Patents

Literature

114results about How to "Improve burnability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fuel for firing into rotary kiln cement clinker

A fuel which is used for rotary kiln cement clinker firing is composed of raw materials with the following weight percentage: coal 3-80, straw substances 0-90, forest products wastes 0-95 and food industry by-product residues 0-70. The straw substances refer to rice straws, wheat straws, cotton stalks, sesame stalks, soybean straws, corn stalks, sorghum stalks, rice husks, peanut shells, soybean shells and corn sticks, the forest products wastes refer to defective bamboo, wood, tree branches, leaves, shrubs, faggot straws and sawdust and wood wool corner scrap materials in the bamboo and wood-processing industry, the food industry by-product residues refer to bran, wheat skin, squeezing meal cake, bean dregs and wine lees, and the coal refers to bituminite, anthracite and coke coal powder. The flue raw materials which are used for the rotary kiln cement clinker firing have wide selecting range, simple preparation, convenient use and rapid burning speed and are beneficial for protecting atmosphere circumstances.

Owner:吴飞龙

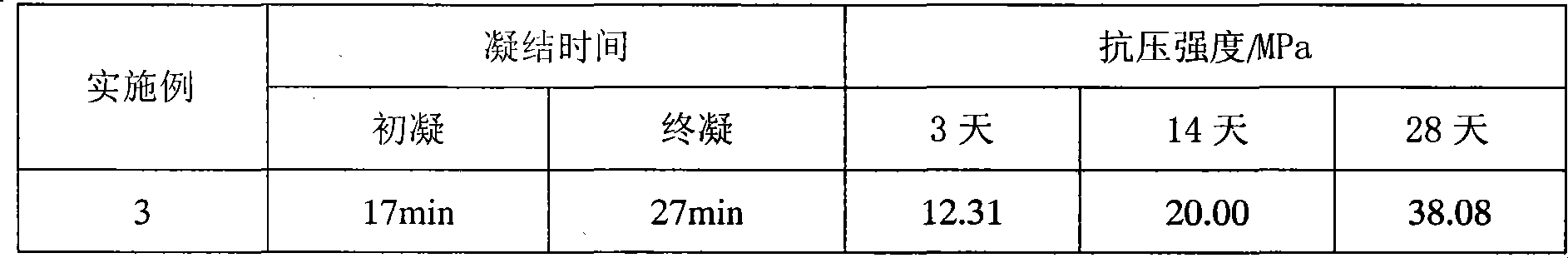

Method for producing sulphate aluminum cement

The invention relates to a method for producing sulphate aluminum cement. The method comprises the following steps: preparing cement raw meal by proportioning limestone, phosphogypsum, low grade alumina and coke; uniformly grinding and calcining at high temperature; in the calcining process, promoting phosphogypsum to be decomposed as much as possible; replacing partial limestone by calcium oxide generated by decomposition; collecting sulfur dioxide to prepare sulfuric acid; and adding natural dihydrate gypsum in the cement clinker and grinding to prepare a cement product. Compared with the existing conventional production methods, according to the method, the utilization of phosphogypsum can be greatly improved, the utilization concentration of sulfur dioxide discharged by decomposition of little gypsum in the production process can be guaranteed to be reached, the use level of limestone is further reduced and emission of carbon dioxide is reduced. Cement calcined is wide in adaptability, can be widely applied to production of sulphate aluminum cement by phosphogypsum, and further can be suitable for producing high early strength cement, expansive cement and the like.

Owner:CHONGQING UNIV

Manufacture of sulphur aluminate cements with electrolytic manganesium residue and method of manufacturing the same

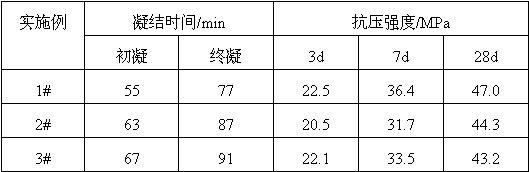

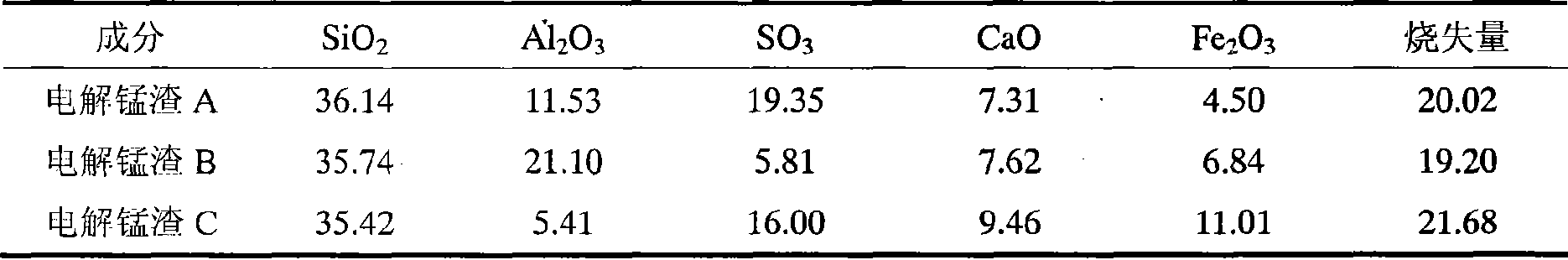

A sulphate-aluminium-like cement produced by using electrolytic manganese slag and the preparation method of the cement relate to the production of the sulphate-aluminium-like by using industrial wastes and the preparation method of the cement. The raw materials of the cement clinker of the invention contain limestone, electrolytic manganese slag, kaolin and soft coal, and dihydrate gypsum is added to the fired cement clinker; the preparation method comprises the following steps: using the limestone, electrolytic Manganese slag, kaolin and soft coal as the raw materials of the clinker; first, levigating and homogenizing the raw materials, and calcining the raw materials into the clinker at a relatively low temperature; then adding the dihydrate gypsum to the clinker according to the requirement and then levigating the mixture to be the finished product. The cement is characterized in that the firing temperature ranges from 150 DEG C to 200 DEG C which is lower than that of the common Portland cement, and the energy-saving advantage is obvious; the mixture proportion range of the components is wide; the mixing amount of the manganese slag is great; and the fired cement has wide application, and so on. The preparation method can be widely used for producing the sulphate-aluminium-like cement by using electrolytic the manganese slag, and is in particular applicable to the production of early strength cement, rapid-hardening high-strength cement, expansive cement and low-alkali cement, and the like.

