Patents

Literature

229results about How to "Technical stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetostatic levitation and propulsion systems for moving objects

InactiveUS20100126374A1High levitating force outputRemove complexitySliding/levitation railway systemsMachines/enginesMagnetic tension forceMagnetic bearing

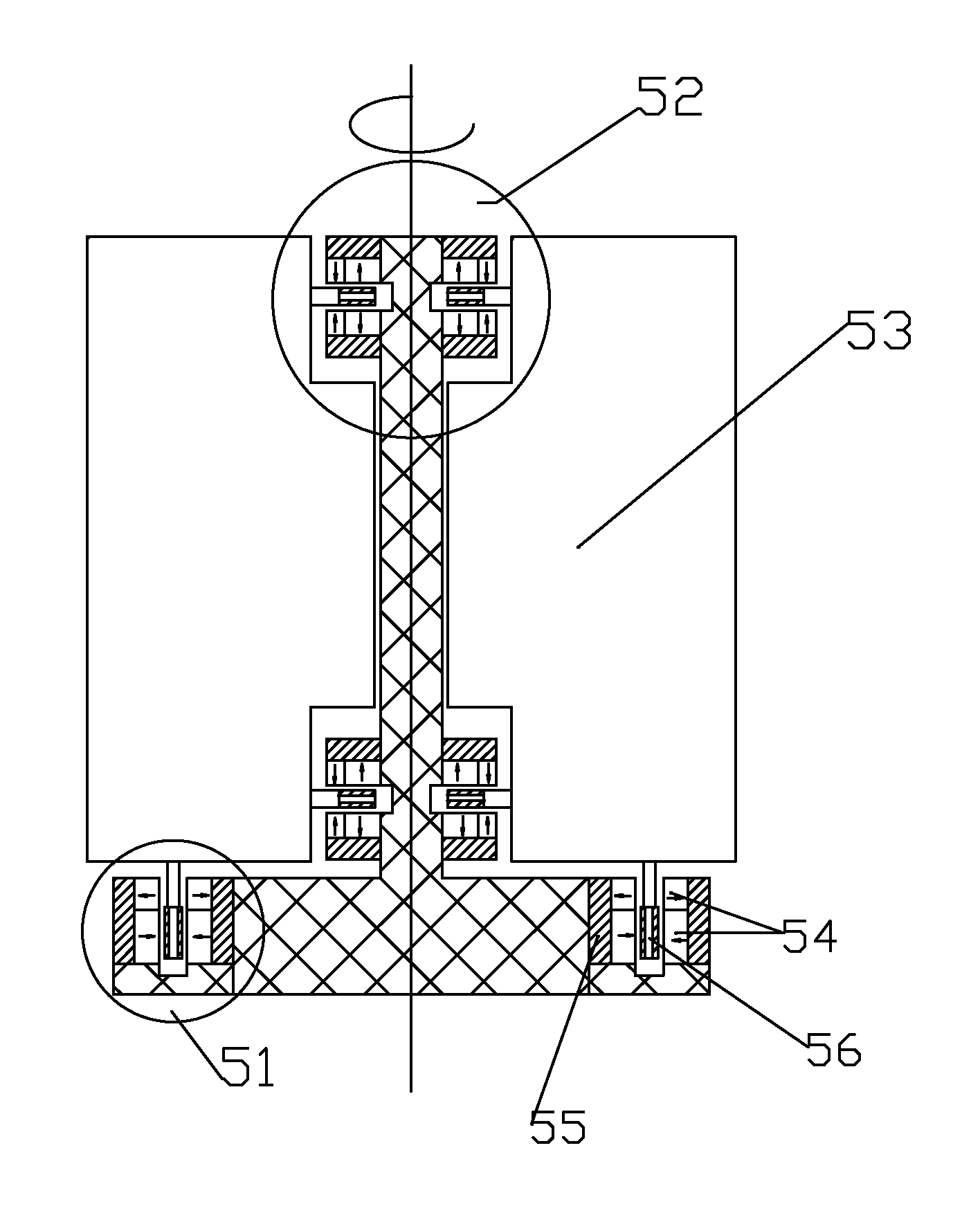

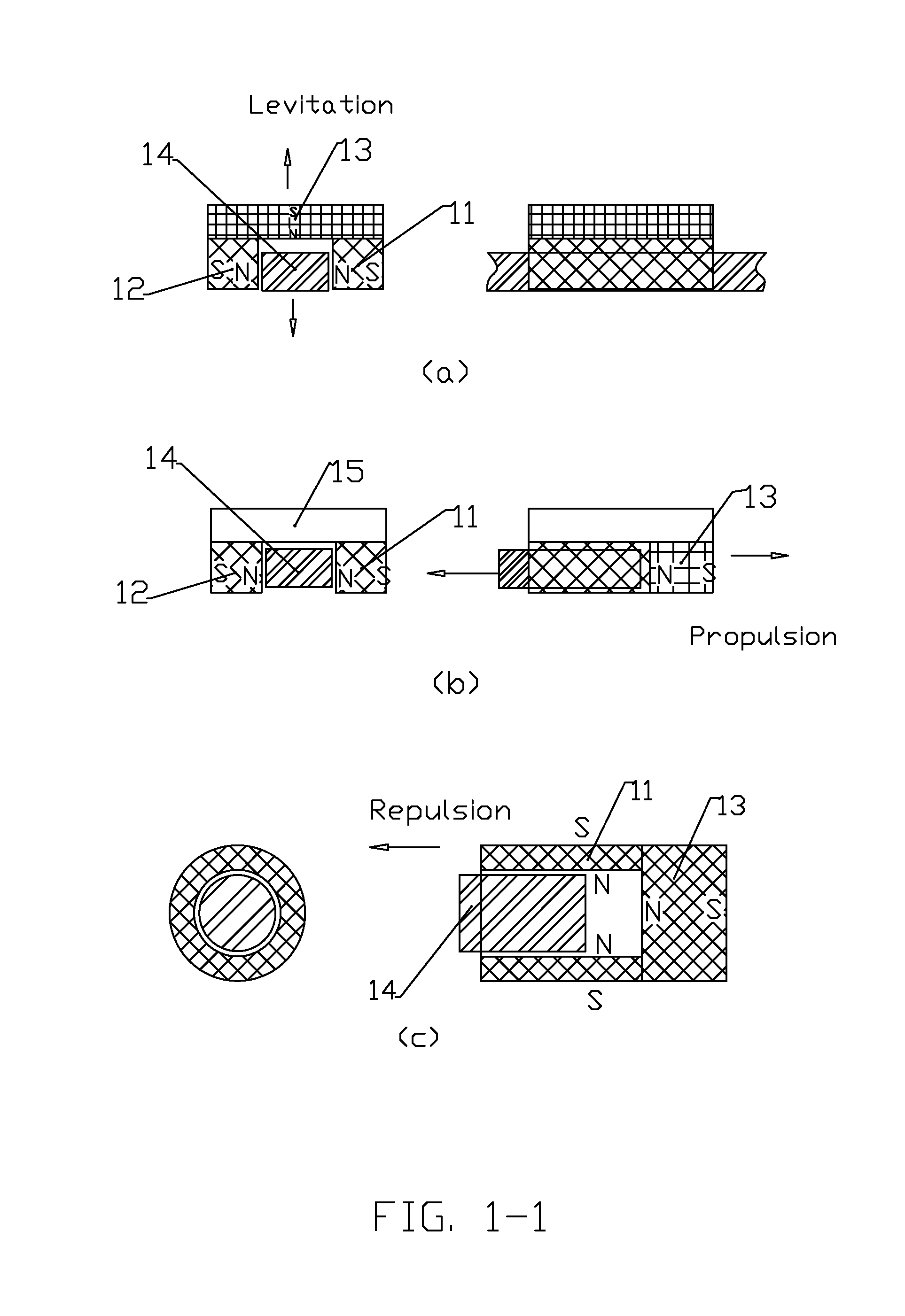

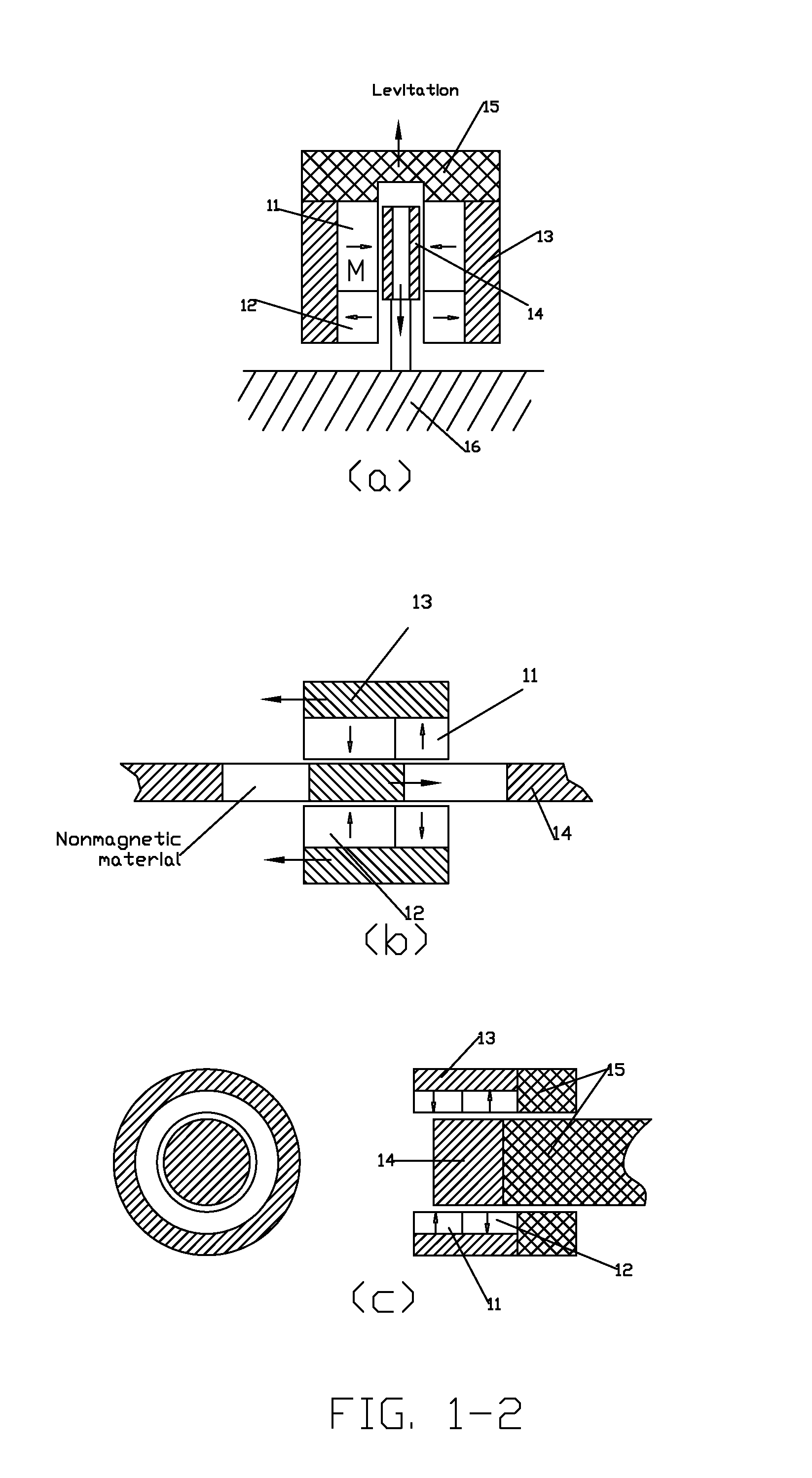

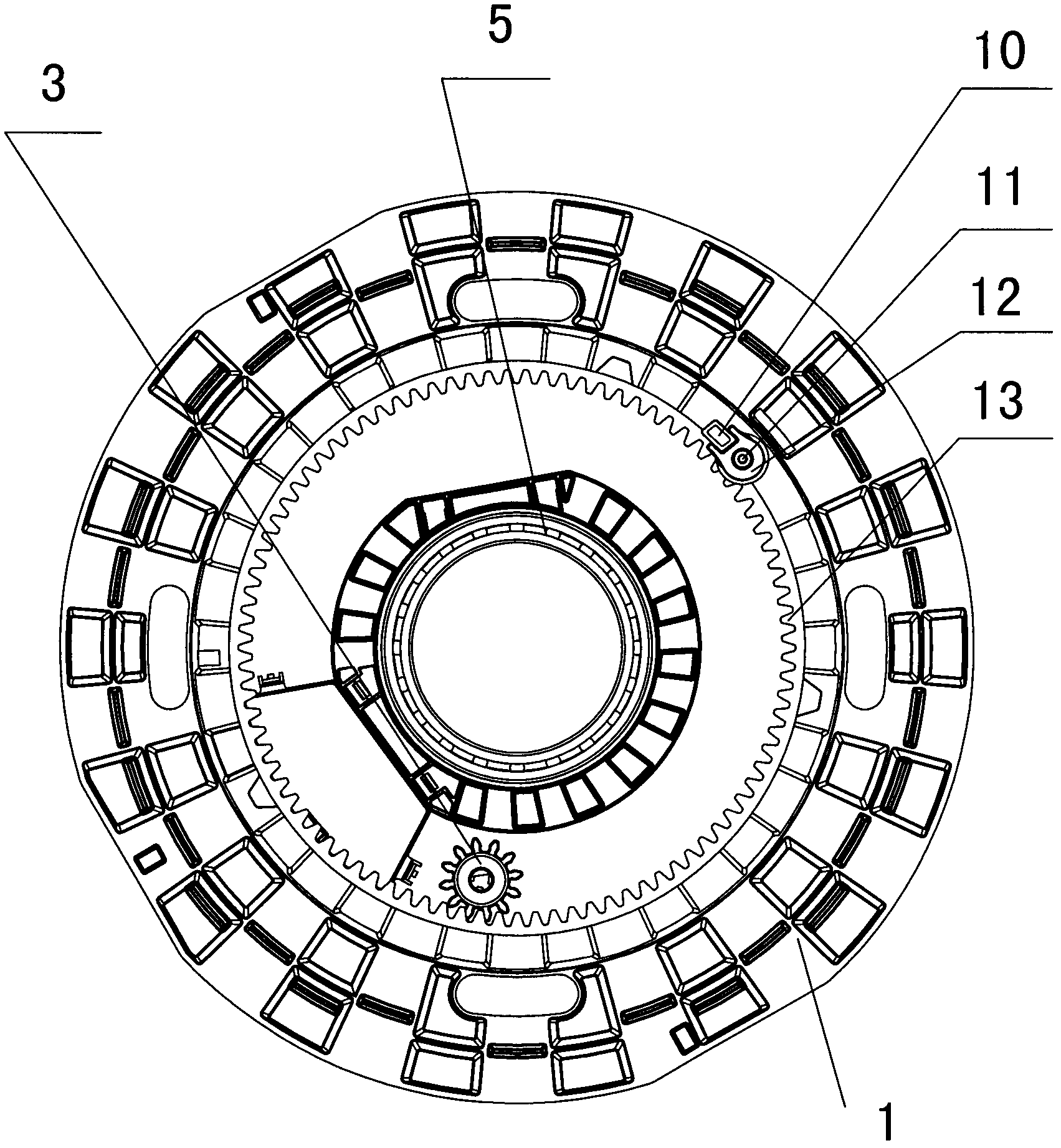

The present invention relates to a novel magnetic suspension and propulsion technologies, which are named as Magnetostatic Suspension (MSS) and Magnetostatic Propulsion (MSP) respectively because of their magnetostatic nature of forces generated. A spring-like magnetic force is produced through interactions between magnets and ferrous materials such as steel. To apply the technologies, four key embodiments of the invention have been invented and described: a MSS and MSP maglev vehicle system in which a vehicle body is lifted up and stabilized by magnetostatic forces above a steel rail both horizontally and vertically; a MSP long-stator linear motor system in which a rotor can be driven up along a magnet-free steel rail or long steel stator; a MSS Permanent Magnet Magnetic Bearing System (PMMB) system in which a steel shaft is levitated standstill by a fully permanent magnets assembly for frictionless rotating; a MSS maglev wind turbine system in which a magnet-free turbine body can hover standstill over a permanent magnet base assembly spinning frictionlessly with low inertia and low cut-in wind speed threshold.

Owner:JI QIGEN

Method for preparing nanometer zirconium oxide for thermal barrier coating

InactiveCN1757605AImprove thermal shock resistanceGuaranteed compactnessZirconium oxidesChlorideZirconium oxychloride

A process for preparing zirconium oxide nano-particles used for coated thermal barrier layer includes such steps as preparing the mixed solution of zirconium oxychloride and yttrium oxide (or chloride), adding ammonia water, washing for dispersing, hydrothermal reaction to generate Y-stabilized ZrO2 nano-particles, separating, coating by aluminium oxide, drying, granulating and heat treating.

