Permanent magnetic DC pump motor

A permanent magnet direct current, pump motor technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of high speed, motor heating, small torque, etc., to reduce the electric load and current density, improve the working system, The effect of reducing the stator flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

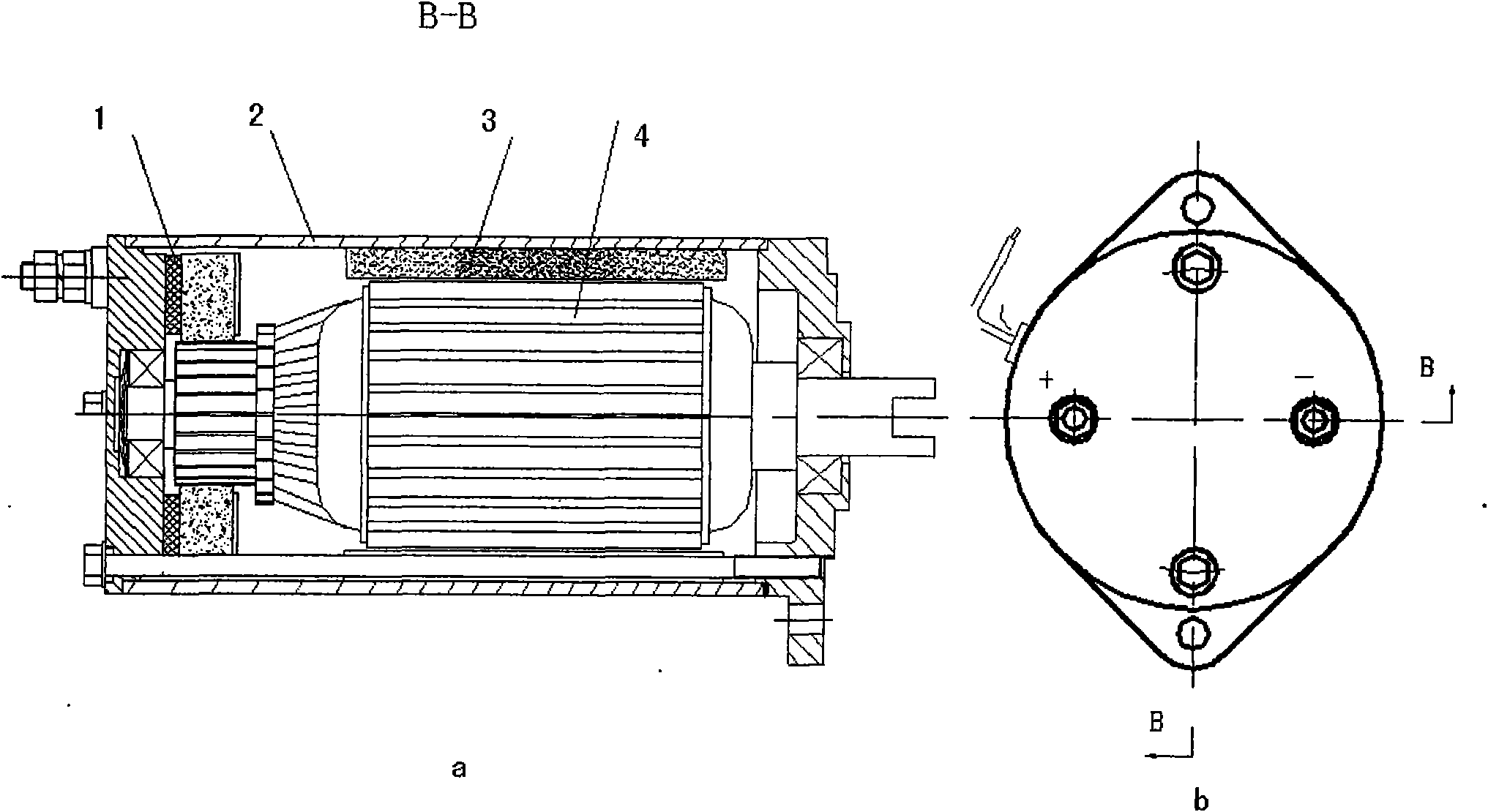

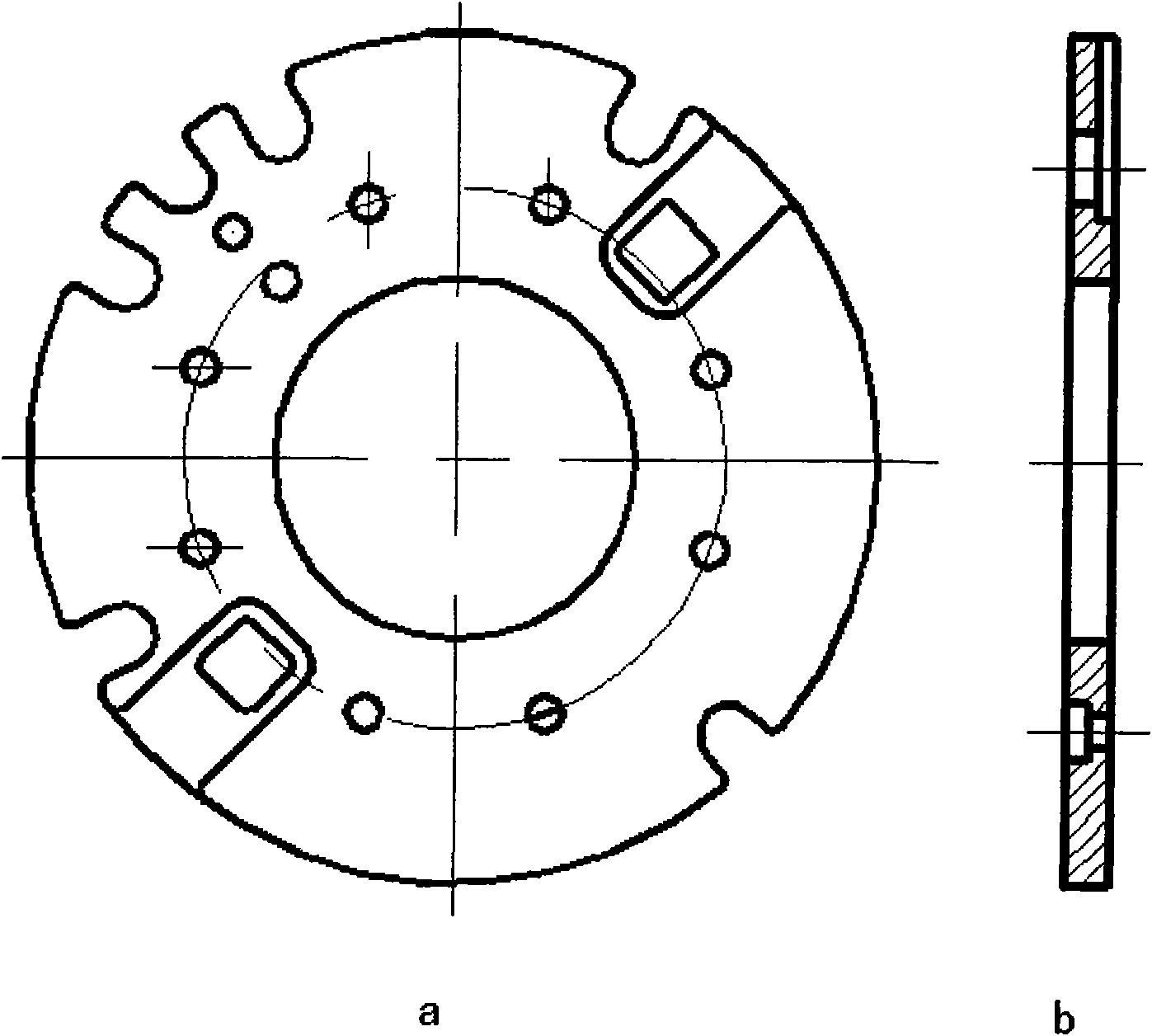

[0029] This example is 3.26 inches Diameter 12V / 24V 500W permanent magnet DC pump motor, see the general structure of the motor figure 1 : Including casing 2, magnetic steel 3, brush holder plate 1 and armature punching plate 4. It is characterized in that the design scheme of the components is as follows:

[0030] Insulation material of the motor: H-class (185°C) insulation is used, and insulation material with high heat resistance level is used to enable the motor to withstand high temperature rise and further improve its working system.

