Patents

Literature

130 results about "Magnetic oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic recording. Iron(III) oxide was the most common magnetic particle used in all types of magnetic storage and recording media, including magnetic disks (for data storage) and magnetic tape (used in audio and video recording as well as data storage).

Magnetic tape and magnetic tape cartridge

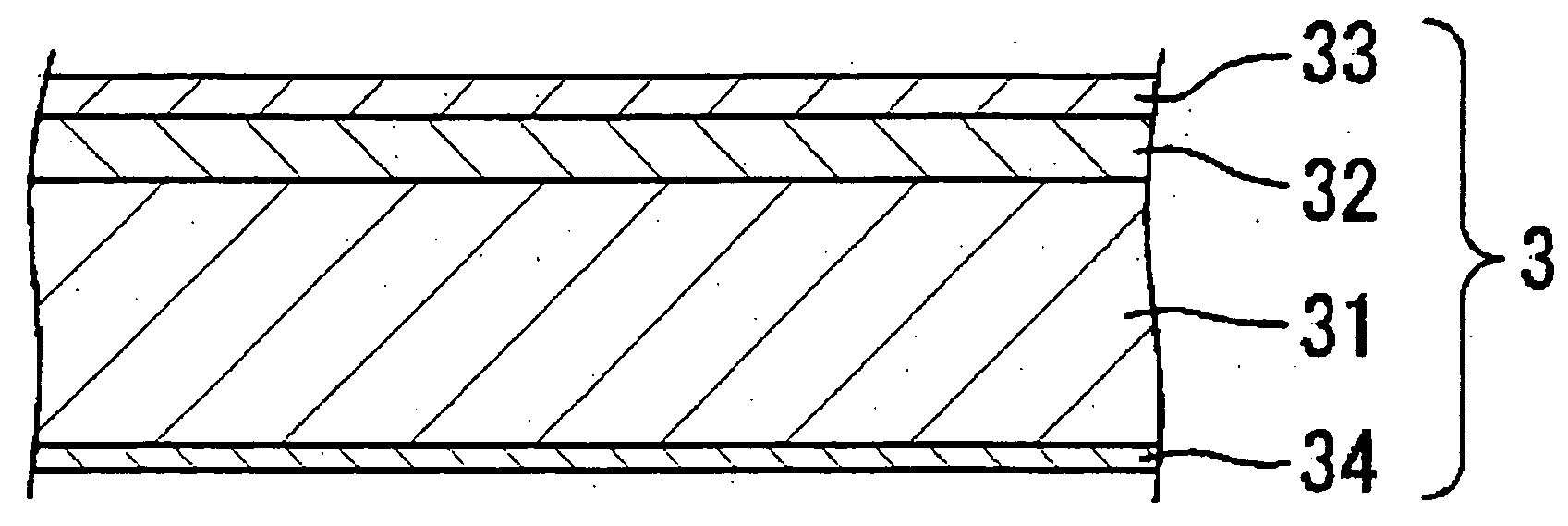

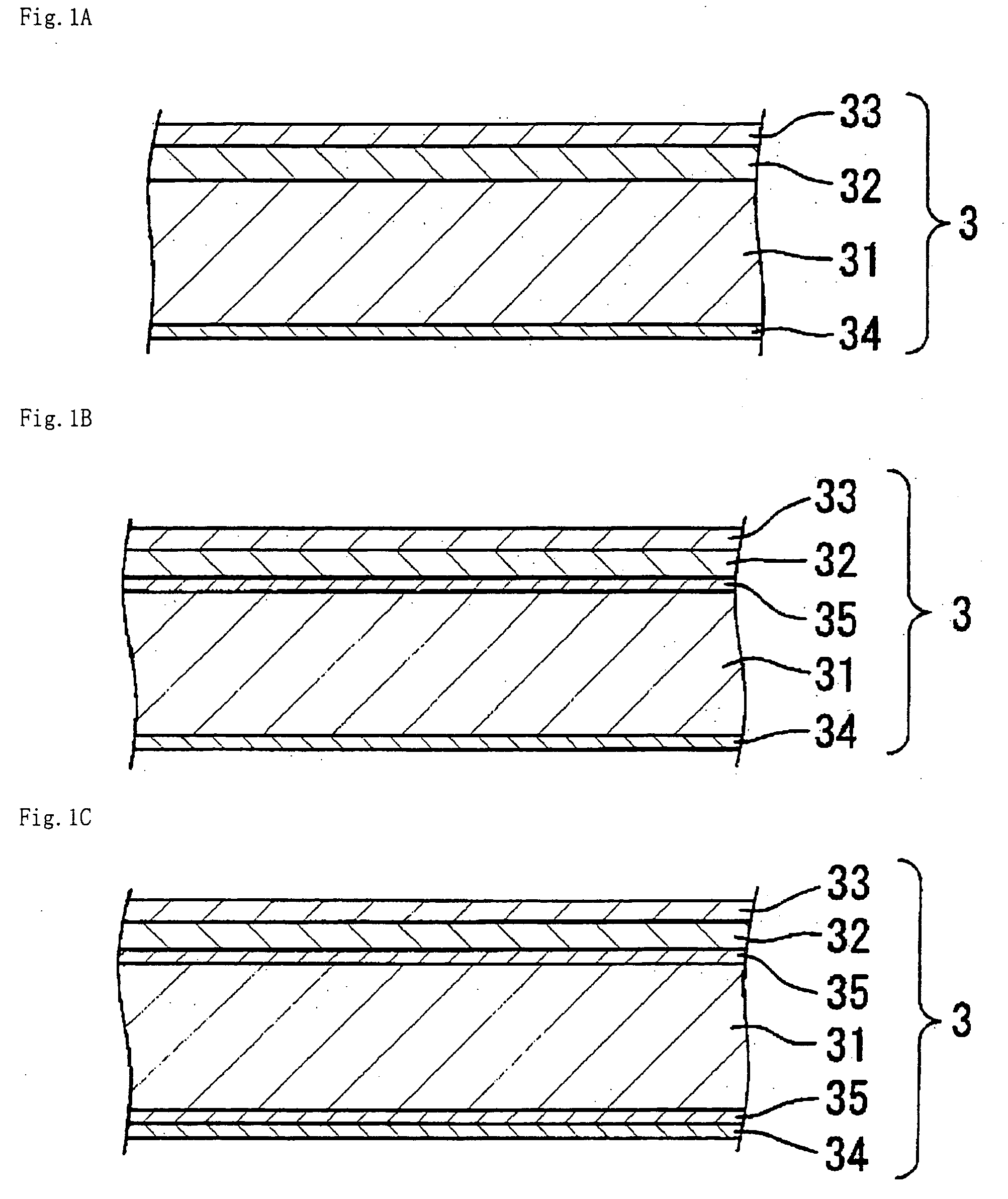

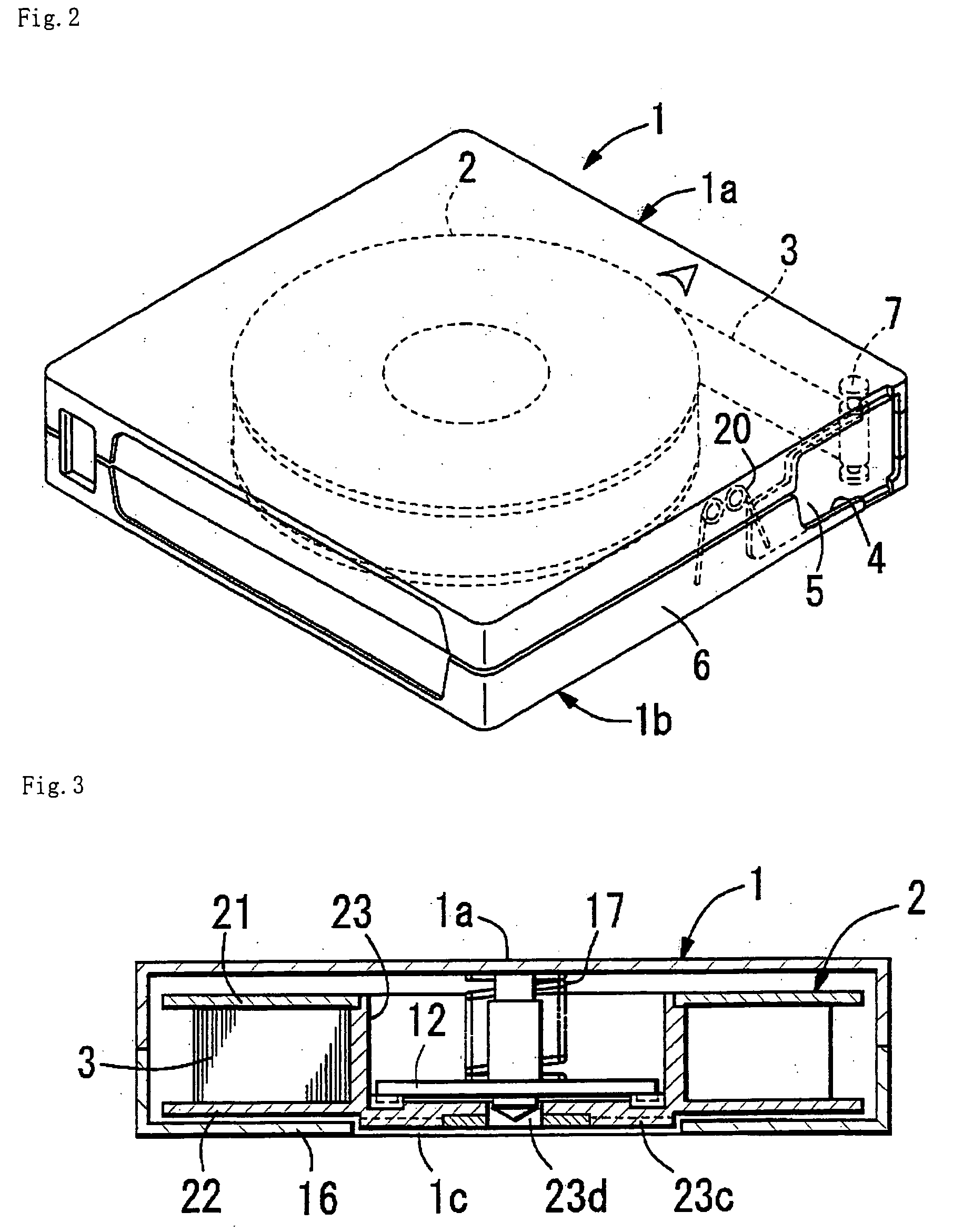

InactiveUS20050153170A1Improved in performanceGood dimensional stabilityMaterials with ironLayered productsMagnetic tapeThermal expansion

There is provided a magnetic tape comprising a non-magnetic support, and a primer layer and a magnetic layer both formed on a surface of the non-magnetic support, and a backcoat layer formed on the other surface of the non-magnetic support, wherein the magnetic layer contains magnetic powder which comprises needle-like iron-based magnetic particles, and has a thickness of 0.09 μm or less; and the primer layer contains non-magnetic powder which comprises plate-like non-magnetic oxide particles with an average particle size of 10 to 100 nm. Further, the thermal expansion coefficient of the magnetic layer in the tape widthwise direction is (0 to 8)×10−6 / ° C., and the humidity expansion coefficient of the magnetic layer in the tape widthwise direction is (0 to 10)×10−6 / % RH; and the amount of edge weave which is formed on either of the edges of the tape serving as the side of reference for the feeding of the tape is 0.8 μm or less. This magnetic tape is excellent in performance for recording / reproducing signals with short wavelengths and hardly causes a decrease in reproducing output due to off-track.

Owner:HITACHT MAXELL LTD

Method for preparing magnetic oxide iron and magnetic oxide iron desulfurizer prepared thereby

ActiveCN101585557AGuaranteed temperatureGuaranteed firing temperatureIron oxides/hydroxidesFerrous saltsSulfur

The invention relates to a method for preparing magnetic oxide iron Fe21.333O32, which comprises the following steps: (a) mixing solid soluble ferrous salt and solid hydroxid according to a molar ratio of iron to hydroxyl being between 1:2 and 1:3; (b) completing reaction of a mixed material prepared in step (a) by kneading, and controlling the temperature of the material not to exceed 70 DEG C in the kneading process; (c) drying a reaction product obtained in step (b) in air; (d) washing and filtering a material obtained in step (c); (e) naturally drying or baking a solid obtained in step (d); and (f) roasting a product obtained in step (e) at a temperature of between 150 and 500 DEG C. The invention further discloses a magnetic oxide iron Fe21.333O32 desulfurizer prepared by the preparation method. Tests show that the desulfurizer has high sulfur capacity reaching 62.0 percent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

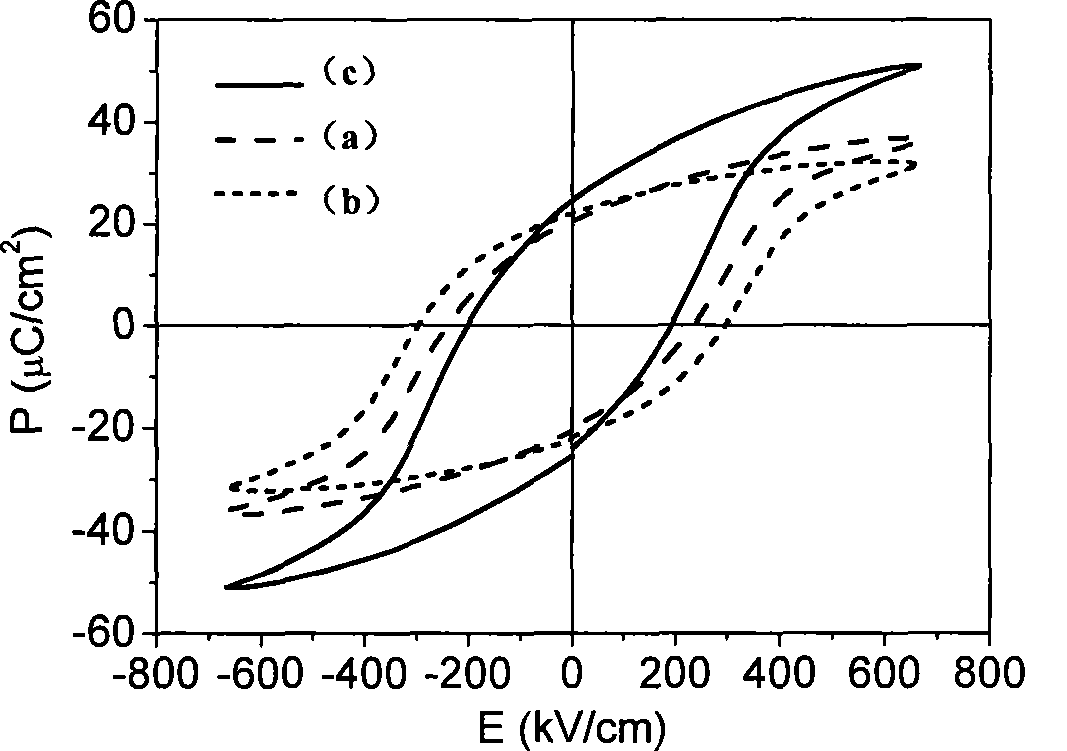

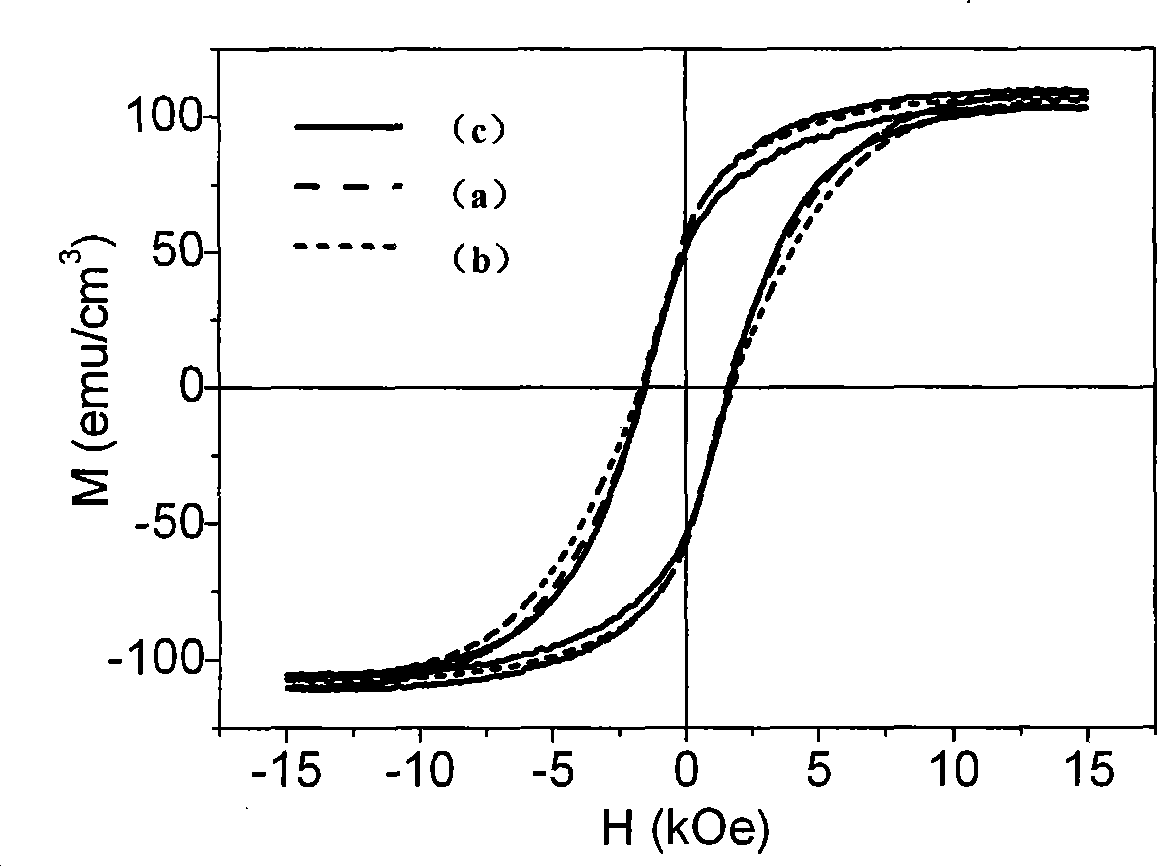

Stack ferro-electricity /magnetic multiferrou magnetoelectric compound film with conductive oxide as buffer layer and preparation thereof

InactiveCN101376600ASimple preparation processImprove magnetoelectric propertiesLayered productsElectricityComposite film

The invention discloses laminated ferroelectric / magnetic multiferroic and magnetoelectric composite film and preparation method thereof. The film comprises a substrate, a ferroelectric oxide layer and a magnetic oxide layer, and also a buffer layer positioned between the substrate layer and the ferroelectric oxide layer or the magnetic oxide layer. The layer can be LaNiO3, YBa2Cu3O7-x or SrRuO3, among which LaNiO3 is preferred. The preparation method comprises the following steps: firstly, buffer layer sol is prepared; secondly, the buffer layer sol is uniformly coated on the substrate to obtain the buffer layer; thirdly, sol of the ferroelectric oxide layer and the magnetic oxide layer is respectively prepared; fourthly, the sol obtained in step 3 is coated on the buffer layer, and then the end product is obtained. After the composite film is introduced into the buffer layer, the stress restraint of the substrate to the composite film is effectively reduced, the magnetoelectric coupling performance of the composite film with laminated structure is obviously enhanced, the cost is reduced, the preparation technique is simple, the requirement on the equipment is low, and the compatibility with the prior technique is good.

