Patents

Literature

205 results about "Prestressed concrete beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

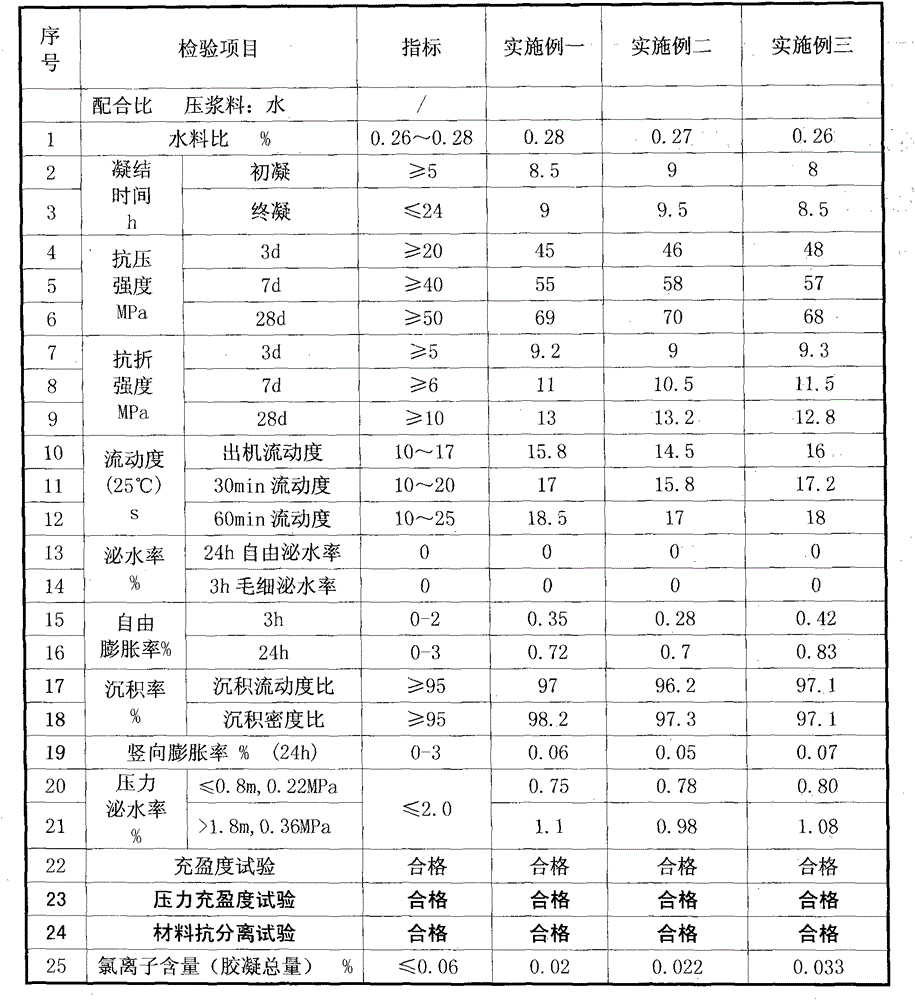

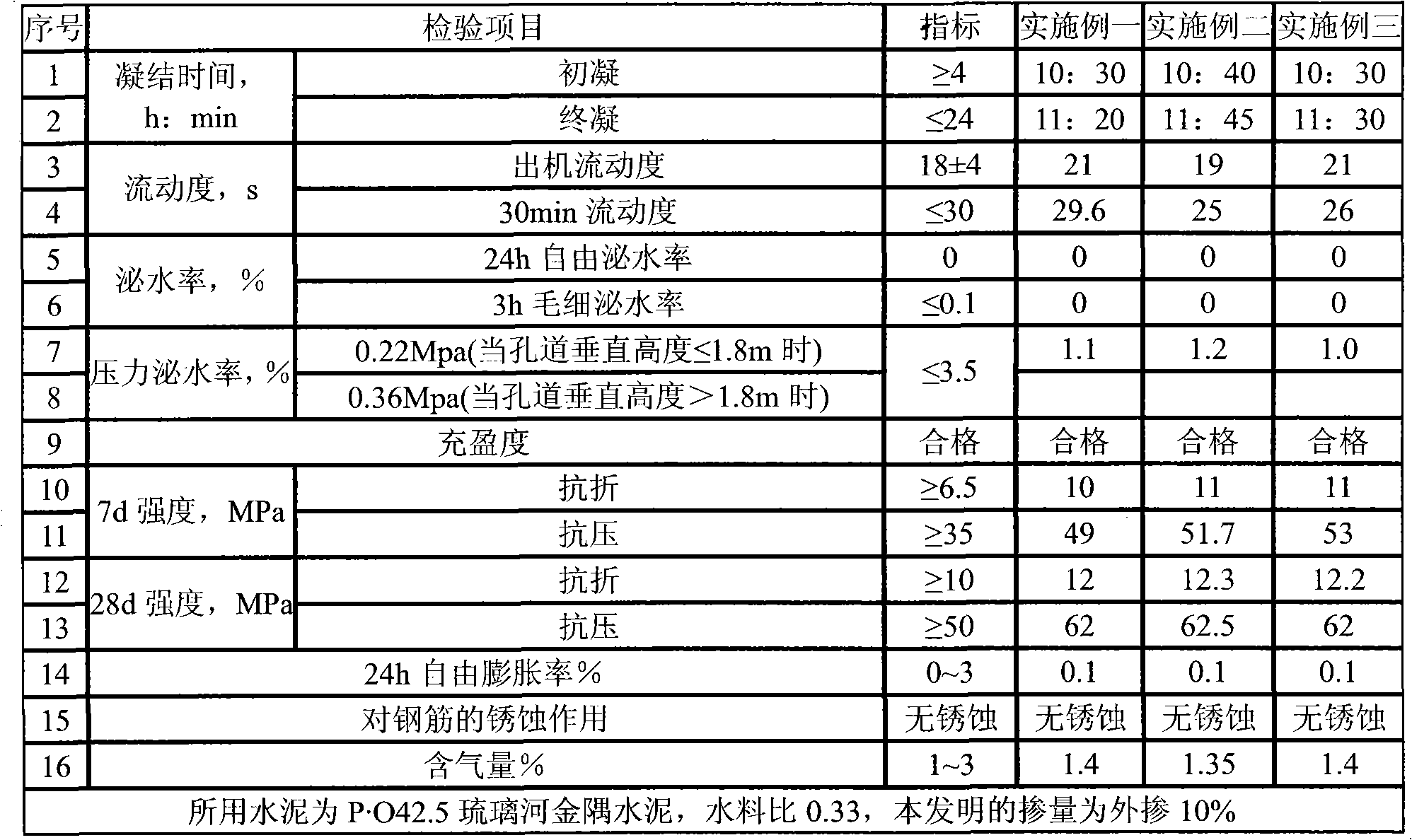

Post stressed concrete beam pipe mudjacking agent

ActiveCN101817656AImprove liquidityHigh micro expansionSolid waste managementPrestressed concrete beamPre stress

The invention provides a post stressed concrete beam pipe mudjacking agent which is characterized by comprising the following components in percent by weight: 1-3 percent of efficient slushing component, 5-10 percent of early-expanded component, 30-50 percent of middle-late expanded component and 40-60 percent of mineral admixture. The invention also provides a preparation method of the post stressed concrete beam pipe mudjacking agent, which comprises the step of uniformly stirring the components in a stirrer according to the weight percent to obtain the post stressed concrete beam pipe mudjacking agent. The post stressed concrete beam pipe mudjacking agent, cement and water are mixed according to a certain proportion to prepare a mudjacking material to be used for construction. The mudjacking agent has optimal flowing property, excellent water holding property, better compactness, full and uniform structure and good early plastic expanded performance, does not contain additives with corrosion on prestressed reinforcing steel, and has very low chloridion content, better adaptability with various cements and lower sensitivity on temperature and humidity.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

High-performance cement-based shrink-free corrosion-proof grouting agent

The invention belongs to a post-tensioned prestressed concrete and girder drill-way grouting material adopting such ingredients as slushing (5-10 percent ), water retention (15-50 percent), plastic stage inflation (1-5 percent), later period microdilatancy (30-55 percent), anti-rust (0.2-0.8 percent), solidification adjustive agent (0.2-0.8 percent) and air-entraining admixture (0.5-0.1 percent). The cement-based non-contraction anti-corrosion grouting admixture preparation method is characterized in that the components get weighed according to the weight fraction and then poured into a mixer to produce the invention after even being stirred. The invention is utilized together with cement and water according to a certain proportion in engineering. The invention has the advantages that the raw material is sourced broadly, and the cost is low; bags are packed with on-spot mixture and the operation is easy with little, thereby causing little pollution; the invention has good fluidity and the operation time can be adjusted; no bleeding and delaminating happen when being positioned statically, and compressive stress causes a limited amount of water bleeding; the invention has good evenness, filling-in and bulk stability, without being contracted; excellent mechanical properties are also embodied; the invention is mixed with novel rust inhibitor to protect the reinforced steel bar.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +2

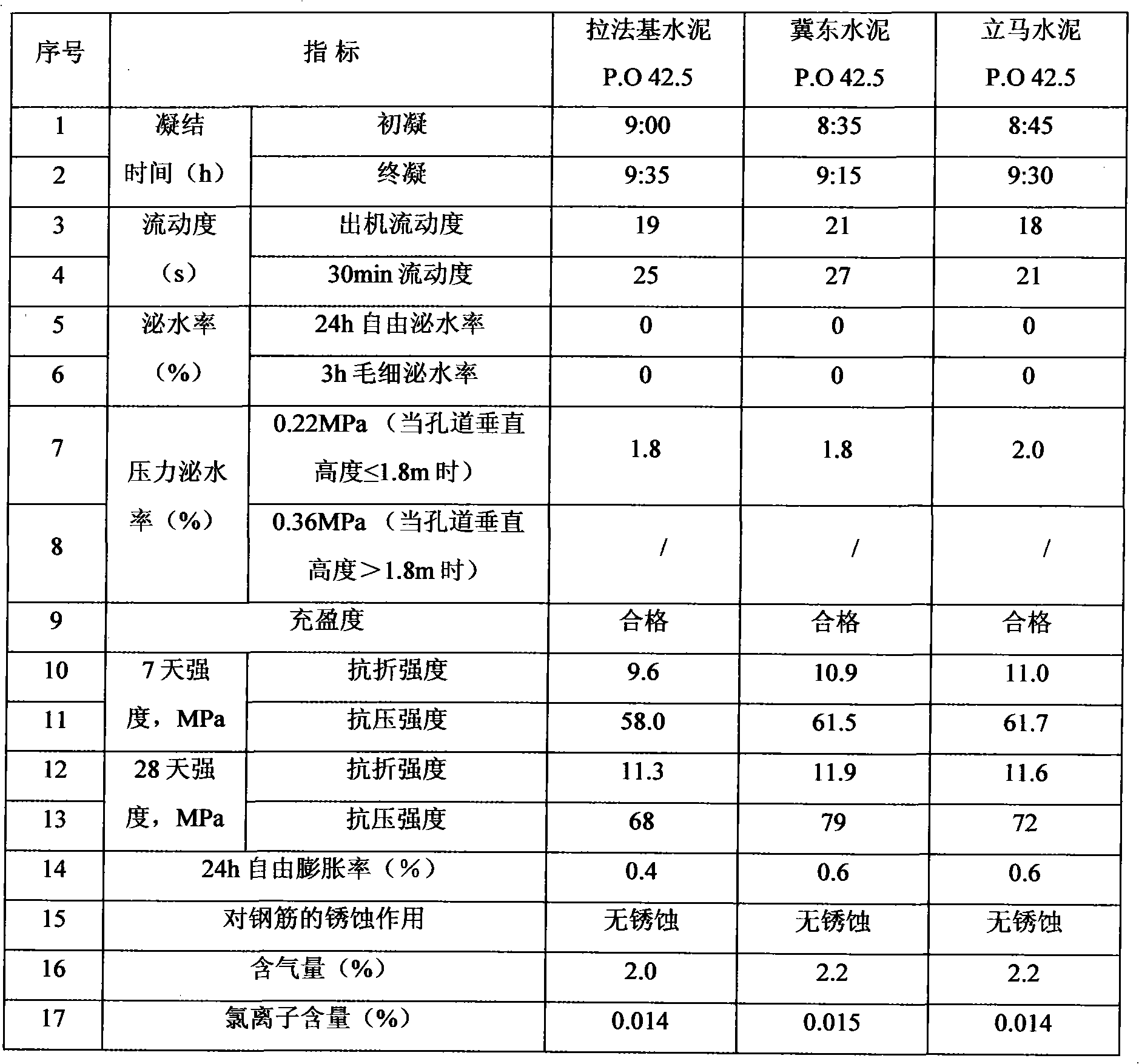

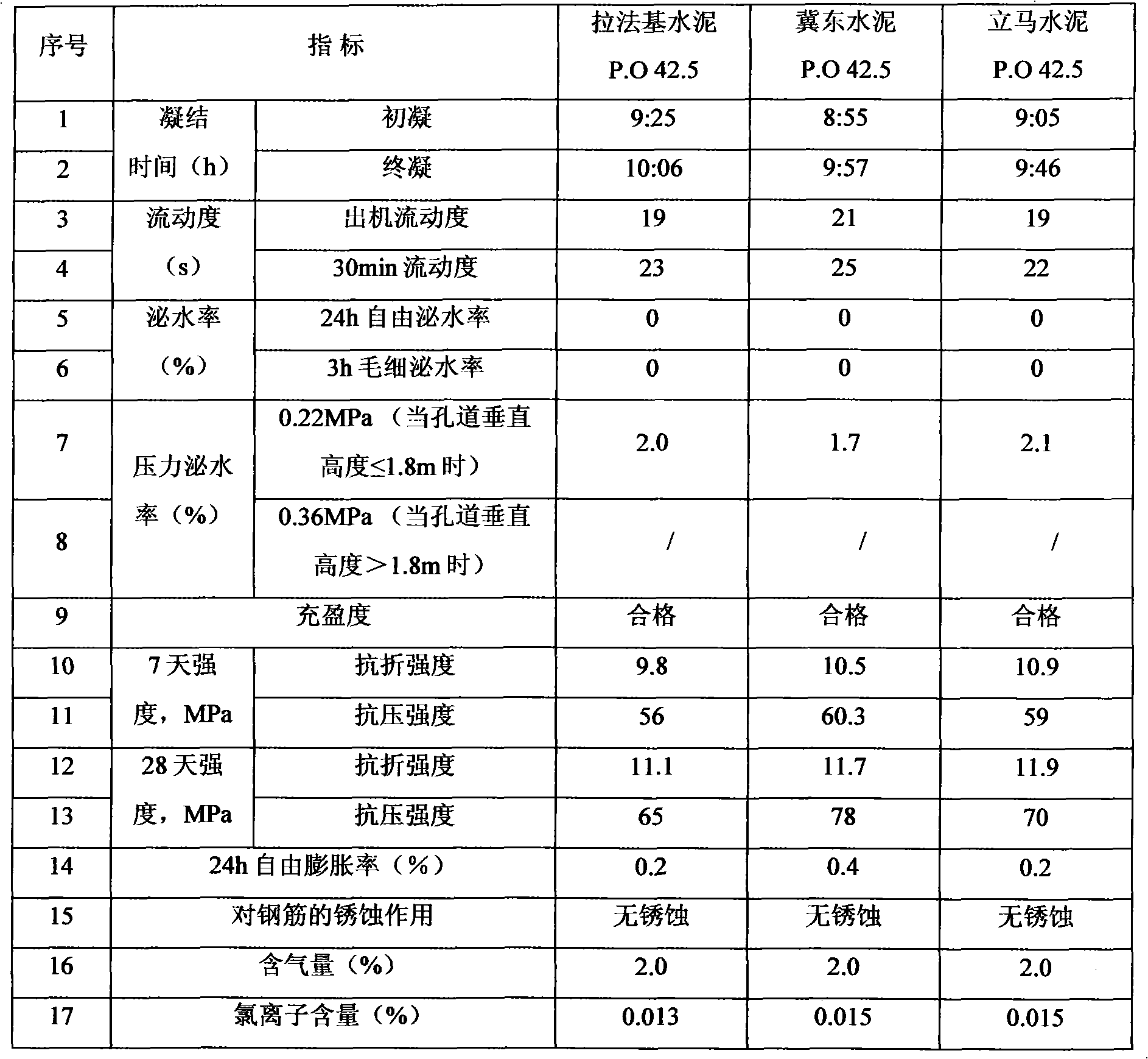

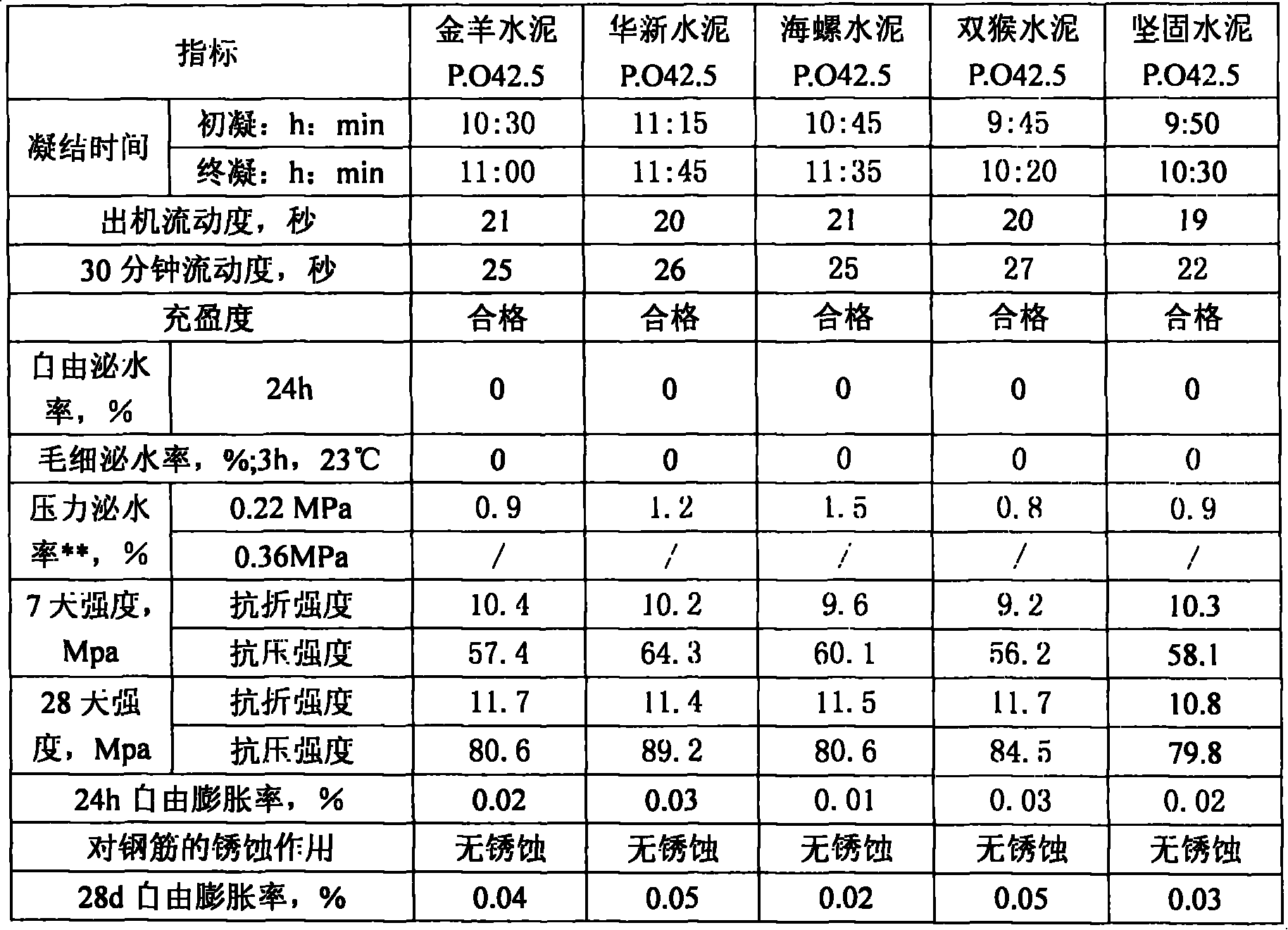

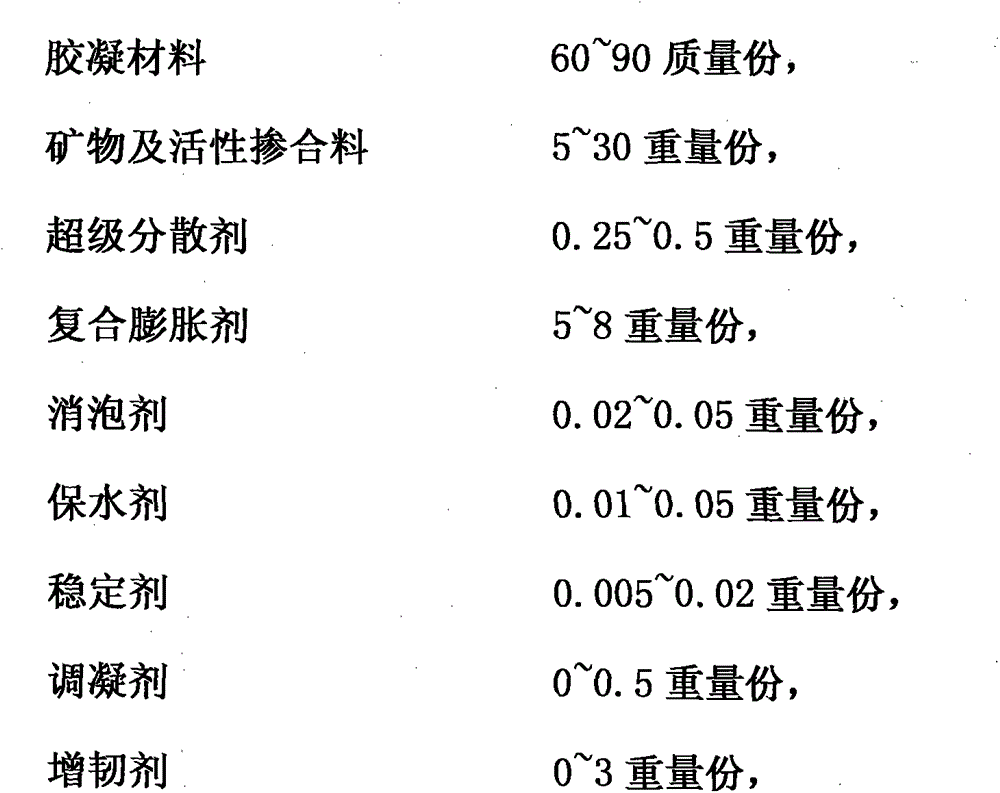

Post-tensioned prestressed concrete beam duct grouting material of highway bridge and preparation method thereof

InactiveCN104529337ASolve problems that do not meet standard requirementsPrestressed concrete beamPre stress

Provided is a post-tensioned prestressed concrete beam duct grouting material of a highway bridge. Raw materials include a cementing material, a mineral and active admixture, a super dispersing agent, a composite expanding agent, a water retaining agent, a stabilizing agent, a lubricating agent, a toughening agent, a cementing adjusting agent and a steel bar rust resisting agent and are mechanically mixed through a double-shaft paddle type gravity-free efficient mortar mixer. Firstly, the mineral and active admixture and 1 / 2 of the cementing material are added into the mixer to be premixed for 1 min-2 min; then, the super dispersing agent, the composite expanding agent, an antifoaming agent, the stabilizing agent, the toughening agent, the cementing adjusting agent and the steel bar rust resisting agent are added into the mixer to be premixed for 1 min-2 min, wherein if the agents are aqueous solutions, the agents can be diluted and mixed with part of the inert mineral admixture in advance; finally, the rest of the cementing material is added into the mixer, all the materials are stirred for 5 min-8 min, and then discharging and packaging can be carried out. The post-tensioned prestressed concrete beam duct grouting material solves the problem that a grouting material prepared through a grouting agent and cement on the site maybe can not meet standards.

