Patents

Literature

97results about How to "No need to add" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

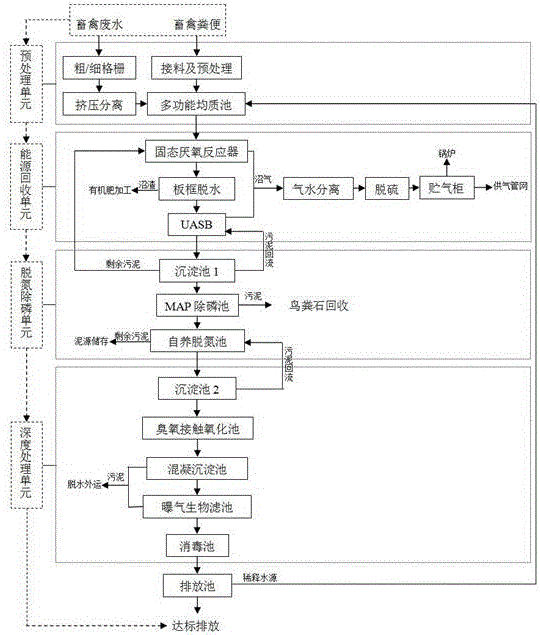

Recycling treatment method for feces and wastewater in large-scale livestock and poultry breeding farm

InactiveCN106242162ANo need to addReduce aerationSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesAnimal fecesEnergy recovery

A recycling treatment method for feces and wastewater in a large-scale livestock and poultry breeding farm includes the following steps: (1) pre-treating the feces and wastewater in the large-scale livestock and poultry breeding farm in a pretreatment unit to form slurry; (2) feeding the slurry into an energy recovery unit, and performing solid anaerobic digestion in a solid anaerobic reactor to obtain an energy gas, methane; (3) performing solid-liquid separation to the digested slurry to generate wastewater, which is then fed into a UASB reactor to perform further anaerobic fermentation to remove organic pollutants from the wastewater; (4) feeding the treated wastewater into a nitrogen and phosphorus removal unit to perform nitrogen and phosphorus removal treatment; (5) separating and purifying a precipitate, which is generated in the nitrogen and phosphorus removal unit and mainly includes magnesium ammonium phosphate, to obtain an organic fertilizer additive, wherein the nitrogen removal process is autotrophic nitrogen removal and can reduce aeration quantity by 62.5% without addition of any carbon sources, thus saving large quantity of operation cost; and (6) feeding the treated wastewater into a deep-treatment unit to remove bio-refractory substances and disinfect the wastewater so as to finally reach emission and recovery standards of wastewater.

Owner:SOUTH VENTURE TIANJIN TECH DEV CO LTD

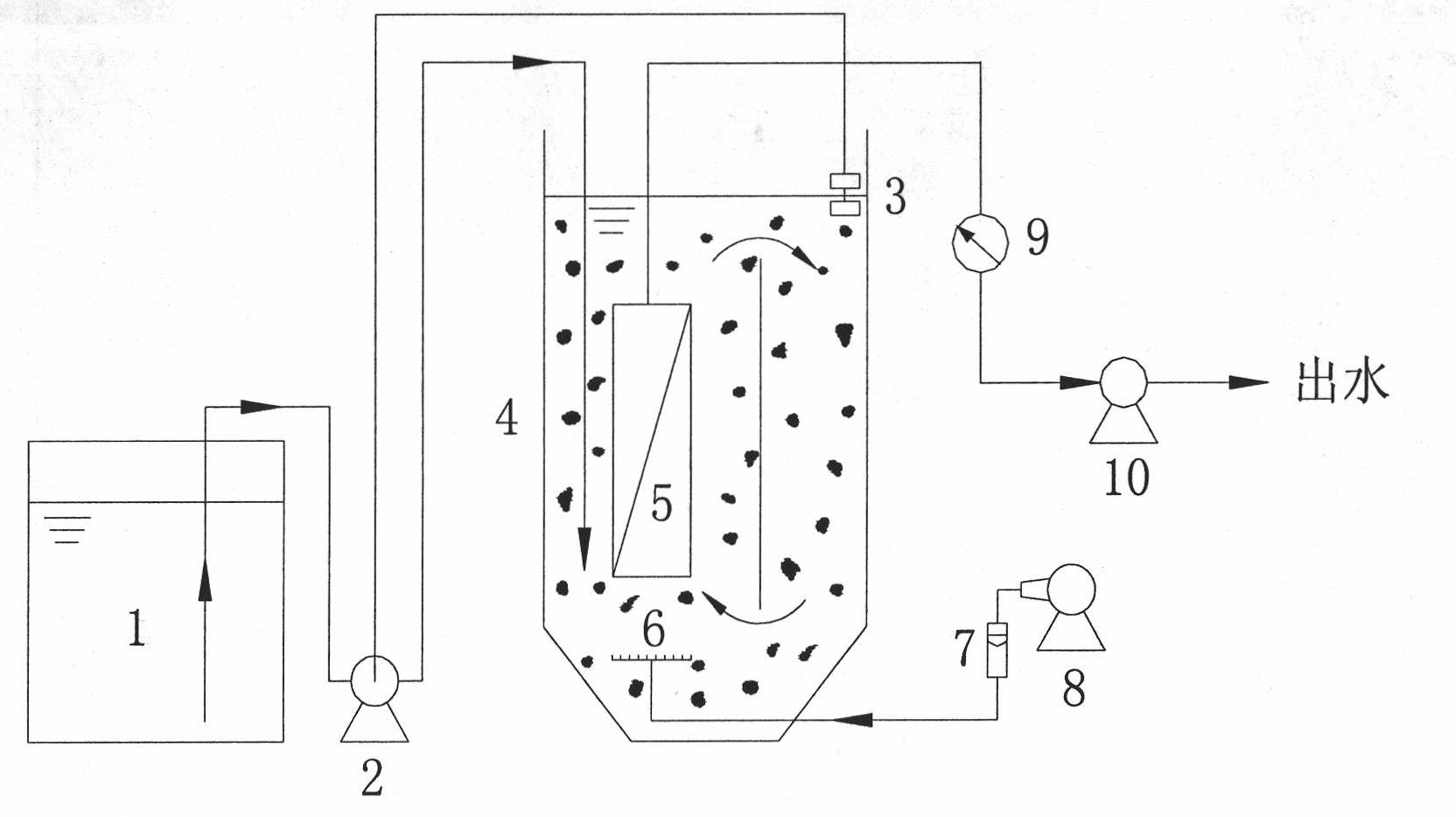

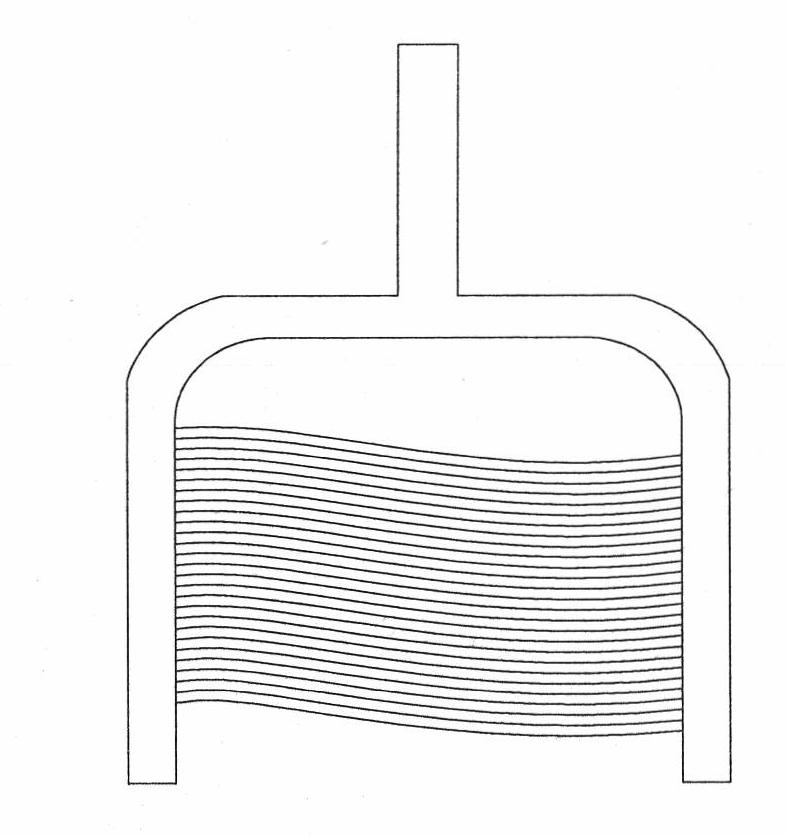

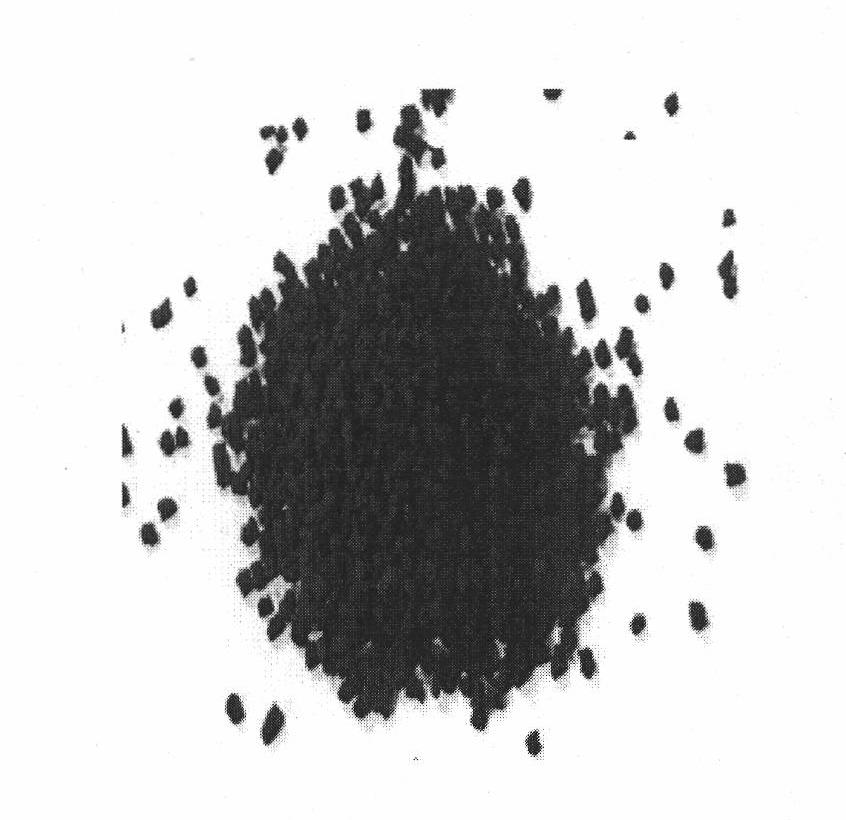

Fluidized bed film bioreactor for sewage treatment

InactiveCN102167469AReduce pollutionExtended service lifeMultistage water/sewage treatmentWaste rubberTotal nitrogen

The invention discloses a fluidized bed film bioreactor for sewage treatment, which belongs to the technical field of water and waste water treatment. The invention utilizes a process combining a biological fluidized bed with a film bioreactor, i.e. the reactor is filled with self-produced carrier granules with a diameter of about 5mm, wherein the carrier granules are made of waste rubber powder, activate carbon and adhesive, and the filling ratio is 10-30% of the effective volume of the reactor. By means of the synergistic effect of the carriers and sludge to finish the film forming process, microorganism is grown on the filler to reduce the concentration of the sludge in the reactor, change the environment running condition of the reactor and slow down the film pollution, thus further prolonging the service life of the film and improving the treatment capacity of the film. By filling the self-produced carrier granules in the film bioreactor and using the filler to change and regulate the interior microenvironment of the fluidized bed film bioreactor, such as dissolved oxygen (DO), the quantity of the filler and the water retention time, a local anoxic zone is formed, thus further realizing the synchronous nitration and denitrification function and improving the removal efficiency of total nitrogen as well as the denitrification efficiency. The fluidized bed film bioreactor for sewage treatment has a simple structure, does not feed the addition of chemical agent, is convenient and efficient to run and operate, can obtain high-quality outlet water, saves energy, can remove various pollutants such as organic matters, total nitrogen and the like, is suitable for treatment of organic waste water such as industrial and domestic waste water and the like, and can be hopefully applied in engineering practice.

Owner:BEIJING FORESTRY UNIVERSITY

Conductivity liquid alloy and preparation method

This invention relates to electroconductive liquid alloy, the design and method for preparing the room temperature liquid and electroconductive alloy GalnSn and GalnSnAg. A metal with its purity being greater than 99.99% is selected and thein is smelted to produce the main alloy Galn. And then, Sn(or Sn and Ag) is (are) added into above mentioned Galn to produce GalnSn or GalnSnAg alloy. The product can be used in fields such as: oral surgery, electronics material and refrigeration system.

Owner:冯本政

AOA coupled anaerobic ammonia oxidation deep nitrogen and phosphorus removal process

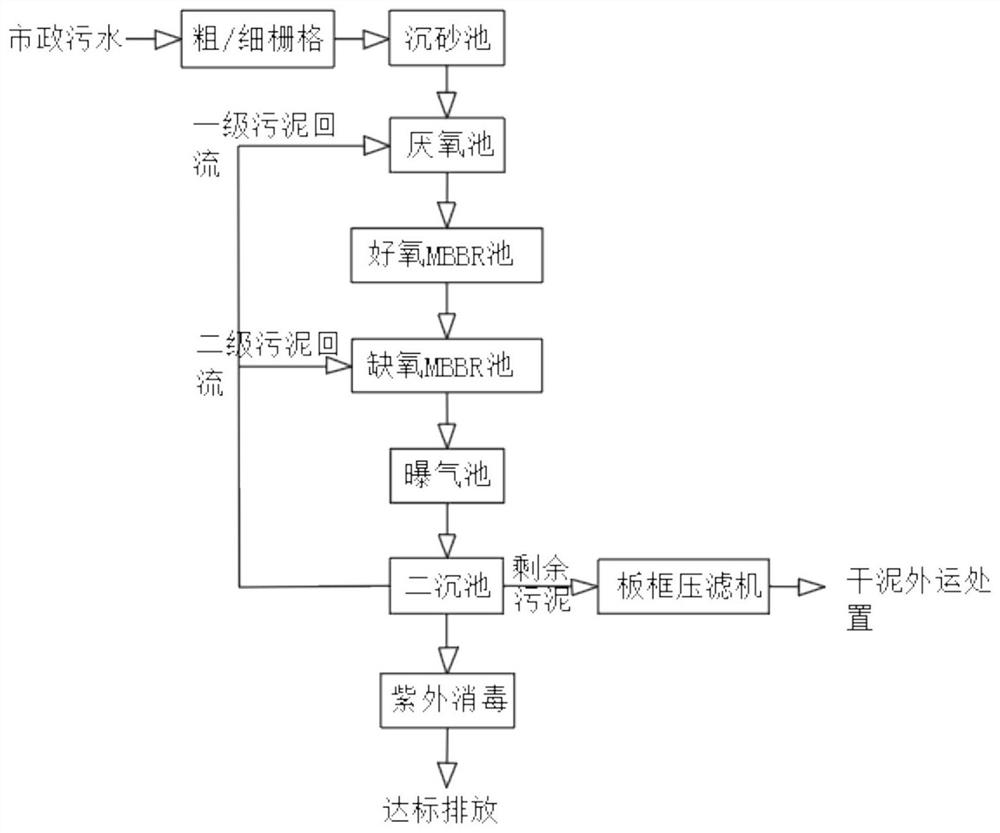

InactiveCN113173640AIncrease hydraulic retention timeReduce lossWater contaminantsTreatment with aerobic and anaerobic processesPhosphateMunicipal sewage

The invention discloses an AOA coupled anaerobic ammonia oxidation deep nitrogen and phosphorus removal process, which comprises an anaerobic zone for internal carbon source storage and phosphate release, an aerobic zone for aerobic excessive phosphorus uptake and short-cut nitrification-anaerobic ammonia oxidation, and an anoxic zone for internal carbon source short-cut denitrification-anaerobic ammonia oxidation, wherein an active biological filler is added into the aerobic zone and the anoxic zone to enrich main functional bacteria, the anaerobic zone has long hydraulic retention time and can store an internal carbon source, the anoxic zone is located at the rear end of the aerobic zone and does not need nitrification liquid backflow, and an aeration zone is added at the rear end of the anoxic zone to improve sludge settleability. The AOA coupled anaerobic ammonia oxidation deep nitrogen and phosphorus removal process solves the problems of insufficient carbon source and incapability of synchronously and deeply removing nitrogen and phosphorus in the nitrogen and phosphorus removal process, reduces the loss of the carbon source, improves the utilization rate of the carbon source, reduces the operation energy consumption of a sewage treatment system, and bring a better application prospect to deep nitrogen and phosphorus removal of urban sewage.

