Patents

Literature

48 results about "Segregation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The effects of racial segregation were that children are indoctrinated into the belief that all people are equal, but some are more equal than others. This leads to people who are willing to sell themselves into slavery in the name of freedom.

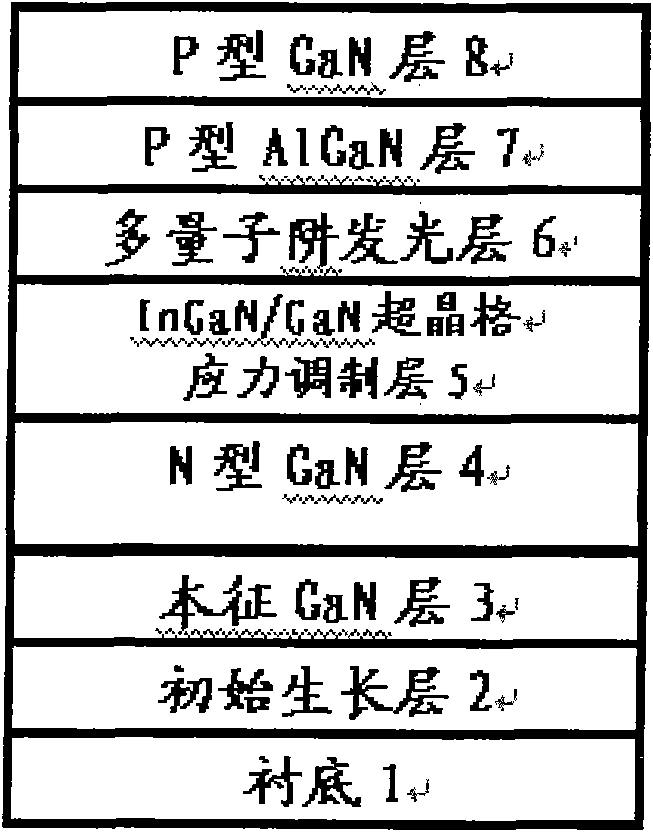

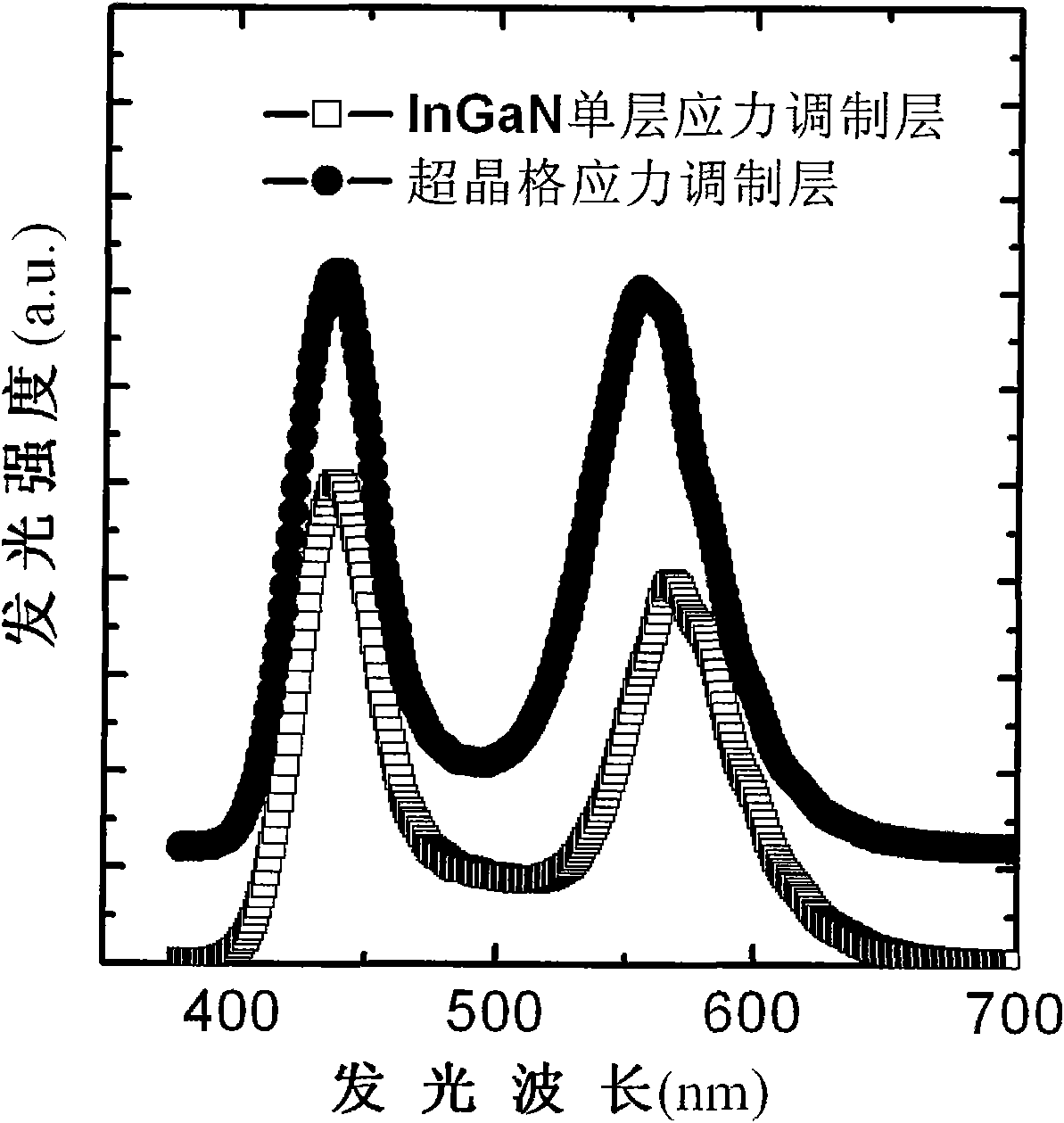

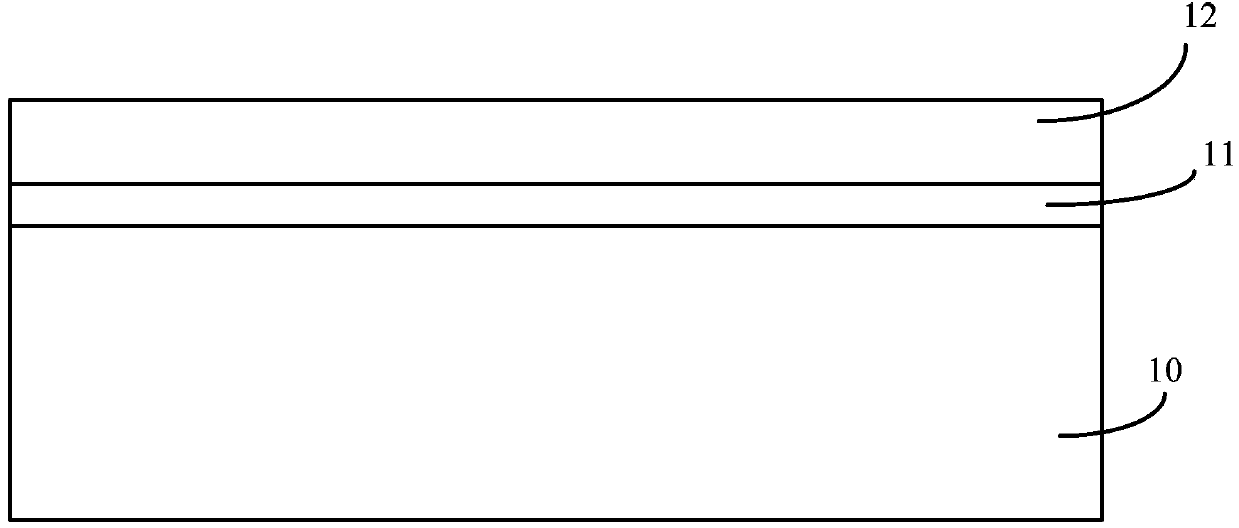

GaN-based Single chip white light emitting diode epitaxial material

InactiveCN101685844AReduce dislocationImprove luminous efficiencySemiconductor devicesStress relaxationWavelength

The invention relates to GaN-based Single chip white light emitting diode epitaxial material comprising a substrate and also comprising an initial growth layer, an intrinsic GaN buffer layer, an n-type GaN layer, a stress relaxation layer, an InGaN multiple quantum well structure light emitting layer, a p-type AlGaN sandwich layer and a p-type GaN layer which grow in sequence on the substrate. Thestress relaxation layer is an InGaN / GaN superlattice stress modulation layer which comprises InGaN layers and GaN layers, which are grown alternatively; the InGaN layers and GaN layers have the growth cycle of 6-500 and the corresponding thickness of 10 nm to 3 Mum; and the In components in the InGaN layers are in the range of 1-35 percent. Because the stress-relaxed InGaN / GaN superlattice stressmodulation layer is added between the n-type GaN layer and a multiple quantum light emitting layer, the In segregation effect is strengthened, InGaN quantum dots with different components are formed,and the mixing of different-wave light emitted by the InGaN quantum dots realizes the white light emitting. The cost of the white light emitting diode is reduced radically, the light emitting efficiency and the light using efficiency are increased and the integral performance of the white light emitting diode is improved.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

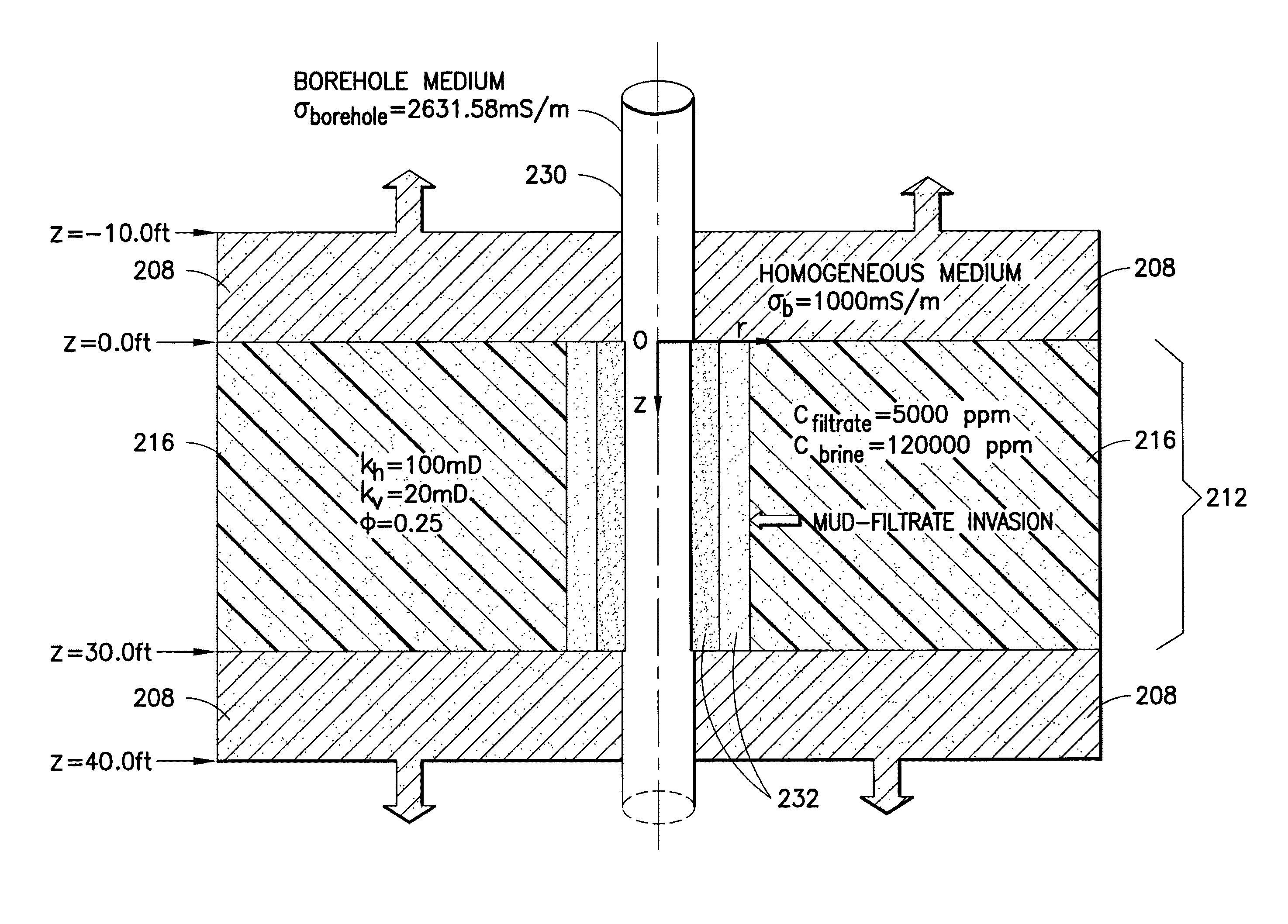

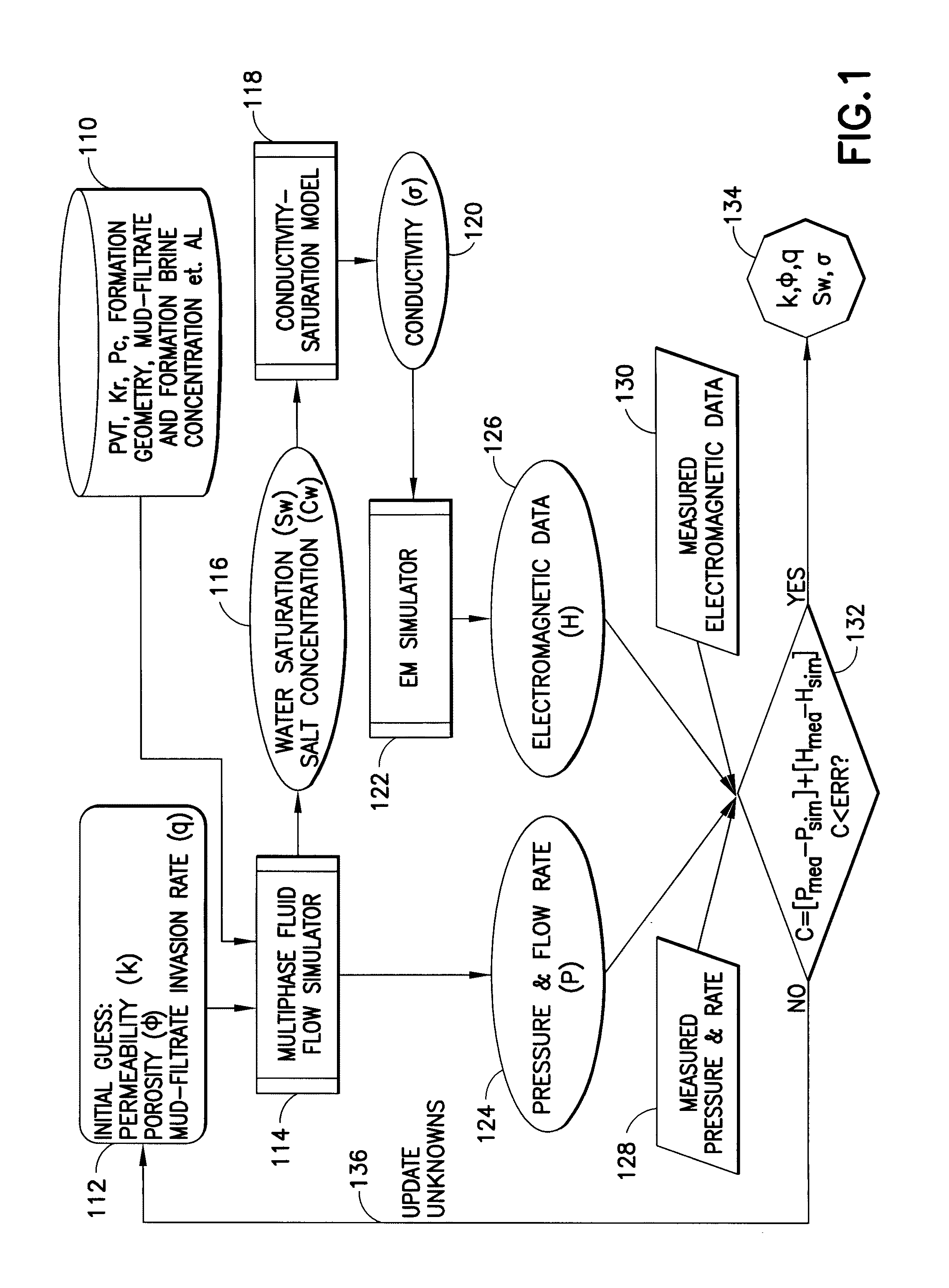

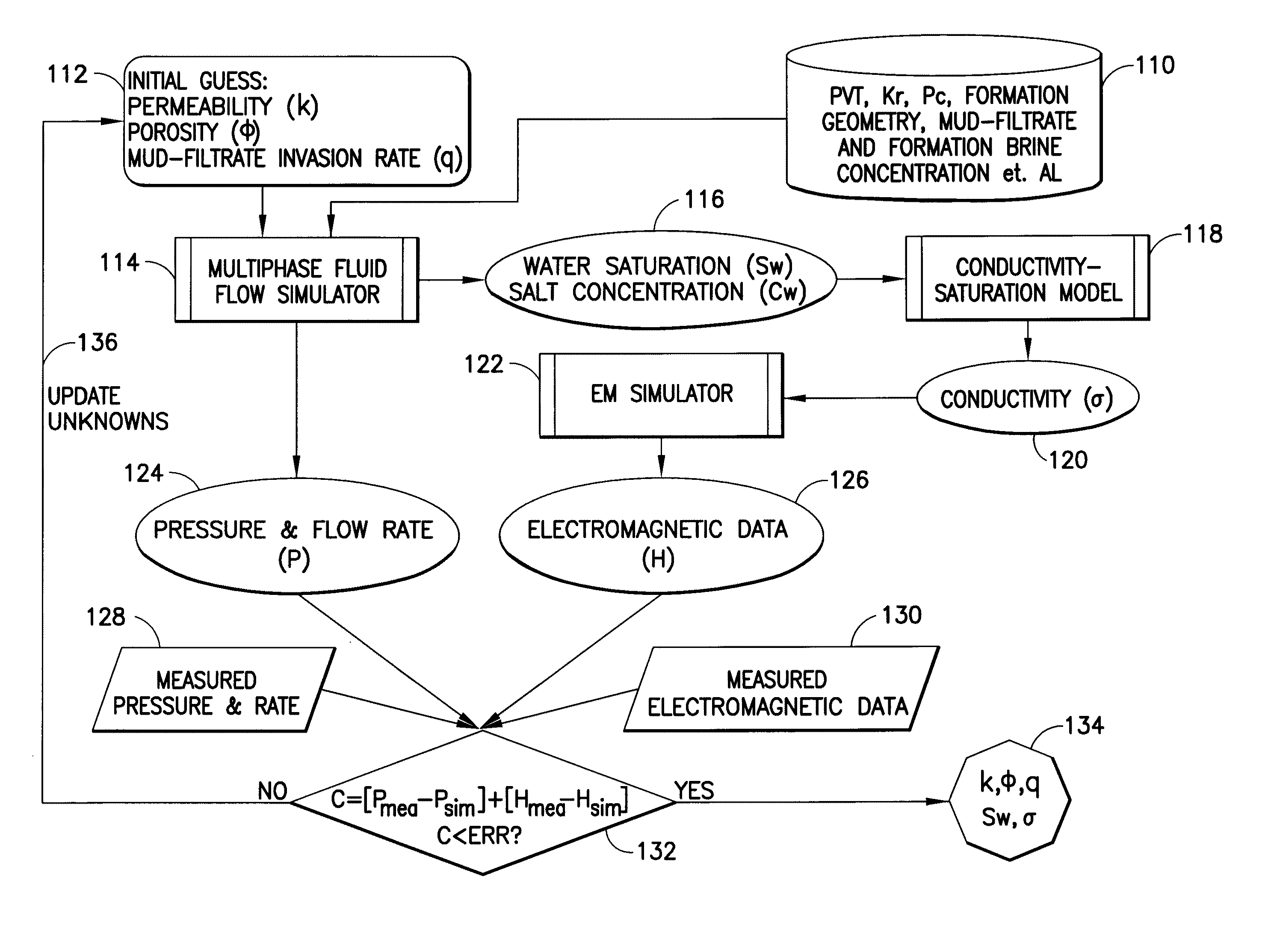

Estimating petrophysical parameters and invasion profile using joint induction and pressure data inversion approach

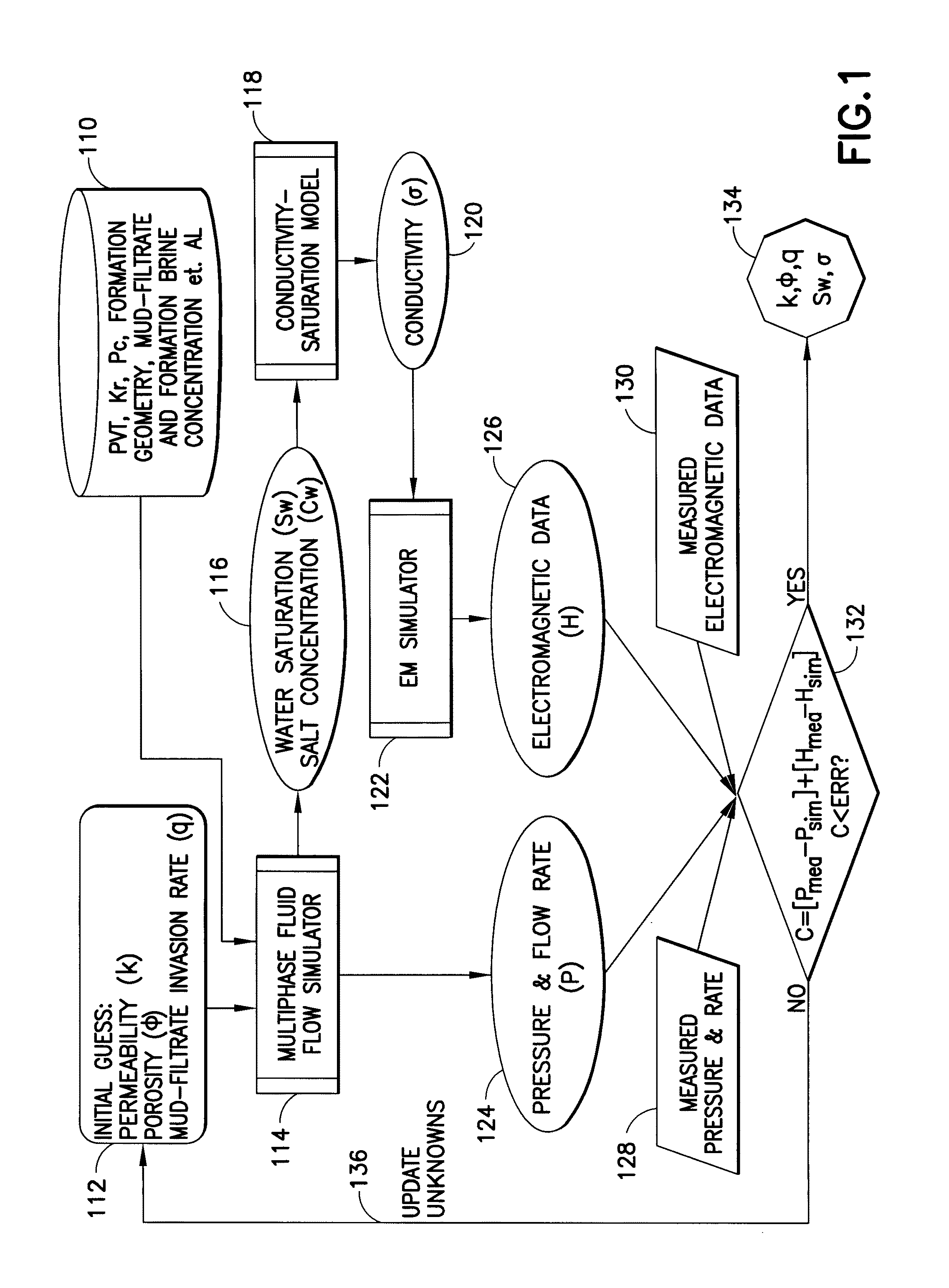

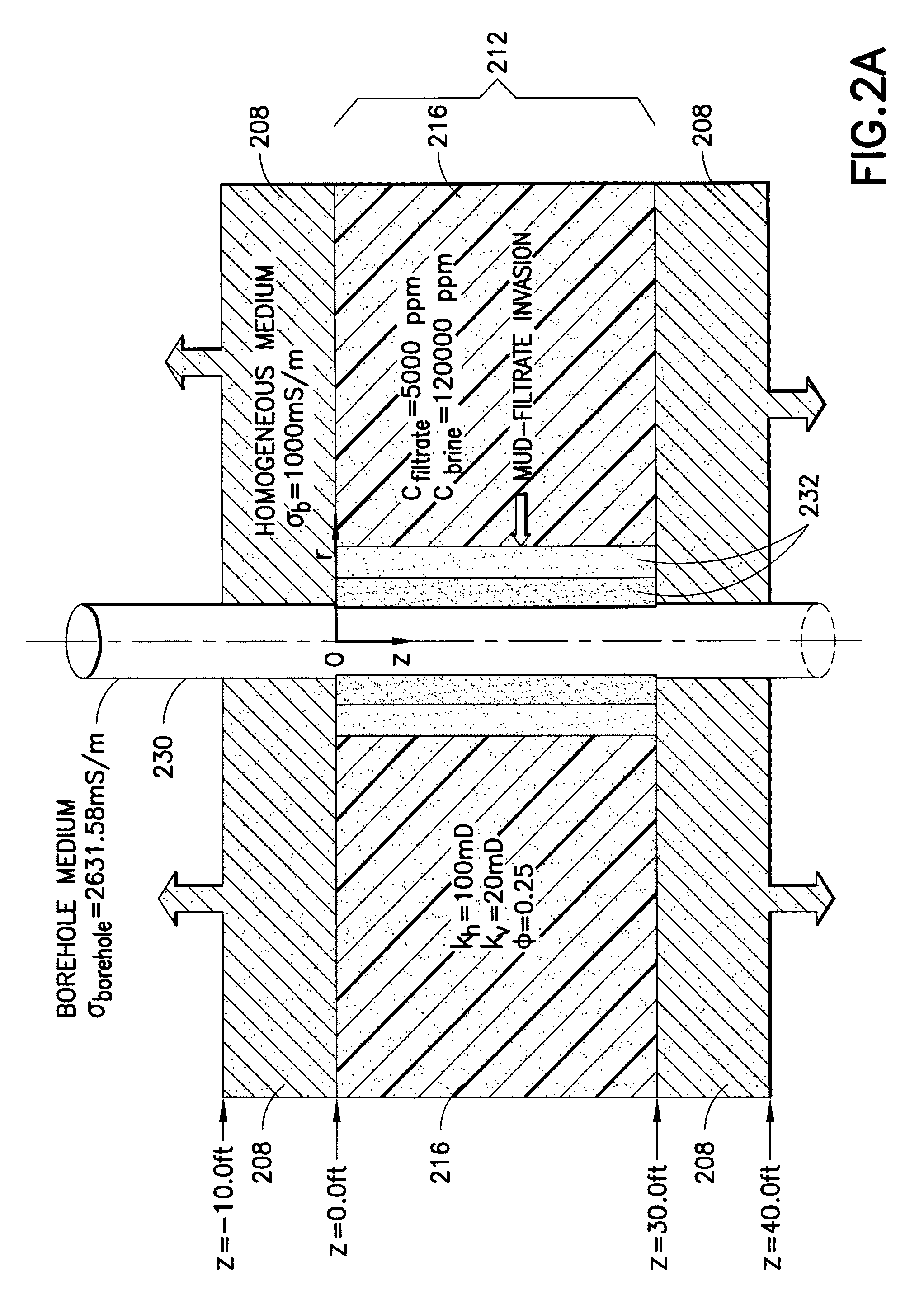

ActiveUS20100185393A1Electric/magnetic detection for well-loggingSurveyRate of penetrationSegregation effect

