Patents

Literature

57results about How to "Inhibition of chemical reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

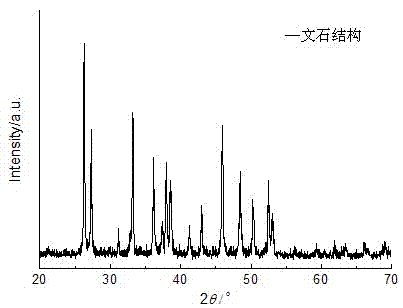

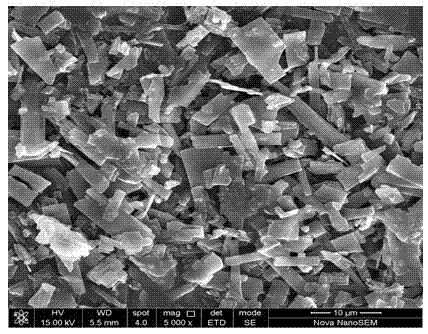

Method for preparing lamellar aragonite calcium carbonate powder from shell under hydrothermal condition

InactiveCN103086415ASubstantial progressSubstantial technological innovationCalcium/strontium/barium carbonatesCarboxylic acidHigh pressure

The invention discloses a method for preparing lamellar aragonite calcium carbonate powder from a shell under a hydrothermal condition, and belongs to the field of inorganic material. The method comprises the following process steps: (1) grinding the shell into powder and screening the powder; (2) adding the shell powder into an aqueous solution of polybasic carboxylic acid, and adding the resulting solution into a high pressure kettle to carry out hydrothermal treatment; and (3) separating, washing and drying the treated shell powder to obtain the aragonite calcium carbonate powder with powder particle size being 1-10mu m. According to the method disclosed by the invention, the lamellar aragonite calcium carbonate powder is prepared from the shell by means of hydrothermal treatment, and the method has the characteristics of low raw material cost, simple production process, environment-friendly production process and the like, and is suitable for recycling waste shells on a large scale and with high added value.

Owner:NANCHANG HANGKONG UNIVERSITY

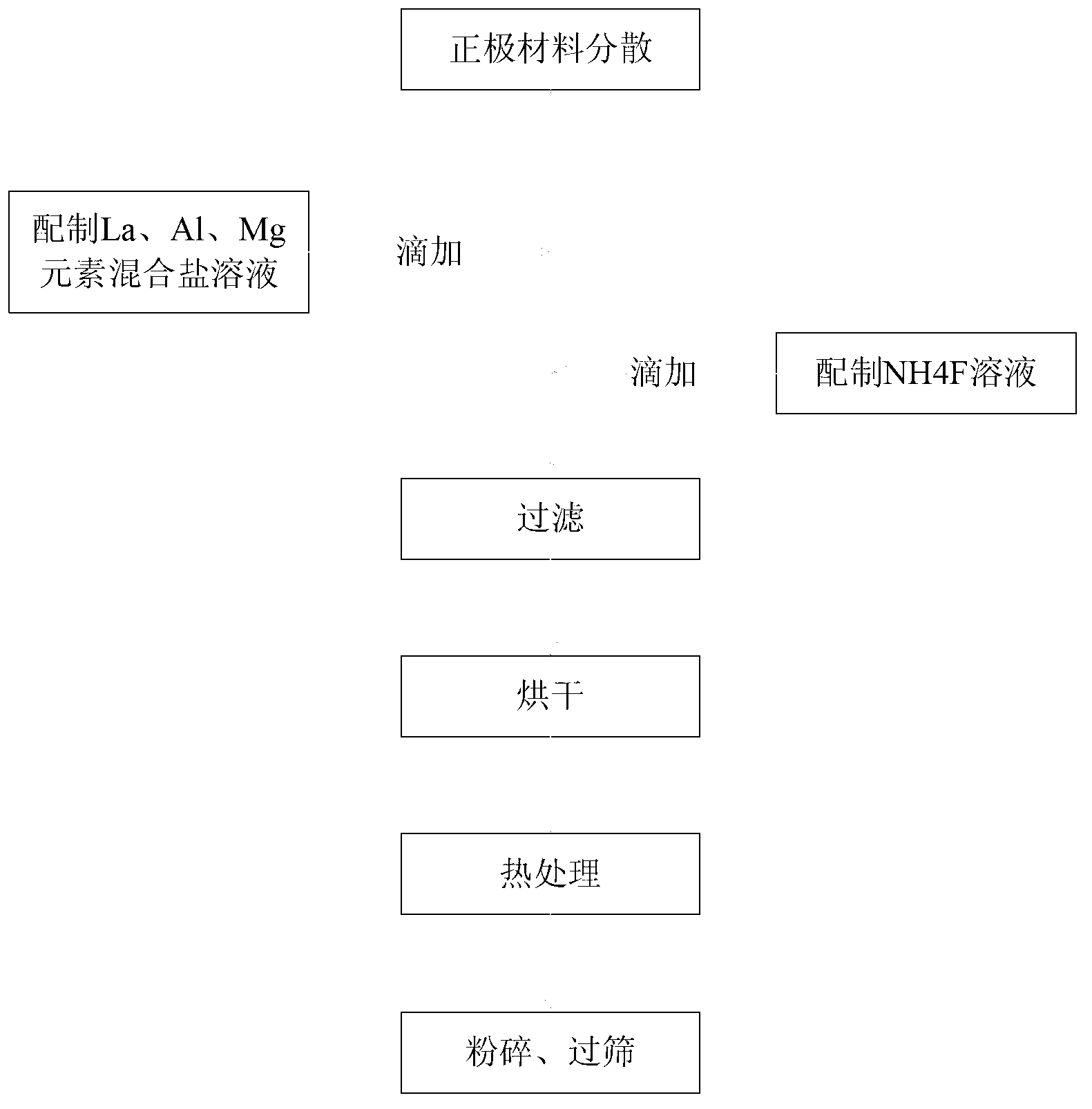

Compounding and coating method of anode material for lithium ion cell

InactiveCN103022502AImprove cycle performanceImprove rate discharge performanceCell electrodesLithiumManganese oxide

The invention discloses a compounding and coating method of an anode material for a lithium ion cell. The compounding and coating method comprises the steps that fluorides of La, Al and Mg are coprecipitated on the surface of a lithium ion anode material in a liquid phase; and then, the anode material for the lithium ion cell cooperatively coated by La3+, Al3+, Mg2+ and F- is obtained by heat treatment. With the adoption of the coating treatment, the circulating property and the rate discharge property of the anode material under the charge cut-off voltage are improved; and the high-temperature circulating property of a spinel manganese oxide lithium material and the ordinary pressure circulating property of a nickelic anode material are improved.