Owner:CHONGQING UNIV

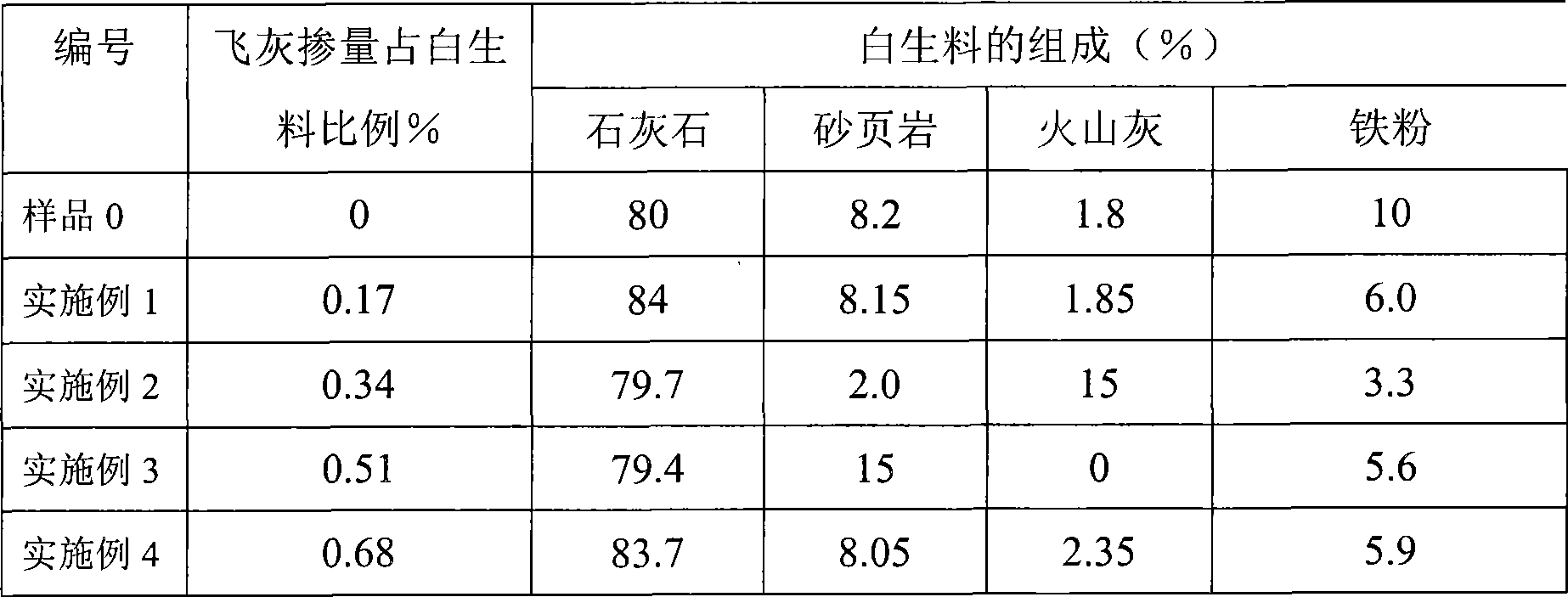

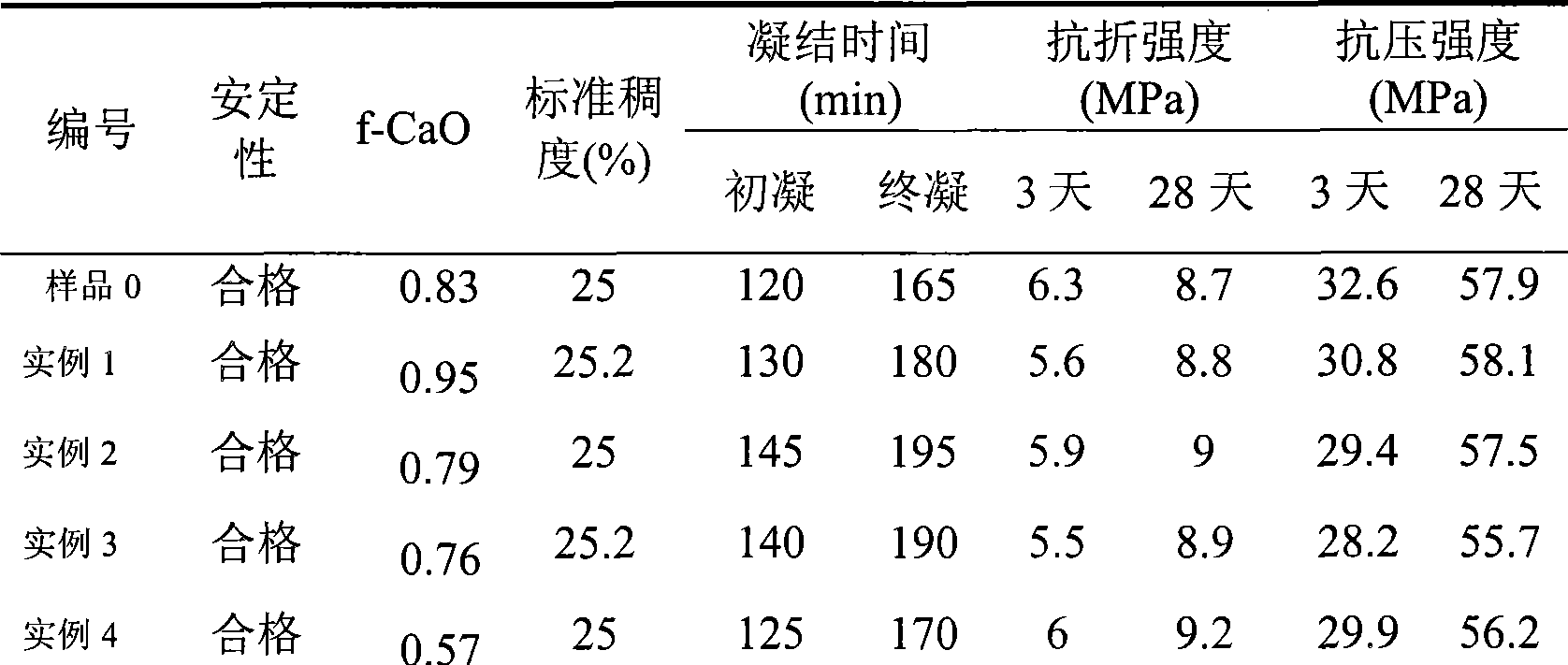

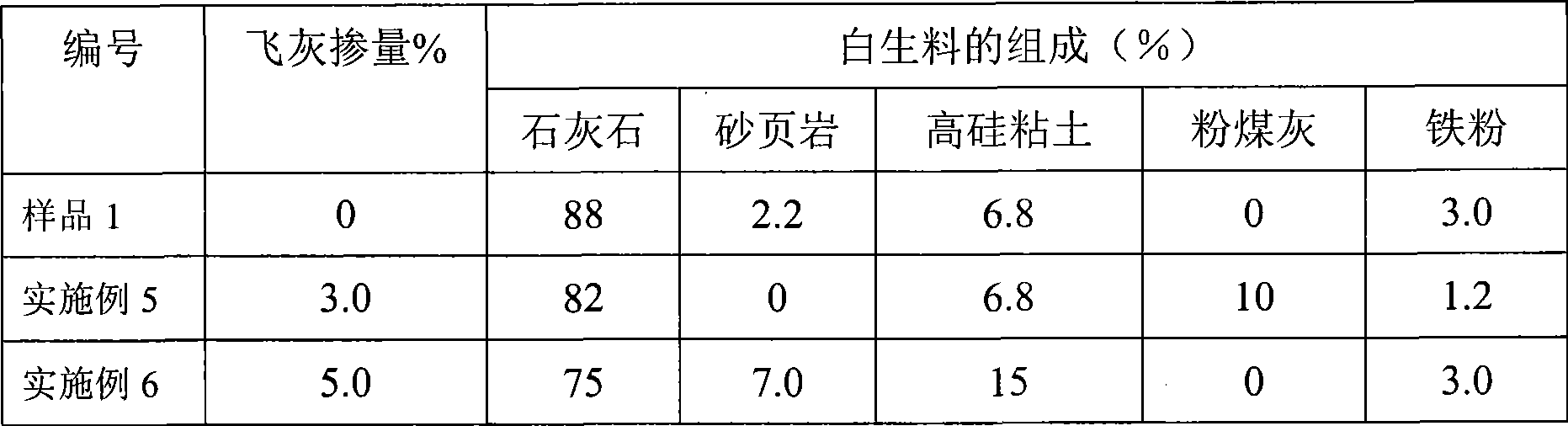

Method for producing portland cement clinker using domestic waste flying ash

The invention relates to a method for producing Portland cement clinker with incineration slag of municipal solid waste. The method solves the problem of crust and blockage caused by chlorine through the reconstruction of the prior kiln which is realized by mounting a by-way air exhaust device. For a kiln system with a kiln row and a furnace row which are independent from each other, the by-way air exhaust device is arranged in an uptake of a kiln end gas chamber in the kiln row close to a five-stage cylinder; while for common industrial kiln, the air exhaust device is arranged between an outlet of decomposing furnace and an inlet of the five-stage cylinder or arranged at an uptake of an outlet of the five-stage cylinder; the fly ash passes through a kiln head, the kiln end gas chamber, or the decomposing furnace and then is sprayed into the kiln. The use frequency of the by-way air exhaust device is between once per four hours and once per three days, the temperature of the air entering the by-way air exhaust device is controlled to be more than 950 DEG C. the method has the advantages of small reconstruction investment, low treatment cost, production of Portland cement clinker having wide application range and meeting JC / T853-1999 standards of Portland Cement Clinker, realization of reclamation, contribution to the development of cyclic economy, and reduction in consumption of natural resources and energy of the cement industry.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing cement clinker by using oil shale waste residues

The invention discloses a method for preparing cement clinker by using oil shale waste residues. The method comprises the following steps of: 1, mixing the following components according to the following proportions: 81 to 84 percent of limestone, 12 to 15 percent of shale waste residues, 1 to 2 percent of iron tailings sand and 2 to 4 percent of moulding sand; and 2, grinding the mixture obtained in the step 1 to obtain raw materials which is screened by a 80um square-hole sieve of which the screen residue is less than 5 percent, calcining the raw materials at temperature of between 1,350 and 1,450 DEG C for 15 to 20 minutes, and cooling to obtain the cement clinker. The method is used for preparing the cement clinker by using the oil shale waste residues replacing clay, so that a large quantity of clay resources are saved, and the production cost of the cement is reduced; furthermore, the doped quantity of the oil shale waste residues is large and up to 13 percent, so that the oil shale waste residues are used fully; therefore, the economic benefit is increased, wastes are turned into treasures, a large quantity of stacked residues are avoided, the land occupied amount is reduced, and the environment pollution is reduced.

Owner:FUSHUN MINING IND GROUP

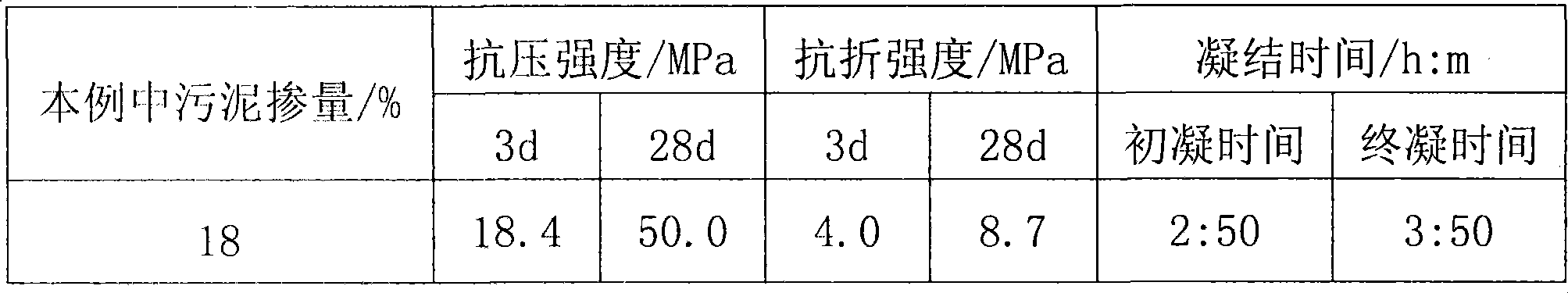

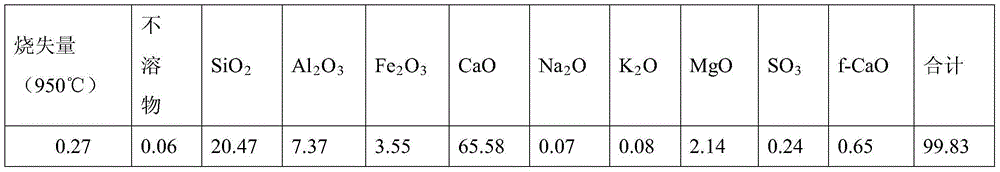

Method for recycling sludge of sewage plant to produce cement

InactiveCN101376573AQuality assuranceAvoid it happening againSludge treatmentCement productionChemical LinkageClay minerals

The invention relates to a method which is used for directly applying the settled sludge of a wastewater treatment plant to the cement production after treatments of iron removing, sterilization and deodorization, dehydration and drying. The method comprises the following steps: firstly, the iron of the sludge is removed; secondly, the sludge is sterilized and deodorized; thirdly, the sludge is dehydrated and dried; fourthly, the mixture amount of the sludge is determined; fifthly, the sludge enters a kiln system for calcining; and sixthly, the clinker obtained by the incineration and gypsum are mixed and made into cement by a cement grinding mill. The method adopting the invention has the following advantages: firstly, the resource utilization of the sludge is realized, a large amount of clay mineral is economized, and the precious land resource is saved; secondly, the abundant heat value of the sludge can be effectively utilized, and the coal resource can be economized; thirdly, the harmless treatment is carried out to the sludge at the temperature higher than 1450 DEG C, both the organic matters and the inorganic matters in the municipal sludge can be cracked and calcined into harmless matters, and the possibilities of producing poisonous gases and waste residues are avoided during the low temperature treating process; fourthly, the heavy metals in the municipal sludge are dissolved in the portland cement clinker minerals in a solid way, and are tightly combined with the cement ingredients by chemical bonds, and the heavy metal pollution phenomenon cannot happen under the usual conditions; and fifthly, the mixed and burnt sludge does not increase the clinker calcination difficulty and does not reduce the cement strength, but also has a certain mineralization promoting effect on the cement clinker calcination to a certain extent.