Owner:TSINGHUA UNIV

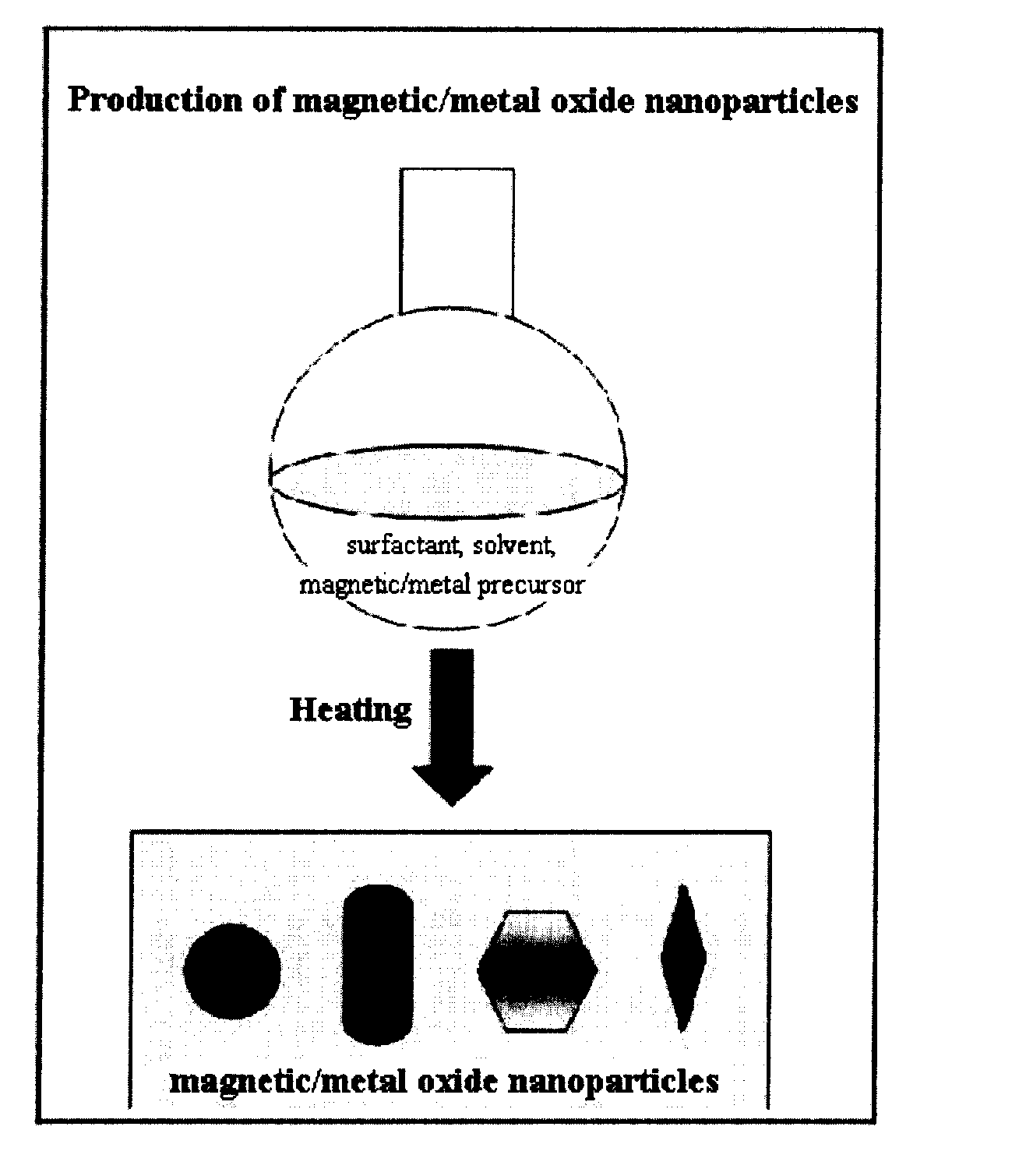

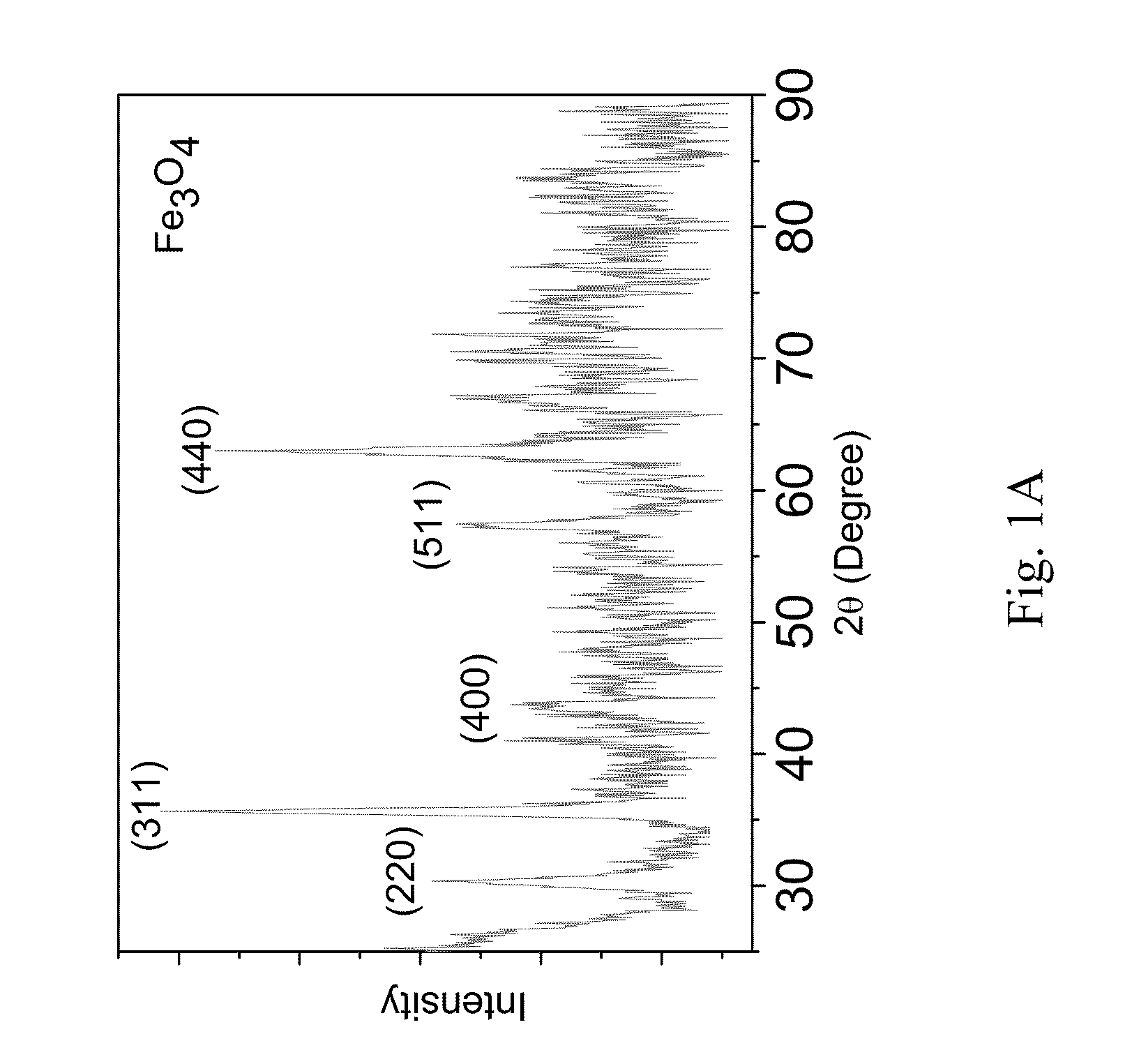

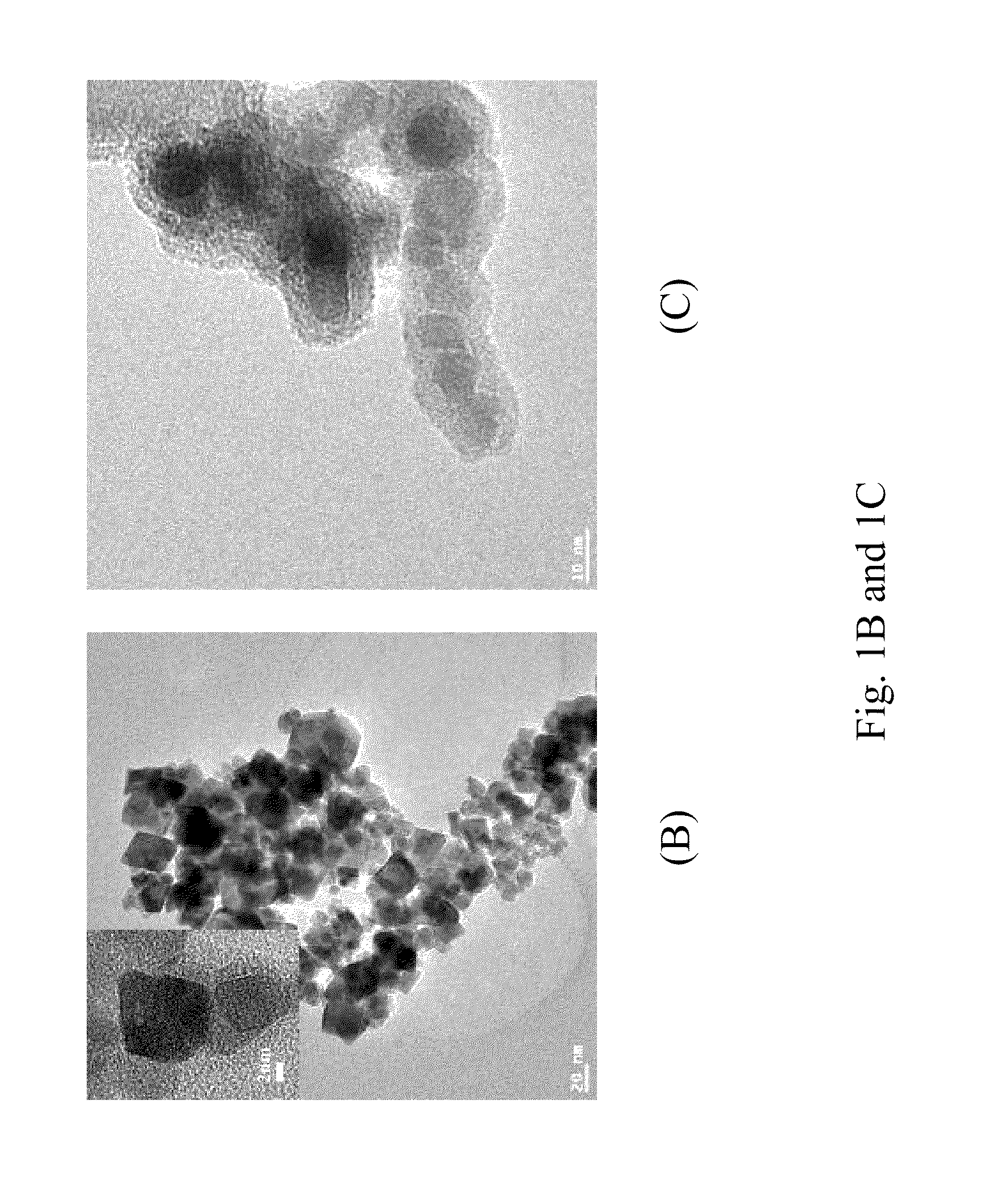

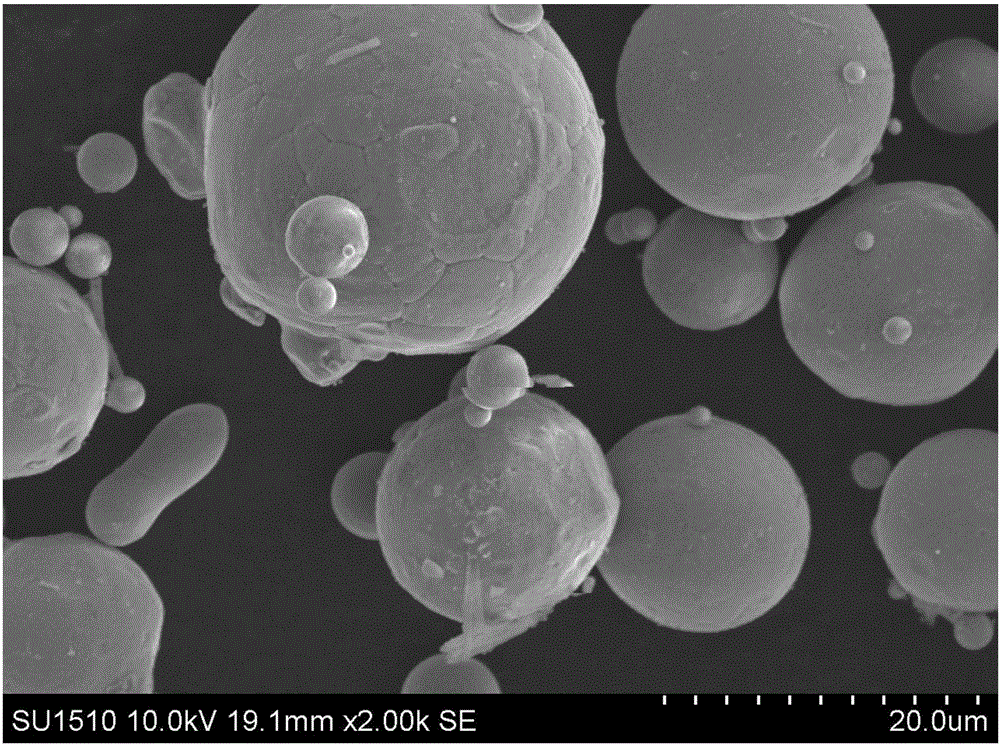

Preparation Method of Magnetic and Metal Oxide Nanoparticles

ActiveUS20080003159A1Efficient mass productionUniform shapeCopper oxides/halidesManganese oxides/hydroxidesMetal oxide nanoparticlesMagnetic oxide

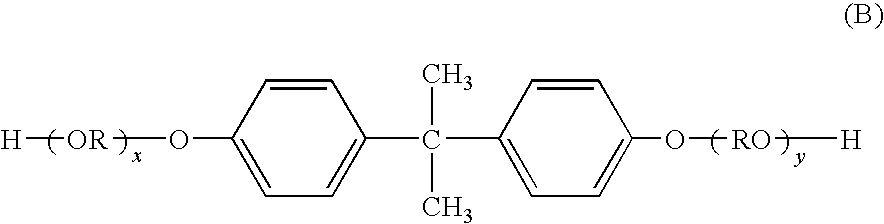

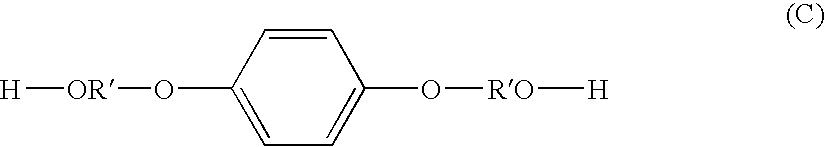

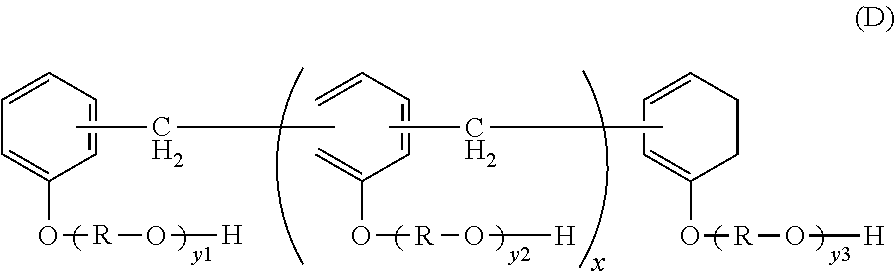

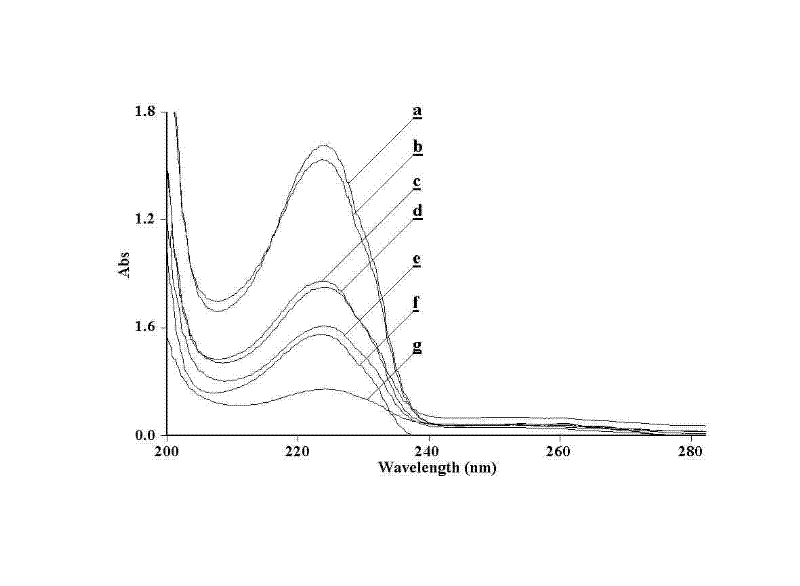

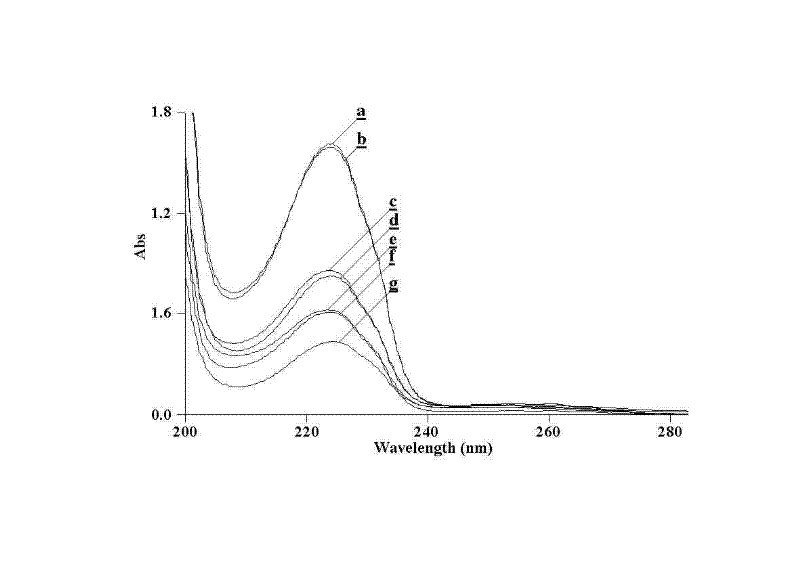

This invention relates, in general, to a method of producing magnetic oxide nanoparticles or metal oxide nanoparticles and, more particularly, to a method of producing magnetic or metal oxide nanoparticles, which comprises (1) adding a magnetic or metal precursor to a surfactant or a solvent containing the surfactant to produce a mixed solution, (2) heating the mixed solution to 50-6001 C to decompose the magnetic or metal precursor by heating so as to form the magnetic or metal oxide nanoparticles, and (3) separating the magnetic or metal oxide nanoparticles. Since the method is achieved through a simple process without using an oxidizing agent or a reducing agent, it is possible to simply mass-produce uniform magnetic or metal oxide nanoparticles having desired sizes compared to the conventional method.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

Magnetic toner

The object of the present invention is to provide a magnetic toner enabling an image with high image density and excellent image reproducibility to be obtained, which is excellent in fluidity, charging stability, and charging uniformity, even for long-term use, and also enabling an image whose fogging, ghost, and scattering are suppressed to be obtained. The magnetic toner has at least a binder resin and a magnetic material, where, the magnetic material is an magnetic iron oxide whose dielectric breakdown voltage of the magnetic material is 160 to 1600 V / cm, and the dielectric loss tangent (tan δ) of the magnetic toner at 100 kHz and 40° C. is 2.0×10−3 to 1.0×10−2.

