Patents

Literature

255 results about "Test beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

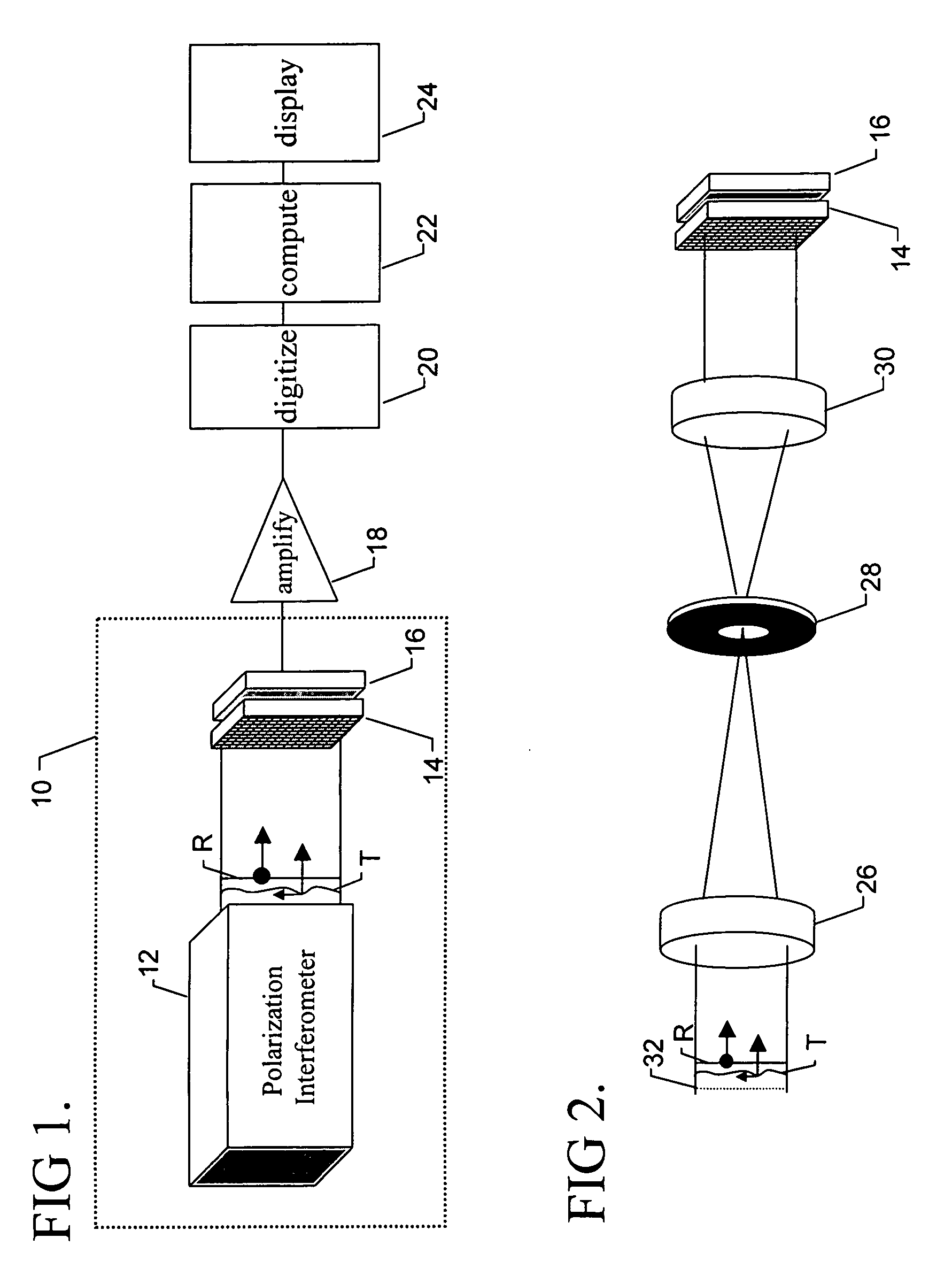

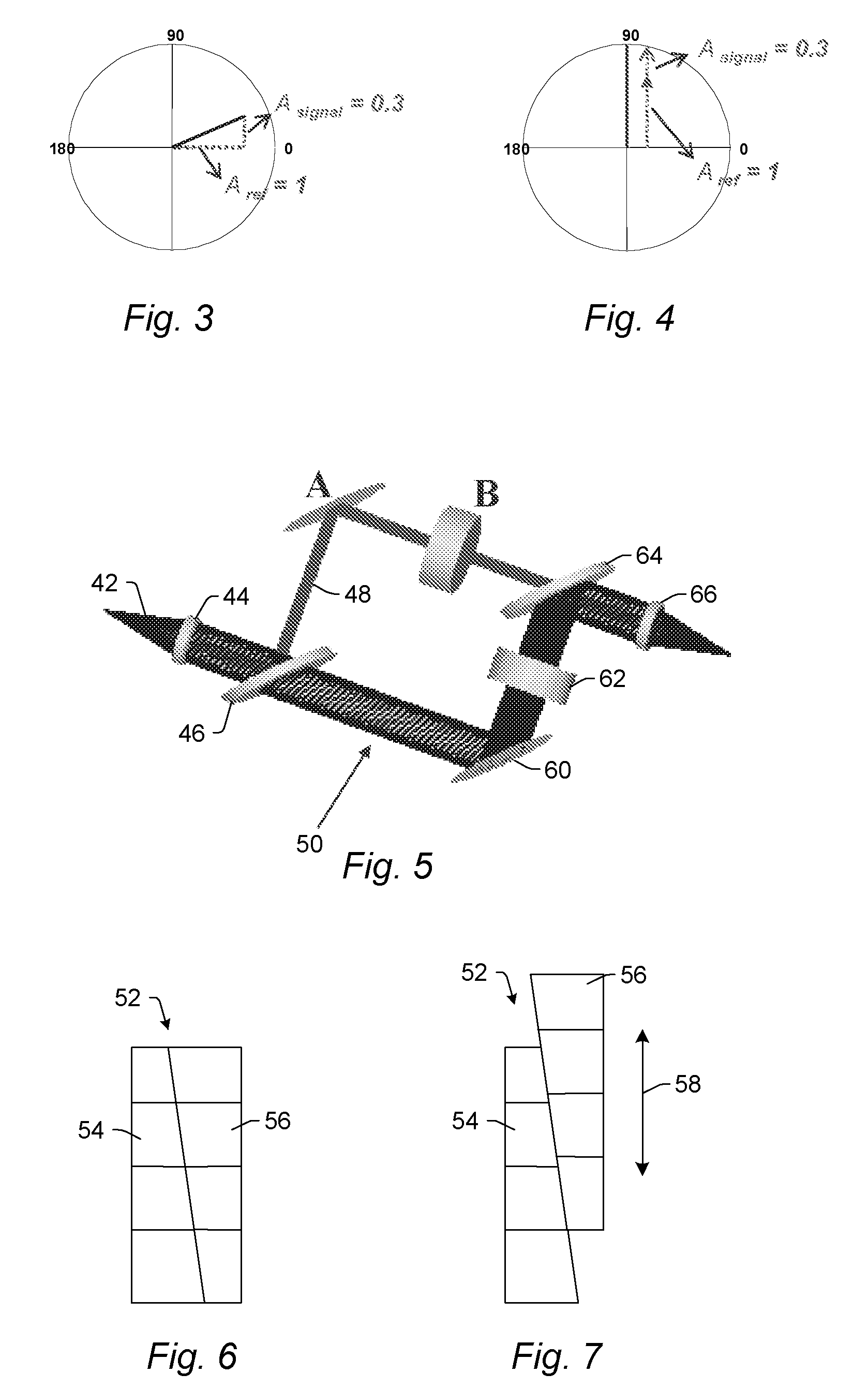

Pixelated phase-mask interferometer

ActiveUS20050046865A1Avoiding chromatic dispersionAvoid complexityInterferometersUsing optical meansPhase differenceDetector array

