Preparation method for phosphorous slag Portland cement clinker

A Portland cement and phosphorous slag technology, applied in cement production, clinker production, etc., can solve problems such as environmental pollution and large space occupation, and achieve the effects of reducing costs, reducing emissions, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

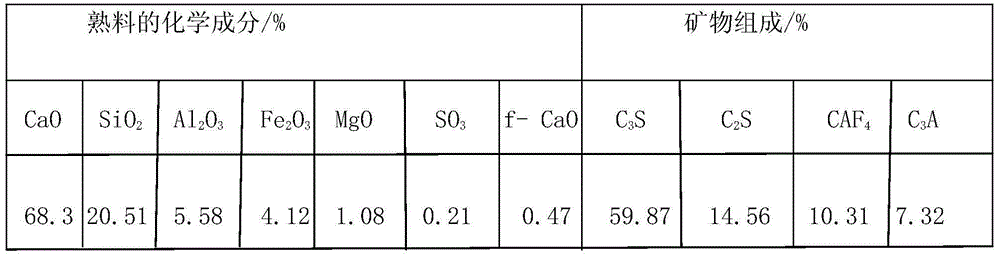

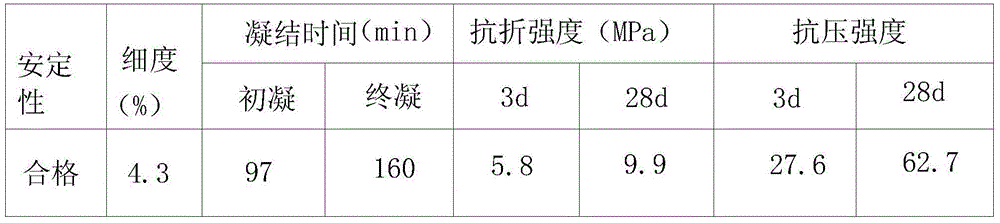

[0024] Embodiment 1: The weight ratio of each raw material is limestone 78, sulfuric acid slag 6, river sand 2.5, phosphorus slag 10, tailings 2, the chemical composition and mineral composition of the phosphorus slag Portland cement clinker product thus obtained See Table 1, and its physical and mechanical properties are shown in Table 2.

Embodiment 2

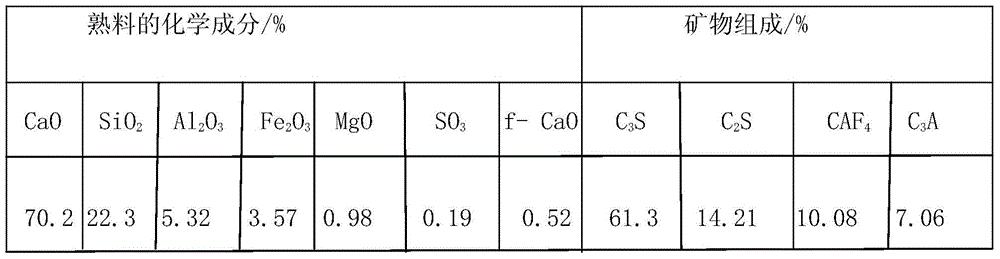

[0025] Embodiment 2: The weight ratio of each raw material is limestone 80, sulfuric acid slag 5.8, river sand 2, phosphorus slag 12, tailings 3.5, the chemical composition and mineral composition of the phosphorus slag Portland cement clinker product thus obtained See Table 3, and its physical and mechanical properties are shown in Table 4.

[0026] Chemical composition and mineral composition of table 1 embodiment one phosphorus slag portland cement clinker product

[0027]

[0028] The physical and mechanical properties of table two embodiment one phosphorus slag portland cement clinker products

[0029]

[0030] Chemical composition and mineral composition of table three embodiment two phosphorus slag Portland cement clinker products

[0031]

[0032] Table four embodiment two phosphorus slag Portland cement clinker product physical and mechanical properties

[0033]

[0034] As can be seen from the above experimental data, the present invention utilizes indu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com