second winding can be adjusted, and the width size of the motor stator is adjusted; by increasing the width of the motor stator, the magnetic conductivity of the motor stator is improved, and the magnetic saturation of the motor is improved.

Owner:GUANGDONG MIDEA WHITE HOME APPLIANCE TECH INNOVATION CENT CO LTD +1

A method for increasing the carbon potential of low-carbon cemented carbide

ActiveCN106637052BIncrease magnetic saturationSolve the problem of difficult carburizationSolid state diffusion coatingCarbon potentialTime ratio

Owner:潜江新锐硬质合金工具有限公司

Coupling signal transmitting device

ActiveCN113376410APrevent closing impactIncrease magnetic saturationElectrical testingMeasurement instrument housingGear wheelMagnet

The invention provides a coupling signal transmitting device, which comprises a handle-free upper pincerlike device, a handle-equipped lower pincerlike device and a handle-equipped driving gear device, wherein the handle-free upper pincerlike device and the handle-equipped lower pincerlike device are both semicircular structures, the handle-equipped driving gear device is fixed at the tail part of the handle-free upper pincerlike device, and the tail parts of the handle-free upper pincerlike device and the handle-equipped lower pincerlike device are combined together through a positioning pin and the positioning table surfaces of the two shells. The handle-free upper pincerlike device comprises a handle-free pincerlike shell, an upper half magnetic core, a first magnet exciting coil, an upper magnetic sleeve and an upper stroke guide rail; and the handle-equipped lower pincerlike device comprises a pincerlike shell with the handle, a lower half magnetic core, a second magnet exciting coil, a lower magnetic conductive sleeve and a lower stroke guide rail. The problem that the test accuracy and effectiveness are influenced by impact deformation and magnetic induction line leakage of the magnetic core can be effectively solved.

Owner:深圳潜宇科技有限公司

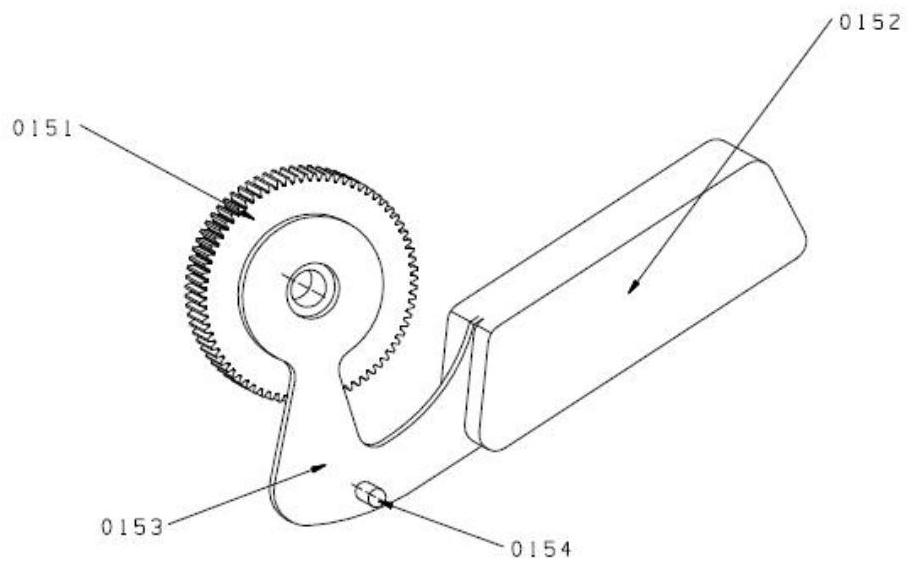

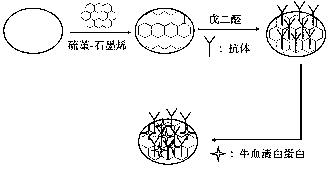

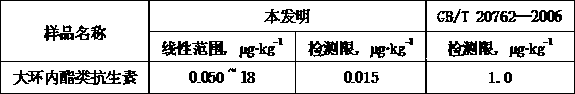

Manufacture method of silver hybridization mesoporous ferroferric oxide antibiotic immunosensor and application thereof

ActiveCN102749442BHigh sensitivitySimple preparation processMaterial analysis by electric/magnetic meansBiological testingCross-linkBovine serum albumin