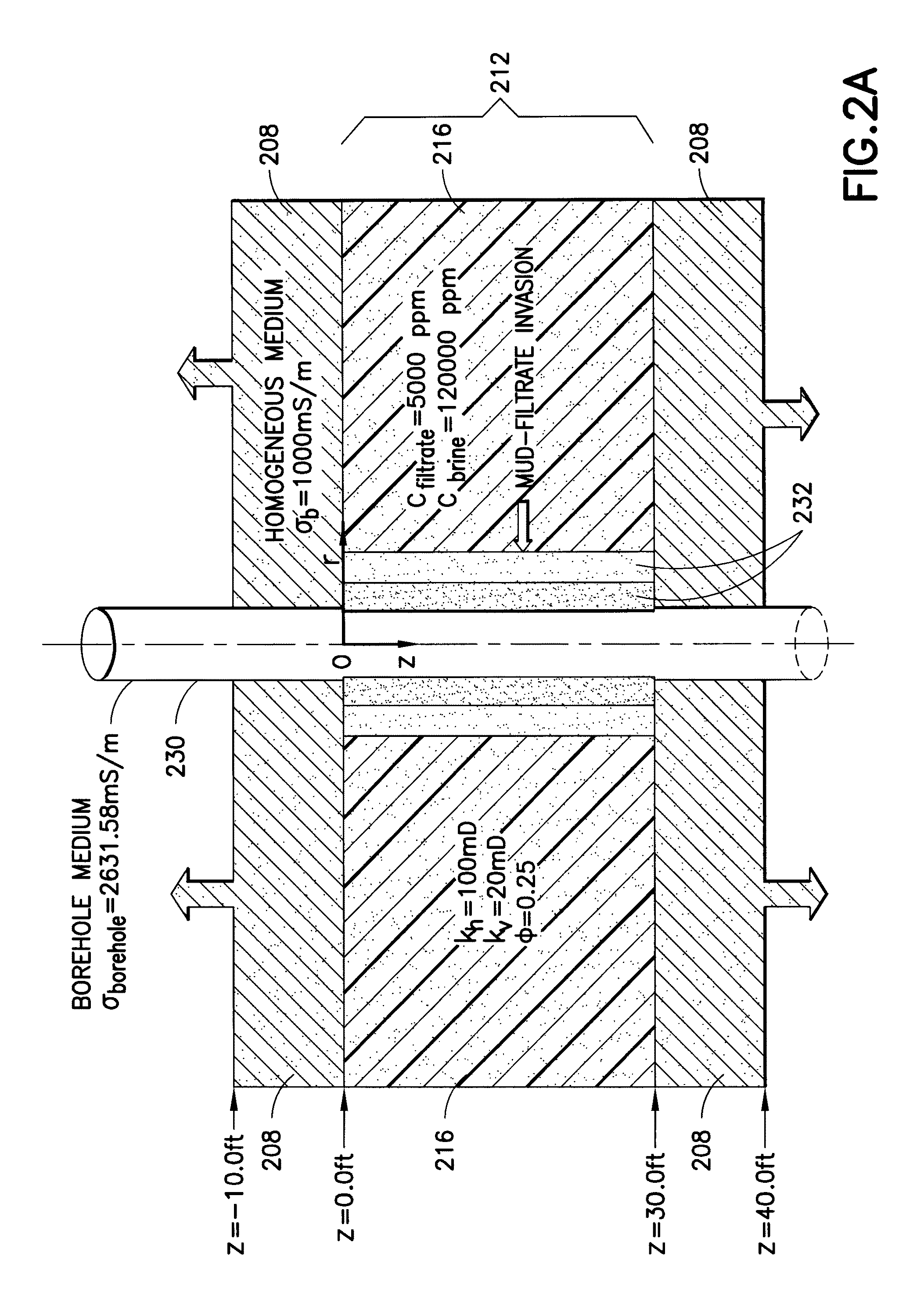

Methods and related systems are described relating to an inversion approach for interpreting the geophysical electromagnetic data. The inversion can be constrained by using a multiphase fluid flow simulator (incorporating pressure data if available) which simulates the fluid flow process and calculates the spatial distribution of the water saturation and the salt concentration, which are in turn transformed into the formation conductivity using a resistivity-saturation formula. In this way, the inverted invasion profile is consistent with the fluid flow physics and moreover accounts for gravity segregation effects. Jointly with the pressure data, the inversion estimates a parametric one-dimensional distribution of permeability and porosity. The fluid flow volume is directly inverted from the fluid-flow-constrained inversion of the electromagnetic data. The approach is not limited by the traditional interpretation of the formation test, which is based on a single-phase model without taking into account invasion or assuming that the fluid, for example mud-filtrate, has been cleaned up from the formation testing zone. The joint inversion of the electromagnetic and pressure data provides for a more reliable interpretation of formation permeability. One advantage of the approaches described herein, is its possible generalization to three-dimensional geometries, for example dipping beds and highly deviated wells.

Owner:SCHLUMBERGER TECH CORP

Preparing method for high-activity and high-stability composite catalyst for fuel cells

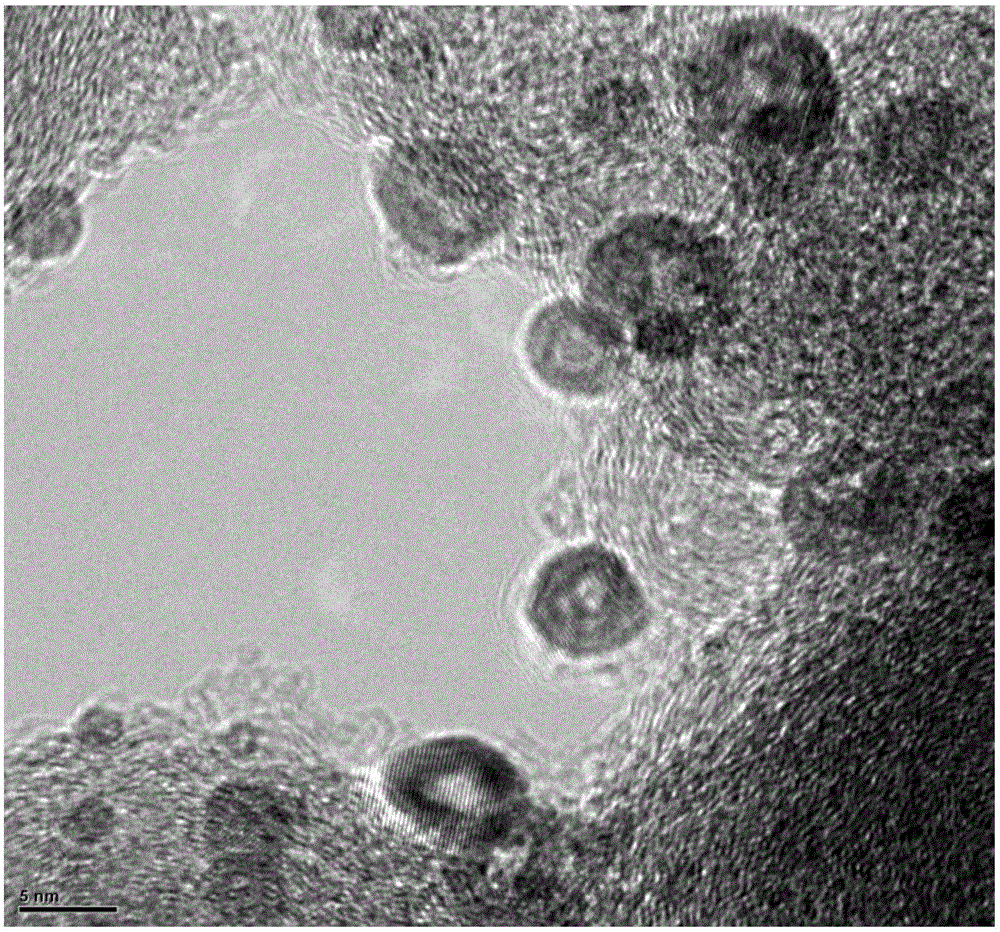

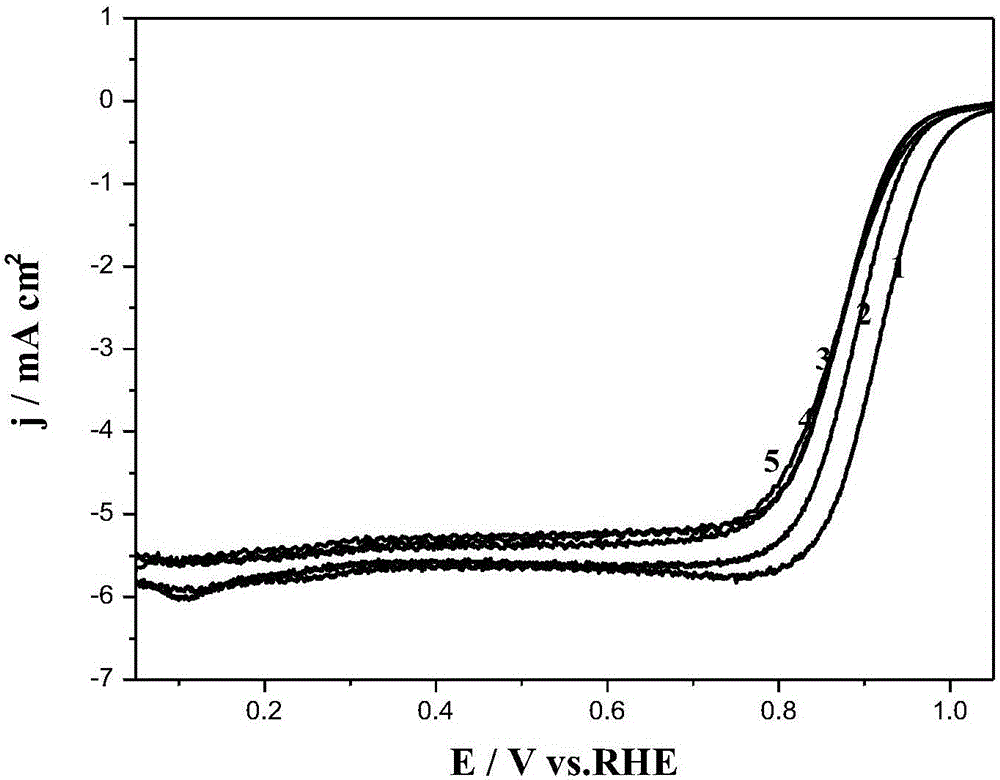

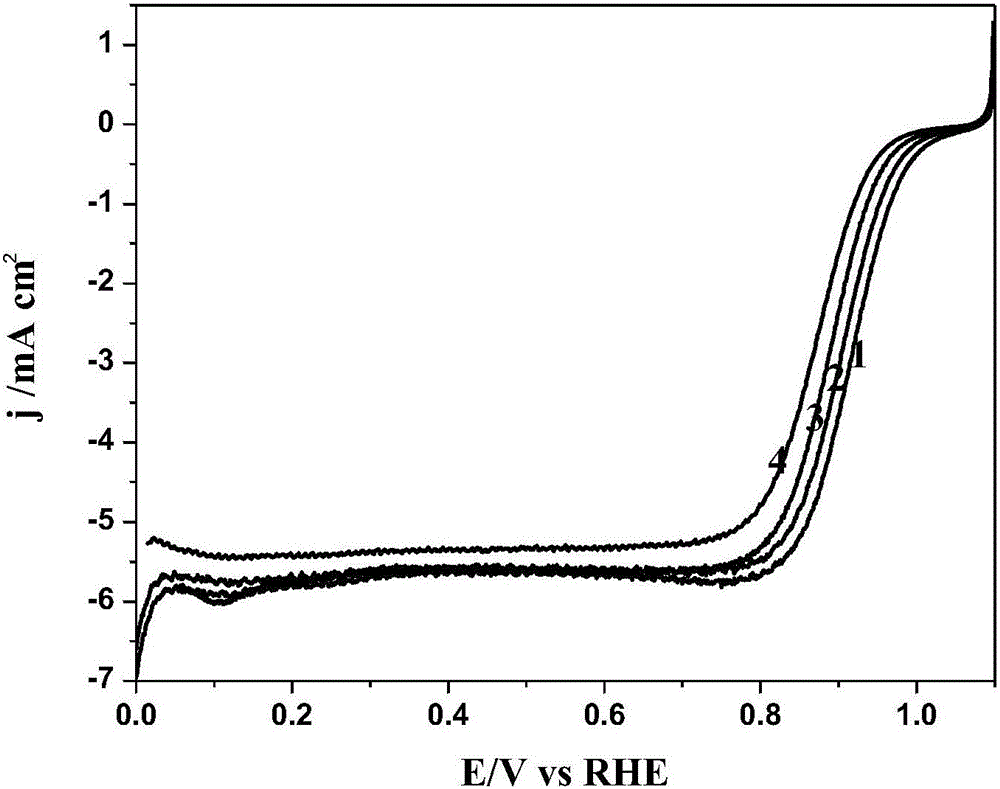

ActiveCN105107541AIncrease profitReduce dosagePhysical/chemical process catalystsCell electrodesHigh activitySilicon dioxide

The invention provides a preparing method for a high-activity and high-stability composite catalyst for fuel cells and belongs to the technical field of fuel cells. The preparing method includes the steps that firstly, the surface of a Pt / C catalyst is wrapped by a layer of dopamine, and the dopamine is used for adsorbing a metal precursor through the good adsorbing performance on metal cations; secondly, silicon dioxide is used for packaging a polymer, the pyrolysis losses and heat treatment morphology conversion of a polymer precursor are controlled through morphology fixing and range limiting functions of the silicon dioxide, alloy nano particles and an N-doped carbon modified layer are further synthesized through high-temperature pyrolysis under the surface segregation effect of platinum and transition metal, and the low-platinum-nonmetal composite structure catalyst with the hollow alloy nano particles wrapped by N-doped carbon is constructed. According to the preparing method for the high-activity and high-stability composite catalyst for the fuel cells, migration agglomerating and growing in the sintering process of the catalyst are overcome, the size of the particles is effectively controlled, the catalyst has high high-activity surface area, operation is simple, industrial production is easy, and the catalyst can be widely applied to the fuel cells with proton exchange membranes serving as electrolytes.

Owner:重庆铈坦新材料技术研究院有限公司

Method and device for coupling and purifying polysilicon and removing phosphorus and metal with electron beams

InactiveCN102120578AEvenly distributedReduce distributionChemical industrySilicon compoundsMelting tankMetal impurities

The invention belongs to the technical field of polysilicon purification with a physical metallurgy technology and particularly relates to a method for coupling and purifying polysilicon and removing phosphorus and metal with electron beams. The method comprises the following steps of: forming a stable melting pool on the top of a low-phosphorous low-metal high-purity silicon ingot with the electron beams; putting silicon powder to be purified into the melting pool and melting to realize the rapid melting of the powder body to remove volatile phosphorous impurity in the silicon powder; simultaneously carrying out directional ingot pulling so that the low-phosphorus polysilicon grows in a directional solidification way; and removing metal impurities in the polysilicon by utilizing a segregation effect. The invention has the remarkable effects that: because ways of melting silicon powder with the electron beams and carrying out directional solidification are simultaneously adopted, the phosphorus impurity is rapidly removed with the electron beams, and the metal impurities with lower segregation coefficient are removed by the directional solidification way, the purity of the polysilicon is effectively improved, and the using requirement of solar grade silicon is achieved. The invention has the advantages of good purification effect, stable technology, simple process, high production efficiency, energy saving, low cost and suitability for batch production.

Owner:谭毅

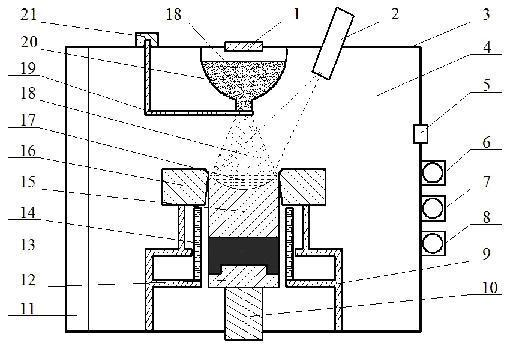

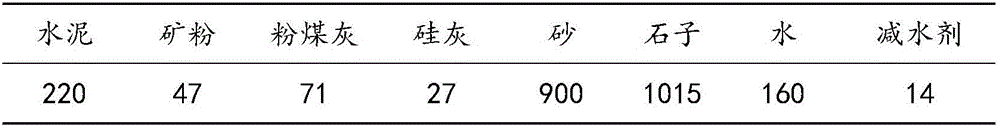

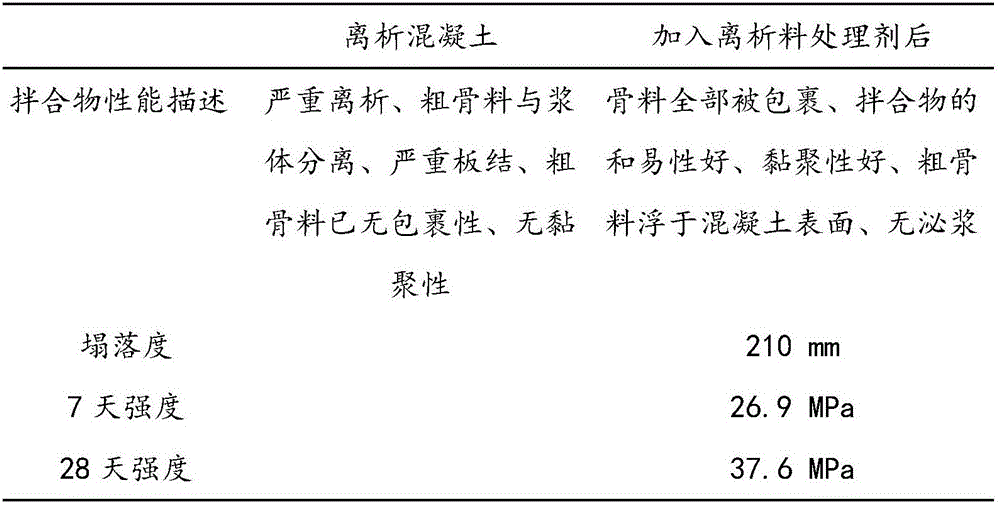

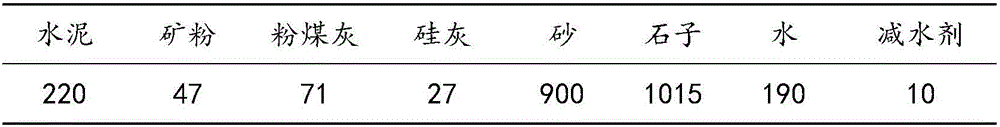

Concrete water-retention anti-segregation agent and preparation method thereof

ActiveCN105669911ASolve the problem of bleeding and separationImprove workabilityBiological materialsSegregation effect

The invention discloses a concrete water-retention anti-segregation agent and its preparation method. The concrete water-retention anti-segregation agent is prepared from, by weight, 100 parts of a propenyl monomer, 104.8-300 parts of TPEG, 3.8-12.5 parts of an organosilicone monomer, 0.5-1.5 parts of a chain transfer agent, 2.9-4.3 parts of an oxidizing agent, 1-3 parts of a reducing agent, 1450-2457 parts of deionized water and liquid alkali for adjusting pH to 6-10. A water-retention anti-segregation agent is directly synthesized through a molecular structure design, thus greatly solving concrete bleeding and segregation problems, avoiding mildew and compatibility problems caused by a biomaterial and achieving water-retention anti-segregation effect. The technology is polymerization at normal temperature, is energy-saving and environmentally friendly, and is easy for large-scale promotion.

Owner:厦门路桥翔通建材科技有限公司

Method for adding additive agent in reducing roasting process of laterite nickle mine

The invention discloses a method for adding an additive in the reduction roasting process of terra rossa nickel ore. The terra rossa nickel ore is ground to -200 to -100 meshes and is 70 to 90 percent of the mass thereof. A chloride is added into the terra rossa nickel ore as a segregation agent; a sodium compound is added into the terra rossa nickel ore as a promoter; and reduced iron powder is taken as a nucleator and a calcium compound is taken as a sulphur-fixing agent. The adding dosage of the chloride is 0 to 10 percent of the mass of the terra rossa nickel ore; the adding dosage of the sodium compound is 1 to 10 percent of the mass of the terra rossa nickel ore; the adding dosage of the reduced iron powder is 0 to 3 percent of the mass of the terra rossa nickel ore; and the adding dosage of the calcium compound is 1 to 10 percent of the mass of the terra rossa nickel ore. The method is suitable for the reduction roasting process of the terra rossa nickel ore with the high nickel silicate content, can greatly reduce the dosage of calcium chloride, and so on, reduce the equipment corrosion and the environmental pollution caused by chlorine, remarkably improve the metallization degree and the segregation effect during the reduction roasting process of the terra rossa nickel ore, and consequently reach the aim of improving the recovery rate or grade of nickel.