Owner:ZHENGZHOU UNIV

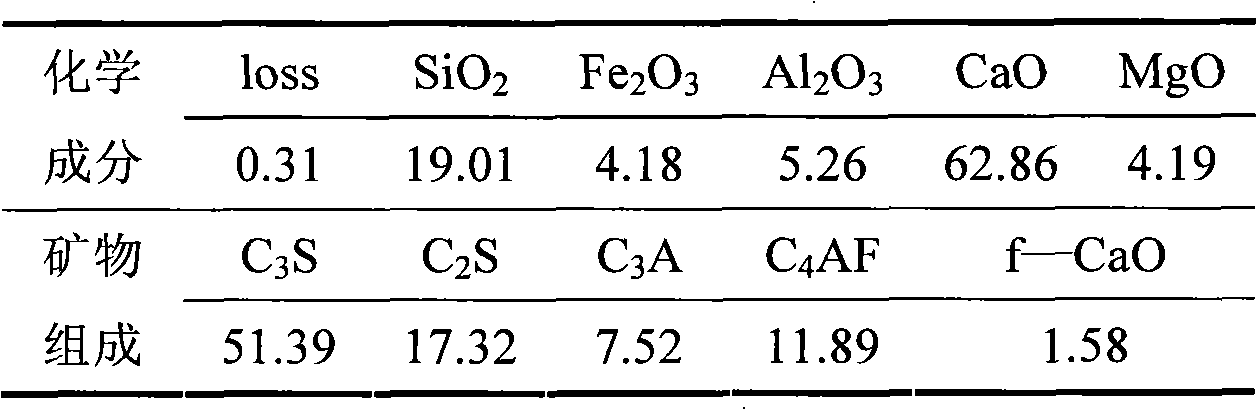

Method for producing cement clinker from stainless steel cold rolling dewatered sludge ingredient

InactiveCN101475325ACalcination temperature is lowBurn completelySludge treatmentWaste water treatment from metallurgical processAdditive ingredientPulverized fuel ash

The invention relates to a method for producing cement clinker through utilization of a stainless steel cold-rolled dehydrated sludge ingredient. The method comprises that: stainless steel cold-rolled dehydrated sludge and other materials of a cement green stock are evenly mixed to prepare the cement green stock; the cement green stock comprises the following compositions in percentage by weight: 70 to 79 percent of limestone, 10 to 14 percent of clay, 1 to 8 percent of the stainless steel cold-rolled dehydrated sludge, 5.3 percent of coal ash, 0 to 3 percent of iron ore powder and 0 to 0.5 percent of gypsum; and the prepared cement green stock is sintered to form silicate cement clinker. The obtained cement clinker and a corresponding cement product have no essential difference with the prior silicate cement clinker and a cement product in composition and performance; the quality of the cement clinker and the corresponding cement product meets the index requirement of national corresponding product standard and can be used as a normal high-quality commodity; and the method effectively utilizes and processes industrial sludge containing harmful metal elements, achieves the effects of resource optimization and utilization and has remarkable environment-friendly benefit.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD +1

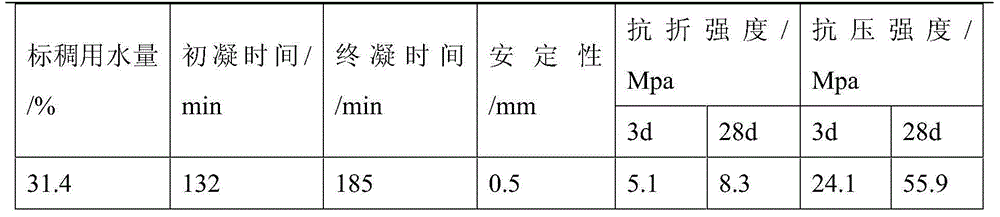

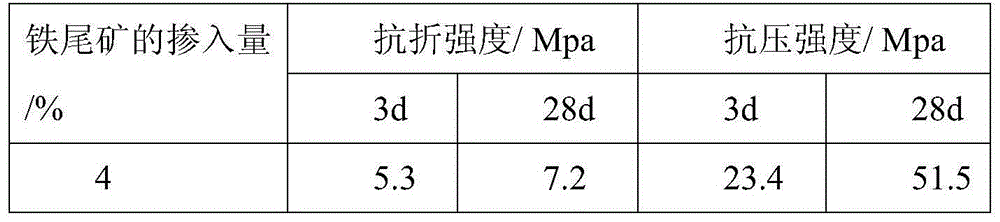

Preparation method for Portland cement with iron tailings

The invention provides a preparation method for Portland cement with iron tailings. The Portland cement comprises at least the following raw materials in percentage by weight: 60-70% of calcium oxide, 12-20% of silicon oxide, 5-20% of the iron tailings and 3-6% of aluminium oxide. The preparation method comprises the following steps: weighing the raw materials according to the mass ratio, and mixing uniformly and fine grinding the weighed raw materials; calcining the fine grinded raw materials in a high-temperature furnace, and drawing out and quenching the calcined raw materials to obtain clinkers; adding the iron tailings to the clinkers, mixing uniformly mixtures of the iron tailings and the clinkers, and fine grinding the mixtures to obtain the Portland cement with the iron tailings, wherein the mass of the added iron tailings is 1-8% of the total mass of the clinkers. The method provided by the invention can effectively use the iron tailings as raw materials for production to prepare the Portland cement with excellent quality, so that the deficiencies in the prior art can be overcome, the use of the iron tailings can be maximized, and the purposes of saving resources, reducing the production cost, protecting environment and the like can be realized.

Owner:北海诚钢矿业股份有限公司

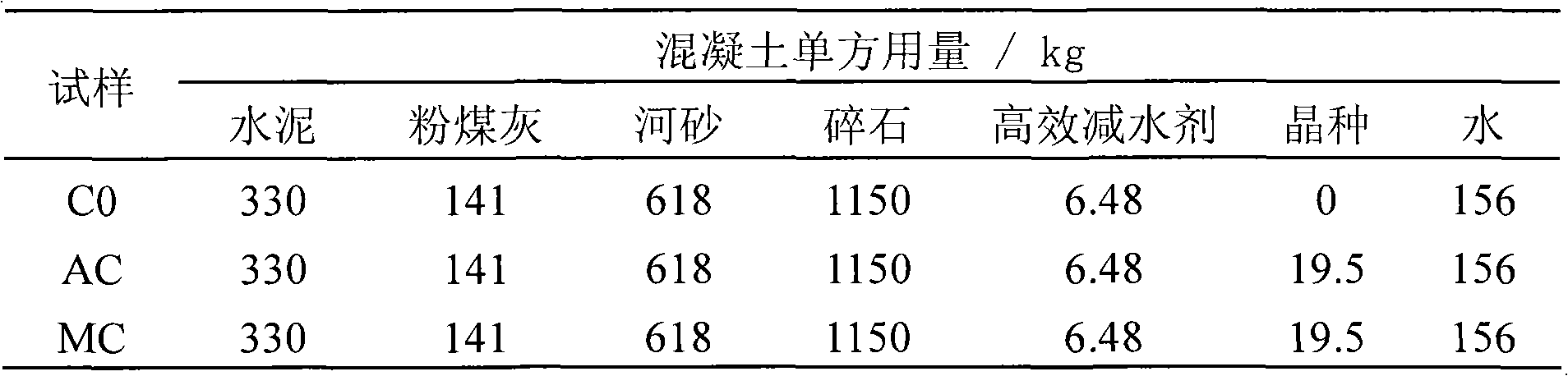

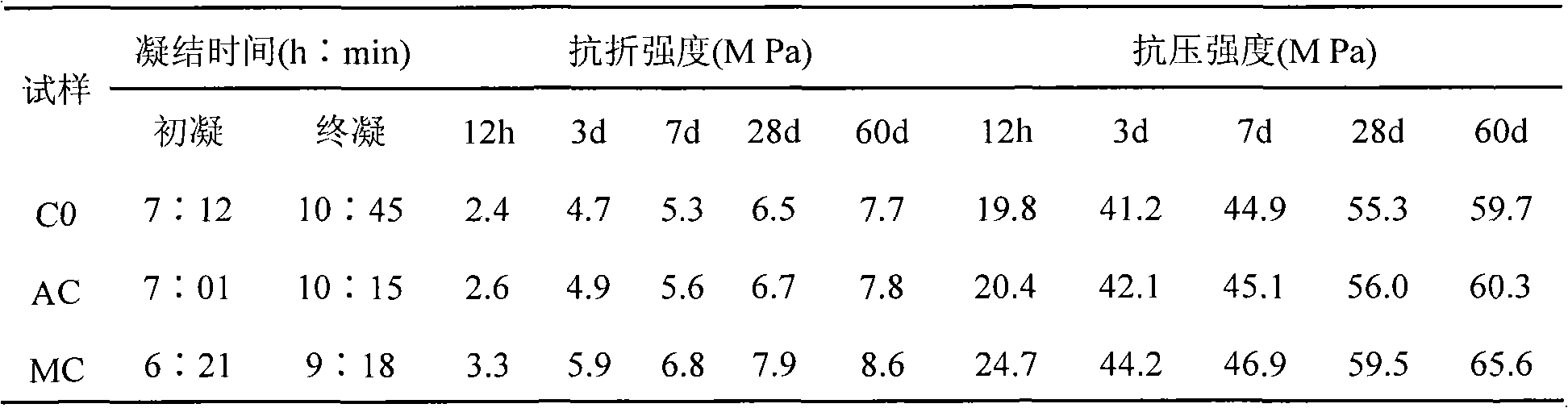

High-activity crystal seed for concrete production and preparation method thereof