Owner:TIANJIN B&M SCI & TECH

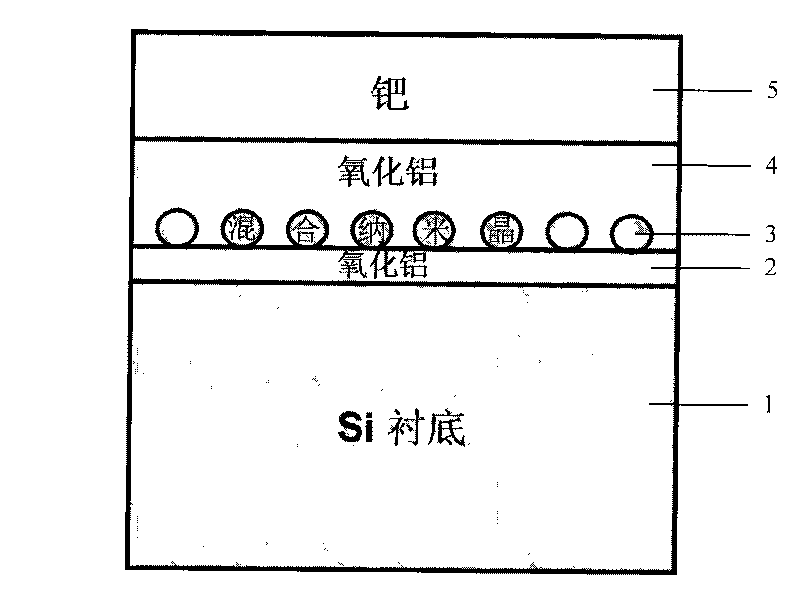

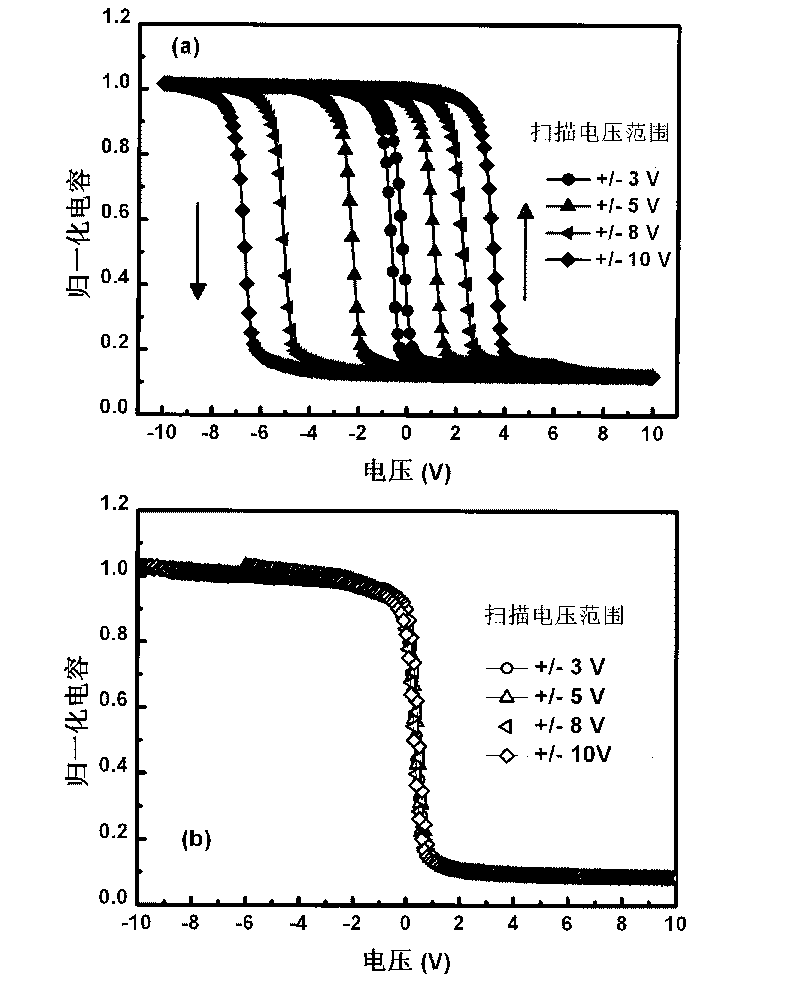

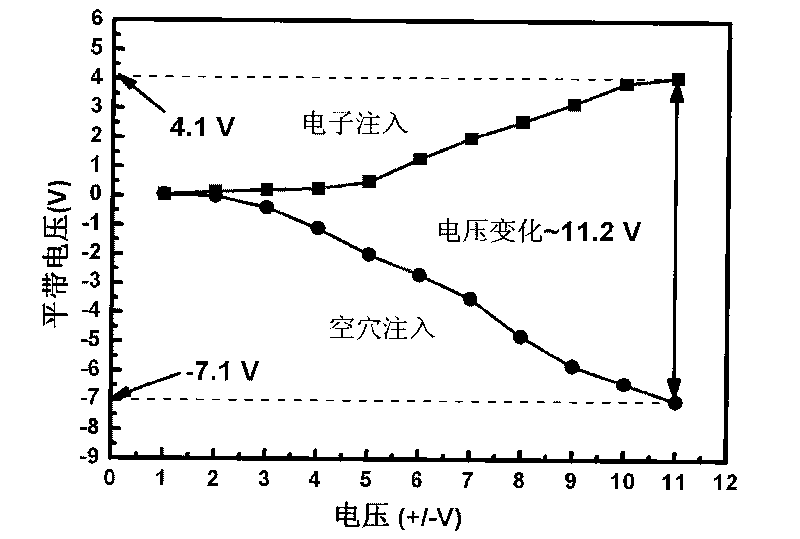

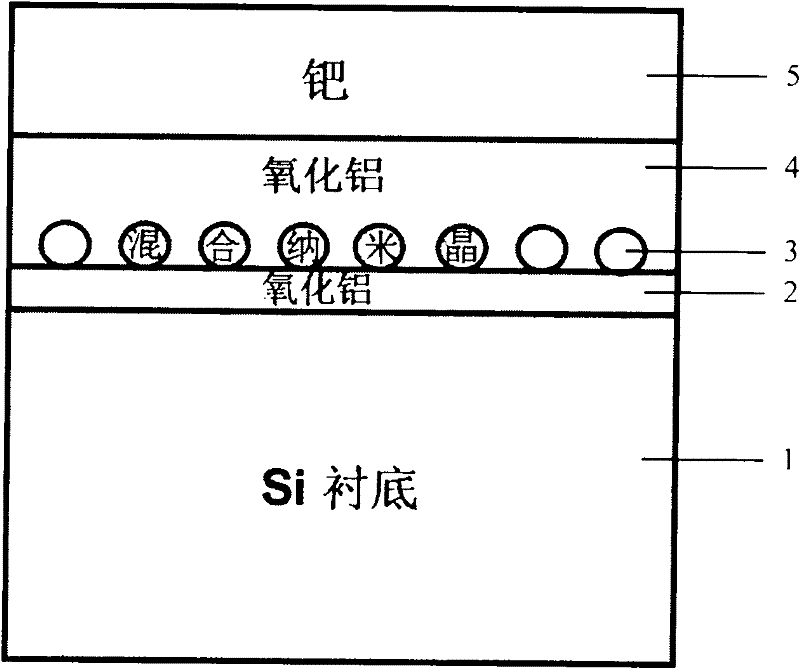

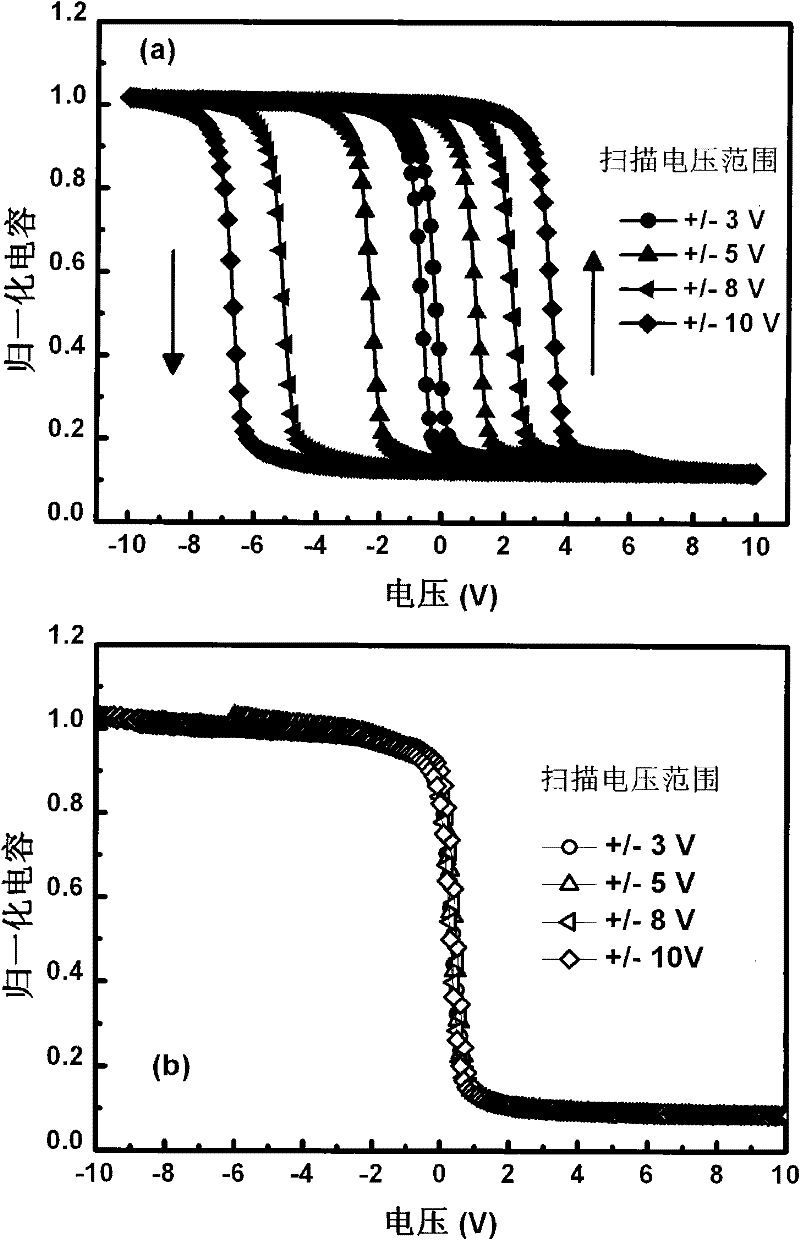

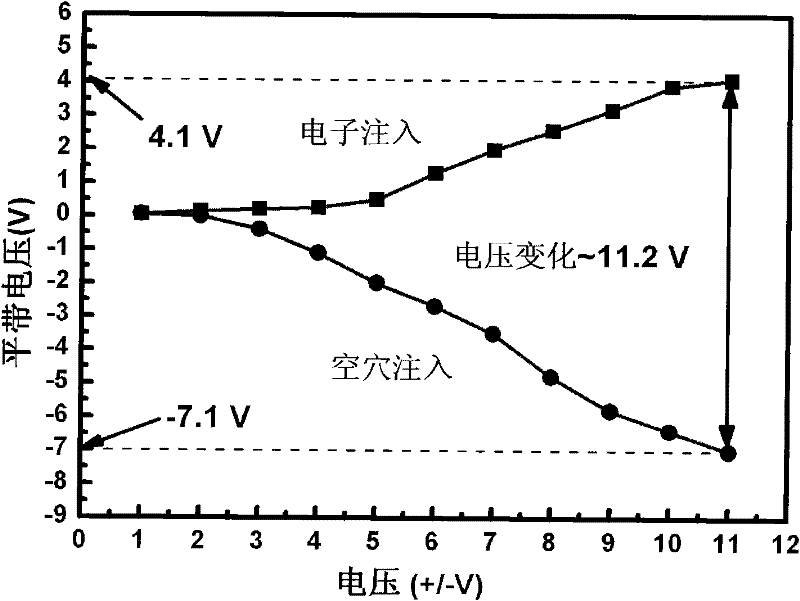

Capacitor structure of mixed nano-crystal memory and preparation method thereof

InactiveCN101692463AHigh densityControl thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceCharge retention

The invention belongs to the technical field of manufacturing semiconductor integrated circuits, and particularly relates to a capacitor of a nano-crystal memory and a preparation method thereof. The capacitor uses P-type monocrystalline silicon as a substrate, and an Al2O3 tunneling layer, a ruthenium and ruthenium oxide mixed nano-crystal, an Al2O3 blocking layer and a palladium electrode layer are arranged on the substrate in turn, wherein the Al2O3 layer is prepared by adopting an atomic layer deposition method; the mixed nano-crystal is formed by depositing a ruthenium layer through magnetron sputtering first and then performing rapid thermal annealing in a mixed gas atmosphere of nitrogen gas and a trace amount of oxygen gas; and the palladium electrode layer is formed by adopting a lift-off method. The capacitor structure of the memory has the excellent characteristics of good programming and erasing properties, long charge retention time and the like, and has a good application prospect on a flash memory.

Owner:FUDAN UNIV

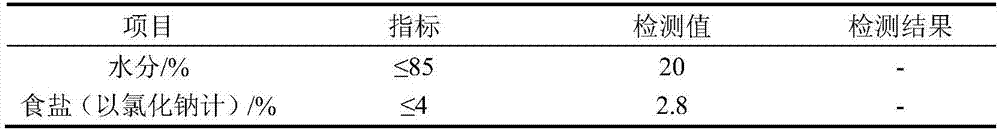

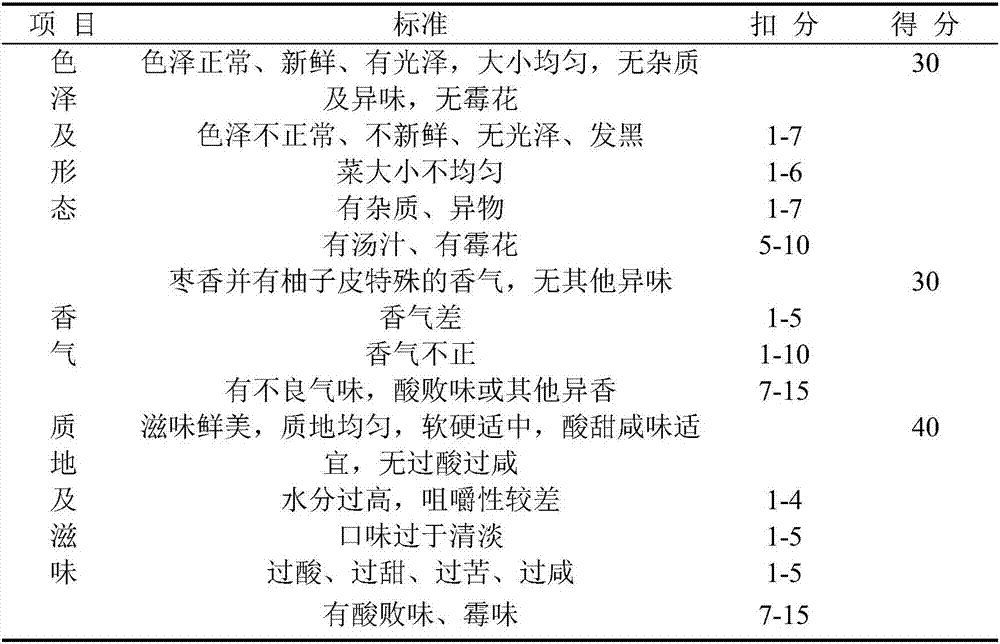

Preparation method of accompaniment pomelo peel and red jujube health-care dish

InactiveCN107568653APrevent fat oxidationPreserve nutritional value and health functionFood scienceZiziphus jujubaFlavor

The invention relates to a preparation method of an accompaniment pomelo peel and red jujube health-care dish. The preparation method comprises the following steps: raw material pretreatment: treatingpeanuts and pomelo peel; performing efficient pickling under pulse transformation; then, performing anaerobic fermentation, and adding lactic acid bacteria and a fermentation aid; and finally, performing cooling, post-curing and drying to form the product. The pomelo peel is adopted instead of condiments so as to prevent oxidation among flavor substances. Aroma substances such as limonene, myrcene, beta-pinene, alpha-Panasinsen and germacrene D in the pomelo peel can cover up unpleasant flavor substances and inhibit combination reaction among various smells, so that the dish can keep a fruitysmell for a long term.

