Patents

Literature

50results about How to "Reduce magnetic density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

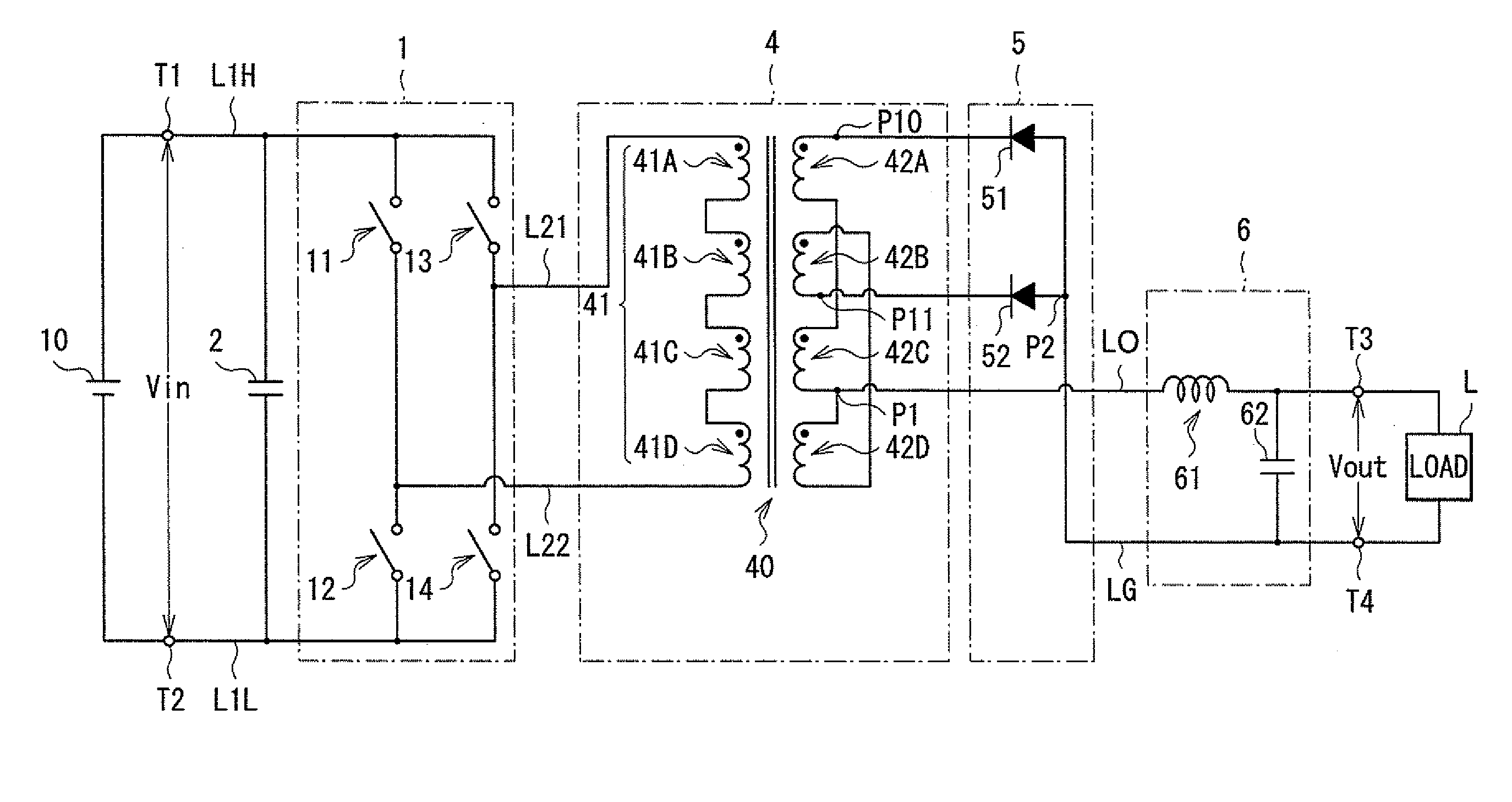

Transformer and switching power supply unit

ActiveUS20100232181A1Reduce flux densityReducing core lossDc-dc conversionTransformers/inductances magnetic coresTransformerDiagonal

Owner:TDK CORPARATION

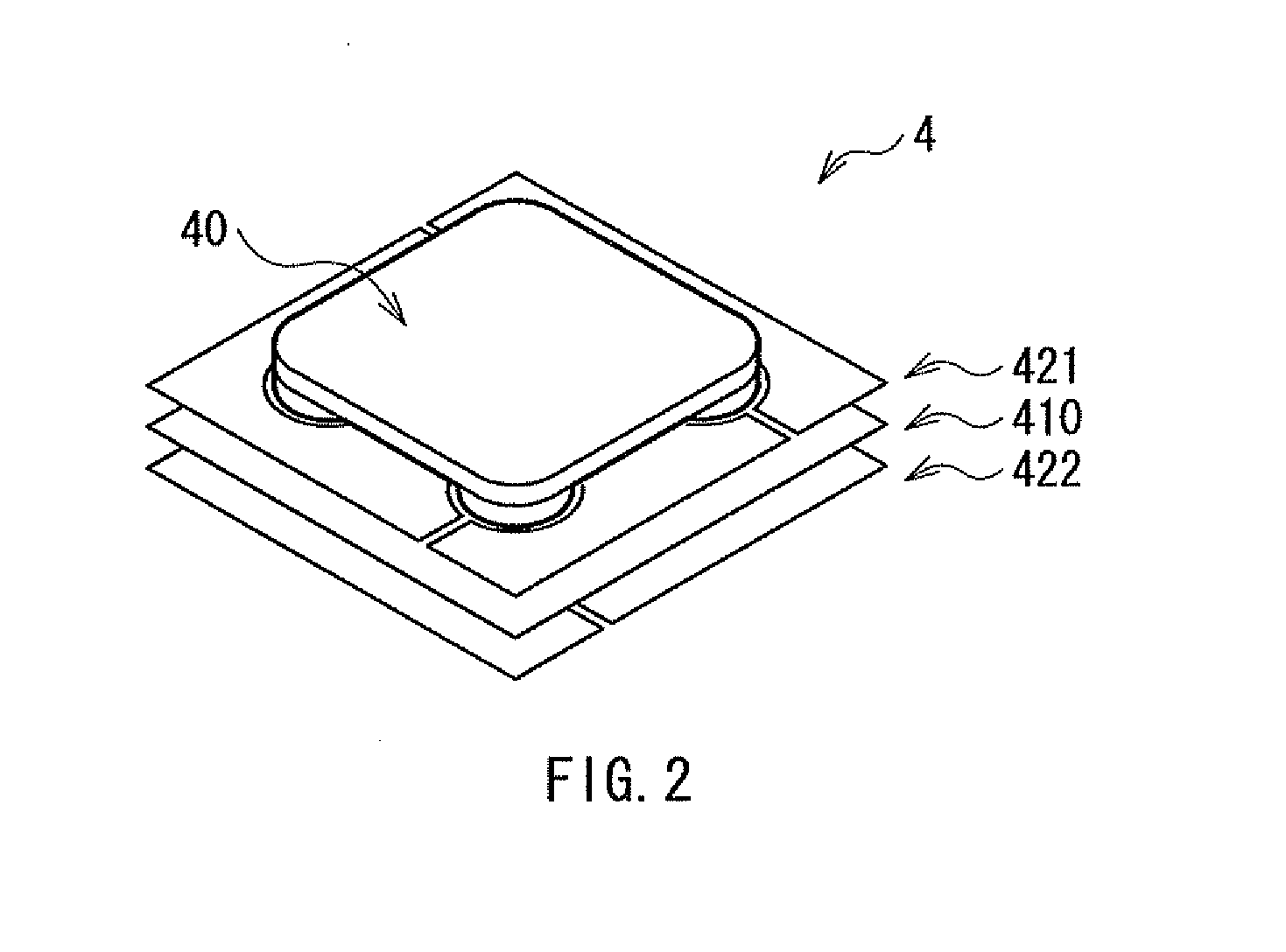

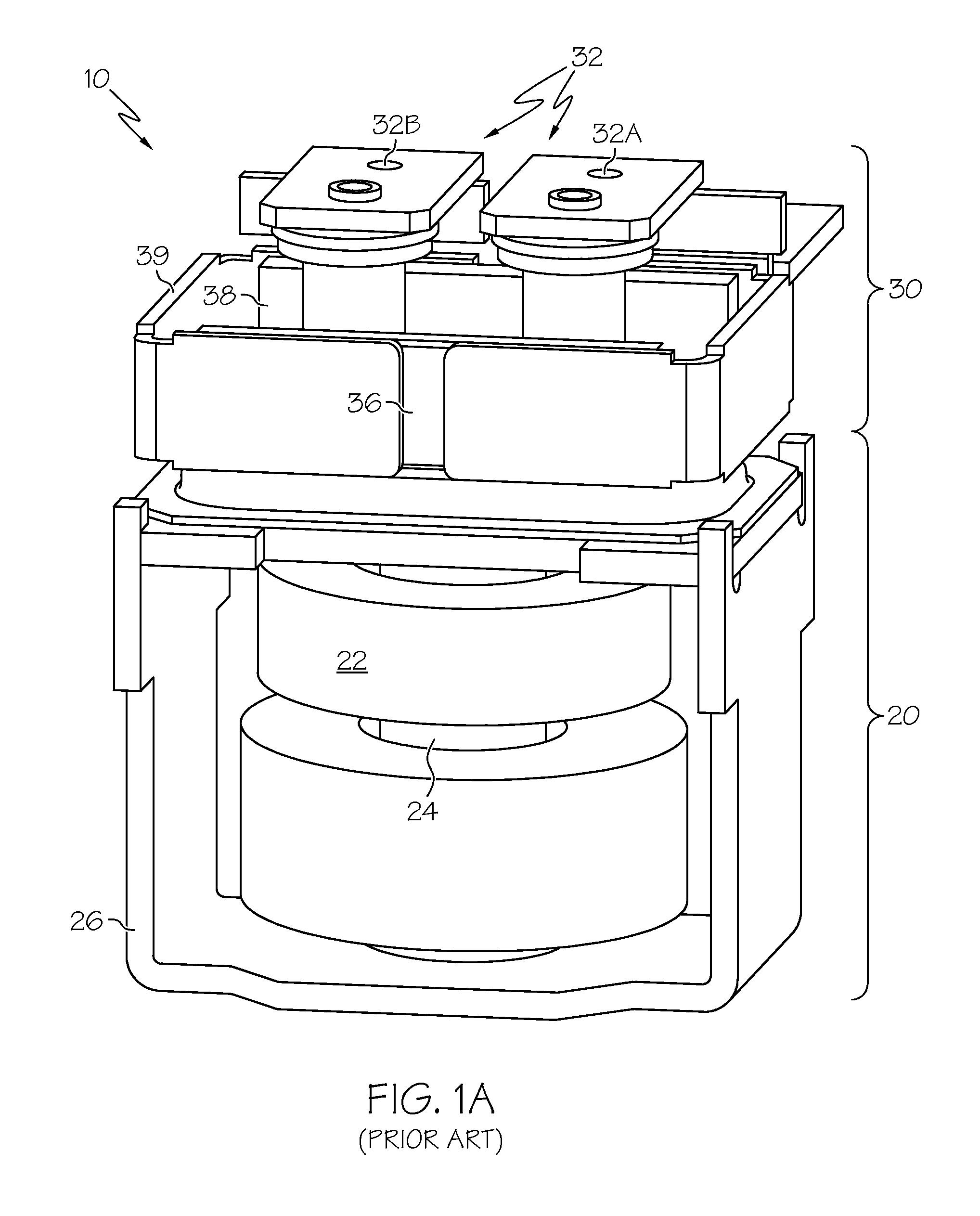

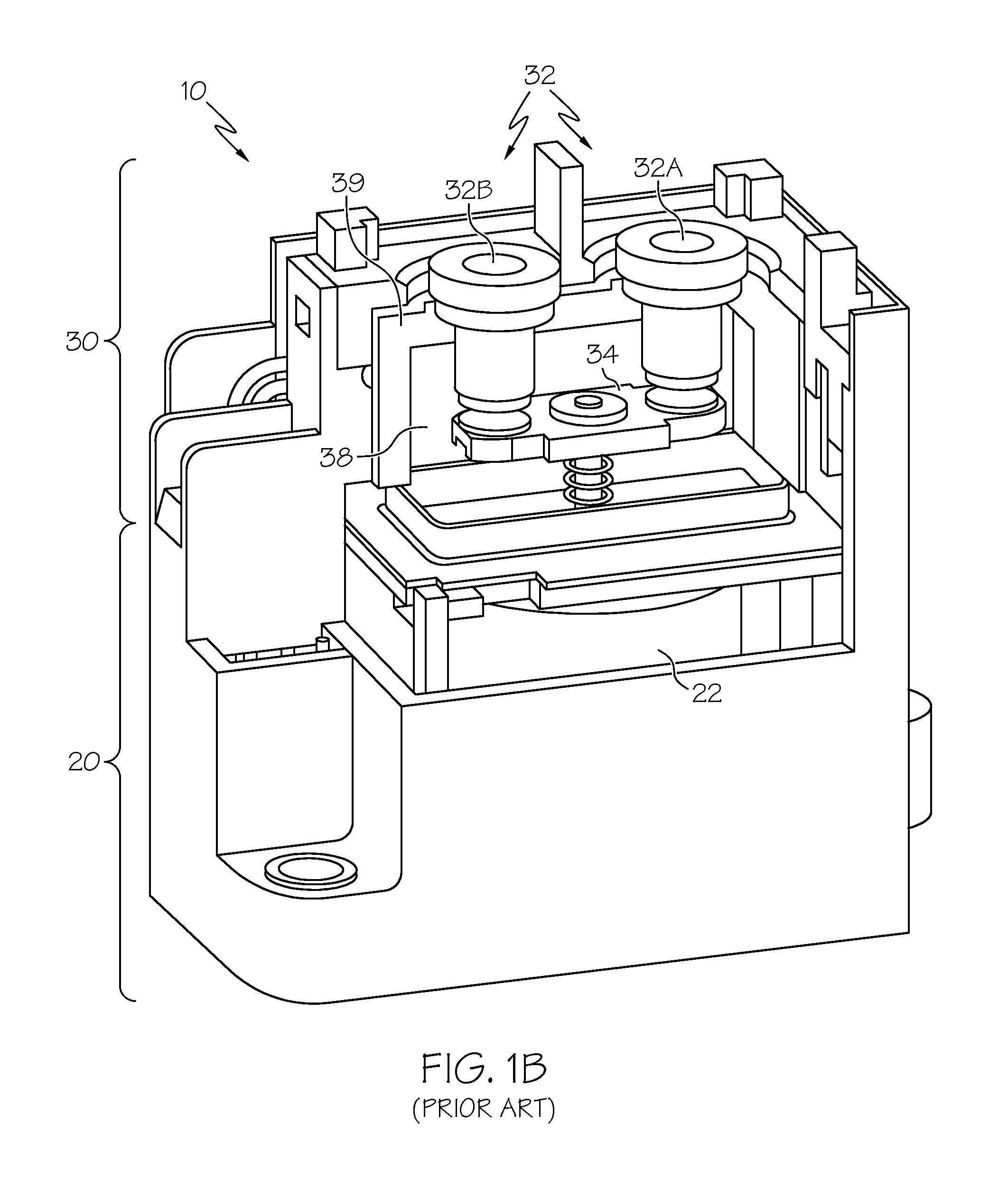

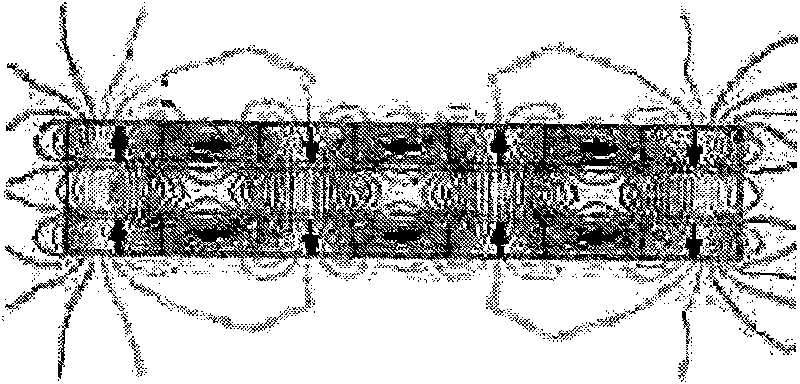

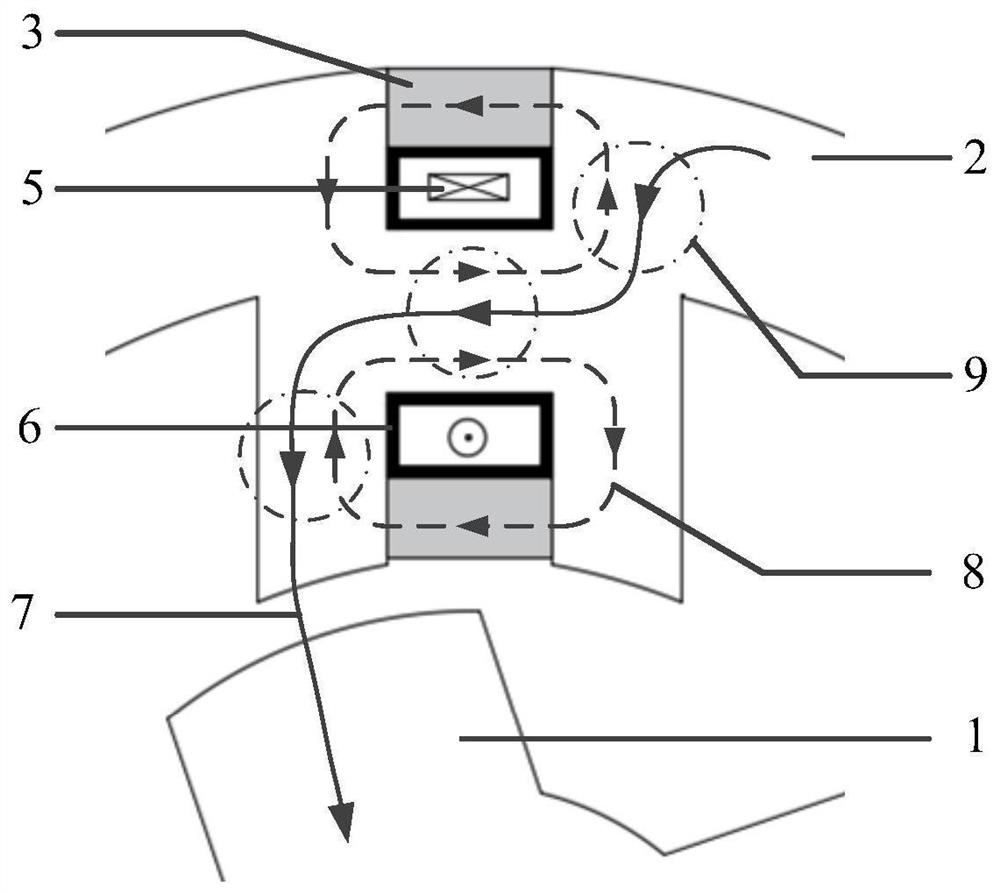

Dual bipolar magnetic field for linear high-voltage contactor in automotive lithium-ion battery systems

InactiveUS8653691B2Reduce chanceImprove stabilityElectric devicesElectric powerAutomotive batteryCombined use

A device and method for operating automotive battery system relays and related switches. By creating a dual bipolar magnetic field adjacent the contactor portion of a switching mechanism in the relay, the magnetic field used to promote arc extinguishing is shifted, which in turn reduces the Lorentz force that forms as a byproduct of the field. Such a configuration has the potential for simultaneously maintaining arc-extinguishing capability and improving short-circuit withstanding capability while reducing the tendency of the Lorentz forces to interfere with the operation of a solenoid or other switch-activating mechanisms. Such devices and methods may be used in conjunction with hybrid-powered and electric-powered vehicles.

Owner:GM GLOBAL TECH OPERATIONS LLC

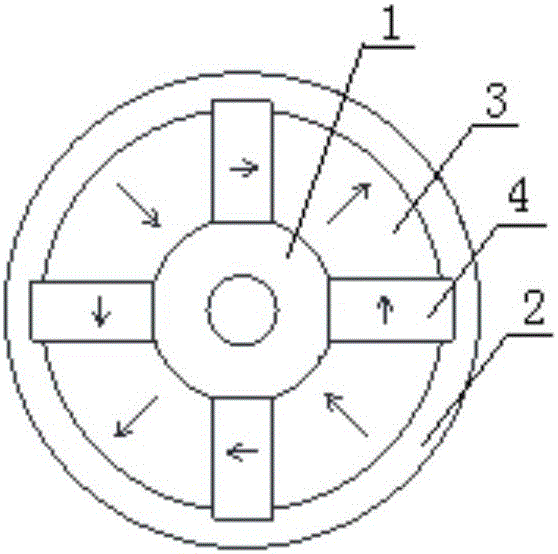

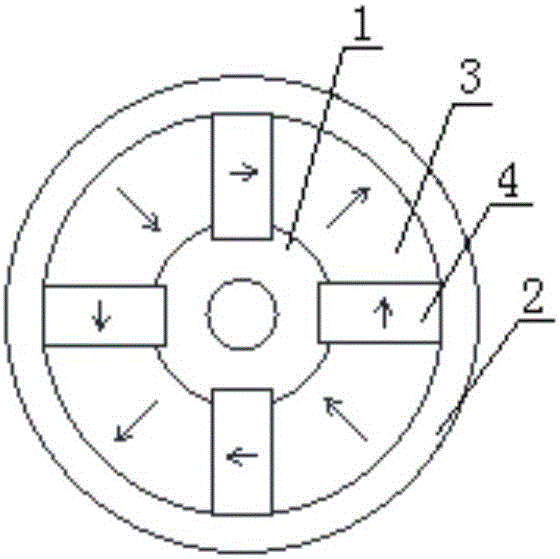

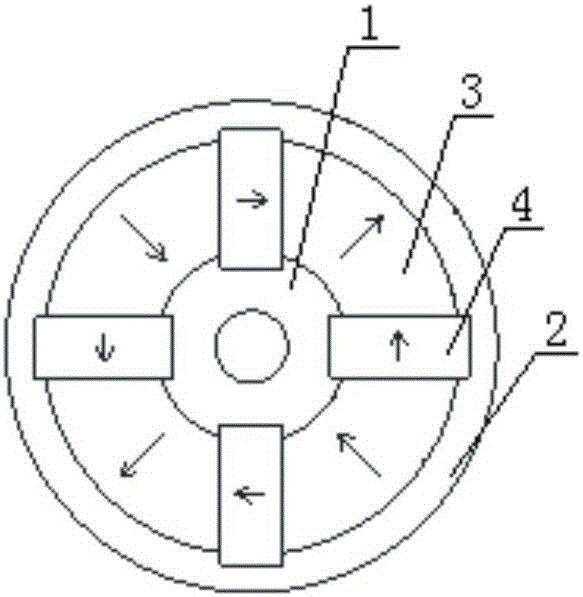

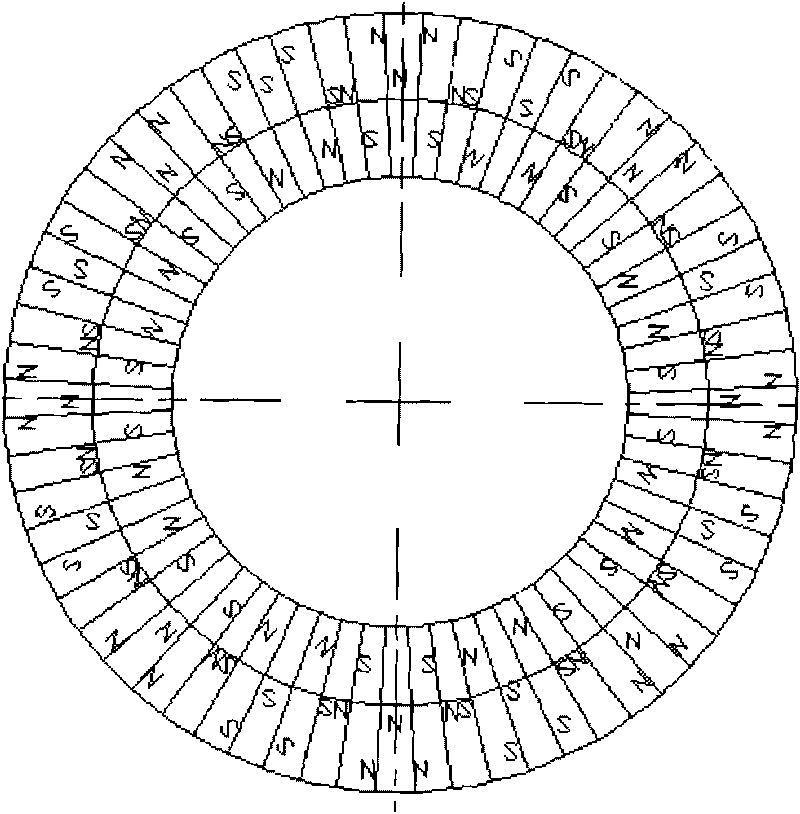

Rotor of high-speed Halbach-type permanent magnet motor

InactiveCN105790468AImprove power densityImprove dynamic response performanceMagnetic circuit rotating partsPermanent magnet motorAir gap flux density

The invention provides a rotor of a high-speed Halbach-type permanent magnet motor. The rotor comprises a Halbach-type permanent magnet structure, a rotor shaft and a rotor sheath, wherein the Halbach-type permanent magnet structure comprises strip-shaped rectangular permanent magnets and strip-shaped arc permanent magnets; the external surfaces of the strip-shaped arc permanent magnets are arc-shaped; the strip-shaped rectangular permanent magnets and the strip-shaped arc permanent magnets are arranged in the peripheral direction of the rotor shaft at intervals; the rotor sheath is arranged outside the strip-shaped rectangular permanent magnets and the strip-shaped arc permanent magnets; the adjacent strip-shaped rectangular permanent magnets and strip-shaped arc permanent magnets are directly laminated; and a groove corresponding to the strip-shaped rectangular permanent magnets or the strip-shaped arc permanent magnets is formed in the rotor shaft or the rotor sheath. Due to the structural design of the rotor, the numerical value of the air-gap flux density of the rotor is improved; the sine degree of the waveform is enhanced; the power density of the motor is improved; the flux density of a rotating shaft yoke is reduced; the hollow rotating shaft provides a cooling channel for the rotor; and the dynamic response ability of the rotor is improved.

Owner:HARBIN INST OF TECH

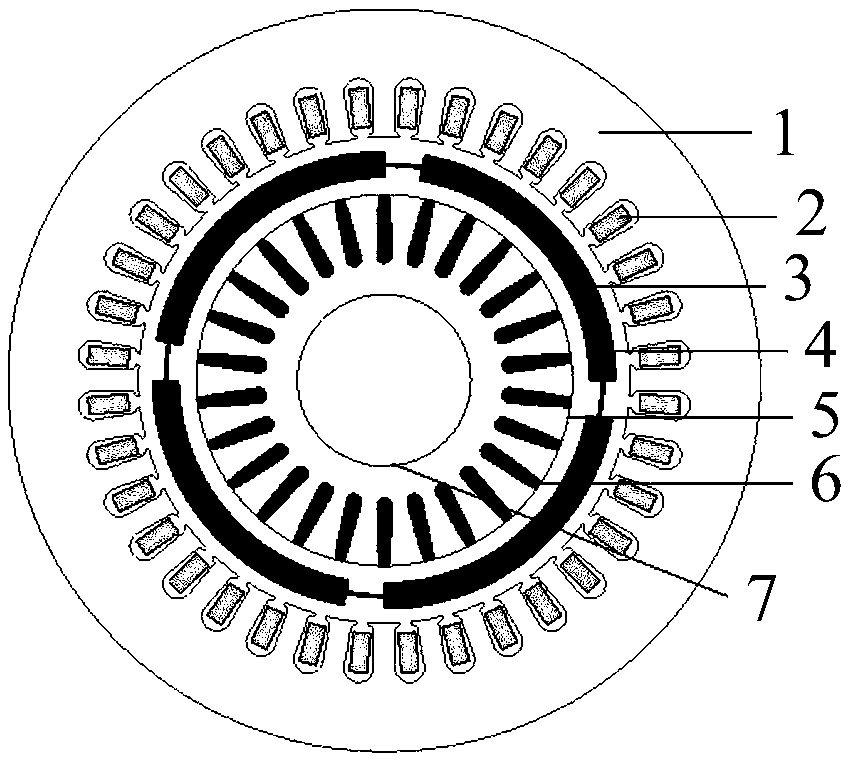

Single-phase permanent magnet brushless direct-current motor with auxiliary teeth and auxiliary windings

InactiveCN105099112ASmooth startEliminate "dead spots"Synchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorMagnetomotive force

The invention discloses a single-phase permanent magnet brushless direct-current motor with auxiliary teeth and auxiliary windings. The single-phase permanent magnet brushless direct-current motor includes a stator and a permanent magnet rotor; the stator is provided with a plurality of stator main pole teeth and stator auxiliary pole teeth which are uniformly distributed along the circumference of the stator, wherein the stator main pole teeth and the stator auxiliary pole teeth are arranged at intervals; the total number of the tooth slots of the stator main pole teeth and stator auxiliary pole teeth is twice of the number of the poles of the permanent magnet rotor of the motor; the width of the stator main pole teeth is 1.55 to 2 times of the width of the stator auxiliary pole teeth; main tooth arc surfaces are formed at the roots of the stator main pole teeth; auxiliary tooth arc surfaces are formed at the roots of the stator auxiliary pole teeth; slot openings are formed between the main tooth arc surfaces of the stator main pole teeth and the auxiliary tooth arc surfaces of the stator auxiliary pole teeth; and the central line of each slot opening deviates from the central line of a corresponding stator auxiliary pole tooth by a certain angle. After the single-phase permanent magnet brushless direct-current motor of the invention is energized, a magnetomotive force F generated by stator current has voltage difference, and therefore, a dead point can be eliminated; and the starting instant magnetomotive force voltage difference can change with the magnitude of the controllable stator current, and therefore, the starting instant magnetomotive force voltage difference can be controlled, and the motor can be started smoothly without vibration.

