Patents

Literature

83 results about "Physical metallurgy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Physical metallurgy is one of the two main branches of the scientific approach to metallurgy, which considers in a systematic way the physical properties of metals and alloys. It is basically the fundamentals and applications of the theory of phase transformations in metal and alloys, as the title of classic, challenging monograph on the subject with this title . While chemical metallurgy involves the domain of reduction/oxidation of metals, physical metallurgy deals mainly with mechanical and magnetic/electric/thermal properties of metals – treated by the discipline of solid state physics. Calphad methodology, able to produce Phase diagrams which is the basis for evaluating or estimating physical properties of metals, relies on Computational thermodynamics i.e. on Chemical thermodynamics and could be considered a common and useful field for both the two sub-disciplines.

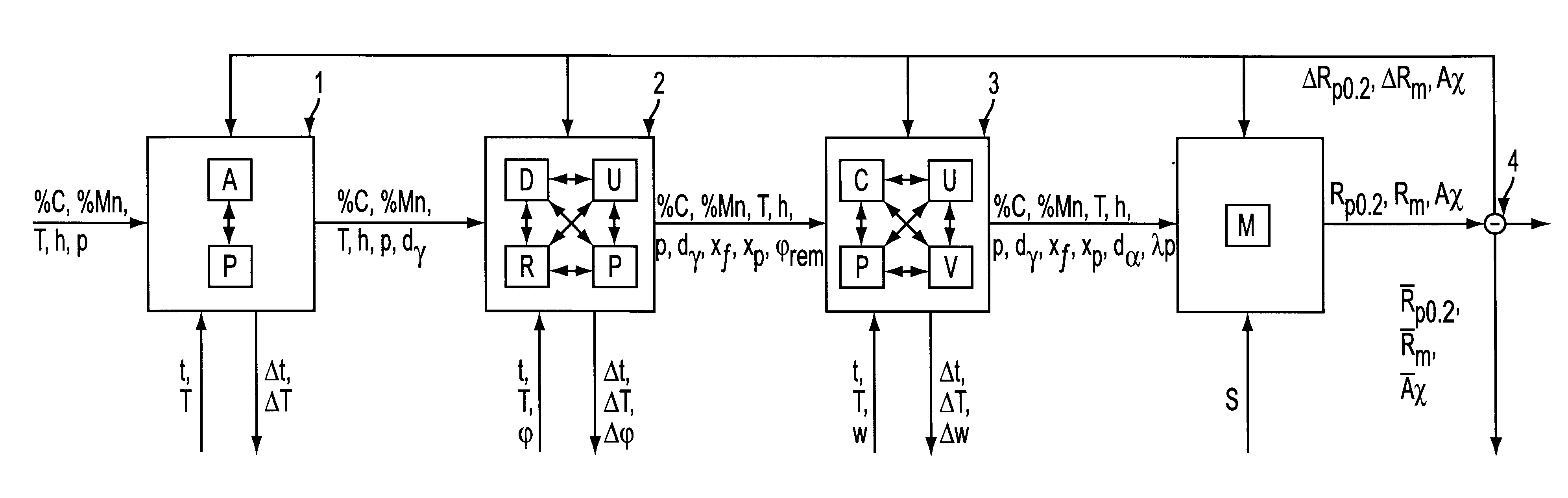

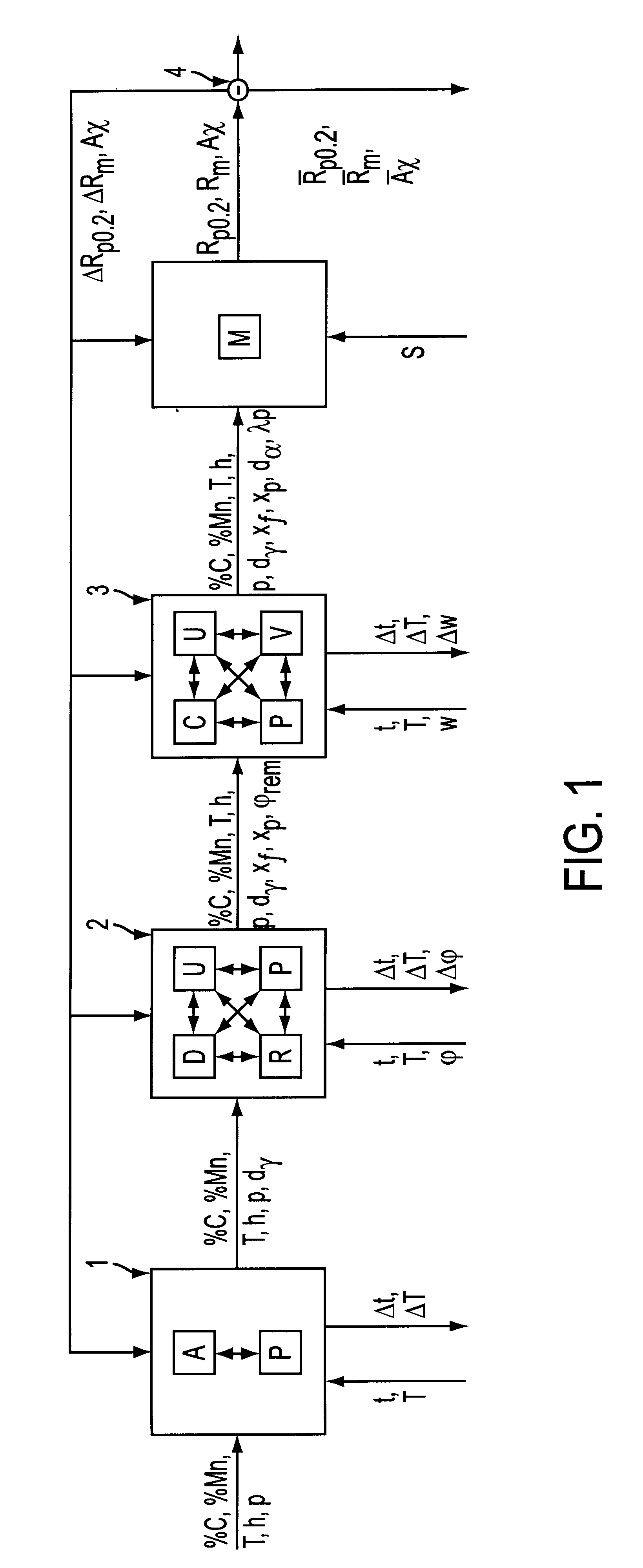

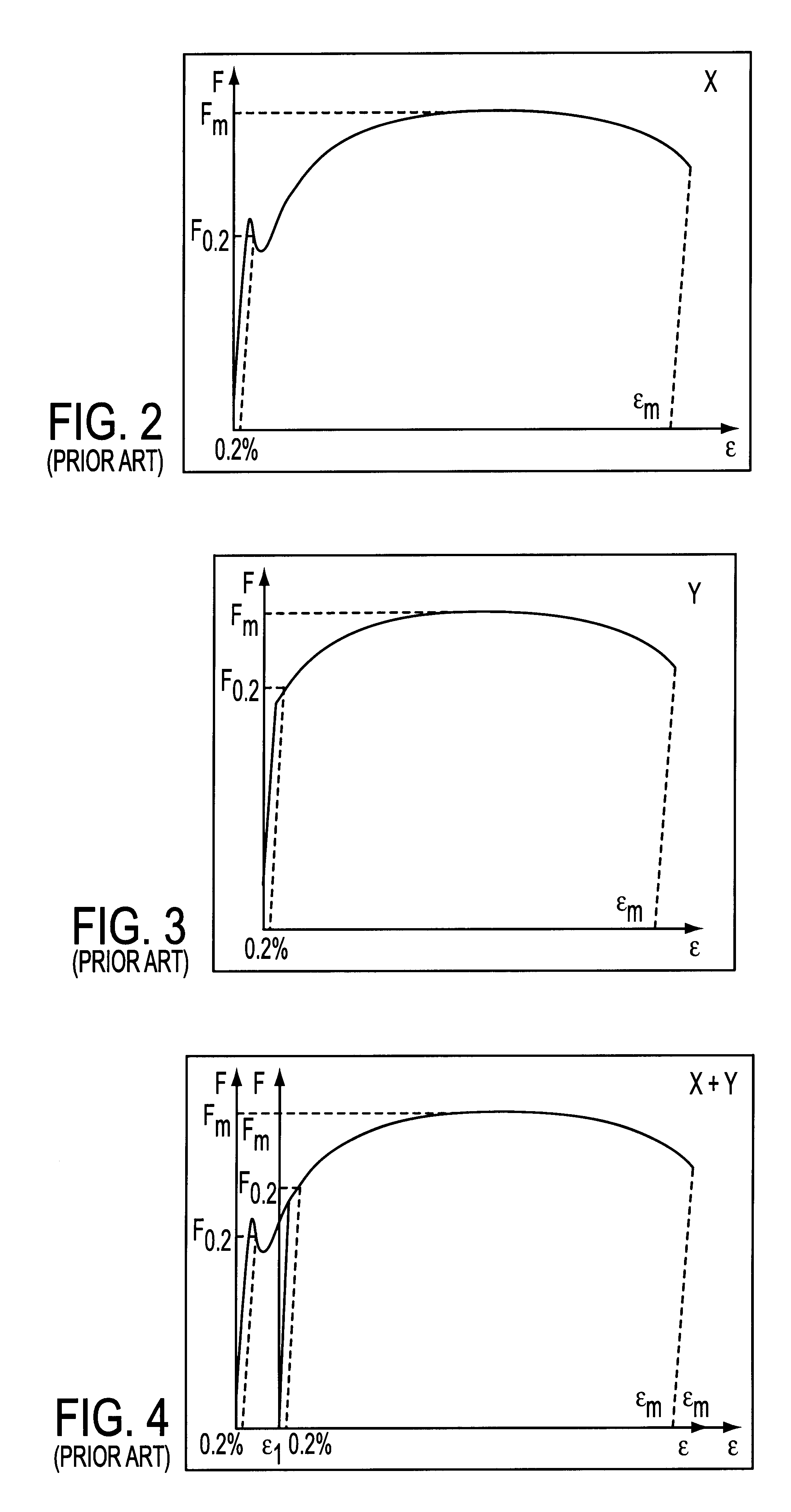

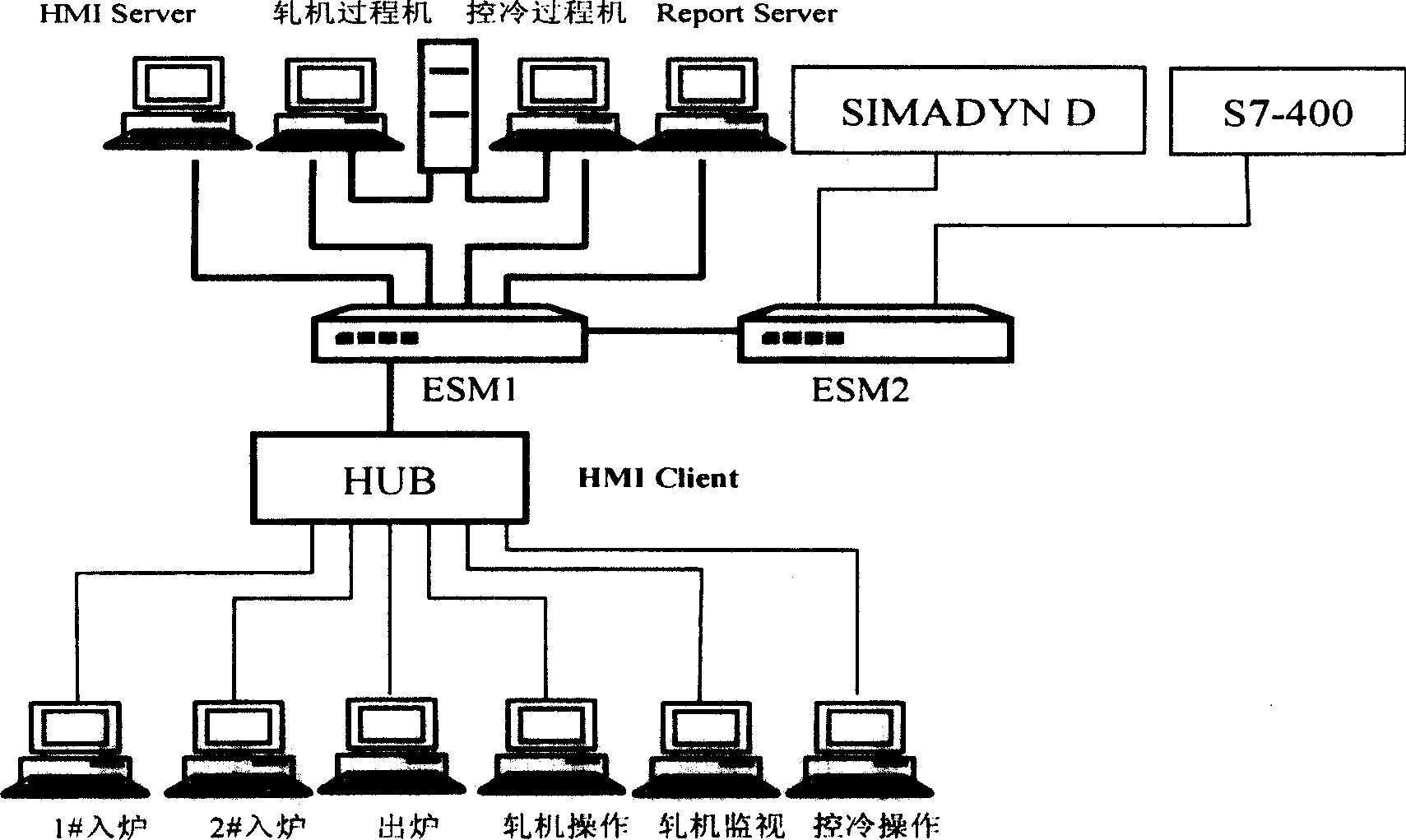

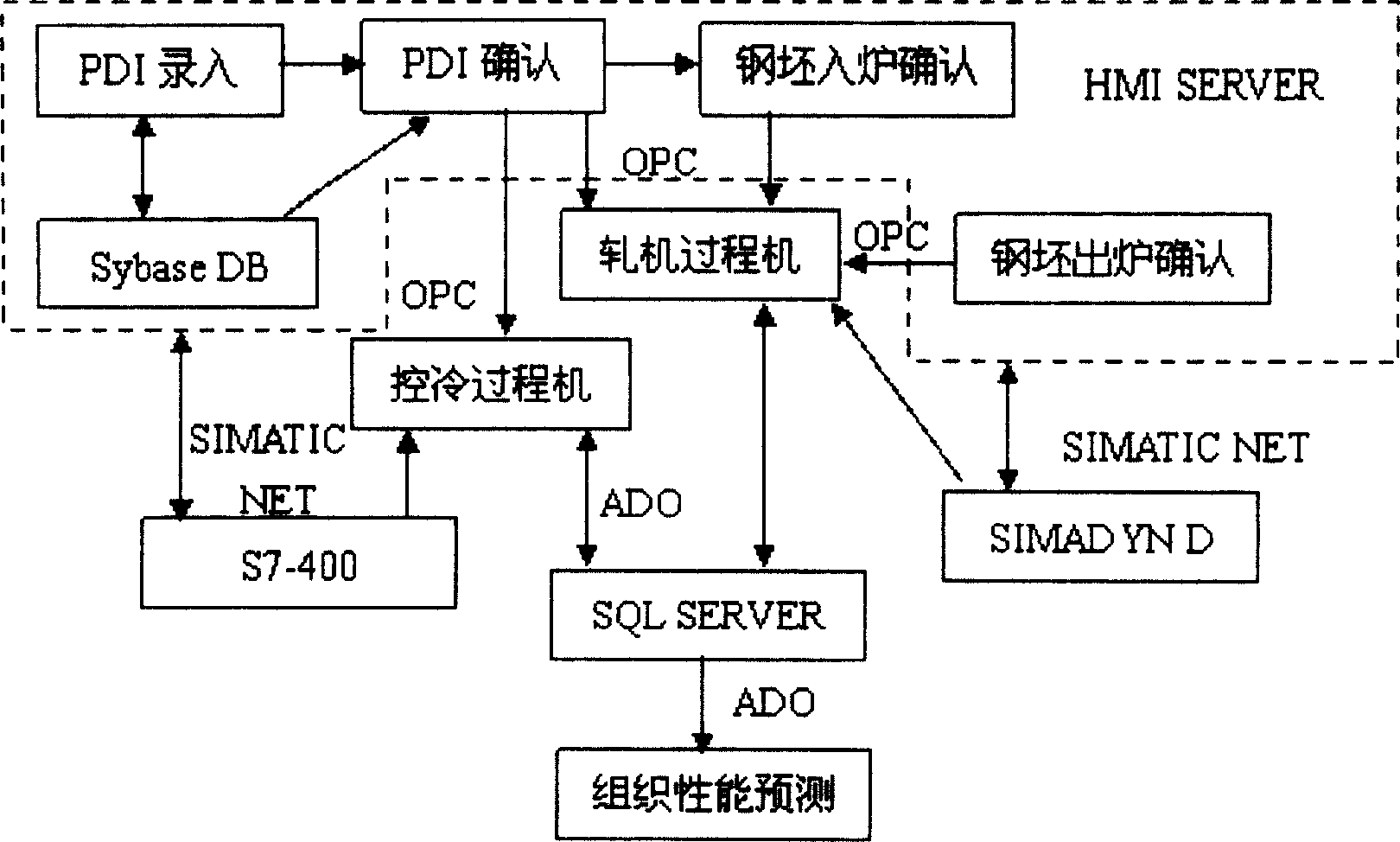

Process for monitoring and controlling the quality of rolled products from hot-rolling processes

InactiveUS6430461B1Simulator controlRoll mill control devicesPhysical metallurgyUltimate tensile strength

