Patents

Literature

201results about How to "Increase electromagnetic force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

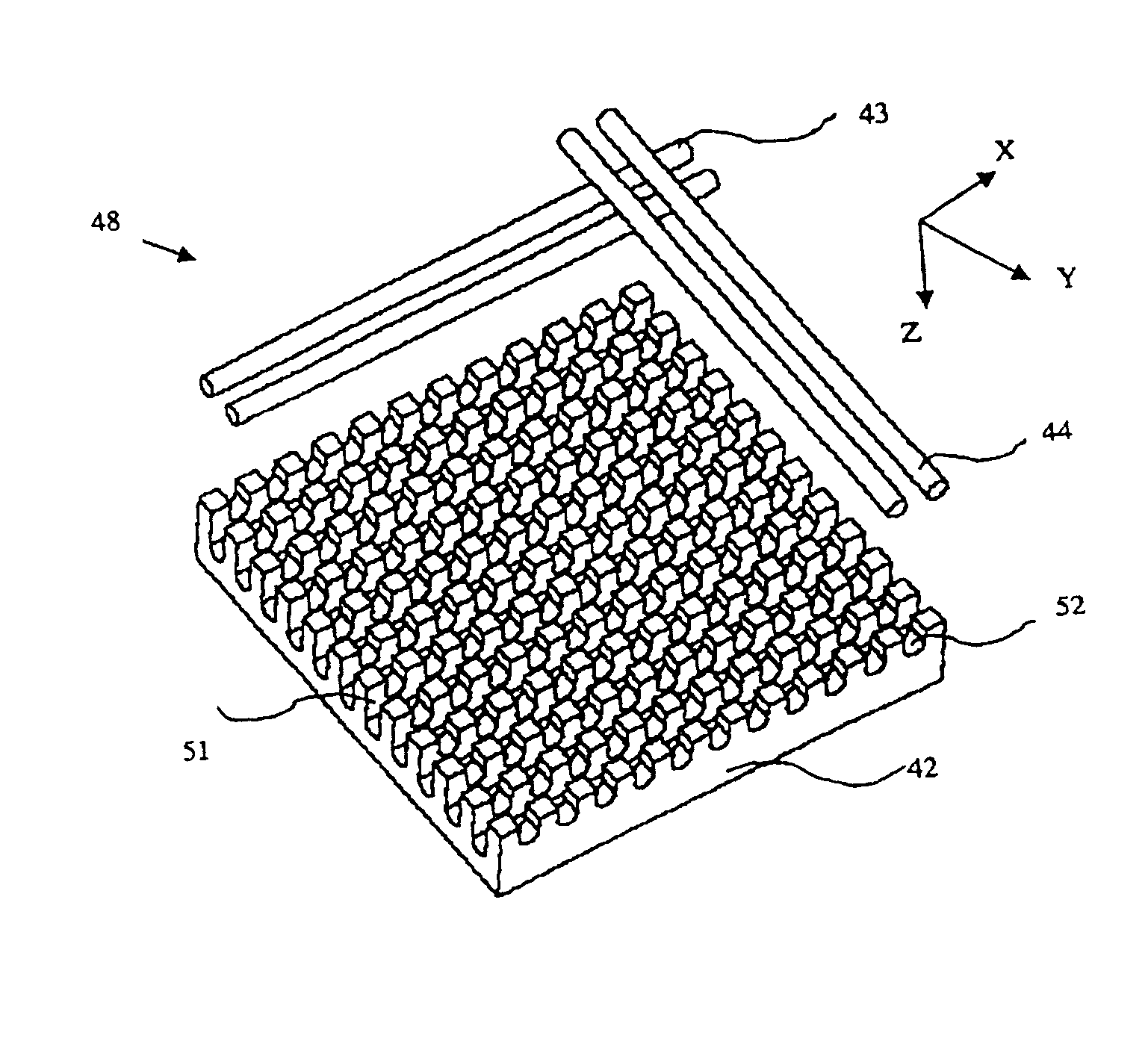

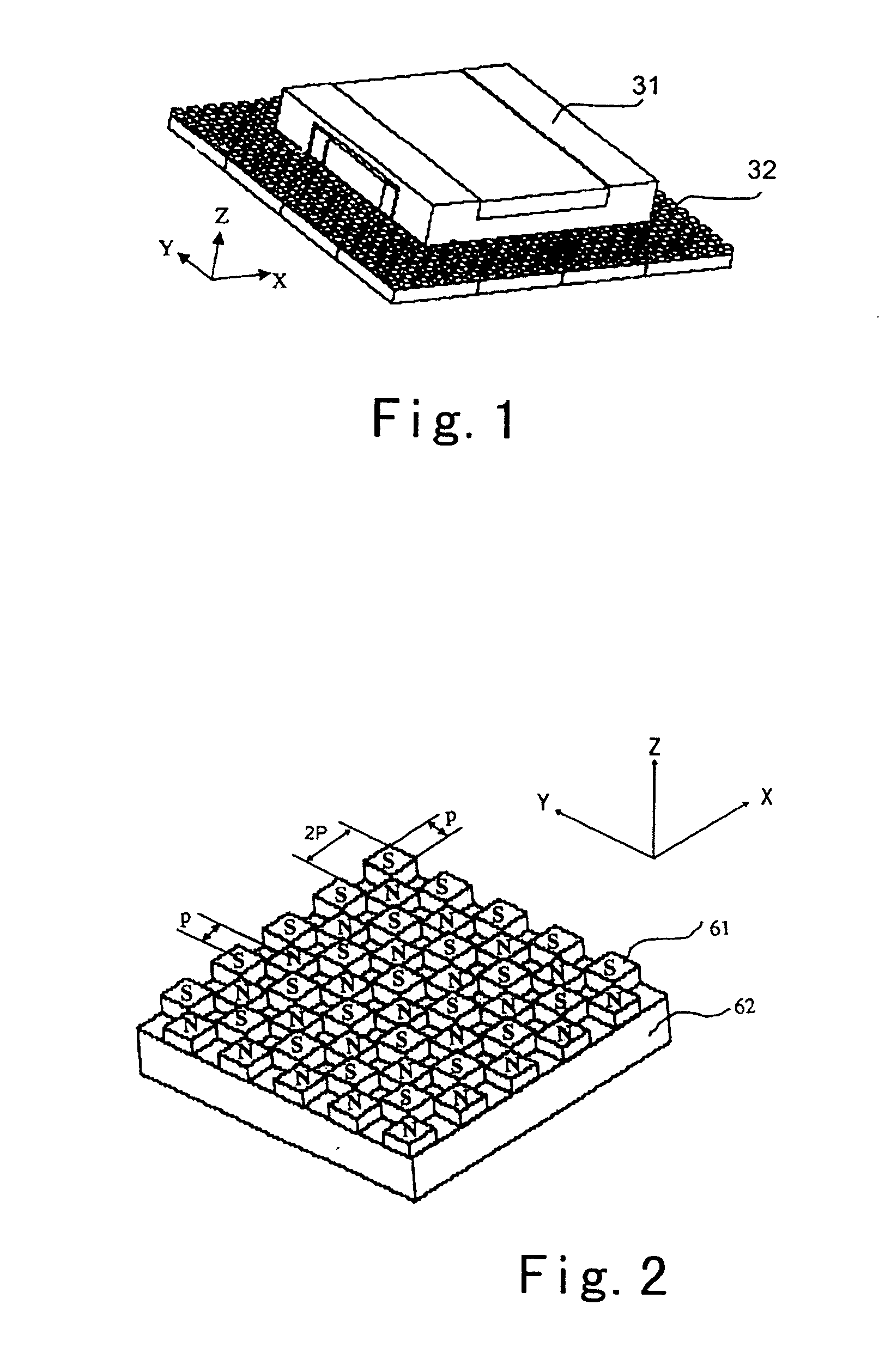

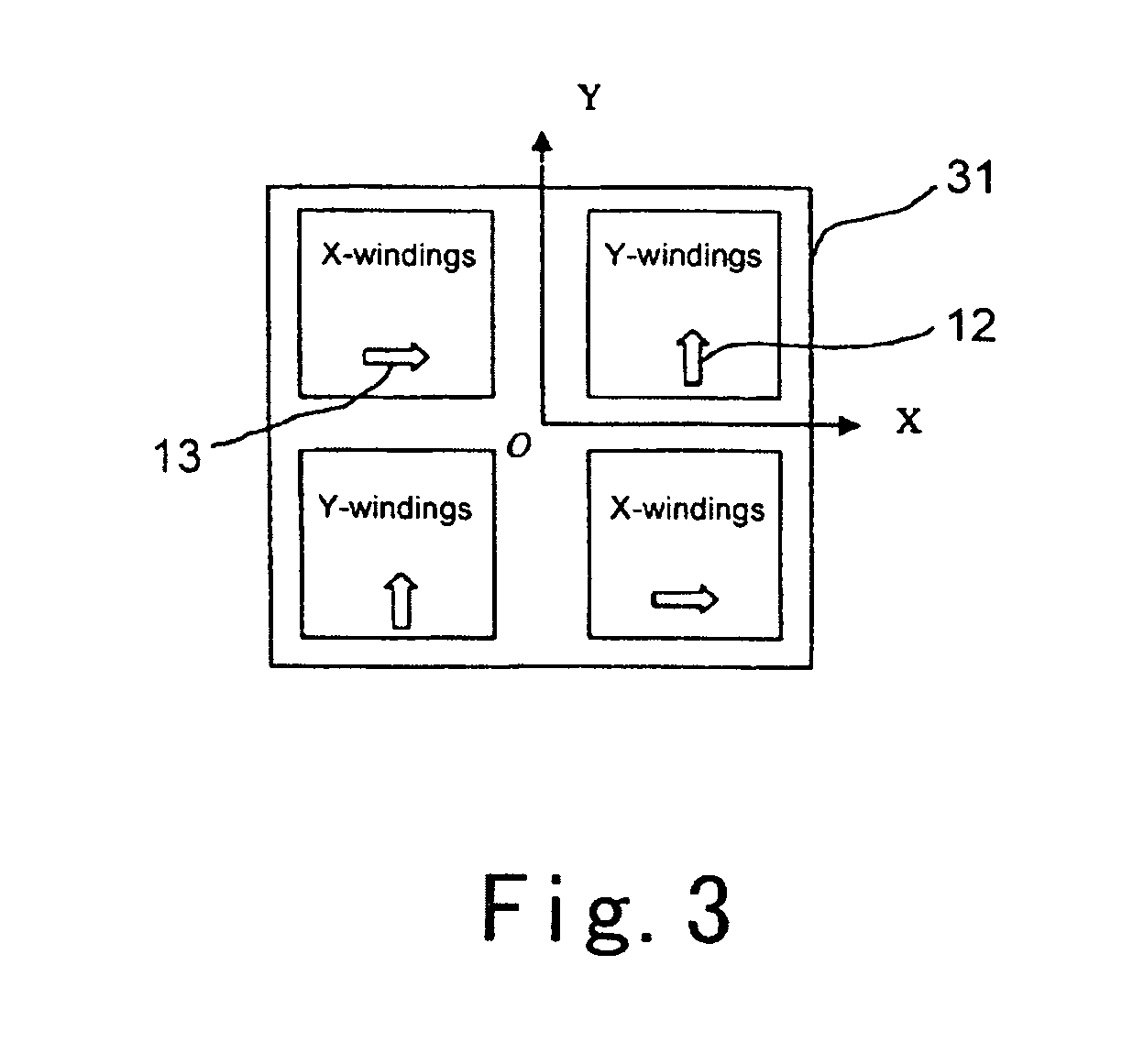

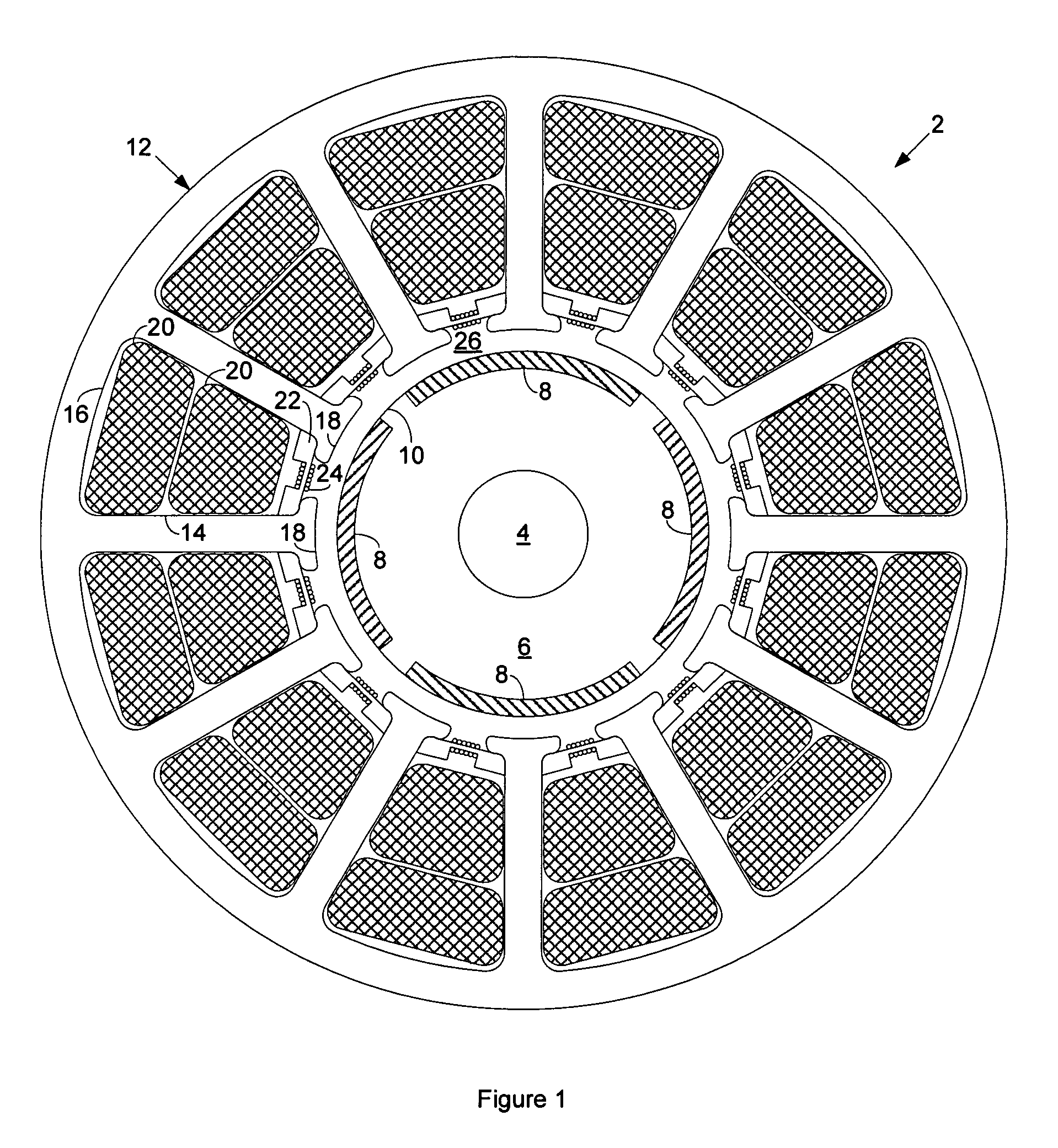

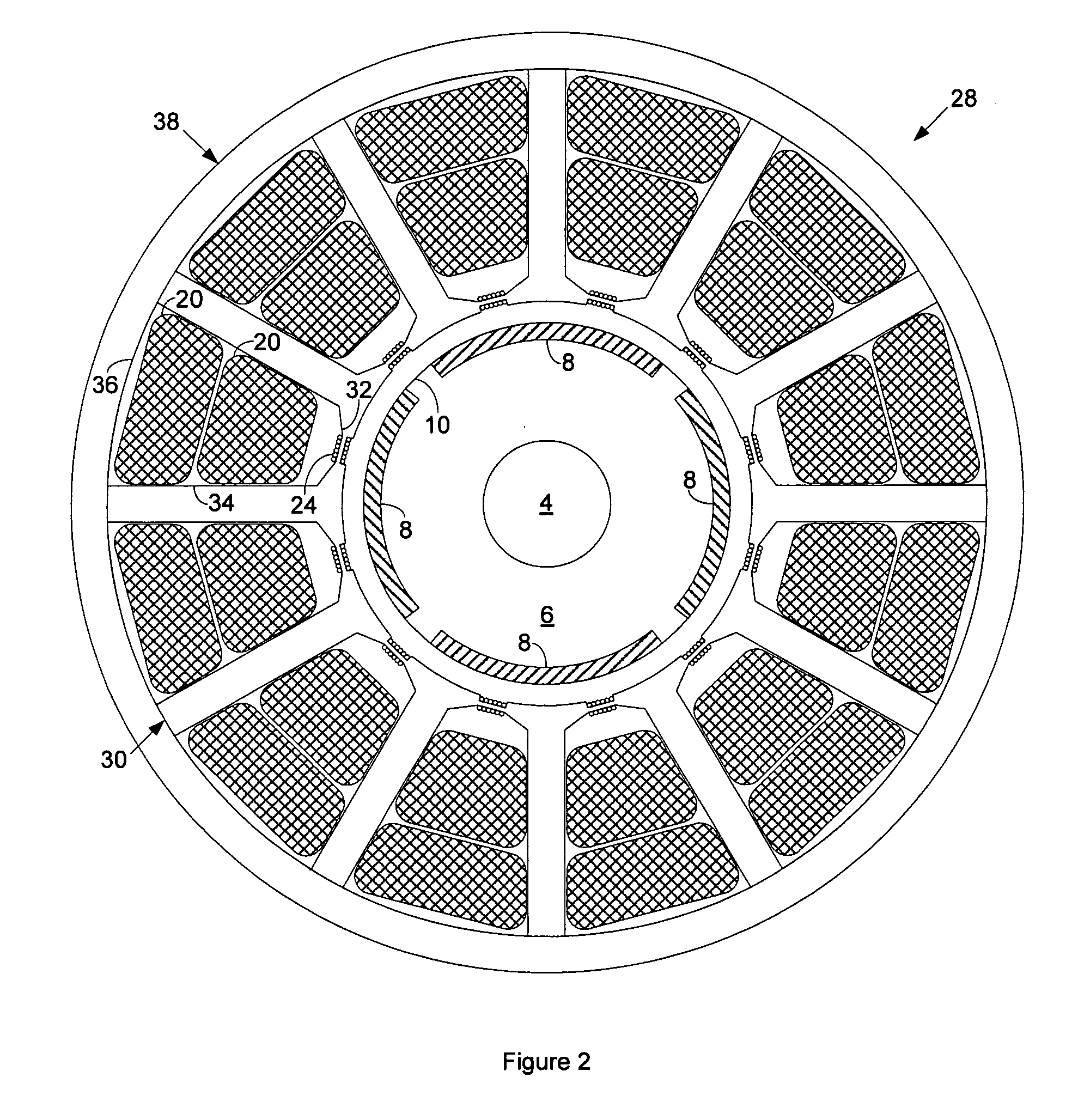

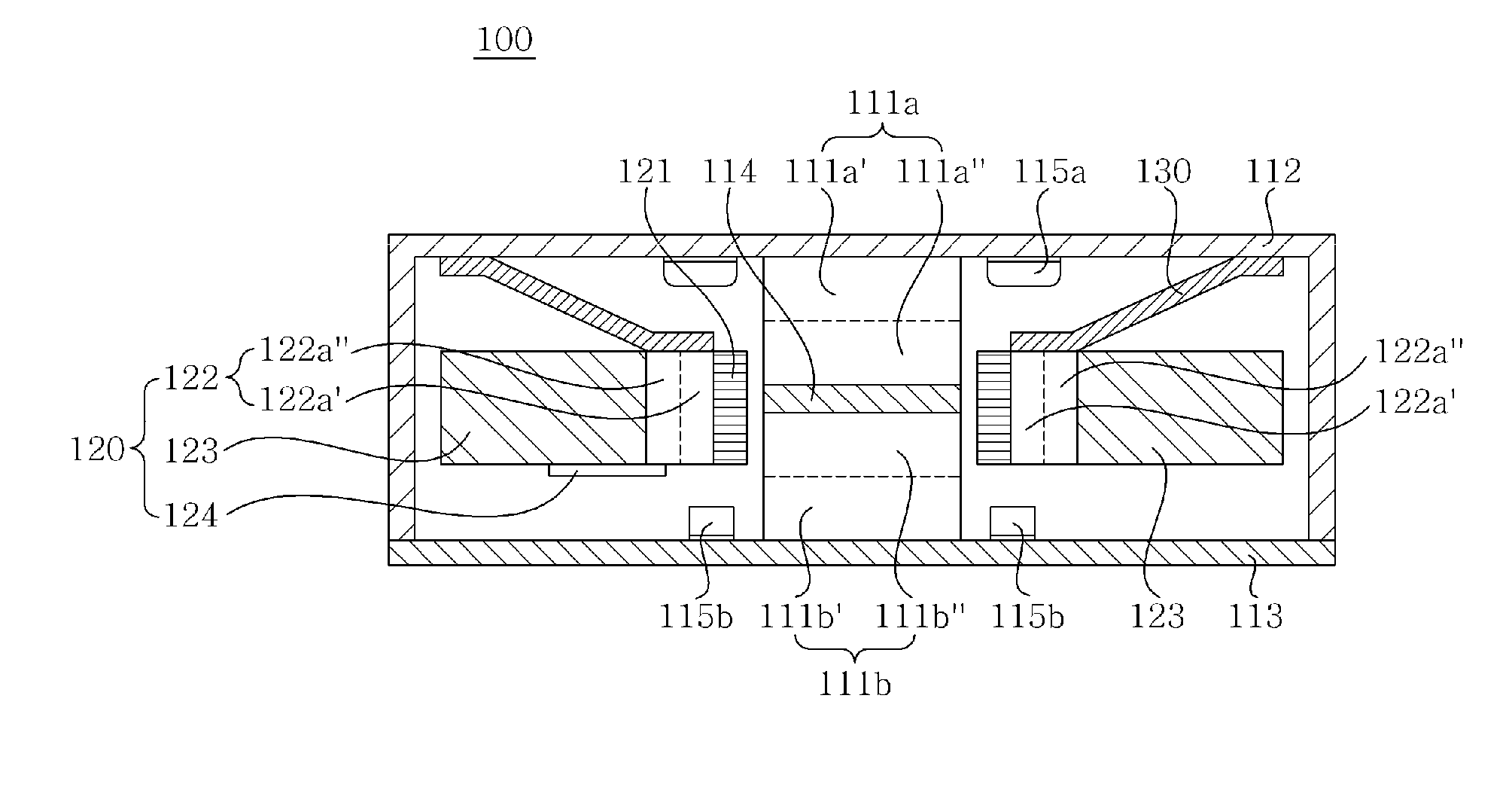

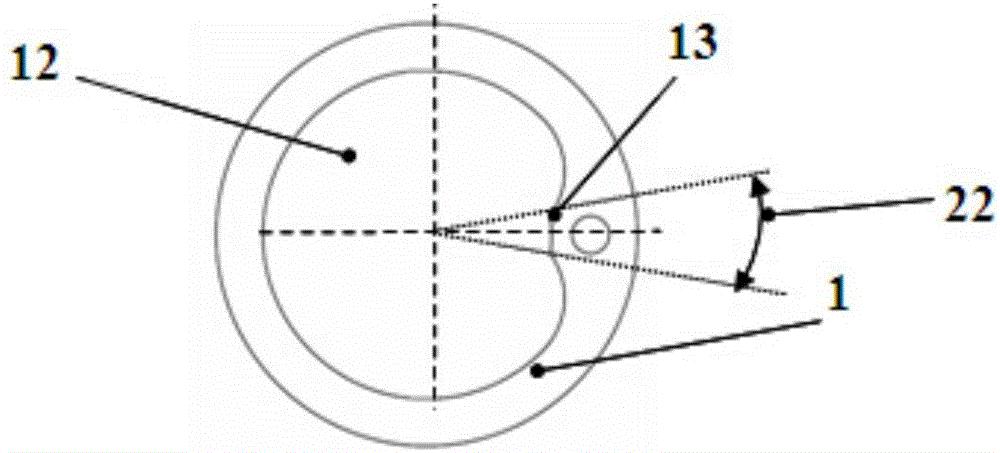

Synchronous permanent magnet planar motor

ActiveUS20060049699A1Number and length of effectiveIncrease electromagnetic forceMagnetic circuitPropulsion systemsMagnetConductor Coil

According to the invention, configurations of X-windings and Y-windings in a synchronous permanent planar motor are improved, X-windings and Y-windings overlap in the direction normal to the planar magnet array and distribute on the entire surface of the thrust core, such that effective wires in the X-windings and Y-windings are lengthened and increased in number, therefore the electromagnetic force generated by the SPMPM of this invention is increased correspondingly; X-windings and Y-windings are mounted on a thrust core made of iron material, thus the electromagnetic force is further increased; in addition, two separated anti-yawing member are provided on the mover for counteracting yawing of the mover, accordingly interference between anti-yawing torque and the electromagnetic force for propelling is eliminated.

