High frequency soft magnetic material composed of rare earth, iron and nitrogen, as well as composite material prepared by same and preparation methods thereof

A soft magnetic material, rare earth iron nitrogen technology, applied in the direction of magnetic materials, inorganic material magnetism, metal material coating technology, etc., can solve the problems of narrow frequency band, high complex magnetic permeability, low magnetic permeability, etc., and achieve wide resonance frequency, the effect of strongly absorbing microwaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 (preparation of high frequency soft magnetic material)

[0022] Weigh 2.43g of praseodymium and 7.71g of iron, and melt them into ingots under the protection of argon. Annealed in a vacuum quartz tube at 1000 °C for one week. Grind the annealed ingot into particles of about 70 microns with an agate mortar, then wet-mill the particles with a planetary ball mill by adding 100ml of isopropanol and 0.2ml of phthalate coupling agent, the ball-to-material ratio is 20:1, and ball mill The speed is 200r / min, the ball milling time is set to 8h, and finally the sample is dried and nitrided at 480°C for 2h to obtain Pr 2 Fe 17 N 3-δ Material. Pressed into test sample by the same method as embodiment 1 and tested, its test result is referring to appendix image 3 And attached Figure 4 .

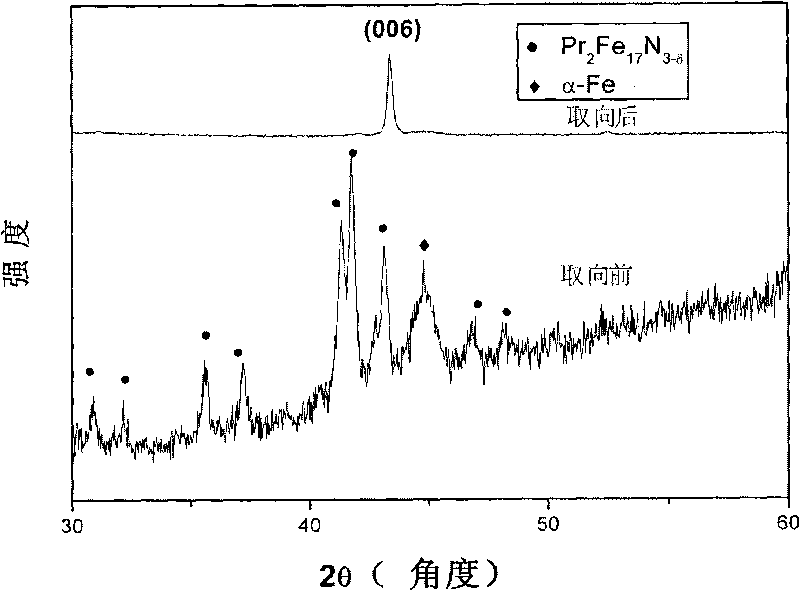

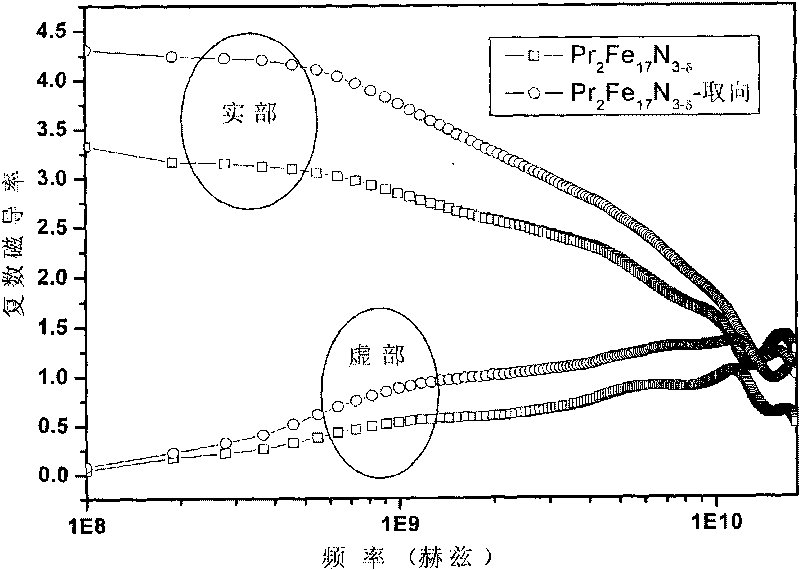

[0023] Depend on figure 1 It can be seen that the material obtained in this example is basically Pr with a small amount of α-Fe 2 Fe 17 N 3-δ sample. Depend on Figure 4...