Owner:SHANDONG UNIV

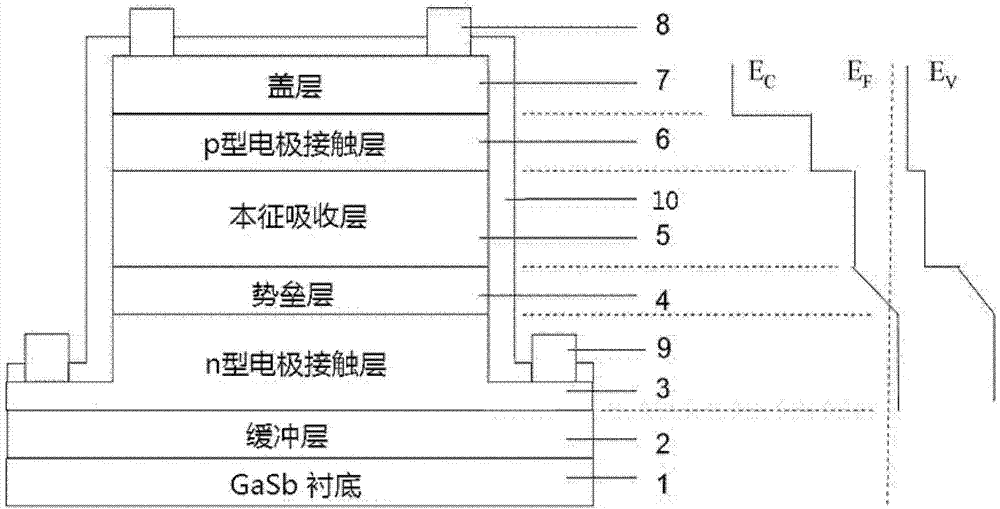

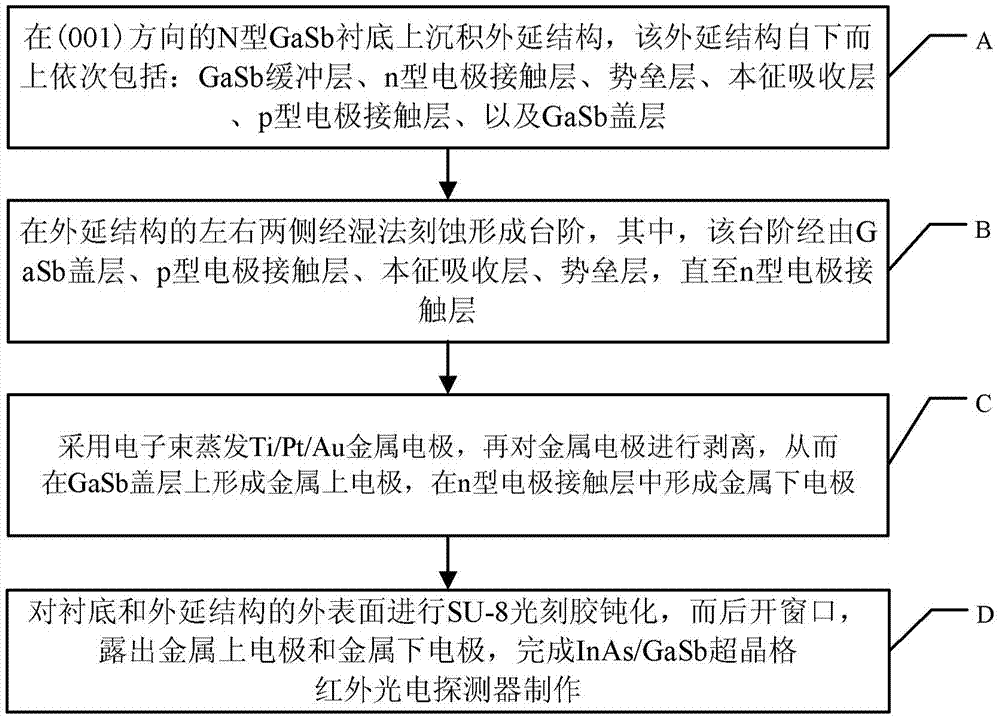

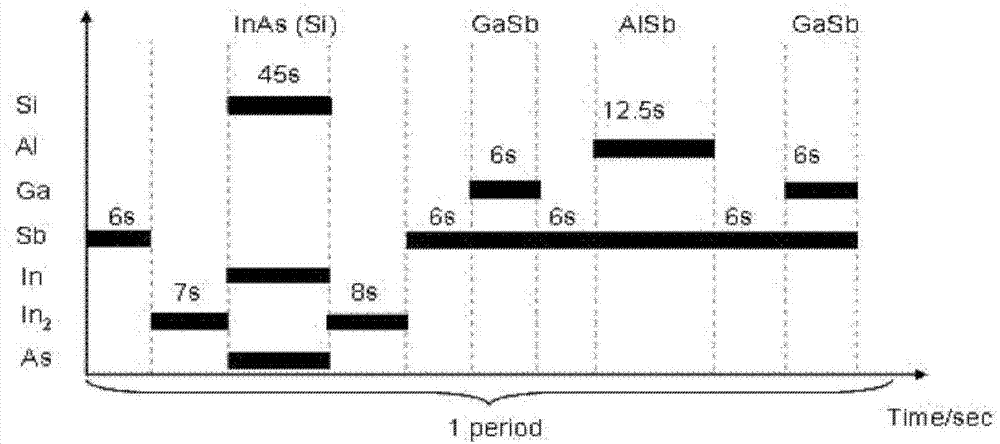

InAs/GaSb superlattice infrared photoelectric detector and manufacturing method thereof

ActiveCN103887360AImprove performanceSuppression-recombination dark currentFinal product manufactureSemiconductor devicesPhotovoltaic detectorsElectrode Contact

The invention provides an InAs / GaSb superlattice infrared photoelectric detector and a manufacturing method thereof. The InAs / GaSb superlattice infrared photoelectric detector comprises a substrate, an epitaxy structure deposited on the substrate, an upper metal electrode formed above steps, a lower metal electrode formed under the steps and a passivation layer, wherein the epitaxy structure comprises an n-type doping buffer layer, an n-type electrode contact layer, a barrier layer, an intrinsic absorption layer, a p-type electrode contact layer and a cover layer, the steps are formed on two sides of the epitaxy structure through etching, the intrinsic absorption layer is composed of a plurality of periodical InAs / InSb / GaSb / InSb superlattice structures. In the InAs / GaSb superlattice infrared photoelectric detector, InSb is respectively inserted into two interfaces of each superlattice period of the intrinsic absorption layer to form strained superlattices, the stress between the superlattices and the substrate is effectively balanced, the material growing quality is improved, and accordingly the photoelectric performance of the detector is improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Press molded concrete ground construction method

InactiveCN104032930AReasonable designEasy to useSidewalk pavingsFlooringSurface layerChemical reaction

The invention provides a press molded concrete ground construction method, which belongs to the technical field of construction engineering. According to the construction method, before concrete is solidified, color hardening agents and color release agents are paved onto the whole concrete surface layer; the color hardening agents and the color release agents take a chemical reaction with the concrete; then, a special concrete press molding construction mold is used for pressing and printing vein patterns of a special concrete press molding construction template onto the wet and soft concrete surface layer; and after the cleaning, drying and solidification, sealing protection agents cover on the concrete surface layer. The press molded concrete ground construction method has the advantages that the construction is simple, the technology is stable, and the construction effect is obvious; and the ground construction quality and the effect after the forming can be obviously improved.

Owner:CHINA CONSTR EIGHTH ENG DIV

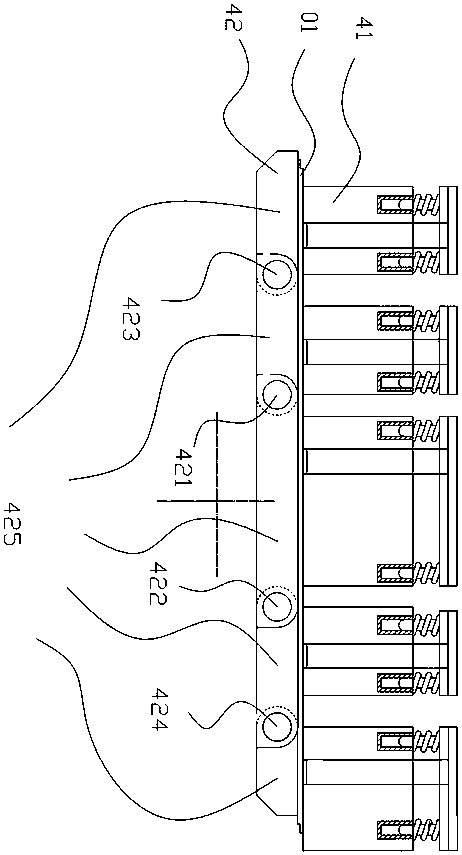

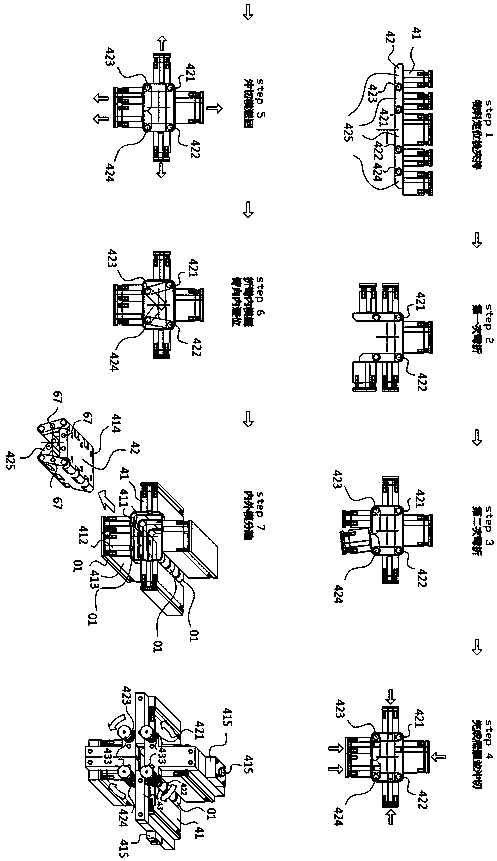

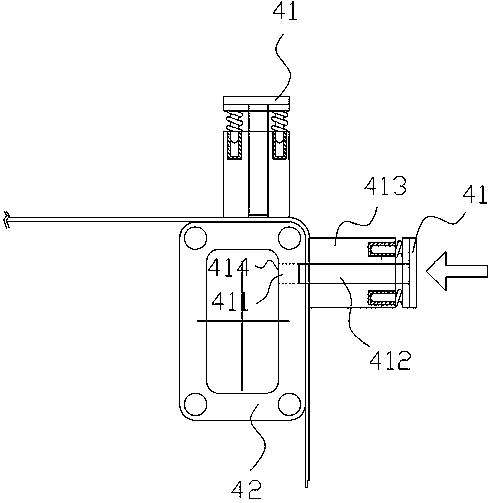

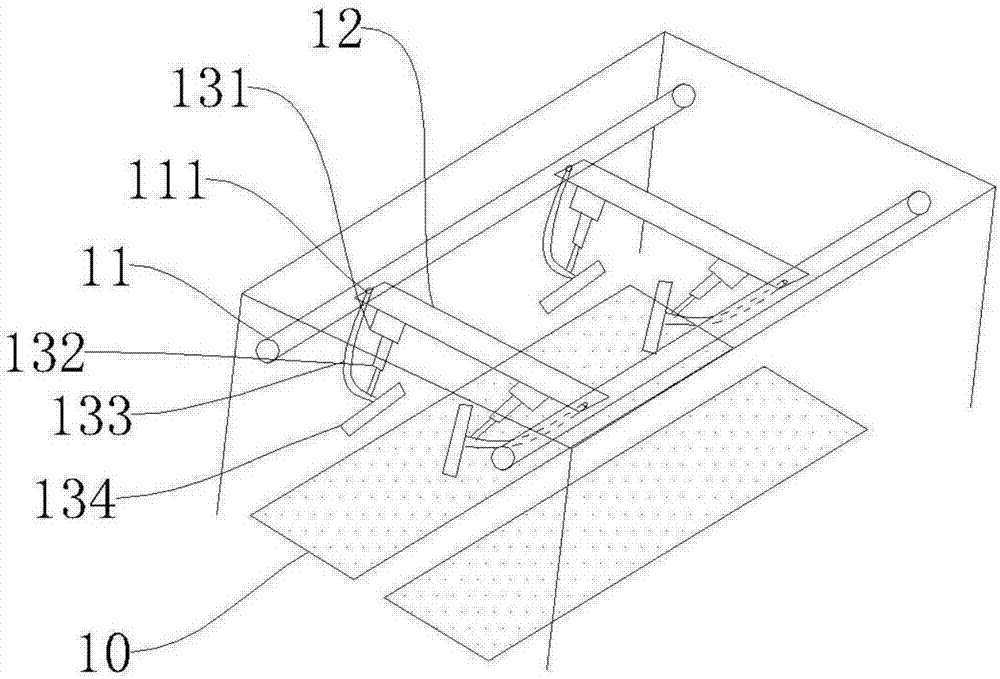

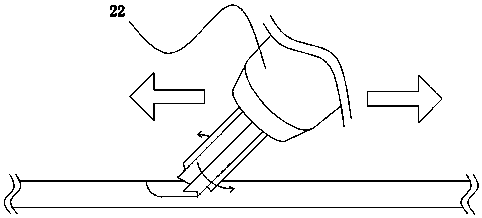

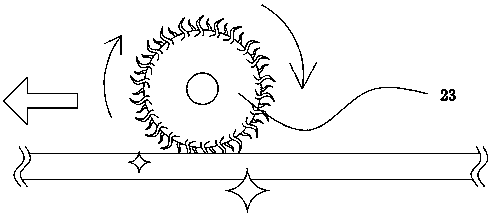

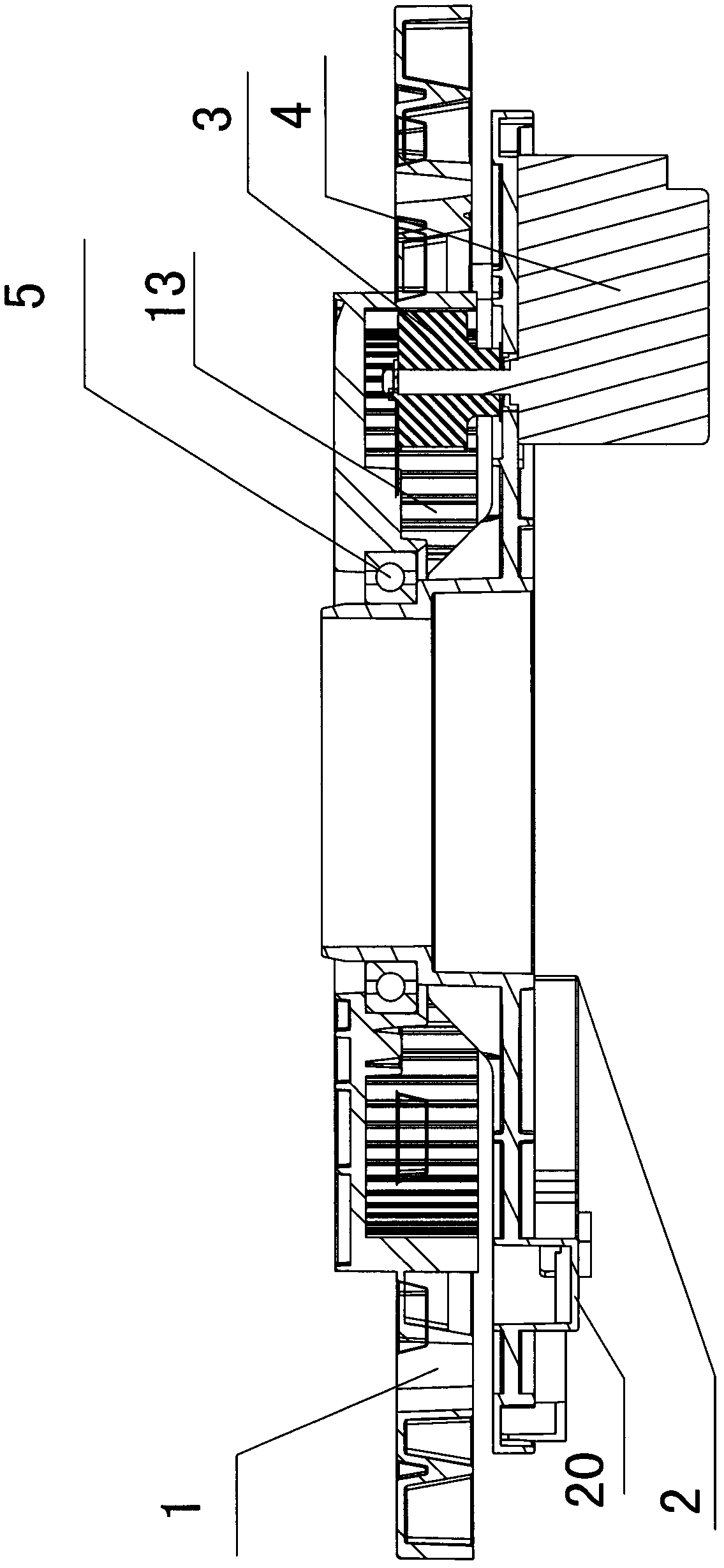

Bending and cutting integrated machine and method thereof

PendingCN107597968AReduce dependenceImprove segmental processingShaping toolsOther manufacturing equipments/toolsNumerical controlPunching

The invention relates to a bending and cutting integrated machine and a method thereof. A punching or cutting unit carries out punching or cutting operation before bending forming or after the bendingforming, and the punching or cutting unit applies force to a punching cutter through a punching driving device (415) to prompt the punching cutter to carry out shape and hole punching on a workpiece,or carries out shape and hole machining on the workpiece through a cutting tool on a numerical control mechanical arm when bending external moulds (41) and bending internal moulds (42) clamp the workpiece and are closed, it is avoided that the precision of a hole and a bend angle of each workpiece is reduced due to resetting after demoulding.