Owner:ZHE JIANG YILIDA VENTILATOR CO LTD

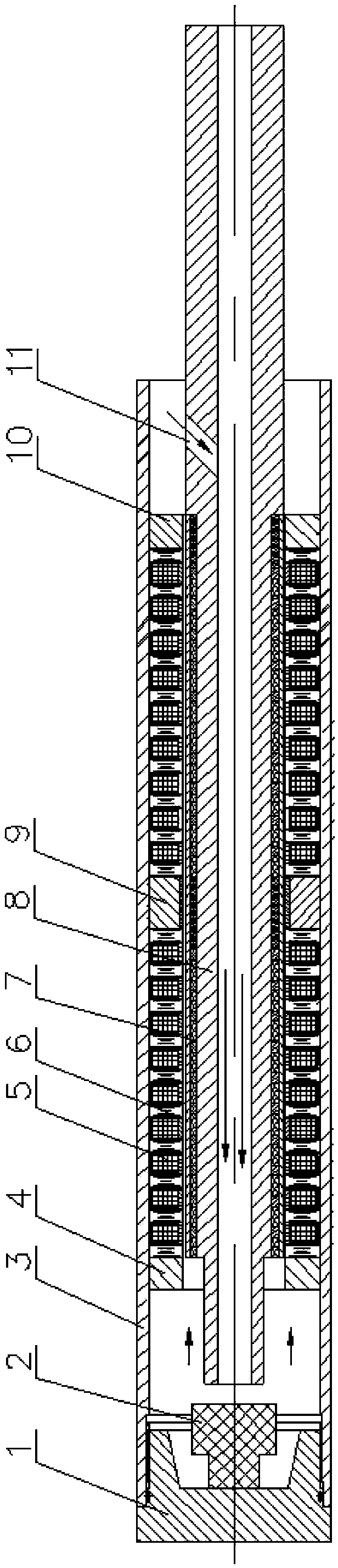

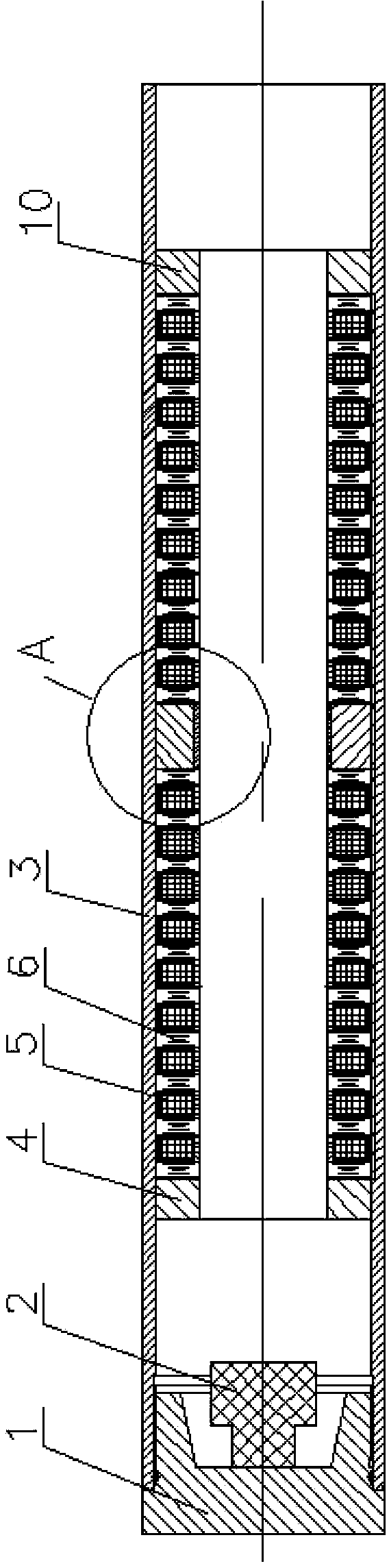

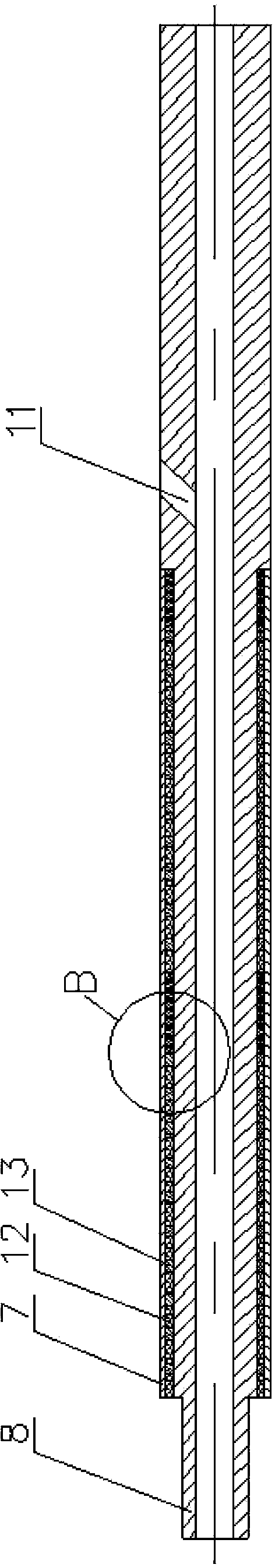

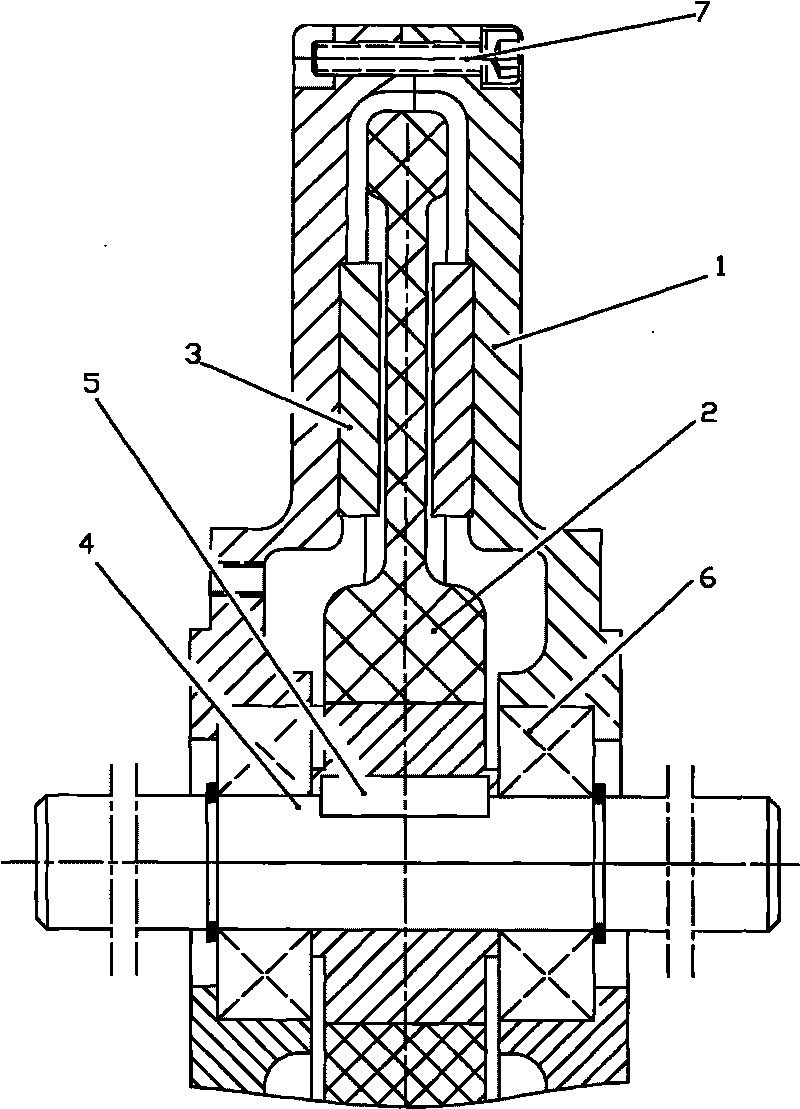

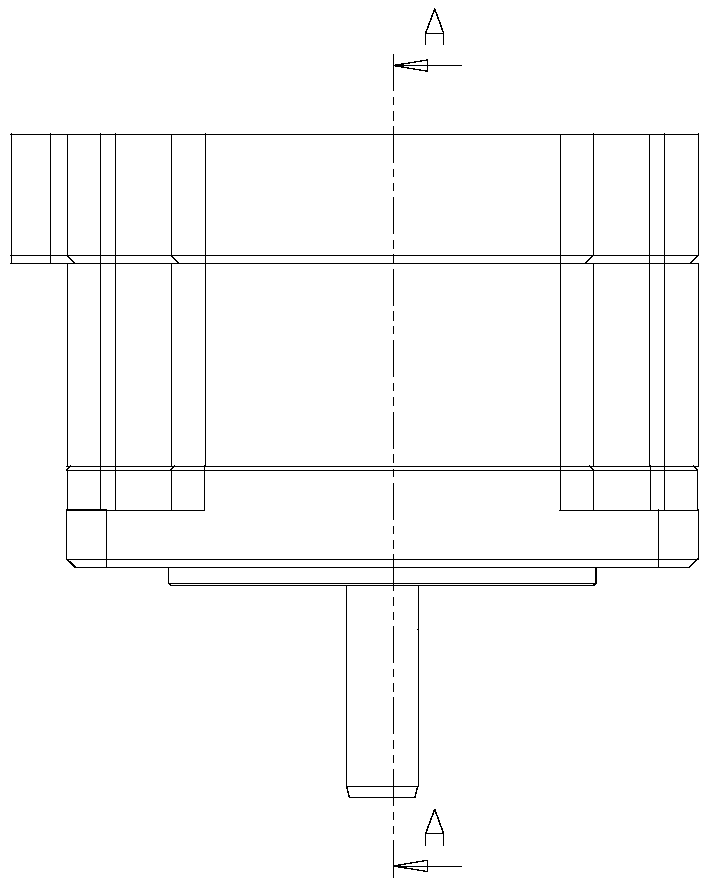

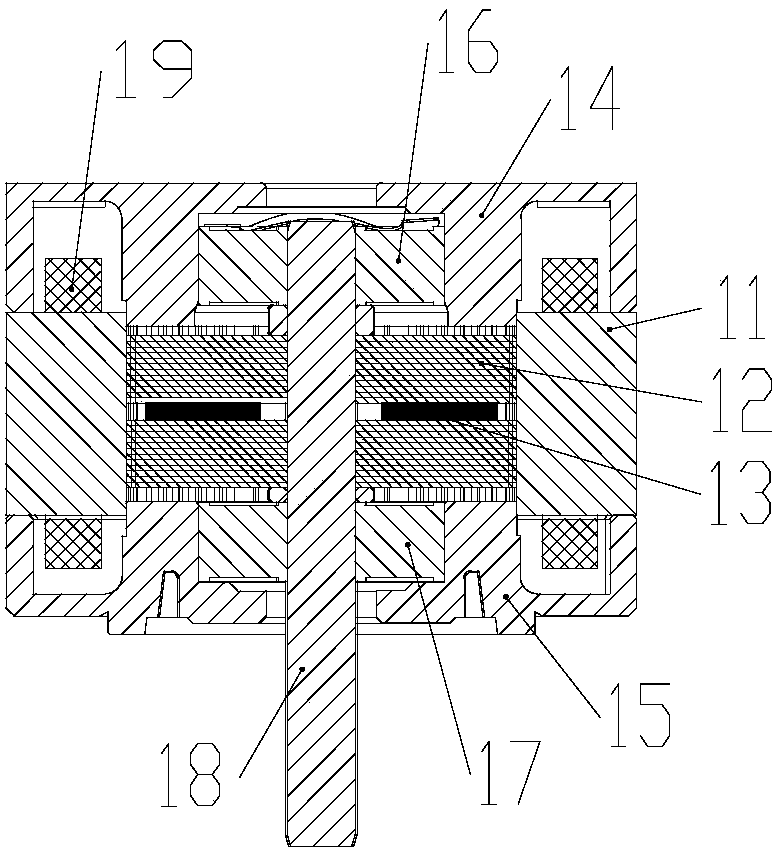

High-thrust tubular linear motor

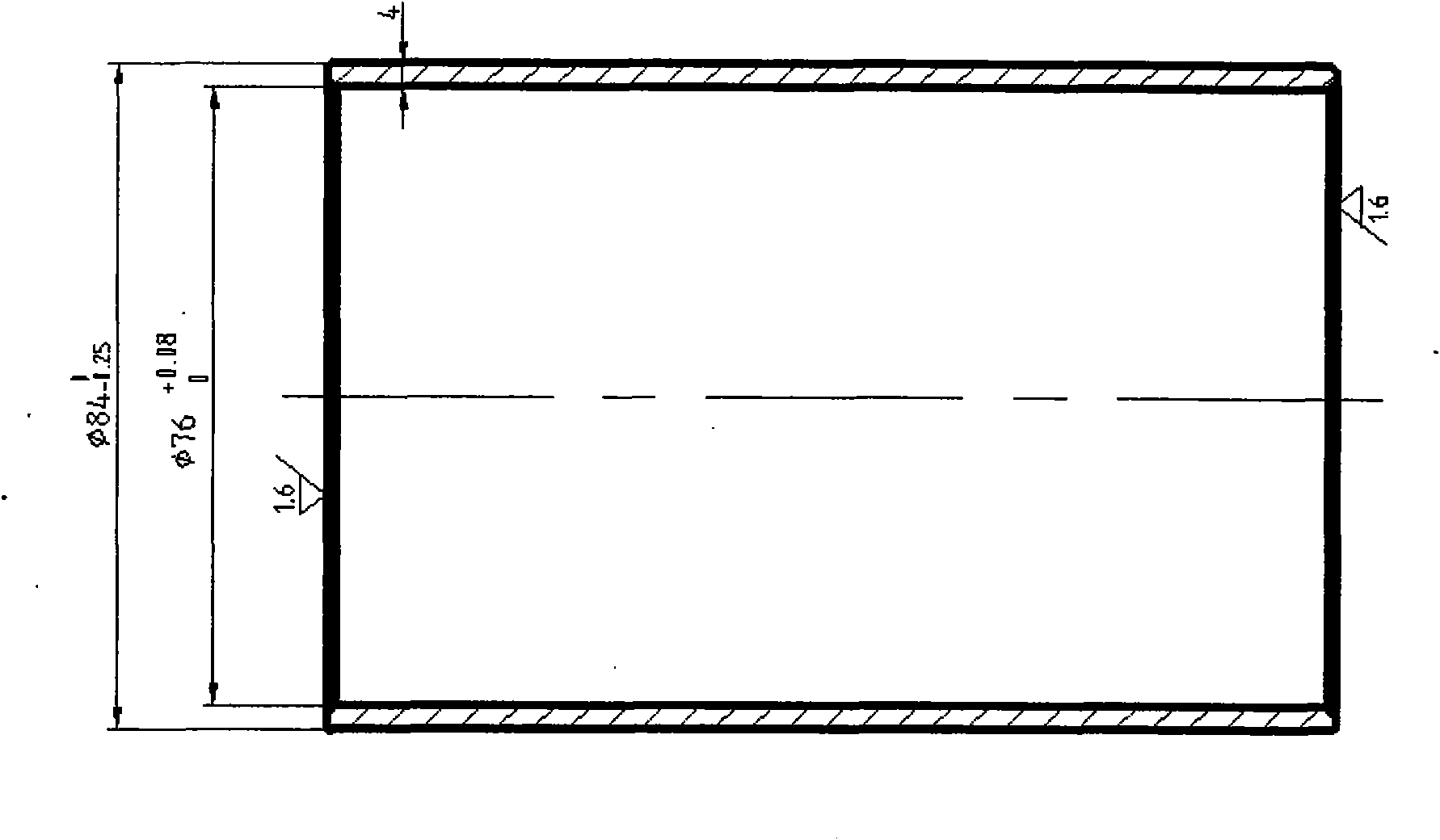

ActiveCN103427587AStrong resistance to demagnetizationReduce magnetic densityPropulsion systemsTubular linear motorConductor Coil

The invention relates to a high-thrust tubular linear motor which comprises a stator shell, a stator and a rotor. The stator is coaxially and fixedly mounted in the stator shell, the rotor is coaxially and slidably mounted in an inner cavity of the stator, the stator comprises silicon steel sheets and windings which are arranged at intervals and fixedly mounted on the stator shell, the rotor comprises a rotor shaft, permanent magnets and magnetic conduction rings, and the permanent magnets and the magnetic conduction rings are arranged at intervals on the rotor shaft. The high-thrust tubular linear motor is characterized in that the rotor shaft is made of hollow soft magnetic materials, a copper tube is coaxially sleeved outside the rotor, the windings and the silicon steel sheets are fixedly mounted at intervals to form the stator, and the windings and the silicon steel sheets correspond to the permanent magnets and the magnetic conduction rings of the rotor. The high-thrust tubular linear motor is ingenious in design, reasonable in structure, large in starting force, fine in tightness and reliable in operation.

Owner:伟力驱动技术(深圳)有限公司

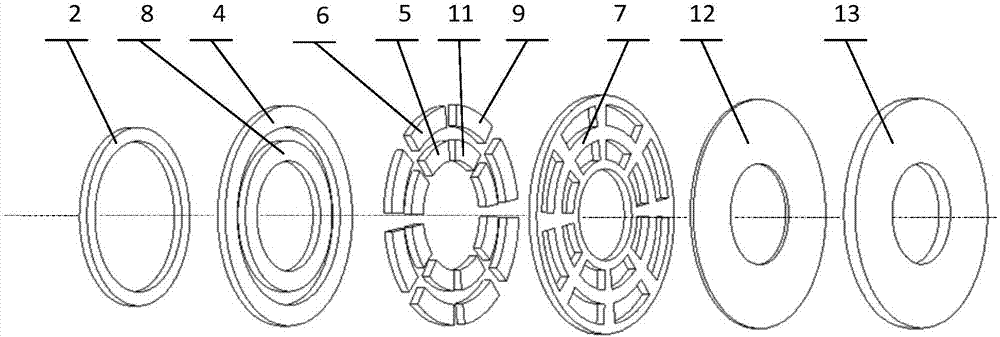

Disc type permasyn motor for electric car hub

InactiveCN101764489AImprove power densityReduce power densityMagnetic circuit rotating partsElectric devicesLow speedPermanent magnet synchronous motor

The invention relates to a disc type permasyn motor for an electric car hub, which comprises a fixed mandrel, a rotor outer casing and a stator armature disc, wherein the rotor outer casing is supported on the fixed mandrel; the stator armature disc is fixedly connected with the fixed mandrel. The left and right sides of the rotor outer casing are symmetrically fixedly connected with parallel magnetic steel discs. A circular air gap of which the cross section is in a rectangle shape is formed between the magnetic steel discs. The stator armature disc is arranged in the circular air gap and is provided with an outgoing line. The stator armature disc has no core, and is directly formed by injection molding. The magnetic steel disc adopts a Halbach type permanent magnet array structure. The invention adopts the stator armature disc without a core for direct injection molding, and the magnetic steel disc with the Halbach type permanent magnet array structure, therefore the motor can greatly enhance power density of the motor, decrease the wear and tear of the motor and has the advantages of small volume, compact structure, stable low-speed running, good controllability, light weight, small vortex consumption of the rotor, small rotating inertia, large power density, small electromechanical time constant and the like.

Owner:TIANJIN UNIV

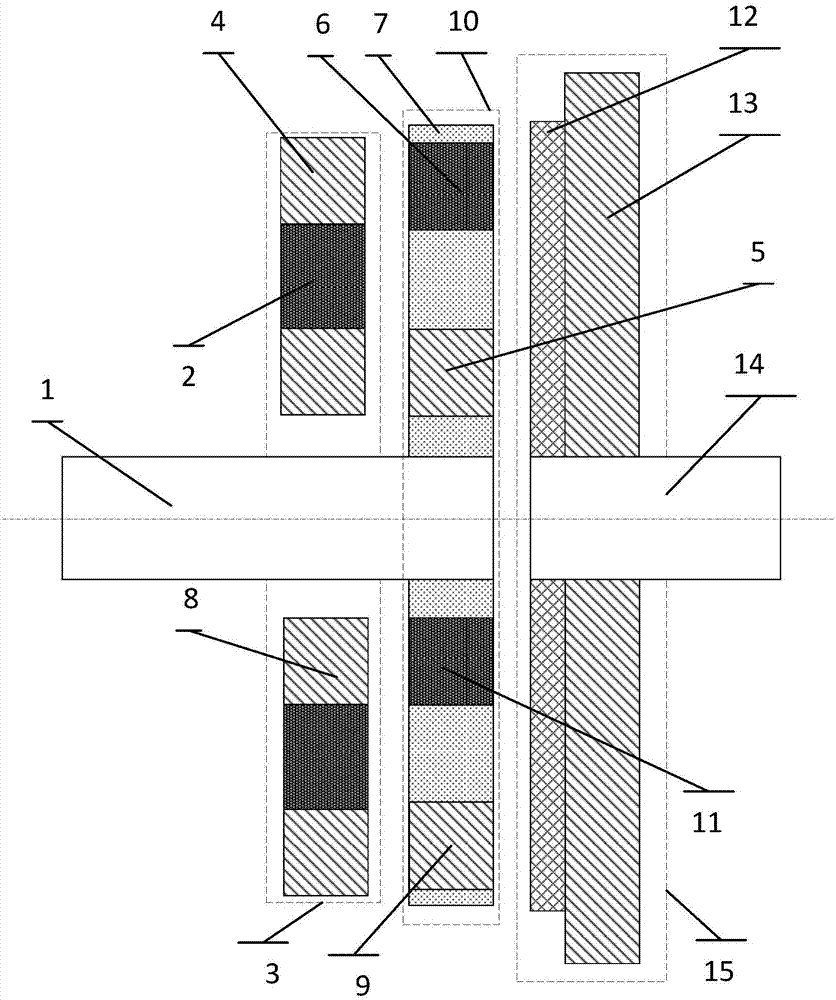

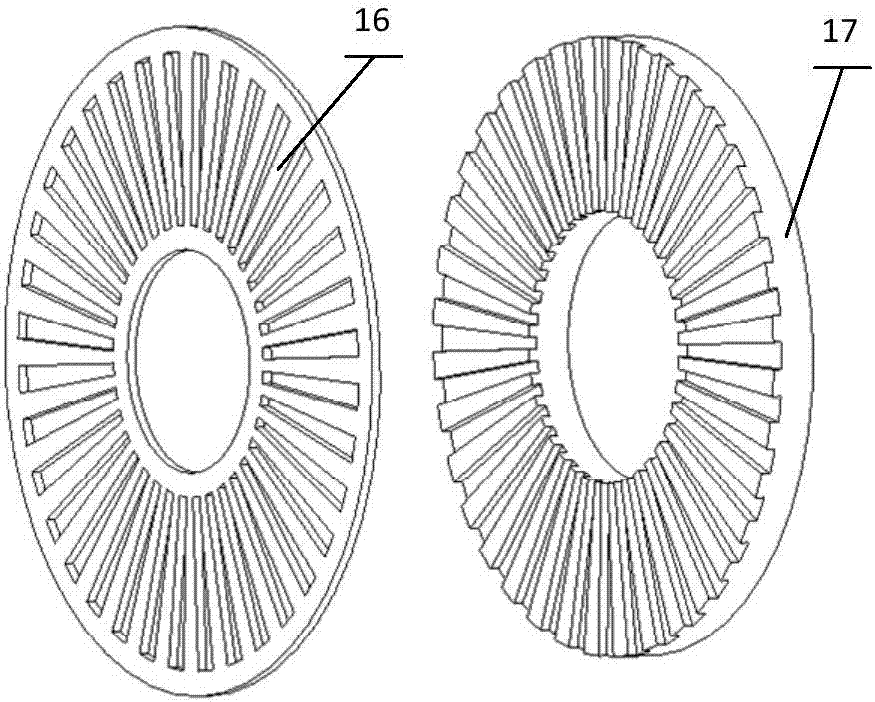

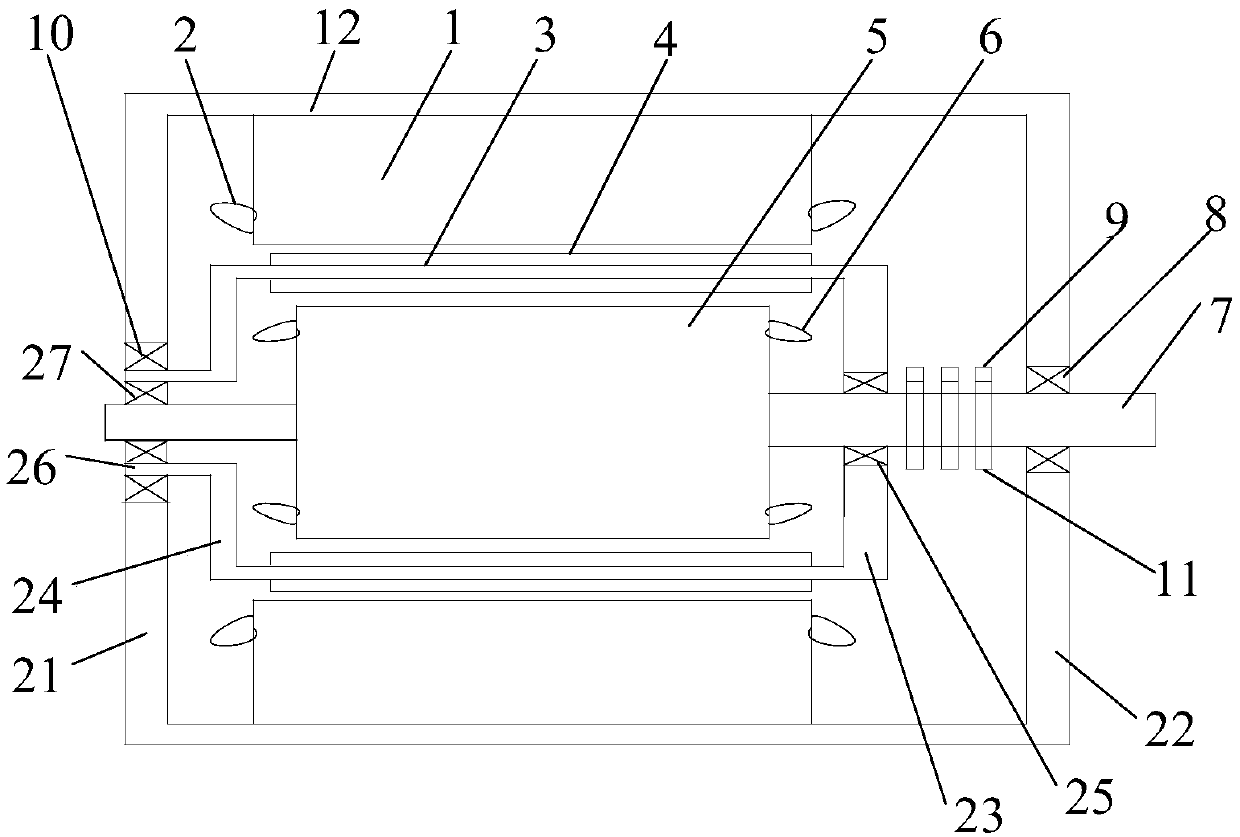

Disk type translation permanent magnetic stator type permanent magnetic vortex speed regulating device

ActiveCN106877627AReduce magnetic densityReduce complexityPermanent-magnet clutches/brakesElectrical conductorMagnetic vortex

The invention discloses a disk type translation permanent magnetic stator type permanent magnetic vortex speed regulating device. The device comprises an input shaft and an output shaft in a concentric arrangement. The input shaft is orderly and concentrically provided with a permanent magnet stator and a magnetic rotor along an axial direction. The permanent magnet stator can translate along the axial direction of the input shaft. The output shaft is concentrically provided with a conductor rotor. The permanent magnet stator comprises an outer ring iron core, a radially magnetized permanent magnet ring and an inner ring iron core nested in order. The magnetic rotor comprises inner and outer ring permanent magnet poles which are in a staggered arrangement along a circumferential direction. Both the inner and outer ring permanent magnet poles are in an interval arrangement with corresponding iron poles, and the polarities of the inner and outer ring permanent magnet poles are the opposite. Compared with the prior art, the device of the invention has the advantages that through axially translating the permanent magnet stator, a speed adjustment function is realized, thus a speed regulating mechanism is simplified, the maintenance cost is reduced, the service life is prolonged, the structure is simple, the operation is convenient, the device is suitable for the occasions of different requirements, and the device has the functions of a permanent magnet coupling coupler, a soft starter and a permanent magnet speed regulator.