Owner:CENT SOUTH UNIV

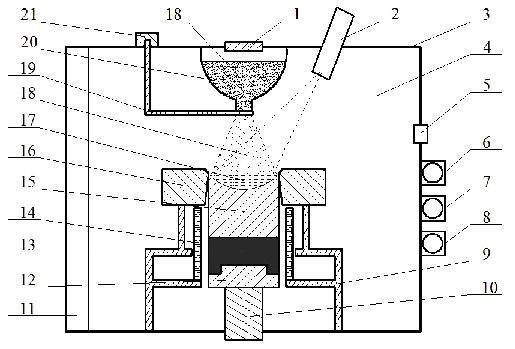

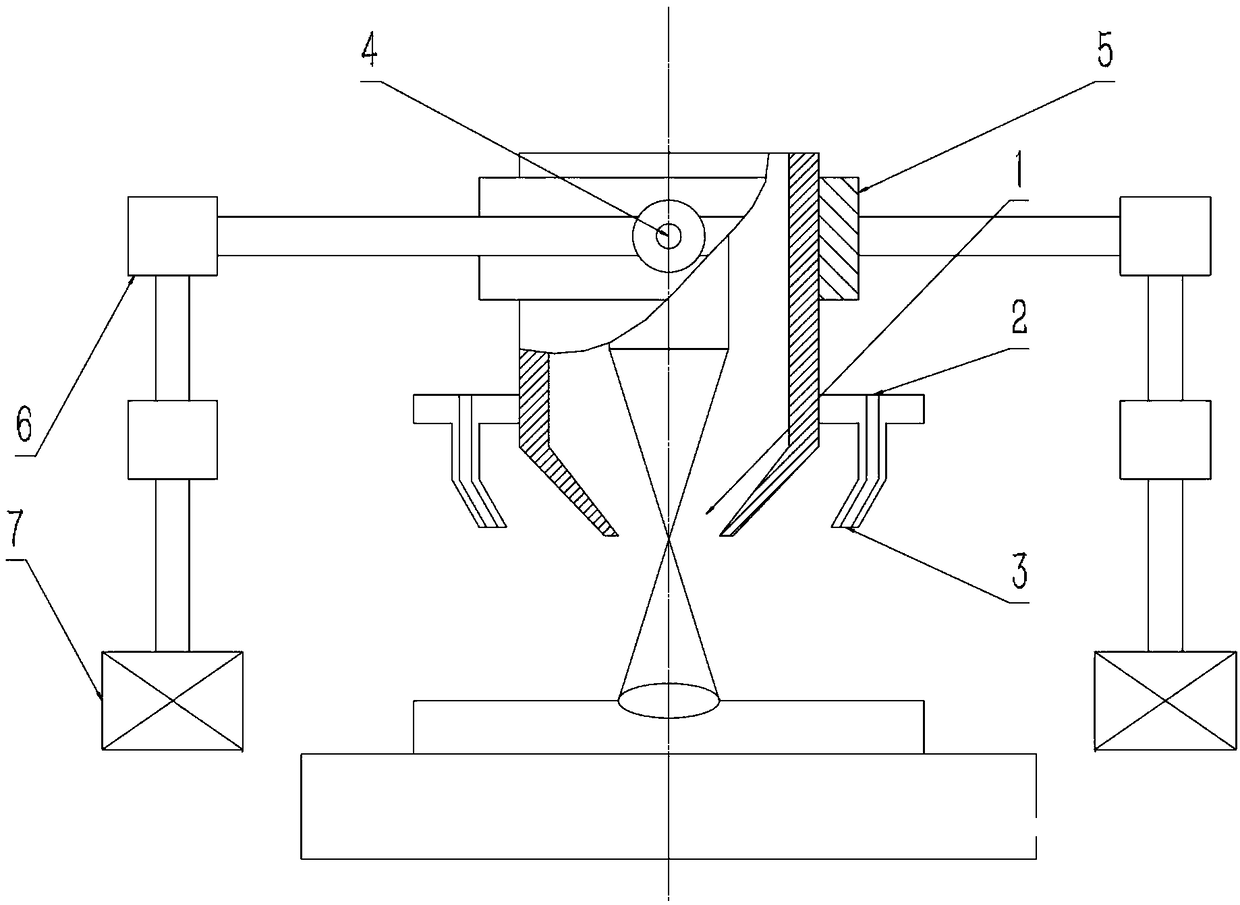

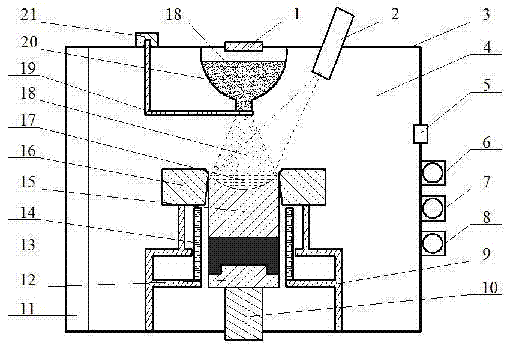

Additive manufacturing device capable of conducting magnetic field control and parent metal transport

ActiveCN108620585ARealize online controlEasy to useAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankLaser transmitter

The invention discloses an additive manufacturing device capable of conducting magnetic field control and parent metal transport. A magnetic field is applied in the metal laser solid forming quick solidification process, a thermoelectric current can be generated at the quickly solidified solid / liquid interface under the action of the magnetic field, the thermoelectric current and the magnetic field interact to generate thermoelectric magnetic force triggering melt flow, shearing is caused after the force effect is conducted on the end of dendritic crystal, thus, the dendritic crystal is broken, a lot of new crystal nucleuses are formed, and the nucleation rate is increased; and metal melt flow is inhibited by the magnetic field, and the segregation effect in the solidification process is relieved. According to the additive manufacturing device, different laser metal additive manufacturing parent metal transport devices are combined, and parent metal transport and structure control under the conditions of powder paving, powder feeding and wire feeding and other various printing conditions are achieved. The magnetic field control device is fixed to a laser transmitter to serve as a parent metal transport device, the effect that a laser molten pool is located at the center of the magnetic field all the time is ensured, control over the magnetic field is facilitated, and the influence of the magnetic field on the laser solid forming quick solidification process is further explored.

Owner:SHANGHAI UNIV

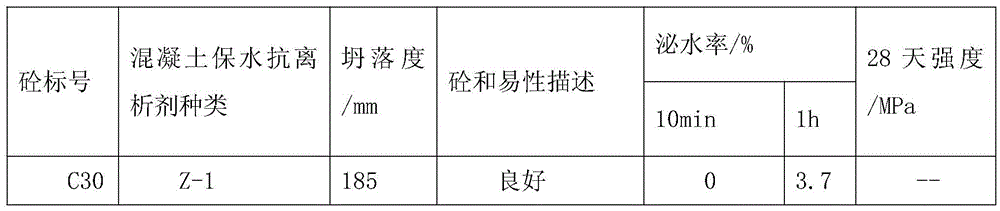

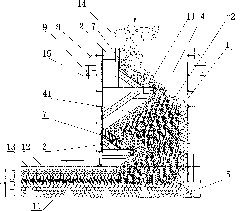

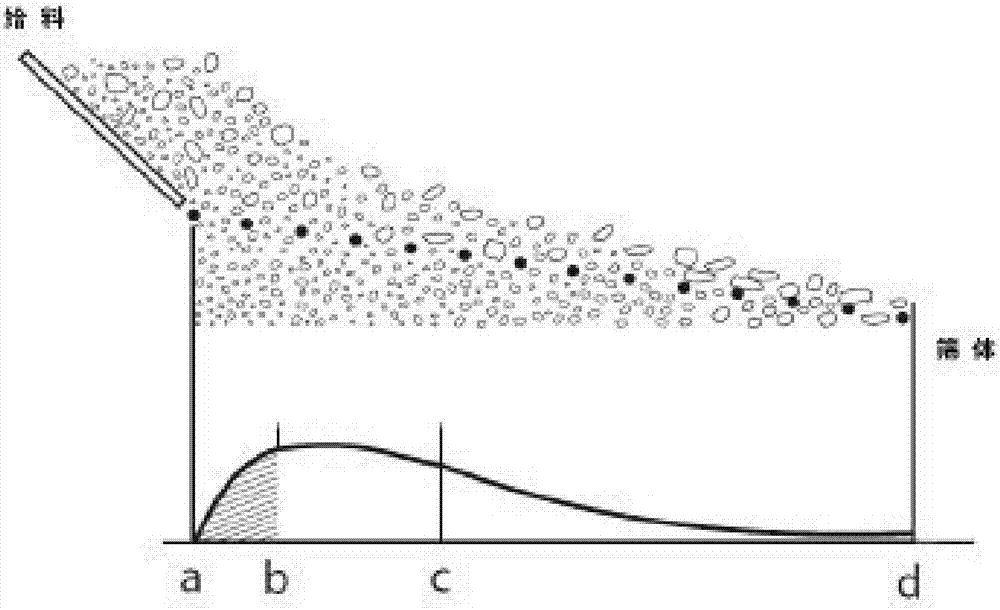

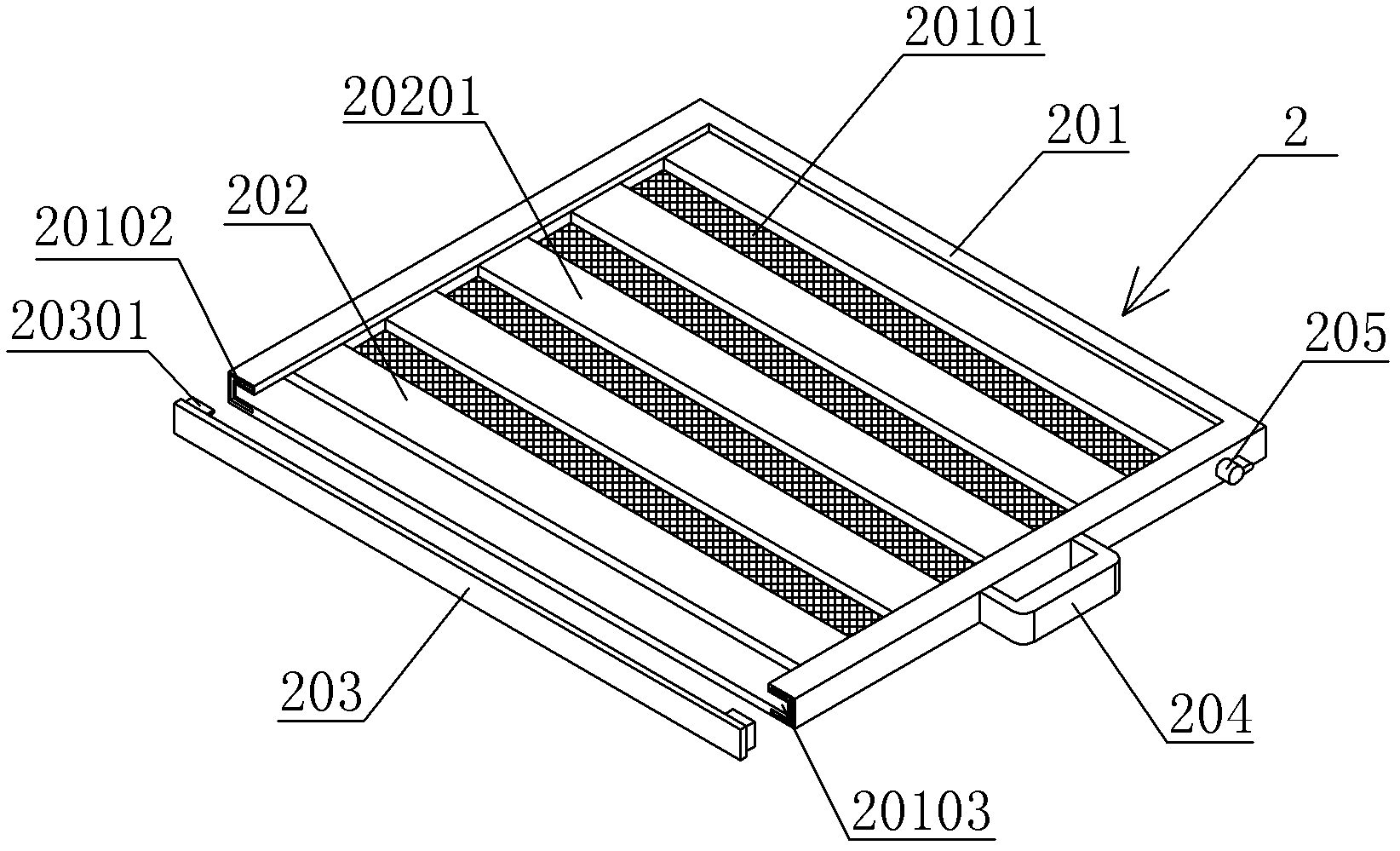

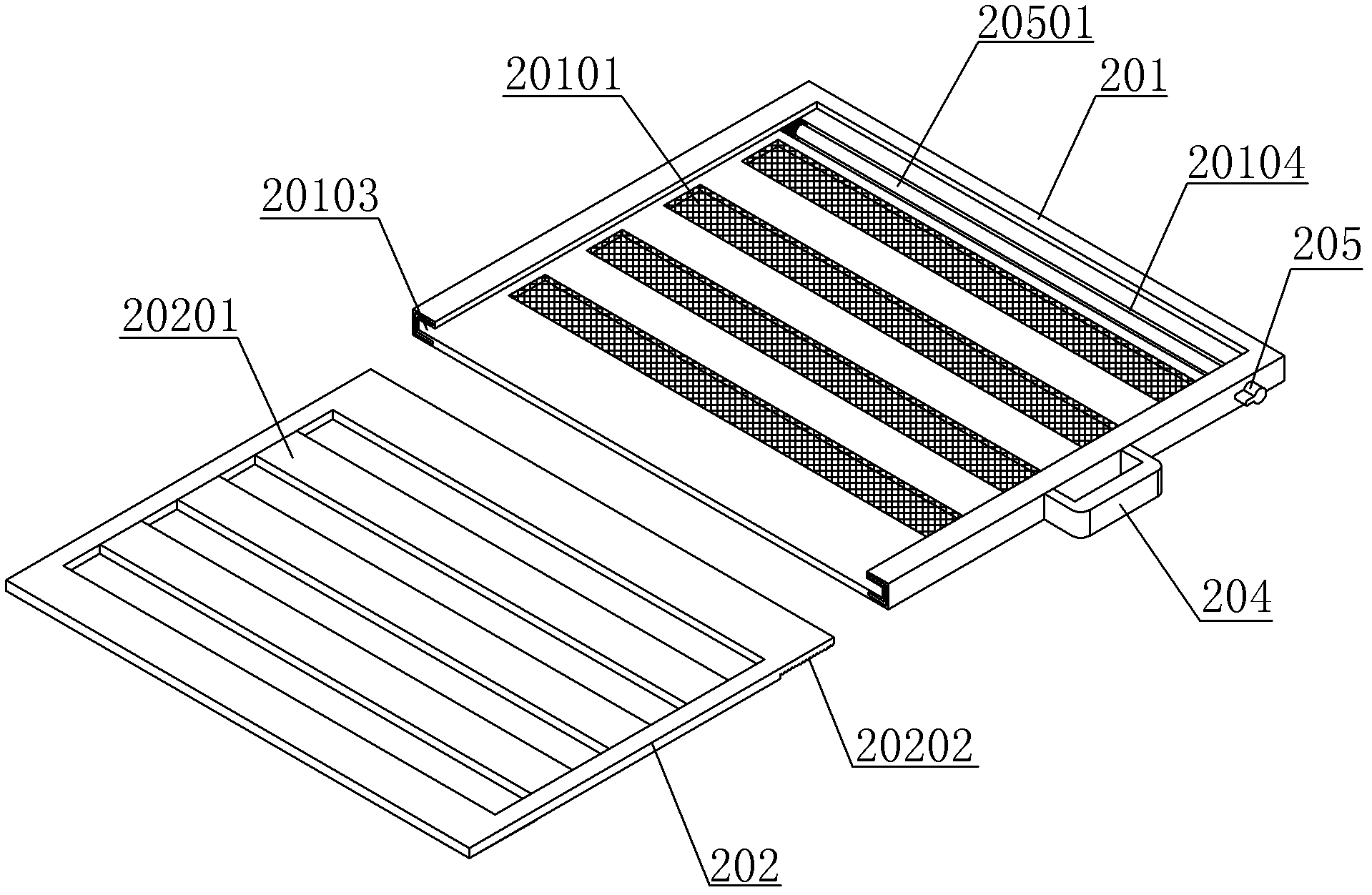

Material distributing method and device of circular cooler

ActiveCN101799243AImprove working environmentImprove work efficiencyCharge manipulationHandling discharged materialWorking environmentSlide plate

The invention discloses a material distributing method of a circular cooler, which is characterized by laying three layers of sinter ore on a trolley of the circular cooler and mainly laying large-grain sinter ore on the bottom layer, small-grain sinter ore on the middle layer and the intermediate-grain sinter ore on the top layer. The method has the advantages of good segregation effect, capability of improving the work environment of the circular cooler and prevention of the waste of the raw material. The invention further discloses a material distributing device of the circular cooler, which is used for the material distributing method of the circular cooler; the material distributing device of circular cooler comprises a material distributing cylinder which is internally provided with a lower slide plate for stacking the sinter ore in the material distributing cylinder; a segregation material distributing slide plate for delivering the sinter ore to the top of the material pile is arranged above the lower slide plate; a front inclined surface and a rear inclined surface are formed on the material pile by the lower slide plate and the segregation slide plate; and the rear inclined surface has the same inclination direction with the segregation slide plate. The device can lay the large-grain sinter ore on the bottom layer of the trolley of the circular cooler, the small-grain sinter ore on the middle layer of the trolley of the circular cooler and the intermediate-grain sinter ore on the top layer of the trolley of the circular cooler.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