Owner:东莞市健耀烨电子科技有限公司

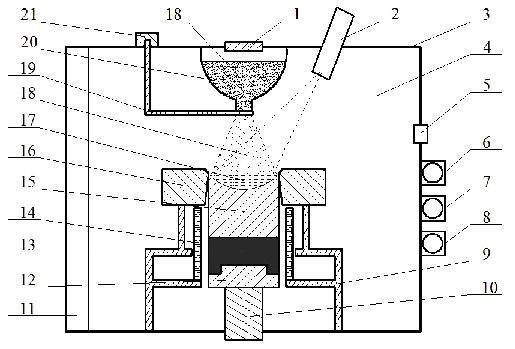

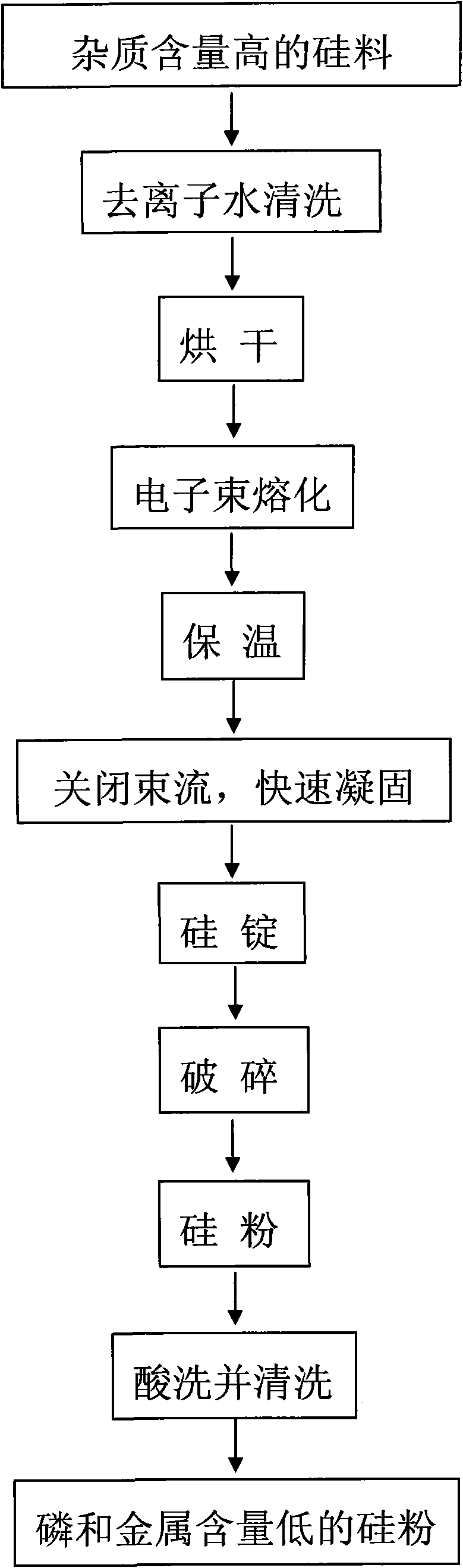

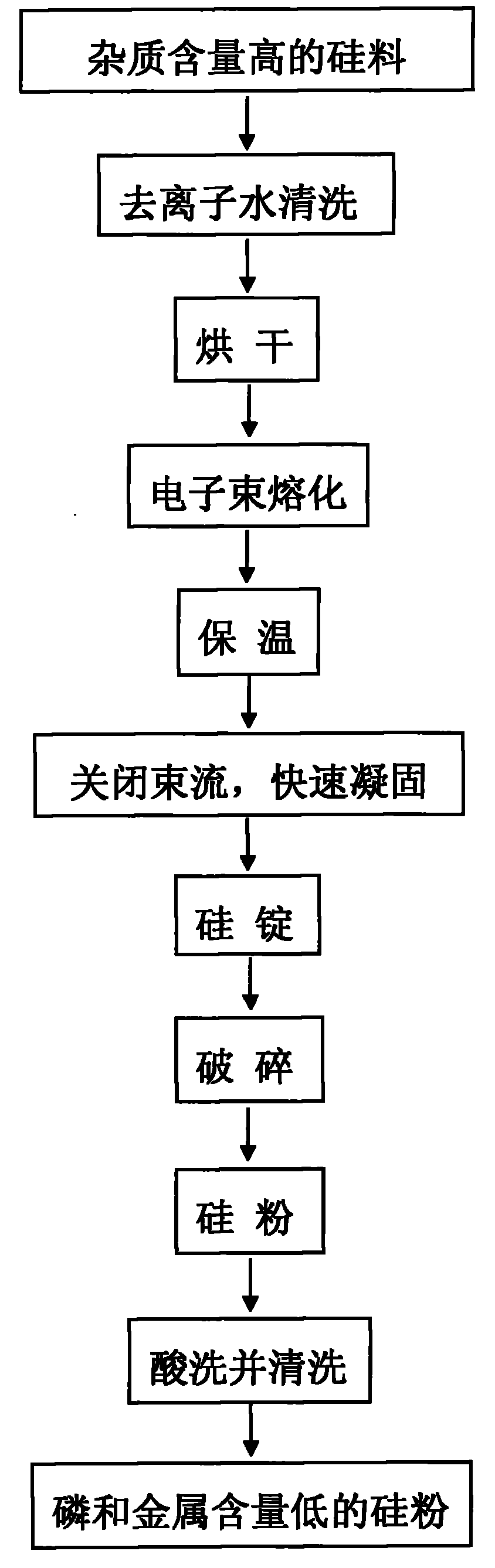

Method and device for coupling and purifying polysilicon and removing phosphorus and metal with electron beams

InactiveCN102120578AEvenly distributedReduce distributionChemical industrySilicon compoundsMelting tankMetal impurities

The invention belongs to the technical field of polysilicon purification with a physical metallurgy technology and particularly relates to a method for coupling and purifying polysilicon and removing phosphorus and metal with electron beams. The method comprises the following steps of: forming a stable melting pool on the top of a low-phosphorous low-metal high-purity silicon ingot with the electron beams; putting silicon powder to be purified into the melting pool and melting to realize the rapid melting of the powder body to remove volatile phosphorous impurity in the silicon powder; simultaneously carrying out directional ingot pulling so that the low-phosphorus polysilicon grows in a directional solidification way; and removing metal impurities in the polysilicon by utilizing a segregation effect. The invention has the remarkable effects that: because ways of melting silicon powder with the electron beams and carrying out directional solidification are simultaneously adopted, the phosphorus impurity is rapidly removed with the electron beams, and the metal impurities with lower segregation coefficient are removed by the directional solidification way, the purity of the polysilicon is effectively improved, and the using requirement of solar grade silicon is achieved. The invention has the advantages of good purification effect, stable technology, simple process, high production efficiency, energy saving, low cost and suitability for batch production.

Owner:谭毅

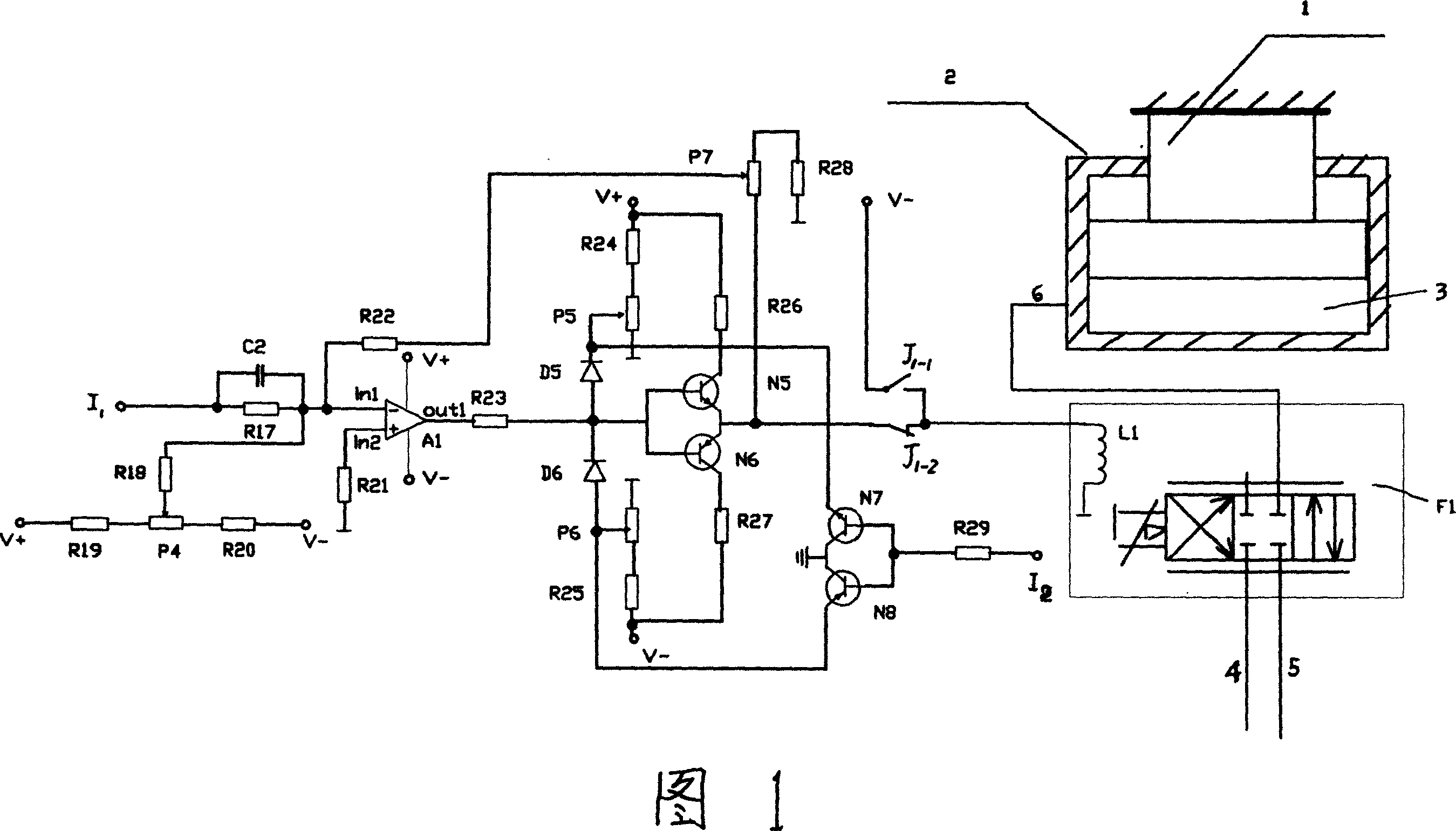

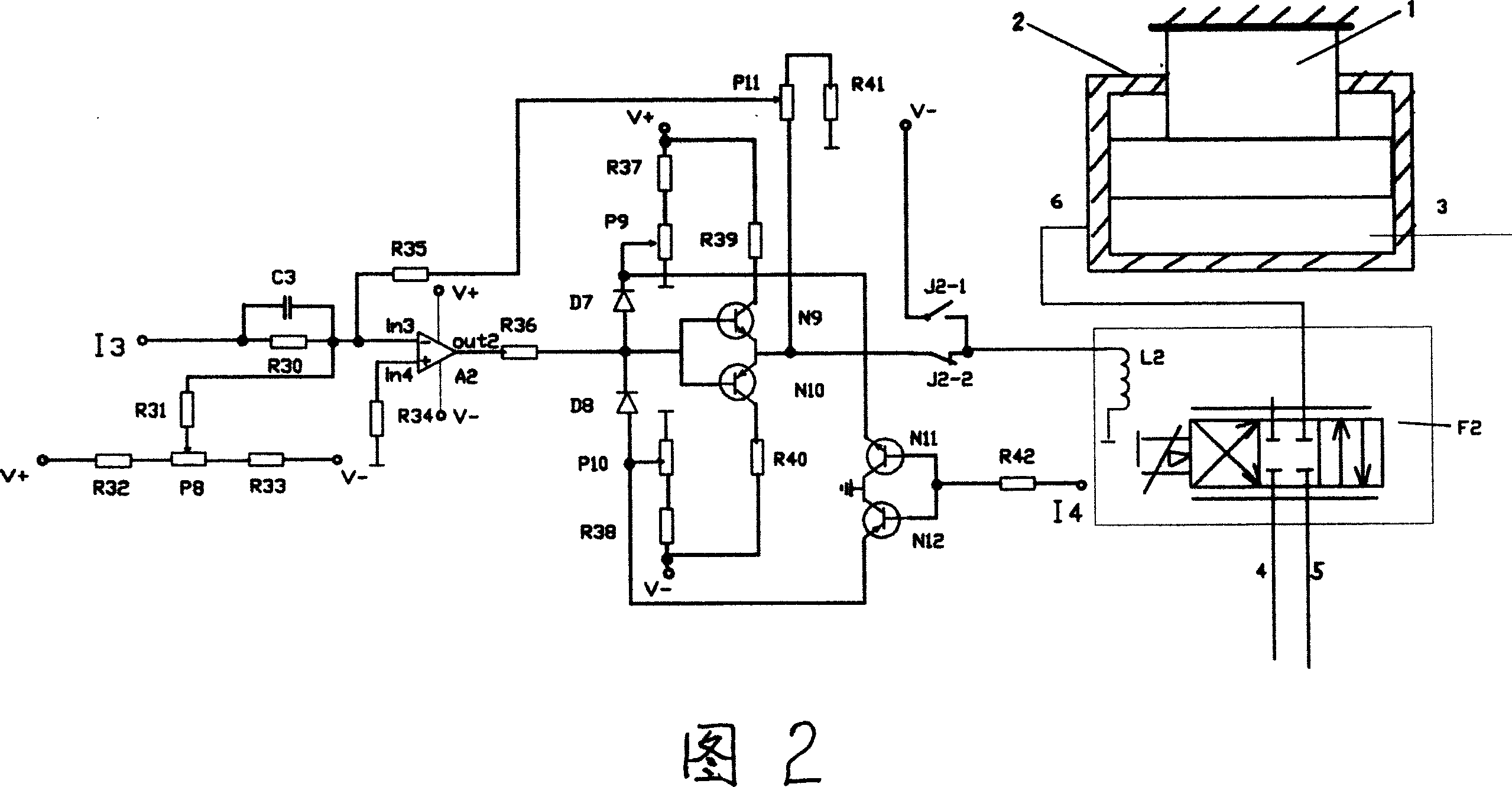

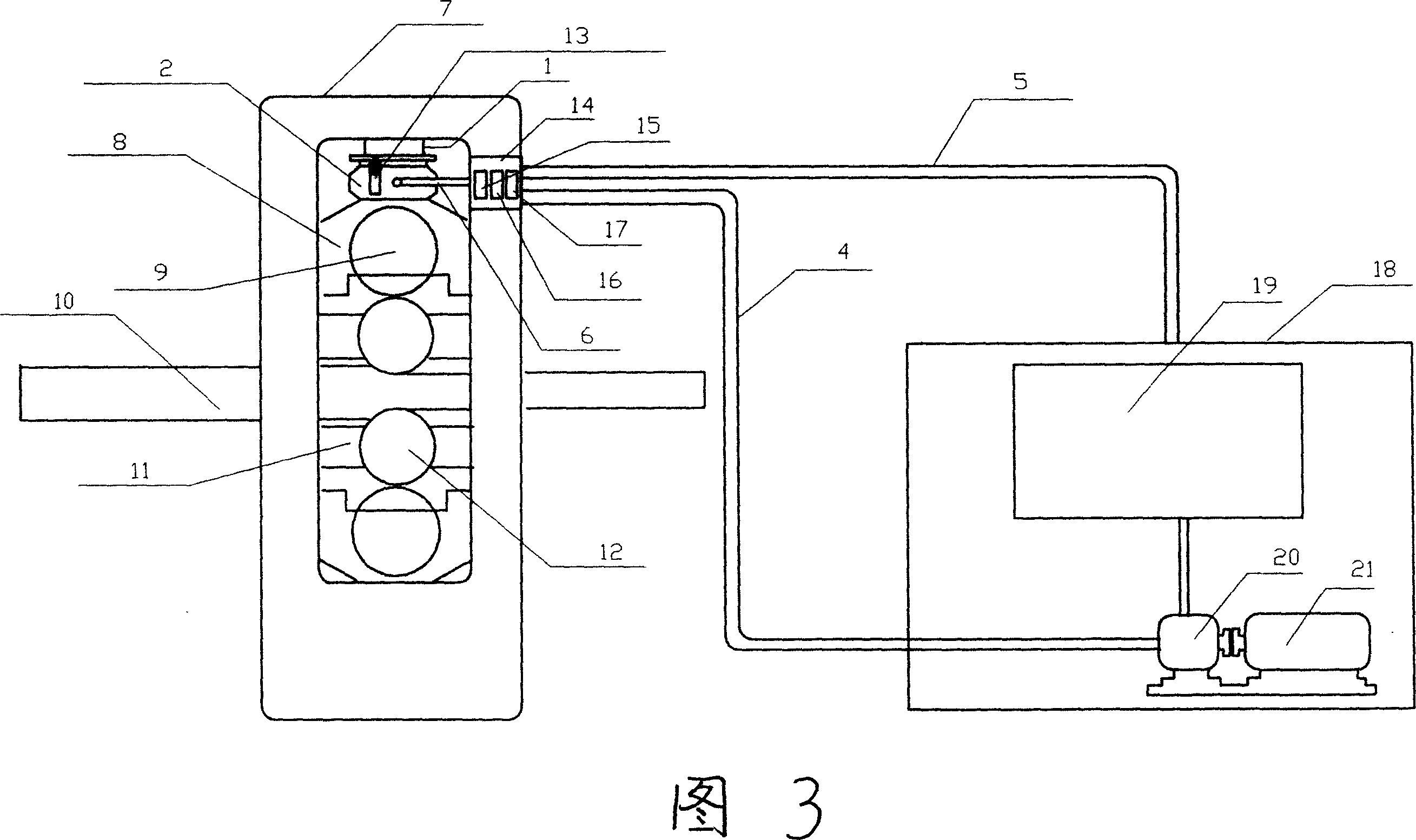

Method and device for synchro controlling high precision screwdown at two side during rolling steel plate

InactiveCN101003062AHigh precisionHigh technology contentHydraulic programme controlComputer controlSynchronous controlPush pull

A method for controlling the high-precision synchronous press-down at both sides of rolled plate features that a technique for high-precision two-stage synchronous control to press-down speed and the in-line real-time computer control to automatic complementary linkage of high-precision synchronizing are used. Its apparatus is composed of two high-precision two-stage press-down speed controlling mechanisms with hydraulic mechanism, computer, push-pull switching circuit and electro-hydraulic servo valve.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

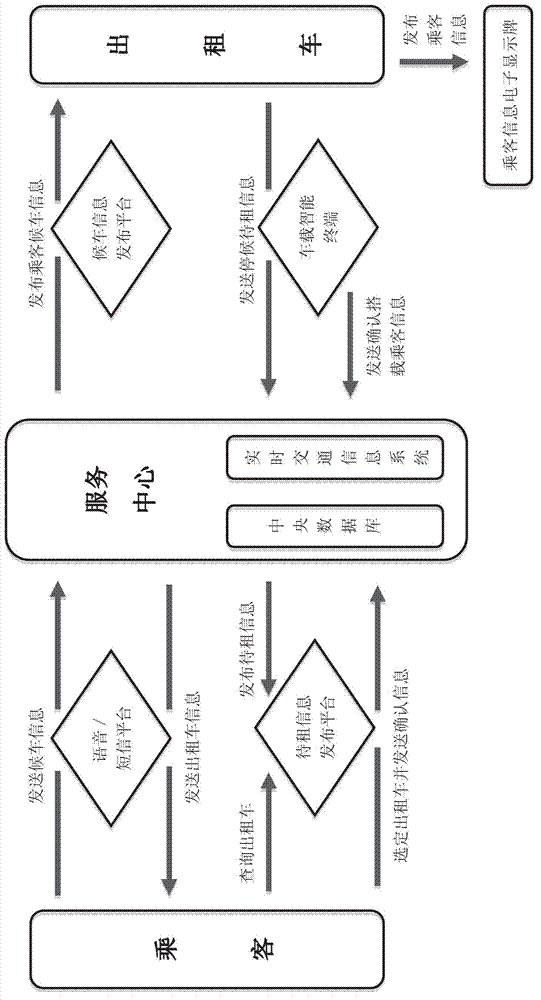

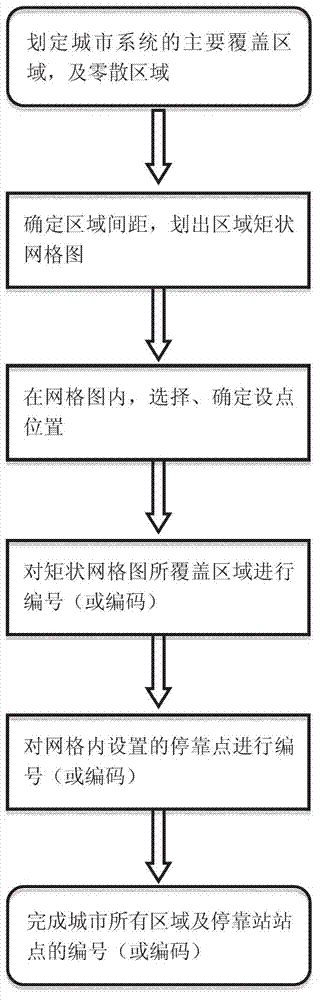

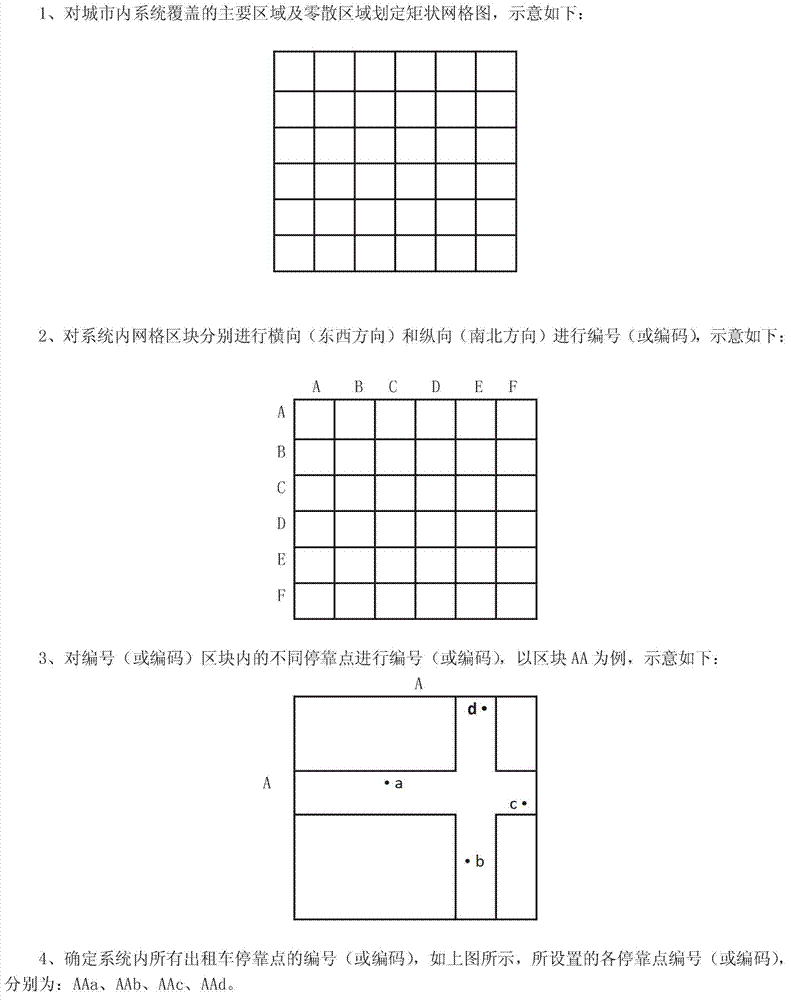

Method and system for smart guide and navigation management service for urban taxies

