Patents

Literature

37results about How to "High magnetic permeability μ" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

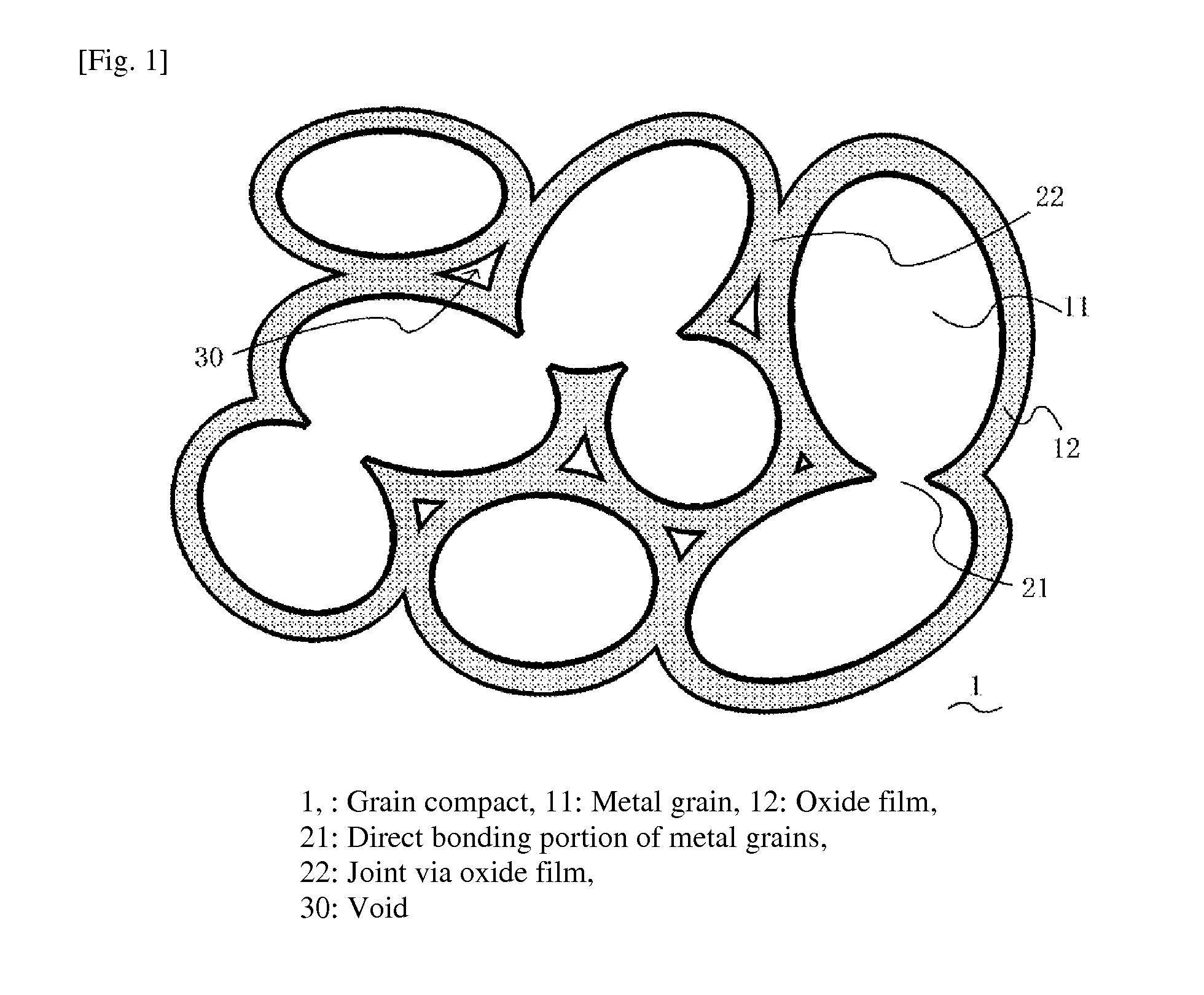

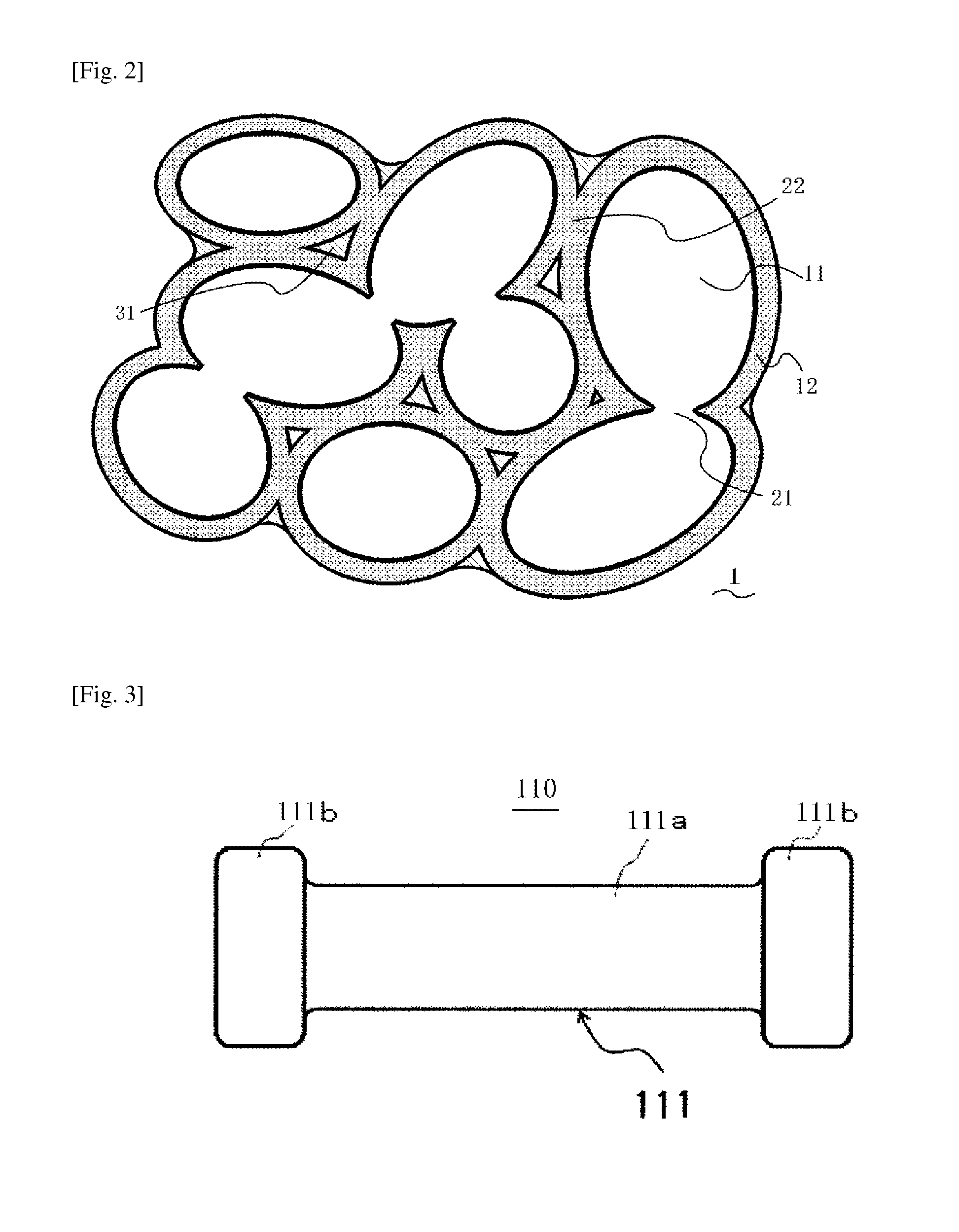

Magnetic material and coil component using the same

ActiveUS20120274437A1High magnetic permeabilityHigh resistanceTransformers/inductances casingsTransformers/inductances coils/windings/connectionsCrystalliteOxide

A magnetic material constituted by a grain-compacted body comprising a plurality of metal grains made of a Fe—Si—M soft magnetic alloy (where M is a metal element more easily oxidized than Fe) and an oxide film formed on the surface of the metal grains; wherein there are bonding portions via the oxide film formed on the surfaces of adjacent metal grains and direct bonding portions of metal grains in locations where the oxide film is not present.

Owner:TAIYO YUDEN KK

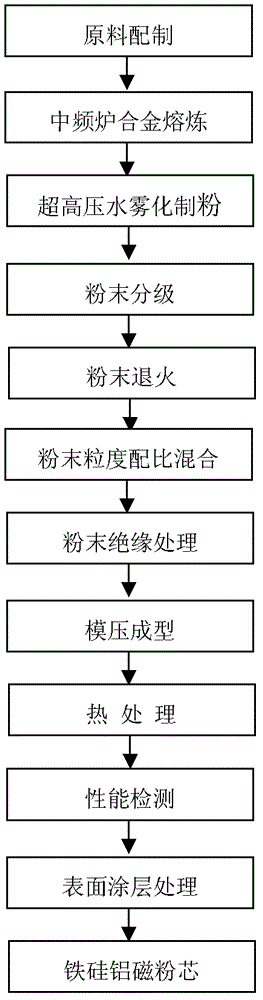

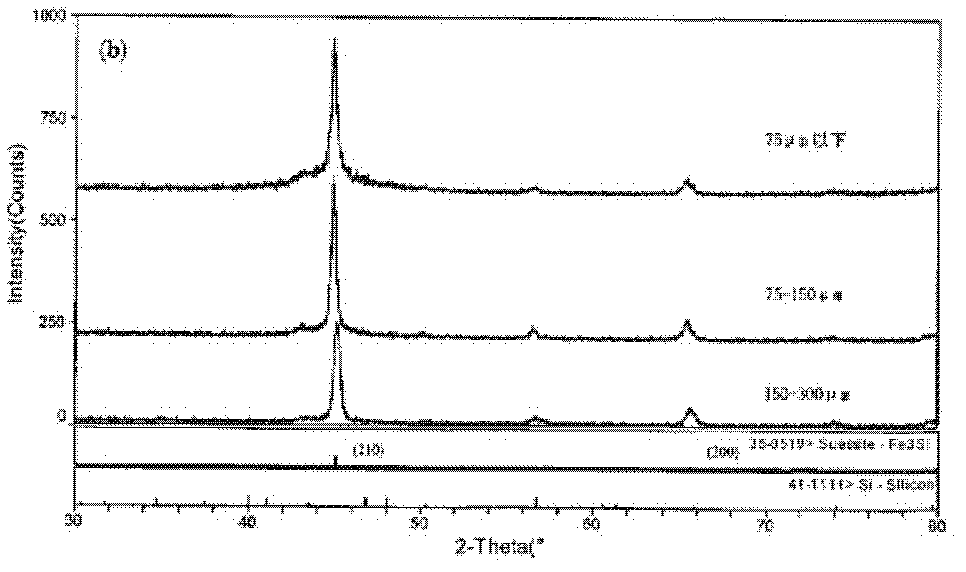

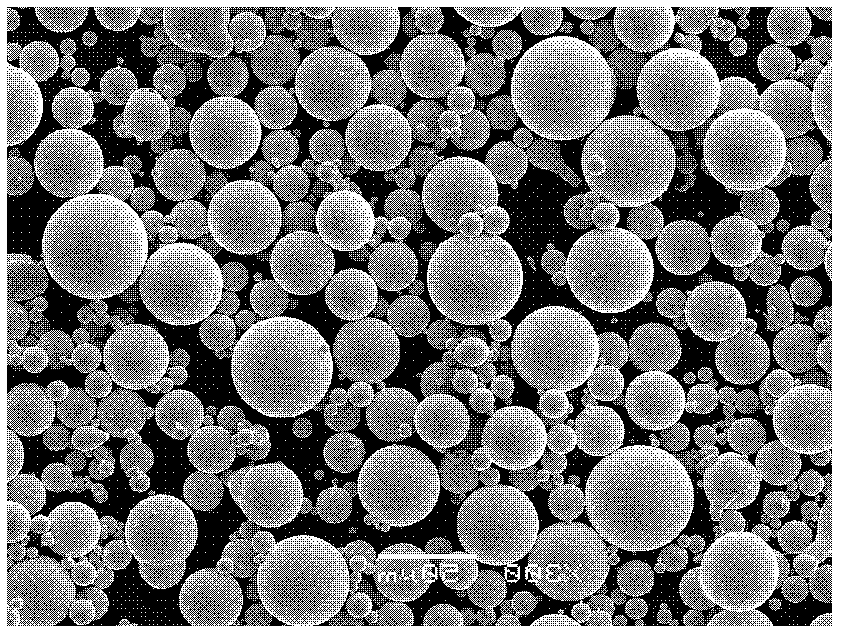

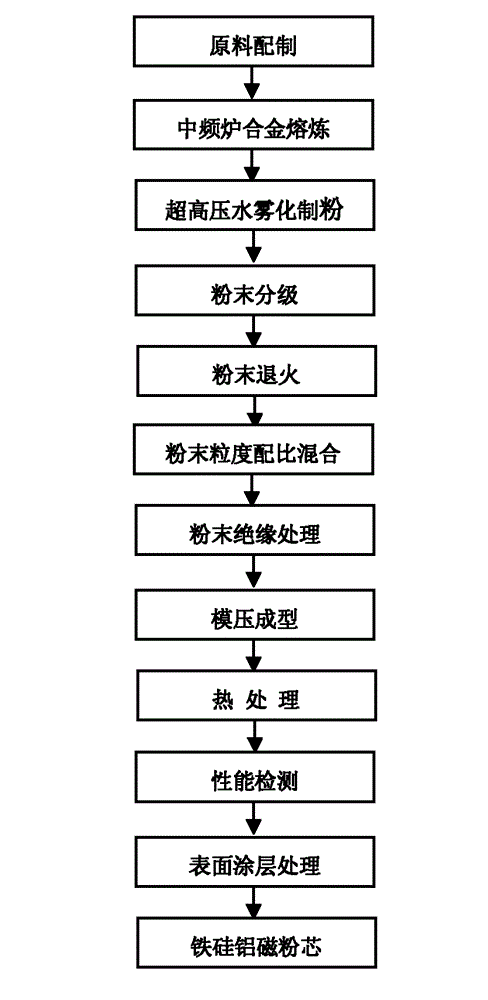

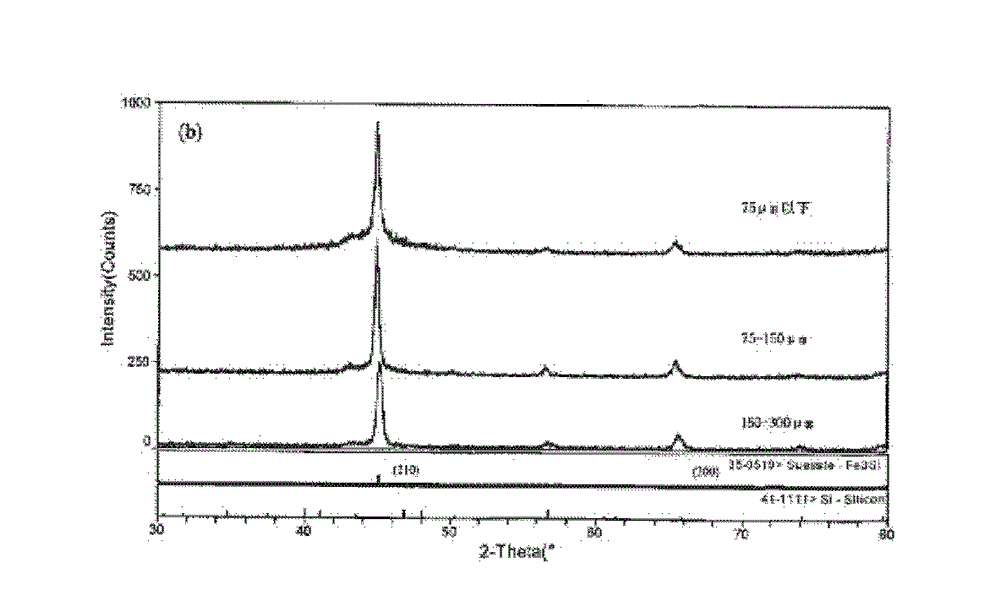

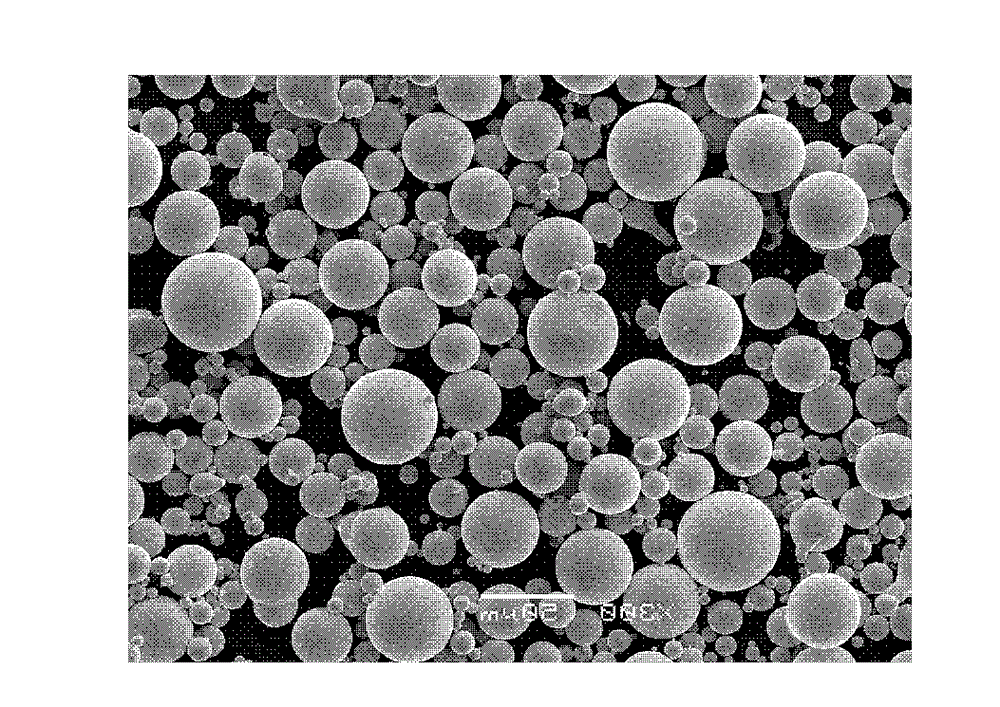

Manufacturing method of high permeability low power consumption Fe-Si-AI magnetic powder cores

InactiveCN103065786AHigh magnetic permeabilityReduce power lossInductances/transformers/magnets manufactureMedium frequencyInduction furnace

The invention relates to a manufacturing method of high permeability low power consumption Fe-Si-AI magnetic powder cores. The method includes the following steps: adopting protective agents to cover a non-vacuum medium-frequency induction furnace for smelting Fe-Si-AI alloy melt; atomizing the Fe-Si-AI alloy melt into alloy powder through an ultrahigh pressure water atomization powder processing device, then carrying out screening and classifying after annealing process on the alloy powder; distributing the powder with the following grain sizes: 15% in -100 meshes-150 meshes, 55% in -150 meshes-250 meshes, 25% in -250 meshes-300 meshes and 5% in -300 meshes; and adopting insulating treatment on the Fe-Si-AI alloy powder, adding binding agents and release agents, molding through compression, and obtaining the Fe-Si-AI magnetic powder cores after heat treatment. The manufacturing method has the advantages of adopting the non-vacuum medium-frequency induction furnace for alloy smelting, being low in smelting cost, small in device investment, and convenient to operate in the production process compared with an existing vacuum medium-frequency induction furnace which is in use. Through reasonable proportioning of size grading and size distribution of the Fe-Si-AI alloy powder, the packing density of the Fe-Si-AI alloy powder is enabled to be the best. Magnetic permeability of the Fe-Si-AI magnetic powder cores is greatly improved, and power loss of the Fe-Si-AI magnetic powder cores is reduced.

Owner:HUNAN KANGLI NEW MATERIAL TECH

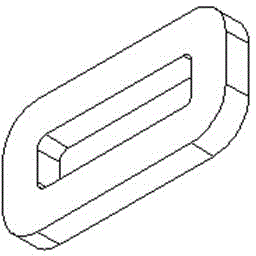

Rectangular amorphous-nanocrystalline magnetic core and preparation method thereof

InactiveCN106298218AHigh magnetic permeabilityReduce manufacturing costInductances/transformers/magnets manufactureMagnetic materialsEpoxyWinding machine

The invention discloses a rectangular amorphous-nanocrystalline magnetic core and a preparation method thereof. The specific preparation process includes the following steps that cobalt is added into an iron-based amorphous-nanocrystalline raw material; a cobalt-based amorphous-nanocrystalline strip is wound into an annular iron core through a winding machine; the annular iron core is put in a rectangular mold; the rectangular mold is put in a vacuum annealing furnace for thermal treatment; the rectangular mold is detached, and a rectangular crystallized magnetic core is obtained; the end face of the rectangular crystallized iron core is spray-coated with stress-free epoxy resin dry glue, the rectangular crystallized iron core is naturally air-dried, and the finished rectangular amorphous-nanocrystalline magnetic core is obtained; the finished rectangular amorphous-nanocrystalline magnetic core obtained in S6 is detected by an MATS-2010S soft magnetic material dynamic tester, and packing and binding are carried out after it is detected that the standard is met. The magnetic permeability of an iron-based amorphous-nanocrystalline magnetic core is improved, iron losses of the iron-based amorphous-nanocrystalline magnetic core are reduced, additional losses caused by the traditional impregnation curing process are avoided, the finished product percent of pass of the amorphous-nanocrystalline magnetic core is increased, and the production cost of a high-power transformer is reduced.