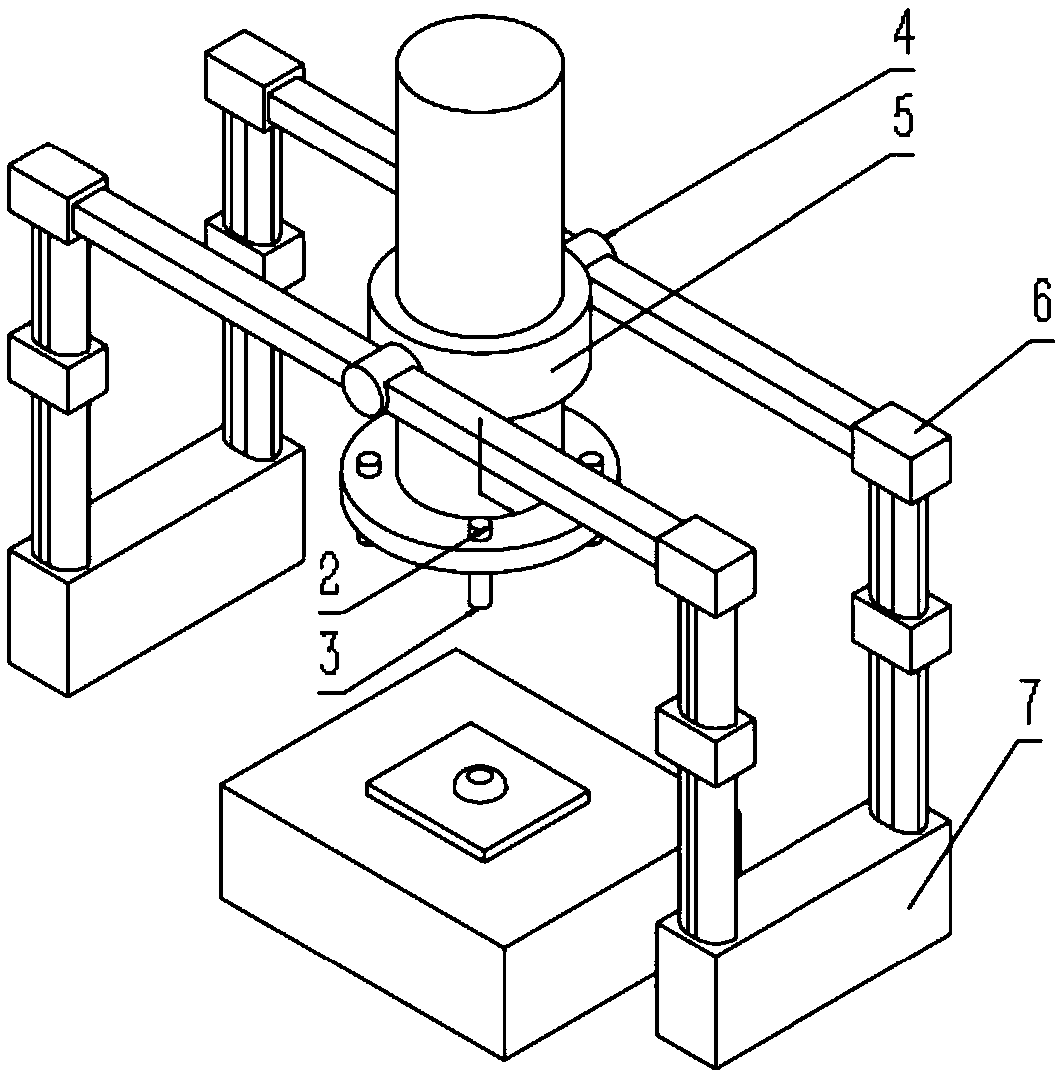

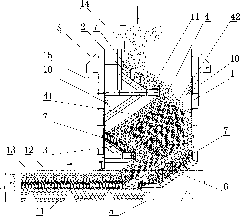

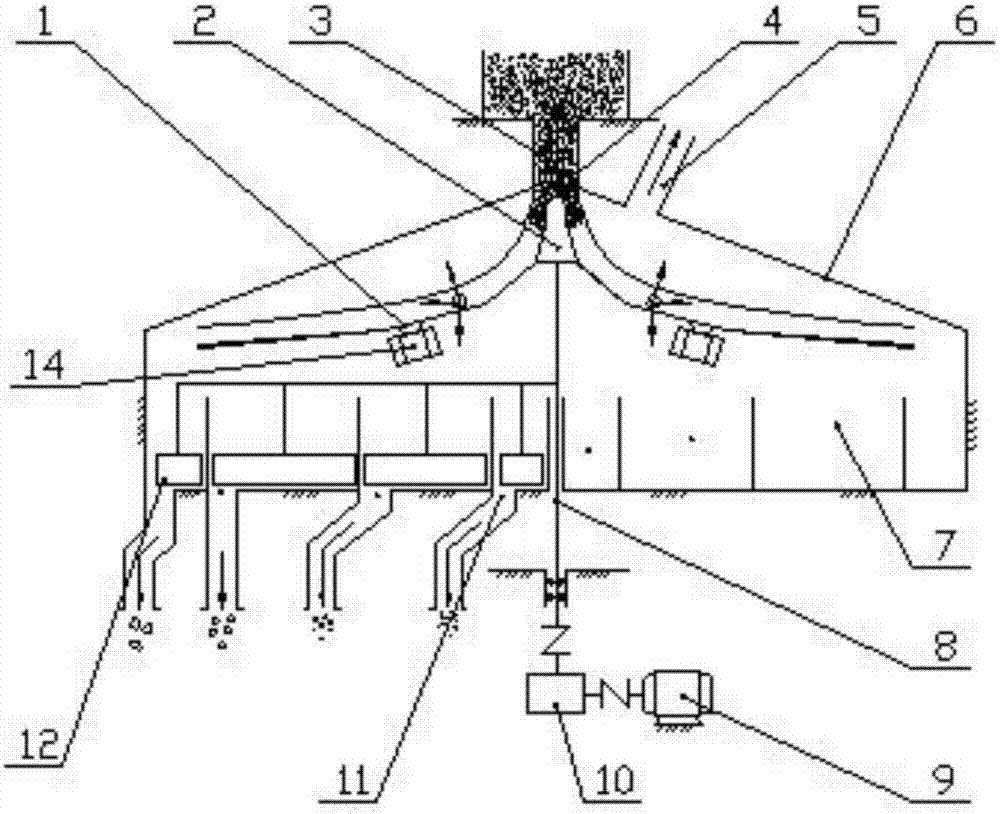

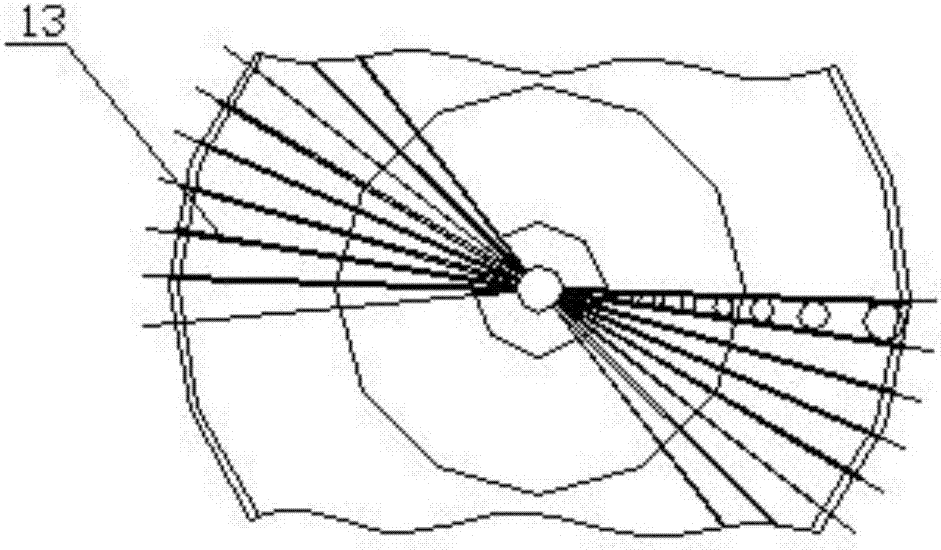

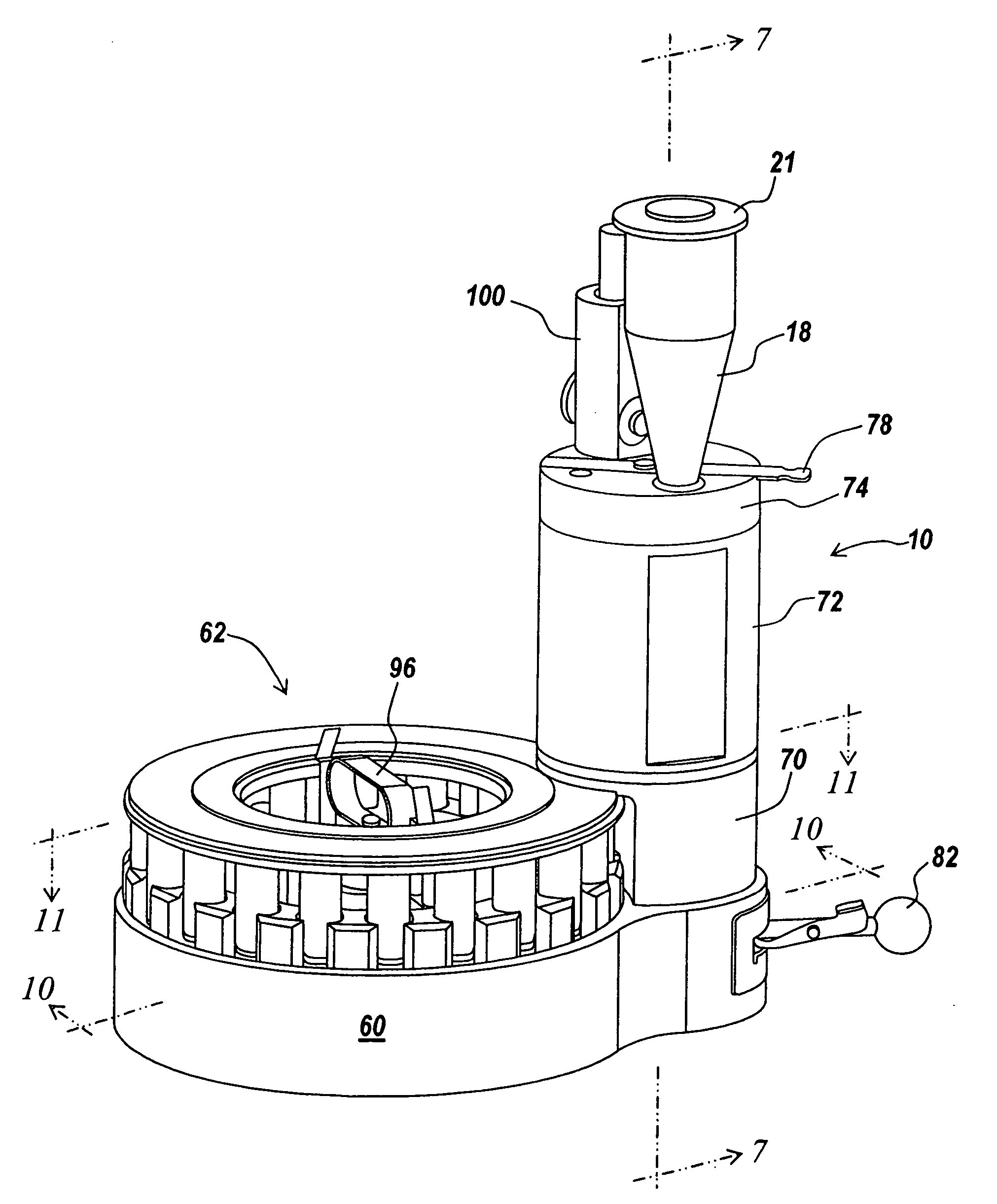

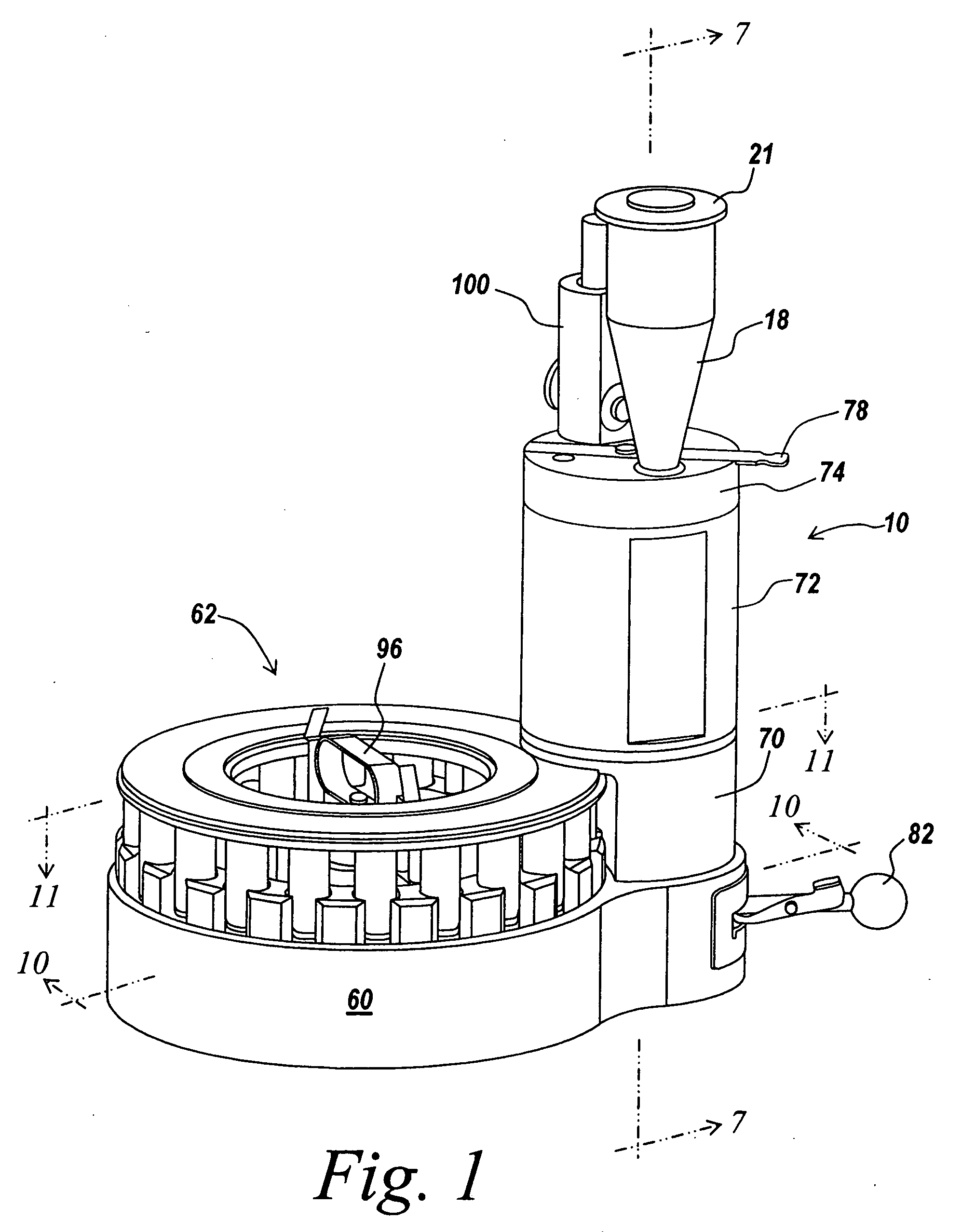

Segregation type centrifugal material screening and grading technology and special device thereof

InactiveCN107344167ARealize the collectionAchieve sievingSievingScreeningEngineeringCentrifugal force

The invention relates to a segregation type centrifugal material screening and grading technology and a special device thereof. Material is fed from a feeding cylinder above the center of a sieve; the material is uniformly fed to the sieve surface through a spiral feeding device at the top of a feeding cone; after leaving the feeding cylinder, under the action of gravity, the material is uniformly distributed through the feeding cone and drop to the sieve surface; under the effect of the segregation effect, the material is firstly preliminarily layered into particles with different particle sizes (r), the small particles accumulated on the periphery of the center of the sieve surface and the larger particles more away from the center; and meanwhile, due to the fact that radiation-shaped sieve strip gaps B (sieve seams) are wider and wider from the center to the outside, and the small particle materials are firstly screened thoroughly through a narrower sieve gap which is close to the center part. According to the technology and the special device thereof, material movement and separation are promoted by virtue of centrifugal force generated by rotation, more energy is saved compared with driving material movement by simply using vibration, screening of moisture-sticking materials and light substances is more efficient, and separation of particle grades of finished product material is more flexible.

Owner:北京百旺环境科技股份有限公司

Estimating petrophysical parameters and invasion profile using joint induction and pressure data inversion approach

Owner:SCHLUMBERGER TECH CORP

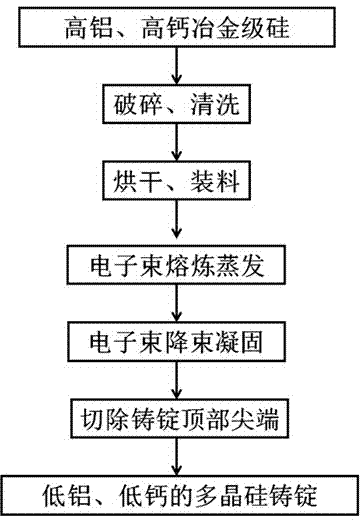

Method for removing impurities through directional solidification with electron beam inducing

InactiveCN102786059AReduce process linksReduce energy consumptionSilicon compoundsEvaporationSolar cell

The invention belongs to the technical field of polysilicon purification, in particular to a method for removing impurities through directional solidification by adopting the technology of electron beam inducing. The method comprises the following steps of selecting, washing and drying metallurgical grade polysilicon with high aluminum content and high calcium content, placing the polysilicon in a crucible, vacuumizing the polysilicon, starting an electron gun to bombard the polysilicon at a beam flow of 400-700 mA till the polysilicon is totally dissolved to form into a molten pool, and continuously smelting the molten pool for 30-60 min; and then reducing the beam flow of the electron beam by adopting a way of logarithmic beam drop, after the beam flow of the electron beam is reduced to 100-150 mA, stopping droping the beam, the melt slowly freezes to form into an ingot, closing the beam flow to obtain a polysilicon ingot with low aluminum and low calcium contents. According to the method provided by the invention, as the evaporation effect and segregation effect of impurities in the silicon are fully utilized, the complementary advantages of two impurity removing ways of electron beam smelting evaporation and directional solidification can be realized; the aluminum and calcium impurities can be ensured to be removed after one step of smelting so as to meet the performance requirements of a solar cell; the process section is reduced, the energy consumption is reduced, and the method can be in favor of the large-scale promotion and application.

Owner:DALIAN UNIV OF TECH

Plastic expanding agent for settlement resistance of high flow state cement based cementing material and preparation method thereof

The invention provides a plastic expanding agent for settlement resistance of high flow state cement based cementing materials and a preparation method thereof. The raw materials include, by weight, 30-50 portions of an azo compound, 10-30 portions of a stabilizing agent, 5-20 portions of a catalyst and 20-40 portions of a rheological additive. The plastic expanding agent provided by the invention can be compounded with efficient water reducer and other additives, and can assist auxiliary additive to realize the flow properties of cement based cementing material, effectively improve the workability, wrapping performance and durability of the cement based materials, has certain compensating shrinkage effect on early age shrinkage of cement based cementing material, and shows anti-settlement and anti-segregation effects while maintaining the high flow state of cement based cementing material.

Owner:武汉品泰新型建材有限公司

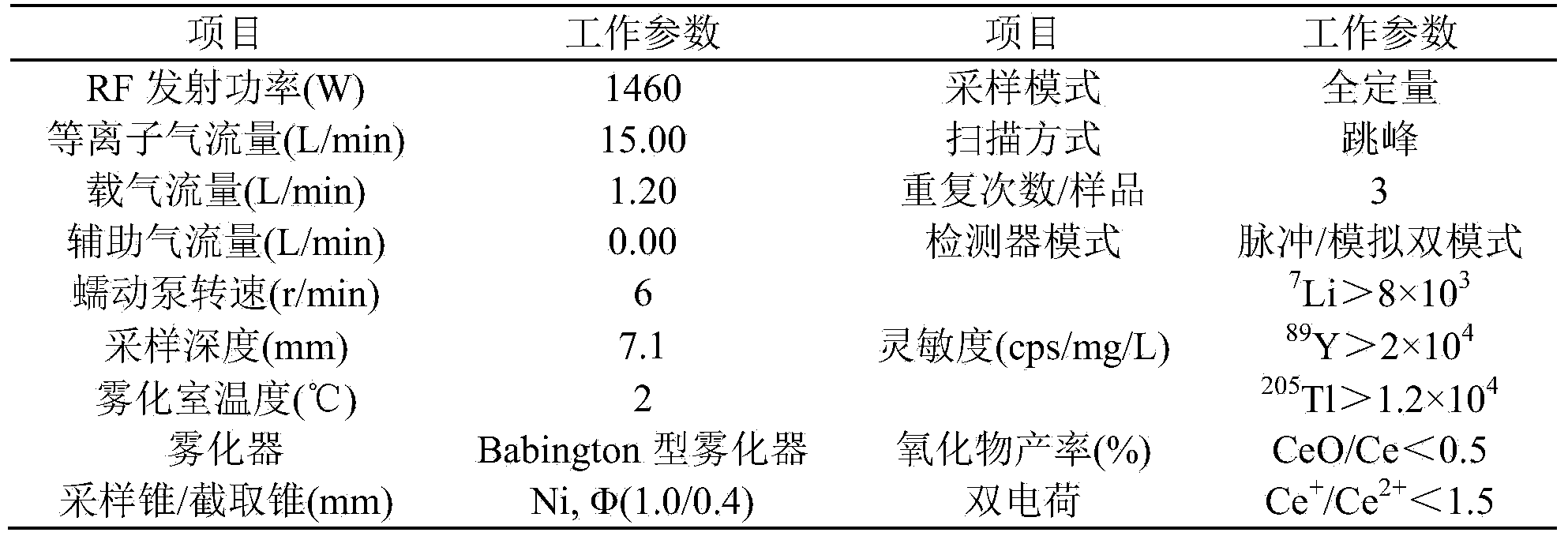

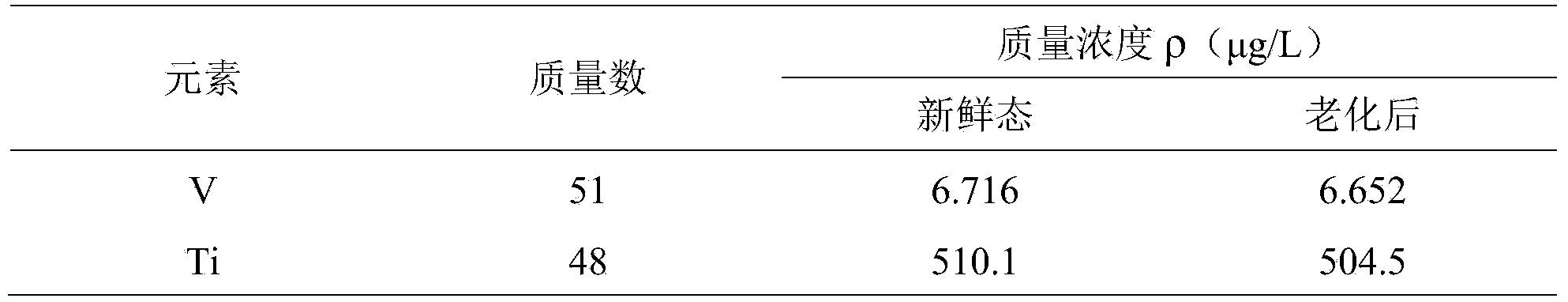

Detection method for vanadium trace amount evaporation rate of vanadium-based selective catalyst

ActiveCN104297100ASolve the problem of the test error of the absolute content of VMeet high-precision testing requirementsPreparing sample for investigationTitaniumSegregation effect

The invention discloses a detection method for the vanadium trace amount evaporation rate of a vanadium-based SCR (Selective Catalytic Reduction) catalyst. According to the detection method provided by the invention, by adopting the method that existing element titanium is taken as a marker to the calculate vanadium trace amount evaporation rate in a catalyst formula, the segregation effect on the result during a sampling process and a sample preparing process is avoided; the marker has the characteristics that the chemical property is stable under usage conditions, and the marker is non-volatile and easy to measure; moreover, the method is reliable, simple and practicable, and is wide in applicability.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

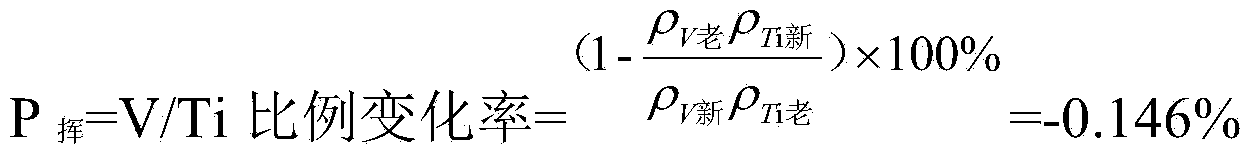

Environment-friendly water-oil automatic segregation water tank

InactiveCN102660982ARealize automatic separationReasonable structural designDomestic plumbingLiquid separationInlet channelWater flow

The invention relates to an environment-friendly water-oil automatic segregation water tank which comprises a water tank body and a water-oil segregation device. The environment-friendly water-oil automatic segregation water tank is characterized in that a drawer-type filter layer is arranged between the water tank body and the water-oil segregation device, the main body of the water-oil segregation device is a water-oil segregation tank, a river diversion converging device is arranged on the top portion of the water-oil segregation tank, an oil outlet and a water outlet are arranged on the lateral face of the water-oil segregation tank, a drain outlet is arranged on the bottom portion of the water-oil segregation tank, and a valve is arranged at the drain outlet. The lower end of the river diversion converging device is connected with a layering separation plate which enables the water-oil segregation tank to be separated into an oil overflowing chamber and a water outlet chamber, the oil overflowing chamber is communicated with the bottom of the water outlet chamber, and a converging port of the river diversion converging device is communicated with the oil overflowing chamber. The bottom horizontal height of the oil outlet is higher than top horizontal height of the water outlet. The water outlet chamber is sequentially separated by the layering separation plate, a first separation plate and a second separation plate to form an upward water inlet channel, a downward water inlet channel and a filter cavity, and a carbon filter layer is arranged in the filter cavity. The environment-friendly water-oil automatic segregation water tank is reasonable in design, simple in operation, capable of achieving water-oil automatic segregation, good in segregation effect and suitable to use of environment-friendly water tanks.

