Patents

Literature

165results about How to "The equipment process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

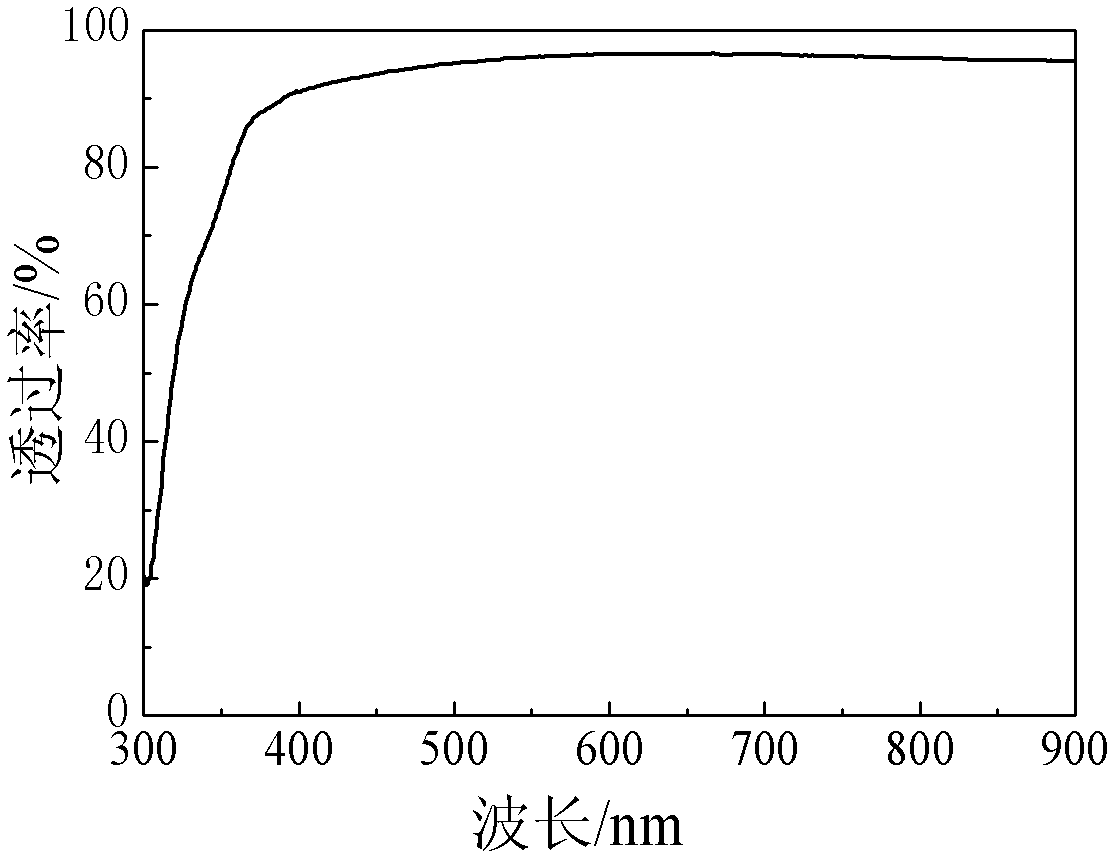

Super-hydrophobic polyurethane/ oxide nano particle hybrid coating material and preparation method thereof

ActiveCN101838496ALow costSimple equipment and preparation processPolyurea/polyurethane coatingsSurface energySelf-assembly

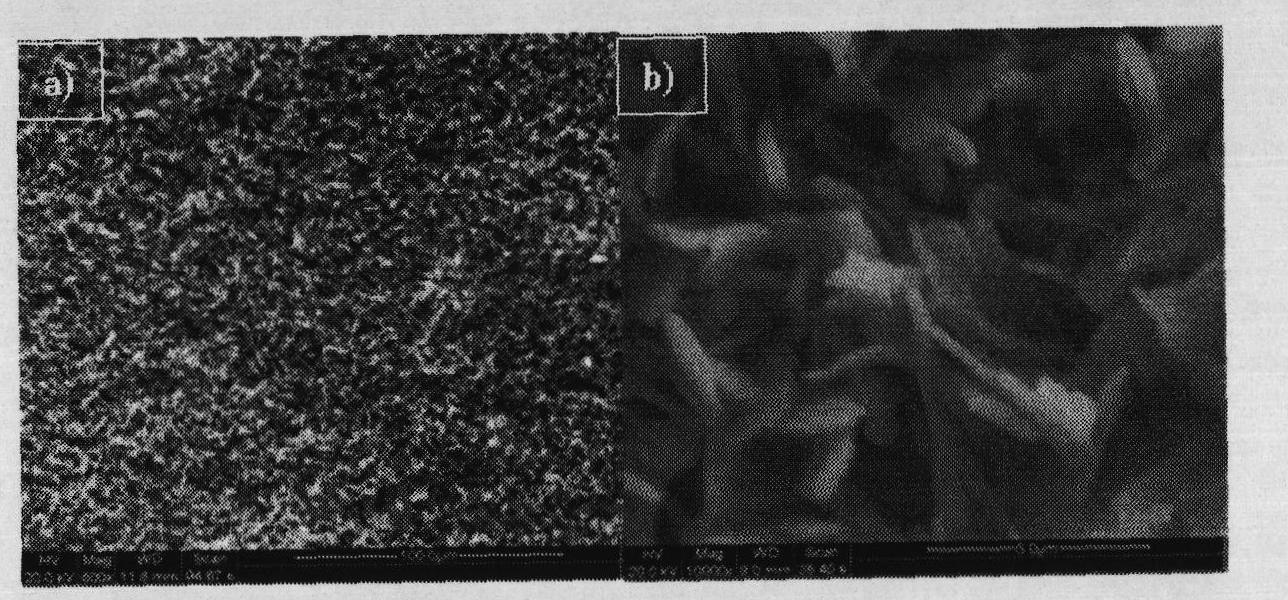

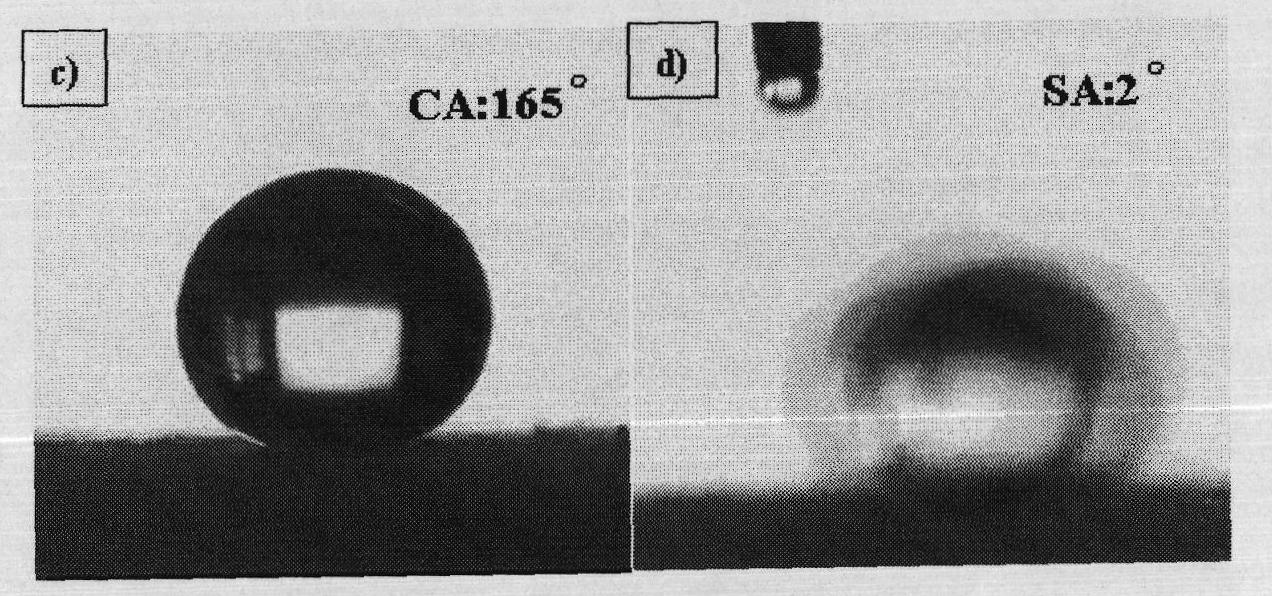

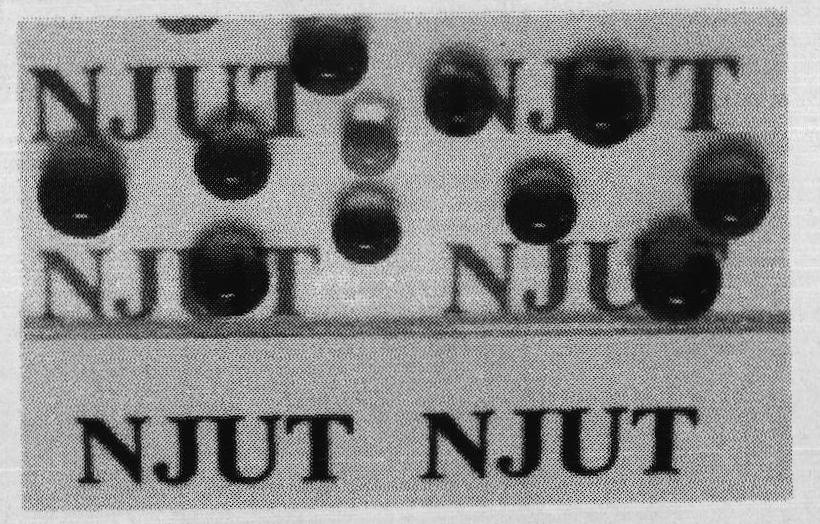

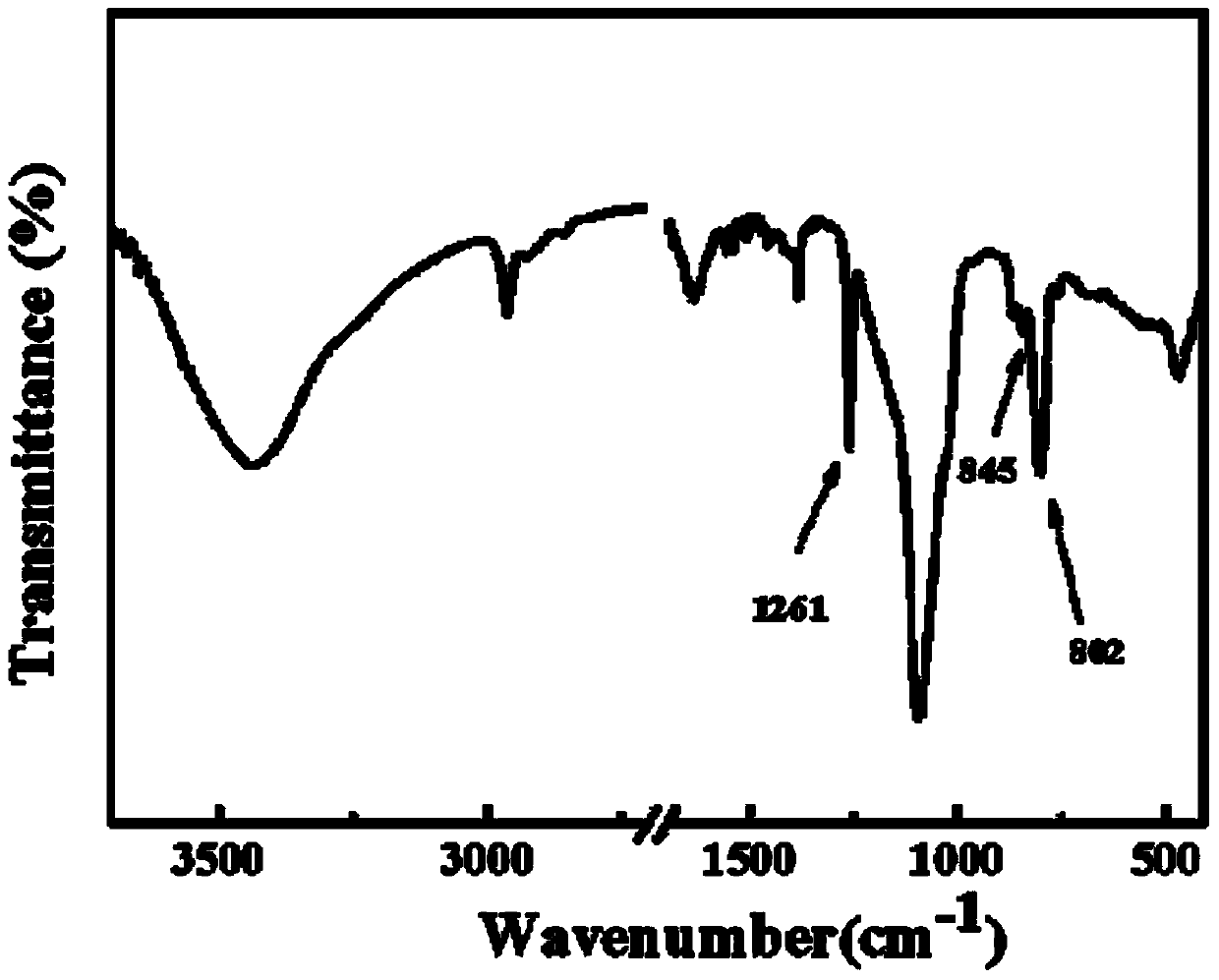

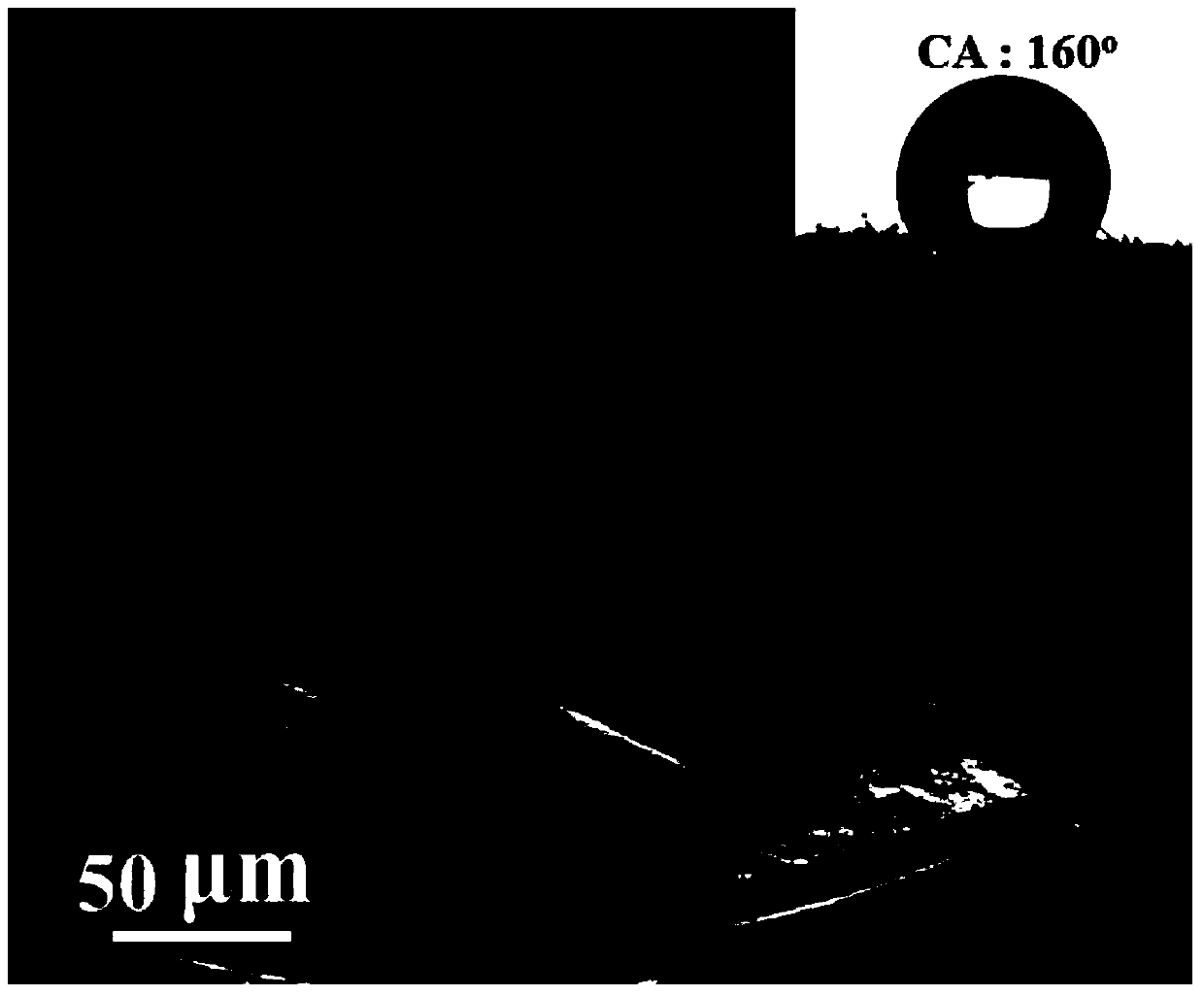

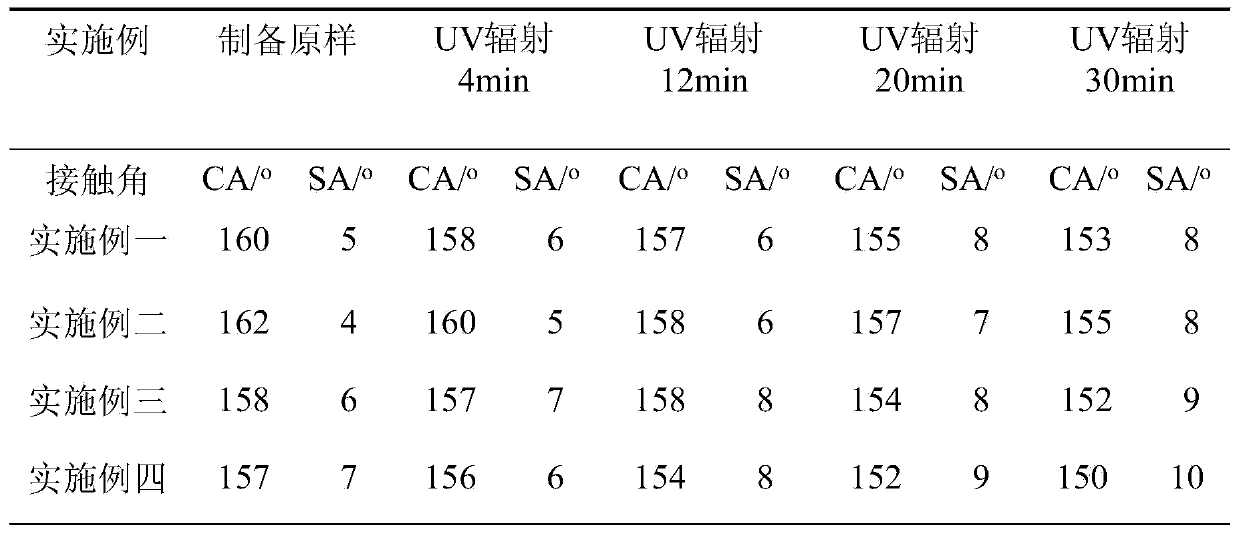

The invention relates to a super-hydrophobic polyurethane / oxide nano particle hybrid coating and a preparation method thereof. The super-hydrophobic coating is prepared by oxide nano particles, silane coupling agent and polyurethane which have wide material source and are easily obtained through a self-assembly method, and has the contact angle of 140-168 degrees and the rolling angle of 1-20 degrees as well as good visible light permeability. The invention solves the problems that the currently prepared transparent super-hydrophobic coating needs extremely low surface energy perfluorinated silane modification, has high production cost and complicated technique, and can not realize large-scale production. The method has simple technique, easily obtained raw material and low cost; and theprepared super-hydrophobic coating can be taken as a dustproof and antifogging protective coating of the surface of solids such as glass and the like, and a waterproof insulating layer used in a micro-electronic device, a sensor and the like.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