Owner:TSINGHUA UNIV +1

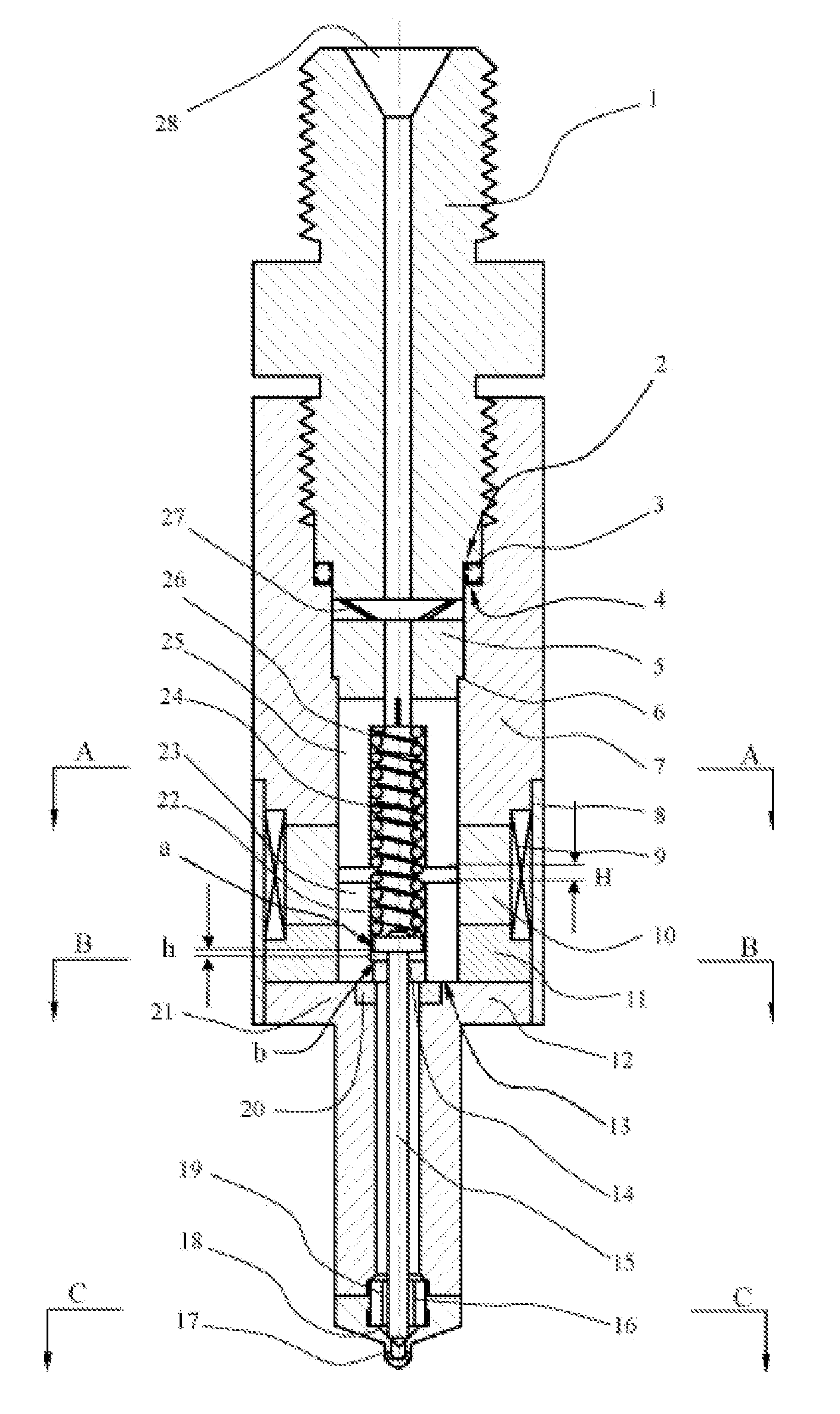

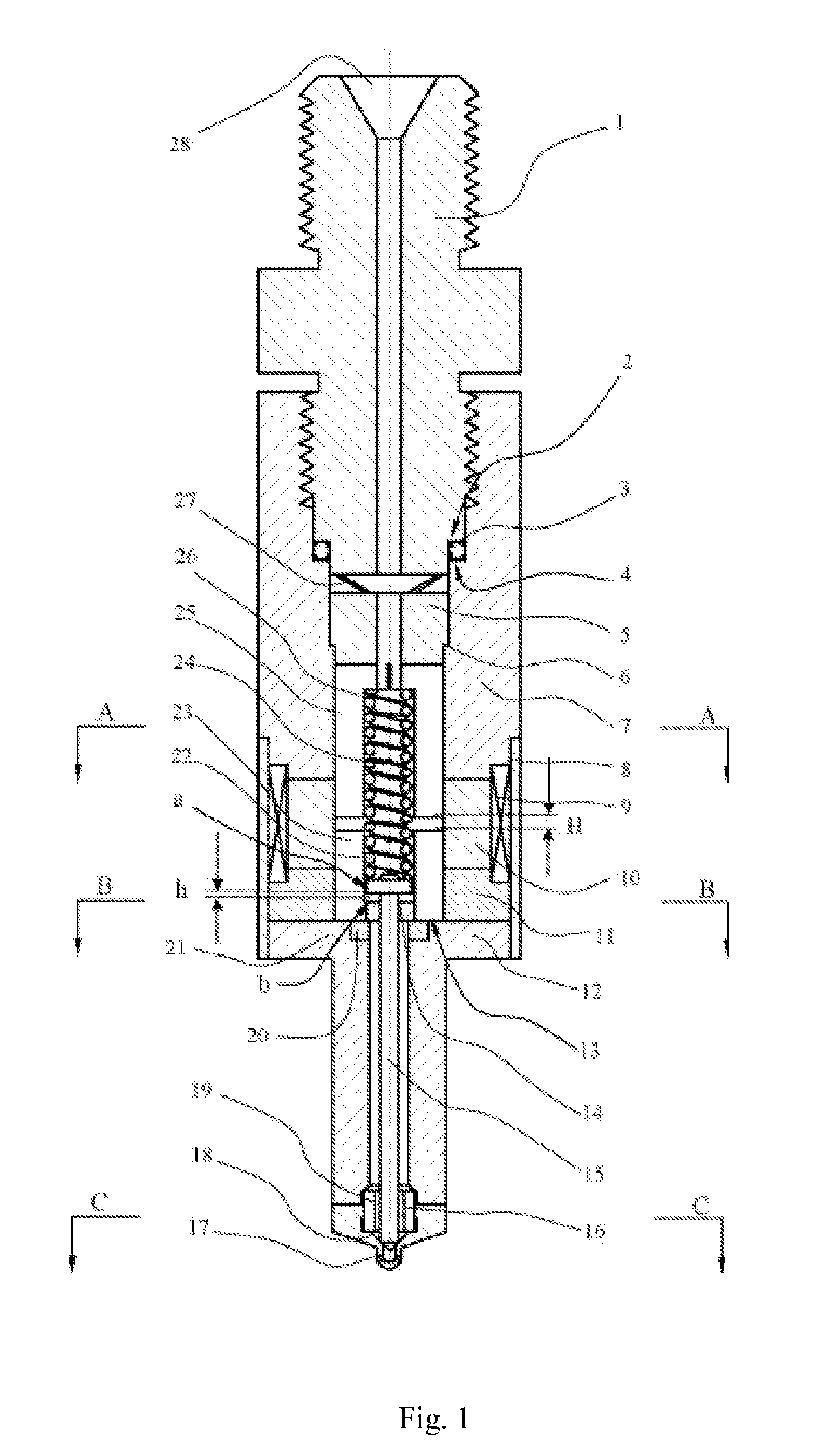

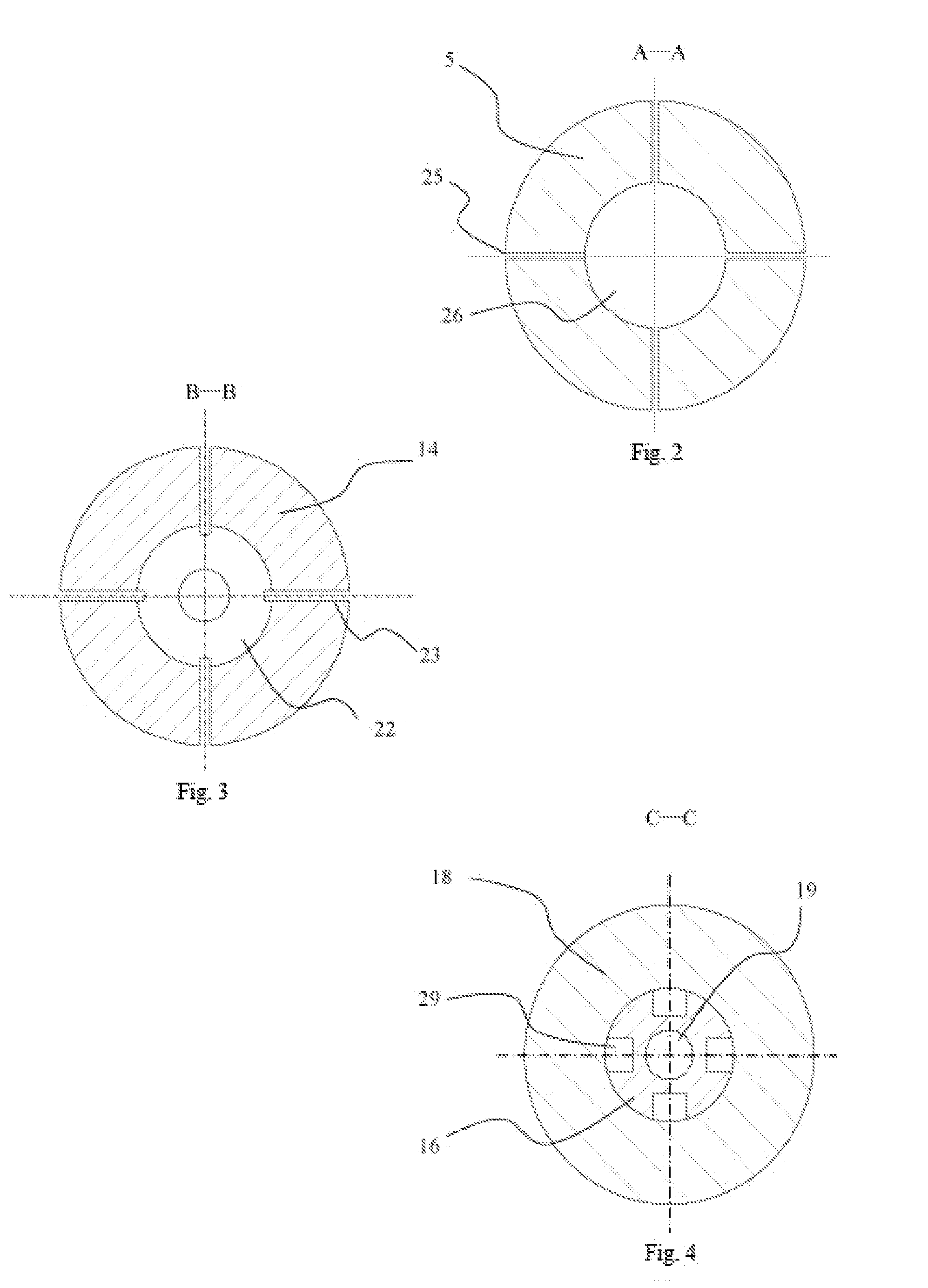

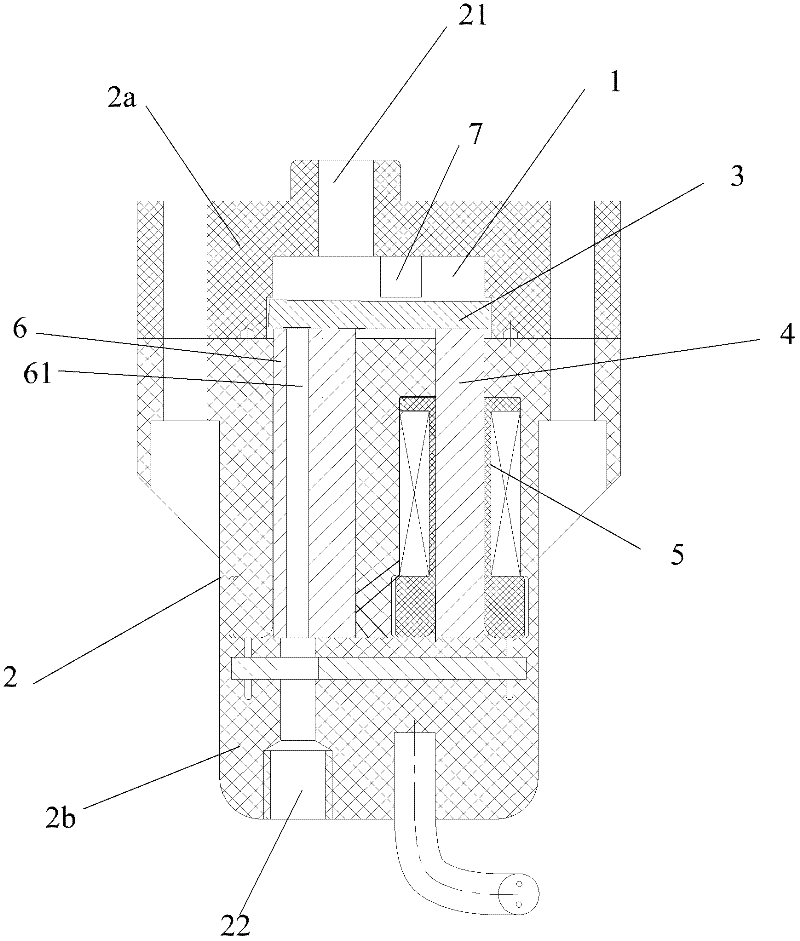

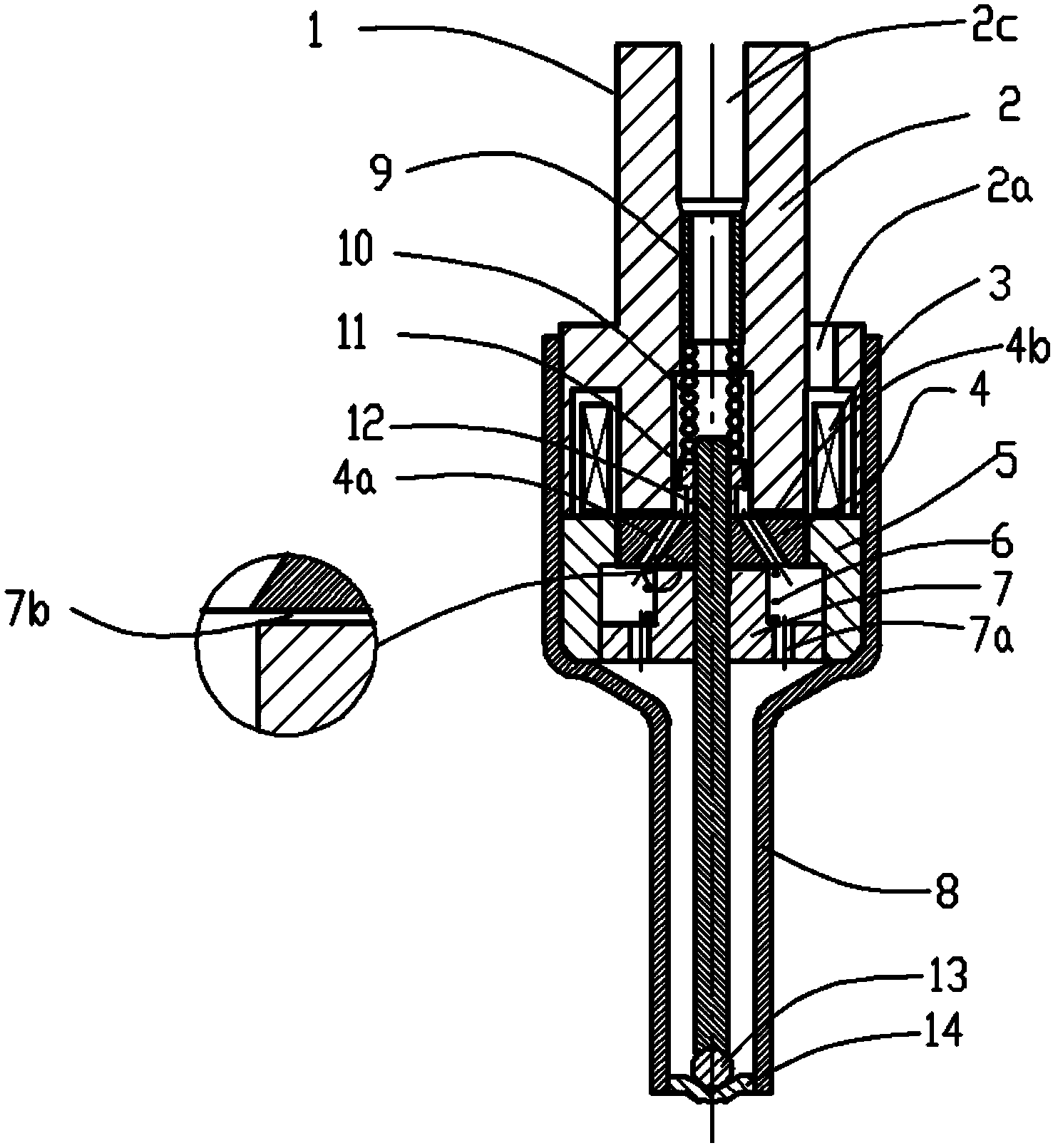

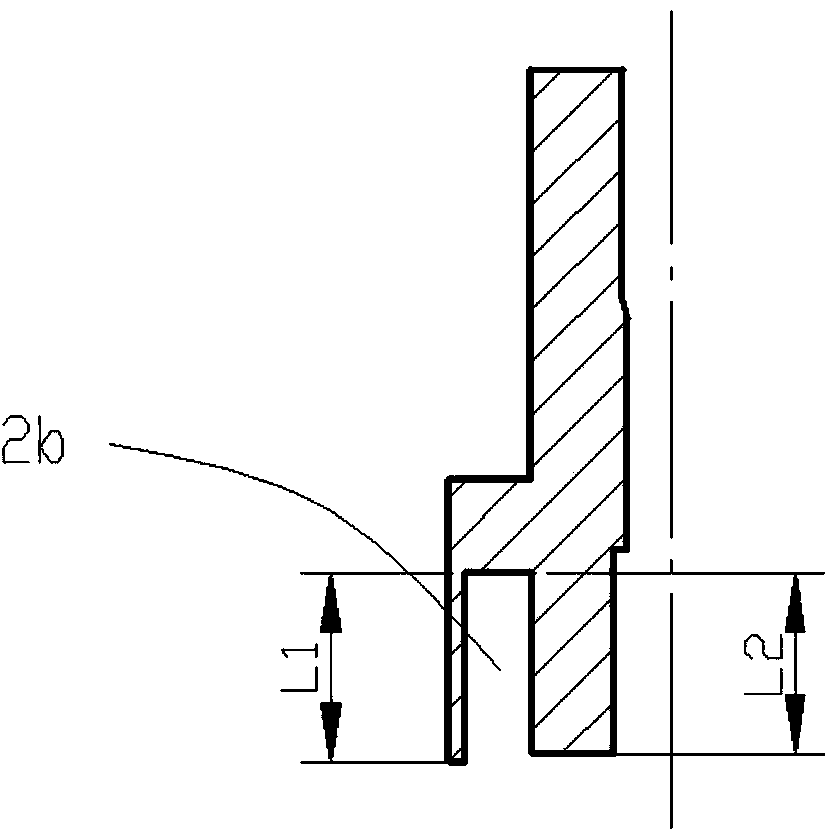

Common rail electronic control injector

InactiveUS20100236526A1High energy efficiencyImprove energy efficiencyWear reducing fuel injectionMagnetic flux influencing fuel injectionNeedle valveNozzle

The present invention relates to a common rail electronic control injector, which belongs to the electronic control fuel injection system technology. The injector includes an oil inlet joint, an oil inlet located at outside the oil inlet joint, an electromagnet device, a nozzle body, a needle valve, a valve seat and spray holes, wherein the electromagnet device includes a static core, an armature and a coil, wherein a working gap between the static core and the armature is H, the armature is moveably connected with the needle valve along an axial direction. The present invention further includes a compression spring applying a force to the needle valve, a force mechanism applying a force to the armature, and a block mechanism providing an axial anti-thrust while the armature is reset. The present invention has advantages of lower manufacturing cost, better reliability and smaller driving energy.

Owner:TIANJIN UNIV

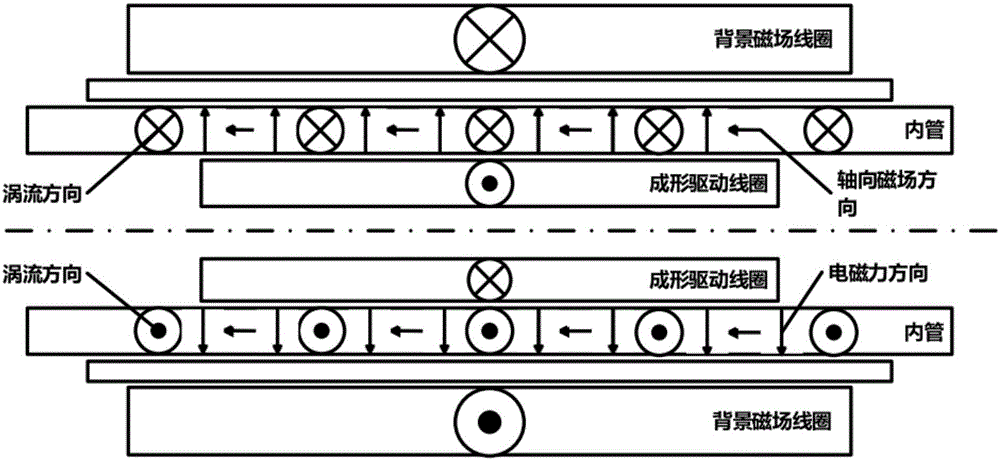

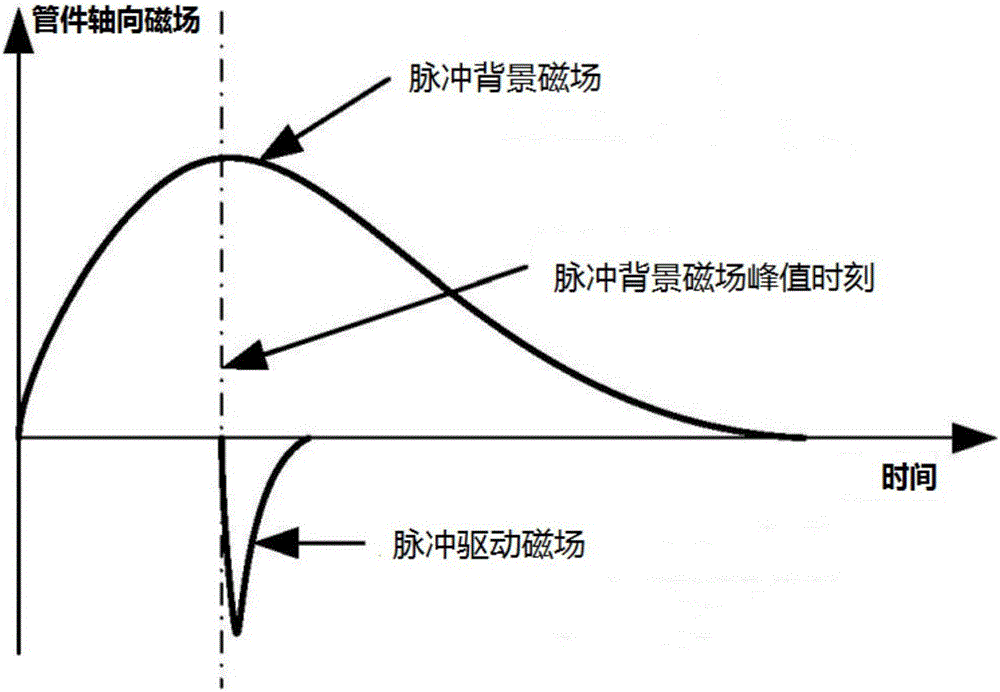

Electromagnetic forming device and method of metal pipe

ActiveCN106694681AHigh strengthSmall electromagnetic forceElectromagnetic formingUltimate tensile strength

The invention discloses an electromagnetic forming device and method of a metal pipe. The device comprises a background magnetic field unit and a metal pipe forming driving coil, wherein the background magnetic field unit is used for generating a pulse background magnetic field on the metal pipe, and a pulse driving magnetic field can generate vortexes on the metal pipe; and the metal pipe forming driving coil is used for generating the pulse driving magnetic field on the metal pipe. Due to the fact that the pulse width of the pulse driving magnetic field is much smaller than that of the pulse background magnetic field, the vortexes generated by the pulse background magnetic field on the metal pipe can be ignored, meanwhile, the influences of the pulse driving magnetic field on a magnetic field on the metal pipe can be ignored, and thus, electromagnetic force is generated on the metal pipe through interaction of the pulse background magnetic field and the vortexes. By independently adjusting the pulse background magnetic field and the pulse driving magnetic field, the electromagnetic force can be improved, the metal pipe high in mechanical strength and low in conductivity can be formed, meanwhile, the design difficulty of the forming driving coil can be lowered, and the service life of the forming driving coil is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

