Patents

Literature

396results about How to "Improve magnetic permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

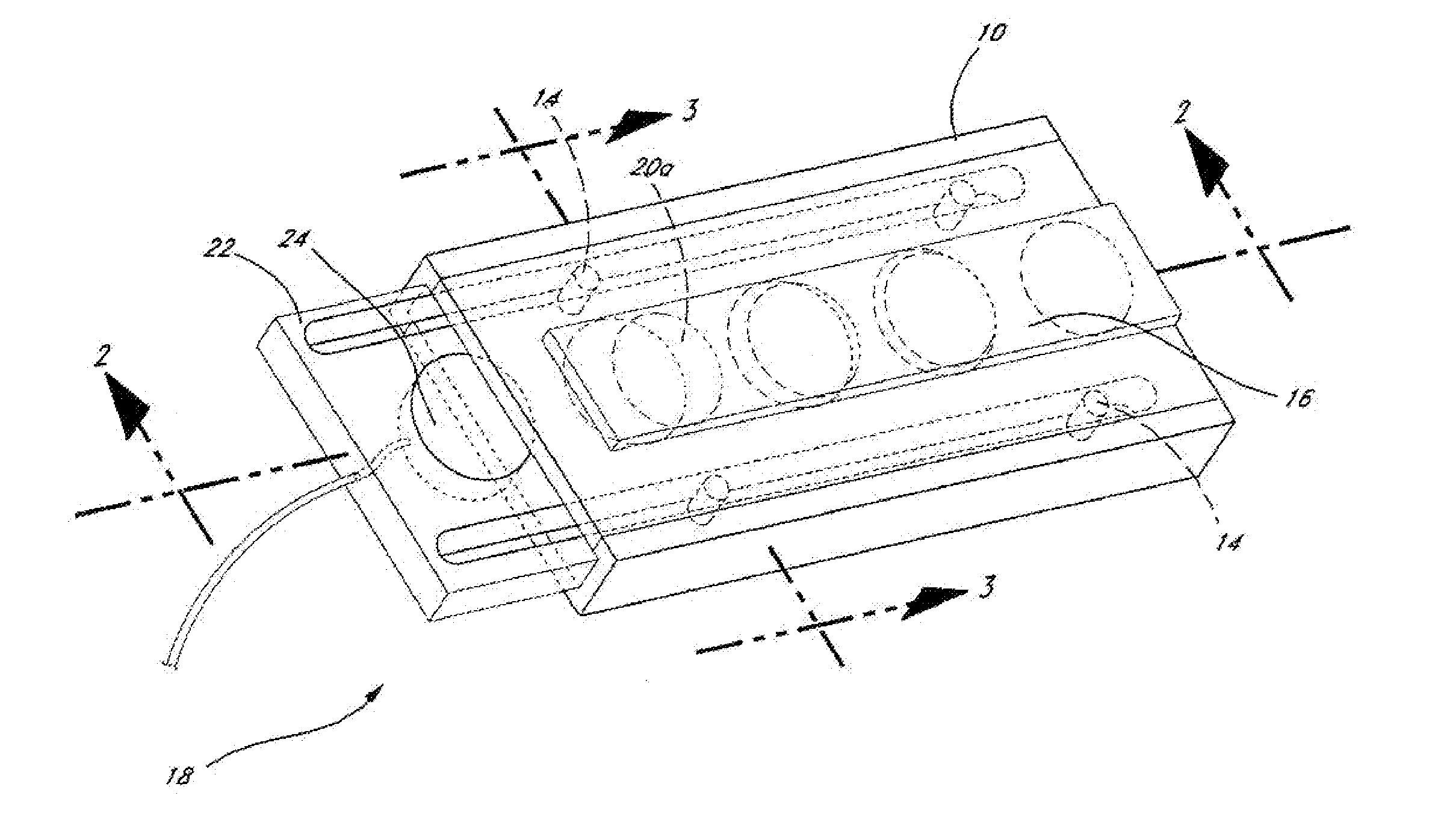

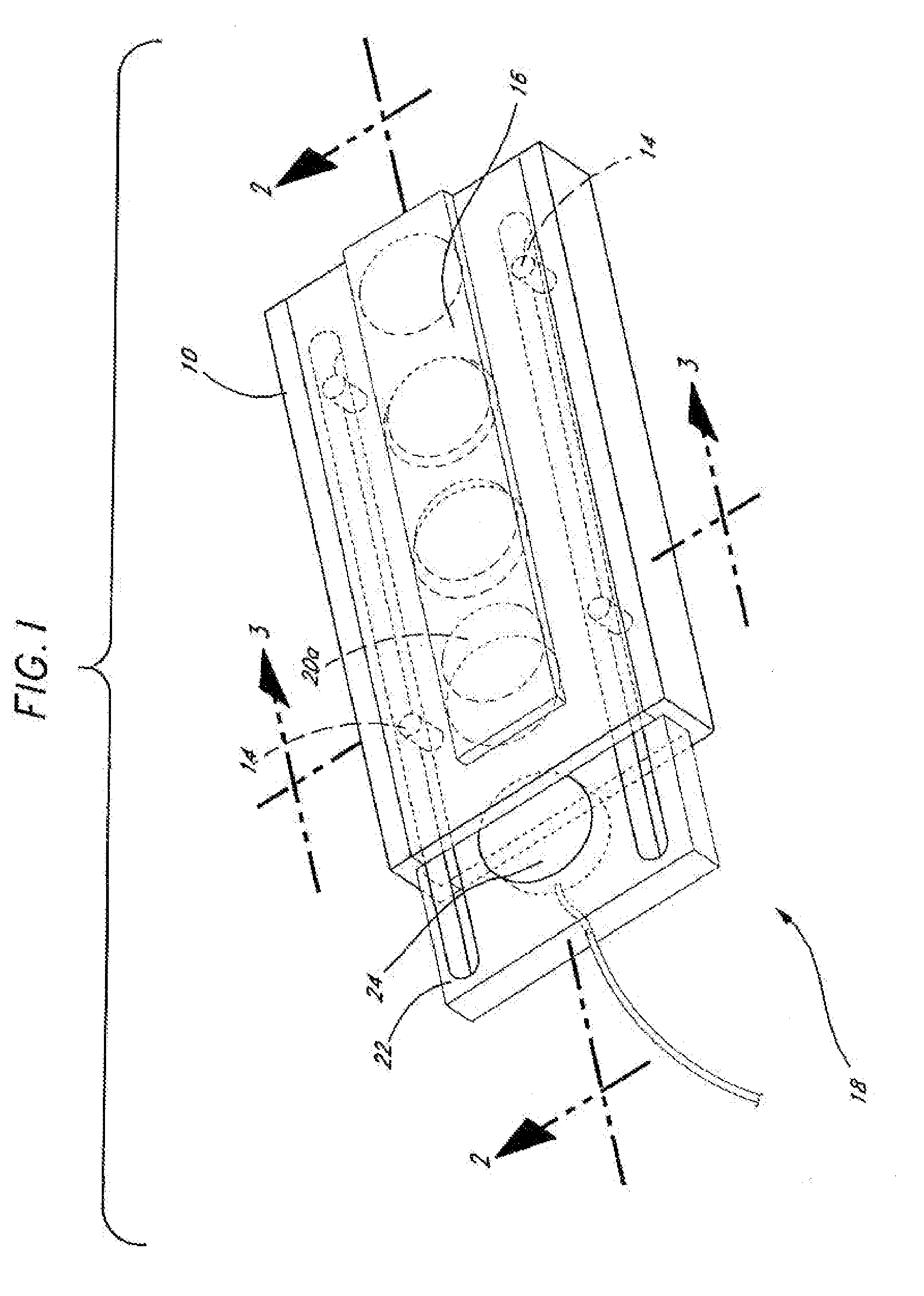

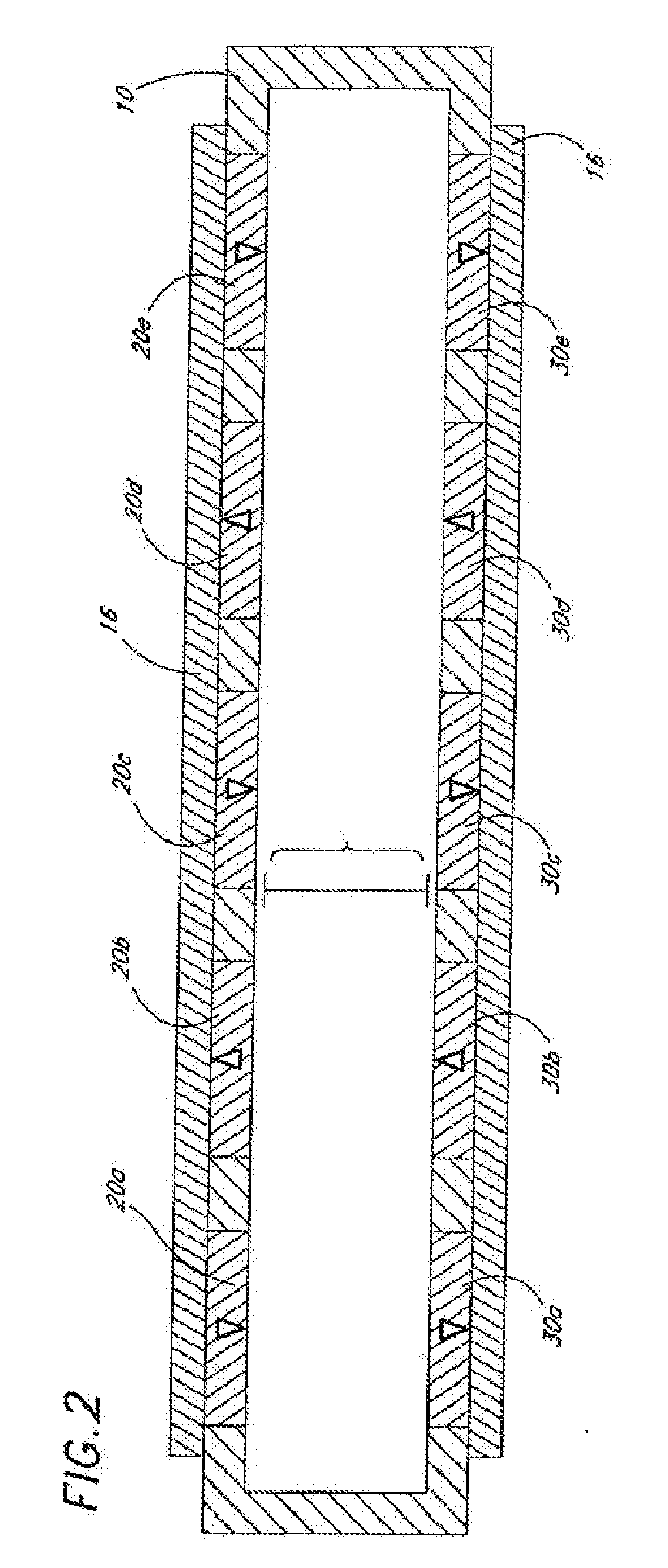

Multiple magnet coil in gap generator

InactiveUS20070052302A1Increasing flux densityImprove magnetic permeabilityWindings insulation materialNanomagnetismPhysicsMagnetic flux

The present invention is an improved energy harvester or generator based on a yoked magnet array design based on a plurality of magnets arranged into at least two spaced apart linear or circular magnet arrays. The spaced apart magnet arrays are juxtaposed with each magnet in one array attractively interacting with the corresponding magnet in the other array across a small gap. The magnetic flux across the gap is further enhanced by having adjacent magnets in each array having alternate magnetic orientation and by providing a magnetic yoke of magnetically permeable material for the magnet ends of each array that do not face the gap. The gap is provided to allow a conductor in the form of a coil fit between the magnets. Relative motion between the coil and the magnets results in maximal generation of electrical power by the coil.

Owner:TELEDYNE SCI & IMAGING +1

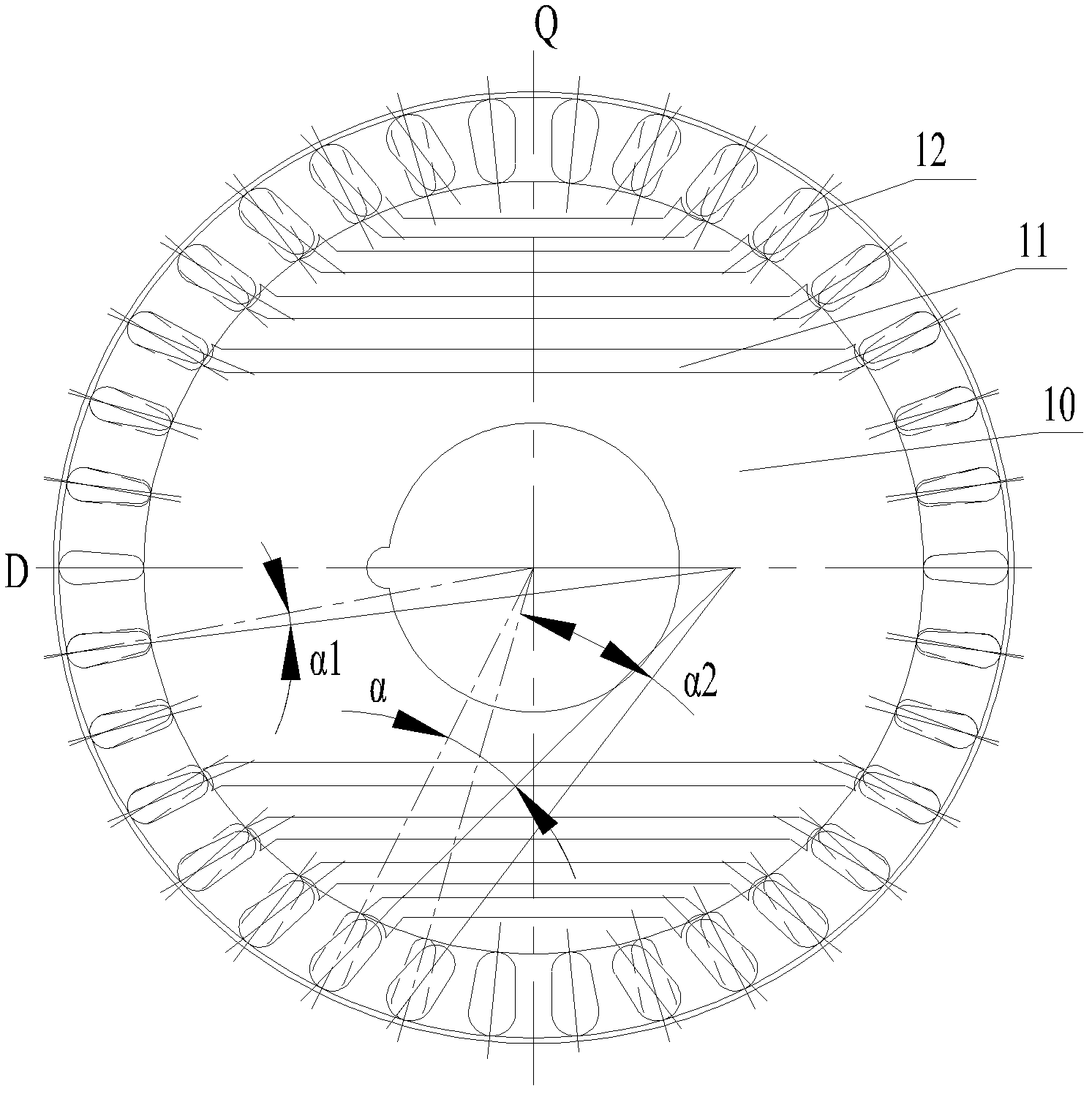

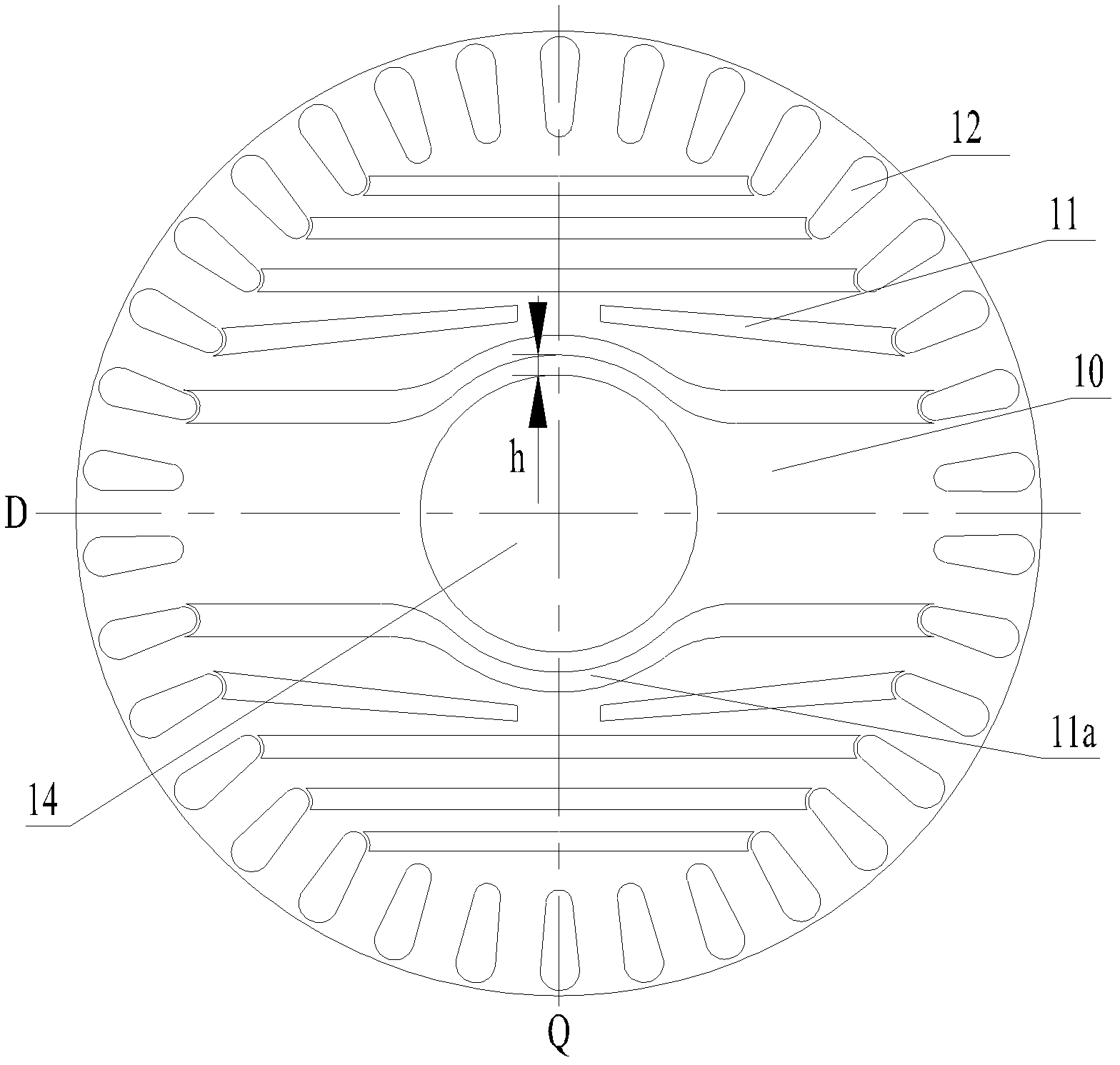

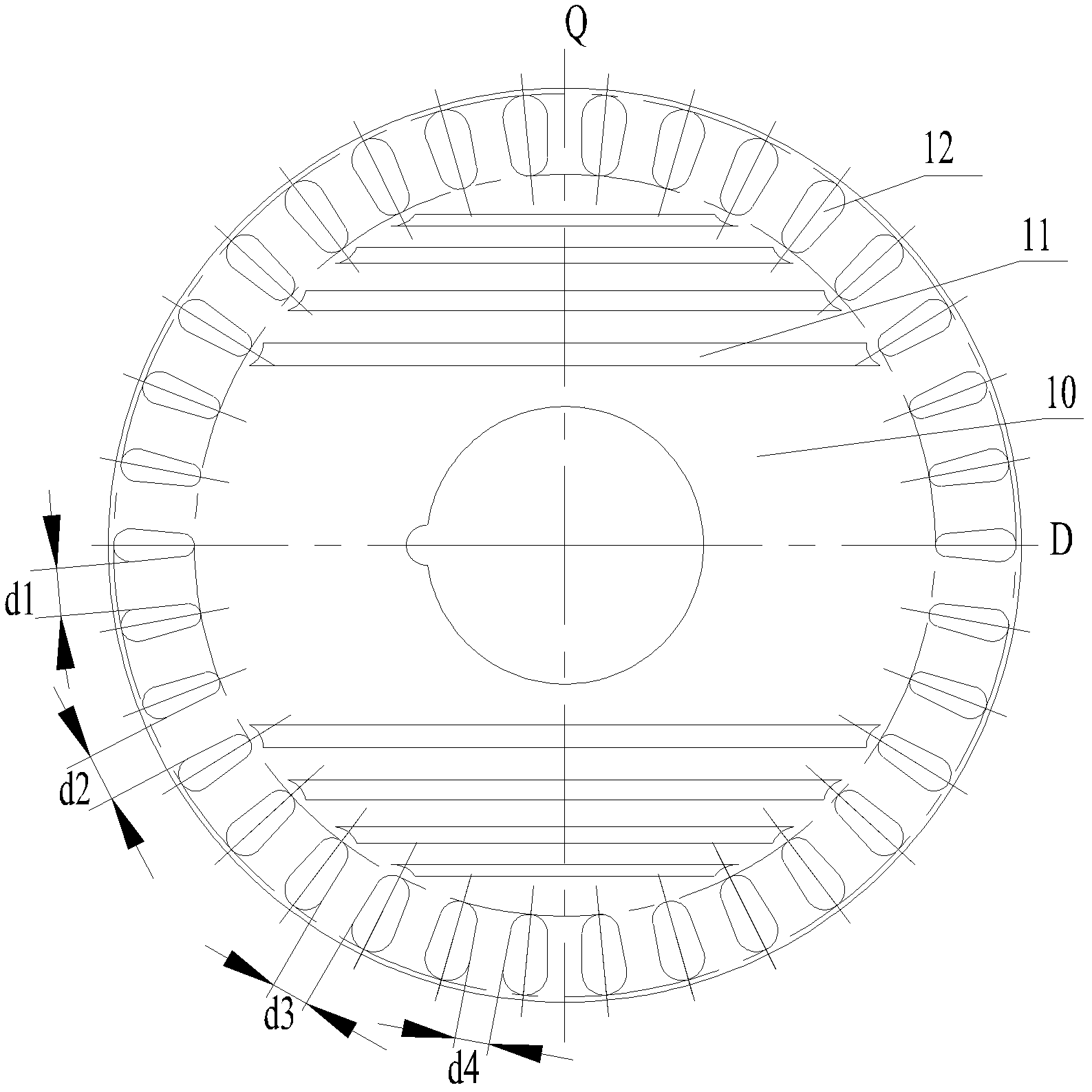

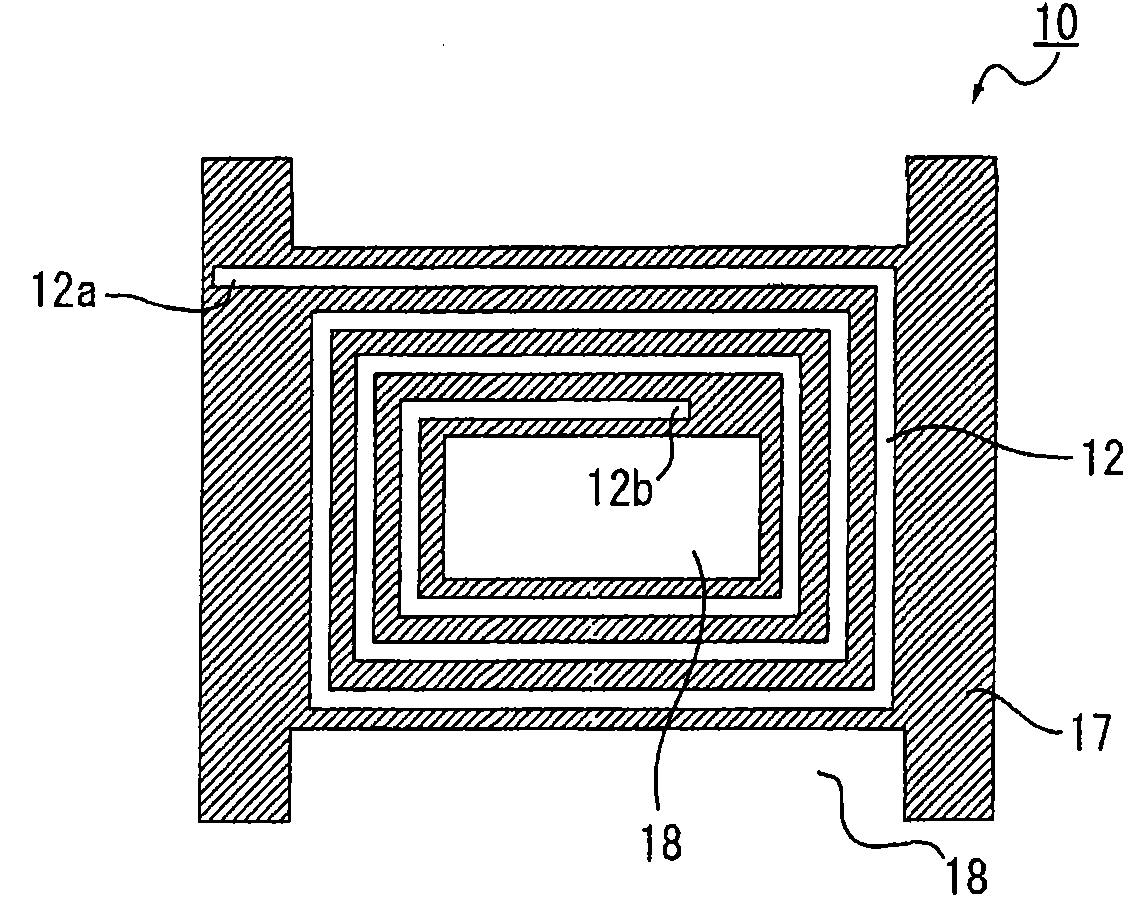

Self-starting synchronous reluctance motor and rotor thereof

ActiveCN103208894ARaise the saliency ratioImprove efficiencySynchronous machinesAsynchronous induction motorsSynchronous reluctance motorInductance

