Patents

Literature

49results about How to "Lower eutectic temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

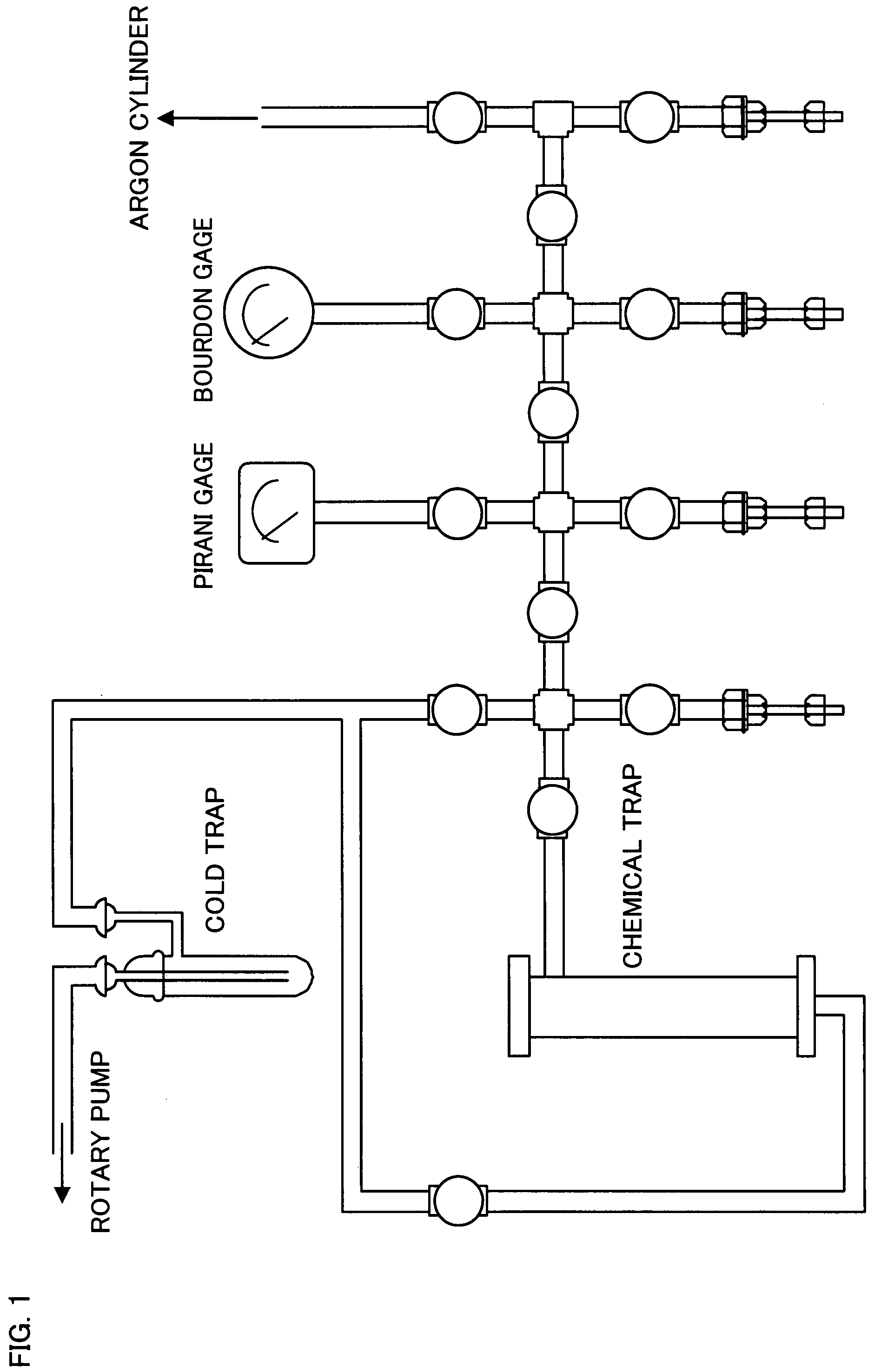

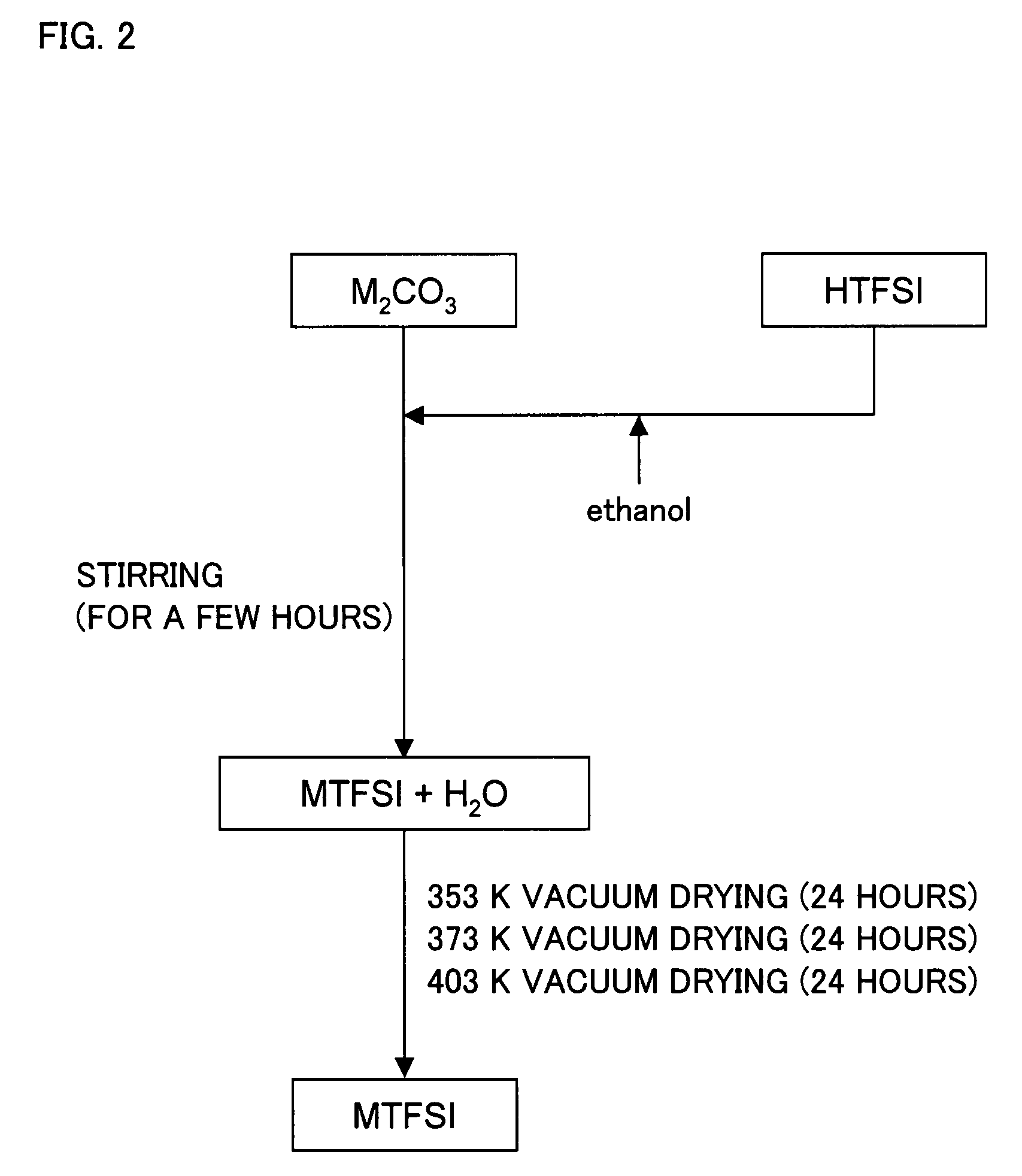

Molten Salt Composition and Use Thereof

ActiveUS20090212743A1High surface finishUniform platingNon-metal conductorsBatteries circuit arrangementsImideMolten salt

