Patents

Literature

156 results about "Residual strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

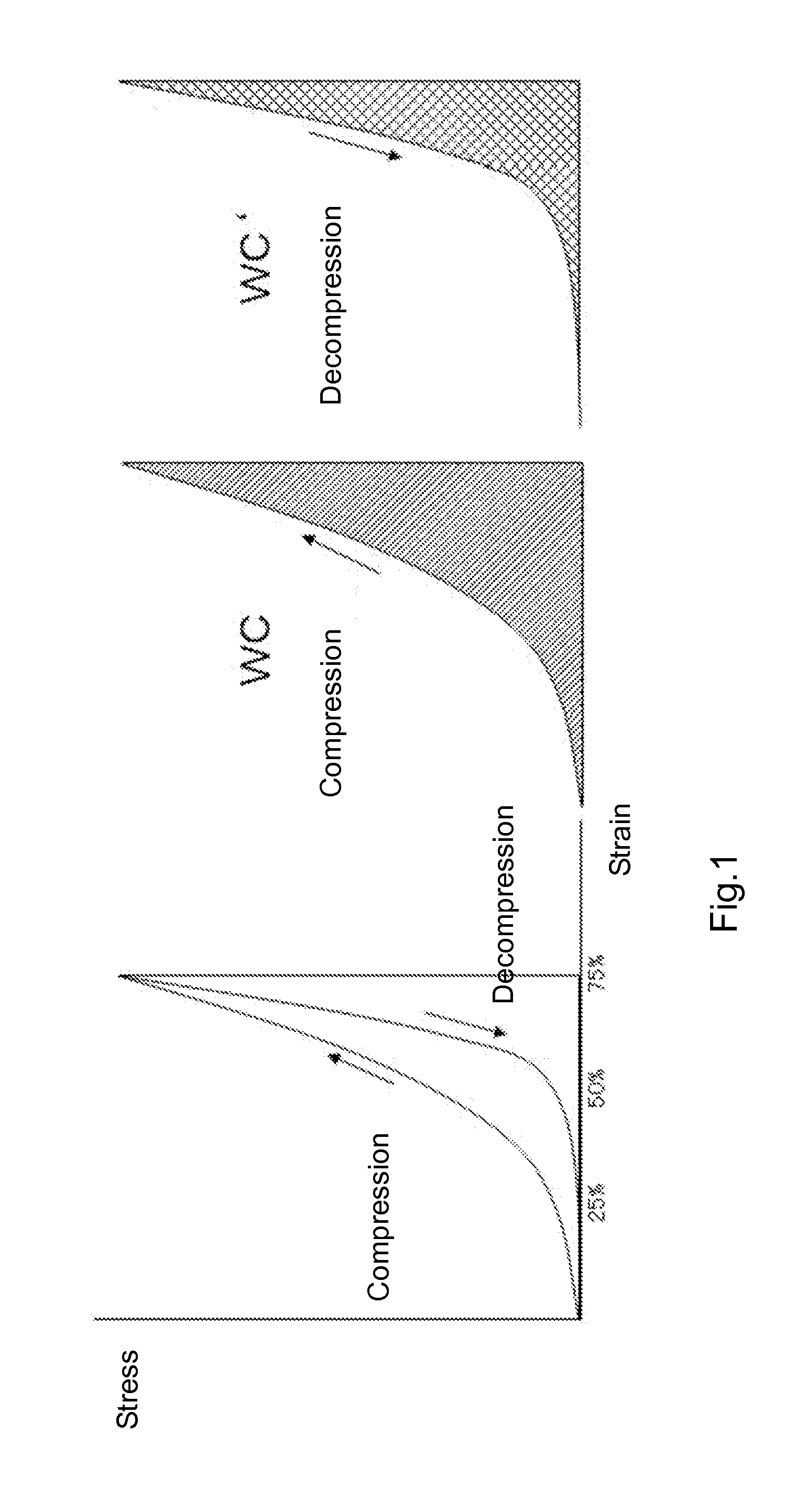

Residual strain is the permanent deformation that remains after removing the stress from a test sample. This deformation can be important for product design and material selection. Standard mechanical test procedures do not take into account the condition of the specimen after stress has been removed.

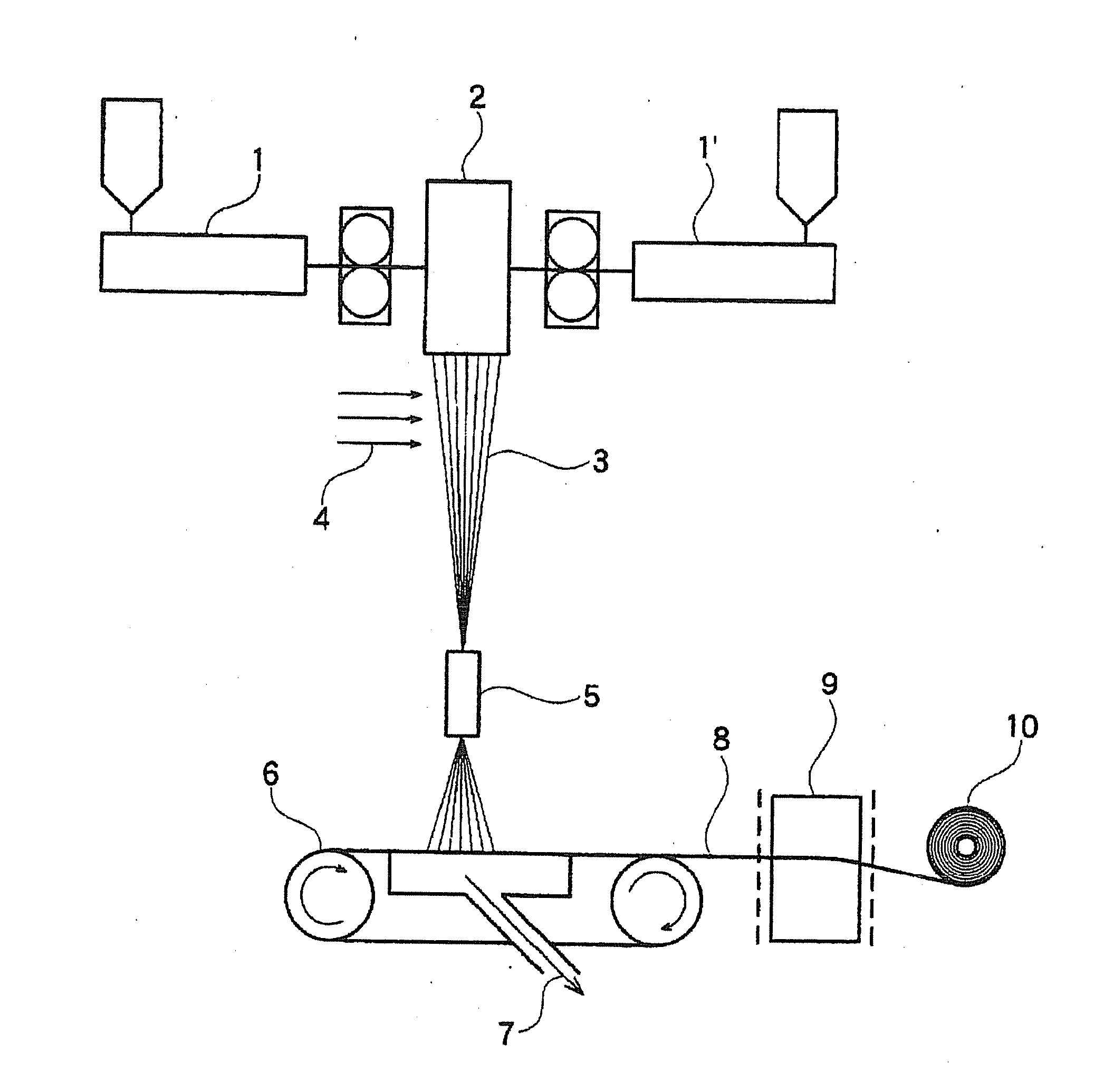

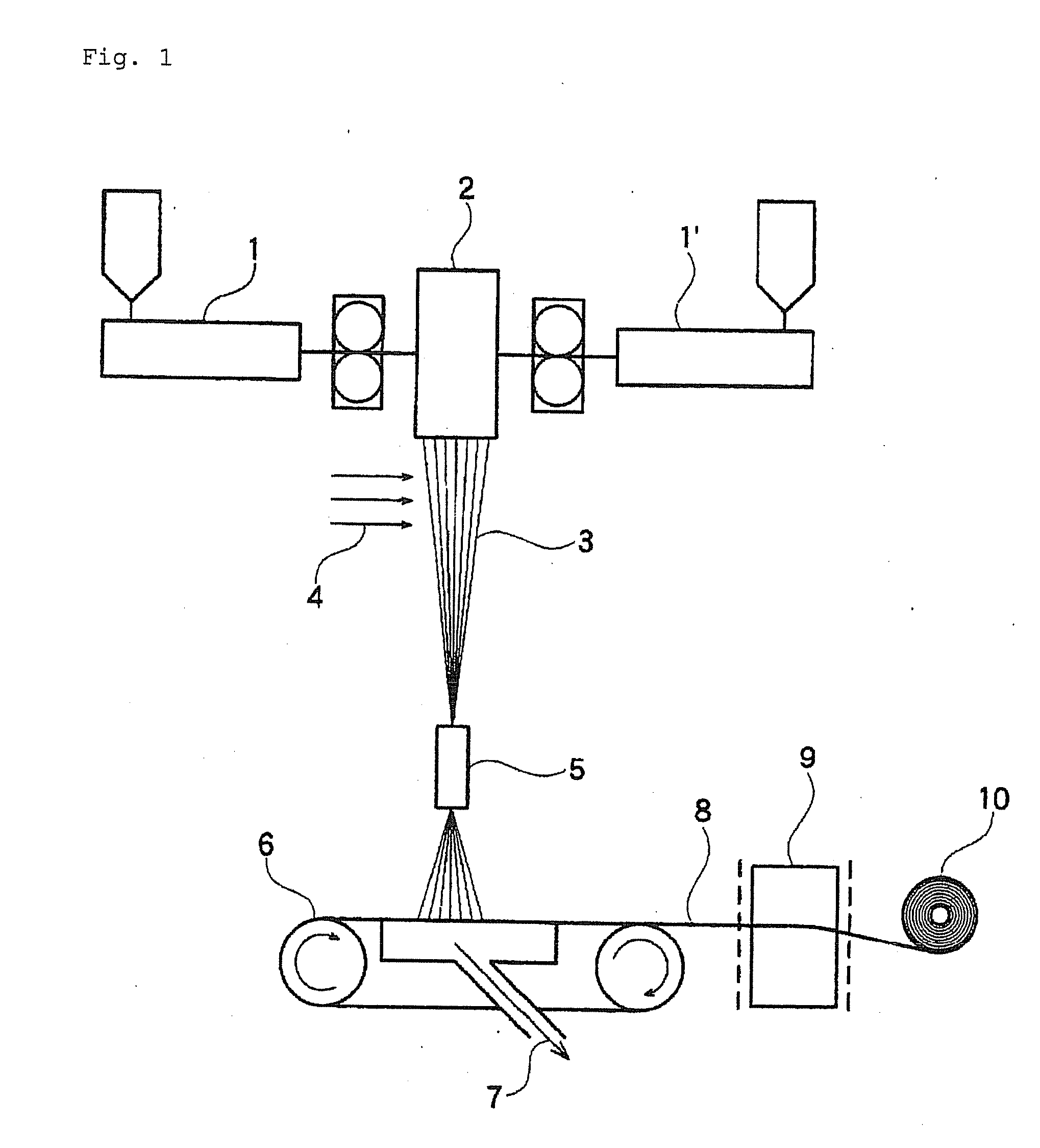

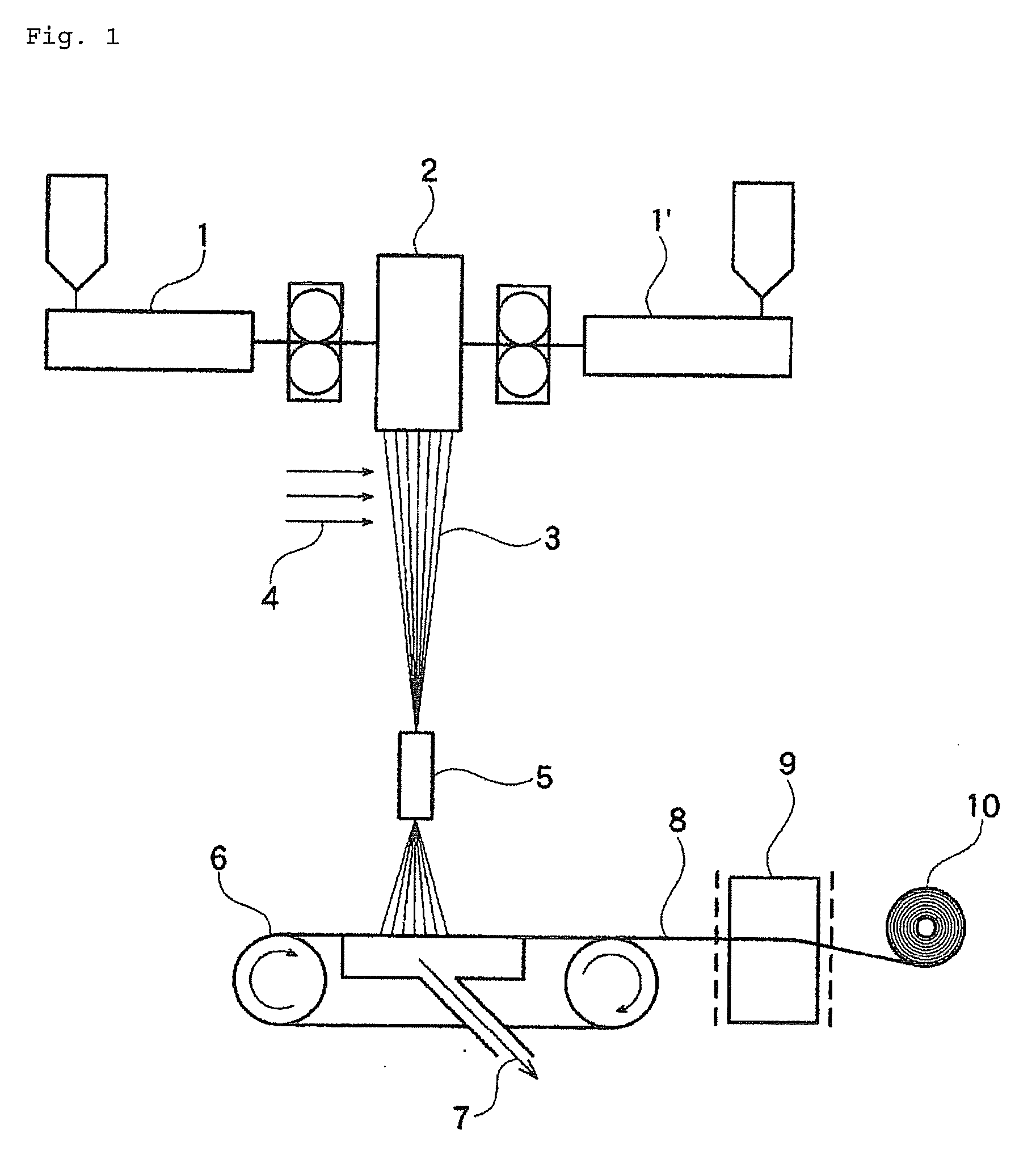

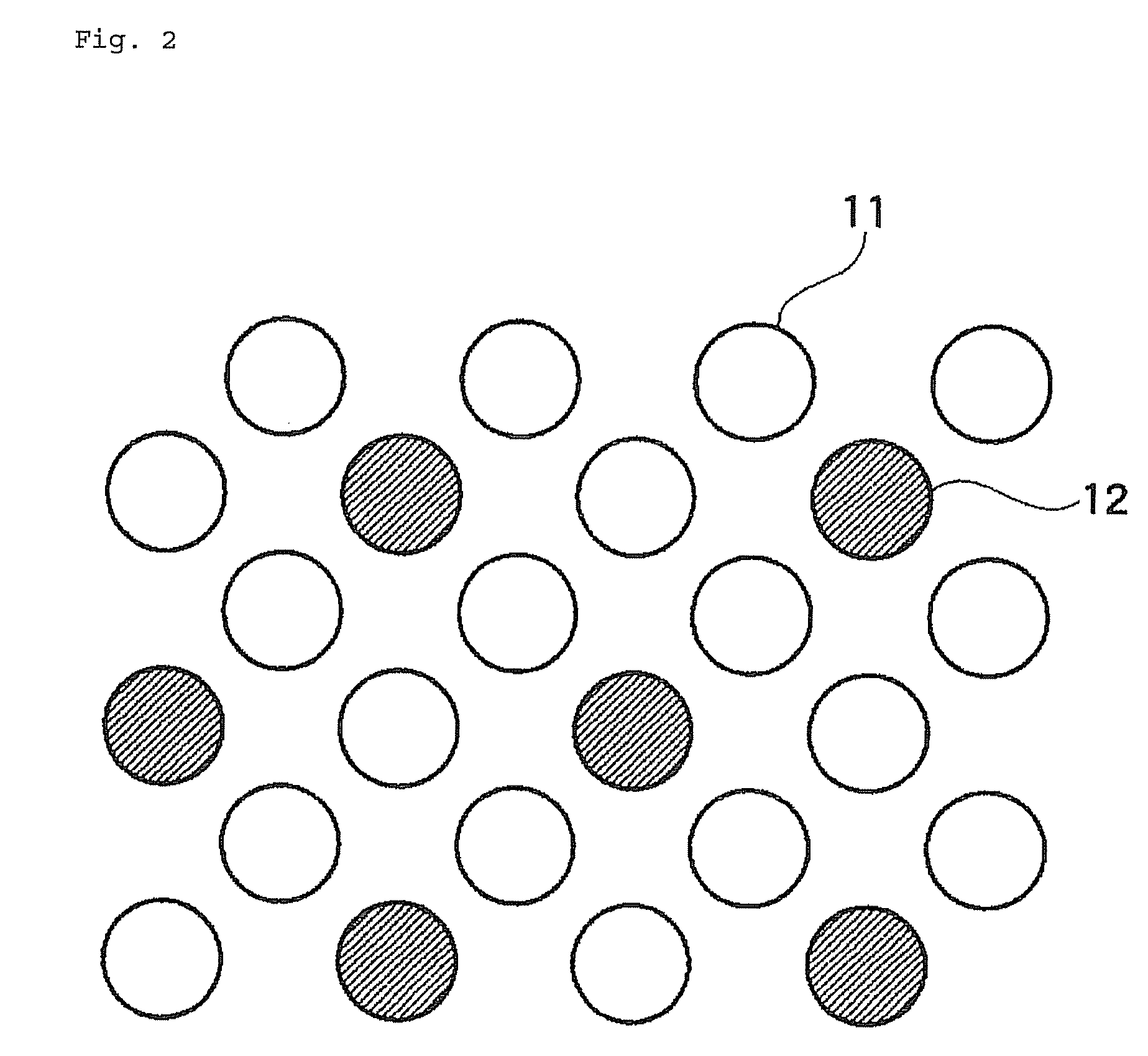

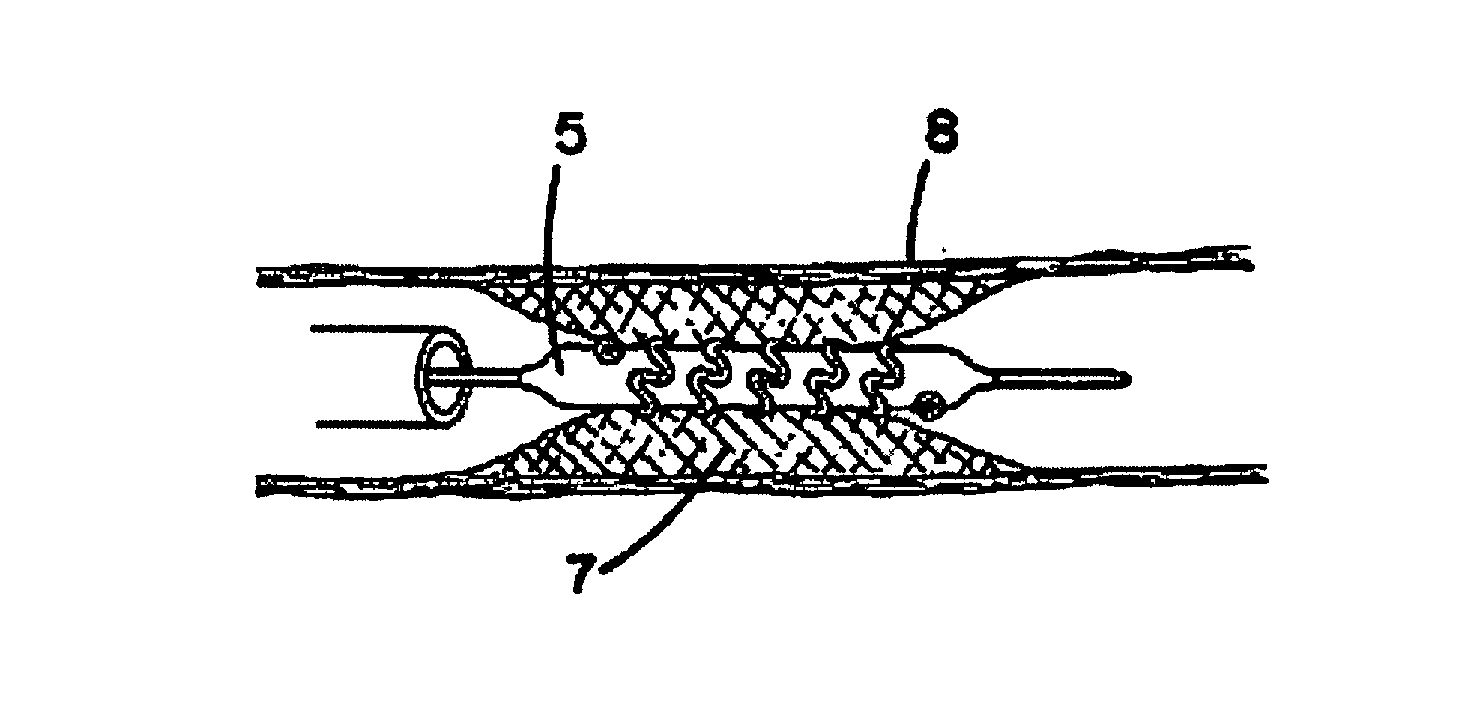

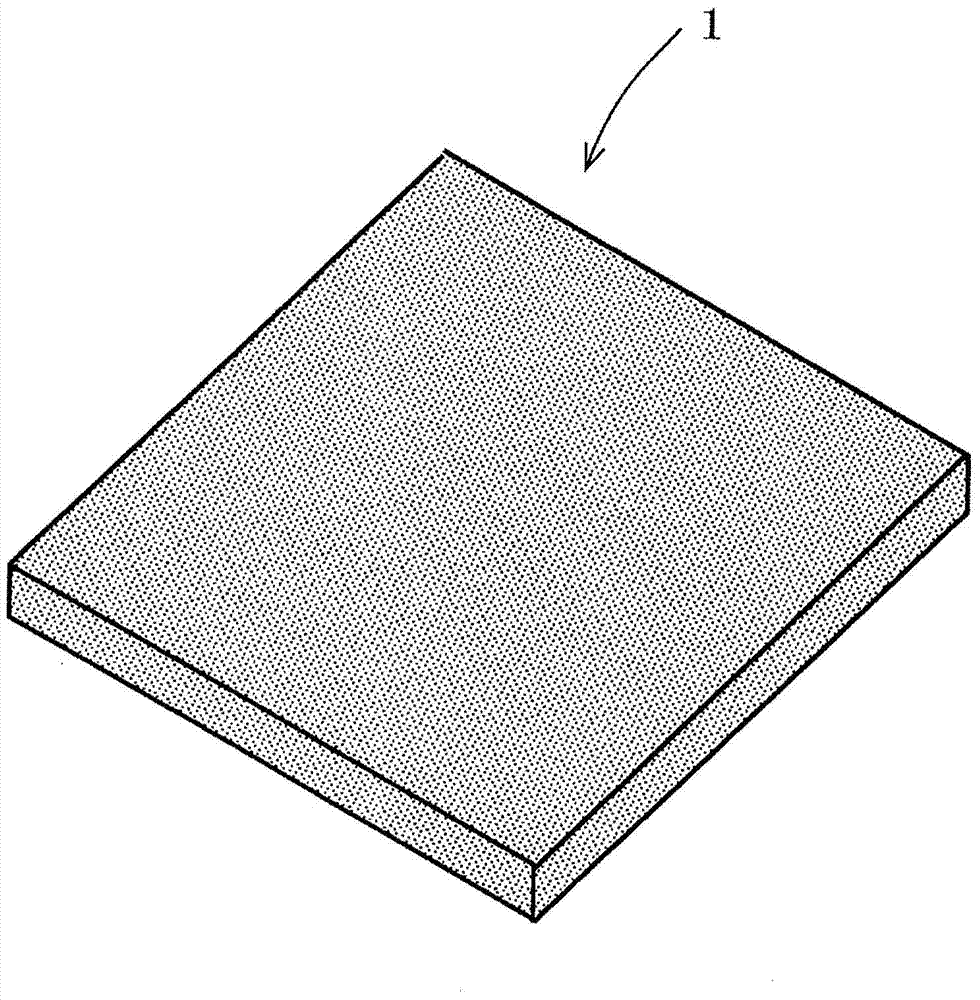

Polypropylene Nonwoven Fabric and Use Thereof

ActiveUS20080014819A1Excellent in appearance propertyExcellent in stretch propertyFilament/thread formingAdhesive dressingsResidual strainPolymer science

A polypropylene based nonwoven fabric is excellent in surface appearance and stretch properties and exhibits a small residual strain and excellent adhesiveness to polyolefins. The nonwoven fabric is obtained by forming a polypropylene resin composition comprising 1 to 40 weight parts of (i) an isotactic polypropylene, and 60 to 99 weight parts of (ii) a propylene / ethylene / α-olefin copolymer obtained by copolymerizing 45 to 89 mole % of propylene, 10 to 25 mole % of ethylene and the balance of α-olefin having 4 to 20 carbon atoms (with the proviso that the copolymerized amount of the α-olefin having 4 to 20 carbon atoms does not exceed 30 mole %), characterized by a small residual strain after stretching at a stretch ratio of 150%. The nonwoven fabric can be effectively used as sanitary materials or the like by virtue of its characteristics including stretch properties.