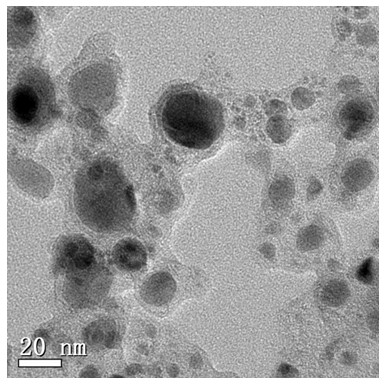

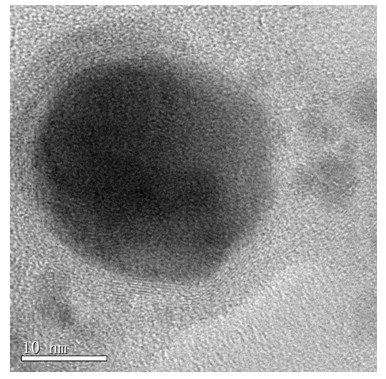

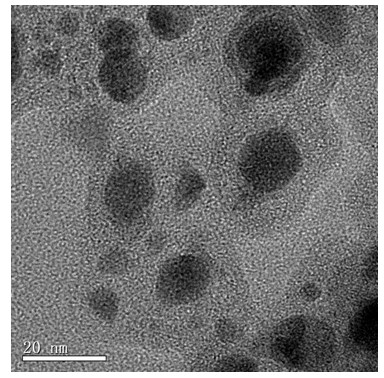

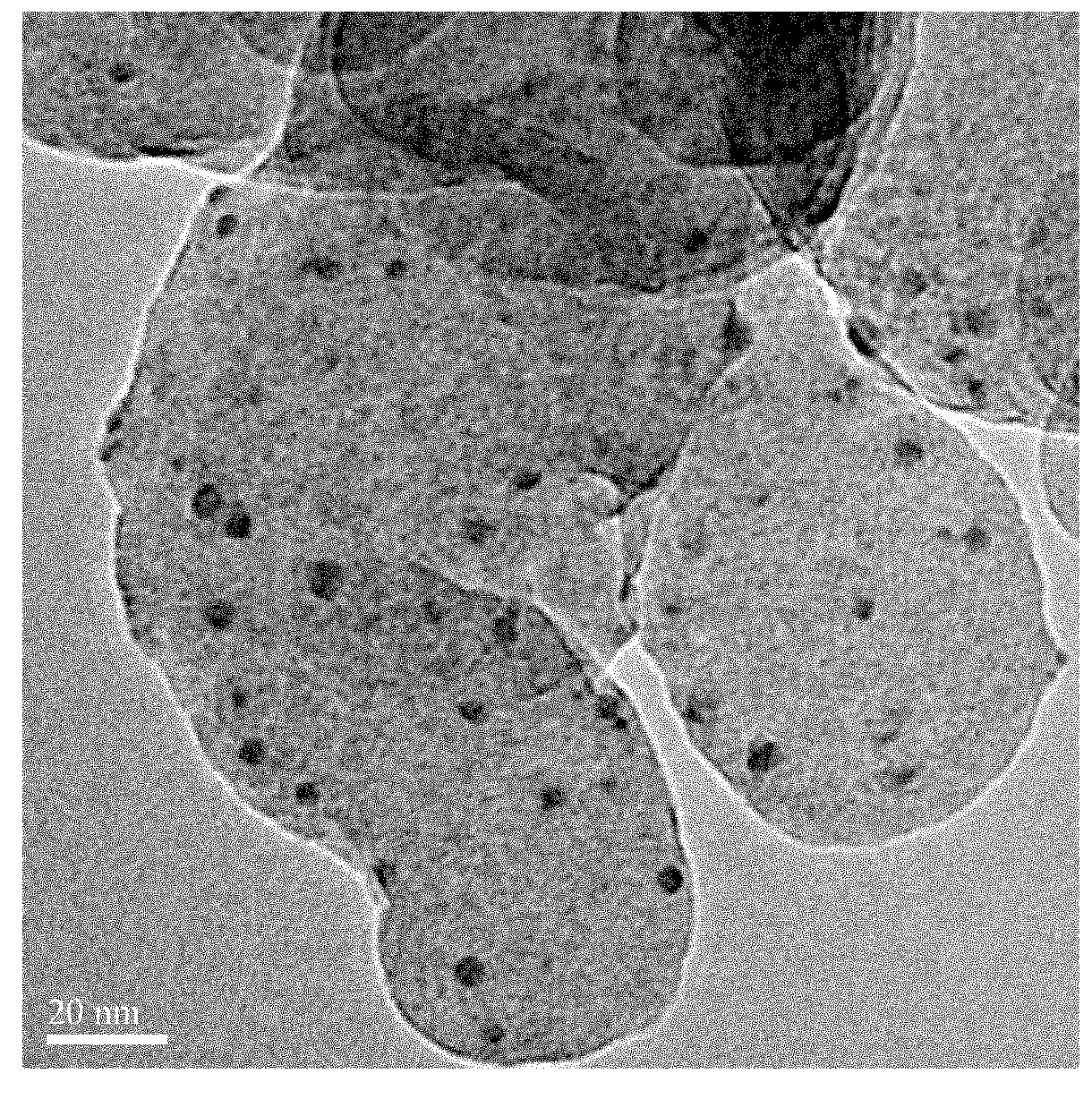

Method for preparing carbon-coated core-shell nanoparticles continuously

The invention relates to a method for preparing carbon-coated core-shell nanoparticles continuously, in particular to a method for preparing carbon-coated metallic oxides, carbon-coated metals, carbon-coated metallic carbides and carbon-coated metal alloy nanoparticles continuously. The method comprises the following steps of: in the process of flame combustion, forming a reducing atmosphere of different degrees in a reactor by controlling the fuel oxygen ratio; atomizing organic solvent solution of a metal salt, adding the atomized solution into the reactor to perform incomplete combustion at the temperature of between 1,000 and 1,800 DEG C; and performing thermal decomposition, nucleating, growing and in-situ carbon coating on a precursor at the high temperature a reducing atmosphere ofdifferent degrees to form the carbon-coated core-shell nanoparticles finally. In the obtained core-shell material, the nanoparticles are coated by carbon effectively and have the good heat stability and acid-base stability. Nanometer core-shell structures of the carbon-coated nanoparticles prepared by the method have the advantages of simple equipment process, no need of substrates, large-scale continuous production and easy industrial implementation.

Owner:EAST CHINA UNIV OF SCI & TECH

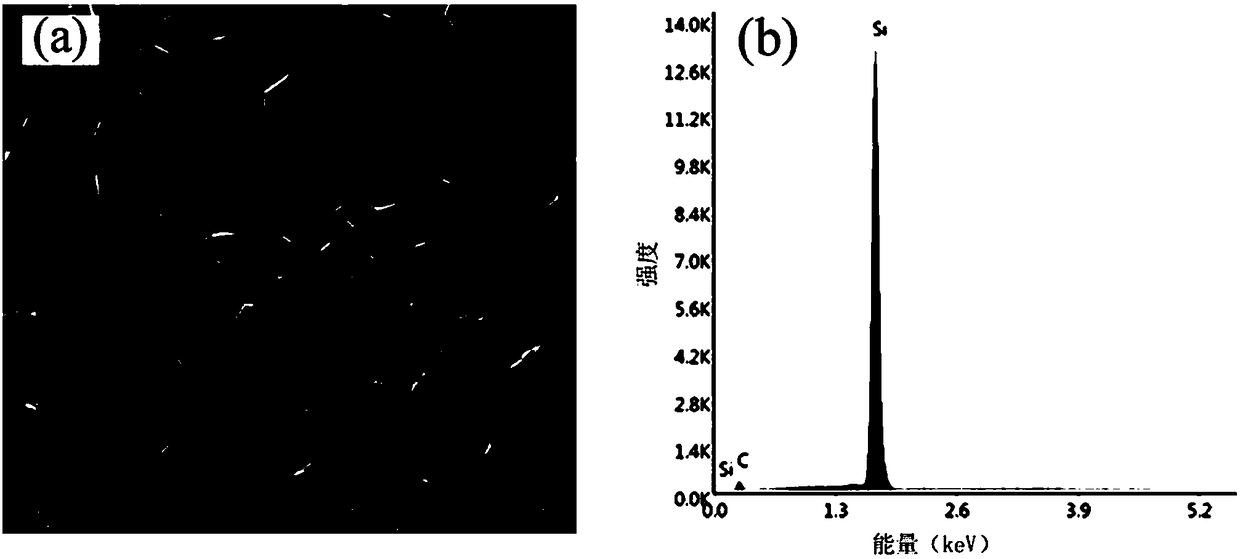

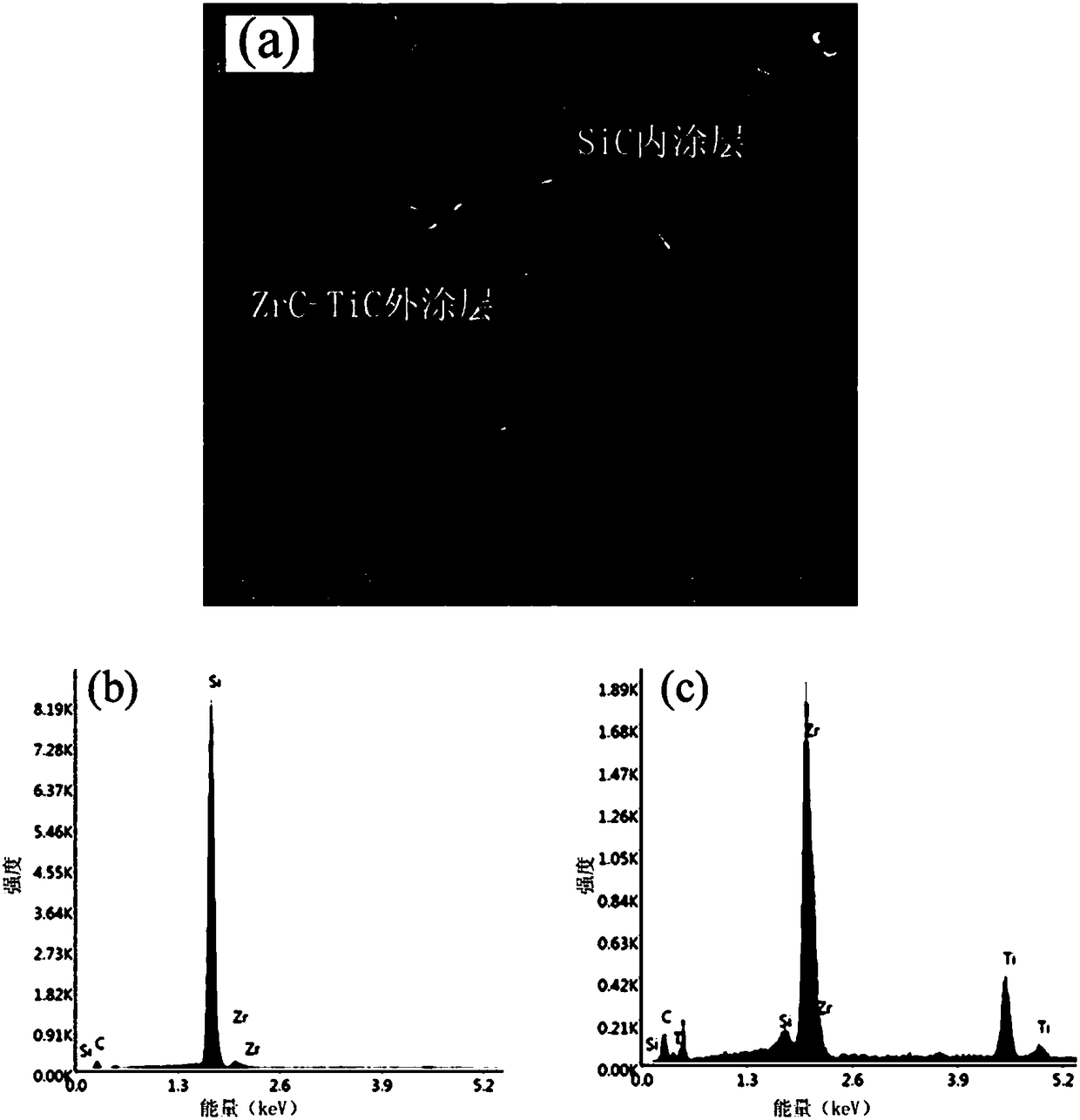

C/C composite material superhigh temperature ceramic coating, and preparation method thereof

InactiveCN108530110AExtended service lifeReduce Mismatch ProblemsUltra-high-temperature ceramicsCeramic coating

The invention discloses a C / C composite material superhigh temperature ceramic coating, and a preparation method thereof. The C / C composite material superhigh temperature ceramic coating is composed of an anti-oxidation SiC transition internal layer and a superhigh temperature ablation-resistant ceramic external layer; the superhigh temperature ablation-resistant ceramic external layer is composedof more than one ingredients selected from SiC, ZrC, HfC, TaC, TiC, ZrB2, HfB2, TaB2, and TiB2. The preparation method is suitable for industrialized production, is simple in equipment, is convenientin operation, is capable of controlling coating thickness, satisfying preparation requirements of large size C / C composite material superhigh temperature ceramic coating with complex shapes, and is asuperhigh temperature ceramic coating preparation method with excellent development potential.

Owner:CENT SOUTH UNIV

Preparation method for multifunctional super-hydrophobic hybrid material

The invention discloses a preparation method for a multifunctional super-hydrophobic hybrid material (coating) which not only has the photocatalysis performance, but also has super-hydrophobic performance. The preparation method comprises the following steps: firstly, preparing stable silicon dioxide gelatin and titanium dioxide gelatin; adding the silicon dioxide gelatin and the titanium dioxide gelatin at the mass ratio of 1.0-4.0 into an organic silane alcohol solution; sealing, and standing at the temperature of 60-75 DEG C; washing for 3-5 times by an alcohol solution after 16-24 h standing; performing centrifugation, drying and crushing to obtain drainage TiO2-SiO2 mixed gelatin powder; adding the TiO2-SiO2 mixed gelatin powder into a polymer organic solvent, performing supersonic treatment for 30-60 min, quickly stirring at the room temperature for 10-30 min to obtain a mixed hybrid emulsifiable solution.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

High-efficiency formaldehyde scavenging agent

InactiveCN101181677AThorough responseTo achieve the purpose of removing formaldehydeDispersed particle separationWastewaterSURFACTANT BLEND

The invention discloses a high effect formaldehyde dispelling agent. The formaldehyde dispelling agent of the invention comprises formaldehyde dispelling factors, a stabilizing agent, a synergistic agent, surfactants and water, etc. The product is nonpoisonous and tasteless, safe and environmental friendly, which can quickly and thoroughly dispel free formaldehyde in air, waste water and various boards and furniture, and a dense protecting film is formed on the surface of solid, working for a long time. The method of the invention is characterized by simple production technique and devices, no three wastes pollution and low production cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