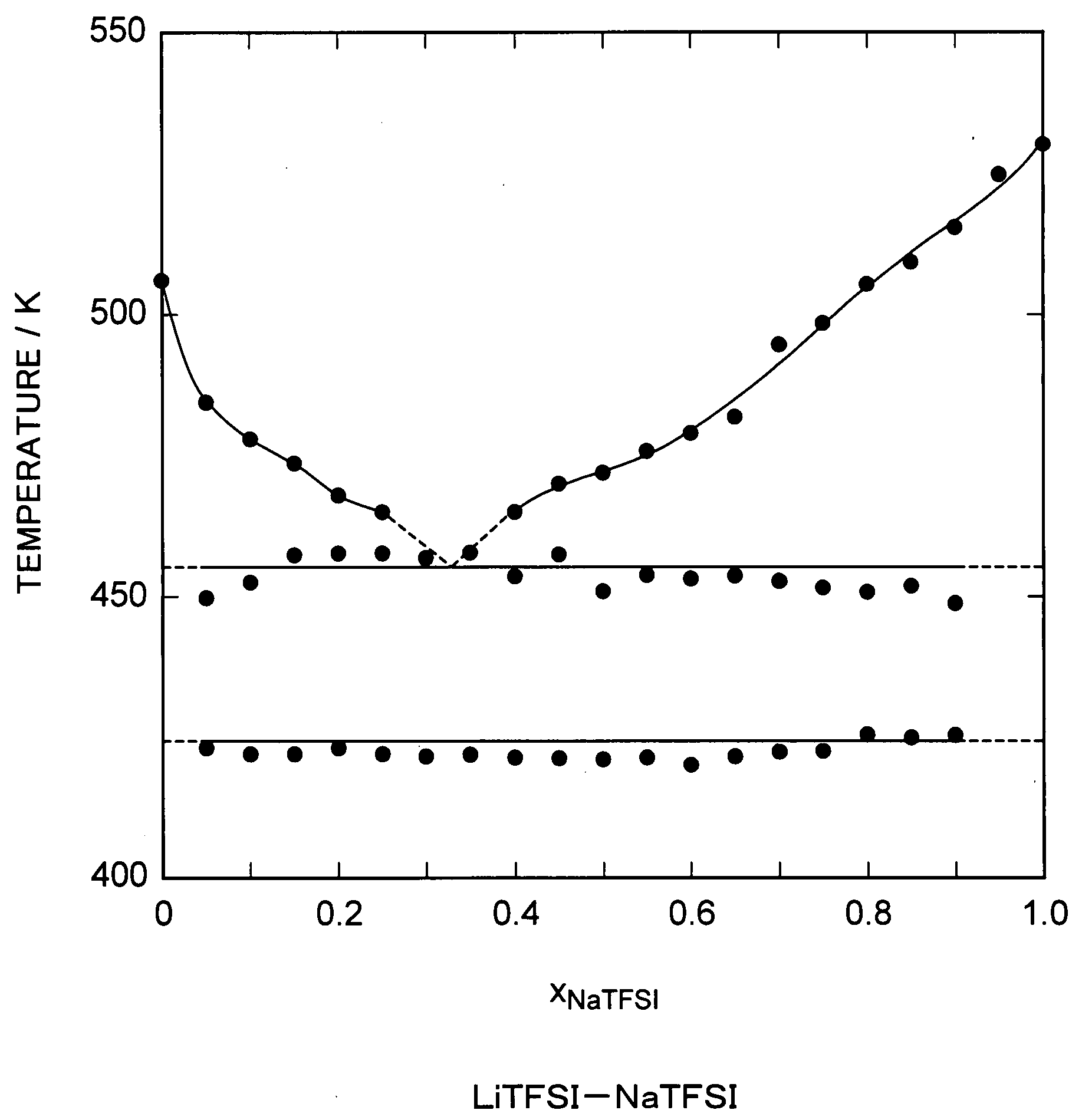

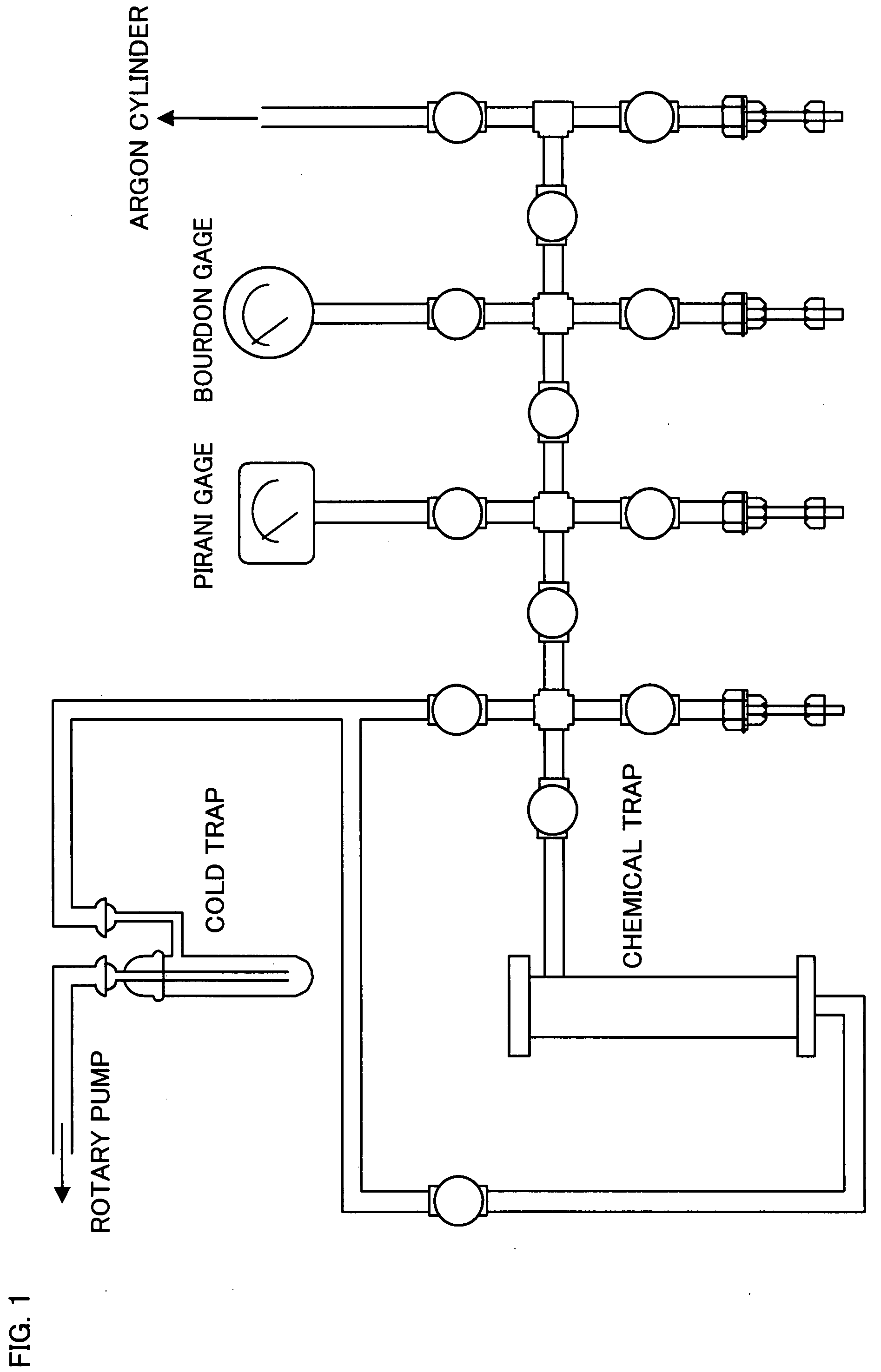

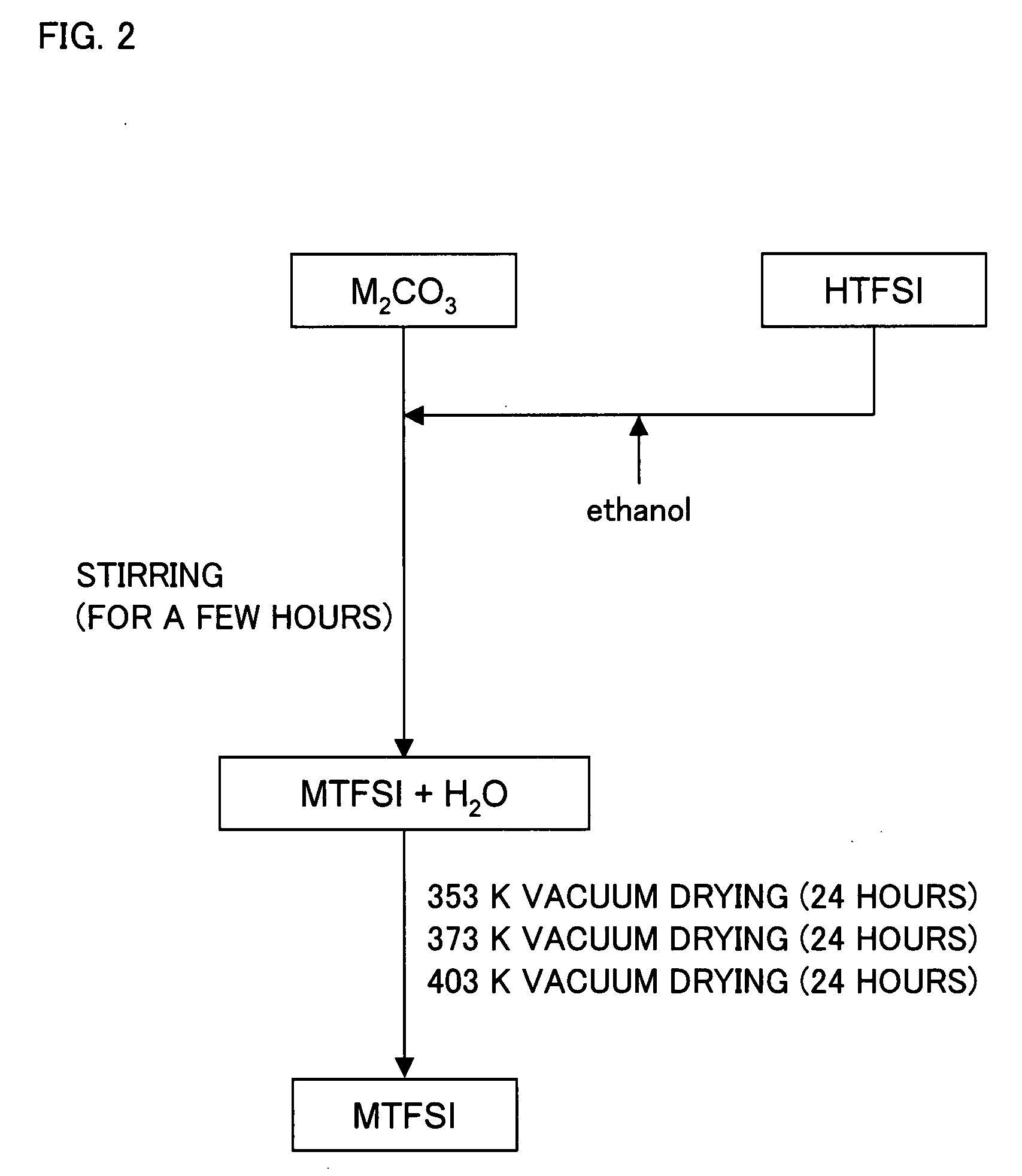

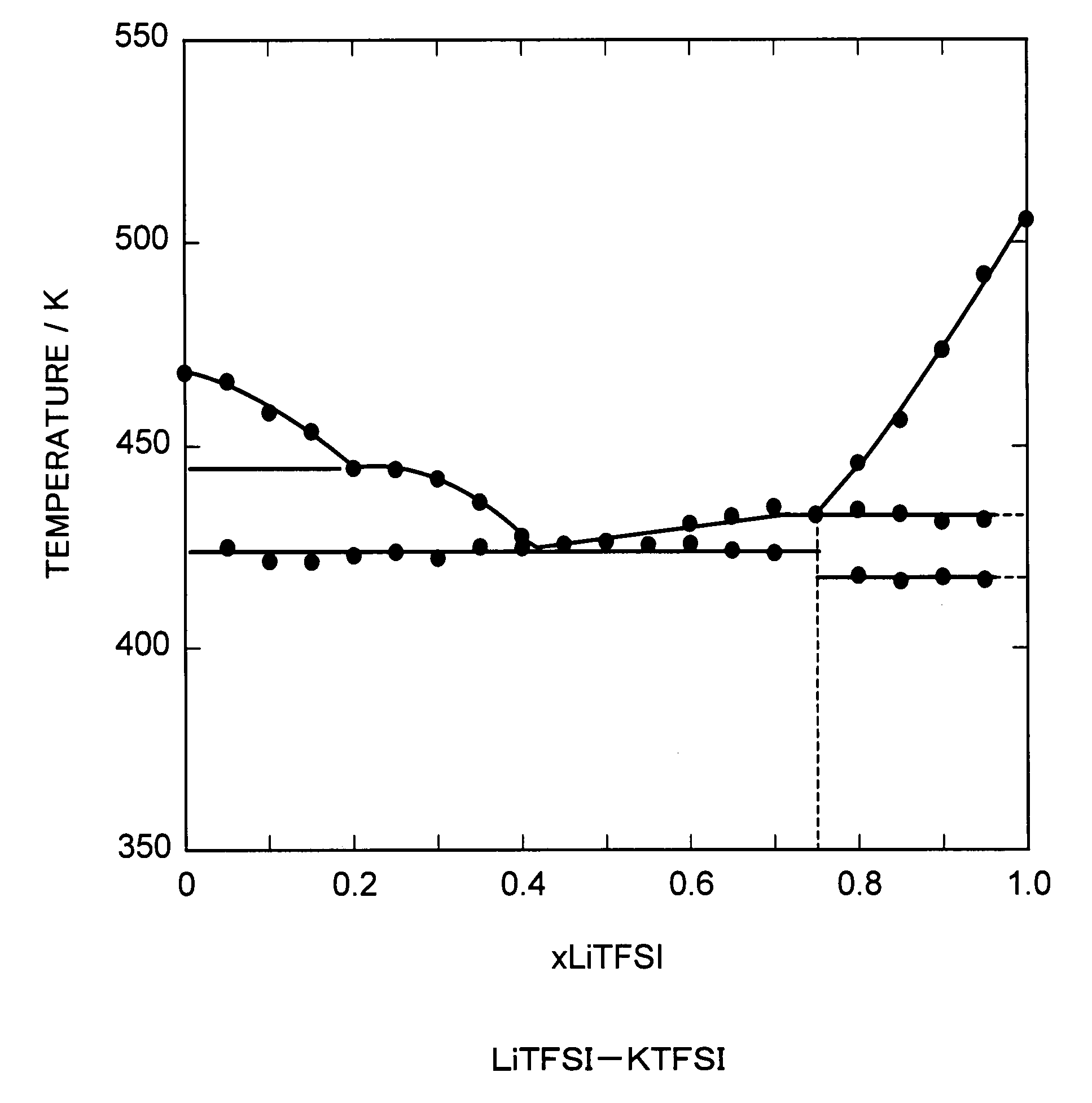

A molten salt composition is disclosed containing two or more types of molten salt MTFSI whose anion is an imide anion TFSI and whose cation is an alkali metal M exhibits a lower electrolyte melting point and a wider operating temperature range than a simple salt does. This brings about various advantages such as a wider range of materials that are chosen for use in batteries and the like.

Owner:KYOTO UNIV

Non-aqueous electrolytic solution

ActiveUS7255965B2Improve battery performanceGood SEIOrganic electrolyte cellsSecondary cellsHigh temperature storageLithium

The use of lithium bis(oxalate)borate (LiBOB) as an additive in a lithium secondary battery provides improved battery performance such as long life and high capacity retention after high temperature storage.

Owner:SHENZHEN CAPCHEM TECH CO LTD

Non-aqueous electrolytic solution

ActiveUS20060240327A1Improve battery performanceGood SEIOrganic electrolyte cellsSecondary cellsLithiumHigh temperature storage

The use of lithium bis(oxalate)borate (LiBOB) as an additive in a lithium secondary battery provides improved battery performance such as long life and high capacity retention after high temperature storage.

Owner:SHENZHEN CAPCHEM TECH CO LTD

High-strength aluminum alloy material formed through metamorphism of salt hexafluorosilicate

The invention discloses a high-strength aluminum alloy material formed through metamorphism of salt hexafluorosilicate. The high-strength aluminum alloy material formed through the metamorphism of the salt hexafluorosilicate comprises, by weight, 2.6-3.2% of Cu, 0.45-0.7% of Mn, 2.0-2.4% of Mg, not more than 0.1% of Zn, not more than 0.15% of Ti, not more than 0.3% of Si, and not more than 0.3% of Fe. Salt hexafluorosilicate alterant accounts for 0.1-1.0% of the total furnace burden, and the rest is Al and unavoidable trace impurities, and the trace impurities comprise, by weight, not more than 0.05% of a single and not more than 0.10% of a total. The high-strength aluminum alloy material formed through the metamorphism of the salt hexafluorosilicate is good in metamorphism refining effect, can purify a furnace body, and is high in strength.

Owner:GUIZHOU ACAD OF SCI

Molten salt composition and use thereof

ActiveUS8257868B2Low melting pointEasy to operateNon-metal conductorsBatteries circuit arrangementsImideMolten salt

A molten salt composition is disclosed containing two or more types of molten salt MTFSI whose anion is an imide anion TFSI and whose cation is an alkali metal M exhibits a lower electrolyte melting point and a wider operating temperature range than a simple salt does. This brings about various advantages such as a wider range of materials that are chosen for use in batteries and the like.

Owner:KYOTO UNIV

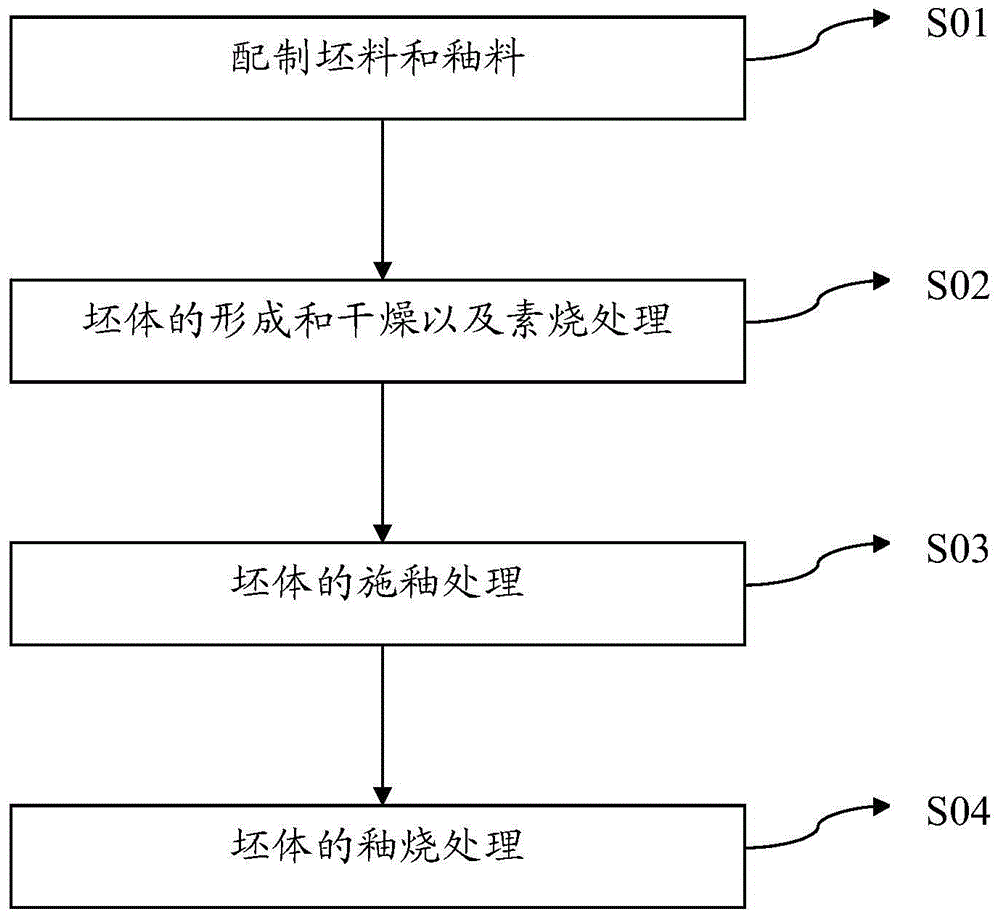

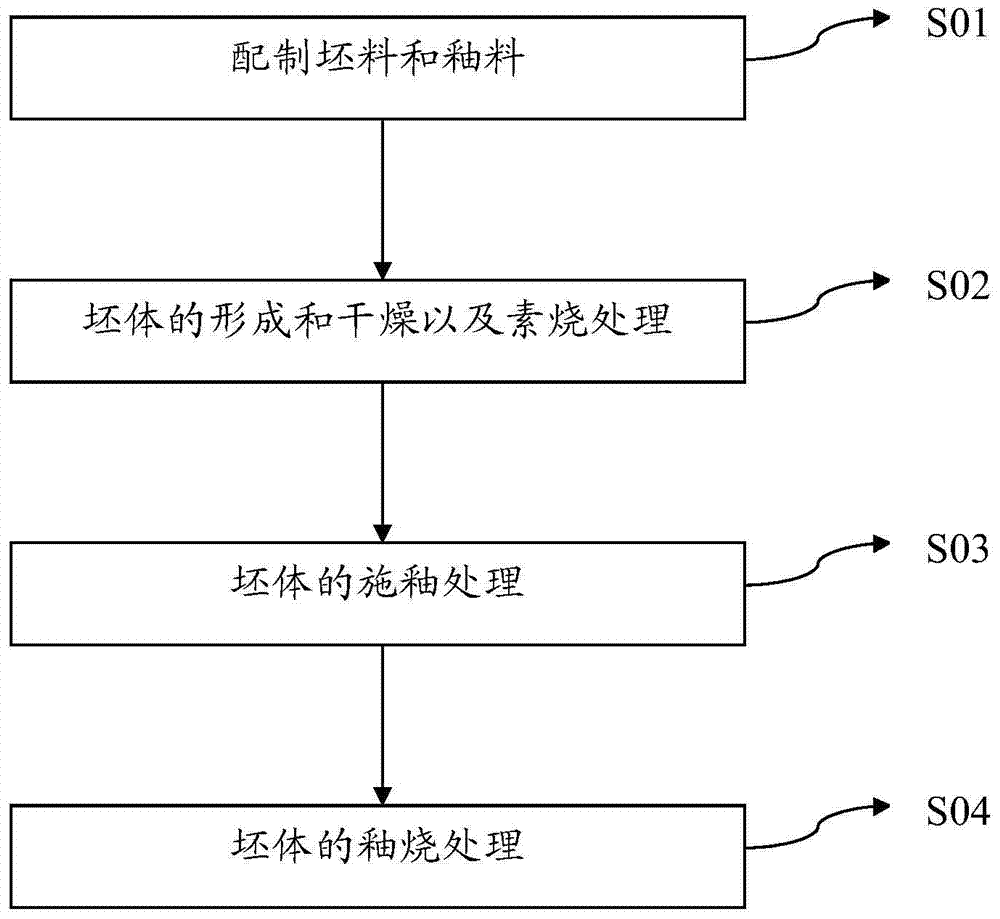

Glazed ceramic tile and preparation method thereof

ActiveCN105130394AHigh strengthReduce shrinkageCeramic materials productionClaywaresCeramic glazeAnaerobic digestion

The invention discloses a glazed ceramic tile and a preparation method thereof. The glazed ceramic tile is prepared by processing a blank material and glaze, and the blank material comprises the following compositions in percent by weight: 50-75% of anaerobic digestion sludge, 10-25% of clay, 5-15% of wollastonite, and 5-10% of talcum. The glazed ceramic tile preparation method comprises preparing blank and glaze, forming a green body, drying, biscuiting, glazing the green body, performing glaze firing on the green body, and the like. The green body of the glazed ceramic tile is high in strength and small in shrinkage degree when being biscuited, the biscuiting temperature scope of the green body is expanded, and phenomena that the green body surface foams, generates black hearts and is reduced in compressive strength and the like because of too large ignition loss are effectively avoided. The glazed ceramic tile preparation method enables the glazed ceramic tile surface to be solid, flat, free of black heart phenomenon, and high in strength, and also the preparation method is simple and easily controllable in technology, high in yield and high in production efficiency, and production cost is effectively reduced.

