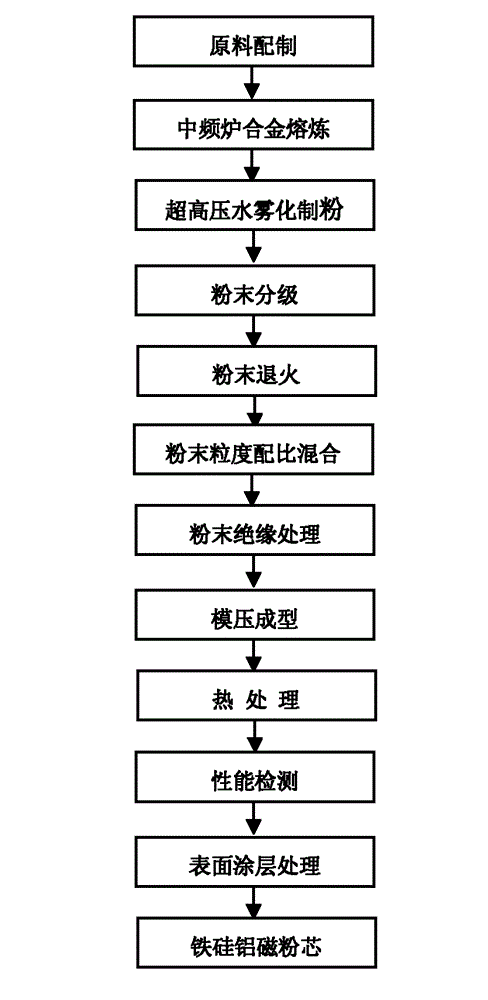

Manufacturing method of high-magnetic-permeability low-power-consumption iron-silicon-aluminum alloy powder for magnetic powder cores

A technology of sendust and high magnetic permeability, which is applied in the field of manufacturing sendust powder for magnetic powder cores with high magnetic permeability and low power consumption, and can solve the problems of performance degradation of sendust magnetic powder cores, high production costs and poor composition Compositional fluctuations and other problems, to achieve the effect of reducing power loss, low production cost, and improving magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

