Electromagnetic forming device and method of metal pipe

A metal pipe fitting and electromagnetic forming technology, applied in the field of metal pipe fitting forming, can solve the problems of limited coil energy, pipe bulging, huge investment, etc., and achieve the effects of reducing discharge voltage, improving service life, and simplifying structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

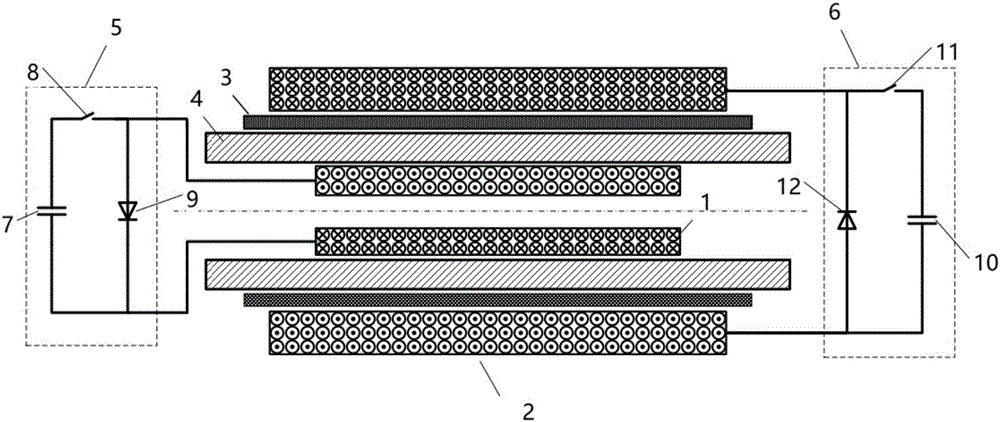

[0030] figure 1 It is the first embodiment of the electromagnetic forming device for metal pipe fittings provided by the present invention. The electromagnetic forming device is used for electromagnetic forming of composite pipes, and the composite pipes are composed of metal pipe fittings 4 and forming dies 3 . The metal pipe fitting 4 is a copper-nickel alloy seamless pipe, which has poor conductivity and shape. The inner diameter of the metal pipe fitting is 46.6mm and the wall thickness is 4.2mm. The forming die 3 is a seamless steel pipe, the inner diameter of the forming die is 57.8 mm, and the wall thickness is 2.6 mm. The forming die 3 is set on the outside of the metal pipe fitting 4. The forming die 3 is used to constrain the shape of the metal pipe fitting 4 during the forming process. Finally, the metal pipe fitting 4 and the forming die 3 are closely attached to form a composite pipe. The outer surface of the composite pipe is a steel pipe. , the inner surface of...

no. 2 example

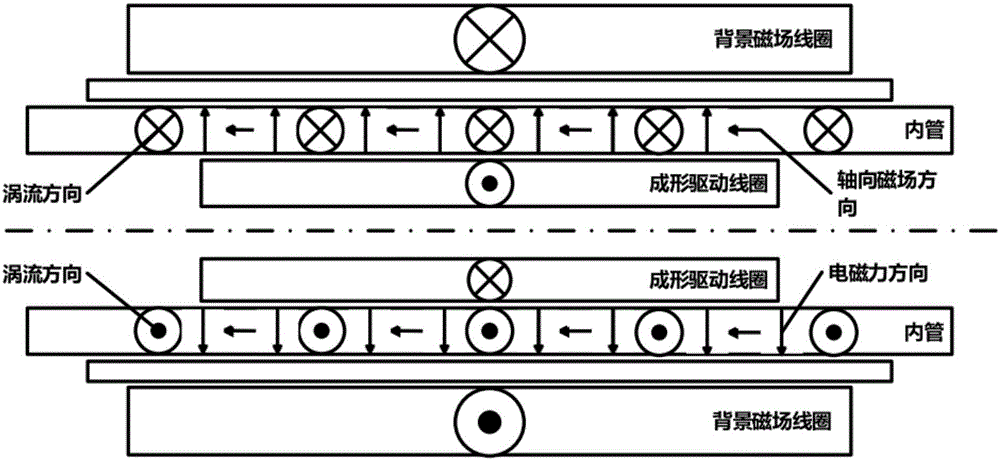

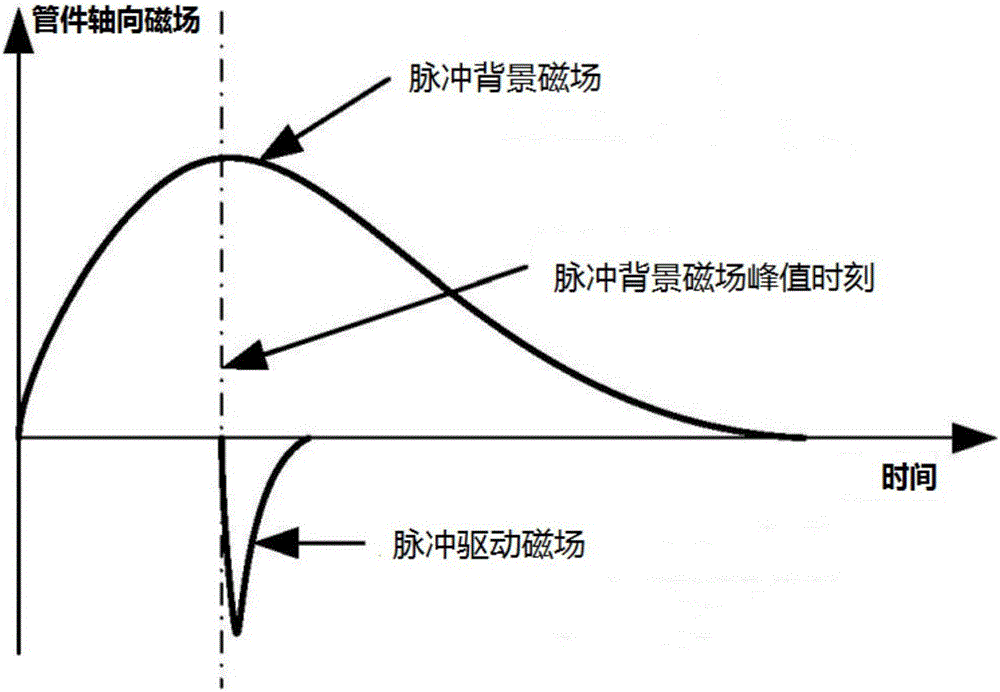

[0038] Figure 4 It is the second embodiment of the electromagnetic forming device for metal pipes provided by the present invention. The electromagnetic forming device is used to process the metal pipe 4 to the shape of the inner cavity of the forming mold 3 , and the metal pipe 4 is located inside the forming mold 3 . The electromagnetic forming device includes a background magnetic field coil 2 and a forming drive coil 1. Both the forming drive coil 1 and the background magnetic field coil 2 are in the shape of a hollow column, the background magnetic field coil 2 is set outside the forming drive coil 1, and the forming drive coil 1 is set on the forming mold 3 The outside is fixed by the upper and lower end clamps 13, so that the metal pipe 4, the forming mold 3, the forming driving coil 1 and the background magnetic field coil 2 are coaxial. The first pulse current whose pulse period is less than 1ms is passed into the forming drive coil 1, the second pulse current whose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com