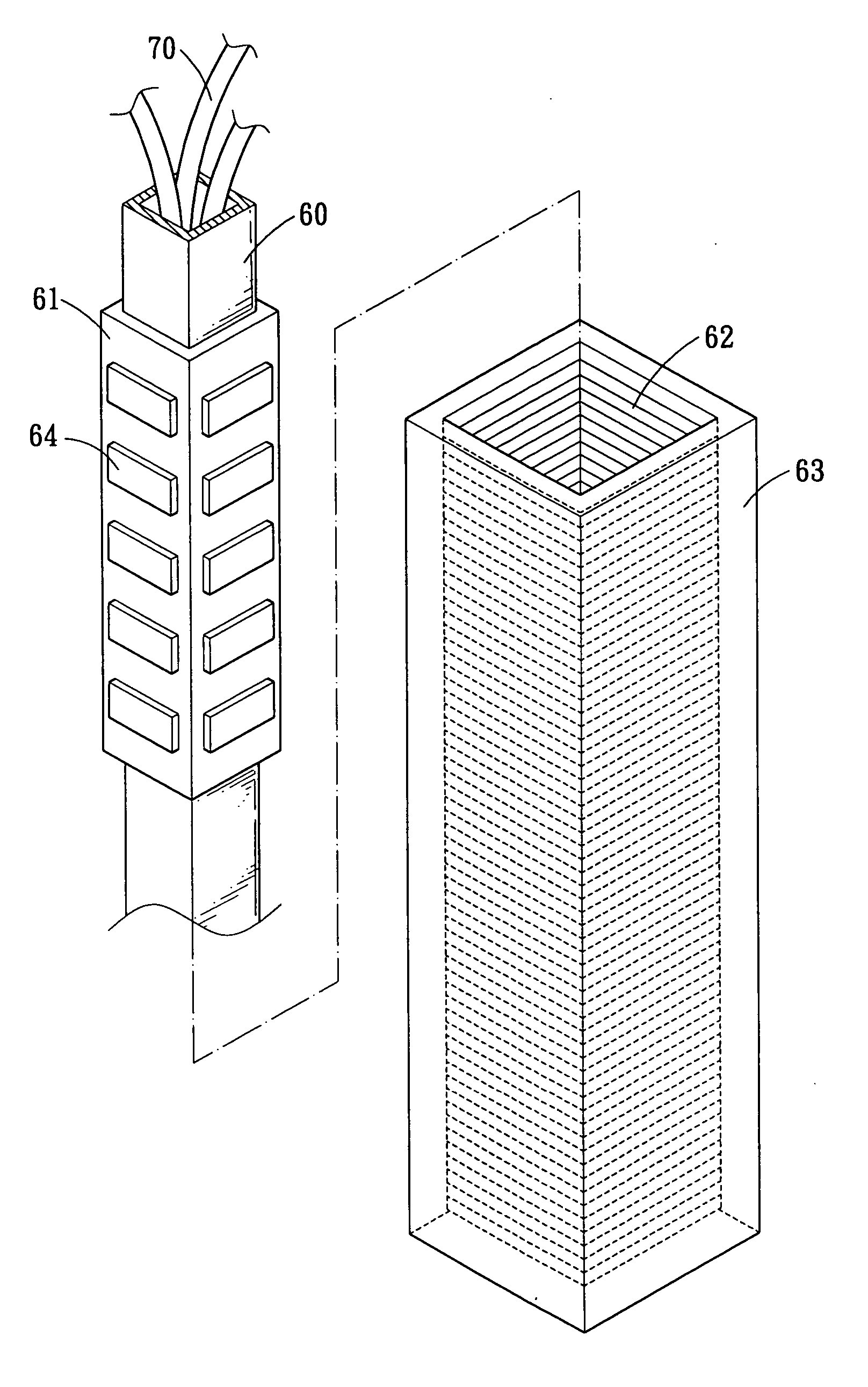

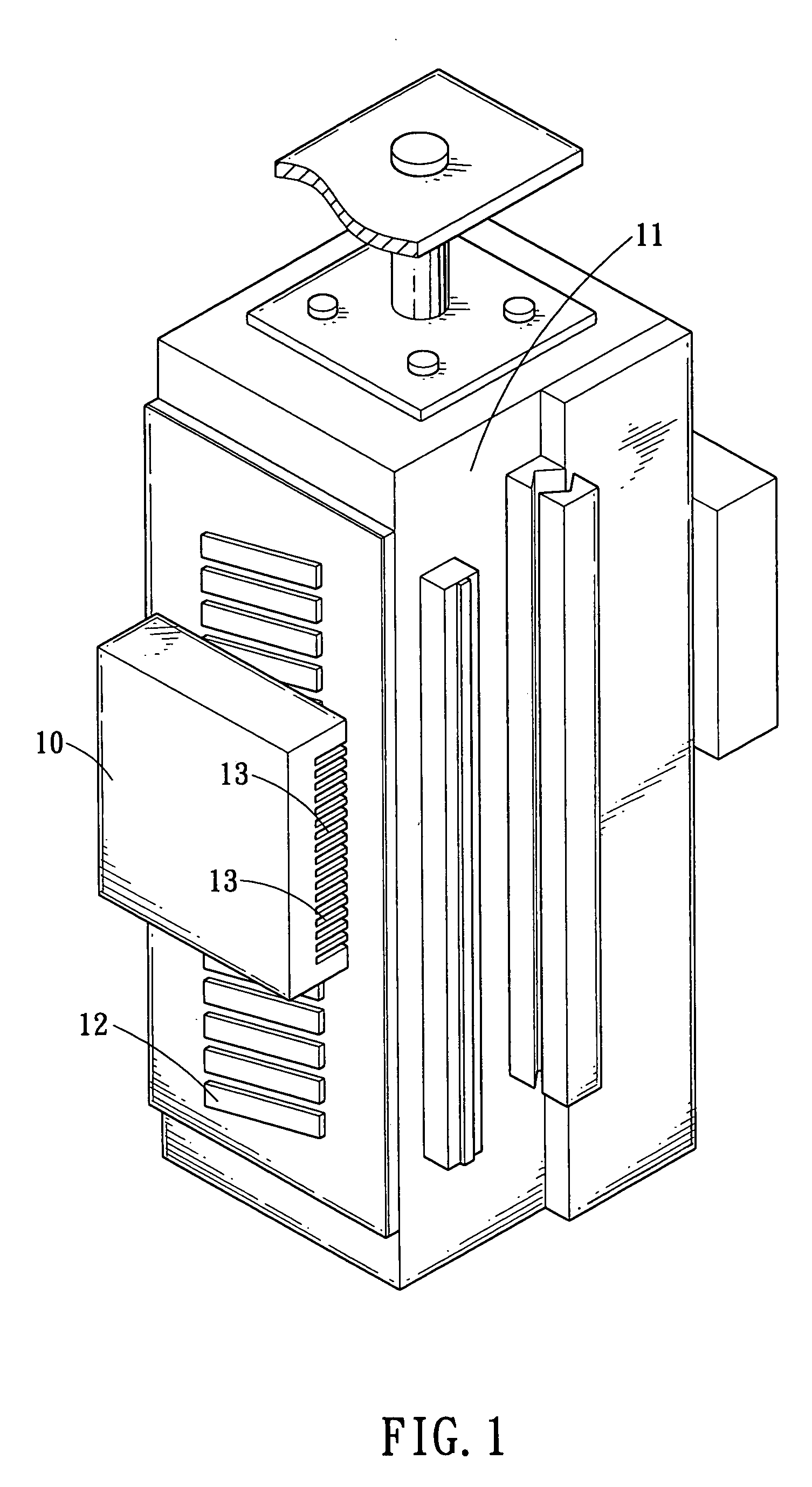

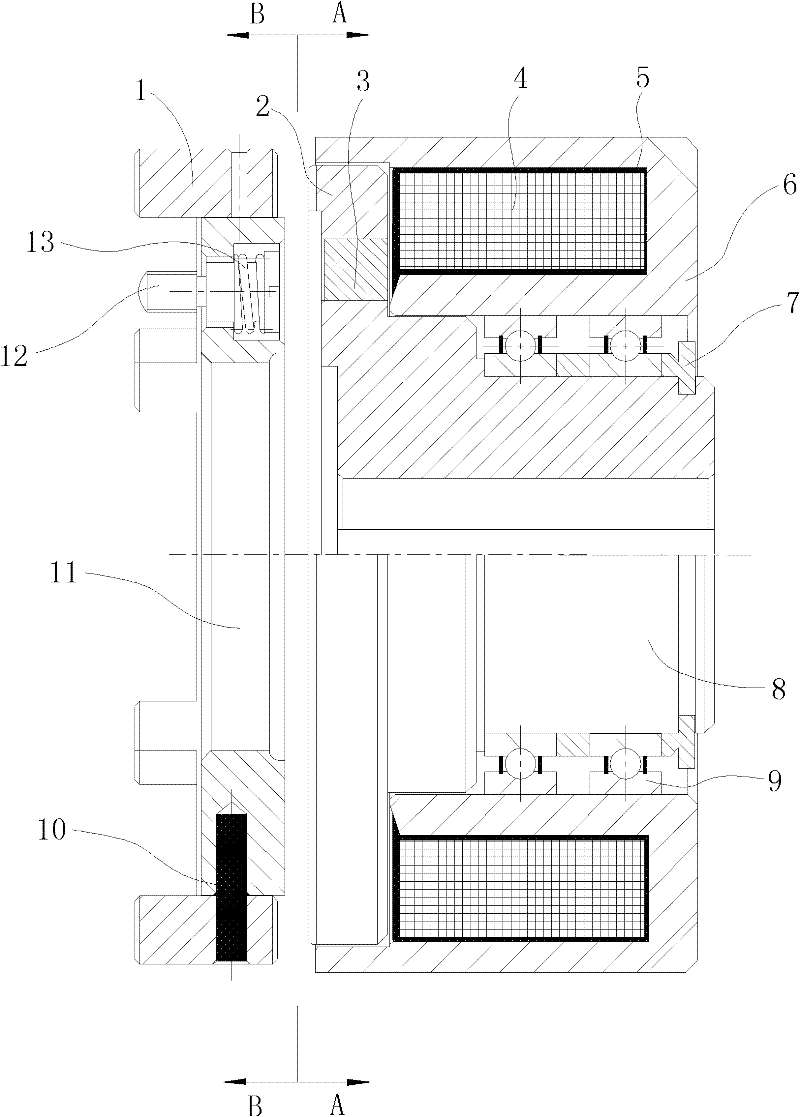

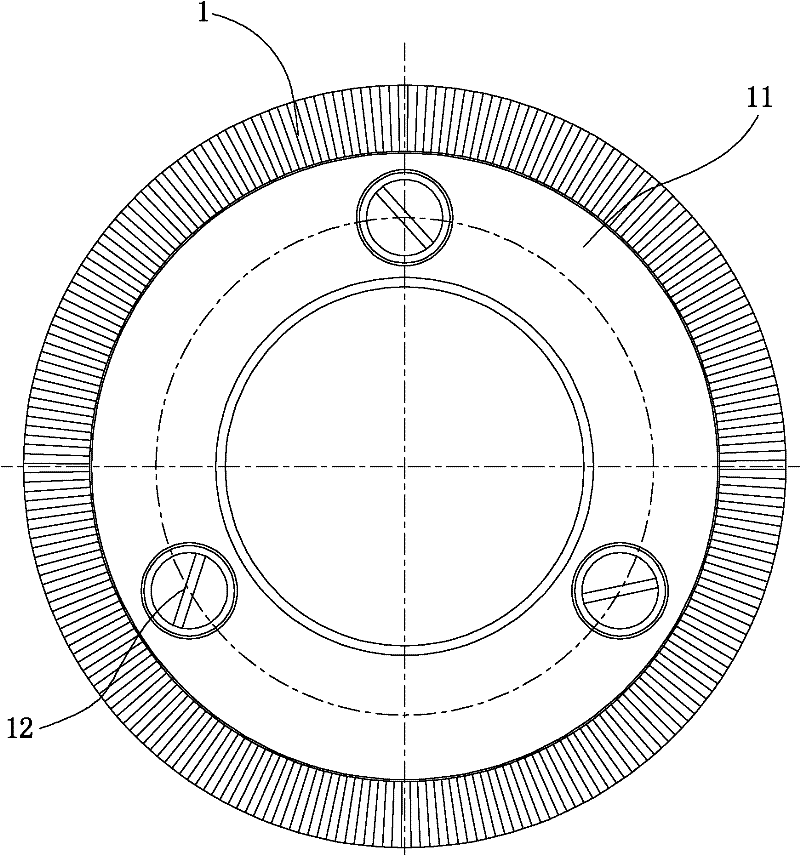

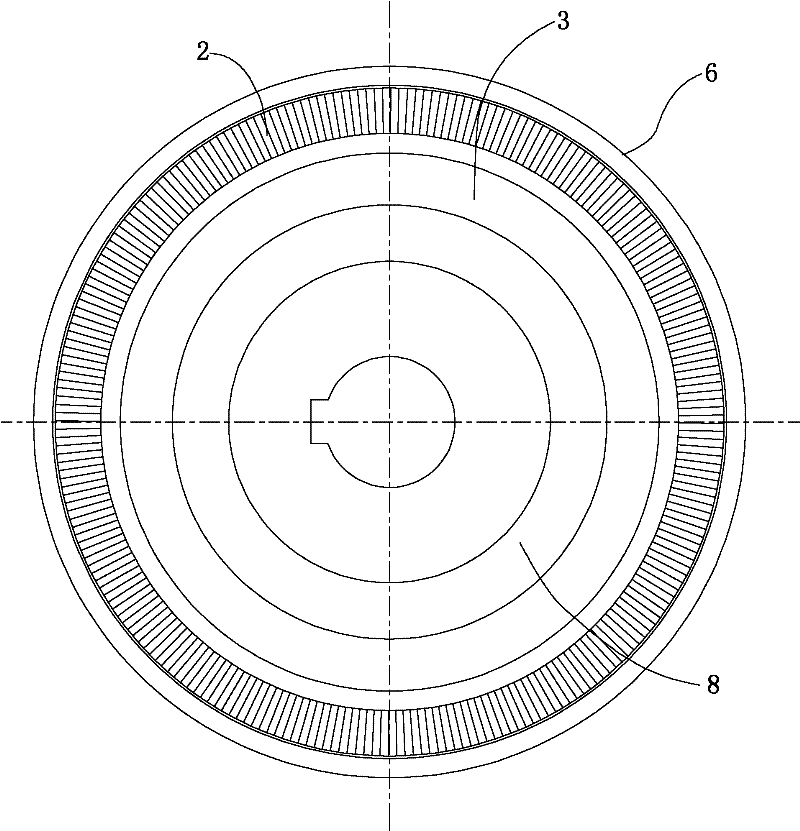

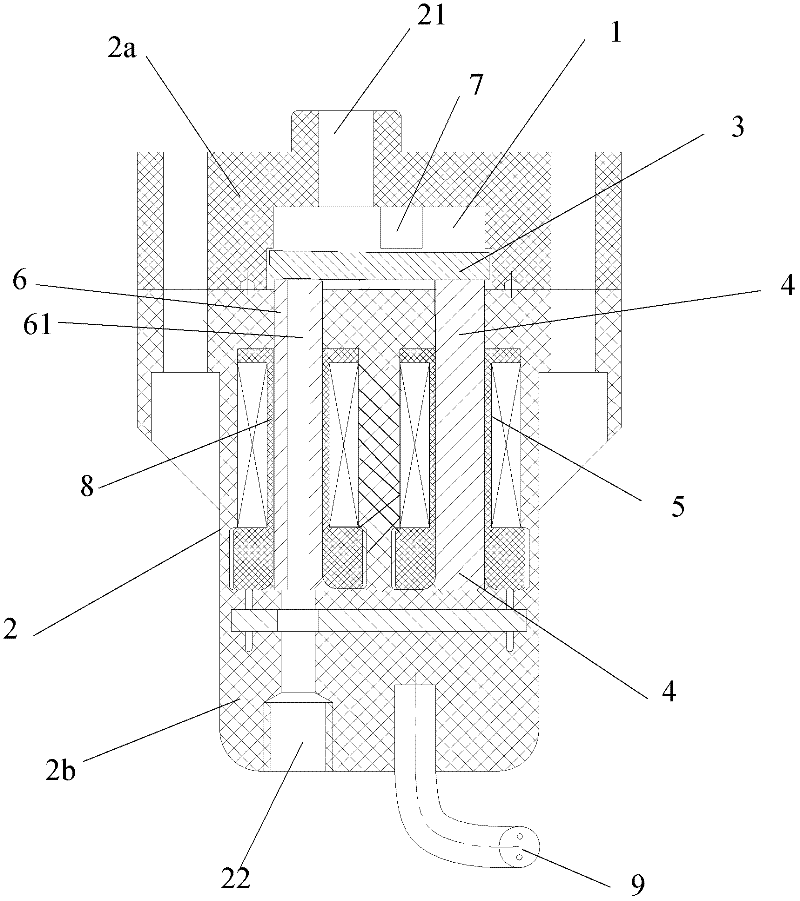

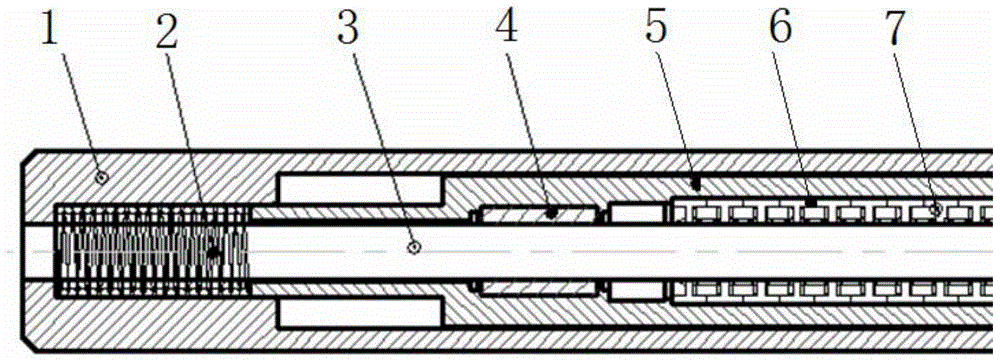

Tubular linear motor for electrical discharge machine

A tubular linear motor for electrical discharge machine generally comprises: a stator, a forcer, a set of coils and a hollow central shaft. The forcer is mounted onto the hollow central shaft, the forcer and the hollow central shaft are slidably disposed at the axial center of the stator, the set of coils is disposed in the stator (or in the forcer). After the coil is powered, the forcer will be driven to reciprocate along the central shaft by the electromagnetic force produced by the set of coils. The central shaft can be interiorly provided with wires, and thus, both the production cost and installation space of the linear motor of the present invention can be substantially reduced.

Owner:HIWIN MIKROSYST

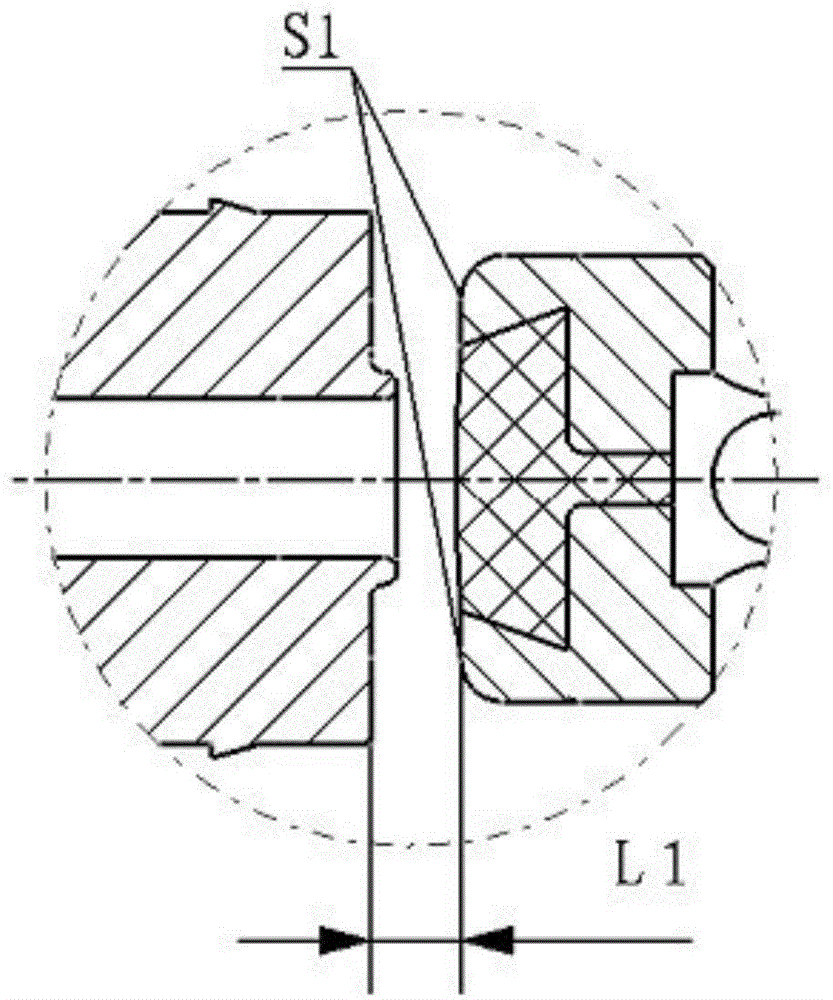

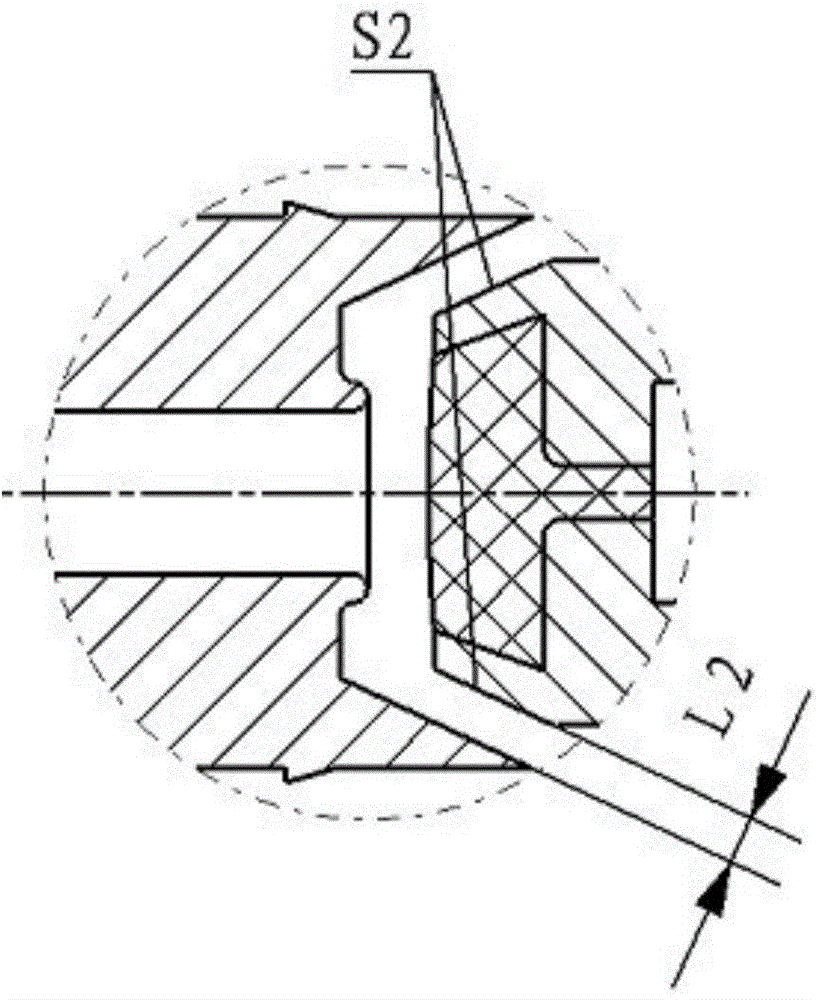

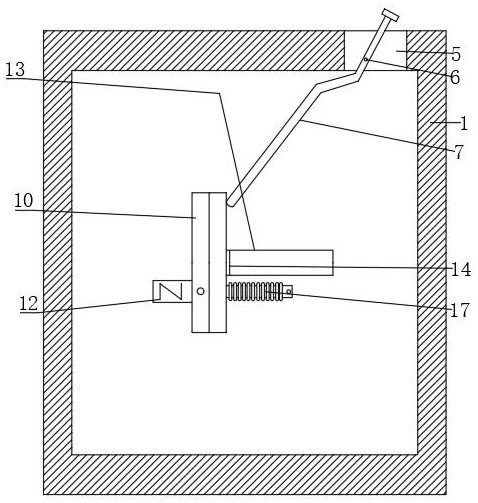

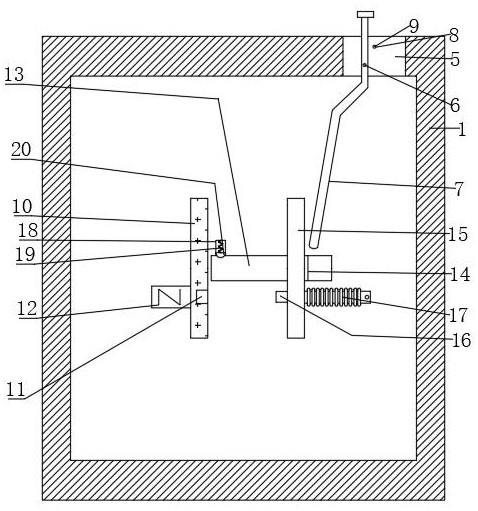

End Tooth Electromagnetic Clutch

InactiveCN102287458AQuick conversionAccurate conversionMagnetically actuated clutchesElectromagnetic clutchTorque transmission

The invention belongs to the technical field of electromagnetic clutches, and relates to an end tooth electromagnetic clutch. The end-tooth electromagnetic clutch includes a driving part and a driven part. The clutch claw, armature flange, and spring are composed of an end gear ring, a magnetic isolation ring, and a core shaft to assemble an end gear shaft, which is set in two 6807 bearings, axially positioned by a retaining ring, and assembled in the inner hole of the yoke. The coil wrapped by insulating paper is placed in the coil groove of the yoke; the armature flange is riveted in the end tooth clutch claw with a hollow pin, and the spring is set on the screw. The end-tooth electromagnetic clutch adopts end-tooth gear connection to transmit power. It has the advantages of simple structure, convenient installation and maintenance, and high transmission ratio precision, which effectively ensures the fast and accurate conversion of mechanical energy in industrial production and the transmission of torque.

Owner:王万年

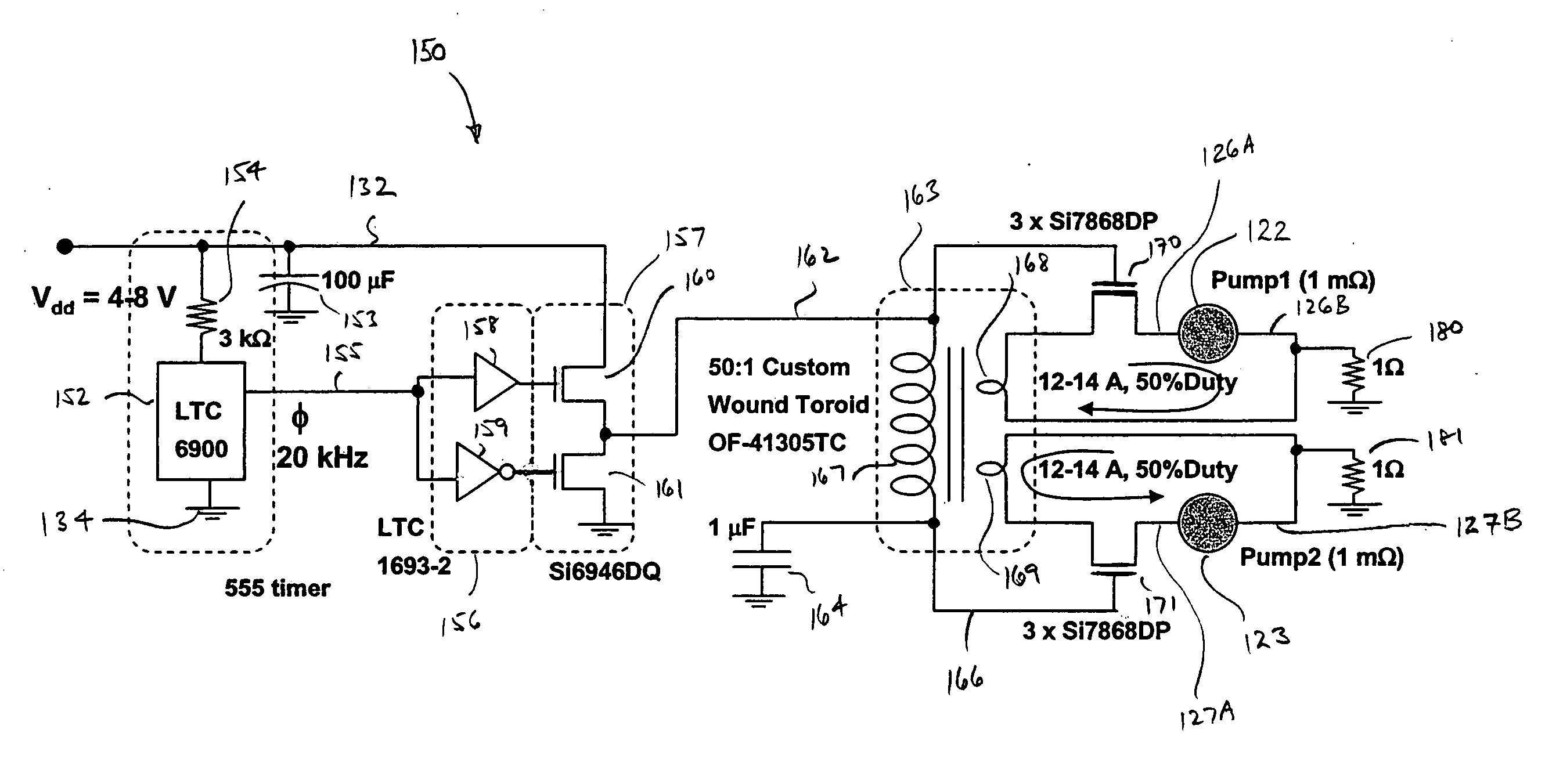

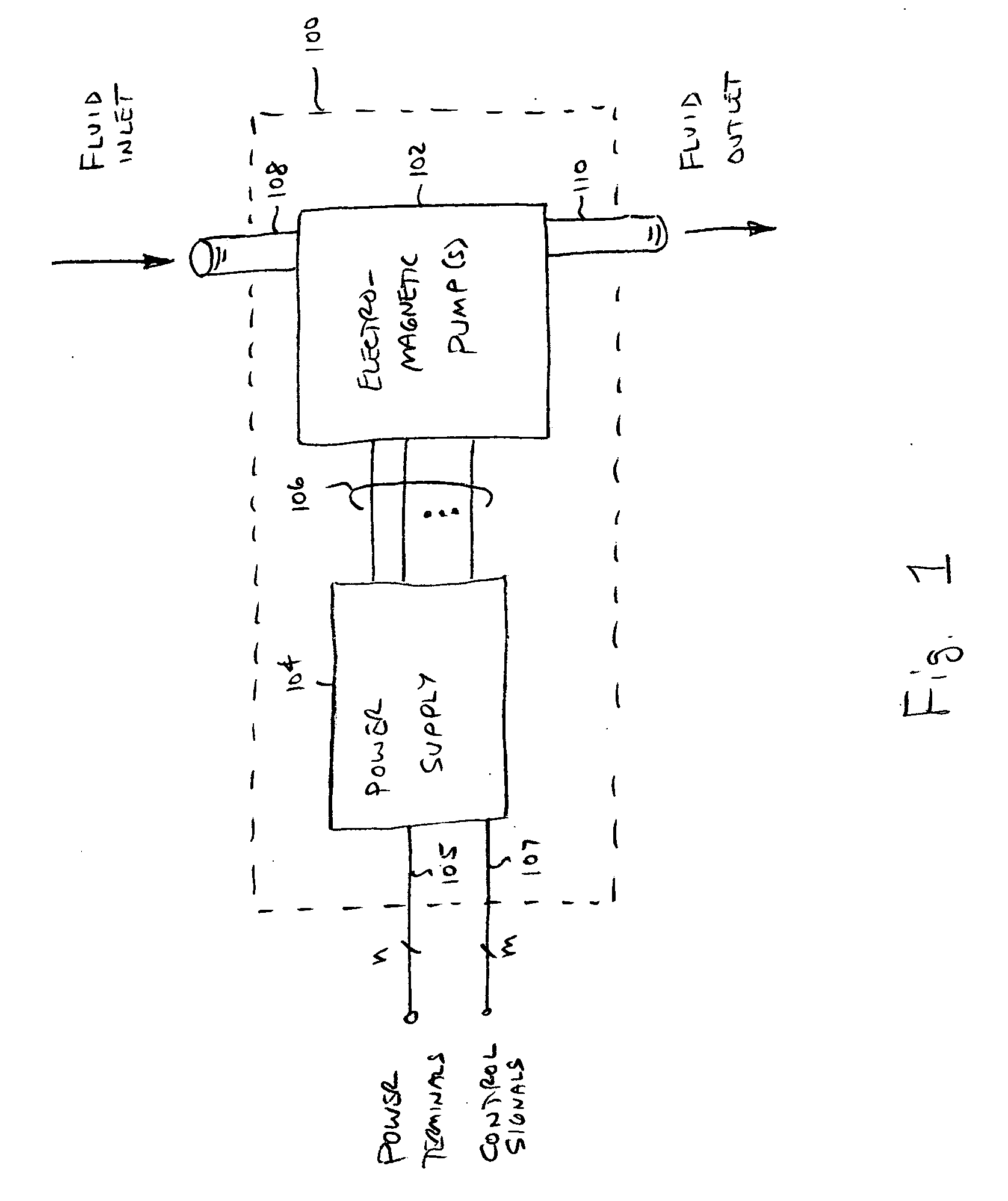

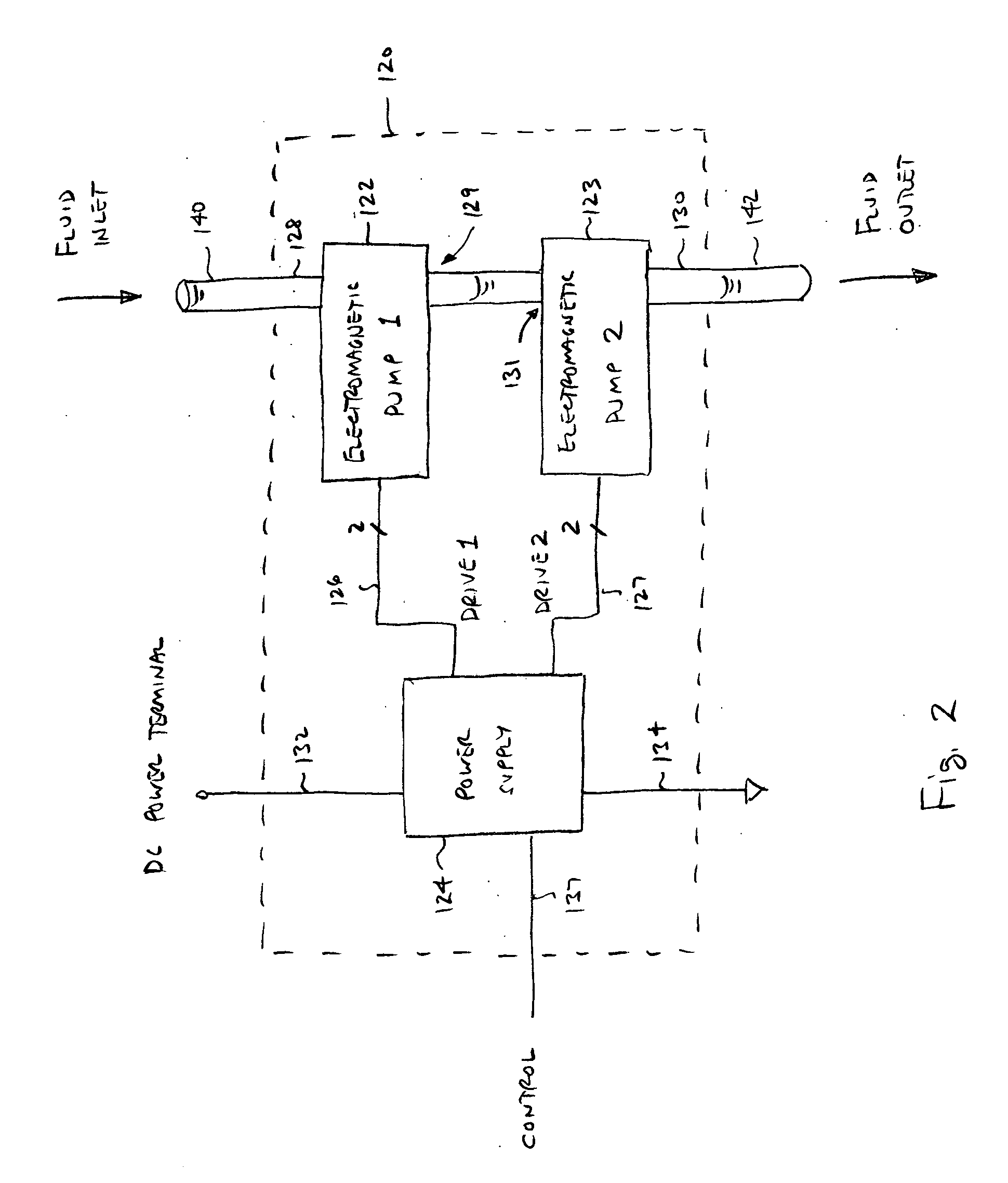

Series gated secondary loop power supply configuration for electromagnetic pump and integral combination thereof

InactiveUS20060073024A1Improve rendering capabilitiesIncrease electromagnetic forceAC motor controlPump componentsTransformerLow voltage

A power supply circuit for an electromagnetic pump includes a switched secondary loop circuit to provide the electromagnetic pump with a low voltage, high current output. In some embodiments, the power supply circuit includes a transformer having a core, a primary coil having first and second terminals, and at least a first secondary coil having first and second terminals, and a first switch device coupled between the first terminal of the first secondary coil and a first output node, and further includes primary-side circuitry for operably impressing a periodic signal across the primary coil. The first switch device includes a control terminal coupled to a node of the primary-side circuitry. The first output node and a second output node are provided for coupling thereto the electromagnetic pump, and the second output node may be coupled to the second terminal of the first secondary coil.

