Method for detecting residual strain of thermal-continuous-rolled high-strength steel plate

A high-strength steel plate, residual stress technology, applied in the direction of testing metals, measuring the properties of piezoelectric resistance materials, material inspection products, etc. Improved, convenient for long-distance measurement, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0034] A test method for residual stress of hot continuous rolling high-strength steel plate, which comprises the following steps:

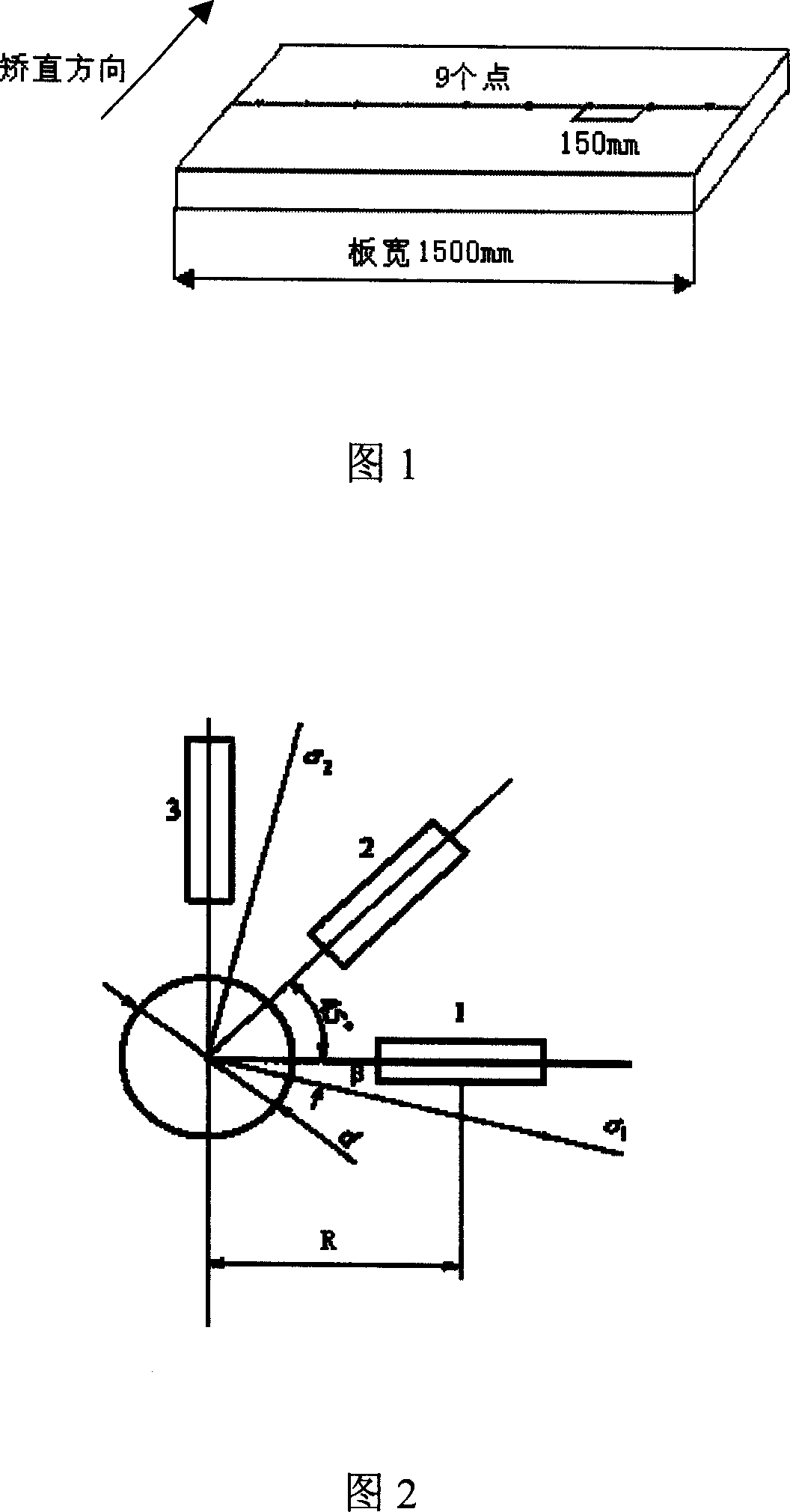

[0035] Step 1. Select measuring points: As shown in Figure 1, on the sample with a length of 1500mm, arrange a measuring point every 150mm, and arrange 9 measuring points in total;