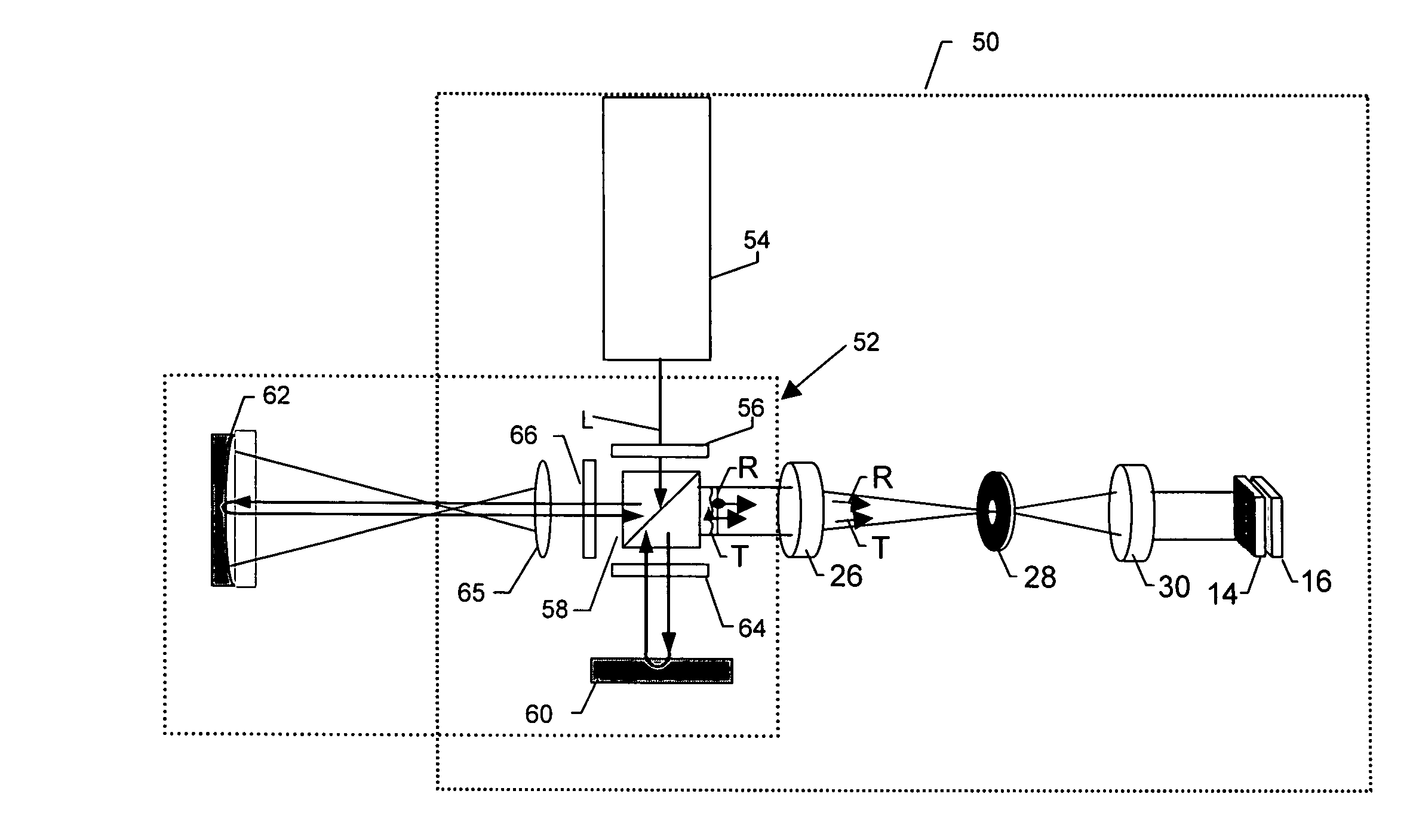

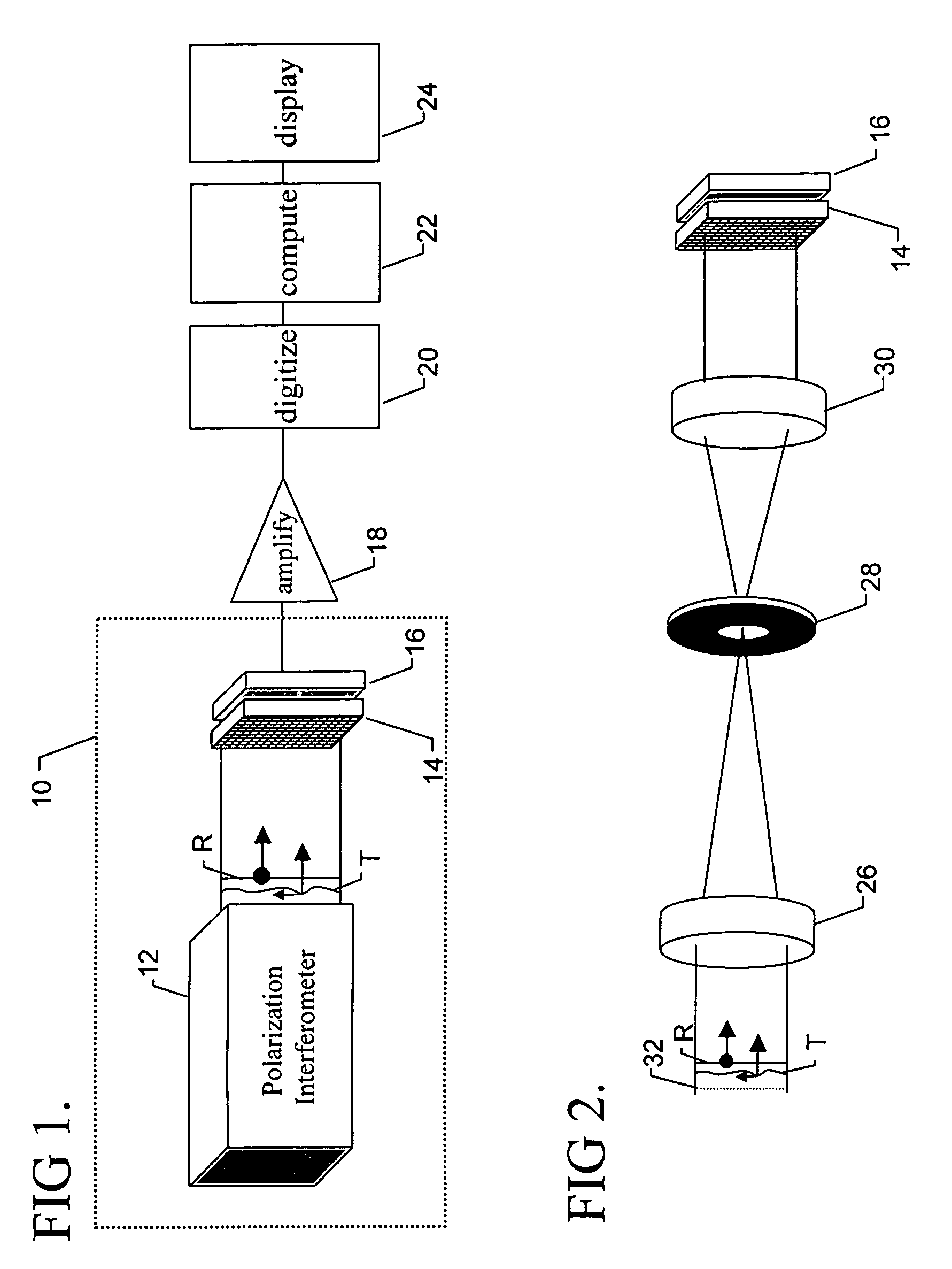

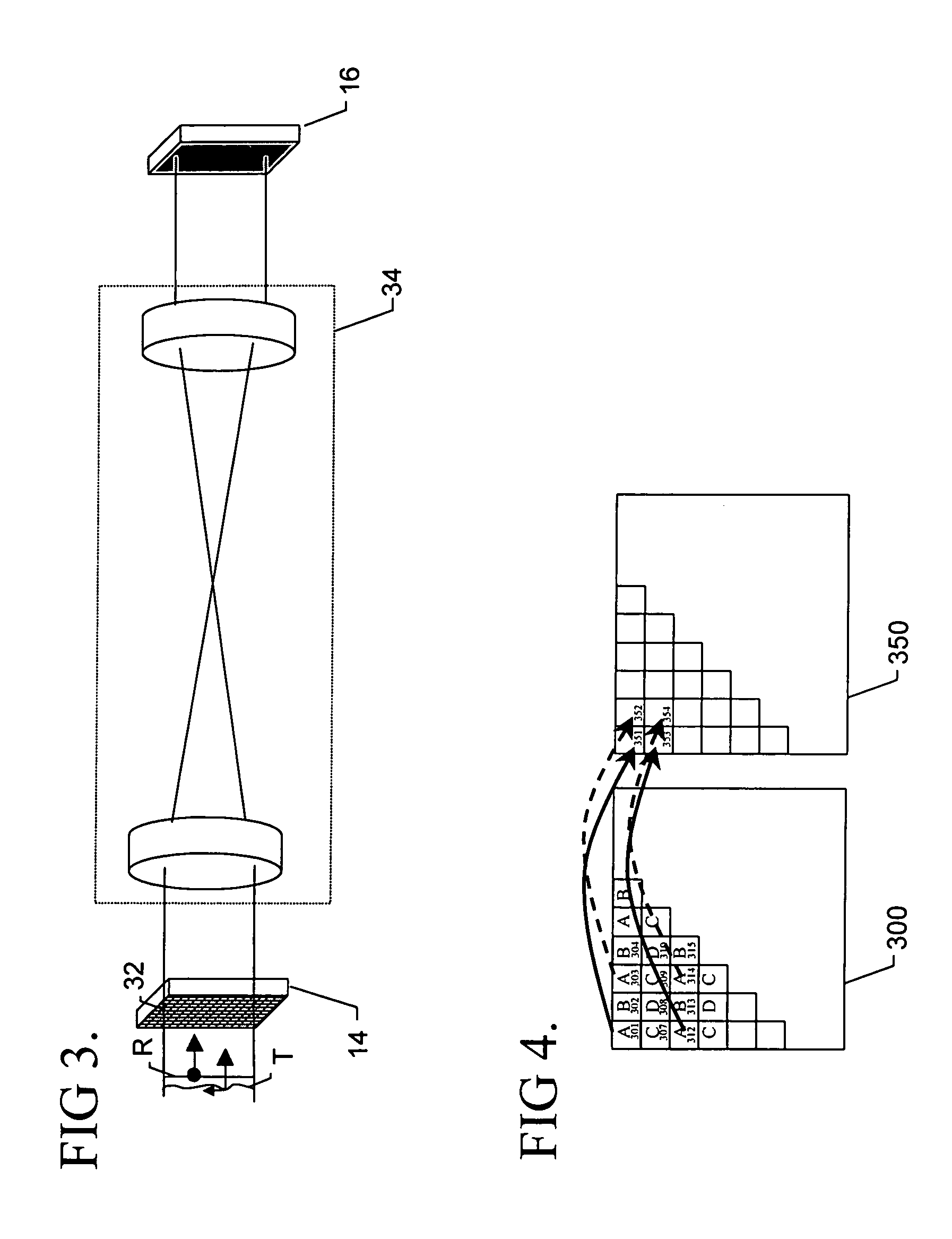

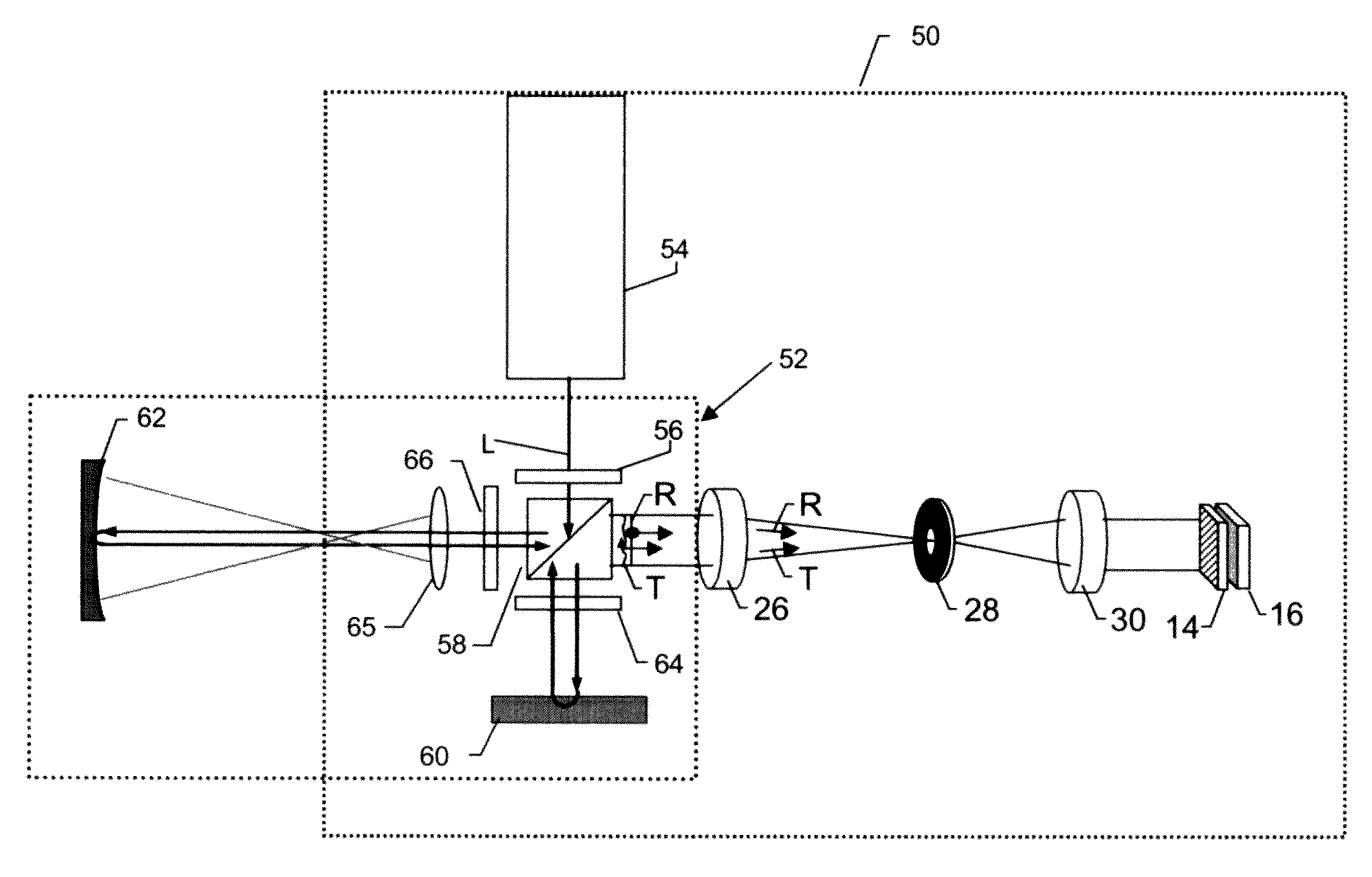

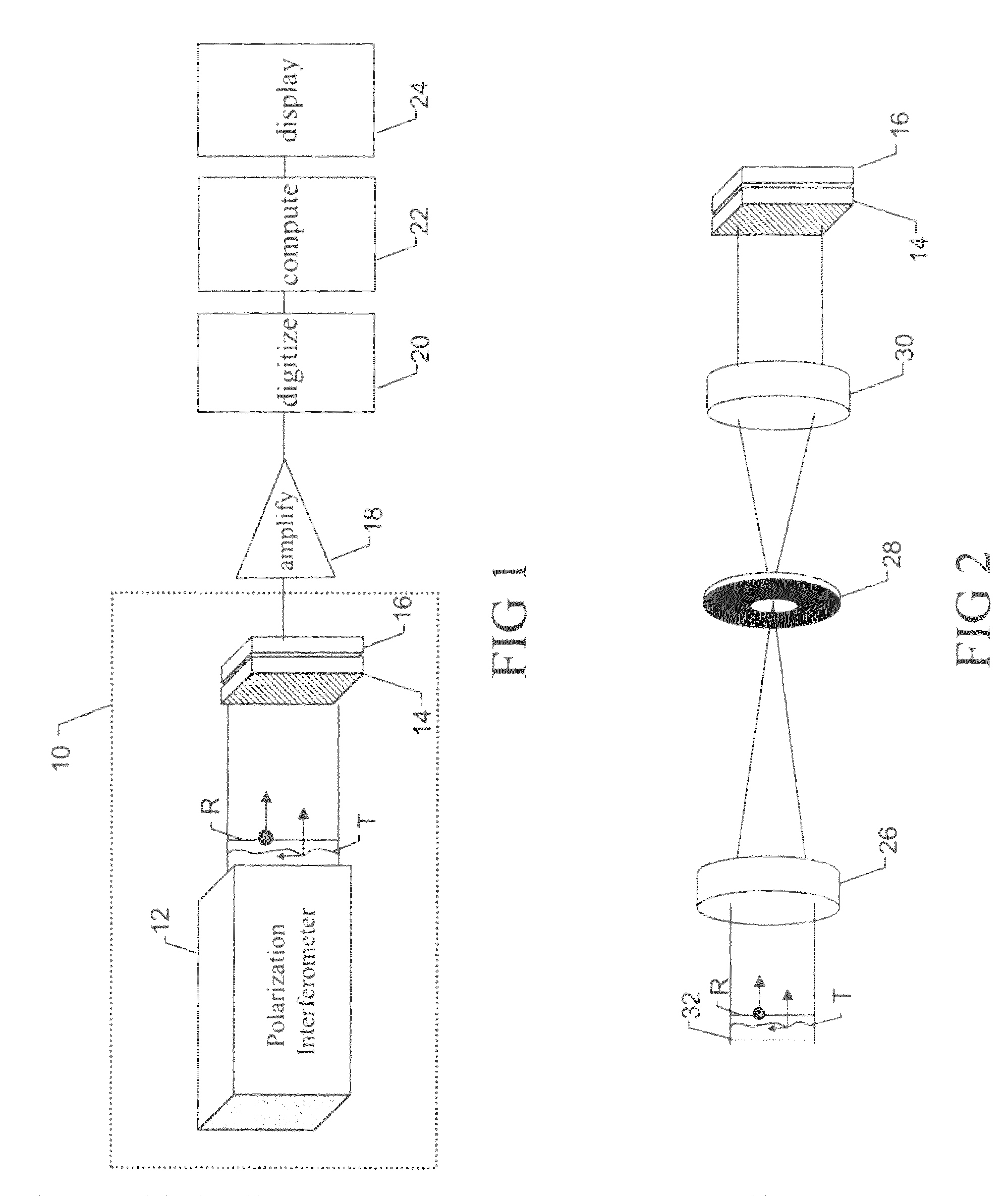

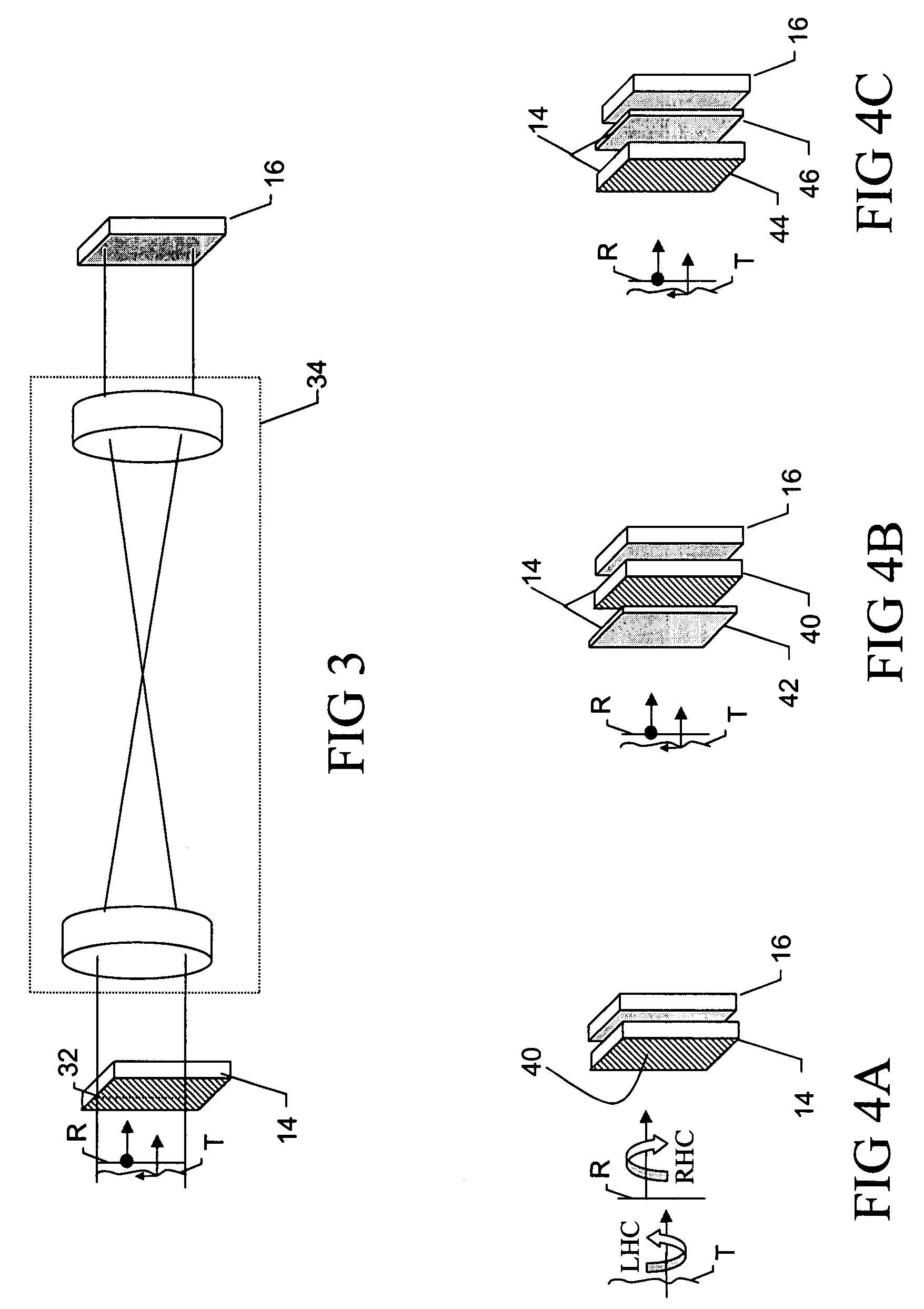

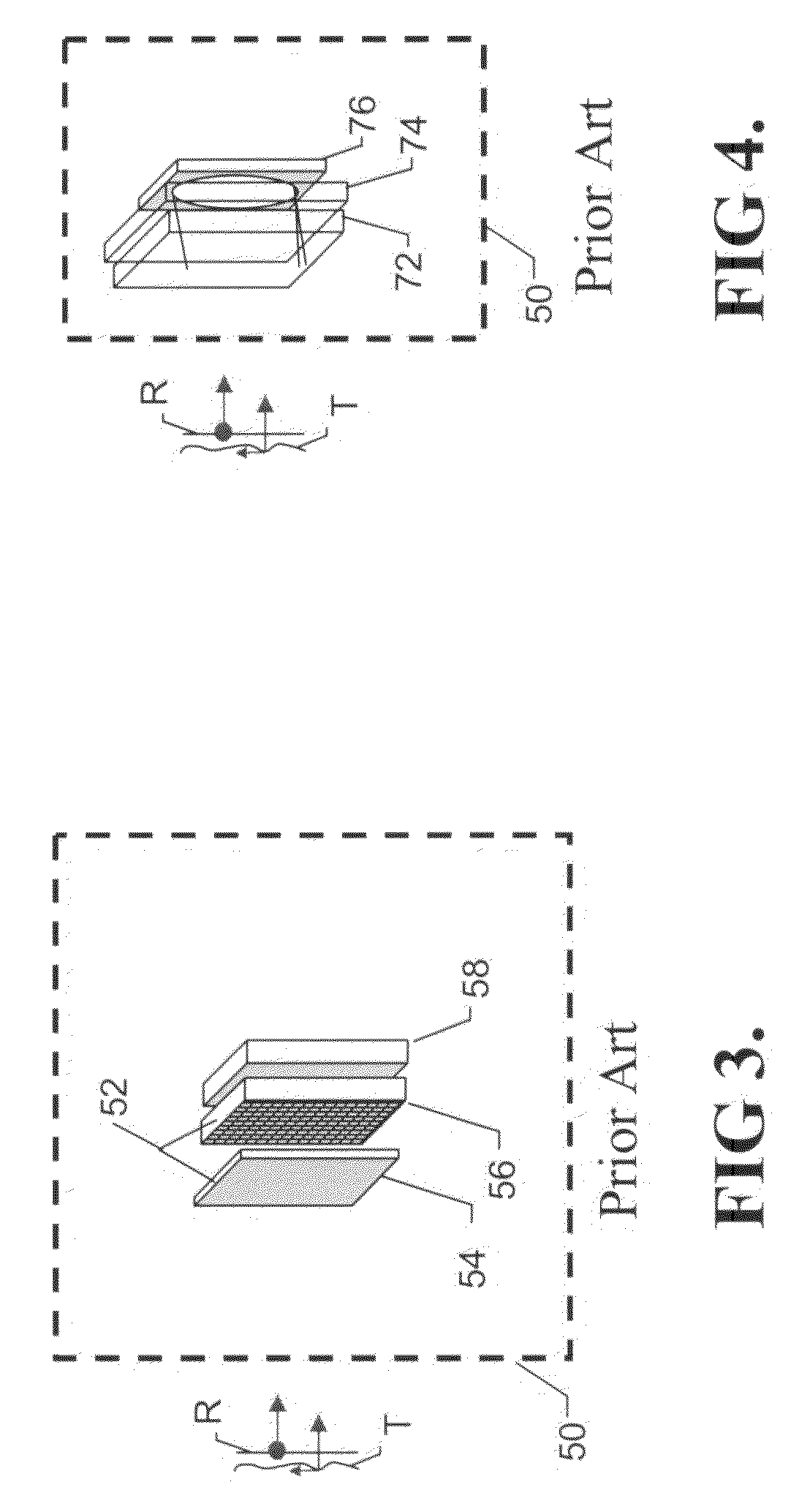

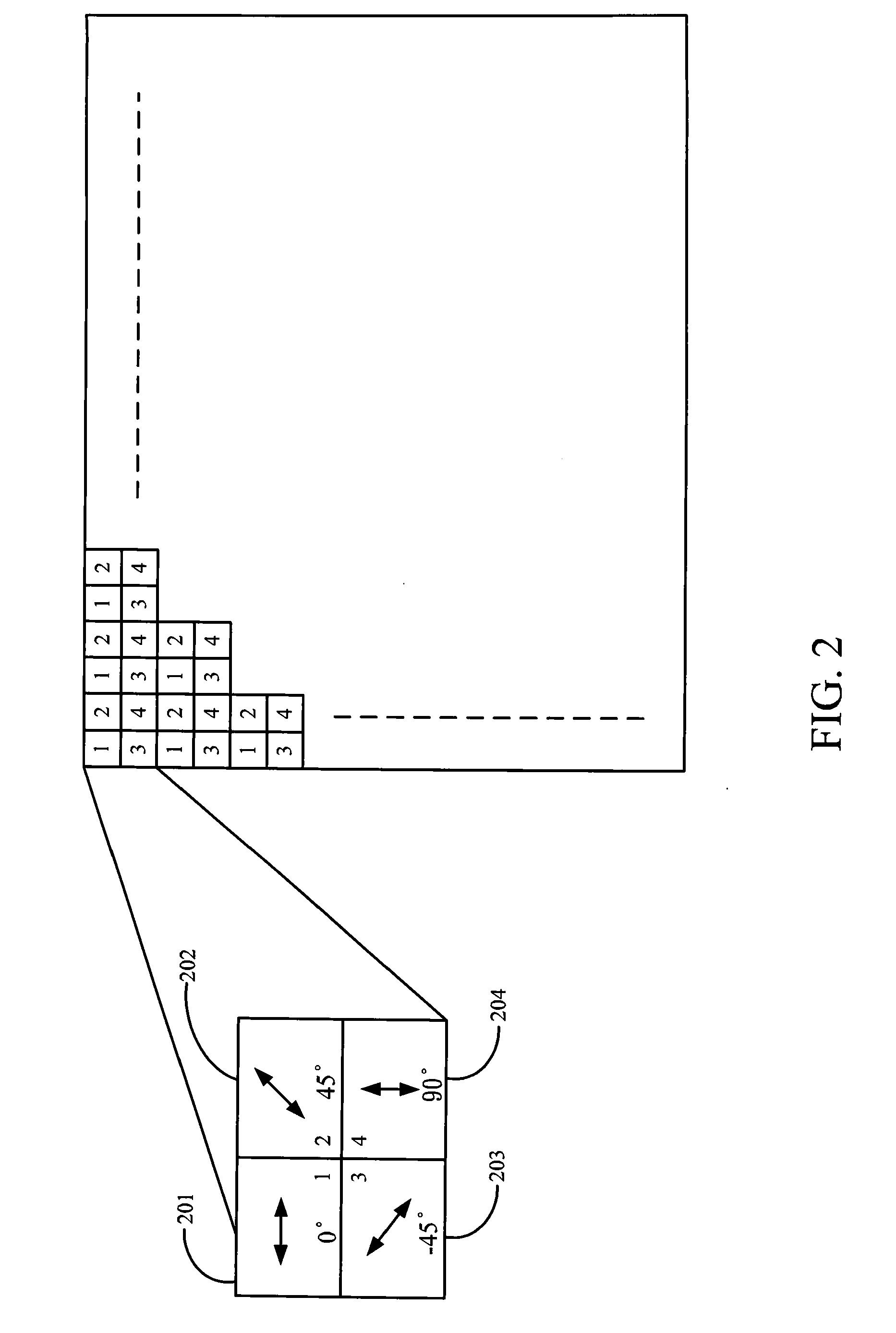

A phase-difference sensor measures the spatially resolved difference in phase between orthogonally polarized reference and test wavefronts. The sensor is constructed as a pixelated phase-mask aligned to and imaged on a pixelated detector array. Each adjacent pixel of the phase-mask measures a predetermined relative phase shift between the orthogonally polarized reference and test beams. Thus, multiple phase-shifted interferograms can be synthesized at the same time by combining pixels with identical phase-shifts. The multiple phase-shifted interferograms can be combined to calculate standard parameters such as modulation index or average phase step. Any configuration of interferometer that produces orthogonally polarized reference and object beams may be combined with the phase-difference sensor of the invention to provide, single-shot, simultaneous phase-shifting measurements.

Owner:ONTO INNOVATION INC

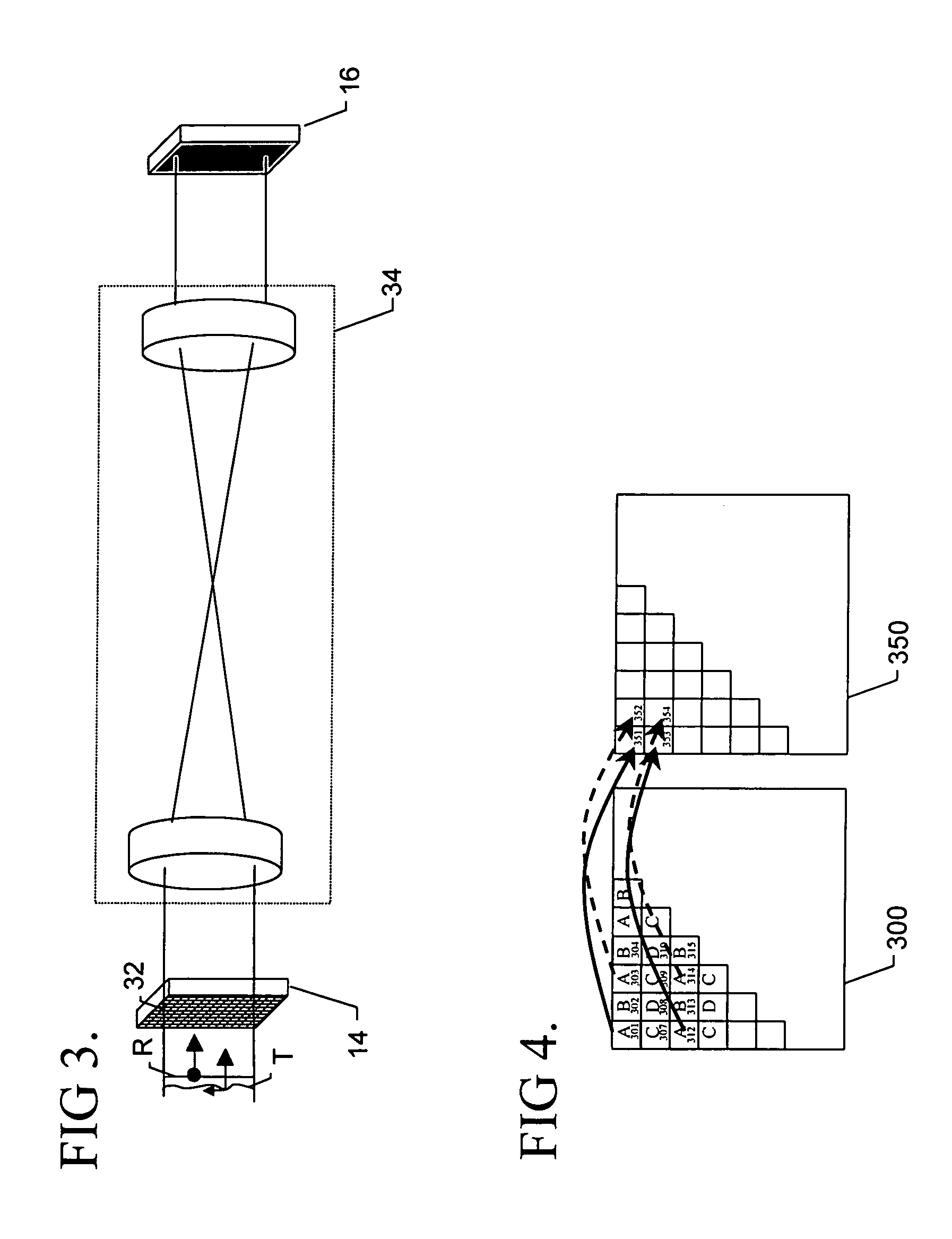

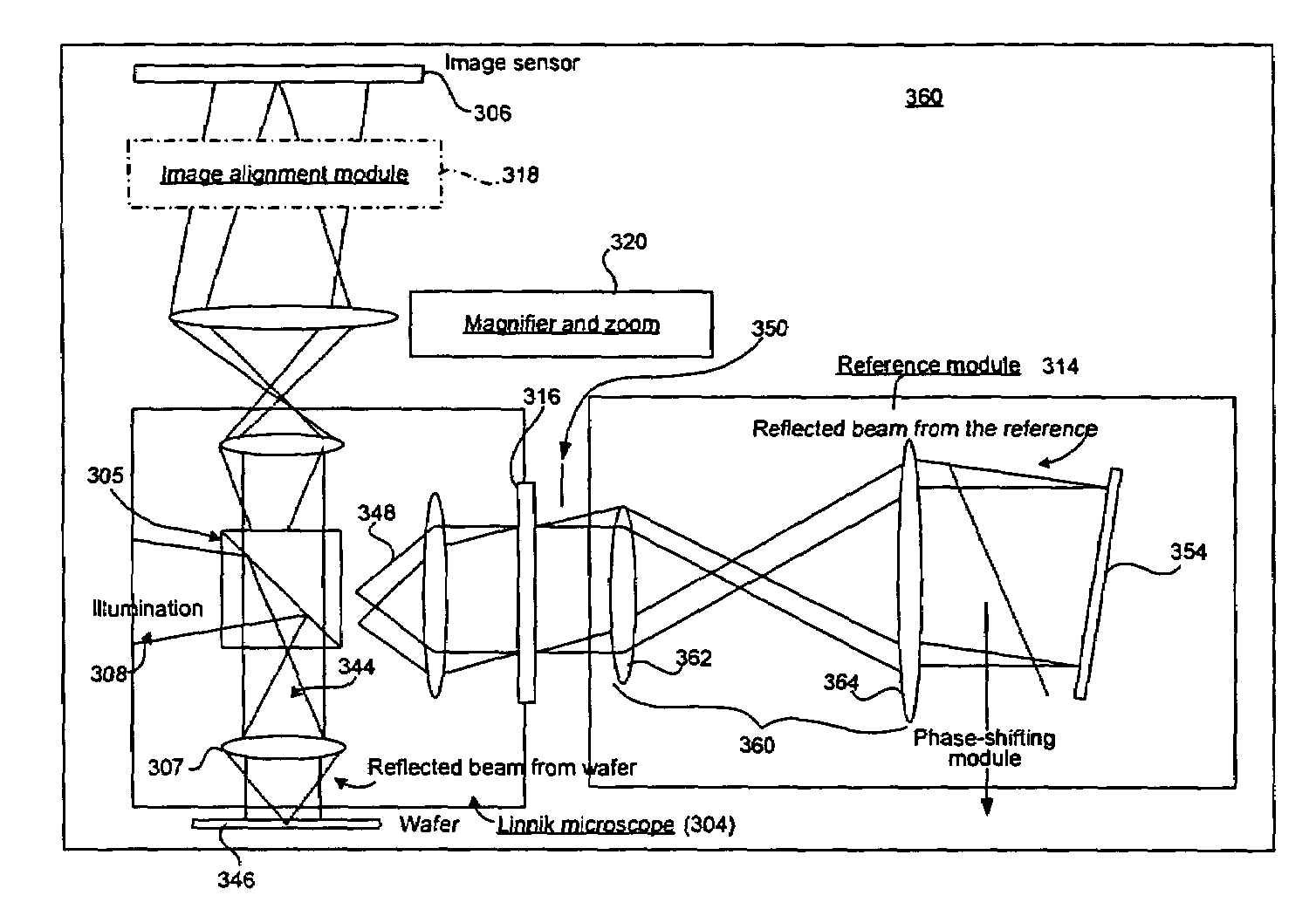

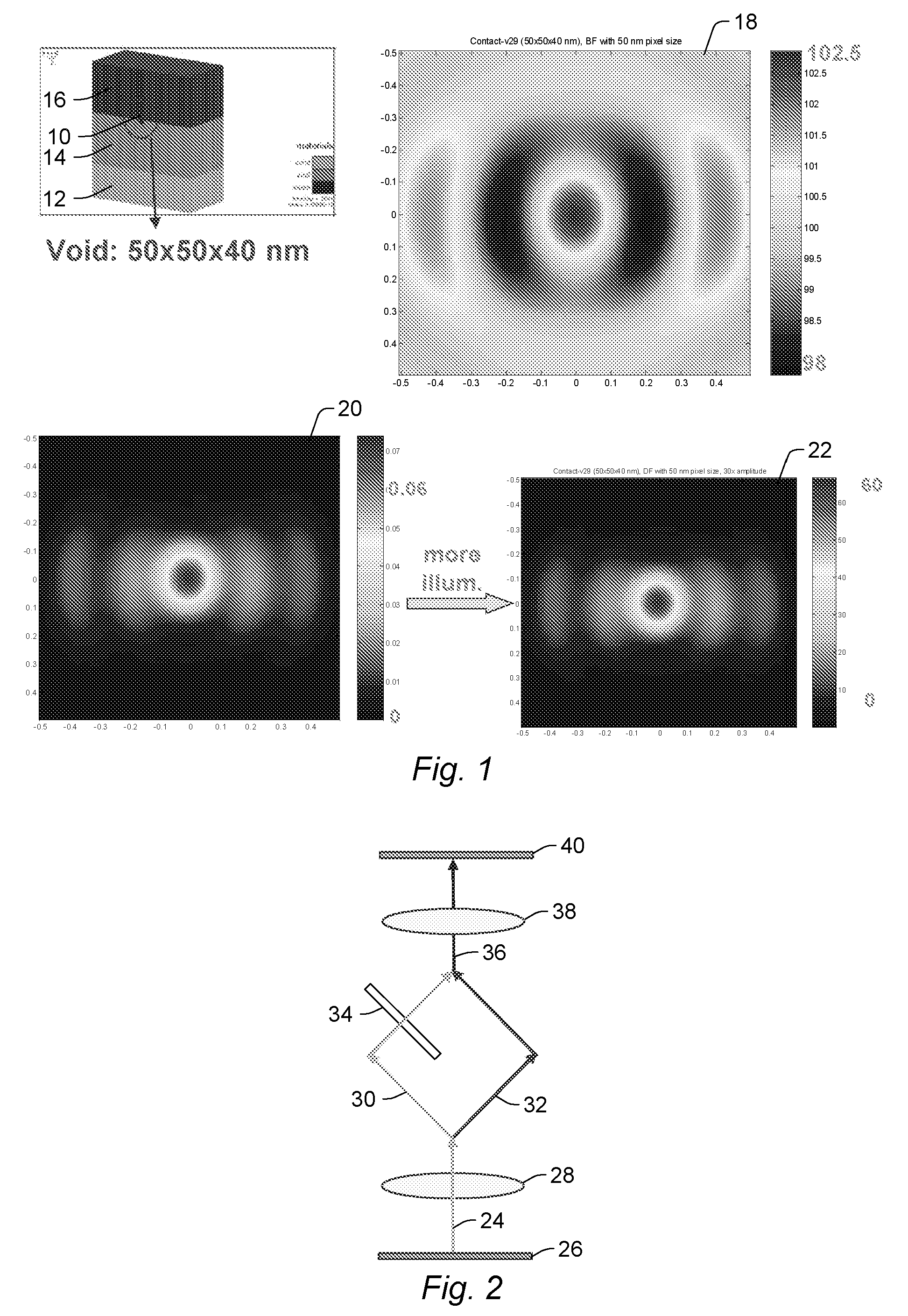

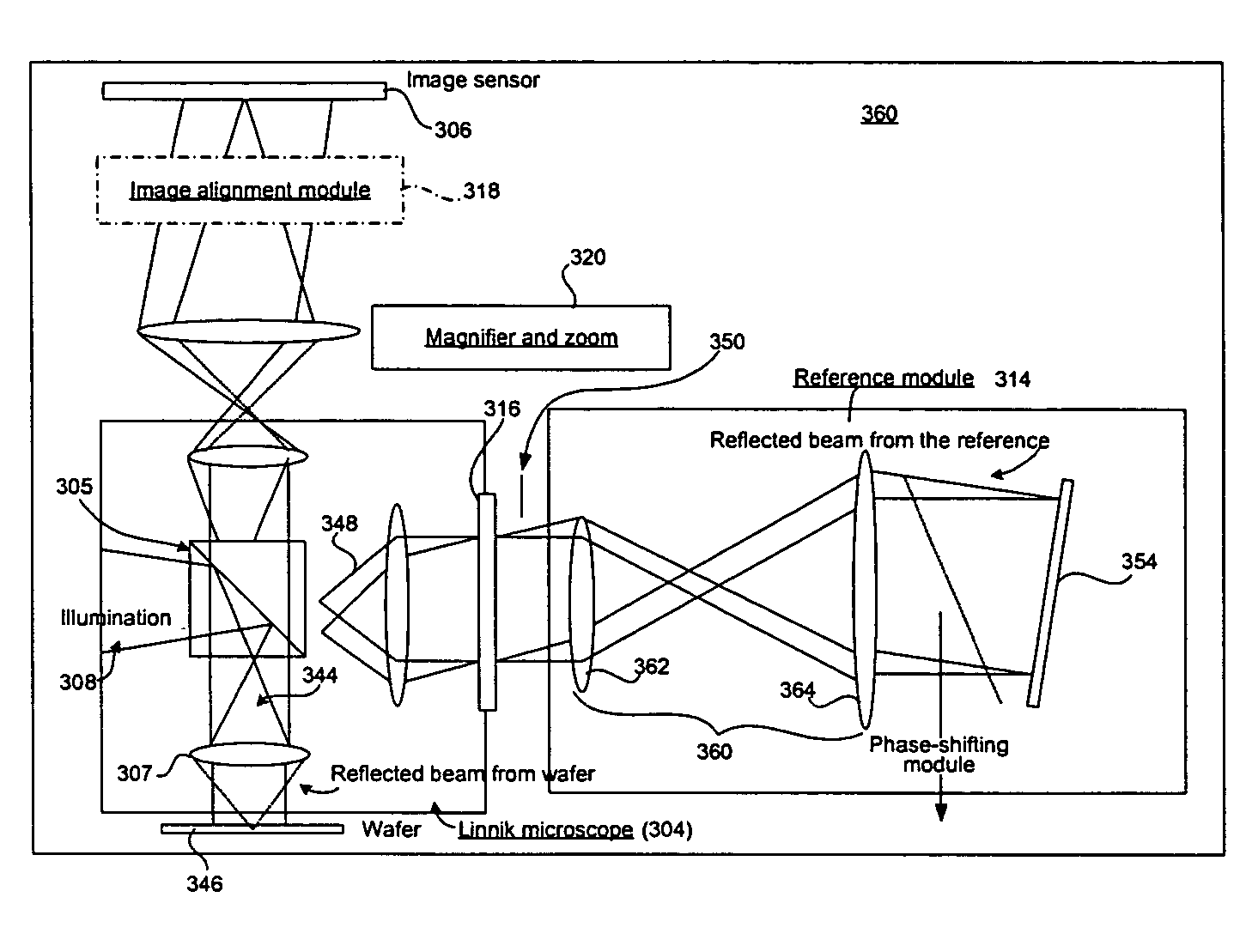

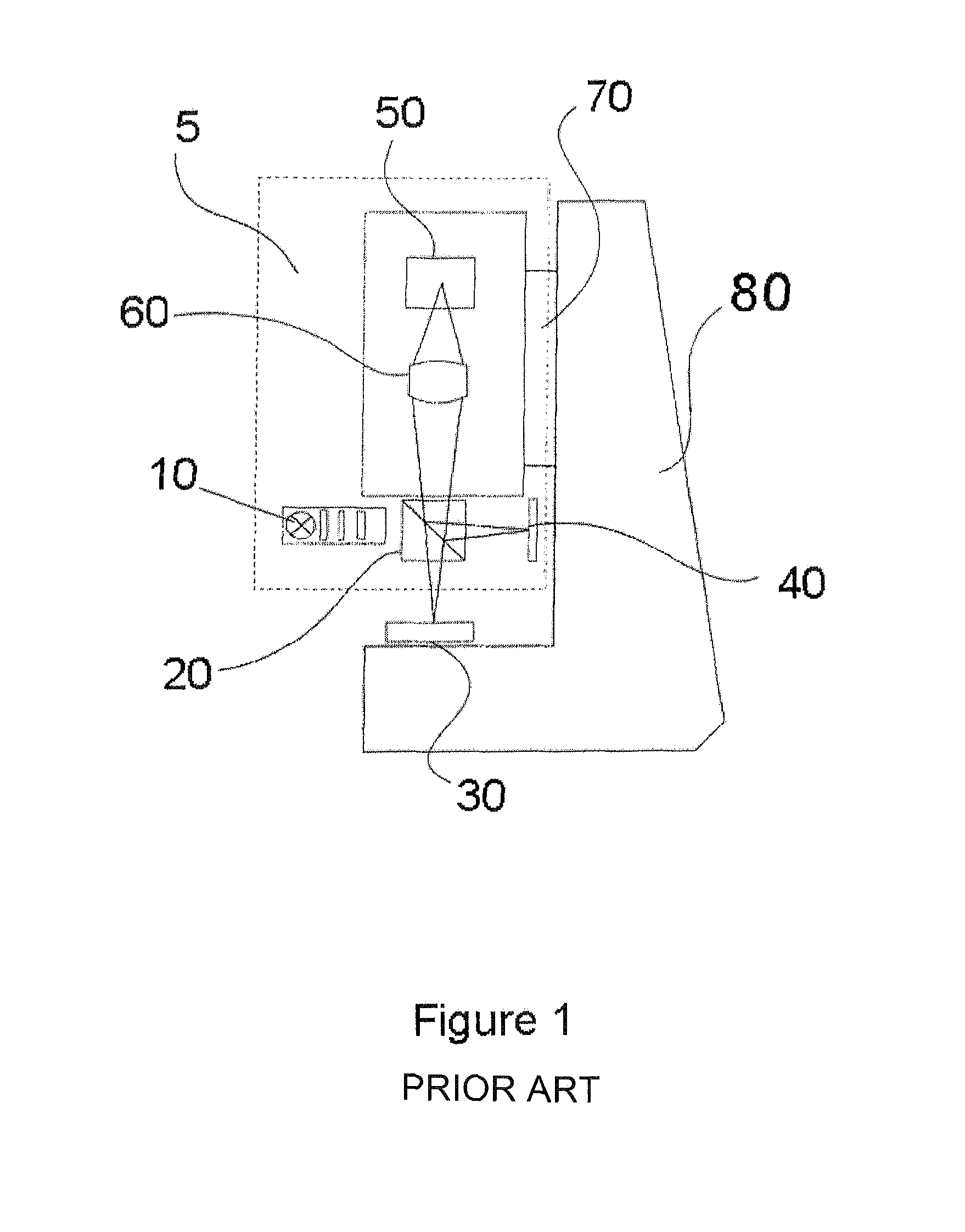

Method and apparatus using interferometric metrology for high aspect ratio inspection

ActiveUS7061625B1Easy alignmentMaterial analysis by optical meansUsing optical meansMetrologyOptical path

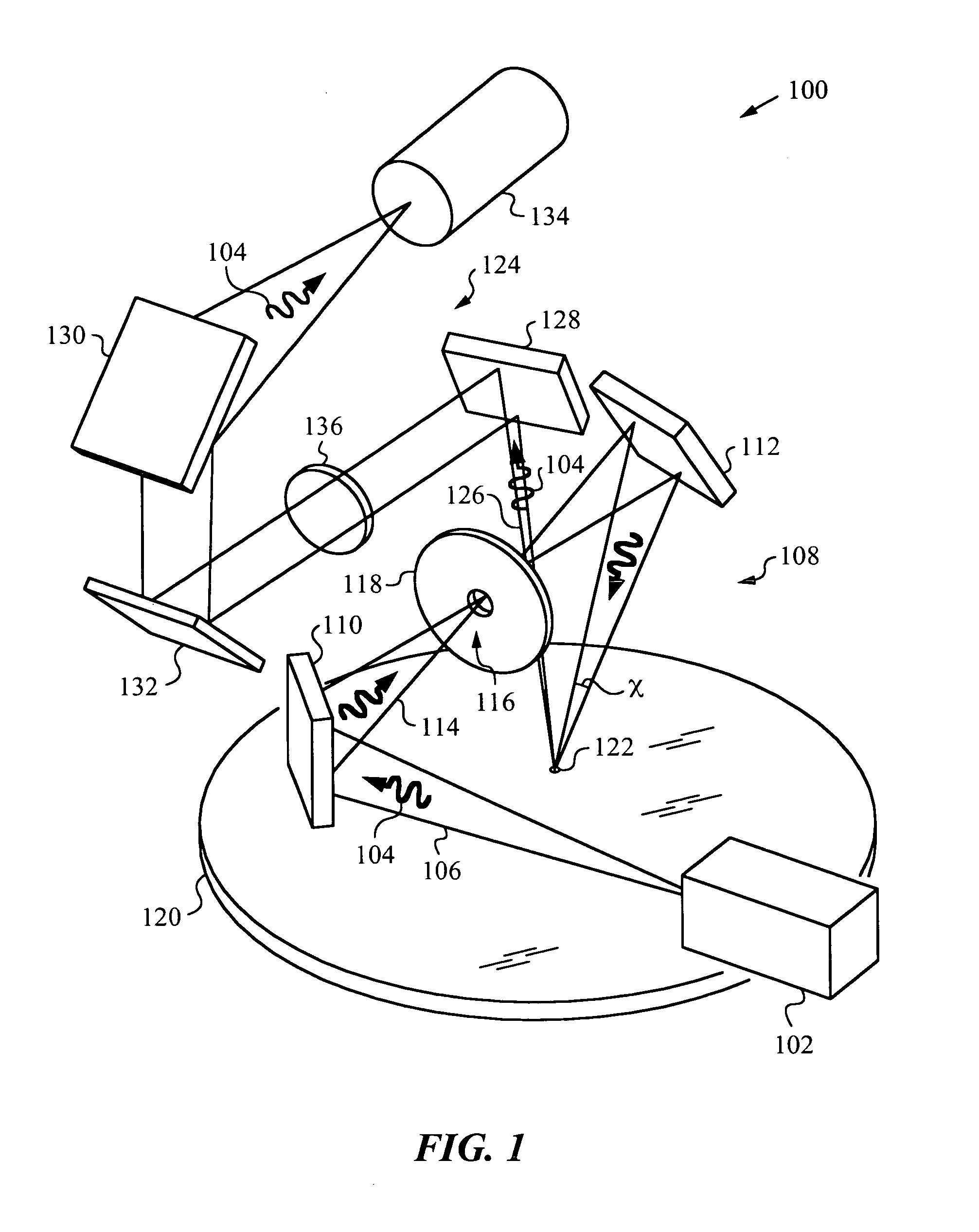

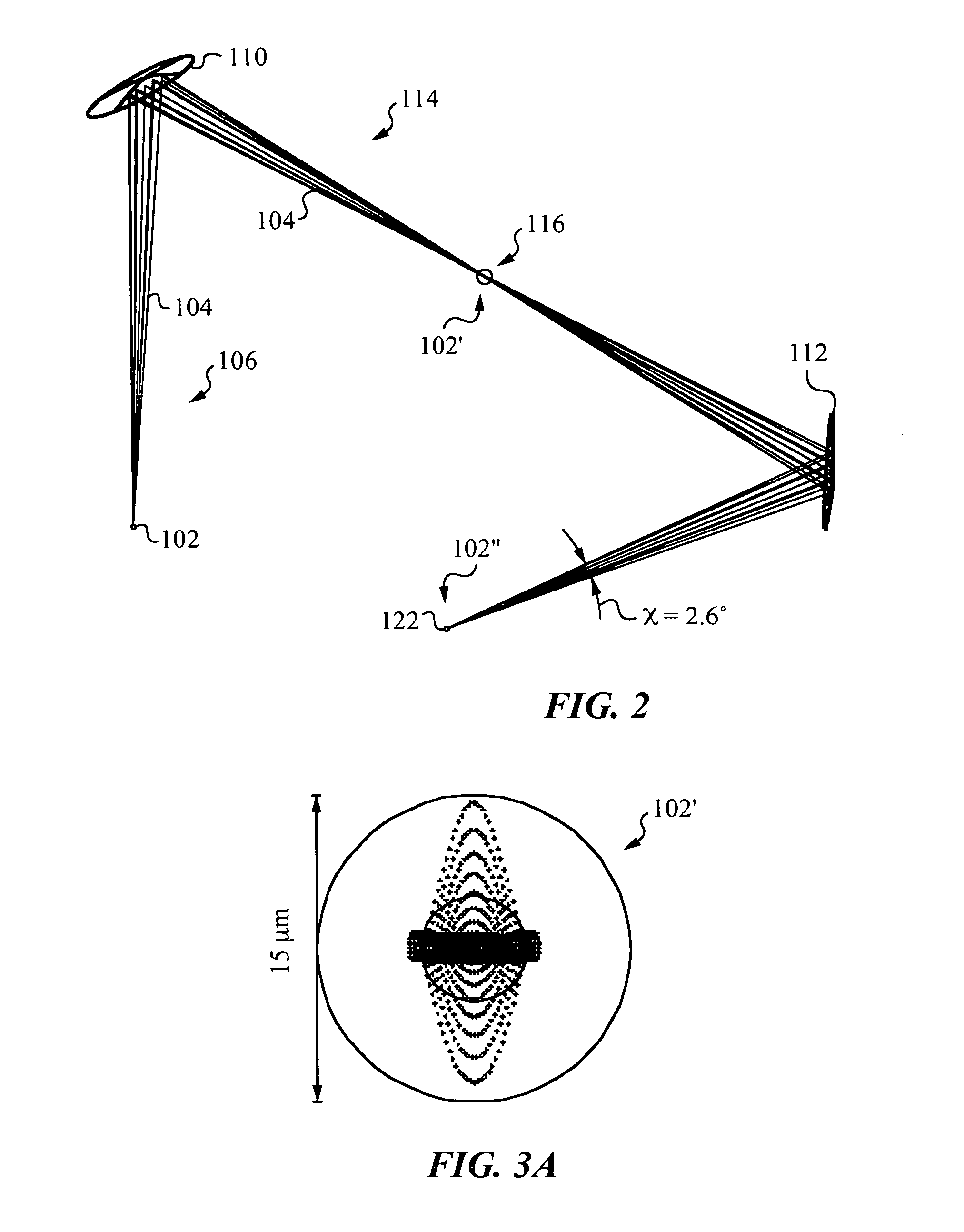

In one embodiment, the present invention provides an interferometric inspection system for inspecting semiconductor samples. The system includes at least one illumination source for generating an illumination beam and an interferometric microscope module for splitting the illumination beam into a test beam directed to the semiconductor sample and a reference beam directed to a tilted reference mirror. The beams are combined to generate an interference image at an image sensor. The tilted reference mirror is tilted at a non-normal angle with respect to the reference beam that is incident on the mirror to thereby generate fringes in the interference image. The system also includes an image sensor for acquiring the interference image from the interferometric microscope module and generates an inherence signal. The system further includes a processing module configured to generate complex field information corresponding to the sample from the interference image signal and an alignment module located in the optical path between the interferometric module and the image sensor. In another embodiment, the processing module is configured to generate complex field information from either spatial fringe analysis or temporal fringe analysis performed on the interference image signal.