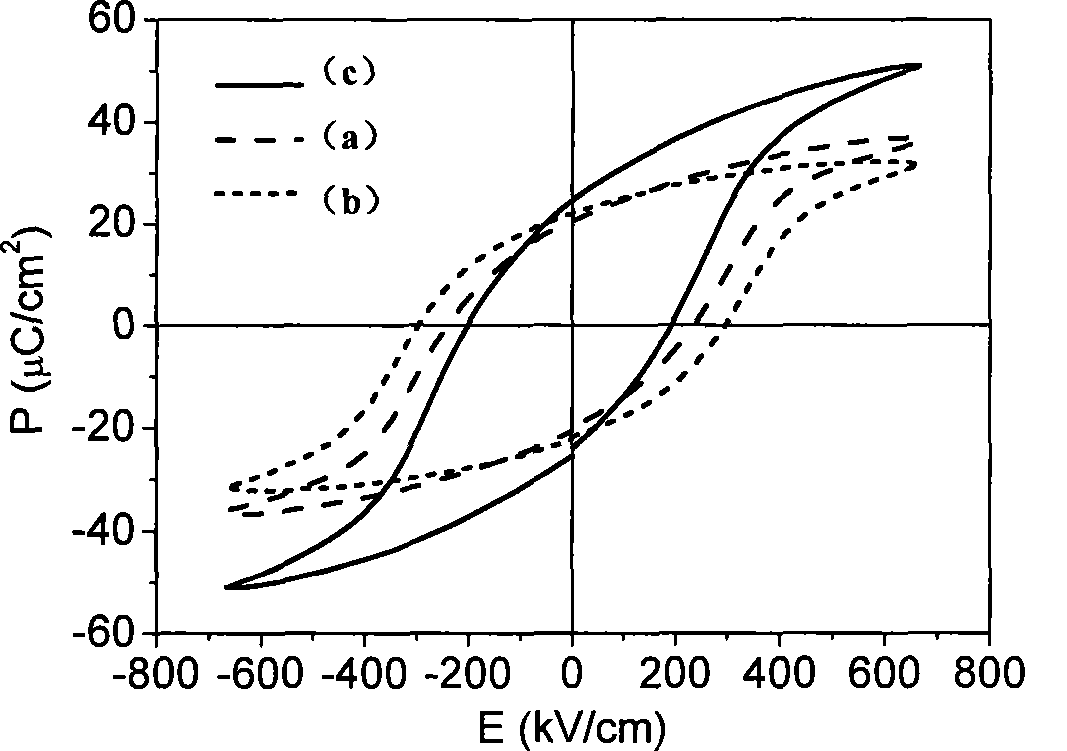

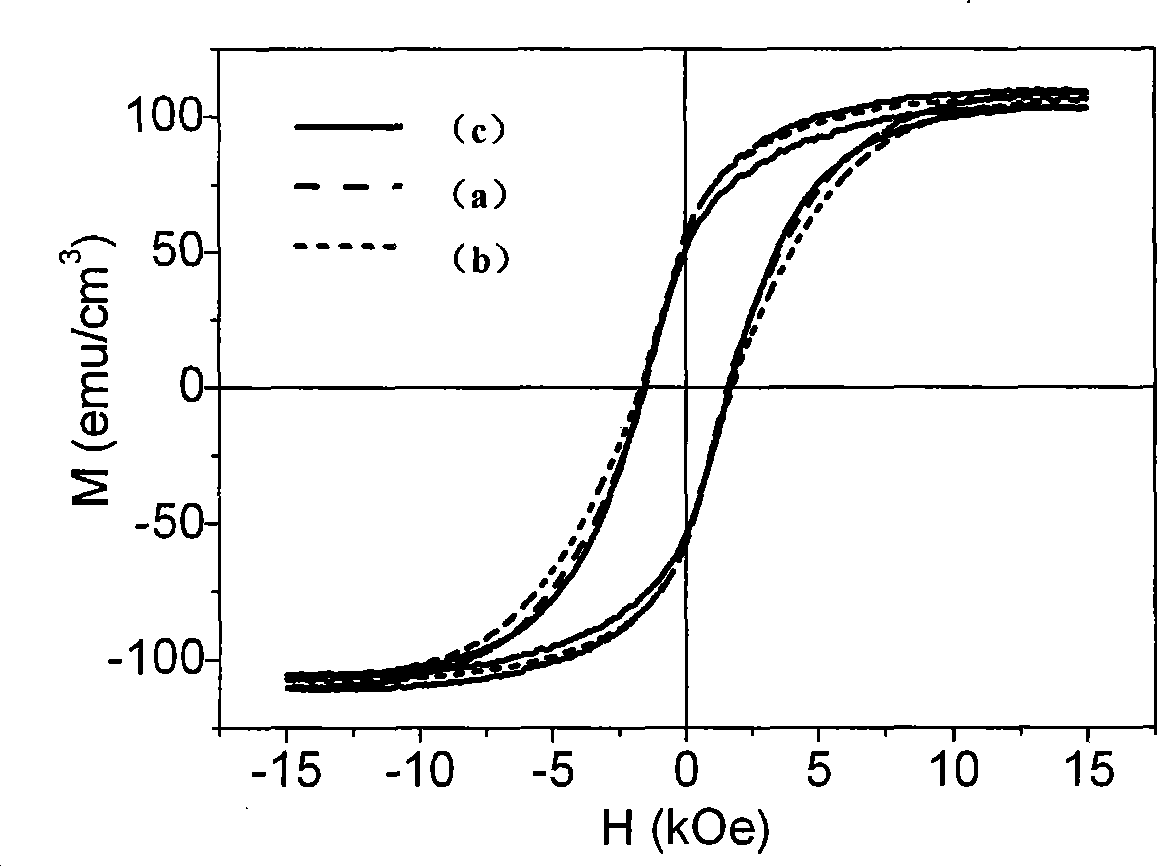

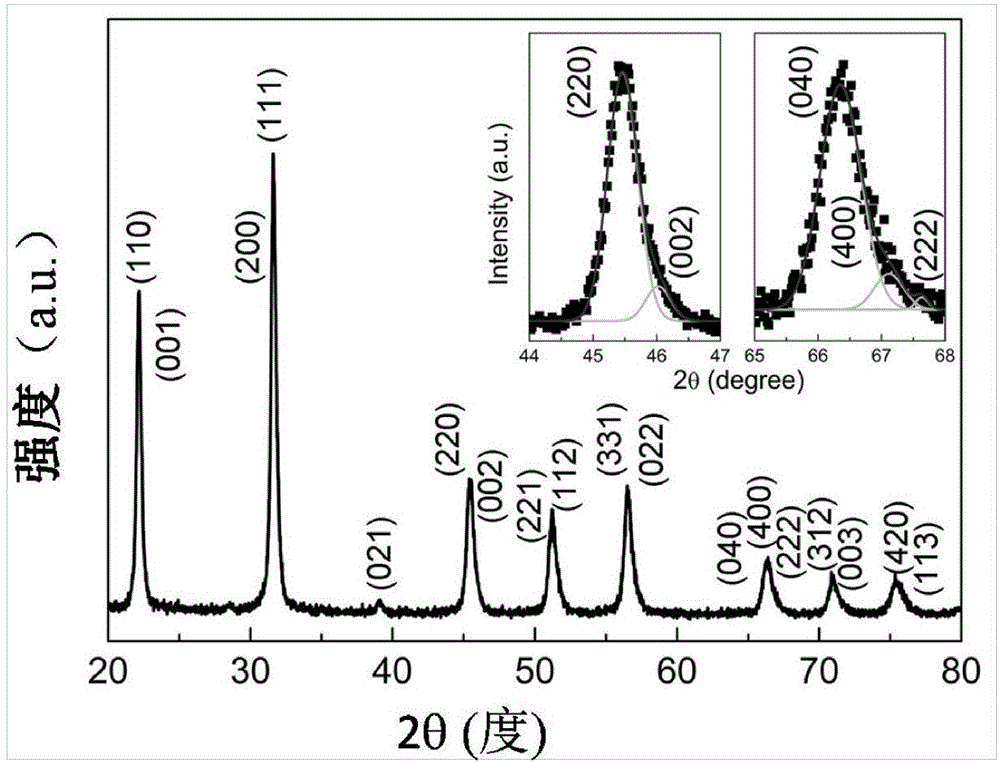

Stack ferro-electricity /magnetic multiferrou magnetoelectric compound film with conductive oxide as buffer layer and preparation thereof

InactiveCN101376600ASimple preparation processImprove magnetoelectric propertiesLayered productsElectricityComposite film

The invention discloses laminated ferroelectric / magnetic multiferroic and magnetoelectric composite film and preparation method thereof. The film comprises a substrate, a ferroelectric oxide layer and a magnetic oxide layer, and also a buffer layer positioned between the substrate layer and the ferroelectric oxide layer or the magnetic oxide layer. The layer can be LaNiO3, YBa2Cu3O7-x or SrRuO3, among which LaNiO3 is preferred. The preparation method comprises the following steps: firstly, buffer layer sol is prepared; secondly, the buffer layer sol is uniformly coated on the substrate to obtain the buffer layer; thirdly, sol of the ferroelectric oxide layer and the magnetic oxide layer is respectively prepared; fourthly, the sol obtained in step 3 is coated on the buffer layer, and then the end product is obtained. After the composite film is introduced into the buffer layer, the stress restraint of the substrate to the composite film is effectively reduced, the magnetoelectric coupling performance of the composite film with laminated structure is obviously enhanced, the cost is reduced, the preparation technique is simple, the requirement on the equipment is low, and the compatibility with the prior technique is good.

Owner:TSINGHUA UNIV

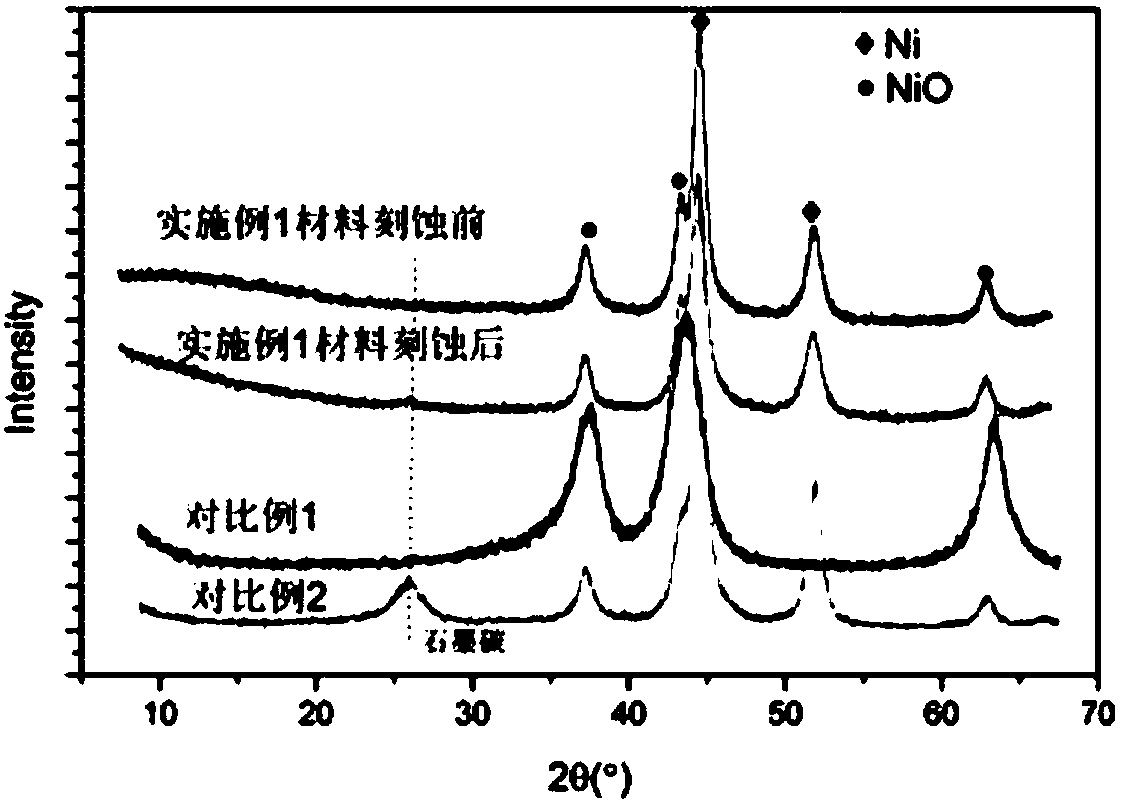

Carbon-coated nickel-aluminium composite material and preparation method and application thereof

ActiveCN108856706ANovel and Unique CompositionNovel and unique structureGas treatmentTransportation and packagingGraphiteCarbon coated

The invention relates to a carbon-coated nickel-aluminium composite material and a preparation method and application thereof. The carbon-coated nickel-aluminium composite material is in a particle shape and comprises a nickel-aluminium inner core and a graphite shell covering the outer surface of the nickel-aluminium inner core. The nickel-aluminium inner core comprises elemental nickel, nickel oxides and aluminium oxides. The composite material comprises, by weight percent, 1-8% of graphite, 45-55% of the elemental nickel, 20-30% of nickel oxides and 15-34% of aluminium oxides. The carbon-coated nickel-aluminium composite material prepared through the preparation method can completely oxidize butane in industrial waste gas under a low temperature, and very good industrial application prospects are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

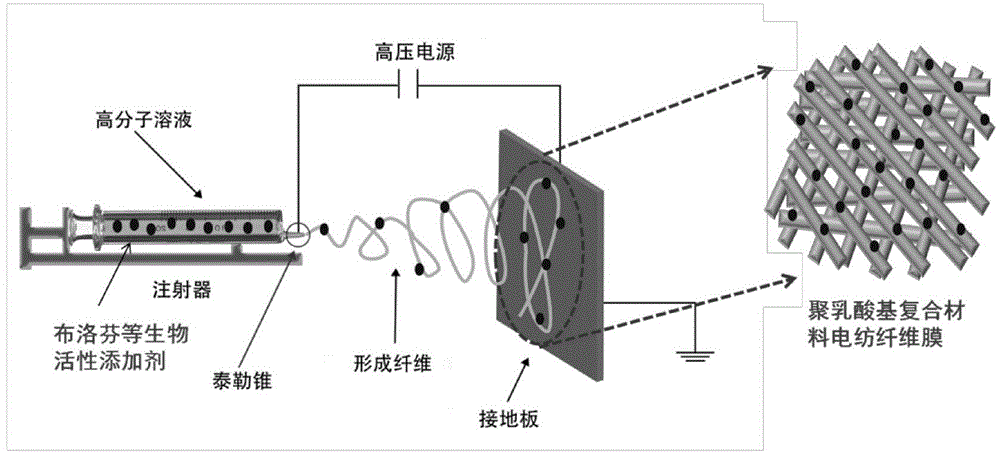

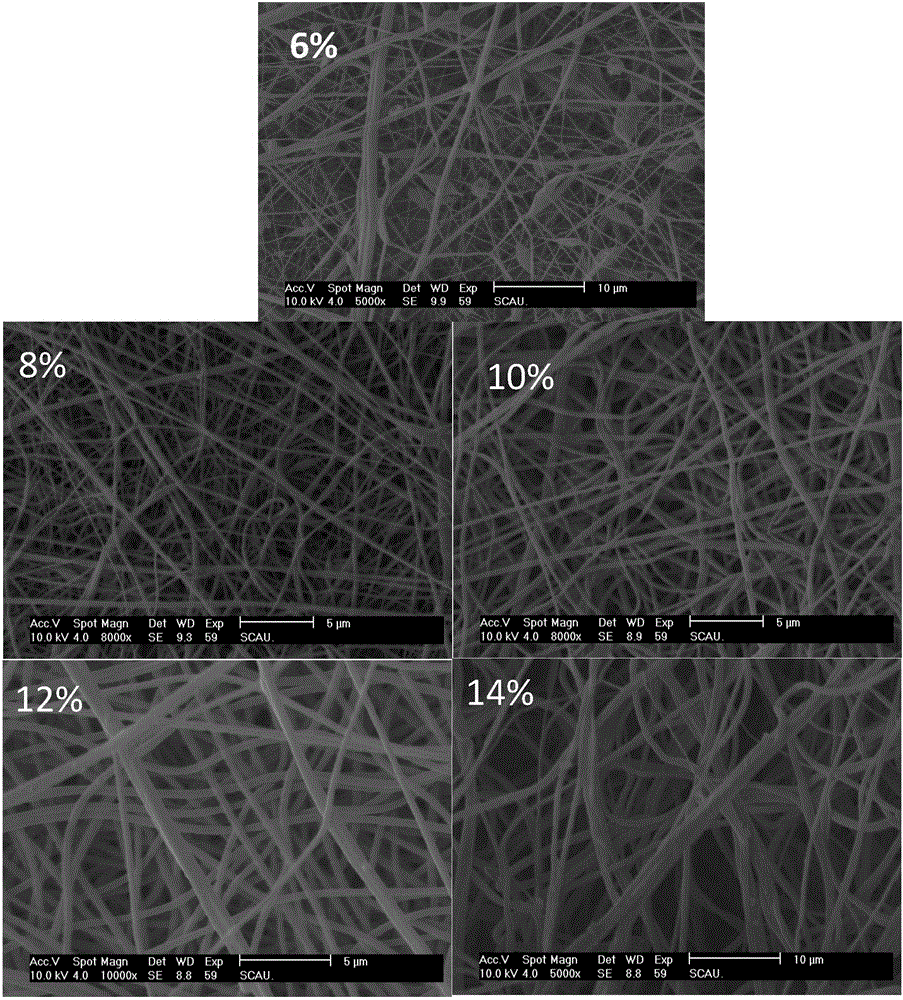

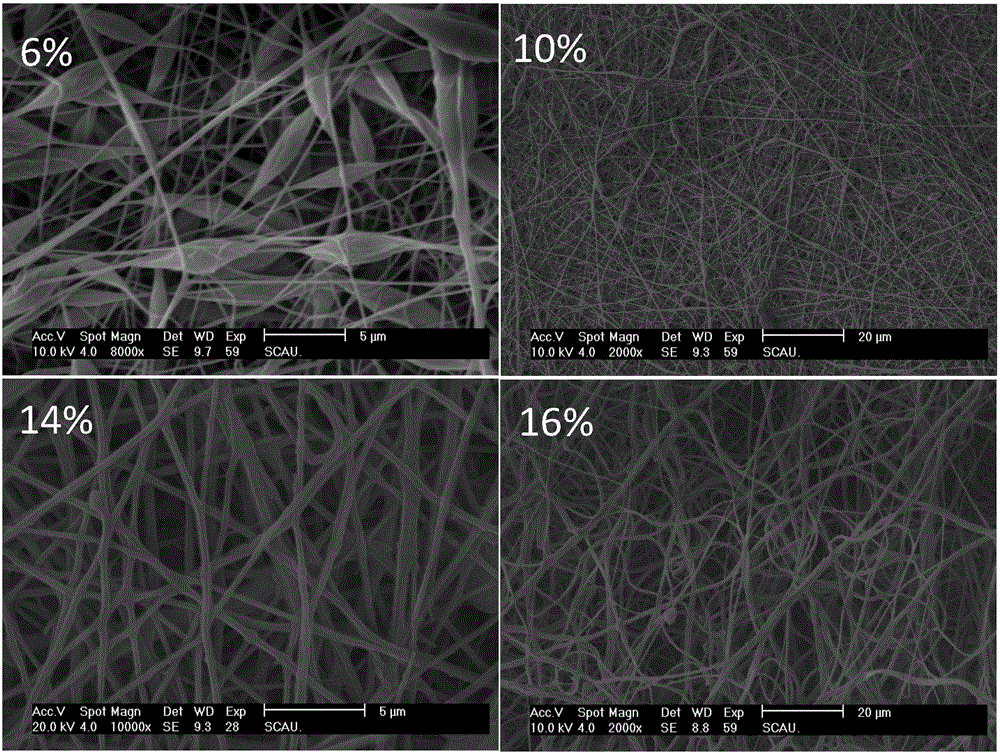

Polylactic acid-based composite material surgical medical film and preparation method thereof

InactiveCN104056297AImprove performanceGood flexibilityAbsorbent padsNon-woven fabricsFiberEnvironmental resistance

The invention discloses a polylactic acid-based composite material surgical medical film and a preparation method thereof. By adopting electrostatic spinning equipment and exploring proper technological parameters, different types of polylactic acid-based composite material macromolecular fiber thin films are finally formed and are applied to the field of biomedicine. In addition, by regulating and controlling composition of a macromolecular composite material system and thickness of an electro-spinning thin film, the surgical medical film which has good flexibility, high tensile strength, controllable degradation rate as well as excellent waterproof, antibacterial and air permeable performances is obtained finally. The surgical medical film is applicable to the field of various biomedicines such as healing film, wound surface dressing and anti-adhesion medicine; the medical film not only can be better adhered to tissues and avoid biotoxicity, but also can effectively promote transmission functions of blood, nutrients and growth factors in a human body due to the nature of semipermeable membrane. The process of the invention is simple and environment-friendly; the preparation method is easy to operate, low in cost, applicable to large-scale production and good in controllability, and is expected to be widely applied to various medical fields.