Owner:HANGZHOU LVYI NEW BUILDING MATERIALS

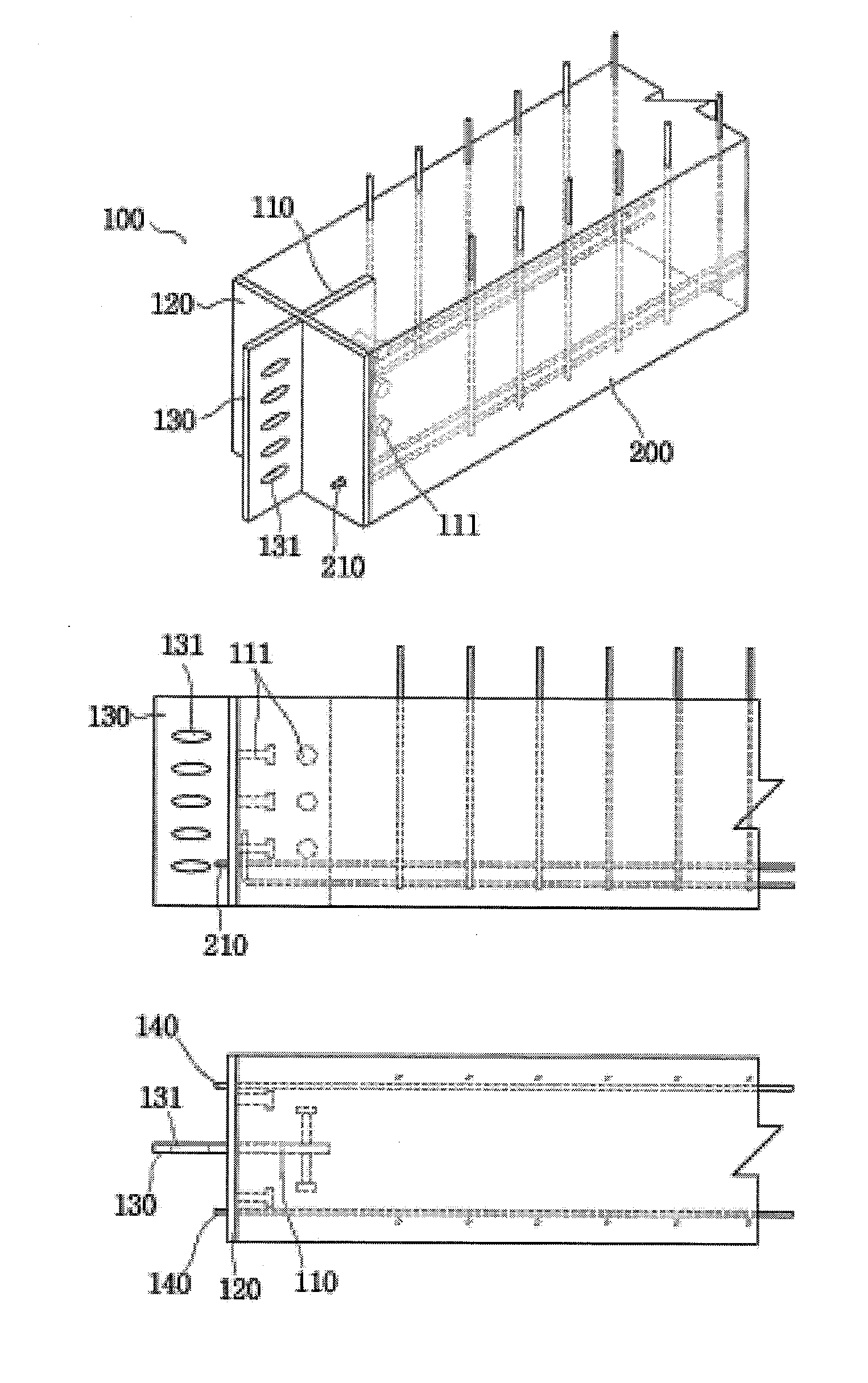

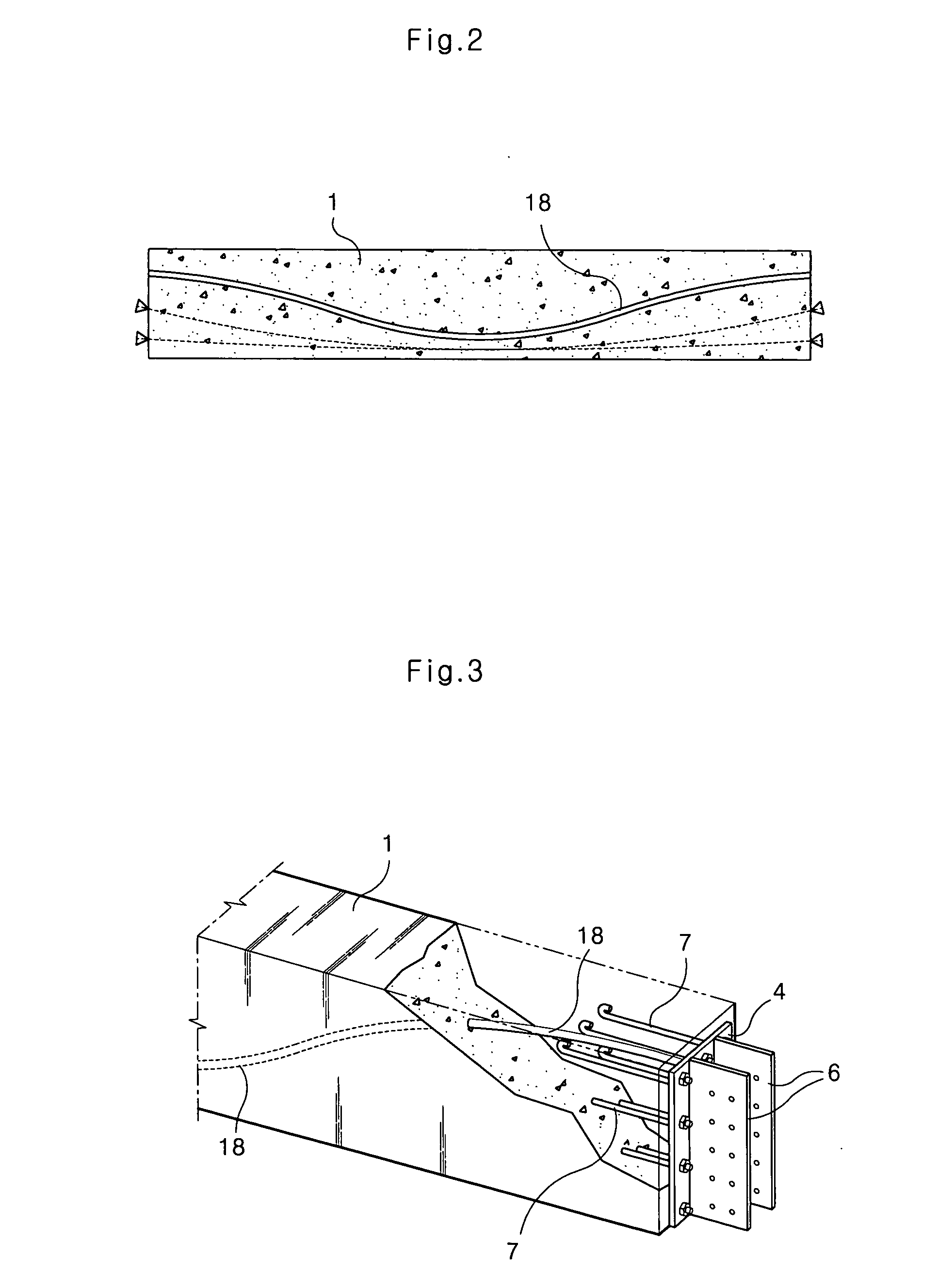

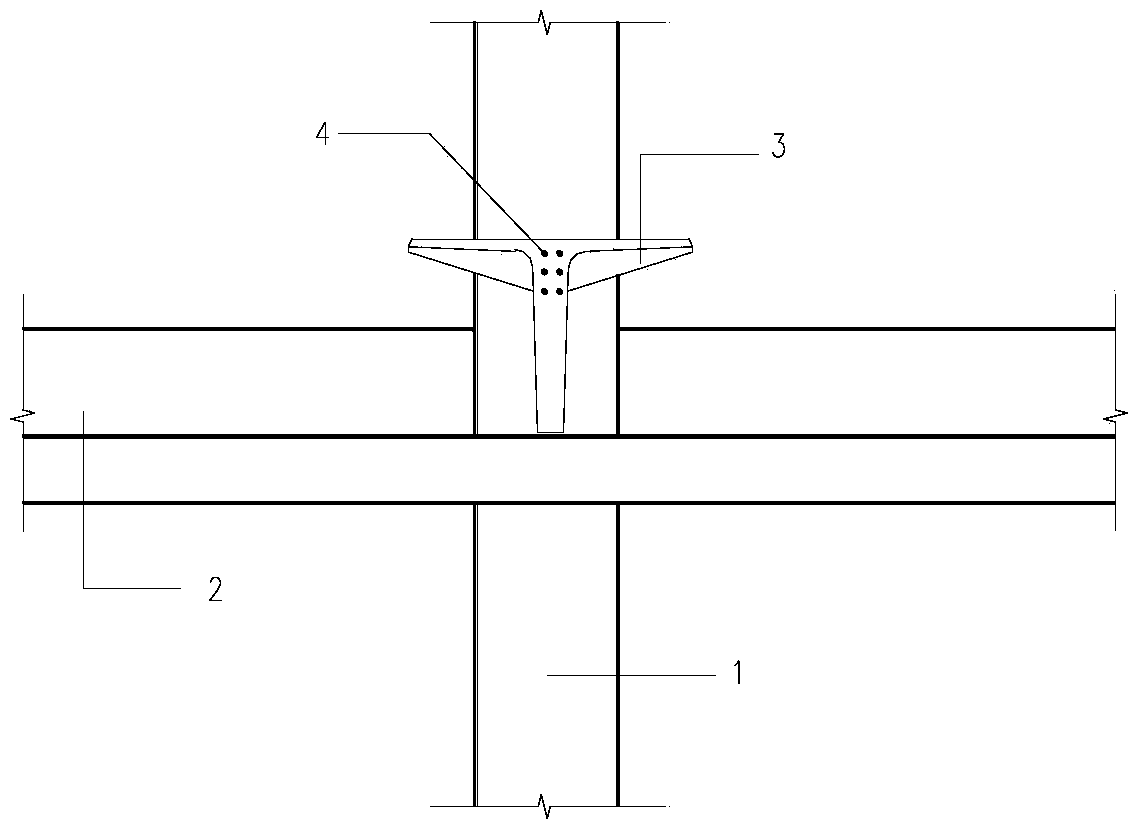

Stiffener for connecting prestressed concrete beam and method of constructing structure using the same

ActiveUS20110094182A1Efficient stress transmissionImprove constructabilityBuilding roofsFloorsPrestressed concrete beamPre stress

Provided are a stiffener for connecting a prestressed concrete beam and a method of constructing a structure using the same, in which the beam such as the prestressed concrete beam which is covered with concrete is connected to a target structure including a column structure or a girder. The stiffener is made up of a buried stiffener, an end face stiffener, and a joint stiffener, thereby enabling simple connection, excellent stress transmission, and very efficient construction of (building) structures.

Owner:CROSS STRUCTURAL CONSULTANT +1

Post-tensioned pre-stressed concrete beam pipeline grouting agent

The invention provides a post-tensioned pre-stressed concrete beam pipeline grouting agent. The post-tensioned pre-stressed concrete beam pipeline grouting agent comprises the following components in parts by weight: 0.5-10 parts of a water reducing agent, 0.1-5 parts of a plastic expanding agent, 5-20 parts of a hardening swelling agent, 5-15 parts of a suspending agent, 0.001-0.05 part of a water-retaining agent, 0.01-0.5 part of an antifoaming agent, 0.1-4 parts of a thixotropic agent, 0.1-8 parts of a lubricating agent and 10-80 parts of a mineral admixture. The post-tensioned pre-stressed concrete beam pipeline grouting agent has the beneficial effects that the pipeline grouting agent has the characteristics of being quick in flow second, good in fluidity retaining, good in slurry stability, un-bleeding and the like, and therefore, the pipeline grouting agent can be used for effectively protecting steel strands, is suitable for post-tensioned pre-stressed concrete beams of road bridges and culverts, and also can be used for concrete structure pipeline grouting of general engineering.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

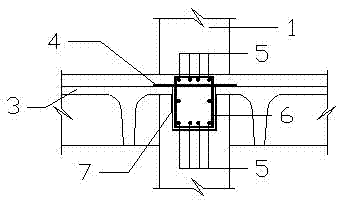

Steel plate-concrete composite structure reinforcement method of structural negative moment region

ActiveCN102561213AEnhanced interface connection reliabilityImprove connection reliabilityBridge erection/assemblyBridge strengtheningPrestressed concrete beamT-beam

A steel plate-concrete composite structure reinforcement method of a structural negative moment region is characterized in that the method comprises the steps of: (1) carrying out interface treatment of a negative moment region of a concrete box girder top plate 3; (2) planting bars on the surface of the negative moment region of the concrete box girder top plate 3; (3) manufacturing a steel plate 9, a welding stud 8 and a corrugated steel plate 14: (4) forming a self-compacting concrete pouring hole 13 and a location leveling hole 17 on the steel plate 9; (5) erecting a reverse ejection support 2 and unloading reverse ejection; (6) binding a reinforcing mesh 10 and installing in position; (7) applying a structural adhesive on the steel plate 9 and spreading fine sands; (8) installing and leveling the steel plate 9 to the design position, applying a pre-stress to the top of the steel plate 9 through a pre-installed apparatus; (9) mixing and pouring self-compacting concrete; and (10) releasing the pre-stress, removing the corrugated steel plate 14, curing concrete, constructing a pavement layer, and removing the reverse ejection support 2. The novel steel plate-concrete composite structure negative moment region reinforcement method can be widely used for negative moment region reinforcement of concrete box girder, T-beam, hollow plate girder, common reinforced concrete beam, and pre-stressed concrete beam, and can be used in the bridge reinforcement with the advantages of almost no reduction of the headroom below the bridge, no requirement for surface levelness of the original structure, low cost, no influences on the appearance, and so on. The steel plate-concrete composite structure reinforcement method is economic, safe, and practical, is easy to ensure the project quality and has wide application prospect.

Owner:CENT SOUTH UNIV +2

Duct grouting agent for post-tensioning prestressed concrete beams

InactiveCN102115314ANo pollution in the processEasy to operateSolid waste managementPrestressed concrete beamPre stress

The invention relates to a duct grouting agent for post-tensioning prestressed concrete beams, which is proportionally mixed with cement and water at a construction site for duct grouting and filling of the prestressed concrete beams. The duct grouting agent is characterized in that the duct grouting agent comprises the following components: 2 to 11 percent of water-reducing component, 0.3 to 0.6 percent of expansion component at a plastic stage, 30 to 40 percent of water-retaining component, 0.2 to 0.5 percent of antifoaming component, 0 to 0.4 percent of retarding component and 40 to 55 percent of expansion component at a later stage, wherein all the components are weighed according to the weight percentages and mixed to obtain the duct grouting agent. The duct grouting agent has the advantages of wide raw material sources, low cost, simpleness and convenience in operation, no pollution, high operability, good and adjustable fluidity, no bleeding under constant pressure, low bleeding rate under pressure, good uniformity, filling degree and volume stability, good protective effect to prestressed steel bars and no rust.