Owner:SOUTHEAST UNIV

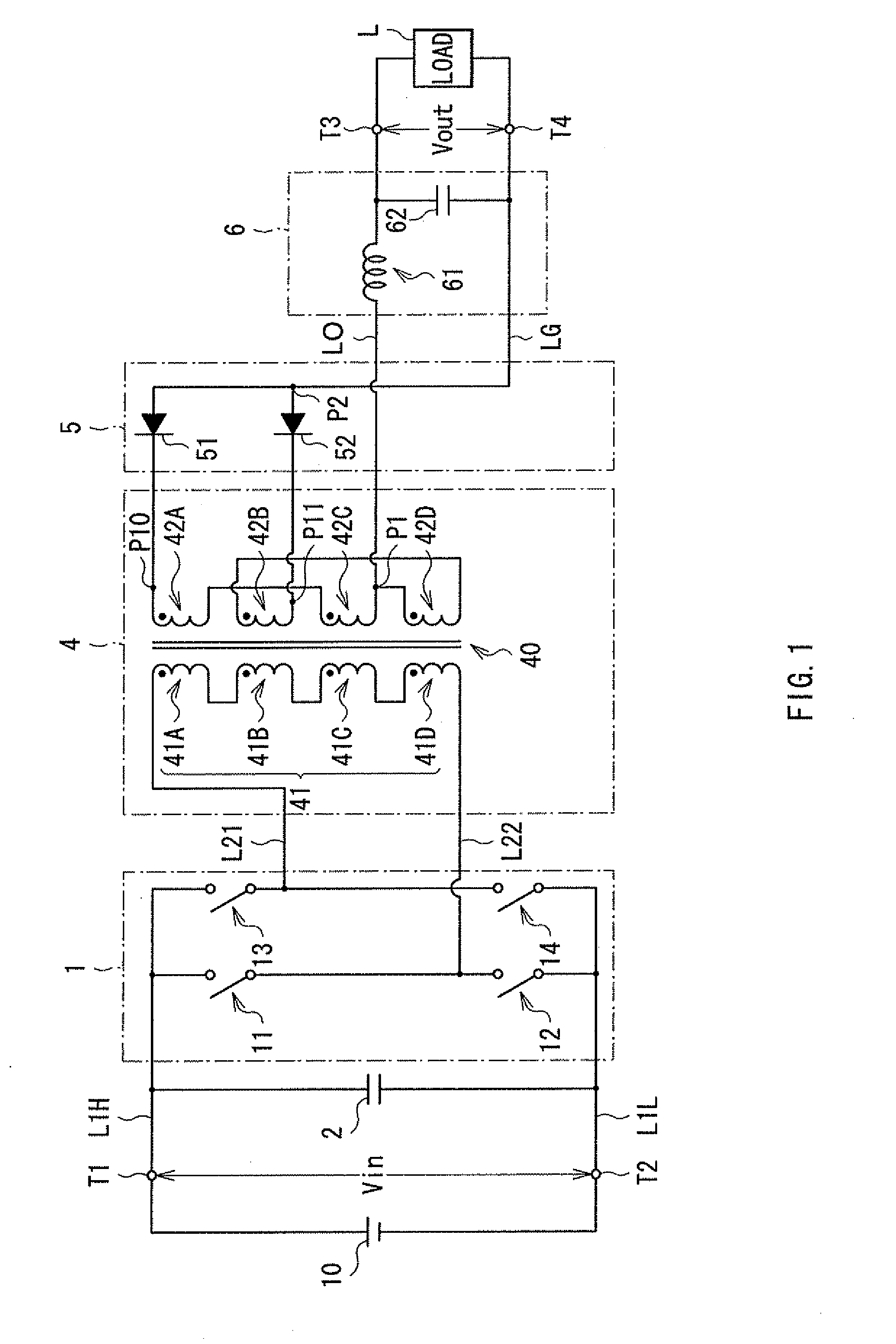

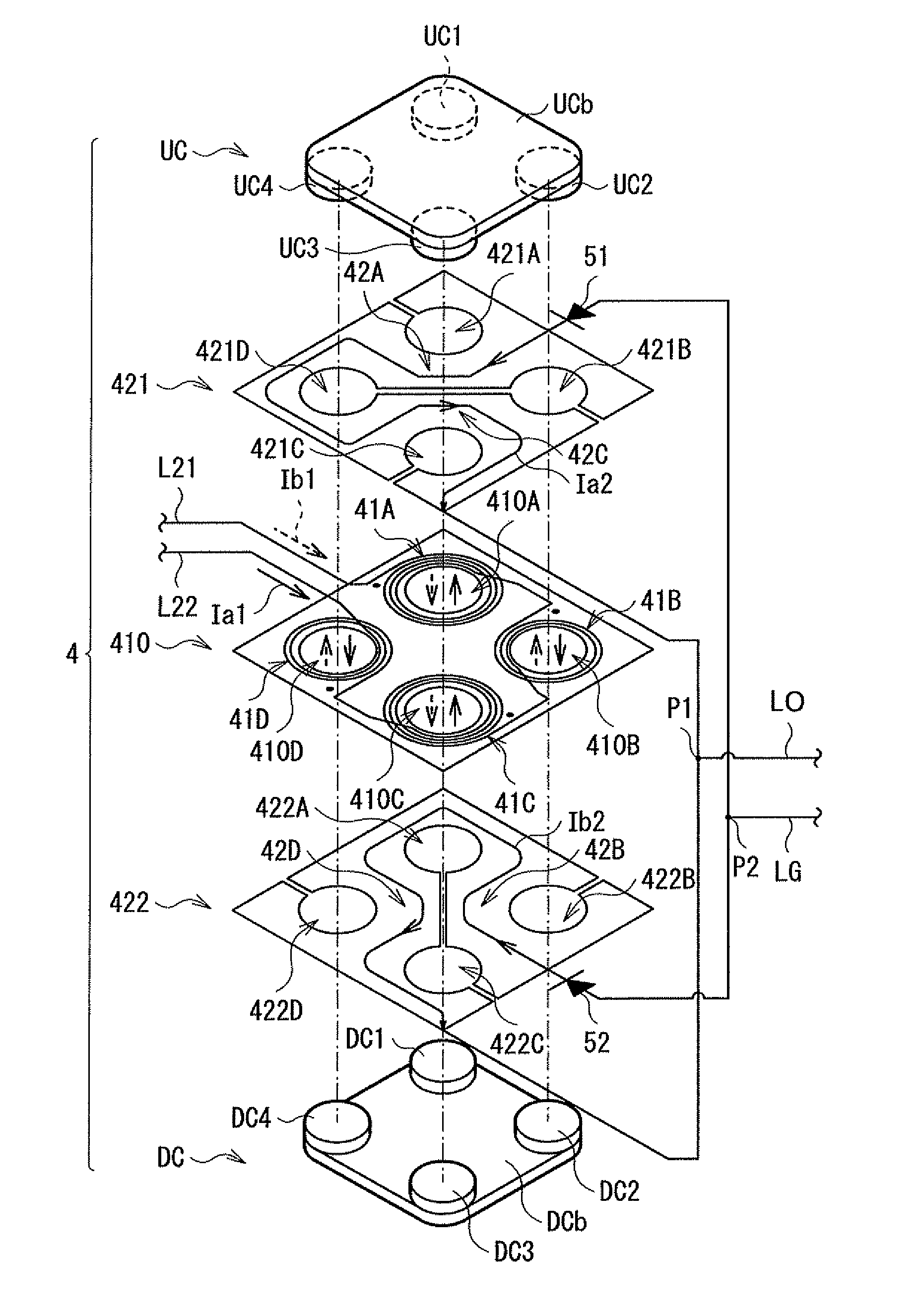

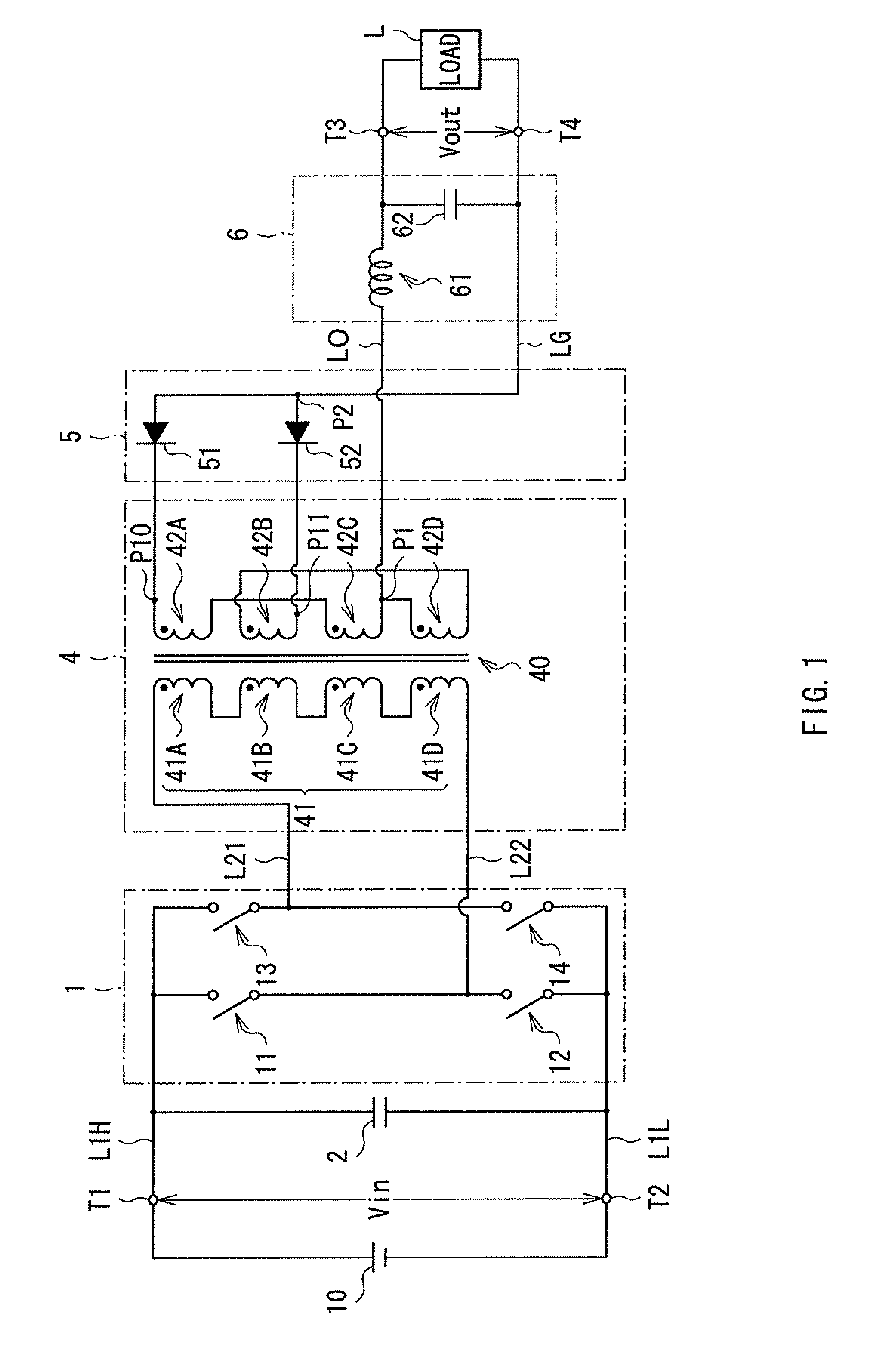

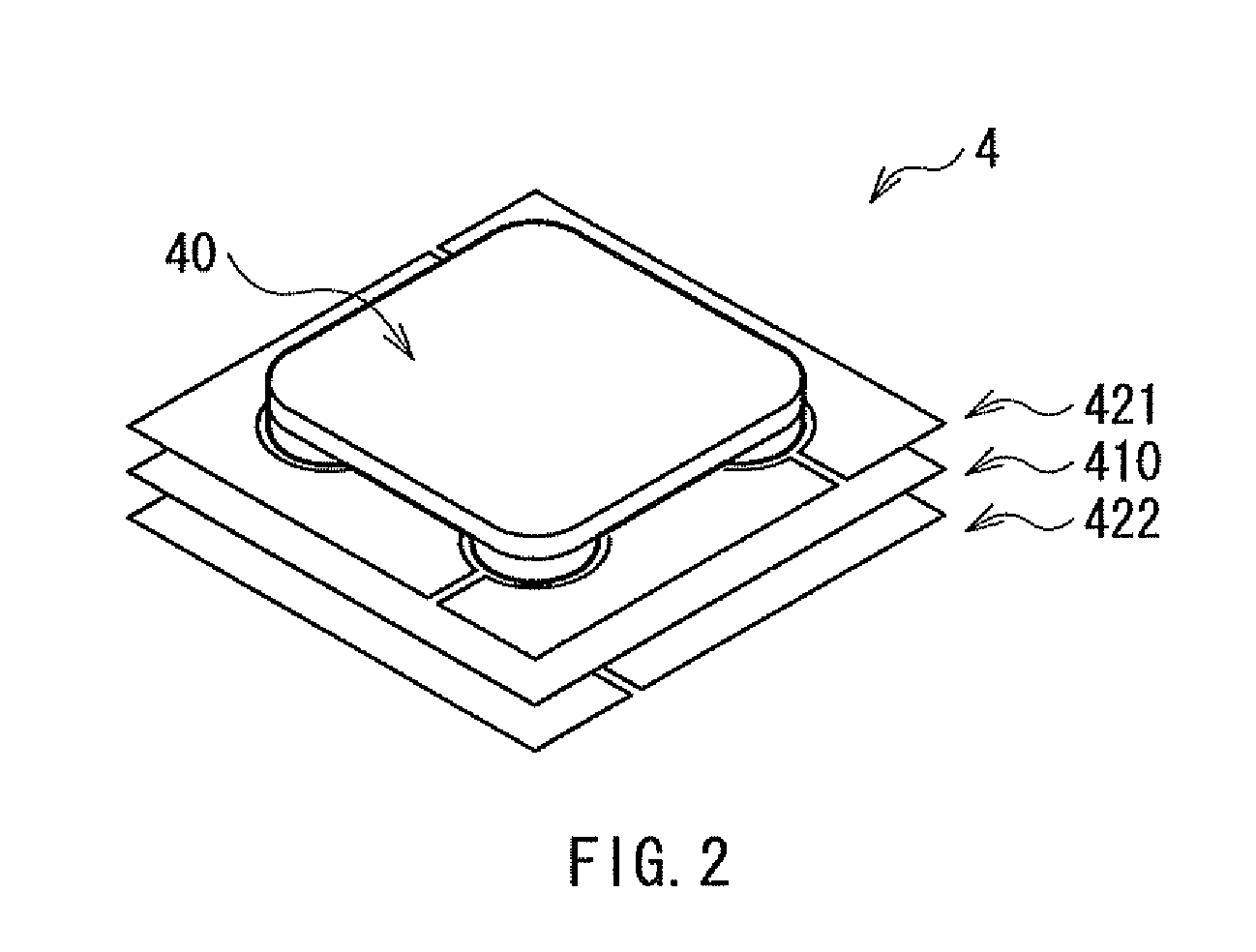

Transformer and switching power supply unit

ActiveUS8188830B2Increasing the thicknessReduce the overall heightTransformers/inductances magnetic coresCoilsTransformerDiagonal

The transformer includes: a magnetic core having two base-plates and four legs; a first conductive member as a first winding, having four through-holes through which the four legs pass, respectively; and one or more second conductive members as a second winding, each having four through-holes through which the four legs pass, respectively. The first and second windings are wound around the four legs. Closed magnetic paths are formed inside the magnetic core from the four legs to the two base-plates due to currents flowing through the first or the second winding. A couple of magnetic fluxes each generated inside each of a couple of legs arranged along one diagonal line are both directed in a first direction, while another couple of magnetic fluxes each generated inside each of another couple of legs arranged along another diagonal line are both directed in a second direction opposite to the first direction.