Owner:NINGXIA ZHONGXI JUJUBE IND LTD LTD

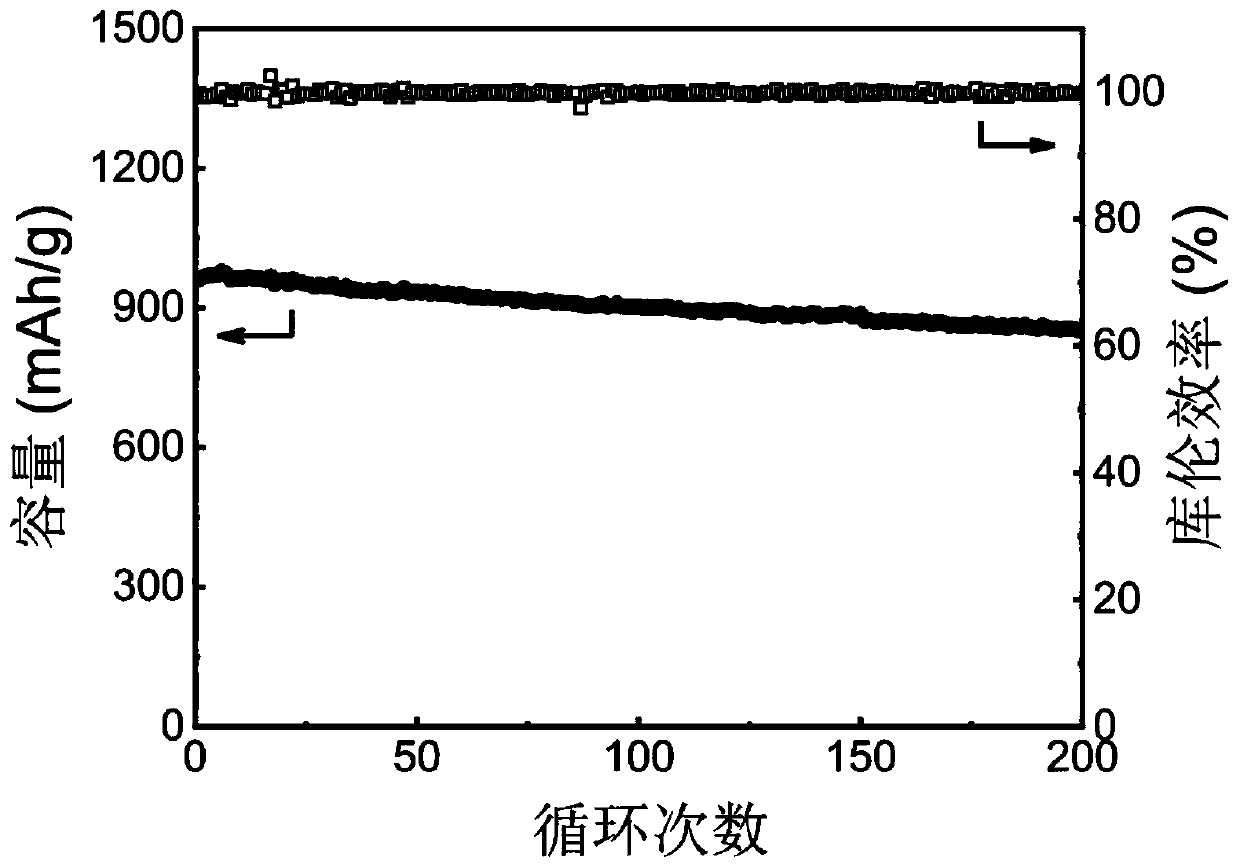

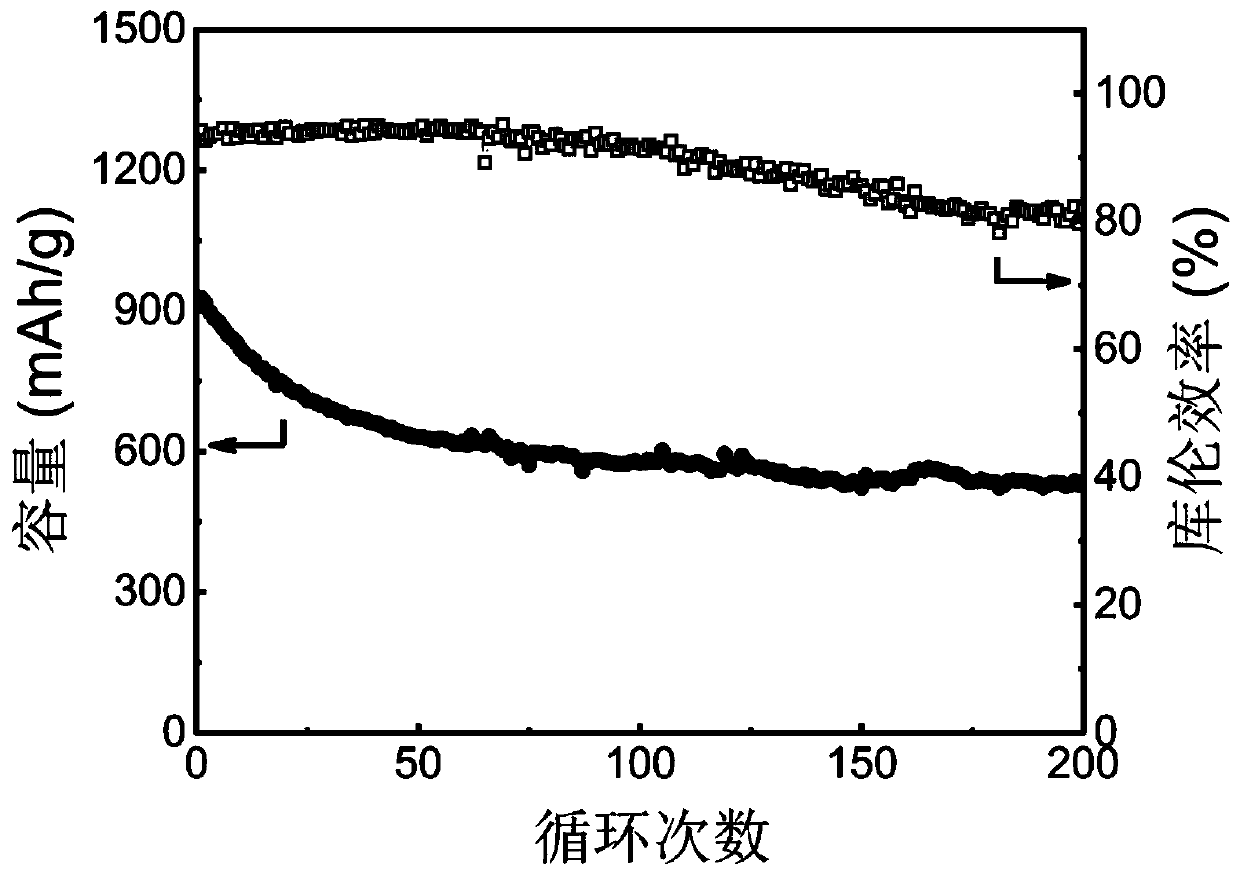

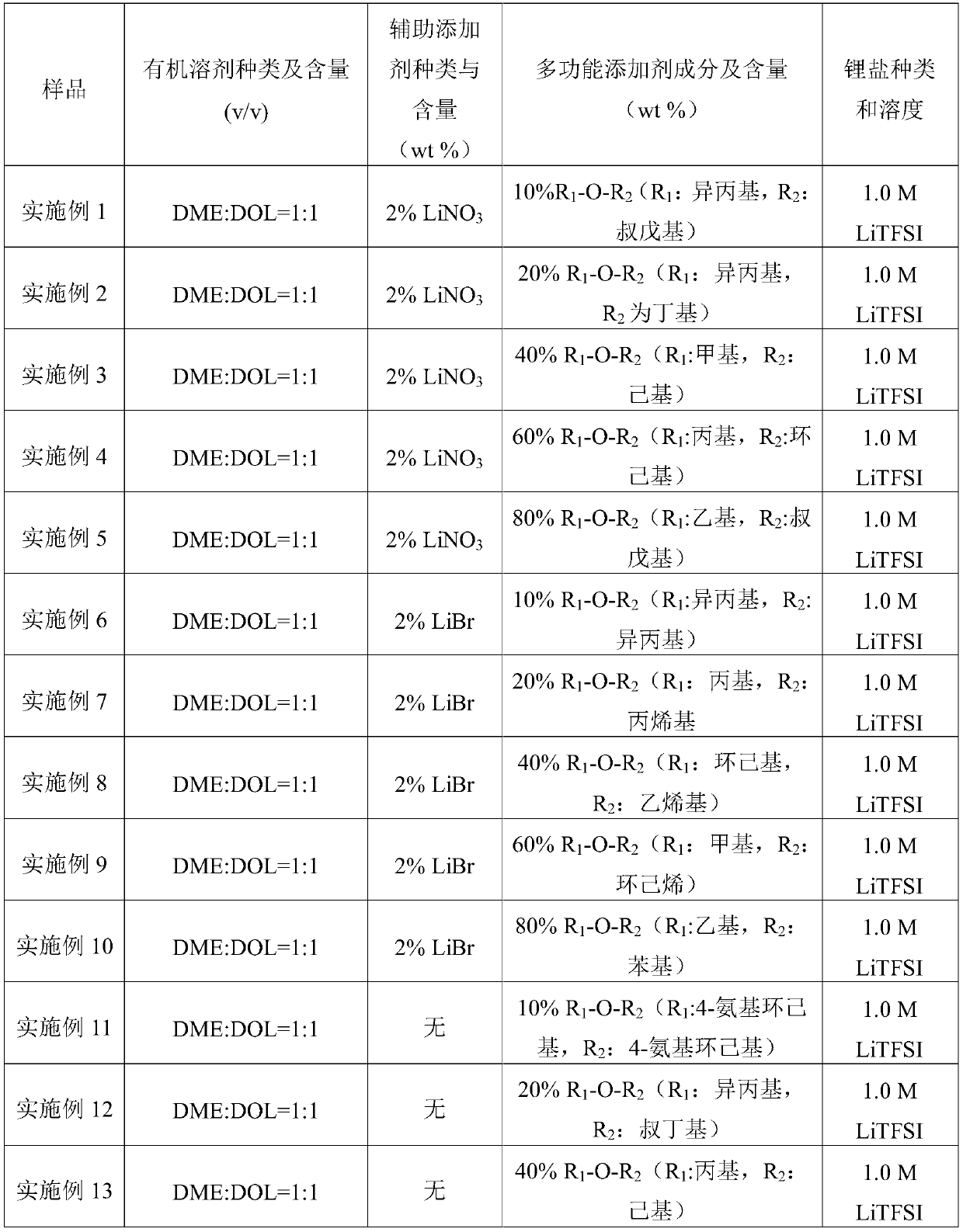

Lithium-sulfur battery electrolyte containing multifunctional additive and application thereof

ActiveCN110854437AImprove Coulombic efficiencyImprove cycle stabilityLi-accumulatorsOrganic electrolytesMetallic lithiumElectrolytic agent

The invention discloses a lithium-sulfur battery electrolyte containing a multifunctional additive and an application thereof, which belongs to the technical field of rechargeable and dischargeable high-specific-energy secondary batteries. The electrolyte comprises an organic solvent, a lithium salt and a multifunctional additive. The multifunctional additive is one or more of compounds with R1-O-R2 chemical structural formulas. R1 and R2 are the same or different, and R1 or R2 is selected from a C1-C8 alkane group, a C2-C8 alkenyl group, a C3-C8 cycloalkyl group, a C3-C8 hetero-cycloalkyl group or a partially unsaturated C3-C8 cyclic hydrocarbon group. The ring structure of the C3-C8 cycloalkyl group, the C3-C8 hetero-cycloalkyl group or the partially unsaturated C3-C8 cyclic hydrocarbongroup contains or does not contain a substituent. By introducing the multifunctional ether additive, the loss of active substances sulfur and lithium is reduced, the cycling stability of the battery is enhanced, the chemical reaction between polysulfide in the electrolyte and metal lithium is inhibited, and the coulombic efficiency of the battery is improved.

Owner:TSINGHUA UNIV

One-way high-heat-conductivity Cf/Al composite material preparing method

ActiveCN108405867AReduce usageImprove thermal conductivityVacuum evaporation coatingSputtering coatingMetallurgyWater cooling

The invention relates to a one-way high-heat-conductivity Cf / Al composite material preparing method. An aluminum wire is utilized for fixing a rough and flat high-heat-conductivity mesophase pitch base carbon fiber continuous filament into one-way cloth, physical vapor deposition is utilized for conducting aluminum plating treatment on the high-heat-conductivity mesophase pitch base carbon fiber one-way cloth, a layer of aluminum film exists on the surface of the carbon fiber, and the carbon fiber one-way cloth pre-deposited material is prepared. The carbon fiber one-way cloth pre-deposited material and aluminum powder are subjected to laminating vacuum hot press, the volume fraction of the prepared high-heat-conductivity carbon fiber composite material fiber is controlled within 15-35%, the heat conductivity of the composite material in the fiber direction is 300-650 W / m.K, and the high-heat-conductivity Cf / Al composite material can be welded to an aluminum material water-cooling plate and is a heat management material with good application prospects. Usage of heat conduction paste and other heat interface materials can be avoided, and compared with ordinary heat diffusion material devices, the heat conduction capability is greatly improved. Due to the fact that the aluminum film exists in the surface of the carbon fiber, densifying of the high-heat-conductivity Cf / Al composite material can be achieved with the low pressure.

Owner:湖南东映碳材料科技股份有限公司

Multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material

InactiveCN103131982AImprove wettabilityImprove bindingHot-dipping/immersion processesInterfacial reactionCerium

The invention discloses a multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material. The alloy comprises the following components: by weight, smaller than or equal to 15% of zinc (Zn), 0.5%-2.5% of silicon (Si), 3% of alloy enhancer copper (Cu), 0.5% of polarization alterant gold (Au), 0.5% of solvent passivator chrome (Cr), 0.3% of sediment hardening agent cadmium (Cd), 0.5% of grain refiner titanium (Ti), 0.5% of rare earth addition cerium (Ce), 1% of matrix interfacial reaction buffering agent, with the balance being aluminum (Al) and inevitable trace impurities. The Multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material effectively solves the problem that the proportion of the hot-dip galvanizing occupying the zinc is high, and the zinc resource is saved. A great quantity of the aluminum is added to replace the zinc in the aluminum alloy coating material for hot dipping, due to the fact that the aluminum resource is rich and the cost is low, the comprehensive cost of the coating material is reduced.

Owner:GUIZHOU ACAD OF SCI

Sr and multi-combination-metamorphism low-zinc hot-dipping-coating aluminum alloy coating materials

InactiveCN103131990AHigh strengthImprove corrosion resistanceHot-dipping/immersion processesSolderabilityAlloy coating

The invention discloses Sr and multi-combination-metamorphism low-zinc hot-dipping-coating aluminum alloy coating materials. According to element weight percentage, alloy constituent is that Zn: 28-30, Sr: 0.01-0.02, Li: 0.1-2.0, solvent deactivator: 0.8-1.0, Bi: 0.025-0.035, grain refiner: 0.1-0.2, rare earth additives: 0.1-0.5, basal body interface reaction buffering agent: 0.1-0.8, and the rest of the alloy constituent is Al and inevitable micro impurity. The Sr and multi-combination-metamorphism low-zinc hot-dipping-coating aluminum alloy coating materials have the advantages of being good in wettability of base steel, strong in combination force, high in strength, good in extensibility, high-temperature-resistant, thin in thickness of a coating layer, strong in corrosion resistance, and good in machinability and weldability and the like.