The invention discloses a manufacture method of a silver hybridization mesoporous ferroferric oxide antibiotic immunosensor and the application thereof. The manufacture method of the electrochemical immunosensor includes modifying thionine-graphene mixed solution on the surface of a glassy carbon electrode, conducting cross linking on an antibiotic antibody incubated by Ag-Fe3O4 mesoporous nanometer particles, closing non-specificity active sites by bovine serum albumin to manufacure the antibiotic electrochemical immunosensor. A detection method of antibiotic is that a reference electrode-saturated calomel electrode, an electrode-platinum filament electrode and a working electrode are correctly connected on an electrochemical working station, and immunodetection is conducted through the square wave voltammetry. The antibiotic electrochemical immunosensor has high sensitivity and selectivity, is simple in detection method and has the advantages of being quick, high in efficiency, good in specificity, low in cost, convenient to operate and the like. It takes to 2-3 minutes to finish one detection process.

Owner:UNIV OF JINAN

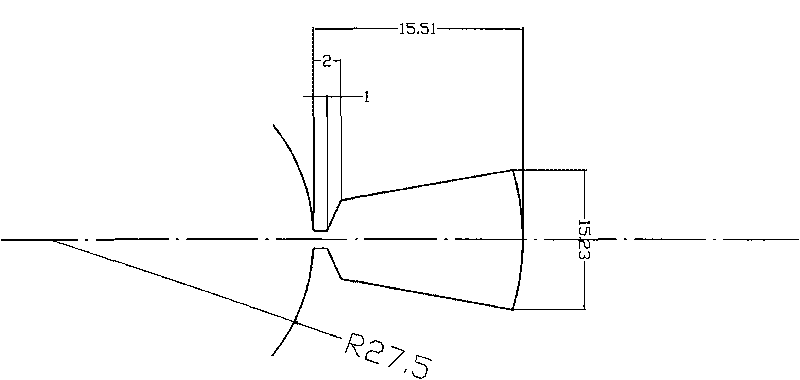

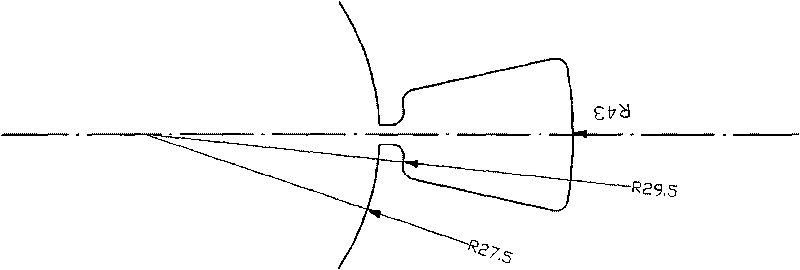

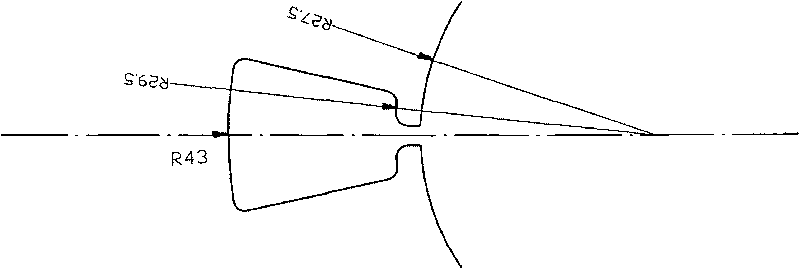

Permanent-magnet DC brushless motor of refrigerator compressor

InactiveCN101752972AReduce Flux LeakageReduce electromagnetic noiseMagnetic circuit rotating partsMagnetic circuit stationary partsBrushless motorsControl system

The invention relates to a permanent-magnet DC brushless motor of a refrigerator compressor. The permanent-magnet DC brushless motor comprises a rotor, a stator and a circuit control system, and is characterized in that the stator is of the shape of a concentric circular groove with the same tooth width and the same yoke part, the curvature radius of the external side of the stator is within 43plus or minus 1mm, the radius of the external side of the yoke part at the bottom of the concentric circular groove is within 29.5plus or minus 1mm and the base radius of the internal side of the yoke part is within 27.5 plus or minus 1mm. Thereby, the invention has the advantages that the magnetic paths are even, the magnetic-flux leakage is reduced and the output torque is improved.

