Patents

Literature

85results about How to "Small electromagnetic force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

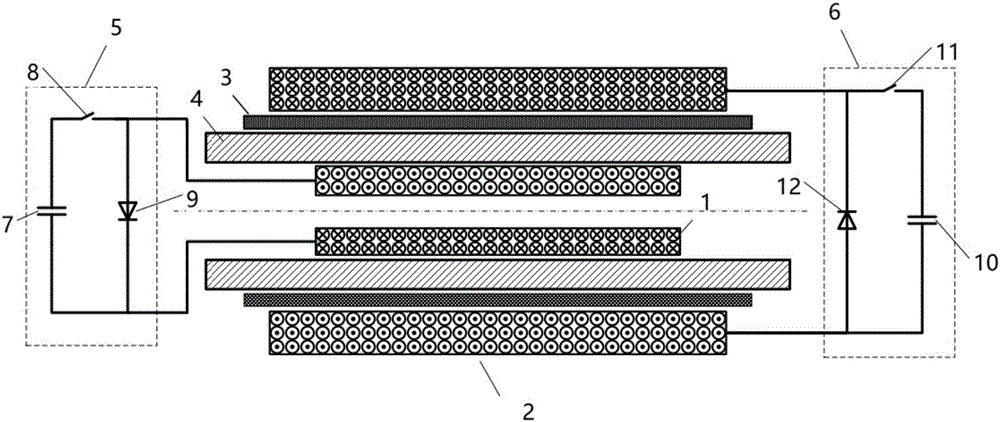

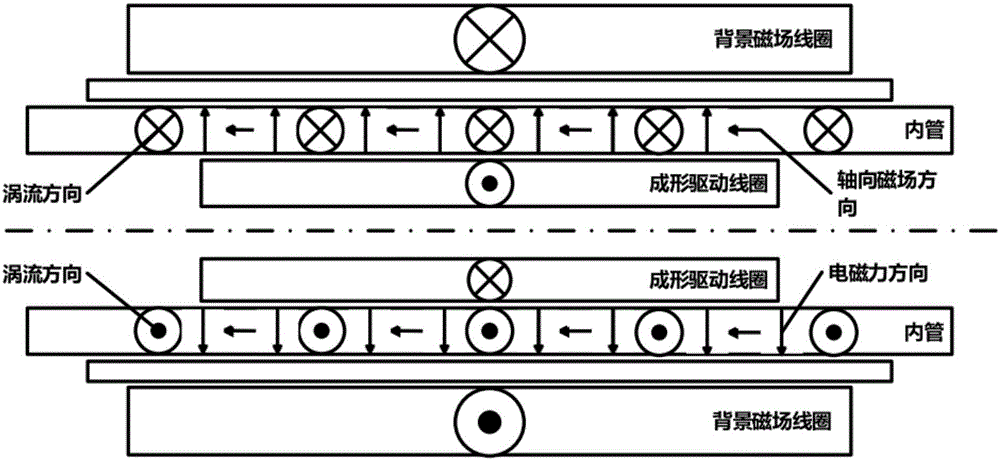

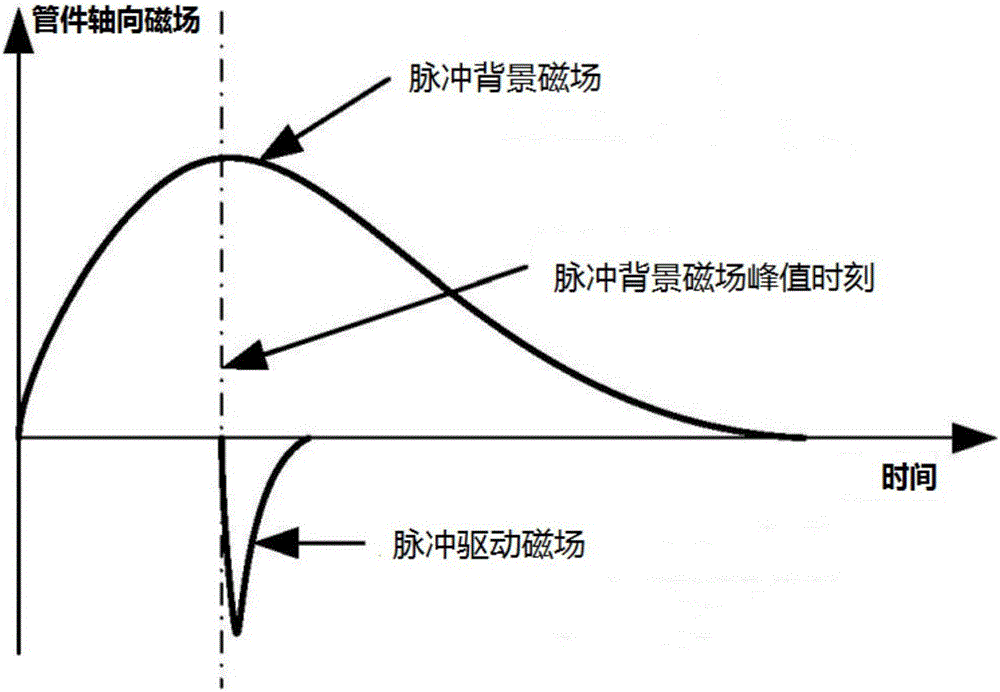

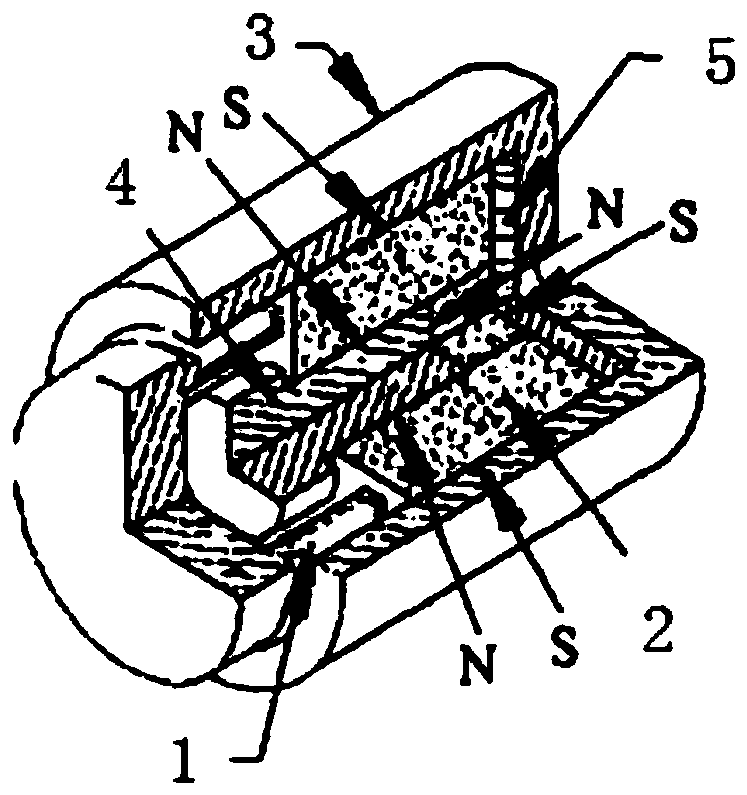

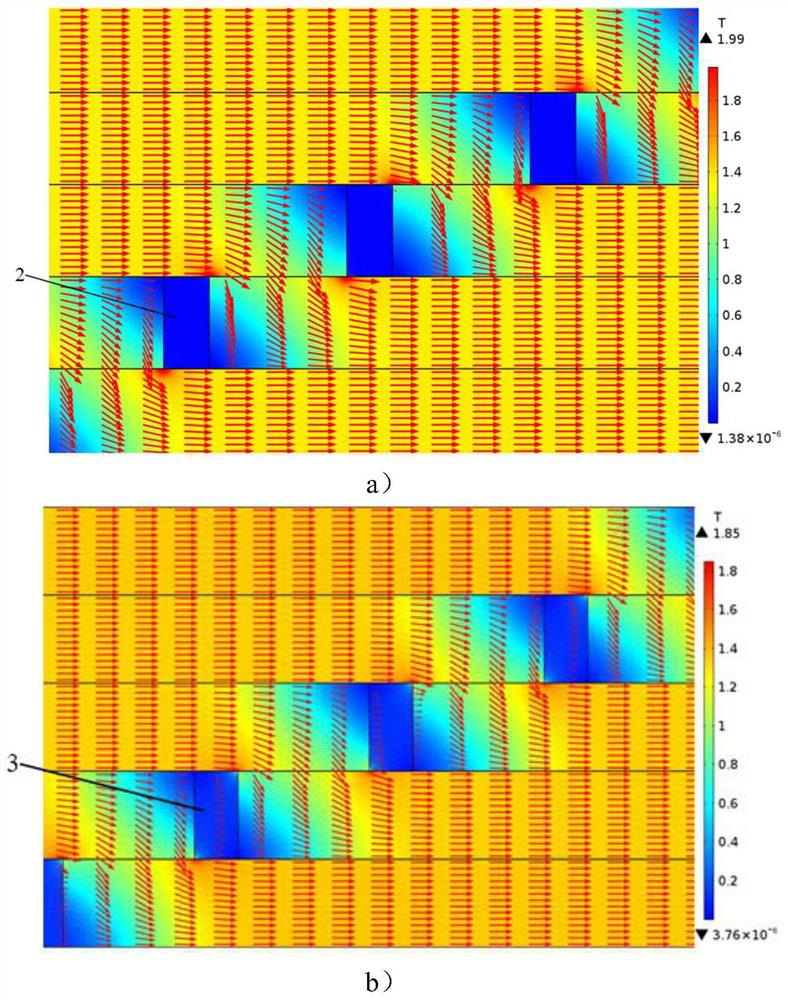

Electromagnetic forming device and method of metal pipe

ActiveCN106694681AHigh strengthSmall electromagnetic forceElectromagnetic formingUltimate tensile strength

The invention discloses an electromagnetic forming device and method of a metal pipe. The device comprises a background magnetic field unit and a metal pipe forming driving coil, wherein the background magnetic field unit is used for generating a pulse background magnetic field on the metal pipe, and a pulse driving magnetic field can generate vortexes on the metal pipe; and the metal pipe forming driving coil is used for generating the pulse driving magnetic field on the metal pipe. Due to the fact that the pulse width of the pulse driving magnetic field is much smaller than that of the pulse background magnetic field, the vortexes generated by the pulse background magnetic field on the metal pipe can be ignored, meanwhile, the influences of the pulse driving magnetic field on a magnetic field on the metal pipe can be ignored, and thus, electromagnetic force is generated on the metal pipe through interaction of the pulse background magnetic field and the vortexes. By independently adjusting the pulse background magnetic field and the pulse driving magnetic field, the electromagnetic force can be improved, the metal pipe high in mechanical strength and low in conductivity can be formed, meanwhile, the design difficulty of the forming driving coil can be lowered, and the service life of the forming driving coil is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

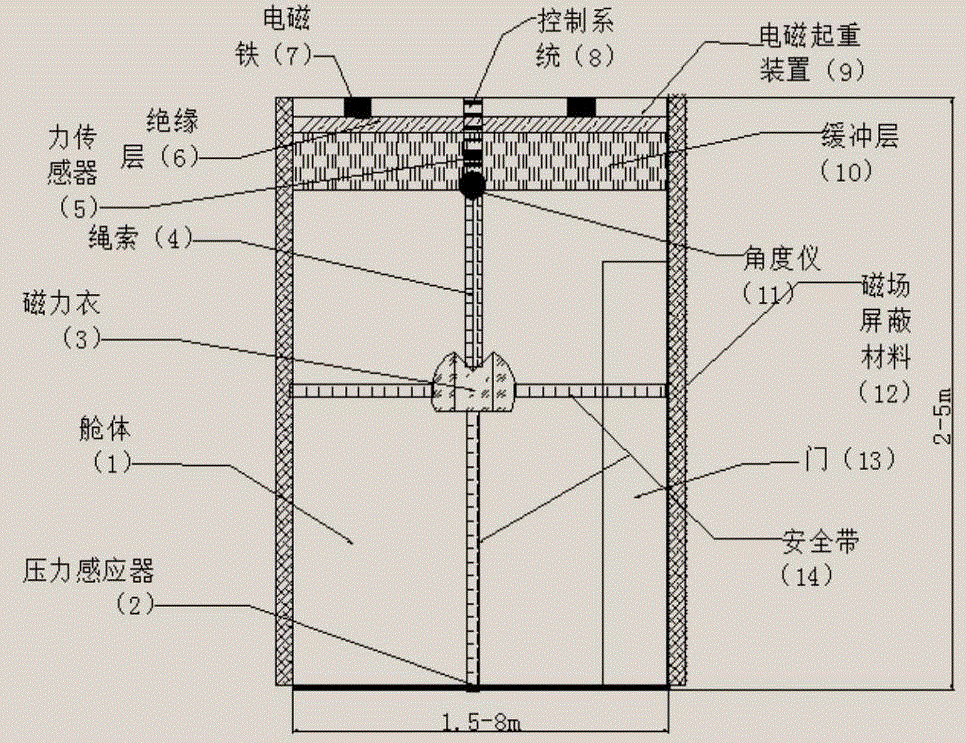

Device for experiencing microgravity

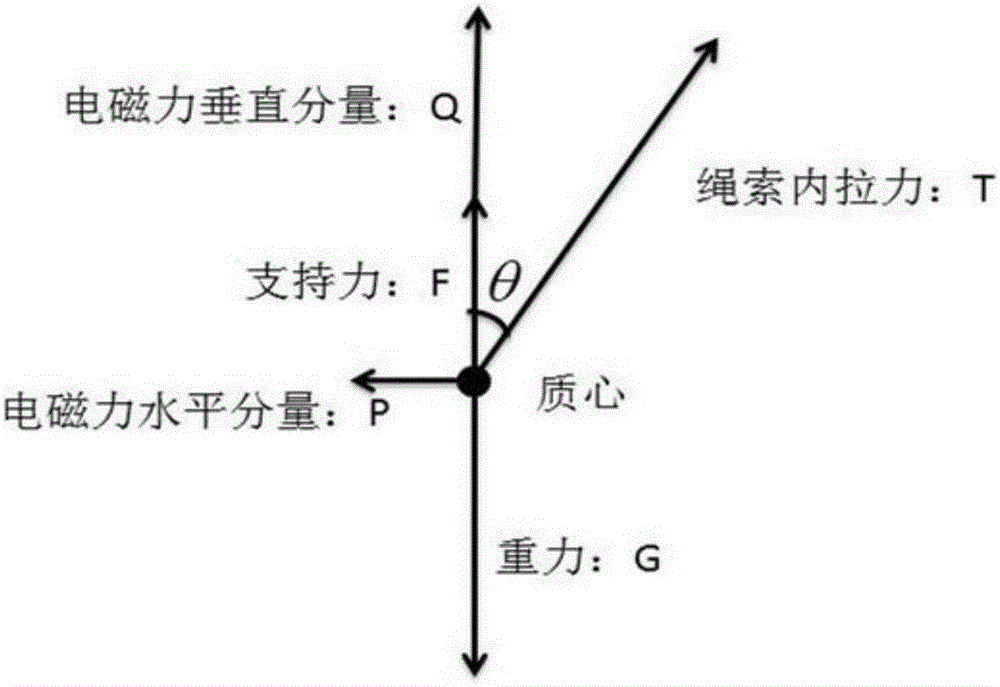

The present invention is applied to the field of aeronautics and astronautics, and aims to simulate the weightless environment for astronauts and people who want to experience the microgravity environment, and conduct simulation tests for the work in capsules. The device is based on the principle of electromagnetic cranes, part of the gravity of the human body is offset through the attraction force, on a magnetic force coat (3), of an electromagnet (7), the stress of the human body is dynamically adjusted in real time through all structures under the tuning of a control system (8), so that the human body has a stronger sense of participation of weightlessness, and the space environment is simulated.

Owner:BEIHANG UNIV

Power-losing trigger device

The invention discloses a power-losing trigger device. The power-losing trigger device comprises a frame, an electromagnet and an impacting rod; the impacting rod vertically and movably penetrates through the frame, the upper end and the lower end of the impacting rod are located outside the frame, a limiting buffer cushion is installed on the upper section of the impacting rod, and the lower end is the impacting end. The electromagnet is installed on the frame; an energy storage piece is arranged and has a downward action force on the impacting rod; when the electromagnet is electrified, the impacting rod is positioned through electromagnetic force; when the electromagnet loses power, the keeping force of the electromagnet on the impacting rod is lost, and the impacting rod performs the downward impacting motion under the action force. The power-losing trigger device is implemented through the electromagnet and a middle mechanism, and the electromagnetic force for maintaining the electromagnet is reduced through the middle amplifying mechanism, so that the current, the energy consumption and the cost of the electromagnet are reduced, the service life of the long-time electrification electromagnet is prolonged, automatic resetting of the electromagnet can be achieved, the electromagnet, an energy storage impacting structure and a resetting structure of the power-losing trigger device are simple, and the power-losing trigger device is convenient to use.

Owner:HANGZHOU HUNING ELEVATOR PARTS CO LTD

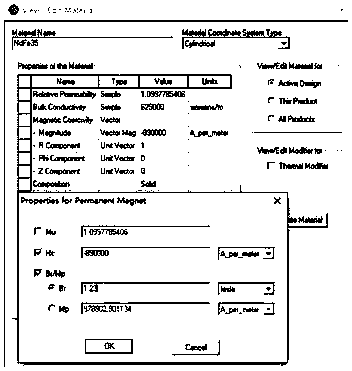

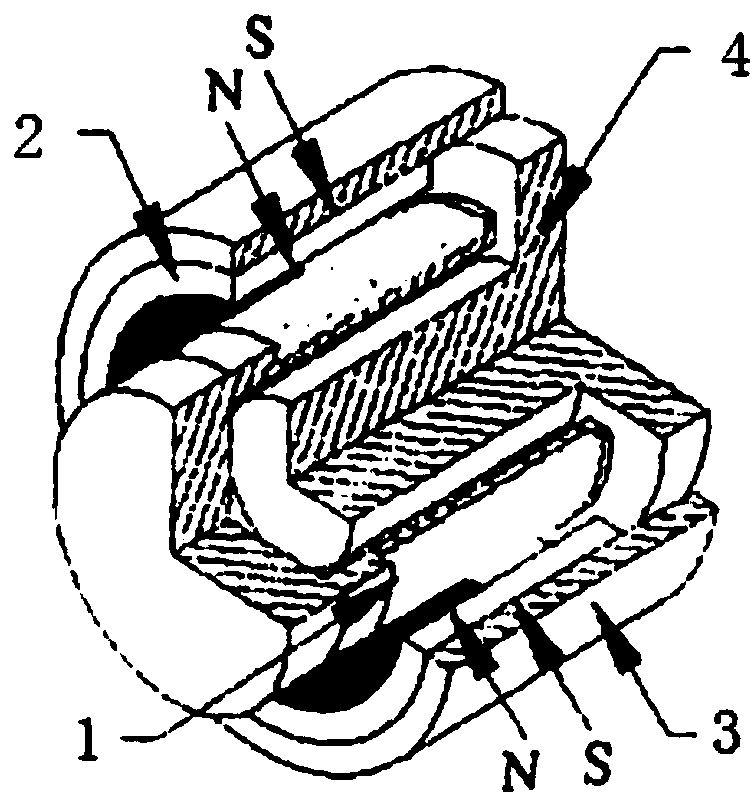

Electric switch operation control mode and operation control structure

InactiveCN1767116ADemagnetization compensationExtended service lifeContact mechanismsHigh-tension/heavy-dress switchesMagnetic tension forceEngineering

The invention relates to a operating mode and operating control mechanism of electrical switch, which adopts the electromagnet force and the permanent magnetic force generated by a group of permanent magnet and a electromagnet coil to overcome force component of energy accumulation lock-dividing mechanism; it disconnects the holding circuit of the electromagnet coil so that the generated electromagnet force disappears; the lock-dividing force of the energy accumulation lock-dividing mechanism overcomes the electromagnet force to do lock-dividing. The resultant force can be aerodynamic, oil-pressure force or electromagnet force. It cuts of the holding current of the electromagnet coil when it does lock-dividing; it uses the lock-dividing force to above the permanent magnetic force to achieve the lock-dividing after the electromagnet force disappears.

Owner:周济

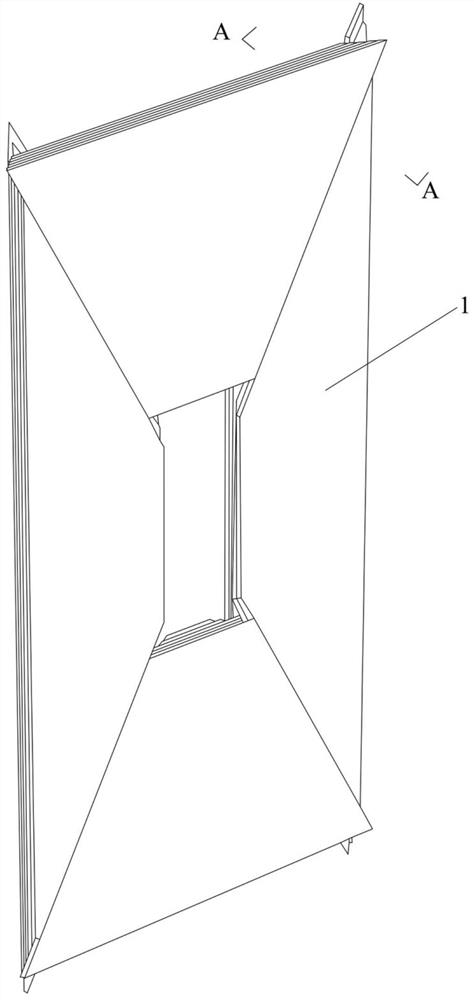

Friction plate assembly, braking device and motor

ActiveCN110645291AMove fastFast response timeBrake actuating mechanismsMechanical energy handlingElectric machineryEngineering

The invention provides a friction plate assembly, a braking device and a motor. The friction plate assembly comprises a first elastic piece, a first friction plate and a second friction plate, whereinthe first friction plate is coaxial with the second friction plate; the first elastic piece is between the first friction plate and the second friction plate, and the restoring force of the first elastic piece makes the first friction plate and the second friction plate away from each other. The friction plate assembly has a high degree of freedom, and the operation balance can be improved. The braking device with the friction plate assembly can q make a quick response, the operation balance is improved, and abnormal wear is avoided.