Owner:BEIJING ACAD OF BUILDING ENG

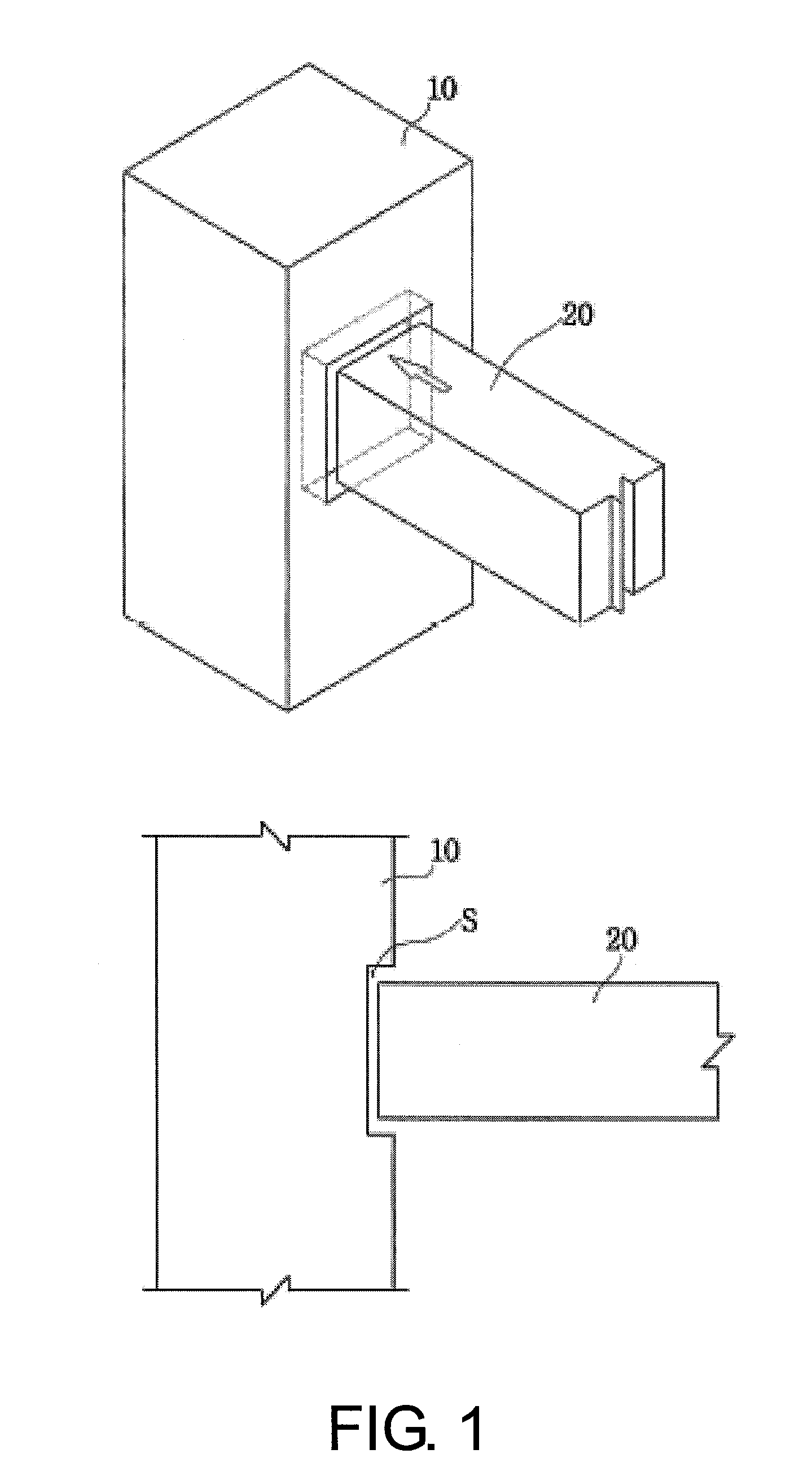

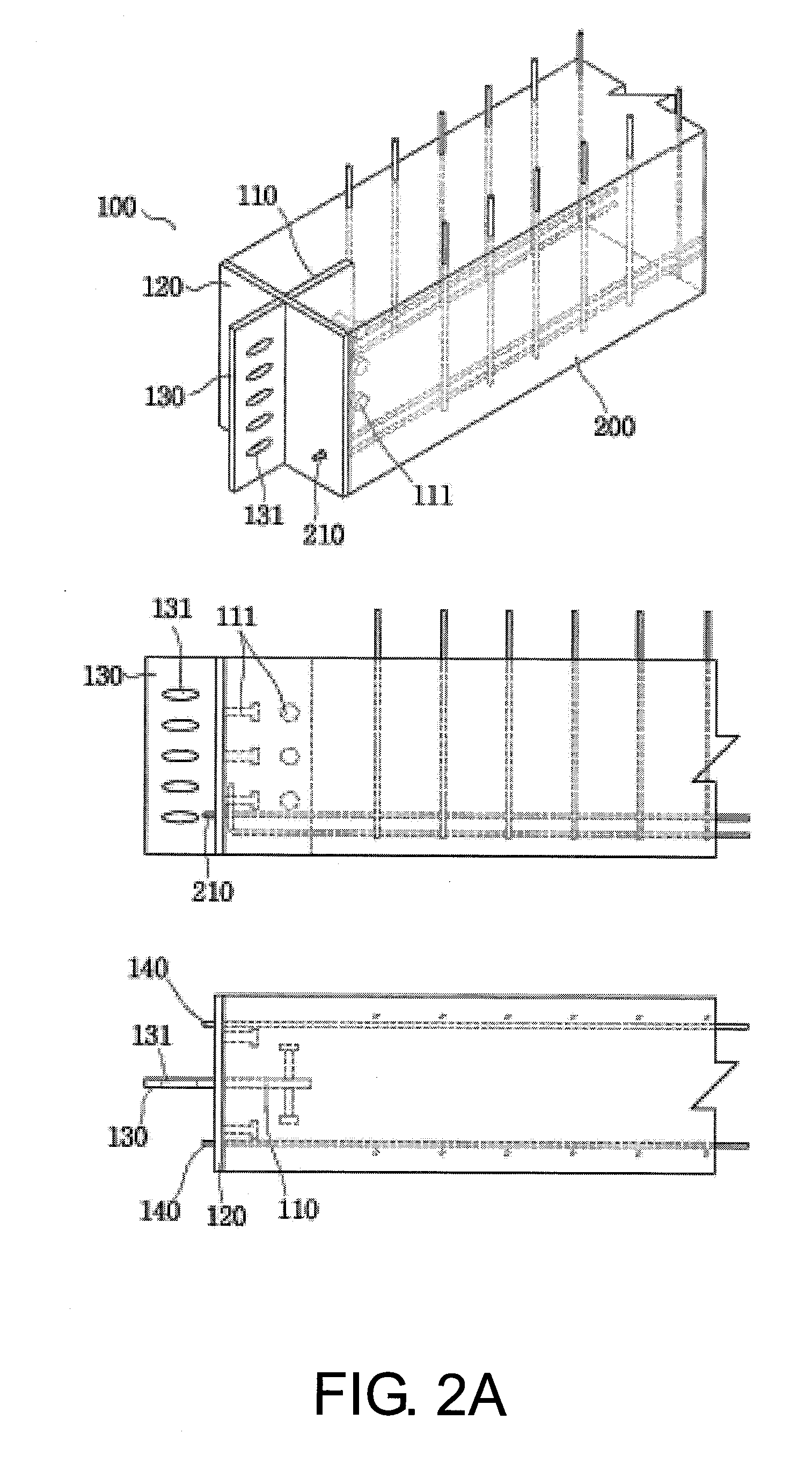

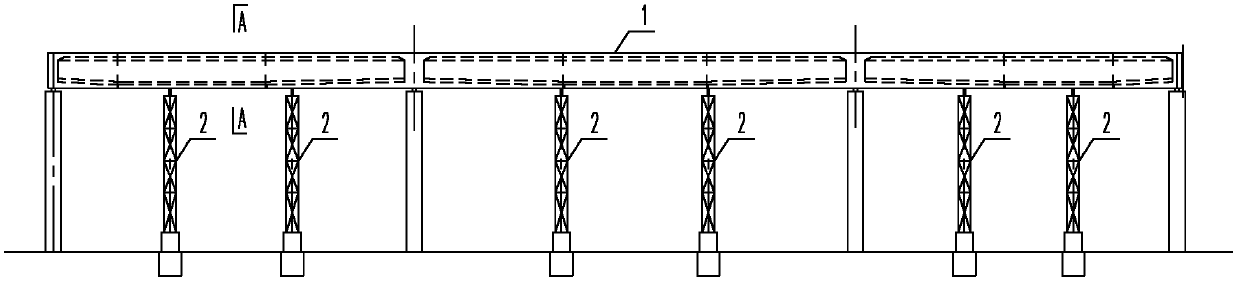

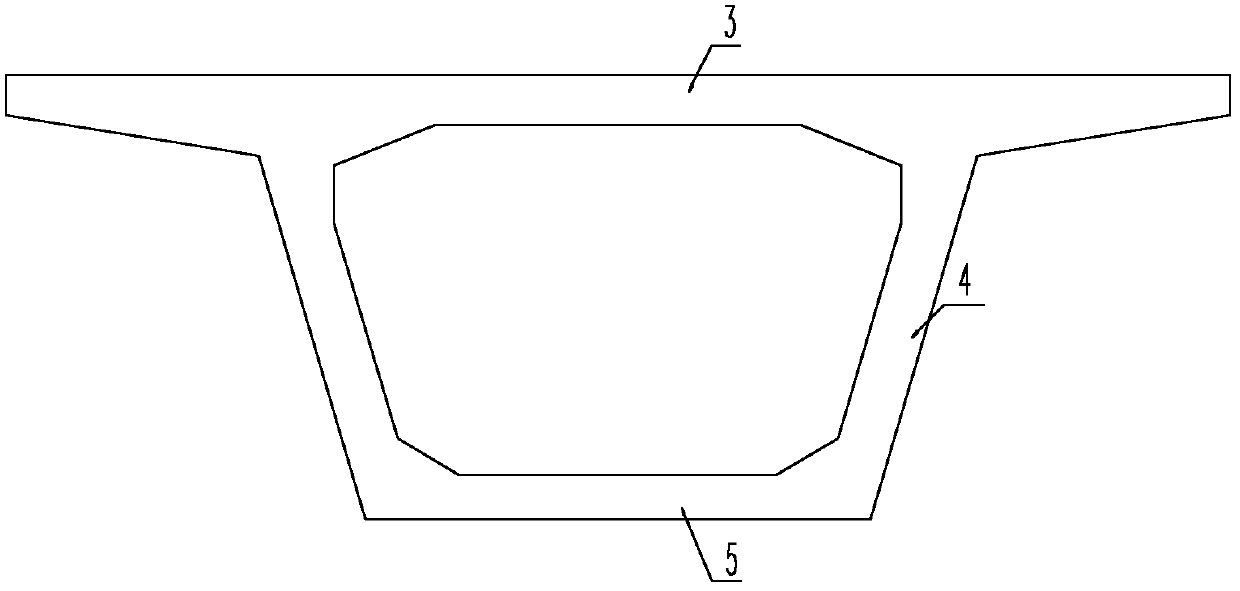

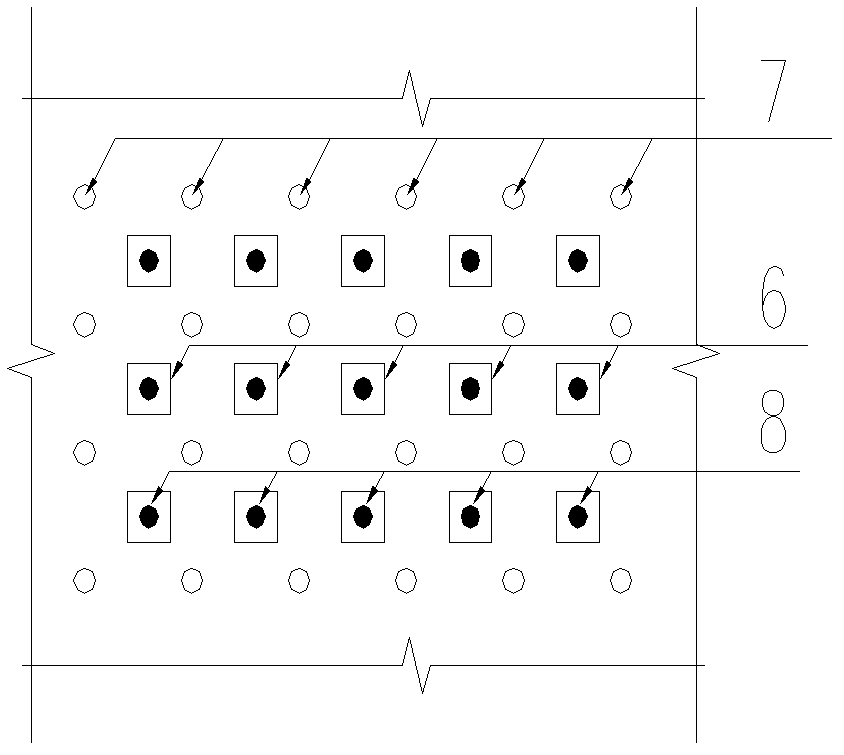

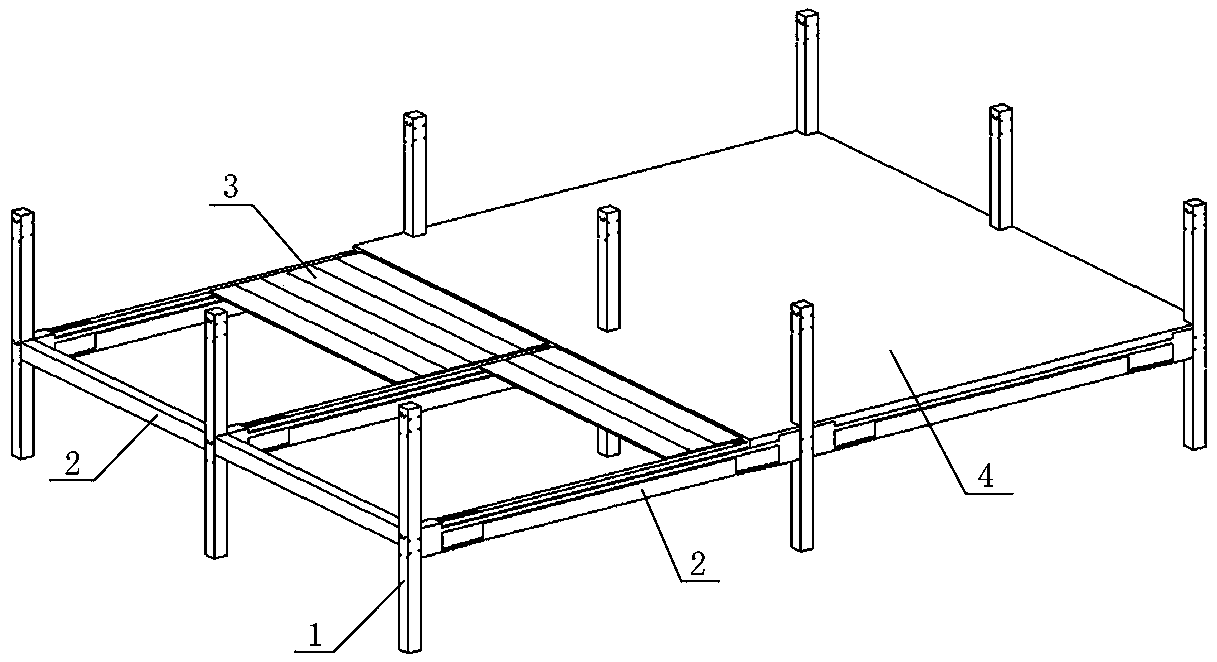

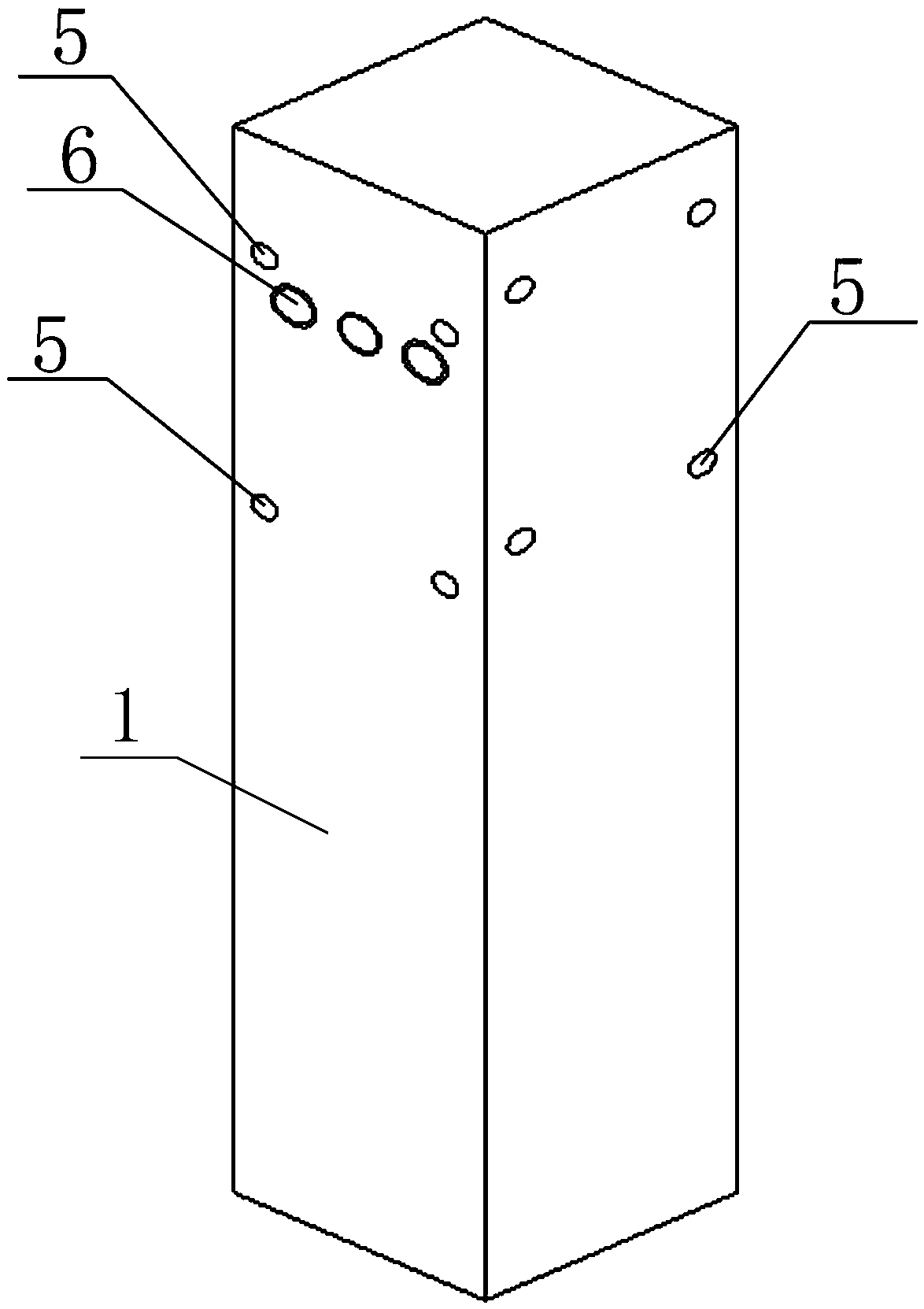

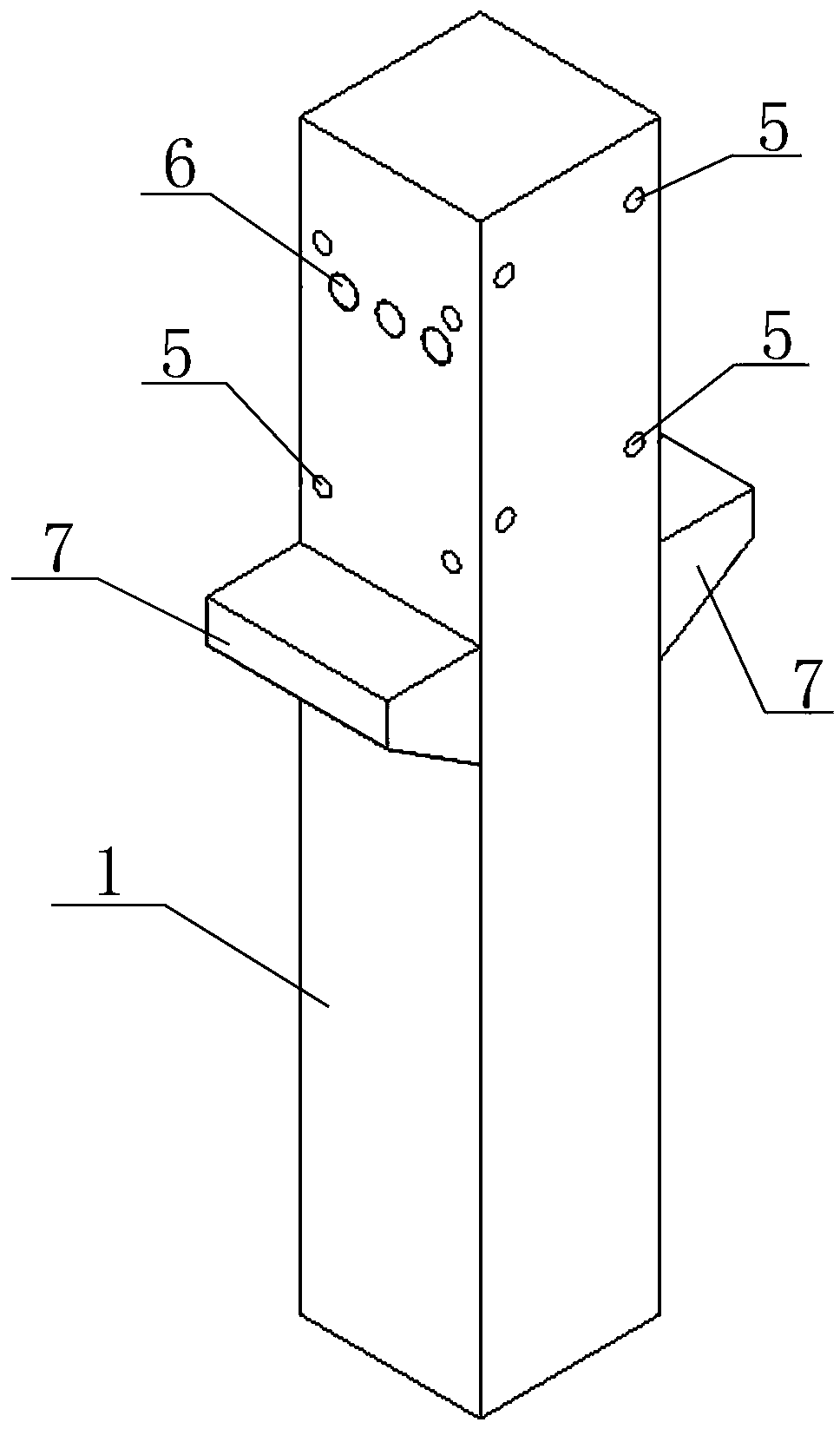

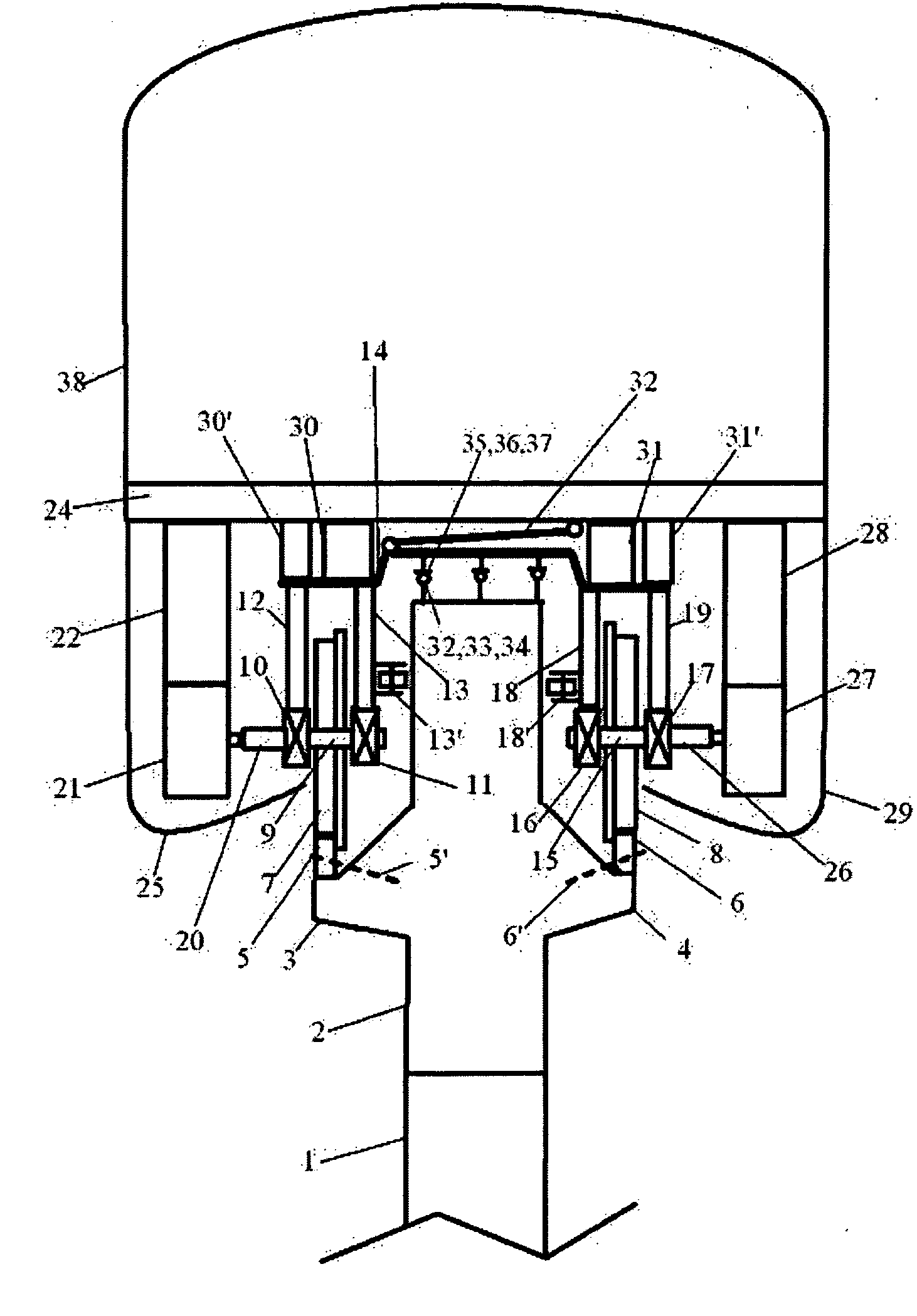

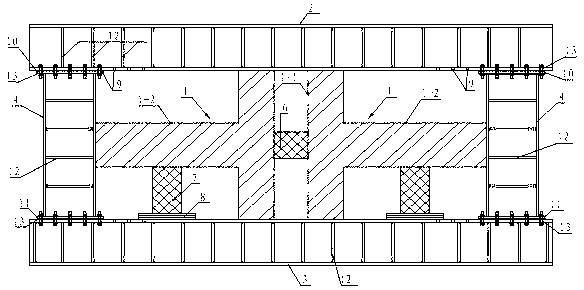

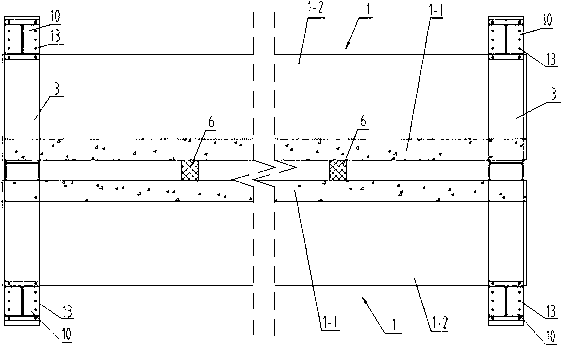

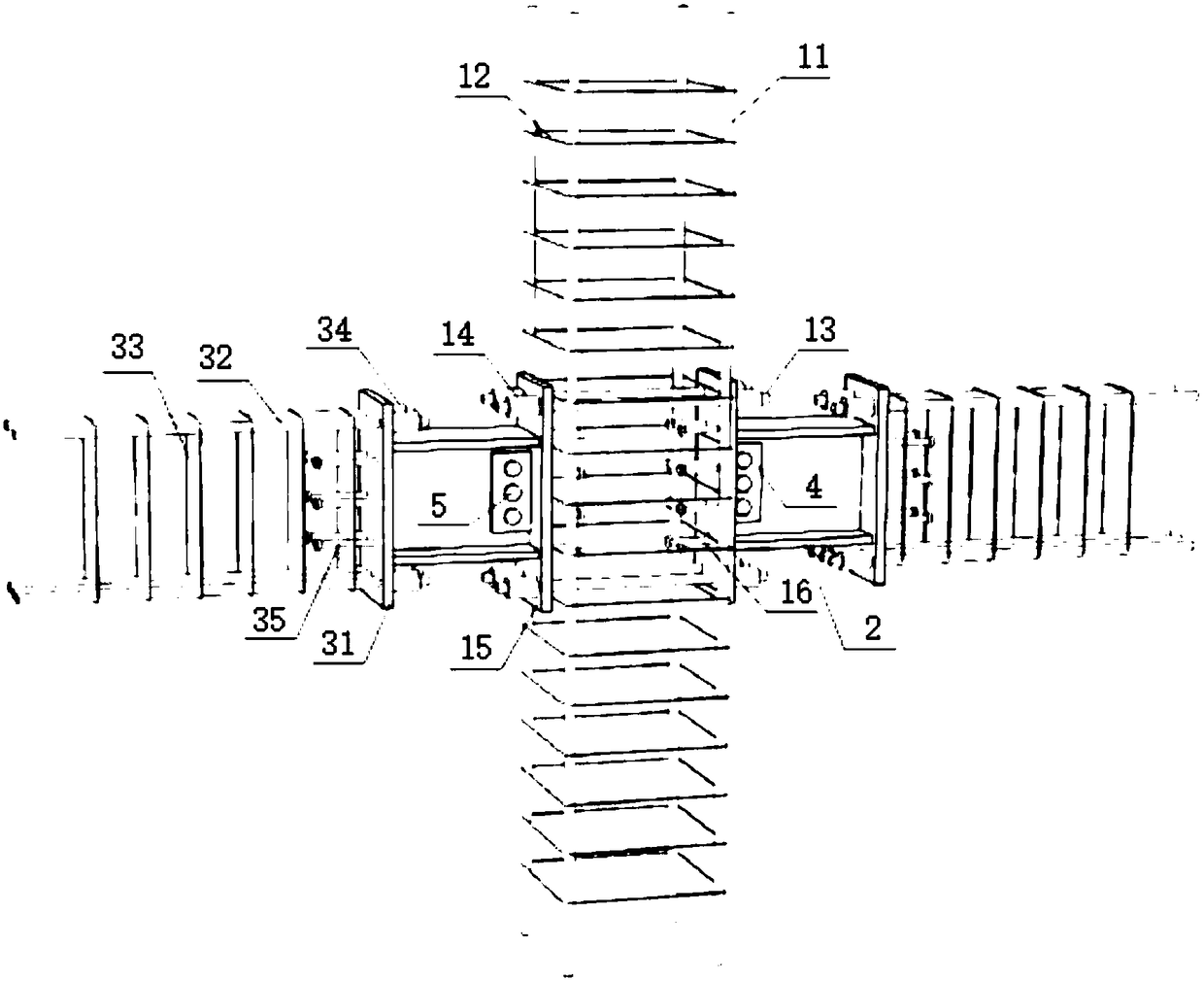

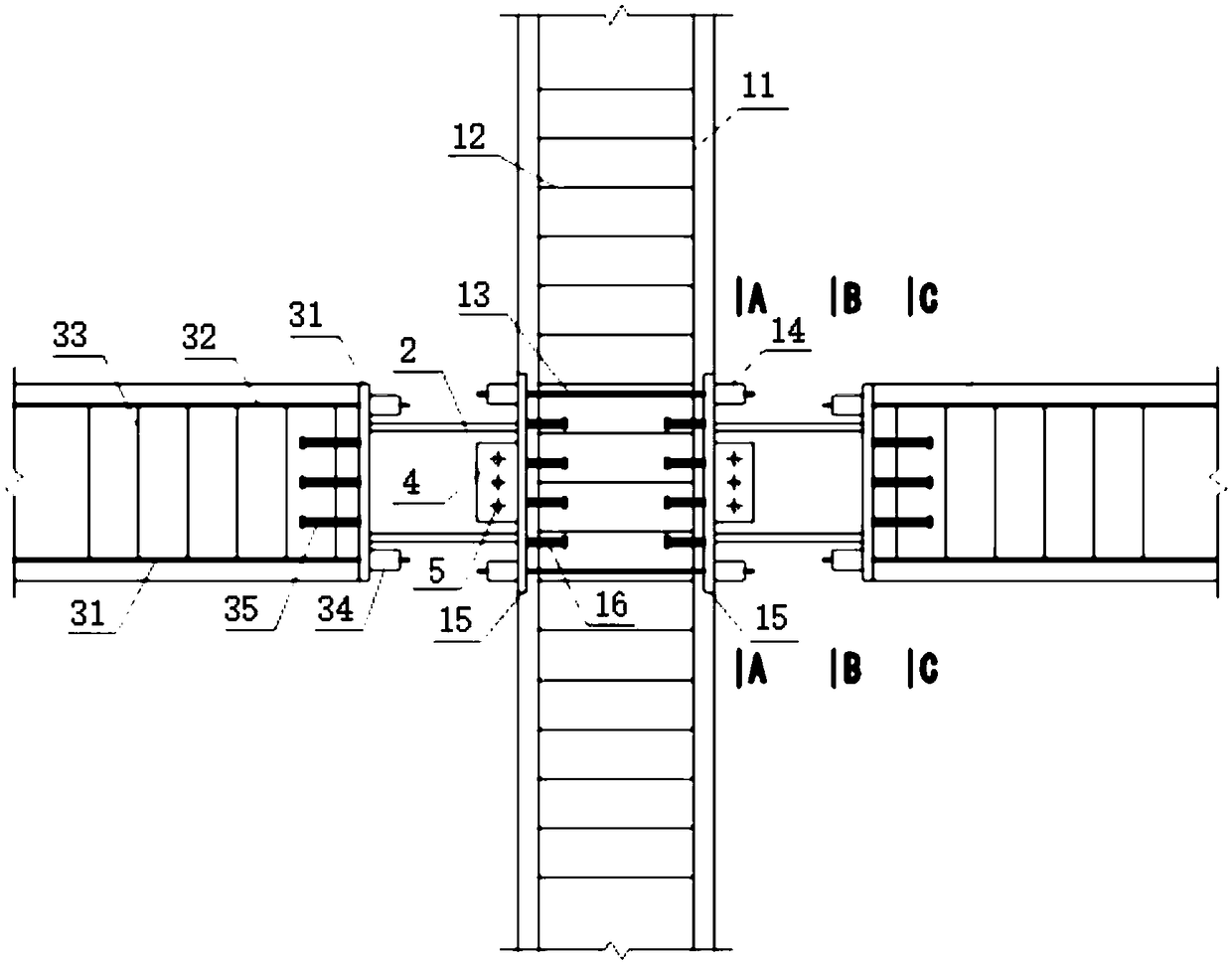

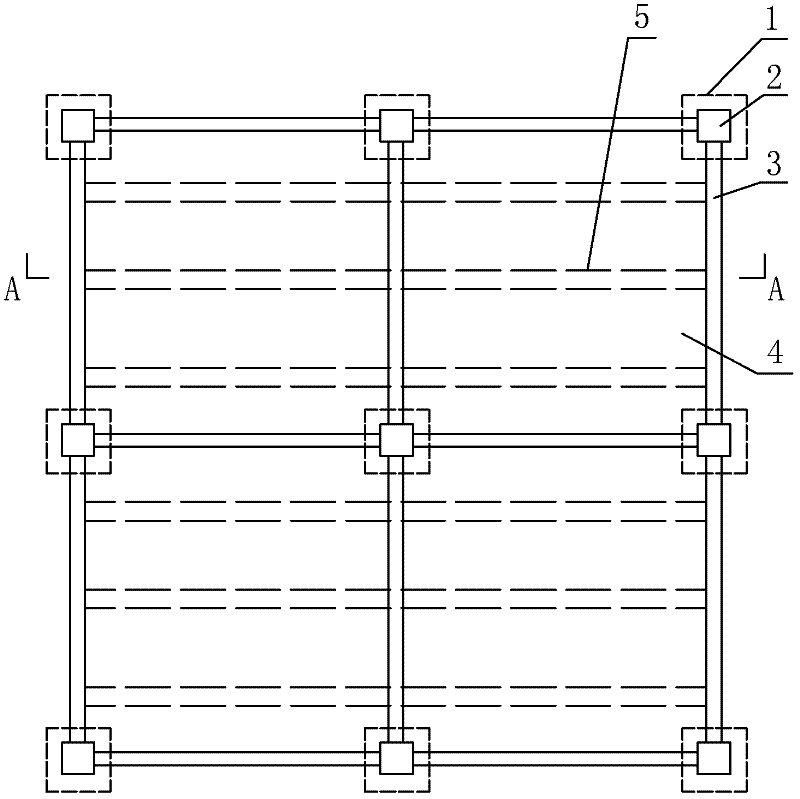

Prestressed assembly integrated concrete frame structure system and construction method thereof

ActiveCN109469202AImprove seismic performanceSimplify the installation processStrutsGirdersReinforced concrete columnPrestressed concrete beam

Disclosed are a prestressed assembly integrated concrete frame structure system and a construction method thereof. The prestressed assembly integrated concrete frame structure system comprises prefabricated reinforced concrete columns, prefabricated prestressed concrete beams, prefabricated prestressed concrete plates and a floor slab laminating layer cast on the prefabricated prestressed concreteplates; the junctions of the prefabricated reinforced concrete columns and the prefabricated prestressed concrete beams are provided with first column hole channels and second column hole channels; the portion, close to the bottom, of each prefabricated prestressed concrete beam is provided with a row of pretensioned prestressed tendons, and the prefabricated prestressed concrete beams are internally provided with first beam hole channels adapting to the first column hole channels and second beam hole channels adapting to the second column hole channels; splicing seams of the prefabricated reinforced concrete columns and the prefabricated prestressed concrete beams are filled with high-strength mortar. The system solves the technical problems that traditional assembly integrated structuresystems are complicated in structural form, difficult in joint connection, large in wet work amount and unlikely to meet the requirements of different seismic fortification zones.

Owner:CHINA BUILDING TECHN GROUP

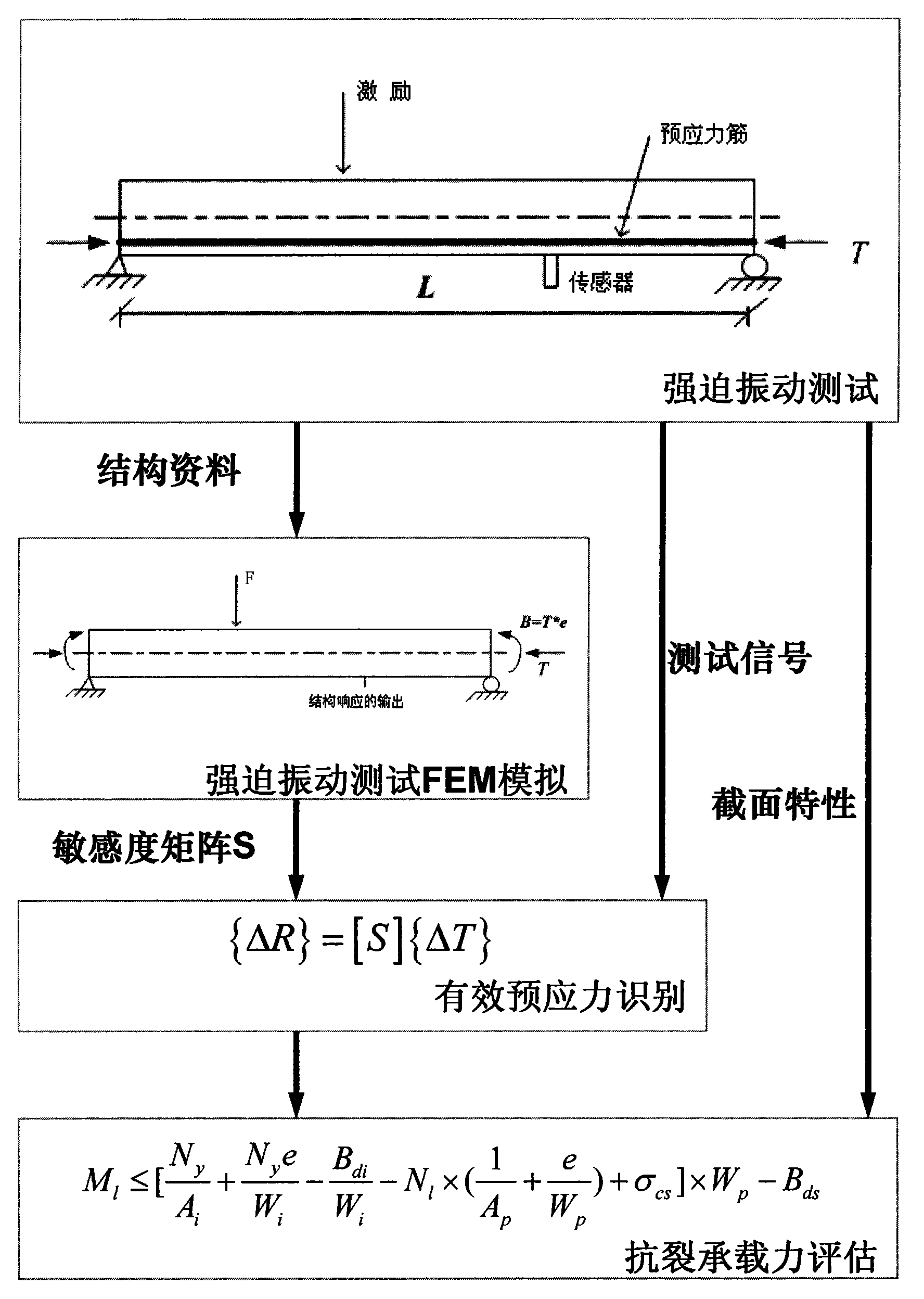

Method for evaluating eccentric straight-line prestressed concrete beam bridge bearing ability based on dynamic measurement process

InactiveCN101587046ANo damageSimple and quick to implementFoundation testingStrength propertiesPrestressed concrete beamPre stress

The invention provides a method for evaluating eccentric straight-line prestressed concrete beam bridge bearing ability based on dynamic measurement process, which includes the steps of: executing forced vibration test for beam bridge structure and acquiring single point vibration movement respond of the structure; establishing structure finite element numeric analysis model for analyzing effect of prestress level to dynamic characteristics of structure; recognizing effective prestress of structure from measured structural power respond variation amount using a method based on sensitivity; calculating anti-crack bearing capacity during test for prestressed concrete beam bridge according to measured effective prestress value. Compared with conventional nondestructive detection method, the method provided by the invention has the advantages of simple and shortcut test process, strict and integral evaluating theory, high precision of test result or the like, and can be conveniently applied to test and evaluation for prestressed concrete beam bridge.

