Resource-saving low-carbon cement clinker and preparation method thereof

A low-carbon cement clinker, resource-saving technology, applied in cement production and other directions, can solve the problems of pollution, waste rock and waste residue not being effectively disposed of, and occupying land and environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

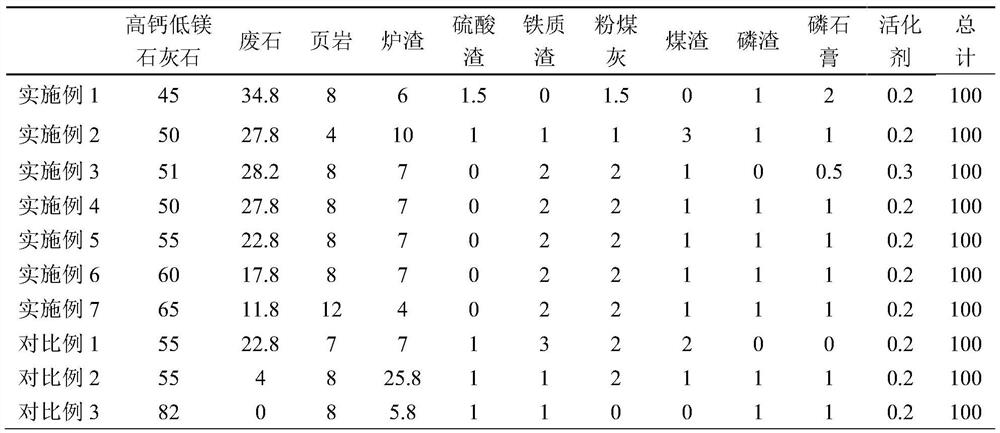

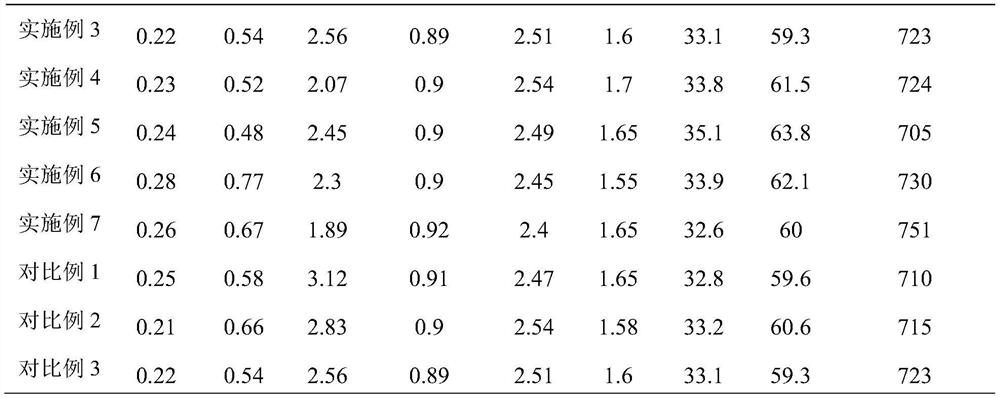

Examples

preparation example Construction

[0040] The preparation method of the resource-saving low-carbon cement clinker comprises the following steps:

[0041] S1. Weigh the raw materials, mix them according to the weight percentage, dry them, put them into the raw meal mill, and grind them into raw meal powder. Mixed fine powder A with less than 15% remaining and less than 1.5% sieved at 200 μm; Among them, the sandstone and shale in the raw materials are stacked according to the quality, crushed and pre-homogenized for later use, and the coal is stacked according to the quality and pre-homogenized spare;

[0042] S2. Put the mixed powder A in a rotary kiln and calcinate at 1300-1350° C. for 30-60 minutes. After the clinker is calcined, enter the cooling machine to cool down rapidly to obtain cement clinker B.

[0043] The above method is applied to the new dry process clinker production line, the scale of the production line is 4000-10000t / d, the raw material mill adopts vertical roller mill, and the preheater is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com