Owner:ZAGORIN OBRIEN GRAHAM

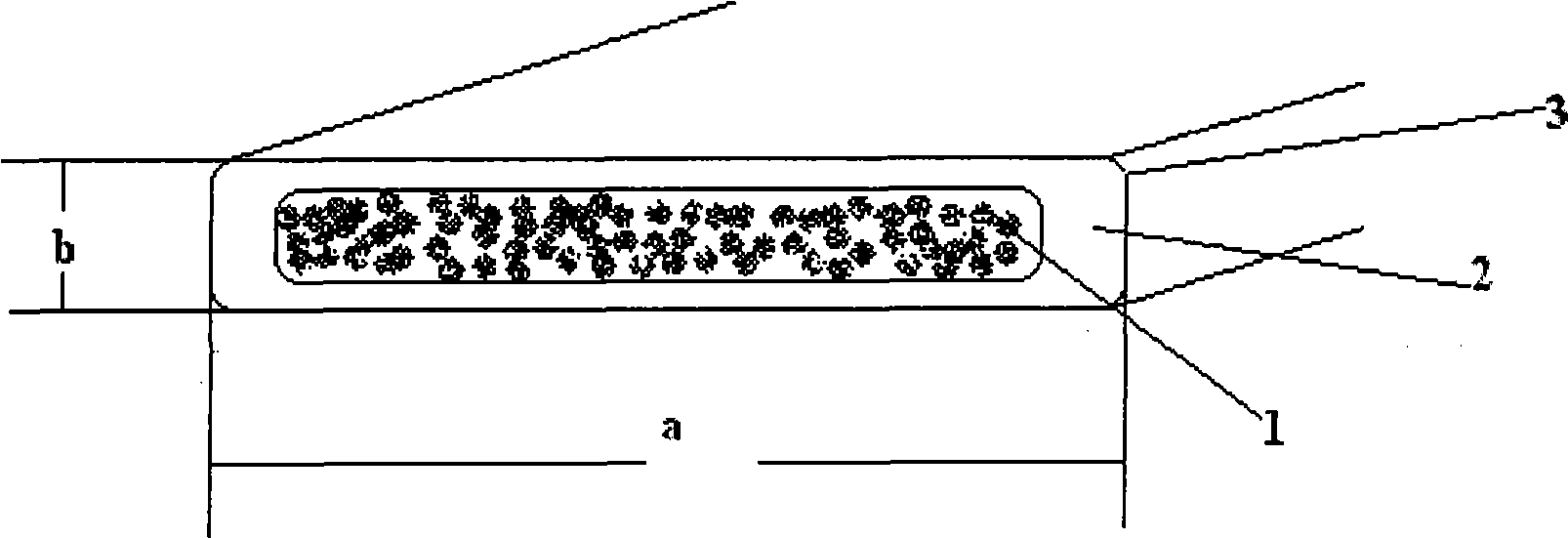

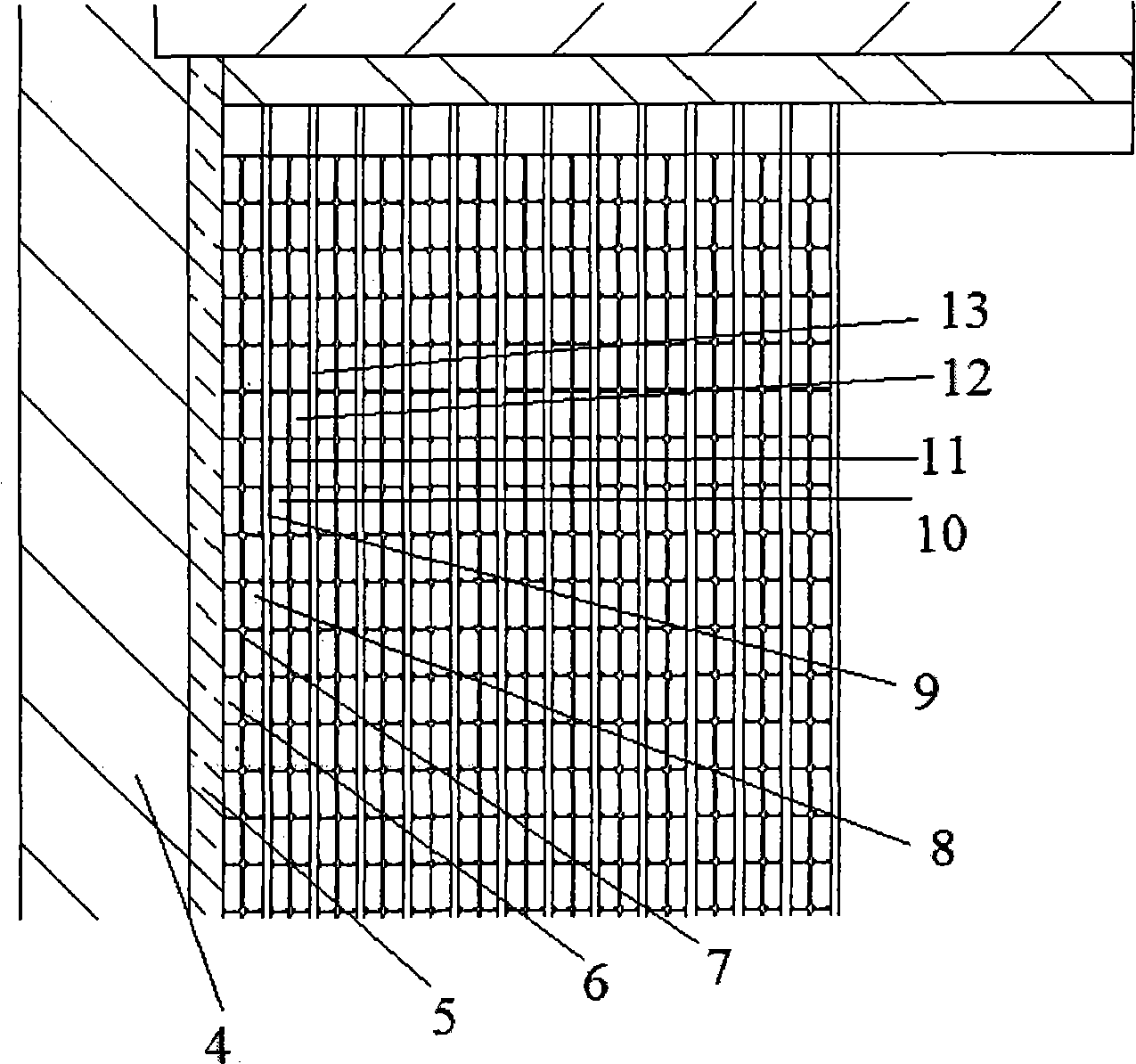

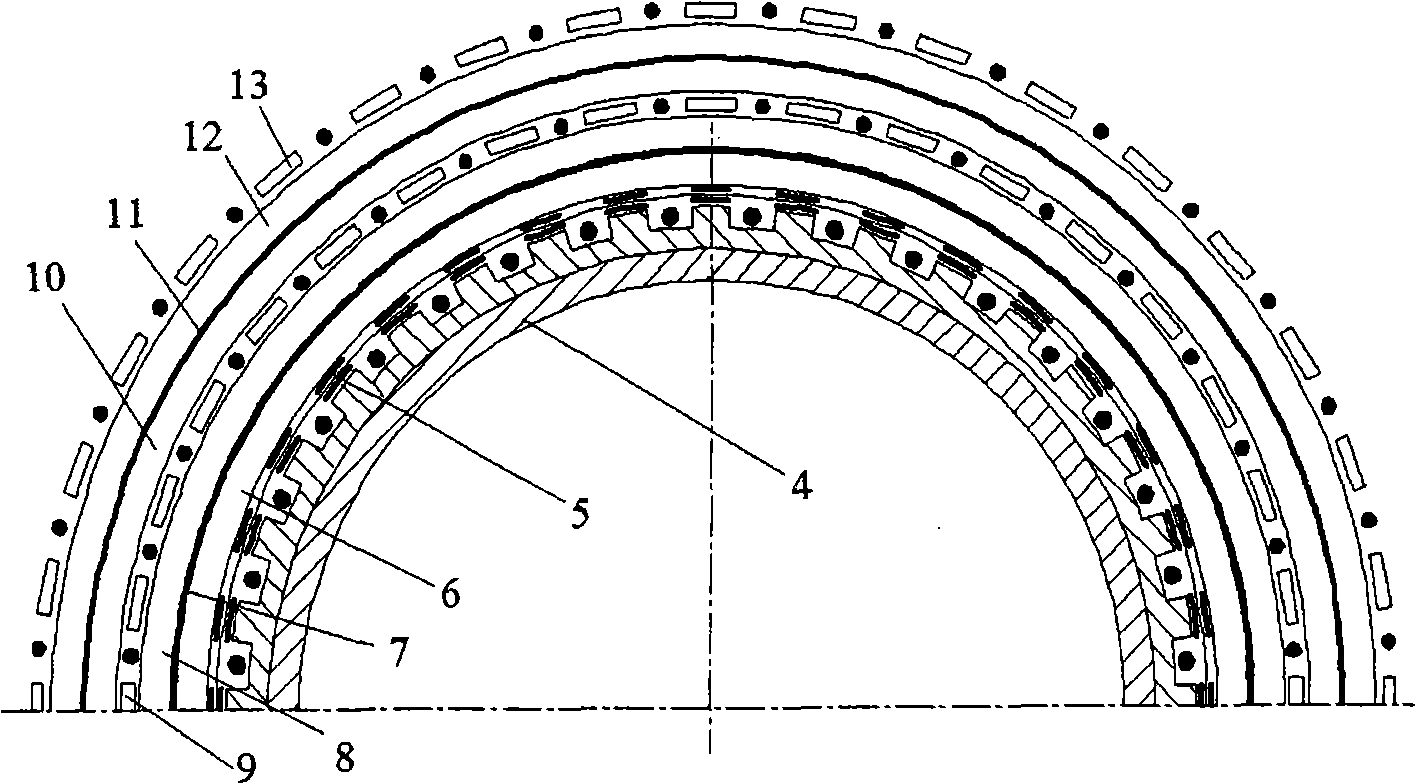

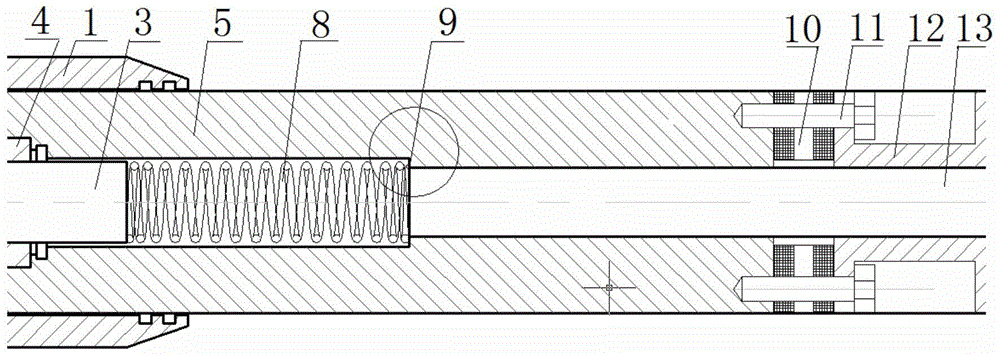

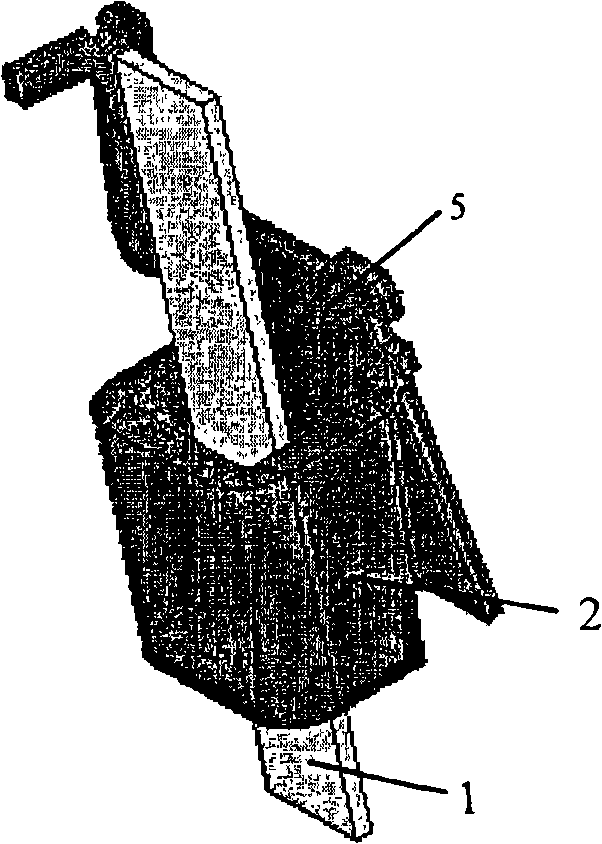

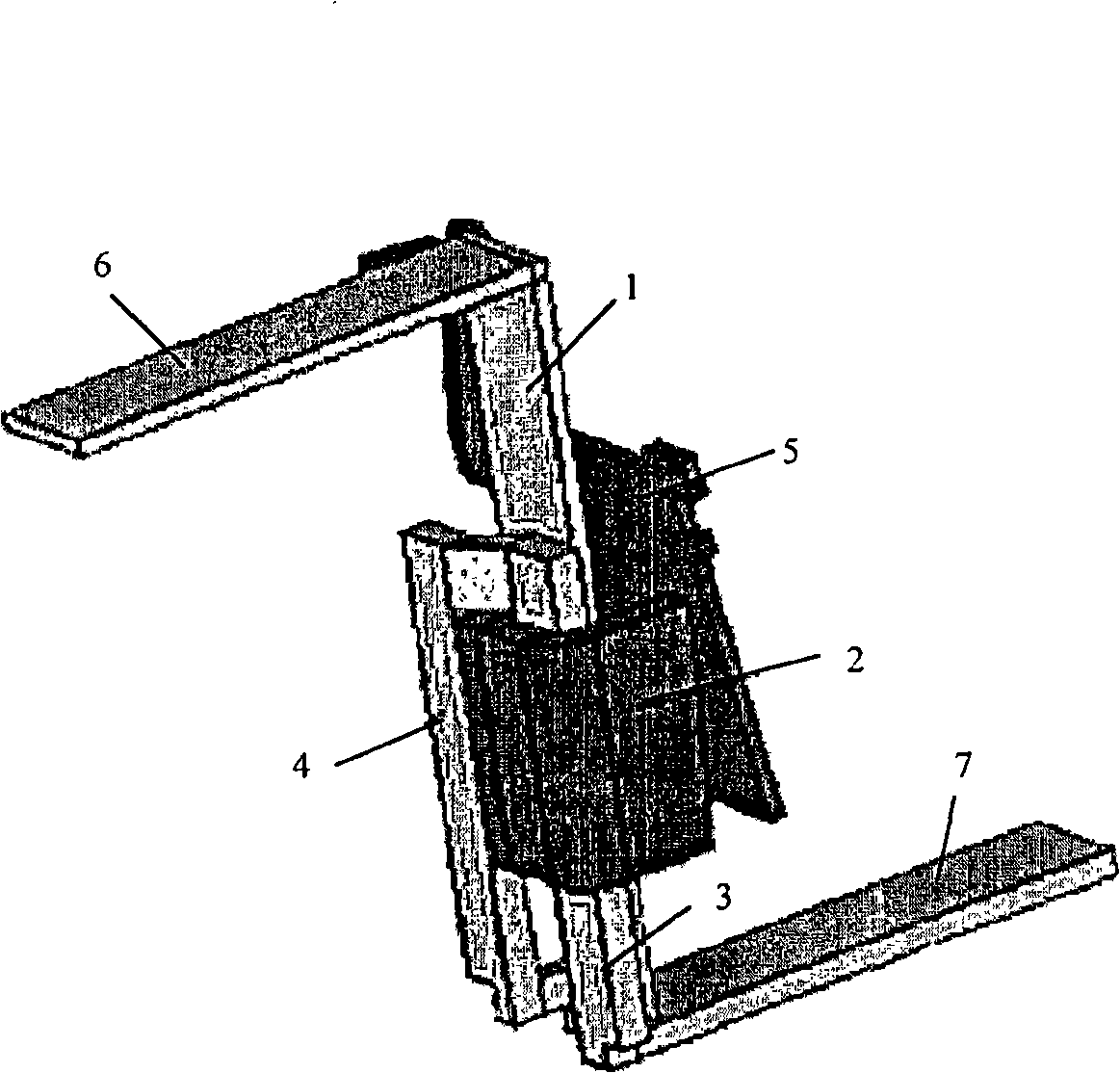

Coil used for fast impulse superconducting magnet winding structure

ActiveCN101499351AHigh mechanical rigidityImprove stabilitySuperconductors/hyperconductorsSuperconductor devicesEpoxyHigh energy

A coil used for fast pulse superconducting magnet winding structure has an epoxy gasket (5) arranged on a frame (4) with a hole; a first layer of superconducting winding (6) is winded on the epoxy gasket (5); a layer of epoxy glass ribbon (7) is winded between the first layer of the superconducting winding (6) and a second layer of superconducting winding (8) which are bonded together by low-temperature epoxy resin; and epoxy glass steel strips (9) are distributed on the surface of the second layer of the superconducting winding (8) at equal intervals along the circumference direction of the winding. The superconducting wire used by the superconducting winding of the coil is formed by coating a composite matrix (2) consisting of CuNi and copper outside a superconductor (1), wherein an insulating layer (3) is coated on the composite matrix (2). The coil has higher mechanical stability and better heat transfer characteristics, and is suitable for a fast-excitation large-scale superconducting coil with high energy-storing density and high magnetic field.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Electromagnetic repulsive force edge pressing method and device based on inertial confinement

PendingCN107413918AHigh edge force amplitudeGuaranteed mechanical stabilityPulsed magnetRepulsion force

The invention discloses an electromagnetic repulsive force edge pressing method and device based on inertial confinement. The method comprises the steps that an edge pressing coil is discharged; the edge pressing coil is arranged on the upper portion of an edge pressing copper ring; the edge pressing copper ring is arranged on the upper portion of the edge of a workpiece; the workpiece is arranged on the upper portion of a female die; the to-be-deformed workpiece is molded through the female die, a pulsed magnet field is generated in the discharging process of the edge pressing coil, induced eddy current correspondingly generated in the edge pressing copper ring and the pulsed magnet field interact, and thus electromagnetic repulsive force is generated between the edge pressing coil and the edge pressing copper ring; and edge pressing force to the edge of the workpiece is provided by the electromagnetic repulsive force between the edge pressing coil and the edge pressing copper ring so that the edge positions of the workpiece can be kept stable in the molding process, meanwhile, workpiece material flowing is controlled, and the workpiece is prevented from being wrinkled and broken in the molding process. Through the electromagnetic repulsive force between two edge pressing coils of between the edge pressing coil and the edge pressing copper ring, the edge pressing force can be flexibly controlled, the device manufacturing cost is reduced, the space size is reduced, and the power source energy of a system can be effectively reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

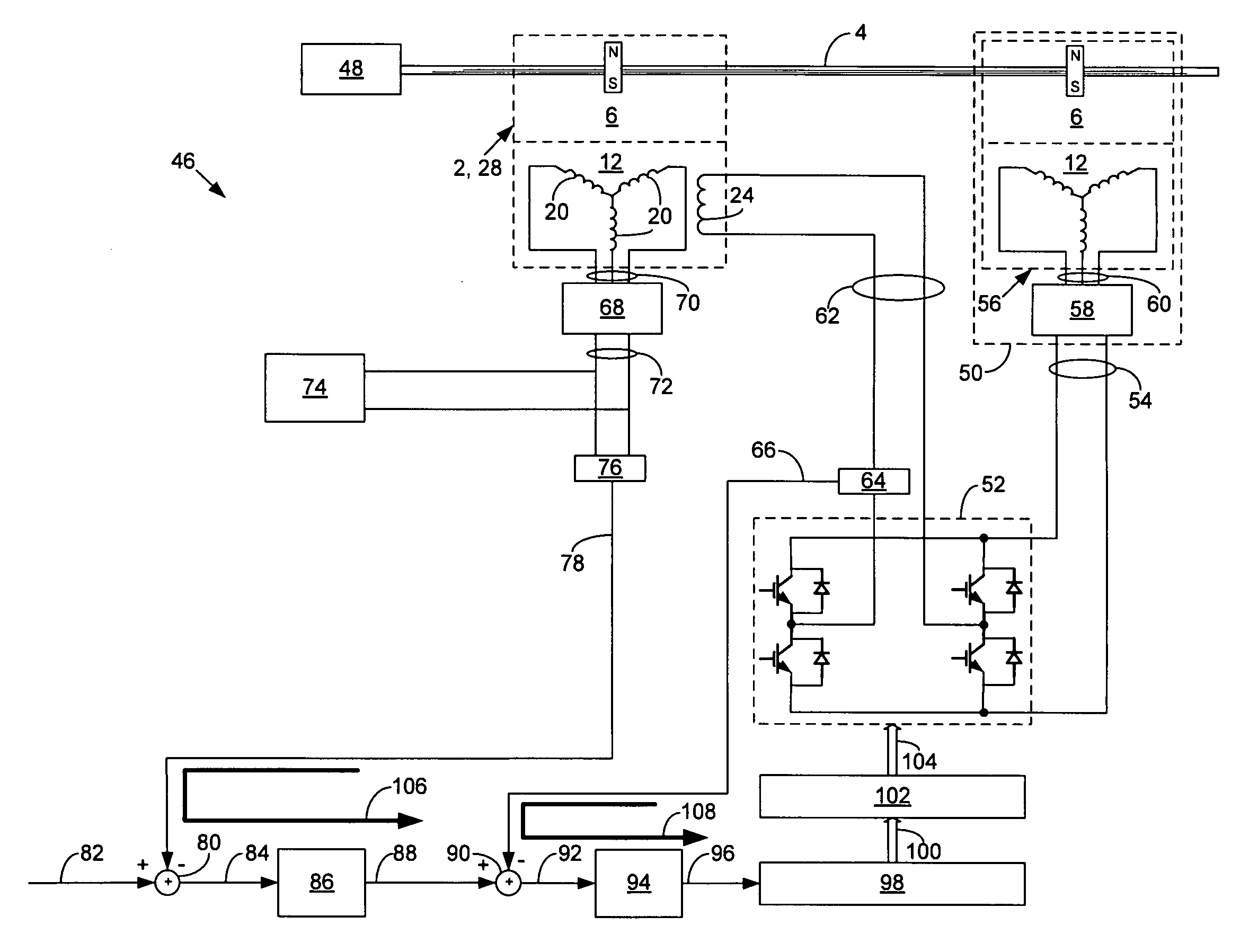

Permanent magnet electric generator with variable magnet flux excitation

ActiveUS20090251112A1Reduce diversionIncrease electromagnetic forceSynchronous generatorsMagnetic circuitDrive shaftStator coil

A permanent magnet (PM) electric generator with directly controllable field excitation control comprises: a drive shaft; a PM rotor assembly with multiple PMs arranged around an outer axial periphery of the rotor assembly; a stator assembly comprising a ferromagnetic stator yoke, multiple ferromagnetic stator teeth mounted to the stator yoke with distal ends proximate the outer axial periphery of the rotor assembly separated by an air gap and multiple stator coils mounted between the stator teeth; multiple saturable ferromagnetic shunts, each shunt coupling adjacent distal ends of the stator teeth to shunt air gap magnetic flux Φg generated by the PMs across the air gap through the distal ends of the stator teeth; and multiple saturation control coils, each saturation control coil wrapped about a saturable region of an associated one of the shunts; wherein application of a control current Ic to the control coils at least partially magnetically saturates the shunts to reduce shunting of air gap magnetic flux Φg, thereby increasing magnetic flux linkage ΨM between the PMs and the stator coils and increasing generated electromagnetic force (EMF) at lower levels of rotor assembly angular velocity.

Owner:HAMILTON SUNDSTRAND CORP

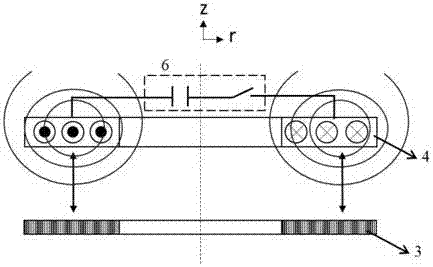

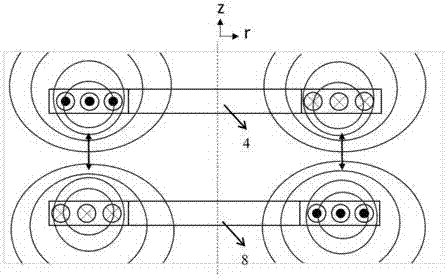

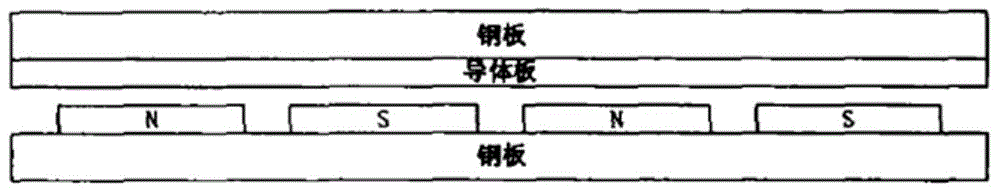

Linear Halbach permanent magnet-arranged superconductive eddy-current brake device with superconductive switch

InactiveCN103552473AIncrease profitIncrease electromagnetic forceElectrodynamic brake systemsEngineeringControllability

The invention discloses a linear Halbach permanent magnet-arranged superconductive eddy-current brake device with a superconductive switch, which is used for the non-contact electromagnetic braking of levitated bodies and comprises linear Halbach combination magnets and a superconductive eddy-current brake, and the superconductive eddy-current brake is arranged on a levitated body for braking. The two linear Halbach combination magnets adopted as the sidewalls of a linear Halbach combination magnet track are vertically mounted over the sides of permanent magnet guide rails for levitation along the longitudinal extension direction of a line; and eddy-current coils of the superconductive eddy-current brake adopt superconductive material to form superconductive coils. The linear Halbach permanent magnet-arranged superconductive eddy-current brake device can obtain higher air gap flux than the conventional arrangement method within an available space, and meanwhile, a good magnetic shielding effect can effectively reduce the affection of a magnetic field on a magnetic levitation system. Moreover, the linear Halbach permanent magnet-arranged superconductive eddy-current brake device has the advantages of high eddy-current braking electromagnetic force and controllability.

Owner:SOUTHWEST JIAOTONG UNIV

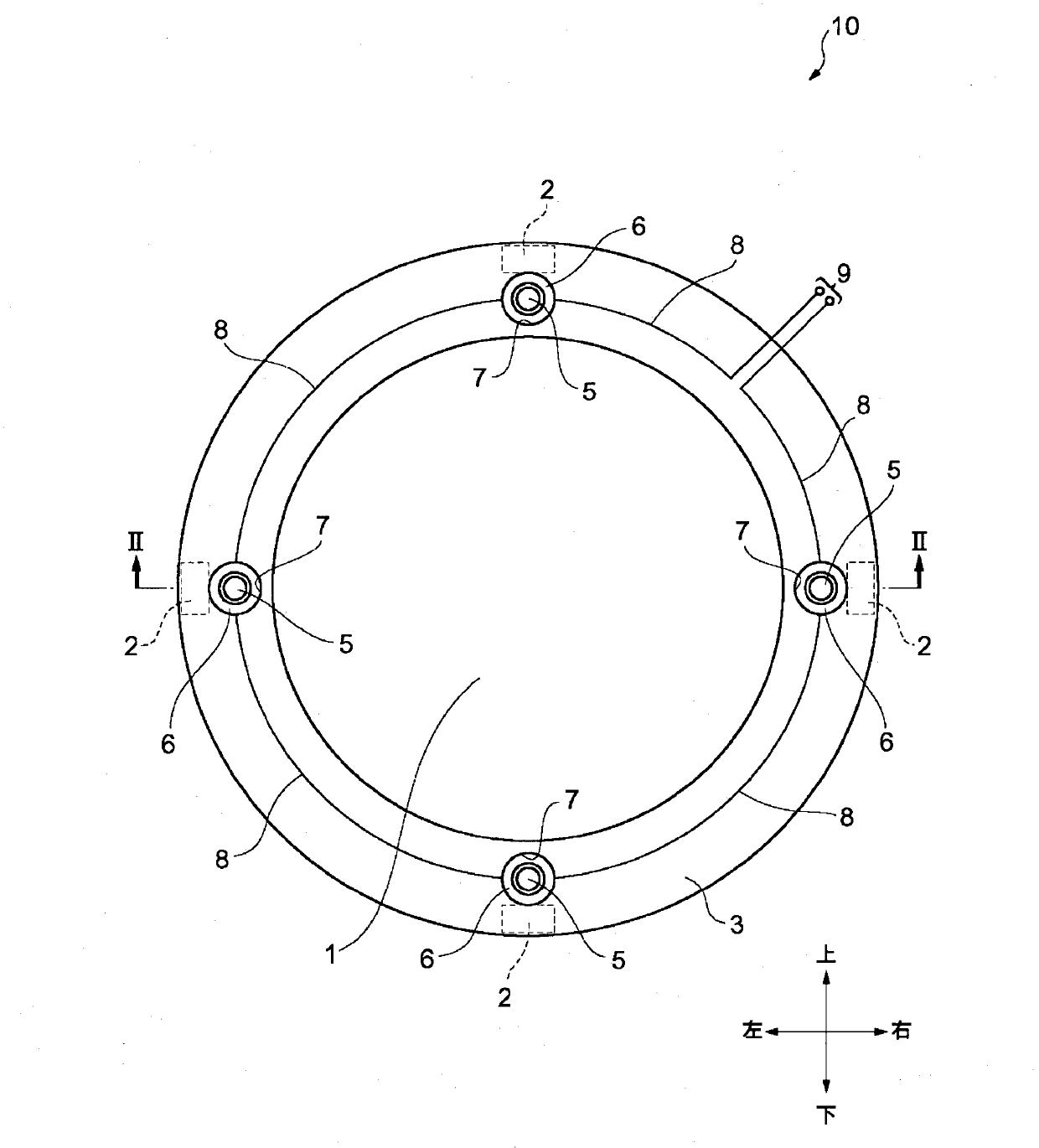

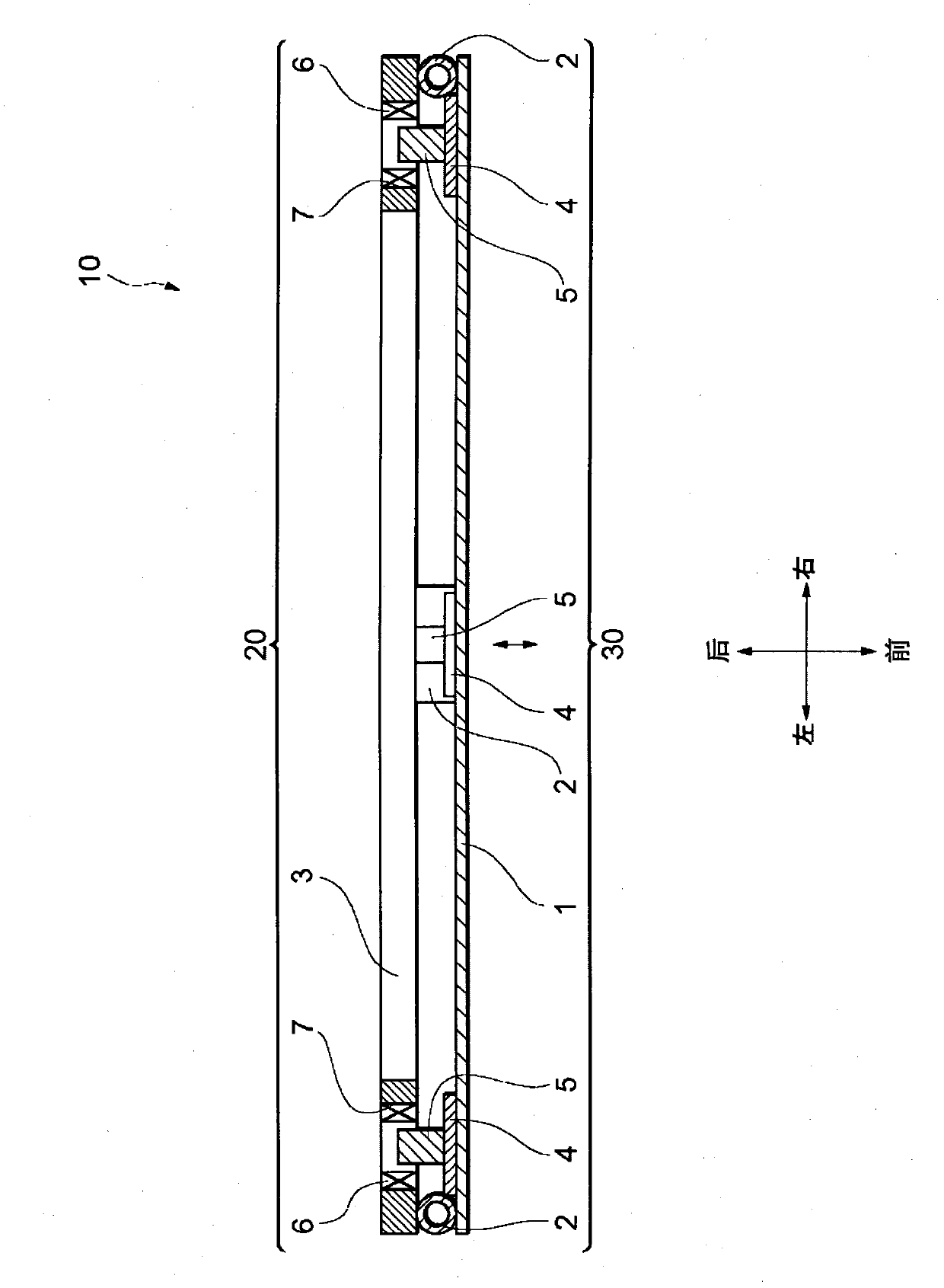

Moving-magnet loudspeaker and method for manufacturing same

InactiveCN102204278AImprove efficiencyMaintain flux densityElectrical transducersLoudspeakerMagnetic flux

Provided is a thin moving-magnet loudspeaker in which a quantitative guideline has been established for the mass of a magnetic circuit, and increases in the inductance of a voice coil are suppressed while maintaining the magnetic flux density of a voice coil. The moving-magnet loudspeaker (10) is configured such that: a diaphragm (1) having a magnetic circuit consisting of a magnet (5) and a magnetic body (4) is made to vibrate so as to generate sound by means of the magnetic circuit according to the magnetic field generated by a voice coil (6) through which a sound current flows; and the total mass of the magnetic circuit is 0.5 to 2.0 times the total mass of an additional mass and the mass of the diaphragm (1). In addition, the voice coil (6) is divided into a plurality of portions so as to reduce the inductance thereof and prevent the reduction of the sound current in a high-pitched sound range.