Owner:TDK CORPARATION

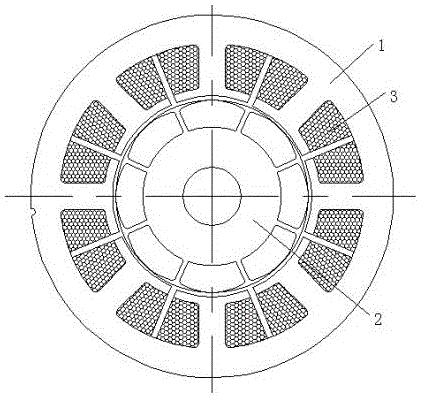

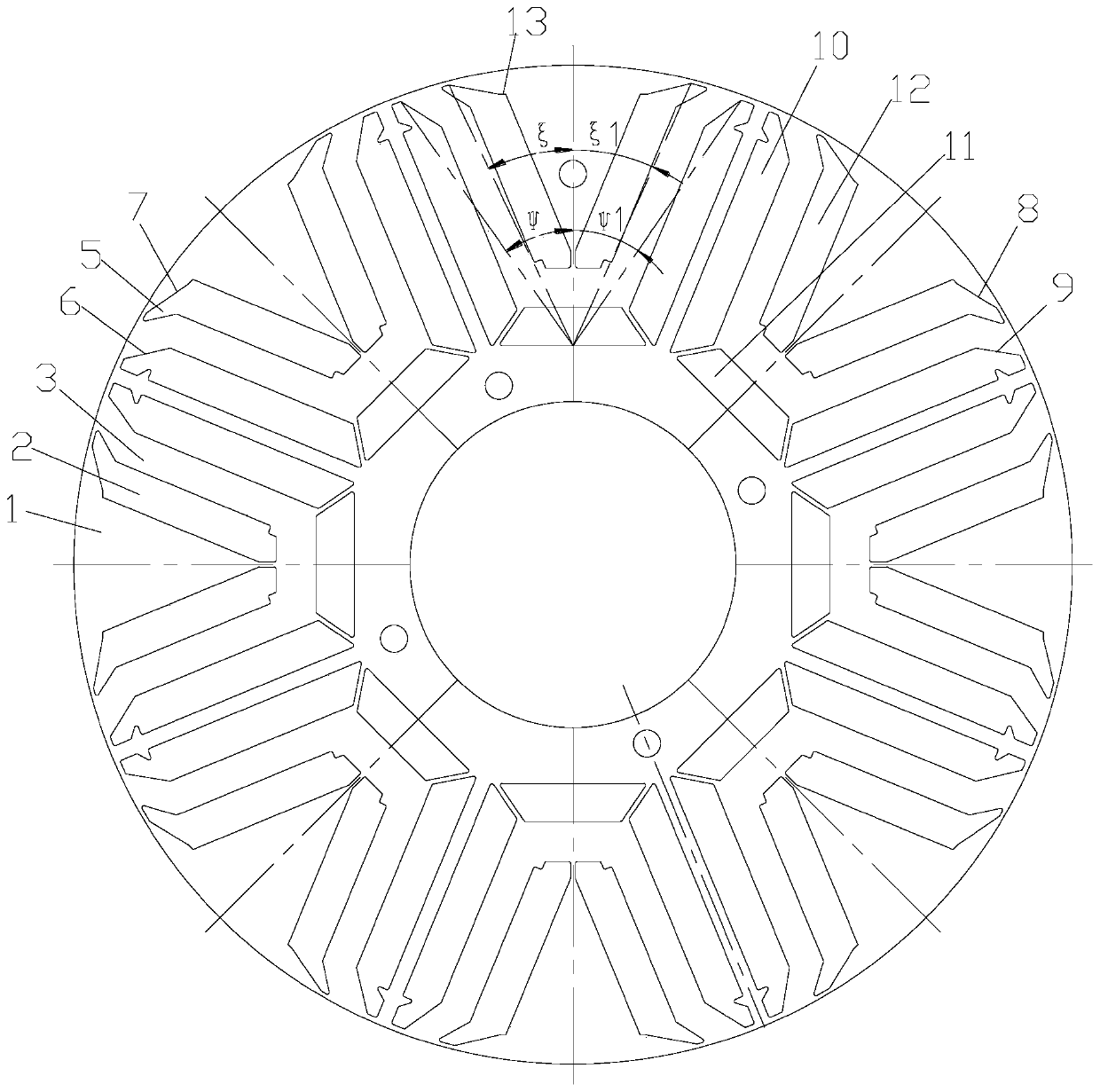

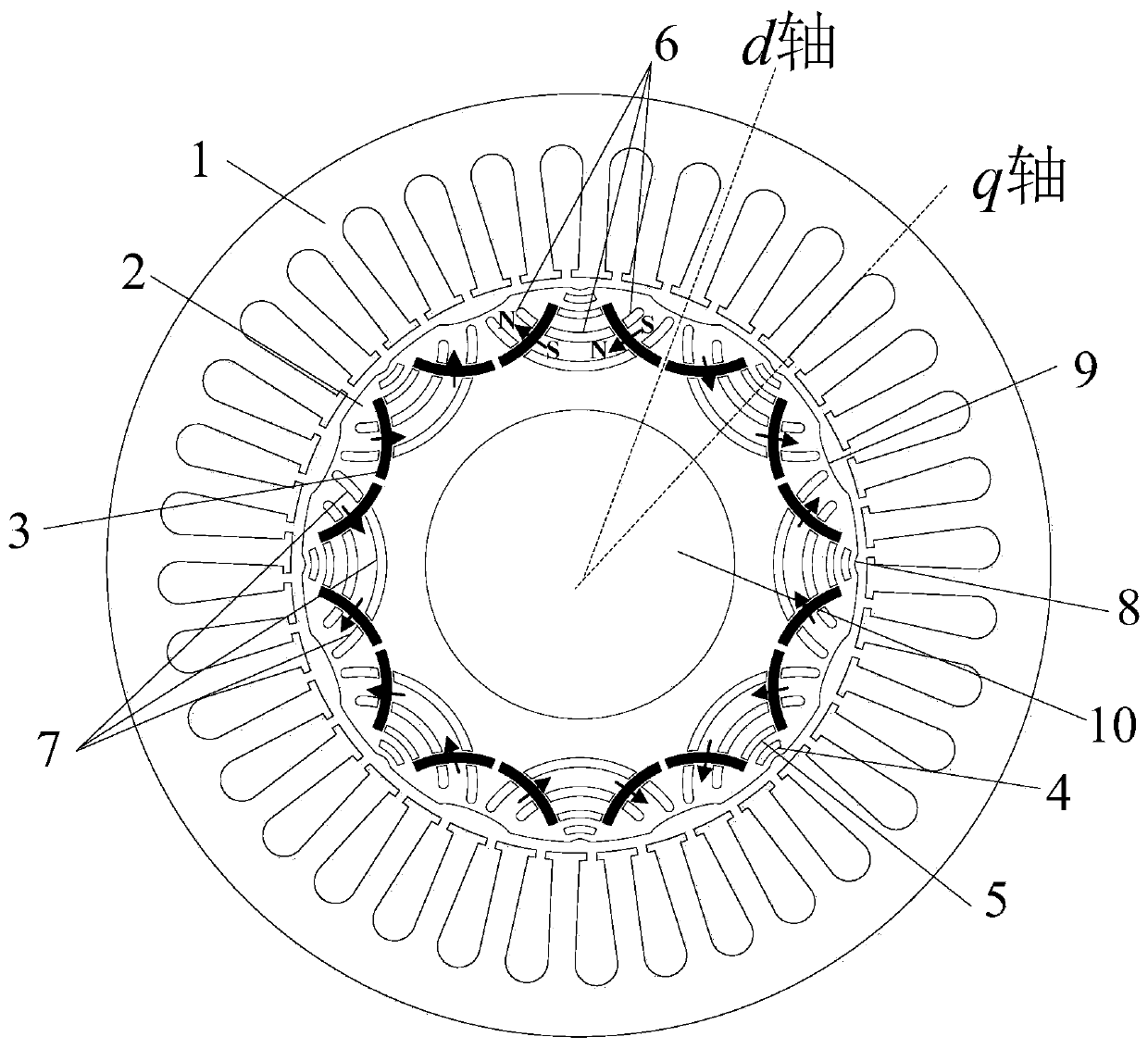

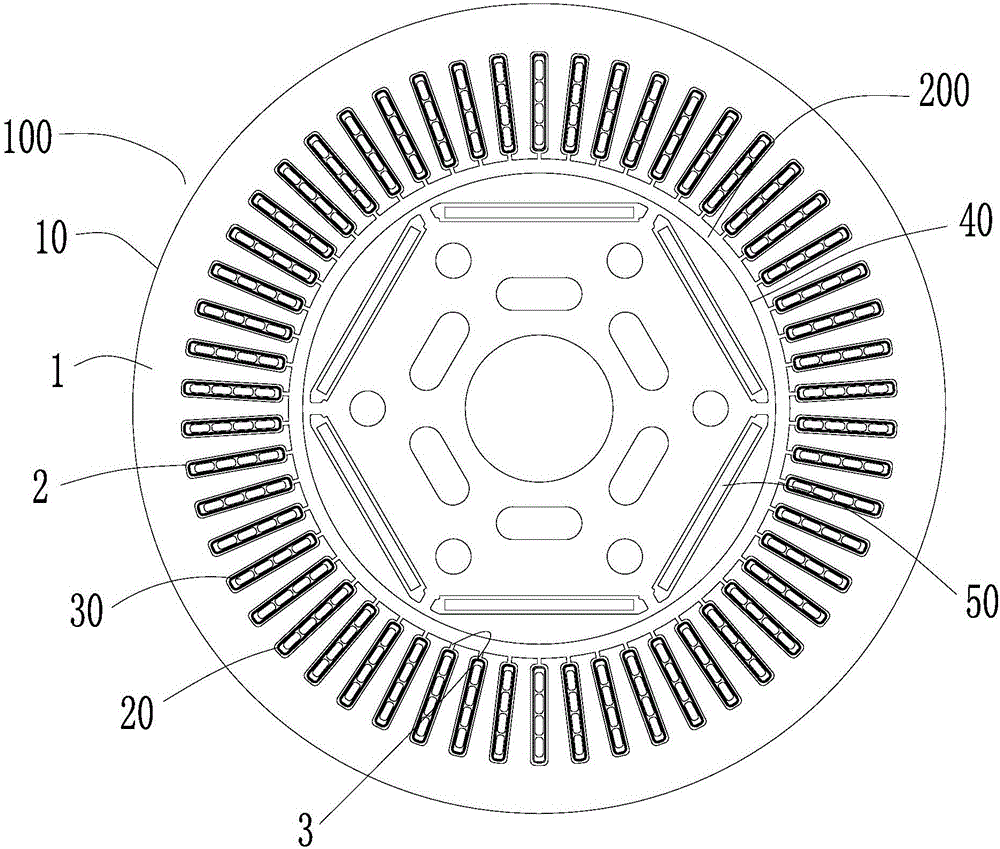

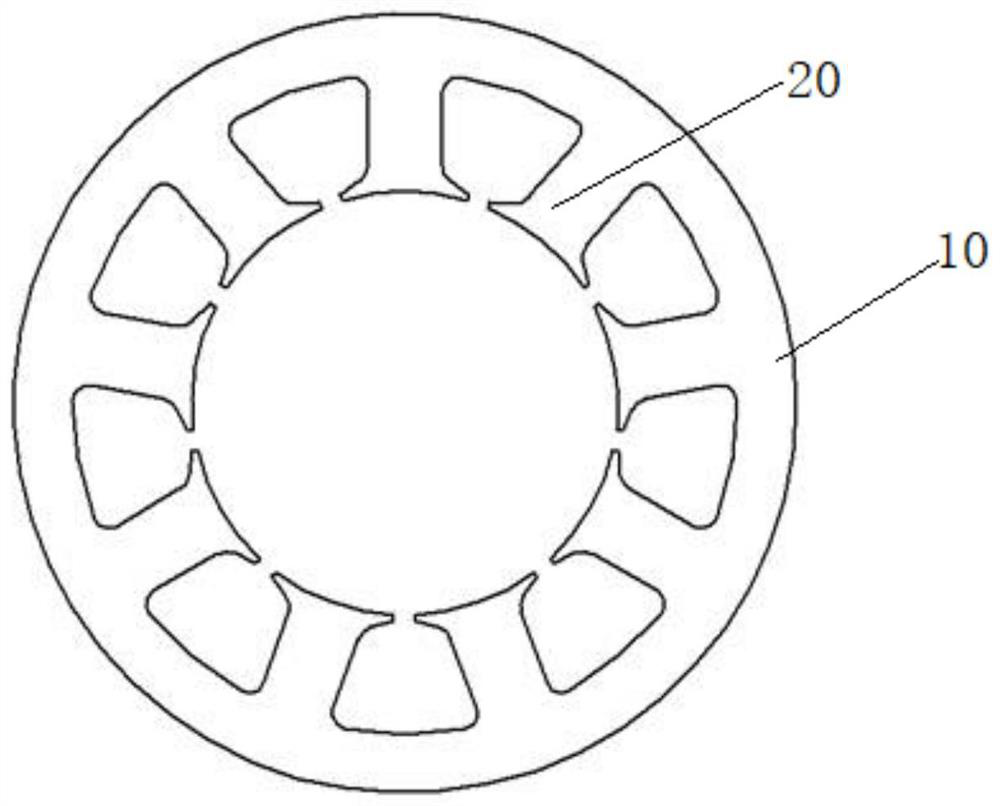

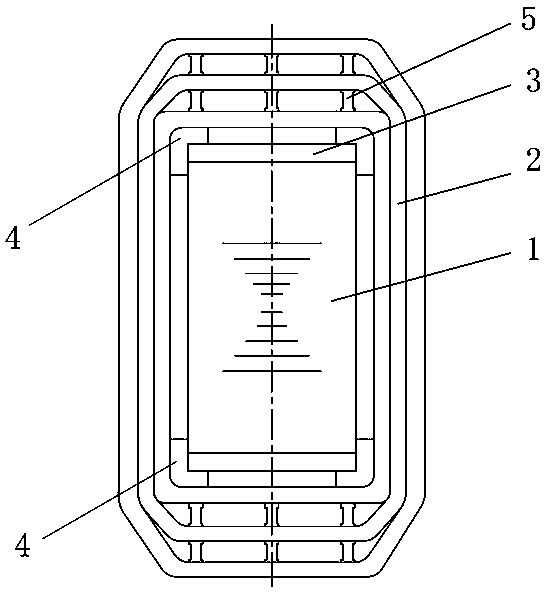

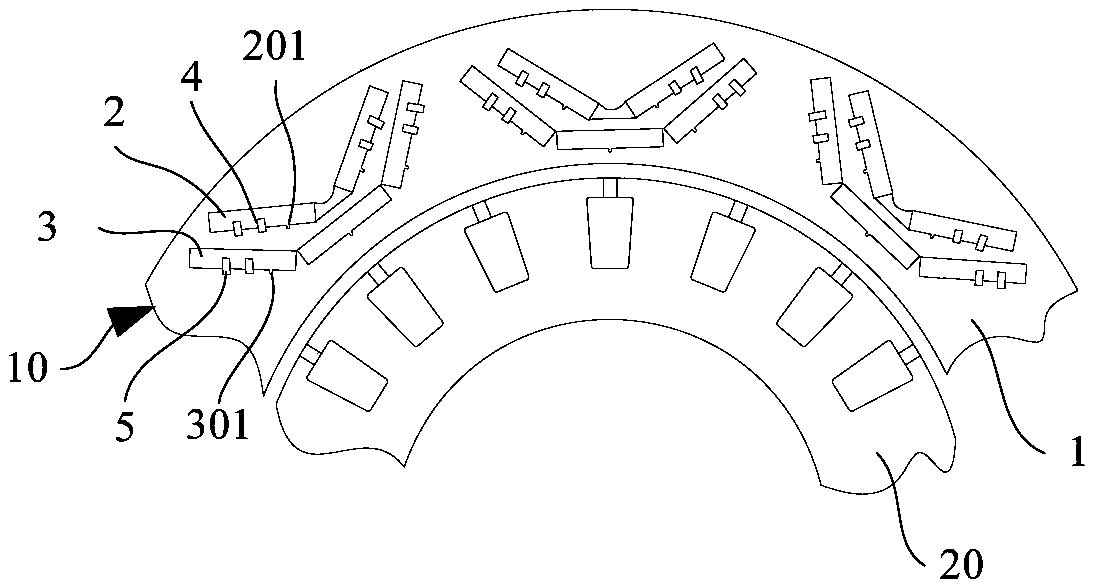

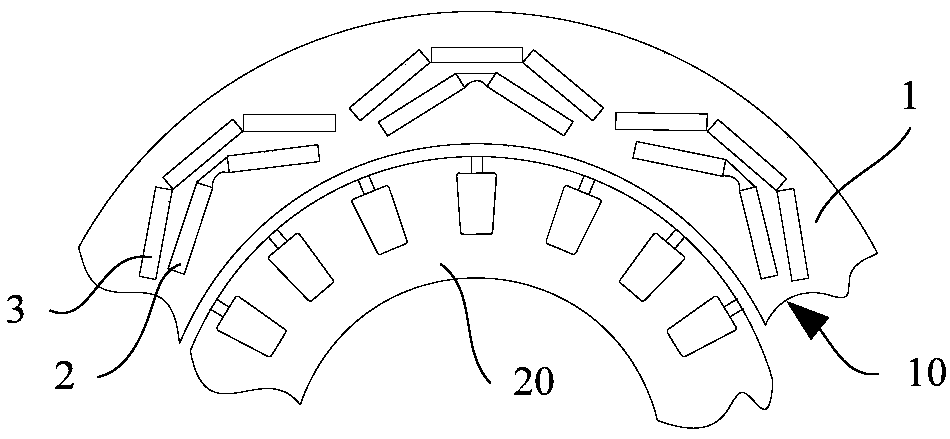

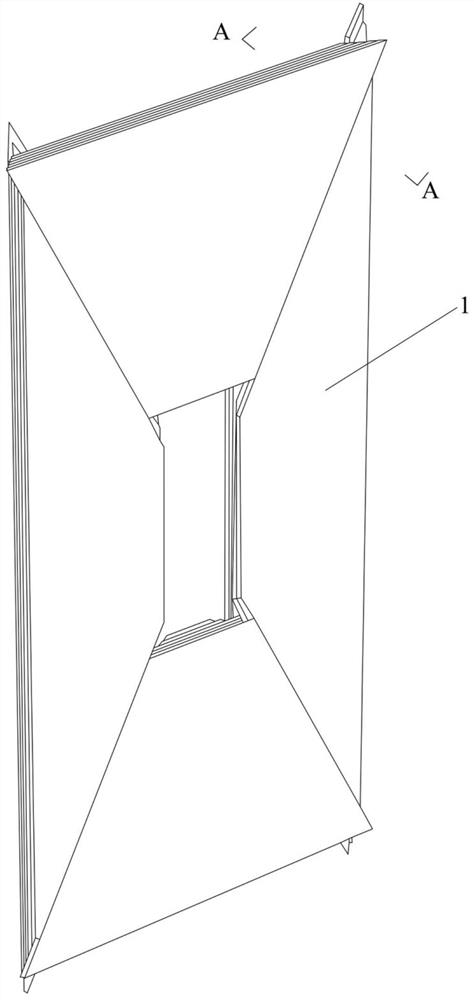

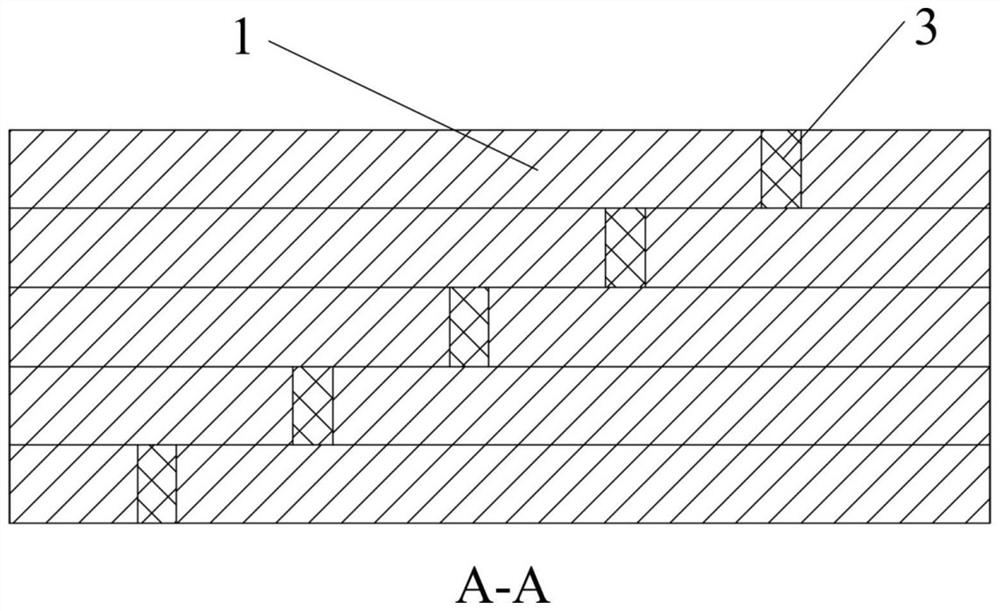

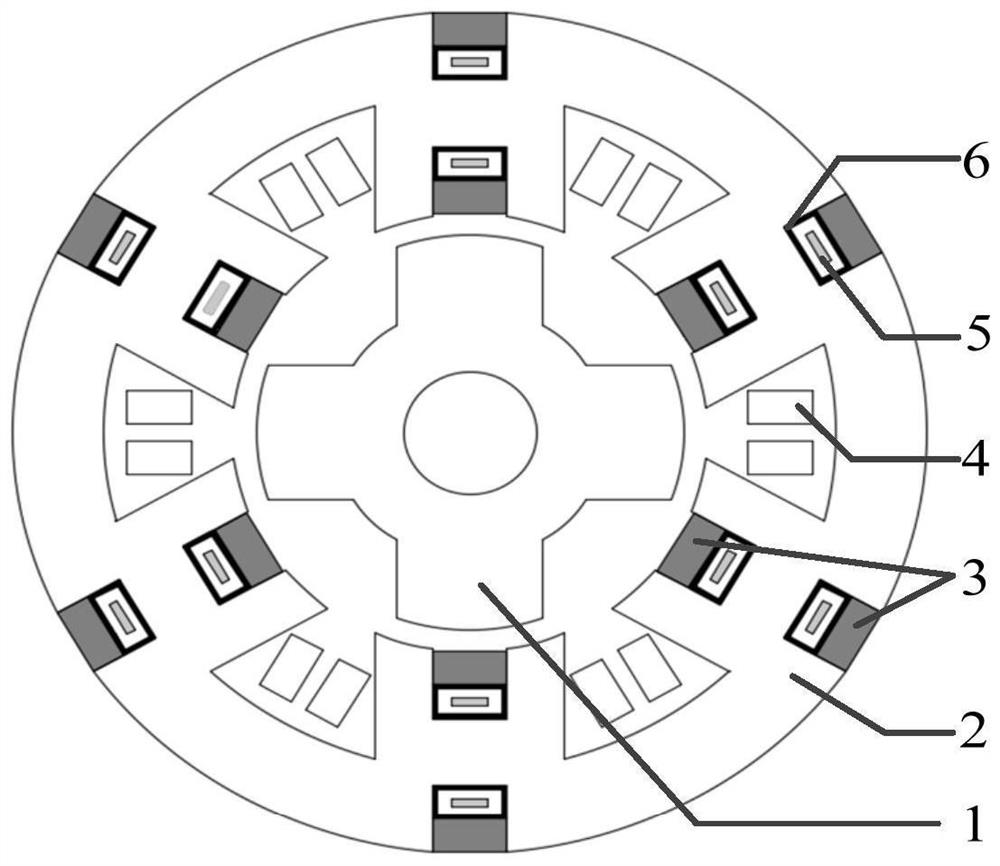

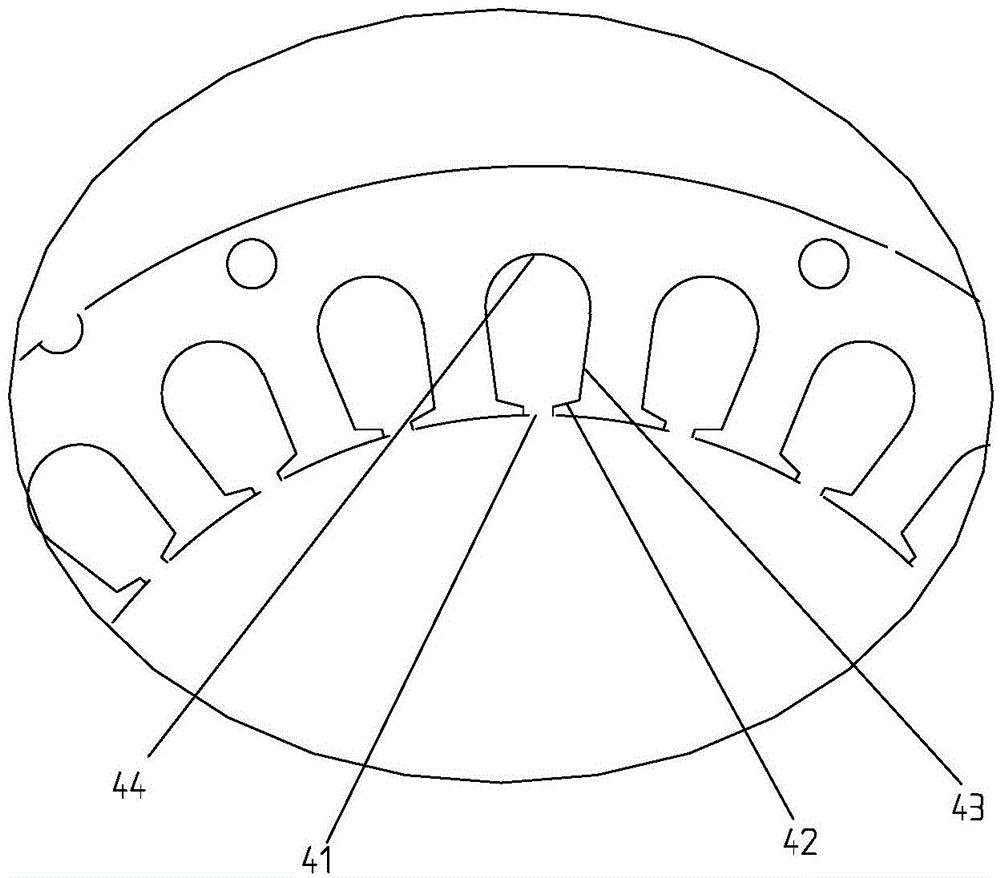

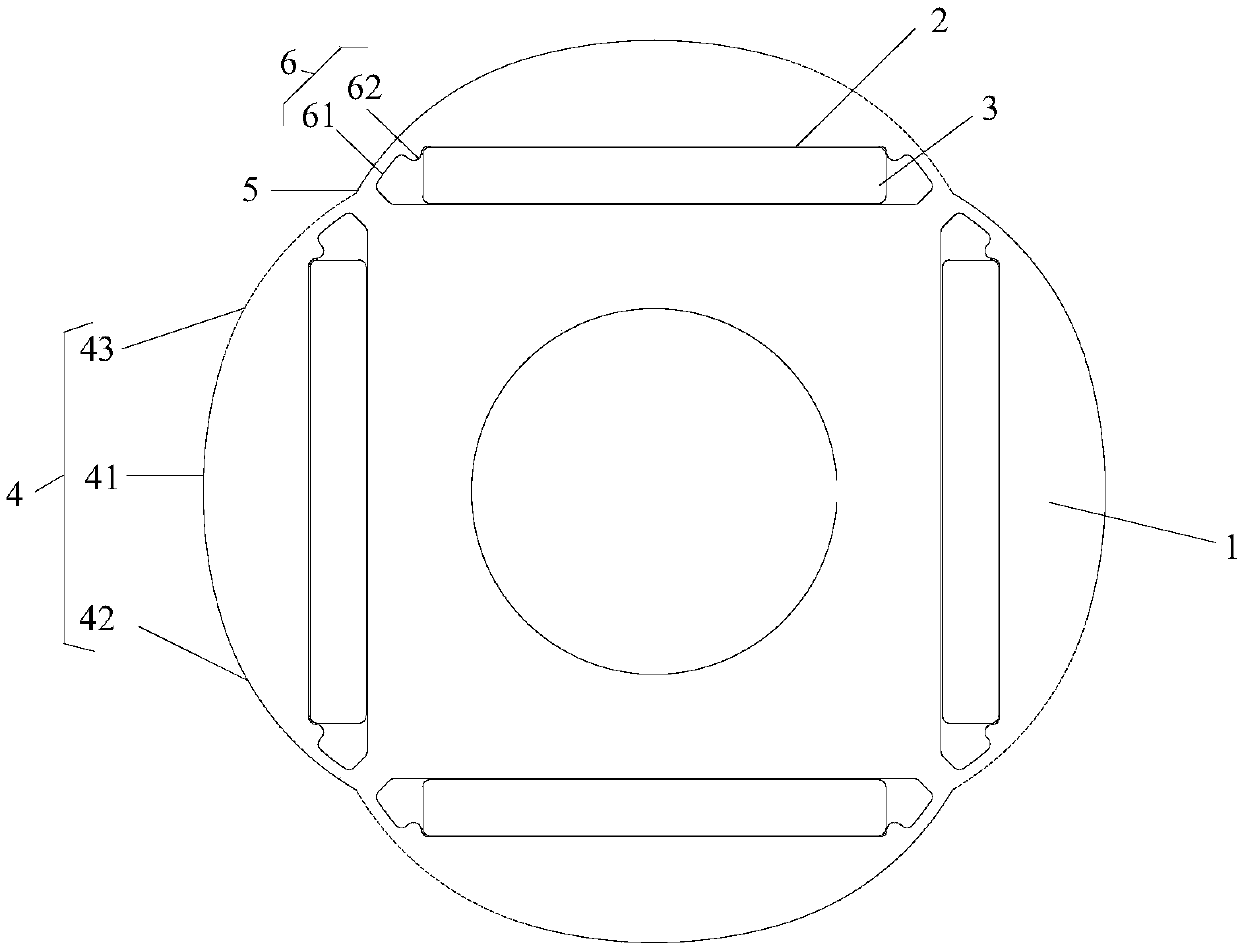

Motor rotor, reluctance motor and electric vehicle

ActiveCN110994837AIncrease output torqueReduce magnetic densityMagnetic circuit rotating partsElectric machinesMagnetic barrierMagnetic reluctance

The invention provides a motor rotor, a reluctance motor and an electric vehicle. The motor rotor comprises a rotor core (1), and the rotor core (1) comprises a plurality of magnetic barrier groups. Each magnetic barrier group comprises at least two magnetic flux barriers (2); magnetic conduction channels (3) are formed between the adjacent magnetic flux barriers (2); permanent magnets (4) are arranged in the magnetic flux barriers (2); and, under the same pole, the pole arc field angle of the flux barrier (2) on the innermost side in the radial direction at the front edge of the D-axis rotation direction is psi; the pole arc opening angle of the radially innermost magnetic flux barrier (2) located at the rear edge of the D-axis rotation direction is psi1, the pole arc opening angle of theradially outermost magnetic flux barrier (2) located at the front edge of the D-axis rotation direction is xi, and the pole arc opening angle of the radially outermost magnetic flux barrier (2) located at the rear edge of the D-axis rotation direction is xi1, wherein psi> psi1, and xi> xi1. According to the motor rotor, the flux density of the leading-edge magnetic conduction channel can be reduced, local magnetic flux leakage is reduced, and the output torque of the motor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

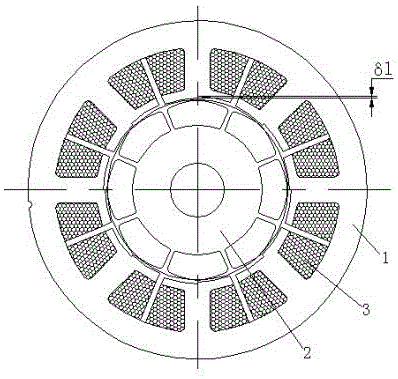

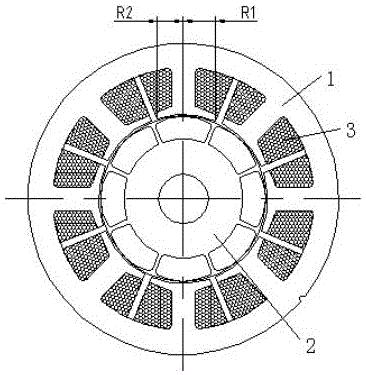

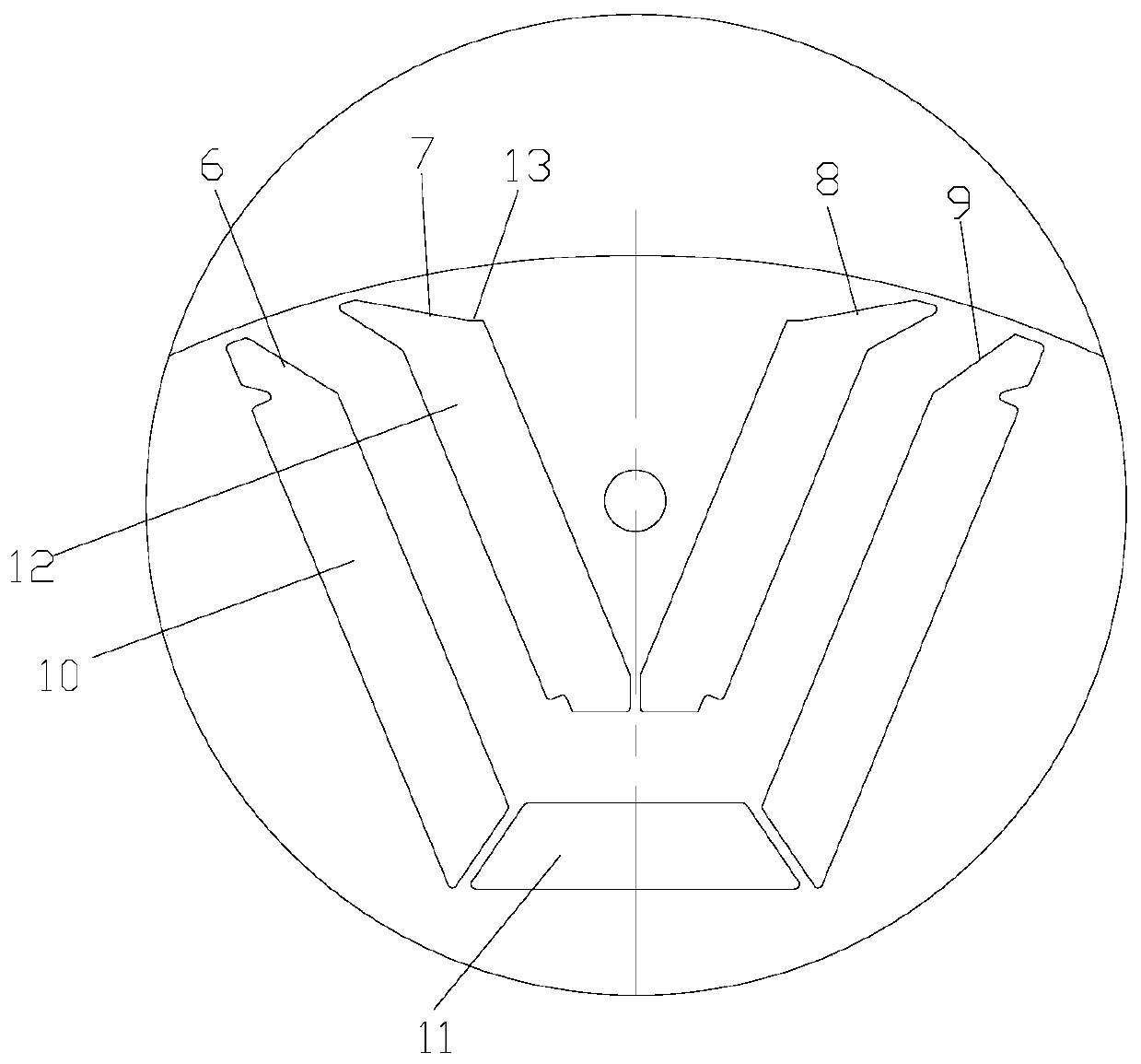

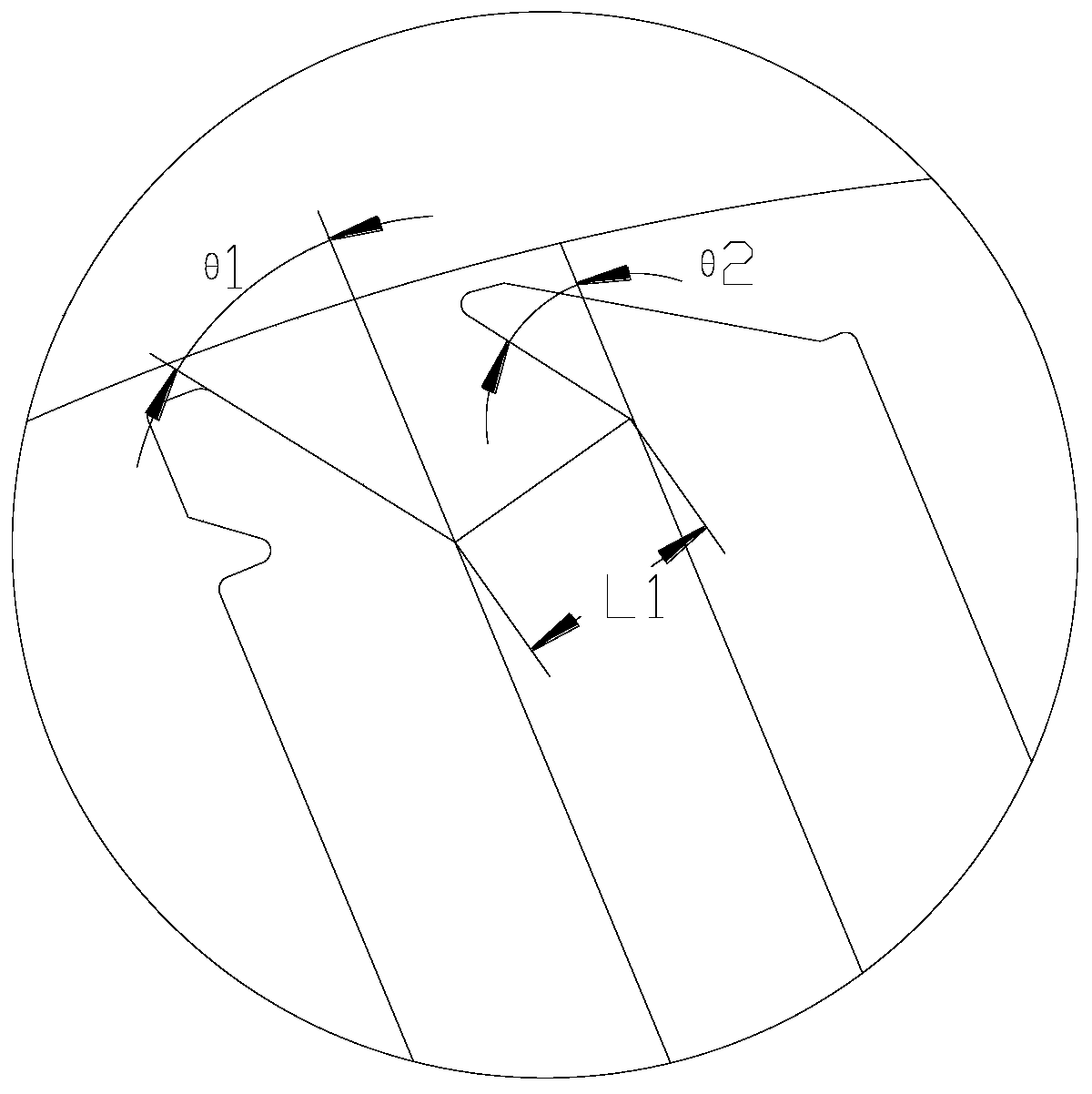

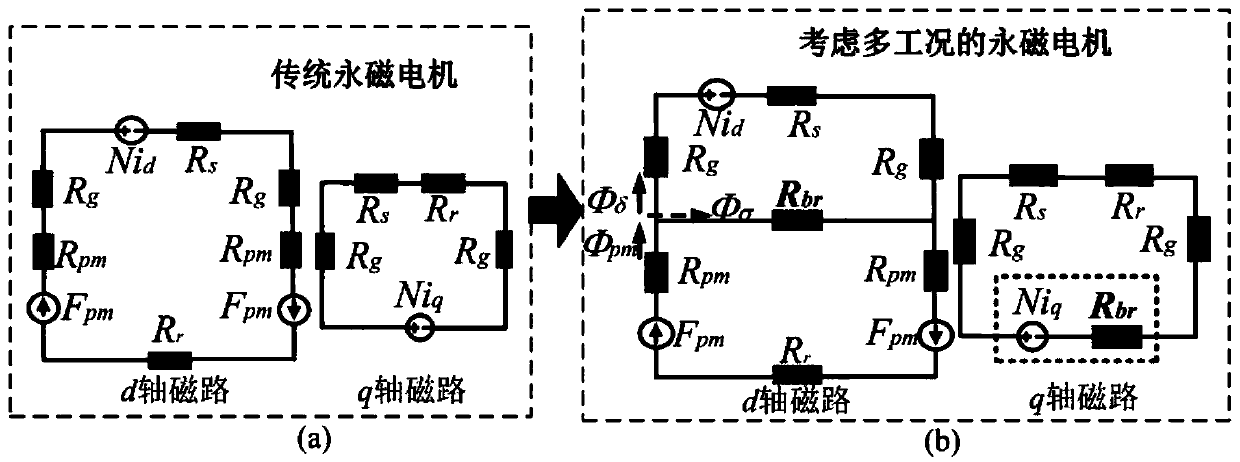

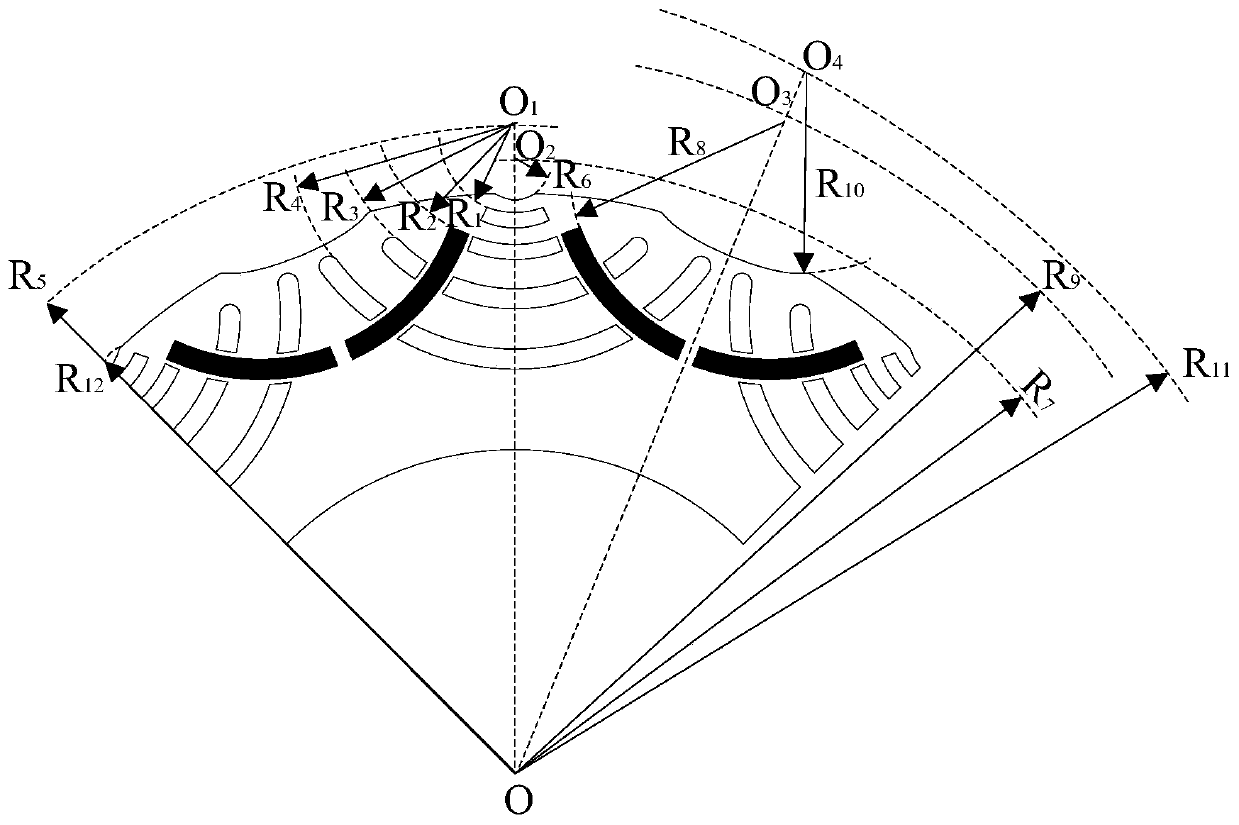

Quadrature-direct axis inductance variable permanent magnet brushless motor and wide-area efficient optimization design method thereof

ActiveCN110994834AEffective adjustment of AC-D axis inductanceSimple structureMagnetic circuit rotating partsBrushless motorsMagnetic barrier

The invention discloses a quadrature-direct axis inductance variable permanent magnet brushless motor and a wide-area efficient optimization design method thereof. The method comprises the following steps of 1, obtaining a quadrature-direct axis inductance ratio through a magnetic circuit diagram of a multi-working-condition permanent magnet motor; 2, when an automobile is in different working conditions, enabling the motor to respectively meet the requirements for torque, speed regulation range, wide area and high efficiency under the corresponding working conditions through the change of thequadrature-direct axis inductance ratio; 3, setting the quadrature-direct axis inductance variable permanent magnet brushless motor; 4, preliminarily optimizing the sizes of a rotor magnetic barrierand an arc-shaped permanent magnet, and giving out an initial size and a constraint condition; and 5, comprehensively optimizing the sizes of the initial rotor magnetic barrier and the arc-shaped permanent magnet in the step 4 according to the requirements of different working conditions. According to the invention, the multi-target requirements under different working conditions that the motor obtains the higher comprehensive efficiency than a traditional permanent magnet brushless motor under the condition of simple structure and has higher torque density under a light-load condition, etc.,are satisfied.