Owner:SICHUAN UNIV

Formaldehyde scavenging agent and preparation method thereof

The invention provides a novel formaldehyde scavenging agent which has high formaldehyde scavenging efficiency, durable action effect and simple production process, and can effectively scavenge formaldehyde from indoor air and simultaneously reduce the formaldehyde release amount of the decoration materials. The formaldehyde scavenging agent is characterized in that: the product is prepared from the following raw materials according to a weight ratio: 2-60% of formaldehyde scavenging factor, 1-10% of film forming agent, 1-10% of film forming aid and 40-80% of water. The formaldehyde scavenging agent is aqueous, can be sprayed to indoor air, wall or furniture, has high formaldehyde capturing rate and is convenient for use.

Owner:BEIJING SHENGHUA ZHONGXING ENVIRONMENTAL PROTECTION TECH

Cold-patch asphalt modified liquid and production method thereof

InactiveCN102702761AImprove technical performanceStrong maneuverabilityBuilding insulationsChemistryGlycerol

The invention provides a cold-patch asphalt modified liquid and a production method thereof. The cold-patch asphalt modified liquid comprises the following components by weight: 5-8% of one or a mixture of butadiene styrene rubber (BSR) and styrene-butadiene-styrene (SBS), 3-5% of naphthenic oil, 3-5% of glycerol, 3-5% of dibutyl ester, 0-3% of an anti-stripping agent and the balance of heavy diesel oil. The production method of the asphalt modified liquid comprises the following steps: (1) screening an asphalt modifying agent through an oscillating screen with sieve pores of 0.6cm, and clearing away caking; (2) adding the asphalt modifying agent and the heavy diesel oil into a stirrer in proportion for stirring for 3-4 hours until the asphalt modifying agent is completely and uniformly dispersed in the diesel oil and turned into a light brown paste; and (3) adding the naphthenic oil, the glycerol, the dibutyl ester and the anti-stripping agent in proportion, together stirring the added components for 30-40 minutes, and then storing for later use. The cold-patch asphalt modified liquid has the advantages of long storage period, good operability, simple production process, abundant material resource, environment friendly production, convenience in use, and the like.

Owner:广东能达公路养护股份有限公司

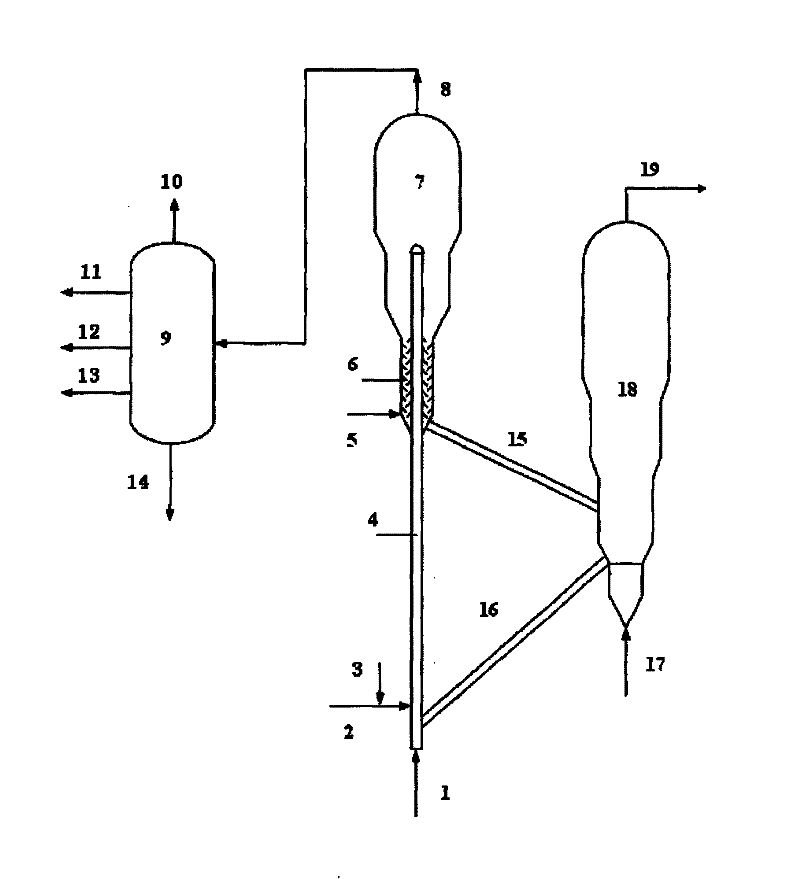

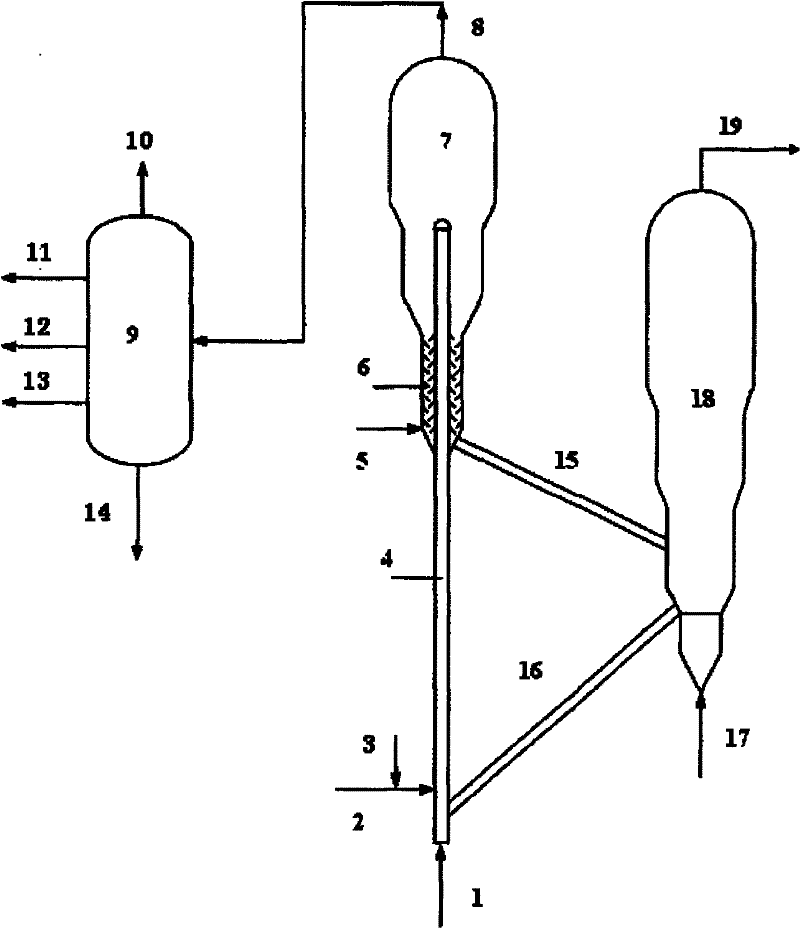

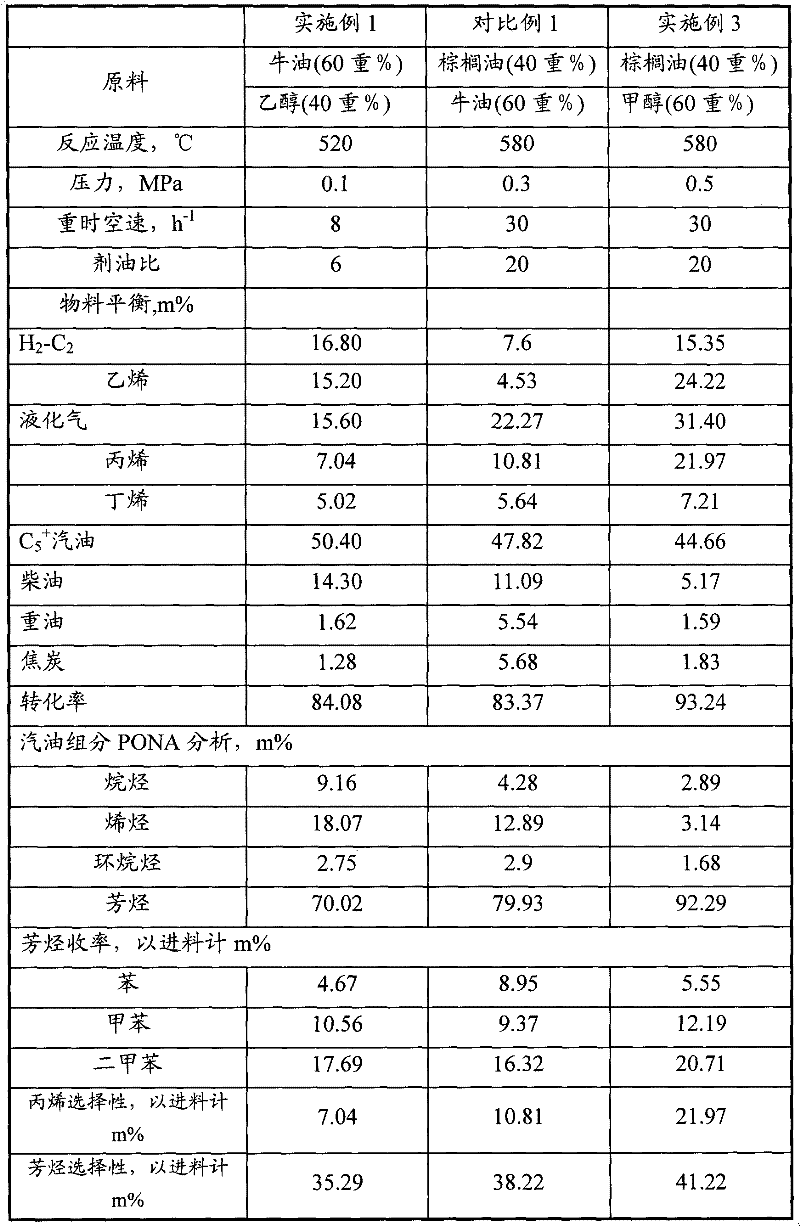

Preparation method of aromatic hydrocarbons and low-carbon olefins through co-processing animal and plant oils and oxygenated chemical

ActiveCN102206502AFacilitate catalytic conversionReduce energy consumptionHydrocarbon purification/separationLiquid hydrocarbon mixture productionOil and greaseReaction temperature

A preparation method of aromatic hydrocarbons and low-carbon olefins through co-processing animal and plant oil and an oxygenated chemical is characterized by: introducing raw materials such as the plant oil and the oxygenated chemical into a catalytic cracking reactor; carrying out a catalytic conversion reaction through contacting with a catalytic cracking catalyst in the reactor with an operating temperature of 500 to 670 DEG C, an operating pressure of 0.1 to 5.0 MPa, a weight hourly space velocity of 0.1 to 100 h<-1> and an agent-oil ratio of 1 to 50; separating a reaction oil gas from the spent catalyst when the reaction is finished; recycling the separated spent catalyst after stripping, burning and regenerating; obtaining fractions such as a liquefied gas, gasoline and the like through fractionating the reaction oil gas and obtaining the low-carbon olefins through a manner that the liquefied gas enters a gas separating system; and obtaining the aromatic hydrocarbon product through carrying out a further aromatic extraction on the gasoline fraction. The method provided by the present invention allows the reaction temperature to be controlled through co-processing the plant oil and the oxygenated chemical, the selectivity of the target product gasoline to be improved, and energy consumption to be reduced. In terms of a reaction apparatus, equipment flow is simplified because heat exchangers which are arranged for removing reaction heat can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for buffering layer material of copper indium gallium selenide film solar battery

InactiveCN102544237AQuality improvementControl reaction speedFinal product manufactureSemiconductor devicesIndiumElectrical battery

The invention discloses a preparation method for a buffering layer material of a copper indium gallium selenide film solar battery. By the method, a precursor of chemical bath reaction is prepared by using a zinc sulfate solution as a Zn<2+> source, a thiourea solution as a S<2-> source, ammonia water as a buffering agent and sodium citrate as a complexing agent; and a Zn(O,S) semiconductor film with uniform and compact grain size distribution and good adhesive force is prepared on a copper indium gallium selenide film and the common glass substrate and serves as the buffering layer of the copper indium gallium selenide film solar battery. The Zn(O,S) instead of CdS serves as the buffering layer of the copper indium gallium selenide film solar battery, so production of the copper indium gallium selenide film solar battery is environment-friendly and economic. The band gap width of the Zn(O,S) is more than that of the CdS, so more incident photons can reach an absorption layer through the buffering layer, short-circuit current of the battery is increased and photoelectric conversion efficiency of the battery is improved.

Owner:GUANGDONG UNIV OF TECH

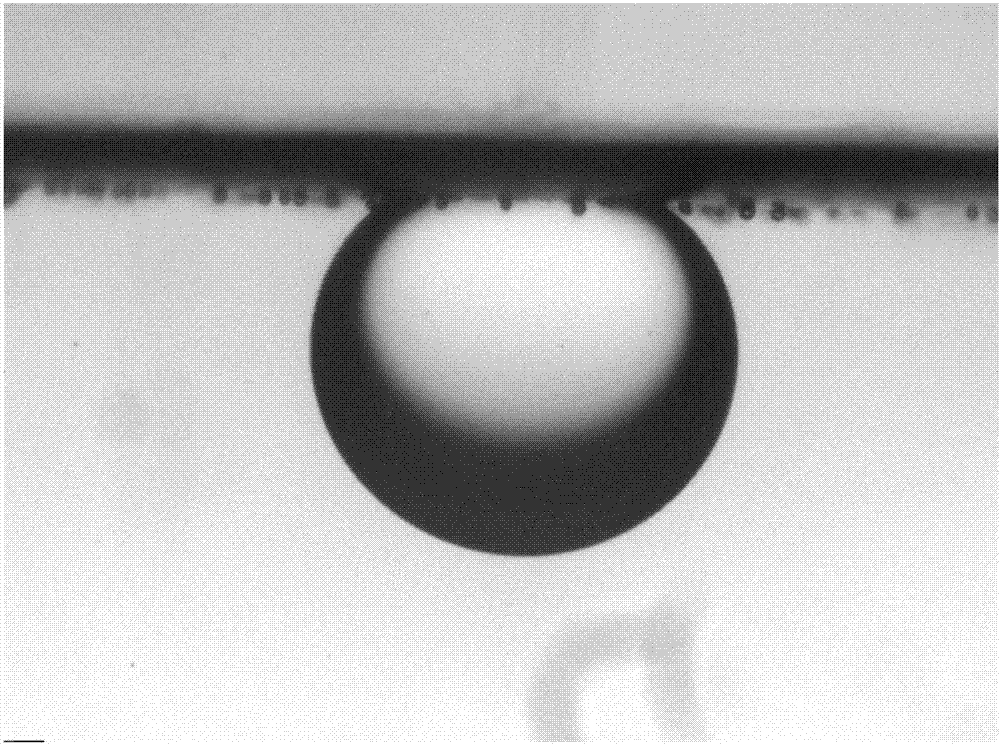

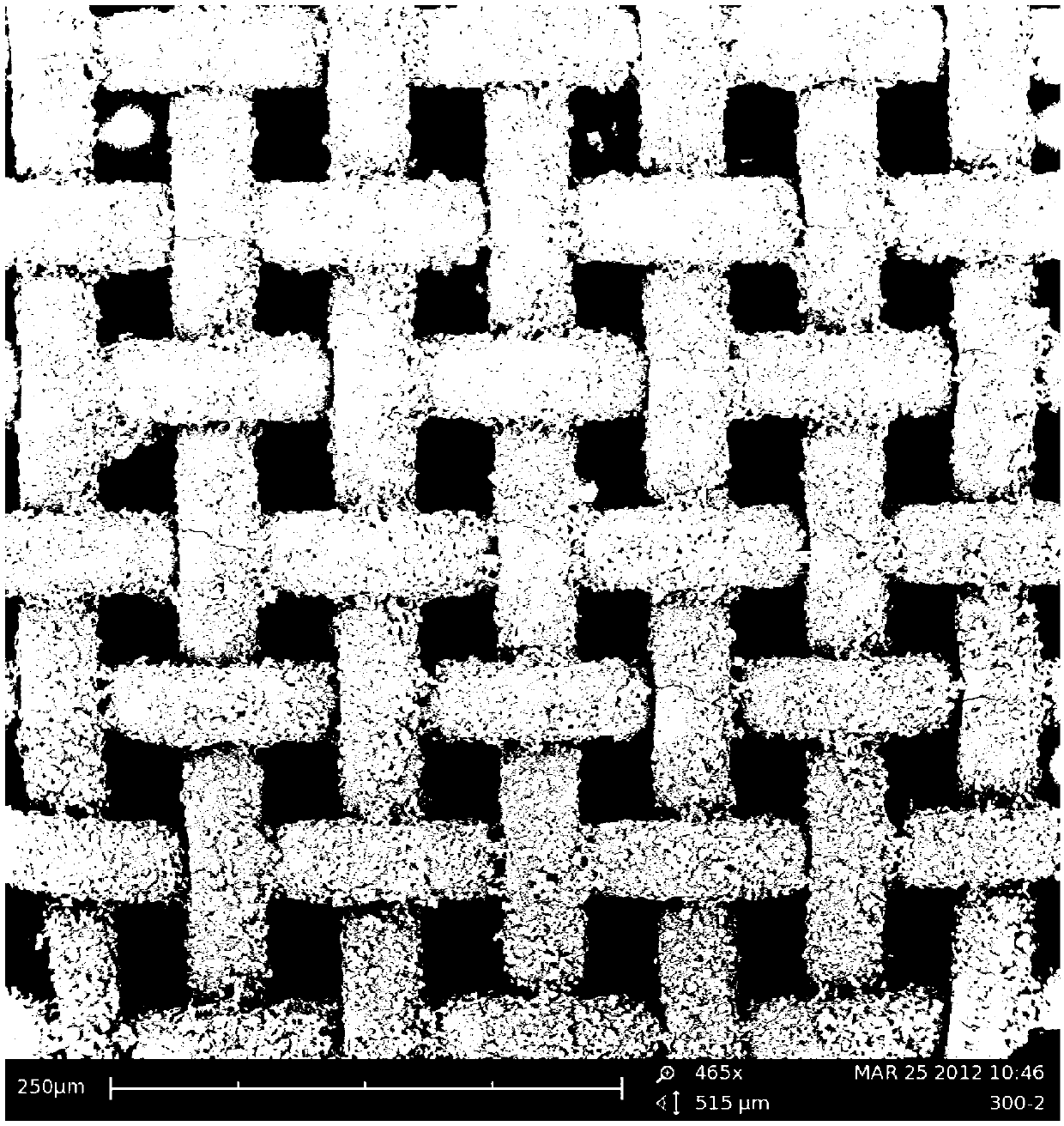

Preparation method of oil-water separation mesh film with super-hydrophilicity and super-lipophobicity

InactiveCN107080975AAchieve the purpose of separationIncrease water fluxFatty/oily/floating substances removal devicesLiquid separationAdhesiveOil water

The invention discloses a preparation method of an oil-water separation mesh film with super-hydrophilicity and super-lipophobicity. The method comprises the steps that a metal net with the mesh size being 400-2,000 is adopted as a substrate, a cold spraying method is adopted, net wires of the metal net are coated with hydrophilic materials in a spraying mode, the hydrophilic materials are one or more of zinc oxide, silicon dioxide, calcium carbonate and titanium dioxide, and the grain size range is 5-200 nanometers; finally sintering is performed under the temperature of 300-750 DEG C for 60-240 min, and the oil-water separation mesh film with super-hydrophilicity and super-lipophobicity is obtained. The metal net does not need to be modified, the binding force is improved with no adhesive, no secondary pollution is generated, cleaning is easy, and the mesh film can be repeatedly used.

