Preparation method for multifunctional super-hydrophobic hybrid material

A multi-functional, super-thinning technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of fluorine-containing monomers such as human health hazards, harsh requirements, and limited application range, and achieve low cost, low surface energy, The effect of simple equipment and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation of silica gel: 9.36g tetraethyl orthosilicate, 3.24g deionized water, and 0.81g acetic acid were added to 19.6g absolute ethanol and stirred for one day, and the pH was adjusted to 9.2 with ammonia water to obtain SiO 2 gel.

[0036] Preparation of titanium dioxide gel: add 5g of titanium isopropoxide and 1g of acetic acid to 108g of absolute ethanol, stir at room temperature for 1h, adjust the pH to 9.2 with ammonia water, and obtain TiO 2 gel.

Embodiment 1

[0038] SiO 2 Gel and TiO 2 The gel was mixed at a mass ratio of 1:1 and placed in a sealed container, treated with methyltrimethoxysiloxane ethanol solution at 70°C for 16 hours, and washed with ethanol three times to obtain a hydrophobic mixed gel powder. Add 0.12g of hydrophobic mixed gel powder into 8mL of chloroform, ultrasonicate for 30min, disperse evenly, add 0.08g of polydimethylsiloxane (PDMS), stir rapidly at room temperature for 20min, and obtain milky white TiO 2 -SiO 2 PDMS hybrid emulsion. The polyester-cotton fabric was soaked in the mixed emulsion for 1 hour, dried at room temperature for 30 minutes, and then dried at 120°C for 2 hours to obtain a fluorine-free superhydrophobic functional polyester-cotton fabric.