Owner:GREE ELECTRIC APPLIANCES INC

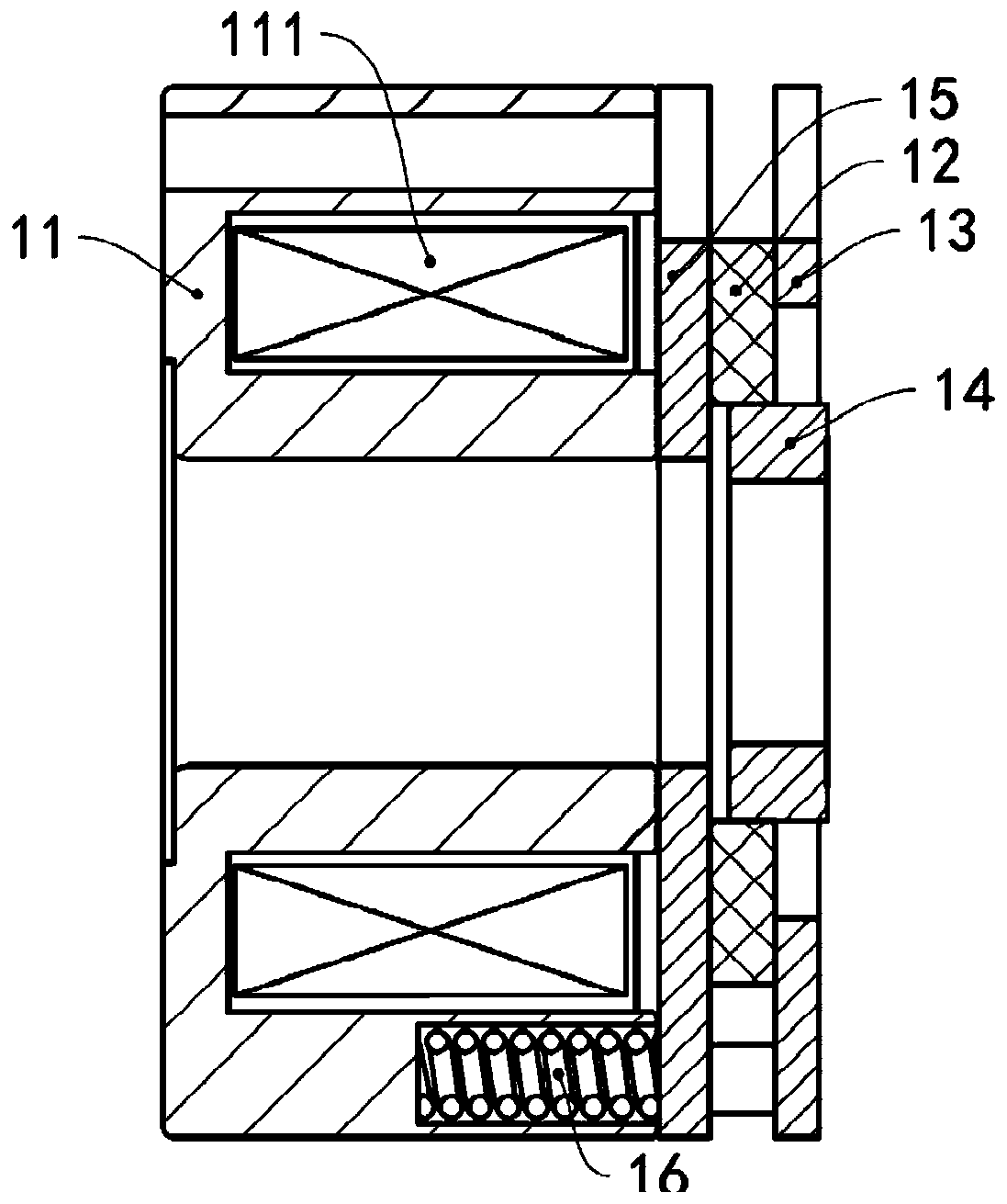

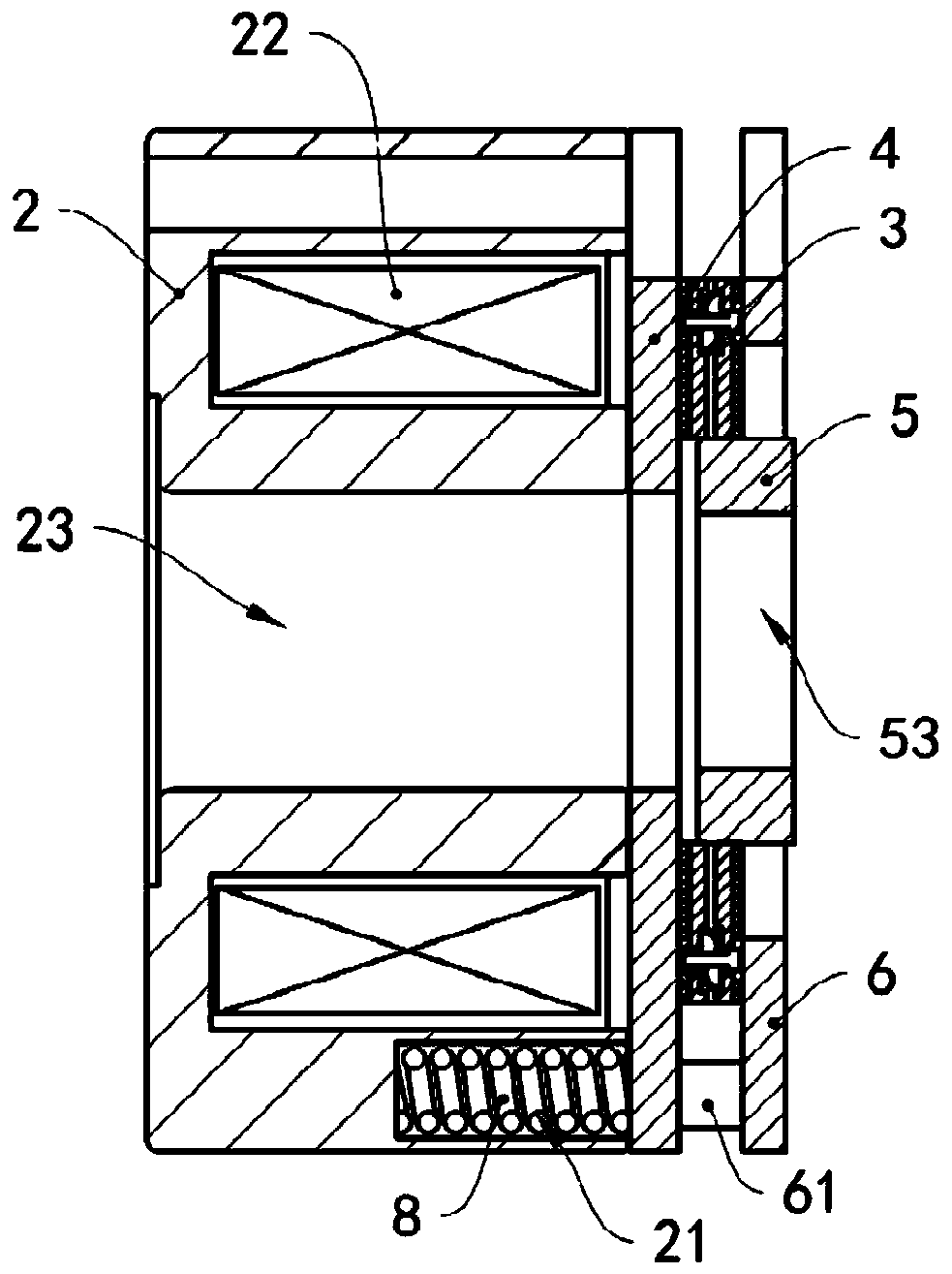

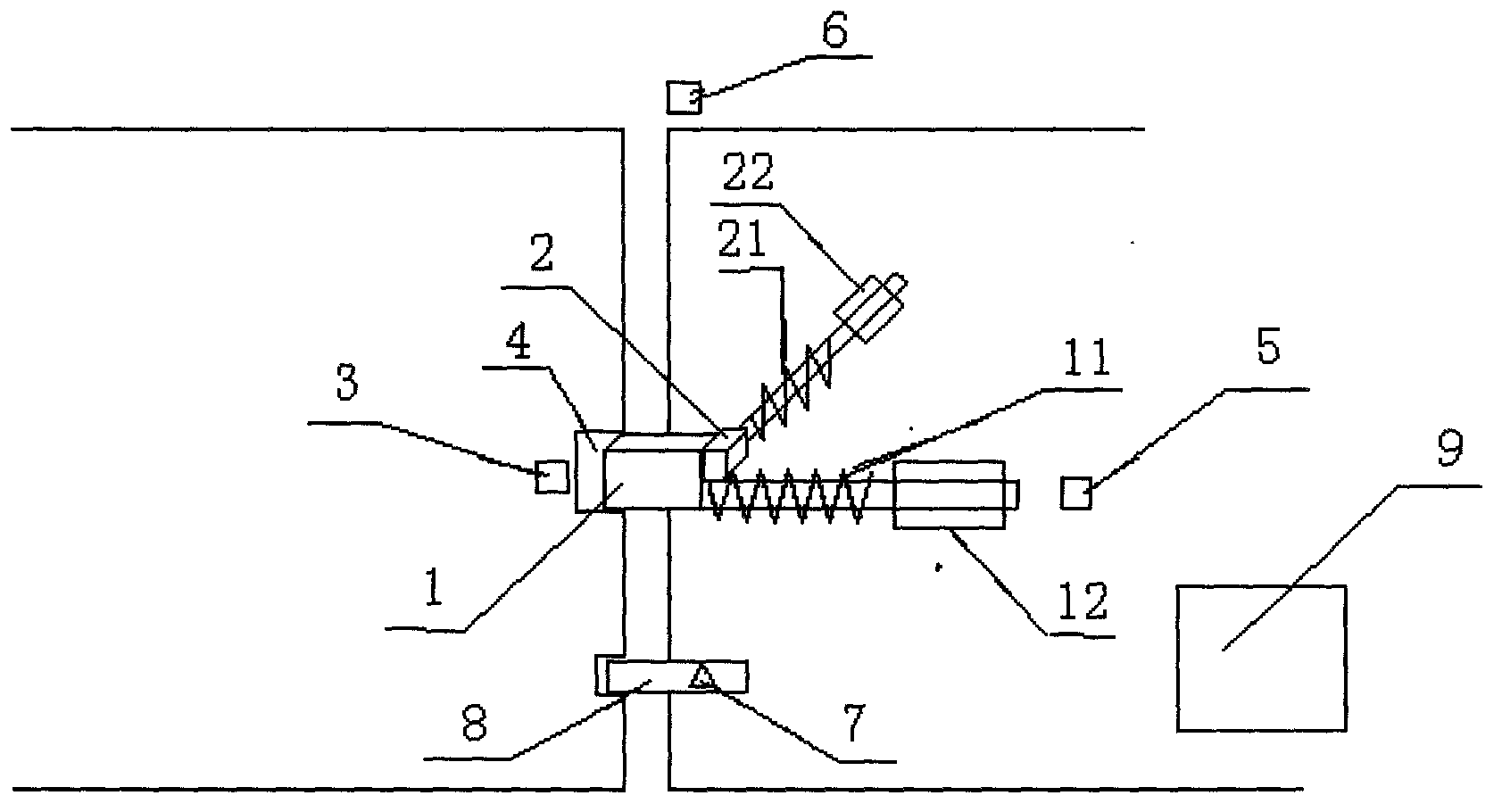

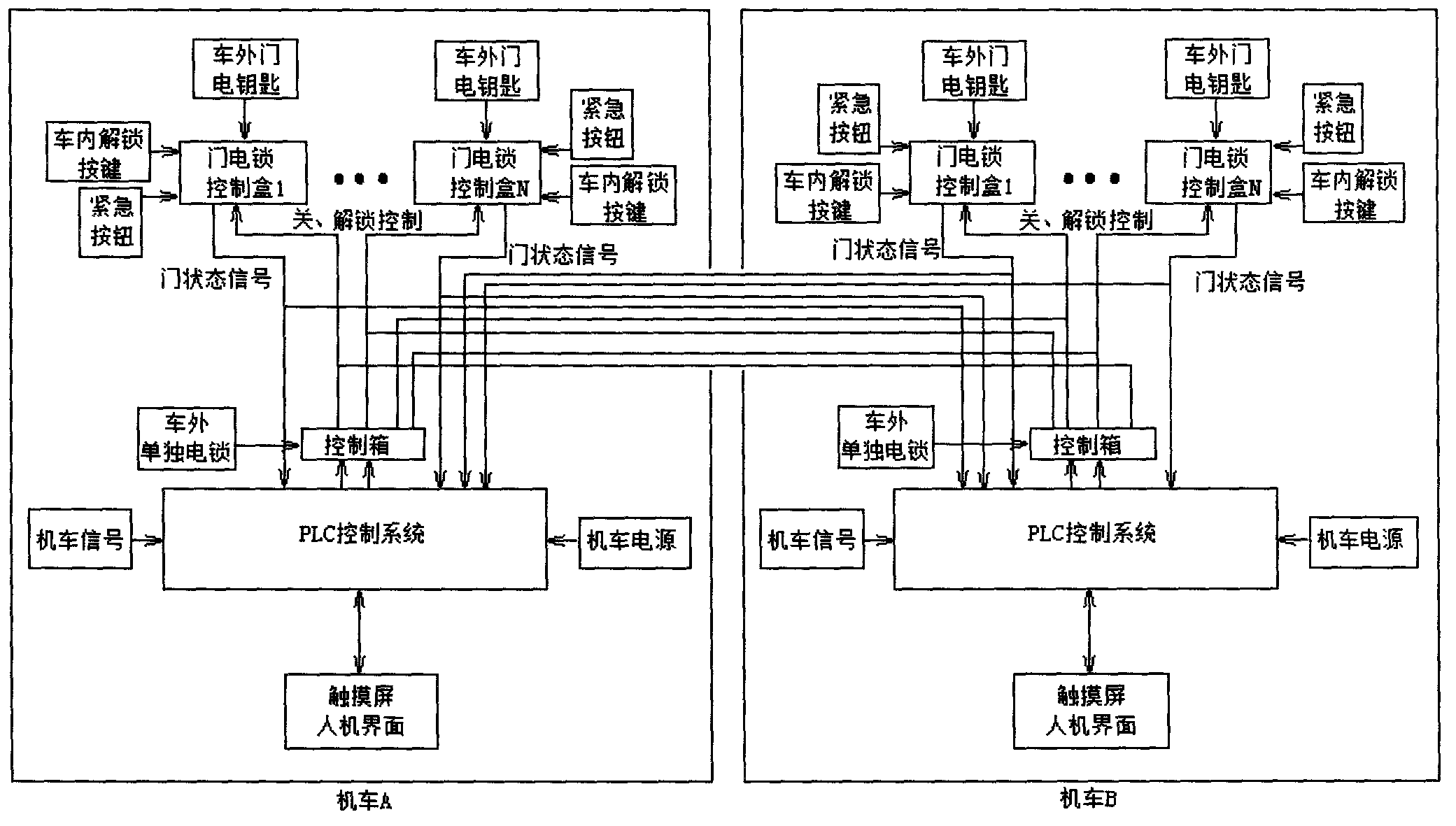

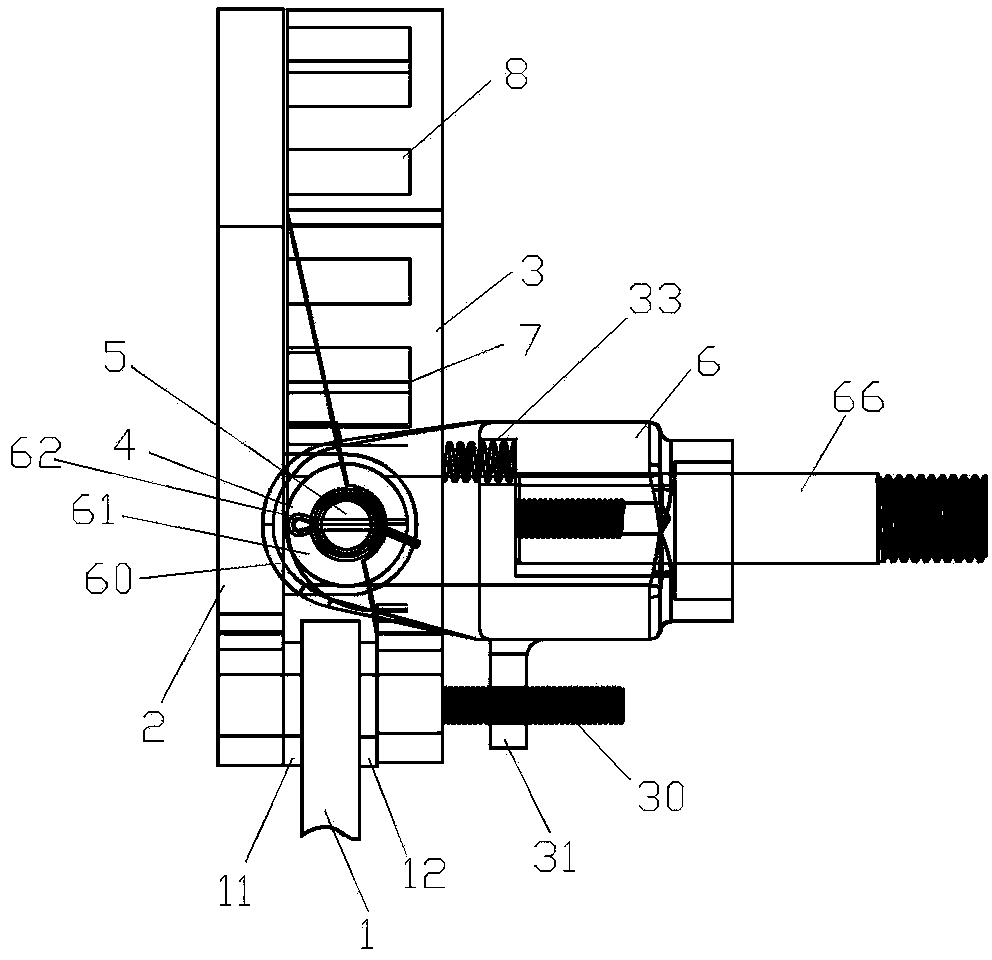

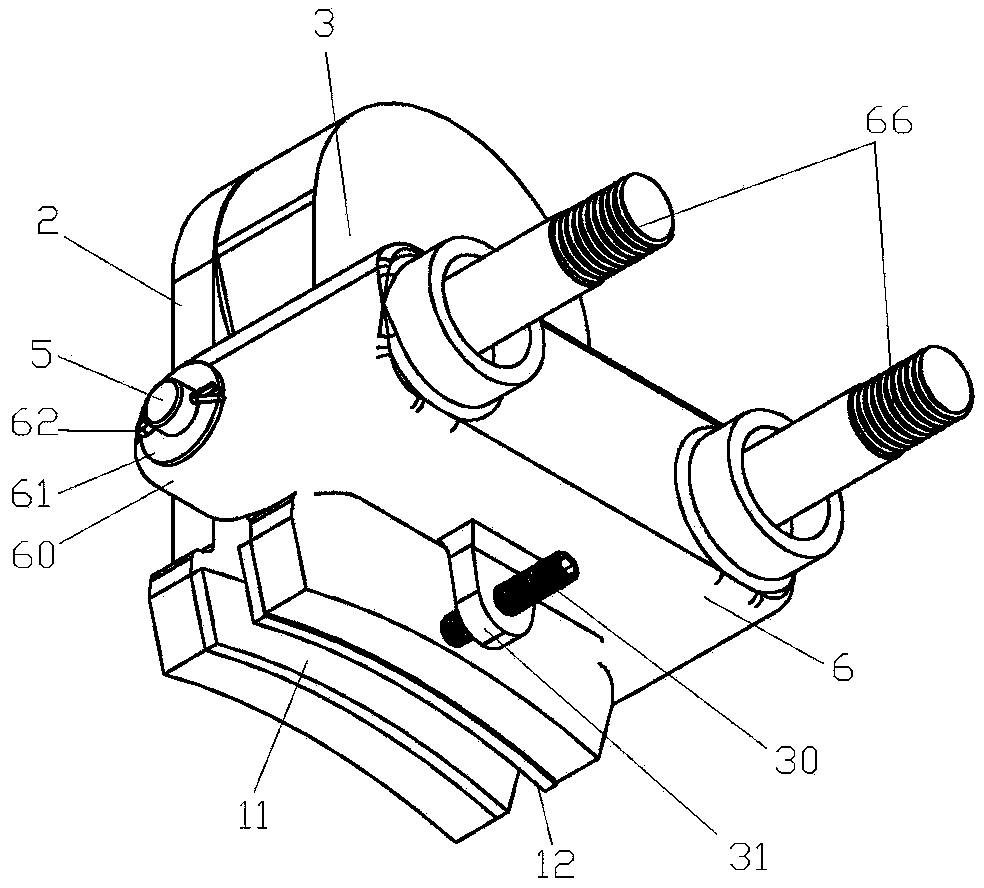

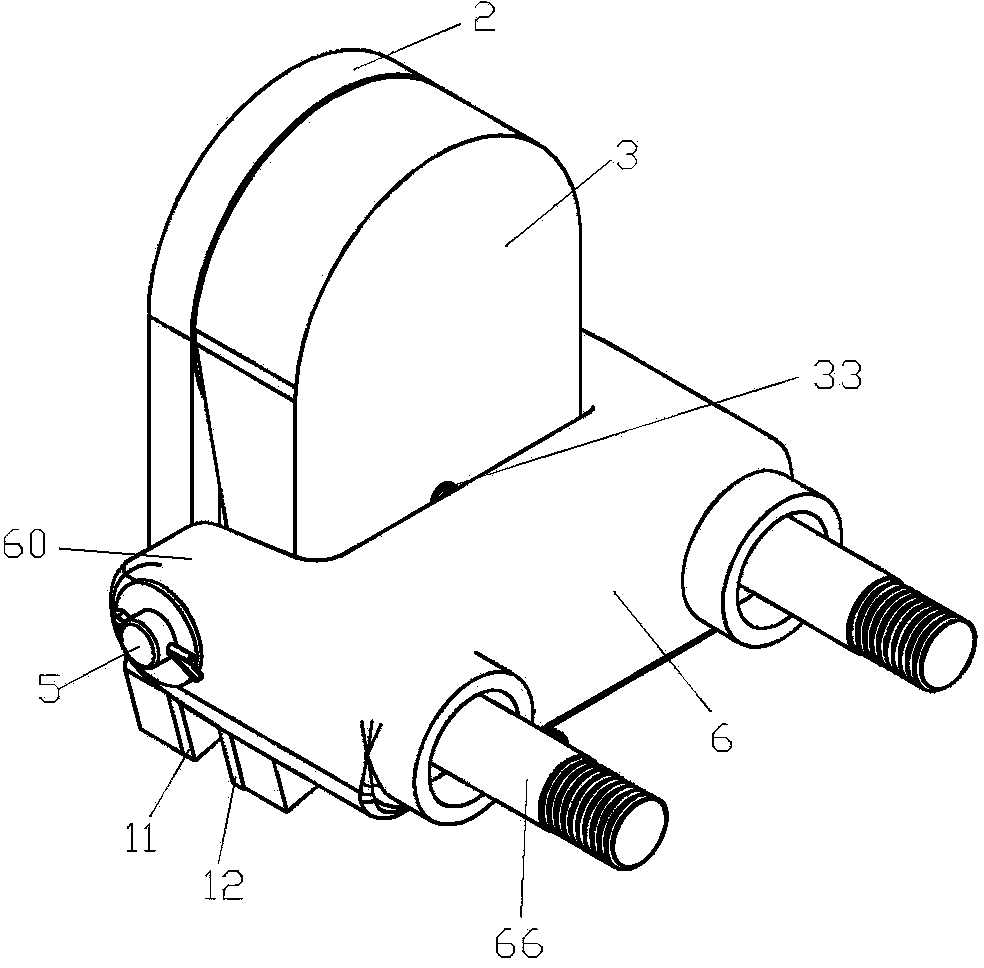

Electric lock for locomotives

ActiveCN103195302AReduce power consumptionHigh power consumptionNon-mechanical controlsPower-actuated vehicle locksElectricityPower flow

The invention discloses an electric lock for locomotives. The electric lock comprises a mechanical part and an electric part and combines mechanical control land electric control. A locomotive door is locked under the electric control. Unpowered unlocking of the door lock is performed in a locomotive. The door can be unlocked manually and mechanically with a triangle key. An electric bolt and an electric pin lower power consumption of the door lock. A first spring of the electric bolt is large in elasticity. Long-term powering requires high power consumption, and a first coil is very hot and burns out easily in long-term operation. The electric pin replaces the first coil of the electric bolt to generate electromagnetic force. A second spring of the electric pin is low in elasticity, low in electromagnetic force, power consumption and current, and suitable for long-term powering. The problem that the existing locomotive door lock is used in the single way causing insecure factors is well solved. In addition, the electric lock is simple in structure, convenient to operate, low in service cost, high in reliable, and well worthy of application.

Owner:HUNAN RAILWAY PROFESSIONAL TECH COLLEGE

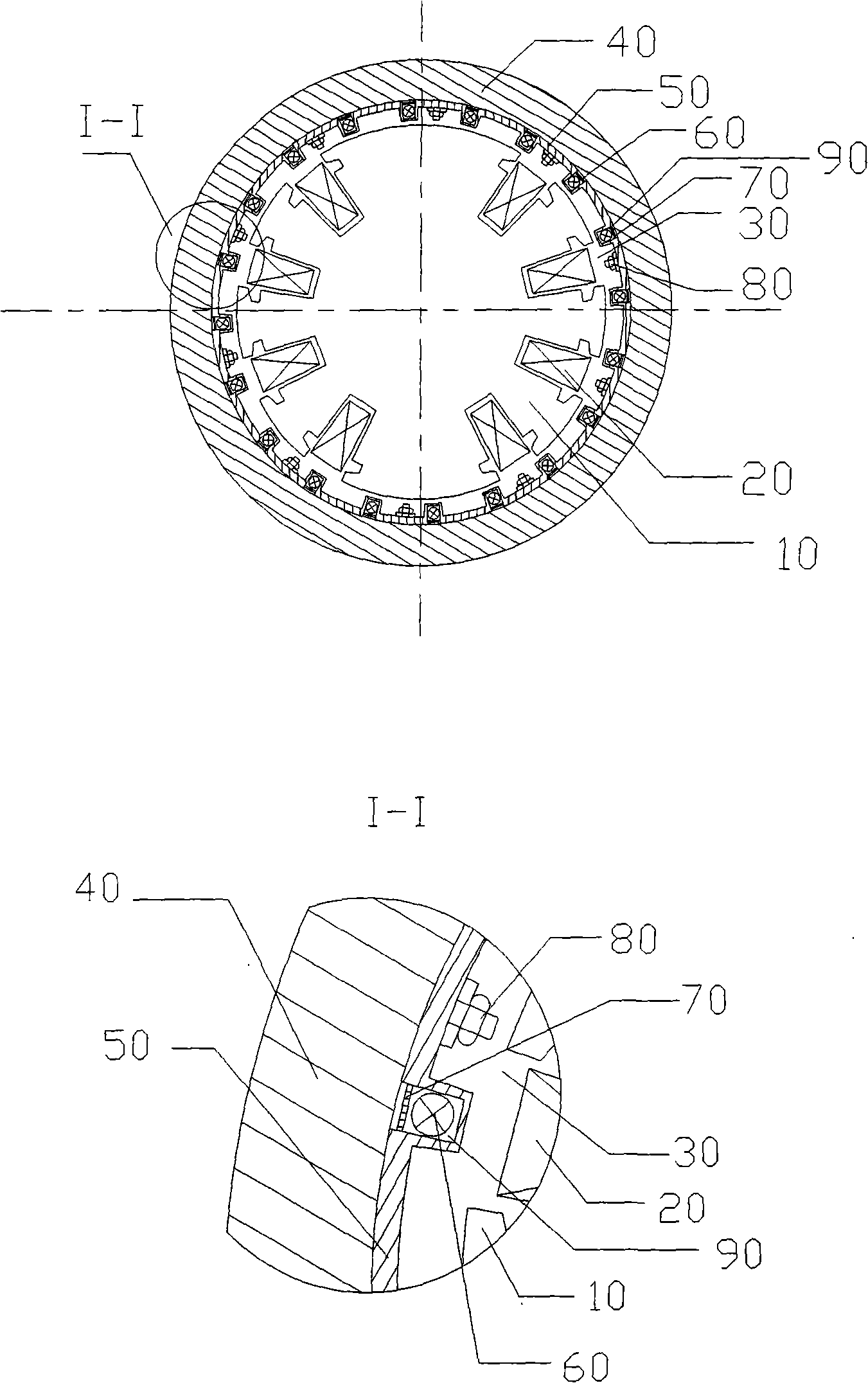

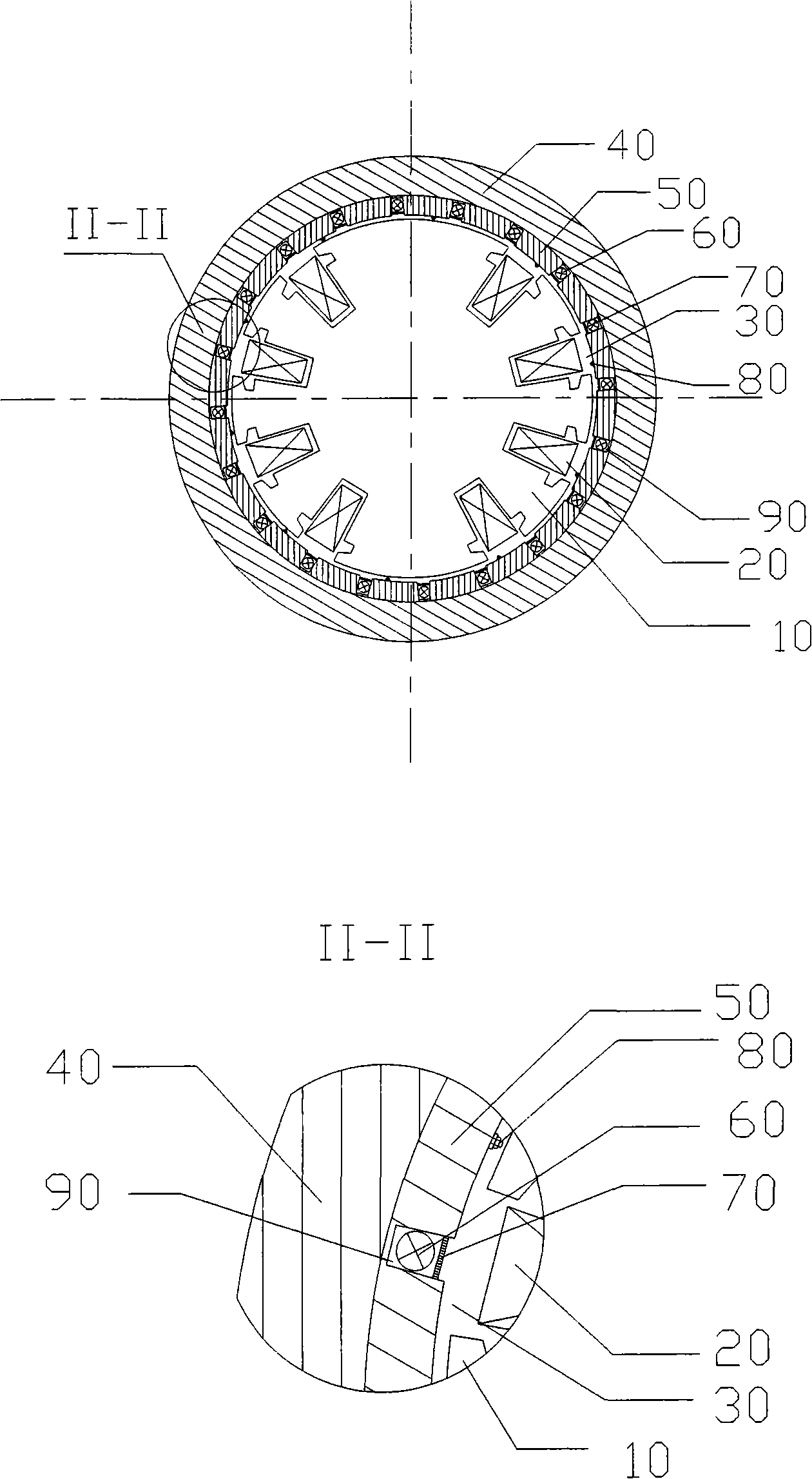

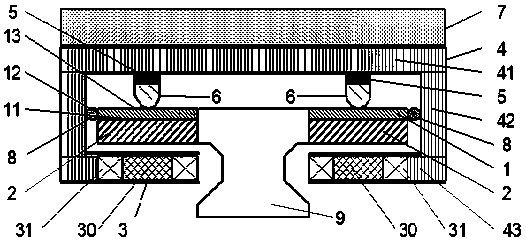

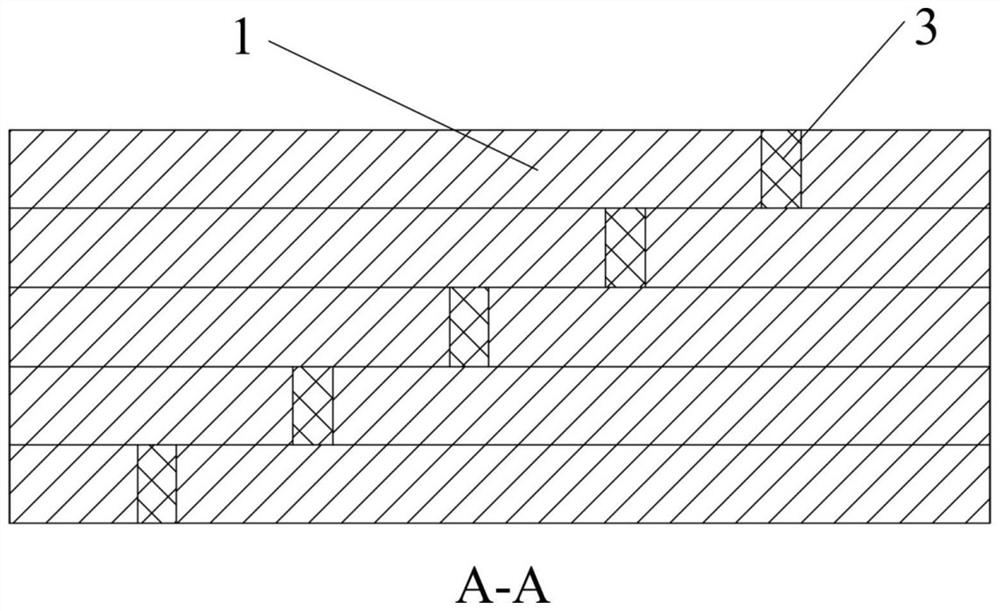

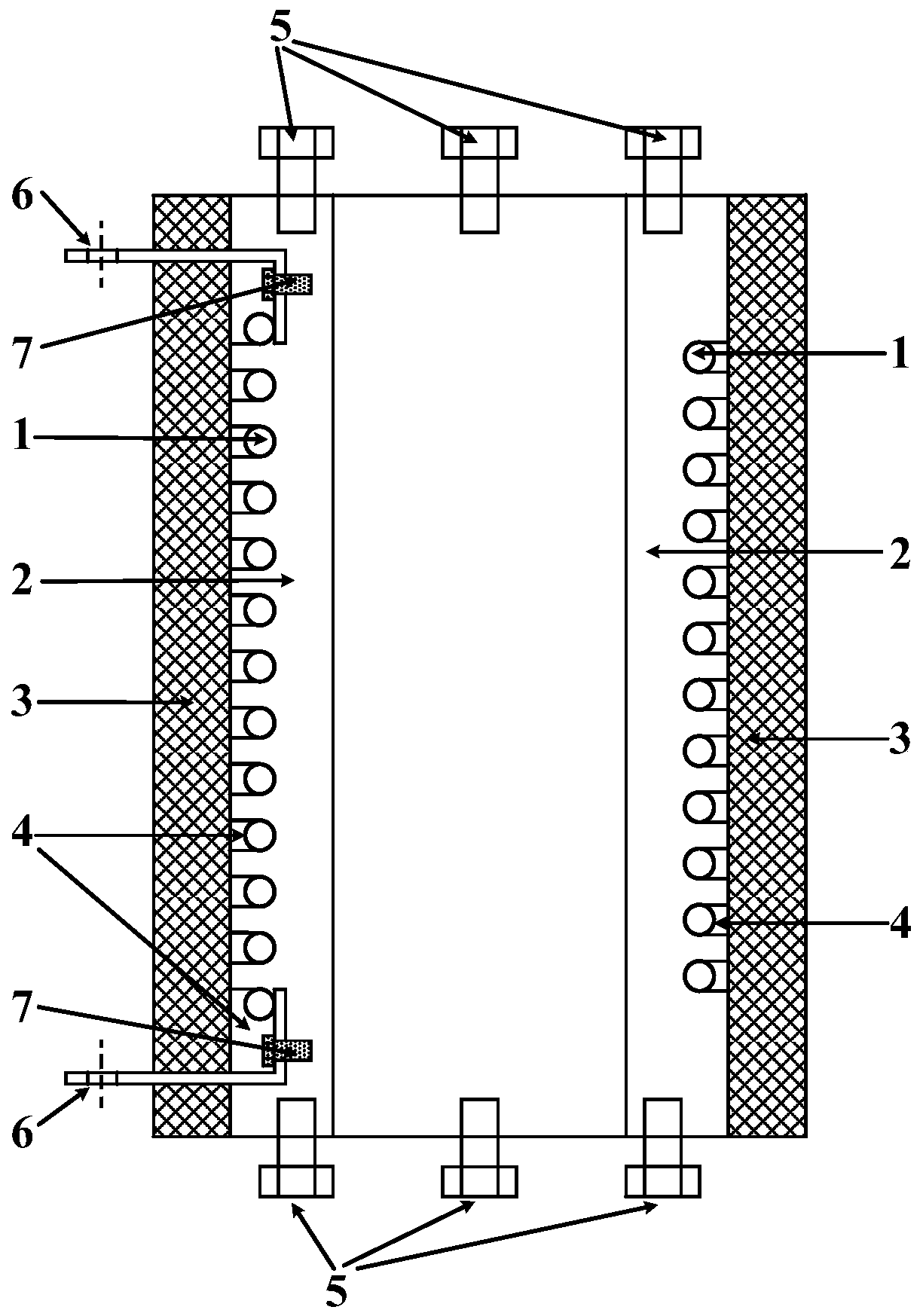

Non-groove stator of evaporative cooling motor

InactiveCN101282050ASmall electromagnetic forceLow powerMagnetic circuit stationary partsWindings conductor shape/form/constructionStator coilPhysics

