Process for preparing tree-shaped carbon nano tube

A carbon nanotube and dendritic technology, applied in the field of preparation of nanomaterials, can solve problems such as dendritic carbon nanotubes that have not yet been seen, and achieve the effects of easy operation, low cost and uniform diameter distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

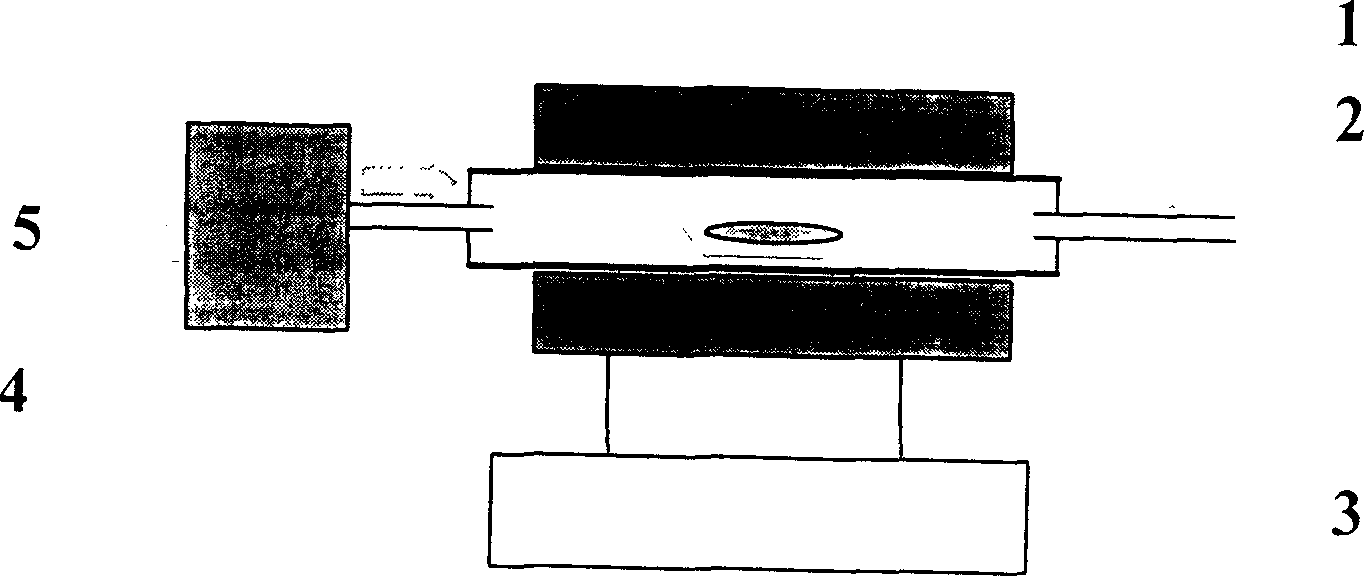

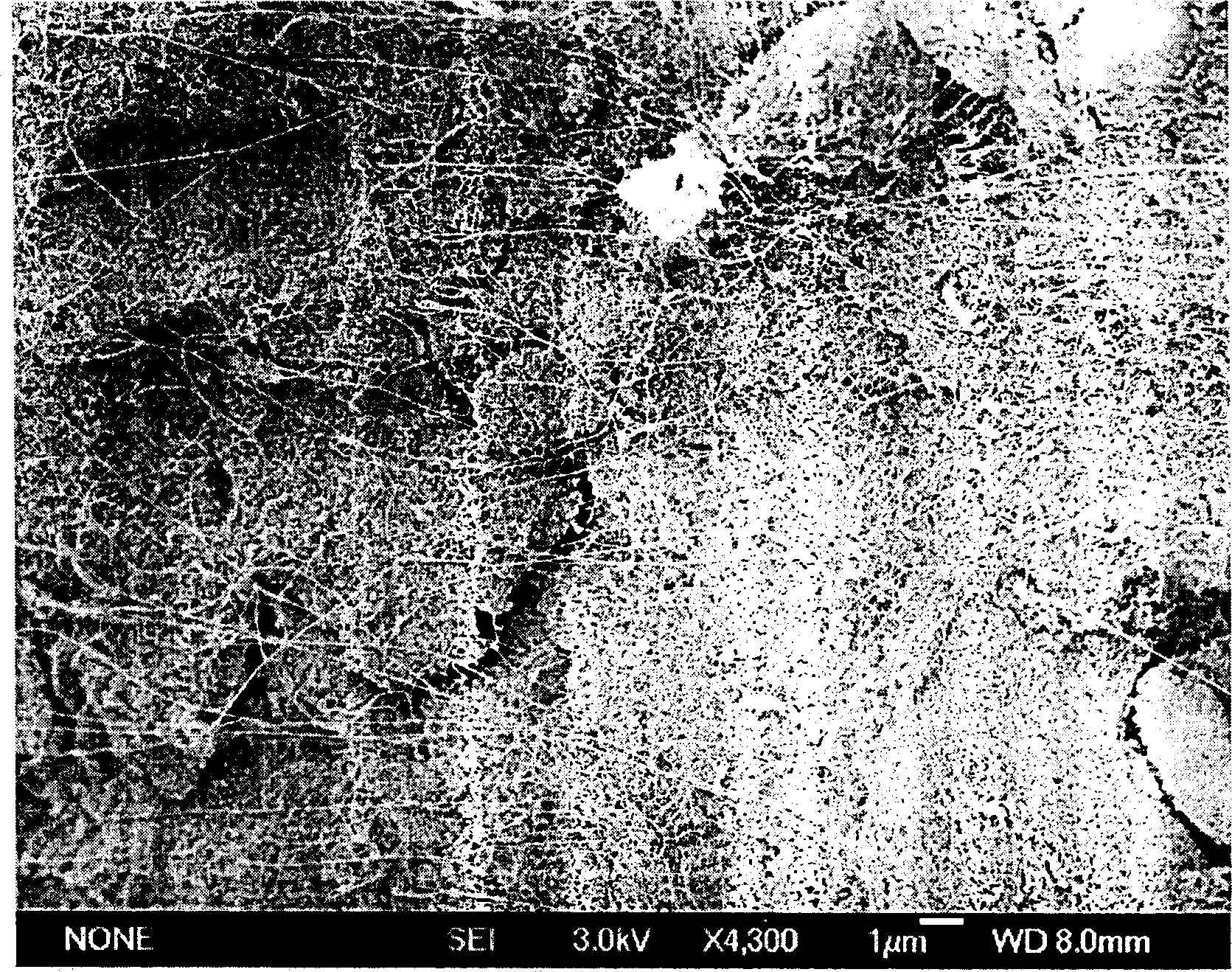

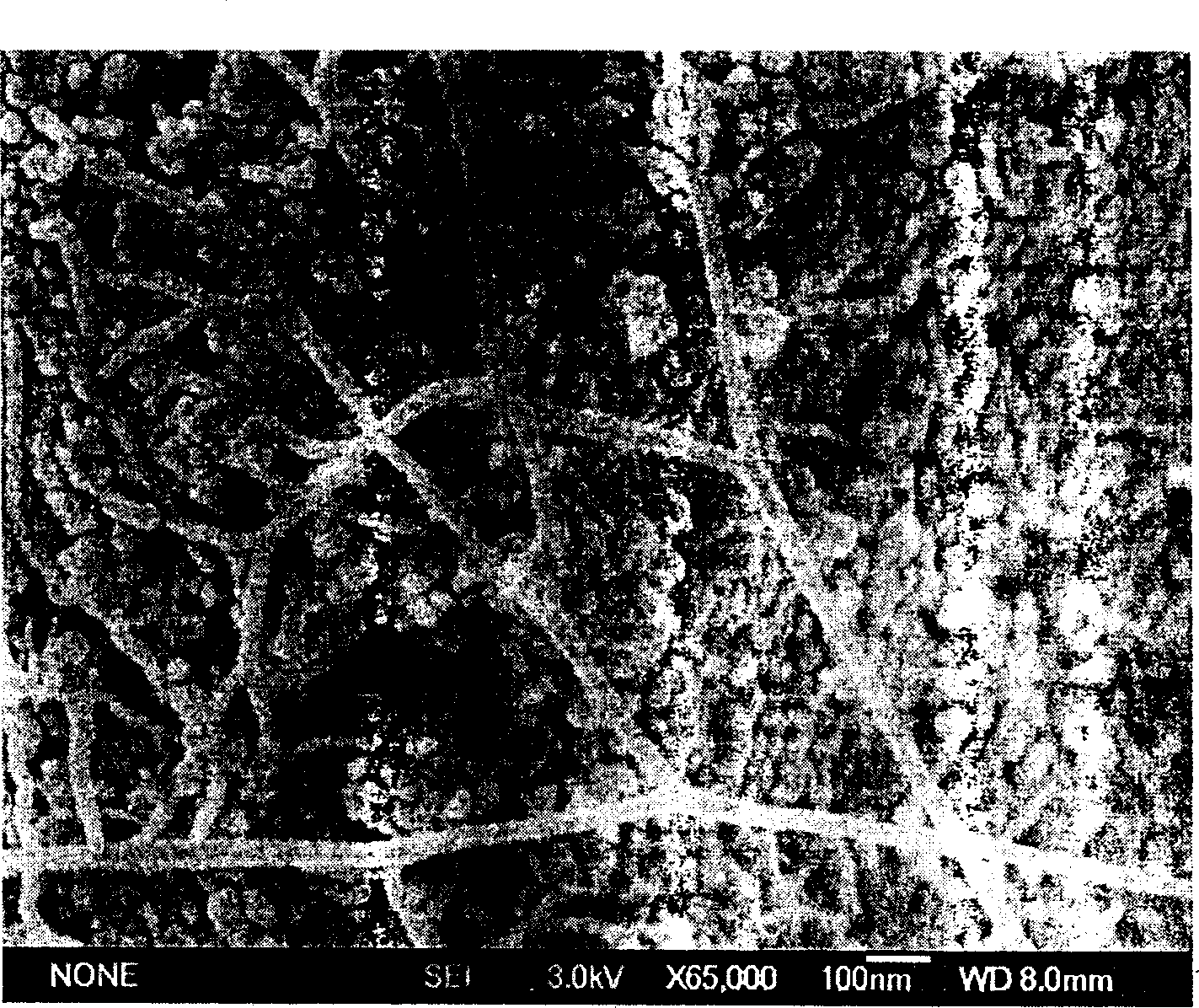

[0027] Example 1 Dissolve 0.356 g of cobalt nitrate hexahydrate in 50 ml of absolute ethanol, and then add 5 g of magnesium oxide powder. The mixture was sonicated for 1 hour to homogenize the solution. The solvent was then