Owner:MITSUI CHEM INC

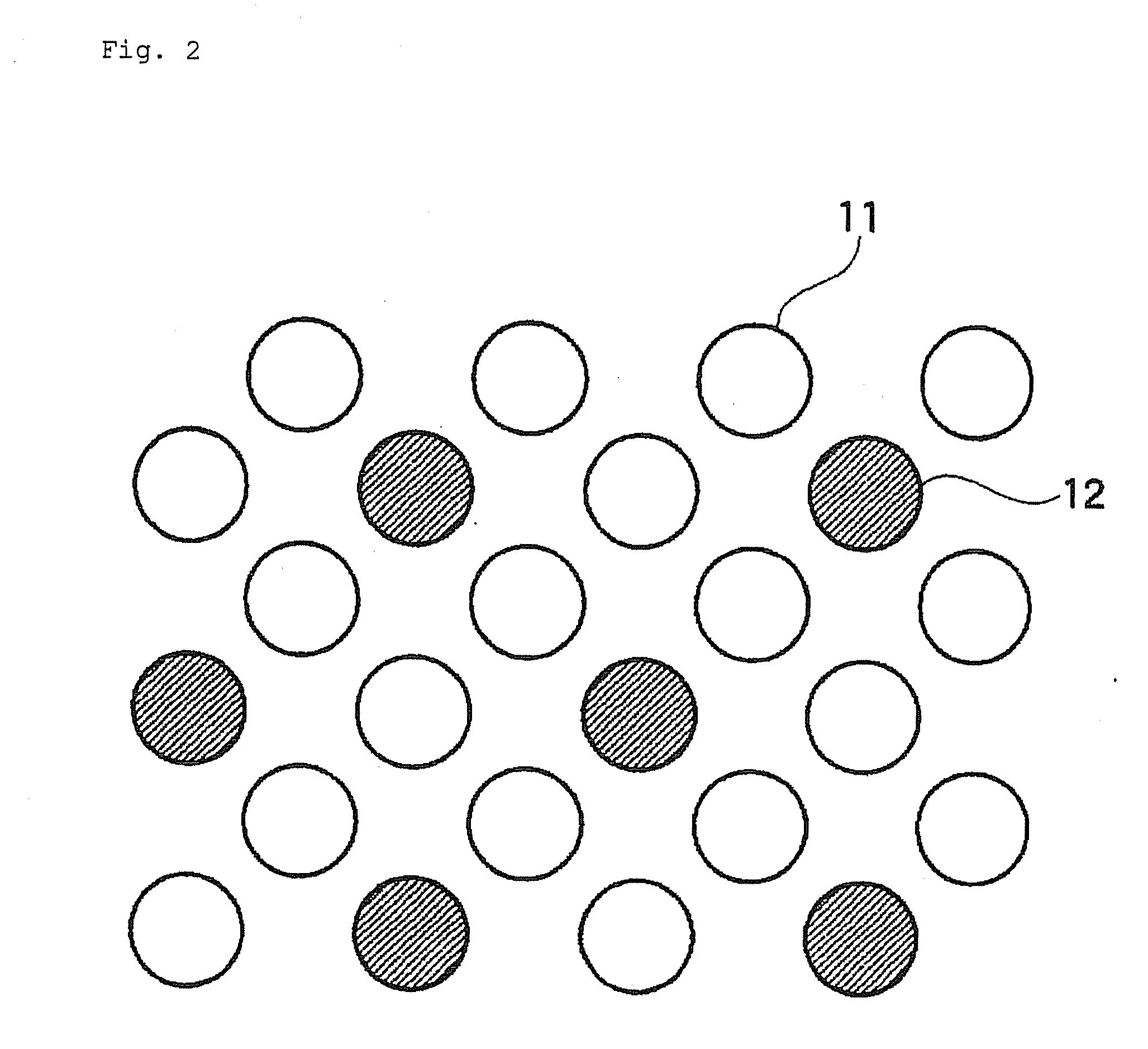

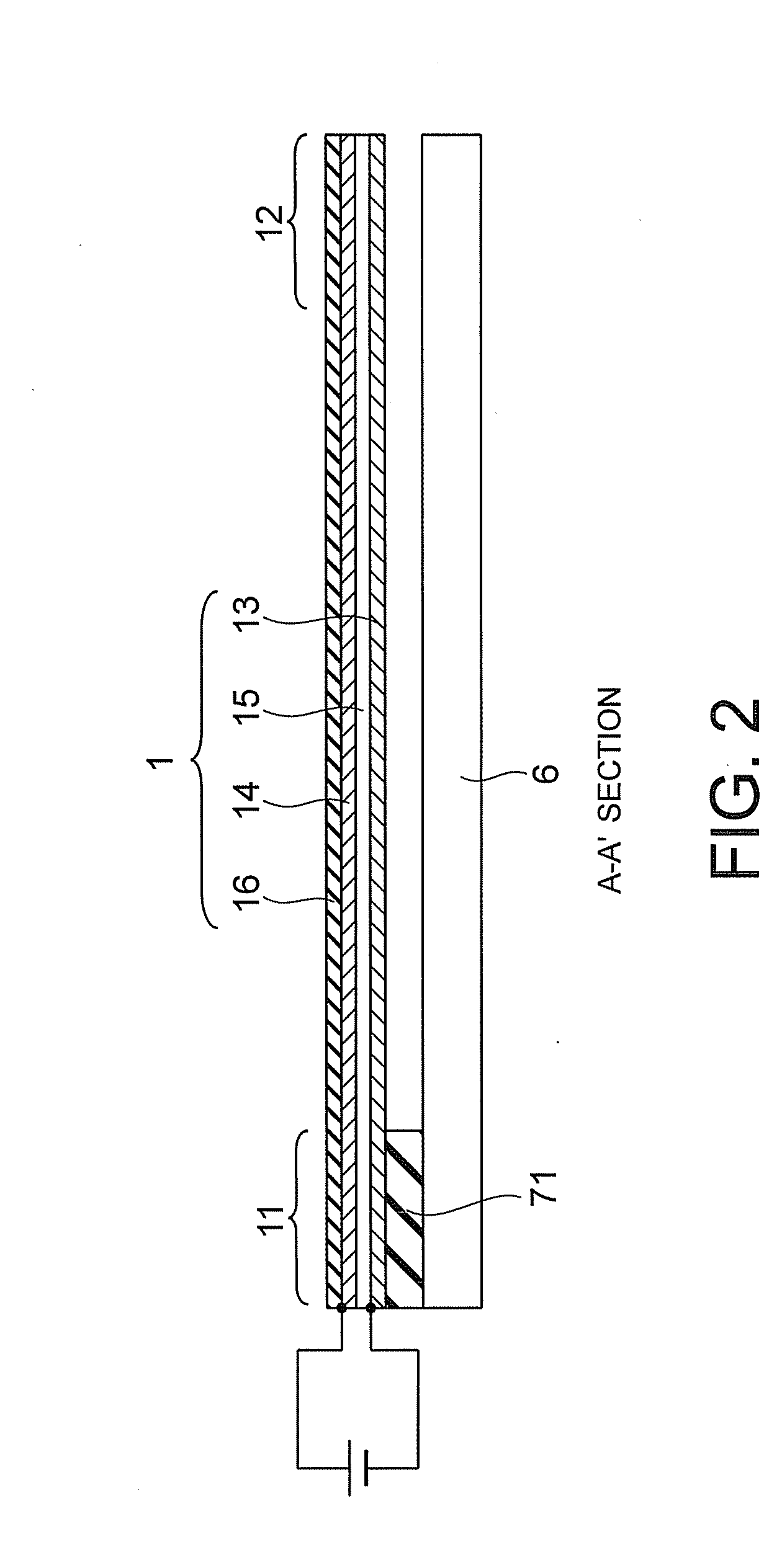

Fiber grating monitoring method for curing residual strain of composite materials

InactiveCN101571491ALittle effect on mechanical propertiesRealize online monitoringMaterial analysis by optical meansUsing optical meansFiberResidual strain

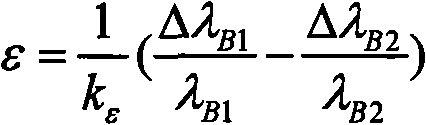

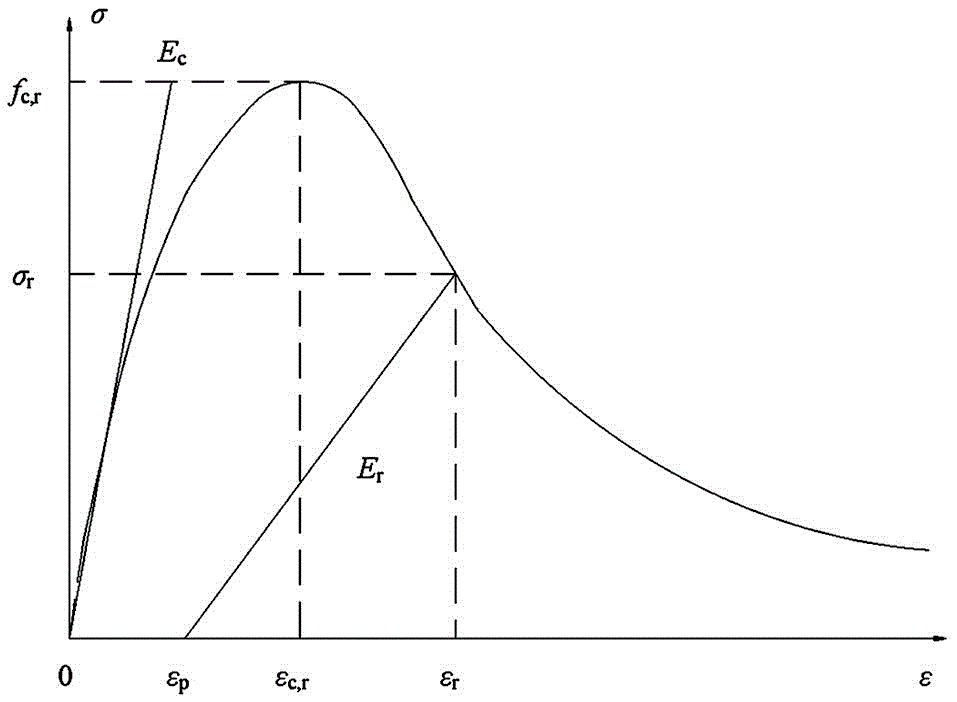

The invention provides a fiber grating monitoring method for the curing residual strain of composite materials. The method comprises the following steps: (1) manufacturing a sensor string comprising grating temperature sensors and grating temperature strain sensors; (2) embedding fiber grating sensors in to-be-monitored parts of a composite material in the process of layering the composite material; (3) reasonably selecting a molding process for the composite material, such as hot-pressing reactor, compression molding and the like; (4) cooling the composite material to room temperature after curing molding is performed and using a grating demodulation instrument to monitor the wavelength value of the highest reflection peak of a reflection spectrum of a fiber grating; and (5) utilizing epsilon=1 / k epsilon((delta lambda B1 / lambda B1)-(Delta lambda B2 / lambda B2)) to calculate the curing residual strain of the composite material. The method can realize the measurement of the residual strain of key parts of the structure of the composite material on the premise of not destroying the structure, and has the advantages of stable reliable measured values and good repeatability; in addition, the embedded grating can continue to play a role in monitoring the structure health of the composite material. The method organically combines the digital manufacturing and the health monitoring of the composite material, thereby realizing the on-line monitoring for the manufacturing process of the composite material.

Owner:SHENYANG INST OF AERONAUTICAL ENG +1

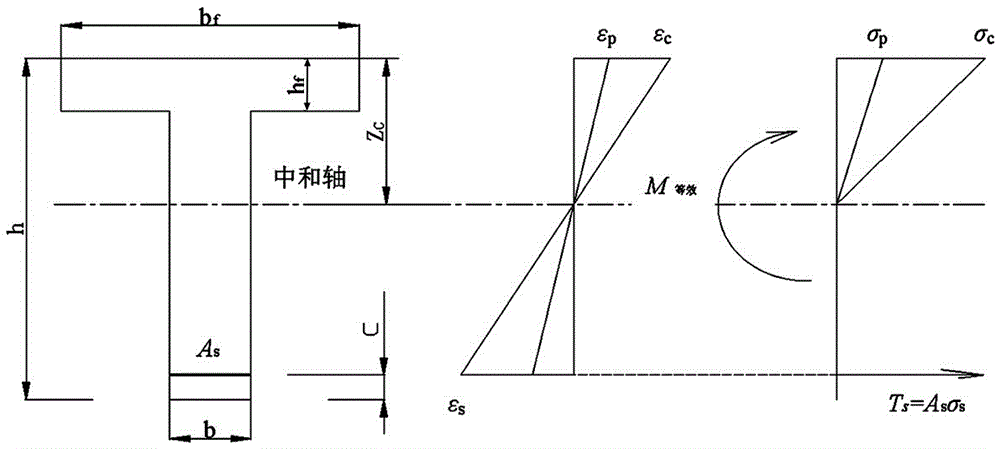

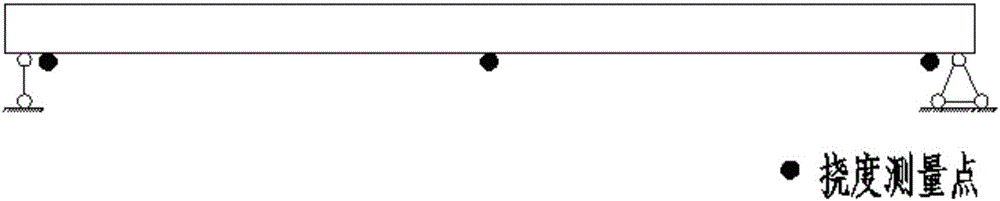

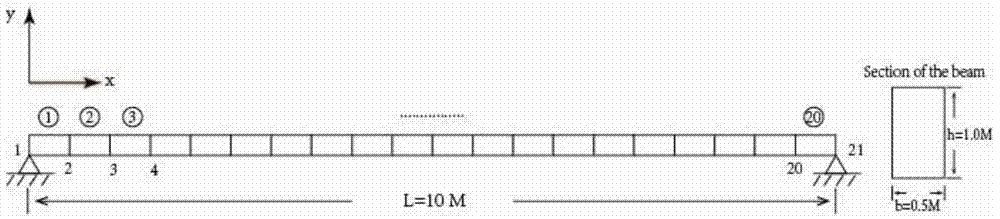

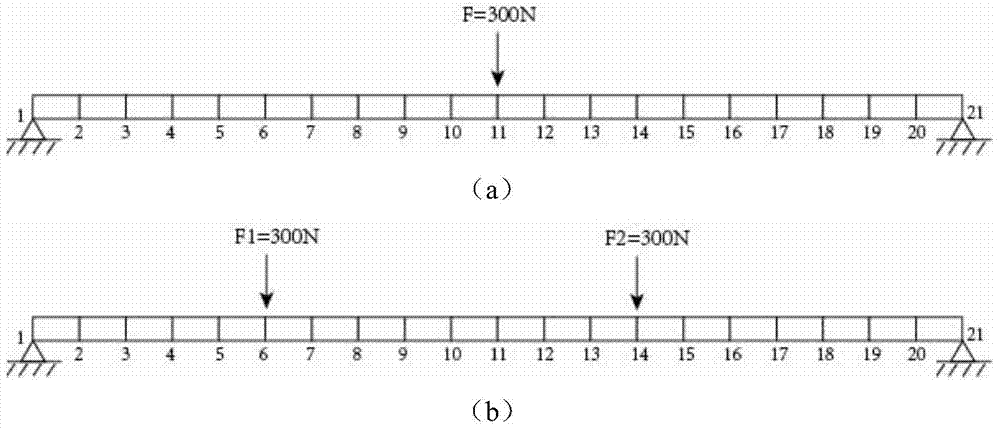

Residual strain based after-damage bearing capacity estimation method of concrete beam bridge

ActiveCN106485029AResidual strain solutionAvoid nonlinear damage process analysisDesign optimisation/simulationSpecial data processing applicationsResidual strainEstimation methods

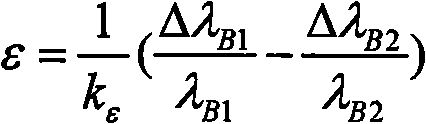

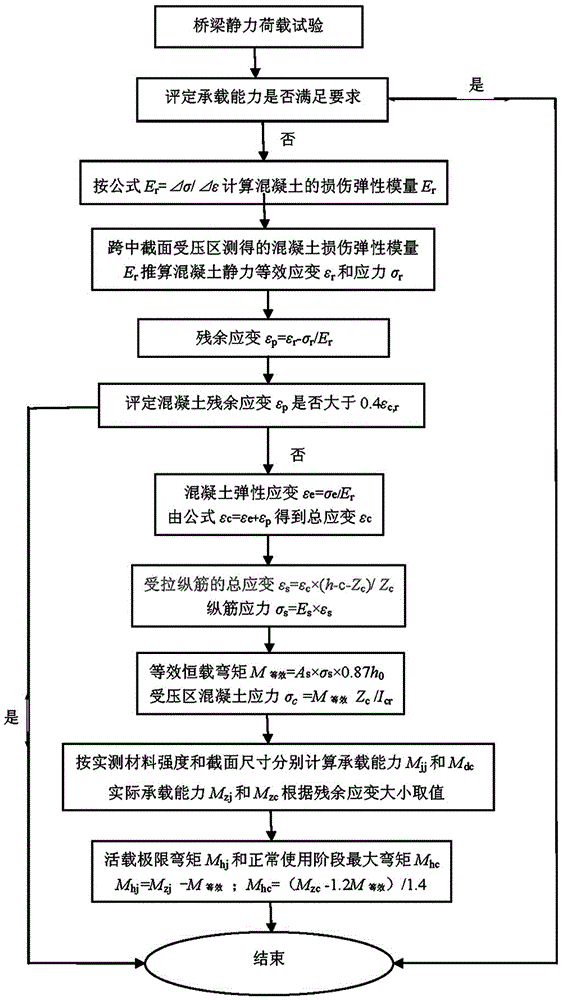

The invention provides a residual strain based after-damage bearing capacity estimation method of a concrete beam bridge. The method is characterized in that the residual strain ep of concrete in a stressed area of the concrete beam bridge which does not meet the requirement by assessing in a static load test according to the concrete damage elasticity modulus Er in the stressed area; the real strain and stress state of a section can be obtained according to the section load balance and plane surface deformation; the standard extreme bearing bending moment Mjj and design bearing bending moment Mdc are obtained according to the actually-measured concrete strength and section size; the damage degree can be determined according to the concrete residual strain, and thus the actual extreme bearing bending moment Mzj and the bending moment Mzc for normal use can be obtained. With the adoption of the method, the technical problems that the assessment of the bearing capacity of an existing concrete beam bridge is highly influenced by subjective factors, only the bridge performance under test load is assessed in the traditional static load test, and the real working state and bearing capacity of the concrete beam bridge cannot be obtained, can be solved.