InactiveCN102930716AComprehensive Navigation ServiceEffectively go toRoad vehicles traffic controlDisplay boardOperational costs

The invention discloses a method and a system for smart guide and navigation management service for urban taxies. The system is composed of a vehicle wireless smart guide and navigation terminal, a passenger information electronic display board, a taxi stop and number (or code), a service center, a wireless communication network, an access platform, a central data bank, an urban realtime dynamic traffic information system, a system management center, a passenger waiting information real-time publication platform, a taxi renting information real-time publication platform and the like. According to the system, daily navigation and realtime passenger waiting information guide can be provided for the urban taxies, safe driving and stopping of the taxies on urban roads can be standardized, dynamic management for the taxies can be strengthened, the using efficiency and transport capacity of the taxies can be improved, taxi waiting and taking are facilitated for citizens. Urban road jam can be relived, energy consumption can be saved, atmospheric pollutants can be reduced, operating costs and labor intensity of taxi drivers can be reduced, and good economic and social benefits can be achieved.

Owner:HANGHANG LINK INFORMATION TECH BEIJING

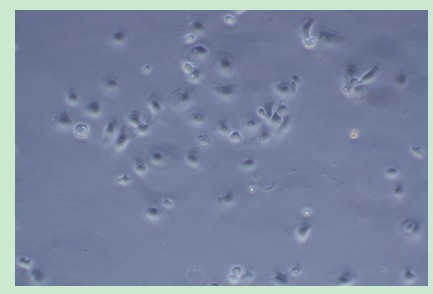

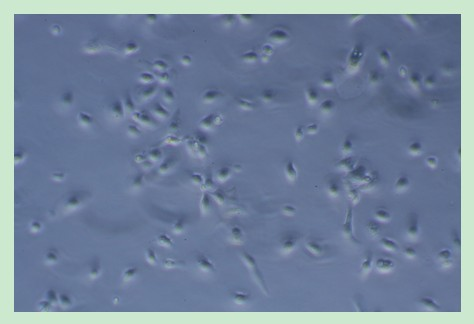

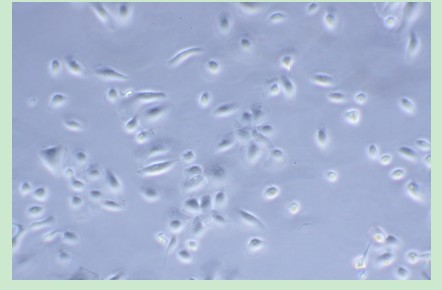

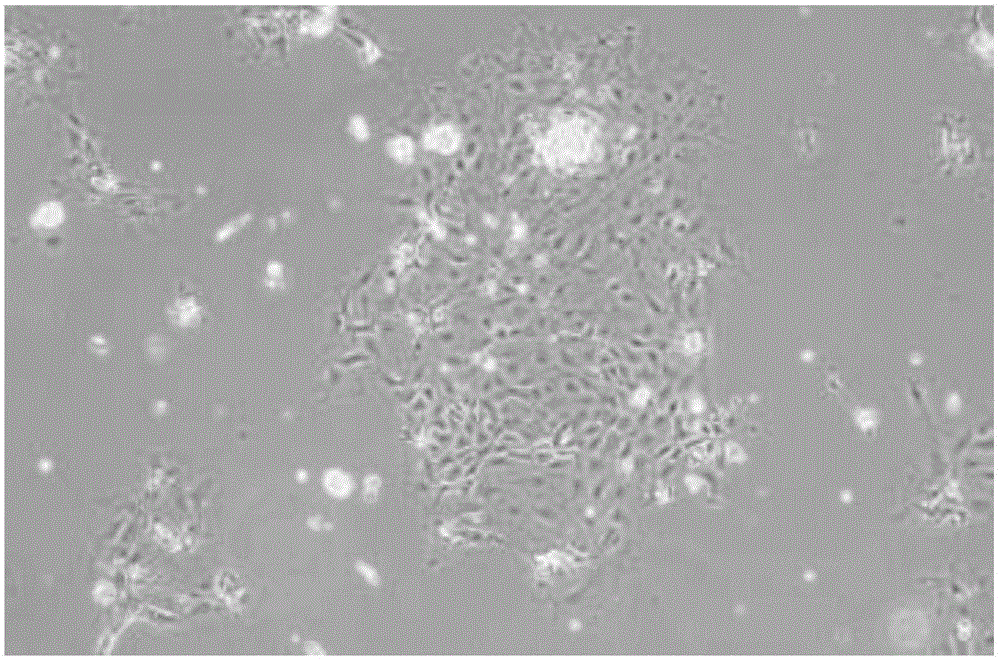

Method for culturing human airway epithelial cells

InactiveCN102433296AHigh purityUniform shapeVertebrate cellsArtificial cell constructsHuman airwayPhosphoric acid

The invention discloses a method for culturing human airway epithelial cells. The method comprises the following steps of: (1) acquiring human airway epithelial cells which are subjected to primary culture; and (2) acquiring human airway epithelial cells which are subjected to subculture, namely cleaning by using a phosphoric acid buffer solution when the fusion density of primary cells reaches 70 to 90 percent, adding a 0.25 percent trypsin solution, digesting at room temperature for 5 to 10 minutes, collecting cell suspension when cells are retracted and suspended, adding an equal amount of solution containing a protease inhibitor, performing centrifugal collection on the cells, inoculating in a novel culture dish containing a complete medium at the concentration of between 1 and 6*10<6> cells / ml, culturing, and thus obtaining the human airway epithelial cells which are subjected to subculture when the cells grow to a logarithmic growth phase after 3 to 5 days. The method for culturing the human airway epithelial cells has a stable technology and is high in repeatability; and the cultured cells have high purity and uniform morphology, grow well and can be subjected to continuous passage.

Owner:THE FIRST AFFILIATED HOSPITAL OF GUANGZHOU MEDICAL UNIV (GUANGZHOU RESPIRATORY CENT) +1

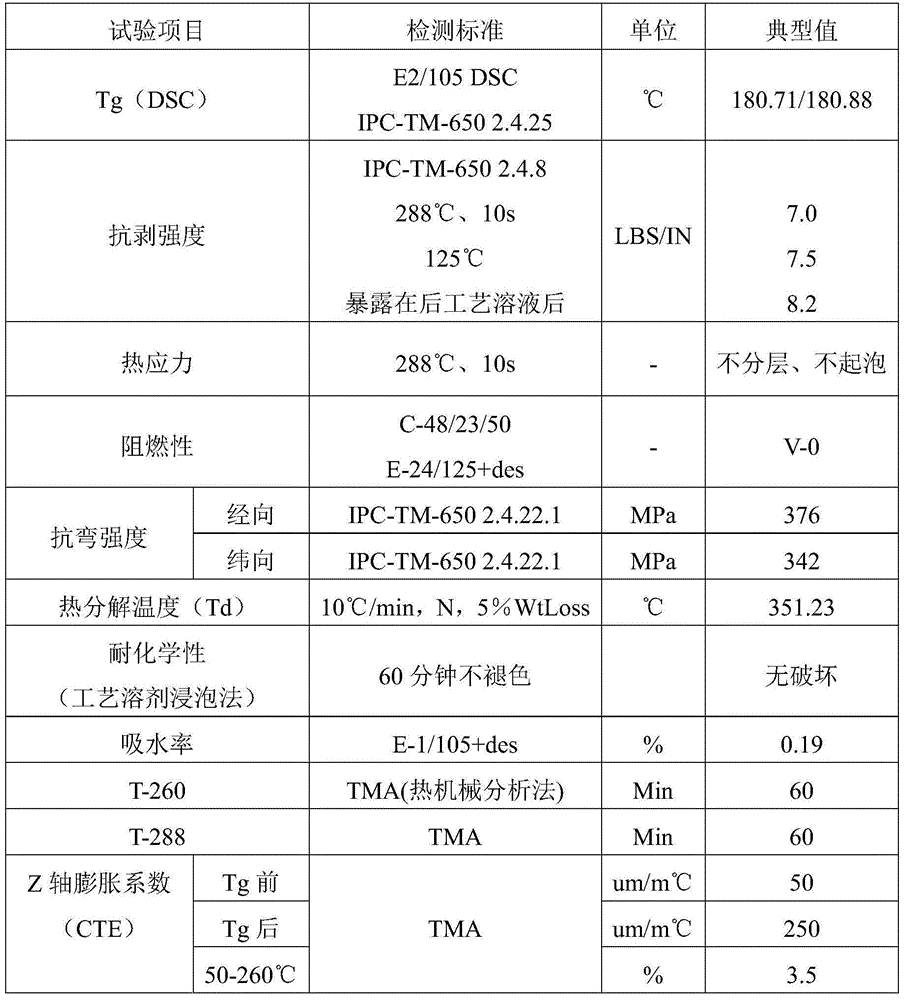

Resin composition, glue solution, prepreg and copper-clad plate containing same and preparation methods

The invention discloses a resin composition, a glue solution, a prepreg and a copper-clad plate containing the same and preparation methods. The resin combination is prepared from, by weight, 380-500 parts of epoxy resin, 80-110 parts of curing agent, 0.2-0.4 part of curing catalyst, 80-140 parts of solvent and 70-150 parts of inorganic filler. The curing agent is linear phenolic resin. In the preparation methods of the glue solution, the prepreg and the copper-clad plate, the resin composition is adopted, their preparation methods are simple in process, low in cost, environmentally friendly, technologically stable, low in defective rate, strong in process controllability and suitable for mass production. The copper-clad plate has good comprehensive performance, and especially the acid, alkali, solvent and heat resistance is good.

Owner:SHANGHAI GUOJI ELECTRONICS MATERIALS CO LTD

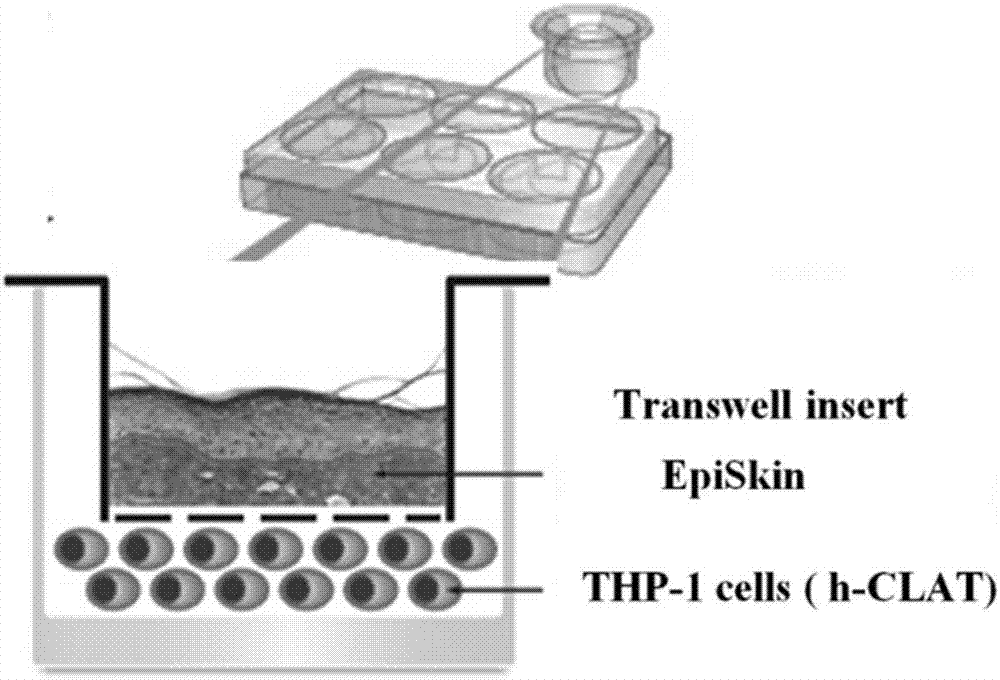

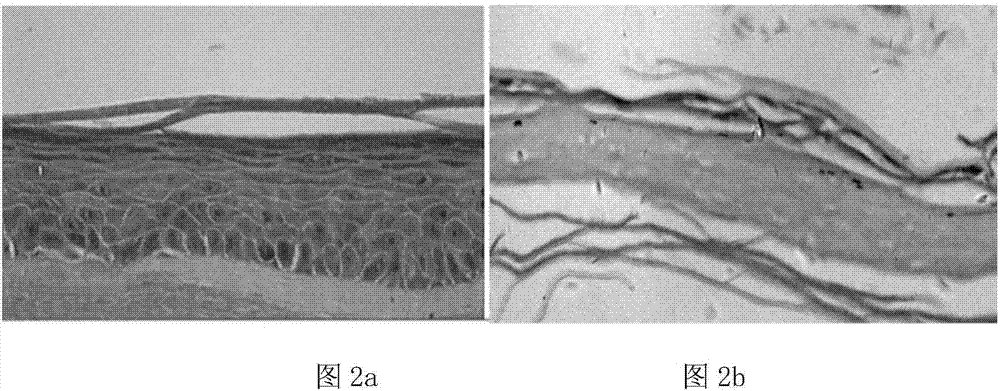

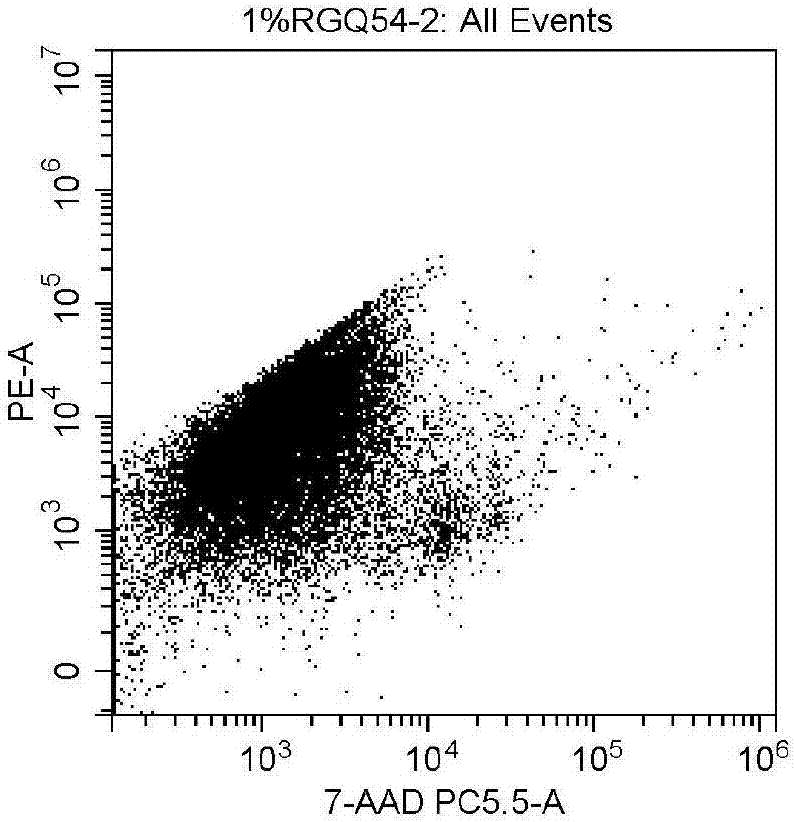

Cutaneous sensitization detecting method based on co-culturing mode of three dimensional skin model and dendric cell

InactiveCN107446993ATechnical stabilityHigh degree of standardizationMicrobiological testing/measurementIndividual particle analysisSensitizationSecretion

The invention discloses a cutaneous sensitization detecting method based on a co-culturing mode of a three dimensional skin model and dendric cells. The cutaneous sensitization detecting method comprises the following steps : (1) preparing of the skin model in an early stage, (2) preparing and culturing of dendric cells, (3) constructing of co-culturing of the skin model and the dendric cells and exposing to-be-tested substances, (4) testing of activity of the skin model, (5) detecting of genome of the skin model, (6) detecting of secretion of lower layer cells of the co-culturing model, (7) detecting of expression of surface markers on the dendric cells, and (8) predicting of a statistic method and result. According to the cutaneous sensitization detecting method based on the co-culturing mode of the three dimensional skin model and the dendric cells, 3D skin which is reconstructed in vitro and has functions of barrier and metabolism and the dendric cells with the immunity function are combined together, a co-cultured novel experiment system is constructed and has similar functions and sensitization reaction with human bodies; the cutaneous sensitization of the to-be-tested substances can be evaluated from qualitative and quantitive aspects; and living animals and human bodies can be replaced through the method, and possible cutaneous sensitization caused by chemicals, cosmetics and drugs can be predicted directly.