Owner:KLA TENCOR TECH CORP

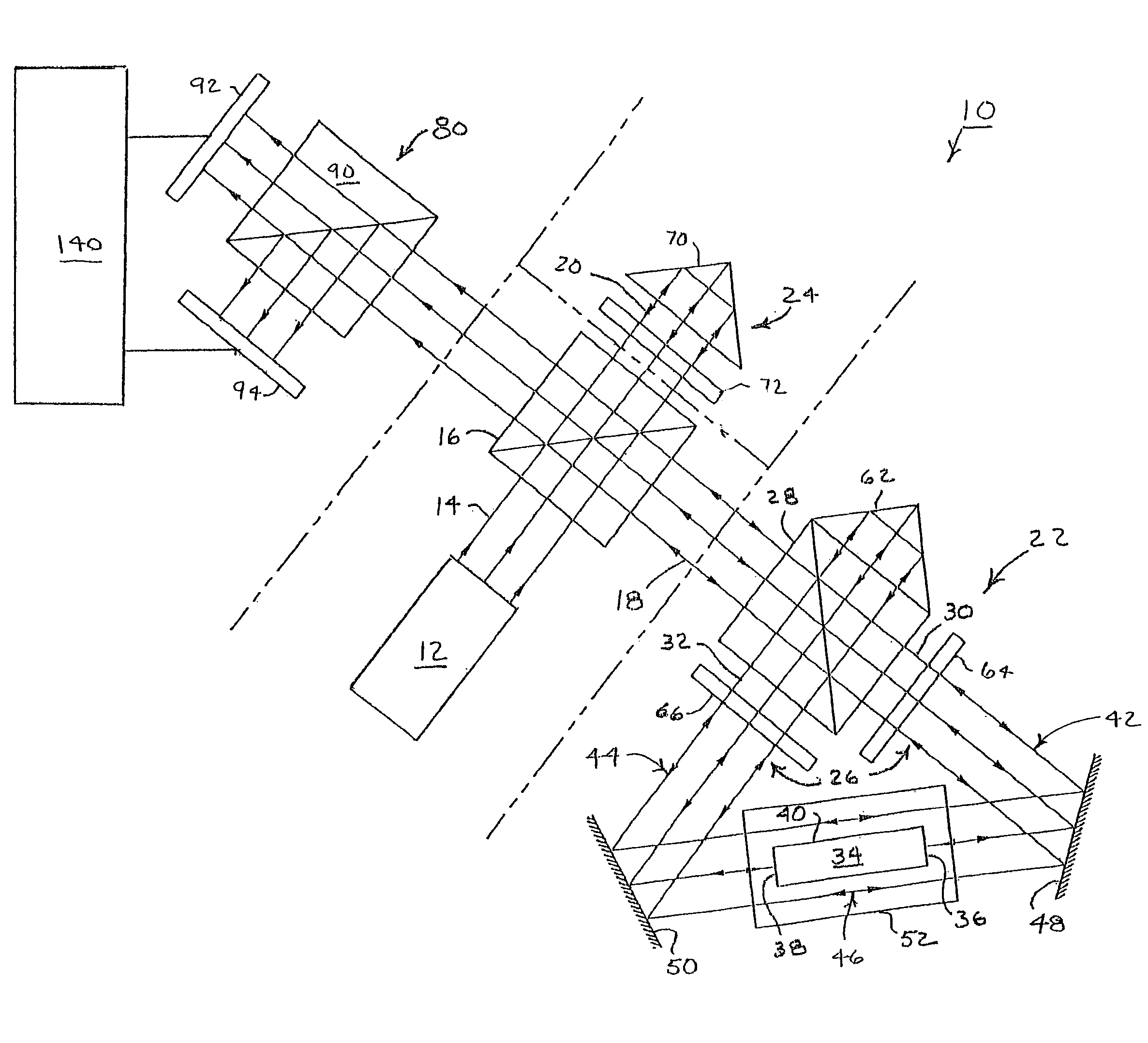

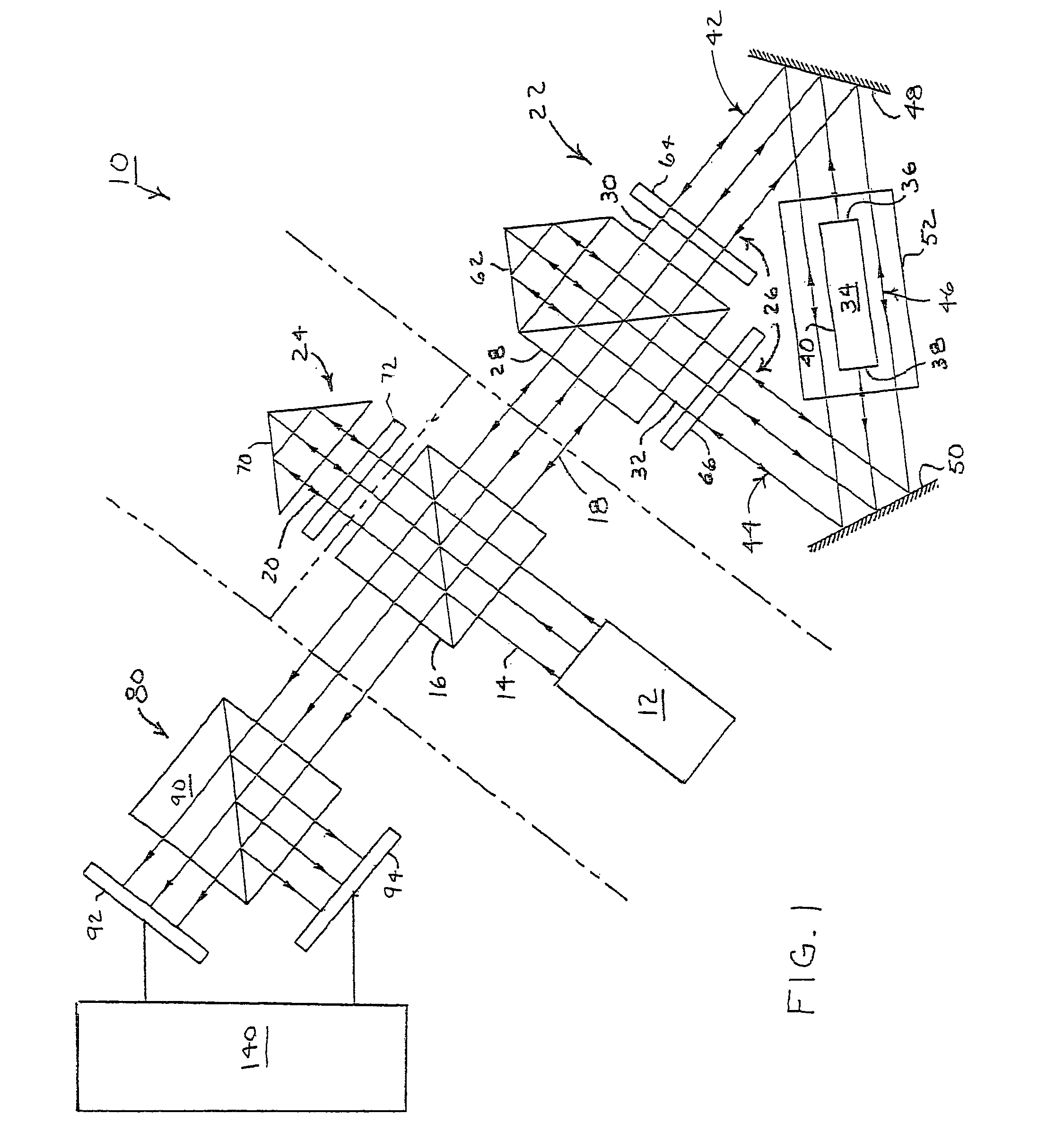

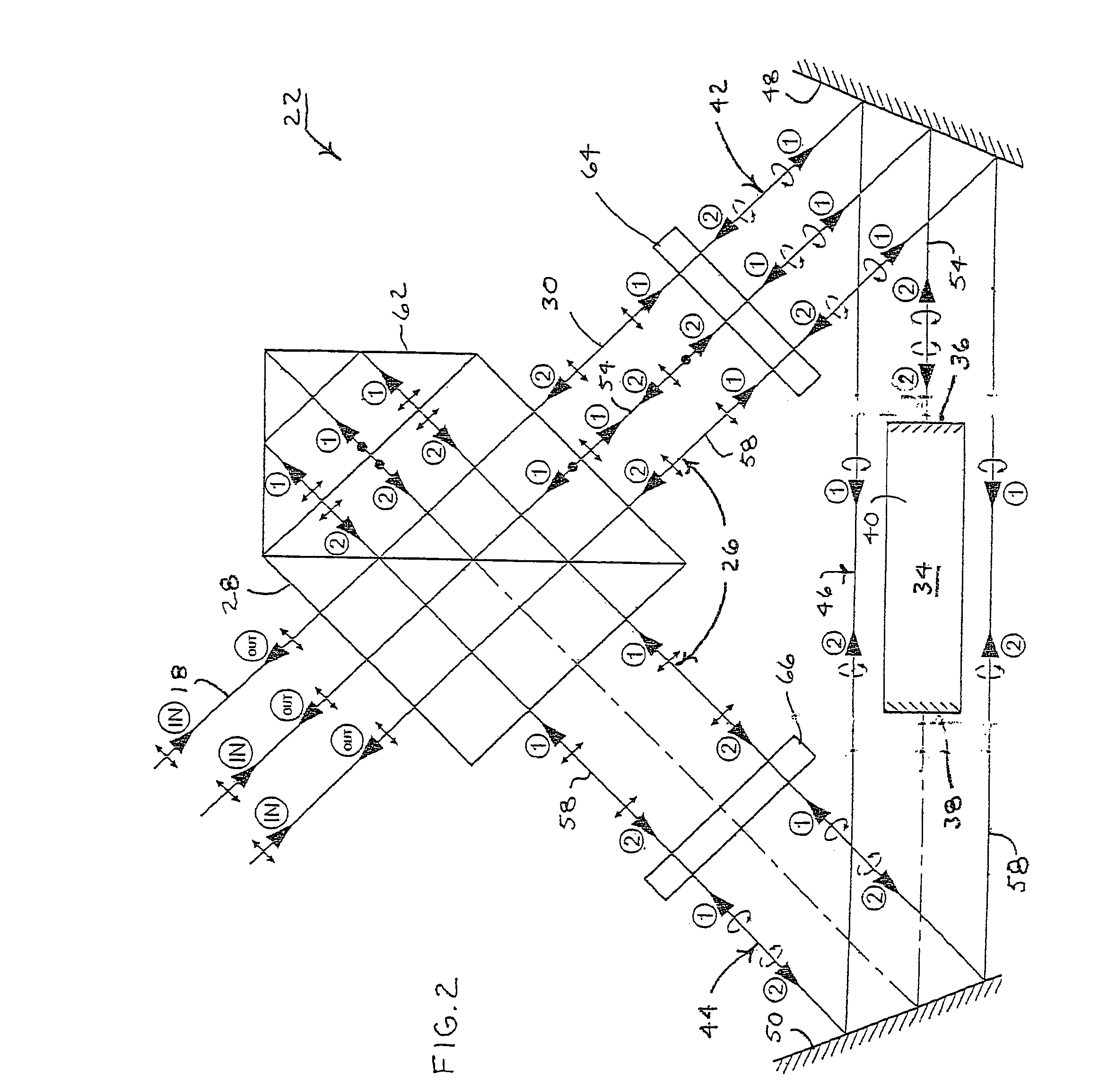

Method and apparatus for detecting a multitouch event in an optical touch-sensitive device

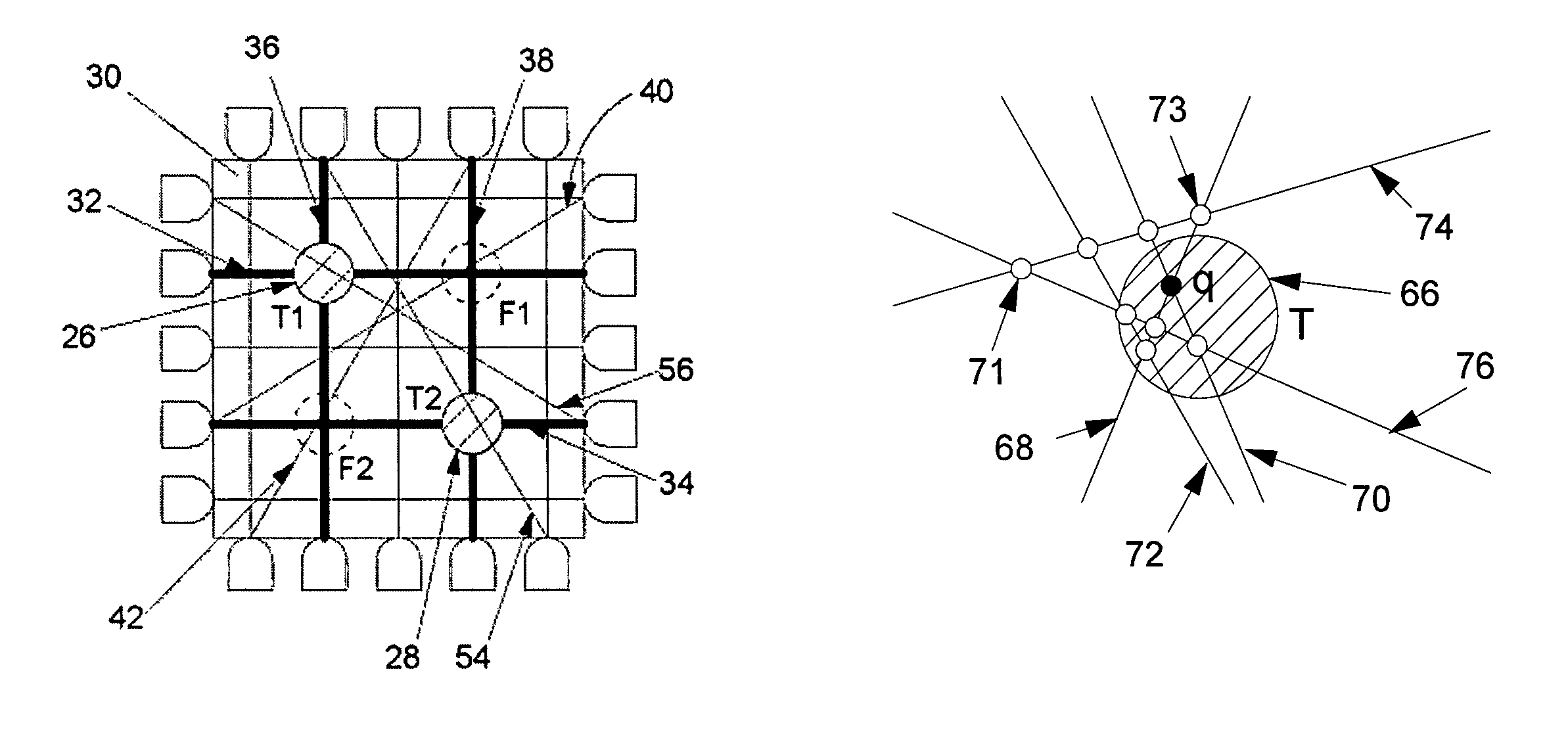

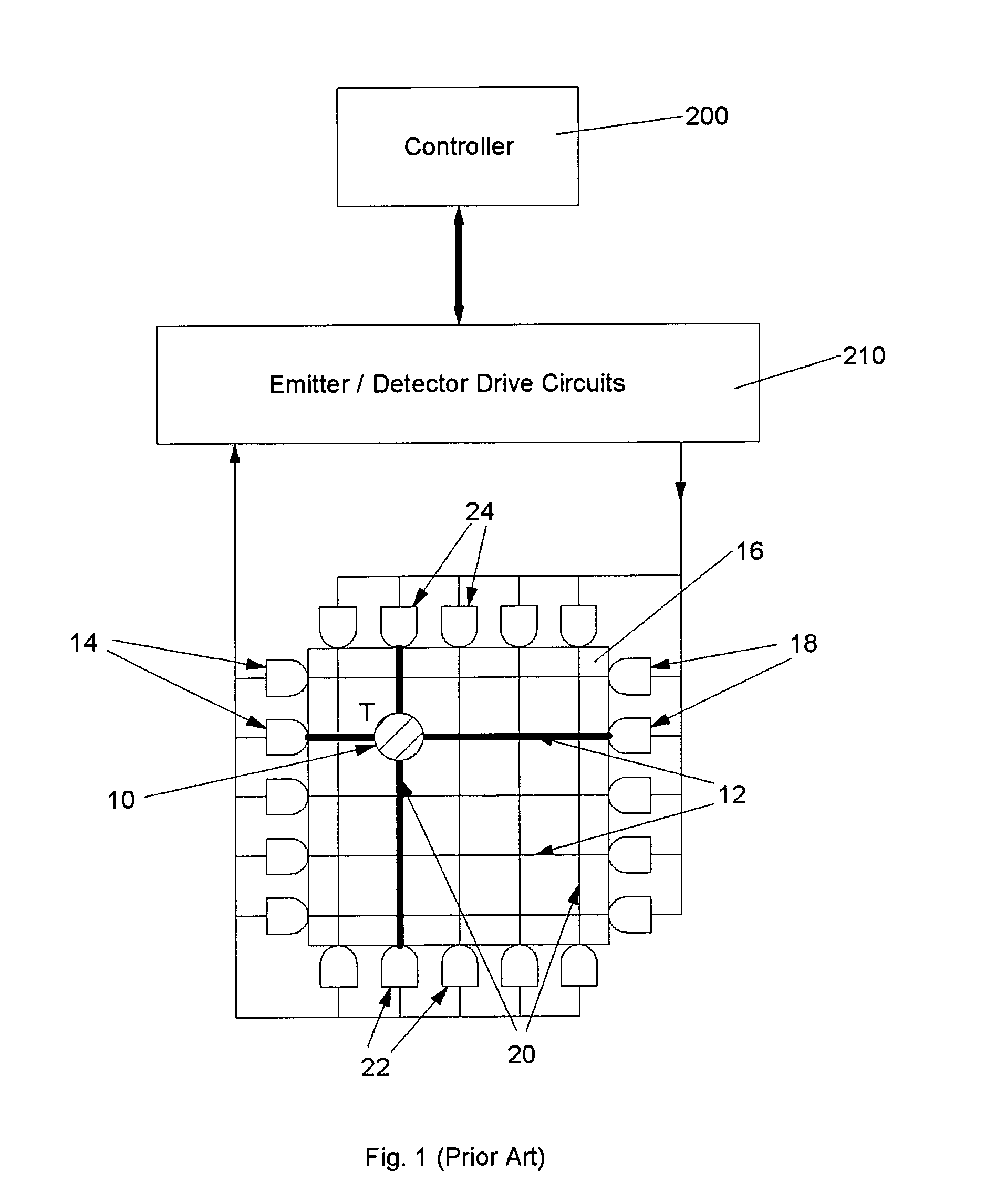

ActiveUS8350831B2Low costHigh resolutionInput/output processes for data processingTest beamLight beam

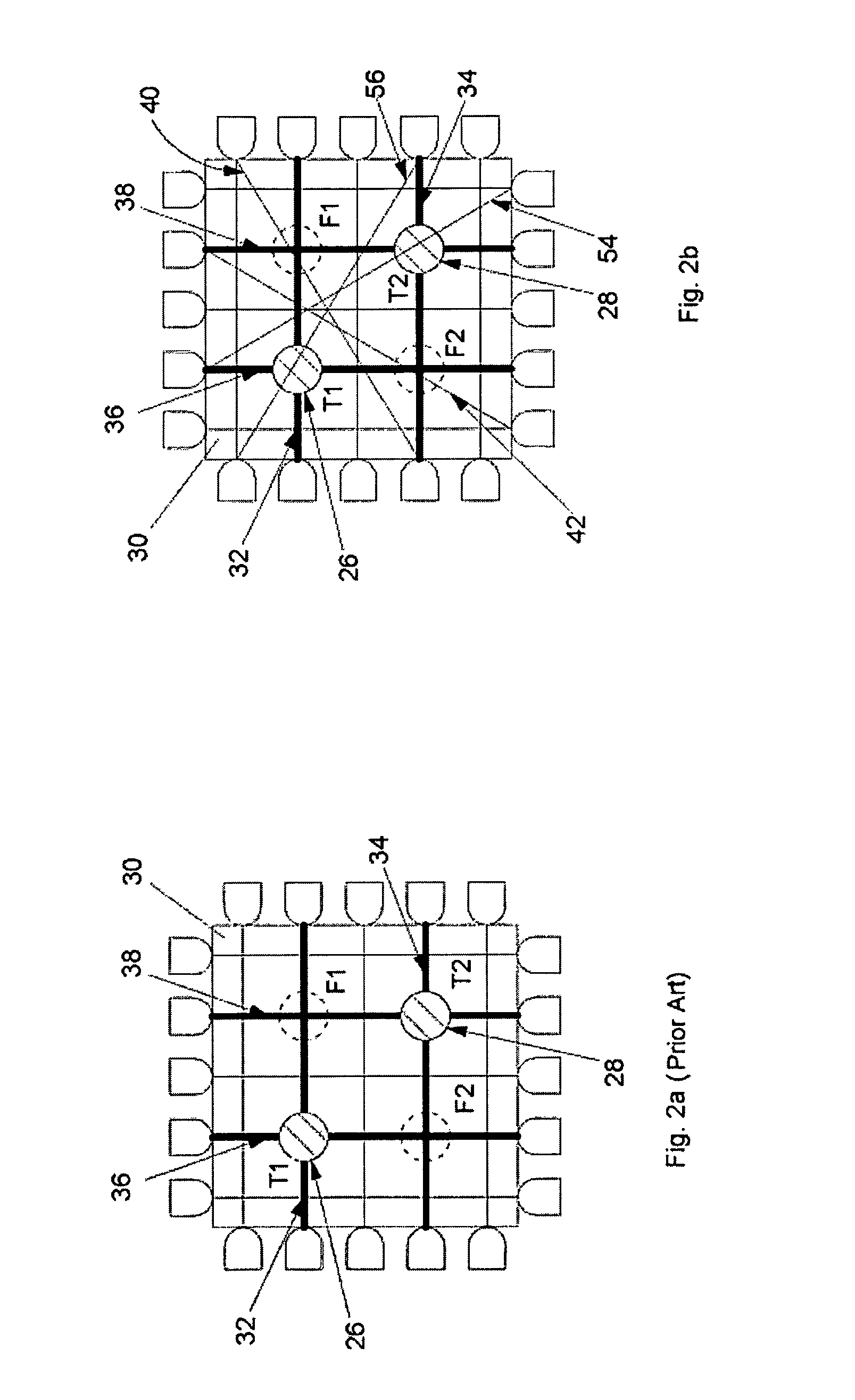

A touch sensitive optical control device comprising a set of light emitters 14, 22 and light detectors 18, 24 arranged relative to a touchable surface 30 such that light transmitted by the emitters is received by the detectors along multiple intersecting beams which pass transversely of the surface and touching the surface at a beam interrupts the light transmitted along the beam. Candidate touch points T1, T2, F1, F2 are defined at the intersections of interrupted beams and are confirmed or not as actual touch points by examining test beams 40, 42, 54, 56 near to or coincident with the candidate touch point.

Owner:BEECHROCK LTD

Pixelated phase-mask interferometer

ActiveUS7230717B2Increase rangeReduce complexityInterferometersUsing optical meansPhase differenceDetector array

A phase-difference sensor measures the spatially resolved difference in phase between orthogonally polarized reference and test wavefronts. The sensor is constructed as a pixelated phase-mask aligned to and imaged on a pixelated detector array. Each adjacent pixel of the phase-mask measures a predetermined relative phase shift between the orthogonally polarized reference and test beams. Thus, multiple phase-shifted interferograms can be synthesized at the same time by combining pixels with identical phase-shifts. The multiple phase-shifted interferograms can be combined to calculate standard parameters such as modulation index or average phase step. Any configuration of interferometer that produces orthogonally polarized reference and object beams may be combined with the phase-difference sensor of the invention to provide, single-shot, simultaneous phase-shifting measurements.

Owner:ONTO INNOVATION INC

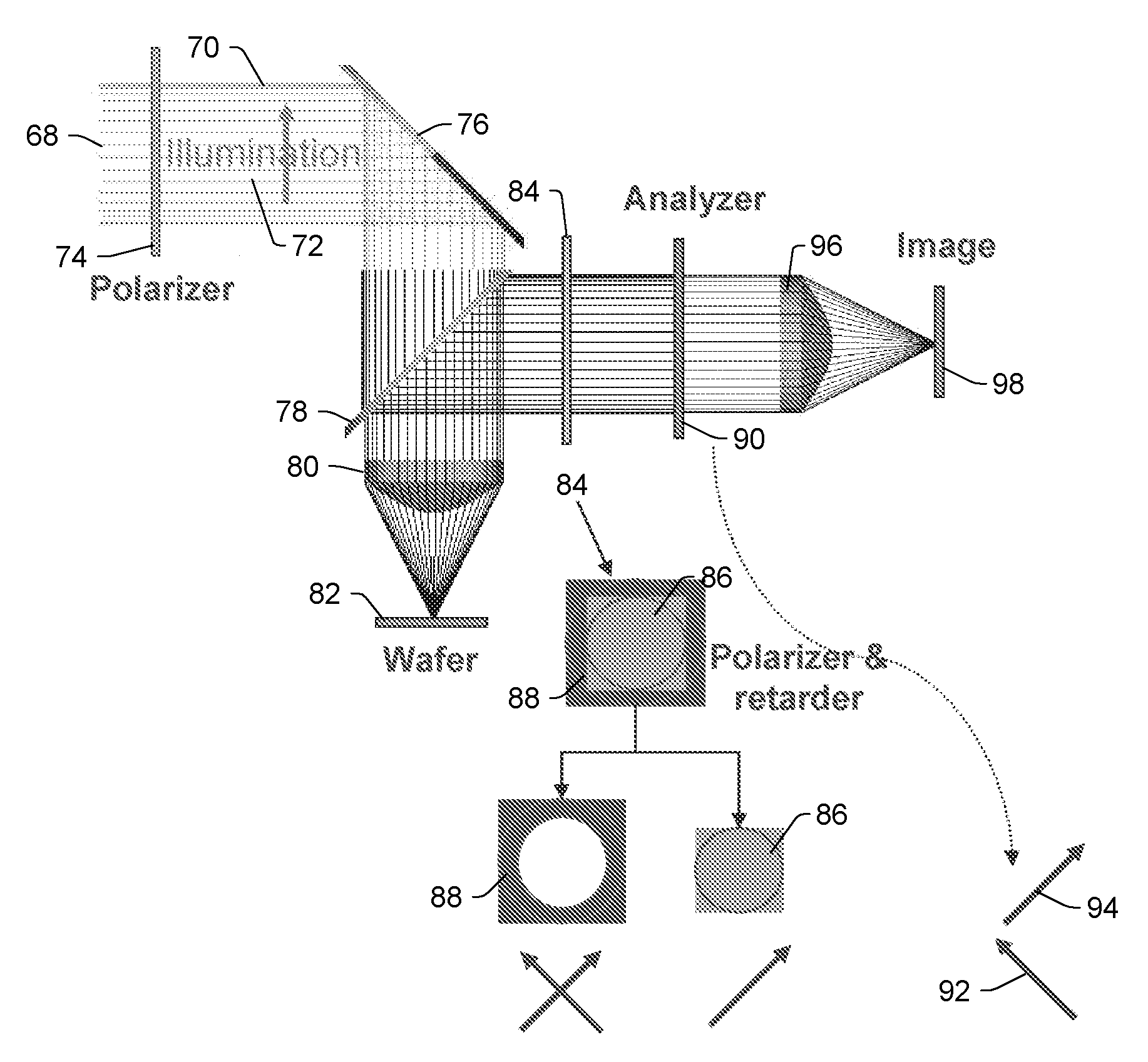

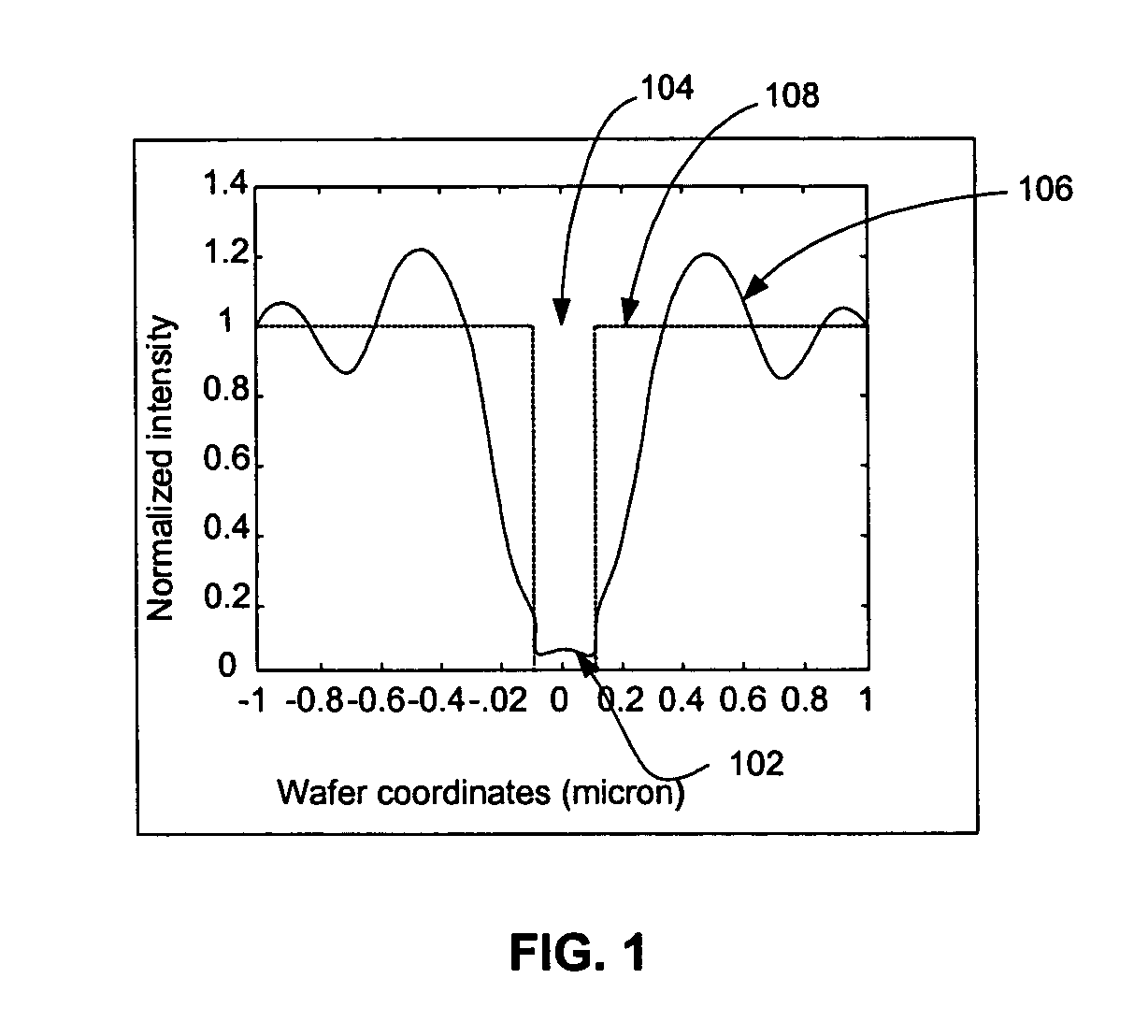

Systems Configured to Generate Output Corresponding to Defects on a Specimen

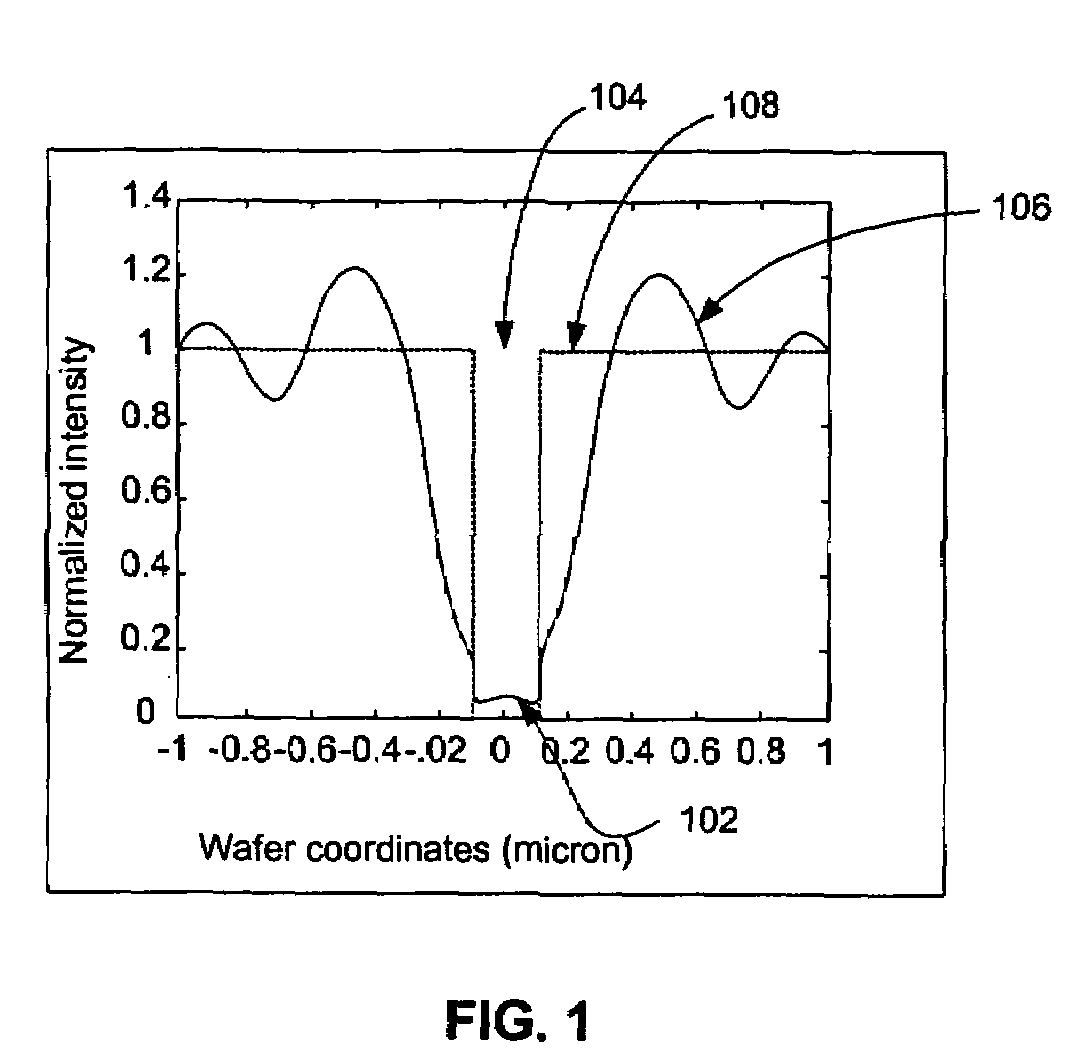

InactiveUS20070030477A1Reduce resolutionIncrease contrastPolarisation-affecting propertiesPhase-affecting property measurementsTest beamLight beam

Systems configured to generate output corresponding to defects on a specimen and systems configured to generate phase information about defects on a specimen are provided. One system includes an optical subsystem that is configured to create interference between a test beam and a reference beam. The test beam and the reference beam are reflected from the specimen. The system also includes a detector that is configured to generate output representative of the interference between the test and reference beams. The interference increases contrast between the output corresponding to the defects and output corresponding to non-defective portions of the specimen.