Owner:CANON KK

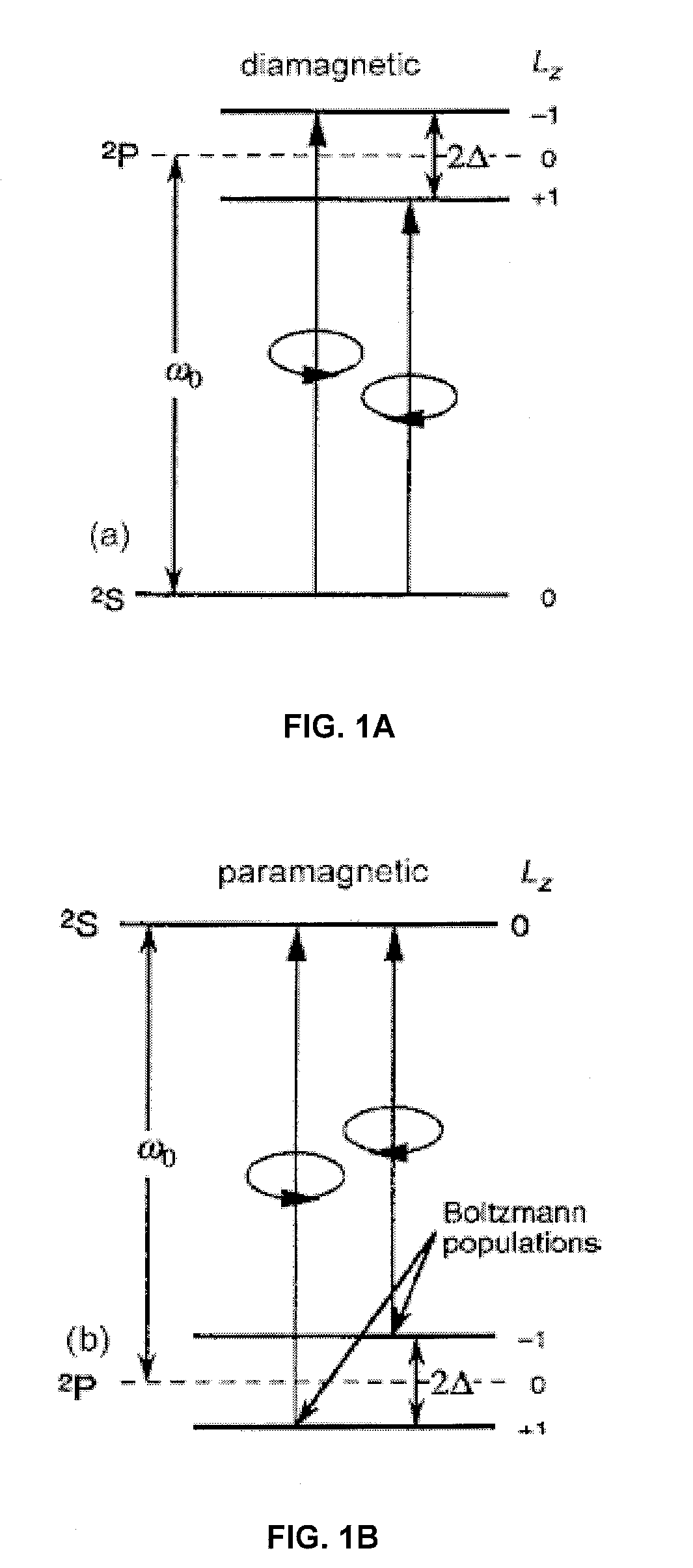

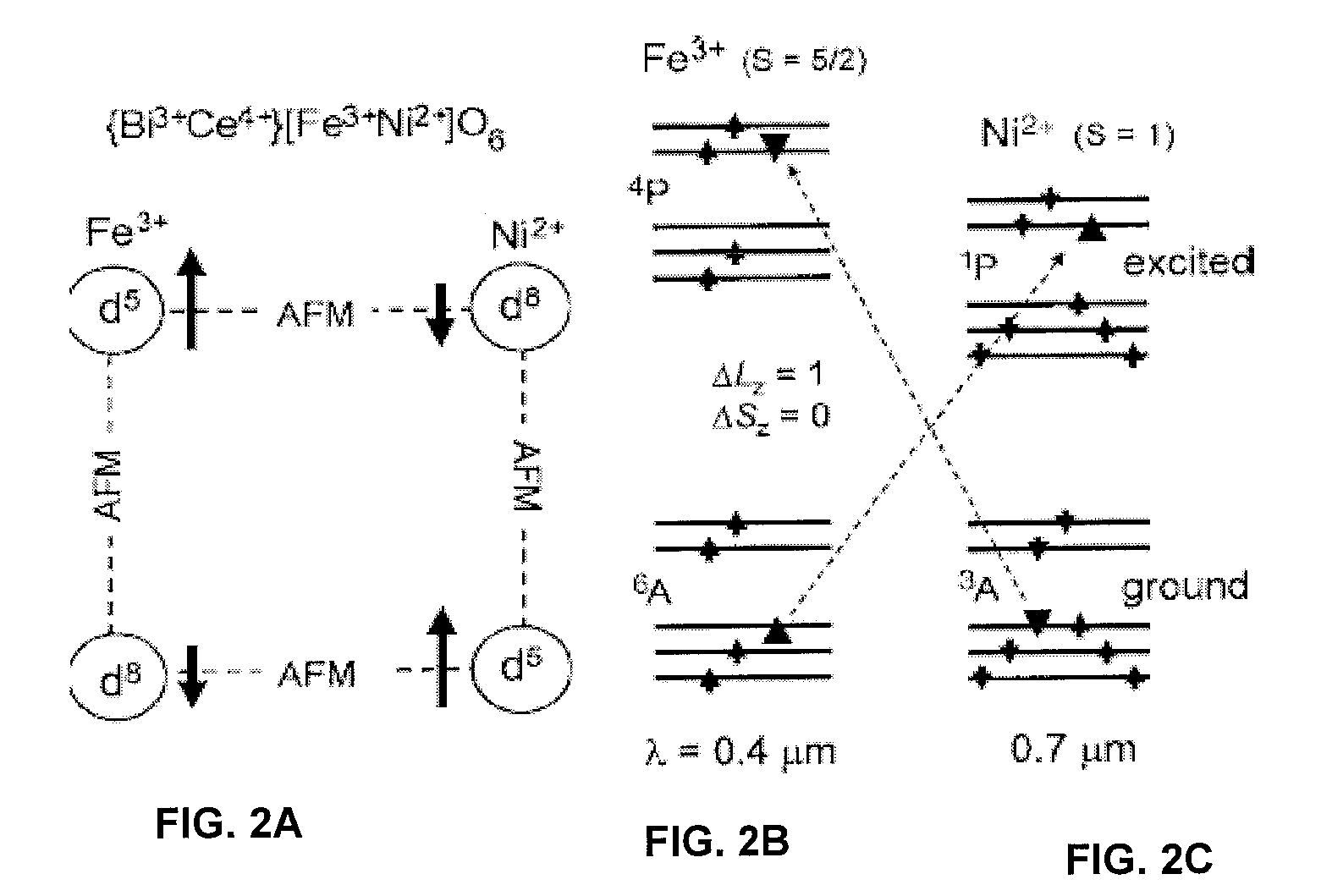

Magnetic material for magneto-optical isolator

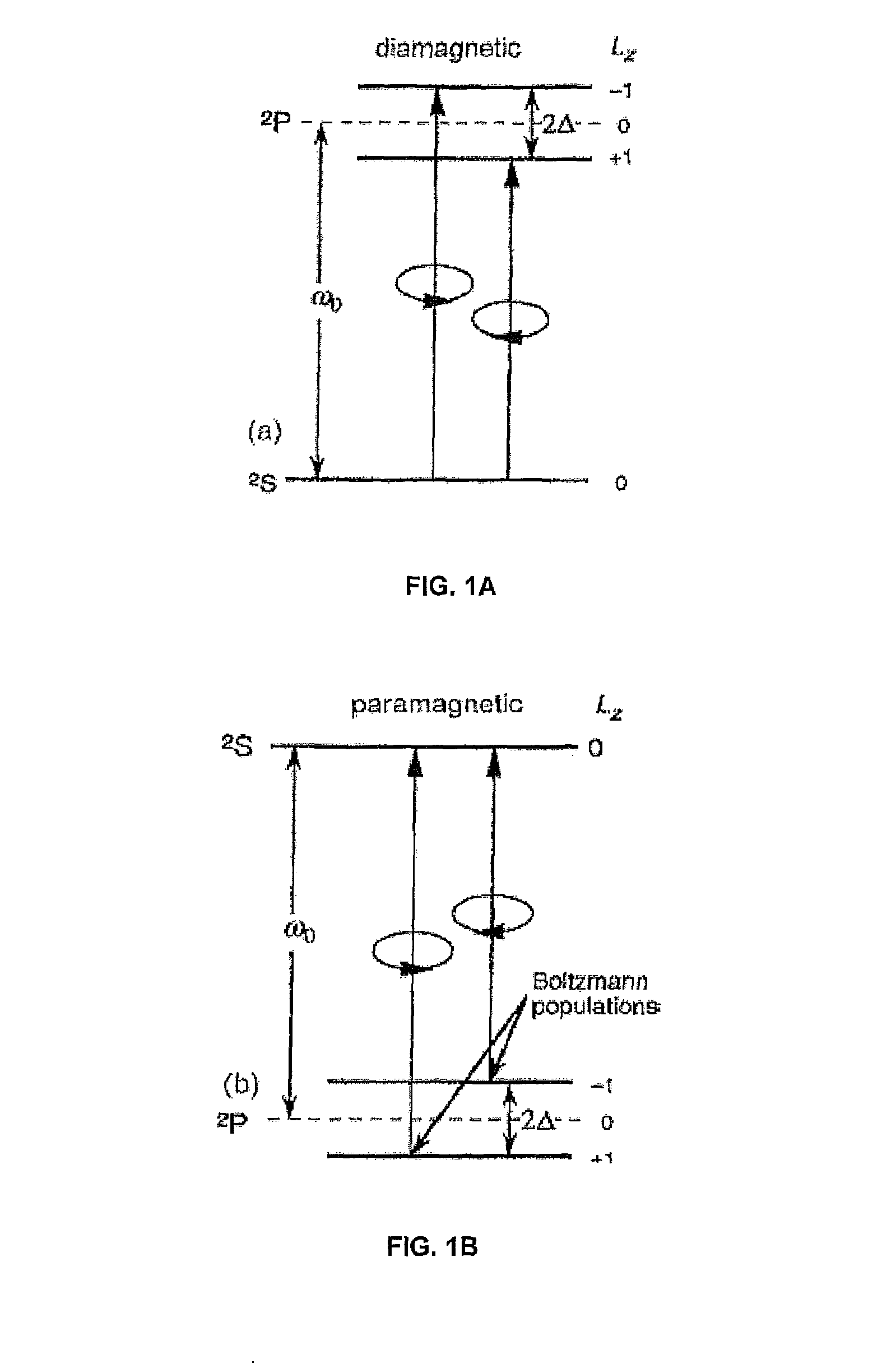

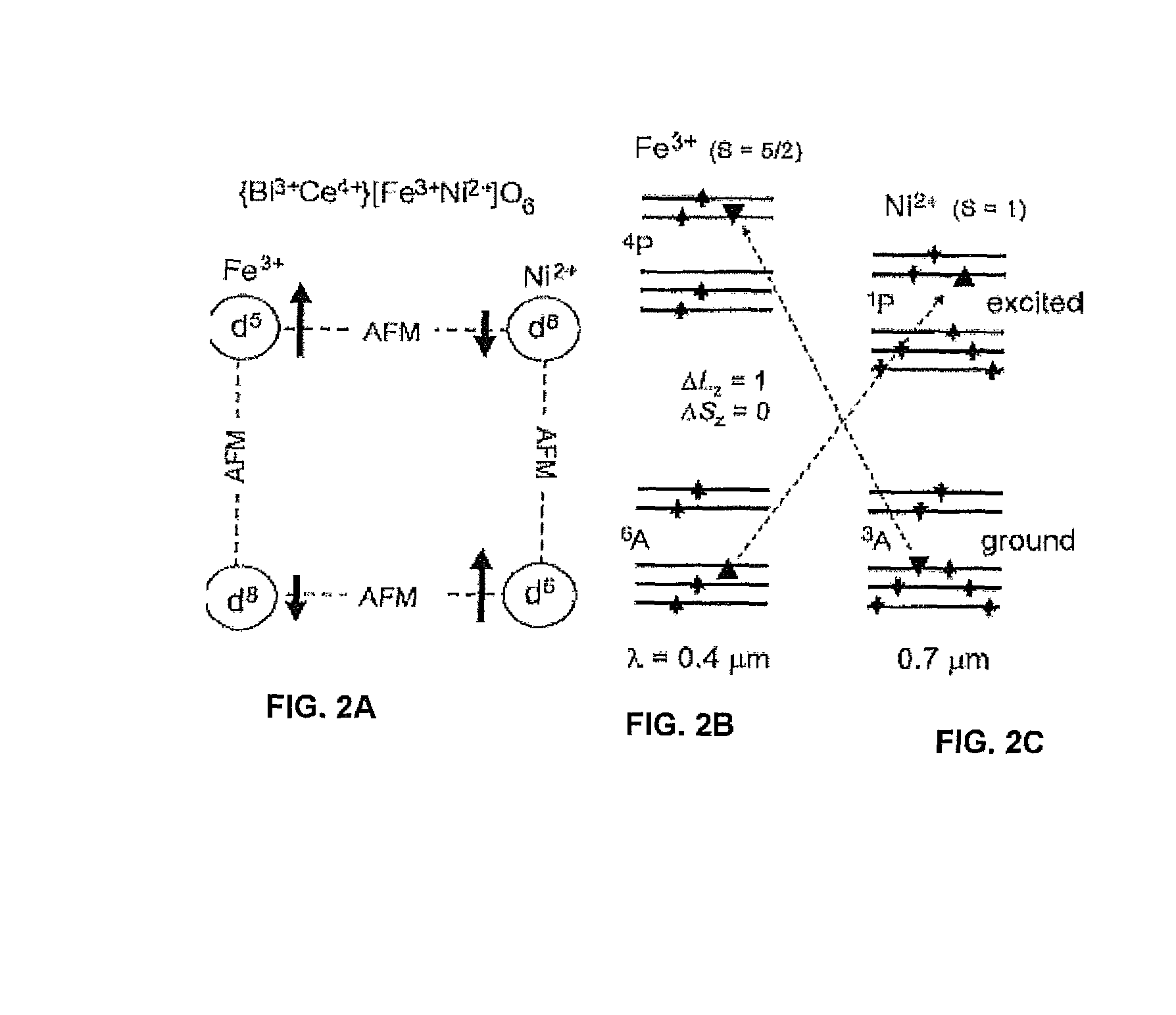

InactiveUS7995893B2Glass making apparatusSemiconductor/solid-state device manufacturingMagnetic oxideElectromagnetic radiation

A magneto-optical structure is provided. The magneto-optical structure includes a substrate. A waveguide layer is formed on the substrate for guiding electromagnetic radiation received by the magneto-optical structure. The waveguide layer includes magnetic oxide material that comprises ABO3 perovskite doped with transition metal ions on the B site, or transition metal ions doped SnO2, or transition metal ions doped CeO2.

Owner:MASSACHUSETTS INST OF TECH

Magnetic material for magneto-optical isolator

InactiveUS20090136191A1Glass making apparatusOptical fibre with multilayer core/claddingMagnetic oxideElectromagnetic radiation

A magneto-optical structure is provided. The magneto-optical structure includes a substrate. A waveguide layer is formed on the substrate for guiding electromagnetic radiation received by the magneto-optical structure. The waveguide layer includes magnetic oxide material that comprises ABO3 perovskite doped with transition metal ions on the B site, or transition metal ions doped SnO2, or transition metal ions doped CeO2.

Owner:MASSACHUSETTS INST OF TECH

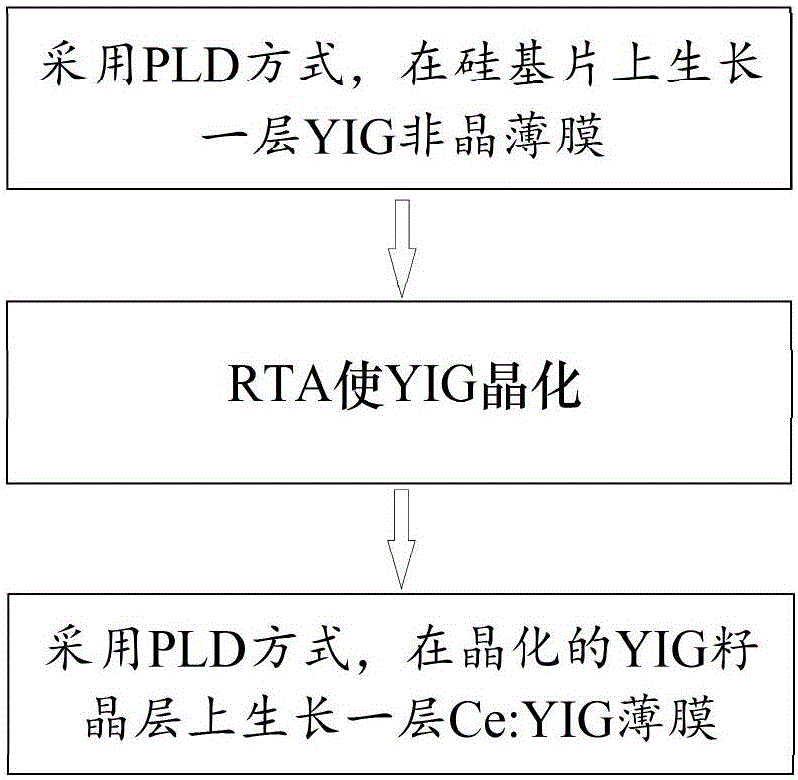

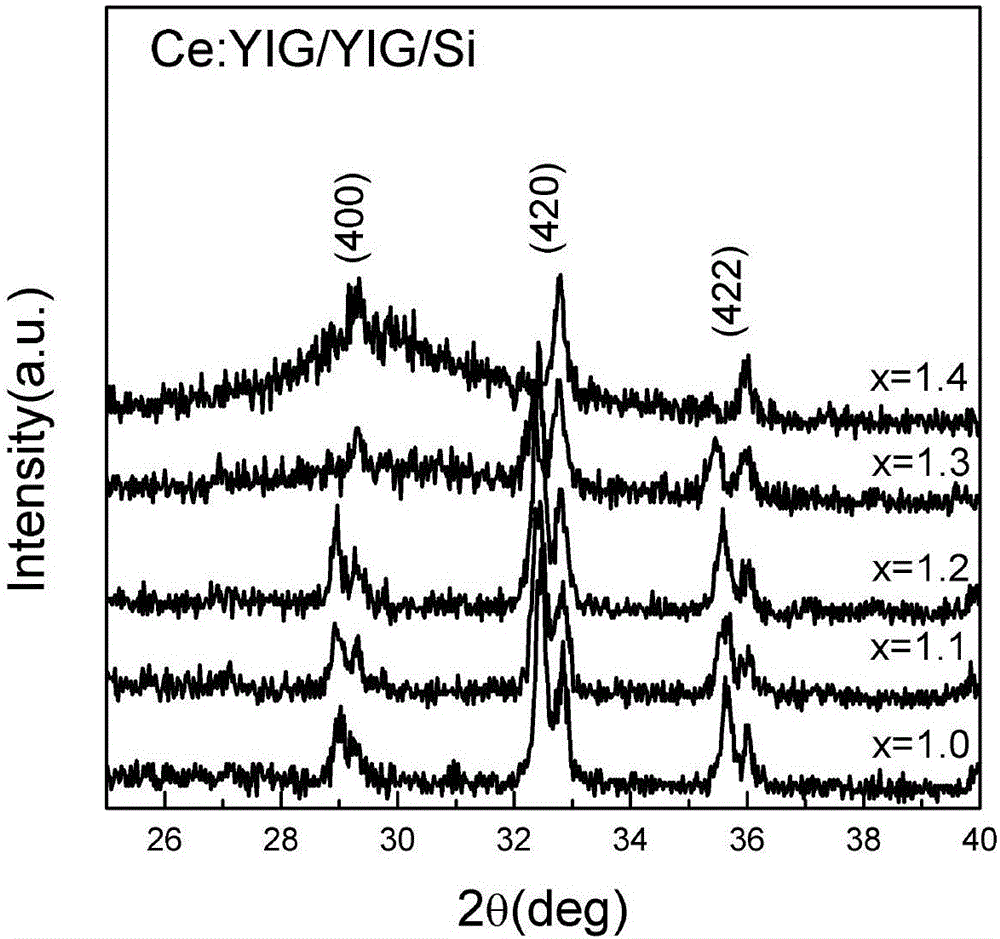

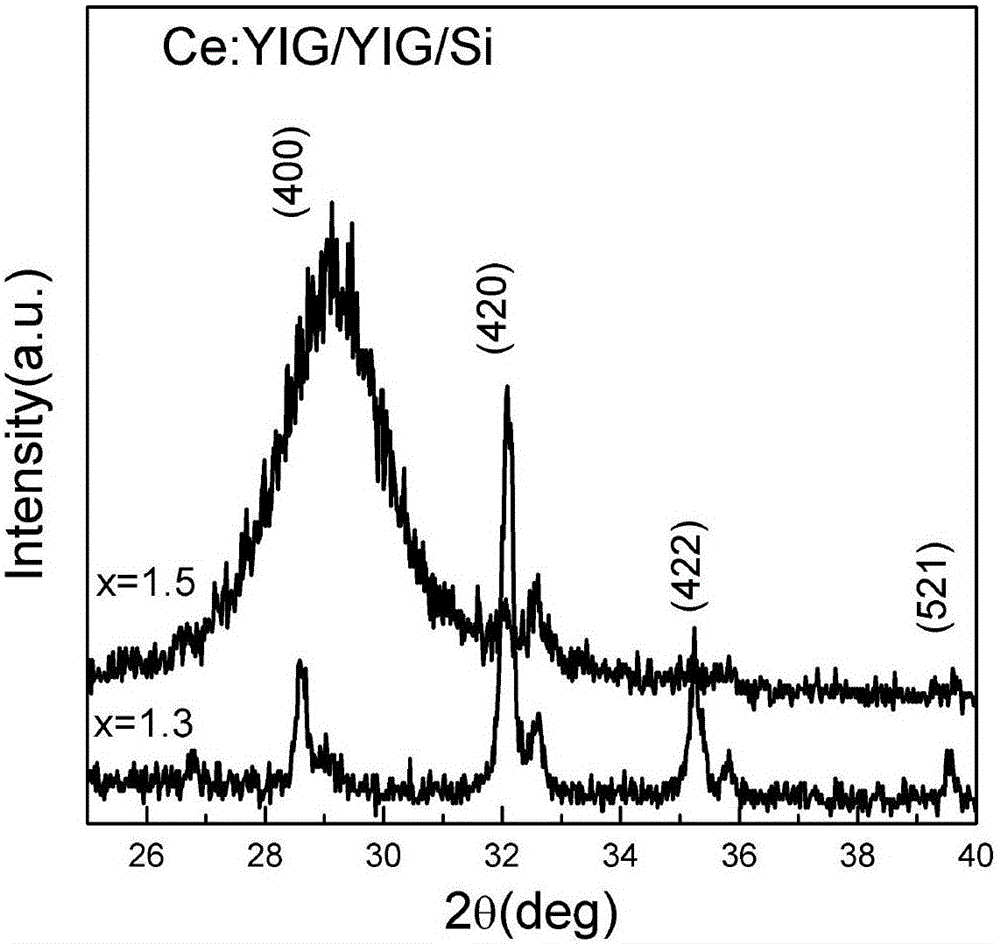

Preparation method for directly growing highly-doped yttrium iron garnet film on silicon

ActiveCN105714379AEnhanced magneto-optical performancePolycrystalline material growthFrom condensed vaporsDeposition temperatureRare earth

The invention belongs to the technical field of production of magnetic oxide films, and particularly relates to a preparation method for directly growing a highly-doped yttrium iron garnet film on silicon. The laser energy density in the growth process of a rare earth-doped yttrium iron garnet film is changed from 1.8 J / cm<2> to 4.0 J / cm<2>, the film deposition temperature is changed from 400 DEG C to 850 DEG C, and the film deposition air pressure is changed from 1 mTorr to 20 mTorr, so that the rare earth doping concentration in the yttrium iron garnet film growing on a silicon substrate is improved from 33% to 50%, the Faraday optical constant of the material in photo-communication 1550 nm wavelengths is improved from 2800 degrees / cm to 6000 degrees / cm, and the magneto-optical property of the material is greatly enhanced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

