Preparation method of continuous fiber-reinforced thermoplastic compound prepreg tape pipe

A technology of continuous fiber and prepreg tape, applied in the direction of tubular objects, household appliances, and other household appliances, which can solve the problems of low industrial production efficiency, complex equipment, and cumbersome process, and achieve light weight, simple equipment, and shortened process. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In the continuous glass fiber reinforced polypropylene thermoplastic resin composite prepreg tape of the present invention, the glass fiber content is 40%, and the polypropylene resin matrix content is 60%. The cutting width of the composite prepreg tape is 0.5-3cm.

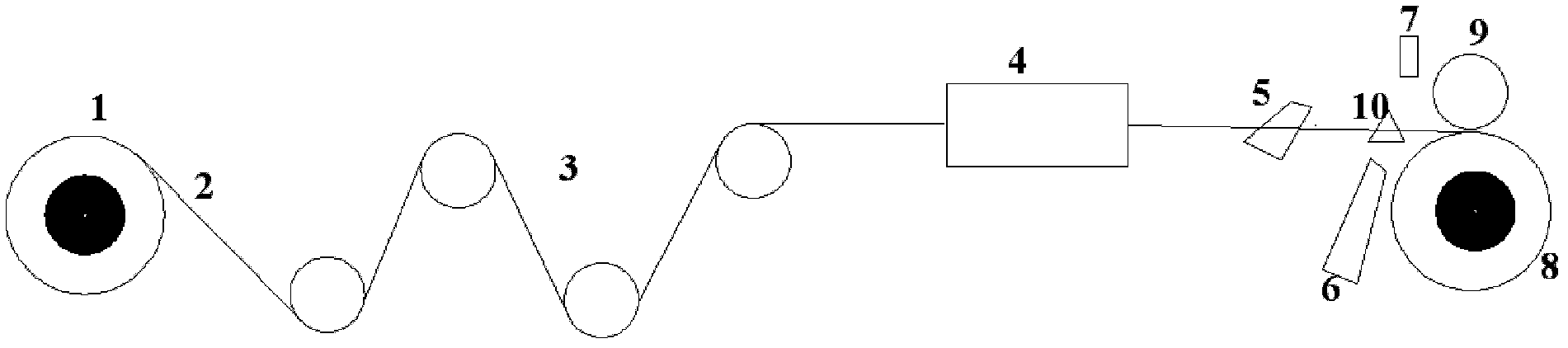

[0038] (1) The glass fiber reinforced polypropylene resin composite prepreg tape 2 placed in the rolling device 1, the composite prepreg is manually paved and then enters the tension roller group 3, so that the composite tape enters the next stage smoothly;

[0039] (2) Enter the infrared preheating device 4 driven by the tension roller group 3, and the infrared preheating temperature is 60°C, so that the fibers have a certain temperature, speed up the winding speed, and improve the heating efficiency;

[0040] (3) Then the composite prepreg tape enters the winding nozzle 5, and the winding angle and winding direction of the prepreg tape are controlled by the winding nozzle; then the composite prepreg tape...

Embodiment 2

[0044] In this embodiment, in the continuous glass fiber reinforced polypropylene thermoplastic resin composite prepreg tape, the glass fiber content is 50%, and the polypropylene resin matrix content is 50%. The cutting width of the composite prepreg tape is 0.5-3cm.

[0045] (1) The glass fiber reinforced polypropylene resin composite prepreg tape 2 placed in the rolling device 1, the composite prepreg is manually paved and then enters the tension roller group 3, so that the composite tape enters the next stage smoothly;

[0046] (2) Enter the infrared preheating device 4 driven by the tension roller group 3, and the infrared preheating temperature is 70°C, so that the fibers have a certain temperature, speed up the winding speed, and improve the heating efficiency;

[0047] (3) Then the composite prepreg tape enters the winding nozzle 5, and the winding angle and winding direction of the prepreg tape are controlled by the winding nozzle; then the composite prepreg tape is f...

Embodiment 3

[0051] In this embodiment, in the continuous glass fiber reinforced polypropylene thermoplastic resin composite prepreg tape, the glass fiber content is 50%, and the corresponding polypropylene resin matrix content is 50%. The cutting width of the composite prepreg tape is 0.5-3cm.

[0052] (1) The glass fiber reinforced polypropylene resin composite prepreg tape 2 placed in the rolling device 1, after the composite prepreg is manually paved, enters the tension roller group 3, so that the composite tape enters the next stage smoothly;

[0053] (2) Enter the infrared preheating device 4 driven by the tension roller group 3, and the infrared preheating temperature is 80° C., so that the fiber has a certain temperature, speeds up the winding speed, and improves the heating efficiency;

[0054] (3) Then the composite prepreg tape enters the winding nozzle 5, and the winding angle and winding direction of the prepreg tape are controlled by the winding nozzle; then the composite pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com