Low-noise relay

A relay and low-noise technology, which is applied in the field of low-noise relays, can solve the problems of loud electromagnet noise and high electromagnetic force of relays, and achieve the effects of reducing noise, reducing electromagnetic force, and reducing oversaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows in conjunction with the accompanying drawings.

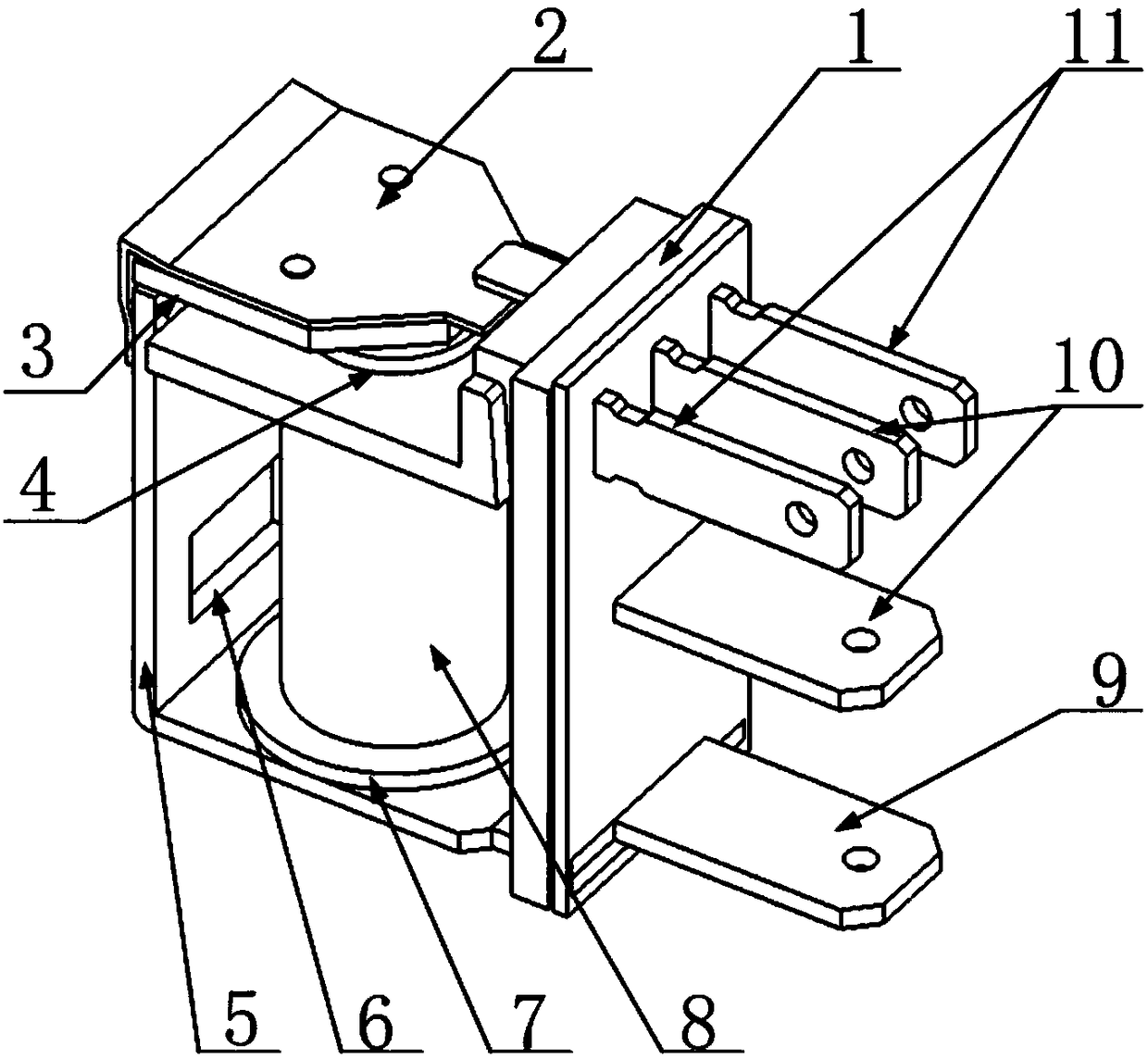

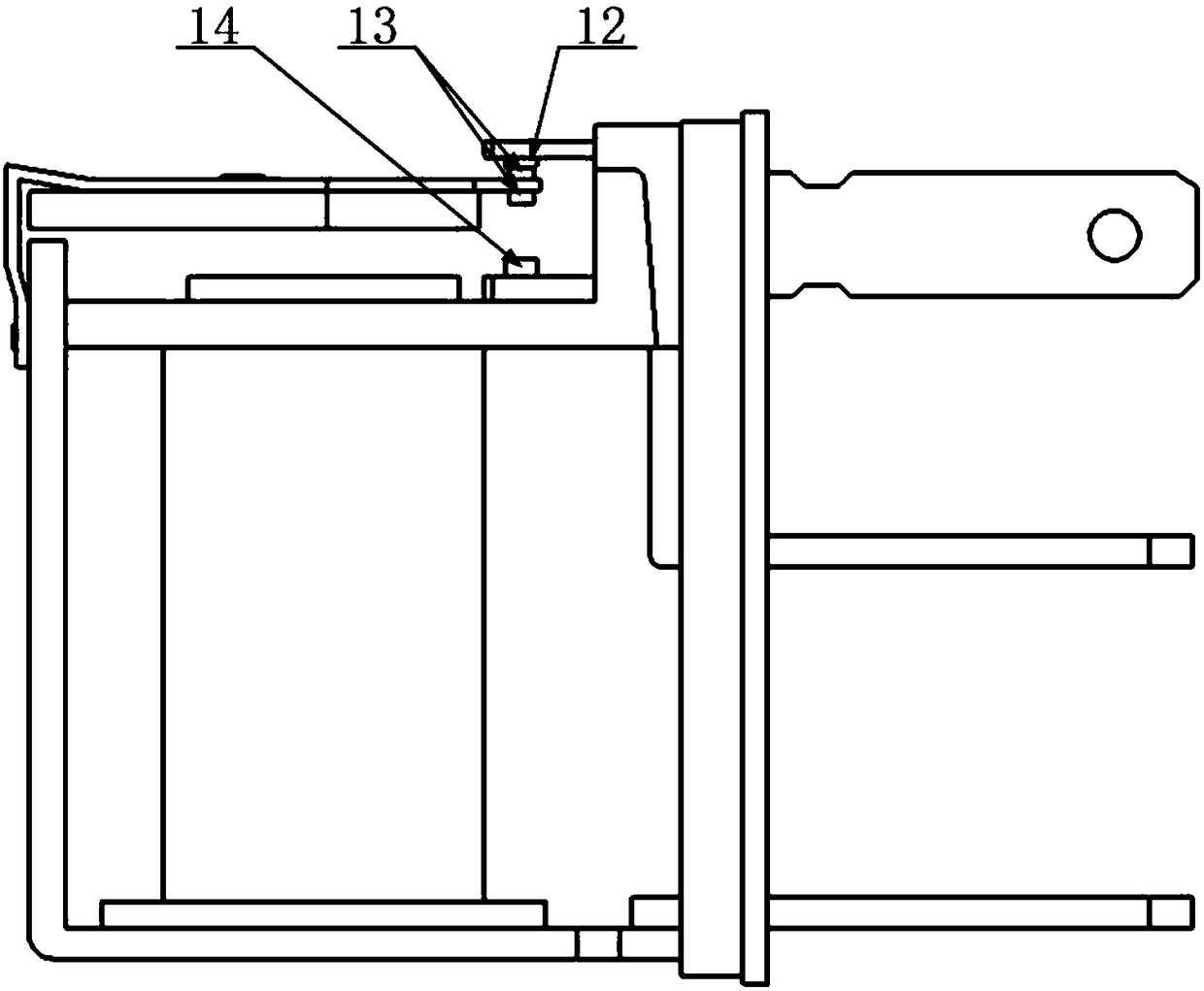