Owner:JIANGSU YULONG ENVIRONMENTAL PROTECTION

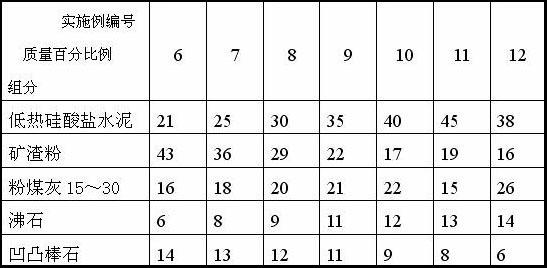

High-salt high-alkali Medium-low-level radioactive liquid waste cement solidified body and preparation method thereof

InactiveCN102169737AStrong adsorption capacityIncrease retention capacityRadioactive decontaminationSlagCoal

The invention discloses a high-salt high-alkali medium-low-level radioactive liquid waste cement solidified body which is composed by mixing the following components: high-salt high-alkali medium-low-level radioactive liquid waste and, solidification material, water glass and cellulose ether, wherein the high-salt high-alkali medium-low-level radioactive liquid waste to the solidification material is 0.55-0.75: 1 in mass proportion; the modulus of the water glass is 2.5-3.5 based on Na2O in the water glass and the mass of the solidification material is 1-3% of the mass of the water glass ; the mass of the solidification material is 0.05-0.5% of the mass of the cellulose ether; the component mass percent of the solidification material is as follows: 20-40% of low-heat Portland cement, 15-50% of slag powder, 15-30% of coal ash, 5-15% of zeolite and 5-15% of attapulgite; and the cement solidification body with various properties meeting the requirements is obtained by carrying out normal-temperature maintenance on the mixed slurry which obtained by mixing and stirring. The high-salt high-alkali medium-low-level radioactive liquid waste cement solidified body is suitable for the solidification of the medium-low-level radioactive liquid waste, which has the total salt concentration being 100-400g / L, the pH value being larger than 13 and the nuclide being 90Sr or / and 137 Cs.

Owner:SOUTHWEAT UNIV OF SCI & TECH

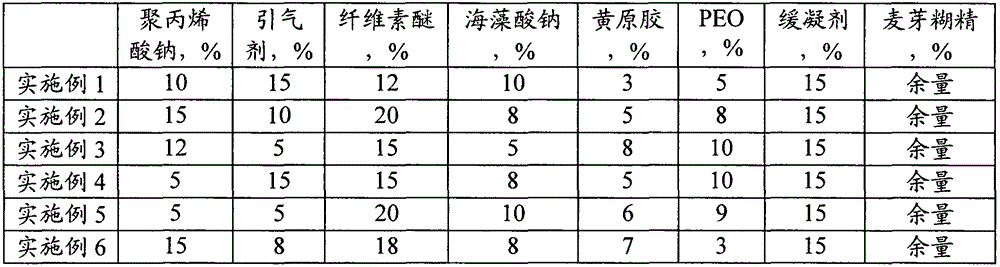

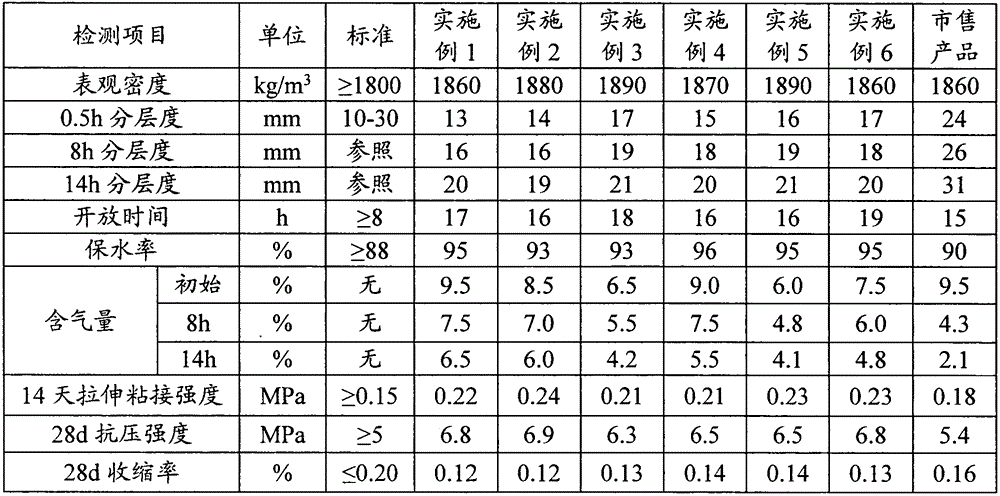

Wet-mixed mortar additive

Owner:张伟

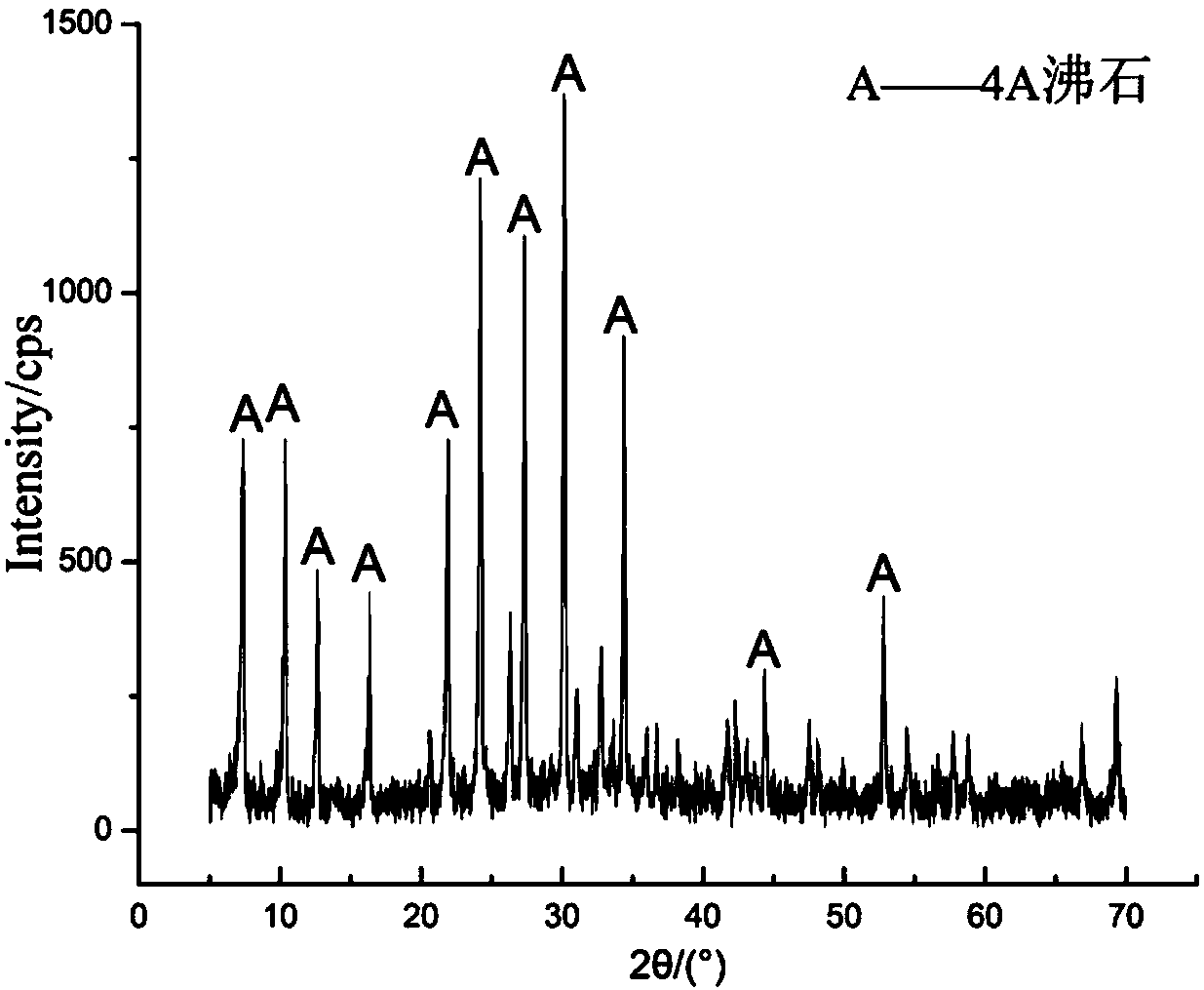

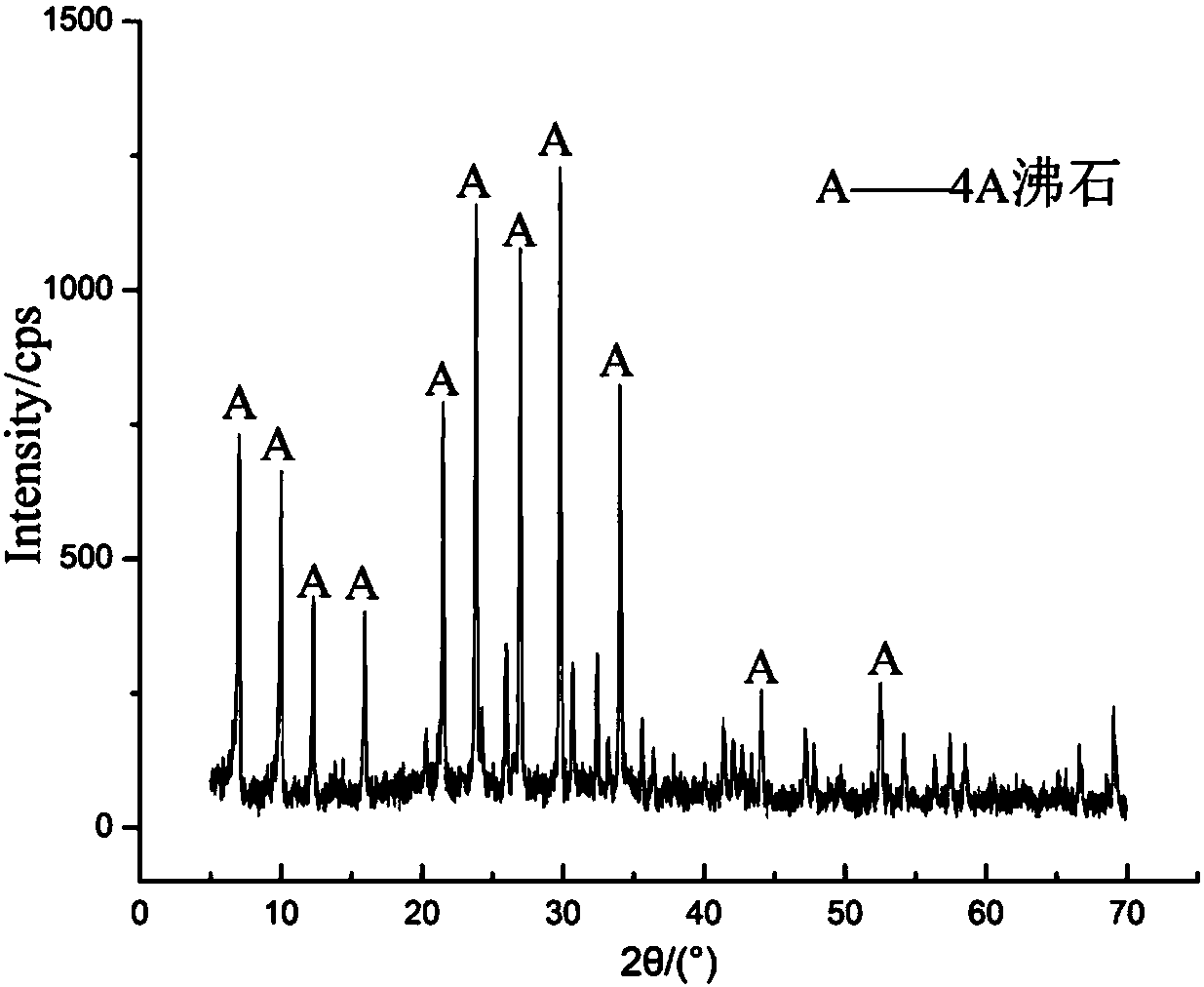

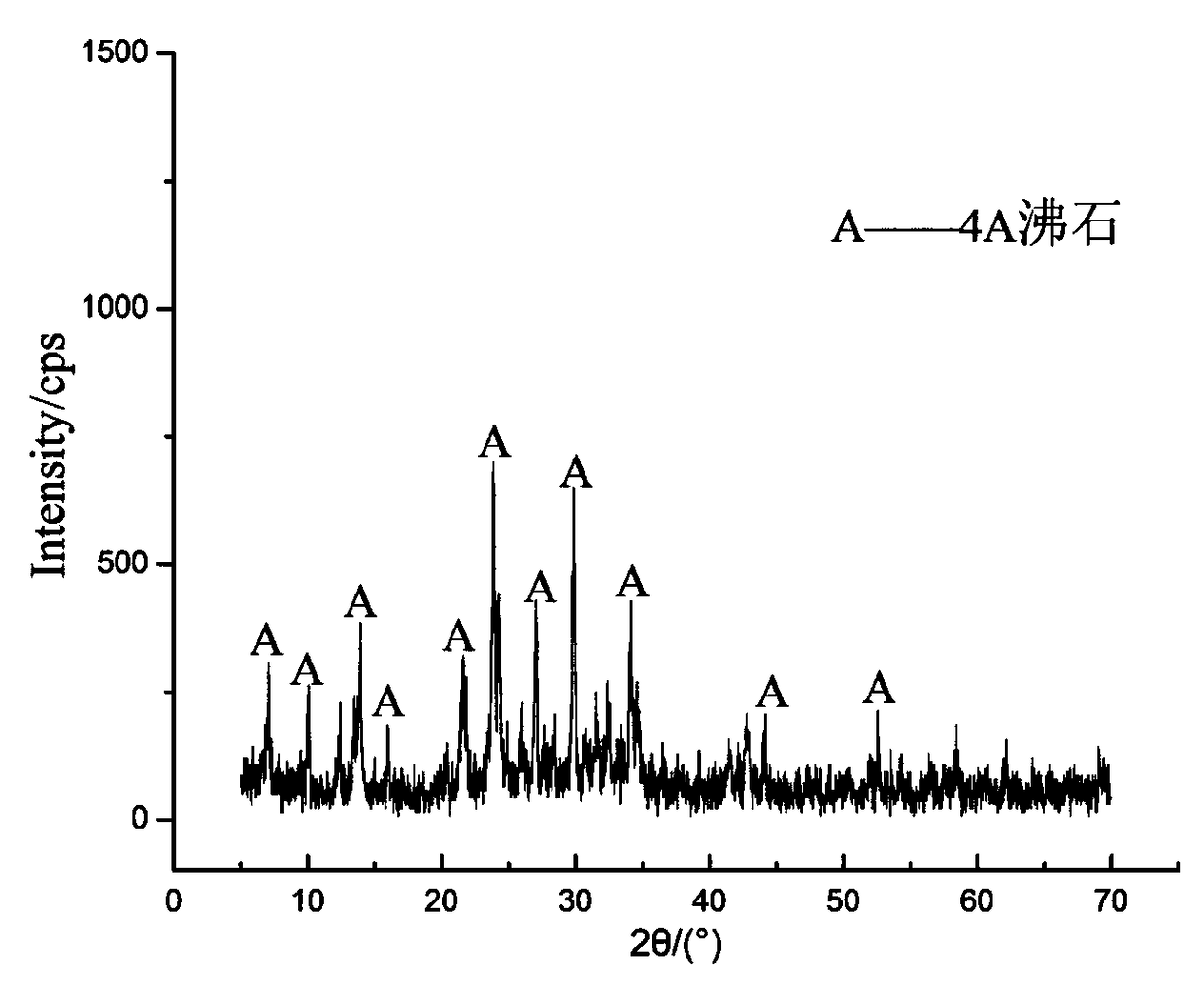

Method for preparing 4A zeolite from gangue serving as raw material through two-step hydrothermal synthesis

PendingCN108483460AIncrease the precipitation rateUniform particle sizeAluminosilicate zeolite type-ASynthesis methodsDissolution

The invention discloses a method for preparing 4A zeolite from gangue serving as a raw material through two-step hydrothermal synthesis. The method comprises the following steps: firstly, crushing andgrinding gangue, performing thermal activation pretreatment, mixing the gangue subjected to thermal activation and sodium carbonate uniformly, and melting at high temperature to obtain a molten mixture; secondly, mixing the molten mixture and water under the water solution condition to dissolve out sodium silicate, filtering to obtain filter residues and drying the filter residues; thirdly, completely stirring the dried filter residues and a sodium hydroxide solution under the alkali dissolution condition, filtering to obtain a silicon aluminum solution, and ageing the silicon aluminum solution to obtain a precursor; finally, performing hydrothermal crystallization treatment on the precursor, and filtering, water-washing and drying to obtain the 4A zeolite. According to the synthesis method, the gangue serves as the raw material, the gangue is subjected to high-end resource-based development and utilization, and the gangue does not need to be subjected to acid leaching pretreatment, so that secondary pollution on the environment is reduced; and an aluminum source does not need to be added in the synthesis process, so the method is simple, high in operability and low in cost.