Owner:BEIJING MUNICIPAL ENG RES INST

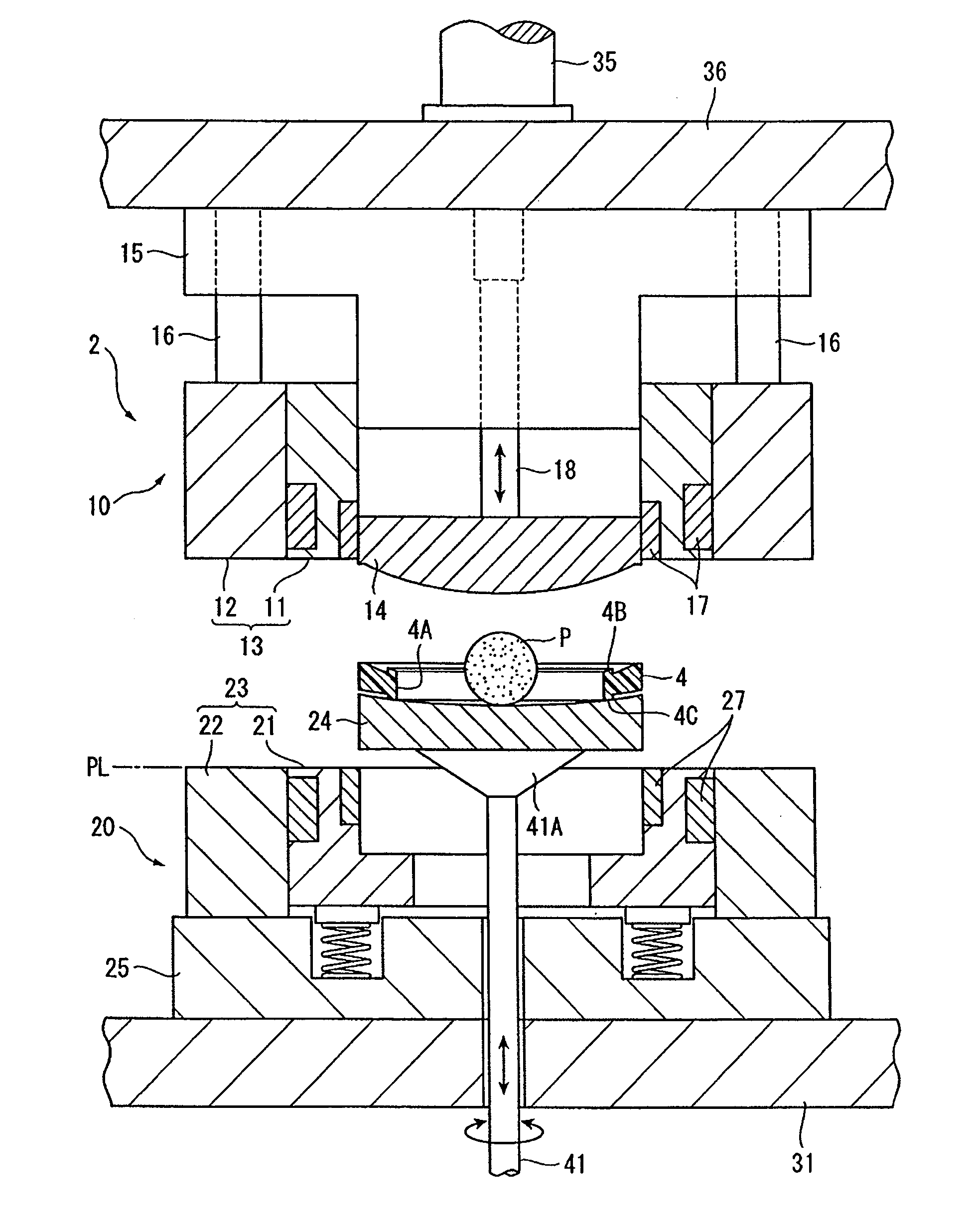

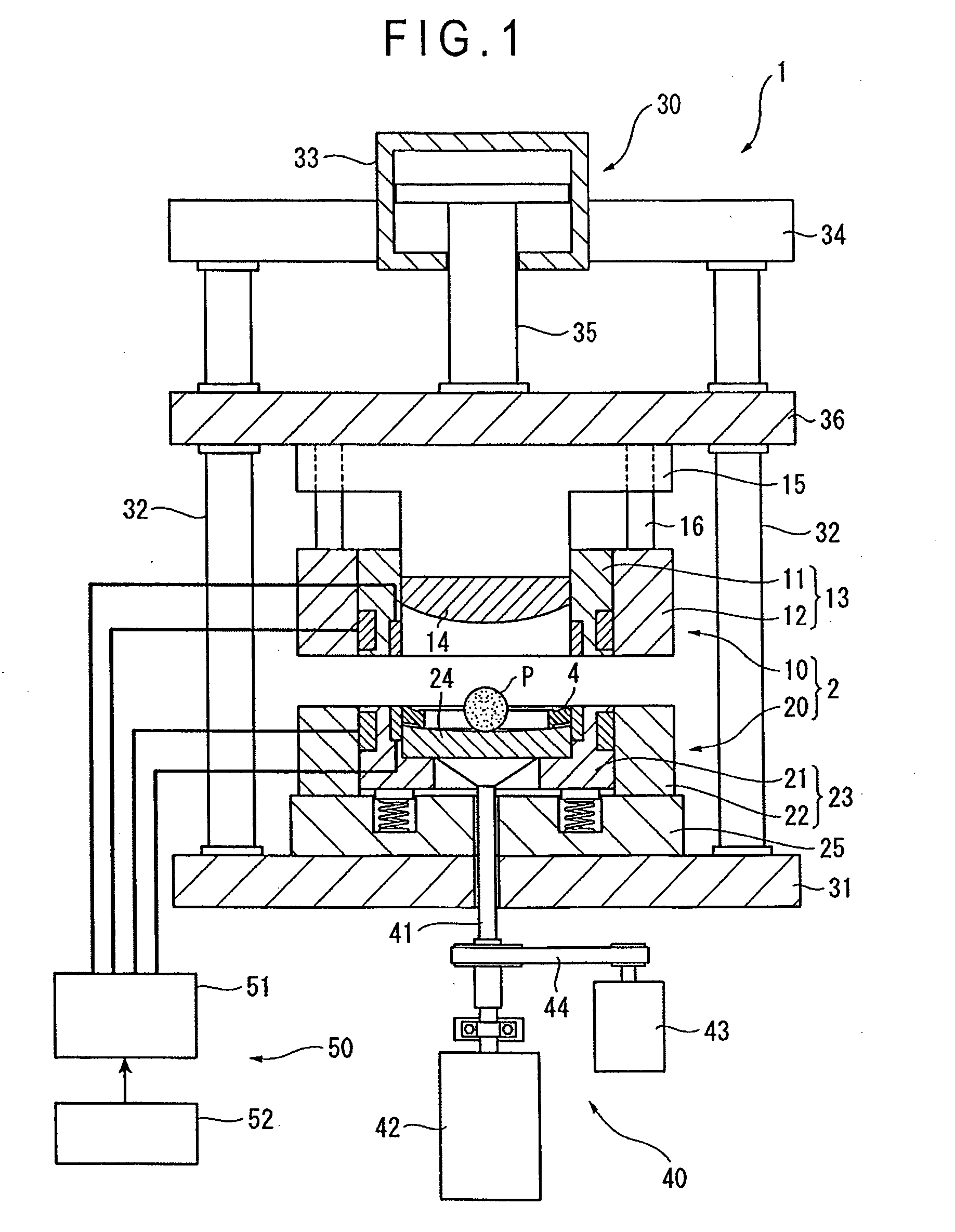

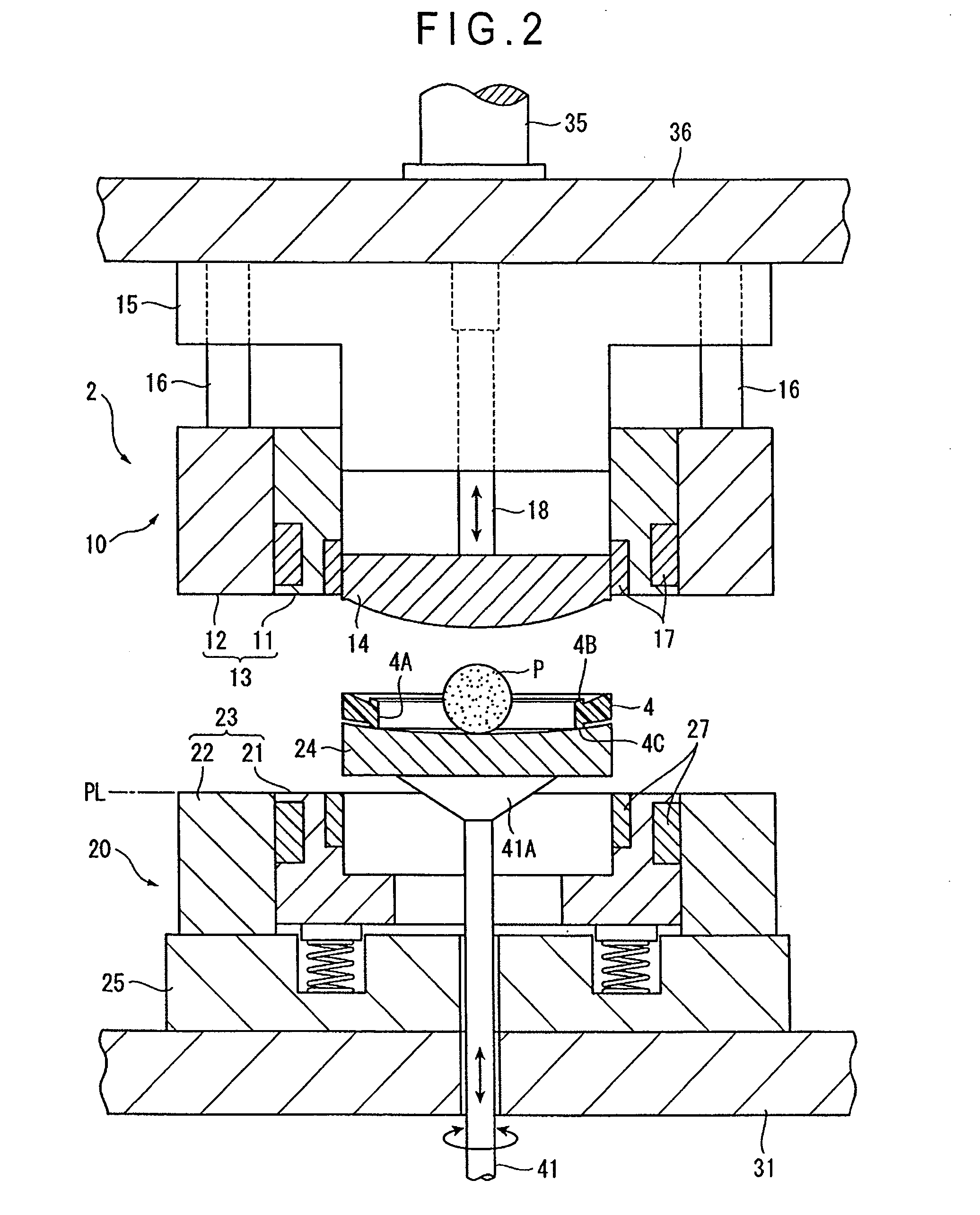

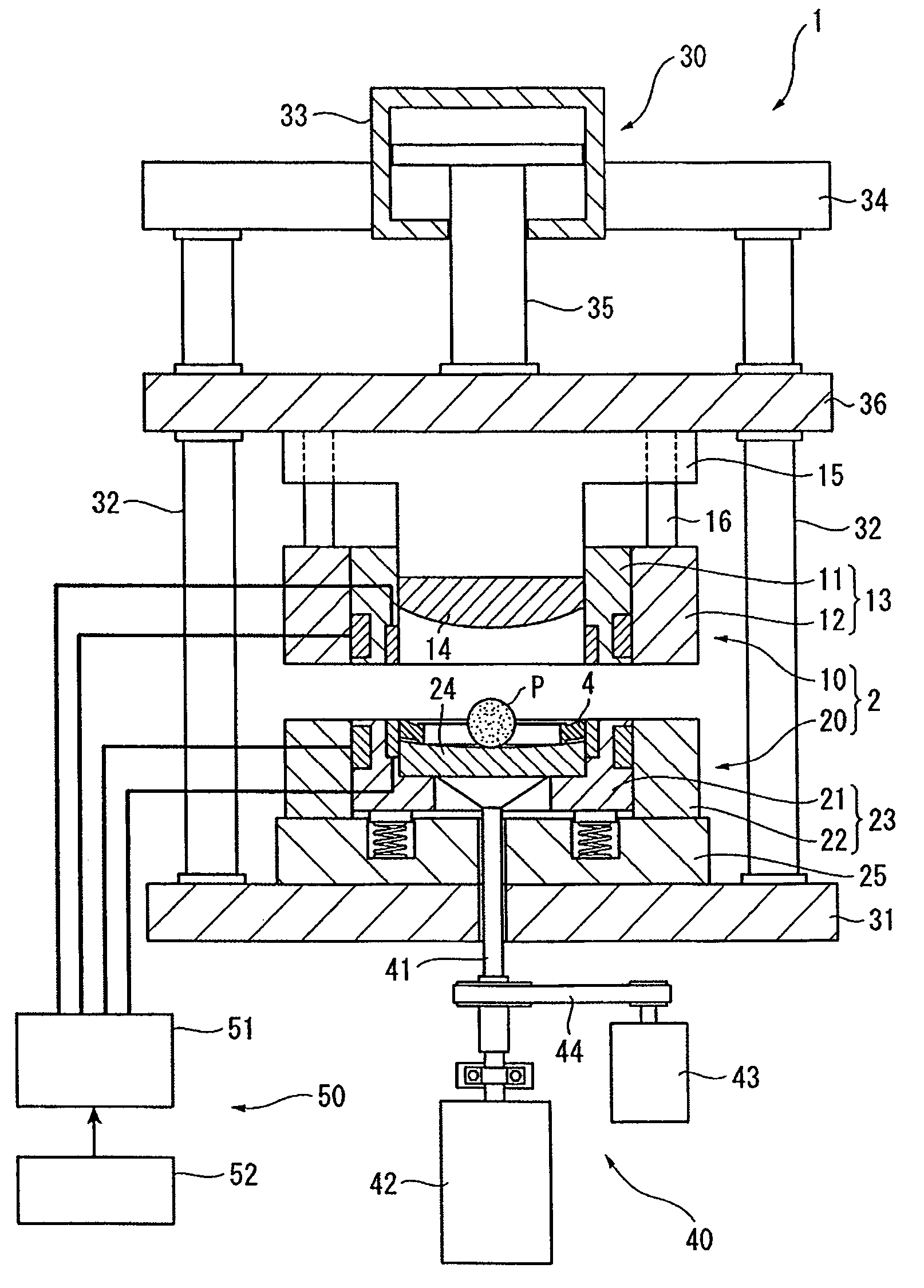

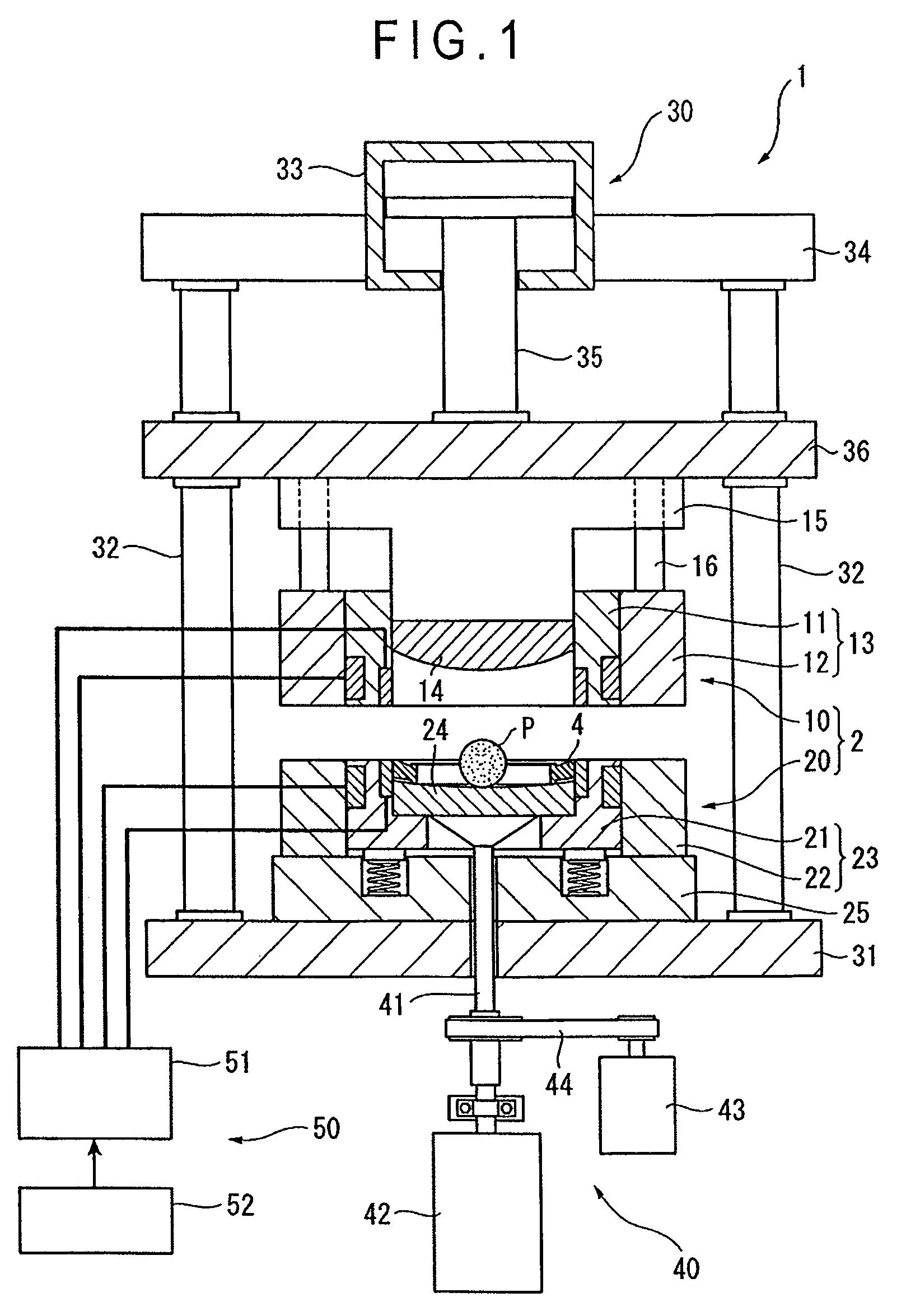

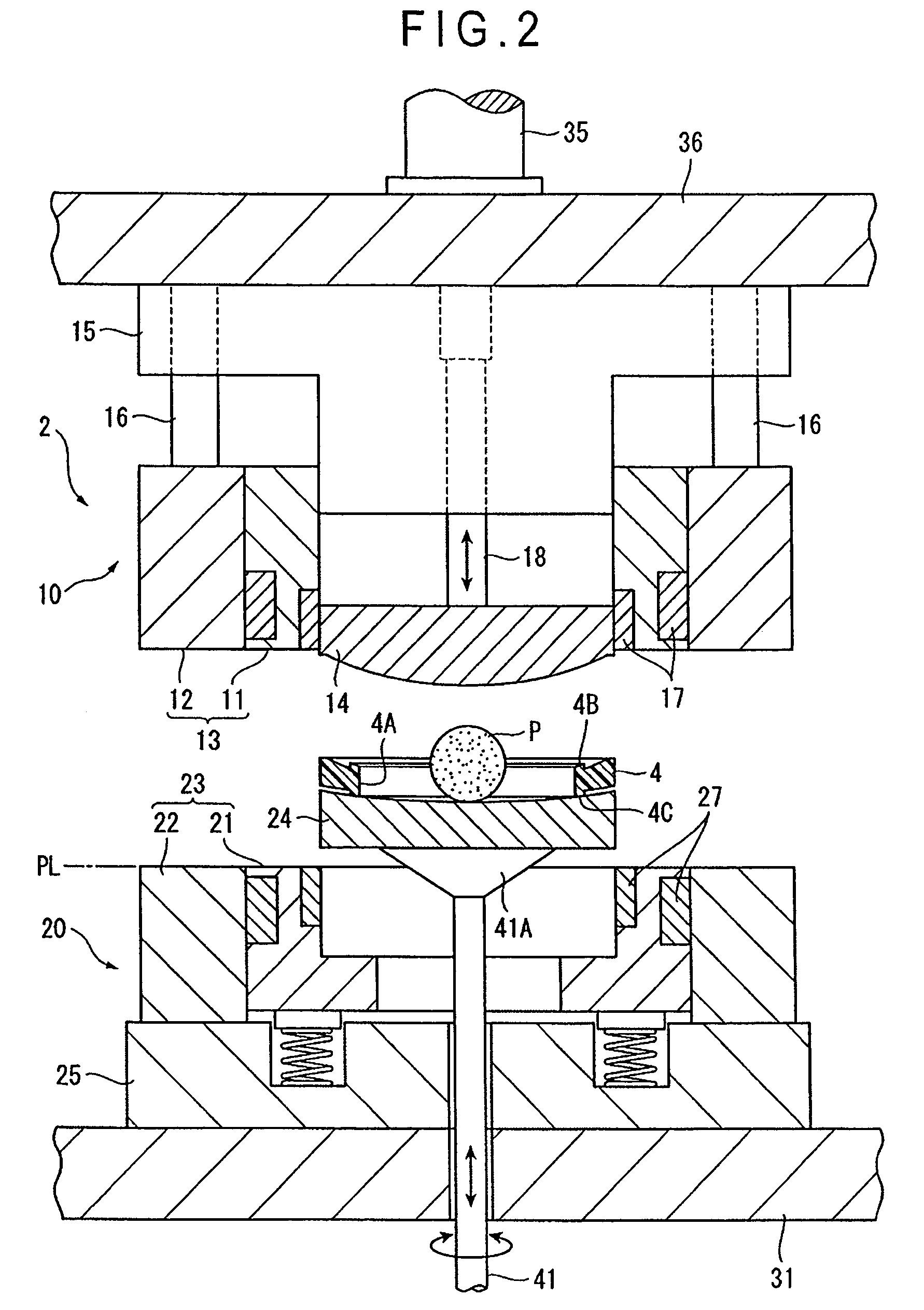

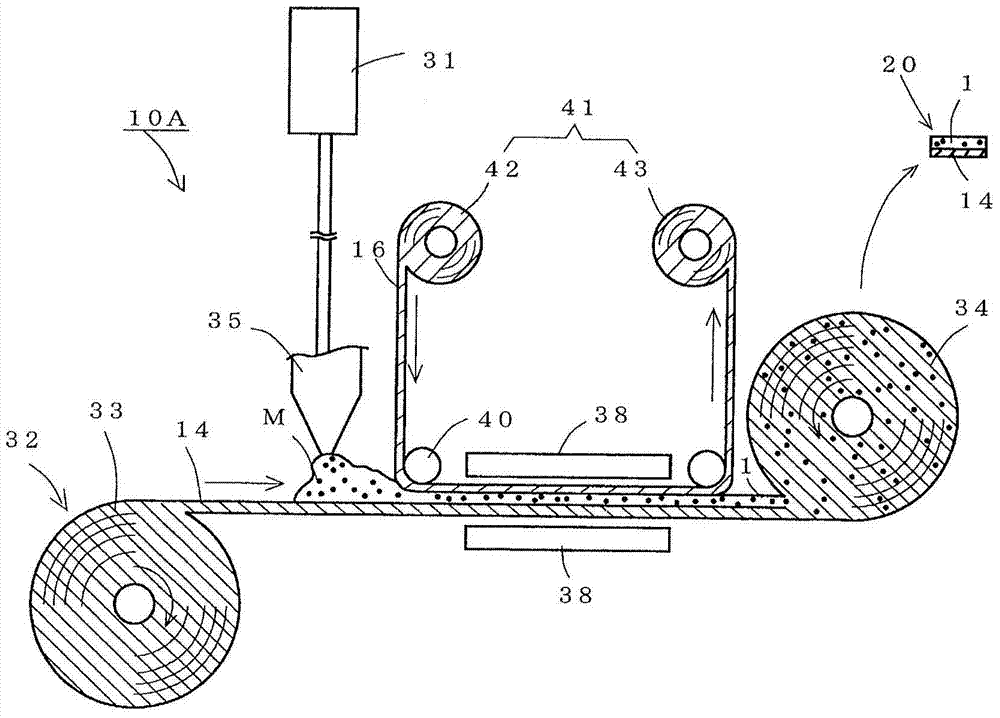

Method and device for producing optical part

InactiveUS20050212154A1Equally distributedImprove profile accuracyConfectioneryOptical articlesResidual strainOptical property

An annular insert (4) is arranged in the optical component molding cavity of a mold to surround an outer periphery of raw material resin in a direction in which the resin is distributed in the cavity to limit the distribution of the raw material resin and define an outer profile of a lens (L). With this arrangement, it is only necessary to provide raw material resin only by a quantity equal to the volume of the region surrounded by the molding surfaces of upper and lower mold inserts (14, 24) and the inner peripheral edge of the annular insert (4) of the mold, so that the required volume of the raw material resin can be reduced. Since the pressure is preserved at the outer periphery of the distributed resin by the presence of the annular insert (4), the residual strain of the resin is minimized to prevent generation of sink mark, thereby providing excellent optical characteristics on the lens (L).

Owner:HOYA CORP

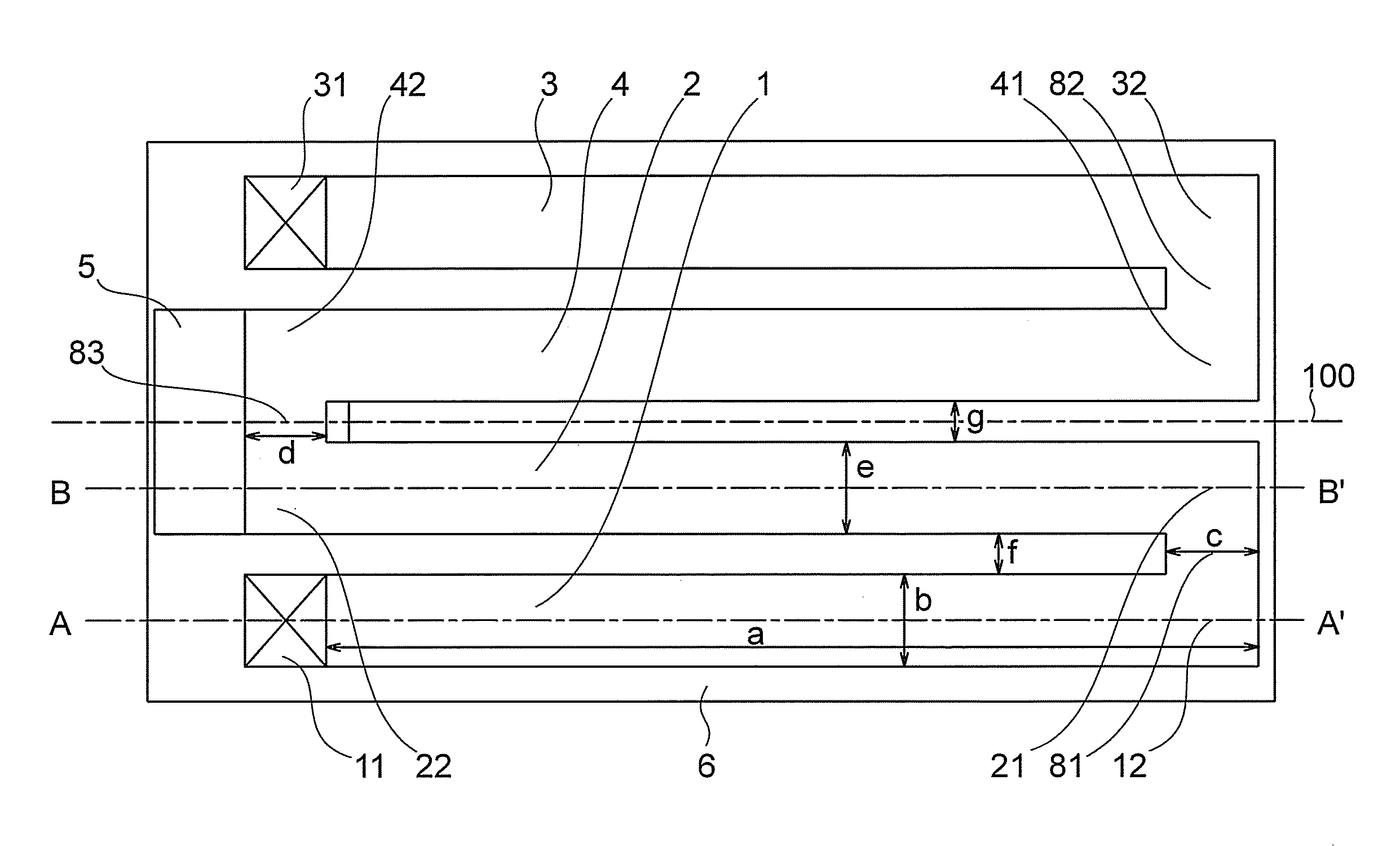

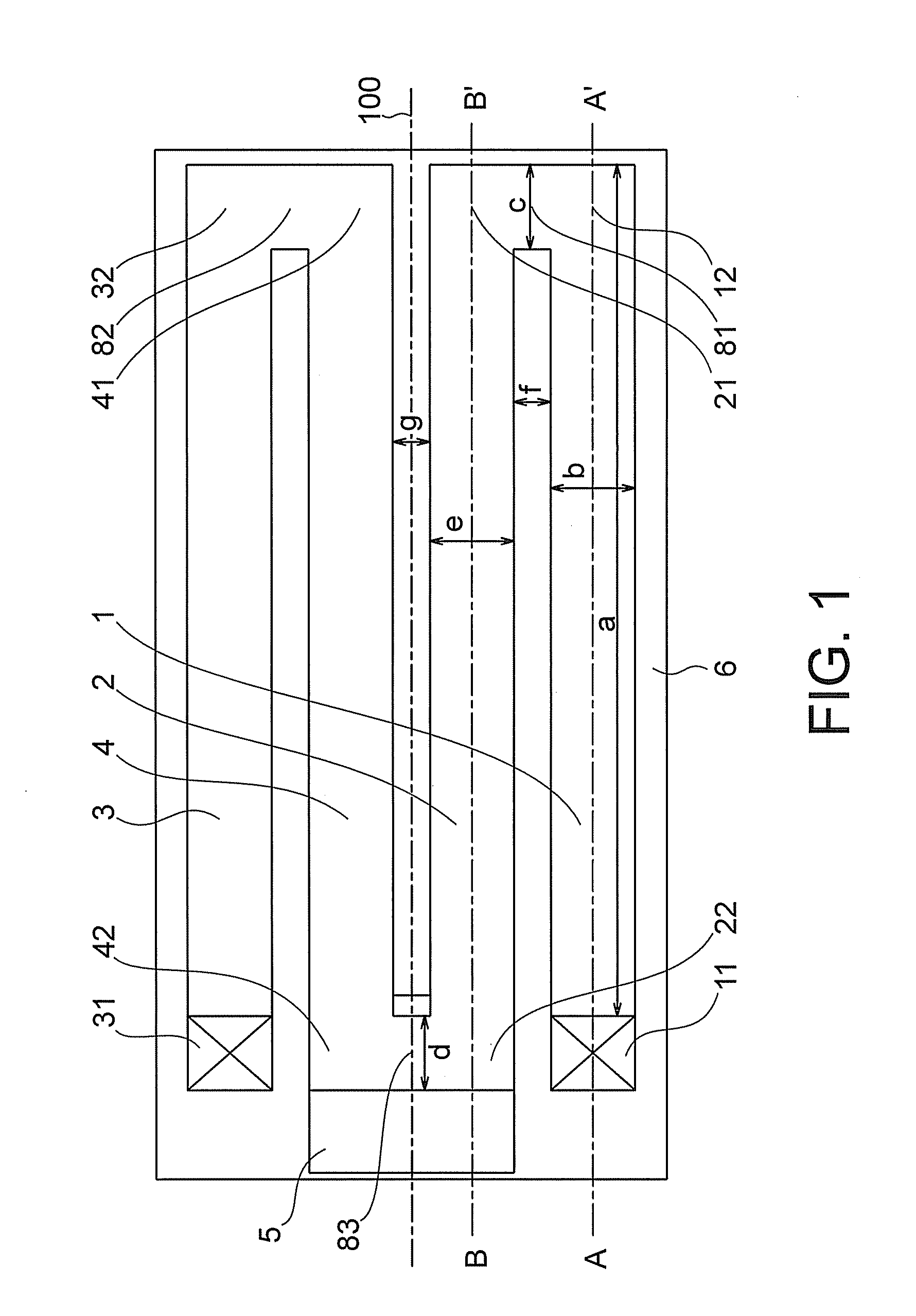

Piezoelectric driven MEMS device

InactiveUS20080042521A1Good reproducibilityImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesCapacitor with electrode distance variationResidual strainEngineering

It is made possible to provide a piezoelectric driven MEMS device having the distance between the action end and the fixed electrode which is kept constant regardless of whether the residual strain is large or small and having a mechanism which is excellent in reproducibility and reliability. Two piezoelectric driven actuators each having a folded beam structure are disposed in parallel and in a line-symmetric manner, and connected to each other in the vicinity of an action end.

Owner:KK TOSHIBA

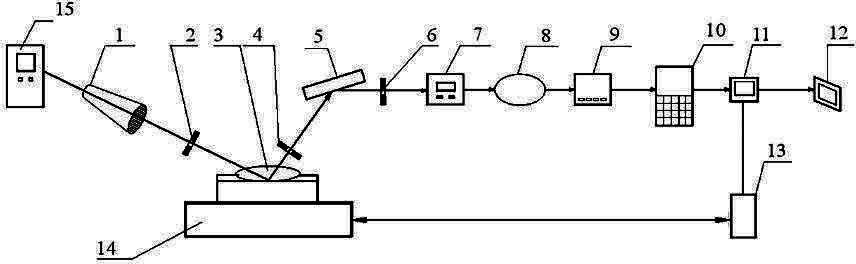

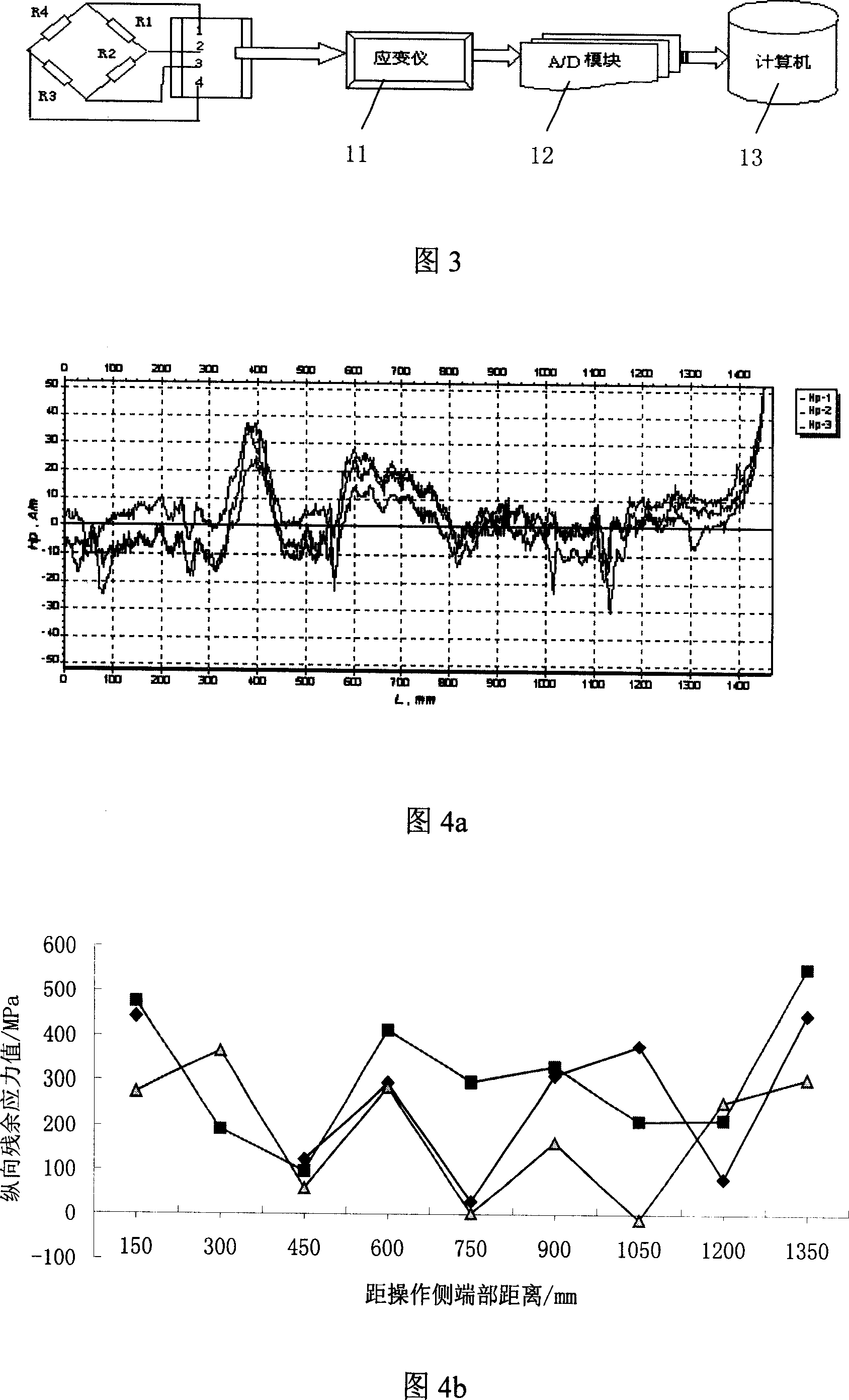

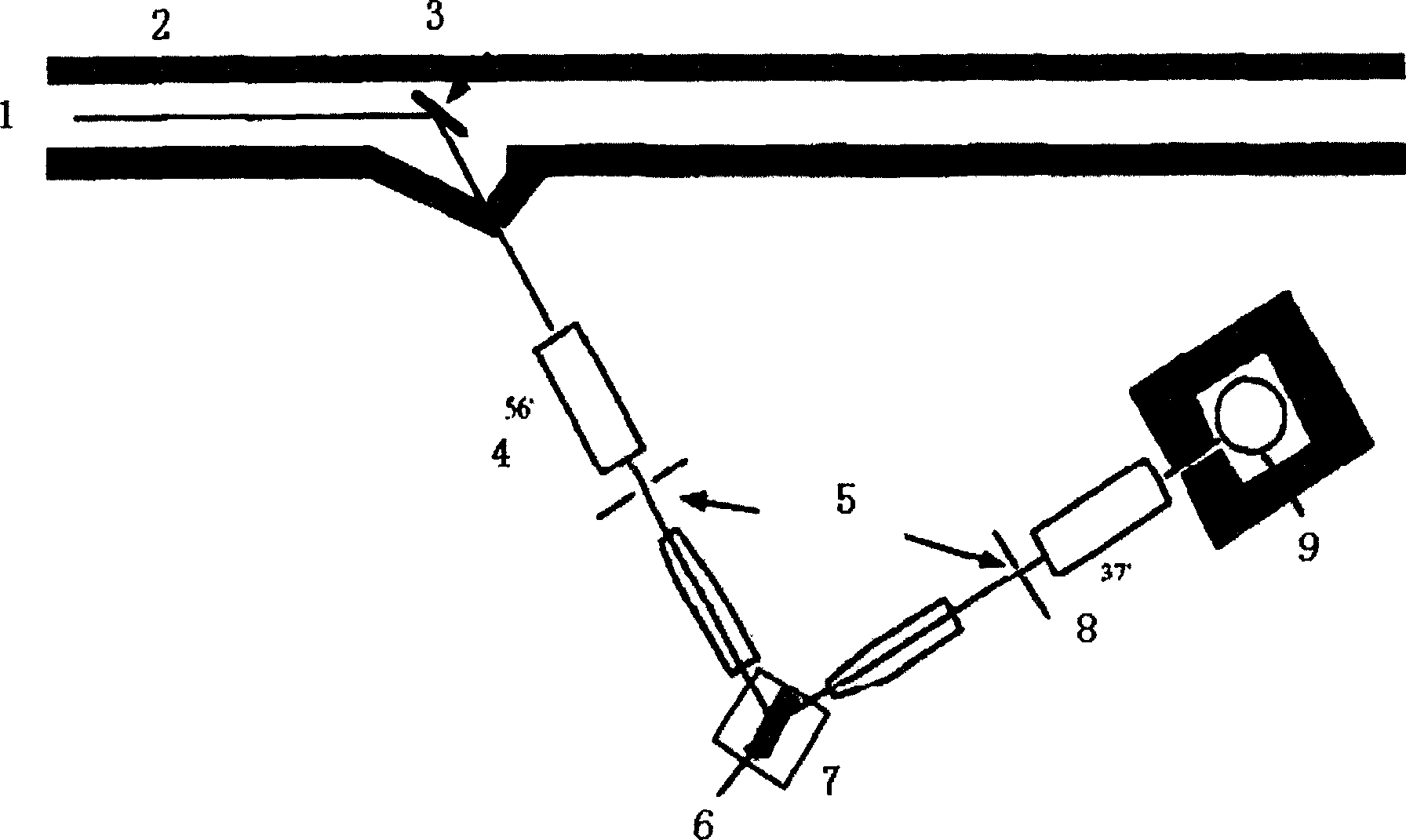

Device and method for measuring three-dimensional distribution of residual stress in metal microstructure

InactiveCN102608144AThe determination workload is smallHigh measurement accuracyMaterial analysis using radiation diffractionResidual strainSoft x ray

The invention discloses a device for measuring three-dimensional distribution of residual stress in a metal microstructure, which comprises an X-ray generating system, a microdiffraction and light path guide system, a work system, a detection system, a computer and a control system; the X-ray generating system generates X-rays with short wavelengths; the X-rays irradiate on points to be measured on a metal microstructural sample to be measured in the work system through the microdiffraction and light path guide system; then the X-rays enter the detection system through the microdiffraction and light path guide system after being subjected to diffraction by the sample; the detection system receives the X-rays entering the detection system for detection and sends obtained detection data to the computer; the computer takes analysis process on the received detection data to obtain residual strain and residual stress data of the point to be measured of the metal microstructral sample and take error analysis and parameter amendment; and after the test for the current point is finished, the computer sends a command to the control system for changing the detection point of the sample. According to the invention, the three-dimensional distribution of the residual strain and the residual stress in the penetrating range of the X-ray in a metal microstructure can be measured automatically and factually in a lossless way; therefore, the device provided by the invention is efficient and lossless and is convenient to operate.