Owner:KLA TENCOR TECH CORP

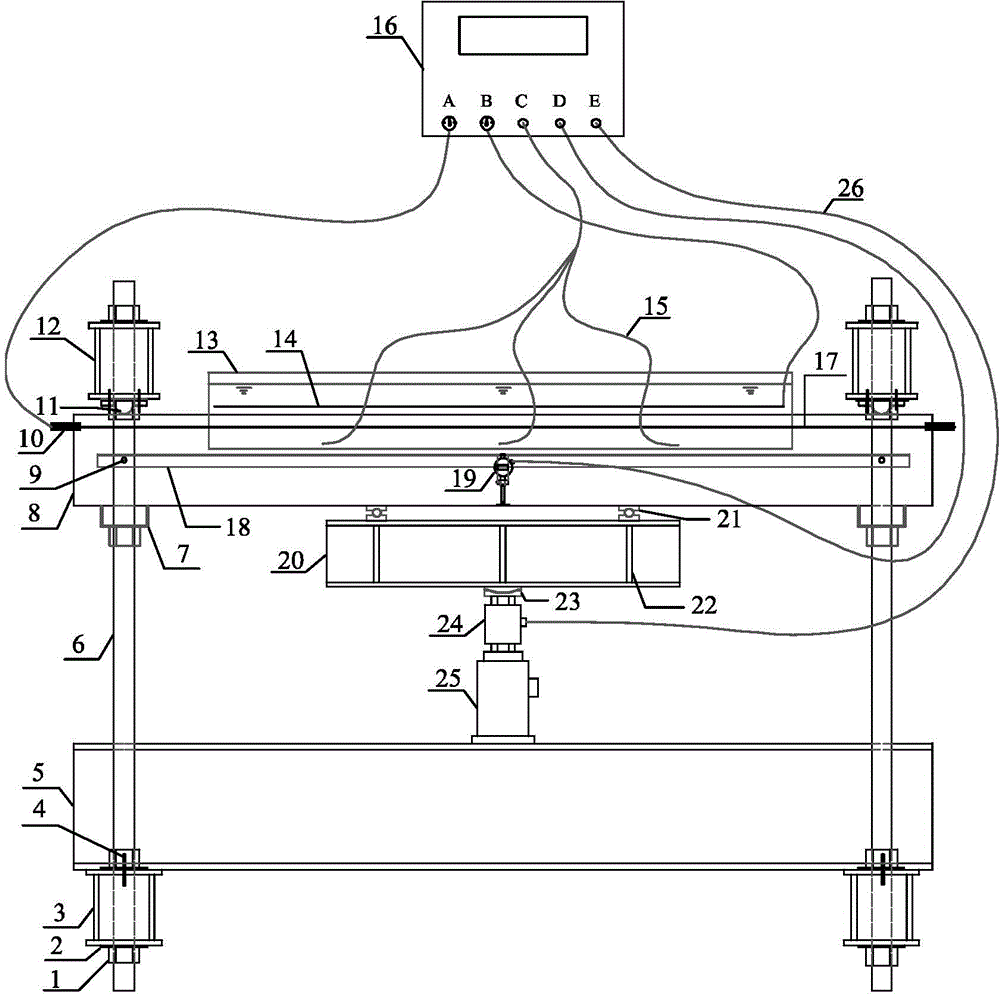

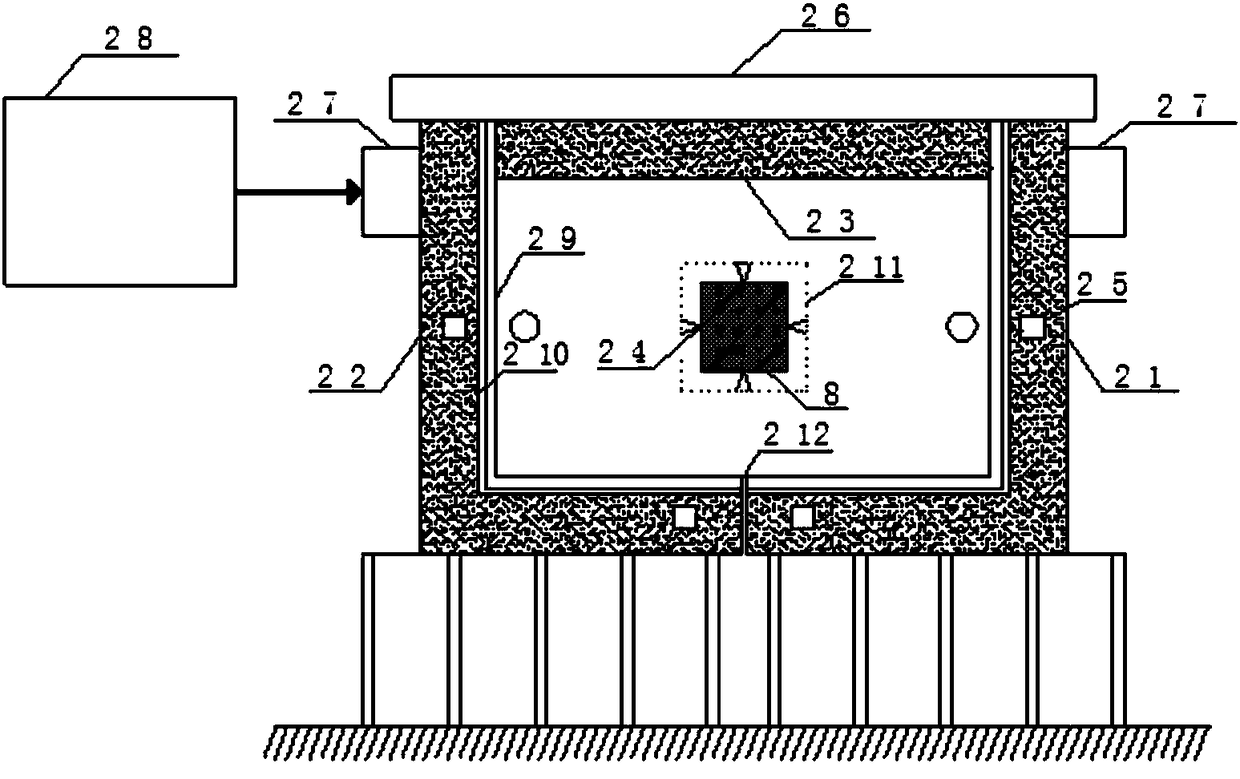

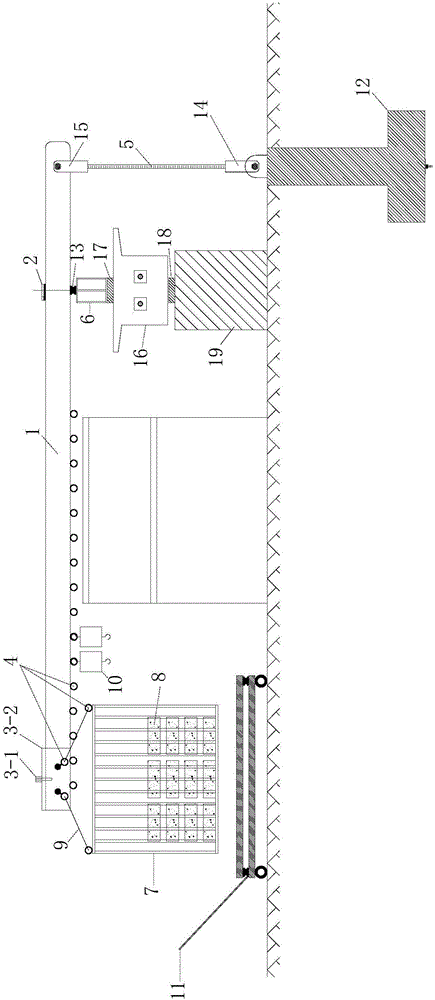

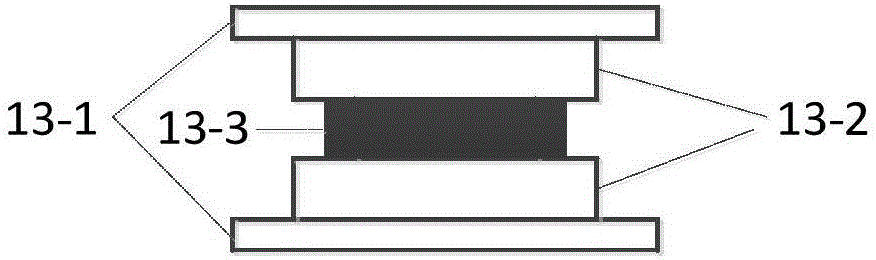

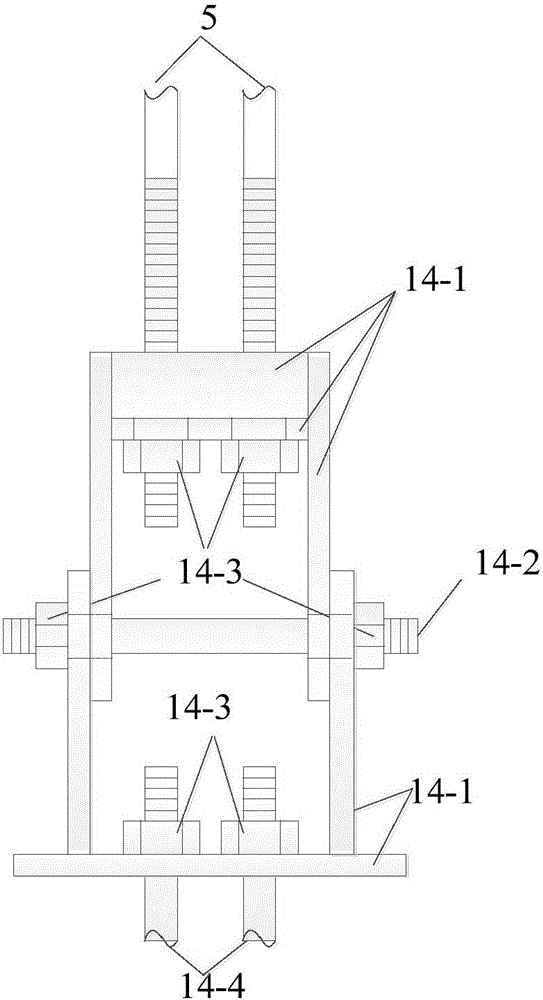

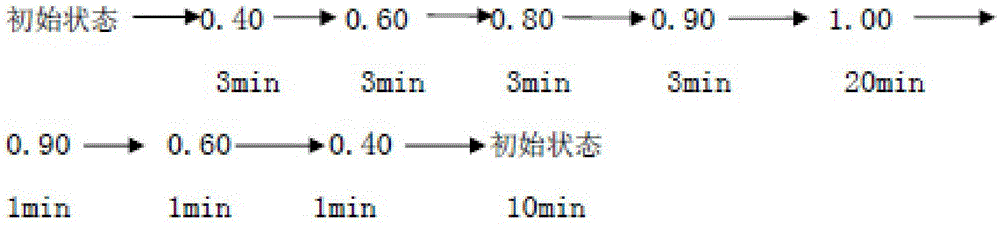

Device and method for testing chloride corrosion of reinforced concrete member under continuous load

ActiveCN104132847ATroubleshoot test setup issuesSolve the real problemMaterial strength using tensile/compressive forcesMicrocontrollerData acquisition

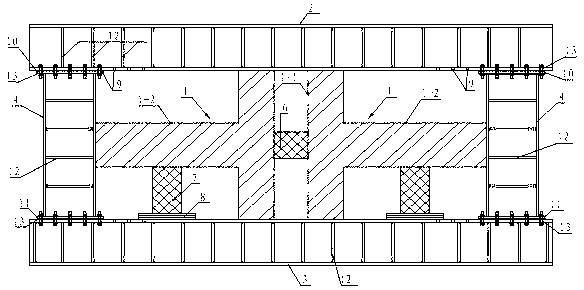

The invention provides a device and method for testing chloride corrosion of a reinforced concrete member under a continuous load. The device comprises a continuous load loading device, a rapid chloride corrosion device and a measurement and control device. A continuous load is applied by a loading frame and a drive device, a frame body is filled with a chloride solution and is fixed at the upper-middle part of a test beam in a sealing manner, air is continuously injected in the chloride solution by adopting an air pump, and direct current is introduced into reinforced steel bars of the test beam to implement the rapid corrosion. Relevant data acquirers, electrochemical testers and output equipment which are controlled through a single chip microcomputer in a unified manner are integrated in the main control box, the continuous load is measured in real time, and periodically corrected to a target level, corrosion behaviors of a corroded member are periodically tested, and data are acquired, displayed, stored, printed and output in real time. The device is capable of effectively simulating an actual corrosion working condition of the on-active service reinforced concrete structure member under the coupling effect of a chloride environment and the load, and provides a scientific basis for evaluating the durability of engineering structures under chloride environments such as sea and salt lakes.

Owner:HOHAI UNIV

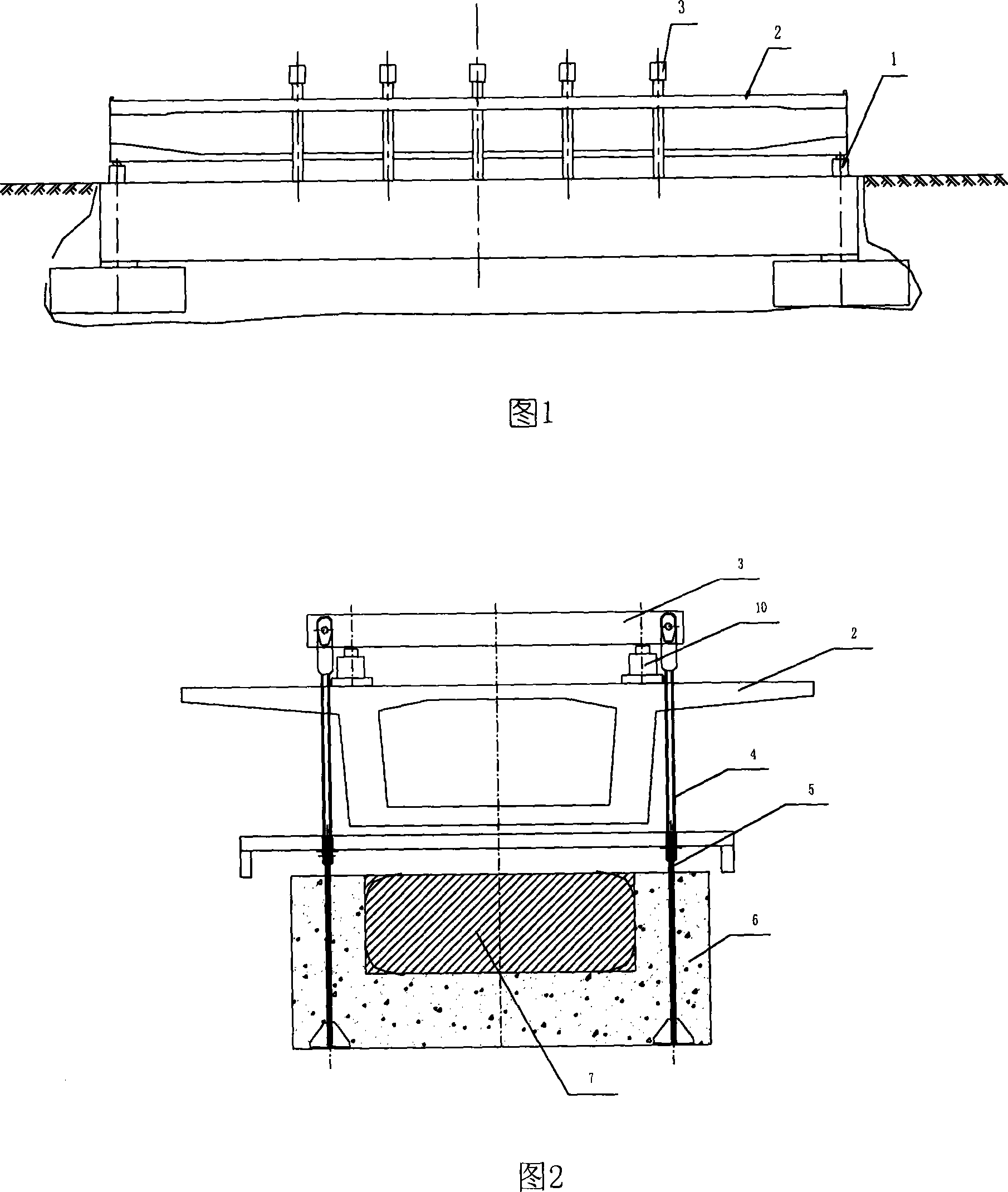

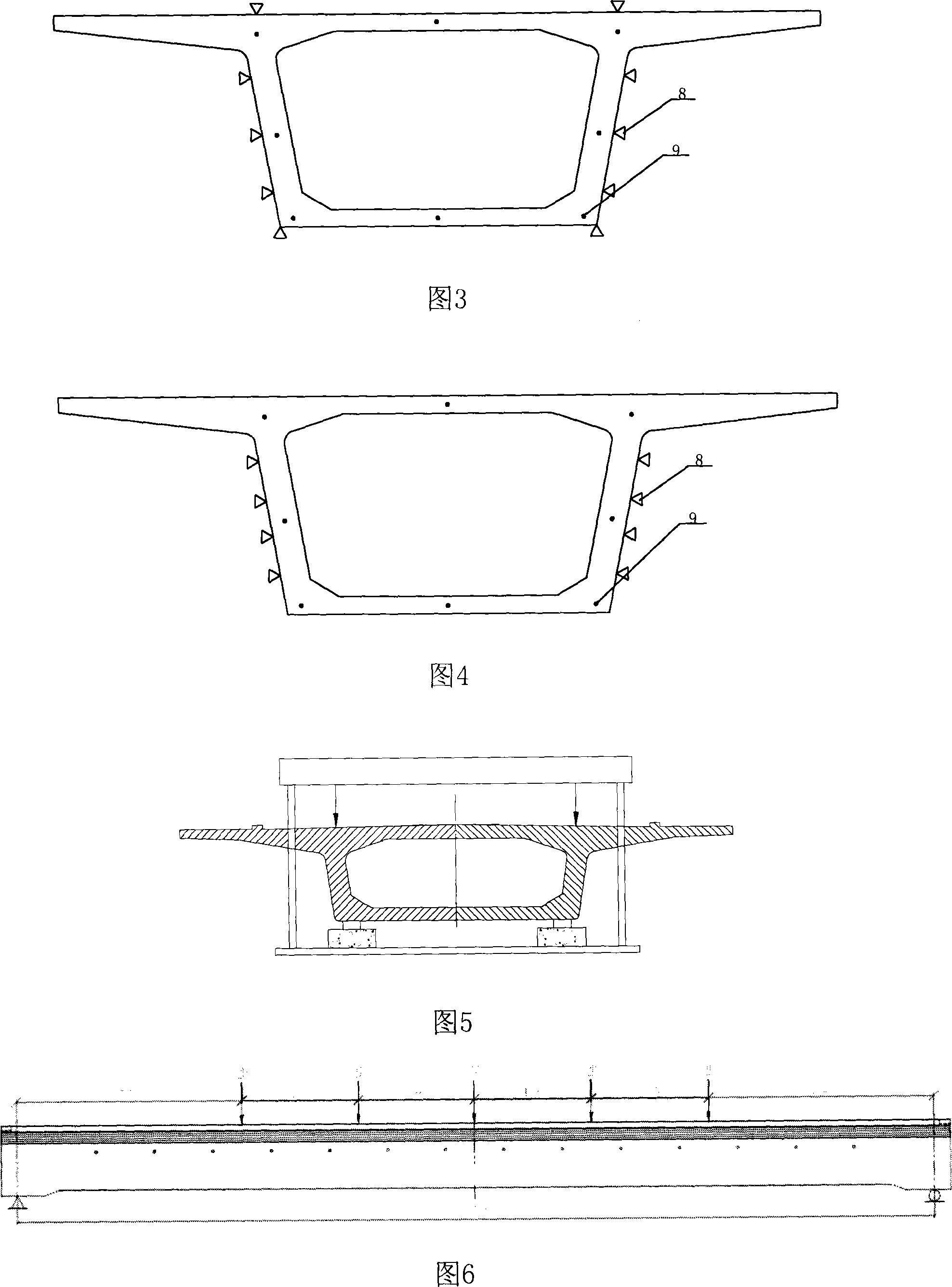

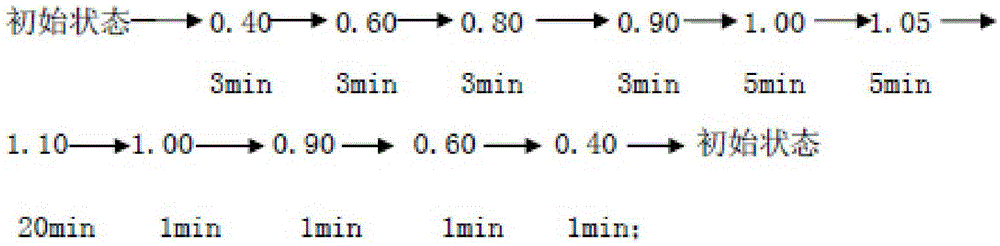

32m/900t prestressed concrete pretension box beam static loading test method

ActiveCN101101249AVerify crack resistanceAuthentication strengthFoundation testingMaterial strength using tensile/compressive forcesTest beamPre stress

The invention discloses a test procedure of 32m / 900t pre stress pre open box girder concrete box, it includes building testing counter, laying test beam body, fixing balance weight and setting test equipment, and doing load test of three circulation by ordering step by step, and dong crack test for the 32m / 900t pre open box girder effectively, splitting test and breaking test, dong experiment for the design of 32m pre open box girder, construct artwork, workmanship and the anti split and intensive properties of box girder.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