Owner:深圳市正源清环境科技有限公司

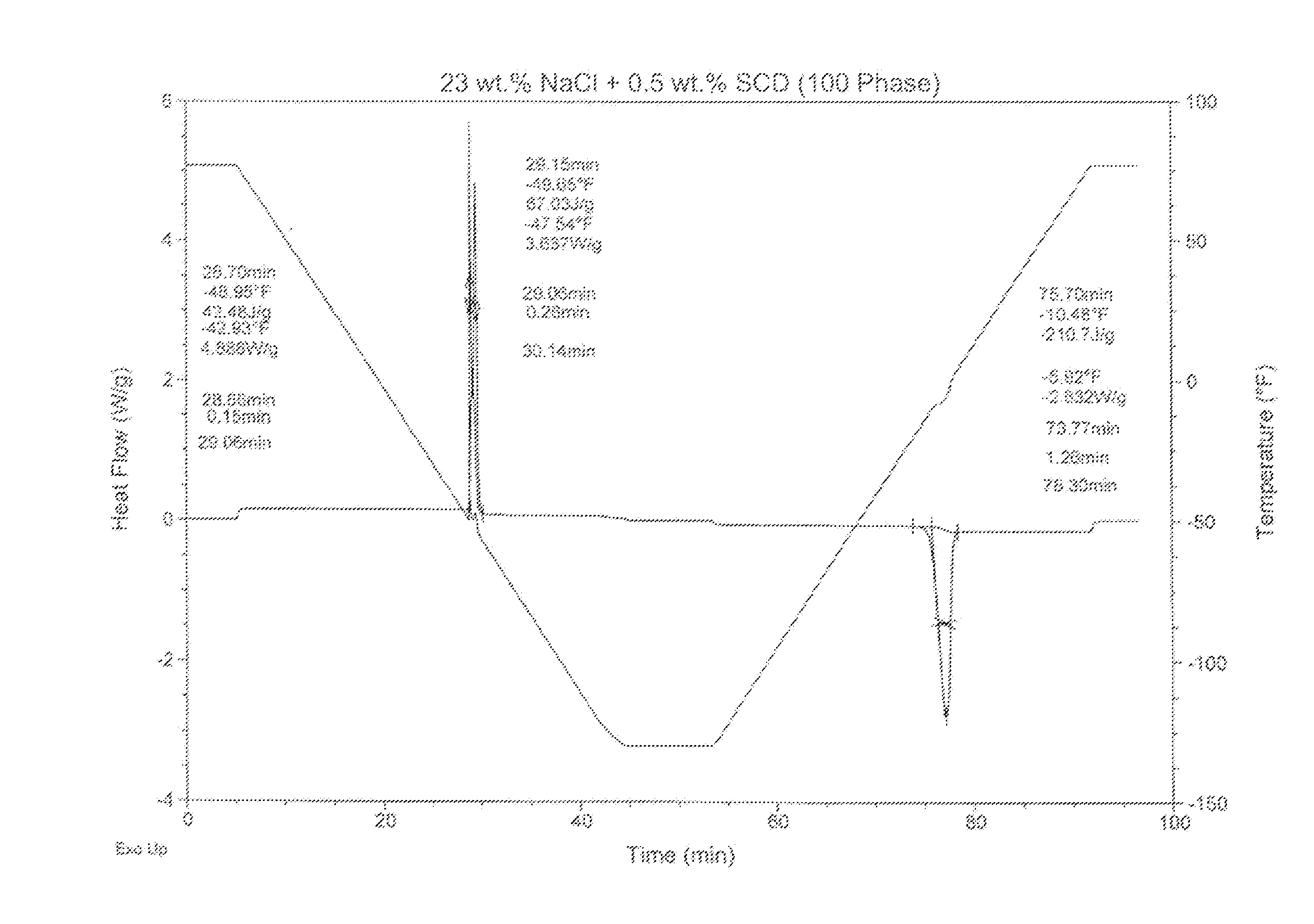

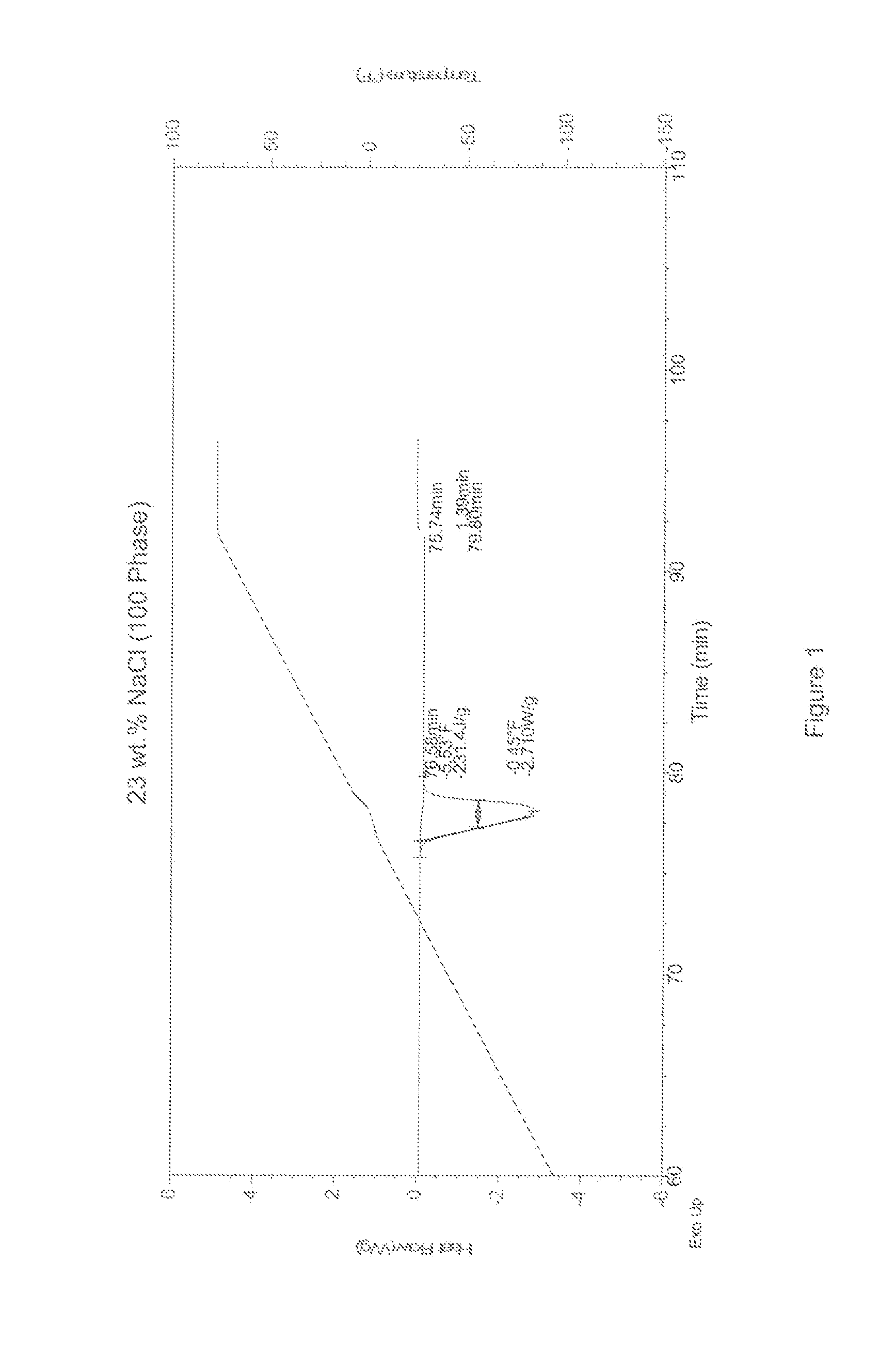

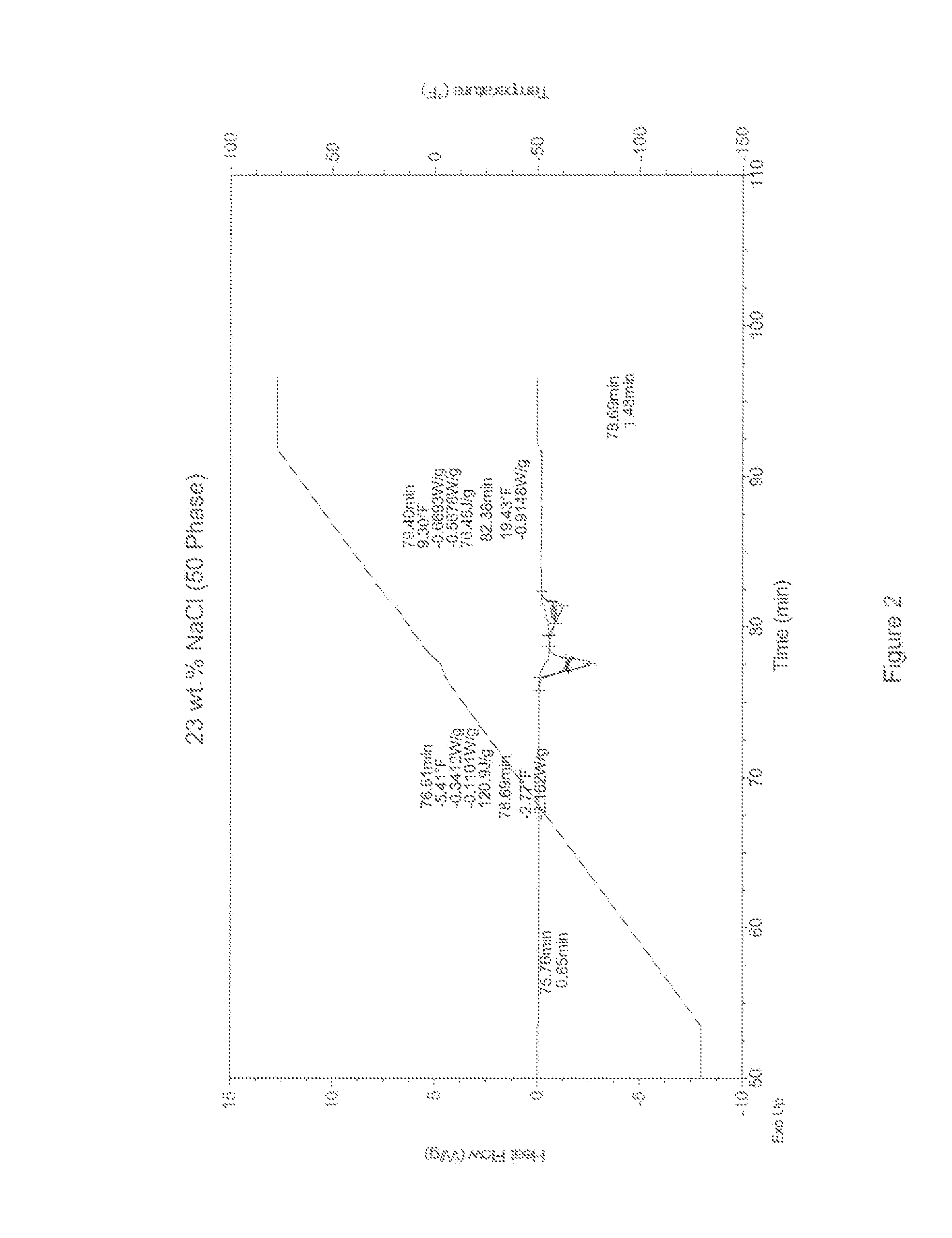

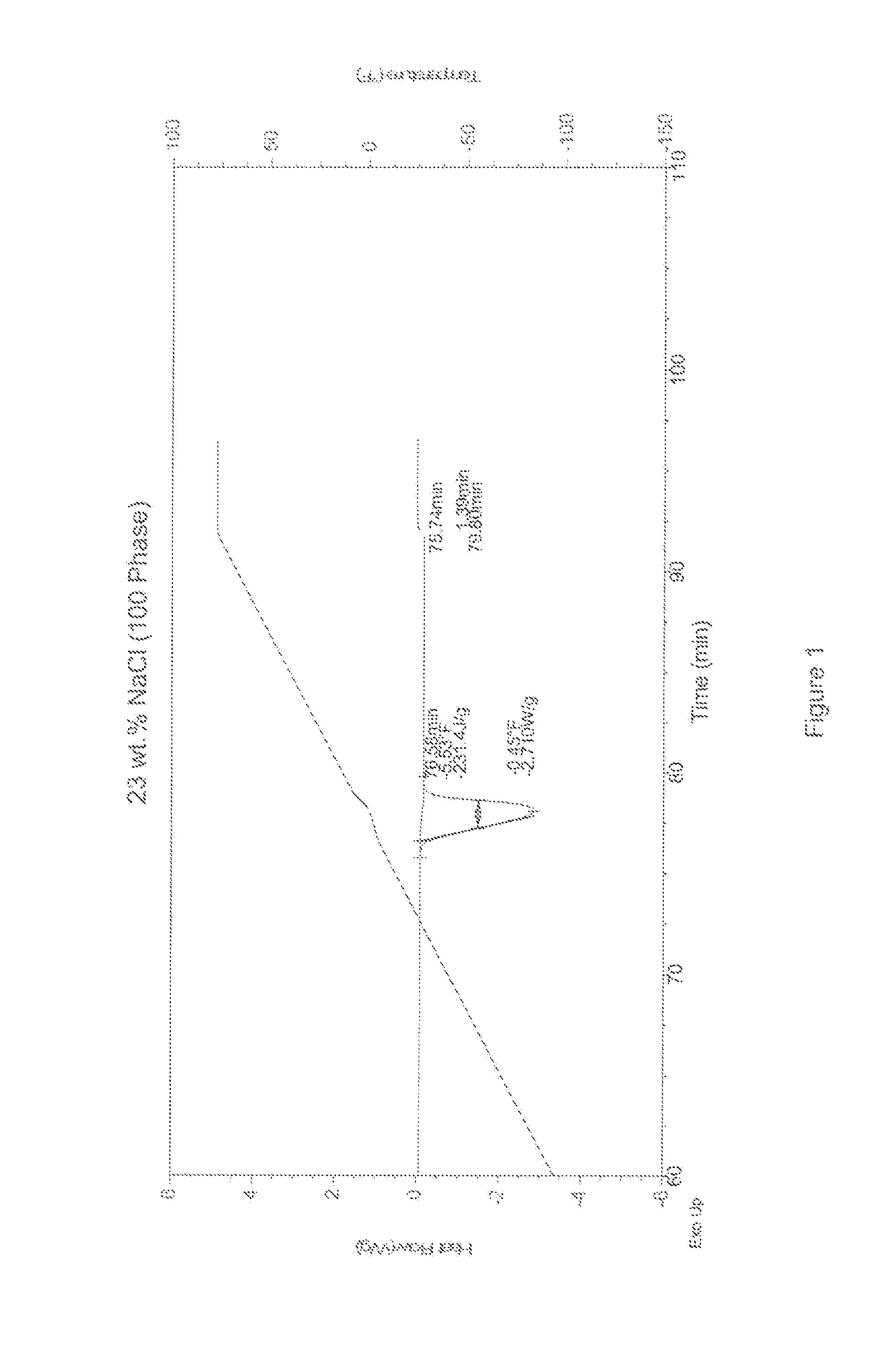

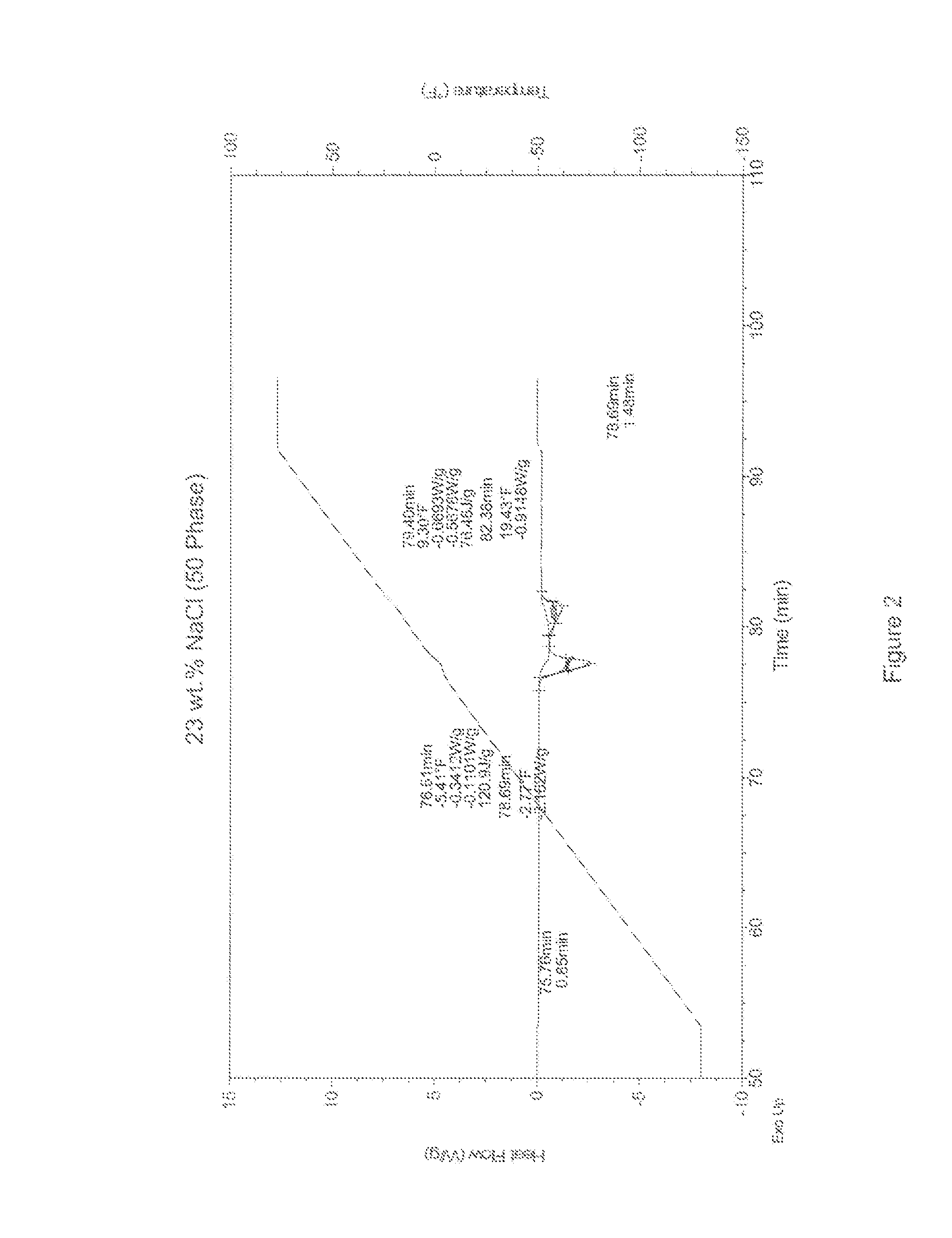

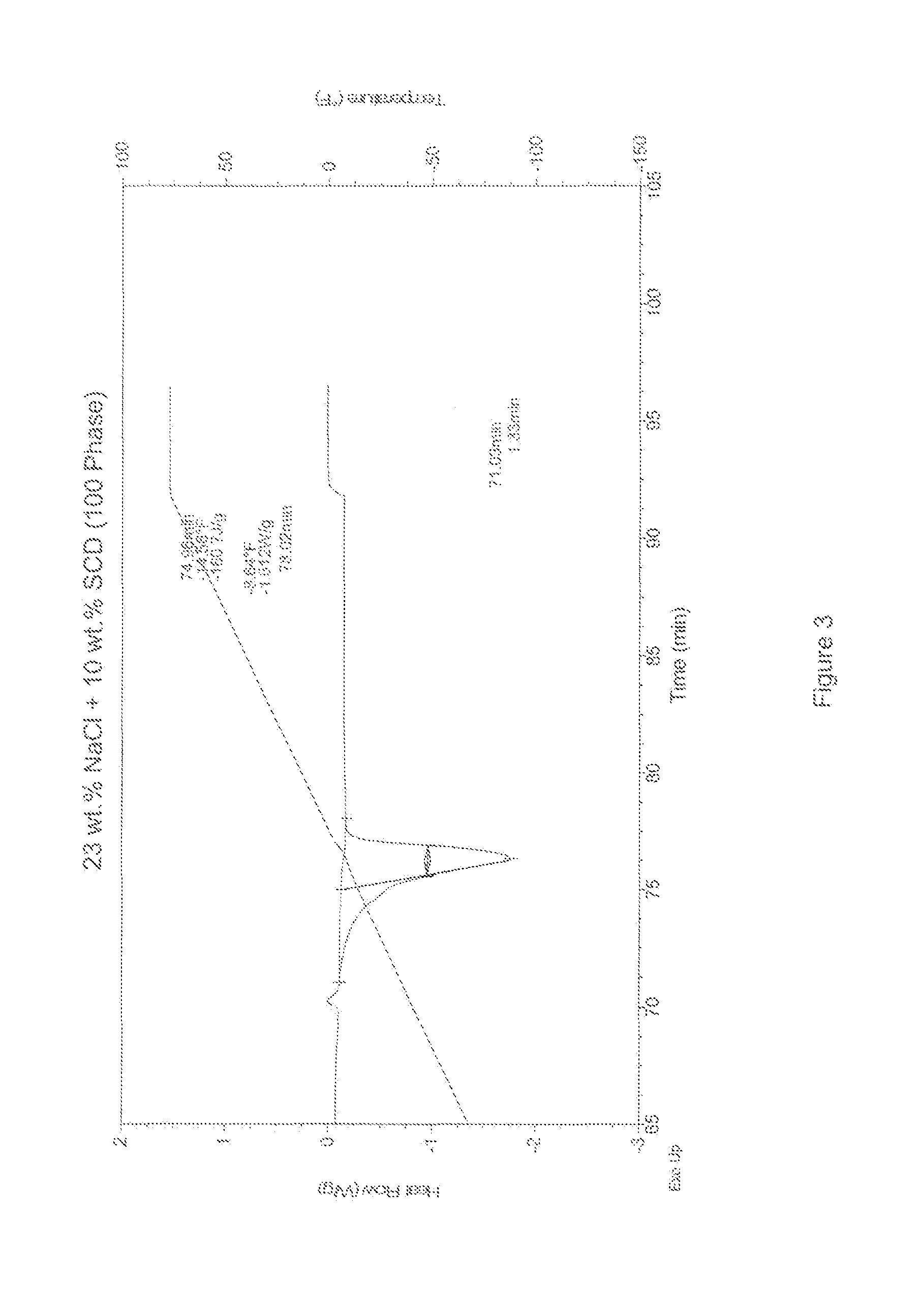

Citrate containing deicing compositions with improved eutectic temperatures

InactiveUS20130306904A1Reduce the amount requiredLower eutectic temperatureOther chemical processesCITRATE ESTERAqueous solution

Deicing compositions are described for reducing an amount of ice formed on a surface. The deicing compositions may include about 1 wt. % to about 15 wt. % of a salt of citric acid. The compositions may further include about 23 wt. % to about 28 wt. % sodium chloride when the deicing composition forms an aqueous solution.