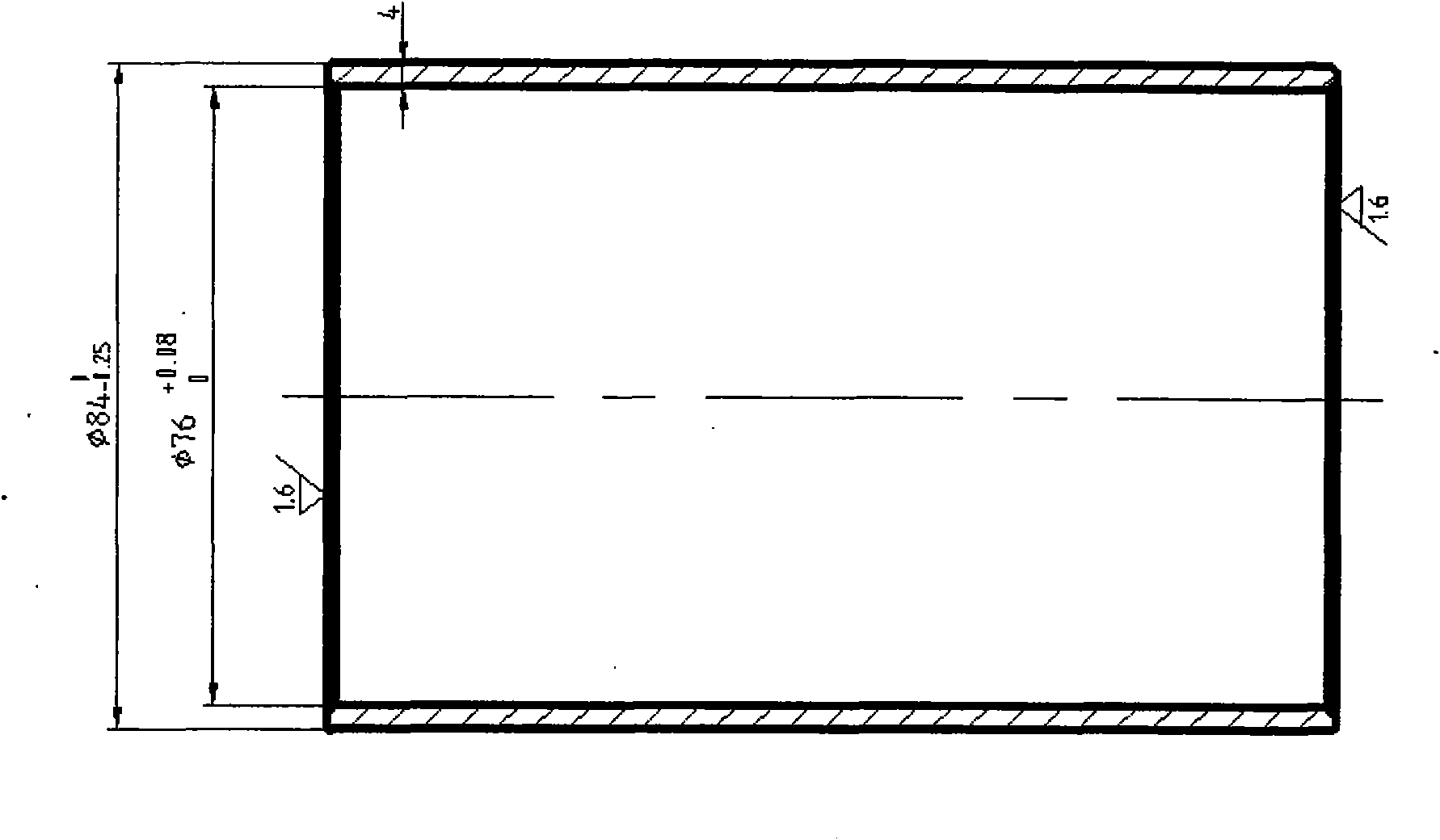

[0031] Chassis such as figure 2 : 4mm thick 10# steel pipe is used, the thickness of the yoke is increased by 53%, the magnetic permeability of the material is increased, the magnetic permeability of the material is increased by 1 / 3, the magnetic density of the stator is reduced, and the heating of the stator is reduced....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com