Ultra-micro capsule material, preparation method and application thereof

A capsule and ultra-micro technology, which is applied in the direction of microcapsule preparation, microsphere preparation, electrical components, etc., can solve the problems of insufficient complex dielectric constant value and low microwave absorption performance, and achieve excellent microwave absorption performance and low production cost , easy to amplify the effect of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

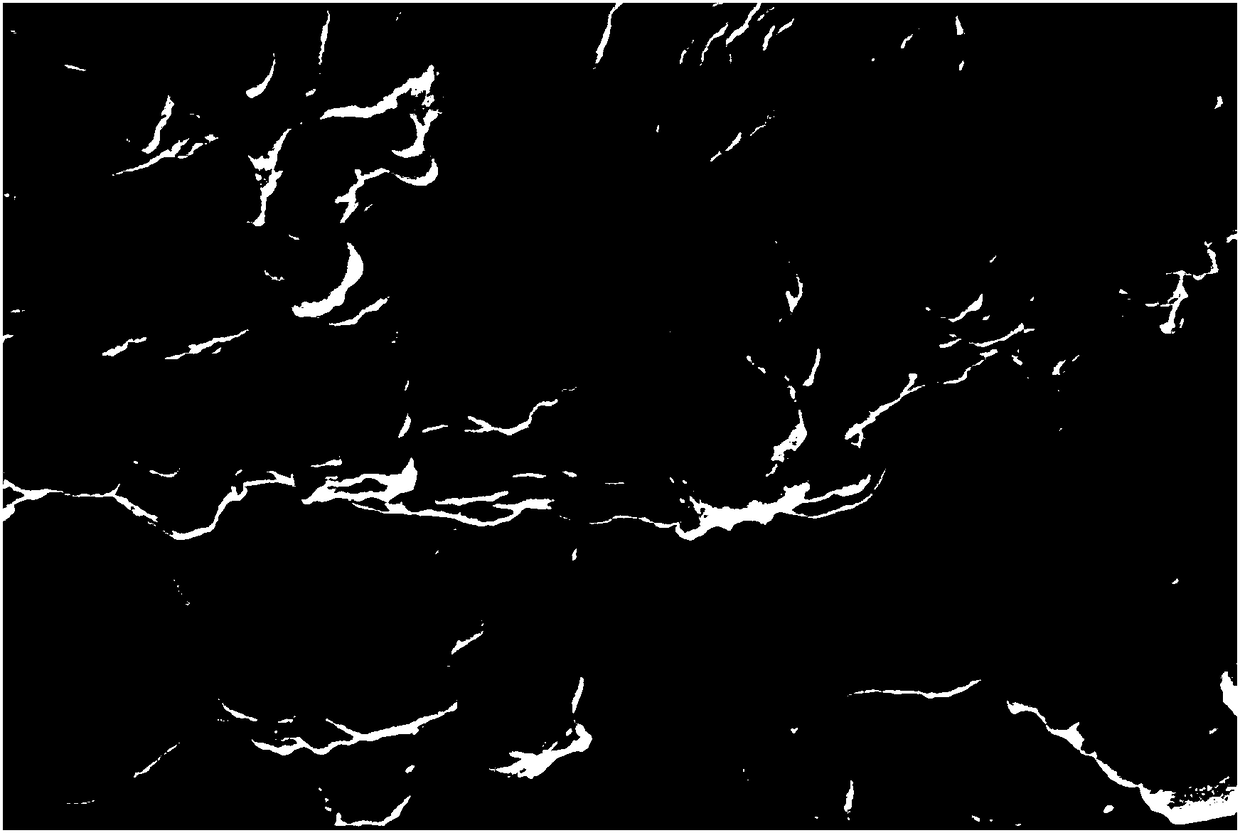

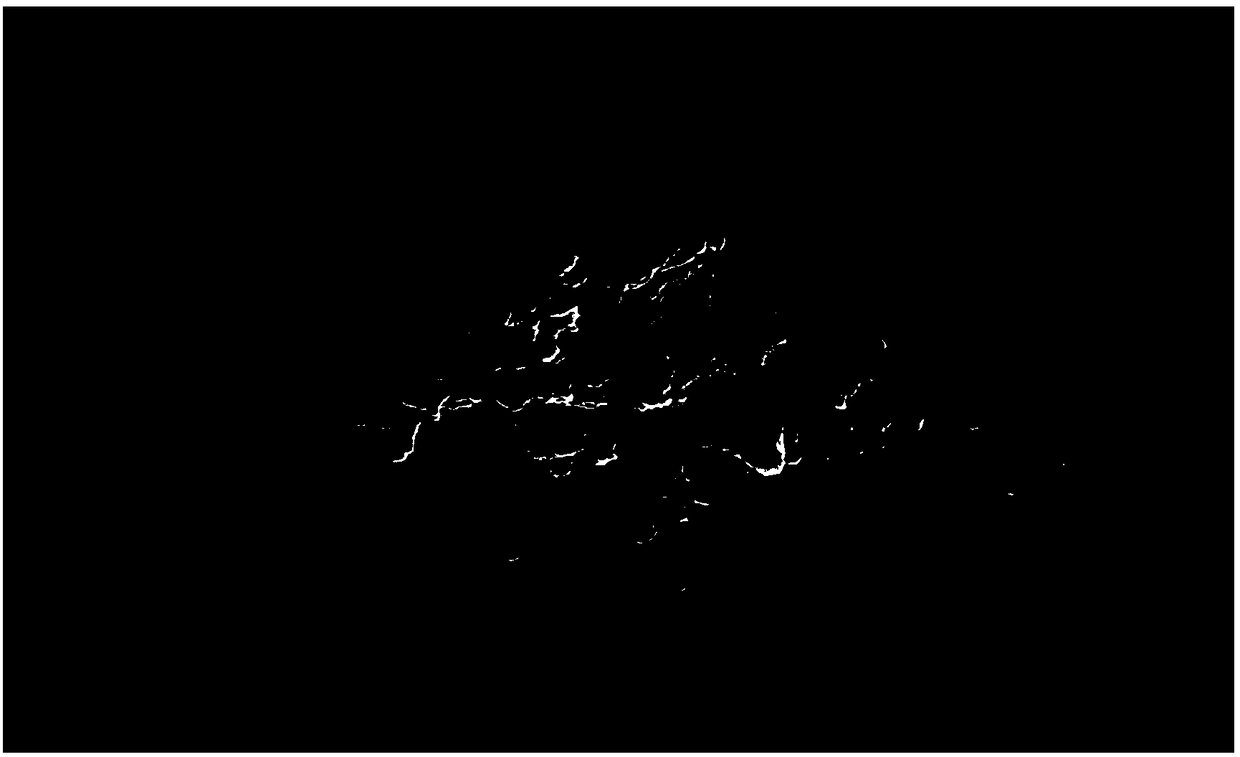

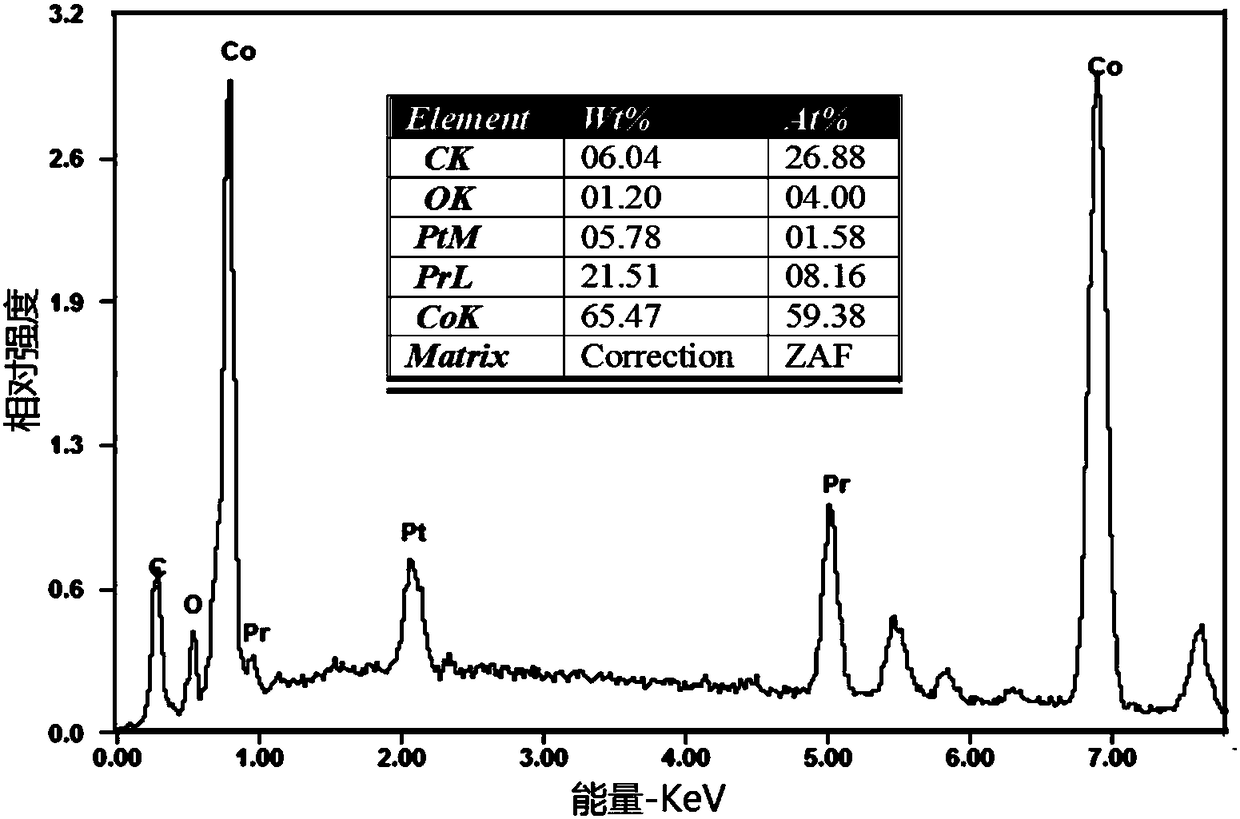

[0033] A kind of ultramicrocapsule material that present embodiment proposes, its structure is core-shell structure, by the rare earth cobalt magnet Pr 2 co 17 It consists of micron-sized particles and protonated polypyrrole as the outer shell covering the surface.

[0034] The preparation method of the ultramicrocapsule material of the present embodiment comprises the following steps:

[0035] Step 1: First prepare the rare earth cobalt magnet Pr 2 co 17 bulk body; then the rare earth cobalt magnet Pr 2 co 17 Lumps are crushed into rare earth cobalt magnets Pr 2 co 17 Powdery