Owner:ENVIROTECH SERVICES

Lead-free welding flux alloy

InactiveCN101007373AImprove solderabilityImprove connection strengthWelding/cutting media/materialsSoldering mediaReflow solderingDip soldering

Lead-free solder alloy. The invention involves an alloy, particularly a lead-free solder alloy. The components weight percentages of the solder alloy are: Silver 0.1%~4.0%, copper 0.1% ~ 2%, Sb 0.002% ~ 0.2% and the rest is tin. The formula of said solder alloy in the invention is reasonable, has characteristics of unleaded, low prices, excellent weldability, it can prevent lead damage the human body when welding; it can replace the solder containing lead and can the prevent the welding silver plate eroded by silver; it is suitable to wave soldering, dip-soldering and reflow soldering,etc.

Owner:YUNNAN TIN GROUP HLDG

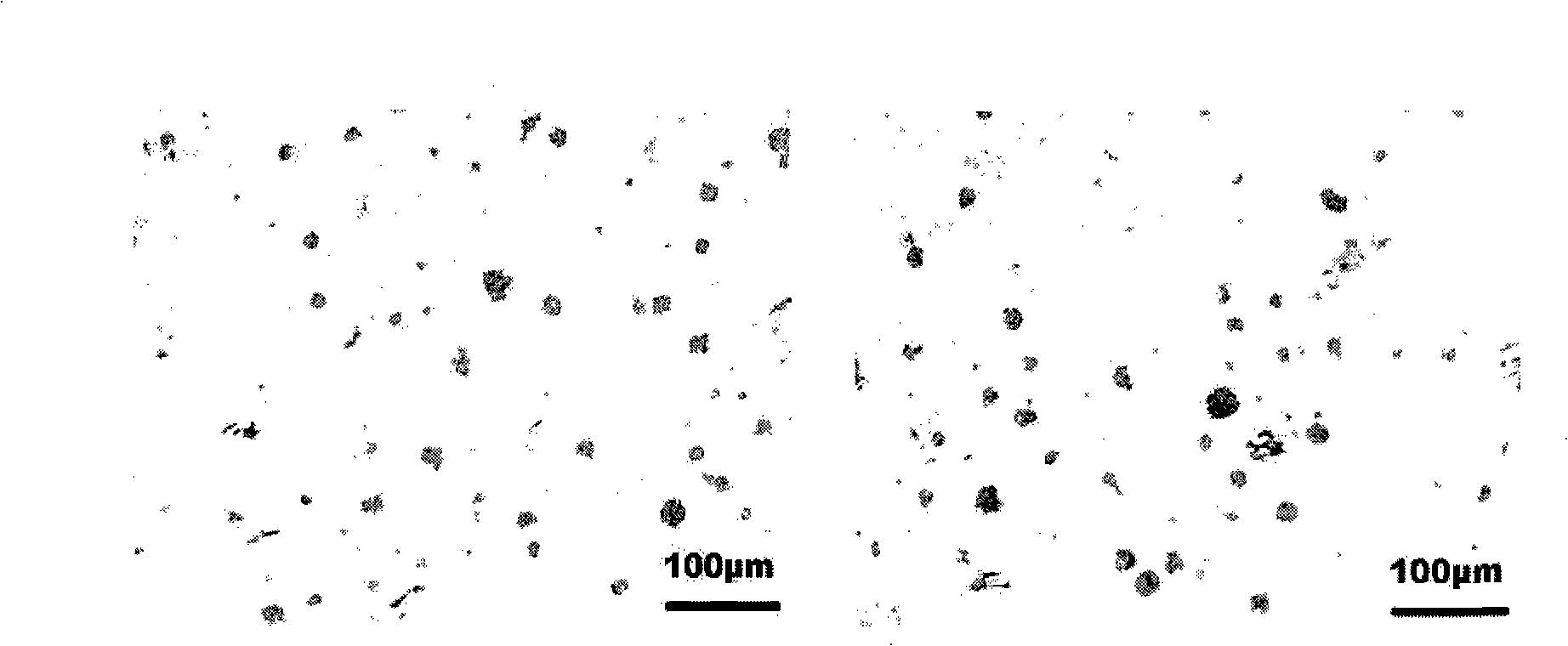

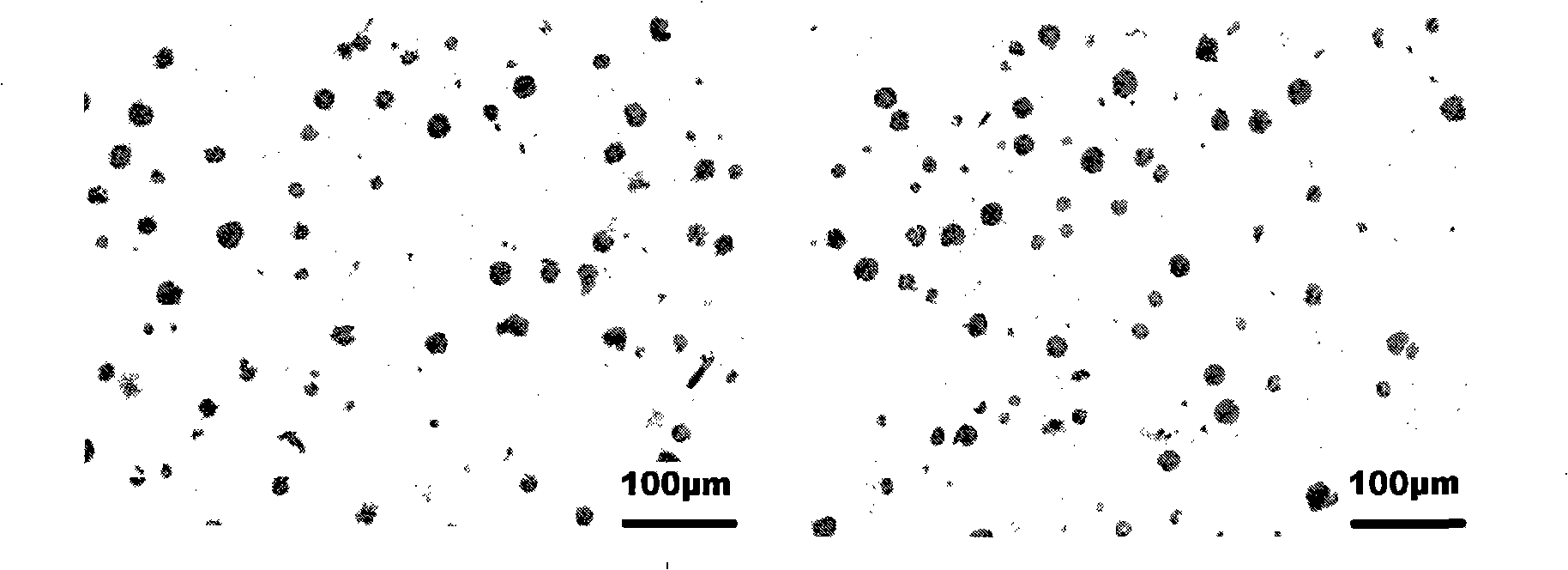

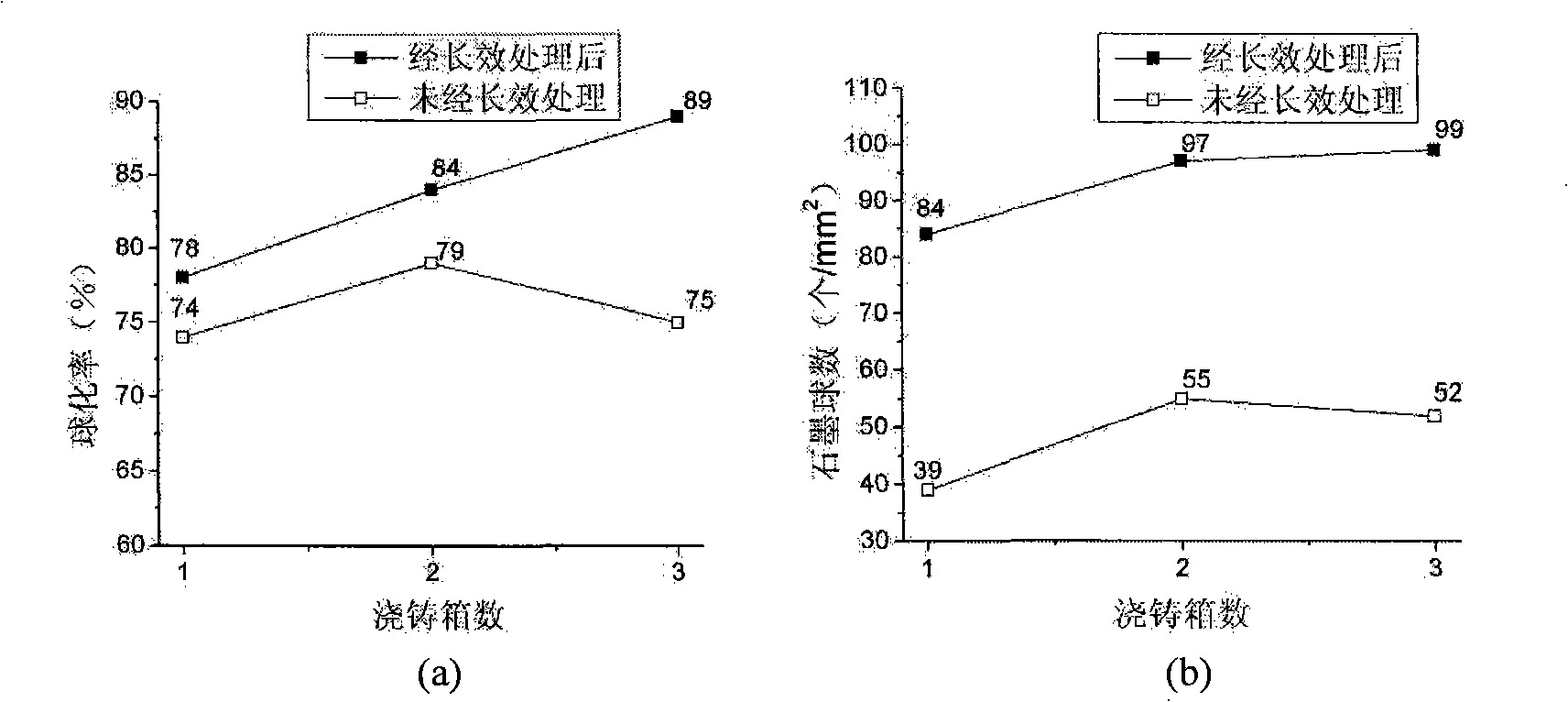

Long-acting synthesizing process of heavy sectioned ductile iron

InactiveCN101333618ARaise the eutectic temperatureLower eutectic temperatureMedium frequencyRare earth

The invention relates to a long-acting comprehensive treatment process of heavy wall ductile iron. The process comprises: placing ductile iron special pig iron materials and scrap steel in an appropriate amount in a medium frequency induction furnace, and smelting the materials at a temperature between 1350 and 1450DEG C according to the conventional method of: adding 0.1 to 2.0 percent of Cu; then adding 1 to 5 percent of nodulizer into a nodulizing ladle for nodulizing graphite, wherein the compositions of the nodulizer include: 10.0 to 12.0 percent of Mg, 2.0 to 3.0 percent of rare earth, 40.0 to 45.0 percent of Si, 2.5 to 3.0 percent of Ca, 2.5 to 2.9 percent of Ba, less than 1.5 percent of Al, balance Fe; and putting 0.1 to 1 percent of inoculant in a casting ladle in advance and pouring liquid iron into the casting ladle, the compositions of the inoculant have: 70.0 to 75.0 percent of Si, 0.5 to 0.6 percent of Ca, less than 1.5 percent of Al, 1.0 to 1.2 percent of Bi, balance Fe, and finally casting products. The process has the advantages of: improving the form of graphite, reducing degenerating graphite, and obviously improving the nodularity of heavy wall nodular iron and comprehensive mechanical properties of castings.

Owner:SHANGHAI UNIV

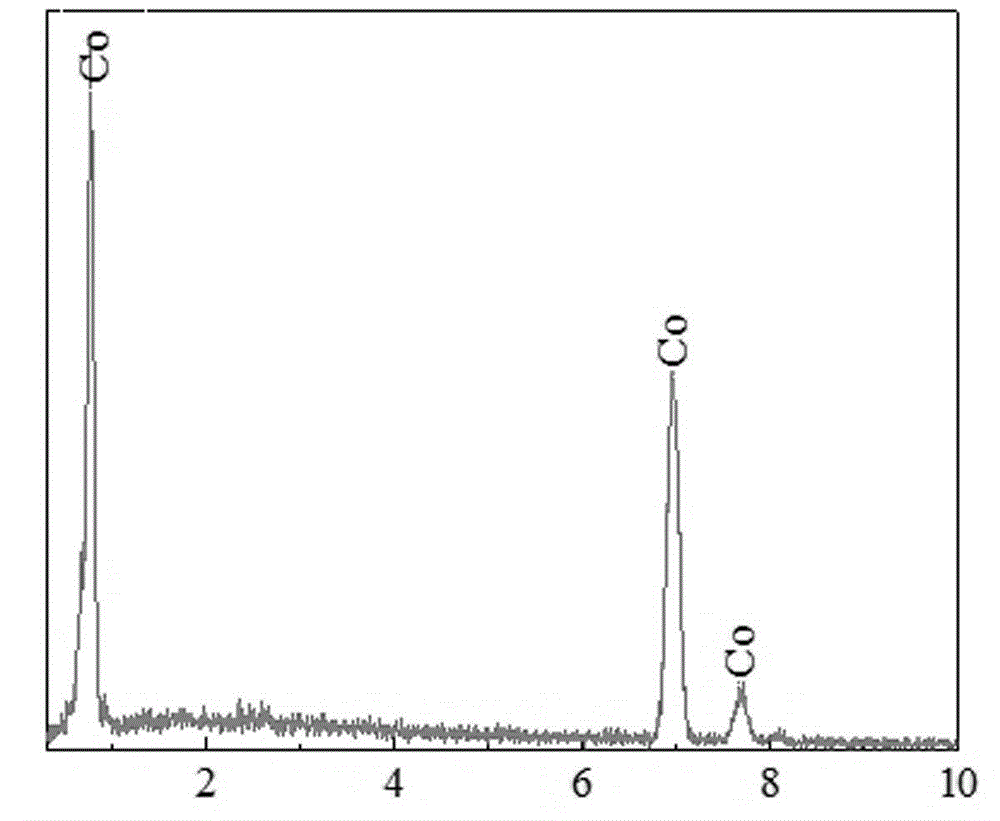

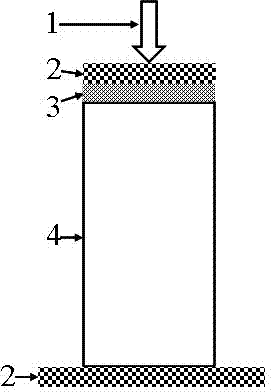

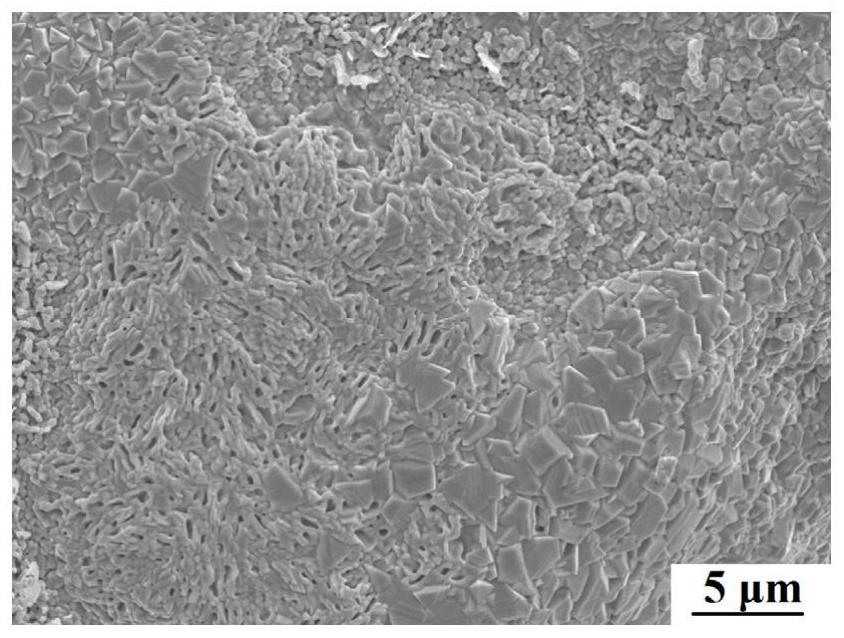

Method of preparing transition metal and alloy thereof through low temperature molten salt electro-deposition

A method of preparing transition metal and alloy thereof through low temperature molten salt electro-deposition is characterized by comprising the steps of (1) mixing anhydrous urea, acetamide and anhydrous LiX uniformly and heating and stirring the mixture to form a colorless uniform liquid molten salt; (2) dissolving a transition metal chloride TMCl2 in low temperature molten salt and stirring and mixing the mixture uniformly to form a low temperature molten salt electrolyte; (3) with a copper sheet or stainless steel as a cathode and graphite as an anode, performing electro-deposition in the low temperature molten salt electrolyte at the electrolyzing temperature of 70-90 DEG C in a manner of constant potential and constant current to control the potential or cathode current density; and (4) when the electrolysis is finished, taking the copper sheet or stainless steel out and cleaning and drying it to obtain the transition metal and alloy thereof deposited on the surface of the cathode. The molten salt is low in price and is low in eutectic temperature so that the method is low in cost, is low in electrolysis temperature, is energy-saving, is less in pollution and is slight in corrosion on equipment.