Owner:朱锡军

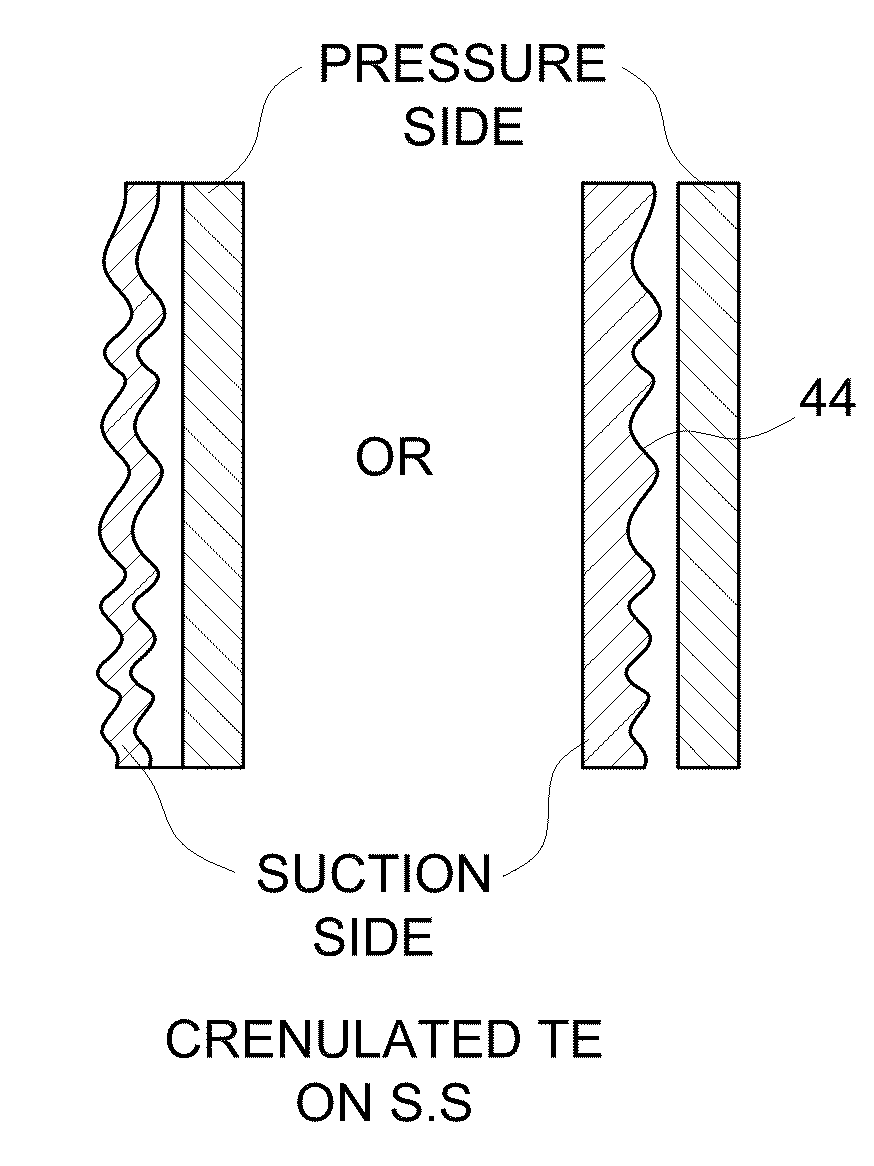

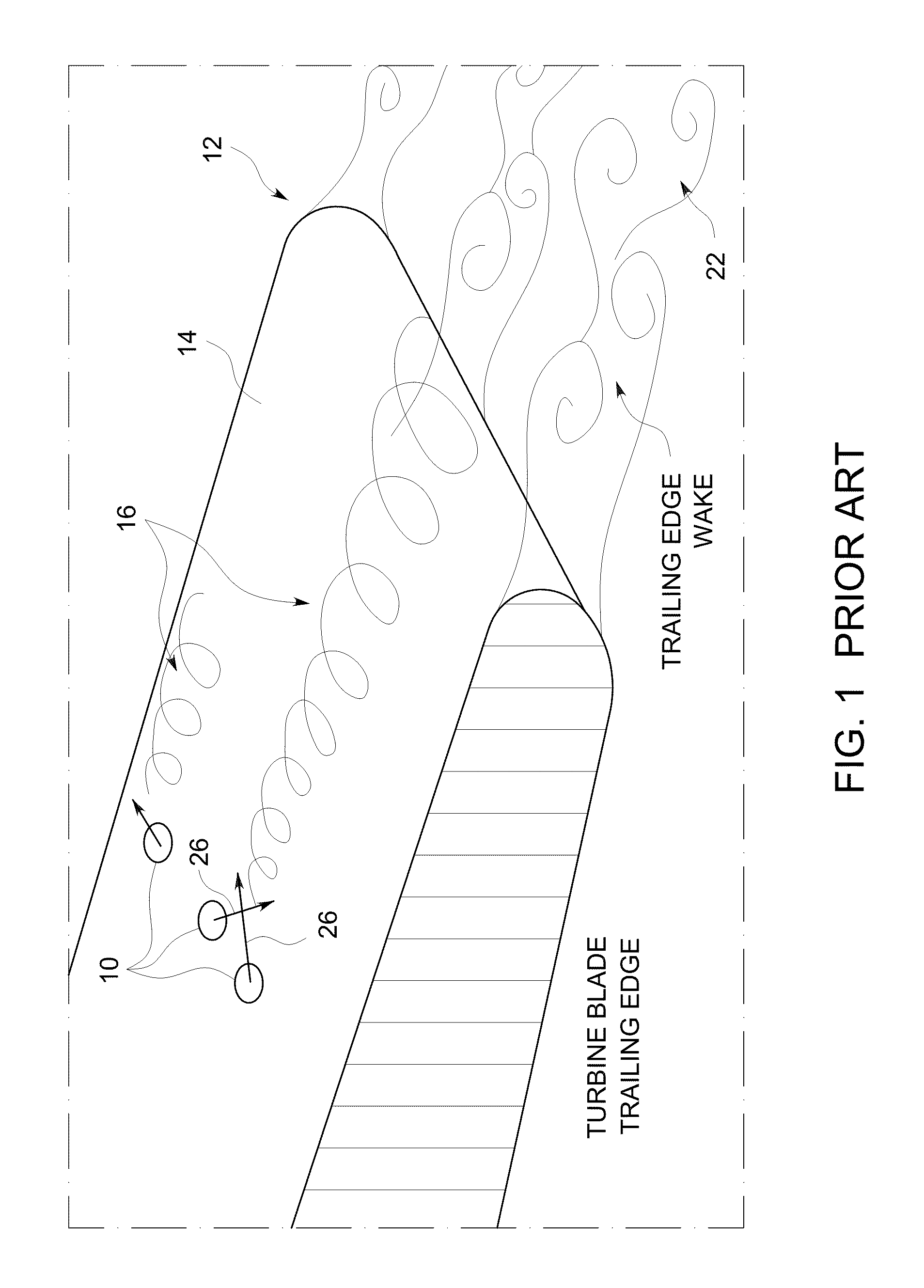

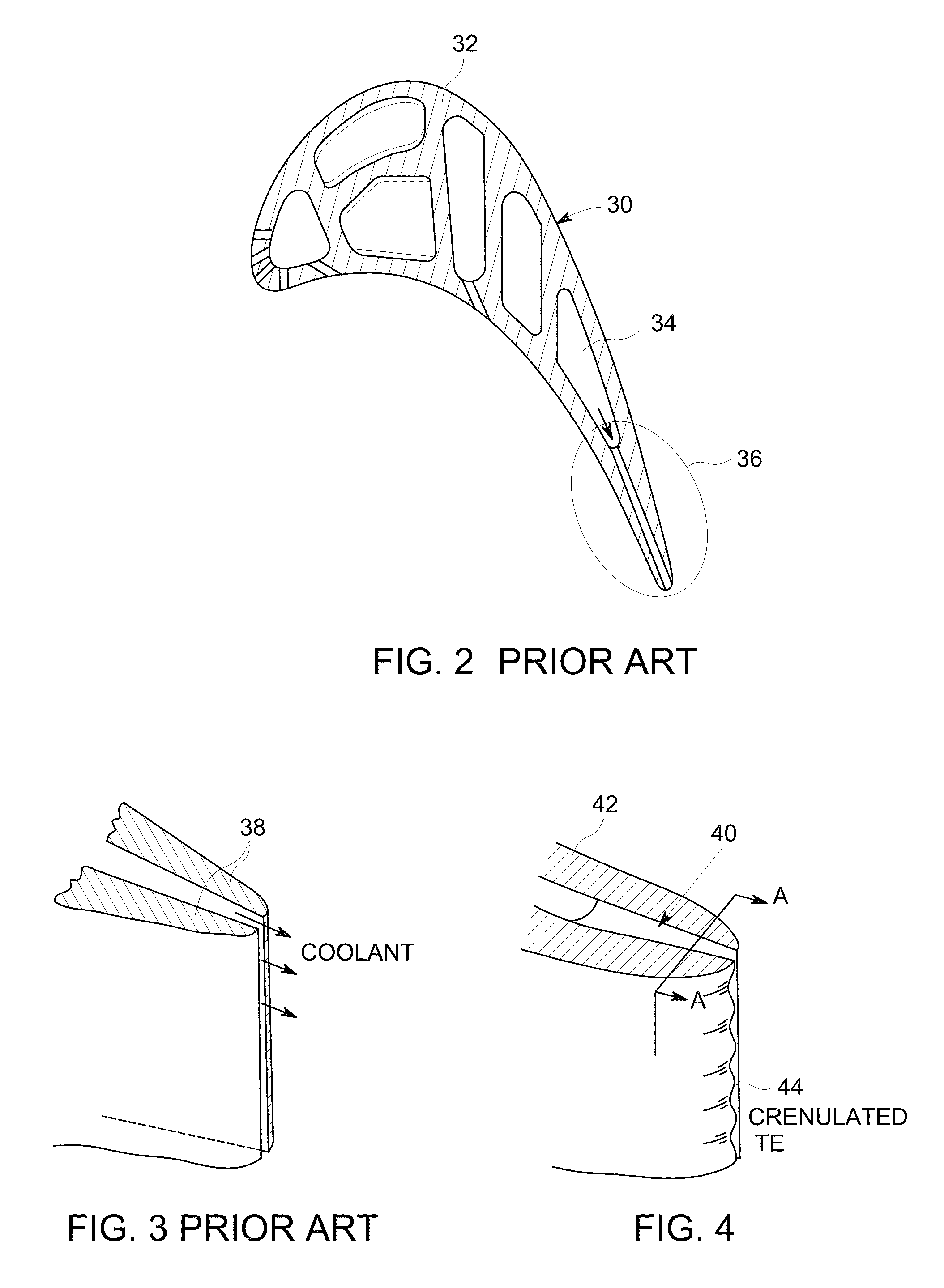

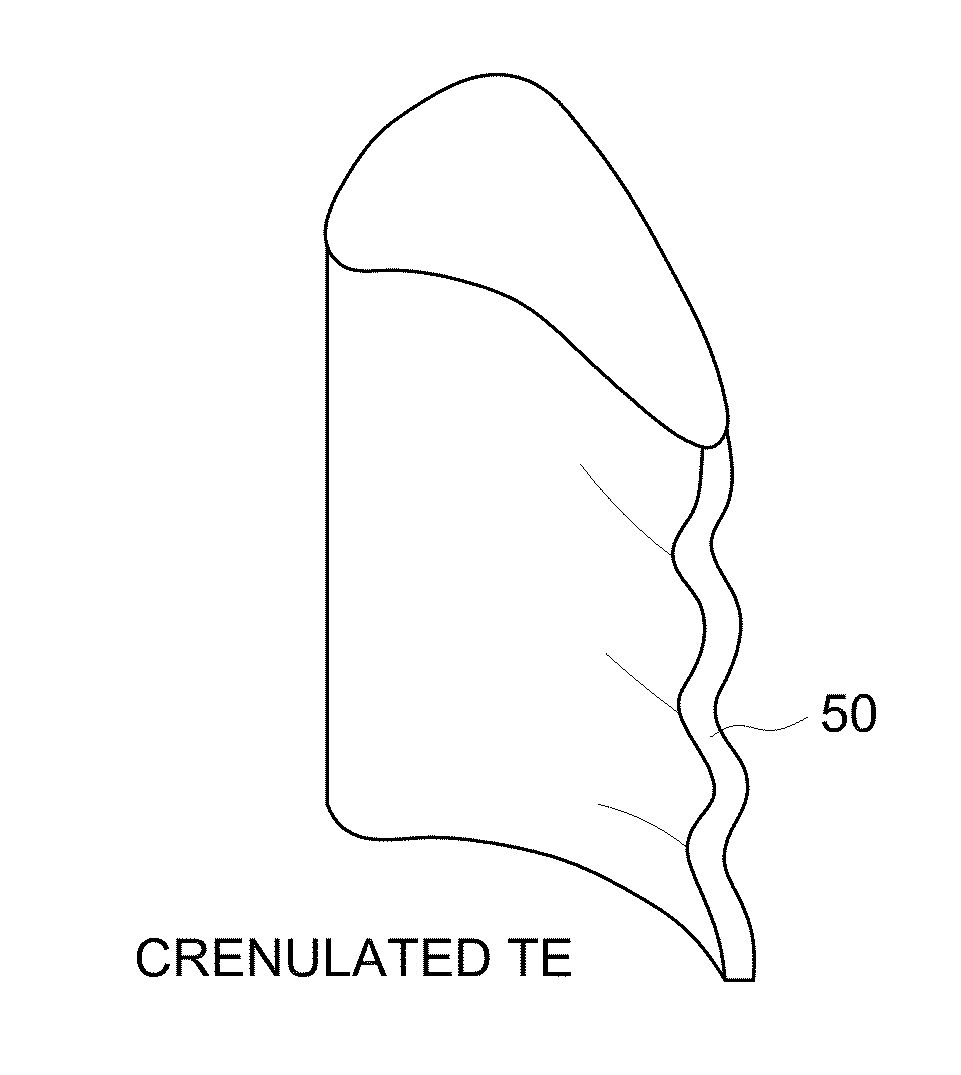

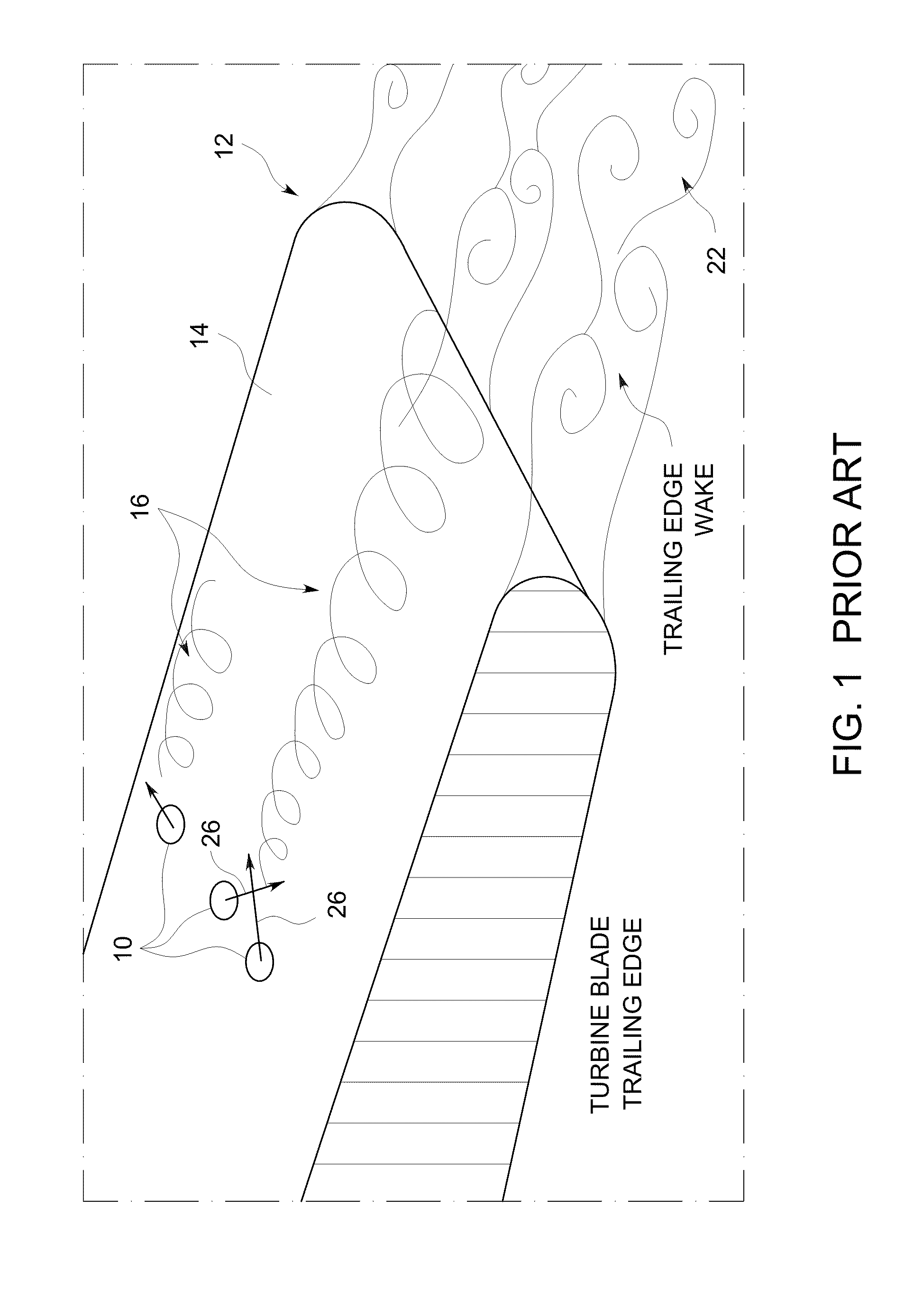

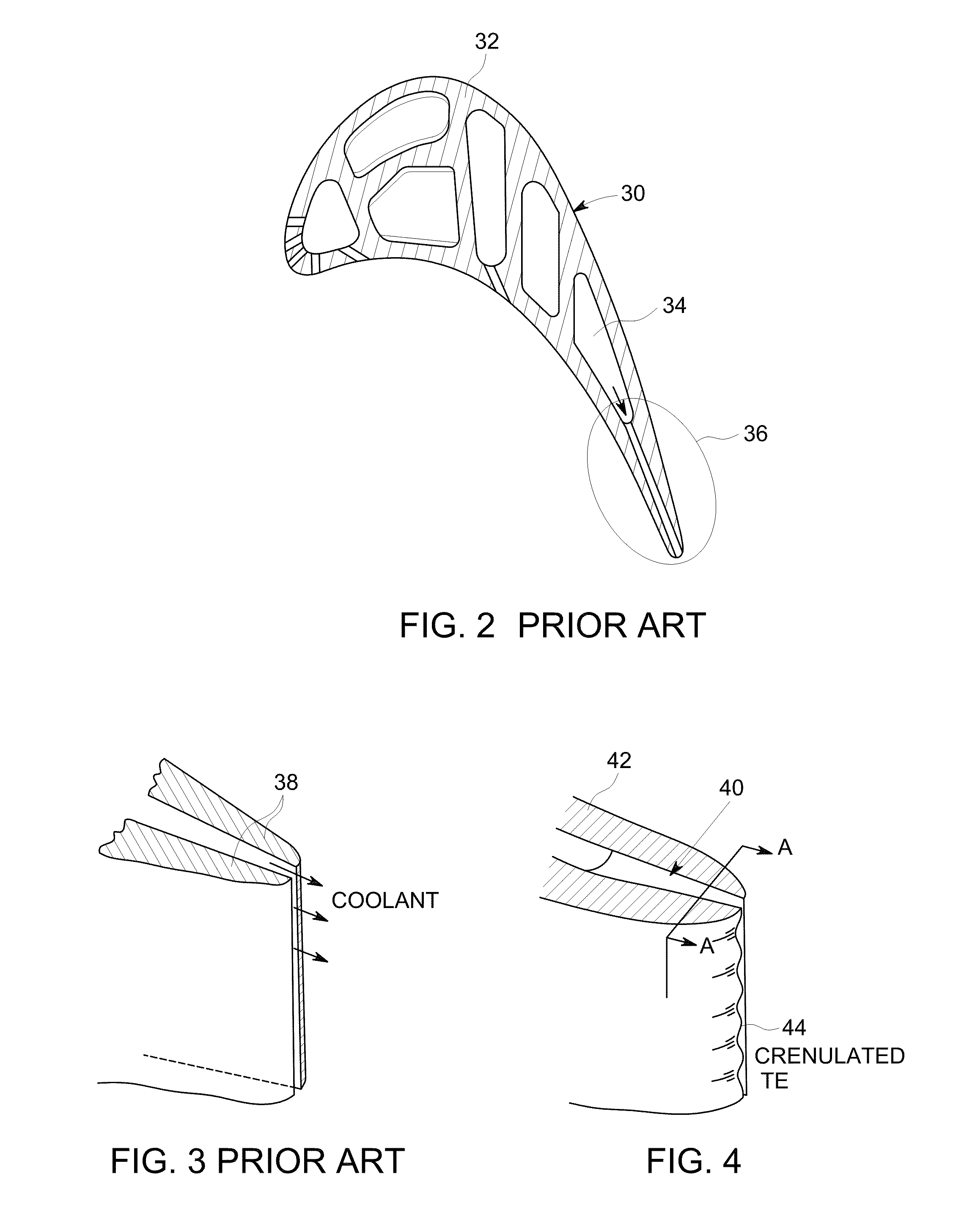

System and method for enhanced turbine wake mixing via fluidic-generated vortices

ActiveUS8608429B2Reduce aerodynamic lossesReduce impactPropellersEngine manufactureEngineeringTrailing edge

A high pressure turbine (HPT) blade includes a substantially arcuate trailing edge including one or more fluid injection elements disposed therein. Each fluid injection element injects a fluid such as air into a desired trailing edge region of the HPT blade or vane to enhance mixing out of the wakes generated via the HPT blade or vane. The enhanced mixing out reduces HPT / LPT interaction losses and / or the axial gap between the HPT and LPT components in a gas turbine engine. The interaction losses include unsteady thermal wake segregation effects that lead to unexpected heat-up of endwalls (planforms and blade / vane-tips) of downstream blades / vanes, and further include aerodynamic losses, both transonic and subsonic.

Owner:GENERAL ELECTRIC CO

System and method for enhanced turbine wake mixing via fluidic-generated vortices

ActiveUS20110293422A1Reduce the impactEnhanced mixing processPropellersEngine manufactureTurbine bladeEngineering

A high pressure turbine (HPT) blade includes a substantially arcuate trailing edge including one or more fluid injection elements disposed therein. Each fluid injection element injects a fluid such as air into a desired trailing edge region of the HPT blade or vane to enhance mixing out of the wakes generated via the HPT blade or vane. The enhanced mixing out reduces HPT / LPT interaction losses and / or the axial gap between the HPT and LPT components in a gas turbine engine. The interaction losses include unsteady thermal wake segregation effects that lead to unexpected heat-up of endwalls (planforms and blade / vane-tips) of downstream blades / vanes, and further include aerodynamic losses, both transonic and subsonic.

Owner:GENERAL ELECTRIC CO

Phase change storage unit and preparing method thereof

ActiveCN103346258AReduce power consumptionReduced operating power consumptionElectrical apparatusUnit operationOperability

The invention provides a phase change storage unit and a preparing method of the phase change storage unit. A phase change material layer with the thickness identical to the size of a single unit cell or a plurality of unit cells is adopted, interfacial characteristics are fundamentally expressed by the phase change material layer, volume material characteristics are weakened, so that the two-dimensional phase change storage unit which stores information through interface resistance change is prepared, and the two-dimensional phase change storage unit is high in density, low in power consumption and high in speed. The phase change material layer is thin and a small number of shortages exist on an interface of the phase change material layer, so that the operation power consumption of the phase change storage unit is reduced, and the operation time of the phase change storage unit is shortened, damage to a phase change material in every operation process is reduced, the element segregation effect of the material in every operation process is decreased, the maximum operability number of times of the phase change storage unit is increased, and therefore the capacity of circulating operation number of times of a device can be increased. Further, a graphene electrode used in the phase change storage unit has the advantages of being fast in signal response, large in mechanical strength, small in energy loss and the like. Meanwhile, the phase change storage unit is compatible with a novel CMOS.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Technology for centrifugal casting of high-nitrogen austenitic stainless steel pipe at normal pressure

ActiveCN105108098AImprove corrosion resistanceLow requirements for process conditionsFurnace typesHeat treatment furnacesAlloyNitrogen gas

The invention relates to a technology for centrifugal casting of a high-nitrogen austenitic stainless steel pipe at normal pressure. The technology includes the steps of preparing ingredients, preparing a casting mold and a casting machine, conducting alloy smelting and pouring, carrying out shaping cleaning and heat treatment, recording and checking. The cast pipe is made of high-nitrogen austenitic stainless steel, the nitrogen content of the alloy melt or oversaturated alloy in the solidification process is larger than or equal to 0.65% N at the normal pressure, spontaneous gas can be generated in the normal-pressure casting process, and nitrogen bubbles overflow. Under the normal-pressure smelting condition, high-nitrogen-content austenitic stainless steel molten metal obtained by smelting meets the pouring temperature condition, and then enters in the pouring step rapidly in 90 seconds, and centrifugal casting of all the smelting molten metal is completed in three minutes. The auxiliary segregation effect of centrifugal force is utilized, and the overflowing nitrogen bubbles deviate from the quality specification portion of the cast pipe. By the adoption of the technology, the nitrogen content, the bubble positions and the bubble number can be controlled stably and effectively, and thus the surface and overall quality requirement can be met.