Owner:VOEST ALPINE AG

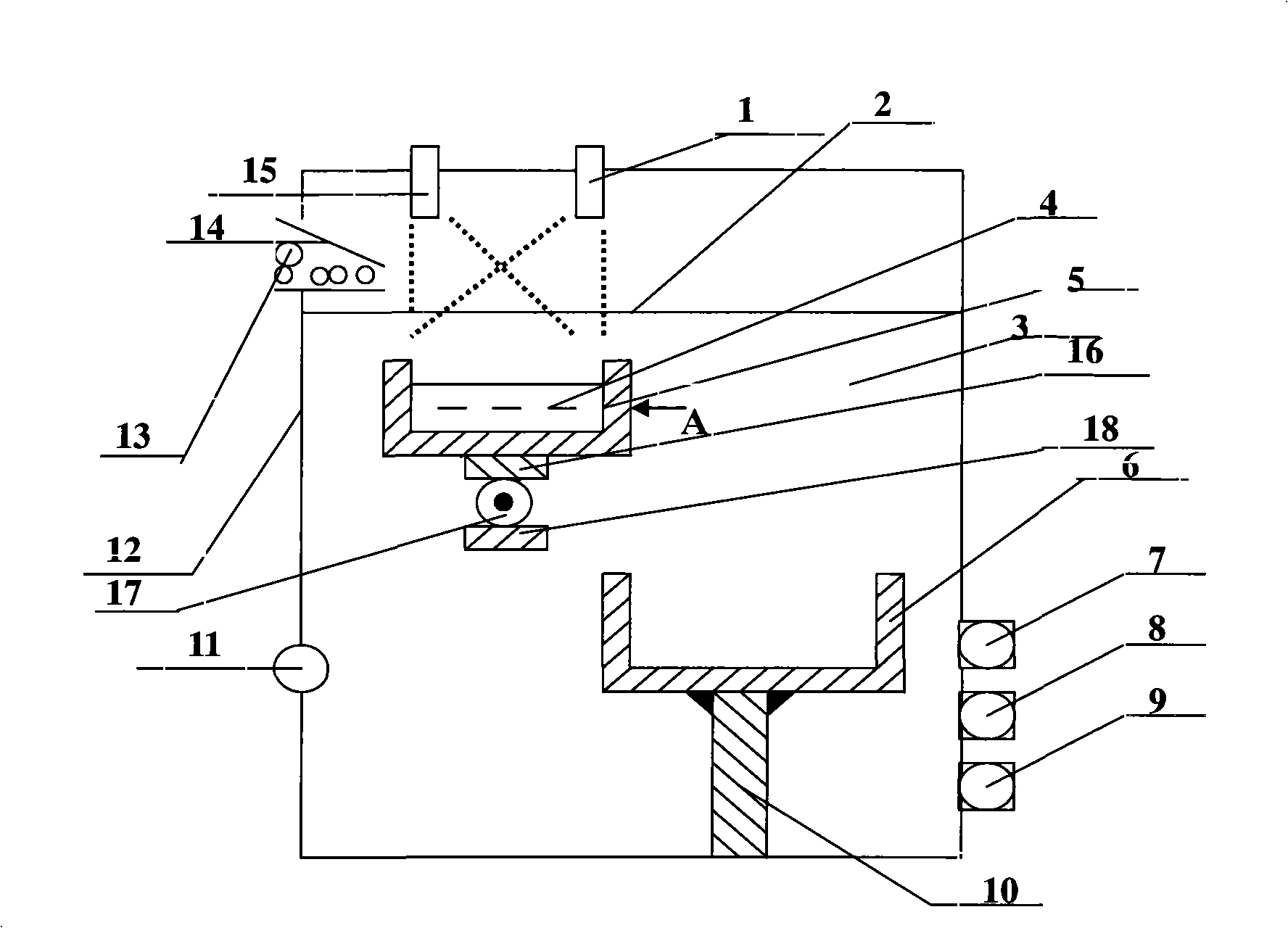

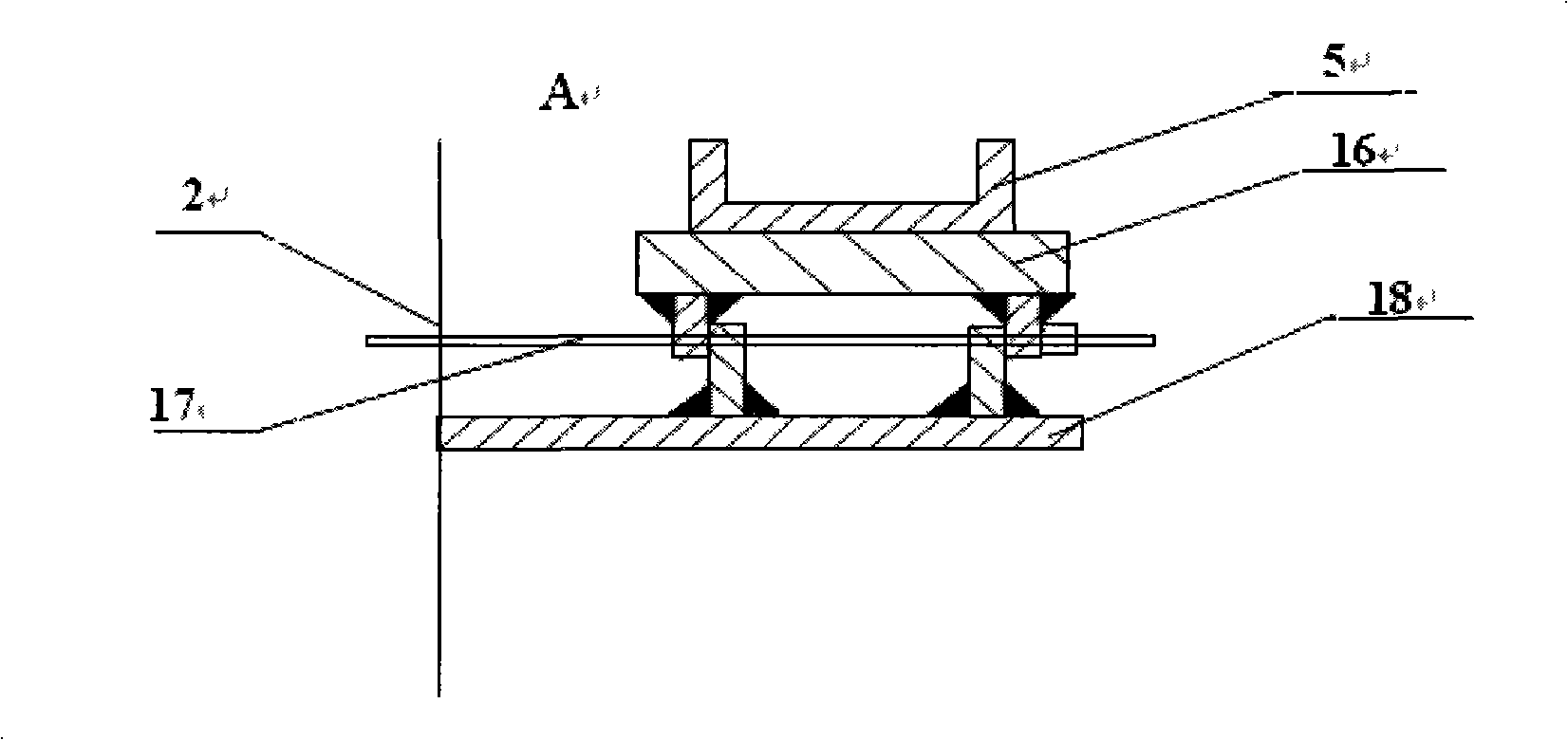

Process and device for removing phosphorus and metal impurities in polycrystalline silicon

InactiveCN101289188AHigh purityImprove efficiencyChemical industrySilicon compoundsMetal impuritiesLow vacuum

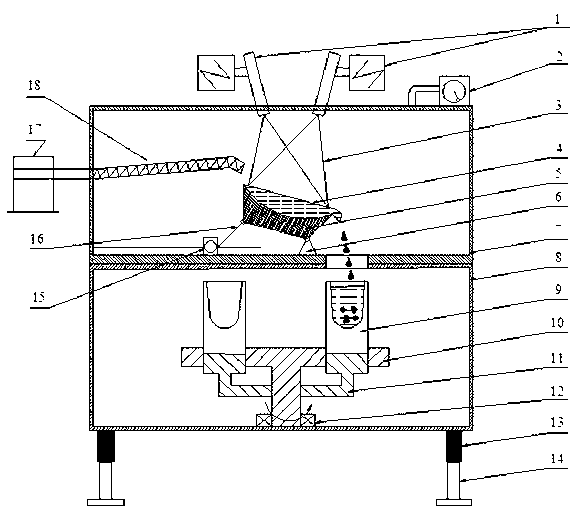

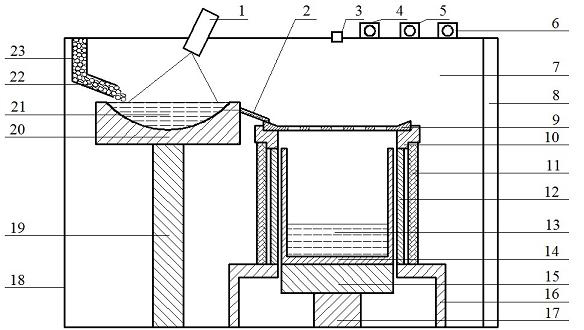

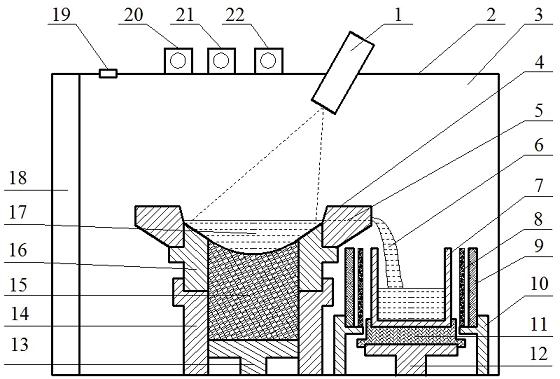

The invention relates to a method and a device for removing impurity phosphorus and metal impurities in polycrystalline silicon, which pertains to the technical field of purifying the polycrystalline silicon by a physical metallurgy technology, particularly relates to the method for removing the impurity phosphorus and the metal impurities in the polycrystalline silicon by an electron-beam fusion technology. Cooperative ways of electron-beam fusion and induction heating are used for completing the fusion and solidification process of the polycrystalline silicon. Silicon powder with high purity is used for spreading in a hollow-out space at a water cooled copper base which is filled with quartz crucibles; polycrystalline silicon material is put into the quartz crucibles and the cover of a vacuum device is closed; in the process of vacuumization, a mechanical pump and a lodz pump are firstly used for vacuumizing a vacuum room to low vacuum and then a diffusion pump is used for vacuumizing to high vacuum; the device used is provided with a vacuum device cover and a vacuum drum which are formed into the outer shell of the device; the inner cavity of the vacuum drum is the vacuum room, in which a fusion system is arranged. The method and the device of the invention effectively improve the purity of the polycrystalline silicon, which have the advantages of high efficiency, simple device and saving energy.

Owner:QINGDAO NEW ENERGY SOLUTIONS

Method for predicting hot-rolling Nb-containing band steel organization and mechanical properties

InactiveCN101046682AAccurate predictionImprove scalabilityTesting metalsAdaptive controlRelational modelPhysical metallurgy