The invention provides a self-starting synchronous reluctance motor and a rotor thereof. The rotor of the self-starting synchronous reluctance motor comprises an iron core and squirrel-cage grooves, wherein magnetic flux separation grooves are arranged on the iron core, and the squirrel-cage slots are distributed along the periphery of the iron core. In the cross section of the rotor, the center line of the cross sections of the squirrel-cage slots deviates from the center circle of the iron core. The self-starting synchronous reluctance motor comprises a stator and the rotor of the self-starting synchronous reluctance motor. According to the self-starting synchronous reluctance motor and the rotor, the center line of the cross sections of the squirrel-cage grooves is led to deviate from the center circle of the iron core by adjusting the angle of the squirrel-cage grooves arranged on the rotor, magnetic permeability in the direction of the D axis is improved, magnetic permeability in the direction of the Q axis is reduced, inductance Ld in the direction of the D axis is increased and inductance Lq in the direction of the Q axis is reduced, namely salient pole ratio (Ld / Lq) of the motor is improved, and further motor efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

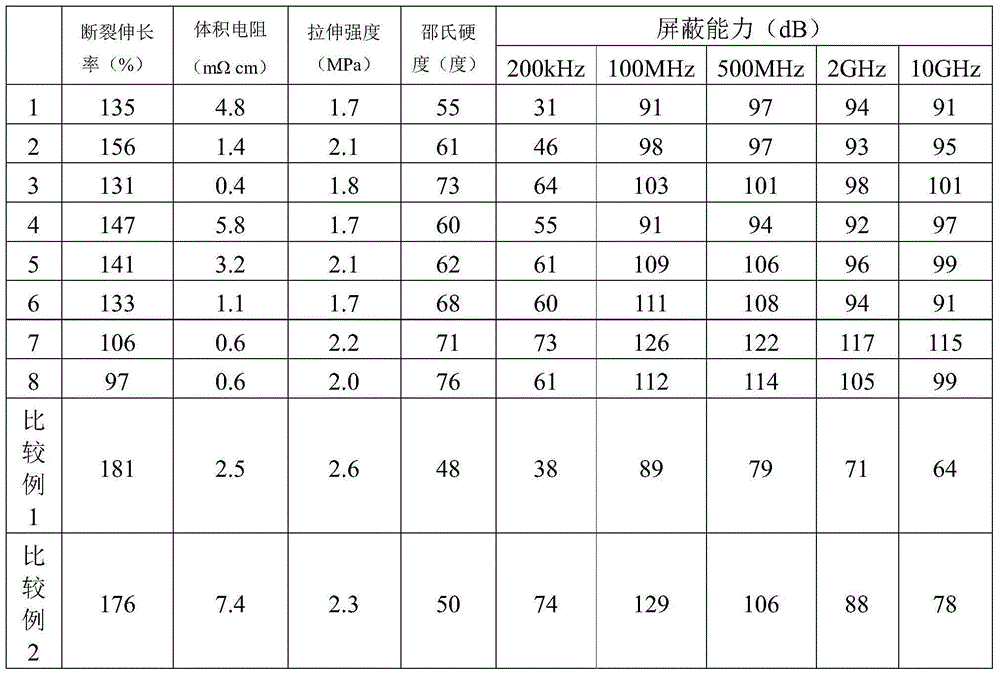

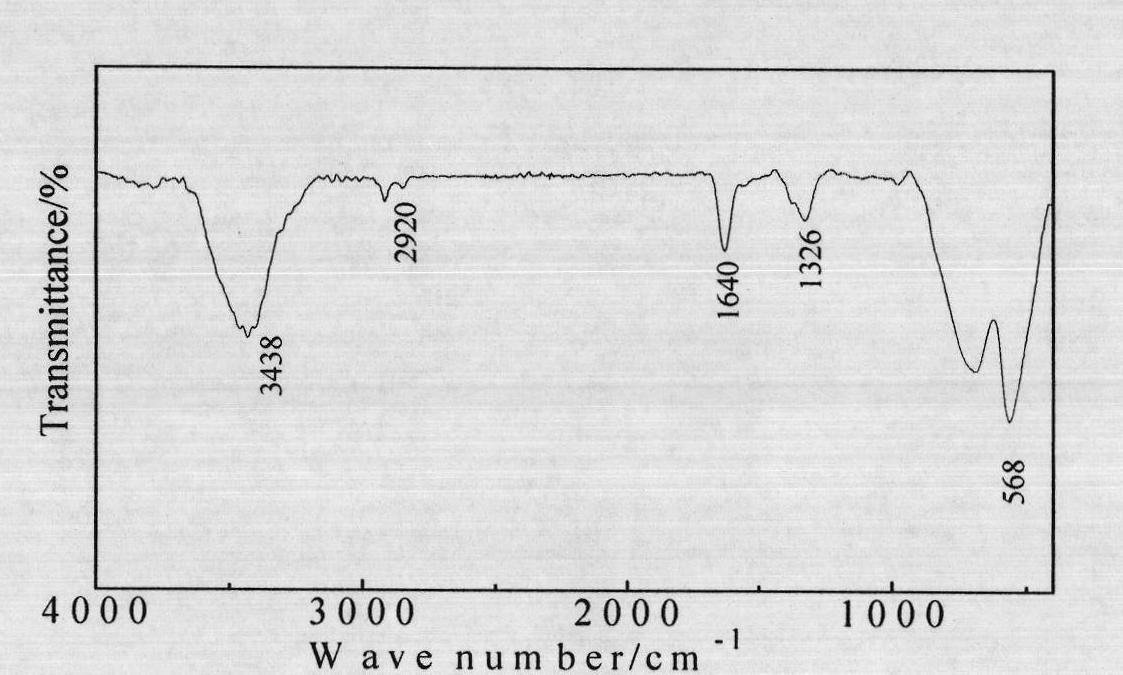

Conductive silicone rubber with electromagnetic shielding performance and manufacturing method

InactiveCN103602072AMeet electromagnetic shielding requirementsGood electromagnetic shieldingElastomerElectromagnetic shielding

The invention provides conductive silicone rubber with electromagnetic shielding performance and a manufacturing method, and belongs to the field of preparation of organic polymer / metal composite material and chemical processing. The conductive silicone rubber employs silicone rubber elastomer as a base and employs silvered nickel powder and silvered copper powder for enhancing the magnetic conductibility and the electric conductivity of the material and for further enhancing the comprehensive mechanical properties and the electromagnetic shielding performance of the composite material, and the conductive silicone rubber material has relatively good electromagnetic shielding performance at a frequency range of 200 KHz-10 GHz, is applicable to electromagnetic shielding of transformer stations, and can satisfy the material installation construction technology because of the good strength and toughness.

Owner:STATE GRID CORP OF CHINA +1

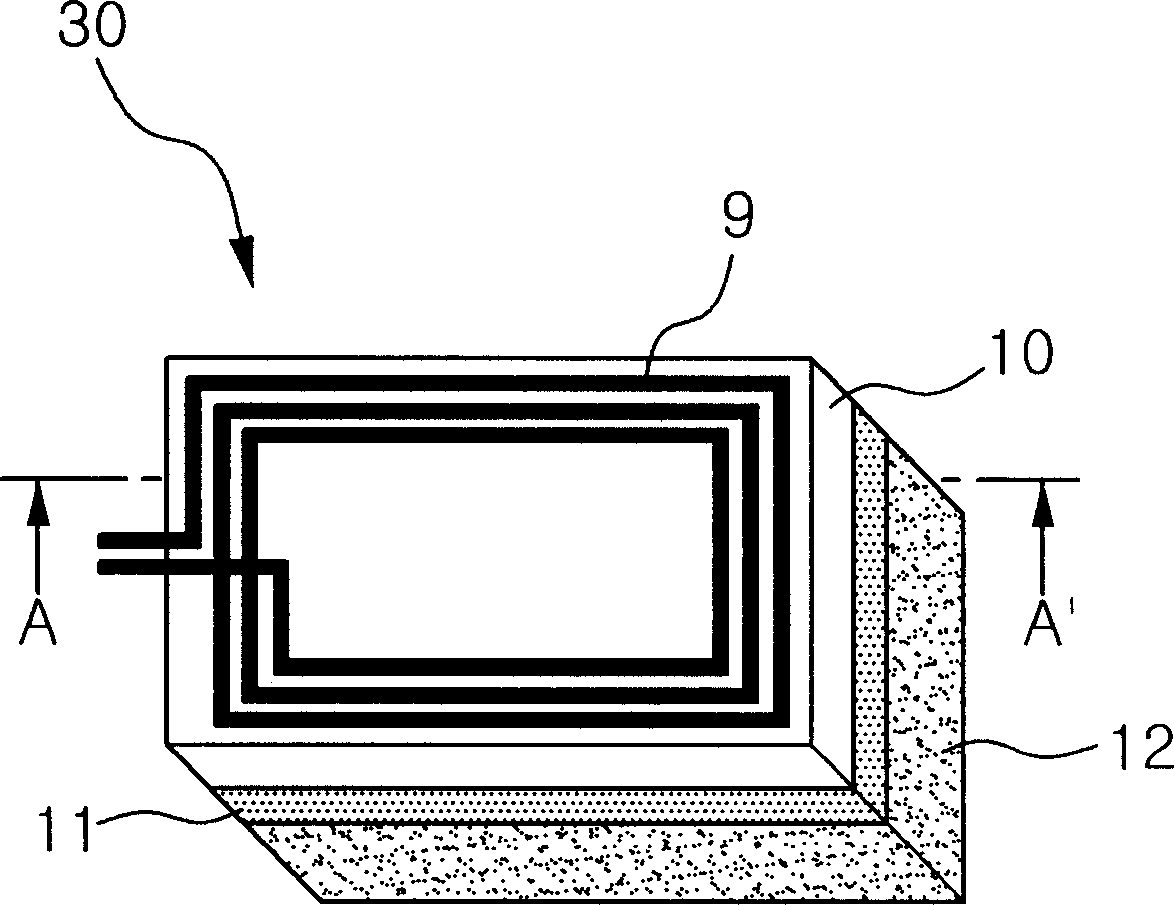

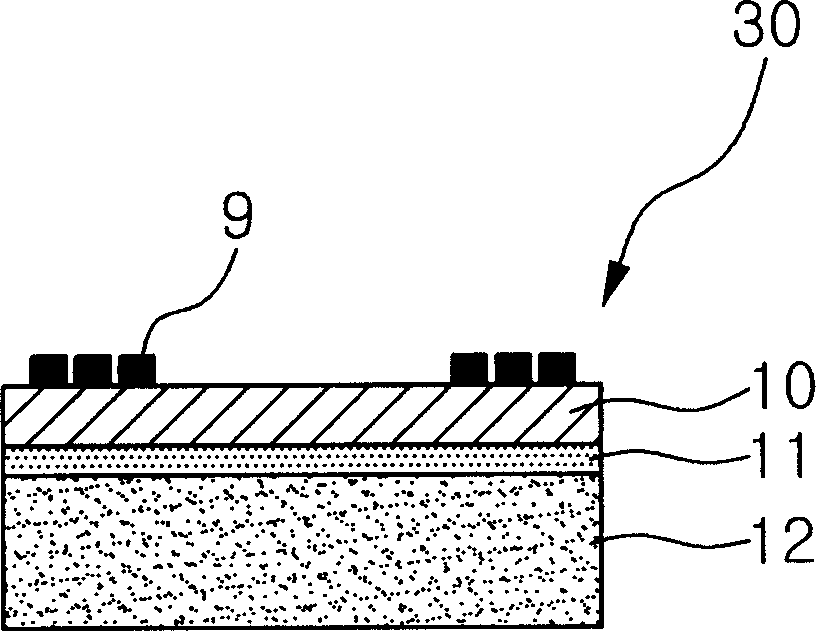

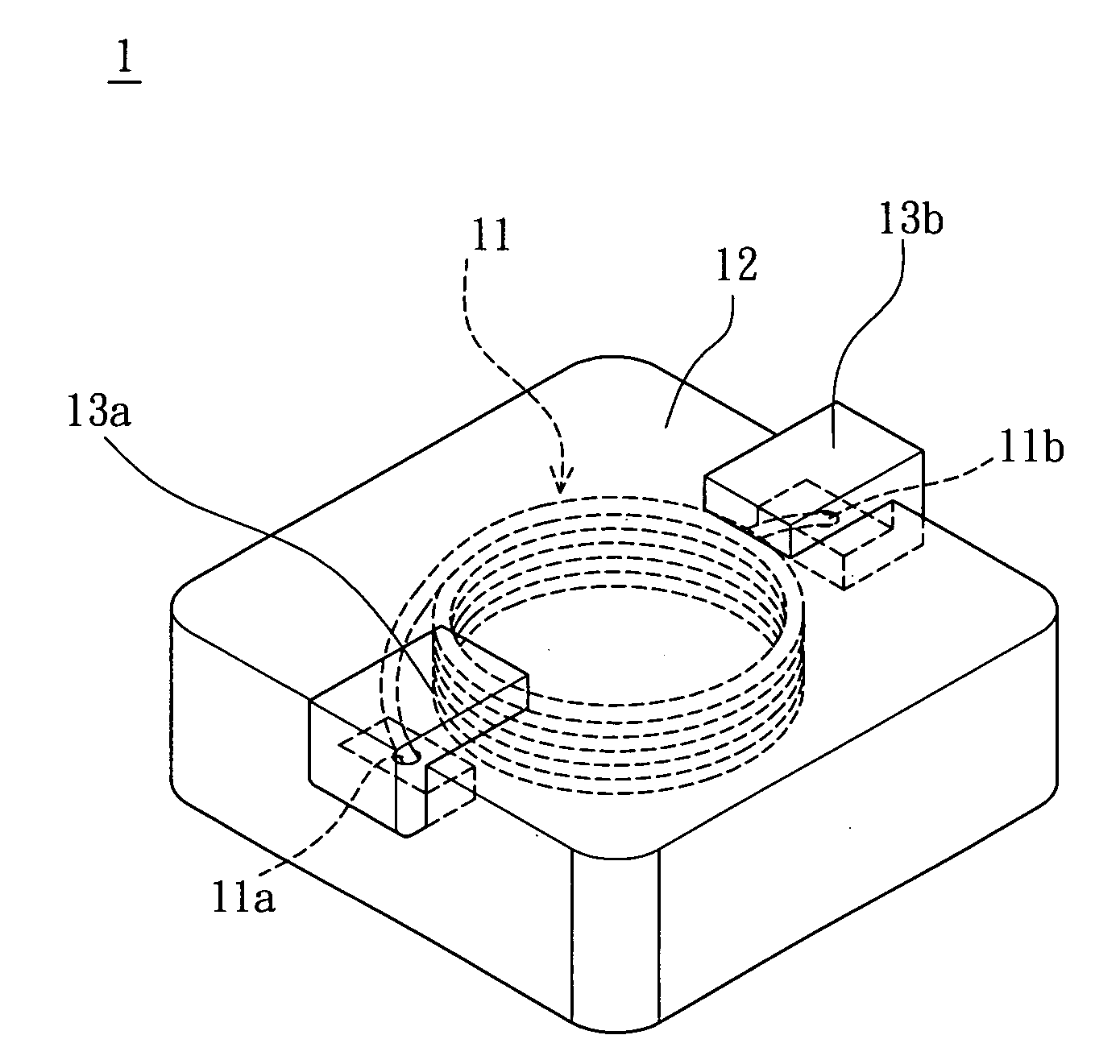

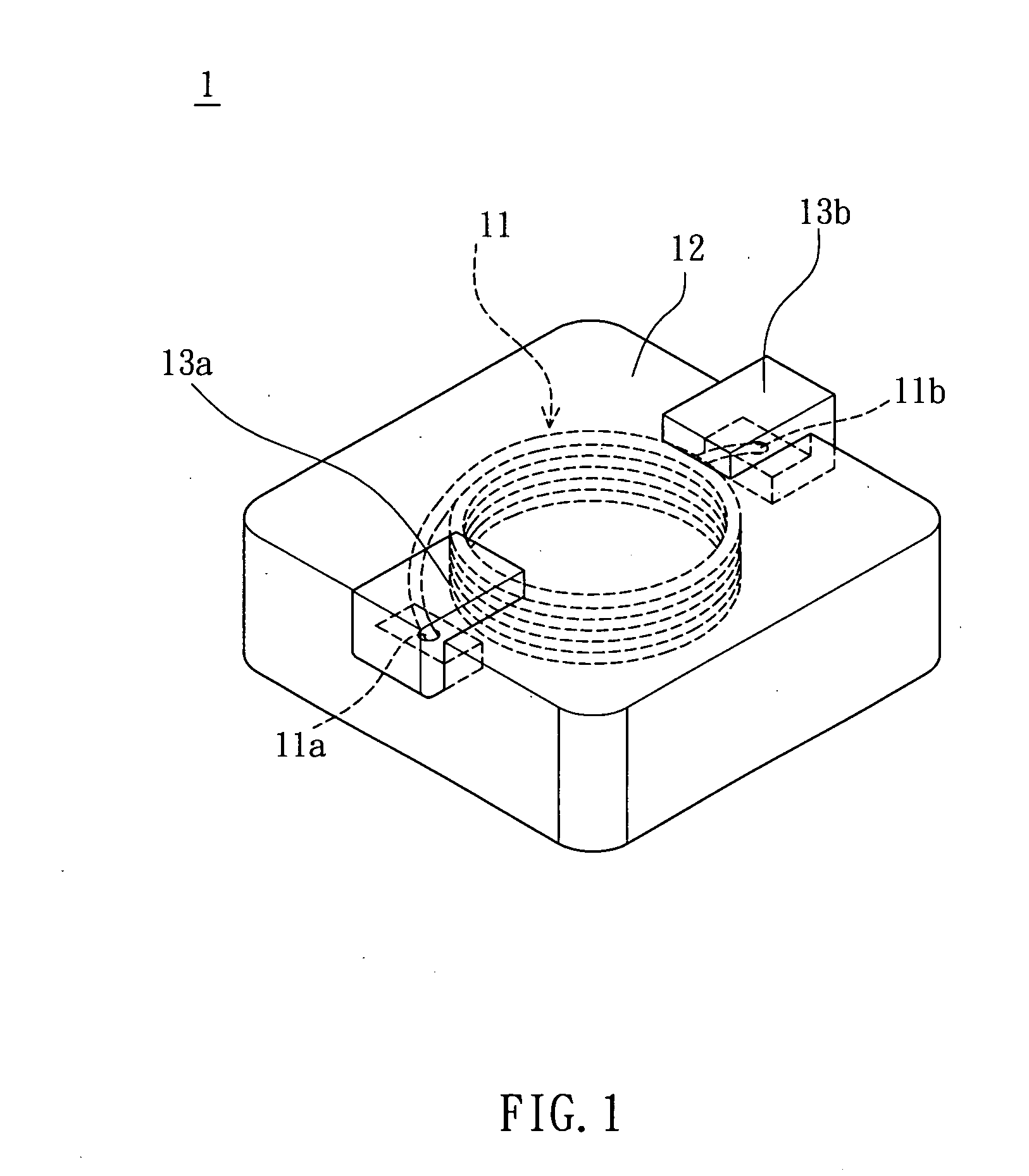

Coil component

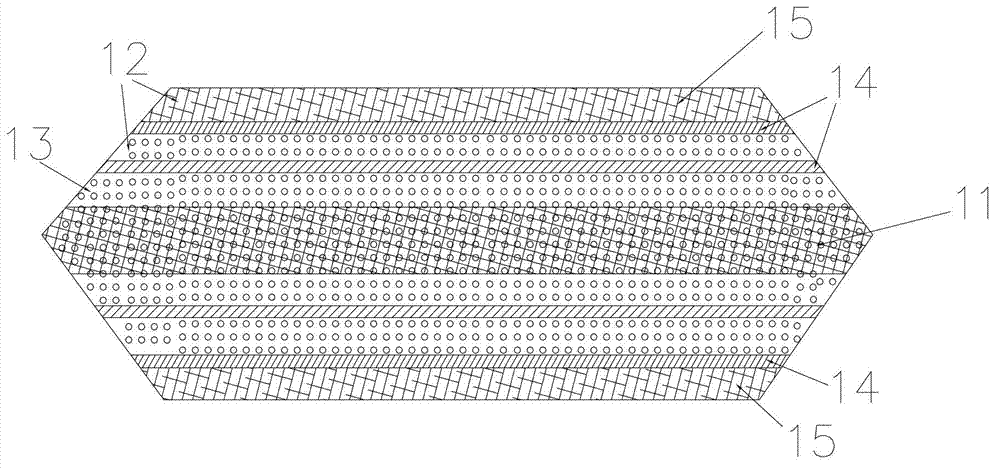

InactiveCN101615490AFlexibleNo brittle failureTransformers/inductances coils/windings/connectionsPrinted inductancesIn planeHigh resistance

A coil component is provided, and the coil component for an inductor is deformable dependent on flex of a flexible printed board due to elapse of time when mounted thereon, and has high resistance against dropping impact and has an inductance value. The coil component includes an anisotropic compound magnetic sheet which is layered on at least any one or both of the upper surface and the lower surface of an air core coil formed spirally in a plane and which is composed of flat or needle-shaped soft magnetic metal powder, which has a major axis and a minor axis and is dispersed in a resin material, the major axis of which corresponds to an in-plane direction of the air core coil.

