Method for characterizing fatigue damage state of prestressed concrete beam and testing device

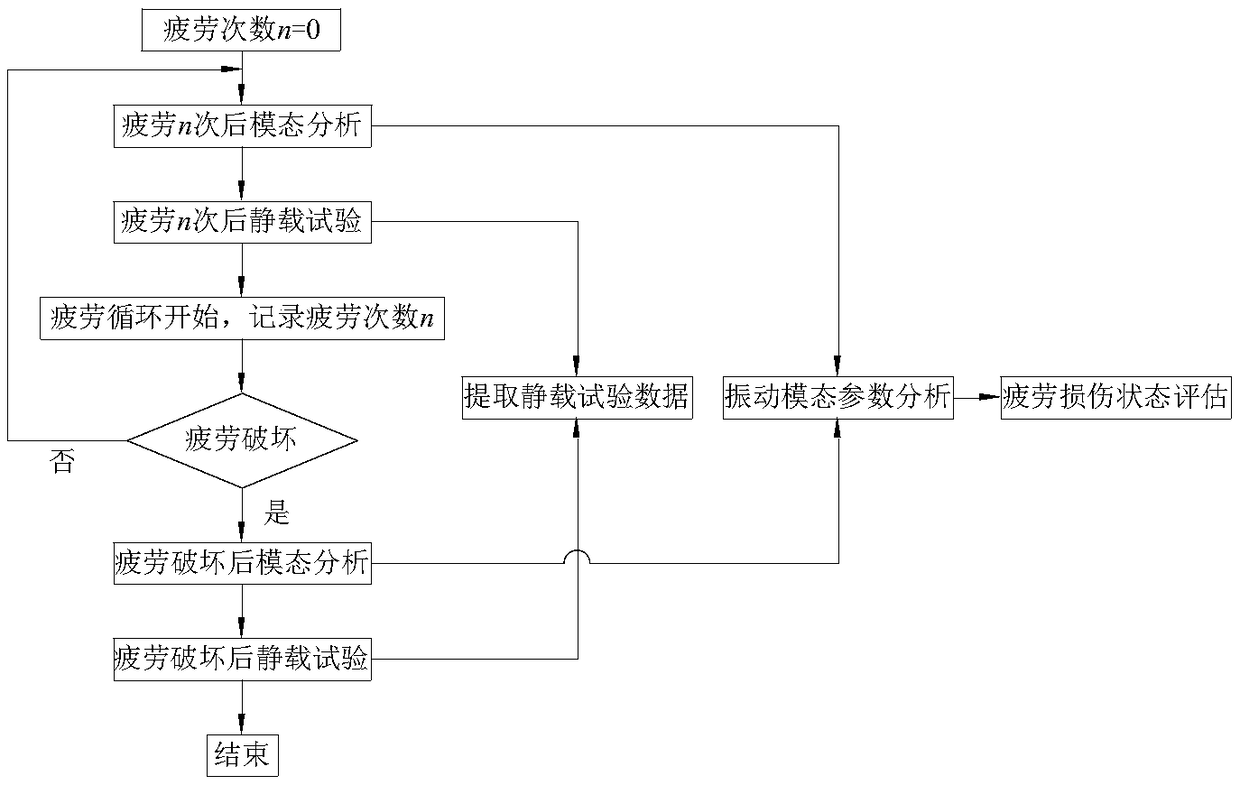

A technology for concrete beams and fatigue damage, which is used in measuring devices, using repetitive force/pulse force to test material strength, and using sonic/ultrasonic/infrasonic waves to analyze solids, etc. It is difficult to reveal the development process of fatigue damage and fatigue failure mechanism of prestressed concrete beams, so as to achieve the effect of simple structure and convenient testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

