Special grouting agent for post-tensioned prestressed concrete beams of highway bridges and culverts and preparation method thereof

A post-tensioned prestressed, concrete beam technology, applied in the field of building materials, can solve the problems of limited expansion performance, uneven gas generation of aluminum powder, difficult gas generation, etc., and achieves good cement adaptability, simple construction operation, and excellent water retention. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

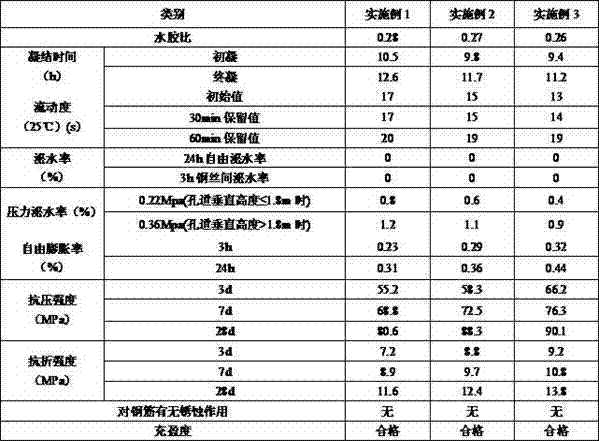

Embodiment 1

[0037] The post-tensioned prestressed concrete beam grouting agent for highway bridges and culverts of this embodiment has a weight component of: polycarboxylate powder water reducer 5%, plastic expansion agent 15%, calcium sulfoaluminate and anhydrite 60% additive, 0.18% polyvinyl alcohol rheology additive, 0.20% xanthan gum water retaining agent, 0.10% composite retarder of citric acid and sodium gluconate, 0.30% organic silicon defoamer, ultrafine slag and finely ground calcined The kaolin mixture is 19.22%, and the above-mentioned components are accurately weighed by weight percentage and uniformly stirred to obtain the present invention.

Embodiment 2

[0039] The post-tensioned prestressed concrete beam grouting agent for highway bridges and culverts in this embodiment has the following components by weight: 8% composite water reducing agent of polycarboxylic acid powder and melamine powder, 20% of plastic expansion agent, calcium sulfoaluminate and hard 50% expansion agent prepared by gypsum, 0.30% sodium polyacrylate rheology additive, 0.25% redispersible latex powder water retention agent, 0.35% sodium tripolyphosphate retarder, 0.40% organic silicon defoamer, finely ground slag and Silicon powder mixture 20.7%, the present invention is obtained by accurately weighing the above-mentioned components by weight percentage and stirring uniformly.

Embodiment 3

[0041] The post-tensioned prestressed concrete beam grouting agent for highway bridges and culverts in this embodiment has the following components by weight: 15% of naphthalene-based powder and calcium lignosulfonate composite water reducer, 25% of plastic expansion agent, calcium aluminate, Dickite and anhydrite compound expansion agent 50%, organic bentonite and polyvinyl alcohol compound rheological additive 0.45%, Wenlun glue water retention agent 0.45%, citric acid and sodium gluconate compound retarder 0.10%, organic fluoride 0.40% of defoaming agent, 8.6% of the mixture of silicon powder and zeolite powder, the above-mentioned components are accurately weighed according to the weight percentage, and the invention is obtained by stirring evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com