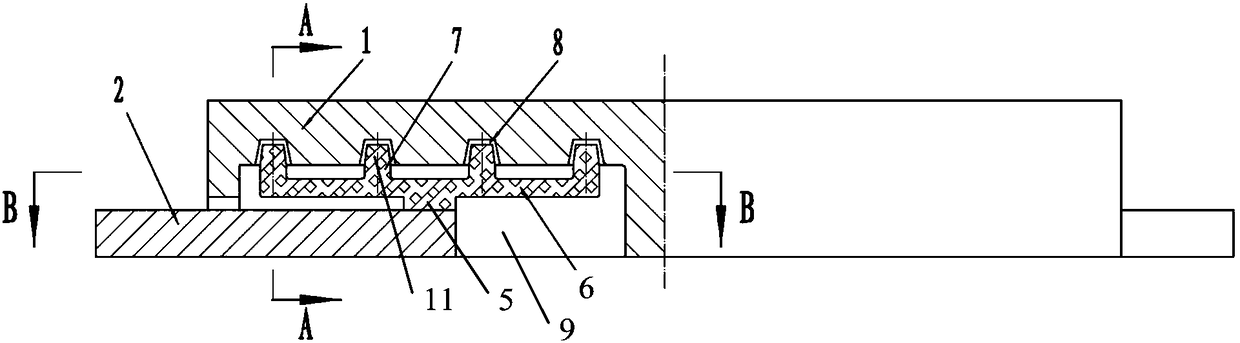

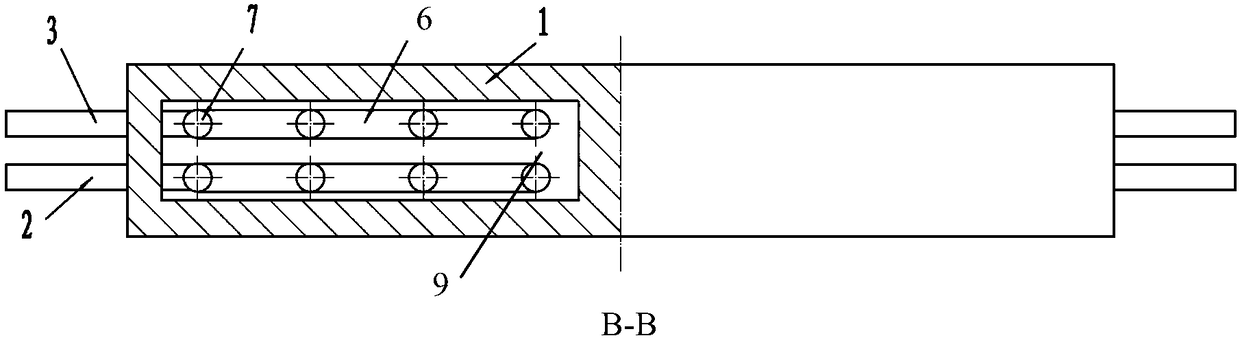

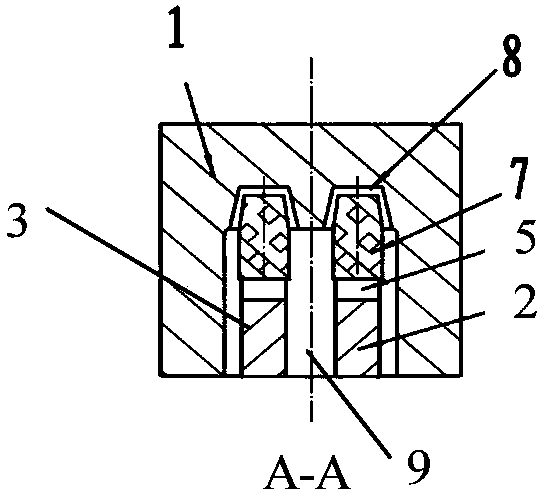

The invention discloses a stator structure without slot, a rotor coil 20 is arranged in the rotor core slot 10, a stator core 40 is not provided with a stator slot, is sleeved on the non ferromagnetic material barrel 50 and is fixed by a plurality of bolts 80 arranged along circumference, the non ferromagnetic material barrel 50 is provided with a plurality of non ferromagnetic material slots 90 along circumference direction. Meanwhile, a stator slot wedge 70 is arranged in the non ferromagnetic material slot 90 opening to fix the stator coil 60, air gap is provided between the stator core 40 and the stator core 10. The slot opening of the non ferromagnetic material slot 90 provided on the non ferromagnetic material barrel 50 faces to the stator direction or the rotor direction.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

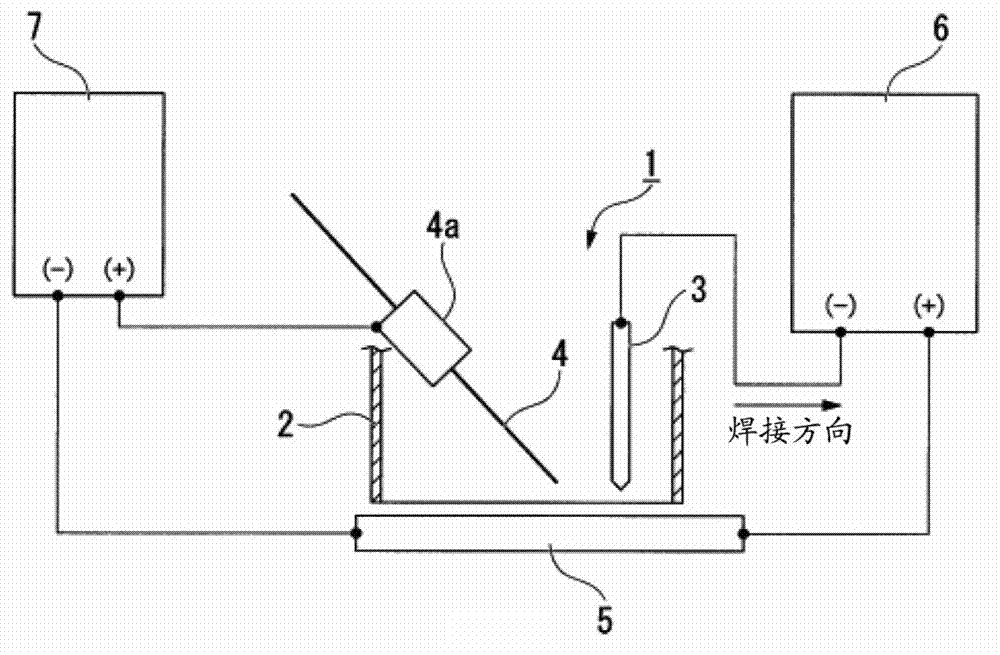

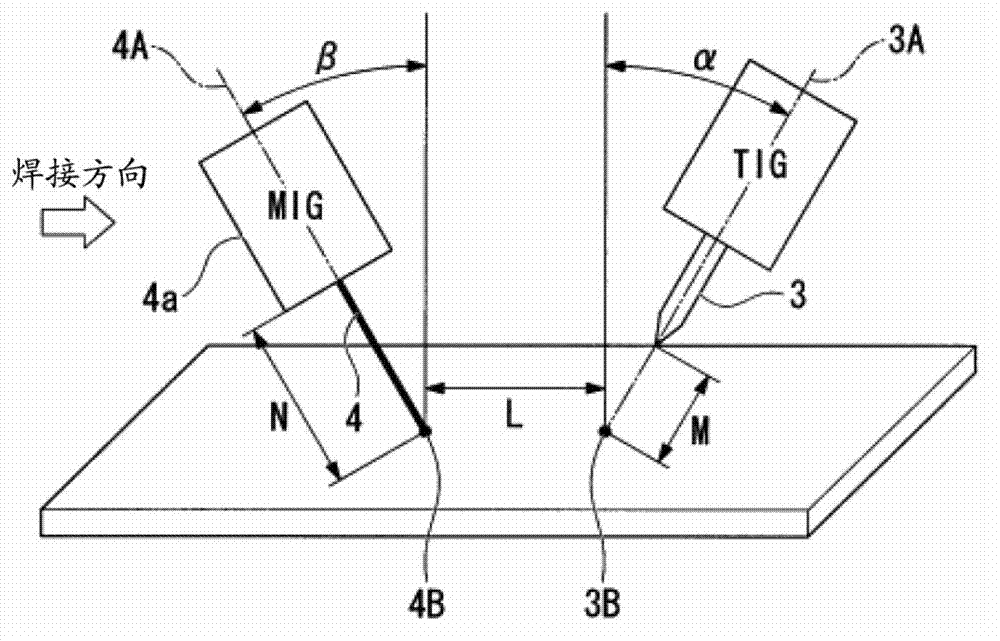

Complex weld method and welding torch for complex welds

InactiveCN103118827ANot easy to be unstableImprove stabilitySupport devices with shieldingWelding/cutting media/materialsArc stabilityEngineering

Provided is a complex weld method that is able to increase arc stability and to improve weld speed and work efficiency. The disclosed complex weld method generates a tungsten inert gas (TIG) arc on the side ahead of the weld direction and a metal inert gas (MIG) arc on the side behind and welds a base metal. Provided is a complex weld method characterised by a TIG current set higher than the MIG current and by an absolute value of the separation between the point of intersection of the base metal and the TIG electrode central axis and the point of intersection between the surface of the base metal and the MIG electrode central axis of 4 mm or less.