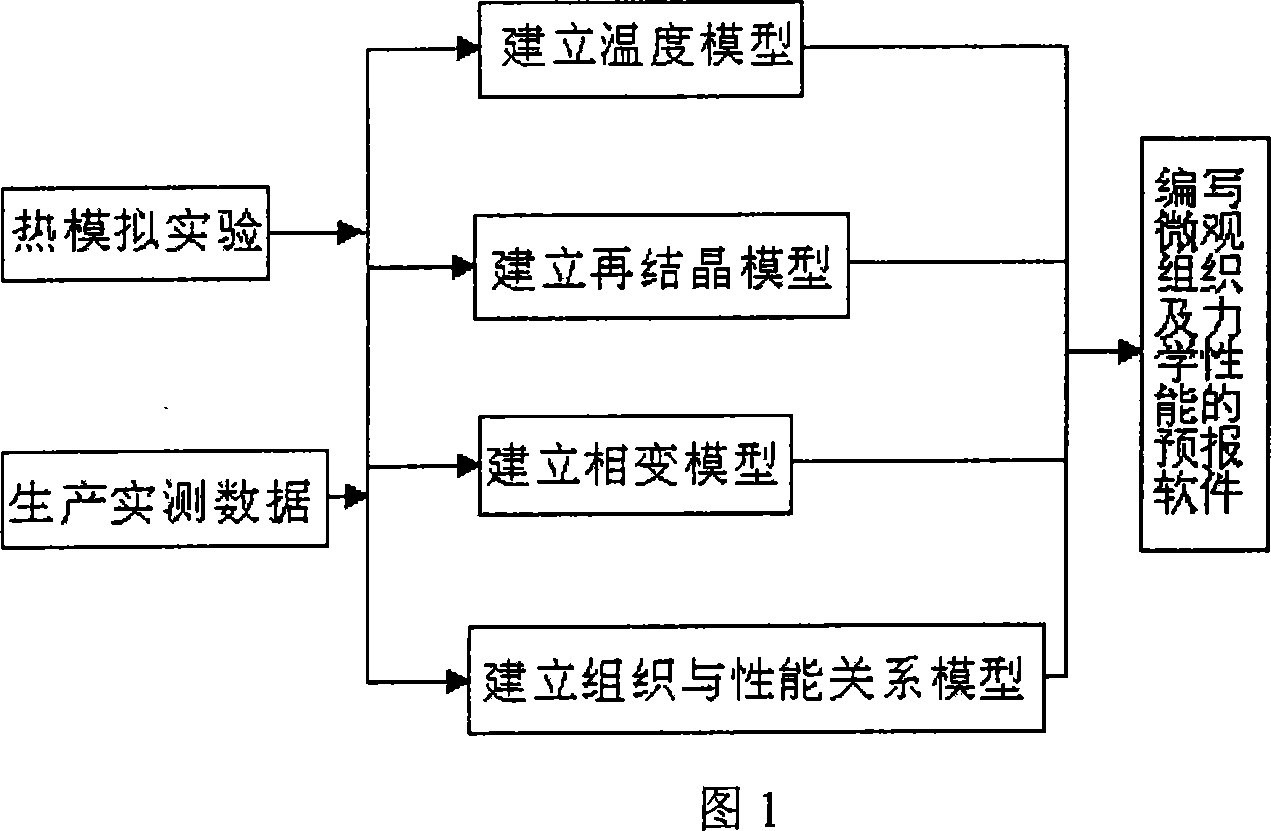

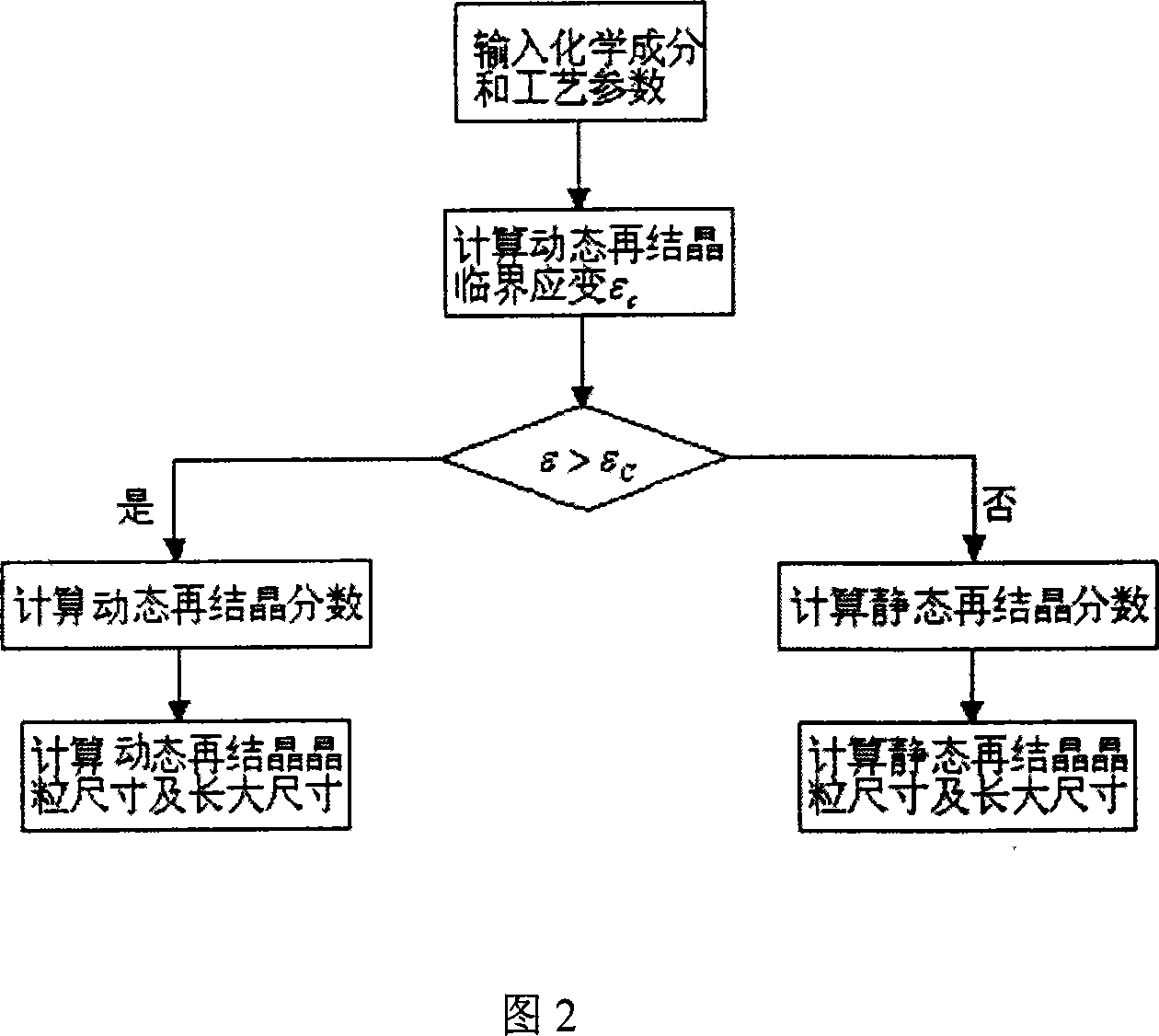

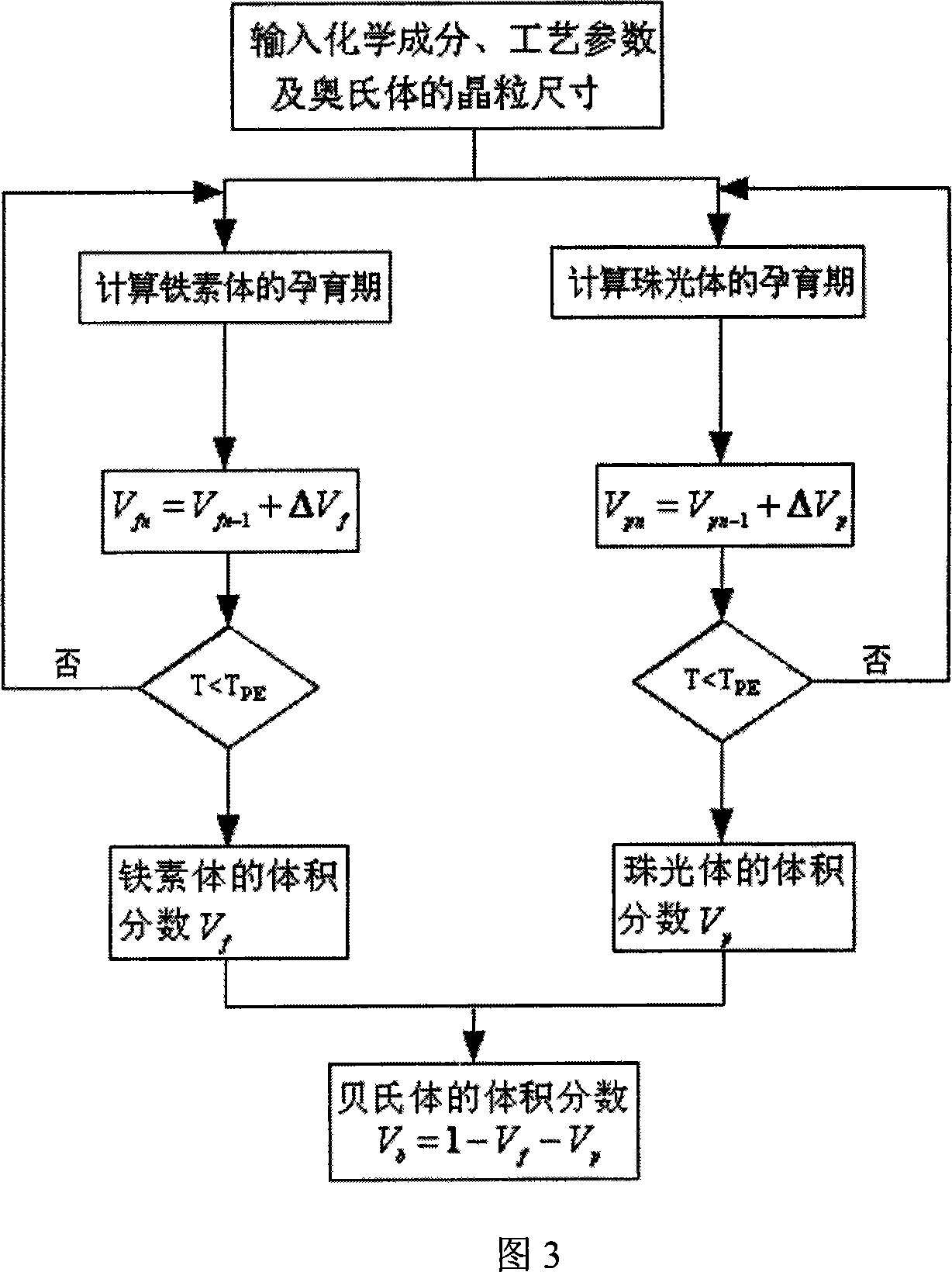

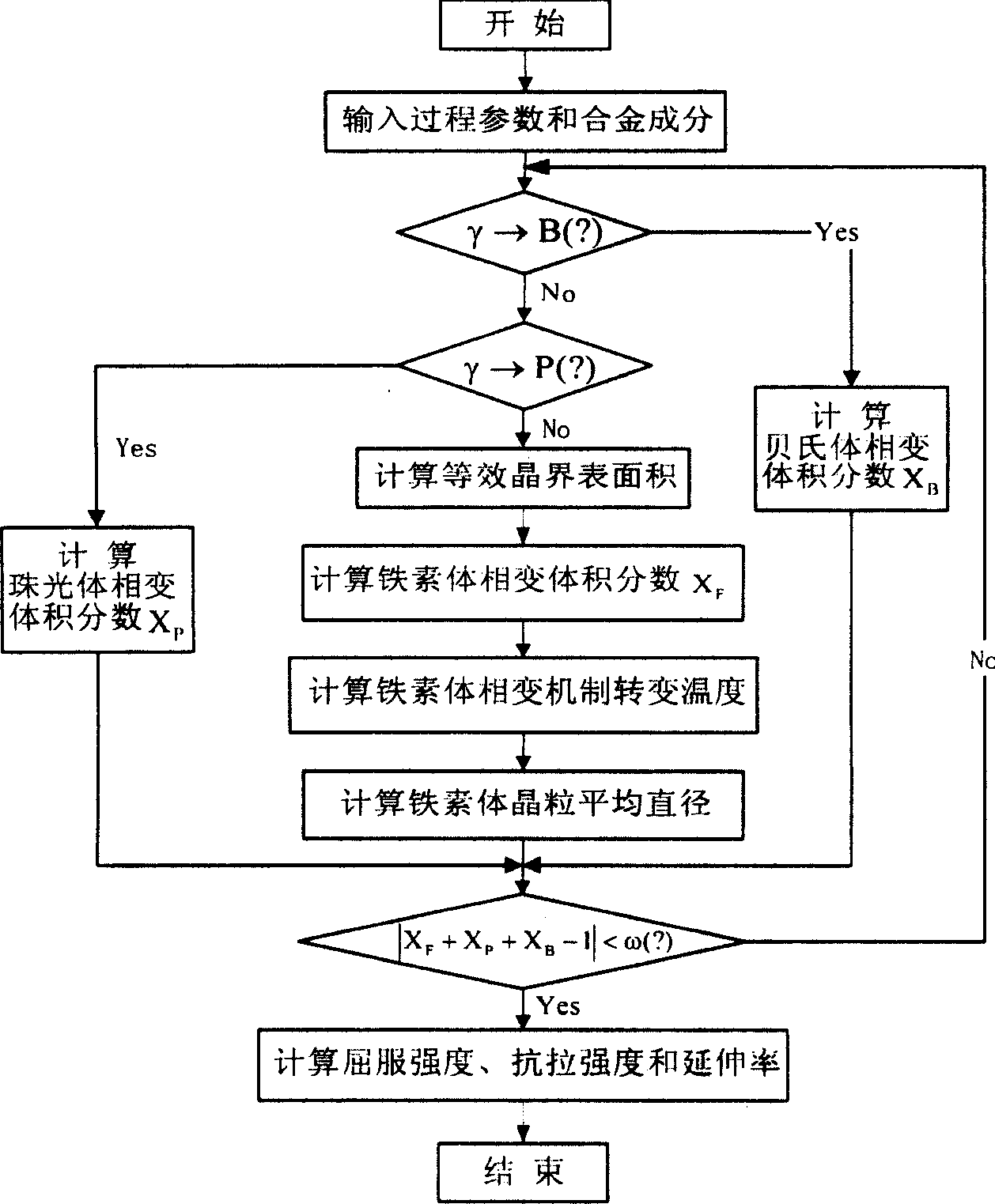

The present invention relates to a method for predicting hot-rolled Nb-contained band steel tissue and mechanical performance. Said method is characterized by that it uses physical metallurgical model as basis, adopts a method of making thermal simulation experiment be combined with industrial production actually-measured data analysis, creates mathematical models for hot-rolled Nb-contained band steel tissue and mechanical performance, including temperature model, austenite recrystallization model on the hot-rolling line, phase change model in cooling process and tissue and performance relationship model and selects VB language to originate predictive software for hot-rolled Nb-contained band steel tissue and mechanical performance.

Owner:WUHAN UNIV OF SCI & TECH +1

Method for online test of steel plate mechanic property during rolling process

InactiveCN1664550ASufficient reliabilityHigh precisionInvestigating material ductilityInvestigating material hardnessOnline testModel parameters

The invention relates to a method for testing the mechanical of the steel plate on line when rolling, providing a comprehensiveness on-line predicting method based on the physico-metallurgy model and combined with the database, information technology through setting up a corresponding model of microscopic structure, finished size, art component to the mechanical. The method including the following steps: (a) selecting and confirming the parameter of the model; (b) setting up the real-time traffic to the processing machine, calling the art parameter and alloying component dynamic data from the processing database; (c) predicting the ferrite grain size and temperature (d) predicting mechanical of the finished plate. The invention is used specially for low-carbon steel and mini alloyed steel, the adaptive process is heavy and medium plate mill or big mill and finisher in rolling process.

Owner:NORTHEASTERN UNIV

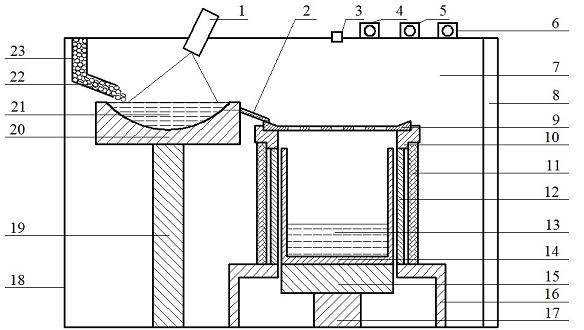

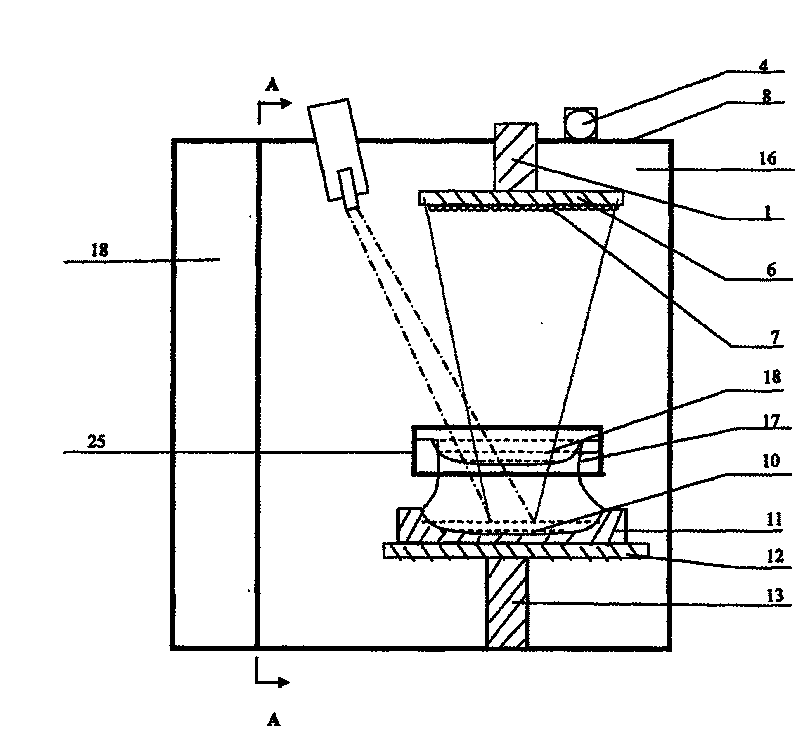

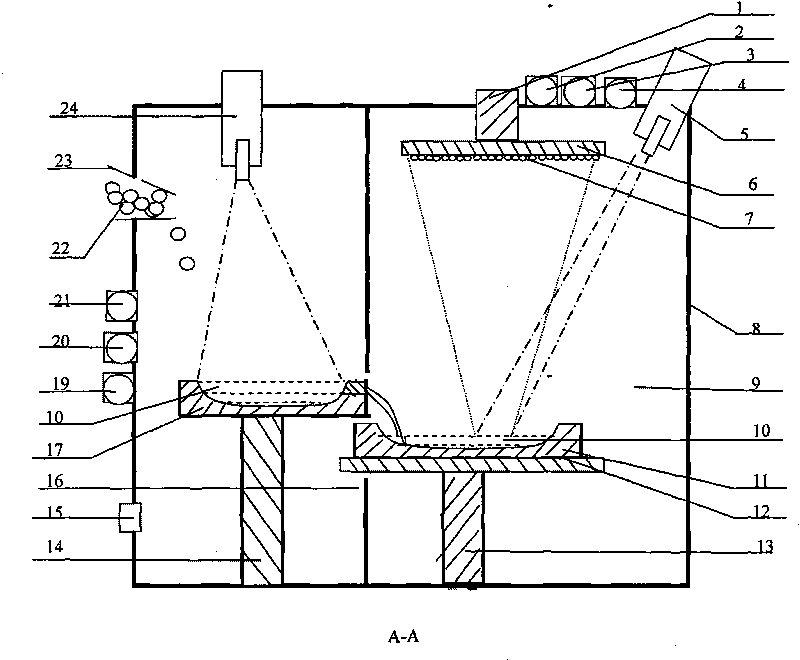

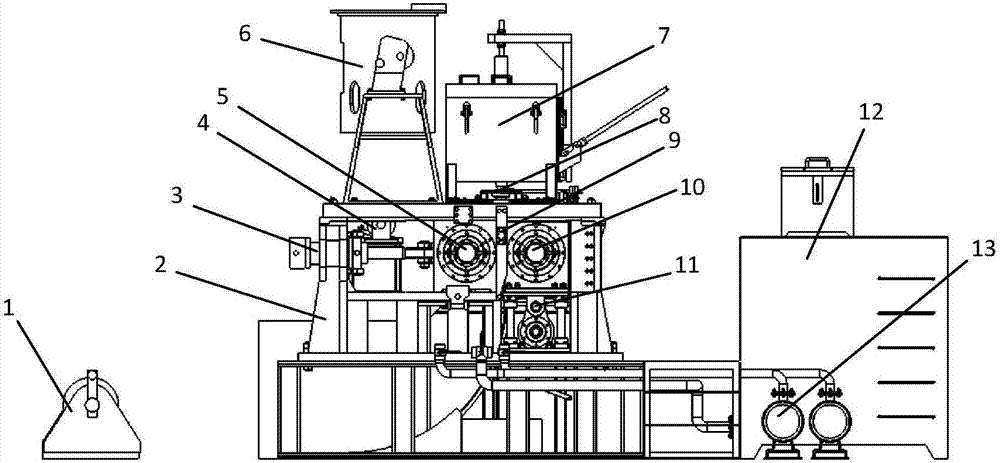

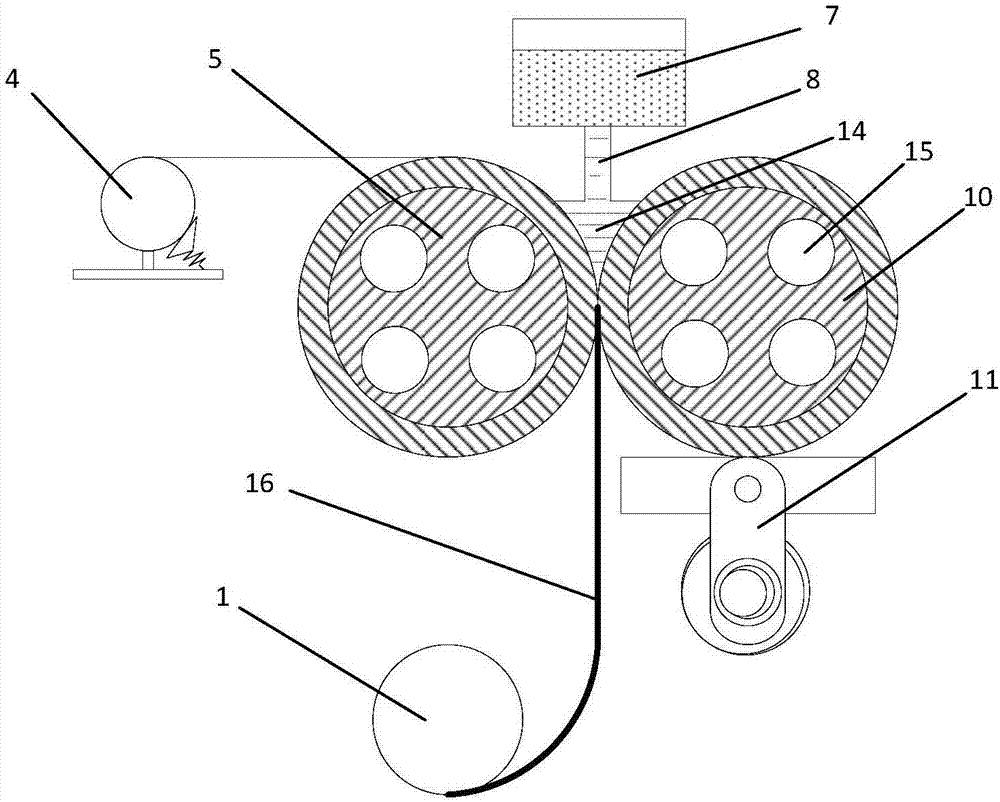

Method and device for removing foreign matter of phosphor in polysilicon

InactiveCN101318655AHigh purityImprove efficiencyPolycrystalline material growthSilicon compoundsForeign matterTorch

The invention relates to a method for removing impurity phosphor from polysilicon and a device thereof, in particular to a method for removing impurity phosphor from polysilicon by electronic torch melting technology and the device thereof, which belongs to the technical field of purifying polysilicon by physicometallurgy technology. The method is characterized in that polysilicon can be fully melted by the dual electron beams while water cooled copper crucible is rotated, polysilicon can be added in the melting process to realize continuous operation, thus removing the impurity phosphor from polysilicon. Polysilicon is put into the water cooled copper crucible, the cover of a vacuum apparatus is closed; and then the water cooled copper is vacuumized, a left electron gun and a right electron gun are preheated. The shell of the device consists of a vacuum apparatus cover and a vacuum drum, the internal cavity of the vacuum drum is a vacuum chamber. The harmful impurity phosphor in polysilicon is thoroughly removed by the electron beam melting, which effectively improves the purity of polysilicon and realizes the continuous operation. The method has high efficiency; the device is simple and saves energy.