Owner:SUZHOU UNIV OF SCI & TECH

Electorically conductive film

ActiveUS20150373838A1Transparent dielectricsNon-conductive material with dispersed conductive materialResidual strainPhysical chemistry

The present invention relates to an electrically conductive film characterized by being able to undergo elastic deformation, having little residual strain rate and exhibiting stress relaxation properties. More specifically, the present invention relates to an electrically conductive film wherein the stress relaxation rate (R) and the residual strain rate a, as measured in a prescribed extension-restoration test, are as follows: 20%≦R≦95% and 0%≦α≦3%.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

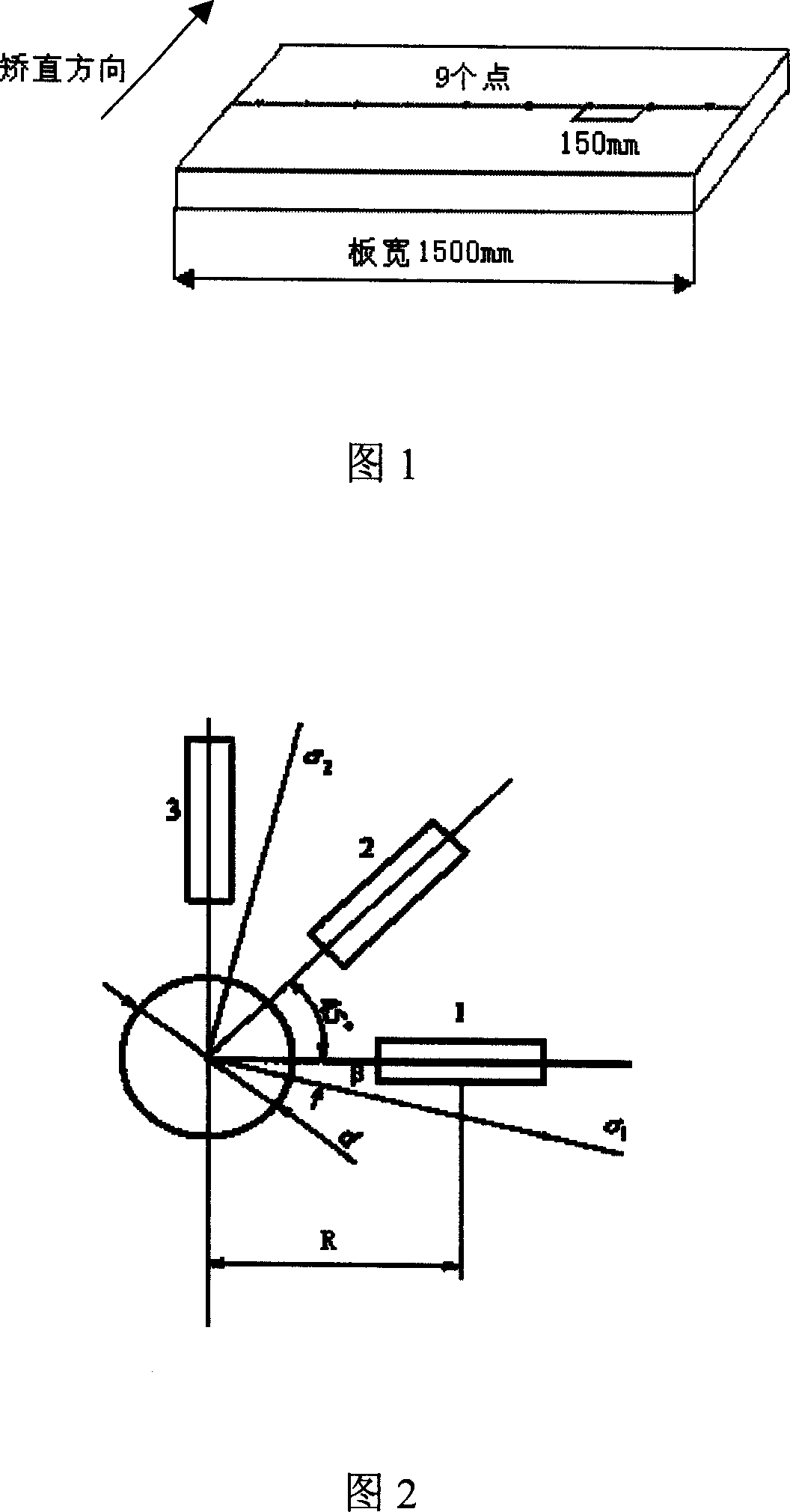

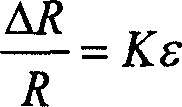

Method for detecting residual strain of thermal-continuous-rolled high-strength steel plate

InactiveCN1979161AHigh sensitivityEasy to measure from a distanceForce measurement using piezo-resistive materialsTesting metalsResidual strainElectrical resistance and conductance

The invention relates to a measuring method for testing hot continuous rolling dead-hard steel board residual stress. It uses electric resistance strain gauge to take measuring to residual stress of the sample and calculating the value, analyzing the distribution of the full sample residual stress. The method has stable reliability, accurate result, and could rapidly measure hot continuous rolling dead-hard steel board residual stress. It supplies theory foundation and technology support for hot continuous rolling dead-hard steel board, and improves the quality of the product.

Owner:BAOSHAN IRON & STEEL CO LTD +1

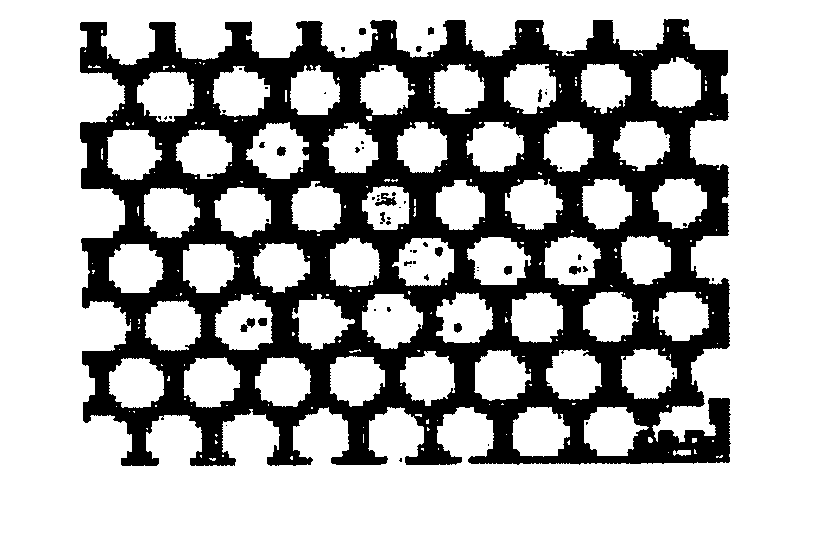

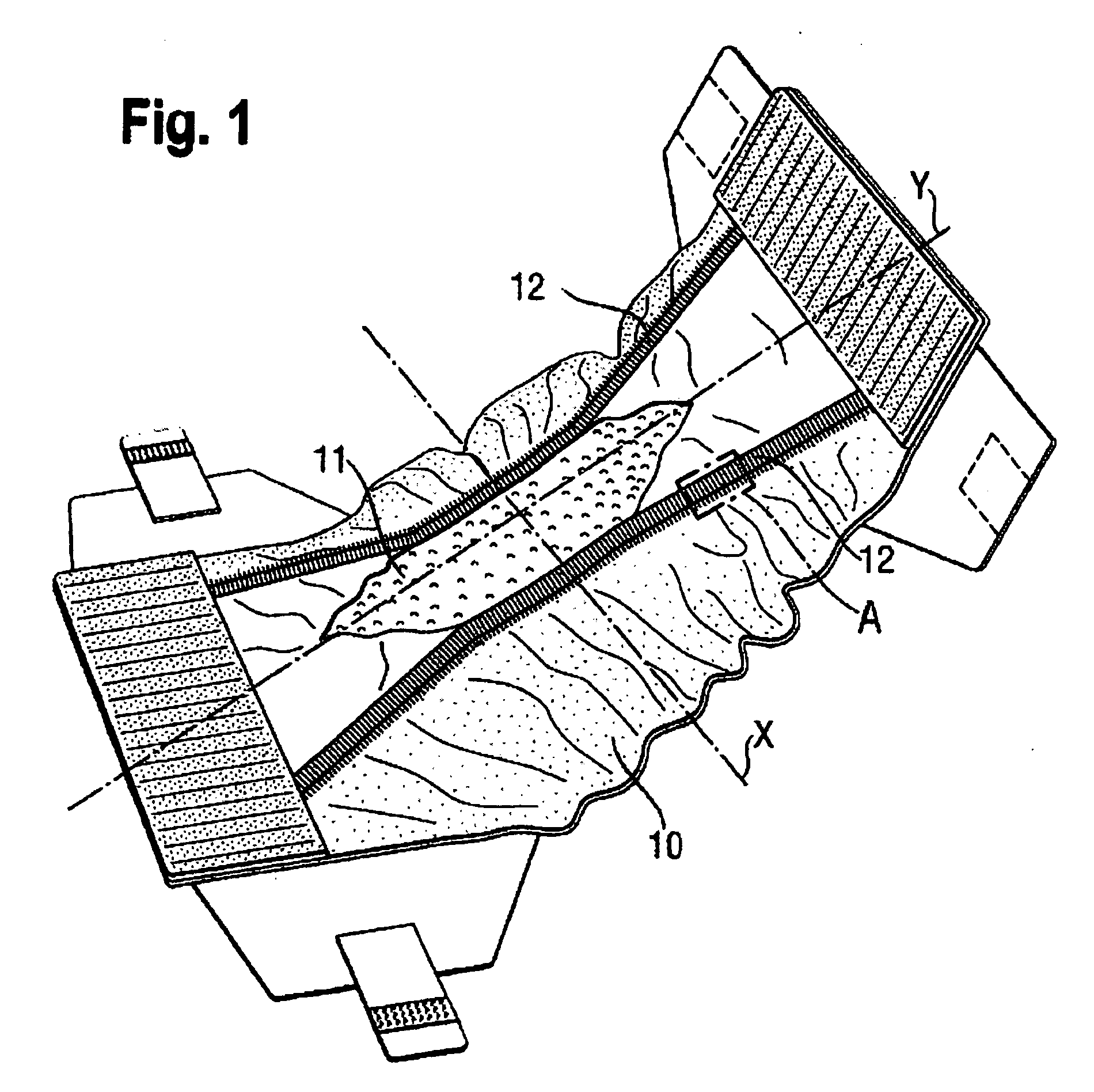

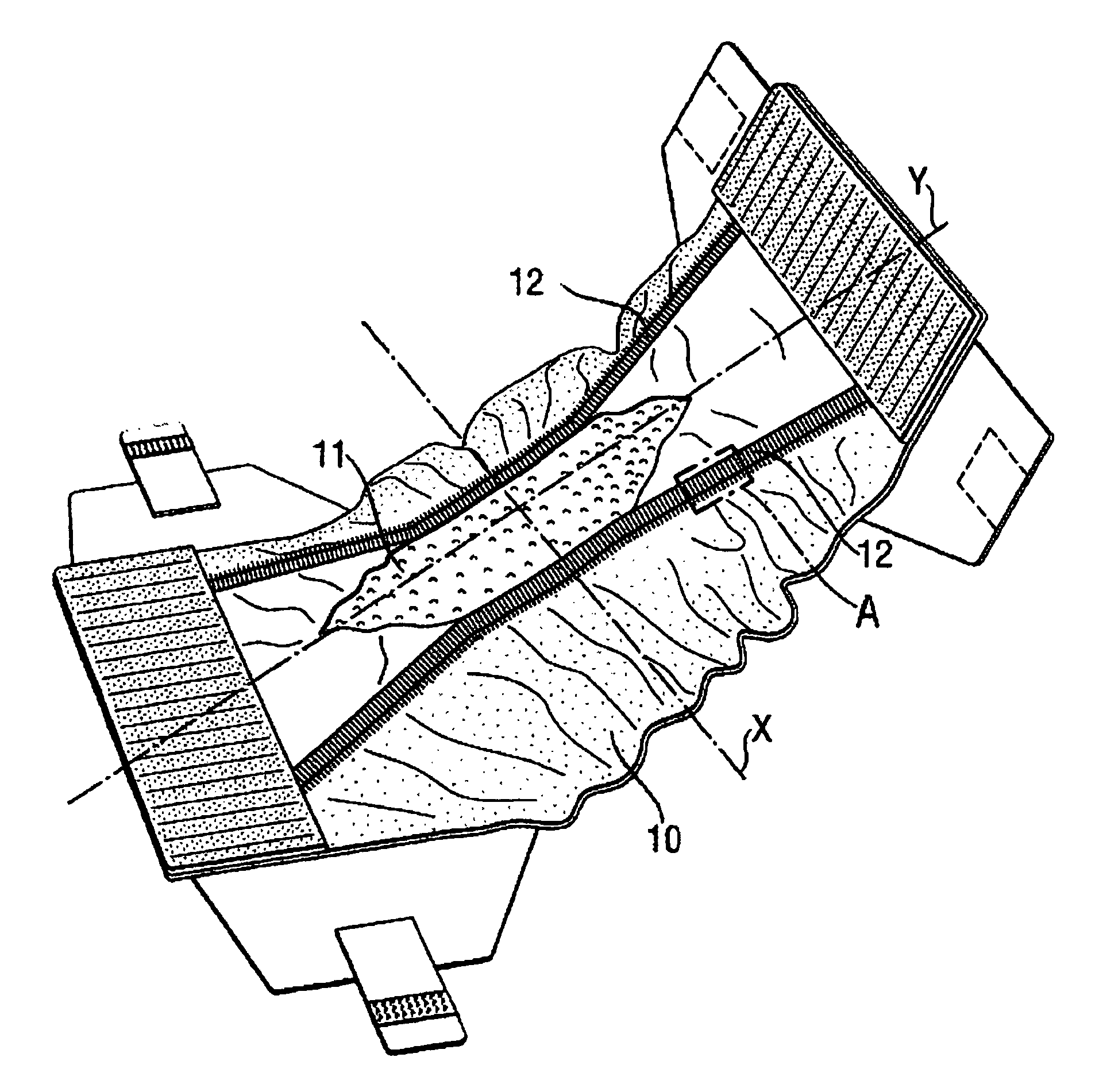

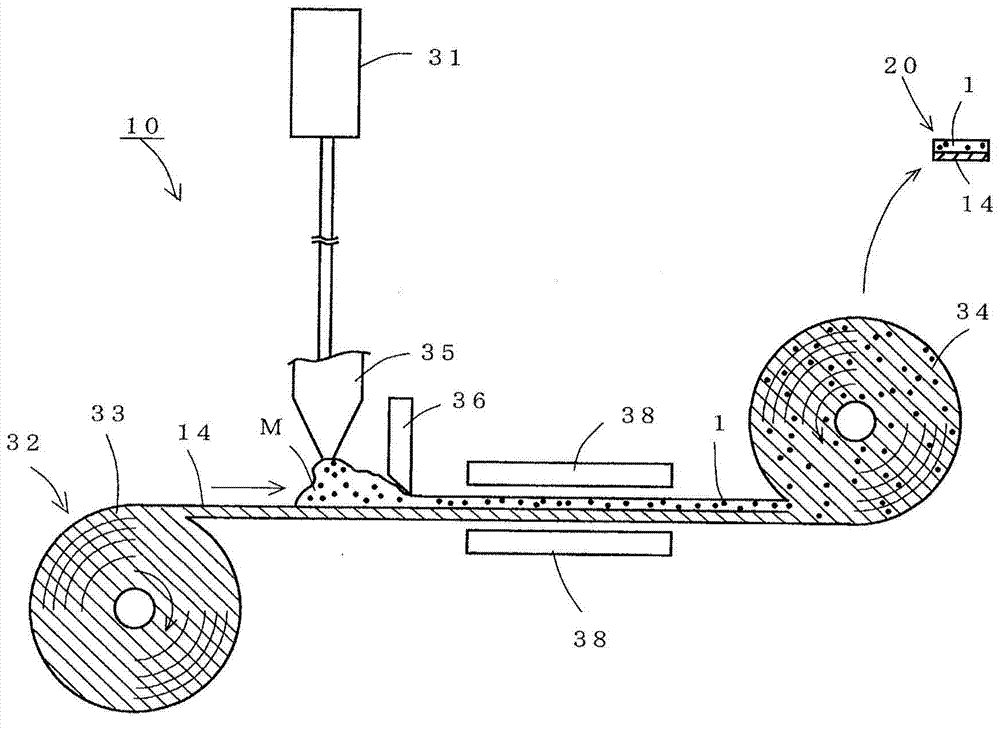

Absorbent Article with Composite Sheet Comprising Elastic Material

InactiveUS20090157035A1Strengthen the strength of attachmentIncrease elasticityMechanical working/deformationBaby linensWrinkle skinResidual strain

A process is claimed for making a composite sheet useful as topsheet with one or more openings to receive fecal material useful for an absorbent article, said composite sheet comprising a wrinkled, patterned elasticized region that comprises a patterned first sheet and an elastic material said first sheet being patterned with troughs, that are typically compacter, i.e. of higher density, prior to attachment to the elastic material. The troughs are attached to the elastic material. The resulting composite sheet has a uniform wrinkle pattern. Also claimed are specific absorbent articles. Also claimed are composite sheets with a specific residual strain and peel force value.

Owner:THE PROCTER & GAMBLE COMPANY

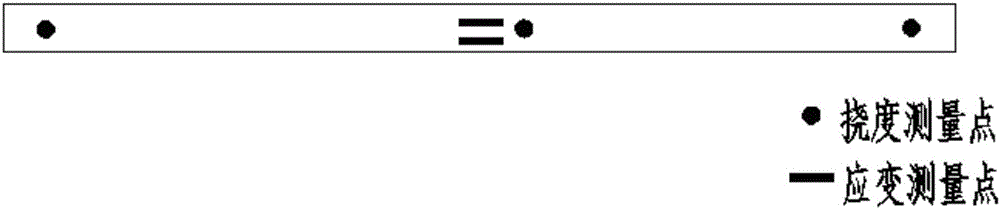

Method for load test of single beam

ActiveCN105865819AEasy to crackTo achieve the purpose of load testGeometric CADStructural/machines measurementResidual strainStructural deformation

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

Method of producing polymer spherical bodies

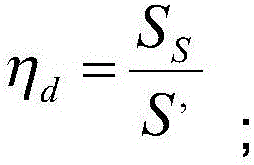

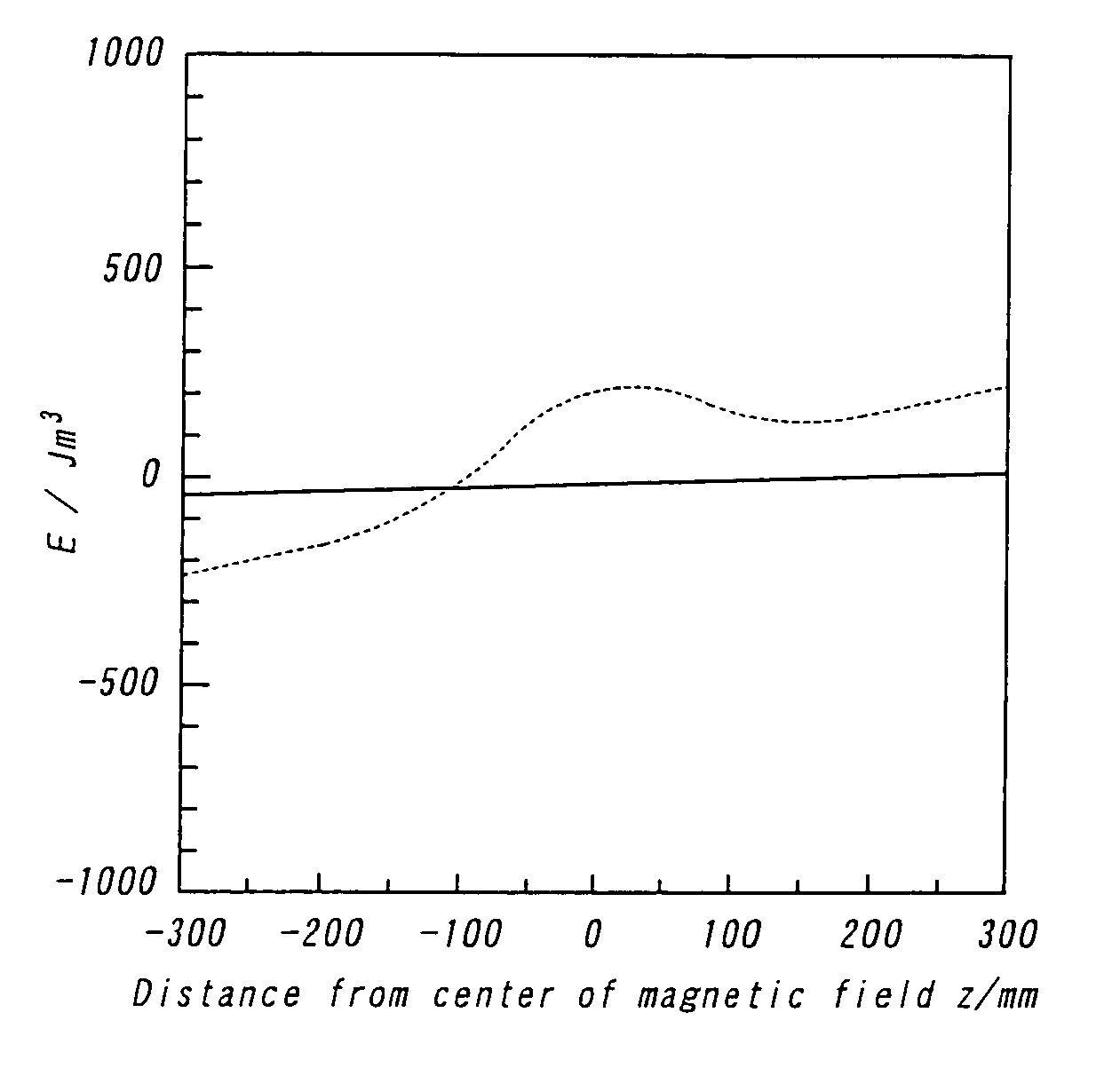

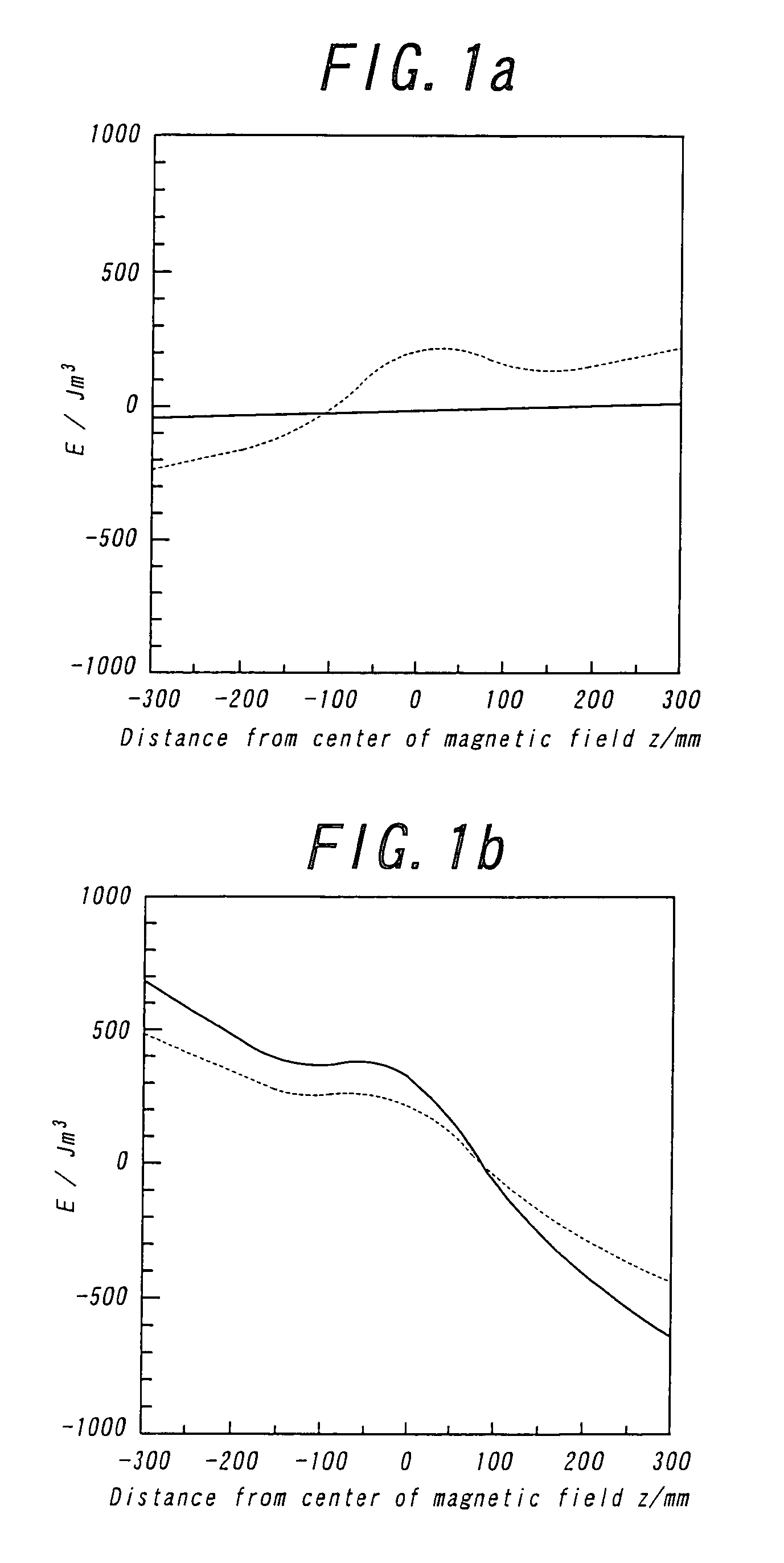

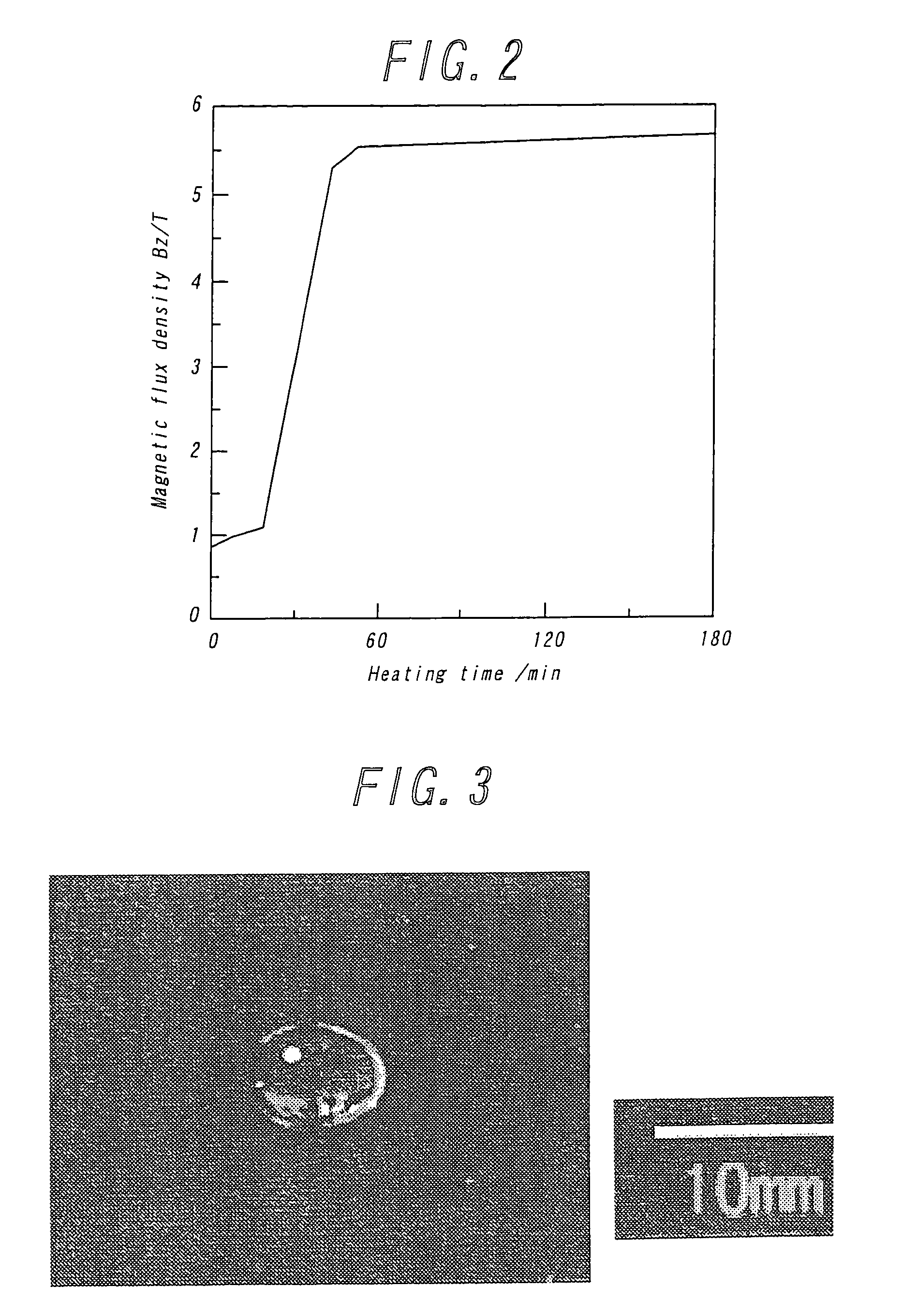

InactiveUS7008572B2Weaker magnetic fieldPrecise positioningElectric discharge heatingEnergy based chemical/physical/physico-chemical processesMagnetic susceptibilityResidual strain

This invention relates to a method of producing polymer spherical bodies and is to produce a large size spherical body having no residual strain. This method comprises suspending a liquid monomer in a supporting liquid having a magnetic susceptibility χ2 larger than a magnetic susceptibility χ1 of any one of the monomer and the resulting polymer and not dissolving substantially the monomer, and applying a gradient magnetic field to the supporting liquid to float droplets of the monomer at a given position in the supporting liquid, and polymerizing and solidifying the droplets while maintaining a state that the droplet is substantially shaped into a sphere through surface tension. This method is made possible to produce polymer spherical bodies capable of using in optical application and the like.

Owner:TOKYO METROPOLITAN UNIV OF PUBLIC UNIV CORP

Absorbent article with composite sheet comprising elastic material

InactiveUS8235959B2High strengthIncrease elasticityMechanical working/deformationBaby linensResidual strainHigh density

A process is claimed for making a composite sheet useful as topsheet with one or more openings to receive fecal material useful for an absorbent article, said composite sheet comprising a wrinkled, patterned elasticized region that comprises a patterned first sheet and an elastic material said first sheet being patterned with troughs, that are typically compacter, i.e. of higher density, prior to attachment to the elastic material. The troughs are attached to the elastic material. The resulting composite sheet has a uniform wrinkle pattern. Also claimed are specific absorbent articles. Also claimed are composite sheets with a specific residual strain and peel force value.

Owner:THE PROCTER & GAMBLE COMPANY

Method for measuring residual stress on surface of metal sample based on micro indentation

InactiveCN103969108AAccurate measurementThe operation process is simple and convenientMaterial strength using tensile/compressive forcesInvestigating material hardnessResidual strainMeasurement cost

The invention discloses a method for measuring residual stress on surface of a metal sample based on micro indentation. The method comprises the following steps: performing a micro indentation test on the surface of the sample by utilizing a Vickers microhardness tester, recording the indentation morphology by adopting a scanning electron microscope, and obtaining the nominal projection area and actual projection area of the indentation on the surface of the sample through calculation for diagonal length and side length of the micro indentation; obtaining a strength coefficient and strain hardening index of the material through a standard tensile test; and obtaining a theoretical formula for measuring the residual stress through an indentation method and containing the ratio of the actual projection area to the nominal projection area of the micro indentation, the strength coefficient and strain hardening index based on the hypothesis for the two-dimension isometric residual stress field on the surface of the sample, and further obtaining the residual strain and residual stress on the surface of the sample. The measurement method belongs to basically nondestructive or micro-damage measurement and has the advantages of low measurement cost, simplicity and convenience in operation and high measurement efficiency. If being combined with a portable high-power optical microscope with a distance measurement function, the method can be popularized and applied in the field of engineering.