Owner:HEBEI UNIV OF TECH

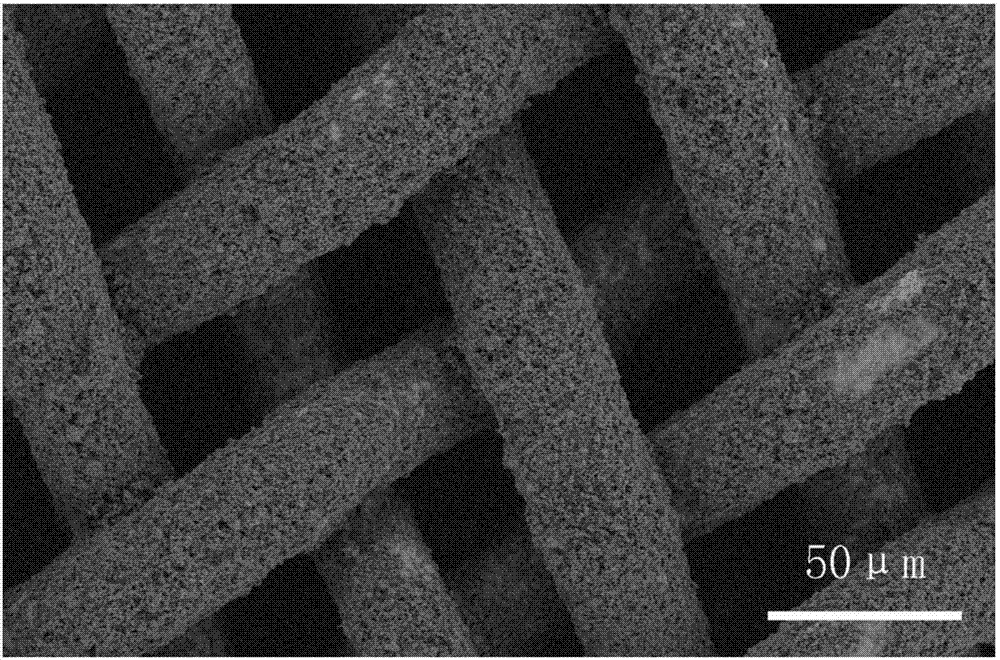

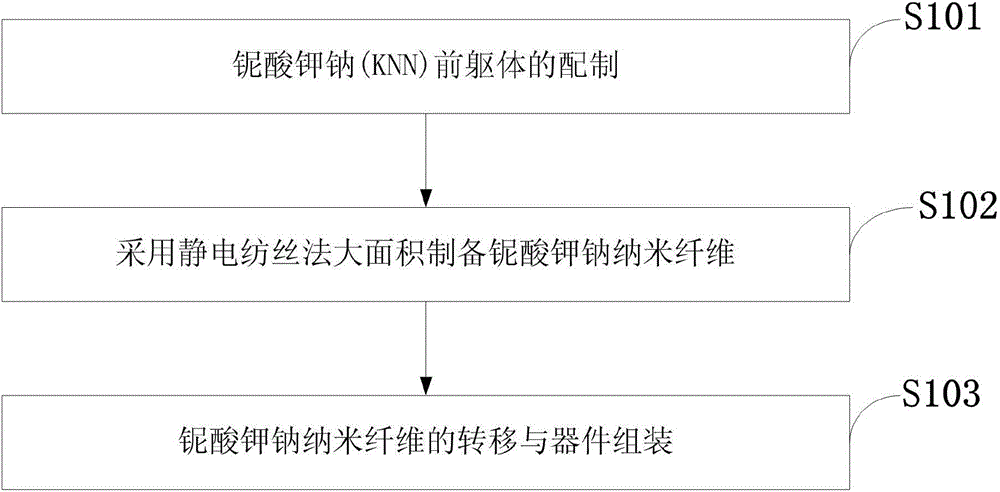

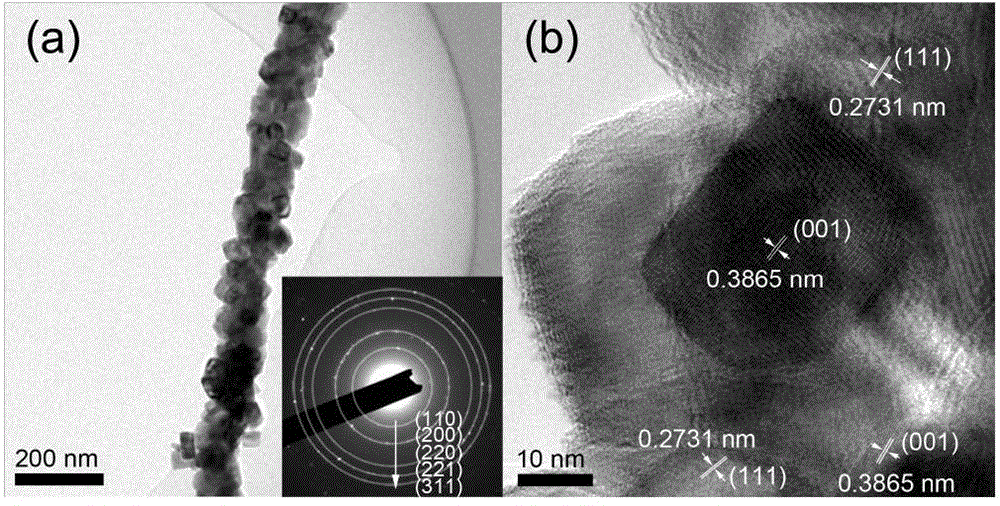

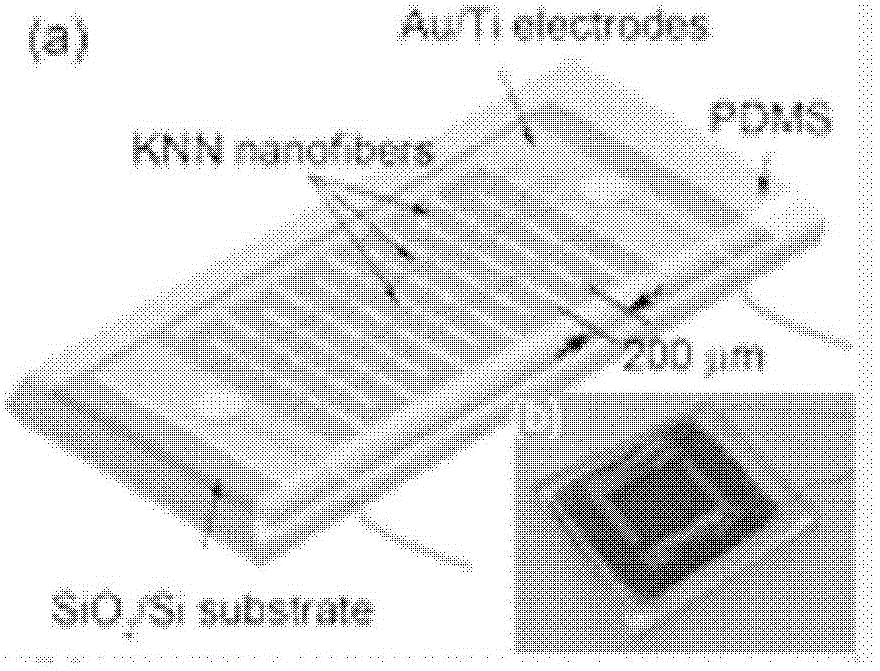

Preparing method of KNN piezoelectric nanofiber flexible electricity generating element

InactiveCN104409625AHigh aspect ratioIncrease mechanical deformationPiezoelectric/electrostrictive device manufacture/assemblyFilament/thread formingElectricityFiber

The invention discloses a preparing method of a potassium sodium niobate (KNN) piezoelectric nanofiber flexible electricity generating element. According to the method, the preparation of a KNN precursor is provided; KNN nanofiber is prepared in a large area by an electrostatic spinning method; and the KNN nanofiber transfer and the device assembly are carried out, and the KNN piezoelectric nanofiber flexible electricity generating element is obtained. The preparing method has the advantages that excellent lead-free piezoelectric materials are adopted; the KNN nanofiber is used for forming the flexible piezoelectric electricity generating element; the element can be enabled to have high electric output; the length-diameter ratio of the nanofiber prepared by the electrostatic spinning method is high; the nanofiber crystallization can be realized through sintering treatment; equipment and preparation processes are simple; the cost is low; the preparing method can be used for batch production of the elements; the mechanical deformation of the nanofiber under the specific external force effect can be improved through good flexibility of the element; and the collection efficient of the element on mechanical energy is improved.

Owner:HUBEI UNIV

Method for recovering metal from waste lithium battery

InactiveCN102251097AThe equipment process is simpleHigh extraction rateProcess efficiency improvementSolventManufacturing Factories

The invention relates to a method for recovering metal from a waste lithium battery. The method is characterized by comprising the following steps of: discharging, crushing and screening the waste lithium battery; magnetically sorting and separating riddlings; heat-treating and smelting an oversize steel shell and screenings in vacuum respectively; and adding a solvent and cokes when the screenings are smelted, wherein weight percentages of respective components are as follows: 50-97% of screenings, 3-30% of solvent and 0-20% of cokes. Compared with the prior art, the method has the advantages of simplicity in equipment and process, high extraction rate of noble metal and the like, is particularly suitable for hydrogen storage alloy manufacturing factories to recover the metal in lithium batteries, and can be used for extracting an iron and nickel-based alloy and a cobalt-based alloy from the waste lithium battery; acid and organic solvent are not used in the whole recovery process; organic matters and metal-containing materials are effectively separated from each other through a method of physical separation; and smoke pollution and the like caused by burning the organic matters cannot be produced, so that the method is a safe and environment-friendly method for disposing waste batteries.

Owner:鞍山鑫普新材料有限公司

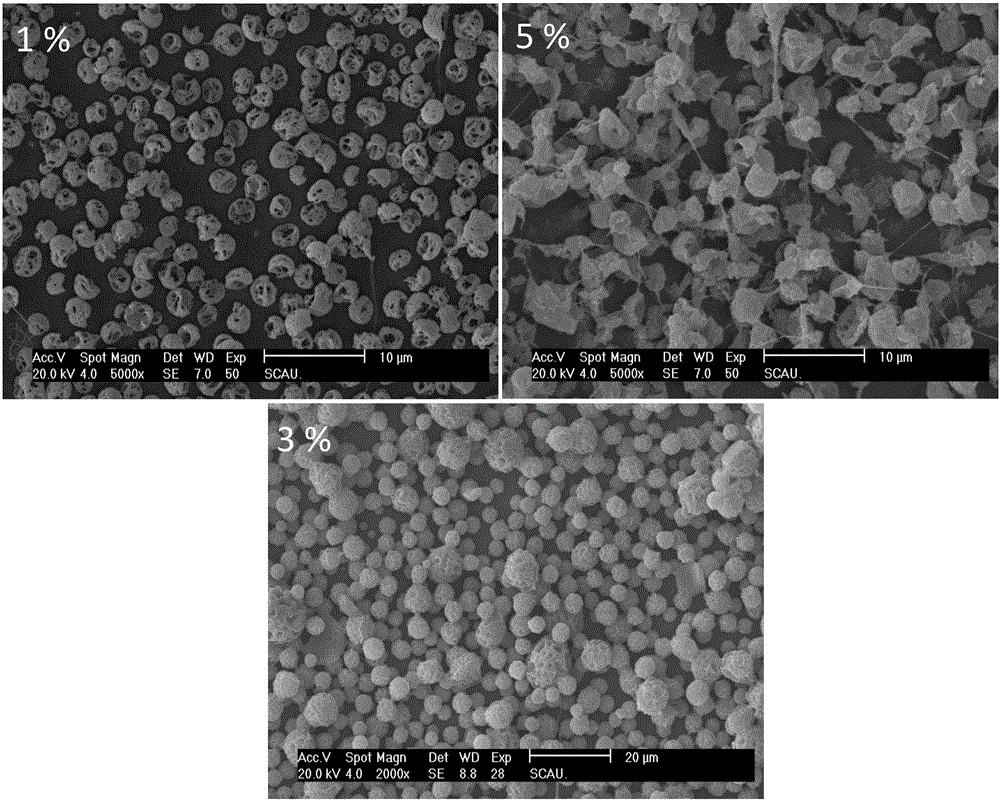

Static spraying composite film and preparation method and application thereof

ActiveCN105908363AAvoid breedingAchieve bi-directional performanceElectro-spinningAbsorbent padsFiberComposite film

The invention discloses a static spraying composite film and a preparation method and application thereof. A PVDF nanofiber thin film is spun on a roller receiver through electrostatic spinning to serve as a supporting material, then a layer of Cur-PLA microspheres is sprayed through an electrostatic spraying method, and a double-layer film is obtained; an Enro-PLA nanofiber film is spun on the double-layer film through an electrostatic spinning method, drying is carried out, and the electrostatic spraying composite film is obtained. Medicine is carried on polylactic acid fibers and the microspheres, so that the biological activity and antibacterial property of the electrospinning film are achieved; compared with like products, a hydrophilic face formed by the PLA microspheres and the PLA fibers is not single in medicine release capacity, wider in antibacterial performance and larger in contact area with the skin surface. PVDF is adopted as an outer layer for isolating invasion of water vapor and bacteria. The preparation method is simple, the production cost is low, large-scale production can be achieved, application and popularization are convenient, and the final product can completely meet various clinical needs.

Owner:SOUTH CHINA AGRI UNIV

Recycling process of tin-removing waste liquid

InactiveCN104894599APrecipitation will notWill not cause secondary pollutionPhotography auxillary processesProcess efficiency improvementTin dioxideLiquid waste

The invention discloses a recycling process of tin-removing waste liquid. The method includes the steps of S1, feeding the tin-removing waste liquid into a distilling device, and performing pressure reduction distillation under the temperature of 65-80 DEG C and the pressure of (0.2-0.5)*1.03*10<5>Pa to recycle nitric acid; S2, feeding distillation residual liquid into an electrolytic tank with an ion exchange membrane for electrolysis, controlling current density and cathode potential to recycle copper in the residual liquid through electrolysis, acquiring tin dioxide at the anode of the electrolytic tank, and acquiring metal copper at the cathode of the electrolytic tank; S3, controlling current density to be unchanged after metal copper is recycled, and changing cathode potential to recycle tin through electrolysis, constantly adding sulfuric acid solution in a cathode chamber during the electrolysis process until the electrolysis is ended, acquiring the tin dioxide at the anode of the electrolytic tank, and acquiring metal tin at the cathode of the electrolytic tank, wherein the current density is 100-200A / m<2>. The recycling process has the advantages that no chemical reagent is added, and secondary pollution is avoided.