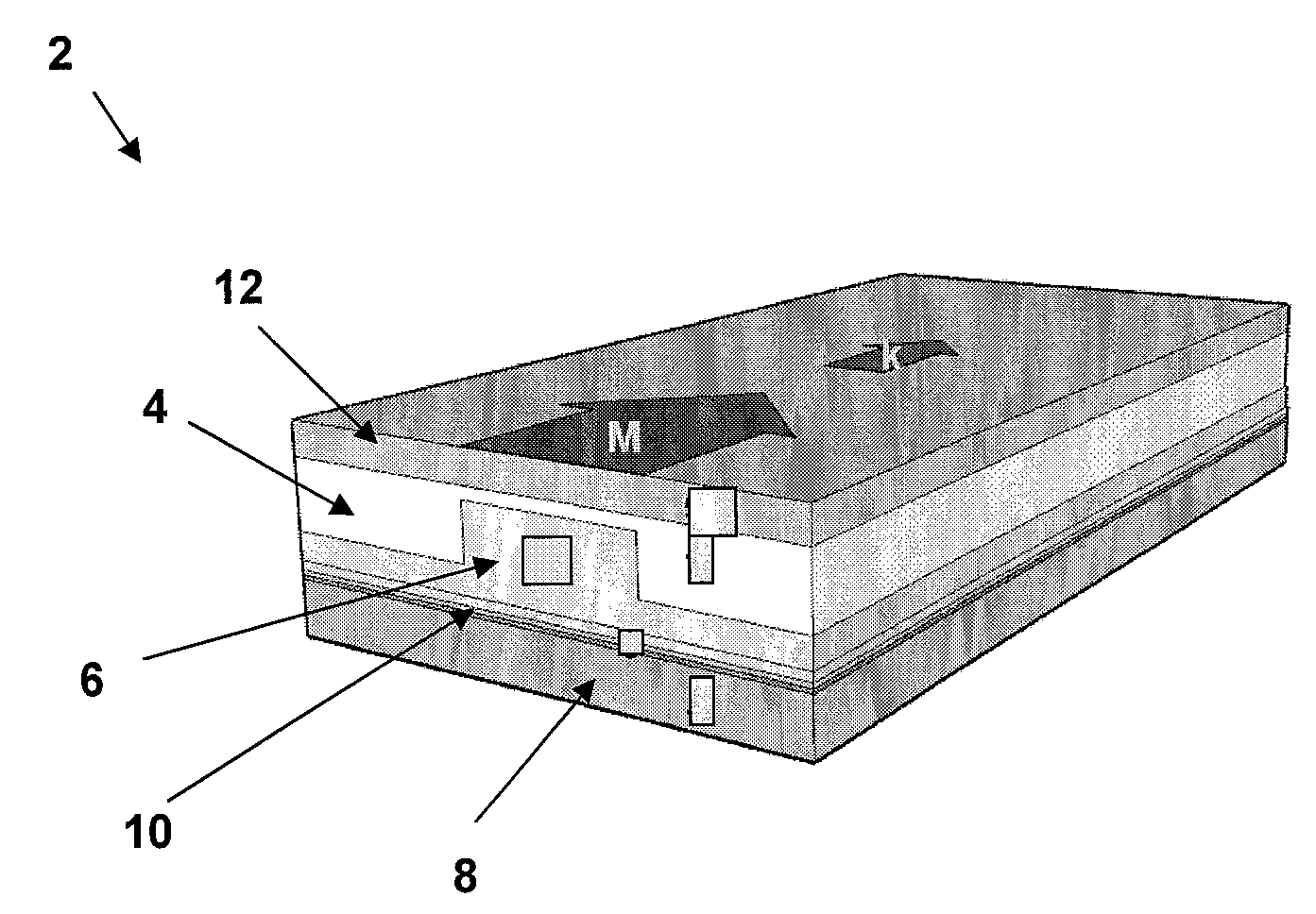

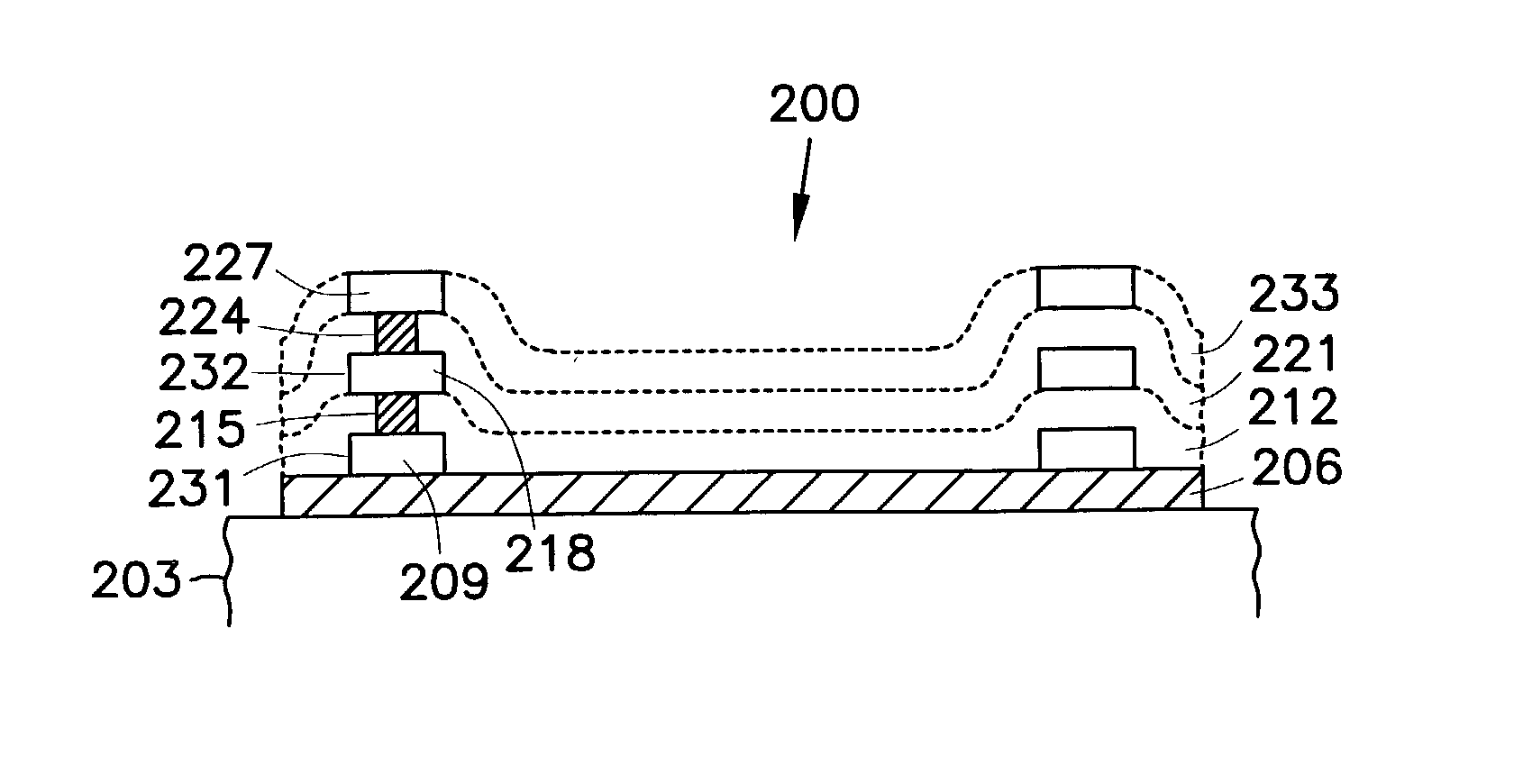

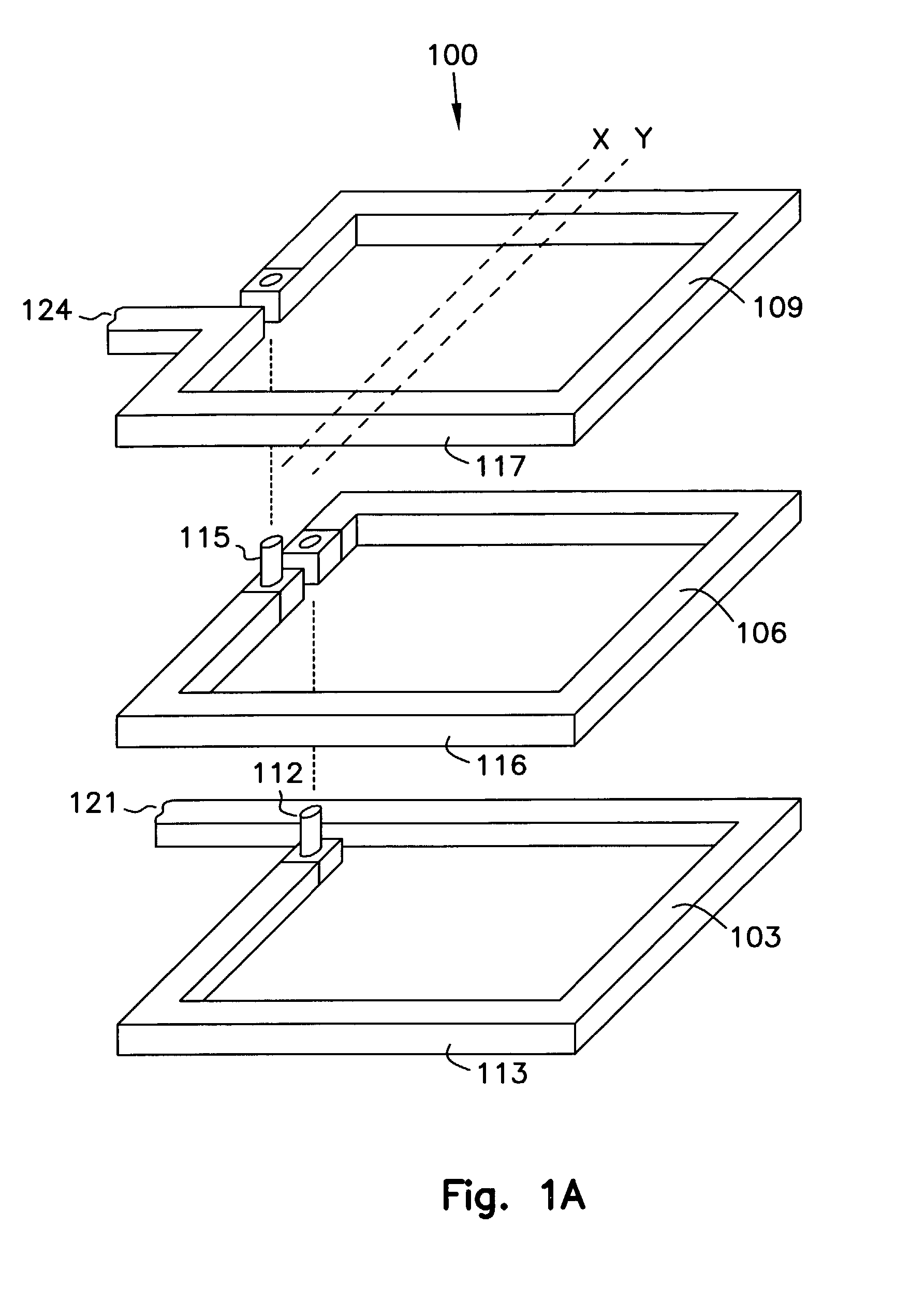

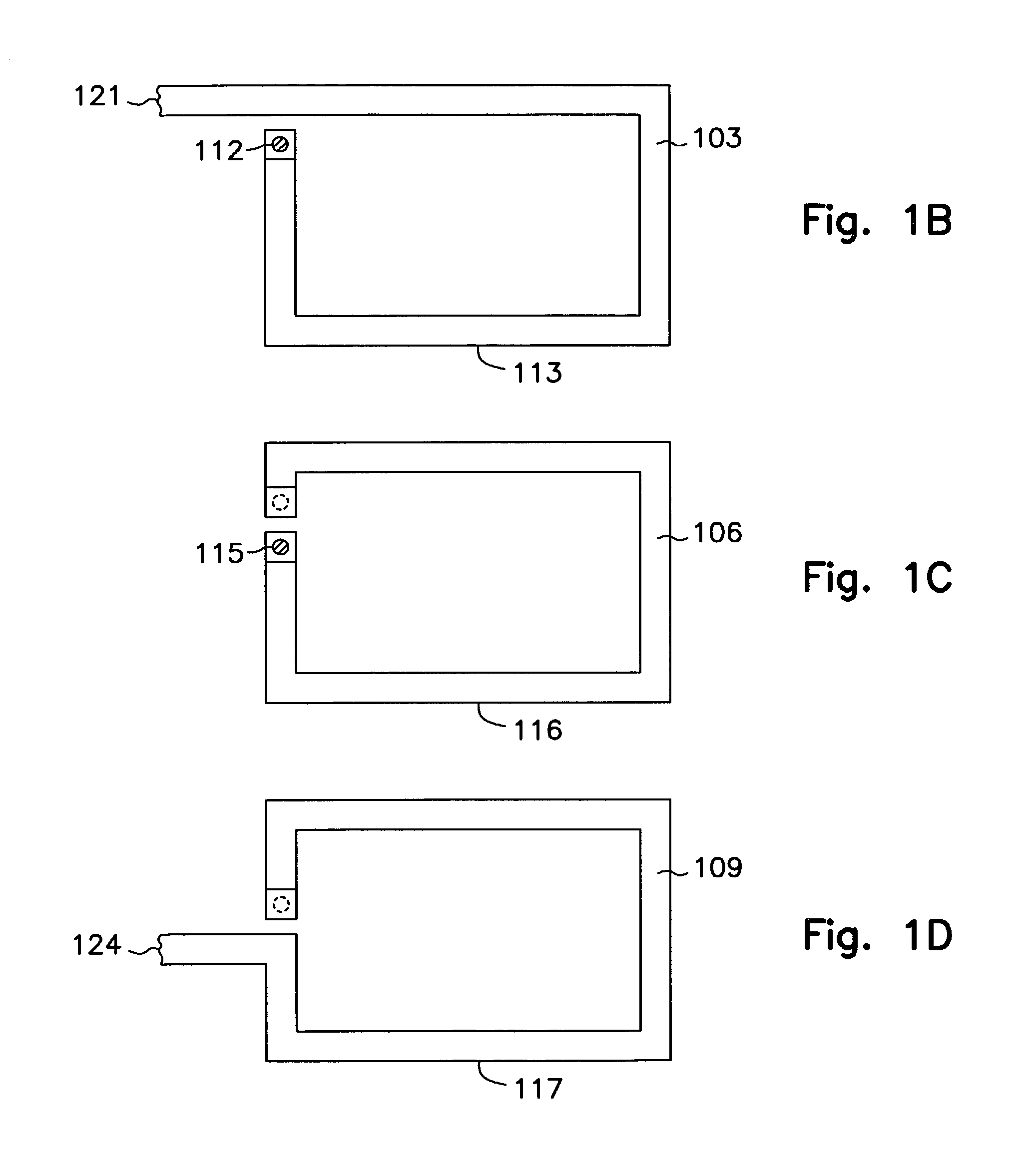

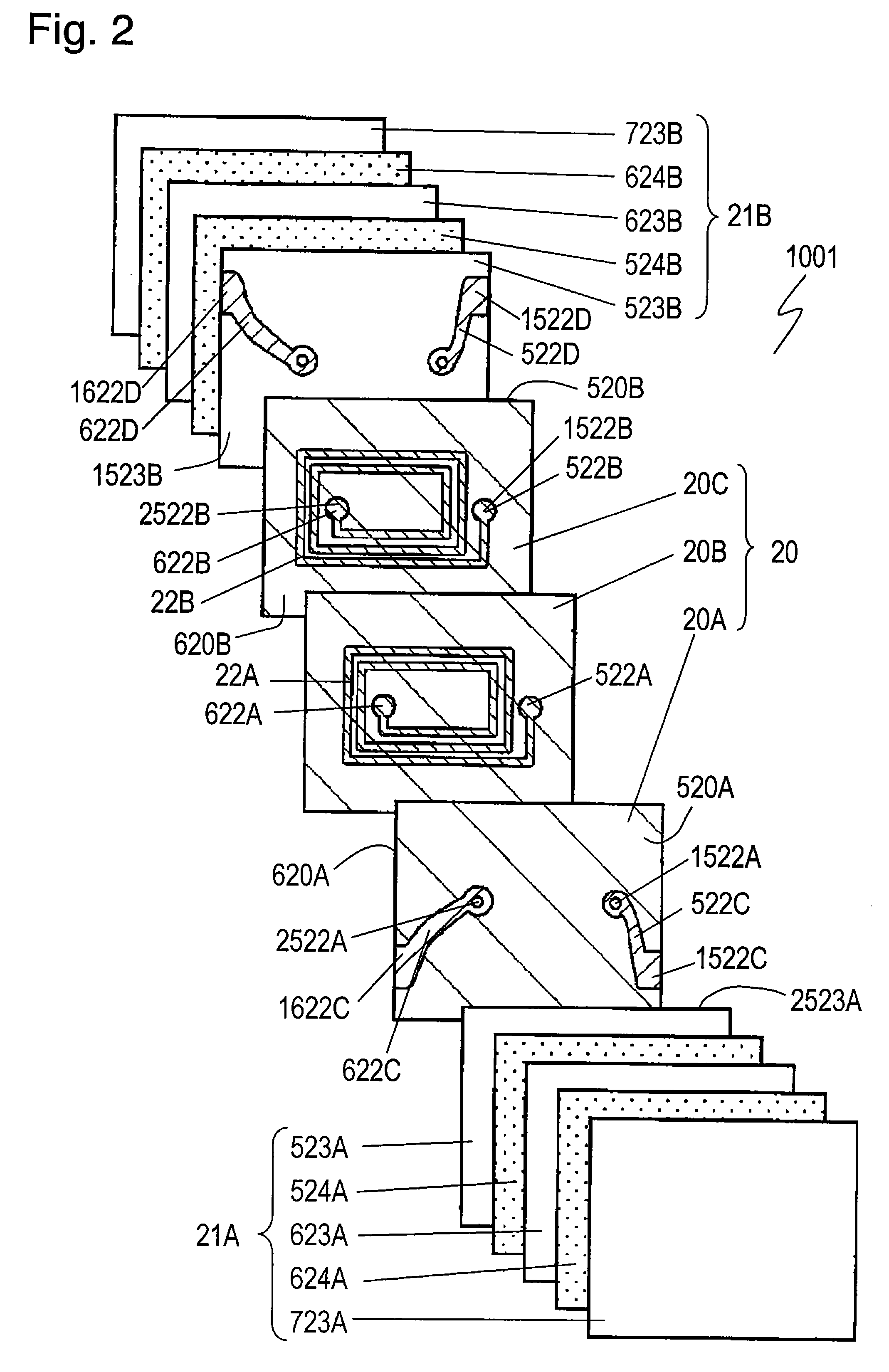

Open pattern inductor

InactiveUS7091575B2Increase inductanceSolid-state devicesSemiconductor/solid-state device manufacturingIntegrated circuit manufacturingComputerized system

The invention includes a stacked open pattern inductor fabricated above a semiconductor substrate. The stacked open pattern inductor includes a plurality of parallel open conducting patterns embedded in a magnetic oxide or in an insulator and a magnetic material. Embedding the stacked open pattern inductor in a magnetic oxide or in an insulator and a magnetic material increases the inductance of the inductor and allows the magnetic flux to be confined to the area of the inductor. A layer of magnetic material may be located above the inductor and below the inductor to confine electronic noise generated in the stacked open pattern inductor to the area occupied by the inductor. The stacked open pattern inductor may be fabricated using conventional integrated circuit manufacturing processes, and the inductor may be used in connection with computer systems.

Owner:MICRON TECH INC

Magnetic oxide supporting active carbon catalytic microwave degradation method of surfactant

ActiveCN102225792AIncrease inhomogeneityPromote degradationWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsNeutral phWastewater

The invention relates to a magnetic oxide supporting active carbon catalytic microwave degradation method of a surfactant. The technical scheme of the method comprises: (a) a magnetic oxide supporting active carbon preparation process comprising dipping active carbon into Fe (NO3)3 or Ni (NO3)2 solution, carrying out a magnetic stirring process for 10 to 13 hours, filtering and collecting precipitates, washing the precipitates to a neutral pH through deionized water, drying, calcining at a temperature of 250 to 350 DEG C for 1 to 4 hours, and cooling to obtain a magnetic oxide supporting active carbon catalyst, and (b) a microwave degradation process comprising adding the magnetic oxide supporting active carbon catalyst obtained from the process (a) into surfactant-containing solution andcarrying out an irradiation process on the mixed solution by a microwave power of 150 to 750 W for 0.5 to 3.0 minutes, wherein a weight ratio of a surfactant to the magnetic oxide supporting active carbon catalyst is 1: (4 to 24). The method provided by the invention is a novel method for processing surfactant-containing wastewater and has the advantages of high degradation efficiency, fast degradation speed, low cost, no secondary pollution and the like.

Owner:LIAONING UNIVERSITY

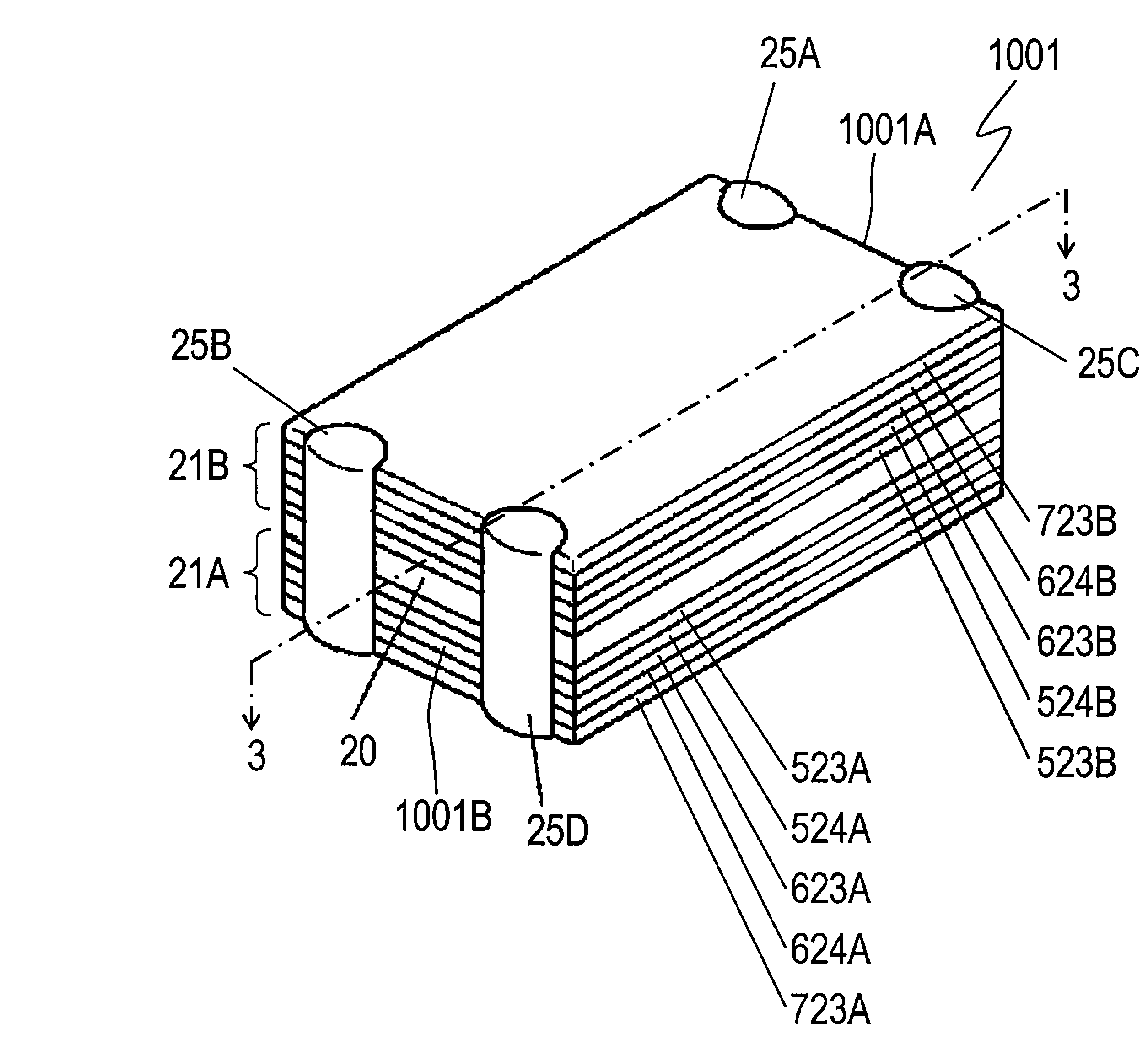

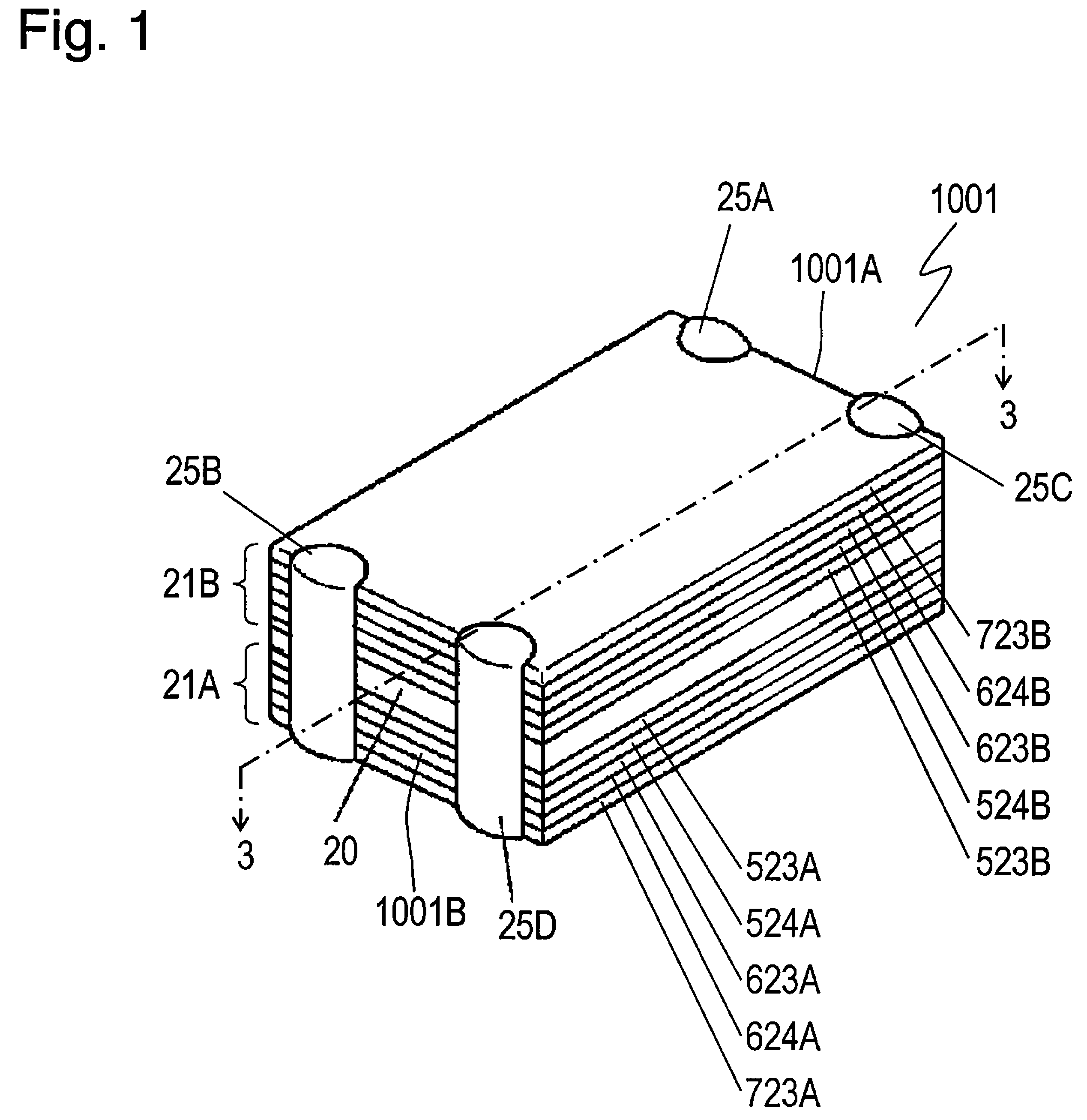

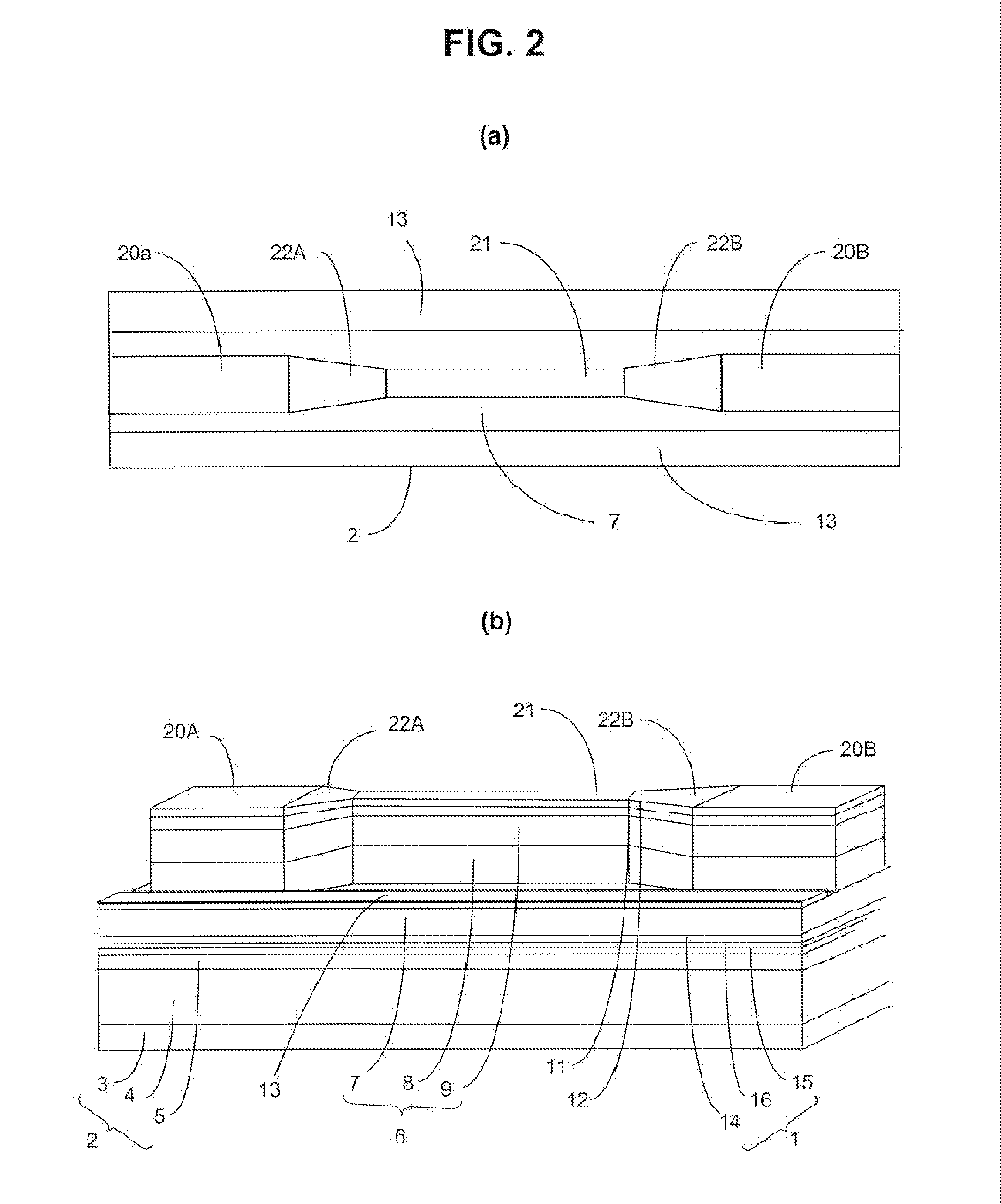

Common mode noise filter

ActiveUS7911295B2Multiple-port networksTransformers/inductances coils/windings/connectionsMagnetic oxideNon magnetic

A common mode noise filter includes a nonmagnetic layer, first and second magnetic layers sandwiching the nonmagnetic layer between the magnetic layers and contacting the nonmagnetic layer, a plane coil provided between the first and second magnetic layers and contacting the nonmagnetic layer, and an external electrode connected electrically with the plane coil. The first and second magnetic layers include a magnetic oxide layer and an insulator layer provided on the magnetic oxide layer. The insulator layer contains glass component. This common mode noise filter has a large bonding strength between the external electrode and the insulator layer.