Owner:NIPPON SANSO CORP

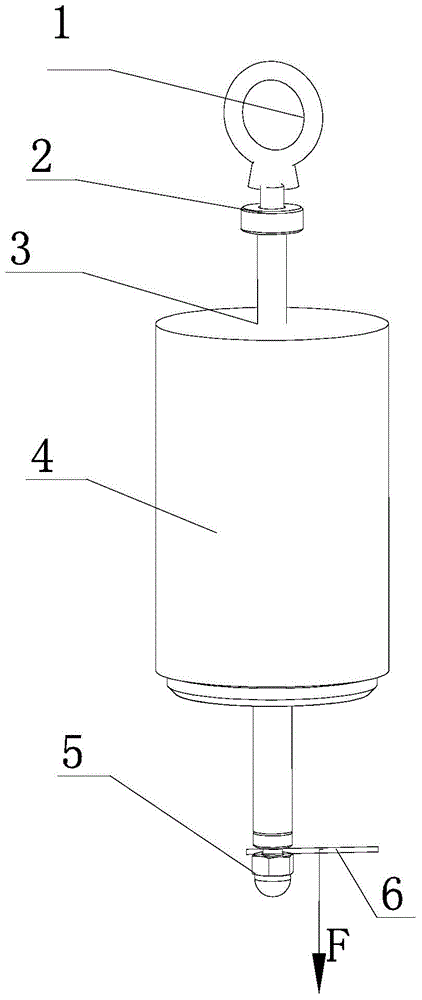

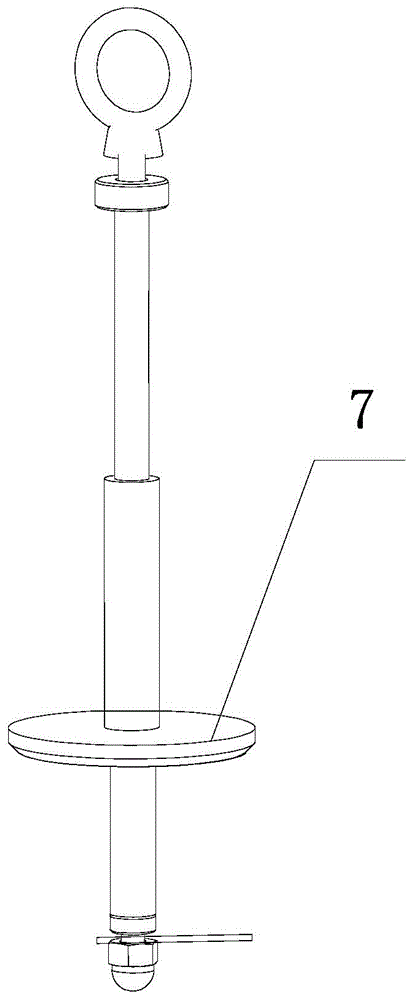

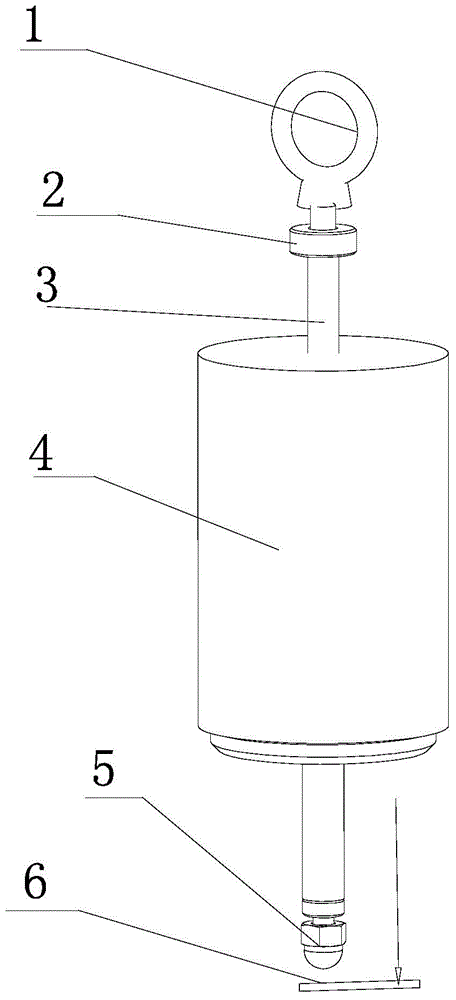

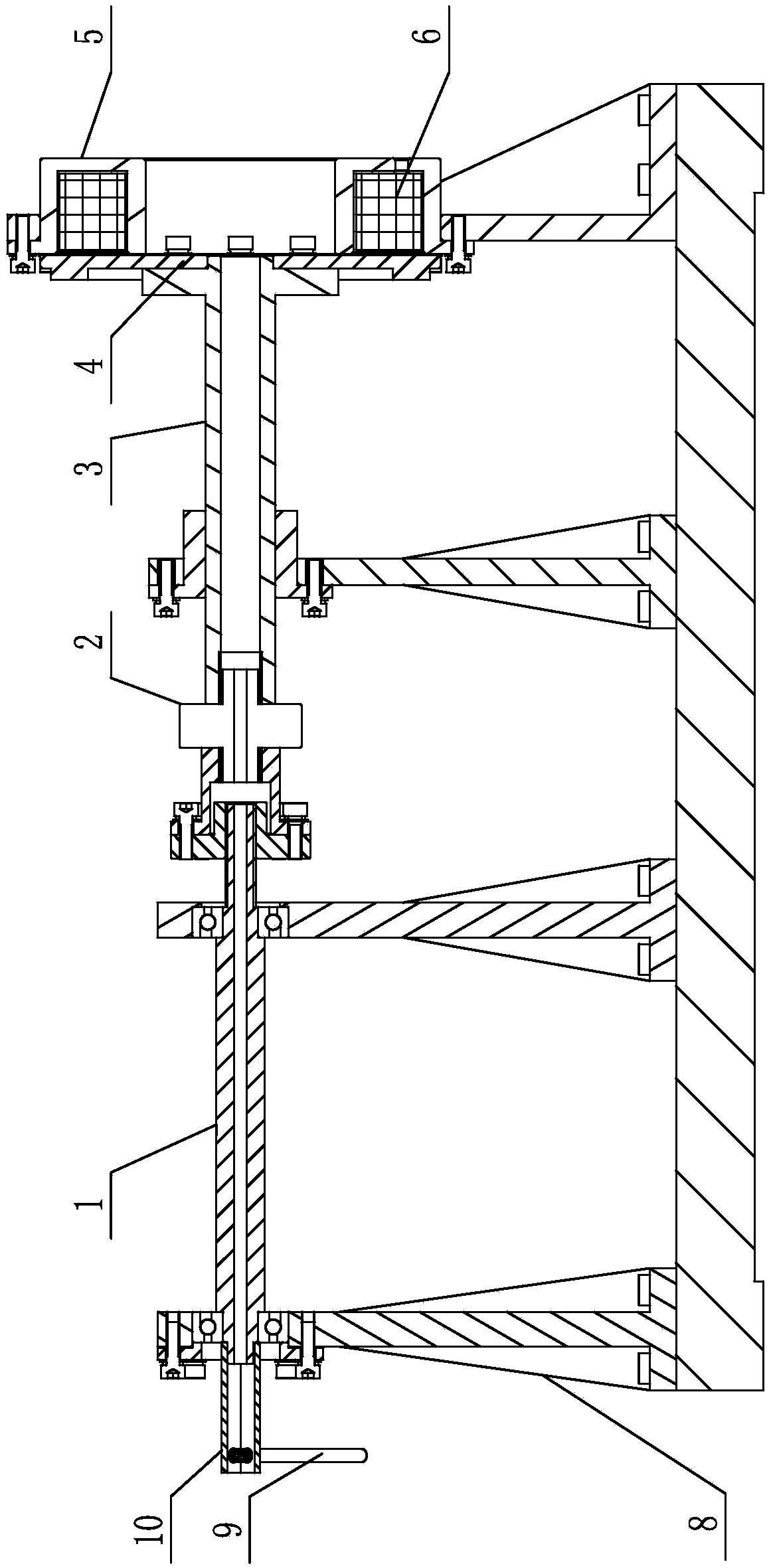

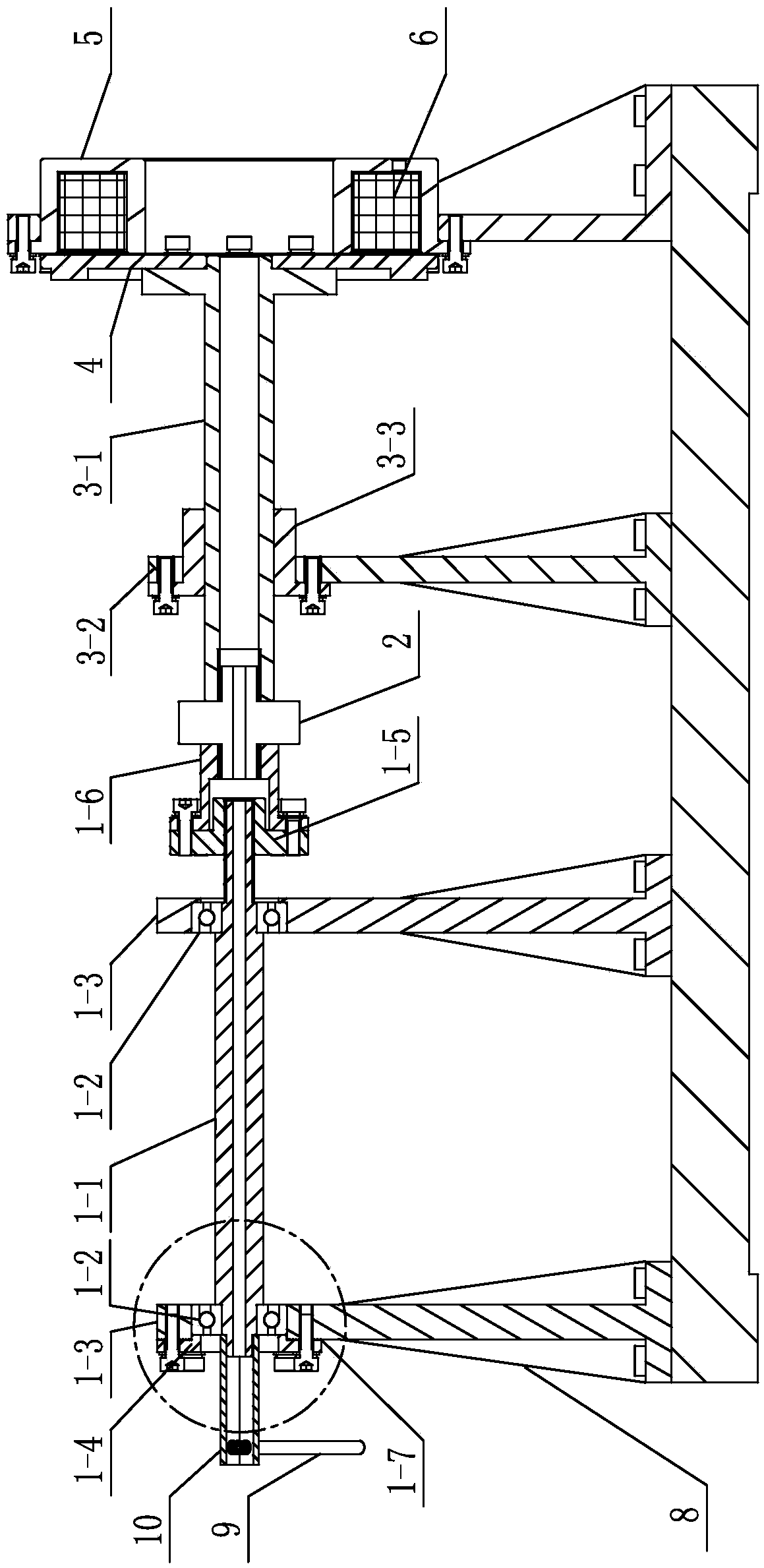

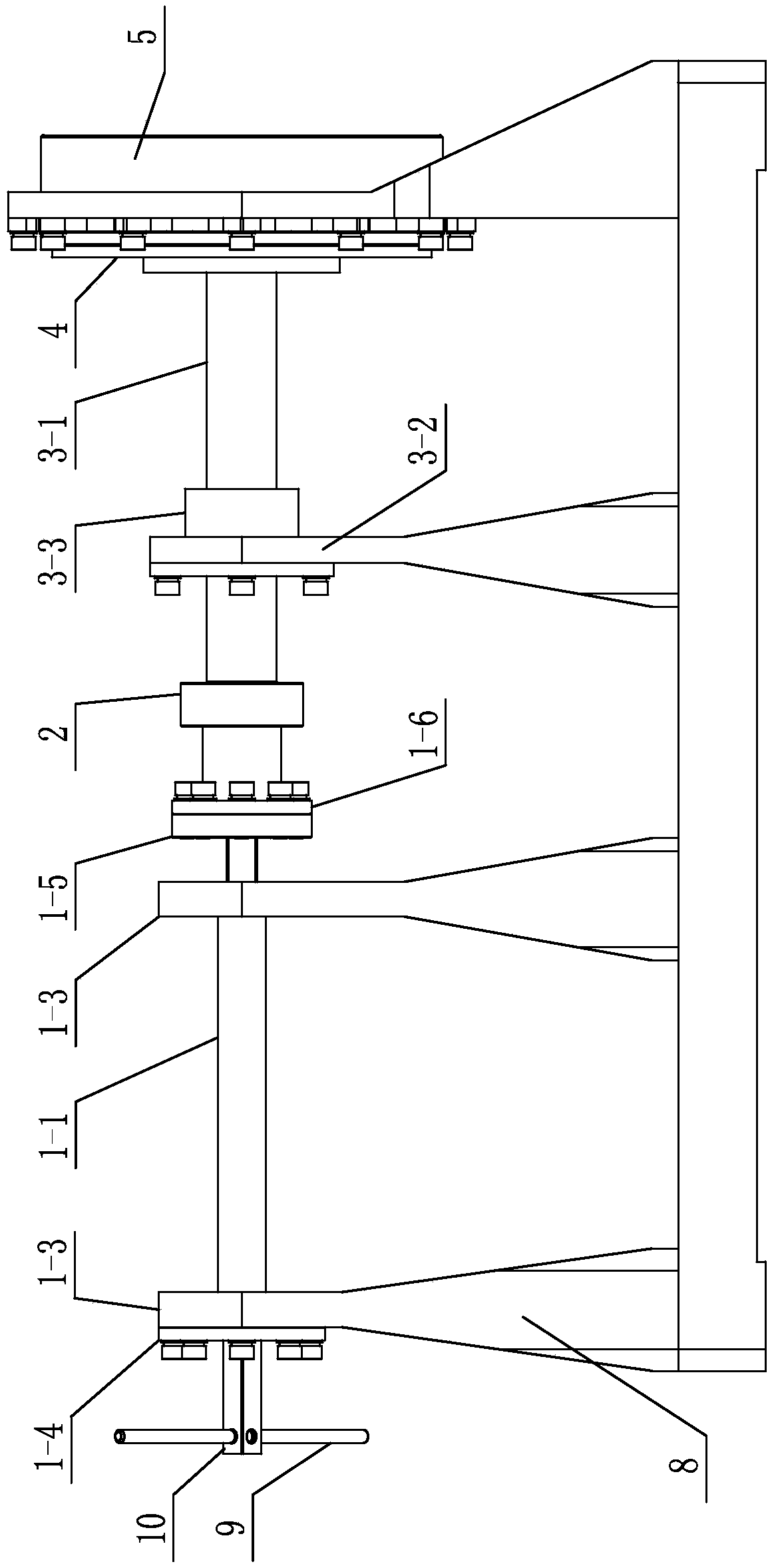

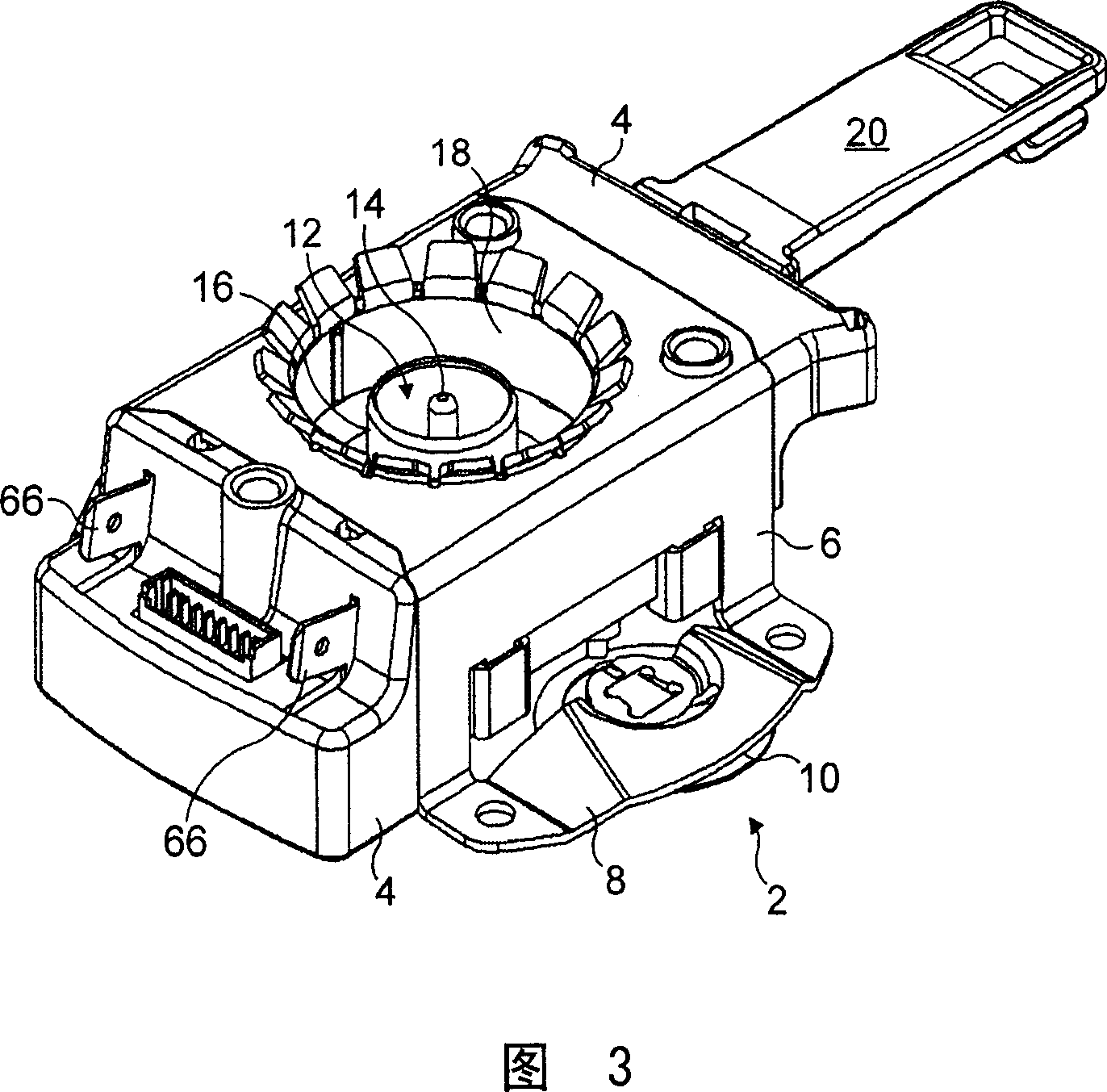

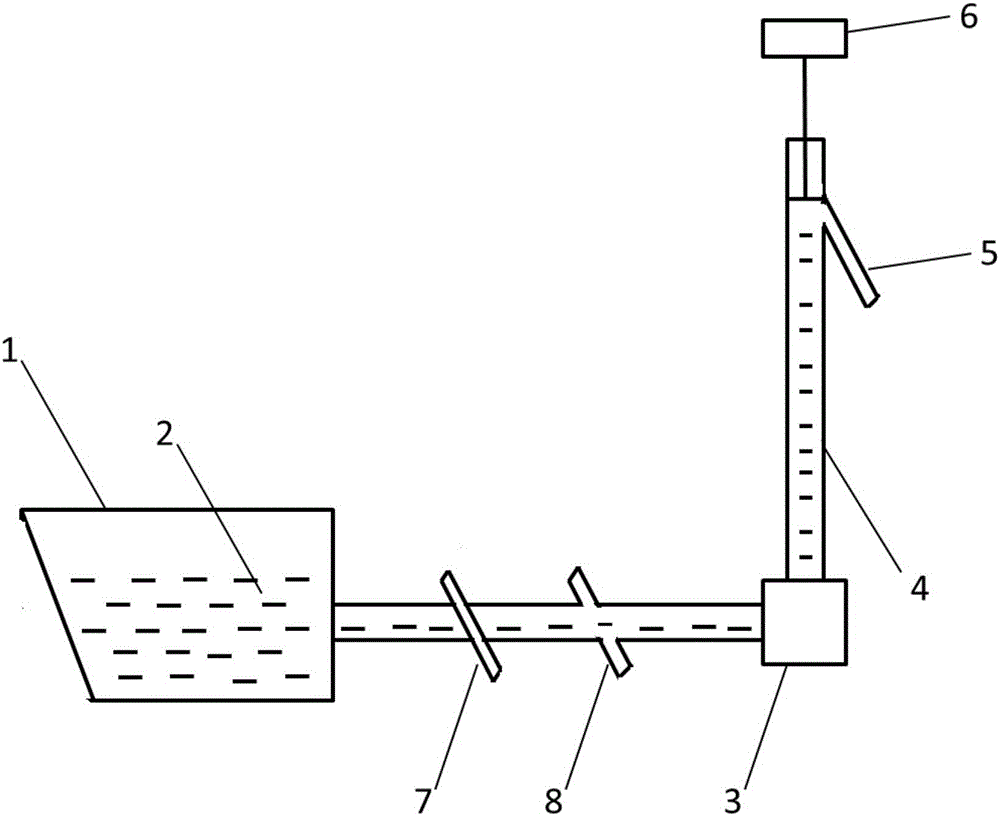

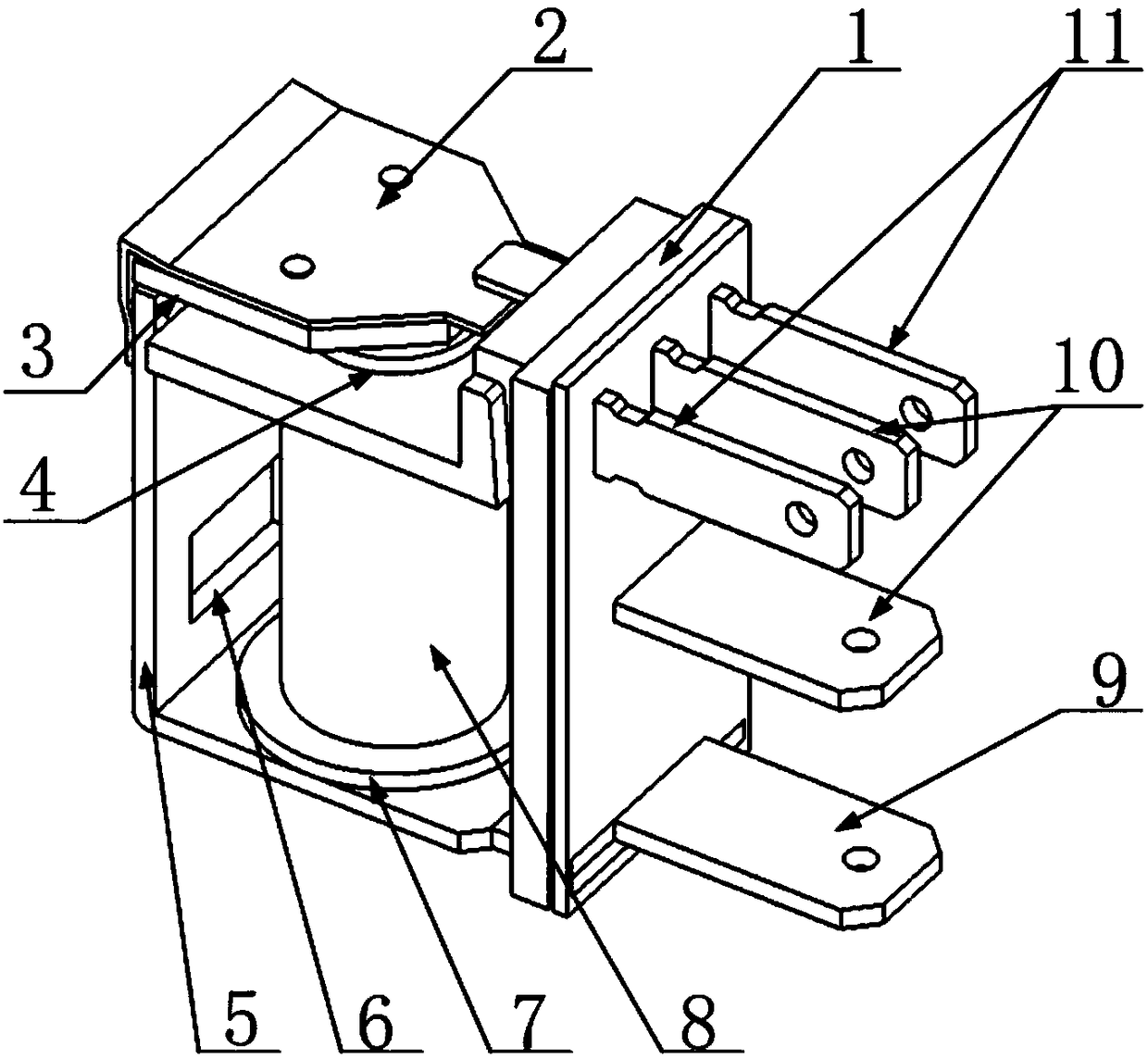

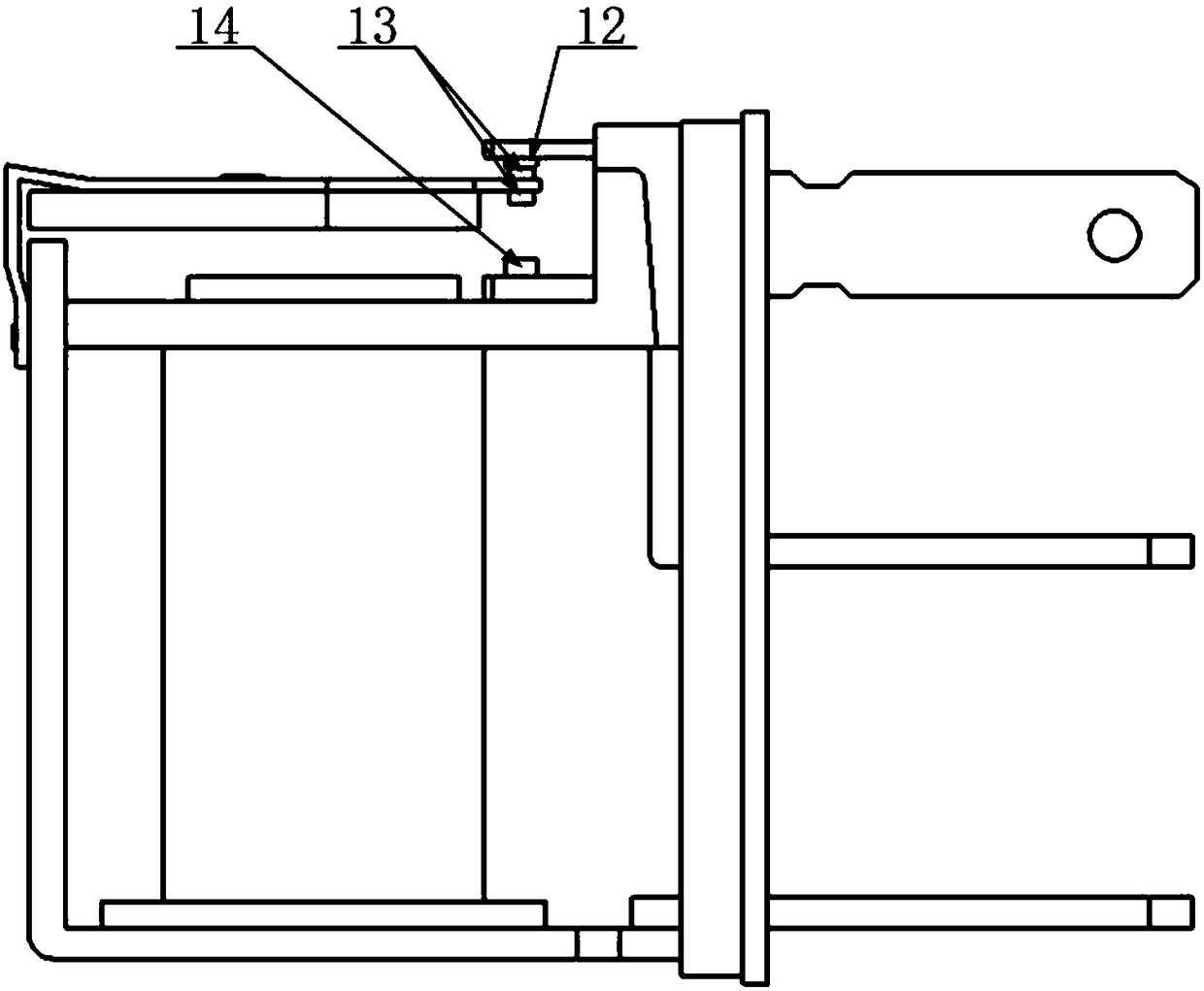

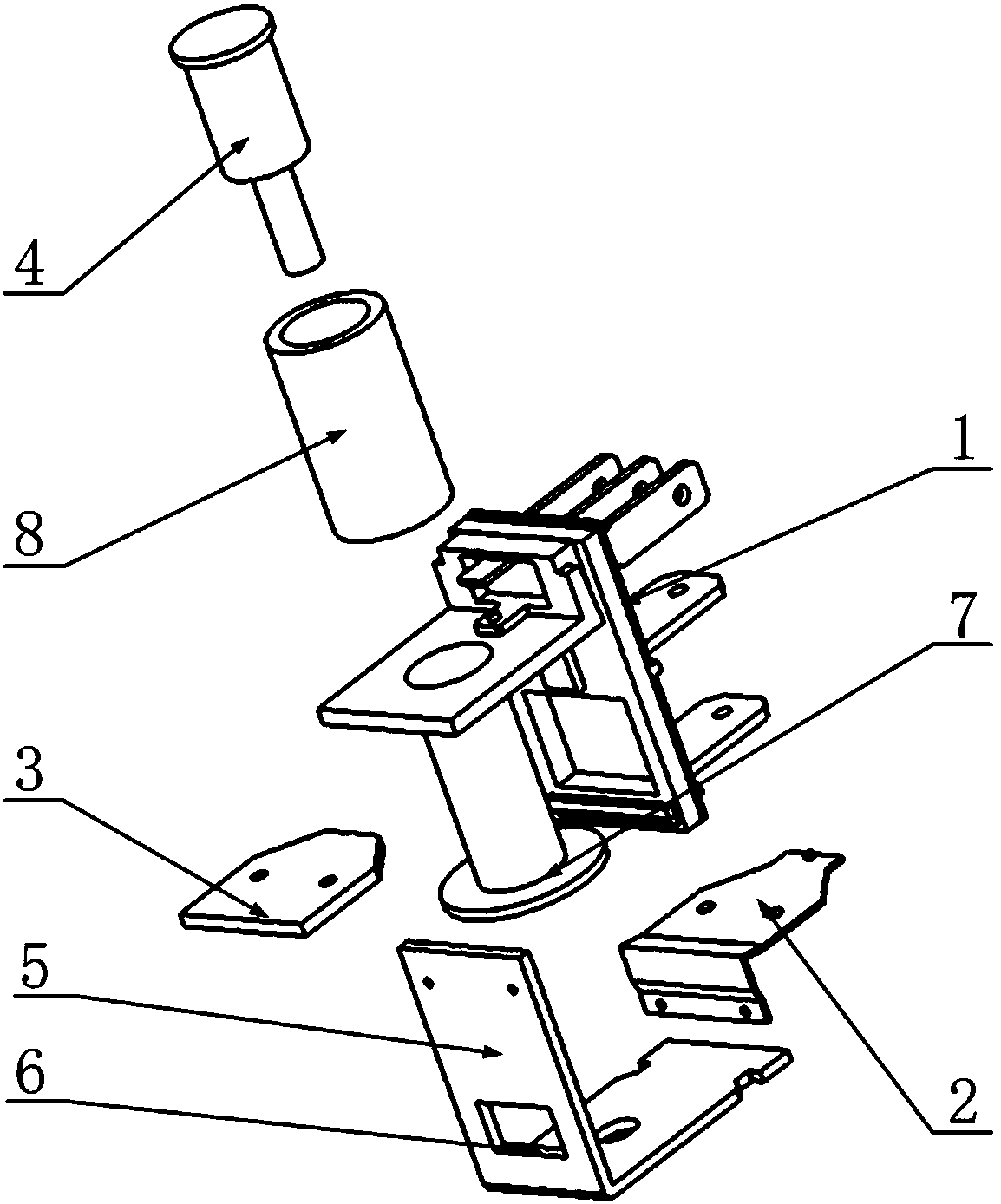

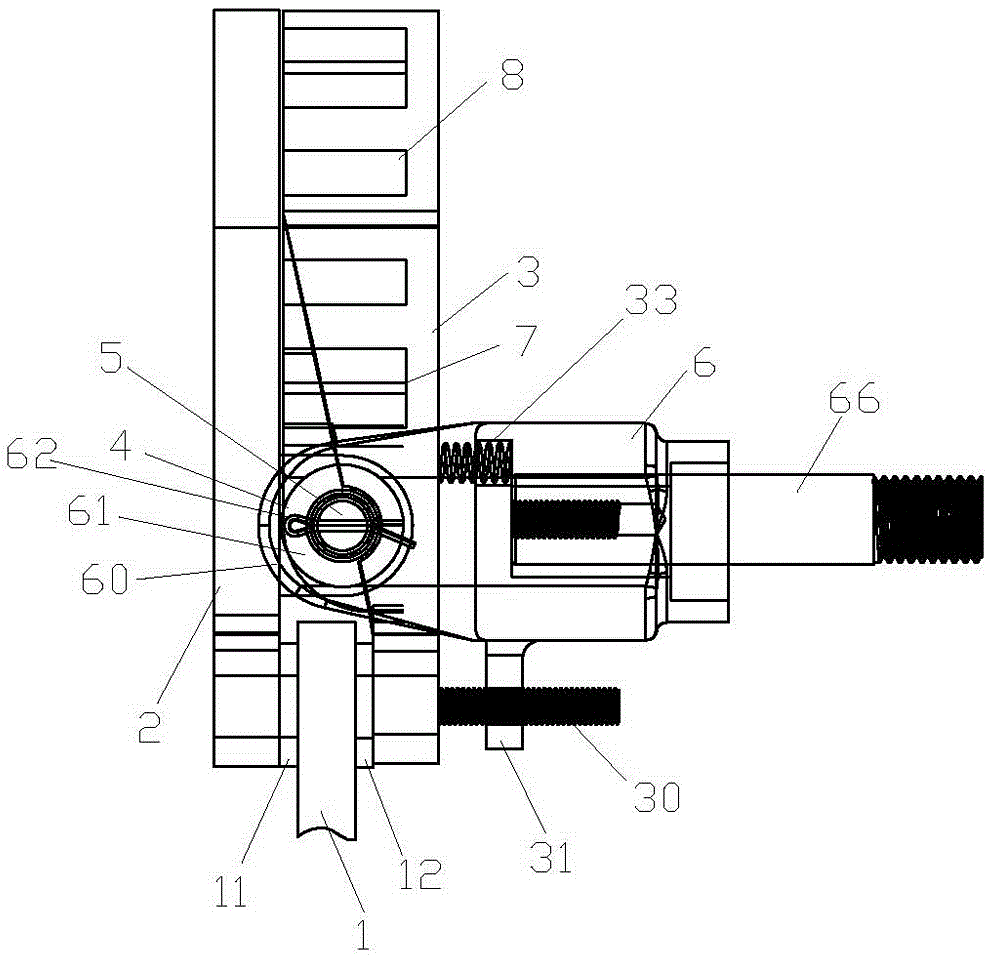

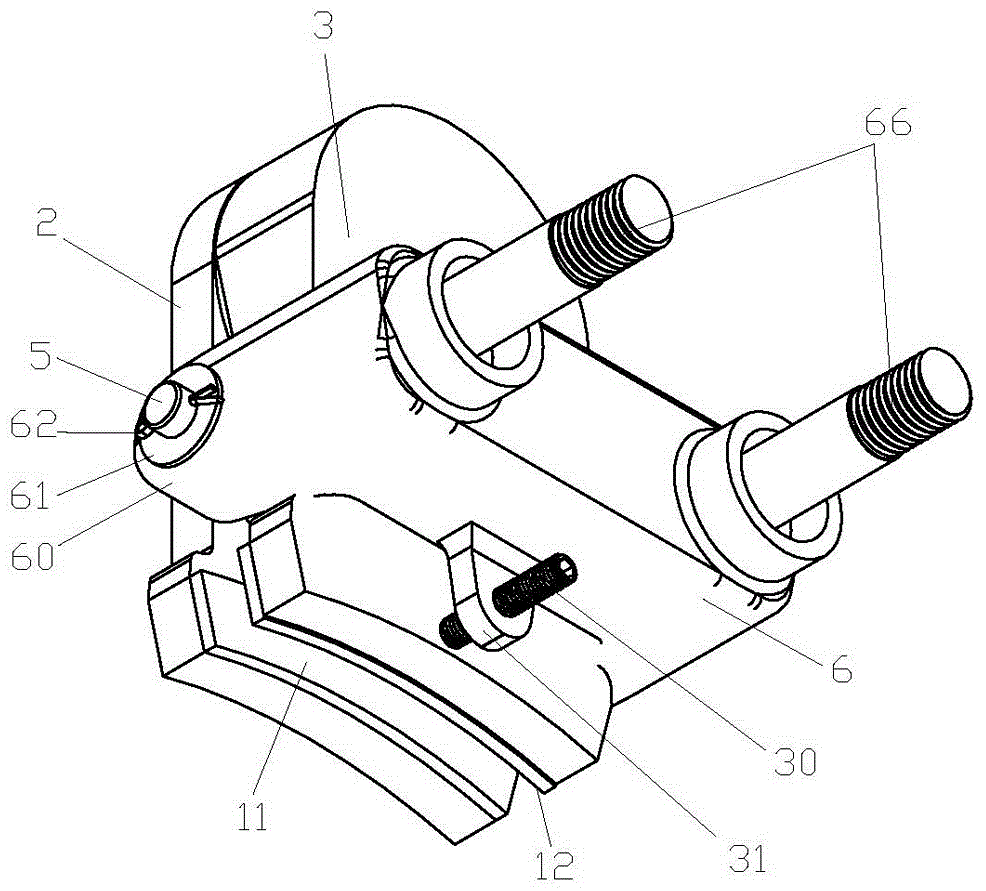

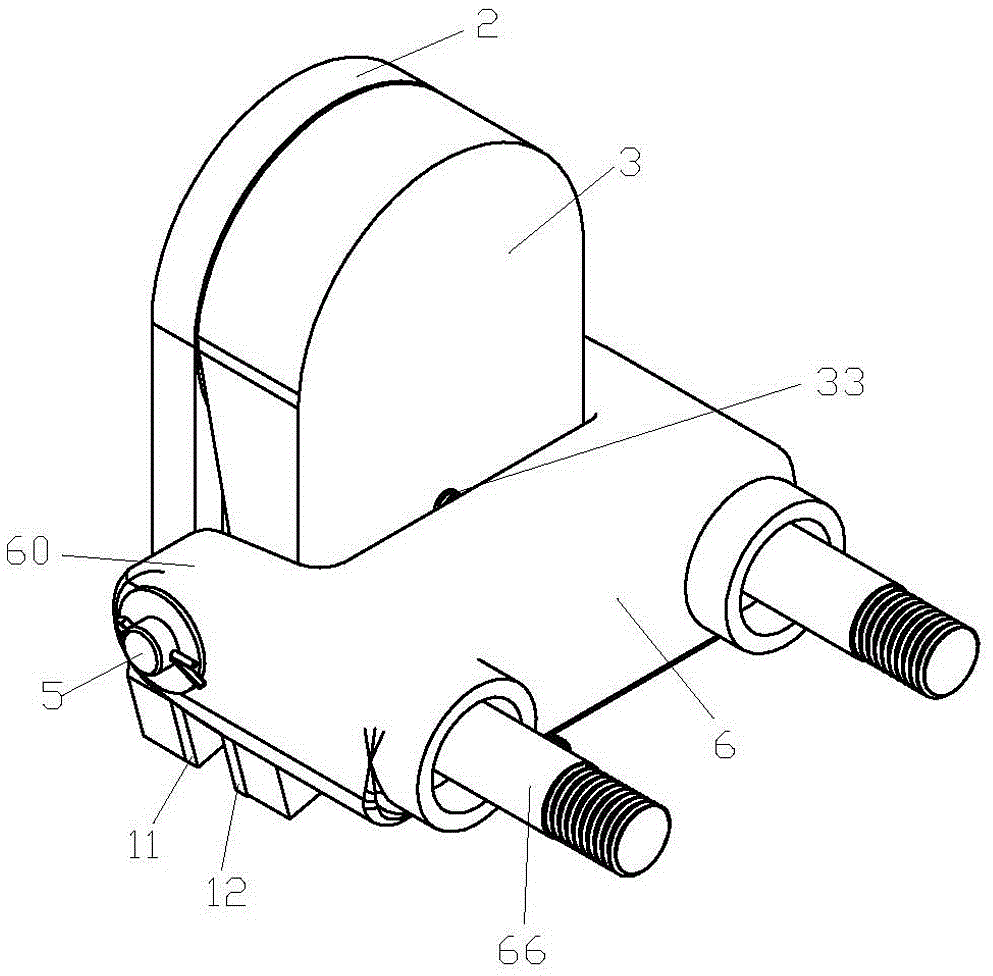

Electromagnetic-type power-off brake suction force testing device

ActiveCN109115389ASmall electromagnetic forceApparatus for force/torque/work measurementEngineeringSuction force

The invention discloses an electromagnetic-type power-off brake suction force testing device, and relates to a brake testing device. The invention aims at solving a problem that a conventional suctionforce testing device cannot meet the requirements of precise measurement of the electromagnetic suction force of a brake. The device comprises an axial displacement precision adjustment device, a load cell, an armature friction disc support device, an armature friction disc, a brake housing, an electromagnetic coil and a support frame. One end of the load cell is connected to the axial displacement precision adjustment device, the other end is connected with one end of the armature friction disc support device, and the other end of the armature friction disc support device is fixedly connected with one side of the armature friction disc. The load cell moves in the stroke direction of the load cell under the drive of the axial displacement precise adjustment device. The electromagnetic coil is installed in an annular groove in the brake housing, and the brake housing and the armature friction disc are magnetically connected by an electromagnetic force generated by the electromagnetic coil. The device is used for accurately measuring the suction force of the electromagnetic coil to the armature friction disc.

Owner:HARBIN INST OF TECH

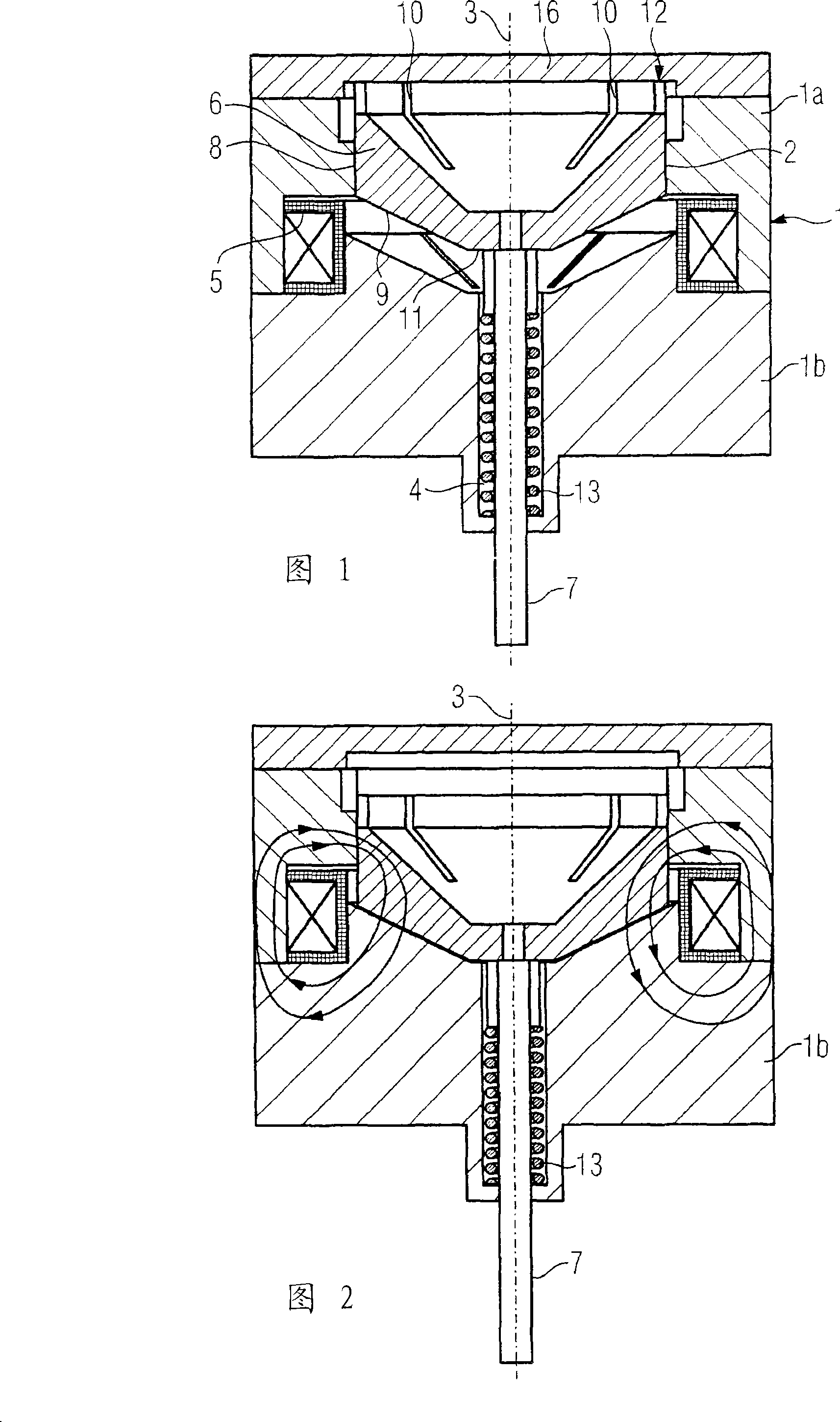

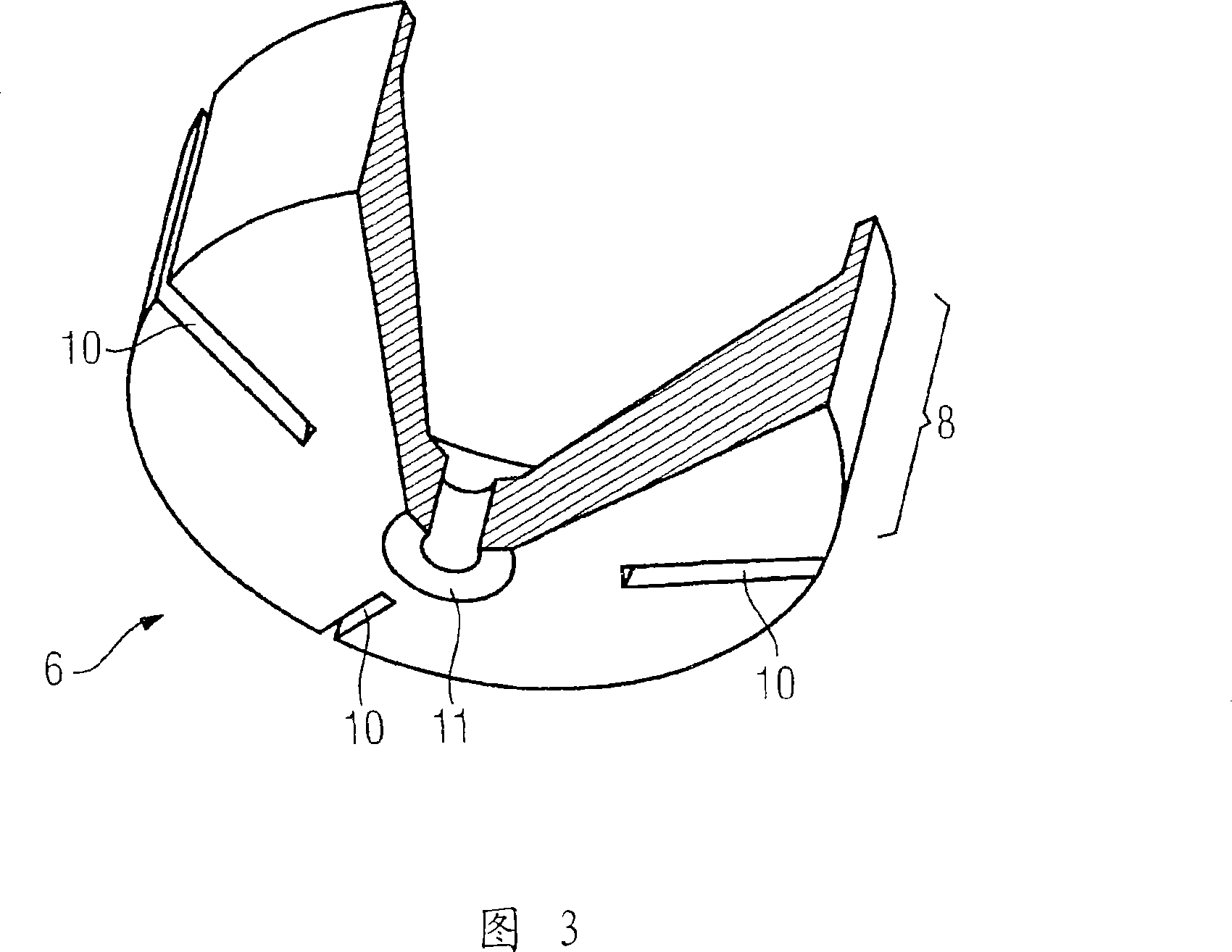

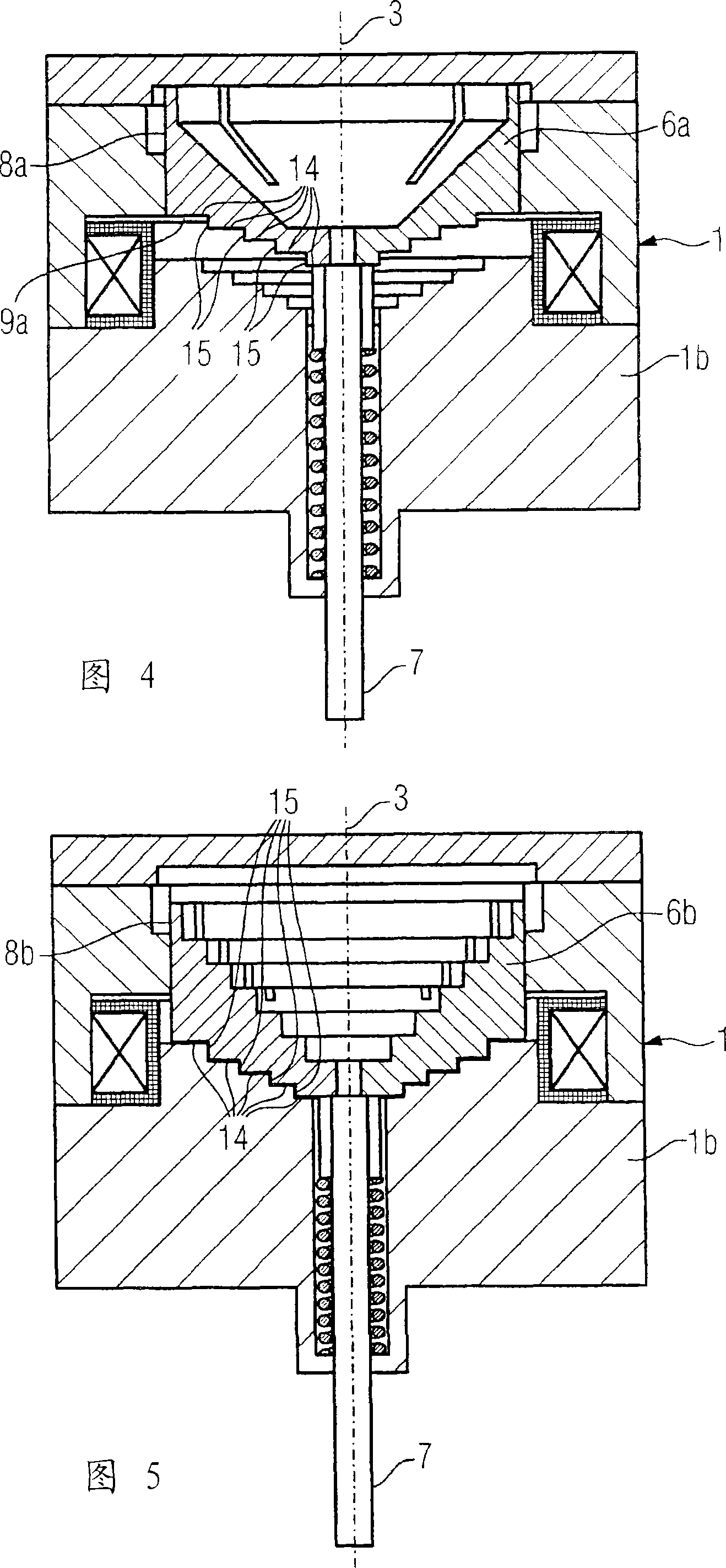

Electromagnetic drive system

InactiveCN101189690ASmall electromagnetic forceAvoid damageElectromagnets with armaturesEngineeringPiston

An electromagnetic drive system comprises an armature (6, 6a, 6b) that can be displaced along an axis (3). The armature (6, 6a, 6b) comprises a piston-shaped section (8, 8a, 8b). Said piston-shaped section (8, 8a, 8b) is guided in a cylindrical section (2) of the stator (1). A recess (10) extends through the piston-shaped section (8, 8a, 8b) substantially in the direction of the axis (3).

