Electric motor winding with pole and power variable combination

A technology of motor windings and phase windings is applied in the field of improvement of motor winding connection methods, which can solve the problems that variable power motors cannot change poles at the same time, and pole changing motors cannot change output power, etc., so as to avoid large horse-drawn carts and improve efficiency. and the effect of power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

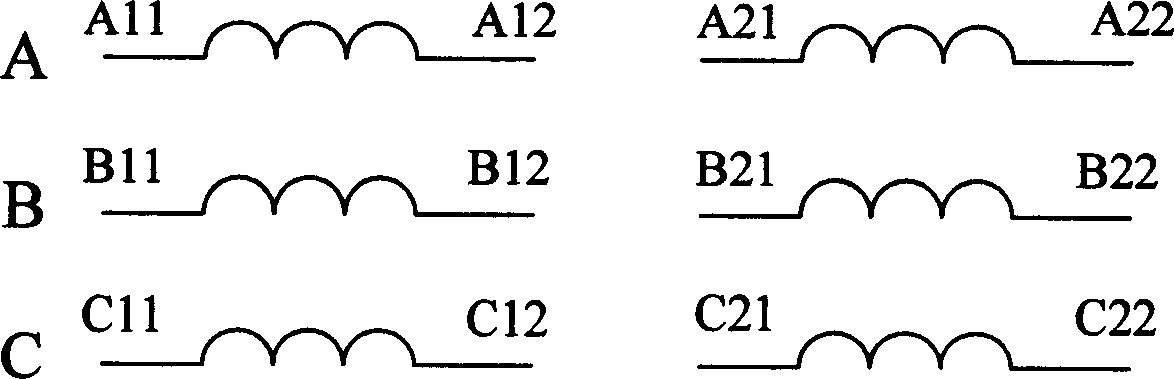

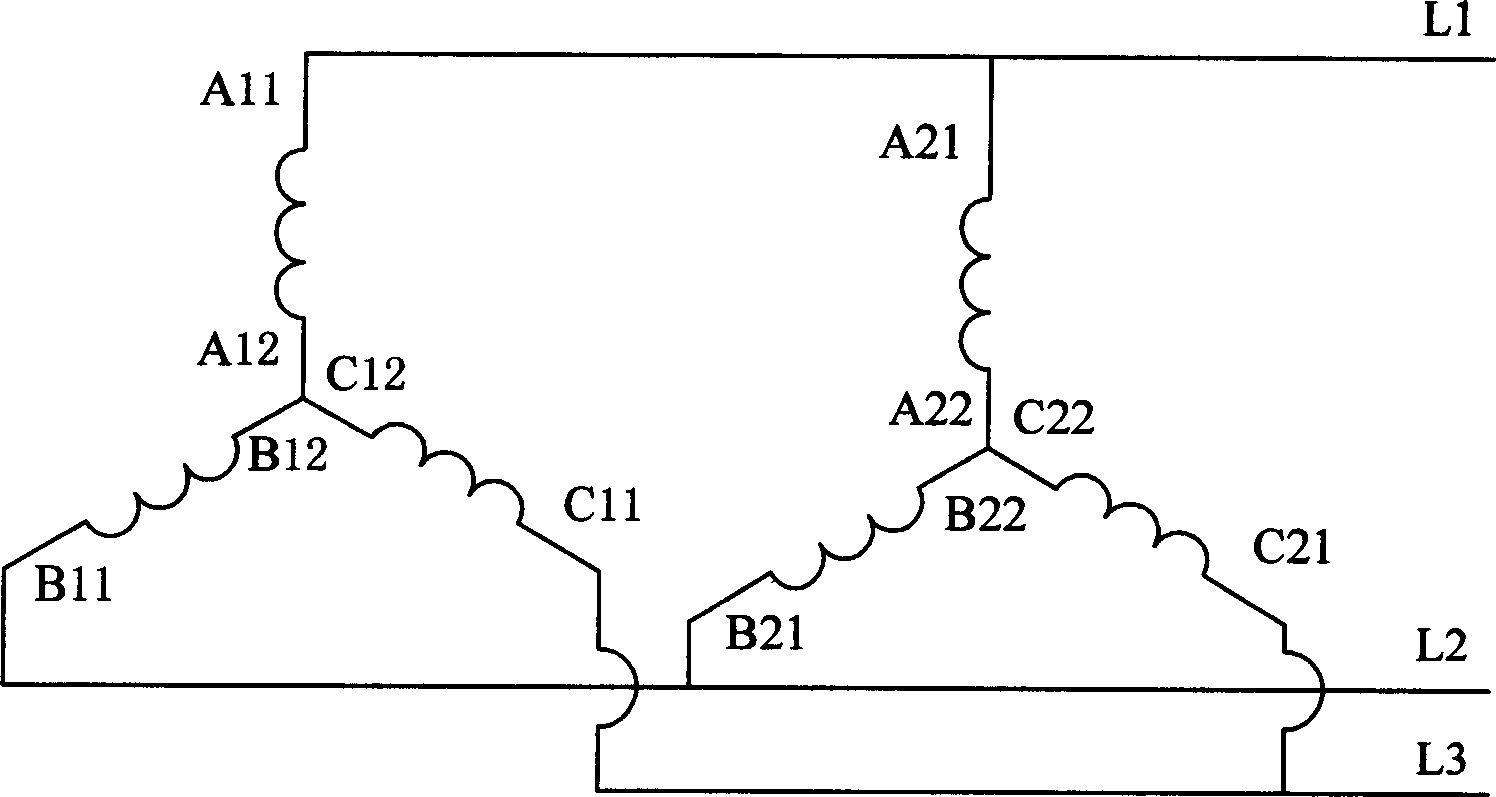

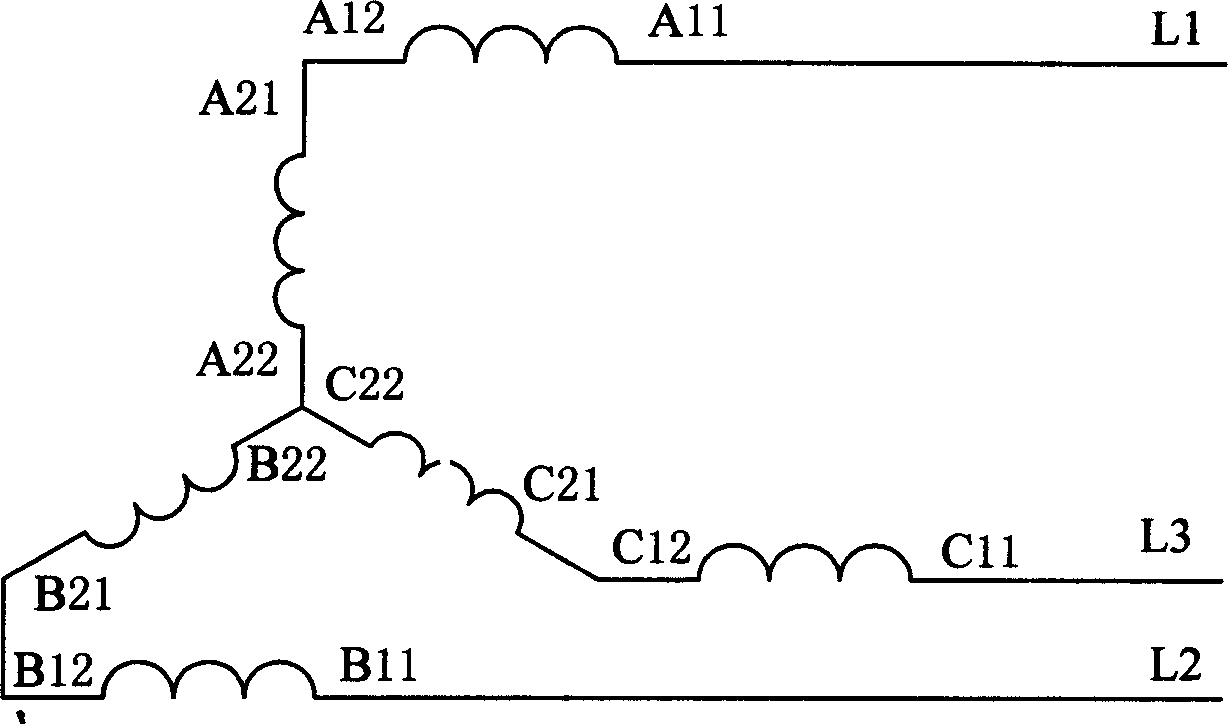

[0006] The motor winding in this specific embodiment includes A, B, and C three-phase windings, and each of the above-mentioned winding phases is divided into two subsections, each subsection has two lead-out ends at the beginning and the end, and each subsection contains 6 coils. The number of slots embedded in the motor winding is 36, and the pole-changing ratio is P / Q=4 / 6. The slot numbers of the A, B, and C three-phase windings of the motor winding are arranged in the following order:

[0007] Phase A winding first segment: 2 3 -10 -11 -12 19

[0008] Phase A winding second segment: 20 21 -28 -29 -30 1

[0009] Phase B winding first segment: -36 7 8 9 -16 -17

[0010] Phase B winding second segment: -18 25 26 27 -34 -35

[0011] Phase C winding first section: -4 -5 -6 13 14 15

[0012] Phase C winding second section: -22 -23 -24 31 32 33

[0013] (The number indicates the slot number, and the minus sign indicates reverse connection)

[0014] The first leading end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com