Owner:SUMIDA CORP

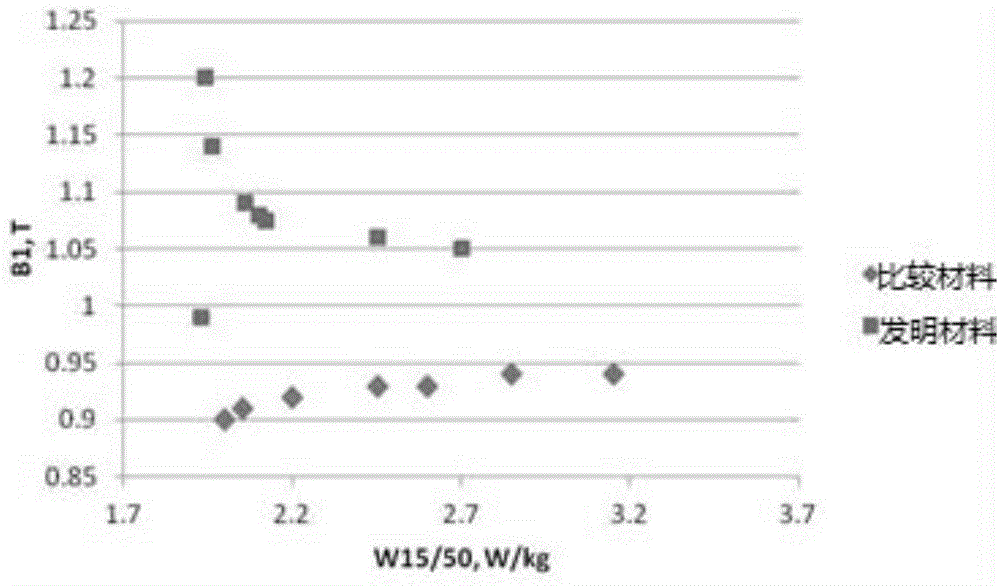

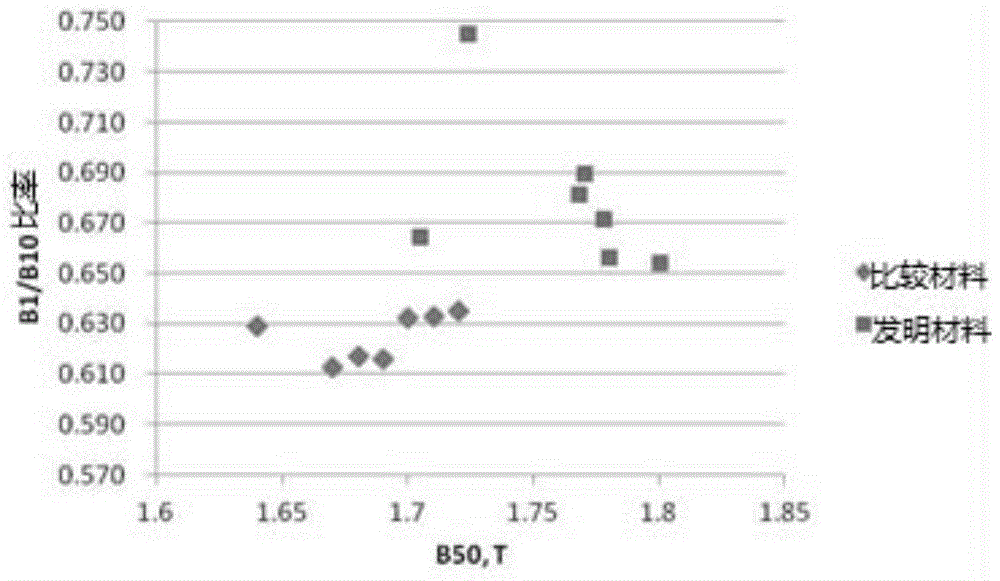

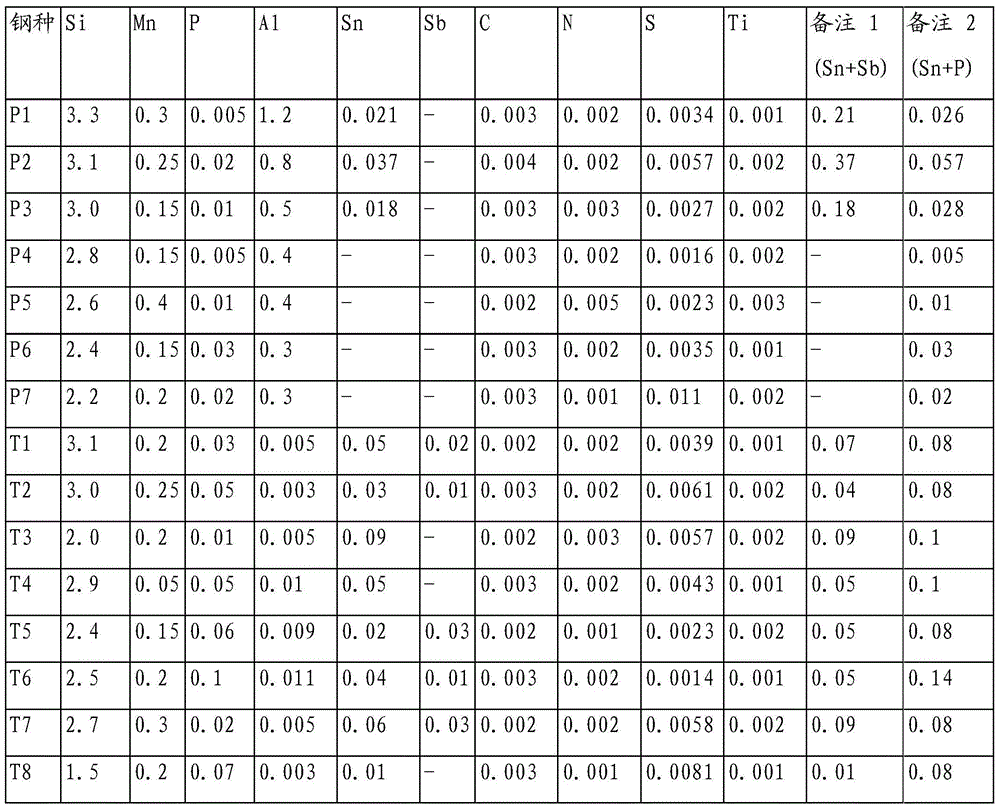

Non-oriented electrical steel sheet excellent in magnetic permeability and method for manufacturing the same

The invention relates to a non-oriented electrical steel sheet and a method for manufacturing the same, and more concretely relates to a non-oriented electrical steel sheet that includes 1.5-4.0 wt% Si, 0.01-0.50 wt% Mn, 0.0005-0.02 et% Al, 0.001-0.15 wt% P, less than 0.004 wt% (except 0 wt%) C, 0.0001-0.01 wt% S, less than 0.003 wt% (except 0 wt%) N, less than 0.003 wt% (except 0 wt%) Ti, 0.01-0.15 wt% Sn, less than 0.15 wt% Sb, and the balance F and other inevitable foreign matters. The Al, Sn, Sb and P in the sheet satisfies the relation: [Al]<[Sn]+[Sb] and [Al]<[Sn]+[P], wherein [Al], [Sn], [Sb] and [P] respectively represent contents of Al, Sn, Sb and P by means of wt%.

Owner:浦项股份有限公司

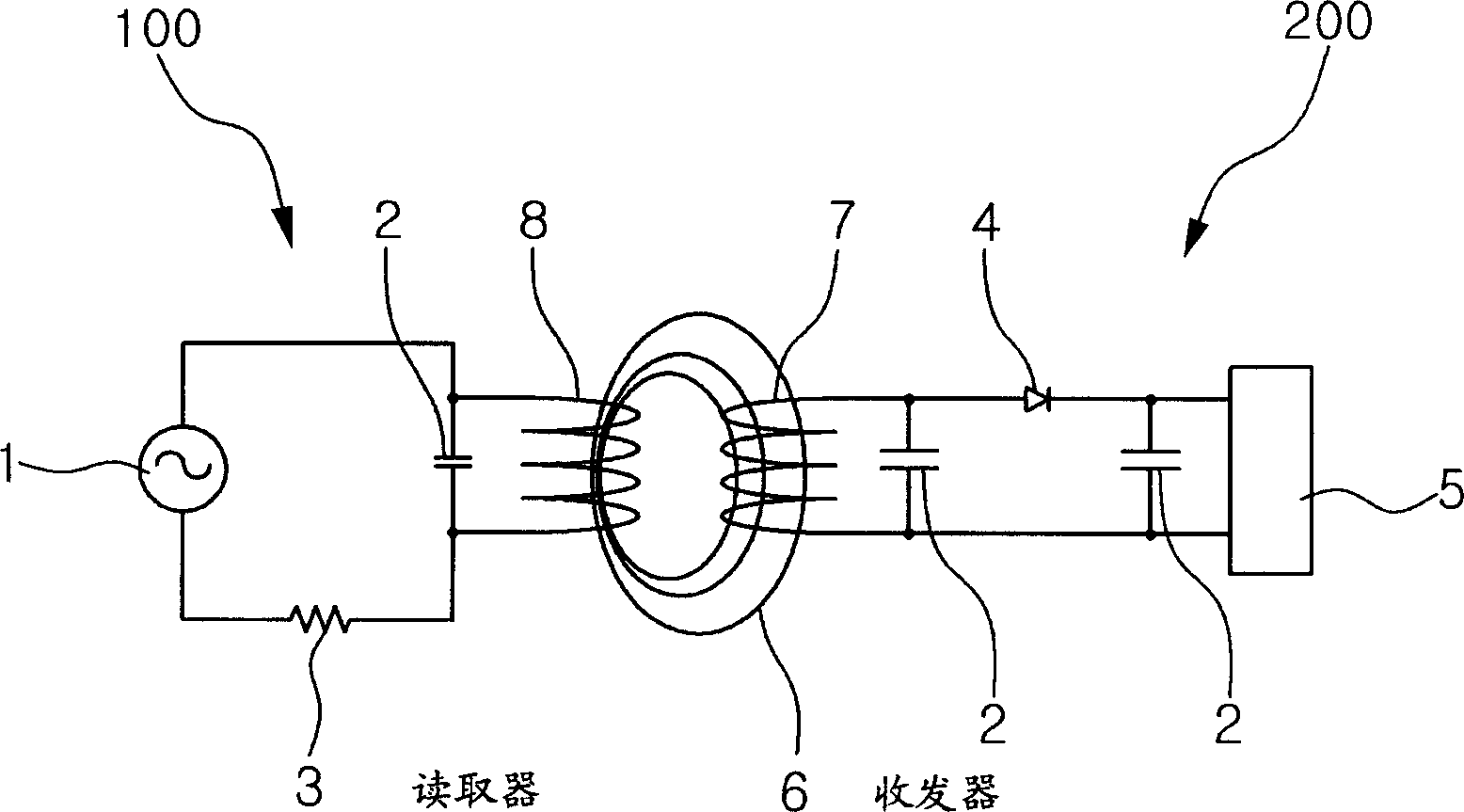

Absorber for radio-frequency identificating antenna and radio-frequency identificating antenna using the same

ActiveCN1855623AImprove magnetic permeabilityIncrease inductanceLoop antennas with ferromagnetic coreAntenna adaptation in movable bodiesRadio frequencyRadio-frequency identification

Provided are a magnetic sheet for use in a radio frequency identification (RFID) antenna, an RFID antenna including the magnetic sheet, and a method of manufacturing the magnetic sheet, in which the magnetic sheet includes an amorphous alloy selected from the group consisting of Fe-Si-B, Fe-Si-B-Cu-Nb, Fe-Zr-B and Co-Fe-Si-B. The magnetic sheet is made by laminating amorphous alloy ribbons made of an amorphous alloy between magnetic sheet layers formed of alloy powder including at least one amorphous alloy and then compression-molding the amorphous alloy ribbons, to thereby control microcrack of the amorphous alloy ribbons and enhance characteristic of an end-product. The magnetic sheet is also thin, and has an excellent magnetic permeability, and a simple manufacturing process.

Owner:AMOTECH

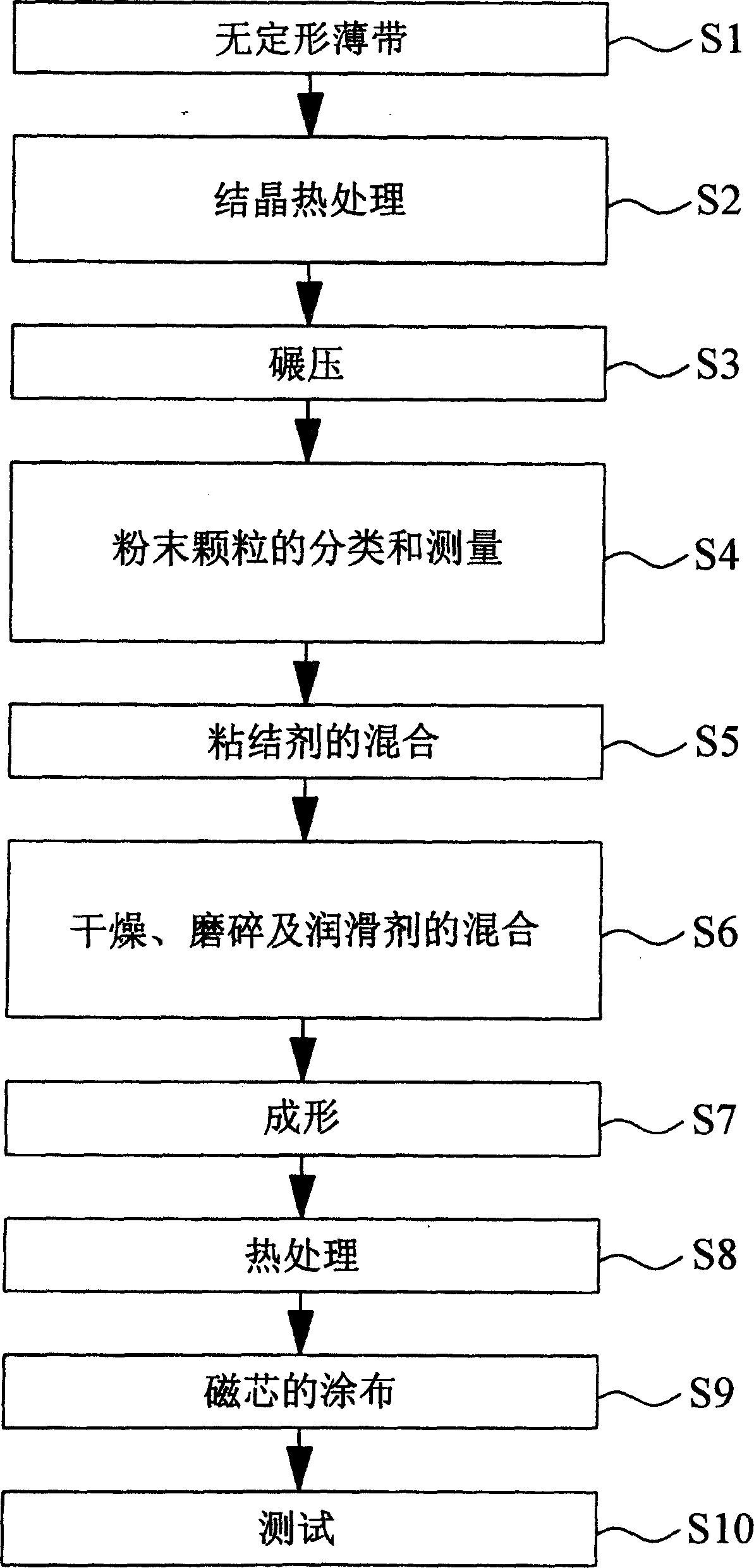

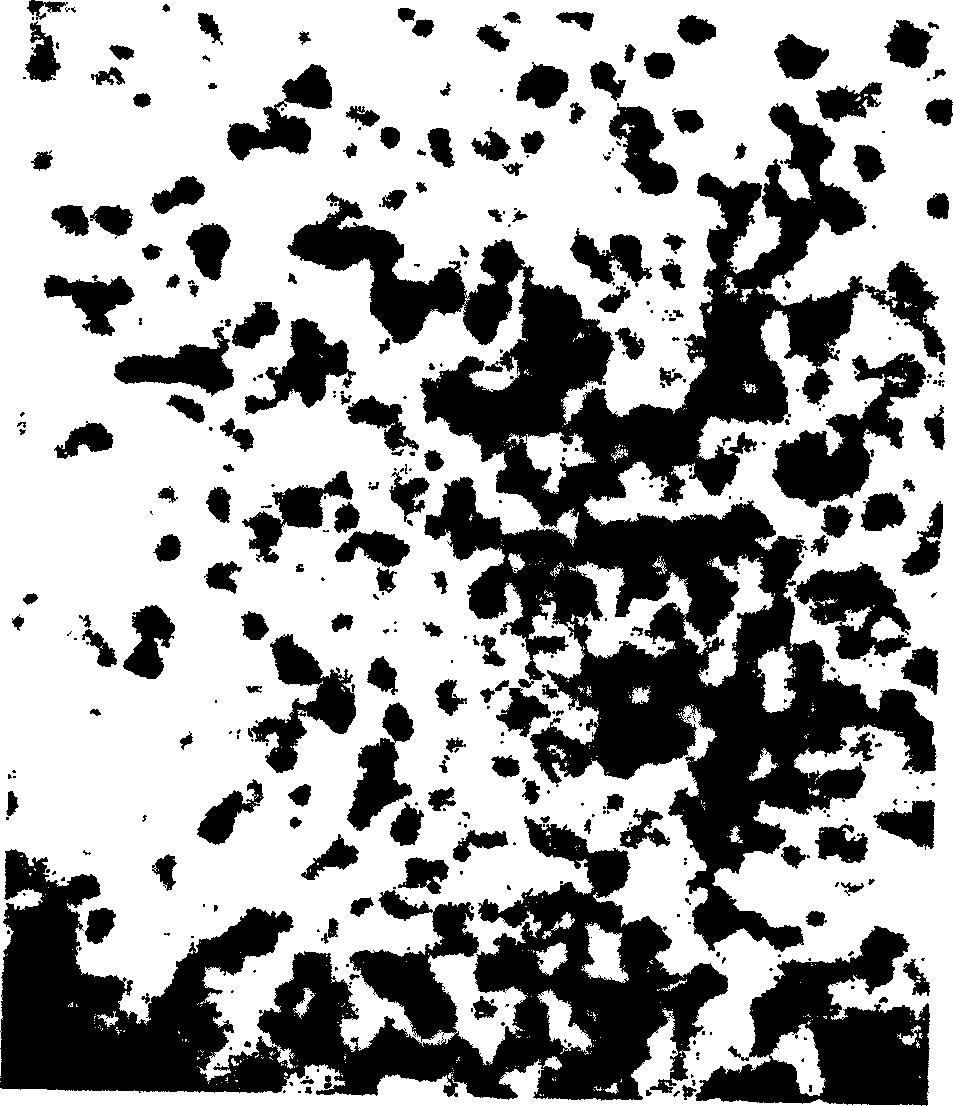

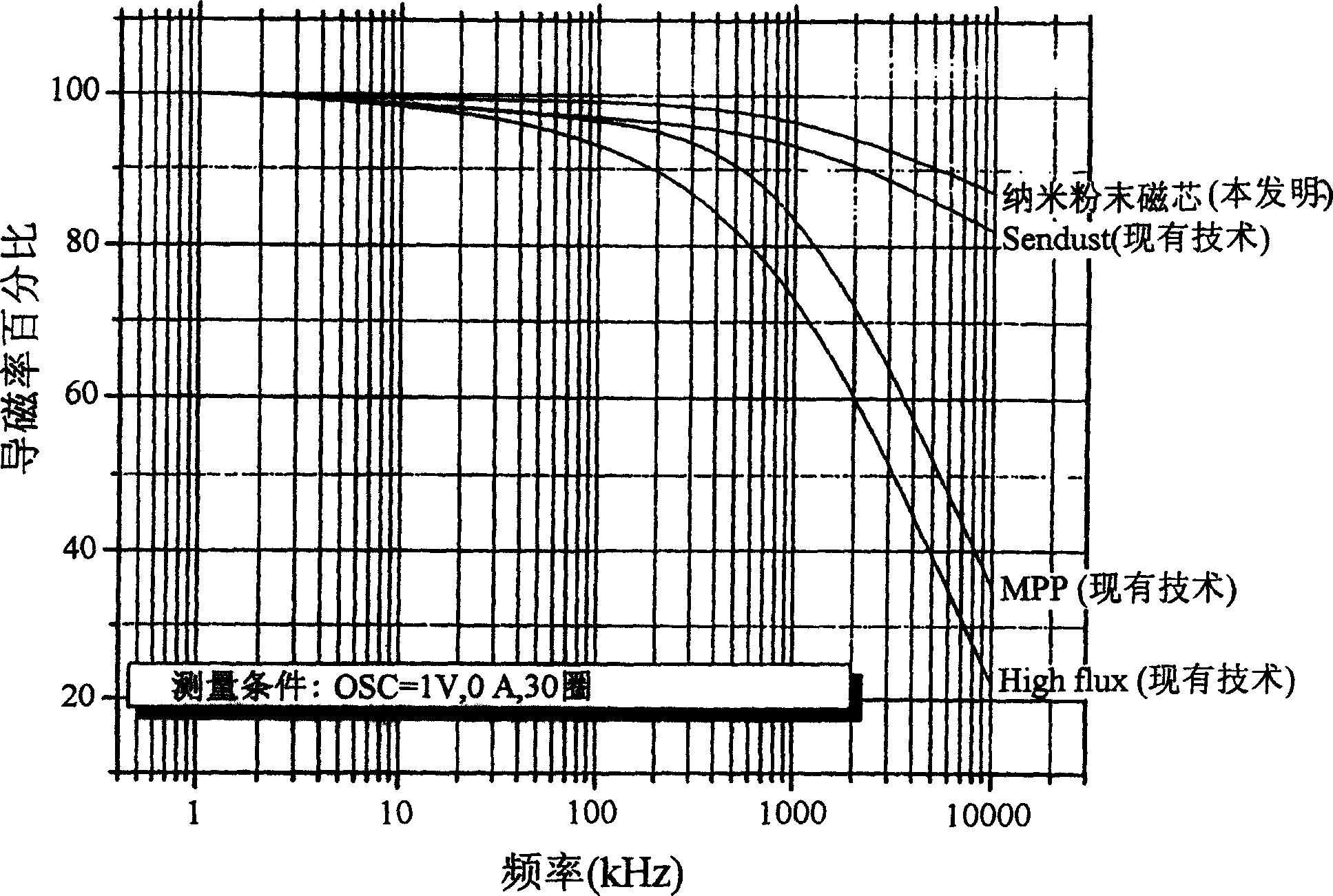

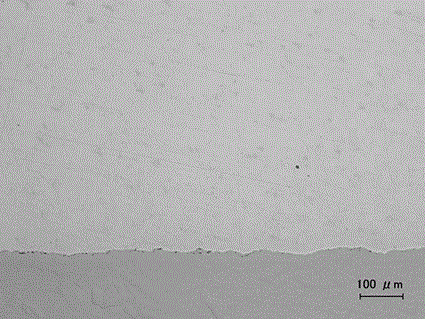

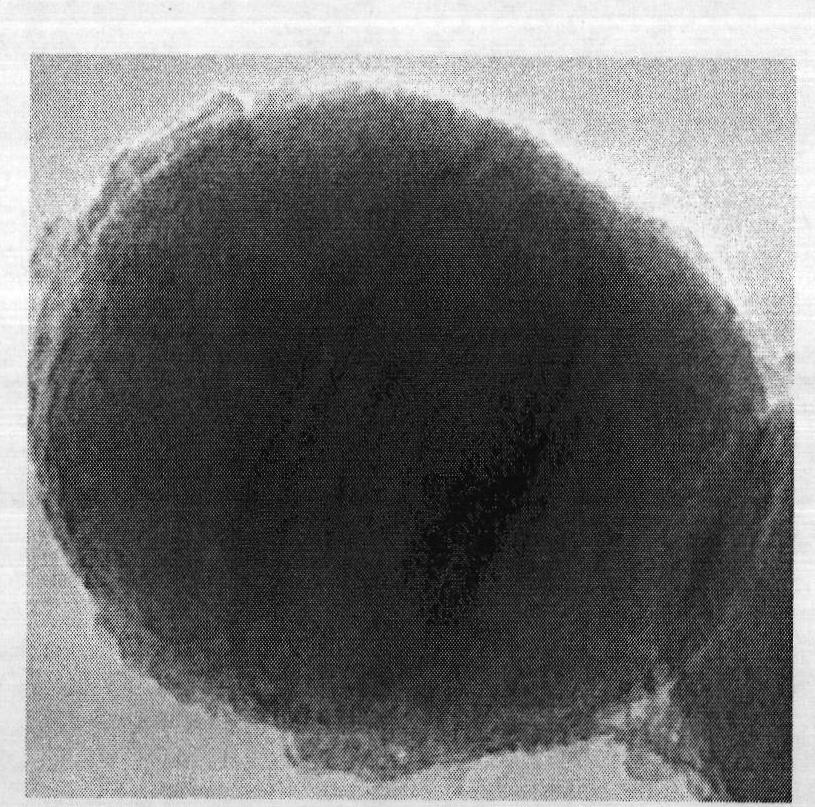

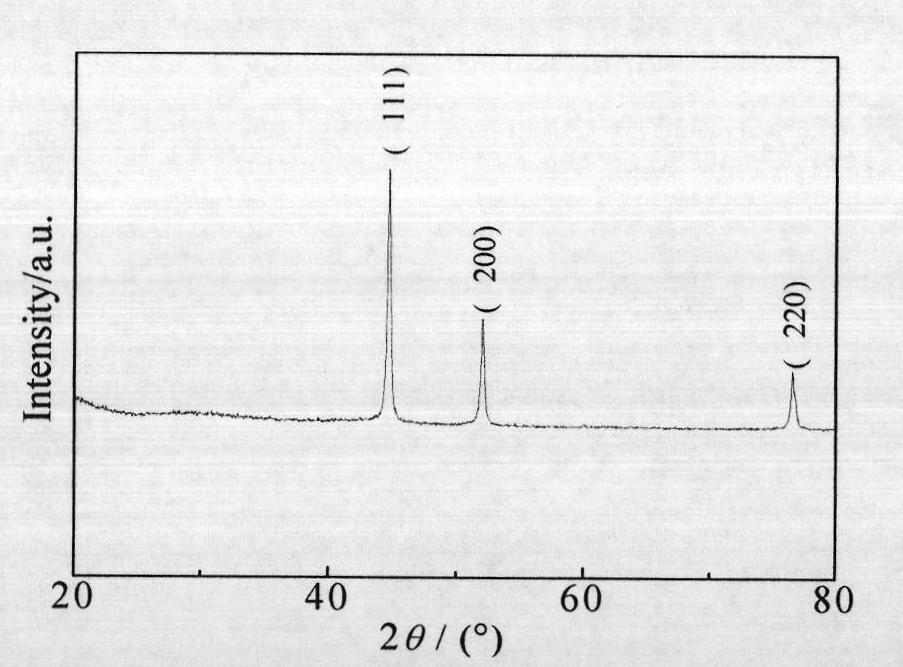

Method for making nano-scale metal powder and method for making high-frequency soft magnetic core using same

InactiveCN1579682AImprove economyReduce lossNanostructure manufactureTransportation and packagingMetal powderAmorphous metal

A method for making a nano-scale amorphous soft magnetic powders obtained by thermally processing and crystallizing amorphous ribbons produced using a rapid solidification process (RSP) and crushing the same. The amorphous soft magnetic core having an excellent high-frequency characteristic is obtained by performing a preliminary thermal treatment of Fe-based amorphous metal ribbons produced by using RSP to then be converted into nano-scale grain metal ribbons, crushing the metal ribbons to thereby obtain nano-scale grain metal powders, classifying the nano-scale grain metal powders to then be mixed into a distribution of powder particles having an optimal uniform composition, mixing the mixed powder with a binder, and then forming a core, and annealing the formed core to then coat the core with an insulating resin.

Owner:AMOXIANSI ELECTRONICS & ELECTRICAL CO LTD

Electromagnetic coating of high-performance cooker and manufacturing method of electromagnetic coating

InactiveCN106435564AImprove magnetic permeabilityLow power utilizationCooking-vessel materialsHeat inorganic powder coatingGlass matrixCooker

The invention relates to an electromagnetic coating for the bottom of a liner of a cooker such as an electric cooker and a manufacturing method of the electromagnetic coating. The highest power utilization ratio of the electromagnetic coating can reach 97%. The coating is prepared from mixed powder composed of nickel and 430 stainless steel by using a high-pressure cold spraying process, so that the electromagnetic coating is formed at the bottom of the cooker prepared from a matrix such as an aluminum matrix and stainless steel. By using the coating, the bottom of the liner of the cooker such as the electric cooker prepared from a metal matrix, a ceramic matrix or a glass matrix without magnetic conductivity or with poor magnetic conductivity not only has excellent magnetic conductivity and very high electromagnetic heating efficiency, but also has ideal corrosion resistance, and the overall performance of an electromagnetic cooker is improved.

