Super-hydrophobic polyurethane/ oxide nano particle hybrid coating material and preparation method thereof

A nanoparticle and coating material technology, applied in the field of superhydrophobic polyurethane/oxide nanoparticle hybrid coating and its preparation, can solve the problems of complex process, high production cost, inability to large-scale production, etc., and achieve chemical stability Good, low cost, low dielectric constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

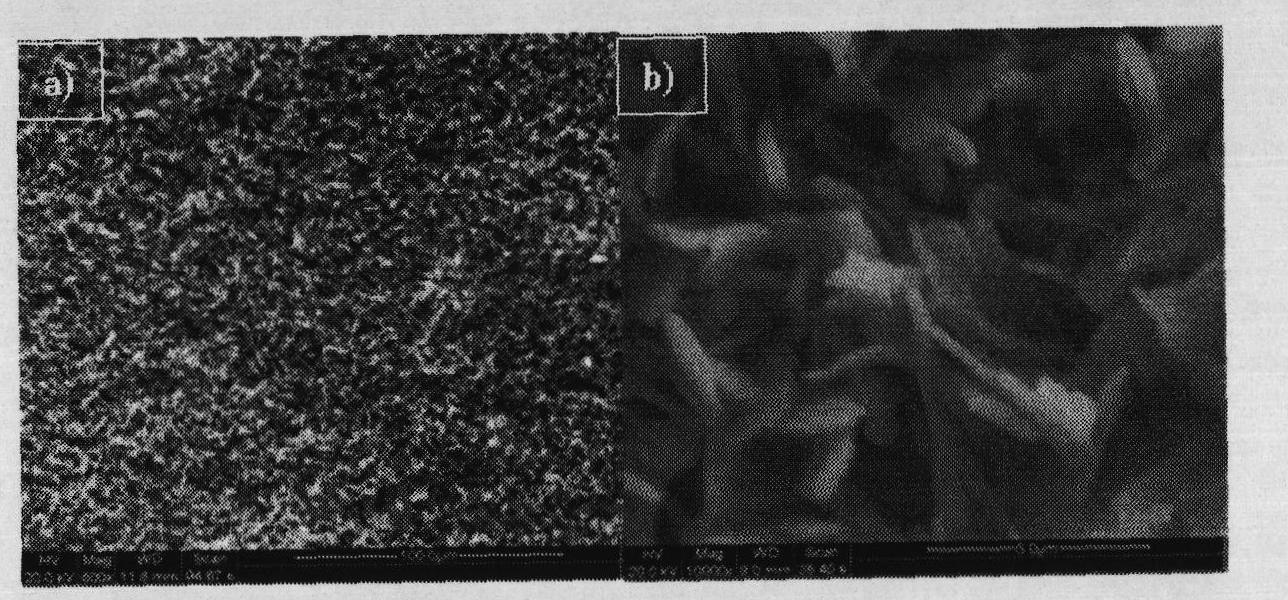

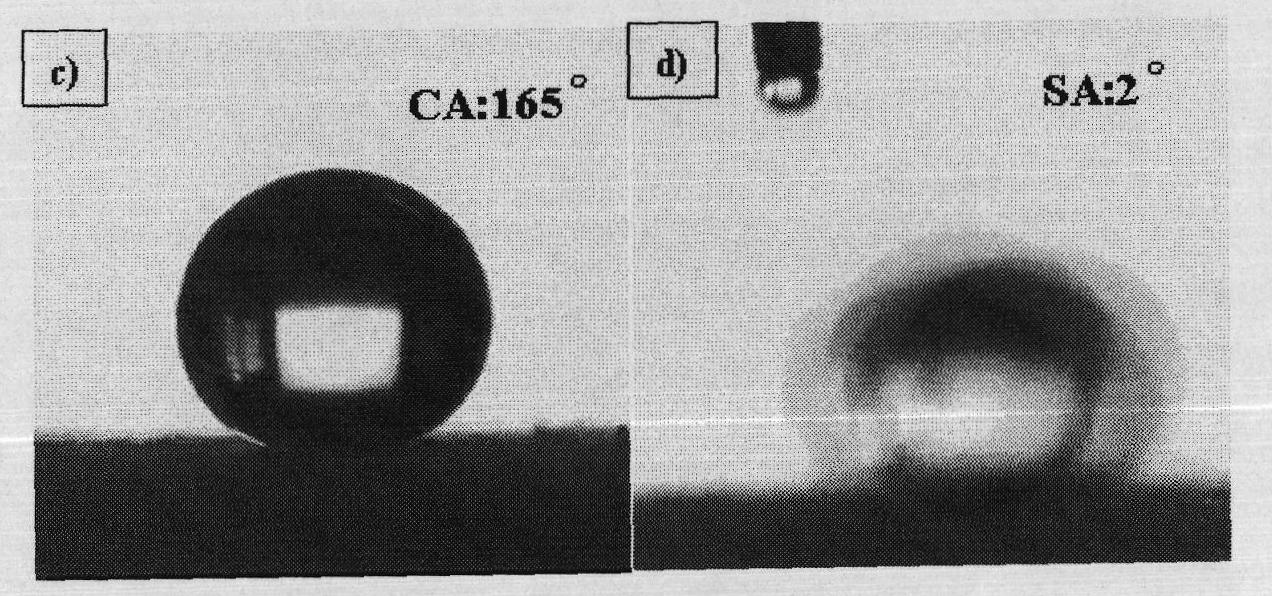

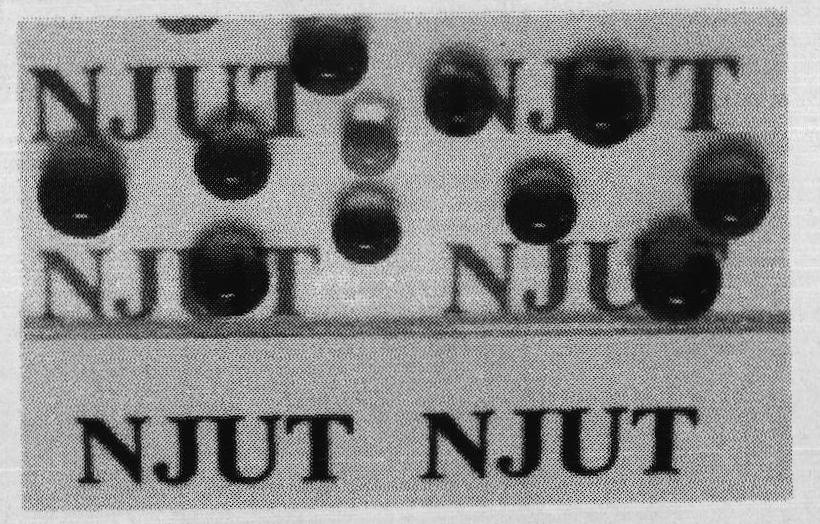

Image

Examples

Embodiment 1

[0038] 1. Nano silica pretreatment

[0039] Weigh 3g of precipitated nano-silica (average particle size 50nm, specific surface area 150m 2 / g), dried in an oven at 100°C for 2 hours and then placed with 30g of toluene in a 250ml three-necked flask for uniform ultrasonic dispersion; heated to 80°C, and added dropwise 6.4g of γ-glycidoxypropyltrimethoxy hydrolyzed by 20g of toluene Add silane for 30 minutes. After stirring for 30 minutes, heat to 110°C and reflux for 10 hours to fully react; finally, the product was washed 4 times with absolute ethanol, centrifuged, and dried in a vacuum oven at 110°C The modified silica was obtained in 17 hours and placed in a desiccator for later use.

[0040] 2. Preparation of superhydrophobic silica:

[0041] Take 1.5g of the above-mentioned modified silica and disperse ultrasonically in 75g of toluene to prepare a silica solution; then disperse 2.25g of octadecyl amide in 50g of N,N-dimethylformamide ultrasonically, and stir under magnetic force....

Embodiment 2

[0048] 1. Nano silica pretreatment