Owner:NORTHEASTERN UNIV LIAONING

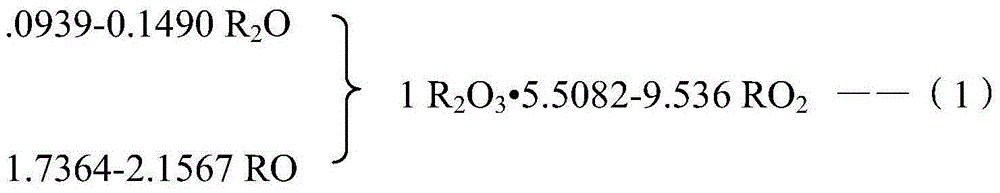

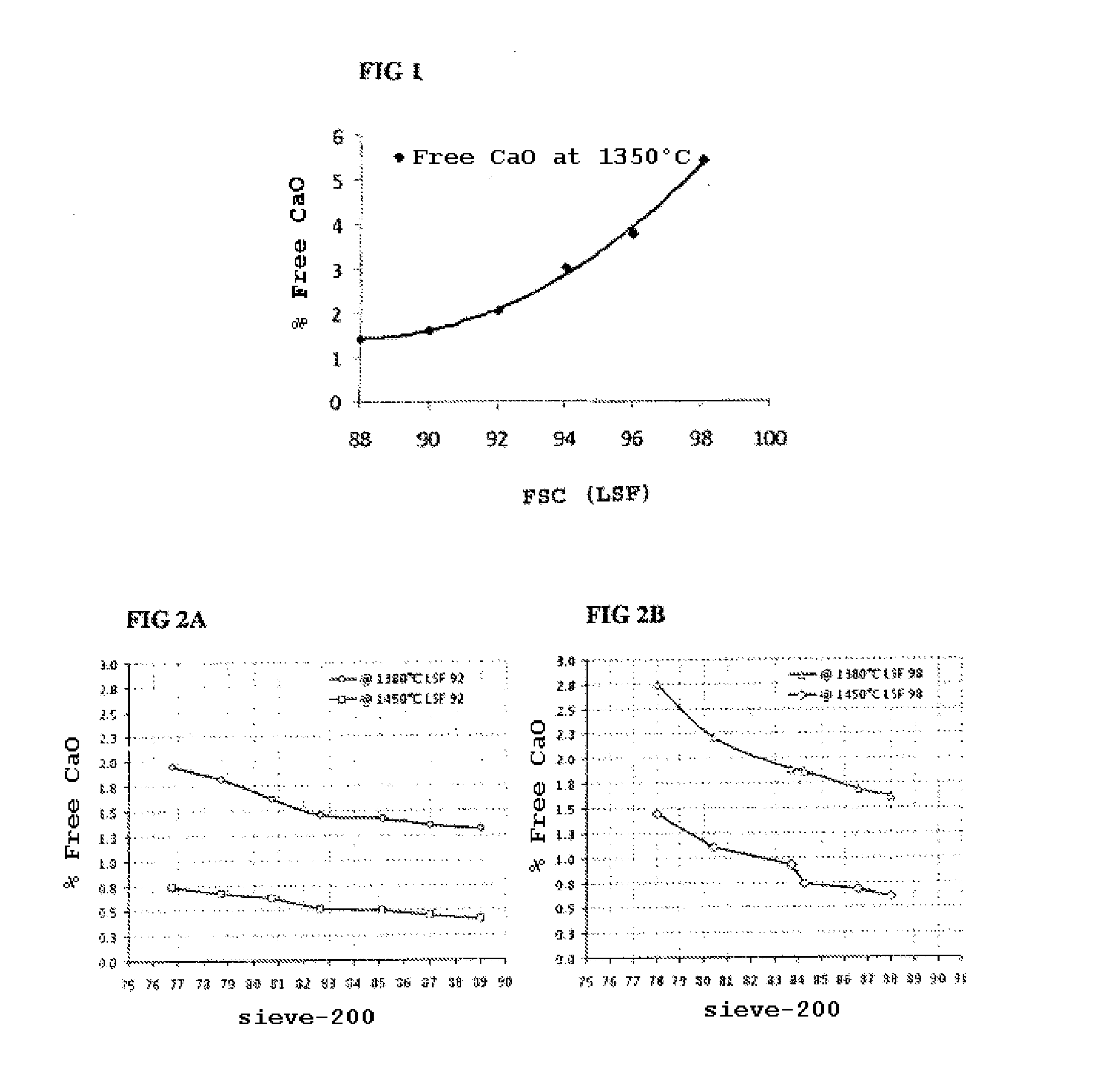

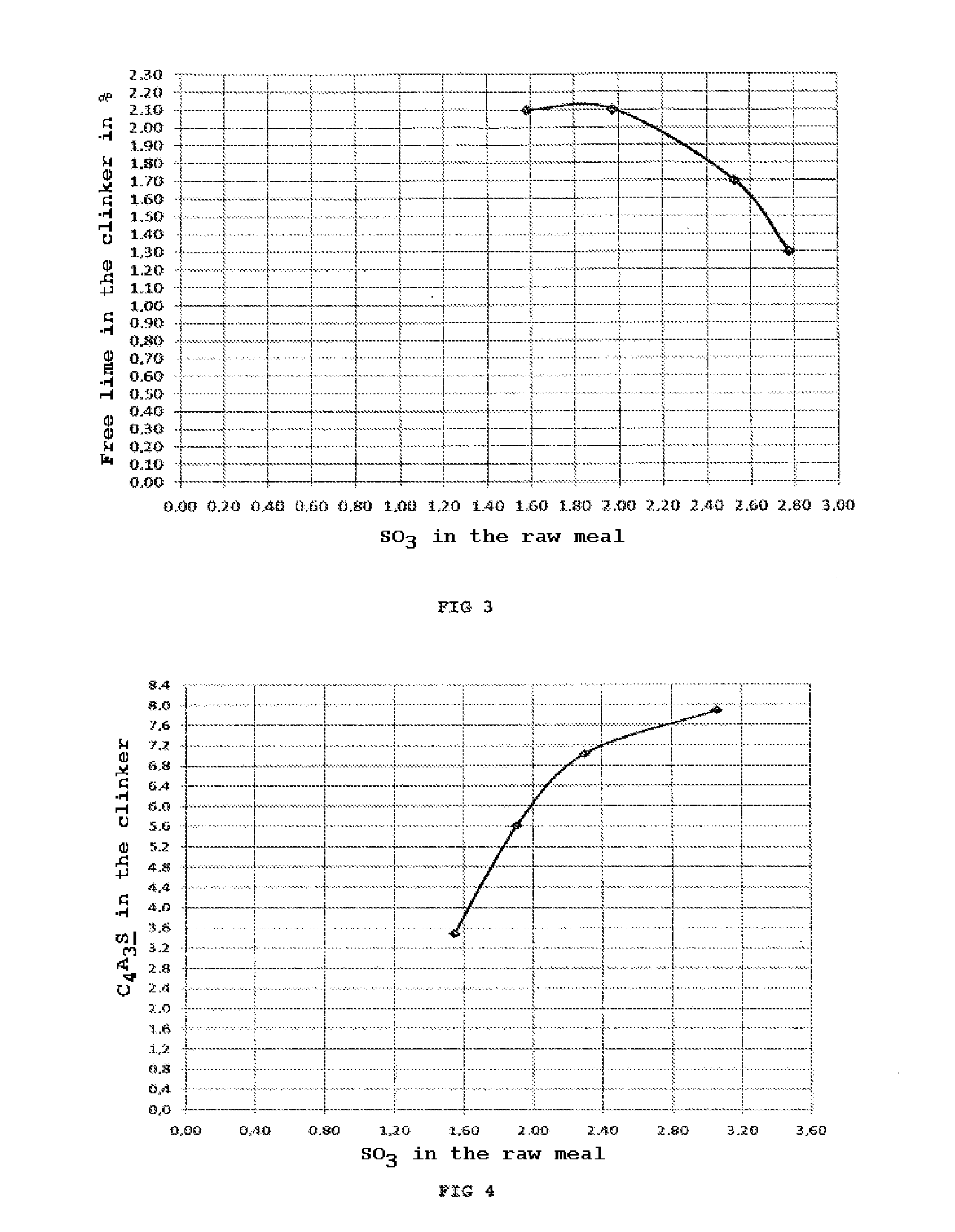

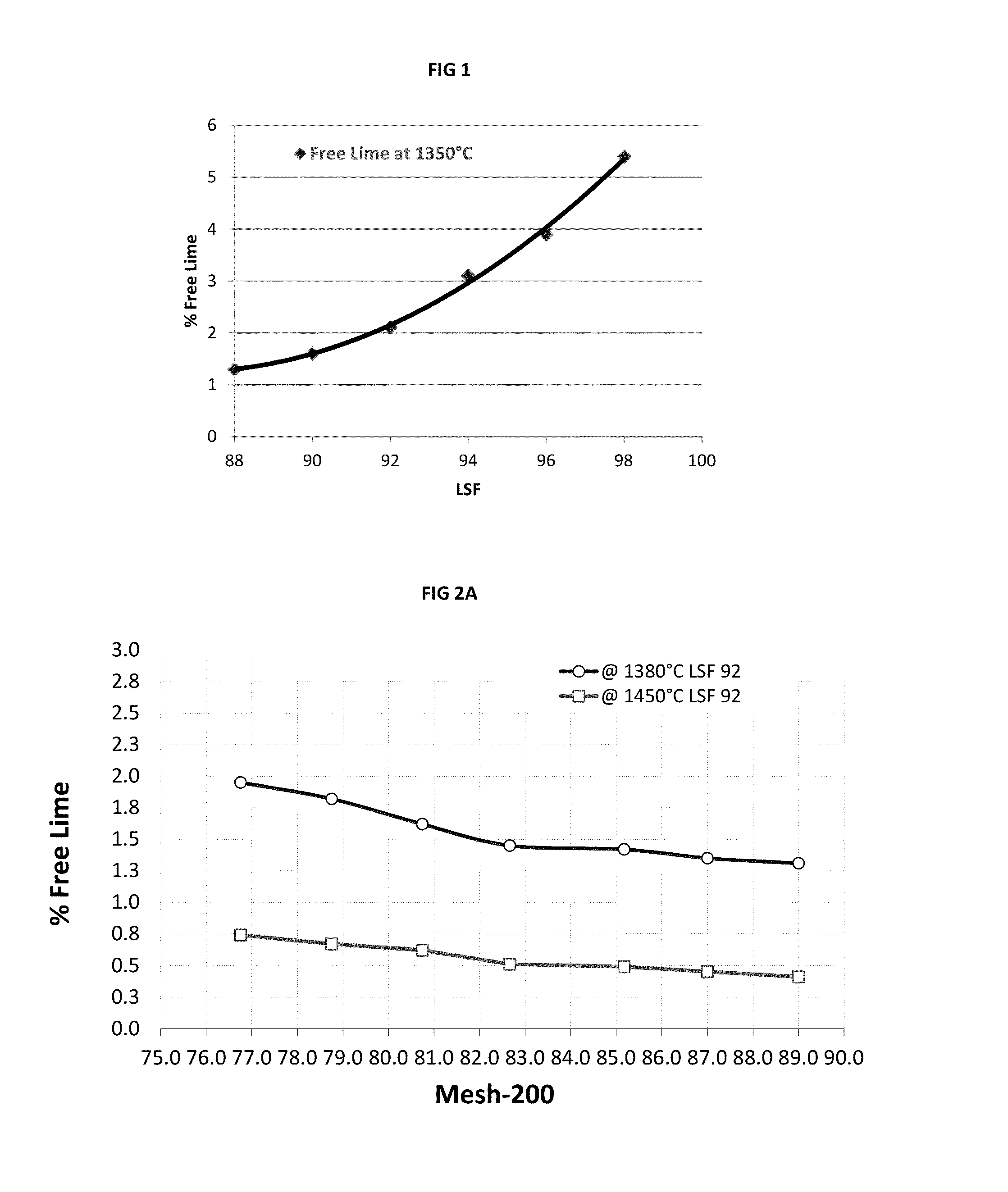

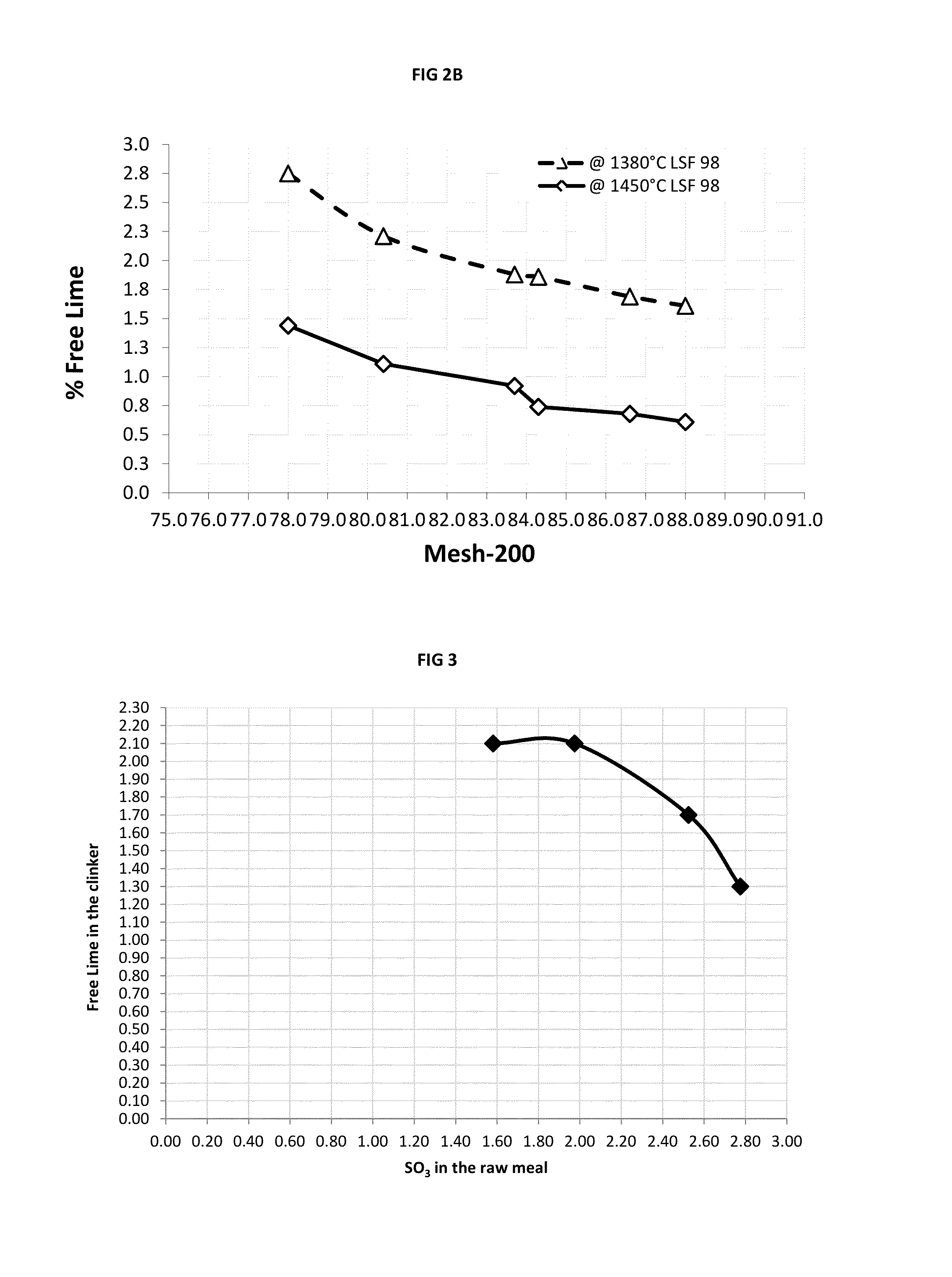

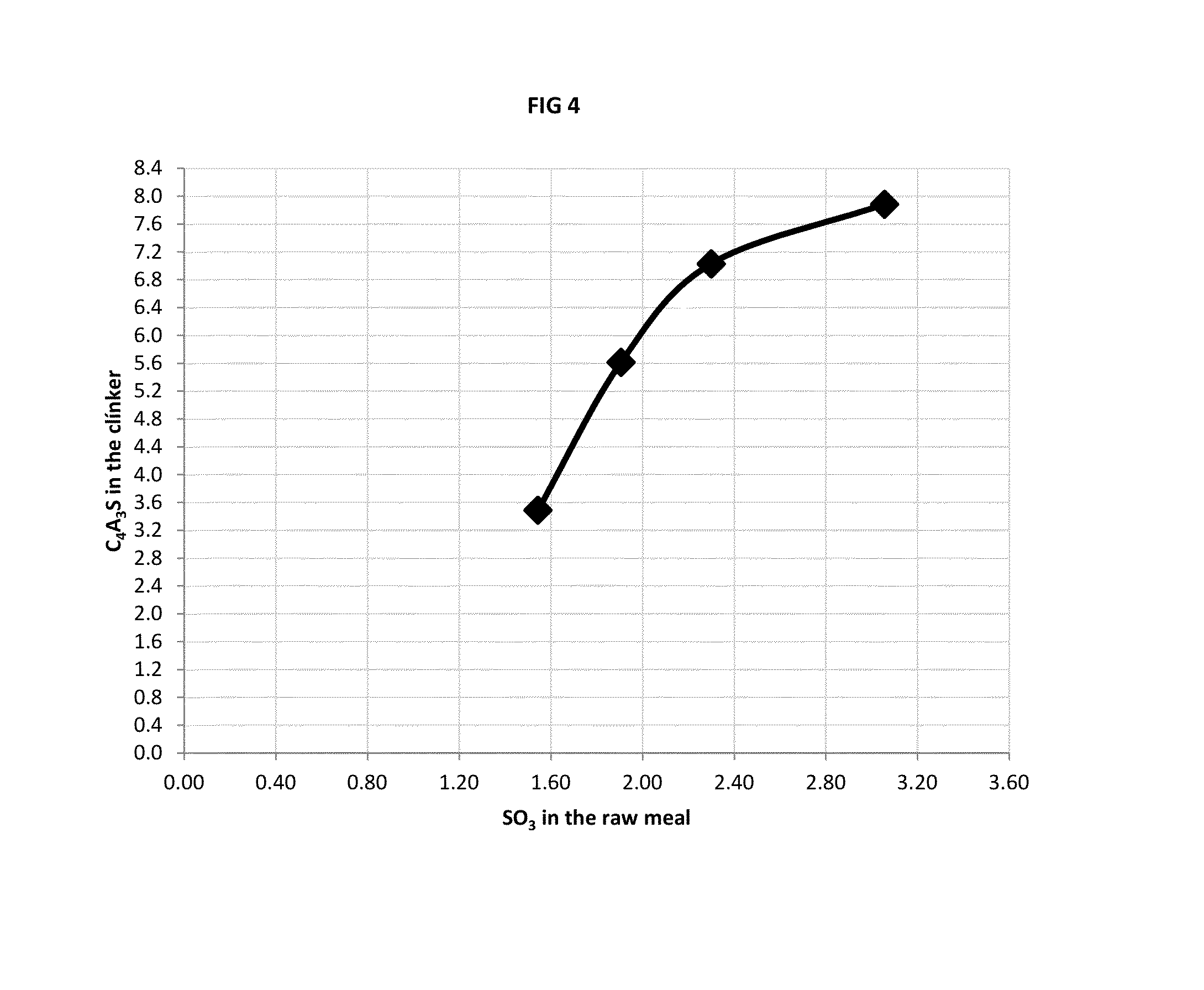

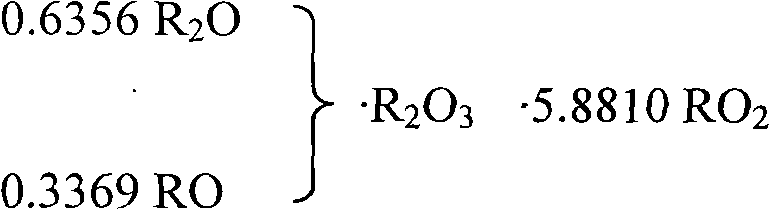

Method for producing a clinker for hydraulic cement with low co2 emission and high resistance