Owner:QINGDAO NEW ENERGY SOLUTIONS

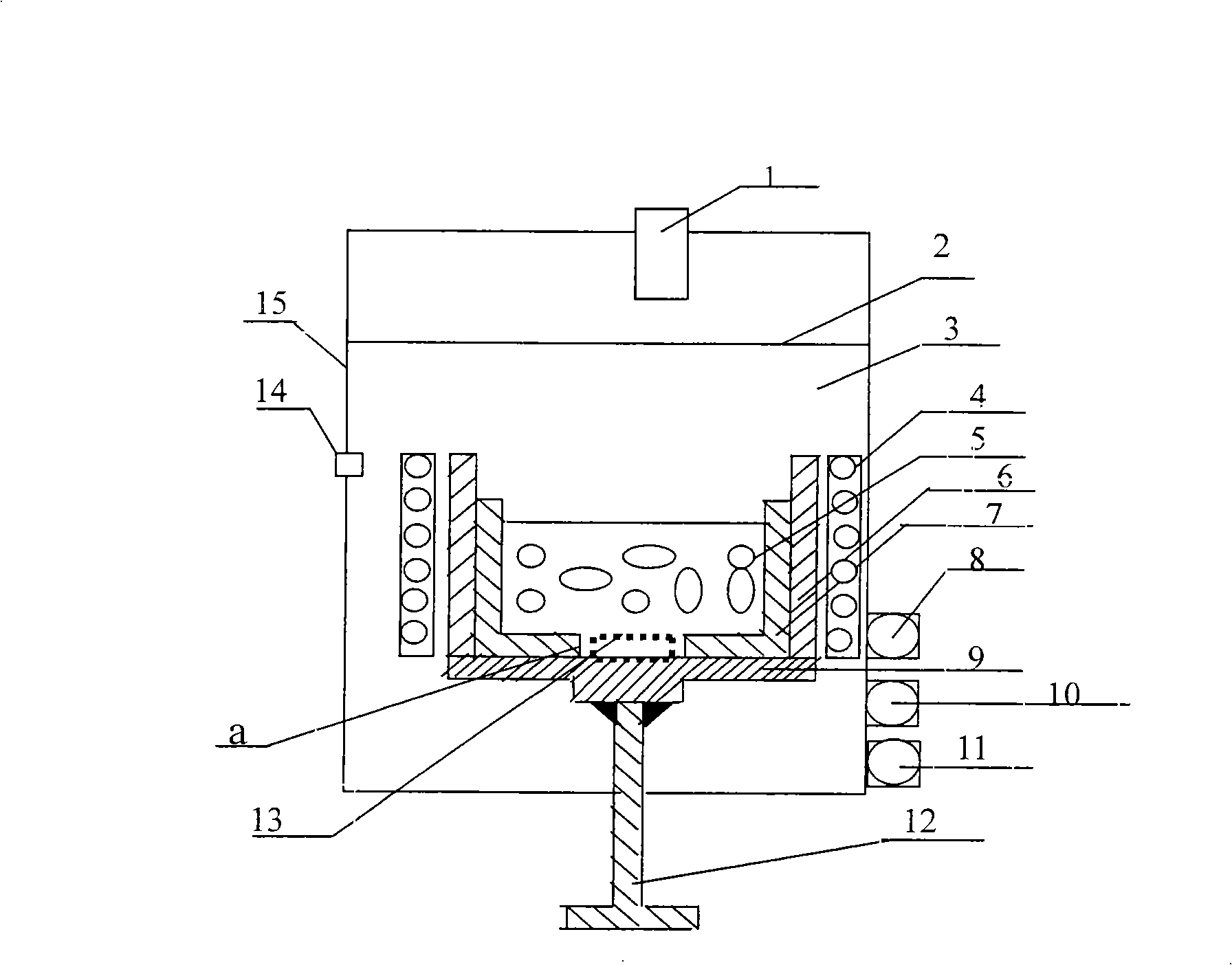

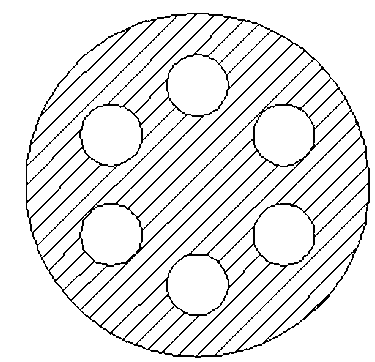

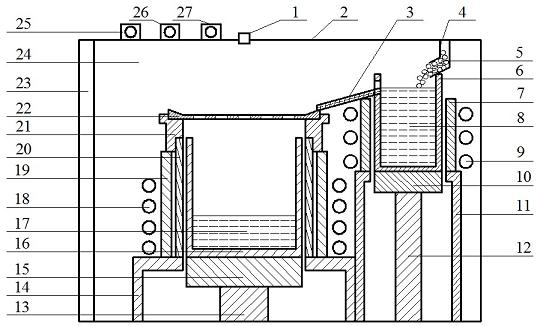

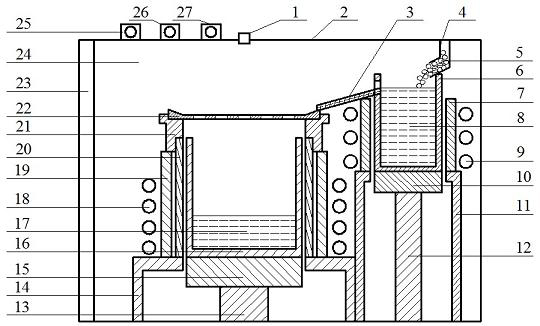

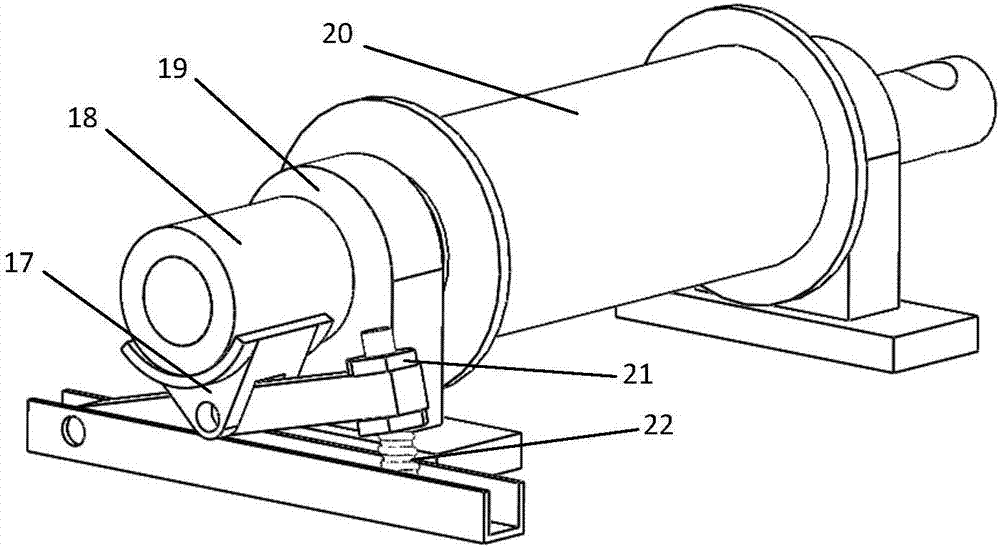

Polysilicon directional freezing equipment

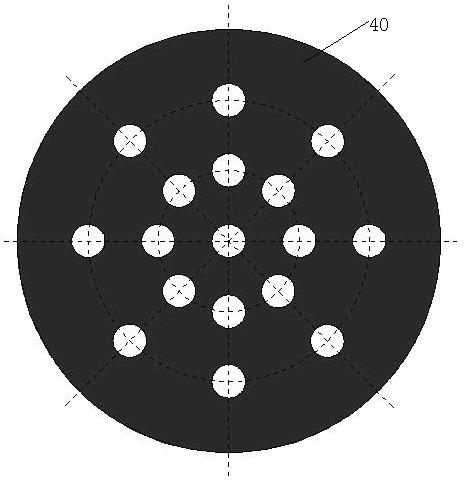

InactiveCN101323972AEffective control of heat dissipationReduce energy consumptionPolycrystalline material growthSingle crystal growth detailsFiberPhysical metallurgy

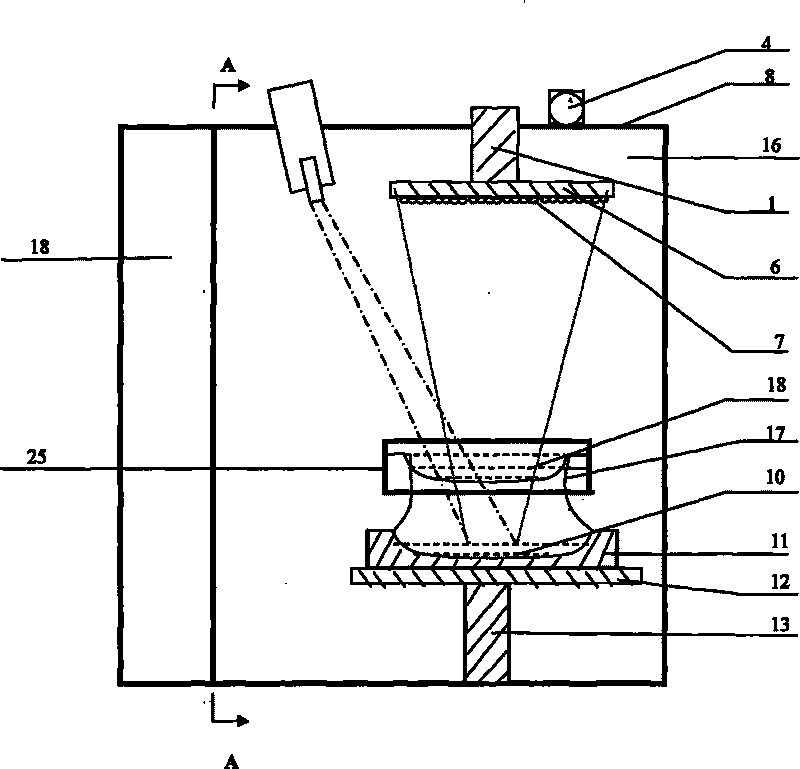

The invention discloses a directional freezing device for polysilicon, which belongs to the technical field of purifying the polysilicon through physical metallurgy techniques, and particularly relates to a polysilicon smelting device that uses a directional freezing method. An inner chamber of a shell of the directional freezing device for polysilicon is a vacuum chamber, and a closed heat preserving region inside the vacuum chamber is composed of an upper heat resisting and insulating fiber sleeve, a lateral quadrate heat resisting and insulating fiber sleeve and a lower heat resisting and insulating fiber sleeve; the middle part of the lower heat resisting and insulating fiber sleeve is opened with a tapered orifice, and a heat resisting and radiating fiber screen that is fixedly connected with a pull rod is inserted into the tapered orifice; the directional freezing device for polysilicon has a supporting platform which consists of a frame-shaped bracket, and a left slide pull rod and a right slide pull rod that are arranged on the frame-shaped bracket; the shell of the directional freezing device for polysilicon is fixed on the frame-shaped bracket. The directional freezing device for polysilicon effectively controls the radiating methods of the liquid polysilicon, ensures the temperature gradient to be kept in a same direction consistently, leads the liquid polysilicon to radiate in a single direction along the bottom, and finishes the directional freezing of the polysilicon. The directional freezing device for polysilicon has the advantages of low energy consumption and little environmental pollution.

Owner:QINGDAO NEW ENERGY SOLUTIONS

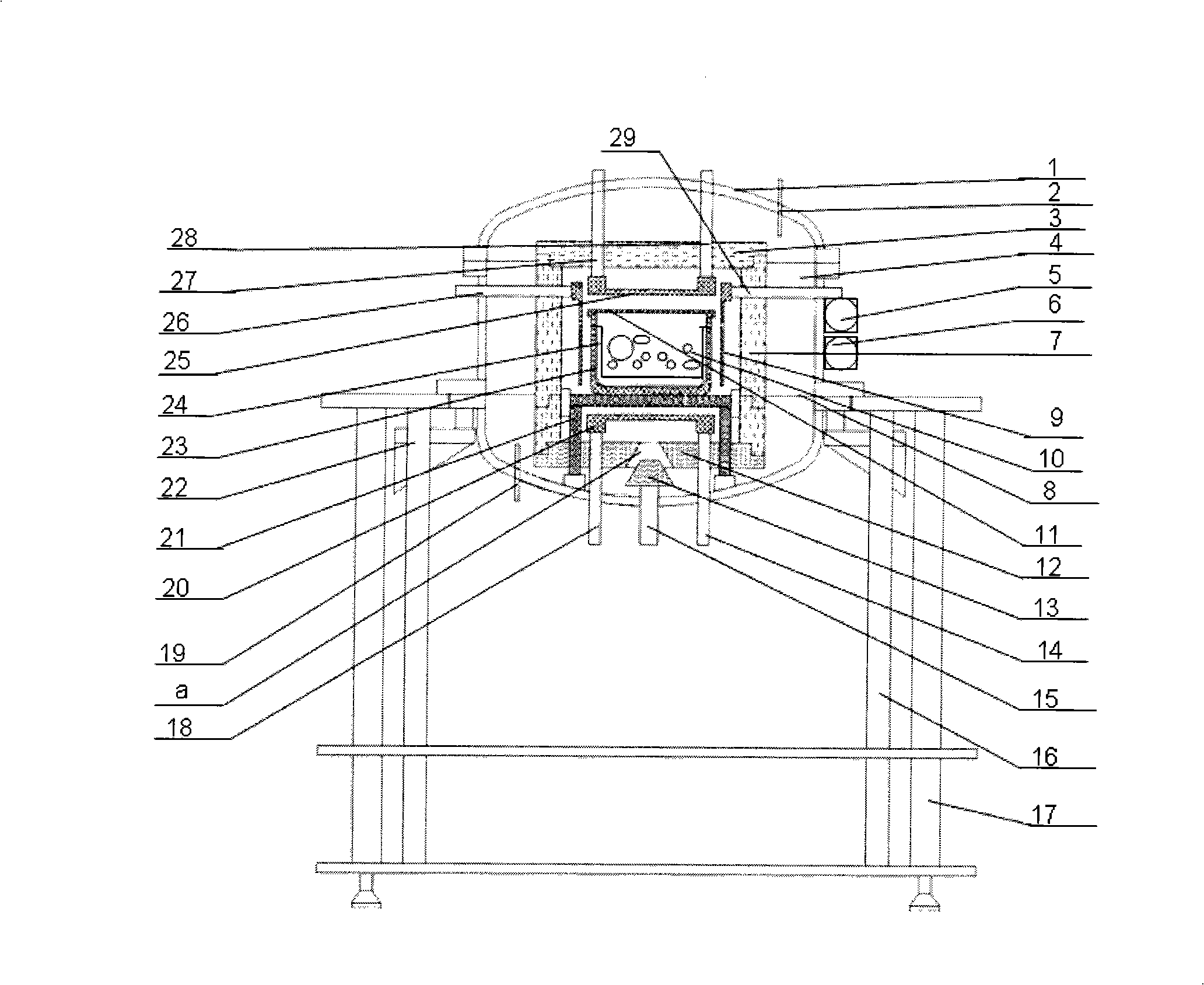

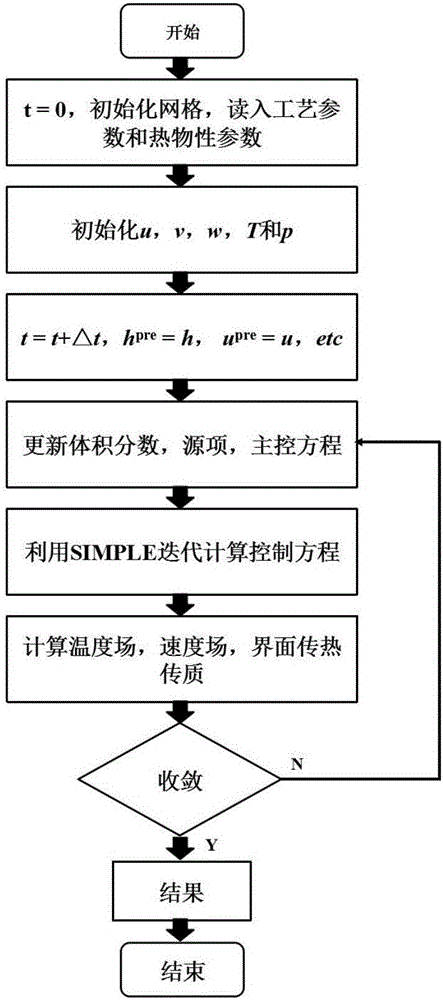

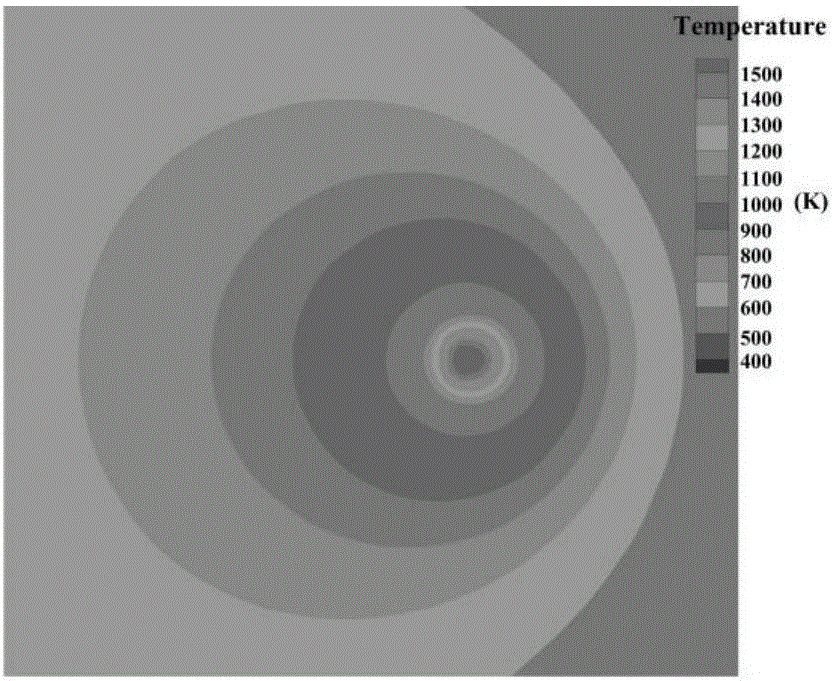

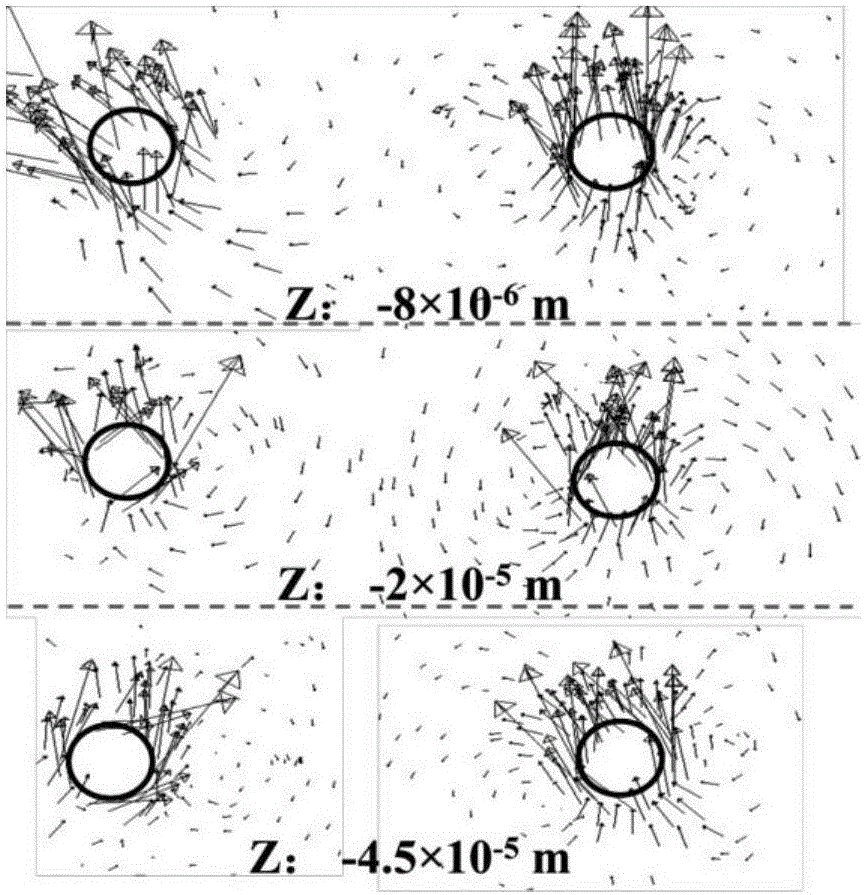

Method for simulating heat and mass transfer of reinforcement phase and melt interface in laser 3D printing composite material molten pool

ActiveCN105868434AAccurate prediction of heat and mass transferImprove distributionSpecial data processing applicationsMelting tankPhysical model

The invention relates to a method for simulating heat and mass transfer of a reinforcement phase and a melt interface in a laser 3D printing composite material molten pool, and aims at the temperature fields and velocity fields in the neighborhood of reinforced particles in the molten pool as well as distribution condition of the particles in samples after the final solidification. The method comprises the following steps: establishing a physical model of heat and mass transfer between the reinforced particles and melts; controlling the heat and mass transfer through a master control equation; and solving a control equation on the basis of calculation fluid dynamics software so as to obtain the temperature fields, the velocity fields and the distribution condition of the reinforced particles. According to the method for simulating the heat and mass transfer of the reinforced particles and the melt interface in the laser processing molten pool, a flow field model for disturbing the interior of the molten pool via laser and influencing the heat and mass transfer process between the reinforced particles and the melts is established aiming at a process of processing and preparing metal-matrix composite materials (MMCs) via laser, and the problems of powder, phase change and solidification in the laser processing process are considered, so that physical metallurgical behaviors of the reinforced particles and matrixes are correctly obtained, and the calculation results are favorably identical with experiments.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

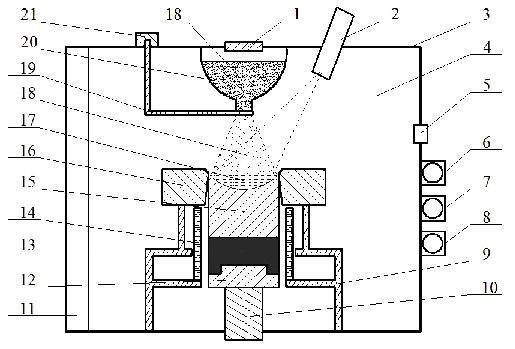

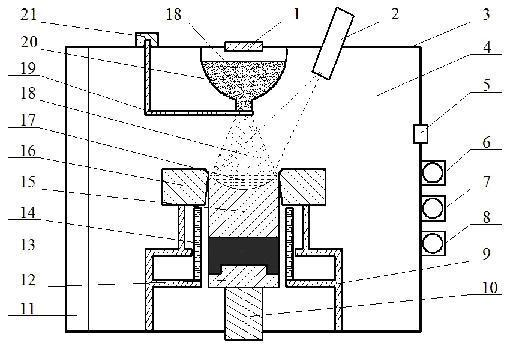

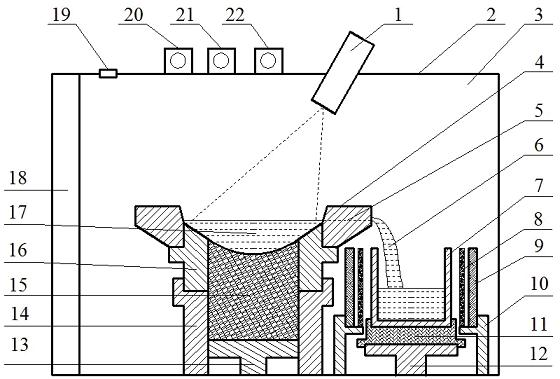

Method and equipment for purifying polycrystalline silicon through solidification crucible rotary electron beam melting

The invention belongs to the technical field of physical metallurgy technological purification, and in particular relates to a method and equipment for purifying polycrystalline silicon through electron beam melting. A high-phosphorus silicon material is molten through electron beams under the vacuum condition to obtain low-phosphorous molten silicon, and the low-phosphorous molten silicon is poured into a solidification crucible to be solidified; the processes of charging, smelting and purifying and pouring are repeated until the solidification crucible is fully loaded; another hollow solidification crucible is rotated below a molten liquid pouring port, and the processes of charging, smelting and purifying and pouring are repeated until the solidification crucible is fully loaded; and the processes of fully charging one solidification crucible and rotating another hollow solidification crucible below the molten silicon pouring port are repeated until all the solidification crucibles are fully loaded, and after the low-phosphorous molten silicon in all the solidification crucibles is solidified, ingots are taken out. By the method, the whole purifying time of a plurality of times of smelting is reduced, and the times for vacuumizing and preheating of electron guns are reduced, so that the production efficiency is increased; and the equipment is compact in structure, is easy to operate, is safe and controllable and has high production efficiency.