Owner:PANASONIC CORP

MULTIFUNCTIONAL Fe3O4 CORED MAGNETIC-QUANTUM DOT FLUORESCENT NANOCOMPOSITES FOR RF NANO-HYPERTHERMIA OF CANCER CELLS

A magnetic oxide-quantum dot nanocomposite and methods of synthesizing it. In one embodiment, the magnetic oxide-quantum dot nanocomposite has at least one magnetic oxide nanoparticle coated with a silica (SiO2) shell and terminated with at least one thiol group (—SH), and at least one CdSe / ZnS quantum dot linked with the at least one SiO2-coated magnetic oxide nanoparticle via the at least one thiol group. In one embodiment, the at least one magnetic oxide nanoparticle comprises at least one iron oxide (Fe3O4) nanoparticle.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

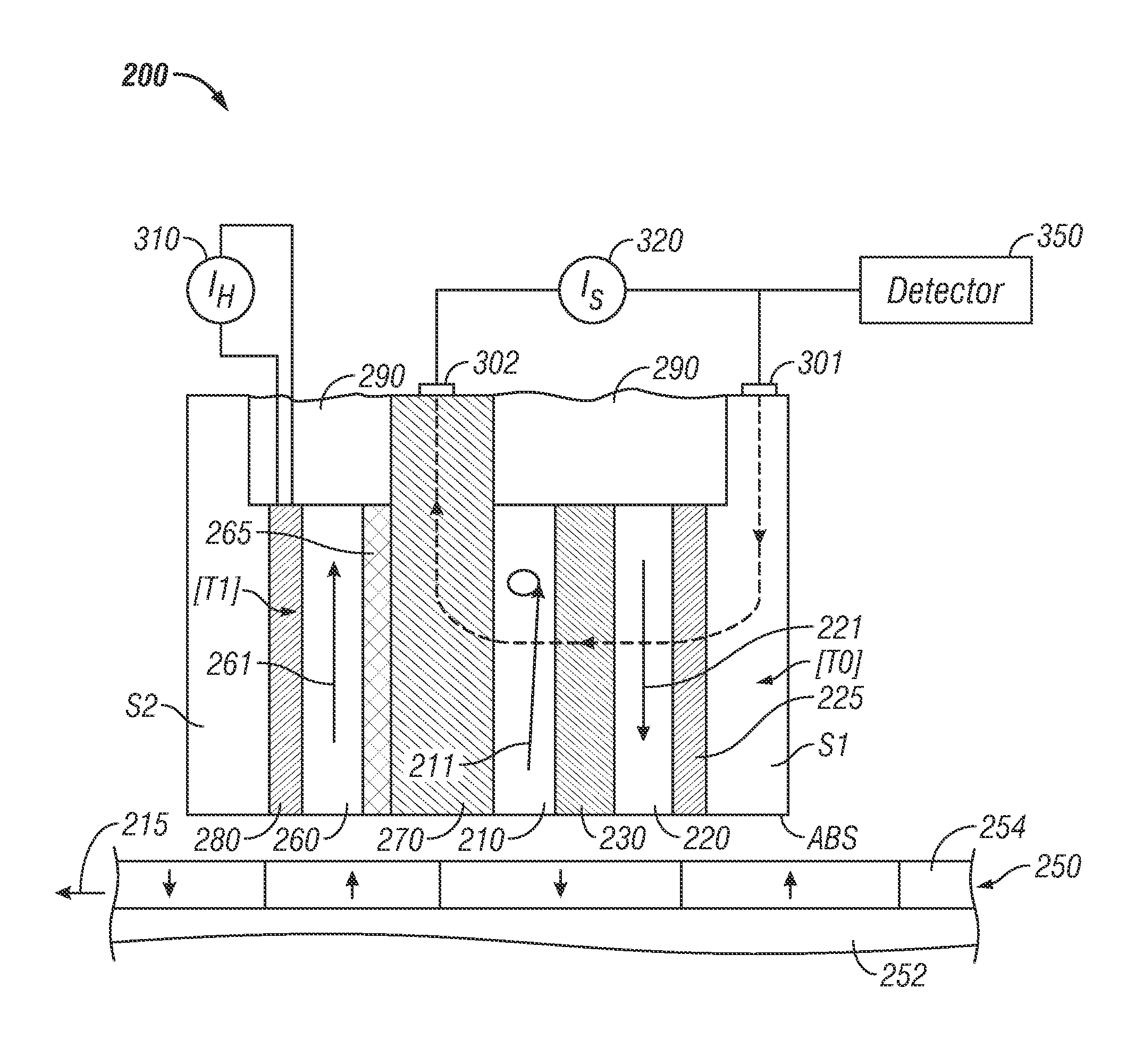

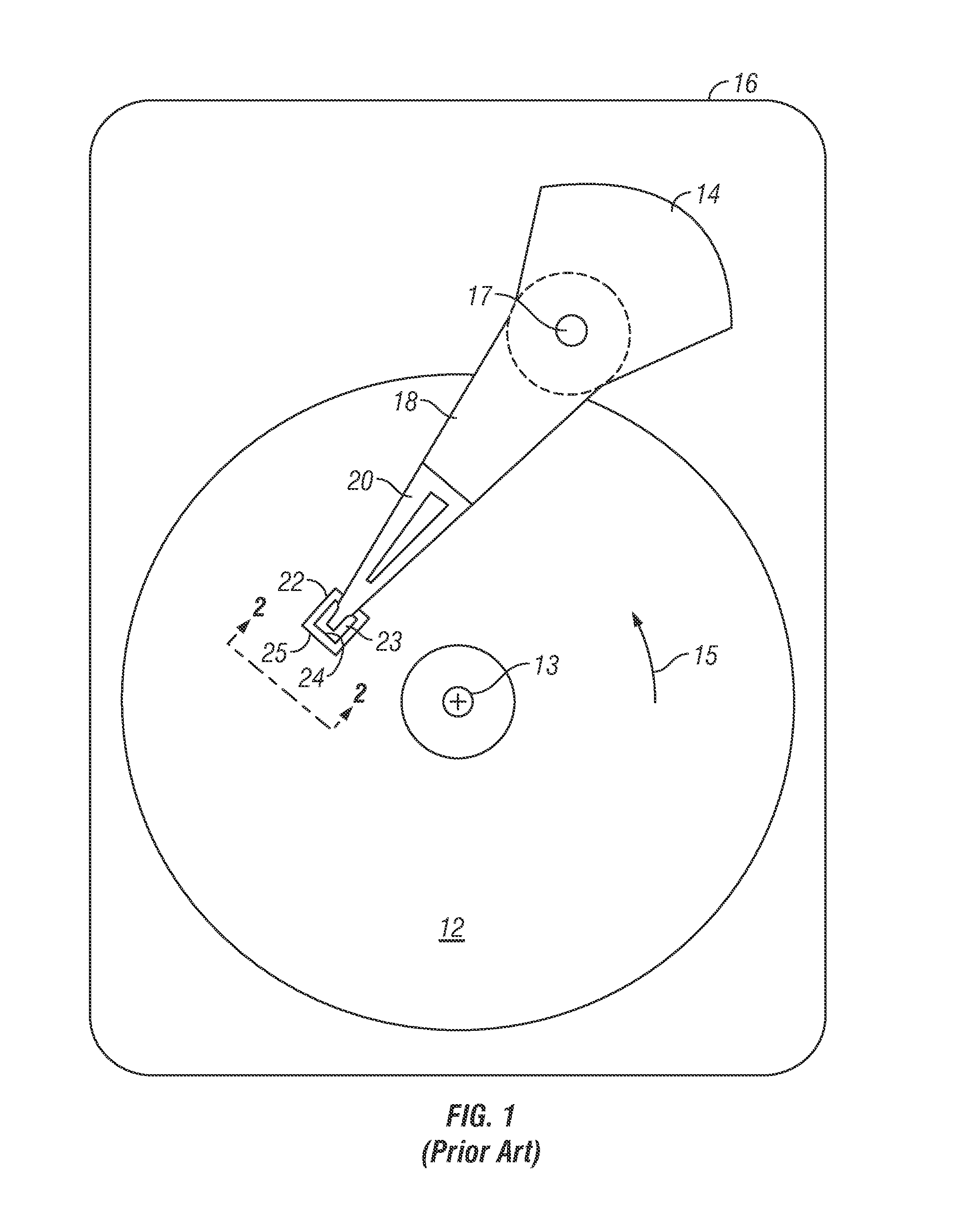

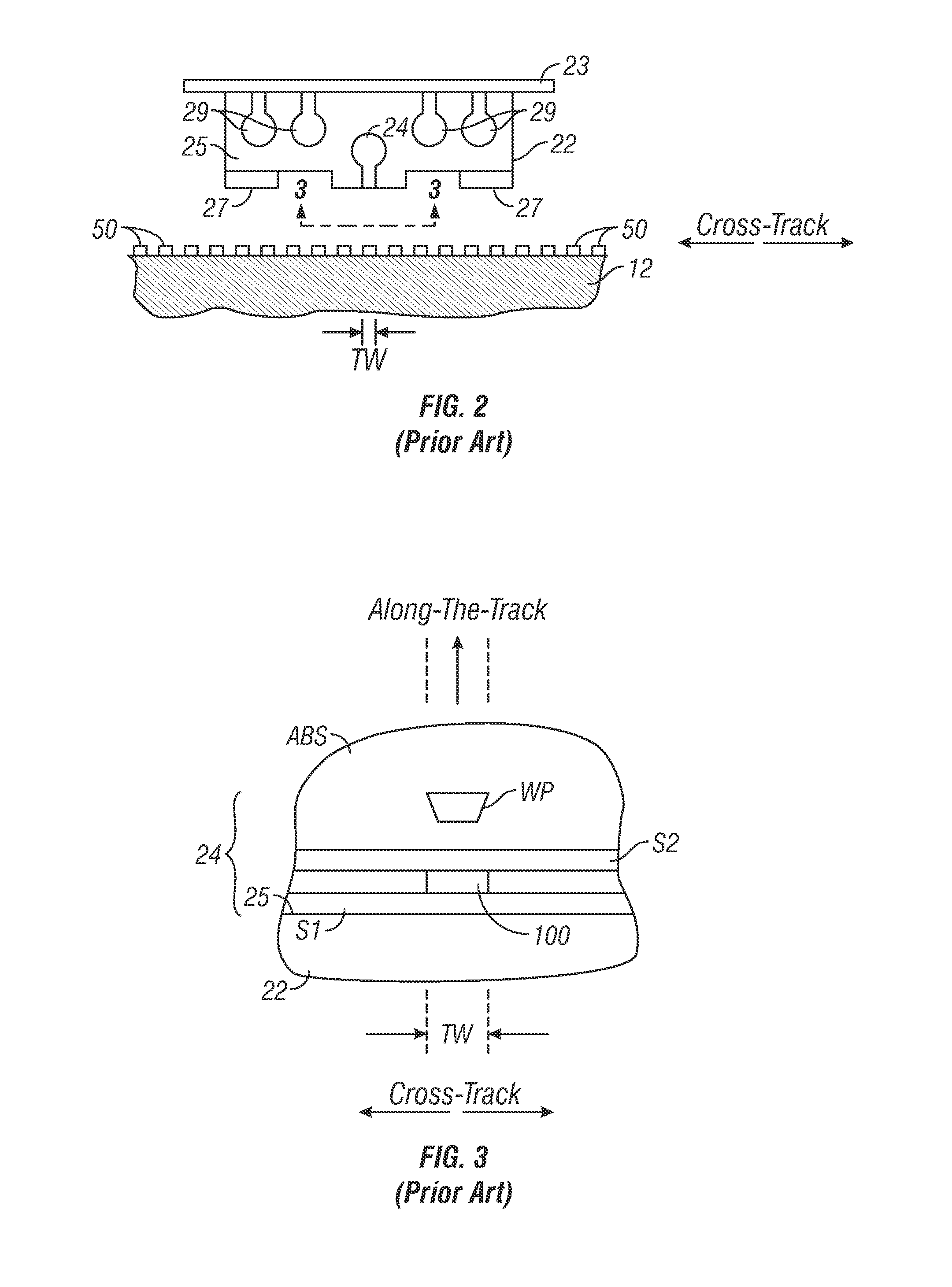

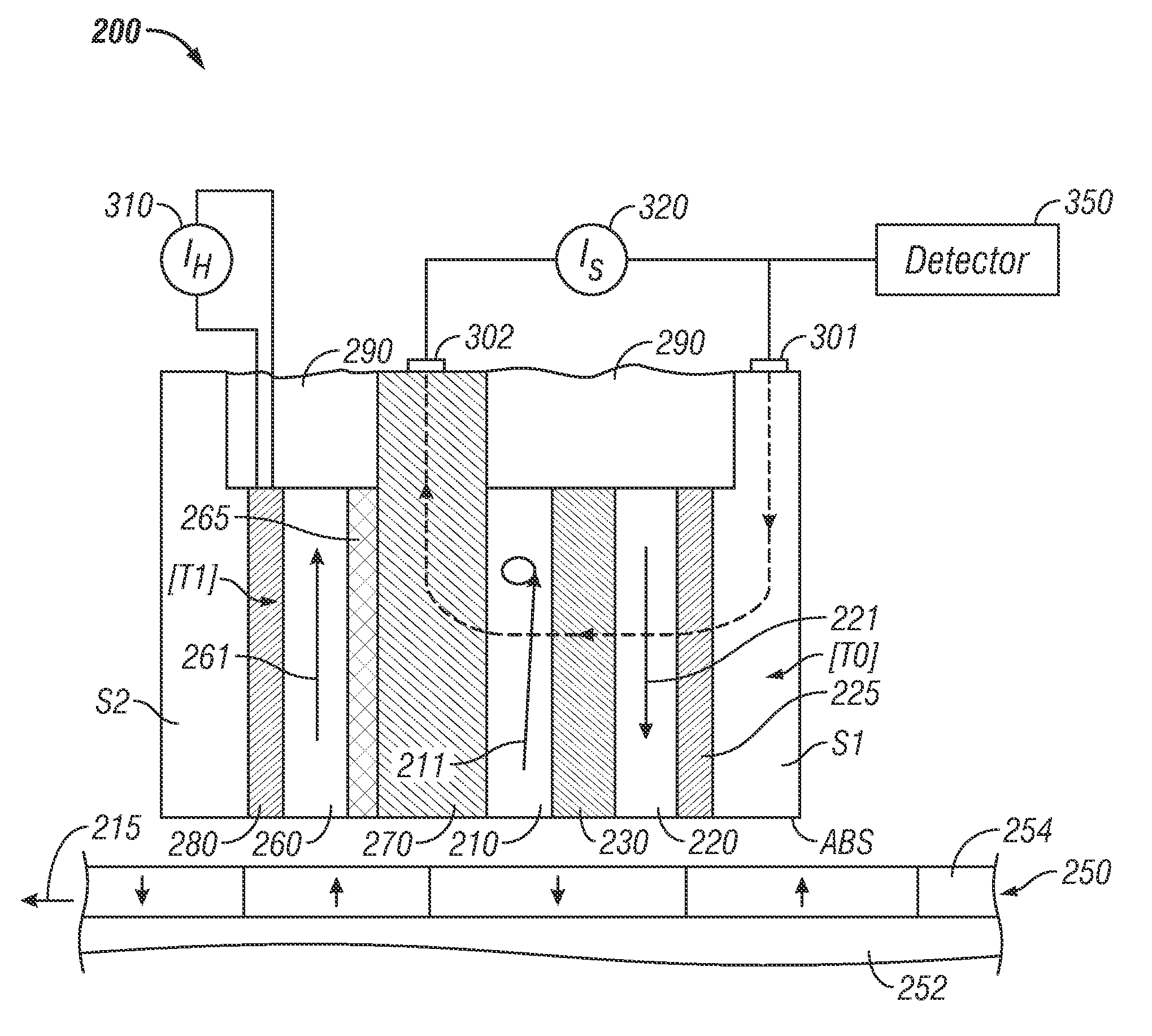

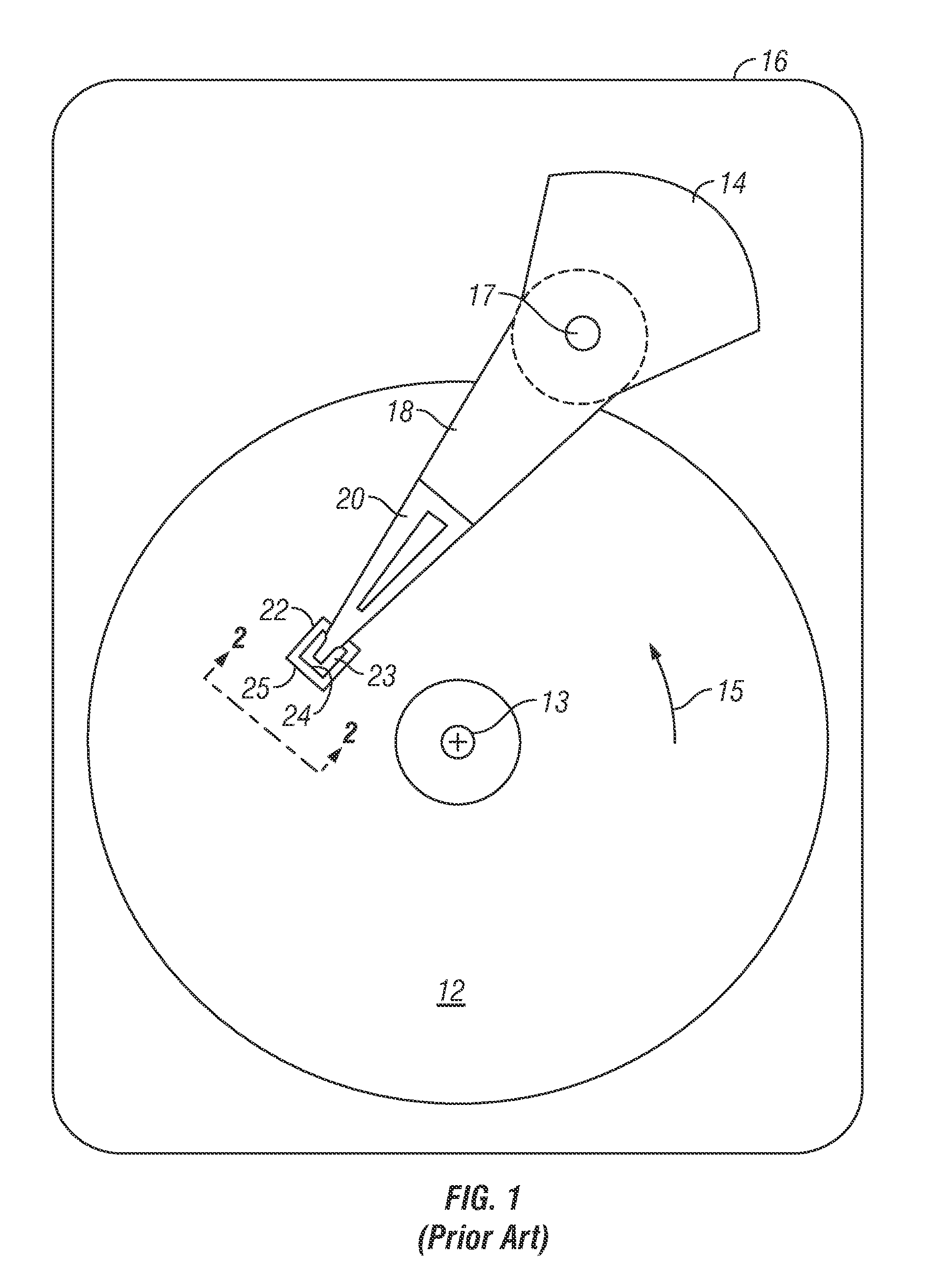

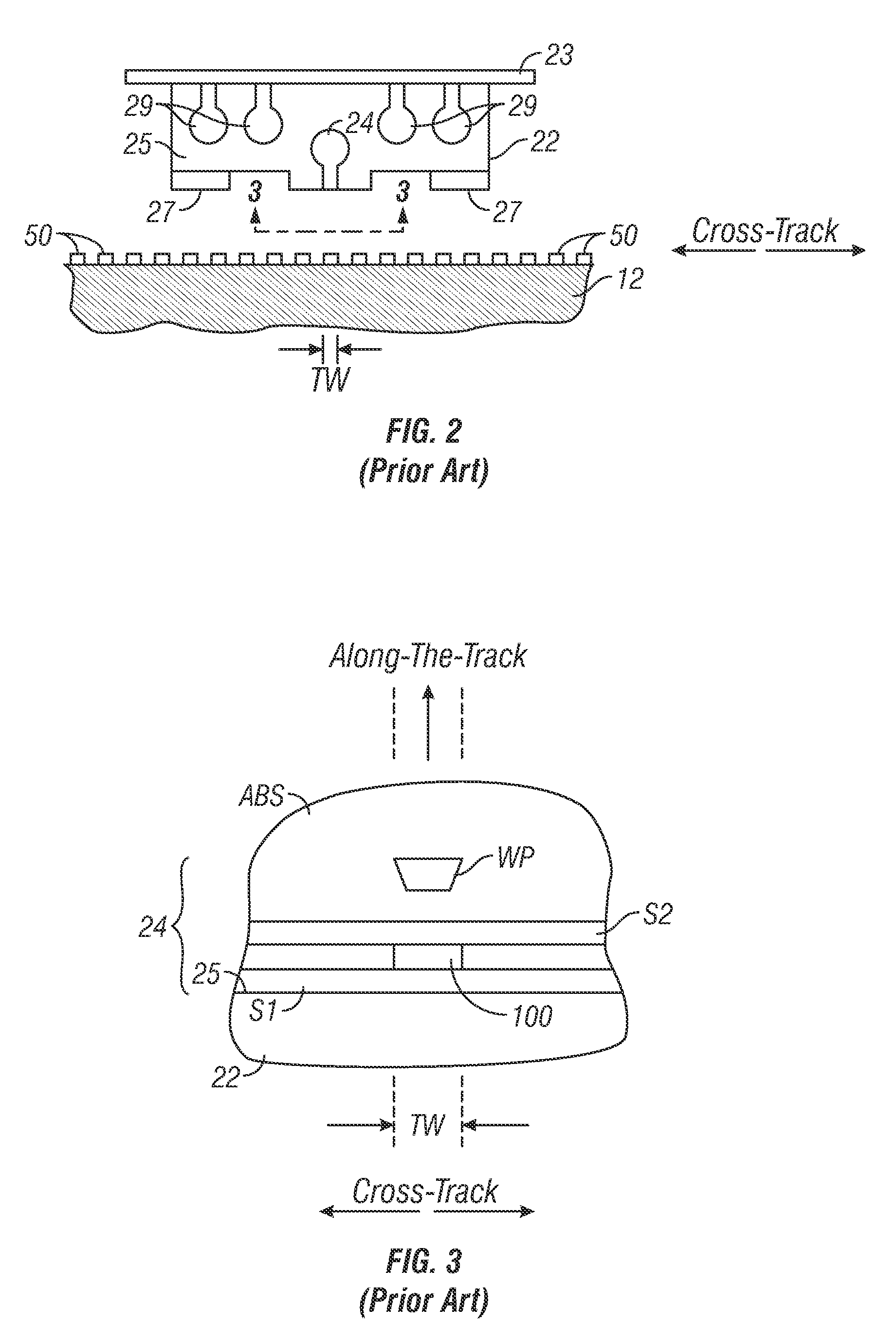

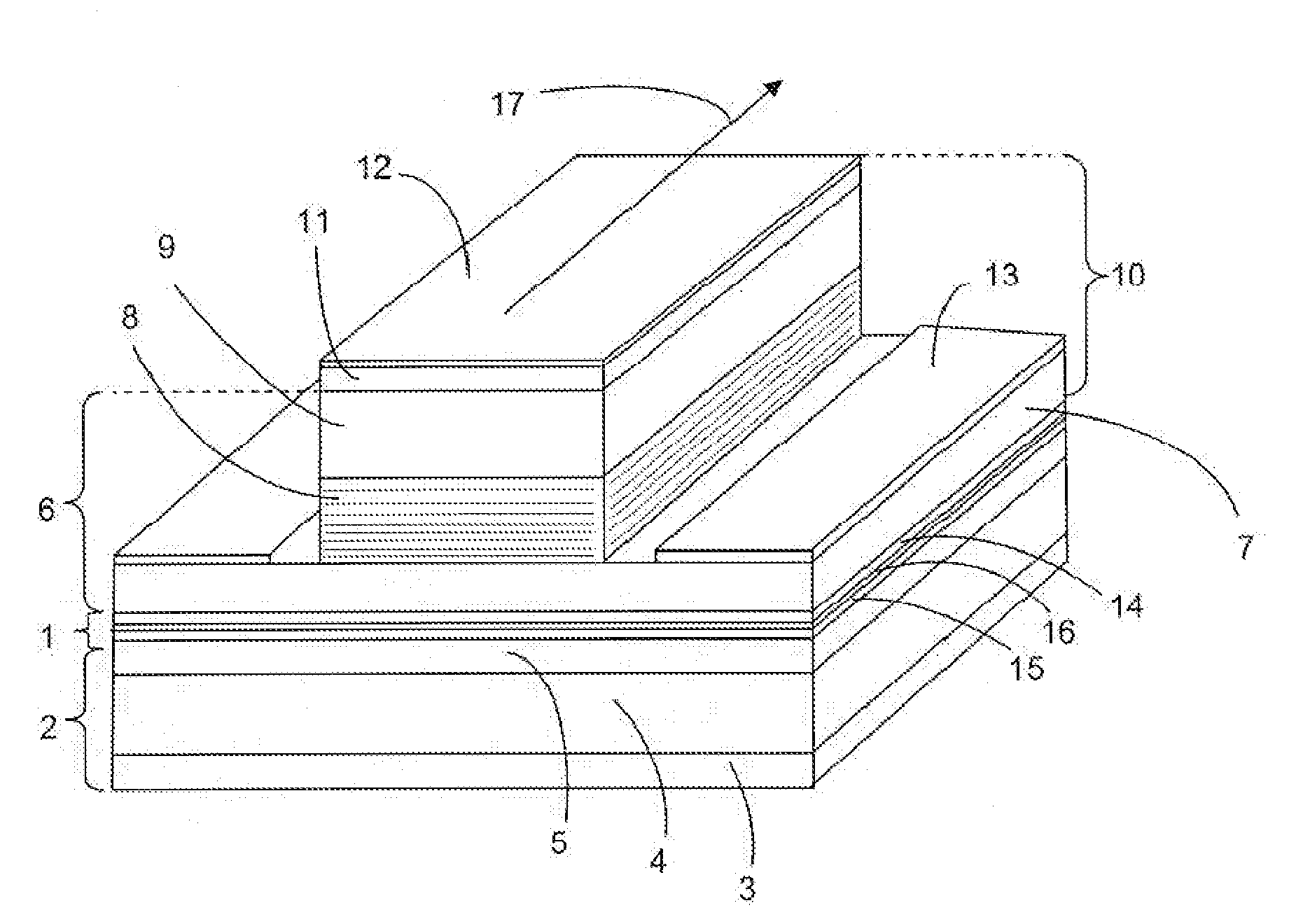

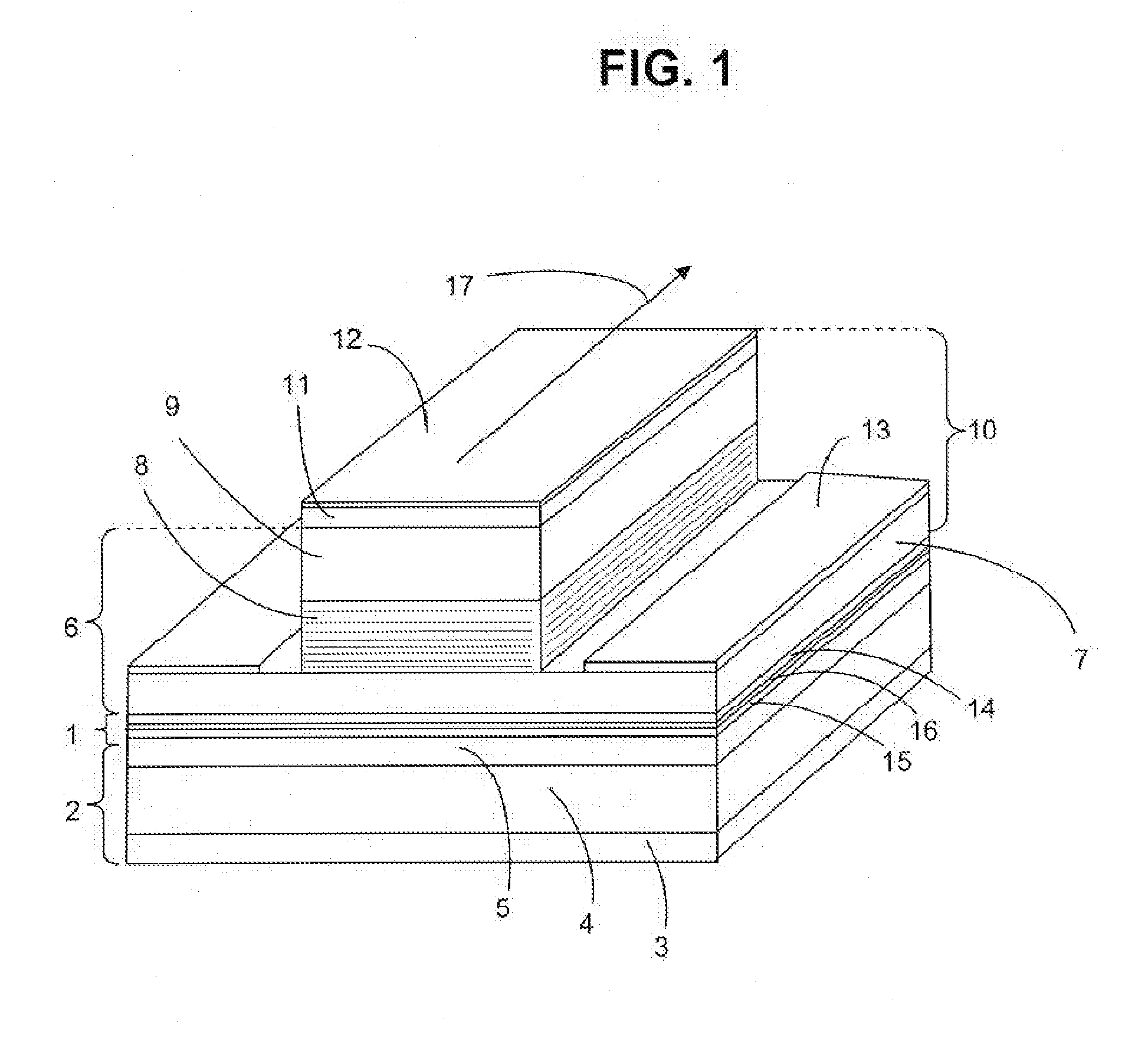

Thermagnonic spin-torque oscillator(STO) and sensor utilizing same to detect shifts in the free layer magnetization oscillation frequency

ActiveUS8379352B1Increase powerDisposition/mounting of recording headsMagnetic measurementsIn planeSustained oscillations

A “thermagnonic” spin-torque oscillator (STO) uses heat flow alone to cause the spin-torque (ST) effect and generate the persistent oscillation of the free layer magnetization. In addition to the conventional free and reference layers, the thermagnonic STO also includes a magnetic oxide layer having a fixed in-plane magnetization, a ferromagnetic metallic layer on one surface of the magnetic oxide layer, a nonmagnetic electrically conductive layer between the free layer and the metallic layer, and an electrically resistive heater on the other surface of the magnetic oxide layer. Due to the thermagnonic effect, heat flow from the magnetic oxide layer through the metallic layer, conductive layer and free layer ultimately results in a spin transfer torque (STT) to the free layer. Electrical sense current flowing in the opposite direction as the heat flow is used to monitor the frequency of oscillation of the free layer magnetization.

Owner:WESTERN DIGITAL TECH INC

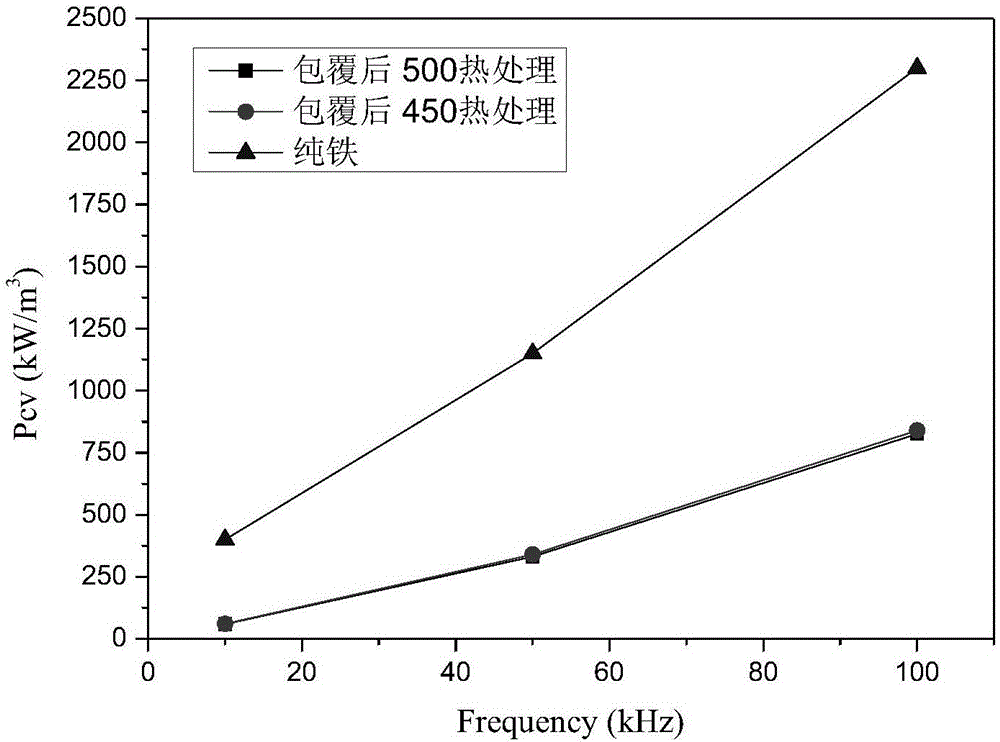

Soft magnetic composite material and preparation method thereof

ActiveCN106782982ALittle influence on magnetic propertiesCoated evenlyTransportation and packagingMetal-working apparatusIron powderMagnetic oxide