Owner:SHAANXI NORMAL UNIV

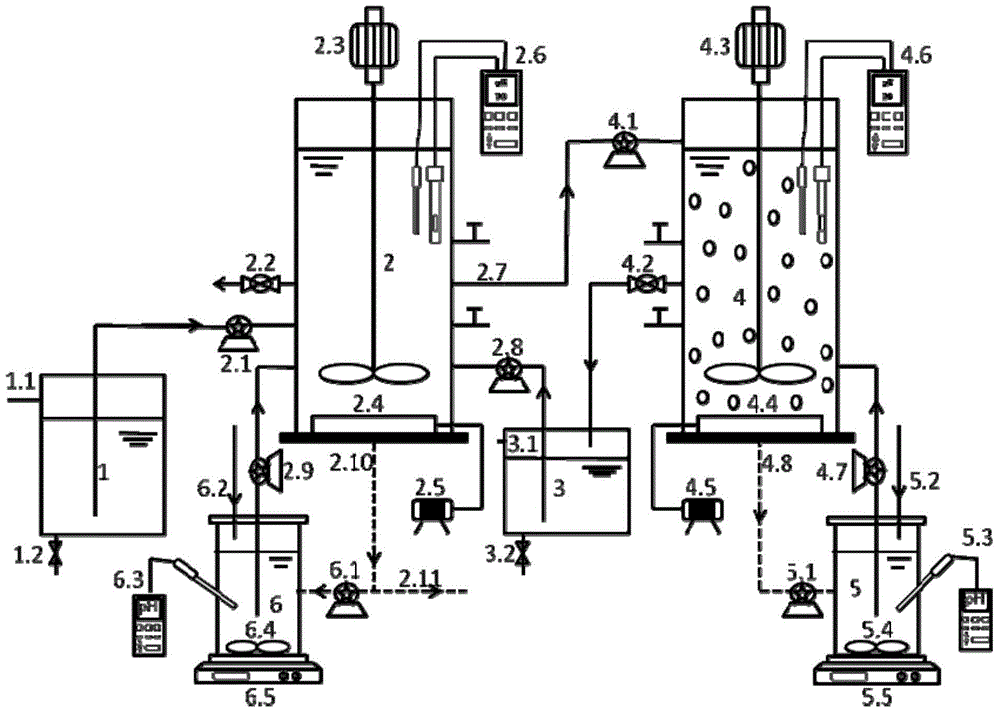

Device and method for synchronous SBR denitrifying phosphorus removal and internal source short-range denitrifying anaerobic ammonia oxidation

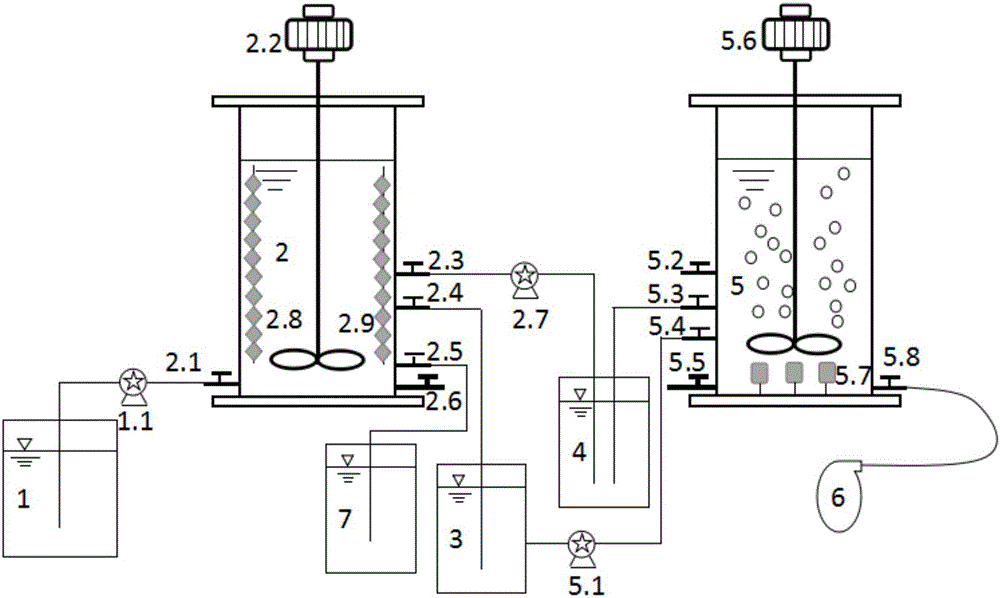

ActiveCN106006963ARealize synchronous removalEfficient use ofTreatment with aerobic and anaerobic processesSustainable biological treatmentDenitrifying bacteriaWastewater

The invention provides a device and method for synchronous SBR denitrifying phosphorus removal and internal source short-range denitrifying anaerobic ammonia oxidation, and belongs to the field of biological treatment of sewage. The device mainly comprises an urban sewage raw water tank, an anaerobic / anoxic SBR, an intermediate water tank, an all-way nitrifying SBR, a blast aerator and a water drainage tank. Urban sewage with low C / N enters the anaerobic / anoxic SBR at first, PAOs carries out anaerobic phosphorus release, and meanwhile, the urban sewage is stored as an internal carbon source PHA by COD in raw water. Anaerobic / anoxic SBR denitrifying phosphorus-accumulating bacteria exist as bio-flocculate, short-range denitrifying bacteria and anaerobic ammonium oxidation bacteria which have long sludge age exist as biological membranes and grow in packing of a reactor, and the SBR discharges flocculate sludge at regular intervals to remove phosphorous, so that competition of different bacteria to the sludge age is avoided. By the device and method, N, P and COD of the urban sewage with low C / N can be removed effectively, and an external carbon source is not required; the problem that NO2<-> is difficult to obtain stably by short-range nitrifying is solved; a new treatment mode is provided for wastewater containing NO3<-> and P.

Owner:BEIJING UNIV OF TECH +1

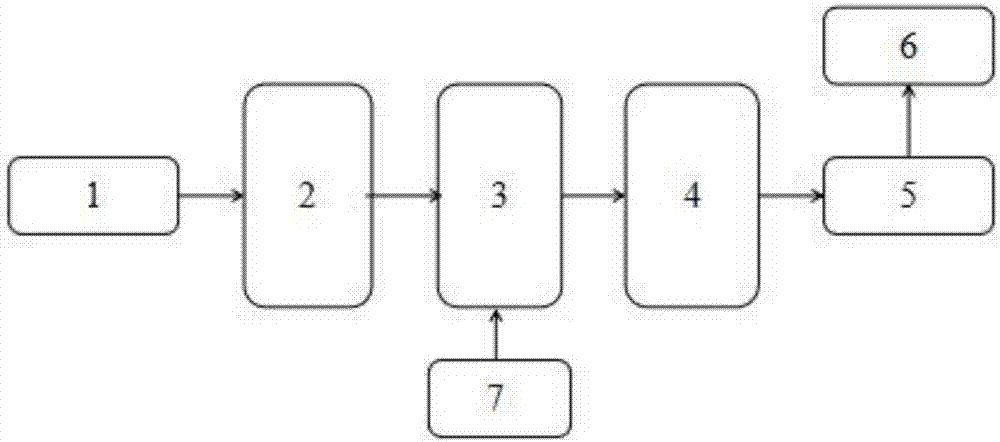

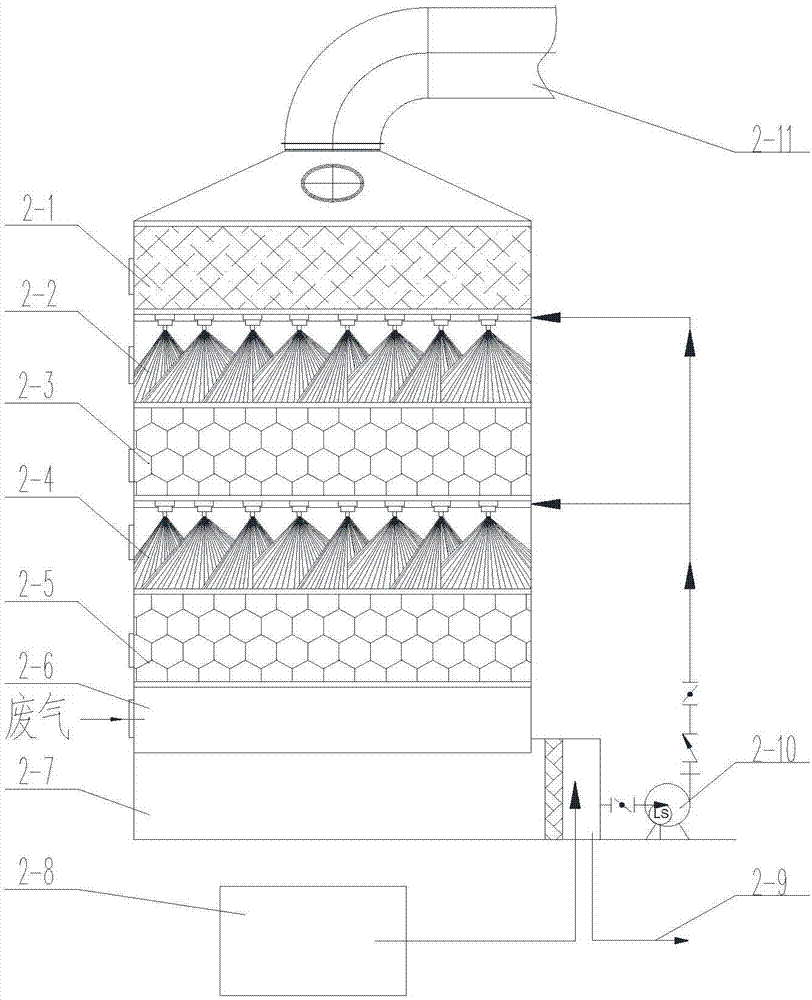

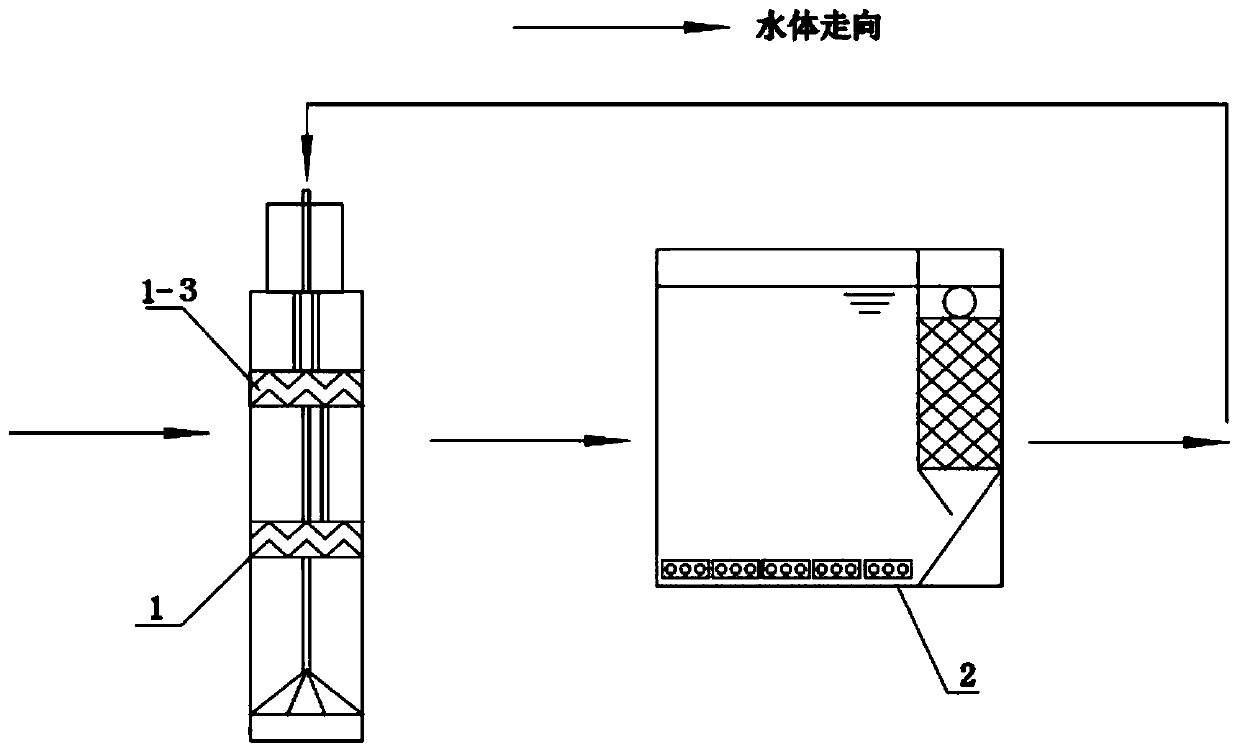

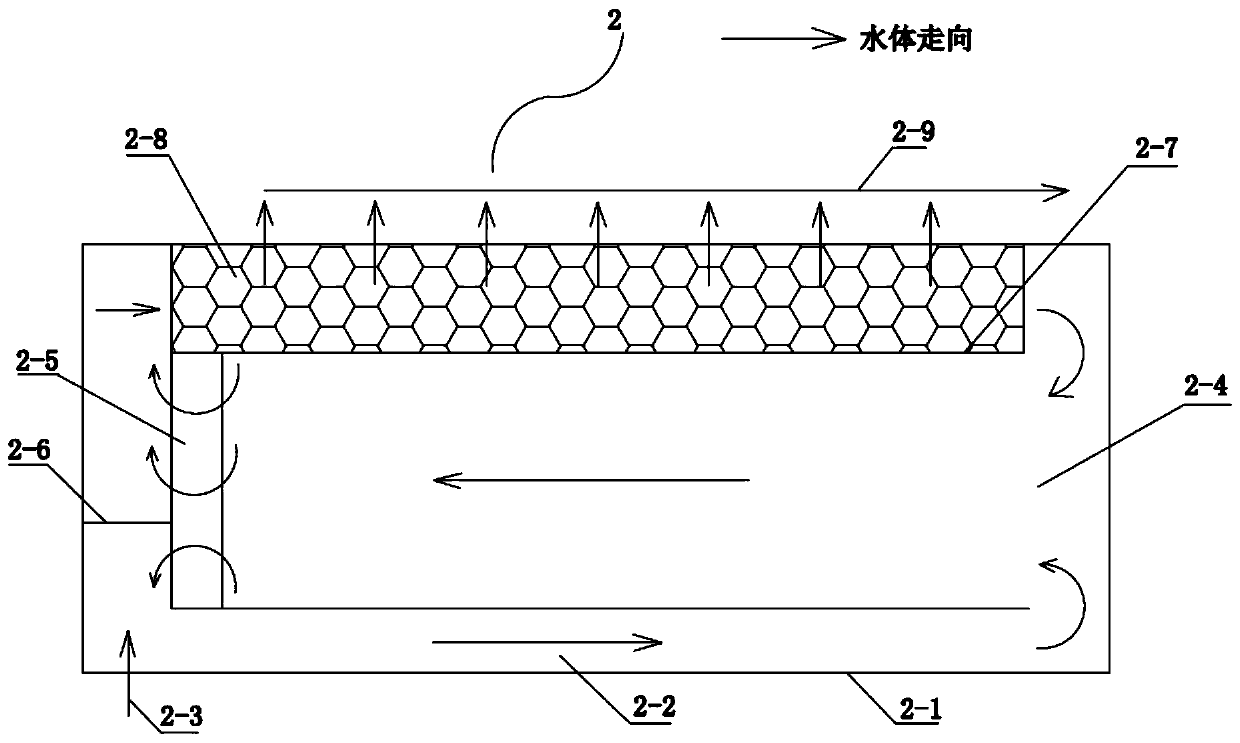

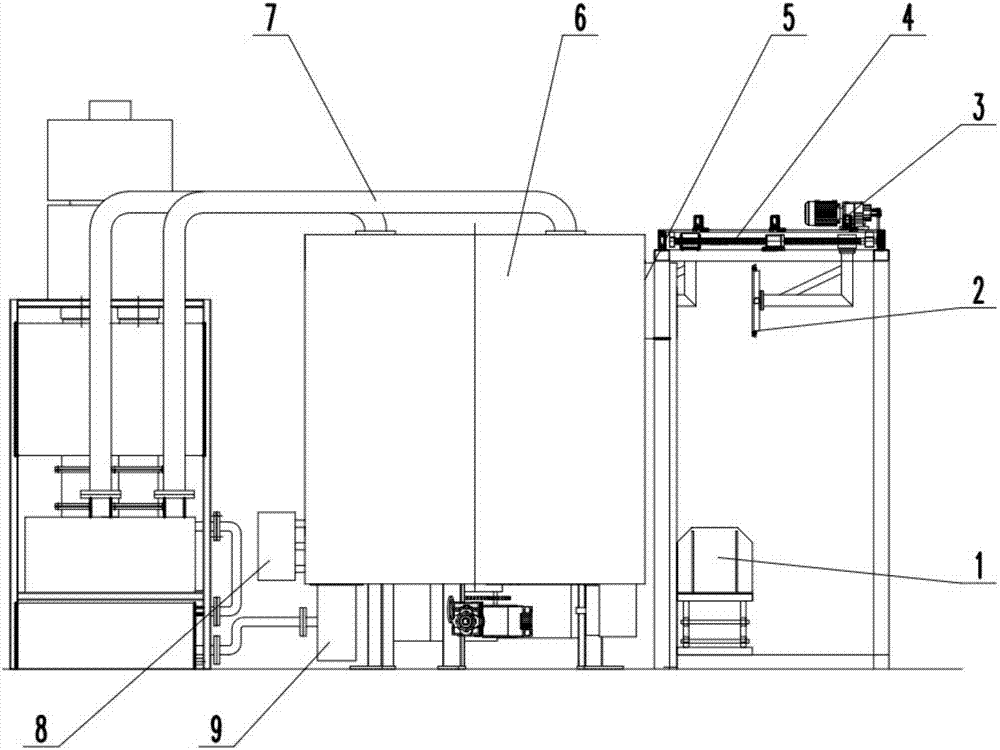

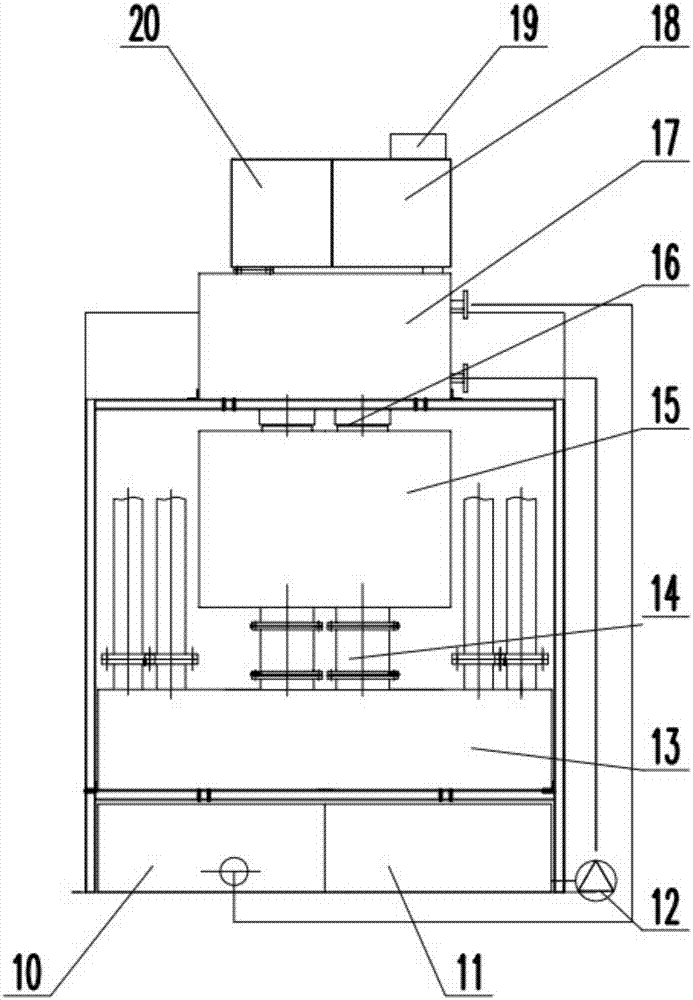

Oxidation treatment system for waste gas produced during innocent treatment of animal manure

InactiveCN106861395AThorough treatmentImprove securityGas treatmentWaste water treatment from animal husbandryEnvironmental resistanceEngineering

The invention relates to an oxidation treatment system for waste gas produced during innocent treatment of animal manure. The system comprises a waste gas collection area (1), an acid pickling spray tower (2), an oxidation spray tower (3), an acid-base neutralization tower (4), an exhaust fan (5), a chimney (6), a positive charge ozone generator (7) and the like. The waste gas oxidation system can specifically remove waste ammonia gas, hydrogen sulfide, volatile organic compounds and the like produced in the composting fermentation engineering, and has the advantages of thorough waste gas treatment, good effect, low cost, stable process, high safety and high cost performance; and the ammonium sulfate rich waste liquid produced by the waste gas oxidation treatment system is not discharged to the outside but serves as a nitrogen element and water supplement liquid in the biological organic fertilizer granulation process, so that the system does not produce secondary pollution, realizes reuse of waste resources and is beneficial to environment protection.