Owner:上海煦韵电子科技有限公司

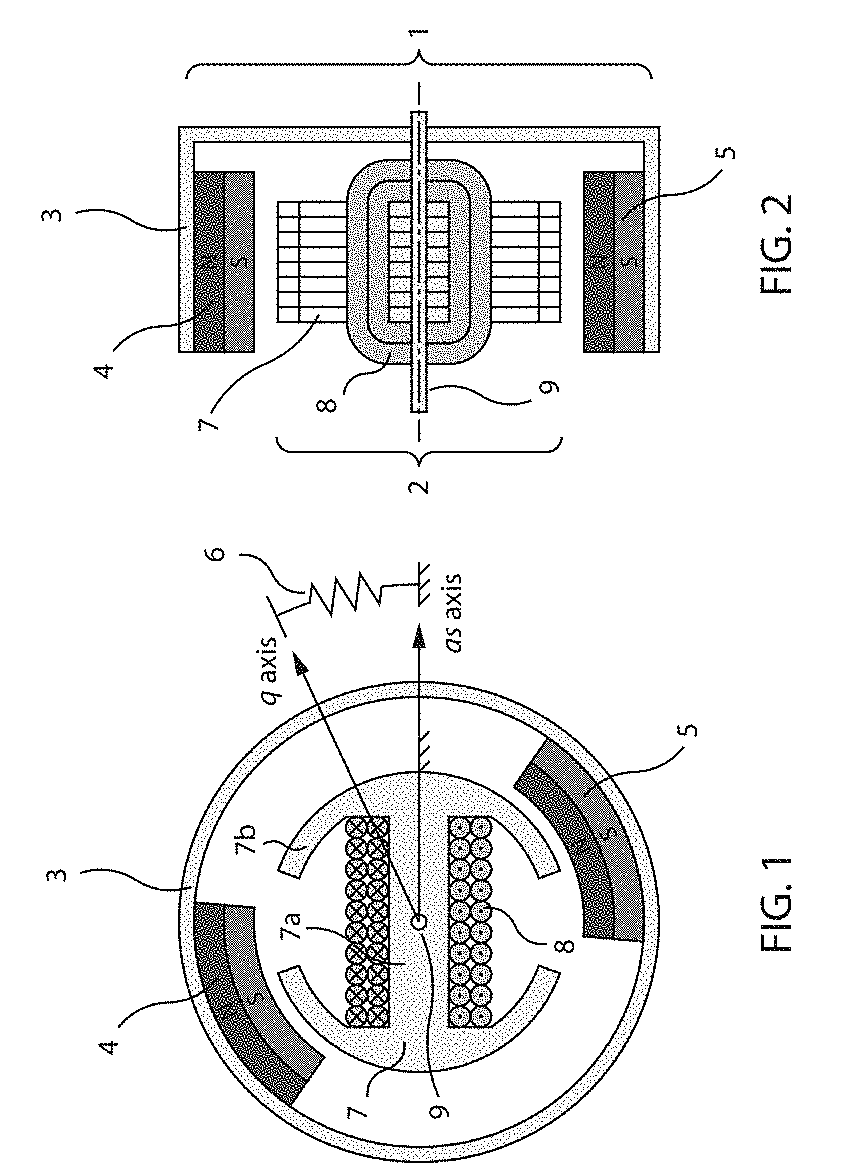

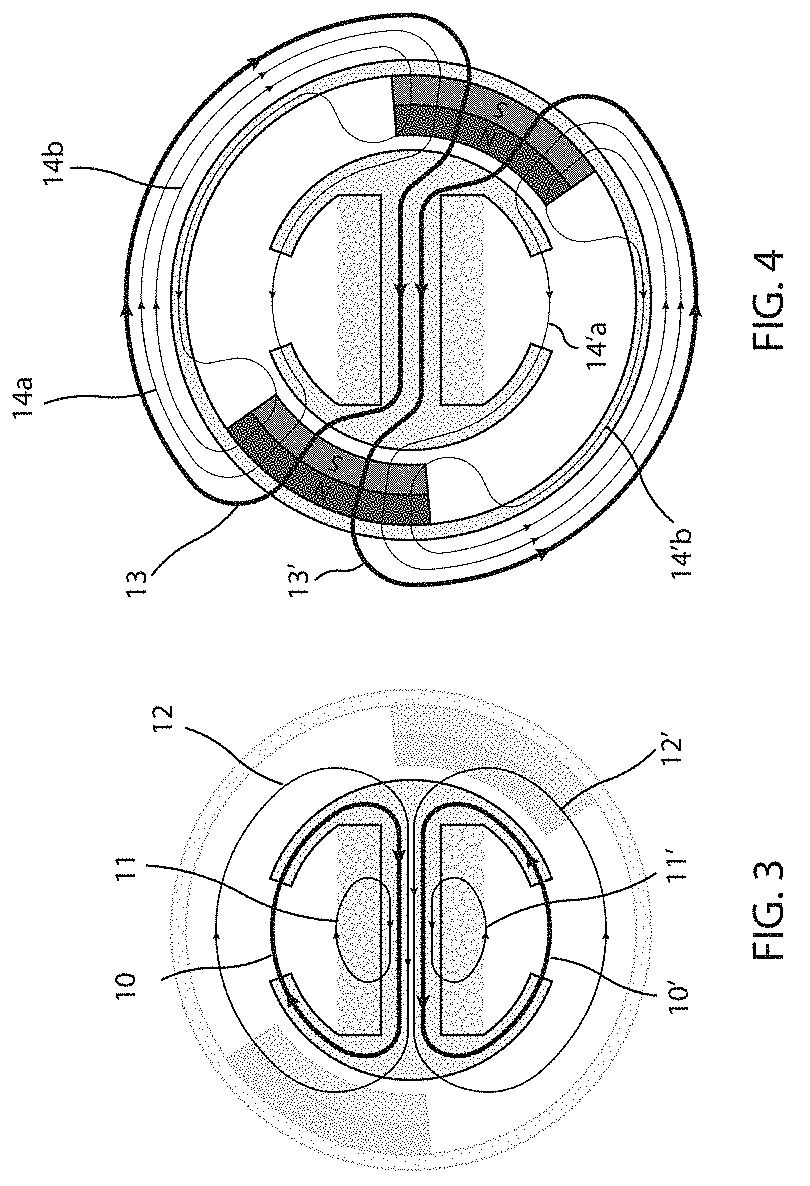

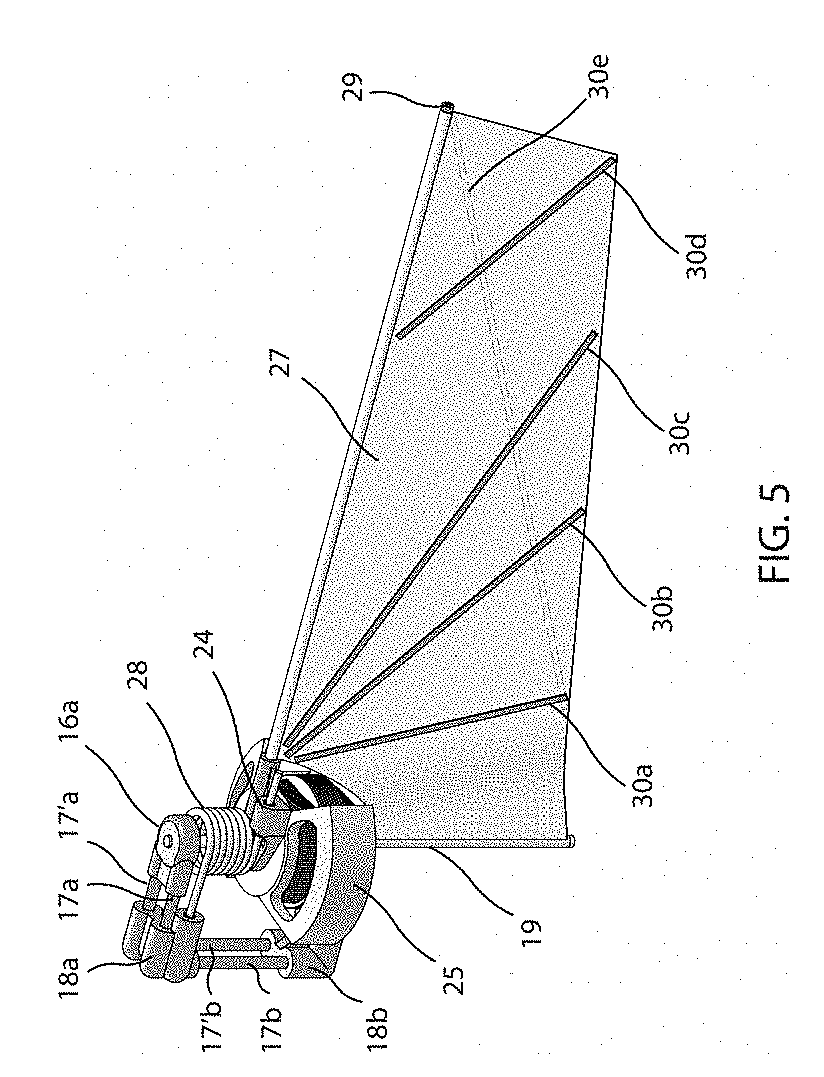

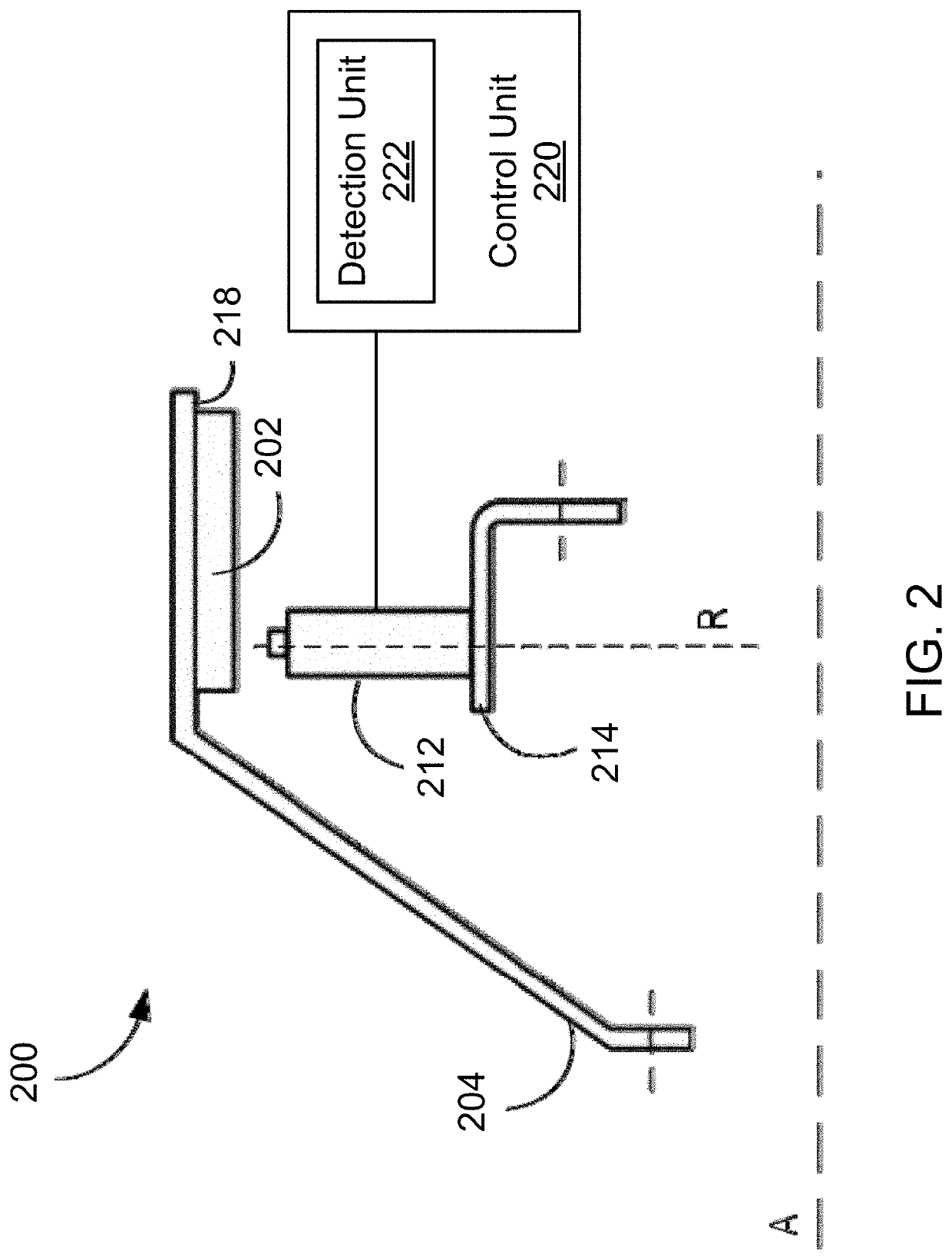

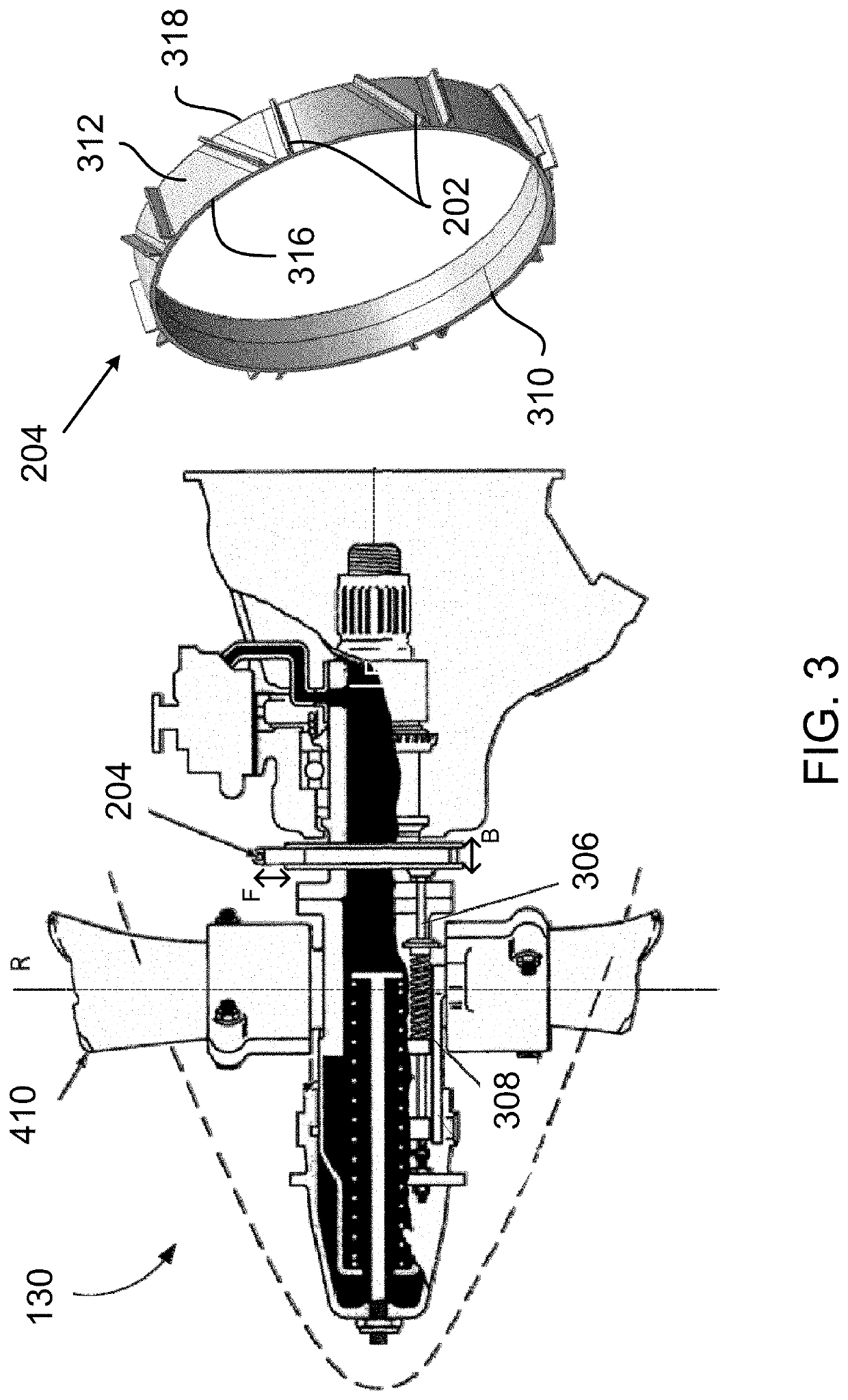

Actuating devide and method of making the same

ActiveUS20180342938A1Reduce momentHigh magnetic permeabilityMagnetic circuit rotating partsMagnetic circuit stationary partsFlight vehicleUnderwater vehicle

Disclosed herein are permanent magnetic AC machine direct-drive resonant flapper system for flapping wing micro air vehicles and flapping fin autonomous underwater vehicles.

Owner:PURDUE RES FOUND INC

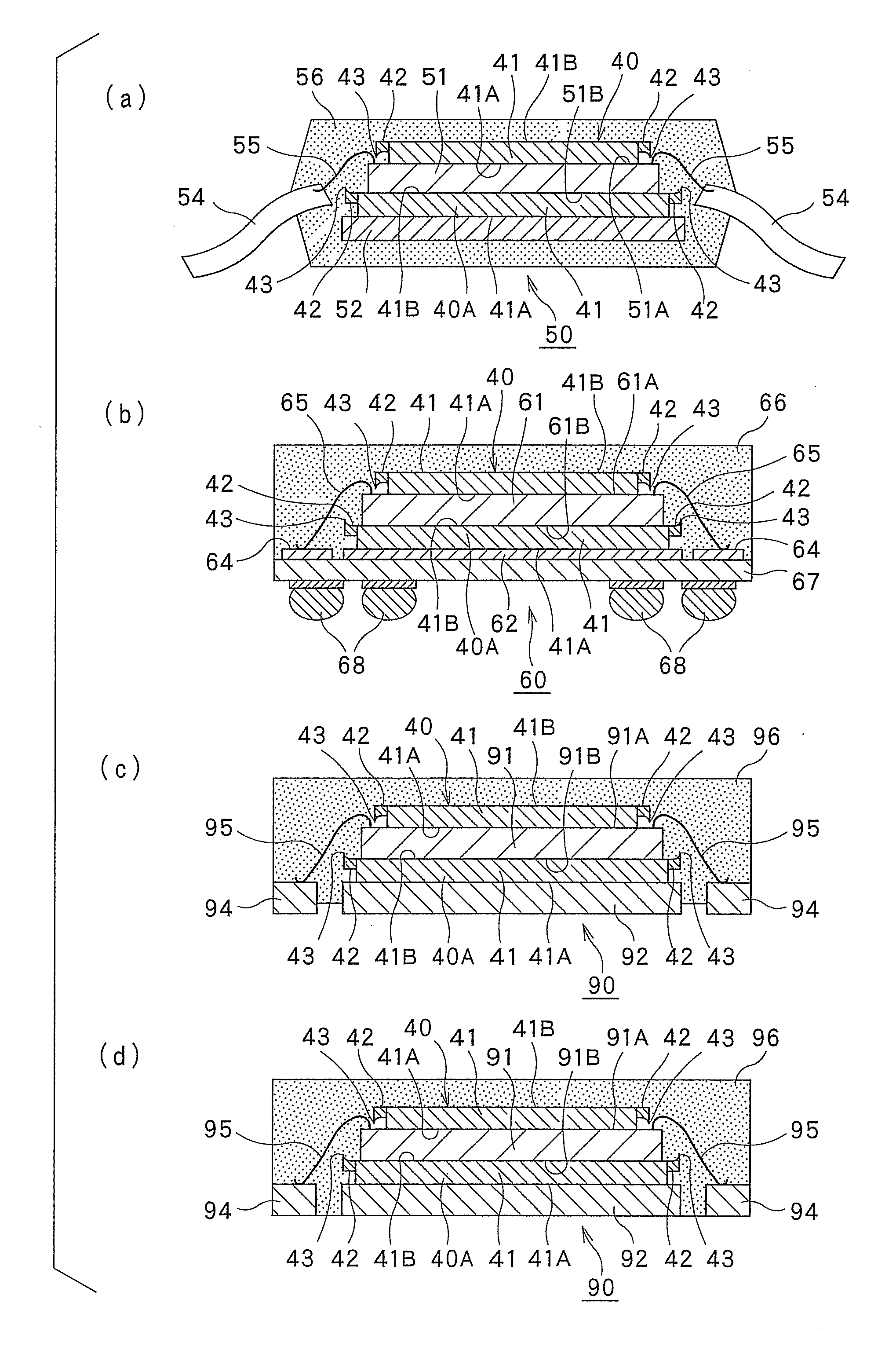

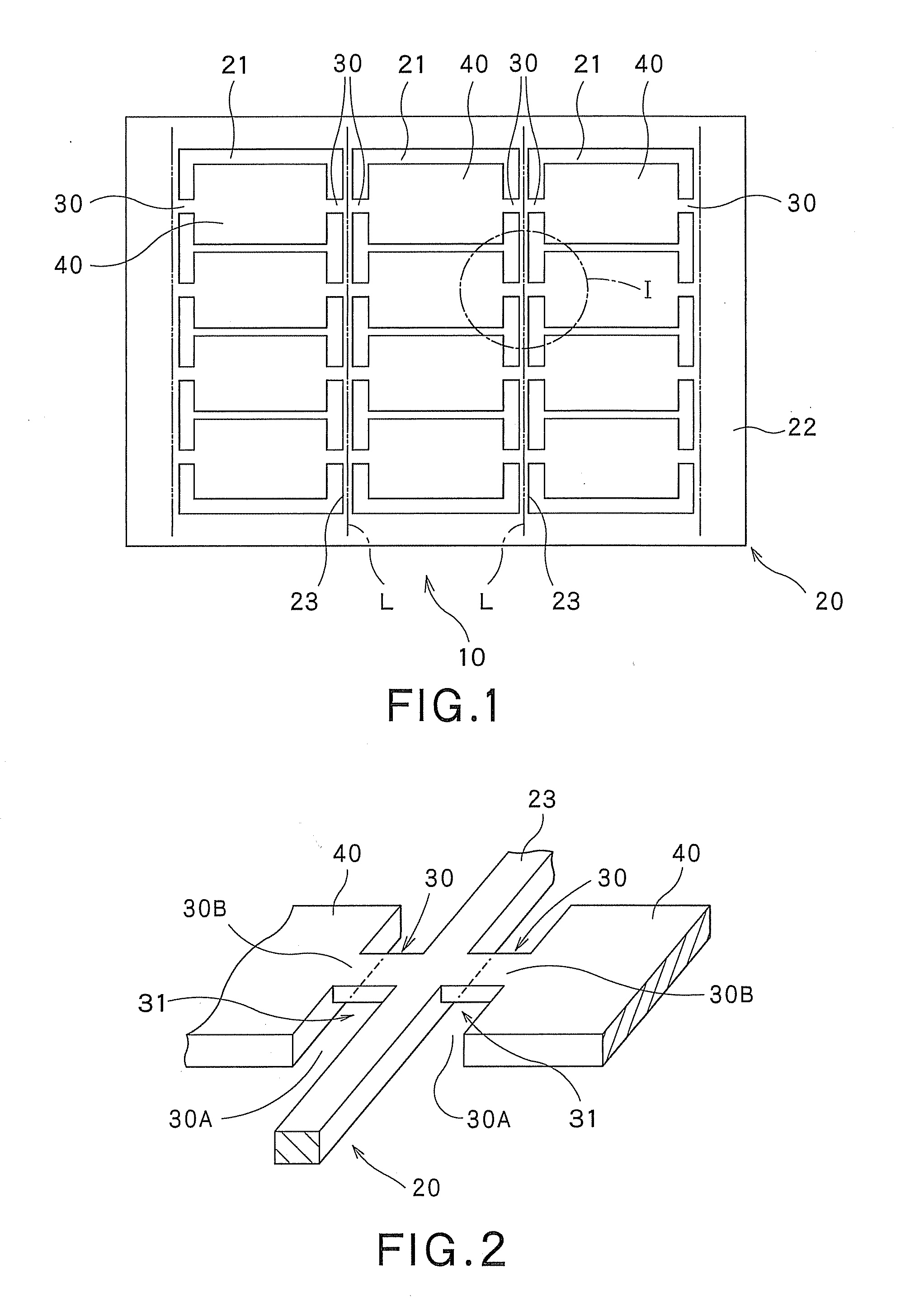

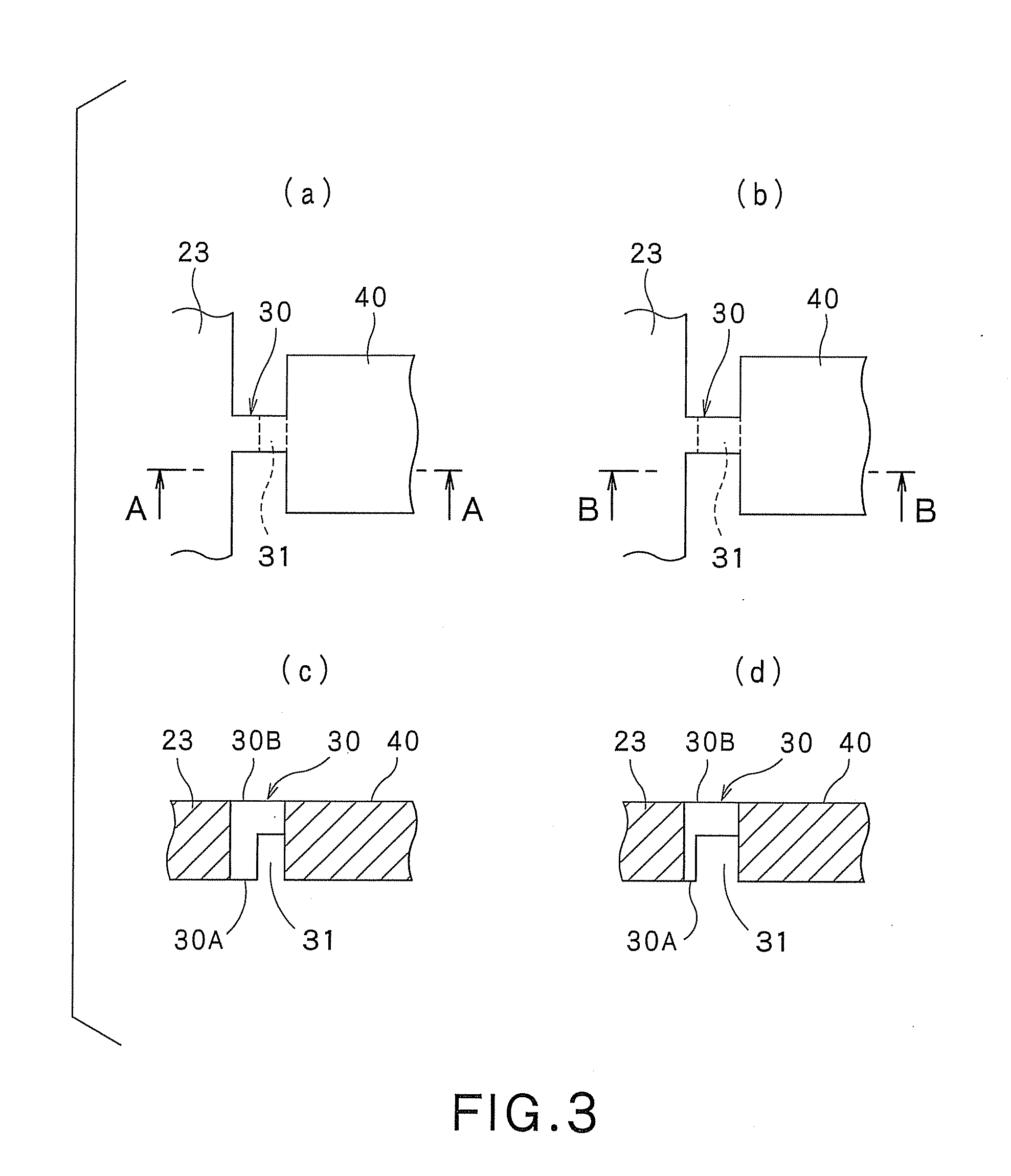

Semiconductor device and method for manufacturing metallic shielding plate

ActiveUS20100270660A1Efficiently fabricateHigh magnetic permeabilityWave amplification devicesSemiconductor/solid-state device detailsMetalSemiconductor chip

Provided is a semiconductor device capable of preventing a semiconductor chip from being damaged by any sharp burrs of a metallic shielding plate. The semiconductor device includes a semiconductor chip and a metallic shielding plate provided on a circuit surface of the semiconductor chip. The metallic shielding plate is disposed in such a manner that a second surface of a shielding plate body is directed towards the circuit surface of the semiconductor chip, and burrs are positioned contiguous to the second surface of the shielding plate body. At distal ends of the burrs, cutting burrs are formed in a direction orthogonal to the second surface. The sharp burrs extend in a direction opposite to the semiconductor chip, so that the sharp burrs are prevented from damaging the circuit surface of the semiconductor chip.