Owner:CHANGCHUN SHIYUE ENERGY SAVING MATERIAL CO LTD

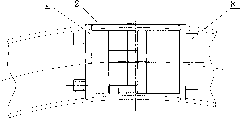

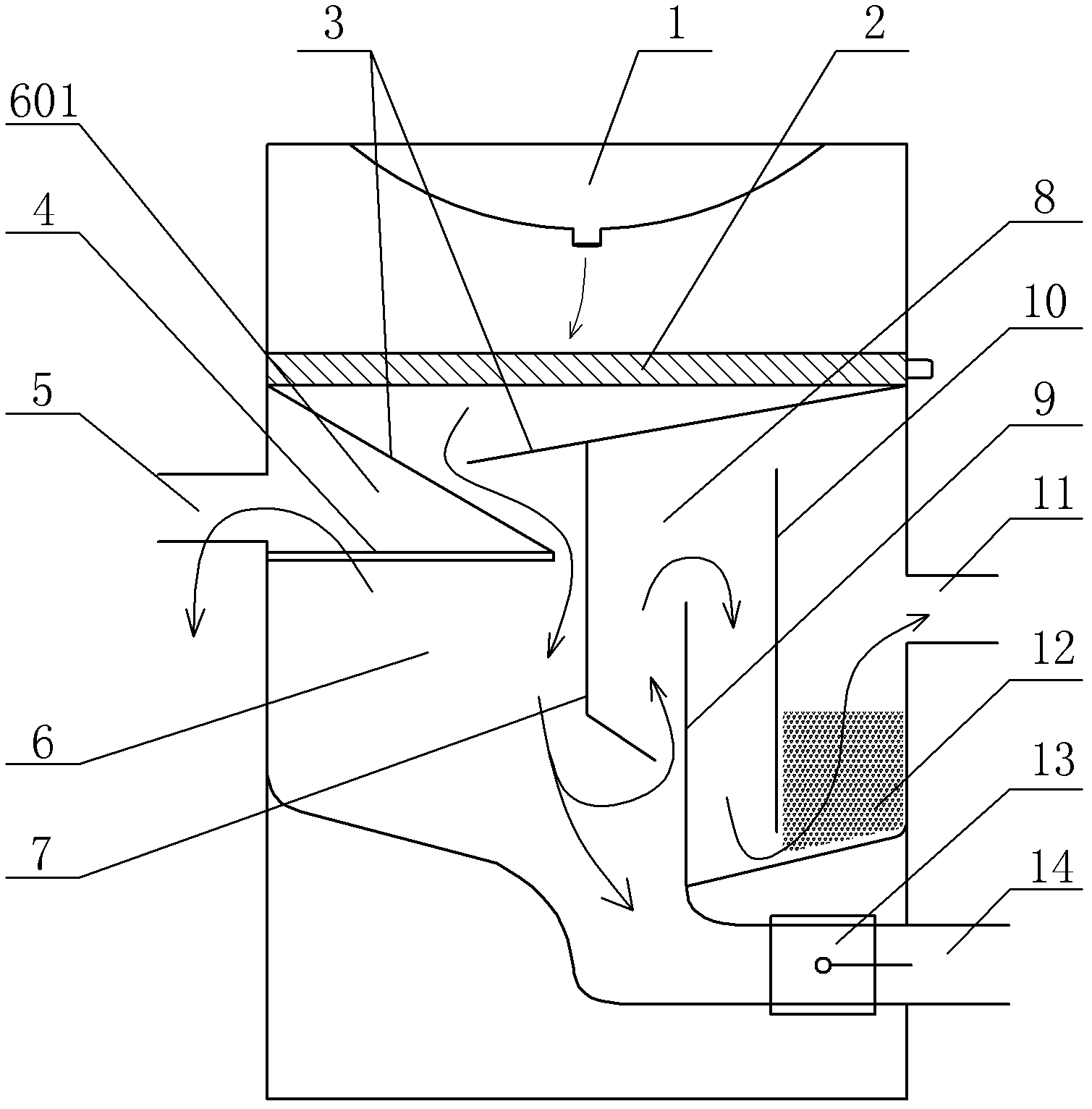

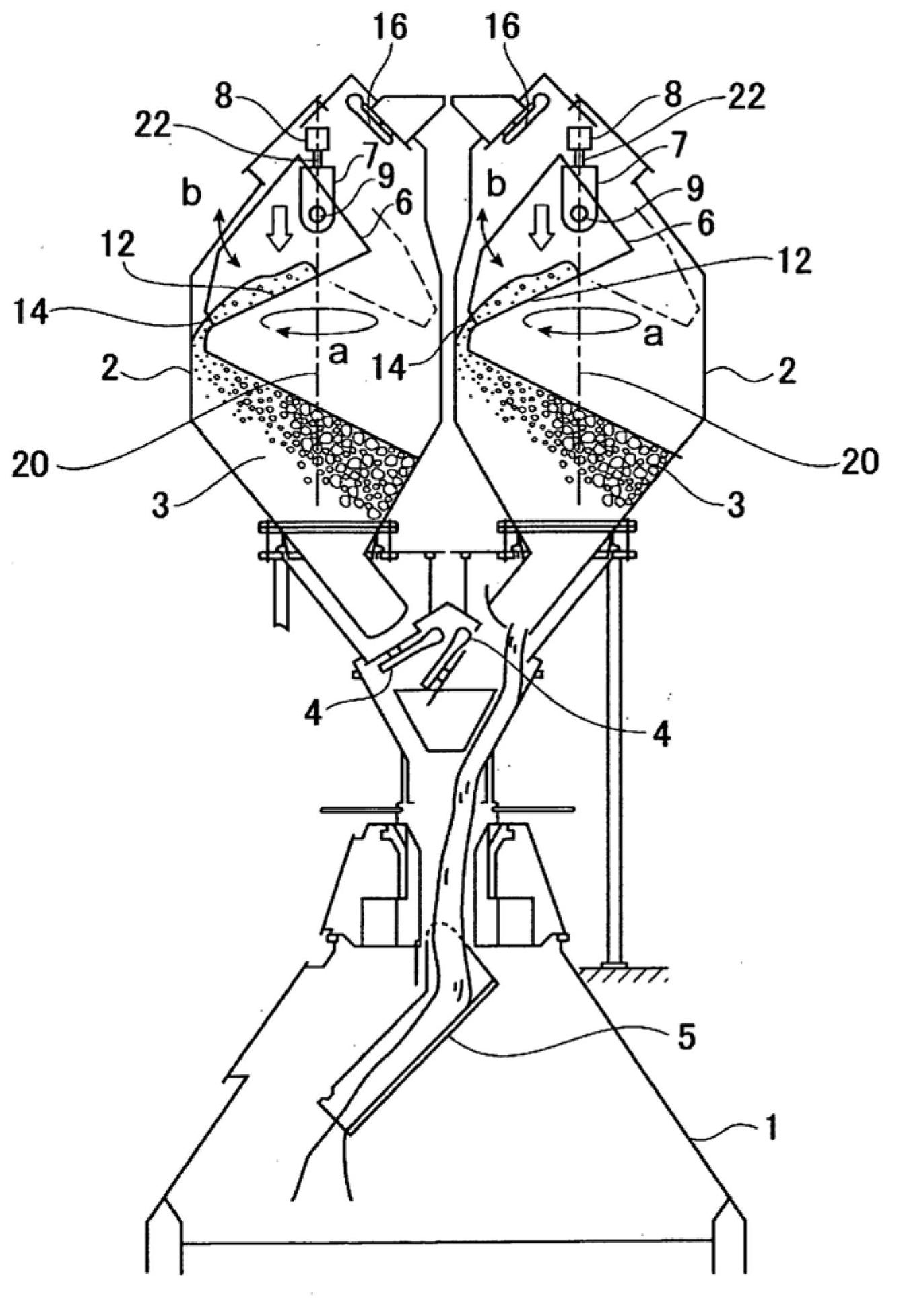

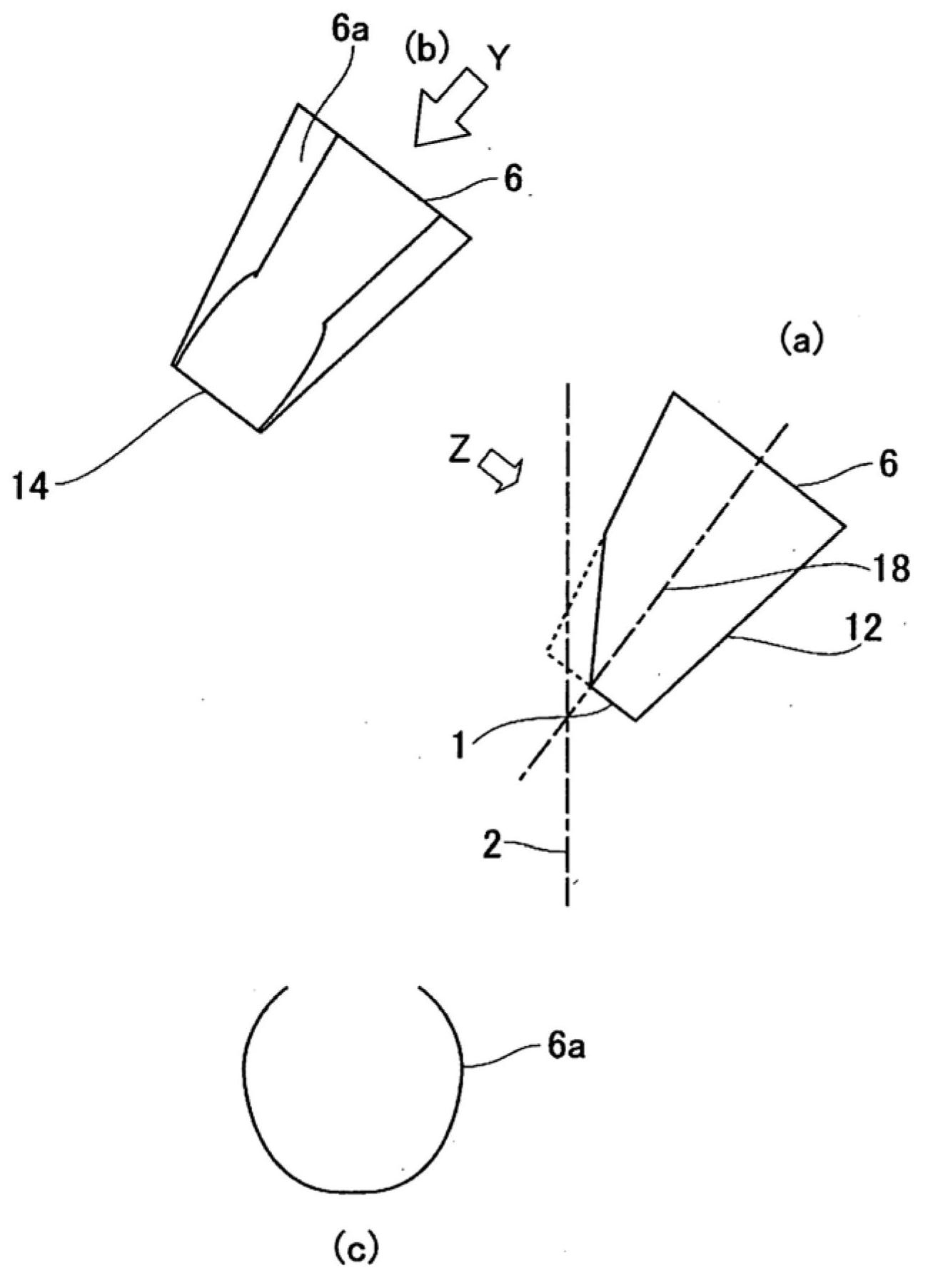

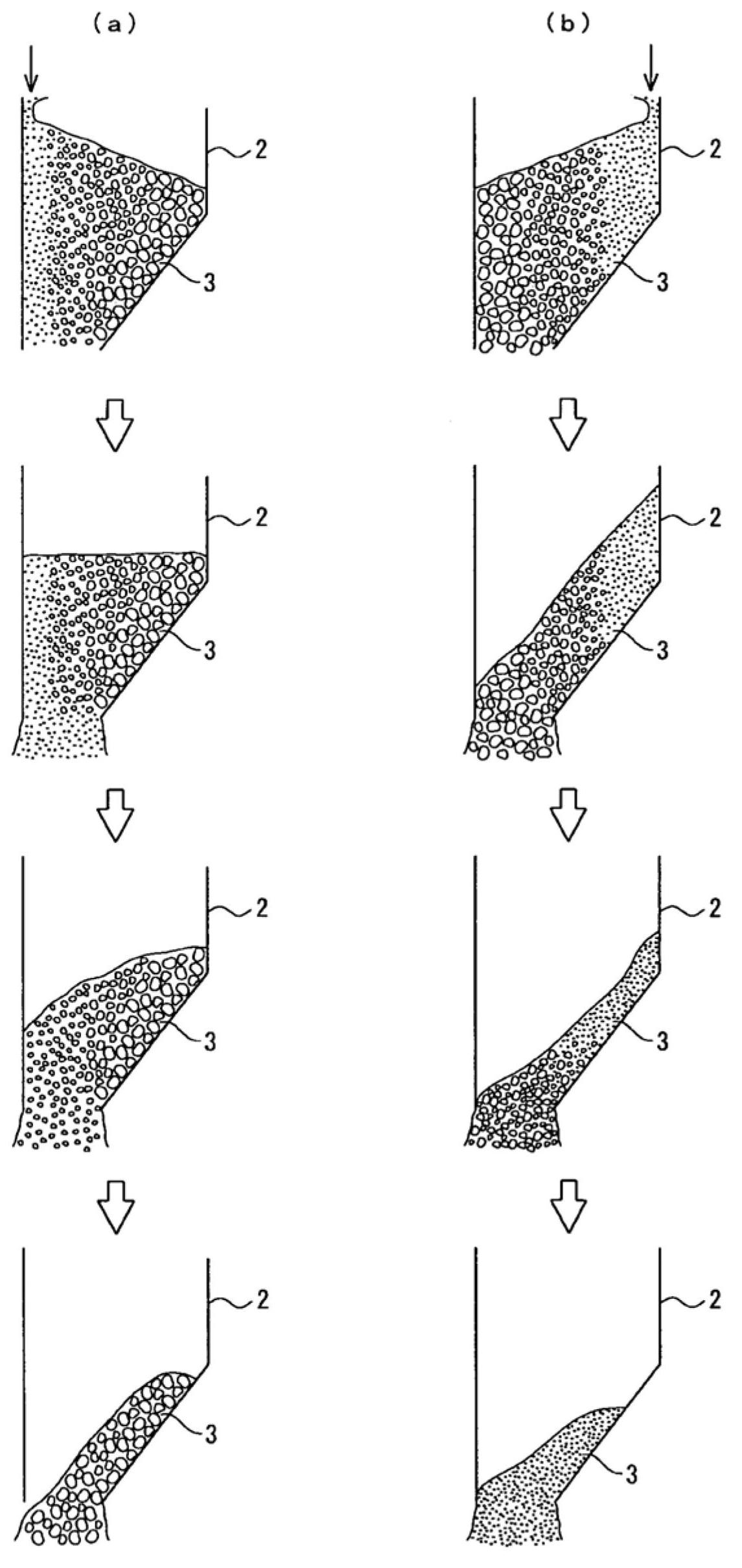

Material segregation apparatus for blast furnace top bunker

ActiveCN102666882AImprove segregation effectAvoid interferenceBell-and-hopper arrangementCharge manipulationBunkerEngineering

Disclosed is a material segregation apparatus for a blast furnace top bunker, said material segregation apparatus being capable of charging material into the vicinity of the inner wall of the bunker to enhance the material segregation effect. A segregation distributor (6) is disposed at the top of a bunker (2) in such a manner that the segregation distributor (6) is rotatable about the central vertical axis (20) perpendicular to a horizontal cross-section of the bunker (2) and that the vertically lower surface of the segregation distributor (6) receives material (3) charged from above and has an angle greater than the angle of repose of the charged material (3). As a result, the segregation distributor (6) is not liable to interfere with the inner wall of the bunker (2) when the orientation of the segregation distributor (6) is changed, and the charged-material outlet (14) of the segregation distributor (6) can be brought into the vicinity of the inner wall of the bunker (2). Further, the segregation distributor (6) may have a hollow circular truncated cone shape which has an axis line (18) extending at a downward angle and which includes a cutout portion on the side thereof facing the inner wall of the bunker (2) to stabilize the outlet (14) for the charged material (3) and reliably prevent interference with the inner wall of the bunker (2).

Owner:JFE STEEL CORP

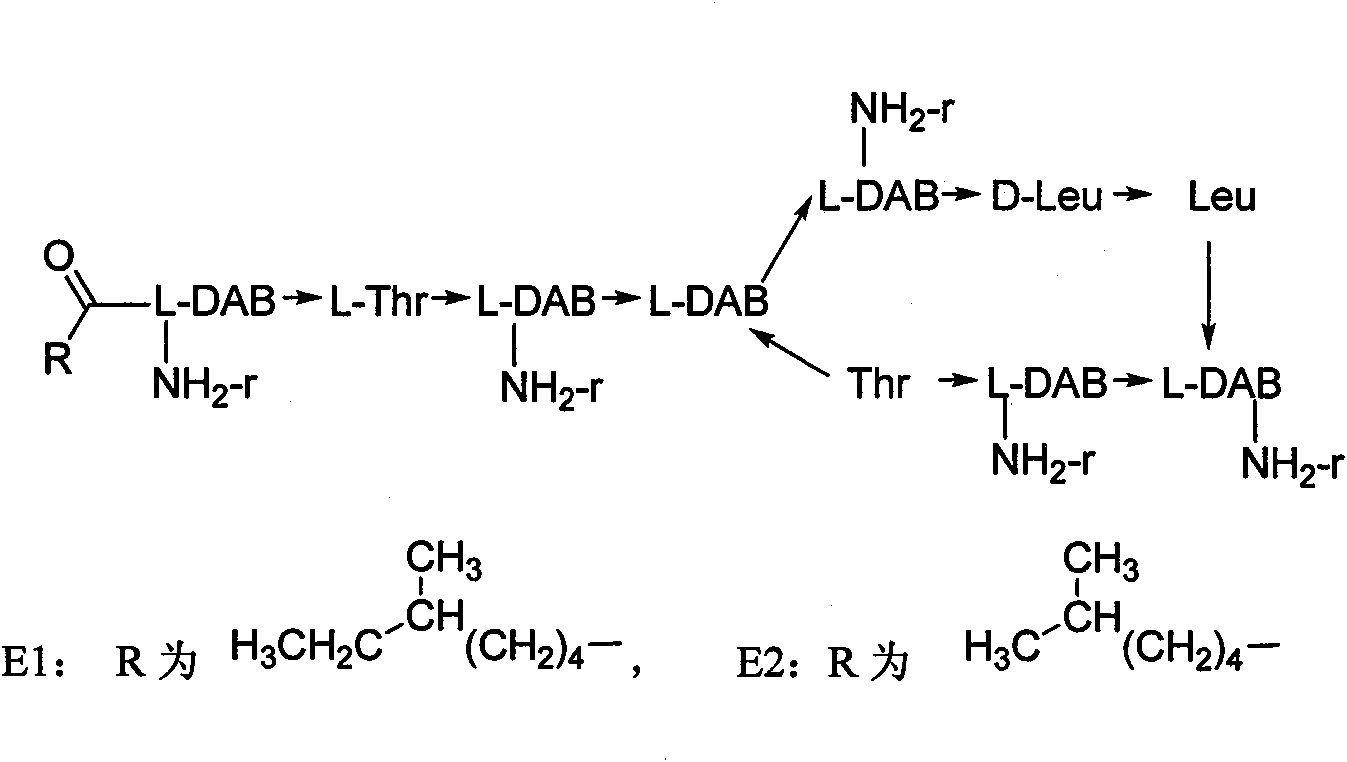

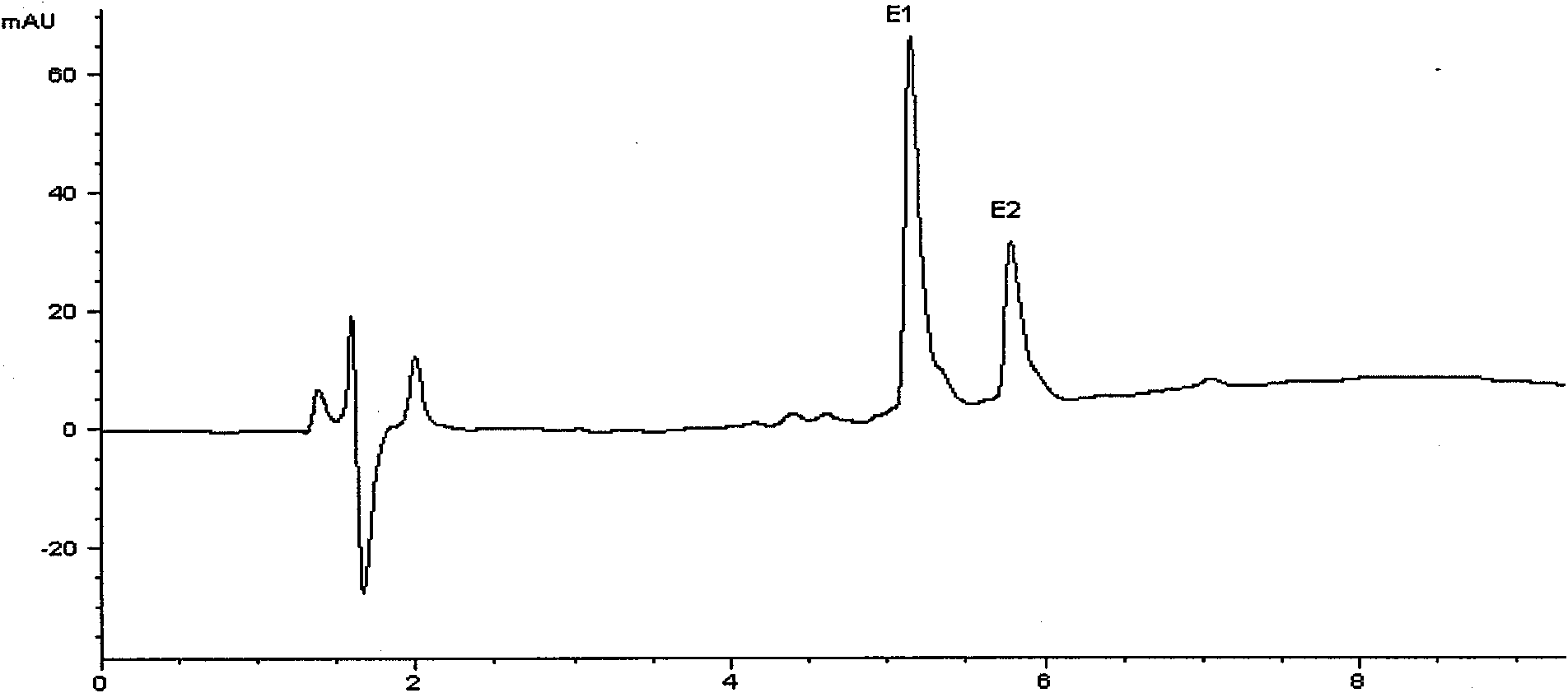

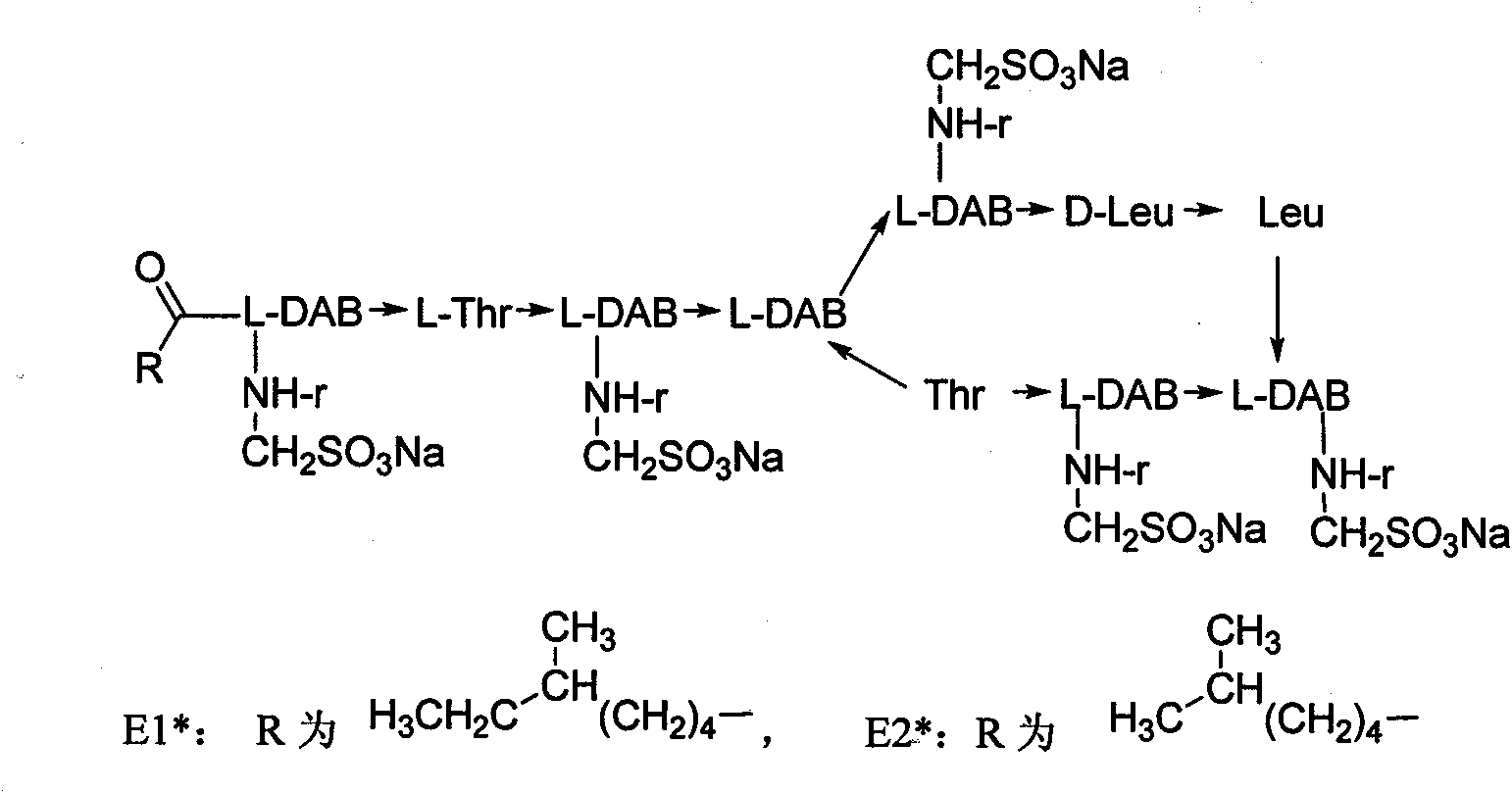

Antiphase high efficiency liquid chromatography method for segregating polymyxin E methyl sodium sulfnate and analog thereof

The invention discloses a method for segregating and analyzing polymyxin E methyl sodium sulfnate and isomer or analog thereof successfully by utilizing alkyl bonded silica packed column. The method provided by the invention is characterized in that the condition of the liquid chromatography is that the alkyl bonded silica packed column is a stationary phase, and a mobile phase is a mixed solvent composed of an organic solvent and aqueous acid, wherein the C18 alkyl bonded silica gel packed column of Optimapak corporation is taken as the stationary phase, and when acetonitrile and 0.05% of trifluoroacetic acid water solution gradient are eluted based on the volume ratio of (20:80)-(50:50), the good segregation effect is achieved.

Owner:杨更亮

Concrete anti-segregation method

InactiveCN106517859AThe segregation effect is obviousEasy to useSegregation effectUltimate tensile strength

The invention relates to a concrete anti-segregation method. The method is characterized in that when concrete is segregated, polyacrylamide is added after metering in the segregated concrete, workability of the segregated concrete is improved, the construction performance is improved, so that the segregated concrete has good cohesive force and can reach the construction requirement; 30-80 g of polyacrylamide is added in each 1 m<3> of the concrete, the molecular weight of polyacrylamide is 1 million-3 millions; and the intensity of the segregated concrete is C30-C70. The method has the advantages that 1) the concrete anti-segregation effect is obvious, the conveying performance and construction performance can be rapidly improved when the concrete is segregated; 2) the operation is simple, the usage of polyacrylamide is convenient; 3) the labor intensity of the building workers is reduced; and 4) no pollution residue is generated. The concrete anti-segregation method is suitable for all the building construction units for using the concrete.

Owner:贵州建工混凝土有限责任公司

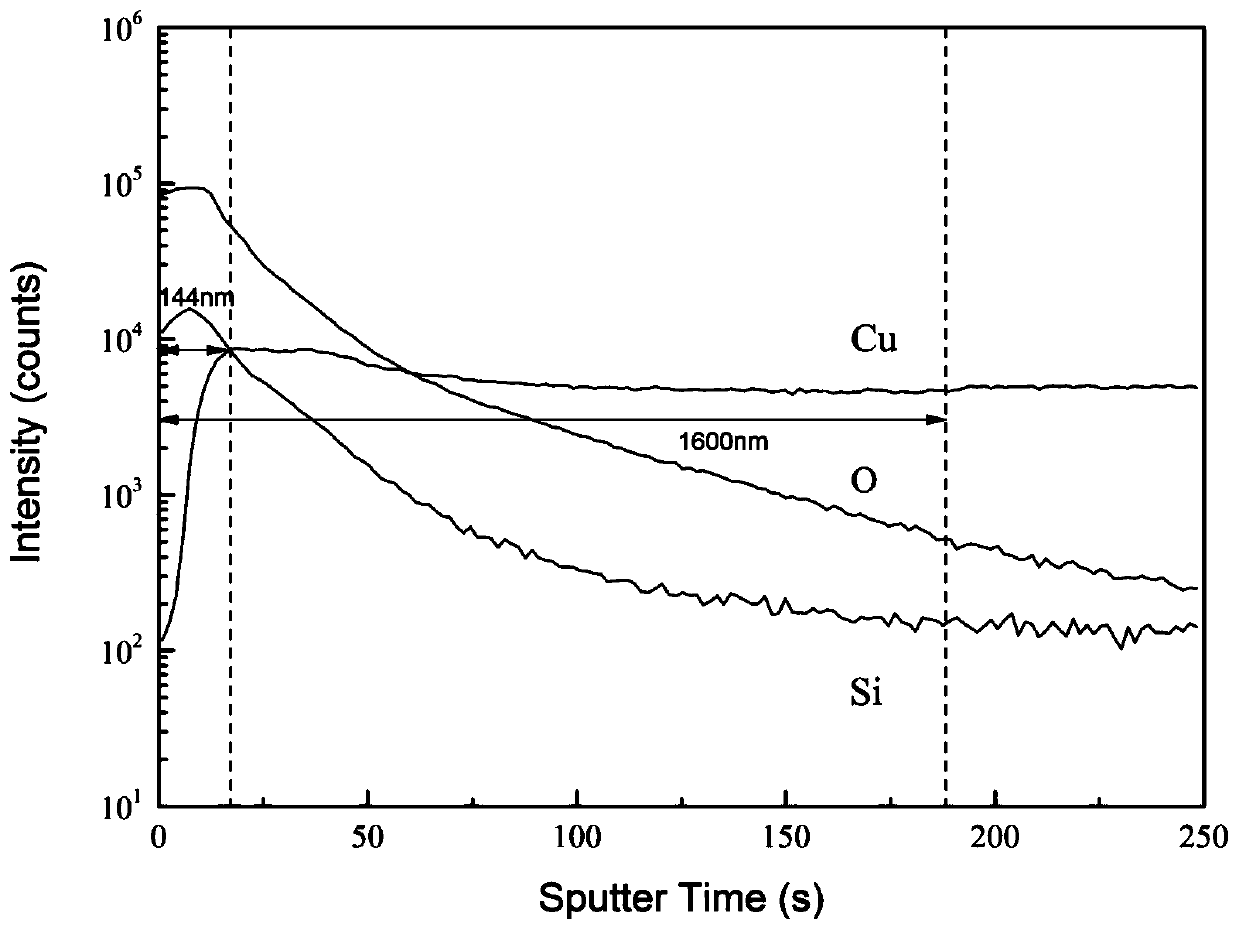

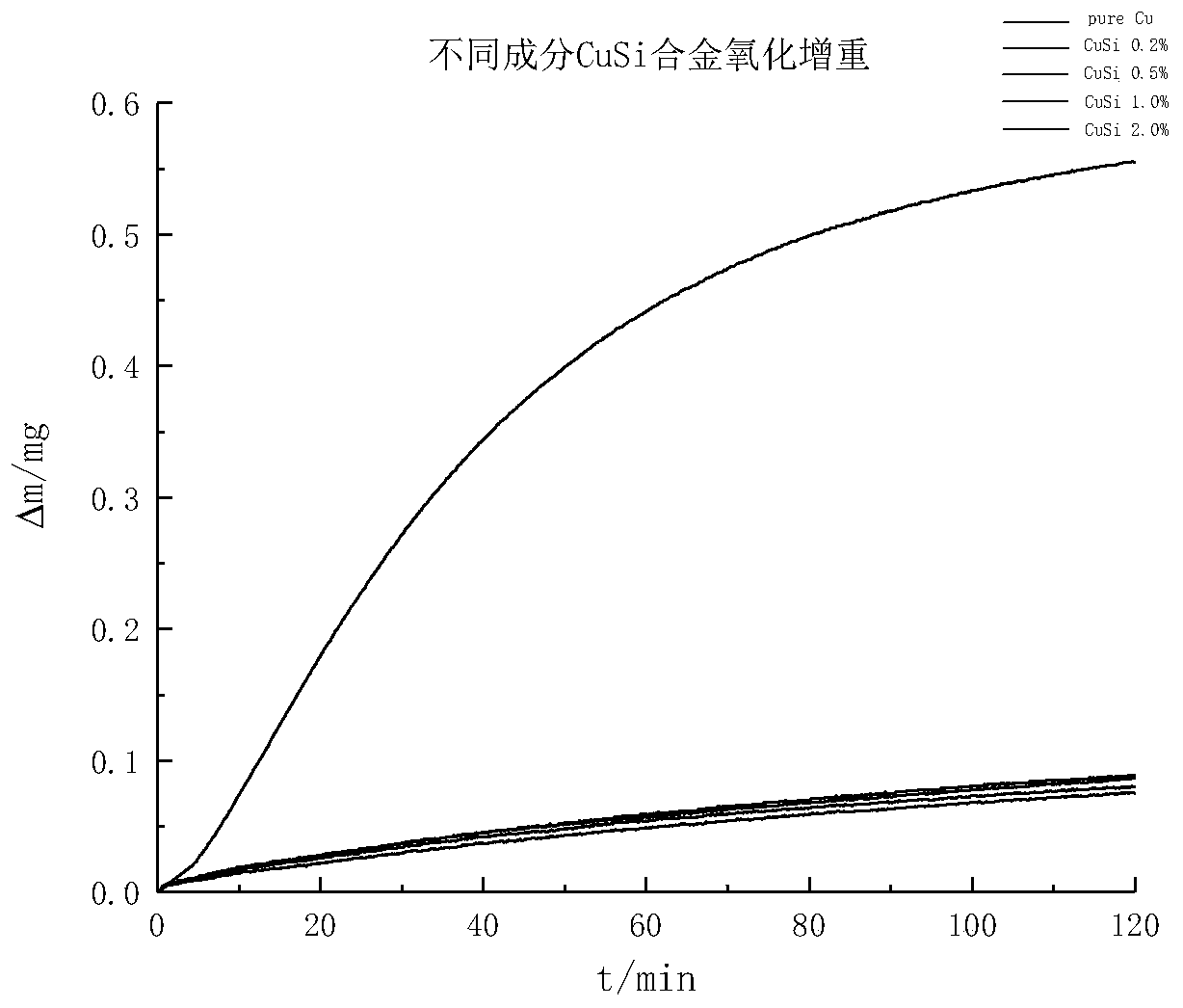

Method for improving copper oxidation resistance of authigenic nonmetal oxide composite film

The invention provides a method for improving copper oxidation resistance of an authigenic nonmetal oxide composite film. Trace of Si elements are added into Cu so that a Cu@SiO2 composite attachmentfilm can be formed on the surface of Cu, and high-temperature oxidation resistance of the metal Cu and a product of the metal Cu is improved. By means of the method, trace of Si is mixed with Cu, repeated smelting is conducted in a vacuum smelting furnace, and a light doped CuSi alloy is manufactured. The added trace of Si elements are annealed in the Ar-20%H2 atmosphere, the trace of Si in the alloy is segregated to the surface of the alloy through the segregation effect and is reacted with residual O2 in the annealing atmosphere to generate SiO2, and therefore the Cu@SiO2 composite attachment film with a high melting point and stable performance can be formed, and it is ensured that a Cu metal matrix of the CuSi alloy is not oxidized under the high-temperature and pure-oxygen condition.By means of the method, the use reliability of copper-based parts and equipment is ensured, the cost is reduced, and industrial waste is reduced.