Owner:QINGDAO NEW ENERGY SOLUTIONS

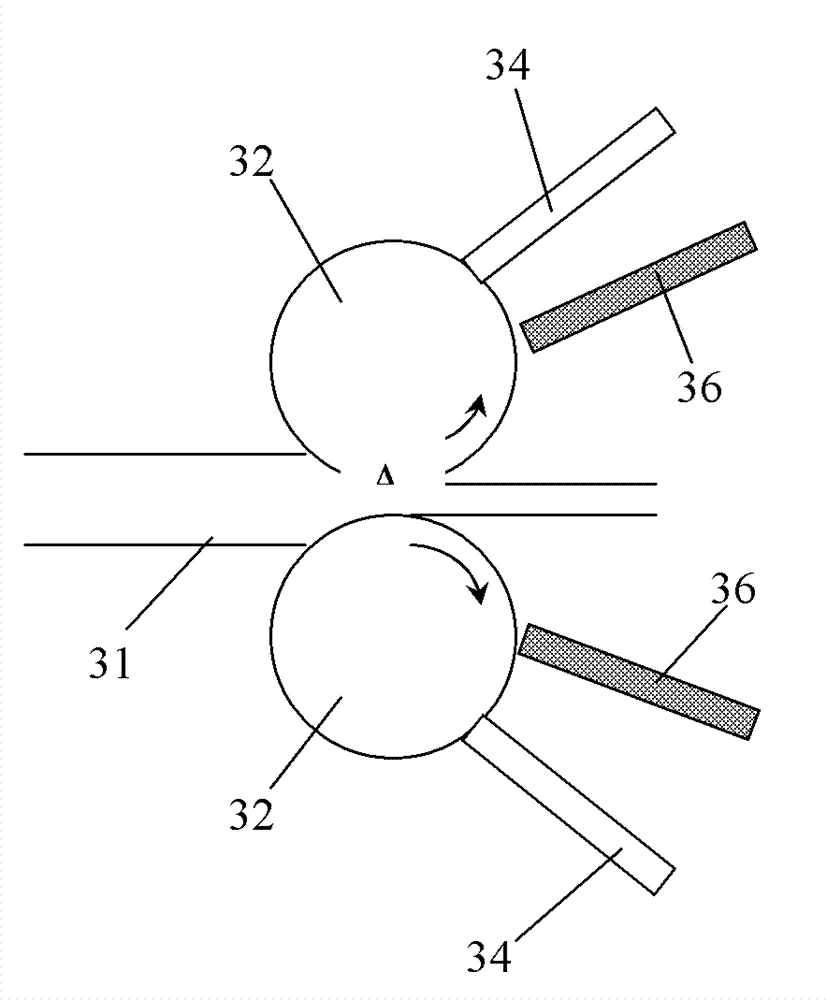

Method and device for coupling and purifying polysilicon and removing phosphorus and metal with electron beams

InactiveCN102120578AEvenly distributedReduce distributionChemical industrySilicon compoundsMelting tankMetal impurities

The invention belongs to the technical field of polysilicon purification with a physical metallurgy technology and particularly relates to a method for coupling and purifying polysilicon and removing phosphorus and metal with electron beams. The method comprises the following steps of: forming a stable melting pool on the top of a low-phosphorous low-metal high-purity silicon ingot with the electron beams; putting silicon powder to be purified into the melting pool and melting to realize the rapid melting of the powder body to remove volatile phosphorous impurity in the silicon powder; simultaneously carrying out directional ingot pulling so that the low-phosphorus polysilicon grows in a directional solidification way; and removing metal impurities in the polysilicon by utilizing a segregation effect. The invention has the remarkable effects that: because ways of melting silicon powder with the electron beams and carrying out directional solidification are simultaneously adopted, the phosphorus impurity is rapidly removed with the electron beams, and the metal impurities with lower segregation coefficient are removed by the directional solidification way, the purity of the polysilicon is effectively improved, and the using requirement of solar grade silicon is achieved. The invention has the advantages of good purification effect, stable technology, simple process, high production efficiency, energy saving, low cost and suitability for batch production.

Owner:谭毅

Method for preventing 65 Mn hot rolled steel coil from collapsing by phase-change thermal expansion

InactiveCN103143563APrevent collapsePrevent the phenomenon of flat rollTemperature control deviceMetal rolling arrangementsPhysical metallurgyThermal expansion

Owner:唐山凯昂实业有限公司

Method and device for smelting and purifying polysilicon by using electron beams and adopting slag filtering

The invention belongs to the technical field of polysilicon purification adopting the physical metallurgy technology and provides a method for smelting and purifying polysilicon by using electron beams and adopting slag filtering. The method comprises the following steps: heating and melting a slag former in a melting crucible to form slag former melt, keeping the liquid state of the slag former melt while adding a high-phosphorus, high-boron and high-metal polysilicon material in a water cooled copper crucible by a charging device, melting the silicon material into silicon melt under the bombardment of the electron beams, removing impurity phosphorus through smelting; and leading the obtained low-phosphorus silicon melt to enter the slag former melt, removing the impurity boron by reacting the impurity boron of the silicon melt with the slag former in the fusing process, heating the melt in the melting crucible and keeping liquid smelting for 3-10 minutes after charging, performing directional solidification, and cutting the top waste residue of the silicon ingot and the high metal content silicon briquet to obtain the polysilicon product. The method comprehensively utilizes the technologies of electron beam smelting dephosphorization, slag filtering smelting boron removal and directional solidification metal removal to remove phosphorus, boron and metal impurities in polysilicon, thus the purification effect is good, the production efficiency is high and the method is suitable for mass production.

Owner:DALIAN LONGSHENG TECH CO LTD

Direct laser synthesis and making process of hard alloy coating

InactiveCN1417380AReduce manufacturing costSolve the problem of stomataMetallic material coating processesLaser beam welding apparatusMicro structureMelting tank

The present invention relates to a direct laser synthesis and making process of hard alloy coating, and belongs to the field of hard alloy making and applying technology. By means of the hard alloy forming material system and high-energy laser to produce special physical and chemical metallurgical and fast solidification characteristic, hard alloy coating is formed directly through reaction in melting bath. The hard coating is dense, gas hole free and without crack and other faults, combines metallurgically with the base material, has the components, micro structure and performance of the hard alloy and any required shape. The coating may be formed in the surface of various engineering metal parts, and may be used widely in hard alloy cutter, mold antiwear part, etc.

Owner:TSINGHUA UNIV +1

Method and equipment for purifying polycrystalline silicon by directional solidification and filter slag melting

InactiveCN102219219AHigh purityMeet the requirementsChemical industrySilicon compoundsCruciblePhysical metallurgy

The invention belongs to the technical field of purifying polycrystalline silicon by physical metallurgy technology. A method for purifying polycrystalline silicon by directional solidification and filter slag melting comprises the following steps: heating slag former in a melting crucible, keeping the slag former in a liquid state, simultaneously, melting polycrystalline silicon material with high boron and high metal in the other small crucible; introducing and dispersing polycrystalline silicon melt into the liquid slag former, conducting melting reaction to remove impurity boron, and when the melting crucible is fully filled with liquid, stopping adding polycrystalline melt, heating so as to lead the mixture in the melting crucible to be in a liquid state, conducting directional solidification on the mixture after melting, cutting polycrystalline silicon and waste residue with higher impurity content at the top of a silicon ingot, thus obtaining the polycrystalline silicon ingot with a lower boron and metal impurity content. The impurity boron and metal in the polycrystalline silicon are removed by filter slag melting and directional solidification, therefore, the purity of the polycrystalline silicon is improved effectively, the using requirement of solar silicon is achieved, the purifying effect is good, the technique is stable, the process is simple, the energy is saved, the cost is low and the production efficiency is high.

Owner:DALIAN LONGSHENG TECH CO LTD

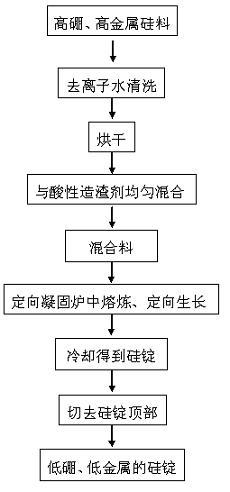

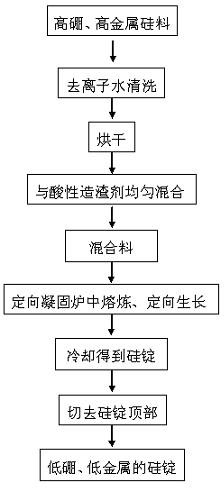

Method for purifying polycrystalline silicon by directional solidification and slag refining

InactiveCN102219221AQuick removalEfficient removalPolycrystalline material growthFrom frozen solutionsPhysical metallurgySlag

The invention belongs to the technical field of purifying polycrystalline silicon by physical metallurgy technology. A method for purifying polycrystalline silicon by directional solidification and slag refining comprises the following steps: firstly, mixing polycrystalline silicon material and acid slag former uniformly so as to form mixture, then arranging the mixture into a melting crucible ofa directional solidification furnace, slagging and melting the mixture in the melting crucible, simultaneously, conducting directional solidification so as to concentrate metal impurity and waste slag on the top of a silicon ingot, removing boron and metal impurity, and finally cutting the top of the silicon ingot, thus obtaining polycrystalline silicon ingot with low boron and metal content. Themethod has the following obvious effects: the acid slag former for slagging and melting and the directional solidification are adopted simultaneously, the impurity boron in the polycrystalline silicon is removed by the slagging of the acid slag former and the refining, simultaneously, the metal impurity with a smaller segregation coefficient in the polycrystalline silicon is removed by the directional solidification technology, the purity of the polycrystalline silicon material is improved, so that polycrystalline silicon material achieves the using requirement of solar-level polycrystalline silicon material.

Owner:DALIAN UNIV OF TECH

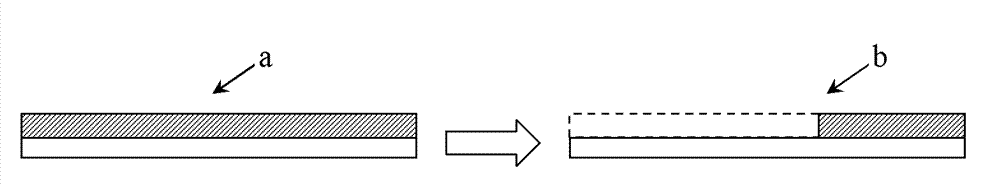

Pole lug single body with embedded composite metal structure, row type pole lug, and manufacturing method of pole lug single body

InactiveCN103928651ADoes not affect aestheticsHigh bonding strengthCell component detailsPhysical metallurgyAluminum substrate

The invention relates to a pole lug single body with an embedded composite metal structure, a row type pole lug, and a manufacturing method of the pole lug single body. The pole lug single body is in a strip sheet shape, the whole thickness is 0.05-0.3mm, and the pole lug single body comprises a strip-shaped aluminium substrate and an easily-welded part at one end or the middle position of the aluminium substrate, wherein the easily-welded part is an easily-welded layer rolled and combined with a concave part of the aluminium substrate, the side part and the whole bottom part of the easily-welded layer and the concave part of the aluminum substrate form a physical metallurgy layer, and the thickness of the easily-welded layer is 1-95% of the total thickness of the pole lug single body. The row type pole lug is formed by combining a plurality of the pole lug single bodies through pole lug glue. The manufacturing method comprises: inlaying an easily-welded metal belt in a groove on an aluminium belt surface, and rolling; performing continuous bright annealing and rolling on the rolled composite metal belt; shearing to obtain the pole lug single body; and performing surface de-oiling, passivation and drying processing on the pole lug single body. The pole lug is high in combination strength and small in contact resistance. The method is low in cost and easy to realize.

Owner:徐卓辉 +1

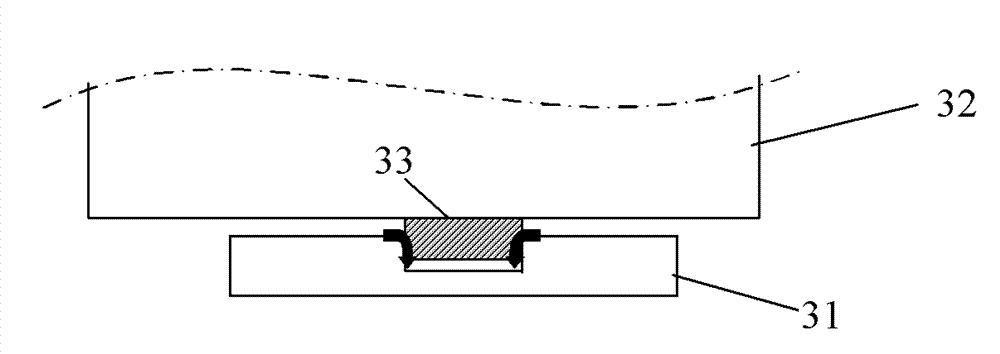

Method and equipment for purifying polycrystalline silicon by melting in electron beam shallow pool

The invention belongs to the field of purification of polycrystalline silicon by adopting a physical metallurgy technology, and discloses a method for purifying polycrystalline silicon by melting in an electron beam shallow pool. The method comprises the following steps of: putting a large high-phosphorus and high-metal polycrystalline silicon ingot needing to be purified on a water-cooled elevating tray; melting the top of the silicon ingot by adopting electron beams; making a molten silicon solution form the shallow pool in a space formed by the top of the silicon ingot, a water-cooled copper sheathing and a graphite ferrule; melting for a certain period of time to remove phosphorus impurity; lifting the water-cooled elevating tray; raising the liquid level of a low-phosphorus silicon melt and making the low-phosphorus silicon melt flow into a quartz crucible through a diversion port; pulling the ingot downwards under the action of heat preservation; performing directional solidification growth; enriching metal impurities towards the top of the silicon ingot; cutting the top of the silicon ingot after solidifying; and removing the metal impurities. By adopting the method, phosphorus and metal impurities in silicon are removed by melting in the electron beam shallow pool and directional solidification, the purity of polycrystalline silicon meets the using requirement of solargrade silicon and energy sources are saved. The method has the advantages of simple process and high production efficiency, and is suitable for batch production.

Owner:DALIAN LONGTIAN TECH

Method and device for efficiently and continuously smelting and purifying polysilicon with electron beams

The invention belongs to the technical field of polysilicon purification with a physical metallurgy technology and particularly relates to a method for efficiently and continuously smelting and purifying polysilicon with electron beams. The method comprises the following steps of: forming a stable high-purity silicon smelting pool in a crucible with the electron beams; putting silicon powder to be purified into the smelting pool through a vacuum feeding gate, rapidly smelting and then smelting to remove phosphorous impurity in the silicon powder, wherein the obtained low-phosphorous silicon liquid periodically overflows from the crucible and forms a silicon block in a water-cooling inclined copper cell, and the silicon block drops to a collection barrel to be cooled; and finally carrying out continuous discharging through a vacuum discharging gate to finish the process flow of continuously purifying the polysilicon. In the invention, smelting ways of continuously feeding and continuously discharging are adopted, and the volatile phosphorus impurity with high saturated steam pressure can be removed by smelting the polysilicon with the electron beams, therefore, the aims of efficiently and continuously smelting and removing impurities are achieved, and the purify achieves the using requirement of solar grade silicon. The invention has the advantages of stable technology, low energy consumption, low cost and suitability for large-scale industrial production.

Owner:谭毅

X90 level heterogeneous structure pipeline steel plate for longitudinal welded pipe and manufacturing method of pipeline steel plate

The invention relates to an X90 level heterogeneous structure pipeline steel plate for a longitudinal welded pipe and a manufacturing method of the pipeline steel plate. According to the research and practice of the physical metallurgy principle, recrystallization rule and phase change rule of materials, innovative X90 level high-strength pipeline steel is invented. The pipeline steel has a heterogeneous microstructure, and the implementability of the process is researched, so that perfect combination of high strength, high toughness and high plasticity is realized. The X90 level pipeline steel plate used for longitudinal submerged arc welding refers to a pipeline steel plate which integrates the high strength, high toughness and high plasticity into a whole, wherein the yield strength (RP 0.2) is more than or equal to 555MPa, the tensile strength (Rm) is more than or equal to 695MPa, the yield ratio (RP 0.2 / Rm) is less than or equal to 0.75, the uniform elongation (UEL) is more than or equal to 11 percent, KV2 at the temperature of 20 DEG C below zero is more than or equal to 300J, and DWTT at the temperature of 15 DEG C below zero is more than or equal to 85 percent.