Owner:DAI NIPPON PRINTING CO LTD

Manufacturing method of high-magnetic-permeability low-power-consumption iron-silicon-aluminum alloy powder for magnetic powder cores

InactiveCN103060677AHigh magnetic permeabilityReduce power lossVolumetric Mass DensityLow power dissipation

The invention relates to a manufacturing method of a high-magnetic-permeability low-power-consumption iron-silicon-aluminum alloy powder for magnetic powder cores, which comprises the following steps: 1. smelting an iron-silicon-aluminum alloy melt while covering a non-vacuum medium-frequency induction furnace with a protective agent; and 2. atomizing the alloy melt into an alloy powder by using a superhigh-pressure water atomization pulverization device, and carrying out annealing treatment and sieve classification to obtain the finished product. Since the non-vacuum medium-frequency induction furnace is utilized to smelt the alloy, compared with the presently used vacuum induction furnace, the manufacturing method provided by the invention has the advantages of lower cost and less equipment investment, and the production process is convenient to operate. By adjusting the atomization technological parameters of the superhigh-pressure water atomization method, the invention implements control on the particle size distribution and particle shape of the iron-silicon-aluminum alloy powder; and by reasonably adjusting the particle size grading and particle size distribution of the iron-silicon-aluminum alloy powder, the invention can enable the packed density of the iron-silicon-aluminum alloy powder to reach the optimal value, obviously enhance the magnetic permeability of the iron-silicon-aluminum magnetic powder core and lower the power loss.

Owner:HUNAN KANGLI NEW MATERIAL TECH

Corrosion resistant brake block and machining method thereof

InactiveCN108716517AImprove performanceIncrease coefficient of frictionOther chemical processesFriction liningFiberAdditive ingredient

The invention relates to the field of car machines, and provides a corrosion resistant brake block. The corrosion resistant brake block comprises the following raw materials including aluminum fibers,glass fibers, nitrile butadiene rubber powder, tire powder, cashew nut shell oil friction powder, Tung oil modified phenolic resin, red copper fibers, white zi stone powder, fluorite powder, apocynumvenetum fibers, iron oxide green, barite, petroleum coke, graphite, potassium hexatitanate whiskers, ceramic hollow microspheres, barium sulfate, molybdenum disulfide and a soft magnetic material. The invention further provides a machining method of the corrosion resistant brake block. The corrosion resistant brake block and the machining method have the advantages that in the formula research process, a large quantity of experiments show that multiple ingredients are reasonably matched, it is guaranteed that advantages of all materials are sufficiently played in the materials, shortcomings about performance of the raw materials can be offset mutually, and the better performance is achieved through mutual matching. In the using process, the high and stable friction coefficient and the lowwear rate are achieved, and abrasion is not prone to being borne.

Owner:ANHUI XIANGCHI VEHICLE IND CO LTD

Heat treatment process for medium and small cold rolled silicon steel sheet

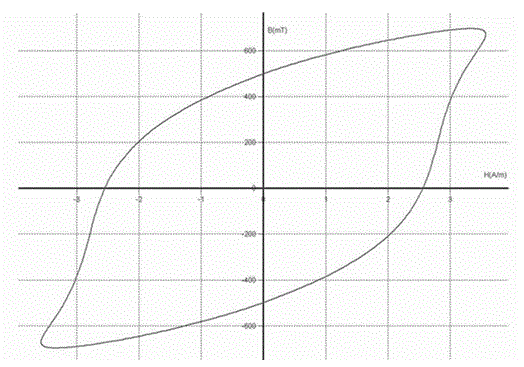

InactiveCN1986845AMeet processing requirementsPut an end to cementiteHeat treatment process controlBell type furnacesHysteresisWater vapor

The heat treatment process for medium and small cold rolled silicon steel sheet completed in common bell type electric furnace includes the following steps: loading, vacuumizing and filling with nitrogen, heating while introducing nitrogen-hydrogen mixed gas and water vapor to form water vapor diaphragm between silicon steel sheets to avoid adhesion; decarbonizing to form ferrite completely for silicon steel sheet to reach low carbon content, low hysteresis loss and low magnetic resistance; and slowly cooling after decarbonizing for silicon steel sheet to separate out [100] crystal direction ferrite crystal completely under austenitic state so as to increase magnetic conductivity and magnetic flux and lower iron loss P15 / 50. The said process can reach excellent heat treatment effect, and the treated cold rolled silicon steel sheet can meet the requirement for use in motor.

Owner:JINHAI ELECTROMECHANICAL SCI TECH SUZHOU

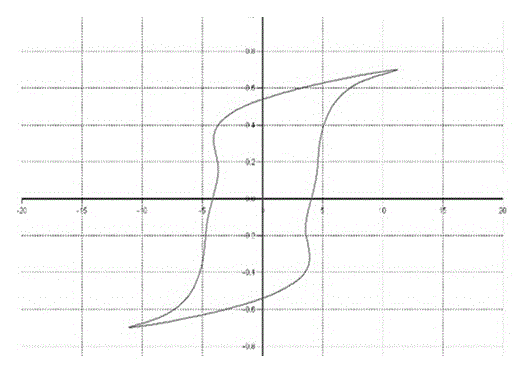

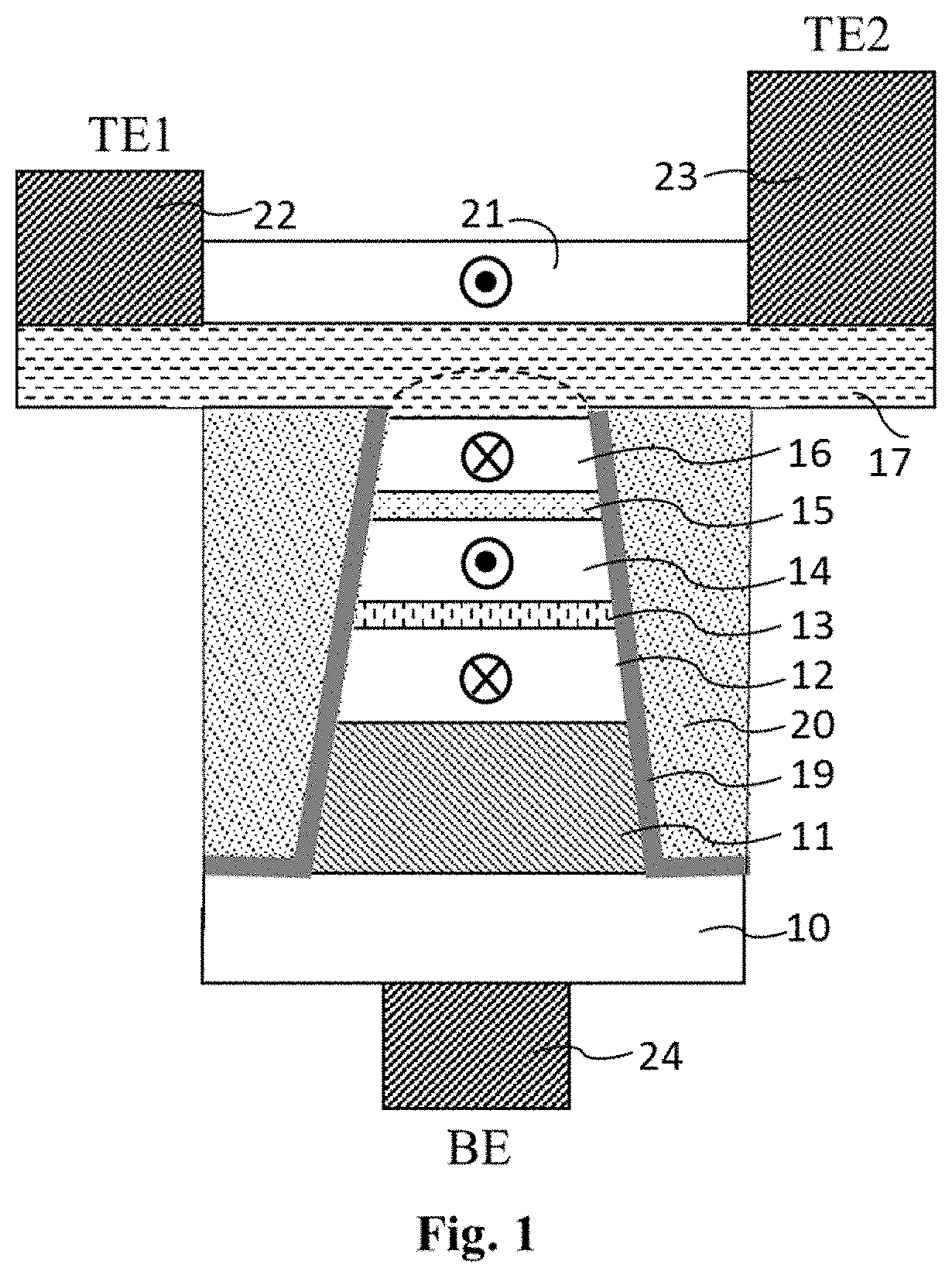

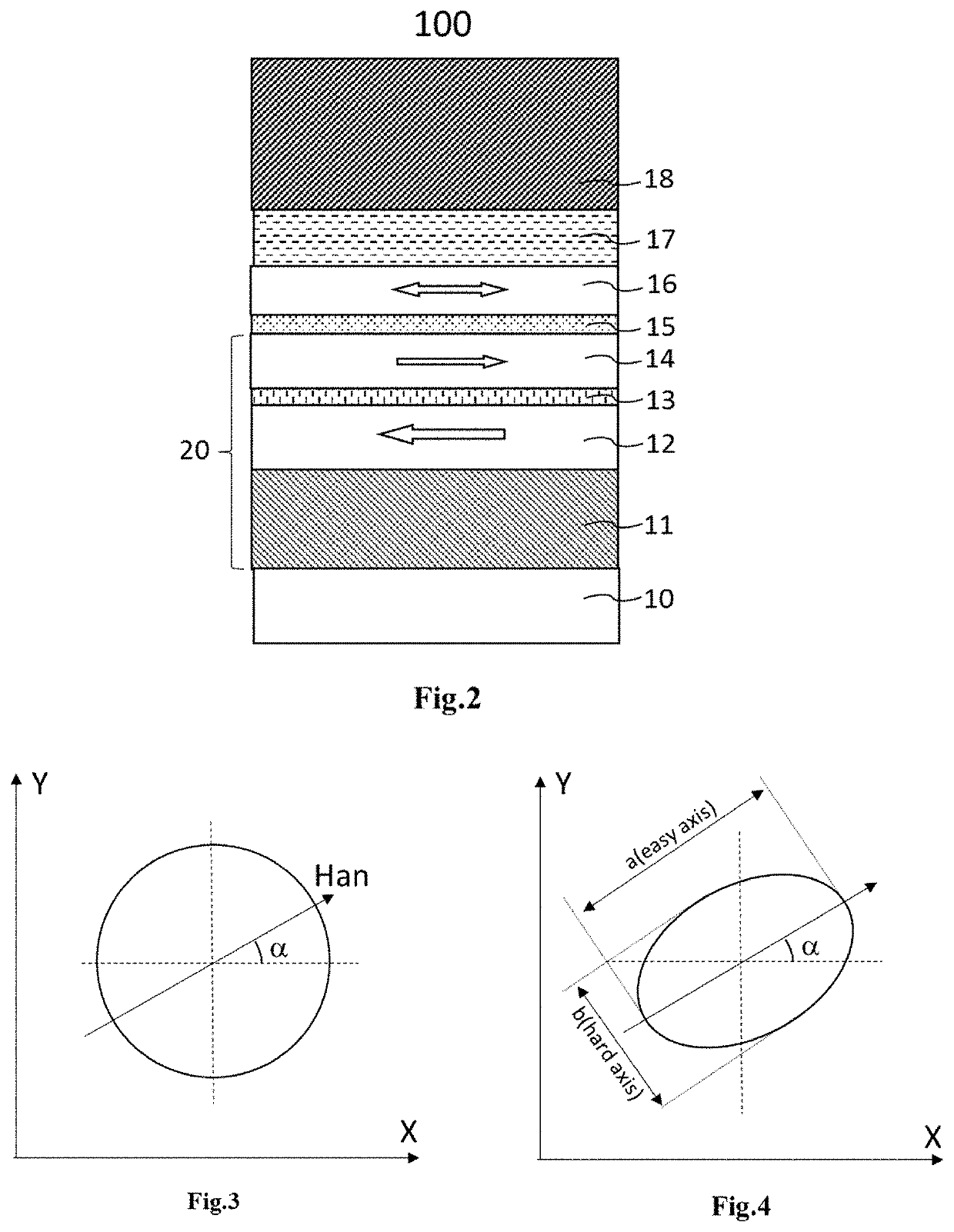

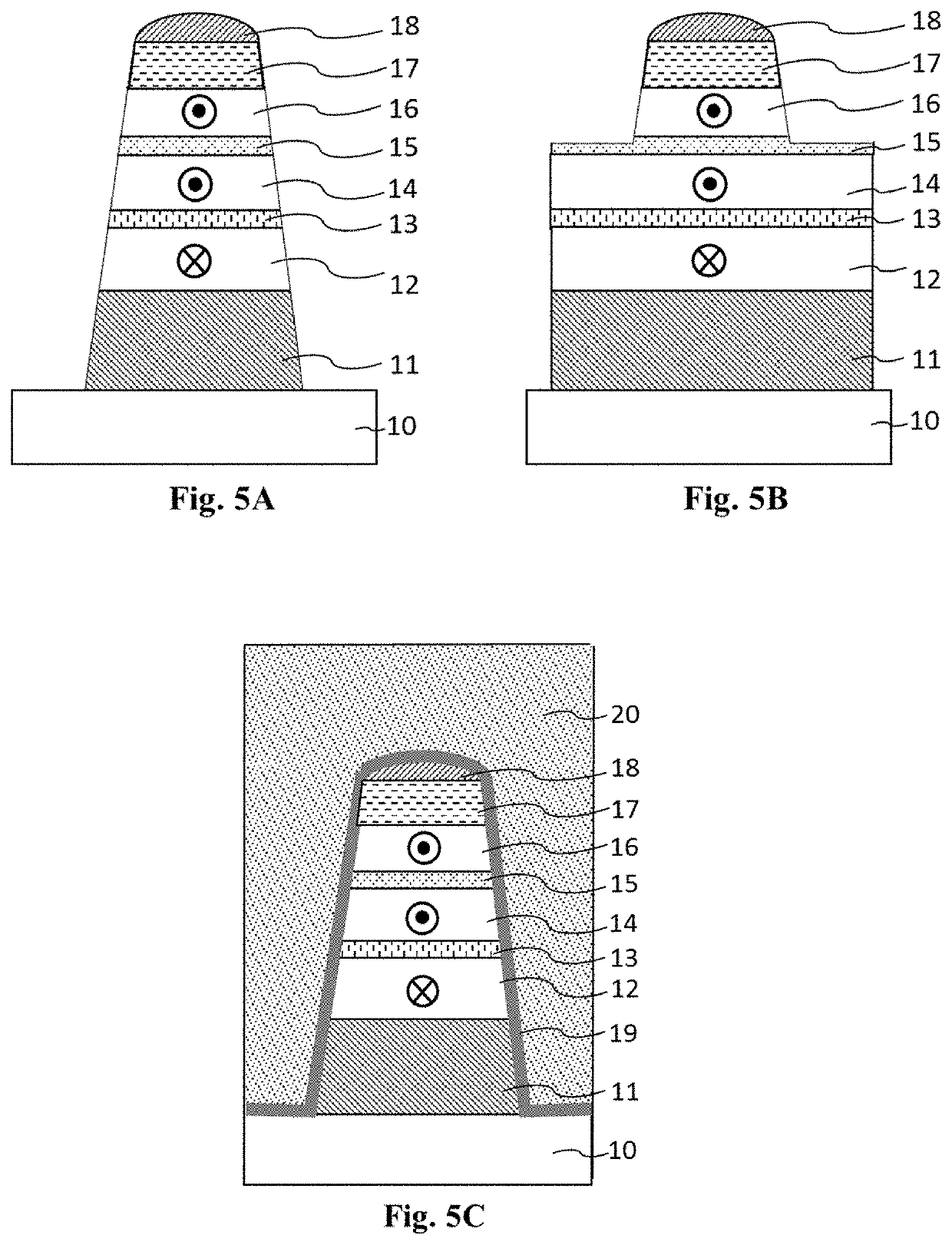

Bottom-pinned magnetic random access memory having a composite sot structure

ActiveUS20210327960A1High magnetic permeabilityEnhance thermal stabilityMagnetic-field-controlled resistorsSolid-state devicesRandom accessSpin-transfer torque

An ultra-fast magnetic random access memory (MRAM) comprises a three terminal bottom-pinned composite SOT magnetic tunneling junction (bCSOT-MTJ) element including (counting from top to bottom) a magnetic flux guide (MFG) having a very high magnetic permeability, a spin Hall channel (SHC) having a large positive spin Hall angle, an in-plane magnetic memory (MM) layer, a tunnel barrier (TB) layer, and a magnetic pinning stack (MPS) having a synthetic antiparallel coupling pinned by an antiferromagnetic material. The magnetic writing is significantly boosted by a combined effort of enhanced spin orbit torque (SOT) and Lorentz force generated by current-flowing wire (CFW) in the SHC layer and spin transfer torque (STT) by a current flowing through the MTJ stack, and further enhanced by a magnetic close loop formed at the cross section of MFG / SHC / MM tri-layer. Such bCSOT-MTJ element will have a very fast (down to picoseconds) switching speed and consume much less power suitable level 1 or 2 cache application for SMRAM, CPU, GPU and TPU.

Owner:XIAO RONGFU +2

Low noise brake pad and processing method thereof

InactiveCN108730385AImprove performanceIncrease coefficient of frictionOther chemical processesFriction liningFiberLow noise

The invention relates to the technical field of automobiles, provides a low noise brake pad, and further provides a processing method of the low noise brake pad. The low noise brake pad comprises following raw materials of adhesive-sprayed aluminum silicate fiber, glass fiber, nitrile rubber powder, tire powder, cashew nut shell oil frictional powder, tung-oil-modified phenolic resin, red copper fiber, white zi stone powder, diatomaceous earth, apocynum fiber, iron oxide green, potassium feldspar, petroleum cokes, graphite, expanded perlite, floating beads, barium sulfate, boron nitride and soft magnetic materials. The low noise brake pad and the processing method thereof have the advantages that in the research process of a formula, after a large number of experiments, a reasonable combination of various components is achieved, and the advantages of each material are fully utilized in the materials, so that the raw materials can compensate each other for deficiencies of own performance, and better performance can be generated due to mutual cooperation. The low noise brake pad has a high and stable friction coefficient and a low wear rate during use, and at the same time, low noiseis achieved during braking.