Owner:SHANGHAI TONGJI CONSTR QUALITY INSPECTION STATION

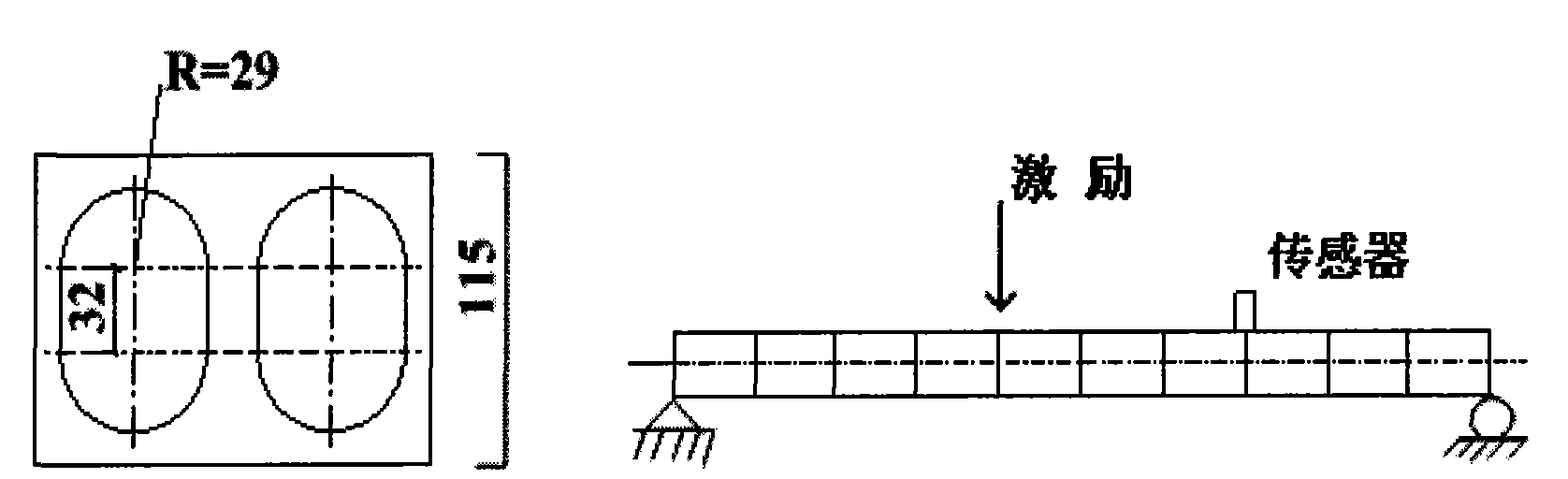

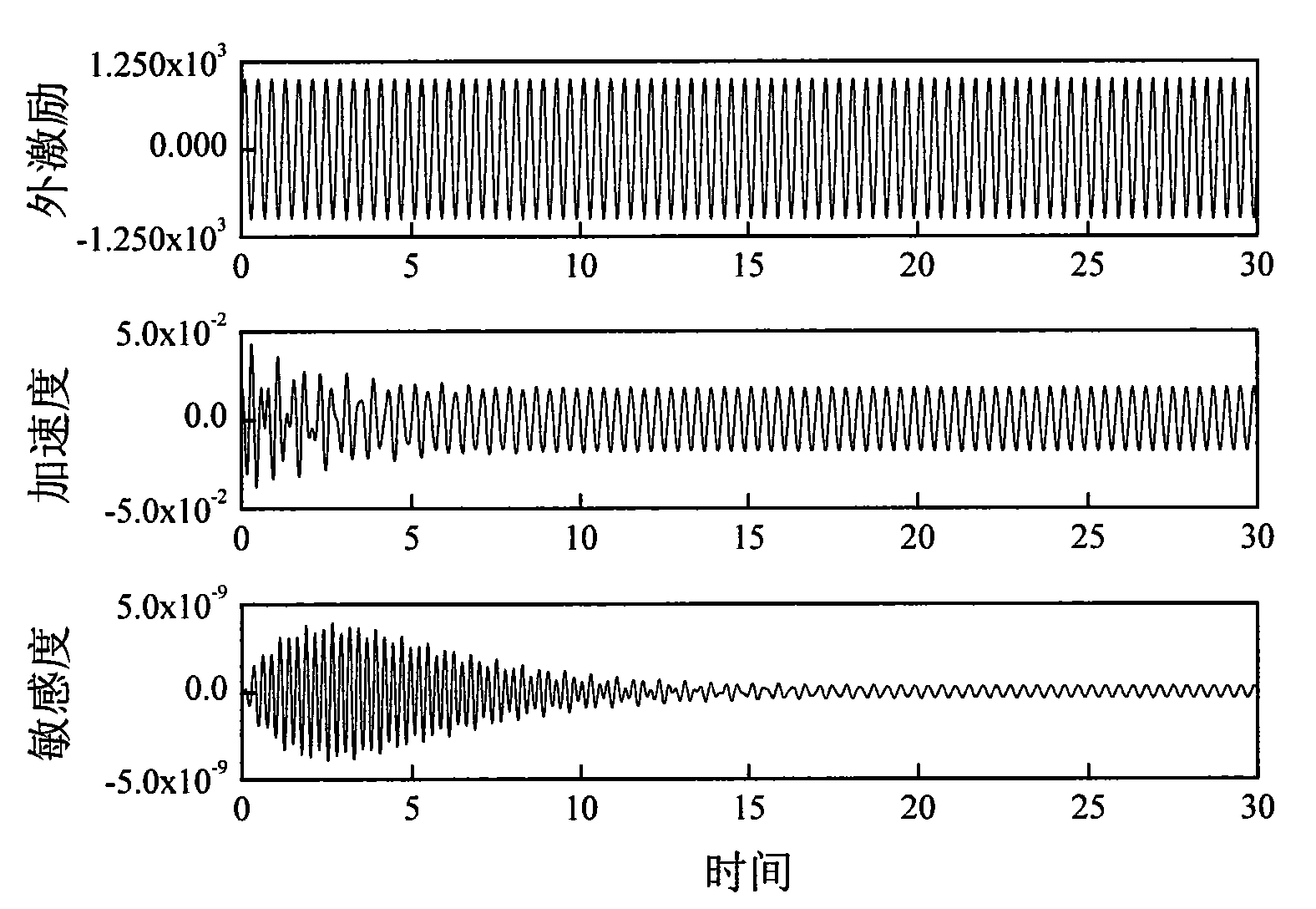

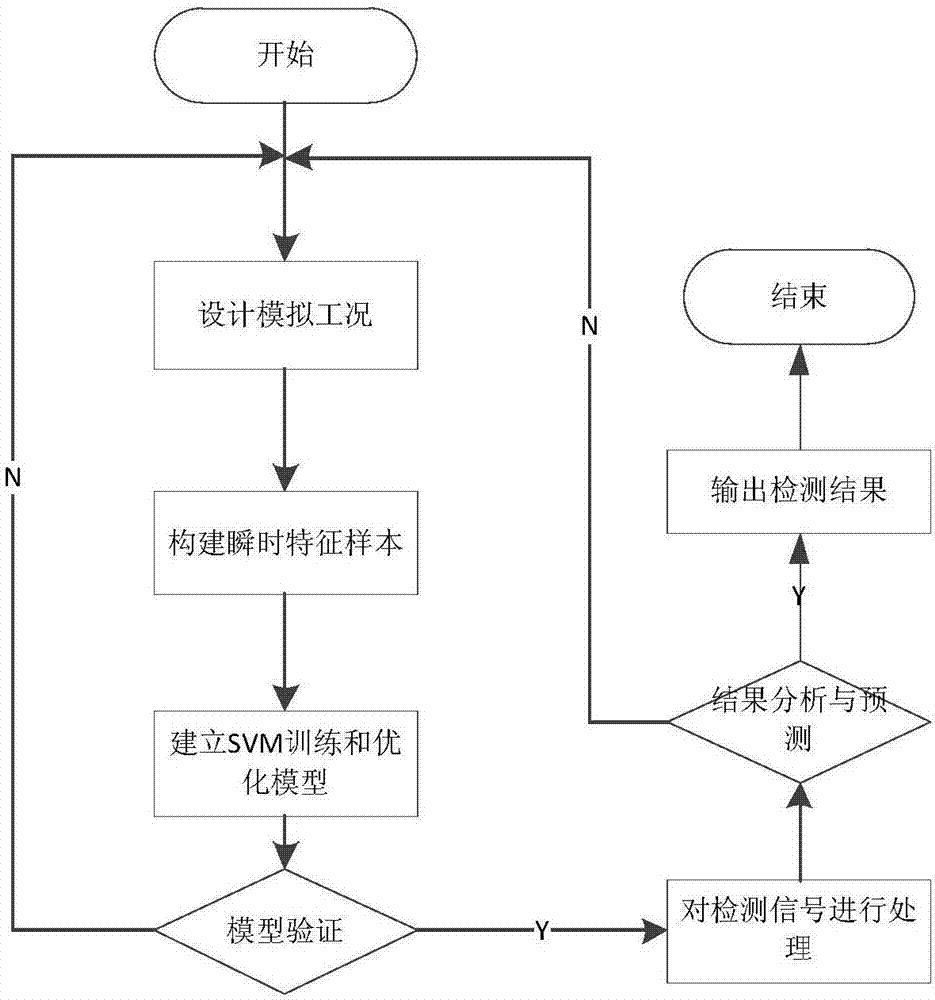

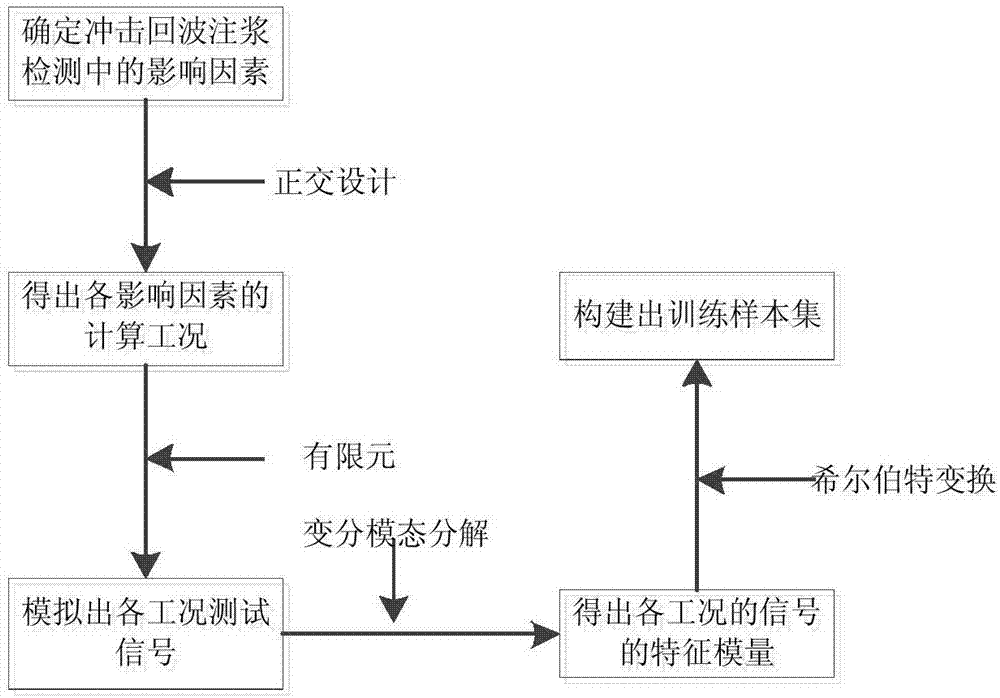

Intelligent identification method for prestressed concrete beam grouting compactness

ActiveCN106990018AOvercome efficiencyOvercome precisionDesign optimisation/simulationSpecial data processing applicationsSupport vector machinePrestressed concrete beam

The invention discloses an intelligent identification method for prestressed concrete beam grouting compactness. According to the method, variational mode decomposition, finite element simulation, support vector machine and other technologies are used, wherein impact echo vibration signals under different working conditions are simulated through finite elements, a support vector machine training sample is constructed by using variational mode decomposition and hilbert transform, and finally the prestressed concrete beam grouting compactness is quantitatively predicted with the trained support vector machine according to an impact echo detection signal. According to the present invention, with the intelligent identification method, the disadvantages of low efficiency, poor precision and the like during the existing impact echo detection process can be effectively overcome, the influence of the human factors in the detection process can be eliminated, and the detection precision and the working efficiency can be improved to the greatest extent.

Owner:HOHAI UNIV

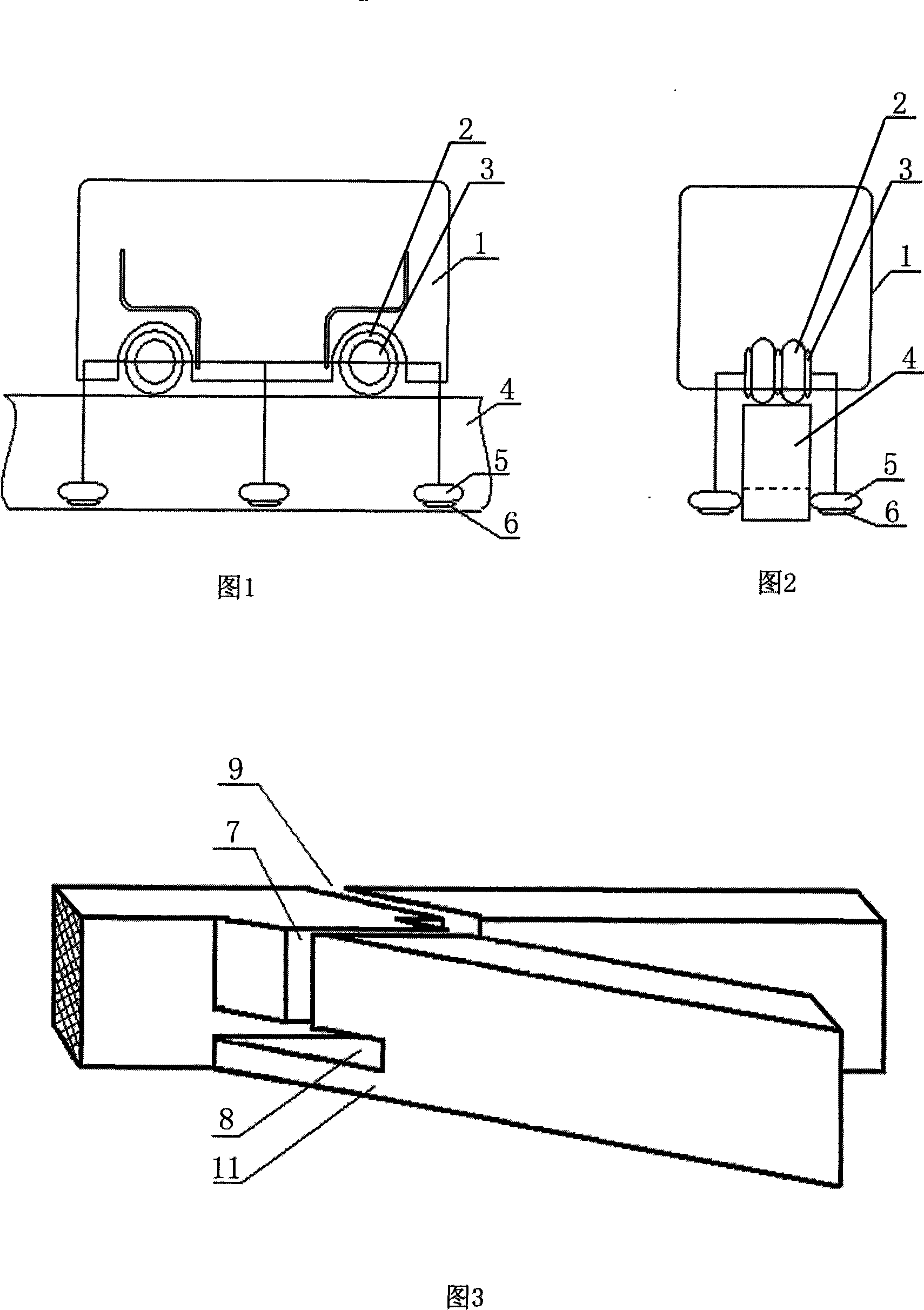

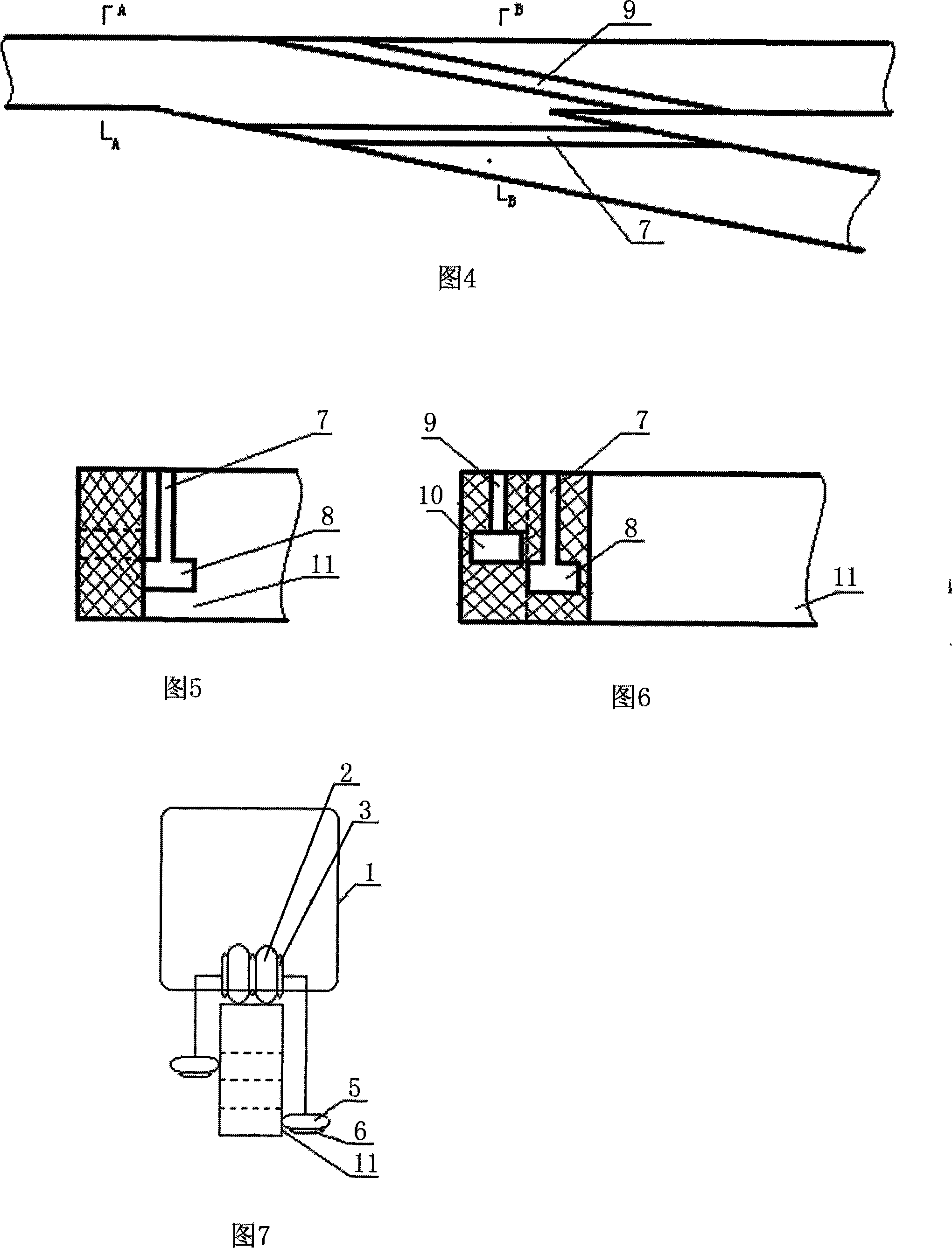

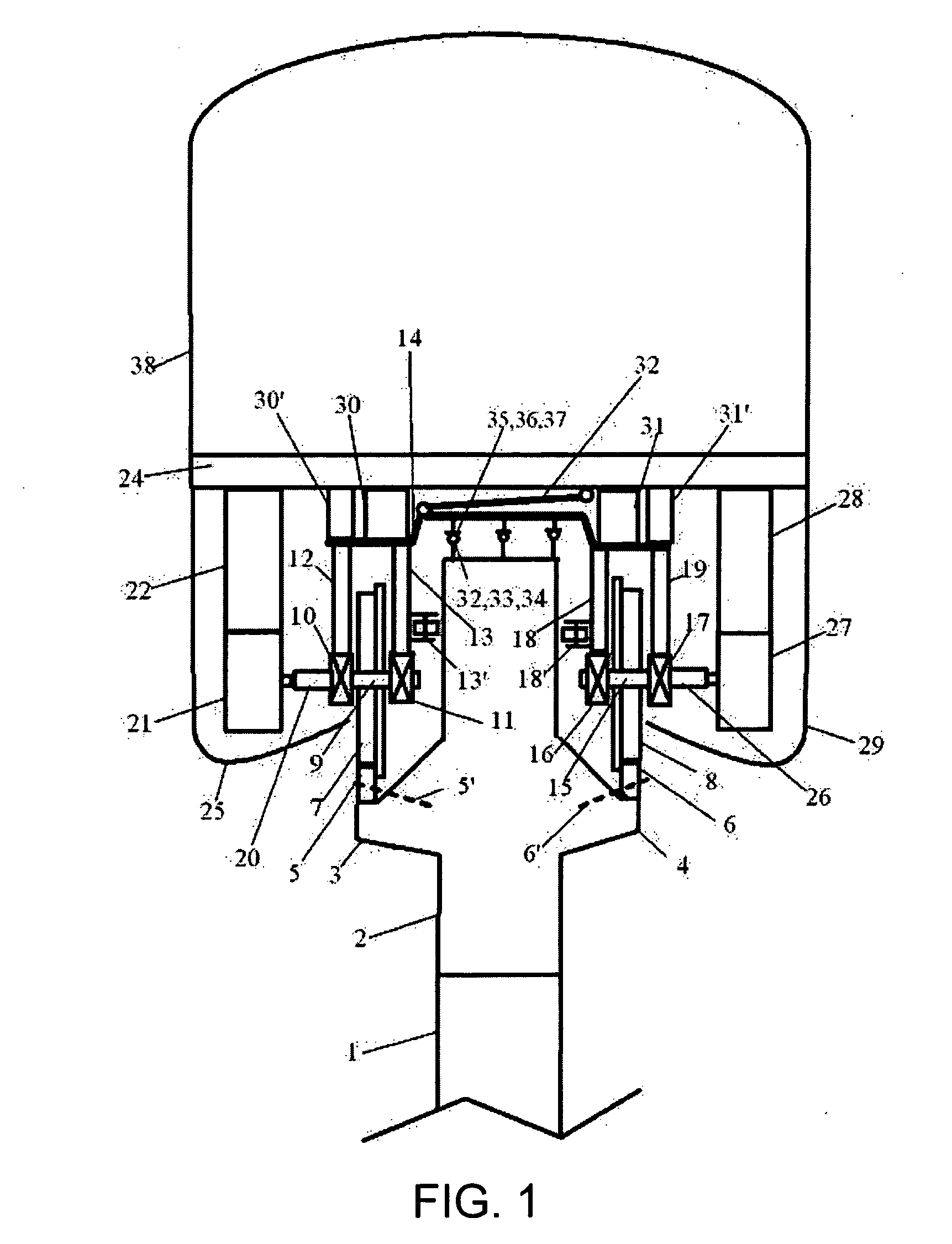

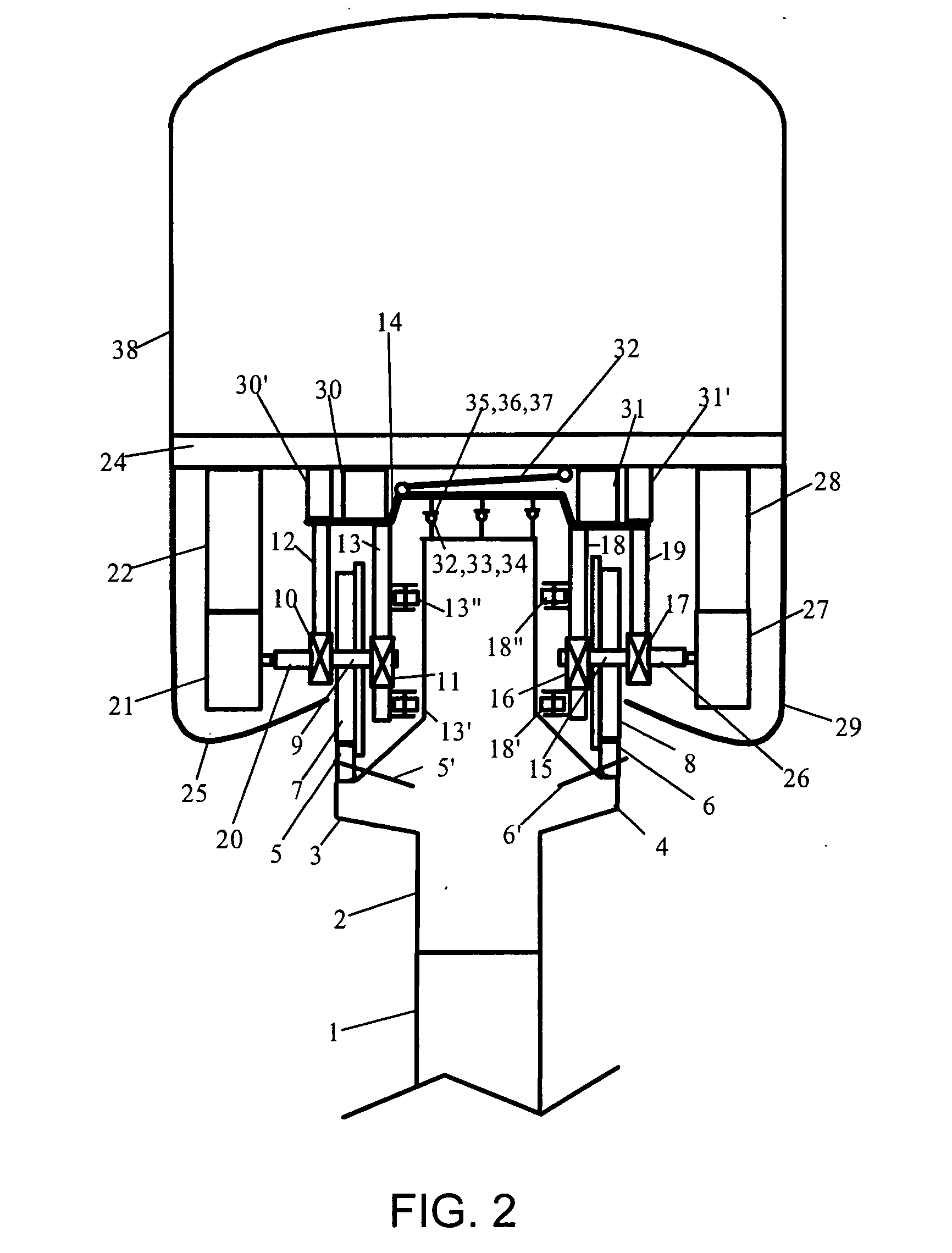

Straddle type monorail individual fast public transport mechanism

InactiveCN101214818AReduce initial investment costRealize peer-to-peer serviceMonorailsRailway tracksPrestressed concrete beamTraffic network

The invention relates to an urban rail transportation mechanism, in particularly a straddle monorail personal fast transportation mechanism. The mechanism comprises a rail girder with a switch beam and a rail car. The rail car is equipped with a travel wheel traveling on the top surface of the rail girder and a guide wheel moving on the two sides of the rail girder. The invention is characterized in that the switch beam is equipped with a vertical guide wheel axle channel and a horizontal guide wheel channel. The rail car is equipped with a rise-and-fall guide wheel axle. The invention relates to a straddle monorail personal fast transportation mechanism, utilizes a prestressed concrete beam as the rail girder, utilizes a miniature rail car such as four seats, adopts the design of special switch and car to enable the car to rapidly pass through the switch, thereby forming the cross-line transportation and the straddle monorail transportation network, enabling passengers to directly arrive the destination without changing car, and realizing the point-to-point service.

Owner:董守义

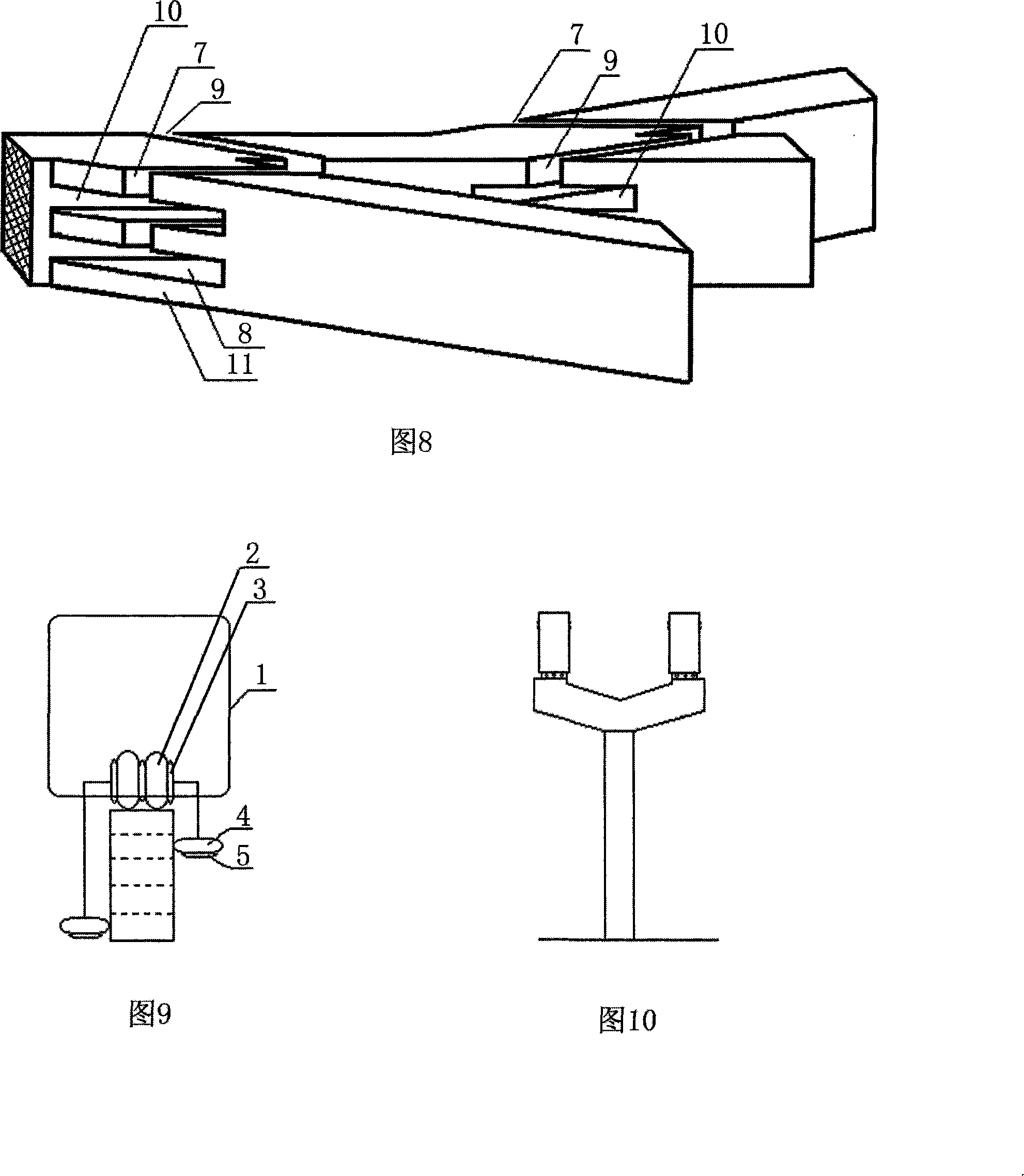

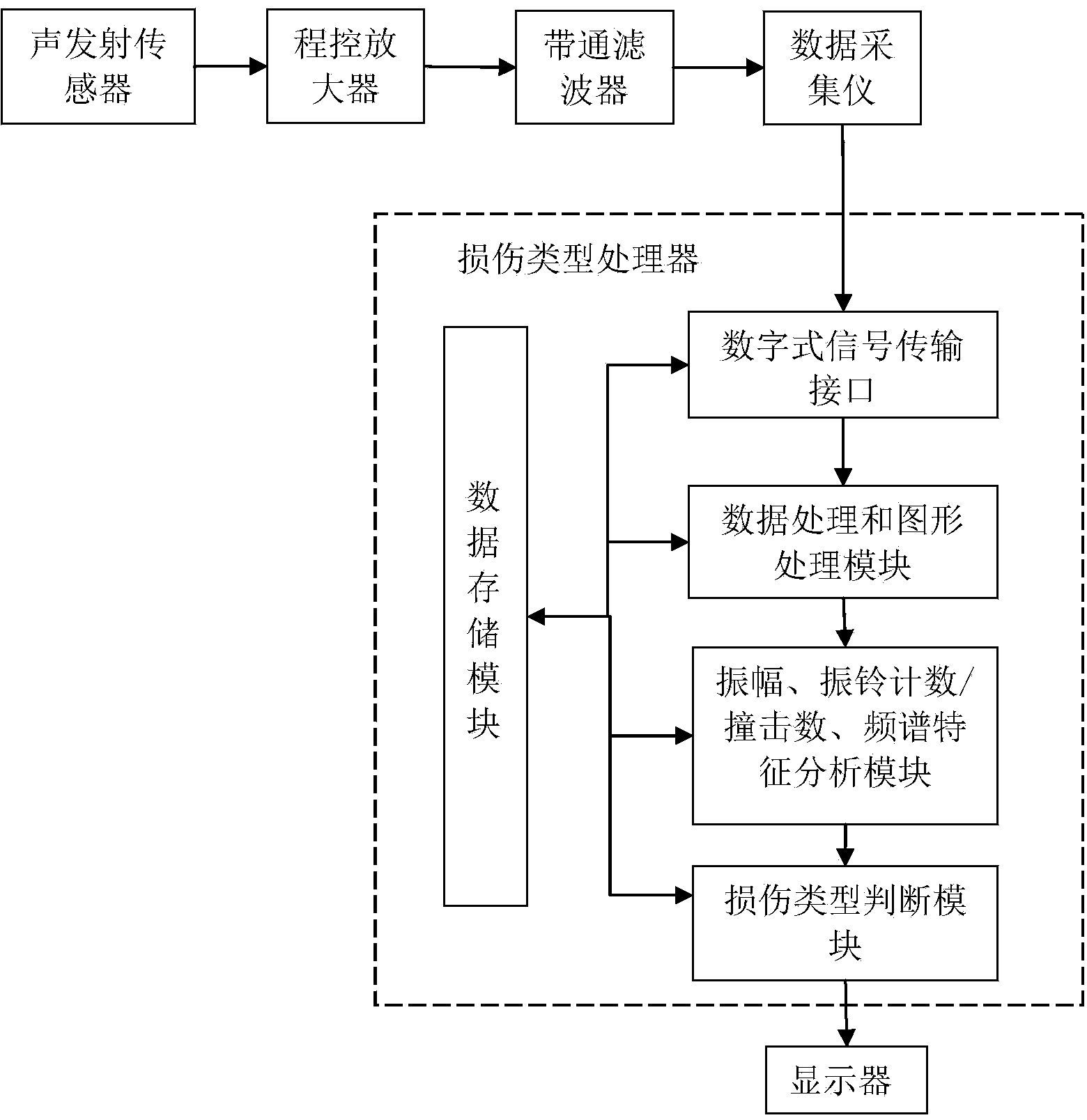

System and method for judging structural damage type of prestress concrete beam based on acoustic emission technique

ActiveCN103852523AAnalyze health statusHigh sensitivityMaterial analysis using acoustic emission techniquesPrestressed concrete beamConcrete beams

The invention provides a system and a method for judging the structural damage type of a prestress concrete beam based on an acoustic emission technique. The method comprises the following steps: acquiring a correlation diagram of amplitude-ring count, amplitude-collision count, ring count / collision count-accumulative collision count according to a detected acoustic emission signal; acquiring the ring count / collision count corresponding to the amplitude distribution range, the frequency distribution range and the peak value of the accumulative collision count as well as the damage type judgment standard; classifying the damage degree, thereby obtaining the damage type. According to the invention, the damage type of a prestress concrete beam structural element at each stress stage can be determined accurately and dynamically in real time, and a technical support can be provided for the damage prewarning. The system and the method are high in flexibility, are simple to operate, can be used for analyzing the health status of the structural element locally and integrally, and is suitable for predicating the damage degree of reinforced and rebuilt prestress concrete structures.