InactiveCN101830660AImprove burnabilityLower firing temperatureSolid waste managementSolid waste disposalSlagSeed crystal

Owner:EAST CHINA JIAOTONG UNIVERSITY

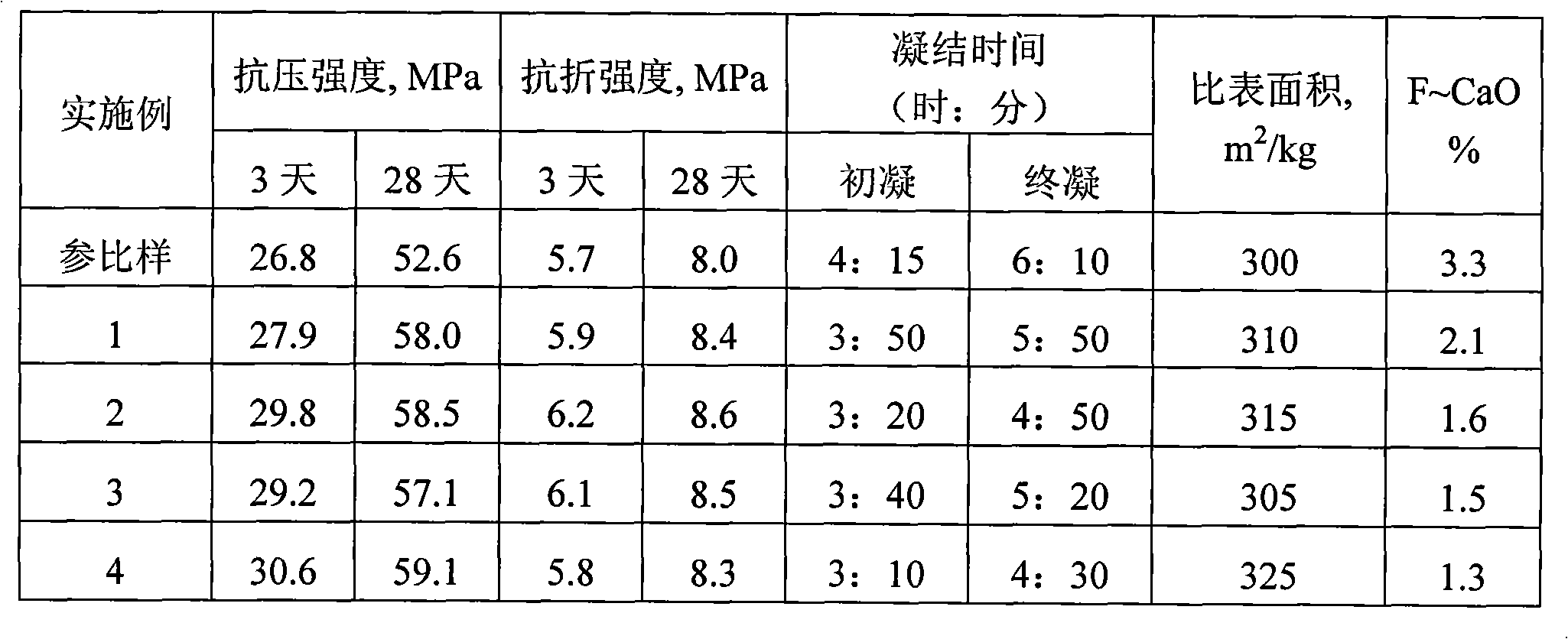

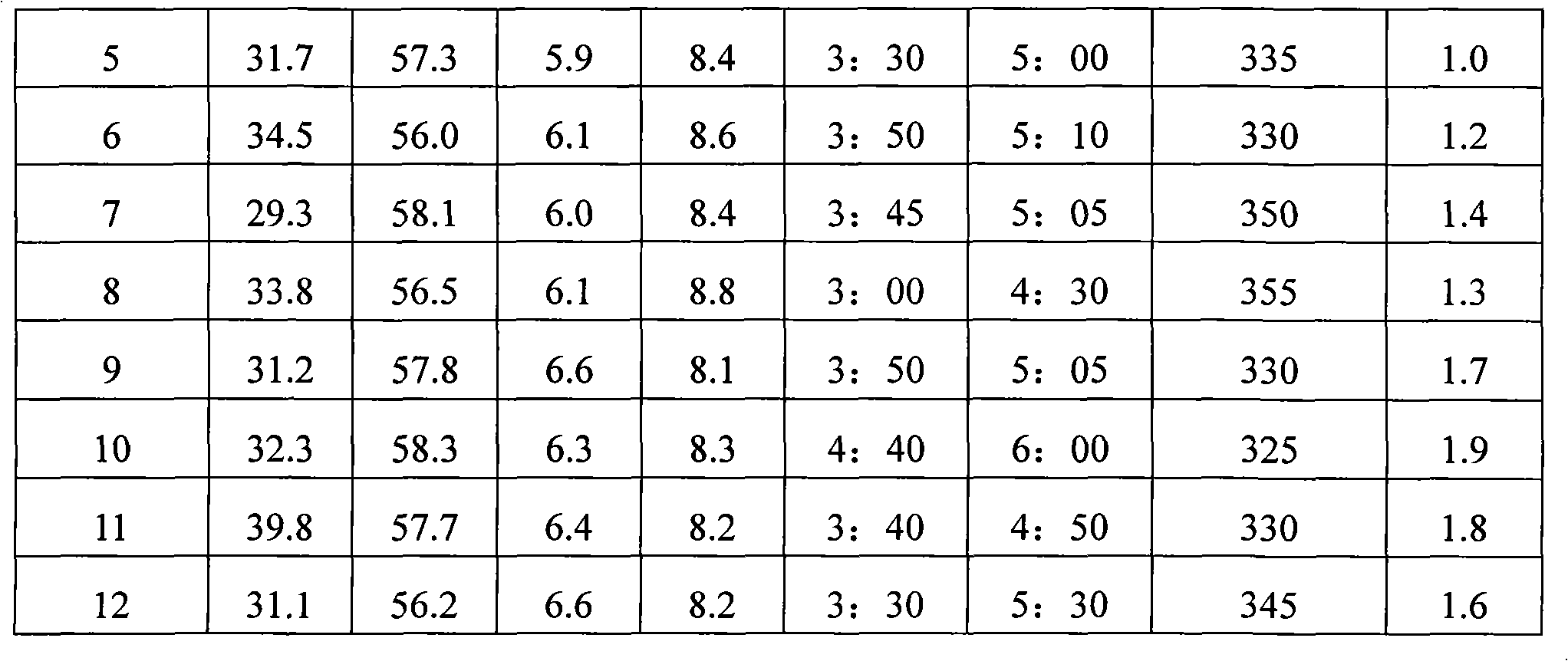

Composite industrial residue mineralizer cement clinker and preparation method thereof

The invention relates to a composite industrial residue mineralizer cement clinker and a preparation method thereof. The mineralizer doped into a cement green stock is between 5 and 20 percent by weight, and the cement clinker is characterized in that raw materials consist of 50 to 80 percent of metallic slag and 20 to 50 percent of inorganic non-metallic slag, wherein the metallic slag comprises the following components in portion by weight: 25 to 45 portions of steel slag, 15 to 40 portions of barium slag, 15 to 35 portions of chromium slag, 5 to 30 portions of zinc slag, 5 to 15 portions of copper slag, and 5 to 10 portions of tungsten slag; and the inorganic non-metallic slag comprises the following components in portion by weight: 25 to 45 portions of sulfuric acid slag; 25 to 40 portions of iron purite slag, 5 to 15 portions of phosphogypsum slag, 5 to 15 portions of coal slag, 5 to 10 portions of coal gangue slag, and 5 to 10 portions of rare-earth slag. The preparation method comprises the following steps: (1) mixing the metallic slag and grinding the metallic slag into fine powder; (2) mixing the inorganic non-metallic slag and grinding the inorganic non-metallic slag into fine powder; (3) mixing the metallic slag with the inorganic non-metallic slag evenly according to weight proportion; (4) activating the fine powder; and (5) blending the clinker fine powder into cement green stock.

Owner:常熟紫金知识产权服务有限公司

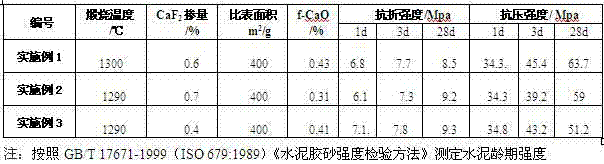

Method using titanium gypsum and acetylene sludge to prepare high-calcium sulphoaluminate or high-sulfur clinkers

A method using titanium gypsum and acetylene sludge to prepare high-calcium sulphoaluminate or high-sulfur clinkers includes the steps: (1) compounding; (2) homogenizing; and (3) calcining. According to the method using the titanium gypsum and the acetylene sludge to prepare the high-calcium sulphoaluminate or the high-sulfur clinkers, drying and grinding of wet sludge titanium gypsum and the acetylene sludge are omitted, energy consumption in drying and grinding is reduced, the firing temperature is low, firing energy consumption is low, production cost of the clinkers is low, and waste recycling benefits are good.