Owner:秦皇岛领先康地农业技术有限公司

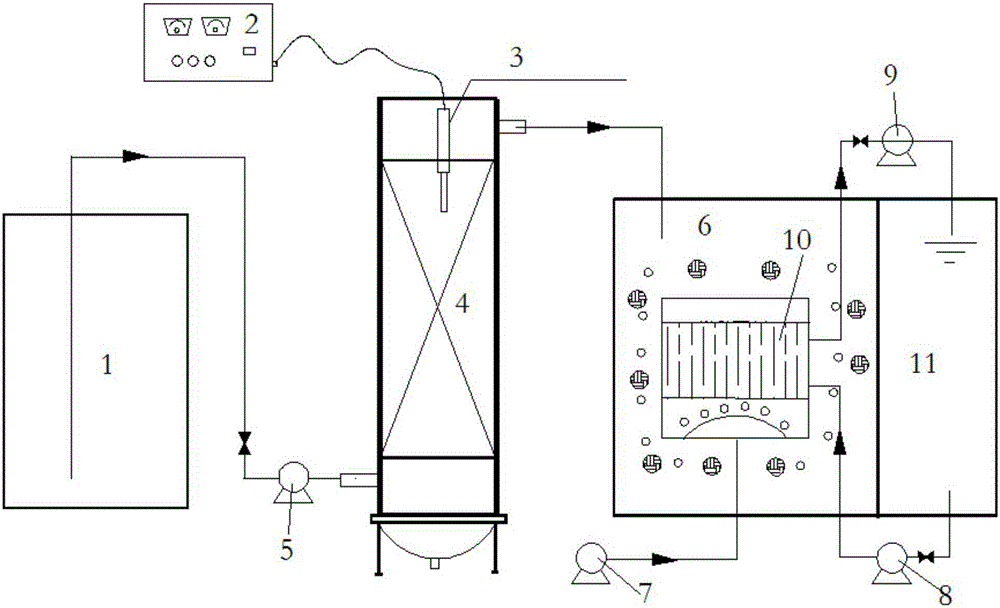

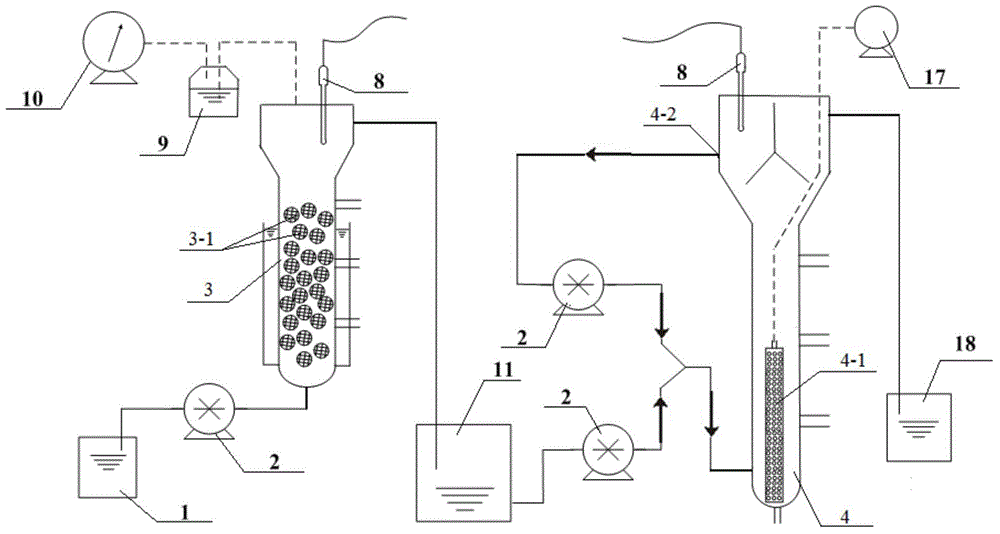

Device and method for treating ship sewage through ultrasonic strengthening internal electrolysis coupling biological method

InactiveCN105174632AImprove contact efficiencyImprove removal efficiencyAuxillariesWater/sewage treatment with mechanical oscillationsActivated sludgePeristaltic pump

The invention provides a device and method for treating ship sewage through an ultrasonic strengthening internal electrolysis coupling biological method. Ship sanitary sewage in a raw water tank enters a catalytic iron internal electrolysis column through a peristaltic pump, an ultrasonic vibration bar mounted in the catalytic iron internal electrolysis column emits ultrasonic waves to strengthen an internal electrolysis reaction, the sewage subjected to the ultrasonic strengthening internal electrolysis reaction enters an aeration tank, pollutants in the sewage are further treated through activated sludge in an MBR, a time relay controls an aeration pump to be started and stopped, and when the aeration pump runs, nitrobacteria in the aeration tank are subjected to an aerobiotic nitration reaction, and meanwhile a reverse suction pump carries out suction and water output; when the aeration pump is stopped, nitrogen removal by denitrification effect is achieved in the aeration tank, and the suction pump stops suction. According to the device and method, the requirement in a guide rule for the emission of nitrogen and phosphorus in the ship sanitary sewage can be effectively met, by means of the device, the space of a ship is saved, nitration liquid does not need to flow back, operation and management are convenient, and the device and method are suitable for being used for the ship.

Owner:HARBIN ENG UNIV

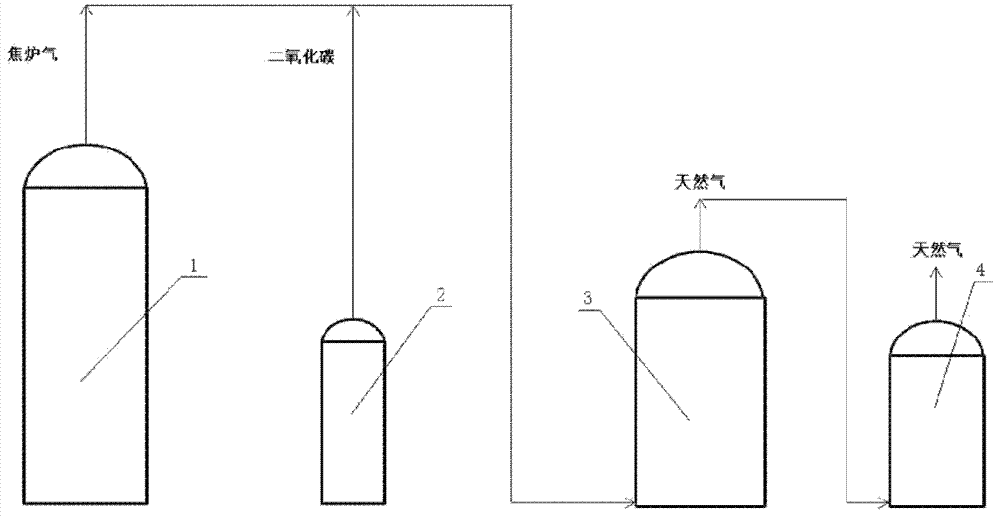

Process for realizing natural gas preparation with coke oven gas by using anaerobic microbes

InactiveCN103087793ANo need to addNo need for high temperature and high pressureChemical industryGaseous fuelsCo2 storageAnaerobic reactor

The invention discloses a process for realizing natural gas preparation with coke oven gas by using anaerobic microbes. The process comprises the steps that: a, coke oven gas in a coking furnace and CO2 gas in a CO2 storage tank are mixed, such that mixed gas is obtained; b, the mixed gas is delivered into an anaerobic reactor with high-activity anaerobic microbes; in the anaerobic reactor, CO2, H2 and CO in the original coke oven gas are utilized, and CH4 is produced; H2S in the original coke oven gas is produced into elemental S through sulfur bacteria in the high-activity anaerobic microbes; and c, N2 and other impurities are separated with a pressure-swing adsorption separation device or a cryogenic separation device, such that natural gas with high methane content is obtained. According to the invention, with a microbial process, CO2 is supplemented, and natural gas is prepared. The process is highly economical. With the process, catalyst is not needed, and high-temperature and high-pressure are not needed. Most components except methane in the coke oven gas can be converted into methane, such that CO2 emission is reduced, and effects of energy saving and environment protection are achieved.

Owner:SHANGHAI BAIWOSI WATER TREATMENT TECH

Short-range denitrification/dephosphorization device and method based on sludge side pretreatment

ActiveCN104817178AFully absorbedInhibit growthTreatment with aerobic and anaerobic processesNitrationMunicipal sewage

The invention relates to a short-range denitrification / dephosphorization device and method based on sludge side pretreatment, belonging to the field of sewage treatment. The device comprises a municipal sewage raw water tank, a denitrification / dephosphorization reactor, an intermediate water tank, a short-range nitration reactor, a first sludge pretreatment reactor and a second sludge pretreatment reactor. The method comprises the following steps: municipal sewage enters the denitrification / dephosphorization reactor, sludge subjected to FNA pretreatment is added, and microbes convert organic matters in raw water and pretreated sludge into PHAs; the sewage enters the short-range nitration reactor to perform short-range nitration; and on the basis of sludge side pretreatment, part of surplus sludge is subjected to FNA treatment and flows back into the reactor to inhibit the propagation of nitrite oxidizing bacteria, thereby implementing and maintaining the short-range nitration of the system stable. The sewage subjected to short-range nitration is synchronously denitrified and dephosphorized. The method quickly and stably implements the short-range denitrification / dephosphorization, saves the carbon sources, reduces the sludge amount, and lowers the sewage treatment energy consumption.

Owner:BEIJING UNIV OF TECH

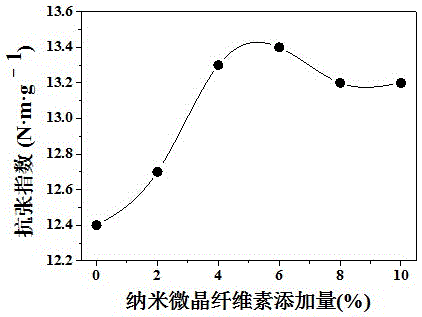

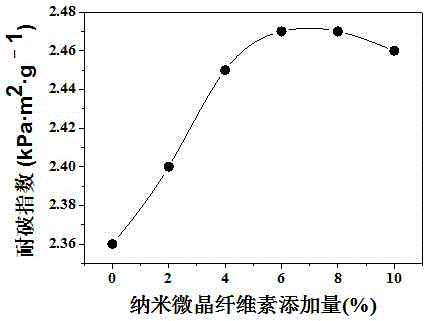

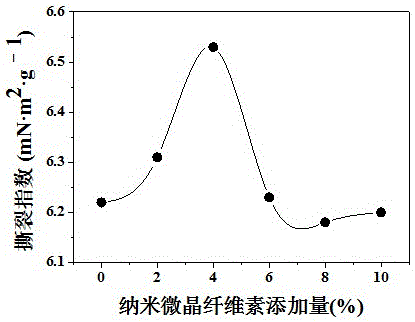

Method for improving strength of wastepaper fibers based on nanometer microcrystalline cellulose

InactiveCN105113320AImprove tensile strengthHigh burst resistancePaper/cardboardInorganic compound additionFiberUltimate tensile strength

The invention relates to a method for improving the strength of wastepaper fibers based on nanometer microcrystalline cellulose. The method comprises the following steps: preparing the nanometer microcrystalline cellulose and a wastepaper pulp; taking a certain amount of the pulp, adding a proper amount of water, sequentially adding calcium carbonate, a cationic polyacrylamide solution and a nanometer microcrystalline cellulose suspension, and defibering in a GBJ-A fiber standard dissociator; shaping the defibered pulp in the shaping position of a ZQJ1-B-II paper handsheet former to obtain wet paper; and transferring the wet paper to a position between two dry cloths, carrying out a squeezing technology to remove a certain amount of water, and carrying out vacuum drying at 105DEG C for 15min to obtain dry paper. The method has the advantages of simple process, no need of arrangement of any devices, and easy operation control, and is of great guiding significance to efficient application of wastepaper fibers and enterprise production adopting wastepaper as a raw material.

Owner:ZHEJIANG SCI-TECH UNIV

Method for synchronous implementation of methanation of coke oven gas and in-situ purification of marsh gas

InactiveCN103113010AAchieve in-situ purificationNo need to addHydrocarbon from carbon oxidesGaseous fuelsMethanationCoke oven

The invention relates to a method for synchronous implementation of methanation of coke oven gas and in-situ purification of marsh gas. The method comprises the following steps: (a) introducing the coke oven gas and organic wastes into an anaerobic reactor; (b) in the anaerobic reactor, degrading the organic wastes with microbes to generate CH4 and CO2, enabling produced CO2 to combine with H2 in the coke oven gas to generate CH4 under the action of the microbes, and reacting CO and CO2 in the coke oven gas with H2 to generate CH4 to get the marsh gas which mainly contains CH4; and (c) separating and removing impurities in the marsh gas obtained in the step (b) to get natural gas with high content of methane. Compared with the prior art, according to the method disclosed by the invention, a microbial process is adopted for introducing the coke oven gas into the anaerobic reactor, the in-situ purification of the marsh gas is simultaneously implemented during the preparation of the natural gas, a catalyst is not required, high temperature and high pressure are not required, and most of components except methane in the coke oven gas and the marsh gas can be converted to methane, so that the new method is provided for solving the problems of shortage of resources, environmental pollution, unreasonable energy structure and the like in the energy field in China.