Owner:河南省第二公路工程有限公司 +1

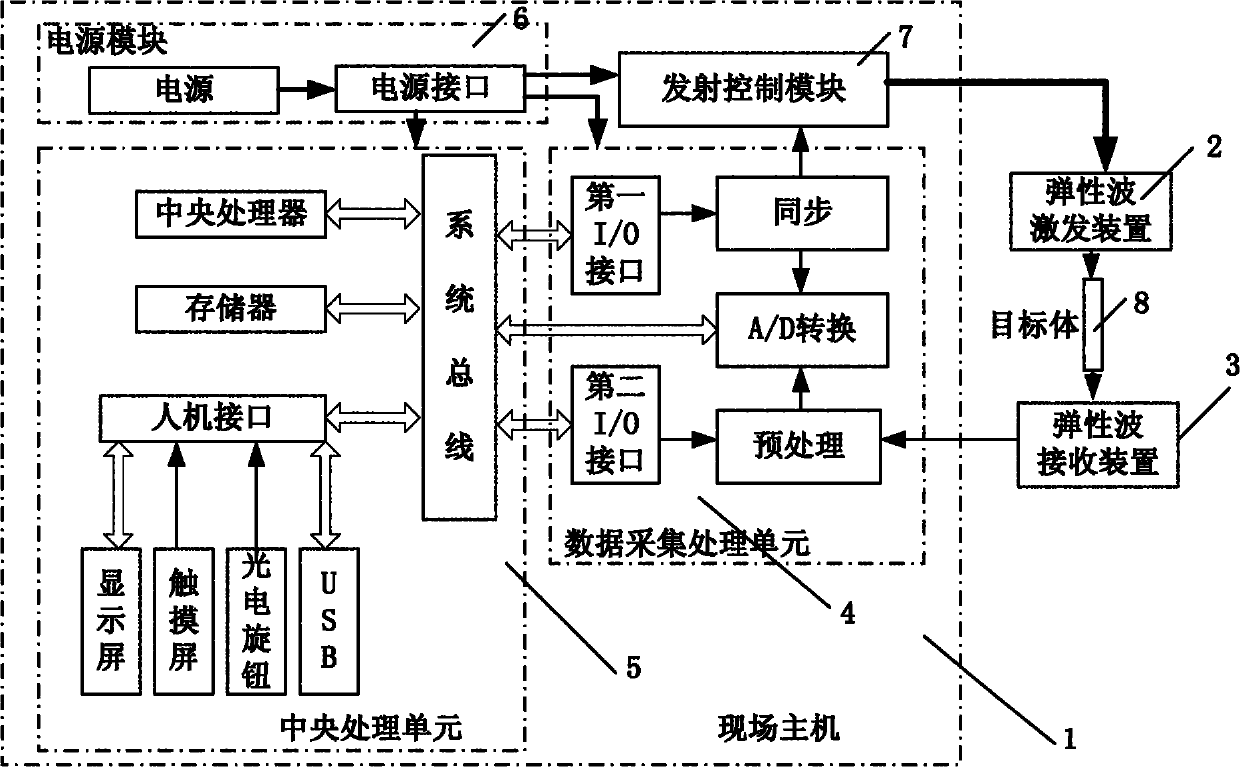

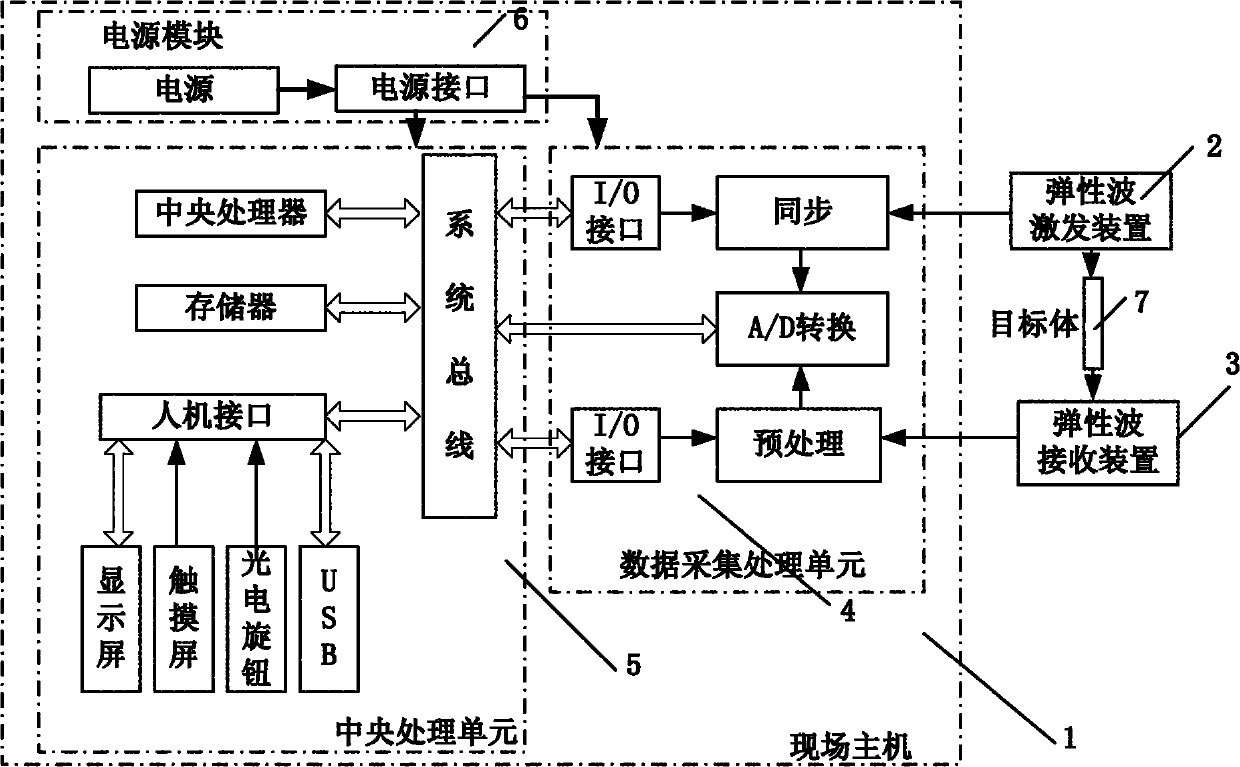

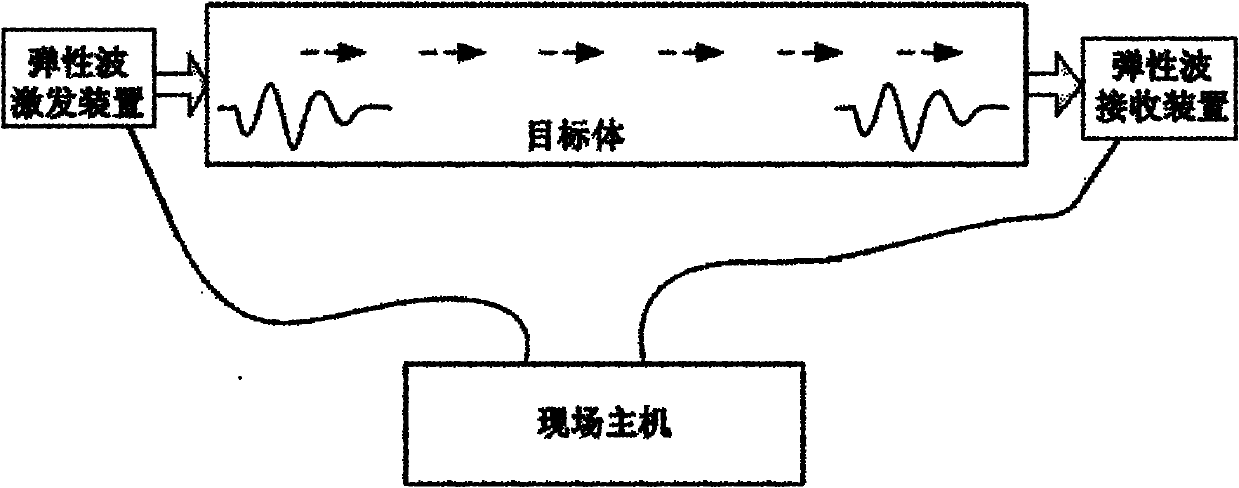

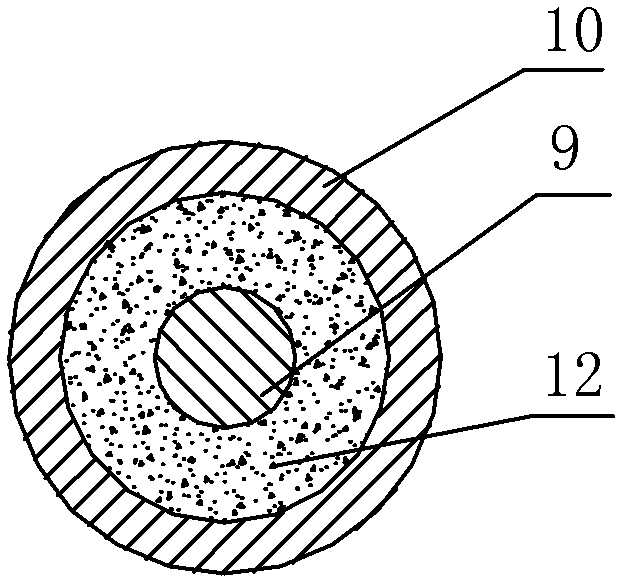

Method and device for detecting mudjacking saturation of post-tensioned prestressed concrete beam pipe

InactiveCN102183584ARealize the fullness detection of groutingImprove accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesPrestressed concrete beamPre stress

The invention discloses a method and device for detecting mudjacking saturation of a post-tensioned prestressed concrete beam pipe. The method comprises the following concrete steps: 1, a target body is determined to be a prestress anchor cable, two ends of the anchor cable are provided with an elastic wave exciting device and an elastic wave receiving device, the acoustic time is measured, and the wave speed of the anchor cable is calculated according to the length of the anchor cable; 2, a target body is determined to be a prestressed concrete beam, two ends of the beam with the same height and the same horizontal position are provided with an elastic wave exciting device and an elastic wave receiving device, the acoustic time is measured, the wave speed of the concrete is calculated according to the length of the beam, and each beam is measured once; 3, a target body is determined to be a pipe of the prestressed concrete beam, locksets of two ends of the pipe are provided an elastic wave exciting device and an elastic wave receiving device, the acoustic time is measured, and the wave speed of the pipe induration is calculated according to the length of the pipe and the thickness of the locksets; and 4, the mudjacking saturation of the pipe to be detected is calculated by using the following formula according to the average wave speed C(b)of the anchor cable, measured in the step 1, the wave speed C(m j) of the concrete to be detected, measured in the step 2, and the wave speed C(t j i) of the pipe solidification to be measured, measured in the step 3.

Owner:上海隧道工程质量检测有限公司 +1

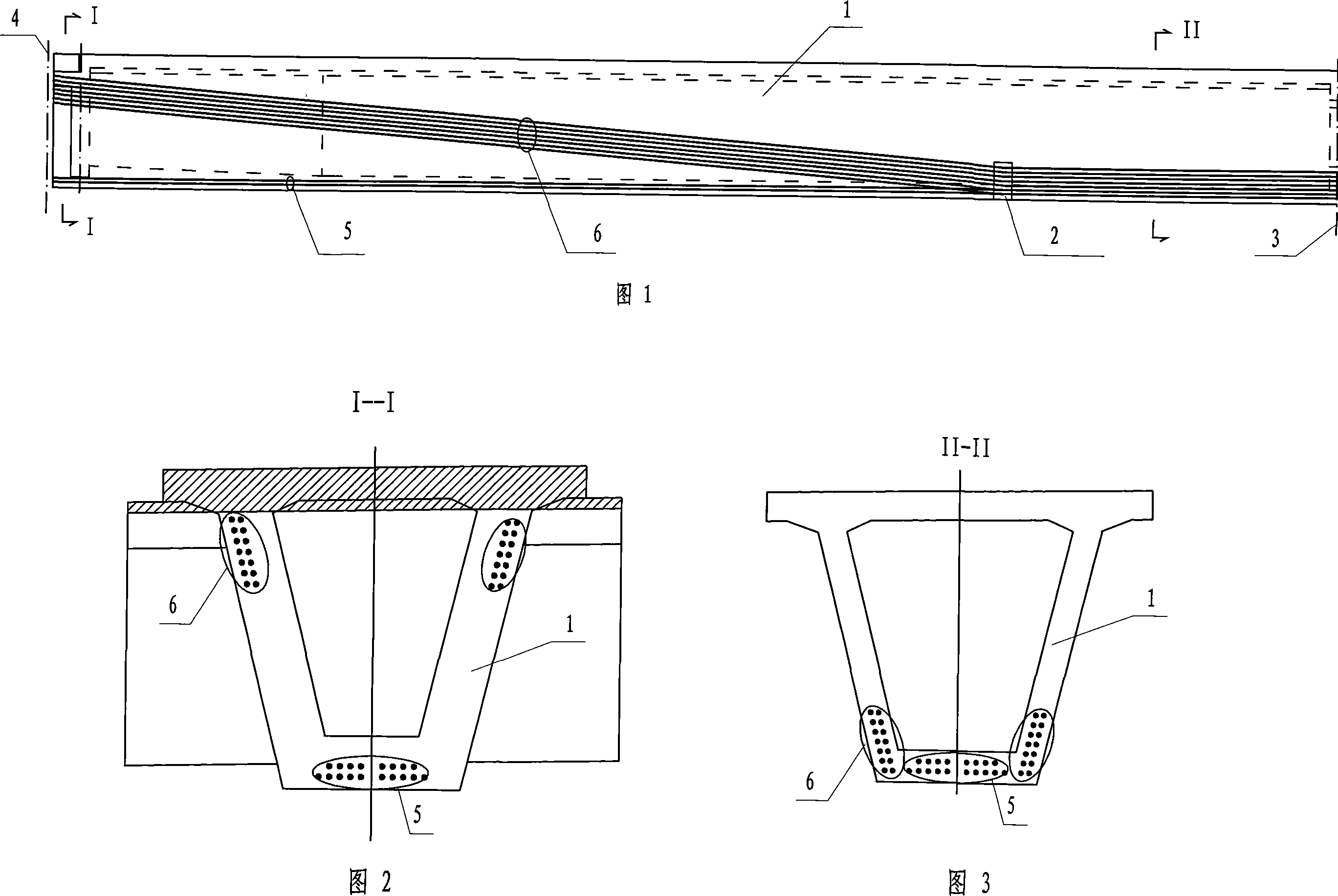

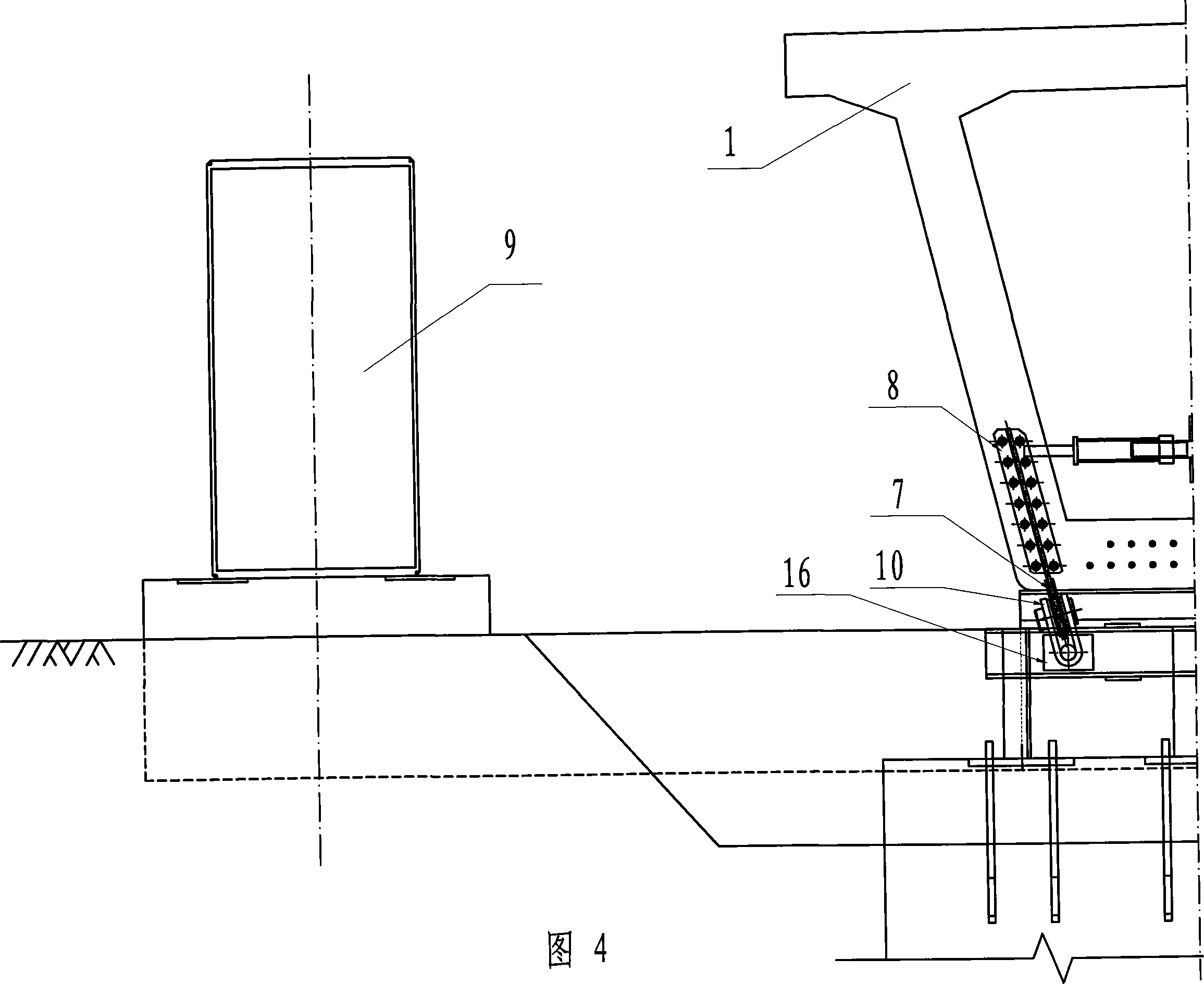

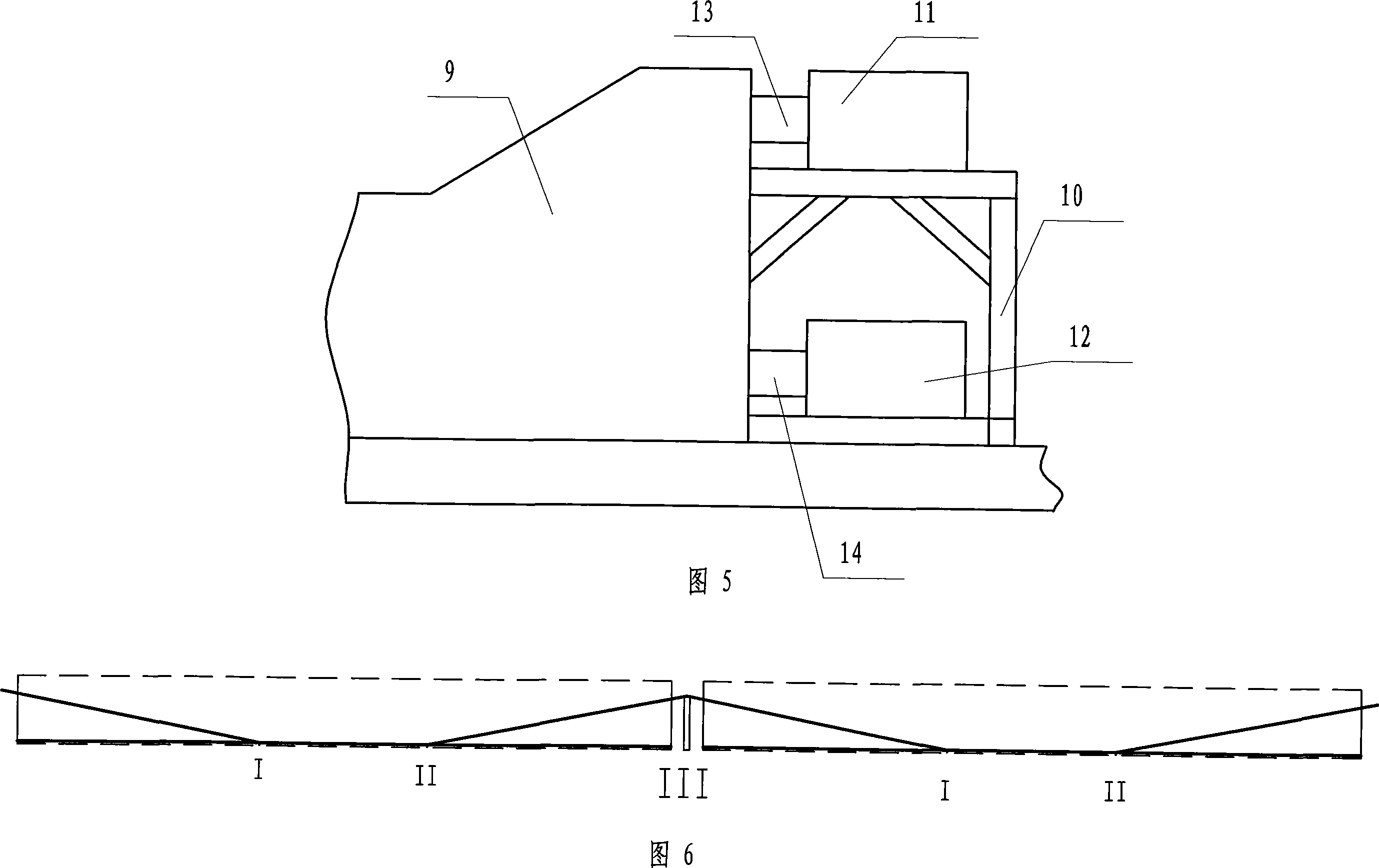

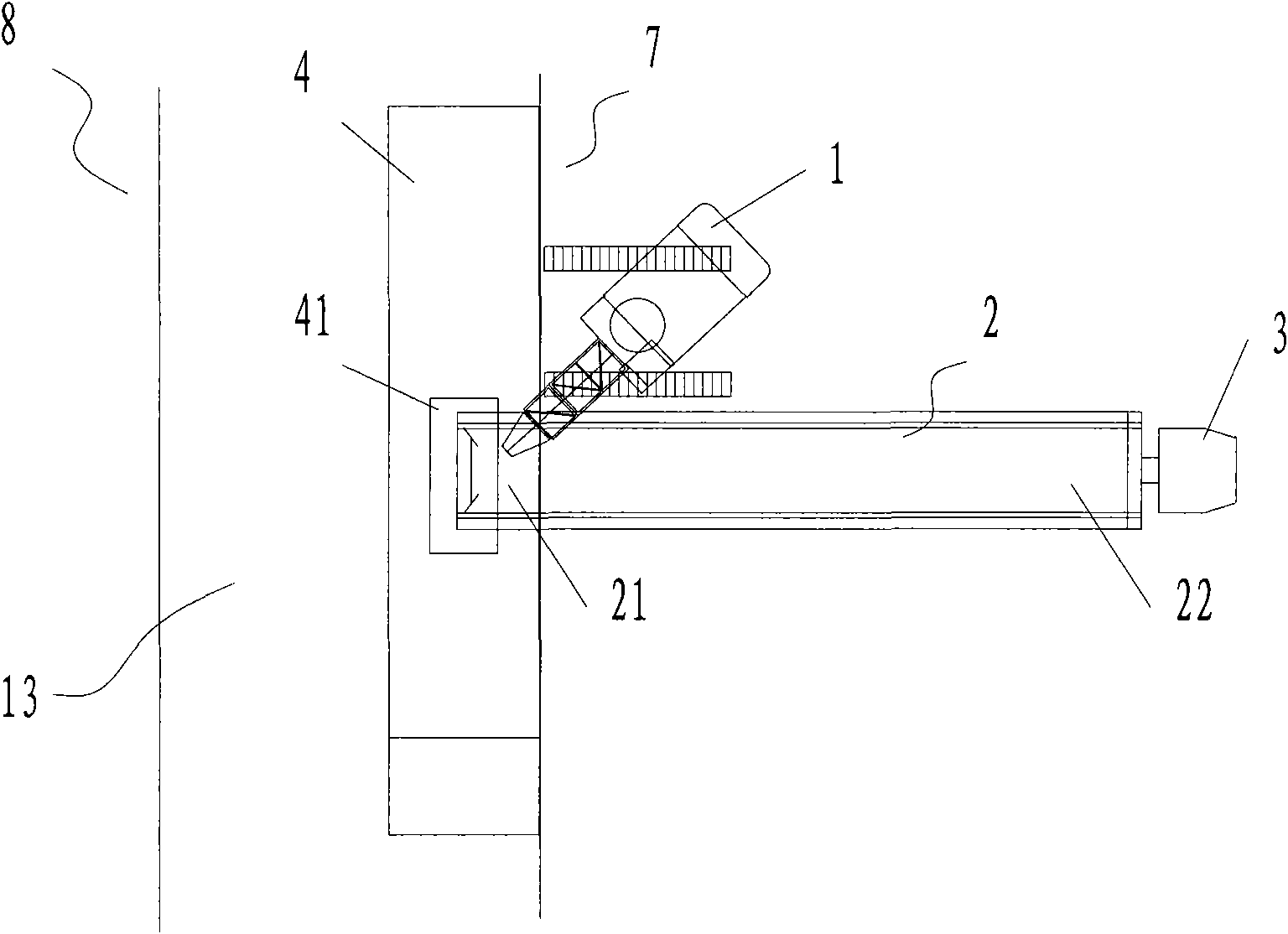

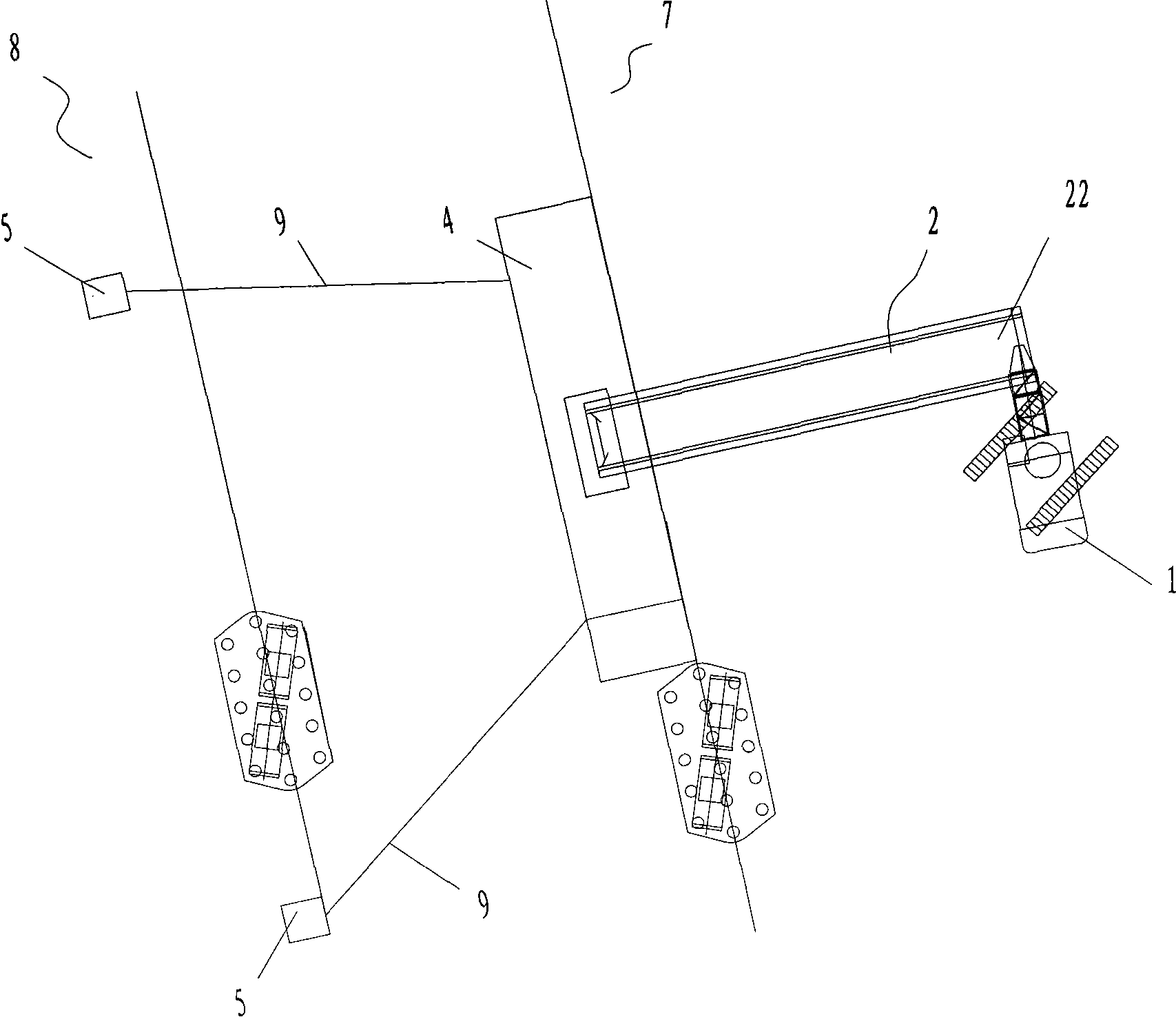

Broken-line reinforcement prestressed concrete pre-tensioned girder construction process

InactiveCN101158238AReduce workloadThe tensioning process is simpleBuilding material handlingPrestressed concrete beamPre stress

The invention relates to a construction process for a pre-tensioned girder with a broken-line prestressed concrete beam. The invention comprises a pulling-tension process and an expanding-tension process, and the pulling-tension process is provided with an upper beam and a lower beam, and a prestressed strand comprises a straight-line steel strand and a broken-line steel strand. The straight-line steel strand is anchored on the lower beam, and the broken-line steel strand is firstly bent by a bending device and then is anchored on the upper beam. And the lower beam and the upper beam are movable beams. The pulling-tension process adopts a two-end tensioning way. The pulling-tension process includes the following procedures: 1, on outer sides of the upper and the lower beams, a jack is respectively used for singly tensioning steel strands on corresponding beams to 30-40 percent of a control stress; 2, on outer sides of the upper and the lower beams, the jack is respectively used for singly tensioning steel strands on corresponding beams to 65-85 percent of the control stress; 3, steel strands on the upper beam and the lower beam are completely and respectively tensioned to 100 percent of the control stress. The invention not only can guarantee an accurate tension tonnage but also can improve the tensioning efficiency, and the construction is safe.