Owner:宁波海诚电器有限公司

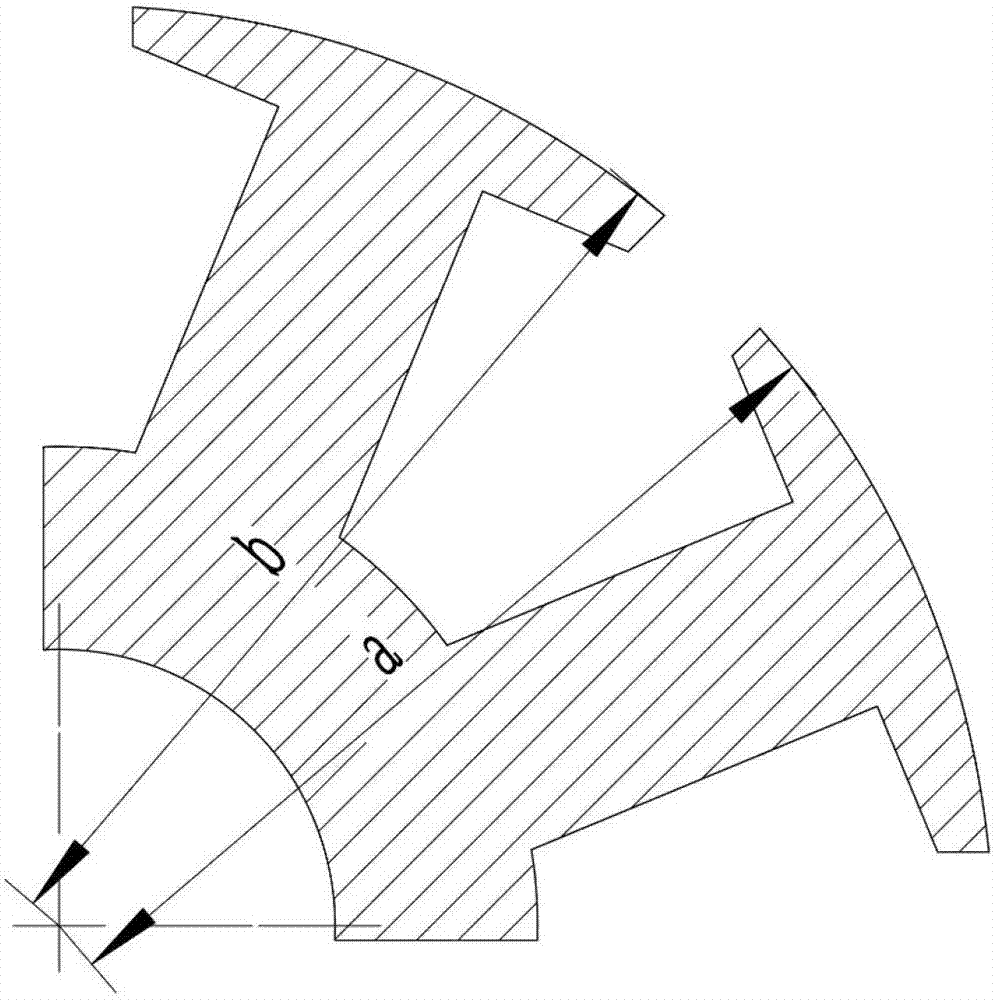

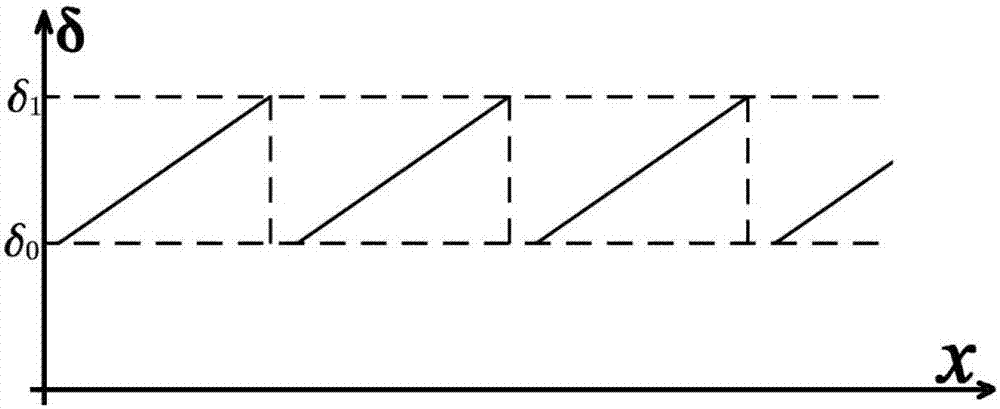

Novel gradient asymmetric air gap electrical excitation motor

InactiveCN107332418AIncrease speedDifficult to enterSynchronous motorsElectric machinesPeriodic excitationPole piece