Owner:贵州铝厂有限责任公司

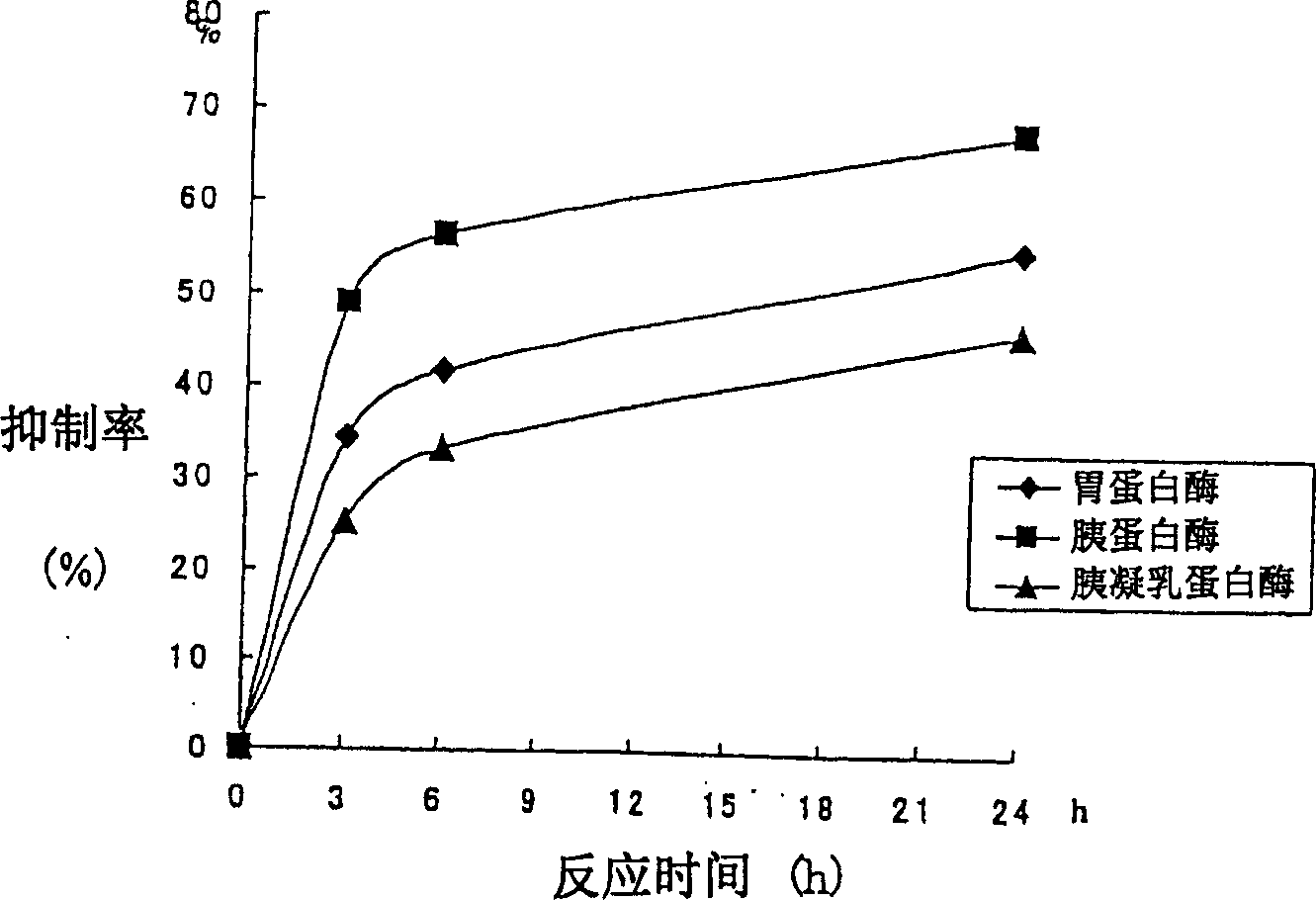

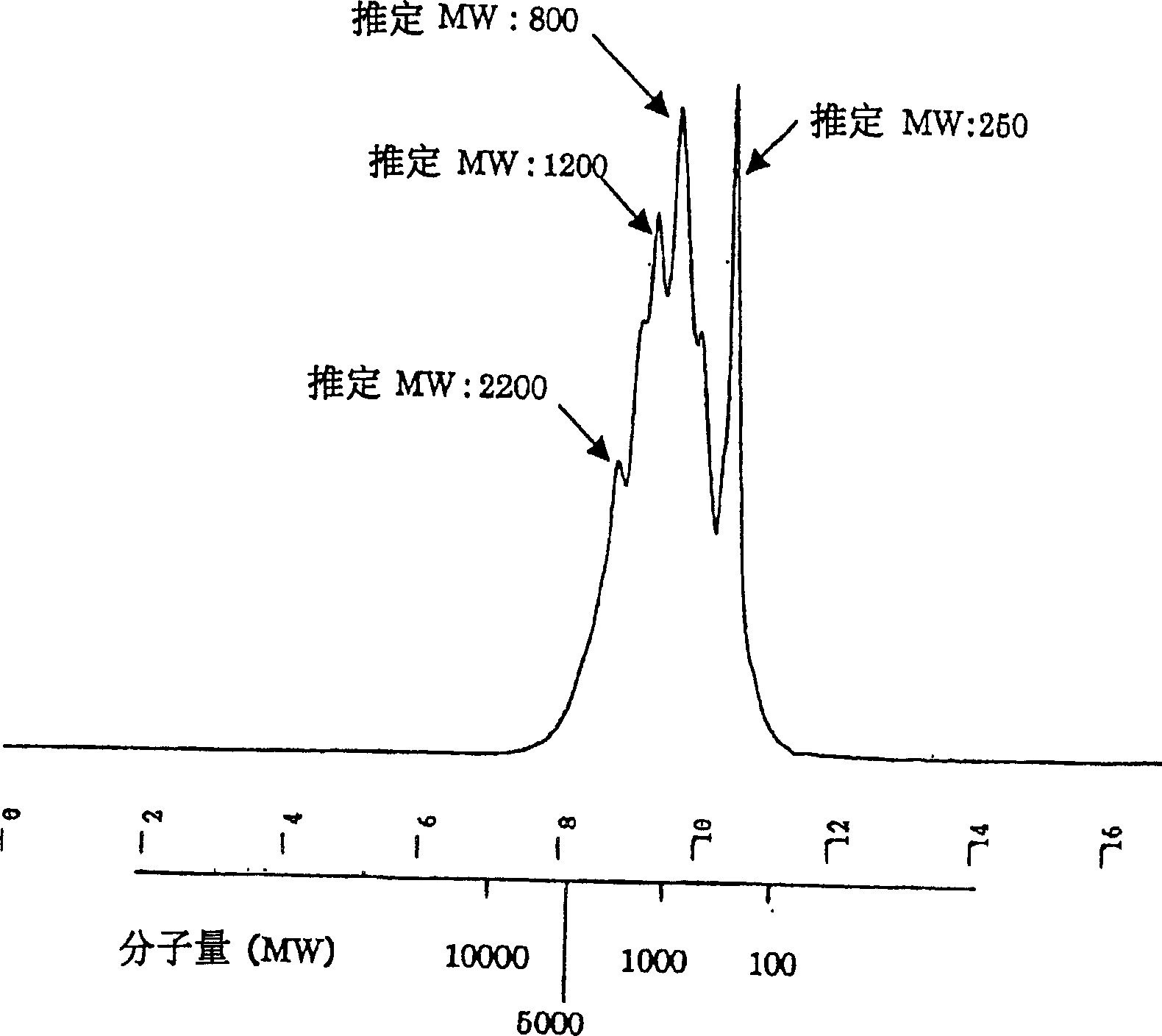

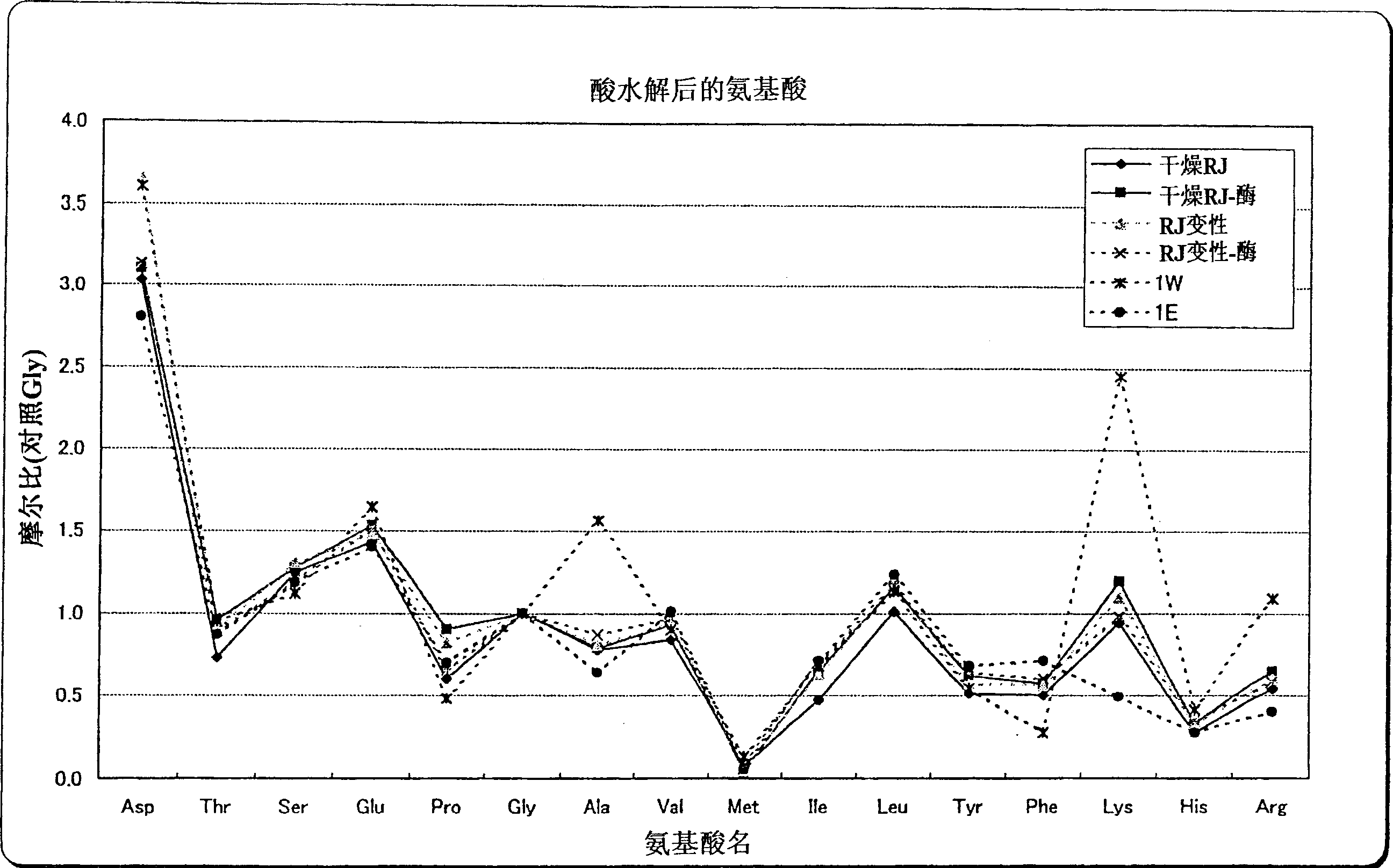

Reduction pressure peptide derived from bee milk

InactiveCN1690219AAllergies are smallLittle side effectsDipeptide ingredientsTetrapeptide ingredientsAngiotensin-converting enzymePeptide

Owner:YAMADA BEE COMPANY INC

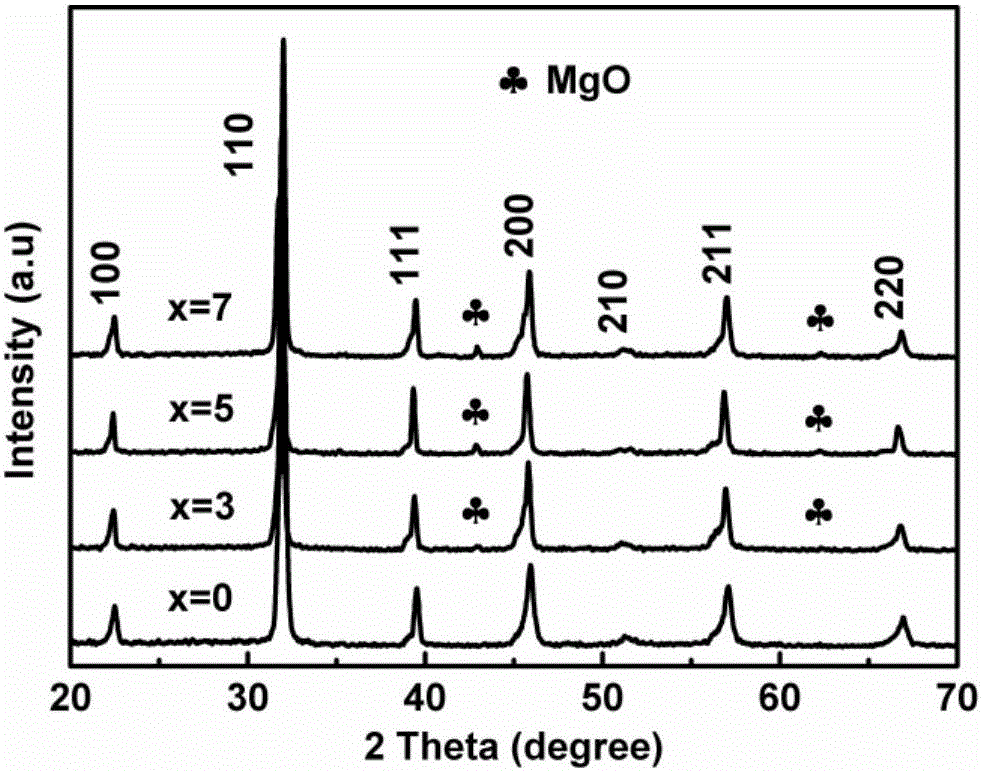

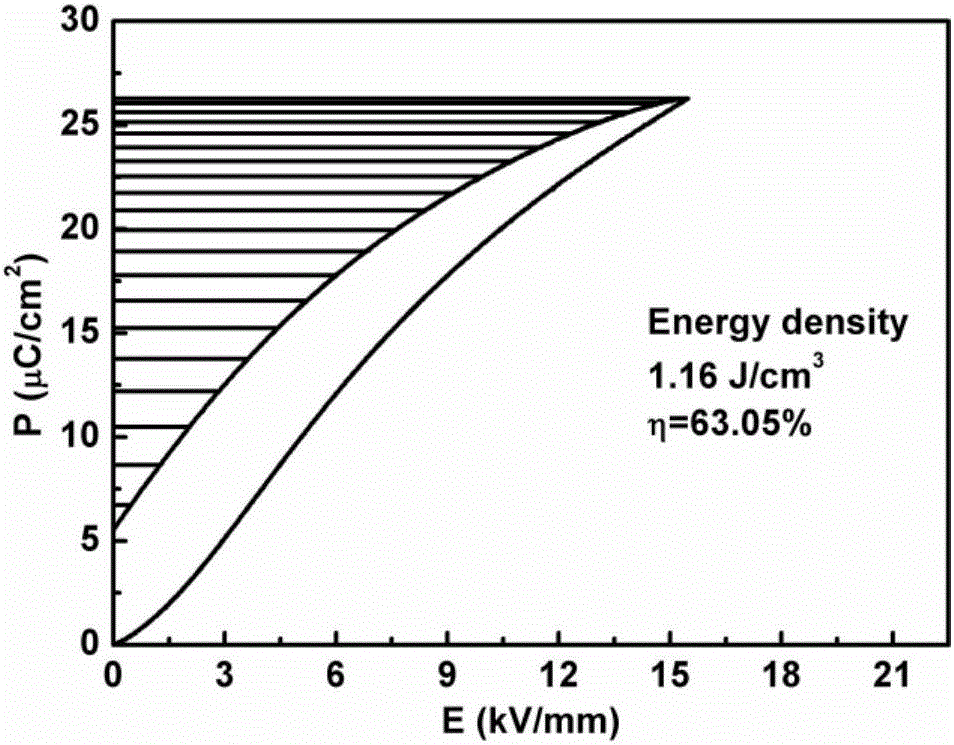

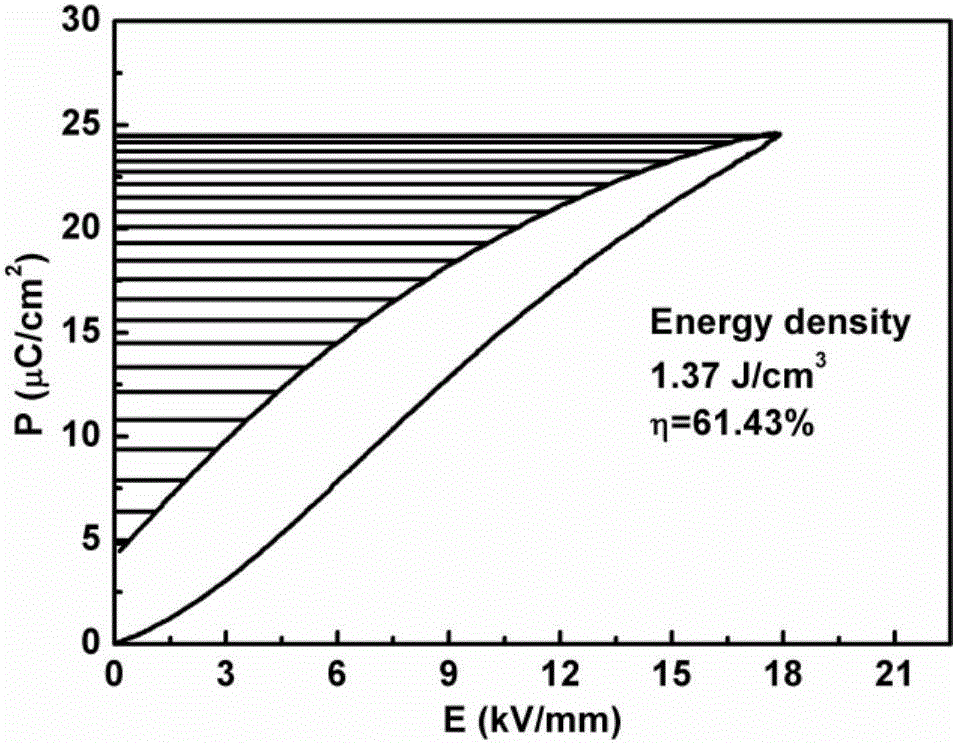

0.5NBT-0.5BCTZ-xwt%MgO high-storage-energy-density ceramic material prepared by microwave sintering and method

The invention relates to a 0.5NBT-0.5BCTZ-xwt%MgO high-storage-energy-density ceramic material prepared by microwave sintering and a method. The method comprises the following steps: firstly, proportioning BCTZ ceramic powder, NBT ceramic powder and magnesium oxide powder according to a stoichiometric ratio of a chemical formula 0.5NBT-0.5BCTZ-xwt%MgO, uniformly mixing, pelletizing and forming; and sintering and forming ceramics by preserving heat for 4 to 20 minutes at a temperature ranging from 900 DEG C to 1100 DEG C in a microwave sintering mode, thereby obtaining the high-storage-energy-density ceramic material, wherein x ranges from 3 to 7. Through microwave sintering, the method has the advantages of high heating speed, uniform heating and the like; reaction of MgO and a matrix material can be effectively restrained at a relatively low sintering temperature within relatively short sintering time, and the microstructure of the material can be optimized to improve the compactness of the material, so that breakdown strength of the material is effectively improved, and the high-storage-energy-density ceramic material is prepared.