Owner:ANHUI XIANGCHI VEHICLE IND CO LTD

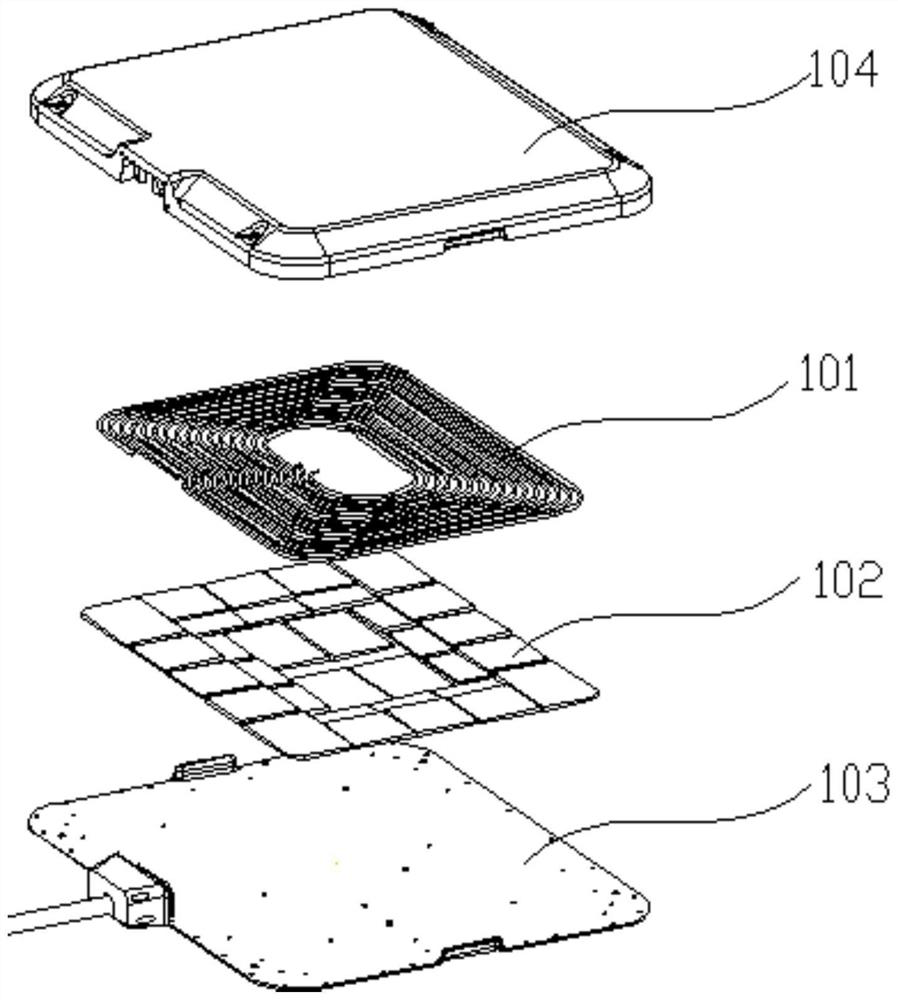

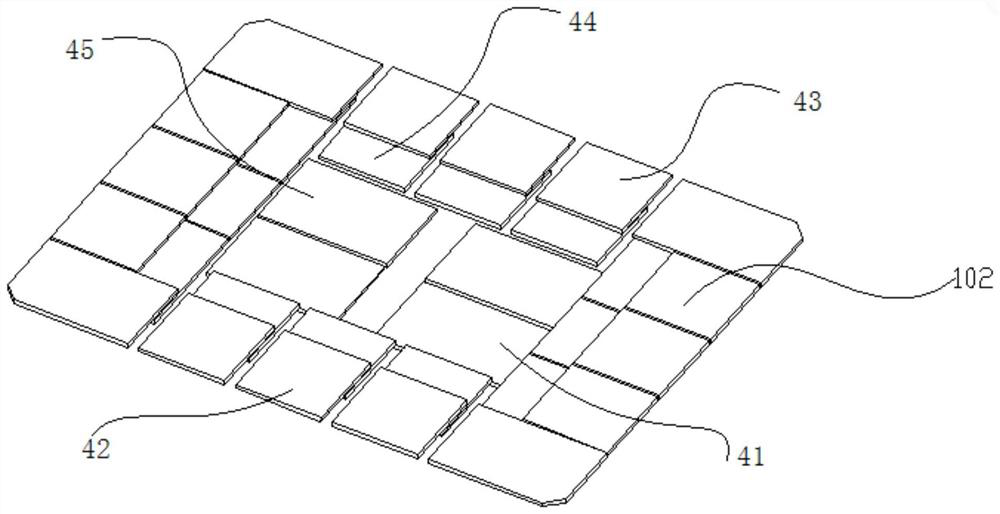

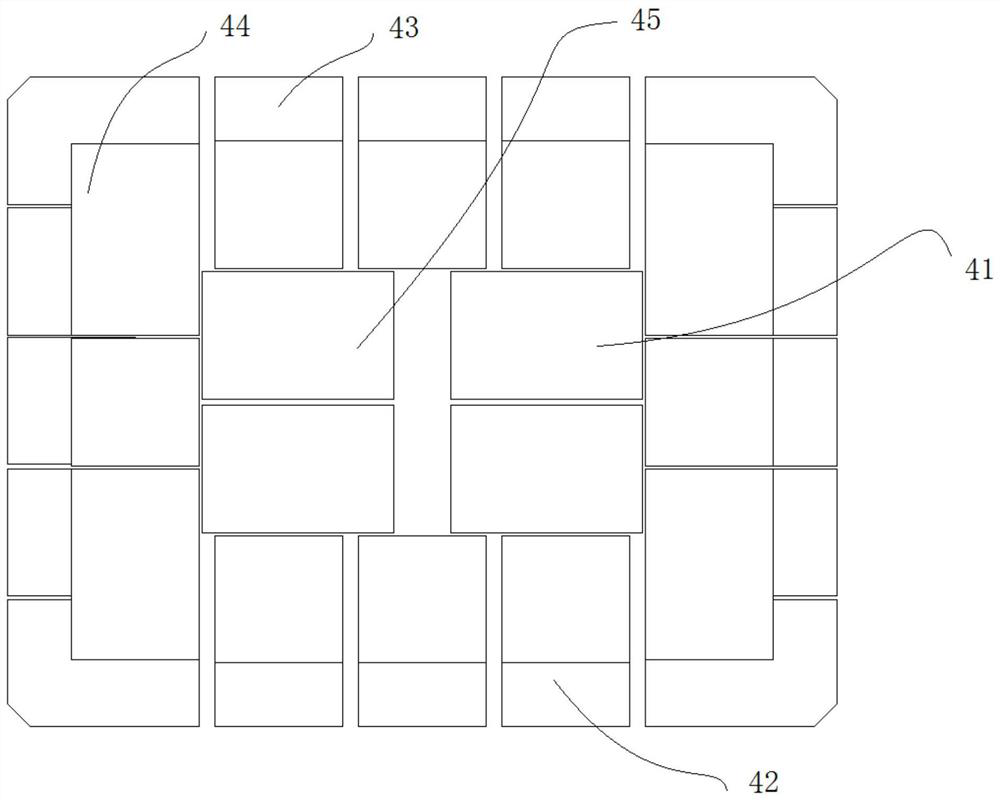

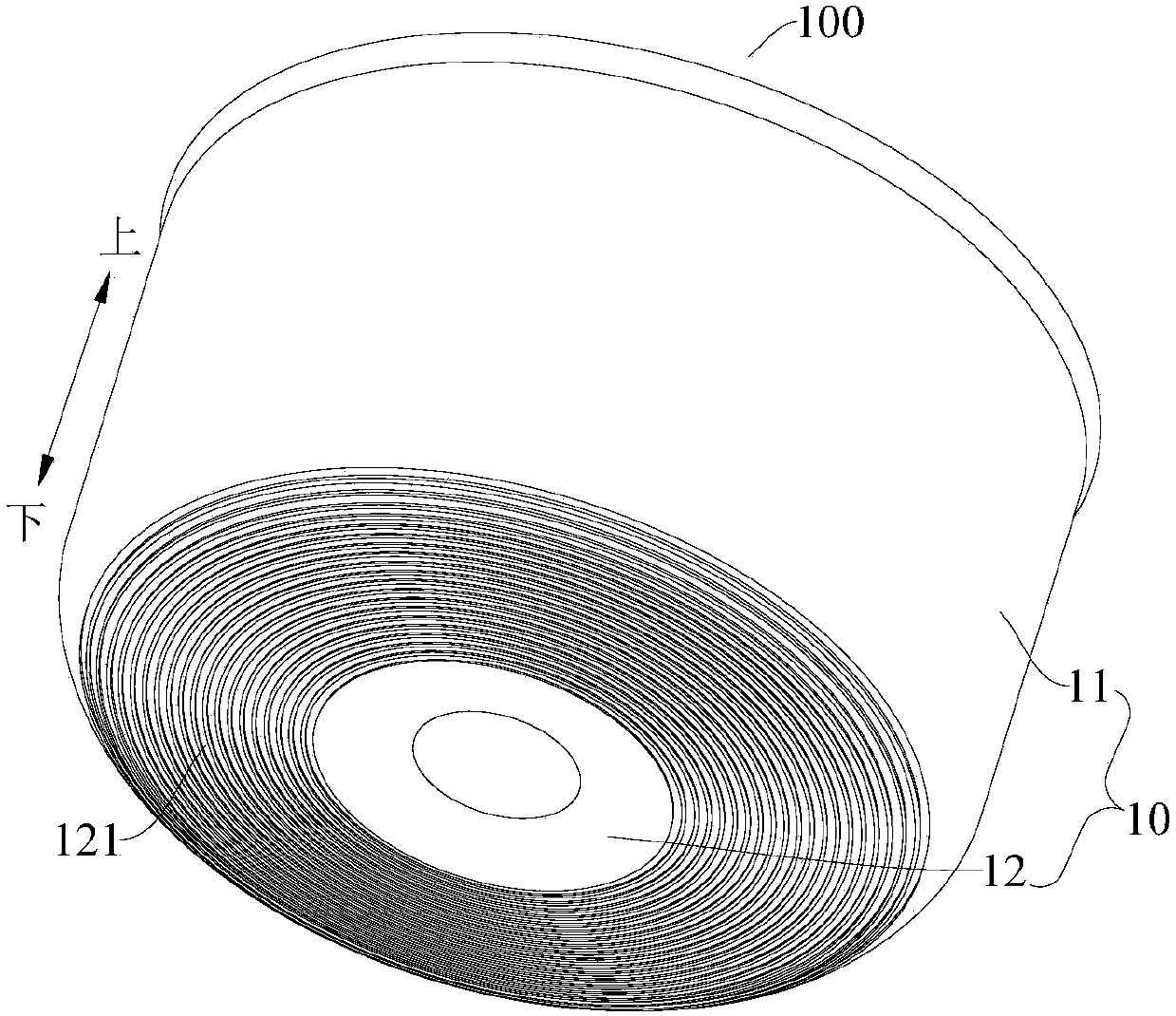

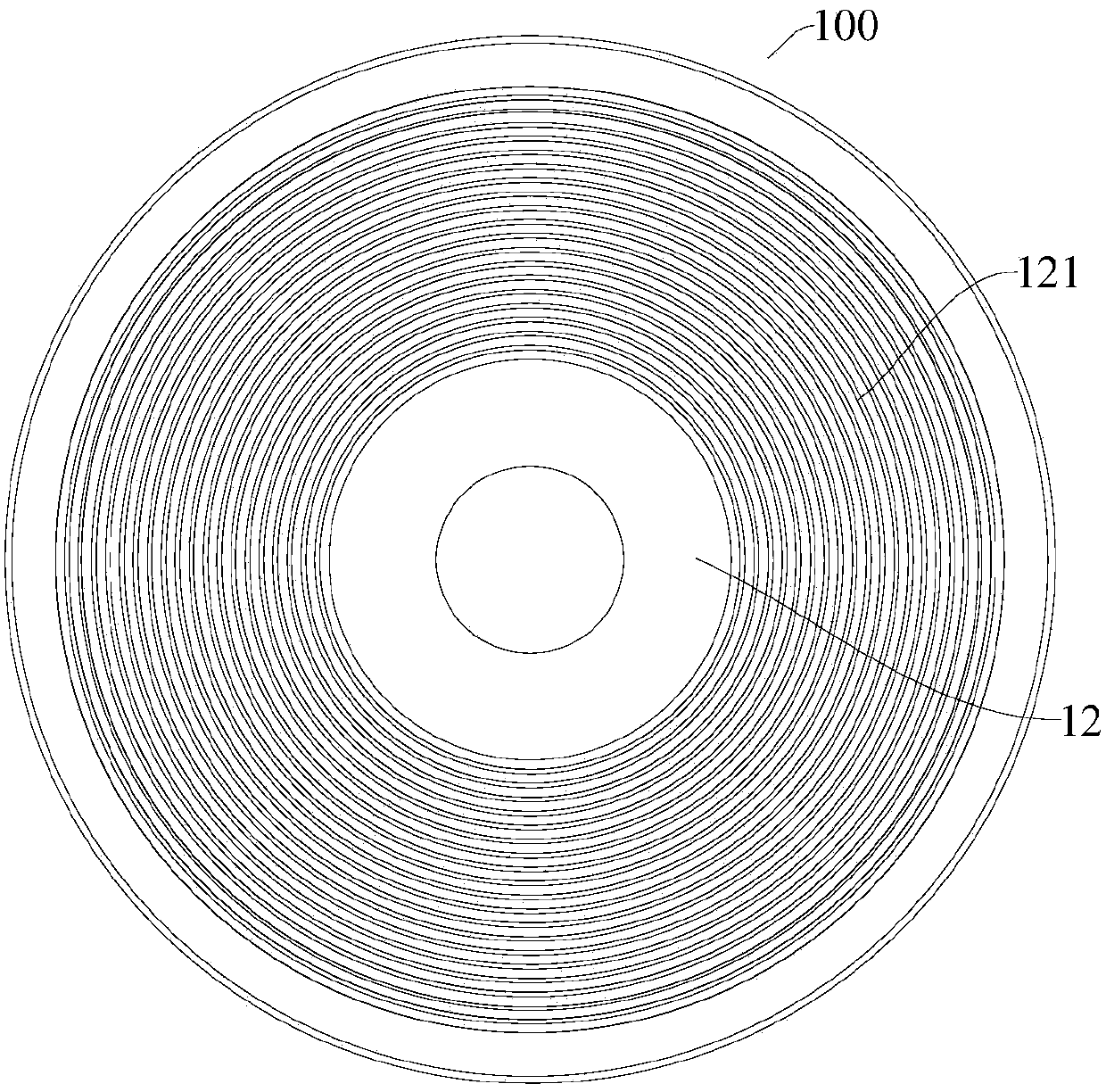

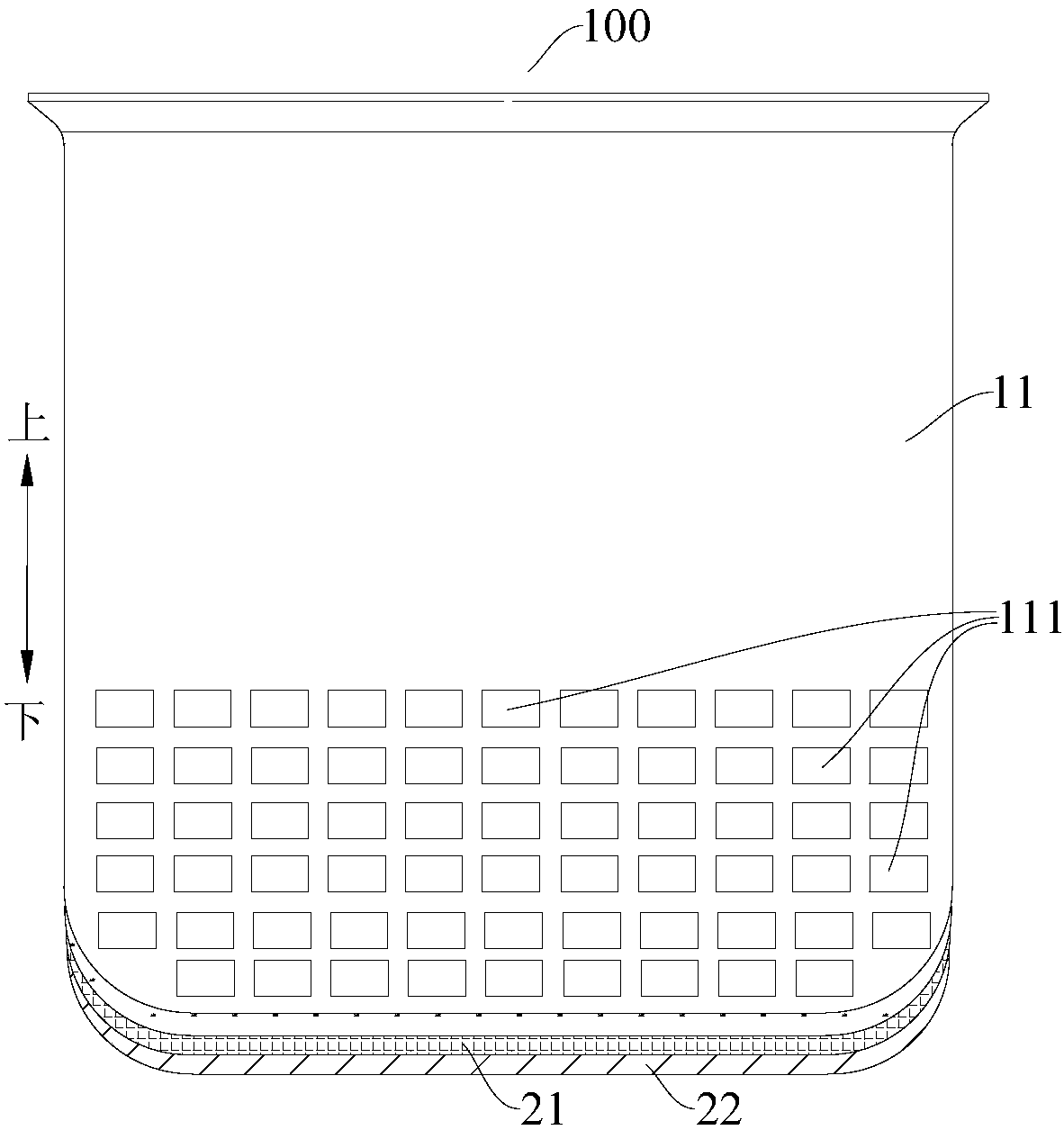

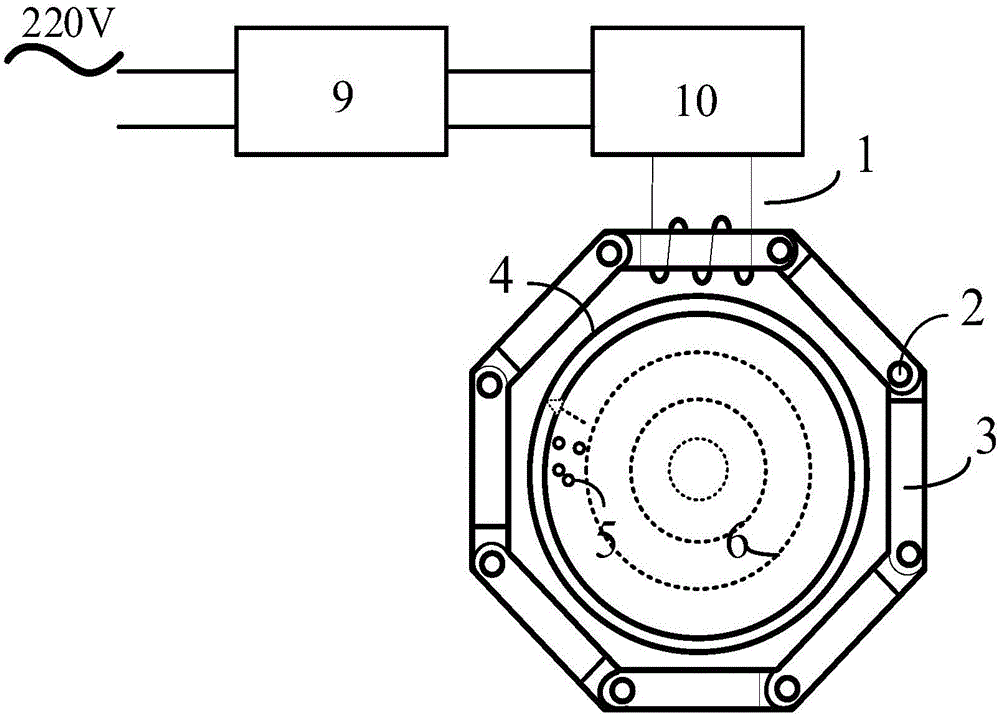

Transmitting assembly and charging assembly structure for wireless charging of electric automobile

PendingCN112002532AHigh magnetic permeabilityReduce power consumptionTransformers/inductances coolingCharging stationsFerrite layerTransmitter coil

The invention discloses a transmitting assembly for wireless charging of an electric automobile. The transmitting assembly comprises a non-metal shell, a transmitting coil, a transmitting magnetic core and a metal shell that are sequentially assembled from top to bottom. The transmitting magnetic core comprises at least two ferrite layers which are stacked in a staggered mode. Each ferrite layer is formed by splicing a plurality of ferrites; the ferrite layer corresponding to the periphery of the transmitting coil is close to the transmitting coil; the rest ferrite layers are sequentially arranged in a retracting manner corresponding to the central position of the transmitting coil and are gradually far away from transmitting coil. The invention further discloses a charging assembly for wireless charging of the electric automobile, wherein the charging assembly comprises the transmitting assembly and the receiving assembly which are arranged in parallel, the problem that a transmittingmagnetic field is uneven in distribution is solved, magnetic saturation is inhibited, and the wireless charging efficiency is improved.

Owner:上海万暨电子科技有限公司

Permanent magnetic direct-current brushless motor of biased mounting structure

ActiveCN104578658AIncrease torqueImprove efficiencyMagnetic circuit rotating partsElectric machinesBrushless motorsInterference fit

A permanent magnetic direct-current brushless motor of a biased mounting structure comprises an end cap, a rotor assembly, a stator assembly and a motor shaft. The end cap is positioned on two sides of the rotor assembly and composed of a fixed end cap and a drum brake end cap, the rotor assembly is composed of a wheel rim, a magnetic conducting ring in left biased mounting, a fixing ring and a permanent magnet and mounted with the stator assembly in a matched manner, the stator assembly is composed of an iron core and a through groove used for mounting of a winding, silicon steel sheets are arranged on the outer circumference of the iron core and are of a stacked structure, a fixing shaft sleeve is arranged at the center of the iron core in a right biased manner, a fixing support is arranged on the outer circumferential side of the fixing shaft sleeve, the fixing shaft sleeve and the motor shaft are in interference fit, and a knurled structure is arranged at a position where the motor shaft and the fixing shaft sleeve are connected. A motor structure is designed in an optimized manner, and a biased mounting mode is adopted, so that diameter size of the stator assembly and the rotor assembly is increased, key performance parameters like torque and efficiency of the motor are enhanced, and load-carrying capacity of a whole vehicle is improved.