Owner:KIMURA SUSUMU

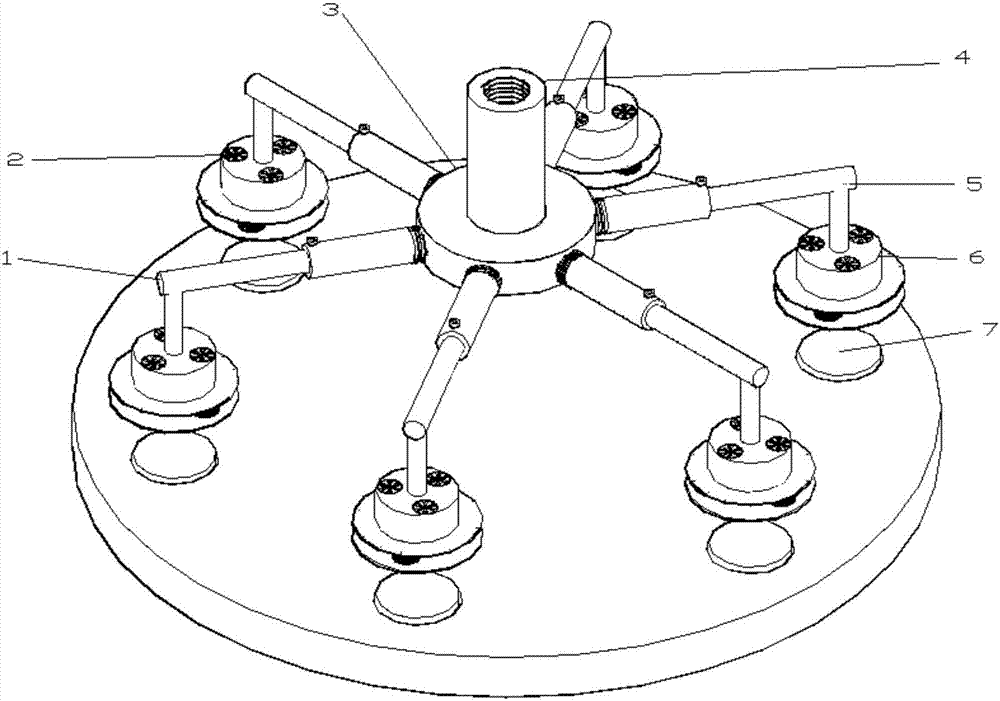

Electromagnetic chuck used for transferring metal press block

InactiveCN107053231AReduce impactWide range of applicationsGripping headsElectromagnetic inductionComputer fan

The present invention is an electromagnetic chuck for transferring metal briquettes, comprising an electromagnetic induction coil and a ventilation hole, the baffle plate is arranged at the bottom of the chuck, and is connected with the electromagnetic induction coil through a buffer spring; the electromagnetic induction coil is arranged on The lower layer of the suction cup, and the outer layer is wrapped with a metal casing. The metal casing is fixedly connected with the upper layer of the suction cup through threads. The electromagnetic sucker used to transfer metal compacts is equipped with a cooling fan, and the ventilation holes of the cooling fan draw the external cold air into the sucker to take away the heat generated by the electromagnetic induction coil, so that the electromagnetic induction coil can maintain normal temperature and work normally. When the coil is energized, a large electromagnetic force will be generated. Adsorbing the metal briquetting block on the suction cup will generate a strong impact force. The buffer spring can effectively buffer the impact force to protect the metal briquetting block from being shattered. Adapt to different briquetting molds, so that the suction cup device body can be used more widely.

Owner:十堰市神针工贸有限公司

Electromagnetic valve and electromagnetic valve system

ActiveCN102518859AReduce travel distanceSmall magnetic resistanceOperating means/releasing devices for valvesMultiple way valvesEngineeringElectromagnetic valve

The invention provides an electromagnetic valve and an electromagnetic valve system. The electromagnetic valve comprises a valve body provided with a valve chamber. A medium inlet communicated with the valve chamber is arranged at one end of the valve body and a medium outlet communicated with the valve chamber is arranged at the other end of the valve body. The electromagnetic valve further comprises a movable piece of the valve and a first iron core fixed at one end of the medium outlet of the valve body and wound with a first coil. A first pillar extending to the valve chamber is arranged at one end of the medium outlet of the valve body. The first pillar is provided with a through hole communicated respectively with the medium outlet and the valve chamber. The movable piece of the valve is located in the valve chamber and presses the first pillar under the effect of medium pressure difference between inside and outside of the valve chamber, forms a seal pair with the first pillar and a gap is formed between the movable piece and the first iron core. The first coil under electrified state generates an electromagnetic force that makes the movable piece of the valve rotate along a pivot so that one end of the movable piece of the valve is attracted away from the first pillar and the other end is adsorbed on the first iron core. The electromagnetic valve and the electromagnetic valve system provided by the invention improve the working frequency and the service life of the electromagnetic valve.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH

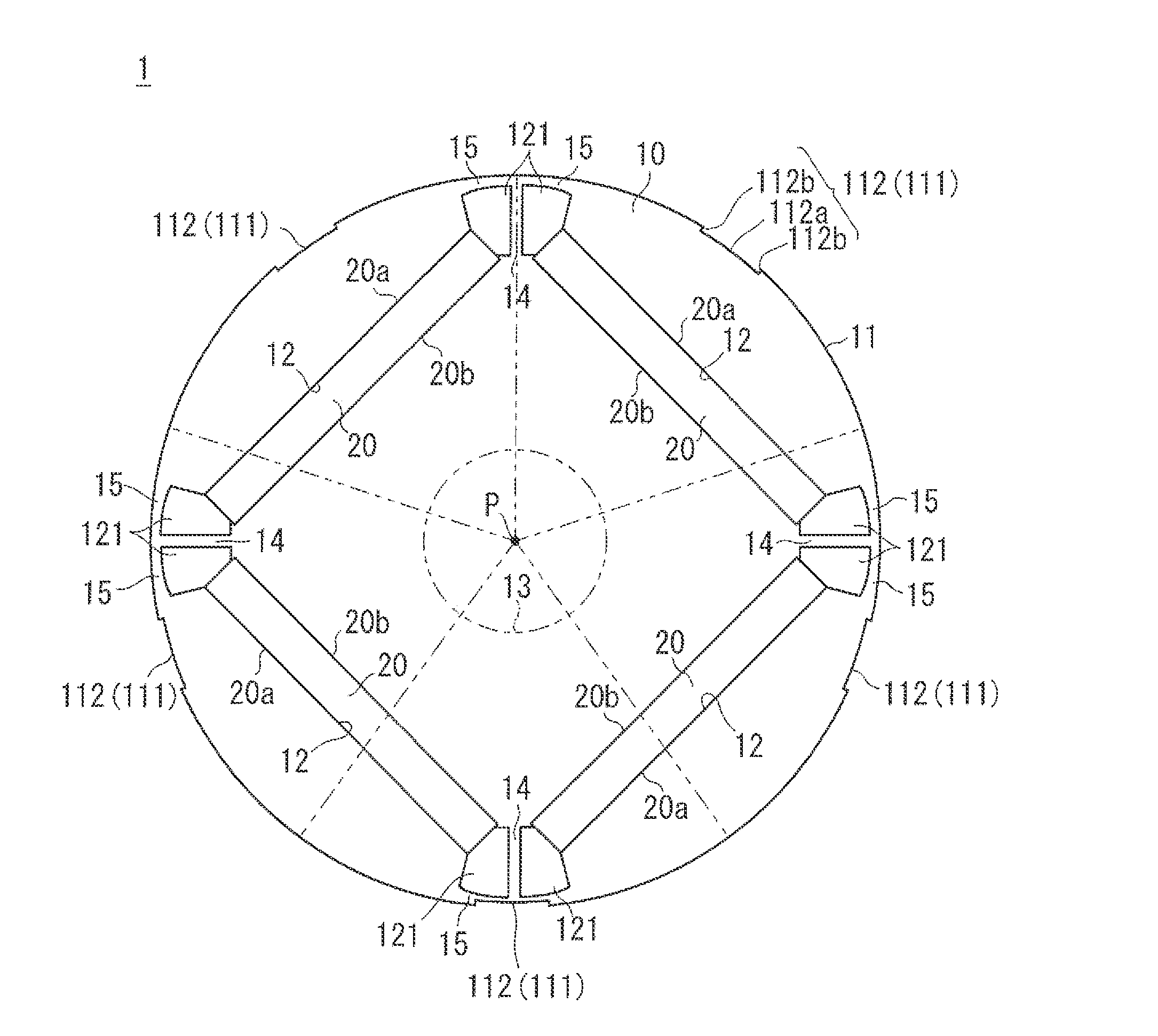

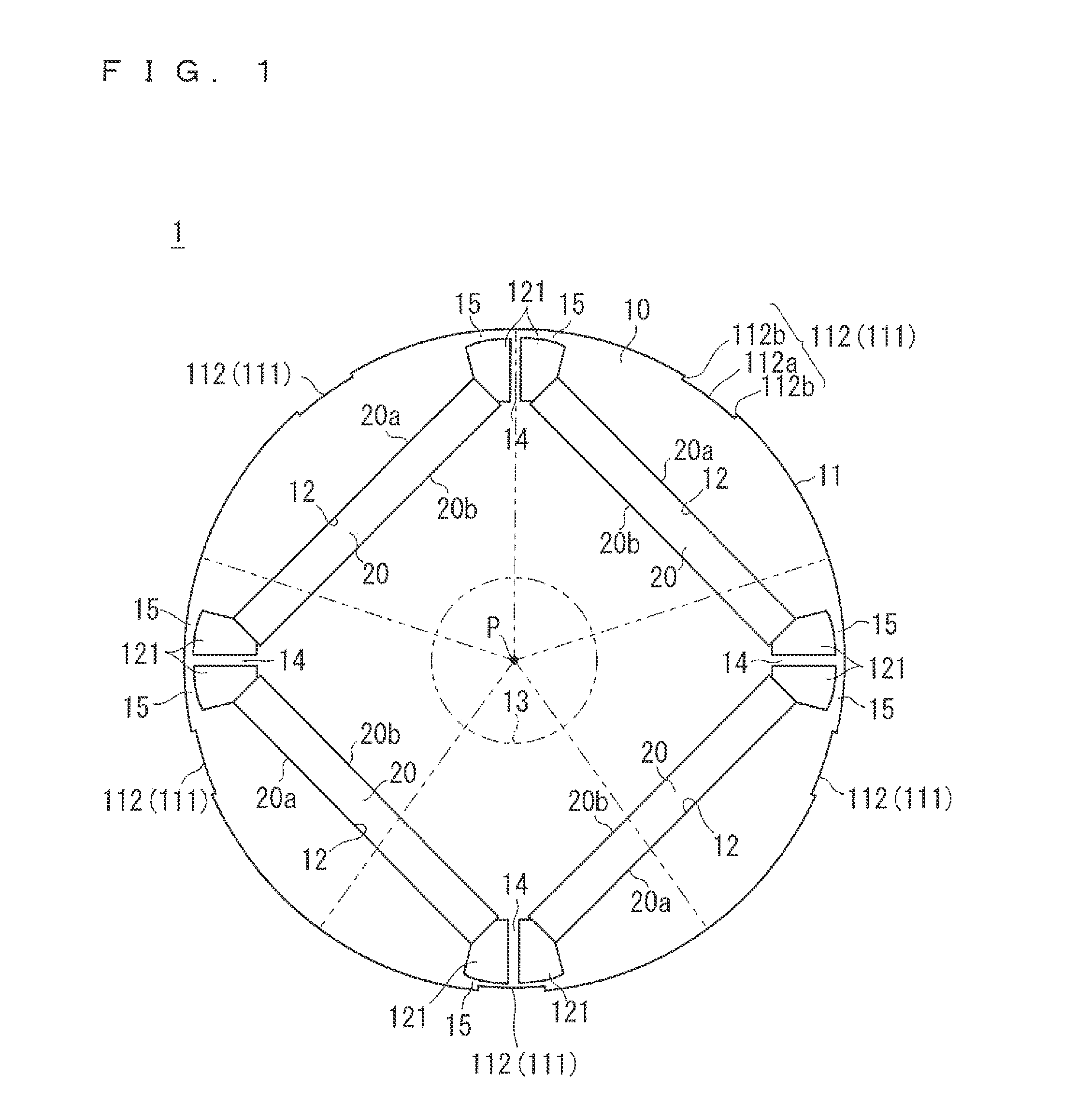

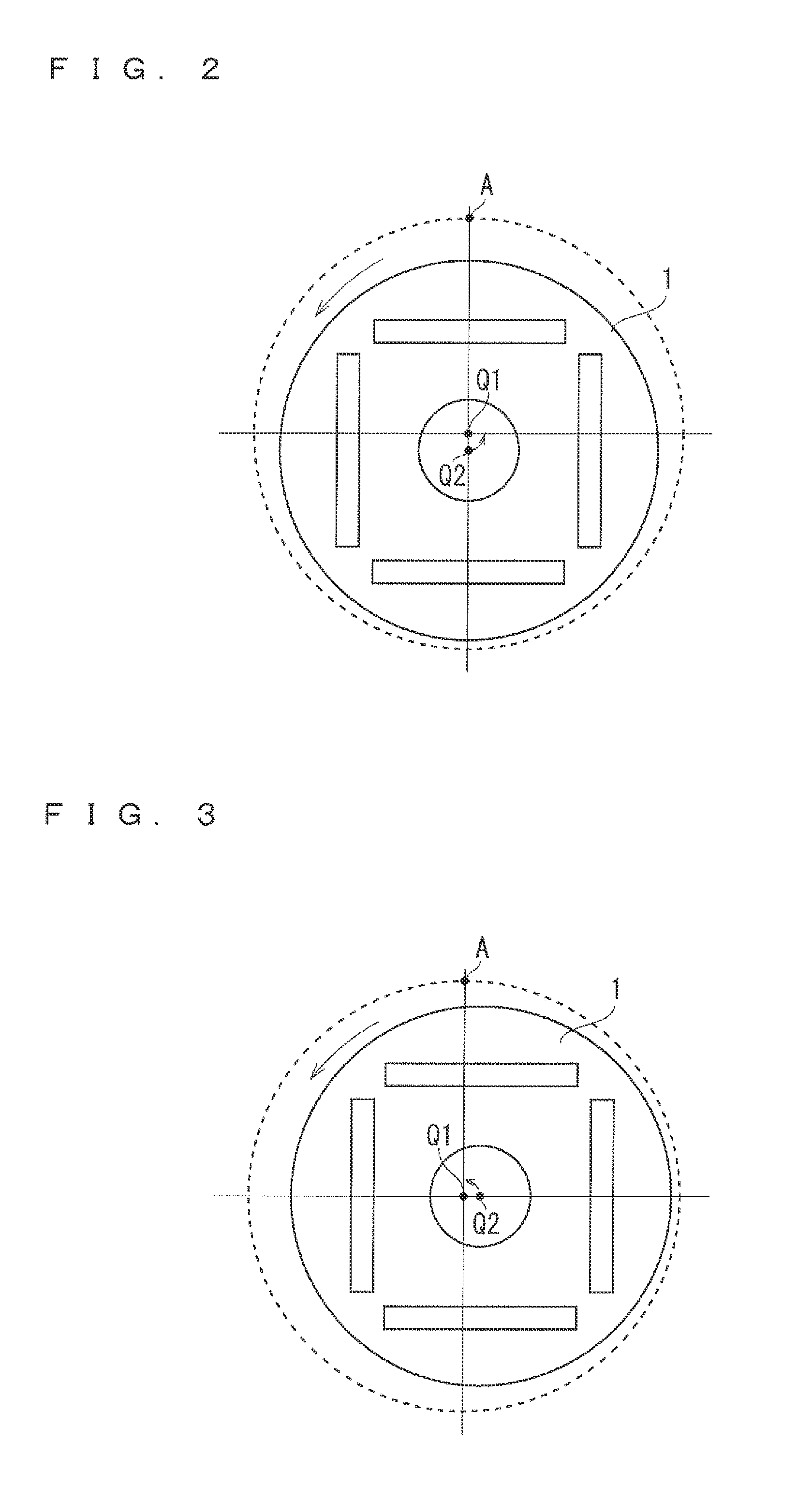

Rotor

ActiveUS20120112593A1Reduce vibrationReduce (2N+1)th harmonic componentMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPhysicsElectrical polarity

A rotor includes a plurality of permanent magnets arranged annularly around an axis and a rotor core. The rotor core includes 2N (where N is a natural number) magnetic pole faces and a plurality of magnetic barriers. The 2N magnetic pole faces produce, due to the plurality of permanent magnets, magnetic poles in a radial direction in such a manner that different polarities can be alternately produced around the axis. The magnetic barriers are provided at a side close to the magnetic pole faces relative to the permanent magnets. At least one of the magnetic barriers is provided in each region obtained by equally dividing the rotor core into (2N+1), ((N+1)×2) or ((N−1)×2) angles around the axis.