The invention discloses a soft magnetic composite material and a preparation method thereof. The preparation method of the soft magnetic composite material includes slowly adding cleaned iron powder into boiling alkaline liquor, heating with stirring for 2-180 minutes, cooling, filtering reaction liquid, and washing filter cakes prior to drying so as to obtain treated iron powder; mixing the treated iron powder with a 10 g / L-40 g / L binder and an acetone solution, performing ultrasonic dispersion and natural air drying, pressing a dried product to mould at 600-2000 MPa, and standing in the atmosphere of nitrogen gas and at 400-1000 DEG C for 30-400 minutes so as to obtain the soft magnetic composite material. The preparation method prepares a magnetic oxide insulation coating layer through in-situ reaction of liquid-phase chemistry and is simple in technology, convenient to operate, low in cost, high in production efficiency, environment friendly and suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV OF TECH

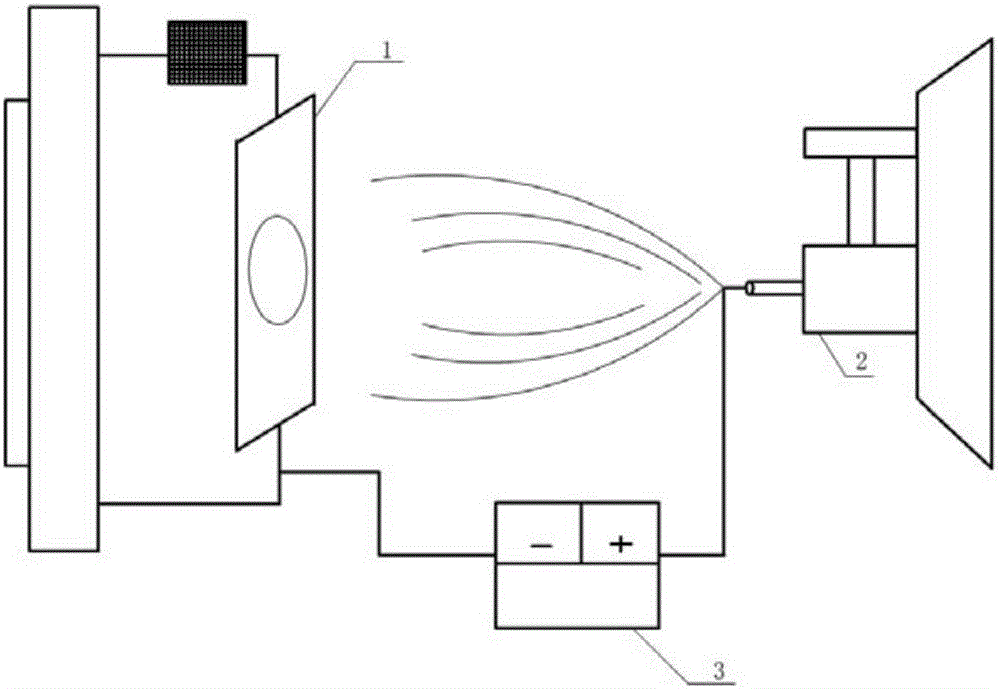

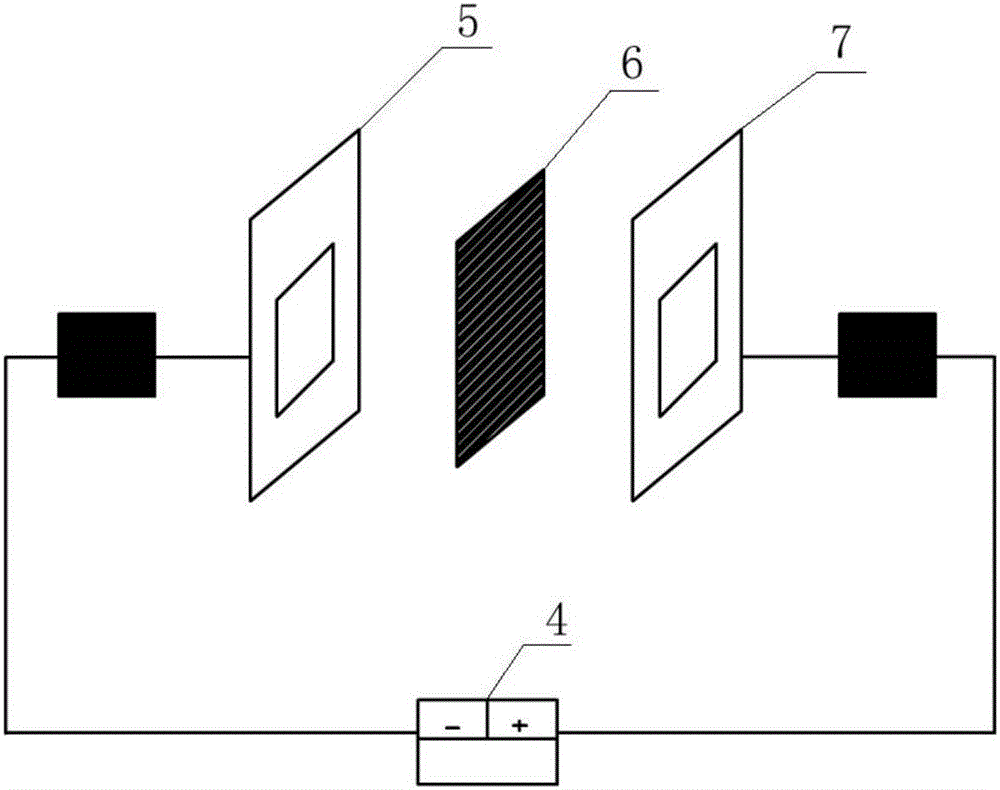

Electromagnetic integrated nanofiber filter material and preparation and activation method thereof

ActiveCN106835325AEasy to prepareImprove capture abilityPhysical treatmentFibre typesFiberActivation method

The invention belongs to the technical field of air purification material and discloses an electromagnetic integrated nanofiber filter material and a preparation and activation method thereof. The preparation and activation method comprises the following steps: adding magnetic oxide nanoparticles into a solvent, carrying out ultrasonic concussion and uniform dispersion, adding strong-polar polymer and uniformly dissolving to obtain a polymer spinning solution containing the magnetic oxide nanoparticles, making the polymer spinning solution onto a substrate through an electrospinning technique to obtain the electromagnetic integrated nanofiber filter material; putting the filter material as a barrier medium into a high-voltage electric field when surface potential of the nanofiber filter material is attenuated to 0-0.1 KV, treating by introducing 5-35 KV high voltage for 5-300 s to obtain the activated nanofiber filter material. The electromagnetic integrated nanofiber filter material has both surface electric field and magnetic field and can greatly achieve the effect of high efficiency and low resistance when being used as an air filter material.