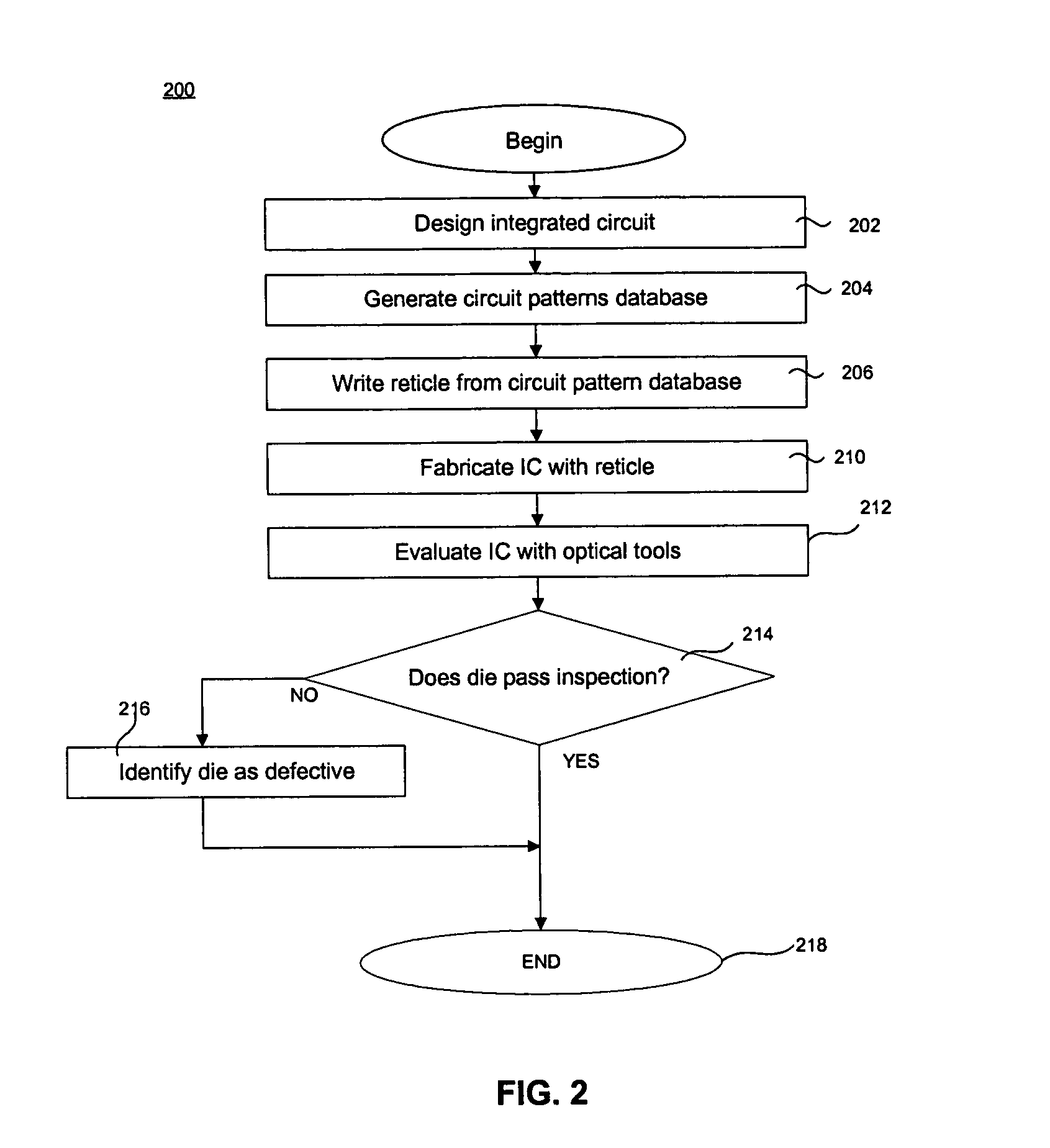

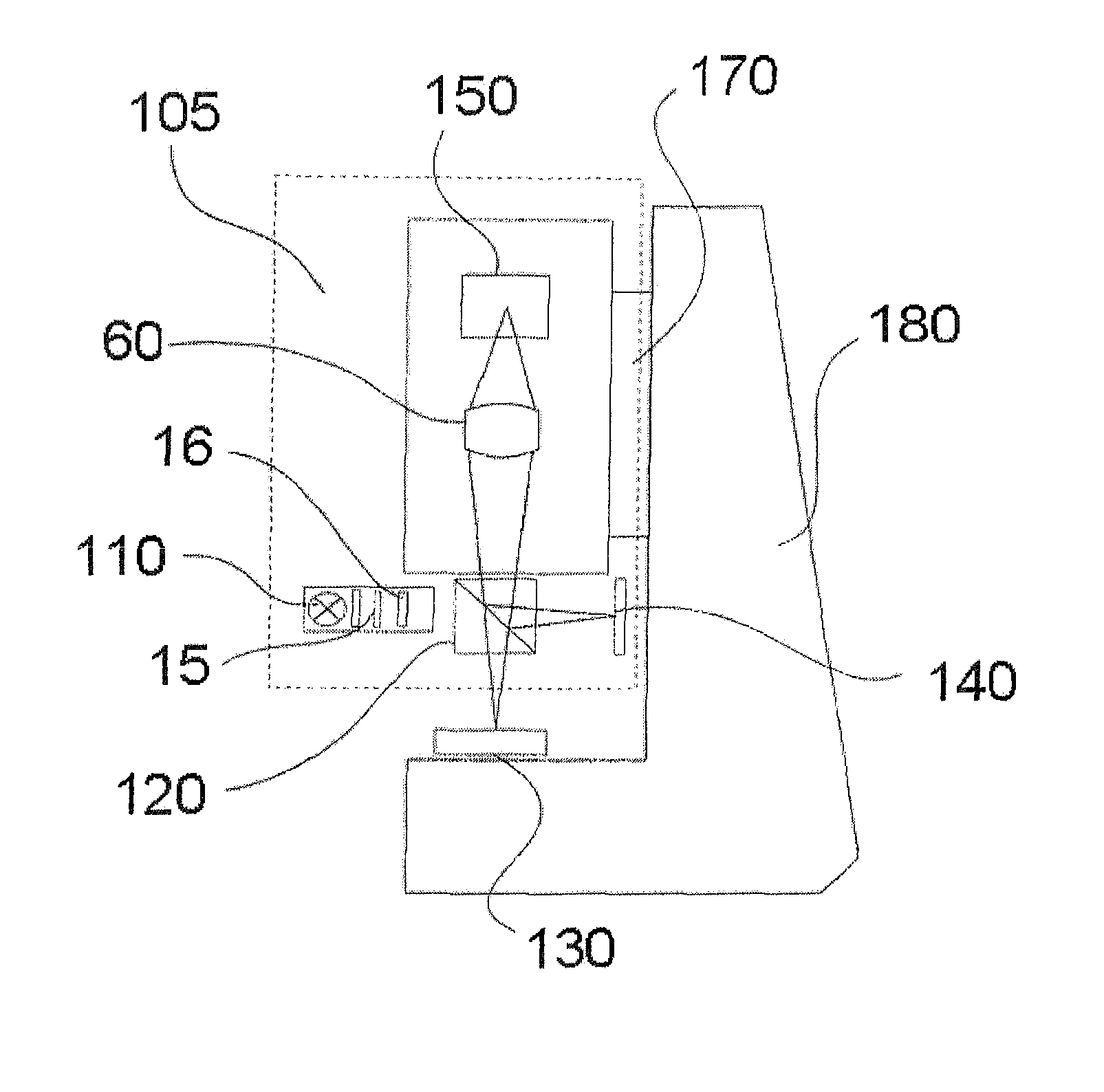

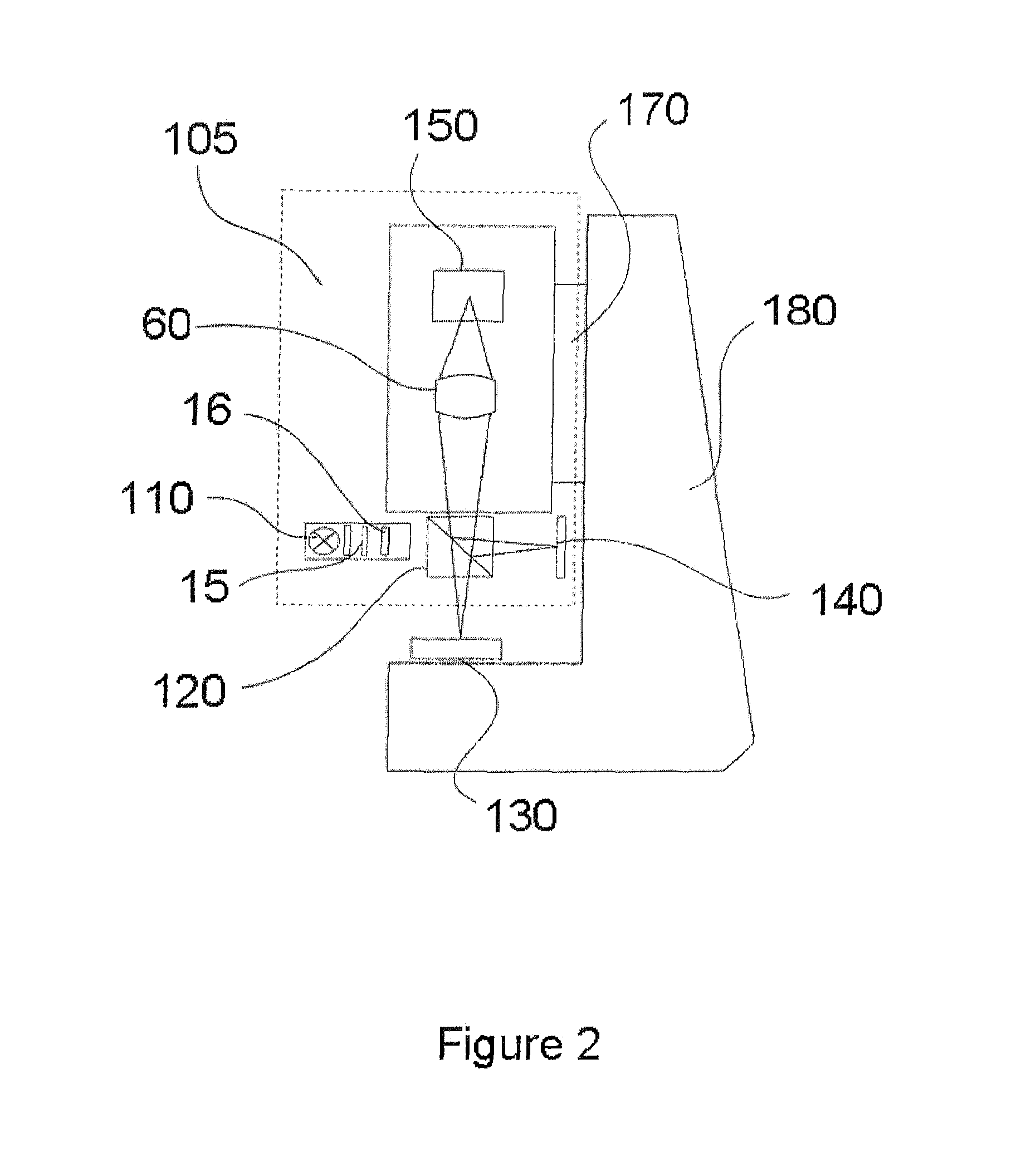

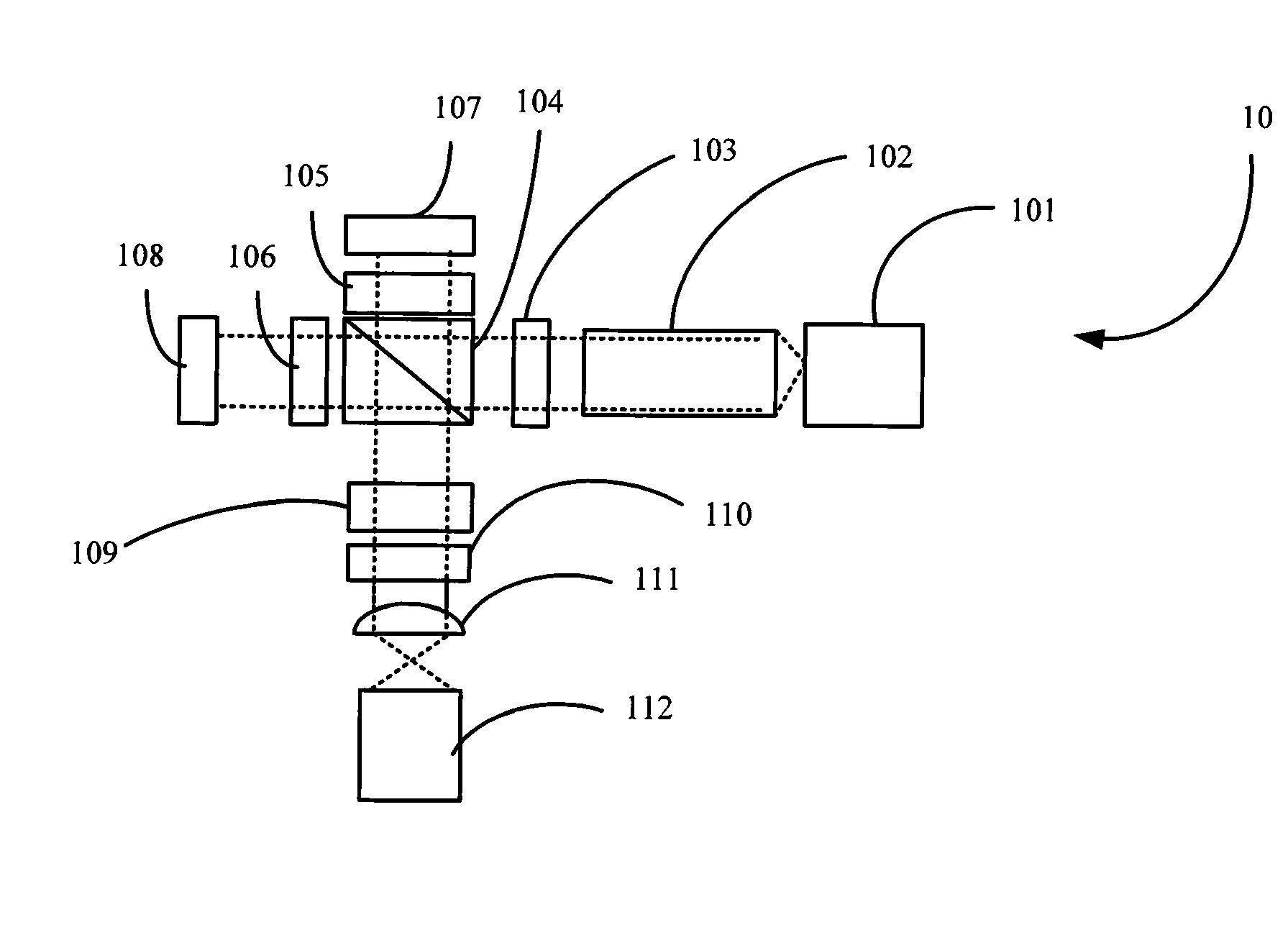

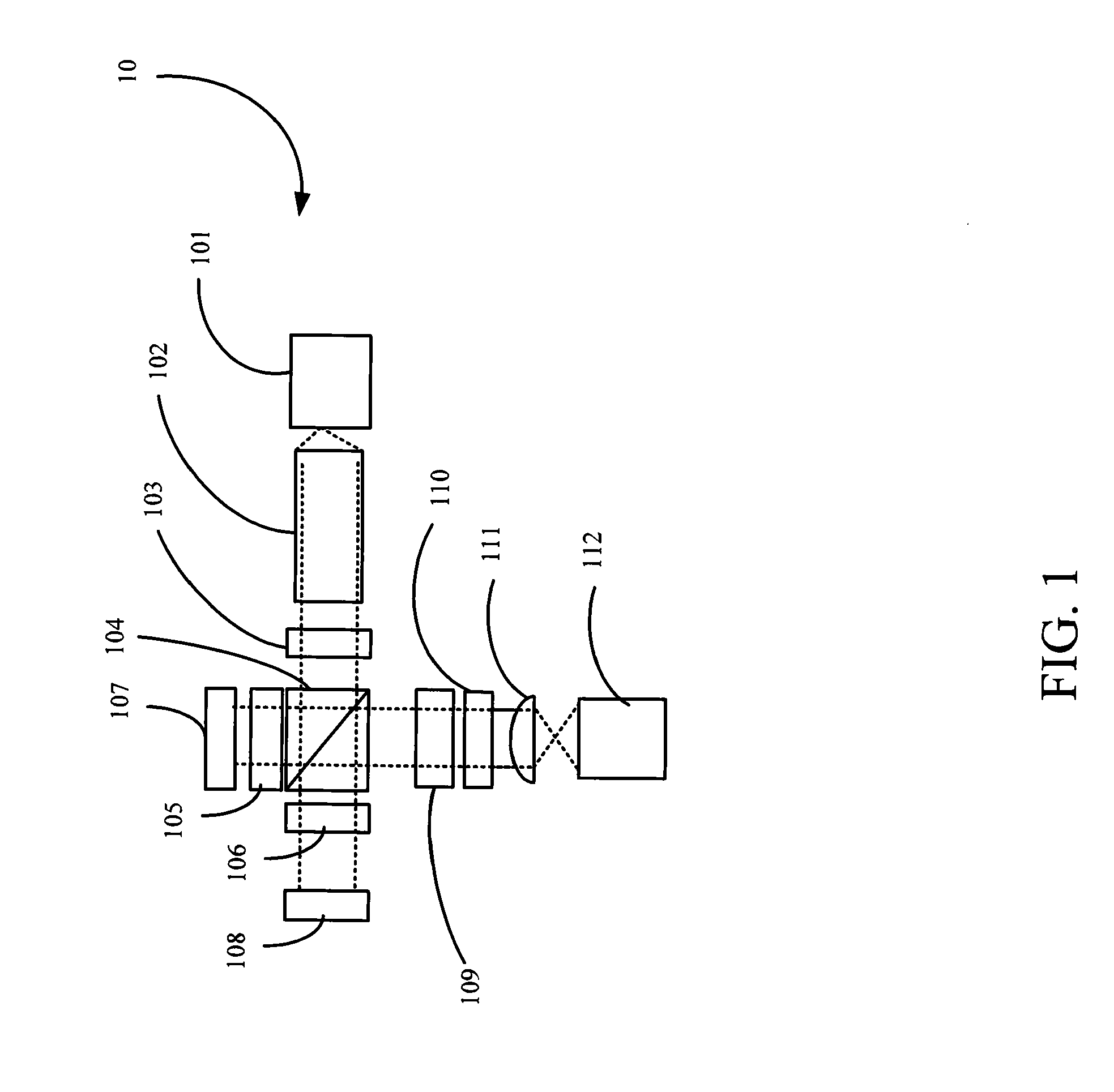

Method and apparatus using microscopic and interferometric based detection

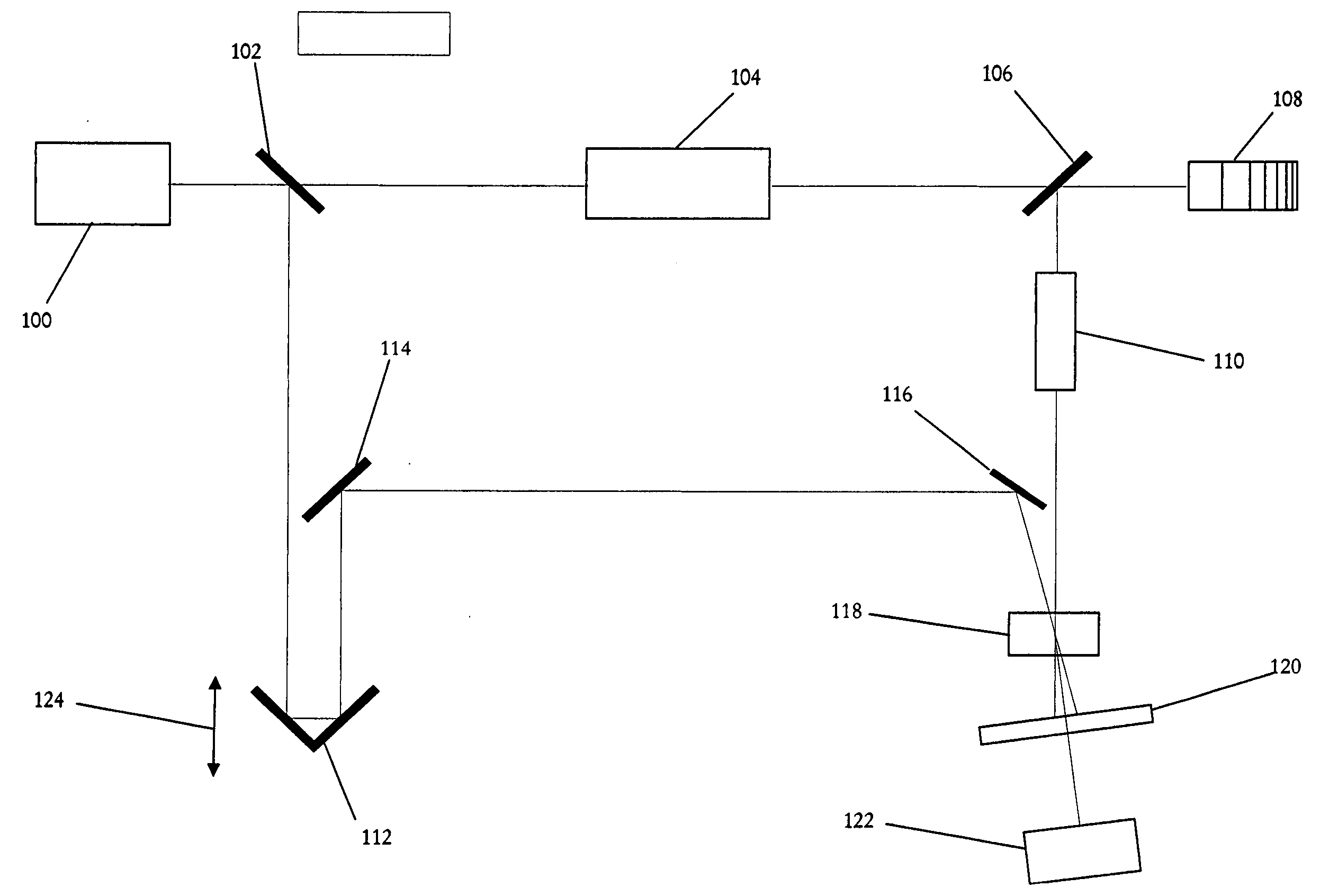

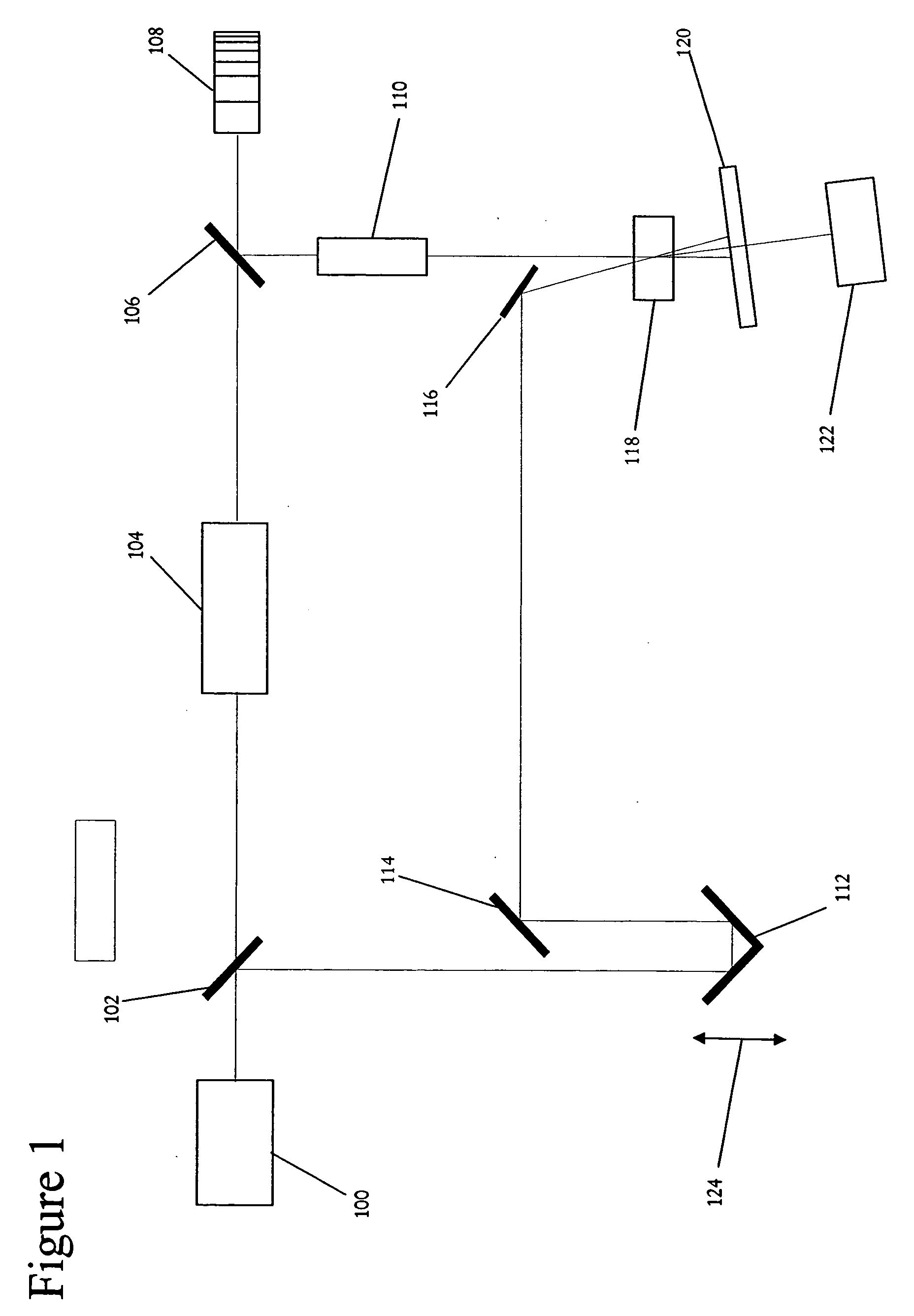

ActiveUS7095507B1Less sensitive to process noiseMaterial analysis by optical meansUsing optical meansMicroscopic examTest beam

An integrated interferometric and intensity based microscopic inspection system inspects semiconductor samples. A switchable illumination module provides illumination switchable between interferometric inspection and intensity based microscopic inspection modes. Complex field information is generated from interference image signals received at a sensor. Intensity based signals are used to perform the microscopic inspection. The system includes at least one illumination source for generating an illumination beam and an integrated interferometric microscope module for splitting the illumination beam into a test beam directed to the semiconductor sample and a reference beam directed to a tilted reference mirror. The beams are combined to generate an interference image at an image sensor. The tilted reference mirror is tilted with respect to the reference beam that is incident on the mirror to thereby generate fringes in the interference image. The system also includes an image sensor for acquiring the interference image from the inteferometric microscope module and intensity signals from the microscopic inspection image.

Owner:KLA TENCOR TECH CORP

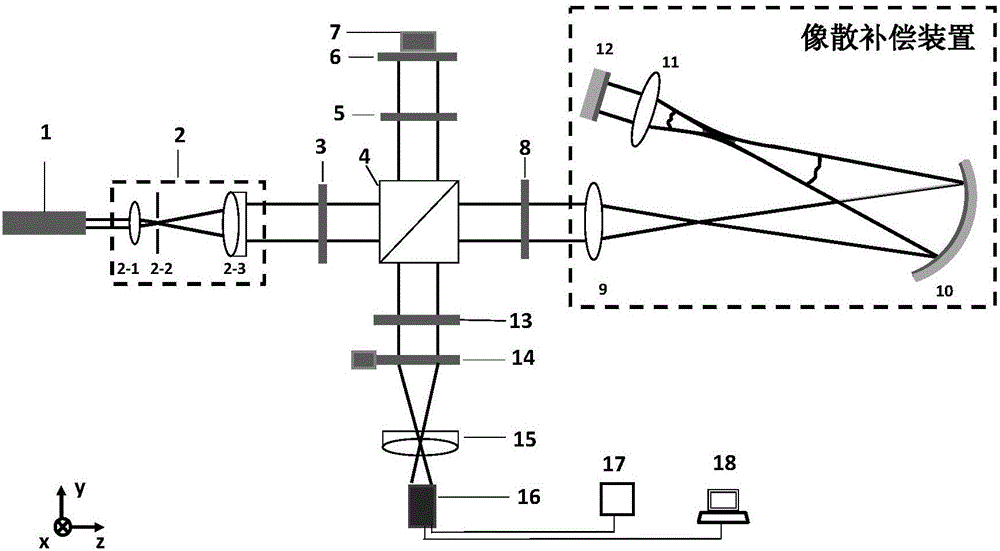

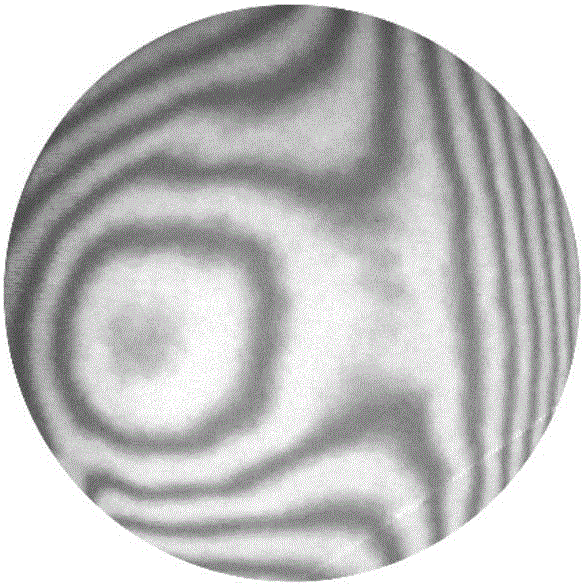

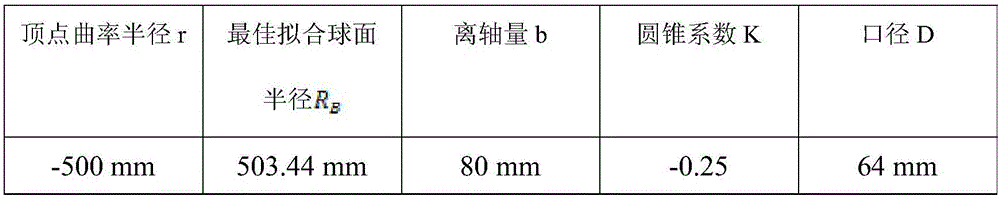

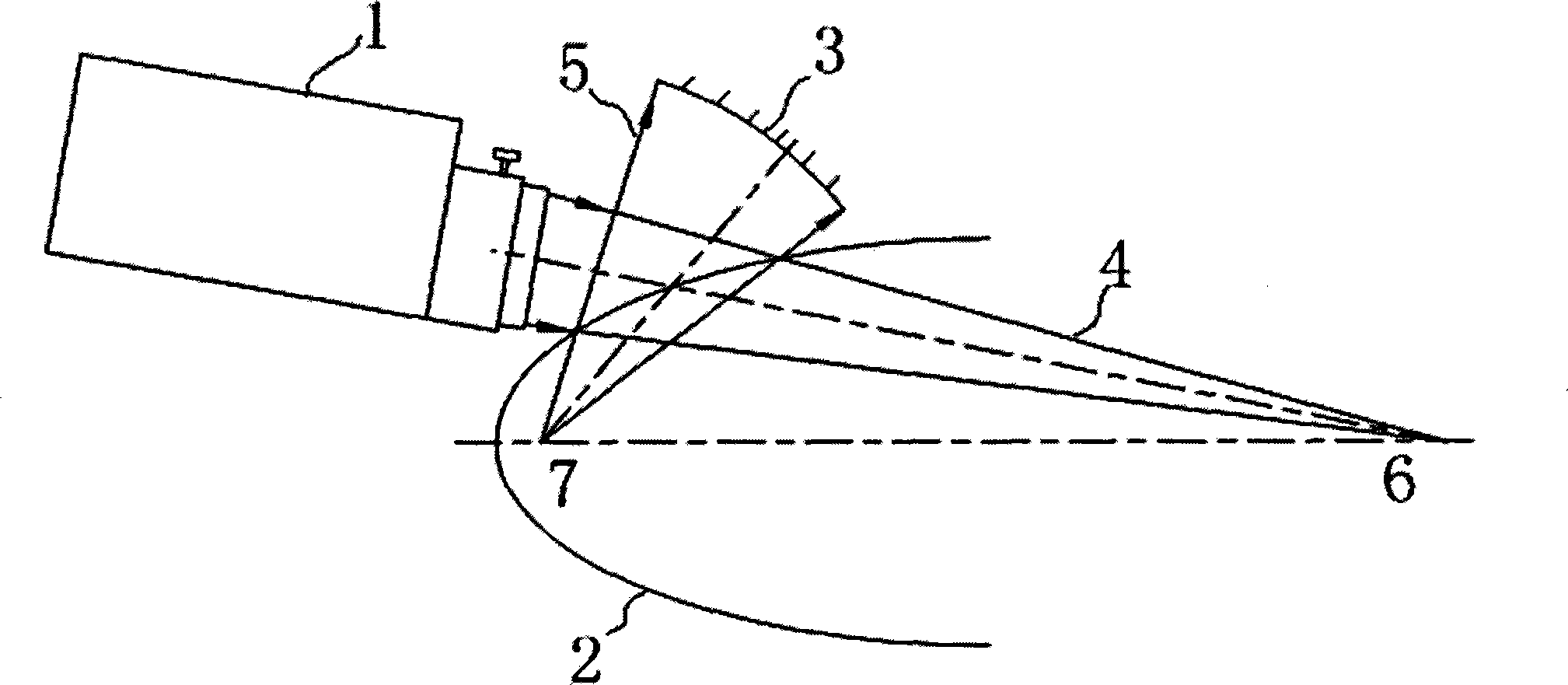

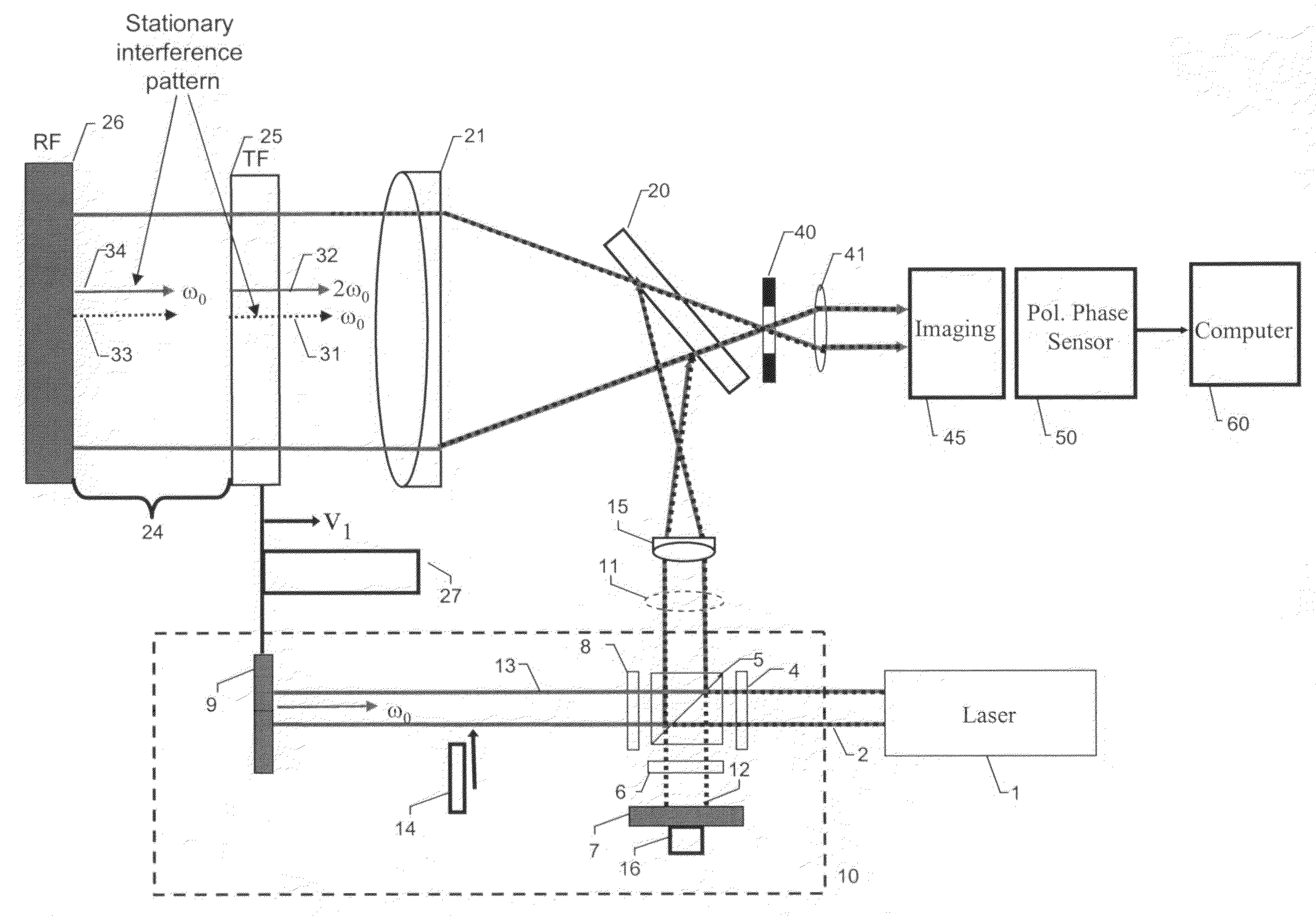

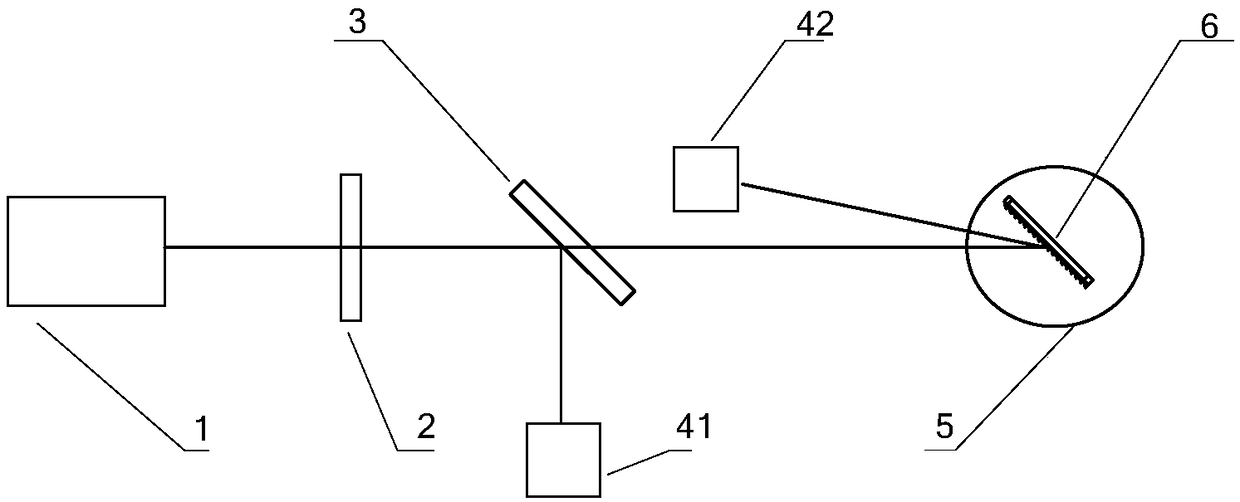

Astigmatic compensation type interference detecting device and method for optic free curved surfaces

The invention discloses an astigmatic compensation type interference detecting device and method for optic free curved surfaces. The device comprises He-He lasers, a beam expander, a 1 / 2 wave plate, a polarized beam splitter, a first 1 / 4 wave plate, a second 1 / 4 wave plate, a standard plane reflector, a phase shifter, a first convergent lens, a to-be-tested free curved surface, a second convergent lens, a plane reflector, a polarizer, a rotating frosted glass screen, an imaging objective lens, a detector, a displayer and a computer. The method comprises the steps of placing the to-be-tested free curved surface in an inclined state to make test beams come in a specific angle in an inclined mode to compensate for main surface shape astigmatic error components of the to-be-tested free curved surface, therefore reducing the degree of divergence of the subsequent test beams, and making the stripes discernable on the detector. The detector collects a series of phase-shifting interferograms which are treated with a wave front reconstruction algorithm to obtain a surface shape of the to-be-tested free curved surface. According to the astigmatic compensation type interference detecting device and method for optic free curved surfaces, the astigmatic compensation method is used for testing optic free curved surfaces for which the main surface shape error components are astigmatism, the stability is high, and the cost is low.

Owner:NANJING UNIV OF SCI & TECH

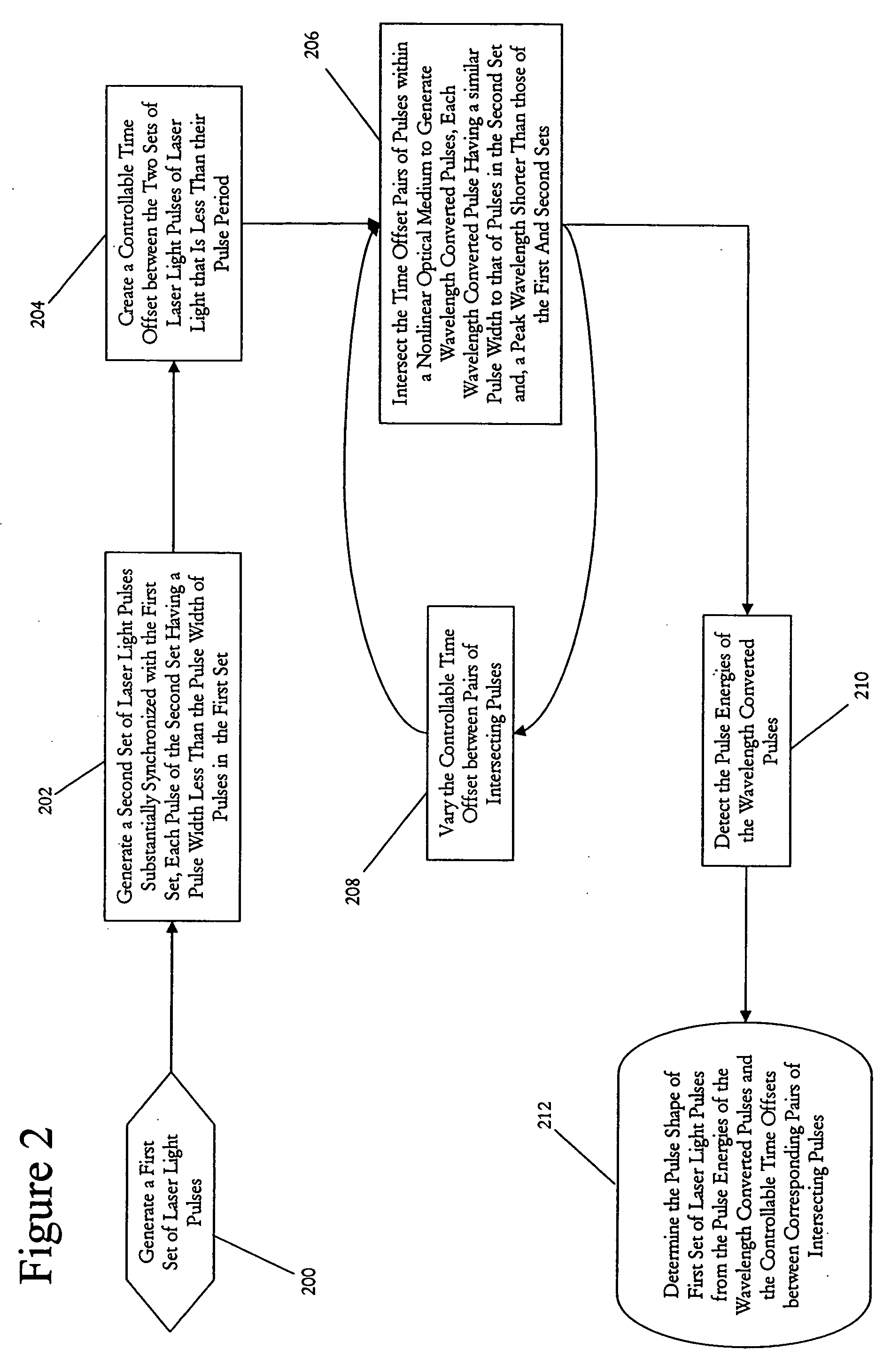

Ultrafast laser pulse shape measurement method and system

A laser pulse shape measuring system to measure the pulse shape of pulses generated by a pulsed laser. Each pulse includes a pulse width and a peak wavelength. The system includes: a beam splitter coupled to the laser to separate each of the pulses into a test pulse and a probe pulse; a pulse width compression means coupled to the beam splitter to compress the pulse width of each probe pulse; a controllable delay means to control a time offset between each test pulse and a corresponding probe pulse; a nonlinear optical medium arranged such that the test beam path and the probe beam path intersect within it to generate wavelength converted pulses corresponding to intersecting pairs of pulses; a detector coupled to the nonlinear optical medium to detect the pulse energies of the wavelength converted pulses; and a processor to determine the pulse shape of the laser pulses.