Owner:UNIV OF SCI & TECH BEIJING

Method and device for producing optical part

InactiveUS7332110B2Economize rate of consumptionExcellent optical propertiesConfectioneryOptical articlesResidual strainOptical property

An annular insert (4) is arranged in the optical component molding cavity of a mold to surround an outer periphery of raw material resin in a direction in which the resin is distributed in the cavity to limit the distribution of the raw material resin and define an outer profile of a lens (L). With this arrangement, it is only necessary to provide raw material resin only by a quantity equal to the volume of the region surrounded by the molding surfaces of upper and lower mold inserts (14, 24) and the inner peripheral edge of the annular insert (4) of the mold, so that the required volume of the raw material resin can be reduced. Since the pressure is preserved at the outer periphery of the distributed resin by the presence of the annular insert (4), the residual strain of the resin is minimized to prevent generation of sink mark, thereby providing excellent optical characteristics on the lens (L).

Owner:HOYA CORP

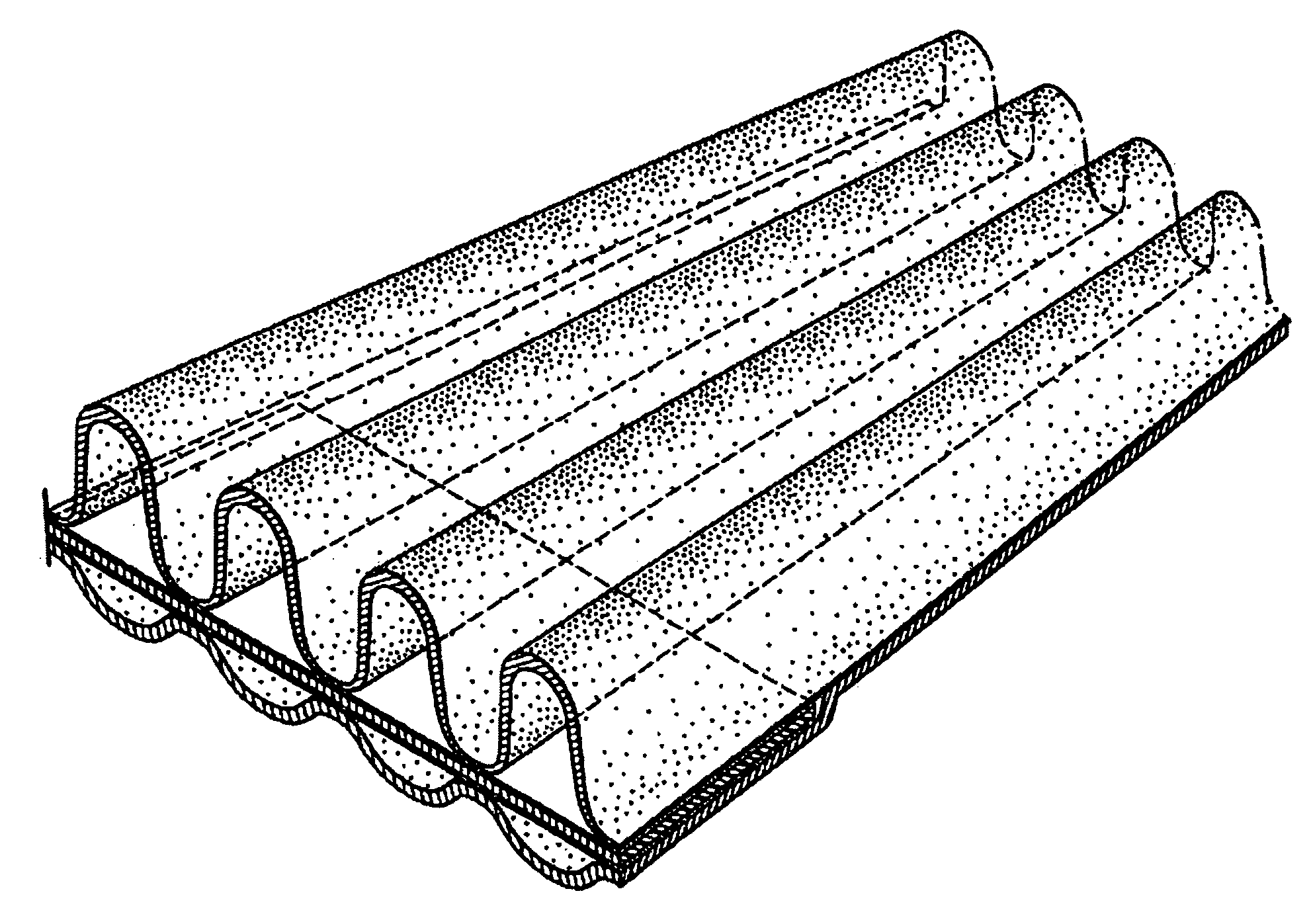

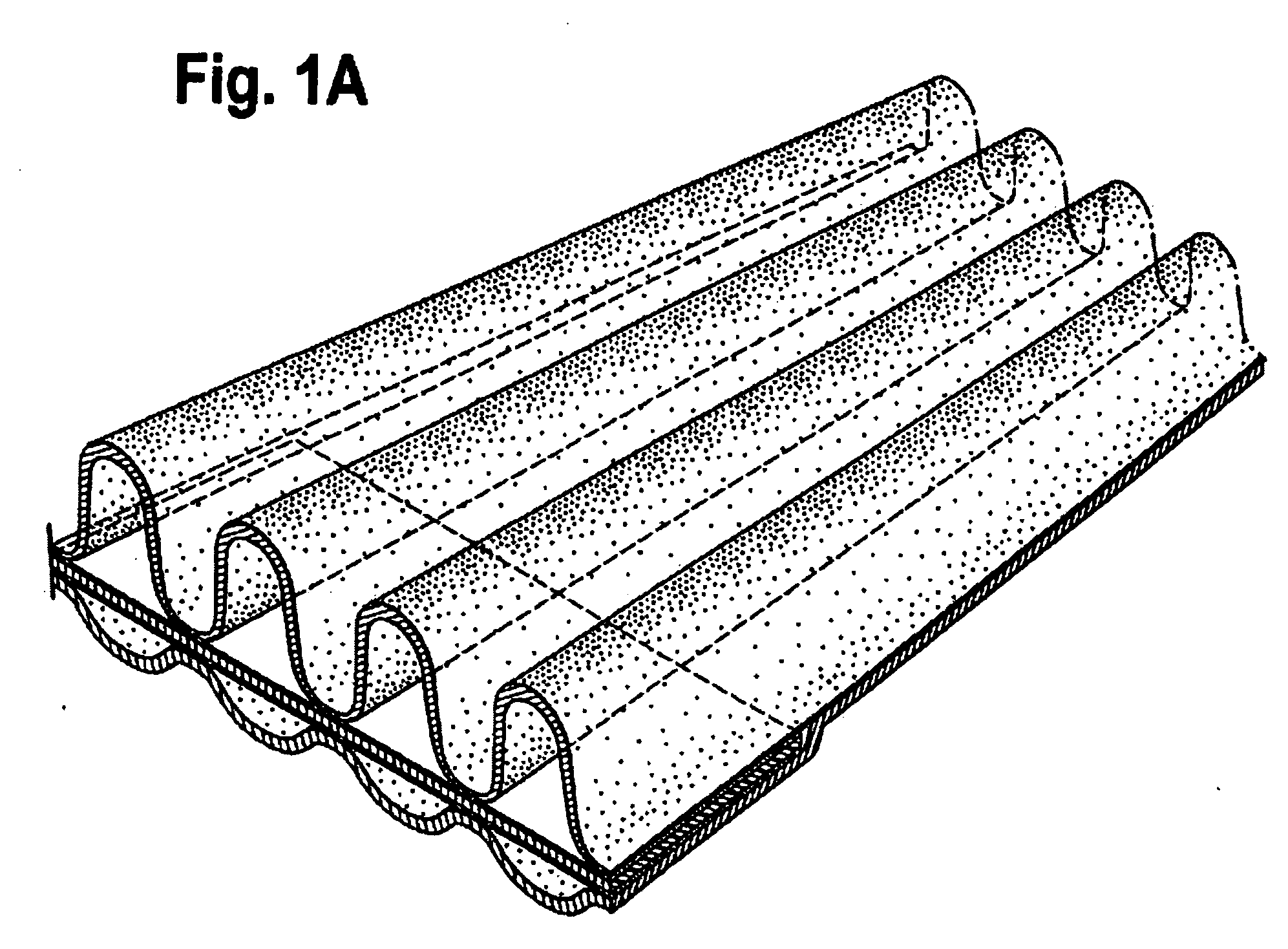

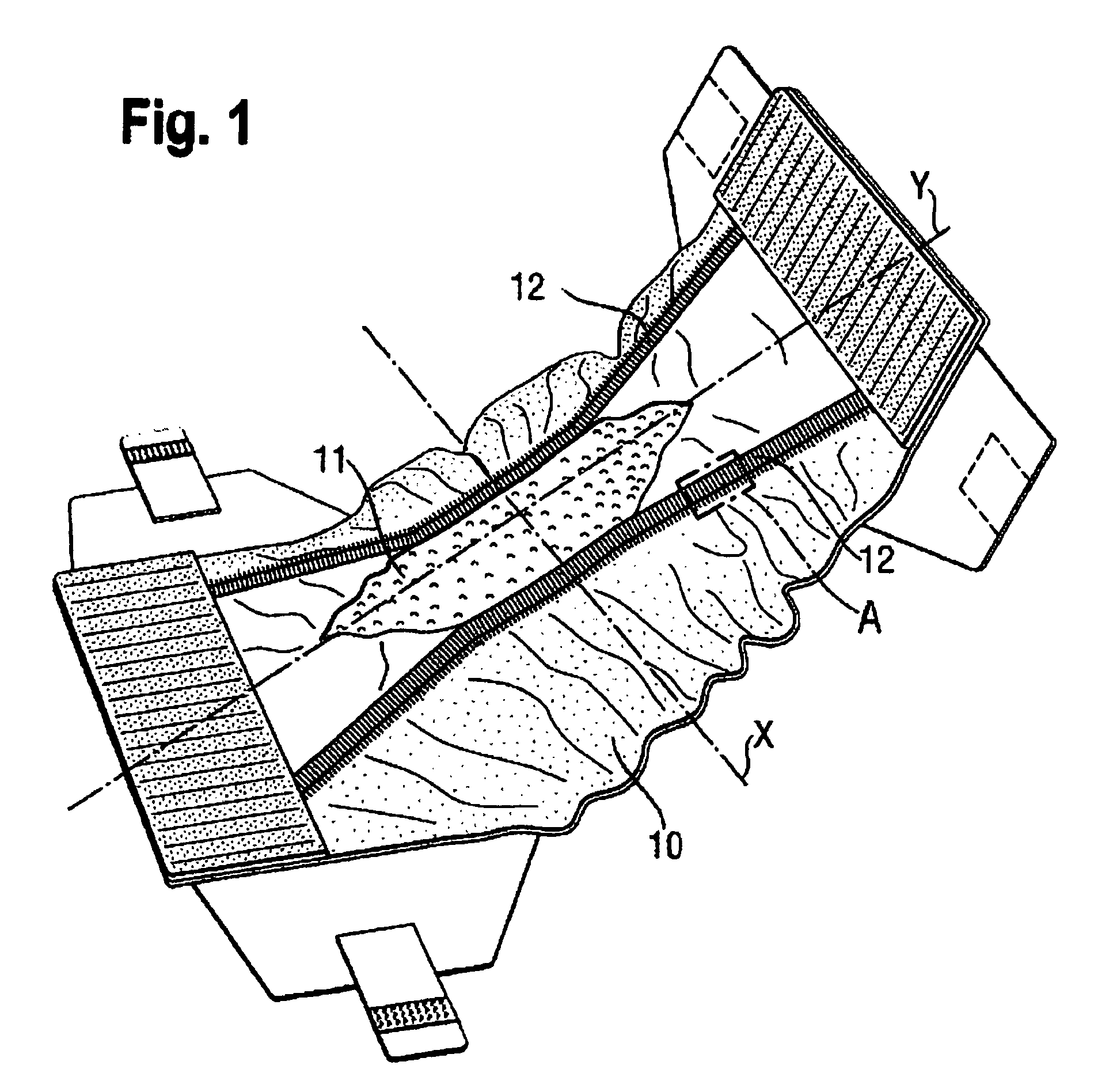

Fibrous Network Structure Having Excellent Compression Durability

InactiveUS20160010250A1Excellent repeated compression durabilityLow repeated compression residual strainMonocomponent polyetheresters artificial filamentSynthetic resin layered productsPolyesterMolten state

The present invention provides a network structure having excellent repeated compression durability, the network structure having a low repeated compression residual strain and a high hardness retention after repeated compression.A network structure comprising a three-dimensional random loop bonded structure obtained by forming random loops with curling treatment of a continuous linear structure including a polyester-based thermoplastic elastomer and having a fineness of not less than 100 dtex and not more than 60000 dtex, and by making each loop mutually contact in a molten state, wherein the network structure has an apparent density of 0.005 g / cm3 to 0.20 g / cm3, a 50%-constant displacement repeated compression residual strain of not more than 15%, and a 50%-compression hardness retention of not less than 85% after 50%-constant displacement repeated compression.

Owner:TOYOBO CO LTD

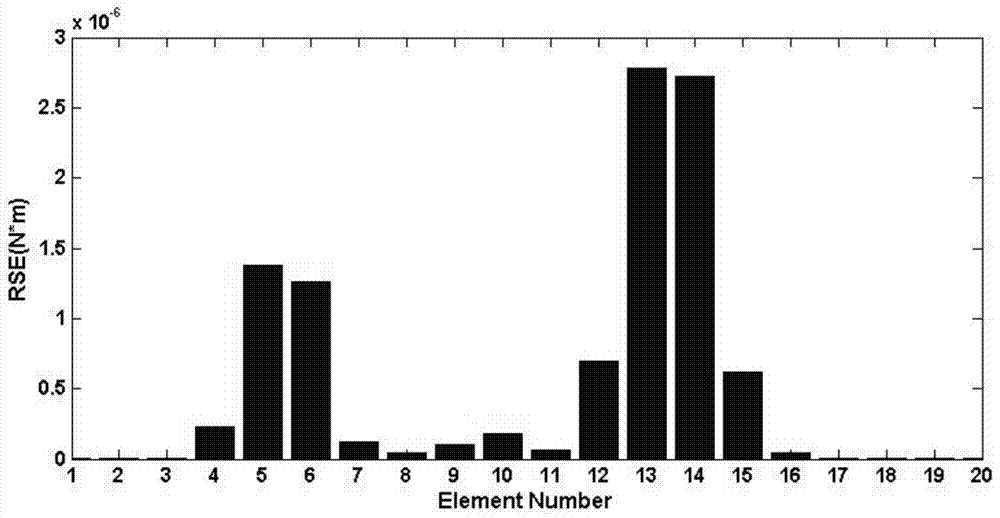

Structural damage location and damage degree identification method based on small amount of static measurement data

ActiveCN103884593AReduce measurement errorImprove recognition accuracyMaterial strength using tensile/compressive forcesResidual strainEngineering

The invention discloses a structural damage location and damage extent identification method based on a small amount of static measurement data. The method comprises the following steps: (1) choosing a loading scheme according to an index Di; (2) calculating residual strain energy (RSE) values of all units; (3) comparing all the RSE values and selecting the unit with the highest RSE value as a doubtful unit; (4) calculating a sensitivity matrix (S) and a response difference (delta Um) of a model to be corrected and a real model; (5) solving the equation (S) (delta alpha)=(delta Um); (6) updating an damage parameter alpha it plus 1, which is equal to alpha it plus delta alpha it, of the doubtful unit; (7) returning to the step (4) for loop iteration if the precision requirement is not met, otherwise, outputting the damage parameter as an identification result. The method defines the concept of RSE and can predict the damage position and reduce the quantity of parameters required to be recognized; the sensitivity static response method is adopted to perform model correction, the required data volume is low, and the recognition efficiency and the recognition precision are high.

Owner:SUN YAT SEN UNIV

Polypropylene nonwoven fabric and use thereof

ActiveUS20080287027A1Nice appearanceMaintain good propertiesFilament/thread formingAdhesive dressingsResidual strainPolyolefin

A polypropylene based nonwoven fabric is excellent in surface appearance and stretch properties and exhibits a small residual strain and excellent adhesiveness to polyolefins. The nonwoven fabric is obtained by forming a polypropylene resin composition comprising 1 to 40 weight parts of (i) an isotactic polypropylene, and 60 to 99 weight parts of (ii) a propylene / ethylene / α-olefin copolymer obtained by copolymerizing 45 to 89 mole % of propylene, 10 to 25 mole % of ethylene and the balance of α-olefin having 4 to 20 carbon atoms (with the proviso that the copolymerized amount of the α-olefin having 4 to 20 carbon atoms does not exceed 30 mole %), characterized by a small residual strain after stretching at a stretch ratio of 150%. The nonwoven fabric can be effectively used as sanitary materials or the like by virtue of its characteristics including stretch properties.

Owner:MITSUI CHEM INC

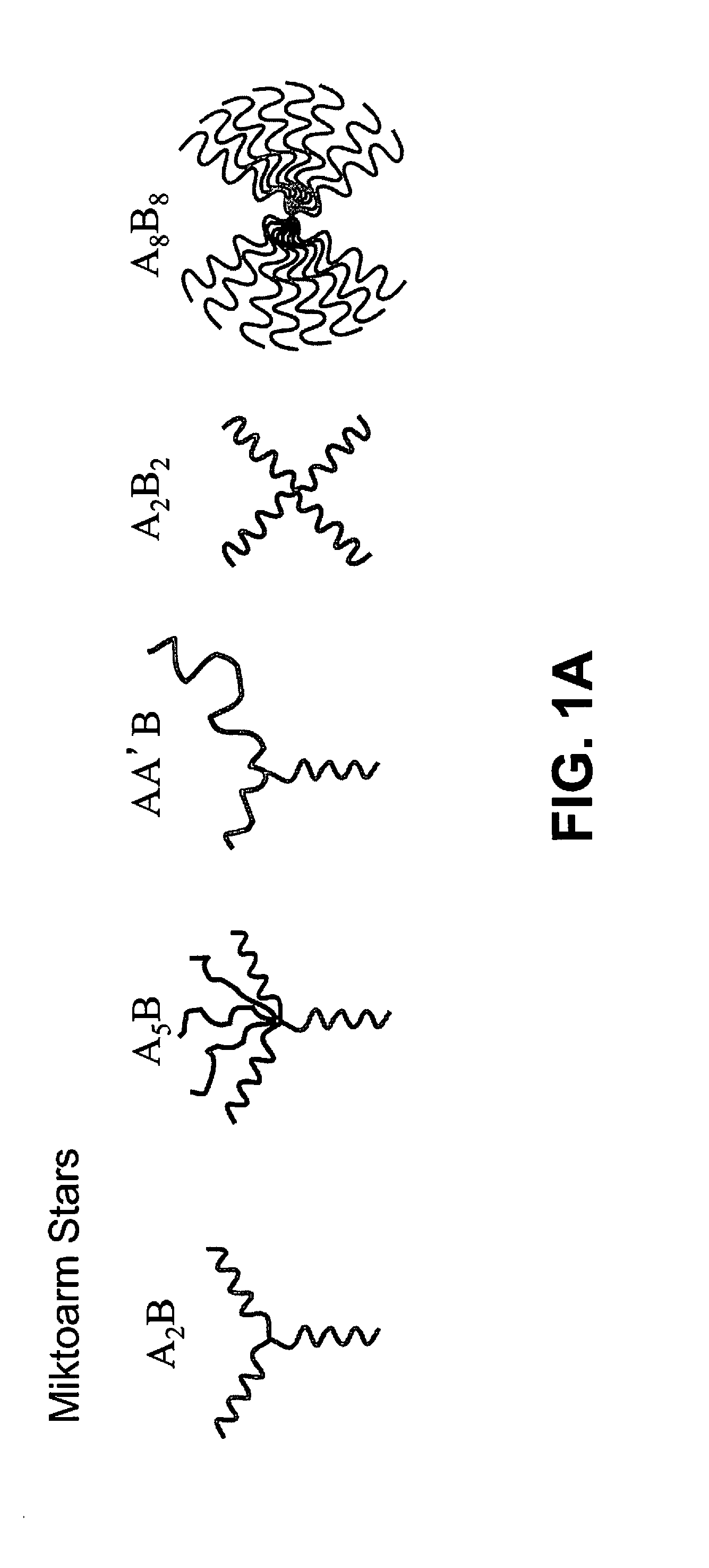

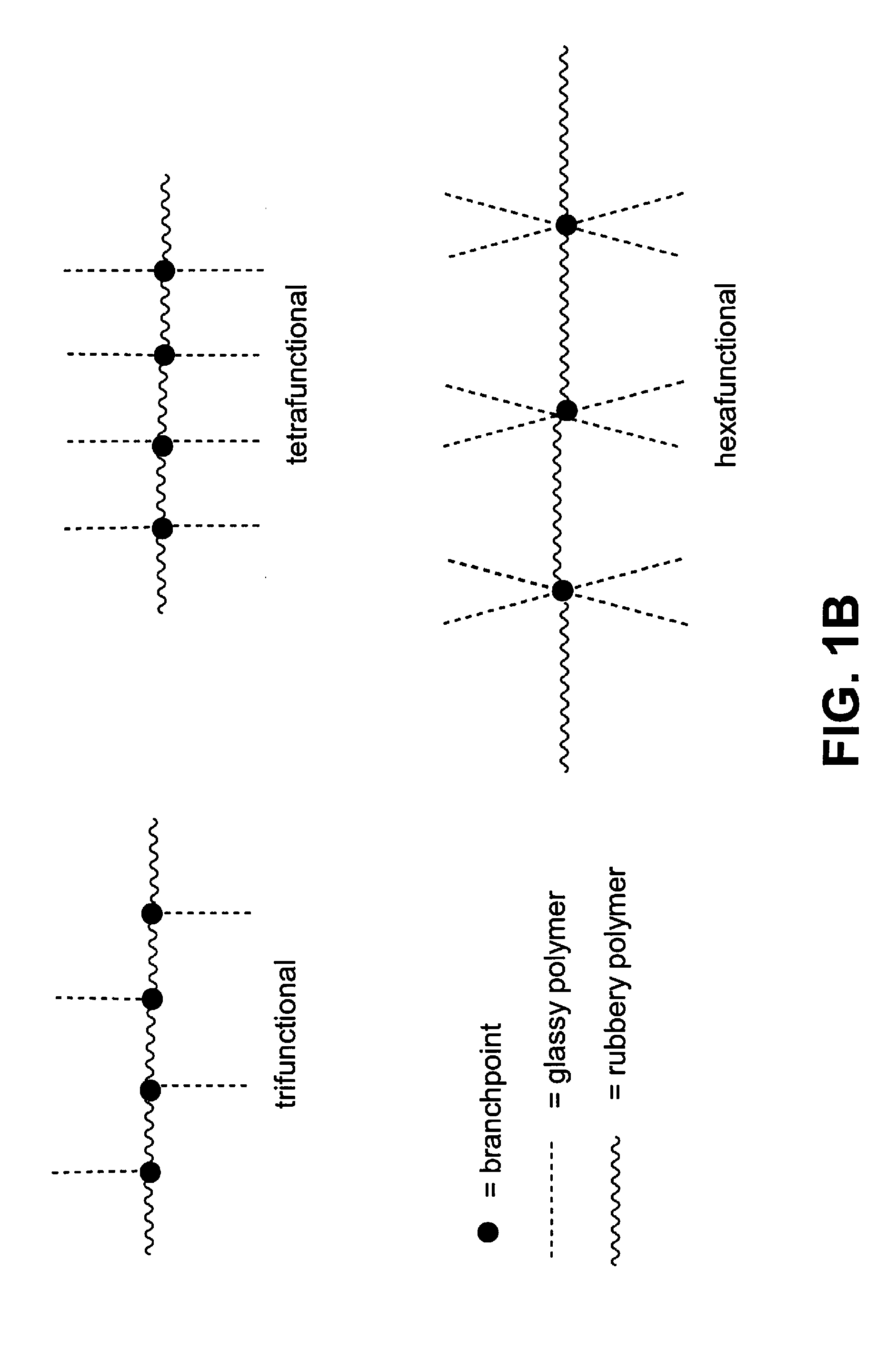

Multigraft Copolymers as Superelastomers

Thermoplastic elastomer compositions are described comprising multigraft copolymers. The multigraft copolymers can comprise a rubbery polymeric backbone and a plurality of glassy polymeric side chains, each attached at one of a plurality of branch points randomly spaced along the backbone. The copolymer materials have high tensile strength, high strain at break, and low residual strain after elongation. The compositions can be used as adhesives and in a wide variety of high tech, medical, and commodity applications.

Owner:UNIV OF TENNESSEE RES FOUND +1

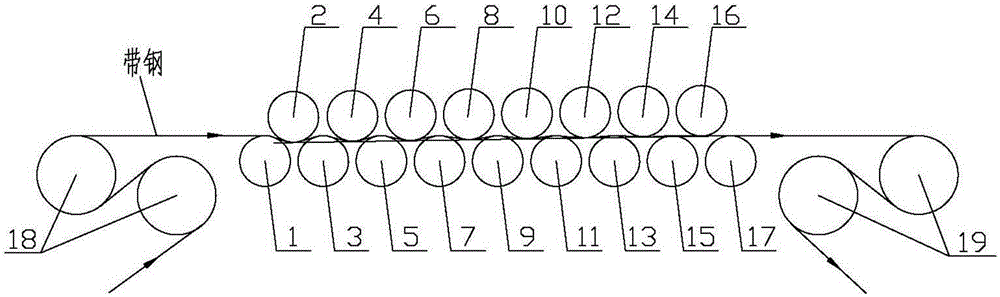

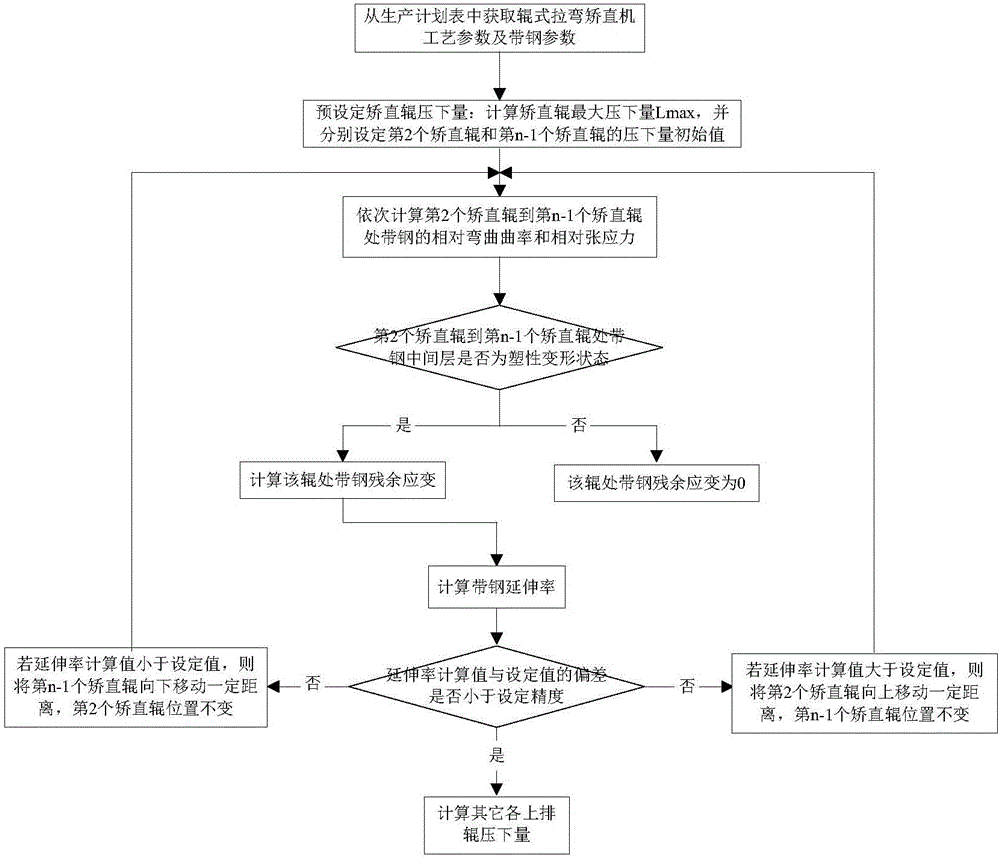

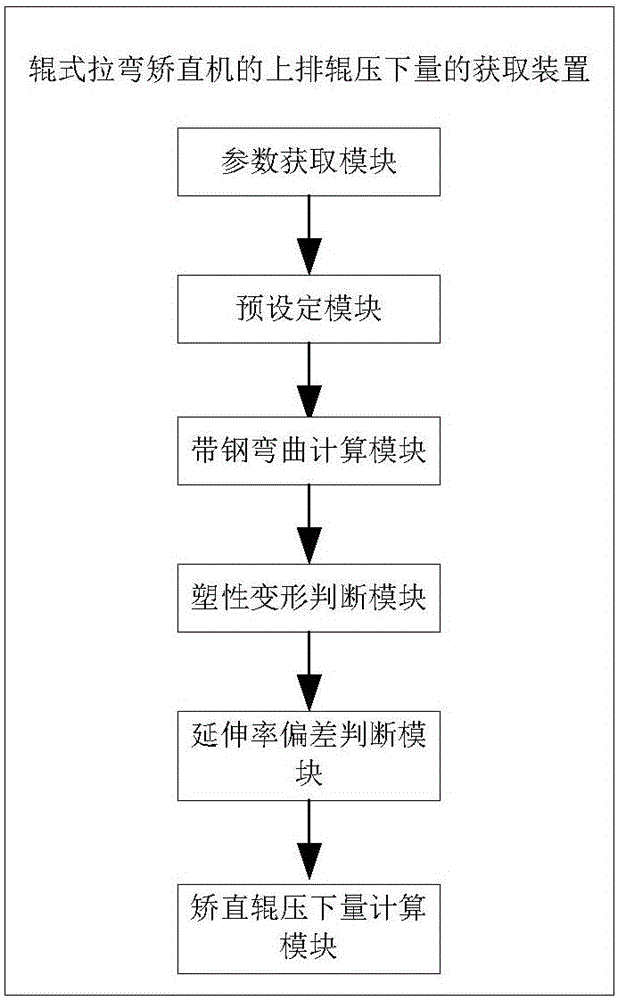

Rolling reduction acquisition method and device for upper-row rollers of roller-type stretch bend straightening machine

ActiveCN106270001APrevent slippingSimple calculationMetal working apparatusResidual strainStrip steel

The invention discloses a rolling reduction acquisition method and device for upper-row rollers of a roller-type stretch bend straightening machine. The method is characterized in that relational expressions between residual strains of interlayers of strip steel during stretch bending and the relative bending curvatures of the strip steel at all straightening rollers, as well as between the residual strains of the interlayers of the strip steel during stretch bending and the relative tensile stresses of strip steel at all the straightening rollers are established through theoretical analysis; then the residual strains of the strip steel at all the straightening rollers are calculated according to given roller-type stretch bend straightening process parameters, and accumulated to work out the ductility of the strip steel, and the calculated ductility values and the actual ductility values are compared to realize optimal calculation of the rolling reduction of upper-row rollers of the roller-type stretch bend straightening machine. The rolling reduction acquisition method is definite and clear in principle, and simple and quick in calculation; the calculated results and the field measured values are identical; the rolling reduction of the upper-row rollers can be accurately matched with the speed difference between an inlet tension roller set and an outlet tension roller set, so that the ductility of the strip steel, which can be provided by the roller-type stretch bend straightening machine, conforms to the actual ductility, and accordingly, the strip steel is prevented from sliding.