The invention provides a novel gradient asymmetric air gap electrical excitation motor. The motor comprises a stator and a rotor. The rotor comprises an electrical excitation iron core and excitation windings. The stator comprises a stator iron core and stator windings. The excitation windings are wound on the pole shoes of the electrical excitation iron core. The stator windings are wound in the slots of the stator iron core. The air gap width between the internal surface of the stator iron core and the external surface of the electrical excitation iron core is gradient and asymmetric, and an asymmetric periodic excitation magnetic field along the external surface of the electrical excitation iron core is provided for the driving motor used for the electric vehicle so that the motor has the advantages of being high in forward efficiency, wide in range of speed regulation and energy-saving and environment-friendly.

Owner:CHINA NORTH VEHICLE RES INST

Ferrite material, small high-current laminated chip broadband magnetic bead and its preparation method

ActiveCN103387388BIncrease magnetic saturationReduce DC resistanceInorganic material magnetismFixed signal inductancesPunchingPower flow

The invention discloses a ferrite material, small large-current laminated-chip wideband magnetic beads, and a preparation method thereof. The ferrite main materials comprise: 49-55mol% of Fe2O3, 25-35mol% of ZnO, 4-8mol% of CuO, 8-15mol% of NiO, 0.1-0.6mol% of Co3O4, 1-3mol% of Bi2O3, and 0.5-1.5mol% of Nb2O5. The magnetic bead preparation method comprises the steps of ferrite slurry preparation, material band dry preparation, cutting, ferrite material sheet punching, ferrite material sheet printing, ferrite material sheet lamination, cutting and forming, and the like. With the ferrite material, magnetic saturation degree is improved, and direct current resistance is reduced, such that larger current can be withstood. According to the magnetic bead preparation method, production period is shortened, and production efficiency is improved. The volume of the magnetic beads is small. The magnetic beads have good electromagnetic interference inhibition capacity from 100MHz to higher than 1GHz.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