Owner:SHAANXI UNIV OF SCI & TECH

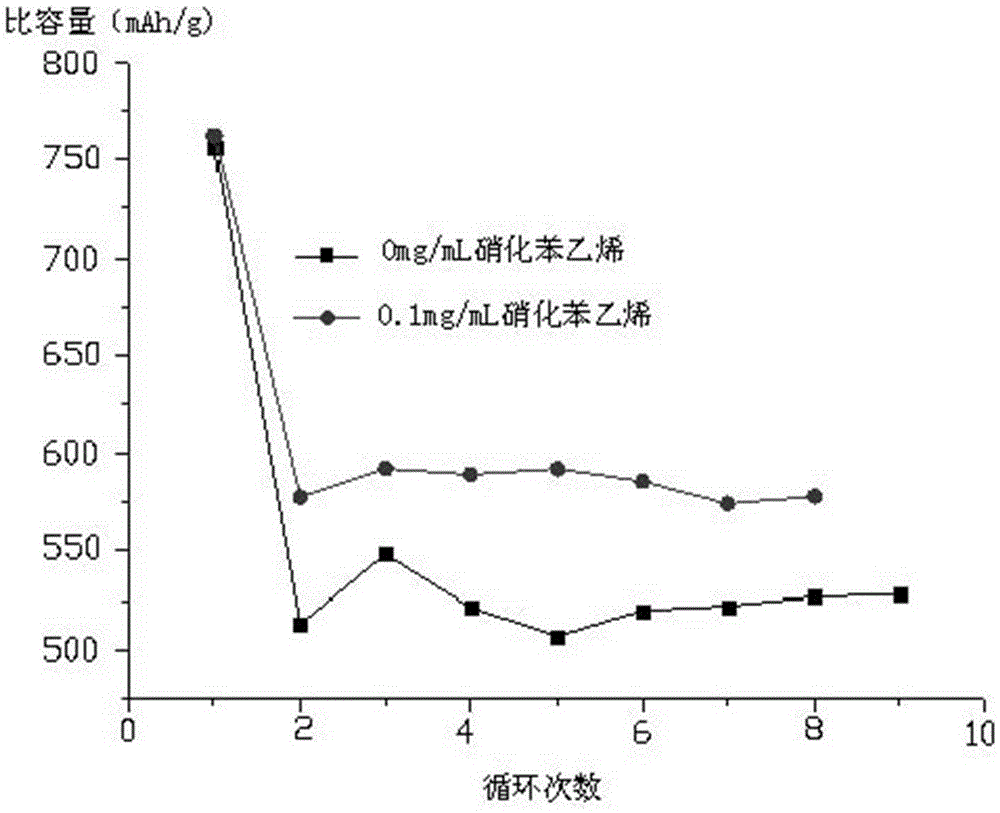

Organic electrolyte and lithium secondary battery

InactiveCN105304933AGood film formingSmooth transmissionSecondary cellsOrganic electrolytesOrganic solventLithium-ion battery

The invention discloses organic electrolyte which comprises an organic solvent, electrolyte salt and an additive, wherein the electrolyte salt and the additive are dissolved in the organic solvent; the additive is a nitro-containing high-molecular compound which comprises n constitutional repeating units; m nitros are distributed on the n constitutional repeating units; n is larger than or equal to 100; the ratio of m to n is larger than or equal to 0.01 and is smaller than or equal to 1. The invention further provides a lithium secondary battery containing the organic electrolyte.

Owner:TSINGHUA UNIV

Immersion plating aluminum alloy coating materials with low cost and high property

The invention discloses immersion plating aluminum alloy coating materials with low cost and high property. By element weight percentage, components of the alloy comprise 5-15 parts of zinc, 10-4-10-3 parts of polarization metamorphic agent, 0.1-1.0 part of lithium, 0.1-0.2 part of carbonic oxide, 0.25-0.5 part of precipitation hardening agent, 0.2-0.3 part of grain refiner, 0.01-0.1 part of lanthanum, 0.3-0.8 part of substrate interface reaction buffer, aluminium and inevitable microimpurity. The immersion plating aluminum alloy coating materials are low in cost and high in property.

Owner:贵州铝厂有限责任公司

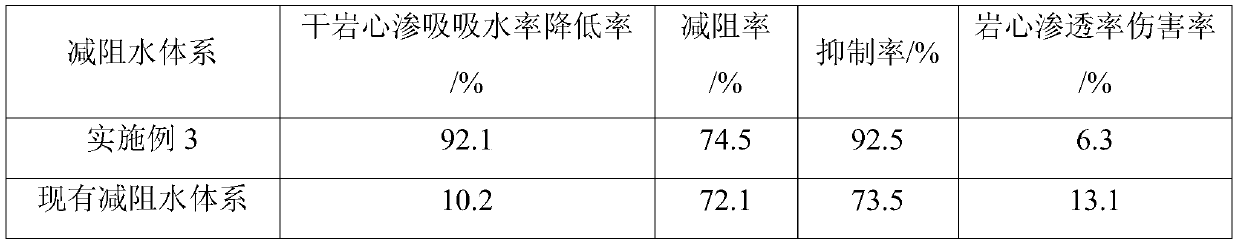

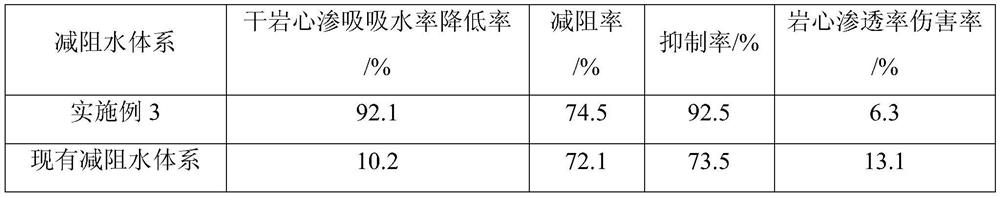

Multifunctional drag reduction water system for continental shale gas fracturing and preparation method thereof

ActiveCN110760299AReduce harmConducive to promoting green developmentDrilling compositionClay mineralsChemical reaction

The invention relates to a multifunctional drag reduction water system for continental shale gas fracturing and a preparation method thereof. The multifunctional drag reduction water system for continental shale gas fracturing comprises the following components in percentages by mass: 0.02% to 0.05% of a resistance reducing agent, 0.5% to 1% of an inhibitor, 0.1% to 0.3% of an antiscaling agent, 0.001% to 0.003% of a synergist, 0.2% to 0.5% of a regulator and the balance of water. The multifunctional drag reduction water system provided by the invention has the characteristics of high drag reduction rate, high inhibition, permeability reduction, adsorption reduction and the like, clay mineral expansion and clay particle migration can be inhibited, a seepage channel is kept smooth, water-rock physical and chemical reactions are effectively inhibited, a fracturing fluid is promoted to flow back quickly, the adsorption damage of the fracturing fluid is reduced, the requirement of continental shale gas fracturing construction is met, the damage of the drag reduction water fracturing fluid to a reservoir is reduced, and efficient development of terrestrial shale gas is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

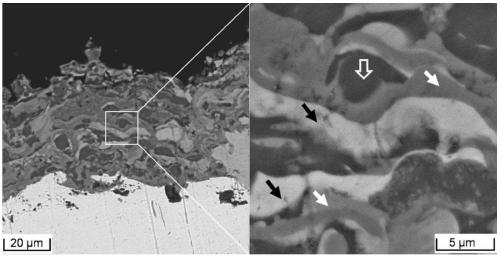

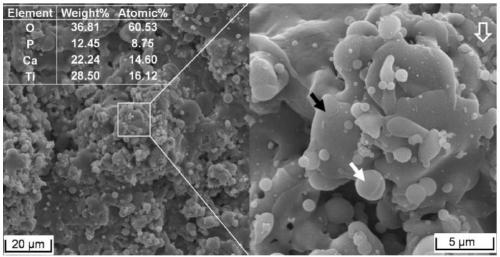

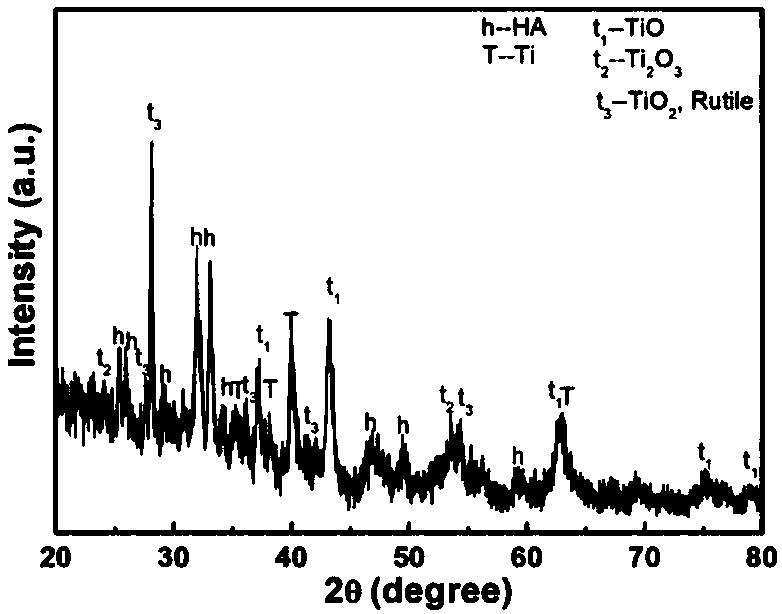

Nano structure hydroxyapatite/titanium composite coating and preparing method thereof

InactiveCN109321863AAvoid thermal decompositionArbitrary modulatorMolten spray coatingNanotechnologyNano structuringThermal expansion

The invention provides a preparing method of a nano structure hydroxyapatite / titanium composite coating, and belongs to the technical field of coating preparing. The nano hydroxyapatite and titanium are mixed to form composite particle suspension liquid, and the proportion of the hydroxyapatite to the titanium can be adjusted at will; after the composite particle suspension liquid is mixed with atomization gas, the mixture enters a supersonic speed flame spray gun through micro holes, the temperature of mixed particles in flames is reduced, compared with conventional supersonic speed flame spraying, a solvent wrapping the peripheries of the mixed particles can absorb part of heat through volatilization, and thermal decomposition or non-crystallizing of a nano hydroxyapatite particle phasestructure is avoided; the nano hydroxyapatite and the titanium particles are sufficiently mixed in the suspension liquid, and uniformity of two phases in the composite coating is improved; part of thetitanium particles and titanium particle surface layers are oxidized in oxygen containing high-temperature flames, the problem about thermal expansion mismatching between the hydroxyapatite and the titanium particles can be solved through titanium particle oxide, the titanium particle oxide can serve as a reinforcing phase to exist in the composite coating, and the hardness and elasticity modulusof the composite coating are improved.

