A traction machine brake

A machine brake and brake technology, applied in the direction of the hoisting device, can solve the problems of magnetic steel demagnetization, high processing difficulty, difficult adjustment, etc., and achieve the effects of cost reduction, high operation safety and stability, and structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

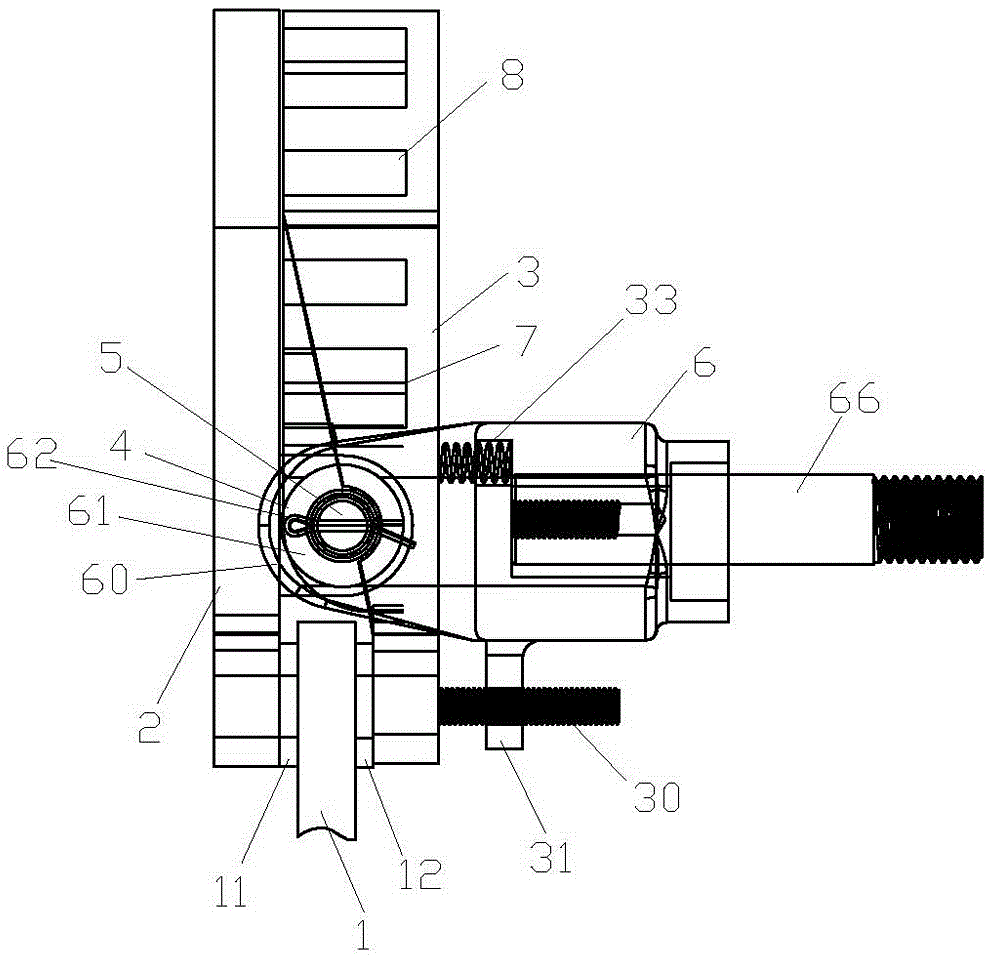

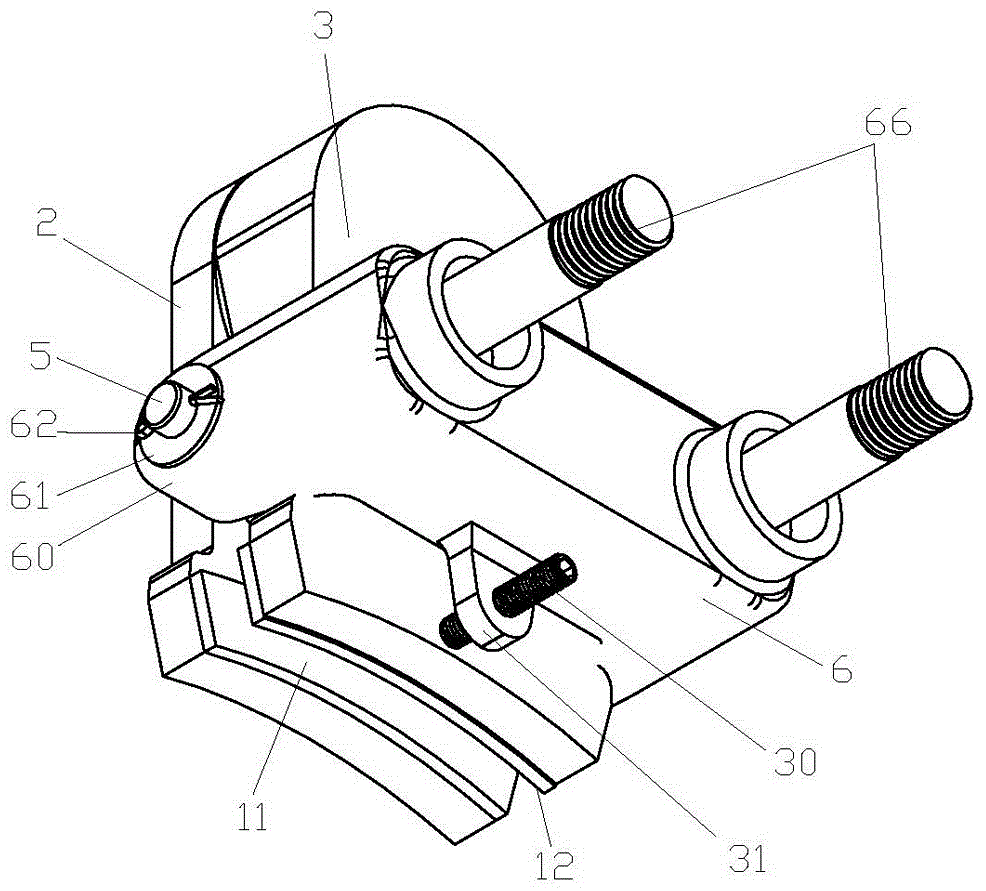

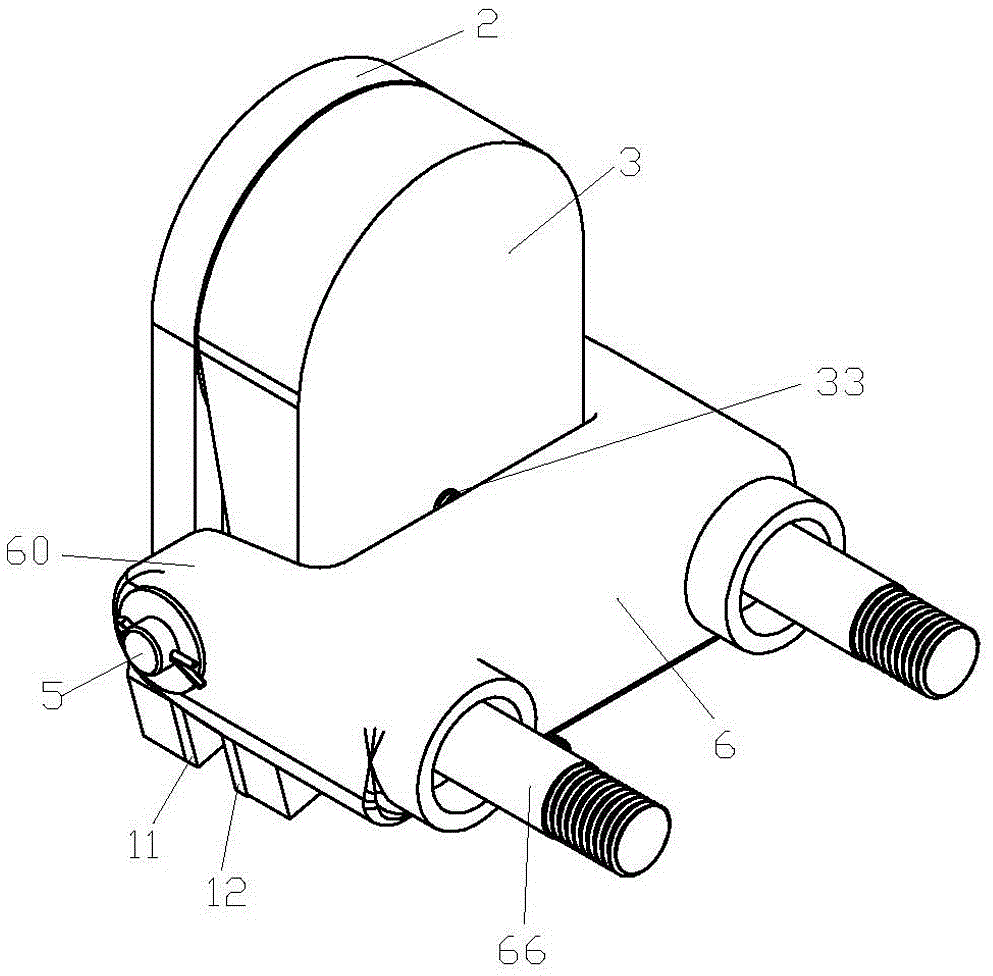

[0017] Example 1 , as shown in the figure 1 、 2 、 3 As shown, a traction machine brake, including a brake disc 1 , brake disc 1 There are left brake pads on both sides of the left and right discs 11 and right brake pad 12 , left brake pad 11 facing away from the brake disc 1 Fixed on one side to an armature plate 2 upper right brake pad 12 back to brake disc 1 One side fixed to the armature plate 2 a core board 3 upper, armature plate 2 by brake disc 1 brake disc on one side 1 Upper part and core plate 3 by brake disc 1 brake disc on one side 1 The upper parts are respectively fixed with connecting parts that can cross along the left and right directions, and the armature plate 2 connection part and core plate 3 The connecting parts of the cross to form a combined connecting part 4 And through the connecting shaft arranged along the front and rear direction 5 connected in series, connecting shafts 5 on t...

Embodiment 2

[0019] Example 2 , which with the example 1 The difference is: brake mount 6 Lean on core plate 3 One side is located on the connecting shaft 5 The upper part is equipped with a core plate for resisting the 3 adjustment spring 33 , core plate 3 Back to armature plate 2 One side is located on the connecting shaft 5 The lower part is fixed with the armature plate facing away from the 2 Adjusting screw extended on one side 30 , brake mount 6 The lower part is fixed with the adjustment screw 30 matching adjustment plate 31 , adjustment board 31 screw for adjustment 30 Through hole through, adjusting screw 30 Equipped with corresponding adjusting nuts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com