Owner:北京联合涂层技术有限公司

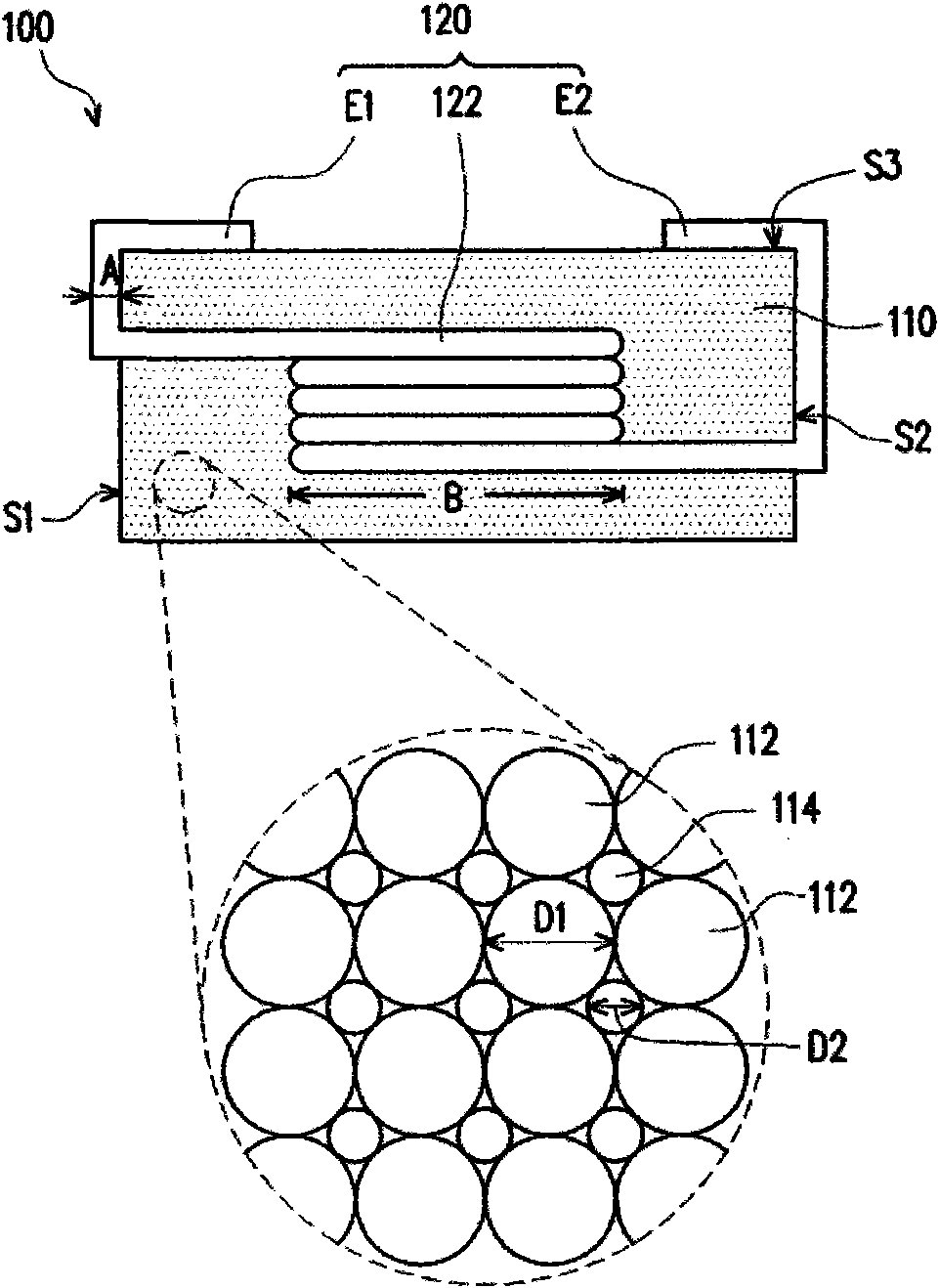

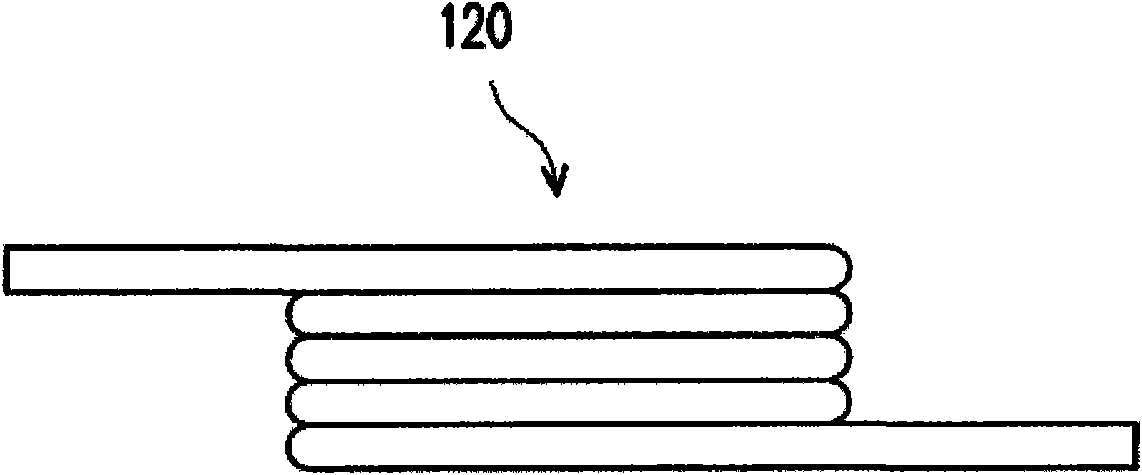

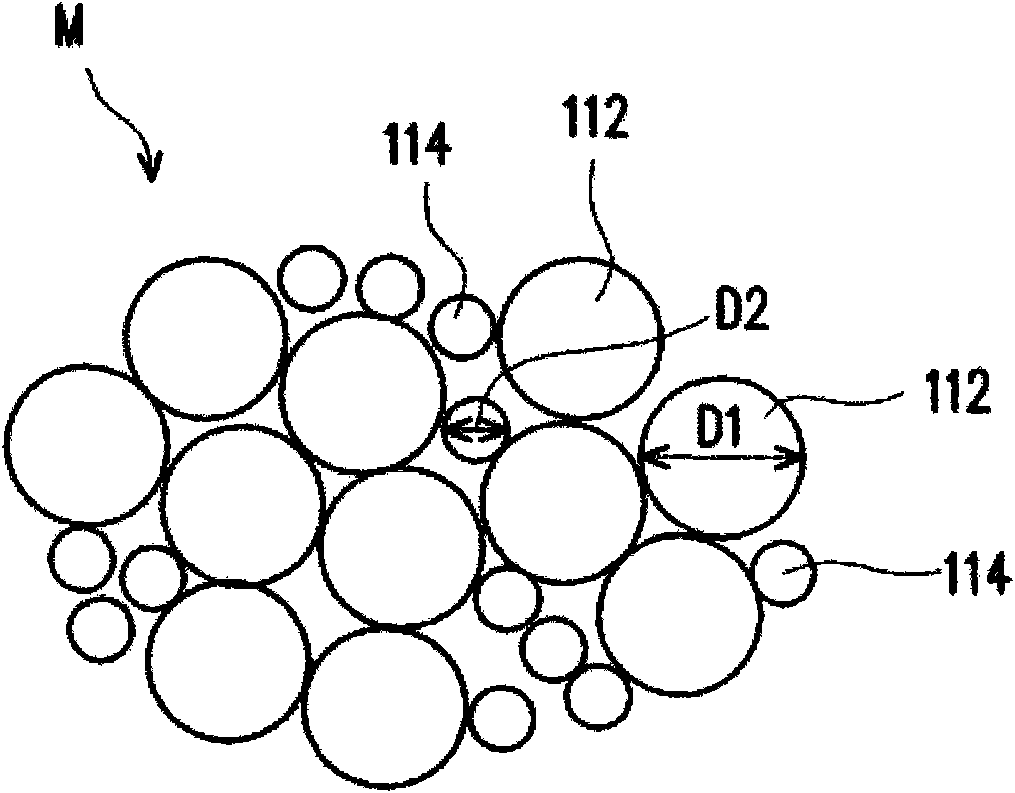

Inducer and production method thereof

ActiveCN101901668AHigh magnetic permeabilityReduce magnetic lossTransformers/inductances coils/windings/connectionsInorganic material magnetismHardnessMaterials science

The invention relates to an inducer and a production method thereof. The inducer comprises a magnetic body and a lead, wherein the magnetic body comprises first magnetic powder and second magnetic powder; the Vickers hardness of the first magnetic powder is greater than that of the second magnetic powder; the average grain diameter of the first magnetic powder is greater than that of the second magnetic powder; and the first magnetic powder is mixed with the second magnetic powder.

Owner:CYNTEC

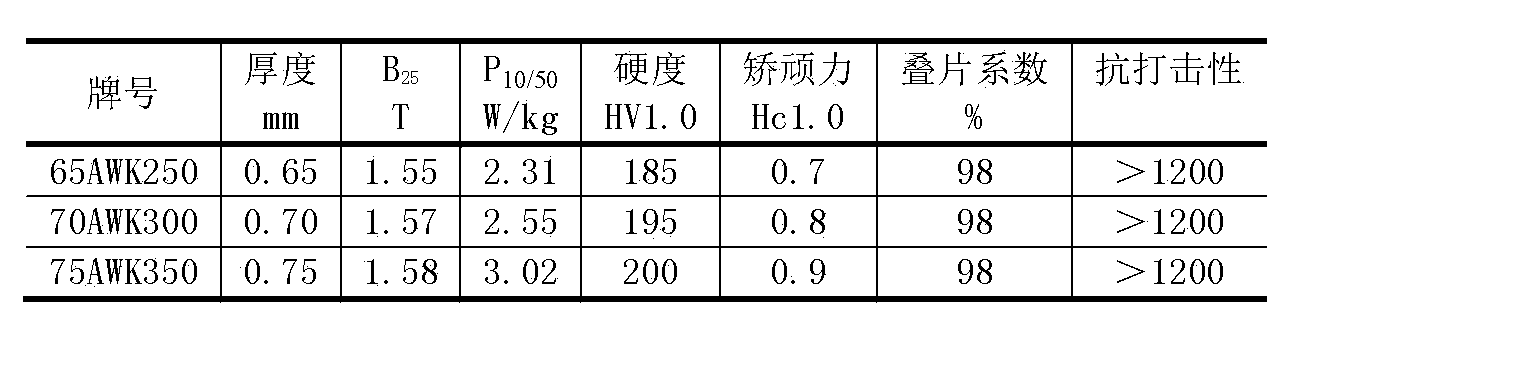

High-strength special-purpose cold-rolled non-oriented electrical steel and producing method thereof

The invention provides high-strength special-purpose cold-rolled non-oriented electrical steel and a producing method thereof. The steel comprises following chemical components by weight: not more than 0.0030% of C, 2.5-3.0% of Si, 0.10-0.5% of Mn, 0.005-0.20% of P, not more than 0.0015% of S, not more than 0.0040% of N and 0.140-1.10% of Als, with the balance being Fe and other unavoidable residual elements. The producing method includes smelting, continuous casting, hot rolling, normalizing, cold rolling and annealing. The electrical steel is low in coercive force, high in hardness, free of magnetic aging, high in strength and high in impact resistance. The product is flexible in production and can be produced in the same line with a high-grade product. The electrical steel has excellent electromagnetic performances, and can be widely used for manufacturing iron core materials of electromagnetic switches. The application field of the electrical steel is broadened.

Owner:ANGANG STEEL CO LTD

Method for manufacturing super-magnetic conducting nanocrystalline alloy and nanocrystalline alloy

The invention relates to a manufacture method for super magnetic conductive nanocrystal alloy, wherein a master alloy includes 72.5 to 74.5 at% of Fe, 0.5 to 1.5 at% of Cu, 2.5 to 3.5 at% of Nb, 12.5 to 14.5 at% of Si and 8 to 10 at% of B. The method comprises the following steps: the master alloy is prepared by vacuum furnace smelting, the vacuum degree is less than 0.026*10<-6>MPa; when the temperature reaches to 1400 DEG C to 1450 DEG C, C is added to the vacuum furnace for deoxidation and refined, the temperature is lowered to deflate, and an ingot is cast; under argon protection, quenched amorphous nanocrystal alloy is formed by single roller fast cooling through a nozzle packet; the nozzle packet is provided with 25-30PPI Al2O3 ceramic filter to filter steel liquid, making SiO2 less than 0.026% (wt%) and B2O3 less than 0.019% (wt%). The magnetic conductivity mu of the iron core of the super magnetic conductive nanocrystal alloy manufactured by the method satisfies the following conditions: mu50Hz (H=5mOe) >=60*10<4>, and mu1kHz (H=5mOe)>=20*10<4>.

Owner:北京冶科电子器材有限公司

Adhesive film

ActiveCN104910823AImprove magnetic permeabilityImprove reliabilityNon-macromolecular adhesive additivesPrinted circuit detailsFilling materialsChemistry

An adhesive film capable of forming an insulating layer is provided. The insulating layer improves magnetoconductivity, reduces magnetic loss and is excellent in reliability. The adhesive film comprises a support body and a resin composition layer arranged on the support body, wherein the resin composition layer contains (A) thermosetting resin, (B) magnetic filler, and (C) inorganic filling material. When the involatile constituent in the resin composition of the resin composition layer is set as 100 volume %, the content B is greater than 100 volume %, and the content of the C divided by the content B falls in the scope of 0.3-3.0.

Owner:AJINOMOTO CO INC

Magnetic conducting pot and manufacturing method thereof

InactiveCN104223957AImprove magnetic permeabilityQuality improvementCooking-vessel materialsEngineeringOrganic matter

The invention provides a magnetic conducting pot and a manufacturing method thereof. The magnetic conducting pot comprises a pot body, a magnetic conducting layer and a protecting layer, the pot body is made by aluminum, the magnetic conducting layer is formed on the outer surface of the pot body, the protecting layer is formed on the outer surface of the magnetic conducting layer, and the magnetic conducting layer is composed of the following magnetic conducting materials including, by weight, 10-30 parts of resin, 30-90 parts of magnetic conducting metal pigment and 1-5 parts of additive organic matter. The magnetic conducting pot can be used for electromagnetic heating and has the advantages of low cost and excellent magnetic conducting performance.

Owner:MIDEA GRP CO LTD +1

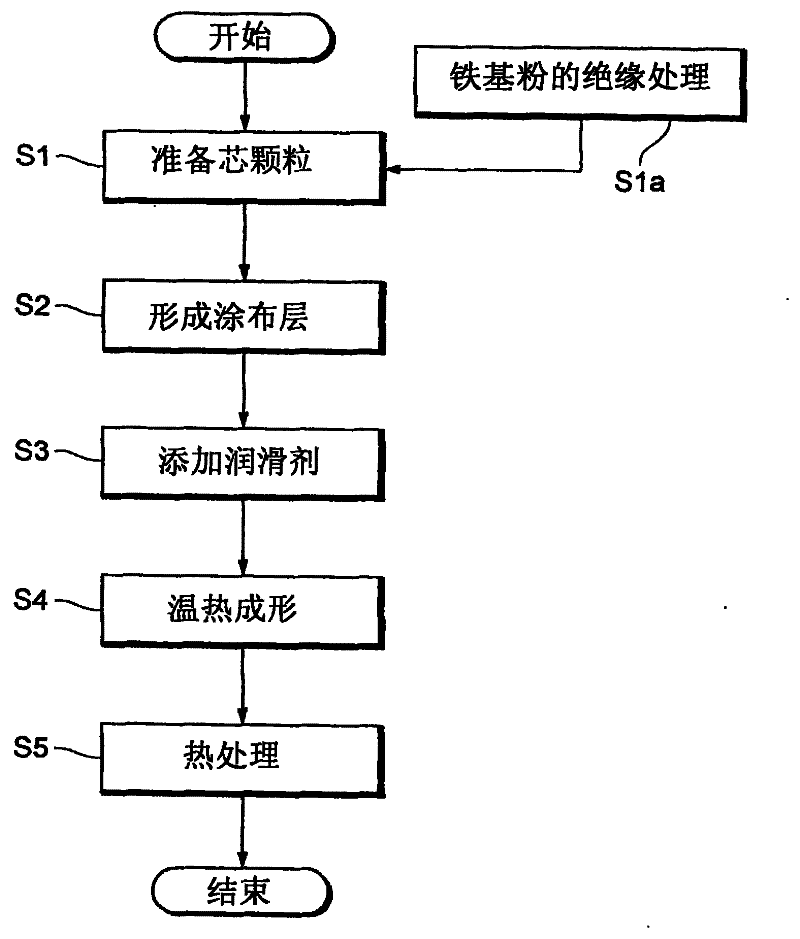

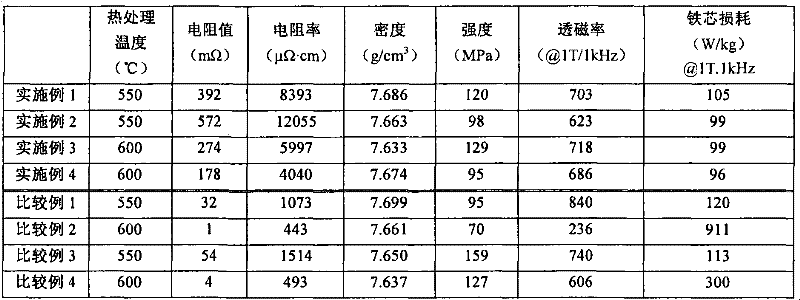

Soft magnetic material, powder magnetic core and method for manufacturing the same

InactiveCN102054551AHigh core resistanceImprove magnetic permeabilityMetal-working apparatusInorganic material magnetismCore ParticleMetal

It is an object to provide a novel soft magnetic material that enables the fabrication of a powder magnetic core capable of suppressing degradation in performance due to a high-temperature treatment and achieving high core resistance and low loss. A soft magnetic material comprising: a core particle each having a soft magnetic particle comprising iron as a main component and an insulating film formed on a surface of the soft magnetic particle; and a coating layer formed on the core particle, wherein the coating layer comprises a metal complex having nonferrous central metal and at least one organic ligand.