Owner:TONGJI UNIV

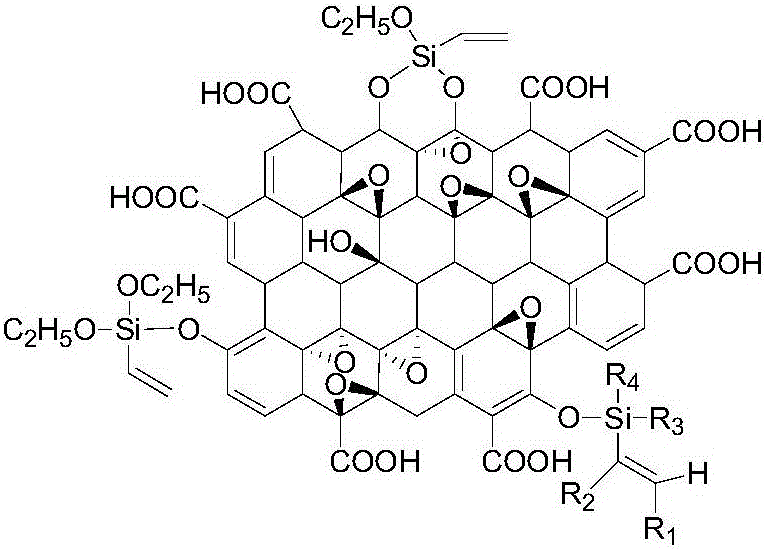

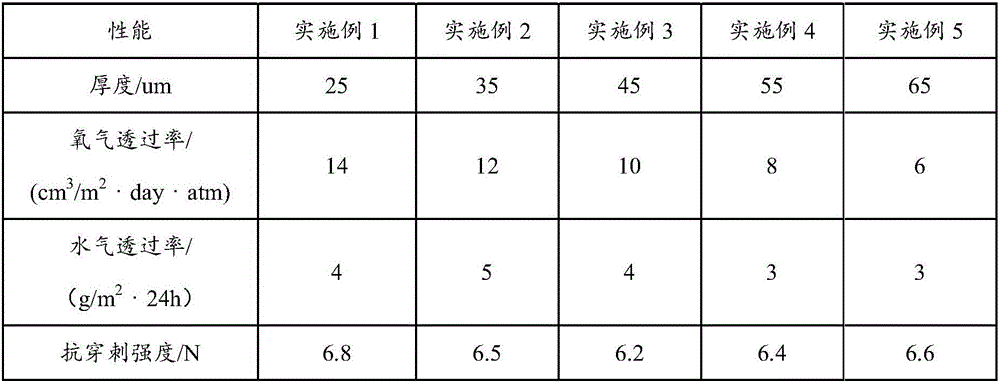

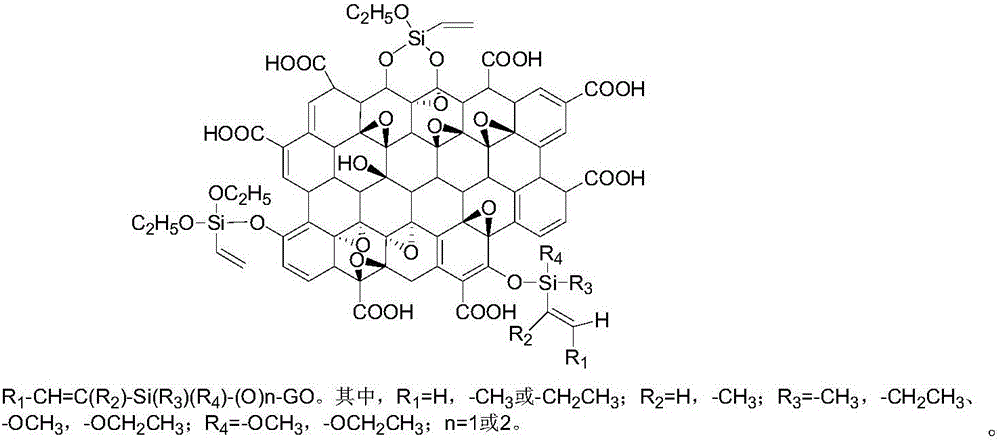

High-barrier double-bond functionalized graphene oxide/polyethylene film and preparation method thereof

ActiveCN106832534ANo need to addGood compatibilityFlat articlesLow-density polyethyleneComposite film

The invention discloses high-barrier double-bond functionalized graphene oxide / polyethylene film and a preparation method thereof; the high-barrier double-bond functionalized graphene oxide / polyethylene film comprises double-bond functionalized graphene oxide component; the preparation method comprises the specific steps of mixing the double-bond functional group modified graphene oxide with low-density polyethylene resin at a certain ratio, and performing longitudinal stretching and then transverse stretching processes to prepare the graphene oxide / polyethylene composite film; the prepared double-bond functionalized graphene oxide / polyethylene film is simple to prepare, high in barrier property, adjustable in thickness and suitable for large-scale industrial preparation, and has a promising market prospect in food packaging, electronic encapsulating and other application fields.

Owner:XIAMEN UNIV +1

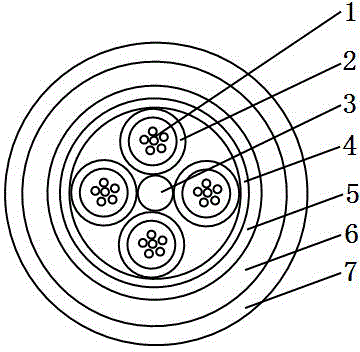

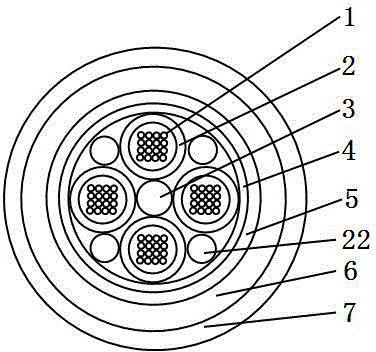

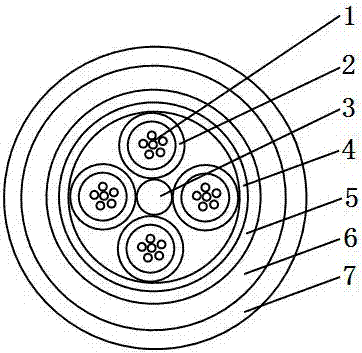

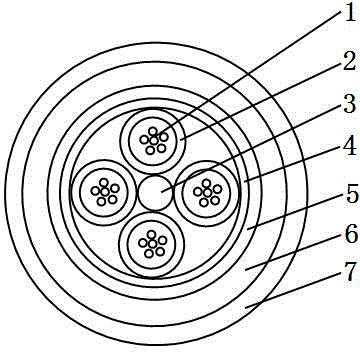

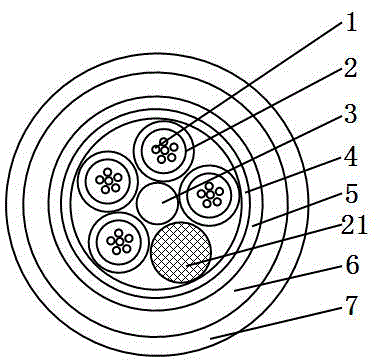

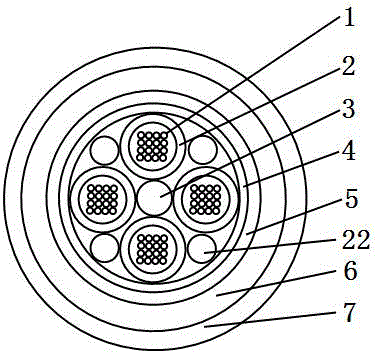

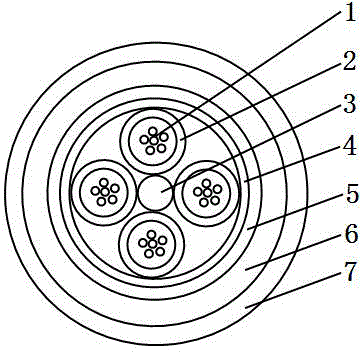

Bird pecking prevented optical cable and manufacturing method thereof

ActiveCN104656216AStrong pressureStrong impact resistanceFibre mechanical structuresEpoxyStructural engineering

The invention belongs to the technical field of cables and particularly relates to a bird pecking prevented optical cable. The bird pecking prevented optical cable comprises a plurality of loose sleeves, a protective layer, an inner protecting layer and an outer sheath, wherein the loose sleeves are distributed outside a reinforcing member, the protective layer is located outside the loose sleeves, the inner protecting layer is located outside the protective layer, and the outer sheath is located outside the inner protecting layer; each loose sleeve at least contains one optical fiber. The bird pecking prevented optical cable is characterized in that a bird pecking preventing layer is arranged between the inner protecting layer and the outer sheath and is prepared from the following raw materials: medium-density polyethylene or low-density polyethylene or high-density polyethylene, epoxy resin, superfine steel fibers or glass fibers or silica optical fibers, an EVA (Ethylene Vinyl acetate Copolymer) hot-melt adhesive, an antioxidant, aluminum hydroxide, paraffin and carbon black master batches. The invention further discloses a manufacturing method of the bird pecking prevented optical cable. The bird pecking prevented optical cable and the manufacturing method thereof have the following main beneficial effects that the manufacturing is easy, the bird pecking preventing effect is good, the production speed is high, and finished products are high in qualified rate and are more pressure-resistant and more impact-resistant.

Owner:郑州天河通信科技有限公司

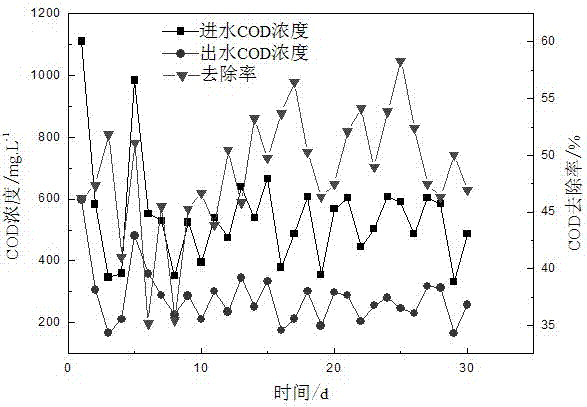

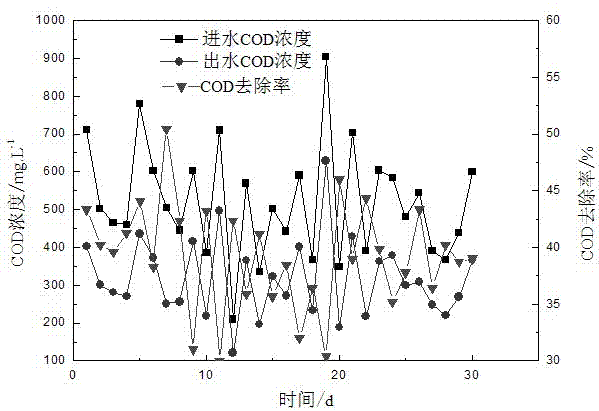

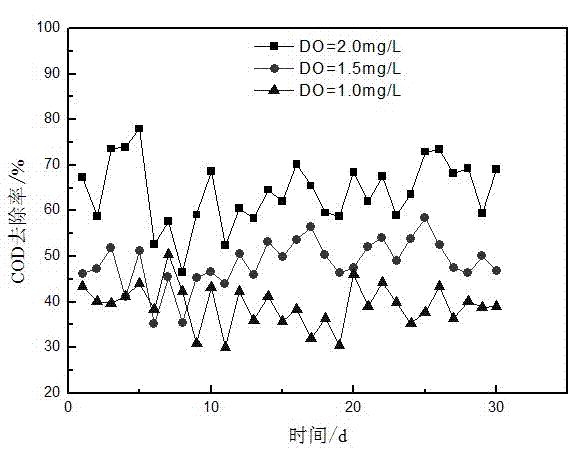

Optimization method for fertilizer wastewater treatment process

ActiveCN102225828AAccelerated settlementImprove compactnessMultistage water/sewage treatmentRefluxChemical oxygen demand

The present invention provides an optimization method for a fertilizer wastewater treatment process. The original process comprises the following steps of: homogenizing and weight-equalizing fertilizer wastewater by an adjusting tank, pumping the wastewater from the adjusting tank to a primary aeration tank by a wastewater pump to remove part of COD (chemical oxygen demand) and toxic and harmful substances in the wastewater; and introducing the primarily settled wastewater into the front denitrification biological denitrogenation section and subsequent physical and chemical advanced treatmentsection of an anoxic tank / aerobic tank, and simultaneously adding high-efficiency microbial flora to a biochemical system. By optimizing the dissolved oxygen concentration of the primary aeration tank and nitrification liquid reflux ratio R and sludge reflux ratio r2 of the front denitrification biological denitrogenation section of the anoxic tank / aerobic tank, the optimization method improves the total nitrogen removal rate of the fertilizer wastewater from 41.1% to 66.7% (increased by 25.6%) and improves the COD and ammonia nitrogen removal rates to 95.8% and 98.8%, respectively.

Owner:SOUTH CHINA UNIV OF TECH +1

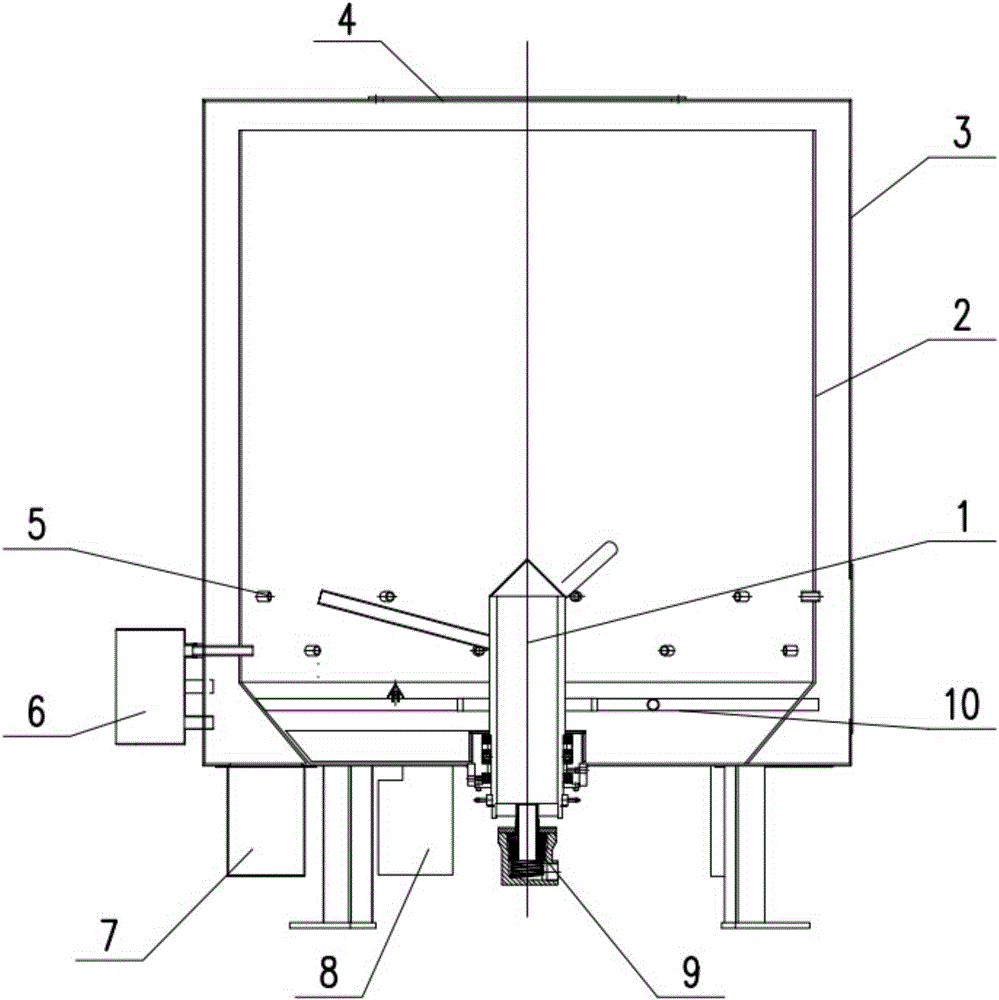

Magnetization cracking device with stirring mechanism

PendingCN106765157ANo need to addAvoid secondary pollutionIncinerator apparatusMagnetizationNational standard

The invention discloses a magnetization cracking device with a stirring mechanism. Discharged tail gas meets the national standard requirement, harmful gas does not need to be separated from primary air, the harmful gas is directly converted into harmless matter, secondary pollution is avoided, and heat can also be recycled to be comprehensively utilized. The lower end of an inner container is connected to the bottom of an outer container in a sealed manner, and multiple air inlets are formed in the lower end of the inner container. The upper end of the outer container is movably connected with a feeding port, and multiple magnetization boxes are fixedly connected to the outer side of the outer container. The magnetization boxes are connected with the air inlets through pipelines. A stirring shaft is movably connected to the middle position of the bottom of the inner container and the middle position of the bottom of the outer container. A through ventilation hole is formed in the stirring shaft, and the inlet end of the ventilation hole is connected with a rotating connector. The stirring shaft is fixedly connected with multiple tentacle branches and a scraper plate. A grate is arranged at the lower end of the inner container, and the grate is arranged at the position, between the tentacle branches and the scraper plate, on the stirring shaft in a sleeving manner. The bottom of the outer container is provided with an ash outlet and a water outlet. An ash box and a water box are connected to the position under the ash outlet and the position under the water outlet of the bottom of the outer container correspondingly.

Owner:鑫源昊(浙江)环保能源科技有限公司

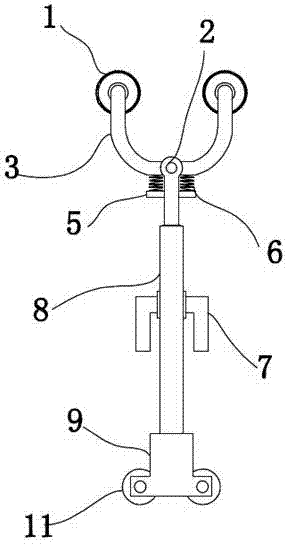

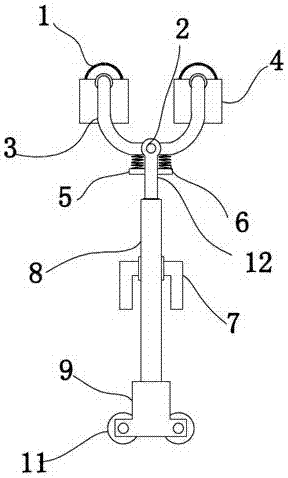

Ceiling painting device for decoration construction

InactiveCN106894616ASimple structureNo need to addBuilding constructionsEngineeringMechanical engineering

The invention discloses a ceiling painter for decoration and construction, which comprises a support base, the upper end of the base has a support shaft, and a shaft hole is opened on the top of the support shaft, and a first spring is installed in the shaft hole. , a telescopic rod is inserted into the shaft hole, the bottom of the telescopic rod is inserted into the shaft hole and contacts the upper end surface of the first spring, and the top of the telescopic rod is rotated by a hinge structure to install two brackets. A painting roller is installed on the top of the support, and a material storage box is installed on the bottom support of the painting roller, paint is placed in the material storage box, and the bottom of the painting roller is submerged under the paint liquid level in the material storage box. The invention has a simple structure, is mainly used for painting the ceiling, does not need to touch the support frame to obtain height, and is safer to operate, and is independently equipped with a material storage box without adding materials, which is very convenient and greatly improves work efficiency.

