Preparation method for magnetic water-based ink with nano-gold magnetic powder

A technology of water-based ink and nano-gold, which is applied in inks, household utensils, applications, etc., and can solve problems such as easy reunion, affecting writing, printing quality, and chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

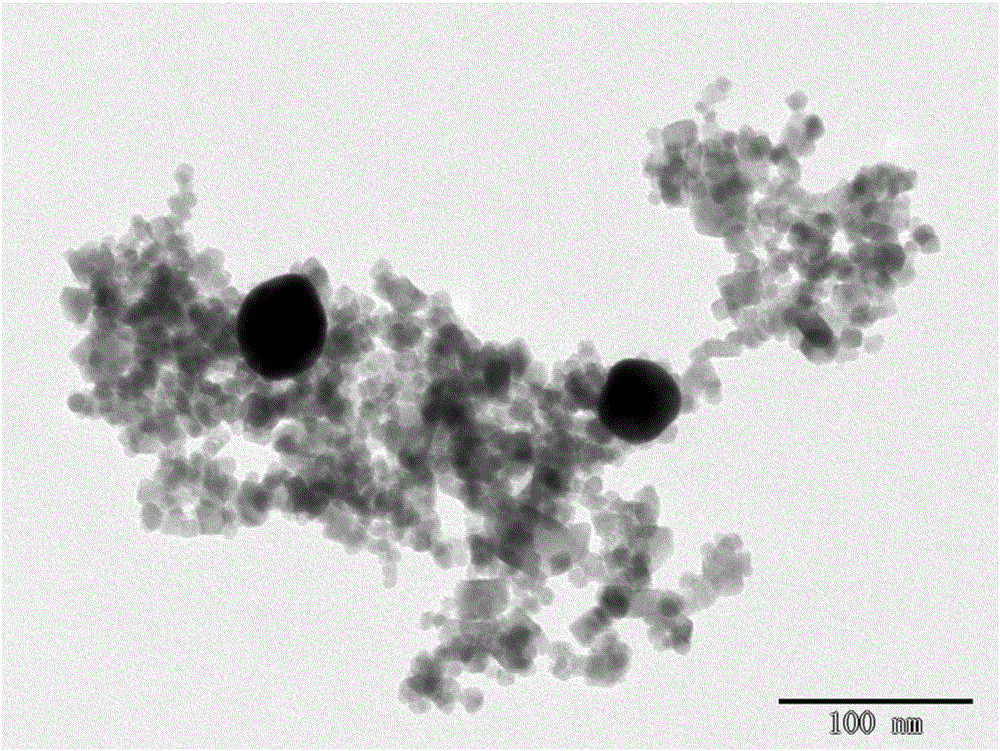

Image

Examples

Embodiment 1

[0022] (1) Fe 3 o 4 For the preparation of nanoparticles, 10.8g FeCl 3 ·6H 2 O and 4.0 g FeCl 2 4H 2 O was dissolved in 50ml of HCl (0.01M) and added dropwise to 500ml of NaOH (1.5M) with stirring. The temperature was maintained at 80 °C during the whole dropwise synthesis process and nitrogen was passed through 2 Divide O 2 , the reaction immediately generates a black precipitate, and the synthesized Fe 3 o 4 The nanoparticles are separated, washed 3 times with 100ml of water, and dispersed in 500ml of tetramethylammonium hydroxide pentahydrate (0.1M) for subsequent use;

[0023] (2) Fe 3 o 4 / Au preparation, take the above 75ml Fe 3 o 4 The nanoparticles were diluted 20 times, then 75ml of sodium citrate (0.1M) was added, stirred at 1000rpm for 15 minutes, the solution was heated to 80°C, and then 7.5ml of hydroxylamine hydrochloride (0.2M) and 6.3ml of 1 % of chloroauric acid (HAuCl 4 ), at this moment, the color of the solution changes from black to deep red,...

Embodiment 2

[0026] (1) Fe 3 o 4 For the preparation of nanoparticles, 8 g FeCl 3 ·6H 2 O and 5g FeCl 2 4H 2 Dissolve O in 60ml of HCl (0.01M), and add it dropwise to 600ml of NaOH (1.5M) under stirring conditions, and keep the temperature at 80°C during the whole dropwise synthesis process and pass N 2 Divide O 2 .The reaction immediately generates a black precipitate, and the synthesized Fe 3 o 4 The nanoparticles are separated, washed 3 times with 100ml of water, and dispersed in 500ml of tetramethylammonium hydroxide pentahydrate (0.1M) for subsequent use;

[0027] (2) Fe 3 o 4 / Au preparation, take the above 75ml Fe 3 o 4 The nanoparticles were diluted 20 times, then 60ml of sodium citrate (0.15M) was added, stirred at a speed of 1000rpm for 15 minutes, the solution was heated to 80°C, and 9ml of hydroxylamine hydrochloride (0.2M) and 6.3ml of 1% Chlorauric acid (HAuCl 4 ), at this moment, the color of the solution changes from black to deep red, and the reaction is conti...

Embodiment 3

[0030] (1) Fe 3 o 4 For the preparation of nanoparticles, 9.6g FeCl 3 ·6H 2 O and 4.5 g FeCl 2 4H 2 Dissolve O in 55ml of HCl (0.01M), and add it dropwise to 500ml of NaOH (1.5M) under stirring conditions, and keep the temperature at 80°C during the whole dropwise synthesis process and pass N 2 Divide O2 , the reaction immediately generates a black precipitate, and the synthesized Fe 3 o 4 The nanoparticles are separated, washed 3 times with 100ml of water, and dispersed in 500ml of tetramethylammonium hydroxide pentahydrate (0.1M) for subsequent use;

[0031] (2) Fe 3 o 4 / Au preparation, take the above 85ml Fe 3 o 4 The nanoparticles were diluted 20 times, then 85ml of sodium citrate (0.1M) was added, stirred at a speed of 1000rpm for 15 minutes, the solution was heated to 80°C, and then 9.5ml of hydroxylamine hydrochloride (0.2M) and 6.3ml of 1 % of chloroauric acid (HAuCl 4 ), the color of the solution changed from black to dark red at this time, and the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com