Owner:SHANDONG IRON & STEEL CO LTD

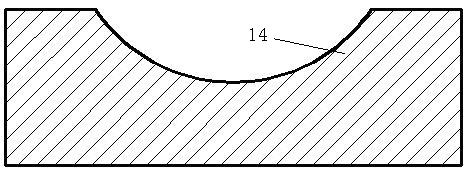

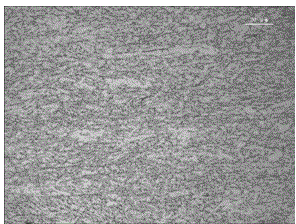

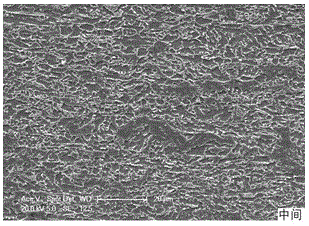

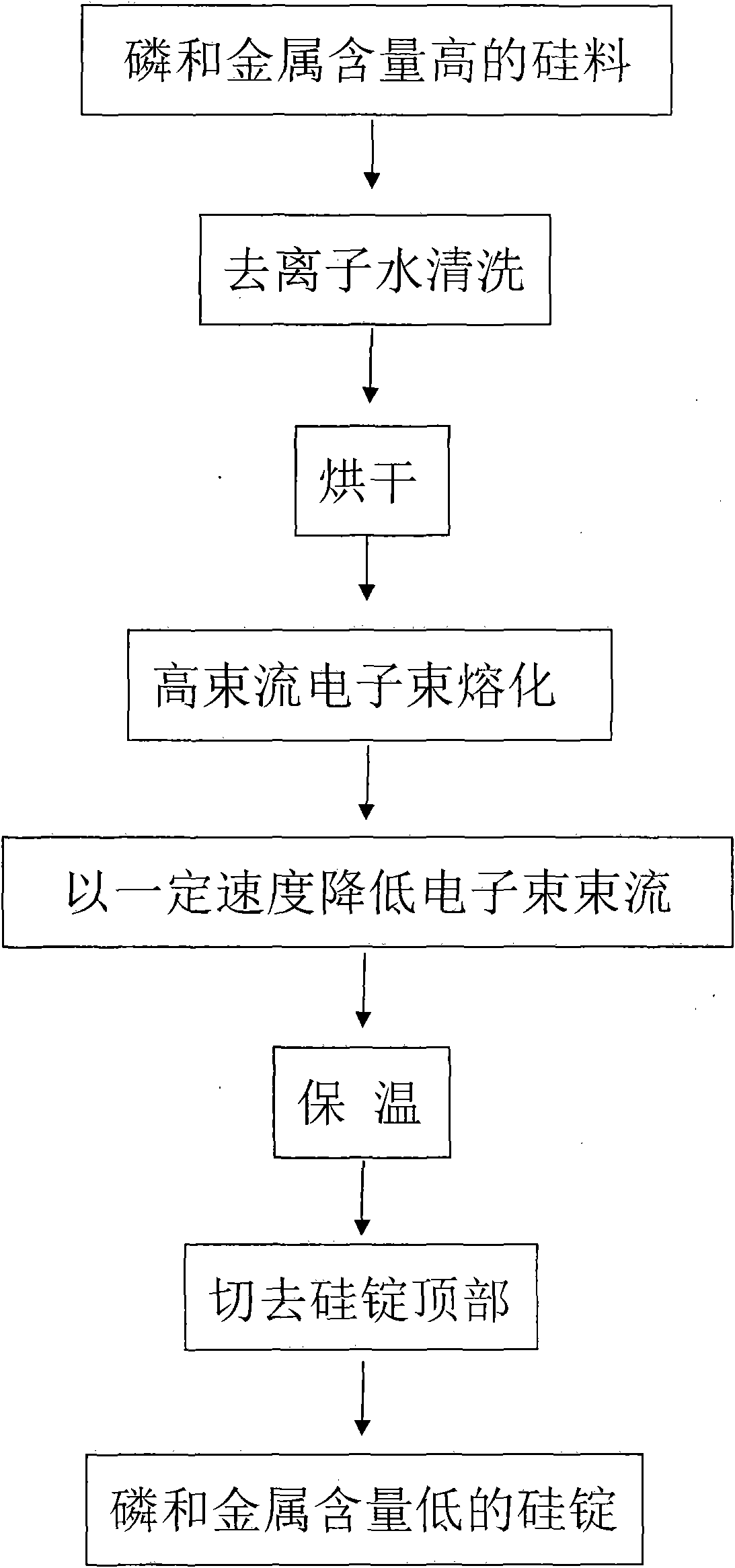

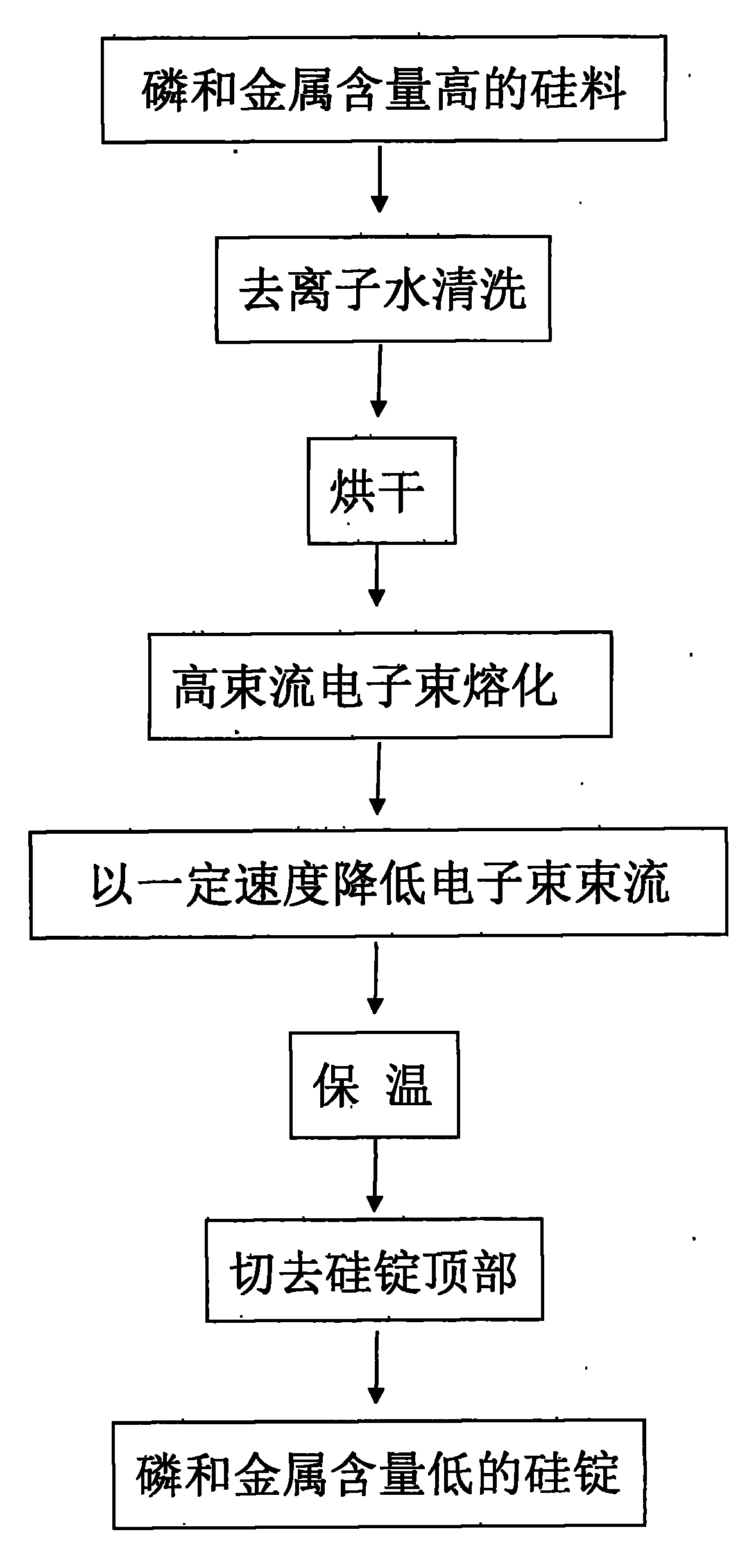

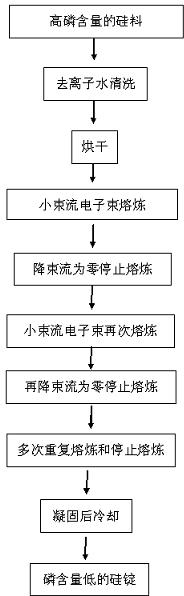

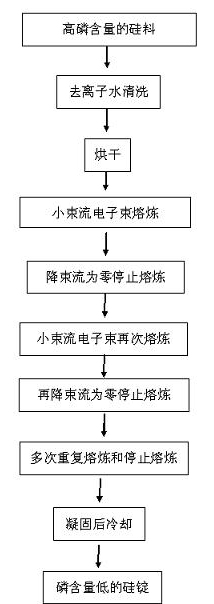

Method for purifying polycrystalline silicon by electron beam gradient smelting

InactiveCN101905886AMeet the use requirementsImprove purification efficiencyChemical industrySilicon compoundsElectronImpurity

The invention discloses a method for purifying polycrystalline silicon by electron beam gradient smelting, belonging to the technical field of polycrystalline silicon purification by using a physical metallurgy technology and relating to a method for removing phosphorus and metal impurities in the polycrystalline silicon by utilizing an electron beam smelting technology. The method realizes the directional solidification effect while removing volatile impurity phosphorus by changing beam current of electron beams to generate different energy distributions. The method comprises the following steps of: weighing silicon materials with high content of phosphorus and metal impurities, cleaning, drying and then putting into an electron beam smelting furnace, and completely smelting the silicon materials by using the electron beams with high current; then gradually reducing the beam current of the electron beams, and preserving the temperature under the low beam current; shutting the beam current off and then cooling, finally taking a silicon ingot out, and cutting the top of the silicon ingot off to obtain the silicon ingot with lower content of phosphorus and metal impurities. The invention has good removal effect on the phosphorus and the metal impurities and the dual effects of removing phosphorus by adopting the electron beams and removing metals by adopting directional solidification, improves the purification efficiency, reduces the process loops, and also has the advantages of stable technology, short cycle, energy source saving and low cost.

Owner:DALIAN UNIV OF TECH

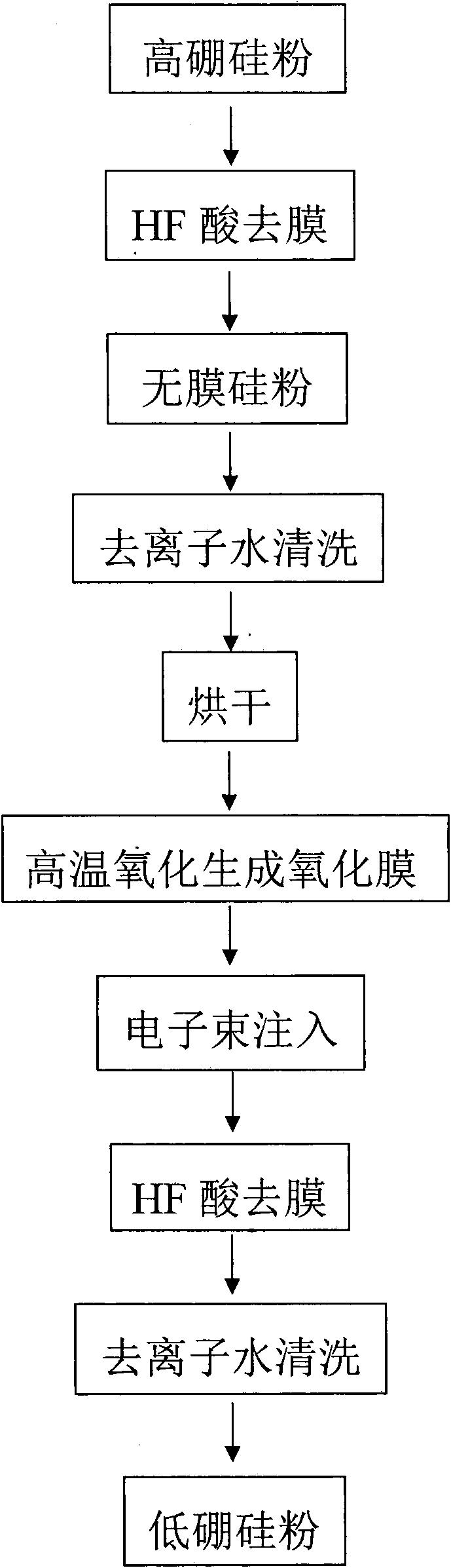

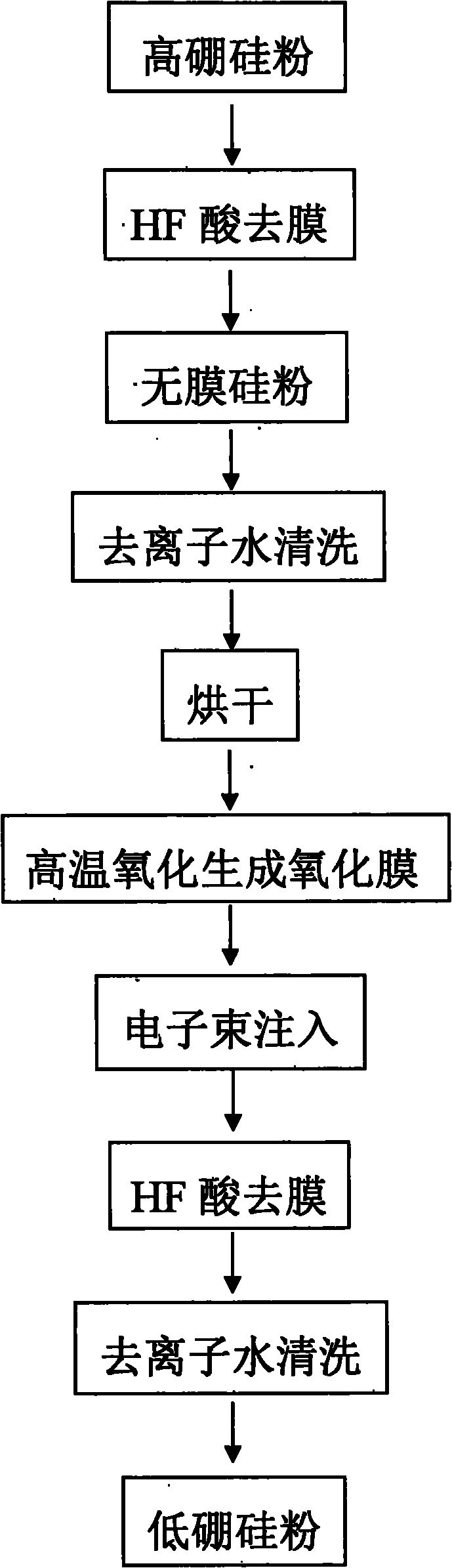

Method for removing boron impurities contained in polysilicon by injecting electron beams

InactiveCN101891202AEnhanced micro electric fieldMeet the use requirementsSilicon compoundsElectron injectionSilicon dioxide

The invention relates to a method for removing boron impurities contained in polysilicon by injecting electron beams, in particular to a method for removing the boron impurities contained in the polysilicon by carrying out electron injection by utilizing the electron beams, belonging to the technical field of polysilicon purification by using a physical metallurgy technology. The method comprises the following steps of: firstly, heating silicon powder by utilizing a high-temperature heating furnace; then placing the silicon powder into an electron beam smelting furnace, and bombarding the silicon powder by using low-beam current electron beams; and finally removing a surface oxidation film of the silicon powder to obtain low-boron silicon powder by using an HF (hydrogen fluoride) acid solution. The invention has the outstanding advantages of showing the electrical effect of negative electricity by releasing electrons by adopting the electron beams, strengthening self electric microfields of silicon materials by combining with the self characteristics of the silicon materials, enabling the boron to be diffused to an interface by being driven by temperature and further enter a silicon dioxide layer and finally removing a silicon dioxide layer containing the boron through acid cleaning, thereby achieving the purpose of removing the boron impurities to meet the using requirements on solar grade silicon; in addition, the invention has the advantages of good purification effect and stability, little energy consumption, low cost, simple process, short period and higher production efficiency.