Owner:PANASONIC CORP

Linear-carrier phase-mask interferometer

Owner:ONTO INNOVATION INC

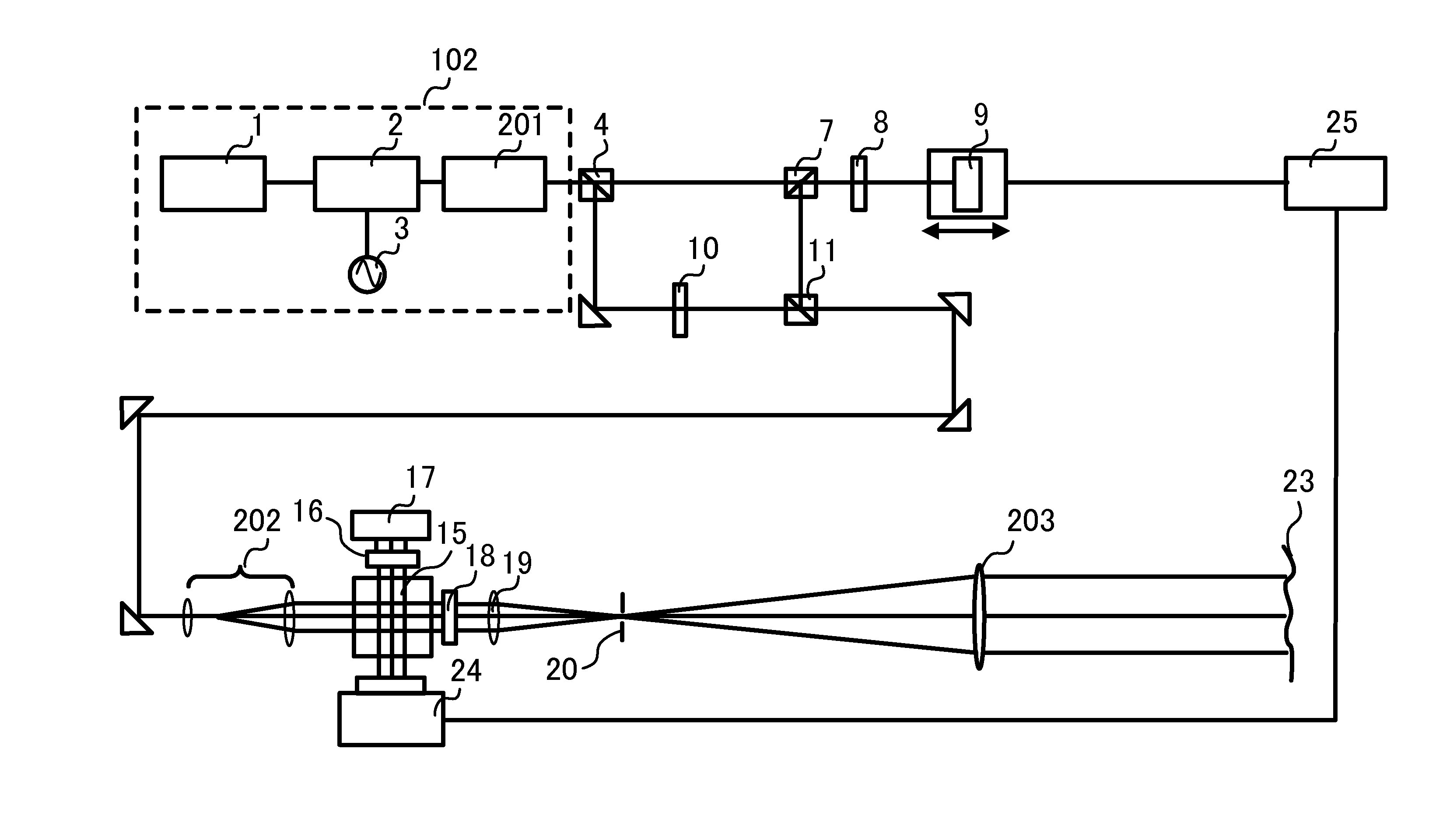

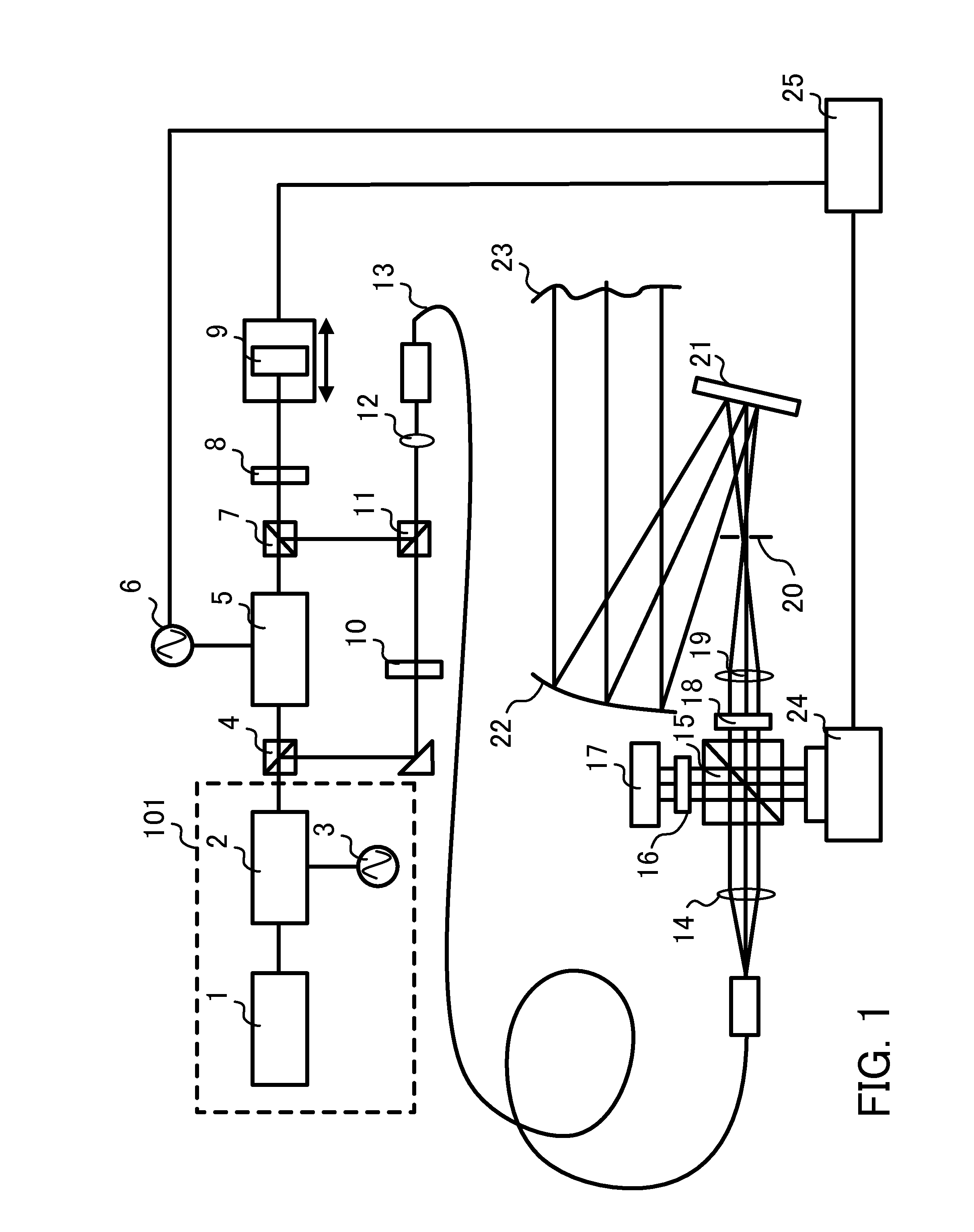

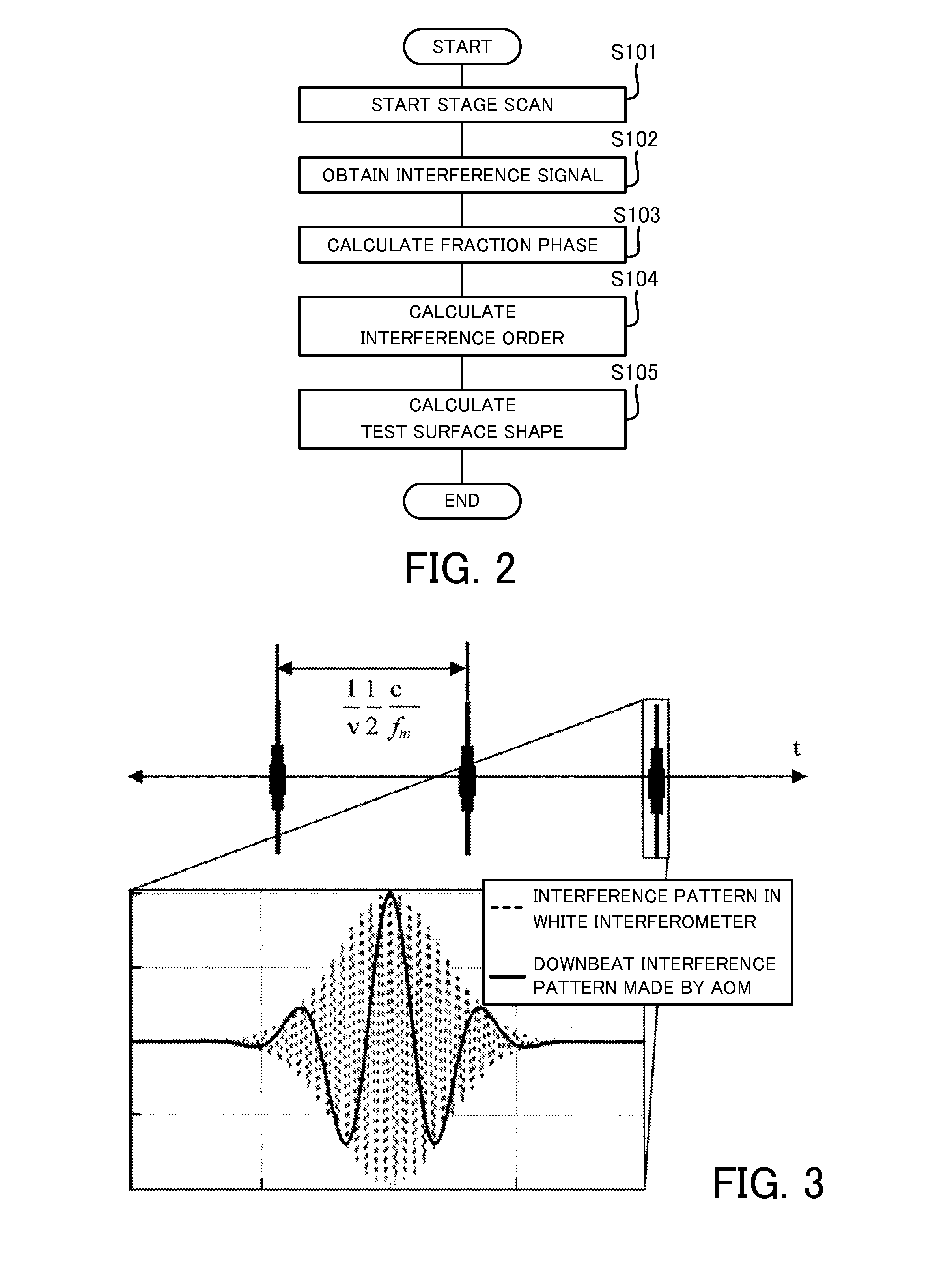

Measuring apparatus

ActiveUS20130063728A1Quickly and precisely measureInterferometersUsing optical meansBeam splitterMeasuring instrument

A measuring apparatus includes an optical frequency comb source configured to emit an optical frequency comb in which a plurality of frequency components are arranged at equal frequency intervals, a beam splitter configured to split a beam emitted from the optical frequency comb source into a test beam to be irradiated onto a test surface and a reference beam to be irradiated onto a reference surface, an optical path difference changing element configured to change an optical path difference between the reference beam and the test beam, an image sensor configured to capture an interference pattern formed by interference between the test beam and the reference beam, and an analyzer configured to calculate a position of the test surface based upon a signal of the interference pattern captured while the optical path length difference is being changed by the optical path difference changing element.

Owner:CANON KK

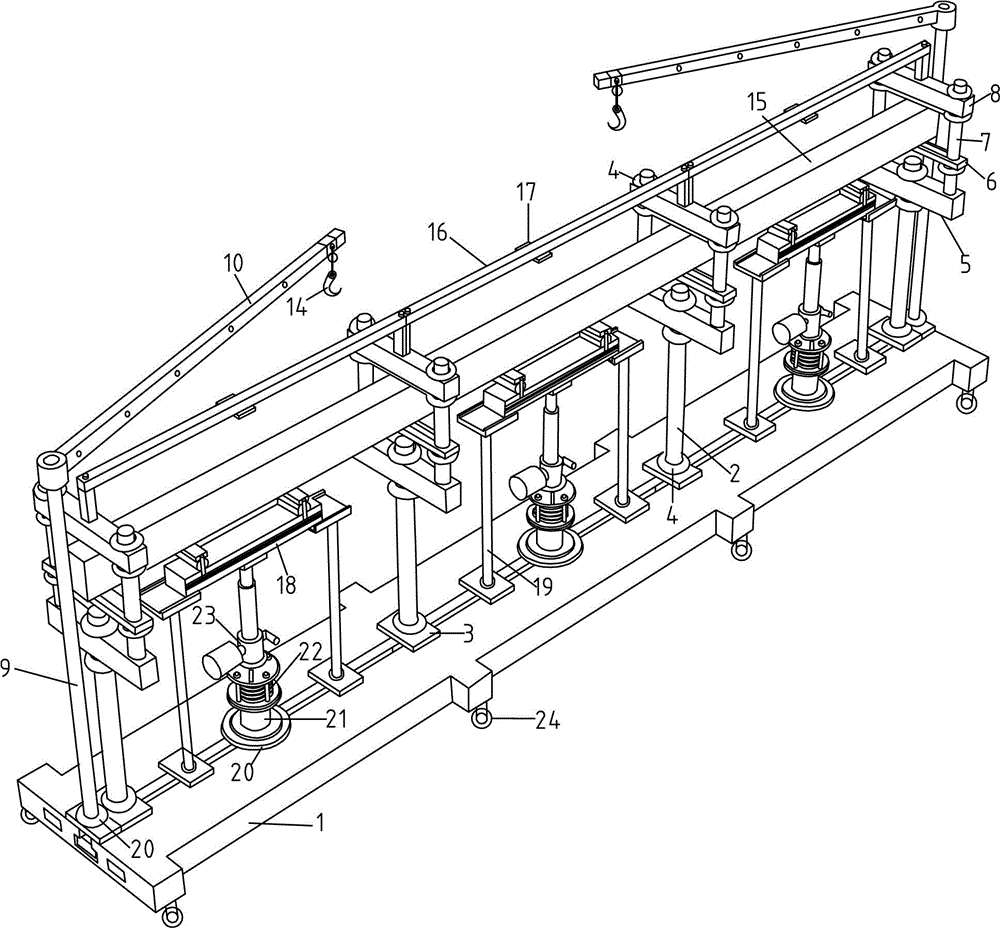

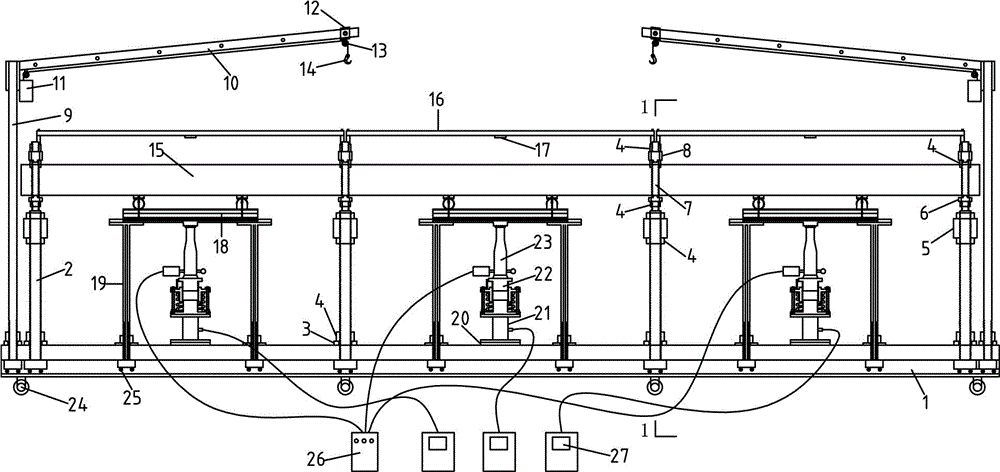

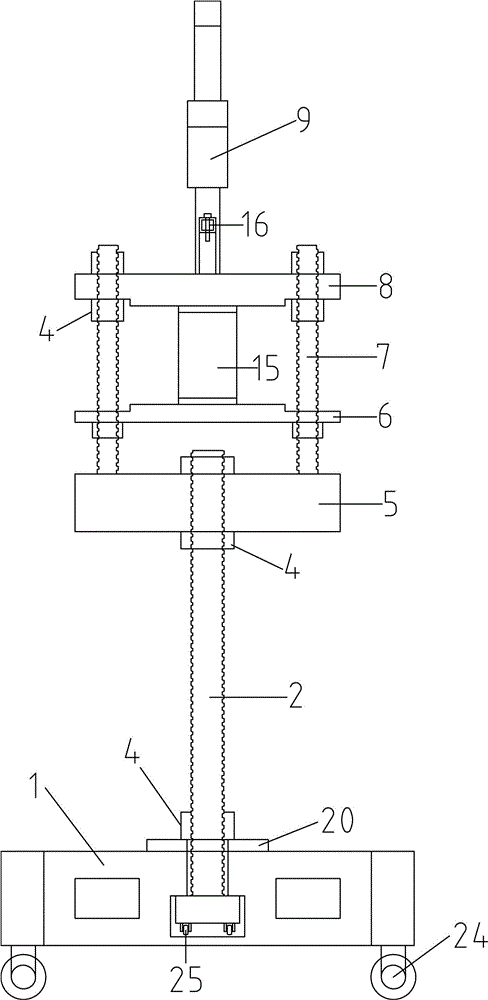

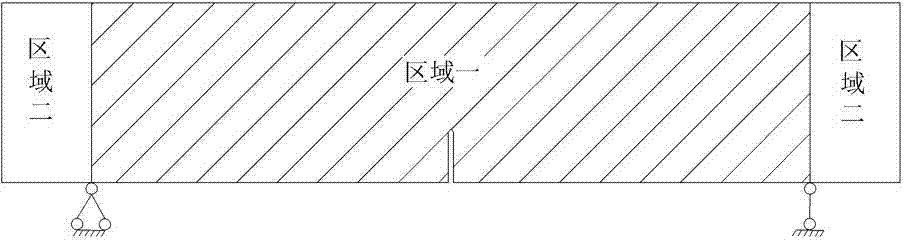

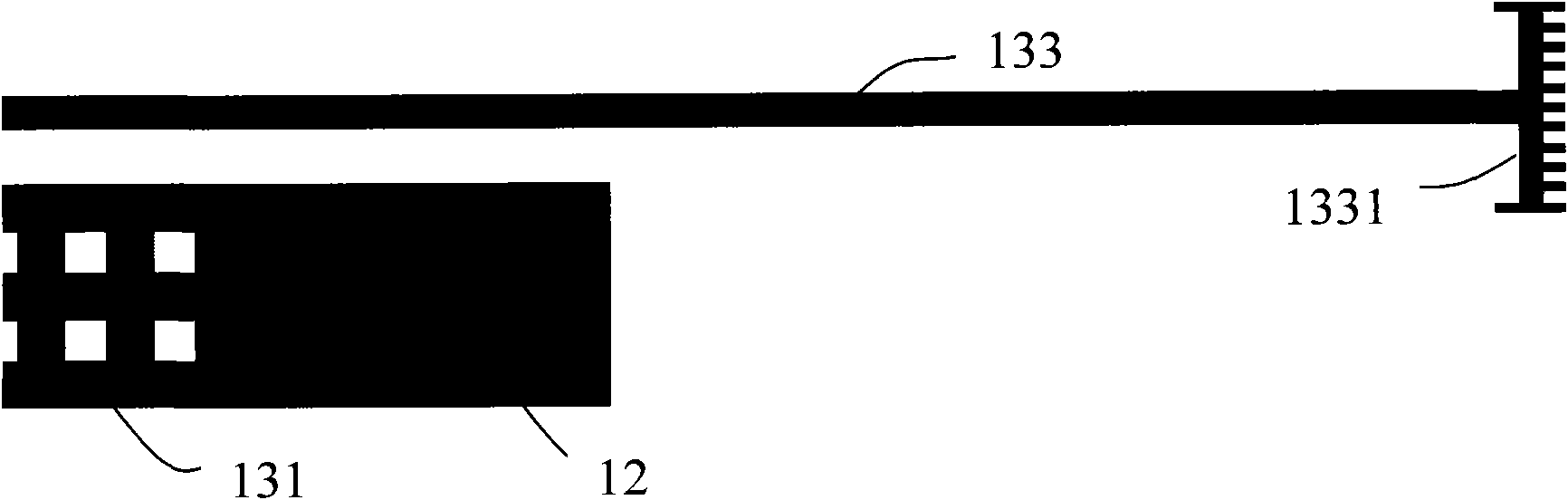

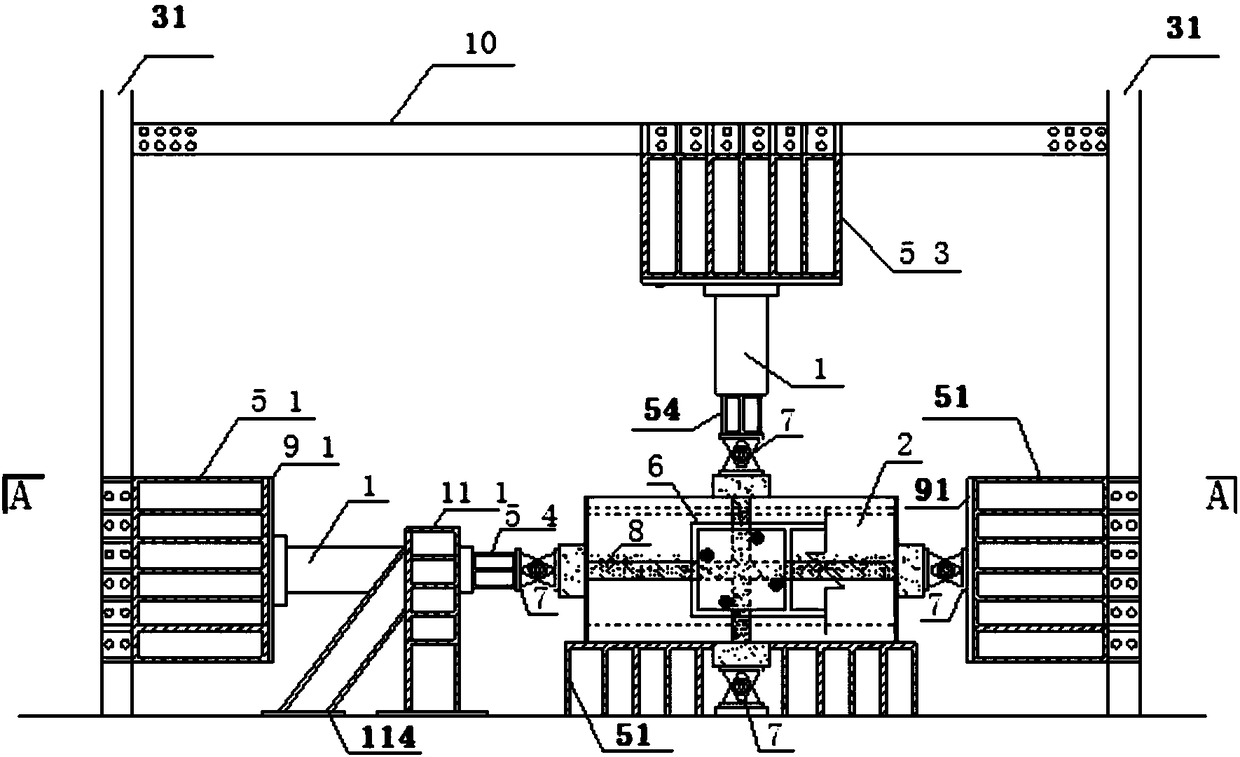

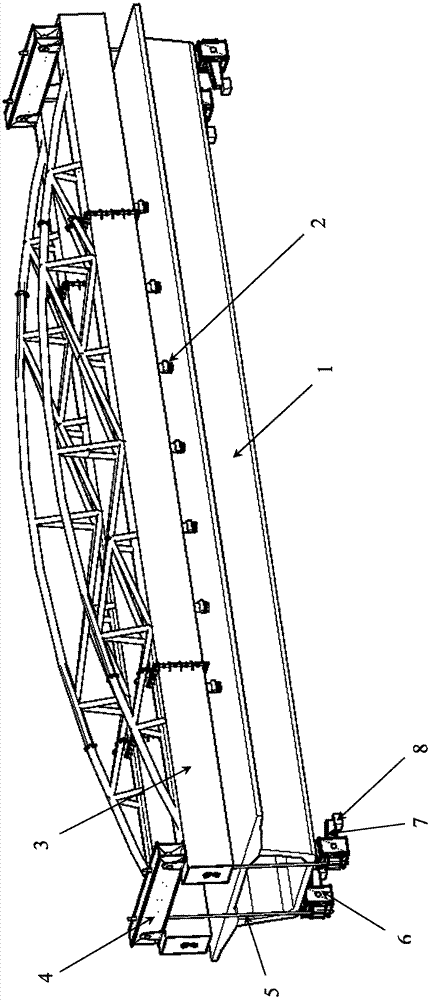

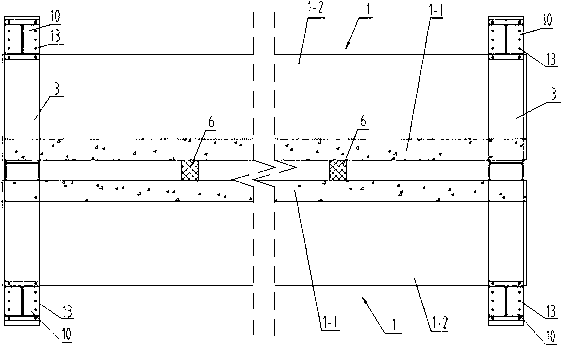

Counterforce loading frame for multifunctional self-balancing type continuous beam test

ActiveCN105158064AEasy to replaceAccurate and fast positioningStrength propertiesTest beamContinuous beam

The invention relates to a counterforce loading frame for a multifunctional self-balancing type continuous beam test. A longitudinal sliding groove is machined in the middle of the upper surface of a counterforce frame bottom plate. Electric hoisting devices, counterforce loading frame stand columns and distribution beam supports are arranged on the slide groove. Full threads are machined in the counterforce loading frame stand columns. Orientation wheels are arranged at the bottoms of the counterforce loading frame stand columns. Lower beams are arranged on the tops of the counterforce loading frame stand columns through screw thread fit. Middle beams and upper beams are fixedly arranged on beam stand columns through nuts. Test beams are arranged between the middle beams and the upper beams. Displacement monitoring device supports are arranged on the tops of the upper beams. Distribution beams are placed on the distribution beam supports. The two sides of the distribution beams are provided with rulers and slide grooves, wherein hooks are arranged on the slide grooves. Roller supports are located on the distribution beams. Jacks are arranged on the lower portions of the distribution beams. The counterforce loading frame is suitable for tests of continuous beams, simply supported beams and columnar components, and the span can be changed so that the counterforce loading frame can be used for components of different sizes.