Owner:王宏斌

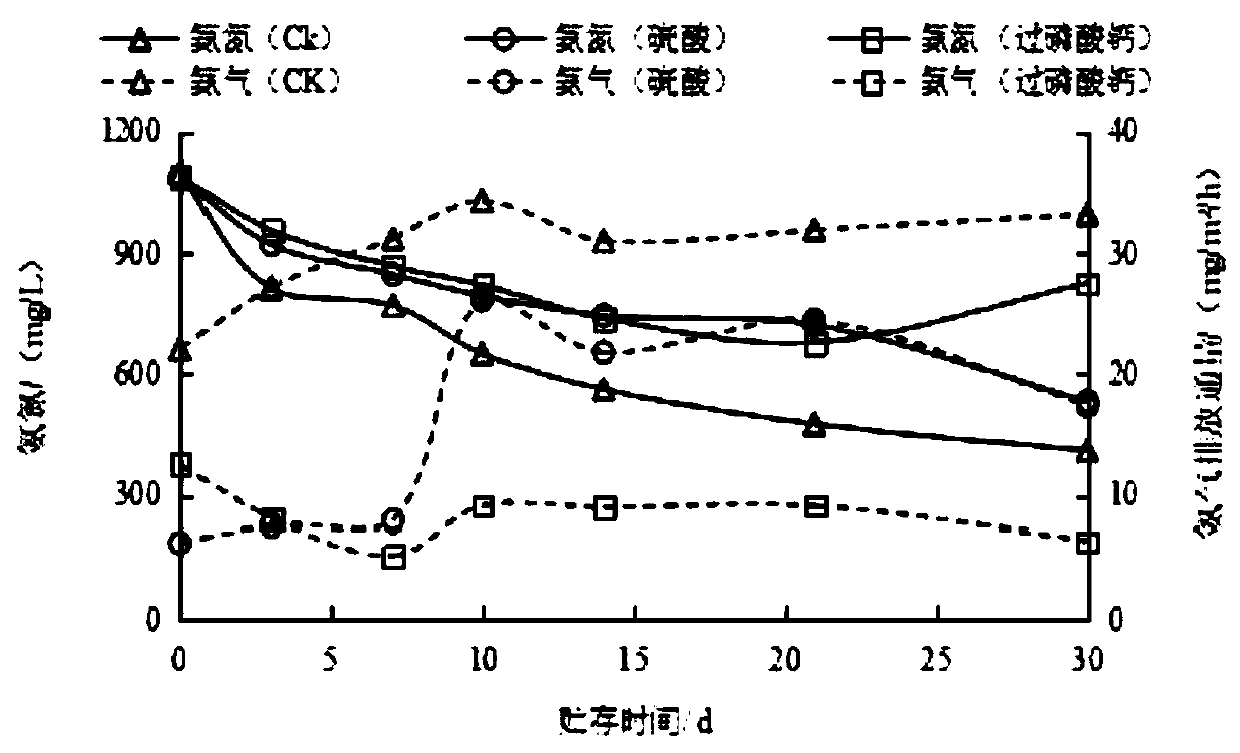

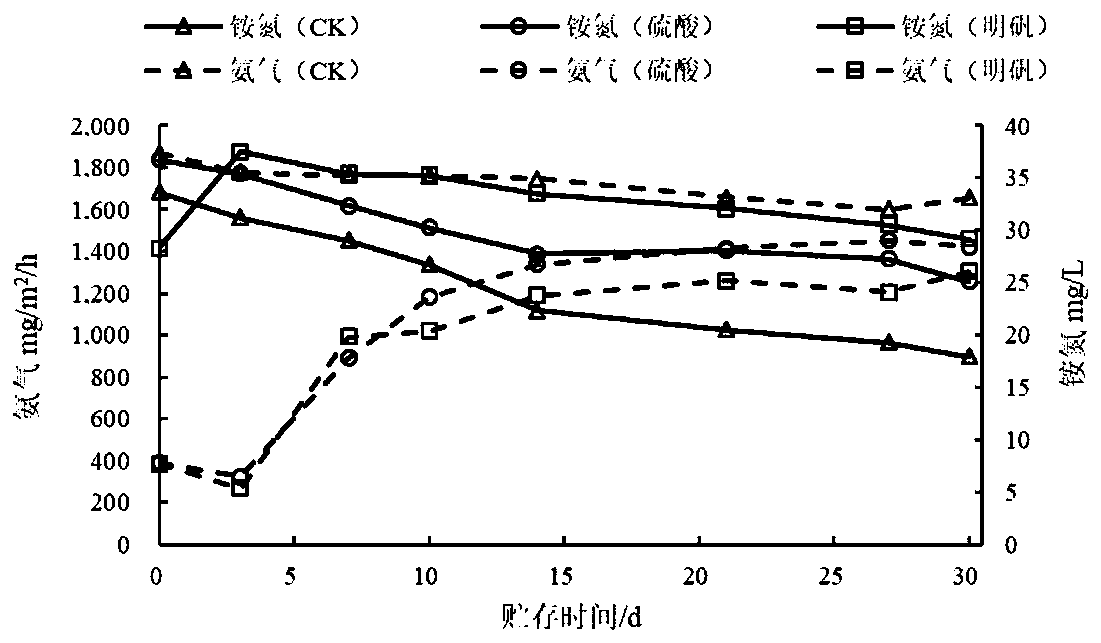

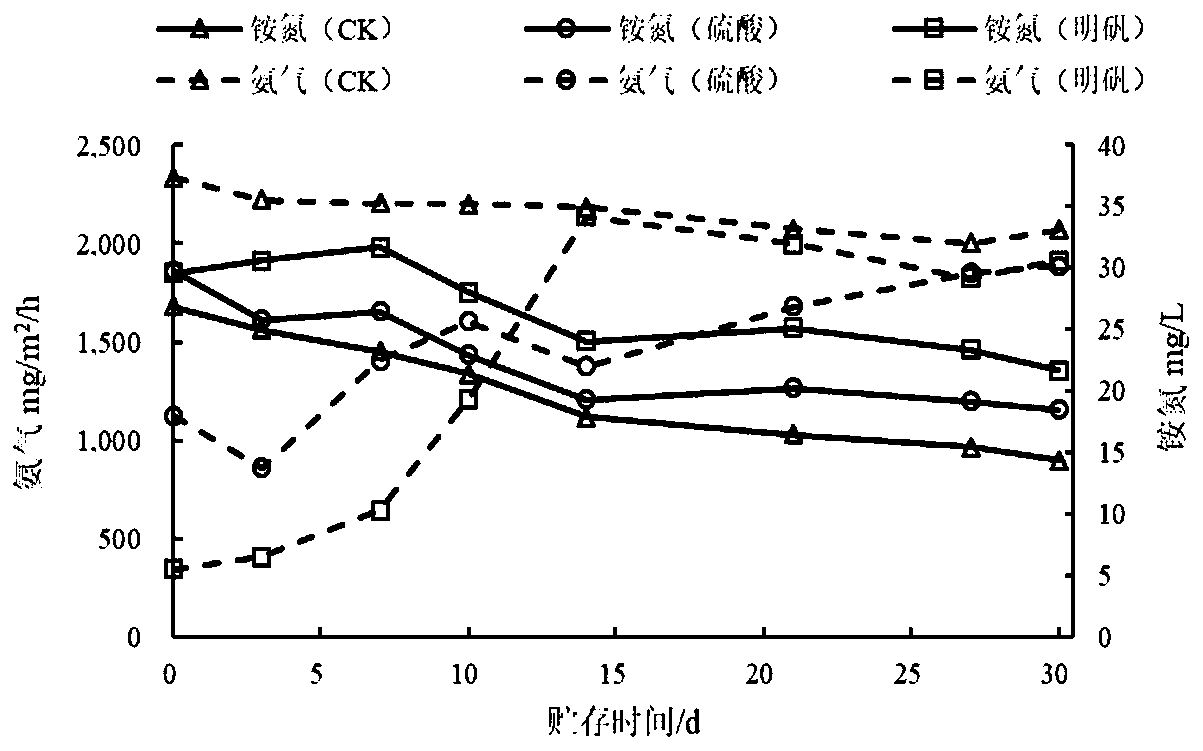

Method for immobilizing nutrients in pig breeding liquid dung

InactiveCN110713420AImprove manure fertilizer efficiencyEasy to operateSuperphosphatesFertilizer mixturesLivestockAnimal science

The invention provides a method for immobilizing nutrients in pig breeding liquid dung. The method comprises the following steps: slowly adding calcium superphosphate into livestock liquid dung in anadjusting tank, continuously stirring the mixture, and adjusting the pH value of the livestock liquid dung to 6.0-6.5; wherein the mass of the added calcium superphosphate is 2-5.5% of the mass of thelivestock liquid dung. According to the method, the ammonia gas emission flux can be reduced by 43%-99% in the liquid dung storage process; the fertility of the liquid dung is improved, the number offecal coliform groups in the liquid dung meets the national standard requirement, after the calcium superphosphate is added into the liquid dung, the mixture is stored, and the pig breeding liquid dung is returned to the field for application, the crop yield can be increased, ammonia emission and nitrogen leaching loss in the farmland are reduced, and good ecological and environmental benefits are achieved.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

Method for treating high-concentration organic wastewater by anaerobic-aerobic deep coupling

InactiveCN111333191ALight inhibitionImprove efficiencyWater treatment parameter controlWater contaminantsActivated sludgeAmmoniacal nitrogen

The invention relates to a method for treating high-concentration organic wastewater by anaerobic-aerobic deep coupling. The method comprises the following steps: introducing organic wastewater into an anaerobic reaction unit, and sufficiently mixing the organic wastewater with anaerobic granular sludge added into the anaerobic reaction unit in advance to perform anaerobic reaction; enabling anaerobic effluent obtained after anaerobic reaction to enter an aerobic reaction unit, and removing nitrogen through a synchronous nitrification and denitrification process; flowing part of effluent of the aerobic reaction unit back to the anaerobic reaction unit and fully diluting and mixing the part of effluent with the raw organic wastewater and granular sludge to carry out anaerobic reaction, andenabling the other part of effluent to enter a next treatment process or discharging the other part of effluent after reaching the standard. According to the invention, the anaerobic and aerobic reaction units are coupled to treat wastewater; anaerobic effluent enters the aerobic unit, the DO value in the water body of the aerobic unit is controlled, denitrification is effectively completed, thereflux ratio of the aerobic effluent is controlled, and the aerobic effluent returns to the anaerobic unit again, so that the ammonia nitrogen concentration in the anaerobic reactor is reduced, the activated sludge amount in the anaerobic reactor is ensured, and the anaerobic reaction efficiency is effectively improved.