Owner:TAIZHOU JINYU ELECTROMECHANICAL

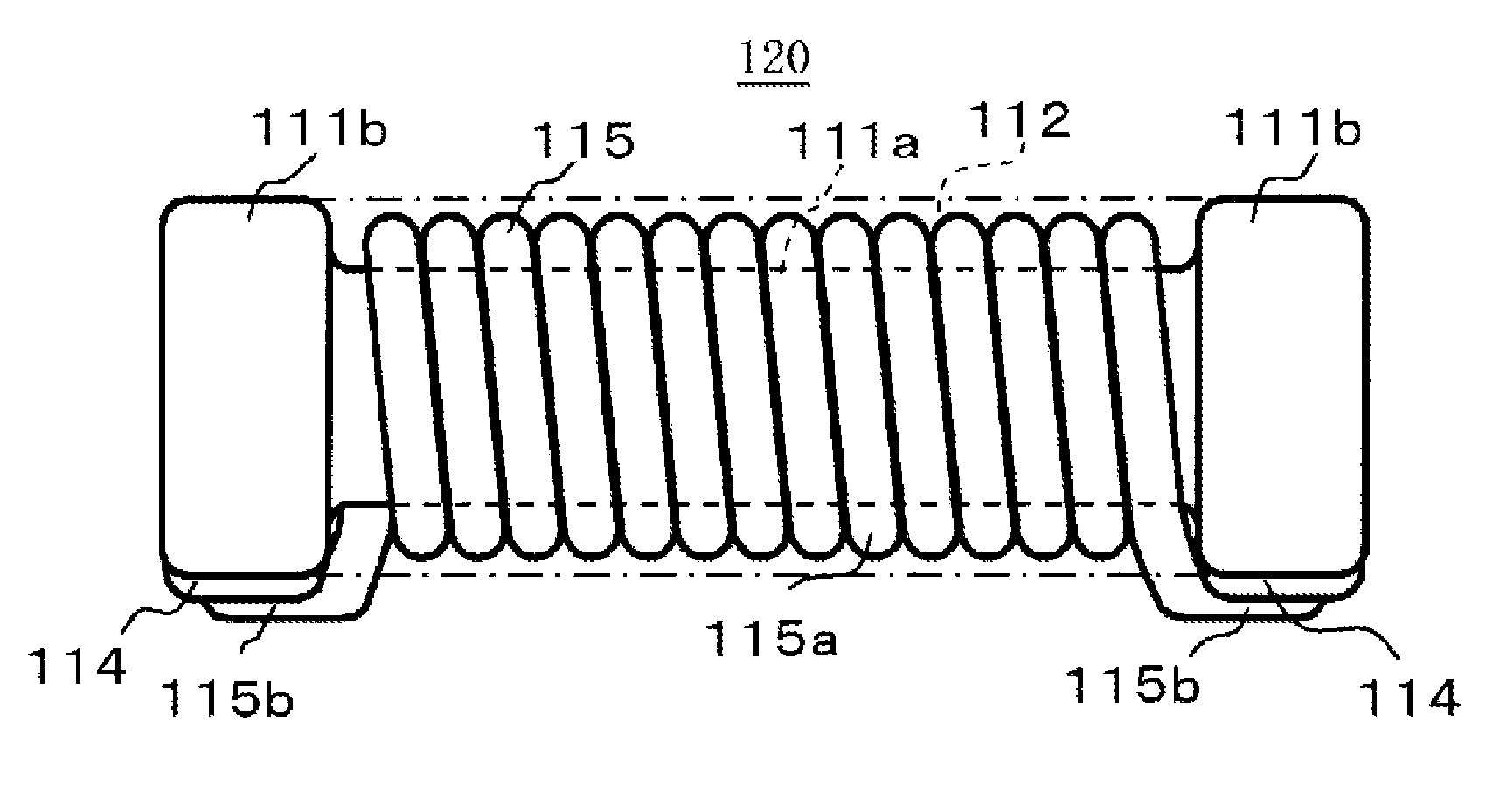

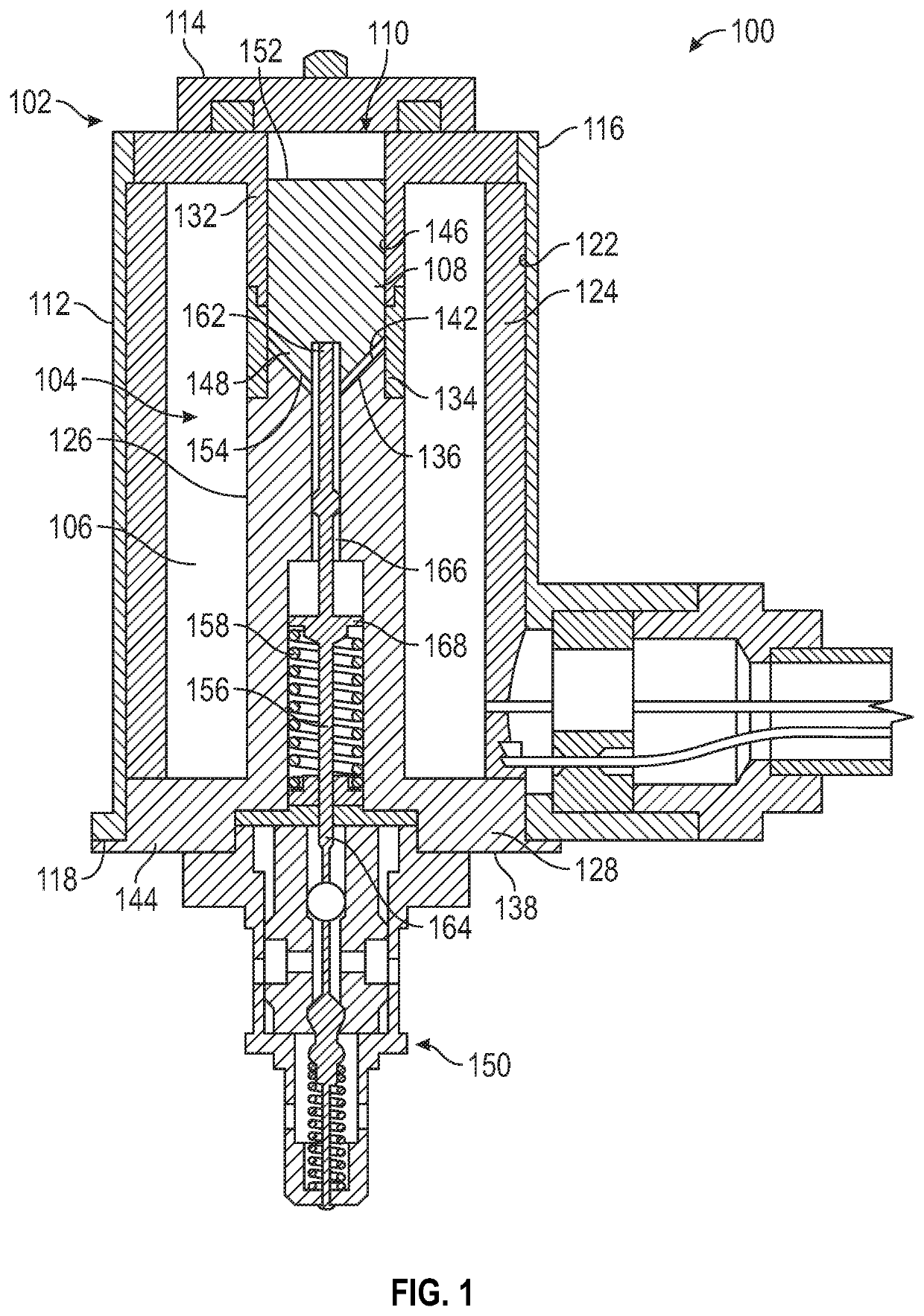

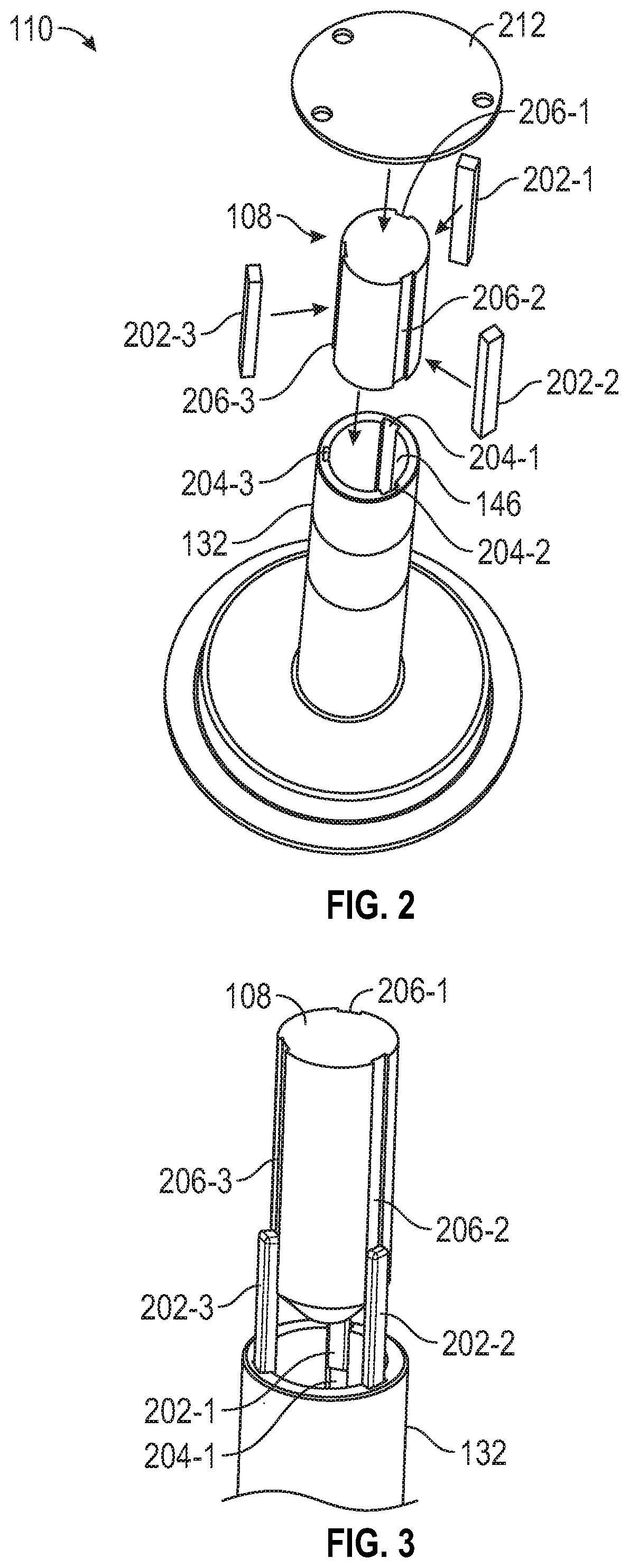

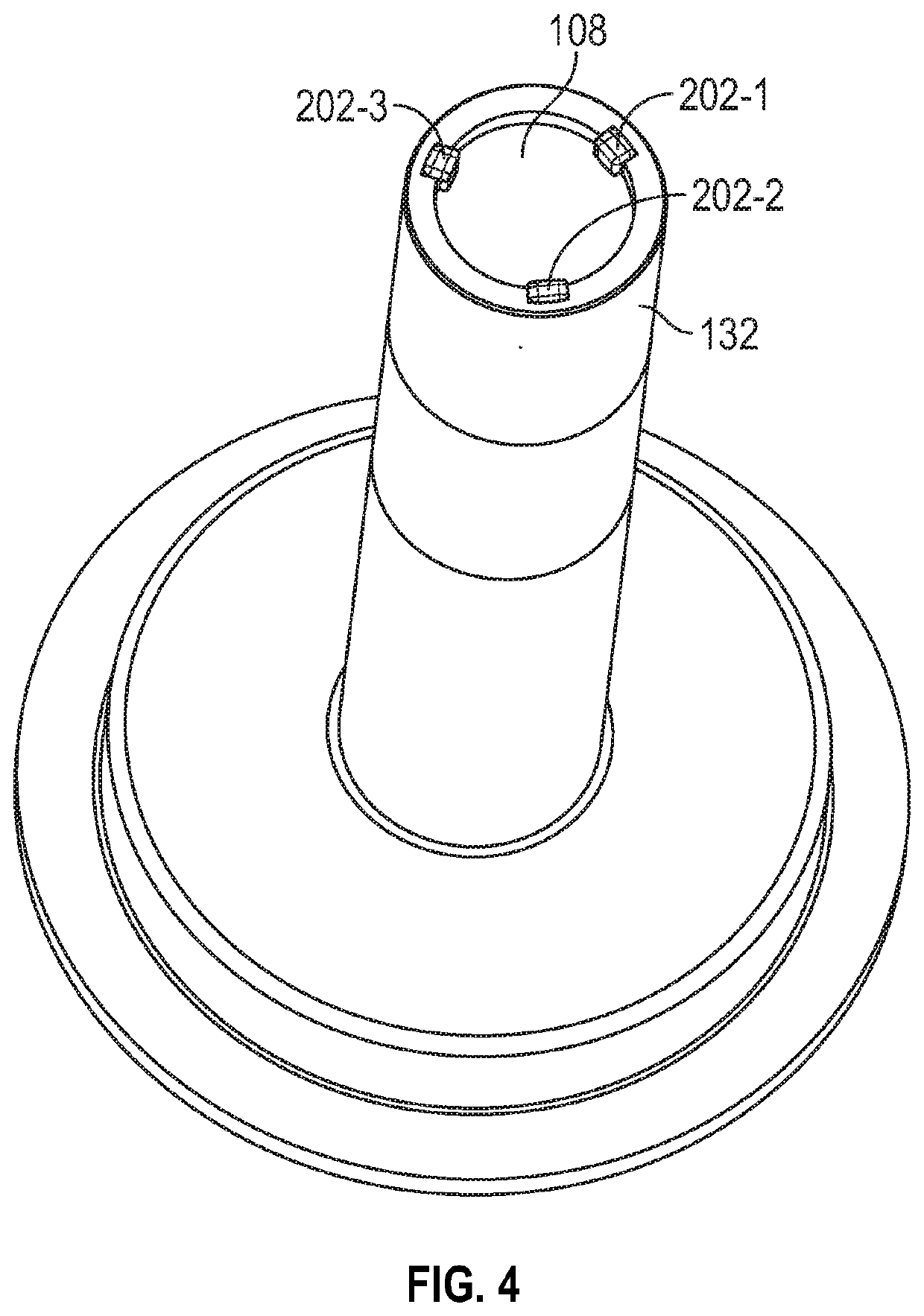

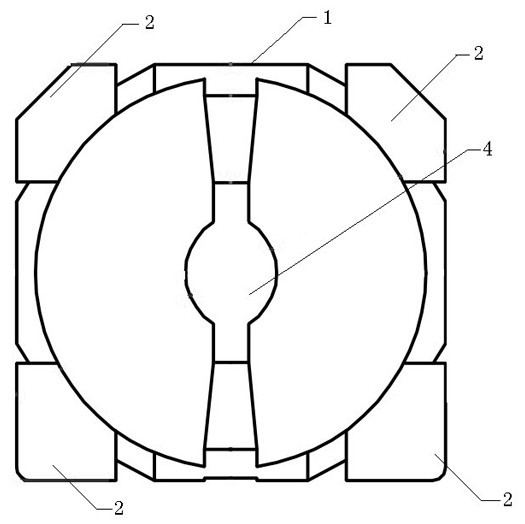

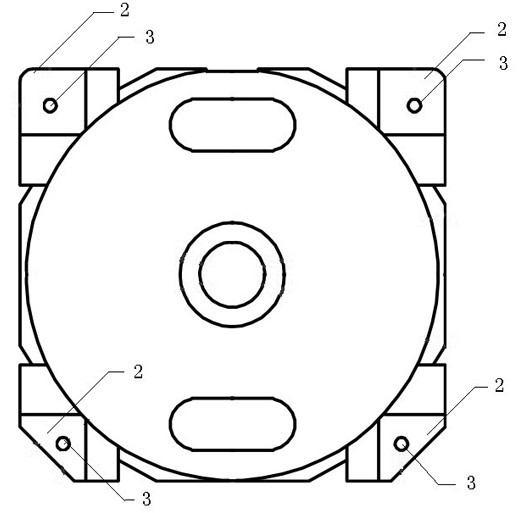

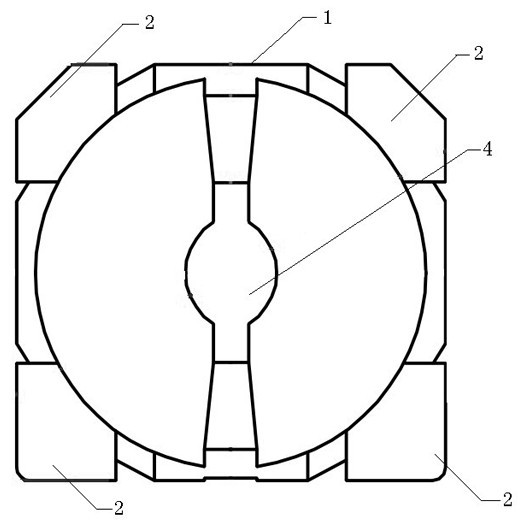

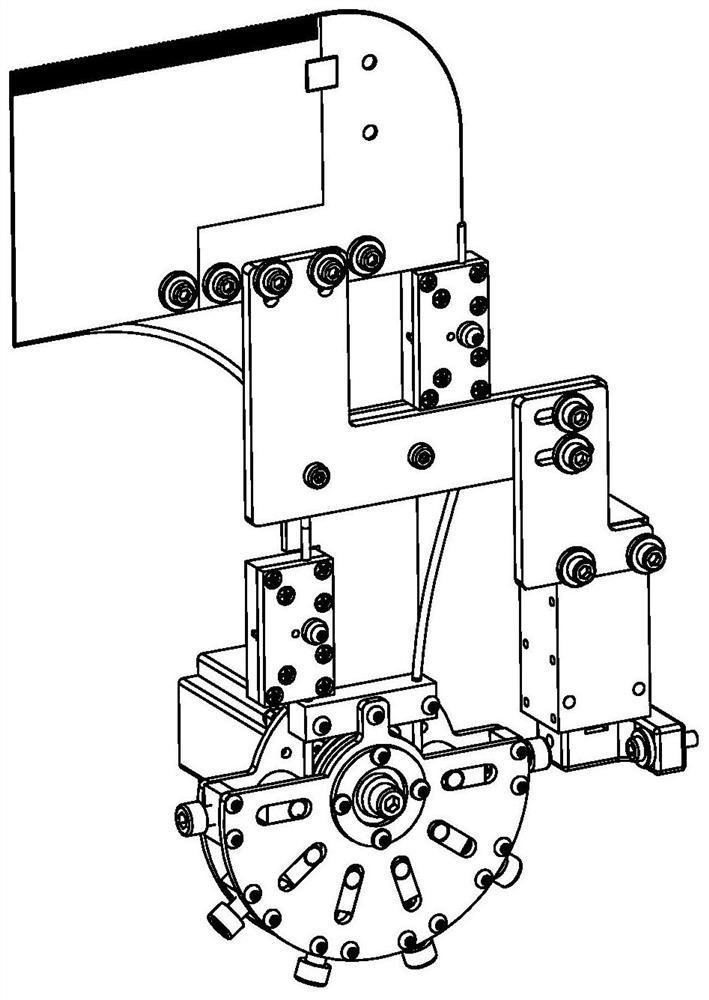

Solenoid including armature Anti-rotation structure

ActiveUS20200051723A1High magnetic permeabilityElectromagnet terminals/connectorsElectromagnets with armaturesStructural engineeringBobbin

A solenoid actuator includes a housing assembly, a bobbin assembly, a coil, an armature, and an anti-rotation structure. The bobbin assembly is disposed at least partially within the housing assembly and includes a return pole and a yoke. The yoke has an inner surface that defines an armature cavity. The coil is disposed within the housing assembly and is wound around at least a portion of the bobbin assembly. The armature is disposed within the armature cavity and is axially movable relative to the yoke. The anti-rotation structure is disposed within the housing assembly and engages at least a portion of the armature. The armature and the anti-rotation structure each have at least one feature formed thereon that mate with each other and thereby prevent rotation of the armature.

Owner:HONEYWELL INT INC

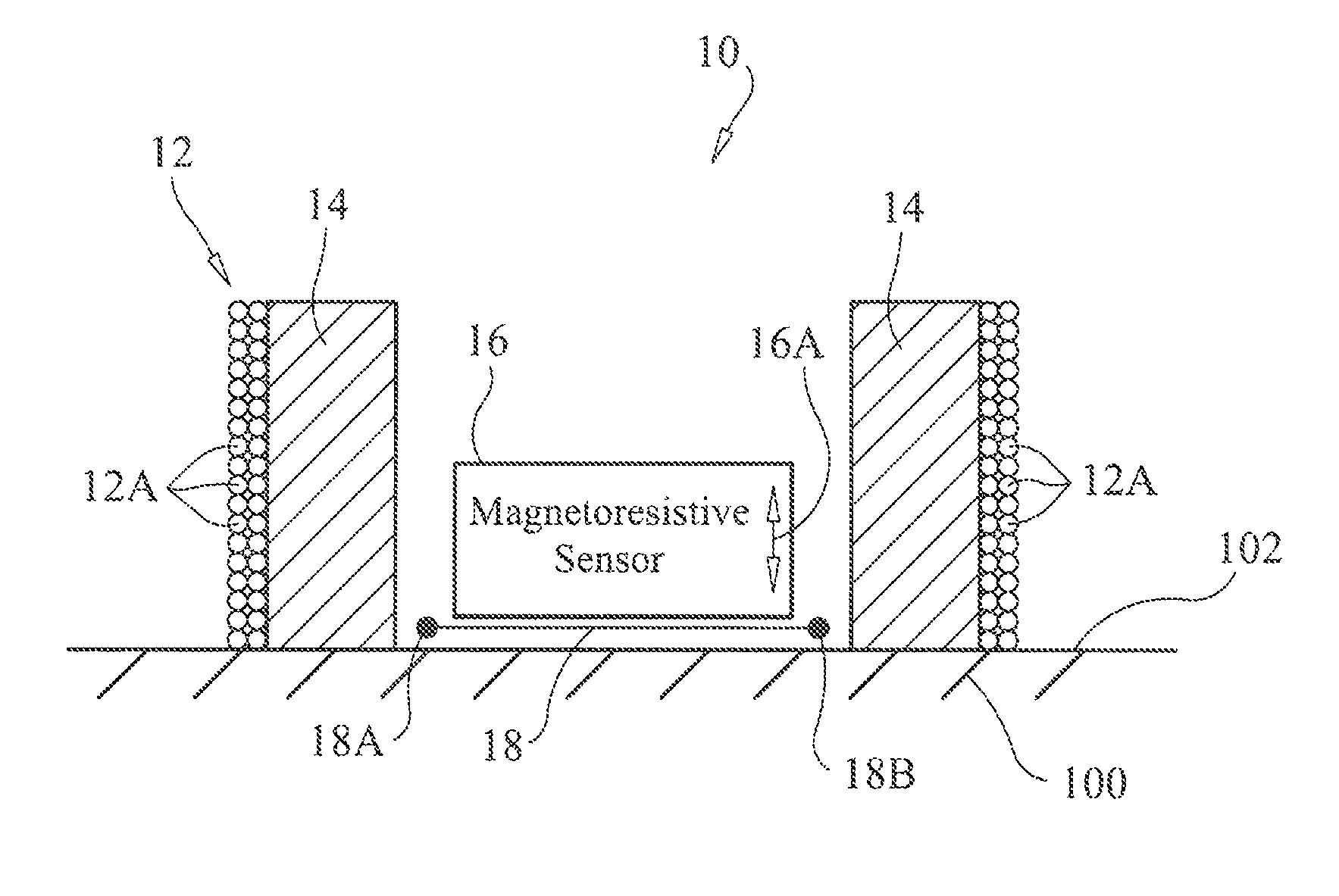

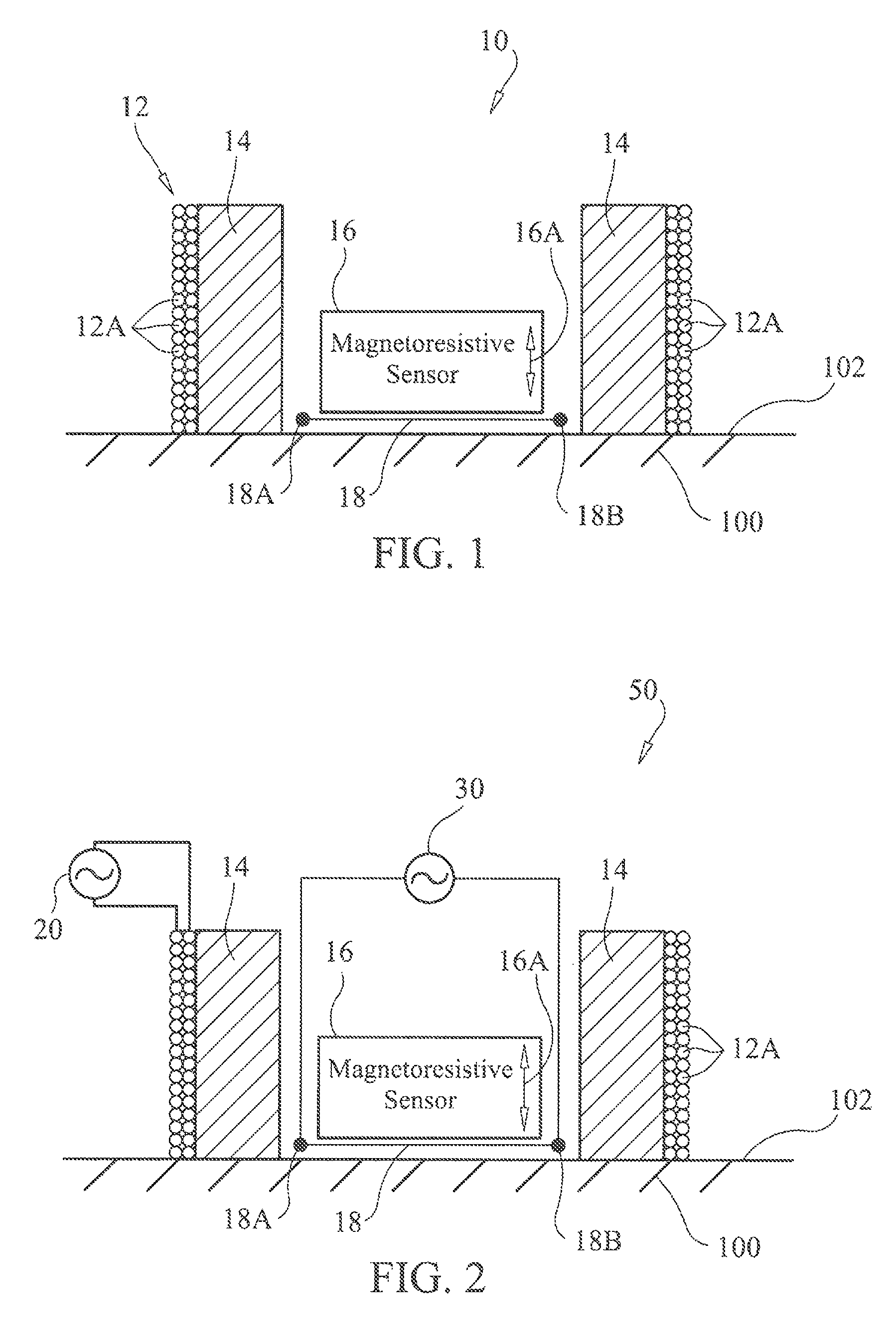

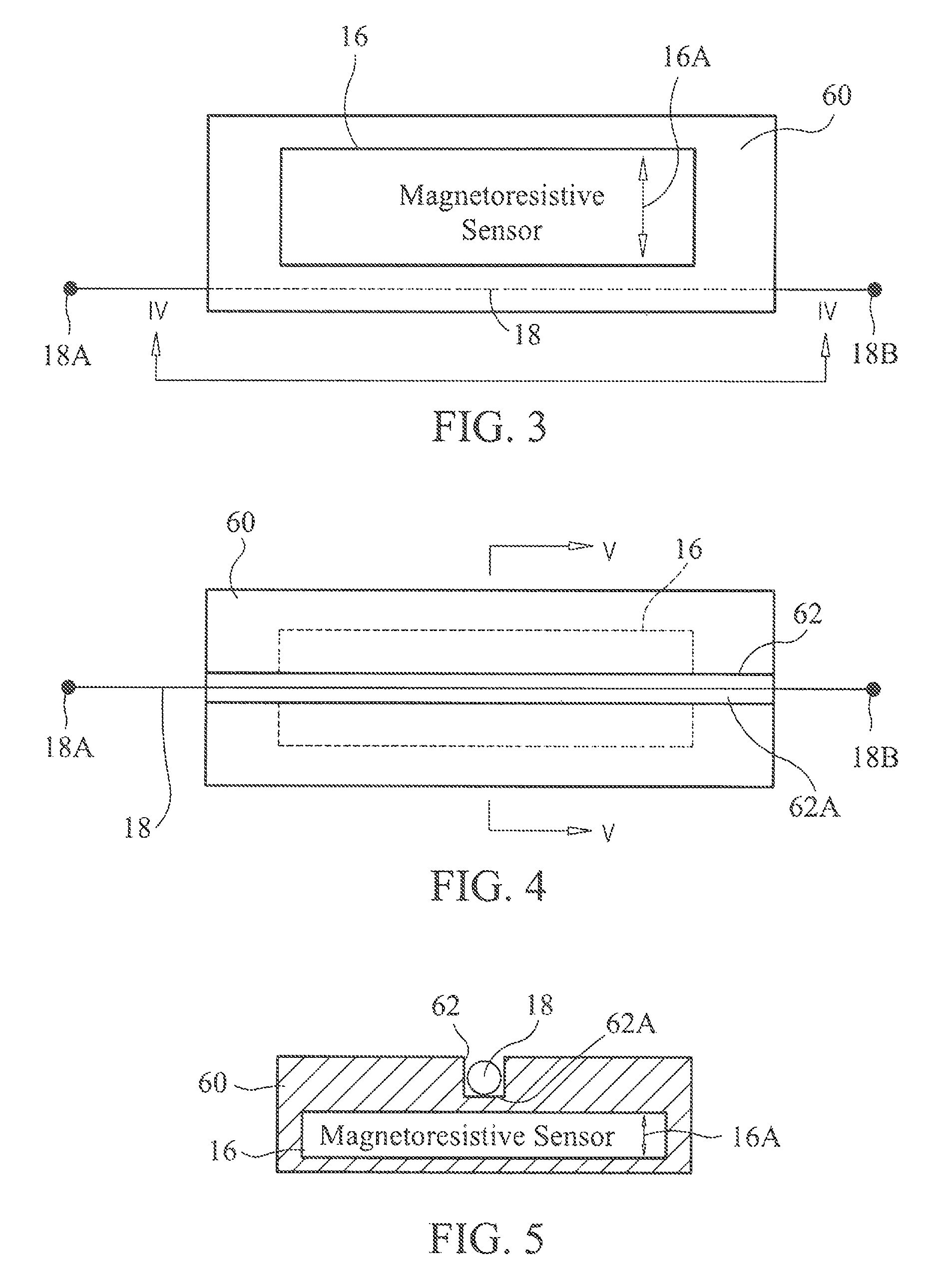

Eddy current probe for surface and sub-surface inspection

InactiveUS8717012B2Prevent couplingHigh magnetic permeabilityTesting/calibration apparatusForce measurementPhysicsHigh frequency

An eddy current probe includes an excitation coil for coupling to a low-frequency alternating current (AC) source. A magnetoresistive sensor is centrally disposed within and at one end of the excitation coil to thereby define a sensing end of the probe. A tubular flux-focusing lens is disposed between the excitation coil and the magnetoresistive sensor. An excitation wire is spaced apart from the magnetoresistive sensor in a plane that is perpendicular to the sensor's axis of sensitivity and such that, when the sensing end of the eddy current probe is positioned adjacent to the surface of a structure, the excitation wire is disposed between the magnetoresistive sensor and the surface of the structure. The excitation wire is coupled to a high-frequency AC source. The excitation coil and flux-focusing lens can be omitted when only surface inspection is required.