Owner:JIANGSU UNIV

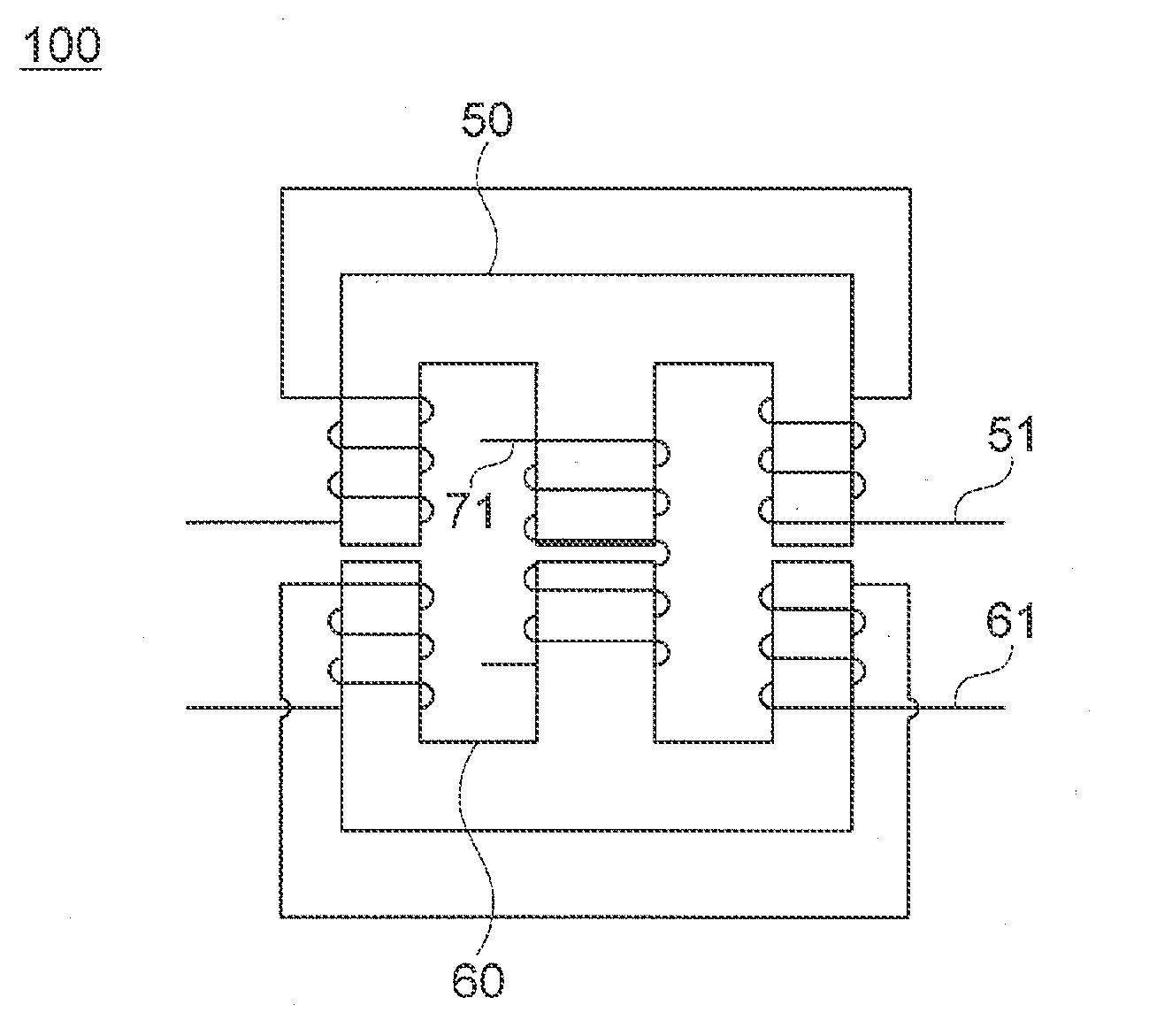

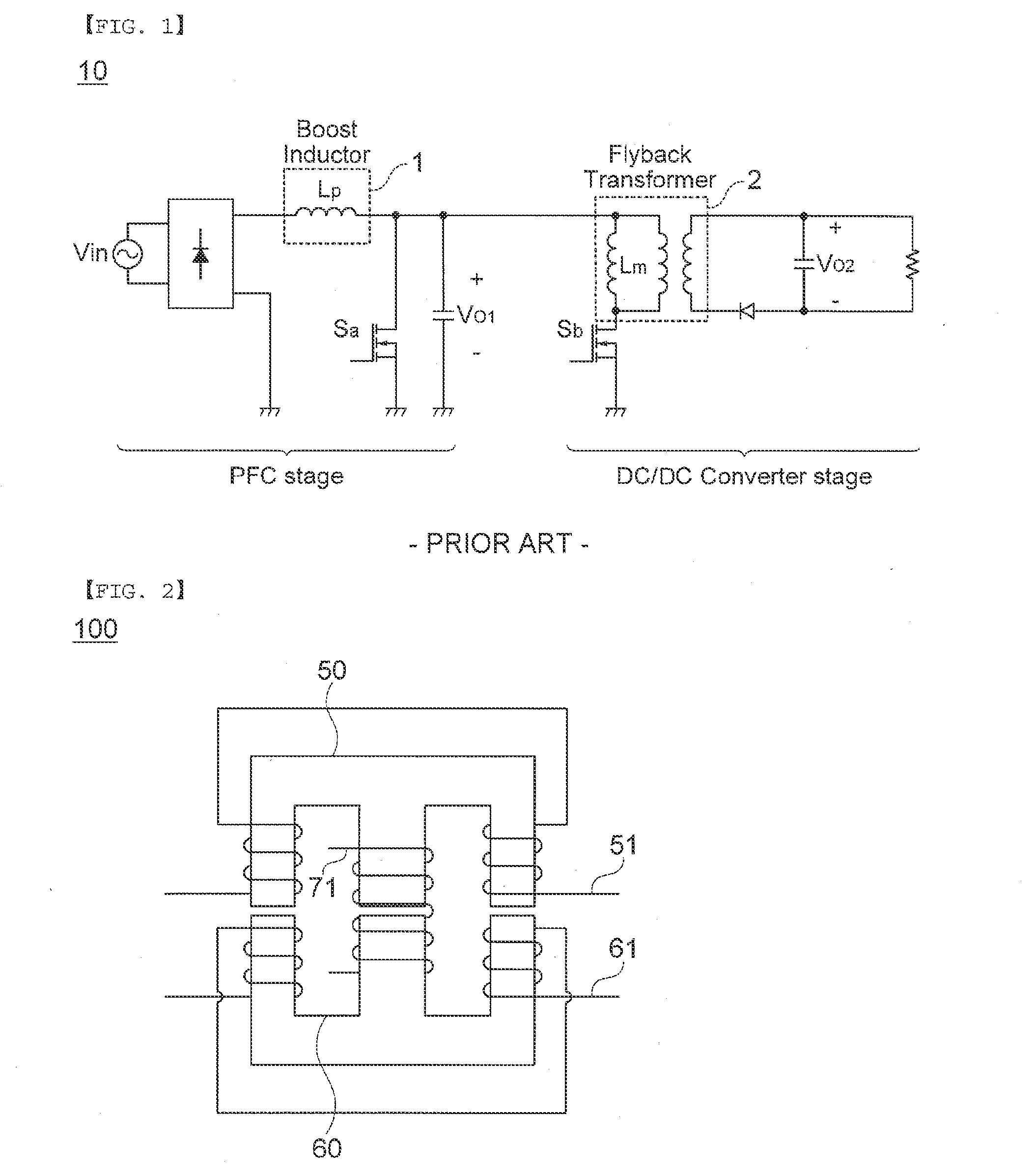

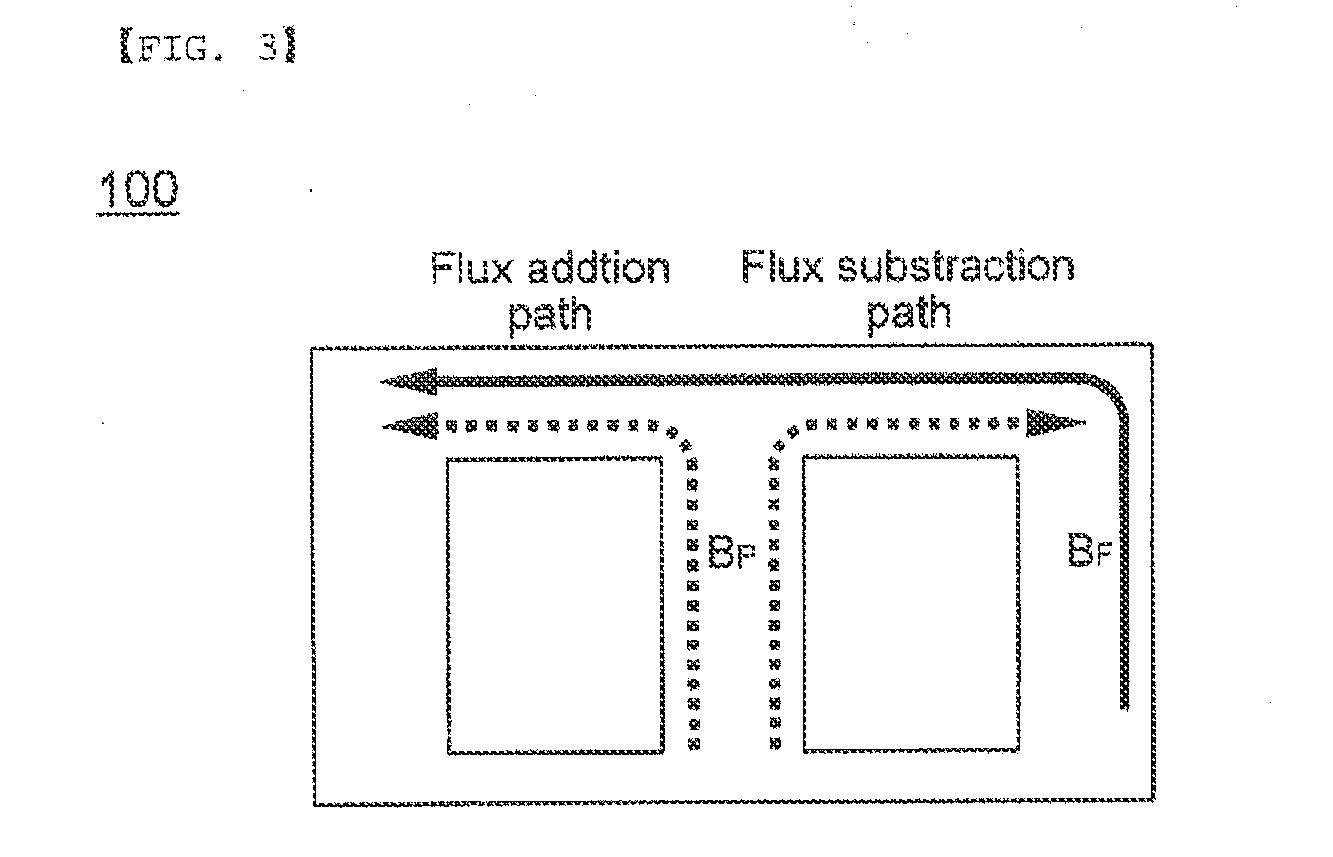

Integrated magnetic circuit and method of reducing magnetic density by shifting phase

InactiveUS20150092455A1Lower the volumeReduce manufacturing costTransformersEfficient power electronics conversionEngineeringInductor

Disclosed herein are an AC-DC converter in which an inductor of boost PFC and a flyback transformer are integrated in one and a method of preventing a magnetic density from being saturated by shifting a phase. The integrated magnetic circuit according to an exemplary embodiment of the present invention includes: a power factor correction stage (PFC-stage) including a boost inductor; and a flyback transformer including a primary winding and a secondary winding, wherein the boost inductor and the primary winding of the flyback transformer and the secondary winding of the flyback transformer are wound around a single core.

Owner:SOLUM CO LTD +1

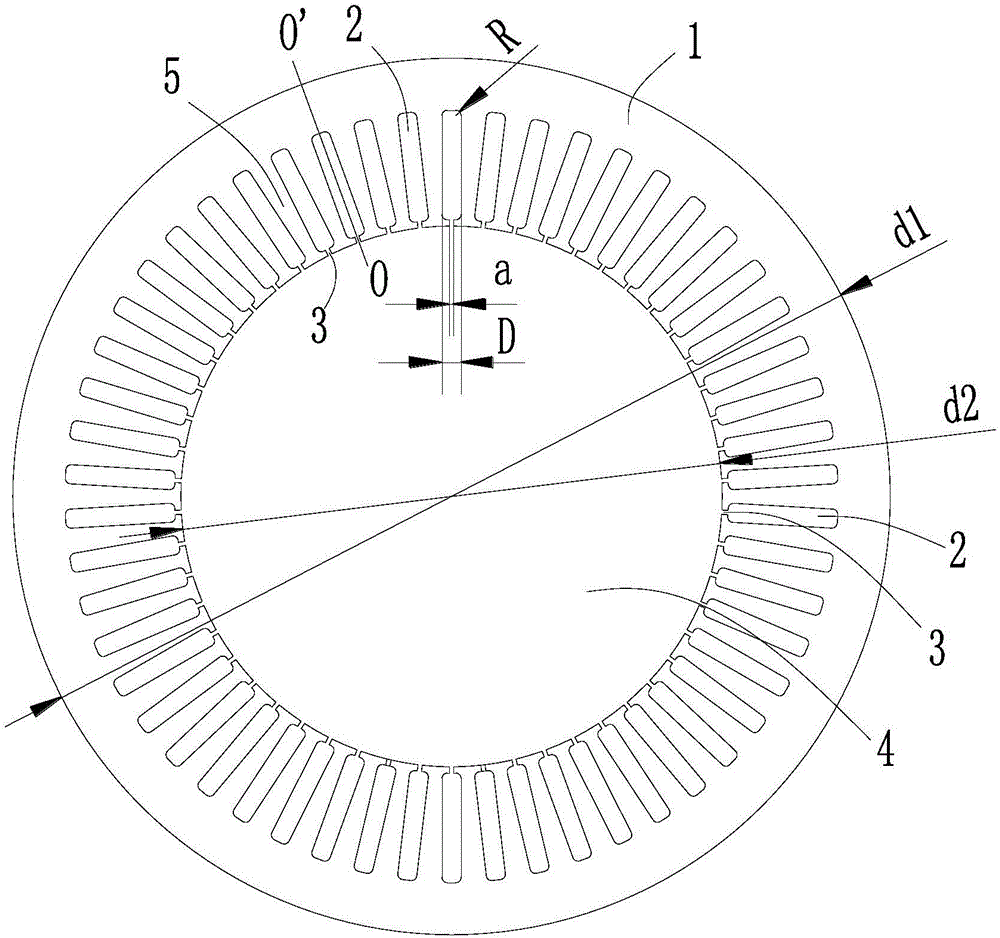

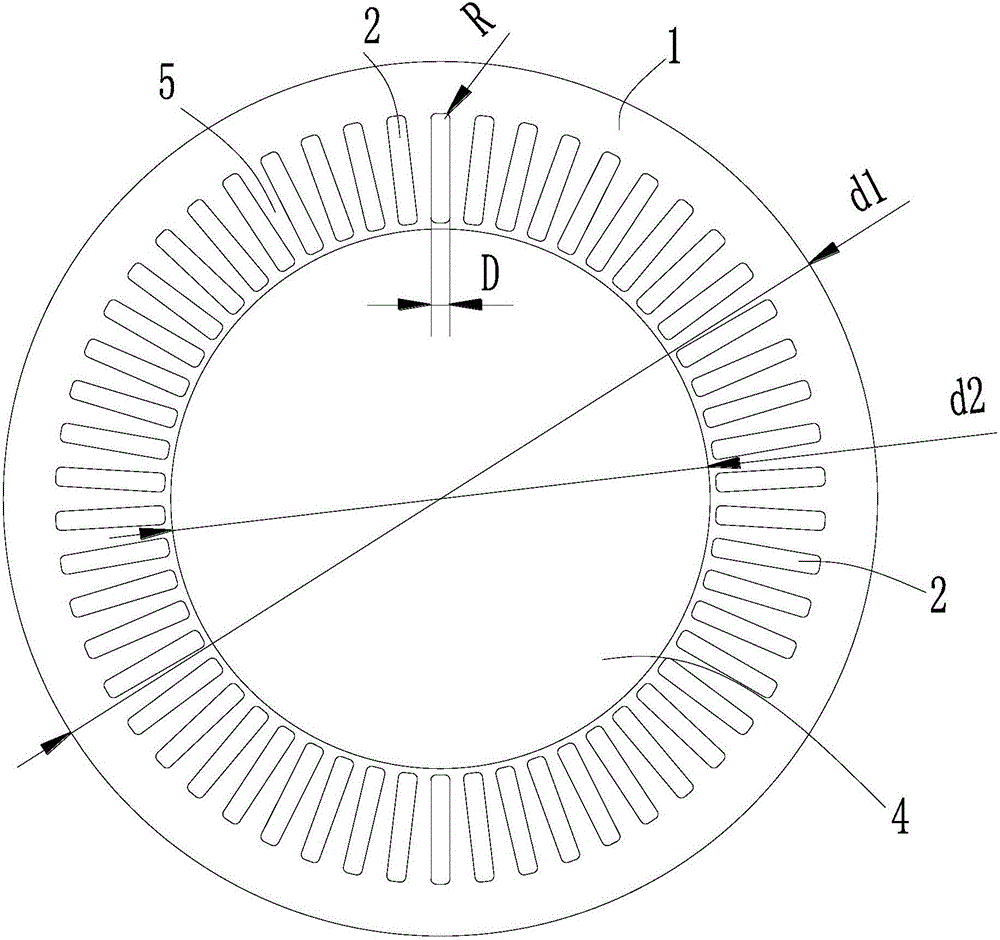

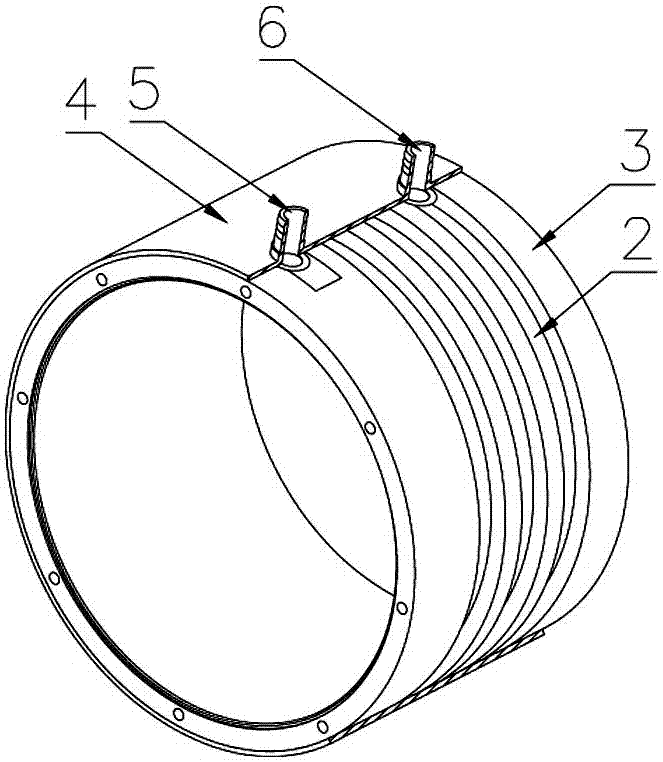

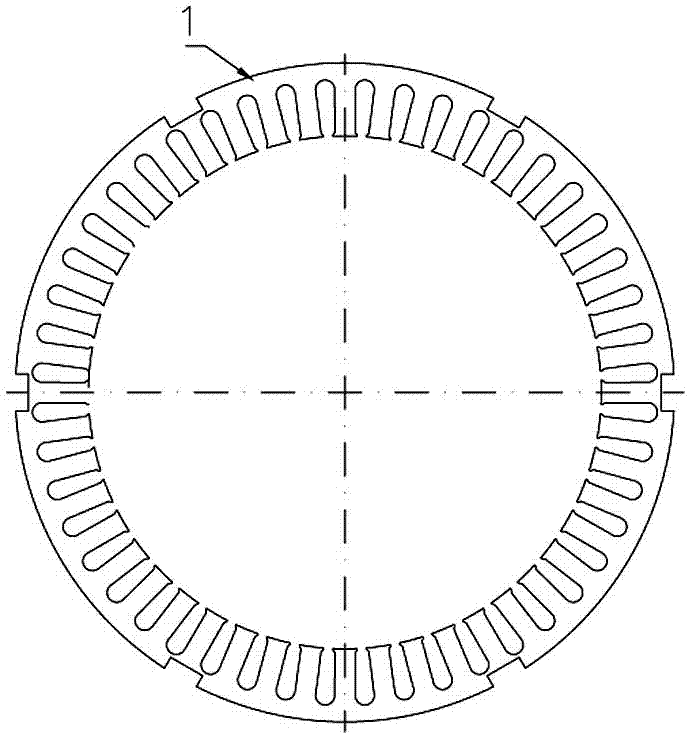

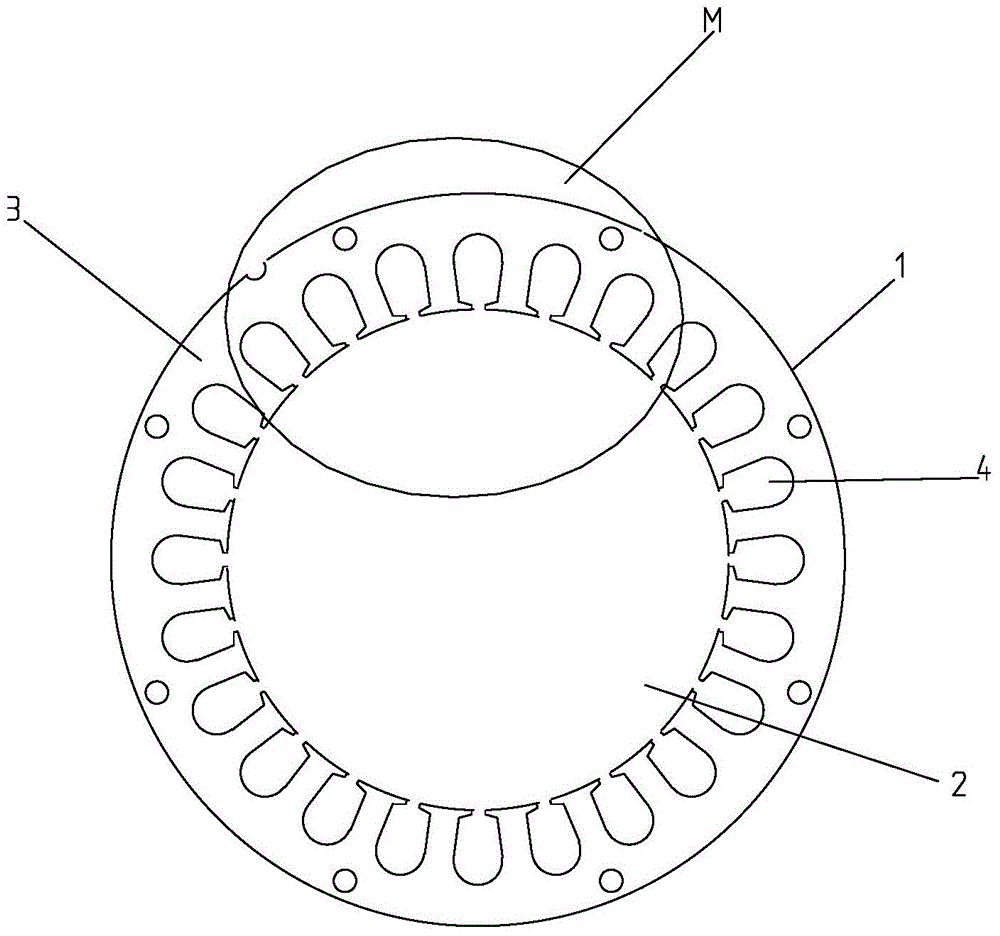

Compressor and air conditioner

ActiveCN106787568AImprove stator slot fullnessImprove work efficiencyMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsElectrical conductorPunching

The invention discloses a compressor and an air conditioner. The compressor (300) comprises a driving motor, wherein the motor comprises a plurality of stacked stator punching sheets (1), the stator punching sheets are annular sheets, a plurality of stator grooves (2) are formed in annular faces of the stator punching sheets, penetrate through in the axial direction and are distributed in the peripheral direction at intervals, the stator grooves are rectangular grooves extending in the radial direction, and corners of the rectangular grooves are formed into round chamfers (21), wherein the short edge length D of each stator groove is 1.6mm to 4.2mm, the corner radius of each round chamfer is R, and a requirement that D / R is equal to 2 to 4 is met. According to the compressor, shapes of the rectangular stator grooves are designed in a targeted mode, the round chamfers of the corners are optimized and designed based on not changing approximate rectangular primary profiles, the minimum widths and the areas of stator teeth are increased, flux density of stator tooth shoes is reduced, and main flux conduction is improved. In addition, the design of the round chamfers can enable the round chamfers to be matched with technological corners of winding conductors in the grooves, the areas of the grooves can be utilized to the maximum degree, the motor can obtain a higher stator groove full rate, and accordingly efficiency of the motor is finally improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