Owner:恩格拜(武汉)生态科技有限公司

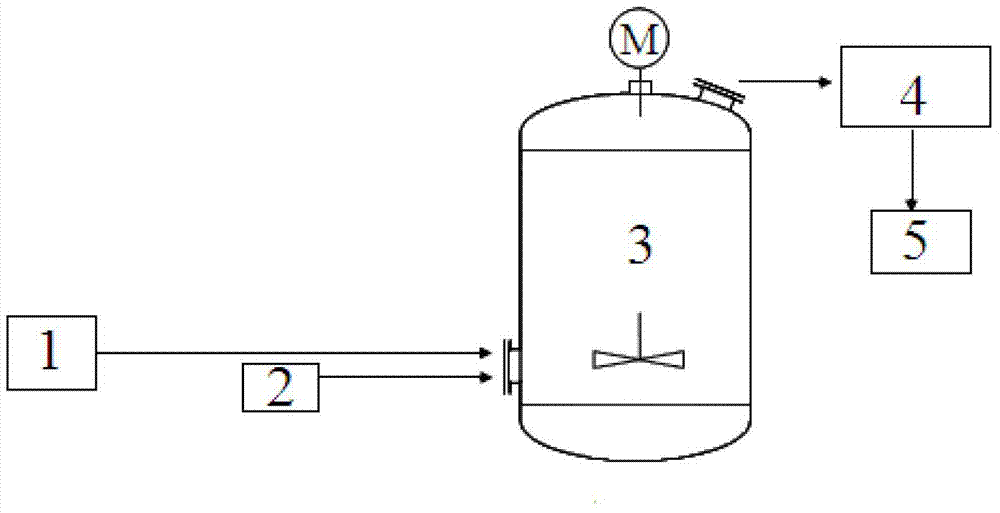

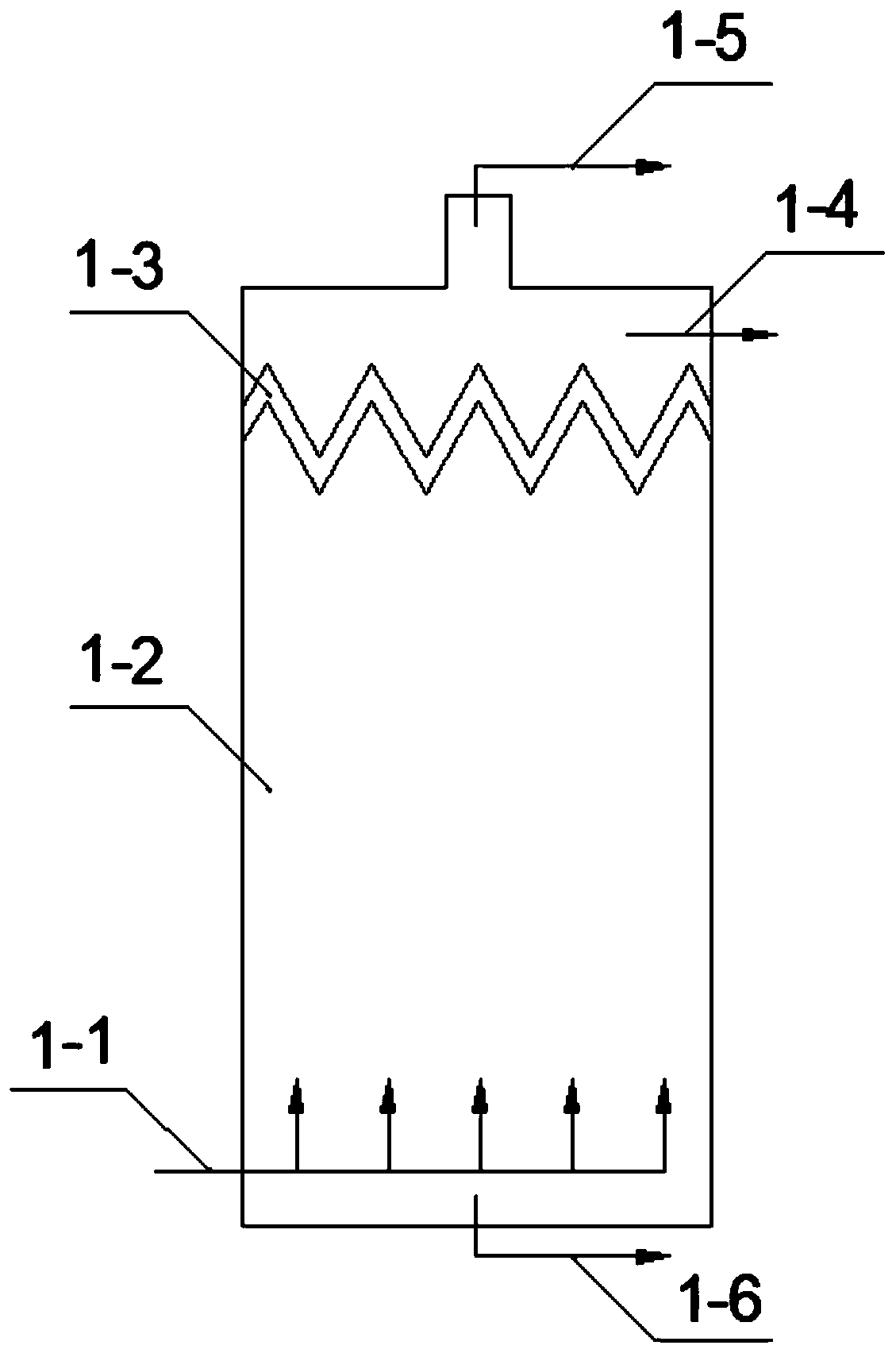

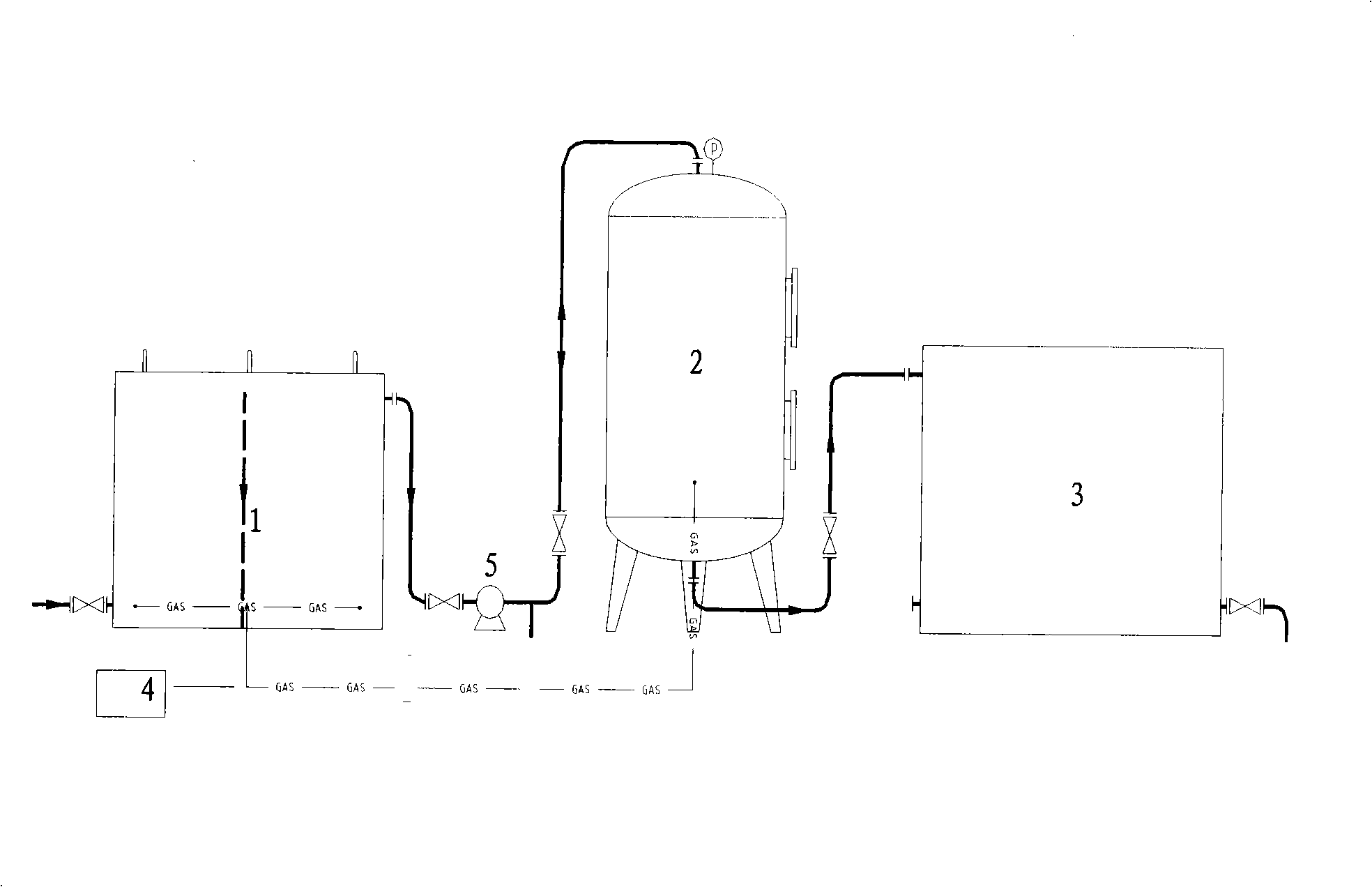

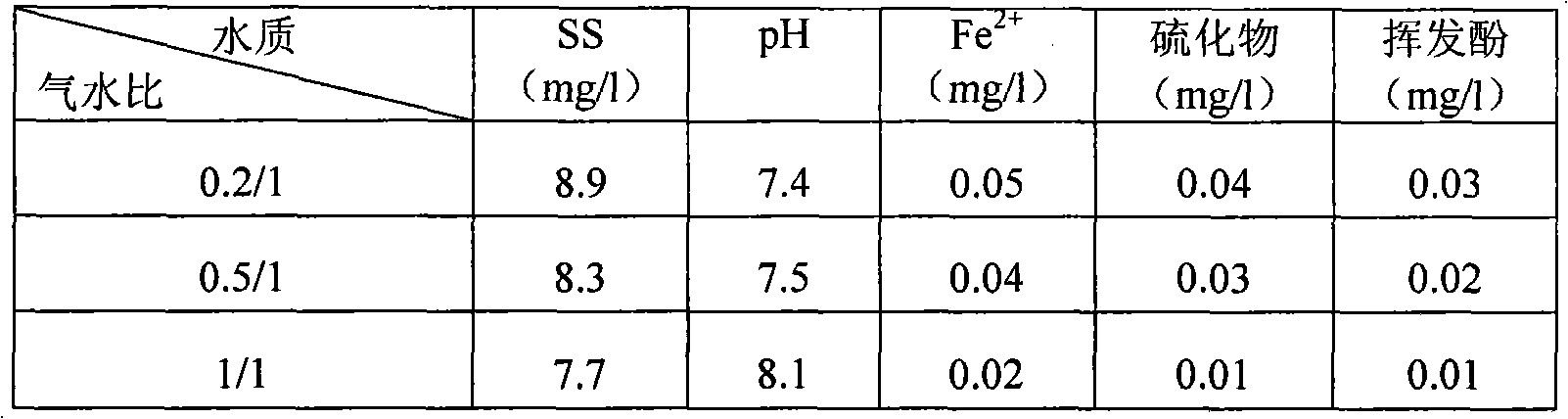

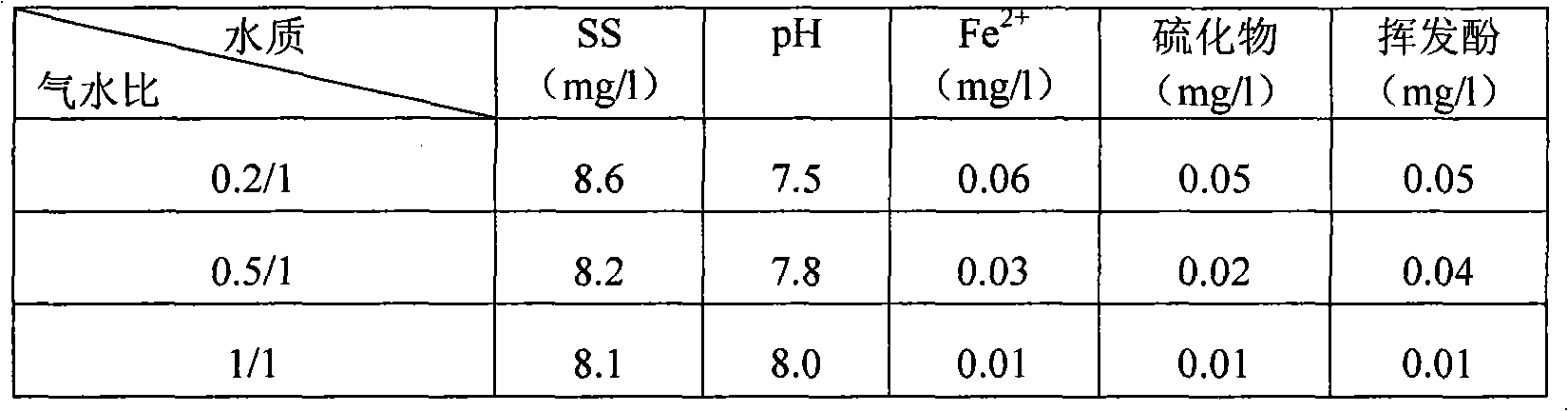

Catalysis treatment method for oil field wastewater re-injection

InactiveCN101402483AReduce dosageLow running costWater/sewage treatment by oxidationComing outFiltration

The invention relates to the field of oil field waste water treatment and reinjection, in particular to the field of the catalytic treatment of the oil field polymer contained waste water reinjection. The catalyst used for the oil field waste water reinjection is one or a plurality of Fe oxide, Mn oxide or Cu oxide. The waste water firstly enters an aeration catalytic oxidation pond 1. A micropore aerator connected with an air compressor 4 is arranged on the bottom of the aeration catalytic oxidation pond 1; baffle plates with micropores are arranged above the aerator; and a catalyst layer is filled in each baffle plate. An aeration catalytic reaction is carried out through bottom aeration for 5 to 15 minutes in the aeration catalytic oxidation pond 1 in a gas water ratio of 0.3 to 1 / 1 at a temperature of between 40 and 65 DEG C. The outputted water is lifted into a catalytic reaction filter tank 2 by a water pump 5 for continuous catalytic oxidation and simultaneous filtration; and the water coming out of the pond 1 through the bottom enters a reinjection water tank 3. Two paralleled baffle plates with micropores are arranged in the catalytic reaction filter tank 2; each catalyst layer is filled in each baffle plate; the water feeding is carried out by the water pump; and the time of the catalytic reaction is 3 to 10 minutes. The catalytic reaction filter tank 2 is regularly backflushed by air and water for 1 to 2 times every day. The method has the advantages that the method has low running cost, no addition of a flocculant and a floating agent, and high practical application value; in addition, the air heterogeneous catalysis process has simple operation and moderate reaction conditions. The reaction is carried out at the normal temperature and normal pressure.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

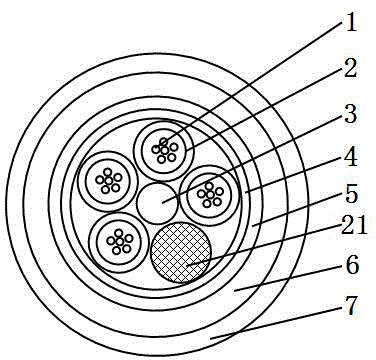

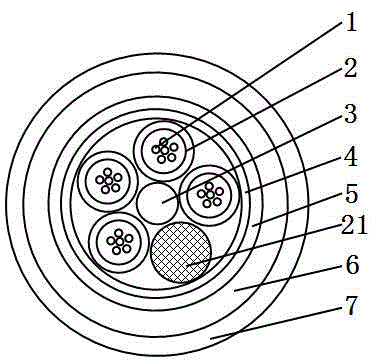

Bird-peck preventing cable and manufacture method thereof

InactiveCN107577021AStrong pressureStrong impact resistanceOptical articlesFibre mechanical structuresFiberEpoxy

Owner:沈群华

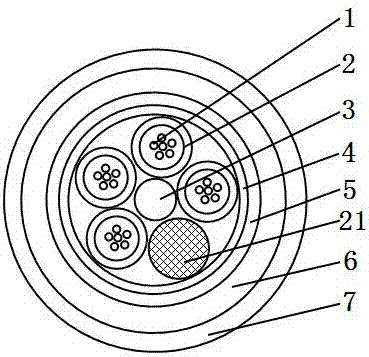

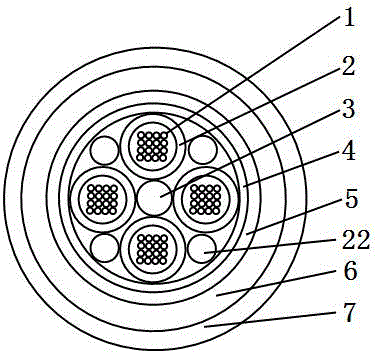

Anti-bird pecking cable and producing method thereof

ActiveCN104614829AStrong pressureStrong impact resistanceFibre mechanical structuresEpoxyParaffin wax

The invention belongs to the technical field of cables, in particular to an anti-bird pecking cable which includes a plurality of loose tubes distributed outside a reinforcer, a protective layer positioned outside the loose tubes, an inner protective layer positioned on the outer side of the protective layer and an outer sheath positioned on the outer side of the inner protective layer, wherein at least one optical fiber is contained in each loose tube. The cable is characterized in that an anti-bird pecking layer is arranged between the inner protective layer and the outer sheath. The anti-bird pecking layer is composed of the following raw materials: mediate density polyethylene, low density polyethylene or high density polyethylene, epoxy resin, ultra-fine steel fibers, glass fibers, silica fibers, EVA hot melt glue, an antioxidant, aluminum hydroxide, paraffin wax and carbon black master batch. The invention also discloses a method for producing the cable. The cable has the main benefits of being easy to produce, good in anti-bird pecking effect, and high in production speed, qualified rate of finished products, pressure resistance and impact resistance.

Owner:四川天府江东科技有限公司

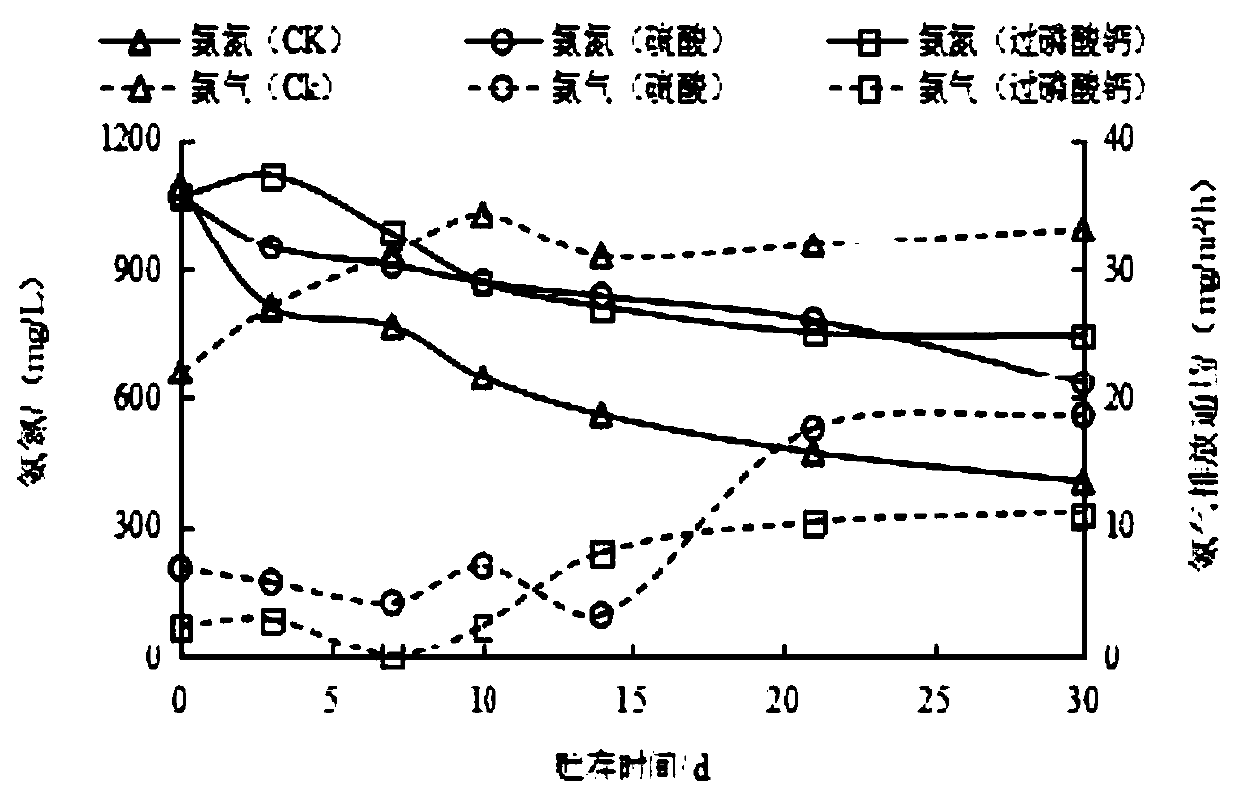

Method for immobilizing nutrients in cow dung water by alum

PendingCN110903133AImprove fertilizer efficiencyEasy to operateLiquid fertilisersPotassium fertilisersNutrientEnvironmental chemistry

The invention provides a method for immobilizing nutrients in cow dung water with alum, which comprises the following steps: slowly adding the alum into the cow dung water in an adjusting tank, continuously stirring, and adjusting the pH value of the cow dung water to 5.5-6.5; wherein the addition amount of the alum is 1.2-3.5% of the mass fraction of the cow dung water. According to the invention, the alum is used as an additive, ammonia gas emission of the cow dung water can be effectively reduced, the nutrient immobilization effect is stable, the nutrient immobilization process flow of thecow dung water is simplified, ammonia gas emission and nitrogen leaching loss in the cow dung water are reduced, and the method has good ecological and environmental benefits.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

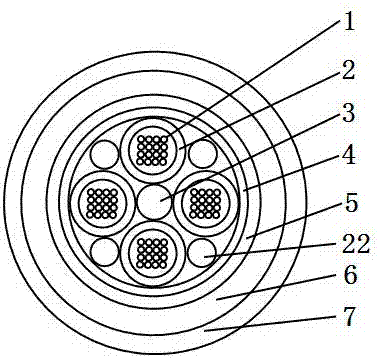

Anti-bird pecking cable and producing method thereof

InactiveCN104614828AStrong pressureStrong impact resistanceFibre mechanical structuresEpoxyParaffin wax

The invention belongs to the technical field of cables, in particular to an anti-bird pecking cable which includes a plurality of loose tubes distributed outside a reinforcer, a protective layer positioned outside the loose tubes, an inner protective layer positioned on the outer side of the protective layer and an outer sheath positioned on the outer side of the inner protective layer, wherein at least one optical fiber is contained in each loose tube. The cable is characterized in that an anti-bird pecking layer is arranged between the inner protective layer and the outer sheath. The anti-bird pecking layer is composed of the following raw materials: mediate density polyethylene, low density polyethylene or high density polyethylene, epoxy resin, ultra-fine steel fibers, glass fibers, silica fibers, EVA hot melt glue, an antioxidant, aluminum hydroxide, paraffin wax and carbon black master batch. The invention also discloses a method for producing the cable. The cable has the main benefits of being easy to produce, good in anti-bird pecking effect, and high in production speed, qualified rate of finished products, pressure resistance and impact resistance.

Owner:重庆成瑞光电科技有限公司

Anti-bird pecking cable and method for producing anti-bird pecking cable

ActiveCN104614830AStrong pressureStrong impact resistanceFibre mechanical structuresEpoxyParaffin wax

The invention belongs to the technical field of cables, in particular to an anti-bird pecking cable which includes a plurality of loose tubes distributed outside a reinforcer, a protective layer positioned outside the loose tubes, an inner protective layer positioned on the outer side of the protective layer and an outer sheath positioned on the outer side of the inner protective layer, wherein at least one optical fiber is contained in each loose tube. The cable is characterized in that an anti-bird pecking layer is arranged between the inner protective layer and the outer sheath. The anti-bird pecking layer is composed of the following raw materials: mediate density polyethylene, low density polyethylene or high density polyethylene, epoxy resin, ultra-fine steel fibers, glass fibers, silica fibers, EVA hot melt glue, an antioxidant, aluminum hydroxide, paraffin wax and carbon black master batch. The invention also discloses a method for producing the cable. The cable has the main benefits of being easy to produce, good in anti-bird pecking effect, and high in production speed, qualified rate of finished products, pressure resistance and impact resistance.