Owner:王用中 +1

Interstate highway train system

InactiveUS20060162609A1Minimal energyOptimize spaceRailway tracksRope railwaysTransportation infrastructurePrestressed concrete beam

This is an elevated pile supported pre-stressed concrete beam electric high-speed remote-controlled modular train system, including compact high-rise terminals installed within the interstate highway rights-of-ways, a train module astride elevated support beams at standard gage rail widths to fully integrate train modules into existing rail, and since it's within existing interstate highways, fully integrates the new train system with other transportation infrastructures.

Owner:LEW HLDG

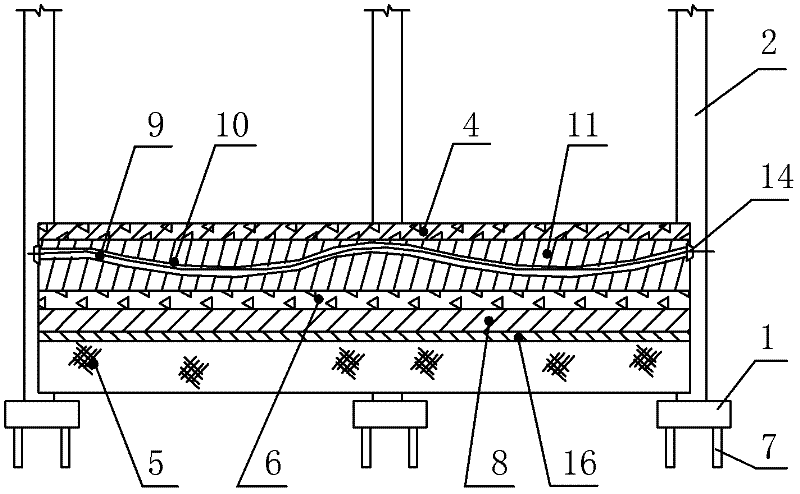

Construction method for high-rise concrete structure

ActiveCN102493647AFast constructionLow costBuilding material handlingPrestressed concrete beamConcrete beams

The invention relates to a construction method for a high-rise concrete structure. The method comprises the following steps of: (1) concrete column construction; (2) concrete beam construction: mounting a high-strength prestressed concrete beam duct piece prefabricated in a factory for prefabrication by using a tower crane, mounting a reinforcement cage processed in a factory in the high-strength prestressed concrete beam duct piece in sections, pouring concrete by using a concrete pump truck, and forming a concrete beam after maintenance is finished; (3) concrete slab construction: mounting a corrugated sheet on the concrete beam, laying a board bar-mat reinforcement mesh processed in a processing factory, then pouring concrete by using the concrete pump truck, and forming the concrete slab after the maintenance is finished, thus the construction of the first layer structure of the concrete structure is finished; and repeatedly carrying out the steps (1)-(3) to perform the construction of the second layer structure of the concrete structure until the construction of the whole high-rise concrete structure is finished. The method in the invention is simple and practicable, does not need to support a scaffold and a template, effectively shortens the construction time, improves the construction efficiency, lowers the construction cost, improves the construction quality, and is a safe and reliable construction method for the high-rise concrete structure.

Owner:MCC TIANGONG GROUP

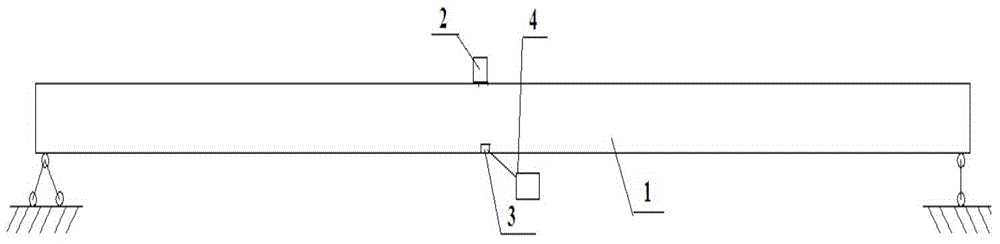

Fixing device for load test of pre-stressed concrete beam and testing method

InactiveCN102998168ASimple structureEasy to manufactureStrength propertiesTest beamPrestressed concrete beam

The invention provides a fixing device for a load test of a pre-stressed concrete beam and a testing method. The fixing device comprises two horizontal test beams with opposite flange boards which are taken as counter-force frames; fixing frames for surrounding the periphery of the end parts of the test frames are respectively arranged at the two ends of the two test beams; each fixing frame comprises an upper bearing board, a lower bearing board, a left bearing board and a right bearing board, and the end parts of all the bearing boards are connected with one another to define a framework structure; the lower lateral faces of flange boards of the test beams are located on the lower bearing boards; the left bearing boards are in contact with the bottom face of the end part of a web plate of one test beam, and the right bearing boards are in contact with the bottom face of the end part of a web plate of the other test beam; and a transverse load jack is arranged between the two test beams. The fixing device provided by the invention has the advantages of simple structure, convenience in manufacturing and use, and no damage on the beam; and the testing method in the load test with the fixing device has no need of a great number of real objects with load, and facilitates the test in situ.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for comprehensively detecting grouting compactness of prestressed pipeline of cast-in-situ prestressed concrete beam

ActiveCN104807721AEasy to detectImprove grout densitySpecific gravity measurementPrestressed concrete beamSmall sample

The invention discloses a method for comprehensively detecting grouting compactness of a prestressed pipeline of a cast-in-situ prestressed concrete beam. A practical and efficient detection method is explored in combination of years of engineering practice experience and in-vitro simulation tests. Small sample detection shows that the accuracy is higher, the detection effect of the grouting quality of the prestressed pipeline can be effectively improved, and the method can improve the grouting compactness of the prestressed pipeline as well as the safety and the durability of the structure.

Owner:陈熙贵 +2

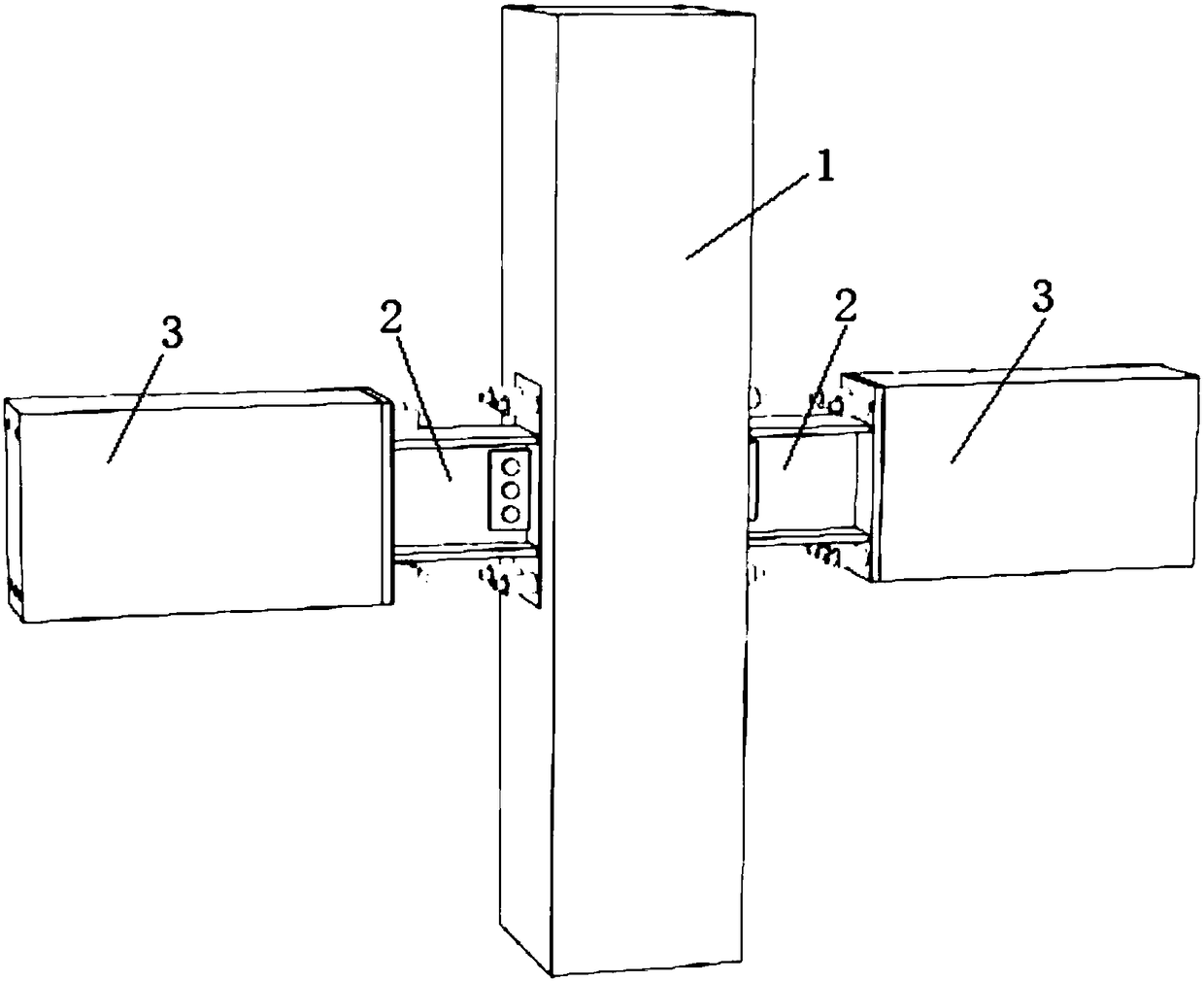

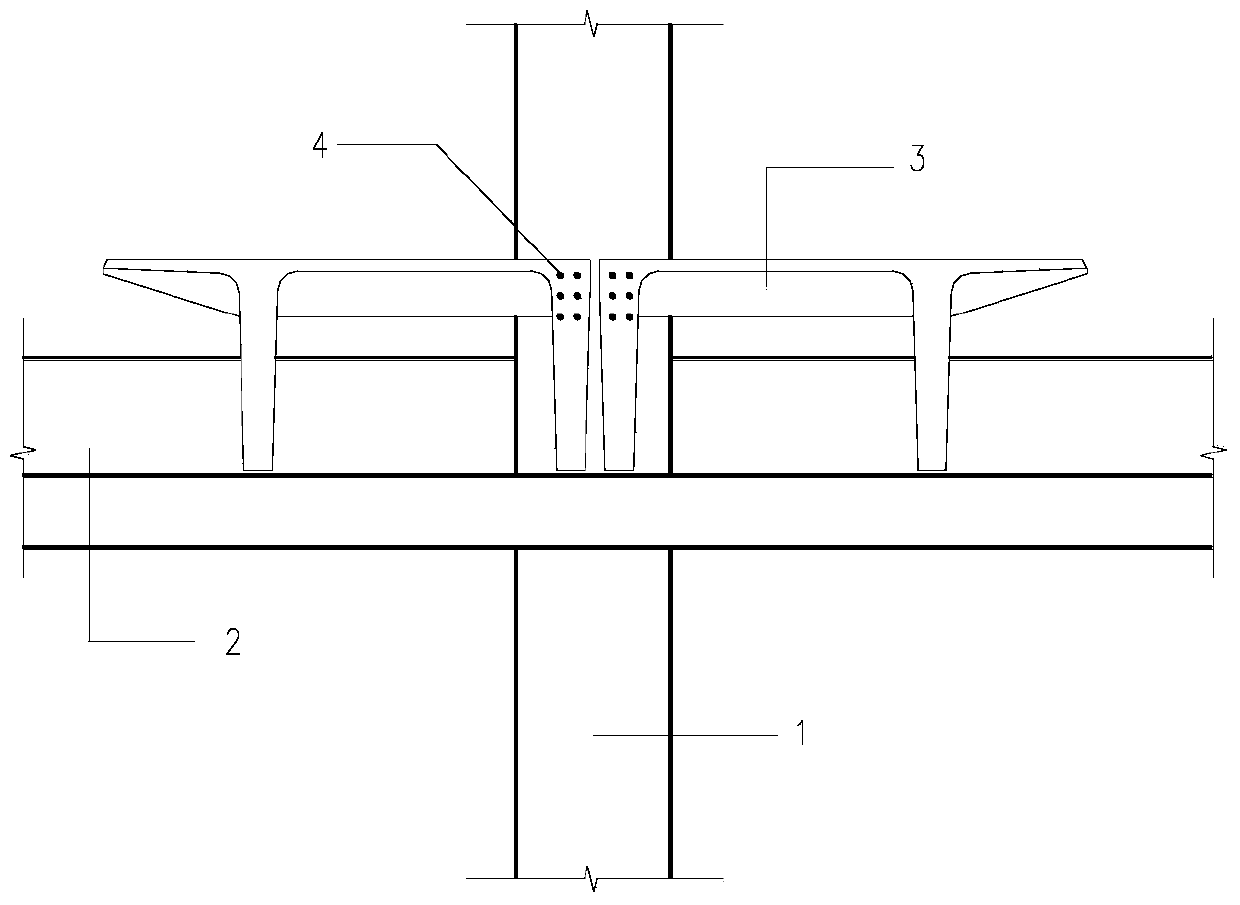

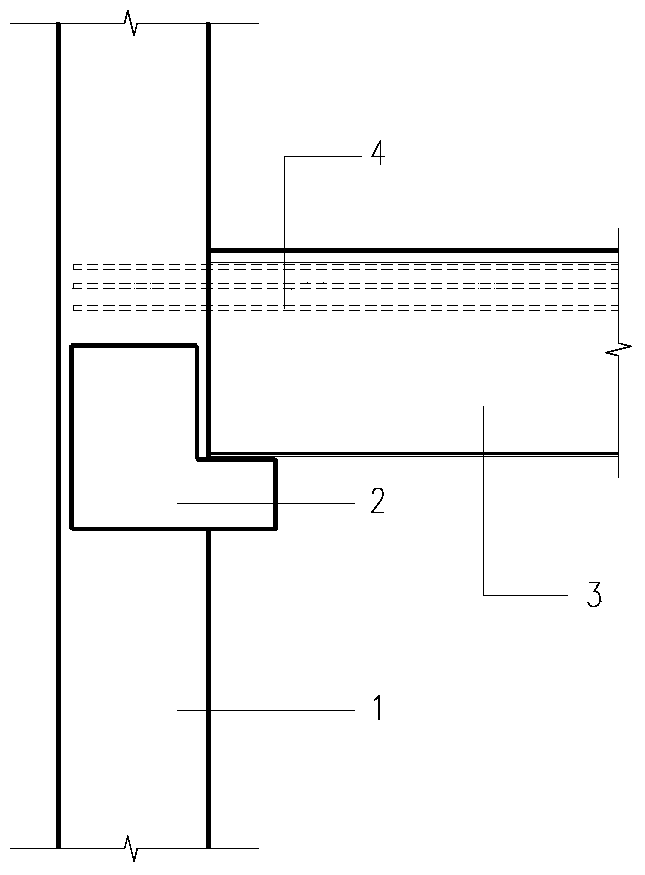

Assembled prestress concrete beam post connection node and construction method

PendingCN108571071AReduce difficultyPrecise positioningBuilding material handlingPrestressed concrete beamConcrete beams

The invention relates to an assembled prestress concrete beam post connection node and a construction method, wherein the node comprises a concrete post and at least one concrete beam, wherein the concrete beam and the concrete post are fixedly connected through H-shaped steel. A post side steel plate is further arranged on at least one side surface of the concrete post; the end part of the concrete beam is provided with a beam end steel plate; the post side steel plate and the beam end steel plate are fixedly connected through the H-shaped steel. The assembled prestress concrete beam post connection node and the construction method have the advantages that the construction is easy; the stress performance in the connection position is excellent; high intensity is realized; the technical problem of connection difficulty of the beam post node connection in the assembled concrete framework structure is solved.

Owner:SHANGHAI INST OF TECH

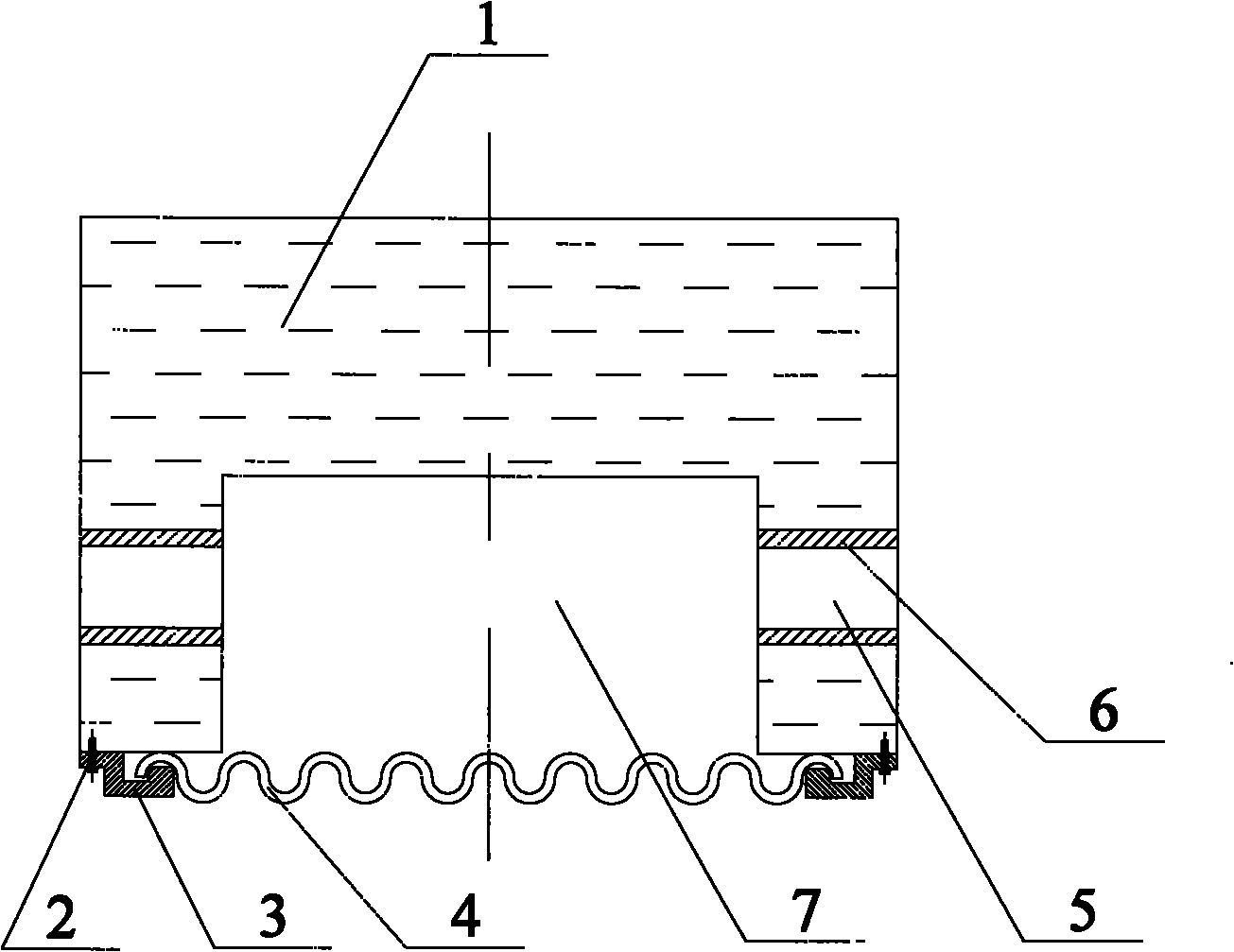

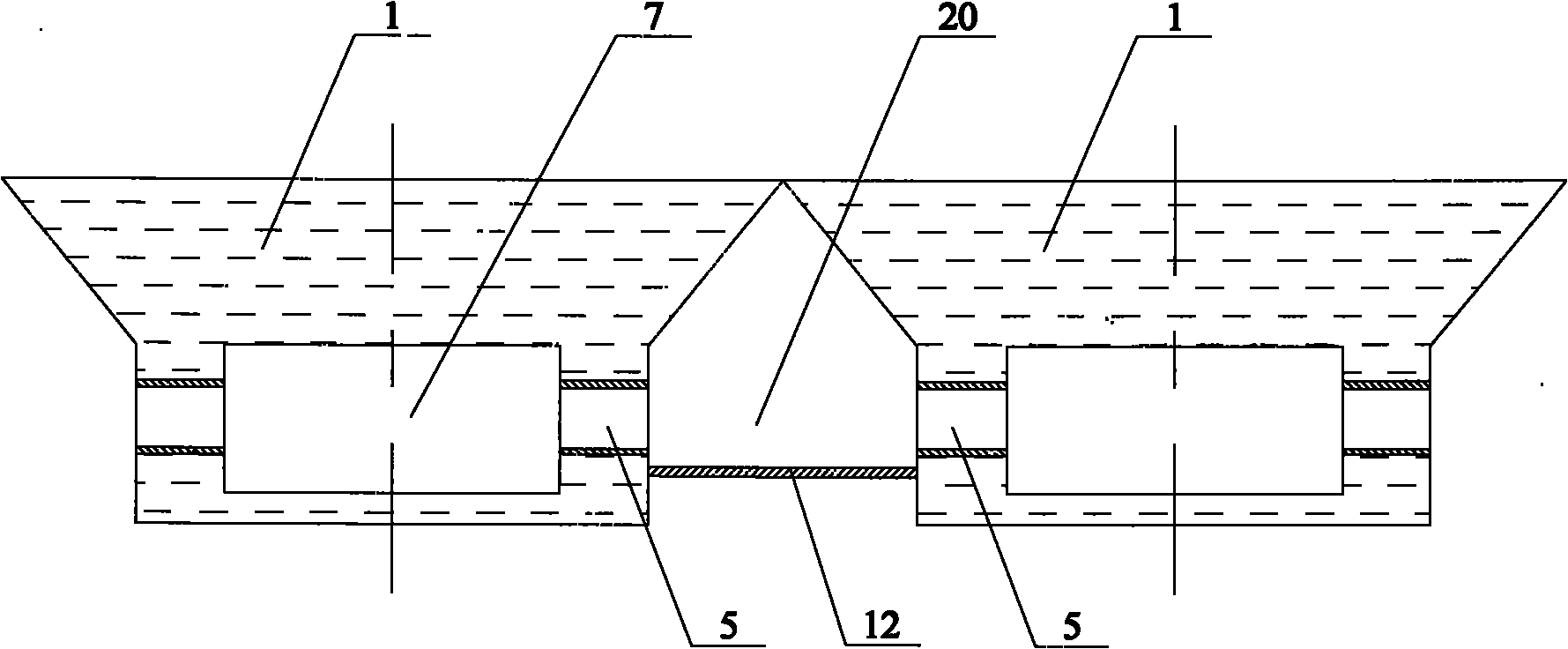

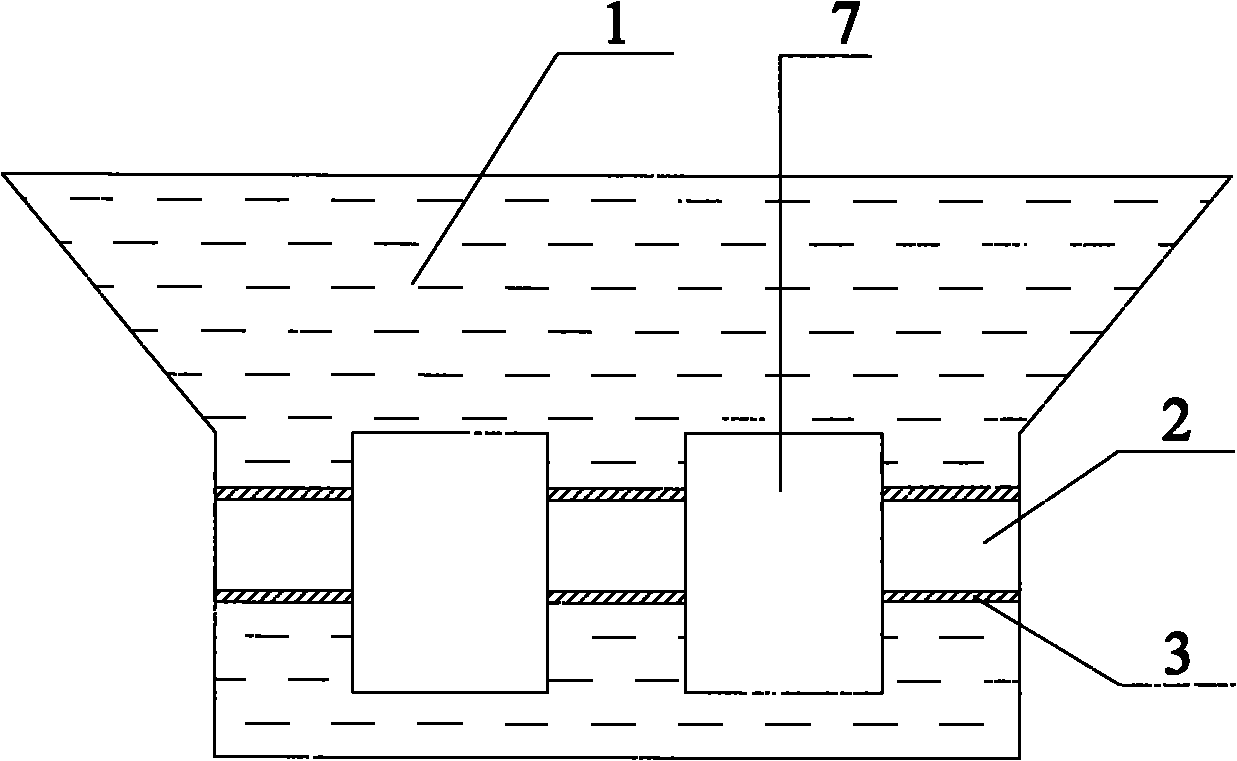

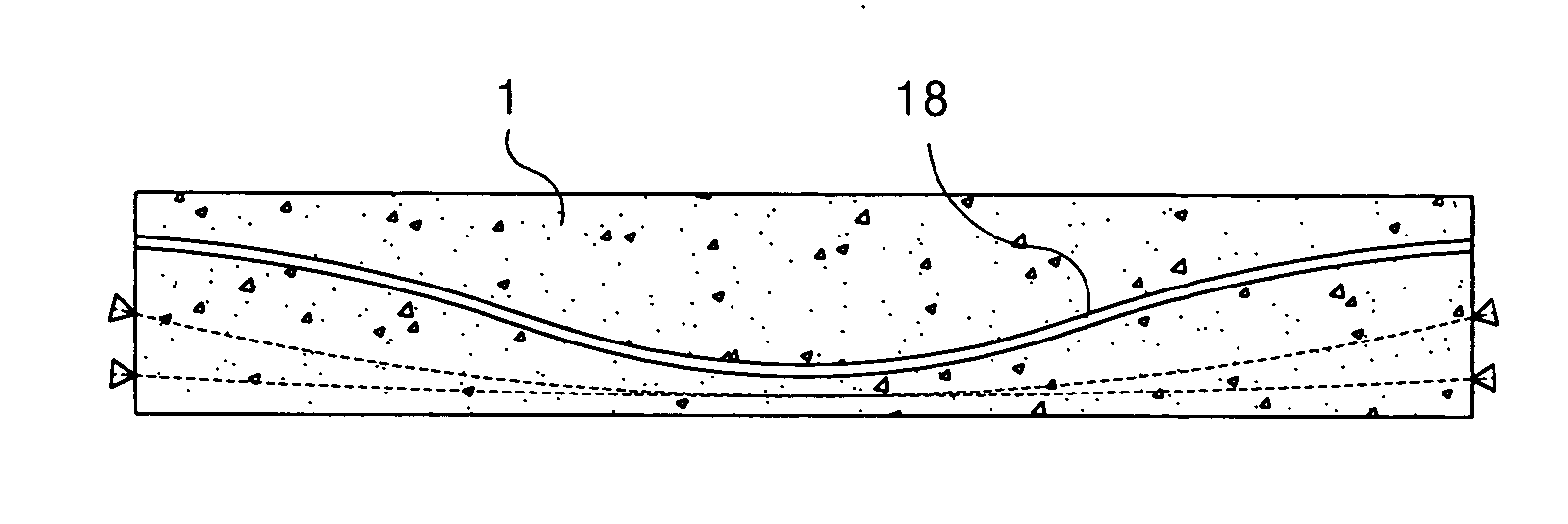

Method for preventing settling and cracking of terrace with large area by utilizing combined prestressing concrete beams at region with soft soil layer

ActiveCN102535502AImprove jacking capacityExpand the scope of influenceSoil preservationPrestressed concrete beamPre stress

The invention relates to a method for preventing the settling and the cracking of a terrace with large area by utilizing combined prestressing concrete beams at a region with a soft soil layer. The invention is characterized in that the method for preventing the settling and the cracking of the terrace with the large area by utilizing the combined prestressing concrete beams at the region with the soft soil layer comprises the following steps that: (1) a tamped belt-shaped plain soil belt is arranged; (2) a belt-shaped geotextile or a belt-shaped geogrid is arranged; (3) a belt-shaped broken-stone cushion layer or a belt-shaped sand-stone cushion layer or a belt-shaped cement-stabilizing sand layer is arranged; (4) a belt-shaped plain concrete cushion layer is arranged; (5) a prestressing steel stranded wire combining body is the combination of two random kinds or three random kinds of a steel stranded wire with adhesive prestressing force, a steel stranded wire with slow adhesive prestressing force and a steel stranded wire with no adhesive prestressing force, and the prestressing steel stranded wire combining body is arranged by adopting one random mode of the two following modes: (1) the prestressing steel stranded wire combining body is arranged in the same prestressing concrete beam; and (2) the combination of the two random kinds or the three random kinds of the steel stranded wire with the adhesive prestressing force, the steel stranded wire with the slow adhesive prestressing force and the steel stranded wire with no adhesive prestressing force is respectively arranged in different prestressing concrete beams; (6) the concrete of the prestressing concrete beams is poured, and then the concrete of a reinforced concrete terrace is poured; and (7) the operation of stretching is carried out. The method is simple and easy and can be used for preventing the settling and the cracking of a terrace with large area.

