Stack ferro-electricity /magnetic multiferrou magnetoelectric compound film with conductive oxide as buffer layer and preparation thereof

A technology of magnetoelectric composite and composite film, applied in the direction of layered products, etc., can solve the problems of poor magnetoelectric performance of composite film, and achieve the effects of high magnetoelectric performance, improved leakage current performance, and simple equipment and preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

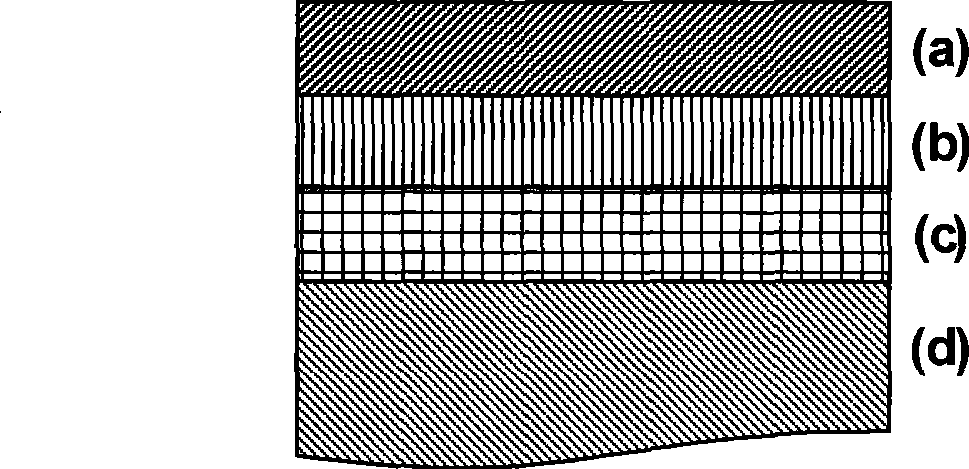

[0039] Example 1. Preparation of laminated PZT / CFO multiferroic magnetoelectric composite film on Si substrate and its performance detection

[0040] 1. Preparation of laminated PZT / CFO multiferroic magnetoelectric composite thin films

[0041] (1) Preparation of LaNiO 3 (LNO)sol

[0042] Nickel acetate (Ni(CH 3 COO) 2 4H 2 O) and lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) as raw material, with acetic acid and deionized water as solvent, and formamide as additive, wherein the molar ratio of lanthanum nitrate and nickel acetate is 1:1, and the volume ratio of acetic acid, deionized water and formamide is 20-30:4 -6: 1-2.

[0043] First weigh 0.01mol of nickel acetate, dissolve it in 30ml of acetic acid by heating and stirring, then add 0.01mol of lanthanum nitrate and 20ml of deionized water, add 0.001mol of formamide after completely dissolving, adjust the concentration and filter, then let it stand for aging. 50 ml of LNO sol with a concentration of 0.2 mol / L was obtain...

Embodiment 2

[0067] Embodiment 2, in Pt / Ti / SiO 2 / Si substrate using LaNiO 3 Preparation of Laminated PZT / CFO Multiferroic Magnetoelectric Composite Thin Films with Buffer Layer

[0068] In the preparation method of this embodiment, the raw materials used and the preparation process are exactly the same as in Example 1, only the substrate is changed to Pt / Ti / SiO 2 / Si.