Owner:TDK CORPARATION

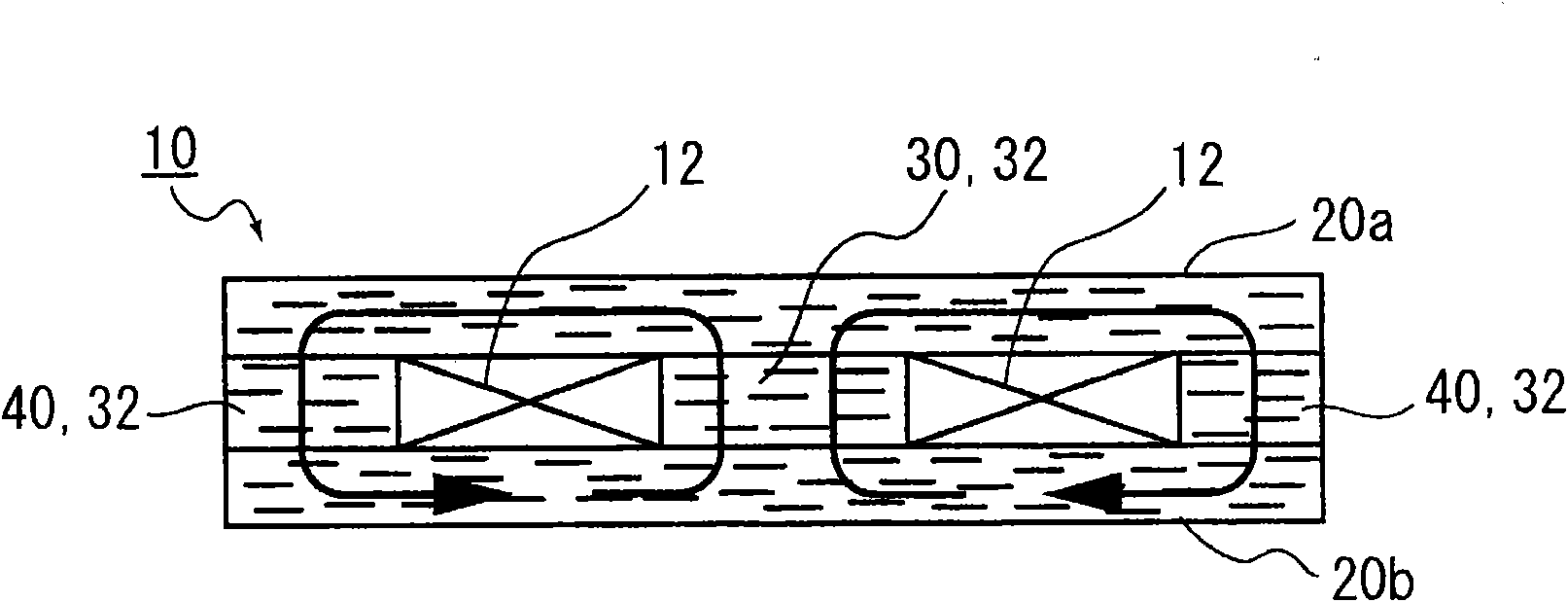

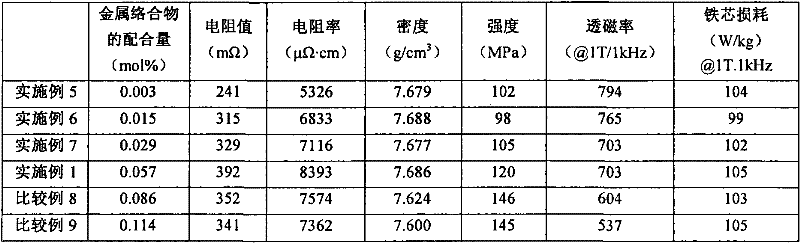

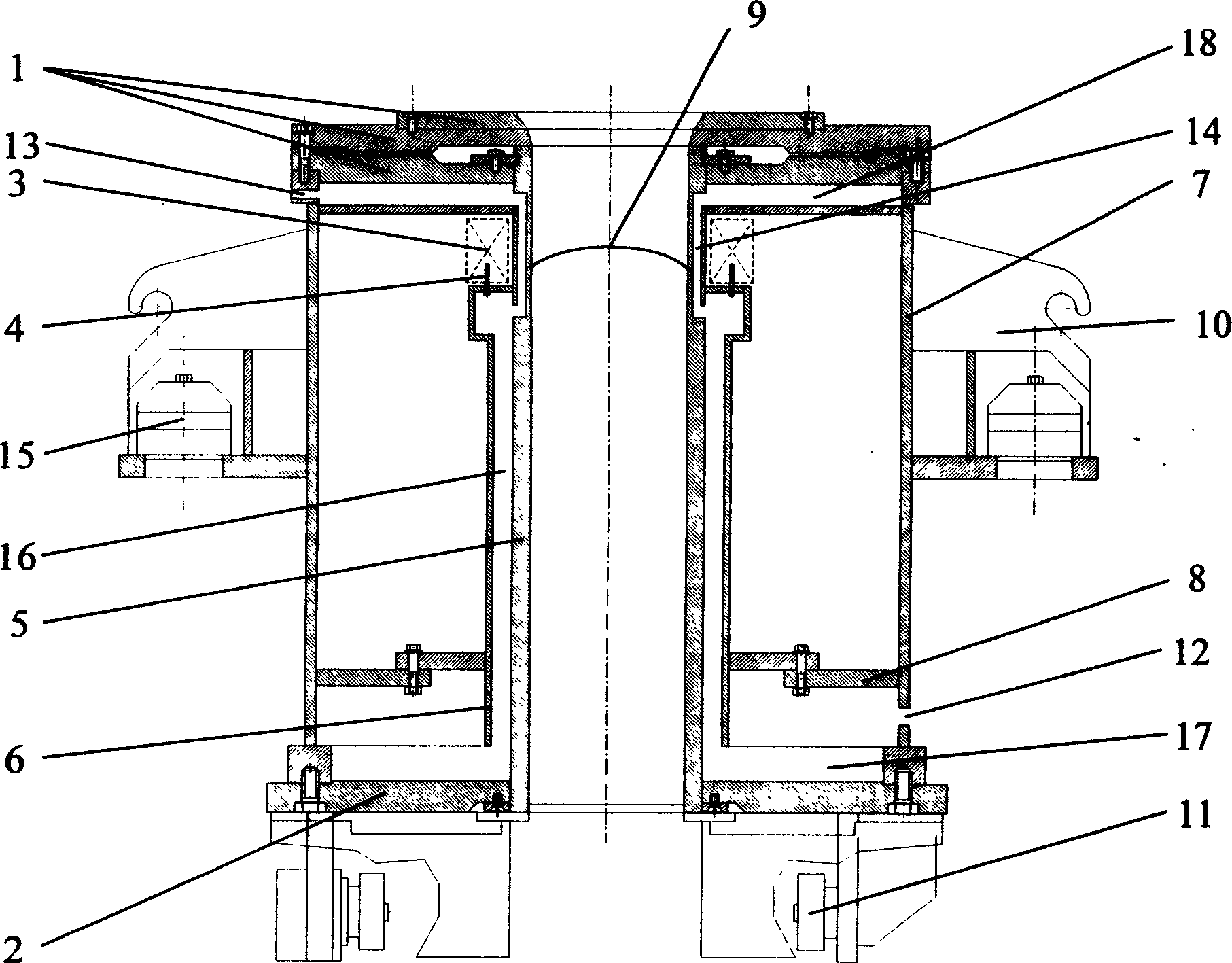

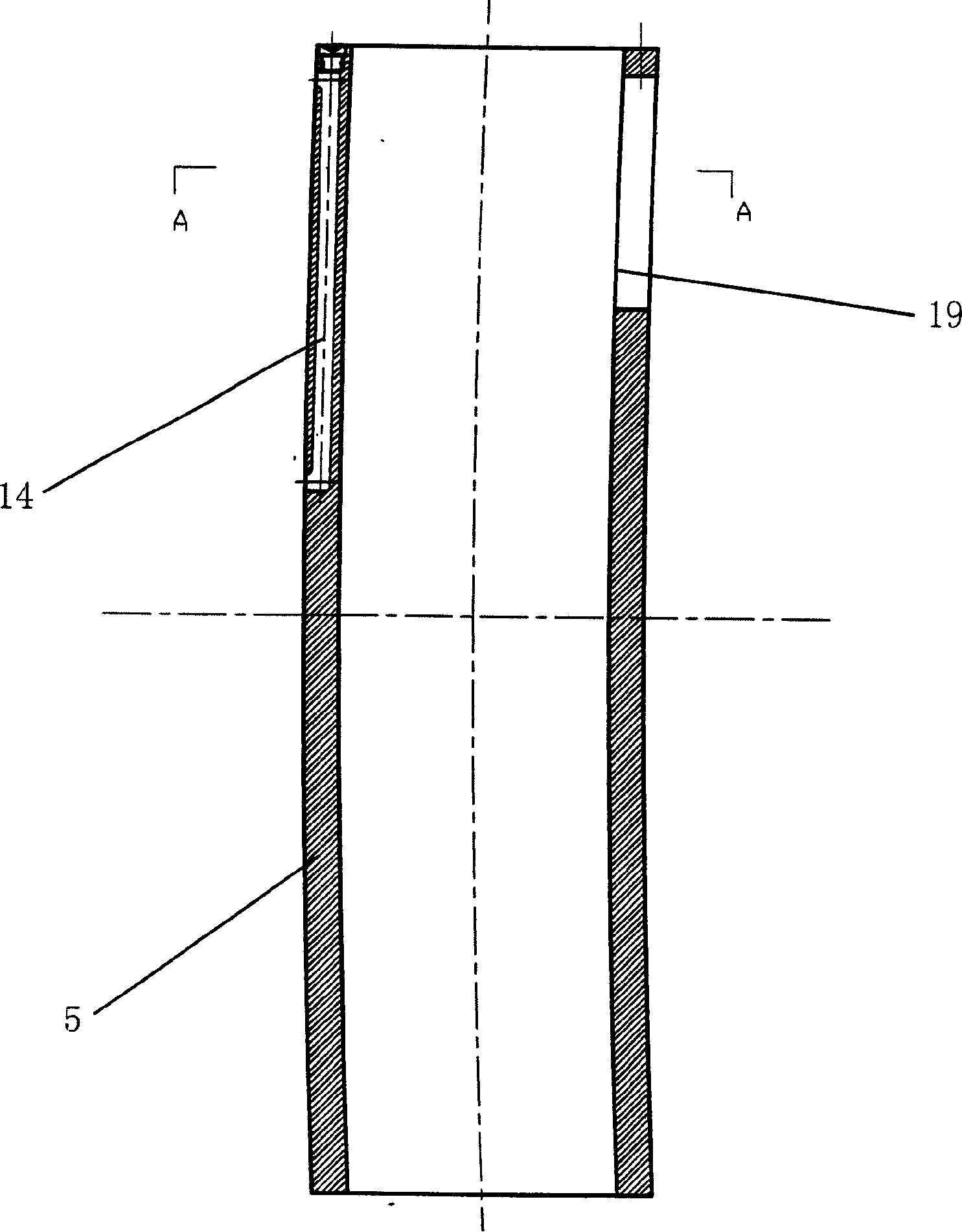

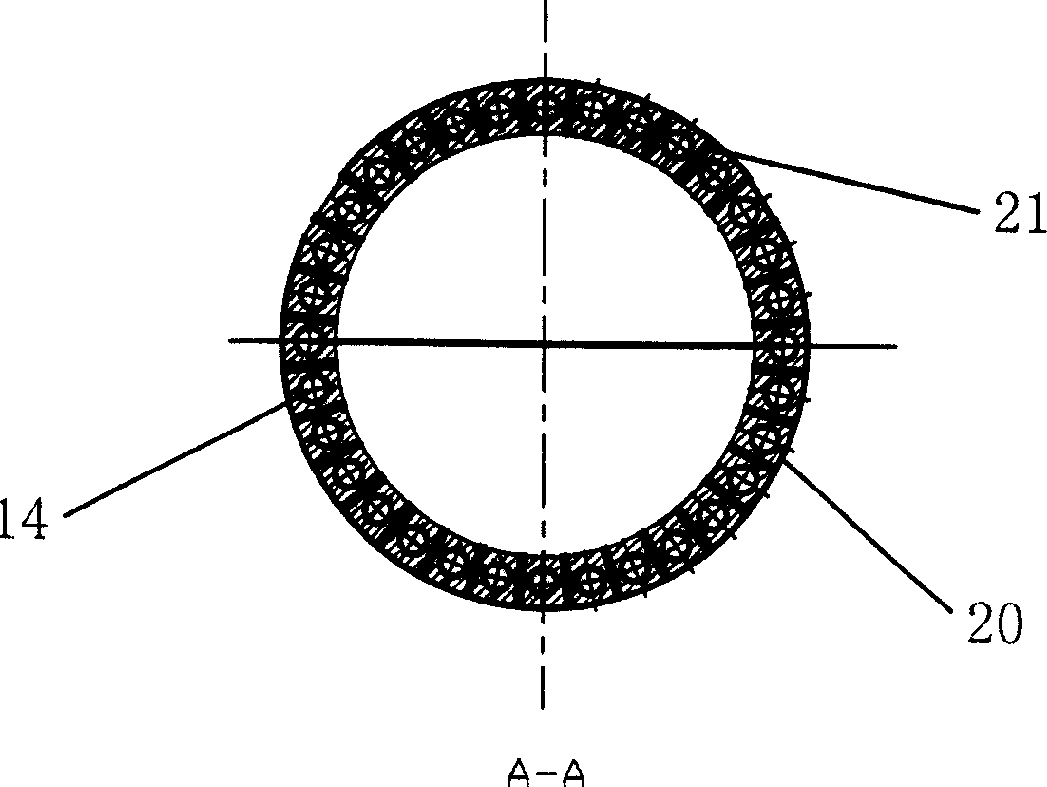

Water seam-split body internal water cooling type flexible contact electromagnetic continuous casting crystallizer

A water cooled electromagnetic crystallizer for conticasting is composed of upper and lower flanges, coil, sleeve pipe of crystallizer, cooling water jacket, cooling water tube, connection part and lifting gear. It features that the upper part of said sleeve pipe has local slit structure, the cooling water tube is arranged in split body and a water seam structure is formed between the lower part of said sleeve pipe and cooling water jacket.

Owner:NORTHEASTERN UNIV

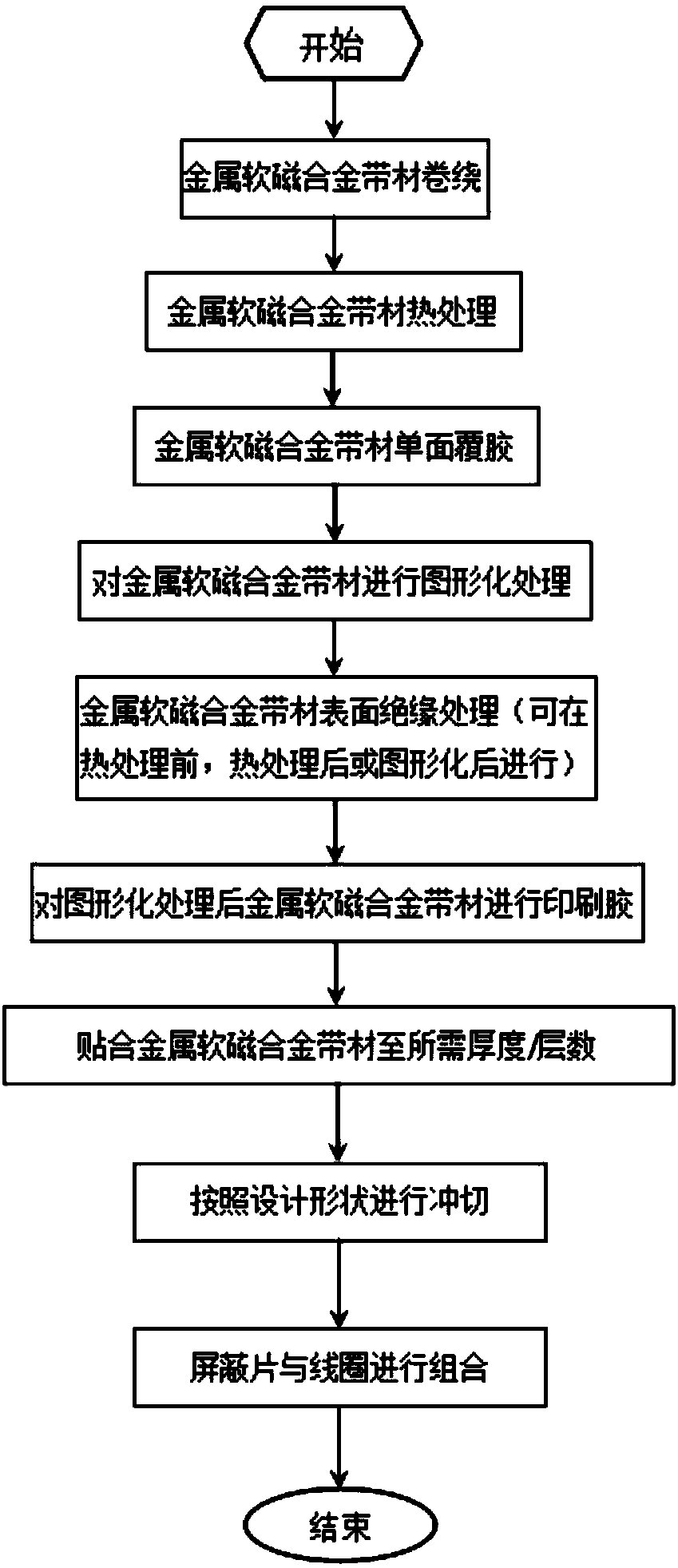

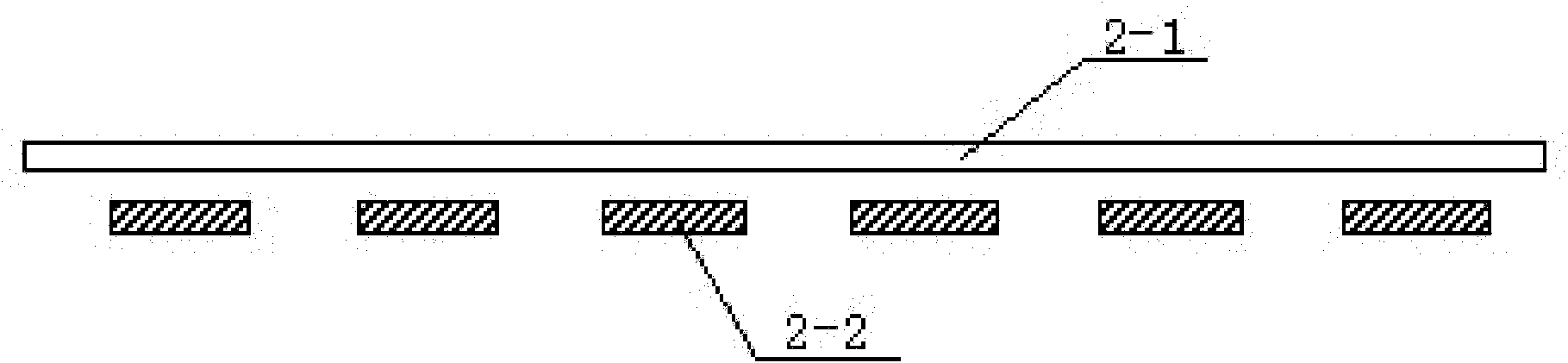

Preparation technology of magnetic conductive plate used for wireless charging

InactiveCN107610923AReduce lossImprove magnetic permeabilityTransformersCircuit arrangementsPunchingAlloy

The invention discloses a preparation technology of a magnetic conductive plate used for wireless charging, and relates to the field of magnetic materials. According to the preparation technology of the magnetic conductive plate used for wireless charging, a series of treatment process such as winding, heat treatment, single-sided coating, graphical treatment, insulating treatment, secondary coating, gluing, lamination and punching is carried out on a metal magnetically soft alloy strip to obtain the magnetic conductive plate with more excellent performance, the magnetic conductive plate is combined with a coil for carrying out efficiency testing, so that the charging efficiency and specific resistance level are further improved, and the loss of the magnetic conductive plate is further reduced.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD

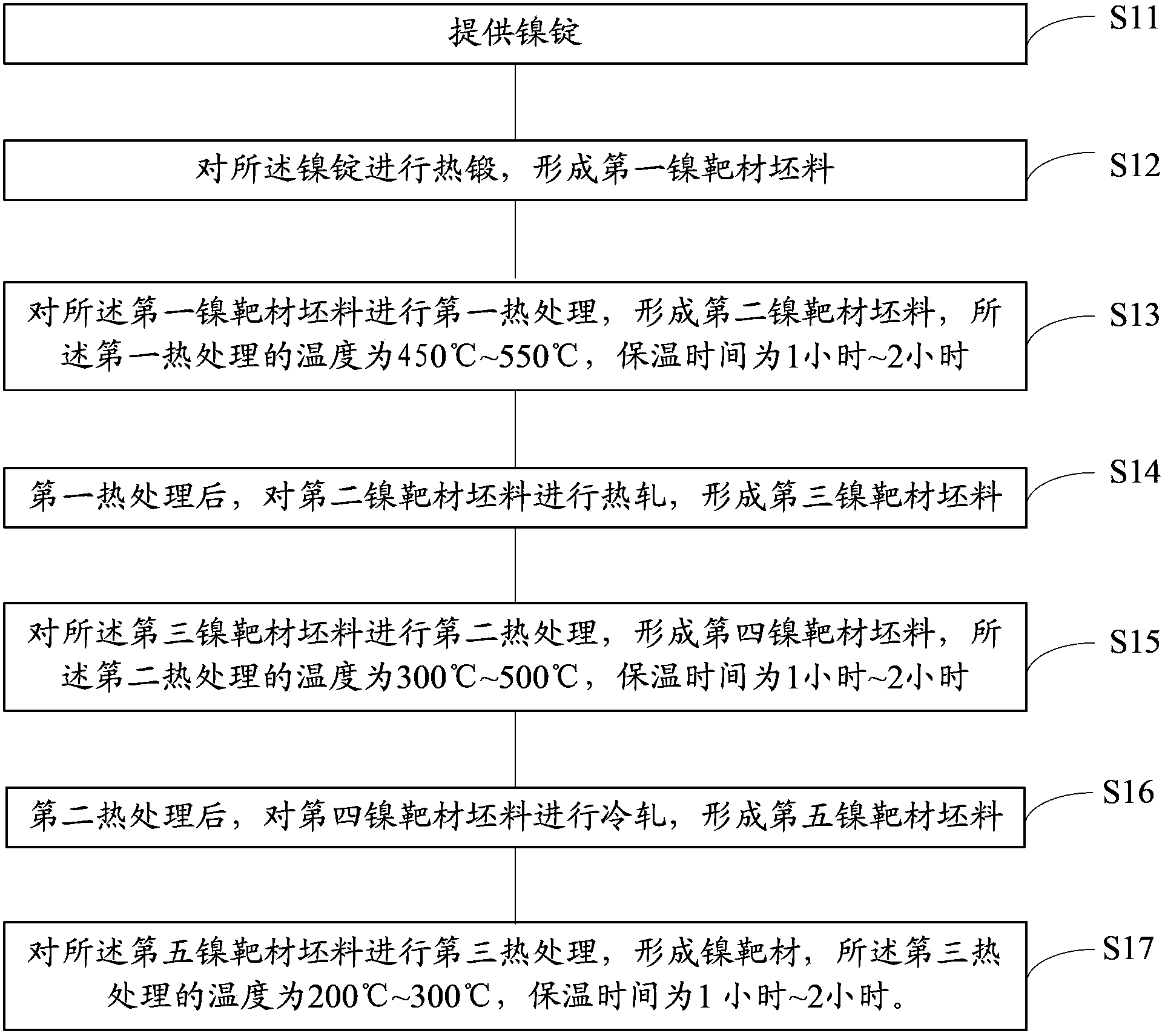

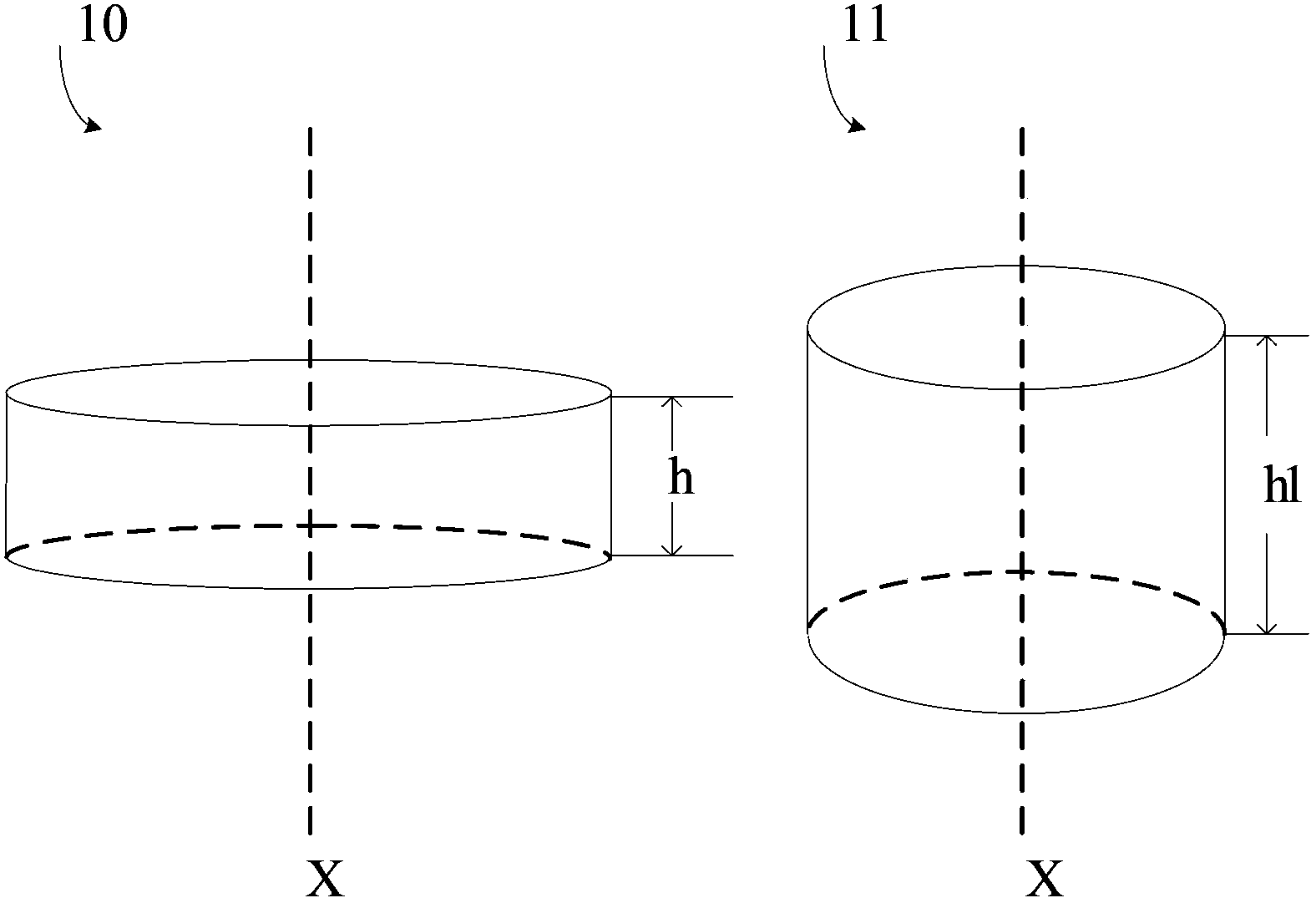

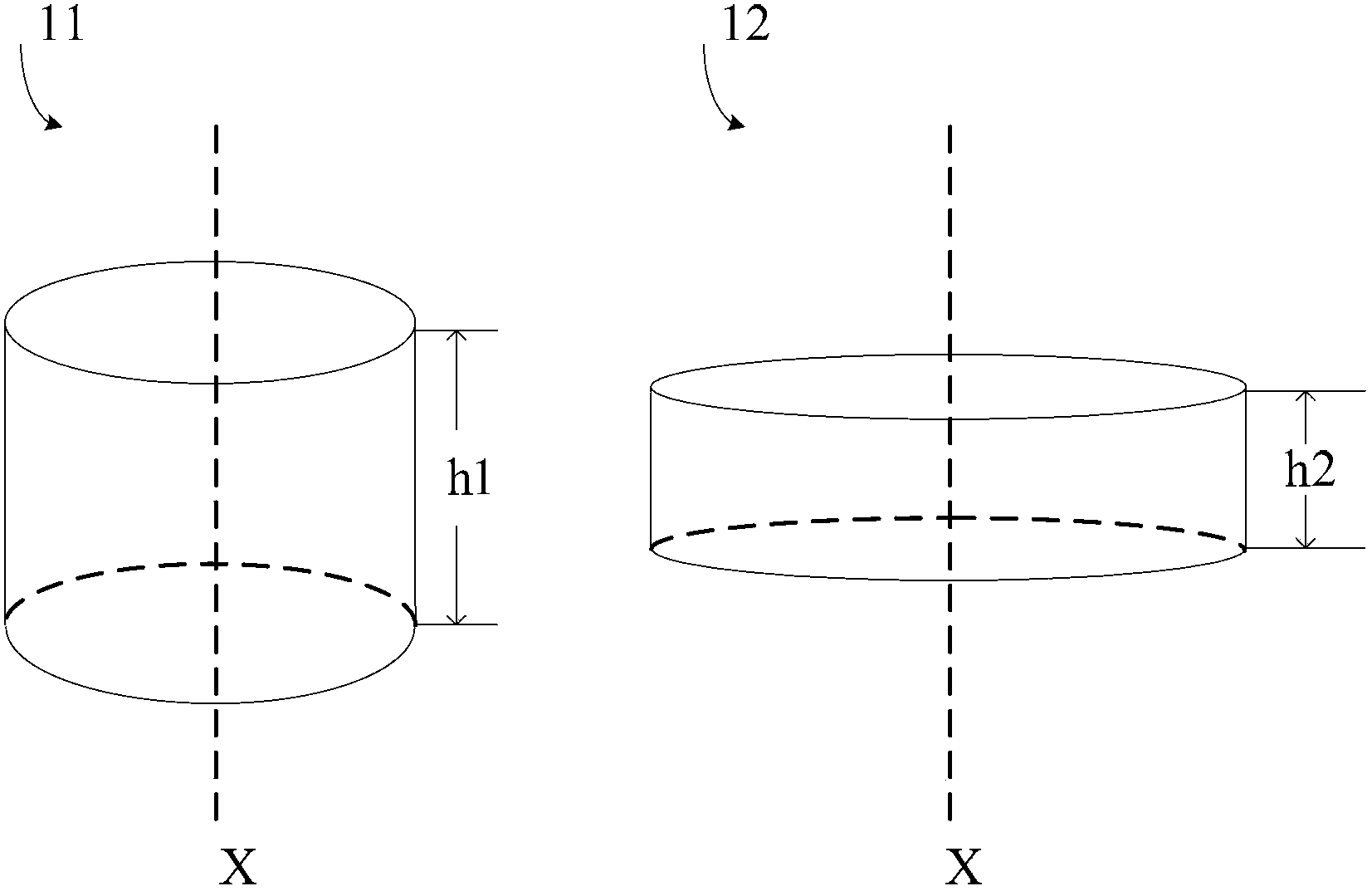

Production method of nickel target and nickel target component

ActiveCN103572224ADense tissueReduce hardnessVacuum evaporation coatingSputtering coatingIngotMaterials science

The invention provides a production method of a nickel target and a nickel target component. The production method of the nickel target comprises the following steps of providing a nickel ingot; performing hot forging on the nickel ingot to form a first nickel target blank; performing first heat treatment on the first nickel target blank to form a second nickel target blank, wherein the temperature of the first heat treatment is 450-550 DEG C, and the temperature is maintained for 1-2 hours; after the first heat treatment, performing hot rolling on the second nickel target blank to form a third nickel target blank; performing second heat treatment on the third nickel target blank to form a fourth nickel target blank, wherein the temperature of the second heat treatment is 300-500 DEG C, and the temperature is maintained for 1-2 hours; after the second heat treatment, performing cold rolling on the fourth nickel target blank to form a fifth nickel target blank; performing third heat treatment on the fifth nickel target blank to form the nickel target, wherein the temperature of the third heat treatment is 200-300 DEG C, and the temperature is maintained for 1-2 hours. By adopting the technical scheme, the produced nickel target has relatively uniform internal organization and good magnetic property.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