Owner:JILIN UNIV

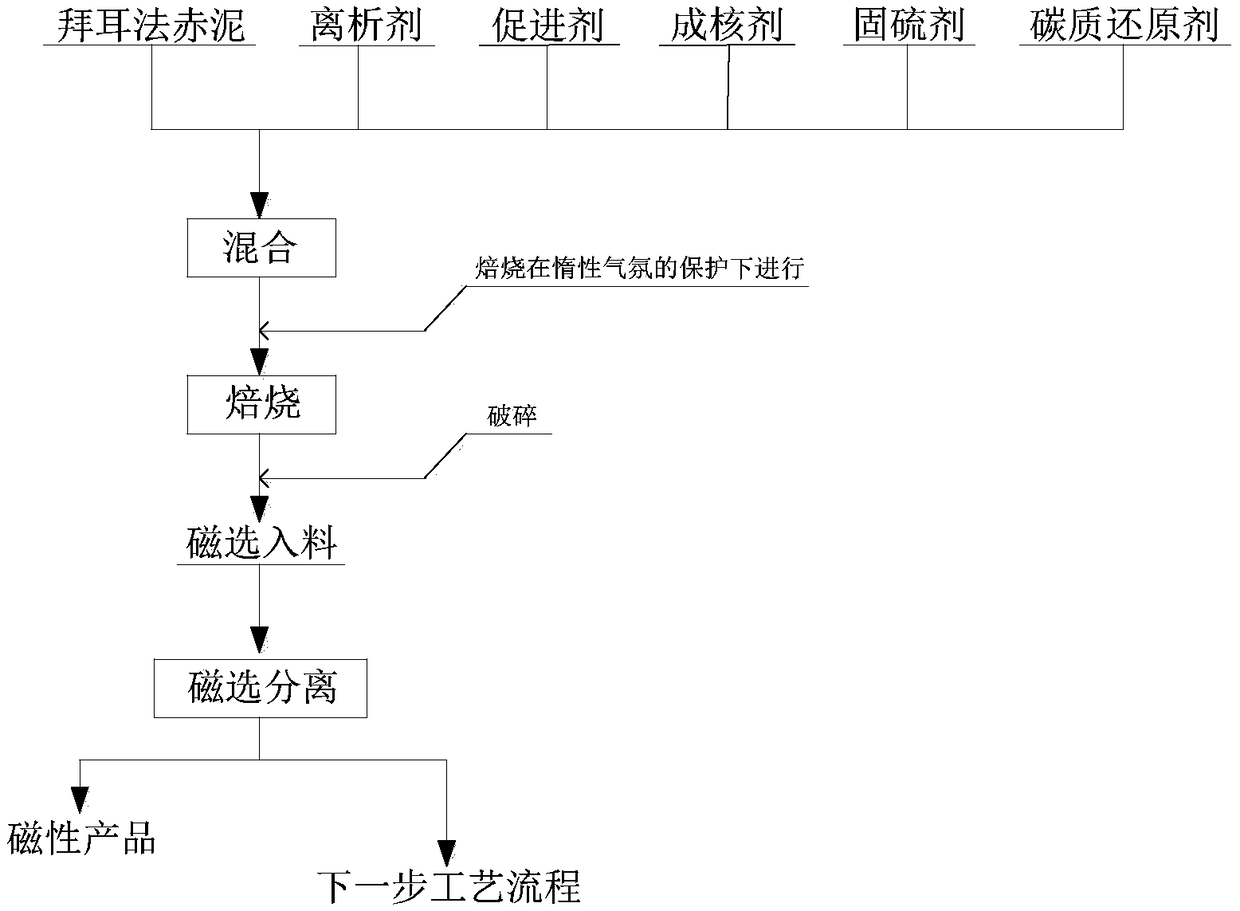

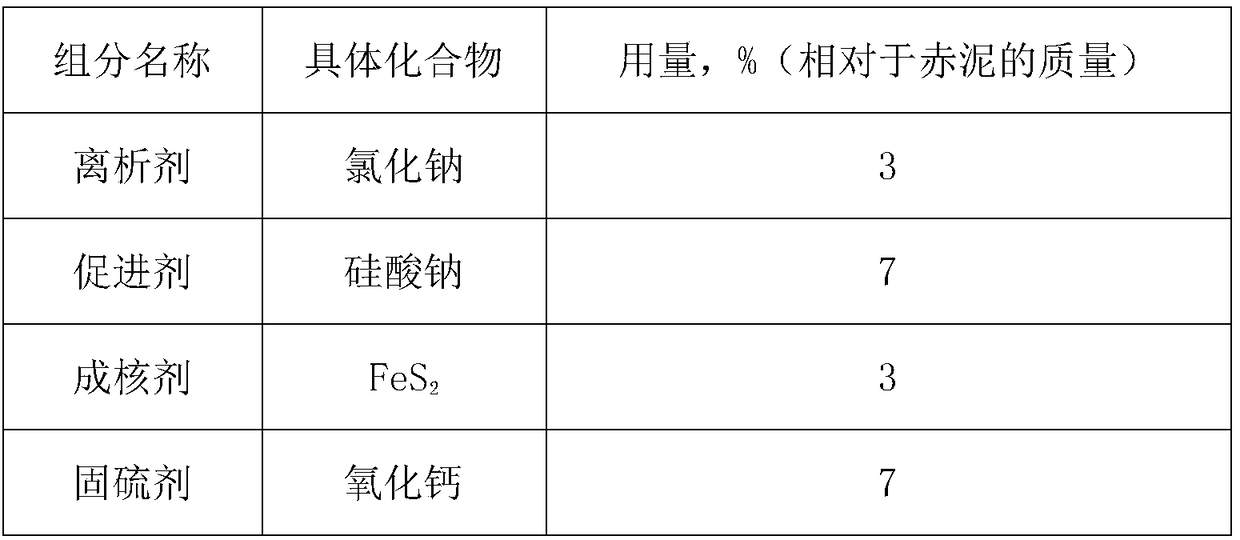

Method for extracting iron through reducing roasting red mud in bayer process

ActiveCN108950180APromote metallizationImprove and increase recoveryMagnetic separationProcess efficiency improvementMass ratioRed mud

The invention discloses a method for extracting iron through reducing roasting a red mud in a bayer process. A chloride-containing compound used as a segregation agent, a sodium-containing compound used as an accelerant, an iron-containing compound used as a nucleating agent, a calcium-containing compound used as a sulphur-fixing agent, and a carbonaceous reducing agent are added into the red mud;and according to the mass ratio of the red mud, the adding dosage of the chloride-containing compound is 3 to 10 percent by weight, the adding dosage of the sodium-containing compound is 5 to 15 percent, the adding dosage of the iron-containing compound is 3 to 8 percent, the adding dosage of the calcium-containing compound is 5 to 12 percent, and the adding dosage of the carbonaceous reducing agent is 5 to 15 percent. According to the method provided by the invention, a method for reducing roasting the red mud is adopted, so that iron in the red mud is reduced into low-price magnetic matterswhich are gathered together under the action of a nucleating agent so as to form large-grained crystal grains and be sorted through weak magnetism. According to the method, the metal conversion rateand a segregation effect in red mud reducing roasting can be remarkably improved, so that an effect on improving the iron recovery rate or the grade is achieved.

Owner:CENT SOUTH UNIV

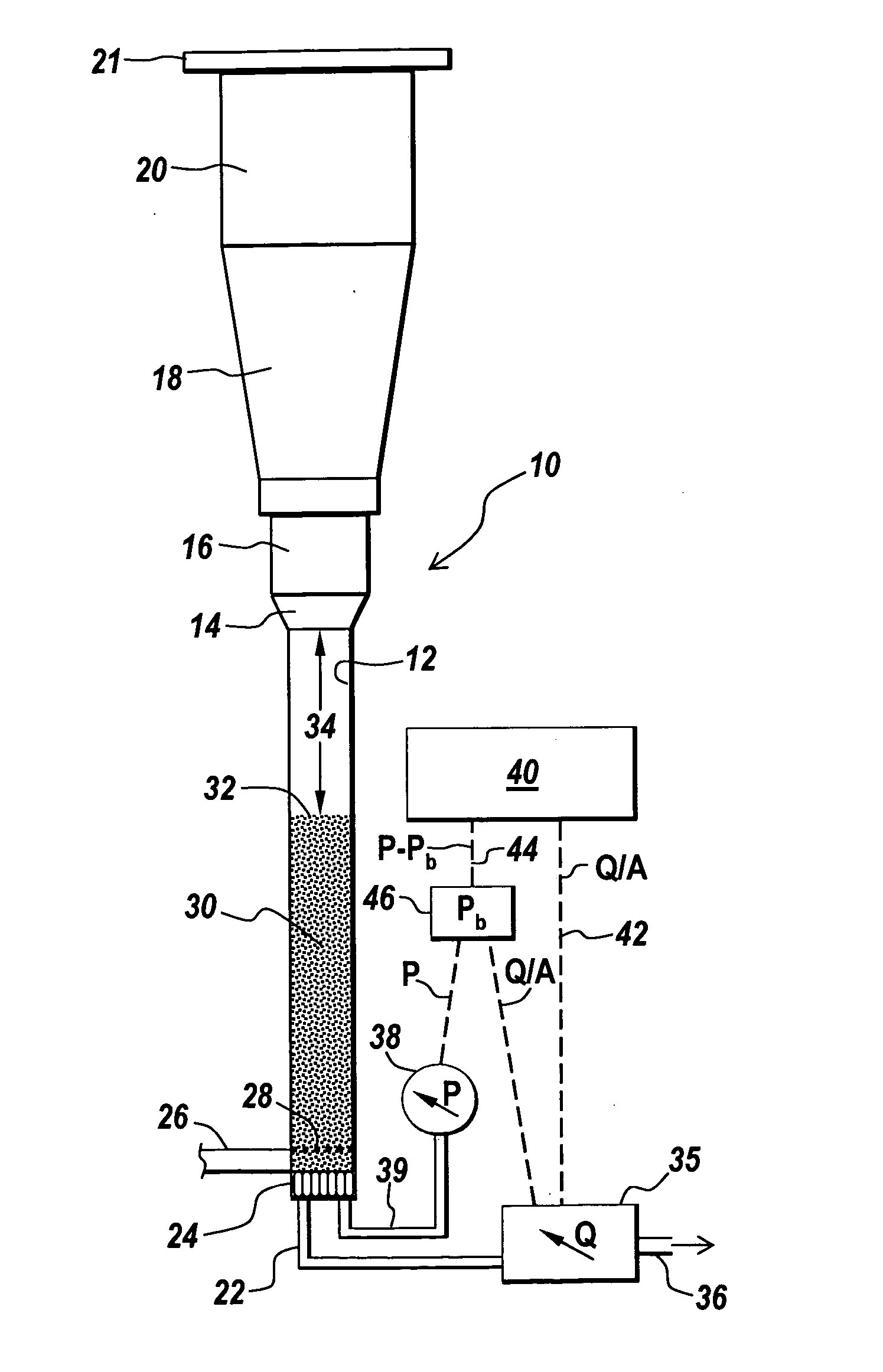

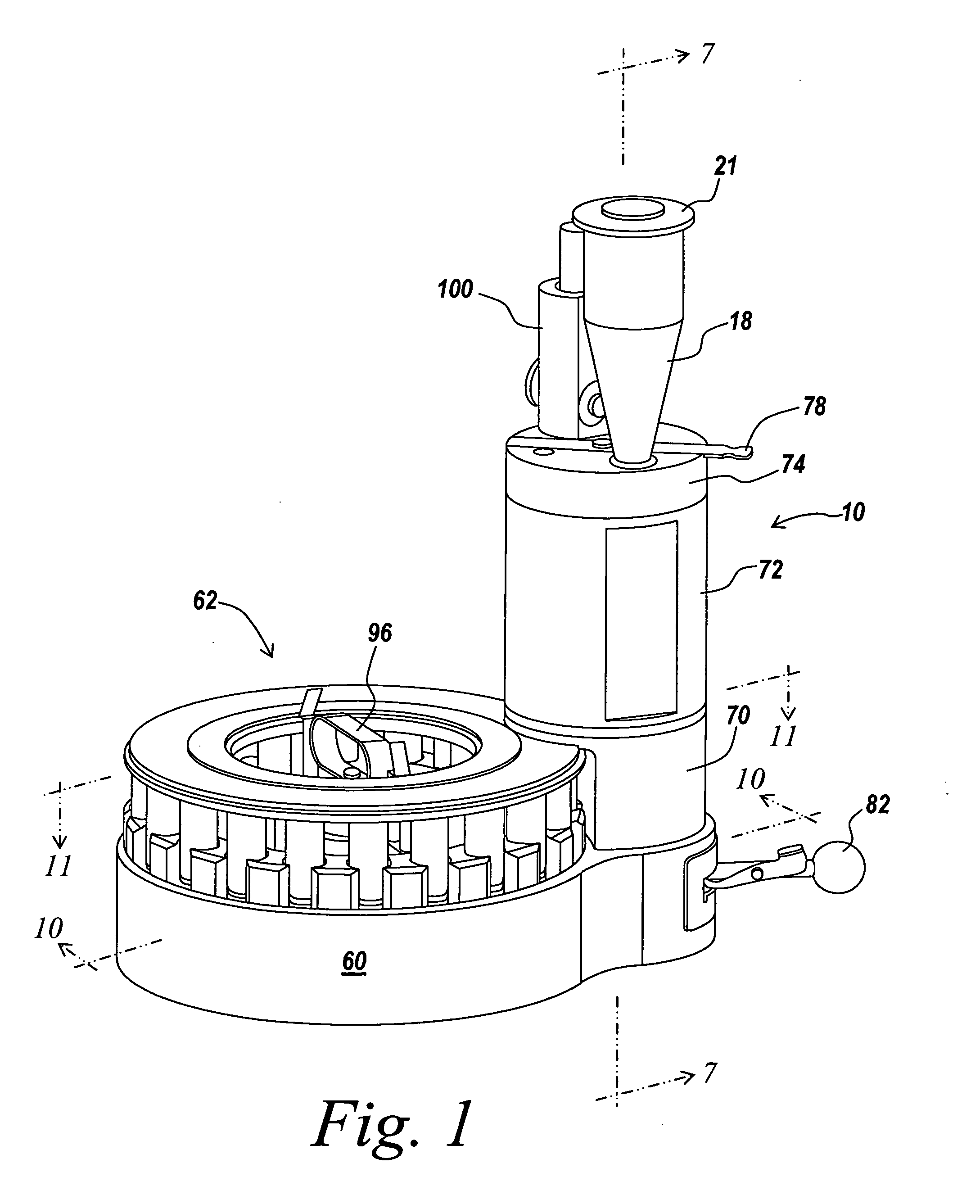

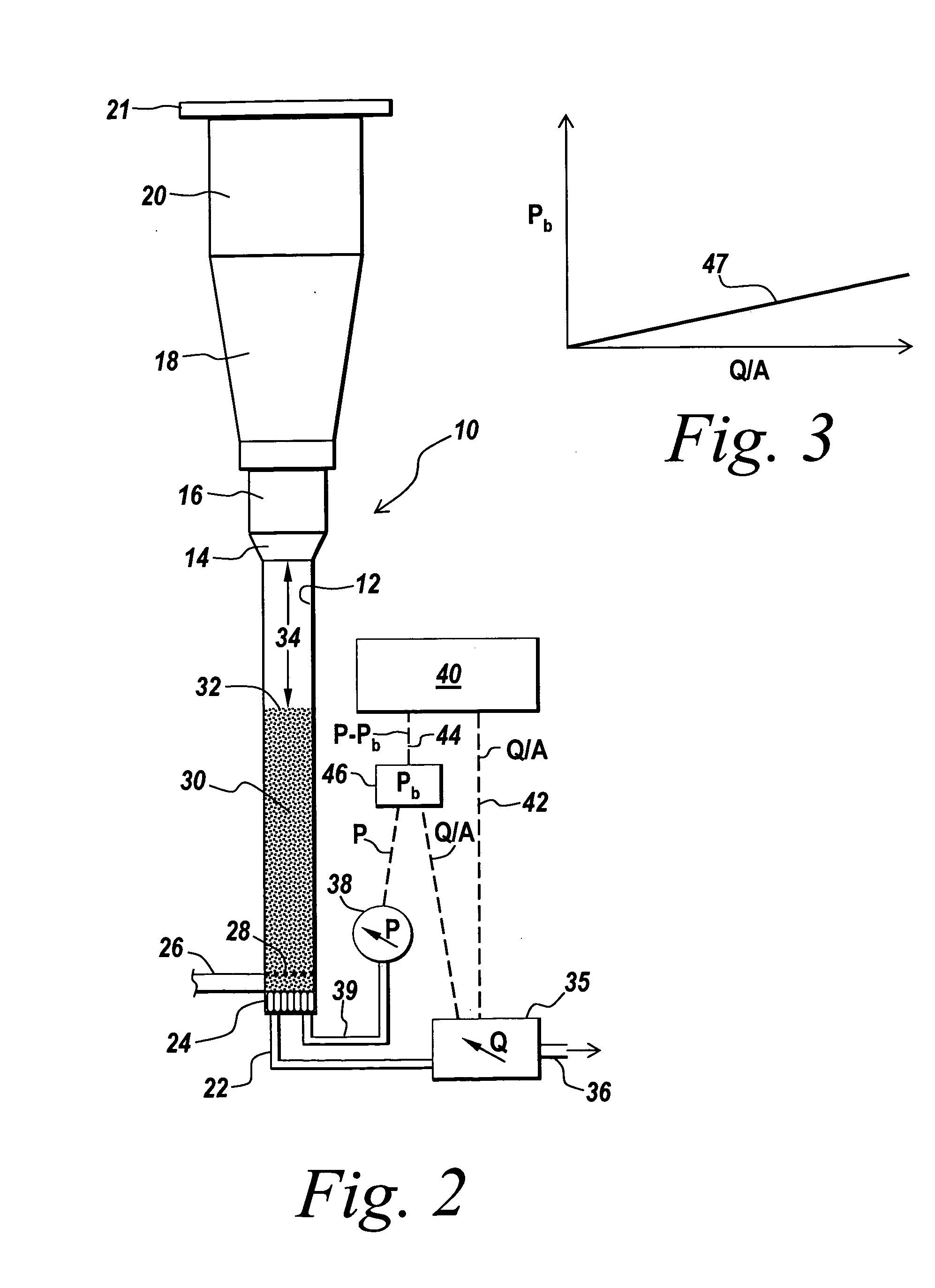

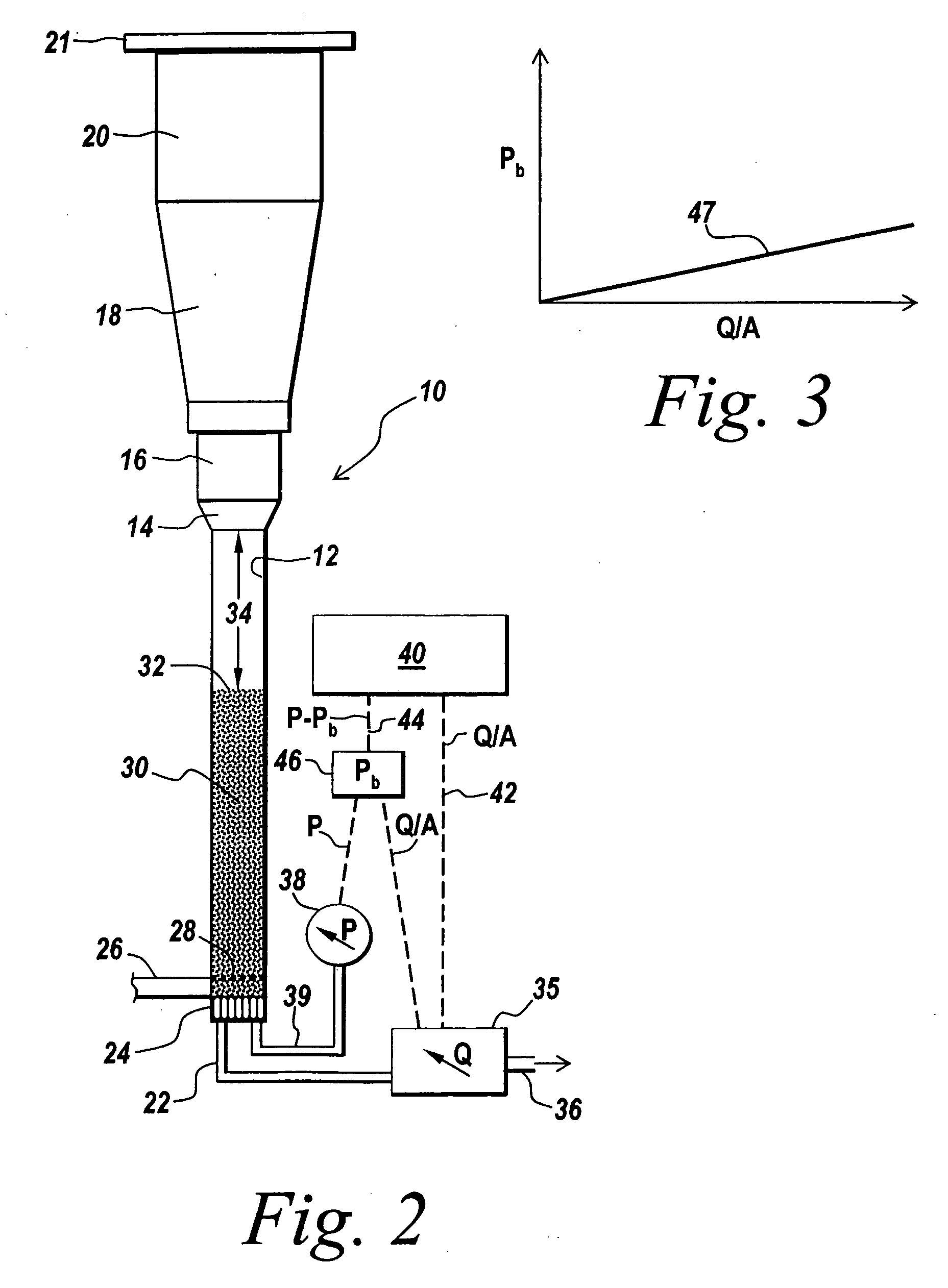

Method and apparatus for segregation testing of particulate solids

A bed of particulate solids is fluidized in a test chamber to yield multiple test samples for subsequent evaluation of segregation effects. A controlled stream of gas enters the chamber in a series of flow rate cycles each progressively increasing to a maximum rate of gas flow and then decreasing, the maximum rate increasing for successive cycles. An indicating function is formed from measurements of corresponding rates of gas flow and pressure across the bed. Upon termination of the fluidization, multiple samples are sequentially extracted from a single space at the bottom of the test chamber.