Owner:DALIAN UNIV OF TECH

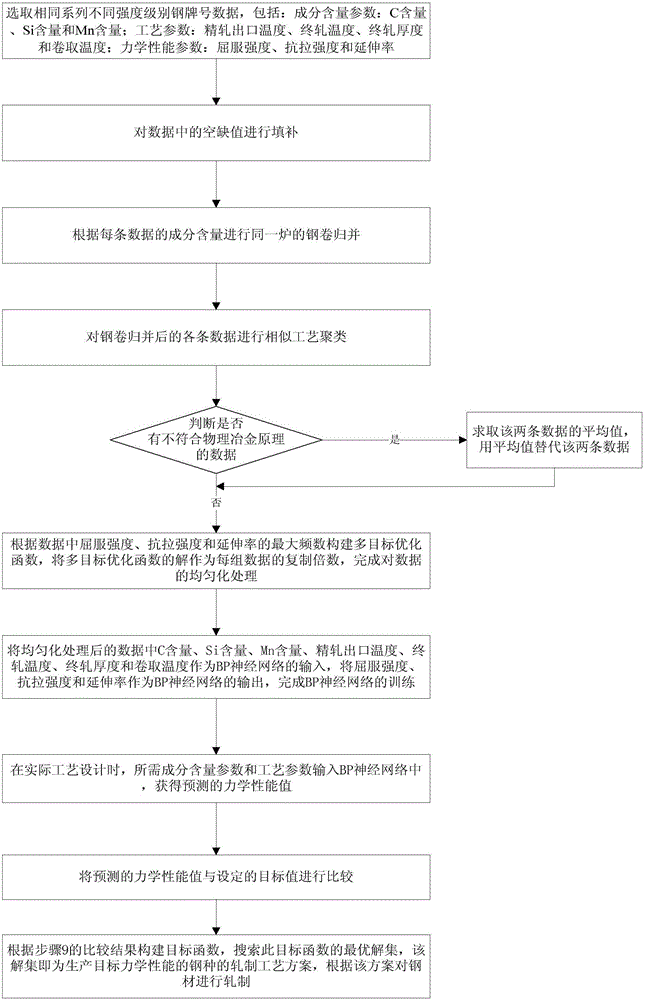

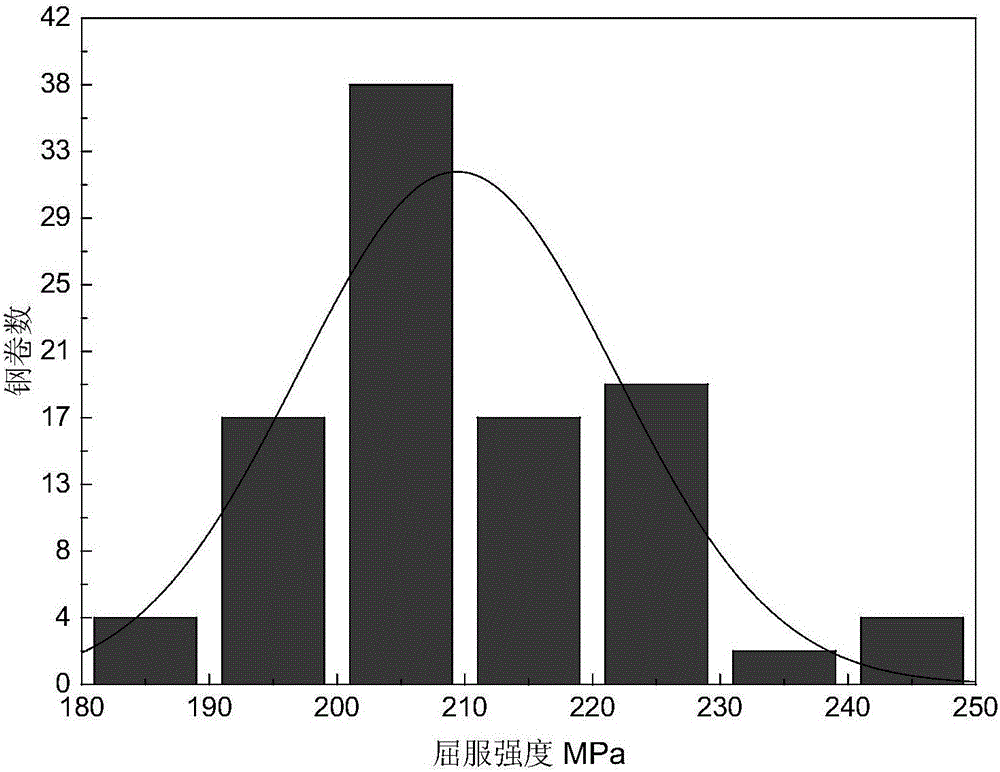

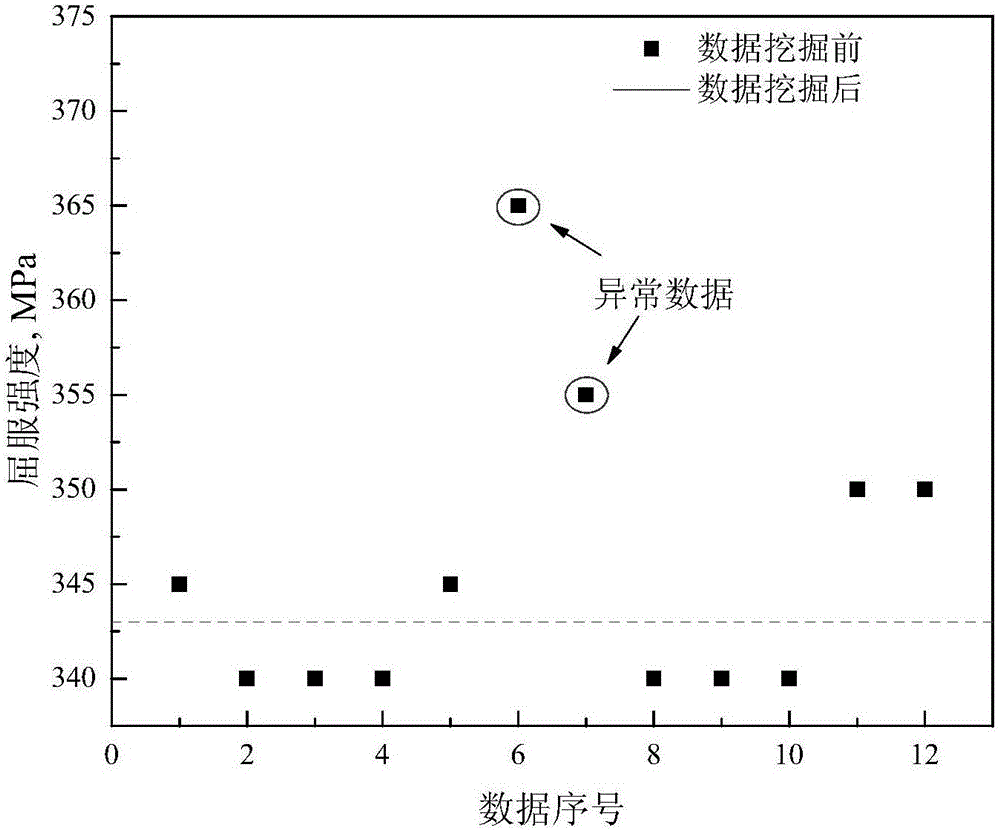

Mining method for C-Mn steel industry big data

ActiveCN105740467AObjective Physical Metallurgical LawsWide applicabilityRelational databasesSpecial data processing applicationsPhysical metallurgyNetwork model

The invention provides a mining method for C-Mn steel industry big data and belongs to the field of cross technologies of steel industry production and data statistics modeling.The method includes the steps of data sample selection, steel coil merging, similar process clustering and training data uniformization.Through selecting data of multiple steel brand numbers, a data sample includes comprehensive parameter information, a more objective physical metallurgy rule is reflected, and a model has higher adaptability; through judging components of a steel blank to be detected and adopting the clustering method, multiple sets of data of a similar process are corrected to be one set of data, in this way, the data volume is simplified, and redundant data is deleted; in the process, abnormal data is rejected, errors are reduced, and data regularity is more obvious; through performing statistics on distribution of three kinds of mechanical properties of training data, the distribution balance of the training data is adjusted; by the adoption of a balanced data training neural network, a network model can learn about balanced information, and the regularity and accuracy of the model are improved.

Owner:NORTHEASTERN UNIV

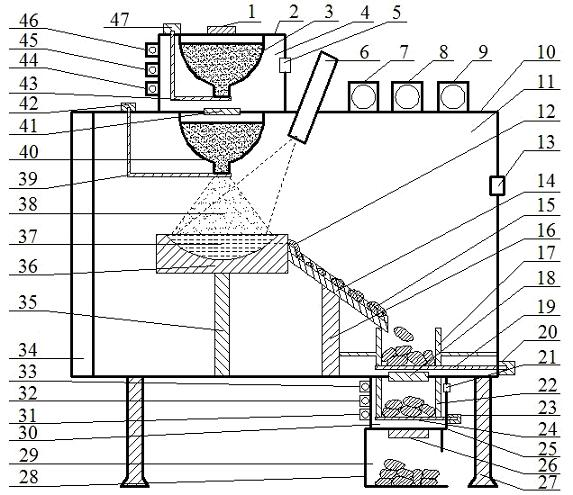

Method and device for removing phosphorus and boron in polysilicon by continuous smelting

InactiveCN101708850AHigh purityMeet the requirementsSiliconFinal product manufacturePolycrystalline siliconPhysical metallurgy

The invention belongs to the technical field of polysilicon purification by a physical metallurgy technology, in particular to a method for removing phosphorus and boron of impurities in polysilicon by an electron beam smelting technology. In the method, two electron guns are used for emitting electron beams to respectively smelt the polysilicon; meanwhile, the phosphorus and the boron in the polysilicon are removed by a dual technology; the phosphorus in the polysilicon is removed at first, the polysilicon with low phosphorus is further smelted and evaporated to remove the boron; and the polysilicon with low phosphorus and boron, which is evaporated, on a depositing plate is collected. The adopted device comprises a shell and a vacuum chamber, wherein the shell comprises a vacuum cover and a vacuum barrel; an inner cavity of the vacuum barrel is the vacuum chamber; and the vacuum chamber comprises a left cavity and a right cavity which are partitioned by an isolating plate. The invention effectively improves the purity of the polysilicon, reaches the use requirement of solar energy-grade silicon and has good purifying effect, stable technology and high efficiency.

Owner:DALIAN UNIV OF TECH

Phosphorus diffusion method for physical metallurgy polycrystalline silicon solar cell

InactiveCN104404626AImprove the final photoelectric conversion efficiencyEvenly distributedDiffusion/dopingDiffusion methodsPhysical metallurgy

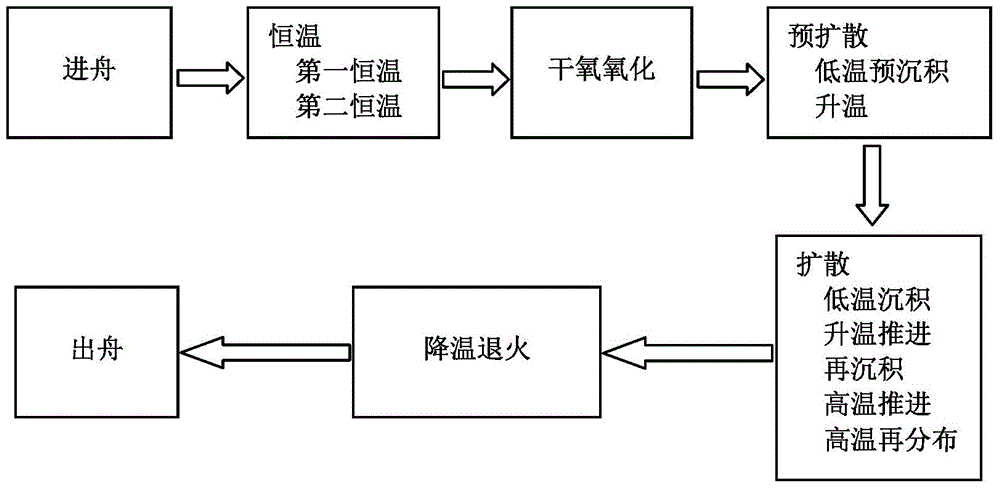

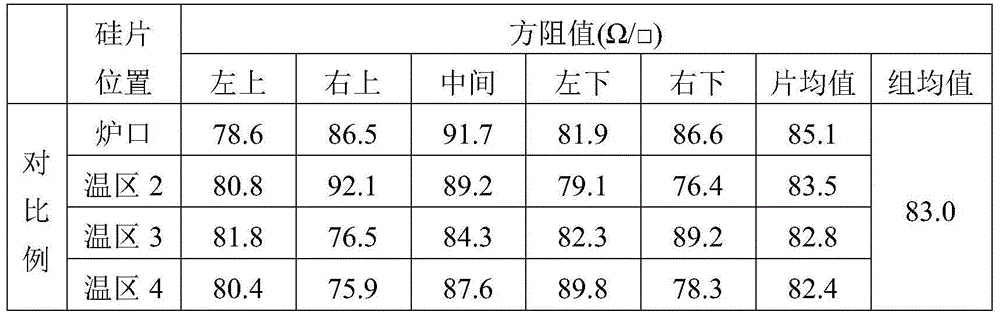

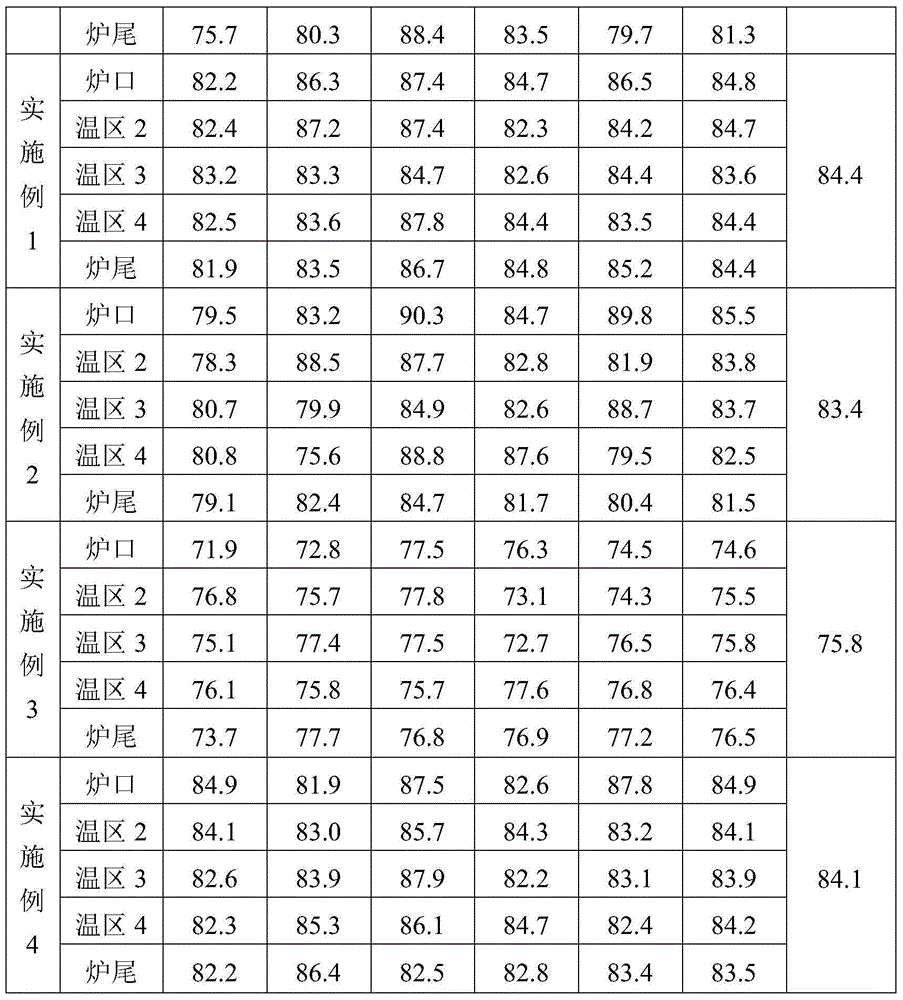

The invention provides a phosphorus diffusion method for a physical metallurgy polycrystalline silicon solar cell. The phosphorus diffusion method comprises the steps: (1) performing primary constant-temperature thermal treatment on a silicon slice subjected to cleaning and texturing; (2) performing secondary constant-temperature thermal treatment on the silicon slice subjected to the treatment in the step (1); (3) performing oxidization treatment on the silicon slice subjected to the treatment in the step (2); (4) performing phosphorus diffusion treatment on the silicon slice subjected to the treatment in the step (3) through a phosphorus source; (5) performing annealing treatment on the silicon slice subjected to the treatment in the step (4). The diffusion method disclosed by the invention is applied to preparation of the physical metallurgy polycrystalline silicon solar cell, so that the cost can be reduced, and the yield is increased; the concentration of impurities on the surface of a formed PN node is low, the impurity distribution is uniform, the dispersion uniformity is high, the dead layer effect is reduced, collection of electrons is facilitated, and the efficiency loss of the solar cell due to compounding is reduced, so that the final photoelectric conversion efficiency of a cell slice is improved.

Owner:INNER MONGOLIA RIYUE SOLAR ENERGY TECH

Method for purifying polysilicon by adopting electron beam to carry out fractionated smelting

InactiveCN102145893AReduce evaporation lossReduce removal efficiencyChemical industrySilicon compoundsPhysical metallurgyCrucible

The invention belongs to the technical field of purification of polysilicon by a physical metallurgical technology. A method for purifying the polysilicon by adopting an electron beam to carry out fractionated smelting comprises the following steps: firstly preparing a material; placing a cleaned and dried silicon material into an electronic beam smelting furnace; carrying out preprocessing; carrying out water cooling on a crucible and preheating an electronic gun; and finally purifying, i.e. melting and smelting for a certain time by adopting the electron beam with a small beam current of 200 to 300mA, then reducing the beam current to zero, smelting the polysilicon for a certain time by the small beam current of 200 to 300mA and stopping the beam current after a silicon ingot is completely darkened and silicon steam is condensed back into a molten pool, repeatedly repeating the operation of smelting small beam current and stopping beam current, and finally carrying out cooling and condensing to obtain a polysilicon ingot with low phosphorus content. The method has the obvious effects that due to the adoption of the technology of carrying out electro beam fractionated smelting, the evaporation loss of silicon is reduced; the method has good purifying effect, stable technology, simple process, short period and high production efficiency; energy is saved; and consumption is reduced.

Owner:DALIAN LONGSHENG TECH CO LTD

Method for abstracting solar energy level silicon by physics metallurgical method

InactiveCN101143722ARich sourcesSimple processing methodSilicon compoundsChemical reactionThermal insulation

The invention discloses a solar grade silicon refinery method by using physical metallurgy. The method includes the following steps: firstly, a vacuum induction melting furnace is utilized and a high purity oxide crucible is selected to avoid carbon pollution; secondly, the vacuum pumping is operated simultaneously during the heating process; thirdly, the protective gases are injected into the furnace; when the melting temperature reaches a certain value, strong oxidative gases (chlorine) are injected into the bottom of the crucible; fourthly, while stirring the silicon solution, the strong oxidative gases carry out chemical reactions with Fe-Al-Ca-P-V etc impurity elements, which lead to the gasification and thermal insulation of the elements; fifthly, the refined silicon is injected into the tundish, and the directional crystallization program is processed. The invention has a simple method, an easy operation, rapid heating and no pollution. The silicon material refined by the invention can reach 5N or higher purity.

Owner:JIAWEI SOLAR WUHAN

Method for Refining Solar Grade (SoG) Silicon by Using Physical Metallurgy

InactiveUS20100239484A1Simple processing methodShort construction periodSiliconEnergy inputChemical reactionShielding gas

The present invention discloses a method for physically refining solar grade silicon comprises: firstly, by using a vacuum induction furnace, selecting a high oxidizing crucible to avoid carbon pollution; secondly, conducting the vacuum-pumping during the heating process; thirdly, injecting a protective gas, after the smelting temperature reaches a predetermined temperature, the powerful oxidizing gas (chlorine) is injected into the bottom of the crucible; fourthly, producing chemical reaction with the powerful oxidizing gas and impurity such as Fe—Al—Ca—P—V, so that the reaction resultant is gasified, while the power oxidizing gas stirs with the metallic silicon liquation, and preserving the temperature; fifthly, injecting the refined metallic silicon into a pouring box to enter into a oriented crystallization procedure. The present invention has following advantages: being easy and convenient to be implemented, rapid heating, no pollution, and the purity of the silicon material refined by using the method in the present invention can be graded to 5N or more.

Owner:JIWEI SOLAR WUHAN

Double metal composite plate strip solid-liquid vibration cast rolling device and method

ActiveCN107138529AGood strengthening effectImprove bindingMetal rolling arrangementsPhysical metallurgyComposite plate

The invention discloses a double metal composite plate strip solid-liquid vibration cast rolling device and method. The device mainly comprises a self-tensioning uncoiling mechanism, a coiling mechanism, a machine frame, a vibration system, a press-down side casting roller and a vibration side casting roller. The method mainly comprises the steps that a solid metal A strip blank is fed in through the self-tensioning uncoiling mechanism to be tightly attached to the face of the press-down side casting roller, metal B liquid is poured into the roller gap between the vibration side casting roller and the solid metal A strip blank, the surface of the solid metal A strip blank is coated with the metal B liquid, meanwhile, the vibration side casting roller is driven by a vibration system to vibrate, and solid-liquid cast rolling composite forming of a double metal composite plate is completed under the vibration condition. According to the double metal composite plate strip solid-liquid vibration cast rolling device and method, the vibration side casting roller is driven by the vibration system to vibrate, solid-liquid cast rolling composite forming of the double metal composite plate is completed under the vibration condition, vibration is beneficial to refining the metal melt solidification structure, dual-direction shear force can be applied to the composite interface, interface physical metallurgy bonding is promoted, and the interface bonding strength of the double metal composite plate is improved.