Owner:程树军 +1

Artificial nursery stock growing method for Ooctopus ocellatus

InactiveCN101317551AStrong seedling operabilityRealize factory artificial cultivationClimate change adaptationAnimal feeding stuffBiologySeedling

The invention relates to an artificial seedling method for Octopus vulgaris in factory, comprising the seedling steps as follows: parent clam reinforced cultivation of Octopus vulgaris, spawning and hatching, larval rearing, juvenile culture of Octopus vulgaris, etc. The method can lead the Octopus vulgaris to realize the natural spawning indoors, and gain high-quality spermatozoa and ovum and high fecundation rate and hatching rate, realize full-manpower cultivation of Octopus vulgaris seedlings in the factory, successfully cultivate the healthy and high-quality juvenile Octopus vulgaris; furthermore, the seedling process has strong maneuverability and stable technique.

Owner:ZHEJIANG OCEAN UNIV +2

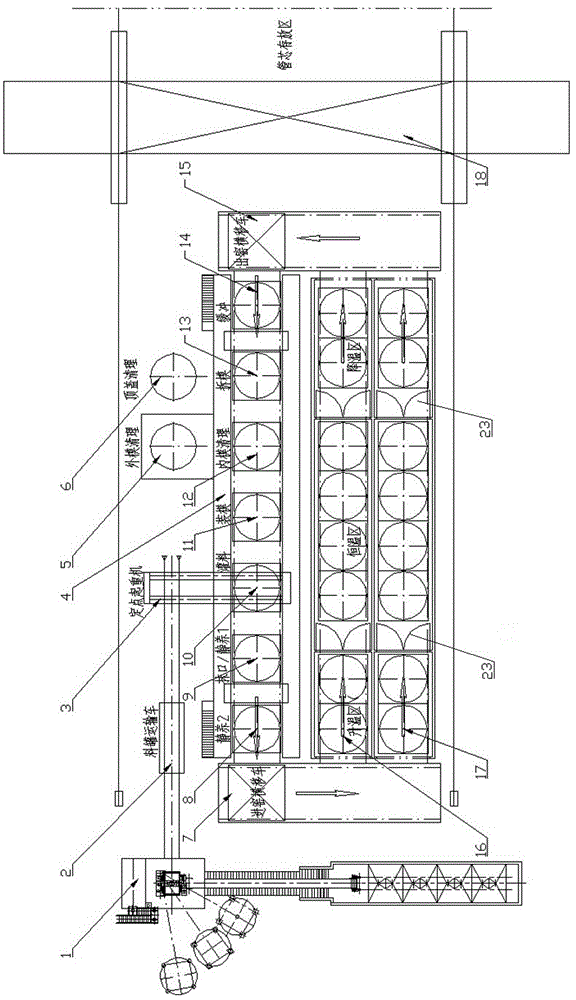

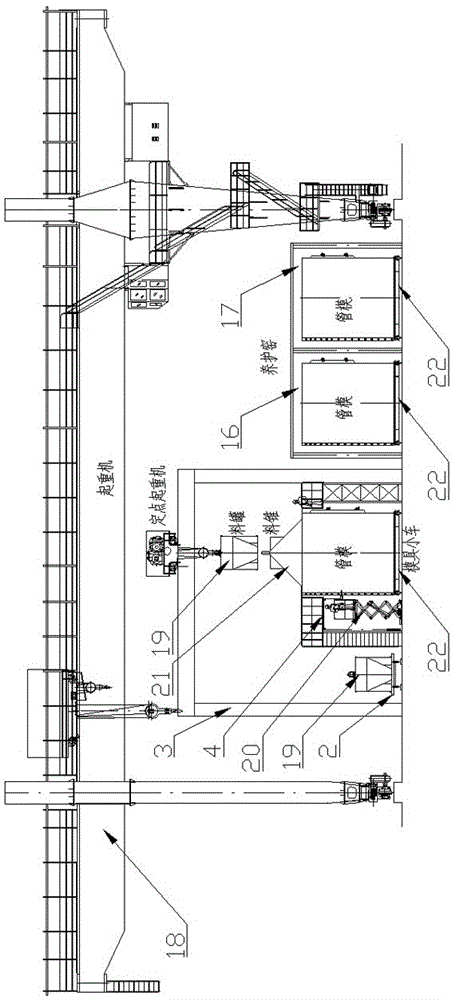

PCCP pipe core vertical molding method automatic production line

InactiveCN105922437AAdvanced technologyReduce manual labor intensityCeramic shaping plantsAuxillary shaping apparatusManufacturing engineeringControl system

The invention provides a PCCP pipe core vertical molding method automatic production line; and the PCCP pipe core vertical molding method automatic production line has such characteristics as stable performance, good reliability, easy maintenance, high safety, automation, high information degree and high production efficiency. The PCCP pipe core vertical molding method automatic production line comprises more than one operation lines, more than one maintenance lines, mold pushing devices, concrete loading and casting systems, mold transfer cars, transverse moving ferry vehicles, a maintenance line control system and a PLC production line control system; multiple sets of PCCP molds are arranged on the operation lines and the maintenance lines; the mold pushing devices are arranged on the operation lines and the maintenance lines; the mold transfer cars can move on the operation lines and the maintenance lines; the transverse moving ferry vehicles are matched with the operation lines and the maintenance lines; the concrete loading and casting systems are arranged on the operation lines for casting PCCP molds on the operation lines; the maintenance line control system is used for performing steam control for molds on the maintenance lines; and the PLC production line control system is used for interworking of all systems to finish prefabricating of PCCP pipe cores.

Owner:SHANDONG ELECTRIC POWER PIPELINE ENG

Method for changing solidifying crucible bottom layering manner in electron-beam polycrystalline silicon purification

InactiveCN106894084AReduced power to irradiate solidified cruciblesImprove qualityPolycrystalline material growthSingle crystal growth detailsCrucibleElectron

A method for changing solidifying crucible bottom layering manner in electron beam polycrystalline silicon purification belongs to the field of electron-beam melting and comprises the following steps: layering 3 Kg of polycrystalline silicon wafers (with thickness of 7-10 mm) at the bottom of a solidifying crucible, and layering 5 Kg of polycrystalline silicon fragments on the polycrystalline silicon wafers; preheating electron guns; gradually increasing the power of an electron gun for irradiating a smelting crucible to 250 KW and the power of an electron gun for irradiating the solidifying crucible to 50 KW, and melting silicon; increasing the power of the electron gun for irradiating the solidifying crucible to 200 KW, and melting silicon; turning off the electron gun for irradiating the smelting crucible, outpouring silicon liquid, and increasing the power of the electron gun for irradiating the solidifying crucible to 250 KW; increasing the power of the electron gun for irradiating the smelting crucible to 250 KW, and melting and smelting silicon; and turning off the electron gun for irradiating the smelting crucible, outpouring silicon liquid, turning on the electron gun, keeping the power at 250 KW for 10 min, keeping the power at 200 KW for 2 min, keeping the power at 150 KW for 3 min, keeping the power at 120 KW for 5 min, keeping the power at 100 KW for 7 min, keeping the power at 80 KW for 8 min, keeping the power at 50 KW for 12 min, keeping the power at 30 KW for 16 min, keeping the power at 20 KW for 20 min, decreasing the power to 0 KW, and reducing the electron beam for solidifying. The method disclosed by the invention can increase product yield, and reduce the energy consumption of electron beam polycrystalline silicon purification.

Owner:DALIAN UNIV OF TECH QINGDAO NEW ENERGY MATERIALS TECH RES INST CO LTD

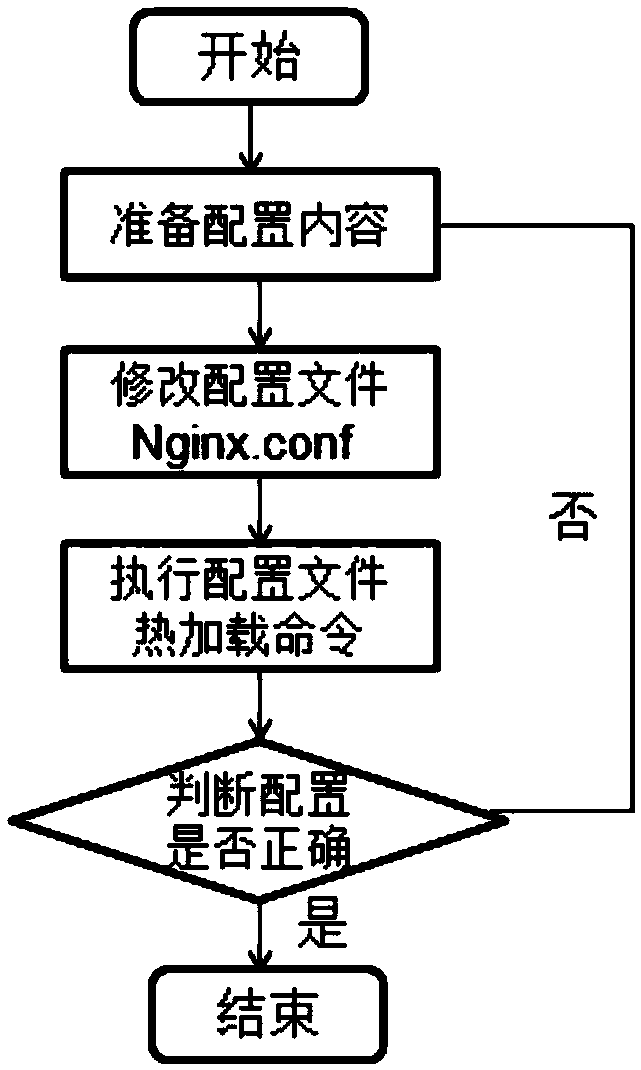

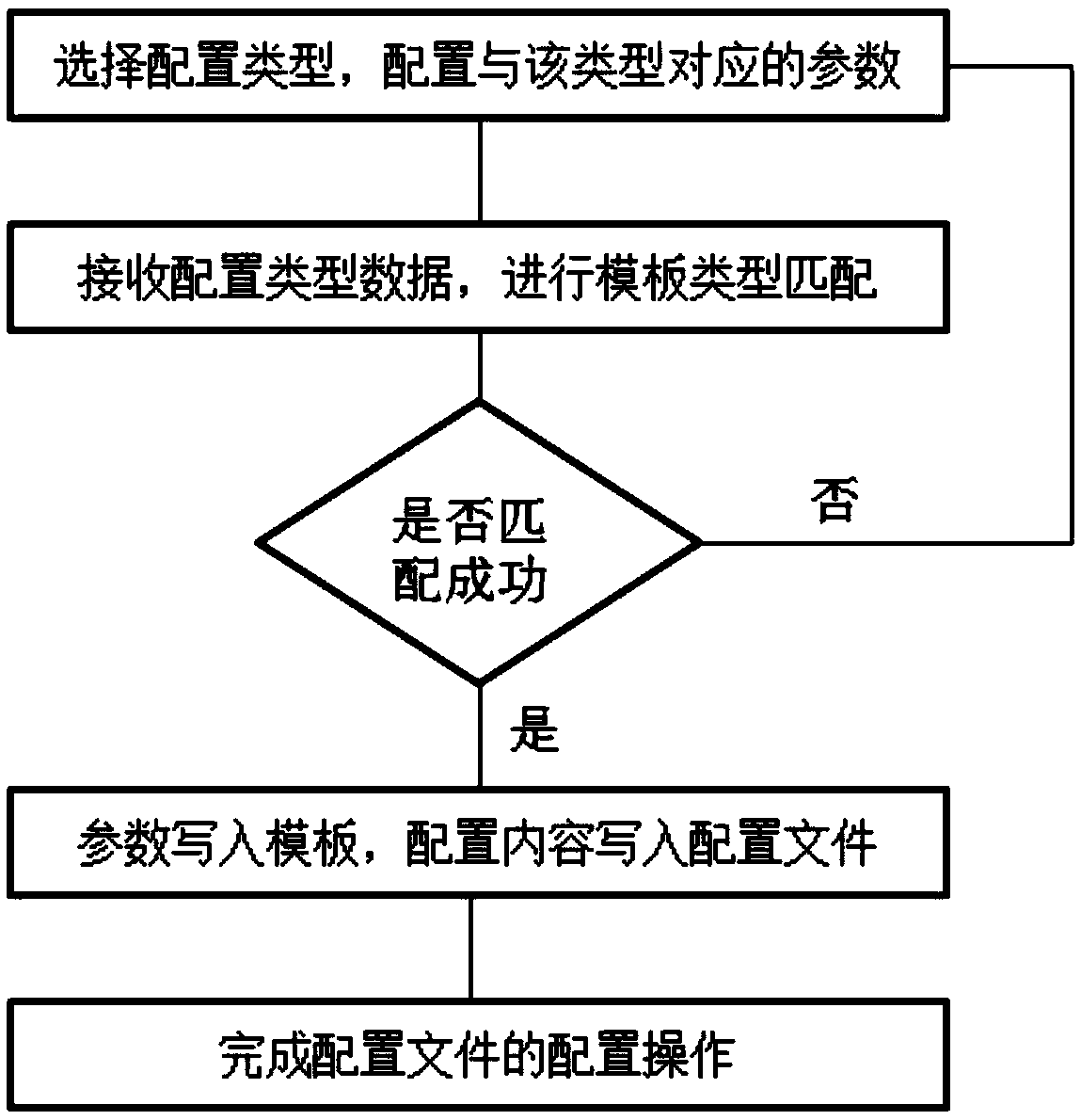

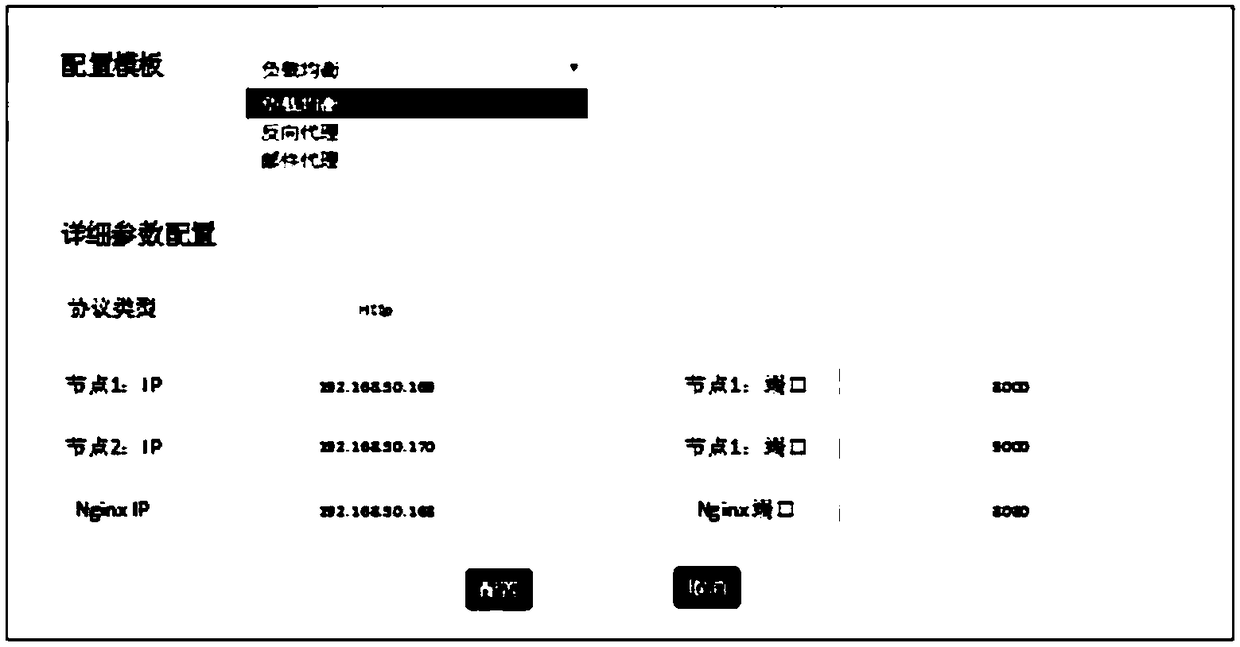

Nginx dynamic configuration method and system

ActiveCN109450708ASimple structureTechnical stabilityData switching networksOperating systemInterface selection

The invention provides an efficient and convenient Nginx dynamic configuration method and system. The method comprises the following steps: selecting a configuration type on a web console interface; configuring a parameter corresponding to the type according to the configuration type; receiving configuration type data sent by a configuration interface; performing template type matching; judging whether the matching succeeds; if the matching succeeds, writing the configuration parameter of a UI interface to a template; generating specific configuration; writing the specific configuration content to a configuration file; and completing a configuration operation of the configuration file so that the configuration takes effect in time. According to the method and the system in the invention, the Ngnix server achieves dynamic configuration, thereby avoiding manual configuration of a user in the background such that the configuration of the Ngnix server is more efficient, convenient, fast and accurate.

Owner:北京明朝万达科技股份有限公司

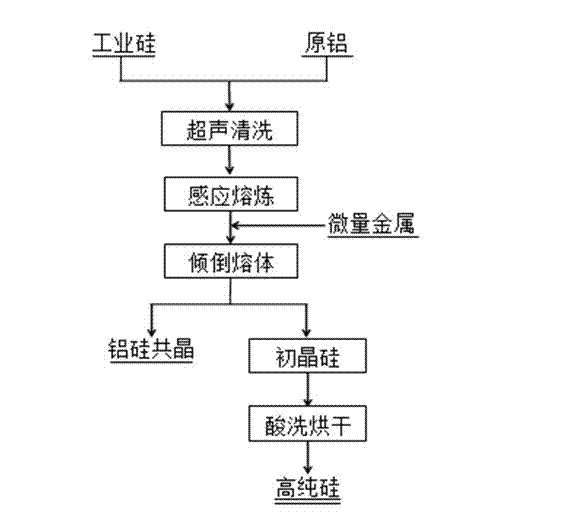

Method for purifying polysilicon through enhanced alloying segregation

InactiveCN102786060AAchieve removalMeeting Solar Grade Silicon RequirementsChemical industrySilicon compoundsBorideAlloy

The invention belongs to the technical field of metallurgical purification, in particular to a method for enhancing purifying polysilicon through enhanced alloying segregation. The method comprises the following steps of firstly pre-washing industrial silicon and primary aluminum, and fully melting the primary aluminum under the protection of argon, and then adding the industrial silicon to the molten aluminum liquid, heating the mixture to 1100-1200 DEG C, and performing alloying melting; after the mixture is fully molten, adding metal or metal oxide, preserving the temperature and then slowly cooling the mixture, separating boride and primary silicon in sequence, and depositing the boride and primary silicon at the bottom of a crucible; dumping and storing the aluminum-silicon melt at the upper part of the crucible, and finally performing inorganic acid treatment on the primary silicon, removing residual metal and boride, and performing drying treatment on the treated primary silicon to obtain the polysilicon with low boron content. According to the method provided by the invention, on the basis of purification of Si-Al alloy, trace metals such as Fe, Ti, TiO2 or metal oxides are added, the purpose of removing boron impurities in the silicon can be realized, so that the boron content can meet the requirement of the solar grade silicon; the practicability is strong, the industrial production period is short, the energy is saved, the consumption is reduced, the environment is protected, the technology is stable and the production efficiency is high.