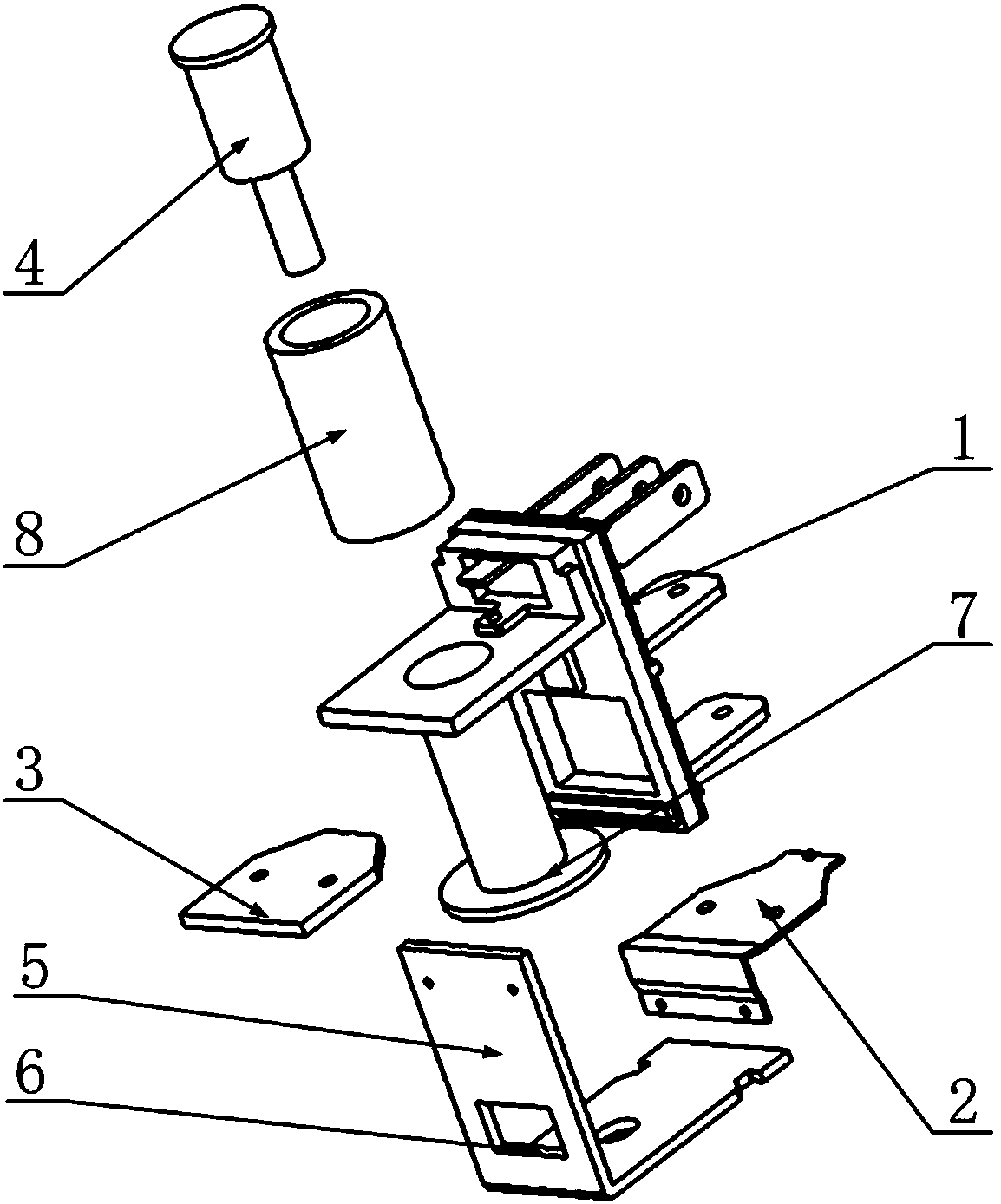

[0016] Such as Figure 1-3 As shown, a low-noise relay includes L-shaped moving reed 2, armature 3, iron core 4, L-shaped yoke 5, coil bobbin 7, coil 8, output static reed 9, input static reed 10 and The coil control pin 11, the coil frame 7 is arranged on the bottom of the L-shaped yoke 5, the outside of the coil 8 is coated with enameled wire and wound on the coil frame 7, the center of the coil frame 7 is provided with a through hole, and the iron core 4 passes through the through hole. The hole is fixedly connected with the bottom of the L-shaped yoke 5, the vertical part of the L-shaped moving reed 2 is fixedly connected with the vertical side of the L-shaped yoke 5, and its transverse part is fixedly connected with the armature 3, and the L-shaped moving reed 2 is horizontally The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com