Owner:CHENGDU HONGHUA ENVIRONMENTAL SCI & TECH CO LTD

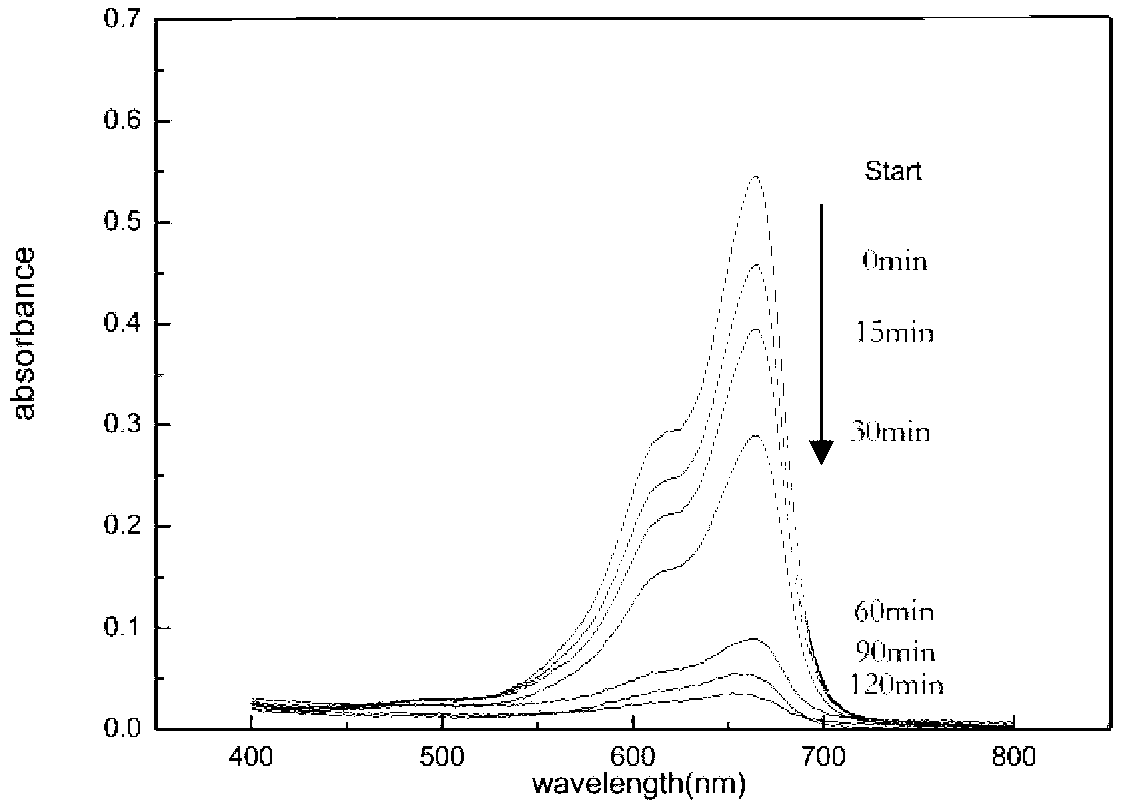

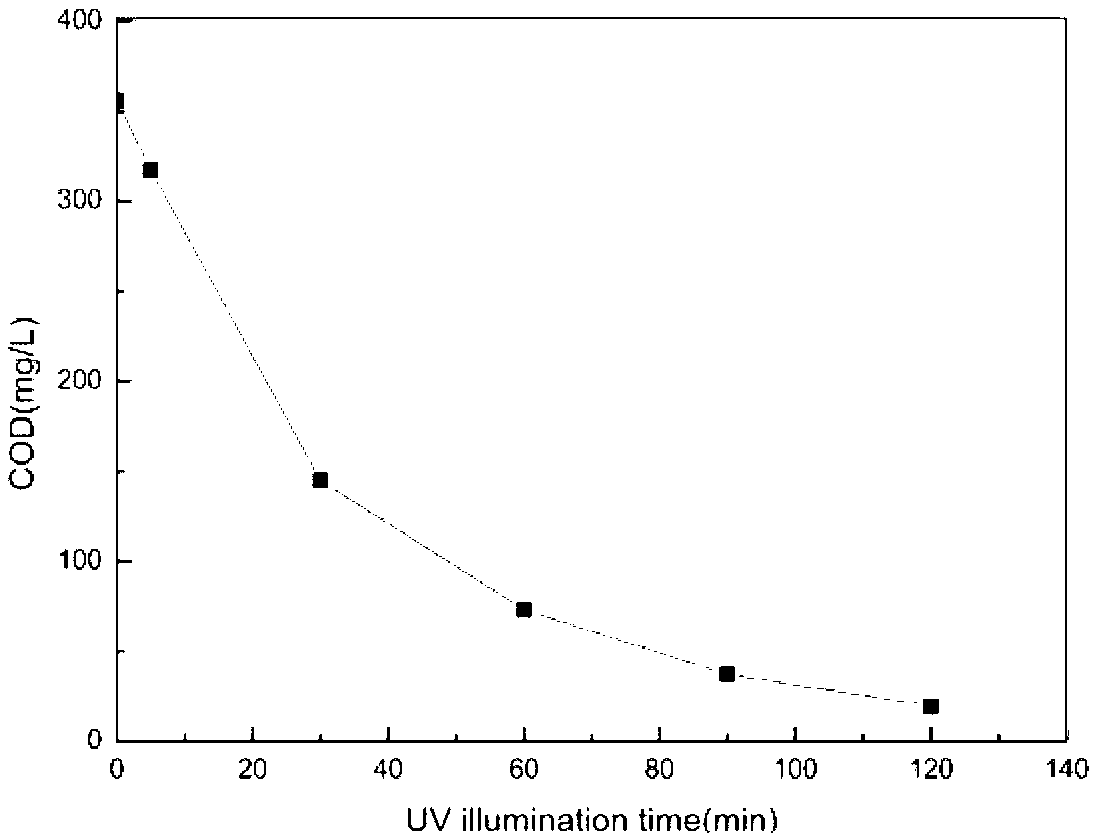

Oily sewage purification net membrane and preparation method and application thereof

ActiveCN102764536AReduce chemical oxygen demandImprove separation efficiencyFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationPollutantChemistry

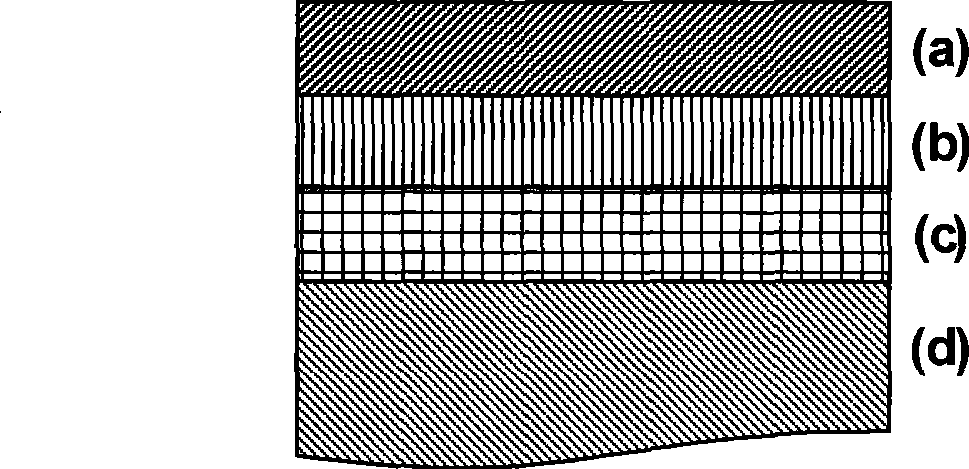

The invention discloses a net membrane with oily sewage purification capability and a preparation method and application thereof. The oily sewage purification net membrane is an A / B double-layer composite net membrane, wherein the A layer of net membrane is formed by depositing a TiO2 coating on the net wire surface of a fabric net; and the B layer of net membrane is arranged on the surface of the A layer of net membrane and provided with a photodegradable hydrophobic modifier layer. The oily sewage purification net membrane can be used for simultaneously implementing oil-water separation of oily sewage and degradation of soluble pollutants. The net membrane has super-hydrophobic and super-oleophyllic properties in air, the contact angle between the net membrane and water in the air is more than 150 degrees, and the net membrane has good photo-catalytic property under ultraviolet. The net membrane can be applied to purification, chemical separation, environmental protection and the like of the oily sewage. The net membrane for sewage purification has the advantages of good separation effect, high purification efficiency, low cost, low energy consumption, convenience and the like.

Owner:TSINGHUA UNIV

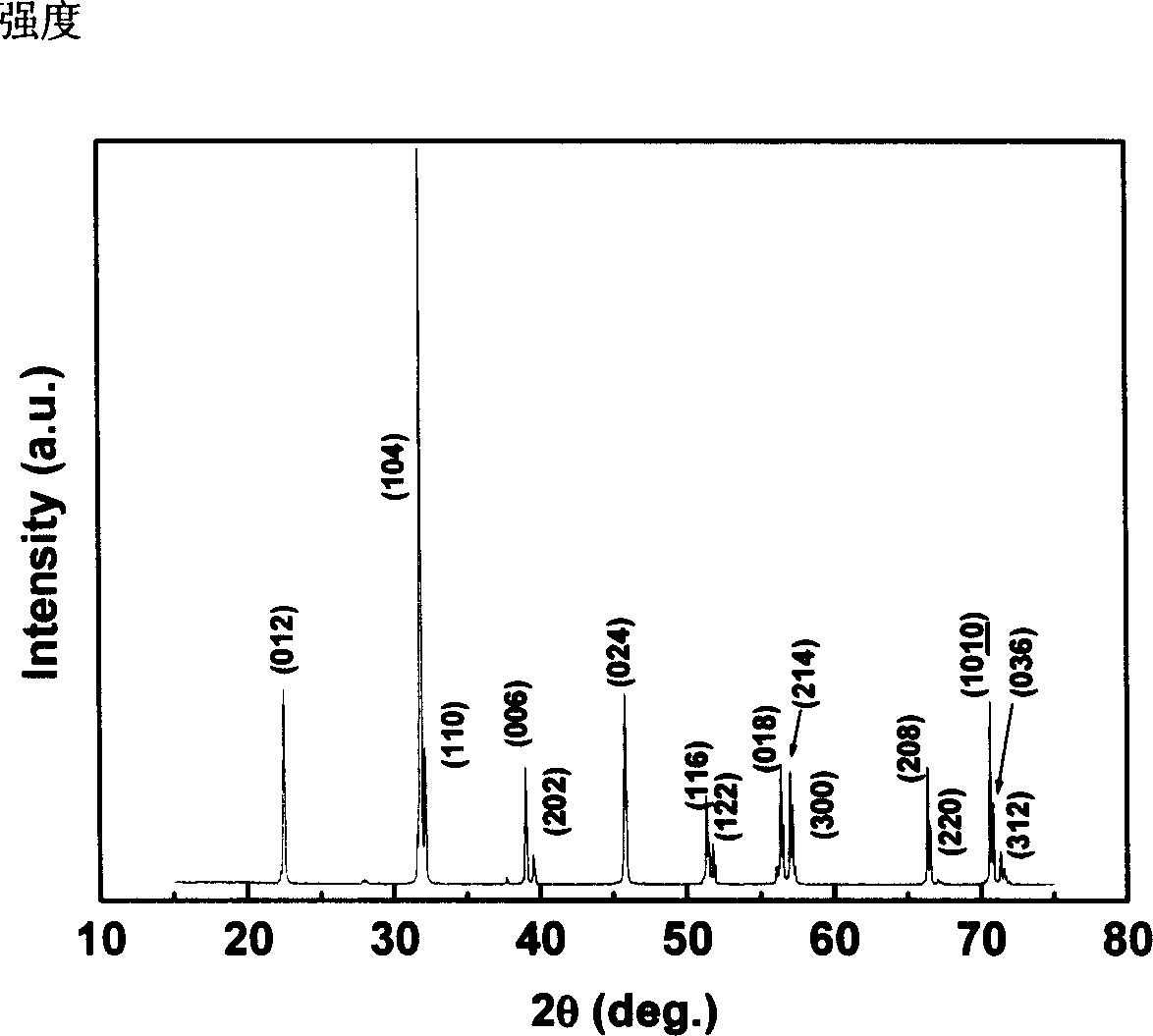

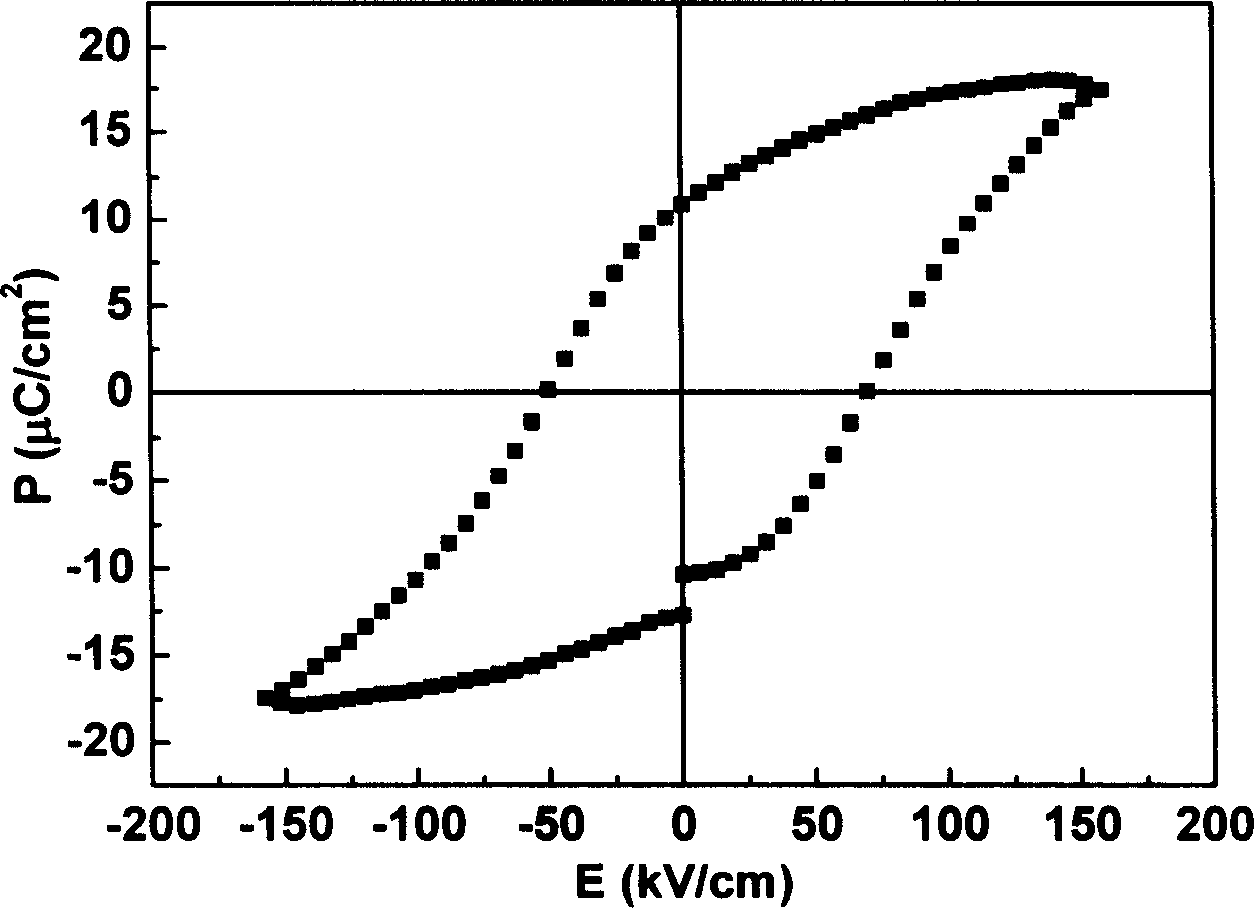

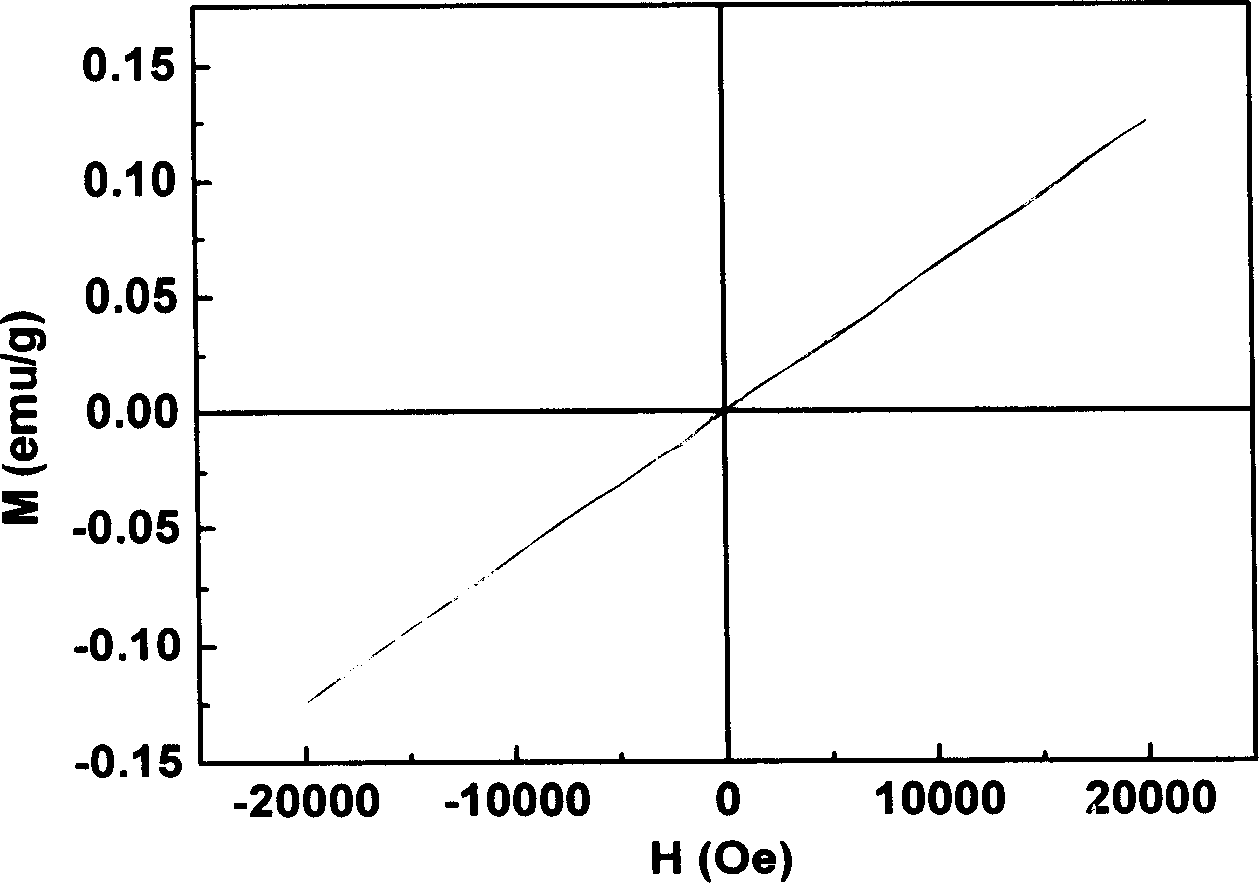

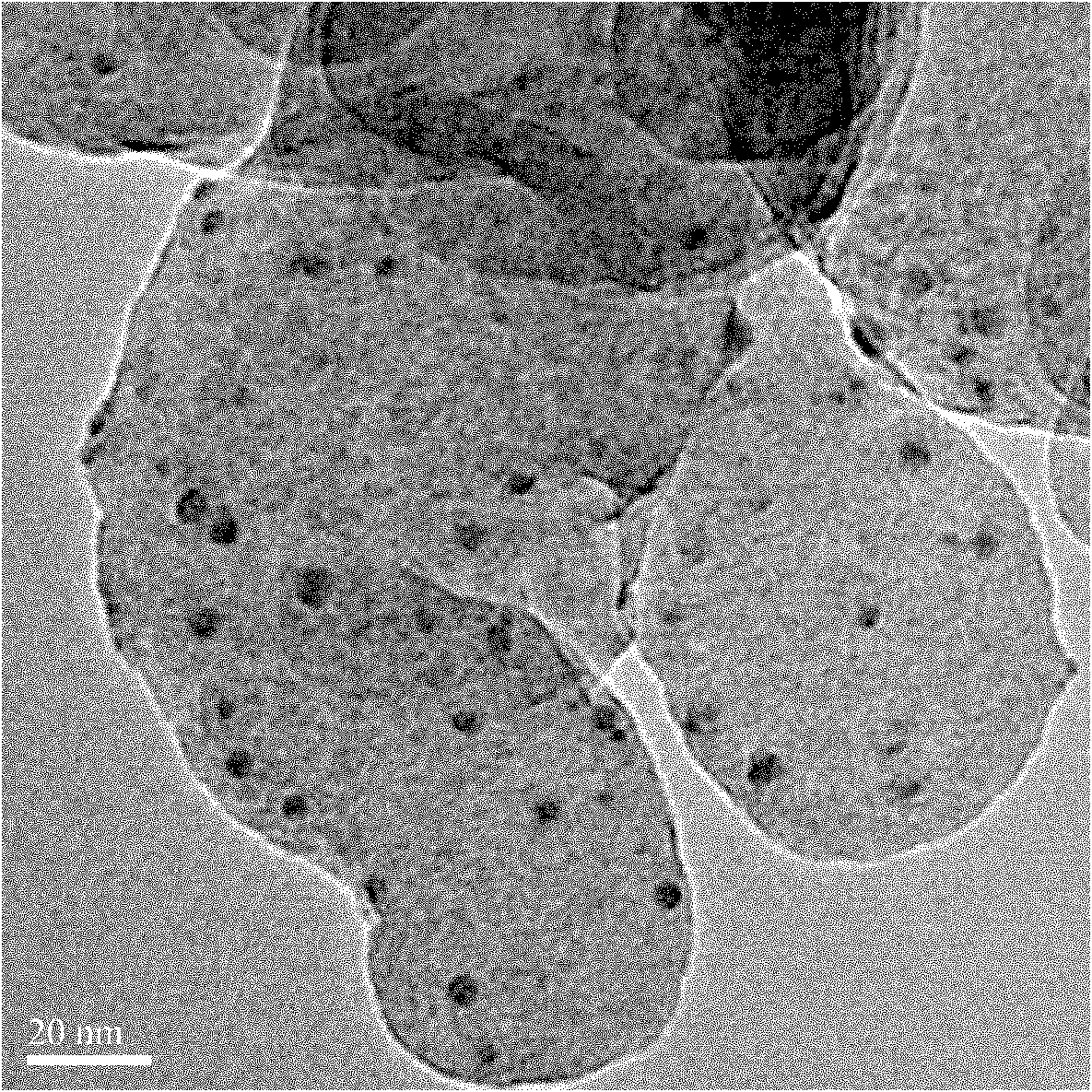

Method for preparing single-phase BiFeO3 ceramics through hardening process

InactiveCN1686932AImprove insulation performanceImprove ferroelectric propertiesCrucibleHeating furnace

The present invention relates to a method for preparing single-phase BiFeO3 ceramic by utilizing quenching process. It is characterized by quickly cooling sintered BiFeO3 ceramic. Said method includes the following steps: weighing Bi2O3 powder and Fe2O3 powder according to the mole ratio of 1:1, ball-grinding for 4-12 hr according to 100-500 rpm, uniformly mixing two powdes, drying the above-mentioned mixed powder, pressing the mixed powder into thin sheet, then placing proper quantity of the above-mentioned mixed powder into Al2O3 crucible, placing the thin sheet into the crucible, and using correspondent powder to cover the thin shet to make the thin sheet and powder be in sealed state, then placing the above-mentioned crucible into heating furnace, heating to sintering temperature, heating speed is 2-8 deg.C / min, sintering temperature is 830-920 deg.C and sintering time is 30-60 min., after sintering process is completed, promptly quenching so as to obtain the invented product.