Owner:JIUJIANG UNIVERSITY

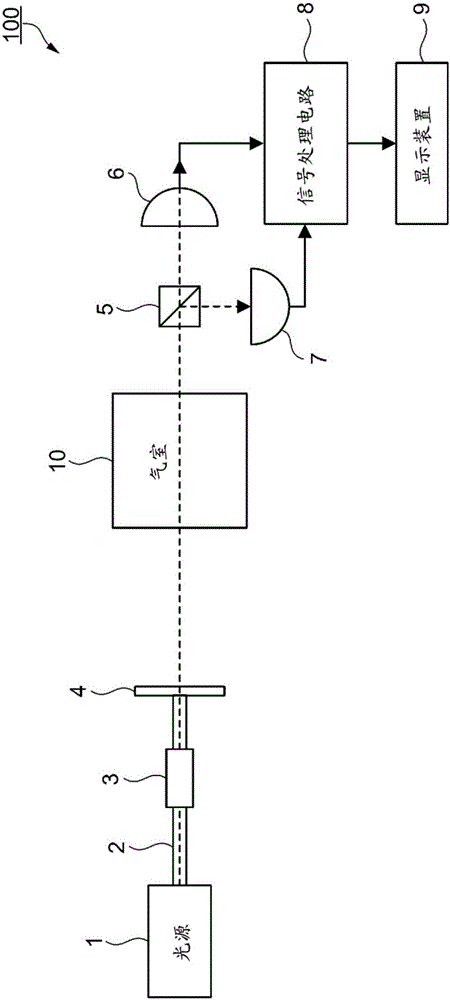

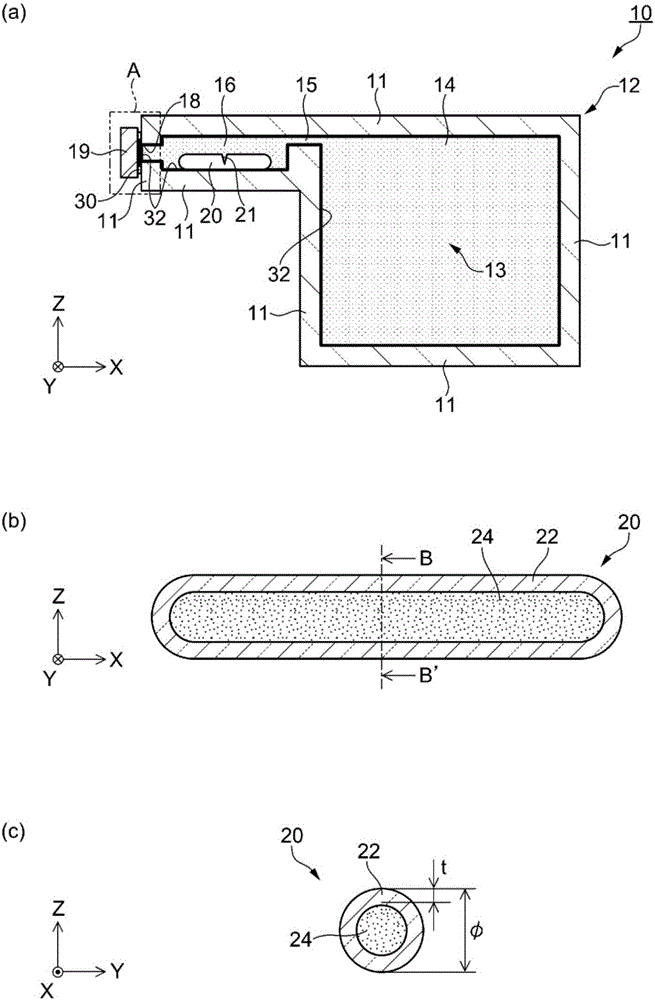

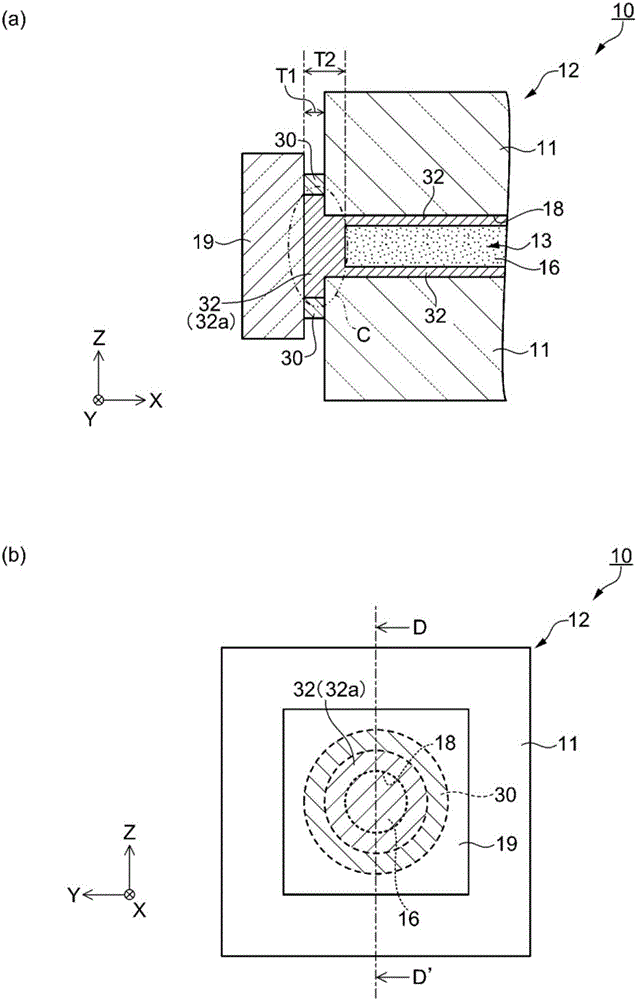

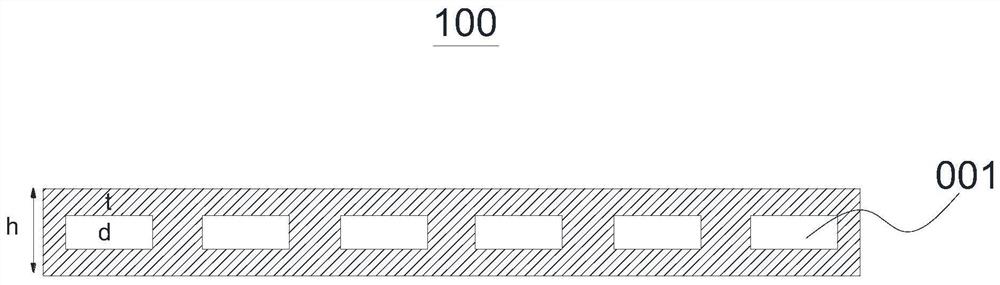

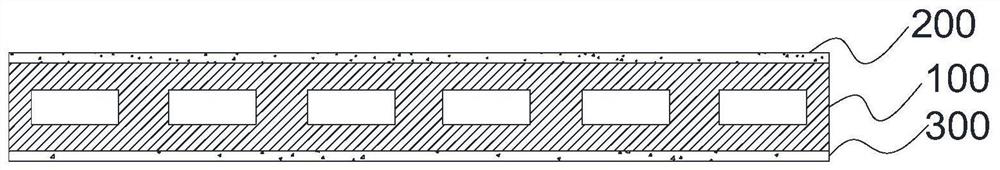

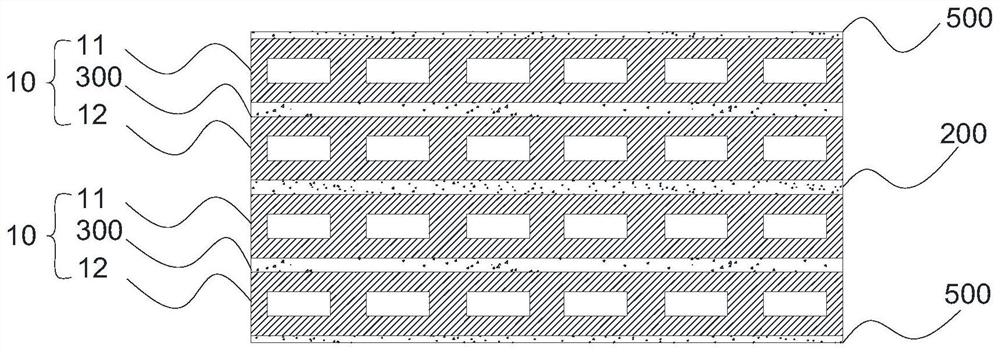

Magnetism measuring device, manufacturing method of magnetism measuring device, gas cell, and manufacturing method of gas cell

InactiveCN106066459AInhibition of chemical reactionsStable manufacturingMagnetic field measurement using magneto-optic devicesMeasurements using magnetic resonanceMeasurement deviceAlkali metal

The invention relates to a magnetism measuring device and a manufacturing method of the magnetism measuring device. The present invention provides a small-sized and long-usage-life gas cell that can be stably manufactured, and a magnetism measuring apparatus having the gas cell, the gas cell and a method of manufacturing the magnetism measuring apparatus. The magnetism measuring device (100) is characterized by including: a wall (11) forming a cell portion (12); an opening (18) which is open to a portion of the wall (11); a sealing material (30) which seals the opening (18); a coating layer (32) which covers the sealing material (30) on an inside of the cell portion (12); and an alkali metal gas (13) which is sealed in the cell portion (12).

Owner:SEIKO EPSON CORP

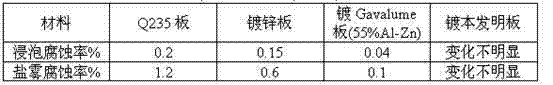

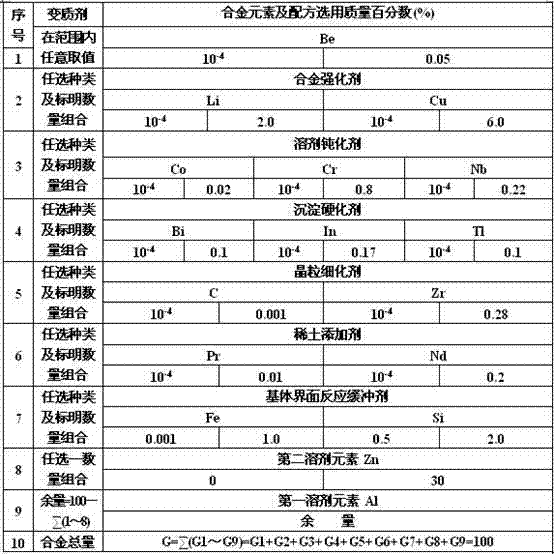

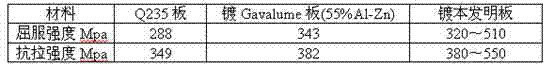

Be and multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material and preparation method thereof

InactiveCN102650026AOrganizational structure optimizationAchieving resistance to acid, alkali and salt corrosionHot-dipping/immersion processesAlloy coatingUltimate tensile strength

The invention discloses a Be and multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material and a preparation method thereof. The alloy comprises the following components in weight percentage: not greater than 30 percent of Zn, 10<-4>-0.05 percent of Be, 10<-4>-6.0 percent of alloy enhancer, 10<-4>-1.0 percent of solvent passivator, 10<-4>-0.5 percent of sediment hardening agent, 10<-4>-1.0 percent of grain refiner, 10<-4>-1.0 percent of rare earth addition, 0.001-2.0 percent of matrix interface reaction buffering agent and the balance Al and unavoidable trace impurities. The aluminum alloy coating material produced according to the technical scheme provided by the invention can be used for forming light and thin high-quality coatings on the surfaces of steel and iron alloy, wherein the light and thin high-quality coatings are attractive and are high in corrosion resistance, abrasion resistance, strength and ductility and good in matrix metallurgical bonding. The aluminum alloy coating material can be used for anti-corrosion coatings on the surfaces of steel and iron alloy products. Production equipment for the aluminum alloy coating material does not need to be specially made; the source of the raw material is rich; the starting cost is low; and the industrial waste can be conveniently and cyclically utilized.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Silicon nitride sintered body and preparation method thereof

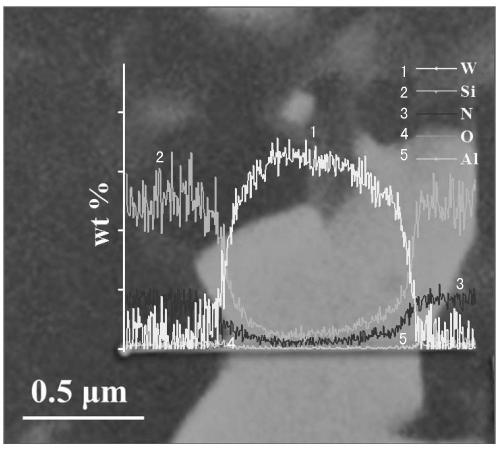

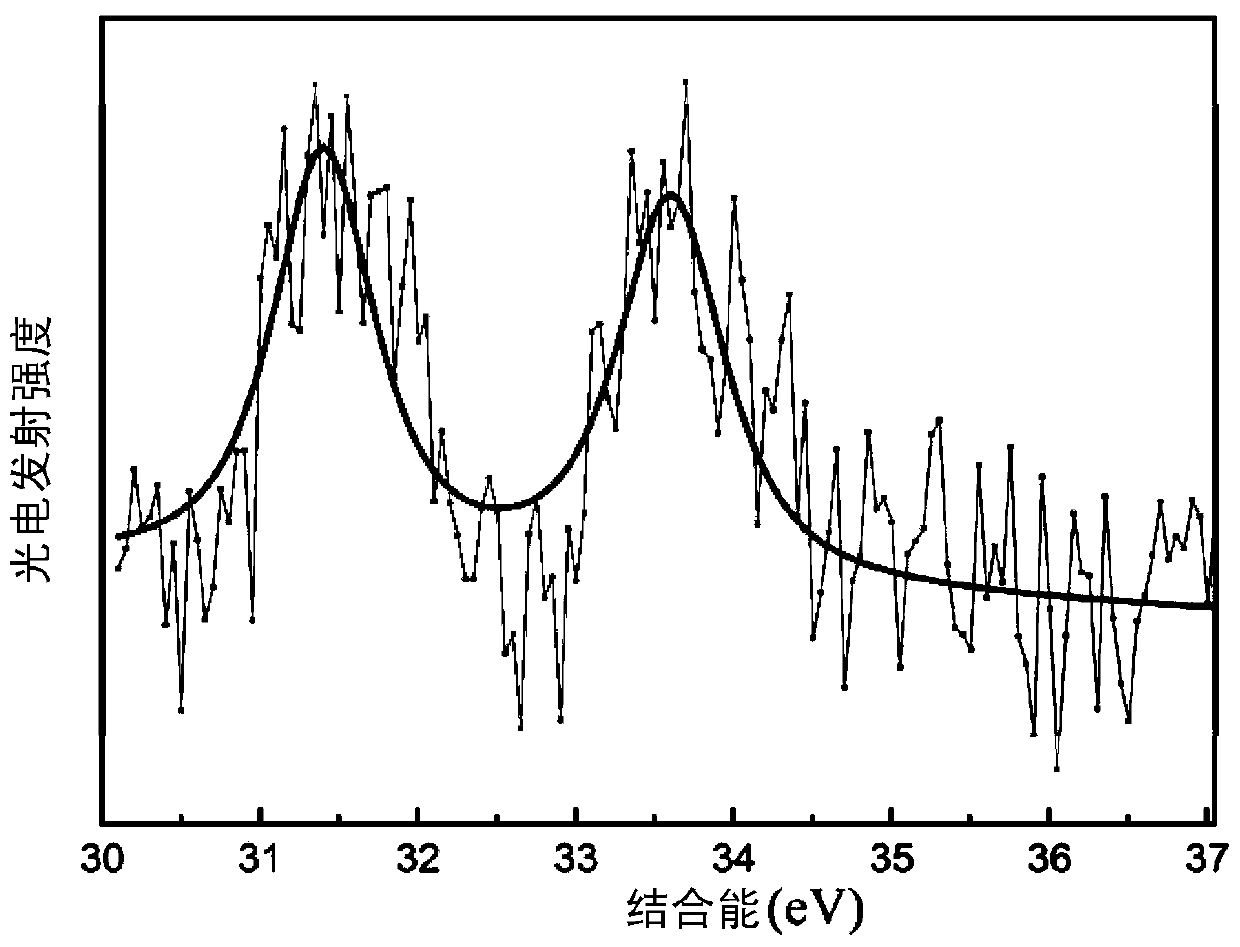

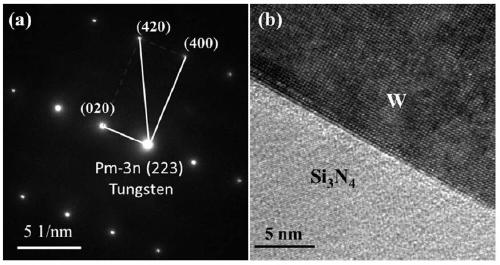

The invention provides a silicon nitride sintered body and a preparation method thereof. The silicon nitride sintered body mainly consists of silicon nitride crystals and a second metal phase dispersed among the silicon nitride crystals, wherein the main components of the second metal phase comprise metal simple substances and / or alloy taking tungsten and / or rhenium as main components. The siliconnitride sintered body has excellent mechanical properties at the normal temperature and the high temperature by introducing the simple substances and / or alloy of tungsten and / or rhenium with the characteristics of non-brittle fracture and high-temperature resistance into silicon nitride.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A kind of multifunctional drag reducing water system and preparation method for continental shale gas fracturing

ActiveCN110760299BReduce harmConducive to promoting green developmentDrilling compositionClay mineralsChemical reaction

The present invention relates to a multifunctional drag-reducing water system for continental shale gas fracturing and a preparation method thereof. The components and mass percentages of the multifunctional drag-reducing water system for continental shale gas fracturing are as follows: Drag reducer 0.02-0.05%, inhibitor 0.5-1%, anti-scaling agent 0.1-0.3%, synergist 0.001-0.003%, regulator 0.2-0.5%, and the balance is water. The multi-functional drag-reducing water system provided by the present invention has the characteristics of high drag-reducing rate, strong suppression, reduced imbibition, and reduced adsorption. , chemical reaction, promote the rapid flowback of fracturing fluid, reduce the adsorption damage of fracturing fluid, meet the requirements of continental shale gas fracturing construction, reduce the damage of drag-reducing water fracturing fluid to reservoirs, and realize continental shale Efficient development of gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low zinc hot dipping aluminium alloy plating material containing Ca multi-combination metamorphism

InactiveCN103131986ALower eutectic temperatureIncrease wetting and fusion abilityHot-dipping/immersion processesExtensibilityLiquid viscosity

The invention discloses low zinc hot dipping aluminium alloy plating material containing Ca multi-combination metamorphism. The composition of alloy comprises, by element weight, 10%-13% of Zn, 5.0% of alloy enhancer Cu, 0.03 % of polarization metamorphic agent Ca, 0.2 % of solvent passivator Mo and 0.5% of rare earth addition, and the rest of the composition of the alloy are A1 and micro impurities which are unavoidable. The low zinc hot dipping aluminium alloy plating material containing the Ca multi-combination metamorphism solves the problems that due to dissolution of iron in a hot dipping plating process, zinc liquid viscosity is enabled to be increased and the capability of the surface of an infiltrating steel matrix is reduced, the thickness of a zinc layer is obviously increased due to the fact that iron content in zinc liquid is increased, and therefore ductility and the appearance of the a plating layer are enabled to be poor, and other problems are solved too. The aluminium alloy plating material for hot dipping is obtained, wherein the aluminium alloy plating material for hot dipping is good in matrix wettability, strong in binding force, high in strength, good in extensibility, high temperature-resistance, thin in plating layer, and strong in corrosion resistance.