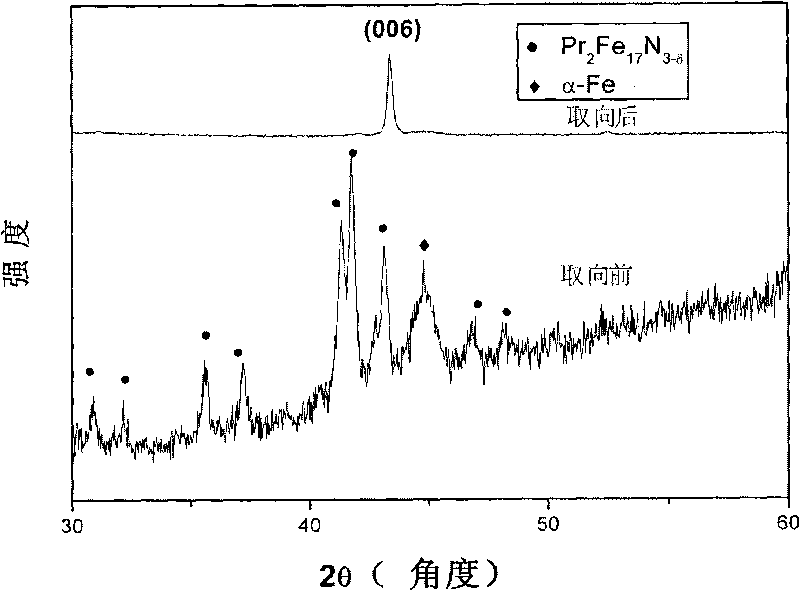

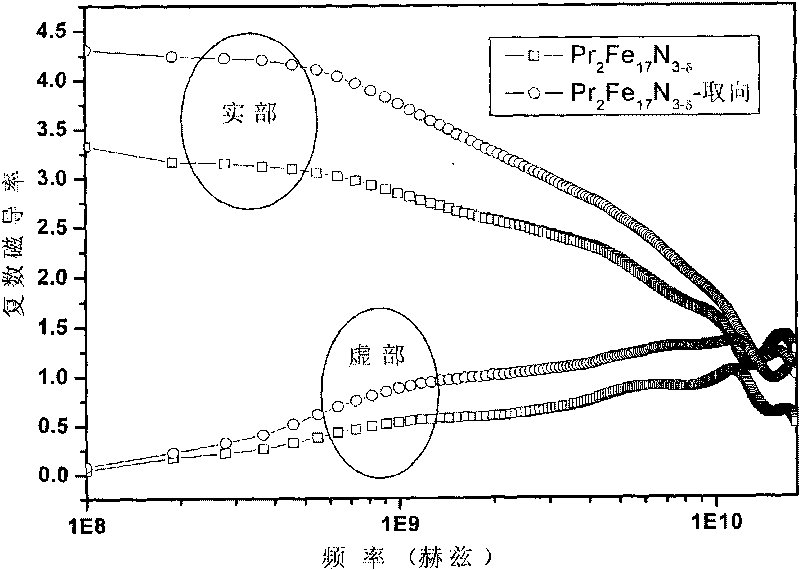

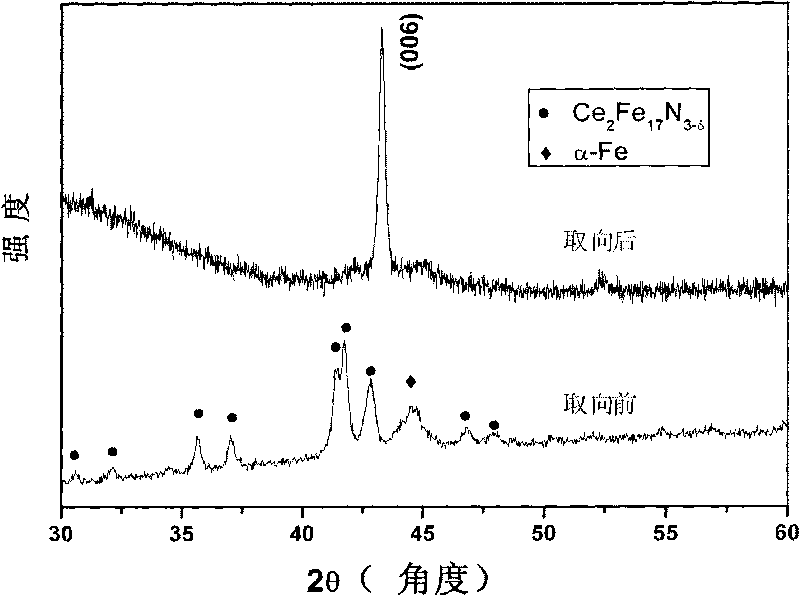

High frequency soft magnetic material composed of rare earth, iron and nitrogen, as well as composite material prepared by same and preparation methods thereof

InactiveCN101699578AHigh Complex PermeabilityRaise the resonance frequencyInorganic material magnetismSolid state diffusion coatingRare-earth elementMetallurgy

The invention discloses a high frequency soft magnetic material and a composite material prepared by the same, as well as respective preparation methods of the high frequency soft magnetic material and the composite material. The high frequency soft magnetic material is composed of rare earth elements, iron and nitrogen, has a general formula of R2Fe17N3-delta, the direction of easy magnetization of the material is vertical to C axis, R is one of Y, Ce, Pr, Gd, Tb, Dy, Ho, Er, Tm, and Lu, or a combination of any two of the above rare earth elements, and dealt is larger than or equal to 0, and is smaller than or equal to 0.5.

Owner:LANZHOU UNIVERSITY

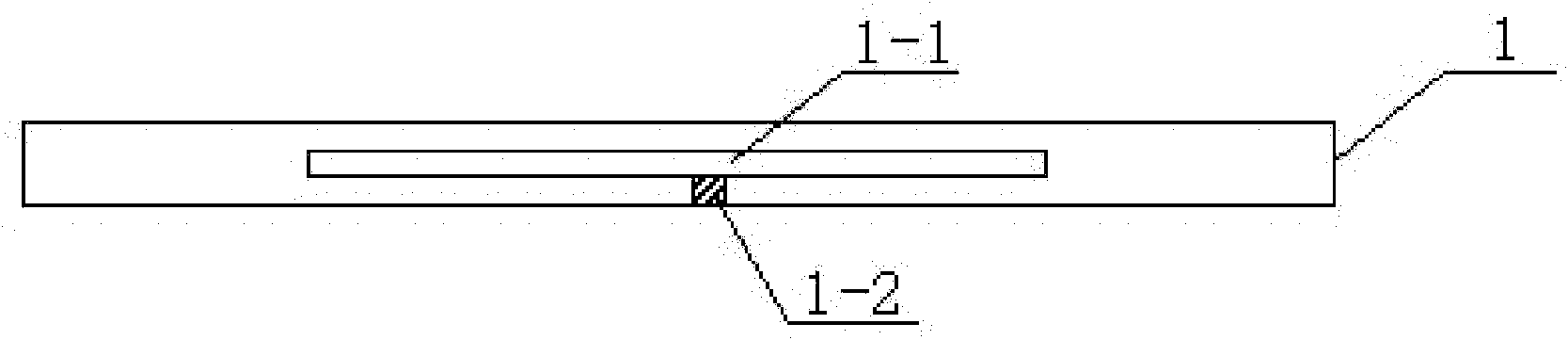

Inductor

InactiveUS20080278273A1Improve insulation effectImprove magnetic propertiesTransformers/inductances casingsInductance with magnetic coreEngineeringInductor

An inductor includes a coil and a magnetic body. The magnetic body covers the coil. The magnetic body includes at least one magnetic material, at least one insulated magnetic material and at least one resin. The magnetic material is enveloped by the insulated magnetic material. Alternatively, the magnetic body is made by mixing the insulated magnetic material with the magnetic material.

Owner:DELTA ELECTRONICS INC

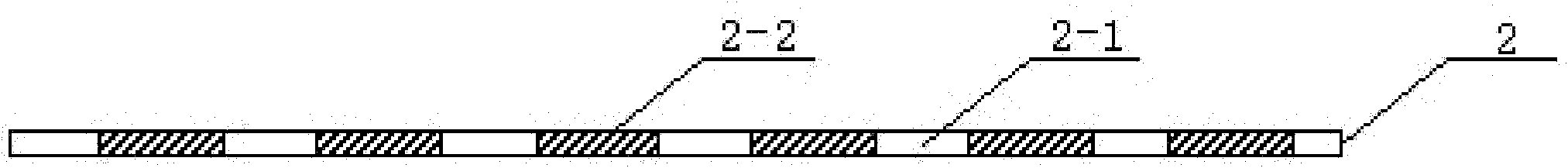

Elongated ultra-high-frequency induction label compounded from amorphous soft magnetic material

InactiveCN102129604AImprove magnetic permeabilityStrong magnetic permeabilityRecord carriers used with machinesConfidentialityEngineering

The invention relates to an elongated ultra-high-frequency induction label compounded from an amorphous soft magnetic material, which comprises a first antenna and a second antenna, wherein the first antenna is used for ultra-high-frequency detection, and the second antenna is used for low-frequency detection and also used for enhancing the ultra-high-frequency detection performance of the first antenna; the first antenna is provided with a hole and a wireless radio-frequency chip, the hole is arranged on the middle part of the first antenna, and the wireless radio-frequency chip is arranged on the transverse middle lower part of the first antenna; the second antenna is provided with a substrate made of an amorphous soft magnetic material, and a plurality of magnetizing / demagnetizing sheets which are arranged alternately and made of a semihard magnetic material; and the magnetizing / demagnetizing sheets are attached to the same surface of the substrate. The substrate of the second antenna of the label provided by the invention is made of the amorphous soft magnetic material, and the amorphous soft magnetic material has high magnetoconductivity and especially has the highest magnetoconductivity in the low-frequency range of 1Hz-7500Hz, thereby ensuring the electromagnetic wave anti-theft function of the label; the label appears elongated, and has a small size, thereby being beneficial to ensuring the confidentiality; and in the high-frequency range, the attribute of the second antenna turns into metal, thereby enhancing the detection property of the first antenna and reducing the size of the label.

Owner:江苏科晶智能科技股份有限公司

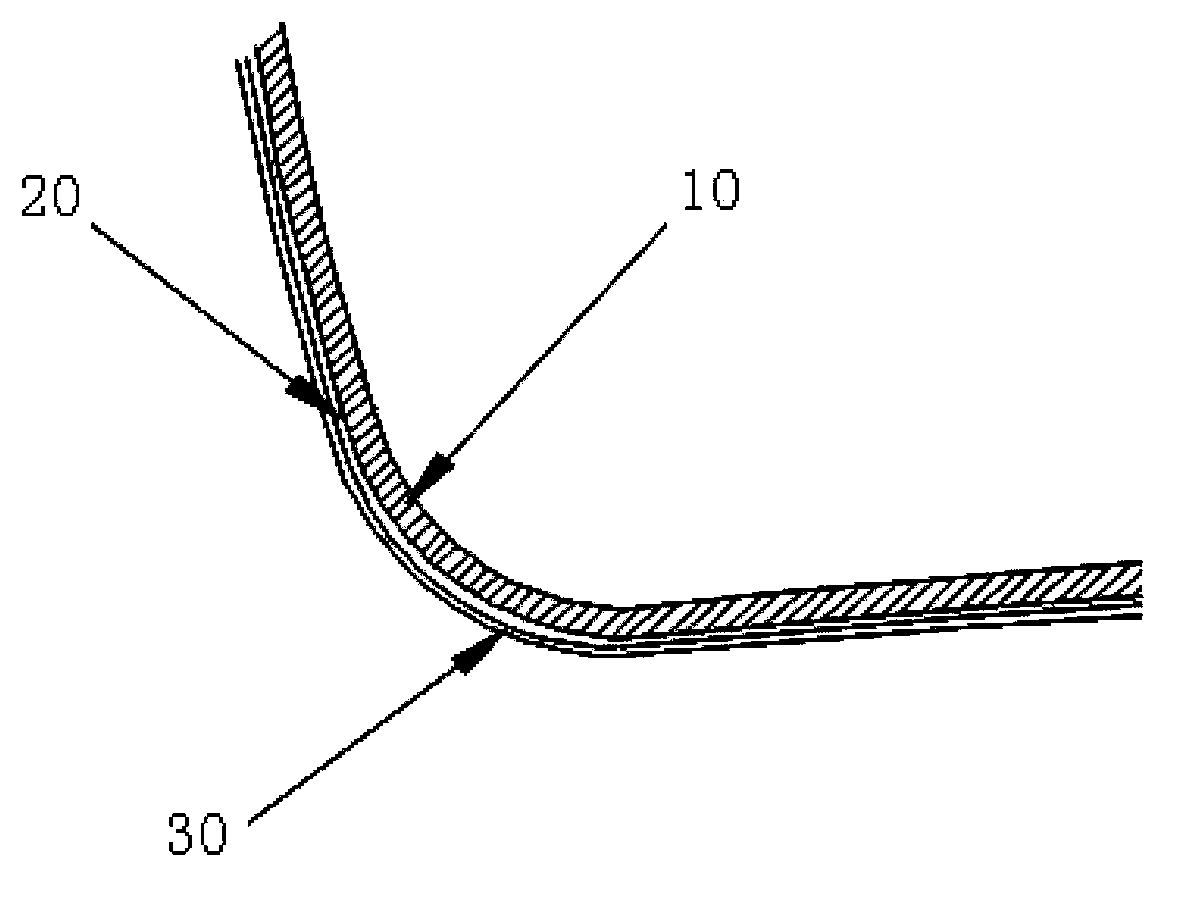

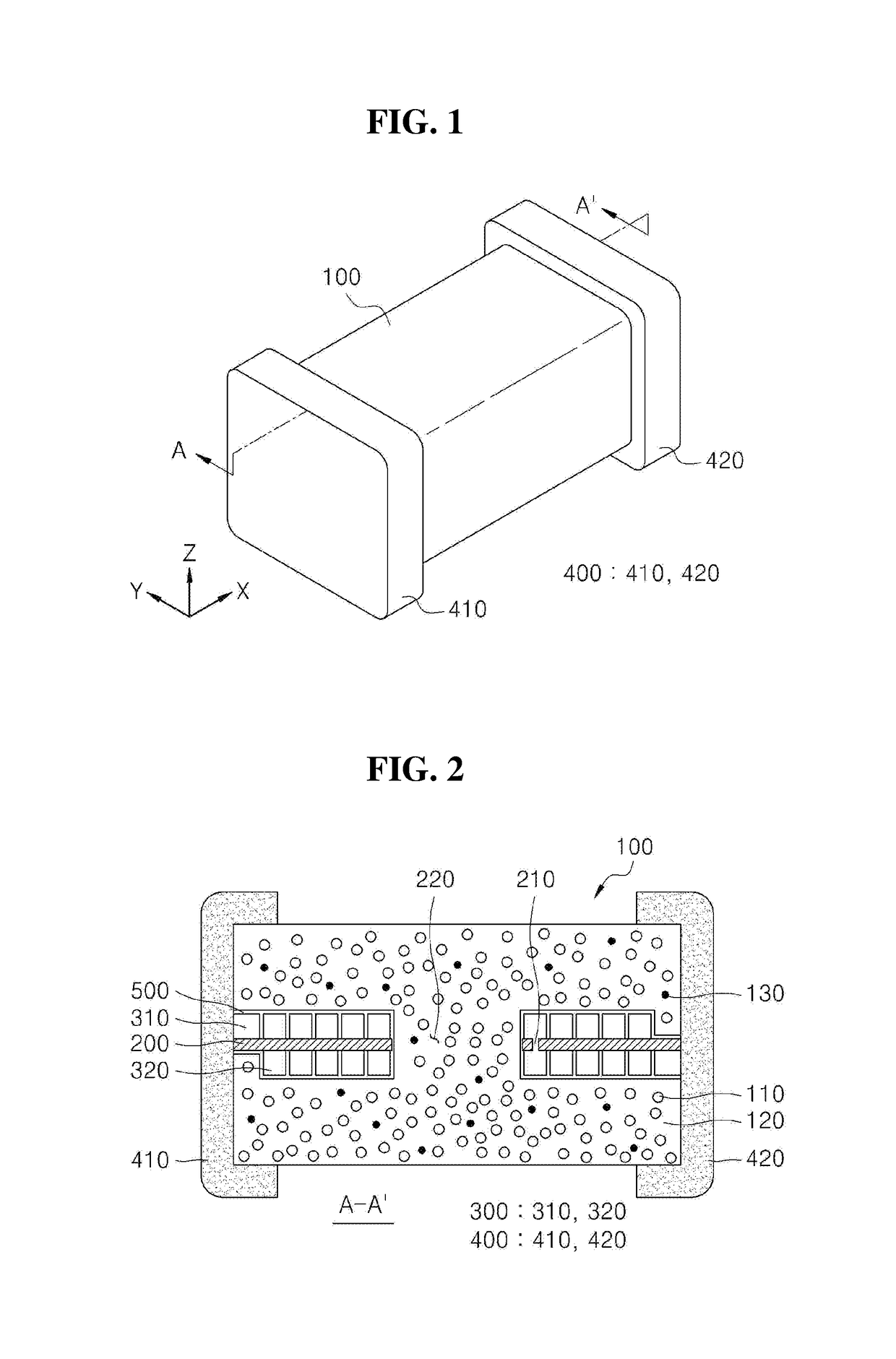

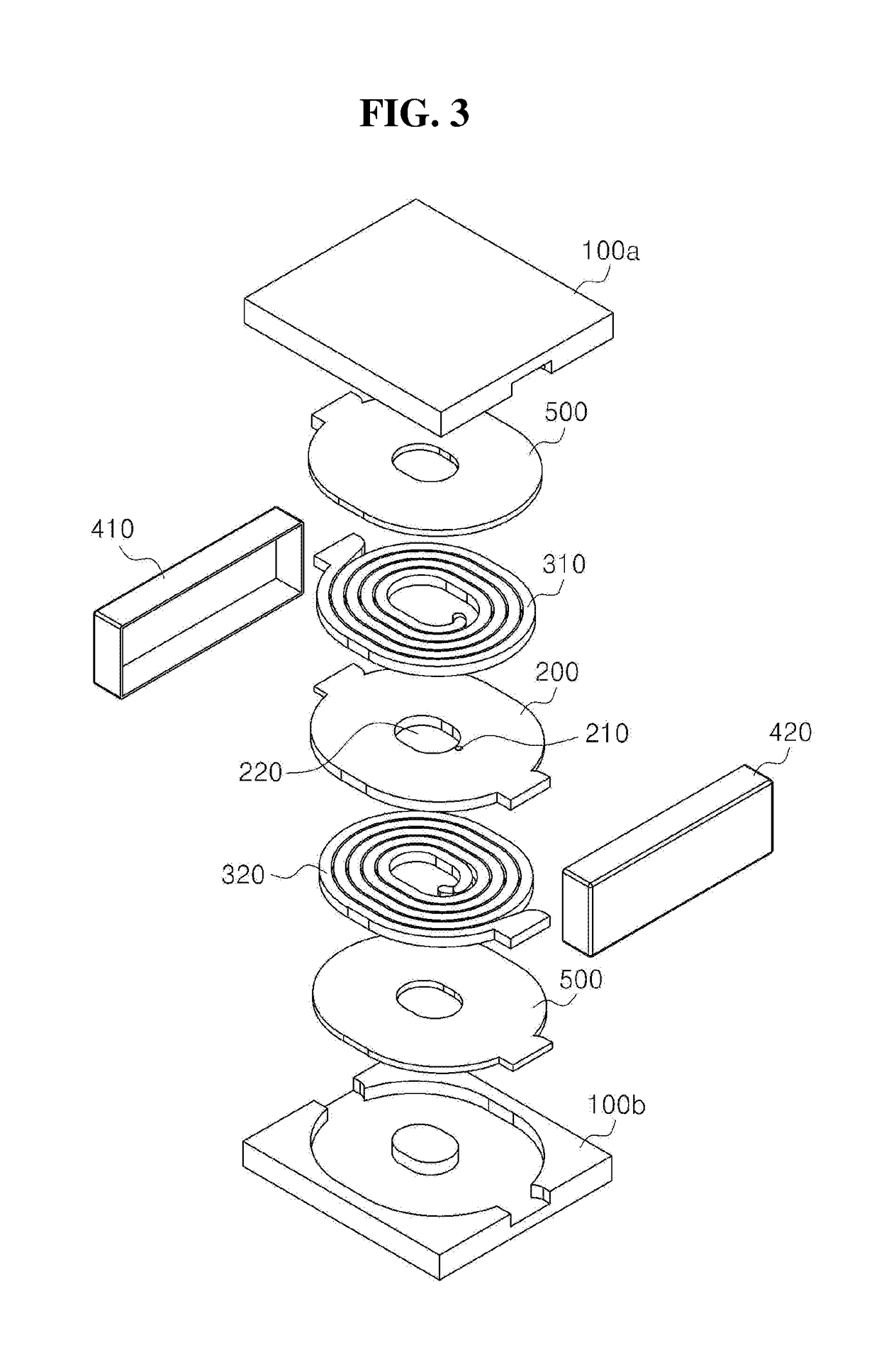

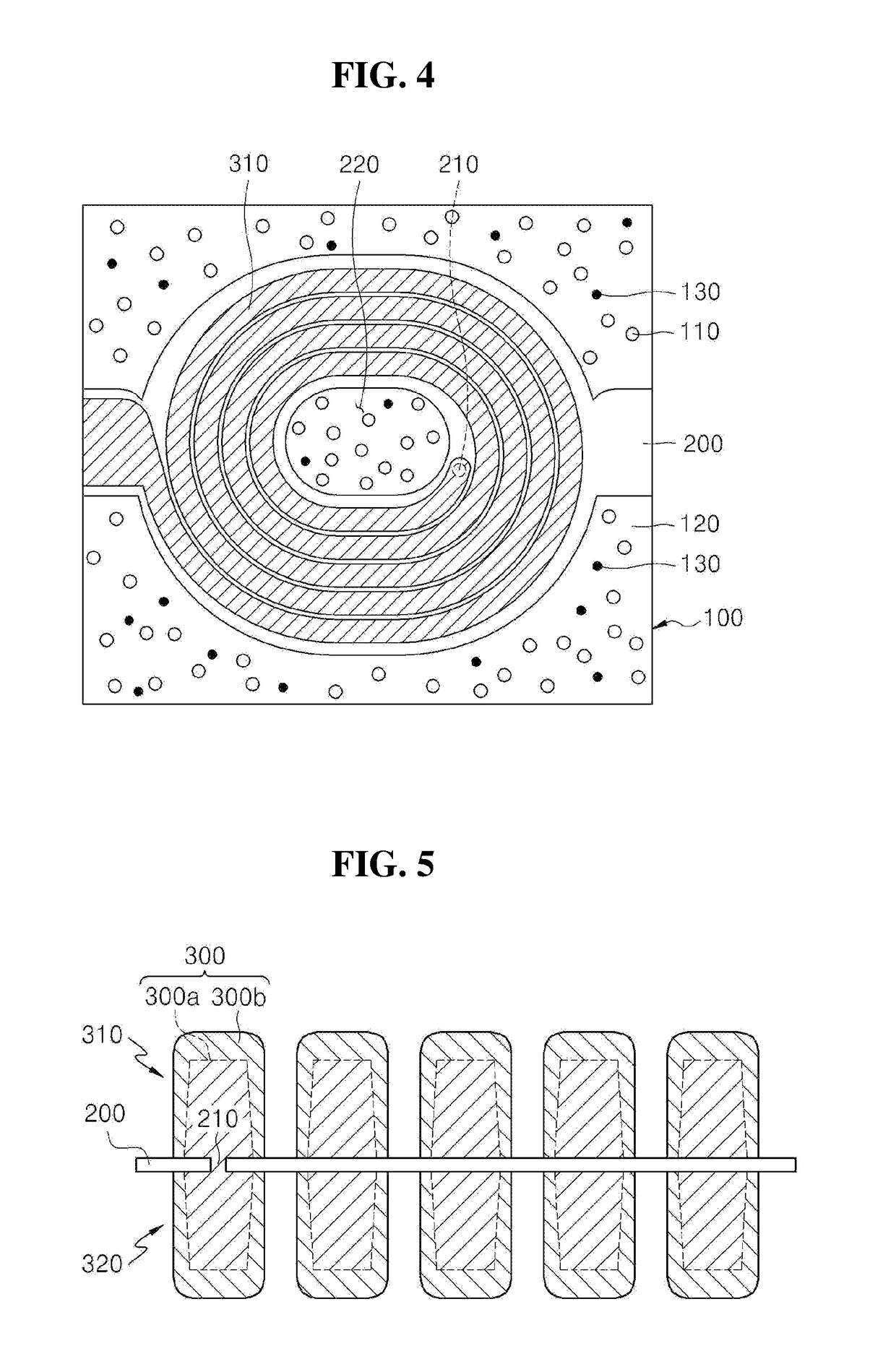

Power inductor

ActiveUS20180366246A1Improve magnetic permeabilityUniform thicknessTransformers/inductances coolingTransformers/inductances with temperature compensationInductorEngineering

Provided is a power inductor. The power inductor includes a body, at least one base material disposed within the body, at least one coil pattern disposed on at least one surface of the base material, an insulation layer disposed between the coil pattern and the body, and an external electrode disposed outside the body and connected to the coil pattern. The body includes a magnetic pulverized material and an insulation material.