Owner:DALIAN UNIV OF TECH

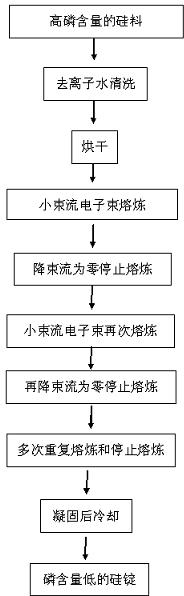

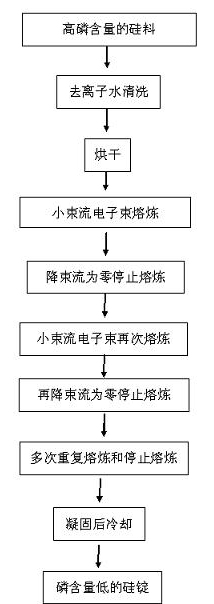

Method for purifying polysilicon by adopting electron beam to carry out fractionated smelting

InactiveCN102145893AReduce evaporation lossReduce removal efficiencyChemical industrySilicon compoundsPhysical metallurgyCrucible

The invention belongs to the technical field of purification of polysilicon by a physical metallurgical technology. A method for purifying the polysilicon by adopting an electron beam to carry out fractionated smelting comprises the following steps: firstly preparing a material; placing a cleaned and dried silicon material into an electronic beam smelting furnace; carrying out preprocessing; carrying out water cooling on a crucible and preheating an electronic gun; and finally purifying, i.e. melting and smelting for a certain time by adopting the electron beam with a small beam current of 200 to 300mA, then reducing the beam current to zero, smelting the polysilicon for a certain time by the small beam current of 200 to 300mA and stopping the beam current after a silicon ingot is completely darkened and silicon steam is condensed back into a molten pool, repeatedly repeating the operation of smelting small beam current and stopping beam current, and finally carrying out cooling and condensing to obtain a polysilicon ingot with low phosphorus content. The method has the obvious effects that due to the adoption of the technology of carrying out electro beam fractionated smelting, the evaporation loss of silicon is reduced; the method has good purifying effect, stable technology, simple process, short period and high production efficiency; energy is saved; and consumption is reduced.

Owner:DALIAN LONGSHENG TECH CO LTD

Fast propagation technology for wild buckwheat rhizome

InactiveCN101946698AStrict quality controlRule out invasionCultivating equipmentsHorticulture methodsShootGreenhouse

The invention provides a fast propagation technology for wild buckwheat rhizome. The method comprises the following steps: culturing tender tissues such as fresh tender shoots and stems of the wild buckwheat rhizome on an MS culture medium; inoculating the tender tissues on the culture medium consisting of 2 mg / L of (MS+2,4-D) and 0.5 mg / L of (6-BA), wherein the success rate of callus induction is over 98%; transferring to a differential medium consisting of 1.5 mg / L of (MS+ KT) and 1.5 mg / L (6-BA) for differential culture, wherein a large number of seedlings appear after 15 days; transferring about 1.5 to 3.5-cm seedlings to a hormone-free MS rooting medium, wherein roots appear after about 12 days and the rooting rate reaches 100%; opening the cover of the culture bottle to culture for three days, taking out the tissue culture seedlings of the wild buckwheat rhizome, cleaning the rooting medium, and transplanting the seedlings to a greenhouse and growing on special nutrient soil for tissue culture, wherein the survival rate reaches 98%; and after three months, transplanting the seedlings to fields for large-scale planting. The method of the invention has the advantages of high stability, simple operation, fast propagation, low production cost, reached industrial level and the like.

Owner:石国荣

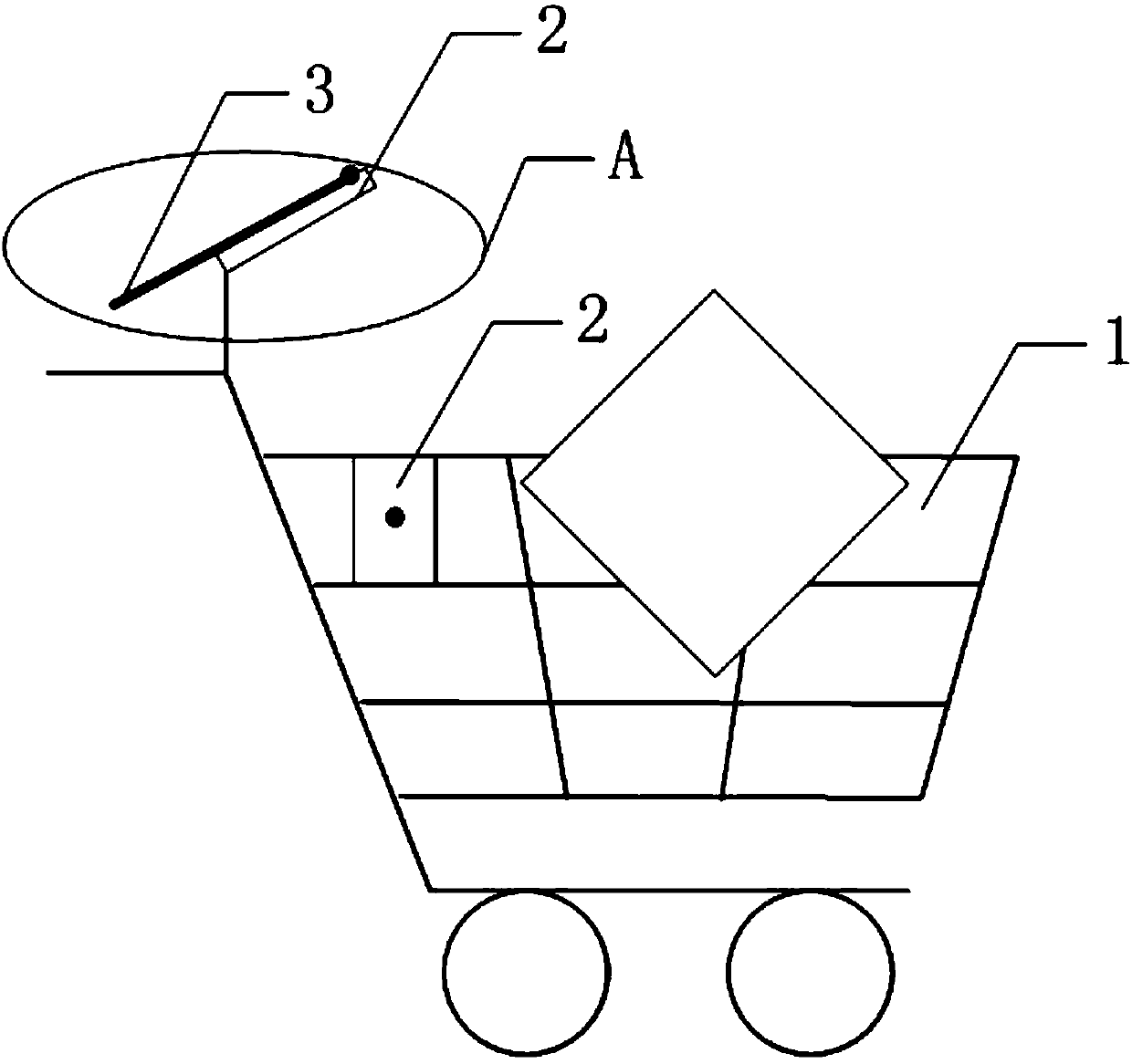

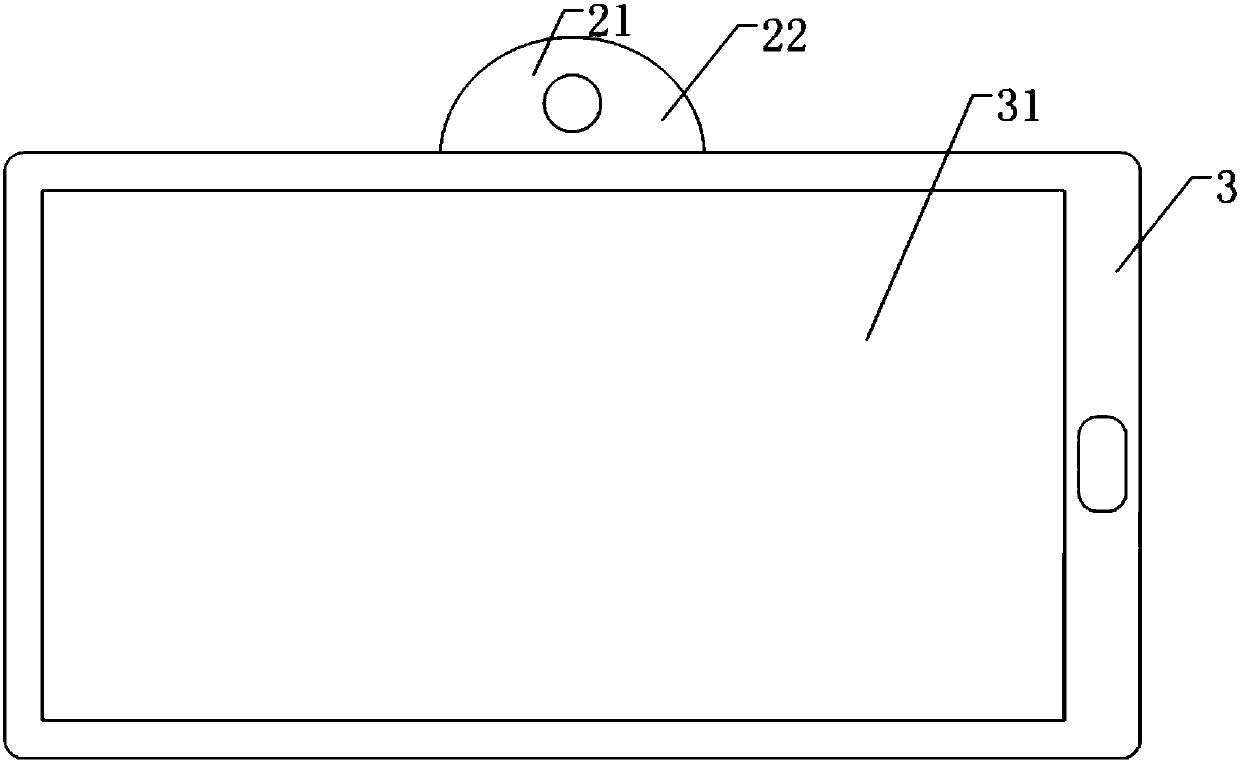

A navigation shopping cart based on two-dimensional code scanning positioning and a navigation method thereof

ActiveCN109685162AEasy to scan codeEasy to viewCo-operative working arrangementsPosition/course control in two dimensionsComputer hardwareDirection information

The invention relates to the field of positioning navigation, in particular to a navigation shopping cart based on two-dimensional code scanning positioning and a navigation method thereof. A navigation shopping cart based on two-dimensional code scanning positioning comprises a shopping cart body. The code scanning device is arranged on the shopping cart body, and the code scanning device is usedfor scanning an indoor two-dimensional code, obtaining two-dimensional code information and then transmitting the two-dimensional code information to a background server; The intelligent terminal isarranged on the shopping cart body, the intelligent terminal comprises a display screen, and the intelligent terminal is used for receiving and displaying the position and direction information foundby the background server through the two-dimensional code information; Wherein a two-dimensional code storing two-dimensional code information is arranged on the shopping cart body, and the two-dimensional code information comprises an ID number. The technical problems that in the prior art, a two-dimensional code cannot be scanned in real time for positioning, and the positioning precision is nothigh are solved.