Owner:NASA

Preparation method of iron nickel based soft-magnetic material

The invention relates to a preparation method of an iron nickel based soft-magnetic material. According to the preparation method, the iron nickel based soft-magnetic material is prepared from the following alloy materials in atomic proportion: Fe(100-a-b-c-d-e-f)NiaSibAlcCedBeNbf, wherein a=15-20, b=3-4, c=10-15, d=1-2, e=3-5, and f=1-3. The preparation method comprises the following steps: (1) carrying out fusion casting on a mother alloy; (2) preparing an unalloyed strip; and (3) preparing a soft-magnetic material product. According to the soft-magnetic material prepared through the method disclosed by the invention, the magnetic conductivity is enhanced by adopting iron and nickel as main materials; the ductibility of the soft-magnetic material is enhanced by adding higher-proportion aluminum to the soft-magnetic material, so that the mechanical property of the soft-magnetic material is enhanced, and especially the plasticity is enhanced; and the magnetic saturation resistant capacity of the soft-magnetic material is improved by properly adding silicon, cerium, boron and niobium elements.

Owner:东莞市大晋涂层科技有限公司

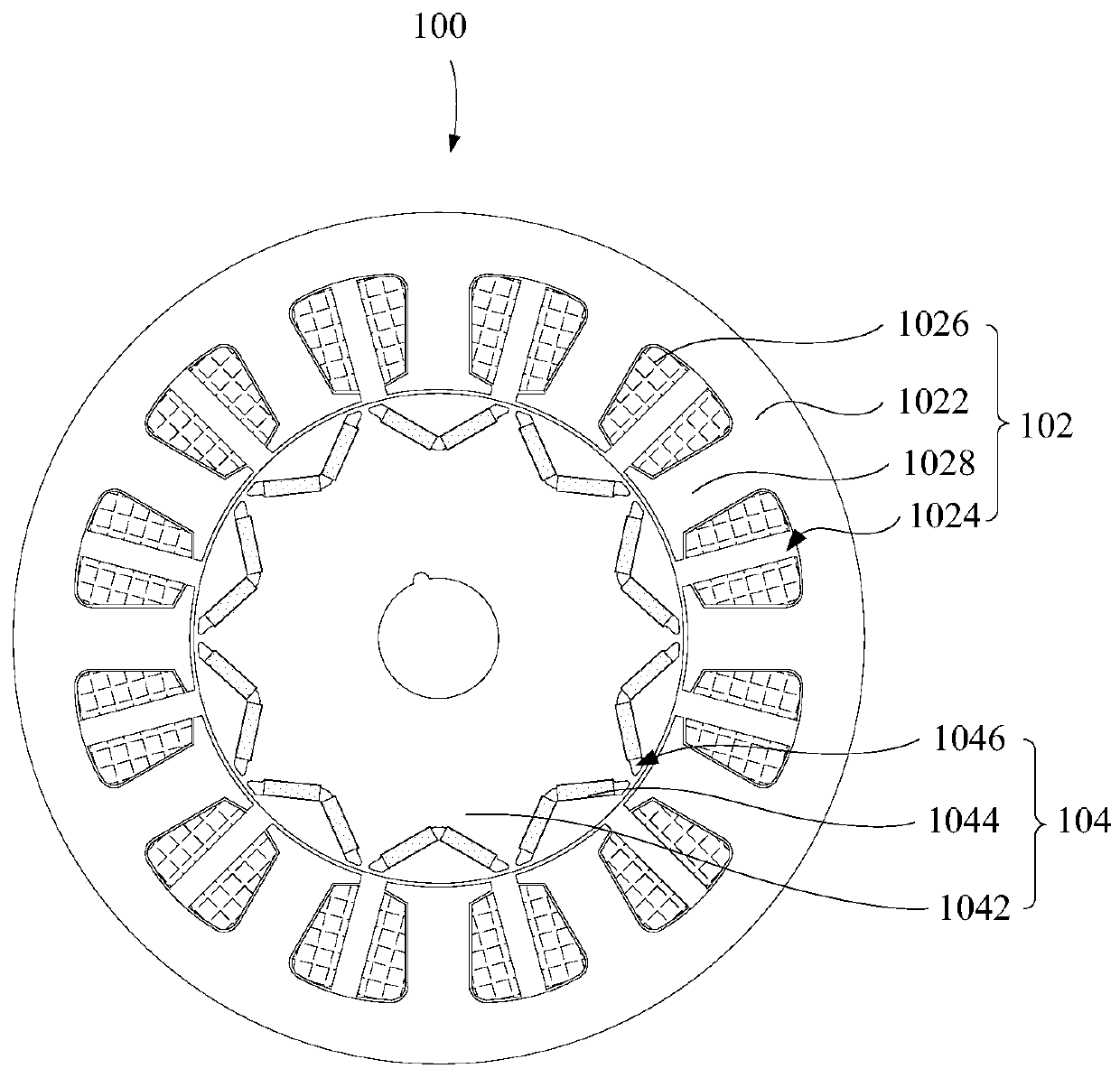

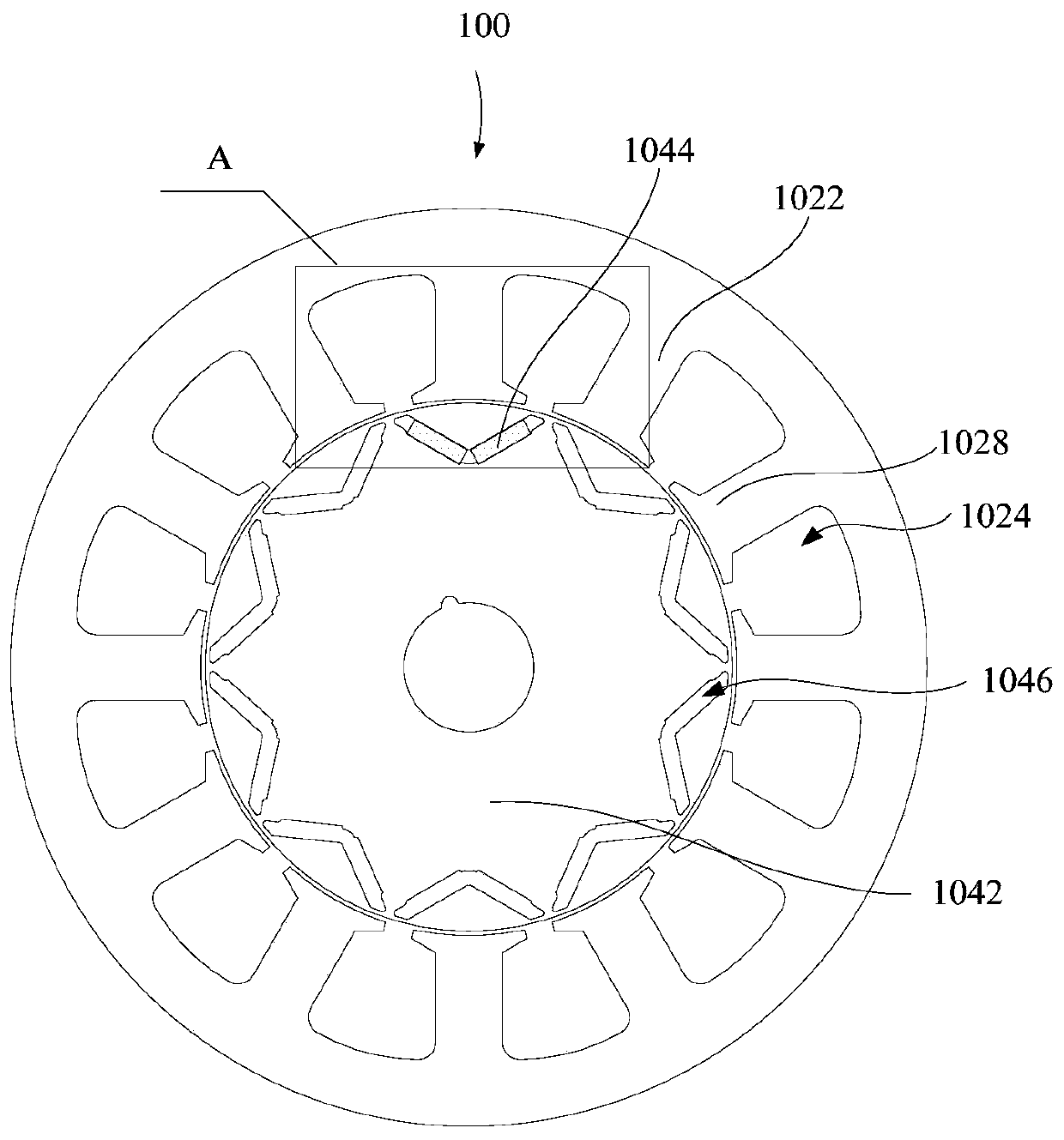

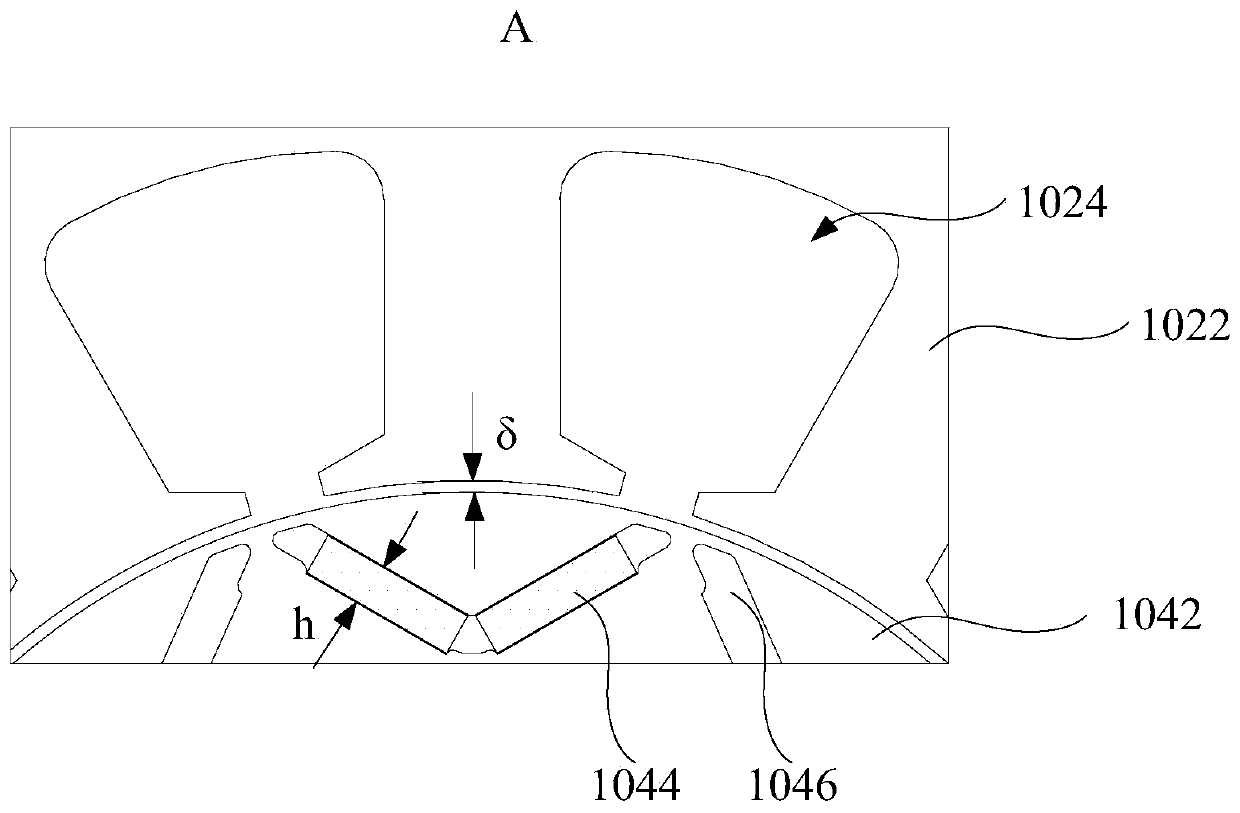

Motor, compressor and refrigeration equipment

ActiveCN111555480AIncrease profitReduce dosageCompressorMagnetic circuit rotating partsRare-earth elementElectric machine

The invention provides a motor, a compressor and refrigeration equipment. The motor comprises: a stator assembly, wherein the stator assembly comprises a stator iron core, and the stator iron core isprovided with a stator slot gap; a rotor assembly which comprises a rotor iron core and a permanent magnet, wherein one of the stator iron core and the rotor iron core is arranged on the outer side ofthe other one in a surrounding manner, and the permanent magnet is arranged on the rotor iron core, wherein in the section perpendicular to the axis of the rotor core, the distance between the statorcore and the rotor core is [delta]mm, the length of the permanent magnet in the magnetization direction of the permanent magnet is h mm, the number of the stator slots is Q, the intrinsic coercive force of the permanent magnet is Hcj kA / m, and Hcj is smaller than or equal to 1800 kA / m, and the numerical value of h meets the equation that h is larger than or equal to 80*(43-Q) / Hcj and smaller thanor equal to 1.6+[delta]. According to the motor provided by the invention, the use of heavy rare earth elements is reduced, the cost is reduced, the use requirements of the compressor can be met, andthe cost performance of the motor is improved.

Owner:ANHUI MEIZHI PRECISION MFG

Pot, electric rice cooker provided with same, and preparation method of pot

ActiveCN107638061AIncrease the outer surface areaImprove permeabilityCooking-vessel materialsMolten spray coatingHeating effectEngineering

The invention discloses a pot, an electric rice cooker provided with the pot, and a preparation method of the pot. The pot comprises a pot body, wherein the pot body is provided with first grooves which sink inwards relative to the outer surface of a bottom wall and / or first bulges which protrude out of the outer surface of the bottom wall, and a magnetic conductive metal layer is arranged on theouter surface of the pot body. According to the pot provided by the embodiment of the invention, the first bulges and / or the first grooves are arranged on the outer surface of the pot body, thus the area of the outer surface of the pot can be increased, the mechanical binding capacity of the magnetic conductive metal layer and the pot body is greatly increased, the magnetic conductive metal layeron the pot body has the effects of reducing noises and realizing silencing, and also has relatively high magnetic permeability, thus the thermal conductivity of the pot is improved, and further, the heating effect of the pot is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

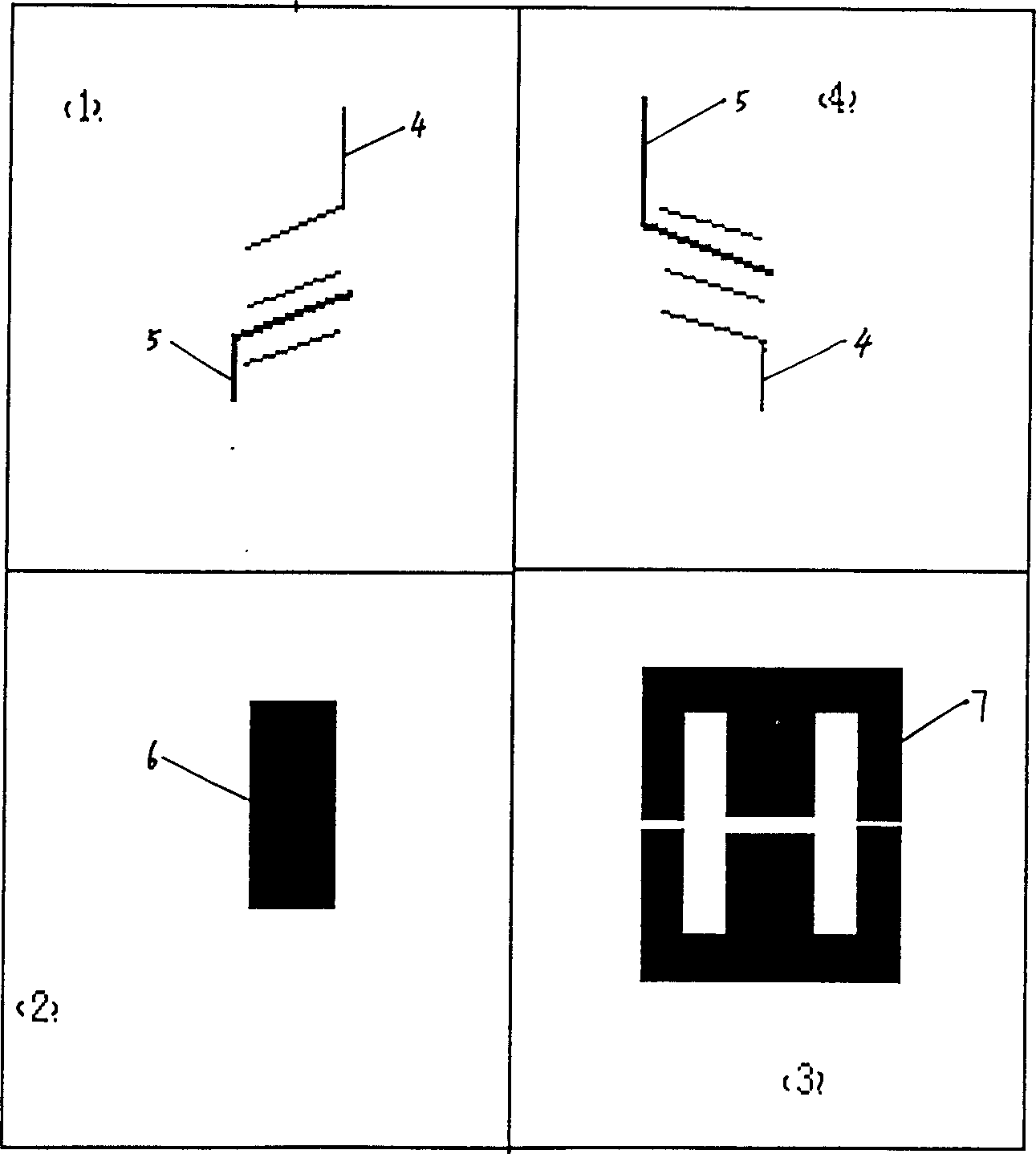

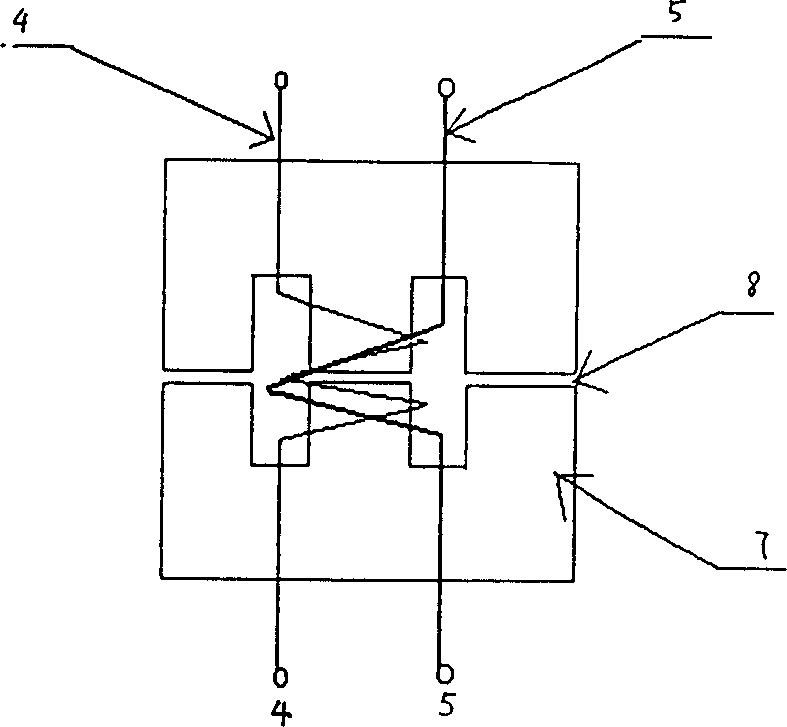

High frequency E-type and I-type film transformer and its preparing method

InactiveCN1157742CImprove coupling efficiencyPrimary and secondary inductance increaseTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerEngineering

The present invention dicloses a film transformer and its producting process. The film transformer consists of primary winding, secondary winding and film magnetic core. The primary winding and the secondary winding are plated to the film magnetic core crossly at the angle of 15 deg and 20 deg to the horizotnal direction separately. During the manufacture, the upper and the lower electrodes are made through a mask or photoetching process; the magnetic core film is prepared through a magnetically controlled sputtering process; the insulating layer is formed through evaporating SiO2 material lump in tungsten boat; and the magnetic core film is finally oriented nanometer crystallized in vacuum and magnetic field. The film transformer is one basic magnetic electronic element and its use will promote the conversion to sheet electronic elements.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