Owner:MODA INNOCHIPS CO LTD

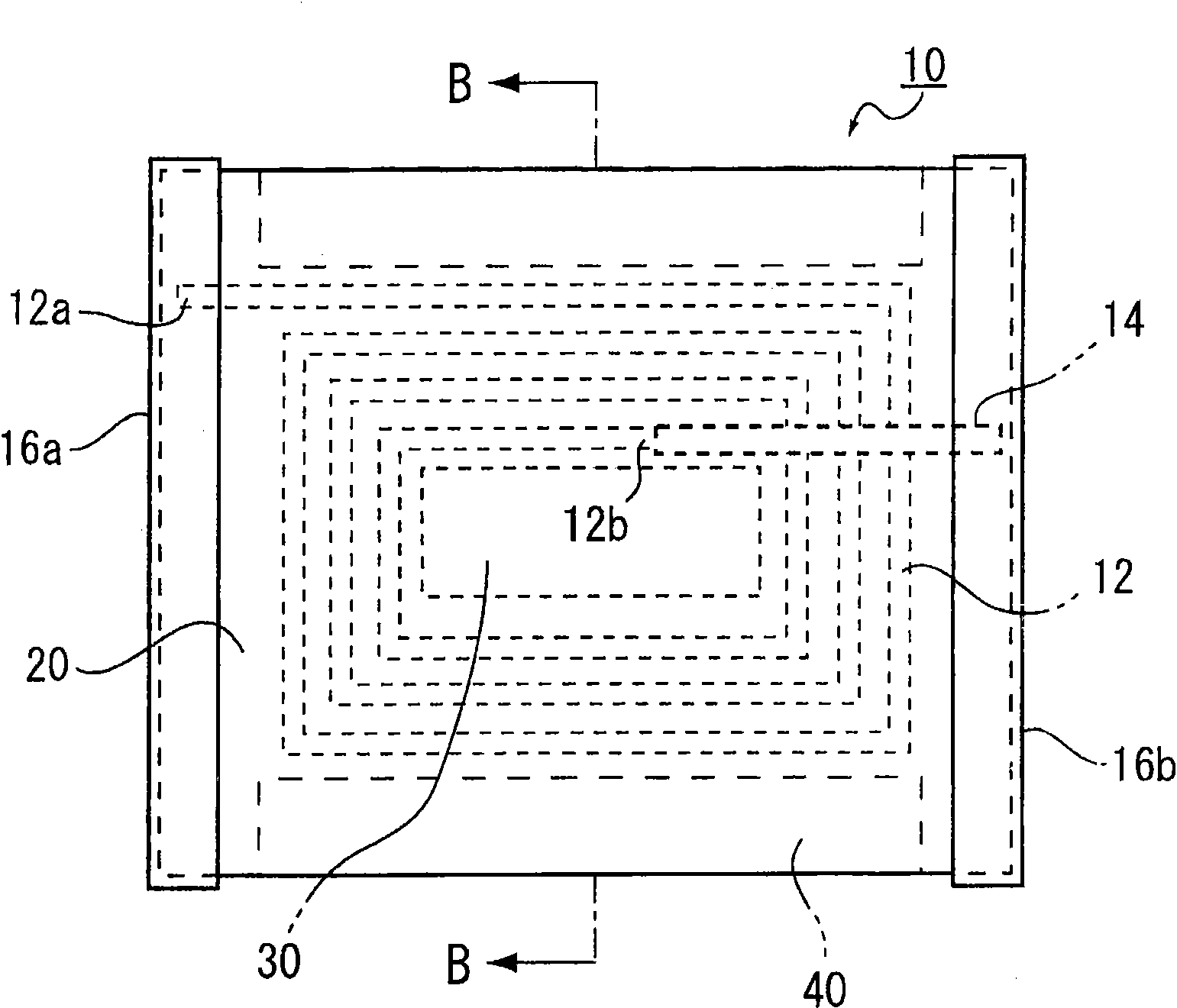

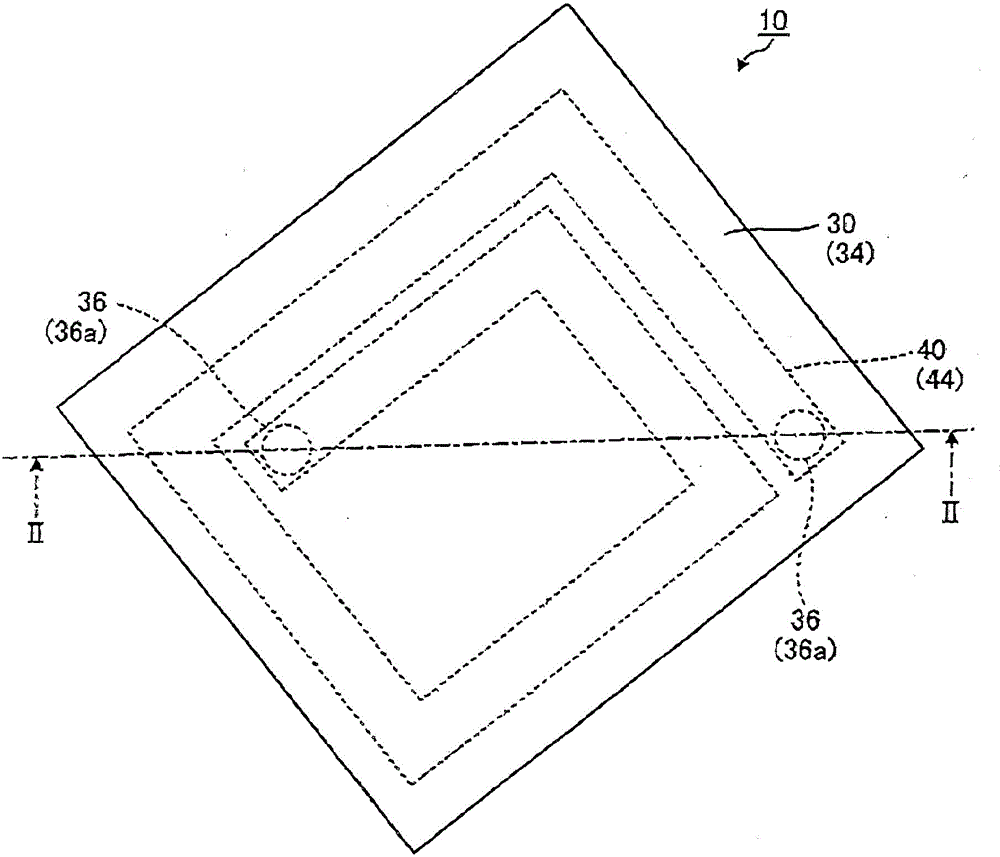

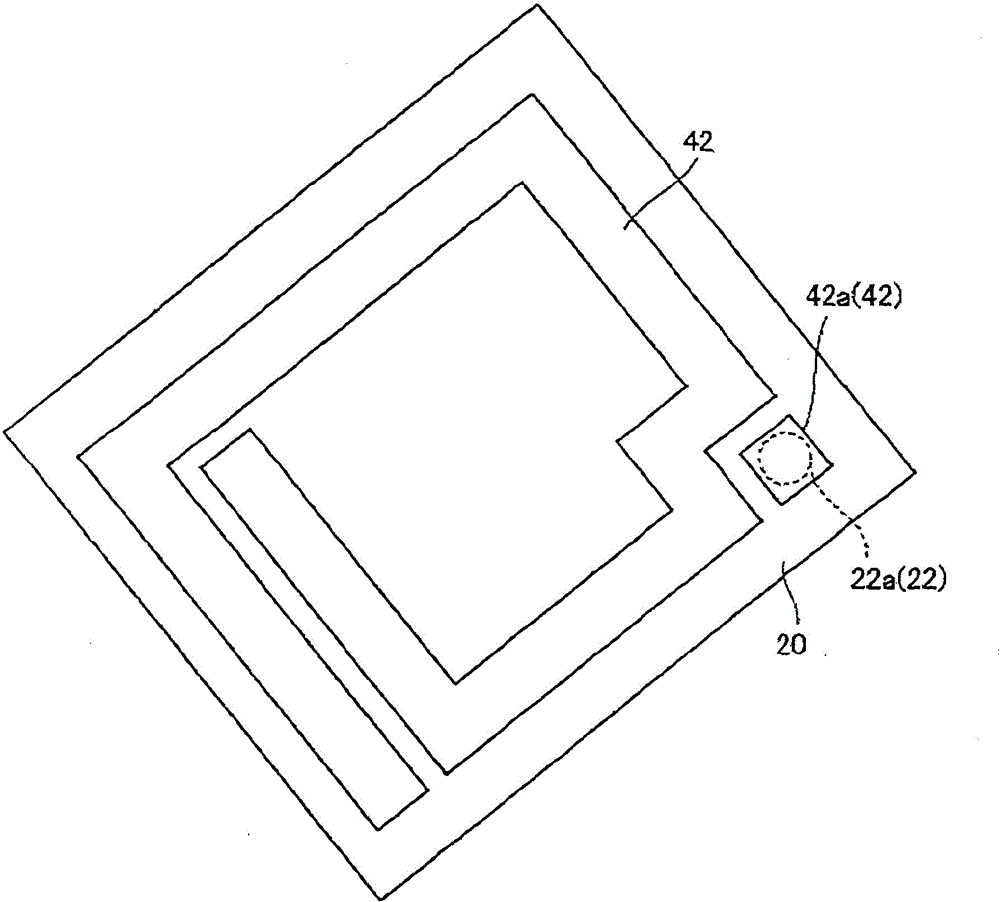

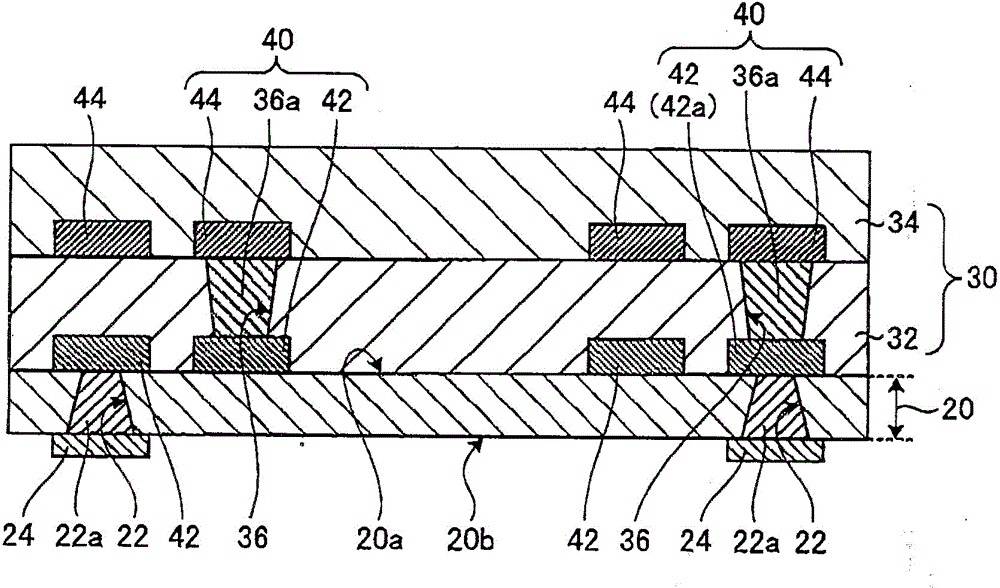

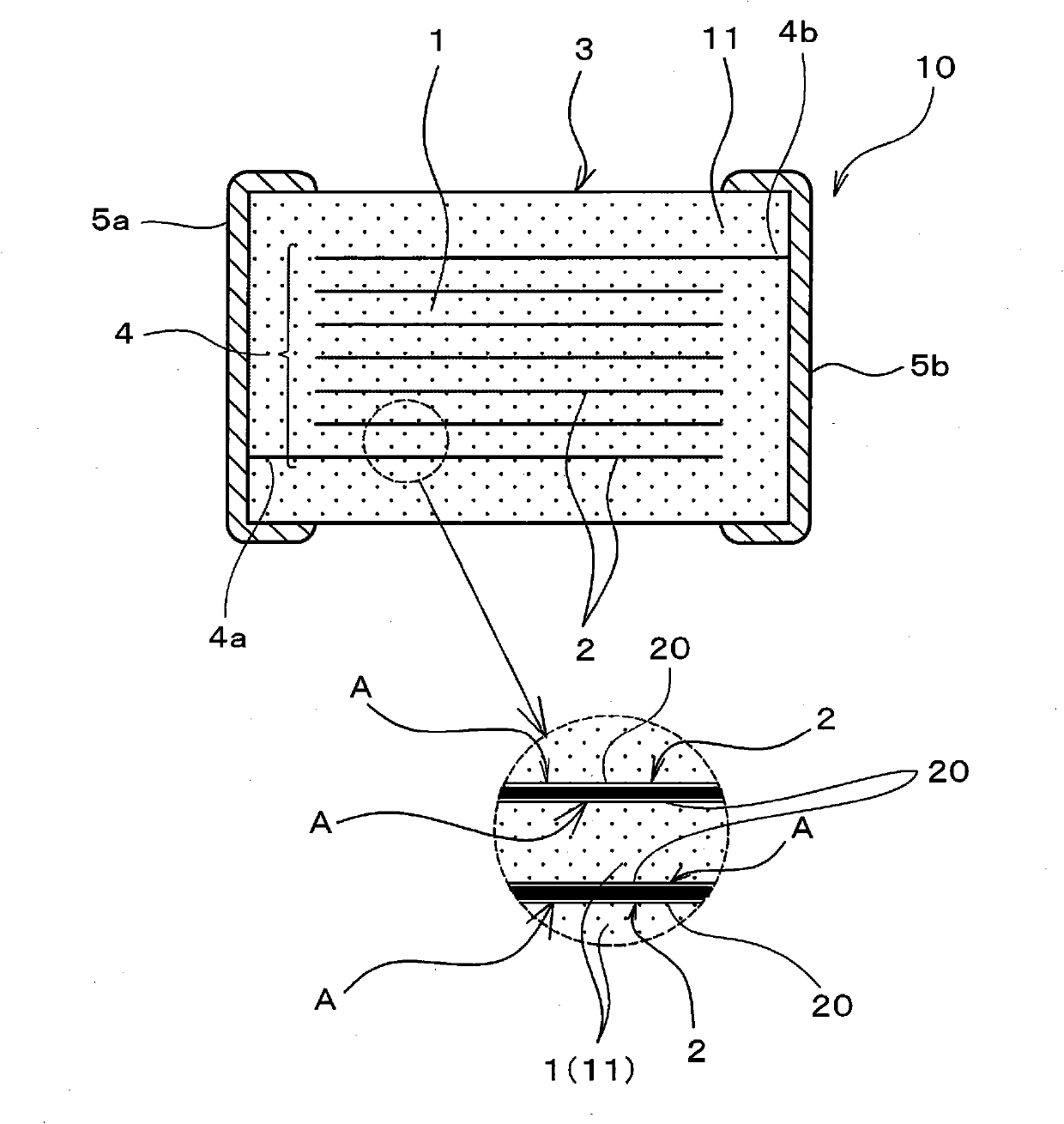

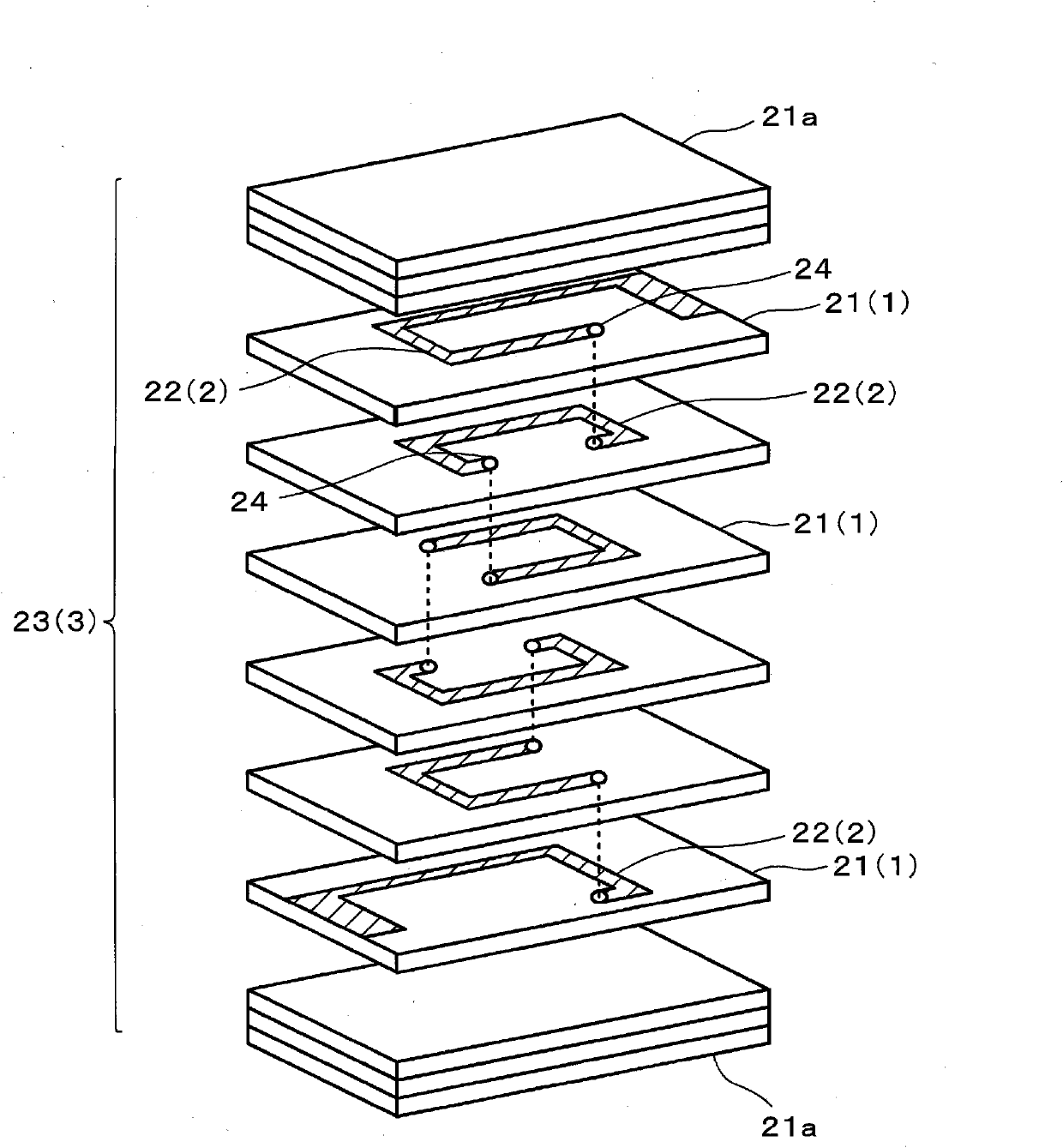

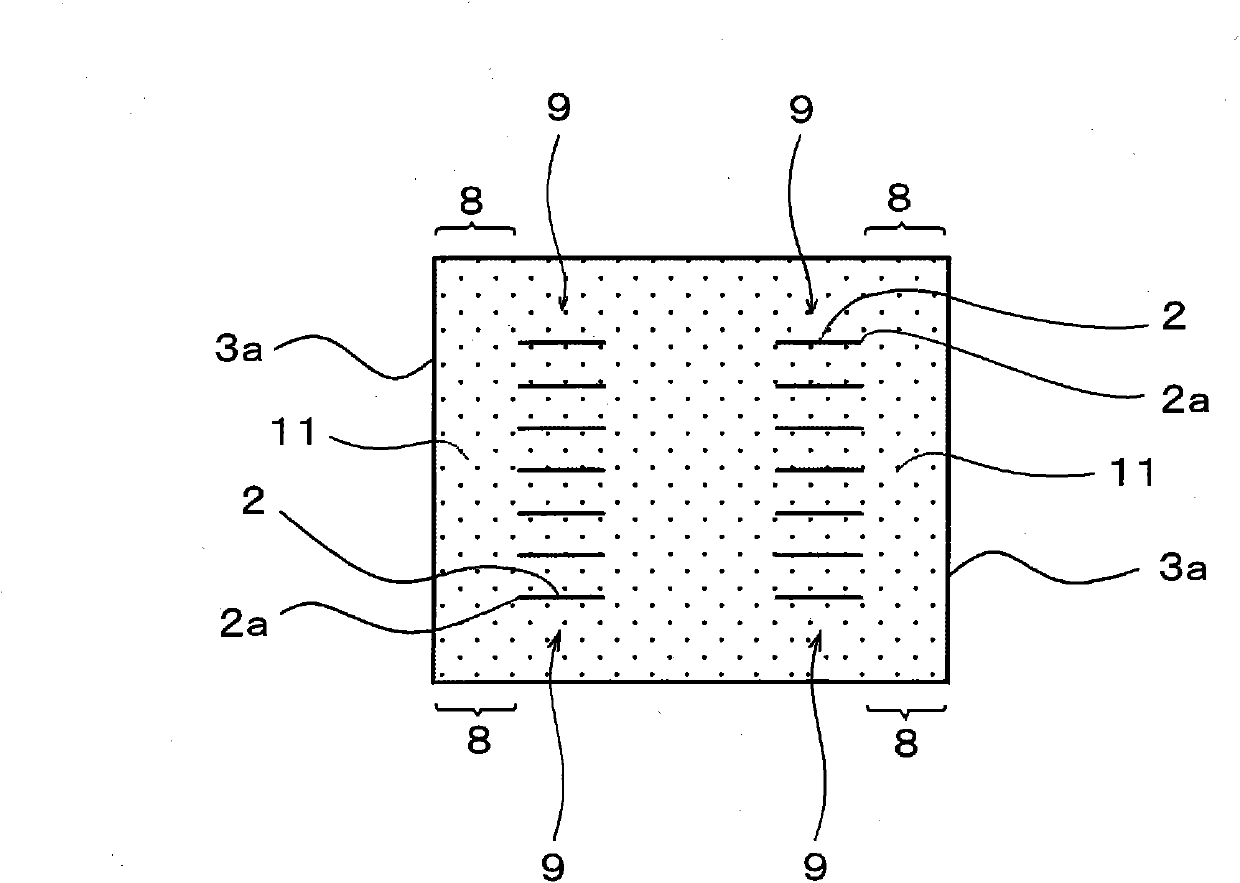

Multilayer coil component and method for manufacturing the same

ActiveCN102007551ASmall characteristic deviationReduce DC resistanceUnwanted magnetic/electric effect reduction/preventionCoils manufactureDc resistanceCeramic

Provided is a highly reliable multilayer coil component wherein migration of Ag constituting an inner conductor is controlled, problem of internal stress is relaxed without forming an air gap between a magnetic ceramic layer and an inner conductor layer, DC resistance is lowered, and disconnection of an inner conductor due to a surge is prevented from occurring easily. A metal film (20) is distributed over the surface of an inner conductor (2), so that an air gap does not exist on the interface (A) of the inner conductor (2) including the metal film (20) and a magnetic ceramic (11) on the periphery of the inner conductor, and the interface (A) of the inner conductor (2) and the magnetic ceramic (11) is in a dissociative state. An acid solution containing a metal is infiltrated from the side surface of a magnetic ceramic element via a side gap portion, i.e. a region between the side portion of the inner conductor and the side surface of the magnetic ceramic element, so as to reach the interface of the inner conductor and the magnetic ceramic on the periphery thereof, and thus the metal is deposited on the surface of the inner conductor.