Owner:YANSHAN UNIV

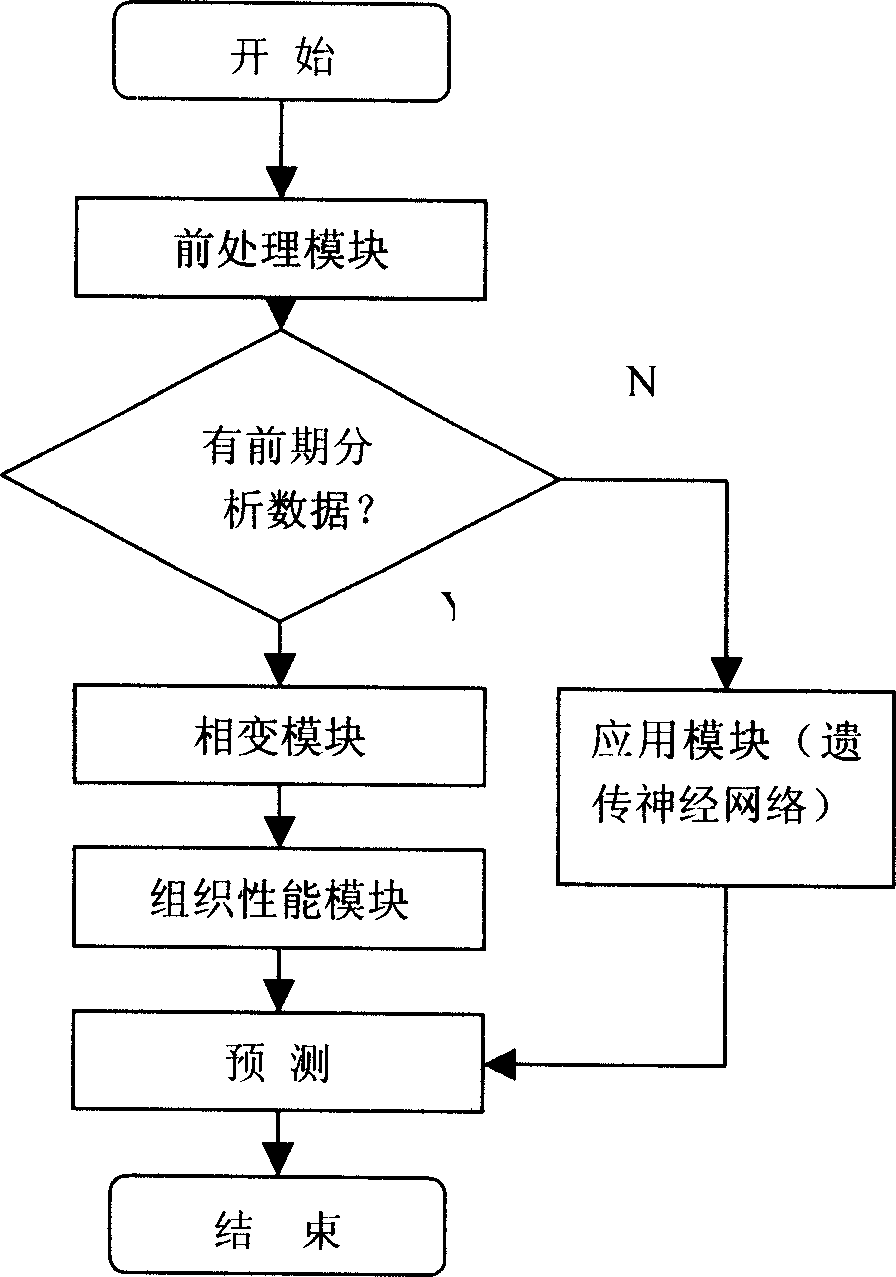

Constituent control method used in thermal simulation experiment of steel

InactiveCN1766594AConsumes a lot of resourcesGuaranteed flexibilitySpecial data processing applicationsInvestigating phase/state changeNetwork connectionNetwork model

The invention relates to an iron thermal analog test material quantity control method in the field of iron researching technology. It adopts tetrahedral prototype based on element, art, organization and capability and adopts modular structure idea to establish intelligent system which has the following modules: a front handling module, a phase-changing module, an organization capacity module and an applied nodule, wherein the front handling module reads the test parameter from database needed by thermal analog test course to provide an initial condition for the subsequent course; the phase-changing module and the organization capacity module is the dynamic analog of each physical metallurgy module of the thermal analog art; the applied module looks for the best value between the network connecting authority and the network structure by establishing the neurotransmission network module to forecast the organization and the capacity of the thermal analog test.

Owner:JIANGSU UNIV

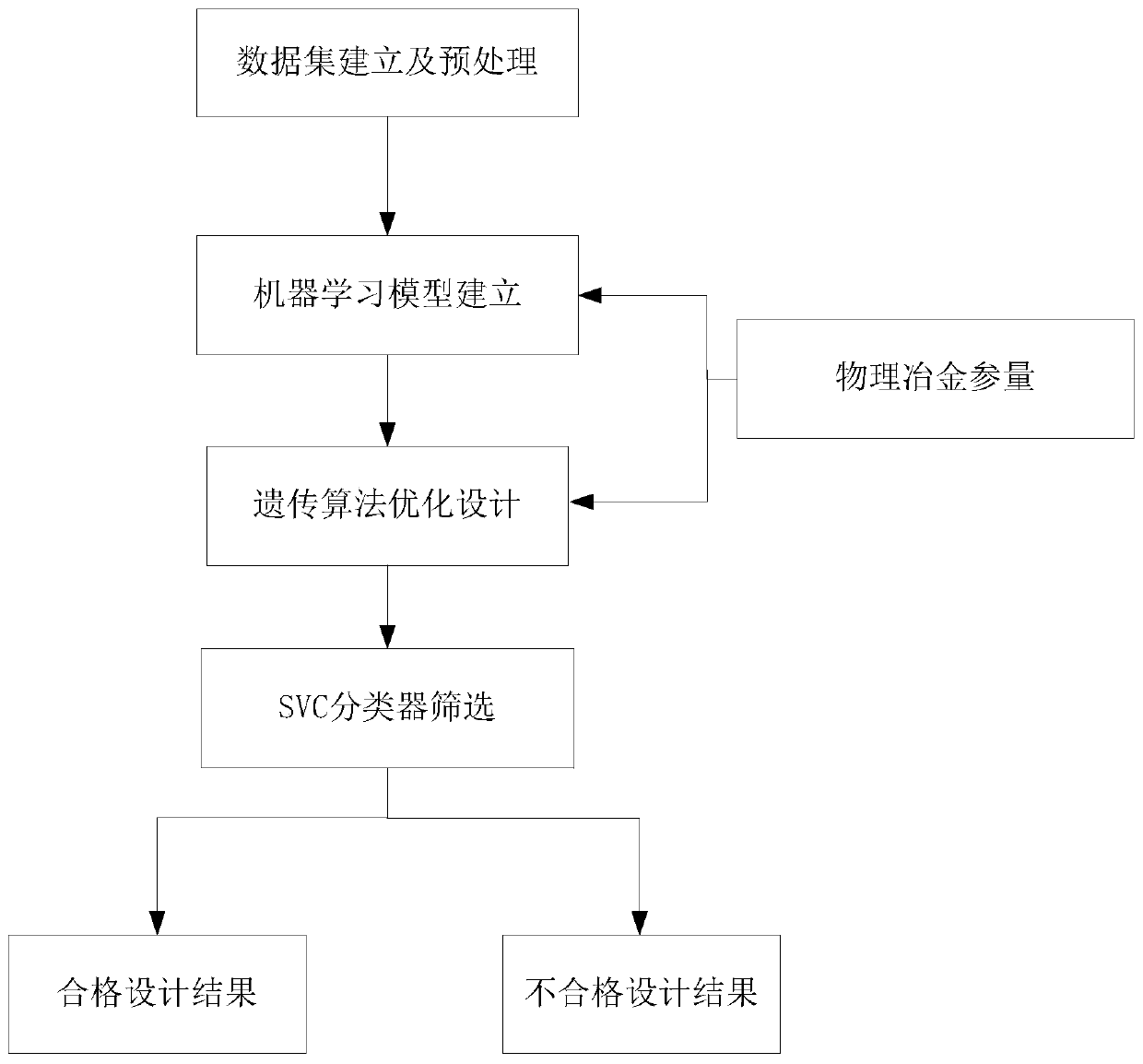

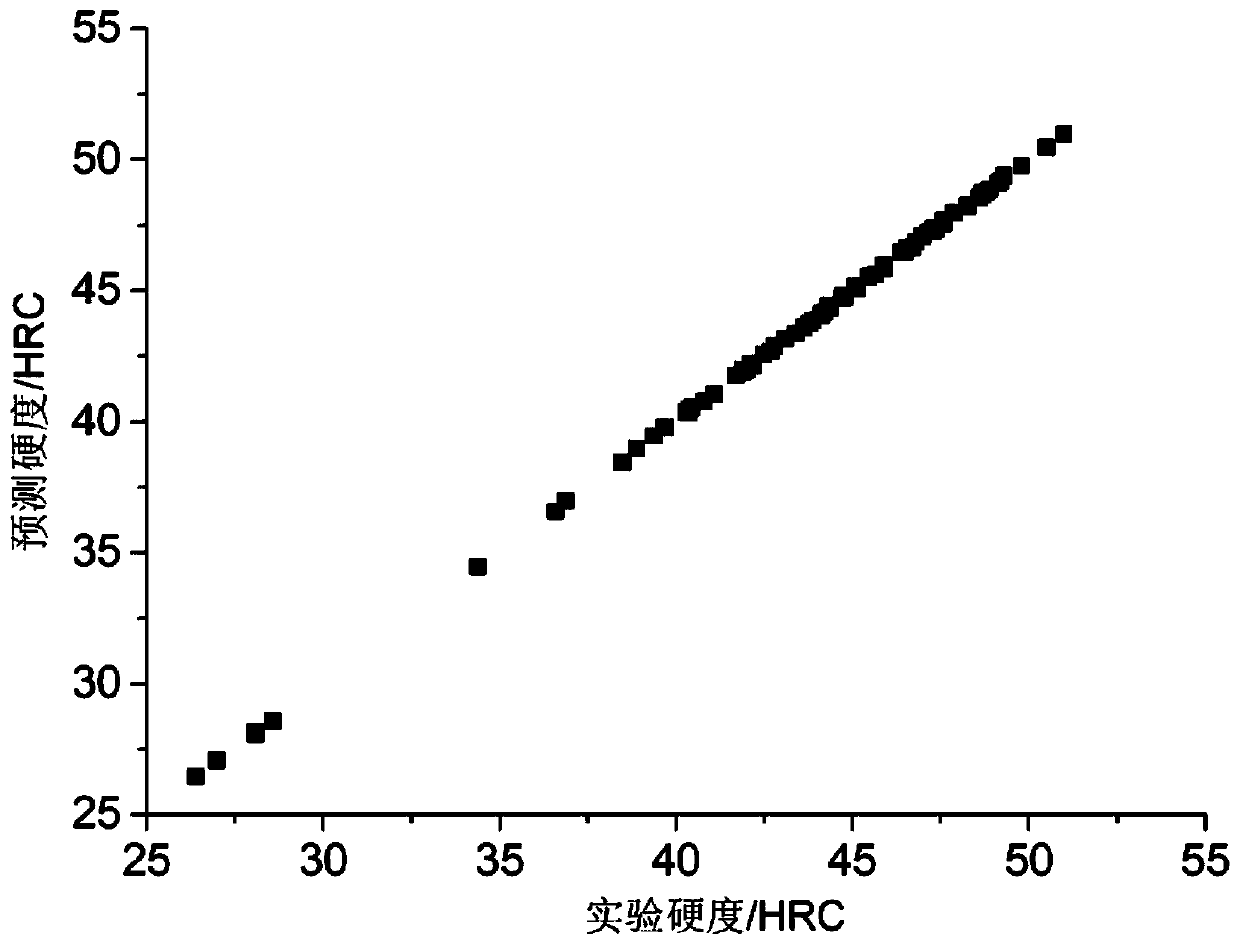

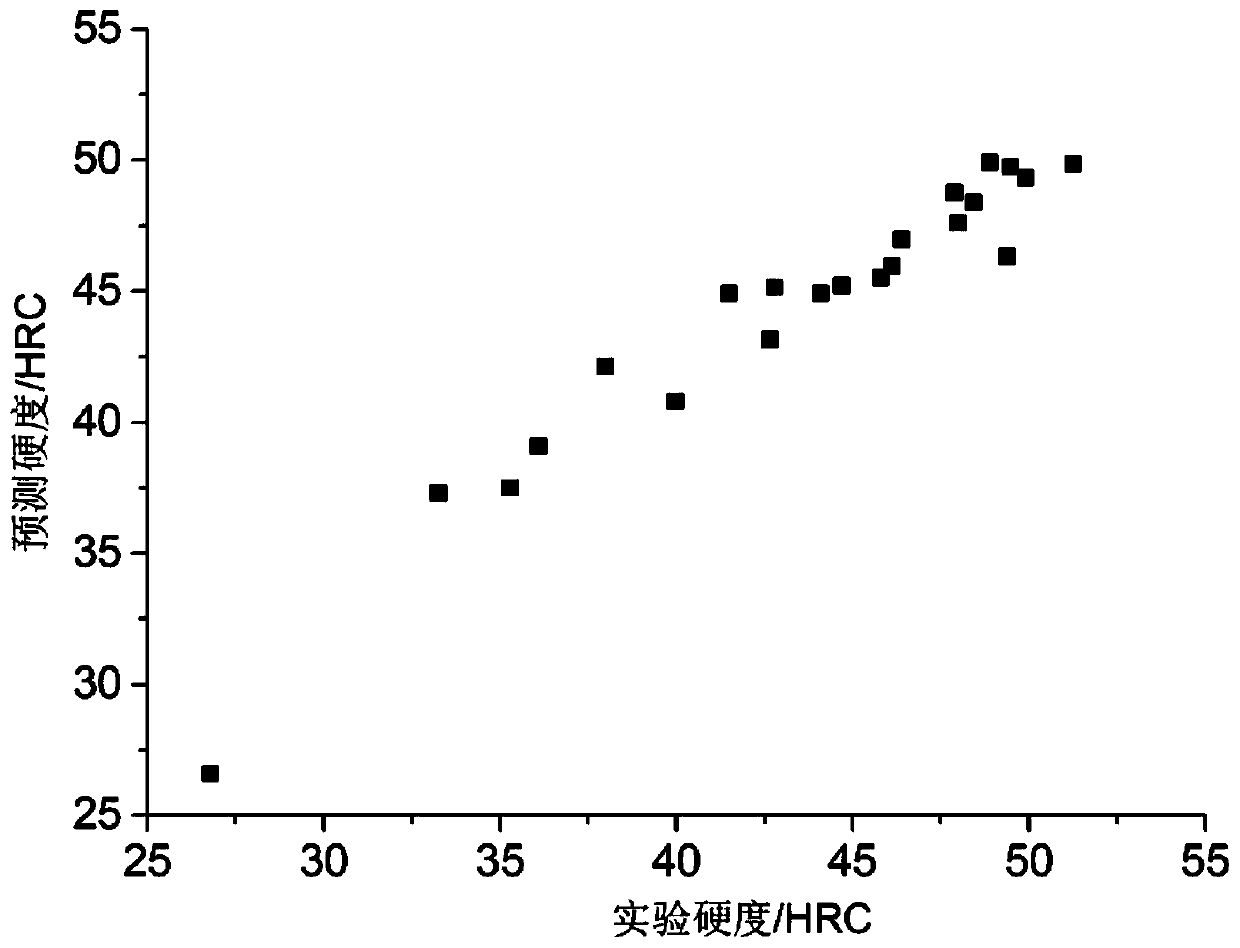

Steel material design method based on physical-guided machine learning algorithm

ActiveCN110428876AImprove generalization abilityEfficient designKernel methodsComputational materials scienceCorrelation coefficientSupport vector machine

The invention provides a steel material design method based on a physics-guided machine learning algorithm, and relates to the technical field of steel material design and machine learning application. The method comprises the steps that at first, data is collected, and divided into a training set and a testing set by adopting a multiple hold-out method; a support vector machine model based on physical metallurgy guidance is established according to the training set; the correlation coefficient, greater than 90%, of the support vector machine model based on physical metallurgy guidance servesas an objective function in a genetic algorithm; optimized composition, process and materials with the best target performance are obtained; a large number of obtained design results are classified and screened through an SVC classifier, and the typical alloy composition, process and target performance are output. Accordingly, a physical metallurgy mechanism is introduced into machine learning, and meanwhile a complete design platform is formed by combining an optimization algorithm, and the design results better conform to the principles of physical metallurgy.

Owner:NORTHEASTERN UNIV +1

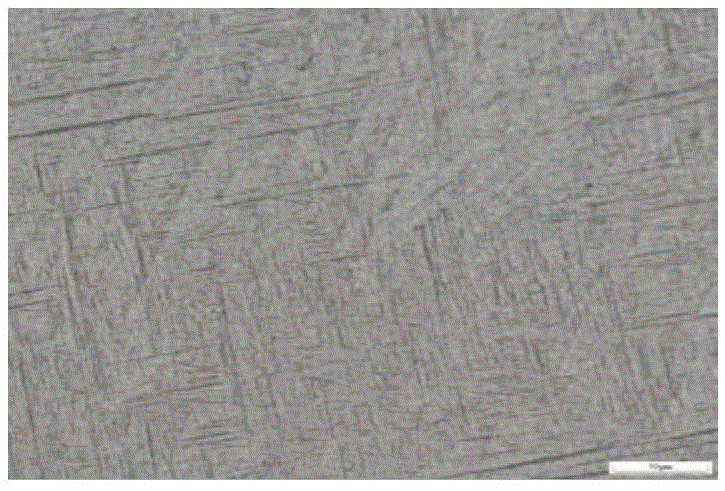

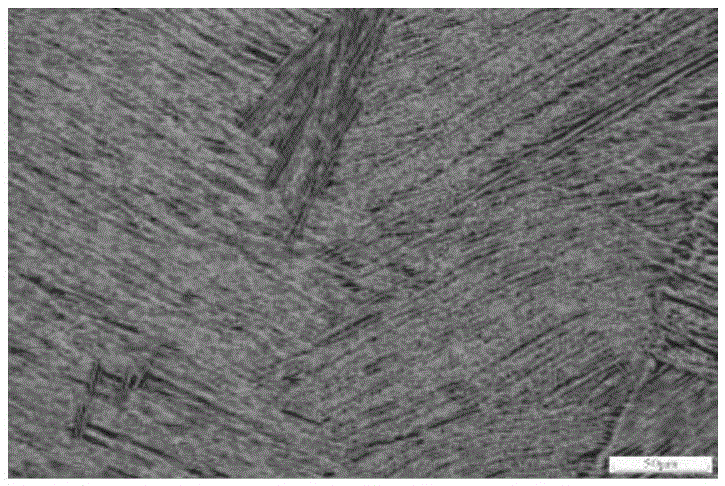

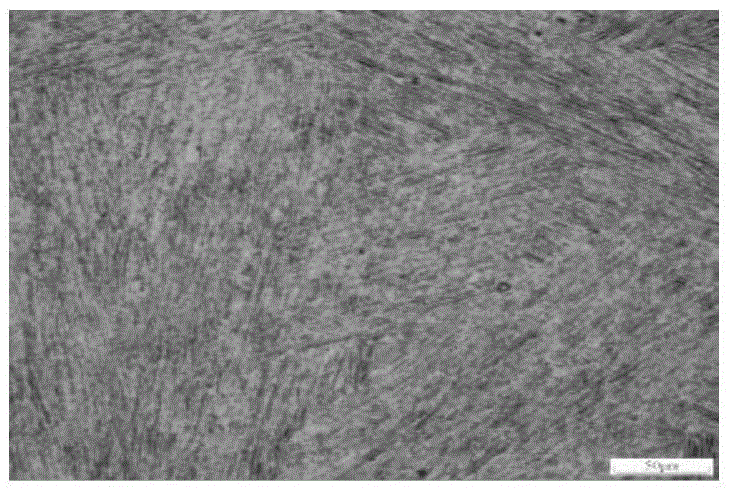

Making and application methods for atlas of microstructure of titanium alloy

InactiveCN105548182AJudging the safety of usePreparing sample for investigationMaterial analysis by optical meansPhysical metallurgyTitanium alloy

The invention specifically relates to making and application methods for the atlas of the microstructure of a titanium alloy, belonging to the technical field of physical metallurgical detection. The making method comprises the following steps: subjecting to-be-detected castings in a casting state and in a hot isostatic pressing state to mechanical property testing; then preparing metallographic samples, carrying out grinding and polishing on the metallographic samples, then observing the metallographic samples with an optical microscope under the condition of magnified times, selecting representative fields of view and shooting the atlas of the microstructure; and classifying pictures of the microstructure according to the characteristics of the microstructure and mechanical testing data and selecting a picture perfectly representing the characteristics of the microstructure as a standard microstructure rating atlas under the condition of the specific characteristics. The applying method comprises the following steps: sampling to-be-detected castings and carrying out mechanical property testing; making statistics of correspondence between microstructure and mechanical testing data; observing the obtained sample with the optical microscope under the condition of magnified times and shooting pictures of the microstructure; and determining whether the casting in the casting state or in the hot isostatic pressing state is qualified according to the standard microporosity atlas. The applying method can effectively rate and evaluate the microstructure of a titanium alloy casting having undergone mechanical property testing.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com