Owner:SIEMENS AG

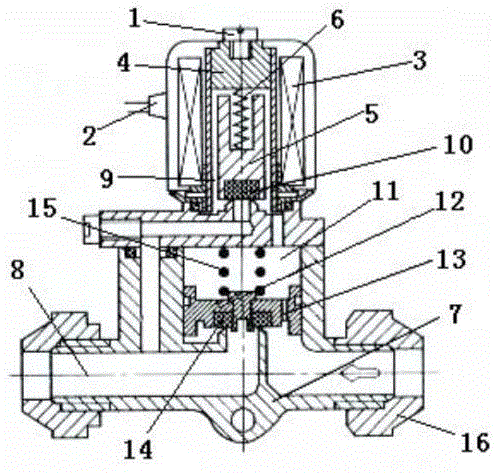

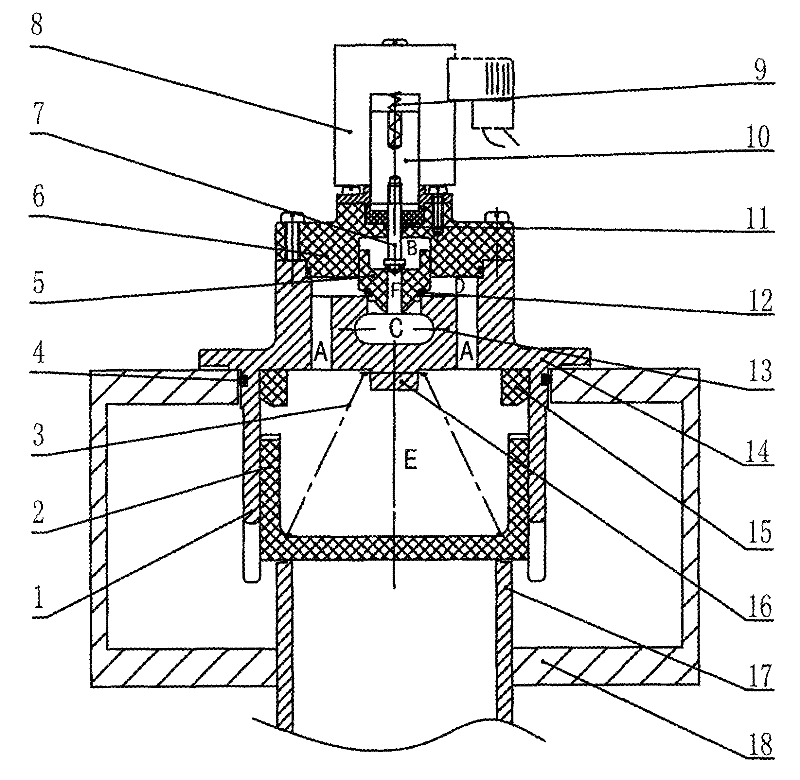

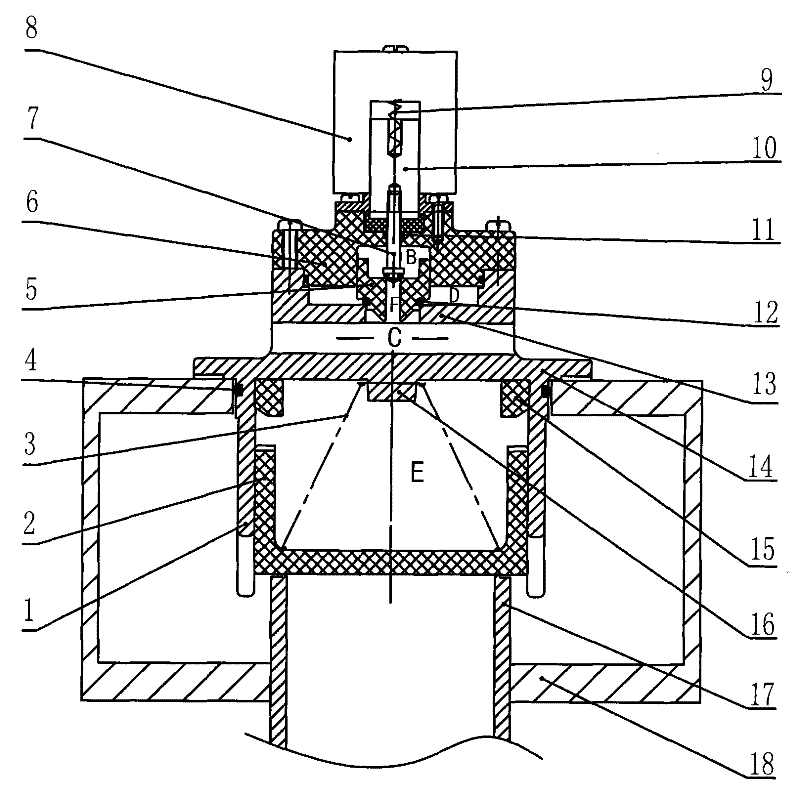

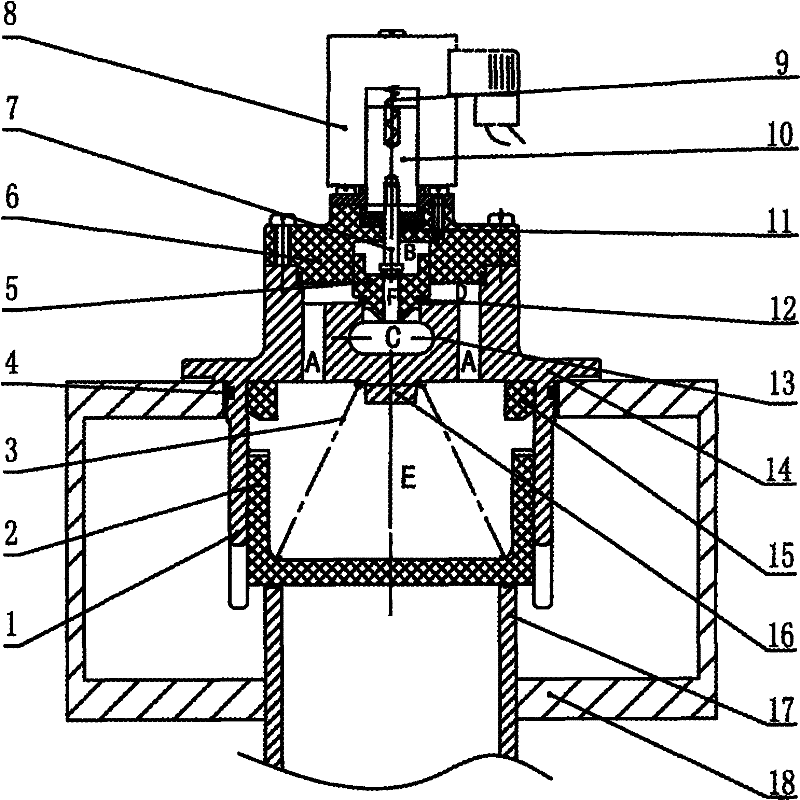

Two-position two-way solenoid valve

InactiveCN104100758ASmall electromagnetic forceReduce power consumptionOperating means/releasing devices for valvesValve housingsSolenoid valveEngineering

The invention discloses a two-position two-way solenoid valve. The two-position two-way solenoid valve comprises a top cover, a socket, a shell, a coil, a static iron core, a movable iron core, a first spring, a valve body, a main valve cavity, an upper cavity, a pilot valve, an upper valve port, a lower cavity, a lower valve port, a piston and a balance hole, wherein the two-way main valve cavity is formed in the valve body; the lower cavity is arranged in the main valve cavity; the lower cavity is communicated with the main valve cavity by the lower valve port; the upper cavity is arranged above the valve body; the upper valve port is arranged in the bottom of the upper cavity; the other end of the upper valve port is communicated with the main valve cavity by a pipe hole; a second pipe hole is formed in the bottom of the upper cavity and is communicated with the lower cavity; the pilot valve is arranged inside the upper cavity; the piston is arranged in the lower cavity; the balance hole is formed in the piston and is used for communicating the inlet of the main valve cavity with the lower cavity. The two-position two-way solenoid valve has the advantages that the electromagnetic force is small, the power consumption is low, the structure is simple and compact, the shape is small, and the nominal dimension range is wide.

Owner:SUZHOU GUJI ELECTRONICS TECH

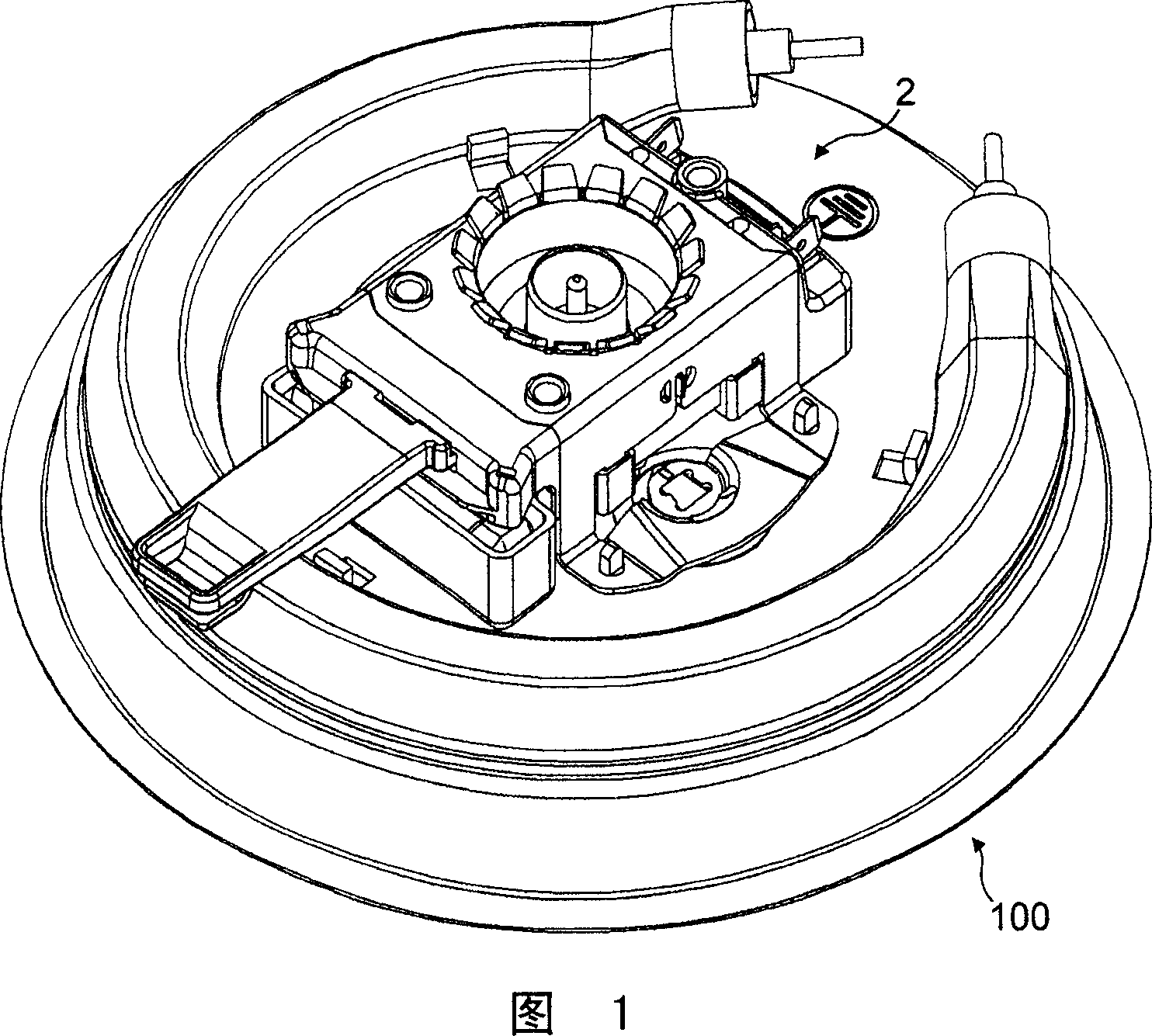

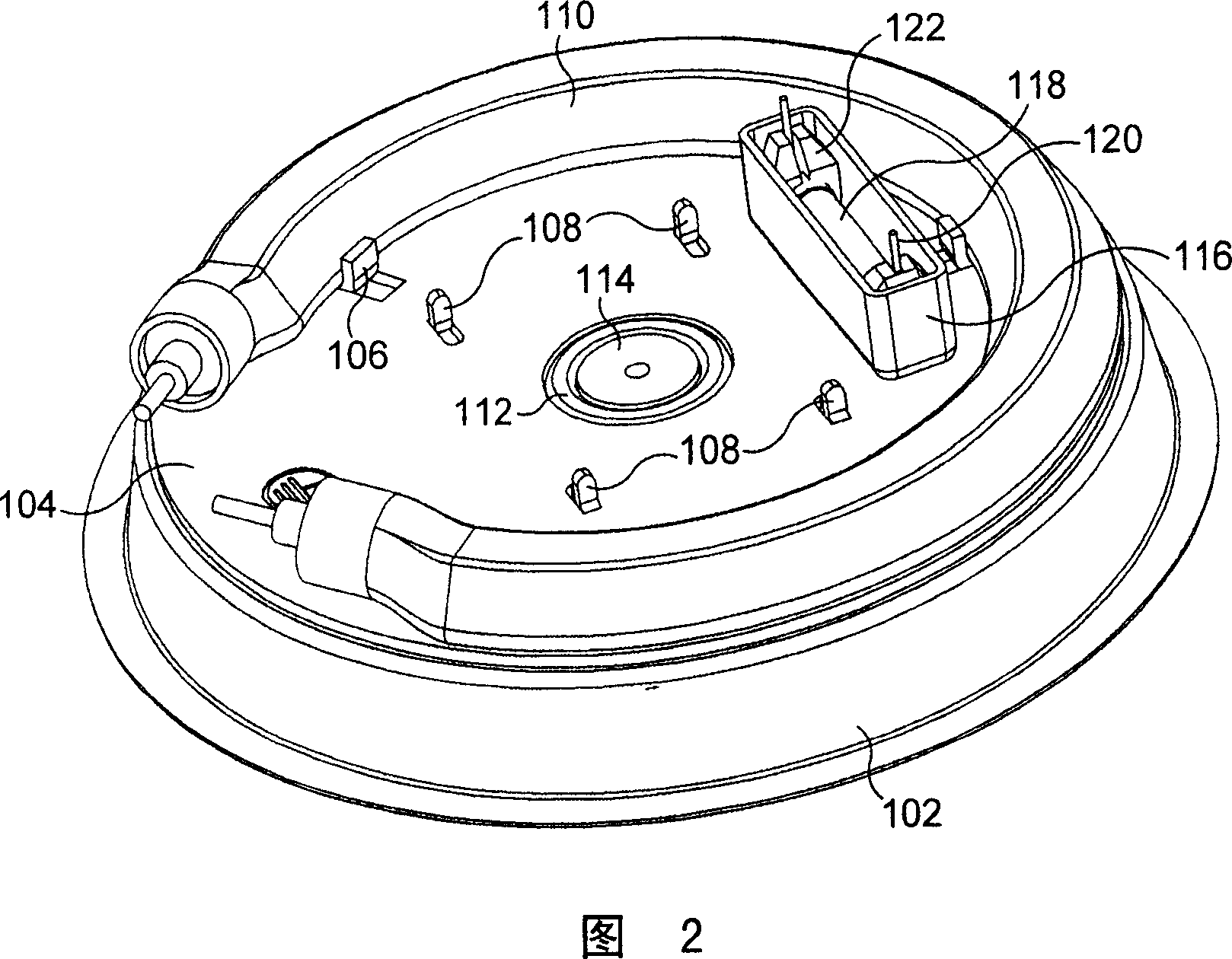

Liquid heating vessels

ActiveCN1940399AImprove bindingSmall electromagnetic forceWater-boiling vesselsImmersion heating arrangementsLiquid temperatureEngineering

A liquid heating vessel comprises heating means (110) for heating liquid in the vessel, electronic control means (80), electromagnetic switching means (60) for interrupting or reducing power to the heating means (110), and temperature sensing means (26) for providing a signal dependent on the temperature of liquid in the vessel to the control means (80). The control means (80) is arranged to operate the electromagnetic switching means (60) to interrupt or reduce power to the heating means (11) in response to the control means (80) determining that a pre-determined temperature condition has been reached.

Owner:STRIX LTD

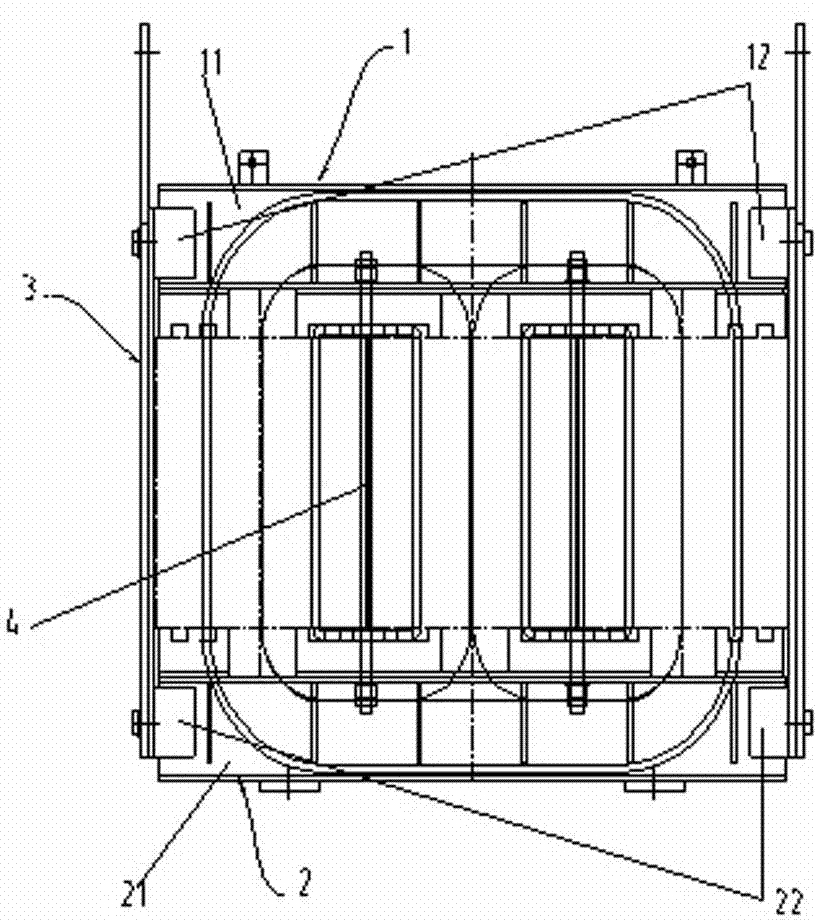

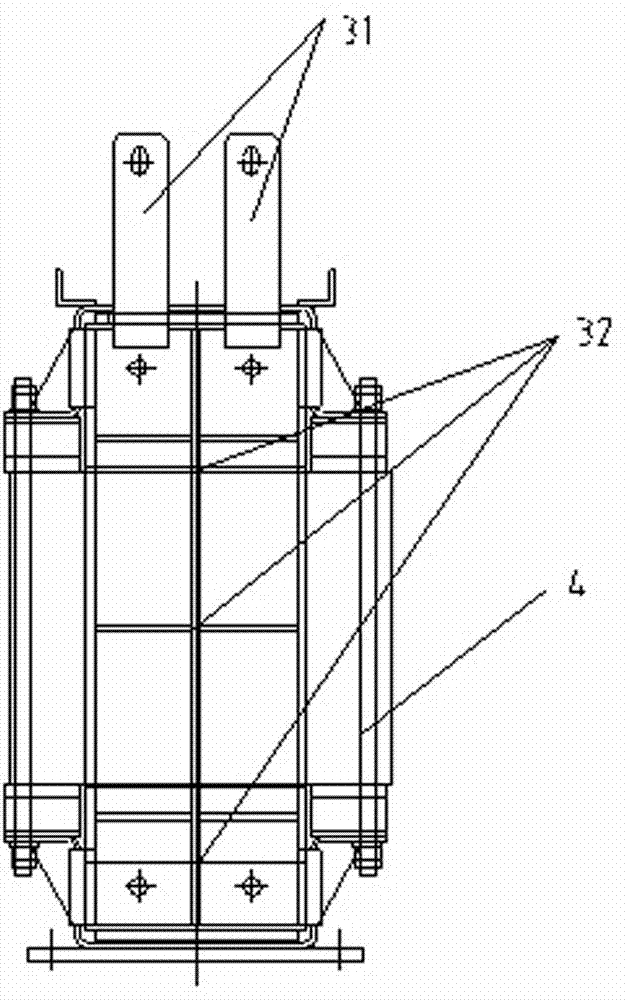

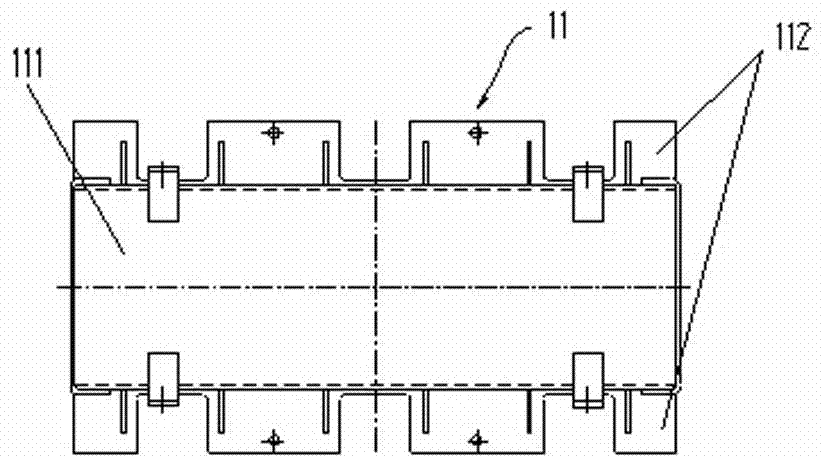

Transformer body structure

InactiveCN103050236AAchieve axial compressionIncrease axial pressureTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerFlux loop

The invention relates to a transformer body structure, in particular to a body structure of an open type winding iron core transformer. The transformer body structure comprises a magnetic flux loop formed by splicing multiple silicon steel sheets, an upper clamping part arranged on the upper portion of the magnetic flux loop, a lower clamping part arranged on the lower portion of the magnetic flux loop and two side plates positioned on the left and right sides of the body structure, the upper clamping part comprises an upper body and upper fixed plates fixedly arranged on the left and right sides of the upper body, the lower clamping part comprises a lower body and lower fixed plates fixedly arranged on the left and right sides of the lower body, the side plates are detachable and connected with the upper fixed plates and the lower fixed plates respectively, a storage space of the magnetic flux loop is formed among the upper clamping part, the two side plates and the lower clamping part, and a connecting mechanism capable of being in detachable connection is arranged between the upper clamping part and the lower clamping part. The transformer body structure is compact in structure, high in strength, small in noise and high in short-circuit resistance.