removed by a rotary evaporator, followed by drying at 130° C. for 13 hours to obtain a completely dried catalyst. The dried solid mixture is ground into a finer powder. In this way, a catalyst containing 1.25% by weight of cobalt element is obtained. The device shown in the picture (the tube furnace is produced by Beijing Electric Furnace Factory, the model is SK 2 -4-13), place a quartz boat (5 milliliters) containing 2 grams of the above-mentioned catalyst in the middle of the quartz tube, connect the gas distribution system, feed hydrogen at a flow rate of 300 milliliters per minute, and set the temperature to 1000 °C, quickly raise the temperature to 1000 °C (within 12 minutes), and feed methane gas at a flow rate of 75 ml per minute. After 10 minute...

Embodiment 2

[0028] Example 2 According to the preparation method of Example 1, only the mass of cobalt nitrate hexahydrate was replaced by 0.712 g to obtain a 2.5% catalyst, and a product containing 80% of dendritic carbon nanotubes was obtained by using the catalyst.

Embodiment 3

[0029] Example 3 According to the preparation method of Example 2, only the mixed total gas flow rate is adjusted to 300 milliliters per minute, the volume ratio of hydrogen and methane is adjusted to 4: 1, and the obtained diameter is a dendritic carbon nanotube with a diameter of 52 nanometers And its content reaches 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com