Owner:ZHUHAI HENGQIN GREAT AIM VISIBLE LIGHT COMM TECH

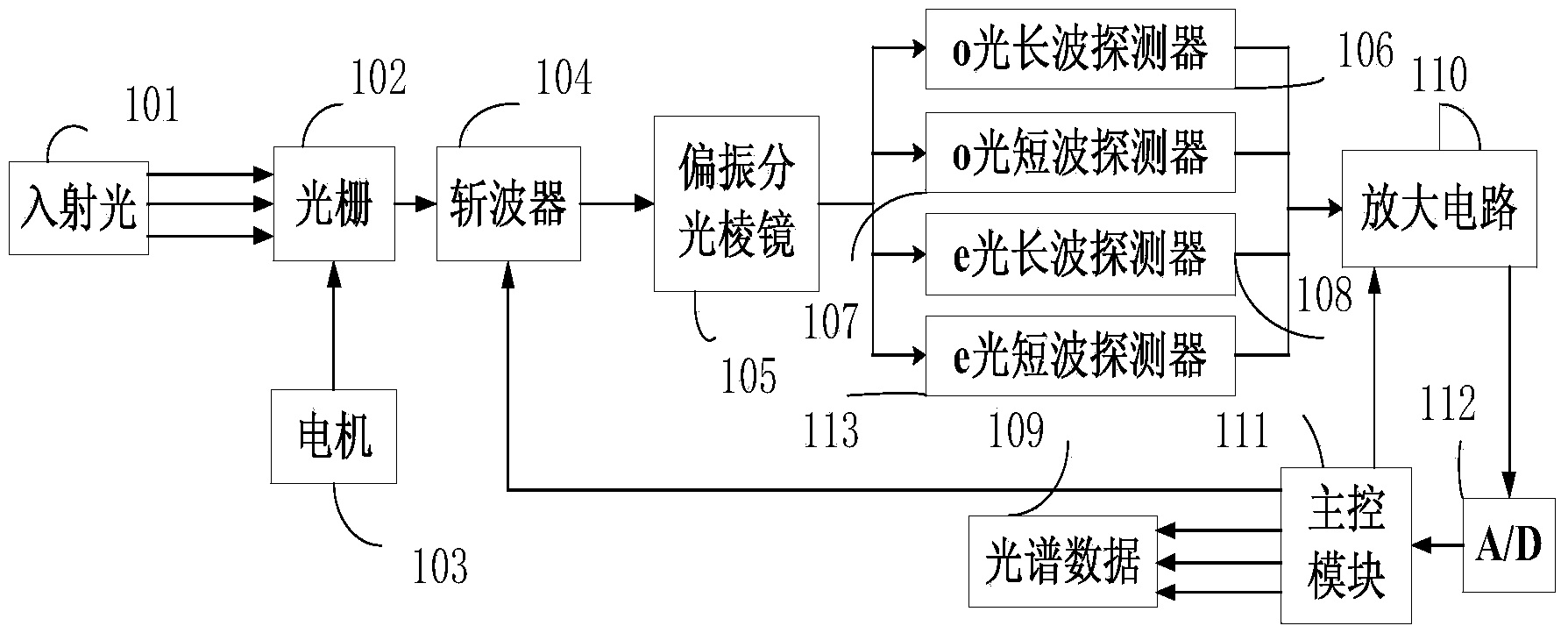

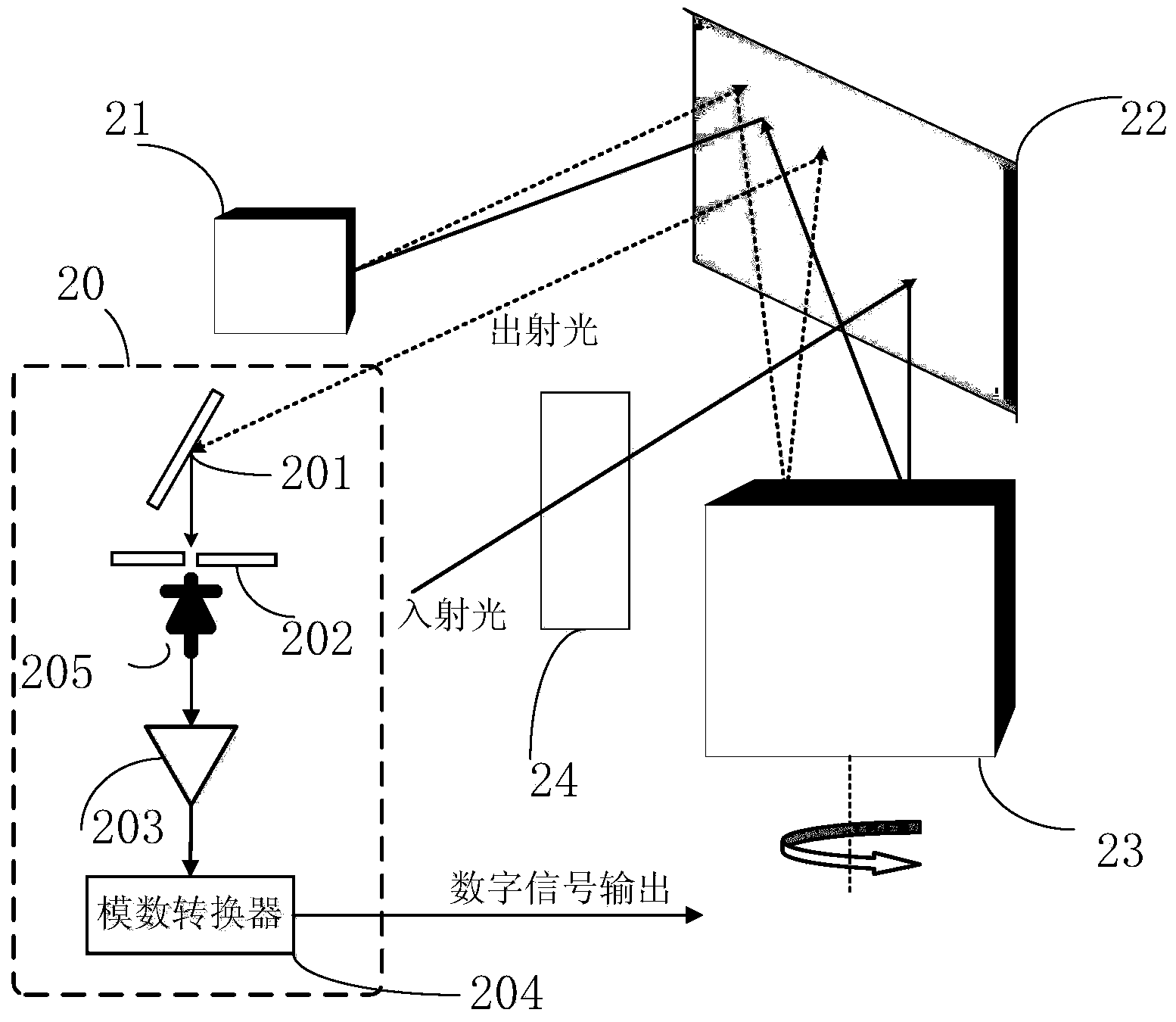

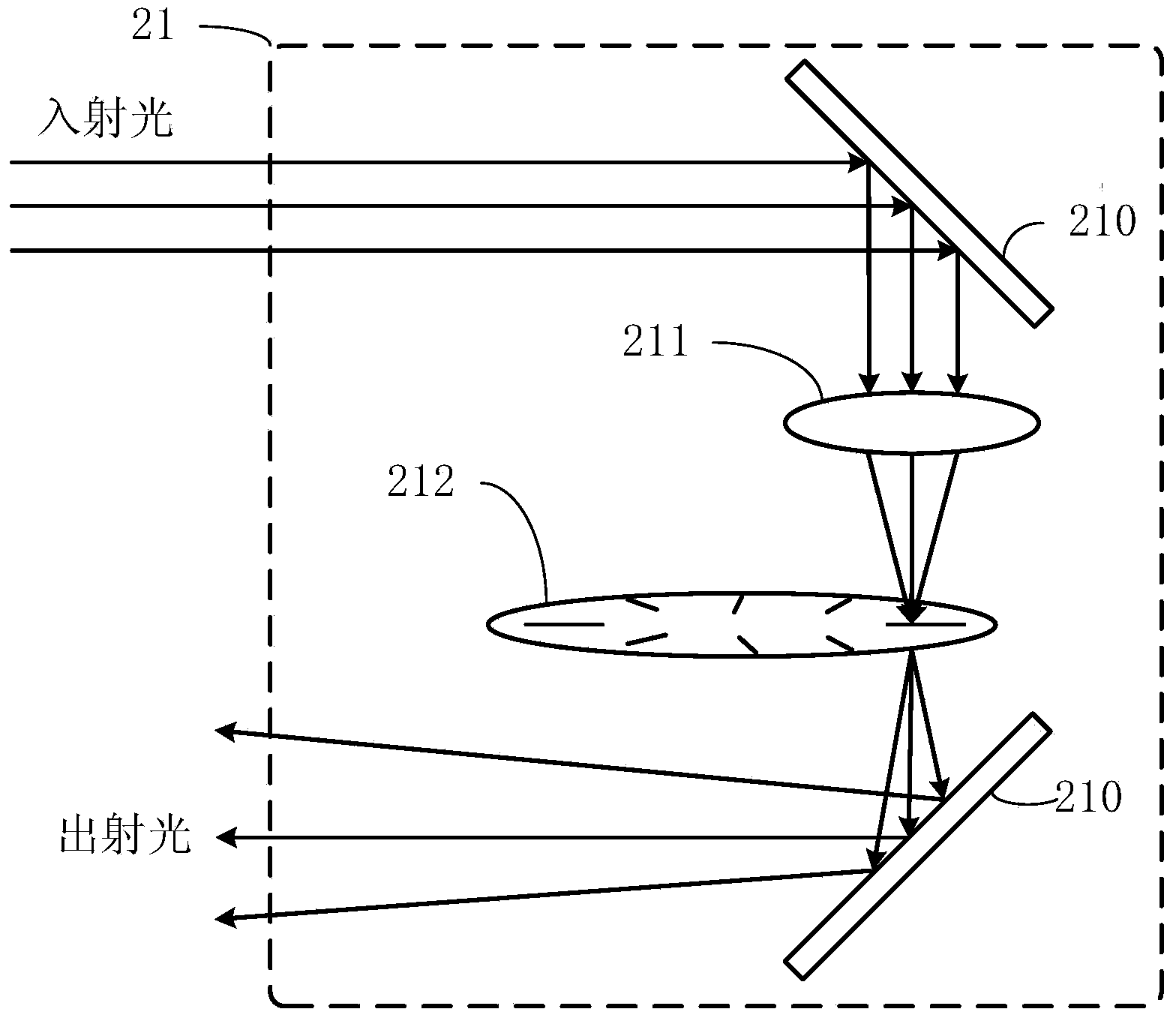

Optical grating rotary light splitting device and method for optical wedge delay polarization elimination

InactiveCN104267505AFlexible and easy commissioningImprove stabilitySpectrum generation using diffraction elementsOptical elementsSpectrographLuminous flux

The invention provides an optical grating rotary light splitting device and method for optical wedge delay polarization elimination. The device comprises emergent light, incident light, an optical wedge delay board, a parabolic reflector, a rotary diffraction grating, a reflecting and focusing system and a data detection system. The optical wedge delay board is used for eliminating polarization sensitivity. The parabolic reflector is used for aligning and focusing light. The rotary diffraction grating is used for conducting chromatic dispersion light splitting on the incident light. The optical grating rotary dual-flux light splitting technology and the optical wedge delay polarization suppression technology under the quasi-Littrow condition are adopted, polarization sensitivity can be eliminated on the premise that small optical flux is lost, the flexibility of a level is effectively improved, a light splitting system and the data detection system at the rear end can be greatly simplified, the size of a spectrograph is reduced, and production cost is reduced.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

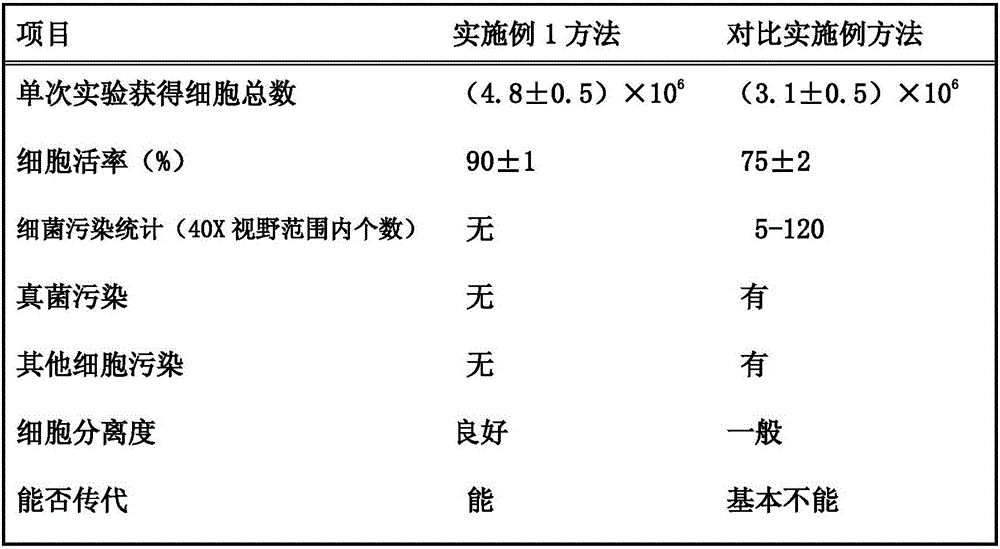

Primary rat or mouse gastric mucosal epithelial cell isolation and culture method

InactiveCN105907700APlay an anticoagulant rolePrevent adhesionCell dissociation methodsGastrointestinal cellsCell culture mediaDigestion

The invention discloses a primary rat or mouse gastric mucosal epithelial cell isolation and culture method. A perfusion method is innovatively introduced into the primary rat or mouse gastric mucosal epithelial cell isolation and culture method, and sufficient perfusion without dead corners is achieved. Prepared compound enzyme digestive juice avoids the problems of low cell viability and poor yield and is capable of digesting more evenly and thoroughly as compared with preheated digestion of traditional single collagenase. Within 12 hours of cell inoculation adherence, a cell culture medium with a pH value of 6-6.5 is adopted, cell adherence rate can be increased greatly and adherence effects are better. The primary rat or mouse gastric mucosal epithelial cell isolation and culture method has the advantages of large total cell number, high isolation degree, high living rate and low contamination probability by bacteria, fungi and other cells as well as capability of achieving subculture so as to provide a favorable cell culture scheme for related fundamental researches.

Owner:王晓冰

Method for restoring dimension discrepancy of bearing utilizing chemical plating nickel

InactiveCN1485460ALow costFix out-of-tolerance dimensionsLiquid/solution decomposition chemical coatingChemical platingWarm water

An application of chemically plating nickel, especially a method of repairing different sizes of bearing by chemically plating nickel. The method comprises : washing bearings with gasoline; washing bearings with methanol; washing bearings with warm water, the temperature of the warm water is 60 -70degree Cú¼washing for 2 min; washing bearings with chemicals, the temperature thereof is 60-70degreeCú”washing with cool water; immersing in an acid and activating for 1-2min, the concentration of the acid is 10í†5ú”washing with cool water; preheating bearings with hot water for 5-10min, the temperature thereof is 80-90 degree C;preparing the chemical plating nickel solution.

Owner:宁夏西北轴承石油机械轴承有限公司

Culture method for ramulus uncariae cum uncis

PendingCN107873516ATechnical stabilityImprove induction efficiencyPlant cultivationCultivating equipmentsHypocotylBud

The invention discloses a culture method for ramulus uncariae cum uncis. The culture method comprises the following steps: firstly, culturing a ramulus uncariae cum uncis seed in a seed culture mediumfor 20-25d to obtain a sterile seedling hypocotyl; secondly, cutting a hypocotyl explant having the length of 0.4-0.8cm and containing no cotyledonary nodes from the sterile seedling hypocotyl, horizontally placing the hypocotyl explant in a first callus culture medium for dark culture for 20-25d, and then, transferring the hypocotyl explant into a second callus culture medium for dark culture toobtain a fresh callus; thirdly, transferring the fresh callus into a differential culture medium for differential culture to obtain a cluster bud; and fourthly, transplanting the cluster bud into a strong seedling culture medium for strong seedling culture, cutting off a basal part of a stem when the length of a single seedling is 3-4cm, transferring the seedling into a rooting culture medium forrooting culture, and growing a root with the length of 1.5-2.0cm to obtain a ramulus uncariae cum uncis seedling. The ramulus uncariae cum uncis obtained by using the culture method is purely natural, high in yield and high in medicinal component content.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

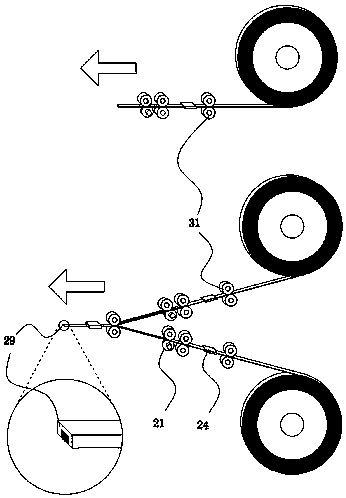

Machine and method for automatic feeding and bending

PendingCN107671150AReduce the amount of cuttingEasy to processMetal-working feeding devicesPositioning devicesStructural engineeringMachine

The invention relates to a machine and a method for automatic feeding and bending. The machine comprises a servo supply device, a bending forming device, a butt riveting device and a demolding blanking device, wherein the servo supply device is used for driving materials to move forwards to achieve the bending forming device or / and carrying out pre-forming adopting a staggered butt riveting technology for the two ends of each material before driving the materials to enter the bending forming device; the bending forming device is used for bending the materials into the needed border structure through the matching of an inner mold and an outer mold; the butt riveting device is used for pressing a male buckle arranged at one tail end of the border structure into a female buckle at the other tail end of the border structure by adopting the staggered butt riveting technology when the bending forming device carries out the last action of bending angle forming, and fixing in a manner of moldpressing, welding or gluing, so as to form a stable border structure; and the demolding blanking device is used for separating the stable border structure from the inner mold and the outer mold of thebending forming device.

Owner:东莞市健耀烨电子科技有限公司

Method for increasing sow ovulation rate and injection thereof

InactiveCN101711513AIncreased number of children bornImprove reproductive performanceOrganic active ingredientsPeptide/protein ingredientsHormones regulationSexual maturity

The invention relates to a method for increasing sow ovulation rate and injection thereof, belonging to the technical field of agricultural biological products. The method of simultaneously injecting PG (cloprostenol sodium) and PMSG (antostab) or a mixture of PG and PMSG before oestrum, and injecting HCG (chorionic corticotrophin) or LHRH-A3 (luteinizing hormone releasing hormone A3) during oestrum is adopted to promote the ovulation rate of young sows or multiparity sows to be 2-3 times of normal ovulation amount, thus improving reproductive performance of sows and obviously increasing the number of young pigs borne by the sows. The method has stable technology and obvious effect, and can not induce ovarian cyst; by using the method, the same superovulation effect can be achieved on standby sows ay any time before sexual maturity.

Owner:INST OF ANIMAL SCI & VETERINARY HUBEI ACADEMY OF AGRI SCI

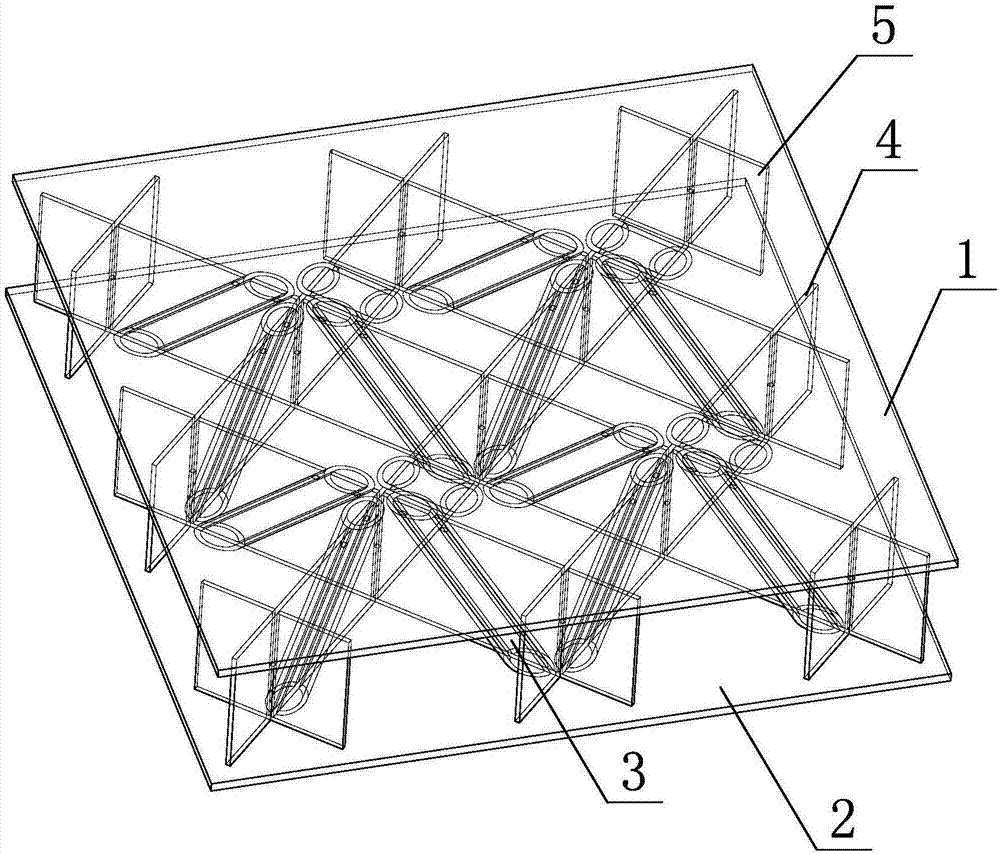

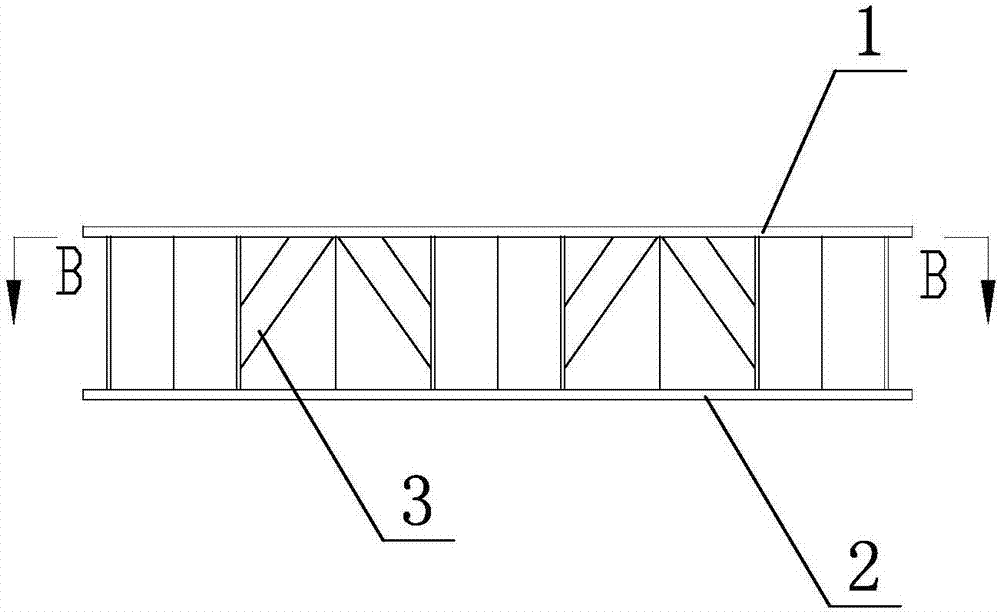

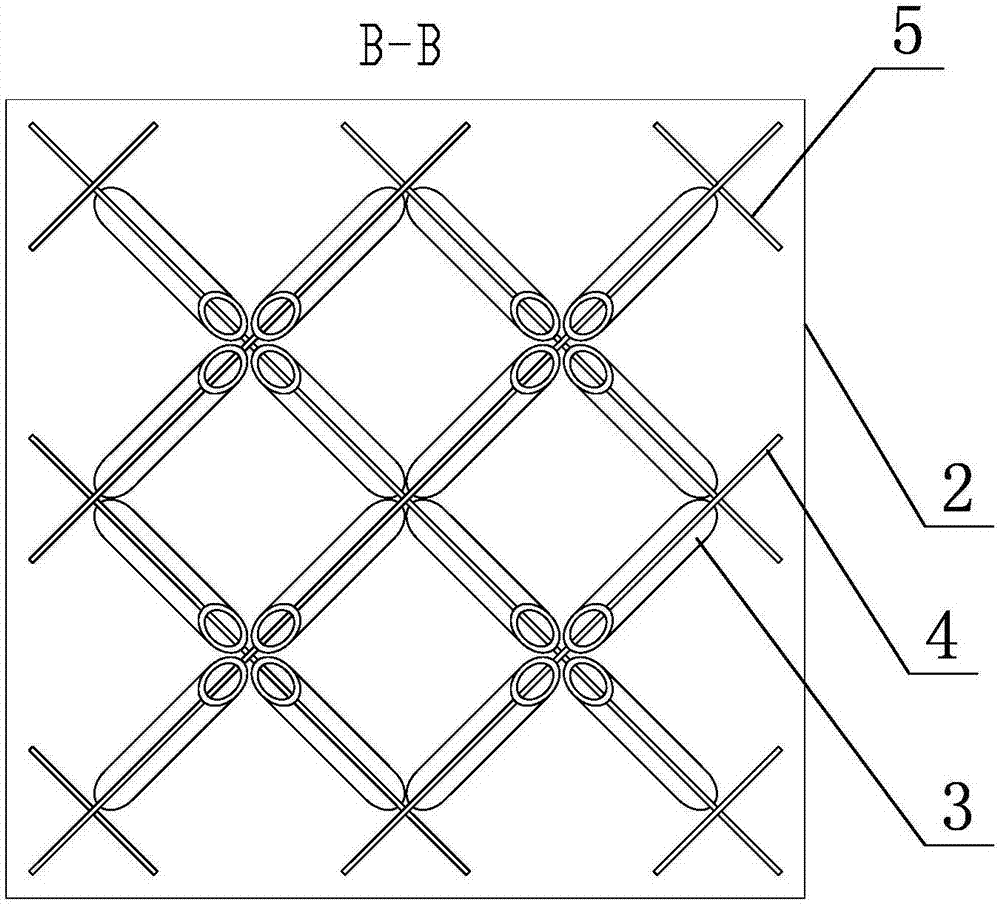

All-metal hollow dot matrix-honeycomb mixed sandwich structure and interlocking preparation method thereof