Owner:贵州铝厂有限责任公司

Mo-complex modified low-zinc hot-dip aluminum alloy coating material

InactiveCN103147032AHigh hardnessImprove high temperature strengthHot-dipping/immersion processesSolderabilityAlloy coating

The invention discloses a Mo-complex modified low-zinc hot-dip aluminum alloy coating material. Based on element weight percentage, the alloy is composed of 28%-30% of Zn, 0.01%-0.02% of Sr, 0.1%-2.0% of Li, 0.8%-1.0% of Nb, 0.025%-0.035% of Bi, 0.1%-0.2% of Ti-B, 0.1%-0.8% of a substrate interface reaction buffer agent, and the balance being Al and inevitable trace impurities; and the modifier Mo(CO)6 accounts for 0.5%-0.6% of a total amount of furnace charging materials. The aluminum alloy coating material provided by the invention is a high-quality aluminum alloy coating material used for steel hot-dip and integrates various advantages such as wettability to base steel, strong bonding force, high strength, good elongation, high temperature resistance, thin coating, good corrosion resistance, workability and weldability together.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Corrosion prevention method of rare earth-containing alloy coating used for ground net protection

InactiveCN104831225AQuality improvementImprove corrosion resistanceMolten spray coatingManganeseCerium

The invention discloses a corrosion prevention method of a rare earth-containing alloy coating used for ground net protection, and relates to the conductive coating corrosion prevention field, according to the method, plasma spraying technology is used, carbon steel is used as a ground net material, and the ground net surface is successively sprayed with a cohesive bottom layer with the thickness of 60-100 microns and a lanthanum, cerium, praseodymium, neodymium and other rare earth-containing functional alloy surface layer with the thickness of 150-200 microns. The method comprises the following steps: (1) purification decontamination and sandblasting processing of the ground net surface; (2) allocation of lanthanum, cerium, praseodymium, neodymium and other rare earth-containing alloy powder in zinc, aluminum, magnesium, nickel, manganese, silicon, chromium, beryllium and titanium alloy powder of a surface layer coating; and (3) formation of the rare earth-containing alloy corrosion prevention coating. The electric power ground net surface is sprayed with the rare earth-containing alloy corrosion prevention coating, so that the ground net service life is improved, the ground net work cost is reduced, and the method is simple and reliable in process, green, low-carbon, non-pollution, and friendly to environment.

Owner:STATE GRID CORP OF CHINA +3

Solid oxide fuel cell stack and preparation method thereof

ActiveCN113488689AReduce thermal stressImprove long-term stabilityFinal product manufactureFuel cellsThin membraneElectrical battery

The invention discloses a solid oxide fuel cell stack and a preparation method thereof, and relates to the technical field of fuel cells. An electrolyte membrane layer and a ceramic connector membrane layer are formed by coating a porous ceramic framework, then back-to-back hot-pressing stacking is performed, and alternate impregnation is performed to obtain a negative electrode and a positive electrode, so that each repetitive unit of the cell stack comprises a negative electrode layer, an electrolyte membrane layer and a positive electrode layer which are sequentially arranged; and the anode layer in each repeating unit is connected with the cathode layer in the adjacent repeating unit through the ceramic connector film layer to form a cell stack structure in which the anode layers and the cathode layers are alternately stacked. The structure has abundant three-phase interfaces, the electrochemical performance of the cell is outstanding, the electrolyte and the connector are both compact ceramic films, the ohmic impedance is small, and the power output of the cell stack is high; and the ceramic connector with the thermal expansion coefficient consistent with that of the porous ceramic framework is adopted, the thermal stress is small, the thermal cycle performance of the cell stack is good, the oxidation corrosion problem does not exist, and the long-term stability of the cell stack can be improved.

Owner:SICHUAN ENERGY INTERNET RES INST TSINGHUA UNIV +1

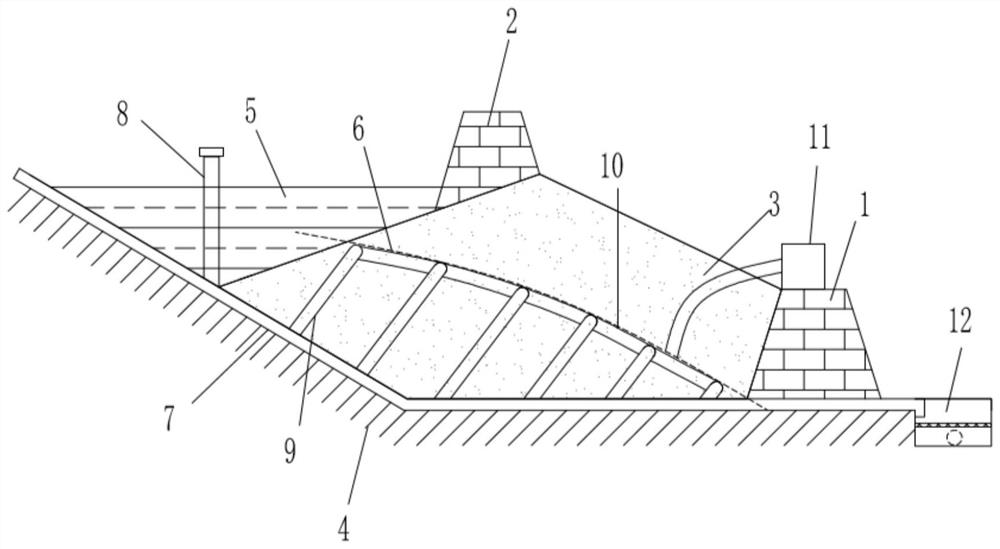

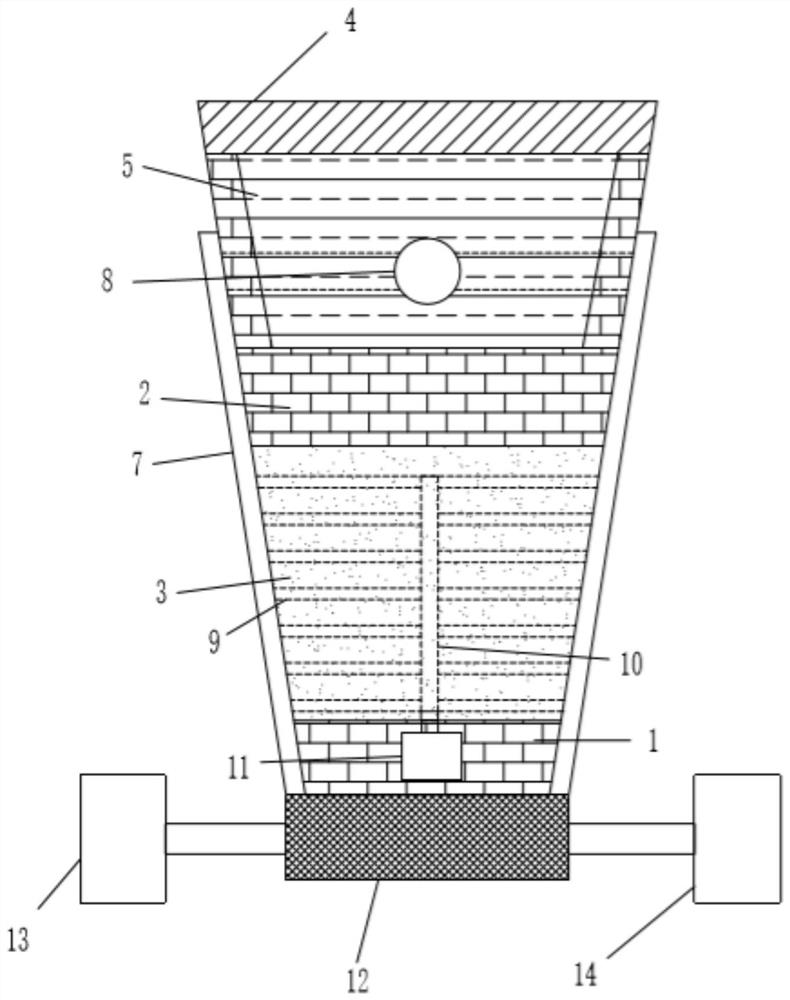

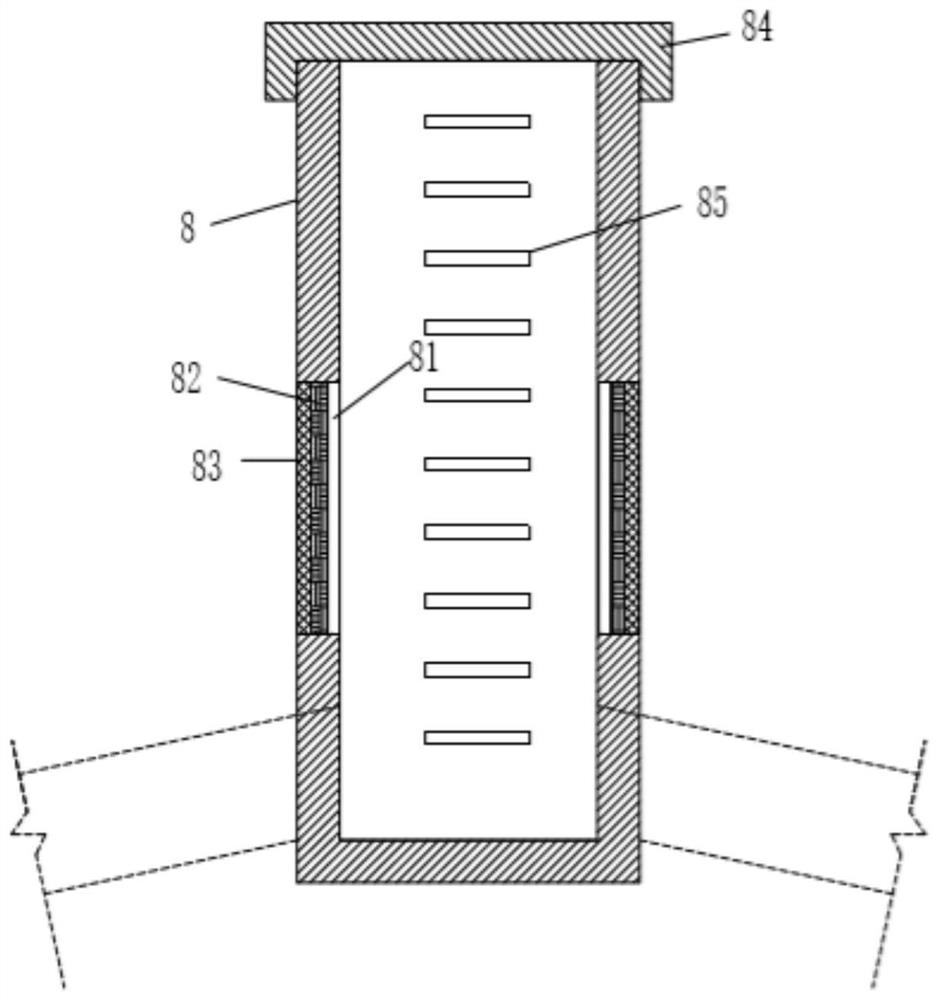

Centralized seepage drainage device for tailing pond and seepage drainage method thereof

InactiveCN113186897AAvoid cloggingInhibition of chemical reactionsFatty/oily/floating substances removal devicesSewerage structuresDitchGeotechnical engineering

The invention belongs to the technical field of mine engineering, and particularly relates to a centralized seepage drainage device for a tailing pond and a seepage drainage method thereof. The centralized seepage drainage device for a tailing pond comprises an initial dam, a sub-dam and the like, and further comprises underground seepage drainage pipes, a seepage drainage well and the like, wherein the initial dam and a fill dam are arranged on the top of a foundation, the initial dam is connected to the tail end of the bottom of the fill dam, the sub-dam is arranged at the tail end of the top of the fill dam, a flood ditch is arranged among the sub-dam, the foundation and the fill dam, the underground drainage pipes are arranged on the two sides of the fill dam, a seepage drainage ditch is arranged on the foundation and located at the right end of the initial dam, the tail ends of the underground seepage drainage pipes extend into the seepage drainage ditch, the seepage drainage well is arranged in the flood ditch and communicates with the underground seepage drainage pipes through a pipeline, and a plurality of dam body seepage drainage pipes are arranged in the fill dam. The seepage drainage device and method achieve the effects that the seepage drainage effect is good, pipeline blockage can be avoided, the structure is simple, seepage drainage is centralized, and meanwhile the centralized treatment effect can be achieved.

