Electromagnetic-type power-off brake suction force testing device

A technology of power-off brakes and testing devices, which is applied in measuring devices, force/torque/power measuring instruments, instruments, etc., and can solve the problems that the brakes cannot exert their maximum performance and cannot meet the requirements of accurate measurement of brake suction force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

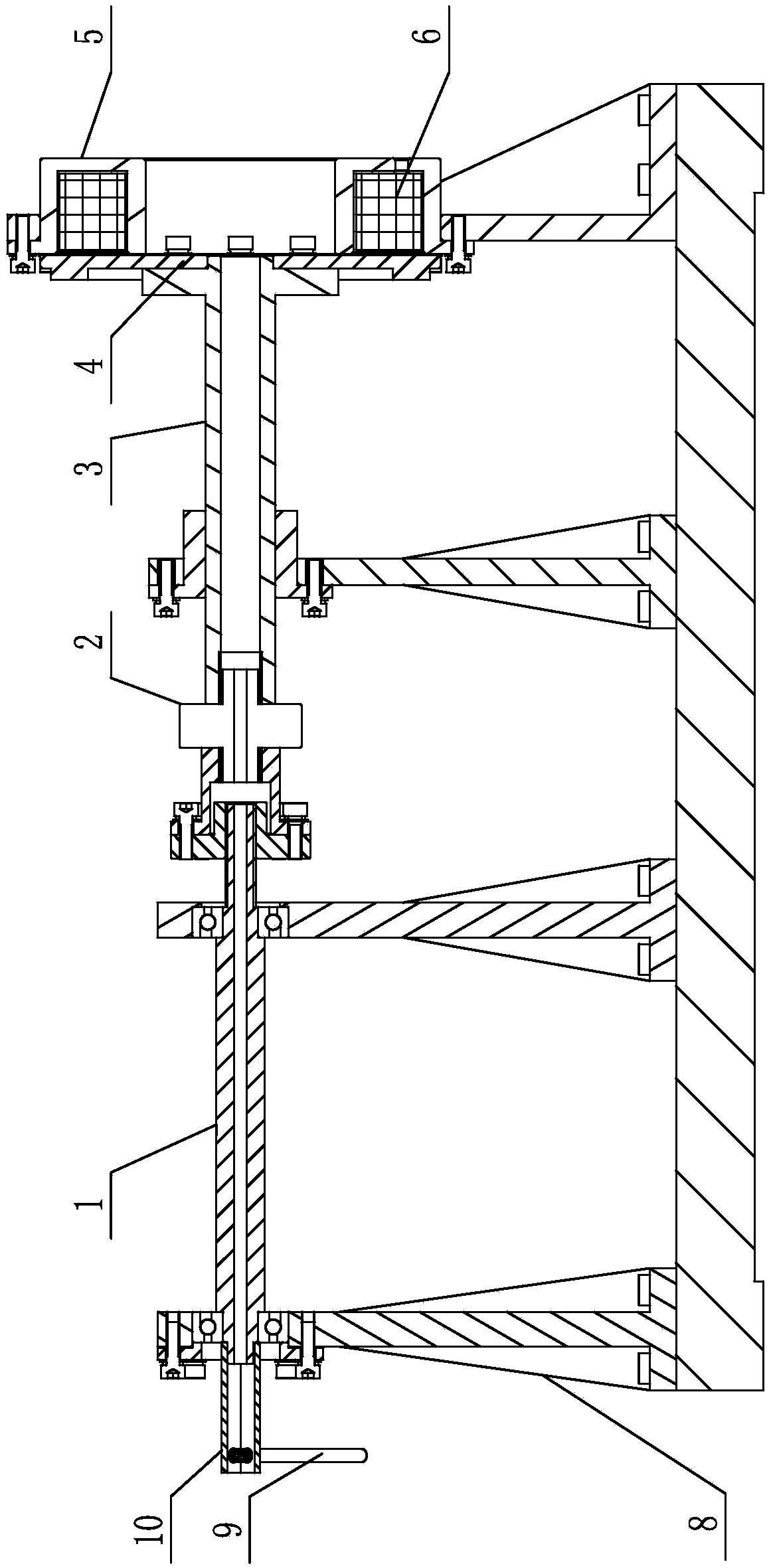

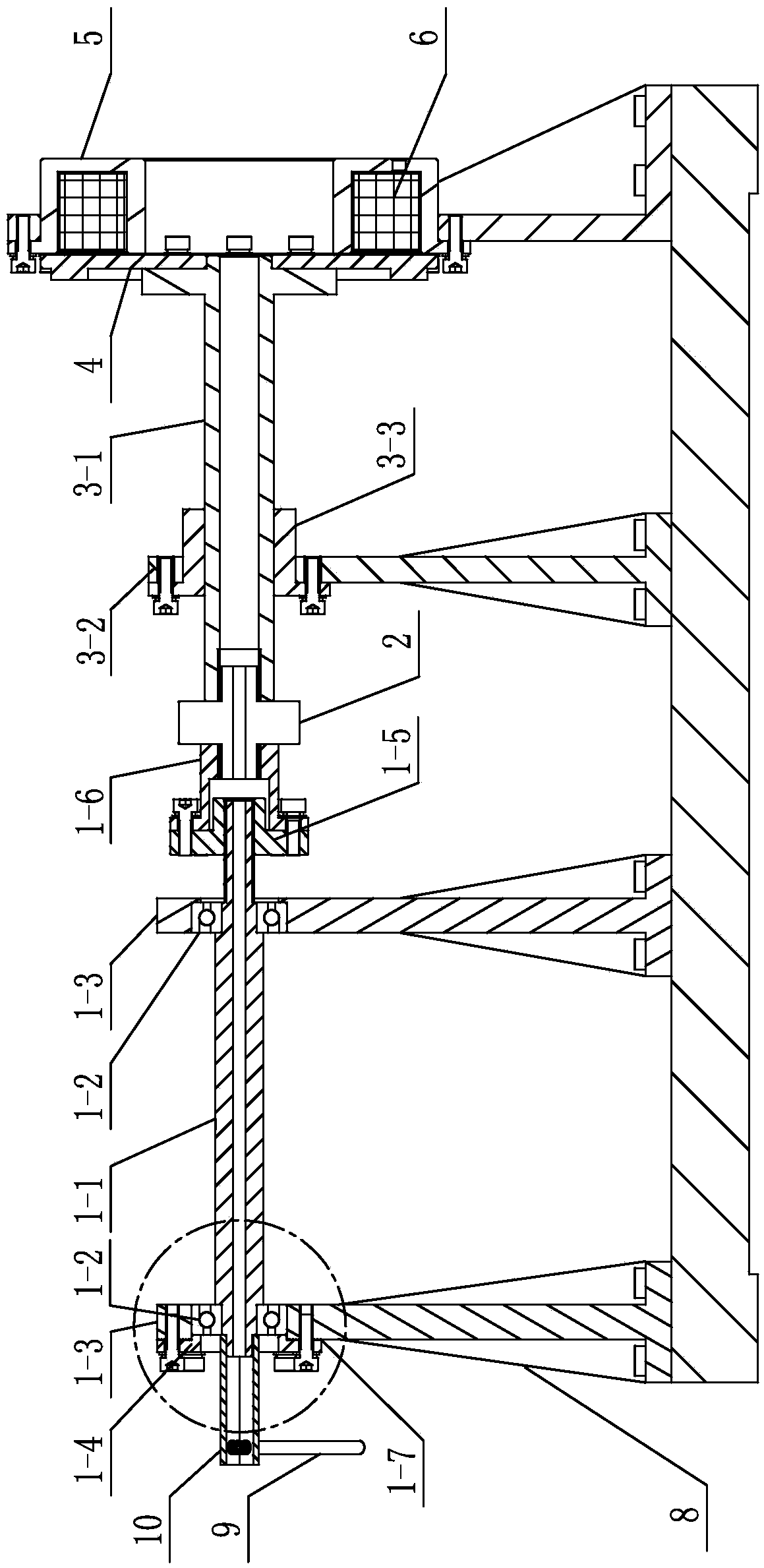

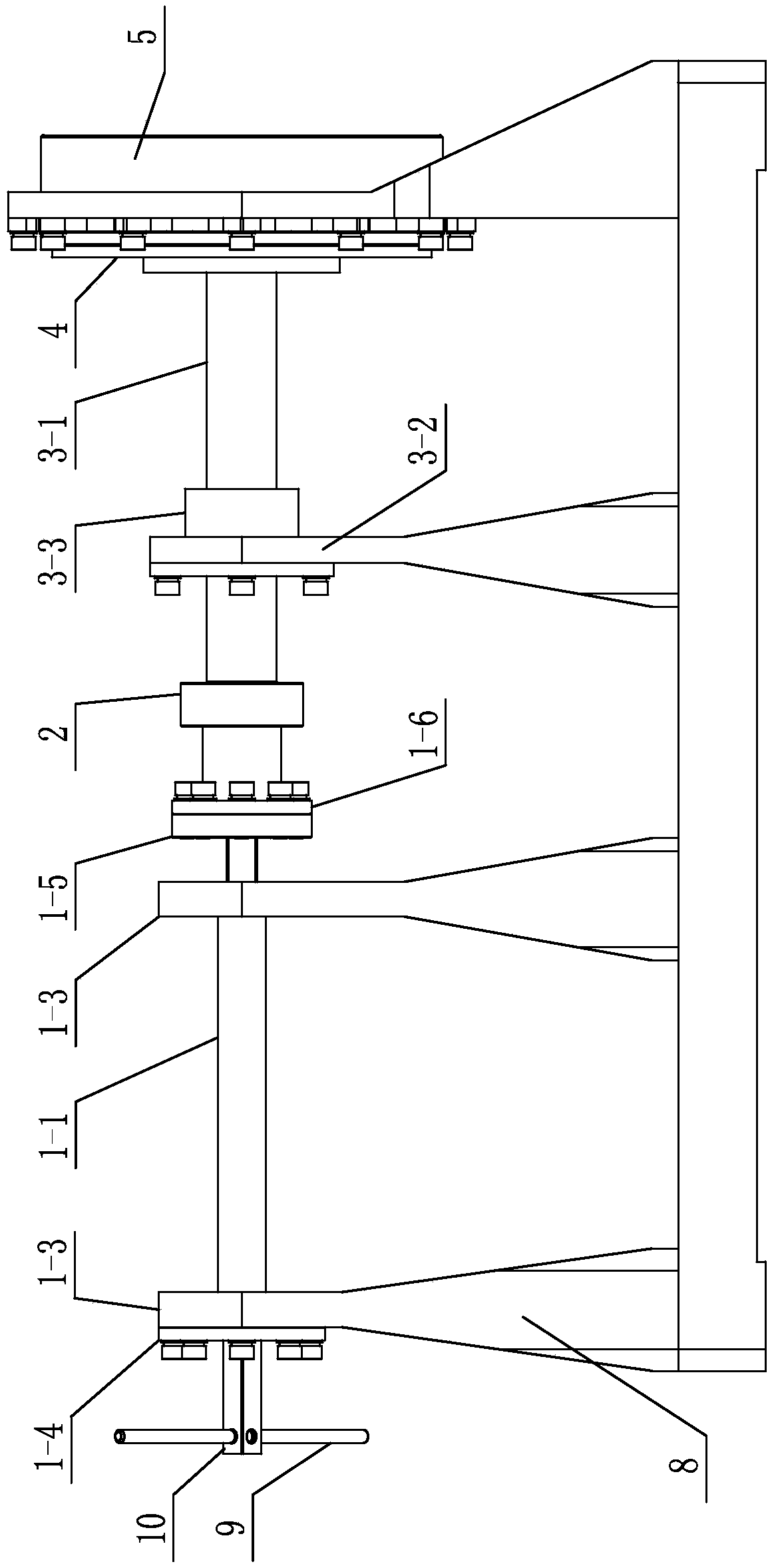

[0016] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, the device for testing the pull-in force of an electromagnetic power-off brake described in this embodiment includes an axial displacement precision adjustment device 1, a load cell 2, an armature friction disc support device 3, an armature friction disc 4, and a brake housing 5 , electromagnetic coil 6 and support frame 8; described axial displacement precise adjustment device 1, armature friction disc support device 3 and brake housing 5 are respectively horizontally installed on the support frame 8 in turn; described support frame 8 is installed by screws on a fixed base;