Owner:长沙紫宸科技开发有限公司

Cement clinker and preparation method thereof

The invention discloses a cement clinker and belongs to the technical field of cement clinker production. The clinker is prepared from the following raw materials in percentage by mass: 30 to 60 percent of calcareous materials, 0 to 25 percent of siliceous materials, 10 to 40 percent of aluminum materials, 0 to 10 percent of ferrous materials and 5 to 20 percent of gypsum materials; a mineral composition of the clinker is prepared from 10 to 40 percent of C4AS, 25 to 40 percent of C2S and 10 to 30 percent of C4AF. According to the clinker disclosed by the invention, the iron content of the cement clinker is low, and the seawater erosion resisting ability of the clinker is improved; the cement clinker is especially suitable for marine engineering.

Owner:JIAHUA SPECIAL CEMENT

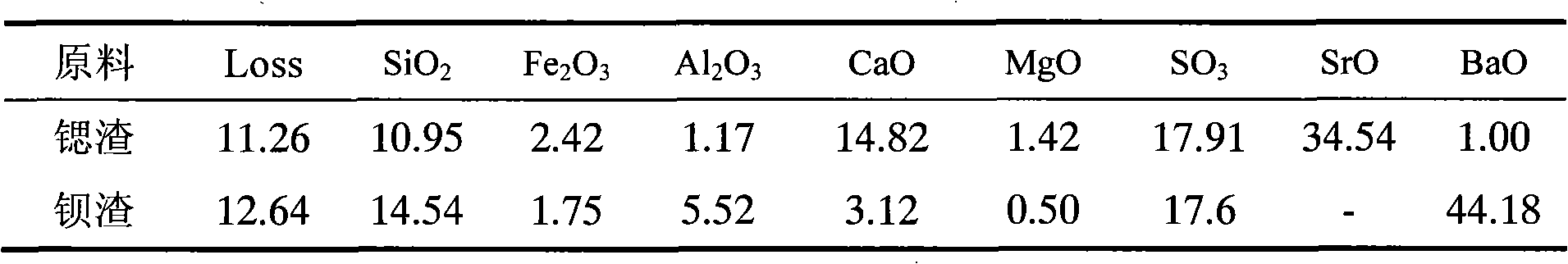

Strontium-barium cement calcination composite mineralizer

The invention relates to a strontium-barium cement calcination composite mineralizer, which is mainly made of strontium slag and barium slag, wherein both the weight percentage of the strontium slag and the weight percentage of the barium slag are 15 to 85 percent; the strontium slag is waste residue for producing strontium carbonate, and the weight percentage of SrO is required to be 25 to 40 percent; and the barium slag is waste residue for producing barium carbonate, and the weight percentage of BaO is required to be 20 to 50 percent. The invention utilizes the strontium slag and the barium slag as raw materials to synthesize the composite mineralizer, and achieves the aims of improving the cement strength, accelerating the hydrating and hardening of cement, improving the yield of kilns, reducing the cement cost, saving energy and resources, and reducing environmental pollution through the activation and mineralization of the composite mineralizer during the calcination of cement clinker.

Owner:UNIV OF JINAN

Method for producing belite-gypsum material by using sludge and waste gypsum through dry-process rotary kiln

The invention discloses a method for producing a belite-gypsum material by using sludge and waste gypsum through a dry-process rotary kiln. The method comprises the following steps of (1) melting a sludge ridge grain seed crystal with high water content into modified sludge residues; (2) proportioning raw materials of the modified sludge residues, the waste gypsum and a correcting material according to a certain ratio, and grinding the raw materials by using a vertical mill to form raw material powder; (3) delivering the raw material powder obtained in the step (2) into a dry-process rotary kiln system, and calcining the raw material powder to form clinker; and (4) grinding the obtained clinker to obtain powder with the fineness of 0.08mm and the screen residue content of less than 20%. The method disclosed by the invention is simple, low in investment and cost, free of other secondary pollution and capable of absorbing the sludge and the waste gypsum on a large scale and in a recycling way, greatly reducing the energy consumption and relieving the environment pollution.

Owner:长沙紫宸科技开发有限公司

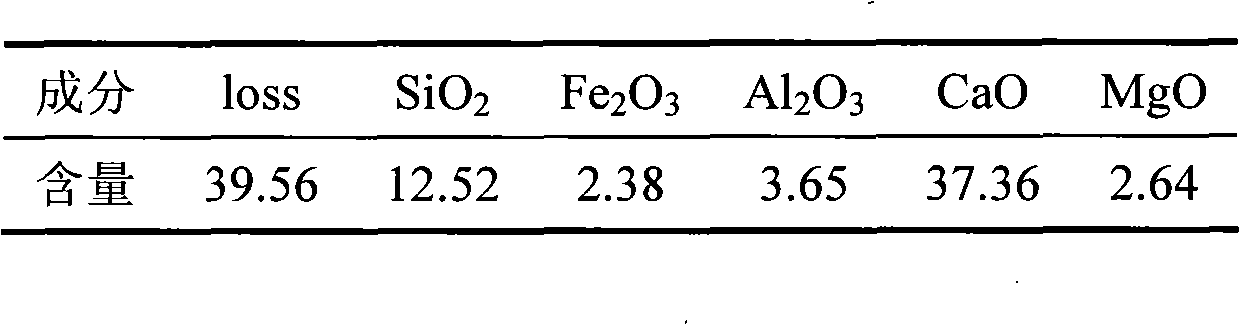

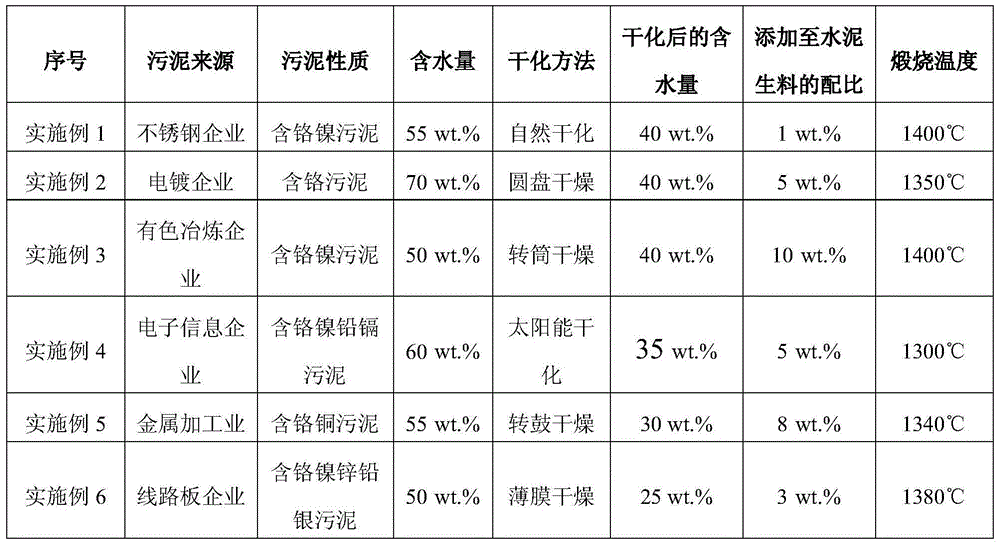

Method for synergistically treating heavy metal sludge in cement production

InactiveCN105000815AImprove burnabilityReduce firing heat consumptionCement productionPre treatmentCo-processing

The present invention discloses a method for synergistically treating heavy metal sludge in cement production. The method comprises: (1) carrying out a drying pretreatment on heavy metal sludge so as to make the moisture content be less than or equal to 40 wt%; (2) mixing the obtained heavy metal sludge and a cement raw material to prepare a raw material for cement; and (3) after the raw material for cement is homogenize, firing into a cement clinker. According to the present invention, with the method, the harmless treatment of the sludge and the production of the cement clinker and the product thereof can be simultaneously achieves, such that the heavy metal sludge with characteristics of complex components and difficult recycling is completely digested, and the quality performance of the cement product is not affected.