Owner:WUJIANG TRANSFORMER CO LTD

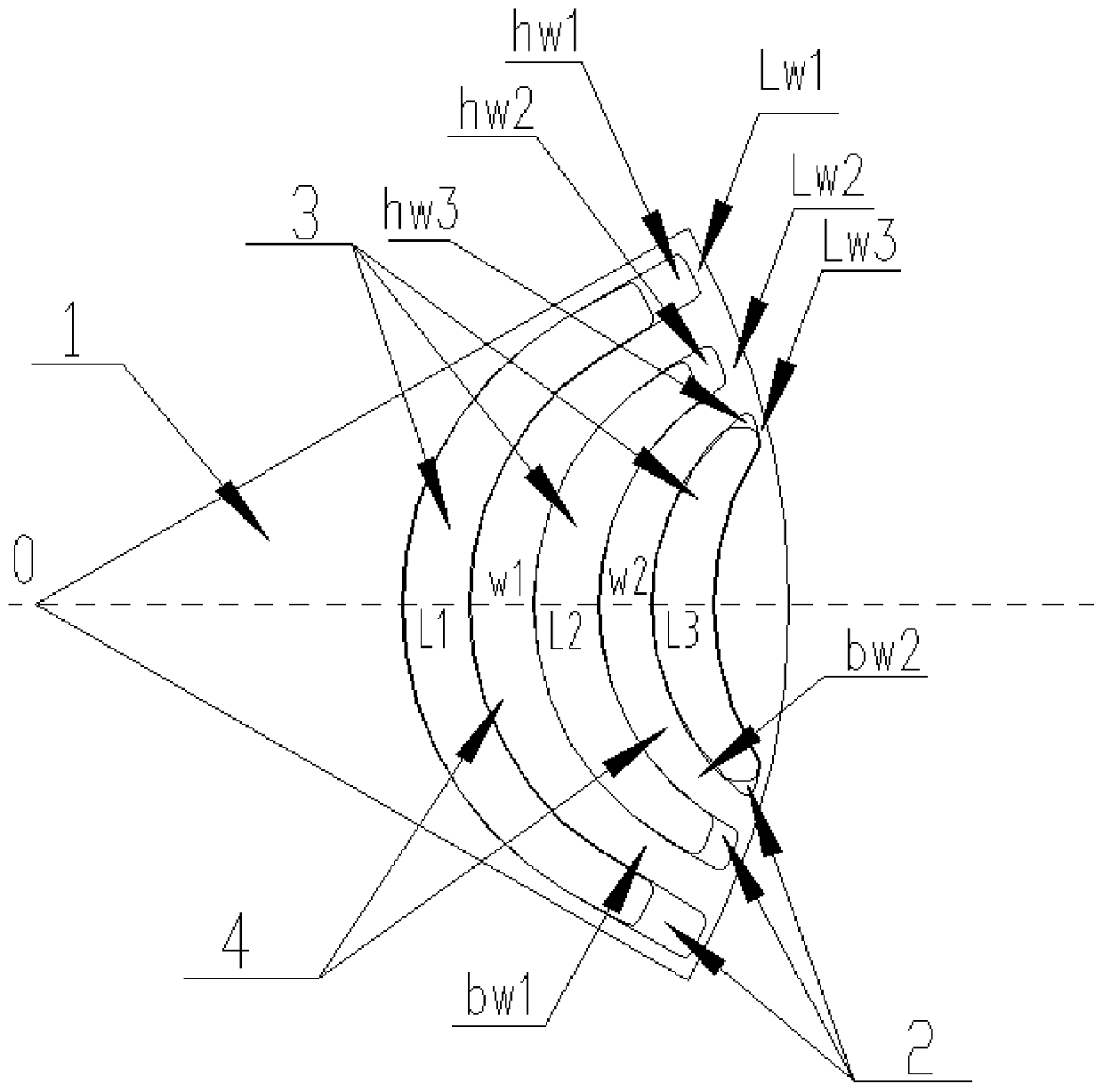

Voice coil motor used for large-aperture adaptive deformable mirror

InactiveCN108712055ASimple structureReduce volumePropulsion systemsOptical elementsMagnetic tension forceAstronomical telescopes

The invention provides a voice coil motor used for a large-aperture adaptive deformable mirror. A cylindrical coil is arranged. A tiny gap is formed between the top of the cylindrical coil and a magnet. A soft iron shell is arranged on the exteriors of the magnet and the central shaft. The voice coil motor is of a moving iron type structure and is characterized in that the cylindrical coil is installed in the soft iron shell at the bottom; the cylindrical coil and a mirror plane isolation permanent magnet are arranged in a position which is arranged in the axial direction of the cylindrical coil and are directly adhered to and fixed to the mirror plane of an astronomical telescope. According to the invention, the radial size and the occupied space of the voice coil motor are reduced; traditional hidden risks of short-circuit faults are eliminated; mover quality and movement inertia are reduced; effects on the mirror plane imposed by heating of the coil of the voice coil motor are overcome; through design of optimized magnetic fields, the voice coil motor has quite high motor efficiency; quite big pushing force can be achieved through high frequency small current; the electromagnetic force can reach 1N or over and reaches 0.6 N; the efficiency of the motor reaches 0.45N / W; and requirements of the large-aperture adaptive deformable mirror can be met.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

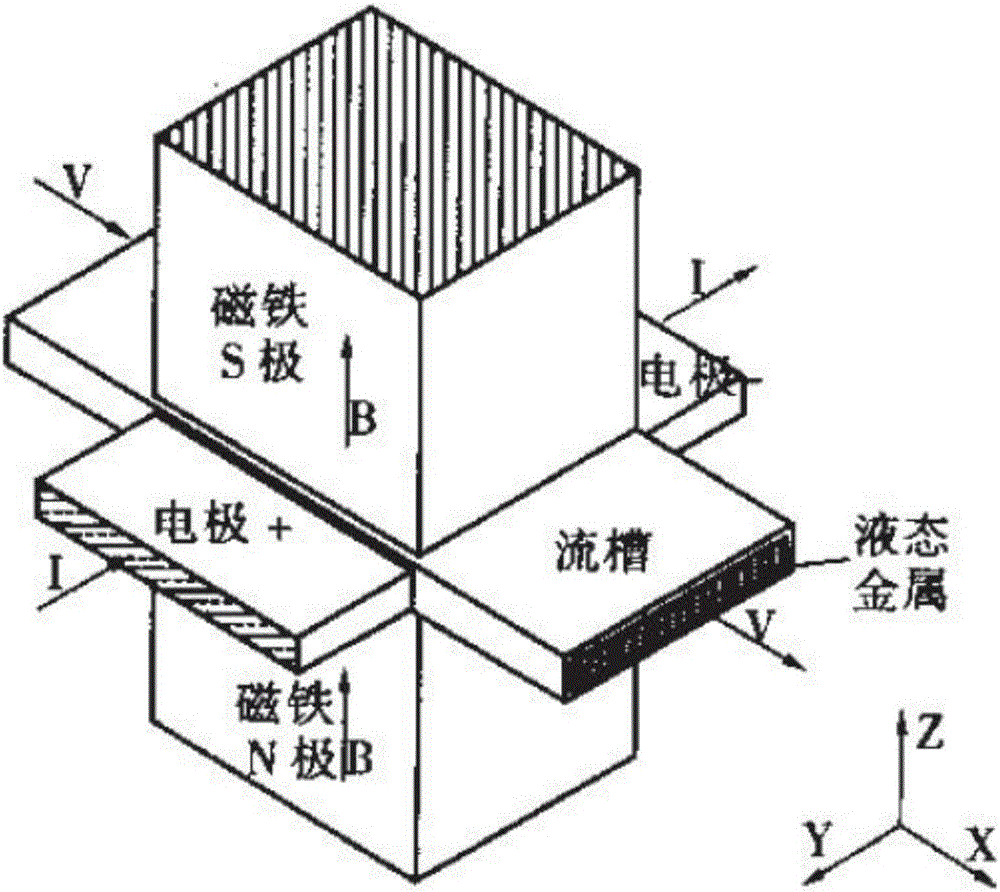

Aluminum alloy suspending quantitative casting control method

The invention relates to an aluminum alloy suspending quantitative casting control method. The method is achieved by adopting a control device which comprises a crucible, a main electromagnetic pump, a liquid lifting pipe, a liquid outlet, a laser range finder, a first auxiliary electromagnetic pump and a second auxiliary electromagnetic pump; aluminum liquid sequentially flows through the first auxiliary electromagnetic pump, the second auxiliary electromagnetic pump, the main electromagnetic pump, the liquid lifting pipe and the liquid outlet; the first auxiliary electromagnetic pump is parallel to the second auxiliary electromagnetic pump, and an included angle of 30-60 degrees is formed between the first auxiliary electromagnetic pump and an aluminum liquid conveying pipeline and formed between the second auxiliary electromagnetic pump and the aluminum liquid conveying pipeline; the magnetic induction intensity B of the first auxiliary electromagnetic pump and the magnetic induction intensity B of the second auxiliary electromagnetic pump are same in size and direction; the metal liquid in a magnetic gap of the first auxiliary electromagnetic pump and the metal liquid in a magnetic gap of the second auxiliary electromagnetic pump are same in length; a current of the first auxiliary electromagnetic pump and a current of the second auxiliary electromagnetic pump are same in size and opposite in direction, therefore, the aluminum liquid can be stirred in the direction of being perpendicular to the flowing direction, gas and residues which are mixed in the aluminum liquid can be relatively uniform, and then the quantitative precision is improved.

Owner:ZHONGBEI UNIV +2

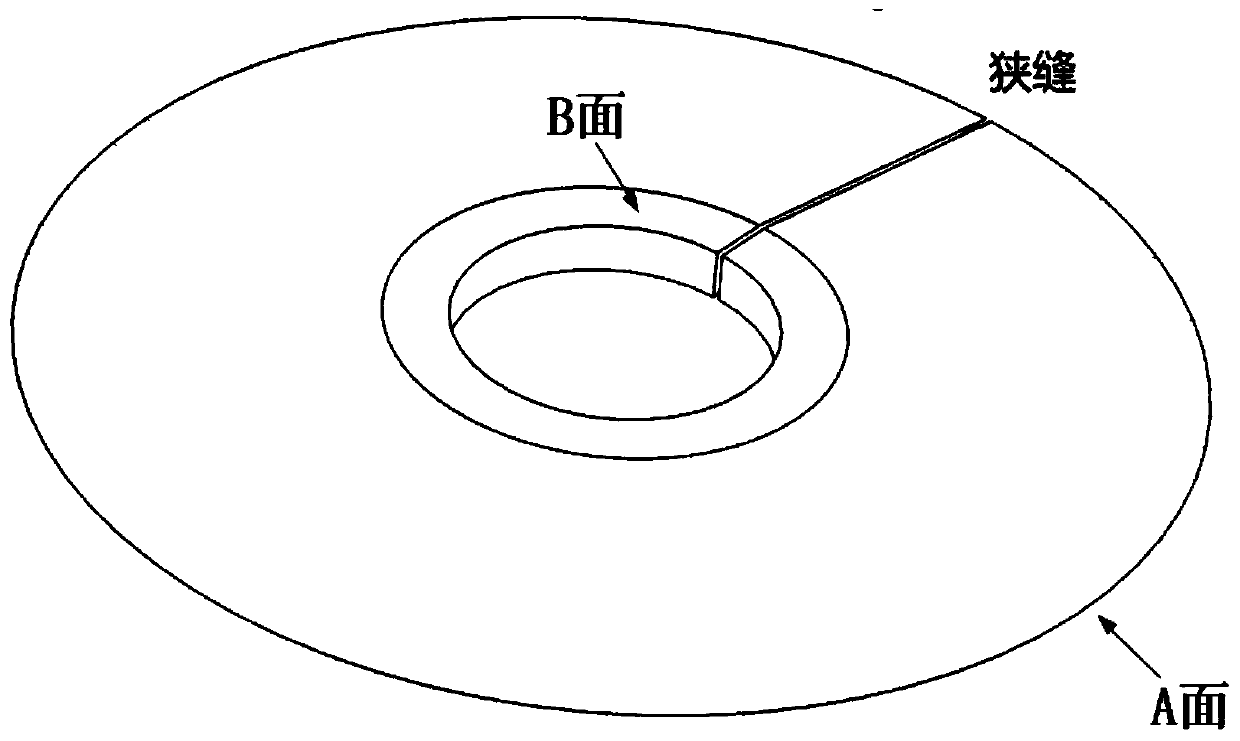

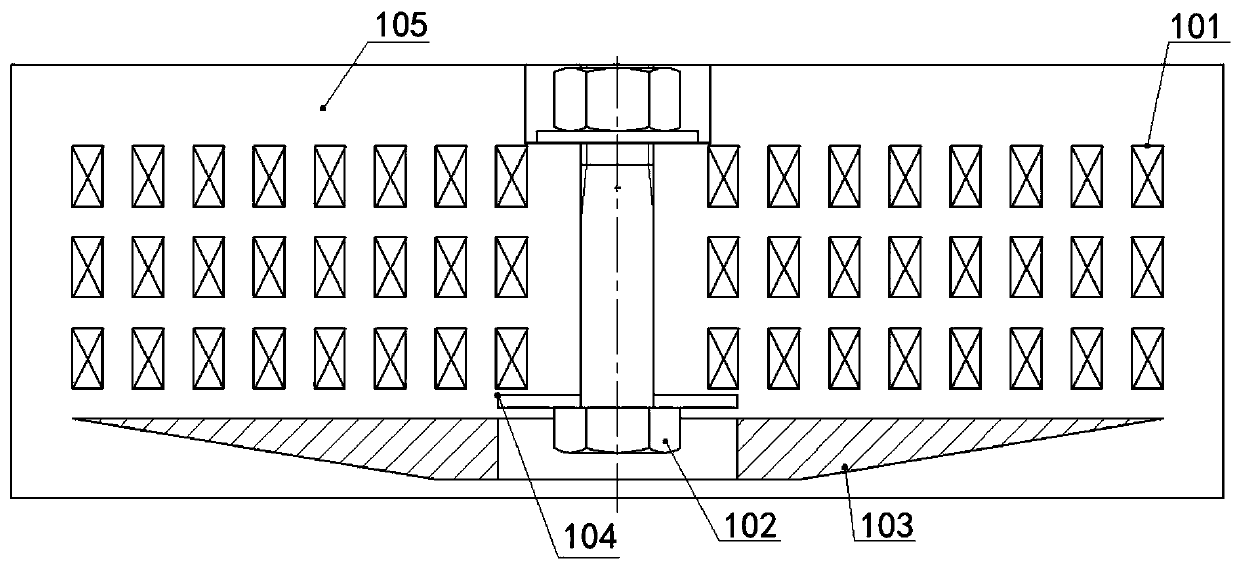

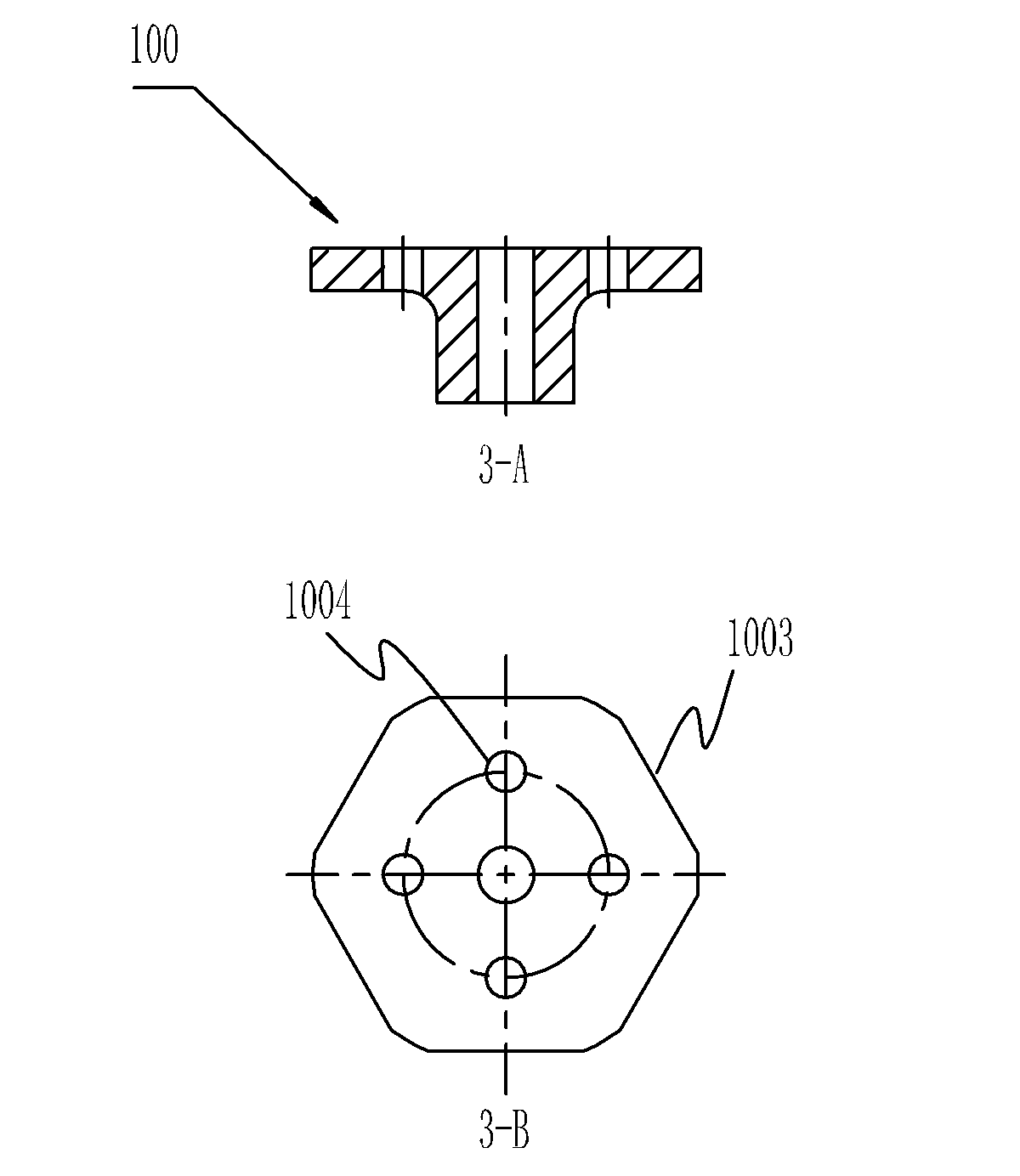

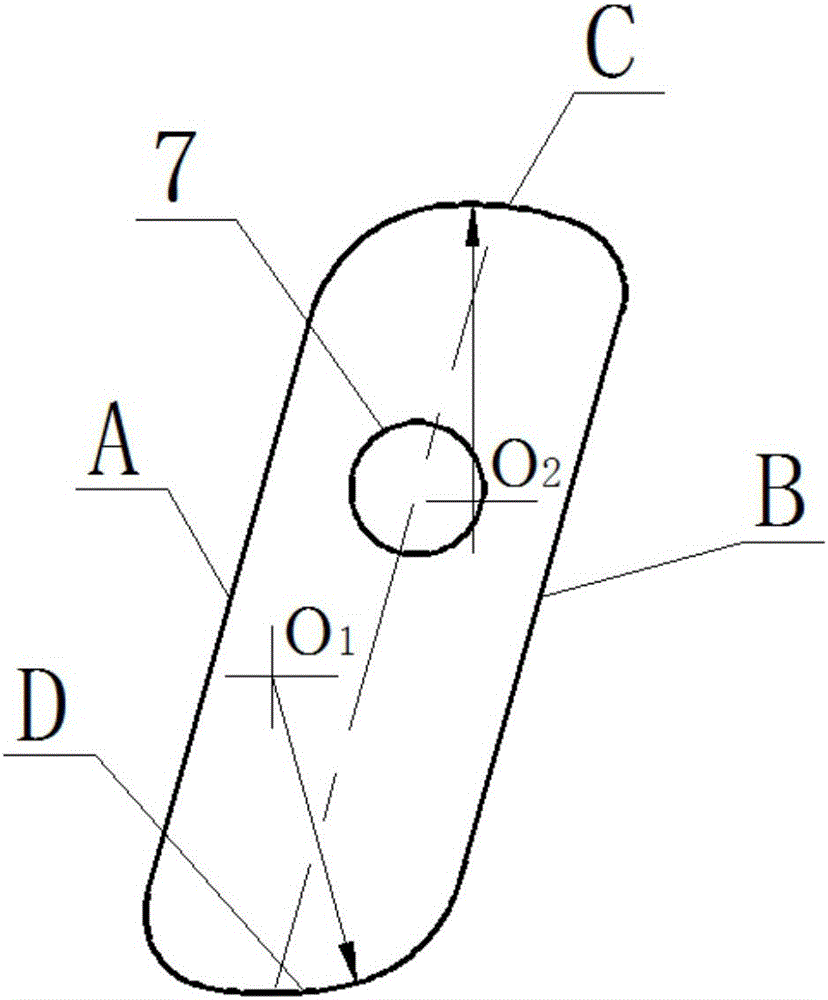

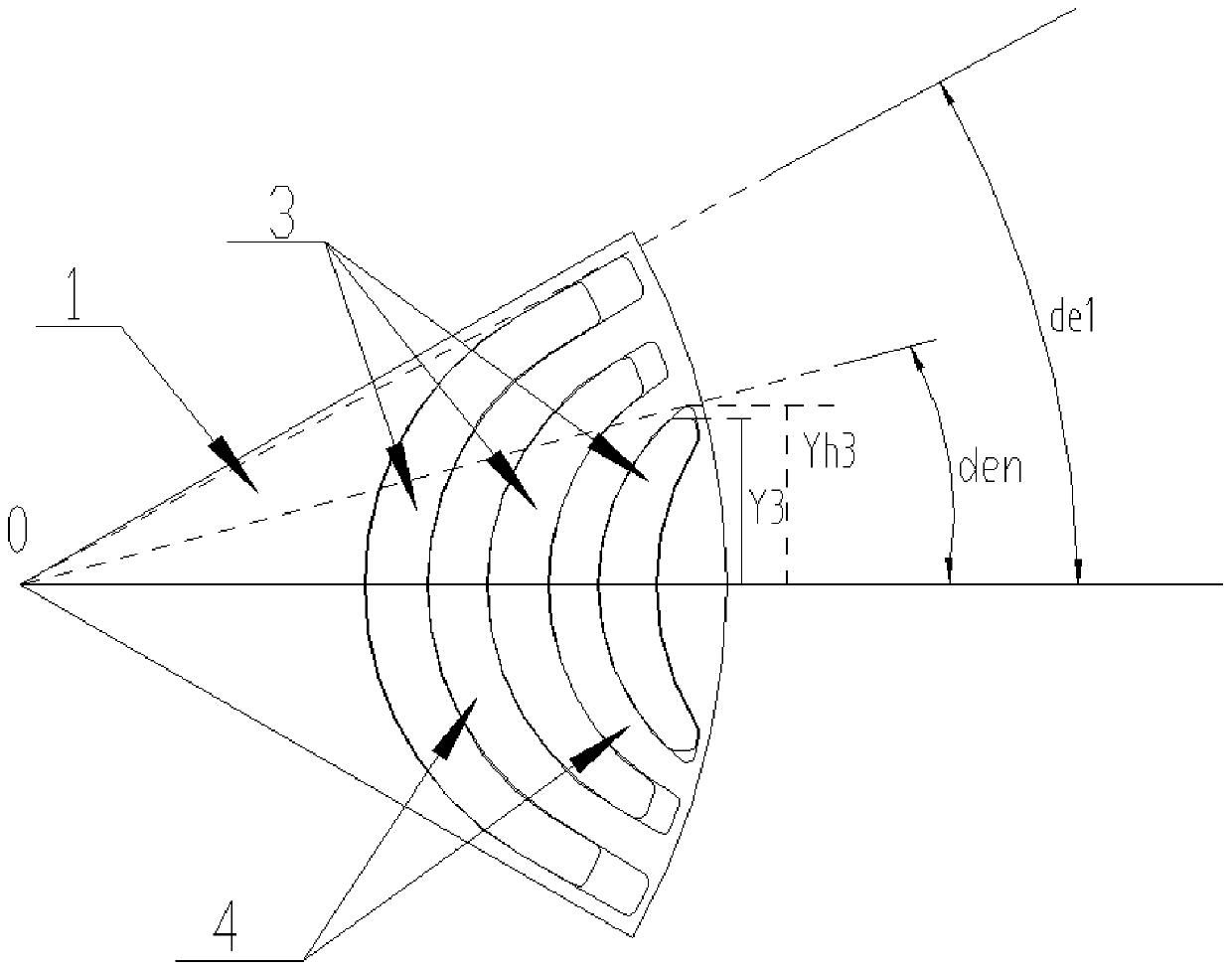

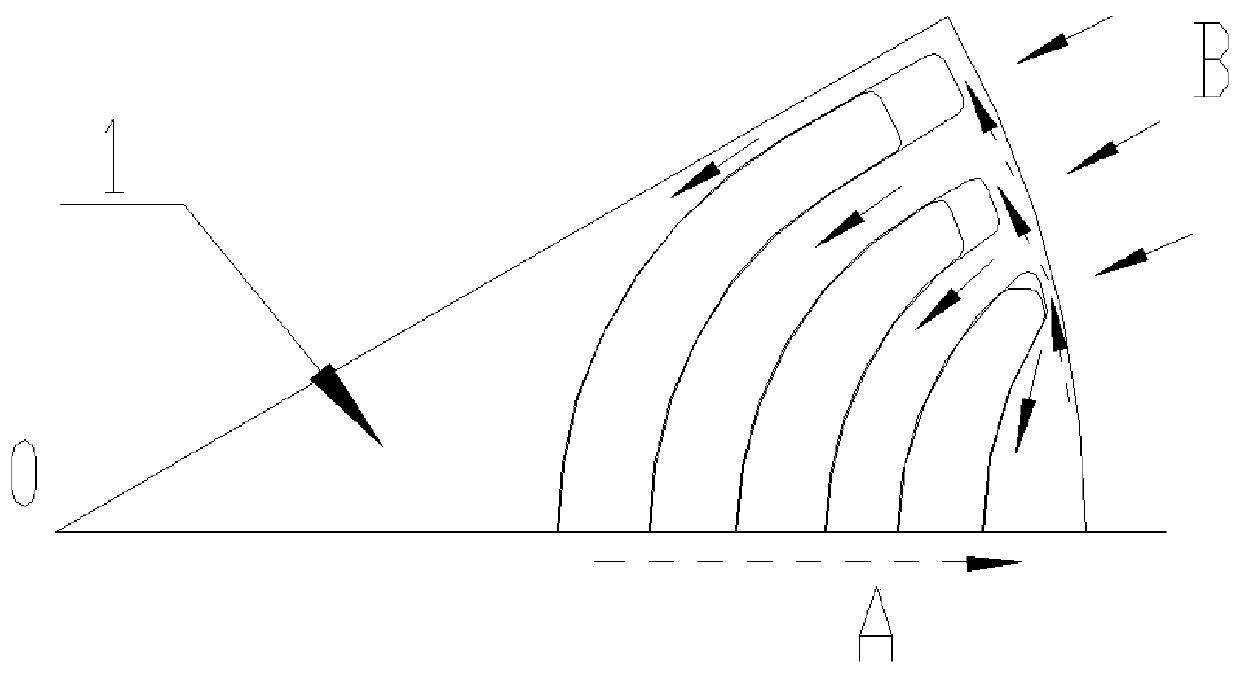

Electromagnetic pulse hole-flanging and forming device for thick plate or thick arc-shaped piece

The invention belongs to the field of plastic forming of materials, and discloses an electromagnetic pulse hole-flanging and forming device for a thick plate or a thick arc-shaped piece. The forming device for the thick plate includes a coil and a field shaper (103) on one side of the coil, and the field shaper (103) is disc-shaped and has two disc surfaces with different surface areas. The surface with the larger surface area is the A surface, the surface with the smaller surface area is the B surface, the A surface is closer to the coil, and the B surface is used for being close to a workpiece to be formed. By using the area difference, greater current density can be generated at the end, near the B surface, of the field shaper (103), and the workpiece to be formed is subjected to greater electromagnetic force, so that electromagnetic pulse hole-flanging and forming are facilitated. According to the electromagnetic pulse hole-flanging and forming device, the overall structure designand the like of the device are improved, the field shaper is added between the coil and the plate, through cooperation with the multilayer coil, particularly the design of the A surface and B surfaceof the field shaper with the difference in the surface areas, the electromagnetic force is concentrated on the forming area corresponding to the B surface of the field shaper, and a good forming effect can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

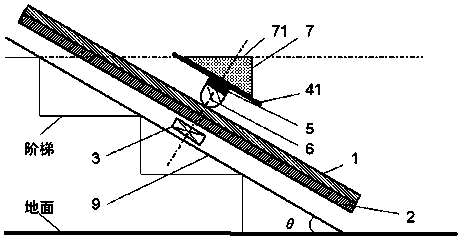

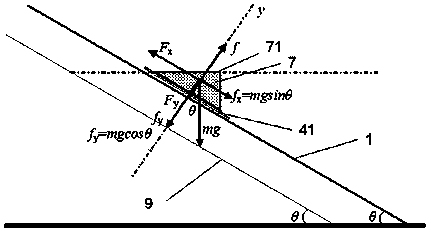

A non-traction inclined elevator and its control method

The invention relates to a non-traction type inclined elevator and a control method thereof. The inclined elevator comprises an inclined track, a support system, a driving system, a control system, weight sensors, a pedal, guiders and an inclined supporting pier. The driving system comprises two pairs of same stators and rotors. The stators are laid along the inclined track and fixed with the inclined track. The rotors are located below the stators and fixed with a support frame. The control system comprises following steps: controlling the exciting current of rotor windings through the difference between given values of resultant force and actual values detected by the weight sensors and by given values of exciting current of the rotor windings outputted by a PI regulator such that closed-loop control of resultant force is realized, wherein the resultant force is vertical to the direction of the inclined track; and obtaining given values of traction force through given speed, the acceleration curve and loads detected in real terms such that input current of the stator windings is controlled and closed-loop control is achieved over elevator speed, and the accelerated speed. The non-traction type inclined elevator and the control method thereof have following beneficial effects: there is no need to use a traction machine or a traction rope; control is easy; operation is safe; power consumption is little; and installation and maintenance are easy and convenient.