Owner:MURATA MFG CO LTD

Ni/TiO2-based electromagnetic rheological liquid with electromagnetic coupling effect and preparation method thereof

InactiveCN101967421AImprove stabilityWith performanceLubricant compositionMagnetic currentMicroparticle

The invention relates to Ni / TiO2-based electromagnetic rheological liquid with electromagnetic coupling effect and a preparation method thereof. The dispersed phases of the electromagnetic rheological liquid are composite particles which are respectively in a core-shell structure, wherein nano-metallic conductive particles (Ni) are taken as a core, titanium dioxide (TiO2) is taken as a coating shell, and the composite particles are modified by polar molecules. The preparation method comprises the following steps: preparing nano-nickel particles by using a physical method, wherein the particlediameter is 30-200nm; carrying out hydroxylation treatment on the nano-nickel particles to obtain particles A; coating TiO2 on the particles A to obtain particles B; carrying out heat treatment on the particles B to obtain Ni / TiO2 composite particles or coating urea and SDBS polar molecules at the outer layers of the particles B to obtain particles C; carrying out heat treatment on the particles C to obtain Ni / TiO2 / Urea and Ni / TiO2 / SDBS composite particles; and dispersing the composite particles into the basic liquid to obtain the electromagnetic rheological liquid in which the volume concentration of the composite particles is 10-50%. The preparation method of the invention is simple and can be operated easily; a sol-gel method and a controllable molecule synthesizing technology are adopted; and the prepared electromagnetic rheological liquid not only has the properties of the electro-rheological liquid but also has the properties of the magneto-rheological liquid.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

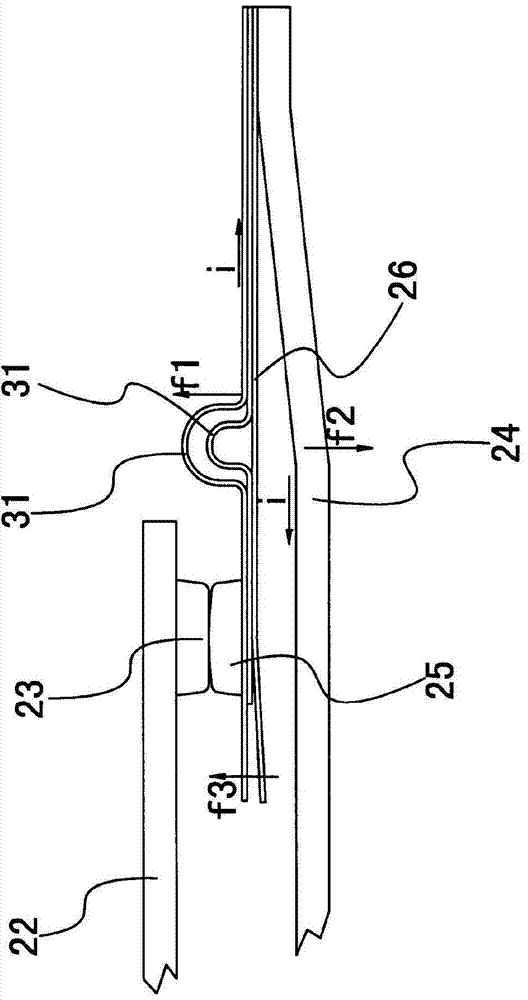

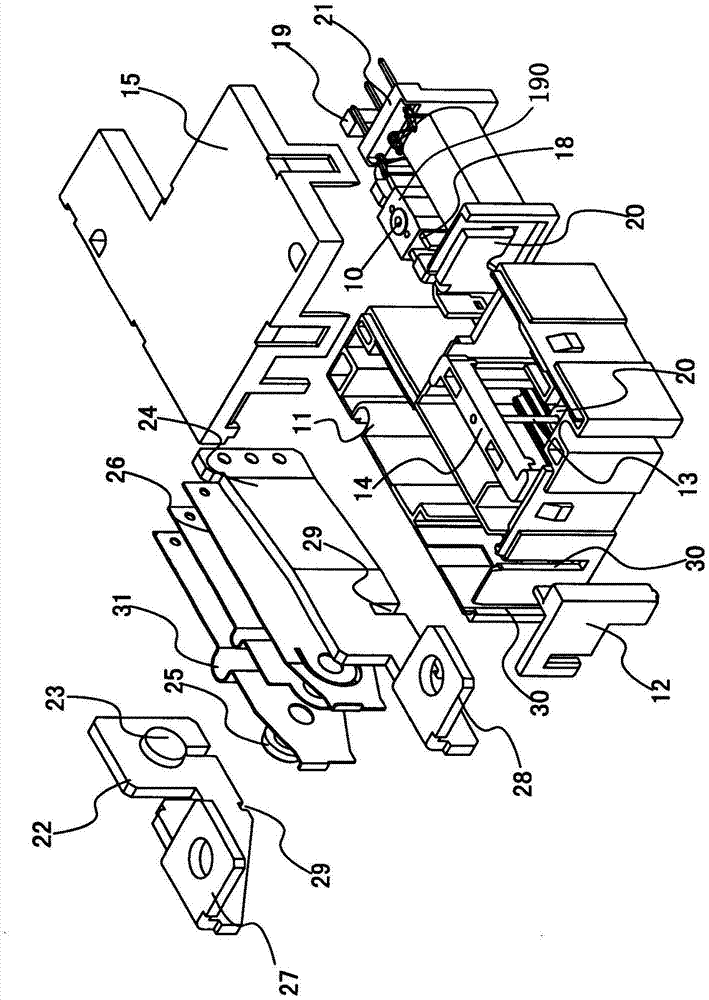

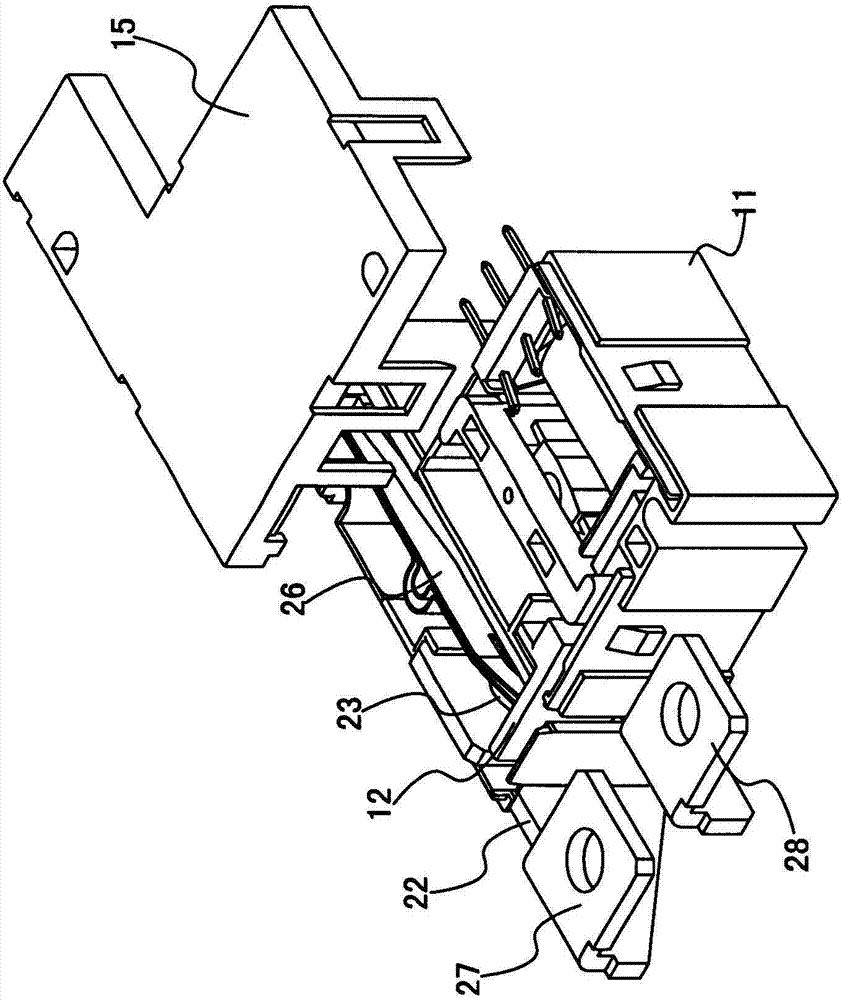

Electromagnetic relay and movable contact spring thereof

ActiveCN103794415AImprove flexibilityImprove mechanical propertiesElectromagnetic relay detailsNon-polarised relaysUltimate tensile strengthElectric signal

The invention provides an electromagnetic relay and a movable contact spring of the electromagnetic relay. The electromagnetic relay comprises a contact assembly, an electromagnetic assembly, an armature assembly and a push card. The contact assembly is kept in a normally-open state or a normally-closed state through the magnetic attraction action of a permanent magnet in an armature. Conversion between the normally-open state and the normally-closed state of the contact assembly is triggered through a pulse electric signal, so that the electromagnetic assembly drives the armature assembly to drive the push card to move, and state conversion of the contact assembly is achieved through movement of the push card. The first end, located in the contact assembly, of the movable contact spring is fixedly connected to a leading-out piece, and a movable contact is fixed to the second end of the movable contact spring. The second end of the movable contact spring is connected with the push card. The movable contact spring comprises a plurality of overlapped reeds, and at least one reinforcing rib is formed at the second end of one of the reeds. Concave and convex ribs are additionally arranged at the head portions of all the reeds, the head portions of the reeds can be selectively hardened, and the mechanical strength of the reeds is improved.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

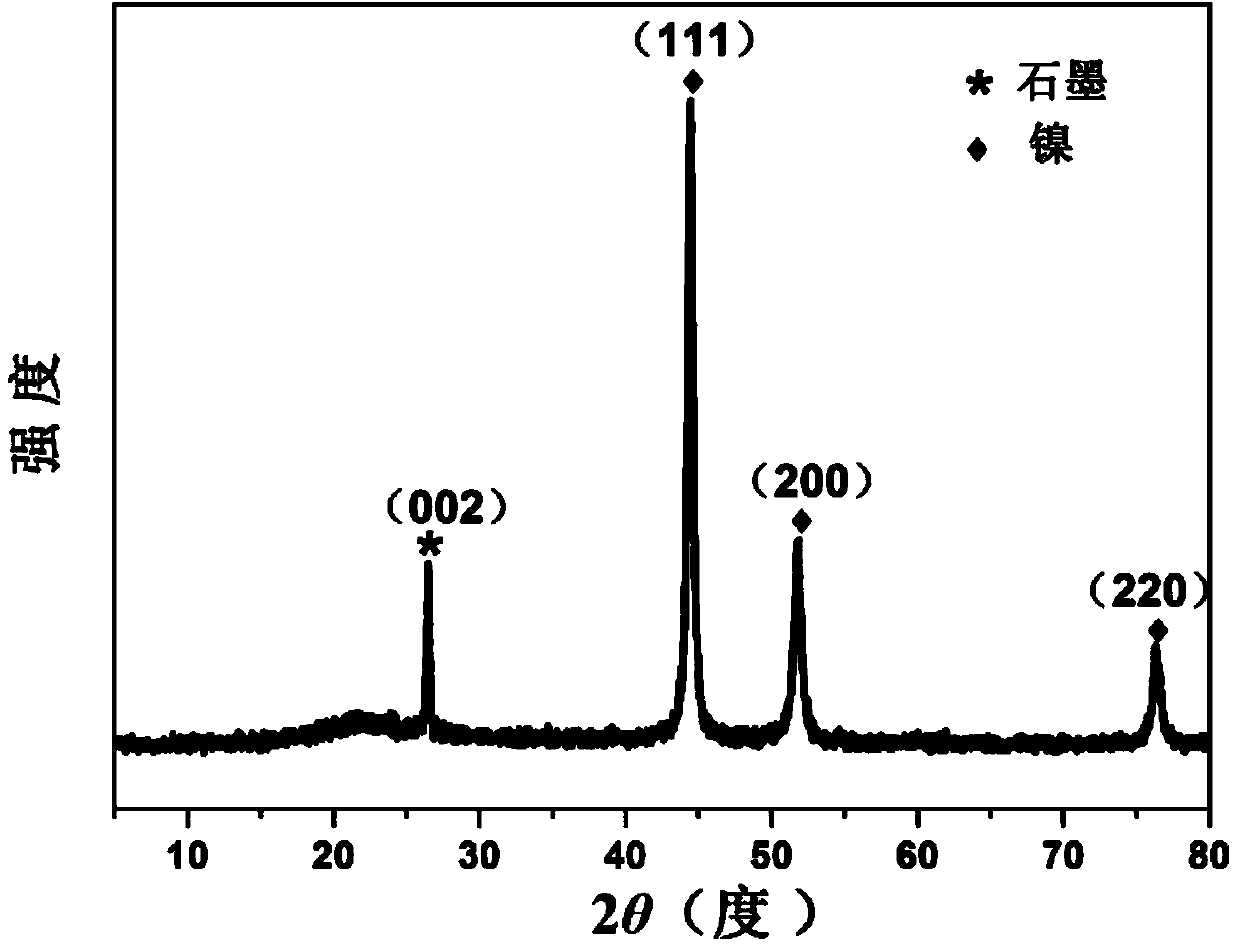

Nickel-coated graphite composite particle preparation method

ActiveCN103691937AImprove conductivityImprove magnetic permeabilityLiquid/solution decomposition chemical coatingSulfateCompound (substance)

The invention relates to a nickel-coated graphite composite particle preparation method including the steps of 1) cleaning, filtering and drying surfaces of flake graphite particles, 2) placing the cleaned flake graphite particles into nickel sulfate solution to adsorb nickel ion and then filtering and drying, 3) reducing the nickel ion on the surfaces of the flake graphite particles and then filtering, washing and drying, and 4) placing the flake graphite particles subjected to treatment of the step 3) into chemical nickel plating solution, stirring to react at the temperature of 80-90 DEG C, and then filtering, washing and drying to obtain the nickel-coated graphite composite particles. The nickel-coated graphite composite particle preparation method is easy and low in cost, and the composite particles prepared by the method have excellent electric conductivity and magnetic conductivity.

Owner:WUHAN UNIV OF TECH

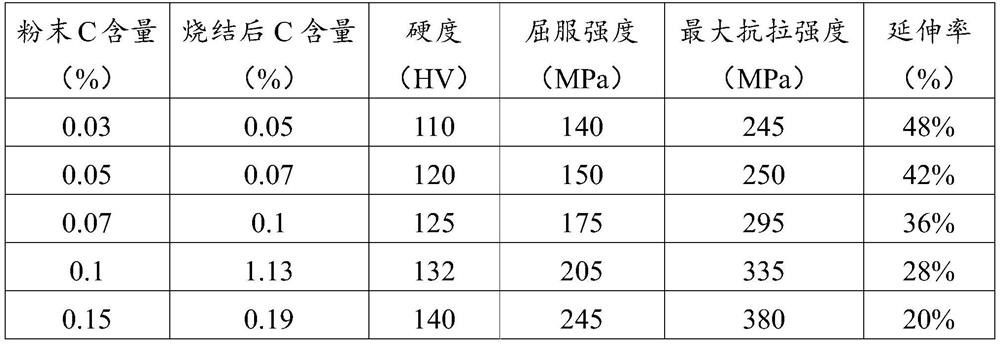

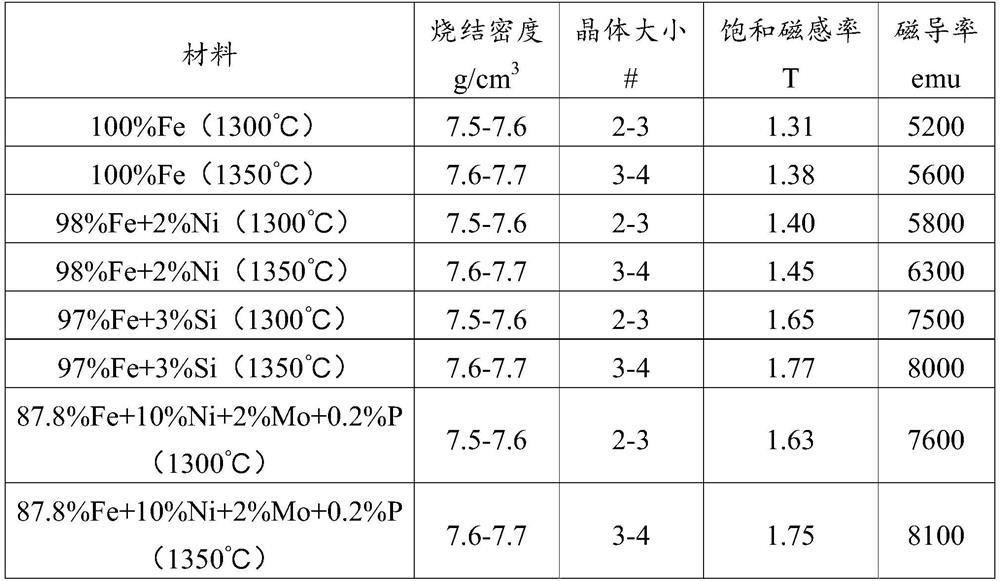

Powder material and machining method for metal injection molding

PendingCN111774570AImprove uniformityHigh magnetic permeabilityTransportation and packagingMetal-working apparatusMolding machineMetal machining

The invention discloses a machining method for metal injection molding, and belongs to the technical field of metal machining. The method comprises the following steps: preparing metal powder, whereinthe metal powder comprises the following components in percentage by mass: 87.8% of iron, 10% of nickel, 2% of molybdenum and 0.2% of phosphorus; adding a binder into the prepared metal powder, and carrying out mixing and granulating to obtain a metal powder injection feed; putting the metal powder injection feed into a metal powder injection molding machine to obtain a green body; degreasing thegreen body at the temperature of 100-140 DEG C for 3-5 hours, wherein nitric acid is added at the speed of 2-4 ml / min in the degreasing process, nitrogen is introduced at the speed of 80-90 L / min, and thus a degreased green body is obtained; and sintering the degreased green body at 1200-1350 DEG C, then carrying out cooling to 500-600 DEG C, and carrying out annealing. With the technical scheme,the magnetic permeability of the product can be improved, and the magnetic stability can be improved.

Owner:深圳市泛海统联精密制造股份有限公司

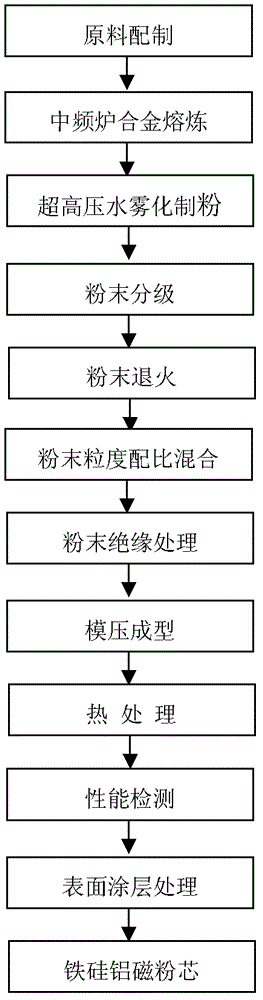

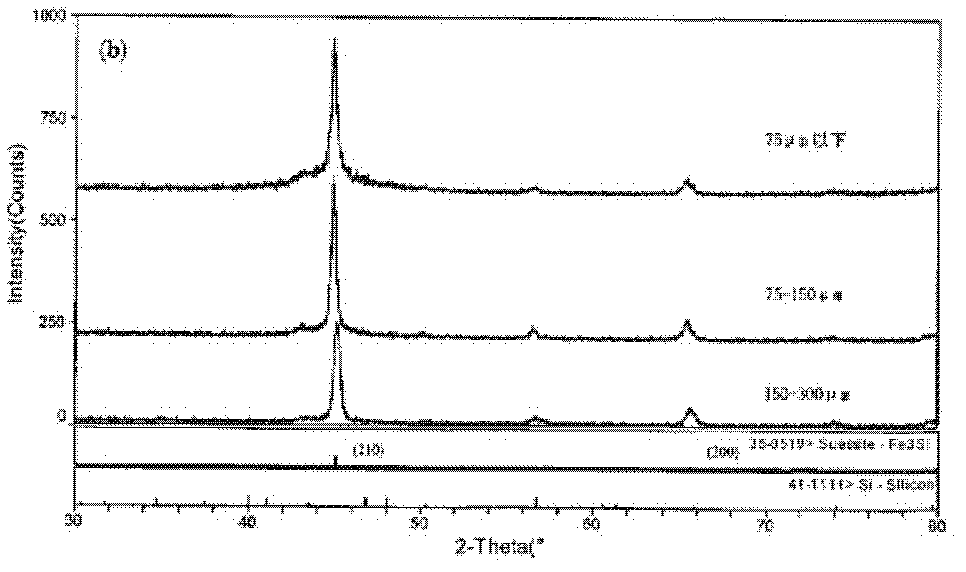

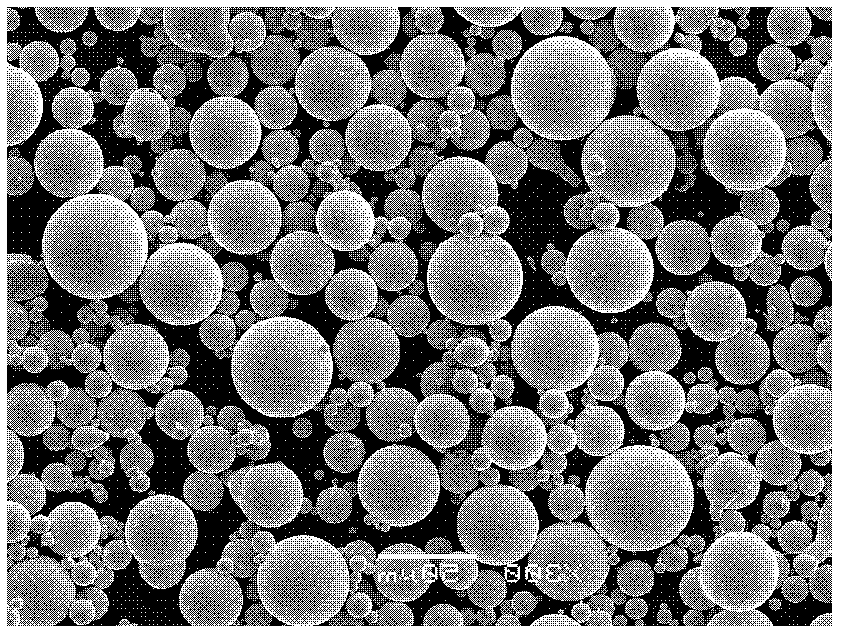

Manufacturing method of high permeability low power consumption Fe-Si-AI magnetic powder cores

InactiveCN103065786AHigh magnetic permeabilityReduce power lossInductances/transformers/magnets manufactureMedium frequencyInduction furnace

The invention relates to a manufacturing method of high permeability low power consumption Fe-Si-AI magnetic powder cores. The method includes the following steps: adopting protective agents to cover a non-vacuum medium-frequency induction furnace for smelting Fe-Si-AI alloy melt; atomizing the Fe-Si-AI alloy melt into alloy powder through an ultrahigh pressure water atomization powder processing device, then carrying out screening and classifying after annealing process on the alloy powder; distributing the powder with the following grain sizes: 15% in -100 meshes-150 meshes, 55% in -150 meshes-250 meshes, 25% in -250 meshes-300 meshes and 5% in -300 meshes; and adopting insulating treatment on the Fe-Si-AI alloy powder, adding binding agents and release agents, molding through compression, and obtaining the Fe-Si-AI magnetic powder cores after heat treatment. The manufacturing method has the advantages of adopting the non-vacuum medium-frequency induction furnace for alloy smelting, being low in smelting cost, small in device investment, and convenient to operate in the production process compared with an existing vacuum medium-frequency induction furnace which is in use. Through reasonable proportioning of size grading and size distribution of the Fe-Si-AI alloy powder, the packing density of the Fe-Si-AI alloy powder is enabled to be the best. Magnetic permeability of the Fe-Si-AI magnetic powder cores is greatly improved, and power loss of the Fe-Si-AI magnetic powder cores is reduced.

Owner:HUNAN KANGLI NEW MATERIAL TECH

Microcrystalline soft magnetic powder material and preparation method thereof

InactiveCN101572150AUse to avoidReduce manufacturing costInorganic material magnetismHigh volume manufacturingUltimate tensile strength

The invention provides a microcrystalline soft magnetic powder material with high saturation magnetization. The material has high magnetic conductivity, is made of common raw materials and has low manufacturing cost. The invention also provides a preparation method for the microcrystalline soft magnetic powder material. The method has simple process and is suitable for industrialized mass production. The microcrystalline soft magnetic powder material comprises the following components by weight: 4 to 7 percent of Al, 7 to 12 percent of Si, 0.05 to 0.2 percent of Cu, 0.1 to 0.5 percent of Zr, 0.5 to 2.5 percent of B, 0.05 to 0.1 percent of Pr, 0.05 to 0.1 percent of La, 0.01 to 0.05 percent of P and the balance of Fe.

Owner:南京深宁磁电有限公司

Rectangular amorphous-nanocrystalline magnetic core and preparation method thereof

InactiveCN106298218AHigh magnetic permeabilityReduce manufacturing costInductances/transformers/magnets manufactureMagnetic materialsEpoxyWinding machine

The invention discloses a rectangular amorphous-nanocrystalline magnetic core and a preparation method thereof. The specific preparation process includes the following steps that cobalt is added into an iron-based amorphous-nanocrystalline raw material; a cobalt-based amorphous-nanocrystalline strip is wound into an annular iron core through a winding machine; the annular iron core is put in a rectangular mold; the rectangular mold is put in a vacuum annealing furnace for thermal treatment; the rectangular mold is detached, and a rectangular crystallized magnetic core is obtained; the end face of the rectangular crystallized iron core is spray-coated with stress-free epoxy resin dry glue, the rectangular crystallized iron core is naturally air-dried, and the finished rectangular amorphous-nanocrystalline magnetic core is obtained; the finished rectangular amorphous-nanocrystalline magnetic core obtained in S6 is detected by an MATS-2010S soft magnetic material dynamic tester, and packing and binding are carried out after it is detected that the standard is met. The magnetic permeability of an iron-based amorphous-nanocrystalline magnetic core is improved, iron losses of the iron-based amorphous-nanocrystalline magnetic core are reduced, additional losses caused by the traditional impregnation curing process are avoided, the finished product percent of pass of the amorphous-nanocrystalline magnetic core is increased, and the production cost of a high-power transformer is reduced.

Owner:上海煦韵电子科技有限公司

Self-adaptive magnetic-conducting slot wedge and preparation method thereof

InactiveCN102780297AReduce churnImprove magnetic permeabilityWindingsManufacturing dynamo-electric machinesGlass fiberVacuum pressure

The invention discloses a self-adaptive magnetic-conducting slot wedge, which is installed at slot opening on a stator / rotor of a motor, and suitable for being treated by a VPI (vacuum pressure impregnation) technical process. The self-adaptive magnetic-conducting slot wedge comprises a magnetic-conducting layer and two layers of second expandable felts with an expansion action, wherein the second expandable felts are arranged at the outer side of the magnetic-conducting layer, and a first expandable felt is arranged at the outer side of each of the two layers of second expandable felts; each first expandable felt comprises a glass fibre cloth layer and a common expandable felt with an expansion action; the second expandable felts and the common expandable felts form expandable layers; and gluing layers are arranged among the various material layers. By adopting the self-adaptive magnetic-conducting slot wedge provided by the invention, the slot wedge can be closely filled in the slot opening, the bonding force between the slot openings and the slot wedge is good, and the mechanical strength is high, so that the magnetic-conducting capacity of the slot wedge is enhanced, flux in slot is uniform, the loss of the motor is reduced, and the efficiency of the motor is increased.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com