Method for improving shale gas well recovery ratio on basis of air knocking

A shale gas well and recovery technology, which is applied in the direction of production fluid, earth drilling, wellbore/well components, etc., can solve problems such as difficult construction, complicated process, and non-compliance with environmental protection requirements, so as to improve the permeability of shale , Simple equipment process and controllable knock energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

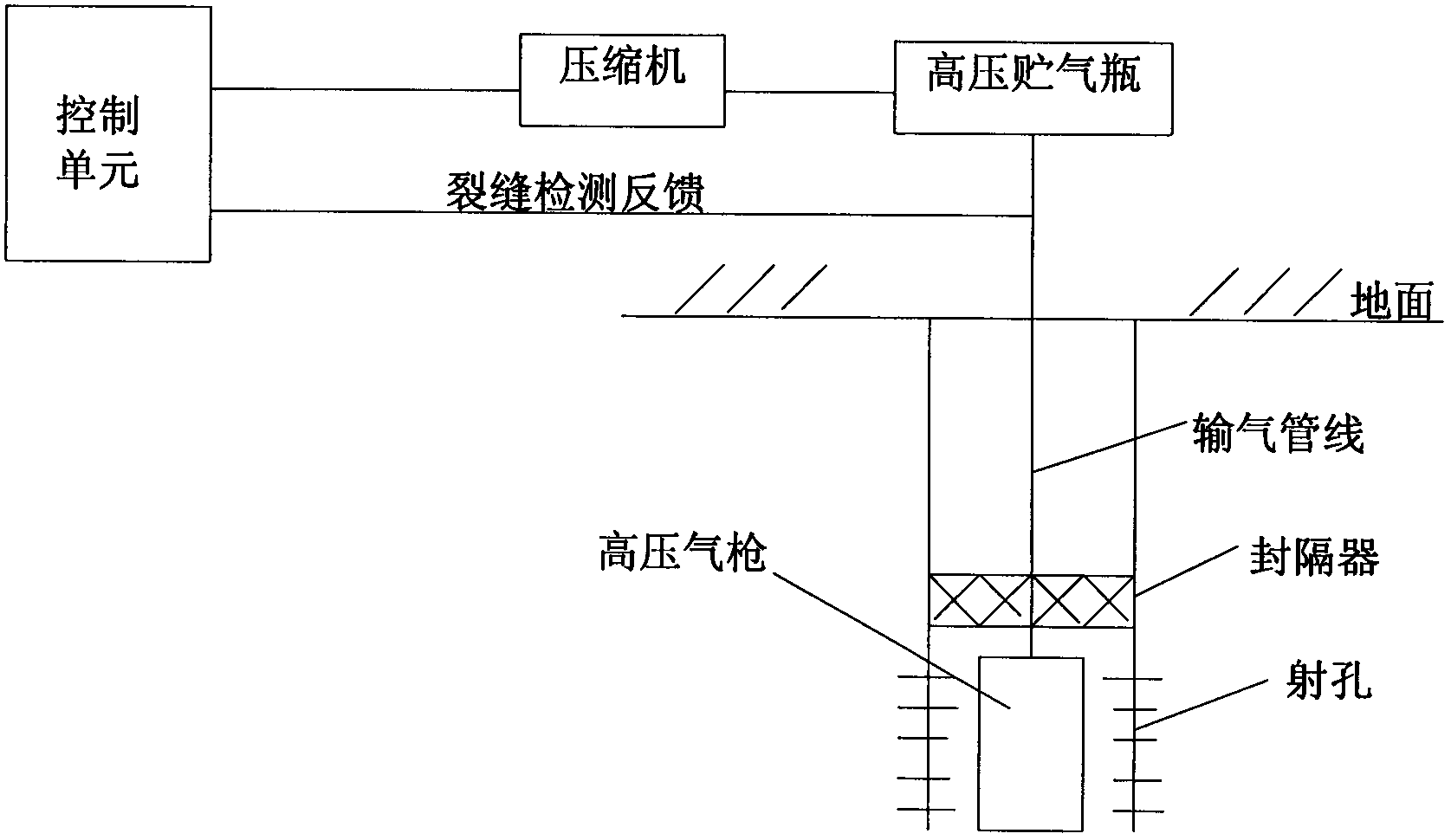

[0027] The high-pressure air in the high-pressure gas cylinder on the ground reaches the downhole high-pressure air gun through a series of pipelines. According to a series of instructions issued by the ground controller, the high-pressure air gun quickly deflates the gas, and generates a high-pressure air detonation underground to form a series of high-pressure air. The pulse vibration acts on the shale, and the pulse vibration is superimposed in the shale, causing pressure expansion in the rock, making the end of the micropores in the rock continue to rupture and expand to the inside, and accelerating the diffusion of shale gas in the shale layer. Desorption process to enhance the recovery of shale gas wells. After the high-pressure air gun releases high-pressure air, high-pressure air detonation is generated in the downhole, and the effect of high-pressure air blasting cracks in the operating well is monitored in real time through the detector installed in the nearby shale g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com