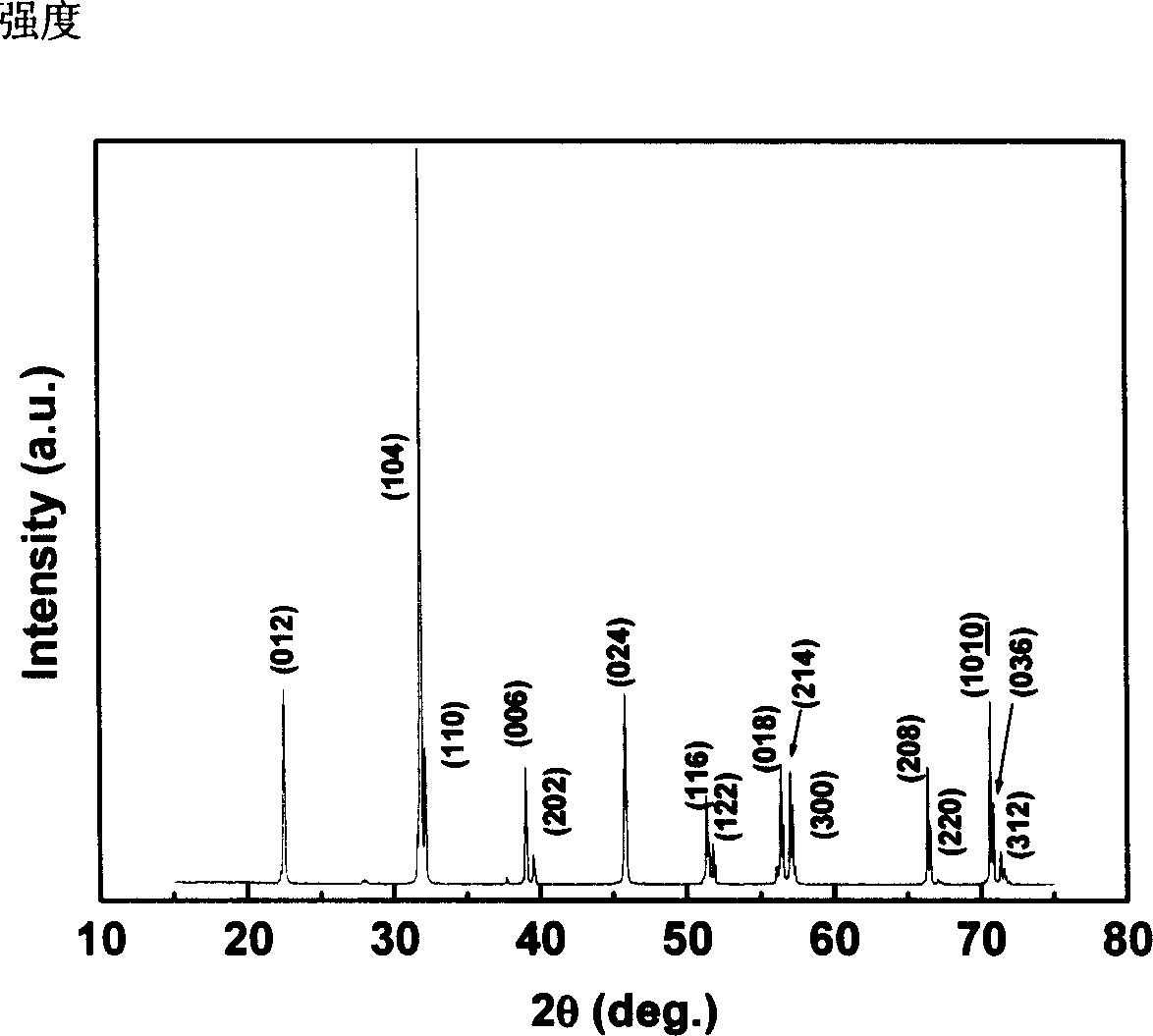

Method for preparing single-phase BiFeO3 ceramics through hardening process

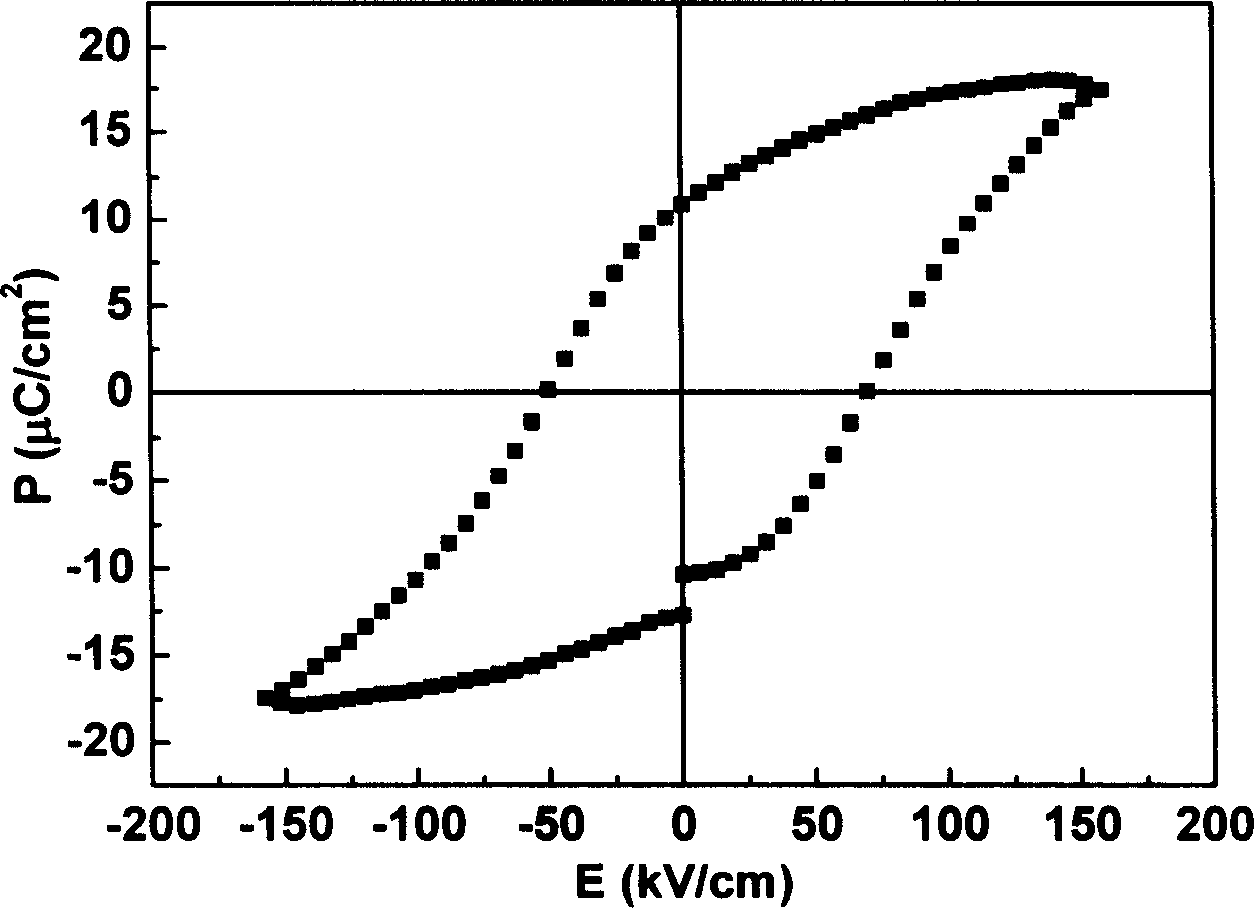

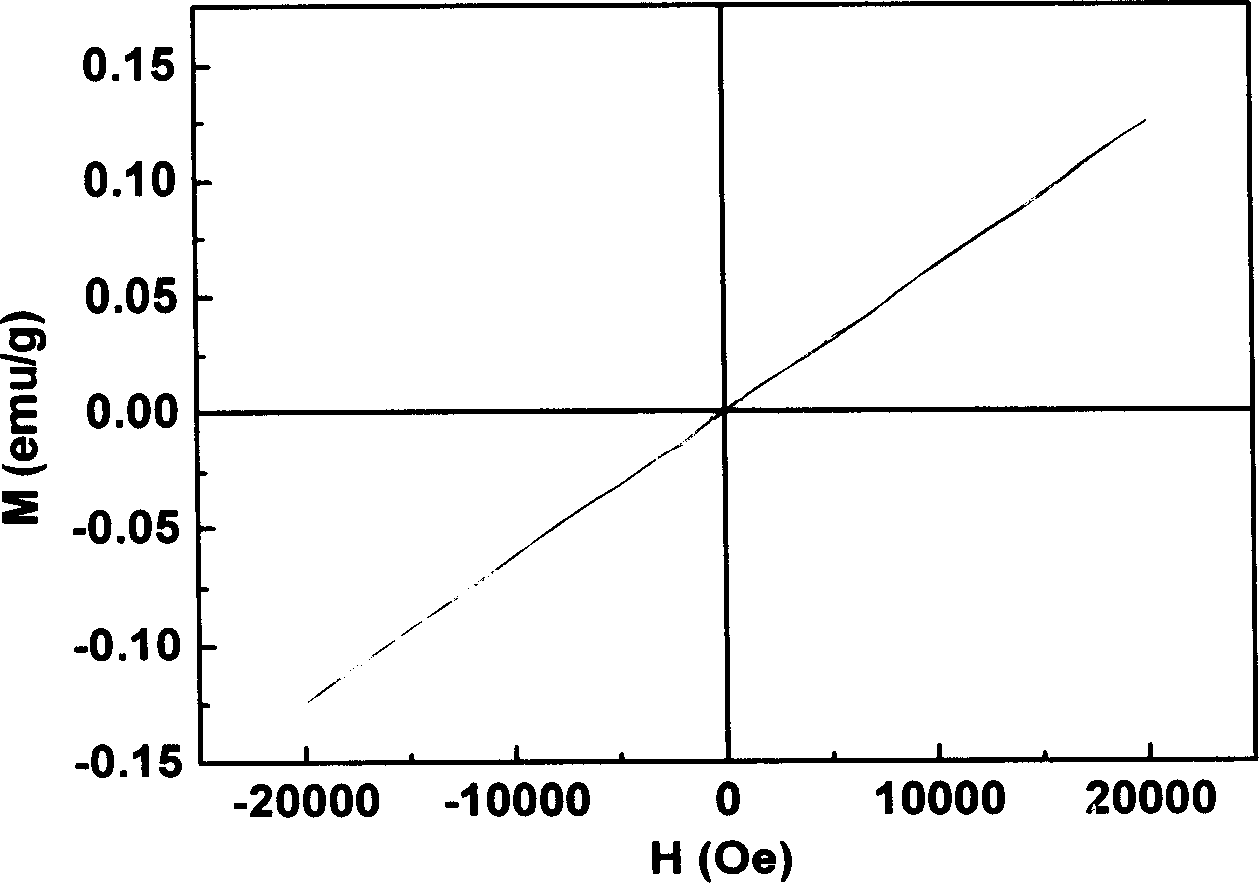

A ceramic and single-phase technology, applied in the field of preparing single-phase BiFeO3 ceramics, can solve the problems of small remanent polarization value and no saturated hysteresis loop, and achieve the effect of simple method, low cost and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Step 1: First weigh the dried Bi with a purity equal to 99.0% 2 o 3 and Fe 2 o 3 powder (the molar ratio is 1:1), alcohol is added to the mixture of the two powders, and then ball milling (320 rpm, 8 hours) is used to mix the two powders evenly.

[0019] The second step: after drying the powder obtained in the first step, add an appropriate amount of binder (polyhexenol), and then grind it with a mortar to make it uniform.

[0020] Step 3: Use a pressure of 10-15MPa to press an appropriate amount of powder into a thin sheet with a diameter of about 15-30 mm and a thickness of about 1-4 mm.

[0021] Step 4: Put appropriate amount of corresponding powder into Al 2 o 3 Crucible, then put the slice into it, and cover the slice with the corresponding powder, and finally use another crucible to buckle upside down on the first crucible, so that the slice is in a sealed state.

[0022] Step 5: Put the crucible sealed with the sheet into the muffle furnace, and control the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com