Owner:WISDRI ENG & RES INC LTD +1

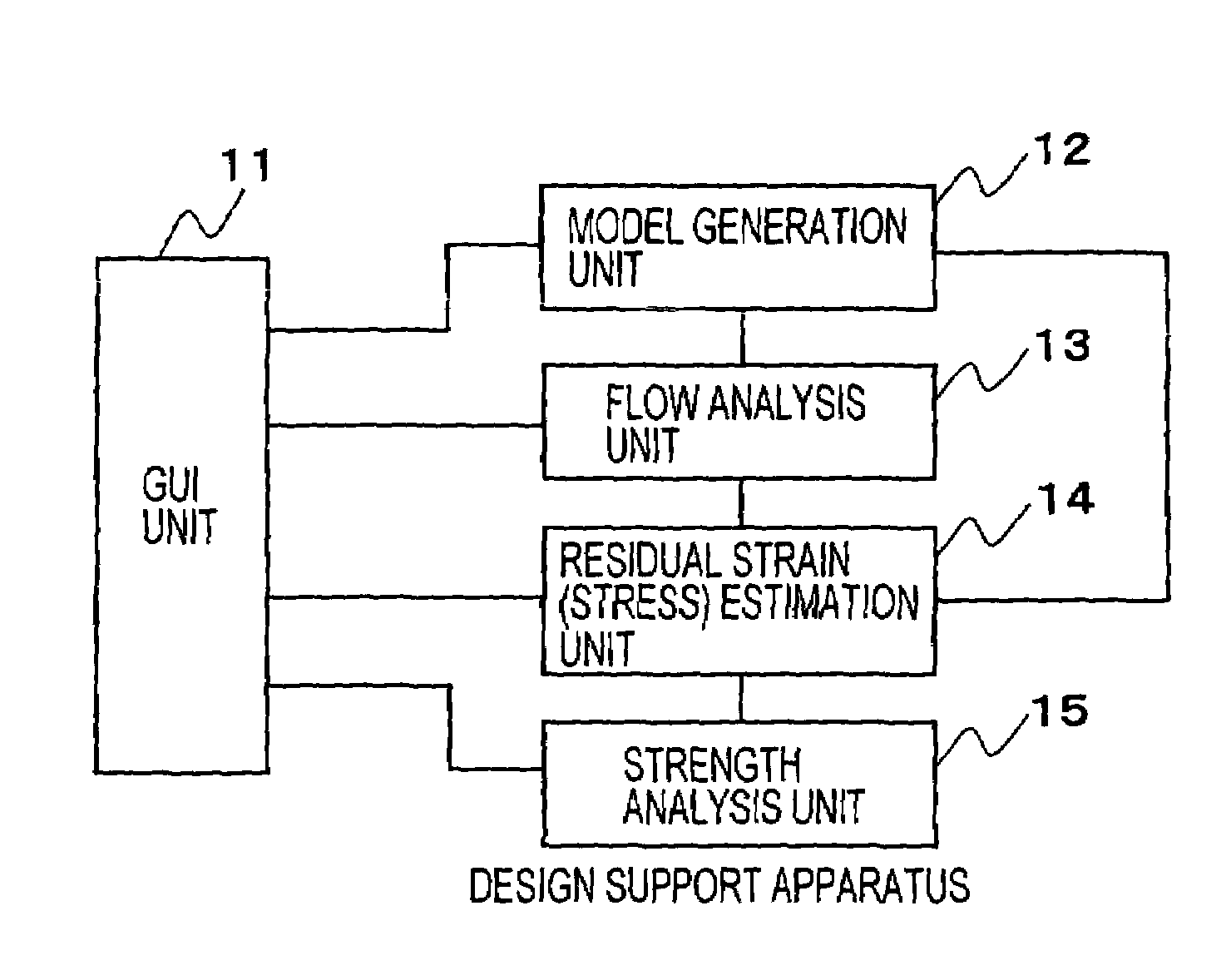

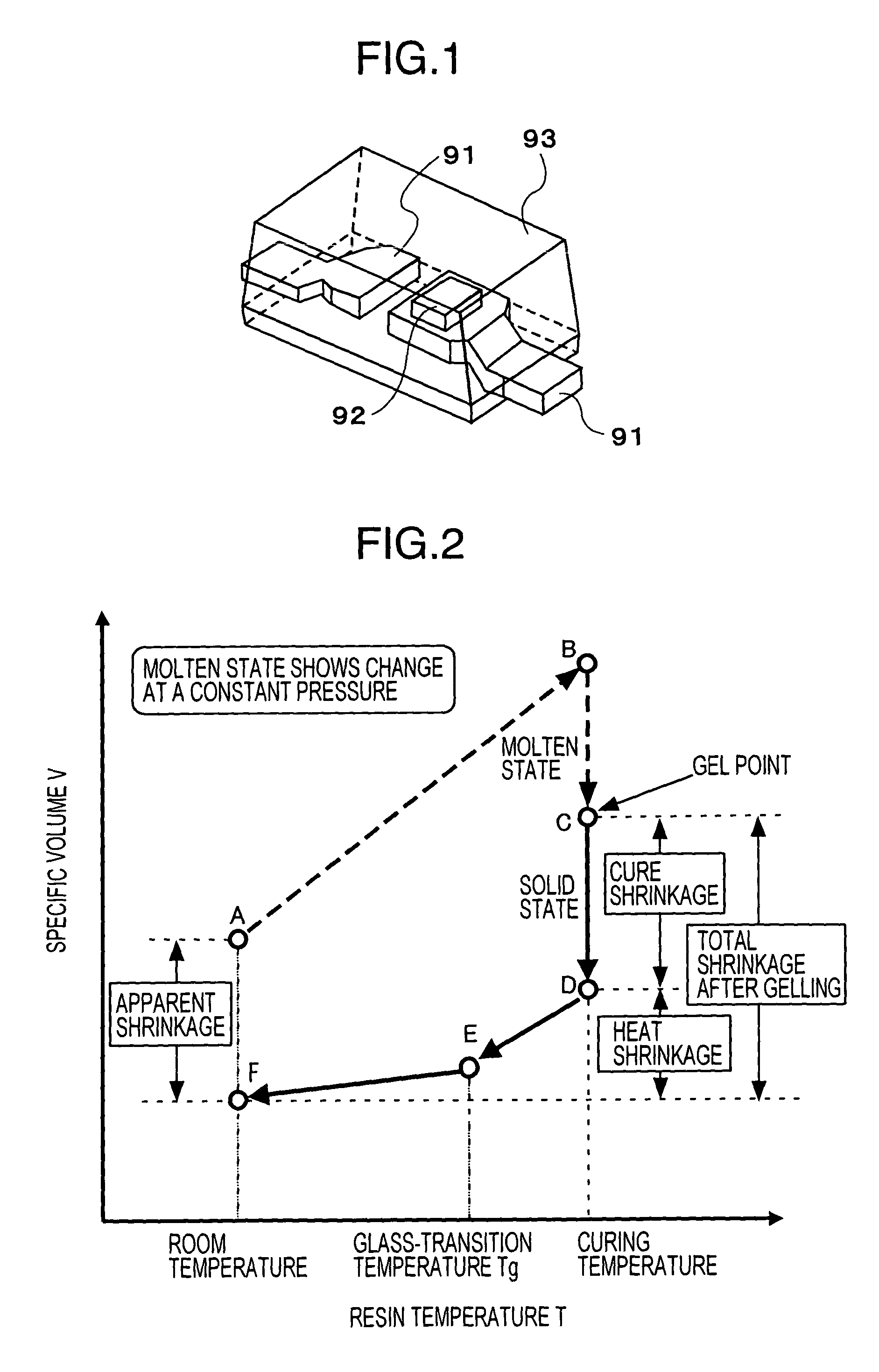

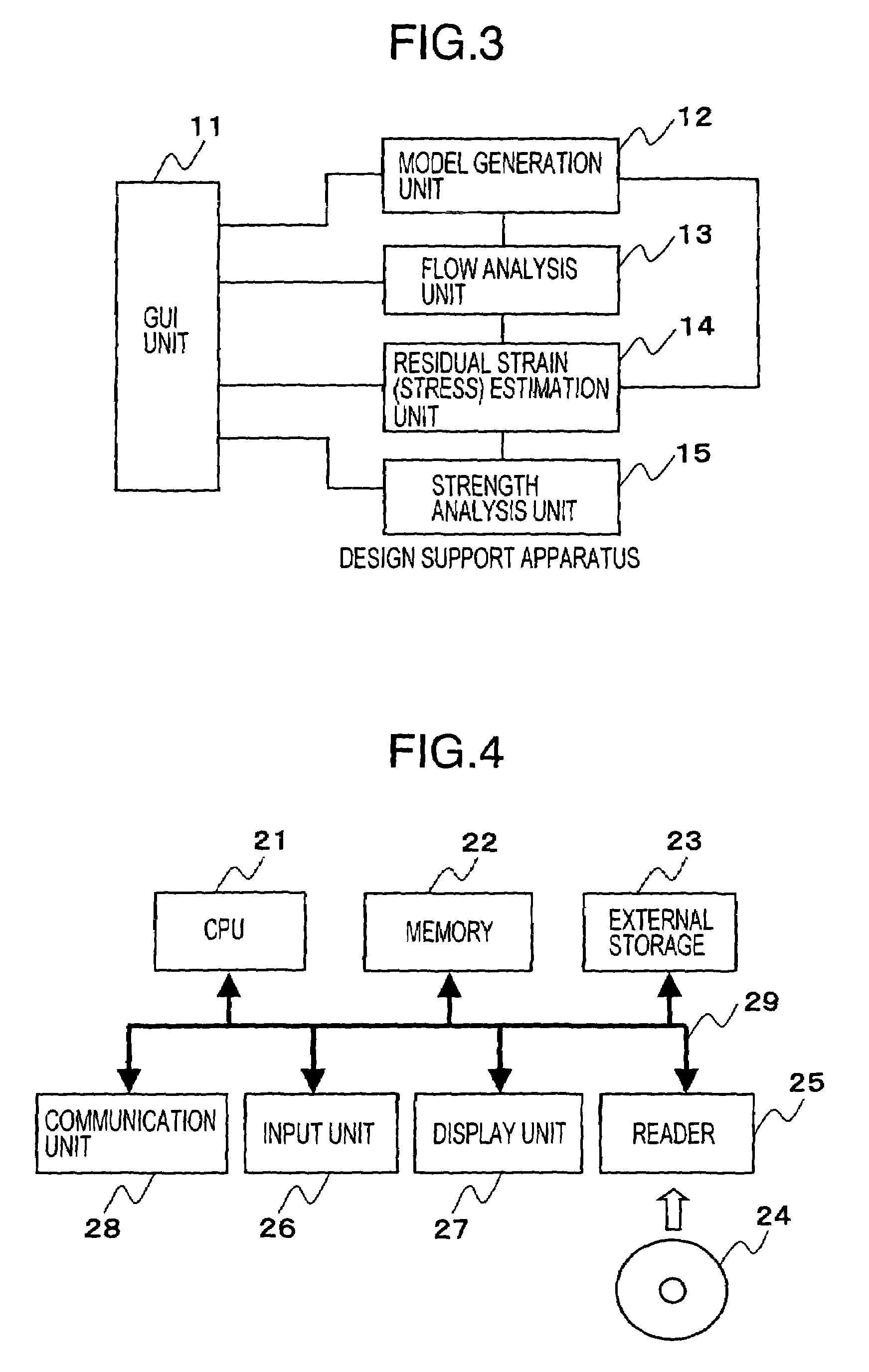

Design support apparatus and method for supporting design of resin mold product

InactiveUS7096083B2Exact strengthPredict strength of the resin mold product more accuratelySolid-state devicesSpecial data processing applicationsResidual strainFinite element method

A design support apparatus including: a flow analyzer for analyzing a flow of thermosetting resin injected into a resin filling cavity to mold a resin mold product made of the thermosetting resin, using a finite difference method or a finite element method; a residual strain calculator for calculating residual strain (or stress) of the thermosetting resin after heat shrinkage of the thermosetting resin injected into the resin filling cavity to mold the resin mold product; and a strength analyzer for analyzing strength of the resin mold product, using a finite element method. According to this arrangement, strength of the resin mold product made of the thermosetting resin can be predicted accurately.

Owner:HITACHI LTD

Cold finished seamless steel tubes

ActiveUS20050191509A1Efficient executionImprove machinabilityLayered productsBearing componentsResidual strainCarbide

Cold finished seamless steel tubes are made such that the residual stress F to be generated at the stage of the correction process after cold working is controlled to be 30 MPa or more and the scattering thereof is 30 MPa or less, when measured by Crampton method. Further, by adjusting the average grain size of spheroidized carbides, the dimensional change which emerges in lathe turning of the outside and inside diameter of relevant steel tubes due to the residual strain can be suppressed, and the strict roundness as well as the excellent machinability can be secured at the final processing stage of the work pieces for bearing parts. Consequently, steel tubes with high dimensional accuracy and less dimensional change at the final steps such as lathe turning, heat treatment and the like, can be made for use as bearing parts.