Owner:NANJING UNIV

Method for preparing hydrotalcite supported silver catalyst and application thereof

InactiveCN102139212AThe equipment process is simpleHigh yieldCarbonyl compound preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsStyrene oxideSilver particles

The invention discloses a method for preparing a supported silver catalyst with low load and high activity by using hydrotalcite as a carrier in the technical field of catalyst preparation. The hydrotalcite is used as the carrier, and silver atoms with catalytic activity are highly dispersed and tightly anchored on the high-energy crystal face of the hydrotalcite by using uniform hydroxyl dot matrix and different crystal face orientation of the hydrotalcite so that more active silver particles are exposed. The invention provides the method for preparing the supported silver catalyst, and the method has the advantages of simple equipment and process, high yield, convenience in industrialized production, low prepared silver granularity and good reproducibility. When the catalyst is applied in synthesis of styrene oxide by catalytic oxidation of styrene, the conversion rate of reactants is high, and the selectivity of a product is high.

Owner:BEIJING UNIV OF CHEM TECH

Biodegradable toughened heat-resistant polylactic acid modified resin and preparation method thereof

The invention discloses biodegradable toughened heat-resistant polylactic acid modified resin and a preparation method thereof. The polylactic acid modified resin comprises the following raw materials in percentage by mass: 30%-90% of polylactic acid, 5%-65% of thermoplastic starch, 3%-40% of a completely biodegradable plant fiber and 1%-10% of an adjuvant, wherein the adjuvant is a lubricating agent, a coupling agent and an antioxidant. The method comprises the following steps: firstly drying various raw materials, adding to a high-speed mixer according to the ratio, and mixing for 5-30 minutes; and adding the obtained mixture to a twin-screw extruder, and plastifying, extruding and pelletizing to obtain the biodegradable toughened heat-resistant polylactic acid modified resin. The preparation method of the polylactic acid modified resin disclosed by the invention is simple in equipment requirements and technological process, low in cost, easy for large-scale production, economical and efficient; and the thermoplastic starch and the completely biodegradable plant fiber are added to polylactic acid matrix, so that the prepared product has relatively good heat resistance and impact property.

Owner:SICHUAN UNIV

Preparation method and application of Cu2ZnSnS4/graphene composite semiconductor film

Belonging to the technical field of semiconductor film preparation, the invention relates to a preparation method and application of a Cu2ZnSnS4 / graphene composite semiconductor film. The preparation method includes: taking ethanol as the solvent, using a cupric chloride hydrate as the copper source, zinc chloride as the zinc source, stannous chloride as the tin source, and thiourea as the sulfur source, and adopting cetyl trimethylammonium bromide (CTAB) as the surfactant to prepare a reaction precursor solution; putting a cleaned FTO glass conductive surface up, adding an ethylene glycol solution of graphene dropwise, putting the FTO glass into a drying box to conduct drying, then putting the FTO glass conductive surface up into a high pressure reaction kettle lining, pouring the prepared reaction precursor solution into the high pressure reaction kettle lining, performing sealing, then putting the high pressure reaction kettle into a blasting drying box, and carrying out constant temperature reaction so as to obtain a Cu2ZnSnS4 / graphene composite semiconductor film on the FTO conductive glass substrate. The method provided by the invention has a simple process and is low in cost. The prepared Cu2ZnSnS4 / graphene composite semiconductor film has good application effect, can be directly used a counter electrode of a dye-sensitized solar cell, and also can be used as an absorption layer of a copper-based film solar cell.

Owner:GUANGDONG UNIV OF TECH

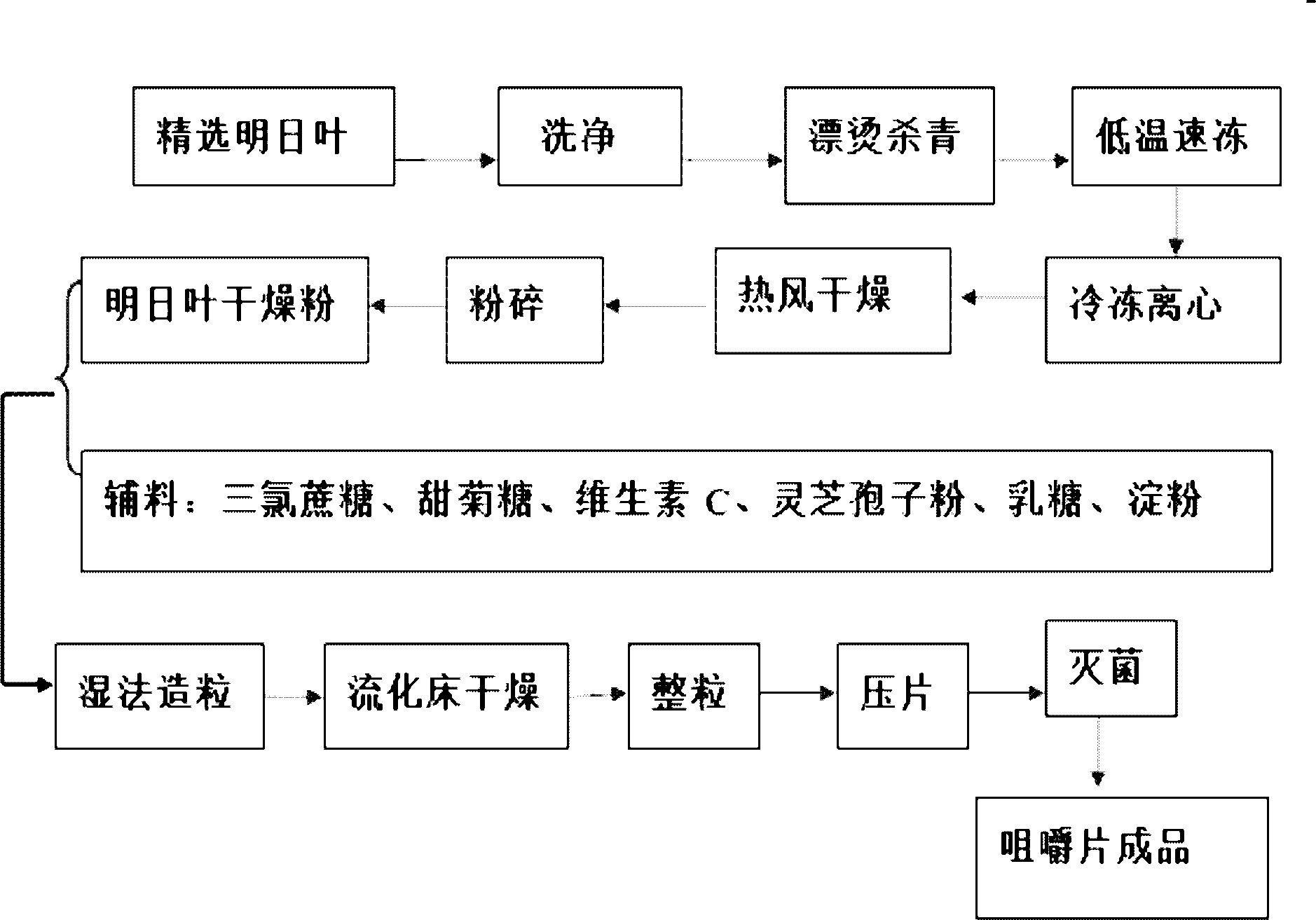

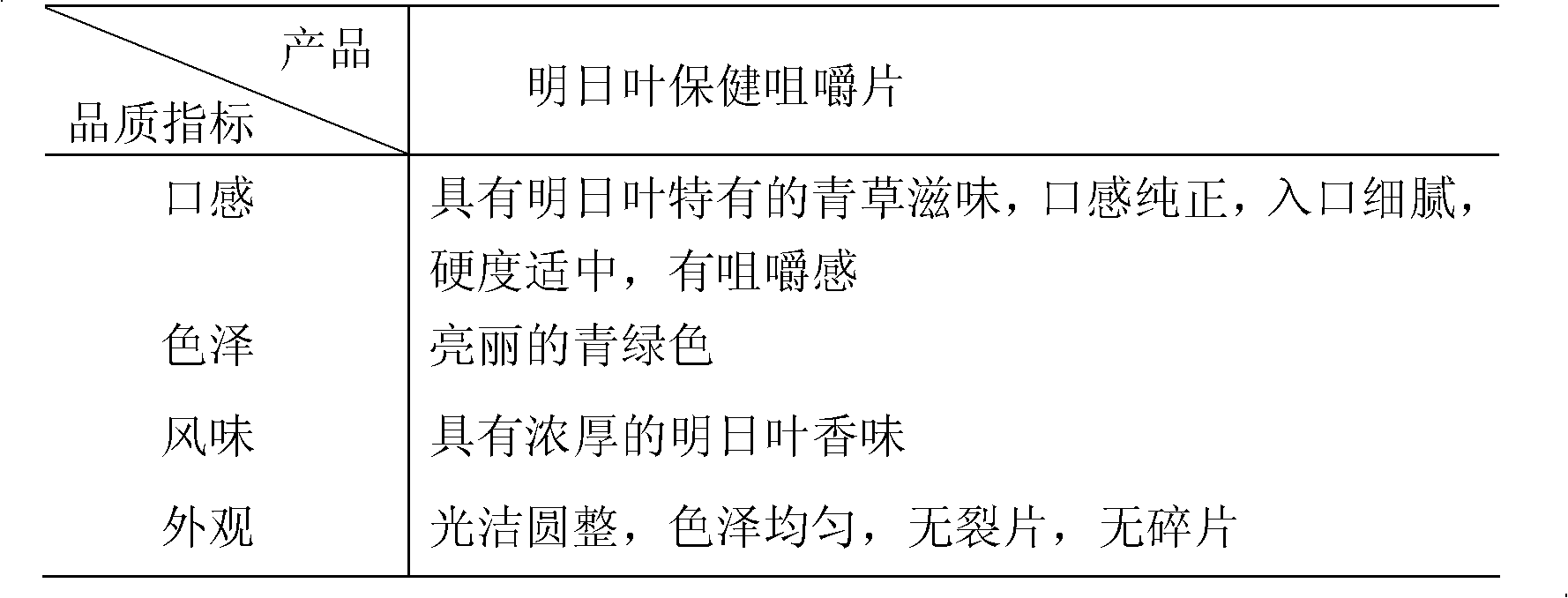

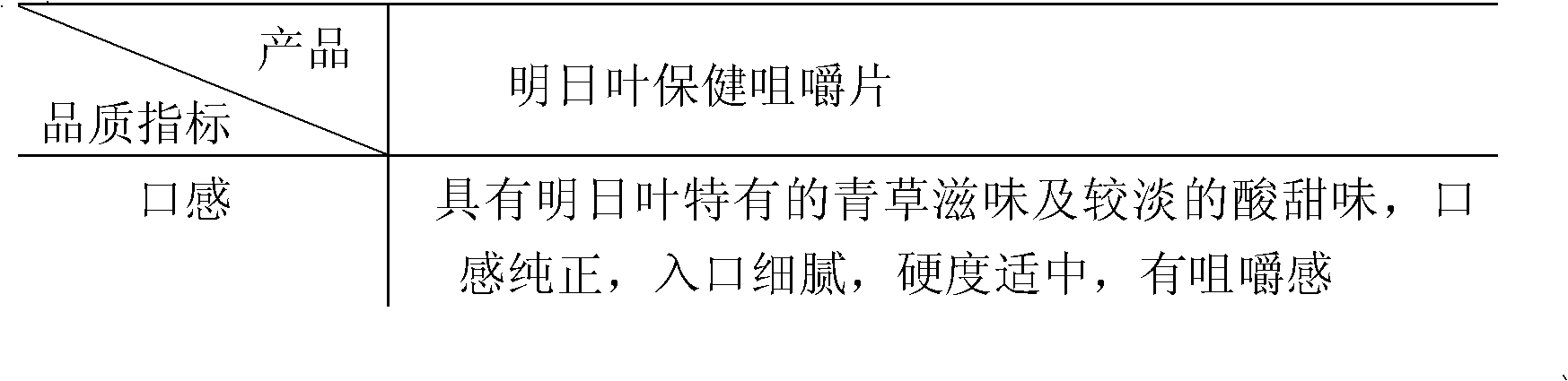

Angelica keiskei health-care chewable tablet and preparation method thereof

The invention discloses an angelica keiskei health-care chewable tablet, which comprises angelica keiskei powder, starch, sucralose, stevioside, vitamin C, ganoderma lucidum spore, lactose and magnesium stearate. The chewable tablet has the advantages of strong flavor, high purity, comprehensive nutrition, delicious sour and sweet tastes, multiple health-care functions, convenience for taking andcarrying and simple preparation process. According to the invention, the food series of angelica keiskei are enriched, the converting way of the angelica keiskei resource is increased, and an important technical reference value and a wide market development prospect are achieved.

Owner:上海鑫钰生物科技有限公司

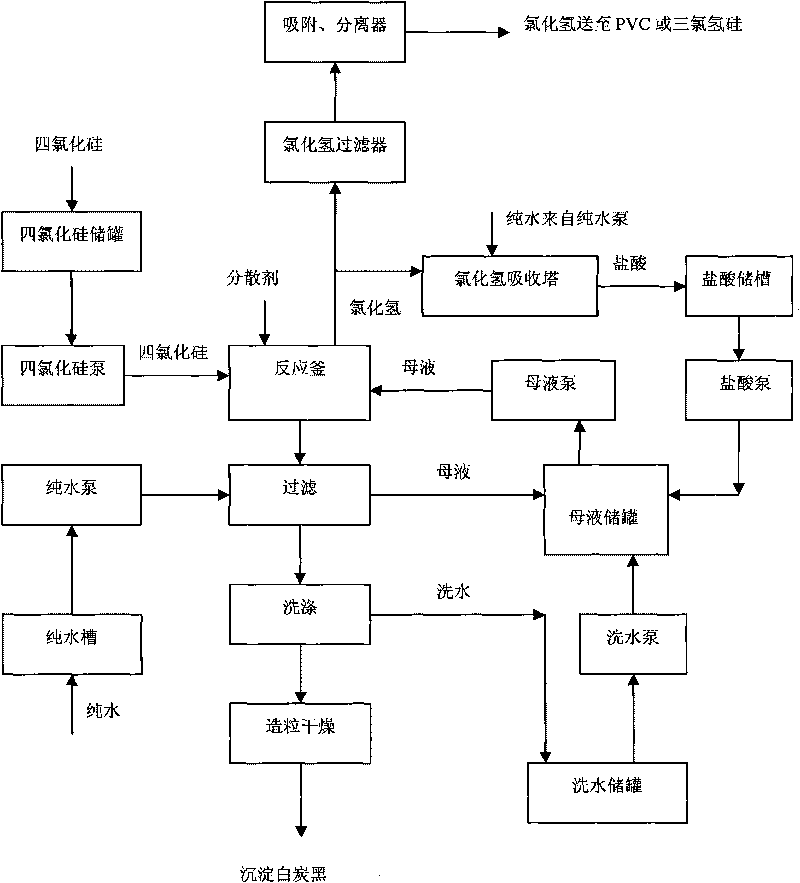

Process for producing precipitated white carbon black by silicon tetrachloride

InactiveCN101734667AIncrease porositySolve the pollution of the environmentSilicaHydrideRaw material

The invention belongs to a process for preparing white carbon black and in particular relates to a process for producing precipitated white carbon black by silicon tetrachloride. The process comprises the following steps: adding the silicon tetrachloride into 29 to 33 mass percent hydrochloric acid aqueous solution which contains a dispersant, controlling the temperature to between 28 and 45 DEG C for reaction to generate silica sol and chlorine hydride gas, standing and ageing the silica sol to form colloidal white flocculent sediment, filtering, separating and washing the sediment, and pelletizing and drying the sediment to obtain the precipitated white carbon black. The process has short flow, relatively simple production equipment and process control, and available raw materials, effectively utilizes the silicon tetrachloride, totally reclaims the product chlorine hydride, reduces the processing expense, the amount of waste acid and the environmental pollution, and has low production cost, wide application and large market capacity.