particles; due to the rare earth cobalt magnet Pr obtained after pulverization 2 co 17 The powder particle size is still large, so the rare earth cobalt magnet Pr 2 co 17 The powdered particles are ball milled and screened to obtain the rare earth cobalt magnet Pr 2 co 17 micron-sized particles. The micron-sized particles have high component purity, uniform size and good thermal stability. ...

Embodiment 2

[0045] A kind of ultramicrocapsule material that present embodiment proposes, its structure is core-shell structure, by the rare earth cobalt magnet Ce 2 co 17 It consists of micron-sized particles and protonated polypyrrole as the outer shell covering the surface.

[0046] The preparation method of the ultramicrocapsule material of the present embodiment comprises the following steps:

[0047] Step 1: First prepare the rare earth cobalt magnet Ce 2 co 17 block; then the rare earth cobalt magnet Ce 2 co 17 Lumps crushed into rare earth cobalt magnets Ce 2 co 17 Powdery particles; due to the rare earth cobalt magnet Ce obtained after pulverization 2 co 17 The powder particle size is still large, so the rare earth cobalt magnet Ce 2 co 17 Powdered particles are ball milled and screened to obtain rare earth cobalt magnets Ce 2 co 17 micron-sized particles. The micron-sized particles have high component purity, uniform size and good thermal stability.

[0048] In thi...

Embodiment 3

[0053] A kind of ultramicrocapsule material that present embodiment proposes, its structure is core-shell structure, is made of rare earth cobalt magnet Nd as inner core 2 co17 It consists of micron-sized particles and protonated polypyrrole as the outer shell covering the surface.

[0054] The preparation method of the ultramicrocapsule material of the present embodiment comprises the following steps:

[0055] Step 1: First prepare the rare earth cobalt magnet Nd 2 co 17 block; then the rare earth cobalt magnet Nd 2 co 17 Lumps crushed into rare earth cobalt magnets Nd 2 co 17 Powdered particles; due to the rare earth cobalt magnet Nd obtained after crushing 2 co 17 The powder particle size is still large, so the rare earth cobalt magnet Nd 2 co 17 Powdered particles are ball milled and screened to obtain rare earth cobalt magnets Nd 2 co 17 micron-sized particles. The micron-sized particles have high component purity, uniform size and good thermal stability.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com