Owner:DAIKIN IND LTD

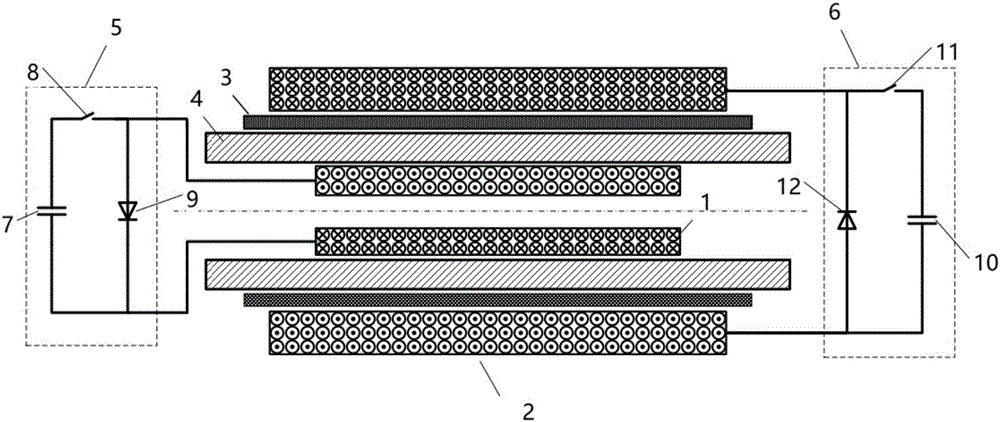

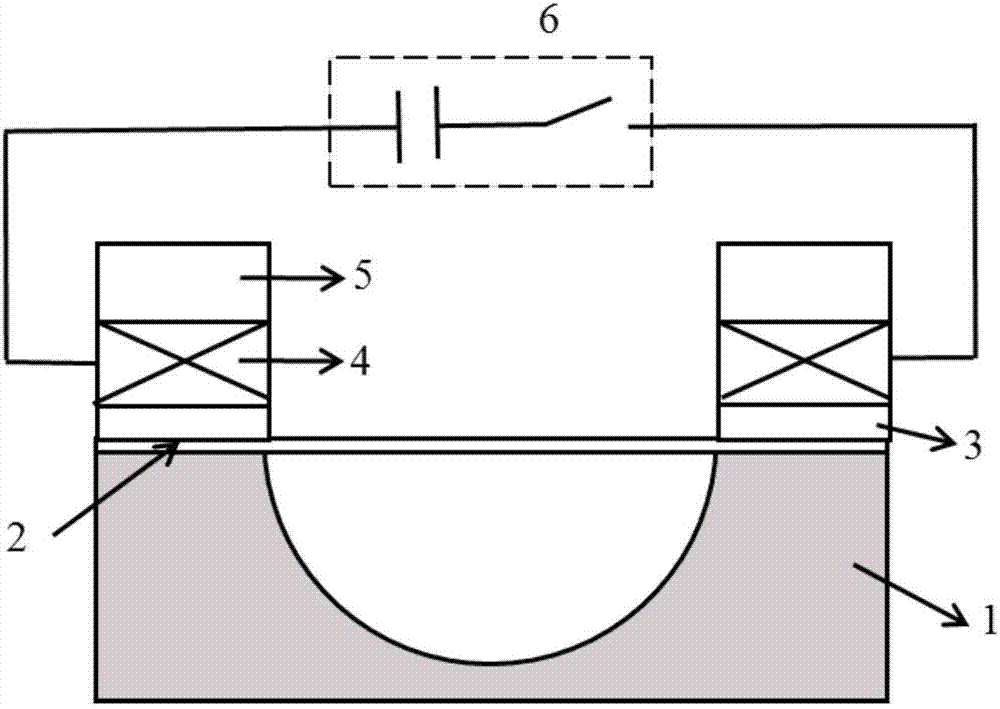

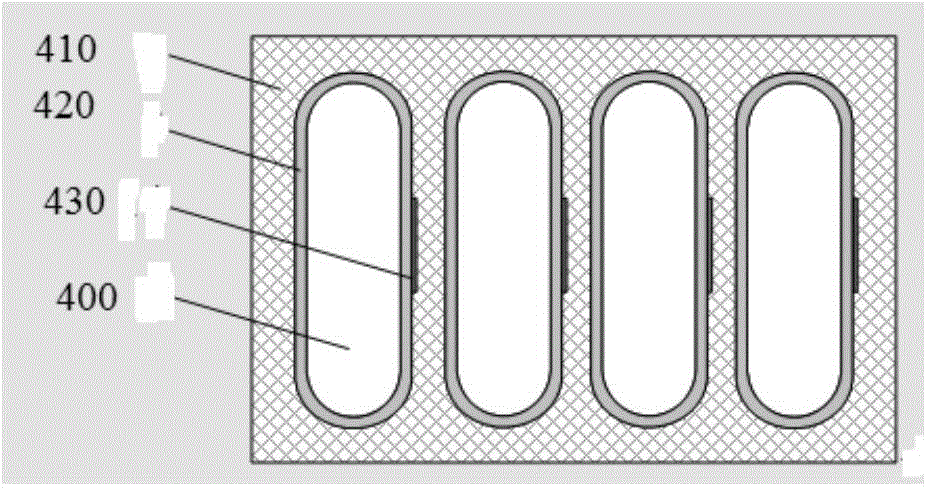

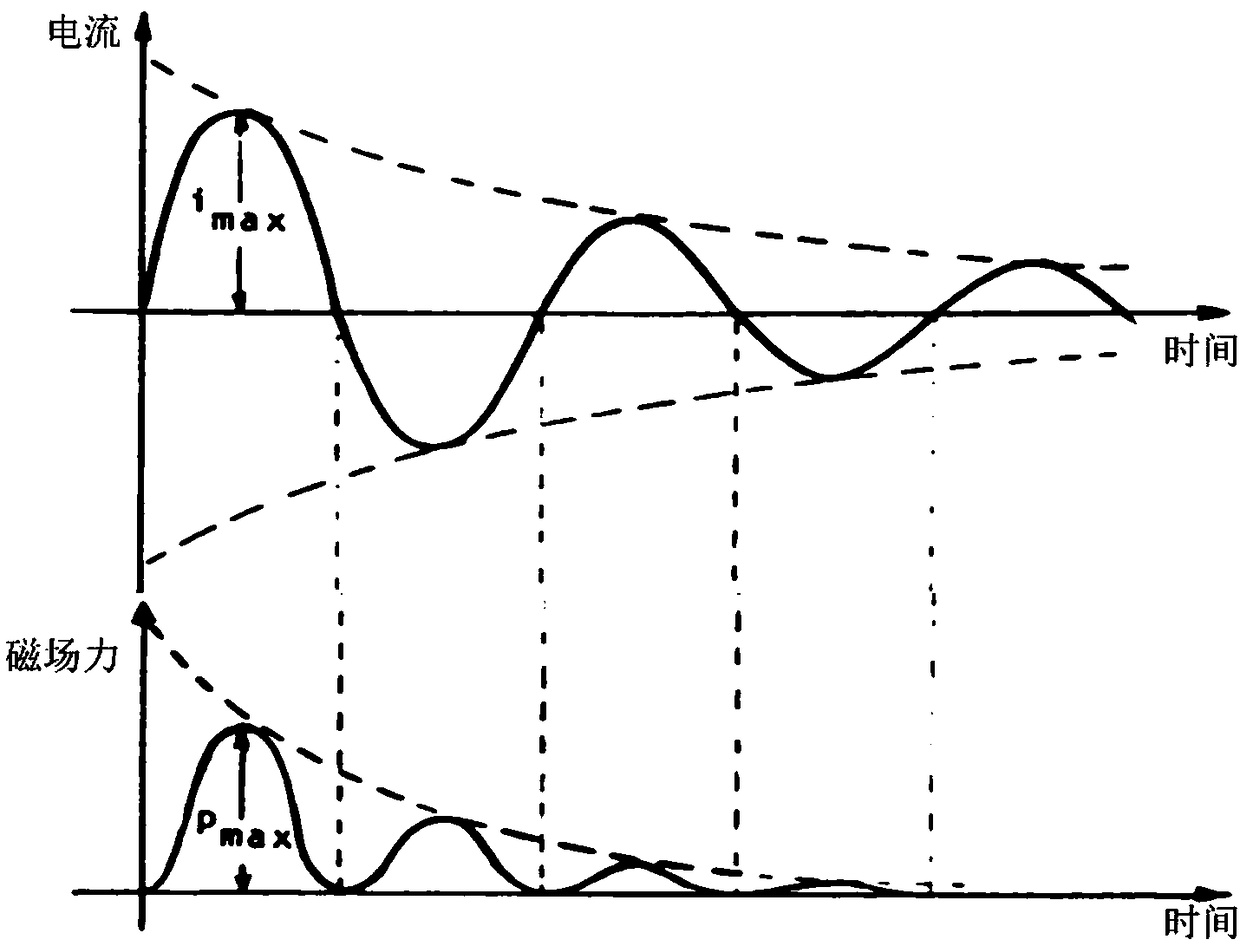

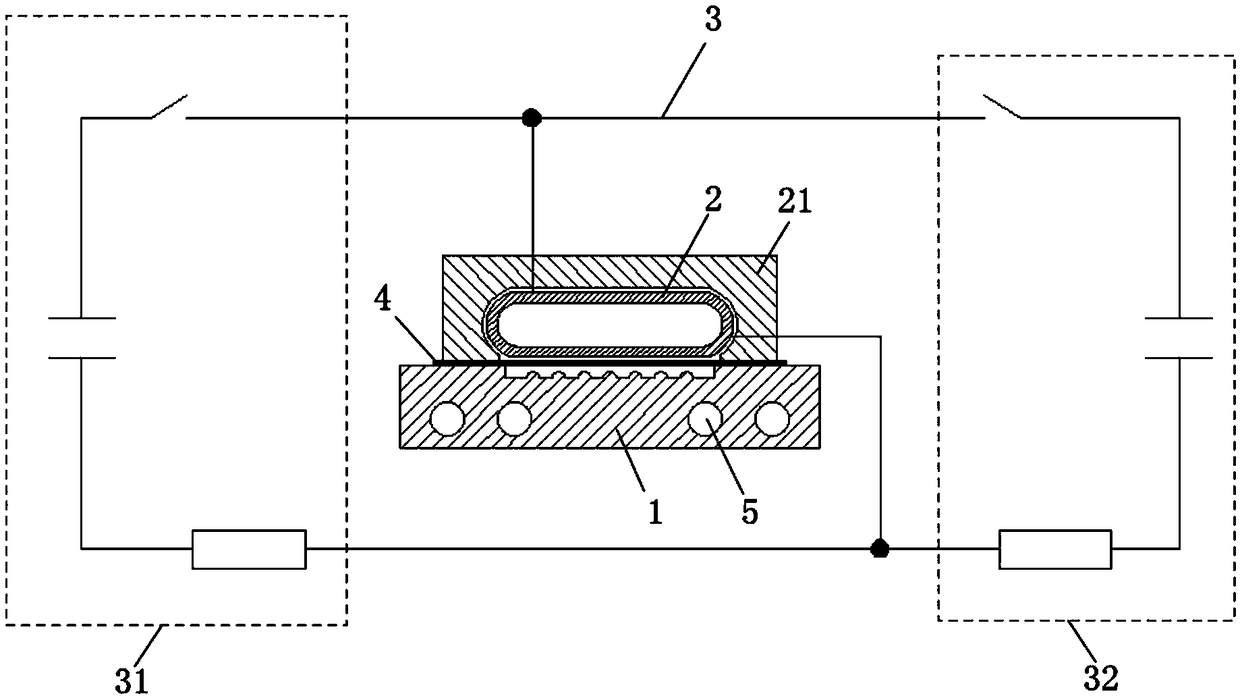

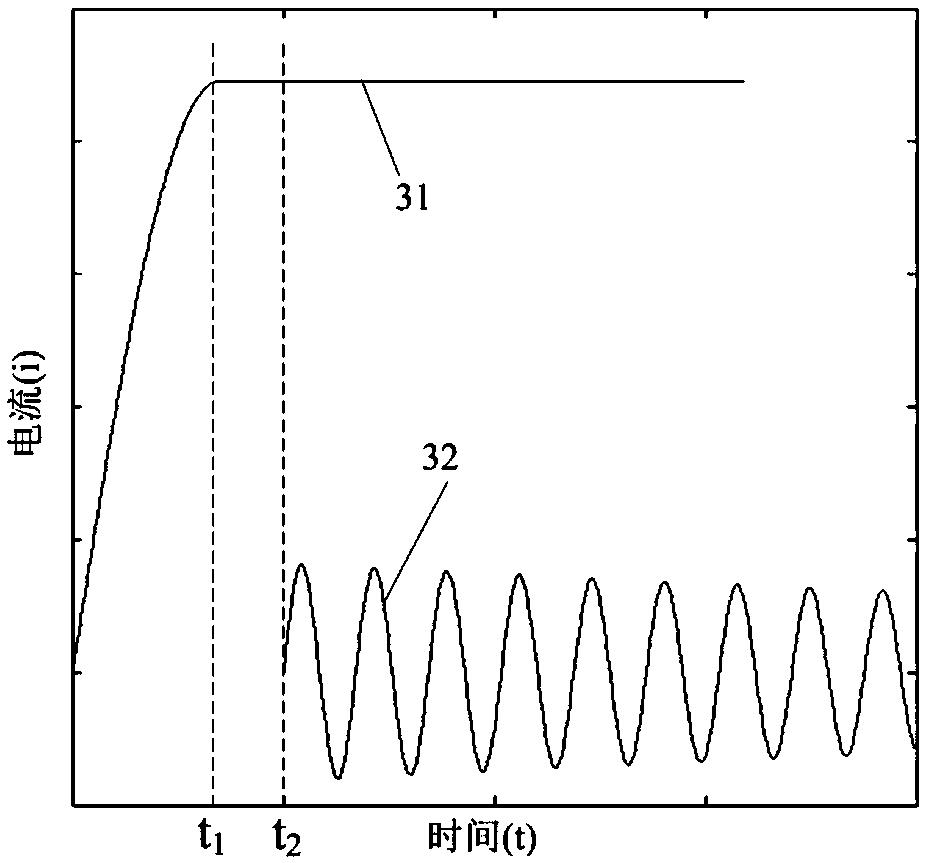

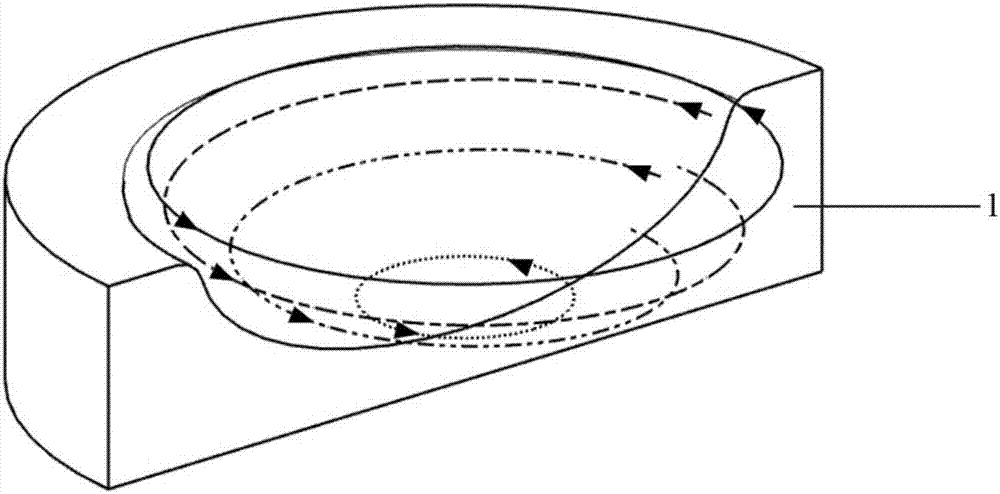

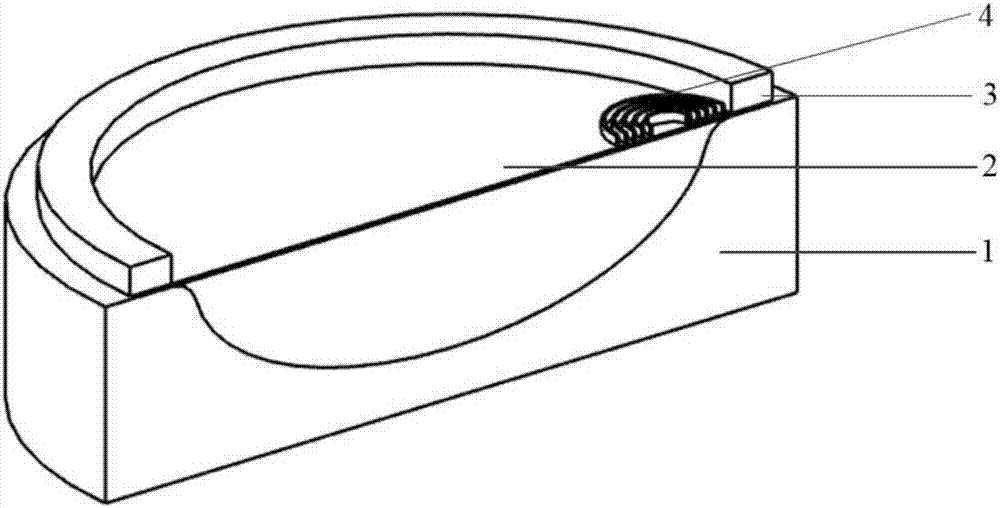

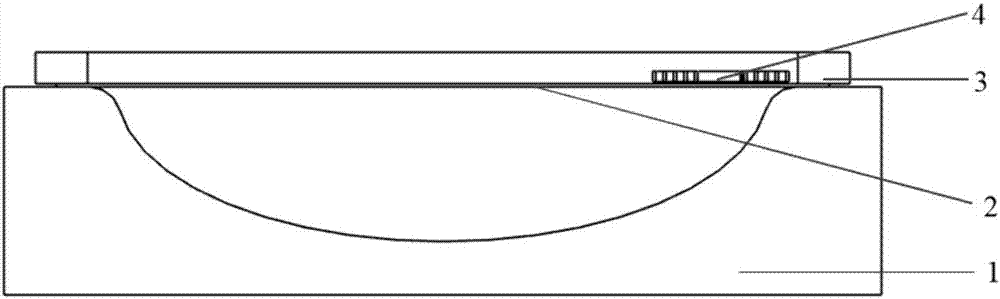

Electromagnetic forming device and method for providing continuous electromagnetic force

ActiveCN108856443APrecise control of magnetic field forceRealize flexible manufacturingShaping toolsElectricityEddy current

The invention discloses an electromagnetic forming device for providing continuous electromagnetic force. The electromagnetic forming device for providing the continuous electromagnetic force comprises a concave die, a coil and a discharging loop. The coil is arranged on the concave die, a sheet to be formed is arranged between the concave die and the coil, the coil is electrically connected withthe discharging loop, the discharging loop comprises a steady-state magnetic field discharging loop capable of generating a steady-state magnetic field and an alternating magnetic field discharging loop capable of generating an alternating magnetic field, and the steady-state magnetic field discharging loop and the alternating magnetic field discharging loop are electrically connected with the coil separately. The invention further discloses an electromagnetic forming method. The electromagnetic forming method comprises the steps of discharging of the steady-state magnetic field discharging loop, discharging of the alternating magnetic field discharging loop, superimposing of the current generated by the steady-state magnetic field discharging loop and the current generated by the alternating magnetic field discharging loop, obtaining induced eddy current by induction of alternating pulse current, forming completing of the sheet under the action of magnetic field force and the like. The electromagnetic forming device for providing the continuous electromagnetic force has the advantages of being high in forming efficiency and good in forming precision, effectively avoiding sheet rebound, being capable of providing the continuous electromagnetic force, accurately regulating and controlling the electromagnetic force to realize flexible manufacturing and the like.

Owner:CENT SOUTH UNIV

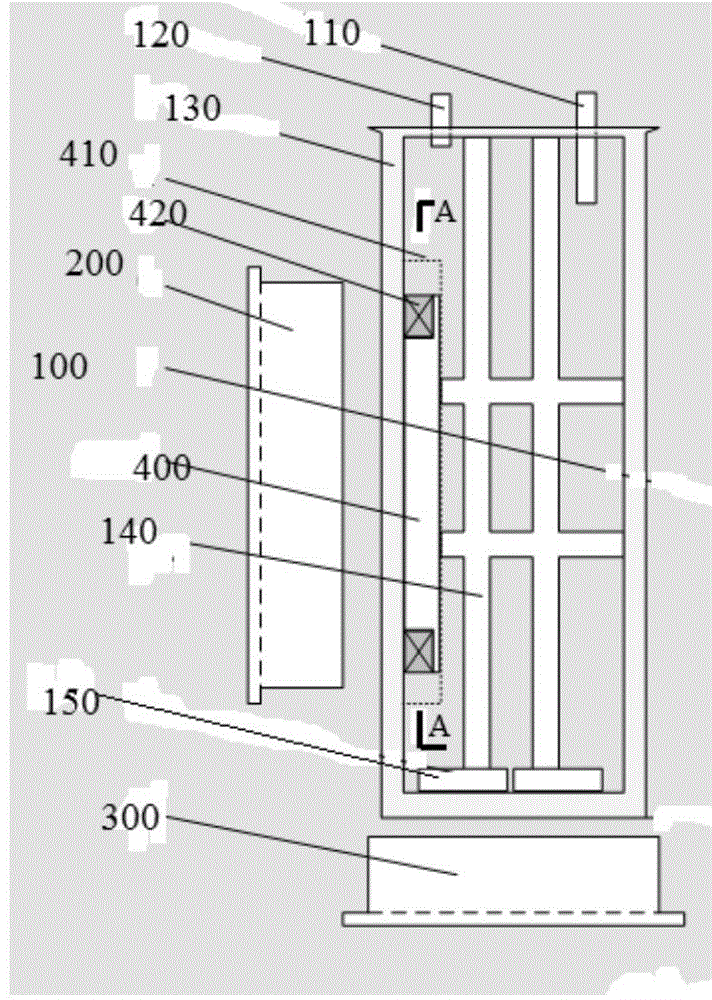

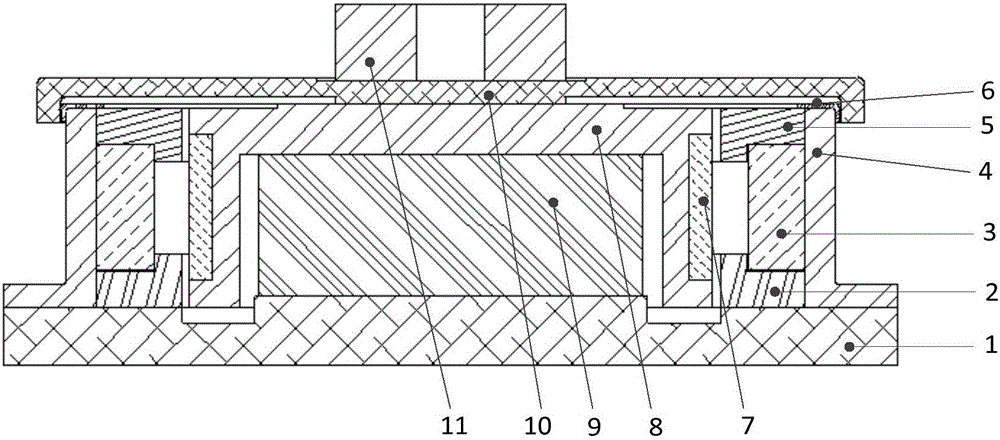

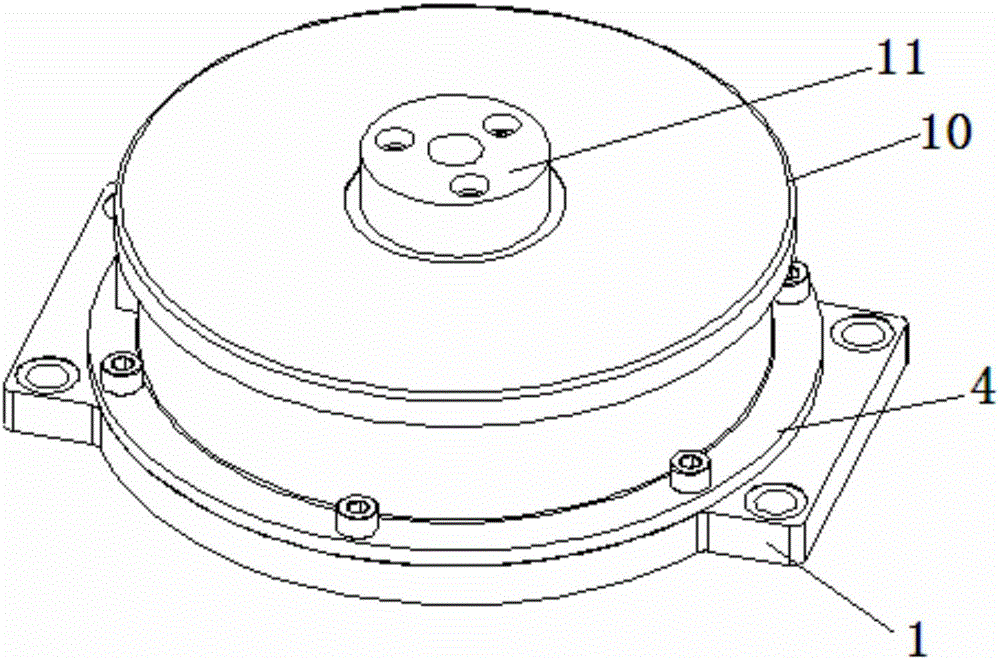

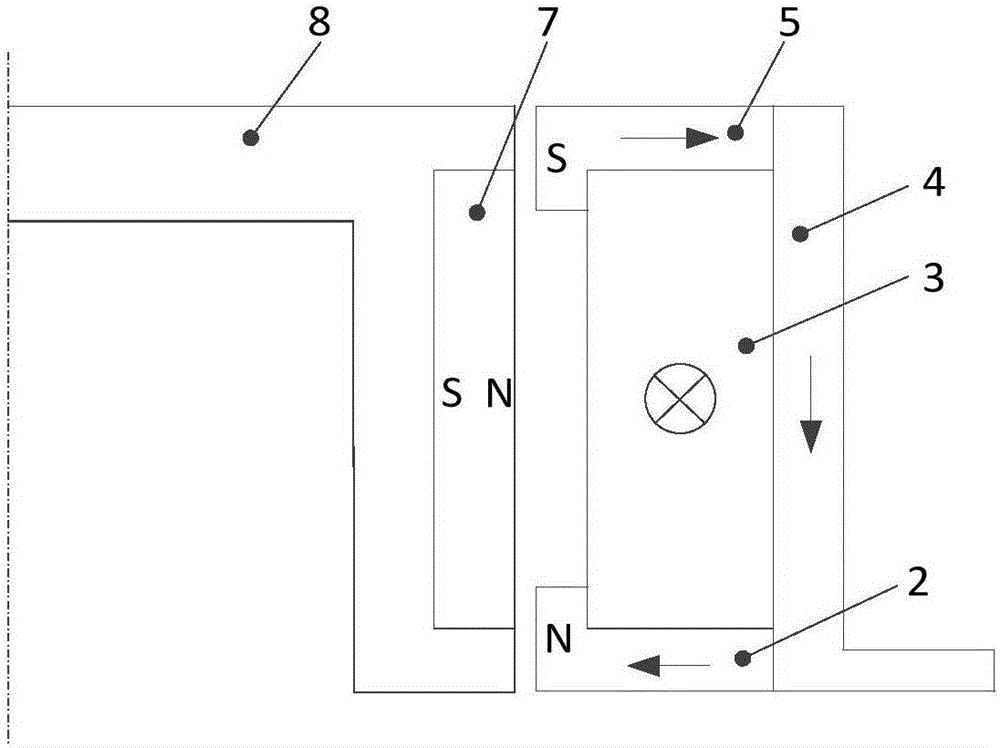

Electromagnetic type active and passive integrated vibration isolator

ActiveCN106438830AGood reliability and robustnessImprove space utilizationNon-rotating vibration suppressionFrequency bandMagnet

The invention discloses an electromagnetic type active and passive integrated vibration isolator. In the structure of the electromagnetic type active and passive integrated vibration isolator, an electromagnetic actuator consists of an actuator stator and an actuator rotor; the actuator rotor is installed inside the actuator stator and is coaxial to the actuator stator; the actuator stator consists of a coil, a stator frame, a stator lower end cover and a stator upper end cover; the coil, the stator frame, the stator lower end cover and the stator upper end cover are adhered to form an overall body by using AB glue; the actuator rotor consists of a permanent magnet and a rotor yoke; the permanent magnet is adhered with the rotor yoke to form one overall body by using the AB glue; a passive vibration isolator and the stator frame of the electromagnetic actuator are fixedly arranged on an actuator pedestal; the rotor yoke and the passive vibration isolator are fixed together, and the passive vibration isolator is positioned inside the rotor yoke; an equipment connecting part and a safety shielding cover are fixed to the rotor yoke; and the equipment connecting part is higher than the safety shielding cover. The electromagnetic type active and passive integrated vibration isolator disclosed by the invention belongs to active and passive combined vibration isolation and has the advantages of low energy consumption, high space utilization rate, high reliability, high adaptability, wide vibration absorption frequency band and the like.

Owner:ZKZS ELECTRONICS TECH CO LTD

Transformer high temperature index self-adhering transposition conductor and preparation method thereof

InactiveCN101299380AImprove high temperature performanceHigh mechanical strengthPlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsEpoxyTransformer

Provided is a transformer high temperature index selfadhesive transposed conductor and the preparation method, belonging to the technical field of the transformer, which solves the problems of low transposed conductor high temperature bonding strength, with the technical projects of consisting of a plurality of enamelling copper flat wire, wherein the surface of the enamelling copper flat wire is coated with the acetal paint film and the selfadhesive paint film from the interior to the exterior. The invention is improved in that, the selfadhesive paint composing the selfadhesive paint film is made of the following materials by weight: low molecular weight epoxy resin 140-160, bisphenol A90-100, quaternary ammonium salt 0.90, cresol 290-310, phenol 260-280, dimethylbenzene 370-390, aminoresin 3-4. The transposed conductor prepared according to the invention has the bonding strength in the operation temperature 75% of that in the normal temperature, and the integral bending strength is two times than that before drying, so the transposed conductor transformer advances the mechanical strength and the anti-short circuit ability of the winding, to bear larger electromagnetic force, thereby prolonging the service life of the transformer.

Owner:BAODING TIANWEI GRP CO LTD

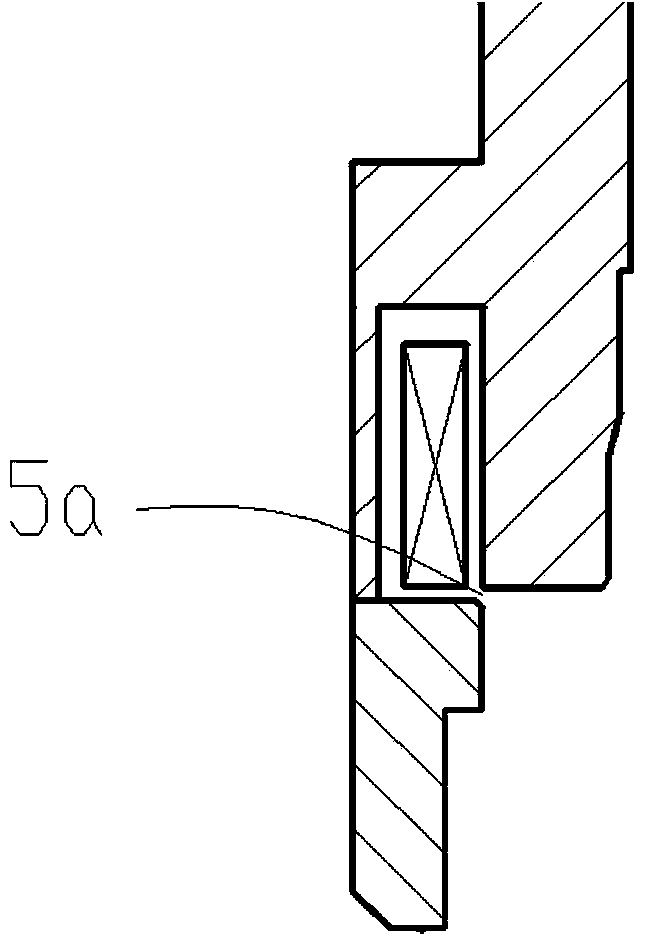

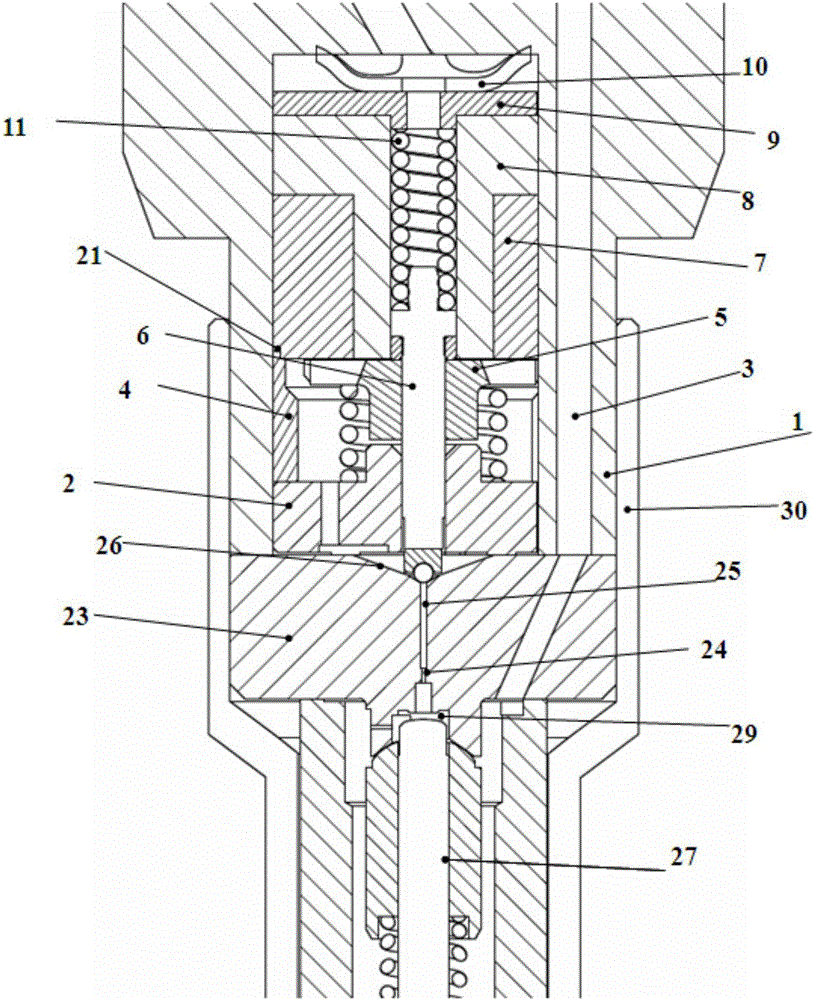

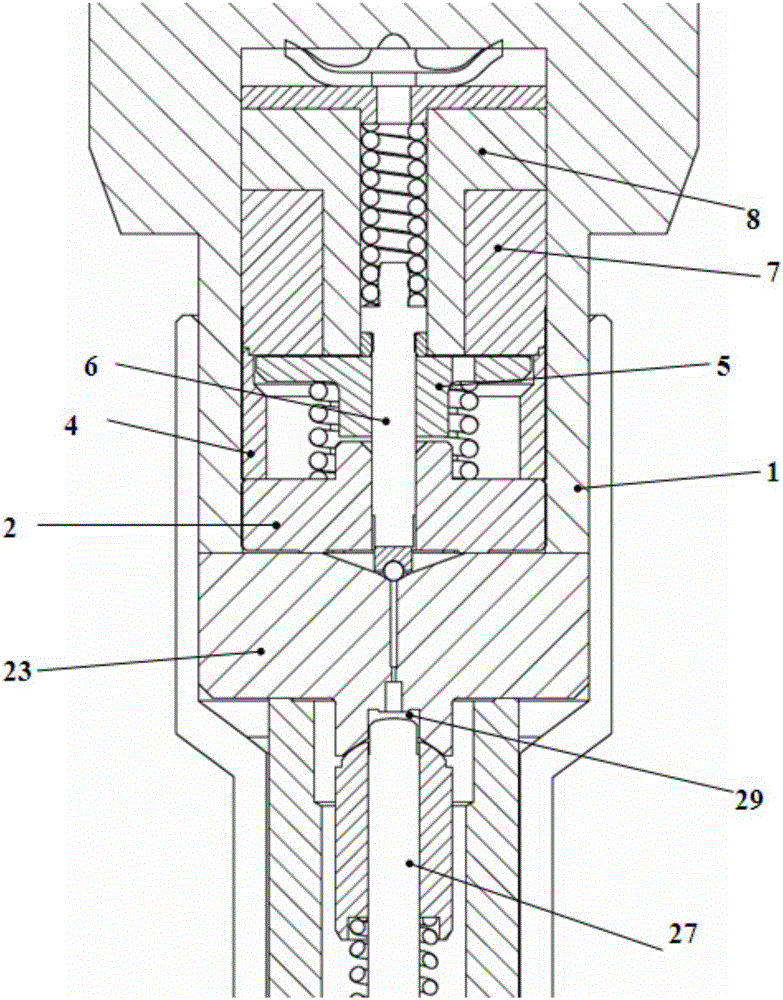

Fuel injection valve

ActiveCN104033300AIncrease electromagnetic forceQuick responseFuel injection apparatusMachines/enginesMagnetic coreNeedle valve

The invention discloses a fuel injection valve which comprises a magnetic valve, a coil, an armature, a magnetic ring, a damping spring, a damping block, a shell, a limiting core, a control spring, a spring seat, a needle valve, a sealing ball and a sealing ball seat. The coil is arranged in an annular coil groove of the magnetic core, the magnetic ring is fixedly arranged below the magnetic core, the armature is arranged on the upper portion of the inner circle of the magnetic ring and arranged on the lower end face of the magnetic core, the damping block is fixedly arranged below the armature in the inner circle of the magnetic ring, the damping spring is arranged between the armature and the damping block, the needle valve is arranged in the magnetic valve and inserted into the armature and the damping block in a sleeved manner, the upper portion of the needle valve is fixedly connected with the spring seat, and the upper portion of the spring seat is abutted on the limiting core inside the magnetic core while the lower portion of the same is abutted on the armature. By the structure, the fuel injection valve has the advantages of small magnetic flux leakage and high injection response speed, and bouncing when the fuel injection valve is closed can be reduced effectively, and multiple-time injection capability is improved.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

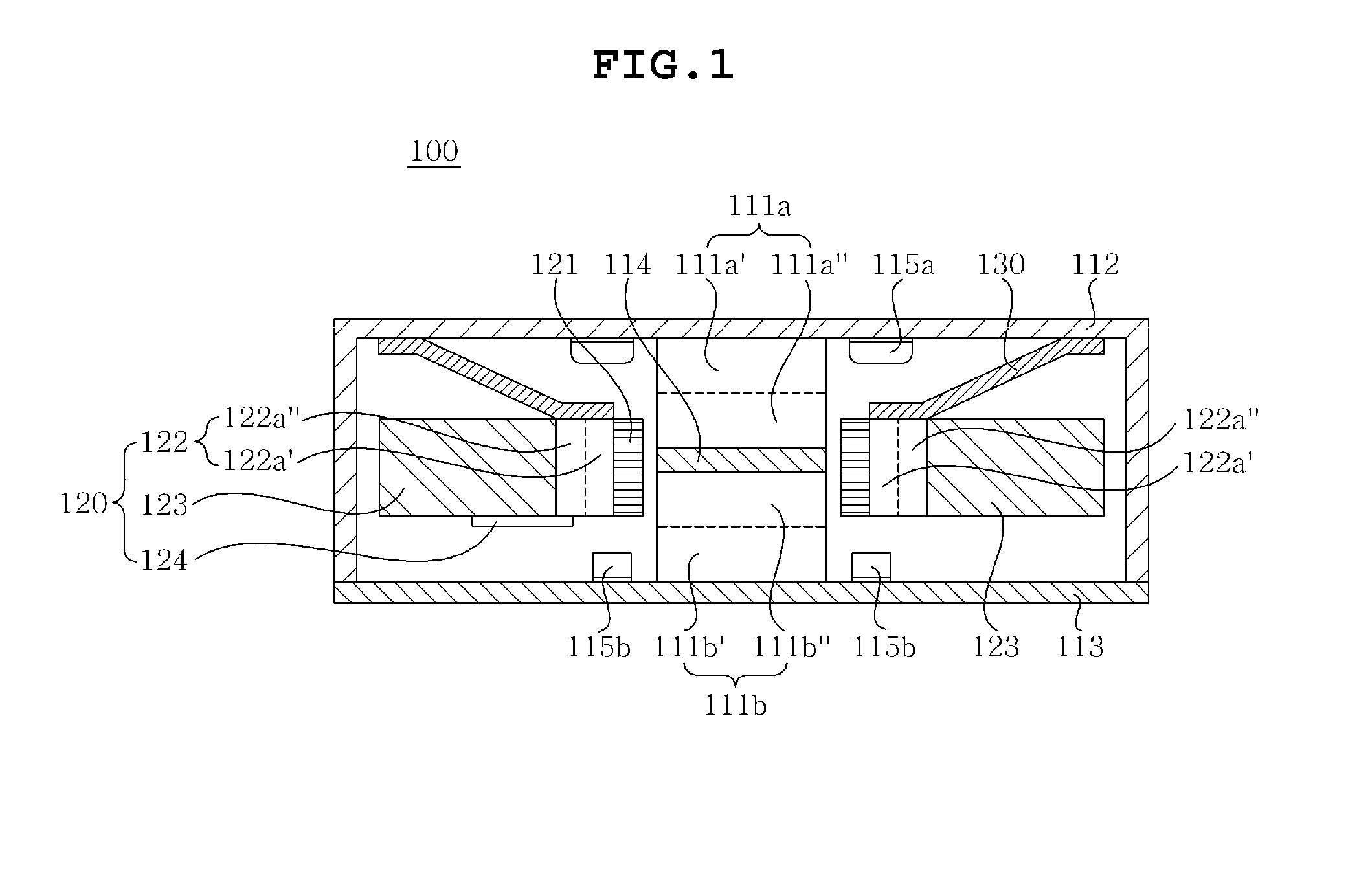

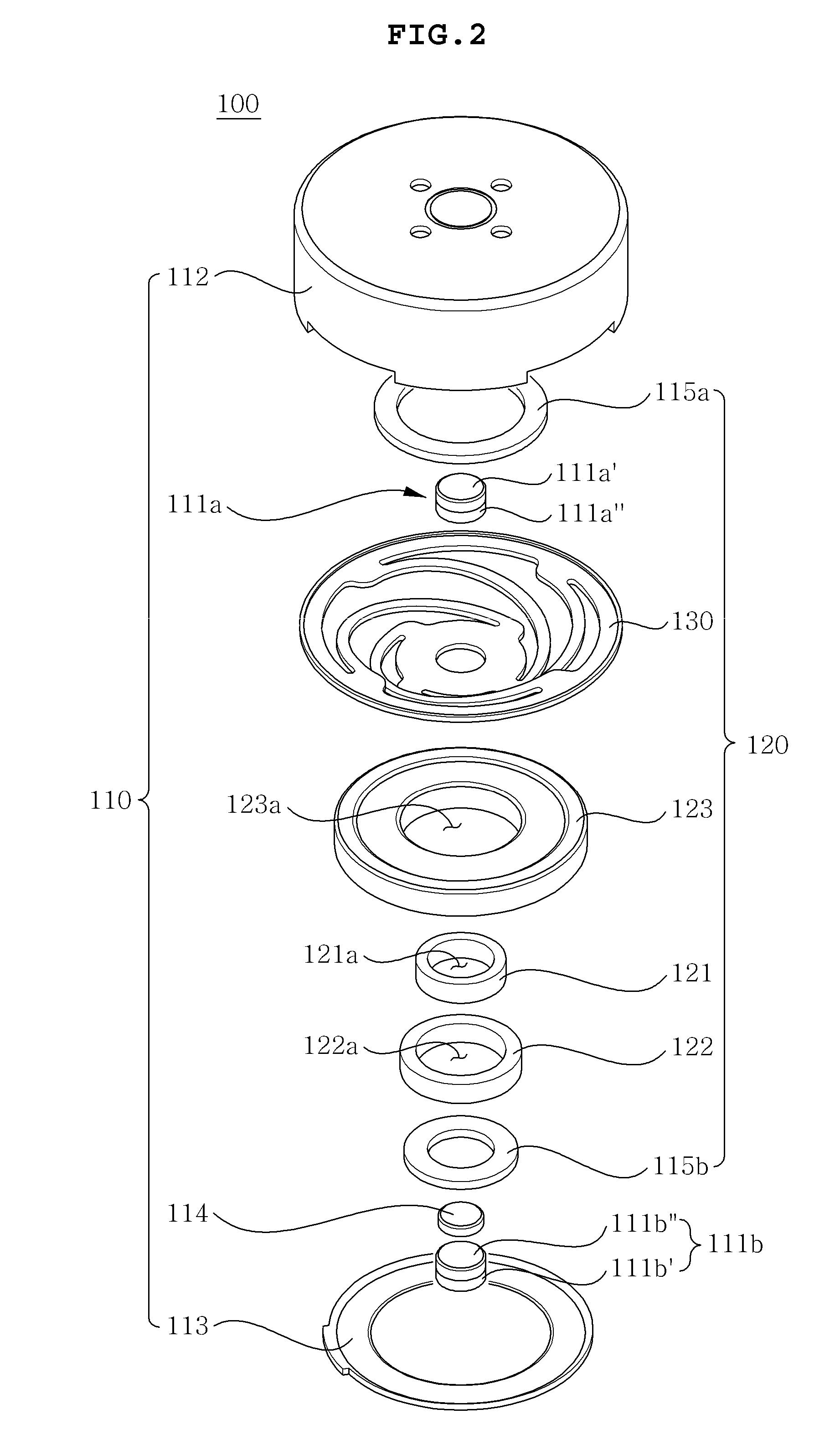

Linear vibration motor

InactiveUS20140159511A1Increase electromagnetic forceIncrease forceMechanical vibrations separationPropulsion systemsEngineeringLinear vibration

Disclosed herein is a linear vibration motor including: a stator part having an internal space formed therein and including a main magnet mounted therein; a vibrator part including a coil disposed to face the main magnet and accommodated in the internal space of the stator part; and an elastic member connecting to the stator part and the vibrator part to each other, wherein the vibrator part further includes an auxiliary magnet disposed to face the main magnet.