Owner:QUFU NORMAL UNIV

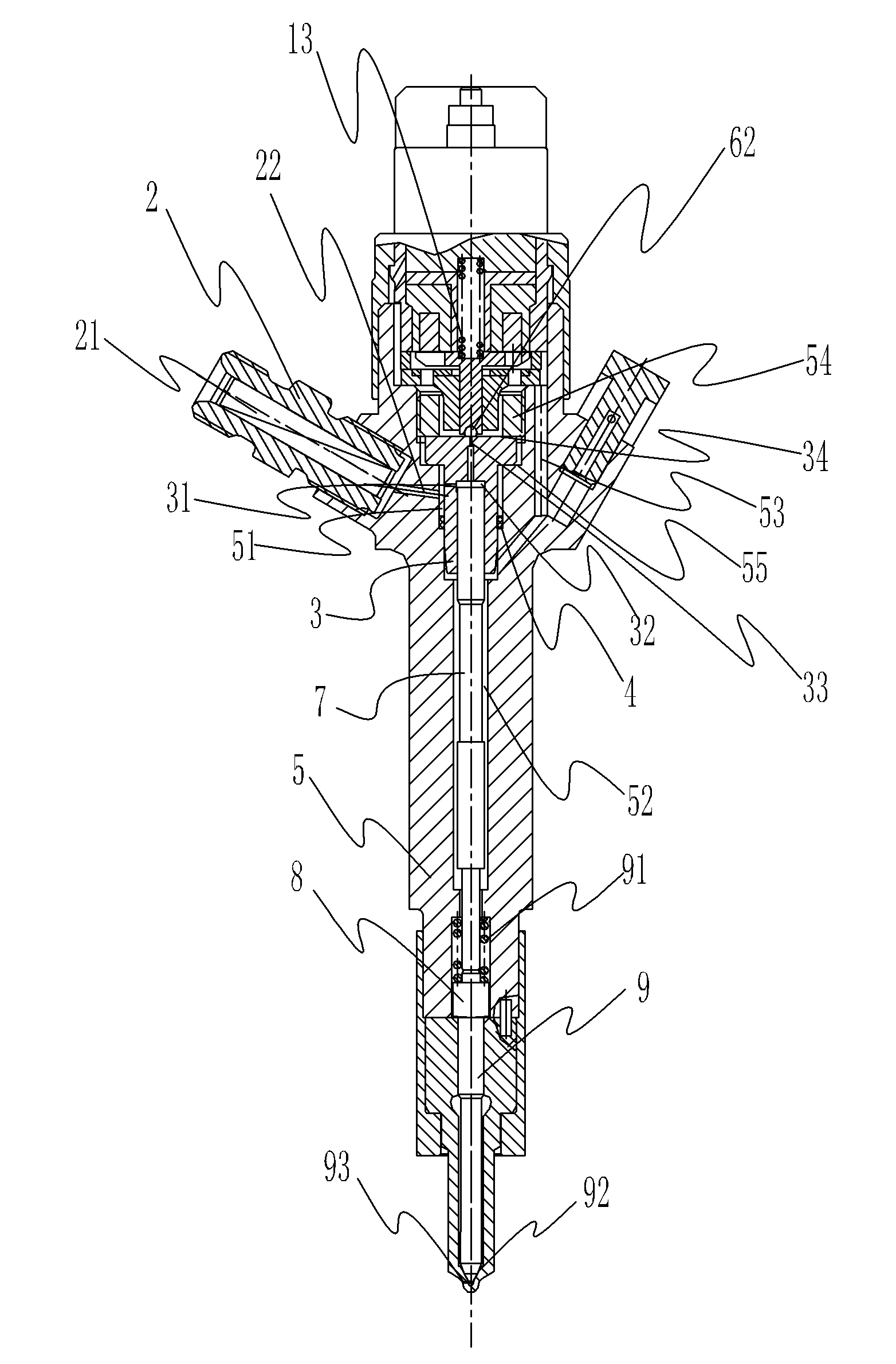

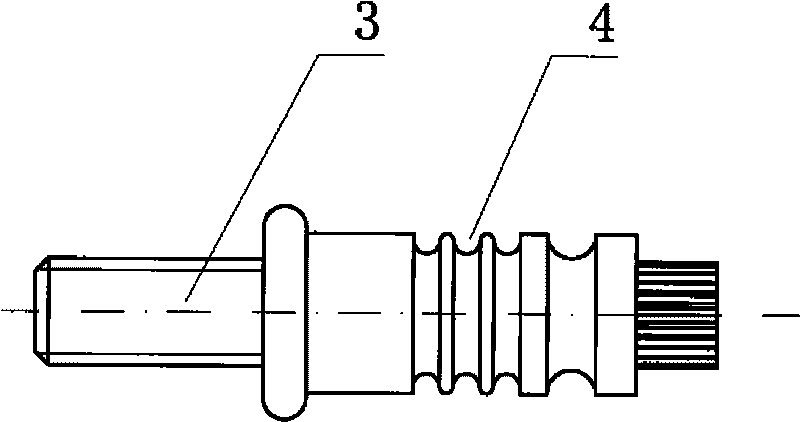

Fuel injection executing valve

InactiveCN102758712AHigh strengthHigh precisionFuel injection apparatusMachines/enginesElectricityEngineering

The invention discloses a fuel injection executing valve which is a part of an electromagnetic valve used in a high-pressure storage type fuel supplying system. The electromagnetic valve is mounted on the upper portion of the fuel supplying system. The fuel injection executing valve comprises an attraction side, a guide shaft and fuel passages. The attraction side is attracted on the lower end face of a thrust sleeve of the electromagnetic when the electromagnetic valve is electrified. The guide shaft in cylindrical structure extends downwards from the center of the back of the attraction side, is penetratingly arranged in a central hole of a guide sleeve fixed in a valve chamber and can slide relatively to the central hole. The guide shaft and the attraction side are integrally formed. The fuel passages are in fuel passage structures communicated with the attraction side and used for guaranteeing that low-pressure fuel flowing out of a fuel outlet throttle hole is sufficiently discharged on the attraction side instantly the executing valve is at high-speed attraction. The fuel passages are uniformly circumferentially arranged along the attraction side at intervals and are communicated with a core portion of the attraction side directly or indirectly. By the executing valve, fuel discharge capability of the attraction side can be effectively guaranteed, electromagnetic force loss can be reduced to the greatest extent, and durability of the integrally formed executing valve is improved effectively.

Owner:北京天纬燃油喷射技术股份有限公司

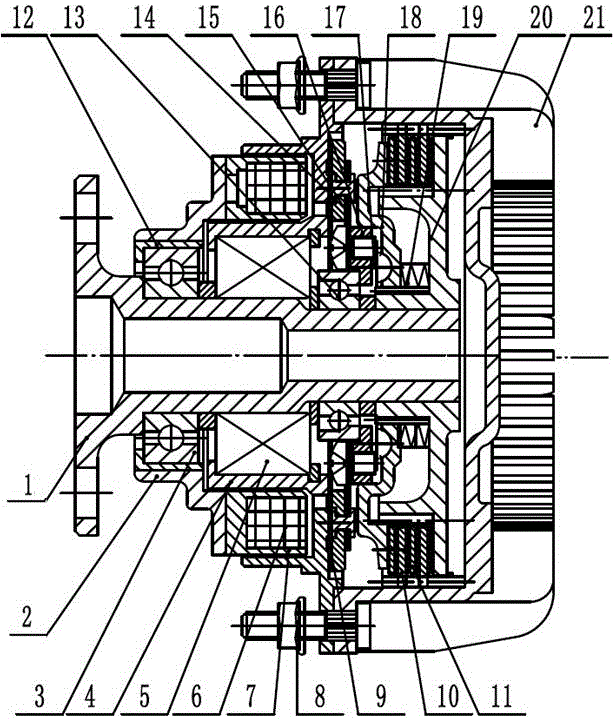

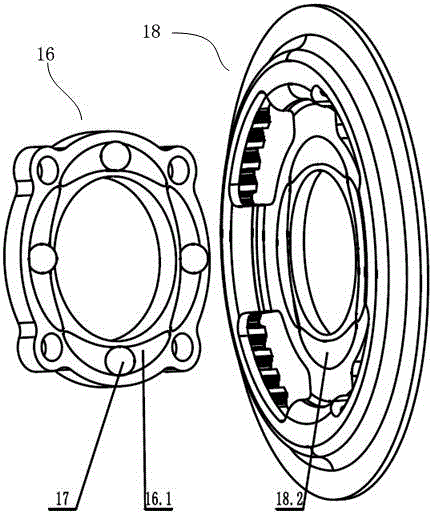

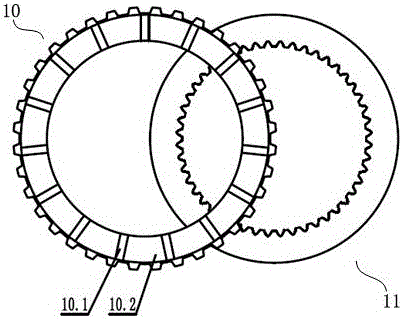

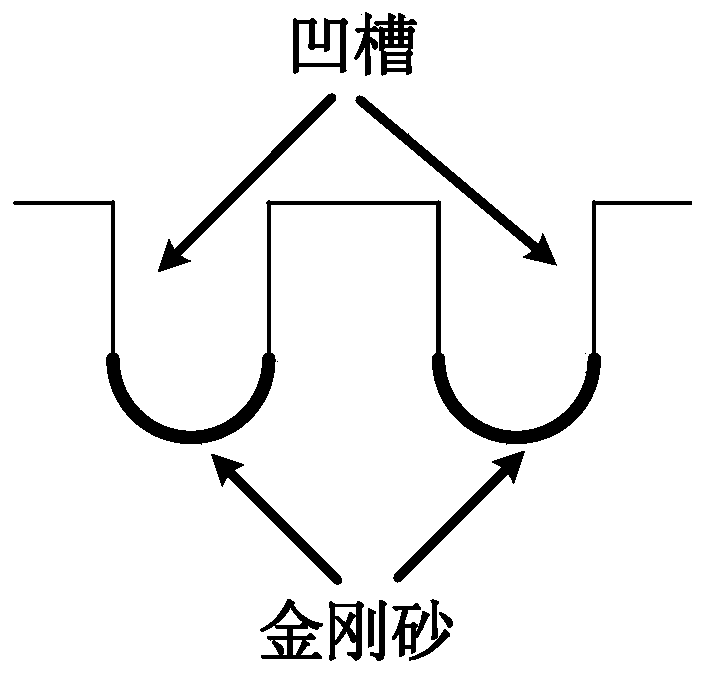

Automobile fan clutch with force amplifier

ActiveCN105065105ASmall electromagnetic forceSmall sizeCoolant flow controlMachines/enginesSteel ballEngineering

The invention relates to an automobile fan clutch with a force amplifier. The automobile fan clutch comprises a drive torque input mechanism, a power transfer mechanism and a force amplifying mechanism, wherein the force amplifying mechanism is used for connecting the drive torque input mechanism and the power transfer mechanism, and amplifying the acting force between the force drive torque input mechanism and the power transfer mechanism. The automobile fan clutch is characterized in that the force amplifying mechanism comprises a driven plate, a driving plate, at least three first groove lanes, at least three second groove lanes and a steel ball; the driving plate is opposite to the driven plate; the at least three first groove lanes are formed in the driven plate; the at least three second groove lanes are formed in the driving plate and correspond to the first groove lanes; the steel ball is arranged between the first groove lanes and the second groove lanes; the depths of the first groove lanes and the second groove lanes are gradually reduced from the middle part to two ends. Compared with the prior art, the automobile fan clutch has the advantages that the size and calorific value of an electromagnetic coil are greatly reduced, and the weight, volume and calorific value of the product are greatly reduced.

Owner:LONGKOU ZHONGYU MACHINERY

Noise-reducing transformer iron core structure and manufacturing method thereof

PendingCN112466630ASmall electromagnetic forceReduce magnetic densityTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerMagneto

The invention discloses a noise-reducing transformer iron core structure and a manufacturing method thereof. The transformer iron core structure is formed by lapping a plurality of silicon steel sheets, and magneto-rheological glue is filled in gaps of adjacent silicon steel sheet laminations lapped at corners of the transformer iron core structure. According to the noise-reducing transformer ironcore structure, the magneto-rheological glue is filled in the lamination gaps of the adjacent silicon steel sheets, part of the magnetic induction lines can pass through the magneto-rheological gluein the lamination gaps due to the magnetic conductivity of the magneto-rheological glue, and compared with the situation that air exists in the lamination gaps, the magnetic lines of force are distributed in the lamination gaps more smoothly; therefore, the magnetic density of the leakage magnetic field around the lamination gap is reduced, the electromagnetic force between the silicon steel sheets is reduced, and the vibration noise between the silicon steel sheet laminations caused by the electromagnetic force is reduced. Meanwhile, due to the damping characteristic of the magneto-rheological glue, part of vibration energy is consumed, and therefore the effects of damping and reducing vibration noise are further achieved.

Owner:SHENYANG POLYTECHNIC UNIV

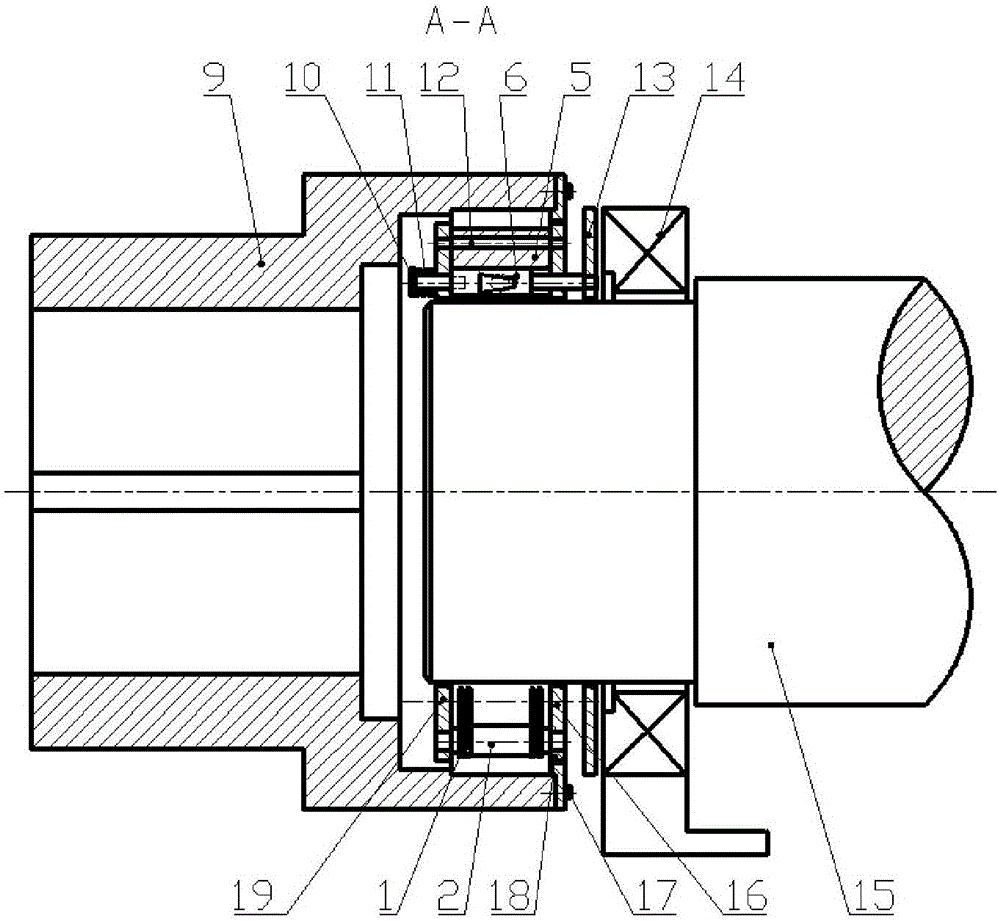

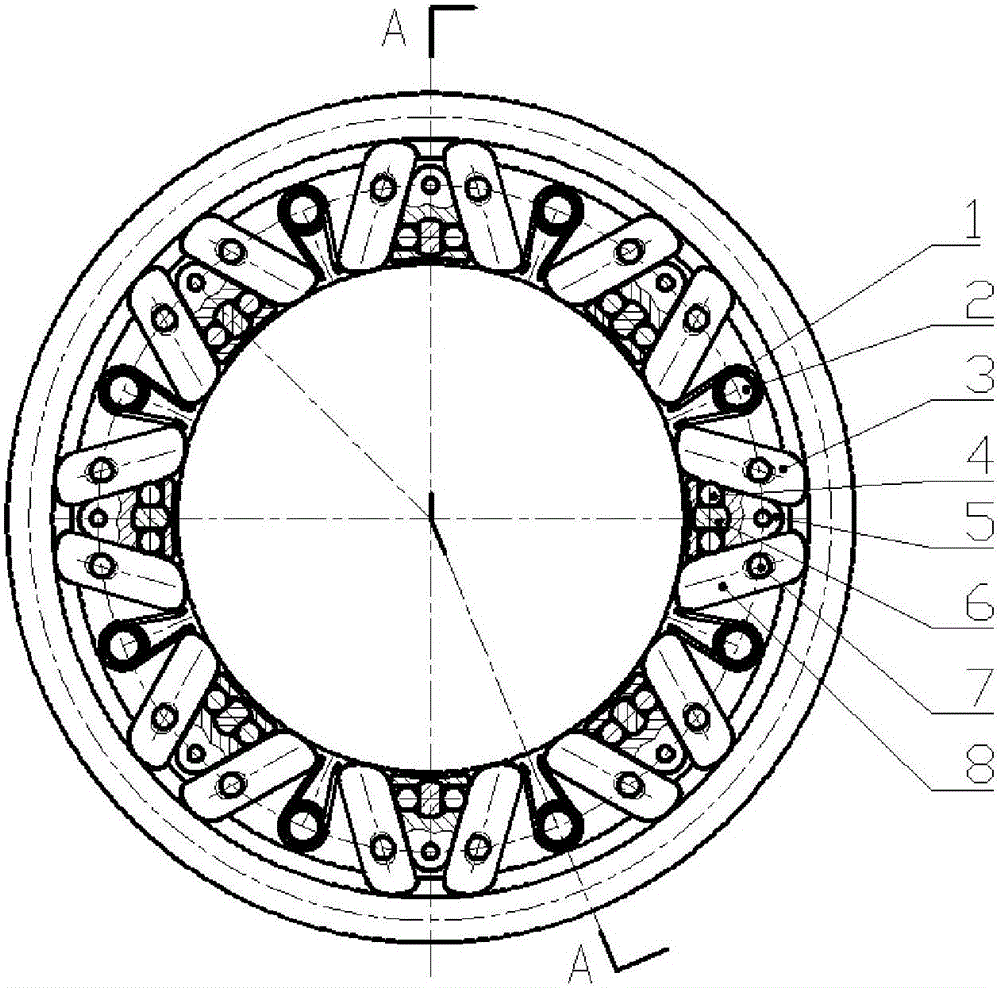

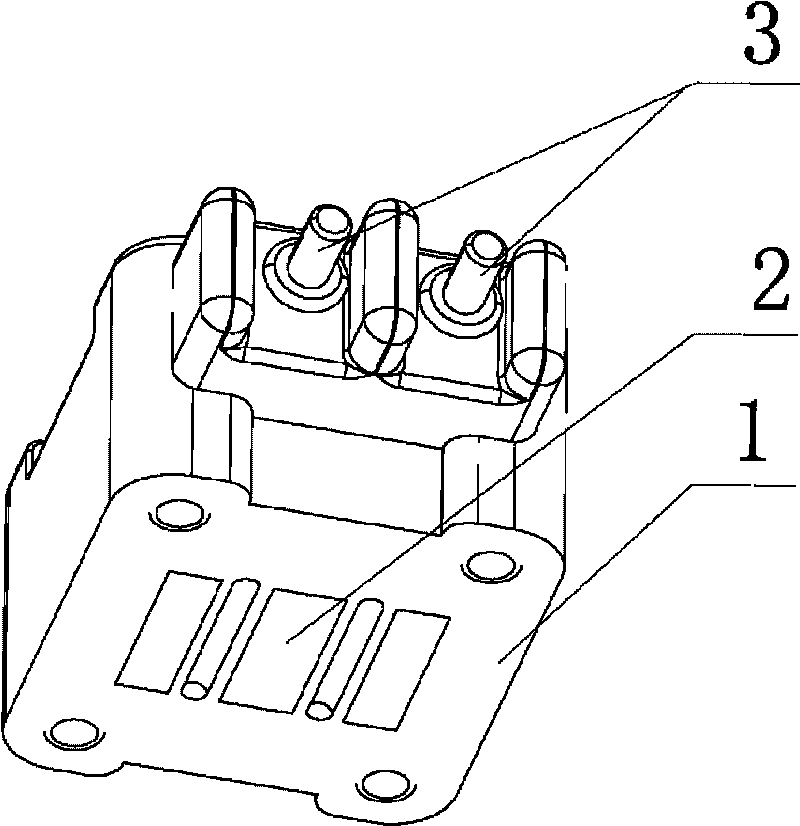

Wedge-block electromagnetic clutch

ActiveCN106678199AImprove carrying capacitySmall structure sizeMagnetically actuated clutchesElectromagnetic clutchCoupling

The invention provides a wedge-block electromagnetic clutch, and belongs to the technical field of mechanical transmission. The electromagnetic clutch comprises a half-coupling, a main shaft, wedge blocks, a retainer, torsion springs, isolation blocks, a compression spring, a clutch pin, an electromagnet and an armature, wherein the axes of the half-coupling and the main shaft are superposed, the retainer is located in an annular space formed by the shaft-diameter surface of the main shaft and the inner cylindrical surface of the half-coupling, a group of the torsion springs is uniformly distributed on the annular retainer, and splayed wedge block groups formed by the wedge blocks and the isolation blocks are also uniformly distributed on the circumference of the retainer; and the clutch pin provided with the compression spring at one end penetrates through the isolation blocks and is fixedly connected to the armature, and the electromagnet movably sleeves the main shaft and is fixed to a rack. The electromagnetic clutch provided by the invention is capable of increasing the transfer torque thereof, fast in engagement reaction, capable of reducing the power and energy consumption of operating the electromagnet, compact in structure, and convenient to install.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

