Wet-mixed mortar additive

A technology of wet-mixing mortar and admixture, which is applied in the field of construction mortar materials, can solve the problems of large loss of mortar air content over time, construction workability, large loss of mortar layering, and high cost, and achieve good construction workability, Good water retention and low cost

Inactive Publication Date: 2016-09-21

张伟

View PDF4 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Many known wet-mixed mortar admixtures have high cost, large loss of mortar layering within the open

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

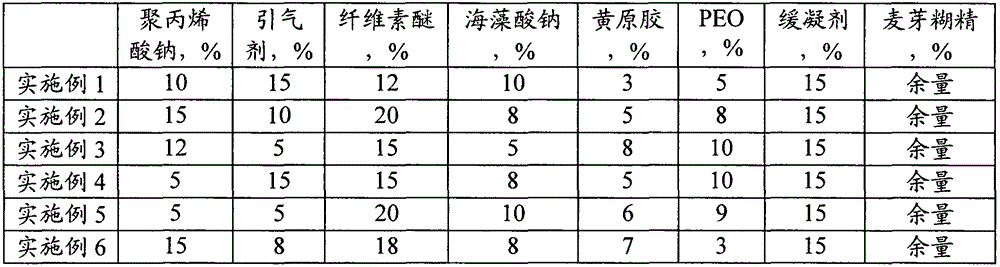

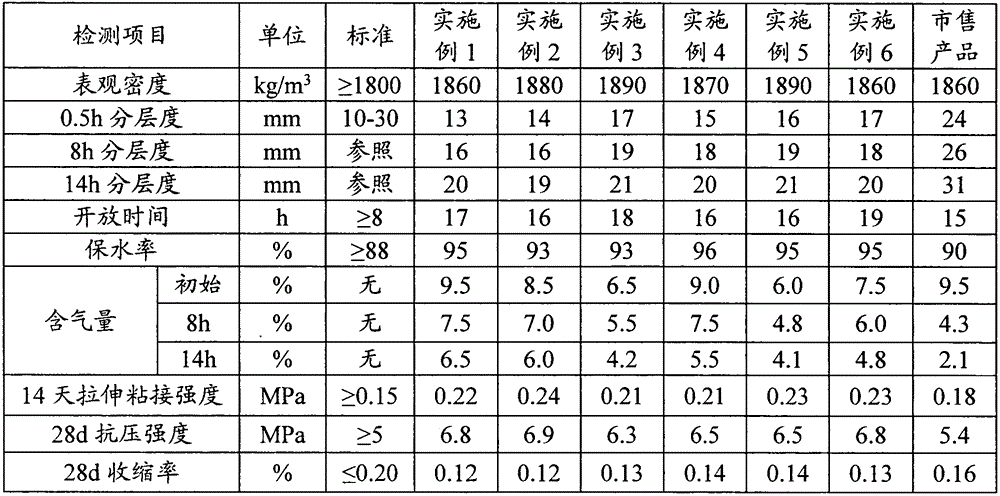

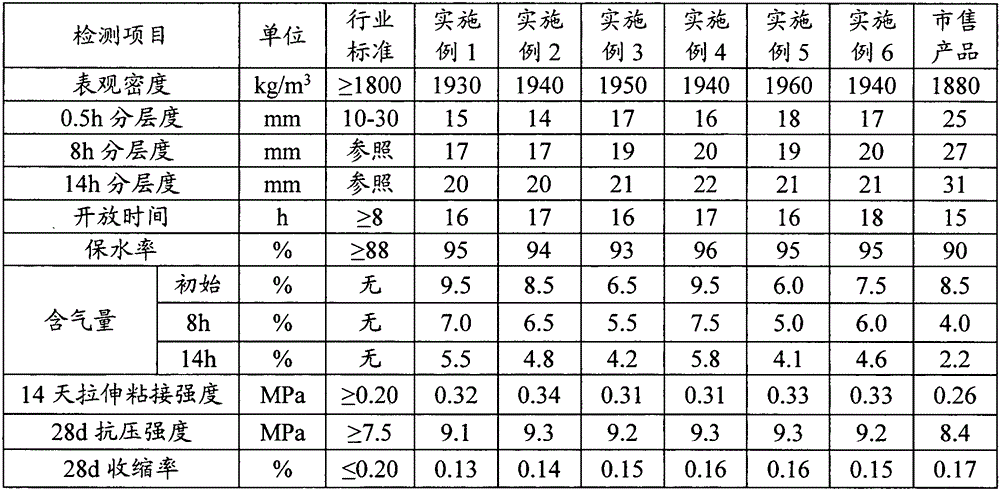

The invention provides a wet-mixed mortar additive. The additive has low cost, can be added in an autoweighing manner, is used for wet-mixed mortar, and has good water-retaining property and delamination degree of mortar, less loss in the range of open time, high adhesive strength, and good construction workability. The wet-mixed mortar additive includes: by mass, sodium polyacrylate 5%-15%, air entraining agent 5%-15%, cellulose ethers thickening water-retaining agent 10%-20%, sodium alginate 5%-10%, polyoxyethylene 3%-10%, retarder 5%-20%, xanthan gum 3%-8%, and the balance maltodextrin, wherein the molecular weight of sodium polyacrylate is more than 30 million, and the molecular weight of polyoxyethylene is more than 2.5 million. The wet-mixed mortar additive is powder, and the mixing amount is 0.05%-0.10% of mortar gel material using amount. The wet-mixed mortar additive can be dissolved in water, and can be diluted to a liquid with concentration of 1.5%-2.0% at mixing plant site to be added in an autoweighing manner.

Description

technical field [0001] The invention relates to a wet-mixed mortar admixture, which belongs to the field of building mortar materials. Background technique [0002] Construction mortar includes masonry mortar and plastering mortar. According to the production method of mortar, ready-mixed mortar can be divided into two categories: wet-mixed mortar and dry-mixed mortar. Among them, the wet-mixed mortar is composed of cement, mineral admixture, fine aggregate, admixture, water and various components determined according to the construction performance. According to the different grades of the mortar, according to a certain proportion, it is measured and mixed in the mixing station. Finally, it is transported to the place of use by a mixer truck, stored in a special container pool, and the mixture is used within the specified time. [0003] Construction requirements The most important technical characteristics of wet-mix mortar are good water retention, high adhesion and good ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B24/38

CPCC04B40/0039C04B24/26C04B24/386C04B24/38C04B24/32C04B2103/304C04B2103/22

Inventor 张伟

Owner 张伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com