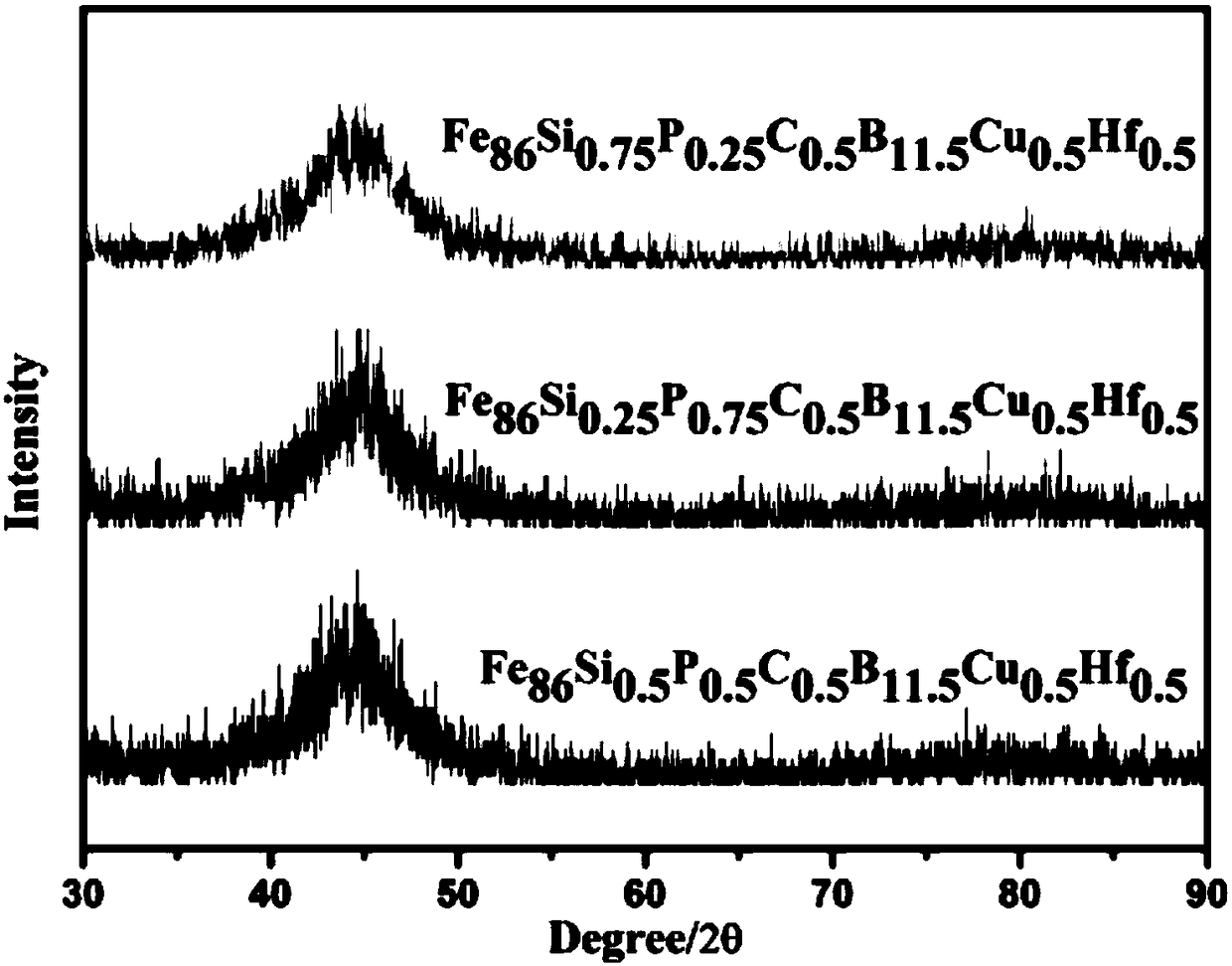

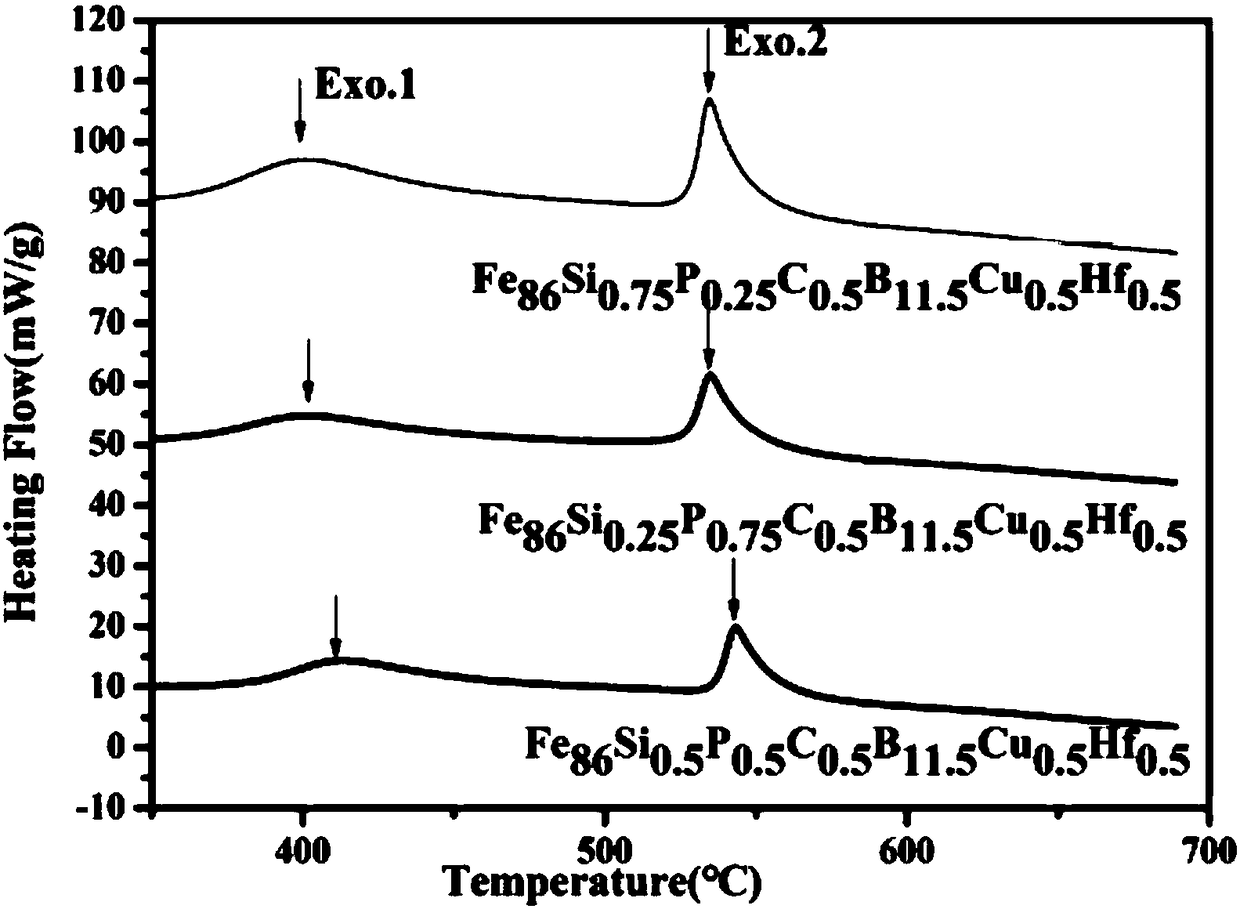

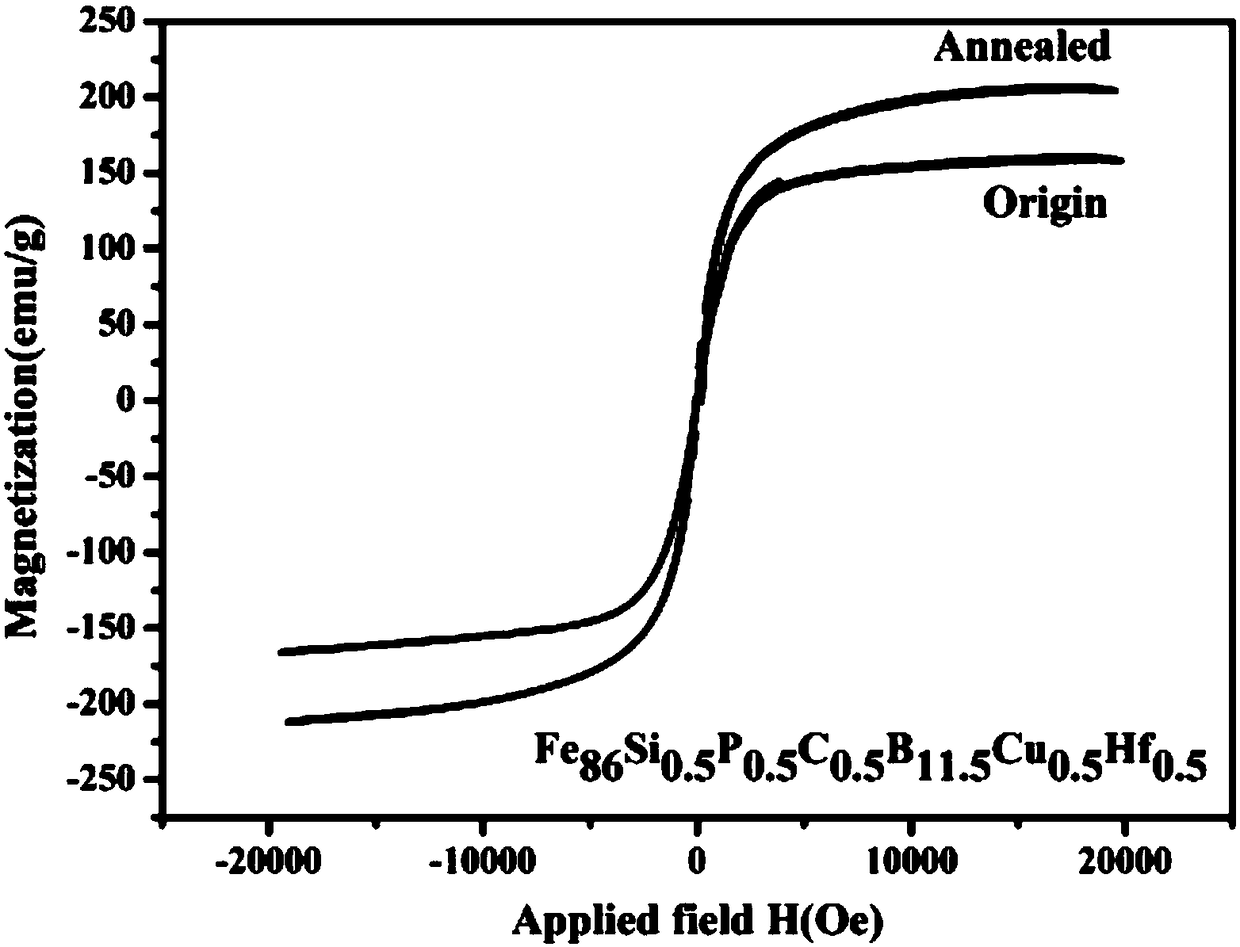

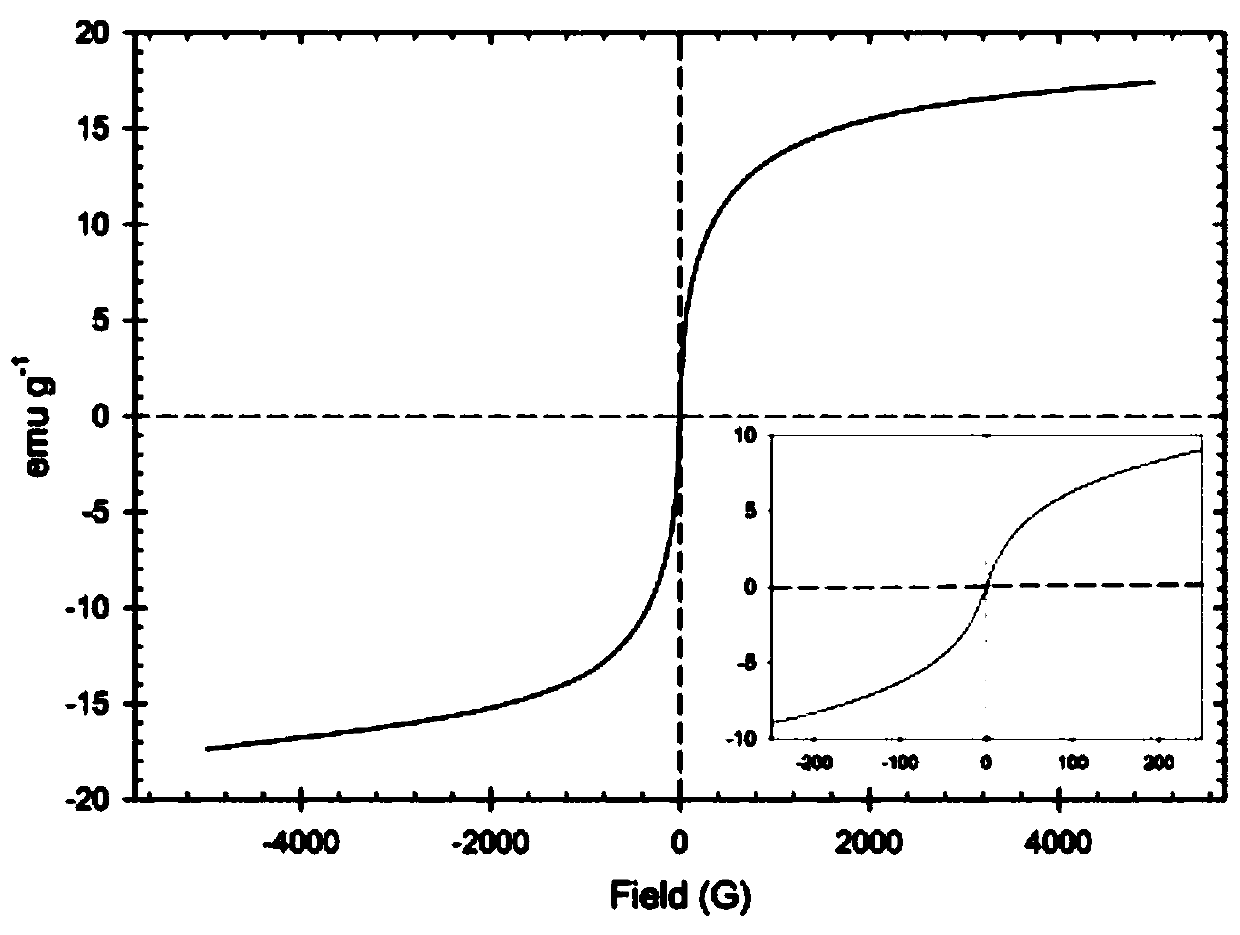

Iron-based nanocrystalline alloy and preparation method thereof

ActiveCN108220776AEnhanced Amorphous Formation AbilityHigh magnetic permeabilityNanocrystalline siliconHeat treated

The invention provides an iron-based nanocrystalline alloy represented by the formula (I), wherein a, b and c represent the atomic percentage contents of the corresponding components respectively, a=86-87, b=12-13, c=1, and a+b+c=100; the atomic percentage content of B is 11-13, the atomic percentage content of Si is 0.01-1, the atomic percentage content of P is 0.01-1, the atomic percentage content of C is 0.01-1, the atomic percentage content of Cu is 0.01-1, and the atomic percentage content of Hf is 0.01-1. The invention also provides a preparation method of the iron-based nanocrystallinealloy. By adjusting the alloy composition and heat treatment system, the amorphous forming ability and the saturation magnetic induction intensity of the iron-based nanocrystalline alloy are improved;the formula (I) is represented by Fea(BSiPC)b(CuHf)c (I).

Owner:GUANGDONG UNIV OF TECH

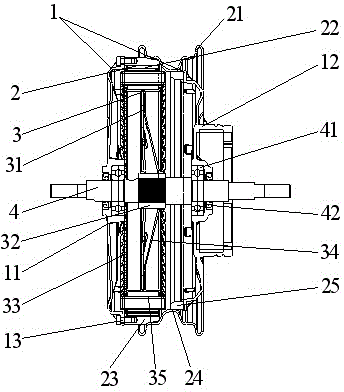

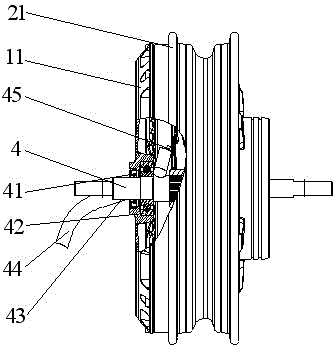

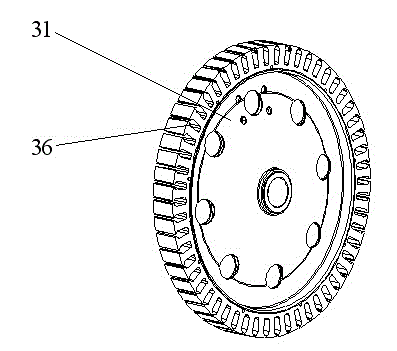

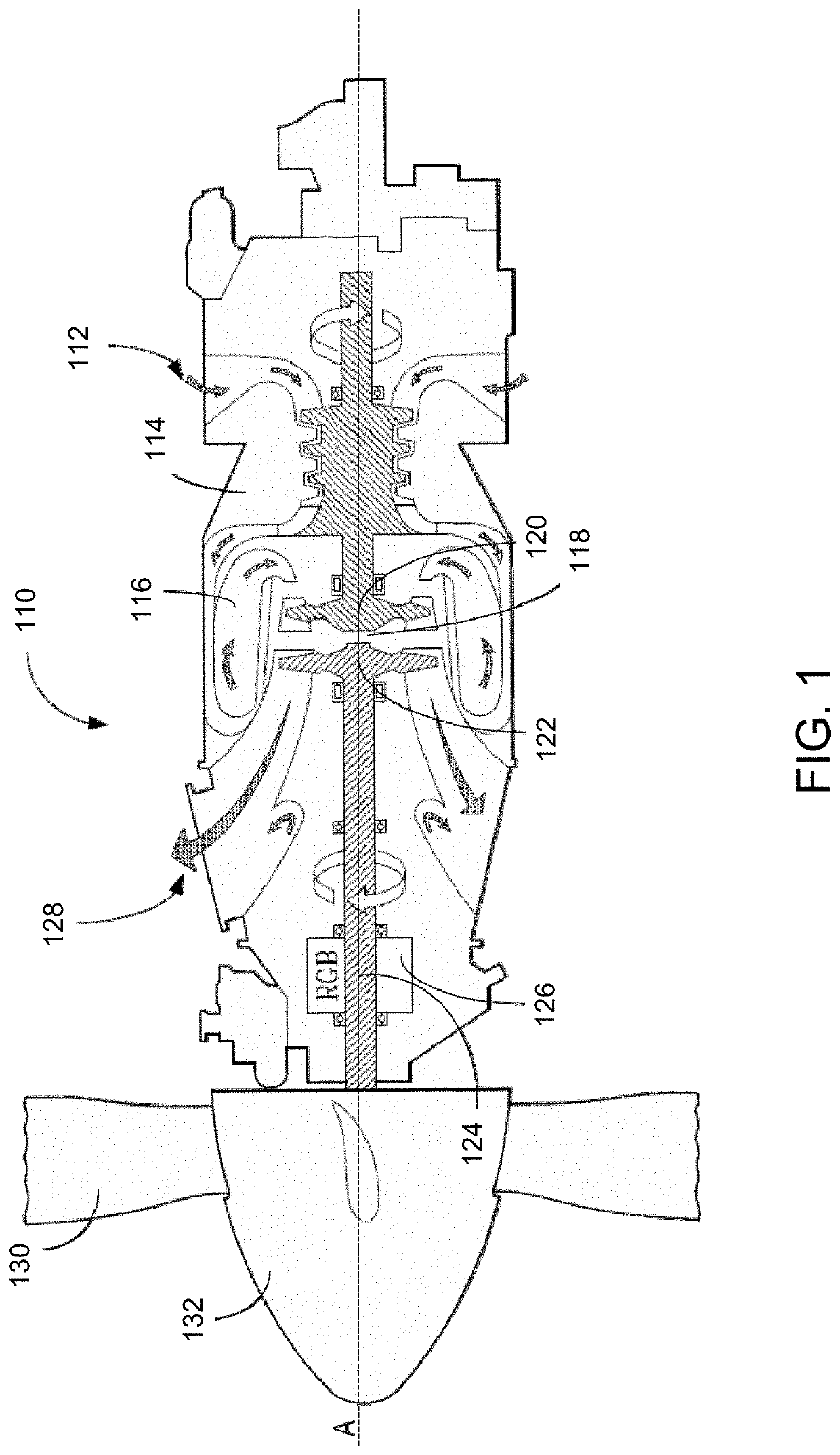

Pitch control assembly for an aircraft-bladed rotor

ActiveUS20210071589A1High magnetic permeabilityTurbine/propulsion fuel supply systemsElectrical controlPhysicsFlight vehicle

A feedback device for use in a gas turbine engine, and methods and systems for controlling a pitch for an aircraft-bladed rotor, are provided. The feedback device is composed of a circular disk and a plurality of position markers. The circular disk is coupled to rotate with a rotor of the gas turbine engine, to move along a longitudinal axis of the rotor, and has first and second opposing faces defining a root surface that extends between and circumscribes the first and second faces. The plurality of position markers extend radially from the root surface, are circumferentially spaced around the circular disk, and extending along the longitudinal axis from a first end portion to a second end portion. At least part of the first end portion and / or of the second end portion comprises a material having higher magnetic permeability than that of a remainder of the position markers.

Owner:PRATT & WHITNEY CANADA CORP

Iron core of transformer wire

InactiveCN101154495AReduce copper lossSimple manufacturing processTransformers/inductances magnetic coresInductances/transformers/magnets manufactureLow noiseTransformer

A transformer core is wound by siliconizing wire. The invention has the advantages of low cost, high magnetic inductivity, low losses, low noise, small temperature rise, light weight, strong commonality of material, good combination property, simple art, low level of difficulty of technique, convenient implementation and application to various power transformers and electronic transformers.

Owner:郭清林

High-magnetic-permeability and low-loss amorphous material for engine

InactiveCN105063516AReduce consumptionReduce hysteresis lossMagnetic circuit characterised by magnetic materialsManganeseAlloy

The invention relates to a high-magnetic-permeability and low-loss amorphous material for an engine. The amorphous material comprises iron being 70-85% of raw materials, nickel being 0.1-2% of raw materials, cobalt being 0.1-0.6% of raw materials, chromium being 0.01-0.2% of raw materials, and manganese being 0.01-0.2% of raw materials; and the amorphous material uses a quick condensation technology for cooling and curing the raw materials to a solid thin strip with a thin rib shape and a thickness of 0.12-0.2 mm by the speed of 130-180 DEG C / S to form an amorphous alloy to obtain a finished product. Compared with the prior art, the amorphous material has the following advantages: the amorphous material is excellent in ferromagnetism, can reduce 80% of energy consumption generated by steel rolling, improves the magnetic permeability, reduces the magnetic hysteresis loss and the iron loss of the engine, has such characteristics as short production period, high yield, high mechanical strength and good corrosion resistance, and is an upgrading product of a traditional silicon steel sheet.

Owner:JIANGSU HUAYUAN EXPLOSION PROOF MOTOR

Sunk plate type filter

InactiveCN102195467AReduce volumeThe overall thickness is thinPower conversion systemsEngineeringFrequency characteristic

The invention discloses a sunk plate type filter, comprising a framework, wherein four corners of the framework are provided with outer edges; pins are vertically connected with the outer edges; a groove is arranged in the middle of the framework; a raised structure is arranged in the middle of the groove; a magnetic core is arranged in the groove and connected with the raised structure; and coils are wound on the magnetic core and connected with the pins. The sunk plate type filter is thin in thickness and is embedded in a circuit board; the height is less than 8mm after the sunk plate type filter is mounted; in the filter, a ferrite core with high-magnetic permeability is adopted, thus increasing the magnetic permeability, reducing the cycles of windings and shortening the filter volume; and a butterfly-shaped threading mode is adopted for the filter, thus improving the frequency characteristics of products and strengthening the inhibition capacity of EMI (electro-magnetic interference).