Owner:SUZHOU SHENGXIN OPTOELECTRONICS TECH

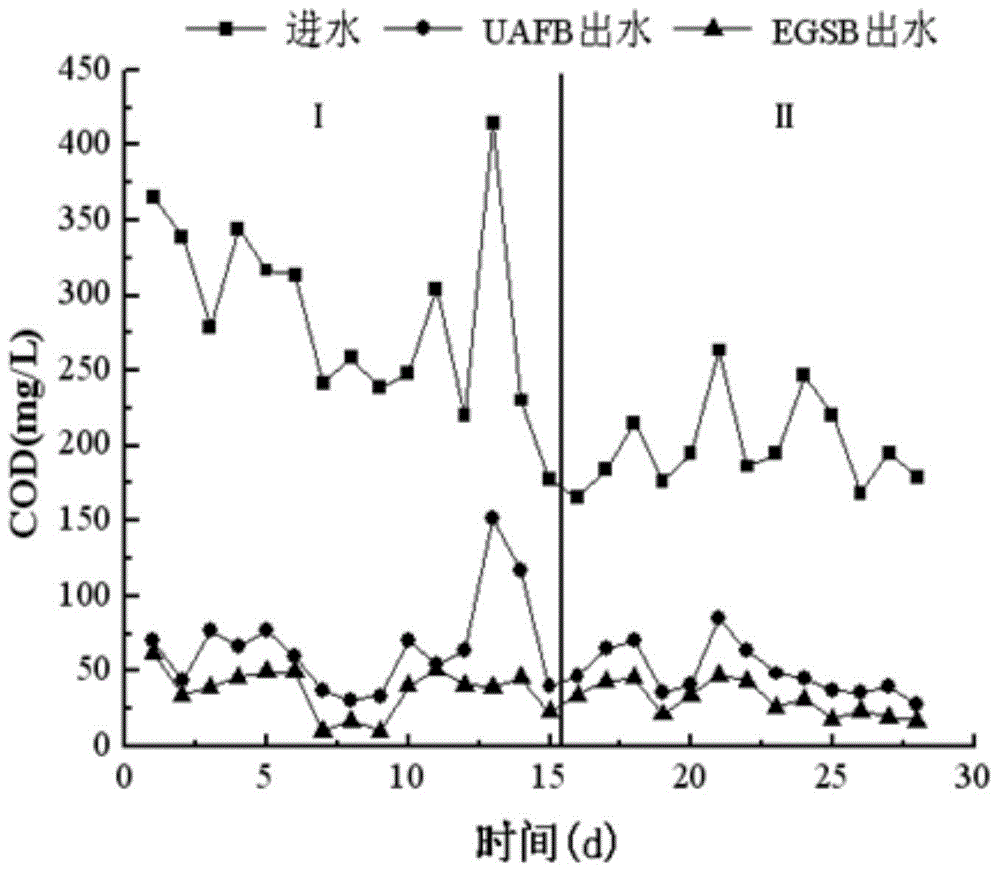

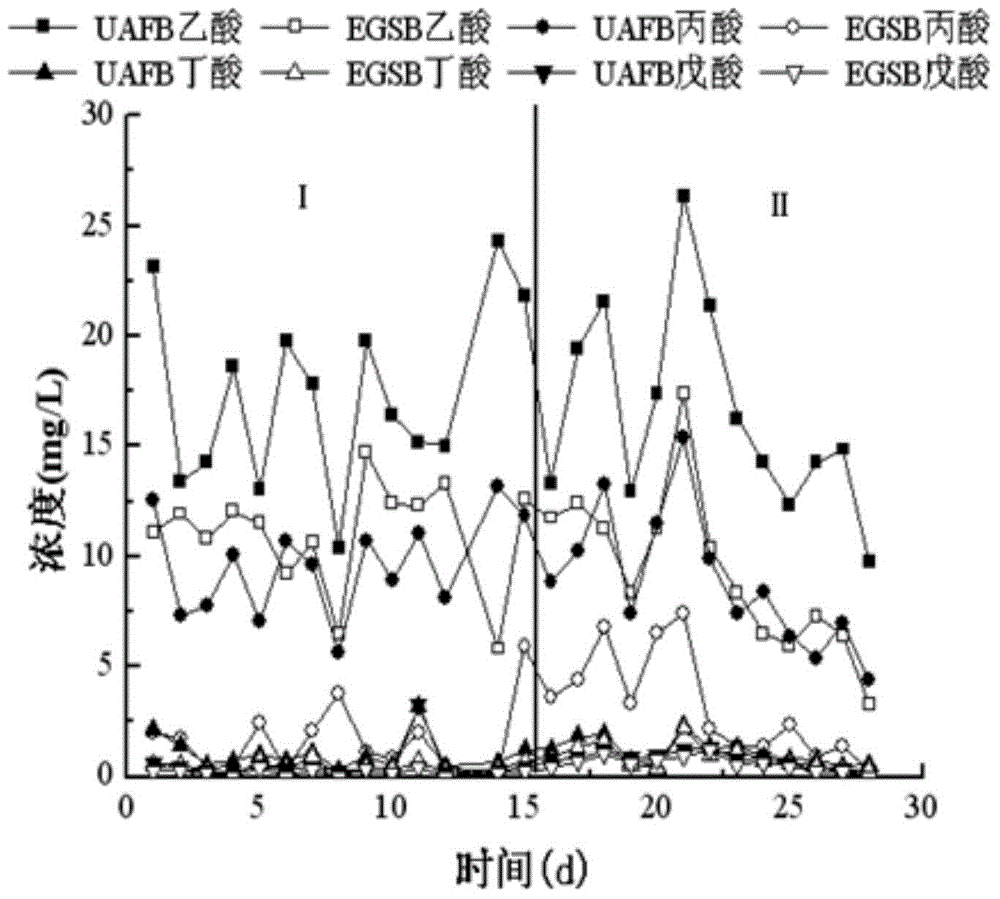

Domestic sewage treatment method and UAFB-EGSB coupled system quick start method

ActiveCN103601347AReduce processing costsNo need to addMultistage water/sewage treatmentActivated sludgeSewage

The invention relates to a sewage treatment method and a UAFB-EGSB coupled system quick start method, particularly a domestic sewage treatment method and a UAFB-EGSB coupled system quick start method. The quick start method comprises the following steps: 1. connecting a UAFB reactor with an EGSB reactor; 2. adding activated sludge into the reactors; 3. performing a first start stage; and 4. performing a second start stage, thereby completing the quick start of the UAFB-EGSB coupled system. The domestic sewage treatment method comprises the following steps: 1. introducing domestic sewage into the UAFB reactor; and 2. introducing effluent water of the UAFB reactor into the EGSB reactor, thereby implementing domestic sewage treatment. The methods are suitable for the field of sewage treatment.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

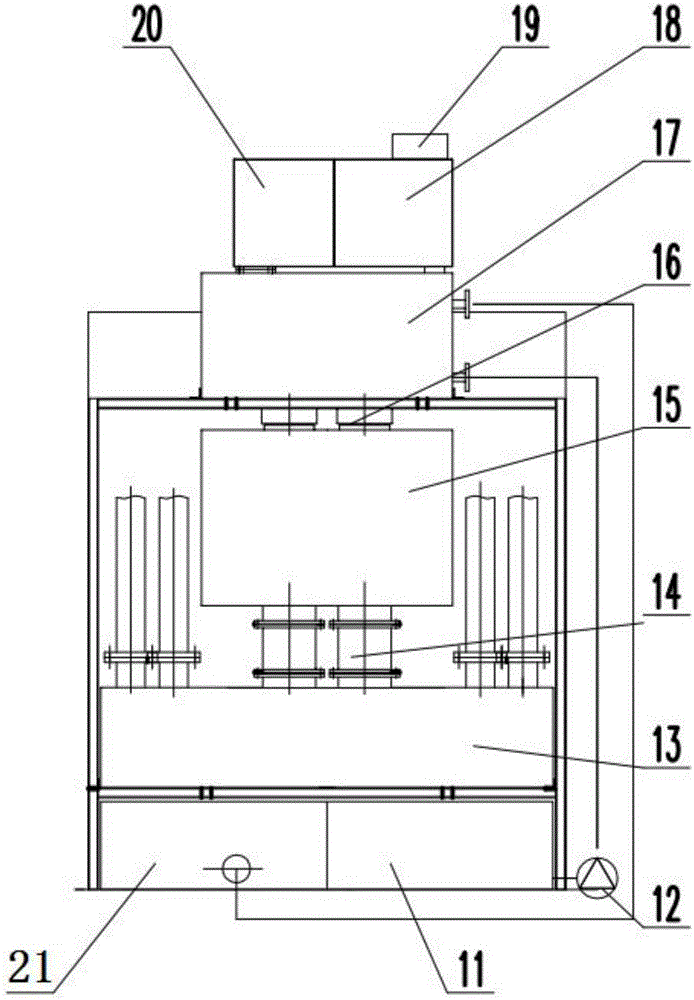

Magnetizing and cracking device with tail gas treatment device

PendingCN107101205ANo need to addAvoid secondary pollutionCombination devicesGas treatmentAlkaline waterActivated carbon

The invention relates to a magnetizing and cracking device with a tail gas treatment device. The magnetizing and cracking device with the tail gas treatment device comprises a magnetizing and cracking device body and the tail gas treatment device, wherein the tail gas treatment device is connected with an exhaust opening of the magnetizing and cracking device body; the magnetizing and cracking device body is used for magnetizing and cracking organic garbage; the tail gas treatment device is used for treating tail gas generated by the magnetizing and cracking device body; the magnetizing and cracking device body comprises a charging wagon, a pushing plate, a feeding speed reducer, a lead screw, a feeding opening, a cracking cavity, a pipe, a magnetizing box, a sewage box and a feeding support; and the tail gas treatment device comprises a heat exchange water tank, a water storage box, a water pump, an alkaline water tank, a butterfly valve, an anoxic combustion barrel, an aerobic combustion opening, a cooling water tank, an activated carbon box, a chimney and a ternary catalyst container. All data of discharged tail gas meets the national standard requirement, particularly, the item of dioxin is remarkably lower than the national standard requirement, harmful gas does not need to be separated from main air flow, but is directly converted into harmless substances, secondary pollution is avoided, and heat can further be recycled for comprehensive utilization.

Owner:鑫源昊(浙江)环保能源科技有限公司

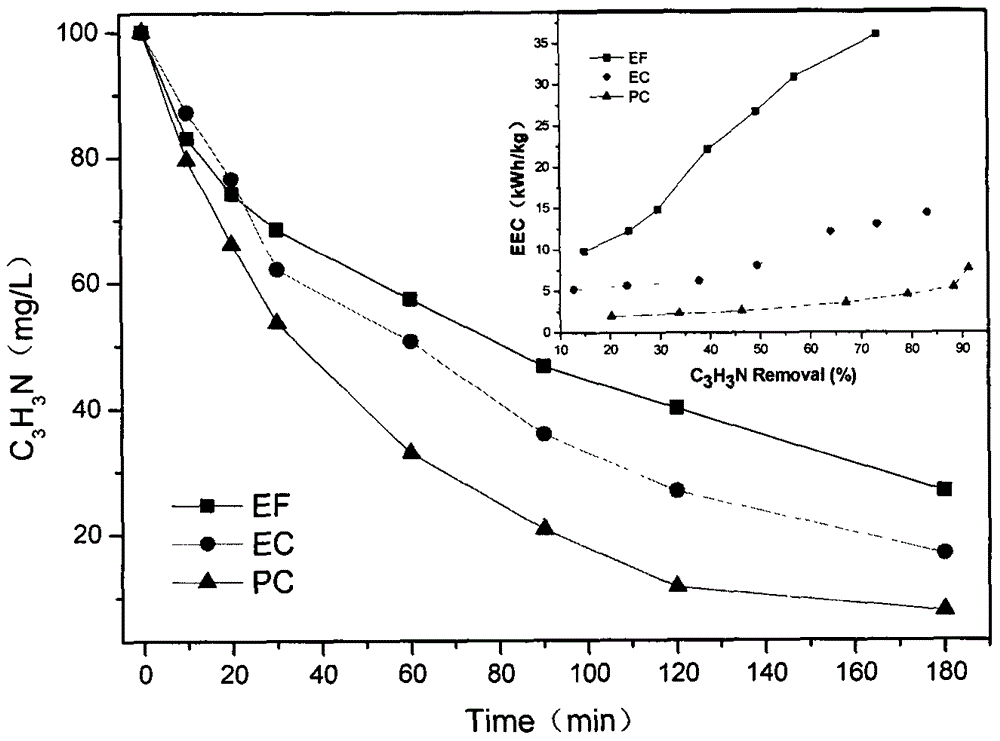

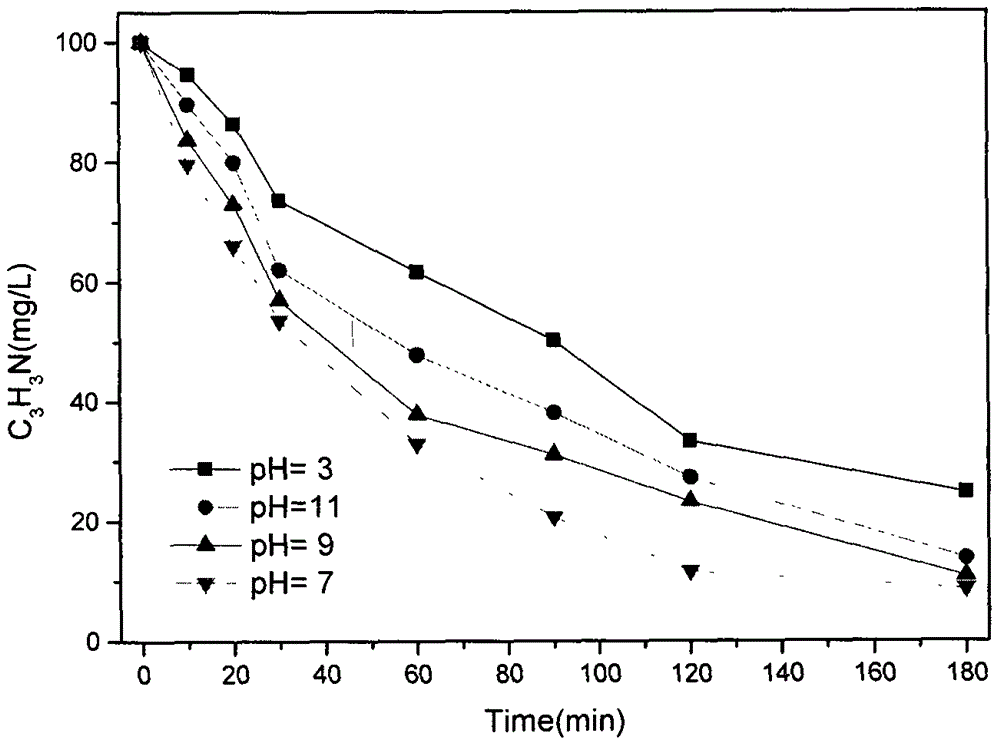

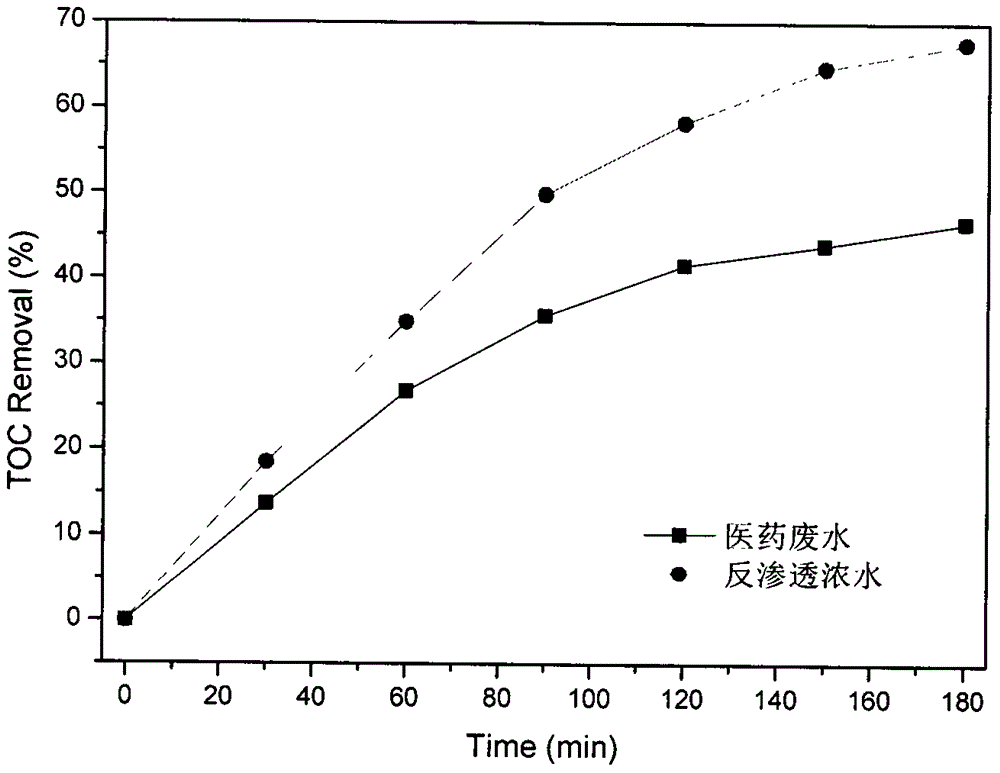

Method for treating organic wastewater by efficient peroxide flocculation technology

InactiveCN105753111AEfficient removalExpand the working areaWater contaminantsWater/sewage treatment using germicide/oligodynamic-processFenton reactionFlocculation

The invention provides a method for treating organic wastewater by an efficient peroxide flocculation technology. According to the method, hydrogen peroxide is generated by a carbon material cathode for efficiently generating hydrogen peroxide in situ; and iron is dissolved in the treatment process as a sacrificial anode for providing a catalyst for Fenton reaction, so that multiple effects of electric flocculation, electro-Fenton, electric oxidation and the like are achieved, and the treatment property of the organic wastewater is significantly improved. The method has the outstanding advantages of good treatment effect and low energy consumption, and is suitable for treatment of non-degradable organic wastewater in dyes, chemical engineering, medicines, membrane concentrate and the like; and the pH value does not need to be adjusted.

Owner:NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com