[0017] One end of the load cell 2 is connected to the precise adjustment device 1 for axial displacement, the other end is connected to one end of the armature friction disc support device 3, and the other end of the armature friction disc support device 3 is connected to the armature friction disc 4 ...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination Figure 2-5 Describe this embodiment, the axial displacement precise adjustment device 1 described in this embodiment includes a screw shaft 1-1, two angular contact ball bearings 1-2, a screw nut 1-5 and two bearing support seats 1- 3. The two bearing support bases 1-3 are located above the support frame 8 and integrally formed with the support frame 8; the two ends of the screw shaft 1-1 are respectively fixed and installed in the two bearing support bases 1-3 In the inner rings of the two angular contact ball bearings 1-2, and extend two bearing support seats 1-3; the end of the screw shaft 1-1 protruding from the bearing support seat is connected with a displacement loading device, and in addition The outer wall at one end has an external thread and is covered with a screw nut 1-5; the screw nut 1-5 is fixedly connected to one end of the load cell 2; the screw shaft is under the action of the displacement loading device ...

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 2-6 To illustrate this embodiment, the screw shaft 1-1 described in this embodiment is a trapezoidal screw, and the inner side walls of the inner rings of the two angular contact ball bearings 1-2 respectively abut against the shoulders at both ends of the screw shaft 1-1 , the outer walls of the outer rings of the two angular contact ball bearings 1-2 are respectively blocked by the card seat in one of the bearing support seats 1-3 and the bearing cover 1-4 screwed to the outer wall of the other bearing support seat 1-3 . Under the action of two angular contact ball bearings, bearing cover and bearing support seat, the screw shaft does not produce displacement in the axial direction. Therefore, the distance that the load cell moves in the axial direction is continuously and gradually increased without repeating movement in the axial direction.

[0024] like Figure 7 As shown: an adjusting gasket 1-7 is also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com