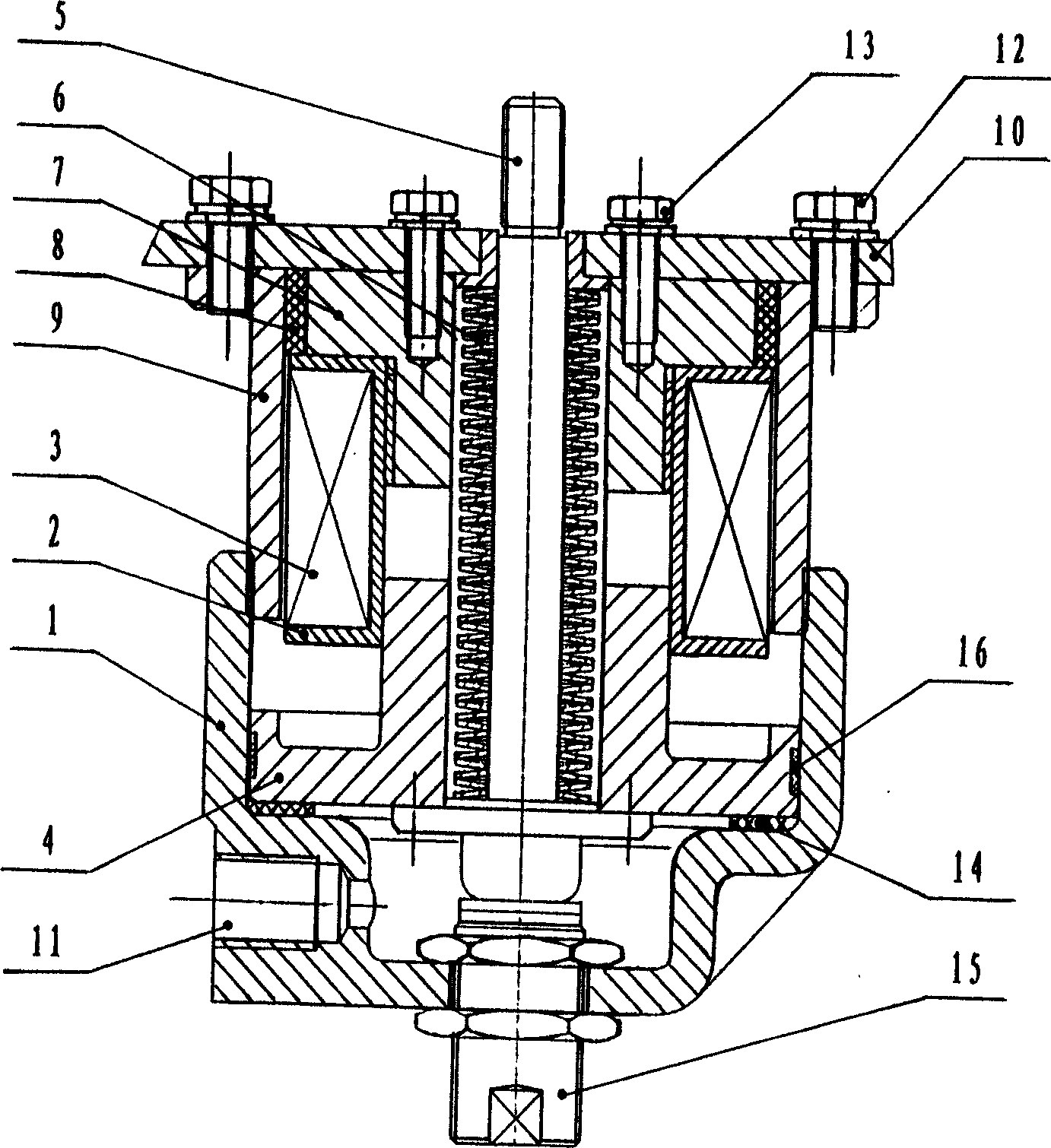

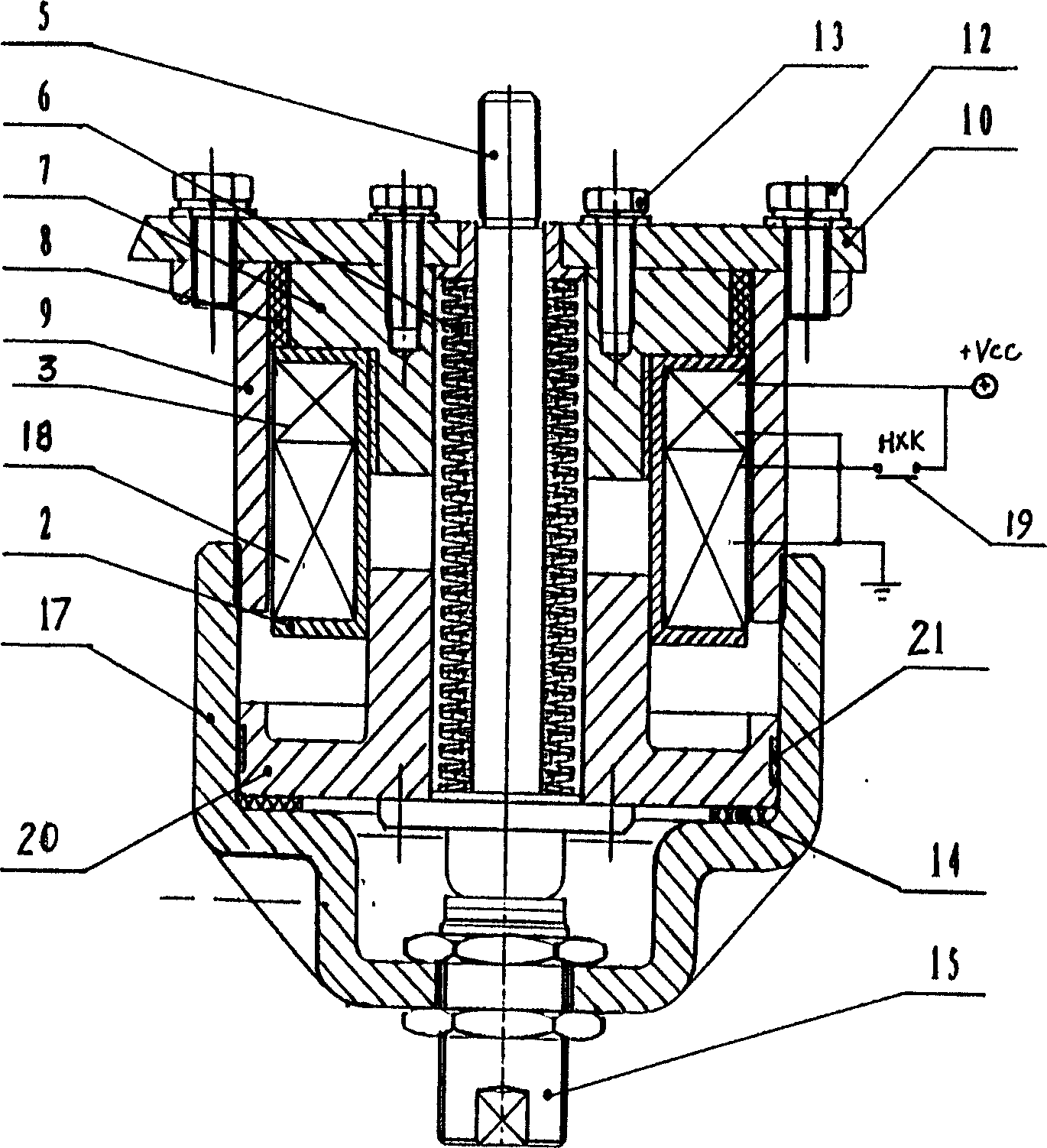

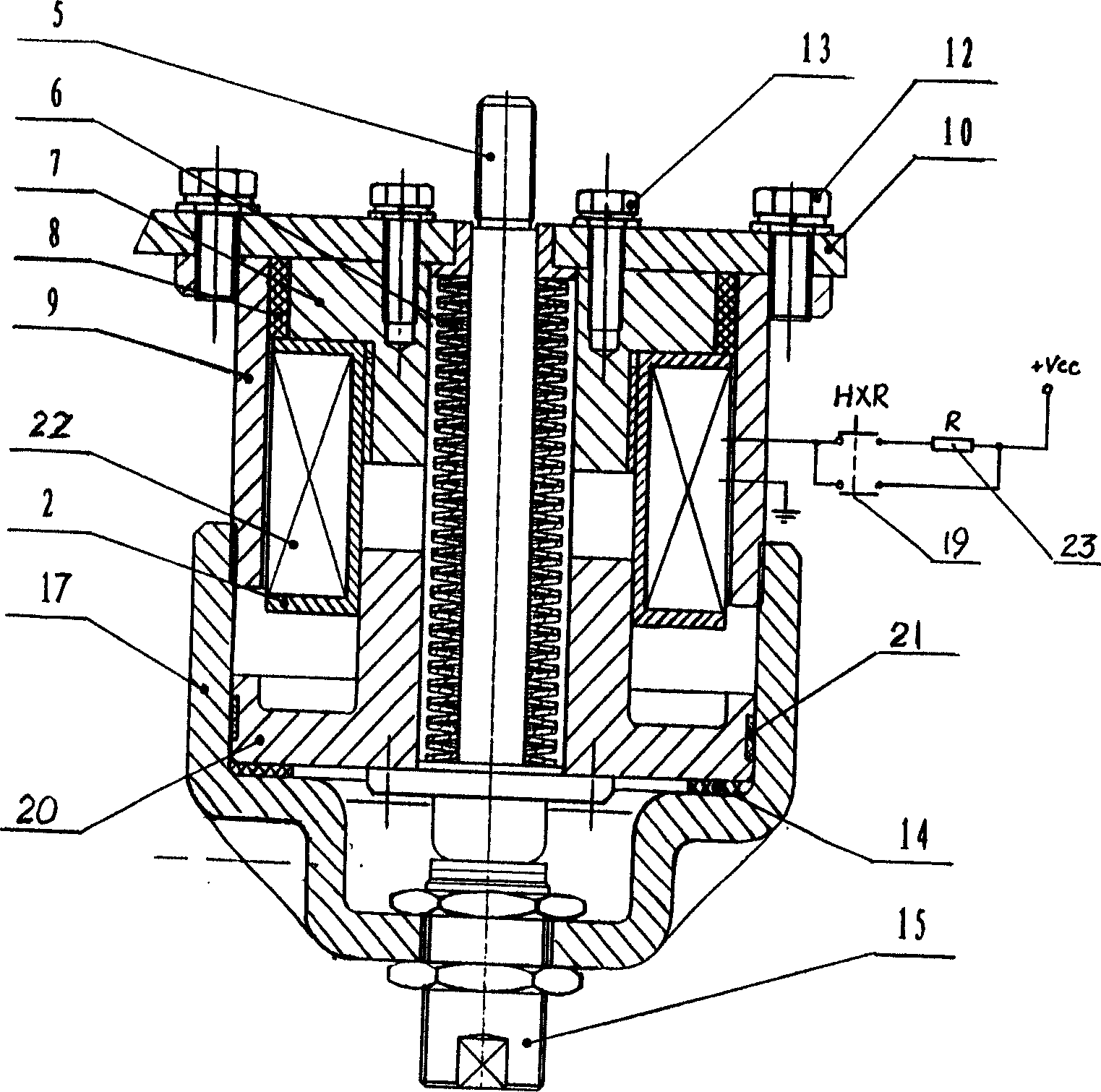

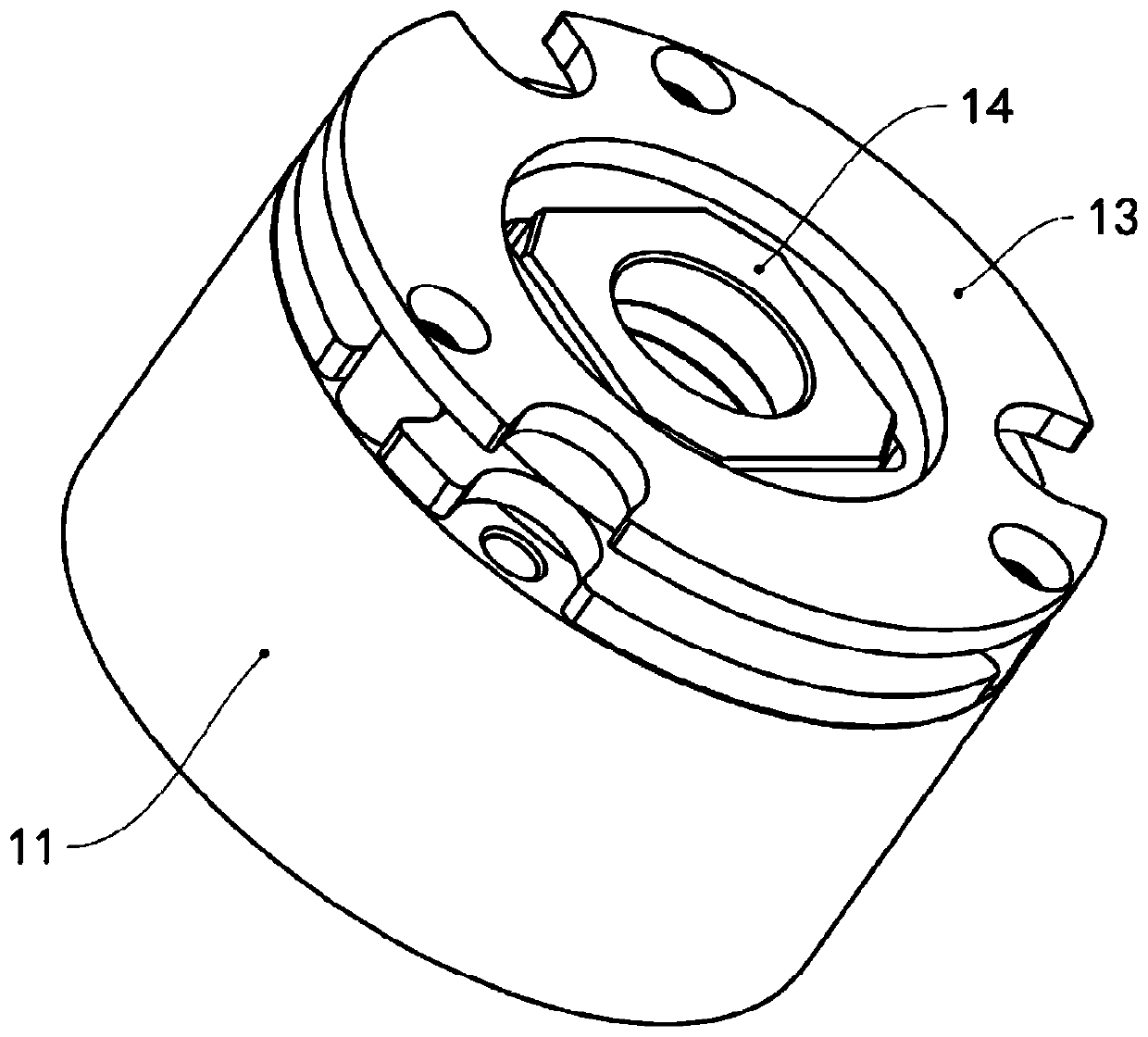

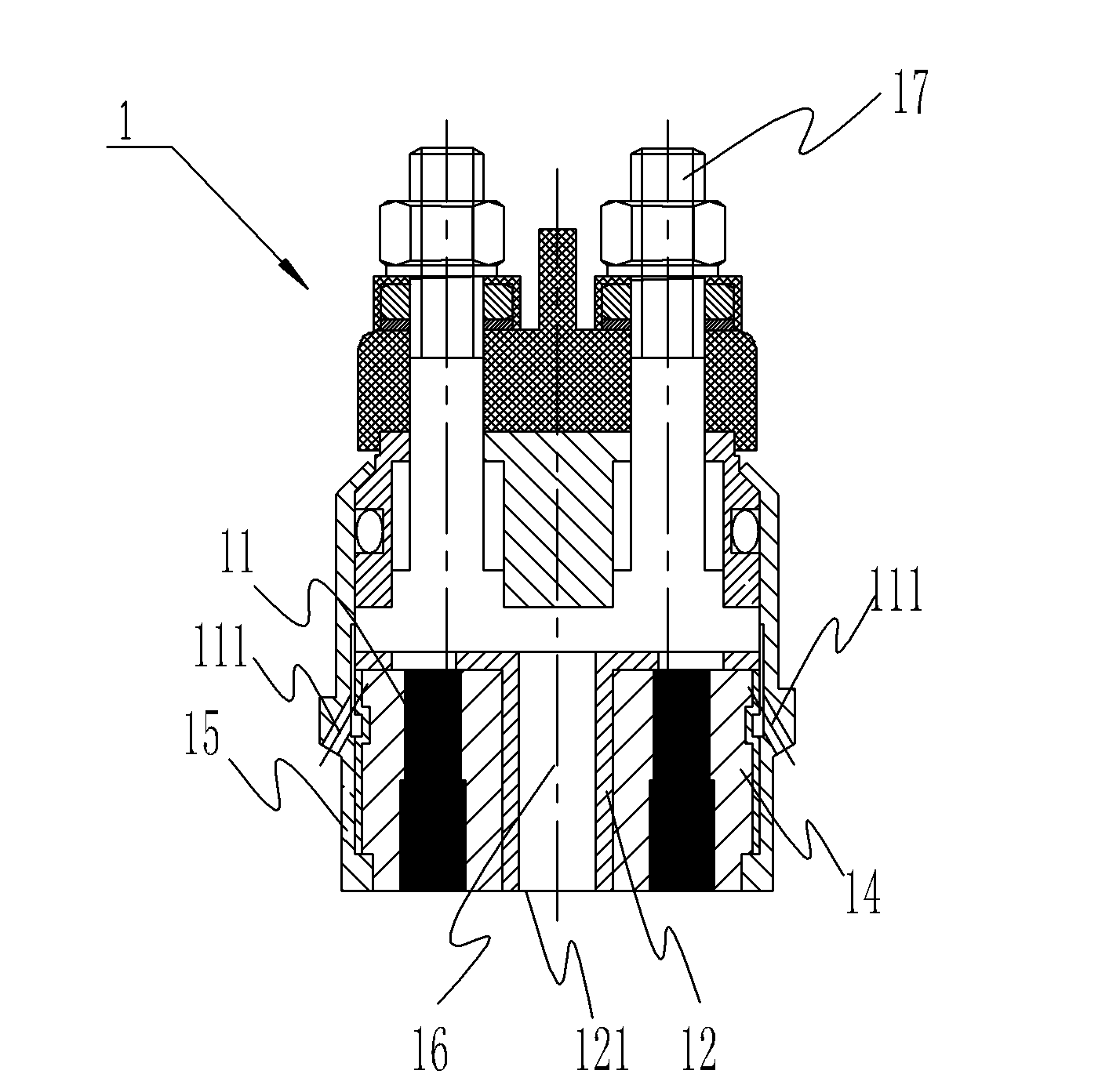

Combined piston type pulse solenoid valve

InactiveCN101632887BSolution to short lifeShort response timeDispersed particle filtrationPilot holeSolenoid valve

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD +1

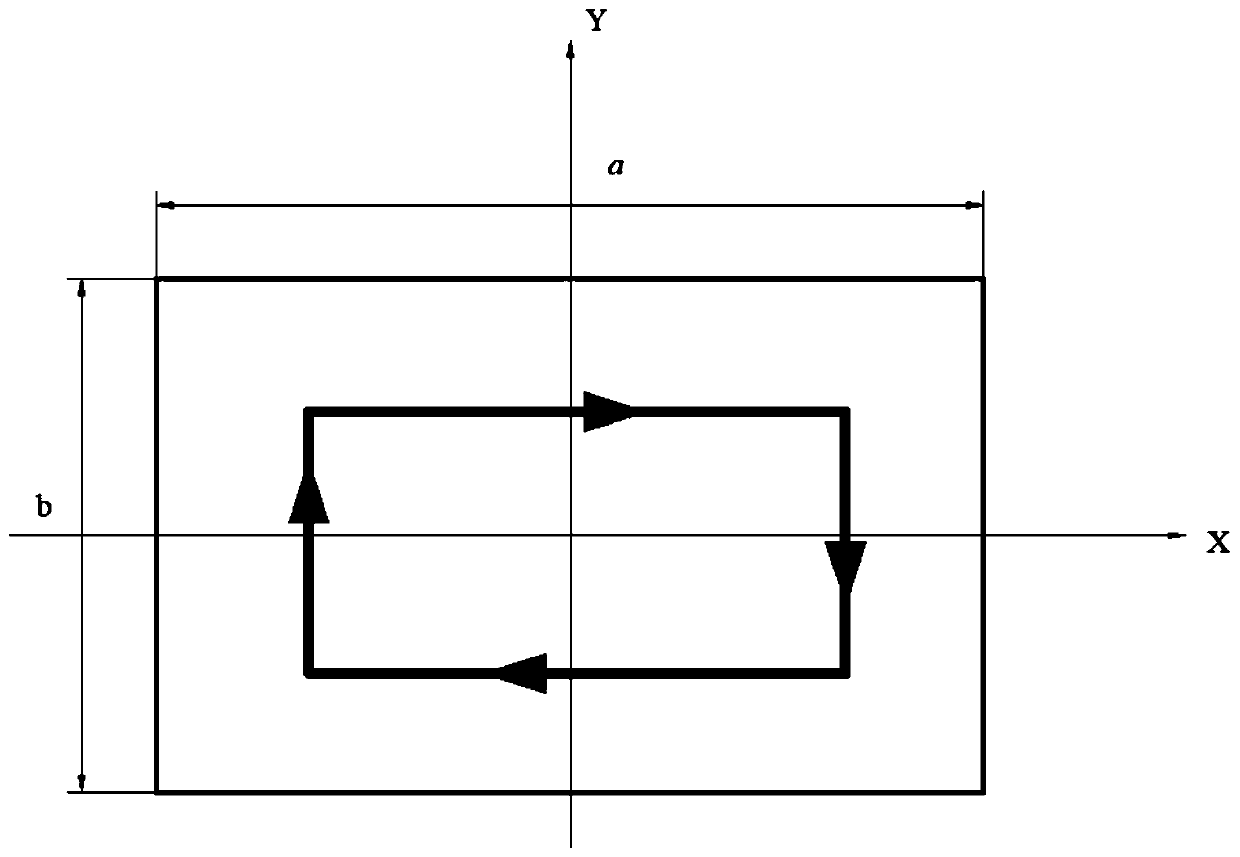

Aluminum cell cathode structure capable of reducing horizontal current and improving current distribution

ActiveCN108396333AUniform current distributionSmall electromagnetic forcePower flowCurrent distribution

The invention discloses an aluminum cell cathode structure capable of reducing horizontal current and improving current distribution. The structure comprises a cathode carbon block and cathode current-conducting rods, one penetrating groove or two coaxial and symmetric long grooves are formed in the bottom face of the cathode carbon block, and grooves are formed in the top face of the cathode carbon block; each cathode current-conducting rod is composed of a rod body, a current conducting claw and claw heads; the current conducting claws are fixedly arranged on the top ends of the rod bodies,three or more claw heads are arranged on each current conducting claw and are located in the grooves, and the positions between the grooves and the claw heads are filled with conductors. According tostructural design, the claw heads can evenly share the current from the cathode carbon block, the current can be more evenly distributed, horizontal current is reduced, the melt interface stability isgood, the groove voltage can be reduced through reducing the electrode distance, and energy consumption reduction is achieved.

Owner:NORTHEASTERN UNIV

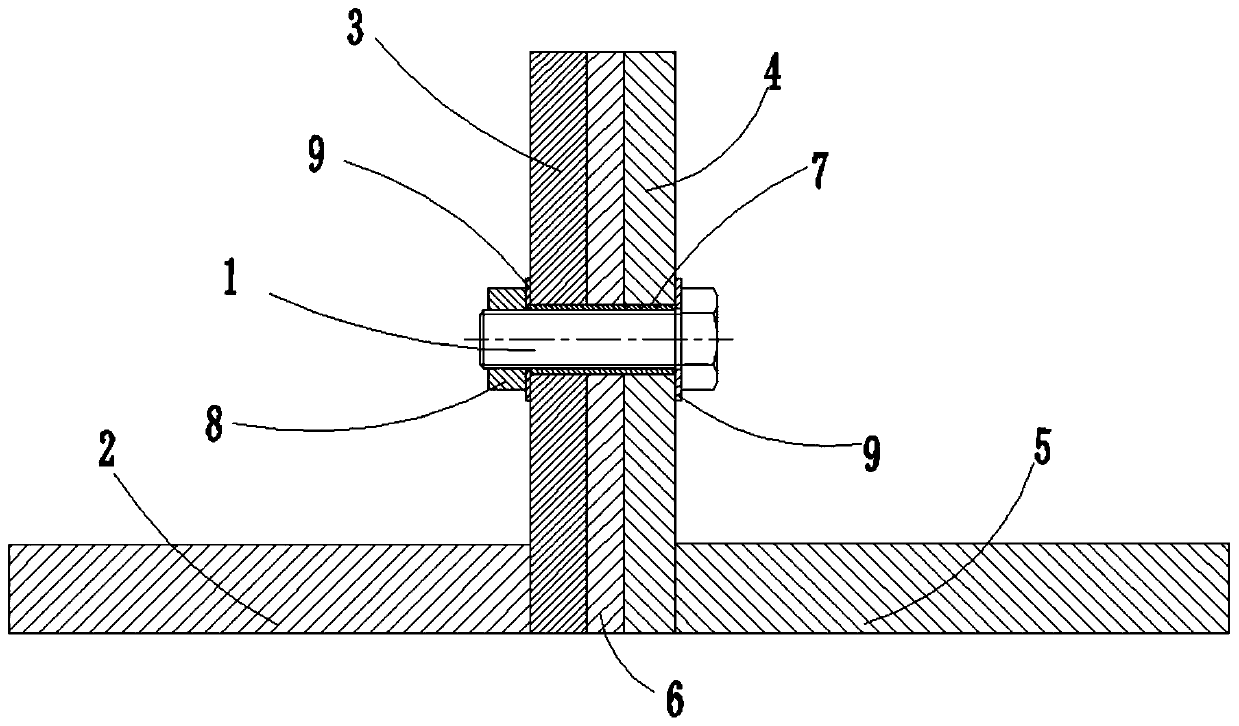

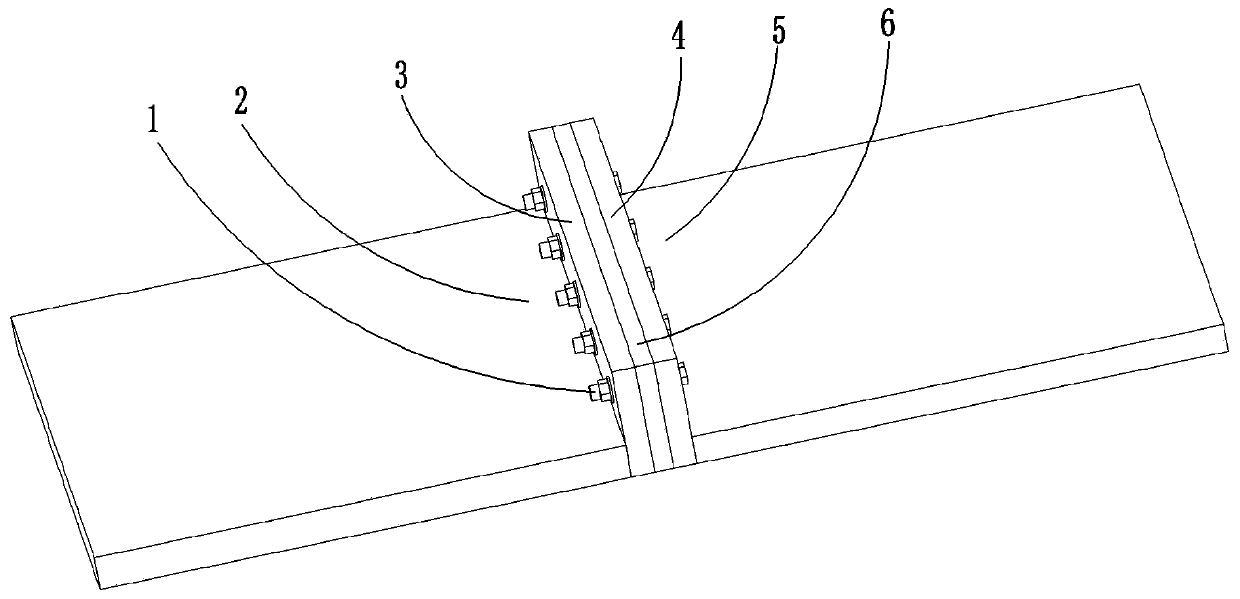

Insulation structure for cold shield of fusion device

InactiveCN110047599AReduce eddy current lossImprove feverNuclear energy generationThermonuclear fusion reactorElectricityModular design

The invention discloses an insulation structure for a cold shield of a fusion device. The insulation structure comprises cooling panels with flanging, fasteners for connecting the cooling panels, a thin insulation board for electrical insulation, an insulation sleeve and insulation gaskets; two adjacent cooling panels are connected through the fasteners and are isolated by the thin insulation board. By means of the structure, eddy-current loss of the cold shield is greatly reduced during operation of the fusion device, the heating condition of the cold shield is improved, and the cooling costis reduced; besides, the insulation structure can reduce electromagnetic force borne by the cold shield and has a certain protection effect on the cold shield structure. Due to insulation treatment ofthe cooling panels, modular design, processing and manufacturing of the cooling panels are better facilitated, and besides, mounting and maintenance are more convenient.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

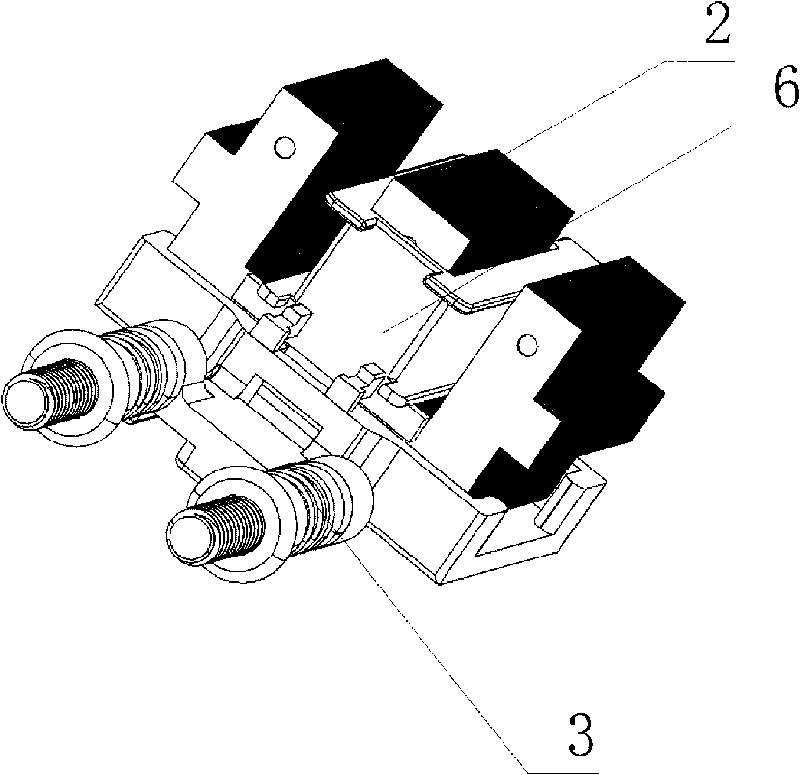

Unit pump electromagnet for automobile engine

InactiveCN101702359AExtend working lifeSuperposition of strong magnetic forceFuel injection apparatusMachines/enginesWorking lifeFuel oil

The invention discloses a unit pump electromagnet for an automobile engine, which comprises a shell (1), a coil, a coil bracket (6), an iron core (2) and binding posts (3), wherein the coil is wound on the iron core (2) to be arranged on the coil bracket (6) and arranged in the shell, and binding terminals of the coil is connected with the binding posts (3). The unit pump electromagnet is characterized in that the binding posts (3) are provided with devices for preventing fuel oil from flowing along the binding posts. In the invention, devices for preventing fuel oil from leaking are arranged on the binding posts, thereby greatly improving the sealing performance of electromagnet packaging, so that when the unit pump electromagnet is used under the condition of high pressure at the temperature of 155 DEG C or -40 DEG C, no leakage occurs, and the continuous working life can reach more than 1500 hours.

Owner:Zhejiang Xinye Electronic Technology Co Ltd

Traction machine brake

ActiveCN104370237AImprove braking effectImprove reliabilityHoisting equipmentsBrake padElectrical and Electronics engineering

The invention relates to the technical field of elevator manufacturing, in particular to a traction machine brake. The traction machine brake comprises a brake disc. A left brake pad and a right brake pad are arranged on the two sides of the left surface and the right surface of the brake disc respectively. The side, backing on to the brake disc, of the left brake pad is fixed to an armature plate. The side, backing on to the brake disc, of the right brake pad is fixed to an iron core plate right opposite to the armature plate. A connecting part is fixed to the side, close to the brake disc, of the armature plate and located above the brake disc, a connecting part is fixed to the side, close to the brake disc, of the iron core plate and located above the brake disc, and the two connecting parts can be crossed in the left-and-right direction. The connecting part of the armature plate and the connecting part of the iron core plate form a combined connecting part after being crossed and are connected in series through a connecting shaft rod arranged in the front-and-back direction, and the part, in front of the armature plate and the iron core plate, of the connecting shaft rod and the part, at back of the armature plate and the iron core plate, of the connecting shaft rod are connected to a brake installation base. The part, above the connecting shaft rod, of the iron core plate is provided with an electrified coil and a brake spring used for abutting against the armature plate. The traction machine brake is high in safety and stability, small in loss and low in noise and cost.

Owner:GIANT KONE ELEVATOR CO LTD

Low-noise relay

ActiveCN108389756AChange the path of flowReduce supersaturationElectromagnetic relay detailsLow noiseBobbin

The invention provides a low-noise relay, which mainly comprises a base, an L-shaped yoke, an armature, a bobbin, a coil, an iron core, a movable contact spring, a fixed contact spring, a movable contact and a fixed contact, wherein a magnetic limiting groove is formed in the lower part of a vertical side of the L-shaped yoke; the iron core is in a stepped form; the axis diameter of one end, far away from the armature, of the iron core is the smallest; and the axis diameter of one end, close to the armature, of the iron core is the biggest. When the coil is electrified, magnetic flux generatedby the coil passes through the magnetic limiting groove and the stepped iron core, so that the electromagnetic force of the relay in later pickup can be greatly reduced on the premise of ensuring that the relay has enough electromagnetic force in early pickup through the magnetic flux path, thereby effectively reducing the noise of the relay at work.

Owner:NANJING UNIV OF SCI & TECH

Reluctance motor and rotor thereof

ActiveCN111541323AImprove reliabilitySmall electromagnetic forceMagnetic circuit rotating partsElectric machineMagnetic poles

The invention provides a reluctance motor and a rotor thereof. A plurality of sets of magnetic pole structures are formed on the rotor, each set of magnetic pole structure comprises n installation grooves and n permanent magnets, each permanent magnet is installed in the corresponding installation groove, n is a natural number and is larger than or equal to 3, and n-1 magnetic conduction channelswide in the middle and narrow in the two sides are formed between the adjacent installation grooves of the n installation grooves. The defect that demagnetization is extremely easy due to the adoptionof ferrite permanent magnets can be overcome, and the motor reliability is improved. Preferably, through the configuration relationship between the magnetic conduction channel 4 and a magnetic isolation bridge part, the defect that the motor rotor is extremely easy to demagnetize is effectively improved, the reliability of the motor is improved, the electromagnetic force of the motor can be further reduced, electromagnetic vibration caused by overlarge electromagnetic force amplitude is reduced, and electromagnetic noise is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

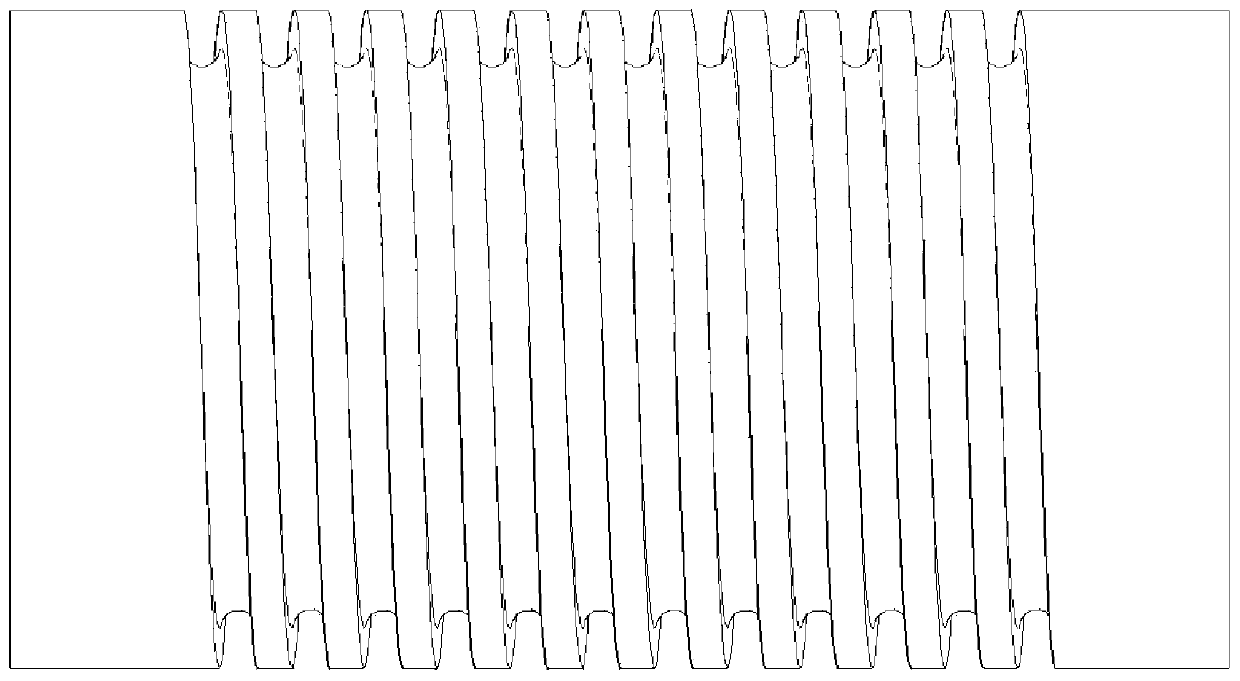

A twisted wire core spiral inductor

ActiveCN108428535BHigh tensile strengthHigh impedanceTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionCopper wireAbsorbed energy

The invention discloses a twisted wire core spiral linear inductor which includes a twisted wire core and an inner sleeve. The twisted wire core is wound in a spiral groove of the inner sleeve. The twisted wire core is formed by spirally twisting a plurality of metal wires and a plurality of aluminum wires. The inner sleeve is in a hollow cylinder shape, the outer wall of the inner sleeve is provided with the spiral groove, the bottom of the spiral groove is provided with a semicircular groove, the radius of the semicircular groove is the same as that of the twisted wire core, and each metal wire is a stainless steel wire or a manganese copper wire. The twisted wire core is formed by spirally twisting the plurality of metal wires and the plurality of aluminum wires. When a capacitor is subjected to internal breakdown, a large current passes through the inductor, the aluminum wires with a low melting point and low yield strength are melted, and stainless steel and the manganese copper wire are high in tensile strength and are still kept intact. The inductor impedance is significantly increased, which is equivalent to absorbing energy of the remaining capacitors to prevent the faultycapacitor from bursting.

Owner:HUAZHONG UNIV OF SCI & TECH

A traction machine brake

ActiveCN104370237BImprove braking effectImprove reliabilityHoisting equipmentsManufacturing technologyControl engineering

The invention relates to the technical field of elevator manufacturing, in particular to a traction machine brake. The traction machine brake comprises a brake disc. A left brake pad and a right brake pad are arranged on the two sides of the left surface and the right surface of the brake disc respectively. The side, backing on to the brake disc, of the left brake pad is fixed to an armature plate. The side, backing on to the brake disc, of the right brake pad is fixed to an iron core plate right opposite to the armature plate. A connecting part is fixed to the side, close to the brake disc, of the armature plate and located above the brake disc, a connecting part is fixed to the side, close to the brake disc, of the iron core plate and located above the brake disc, and the two connecting parts can be crossed in the left-and-right direction. The connecting part of the armature plate and the connecting part of the iron core plate form a combined connecting part after being crossed and are connected in series through a connecting shaft rod arranged in the front-and-back direction, and the part, in front of the armature plate and the iron core plate, of the connecting shaft rod and the part, at back of the armature plate and the iron core plate, of the connecting shaft rod are connected to a brake installation base. The part, above the connecting shaft rod, of the iron core plate is provided with an electrified coil and a brake spring used for abutting against the armature plate. The traction machine brake is high in safety and stability, small in loss and low in noise and cost.

Owner:GIANT KONE ELEVATOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com