Owner:BAOSHAN IRON & STEEL CO LTD

Cement clinker and preparation method and application thereof

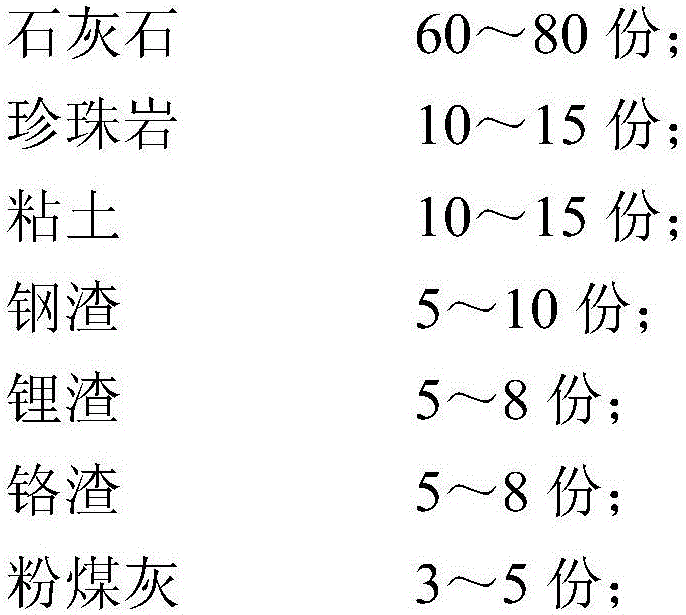

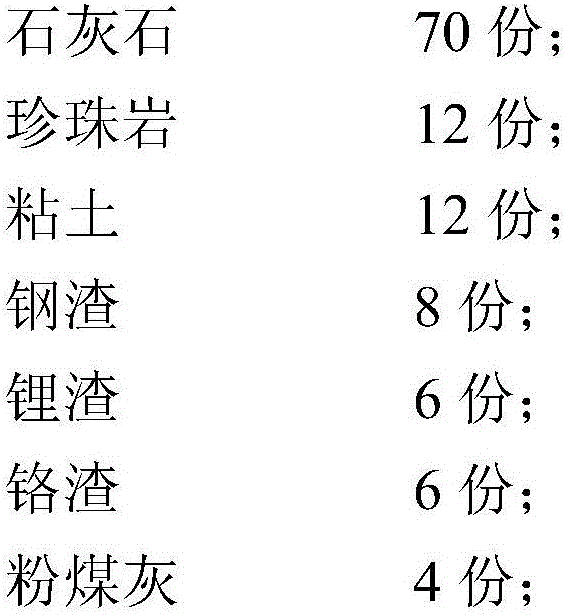

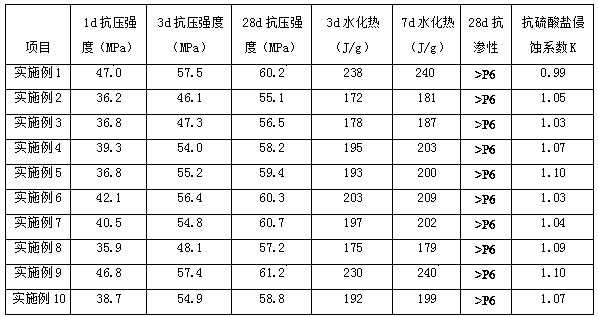

The invention belongs to the field of cement clinker preparation, and in particular, relates to cement clinker and a preparation method and an application thereof. The cement clinker is prepared from the following raw material components in parts by mass: 60-80 parts of limestone, 10-15 parts of perlite, 10-15 parts of clay, 5-10 parts of steel slag, 5-8 parts of lithium slag, 5-8 parts of chromium slag, and 3-5 parts of fly ash. The raw material components are broken, ground, mixed evenly and calcined to obtain the cement clinker; the cement clinker is mixed with gypsum and ground to obtain cement. Based on traditional cement clinker raw materials, the steel slag, lithium slag, chromium slag, fly ash and perlite are added, and play roles in adding a seed crystal, improving the burnability of cement raw material and grindability of the cement clinker, shortening the clinker formation time and setting time and the like; the prepared cement clinker and the cement have the characteristics of low hydration heat, good water retention, strong heat preservation and frost resistance, high strength and the like.

Owner:奎山水泥有限公司

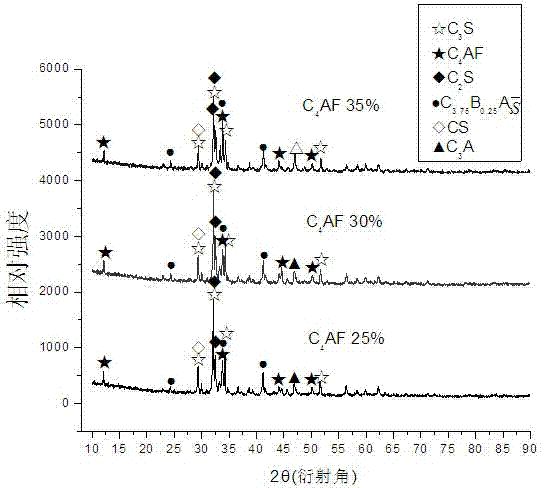

High-iron sulfoaluminate cement clinker and preparation method of same

InactiveCN109020274ASmall shrinkageMake up for drying shrinkageCement productionCalcium in biologyPolymer science

The invention discloses a high-iron sulfoaluminate cement clinker and a preparation method of same. The high-iron sulfoaluminate cement clinker includes, by mass, 45-70% of a calcium material, 5-40% of an aluminum material, 5-30% of an iron material, and 5-15% of a gypsum material. The clinker has mineral composition of: 35-55% of C4A3S, 20-35% of C2S and 15-25% of C4AF. In the invention, the cement clinker is prepared from low-grade calcium material, gypsum material and the like being raw materials, so that the product is higher than ordinary Portland cement in both early strength and later strength; due to the specific mineral composition, the cement clinker is low in overall hydration heat and has a good volume stability.

Owner:JIAHUA SPECIAL CEMENT

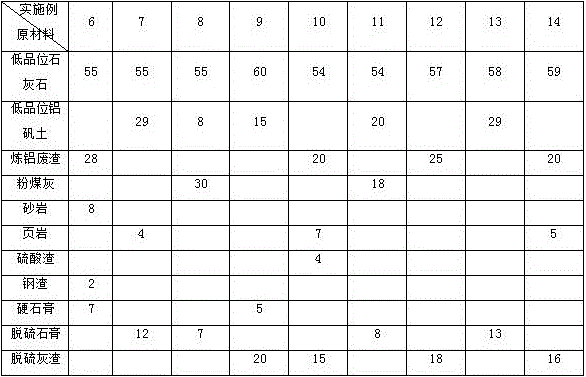

Method for producing cement clinker by employing phosphorus slag

A disclosed method for producing cement clinker by employing phosphorus slag comprises the following steps: (a) crushing rough materials, namely, crushing the rough materials mainly composed of limestone, phosphorus slag, shale, sandstone and iron ore, so as to respectively obtain limestone particle, phosphorus slag particle, shale particle, sandstone particle and iron ore particle; (b) pre-homogenizing the rough materials, namely, performing layered stacking on the various particles obtained in the step (a); (c) preparing raw material; (d) homogenizing the raw material; (e) preheating and decomposing; (f) sintering and obtaining clinker; and (g) grinding the clinker, namely, cooling the sintered clinker, and grinding the clinker to obtain a needed granularity, so as to finish cement production. The method helps to improve the sintering easiness of the raw material, improve the clinker quality, improve the kiln decomposition rate, improve rotary kiln operation ratio, reduce clinker sintering heat consumption and cement comprehensive electricity consumption, increase clinker output, and substantially reduce cement production cost.

Owner:陈永忠

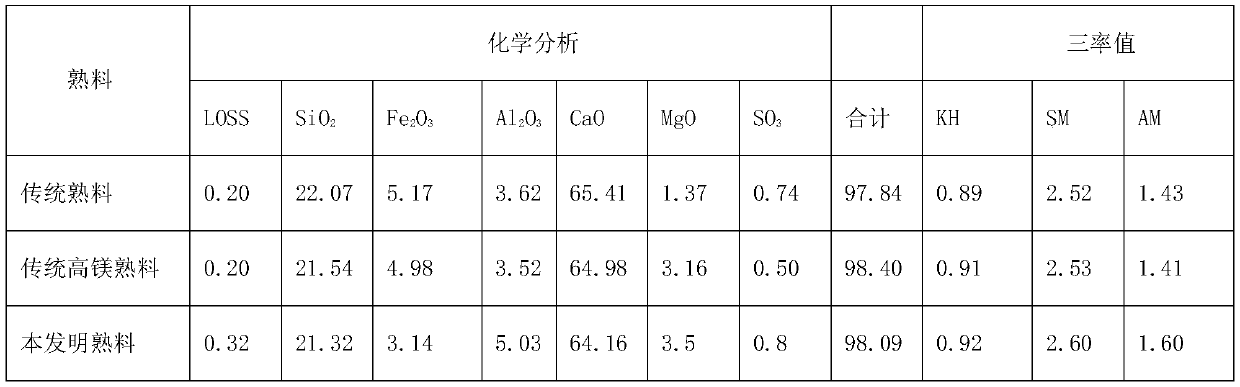

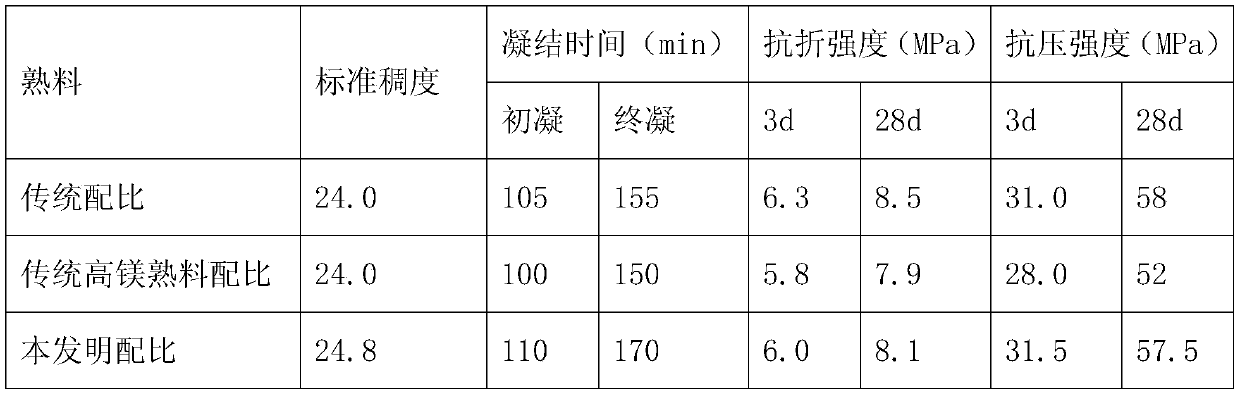

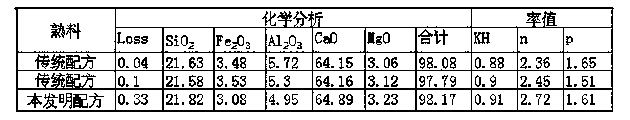

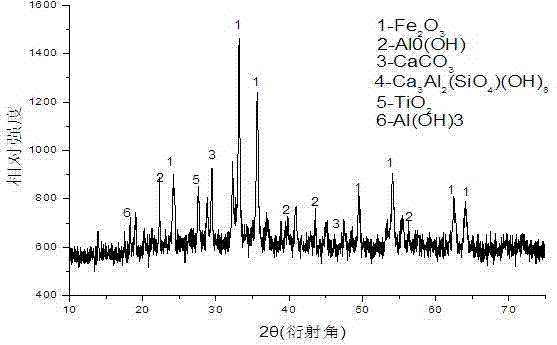

Method for producing high-strength clinker from high-magnesium limestone

The invention relates to a method for producing high-strength clinker from high-magnesium limestone. The method uses the following raw materials in parts by weight: 50-70 g of sulfuric acid slag, 80-200 g of high-magnesium limestone, 600-760 g of low-magnesium limestone, 20-40 g of shale, 20-40 g of sandstone and 20-30 g of coal gangue, summing to 1000 g. According to the invention, the high-magnesium limestone is adopted to replace part of low-magnesium high-calcium high-quality limestone, the coal gangue is added, and the values of the three rates of the clinker are reformulated. Compared with the composition of traditional silicate clinker, the invention has the following advantages: the high-magnesium limestone and the coal gangue are used as substitute materials, so a clinker firing temperature is easily reduced, the burnability of the clinker is improved, and the energy consumption of the clinker is reduced; and since high-magnesium limestone resources and waste coal gangue of amine are effectively utilized, resource problems and environmental pollution problems are solved, a way is found for improving the ecological environment, and high social benefits and environmental benefits are achieved.