Owner:NIPPON STEEL CORP

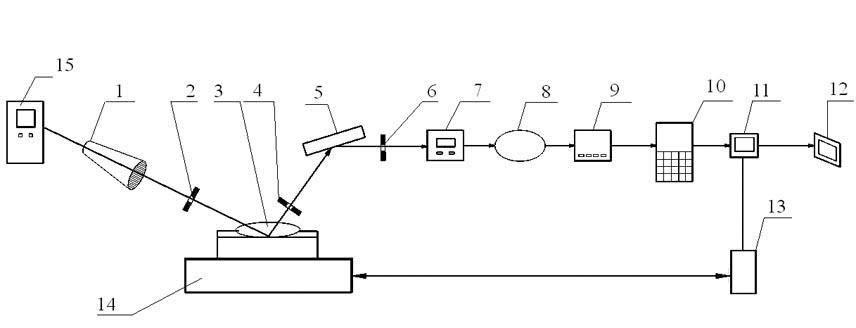

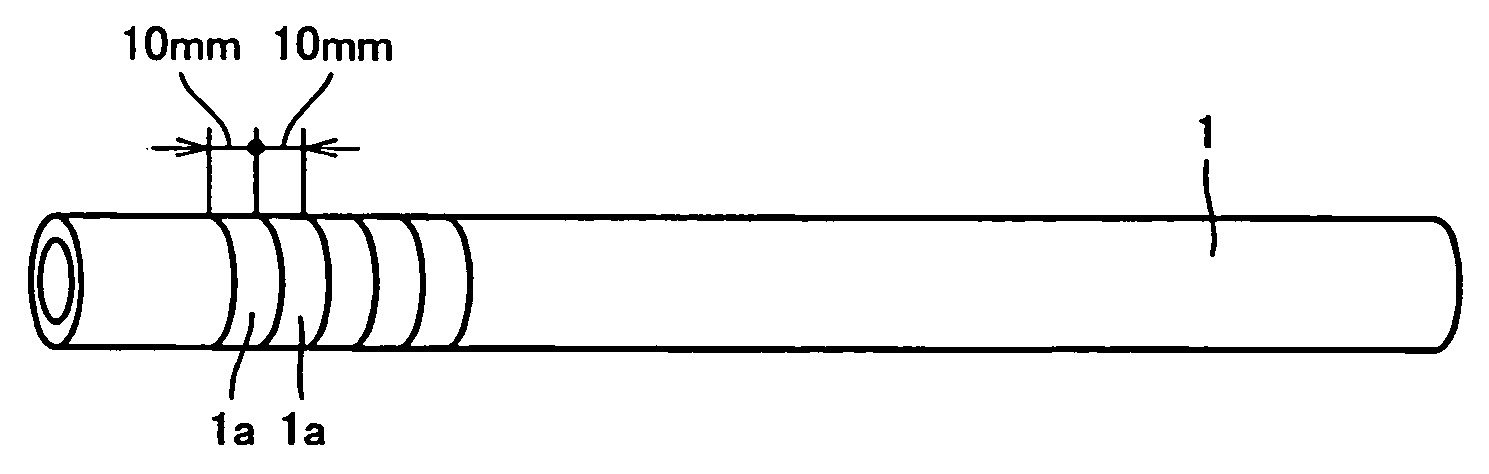

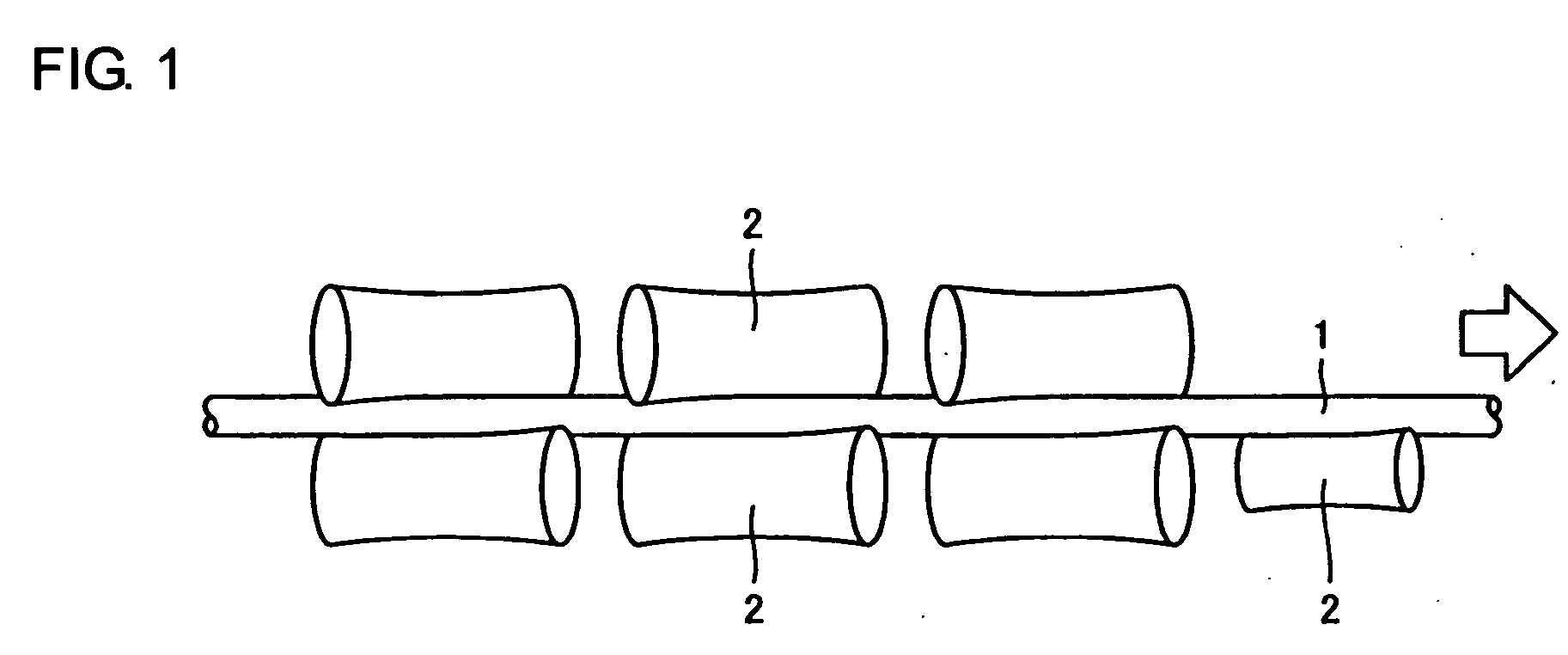

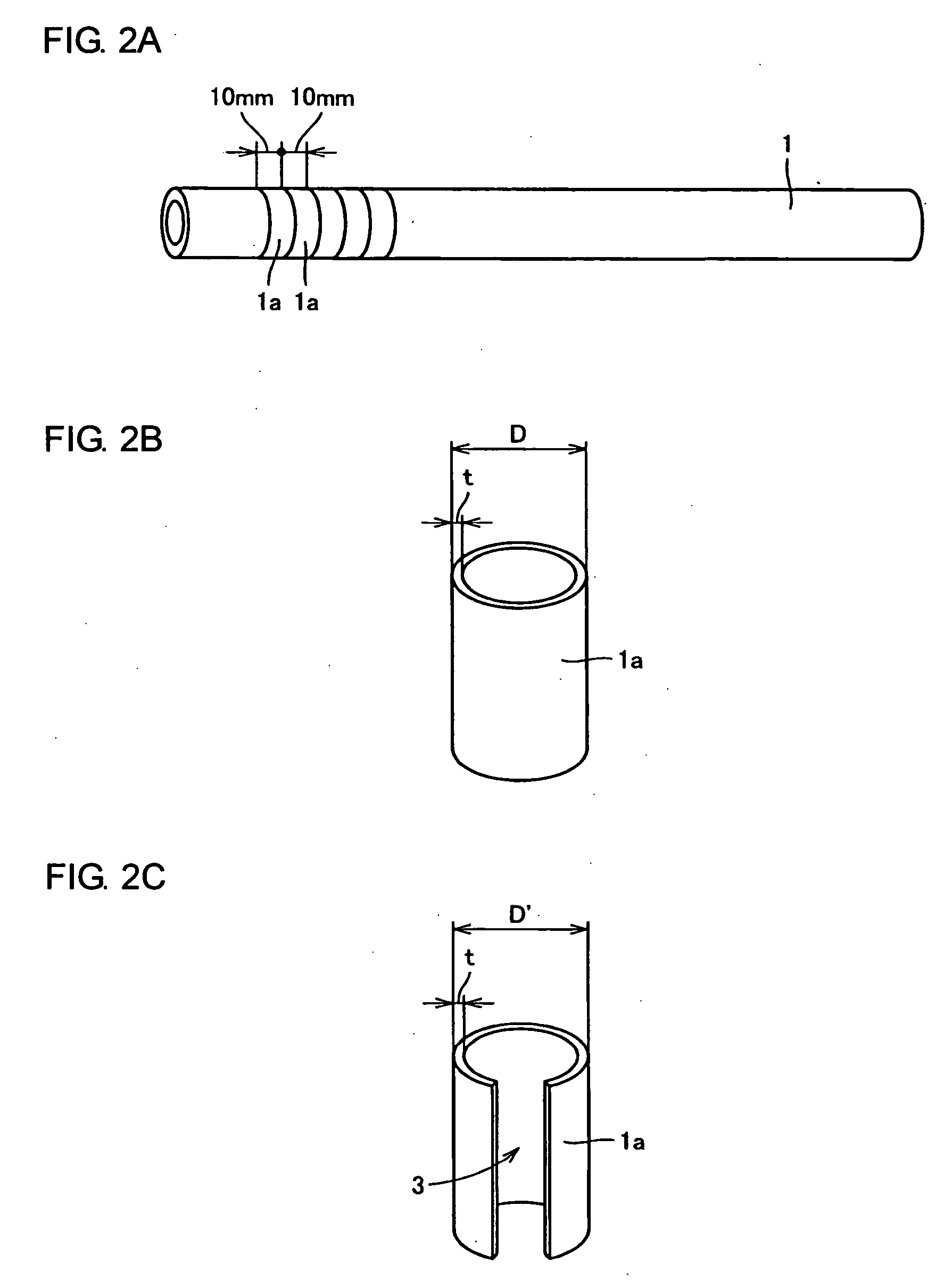

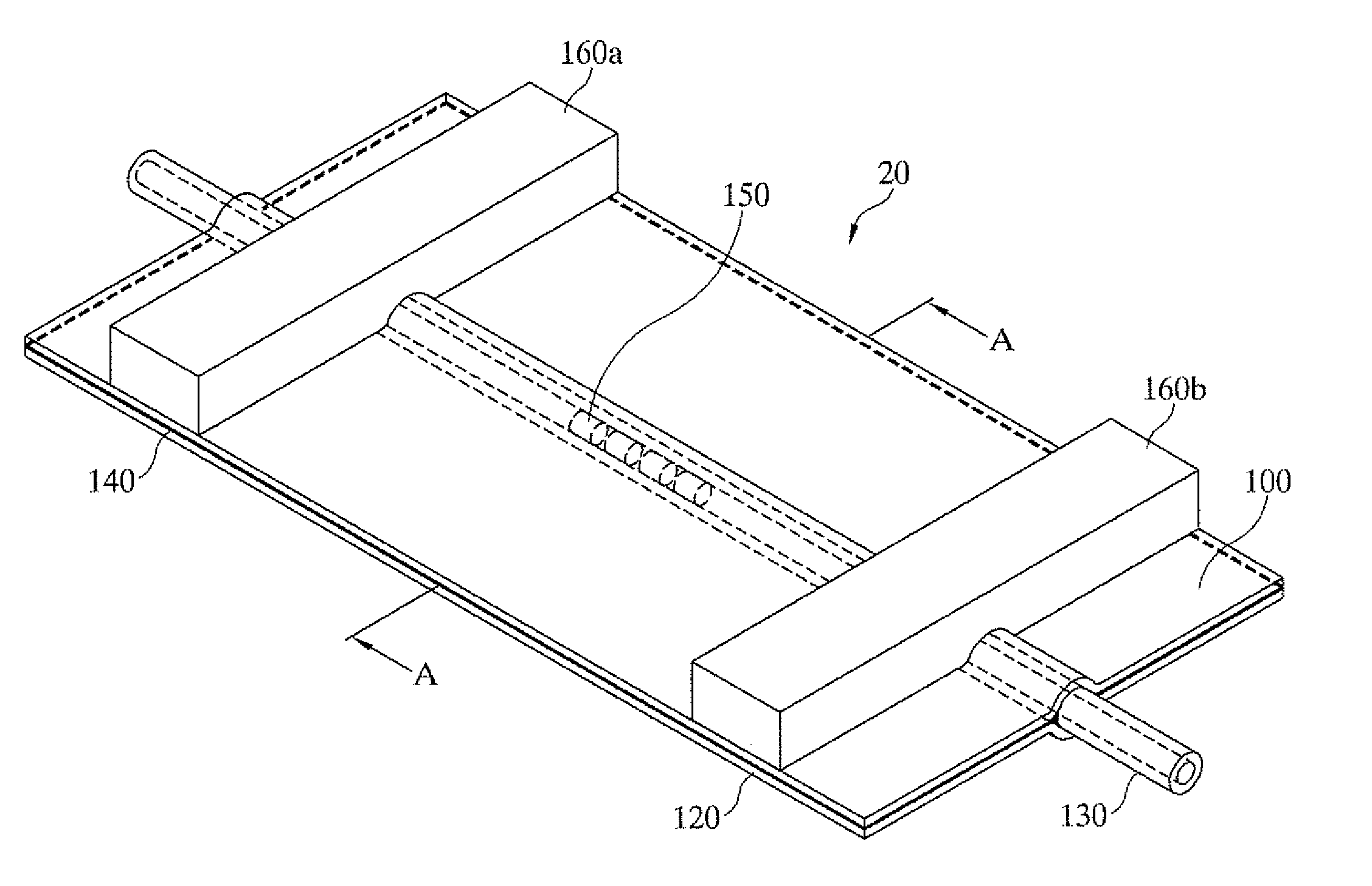

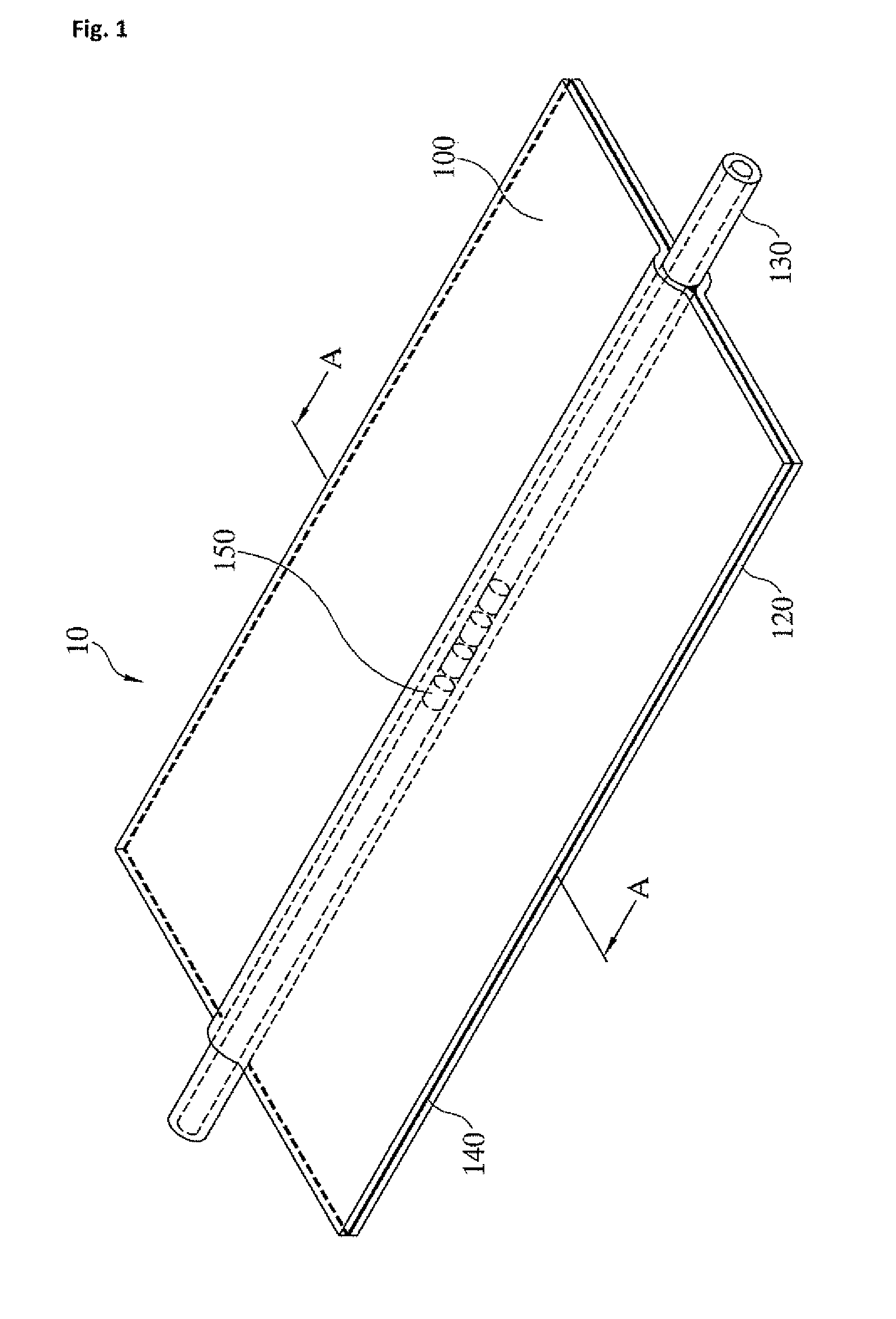

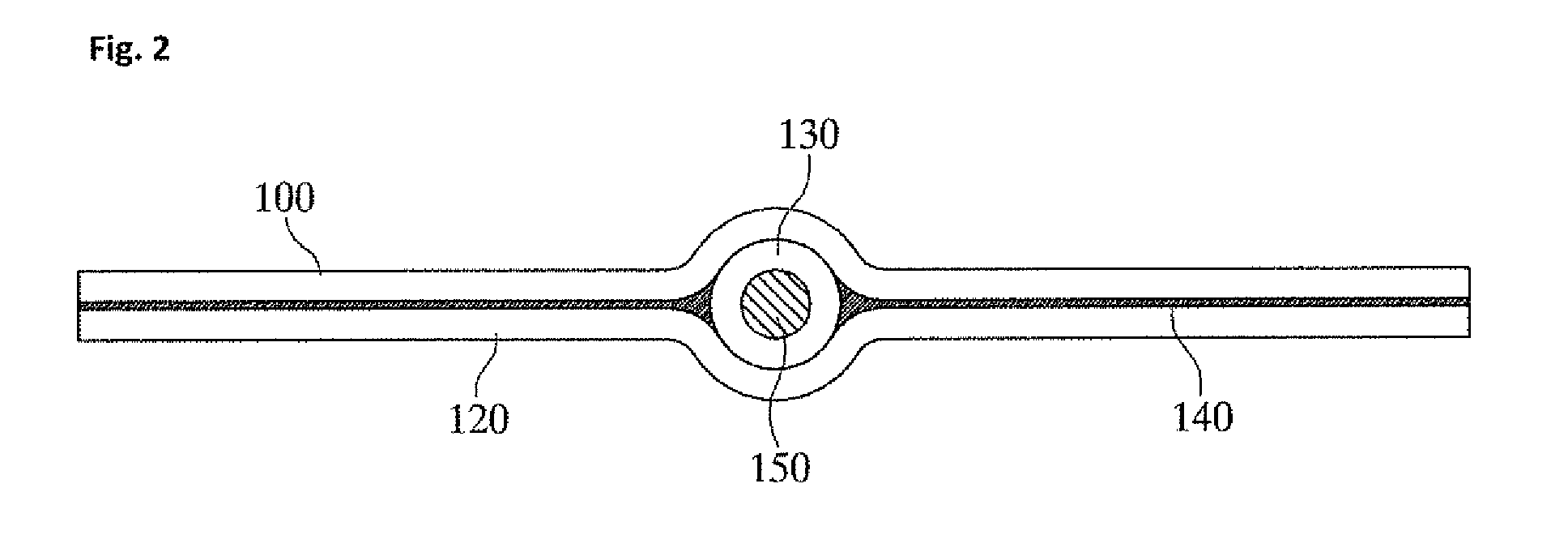

Fbg sensor for measuring maximum strain, manufacturing method and using method

ActiveUS20160216166A1Small sizeLarge strainForce measurement by measuring optical property variationMaterial analysis by optical meansResidual strainMetallic foil

The present invention relates to an FBG sensor for measuring a maximum strain of an object being measured, a method for manufacturing the sensor, and a method of using the sensor. To this end, provided is the FBG sensor for measuring a maximum strain, comprising: an optical fiber (130) having an FBG sensor (150) therein; a first metallic foil (120) contacting the optical fiber (130) on one surface thereof; a second metallic foil (120) which comes into surface-contact with the one surface; an adhesive layer (140) provided between the first and second metallic foils (100, 120); a means for measuring a residual strain of the first and second metallic foils (100, 120) through the FBG sensor (150); and a means for calculating a maximum strain on the basis of the measured residual strain and a sensitivity coefficient (Csen) obtained through experimentation.

Owner:KOREA RES INST OF STANDARDS & SCI

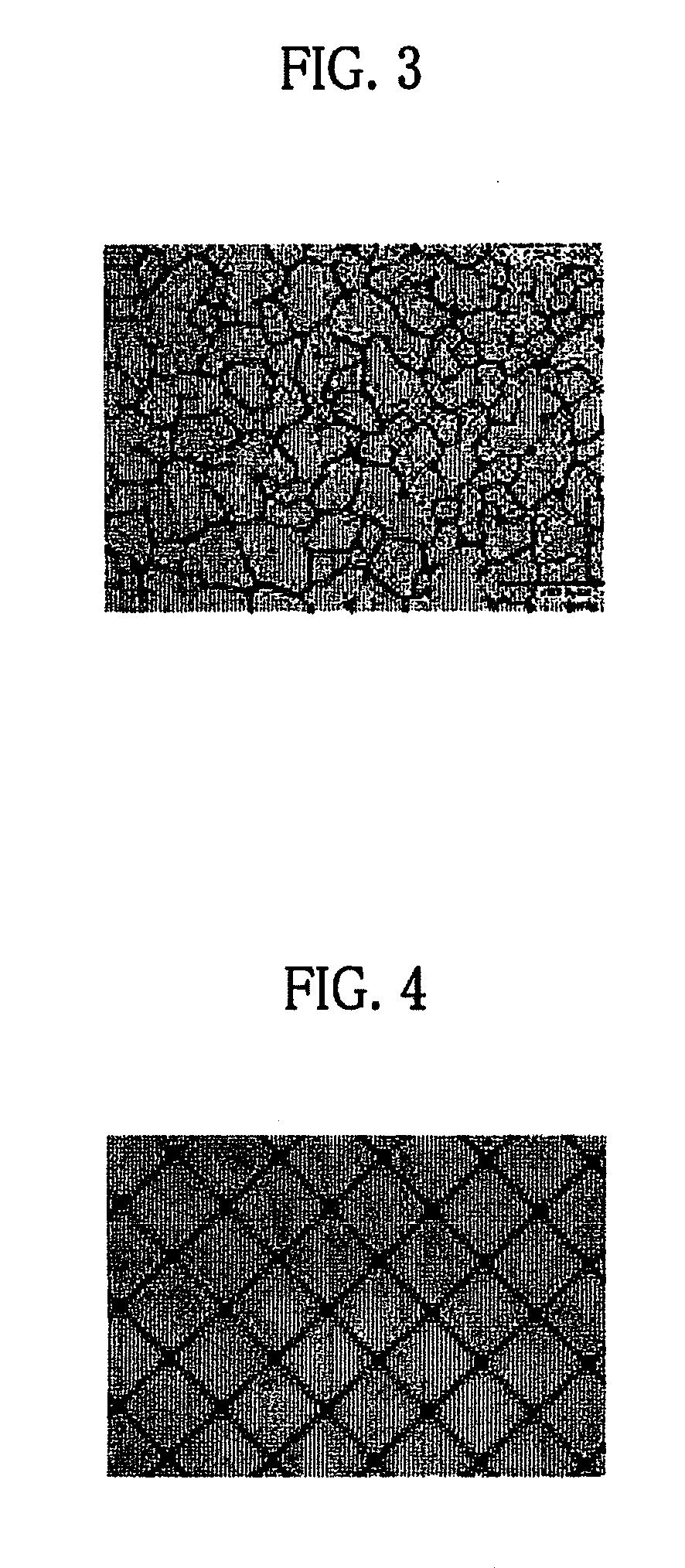

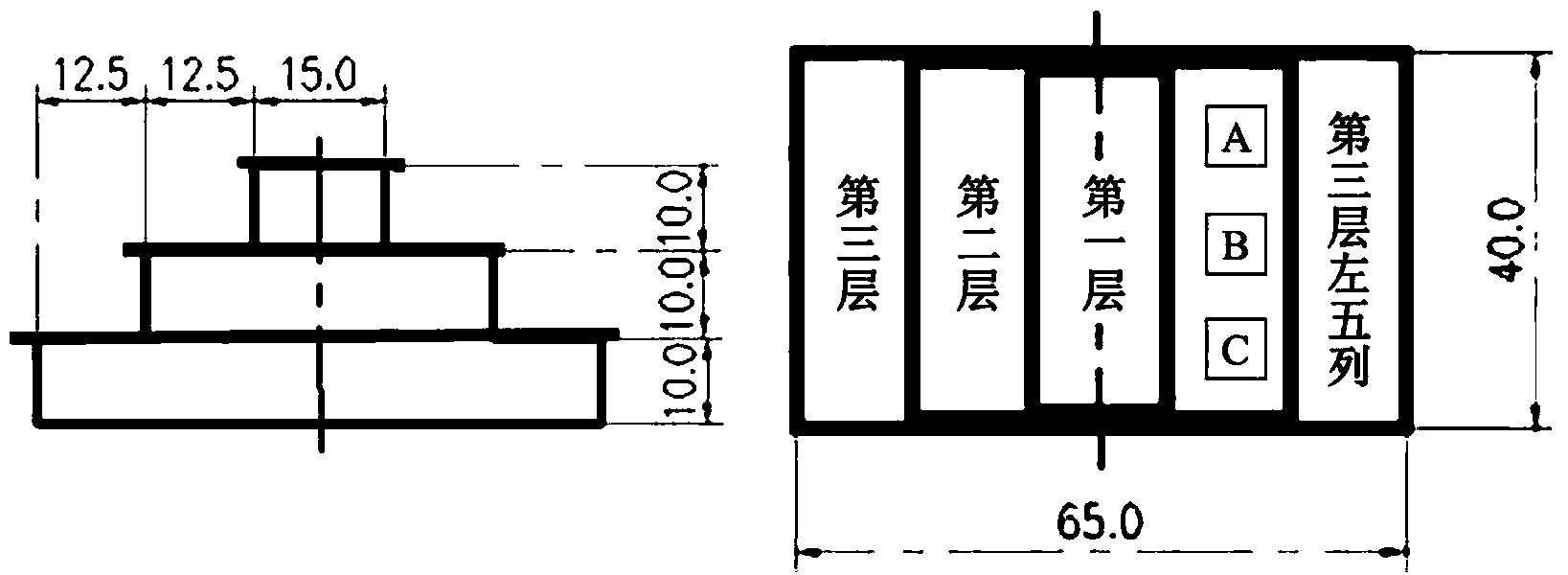

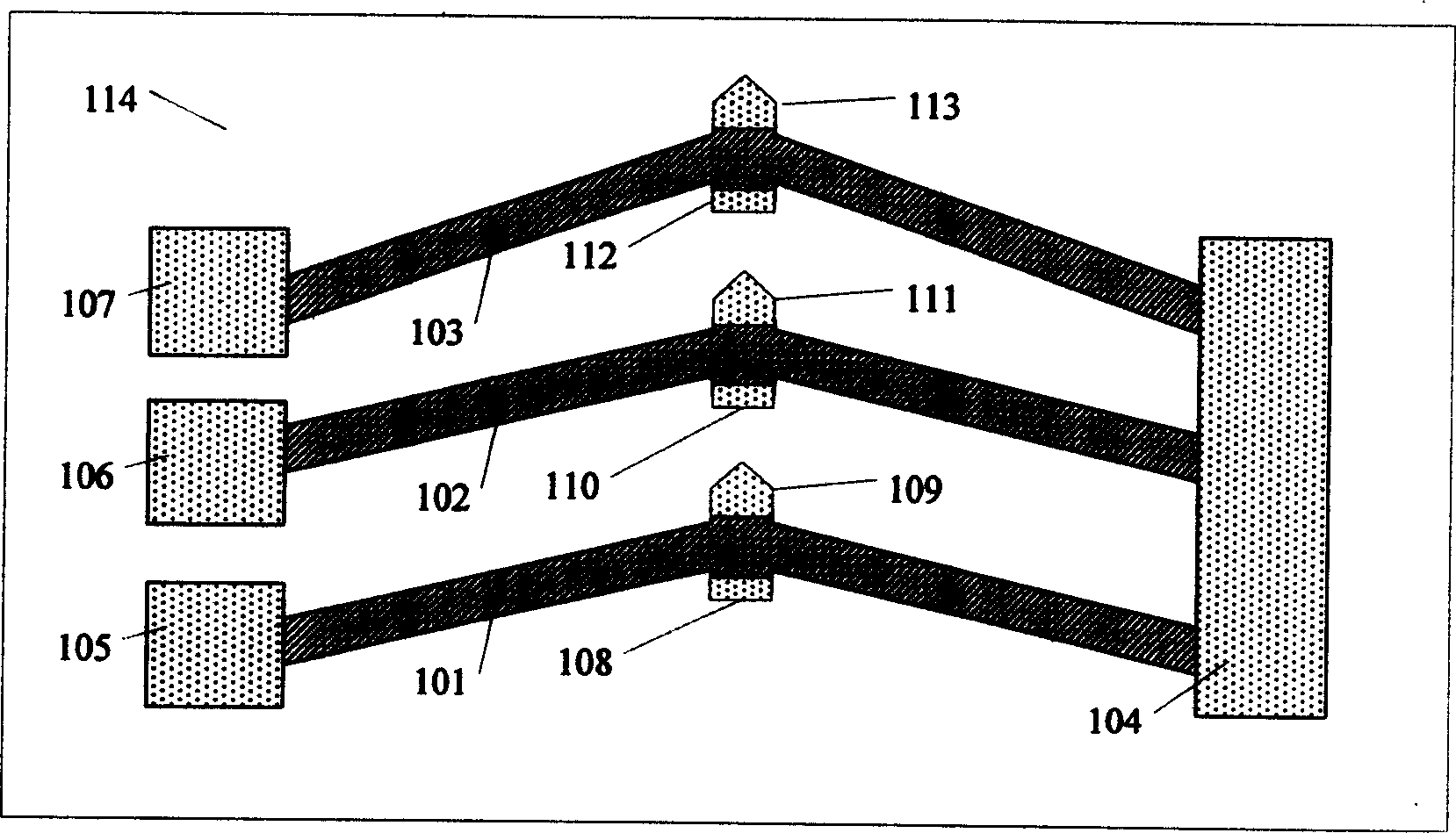

Online measuring structure of residual strain of polysilicon film and testing method

InactiveCN1687698ALower requirementSimple process structureElectrical/magnetic solid deformation measurementResidual strainEngineering

The invention is the online detecting structure and method of polysilicon film residue deformation. The detecting structure comprises the first curved girder, the second curved girder, the third curved girder, the primary pressure welding block, the second pressure welding block, the third pressure welding block and the fourth pressure welding block. The three polysilicon curved girders parallel with each other; the contactors are at the two sides of the central point of the girders and the space between the contactors is equal. The two ends of the first curved girder separately connect the primary and the forth pressure welding blocks; the two ends of the second girder separately connect the second and the forth pressure welding blocks; the two ends of the third girder connect the third and the forth pressure welding blocks. The invention has fast detecting speed and low requirement for the detected equipment.

Owner:SOUTHEAST UNIV

Coated cutting tool for general turning in heat resistant super alloys (HRSA)

InactiveUS8034438B2Improve productivityPigmenting treatmentOther chemical processesResidual strainCrystal structure

The present invention relates to coated cemented carbide inserts, particularly useful in general turning of superalloys. The inserts are characterized by a cemented carbide of WC, about 5.0-7.0 wt-% Co, and about 0.22-0.43 wt-% Cr, where the substrate has a coercivity (Hc) of about 19-28 kA / m. The coating contains a single (TixAl1-x)N-layer, where x is about 0.25-0.50, with crystal structure of NaCl type, total thickness of about 3.0-5.0 μm, (200)-texture, and compressive residual strain of about 2.5×10−3-5.0×10−3, optionally containing an outermost TiN-layer.

Owner:SECO TOOLS AB

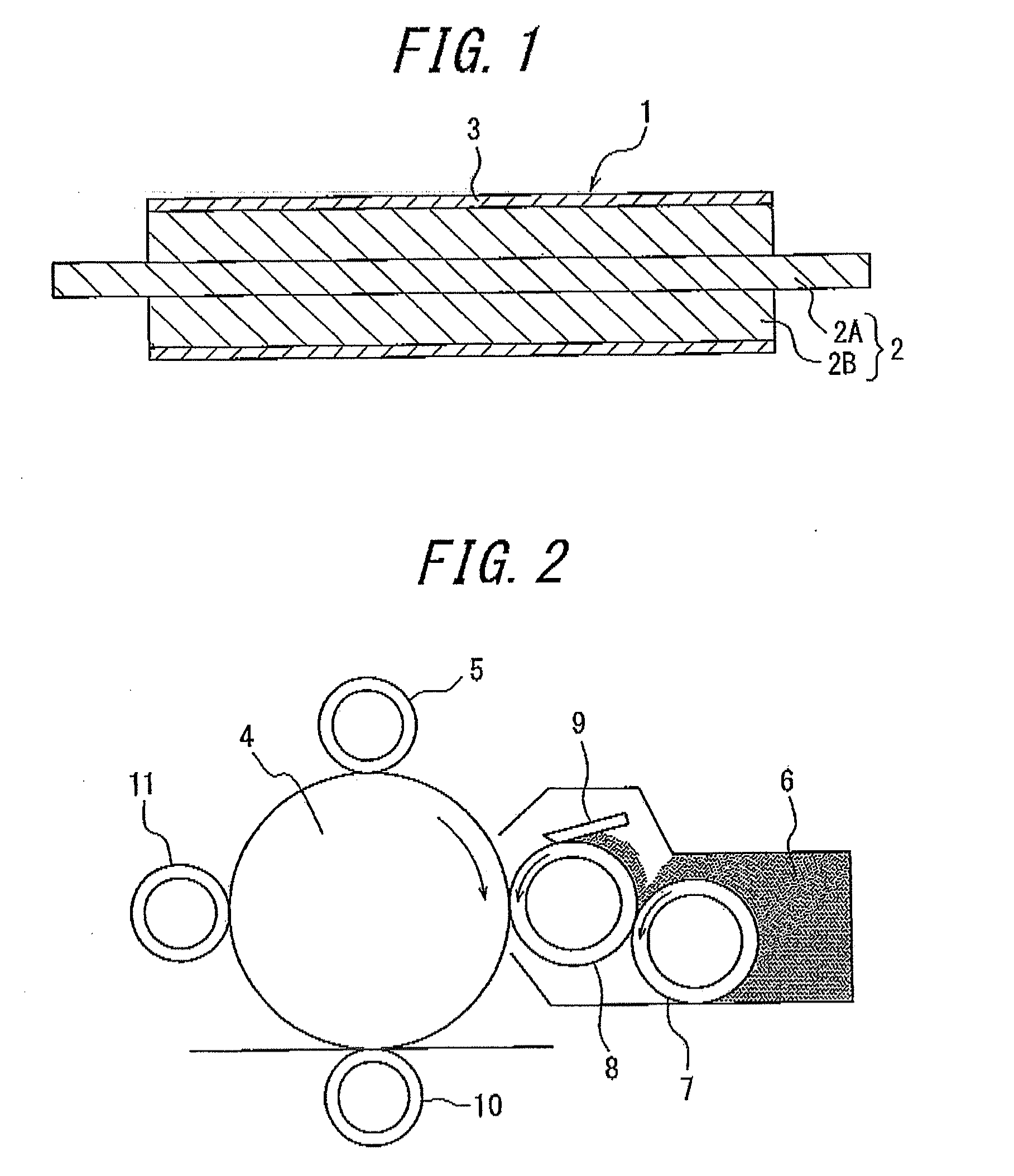

Conductive elastic roller and image forming apparatus comprising the same

ActiveUS20100014891A1Reduce hardnessSmall compression residual strainShaft and bearingsPortable power-driven toolsResidual strainElectrical conductor

This invention is a conductive elastic roller (1) comprising a shaft member (2) and one or more elastic layers (3) disposed on an outside of the shaft member (2) in a radial direction, wherein at least one of the elastic layers (3) is composed of an ultraviolet-curing type resin formed by curing a raw material for the elastic layer comprising a urethane acrylate oligomer (A), a photo-polymerization initiator (B) and a conductive agent (C) through ultraviolet irradiation, and the urethane acrylate oligomer (A) is a urethane acrylate oligomer synthesized by using as a polyol a polyether polyol (a1) having a proportion of primary hydroxyl groups in hydroxyl groups located at molecular ends of not less than 40% obtained by an addition polymerization of propylene oxide to a polyhydric alcohol alone, or the polyether polyol (a1) and another polyol (a2), and provides a conductive elastic roller (1) provided with an elastic layer having a low hardness, a small compression residual strain and an improved stain resistance to an adjoining member such as Organic Photoconductors or the like.

