Method for extracting iron through reducing roasting red mud in bayer process

A Bayer process red mud, roasting technology, applied in chemical instruments and methods, process efficiency improvement, magnetic separation and other directions, can solve the problems of inability to be separated by magnetic separator, difficult dissociation and reduction, etc. The effect of growing up, promoting separation, reducing the degree of harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

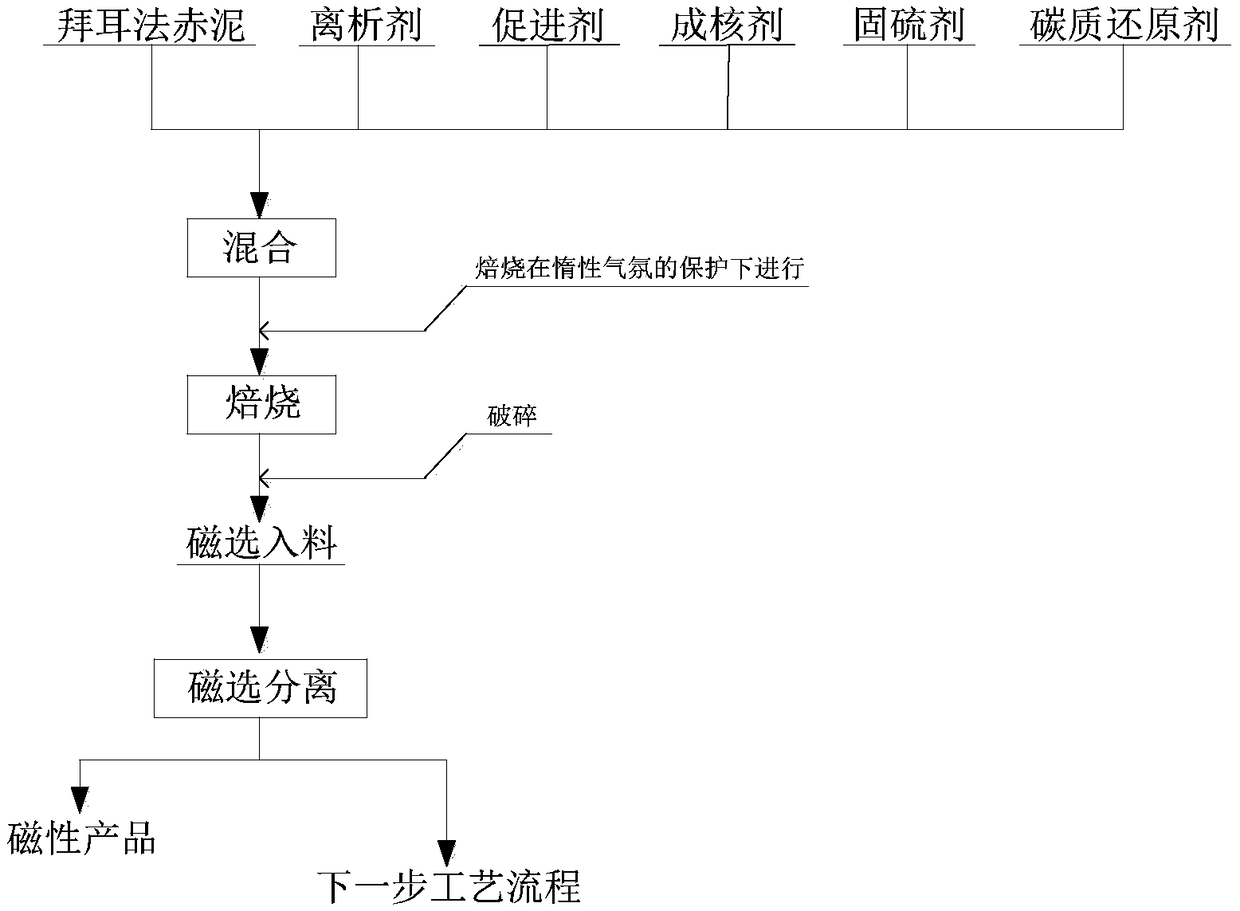

Method used

Image

Examples

Embodiment 1

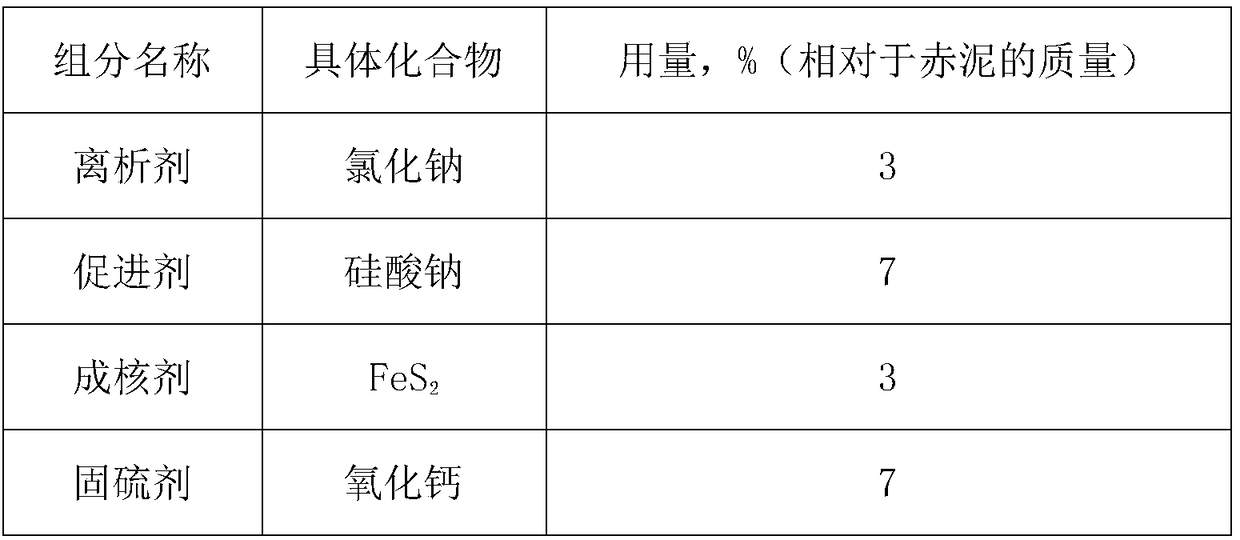

[0051] The Bayer process red mud is taken from a certain place in Henan. The raw materials of the Bayer process are boehmite and boehmite, with a total iron content of 23.17%.

[0052]

[0053]

[0054] Mix with Bayer red mud according to the ratio in the above table; place the mixed raw meal in a high-temperature furnace and roast at 1000°C for 30 minutes; continue to cool to room temperature under inert gas and grind to a fineness of 80%≤0.074mm; The final sintered clinker is separated by magnetic separation to obtain magnetic products and non-magnetic residues, wherein the magnetic field strength of magnetic separation is 1000GS; magnetic products can be directly used as iron concentrate products, and non-magnetic products can be used as raw materials for the next process.

[0055] The technical indicators obtained by the method are as follows: the iron grade of the magnetic iron concentrate is 60.6%, and the iron recovery rate is 90.3%.

Embodiment 2

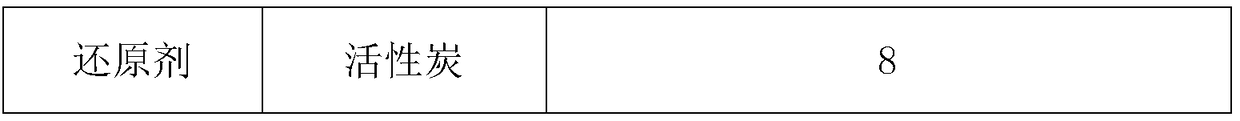