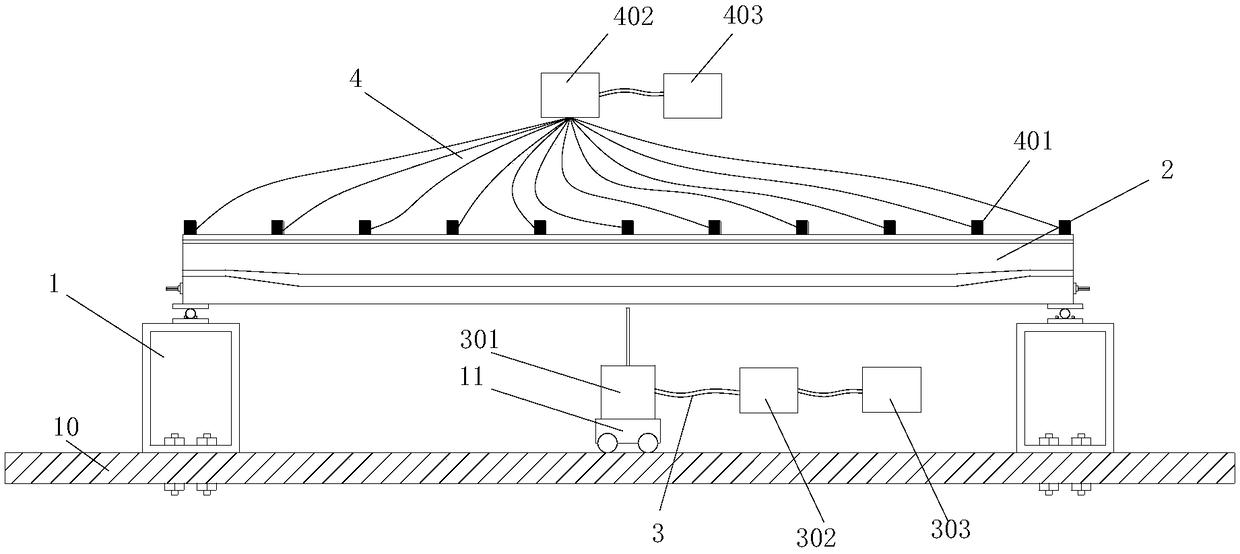

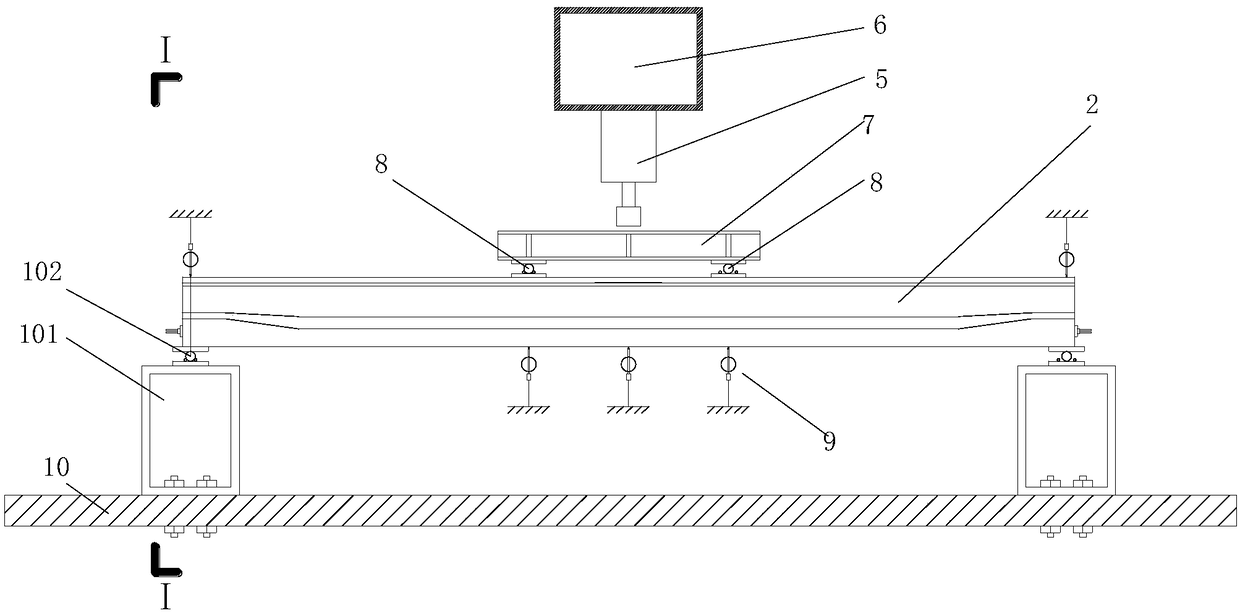

Examples

Embodiment

[0063] The prestressed concrete simply supported T-beam of a standard railway bridge with a height of 32 m is selected as the prototype beam. According to the similarity theory, a 1:6 scale model of the prototype beam is made as the prestressed concrete beam 3 to be tested. The design parameters are shown in Table 1 below. In this embodiment, 3 model beams were prepared, one of which (number No. 1) was used for the static load test to determine the required static limit load P of the fatigue test. u , measured P u =265kN; the other two (No.2, No.3) are used for fatigue test.

[0064] Table 1 model beam design parameter

[0065]

[0066] The concrete mix ratio is cement: water: stone: sand: water reducer = 460: 118: 1092: 735: 4.2, the concrete test blocks are reserved when pouring each test beam, and the mechanical performance test is carried out at the same time as the model beam test. The mechanical properties are shown in Table 2 below:

[0067] Table 2 Measured mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com