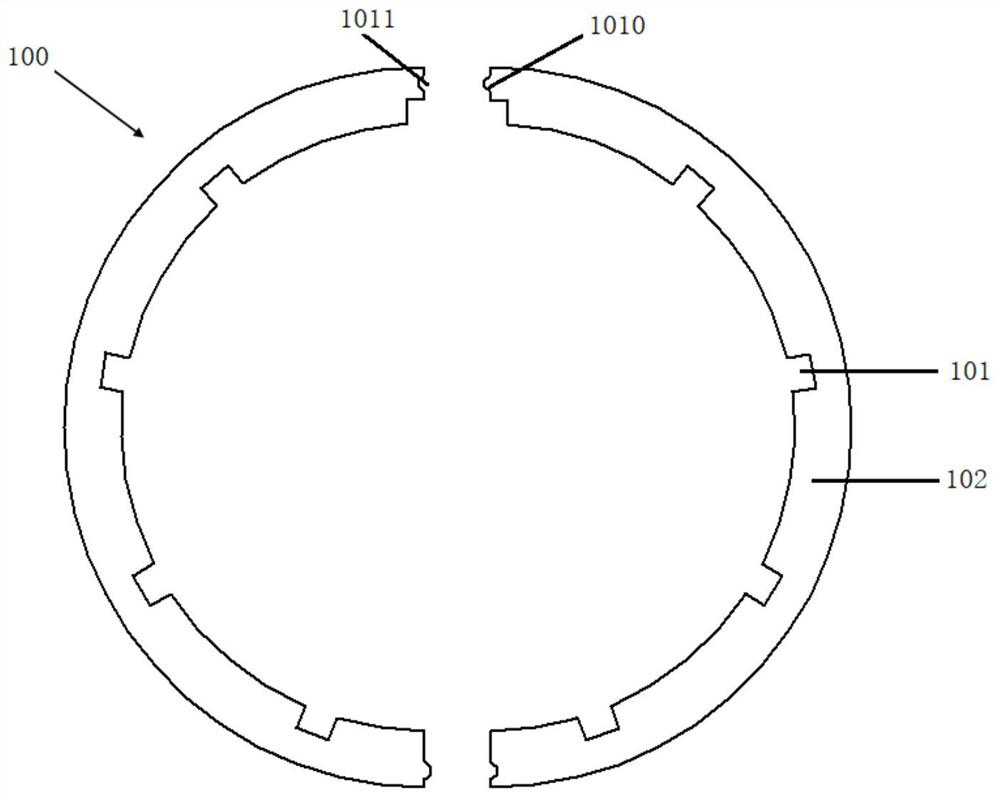

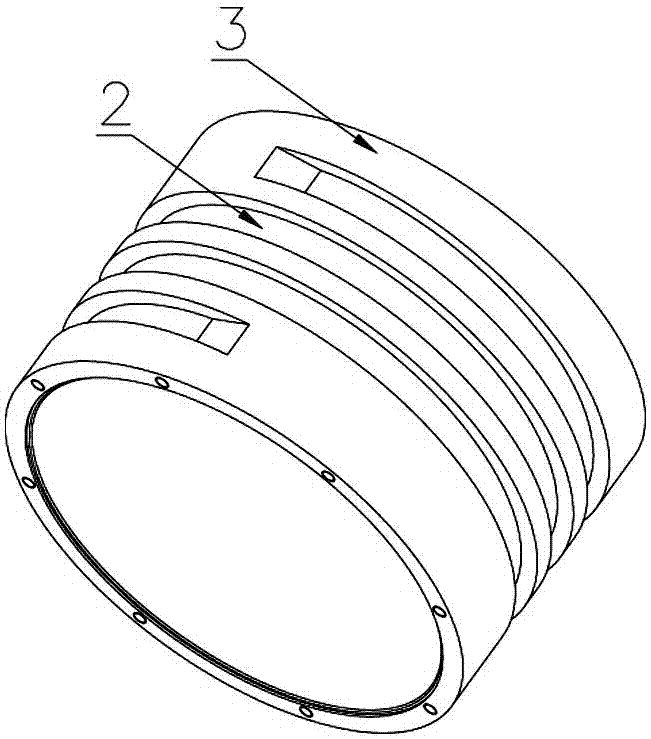

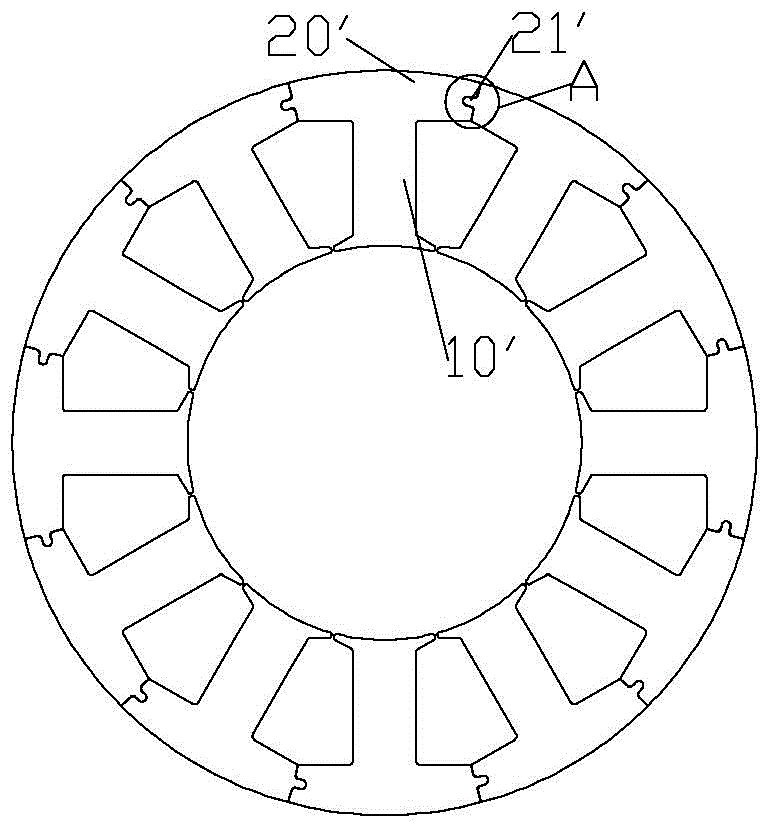

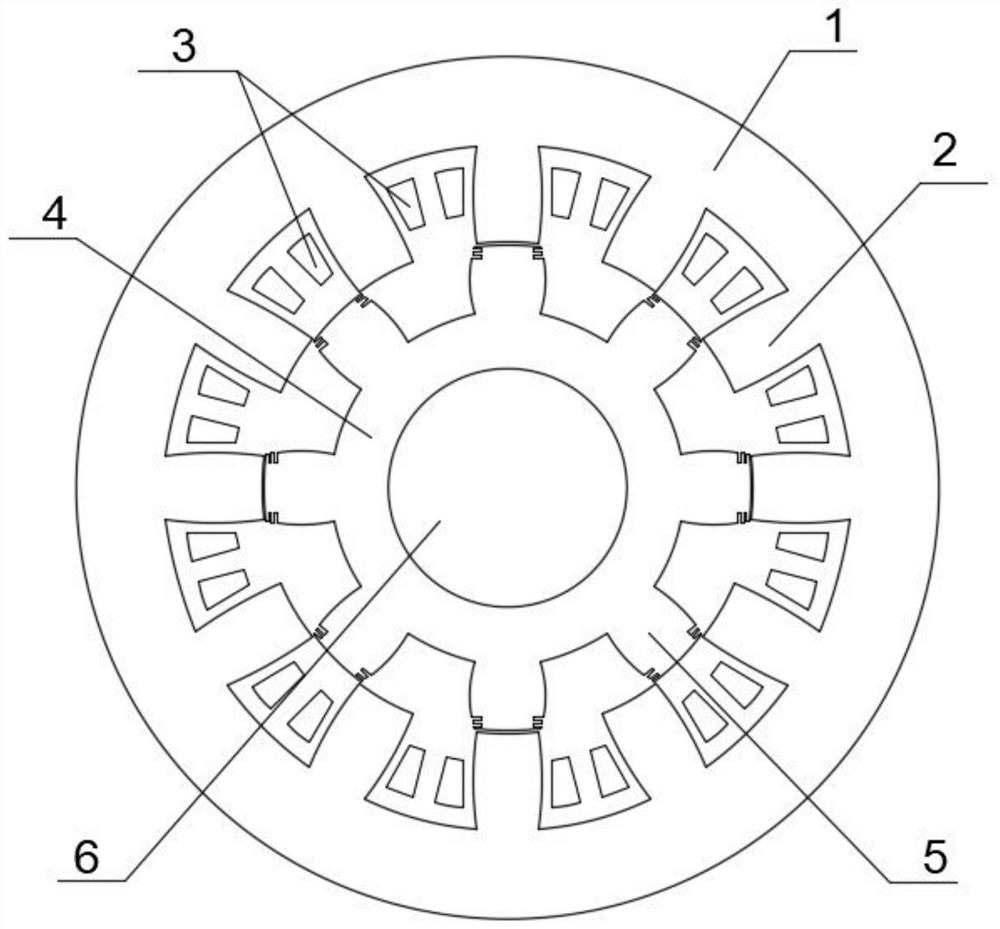

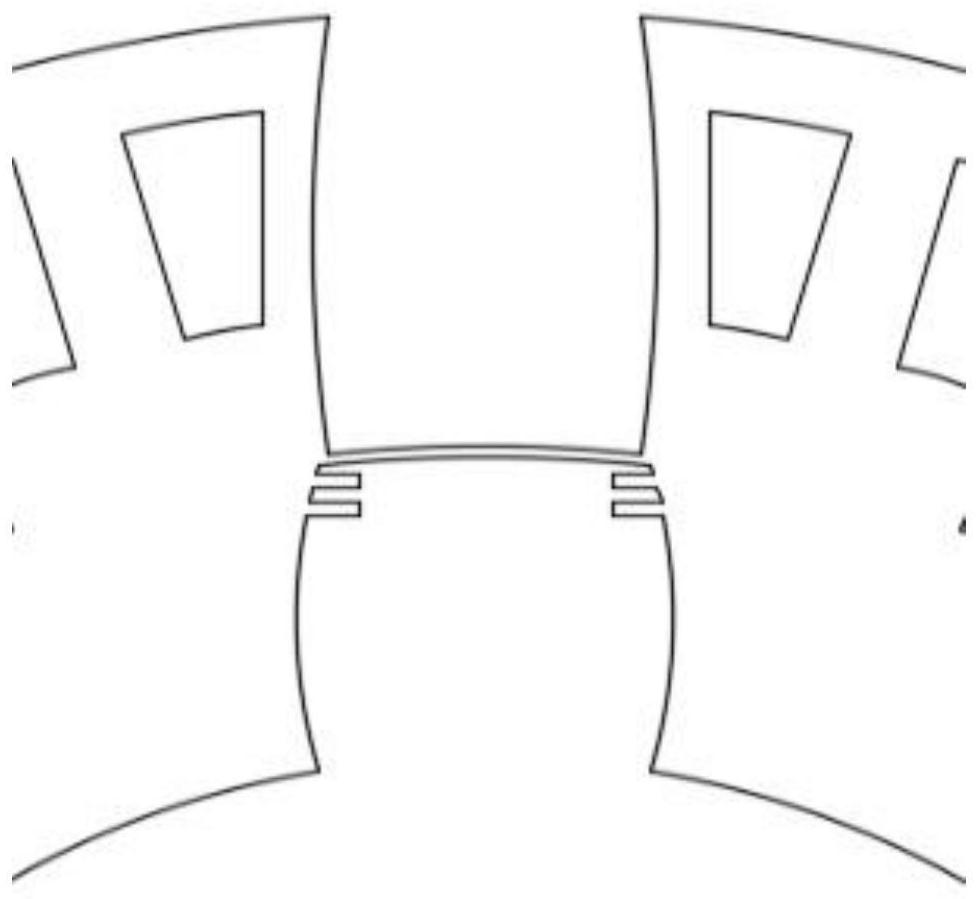

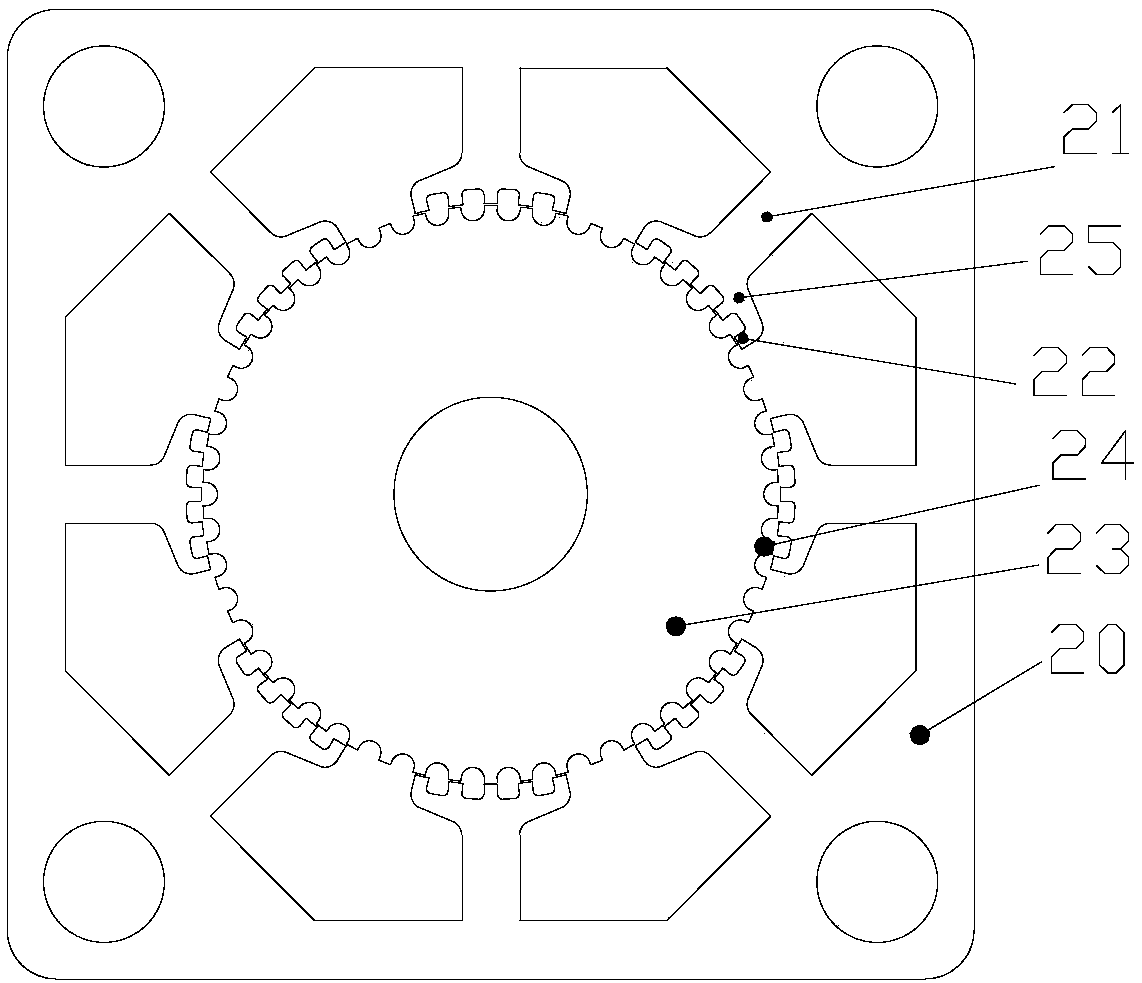

Stator core, winding type stator, concentrated winding motor and production method

InactiveCN112350465AReduce processing difficultyReduce scrapMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineStructural engineering

The invention discloses a stator core, a winding type stator, a concentrated winding motor and a production method. The stator core comprises a yoke structure and a plurality of tooth structures; theyoke structure is divided into a plurality of yoke structure sections with the same number as the tooth structures; each yoke structure section is connected with each tooth structure in a mortise andtenon joint mode; and the yoke structure sections are sequentially connected end to end to form an annular yoke structure, and the tooth structures are located on the same circumferential line. According to the invention, the cost of the stator core is reduced, and the flux density in the tooth structures is reduced, so that the iron loss of the winding type motor is reduced, and the purpose of improving the performance of the winding type motor is achieved.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

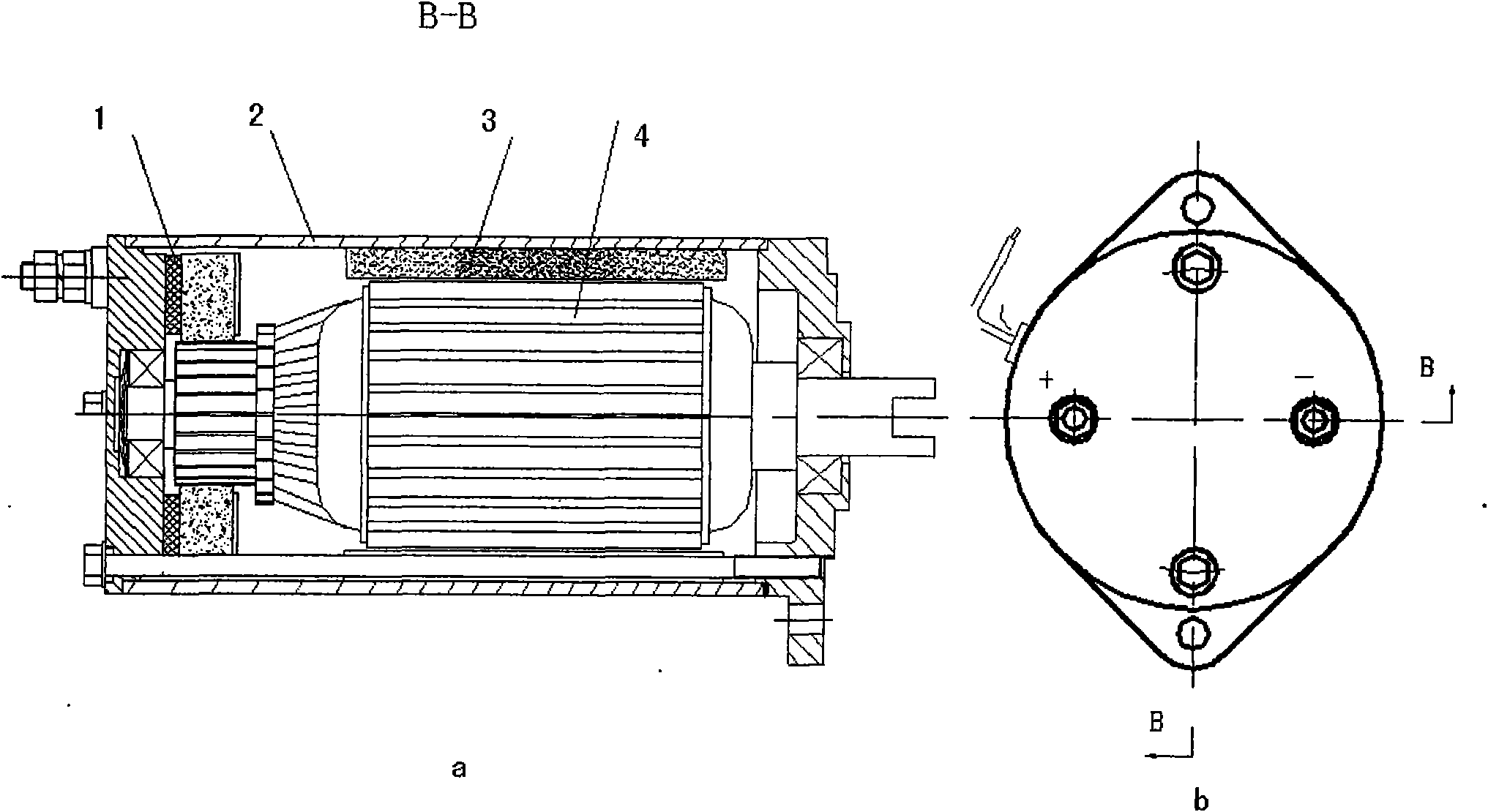

Permanent magnet synchronous motor for high power density electric automobile

InactiveCN106972721AImprove efficiencyImprove power densityMagnetic circuit rotating partsElectric machinesPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a permanent magnet synchronous motor for a high power density electric automobile. The motor comprises a motor body formed by a stator and a rotor. A stator iron core of the stator is of a deep-groove wide-teeth type structure. A stator winding is formed by multiple strands of parallelly wound fin wires. The rotor is of a surface-mounted magnetic steel structure. A stator housing is of an interlayer structure where a spiral water channel is arranged on the inner wall. A rotor iron core is of a hub-type structure. The magnetic steel are of tile-shaped structures with a set pole-arc coefficient which are embedded in the outer circumference of the rotor iron core, and solidified on the outer circumference of the rotor iron core through epoxy resin after being wound by glass fibers. The adjacent magnetic steel polarities are opposite to each other. A hub-type magnetic steel ring or a rotary transformer fixedly sleeves the back end part of a rotor shaft. The motor is advantaged by small size, light weight, big power intensity, strong overload capacity, capability of meeting actual operation working conditions of electric automobiles and increasing endurance journeys and remarkable energy saving effects.

Owner:ZHENGZHOU AIRCRAFT EQUIP +1

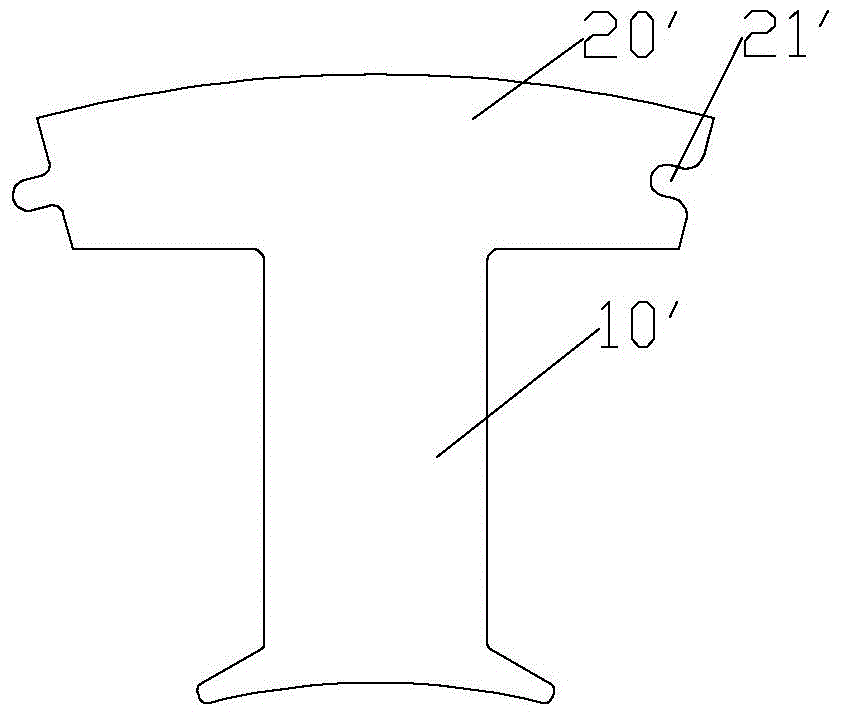

Iron core and motor

InactiveCN105322666AIncrease the effective flux areaIncrease distanceMagnetic circuit stationary partsEngineeringTooth part

The invention provides an iron core and a motor. The iron core comprises a plurality of bodies, and the bodies are orderly connected end to end to be in a cylinder shape. Each body comprises a tooth part and a yoke part. The first end of the yoke part is arranged on the outer surface of the tooth part. The second end of the yoke part is stretched out towards one side of the tooth part, so that the body is in an L shape. A cooperated step is formed between the first end of the yoke part and the outer surface of the tooth part. The cooperated step is a first connecting part, and the second end of the yoke part is a second connecting part. The first connecting part and the second connecting part are connected cooperatively. The first connecting part and the second connecting part are arranged at the relatively thicker part of the yoke part so that the distance between the outer surface of the tooth part and the outer surface of the yoke part is increased. That is to say, the effective magnetic-flow area of the yoke part is increased so that flux density of an iron core is effectively reduced. Furthermore, the iron loss of the motor is lowered, and an overload capability of the motor is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

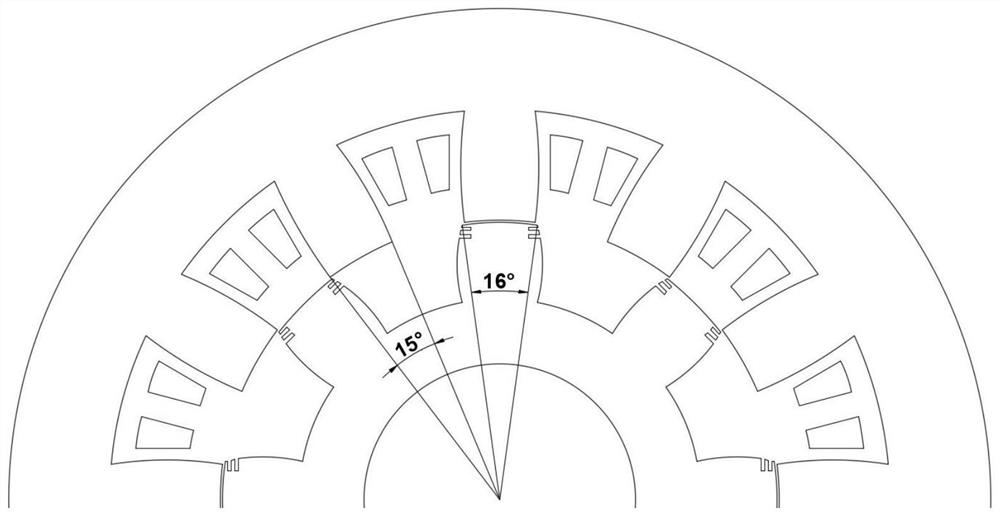

Novel stator and rotor structure of switched reluctance motor

PendingCN112583147AImprove the problem of excessive temperature riseReduce magnetic densityAC motor controlMagnetic circuit rotating partsClassical mechanicsElectric machinery

The invention relates to a novel stator and rotor structure of a switched reluctance motor, and belongs to the technical field of motor structures. A motor body comprises a stator, a winding and a rotor, and a motor structure with the stator arranged outside and the rotor arranged inside is adopted; the stator is composed of stator teeth and a stator yoke, the twelve stator teeth are arranged in the stator yoke at equal intervals in the circumferential direction, unequal-width thickening treatment is conducted on the two sides of the stator teeth, the inter-pole endpoint flux density can be reduced when the stator and the rotor are tangent in the operation process of the motor, and the overall temperature of the motor can be reduced. Winding connection is installed on the stator teeth in aconcentrated winding mode. The eight rotor teeth are distributed on the outer portion of the rotor yoke at equal intervals in the circumferential direction, the two sides of the tooth body are thickened in an unequal-width mode, meanwhile, the two sides of the tooth top are each provided with two symmetrical rectangular grooves, and therefore the radial air gap flux density can be increased, thetangential flux density can be reduced, the average torque of the motor can be increased, and torque pulsation can be reduced.

Owner:HARBIN UNIV OF SCI & TECH

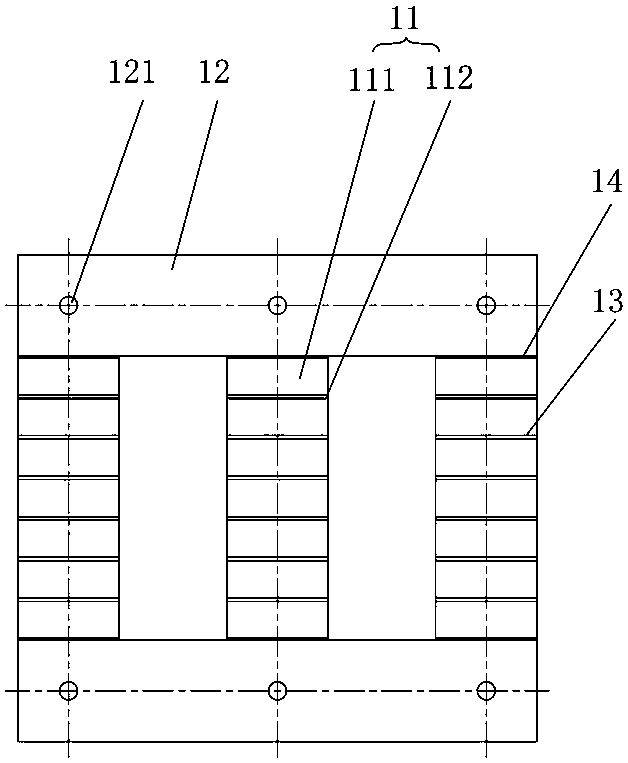

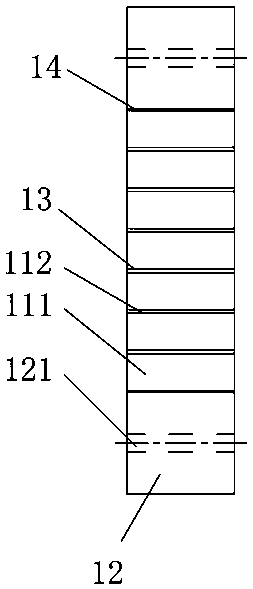

Low-noise iron core reactor and preparation method thereof

InactiveCN109427464AStable structureReduce noiseTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresLow noiseNuclear engineering

A low-noise iron core reactor and a preparation method thereof are provided. The low-noise iron core reactor comprises an iron core and a coil winding; the iron core comprises a core column, and ironyokes arranged at upper and lower ends of the core column; the coil winding is arranged on the core column; the core column comprises a plurality of core column laminations and core air gap plates arranged between two adjacent core column laminations; and a first curing adhesive layer is arranged between the core column lamination and the core air gap plate, and a second curing adhesive layer is arranged between the iron yoke and the core column lamination. The low-noise iron core reactor preparation method comprises the following steps: step 1: pressurizing and laminating the iron core to make the lamination coefficient>0.97; step 2: applying the curing adhesive between the core column lamination and the core air gap plate, and between the iron yoke and the core column lamination, and drying the curing adhesive; step 3: performing vacuum dipping processing on the iron core to form a cured lacquer layer on the surface of the core; step 4: winding the coil winding with the iron core; step 5: assembling the iron core and the coil winding; and step 6: performing vacuum dipping processing on the iron core and the coil winding as a whole. The technical scheme of the present invention has the advantages of low noise, a stable structure, strong capability of bearing the impact and vibration from the train, and the like.

Owner:ZHUZHOU CSR ELECTROMECHANICAL TECH

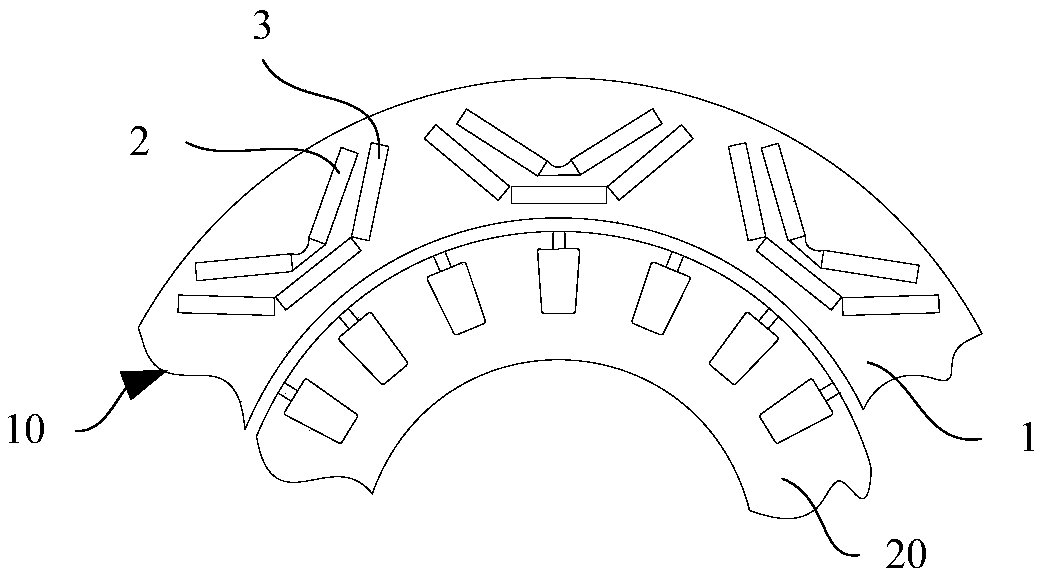

Embedded magnetic steel outer-rotor core assembly and wheel hub motor

PendingCN109450138AReasonably optimize the magnetic circuit effectReduce magnetic densityMagnetic circuit rotating partsTorque densityEngineering

The invention relates to the technical field of wheel hub motors, and in particular relates to an embedded magnetic steel outer-rotor core assembly and a wheel hub motor. The embedded magnetic steel outer-rotor core assembly comprises a rotor core and multiple sets of magnetic steels; each set of magnetic steels comprises a first magnetic steel and a second magnetic steel; furthermore, the two areradially distributed along a stator; the first magnetic steel is a V-shaped segmented magnetic steel; the second magnetic steel is a U-shaped segmented magnetic steel; the rotor core is provided withmultiple sets of embedded grooves; each set of embedded grooves comprises a first embedded groove and a second embedded groove; the first magnetic steel is arranged in the first embedded groove; andthe second magnetic steel is arranged in the second embedded groove. Visibly, the magnetic steel is installed in the embedded groove; the assembly is simple and convenient; furthermore, the V-shaped magnetic steel and the U-shaped magnetic steel are combined; the assembly is flexible and diverse; the magnetism gathering effect of the U-shaped magnetic steel on the V-shaped magnetic steel is compensated; on the basis of the increased magnetic flow, the salient pole rate is greatly changed; magnetic circuit effects of a d axis and a q axis are reasonably optimized; the flux density of the wheelhub motor under high torque is reduced; and the torque density is increased.

Owner:HUMAN HORIZONS (JIANGSU) TECH CO LTD

Noise-reducing transformer iron core structure and manufacturing method thereof

PendingCN112466630ASmall electromagnetic forceReduce magnetic densityTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerMagneto

The invention discloses a noise-reducing transformer iron core structure and a manufacturing method thereof. The transformer iron core structure is formed by lapping a plurality of silicon steel sheets, and magneto-rheological glue is filled in gaps of adjacent silicon steel sheet laminations lapped at corners of the transformer iron core structure. According to the noise-reducing transformer ironcore structure, the magneto-rheological glue is filled in the lamination gaps of the adjacent silicon steel sheets, part of the magnetic induction lines can pass through the magneto-rheological gluein the lamination gaps due to the magnetic conductivity of the magneto-rheological glue, and compared with the situation that air exists in the lamination gaps, the magnetic lines of force are distributed in the lamination gaps more smoothly; therefore, the magnetic density of the leakage magnetic field around the lamination gap is reduced, the electromagnetic force between the silicon steel sheets is reduced, and the vibration noise between the silicon steel sheet laminations caused by the electromagnetic force is reduced. Meanwhile, due to the damping characteristic of the magneto-rheological glue, part of vibration energy is consumed, and therefore the effects of damping and reducing vibration noise are further achieved.