Owner:昊华宇航化工有限责任公司

Method for preparing electromechanical transduction element based on potassium-sodium niobate lead-free piezoelectric nanofibers

InactiveCN102751434AHigh power outputAvoid poisoningNanosensorsPiezoelectric/electrostrictive/magnetostrictive devicesElectricityFiber

The invention relates to a method for preparing an electromechanical transduction element based on potassium-sodium niobate lead-free piezoelectric nanofibers. The method comprises the steps of preparing an electrode, preparing a potassium-sodium niobate precursor, adopting an electrostatic spinning method to preparing potassium-sodium niobate nanofibers, forming and packaging a potassium-sodium niobate nanogenerator and the like. By means of the method, large-area preparation of potassium-sodium niobate nanofibers is achieved, and the potassium-sodium niobate nanofibers are used for forming the electromechanical transduction element, thereby ensuring the element to have high power output capability and avoiding poison to environment and human body.

Owner:HUBEI UNIV

Method for improving tensile mechanical property of fibers

InactiveCN106367947AGood tensile mechanical propertiesUniversalUltrasonic/sonic fibre treatmentChemical vapor deposition coatingFiberEcological environment

The invention in particular relates to a method for improving tensile mechanical property of fibers and belongs to fiber modification technologies. The method comprises the following steps: taking papa-phenylene diisocyanate and ethidene diamine as precursors, and depositing a polyurethane film on the fiber surface by adopting an atomic layer deposition technique. Due to excellent shape preservation of the atomic layer deposition technique, the defects of the original fibers can be effectively reduced, and due to high elasticity of polyurethane, the original fibers can effectively buffer instantaneous mechanical changes in the tensile process, so that the tensile mechanical properties of fibers can be effectively reduced. The preparation method is simple, the deposition process is easy to control, the cost and energy consumption are low, and the method is pollution-free to the ecological environment and suitable for industrial production.

Owner:WUHAN TEXTILE UNIV

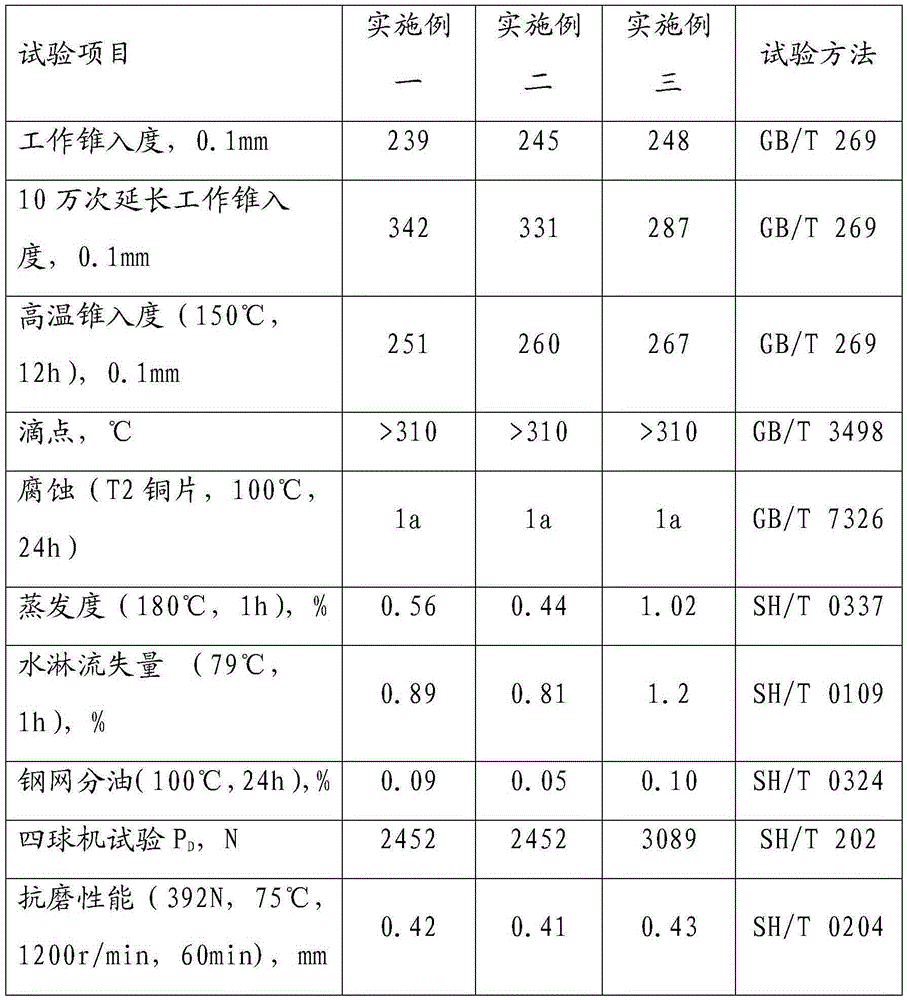

High-temperature lubricating grease for food processing and preparation method thereof

The invention relates to lubricating grease and a preparation method thereof, in particular to high-temperature lubricating grease for food processing and a preparation method thereof, and belongs to the technical field of chemistry. The high-temperature lubricating grease is prepared from base oil accounting for 70%-92% of the total weight of the lubricating grease, an inorganic thickening agent accounting for 3%-20% of the total weight of the lubricating grease, a tackifier accounting for 2%-6% of the total weight of the lubricating grease, an auxiliary dispersant accounting for 0.1%-1.5% of the total weight of the lubricating grease, an antioxidant accounting for 0.3%-1.0% of the total weight of the lubricating grease, a corrosion inhibitor accounting for 0.05%-1% of the total weight of the lubricating grease, a friction modifier accounting for 0.1%-0.5% of the total weight of the lubricating grease and a solid additive accounting for 2%-10% of the total weight of the lubricating grease. The high-temperature lubricating grease has the advantages of being capable of not being fused at high temperature, high in dropping point, few in high-temperature consistence change, good in colloid stability and the like and especially suitable for lubricating and sealing high-temperature food processing equipment.

Owner:JIANGSU LOPALTECH

Ligularia virgaurea extract insecticide and preparation method thereof

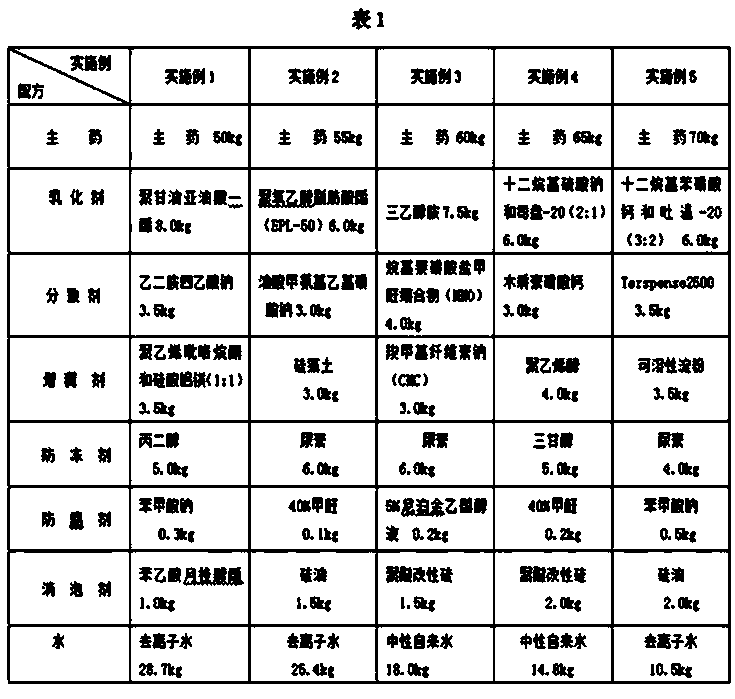

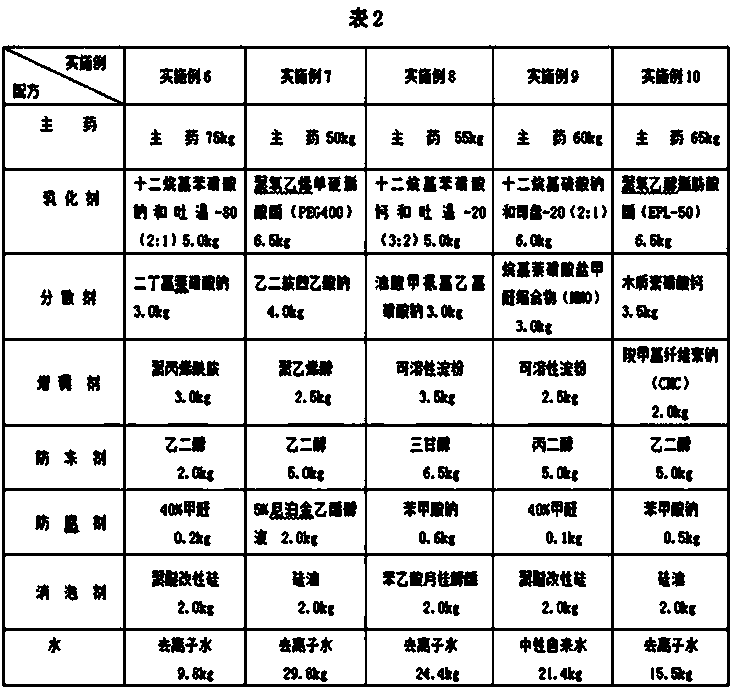

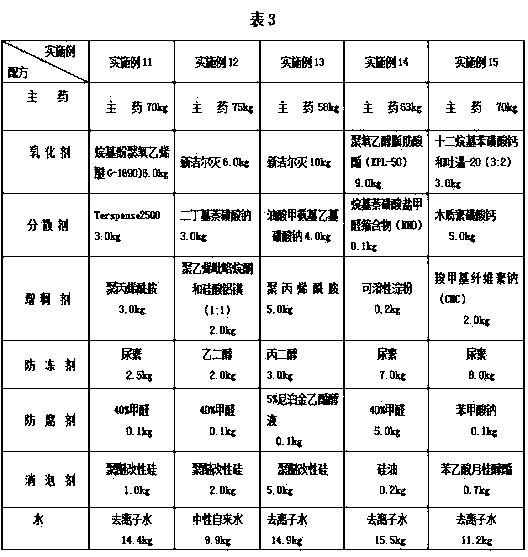

ActiveCN104336085AEffective prevention and controlGood dispersionBiocideAnimal repellantsBiotechnologyCrop pest

The invention discloses Ligularia virgaurea extract insecticide and a preparation method thereof. The Ligularia virgaurea extract insecticide is prepared from a main chemical and assistants, wherein the main chemical is a Ligularia virgaurea extract compound, and the volume content of terpenes and alkaloids compounds is 86.3%; the Ligularia virgaurea extract insecticide is in dosage forms of suspoemulsion and microcapsule; the suspoemulsion is prepared from the following ingredients in weight percentage: 50-75% of main chemical, 3.0-10% of emulsifier, 0.1-5.0% of dispersing agent, 0.2-5.0% of thickening agent, 2.0-8.0% of anti-freezing agent, 0.1-5.0% of preservative, 0.2-5.0% of defoaming agent and the balance of water. The microcapsule is prepared from the following ingredients in weight percentage: 80-86% of main drug, 13.0-19.9% of capsule wall material, 0.1-1.0% of lubricating agent, curing agent which is 10 times of the total amount of the prepared ingredients in volume dose, and diluent which is 10.0-15.0 times of the total amount in volume dose, wherein the pH value of the capsule formation system is regulated to be 4.0-4.5 by a capsule formation agent. The biological insecticide has good prevention and control effect on various crop pests, and is safe to people and livestock, environment and natural enemy.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

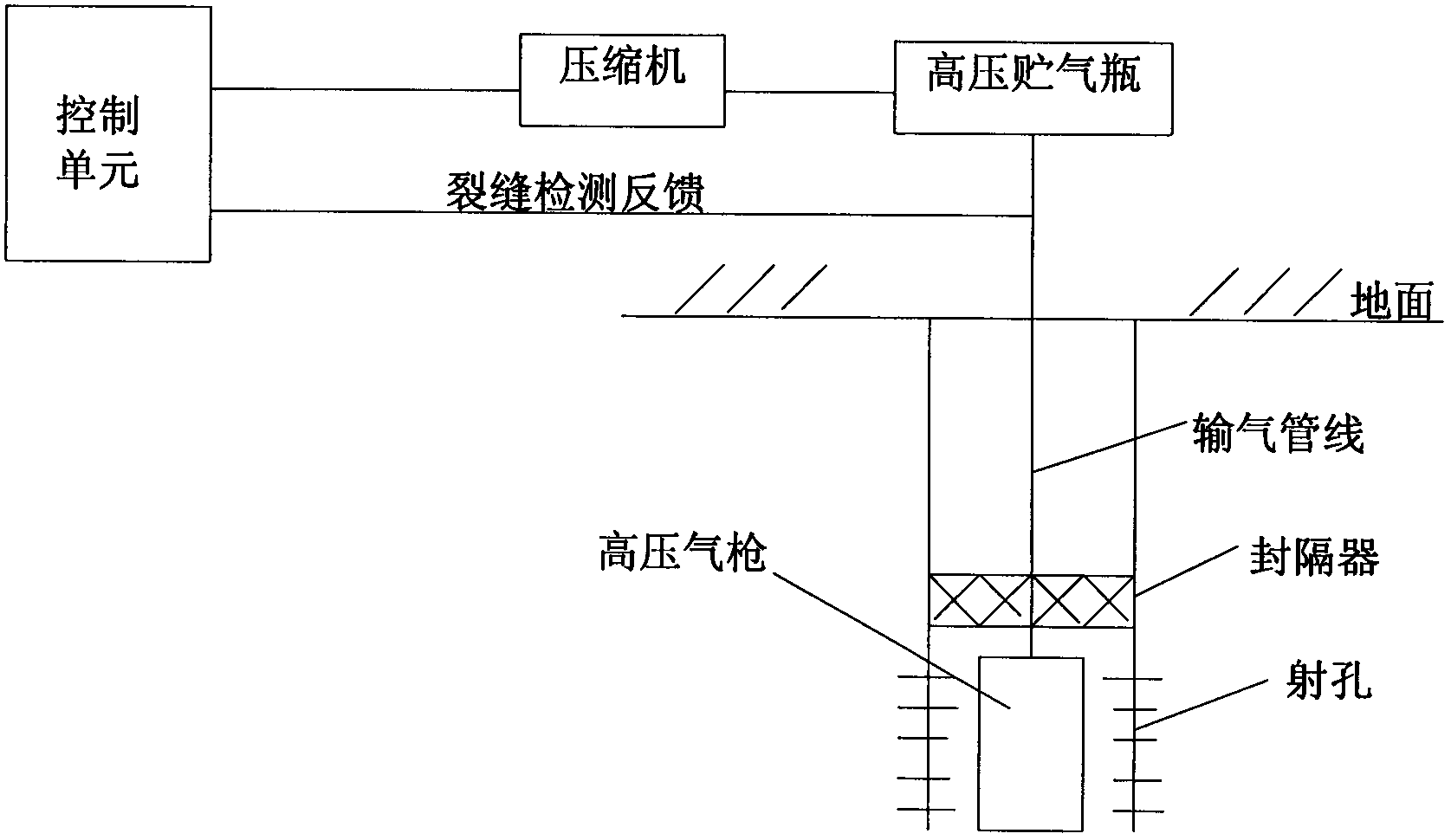

Method for improving shale gas well recovery ratio on basis of air knocking

InactiveCN102828735AThe equipment process is simpleEasy constructionFluid removalShale gasEngineering

The invention discloses a method for improving the shale gas well recovery ratio on basis of air knocking, by which an air knocking method is applied to crack a shale gas well to improve the shale gas well recovery ratio. High-pressure air in a high-pressure air storage bottle on the ground is delivered to an underground high-pressure air gun through a series of pipelines, a ground controller is pressed to give out a series of commands, the high-pressure air gun quickly releases the air to generate underground high-pressure air knocking, so a series of high-pressure air pulse vibrations are formed to be exerted on a shale, the pulse vibrations are superposed in the shale, conditions under which pressing and expanding are generated are formed at the shale part, the tail end of the internal micropore of the shale is continuously cracked and expanded to form shale gaps and cracks, thus, the shale gas dispersion and desorption processes are accelerated, so that the shale gas well recovery ratio is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

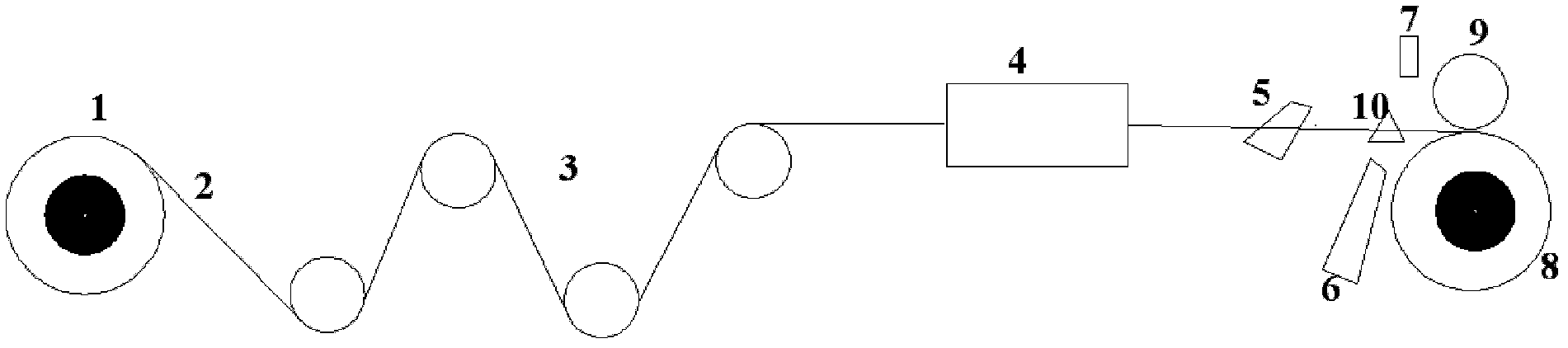

Preparation method of continuous fiber-reinforced thermoplastic compound prepreg tape pipe

The invention belongs to the technical field of high polymer materials and relates to a preparation method of a pipe. The preparation method comprises the following steps of: (1) placing a compound prepreg tape in a winding device, and then enabling the compound prepreg tape to pass through each tension roller in the tension roller group sequentially; (2) pre-heating the compound prepreg tape which is treated in the step (1); (3) heating the compound prepreg tape preheated in the step (2) at a winding point; (4) winding the compound prepreg tape heated in the step (3); and (5) finally, solidifying and shaping in situ to obtain the pipe. Compared with the prior art, the preparation method of the continuous fiber-reinforced thermoplastic compound prepreg tape pipe, disclosed by the invention, has the advantages of low cost, simple equipment, short shaping period and the like; and the produced thermoplastic compound pipe has a light weight, is high-pressure resistant and anticorrosive, and can be applied to the high-end field such as petrochemical engineering.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com