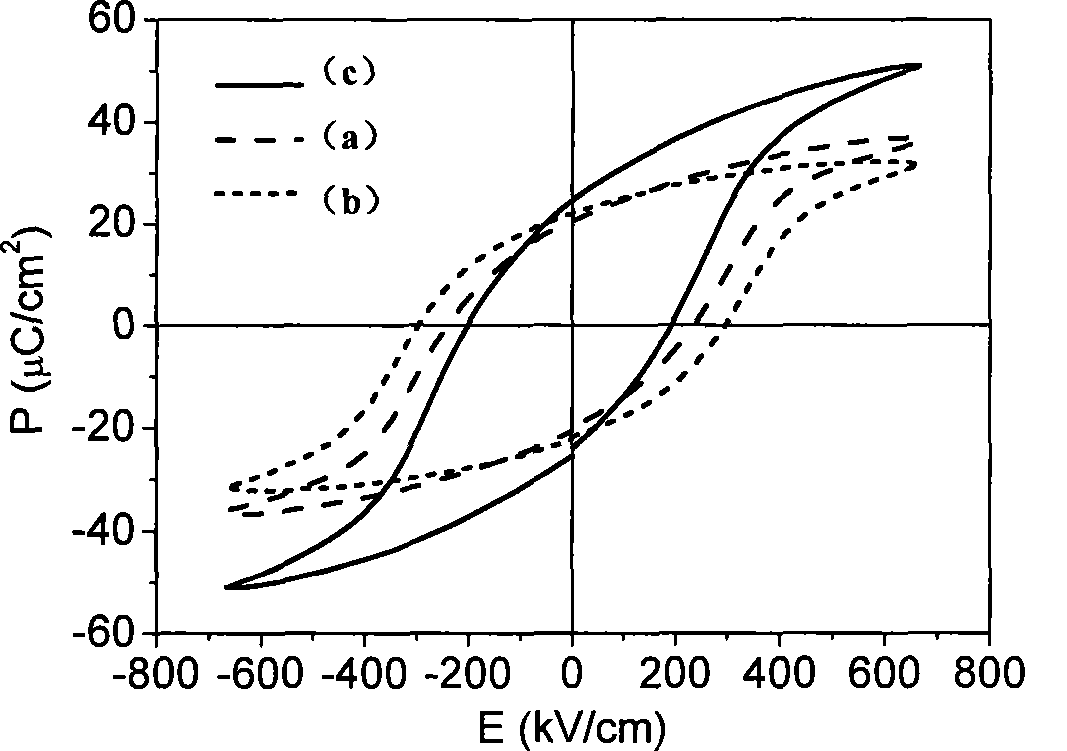

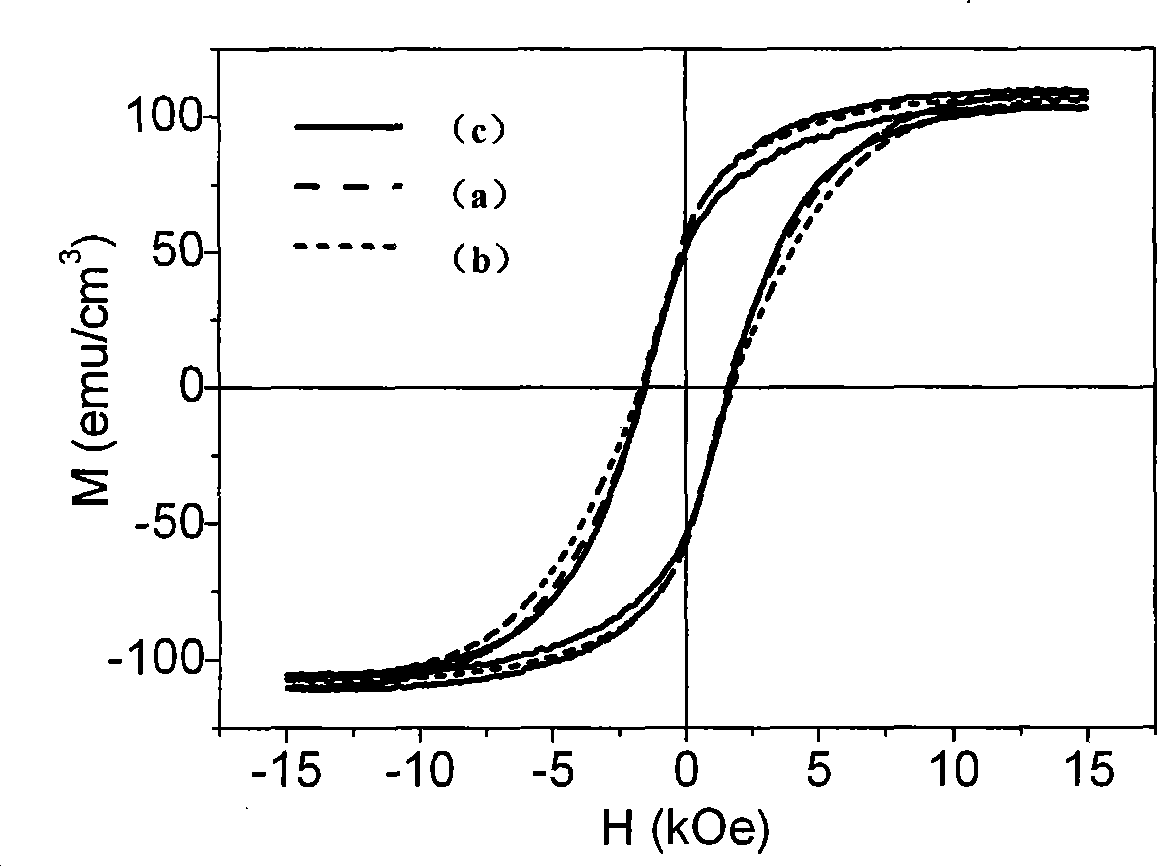

[0069] Pt / Ti / SiO with LNO as buffer layer 2 The ferroelectric properties and magnetic properties of the PZT / CFO composite film on the / Si substrate have no significant difference with the PZT / CFO composite film on the LNO / Si substrate in Example 1, as Figure 2-3 Shown in curve (b).

[0070] Pt / Ti / SiO with LNO as buffer layer 2 The magnetoelectric properties of PZT / CFO composite films on / Si substrates are as follows: Figure 4 and Figure 5 Shown in middle curve (b), when there is no DC magnetic field, the magnetoelectric coefficient of this film is 36mV / cm Oe, when the DC magnetic field is 6.4kOe, the magnetoelec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com