Carbon-coated nickel-aluminium composite material and preparation method and application thereof

An aluminum composite material, carbon-coated nickel technology, applied in separation methods, chemical instruments and methods, catalyst activation/preparation, etc. The composition and structure are novel and unique, and the effect of good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

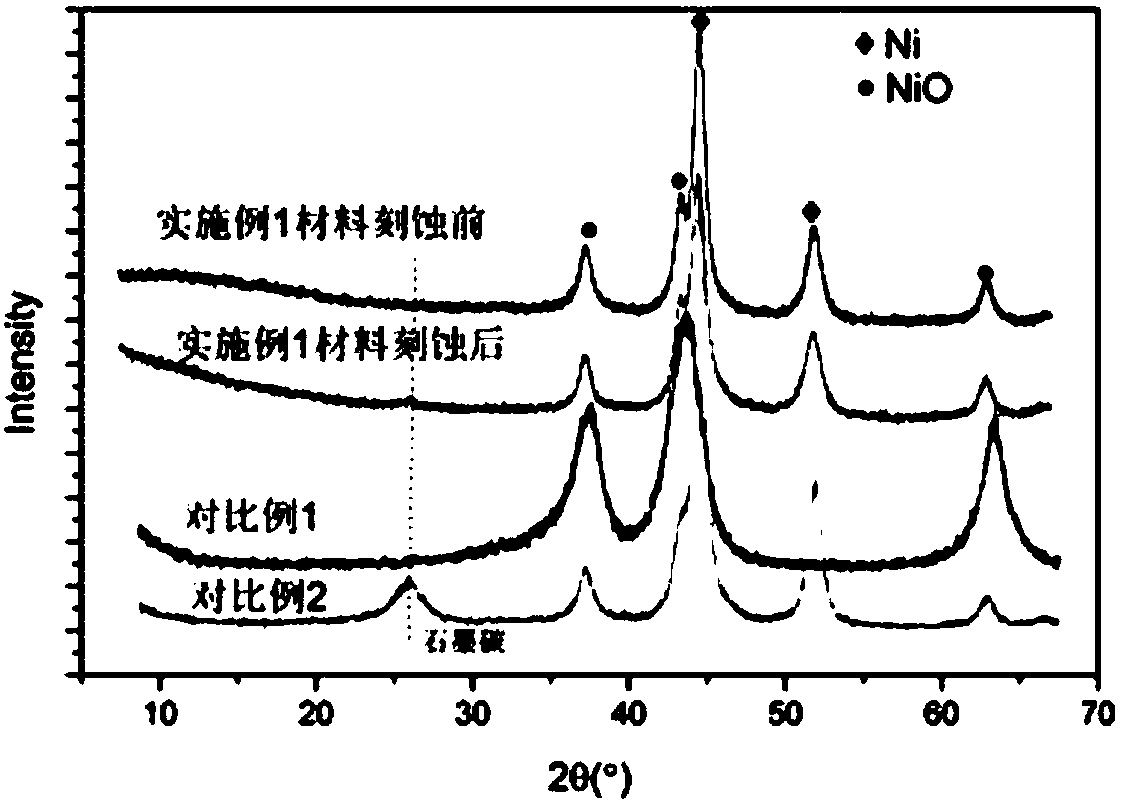

[0049] The present invention also provides a method for preparing the carbon-coated nickel-aluminum composite material. The method includes: a. preparing a nickel-aluminum precursor; Low-carbon alkanes are used as a carbon source gas to vapor-deposit graphite shells at 750°C to 900°C to obtain the carbon-coated nickel-aluminum composite material; wherein, the time for vapor-phase deposition of graphite shells using carbon source gases is 5 to 240 minutes, The flow rate of the carbon source gas is 10-500 ml / (min·g nickel-aluminum precursor).

[0050] In the preparation method provided by the present invention, the nickel-aluminum precursor is prepared first, and then the graphite shell is wrapped on the outer surface of the nickel-aluminum core by vapor deposition. The nickel-aluminum precursor prepared in the present invention generally has a hydrotalcite crystal structure, and those skilled in the art can prepare it in various ways, such as co-precipitation and / or hydrotherma...

Embodiment 1

[0067] Preparation of nickel aluminum precursor: Weigh 11.64g (0.04mol) nickel nitrate hexahydrate and 7.5g (0.02mol) aluminum nitrate nonahydrate plus 60ml deionized water to make a mixed salt solution, and mix 5.40g (0.135mol) sodium hydroxide and 5.08g (0.048mol) of anhydrous sodium carbonate plus 120ml of deionized water to form a mixed alkali solution, and the two mixed solutions are simultaneously added dropwise to a three-necked flask with 100ml of deionized water at a constant temperature of 60°C, while stirring, strictly controlled The pH of trivalent aluminum salt and divalent nickel salt precipitation in the three-necked flask is 8 (that is, controlled between 7.9 and 8.1). After the dropwise addition, continue to stir at 60°C for 30min, age at 80°C for 24h, and centrifugally wash to neutral, and dried at 80°C to obtain highly dispersed nickel-aluminum precursor A1, its XRF elemental analysis is shown in Table 1, and the SEM picture is shown in figure 2 .

[0068]...

Embodiment 2

[0071] Preparation of nickel aluminum precursor: Weigh 11.64g nickel nitrate hexahydrate and 7.5g aluminum nitrate nonahydrate plus 60ml deionized water to make a mixed salt solution, add 5.40g sodium hydroxide and 5.08g anhydrous sodium carbonate plus 120ml deionized water Prepare a mixed alkali solution, and add the two mixed solutions dropwise into a three-necked flask with 100ml of deionized water at a constant temperature of 60°C at the same time, while stirring, strictly control the pH of the precipitation of trivalent aluminum salt and divalent nickel salt in the three-necked flask= 8.5 (that is, controlled between 8.4 and 8.6), continue to stir at 60°C for 30min after the dropwise addition, age at 80°C for 48h, centrifugally wash until neutral, and dry at 80°C to obtain a highly dispersed nickel-aluminum precursor B1.

[0072] Preparation of carbon-coated nickel-aluminum composite material: Weigh 1.0 g of nickel-aluminum precursor and place it in a porcelain boat, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com