ActiveUS20130152825A1Lower eutectic temperatureLower energy levelCement productionHigh resistanceOxygen content

A method for producing a clinker for cement, comprising grinding a raw flour comprising, especially, Al2O3, Fe2O3 and SO3 in contents such that the formula for calculating SO3 content of=0.261×Al2O3−0.638×Fe2O3+k, where 2.5<k<3.5, then by sintering flour in an overn wherein the temperature is between 1250° C. and 1350° C. and oxygen content is between 2.5% and 10% by volume.

Owner:CEMEX INNOVATION HLDG LTD

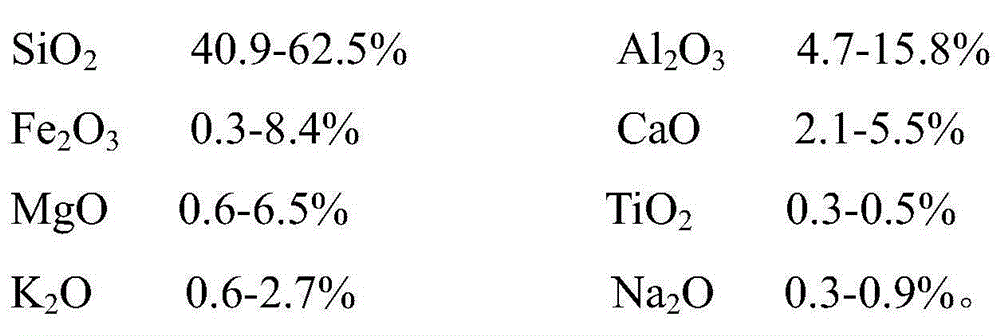

Manufacturing process of high-temperature resistant nixing pottery

ActiveCN106242526AGood thermal shock resistanceHigh mechanical strengthClaywaresUltimate tensile strengthMaterials science

The invention discloses a manufacturing process of a high-temperature resistant nixing pottery. The manufacturing process comprises the steps of preparing a preform body, moulding, finishing, drying and calcining the preform body, and is characterized in that the preform body comprises the following materials in parts by weight: 5-6 parts of white mud, 4-5 parts of purple mud, 1.5-2 parts of TiO2, and 1.5-2 parts of MgO. A high-temperature resistant nixing pottery vessel prepared from the high-temperature resistant nixing pottery has the advantages of excellent spalling resistance and better mechanical strength, can be directly used on various heat sources, does not crack after being used for a long period of time, and meets the requirements of the fine ceramic cookware standard QB / T2580-2002.

Owner:广西古窑坭兴陶文化有限公司

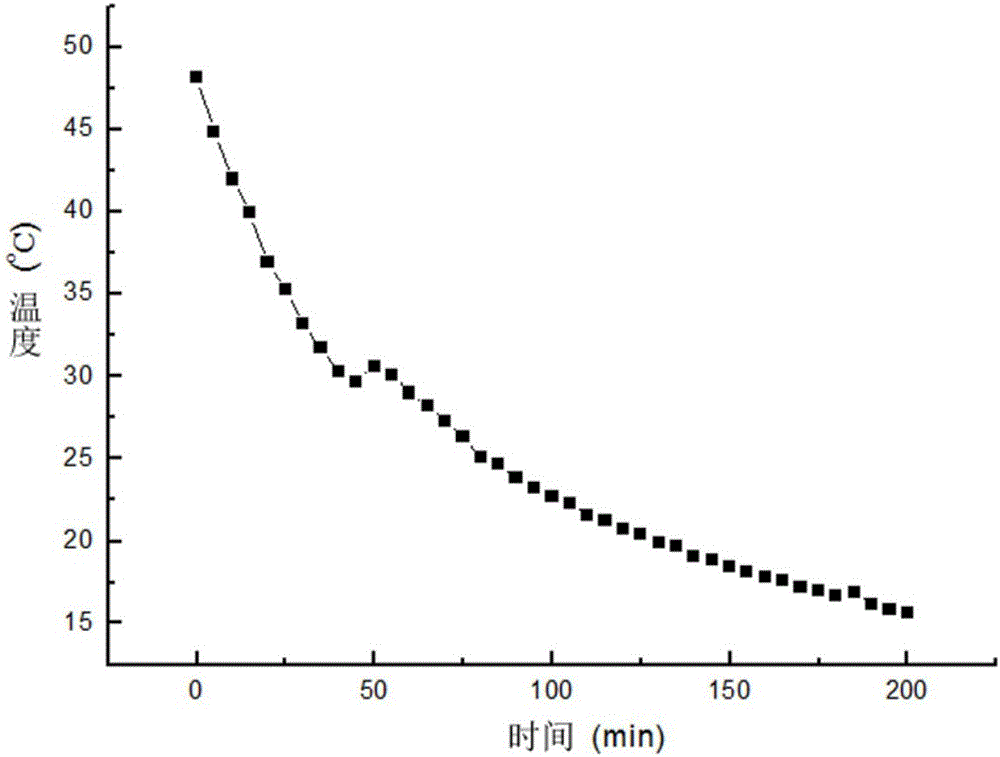

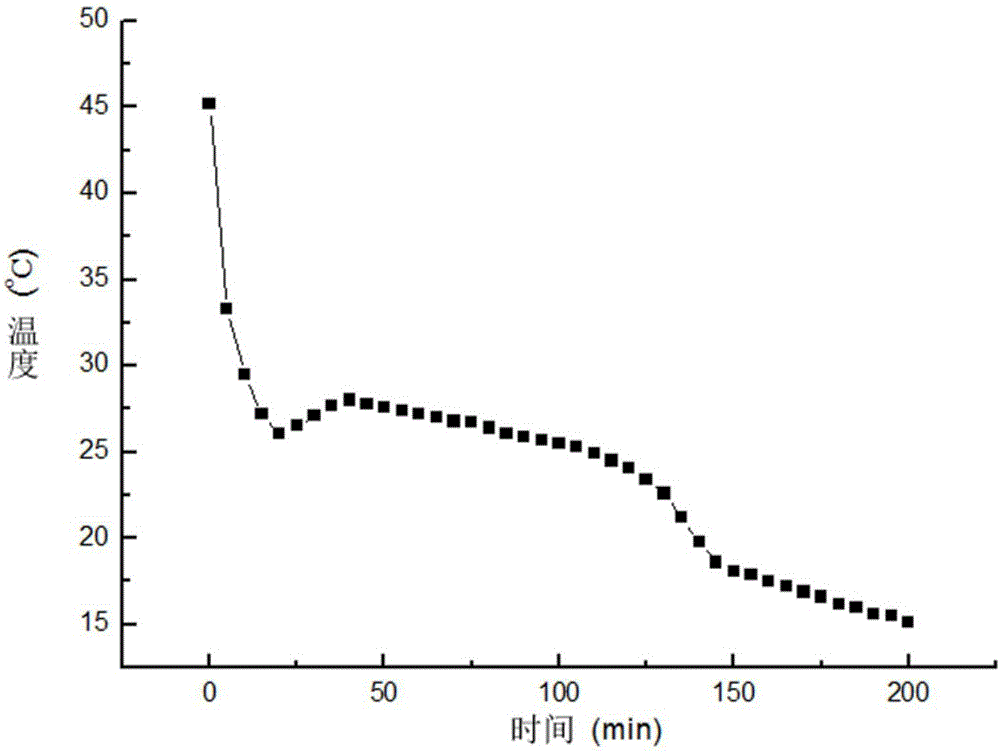

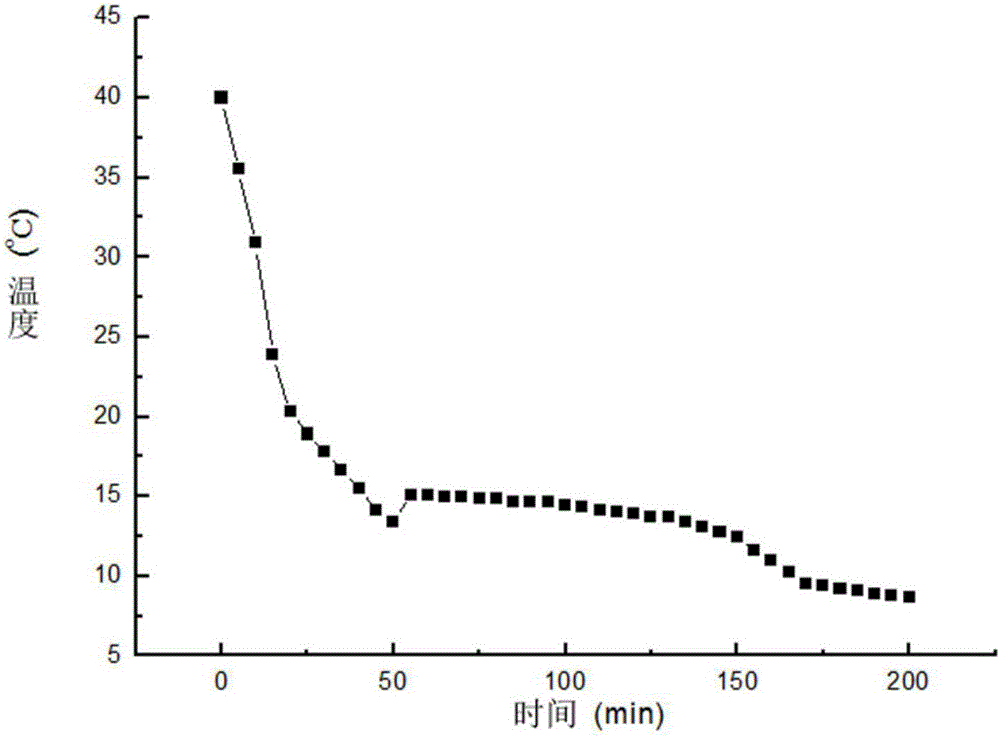

Agricultural low-temperature phase change heat storage material and preparation method thereof

ActiveCN105733517ASuitable for growthLower eutectic temperatureClimate change adaptationChemical industryDischarge efficiencyPotassium

The invention discloses agricultural low-temperature phase change heat storage material and a preparation method thereof. The preparation method specifically includes: mixing crystalized disodium hydrogen phosphate with water, and dissolving under 50-80 DEG C to obtain the aqueous solution of disodium hydrogen phosphate; adding potassium salt and ammonium salt, and dissolving under 30-80 DEG C to obtain mixed liquid; regulating the temperature of the mixed liquid to be 5-30 DEG C; screening the mixed liquid, and drying the screened substances in a blowing drying oven under 20-45 DEG C to obtain the agricultural low-temperature phase change heat storage material. The agricultural low-temperature phase change heat storage material prepared by the method has the advantages that the phase change temperature of the agricultural low-temperature phase change heat storage material is 15.1-34 DEG C, the phase change latent heat range of the agricultural low-temperature phase change heat storage material is 160-200J / g, the condensate depression of the agricultural low-temperature phase change heat storage material is 0.5-2 DEG C, and the agricultural low-temperature phase change heat storage material is high in heat storage and heat discharge efficiency; in addition, the agricultural low-temperature phase change heat storage material is simple in preparation method and applicable to cultivation in facilities such as an agricultural sunlight greenhouse, a multi-span greenhouse and a plastic single greenhouse.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

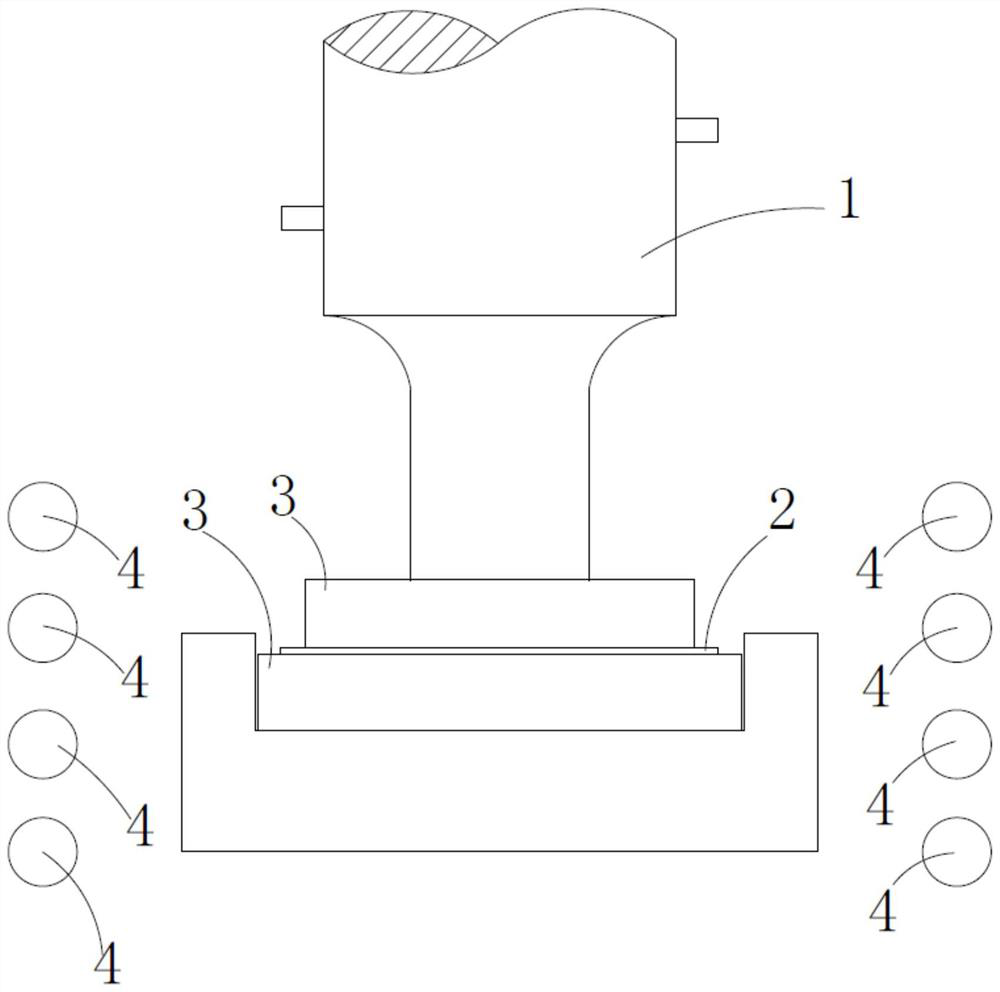

Two-step mode two-temperature transient liquid-phase bonding method for dissimilar metals

InactiveCN102303191APrevent melting and burningAvoid meltingWelding apparatusMelt temperatureDissimilar metal

The invention discloses a two-step mode two-temperature transient liquid-phase bonding method for dissimilar metals, wherein the eutectic temperature between an intermediate layer and high-melting point parent metal is 100-400 DEG C higher than that between the intermediate layer and low-melting point parent metal. The method comprises the following steps of: (1) welding one end of the intermediate layer to the high-melting point parent metal at the temperature T1 by using a transient liquid phase bonding method; and (2) welding the other end of the intermediate layer to the low-melting pointparent metal at the temperature T2, wherein the temperature T2 is lower than the melting temperature of the low-melting point parent metal. The two-step mode two-temperature transient liquid-phase bonding method for the dissimilar metals disclosed by the invention can be used for bonding between the dissimilar metals with significant difference for physical, chemical and metallurgical properties,in particular for bonding between the dissimilar metals with a melting point difference value of 300-700 DEG C, the bonding and the sufficient diffusion between the high-melting point parent metal and the intermediate layer are ensured to be realized, and meanwhile, the occurrence of melting and burning loss of the parent metal with a lower melting point in a welding process can be prevented, so that the effective bonding between dissimilar metal weldments is realized.