InactiveCN107263954AHigh strengthGood energy absorbing propertiesSoldering apparatusBlastingDot matrixEnergy absorption

The invention discloses an all-metal hollow dot matrix-honeycomb mixed sandwich structure and an interlocking preparation method thereof and relates to a sandwich structure and an interlocking preparation method thereof. The invention aims to enhance the energy absorption capability of a metal honeycomb and improve the shear strength. An upper panel and a lower panel are arranged in parallel from top to bottom; square honeycomb interlocking formation sheets are assembled by interlocking and then arranged between the upper and lower panels; multiple oblique round tubes with narrow-long notches are interlocked to the assembly one by one to form a hollow pyramid type dot matrix-square honeycomb mixed core which then is combined with the upper and lower panels to form a sandwich structure. The preparation method comprises the following steps: (I) processing a core component and panels; (II) interlocking to assemble the dot matrix-honeycomb mixed core, and then combining with the upper and lower panels to form a sandwich structure assembly; (III) connecting by a vacuum welding technology to form a whole structure. The all-metal hollow dot matrix-honeycomb mixed sandwich structure disclosed by the invention is applied to the fields such as aerospace, ships and oceans, underwater blast resistance and transportation buildings as an efficient energy absorption protection device.

Owner:HARBIN INST OF TECH

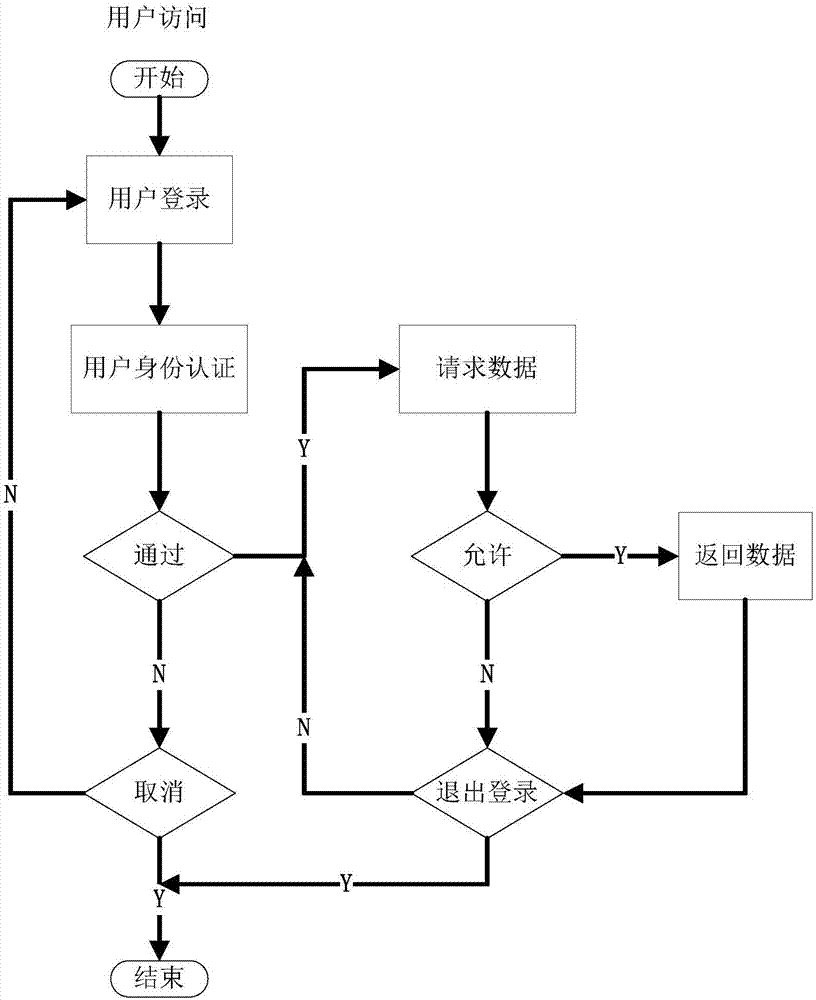

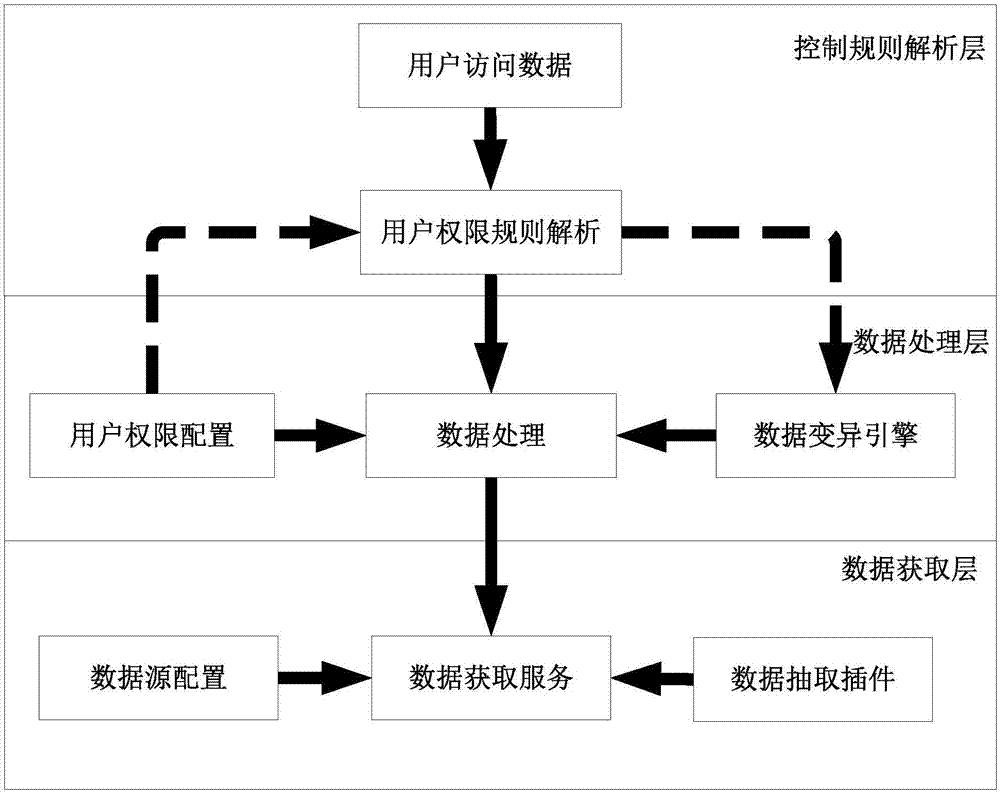

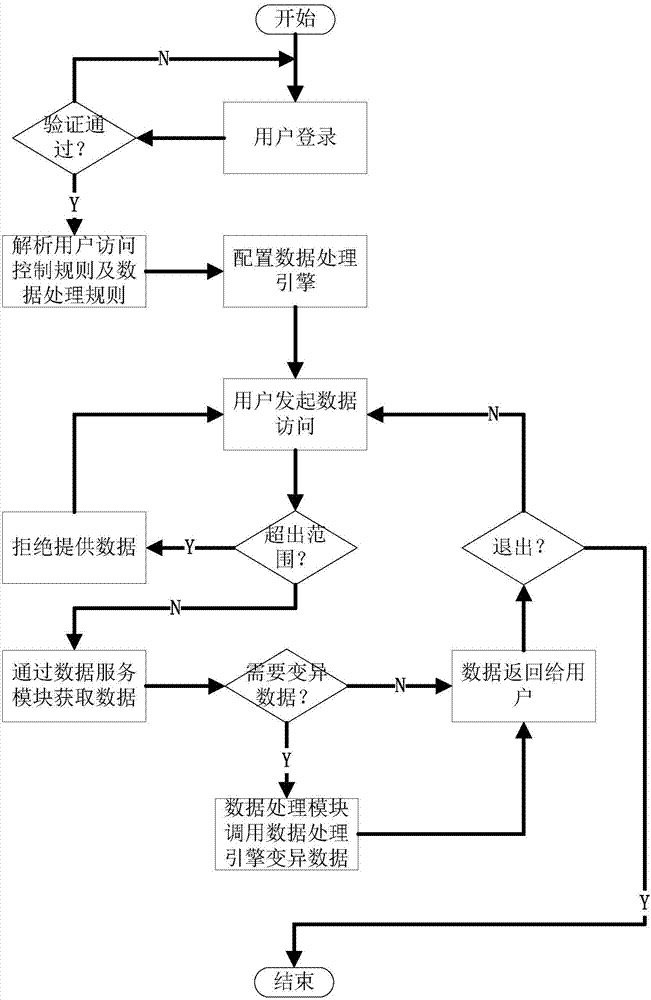

Database access control method and system

InactiveCN107301349ADoes not affect normal useFlexible configurationDigital data protectionAccess control matrixInternet privacy

The invention discloses a database access control method and system. The system includes: a user identity verification module, which verifies the user identity; an analysis module, which invokes user data access control configuration, and analyzes user access control rules and data processing rules; an initialization module , receiving the data processing rules, and initializing the data processing engine; the data response module, responding to the user data access request; the range judgment module, judging whether the user data access request exceeds the control range, and if it exceeds the user control range, refusing to provide the user's data access request service; The data processing judging module judges whether the data needs to be processed, and if so, calls the data processing engine to clean the acquired data. Through the solution of the invention, the range of data accessible to users can be effectively controlled, and some sensitive information of data content can be mutated and replaced to prevent leakage of sensitive information.

Owner:北京明朝万达科技股份有限公司

Paris polyphylla seedling raising method capable of enhancing planting percent

InactiveCN106034705ASolve the problem of low seedling rateSeedling rate shortenedPlant cultivationCultivating equipmentsDiseasePlant disease

The invention discloses a Paris polyphylla seedling raising method capable of enhancing planting percent. The method comprises the steps of seed pretreatment, soil preparation, management and outplanting. The method particularly comprises the following steps: selecting a nursery land, plowing, and solarizing; in a sunny day, making boxes, spreading a bactericide and a pesticide, carrying out spot seeding, line seeding or broadcast sowing, covering humus soil and a moisturizing layer, and watering thoroughly and deeply; after the Paris polyphylla leaves are flat, spraying a foliage fertilizer, and covering humus soil; spraying the bactericide once a month to prevent the seedling diseases; and after the emergence of seedlings, carrying out nursery cultivation for 11-13 month, outplanting and carrying out permanent planting in the field. The method basically solves the problem of low planting percent of the Paris polyphylla, can greatly shorten the seed and seedling outplanting time of the Paris polyphylla, and achieves the goals of stable technique and high planting percent. The method has the advantages of simple operative technique and high rate of emergence; and the rate of emergence is up to 95% or above which is higher than that of the traditional technique by 10-15%. The planting percent is 80% or above which is higher than that of the traditional technique by 15-20%. The method shortens the seed and seedling outplanting period of Paris polyphylla by more than 1 year.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI +1

Vertical air conditioner

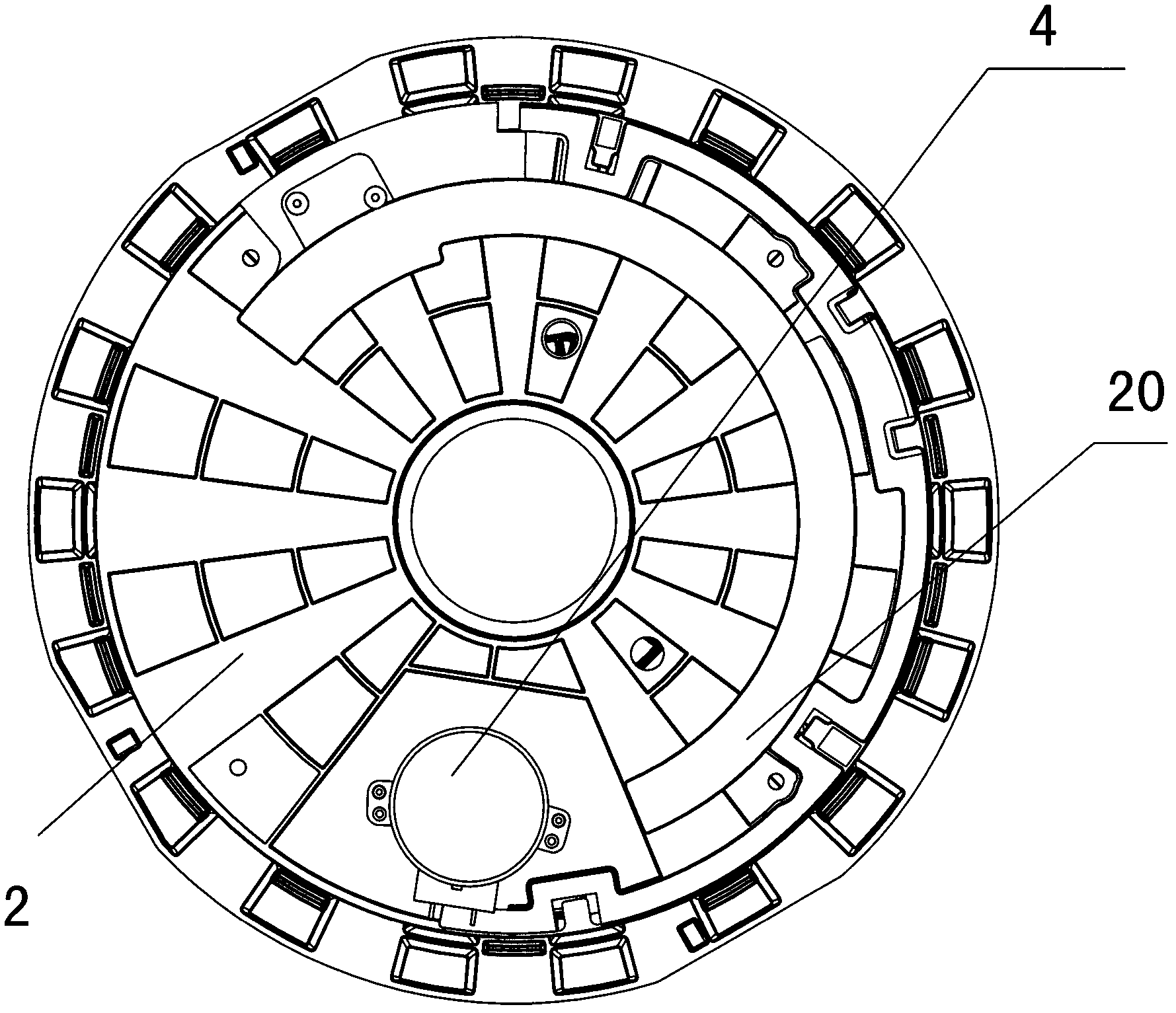

ActiveCN102466274ANovel structureSmooth rotationLighting and heating apparatusNon-rotating vibration suppressionEngineeringMoving parts

The invention provides a vertical air conditioner. The outer unit housing of the vertical air conditioner cannot shake during startup, shutdown and rotation and moves stably. The vertical air conditioner comprises a main body part and a base component and has a columnar structure integrally, wherein the main body part comprises the outer unit housing; the bottom of the outer unit housing is arranged on the base component by a moving part in a rotatable manner; the moving part is provided with a damping slider device which can ensure the stable movement of the outer unit housing; the base component comprises a motor mounting seat, and a stepping motor is fixed on the motor mounting seat; the moving part comprises an inner fluted disk which has a disk shape integrally, and the outer unit housing is fixed on the inner fluted disk; the middle part of the inner fluted disk is matched with the middle part of the motor mounting seat by a plastic bearing; and the damping slider device is a rubber damping block, an arc chute is formed on the motor mounting seat, and the rubber damping block is fixed on the inner fluted disk and slides in the arc chute.

Owner:GREE ELECTRIC APPLIANCES INC

Method for extracting polysilicon through electron beams and acid washing

InactiveCN101935041AMeet the use requirementsImprove purification efficiencyChemical industrySilicon compoundsMetal impuritiesAcid washing

The invention relates to a method for extracting polysilicon through electron beams and acid washing, comprising the following steps of: firstly, placing a silicon material containing high impurity content into an electron beam smelting furnace, carrying out electron beam smelting to remove the volatile impurity of phosphorus, coagulating rapidly to form a silicon ingot, in which numerous fine grains are formed and metal impurities are enriched on the grain boundary of the grains, finally crushing the silicon ingot along the grain boundary to fully expose the grain boundary, and then carrying out acid washing to remove the metal impurities to obtain the silicon ingot with lower content of the phosphorous and the metal impurities. By combining electron beam smelting used for removing the volatile impurity of the phosphorus, acid washing used for removing the metal impurities on the grain boundary, and further phosphorus removal as well as utilizing the effect that electron beams rapidly coagulates after smelting to generate fine grains, the invention completes the removal process of the phosphorus and the metal impurities efficiently and rapidly, thereby meeting the operating requirements on solar grade silicon; and moreover, the invention has the remarkable characteristics of high purification efficiency, stable technology, short period, high production efficiency, low energy consumption and low cost.

Owner:DALIAN LONGSHENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com