Owner:CHINA FIRST METALLURGICAL GROUP

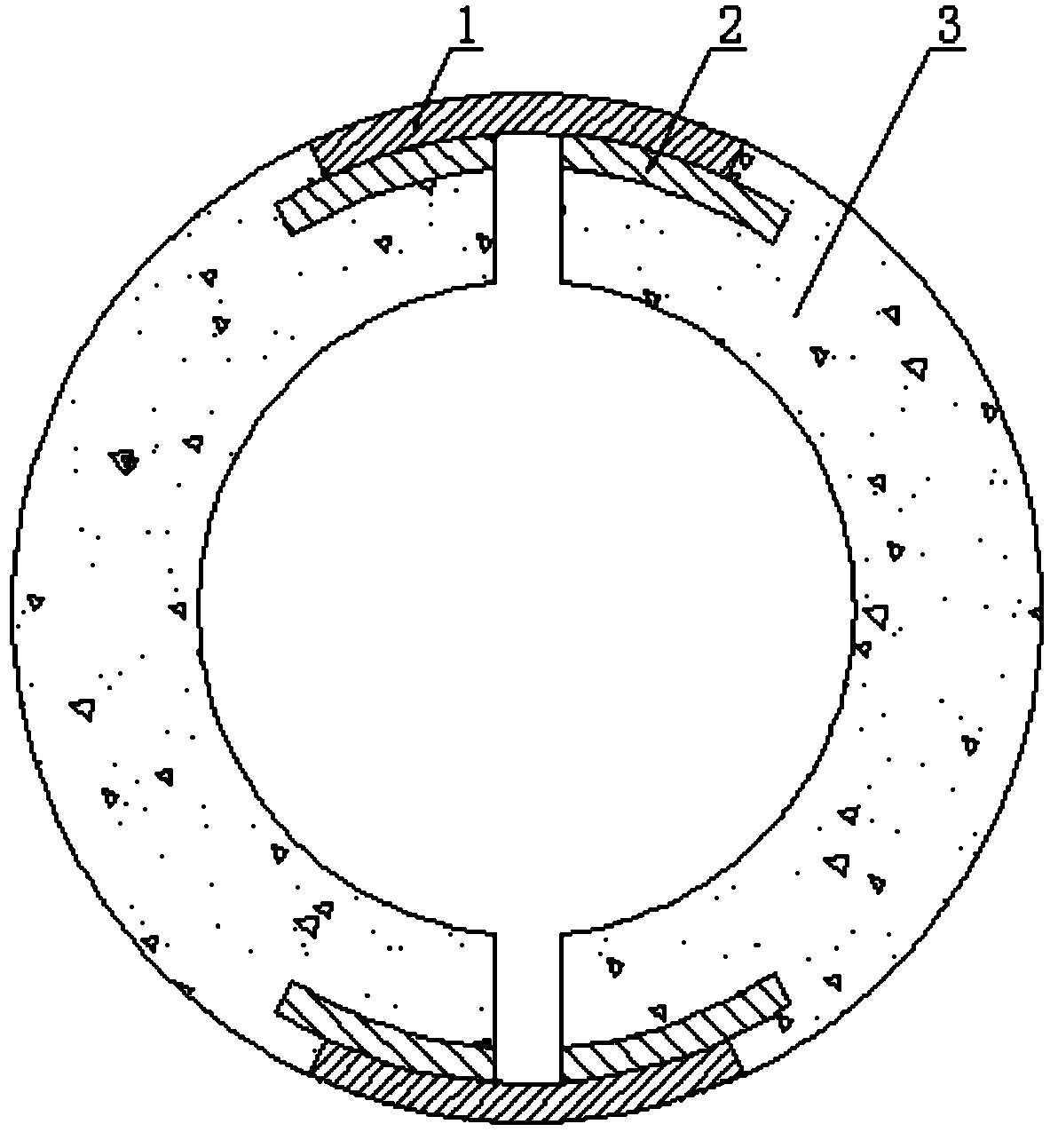

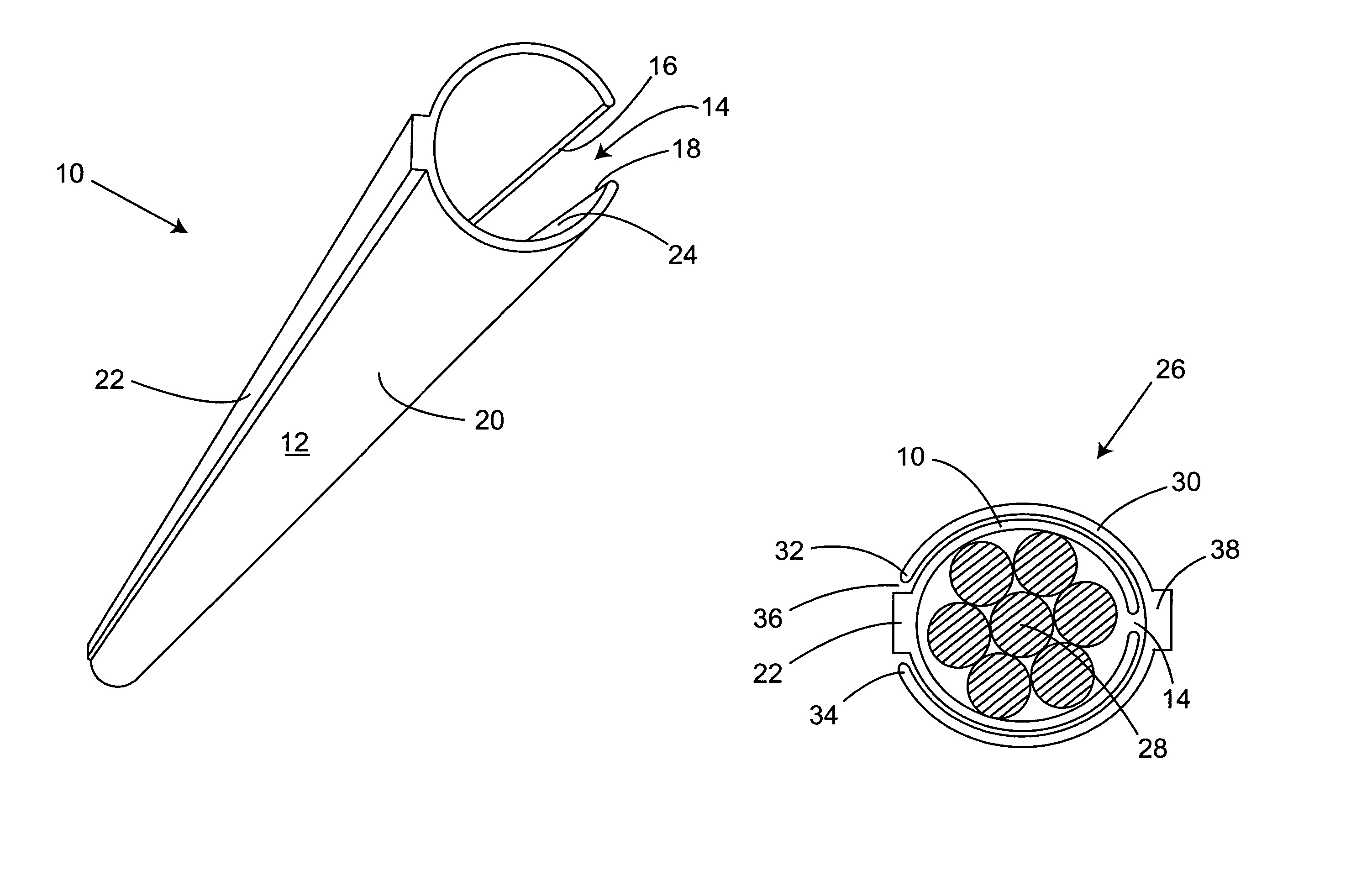

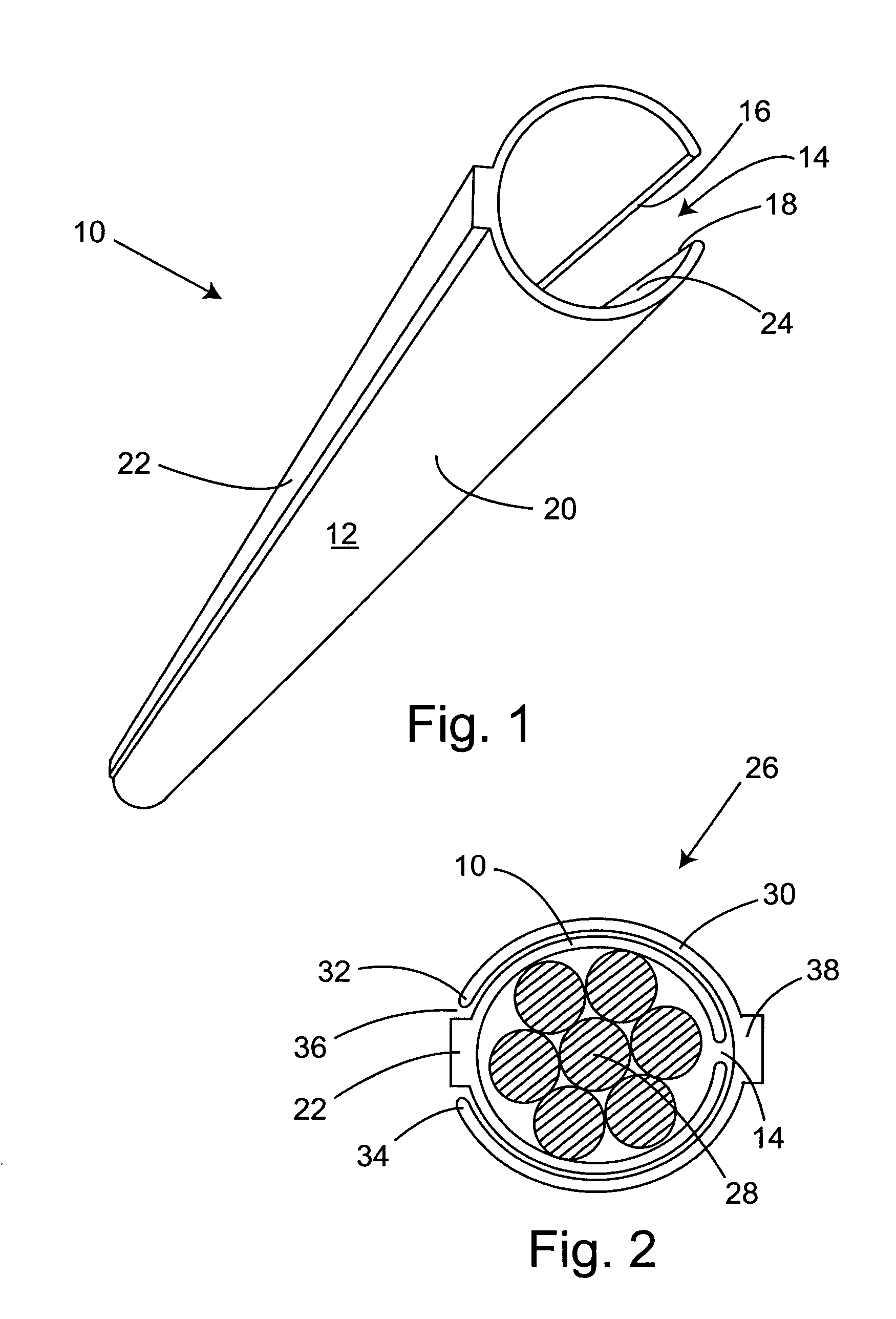

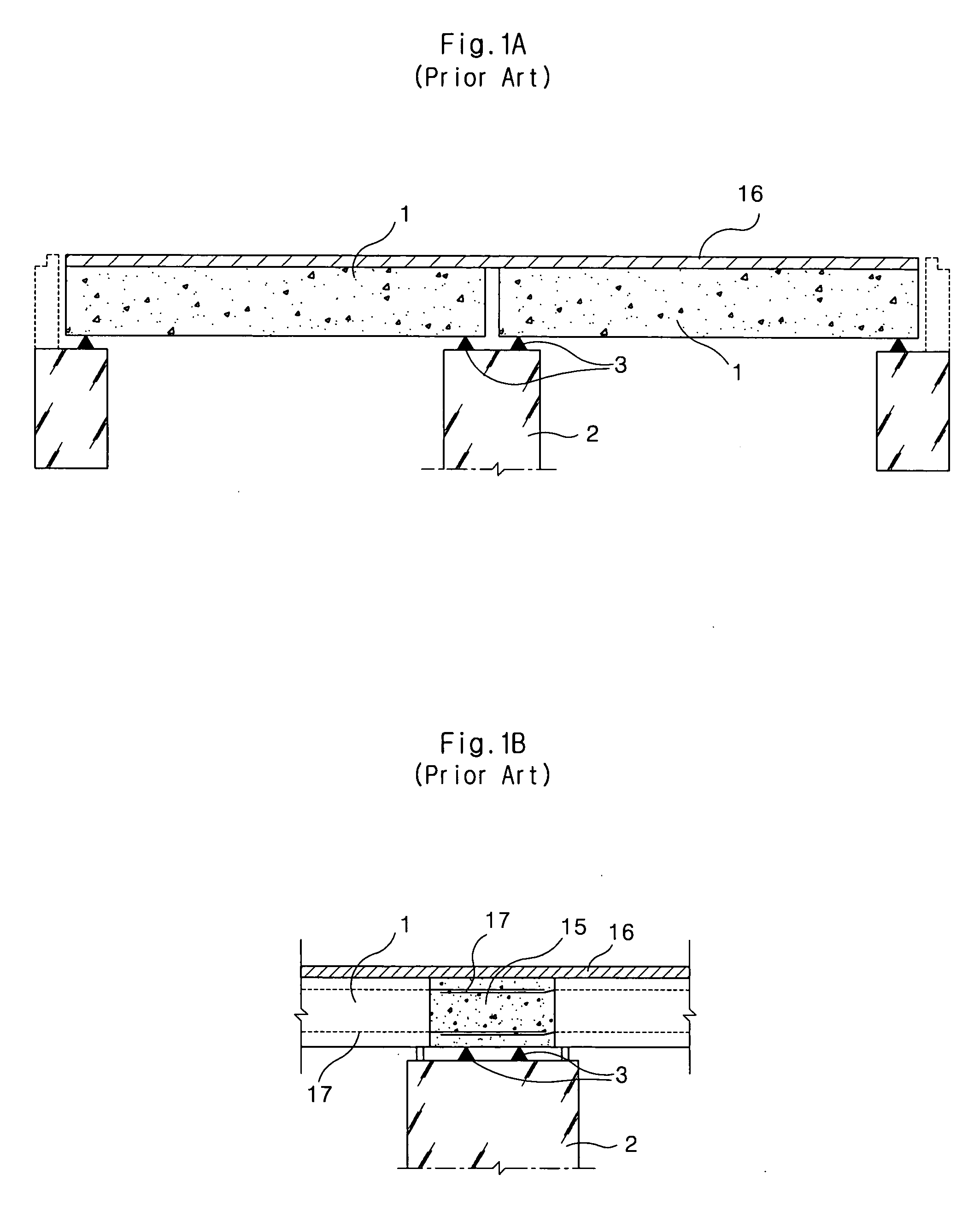

Pre-stressing sheath

InactiveUS7055288B2Minimize manufacturing costAvoid bondingBuilding repairsBuilding reinforcementsPre stressingRidge

A pre-stressing sheath for preventing wet concrete from penetrating between the sheath and strands being debonded, and for covering sections of reinforcing strands in pre-stressed concrete beams such that any potential strand tension transmitted to a beam is nullified by allowing the strands to slide freely within the pre-stressing sheath. The pre-stressing sheath is made up of a first hollow cylindrical sheath section having a longitudinal slit that allows the first sheath section to be opened and placed about the concrete reinforcing element, and a second hollow cylindrical sheath section having a longitudinal slit that allows the sheath section to be opened and placed about both the concrete reinforcing element and the first sheath section. The first sheath section further includes an integral outwardly projecting ridge for interlocking with the longitudinal slit of the second hollow cylindrical sheath section.

Owner:COOGAN DONALD B

Virtual beam used in large-span prestressed concrete beam plate frame structure

The invention belongs to the technical field of construction engineering structures and particularly relates to a virtual beam of a large-span prestressed concrete plate. After frame columns and frame longitudinal beams are installed, a cross constructed erection rebar is arranged on the upper surface of prestressed double T plates or a single prstressed T plate or a hollow plate or an SP plate or a large-span prestressed concrete channel plate or a concrete rectangular beam comprising a hollow rectangular beam plate or a large-span prestressed concrete multiple T-shaped beam plate which are installed close to two sides of the frame columns. The middle portion of two prestressed beam plates on two sides of the frame column and the frame columns are connected with the middle portion of a frame column at the other end, a longitudinal rebar of the virtual beam is in rebar connection with the frame columns at two ends, and the longitudinal rebar is connected with a cross erection rebar or a mesh sheet on the surface of the prestressed concrete beam plate on two sides of the frame columns; the virtual beam is connected through a rebar, and a concrete cast-in-place layer is arranged on the virtual beam. The novel virtual beam achieves using the large-span prestressed concrete plate in a frame structure and can be manufactured in various modes.

Owner:柳忠林

Large-span prestressed concrete beam plate as ventilating channel and ventilating channel system

ActiveCN102116065ASimple structureEasy constructionLighting and heating apparatusFloorsPrestressed concrete beamConcrete beams