Owner:CHONGQING UNIV

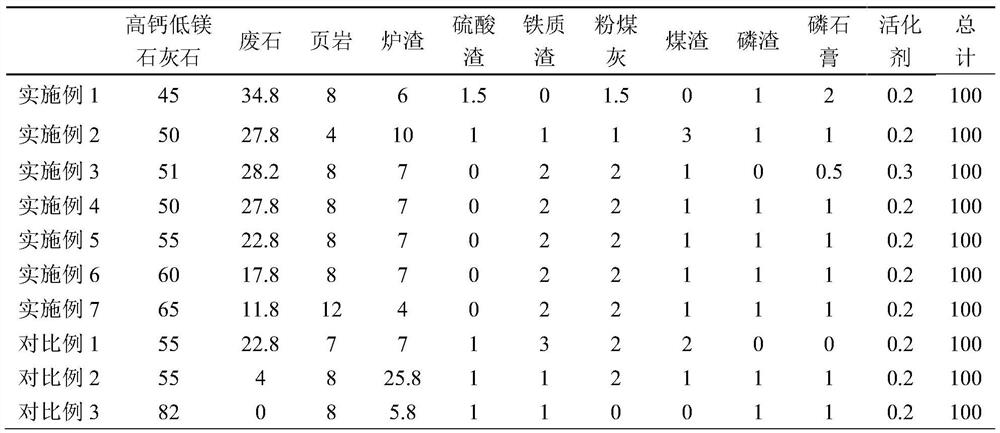

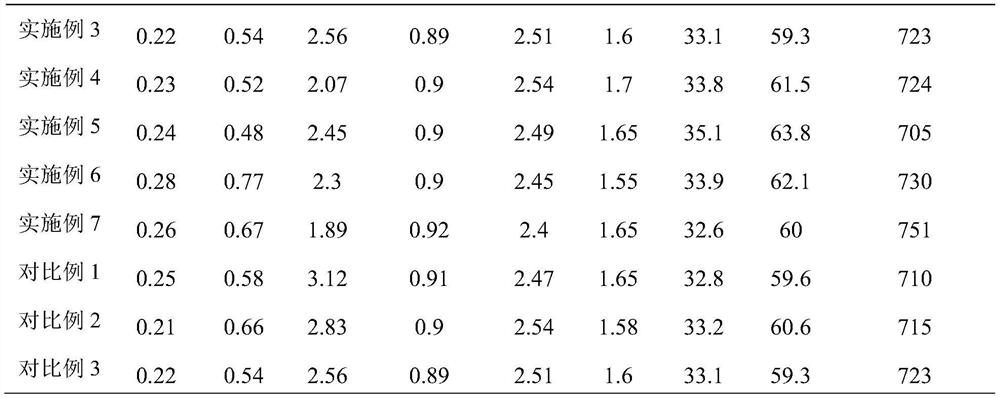

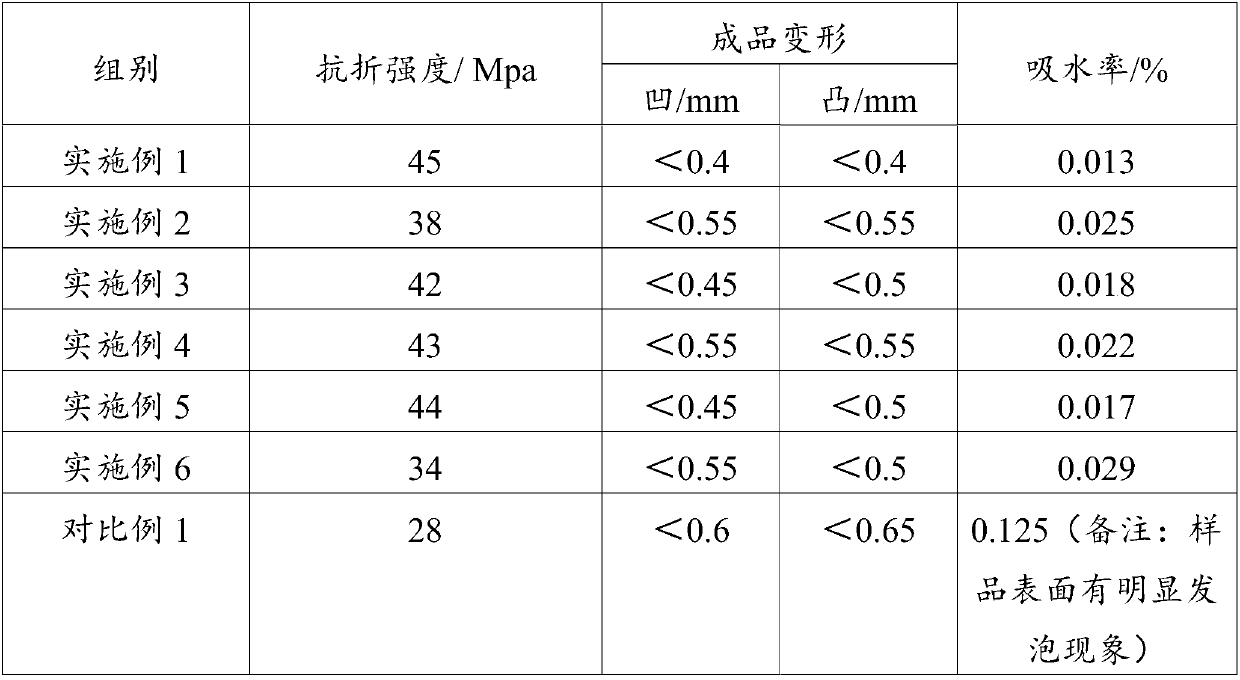

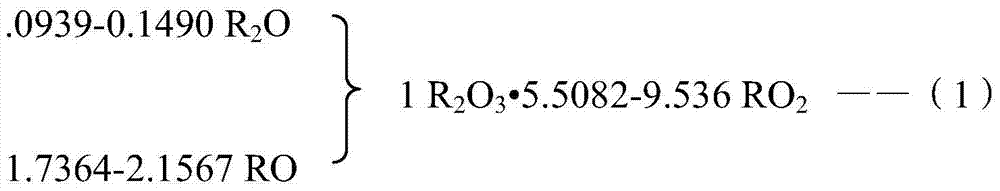

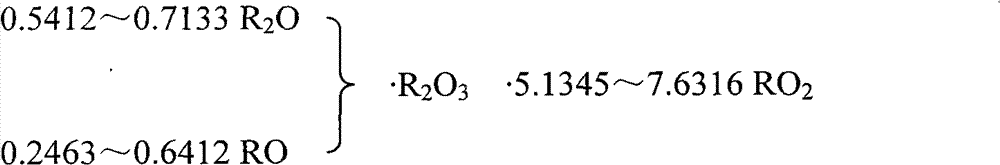

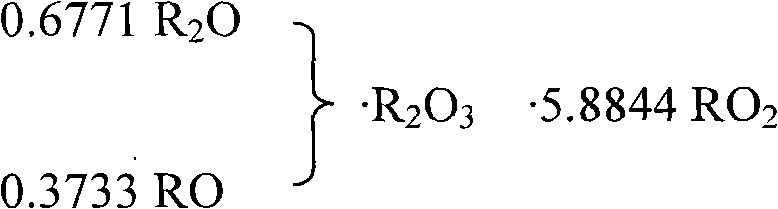

Resource-saving low-carbon cement clinker and preparation method thereof

The invention discloses a resource-saving low-carbon cement clinker and a preparation method thereof, and belongs to the technical field of Portland cement clinker production. The cement clinker comprises the following raw materials in percentage by mass: 45-70% of high-calcium low-magnesium limestone, 10-40% of barren rock, 4-12% of shale or sandstone, 4-12% of slag, 1-3% of sulfate slag or iron slag, 1-3% of fly ash, 0-3% of coal cinder or coal gangue, 0.5-3% of phosphorus slag and phosphogypsum and 0.1-0.3% of an added activating agent. According to the resource-saving low-carbon cement clinker and the preparation method thereof of the invention, a large amount of solid waste is utilized, the adopted industrial waste residue is formed by high-temperature calcination, carbonate hardly exists, and CO2 hardly occurs after high-temperature calcination is performed again; the mixing amount of the industrial waste residues is high, the use amount of limestone is greatly reduced; the mineralization of trace elements in the industrial waste residues is utilized, and the activating agent is added, so that the burnability of the raw materials is improved, the sintering stability of the clinker is reduced, and the performance of the clinker is improved; the firing temperature of the low-carbon cement clinker is reduced by 100-150 DEG C compared with the firing temperature 1450 DEG C of traditional Portland cement clinker, and therefore, the coal consumption is obviously reduced, and the emission of CO2 is reduced.

Owner:阳新娲石水泥有限公司

Low-temperature fast fired marble tile and preparation method thereof

The invention discloses a low-temperature fast fired marble tile. The low-temperature fast fired marble tile comprises raw materials in parts by weight as follows: 15-35 parts of ultrafine-particle marble tile edging waste, 15-25 parts of kalialbite, 15-30 parts of lithium china stone, 0-25 parts of low-temperature sand, 16-25 parts of clay and 3-10 parts of an auxiliary, wherein the ultrafine-particle marble tile edging waste is the waste produced in a marble tile edging procedure. The raw materials of the tile are easily available, the cost is low, product performance indexes of the low-temperature fast fired marble tile can be guaranteed, and by full use of the characteristics of low melting temperature and fine powder particle of the polishing waste as the waste raw material, sinteringtemperature of the product and energy consumption can be reduced while the waste is used. The invention further discloses a preparation method of the low-temperature fast fired marble tile. The marble polishing waste is separated with a simple process, content of impurities in the polishing waste is reduced, components of the polishing waste are more stable, and industrial production is facilitated.

Owner:清远市简一陶瓷有限公司 +1

Method for producing a clinker for hydraulic cement with low CO2 emission and high resistance

ActiveUS8715411B2Lower eutectic temperatureLower energy levelCement productionHigh resistanceOxygen content

A method for producing a clinker for cement, comprising grinding a raw flour comprising, especially, Al2O3, Fe2O3 and SO3 in contents such that the formula for calculating SO3 content of=0.261×Al2O3−0.638×Fe2O3+k, where 2.5<k<3.5, then by sintering flour in an overn wherein the temperature is between 1250° C. and 1350° C. and oxygen content is between 2.5% and 10% by volume.

Owner:CEMEX INNOVATION HLDG LTD

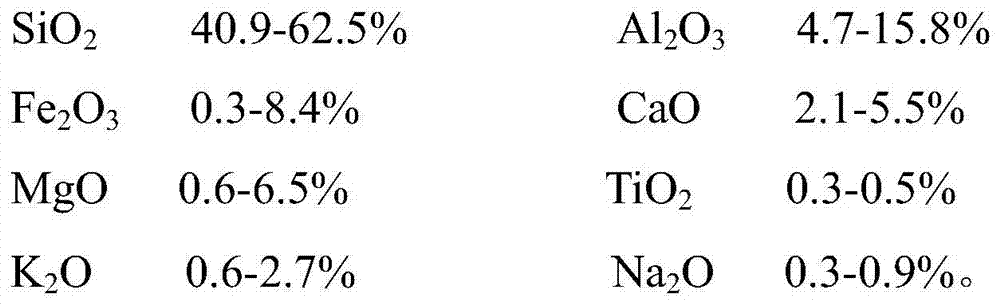

Fabrication process of low expansion Nixing pottery

ActiveCN106348728ALower eutectic temperatureLower sintering temperatureClaywaresUltimate tensile strengthThermal shock

The invention discloses a fabrication process of low expansion Nixing pottery. The process comprises the steps of blank preparation, blank forming, blank trimming, blank stoving and blank firing. The process of low expansion Nixing pottery is characterized in that the blank prepared from, by weight, 5-6 parts of east mud, 4-5 parts of west mud, 0.5-1 part of NiO, 1.5-2 parts of TiO2 and 1.5-2 parts of MgO. The Nixing dishes prepared through the fabrication process of low expansion Nixing pottery have the advantages of excellent thermal shock resistance, good mechanical strength and capable of being used in various heat sources directly without cracking even after being used for a long period. The Nixing pottery dishes prepared through the process of low expansion Nixing pottery can meet the requirements of QB / T2580-2002 <Fine ceramic cookware>.

Owner:钦州六艺龙窑坭兴陶有限公司

Citrate containing deicing compositions with improved eutectic temperatures

InactiveUS8808572B2Good proxyEffect melt performanceOther chemical processesCITRATE ESTERAqueous solution

Deicing compositions are described for reducing an amount of ice formed on a surface. The deicing compositions may include about 1 wt. % to about 15 wt. % of a salt of citric acid. The compositions may further include about 23 wt. % to about 28 wt. % sodium chloride when the deicing composition forms an aqueous solution.

Owner:ENVIROTECH SERVICES

Low zinc hot dipping aluminium alloy plating material containing Ca multi-combination metamorphism

InactiveCN103131986ALower eutectic temperatureIncrease wetting and fusion abilityHot-dipping/immersion processesExtensibilityLiquid viscosity

The invention discloses low zinc hot dipping aluminium alloy plating material containing Ca multi-combination metamorphism. The composition of alloy comprises, by element weight, 10%-13% of Zn, 5.0% of alloy enhancer Cu, 0.03 % of polarization metamorphic agent Ca, 0.2 % of solvent passivator Mo and 0.5% of rare earth addition, and the rest of the composition of the alloy are A1 and micro impurities which are unavoidable. The low zinc hot dipping aluminium alloy plating material containing the Ca multi-combination metamorphism solves the problems that due to dissolution of iron in a hot dipping plating process, zinc liquid viscosity is enabled to be increased and the capability of the surface of an infiltrating steel matrix is reduced, the thickness of a zinc layer is obviously increased due to the fact that iron content in zinc liquid is increased, and therefore ductility and the appearance of the a plating layer are enabled to be poor, and other problems are solved too. The aluminium alloy plating material for hot dipping is obtained, wherein the aluminium alloy plating material for hot dipping is good in matrix wettability, strong in binding force, high in strength, good in extensibility, high temperature-resistance, thin in plating layer, and strong in corrosion resistance.

Owner:贵州铝厂有限责任公司

Method for joining metals

InactiveUS20100147929A1Reduce capillary forceLower eutectic temperatureBuilding constructionsDomestic vesselsMetalCoating

A method for joining two large metal surfaces together by inserting a gasket or coating between two sheets of metal and heating to a temperature above the eutectic temperature of gasket or coating and the metal surfaces. This heating will cause the metal surfaces to fuse weld together while being heated to a point below their melting point

Owner:LINDE NORTH AMERICA

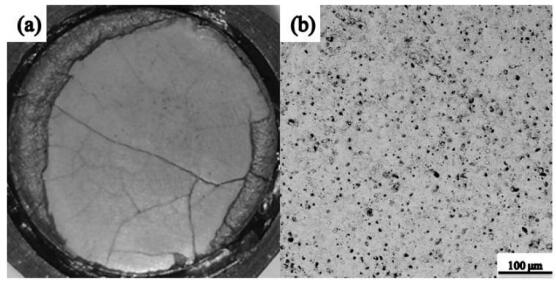

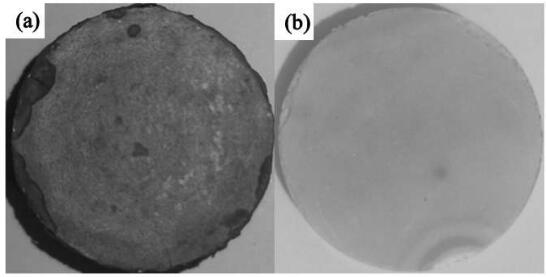

Glazed ceramic tile and its preparation method

ActiveCN105130394BHigh strengthWide firing temperature rangeCeramic materials productionClaywaresWollastoniteCompressive strength

The invention discloses a glazed ceramic tile and a preparation method thereof. The glazed ceramic tile is prepared by processing a blank material and glaze, and the blank material comprises the following compositions in percent by weight: 50-75% of anaerobic digestion sludge, 10-25% of clay, 5-15% of wollastonite, and 5-10% of talcum. The glazed ceramic tile preparation method comprises preparing blank and glaze, forming a green body, drying, biscuiting, glazing the green body, performing glaze firing on the green body, and the like. The green body of the glazed ceramic tile is high in strength and small in shrinkage degree when being biscuited, the biscuiting temperature scope of the green body is expanded, and phenomena that the green body surface foams, generates black hearts and is reduced in compressive strength and the like because of too large ignition loss are effectively avoided. The glazed ceramic tile preparation method enables the glazed ceramic tile surface to be solid, flat, free of black heart phenomenon, and high in strength, and also the preparation method is simple and easily controllable in technology, high in yield and high in production efficiency, and production cost is effectively reduced.

Owner:深圳市正源清环境科技有限公司

Production process of powder sintered alnico permanent magnet alloy

The invention discloses a production process of powder sintered alnico permanent magnet alloy, which is characterized in that the steps are as follows: step 1, weighing materials: weighing Co 24.5-26%, Ni 13.5-14.5%, Cu 2 by weight percentage ‑3%, Al 8‑9%, Nb 0‑0.5%, Ti 0‑0.5%, B 0‑0.3%, Fe 46.2‑52%; Step 2, vacuum melting; Step 3, initial mixing; Step 4, again Mixing; step five, pressing; step six, sintering: the pressed product is sintered in a vacuum sintering furnace for 8 stages, and then cooled to obtain a sintered product; step seven, heat treatment; step eight, tempering. The present invention improves the magnetic properties, and the magnetic properties Br of the finished product produced by the present invention can reach 1232mT, Hcb can reach 53.4kA / m, and BHmax can reach 37.6kJ / m 3 .

Owner:杭州科德磁业有限公司

Manufacturing Technology of Low Expansion Nixing Pottery

ActiveCN106348728BLower eutectic temperatureLower sintering temperatureClaywaresUltimate tensile strengthThermal shock

The invention discloses a fabrication process of low expansion Nixing pottery. The process comprises the steps of blank preparation, blank forming, blank trimming, blank stoving and blank firing. The process of low expansion Nixing pottery is characterized in that the blank prepared from, by weight, 5-6 parts of east mud, 4-5 parts of west mud, 0.5-1 part of NiO, 1.5-2 parts of TiO2 and 1.5-2 parts of MgO. The Nixing dishes prepared through the fabrication process of low expansion Nixing pottery have the advantages of excellent thermal shock resistance, good mechanical strength and capable of being used in various heat sources directly without cracking even after being used for a long period. The Nixing pottery dishes prepared through the process of low expansion Nixing pottery can meet the requirements of QB / T2580-2002 <Fine ceramic cookware>.