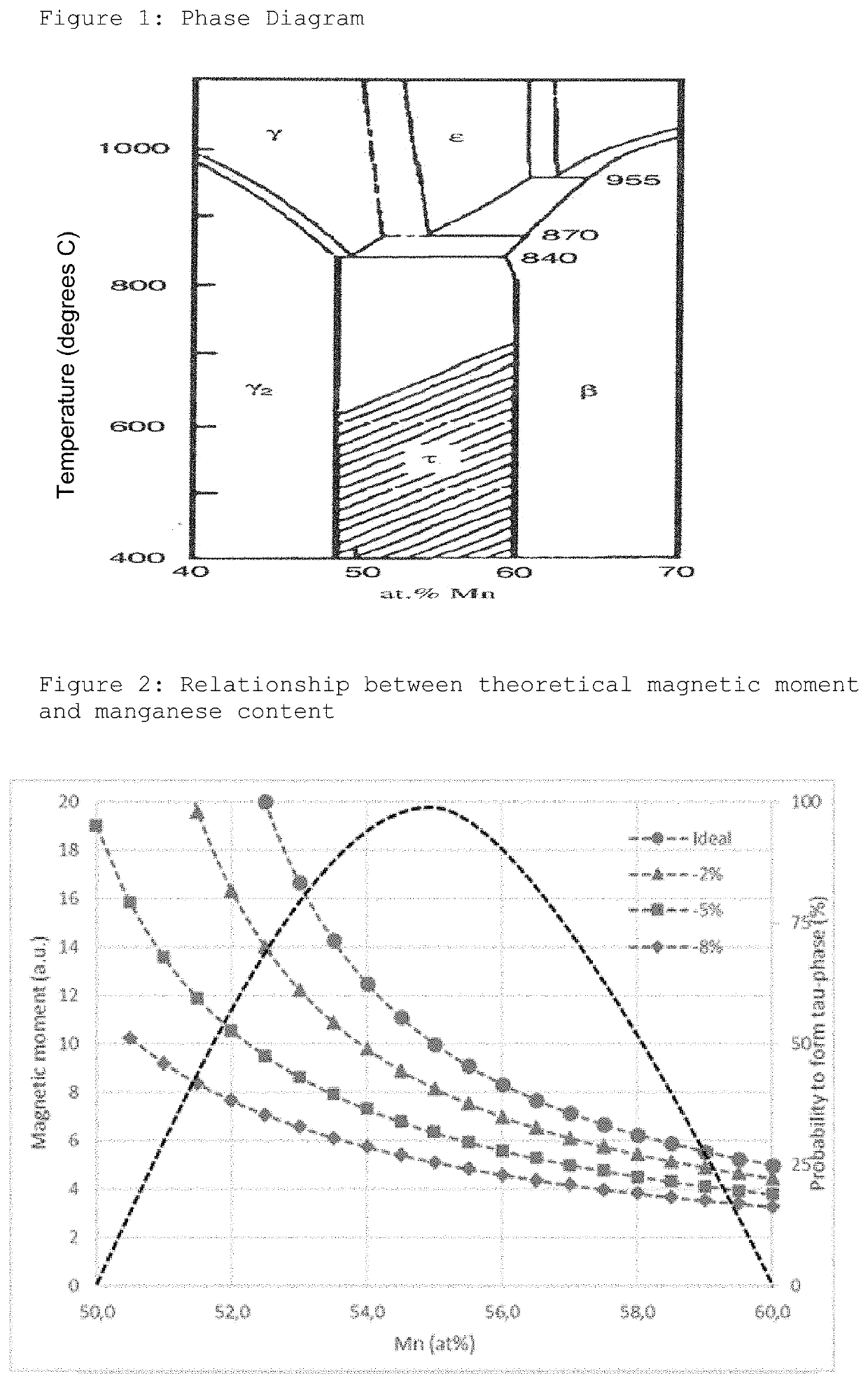

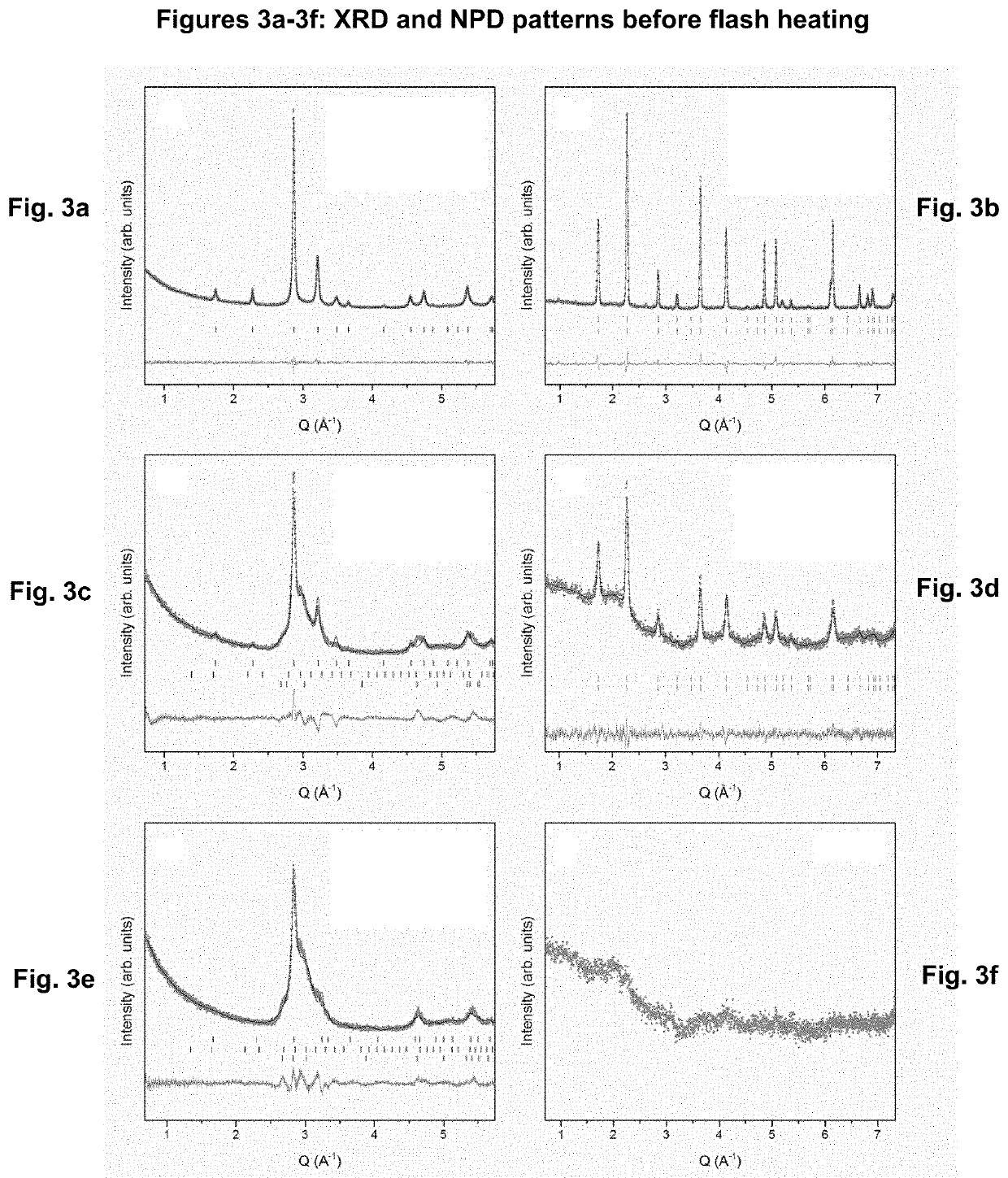

MnAl ALLOY, PARTICLES THEREOF, AND METHOD FOR PRODUCTION

ActiveUS20210062305A1High purityGood homogeneous microstructureTransportation and packagingMetal-working apparatusManganeseImpurity

An alloy represented by the formula (MnxAly)Cz, the alloy being aluminum (Al), manganese (Mn), and carbon (C), and optionally unavoidable impurities; wherein x=56.0 to 59.0 y=41.0 to 44.0 x+y=100, and z=1.5 to 2.4. The alloy is highly suitable for forming the ε and τ phase in high purity and high microstructural homogeneity. A method for processing an alloy of formula (Mnx′Aly′)Cz′, wherein x′=52.0 to 59.0, y′=41.0 to 48.0, x′+y′=100, and z′=0.1 to 3.0, the process including providing the raw materials of the alloy, melting the raw materials, and forming particles of the alloy by gas atomization of the molten alloy.

Owner:HOGANAS AB

Method capable of improving magnetic saturation of hard alloy pre-sintered blanks

The invention discloses a method capable of improving magnetic saturation of hard alloy pre-sintered blanks. The method comprises the following steps that a proper amount of solid paraffin is taken, and is put into a preset utensil; the utensil where the solid paraffin is put into is placed on a heating device for heating, and is heated until the solid paraffin is melted to be in a liquid state; the hard alloy pre-sintered blanks are put into the utensil in a batch mode, and are completely soaked in the paraffin in the liquid state; the temperature in the soaking process is controlled, and thehard alloy pre-sintered blanks are soaked for a certain time according to the carbon content requirements of the pre-sintered blanks; and when the soaking time is up, the hard alloy pre-sintered blanks are taken out, and then are sintered according to a conventional sintering method in the prior art, so that hard alloy products with improved magnetic saturation and uniform magnetic saturation areobtained. According to the method, through the improvement of the process, the magnetic saturation of the hard alloy pre-sintered blanks can be effectively improved, and the magnetic saturation is uniform and controllable.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

Superparamagnetic iron cobalt alloy and silica nanoparticles of high magnetic saturation and a magnetic core containing the nanoparticles

ActiveUS10910153B2High green strengthImprove mechanical propertiesTransportation and packagingMetal-working apparatusCore shell nanoparticlesSuperparamagnetism

Thermally annealed superparamagnetic core shell nanoparticles of an iron-cobalt alloy core and a silicon dioxide shell having high magnetic saturation are provided. A magnetic core of high magnetic moment obtained by compression sintering the thermally annealed superparamagnetic core shell nanoparticles is also provided. The magnetic core has little core loss due to hysteresis or eddy current flow.