Embodiment 2

[0024] Embodiment 2 (composite material preparation)

[0025] Add the nitride obtained in Example 1 into the titanate coupling agent diluted with isopropanol at a mass ratio of 100:1, stir and sonicate for 30 minutes, and dry. After ultrasonication, mix the sample with paraffin wax diluted with n-hexane at a volume ratio of 35:65. When the mixture is in a gel state, put it into a mold made of non-magnetic material (the inner diameter is 3.04mm, the outer diameter is 7.00mm) Inside, put the mold into the magnetic field for rotation orientation, the magnetic field size is 0.8-1.2T (Tesla), the rotation speed is about 120 rpm, and after about 30 minutes, put the mold in an oven to dry the sample , and finally cured at 140°C to obtain a ring-shaped test sample with an inner diameter of 3.04mm, an outer diameter of 7.00mm, and a thickness of 2-3mm. For sample test results, see attached figure 1 And attached figure 2 .

Embodiment 3

[0027] Embodiment 3 (preparation of high frequency soft magnetic material)

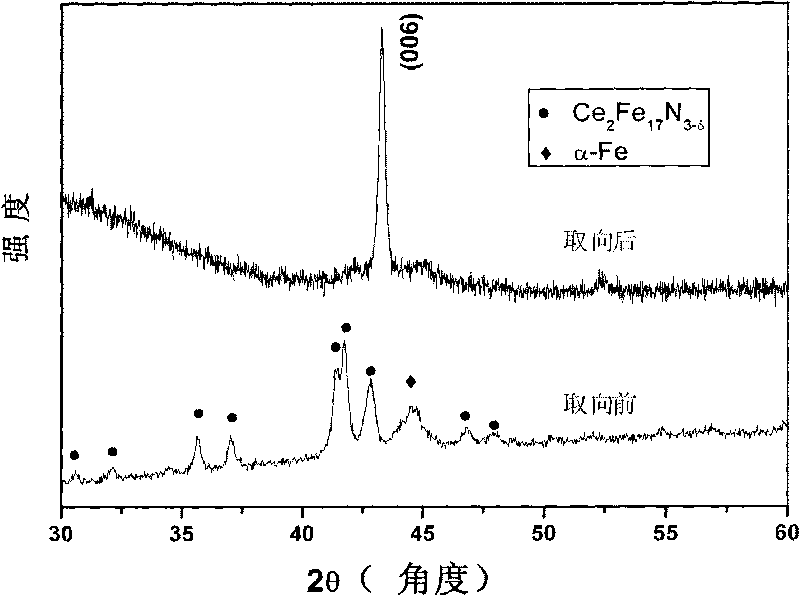

[0028] Weigh 2.43g of cerium and 7.71g of iron, and melt them into ingots under the protection of argon. Annealed in a vacuum quartz tube at 1000 °C for one week. Grind the annealed ingot into particles of about 70 microns with an agate mortar, then wet-mill the particles with a planetary ball mill by adding 100ml of isopropanol and 0.2ml of phthalate coupling agent, the ball-to-material ratio is 20:1, and ball mill The speed is 200r / min, the ball milling time is set to 8h, and finally the sample is dried and nitrided at 480°C for 2h to obtain Ce 2 Fe 17 N 3-δ Material. Add the coupling agent to the obtained material and mix it with paraffin wax diluted with n-hexane at a volume ratio of 35:65, press it into a ring-shaped sample with an inner diameter of 3.04mm, an outer diameter of 7.00mm, and a thickness of 2-3mm for testing. The test results are attached image 3 And attached Figure 4

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com