Owner:CHINA THREE GORGES UNIV

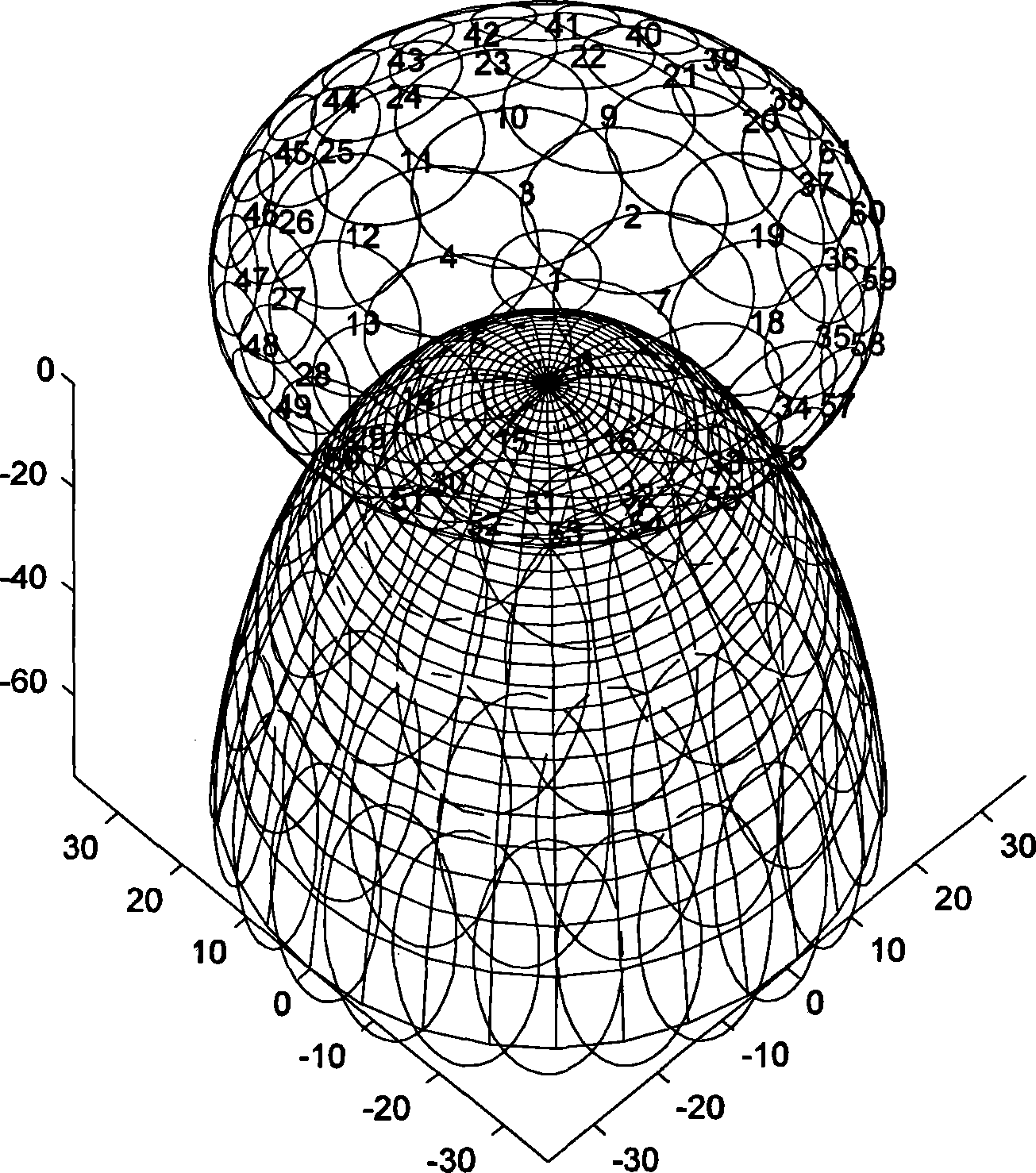

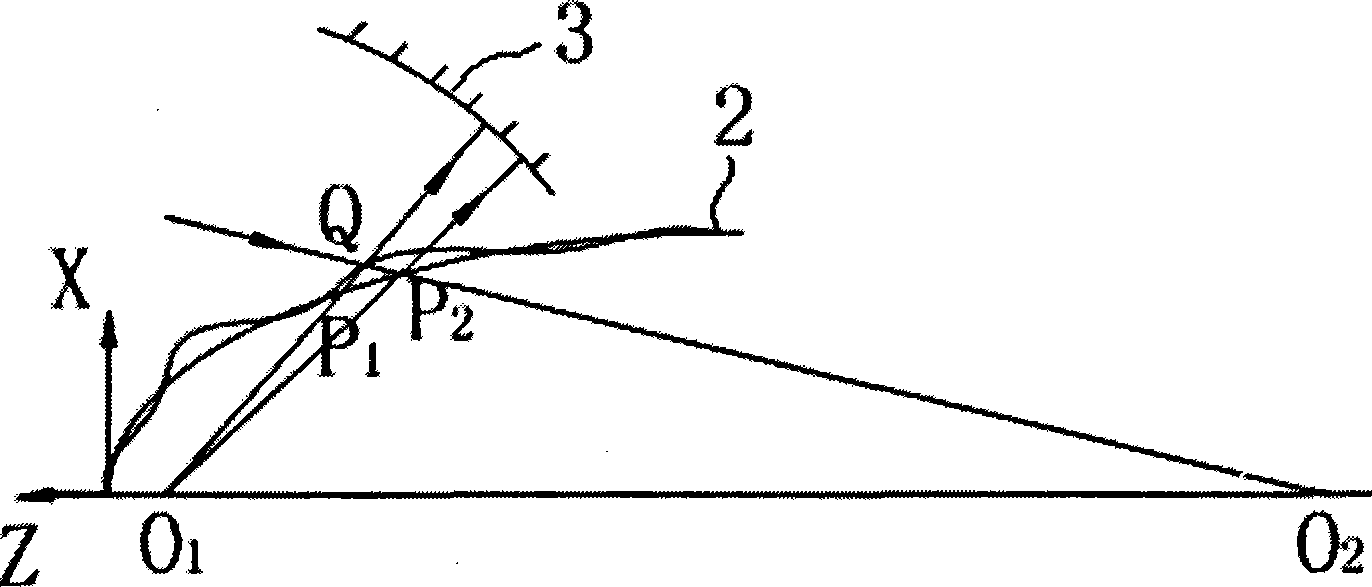

High steepness convex quadric aspherical aberration-free point Sub-Aperture Stitching measurement method

InactiveCN101241000AAvoiding Grazing Incidence ProblemsIncrease horizontal resolutionUsing optical meansTesting optical propertiesThermodynamicsTest beam

The invention discloses a measuring method of non-aberration-point sub-aperture stitching for a high and steep convex second non-spherical surface, which divides the measured second non-spherical surface into a plurality of sub-apertures so that the test beam emitted by a surface wave interferometer roughly irradiates a divided first sub-aperture region thereof, measures the surface error of the sub-aperture with the surface wave interferometer under the test condition of non-aberration-point and saves the data, measures the second sub-aperture region and all the remaining sub-apertures in the same way and inputs all the measured data of the sub-apertures to process, and reconstructs the all-caliber face through non-aberration-point stitching algorithm so as to obtain the surface error of the measured second non-spherical surface. The invention needs no non-spherical surface compensator, and is a measuring method for high and steep convex second non-spherical surface with low cost and high precision.

Owner:NAT UNIV OF DEFENSE TECH

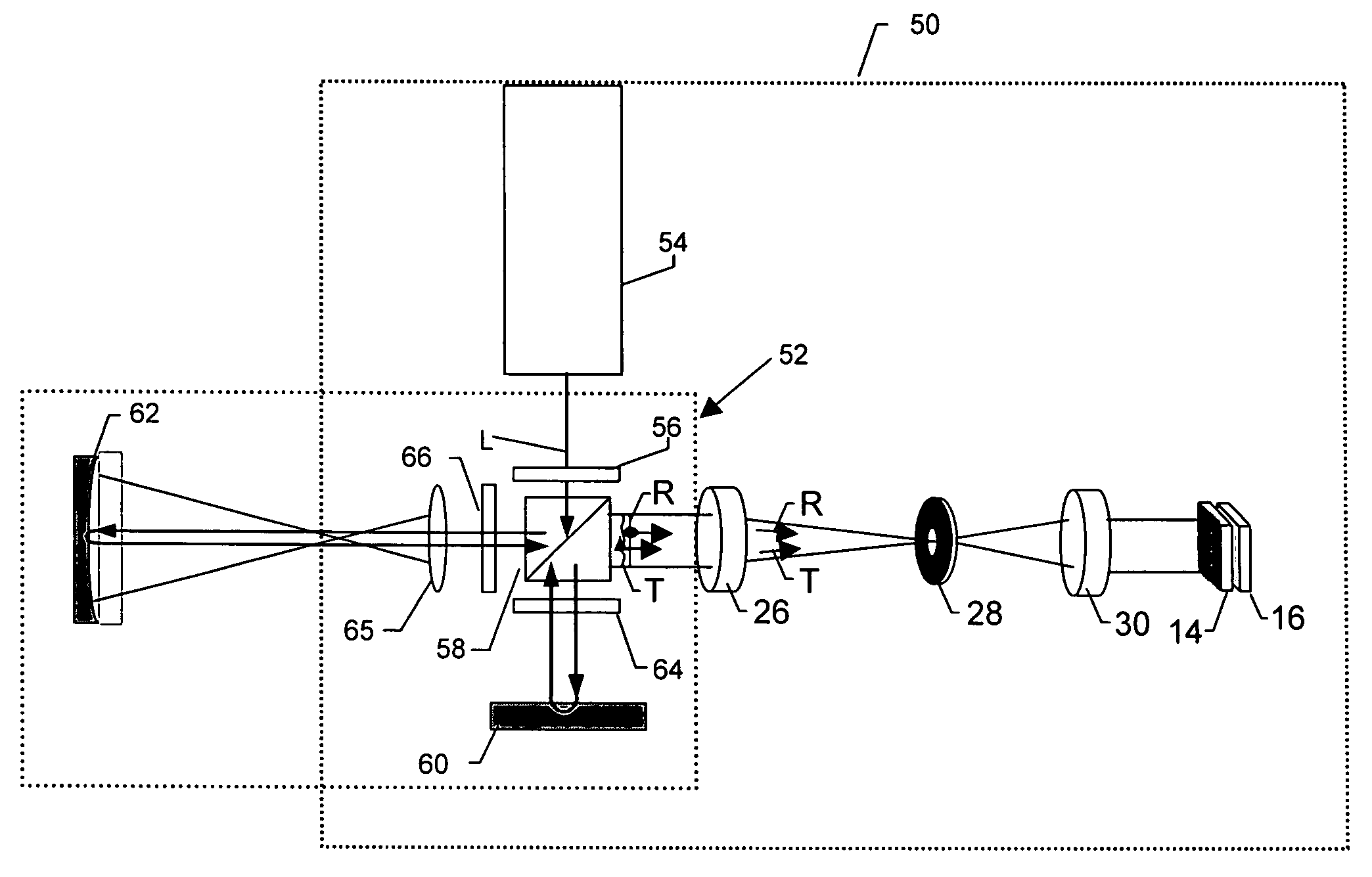

White light scanning interferometer with simultaneous phase-shifting module

InactiveUS8269980B1Fast measurement speedData collection time is shortInterferometersUsing optical meansPhase shift moduleBeam splitter

A simultaneous phase-shifting white light scanning interferometer comprises a white light scanning interferometer, a simultaneous phase-shifting module, and a scanner. Light from a short coherence length light source may be polarized and then split, by a polarization type beam-splitter, into orthogonally polarized reference and test beams. The simultaneous phase-shifting module comprises a plurality of detectors, allows for controlled phase shifts between the reference and test beams, and creates at least three independent interferograms, each with different phase shifts between the reference and test beams. The scanner translates the simultaneous phase-shifting module with respect to an object under measurement.

Owner:ENG SYNTHESIS DESIGN

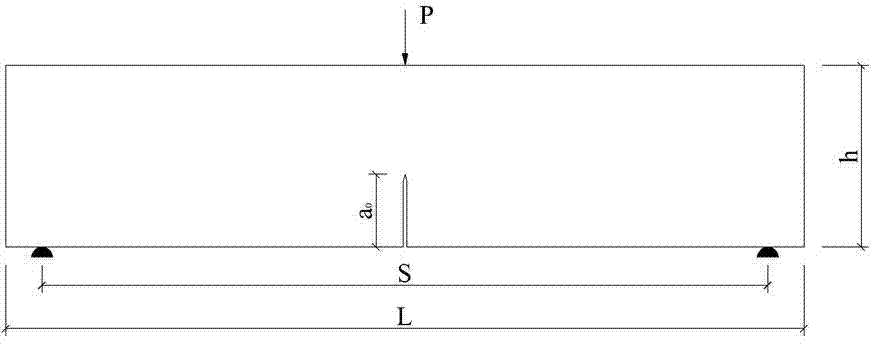

Self-weight influence-free concrete material fracture toughness testing method

ActiveCN103698224AIncreased testable sizeMake up for the inaccurate determination of crack initiation and instability toughness valueMaterial strength using steady bending forcesTest beamEngineering

The present invention relates to a self-weight influence-free concrete material fracture toughness testing method, and belongs to the technical field of physical measurements. The determination method comprises: 1) erecting a test beam on two rolling bearings of the current three-point bending beam test device, and arranging a load measurement device and a strain measurement device on the test beam; 2) measuring the applied maximum load Fmax through the load measurement device, and measuring an initiation fracture load FQ through the strain measurement device; and 3) calculating an unstable toughness and an initiation fracture toughness. With the self-weight influence-free concrete material fracture toughness testing method, influence of the member self-weight on the testing result is eliminated so as to accurately determine the concrete initiation fracture and unstable toughness and meet the initiation fracture and unstable toughness determination requirements of the concrete material (including hydraulic concrete) of the high crack-depth ratio or large size specimen.

Owner:NANJING HYDRAULIC RES INST

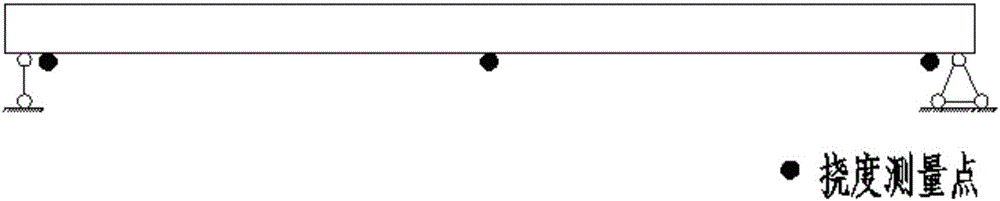

Method for load test of single beam

ActiveCN105865819AEasy to crackTo achieve the purpose of load testGeometric CADStructural/machines measurementResidual strainStructural deformation

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

Membrane stress testing structure and method as well as manufacturing method

ActiveCN101871825AAccurate measurementAccurately reflect the stress characteristicsTelevision system detailsSemi-permeable membranesTest beamEngineering

The invention discloses membrane stress testing structure and method as well as a manufacturing method. The membrane stress testing structure is configured on the surface of a substrate of a micro electro mechanical system and comprises a first fixed base, a second fixed base, a cantilever beam and a main scale, wherein the first fixed base and the second fixed base are both configured on the substrate and consist of a sacrifice layer formed on the substrate and a thin film to be tested, which is formed on the sacrifice layer; the cantilever beam is in a suspended structure formed by the thin film to be tested and comprises a test beam, a slope beam and an indication beam, wherein one end of the indication beam is in a comb structure and forms a vernier; and the main scale consists of the sacrifice layer formed on the substrate and the thin film to be tested, which is formed on the sacrifice layer, and the main scale is in a comb structure configured on the substrate and used for reading the displacement of the indication beam by matching with the vernier. The membrane stress testing structure and method as well as the manufacturing method can accurately measure the membrane stress without using the Poisson ratio of materials to be tested and can also accurately measure the local region stress.

Owner:北方广微科技有限公司

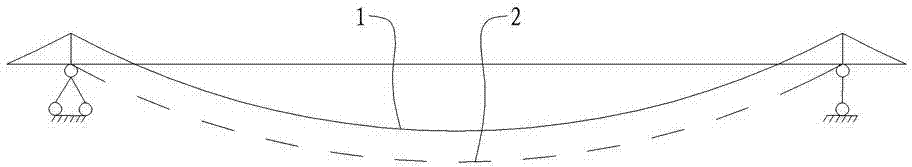

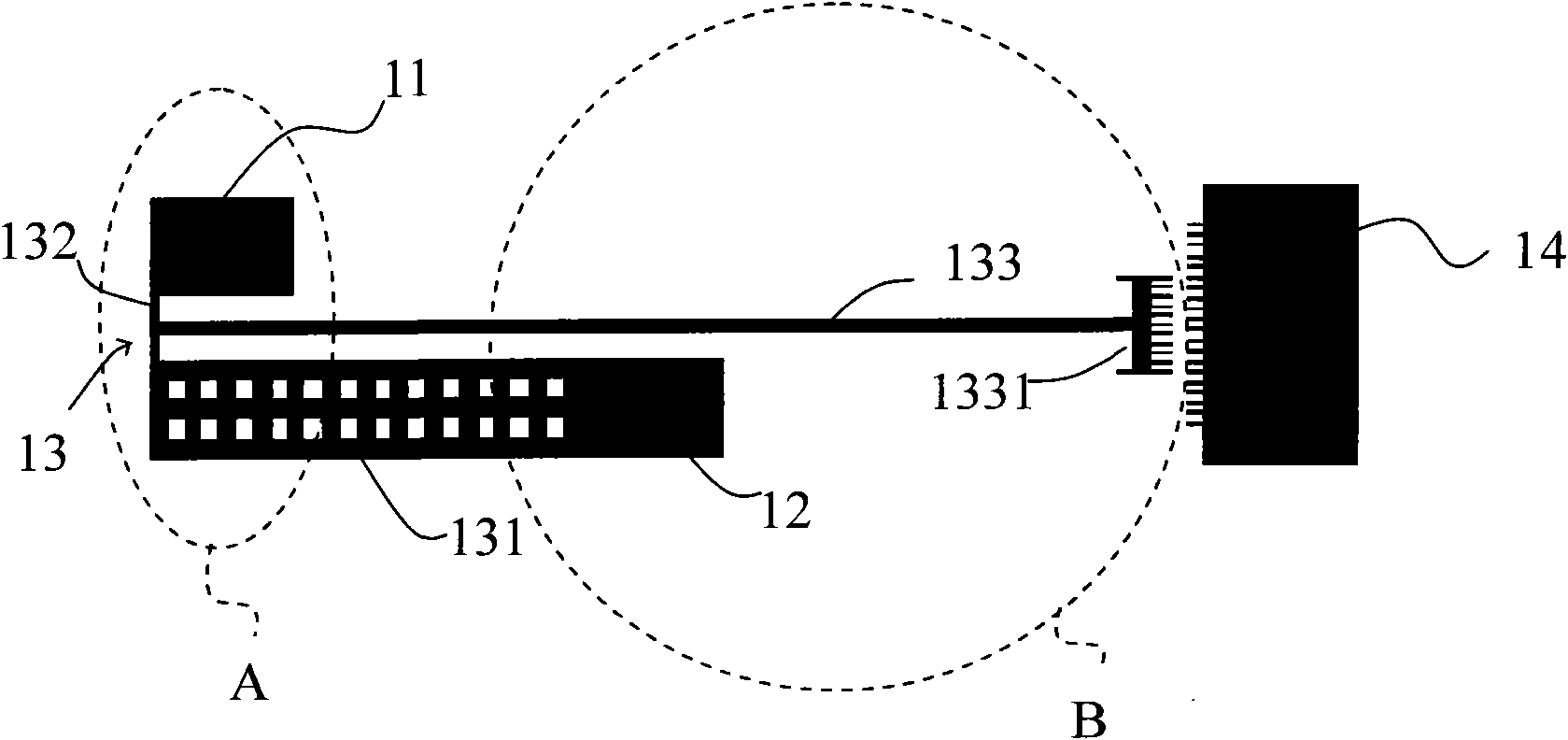

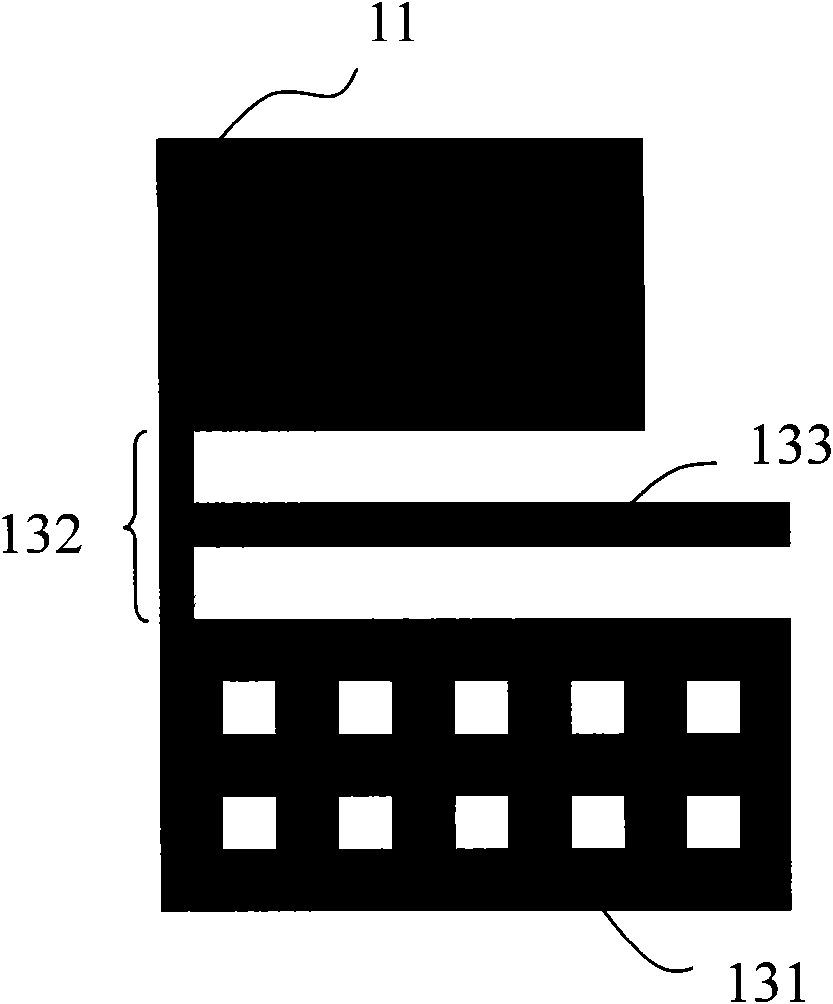

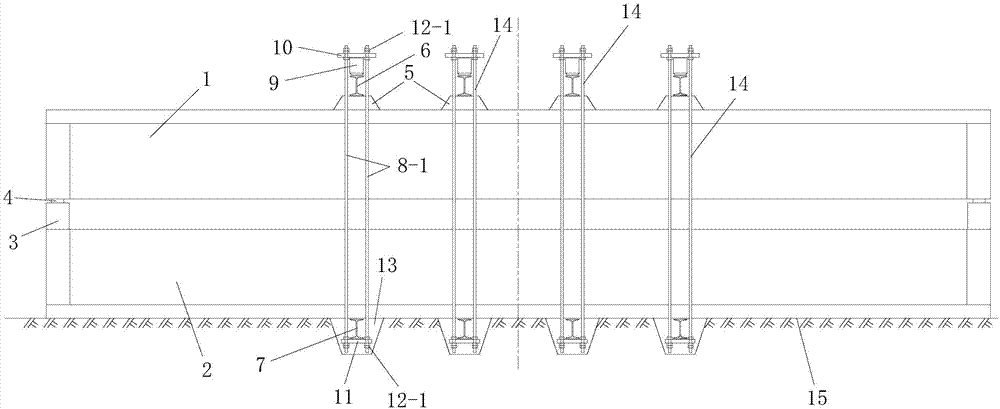

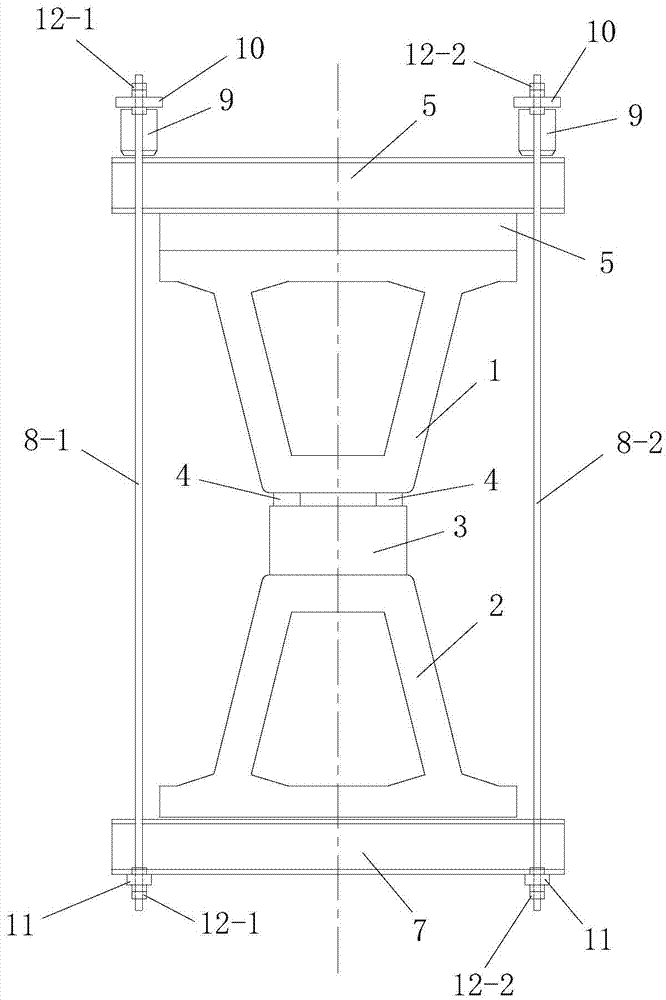

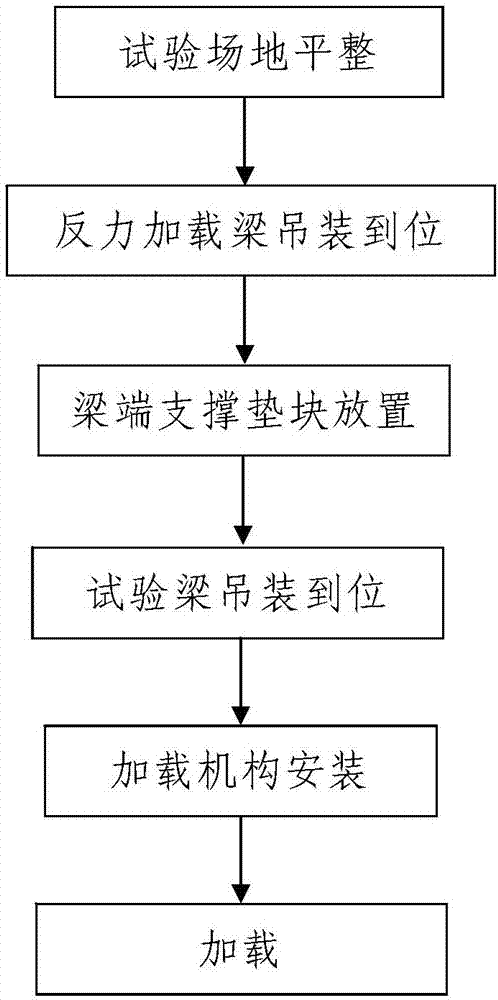

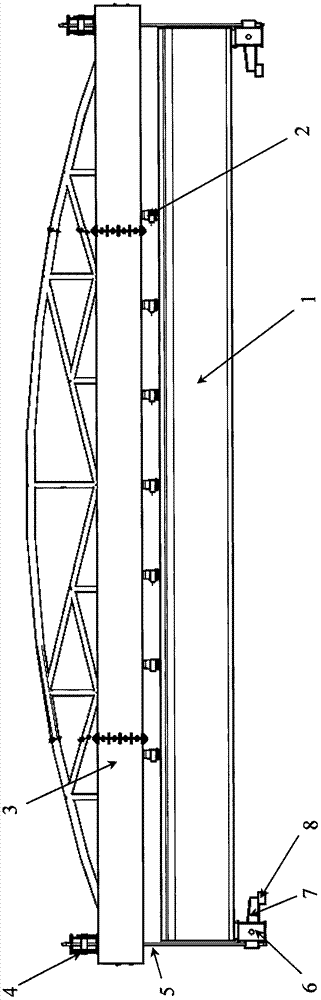

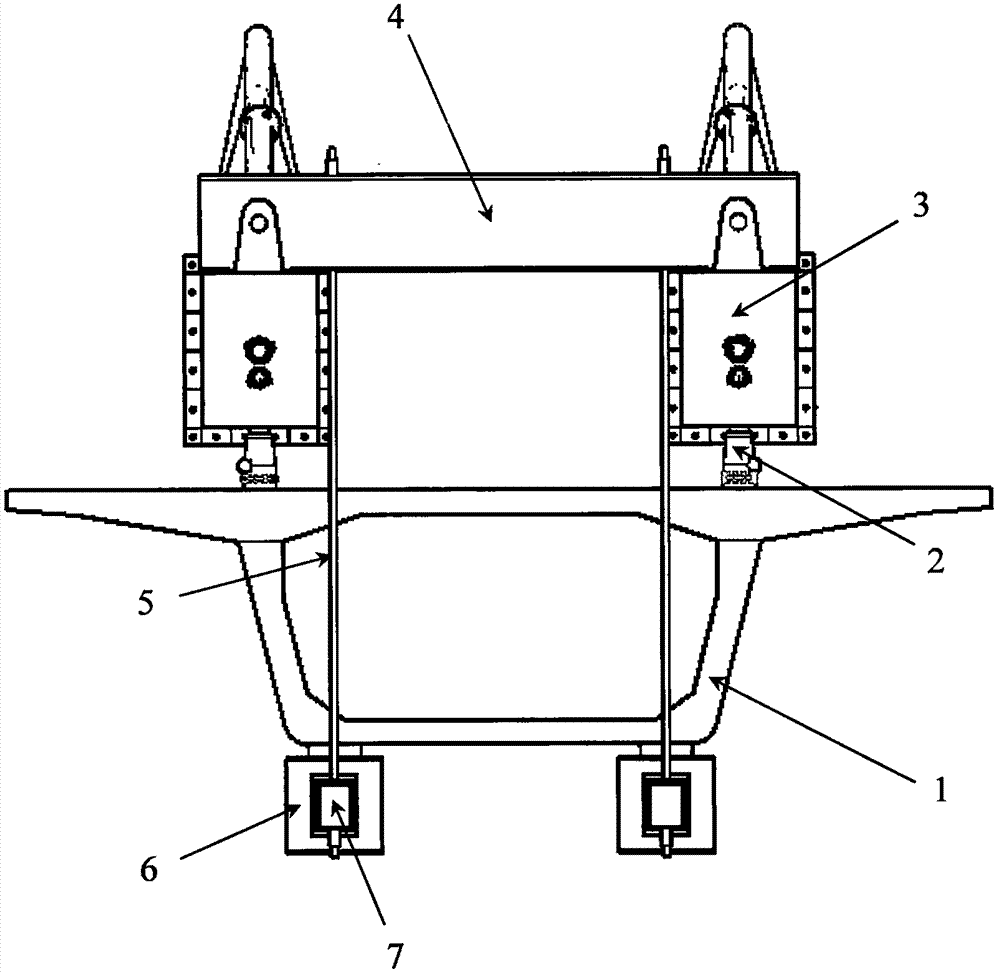

Counterforce beam loading device and loading method for static load test of bridge beam body

InactiveCN104280297ASimple structureReasonable designMaterial strength using tensile/compressive forcesTest beamEngineering physics

The invention discloses a counterforce beam loading device for a static load test of a bridge beam body. The counterforce beam loading device comprises a counterforce loading beam which is arranged right below a test beam and a loading mechanism which is installed on the test beam, wherein the counterforce loading beam and the test beam are symmetrically arranged in the vertical direction, and a beam-end supporting cushion block is arranged between the counterforce loading beam and the test beam in a lining manner; the loading mechanism comprises an upper crossbeam, a lower crossbeam, a pressurizing mechanism, an upper ejector plate and a lower liner plate, and the upper ejector plate and the lower liner plate are connected with each other through a drawing bar. The loading device adopts a beam body which is the same as the test beam as the counterforce loading beam and has advantages of simple structure, low cost, good loading effect, simplicity in loading position adjustment, safety in loading and the like. Meanwhile, the invention also discloses a counterforce beam loading method. The method comprises the following steps of I, leveling a test field; II, hoisting the counterforce loading beam in place; III, arranging the beam-end supporting cushion block; IV, hoisting the test beam in place; V, installing the loading mechanism; and VI, loading. The method is simple in step, convenient to realize, low in investment cost, short in loading time, good in loading effect and wide in application range.

Owner:TONGJI UNIV

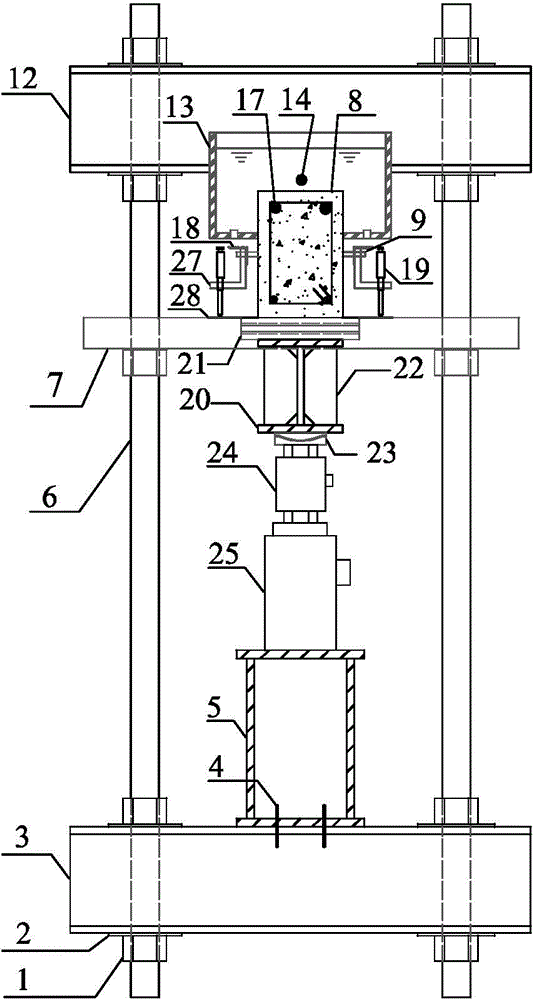

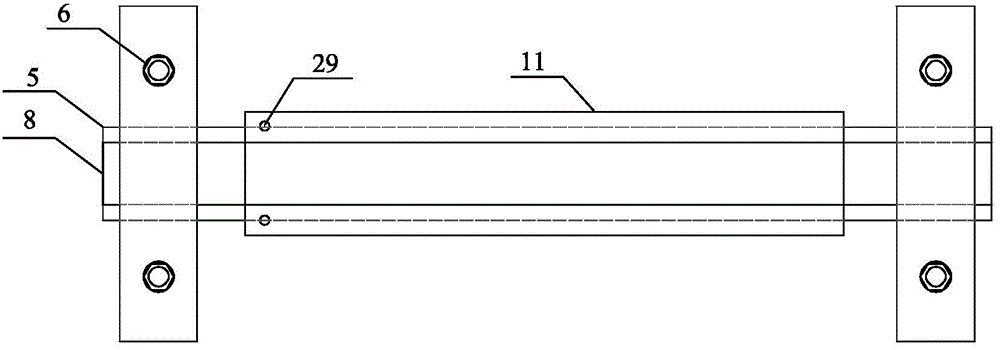

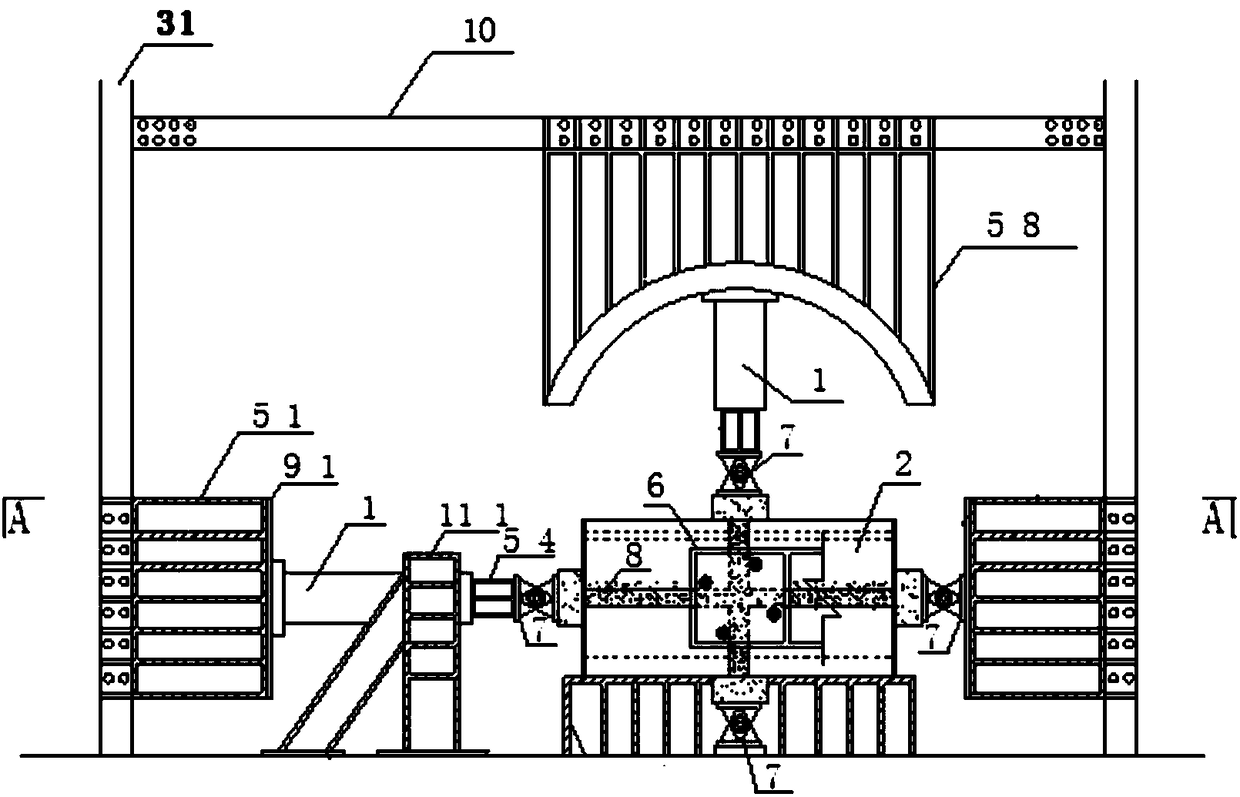

Multi-node fatigue failure test device for steel beam columns and concrete beam columns

ActiveCN108181191AMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesServo actuatorTest beam

The invention discloses a multi-node fatigue failure test device for steel beam columns and concrete beam columns. The device comprises a steel frame system, an electro-hydraulic servo actuator, a test beam column and a test furnace, wherein the test beam column is arranged in the test furnace; the steel frame system is arranged on the periphery of the test furnace; a horizontal fatigue load device, a vertical fatigue load device and a torsional fatigue load device are sequentially arranged between the steel frame system and the test beam column, the horizontal fatigue load device is arrangedin the horizontal direction of the test beam column, the vertical fatigue load device is arranged in the vertical direction of the test beam column, and the torsional fatigue load device is arranged above the test beam column. The eccentric tensile fatigue load to the steel beam columns and the concrete beam columns can be met, the eccentric size can be set according to experimental requirements,and all that is required is to change the relative position of a column head and the test beam column; the fatigue failure test device can also meet requirements of nodes such as cross type, T type, Ltype and the like of the steel beam columns and the concrete beam columns.