Owner:河北京兰水泥有限公司

Steel slag cement clinker

InactiveCN1486950AReduce the amount addedEmission reductionCement productionEcological environmentIronstone

The steel slag cement clinker is produce with limestone 475-525 (in weight portions, the same below), flyash 160-180, reducing slag 200-240, steel slag 60-100 and sandstone 20-40 and through mixing, milling and baking in rotary kiln. The present invention used flyash to replace clay, reducing slag replacing partial limestone and steel slag replacing iron ore, and this can save resource, protect ecological environment and reduce CO2 exhaust while raising yield, lowering power consumption and saving fuel.

Owner:TAIYUAN IRON & STEEL GROUP

Method for preparing cement clinker by using chrome slag as mineralization agent

InactiveCN1477073AReduced heat distribution ratioAct as a seed crystalCement productionSlagCalcination

The method for preparing cement clinker by using chromium slag as mineralizer is mainly in the cement raw material the mineralizer chromium slag can be added, and the high-temp. calcination process is adopted to reduce hexavalent chromium into trivalent chromium, at the same time a catalytic stabilizer can be added in the clinker so as to obtain the invented cement clinker.

Owner:SICHUAN YINHE CHEM

Cement clinker preparation method using converter steel slag to correct iron quality

ActiveCN103992049AImprove grinding efficiencyAdjustable Aluminum RateClinker productionSlagMagnetic separation

The invention discloses a cement clinker preparation method using converter steel slag to correct iron quality. The preparation method comprises the following steps: 1) gradient grinding and magnetic separation; 2) mixing and grinding: a step of fully and uniformly mixing and grinding more than 0 wt% but no more than 5.4 wt% of converter steel slag with a cement raw material; and 3) calcining at a temperature of 1380 to 1400 DEG C so as to prepare the cement clinker. Directed at the characteristic that iron particles and difficult-to-grind phases like an RO phase in the converter steel slag are in the state of enrichment, the method provided by the invention carries out two-stage gradient grinding and sorts out iron particles and difficult-to-grind phases like the RO phase enriched in the converter steel slag by using a strong magnetic field, then the converter steel slag and the cement raw material are mixed, ground and calcined so as to prepare the cement clinker, so grinding efficiency of the cement raw material is improved, the service life of grinding equipment is prolonged, the converter steel slag is finer, the effect of seed induction of the converter steel slag is given to full play in the process of calcining of the cement clinker, the calcining temperature of cement is decreased by more than 50 DEG C, and the refined converter steel slag can adjust the aluminum rate (IM) in the cement raw material and functions as a mineralizer and a promoter.

Owner:宝武环科武汉金属资源有限责任公司

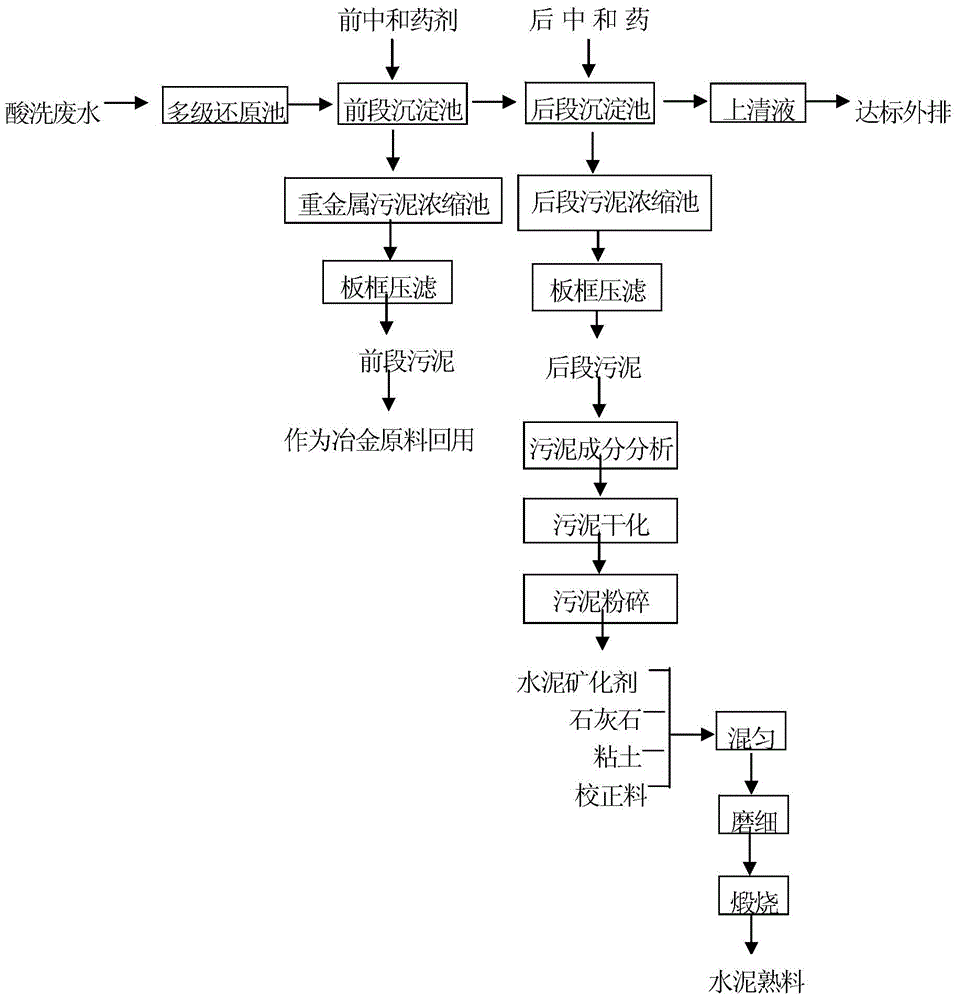

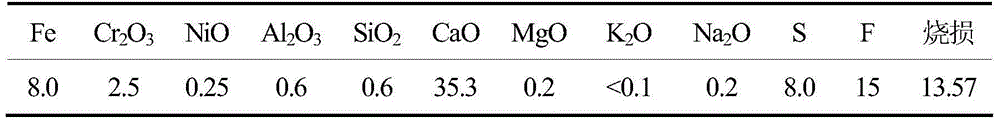

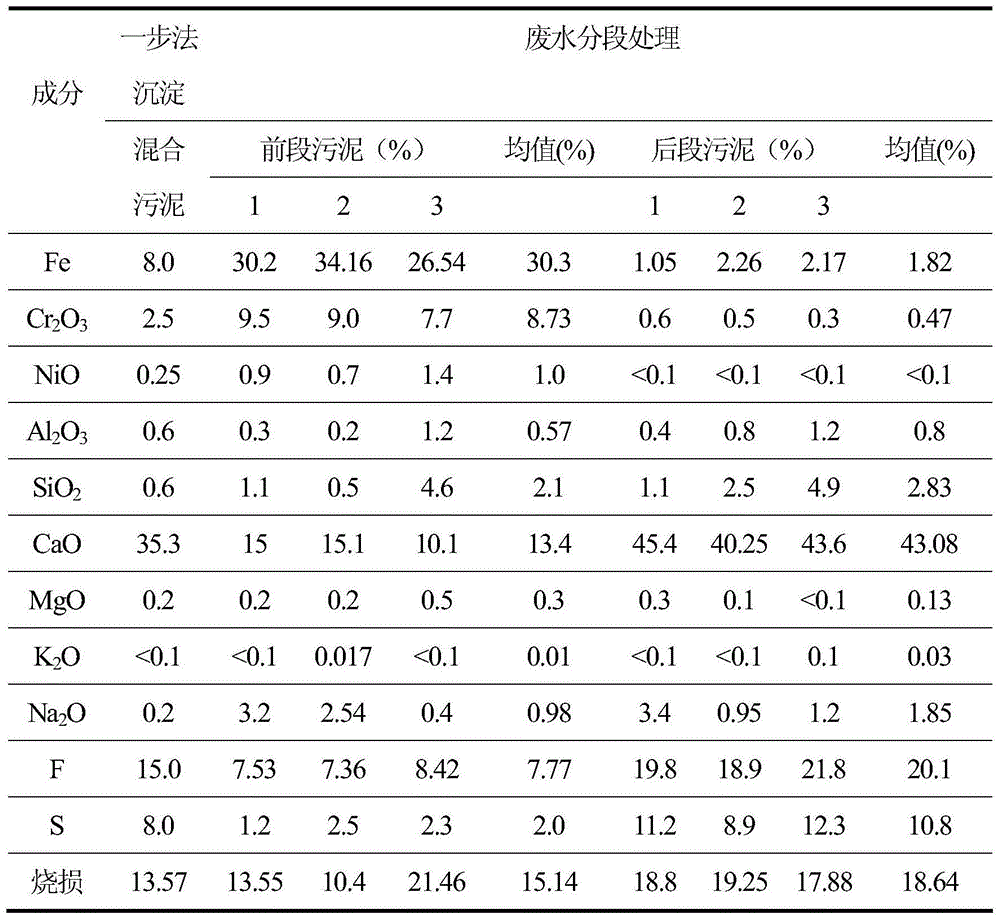

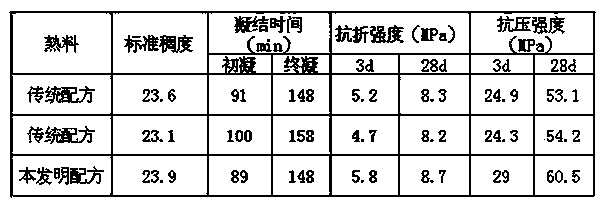

Segment treatment method for fluorine-containing heavy metal wastewater

ActiveCN105217825AFine particleHigh activitySludge treatment by de-watering/drying/thickeningWater contaminantsResource utilizationFiltration