Owner:王思记

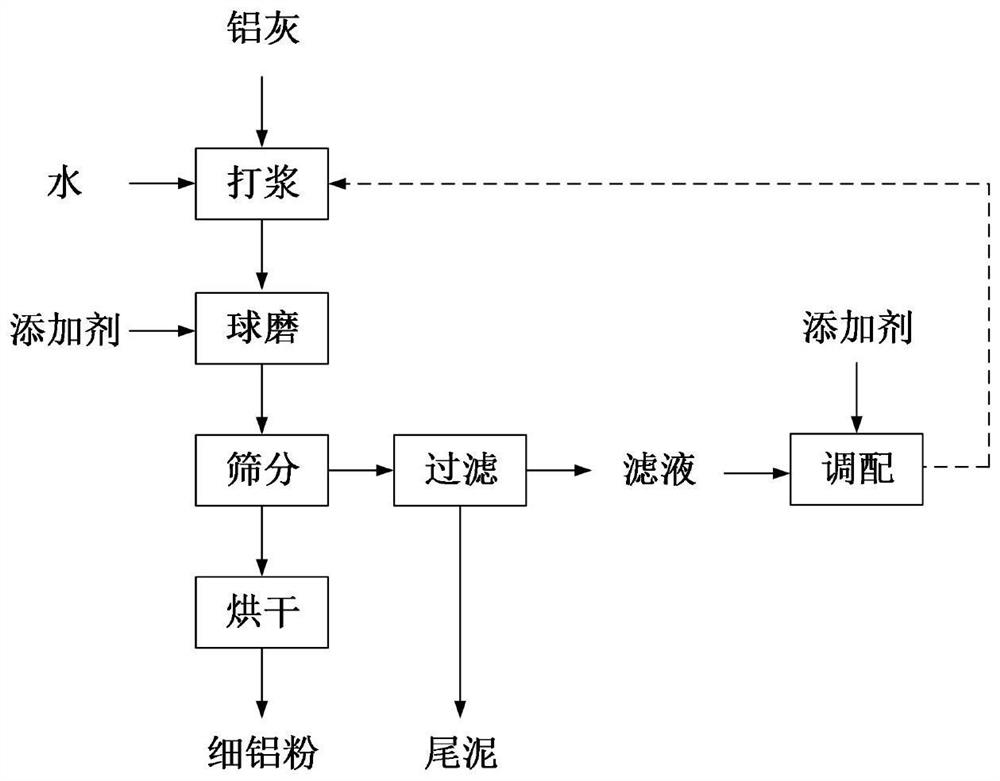

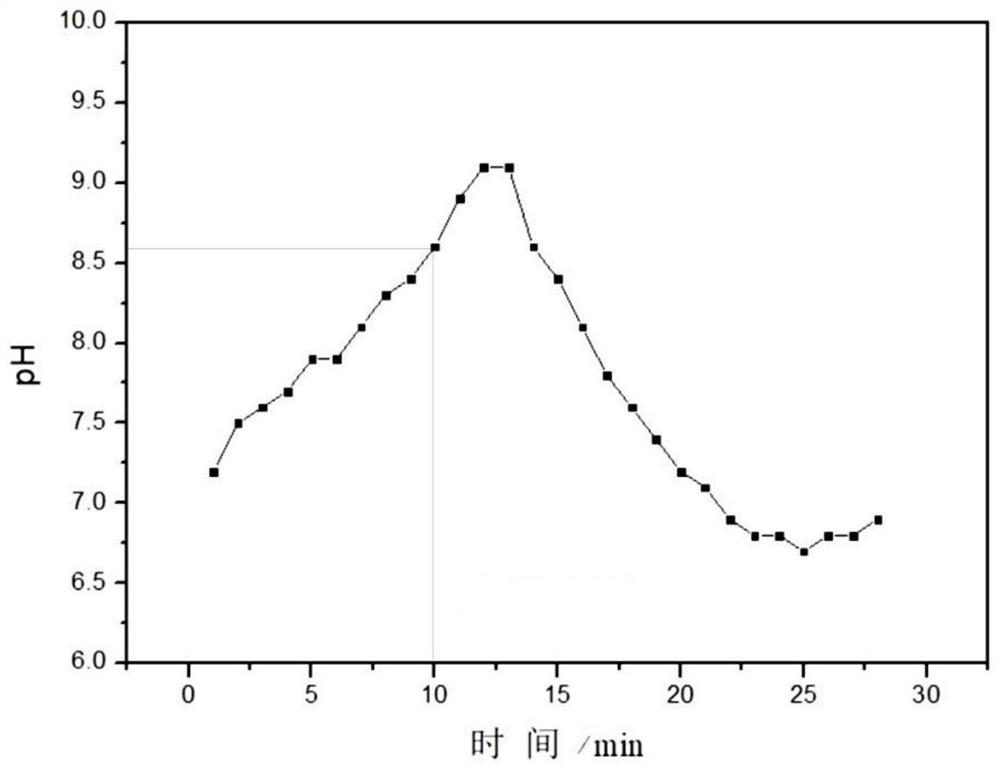

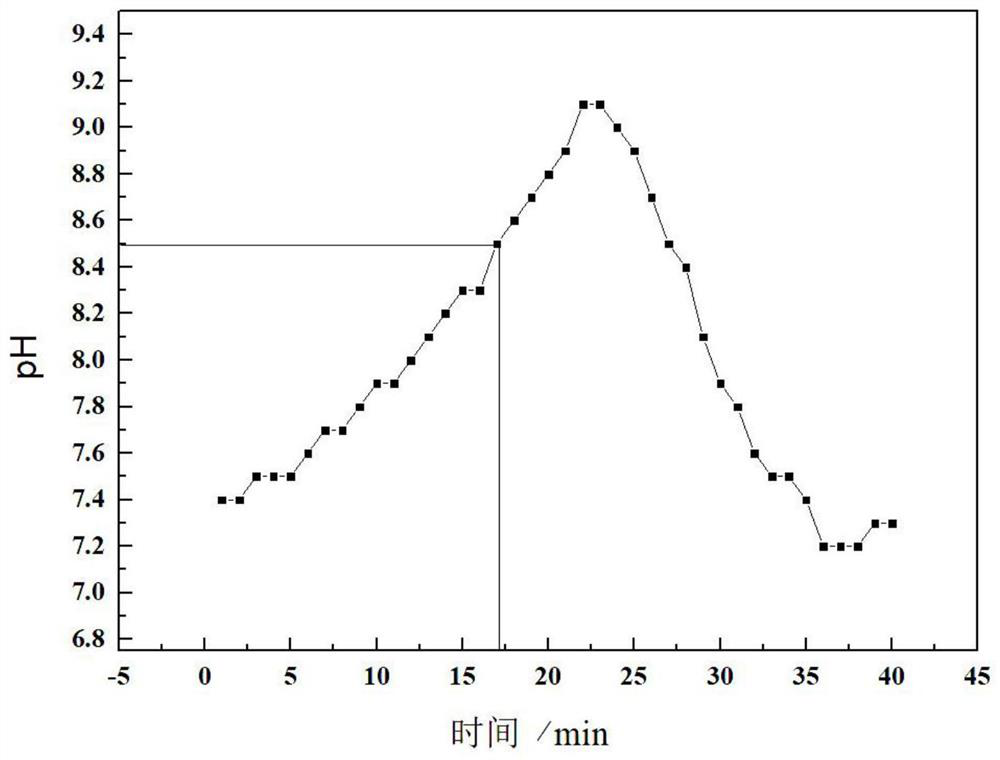

Method for inhibiting reaction loss of metallic aluminum in process of extracting aluminum by using aluminum ash wet method

ActiveCN112813275AInhibition of chemical reactionsReduce security risksProcess efficiency improvementAluminium oxides/hydroxidesWet grindingSeparation process

The invention discloses a method for inhibiting the reaction loss of metallic aluminum in the process of extracting aluminum by using an aluminum ash wet method. The method for inhibiting the reaction loss of the metallic aluminum in the process of extracting the aluminum by using the aluminum ash wet method mainly comprises the following steps that mixing and pulping are carried out on aluminum ash and water according to a certain proportion, then the slurry is conveyed into a ball mill for crushing, and a certain amount of additive is added in the crushing process to adjust the property of the slurry, oversize aluminum powder rich in metal aluminum components and undersize slurry low in metal aluminum components are separated from the slurry subjected to ball milling by adopting a screening manner, and after oversize aluminum powder is washed and dried, a metal aluminum powder product is obtained. According to the method for inhibiting the reaction loss of the metallic aluminum in the process of extracting the aluminum by using the aluminum ash wet method, through chemical property adjustment of the slurry in the aluminum ash wet grinding and separation process, the increase of the pH value of the slurry caused by the hydrolysis reaction of aluminum nitride is controlled, the reaction loss of metal aluminum is greatly reduced, and the economical efficiency of wet-process aluminum extraction is improved; and in addition, the process that the metal aluminum participates in the reaction is inhibited, so that the amount of hydrogen generated in the grinding and separation process is greatly reduced, and the operation safety is further greatly improved.

Owner:洛阳天瑞环保科技有限公司

Production method for processing high-precision lens by using novel polishing solution

PendingCN113560989AQuality improvementImprove efficiencyOptical surface grinding machinesChemical reactionPolishing

The invention discloses a production method for processing a high-precision lens by using a novel polishing solution. The production method is characterized by comprising the following seven production steps that (1), the polishing solution is prepared; (2), the polishing solution is smeared; (3), polishing and grinding are carried out; (4), cleaning and wiping are carried out; (5), secondary smearing, polishing and grinding are carried out; (6), secondary cleaning and wiping are carried out; and (7), coating is carried out to obtain the product. The polishing solution is prepared by mixing cerium oxide polishing powder and an aqueous solution, so that the polishing solution does not have corrosivity, the chemical reaction of the polishing solution is reduced, and damage to the high-precision lens is avoided; and the polishing solution is sprayed on the surface of the high-precision lens in a spraying mode, the high-precision lens is easy to clean, the redundant polishing solution can be recycled after spraying, the manufacturing cost is saved, and the smoothness and the finish degree of the high-precision lens are effectively improved through two times of polishing, grinding and cleaning, so that the technical requirements of the high-precision lens are met.

Owner:JIANGSU YUDI OPTICAL CO LTD

Method of eliminating arsenic in acetylene containing hydrocarbon and dearsenic agent

InactiveCN1273567CInhibition of chemical reactionsOvercome the disadvantage of not being able to use alkyne-containing compounds to remove arsenicRefining to eliminate hetero atomsChemical reactionFixed bed

A process for removing As from the acetylene hydrocarbon includes loading the dearsenicating agent to fixed bed, adding hydrogen gas to the acetylene hydrocarbon, and passing then through said fixed bed at 0-150 deg.C and 4000 / hr under 0.01-3 MPa. Said dearsenicating agent is composed of carrier and the active component which is at least one transition metal and / or transition metal oxide. Its advantages are suppressing the chemical reaction between acetylene hydrocarbon and the active component of catalyst, high effect and activity, and low cost.

Owner:SHANGHAI RES INST OF CHEM IND

Multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material

InactiveCN103131982BReduce solubilityGood casting performanceHot-dipping/immersion processesInterfacial reactionCerium

The invention discloses a multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material. The alloy comprises the following components: by weight, smaller than or equal to 15% of zinc (Zn), 0.5%-2.5% of silicon (Si), 3% of alloy enhancer copper (Cu), 0.5% of polarization alterant gold (Au), 0.5% of solvent passivator chrome (Cr), 0.3% of sediment hardening agent cadmium (Cd), 0.5% of grain refiner titanium (Ti), 0.5% of rare earth addition cerium (Ce), 1% of matrix interfacial reaction buffering agent, with the balance being aluminum (Al) and inevitable trace impurities. The Multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material effectively solves the problem that the proportion of the hot-dip galvanizing occupying the zinc is high, and the zinc resource is saved. A great quantity of the aluminum is added to replace the zinc in the aluminum alloy coating material for hot dipping, due to the fact that the aluminum resource is rich and the cost is low, the comprehensive cost of the coating material is reduced.

Owner:GUIZHOU ACAD OF SCI

A kind of anti-corrosion method of rare earth alloy coating for grounding grid protection

InactiveCN104831225BQuality improvementImprove corrosion resistanceMolten spray coatingCeriumManganese

The invention discloses a corrosion prevention method of a rare earth-containing alloy coating used for ground net protection, and relates to the conductive coating corrosion prevention field, according to the method, plasma spraying technology is used, carbon steel is used as a ground net material, and the ground net surface is successively sprayed with a cohesive bottom layer with the thickness of 60-100 microns and a lanthanum, cerium, praseodymium, neodymium and other rare earth-containing functional alloy surface layer with the thickness of 150-200 microns. The method comprises the following steps: (1) purification decontamination and sandblasting processing of the ground net surface; (2) allocation of lanthanum, cerium, praseodymium, neodymium and other rare earth-containing alloy powder in zinc, aluminum, magnesium, nickel, manganese, silicon, chromium, beryllium and titanium alloy powder of a surface layer coating; and (3) formation of the rare earth-containing alloy corrosion prevention coating. The electric power ground net surface is sprayed with the rare earth-containing alloy corrosion prevention coating, so that the ground net service life is improved, the ground net work cost is reduced, and the method is simple and reliable in process, green, low-carbon, non-pollution, and friendly to environment.

Owner:STATE GRID CORP OF CHINA +3

Pickled compound fruit-flavored red jujube and manufacture method thereof

InactiveCN108606285AIncrease fruity aromaRich varietyFruit and vegetables preservationFood ingredient as taste affecting agentPEARPapaya family

The present invention discloses a pickled compound fruit-flavored red jujube. The pickled compound fruit-flavored red jujube comprises the following components in parts by weight: 70-80 parts of treated red jujubes, 20-25 parts of pear blocks, 15-20 parts of grapefruit peels, 15-20 parts of papaya strips, 10-15 parts of fruit-flavored pressure sensitive microcapsules, 5-8 parts of nutrient particles, 5-8 parts of compound non-metallic particles, 25-30 parts of honey, 10-15 parts of fruit vinegar and 10-15 parts of antiseptic microcapsules. The pickled compound fruit-flavored red jujube is richin nutrients, enriches the variety of food, and greatly meets needs of consumers.

Owner:ZHONGXI TIANJIN JUJUBE TECH ENG CENT

Capacitance structure and preparation method of a hybrid nanocrystalline memory

InactiveCN101692463BHigh densityControl thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceIntegrated circuit manufacturing

The invention belongs to the technical field of semiconductor integrated circuit manufacturing, in particular to a capacitor of a nano-crystal memory and a preparation method thereof. The capacitor uses P-type single crystal silicon as a substrate, on which there are Al2O3 tunneling layer, ruthenium and ruthenium oxide mixed nanocrystal, Al2O3 barrier layer and palladium electrode layer. Among them, the Al2O3 layer is prepared by the atomic layer deposition method. The mixed nanocrystals are first deposited by magnetron sputtering to deposit the metal ruthenium layer, and then formed after rapid thermal annealing in a mixed atmosphere composed of nitrogen and trace oxygen. The palladium electrode layer is formed by lift -off method formation. The memory capacitance structure of the present invention has excellent characteristics such as good programming and erasing properties, long charge retention time, etc., and has good application prospects in flash memories.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com