Owner:CHINA UNIV OF MINING & TECH

Synchronous frequency-shift mechanism in Fizeau interferometer

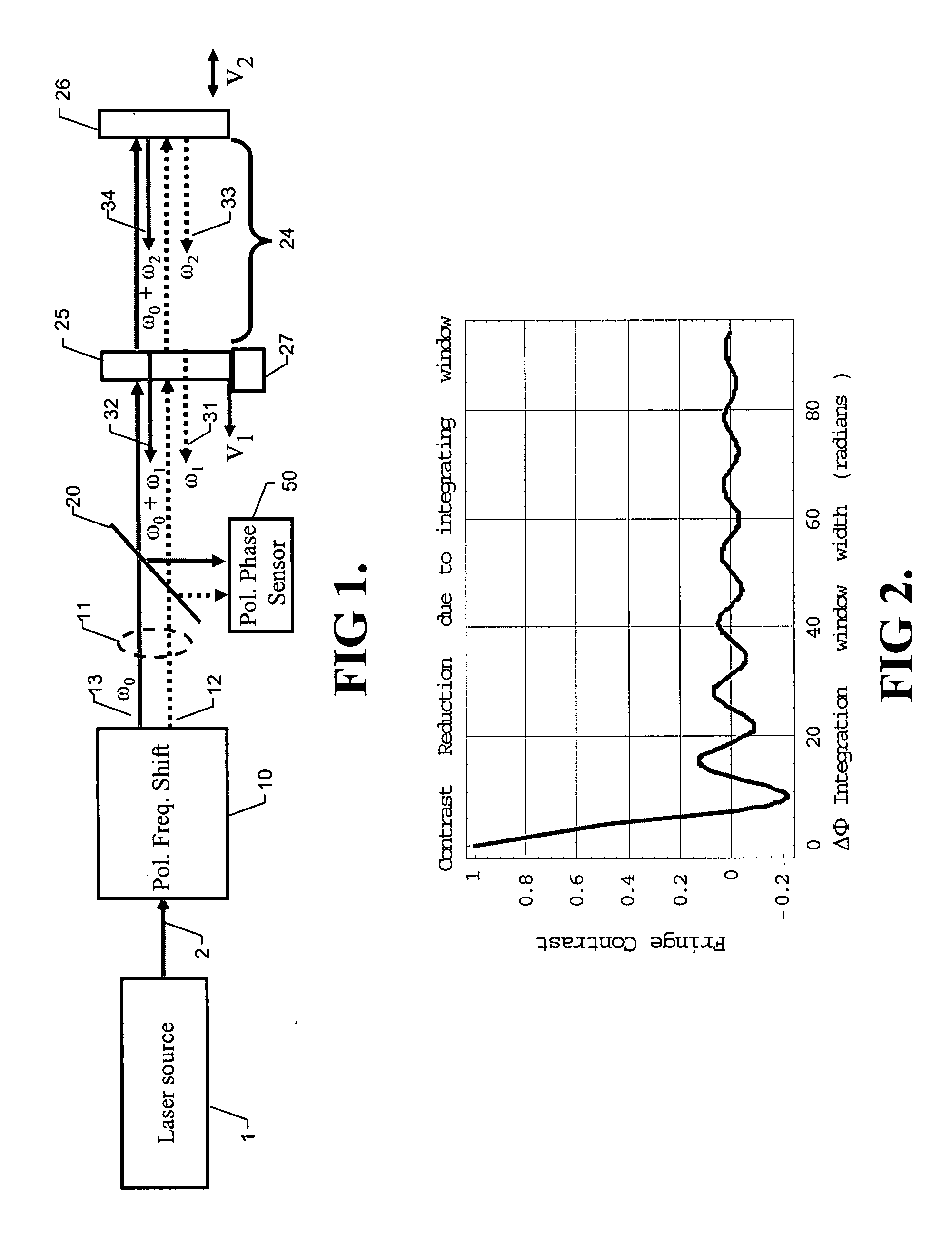

ActiveUS20080062428A1Increase laser powerShort integration timeInterferometersUsing optical meansOptical cavityTest beam

An optical device for characterizing a test surface combines a Fizeau interferometer with a polarization frequency-shifting element. Two substantially collinear, orthogonally polarized beams having respective frequencies differing by a predetermined frequency shift are generated by the polarization frequency-shifting element and projected into the Fizeau optical cavity to produce a pair of test beams and a pair of reference beams, wherein the beams in each pair have orthogonal polarization states and have frequencies differing by the predetermined frequency shift. A second, substantially equal frequency shift is introduced in the Fizeau cavity on either one of the pairs of test and reference beams, thereby generating a four-beam collinear output that produces an interferogram without tilt or short-coherence light. The invention may also be implemented by reversing the order of the Fizeau cavity and the polarization frequency-shifting element in the optical train.

Owner:ONTO INNOVATION INC

Prestress concrete filled steel tube self-balancing type static load test table for bridge static load test

PendingCN107340185AIncrease stiffnessLess consumablesMaterial strength using tensile/compressive forcesTest beamPre stress

The invention relates to a bridge static load test device, in particular to a large-span simple supported beam prestress self-balancing type static load test table. The test table comprises a test beam, jacks, counter-force beams, upper cross beams, vertical pull rods, support piers, lever beams and ground counter-force piers. The counter-force beams are located on the test beam, the jacks are located between the counter-force beams and the test beam, the upper cross beams are located at the two ends of the counter-force beams, and the vertical pull rods are arranged at the two ends of the upper cross beams; the lower ends of the vertical pull rods are connected with the rear ends of the lever beams, the lever beams penetrate through the support piers through pin shaft connection, and the front ends of the lever beams are in contact with the ground counter-force piers to provide test counter-force. The counter-force beams are of a section spliced prestress structure so that a large quantity of materials can be saved. The situation that a bridge deck slab is drilled to allow the vertical pull rods to penetrate for testing is avoided. The test table is scientific in structure, economical and applicable, on-site fabricated beams can be transferred conveniently, the problem is solved that a foundation pit concrete heavy counter-force test table base is used in an existing 40 m beam and accordingly blow-up and second ploughing are caused, and the test table is suitable for static load tests of various spans and beam types.

Owner:BEIJING HUAHENG NEW TECH DEV +2

Device for high-accuracy measurement of dimensional changes

InactiveUS7239397B2Improve accuracyAccurate measurementMaterial thermal coefficient of expansionInterferometersTest beamMeasurement test

Thermal expansion characteristics of test materials of ultra-low thermal expansion material are measured with a test beam that is split into a test material-measuring portion and an instrument-measuring portion. Both measuring portions propagate through common portions of a test arm. The test material-measuring portion encounters a test material, but the instrument-measuring portion does not. Thermal expansion characteristics of the test material are measured to high accuracy by manipulating the measures to distinguish displacements associated with the test material from displacements associated with the instrument structure.

Owner:CORNING INC

Broadband optical metrology with reduced wave front distortion, chromatic dispersion compensation and monitoring

InactiveUS7755775B1Reduced wave front distortionReduce distortion problemsRadiation pyrometryScattering properties measurementsReflectivity measurementOptical metrology

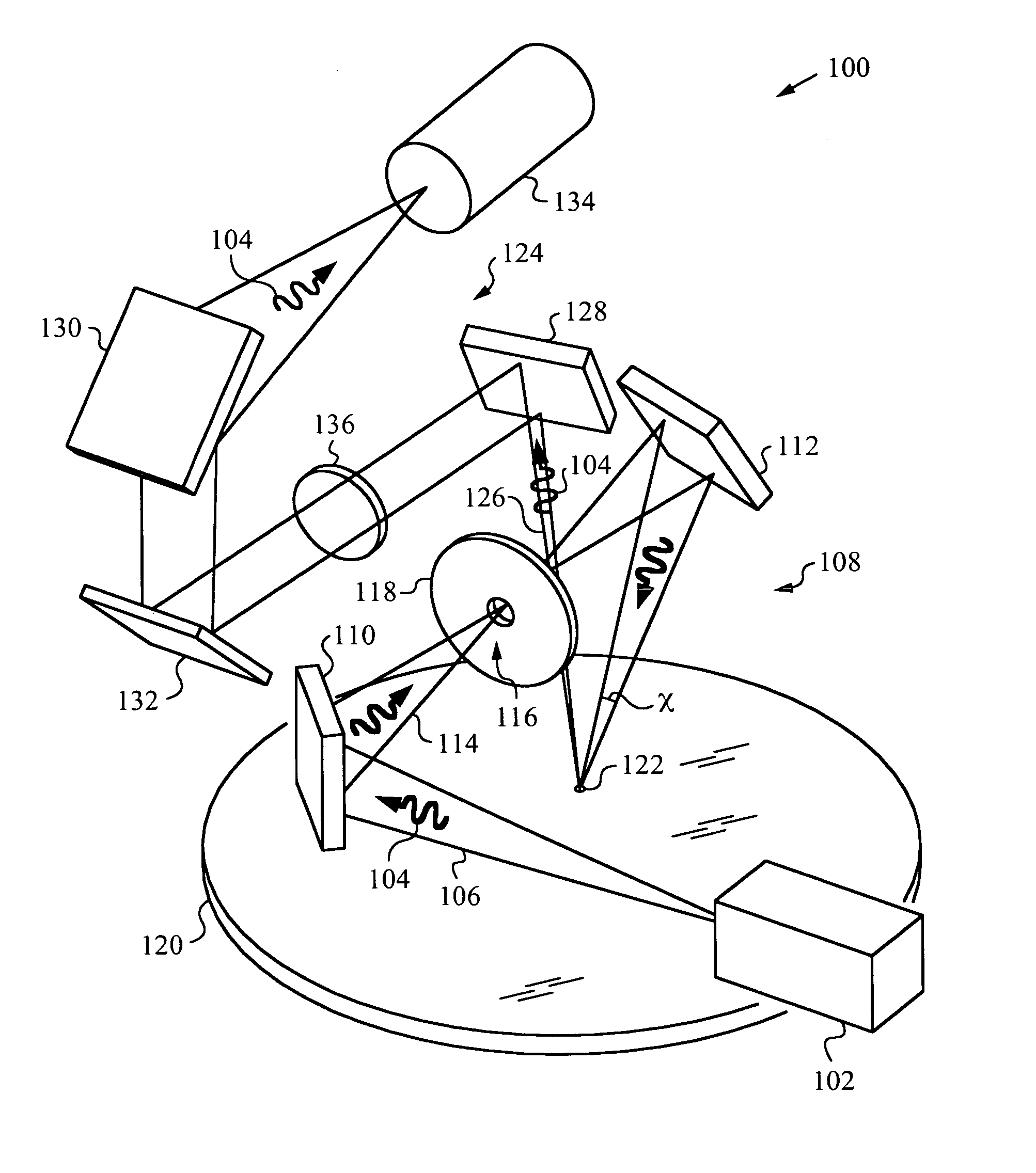

Apparatus and method for examining a sample with a broadband radiation while preserving a small spot and low wave front distortion. The apparatus has a broadband source for generating the broadband radiation and a first reflective optics that employ toroidal mirrors that are barrel or donut-shaped and may be placed in a crossed or parallel arrangement for producing a broadband test beam that is guided to the sample such that it is incident on it at a small spot. A sampling aperture is provided for filtering a certain center portion from the broadband test beam. A second reflective optics is provided for shaping a reflected response beam from the broadband radiation that is reflected from the spot. The response beam is delivered by second reflective optics to a detector for examination. The apparatus and method can be applied to improve wave front distortion in reflectance measurements and for performing transmittance measurements with chromatic distortion compensation. The method and apparatus further provide for efficient monitoring of the broadband test beam.

Owner:N & K TECH

Fixing device for load test of pre-stressed concrete beam and testing method

InactiveCN102998168ASimple structureEasy to manufactureStrength propertiesTest beamPrestressed concrete beam

The invention provides a fixing device for a load test of a pre-stressed concrete beam and a testing method. The fixing device comprises two horizontal test beams with opposite flange boards which are taken as counter-force frames; fixing frames for surrounding the periphery of the end parts of the test frames are respectively arranged at the two ends of the two test beams; each fixing frame comprises an upper bearing board, a lower bearing board, a left bearing board and a right bearing board, and the end parts of all the bearing boards are connected with one another to define a framework structure; the lower lateral faces of flange boards of the test beams are located on the lower bearing boards; the left bearing boards are in contact with the bottom face of the end part of a web plate of one test beam, and the right bearing boards are in contact with the bottom face of the end part of a web plate of the other test beam; and a transverse load jack is arranged between the two test beams. The fixing device provided by the invention has the advantages of simple structure, convenience in manufacturing and use, and no damage on the beam; and the testing method in the load test with the fixing device has no need of a great number of real objects with load, and facilitates the test in situ.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

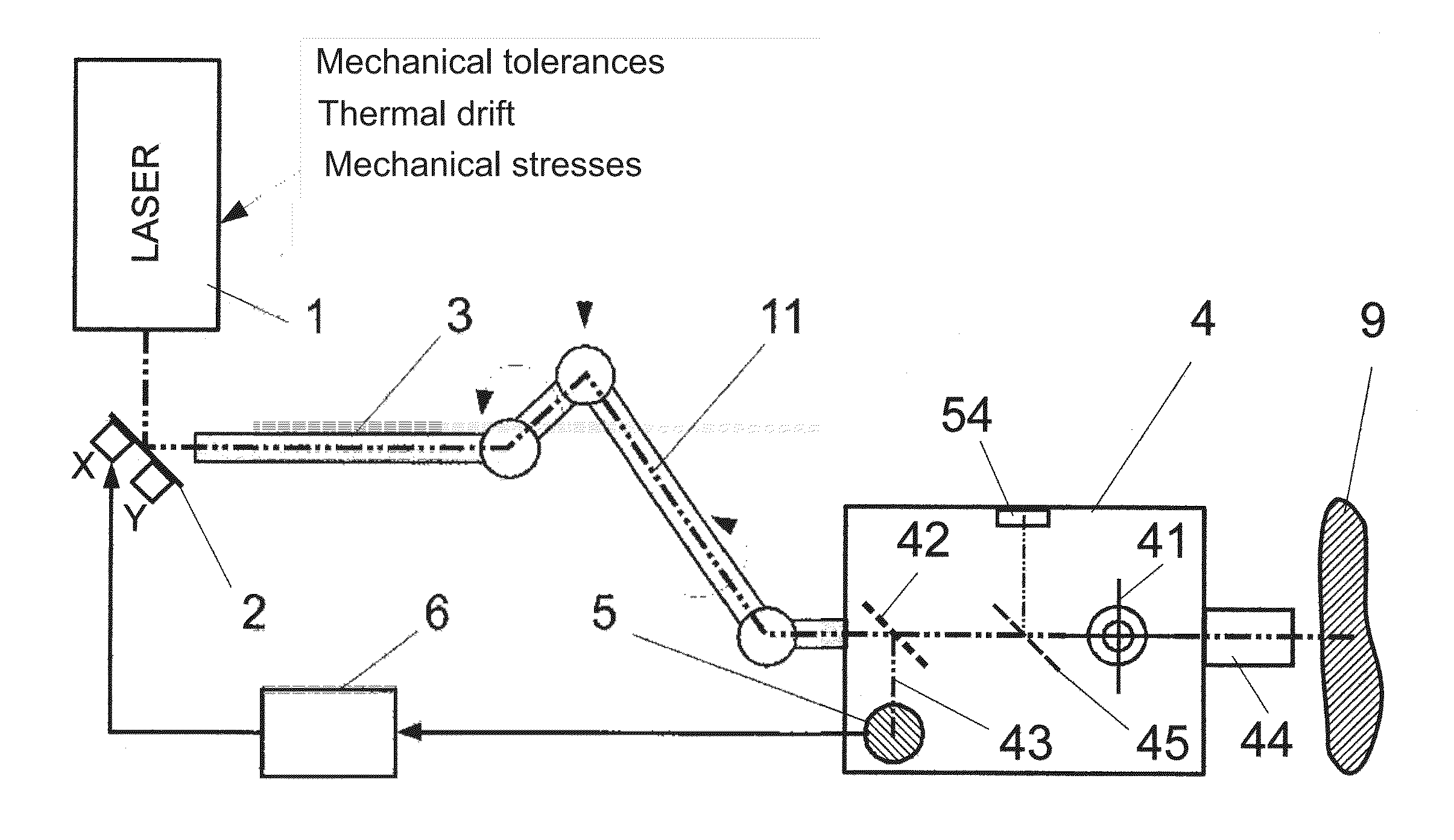

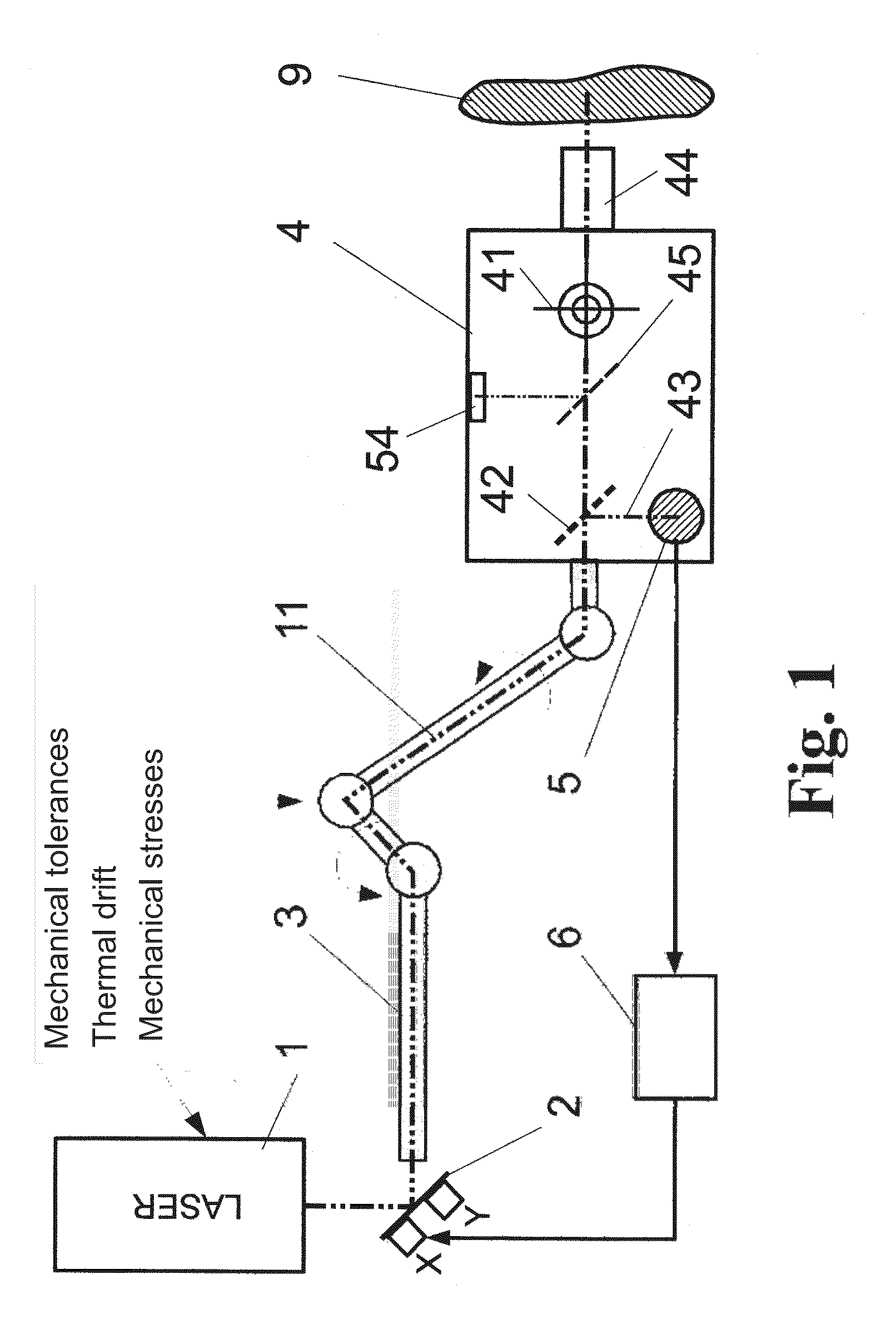

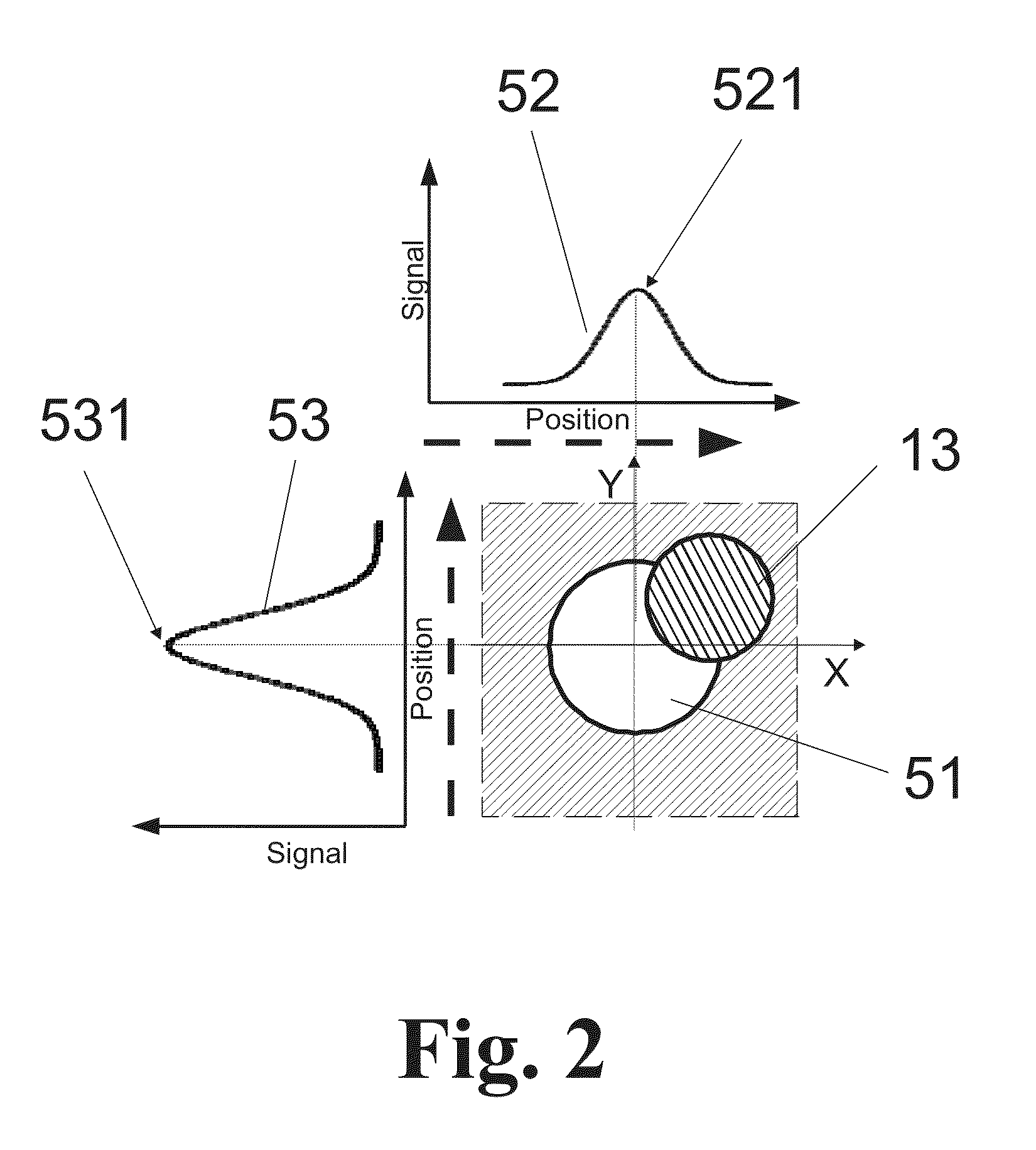

Flexible Nonlinear Laser Scanning Microscope for Noninvasive Three-Dimensional Detection

ActiveUS20130088709A1Unlimited flexibilityAdvantageously determine and correct pointing stability of laserPhotometryRaman scatteringExcitation beamLaser scanning microscope

A nonlinear laser scanning microscope for flexible, noninvasive three-dimensional detection comprising a measuring head which is flexibly connected to at least one radiation source by transmission optics and can be freely positioned in space, at least one controllable tilt mirror is arranged for aligning the excitation beam in order to keep the excitation beam concentric to an aperture-limited optical element of the measuring head, a test beam which is coupled out of the excitation beam onto a spatially resolving photodetector for monitoring the center alignment of the test beam as a conjugate position to the target position of the excitation beam and directional stabilizing the excitation beam by a control unit of the tilt mirror depending on a determined deviation.

Owner:JENLAB

Test beam long-term loading system and method

InactiveCN106679910ASolve the problem that it cannot be loaded stably for a long time continuouslyIncrease load levelElasticity measurementTest beamTest requirements

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

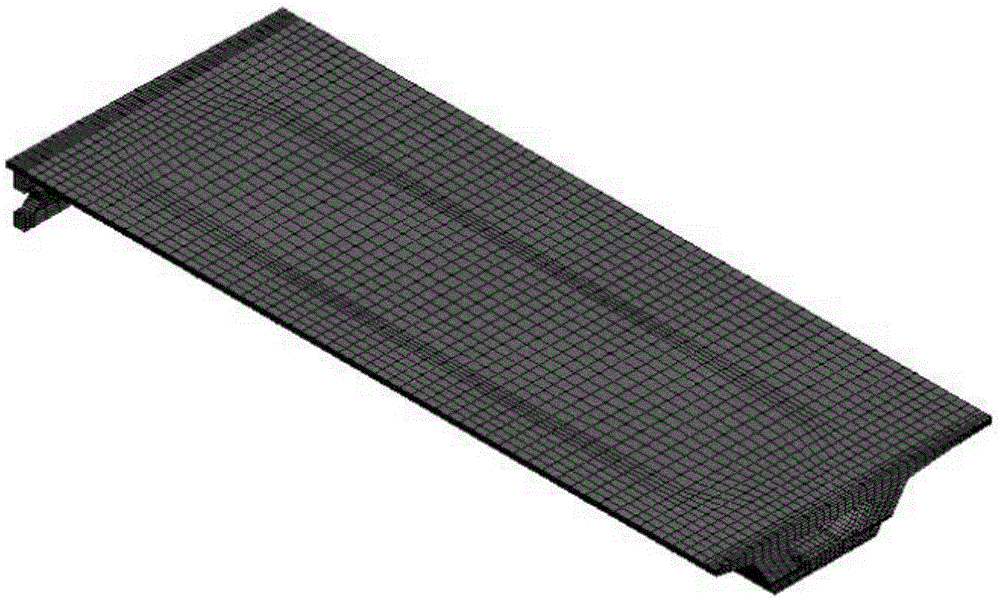

On-beam beam transporting simulation loading test method for prestressed concrete full-hole prefabricated box beam

The invention relates to a construction method of highway bridges and particularly relates to an on-beam beam transporting simulation loading test method for a prestressed concrete full-hole prefabricated box beam. The method is applied to the construction of the highway bridges and comprises the following steps: (A) simulating and testing loading conditions of one of two beams by virtue of a single-side static test; (B) simulating the load of a beam transporting vehicle by virtue of a multipoint loading manner, recording parameter differences of the stress state and the actual beam transporting vehicle effect of the tested beam when loads on 5 points / 7 points / 9 points / 11 points are respectively tested, and making comparison to select loading number of points; (C) carrying out finite element simulation on the specific loading working conditions of the tested beam under the loading number of points selected in the step B; and (D) if the stress state in the step C is normal, carrying out an actual load test, so as to detect the stress state, deflection and crack condition of the tested beam on each tested cross section. The on-beam beam transporting simulation loading test method for the prestressed concrete full-hole prefabricated box beam is applicable to the highway bridges.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Method for measuring the film element using optical multi-wavelength interferometry

InactiveUS20120140235A1Reflection coefficientAvoid influenceUsing optical meansTest beamPhase difference

A method for measuring the film element using optical multi-wavelength interferometry is revealed. The invention uses reflection coefficients of thin films at different wavelengths to measure the thickness and optical constants of thin films. The phase difference coming from the phase difference between test and reference surfaces is distinguished from the phase difference from the spatial path difference between reference and test beams by doing measurements on different wavelengths, because they change in different ways as the measuring wavelength changes. The phase is then acquired. Combining with the measured reflectance of thin film, the reflection coefficient of thin film is obtained. Collecting the reflection coefficients of each point, the thin film thickness and optical constants distribution in 2 dimensions are calculated. The surface profile is known through the spatial path differences between reference and test beams. These can be measured in a interferometer to avoid the vibration influence.

Owner:NAT CENT UNIV

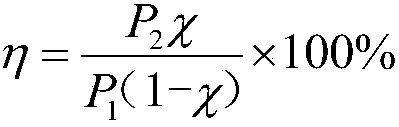

Test system and test method for testing grating diffraction efficiency

InactiveCN108332945AAchieving Diffraction EfficiencyHigh diffraction efficiencyTesting optical propertiesHigh power lasersLine width

The invention discloses a test system for testing the grating diffraction efficiency. The system comprises a wavelength tunable laser device, a polarization control element, a light splitting device and a rotatable diffractive element. The wavelength tunable laser device, the polarization control element, the light splitting device and the rotatable diffractive element are arranged on an optical axis of an optical path in sequence. The system further comprises two light energy detectors. One of the two light energy detectors is matched with the light splitting device to enable a reference light beam to be separated from the light splitting device to directly enter the first light energy detector, while the other one of the two light energy detectors is matched with the diffractive elementto enable a test light beam split from the light splitting device to shoot into the diffractive element and then enter the second light energy detector after being diffracted by the diffractive element. The test system is high in laser wavelength precision, wide in line width and adjustable in polarization direction. By means of the test system, the spectrum, the angle and the polarization characteristics of the grating high-precision diffraction efficiency can be obtained. The test system is simple in configuration, convenient in operation and strong in environment adaptability. The application requirements in the field of high-power laser and spectral analysis can be met. The test system can be applied to the fields of spectral synthesis and spectral analysis.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com