Owner:MPLUS

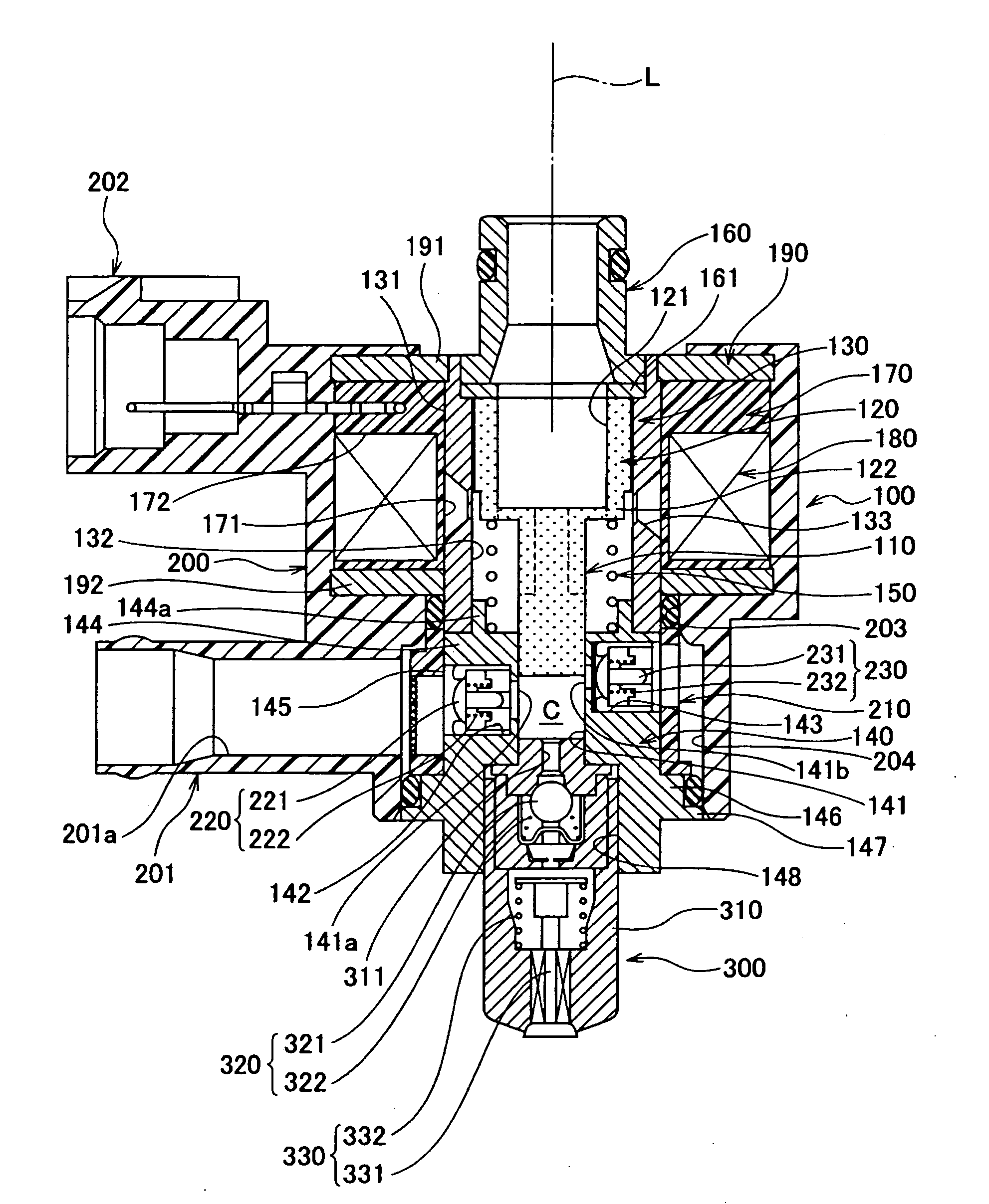

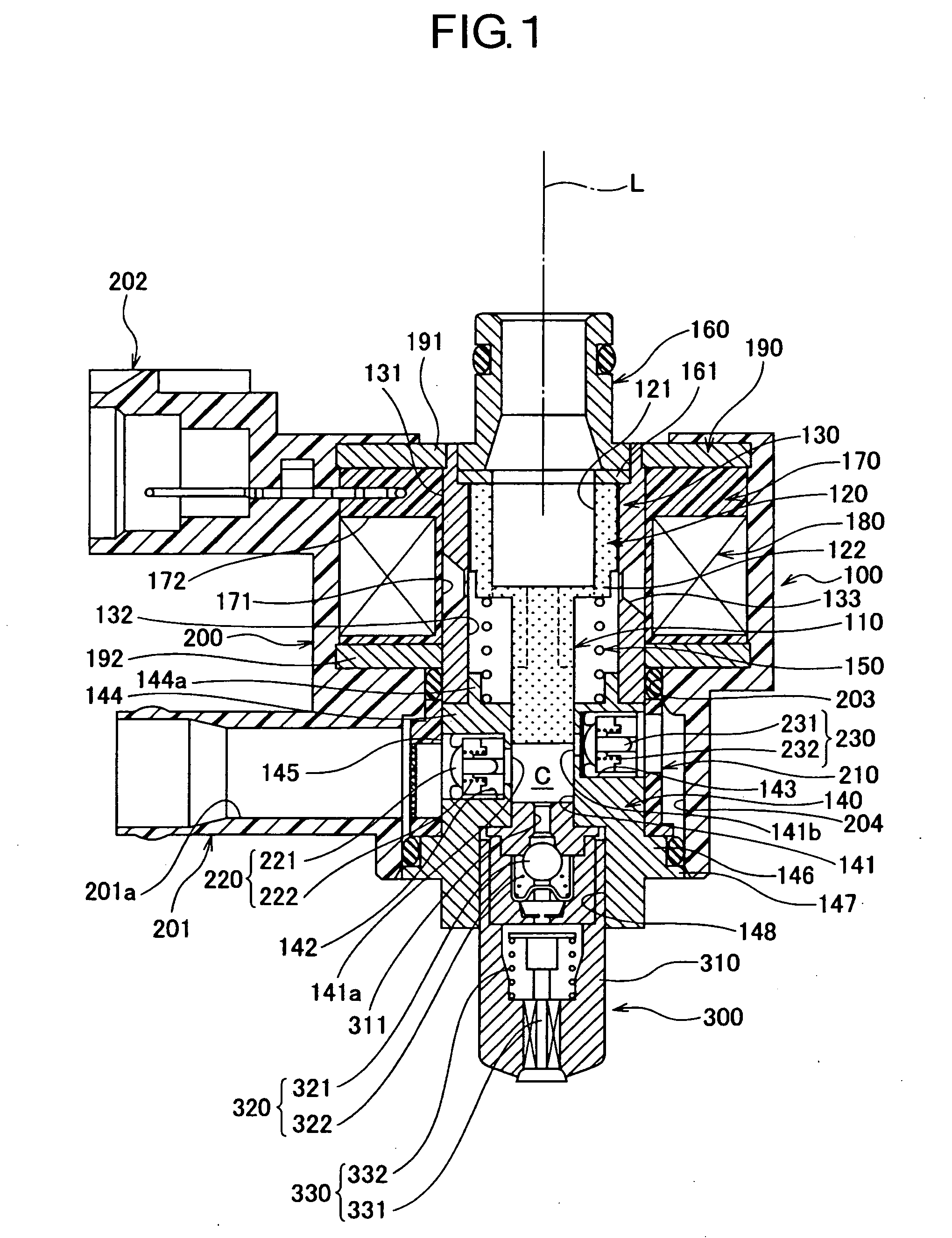

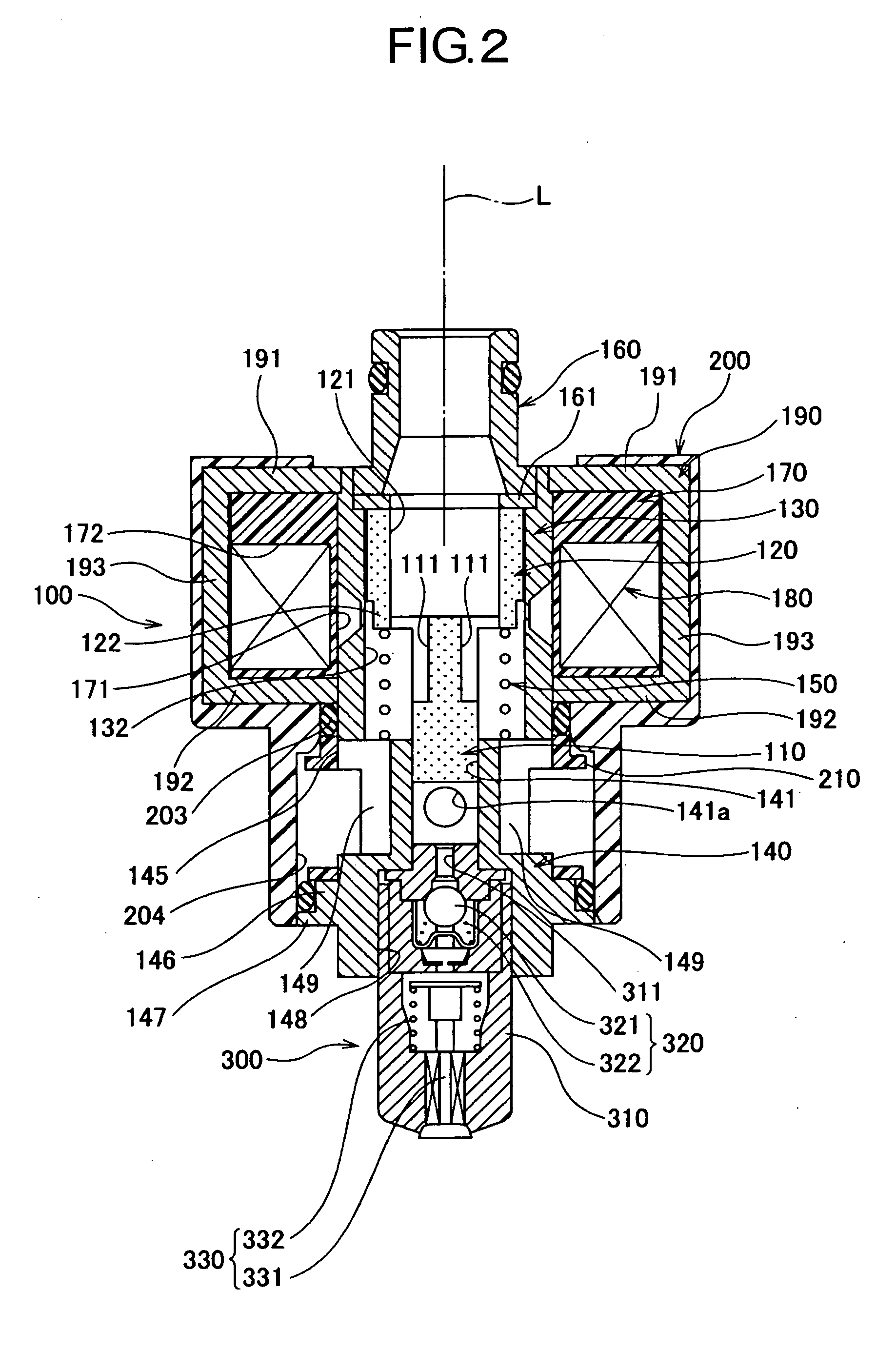

Electromagnetic Actuator and Fuel Injection Device

InactiveUS20090065615A1Increasing and flattening electromagnetic forceImprove responsivenessOperating means/releasing devices for valvesSpray nozzlesRest positionReciprocating motion

[Problem] To reduce the size, lower the cost and increase and flatten the thrust of an electromagnetic actuator in which a plunger moves reciprocally.[Solution] The electromagnetic actuator comprises a yoke 130, a coil 180 arranged around the yoke, an armature 120 slidably arranged inside the yoke and integrally formed with a plunger 110, and a return spring 150 for returning the armature to a rest position, wherein the yoke 130 has, in a predetermined position on the axial direction L, a thickness-reduced annular gap groove 133 over part of an outer peripheral face 131, the thickness-reduced portion having a trapezoidal cross section widening outwards. Such a constitution allows shortening the magnetic path, allows increasing and flattening the electromagnetic force (thrust) generated for the displacement of the armature, allows increasing the acceleration (responsiveness) of the armature, and allows, for instance, reducing the parts count, simplifying assembly operations, and achieving cost reductions, while requiring no high-precision control of assembly positions.

Owner:MIKUNI CORP

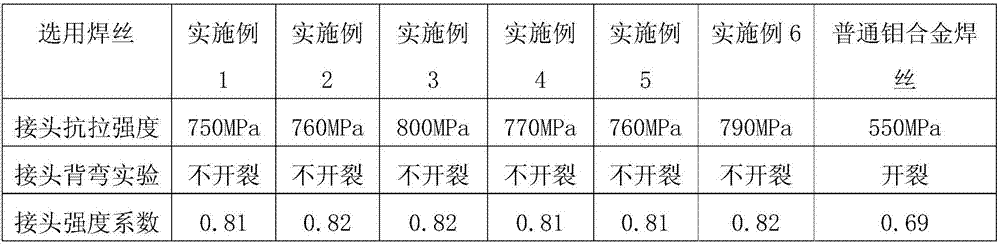

Method for welding molybdenum alloy

ActiveCN106862732AInhibition of sensitization tendencySmall mechanical propertiesArc welding apparatusWelding/cutting media/materialsActive agentDirect current

The invention discloses a method for welding molybdenum alloy, belonging to the technical field of metal welding. The method comprises the steps: (1) after cleaning, drying the welding area of molybdenum alloy; (2) manufacturing a special welding wire for the molybdenum alloy; (3) degassing at high temperature; (4) taking out a molybdenum alloy workpiece, spraying an active agent until the thickness is 0.2-0.8mm on the he welding area of molybdenum alloy, heating the special welding wire for the molybdenum alloy to dry, and then welding the molybdenum alloy workpiece, wherein the welding method adopts TIG wire filling welding, adopts a direct-current straight polarity power supply and determines welding process parameters; (5) cooling; (6) inspection. The method can reduce the quantity of joint holes, improve weldability, reduce cracks, refine parent crystalline grains so as to improve the tensile property of welded joints, and obtain good welding quality.

Owner:宝鸡市蕴杰金属制品有限公司

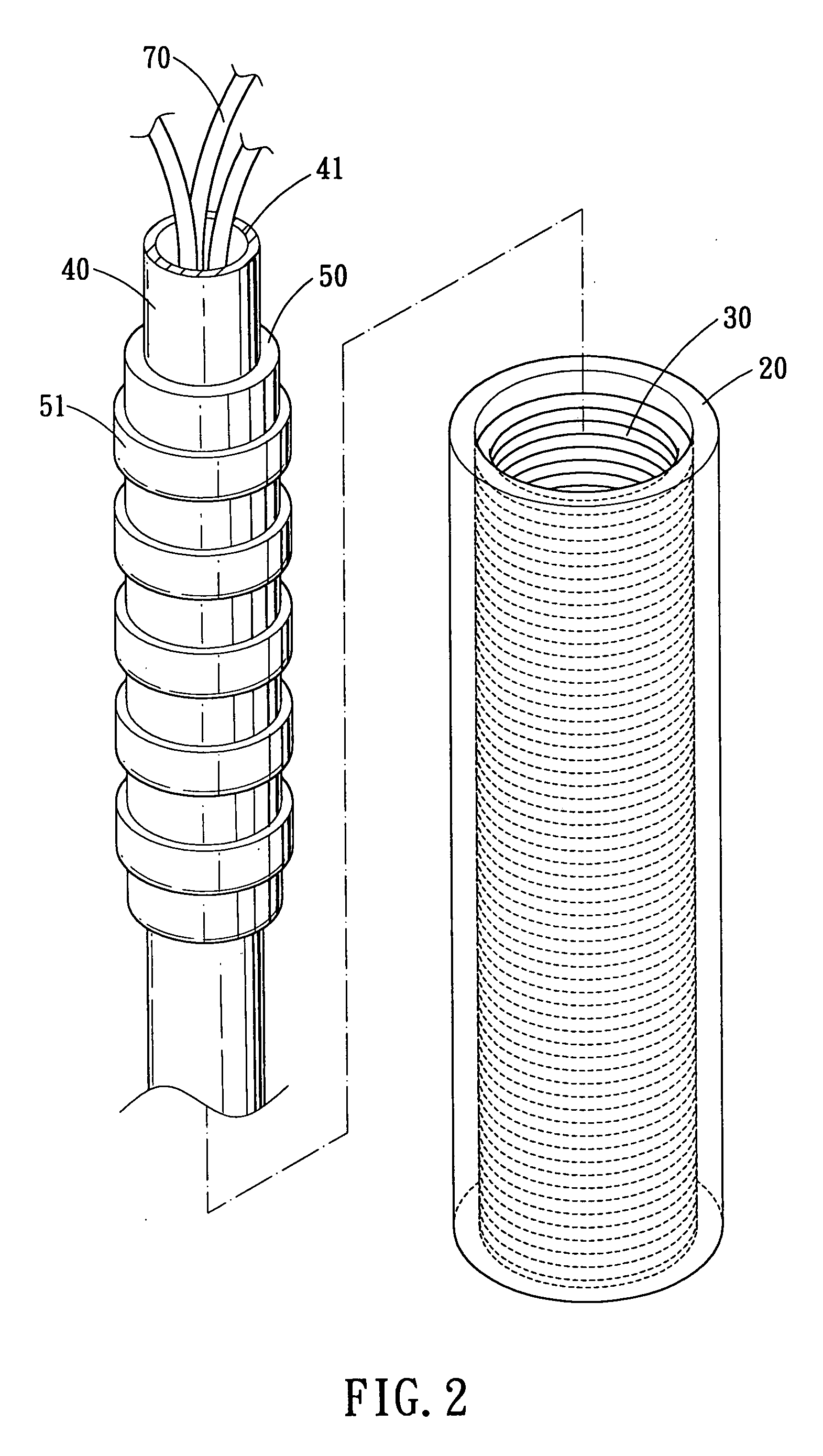

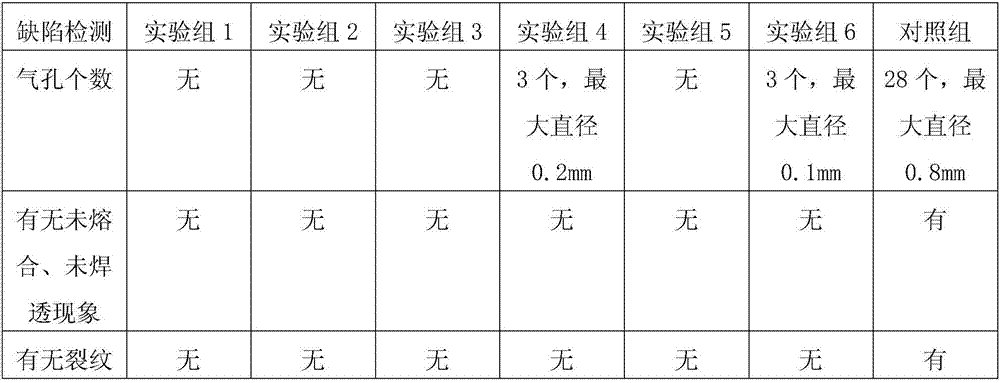

Hole-bottom tubular linear motor electric impactor

InactiveCN104022616AIncrease electromagnetic forceLaunch fastConstructionsReciprocating drilling machinesTubular linear motorBall bearing

The invention relates to a hole-bottom tubular linear motor electric impactor which comprises a motor outer cylinder, a permanent magnet rod, a linear ball bearing, a rotor, rotor silicon steel sheets and a rotor coil. The motor outer cylinder is an outer shell of a linear motor. The permanent magnet rod is fixed to the motor outer cylinder and serves as a stator of the linear motor. The rotor moves relative to the permanent magnet rod through the linear ball bearing. An iron core composed of the rotor silicon steel sheets is inlaid inside the rotor. A groove is formed in the iron core and internally provided with the rotor coil. A three-phase alternating current winding is adopted for the coil, and the three-phase symmetrical alternating current is led into the coil to generate a traveling wave magnetic field coincident with the rotor in the movement direction. Two damping springs are further arranged to be used for buffering shock. According to the hole-bottom tubular linear motor electric impactor, a movable-coil type structure is adopted, namely, the permanent magnet rod and the iron core are fixed, and the coil is movable. Meanwhile, a buffering gasket is designed between the rotor and a base, and the fatigue resistant service life of the hole-bottom tubular linear motor electric impactor is prolonged. The hole-bottom tubular linear motor electric impactor is simple and firm in structure and low in manufacturing and maintenance cost, the impacting stroke speed and the impacting stroke frequency are easy to adjust, and the hole-bottom tubular linear motor electric impactor is high in efficiency and can be used for deep hole drilling.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

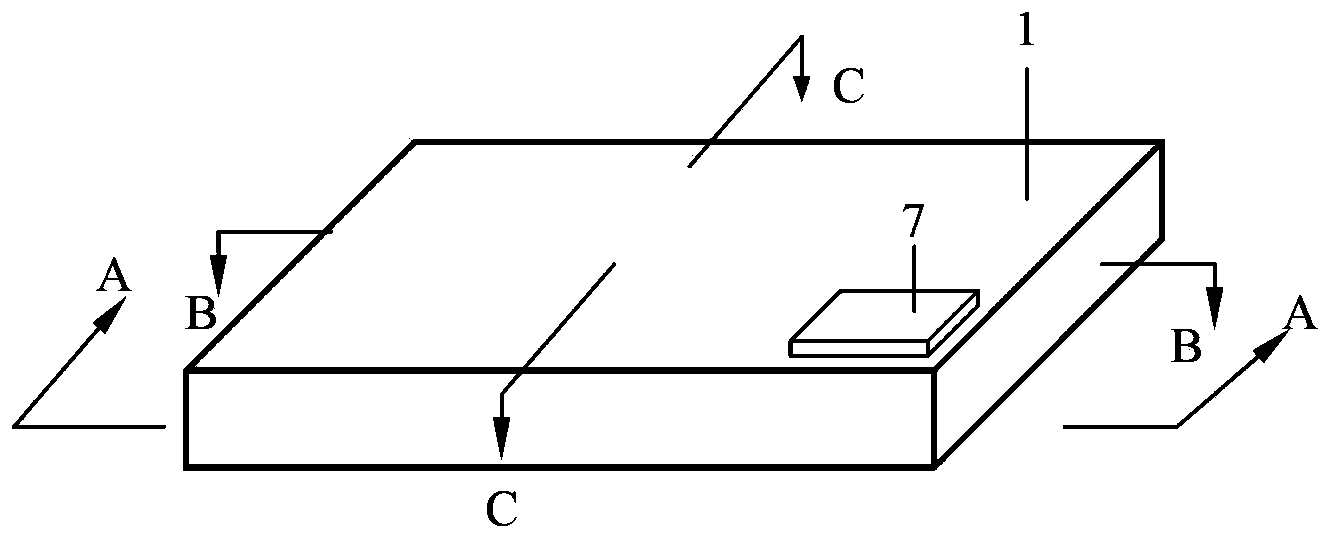

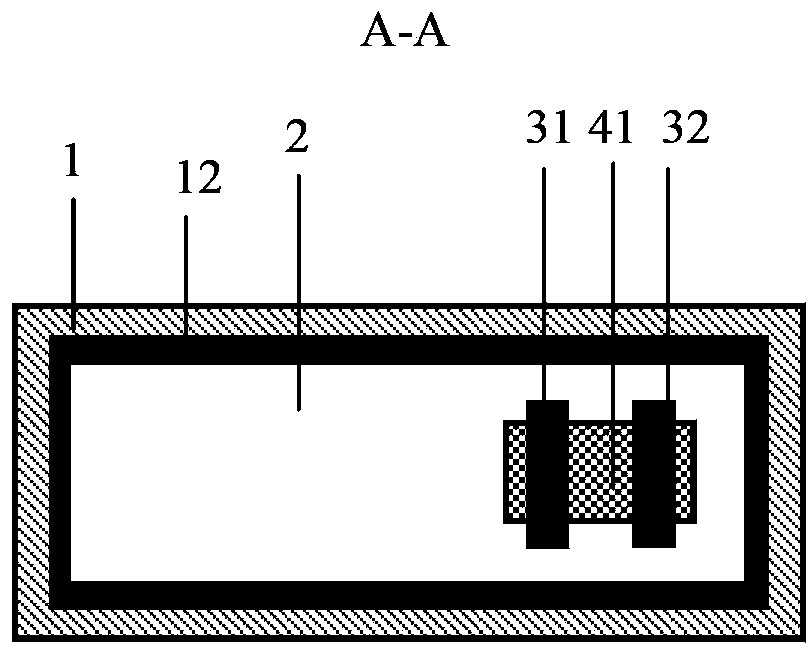

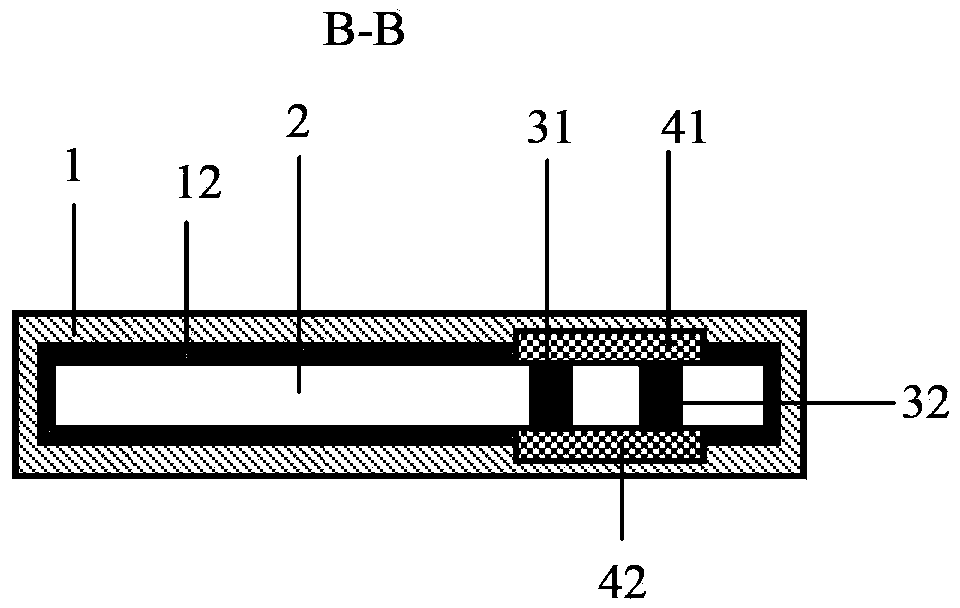

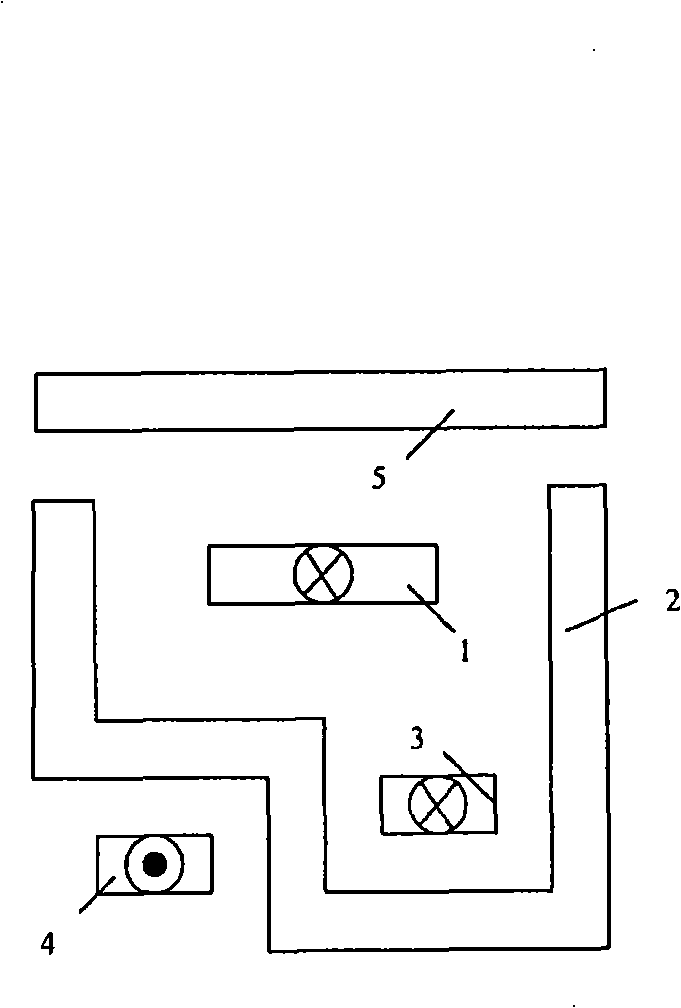

Integrated cavity type conductive fluid heat spreader

ActiveCN104125753AEliminate tightnessPrevent leakageCooling/ventilation/heating modificationsMagnetic polesEngineering