[0057] The Bayer process red mud is taken from a certain place in Guizhou. The raw material of the Bayer process is mainly diaspore, with a total iron content of 20.79%.

[0058] component name

specific compound

Amount, % (relative to the mass of red mud)

4

Accelerator

8

Nucleating agent

FeS2

4

Sulfur fixative

6

12

[0059] Mix with the Bayer process red mud according to the ratio in the above table; place the mixed raw meal in a high-temperature furnace and roast at 1100°C for 40 minutes; continue to cool to room temperature under inert gas and grind to a fineness of 80%≤0.074mm; The final sintered clinker is separated by magnetic separation to obtain magnetic products and non-magnetic residues, wherein the magnetic field strength of magnetic separation is 1200GS; magnetic products can be...

Embodiment 3

[0062] The Bayer process red mud is taken from a certain place in Shandong, and the raw material of the Bayer process is mainly boehmite, with a total iron content of 26.01%.

[0063] component name

specific compound

Amount, % (relative to the mass of red mud)

magnesium chloride

3

Accelerator

5

Nucleating agent

FeS 2

3

Sulfur fixative

7

reducing agent

11

[0064] Mix with Bayer red mud according to the ratio in the above table; place the mixed raw meal in a high-temperature furnace and roast at 1200°C for 50 minutes; continue to cool to room temperature under inert gas and grind to a fineness of 80%≤0.074mm; The final sintered clinker is separated by magnetic separation to obtain magnetic products and non-magnetic residues, wherein the magnetic field strength of magnetic separation is 1600GS; the magnetic products can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com