[0049] Weigh 3g of precipitated nano-silica (average particle size 50nm, specific surface area 150m 2 / g), dried in an oven at 100°C for 2 hours and then placed with 150g of toluene in a 500ml three-necked flask and sonicated until the dispersion is uniform; the temperature is raised to 70°C, and 15g of γ-glycidyl ether oxypropyl trimethyl hydrolyzed by 20g of toluene is added dropwise Add oxysilane for 30 minutes. After stirring for 30 minutes, heat to 110°C and reflux for 5 hours to make it fully react. Finally, the product was washed 4 times with absolute ethanol and centrifuged, and then placed in a vacuum oven at 110°C. After drying for 17 hours, the modified silica was obtained, which was placed in a dryer for later use.

[0050] 2. Preparation of superhydrophobic silica:

[0051] Disperse 0.2g of the above-mentioned modified modified silica in 15g of toluene to prepare a silica solution; then disperse 0.3g of octadecyl amide in 15g of N,N-...

Embodiment 3

[0058] 1. Nano silica pretreatment

[0059] Weigh 3g of fumed nano silica (average particle size 30nm, specific surface area 380m 2 / g), dried in an oven at 100°C for 2 hours and then placed in a 250ml three-necked flask with 90g N,N-dimethylformamide and sonicated until the dispersion is uniform; the temperature is raised to 90°C, and 6.4g gamma hydrolyzed by 20g toluene is added dropwise -Glycidoxypropyltrimethoxysilane, dripping for 30 minutes, after stirring for 30 minutes, heat to 120°C and reflux for 10 hours to make it fully react; finally, the product is washed 5 times with absolute ethanol and centrifuged After drying in a vacuum oven at 110°C for 17 hours, the modified silica is obtained and placed in a desiccator for later use.

[0060] 2. Preparation of superhydrophobic silica:

[0061] Disperse 0.2g of the above-mentioned treated modified silica into 10g of toluene to prepare a silica solution; then disperse 0.3g of octadecyl amide in a mixture of 8g of N,N-dimethylform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com