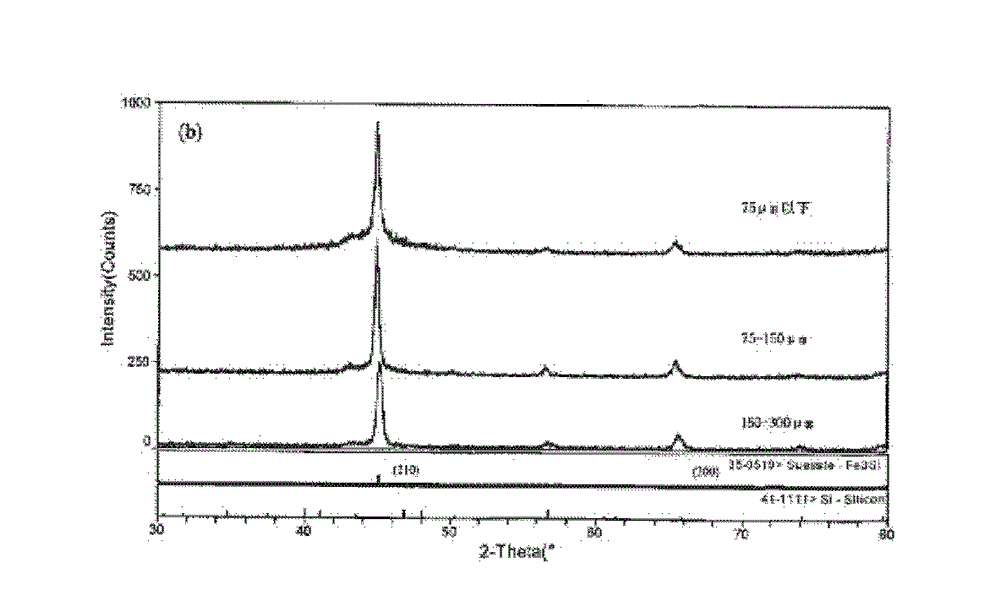

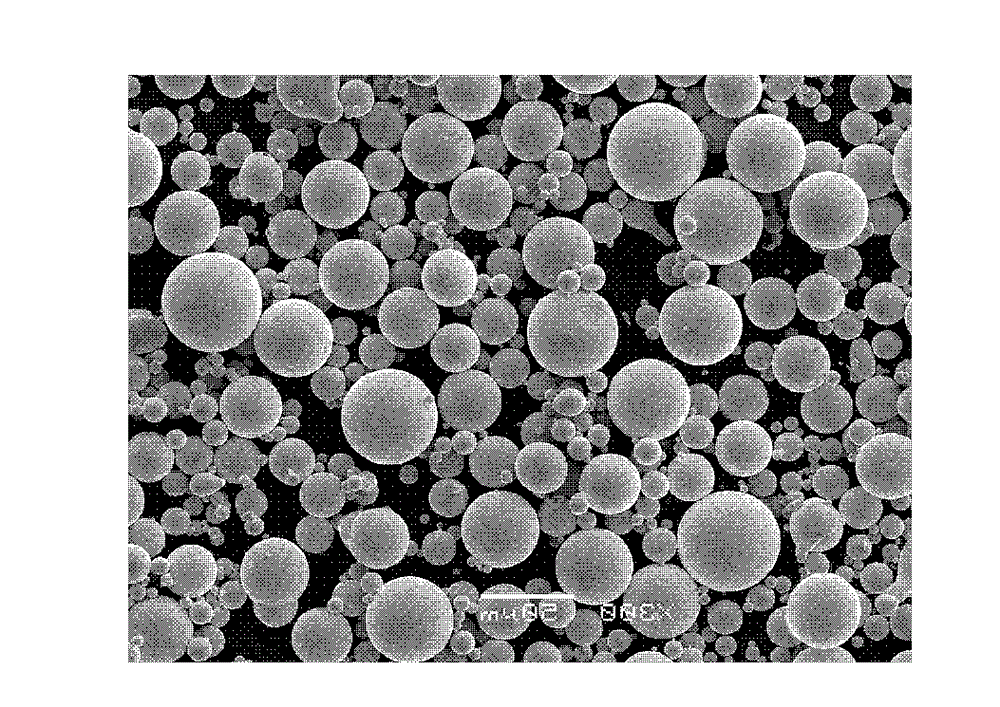

[0022] Put industrial pure iron, polysilicon and pure aluminum into a non-vacuum induction furnace with a nominal 100 kg of raw materials covered with a protective agent for smelting. The protective agent is 0.5 kg. The weight percentage of the protective agent is: calcium carbonate: 35%, fluorite: 25%, alumina: 40%. The melt composition of sendust aluminum alloy in weight percentage is: Si 9.5%, Al 6.0%, C 0.014%, O 0.036%, N 0.008%, and the balance is Fe. The melt is atomized into Alloy powder, and then put the powder into a heat treatment furnace filled with hydrogen atmosphere, heat it at 900-1000°C for 2 hours for annealing treatment, and sieve the alloy powder after annealing treatment, according to -100 mesh ~ +150 mesh accounts for 15%, -150~+250 mesh accounts for 55%, -250 mesh~+300 mesh accounts for 25%, and -300 mesh accounts for 5%. Binder and release agent, so that the density of the finished product is 6.14g / m 3 . Put the molded product into a protective atmos...

Embodiment 2

[0024] The manufacturing process is the same as in Example 1, and the same 100 kilograms of raw materials are put into the nominal amount, and the protective agent consumption is 0.7 kilograms. The protective agent is mixed by calcium carbonate, fluorite, and aluminum oxide, and its weight percentage content is calcium carbonate: 45%. Fluorite: 15%, alumina powder: 40%. The chemical composition of sendust is Si 9.8%, Al 5.6%, C 0.014%, O=0.032%, N=0.008%, and the balance is Fe. The melt is atomized into alloy powder by ultra-high pressure water atomization powder making device. After annealing treatment, the particle size distribution is as follows: -100 mesh to +150 mesh accounts for 20%, -150 mesh to +250 mesh accounts for 50%, and -250 mesh accounts for 50%. ~+300 meshes account for 20%, and -300 meshes account for 10% to carry out insulation treatment, add binding agent and release agent (the addition amount of binding agent and release agent is the same as embodiment 1), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com