Owner:JENIKE & JOHANSON

Method and device for coupling and purifying polysilicon and removing phosphorus and metal with electron beams

InactiveCN102120578BEvenly distributedReduce distributionChemical industrySilicon compoundsMelting tankMetal impurities

The invention belongs to the technical field of polysilicon purification with a physical metallurgy technology and particularly relates to a method for coupling and purifying polysilicon and removing phosphorus and metal with electron beams. The method comprises the following steps of: forming a stable melting pool on the top of a low-phosphorous low-metal high-purity silicon ingot with the electron beams; putting silicon powder to be purified into the melting pool and melting to realize the rapid melting of the powder body to remove volatile phosphorous impurity in the silicon powder; simultaneously carrying out directional ingot pulling so that the low-phosphorus polysilicon grows in a directional solidification way; and removing metal impurities in the polysilicon by utilizing a segregation effect. The invention has the remarkable effects that: because ways of melting silicon powder with the electron beams and carrying out directional solidification are simultaneously adopted, the phosphorus impurity is rapidly removed with the electron beams, and the metal impurities with lower segregation coefficient are removed by the directional solidification way, the purity of the polysilicon is effectively improved, and the using requirement of solar grade silicon is achieved. The invention has the advantages of good purification effect, stable technology, simple process, high production efficiency, energy saving, low cost and suitability for batch production.

Owner:谭毅

Silicon tube and preparation method for silicon-tube solar cell-grade polycrystalline silicon rod

InactiveCN103882519ALow costPolycrystalline material growthBy pulling from meltHeat carrierPhotovoltaic industry

The invention relates to a silicon tube and a method for preparing a solar cell-grade intrinsic polycrystalline silicon rod and a boron-doped P type polycrystalline silicon rod by using the silicon tube. By adopting an intrinsic electroconductive silicon ring as seed crystals, a boron-containing P type or intrinsic electroconductive hyperpure silicon tube is drawn by virtue of a single crystal furnace and a CZ (Czochralski) method. The boron-containing P type silicon tube is taken as a heat carrier in a chemical method-based reduction furnace, when the heating temperature of the carrier is within a range from 1050 to 1100 DEG C, silicon generated by reacting hyperpure hydrogen with trichlorosilane is deposited on the heat carrier to prepare a hyperpure silicon-tube polycrystalline silicon rod. The intrinsic electroconductive silicon tube is taken as a container which is filled with raw material silicon silicon generated by using a physical metallurgy, the silicon tube is subjected to multiple directional solidification by use of an FZ (Float Zone) method, and then a compact silicon-tube solar cell-grade polycrystalline silicon rod with high purity is prepared by virtue of segregation effect. The solar cell-grade intrinsic polycrystalline silicon rod prepared by use of the silicon tube and the method creates conditions for the production of solar cell-grade monocrystalline silicon so as to realize the preparation of high-quality low-cost solar cells, and thus is significant for promoting the development of the photovoltaic industry.

Owner:天津环煜电子材料科技有限公司

Centrifugal casting process of high nitrogen austenitic stainless steel pipe under atmospheric pressure

ActiveCN105108098BImprove corrosion resistanceLow requirements for process conditionsFurnace typesHeat treatment furnacesAlloyNitrogen gas

The invention relates to a technology for centrifugal casting of a high-nitrogen austenitic stainless steel pipe at normal pressure. The technology includes the steps of preparing ingredients, preparing a casting mold and a casting machine, conducting alloy smelting and pouring, carrying out shaping cleaning and heat treatment, recording and checking. The cast pipe is made of high-nitrogen austenitic stainless steel, the nitrogen content of the alloy melt or oversaturated alloy in the solidification process is larger than or equal to 0.65% N at the normal pressure, spontaneous gas can be generated in the normal-pressure casting process, and nitrogen bubbles overflow. Under the normal-pressure smelting condition, high-nitrogen-content austenitic stainless steel molten metal obtained by smelting meets the pouring temperature condition, and then enters in the pouring step rapidly in 90 seconds, and centrifugal casting of all the smelting molten metal is completed in three minutes. The auxiliary segregation effect of centrifugal force is utilized, and the overflowing nitrogen bubbles deviate from the quality specification portion of the cast pipe. By the adoption of the technology, the nitrogen content, the bubble positions and the bubble number can be controlled stably and effectively, and thus the surface and overall quality requirement can be met.

Owner:CHANGCHUN SHIYUE ENERGY SAVING MATERIAL CO LTD

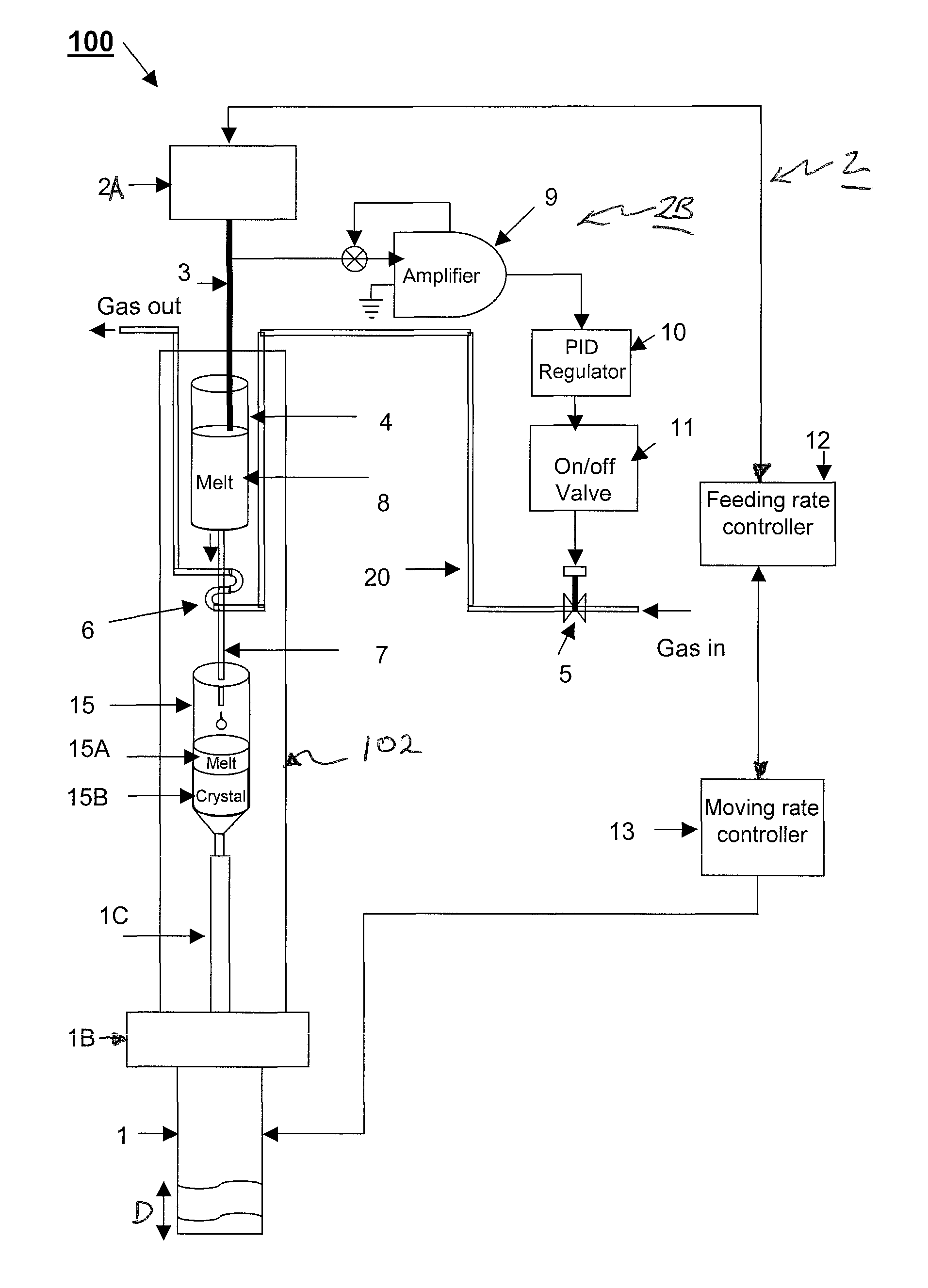

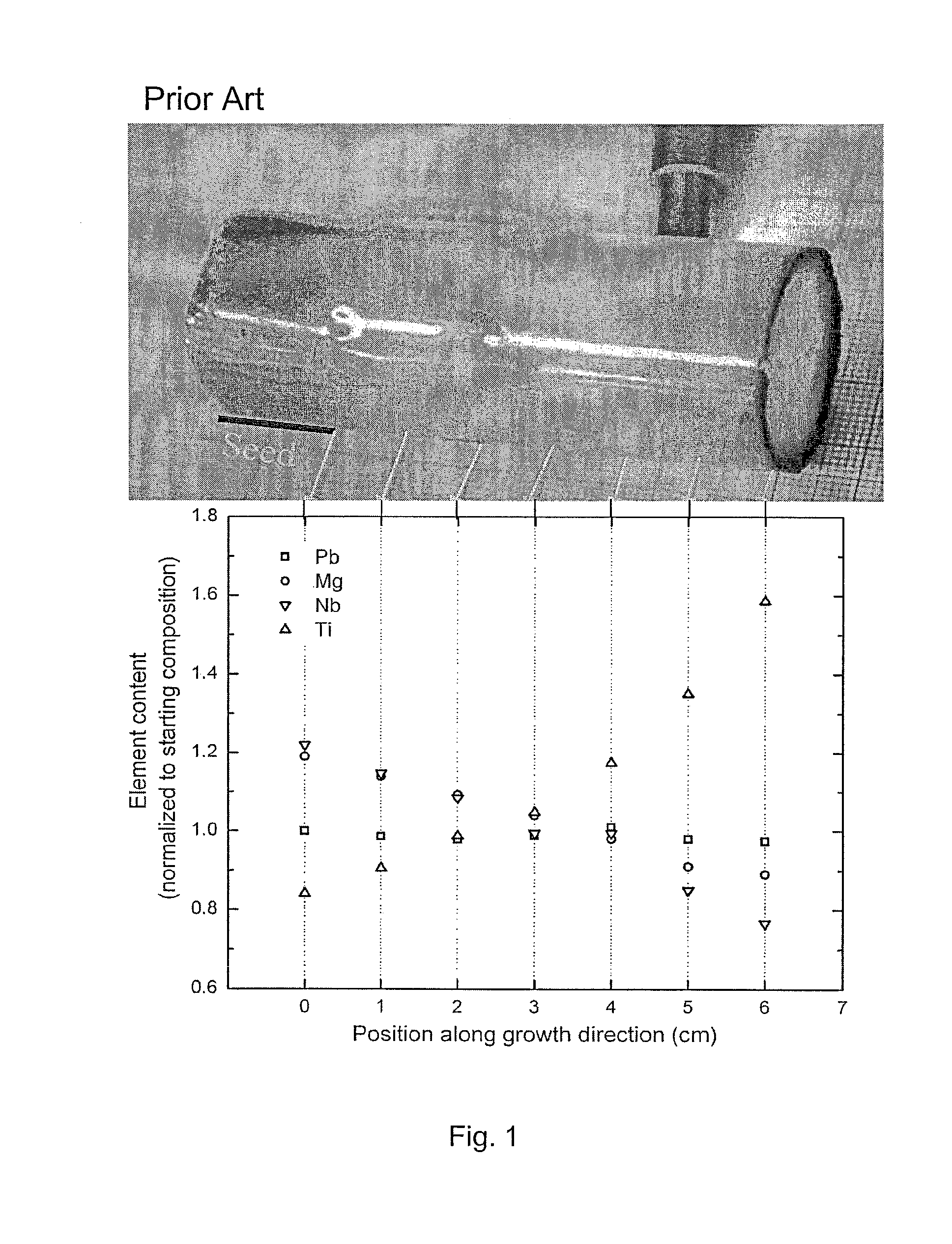

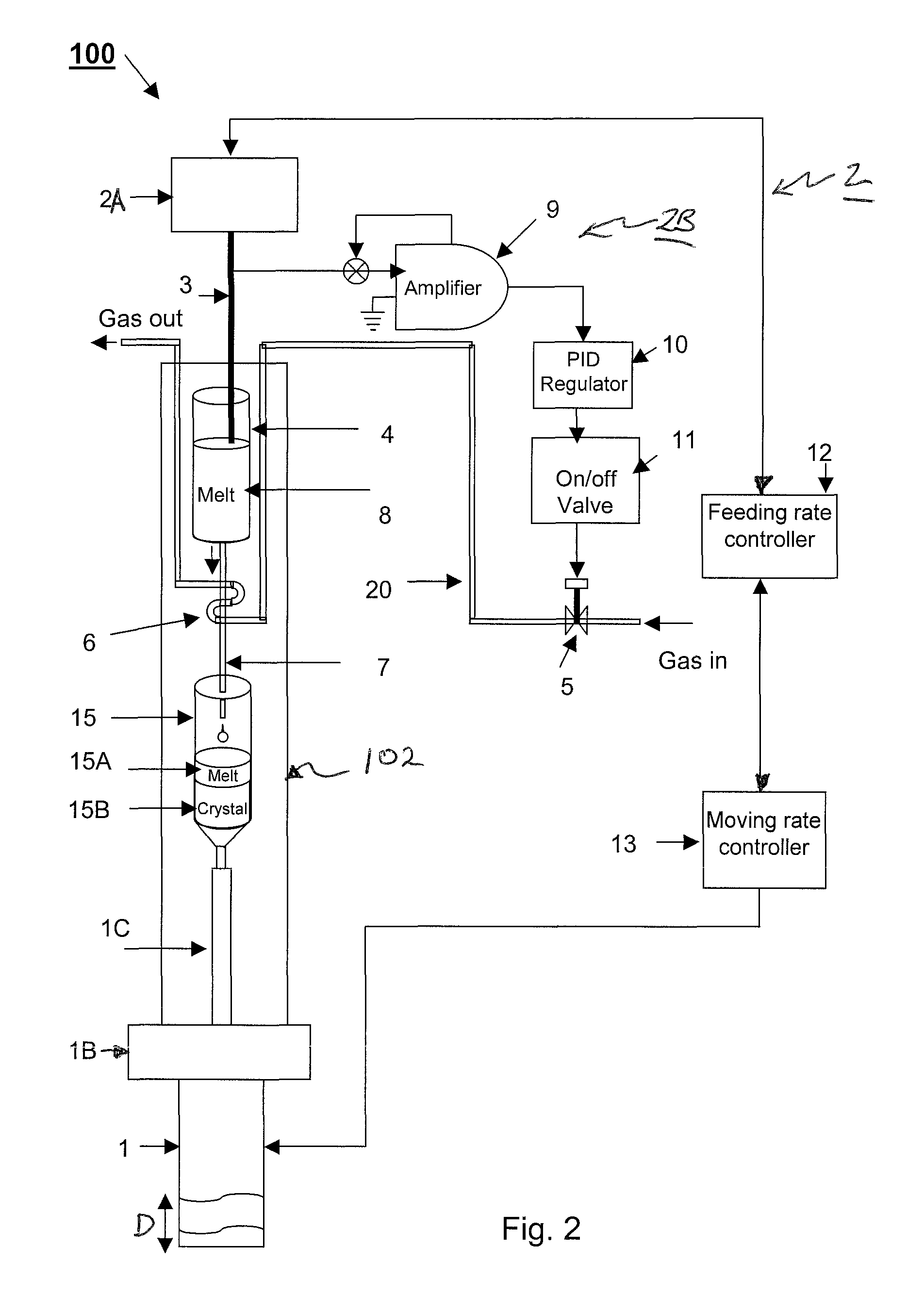

Crystal growth system and method for lead-contained compositions using batch auto-feeding

ActiveUS8535442B2Improve homogeneityImprove utilizationAfter-treatment apparatusPolycrystalline material growthIndiumCrucible

Owner:CTG ADVANCED MATERIALS

Method and apparatus for segregation testing of particulate solids

InactiveUS20070028671A1Reduce the possibilitySimple methodFluid-tightness measurement using fluid/vacuumMaterial analysisParticulatesTest sample

A bed of particulate solids is fluidized in a test chamber to yield multiple test samples for subsequent evaluation of segregation effects. A controlled stream of gas enters the chamber in a series of flow rate cycles each progressively increasing to a maximum rate of gas flow and then decreasing, the maximum rate increasing for successive cycles. An indicating function is formed from measurements of corresponding rates of gas flow and pressure across the bed. Upon termination of the fluidization, multiple samples are sequentially extracted from a single space at the bottom of the test chamber.

Owner:JENIKE & JOHANSON

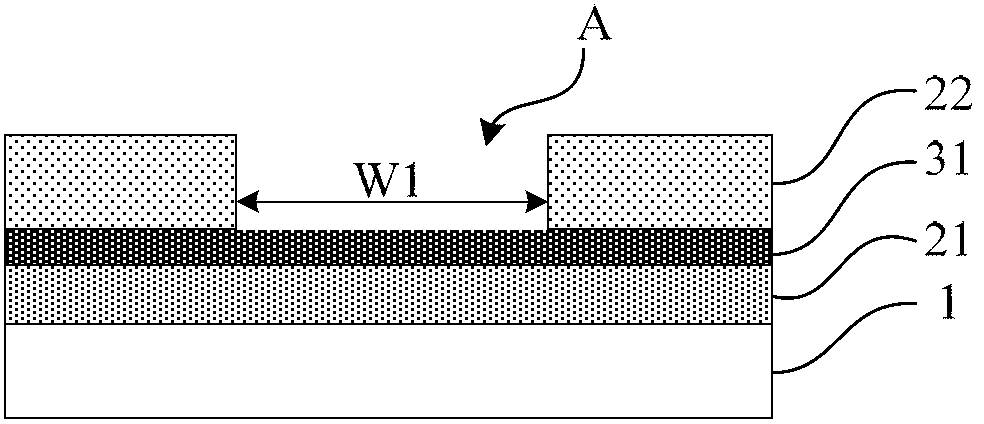

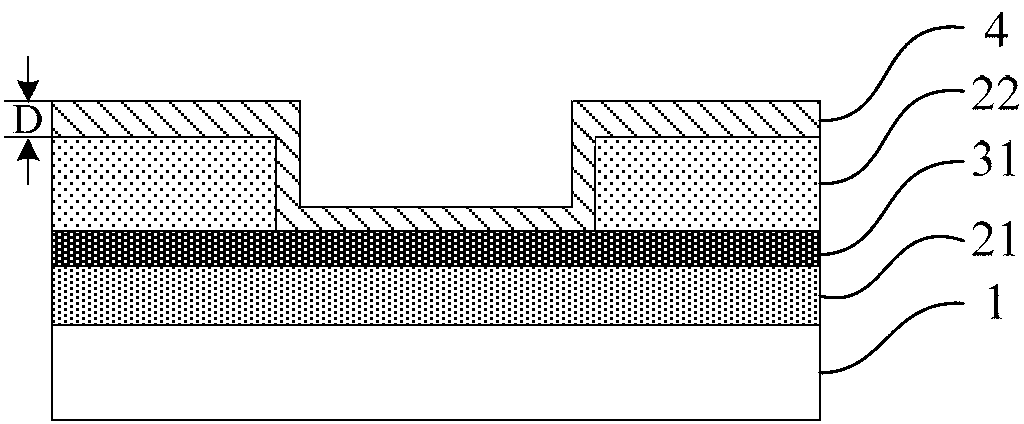

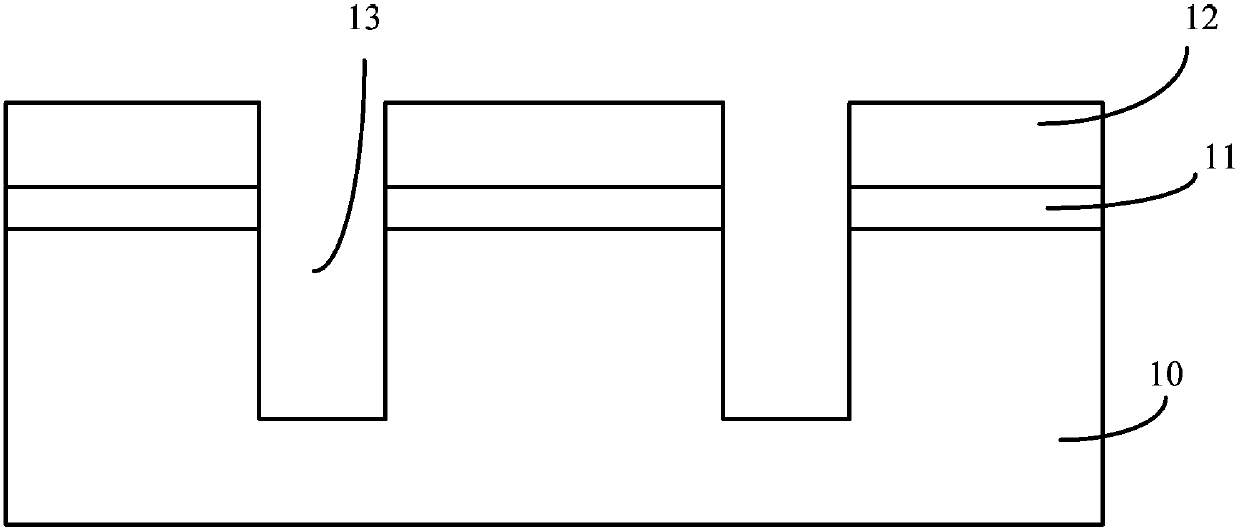

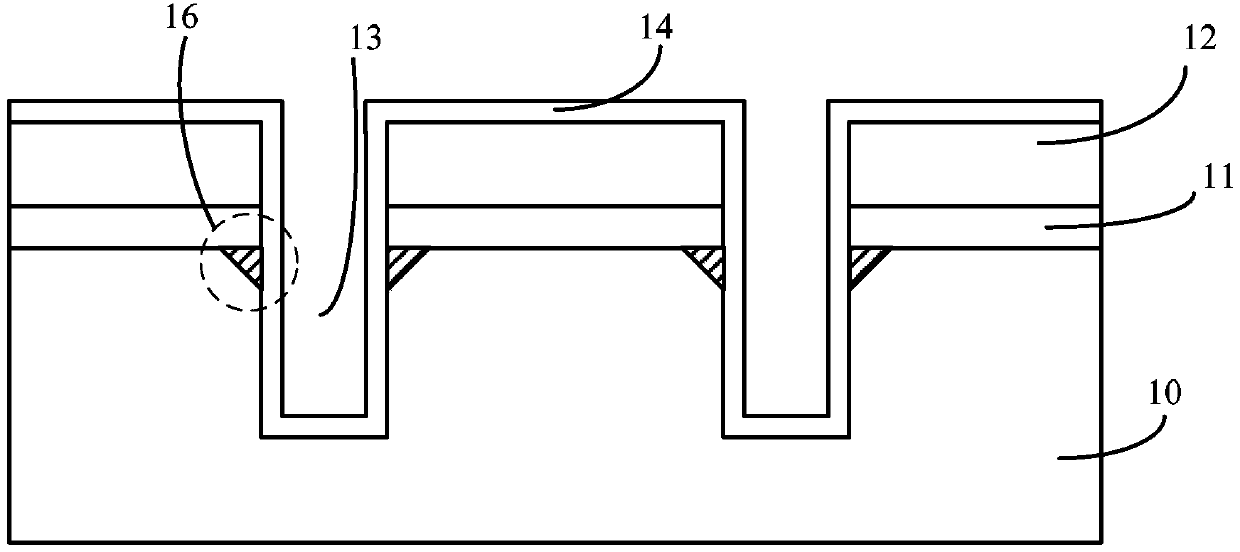

Shallow groove segregation structure and forming method thereof

ActiveCN103377981AImprove the isolation effectImprove performanceSemiconductor/solid-state device manufacturingWork performanceSegregation effect

The invention relates to a shallow groove segregation structure and a forming method of the shallow groove segregation structure. The method comprises the steps that a semiconductor substrate is provided, and a liner oxide layer and a hard mask layer are sequentially formed on the surface of the semiconductor substrate; part of the hard mask layer and part of the liner oxide layer are removed to expose the surface of the semiconductor substrate, the remnant hard mask layer and the remnant liner oxide layer serve as a mask, and a plurality of openings are formed in the semiconductor substrate; a liner layer is formed on the side walls of the openings and the bottoms of the openings and made from silicon doping with carbon or silicon doping with germanium or silicon doping with carbon and germanium; an insulating layer flush with the surface of the hard mask layer is formed on the surface of the liner layer; the hard mask layer, the liner oxide layer and the insulating layer higher than the surface of the semiconductor substrate are removed. According to the forming method of the shallow groove segregation structure, the segregation effect of the shallow groove segregation structure is improved. Furthermore, when a semiconductor device is formed on the surface of the semiconductor substrate segregated by the shallow groove segregation structure, the working performance of the semiconductor device is stable.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com