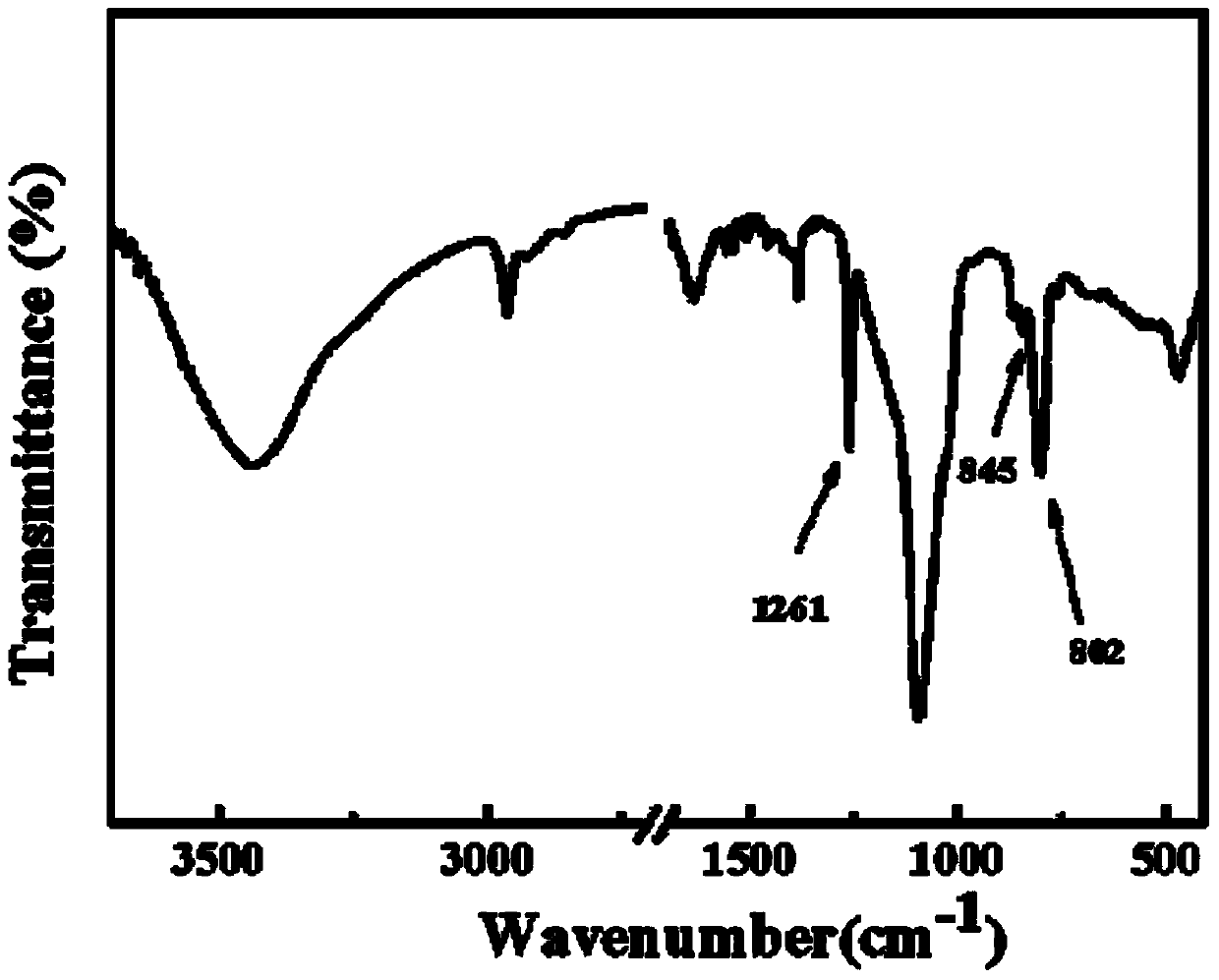

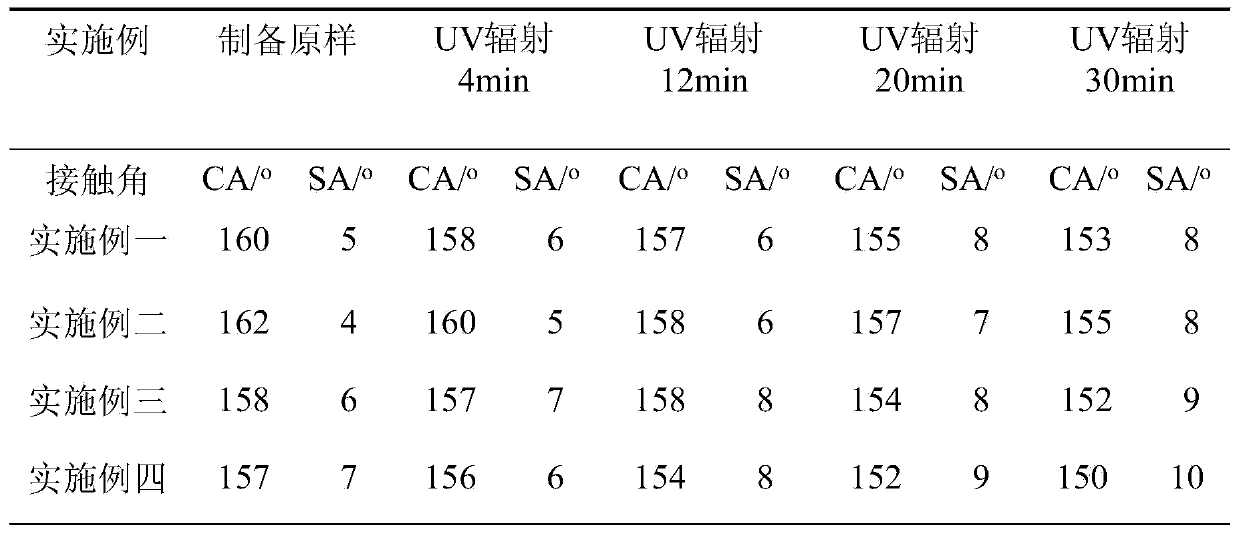

[0039] The hybrid emulsion was mixed with methylene blue to form a film, and irradiated with ultraviolet rays for 30 minutes. The hydrophobicity of the sample film is shown in Table 1. Hydrophobic TiO 2 -SiO 2 Infrared spectrum of PDMS organic-...

Embodiment 2

[0041] SiO 2 Gel and TiO 2 The gel was mixed in a sealed container at a mass ratio of 2:1, treated with hexamethyldisilazane isopropanol solution at 60°C for 18 hours, and washed with isopropanol three times to obtain a hydrophobic mixed gel. powder. Add 0.1g of hydrophobic mixed gel powder into 8mL of toluene, ultrasonicate for 60min, after the dispersion is uniform, add 0.1g of polydimethylsiloxane (PDMS), stir rapidly at room temperature for 30min, and obtain milky white TiO 2 -SiO 2 PDMS hybrid emulsion. The polyester fabric was soaked in the mixed emulsion for 1 hour, dried at room temperature for 30 minutes, and then dried at 140°C for 2 hours to obtain a fluorine-free superhydrophobic functional polyester fabric.