[0036] Step 2, sample surface preparation: the surface of the sample to be prepared is polished with emery cloth to remove rust, and the oil stain is cleaned with acetone;

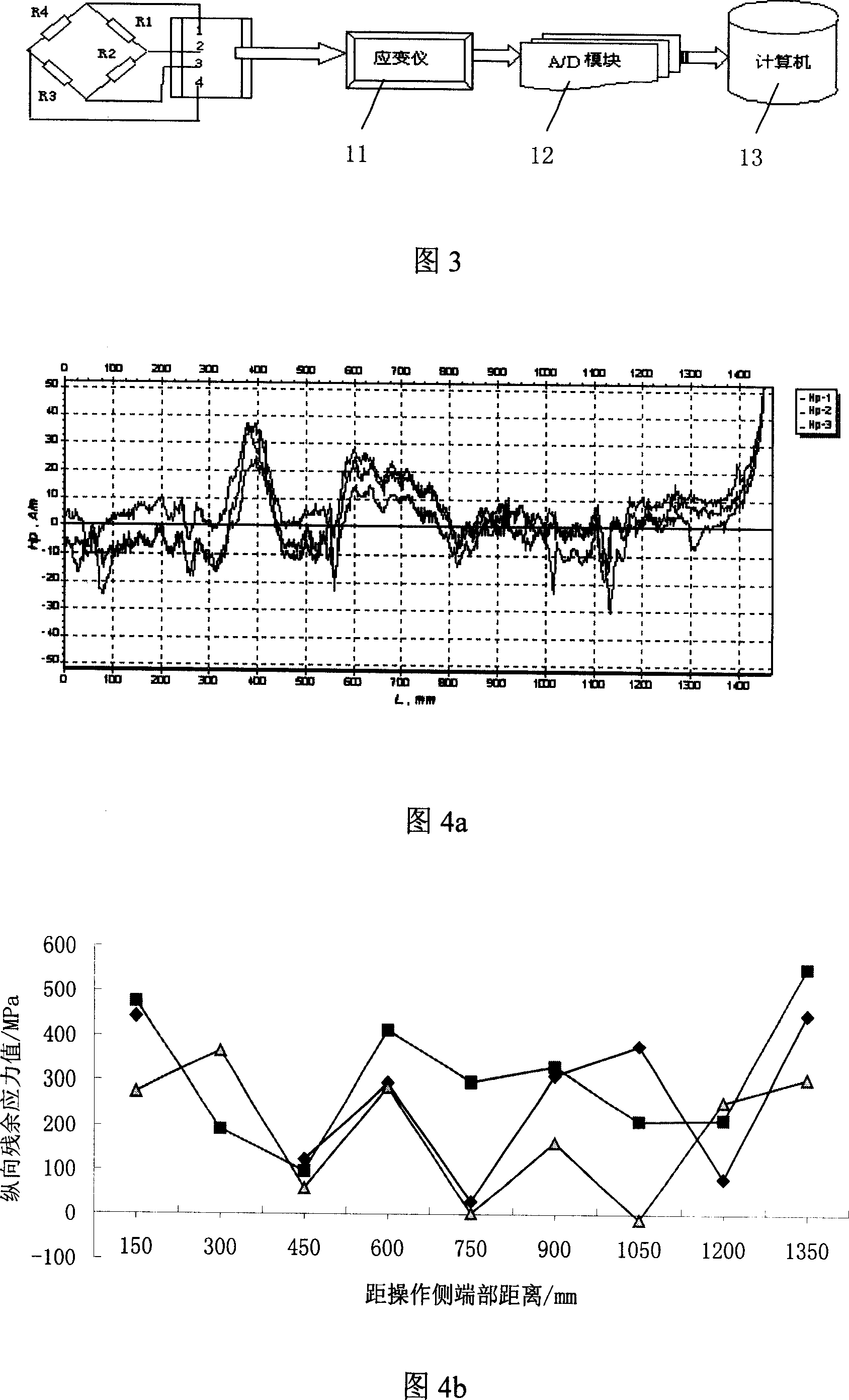

[0037] Step 3. Arrange and paste the strain gauges at the measurement points: as shown in Figure 2, use the BE120-2CA strain rosette to arrange the strain gauges at the measurement points, on the bonding surface of the strain gauges and the position where the strain gauges are to be pasted on the sample measurement points Spread evenly with glue, and put a layer of polytetrafluoroethylene film on the strain gauge, press for 1 to 2 minutes;

[0038] Step 4, signal connection: the lead wire of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com