Owner:江苏泰昌电子有限公司

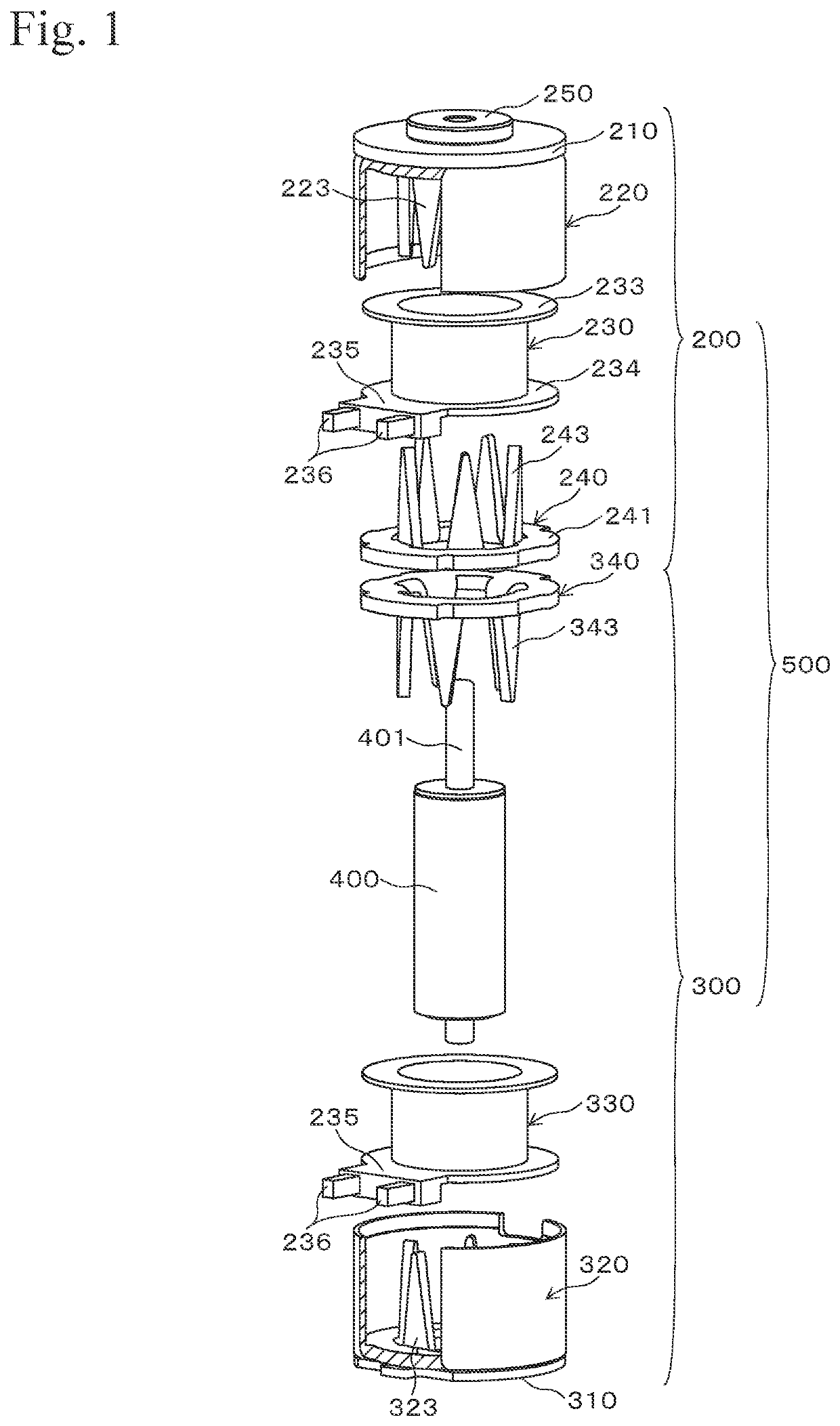

Stepping motor

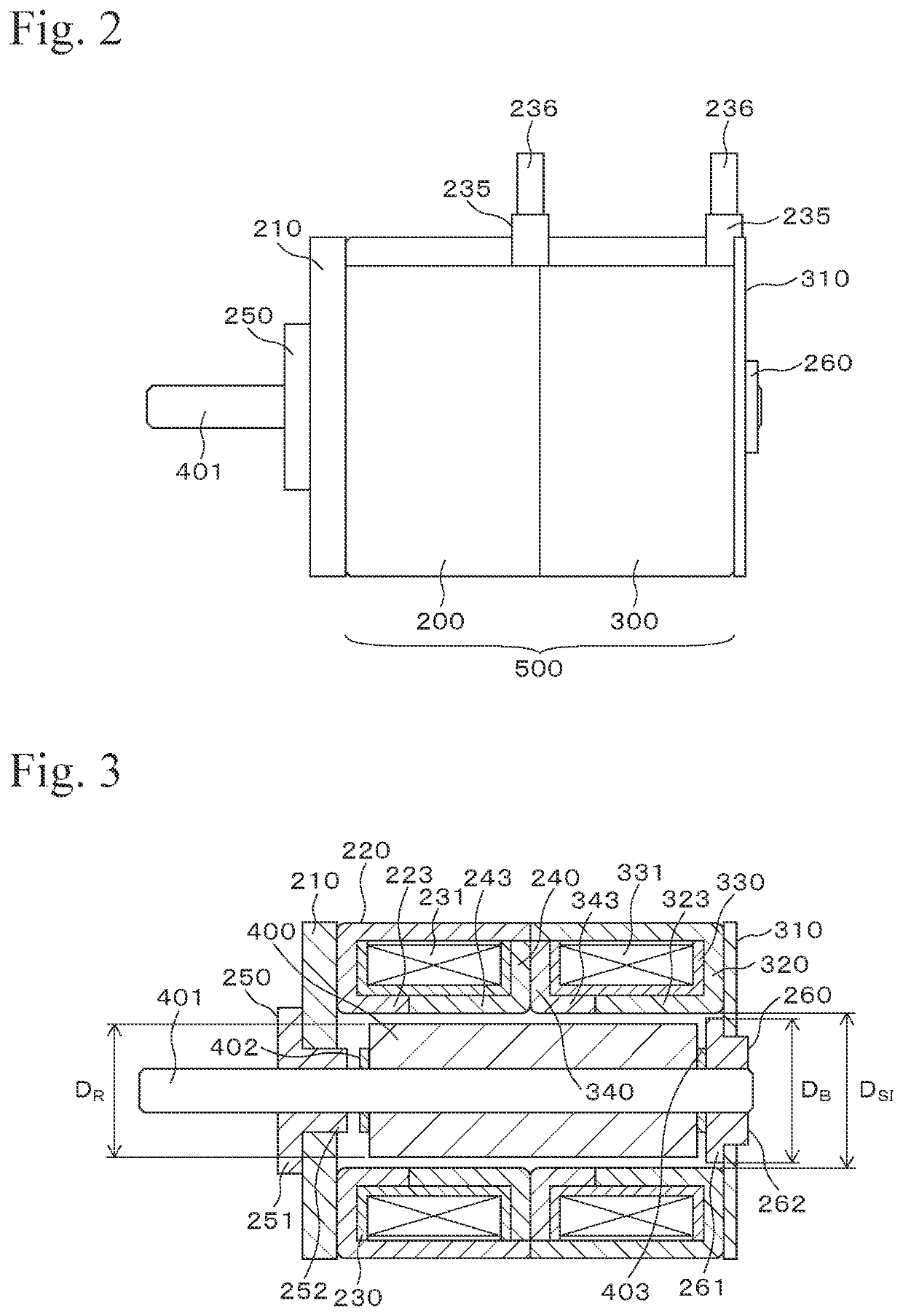

ActiveUS20210044194A1Reduce striking noiseHigh magnetic permeabilityMagnetic circuitMechanical energy handlingPhysicsEngineering

A stepping motor has a relationship between an outer diameter of a rotor and an outer diameter of a bearing made of magnetic material that can be adjusted appropriately so as to impart magnetic attractive force to the bearing, the stepping motor including a rotor 400 made of a permanent magnet, a stator 500 including multiple pole teeth 223, 243, 323 and 343 extending in an axial direction of the rotor arranged at an outer circumferential side of the rotor 400, a bearing 250 rotatably supporting one end portion in the axial direction of the rotor 400, and a bearing 260 rotatably supporting the other end portion in the axial direction of the rotor 400. Magnetic permeability of the bearing 260 is greater than that of the bearing 250, the rotor 400 includes multiple magnetic poles on an outer circumferential surface along a circumferential direction of the rotor 400, and an outer diameter DR of the rotor 400, an outer diameter DB of a portion of the bearing 260 which is facing the rotor 400, and an inner diameter DSI of the stator 500 are set to satisfy the following relationship of formula 1DR<DB<DSI (formula 1)

Owner:MINEBEAMITSUMI INC

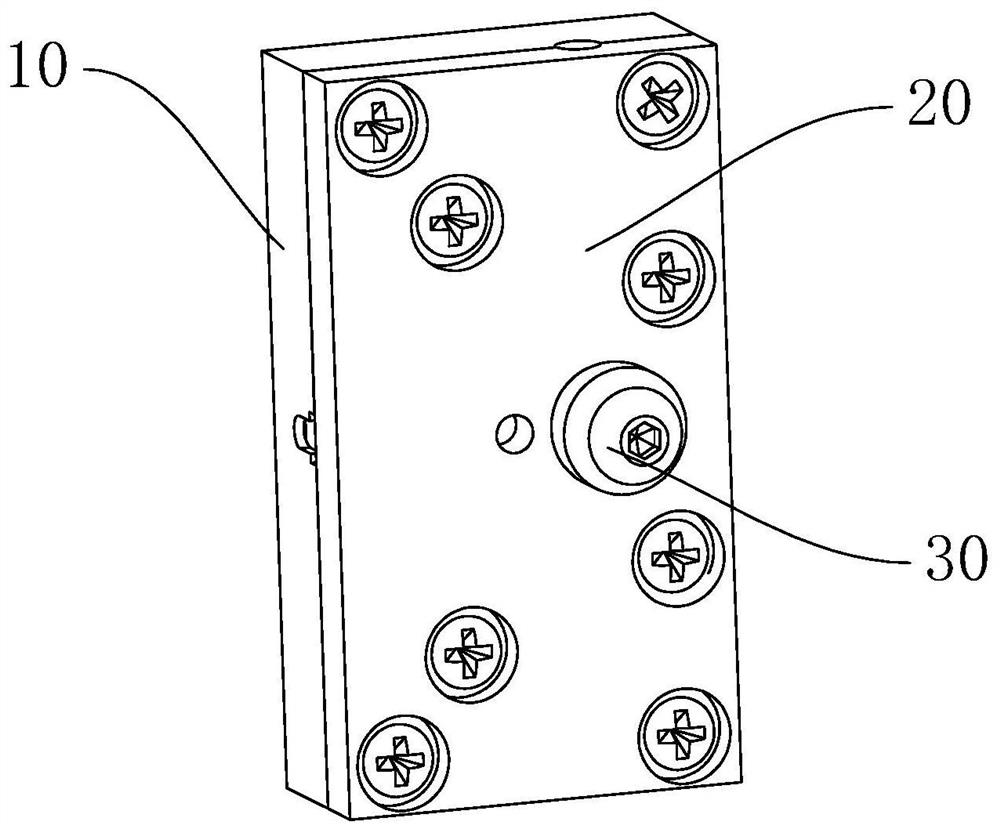

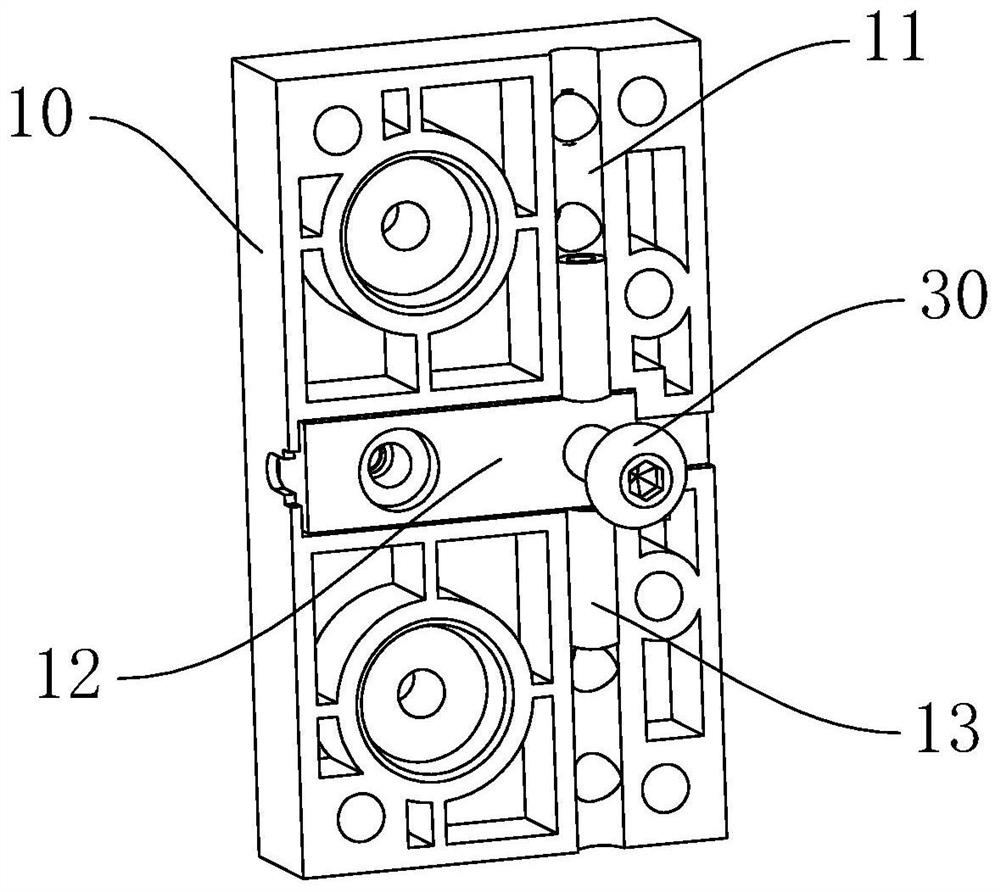

Improved sensor

ActiveCN112197804AHigh magnetic permeabilityHigh sensitivityMeasurement apparatus componentsStructural engineeringMechanical engineering

The invention provides an improved sensor, belongs to the technical field of machinery, and solves a problem that a conventional sensor is poor in sensing effect. The improved sensor comprises a bodywhich is installed on a bottom lifting device, an upper cover covers the surface of the body, and the upper cover and the body define a channel for a steel wire to pass through; the improved sensor also comprises a proximity switch fixedly arranged in the body; and a metal piece which is arranged on the upper cover in a penetrating mode and partially stretches into the channel, wherein the metal piece and the proximity switch are arranged on the two sides of the channel respectively, and when the steel wire penetrates through the sensor through the channel, the proximity switch senses and feeds back information. The sensor has the characteristic of good induction effect.

Owner:嘉兴卓凡机械科技有限公司

High-magnetic permeability thick composite induction plate and manufacturing method for same

InactiveCN102931783AIncrease productivityHigh magnetic permeabilityManufacturing stator/rotor bodiesPropulsion systemsCompound aSheet steel

The invention relates to a composite plate and a manufacturing method, in particular to a manufacturing method for a high-magnetic permeability thick steel aluminum-steel copper composite for a linear motor. A composite induction plate is formed by compounding a steel plate and an aluminum plate or compounding the steel plate and a copper plate. The steel plate has a thickness of 10 to 100mm and yield strength of 345 to 1,000Mpa. The aluminum plate or the copper plate is 3 to 30mm thick. A low-carbon weak-strength steel and aluminum / copper composite material also can be produced. Production cost is low, production efficiency is high, and a product has a uniform thickness and high quality.

Owner:莱芜美澳冶金科技有限公司

Wide-temperature high-quality factor Q value low-power-consumption magnetic core

InactiveCN103943299AImprove permeabilityLow Loss Temperature CoefficientCores/yokesEngineeringMiddle column

The invention discloses a wide-temperature high-quality factor Q value low-power-consumption magnetic core. The magnetic core comprises side legs, a bottom face and middle columns and is characterized in that the number of the side legs is two, the shapes of the inner sides of the two side legs are provided with inner arcs, the two side legs are connected with the two ends of the bottom face respectively, three middle columns are arranged in the central position of the bottom face, the middle columns are cylindrical, and the cylindrical diameter of the middle columns is smaller than the width of the bottom face. The wide-temperature high-quality factor Q value low-power-consumption magnetic core has the advantages of being ultra low in power loss and high in magnetic conductivity.

Owner:山东嘉诺电子有限公司

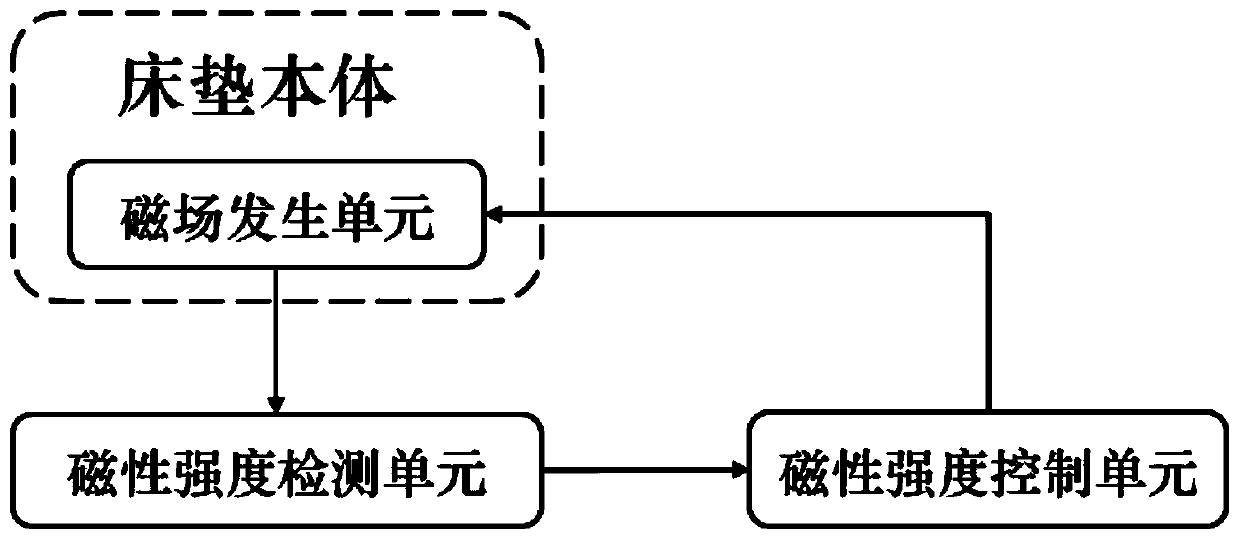

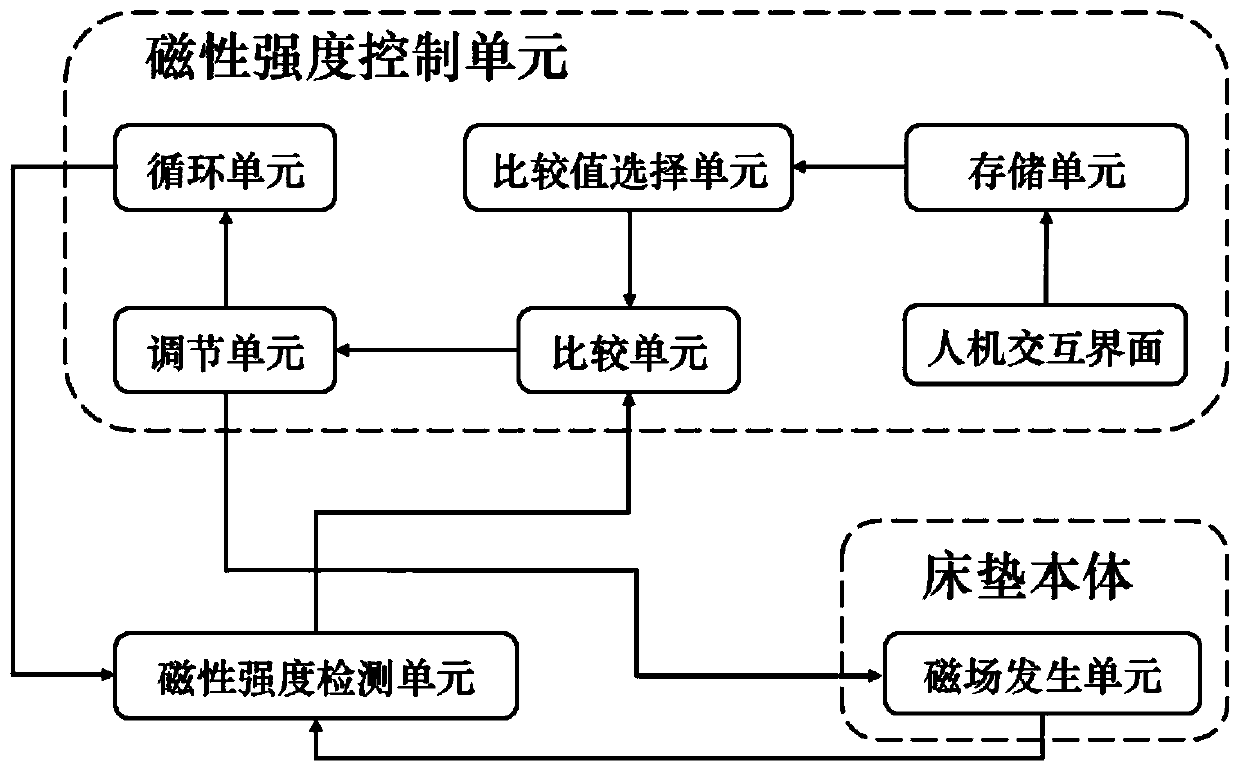

Self-adaptive adjusting mattress

ActiveCN111109931AImprove ferromagnetic propertiesStable temperatureElectrotherapyStuffed mattressesTitanium oxideCondensed matter physics

The invention discloses a self-adaptive adjusting mattress which comprises a mattress body internally provided with a magnetic field generation unit, the magnetic field generating unit comprises a magnetic element and an excitation circuit connected with the magnetic element, and the surface of the magnetic element is coated with a magnetic charcoal titanium dioxide composite nano material layer.The self-adaptive adjusting mattress further comprises a magnetic intensity detection unit which is used for detecting the instant magnetic intensity generated by the magnetic field generation unit inthe mattress body, and a magnetic intensity control unit which is connected with the magnetic intensity detection unit and the magnetic field generation unit and is used for sending a voltage regulation instruction to the excitation circuit according to the instant magnetic intensity detected by the magnetic intensity detection unit and regulating the magnetic intensity value of the magnetic charcoal titanium dioxide composite nano material layer. The magnetic intensity generated by the magnetic field generation unit can be adaptively adjusted, the phenomenon of obvious magnetic therapy effect difference caused by temperature and individual function difference is effectively eliminated, and the self-adaptive adjusting mattress has good antibacterial and self-cleaning functions.

Owner:JIANGSU ZHONGHENG KELAIBI FURNITURE CO LTD

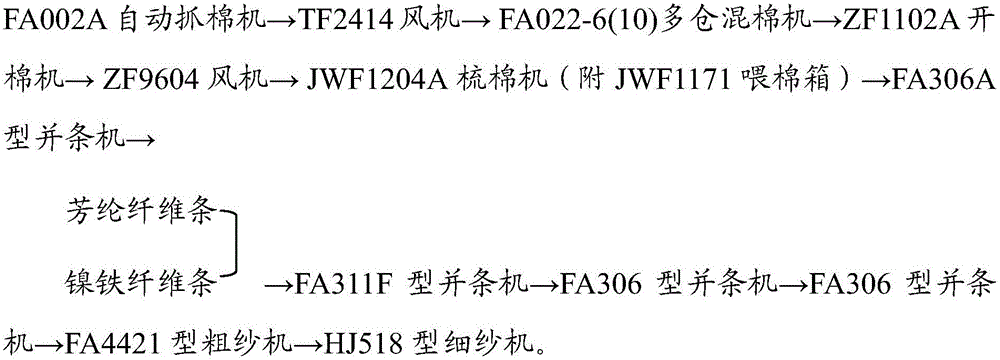

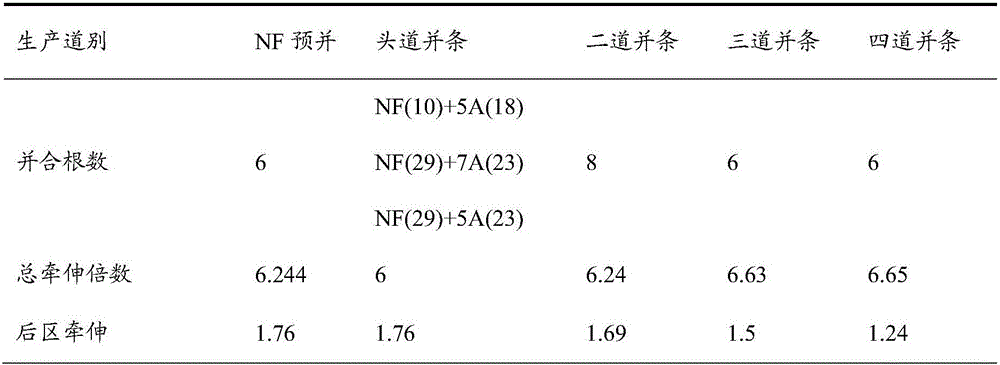

Blended yarn of aramid fibres and nickel-iron fibres and preparation process for blended yarn

The invention discloses a blended yarn of aramid fibres and nickel-iron fibres. The blended yarn comprises 75-95 parts by weight of aramid fibres and 5-25 parts by weight of nickel-iron fibres. The blended yarn of the aramid fibres and the nickel-iron fibres has good mechanical characteristics, relatively high breaking strength and relatively low elongation at break, meets urgent needs, on radar canopy, in space flight and aviation, has excellent flame resistance and excellent heat resistance and stable chemical property; the aramid fibres can be corroded by most of acidic chemicals while mechanical properties of the aramid fibres are hardly affected; and moreover, the blended yarn of the aramid fibres and the nickel-iron fibres has radiation resistance, durability, excellent wear resistance, corrosion resistance and washing resistance, so that strength of the blended yarn still can be kept to be 80% or higher of the original strength of the blended yarn even the blended yarn is worn, chemically corroded and washed by many times.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

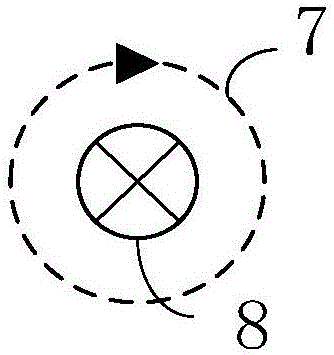

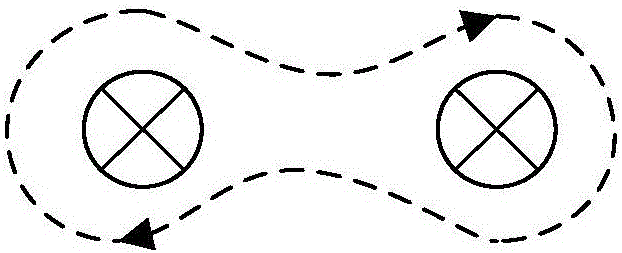

Metal pipeline surface anticorrosive device

The invention discloses a metal pipeline surface anticorrosive device. The metal pipeline surface anticorrosive device is characterized that the metal pipeline surface anticorrosive device comprises an oscillating circuit (10), a coil (1) and a magnetic conductive ring; a metal pipeline (4) is sleeved with the magnetic conductive ring; the coil (1) is wound around the magnetic conductive ring, and moreover the coil (1) and the oscillating circuit (10) are connected to form a current loop; the magnetic conductive ring can be one or a mixture of ferrite, cobalt and nickel, and the included angle between the normal direction of the plane where the magnetic conductive ring is located and the axial direction of the metal pipeline (4) ranges from 0 to 60 degrees; the magnetic conductive ring is used for introducing an alternating electromagnetic field to the metal pipeline (4), and the surface of the metal pipeline (4) is anticorrosive. The metal pipeline surface anticorrosive device is stable in metal anticorrosive effect, impurities can not be introduced additionally, the energy transmission effect is good, safety is high, and practical application is facilitated.

Owner:波思环球(北京)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com