Owner:青岛颐丰瑞和商贸有限公司

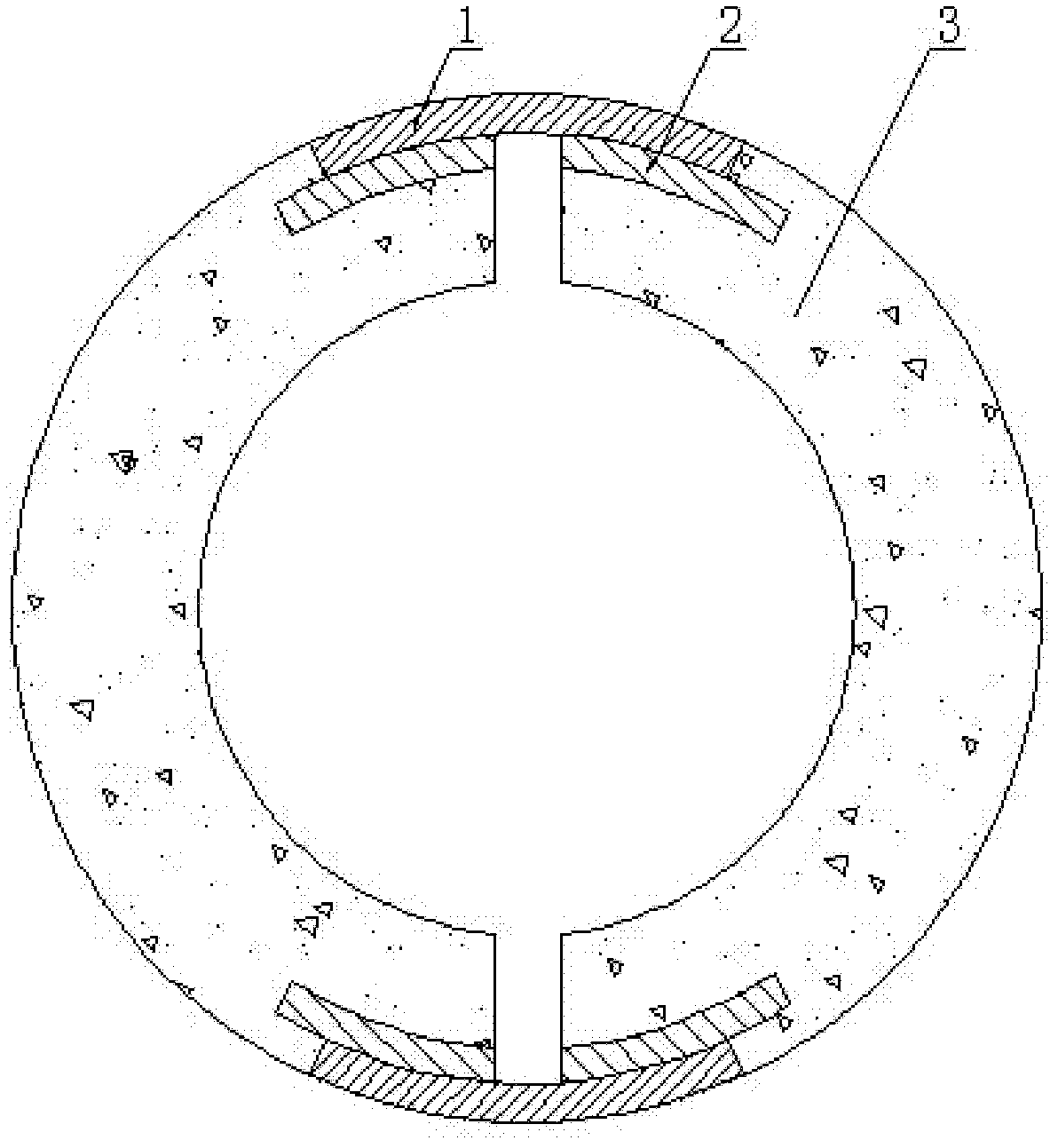

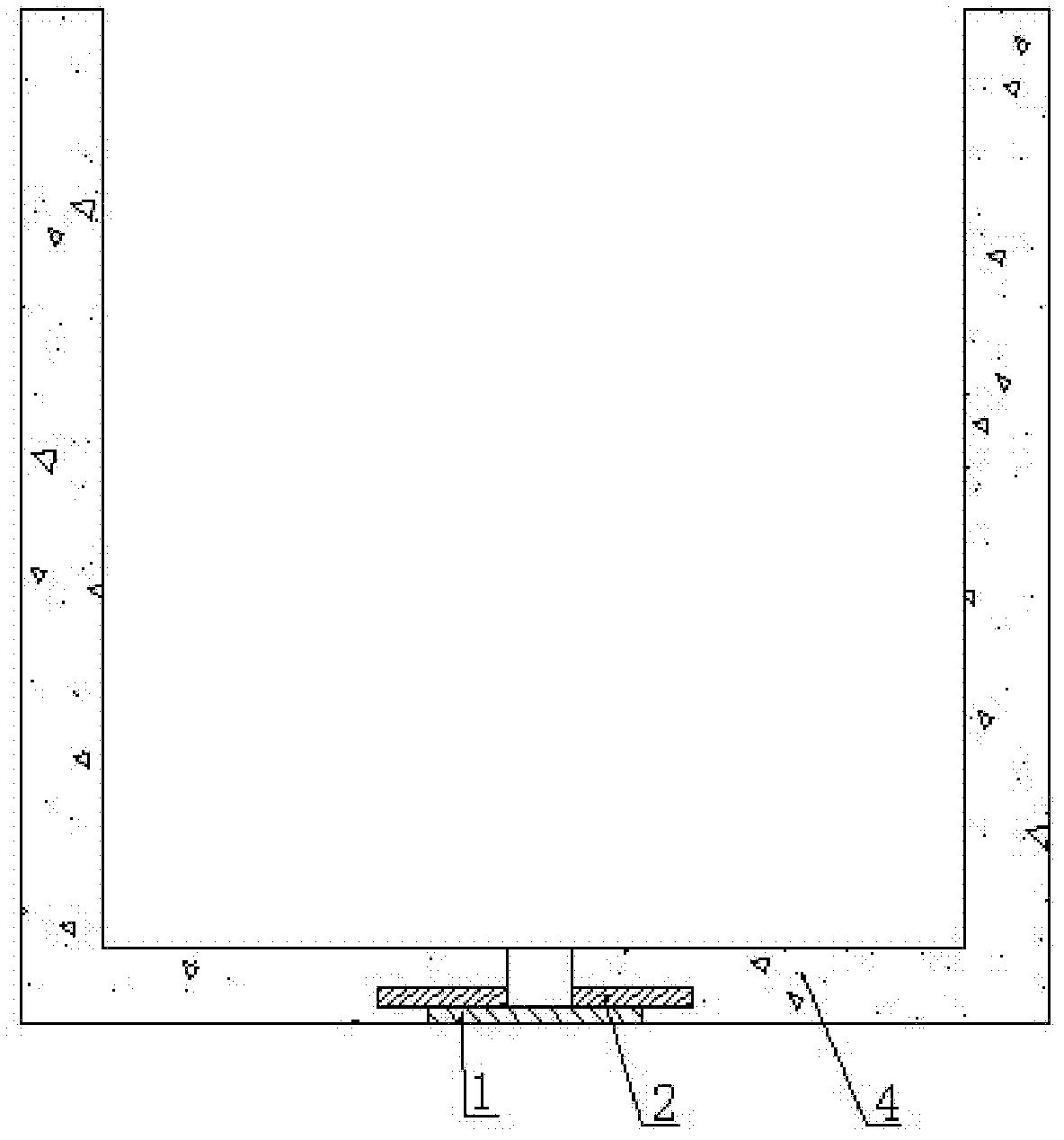

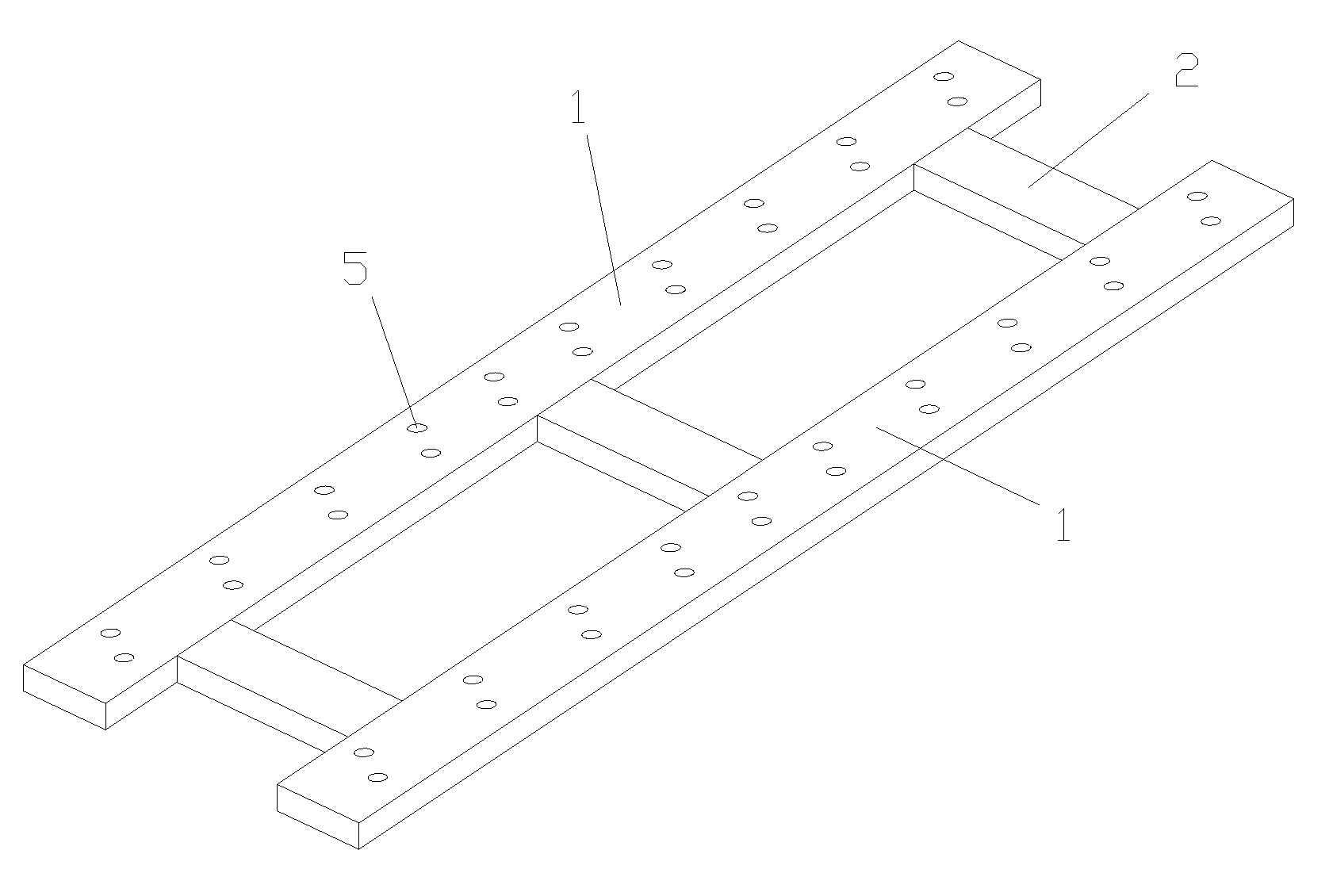

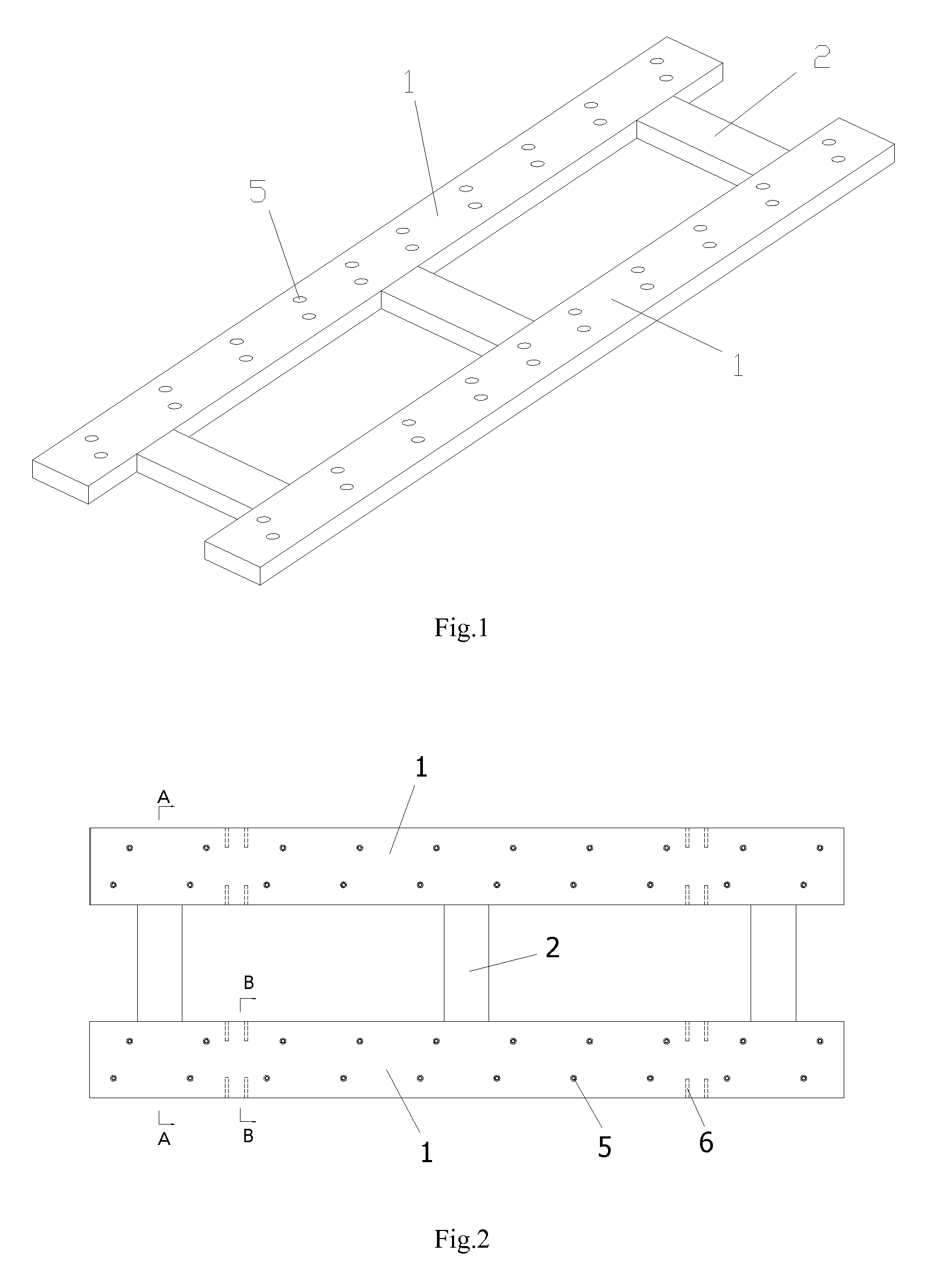

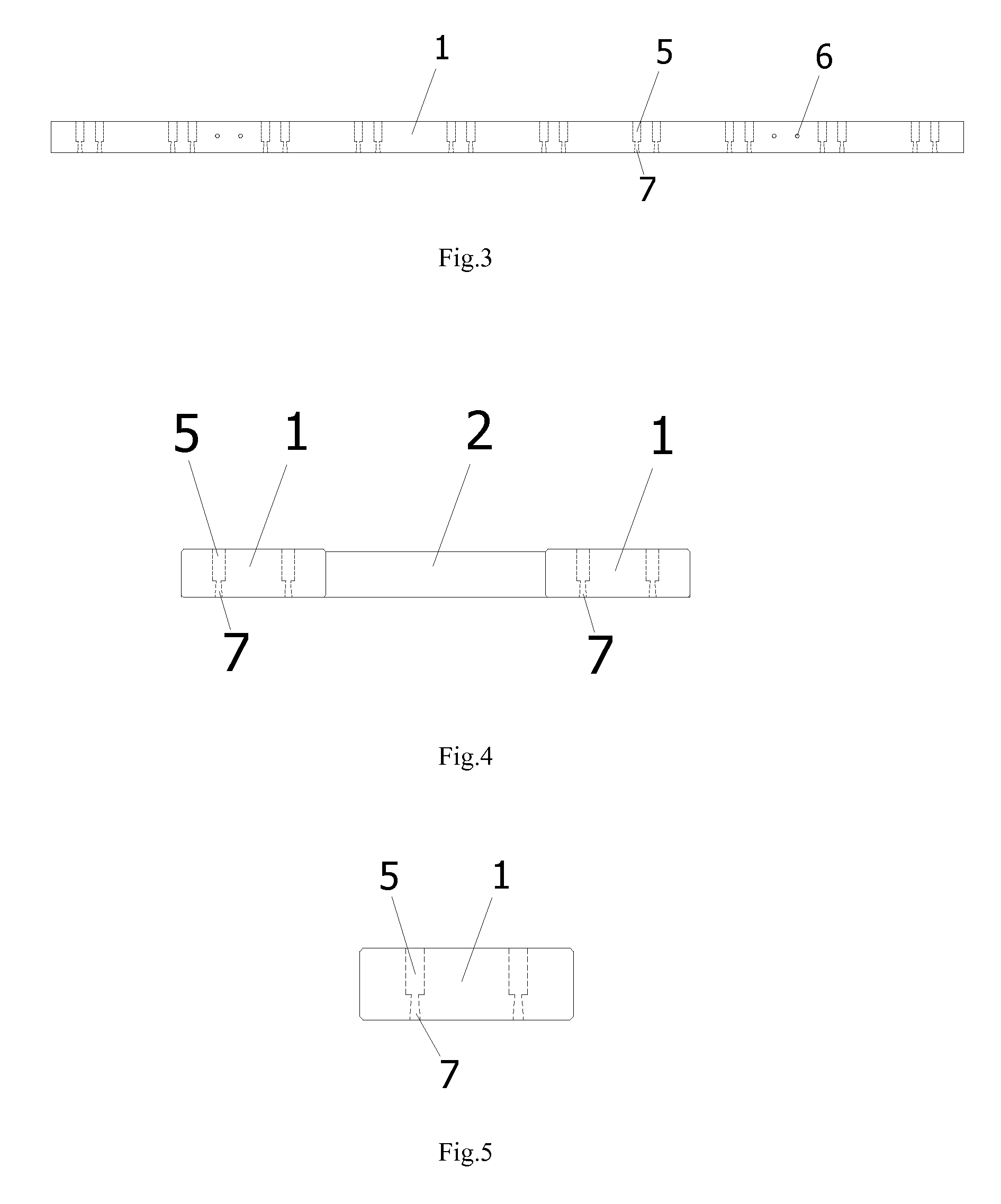

Longitudinal sleeper and damping railway system thereof

A longitudinal sleeper and a damping railway system thereof are provided. The longitudinal sleeper comprises a pair of longitudinal prestressed concrete beams (1) respectively arranged under rails along a longitudinal direction of the rails, and concrete connection boards (2) transversely connected between the pair of the longitudinal prestressed concrete beams (1).

Owner:QINGDAO NIANXIN ENVIRONMENT TECH

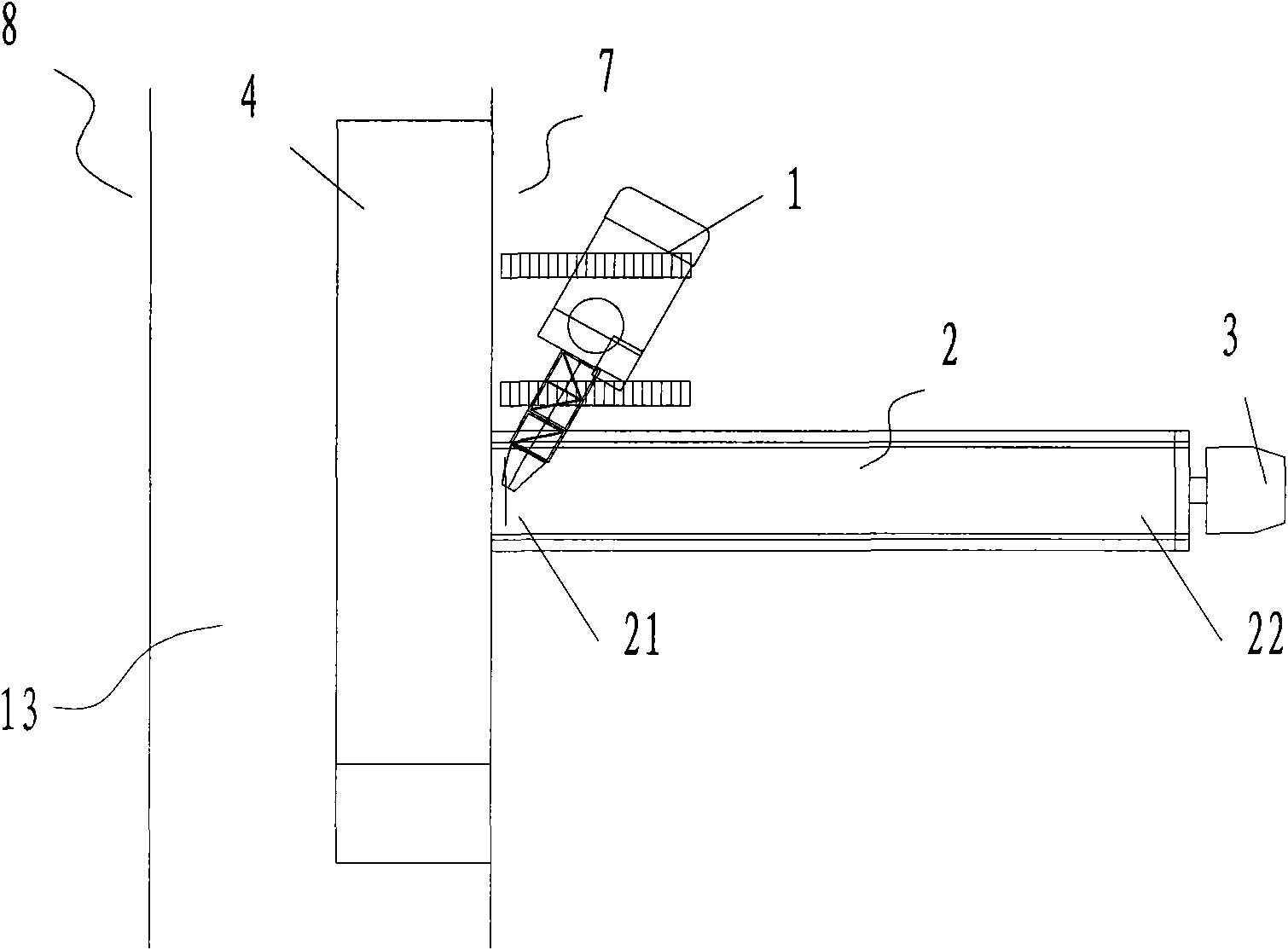

Damaged prestressed concrete flexural member decompression moment test method

InactiveCN104880369AIncreased sensitivityAccurate detectionMaterial strength using steady bending forcesPrestressed concrete beamPre stress

The invention belongs to the technical field of bridge structural engineering, and in particular relates to a damaged prestressed concrete flexural member decompression moment test method. A damaged prestressed concrete flexural member decompression moment test system adopted by the method comprises a bridge, a vertical load applying device, a surface strain gauge and a data acquisition instrument, wherein the vertical load applying device is arranged on a to-be-detected cracking section of the bridge; the surface strain gauge is installed on the surface of outer edge reinforcement without reinforcement cover concrete at a tensile area of the to-be-detected cracking section of the bridge; the data acquiring instrument is connected with the surface strain gauge through a conductor. Compared with the prior art, the damaged prestressed concrete flexural member decompression moment test method is simple to operate, accurate and reliable in result, easily mastered by engineering technicians, and is suitable for detecting and evaluating the cracked prestressed concrete flexural member decompression moment.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Construction method of erecting prestressed concrete beam on river

InactiveCN101858059AImprove applicabilityAbundant resourcesBridge erection/assemblyBridge materialsPrestressed concrete beamPrecast concrete

The invention discloses a construction method of erecting a prestressed concrete beam on river. The method comprises the following steps that: (1) a first crane and a second crane are respectively parked at the first river bank and the second river bank and the back of the prestressed concrete beam reaches the bank of the first river bank, (2) the back of the prestressed concrete beam is suspended and placed on a barge close to the bank of the first river bank, (3) the barge moves to the second river bank and in the process, the first crane hoists the front of the prestressed concrete beam and moves towards the second river bank along with the movement of the prestressed concrete beam, (4) the second crane hoists the back of the prestressed concrete beam placed on the barge and consequently the first crane and the second crane hoist and place the prestressed concrete beam on a bridge stand column. The invention uses two or more than two cranes and barges of medium tonnage together, therefore the invention is economical, practical and high efficient.

Owner:SHANGHAI HIGHWAY BRIDGE (GRP) CO LTD

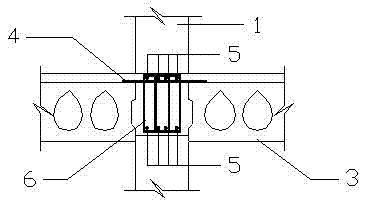

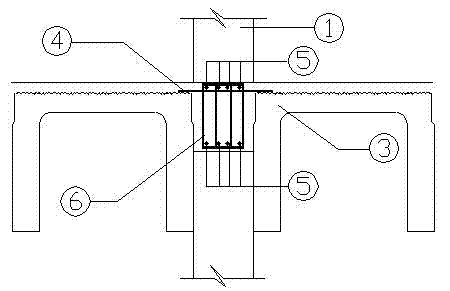

Structure and method of connecting I-type prestressed concrete beams using steel brackets

InactiveUS20050144890A1Improve structural durabilityBridge erection/assemblyBuilding reinforcementsPrestressed concrete beamPre stress

A structure and method of connecting a plurality of PSC-I beams (PSC-I beams) to each other using steel brackets. The beam connecting structure, each having a sheath pipe therein, includes an end plate which is mounted on each of both ends of each of the PSC-I beams, with a through hole provided on an upper portion of the end plate to correspond to the sheath pipe embedded in each of the PSC-I beams; a steel bracket integrally which is provided on the end plate to be perpendicular to the end plate; a bracket coupling plate to integrally couple the aligned steel brackets to each other; a bottom connecting plate which is provided on lower ends of the aligned steel brackets to connect the steel brackets to each other; a connecting sheath pipe which is provided between the PSC-I beams so that both ends of the connecting sheath pipe are respectively inserted into the through holes of the neighboring end plates of the PSC-I beams while the PSC-I beams are arranged linearly; a prestress strand which is inserted in the sheath pipes of the PSC-I beams and the connecting sheath pipe; and a concrete part which is filled in a space between the PSC-I beams to embed the aligned steel brackets, the bracket coupling plate and the connecting sheath pipe in the concrete part.

Owner:DONGYANG CONSTR

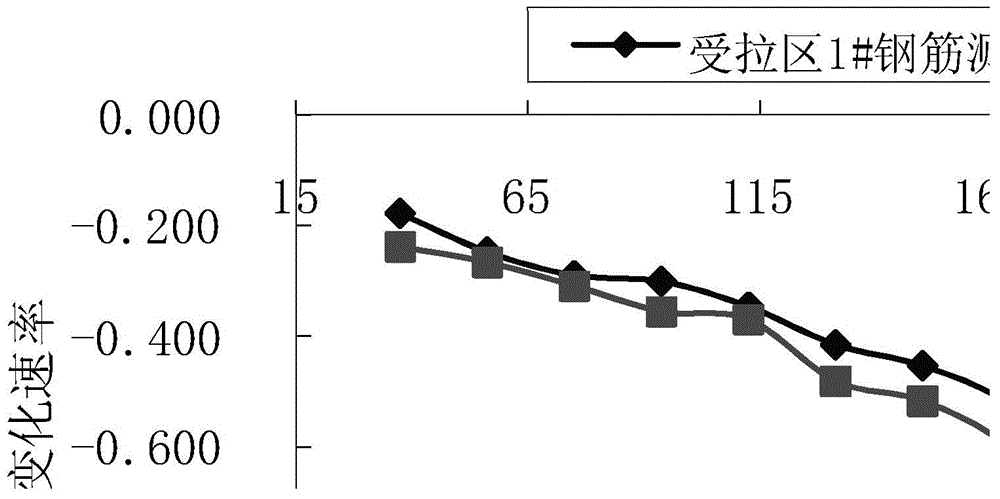

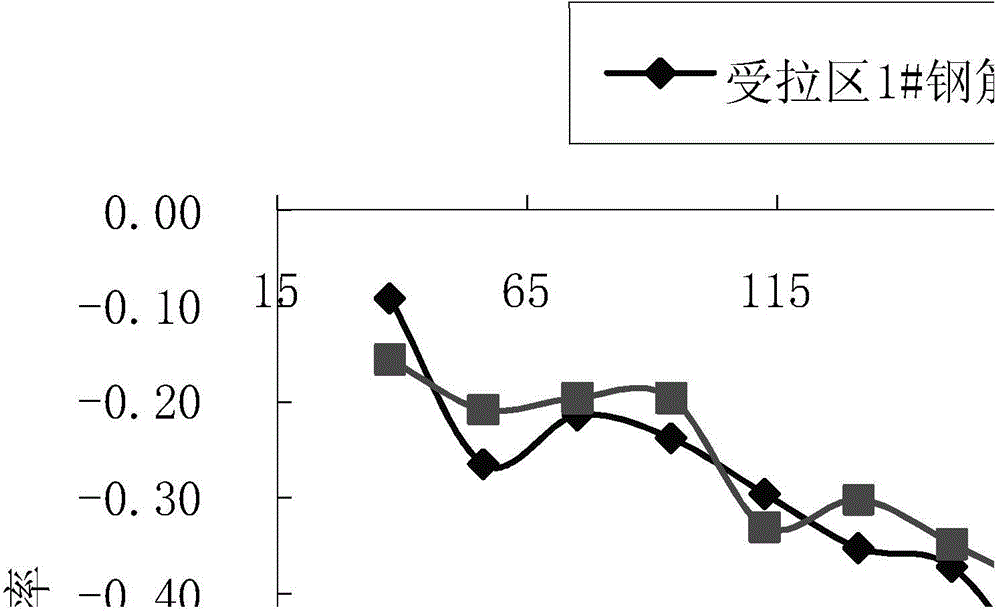

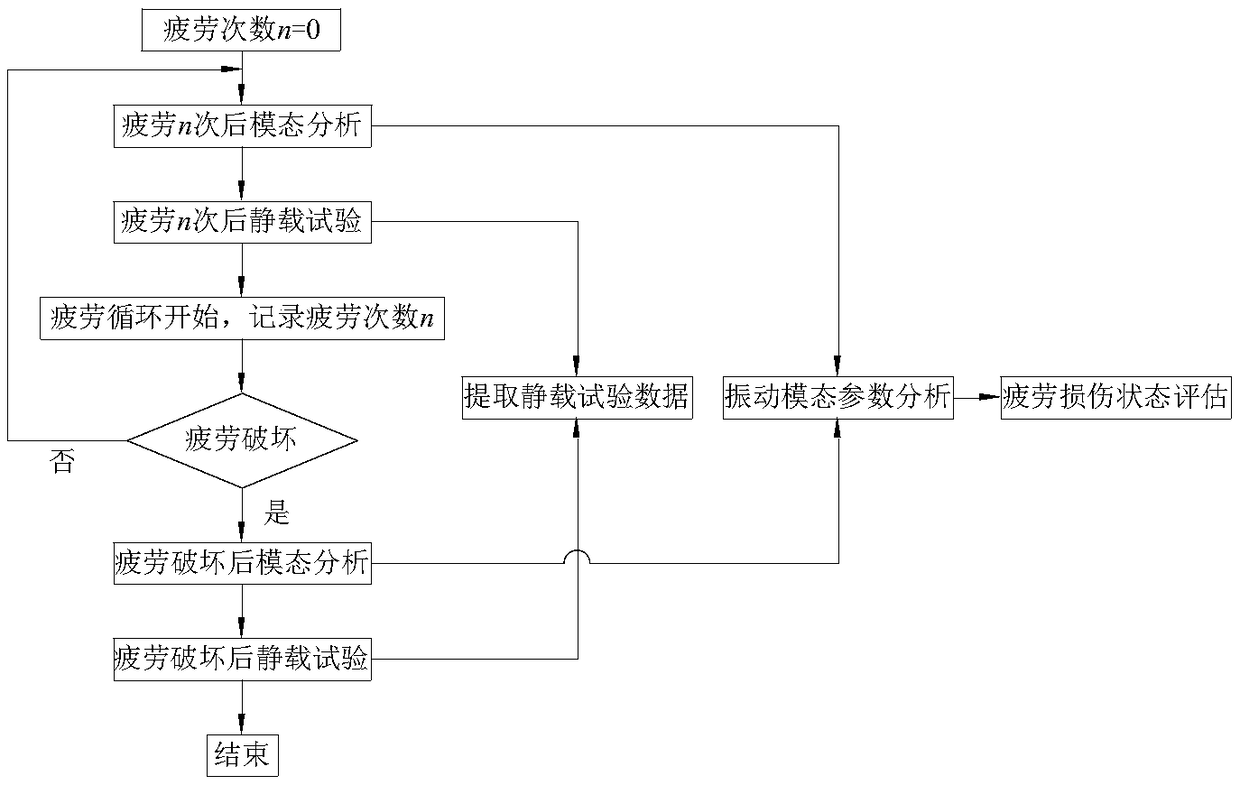

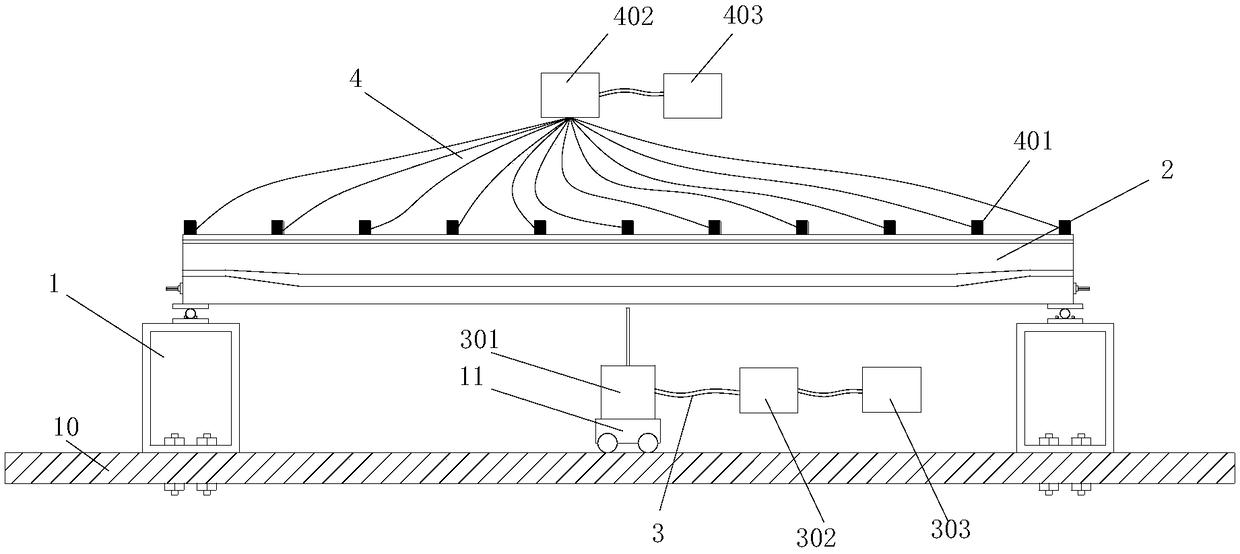

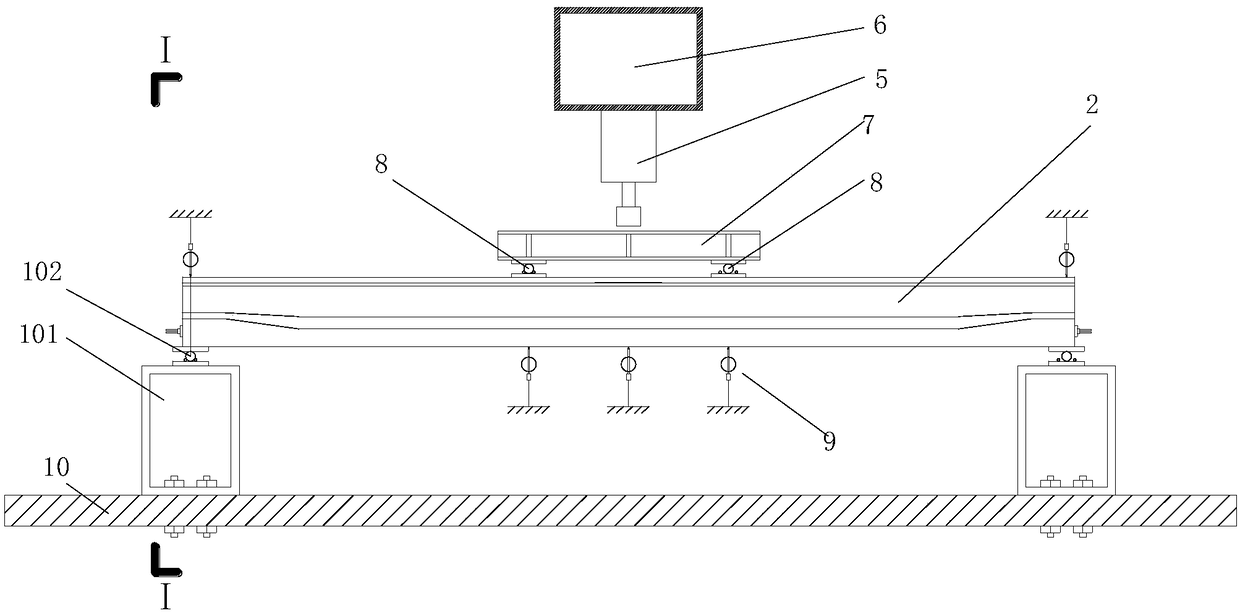

Method for characterizing fatigue damage state of prestressed concrete beam and testing device

PendingCN109374452AFast shippingEasy to testAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using repeated/pulsating forcesFatigue damageFatigue loading

The invention discloses a method for characterizing the a fatigue damage state of a prestressed concrete beam. The method comprises the following steps that initial dynamic parameters of the prestressed concrete beam are determined, and a first-time static load test is conducted; in the fatigue loading process, a static load test and power testing are conducted on the prestressed concrete beam; vibration modal parameters of the prestressed concrete beam are analyzed; and the fatigue damage state of the prestressed concrete beam is evaluated. The invention further discloses a measuring device for realizing the method. According to the method, power testing is carried out in the structural fatigue testing process of the prestressed concrete beam structural fatigue testing process, the fatigue damage position and the damage degree of the prestressed concrete beam are analyzed based on the vibration modal parameters, thus the fatigue damage state of the prestressed concrete beam is characterized based on the modal parameters, and a new idea is provided for study and testing of fatigue performance of the prestressed concrete beam.

Owner:CENT SOUTH UNIV

Concrete beam prestress value and prestress loss monitoring method

InactiveCN104198095AAccurately assess bearing capacityForce measurement using piezo-resistive materialsElectricityPrestressed concrete beam

The invention relates to a concrete beam prestress value and prestress loss monitoring method. The method includes extracting resonant frequency and root-mean-square deviation from piezoelectric admittance signals of piezoelectric ceramic of the prestress concrete beam to recognize prestress value of a prestress concrete beam and extracting resonant frequency deviation indexes and root-mean-square deviation indexes to recognize prestress loss of the prestress concrete beam. The method provides a new way for real-time monitoring of the prestress value and the prestress loss of the prestress concrete. Compared with the prior art, the method can achieve quick monitoring, can obtain the prestress value and the prestress loss quickly of the prestress concrete beam not provided with a sensor for measuring the prestress value, and can accurately evaluate the loading force of the prestress concrete beam in the normal use state.

Owner:SHANGHAI INST OF TECH

Prestressed concrete beam plate with upper portion provided with flexural steel bars and frame structure system

Provided are a prestressed concrete beam plate with the upper portion provided with flexural steel bars and a frame structure system. The flexural steel bars on the upper portion of the large-span concrete beam plate are connected with a column, and accordingly a large-span plate rib has the effect of a frame beam to form a frame structure.

Owner:柳忠林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com