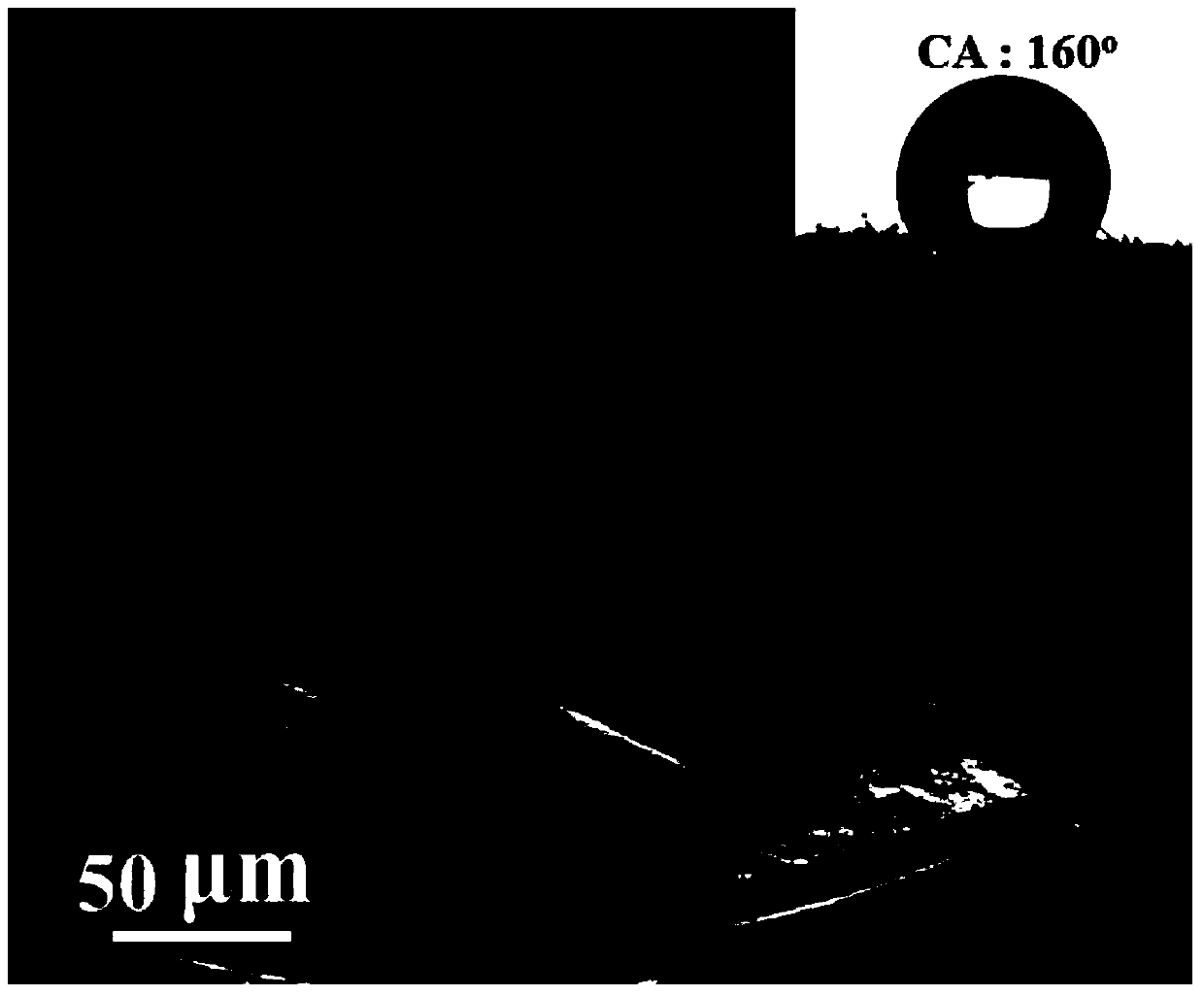

[0042] The hybrid emulsion was mixed with methylene blue to form a film, and irradiated with ultraviolet rays for 30 minutes. The hydrophobicity of the sample film is shown in Table 1. The SEM photo of the surface of the superhydrophobic functional fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com