Owner:广西千叶科技有限公司

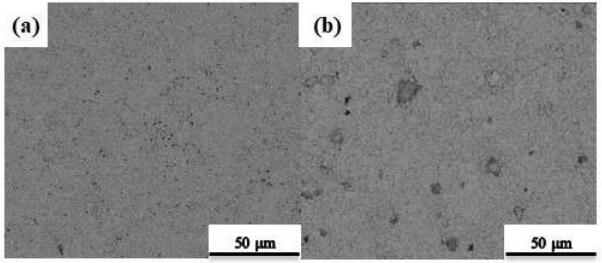

A method for large-scale preparation of hfo2-tho2 ultra-high temperature oxide composite ceramics

ActiveCN113943156BMaximize high temperature performanceOvercome adverse phenomena such as ion conductionCeramic sinteringCompression molding

The invention discloses a large-scale preparation of HfO 2 ‑ThO 2 The method for ultra-high temperature oxide composite phase ceramics comprises the following steps: HfO 2 Powder, ThO 2 powder and sintering additives are mixed to obtain mixed powder, granulated to obtain powder, and the powder is molded to obtain a composite ceramic green body, and then sintered in an oxidizing atmosphere to obtain HfO 2 ‑ThO 2 Ultra-high temperature composite phase ceramics; the compression molding adopts secondary pressure holding; the invention provides a kind of HfO under normal pressure for the first time 2 ‑ThO 2 A method for sintering and densifying ultra-high temperature oxide multi-phase ceramics. The inventors found that in the presence of sintering aids, the green body obtained by using the second pressure during the pressing process can be sintered in an oxidizing atmosphere to obtain a dense HfO 2 ‑ThO 2 Ultra-high temperature oxide composite ceramics. The preparation method of the present invention can realize low-cost and large-scale production because the sintering is carried out under normal pressure without special equipment.

Owner:CENT SOUTH UNIV

Flux-cored aluminum brazing filler metal and preparation method thereof

ActiveCN112621015AReduce generationLow melting pointWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention discloses flux-cored aluminum brazing filler metal which comprises a brazing flux core and aluminum-based brazing filler metal. The brazing flux core is wrapped with the aluminum-based brazing filler metal. The flux-cored aluminum brazing filler metal comprises, by mass percent, 2.1%-9.2% of AlF3 powder, 1.7%-7.5% of CsF powder, 1.2%-5.3% of KF powder, 11%-25.3% of alloy powder, 4%-8% of Si powder and the balance aluminum-based brazing filler metal. The invention further discloses a preparation method of the flux-cored aluminum brazing filler metal. According to the flux-cored aluminum brazing filler metal, an aluminum-silicon eutectic reaction occurs in the brazing process, the melting point is low, fluidity and spreadability are good, and the brazing seam strength is high.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD

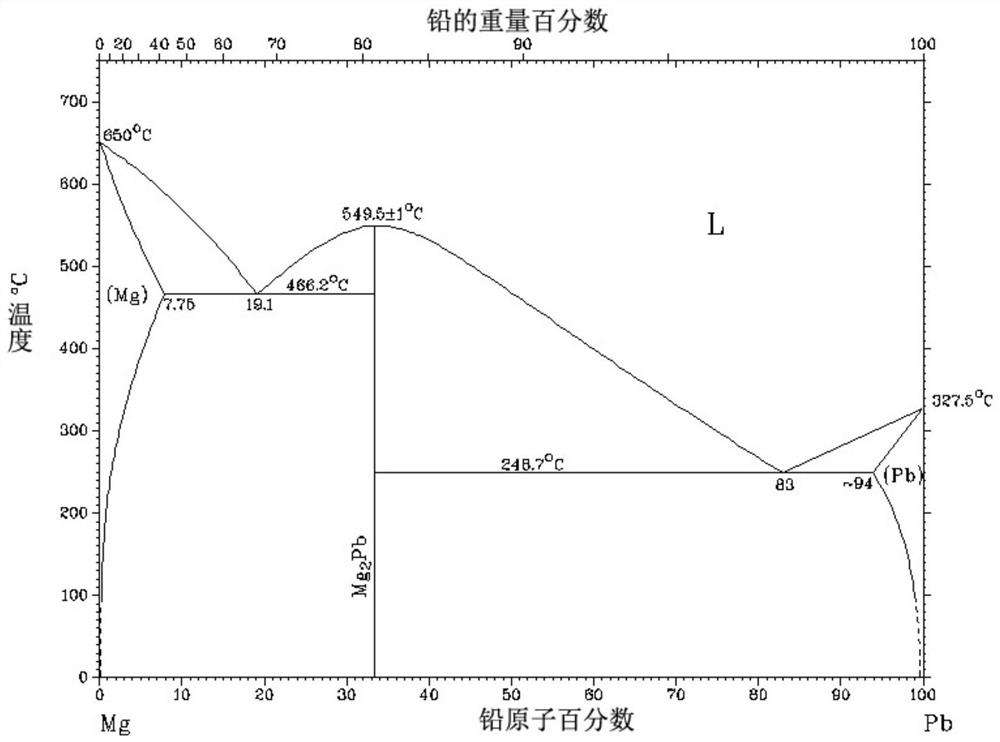

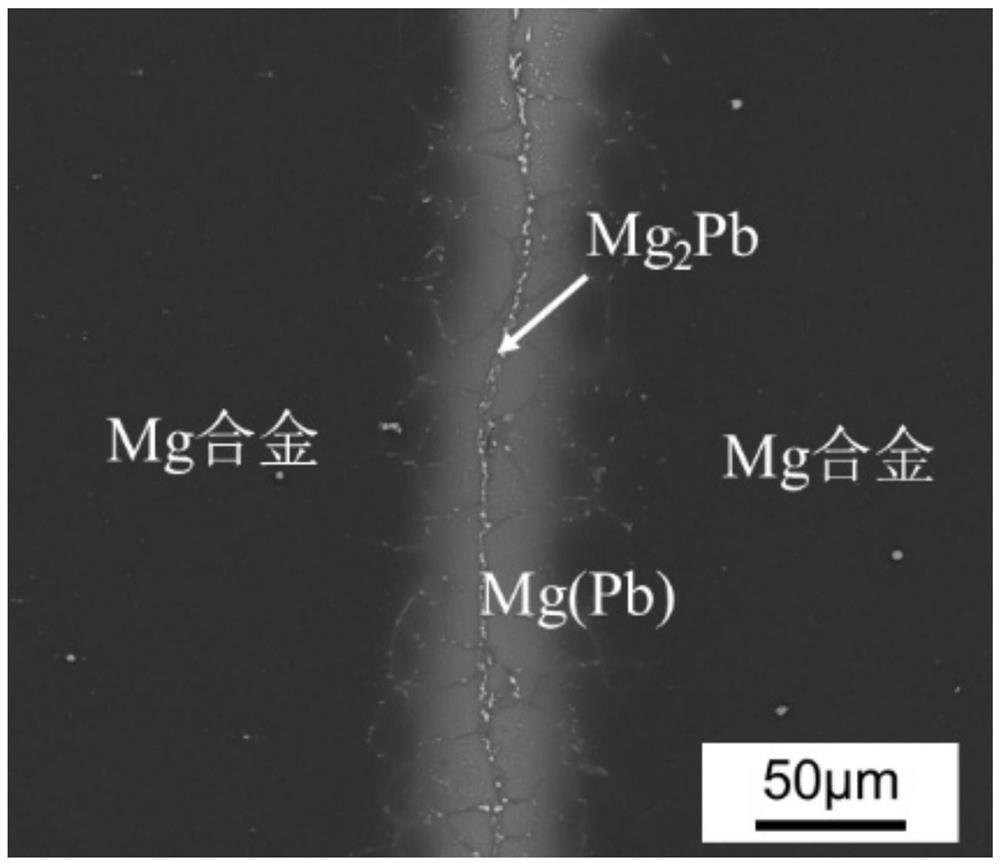

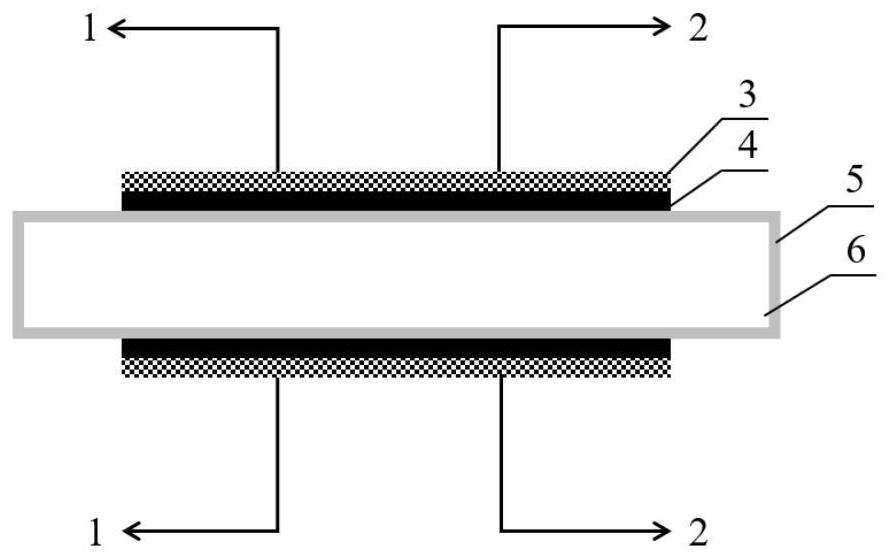

A kind of ultrasonic-assisted welding method of magnesium alloy with pure Pb as intermediate reaction material layer

ActiveCN109396634BImprove mechanical propertiesShort welding timeNon-electric welding apparatusFiller metalMechanical property

The invention discloses a magnesium-alloy ultrasound-assisted welding method by using pure Pb as an intermediate reaction material layer. Through the screening of the design conditions of the intermediate reactive material layer, the pure Pb foil is selected as the intermediate reaction material layer and is welded with the magnesium alloy; the pure Pb foil used as the intermediate reaction material layer is beneficial to reduce the welding temperature; the welding is completed in the atmosphere environment without the assisting of brazing filler metals; the welding method is green and environmentally friendly; only a small amount of brittle intermetallic compounds are produced during the welding process; and a full-Mg based solid solution joint is obtained. The welding time is short, thejoint has a high mechanical property and the welding effect is good.

Owner:东莞市新玛博创超声波科技有限公司

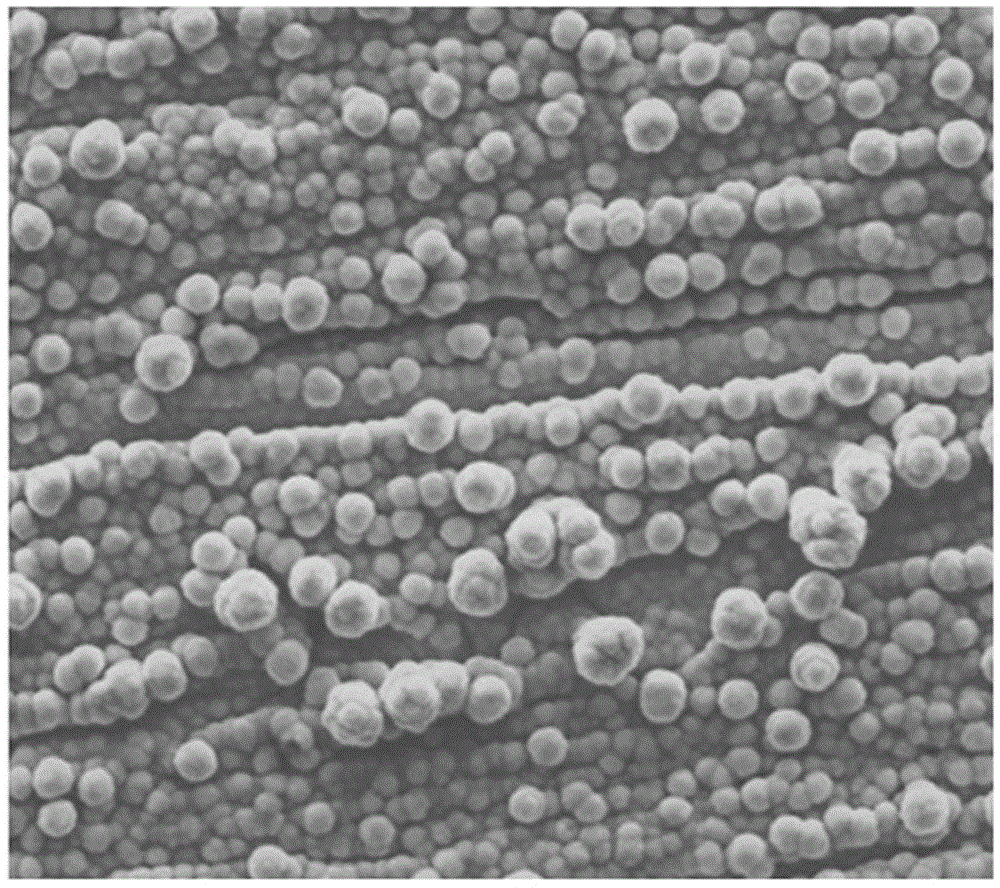

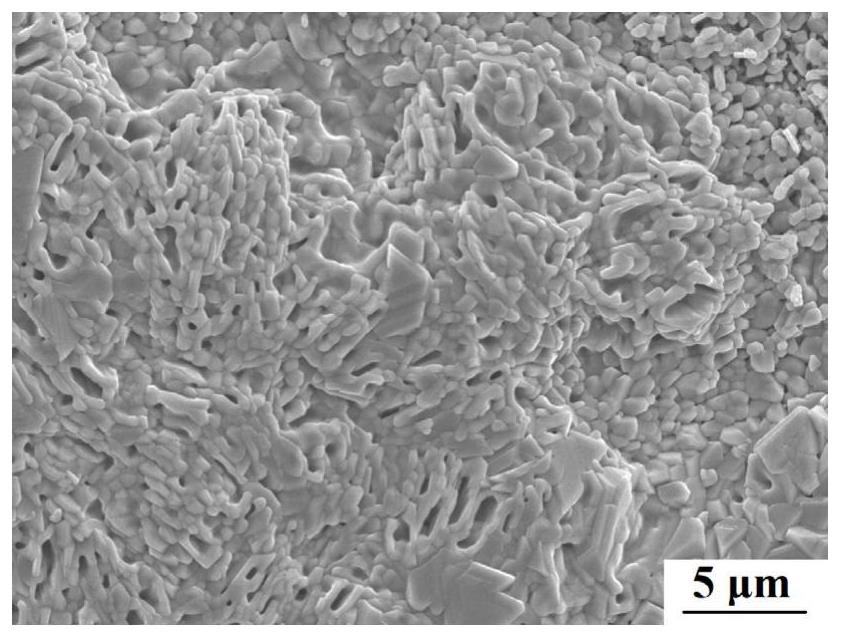

Method for preparing (Mn, Co) 3O4-Li2O coating through liquid phase sintering and application

PendingCN114284510AImprove antioxidant capacityEvenly distributedCell electrodesFuel cellsFluid phasePhysical chemistry

The invention provides a method for preparing a (Mn, Co) 3O4-Li2O spinel coating through liquid phase sintering and application of the (Mn, Co) 3O4-Li2O spinel coating. According to the method, through liquid phase sintering, the densification pre-reduction temperature of the (Mn, Co) 3O4 coating is reduced by adding low-melting-point metal salt LiNO3; according to the method, the coating sintering process of pre-reduction and re-oxidation is adopted, the microstructure of an original material can be rearranged in the sintering process to form new nano particles, particle distribution is more uniform, the uniform microstructure has high hindering capacity on overgrowth of crystal grains, and the oxidation resistance of the coating can be improved.

Owner:SHENHUA NEW ENERGY CO LTD +1

A kind of sintered NdFeB magnet and its preparation method

ActiveCN107845467BImprove corrosion resistanceReduce weightlessnessInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementTempering

The invention discloses sintered neodymium iron boron magnet steel which comprises, in weight percent, 27.5-30.5wt% of rare earth element R, 0.5-1.0wt% of Al, 0.03-0.06wt% of Pr, 0.03-0.06wt% of C, 0.35-0.5wt% of Cu, 0.08-0.12wt% of Nd, 0.2-0.4wt% of Ga, 0.2-0.5wt% of Pm, 0.6-1.2wt% of Co, 0.75-1.35wt% of B and the balance Fe. The rare earth element R is mixture of Ce, Ho, Sm, Dy and Tm, and the mixed weight ratio of Ce, Ho, Sm, Dy to Tm is 5:4:1:0.3:2. The invention further discloses a preparation method of the magnet steel. The preparation method is easy to operate, Ho and the rare earth elements such as Ce, Sm, Dy and Tm are added, part of expensive Nd and Pr is replaced, cost is reduced, corrosion resistance of the sintered neodymium iron boron magnet steel can be effectively improvedby adding Ho, weightlessness is reduced, Ce replaces Nd, eutectic temperature is reduced, so that sintering tempering temperature is reduced, cost is saved, and good performances are kept.

Owner:ZHEJIANG ZHONGHANG NEW MATERIAL

Ultra-low temperature sintered ceramic tiles and preparation method thereof

ActiveCN101979359BWide sintering temperature rangeOvercome the defect of easy deformationMetallurgyPerformance index

The invention discloses ultra-low temperature sintered ceramic tiles and a preparation method thereof. The green tiles have a composite solvent system, so eutectic point is improved; the advanced sintering and gradual occurrence of a liquid phase with high viscosity in areas at different sintering temperatures reduce the sintering temperature greatly and enlarges the range of the sintering temperature of the green tiles; and thus, the performance indexes of the product are guaranteed. The preparation method of the invention fulfills the aim of energy conservation and consumption reduction, greatly reduces the emission of CO2 waste gas, can create economic and social benefit, has a great significance for protecting natural environment and contributes to the sustained development of industrial production.

Owner:JINGDEZHEN CERAMIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com