The invention provides an integrated cavity type conductive fluid heat spreader which includes a cavity (1), the heat absorbing end, flow, liquid, fluid pool, driving pump and a heat radiating end together in one room, the internal cavity structure, and the inner surface is an insulating layer (12); runner type electrode for (31, 32), arranged on the cavity surface, which is used as a channel and the direction of fluid flow regulator; a magnet for (41, 42), in the cavity body and the direction of the magnetic poles and the electrode is arranged on the current direction is vertical range setting; conductive fluid (2), the filling in the cavity; power supply chip (7) which is arranged in the cavity, the outer surface of the electrodes used to provide the input current. According to the heat spreader is provided by the invention greatly reduces the production and packaging process, completely avoid the fluid leakage; the compact volume, heat transfer capacity significantly; the cavity electrode on the position can be set flexibly, significantly enhance the electromagnetic driving force, resulting in the enhancement of heat transfer and flow effect is strong; between different parts of the body temperature of the fluid cavity different mixing efficiency is high, the heat transport capability is strong.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Electromagnetic valve sinking oil sprayer

ActiveCN106050498ALarge installation spaceIncrease electromagnetic forceFuel injection apparatusMachines/enginesInlet channelEngineering

The invention discloses an electromagnetic valve sinking oil sprayer. The electromagnetic valve sinking oil sprayer comprises an oil sprayer body, a control valve seat, an adjusting ring, an armature and an electromagnet assembly. The inside of the oil sprayer body is of a structure of a cylindrical cavity. The control valve seat, the adjusting ring, the armature and the electromagnet assembly are all installed in the cylindrical cavity of the oil sprayer. A radial protruding structure is arranged in the position, adjacent to a high-pressure oil inlet channel, on the inner wall face of the cavity of the oil sprayer body and directly extends from the bottom of the cavity to the top in the axial direction of the oil sprayer body. The control valve seat, the adjusting ring, the armature and the electromagnet assembly are al provided with grooves corresponding to the protruding structure. The armature, an armature rod, a ball valve, a sealing cone face, an oil pump capacity hole and a high-pressure oil channel can be arranged on the same axis, and the axis coincide to the axis of the oil sprayer body. The installation space of an electromagnet is further enlarged in a limited space while the installation requirement of the sinking oil sprayer is met.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

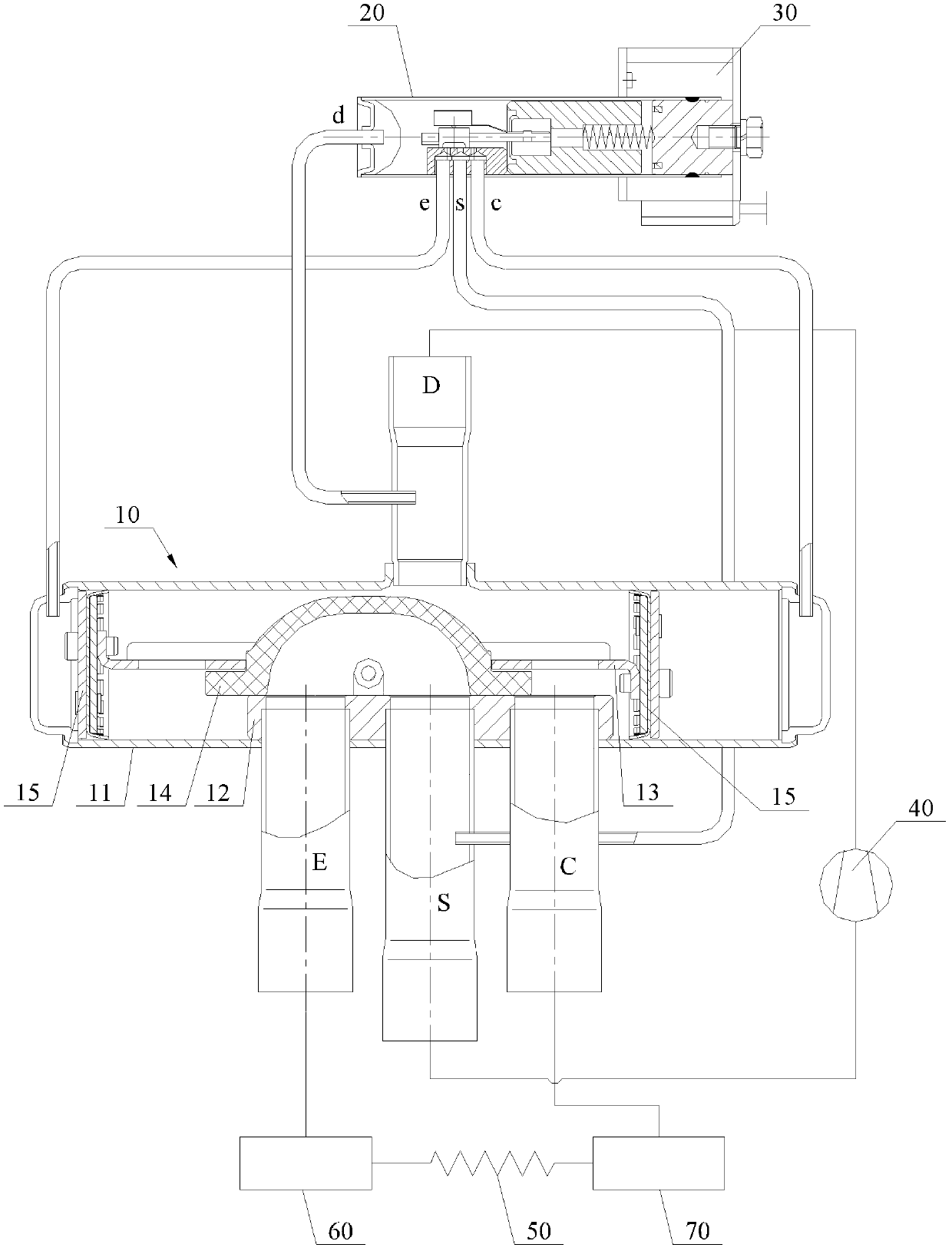

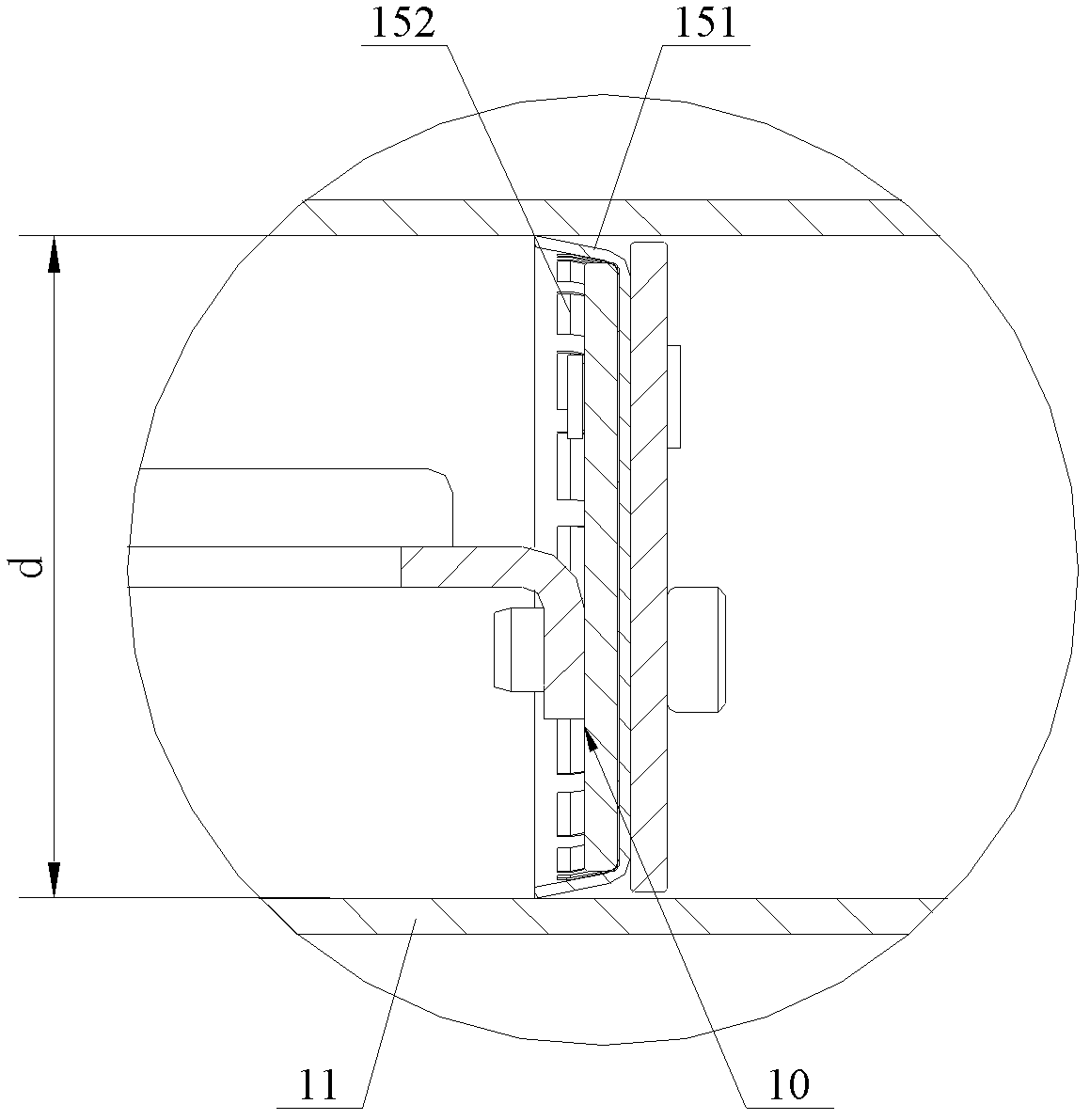

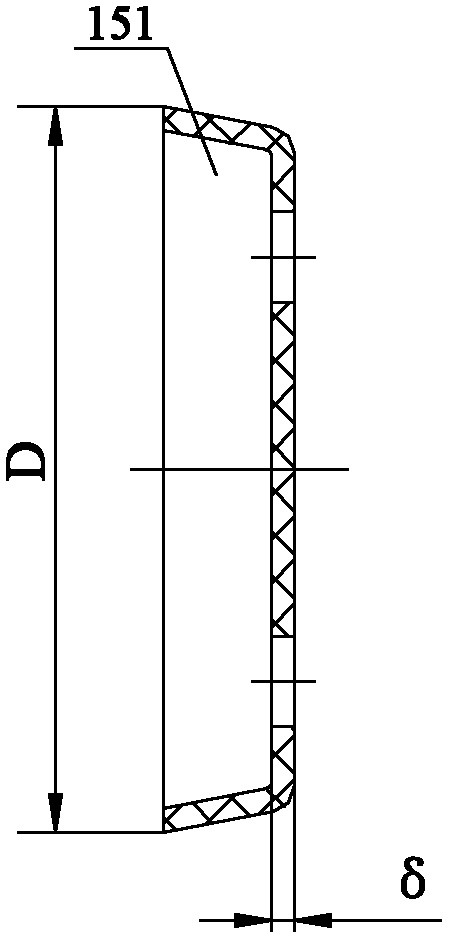

Main valve of four-way reversing valve and four-way reversing valve provided with main valve

InactiveCN103291957AOptimize structure sizeReduce coefficient of frictionOperating means/releasing devices for valvesMultiple way valvesEngineeringAir conditioning

The invention discloses a main valve of a four-way reversing valve. The main valve comprises a valve body, two piston devices and sliding blocks, wherein the piston devices are arranged in the valve body and connected through a connecting rod; the sliding blocks and the piston devices move synchronously; piston cups and piston spring pieces are arranged in the piston devices, the piston cups are glidingly matched with the inner wall of the valve body, and the piston spring pieces are arranged in the piston cups and provide radial action force; the thickness of each piston cup is 0.55-0.65mm, and the thickness of each piston spring piece is 0.11-0.15mm; and the piston cups are made of materials by weight of 85%-95% of a polytetrafluoroethylene base material and 5%-15% of an additive capable of reducing friction coefficients. By means of optimization and improvement in two aspects of structure dimension and material selection, the adaptability of the four-way reversing valve is effectively improved, and configuration requirements of different air conditioning systems can be met. On the basis, the invention further provides a four-way reversing valve provided with the main valve.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Electromagnetic valve core structure with enhanced electromagnetic force

InactiveCN104089072AEasy to processSolve the problem of high starting voltageOperating means/releasing devices for valvesElectromagnetic interferenceEngineering

The invention discloses an electromagnetic valve core structure with an enhanced electromagnetic force. The electromagnetic valve core structure with the enhanced electromagnetic force comprises a movable core and a fixed core forming an electromagnetic passage with the movable core, wherein sealing rubber is arranged on the movable core; the sealing rubber is used for sealing the movable core in the working process; two transverse vent holes which are perpendicular to each other are formed in the side surface of the movable core; a ventilating blind hole is formed in the center of the movable core; vent holes are formed in the center of the fixed core; a chamfer is arranged on the edge of the end surface of the movable core; a conical groove matched with the chamfer on the edge of the end surface of the movable core is arranged on the end surface of the fixed core. The edge of the end part of the movable core is designed to be a shape of a chamfer, and the fixed core and the movable core are matched with each other through the chamfer and the groove, so that flux area is increased, a magnetic air gap is decreased, the electromagnetic force is enhanced, and the problem that the startup voltage of the electromagnetic valve is high is solved; the conical groove is easy to manufacture, the chamfering process is good, and the production process is easy to control.

Owner:贵州新安航空机械有限责任公司

Electric meter and overload protection device for electric meter

ActiveCN112630490AKeep abreast of the trip situationImprove cooling effectTime integral measurementHemt circuitsMagnet

The invention belongs to the technical field of overload protection devices, particularly relates to an electric meter and an overload protection device for the electric meter, and provides the following scheme for solving the problem that an existing overload protection device is complex in structure: the electric meter comprises a shell, a first sliding groove is formed in the inner wall of the rear end of the shell, and a first sliding block is slidably connected in the first sliding groove; a second mounting plate is fixed to the front end of the first sliding block, and a second electrode plate is fixed to the inner side of the second mounting plate; a second spring is fixed to the top of the inner wall of the second groove, and a second clamping block is fixed to the bottom of the second spring; a first mounting plate is fixed to the inner wall of the rear end of the shell, and a first electrode plate is embedded and fixed to the inner side of the first mounting plate; and a permanent magnet is adhered to one side of the first mounting plate. According to the invention, the magnetic field force on the second electrode plate and the permanent magnet interact with each other, so that the first sliding block relieves the constraint of the second clamping block and moves rightwards, the first electrode plate and the second electrode plate are separated from contact, a circuit is cut off, and the circuit and an electric appliance are protected.

Owner:宁夏隆基宁光仪表股份有限公司

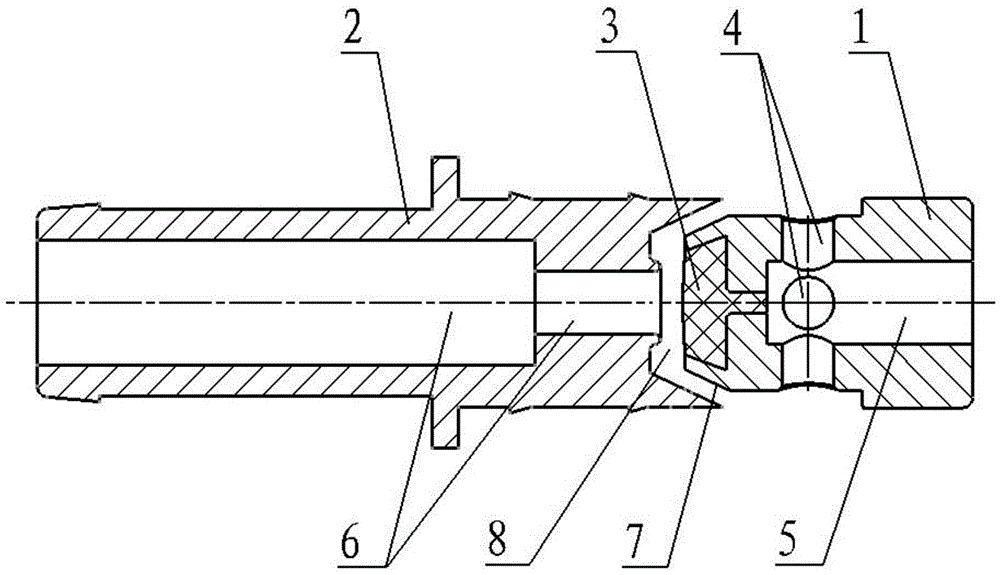

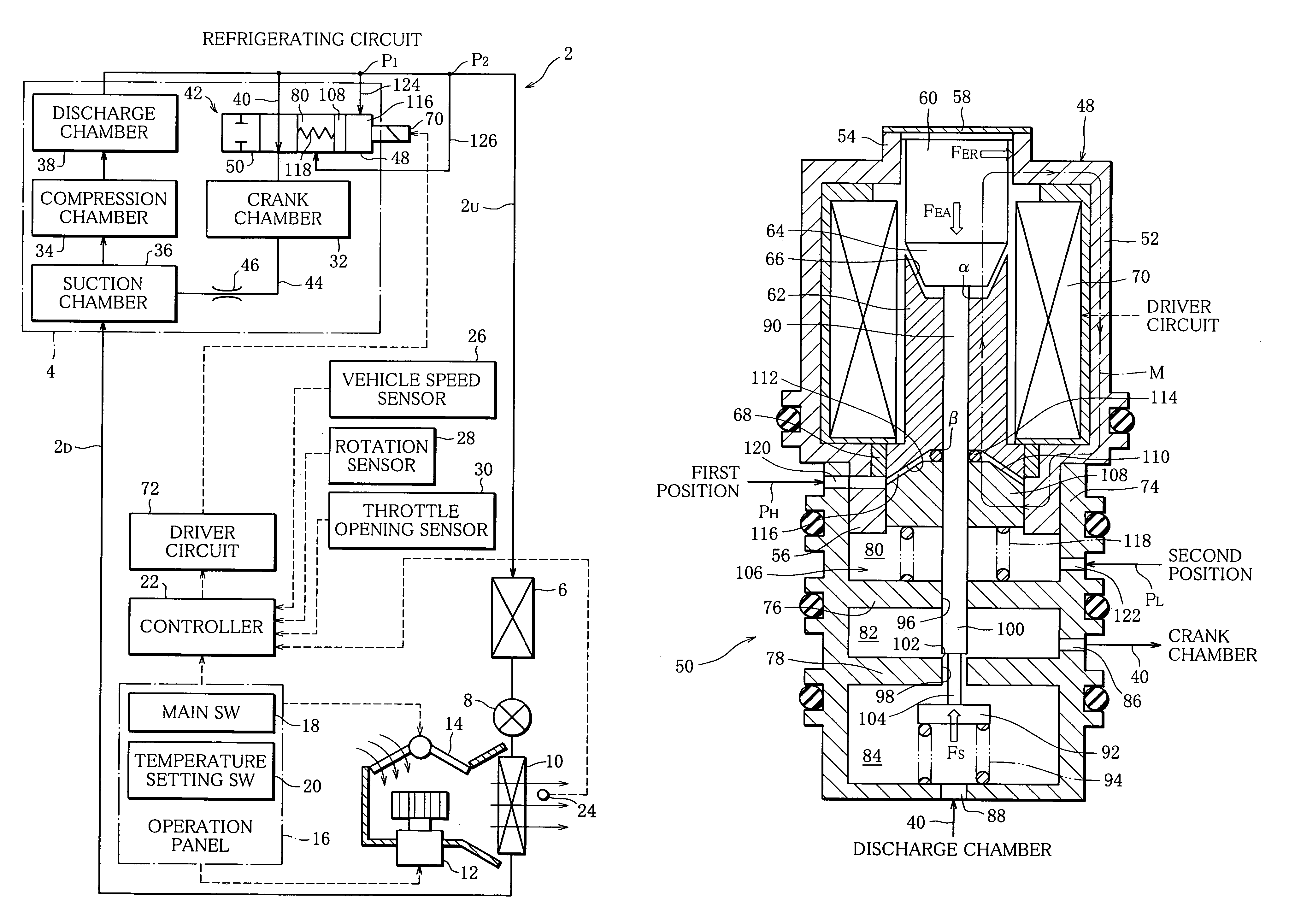

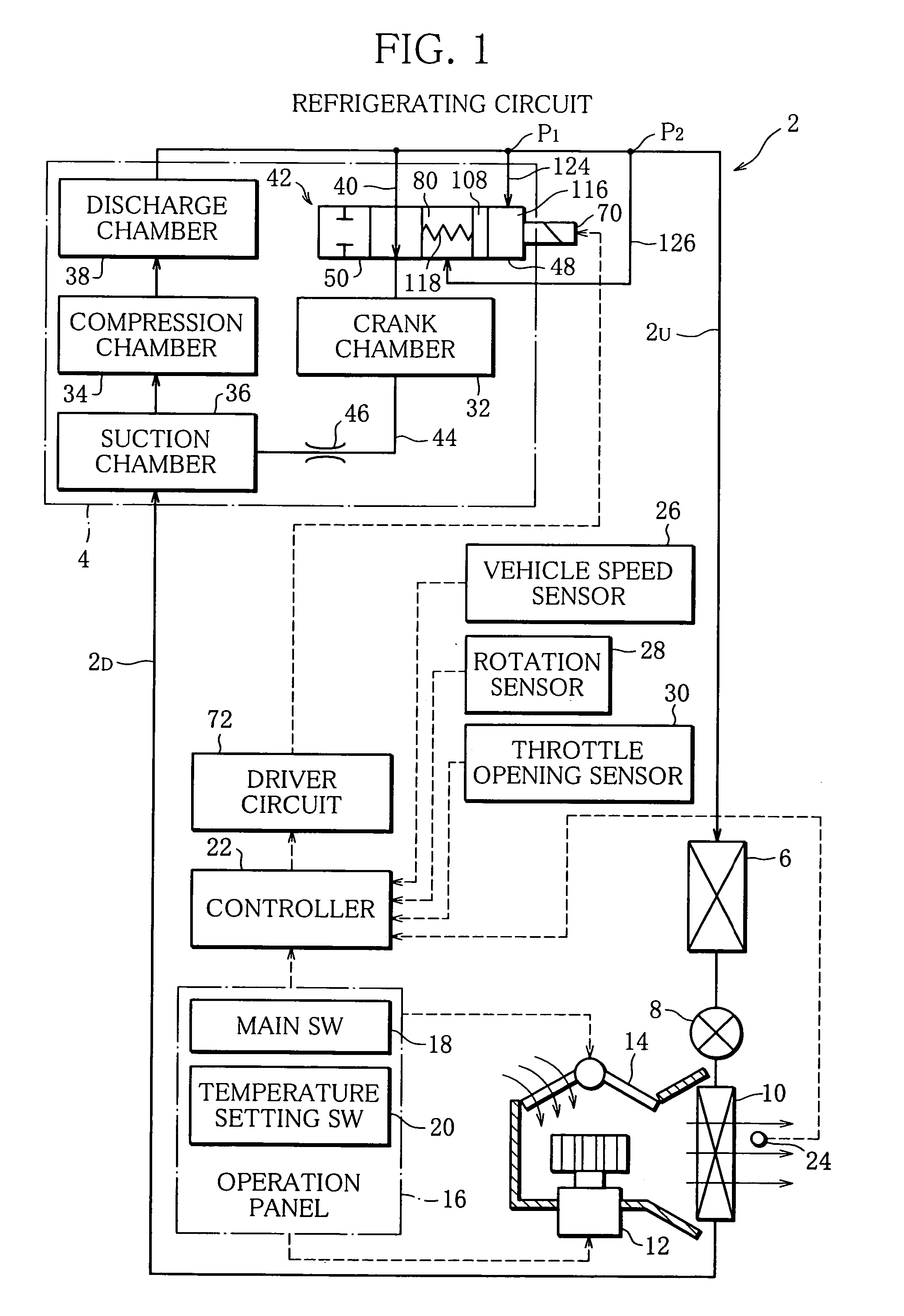

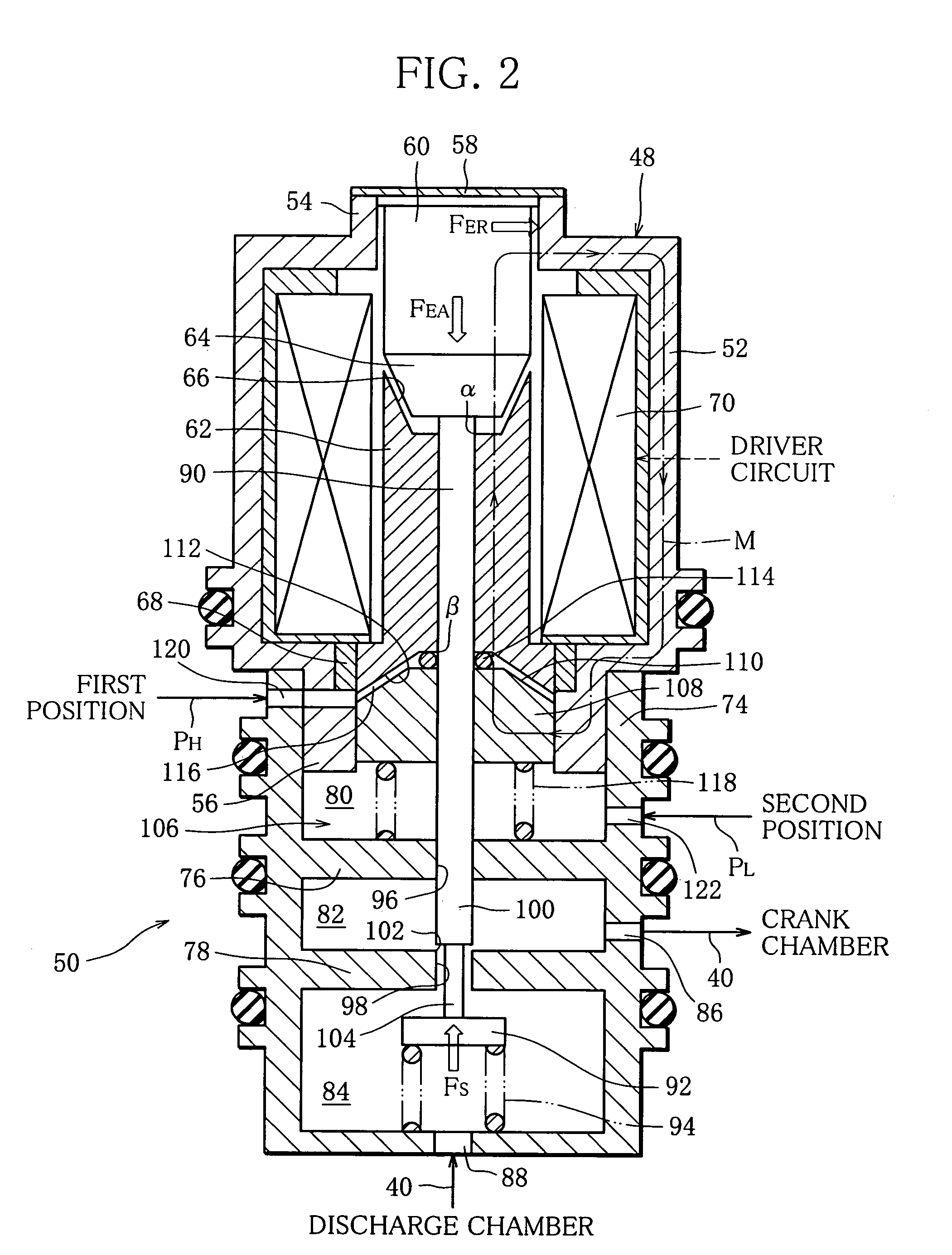

Control valve device for variable capacity type swash plate compressor

InactiveUS7273356B2AbrasionGuaranteed uptimeFluid parameterPump controlElectrical resistance and conductanceDifferential pressure

There is disclosed a control valve device for a variable capacity type swash plate compressor for use in an air conditioning system. The device comprises an introducing passage for connecting a discharge chamber to a crank chamber in the compressor, and a control valve for adjusting a pressure in the crank chamber in an autonomous manner to control a discharge capacity of the compressor. The control valve includes a valve unit for opening / closing the introducing passage and an electromagnetic solenoid assembly for operating the valve unit. The control valve device further comprises a resistance variable mechanism for varying a resistance of the magnetic circuit in the assembly in accordance with a differential pressure of the refrigerant between two points defined between the compressor and a condenser of the system.

Owner:SANDEN CORP

Board shape control based electromagnetic incremental forming method for large sheet metal parts

The invention belongs to the field of electromagnetic incremental forming and particularly discloses a board shape control based electromagnetic incremental forming method for large sheet metal parts. According to the method, the large sheet metal parts are formed in a layered way. The method comprises the following steps: firstly movably discharging electricity by adopting a planar spiral coil according to a contour trajectory to form a first layer of a to-be-formed workpiece; movably discharging electricity by adopting a curved coil according to a helix trajectory to form other layers except the first layer and a bottom layer of the to-be-formed workpiece; and finally movably discharging electricity or discharging electricity many times in a fixed position by adopting the planar spiral coil according to the contour trajectory to form the bottom layer of the to-be-formed workpiece, thereby realizing the electromagnetic incremental forming of the large sheet metal parts. According to the method disclosed by the invention, the sheet local forming can be actively controlled through the coil structure and the moving trajectory, so that the problems of low forming efficiency and poor die fittingness in the electromagnetic incremental forming process are effectively solved; and the method has the advantages of good die fittingness, high forming efficiency, good workpiece quality and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Release with step type yoke structure and circuit breaker with the release

ActiveCN101359561AIncrease electromagnetic forceProtective switch operating/release mechanismsElectrical conductorCircuit breaker

The invention discloses a release which is provided with a step-like yoke structure and a breaker with such a release; wherein the release comprises double sheet metals, an armature iron and a yoke system. The yoke system is composed of a yoke and a pair of conductors which are respectively arranged at the internal side and the external side of the yoke and are electrically connected with the double sheet metals so that the current running through the conductor at the internal side of the yoke is in the same direction with the current running through the double sheet metals. With such release, the electromagnetic force exerted on the yoke can be remarkably increased, thus lowering the action current of the release so as to make the release suitable for small-rated current breakers.

Owner:SCHNEIDER ELECTRIC IND SAS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com