Owner:ARCHEM INC

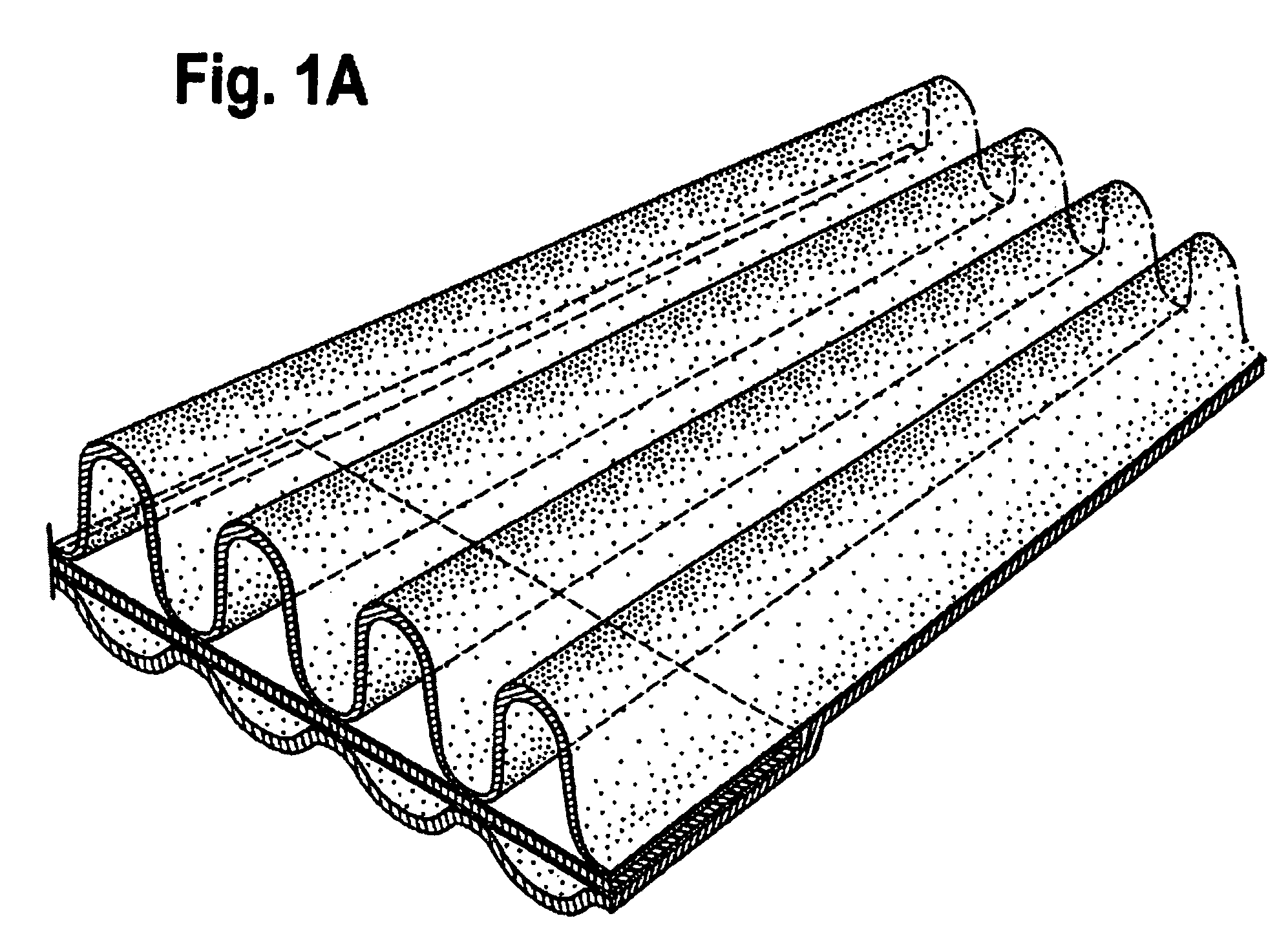

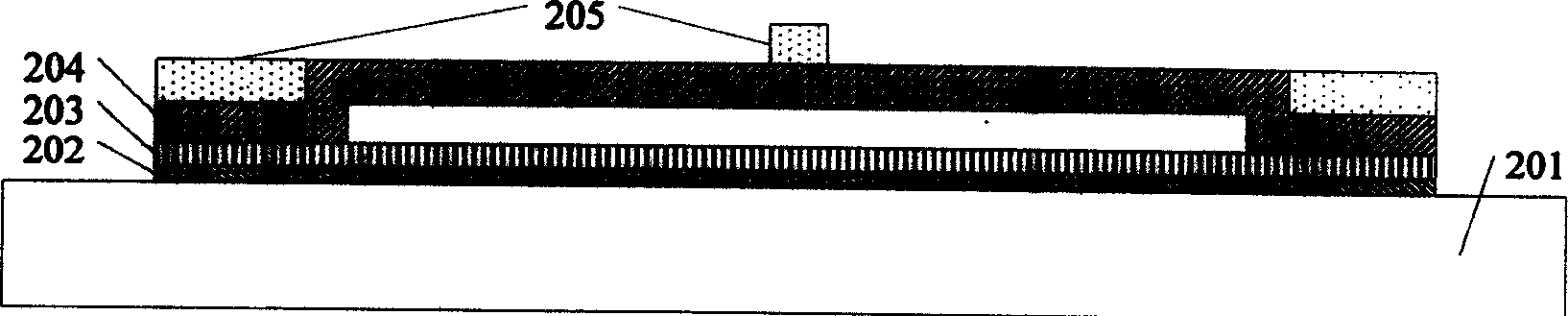

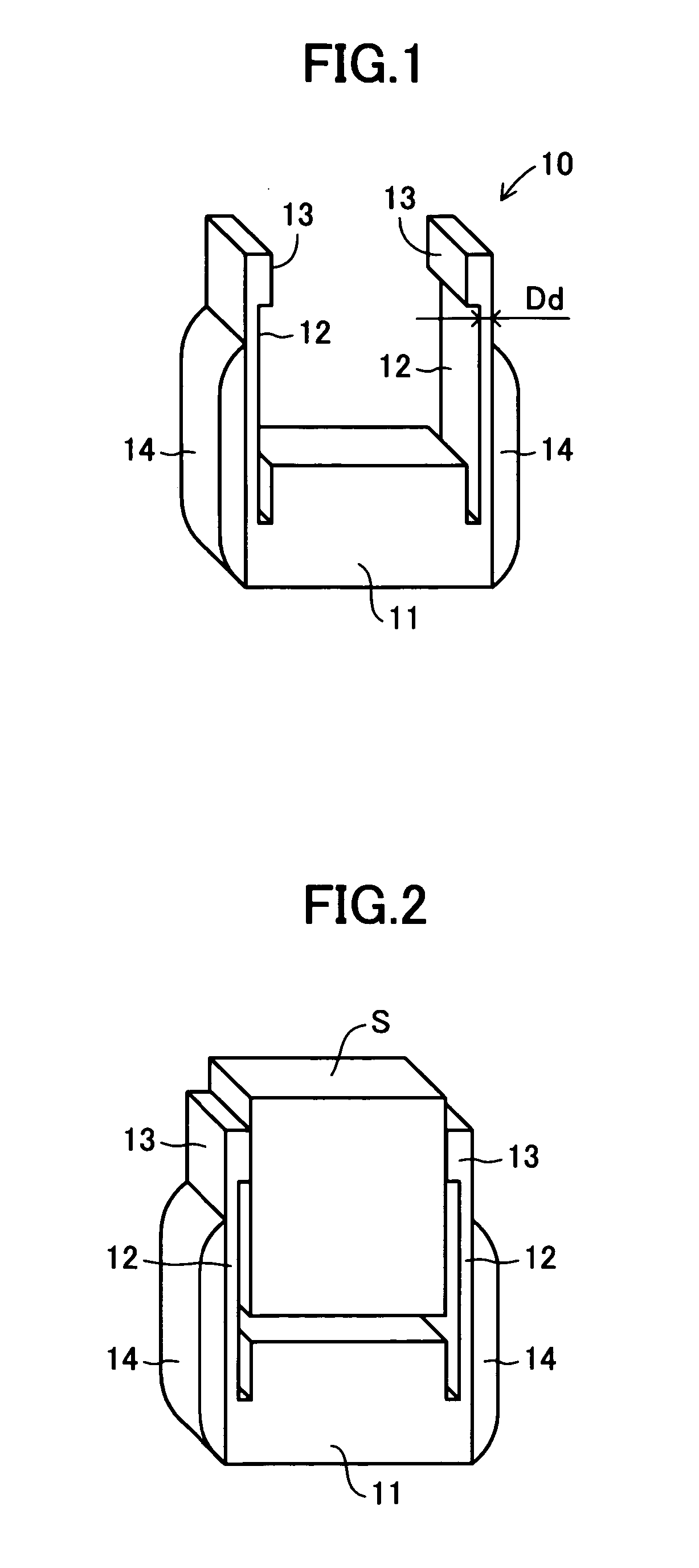

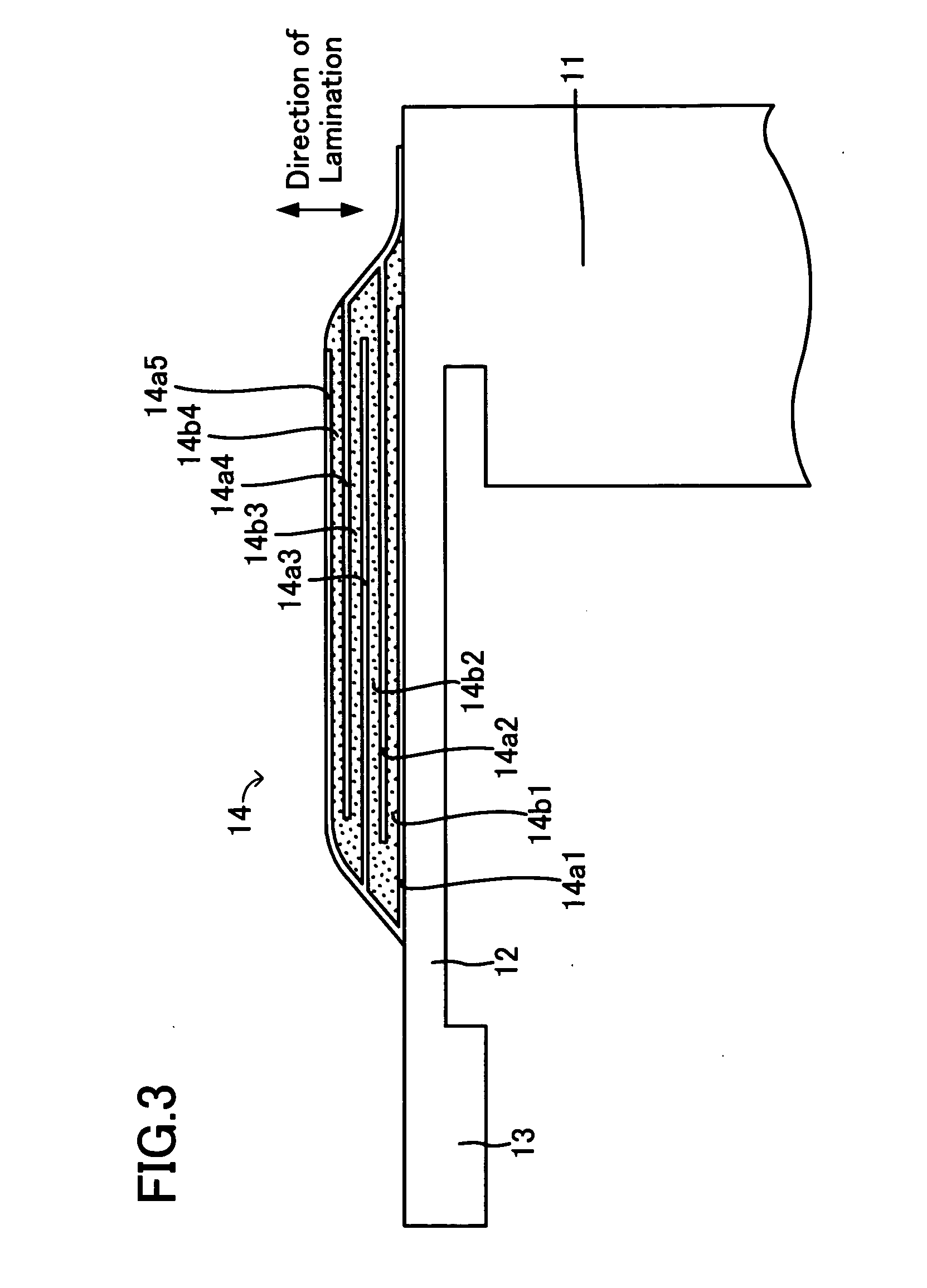

Piezoelectric/electrostrictive device

InactiveUS20060113876A1Easy to manufactureEffective prevention of separationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesResidual strainSurface roughness

A piezoelectric / electrostrictive device 10 includes a stationary portion 11; a thin-plate portion 12 supported by the stationary portion; and a piezoelectric / electrostrictive element 14 including a plurality of electrodes and a plurality of piezoelectric / electrostrictive layers which are laminated alternately. The piezoelectric / electrostrictive device 10 is manufactured as follows: firstly, a piezoelectric / electrostrictive laminate composed of laminar electrodes and piezoelectric / electrostrictive layers is formed on the surface of a thin-plate body which is to become the thin-plate portion 12; subsequently, the thin-plate body and the piezoelectric / electrostrictive laminate are cut; and the resultant cut surface (lateral end surface) is finished through polishing, so as to attain an arithmetic average surface roughness of 0.05 μm or less. This finishing process enables occurrence of uniform residual strain in the vicinity of the lateral end surface, as well as elimination of microcracks generated in the vicinity of the lateral end surface through the above cutting, thereby effectively preventing particle separation from the lateral end surface.

Owner:NGK INSULATORS LTD

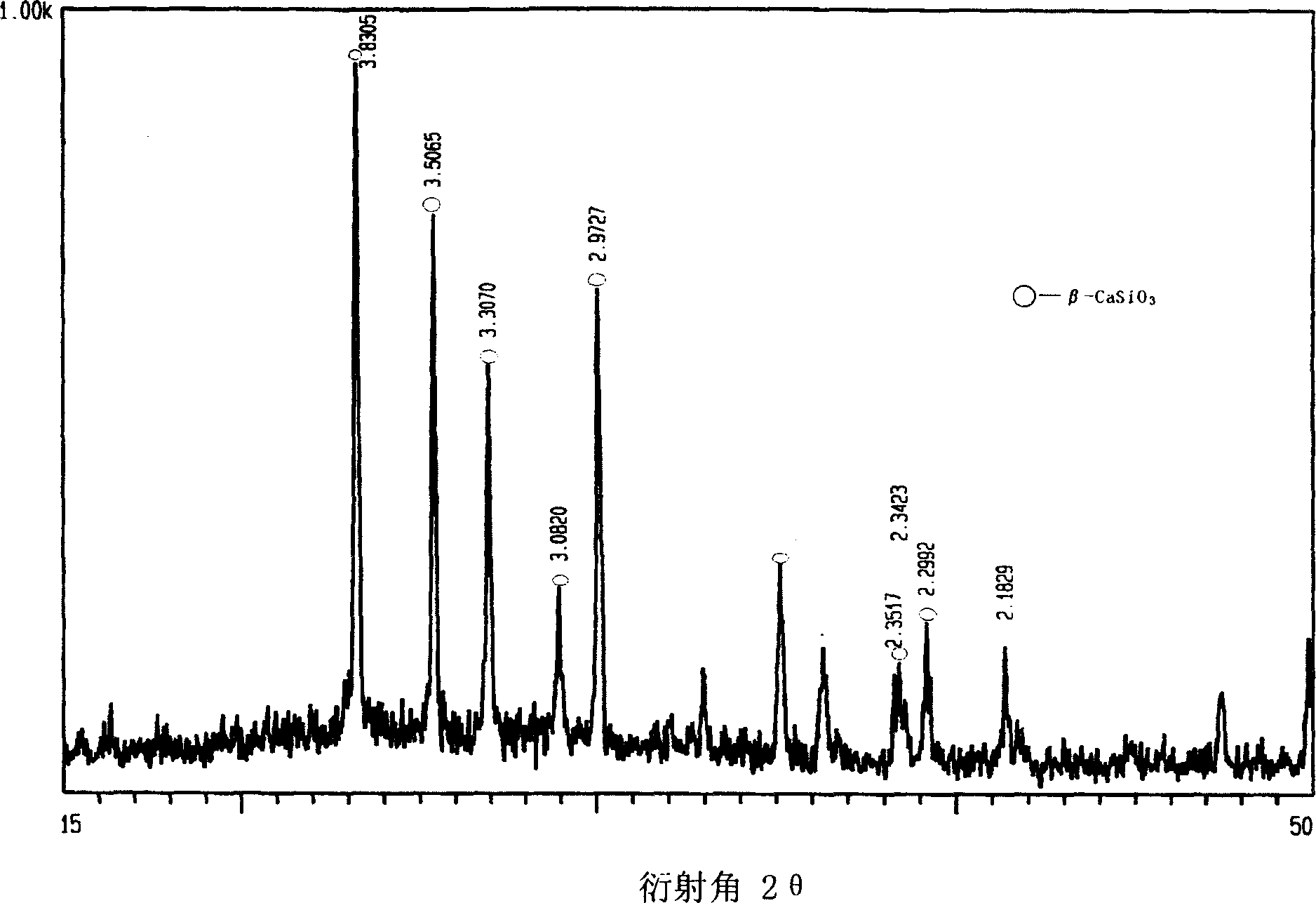

Neutron diffraction measure method for CaO-Al2O3-SiO2 system microcrystalline glass residue stress

InactiveCN1828282AMaterial analysis using wave/particle radiationPreparing sample for investigationResidual strainYoung's modulus

Wherein, first preparing the glass-ceramic; adjusting the neutron monochromator to select opposite monochromatic neutron; irradiating sample surface with neutron beam with diffraction angle 2theta as 10-75Deg; taking strain detection crystal face with principal crystalline phase as beta-wollastonite and obtaining the average strain result as: ªŠ=1 / 3(ªŠ11+ªŠ22+ªŠ33), opposite volume mean strain as í¸=1 / V(íʪŠdV); calculating with formulaªÊ=E / 3(1-2ªÈ)í¸ (wherein, E: Young's modulus; ªÈ: Poisson's ratio), and then obtaining the total strain on three axial directions ªñ=ea+eb+ec; exactly, here, selecting E=70GPa and ªÈ=0.245; repeating former steps to obtain different residual strain values to draw distribution curve. This invention can obtain the inner strain of sample and fit to massive sample.

Owner:WUHAN UNIV OF TECH

Polyurethane foam

In the present invention, a polyurethane foam (1) is obtained by the mechanical floss method from a polyurethane starting material comprising a polyol, isocyanate, foam stabilizer, catalyst and a gas for foaming, wherein the polyol comprises a castor oil-based polyol and a polyether-based polyol having a viscosity of 2,000 mPas or lower at 25 C; the castor-oil based polyol accounts for between 20 and 80 parts by weight of the 100 parts by weight of the polyol; the polyether polyol accounts for between 20 and 80 parts by weight of the 100 parts by weight of the polyol; apparent density is between 100 and 700 kg / m3; and compressive residual strain at 100 C is 20% or lower. This polyurethane foam is ideal as a material for sealing peripheral regions of a heat source.

Owner:INOAC CORP +1

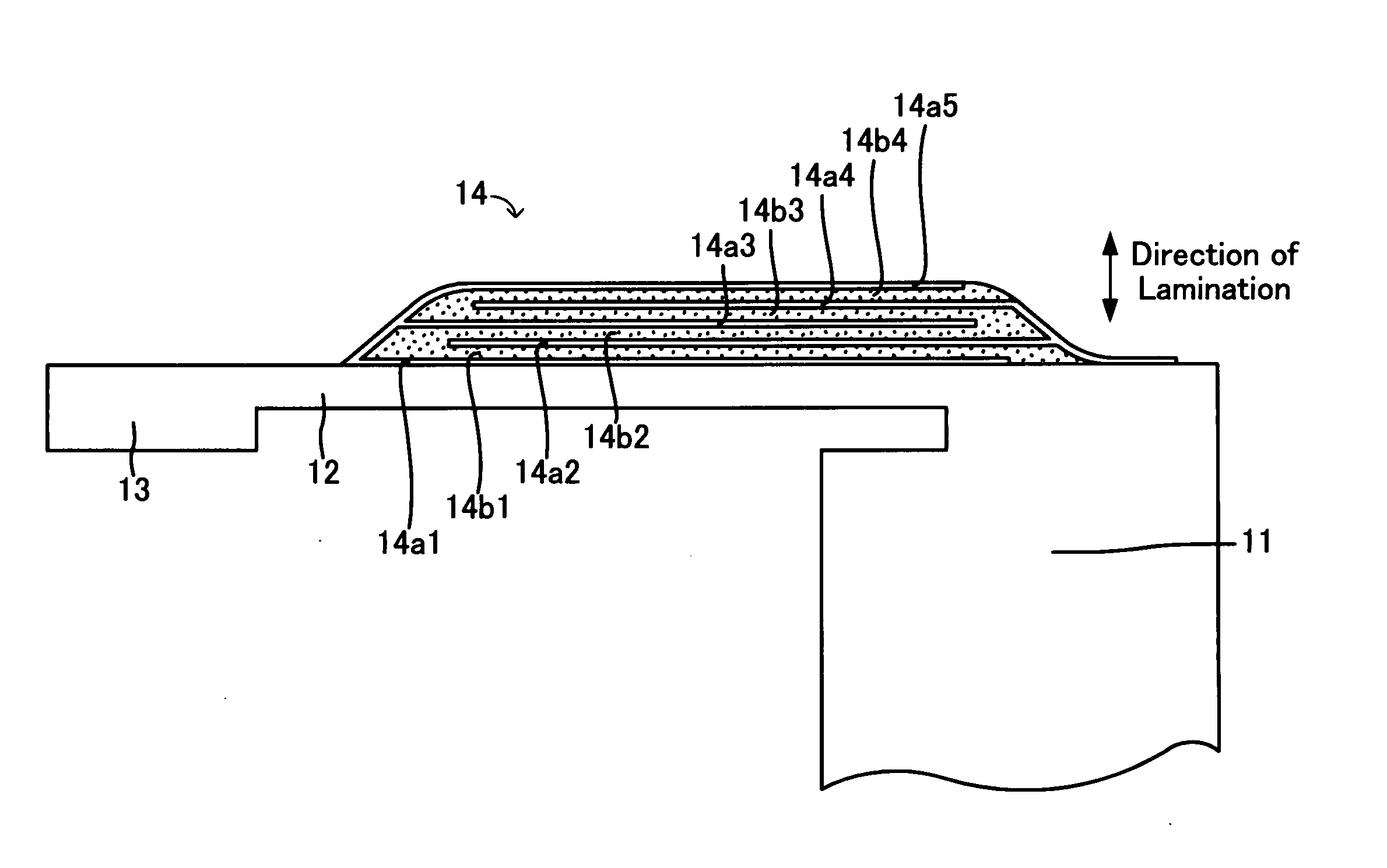

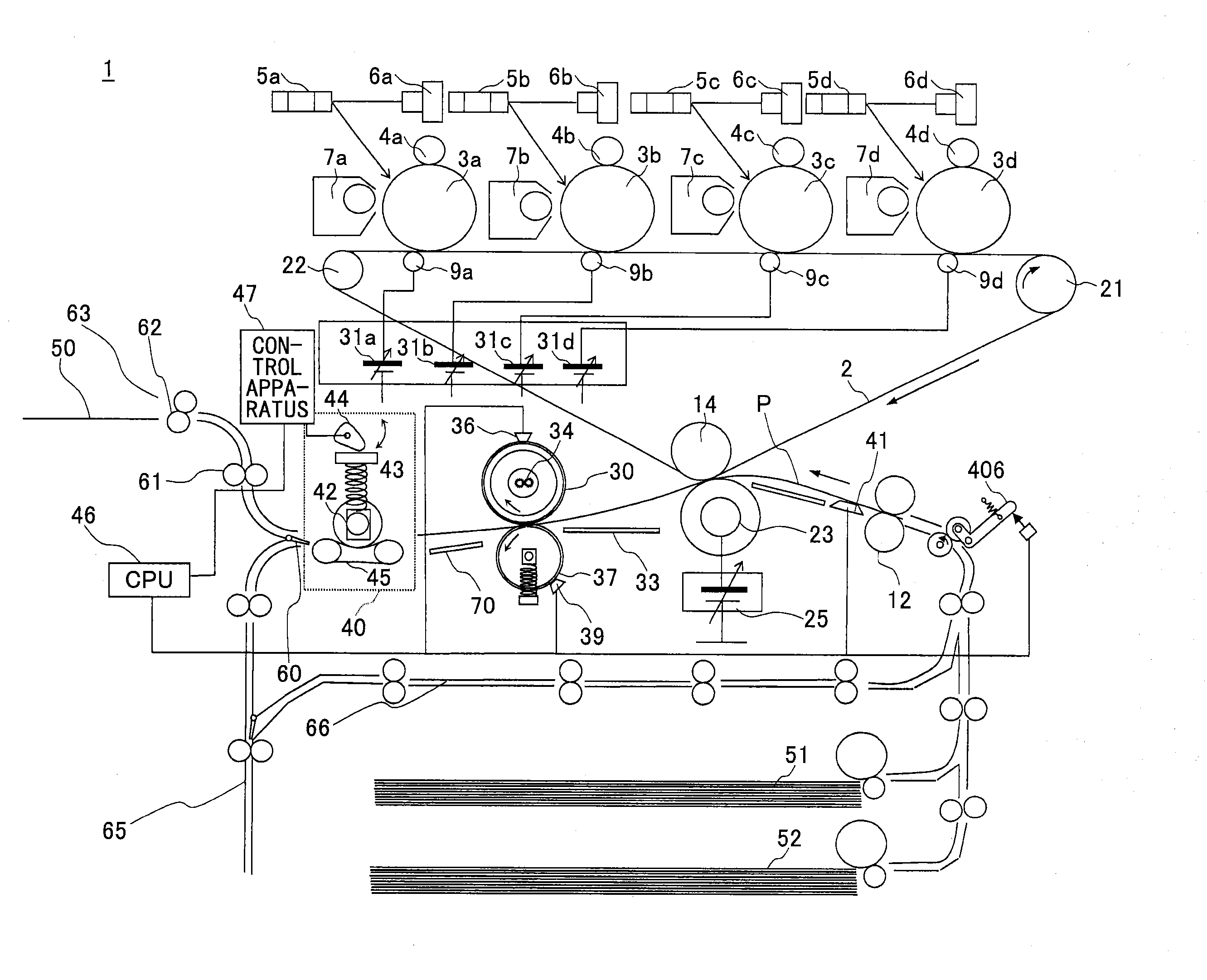

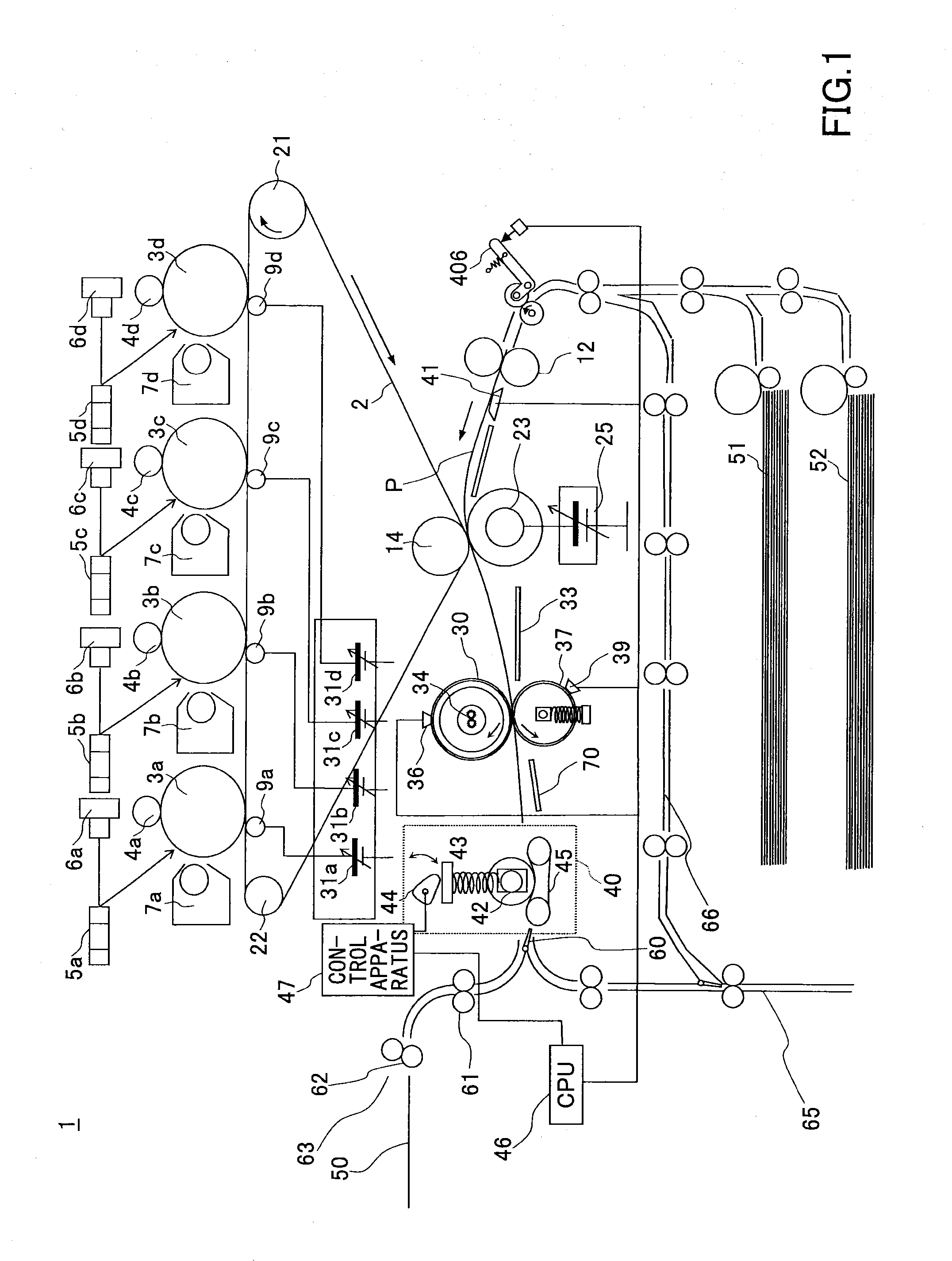

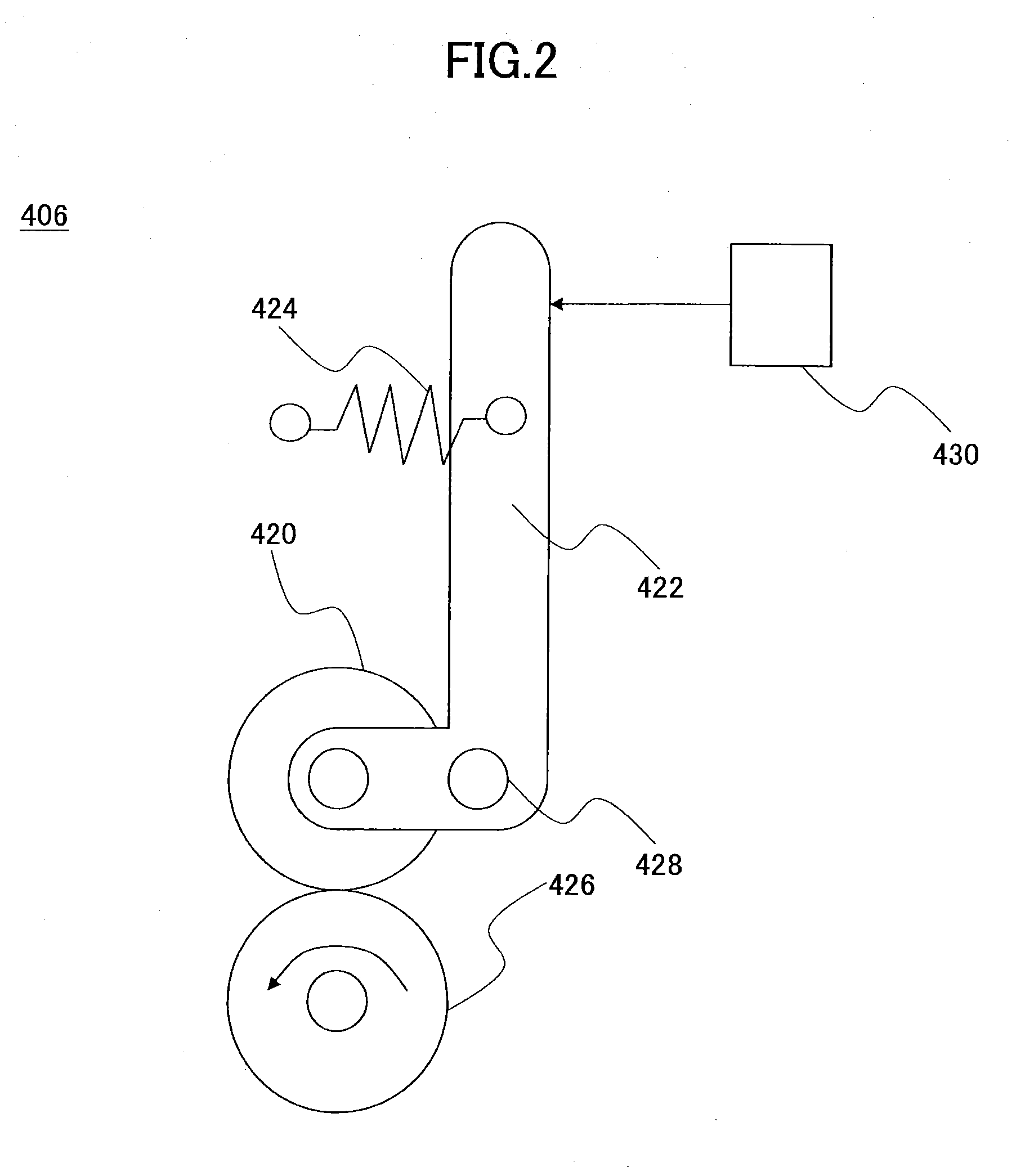

Curl straightening method and image forming apparatus

A curl straightening method in an image apparatus including a fixing apparatus and a curl straightening apparatus is disclosed. The method includes calculating moisture content of a sheet before being supplied to the fixing apparatus; measuring a temperature of a heating unit and a pressurizing unit; calculating a temperature and moisture content of the sheet in the respective conveying sections; calculating a conveying time of the sheet in the respective conveying sections; calculating a residual strain of the sheet in the respective conveying sections from the calculated temperature and the moisture content of the sheet in the respective conveying sections, the calculated conveying time, and the stress relaxation characteristics of the sheet; calculating a final curl amount using the calculated residual strain of the sheet in the respective conveying sections; and controlling the curl straightening apparatus based on the final curl amount obtained.

Owner:RICOH KK

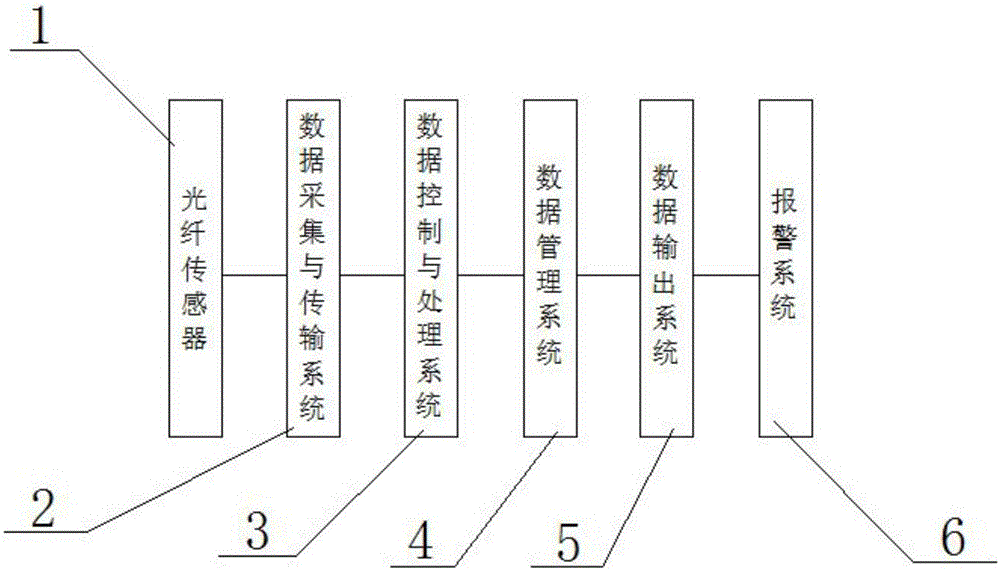

Wireless remote monitor civil engineering building monitoring system

InactiveCN105157753APassivityNo temperature driftTransmission systemsConverting sensor output opticallyMicrocontrollerResidual strain

The invention belongs to building engineering technology field, and discloses a wireless remote monitor civil engineering building monitoring system, which comprises a fiber sensor, a data acquisition and transmission system, a data control and processing system, a data management system, a data output system and an alarm system; the data acquisition and transmission system comprises a fiber sensing multiplex network acquisition subsystem and a fiber sensing signal demodulation data transmission subsystem; the data control and processing system employs a one-chip microcomputer for controlling; the data management system comprises a log record system and a memory; the data output system comprises a display, a printer, a communication port and an outer memory; the alarm system comprises an alarm lamp system, an alarm device system and a preset threshold value monitoring system. According to the invention, important physical indexes like seepage humidity, residual strain degree, crack displacement, viscosity, pressure, temperature and hardness in a reinforced concrete structure can be detected; and networking and remote monitoring can be realized.

Owner:NANYANG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com