Owner:SHENYANG POLYTECHNIC UNIV

Parallel system of 2N inverters and control method of parallel system

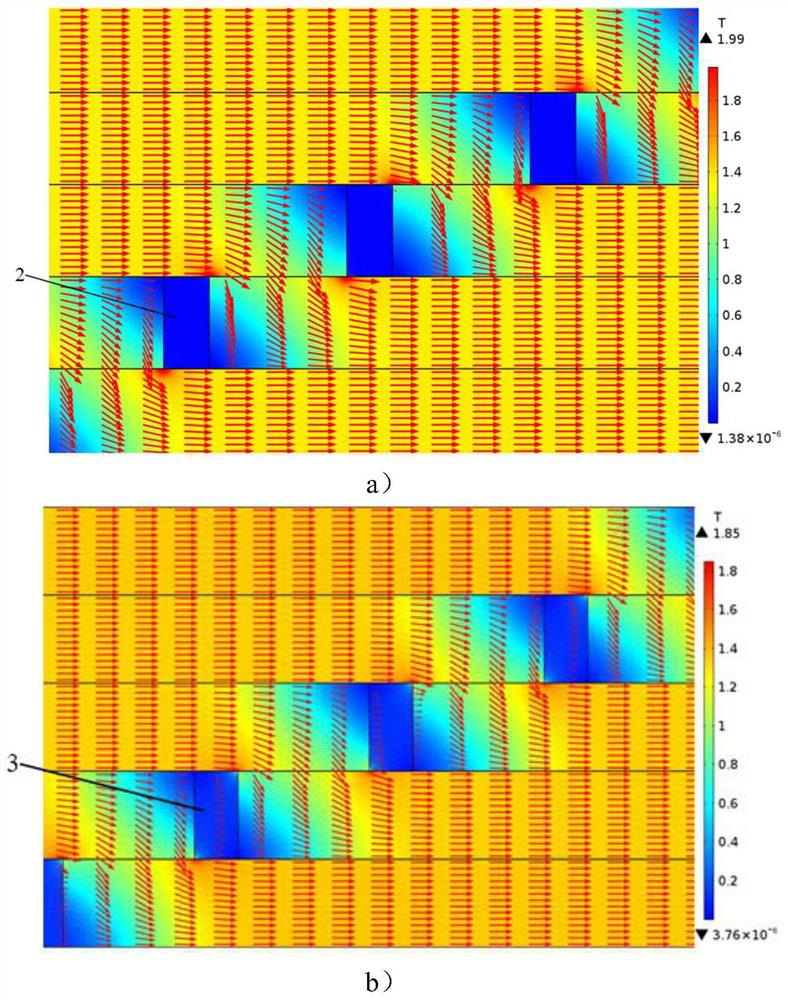

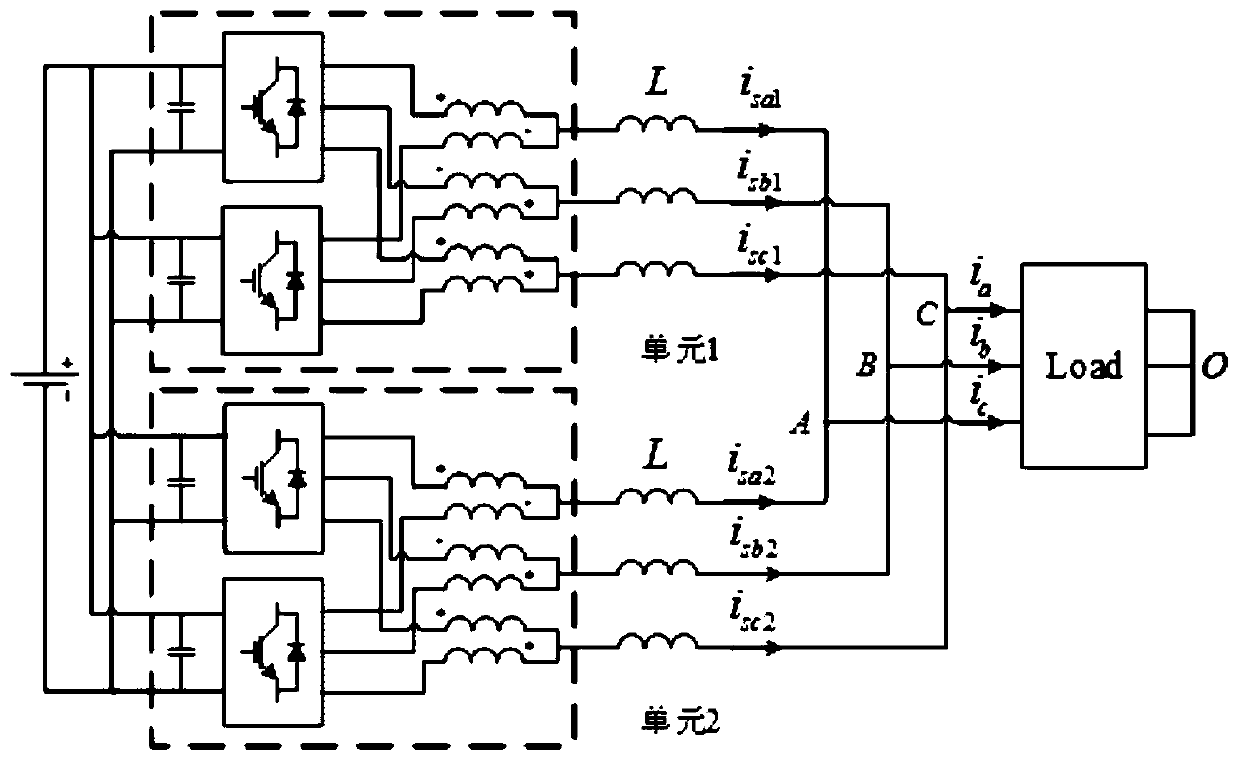

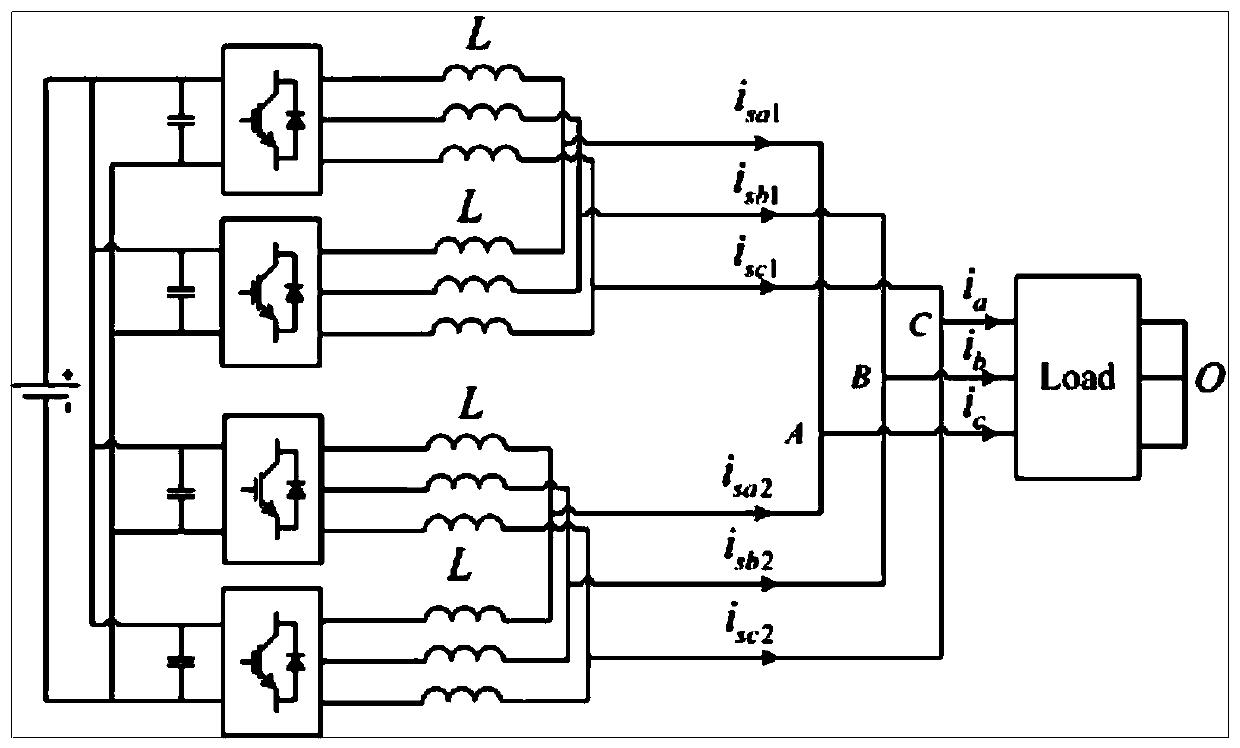

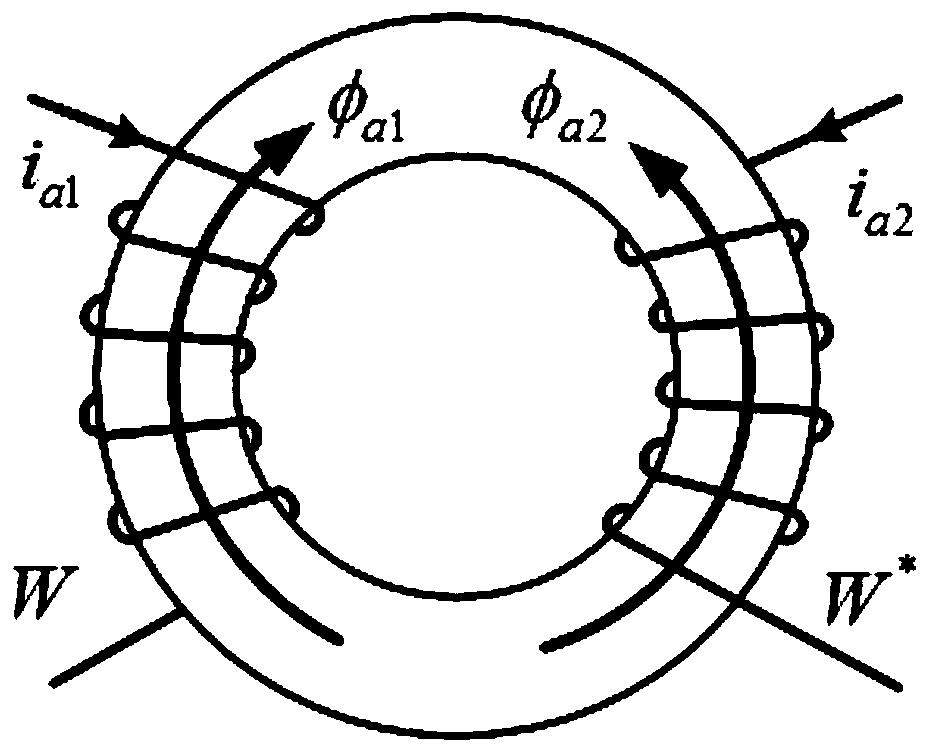

ActiveCN110176866AOvercome the disadvantage of not being able to connect multiple inverters in parallelSolve the problem of circulation suppressionDc-ac conversion without reversalPower inverterPhase shifted

The invention discloses a parallel system of 2N inverters and a control method of the parallel system. A dotted end of a coupling inductor a is connected with phases a of a first inverter and a secondinverter, the other dotted end of the coupling inductor a is connected with an input end of an independent inductor a, similarly, a coupling inductor b is connected with a coupling inductor c, outputends of same independent inductors are connected in parallel, each independent inductor is used for suppressing a ring current between the inverters, and each coupling inductor is used for suppressing a ring current in each inverter unit. On the basis of the inverter parallel systems, the control method comprises the steps of calculating a rising edge and a descending edge of switch pulse according to synchronous sawtooth carrer and a pulse phase-shift angle, and acquiring a PWM signal; and achieving control of a parallel structure of the 2N inverters by the PWM signal. The ring current of the 2N inverters is suppressed by combining advantages of the coupling inductors and the independent inductors, and expansion and control of the coupling inductor-based inverter parallel system are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

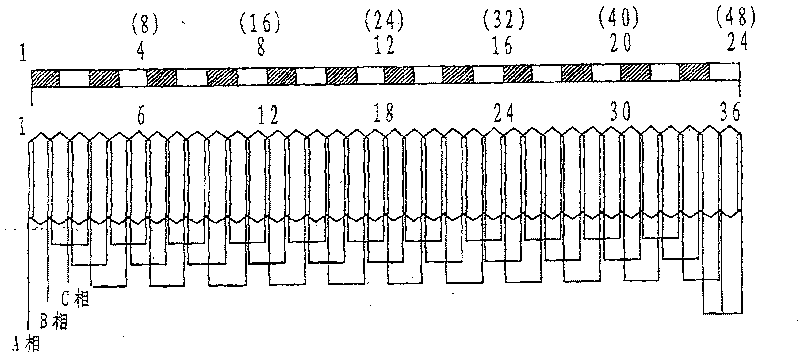

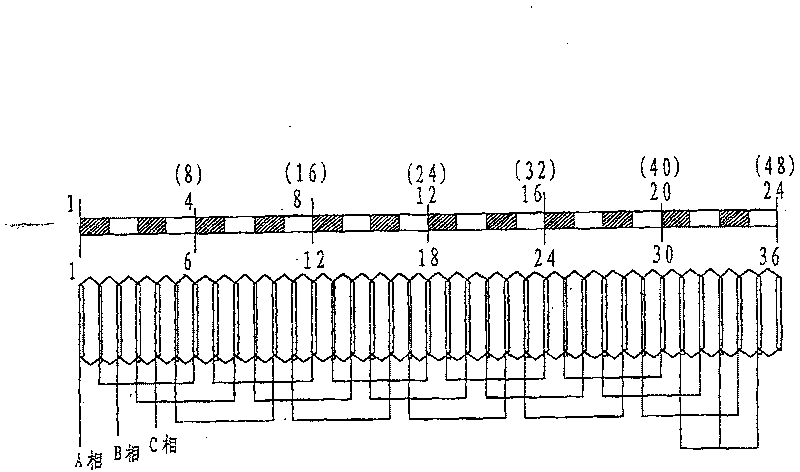

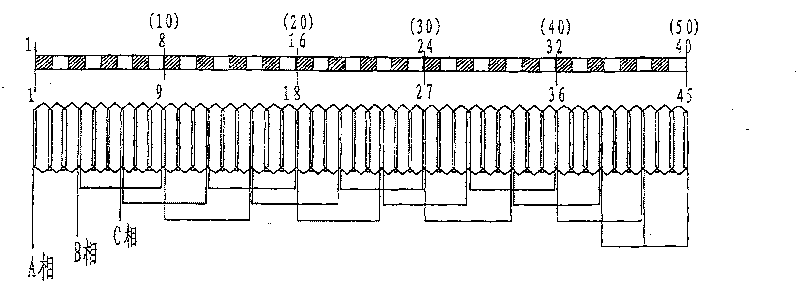

Score slot coil unit for low-speed high torque permanent magnetic brushless electromotor

ActiveCN101262151BReduce lossReduce weightMagnetic circuit rotating partsMagnetic circuit stationary partsBrushless motorsLow speed

The invention relates to a fractional slot winding of a permanent magnet brushless motor, which comprises a stator core of unslotted structure. The coils of the winding are arranged on the end of the stator core and corresponding to magnetic poles which are in alternate arrangement with an N pole and an S pole on a rotor; the pitch of the winding is 1 slot pitch and the winding is in double lap wound. The winding of the invention is characterized in that: number of magnetic poles P, number of core slots Z, phase number M and distribution number Q meet the following conditions: 1) when the distribution number Q is odd, the number of core slots Z equales that Q is multiplied by M and then multiplied by K, number of magnetic poles P equals that Z plus or minus K; wherein, K is a natural number; 2) when the distribution number Q is even, number of core slots Z equals that Q is multiplied by M and then multiplied by K, number of magnetic poles P equals that Z plus or minus 2K; wherein, K is a natural number. The fractional slot winding is applicable to low speed high torque permanent magnet brushless motors of various sizes and power grades and since the pitch of the winding is 1 slot pitch, the end length of the motor winding is obviously shortened, thus winding materials and energy are saved; meanwhile, the winding of the invention has simple production technique, is suitable formass industrial manufacture and can reduce processing cost of a permanent magnet.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Desaturation superconducting switch flux linkage motor

ActiveCN111917201AReduce installation difficultyReduce magnetic densityMagnetic circuit rotating partsMagnetic circuit stationary partsTorque densityEngineering

The invention discloses a desaturation superconducting switch flux linkage motor, and the motor comprises a rotor core, an air gap and a stator core which are sequentially distributed from inside to outside in the radial direction. The motor also comprises an armature winding which is placed in a stator core groove, an excitation winding which is placed in the middle of stator core teeth, magneticsteels which are placed at the top and the bottom of the stator core teeth respectively, and a cryostat which is used for wrapping the excitation winding, wherein the rotor core and the stator core are both made of ferromagnetic materials. According to the invention, the excitation winding and the armature winding are simultaneously placed on the stator, so the motor has only one physical air gapwithout a rotary winding, and the installation difficulty is reduced; meanwhile, the stator iron core and the rotor iron core are made of ferromagnetic materials, so the torque density of the motor can be effectively improved, and the superconducting consumption is reduced; and the modular cryostat is adopted, so the equivalent air gap flux density can be effectively reduced, and the torque density of the motor is further improved.