Owner:SOUTH CHINA UNIV OF TECH

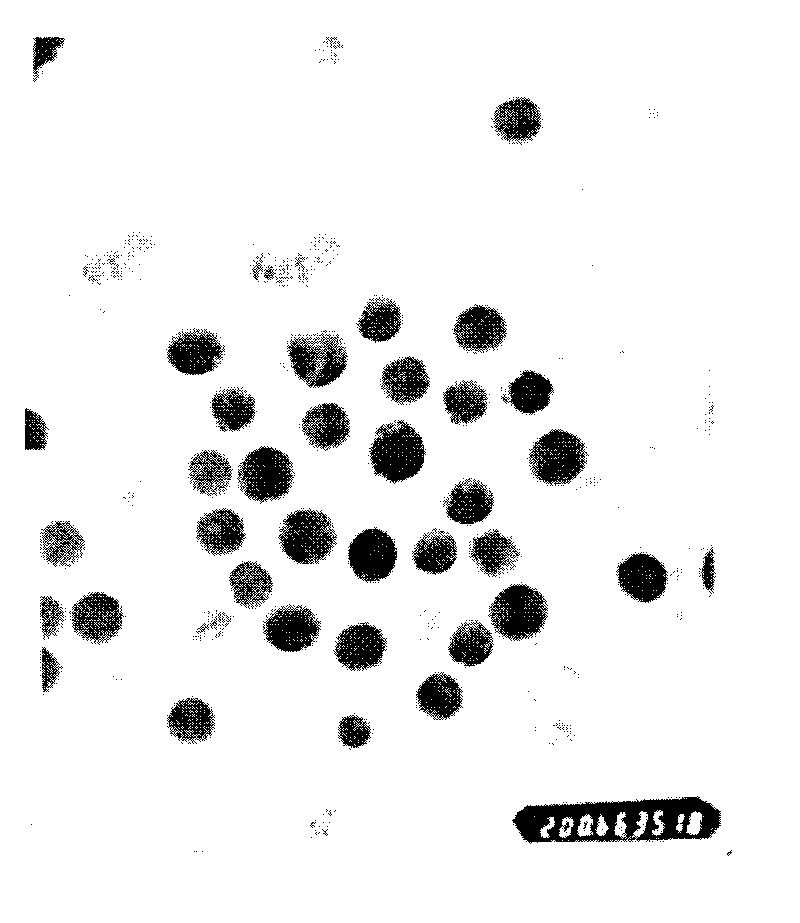

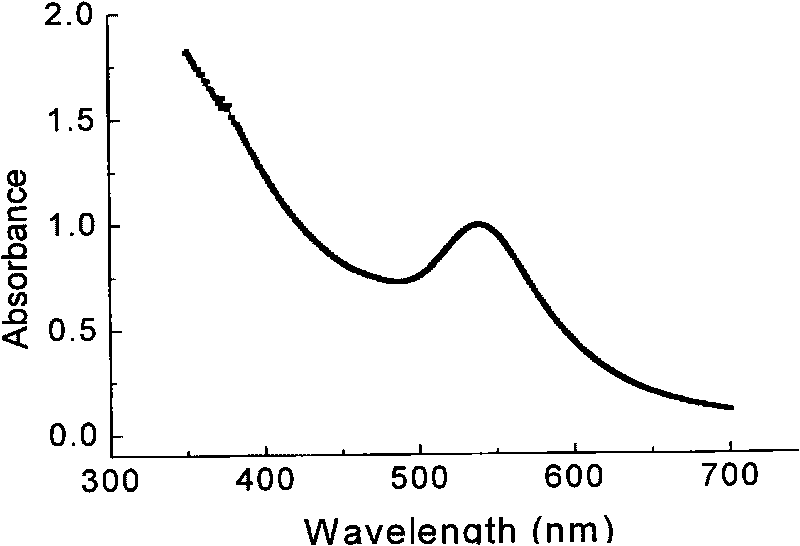

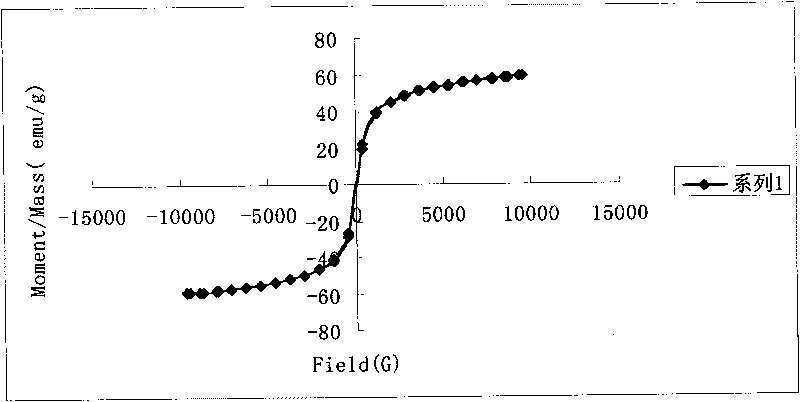

Method for preparing gold magnetic particles

ActiveCN101728044AMild reaction conditionsSimple preparation processInorganic material magnetismSynthesis methodsOil phase

The invention belongs to the field of composite material synthesis, relating to a method for preparing composite material of gold coated magnetic oxide, i.e. gold magnetic particles, in particular to a method for preparing the gold magnetic particles by utilizing positive micro-emulsion and a one-step synthesis method. The method comprises the following steps of: establishing a positive micro-emulsion system by taking an organic reagent dispersed with oil-soluble magnetic oxide as cores and oil phase of the gold magnetic particles; then taking emulsion as a microreactor for producing the composite materials; and adding ethanol for demulsification after reaction; separating and washing the magnetic composite particles by utilizing a magnetic separator to prepare the gold magnetic particles. The method has mild reaction conditions, simple preparation process and water-soluble reagent, can be conveniently applied and is easy to realize large-scale production. AuC14- of chlorogold acid is adsorbed at the surface of the oil-soluble oxide particles by a cation surface active agent selected in the method for further reduction, reunion of the composite is little, and the coating is uniform. The sizes of the particles are controlled by controlling the size of the microreactor, and the sizes of the particles are uniform.

Owner:XIAN GOLDMAG NANOBIOTECH

Anti-ultraviolet exterior wall coating and preparation method thereof

InactiveCN106883689AEffective absorptionImprove cooling effectAntifouling/underwater paintsPaints with biocidesAdhesiveUltraviolet lights

The invention discloses an anti-ultraviolet exterior wall coating and a preparation method thereof, and relates to the technical field of exterior wall coatings. The anti-ultraviolet exterior wall coating is prepared from 30 to 40 percent of a component A and 60 to 70 percent of a component B, wherein the component A is prepared from the following raw materials in parts by weight: 80 to 90 parts of EVA (ethylene-vinyl acetate) emulsion, 30 to 60 parts of nano TiO2, 20 to 30 parts of a filler, 10 to 15 parts of a compound adhesive, 2 to 10 parts of an ultraviolet light absorber, 2 to 8 parts of an assistant and 50 to 60 parts of deionized water; the component B is prepared from the following raw materials in parts by weight: 80 to 90 parts of styrene-acrylic emulsion, 30 to 60 parts of waste glass praseodymium and iron magnetic oxide composite powder, 20 to 30 parts of white Portland cement, 2 to 10 parts of coloring pigment and 30 to 60 parts of deionized water. According to the anti-ultraviolet exterior wall coating disclosed by the invention, an anti-ultraviolet material is added on the basis of waterproof property, so that ultraviolet rays can be effectively absorbed; the anti-ultraviolet exterior wall coating has the advantages of being relatively high in heat dissipating effect and weather fastness, safe and environment-friendly.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

Magnetic recording medium

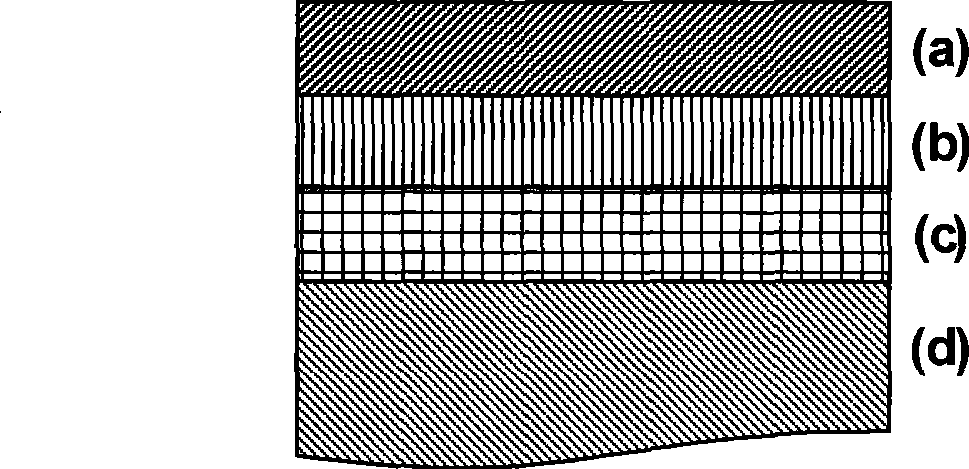

InactiveUS20050064243A1Improve reliabilityHigh densityBase layers for recording layersLayered productsInter layerMetal alloy

A magnetic recording medium comprising a substrate, an underlayer, an intermediate layer, and a magnetic layer in this order, the underlayer being made of Ru, the intermediate layer being made of an RuCo alloy, and the magnetic layer having a granular structure made up of a Co-containing ferromagnetic metal alloy and a non-magnetic oxide.

Owner:FUJIFILM CORP +1

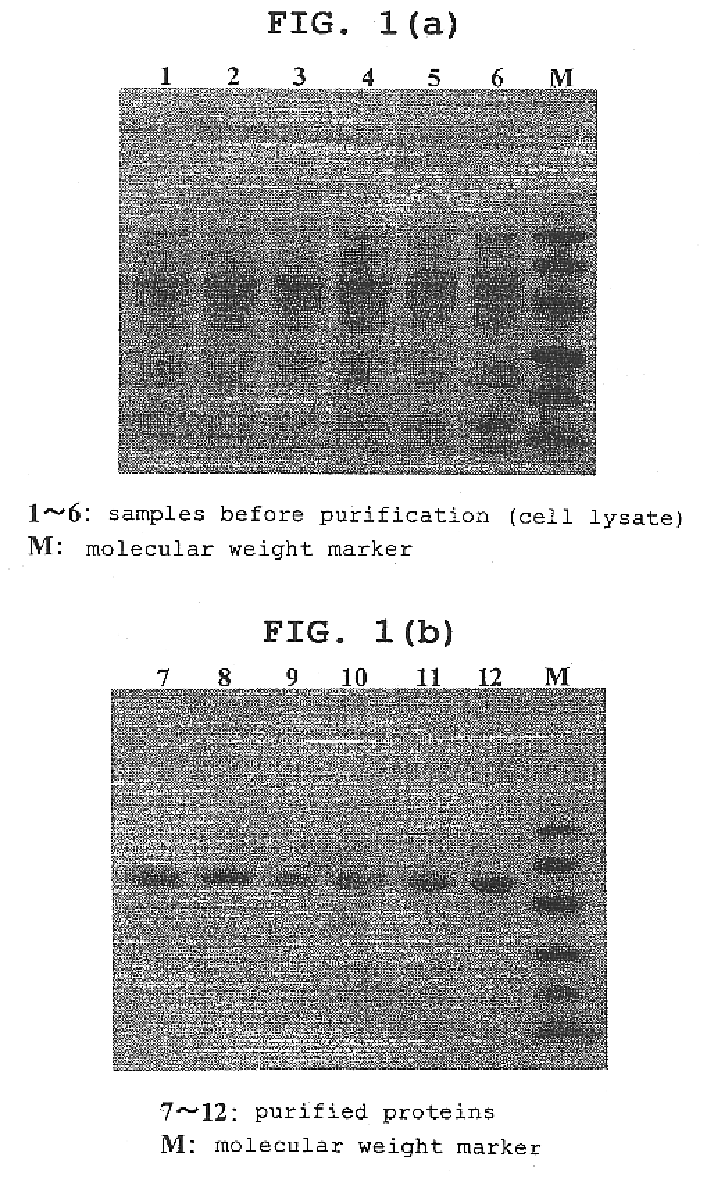

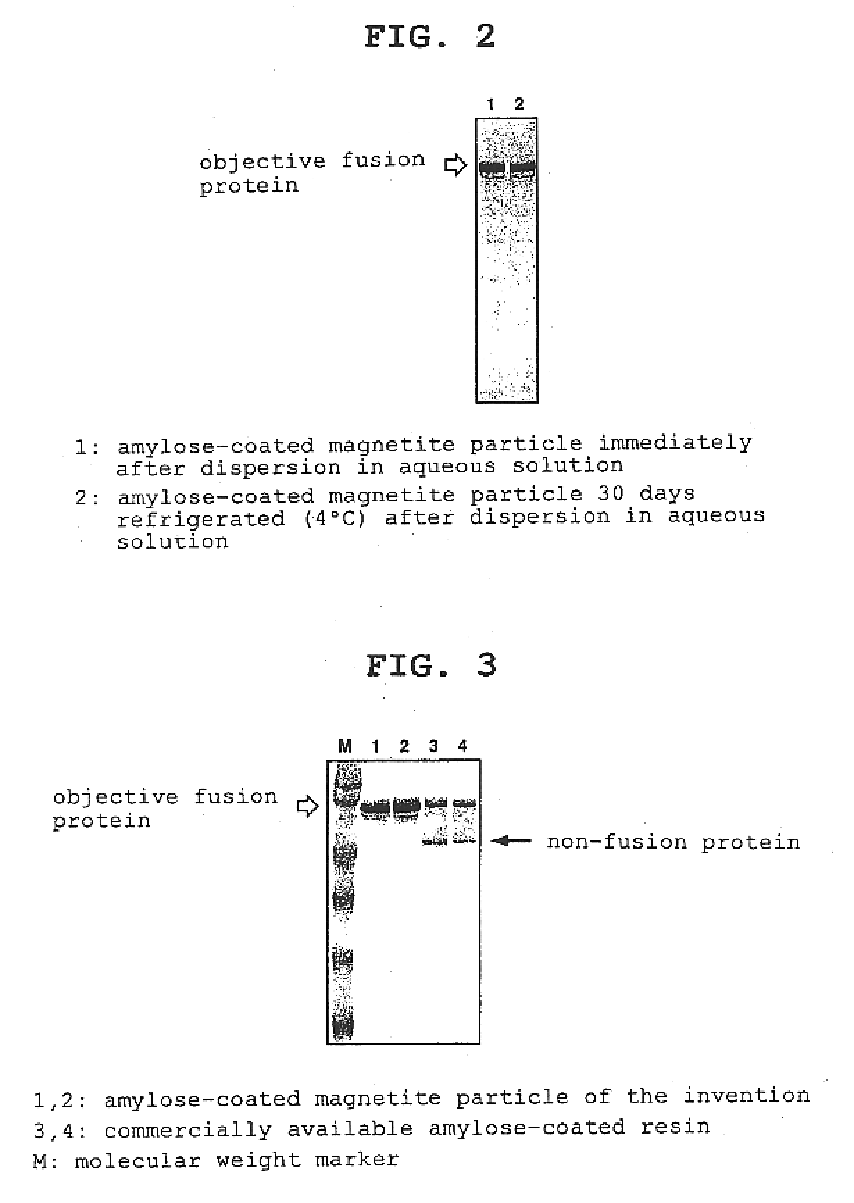

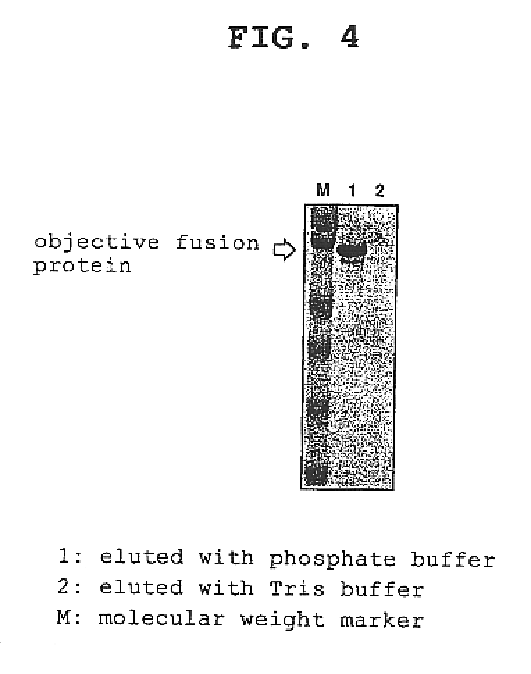

Magnetic carrier capable of binding with protein and purification method of protein utilizing the magnetic carrier

InactiveUS6844426B2Improve throughputEffective isolationPigmenting treatmentPeptide preparation methodsChemistryMagnetic oxide

The present invention provides a strikingly convenient novel purification method of protein, as compared to conventional methods, which affords automation and high throughput, and a material therefor. That is, the present invention provides a magnetic carrier containing a ferromagnetic oxide particle and a carbohydrate layer coating the ferromagnetic oxide particle, a purification method of protein using the carrier, and a reagent kit for purification of protein.

Owner:TOYO TOYOBO CO LTD +1

Core/shell type magnetic particle product and preparing method thereof

ActiveCN101521067AGood dispersionImprove antioxidant capacityInductances/transformers/magnets manufactureMagnetic materialsDispersityMedical product

The invention provides a core / shell type magnetic particle product and a preparing method thereof. The method comprises five steps of: preparation of magnetic oxide nanoparticles, wrapping of organic silicon source, chemical reduction, wrapping of inorganic silicon source, modification of silanized reagent with various functional groups and the like. The prepared core / shell type magnetic particle has good dispersity in water, strong magnetism of inner core matters, compact shell structure of silicon oxide, high chemical stability, strong oxidation resistance, no naked magnetic particles and good leak resistance. The product is applicable to separate and purify biological materials and medical products and can be used as carriers of biological molecules and medical molecules.

Owner:SUNDIA MEDITECH COMPANY LTD

Thermagnonic spin-torque oscillator(STO) and sensor utilizing same to detect shifts in the free layer magnetization oscillation frequency

ActiveUS20130063841A1Disposition/mounting of recording headsMagnetic measurementsIn planeSpin-transfer torque

A “thermagnonic” spin-torque oscillator (STO) uses heat flow alone to cause the spin-torque (ST) effect and generate the persistent oscillation of the free layer magnetization. In addition to the conventional free and reference layers, the thermagnonic STO also includes a magnetic oxide layer having a fixed in-plane magnetization, a ferromagnetic metallic layer on one surface of the magnetic oxide layer, a nonmagnetic electrically conductive layer between the free layer and the metallic layer, and an electrically resistive heater on the other surface of the magnetic oxide layer. Due to the thermagnonic effect, heat flow from the magnetic oxide layer through the metallic layer, conductive layer and free layer ultimately results in a spin transfer torque (STT) to the free layer. Electrical sense current flowing in the opposite direction as the heat flow is used to monitor the frequency of oscillation of the free layer magnetization.

Owner:WESTERN DIGITAL TECH INC

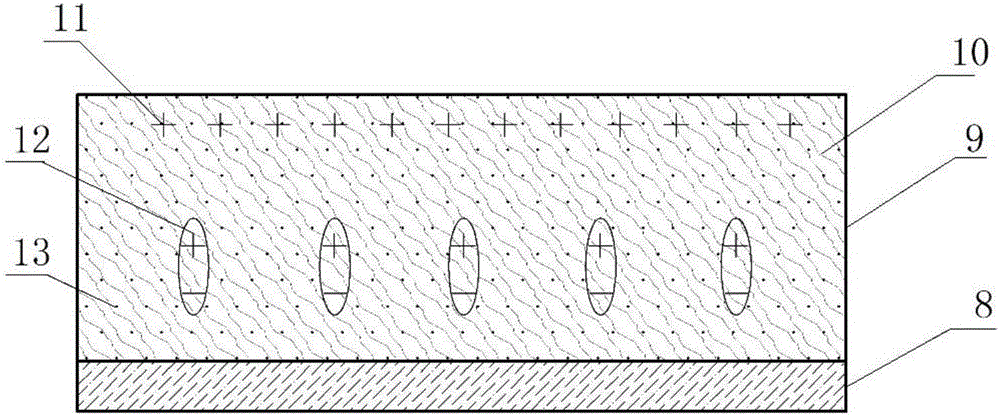

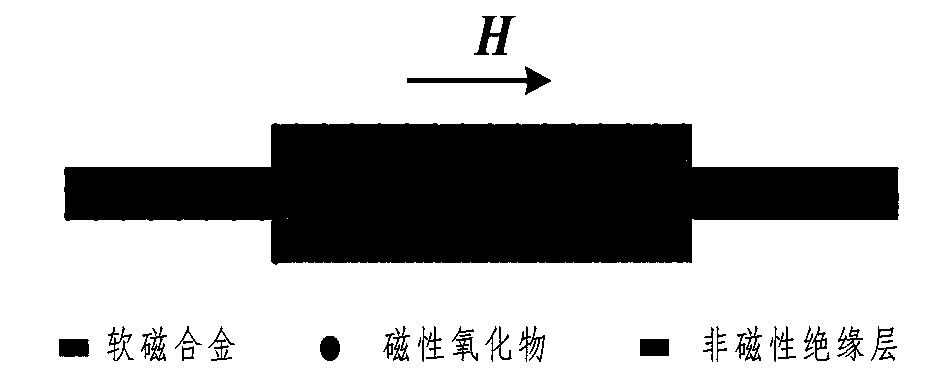

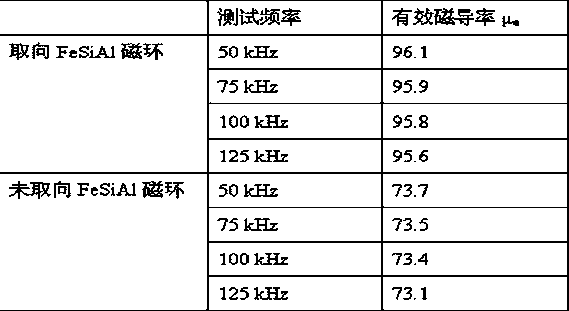

A soft magnetic composite material with high permeability and low loss and a preparation method thereof

ActiveCN108987025AReduce skin effectReduce eddy current lossInorganic material magnetismInductances/transformers/magnets manufactureMaterials preparationHigh resistivity

The invention belongs to the field of magnetic material preparation, in particular to a soft magnetic composite material with high permeability and low loss and a preparation method thereof. The composition and structure of the soft magnetic composite material are as follows: the soft magnetic alloy particles are sheet-like structure, and all the sheet-like particles are arranged in parallel orderalong the magnetic ring plane; Filling high resistivity insulating phase between magnetic particles; The insulating phase comprises nanometer magnetic oxide; This structure improves the permeabilityof the composite material and reduces the magnetic loss in the intrinsic structure. The preparation process comprises the following steps of: fully mixing the passivated soft magnetic alloy particlesand the interface insulation phase to realize the insulation coating of the soft magnetic alloy particles; In the forming process of the magnetic ring, the soft magnetic alloy particles are oriented by magnetic field, and the highly ordered anisotropic magnetic ring is obtained. The soft magnetic composites with high orientation, high permeability and low loss isobtained by further stress relief annealing. The invention has the advantages that the highly oriented and orderly arranged sheet structure can effectively reduce the magnetic loss and improve the magnetic permeability of the compositematerial.

Owner:CHINA JILIANG UNIV

A preparation method of a soft magnetic composite material with high permeability

ActiveCN109036754AReduce hysteresis lossEasily magnetizedInorganic material magnetismInductances/transformers/magnets manufactureMaterials preparationMagnetic oxide

The invention belongs to the field of magnetic material preparation, and particularly relates to a preparation method of a soft magnetic composite material with high permeability. A soft magnetic alloy and an insulating medium are mixed, and a soft magnetic composite material is prepared by a hot pressing and hot deformation process; the soft magnetic alloy in the hot-deformed magnet becomes a flake structure, and all the flake magnetic particles are arranged in parallel order along the magnetic ring plane (working magnetic path direction); at the same time, nanometer magnetic oxide is added into the insulating medium; and finally, high-permeability anisotropic soft magnetic composites are obtained. The invention has the advantages that the sheet structure can effectively reduce the loss and improve the magnetic permeability, the sheet soft magnetic particles oriented along the plane of the magnetic ring can be directly obtained through the hot pressing and hot deformation process, andthe anisotropic ordered magnetic structure can be obtained without the need of a magnetic field.