Owner:TOYOTA JIDOSHA KK

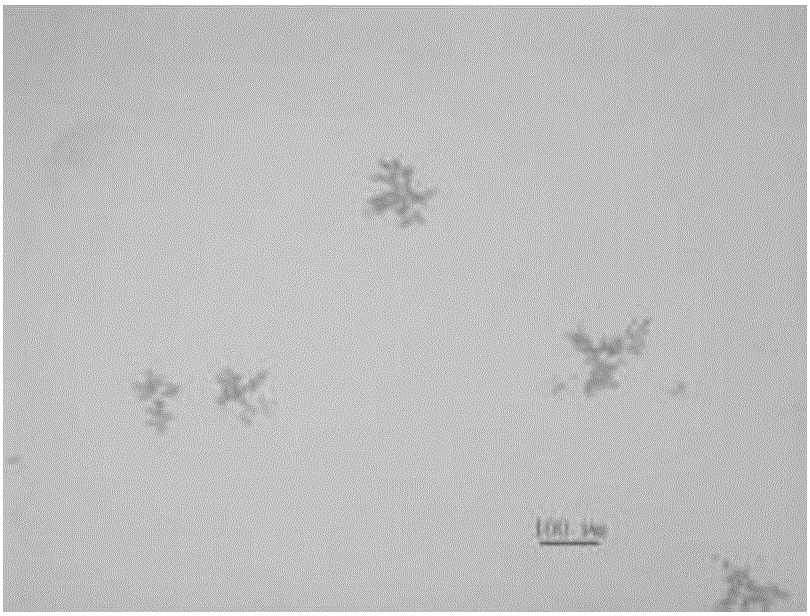

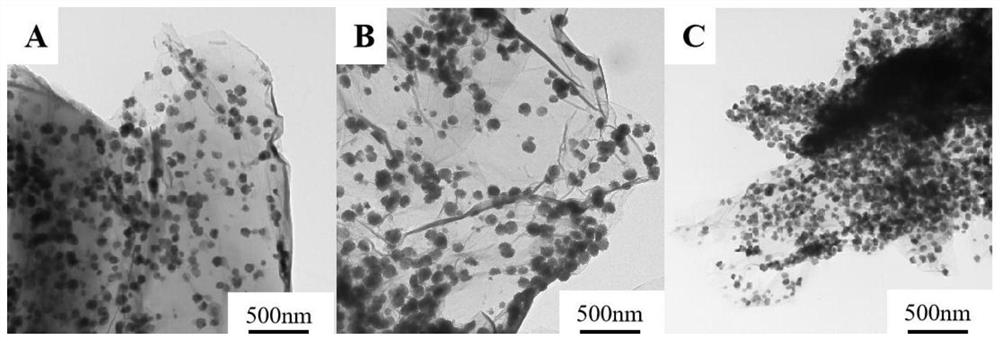

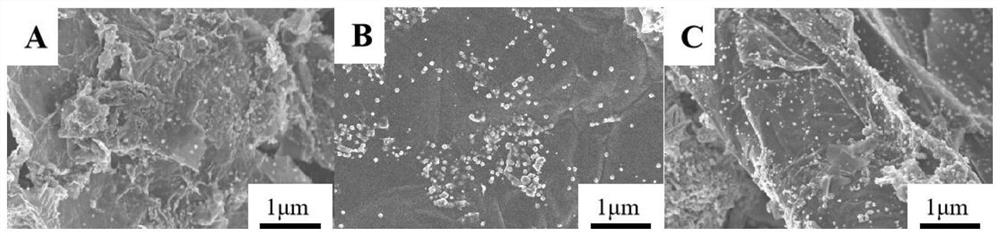

Application of magnetic graphene carbon nanomaterial in aflatoxin adsorption

PendingCN114797769AImprove adsorption capacityUniform particle sizeIon-exchange process apparatusOther chemical processesScanning electron microscopeSolvothermal reaction

The invention discloses application of a magnetic graphene carbon nanomaterial in aflatoxin adsorption, and belongs to the technical field of aflatoxin adsorption materials. Graphene oxide, ethylene glycol, anhydrous ferric chloride and anhydrous sodium acetate are used as raw materials, under the solvothermal reaction condition, the magnetic graphene carbon nanomaterial is prepared, the magnetic graphene carbon nanomaterial is of a transparent single-lamellar or few-lamellar structure under a transmission electron microscope and a scanning electron microscope, a large number of Fe3O4 particles are evenly loaded on the surface of graphene and do not agglomerate, and the magnetic graphene carbon nanomaterial can be used for preparing the magnetic graphene carbon nanomaterial. The magnet has uniform particle size and is a potential aflatoxin adsorbent. When the magnetic graphene carbon nanomaterial is used as an adsorbent for aflatoxin adsorption, the magnetic graphene carbon nanomaterial has the characteristics of low adsorbent usage amount and high adsorption capacity.

Owner:SHANDONG PEANUT RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com