Owner:HUAZHONG UNIV OF SCI & TECH

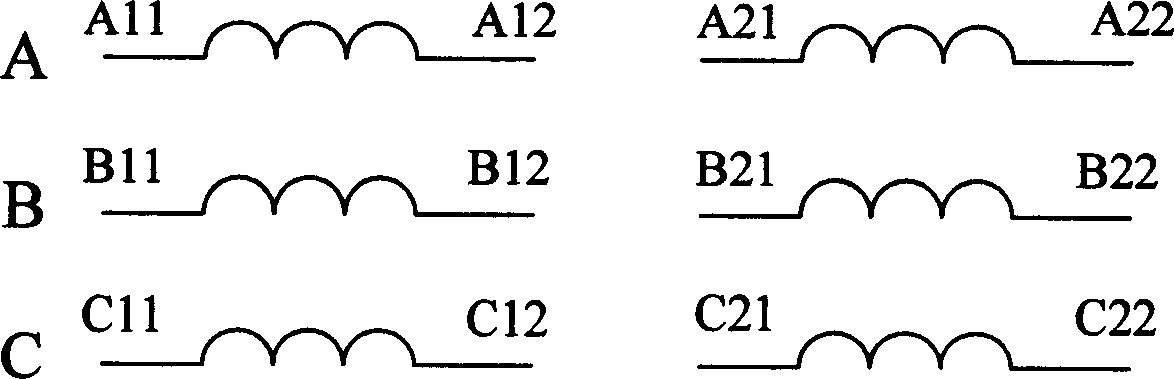

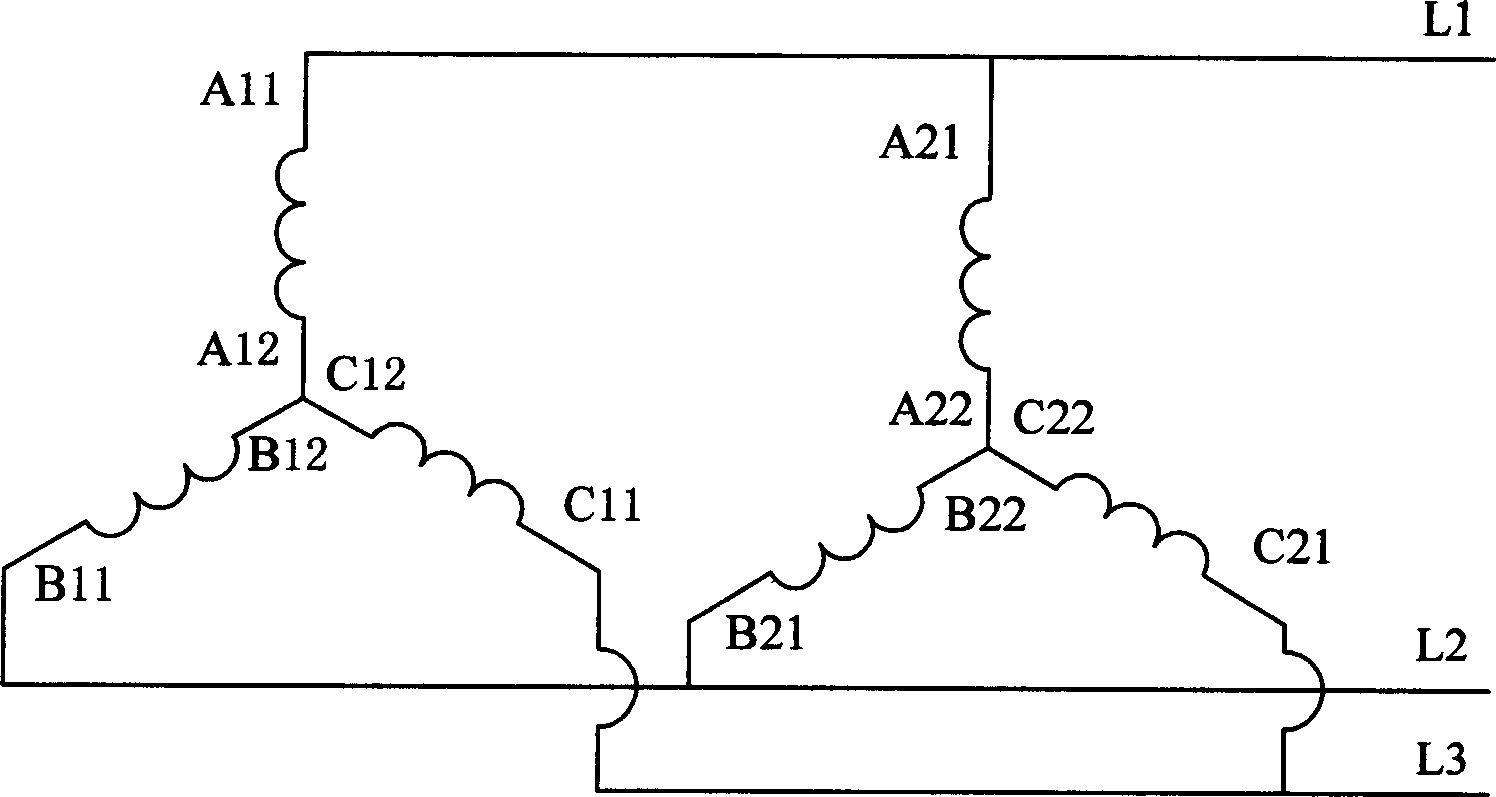

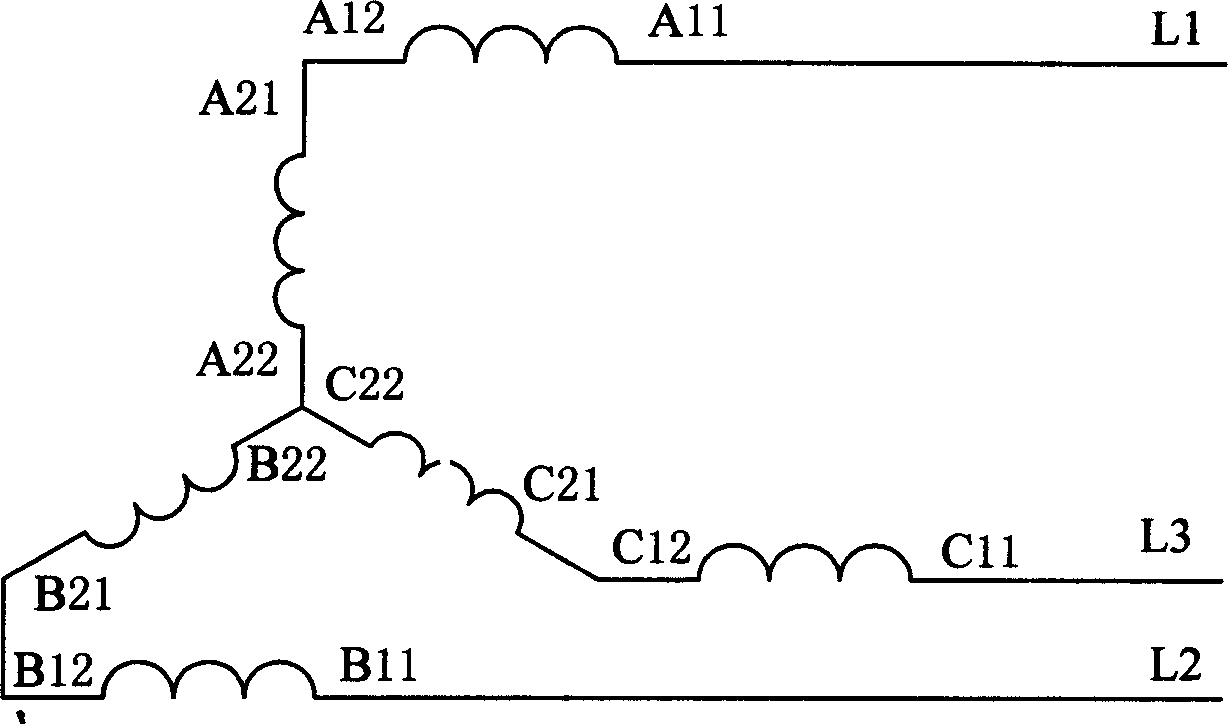

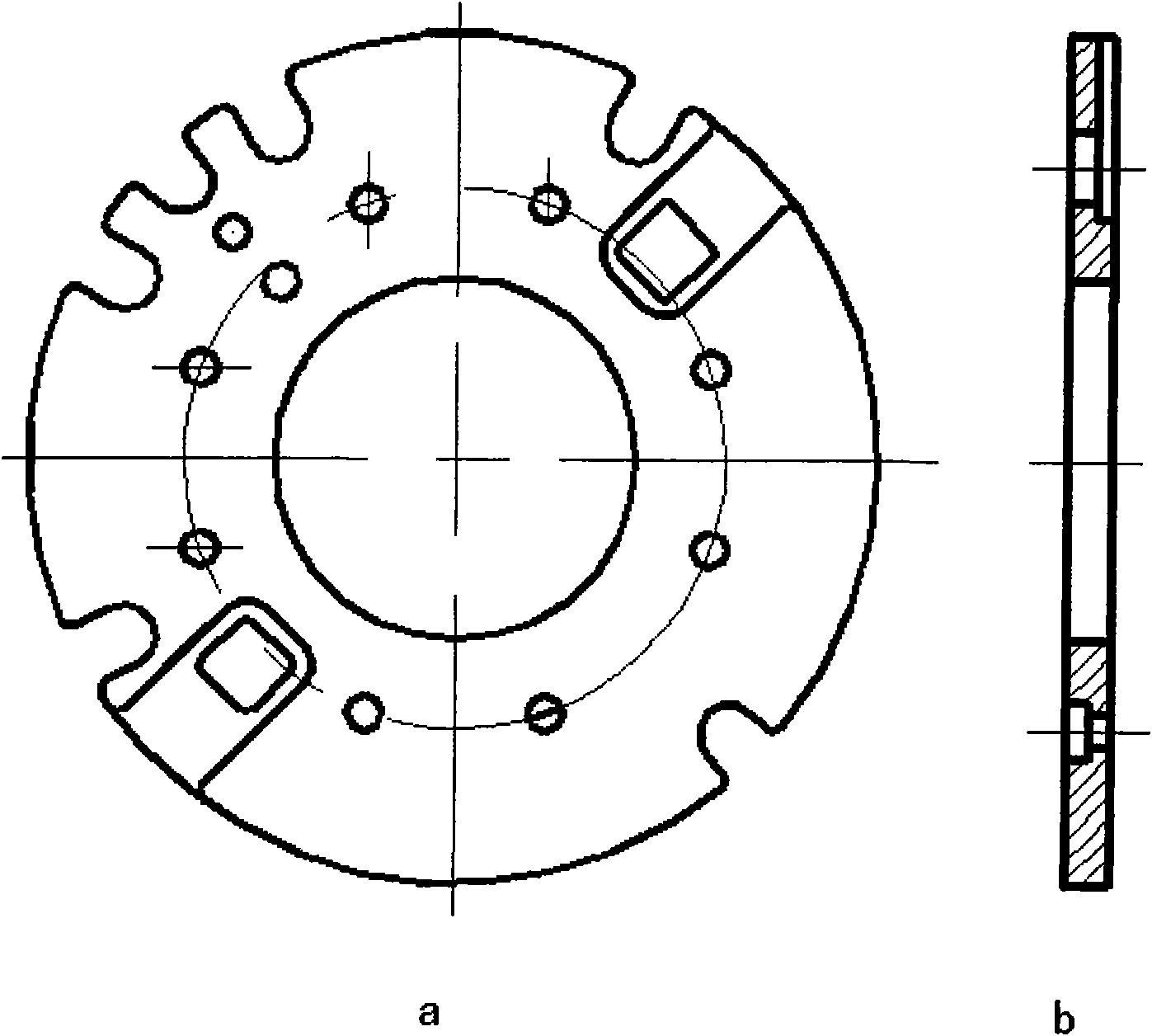

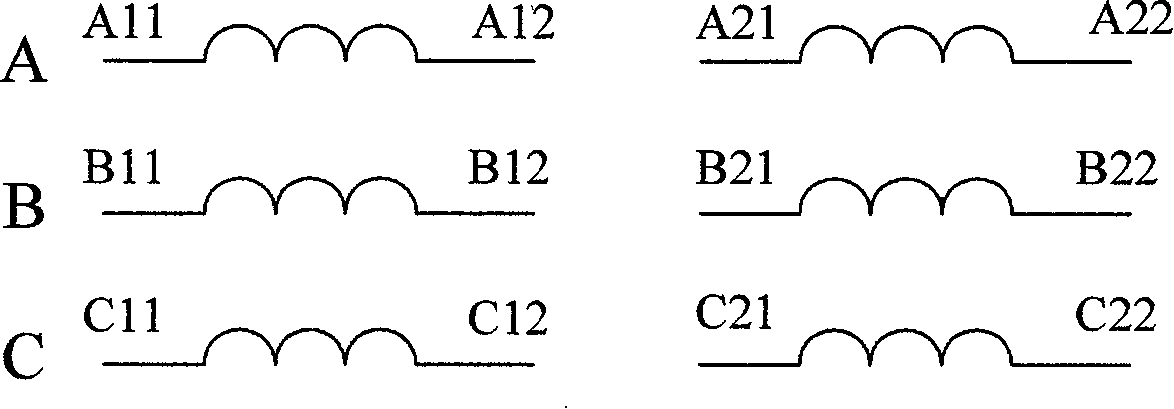

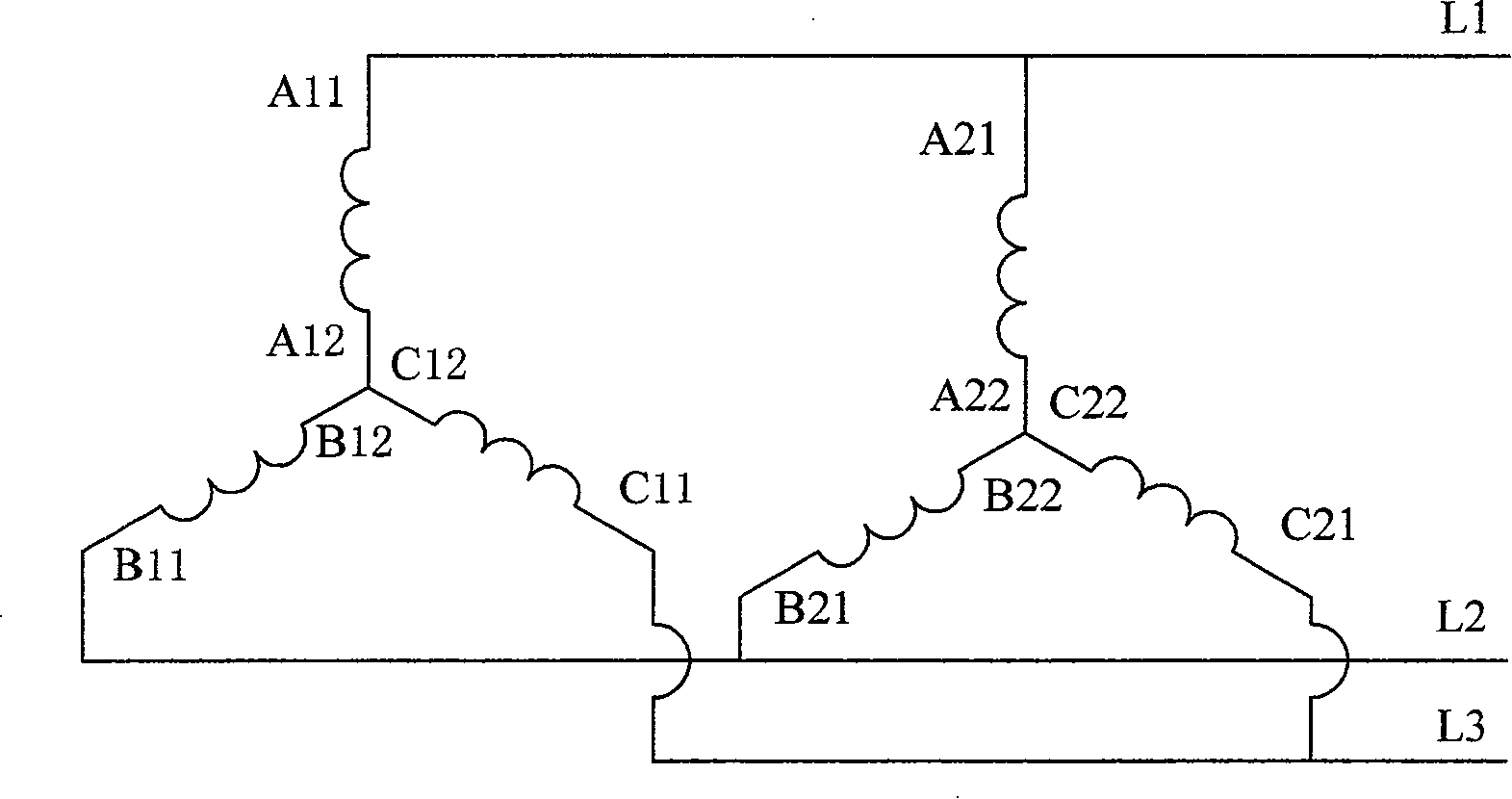

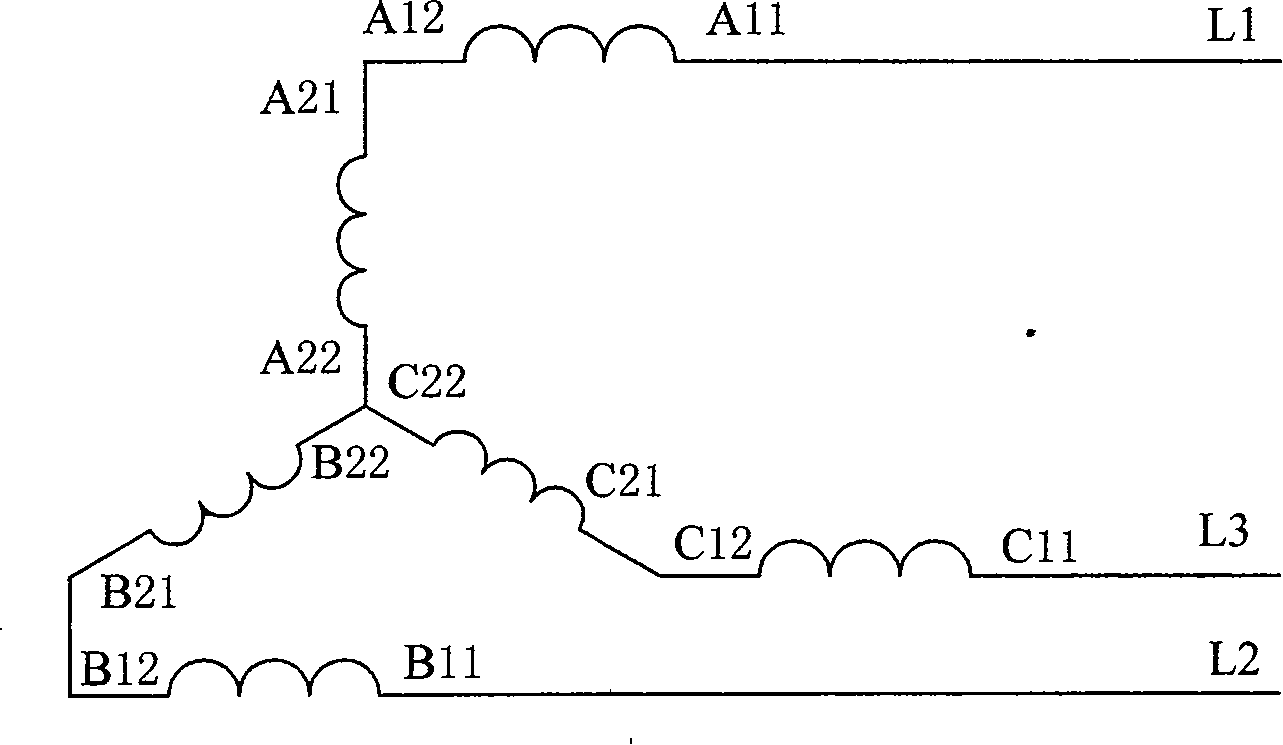

Electric motor winding with pole and power variable combination

InactiveCN1819407AAvoid big horse-drawn cartsImprove efficiency and power factorWindings conductor shape/form/constructionDouble starPole number

The invention solves the problem that is that the pole-changing motor can not change power of output and the power-changing motor can not change poles. The machine winding of the invention includes A, B, C three phases winding. Each phase winding is split into two segments, and each segment has two leading out end separately located in the front and tail. Each segment has m coils (m=1, 2, and the like). There are 12 leading out ends in total motor windings, and they get the following three structures through switching by relay: 1) a double star connection motor winding having P electrodes numbers at first power state; 2) a star connection motor winding having P electrode numbers at second power state; 3) a star connection motor winding having Q poles numbers at second power state.

Owner:HARBIN UNIV OF SCI & TECH +2

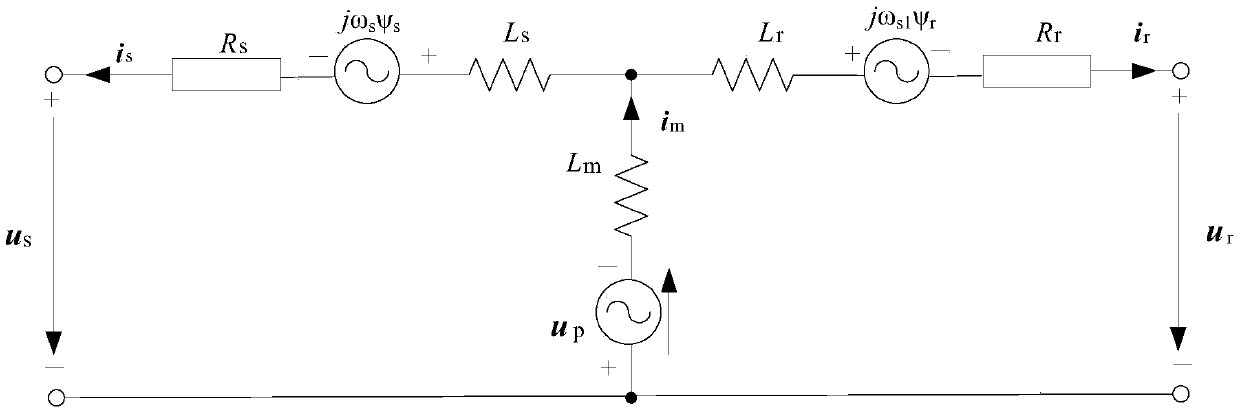

A double-rotor permanent magnet double-fed wind generator and power generation system

ActiveCN108365718BIncrease air gap flux densityIncreased torque densityElectronic commutation motor controlMagnetic circuit rotating partsRotor magnetsElectric machine

The invention provides a dual-rotor permanent-magnet doubly-fed wind power generator and a power generation system. A permanent-magnet outer rotor employs a magnetic conduction material of which an inner surface and an outer surface are pasted with permanent-magnet structures, and the positions of permanent magnets on the inner surface and the outer surface are corresponding to each other. By themagnet structure, the gap flux density of a motor gap can be improved, and the torque density of the motor is in direct proportion to the gas surface area and the gas flux density value of the motor;in the dual-rotor permanent-magnet doubly-fed wind power generator, the gas surface area is expanded, the additionally-arranged outer rotor magnets all employ special magnet structures, the gap flux density is improved, so that the torque density of the motor is improved; and with the adoption of an inner-rotor and outer-rotor structure of the dual-rotor permanent-magnet doubly-fed wind power generator, the gap flux density of the inner rotor and the outer rotor are improved, the flux density of yoke parts of the inner rotor and the outer rotor is reduced, so that the running efficiency and the torque density of the motor are improved, the gap flux density of the inner rotor and the outer rotor is in sine distribution, and a winding potential can be enabled to be in sine distribution.

Owner:临沂益强铸造有限公司

Permanent magnetic DC pump motor

InactiveCN101777808AExtend working hoursReduce electricity loadMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsHydraulic pumpEngineering

The invention relates to a permanent magnetic DC pump motor which comprises an enclosure 2, magnetic steel 3, a brush frame plate and an armature stamping 4, and is characterized in that the armature stamping 4 is in a peariformslot structure, the enclosure 2 adopts No. 10 steel tubes with the thickness of 3.5-4mm, the magnetic steel 3 adopts ferrite Y40 or Y35, the thickness of the magnetic steel is designed to be 9.5-10mm, the brush frame plate 1 adopts a thermosetting material FX-501 phenolic aldehyde glassfiber plastic with the withstanding temperature of 170 to 190 DEG C, and the insulating material of the motor adopts H class insulation with the temperature of 170 to 180 DEG C. The motor of the invention solves the problems of calorification, small moment, high rotate speed of the motor, and reaches the use requirements of a hydraulic pump, such as long time (S2 = 8min), large moment of 2.1N.m and low rotate speed of 2200r / min.

Owner:陕西秦航机电有限责任公司 +1

Electric motor winding with pole and power variable combination

InactiveCN100407552CReduce magnetic densityAvoid the phenomenon of big horses and small cartsWindings conductor shape/form/constructionDouble starThree-phase

The invention solves the problem that is that the pole-changing motor can not change power of output and the power-changing motor can not change poles. The machine winding of the invention includes A, B, C three phases winding. Each phase winding is split into two segments, and each segment has two leading out end separately located in the front and tail. Each segment has m coils (m=1, 2, and the like). There are 12 leading out ends in total motor windings, and they get the following three structures through switching by relay: 1) a double star connection motor winding having P electrodes numbers at first power state; 2) a star connection motor winding having P electrode numbers at second power state; 3) a star connection motor winding having Q poles numbers at second power state.

Owner:HARBIN UNIV OF SCI & TECH +2

Stator punching plate used for air conditioning fan motor

InactiveCN104953730AImprove efficiencyReduce the number of winding turnsMagnetic circuit stationary partsPunchingInduction motor

A stator punching plate used for an air conditioning fan motor relates to the technical field of AC asynchronous motor modification, and is characterized by comprising an annular punching plate body, wherein the middle part of the punching plate body is provided with a hollow inner round hole and an outer circle, a punching plate groove is arranged between the outer circle of the punching plate body and the hollow inner round hole, the punching plate groove is provided with a notch, a groove shoulder, a groove body and a groove top. The stator punching plate provided by the invention has the advantages that the structure is reasonable, the flux density distribution of iron cores is effectively improved, the raw material consumption of coils and the iron cores is reduced, the energy efficiency is high and the service life is long.

Owner:合肥市通得力电气制造有限公司

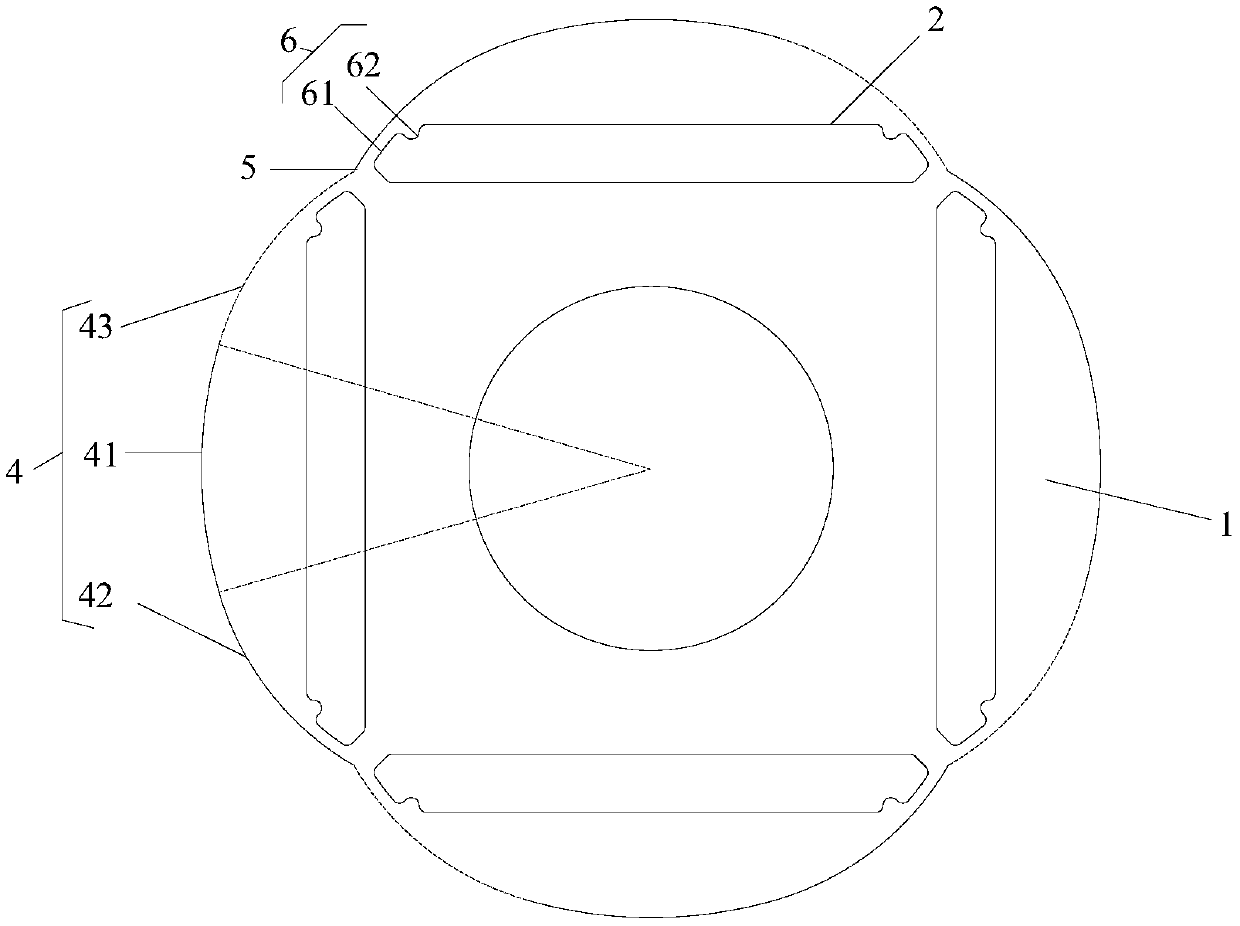

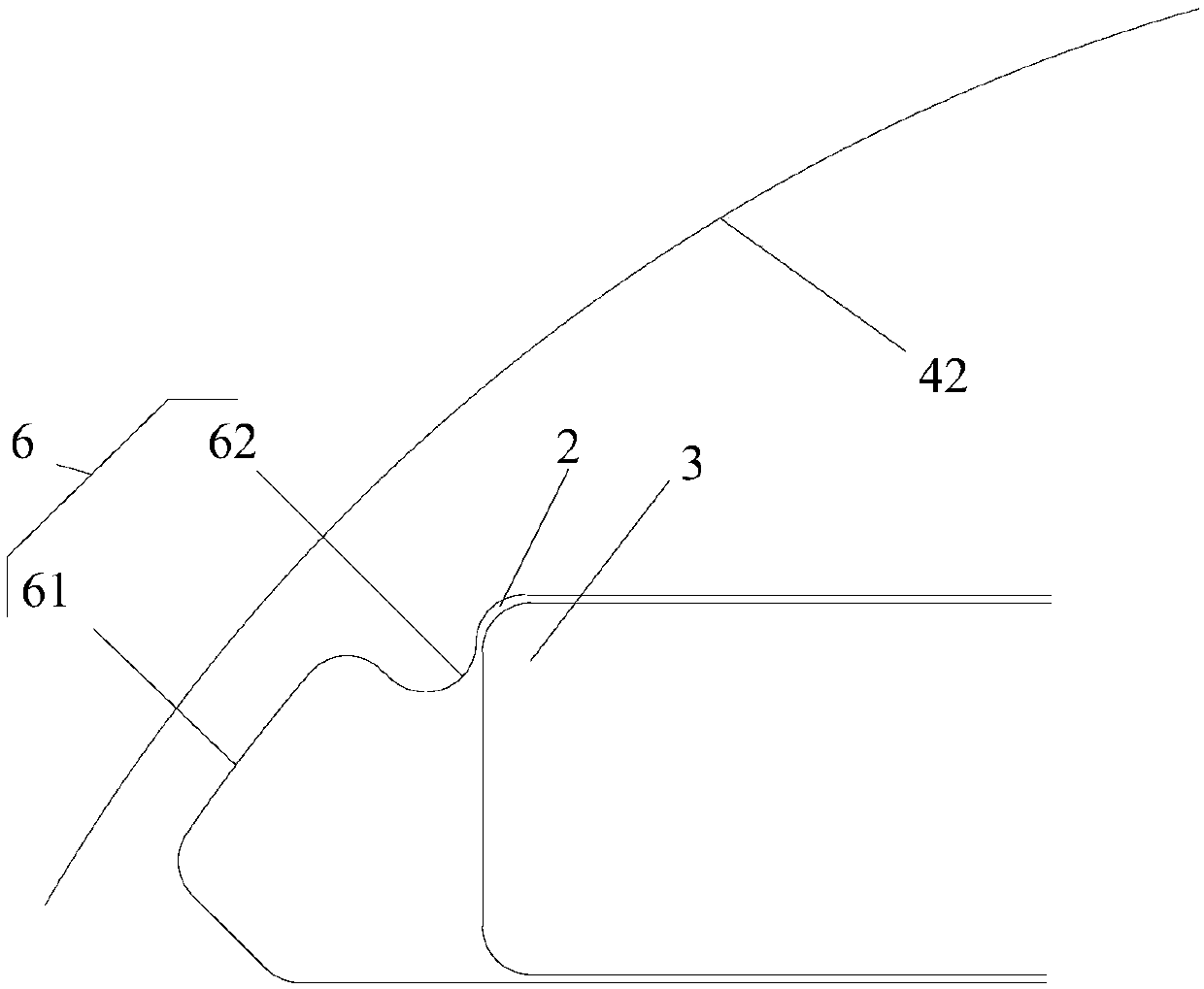

Rotor and motor

PendingCN110971031AFree from stator magnetic fieldImprove resistance to partial demagnetizationMagnetic circuit rotating partsElectric machineEngineering

The invention relates to the field of motors, and discloses a rotor and a motor. The rotor comprises a rotor core (1) and permanent magnets (3). The rotor core (1) is provided with a plurality of installation grooves (2) which are arranged at intervals in the circumferential direction of the rotor core (1). The permanent magnets (3) are arranged in the installation grooves (2), wherein each installation groove (2) is provided with a first edge close to the outer edge of the rotor core (1), a second edge facing the center of the rotor core (1) and a transition edge connecting the first edge andthe second edge, each transition edge is of a multi-section structure (6), and the parts, connected with the first edges, of multi-section structures (6) are arranged to protrude towards the inner sides of the installation grooves (2). By arranging the multi-section structures, the distance between the permanent magnets and the outer edge of the rotor core is increased, and the magnetic densityis reduced, so that a magnetic bridge formed between the permanent magnets and the outer edge of the rotor core can protect the permanent magnets from the action of a stator magnetic field, and the local demagnetization resistance of the permanent magnets is effectively improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

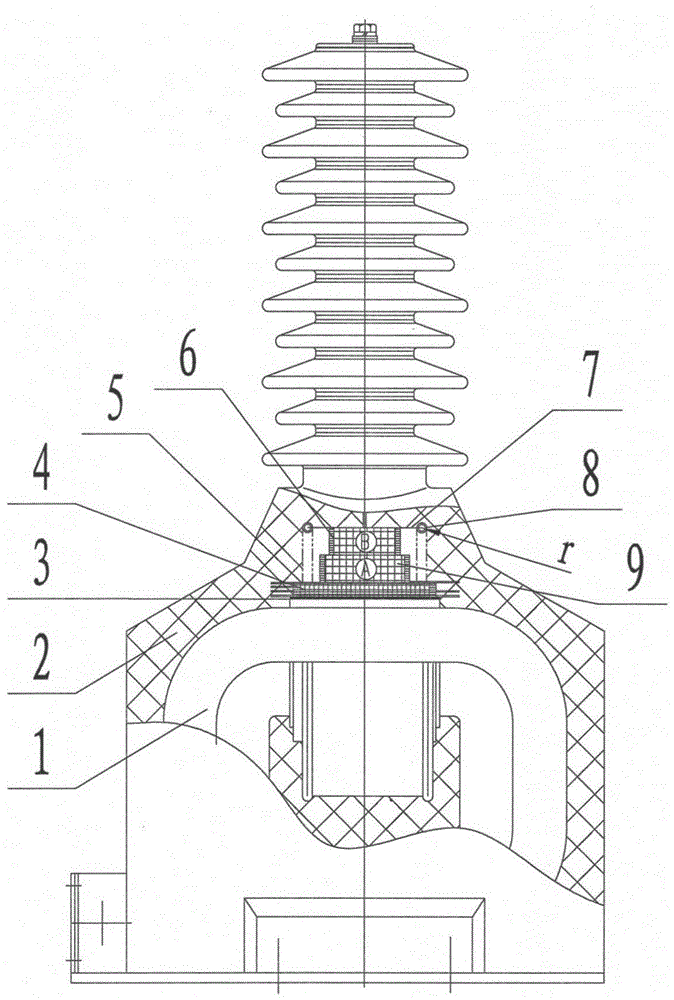

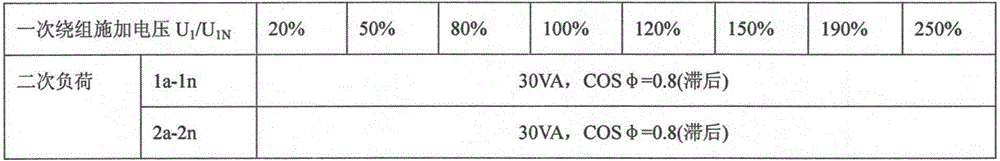

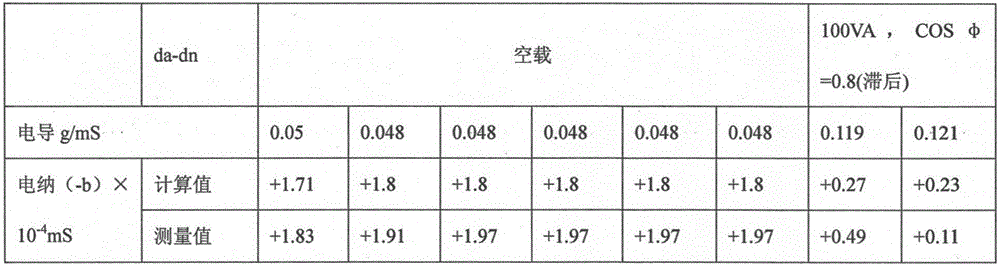

A Capacitive Impedance Epoxy Resin Casting Insulated Electromagnetic Voltage Transformer

ActiveCN104157437BIncrease capacitance to groundHigh dielectric constantTransformersTransformers/inductances coils/windings/connectionsCapacitanceEpoxy

The invention provides an electromagnetic voltage transformer with an insulation function through capacitive impedance epoxy resin casting. The electromagnetic voltage transformer is characterized in that layer insulations with high dielectric constants are adopted, epoxy resin mixtures with high dielectric constants are adopted, the area of a high-low voltage electrostatic screen is increased, the distributed capacitance of the high-low voltage electrostatic screen can be 300-500 pF, and the transformer is still capacitive with perceptual load. The electromagnetic voltage transformer comprises an iron core, a wire wrapping framework, a secondary winding, an inner electrostatic screen, the layer insulation, an outer electrostatic screen and a primary winding. The wire wrapping framework is arranged in the middle of an iron core window, the secondary winding and the primary winding are sequentially wound on the wire wrapping framework from inside to outside, the inner electrostatic screen is arranged on the inner side of the primary winding, the outer electrostatic screen is arranged on the outer side of the primary winding, the layer insulation is arranged between layers of the primary winding, and the iron core, the wire wrapping framework, the secondary winding, the inner electrostatic screen, the layer insulation, the outer electrostatic screen and the primary winding all are arranged in an epoxy resin mixed-casting material layer. The electromagnetic voltage transformer can normally operate under 2.5 times the rated voltage, core saturation is basically avoided, and a ferromagnetic resonance area is avoided.

Owner:陕西正泰智能电气有限公司

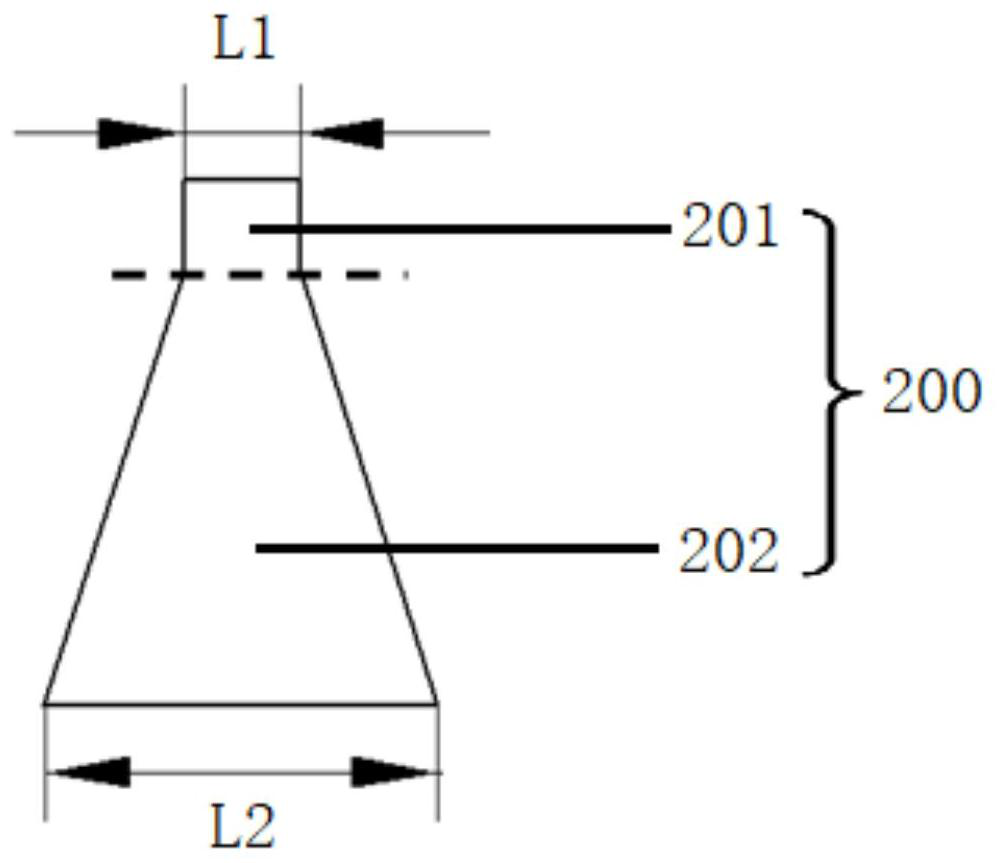

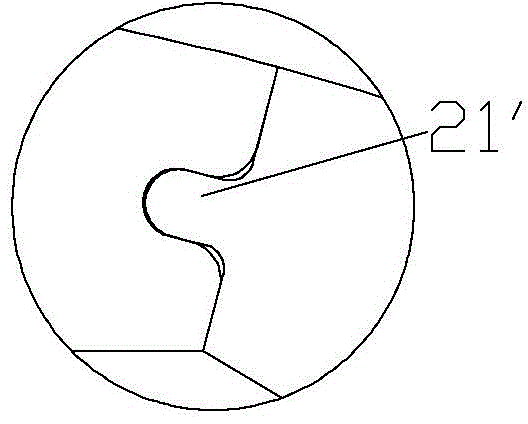

Stepping motor

PendingCN108574389AImprove the magnetic density distribution of the main poleHigh saturationMagnetic circuit stationary partsElectric machineDensity distribution

The invention relates to a stepping motor. The stepping motor includes a stator core (11) and a rotor core (12). The stator core (11) includes a stator core body (20); the stator core body (20) is uniformly provided with eight stator main poles (21) along with a peripheral direction; a pole shoe part (25) of each of the stator main poles (21) is provided with multiple uniformly distributed statortoothlets; and the width of each of the stator main poles (21) is gradually increased from outside to inside. Compared with the prior art, the stepping motor has the advantages of improving the main pole magnetic density distribution of the motor, reducing the saturation degree of the motor, increasing the output torque of the motor, and the like by increasing the width of the main poles near thepole shoe part.

Owner:SHANGHAI MOONS ELECTRICAL APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com