Owner:CHINA JILIANG UNIV

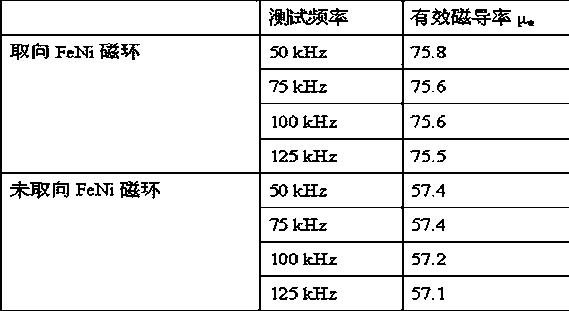

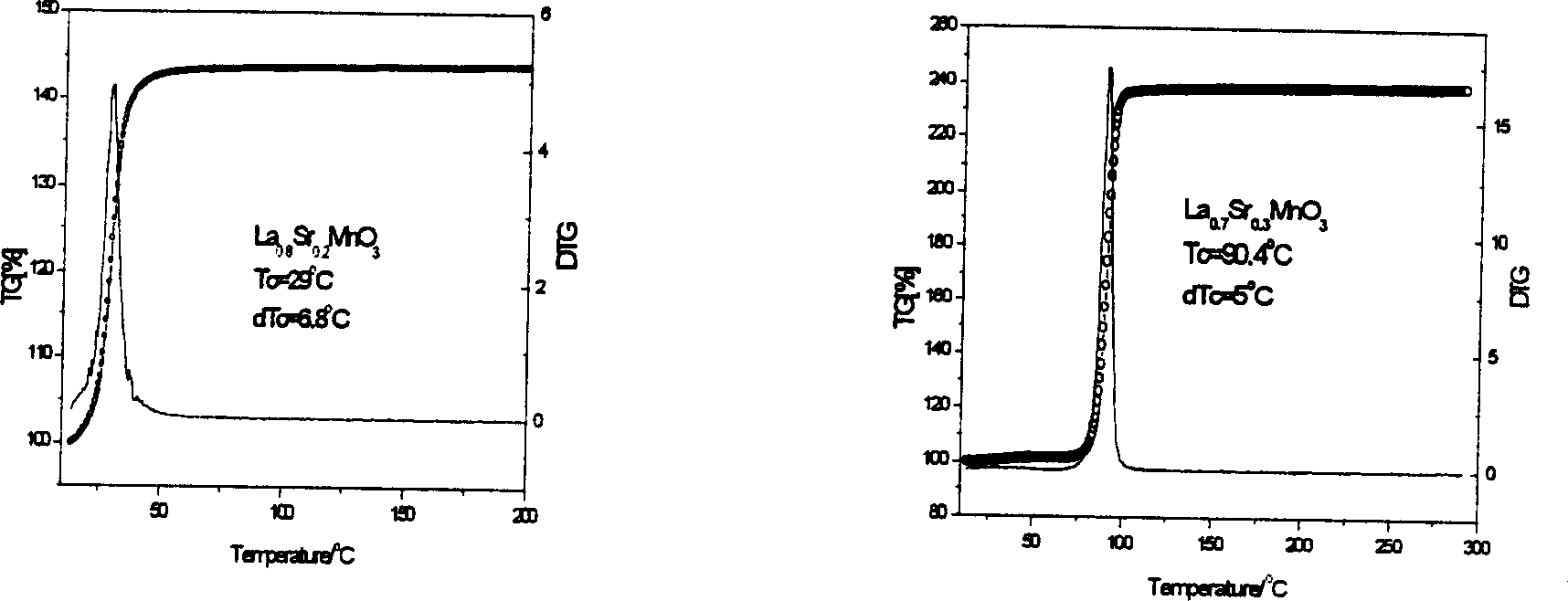

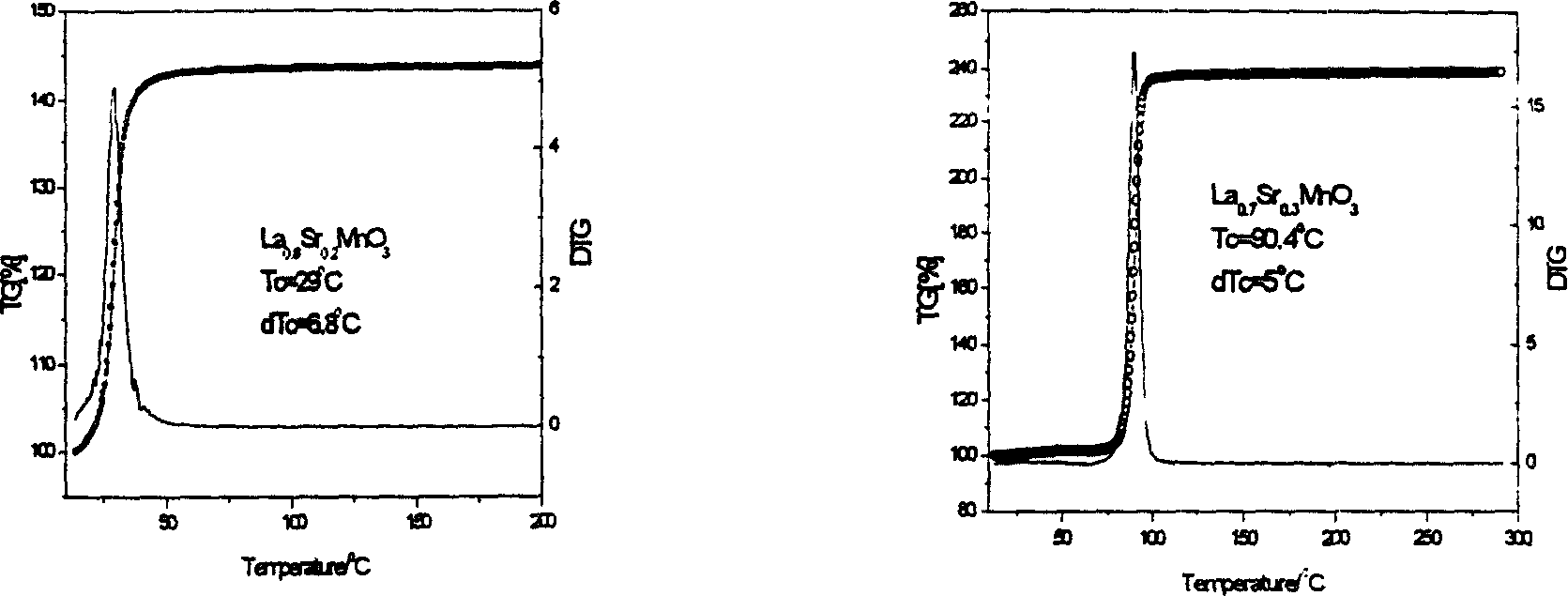

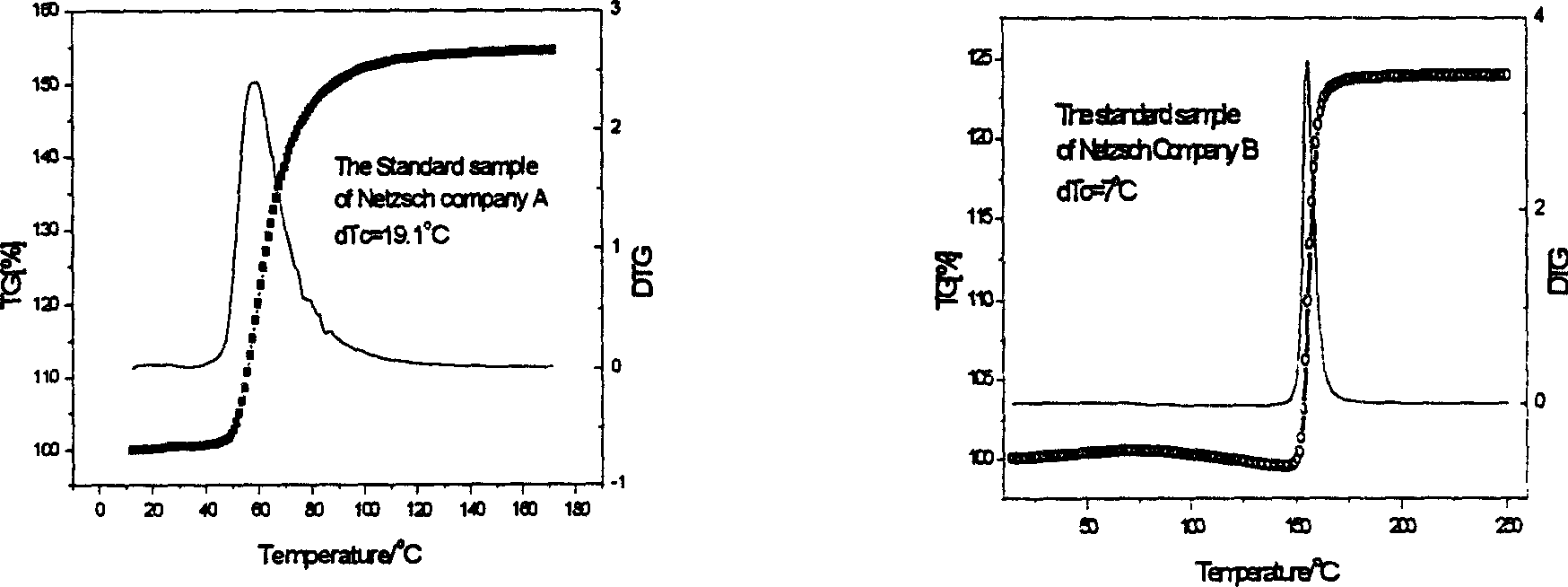

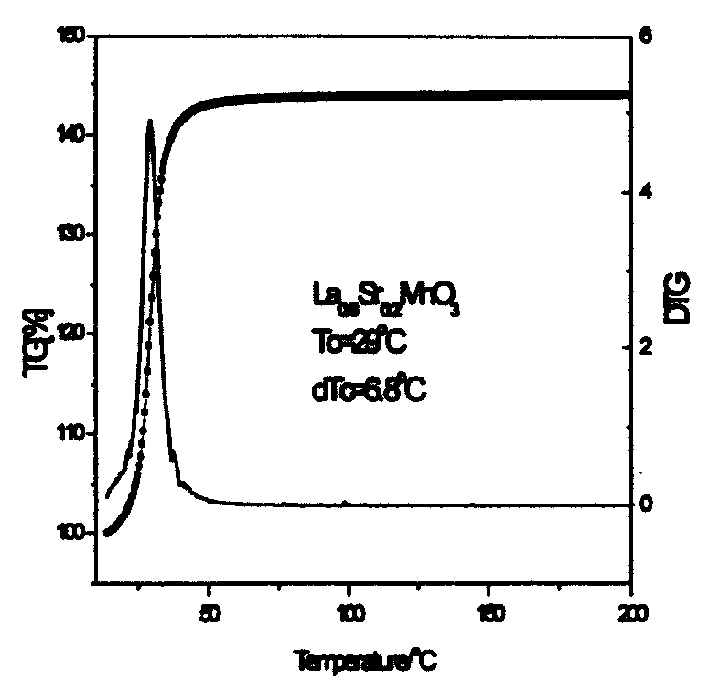

Sample for temp. calibration of thermogravimeter and preparing method thereof

InactiveCN1451957AReduce dosageRapid responseMaterial thermal analysisMaterial weighingGiant magnetoresistanceManganese

A sample for the temp calibration of thermogravimetric analyzer is prepared by sol-gel method, in which the La-series RE, Mn, oxide is used as raw materials to prepare magnetic oxide ceramic. Said product has two samples, whose curie points are 29 deg.C and 90.4 deg.C respectively. Its advantages are high precision and resistance to corrosion and moisture, and low cost.

Owner:SUN YAT SEN UNIV

Composites for removing heavy metal and method of synthesizing the same

ActiveUS20180236435A1Increase surface areaImproved heavy metal adsorption efficiencyOther chemical processesWater contaminantsNanoparticleMetal particle

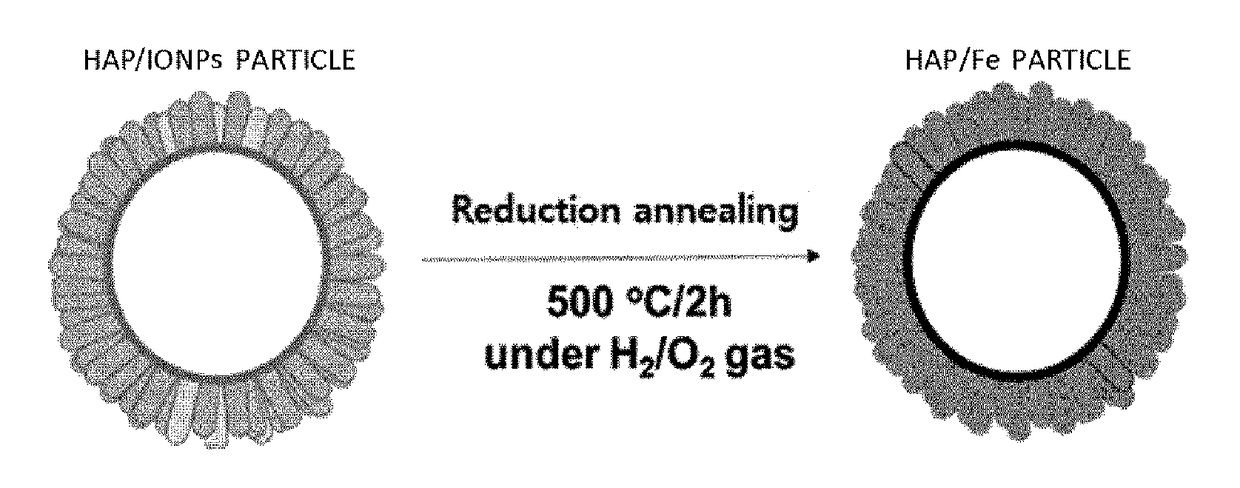

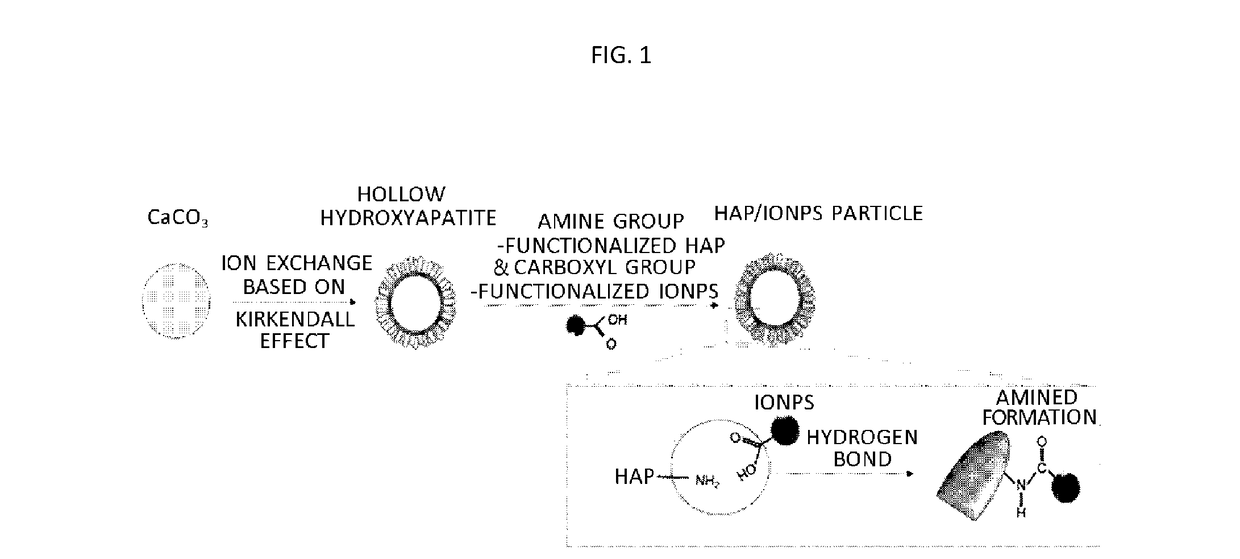

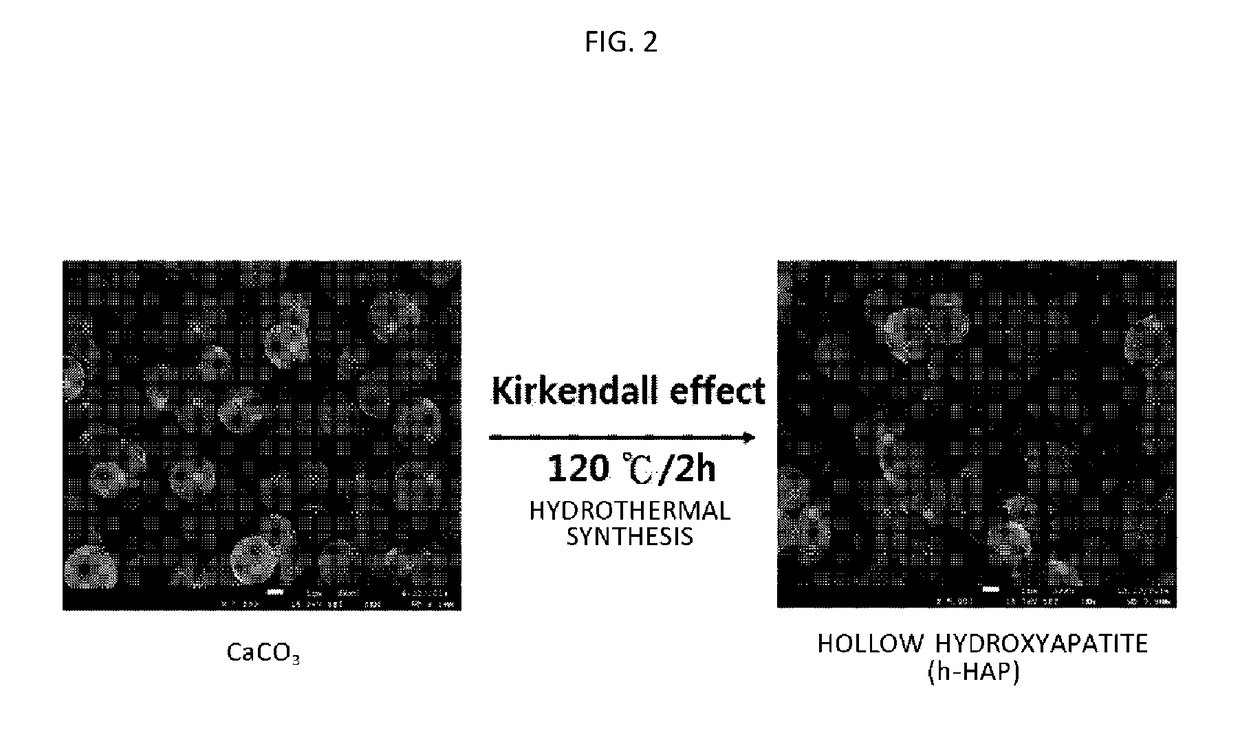

The present disclosure relates to a method of synthesizing composites for removing heavy metals, including: preparing hollow hydroxyapatite particles including a functional group; preparing a composite in which magnetic oxide nanoparticles are combined on the hollow hydroxyapatite; and preparing a composite of hollow hydroxyapatite and metal particles by performing reduction annealing to the composite.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV +1

Magnetic toner

ActiveUS20090186288A1High image densityExcellent image reproducibilityDevelopersDielectric lossImage density

The object of the present invention is to provide a magnetic toner enabling an image with high image density and excellent image reproducibility to be obtained, which is excellent in fluidity, charging stability, and charging uniformity, even for long-term use, and also enabling an image whose fogging, ghost, and scattering are suppressed to be obtained. The magnetic toner has at least a binder resin and a magnetic material, where, the magnetic material is an magnetic iron oxide whose dielectric breakdown voltage of the magnetic material is 160 to 1600 V / cm, and the dielectric loss tangent (tan δ) of the magnetic toner at 100 kHz and 40° C. is 2.0×10−3 to 1.0×10−2.

Owner:CANON KK

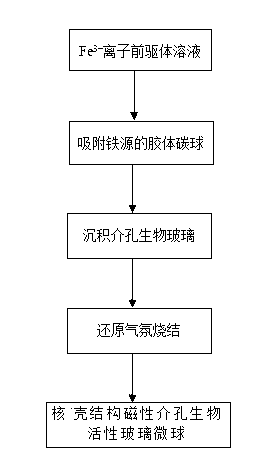

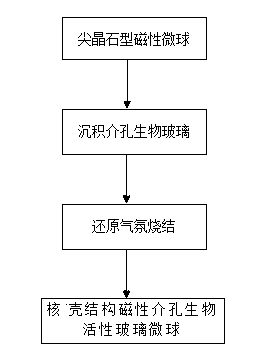

Core/shell structured magnetic meso-porous biological active glass microsphere material and its preparation method

InactiveCN103127506ATo overcome the deficiency of curative effect in the treatment of bone tumorsEnergy modified materialsInorganic non-active ingredientsMicrosphereMagnetic oxide

The invention discloses a core / shell structured magnetic meso-porous biological active glass microsphere material and its preparation method. Ca, P and Si are deposited on the surface of an iron source adsorbed colloidal carbon sphere which is treated as a template or a hydrothermal method synthesized spinel type ferrite microsphere which is treated as a core in a hydrolytic condensation mode, and sintering is carried out in a reducing atmosphere to obtain the magnetic microsphere comprising an magnetic oxide as the core and biological active glass as the shell. The core / shell structured magnetic meso-porous biological active glass microsphere material prepared in the invention simultaneously has the bone tumor medicine treatment and bone defect restoration effects to overcome the curative effect disadvantages of single methods in the bone tumor treatment, so a new idea and a new material are provided for the bone tumor treatment.

Owner:SUZHOU UNIV

Sample for temp. calibration of thermogravimeter and preparing method thereof

InactiveCN1198127CReduce dosageRapid responseMaterial thermal analysisMaterial weighingRare earthCurie temperature

The invention relates to a standard sample used for temperature calibration of a thermogravimetric analyzer and a preparation method thereof, in particular to a sol-gel method for preparing a standard sample product for temperature calibration of a thermogravimetric analyzer. We aim at the current situation that the standard samples of domestic thermal analyzers come from two foreign companies and the current shortcomings of the standard products of these two companies, that is, they are not resistant to acid and alkali corrosion, low precision, easy to rust in humid environments, and lack of room temperature. Based on the characteristics of nearby standard samples, the lanthanide rare earth manganese oxides with giant magnetoresistance effect were used as raw materials to prepare magnetic oxide ceramics for temperature calibration of thermogravimetric analyzers. The product consists of two samples, one sample has a Curie temperature of 29°C, so its calibration temperature is 29°C, and the other has a Curie temperature of 90.4°C, and its calibration temperature is 90.4°C. The product has the advantages of high precision, acid and alkali corrosion resistance, humidity resistance, simple preparation process, cheap price and convenient use.

Owner:SUN YAT SEN UNIV

Novel method for preparing magnetic oxide and perpendicular graphene array composite and application thereof to supercapacitor

ActiveCN108597903AHigh specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceMagnetic oxide

The invention provides a novel method for preparing a magnetic oxide and perpendicular graphene array composite. The nano-material preparation method is characterized by comprising the following steps: firstly, compounding graphene with a perovskite-type magnetic oxides (e.g. ferromagnetic La<0.67>Sr<0.33>MnO<3> nano-powder); uniformly dispersing the nano-powder on the surface of the monolayer graphite by taking the graphene as a skeleton; then applying an external magnetic field to a graphene / magnetic oxide composite; directionally aligning the magnetic oxide with the graphene under the action of the magnetic force of the magnetic field; and forming an array of the perpendicular graphene / magnetic oxide composite material on the surface of a conductive substrate. Through adoption of the method for preparing an electrode of the supercapacitor, preparation of a perpendicular graphite array and a perovskite-type oxide electrode material being highly and uniformly dispersed can be realizedat the same time; a composite supercapacitor with a double-layer capacitor and a pseudo-capacitor can be manufactured; and the energy density of the supercapacitor is increased.

Owner:YUNNAN UNIV

Integrated optical structure comprising an optical isolator

InactiveUS20140247477A1Reduce optical power lossReduce power consumptionLaser detailsSemiconductor/solid-state device manufacturingOptical isolatorSemiconductor package

An integrated optical structure includes at least one optical isolator, having a magneto-optical layer, associated with at least one SOA optical amplifier having a waveguide having an n-doped semiconductor layer, a p-doped semiconductor layer, and an active area disposed between the n-doped semiconductor layer and the p-doped semiconductor layer. The optical isolator is disposed between an SOI base and the SOA optical amplifier's waveguide. The optical isolator's magneto-optical layer is disposed between a lower insulating layer and an upper insulating layer. The optical isolator's magneto-optical layer may be a layer of ferromagnetic metallic material, such as a Fe—Co metallic alloy, or a magnetic oxide layer. An optical device includes at least one integrated optical structure.

Owner:ALCATEL LUCENT SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com