The invention provides a segment treatment method for fluorine-containing heavy metal wastewater. The method comprises the specific steps: after chemical reduction treatment of wastewater, adding a pre-neutralizing agent into a front segment settling tank to allow complexing precipitation of metal ions in the wastewater to occur, and carrying out concentration and plate-frame pressure filtration on sludge to obtain front segment sludge; feeding a supernate into a rear segment settling tank, then adding a post-neutralizing agent, discharging the supernate which meets the standard, allowing complexing precipitation of Ca<2+>, F<->, SO4<2-> and the like in the wastewater to occur, carrying out concentration and plate-frame pressure filtration on sludge to obtain rear segment sludge, and drying and smashing the sludge to obtain a cement mineralizer; and uniformly mixing the cement mineralizer with limestones, clay, a correcting material and the like, and grinding and calcining the mixture according to a conventional cement production and processing process to obtain cement clinker. The method provided by the invention not only realizes resource utilization of stainless steel cold-rolled sludge which can effectively replace natural gypsum and fluorite, thereby better satisfying the demand of low-temperature sintering, high quality and high yield, energy saving and consumption reduction of the cement clinker.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing belite-gypsum material by calcining sludge and waste gypsum through vertical kiln

The invention discloses a method for producing a belite-gypsum material by calcining sludge and waste gypsum through a vertical kiln. The method comprises the following steps of (1) melting a sludge ridge grain seed crystal with high water content into modified sludge residues; (2) carrying out two-stage proportioning on raw materials of the modified sludge residues, the waste gypsum and a correcting material according to a certain ratio, homogenizing, adding a proper proportion of fire coal in the proportioning and homogenizing processes, and molding grains or charging bars to obtain a black raw material molding material; (3) delivering the obtained black raw material molding material into the vertical kiln, and calcining the black raw material molding material at the temperature of 1250-1400 DEG C to form clinker; and (4) grinding the obtained clinker to obtain powder. The method disclosed by the invention is simple, low in investment and cost, free of other secondary pollution and capable of absorbing the sludge and the waste gypsum on a large scale and in a recycling way, greatly reducing the energy consumption and relieving the environment pollution.

Owner:长沙紫宸科技开发有限公司

Silicate clinker and cement prepared with same

The invention belongs to the technical field of building materials, and provides silicate clinker and cement prepared with the same to overcome the defects of high raw material cost, poor burnability of raw batch, low long-term strength of clinker, difficulty in improving the long-term strength of the clinker, limitation of adulteration quantity of the raw batch and the clinker in cement and composite material preparation. The silicate clinker provided by the invention comprises steel slag, magnesium slag, coal ash, sandstone and limestone according to a certain proportion; the cement provided by the invention comprises the silicate clinker, coal ash, mineral waste residue and gypsum according to the certain proportion. As steel slag and magnesium slag are adopted as raw materials, the clinker of relatively high saturation ratio and silica ratio can be prepared easily, the strength of the clinker can be improved effectively, the adulteration proportion of cement admixture is improved, the burnability of the clinker is improved, and heat consumption is reduced; as industrial residues (steel slag and magnesium slag) are utilized effectively, the problems of environmental pollution and resource shortage are solved, and an effective way is provided for industrial residue treatment. Therefore, the social benefit, economic benefit and environmental benefit are very high.

Owner:SHANXI DONGYI GRP SPECIAL CEMENT

Method for preparing high-ferric Alite-calcium barium sulphoaluminate cement by using red mud and barium mud

The invention discloses a method for preparing high-ferric Alite-calcium barium sulphoaluminate cement by using red mud and barium mud. The mineral phases are as follows in percentage by weight: 5-8% of C(4-x)BxA3S, 15-19% of C2S, 30-45% of C3S, 25-45% of C4AF and 4-8% of C3A; the raw materials are as follows in percentage by weight: 10-20% of clay, 8-30% of red mud, 55-65% of limestones, 3-5% of gypsum, 0.3-0.5% of barium mud, 0-2% of bauxite and 0.4-1% of fluorite. The method comprises the following steps: crushing and homogenizing the raw materials and drying and polishing; preparing a round cake-shaped test sample which is 5cm in radius and 2cm in thickness, and calcining and cooling; and (6) crushing, and doping 8-12% of gypsum or dihydrate gypsum based on the total mass of the material, wherein the grinding fineness is 350m<2> / kg-450m<2> / kg or residue on sieve is 5% by a 200mesh sieve. The high-ferric Alite-calcium barium sulphoaluminate cement disclosed by the invention has the characteristics of low sintering temperature and small volume shrinkage, low cost and durability and the like as high-ferric or high-ferric aluminum industrial wastes and barium-containing industrial waste residues are used as raw materials.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

High magnesium slag doped cement

The invention discloses high magnesium slag doped cement. The raw materials of the cement comprise the following main minerals in percentage by weight: 65-82% of limestone, 1-20% of magnesium slag, 5.5-9.4% of sandstone and 4-8% of coal gangue, wherein the magnesium slag comprises the following main chemical components: less than or equal to 55% and greater than or equal to 50% of CaO, greater than or equal to 20% and less than or equal to 30% of SiO2, greater than or equal to 8% and less than or equal to 12% of MgO, greater than or equal to 4% and less than or equal to 6% of Fe2O3, and greater than 0% and less than or equal to 2% of Al2O3. The cement is prepared by sequentially passing blended raw materials through a raw material drying mill, a raw material homogenizing silo, a decomposing furnace and a rotary kiln, blending the prepared clinker with coal ash, desulfurization gypsum and slag, and feeding the above materials into a cement mill. As high as 20% of magnesium slag is doped into the high magnesium slag doped cement, so that not only is the service life of a limestone mine prolonged, but also industrial wastes such as greatly piled magnesium slag are effectively utilized, the burnability of the clinker is also improved, the content of f-CaO in the clinker is reduced, and the national standard is met.

Owner:SHANXI ZHONGTIAOSHAN NEW BUILDING MATERIAL

Composite mineralizer in use for calcinations of barium-copper cement

The invention relates to a mineralizer for producing silicate cement, particularly to a roasting compound mineralizer for cement with main component barium and trace auxiliary component copper. In the invention, barium dregs and copper dregs are used as main raw material, their weight percentage is (wt.%): barium dreg 50-80, copper dreg 20-50.

Owner:UNIV OF JINAN

Method for preparing cement from manganese iron slag

InactiveCN105174756AImprove burnabilityAccelerates the formation of mineralsCement productionDecompositionRotary kiln

The invention discloses a method for preparing cement from manganese iron slag, which comprises the following steps: (a) raw material crushing: crushing the raw materials mainly composed of limestone, manganese iron slag, shale, sandstone and iron ore to respectively obtain limestone particles, manganese iron slag particles, shale particles, sandstone particles and iron ore particles; (b) raw material prehomogenization: carrying out stratified piling on various particles obtained in the step (a); (c) green material preparation; (d) green material homogenization; (e) preheating and decomposition; (f) clinker firing; and (g) clinker milling: cooling the fired clinker, and milling the clinker to the required particle size, thereby completing the cement production. The method can improve the sinterability of the green material, improve the clinker quality, enhance the in-kiln decomposition rate, increase the operation rate of the rotary kiln, lower the clinker firing heat loss and cement comprehensive power consumption, enhance the cement yield and greatly lower the cement production cost.

Owner:SICHUAN MINGCHUAN CHENGYU ELECTRICAL & MECHANICALCO

Preparation method for phosphorous slag Portland cement clinker

InactiveCN104692680AAddress resource shortagesEmission reductionClinker productionIronstonePhosphate

The invention discloses a preparation method for phosphorous slag Portland cement clinker. The clinker is mainly prepared by mixing limestone, sulfuric acid slag, river sand, phosphorus slag and tailings according to a weight ratio of 75-80: 5.5-6.5: 1.8-2.8: 9-13: 1-4.5, wherein the sulfur acid slag is industrial waste of sulfuric acid plants; the phosphorus slag is water-quenched waste slag discharged during preparation of phosphorus by using an electric-furnace sublimation method; and the tailings are residual tailings of mining industry and contain the trace elements Pb and Zn. By using industrial wastes--the phosphorus slag, the sulfuric acid slag and the tailings as raw materials to prepare low environmental coincidence type phosphate cement clinker, the preparation method provided by the invention overcomes the problem of resource shortage of high-quality limestone, clay and iron ore, provides an ideal way for the treatment of industrial wastes, saves resources and energy sources, reduces emission of pollutants and is favorable for protecting environment and reducing cost.

Owner:青岛昊河水泥制品有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com